Patents

Literature

804results about How to "Improve thermoelectric performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

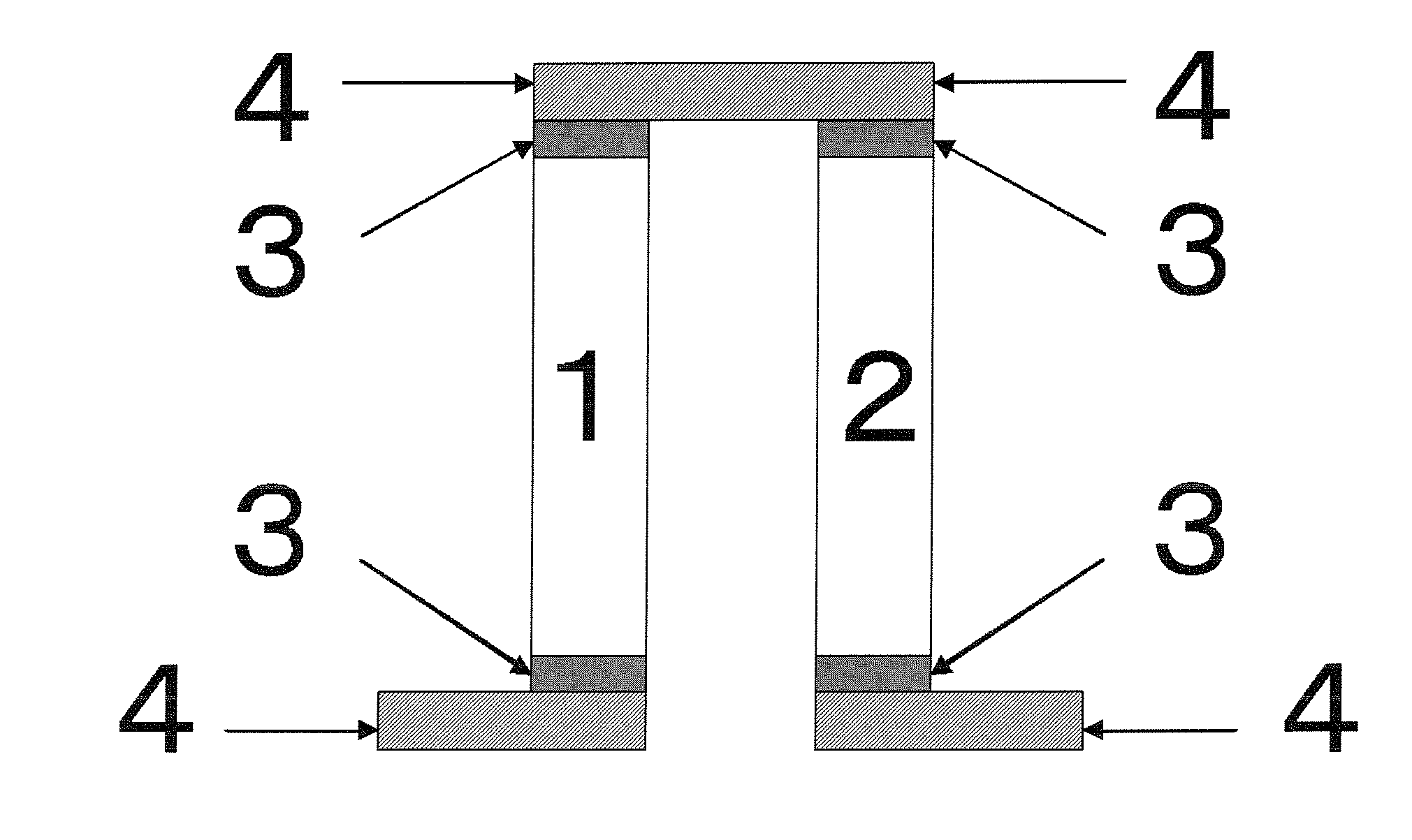

Thermoelectric conversion material and thermoelectric conversion module

ActiveUS20100294326A1Improve thermoelectric performanceThermoelectric device junction materialsRare-earth elementAlkaline earth metal

The present invention realizes a thermoelectric conversion material having excellent thermoelectric performance over a wide temperature range, and a thermoelectric conversion module providing excellent junctions between thermoelectric conversion materials and electrodes.The present invention provides an R-T-M-X-N thermoelectric conversion material that has a structure expressed by the following formula: RrTt−mMmXx−nNn (0<r≦1, 3≦t−m≦5, 0≦m≦0.5, 10≦x≦15, 0≦n≦2),where R represents three or more elements selected from the group consisting of rare earth elements, alkali metal elements, alkaline-earth metal elements, group 4 elements, and group 13 elements,T represents at least one element selected from Fe and Co,M represents at least one element selected from the group consisting of Ru, Os, Rh, Ir, Ni, Pd, Pt, Cu, Ag, and Au,X represents at least one element selected from the group consisting of P, As, Sb, and Bi, andN represents at least one element selected from Se and Te.

Owner:FURUKAWA COMPANY

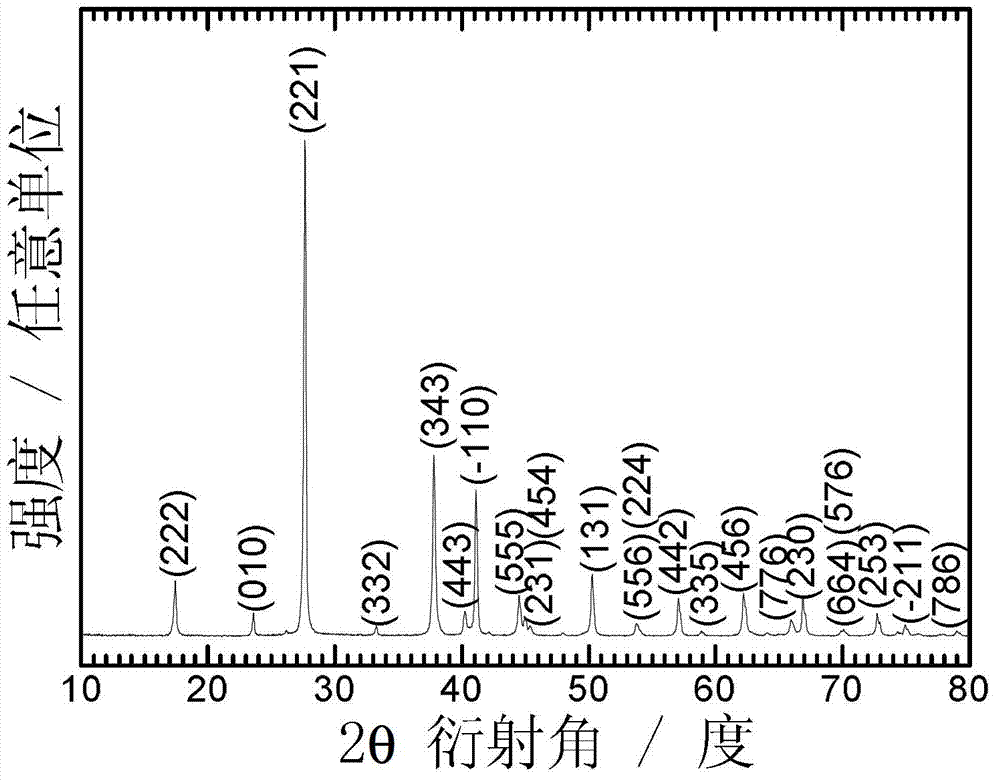

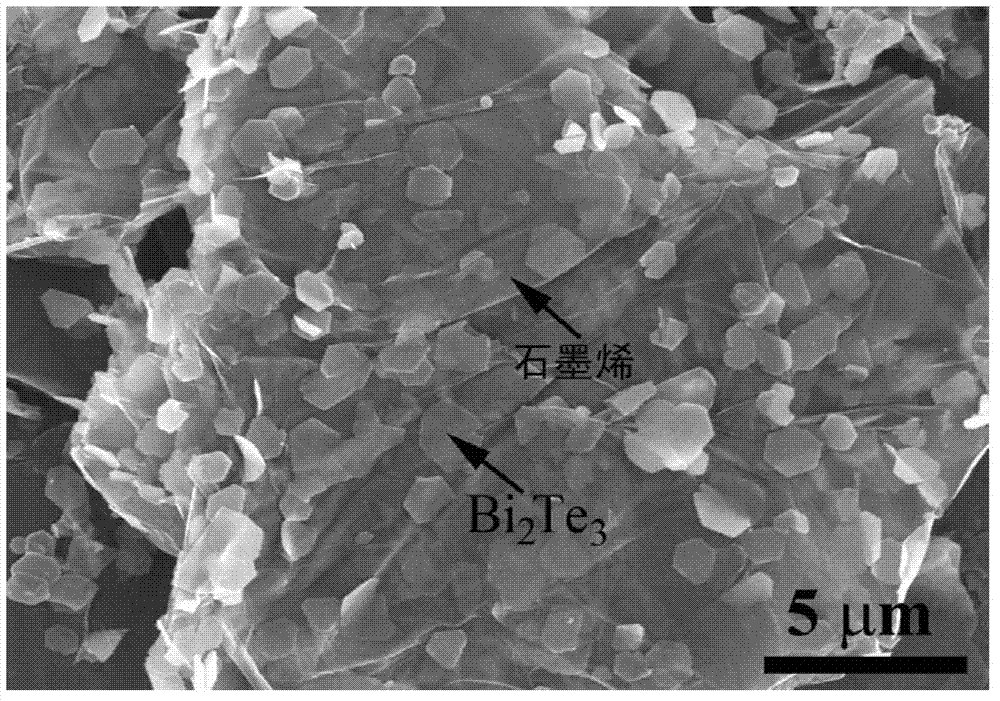

Bi2Te3 thin-piece/graphene composite material, preparation method and applications thereof

InactiveCN102760827AImprove thermoelectric performanceAvoid reunionGrapheneThermoelectric device junction materialsSolventCvd graphene

The invention discloses a Bi2Te3 thin-piece / graphene composite material. The Bi2Te3 thin-piece / graphene composite material consists of a micron-sized Bi2Te3 thin sheet and graphene. Due to the actions of dispersion, bearing and isolation of the graphene, the sintering of the micron-sized Bi2Te3 thin sheet in the heat-treatment process can be effectively prevented for maintaining effective scattering of the crystal boundary to phonons, and the great significance for improving the thermoelectric properties of the Bi2Te3 material is embodied. The composite material can be used as a thermoelectric material. The invention also discloses a preparation method of the composite material by a one-step hydrothermal method or a one-step solvothermal method, and has the advantages of simple process, low cost, short period and low energy consumption and the like.

Owner:ZHEJIANG UNIV

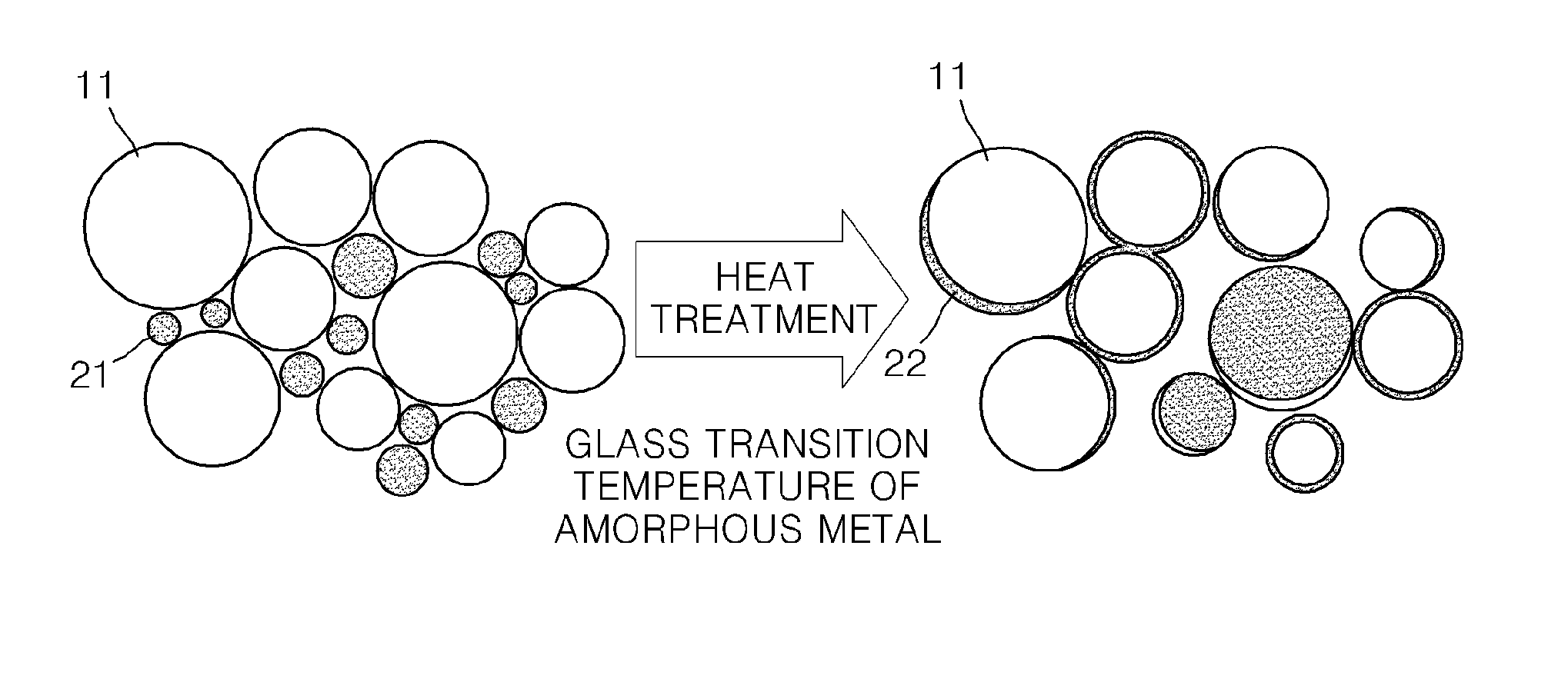

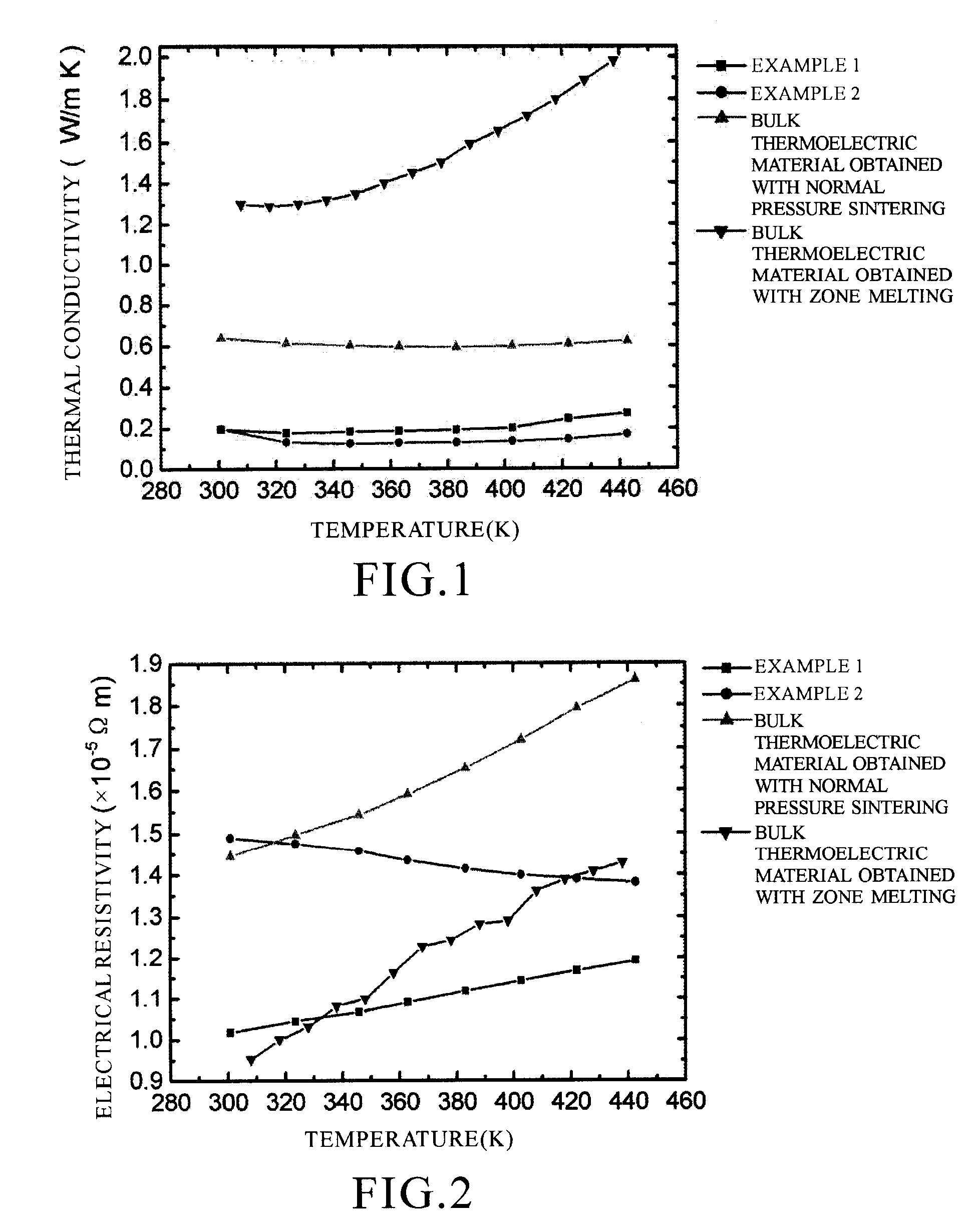

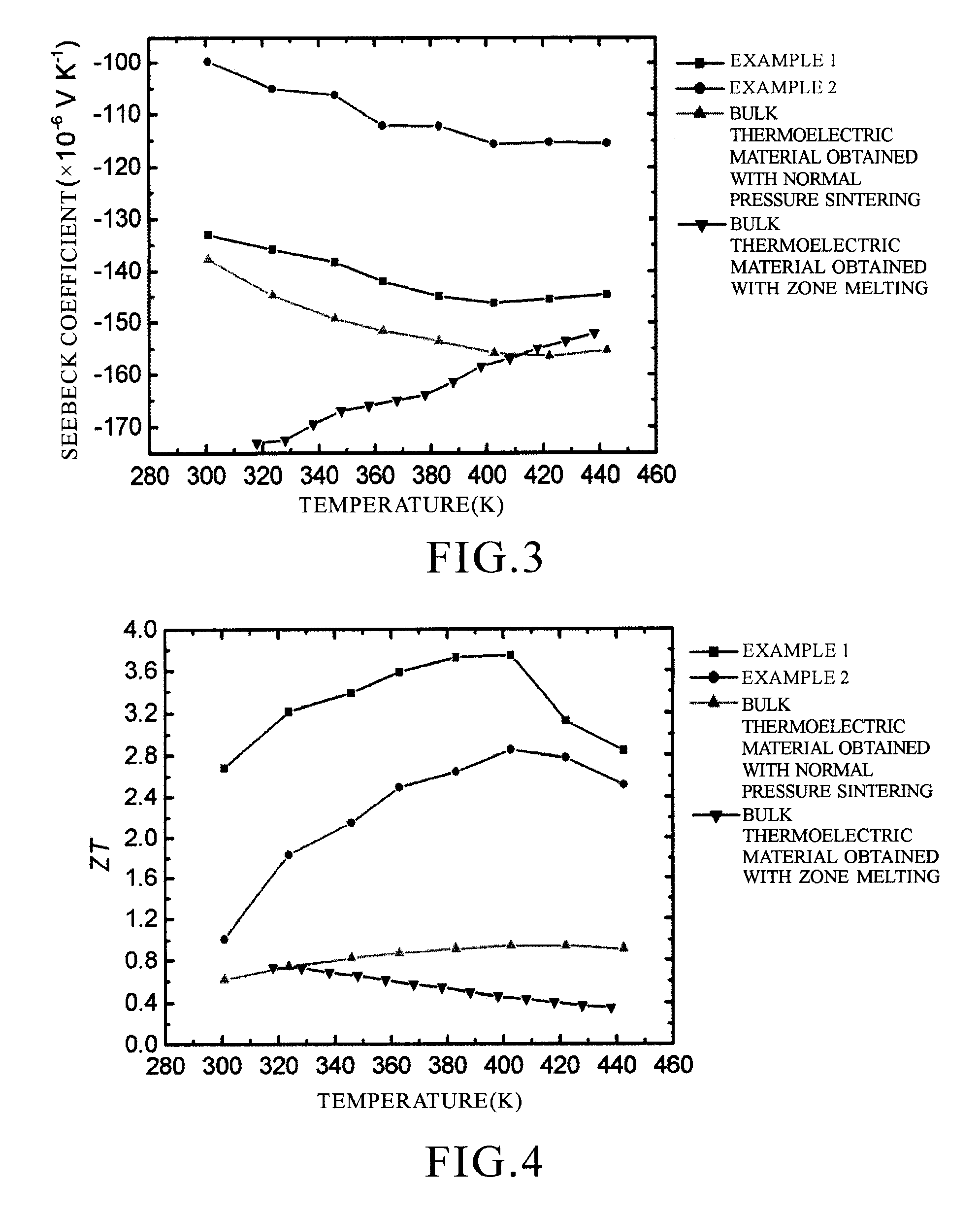

Bulk nanocomposite thermoelectric material, nanocomposite thermoelectric material, and method of preparing the bulk nanocomposite thermoelectric material

InactiveUS20120114961A1Improve thermoelectric performanceNanostructure manufactureThin material handlingThermoelectric materialsVitrification

A bulk nanocomposite thermoelectric material including: a plurality of grains of a thermoelectric material; and a metal nanolayer on a boundary of the plurality of grains, wherein the metal nanolayer is crystalline, and a glass transition temperature and a crystallization temperature of the nanometal are lower than a melting point of the thermoelectric material.

Owner:SAMSUNG ELECTRONICS CO LTD +1

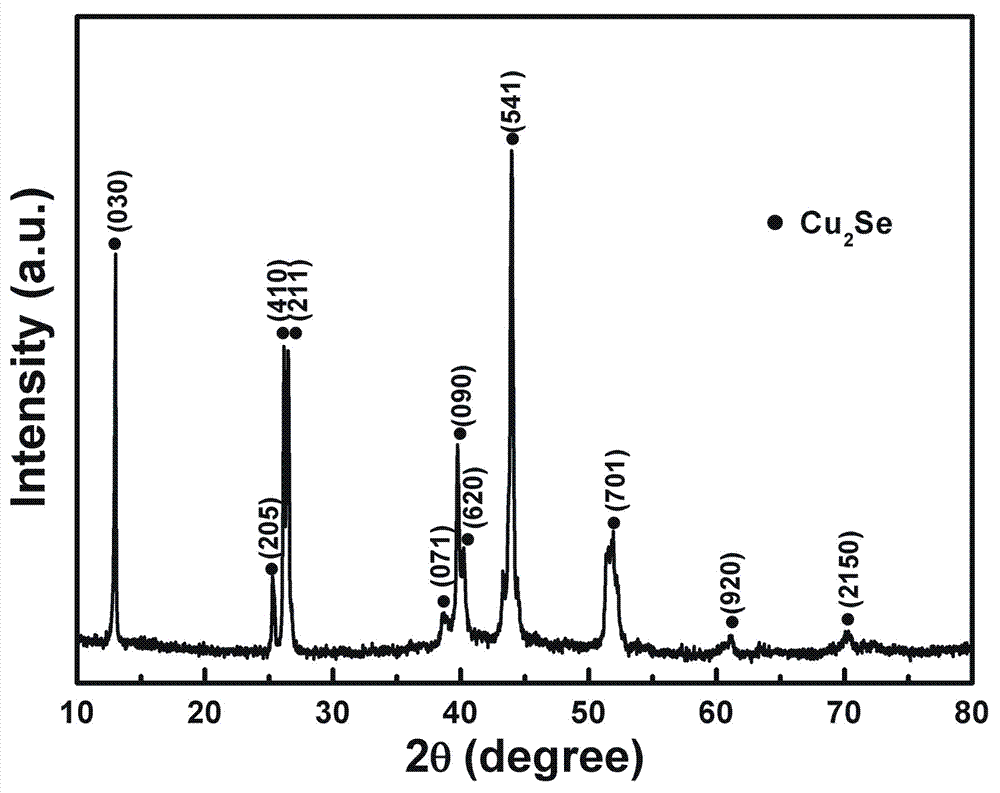

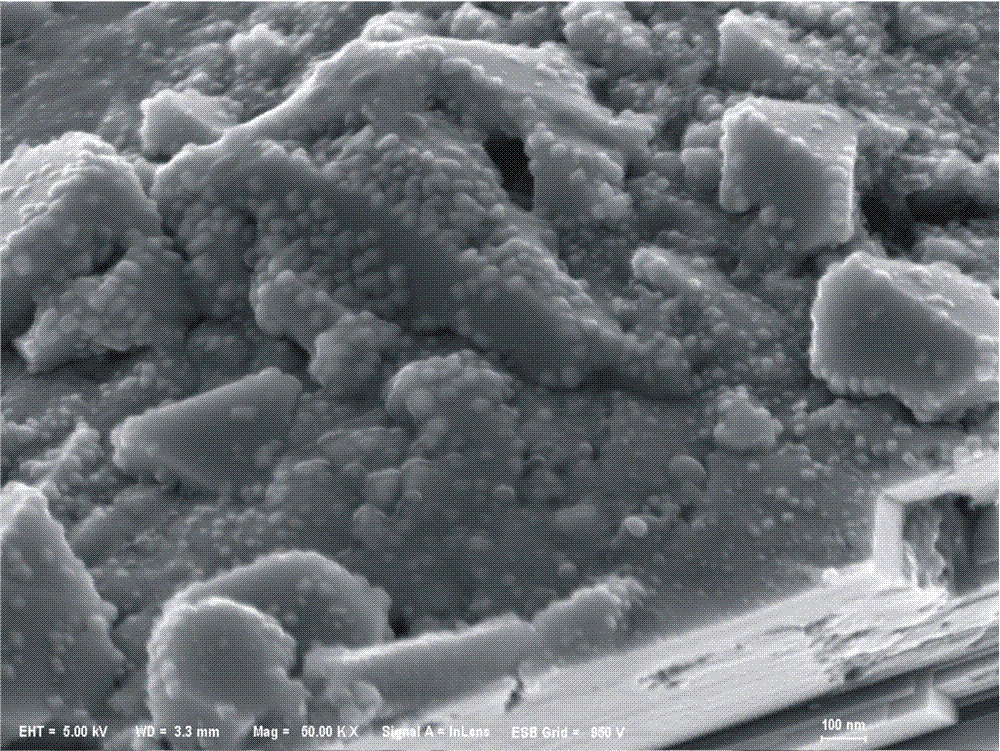

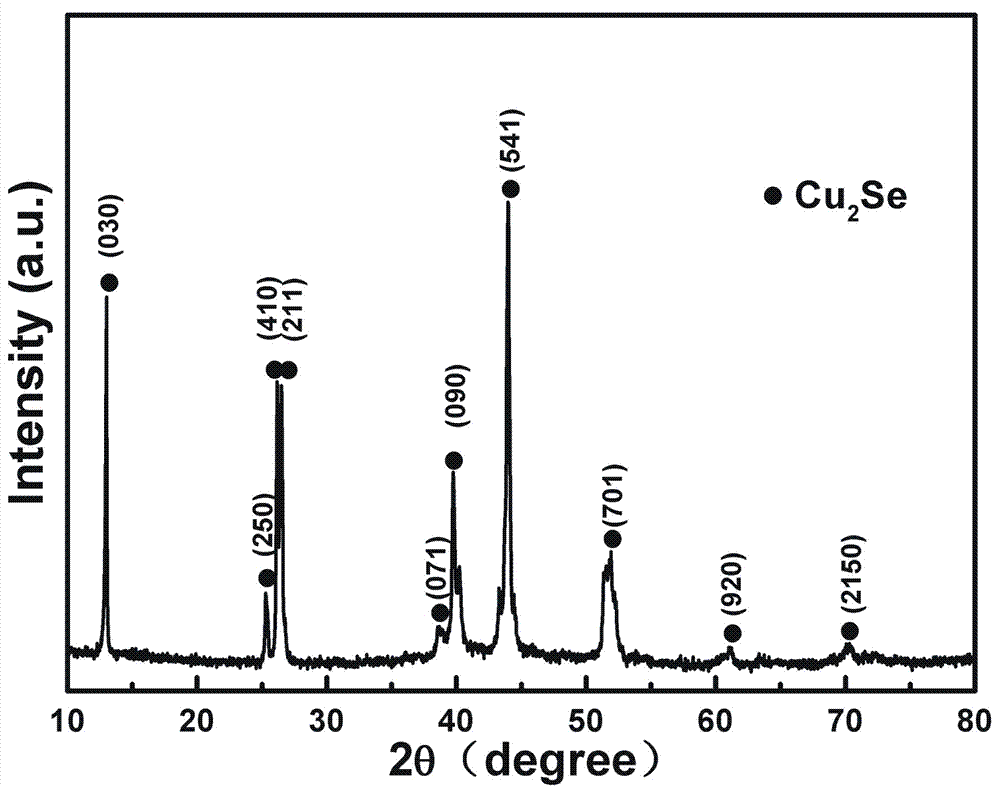

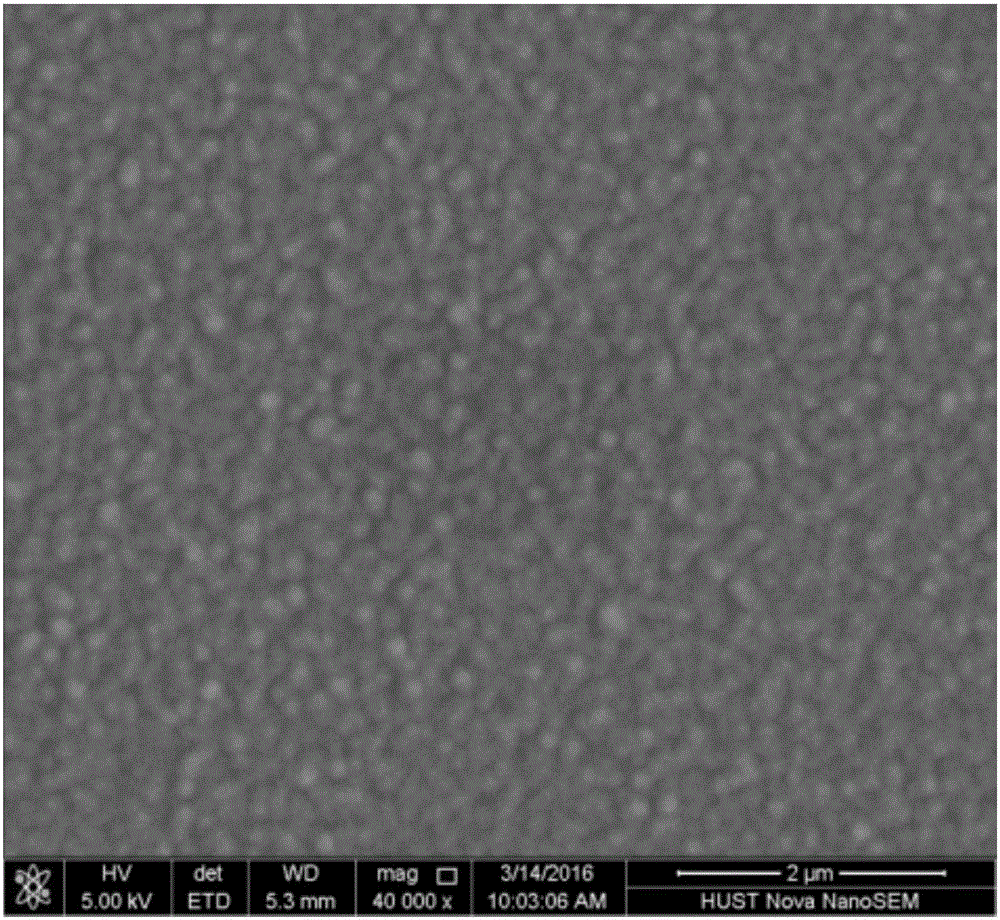

Self-propagating high-temperature rapid one-step synthesis thermoelectric material powder with nanostructure Cu2Se method

ActiveCN103165809APrecise control of stoichiometric ratioQuick responseNanotechnologyThermoelectric device junction materialsThermoelectric materialsSelf-propagating high-temperature synthesis

The invention provides a self-propagating high-temperature rapid one-step synthesis thermoelectric material powder with nanostructure Cu2Se method. The method includes: preparing stoichiometry of Cu powder and Se powder as 2 to 1 as raw materials, evenly mixing Cu powder with Fe powder to have reactants, adopting direct detonating or constant temperature detonating to trigger self-propagating reaction, natural cooling after reaction achievement and acquiring thermoelectric material powder with nanostructure Cu2Se. The method has the advantages of adoption of self-propagating high-temperature synthetic process, reaction for a short time, simple technique, low facility requirement, low energy consumption and environment friendliness. Further, stoichiometry of products is controlled accurately. Even distribution nanostructure is formed at normal positions.

Owner:WUHAN UNIV OF TECH

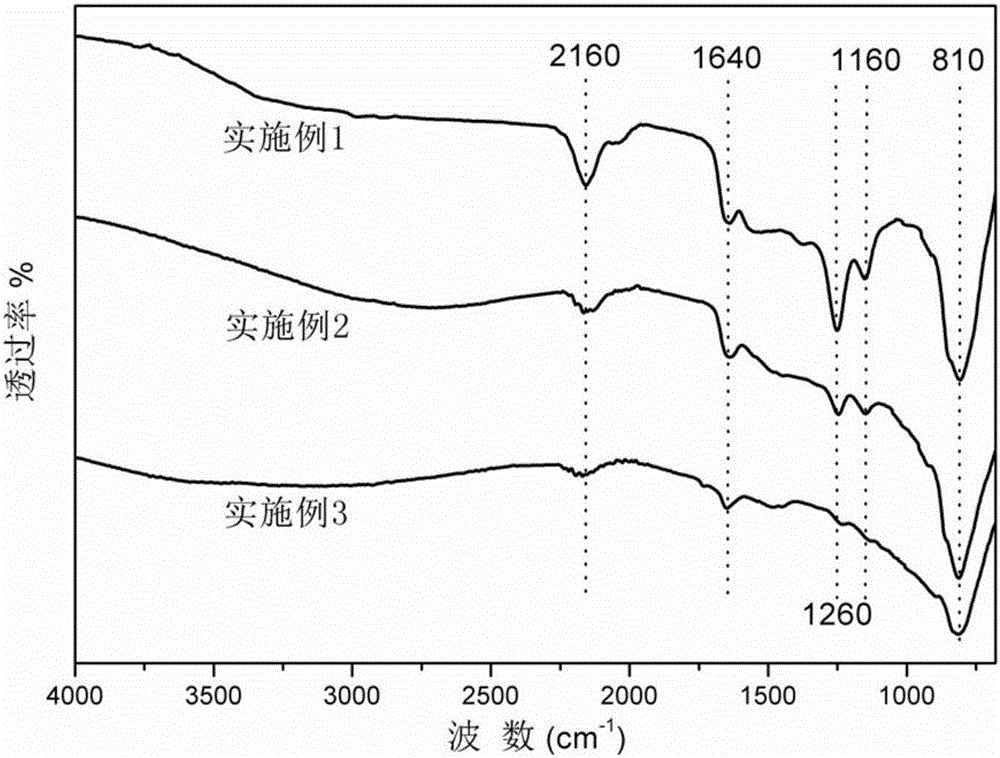

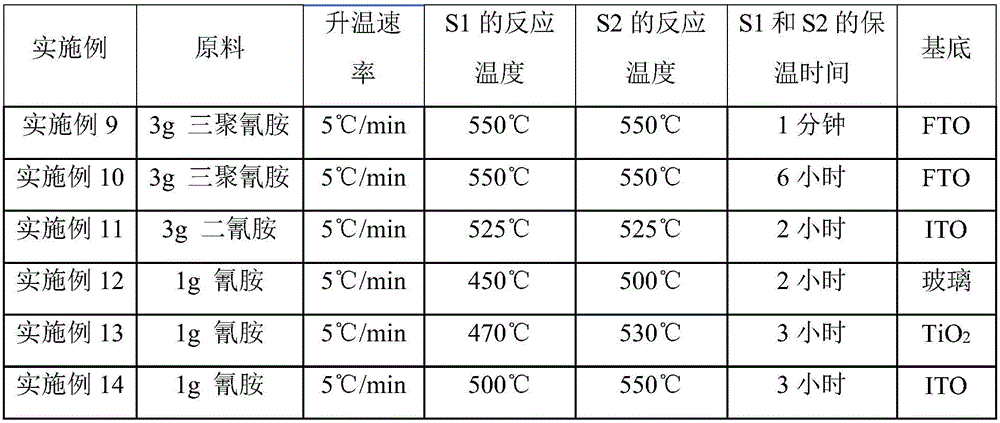

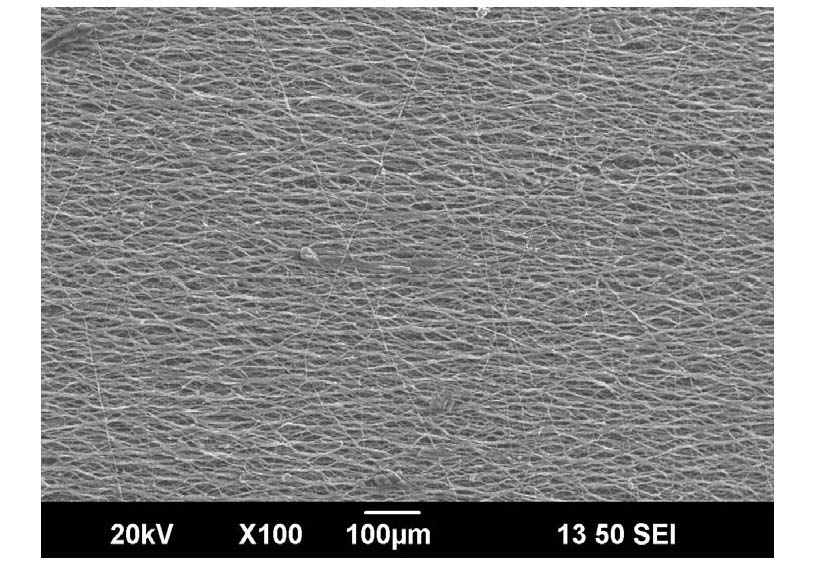

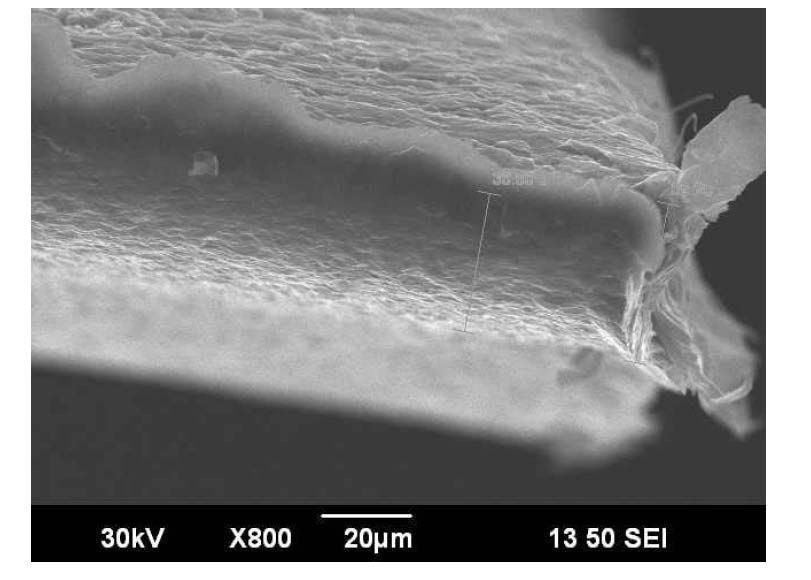

Preparation method for graphite-phase carbon nitride thin film modified electrode

InactiveCN106206773AImprove thermoelectric performanceGreat application potentialFinal product manufactureSemiconductor devicesGas phaseCarbon nitride

The invention discloses a preparation method for a graphite-phase carbon nitride thin film modified electrode. The preparation method comprises the steps of heating a carbon nitride raw material in protective atmosphere at a temperature of 450-550 DEG C for 1min-6h firstly to gasify the carbon nitride raw material, and enabling the gasified carbon nitride raw material to be attached to the surface of a heat-resistant carrier to form a carbon nitride precursor; and then heating the heat-resistant carrier which is adhered by the carbon nitride precursor at a temperature of 500-550 DEG C for 1min-6h to gasify the carbon nitride precursor and to form a graphite-phase carbon nitride thin film with thickness of 10-150nm on the surface of a conductive substrate, and obtaining the modified electrode. According to the preparation method, a vapor deposition method is adopted to modify the graphite-phase carbon nitride thin film on the surface of the conductive substrate, thereby improving the thermoelectric property of the electrode, the uniformity and the stability of the carbon nitride thin film.

Owner:HUAZHONG UNIV OF SCI & TECH

Method for preparing conductive polymer/carbon nanotube composite fiber thermoelectric material

ActiveCN102593342AImprove thermoelectric performanceClosely arrangedThermoelectric device junction materialsFiberThermoelectric materials

The invention provides a method for preparing a conductive polymer / carbon nanotube composite fiber thermoelectric material. The method comprises the following technical processes of: doping conductive polymer monomers with carbon nanotubes, and adsorbing and polymerizing along the surfaces of the carbon tubes; promoting adsorption growth of the polymer by taking the surfaces of the carbon tubes as templates; and depositing the polymer / carbon nanotube composite fiber thermoelectric material of which molecular chains are in orientation arrangement by employing an electrospinning method. By the method, the orientation arrangement of carbon nanotube composite fibers is induced by the electrospinning method by means of inherent anisotropy of magnetoelectric dipole moment of the carbon nanotubes so as to deposit the polymer / carbon nanotube composite fibers of which the molecular chains are in orientation arrangement. The method is simple in conditions, high in controllability, low in production cost and suitable for batch production of the conductive polymer / carbon nanotube composite fiber thermoelectric material.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI +1

SnSe-based thermoelectric material and preparation method thereof

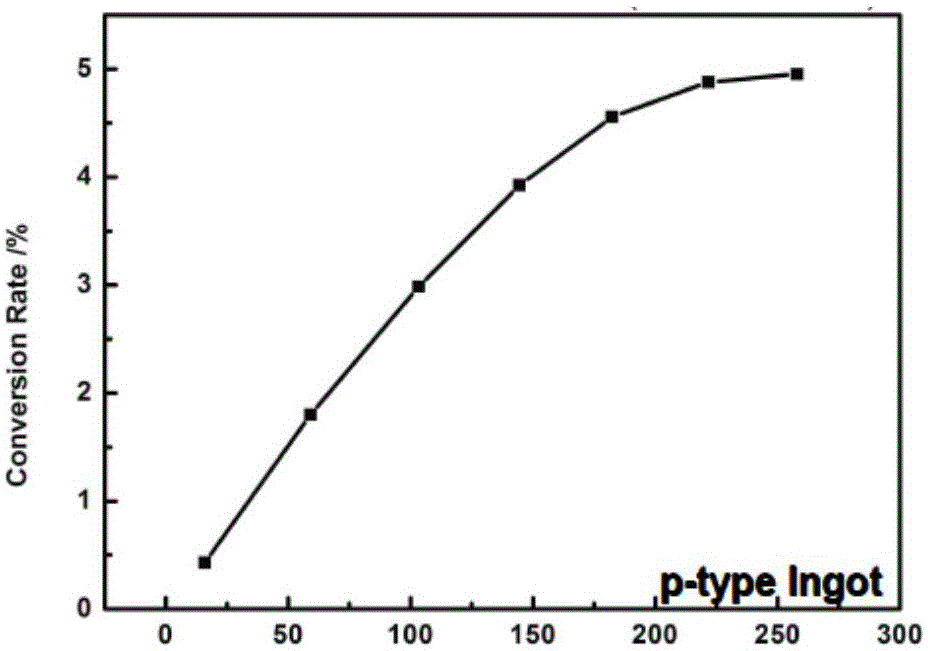

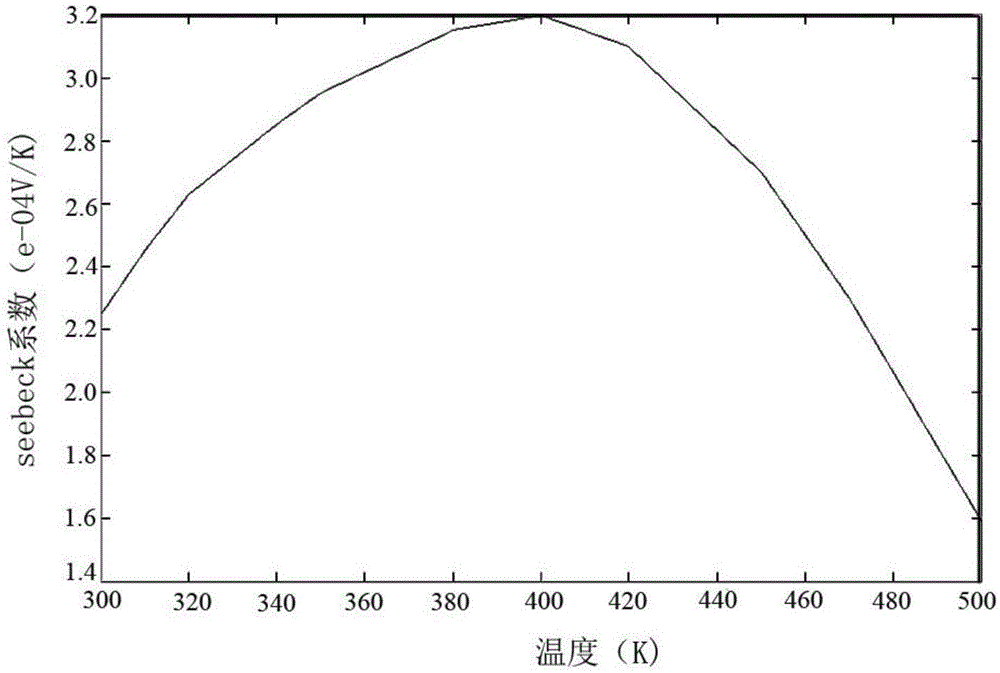

ActiveCN105047809AEasy to prepareShorten the growth cyclePolycrystalline material growthThermoelectric device manufacture/treatmentZone meltingIngot

The invention discloses an SnSe-based thermoelectric material and a preparation method thereof. The preparation method includes steps: S100 weighing reaction raw material according to the stoichiometric ratio of the SnSe-based thermoelectric material; S200 refining the reaction raw material through a melt-refining process to obtain SnSe-based thermoelectric material ingots; and S300 placing SnSe-based thermoelectric material ingots obtained from the S200 in a zone smelting furnace and growing polycrystalline SnSe-based thermoelectric material through a zone melting method. The SnSe-based thermoelectric material obtained through the method is preferential and has better thermoelectric performance. Compared with a method for preparing monocrystalline SnSe-based thermoelectric material, the method is simple and is short in growth period, low in cost, and suitable for mass industrial production.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

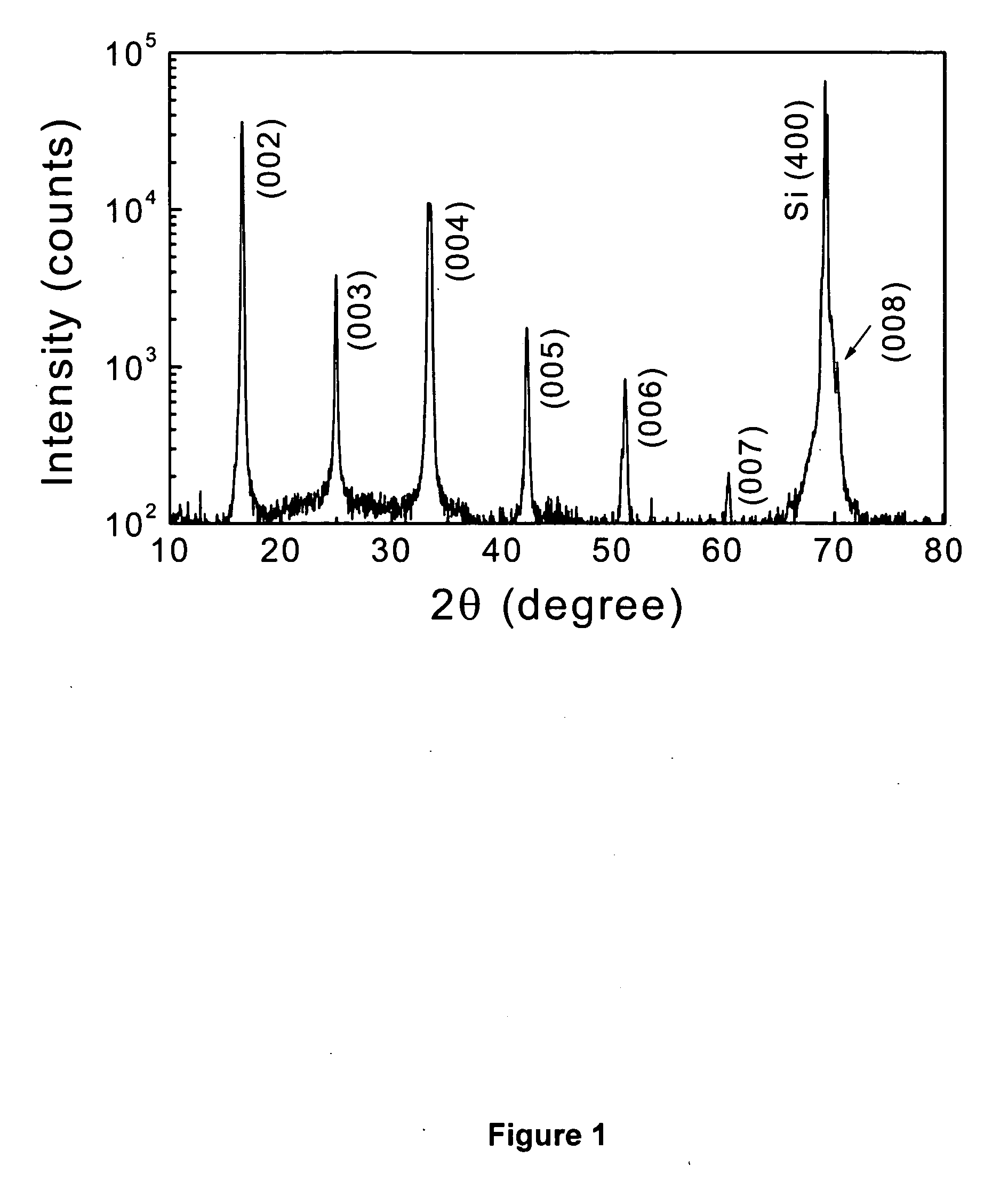

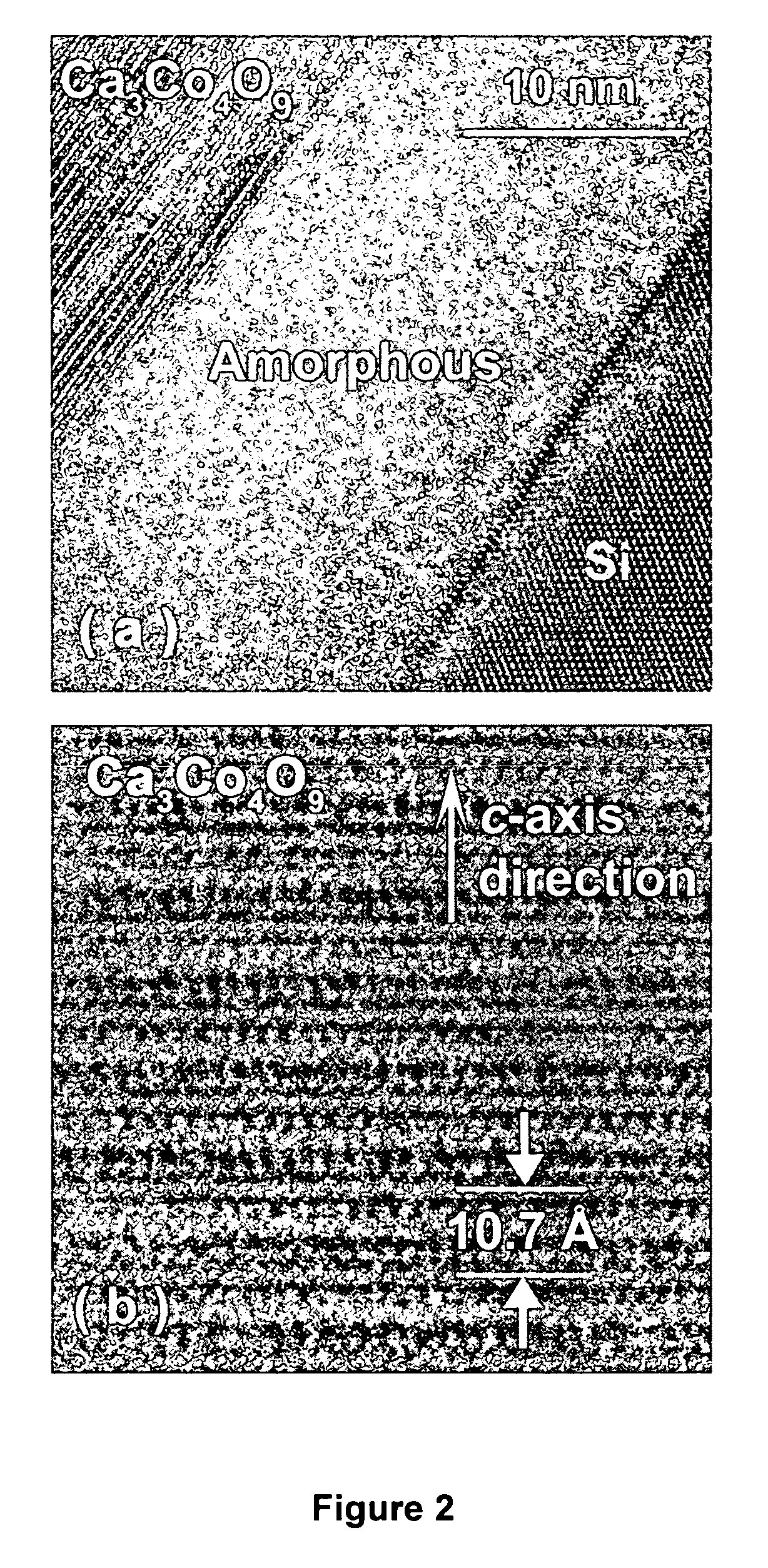

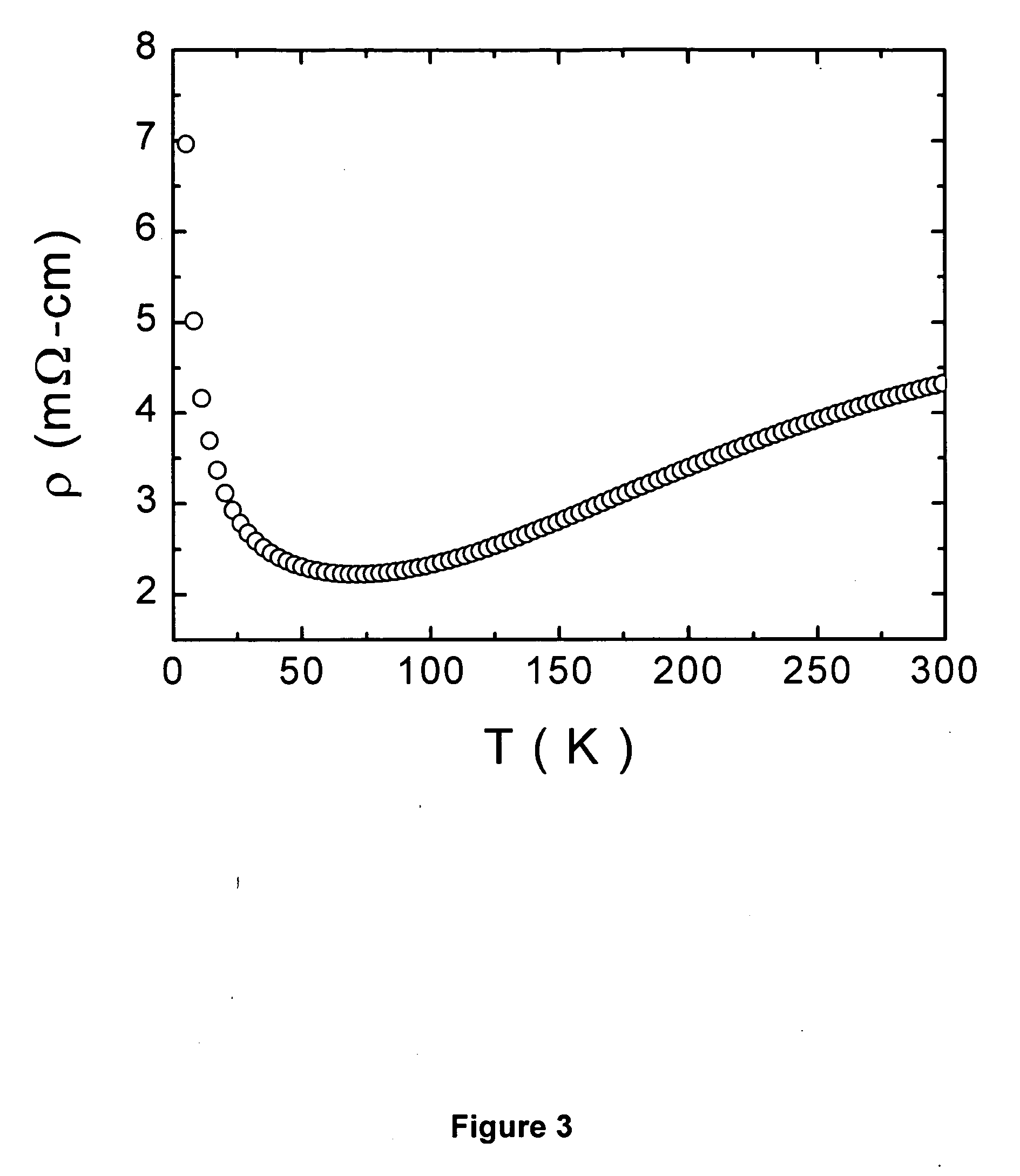

Cobalt oxide thermoelectric compositions and uses thereof

InactiveUS20070039641A1Improve thermoelectric performanceEasy to integrateThermoelectric device junction materialsSiliconMaterials science

Owner:PENTEL OF AMERICA +1

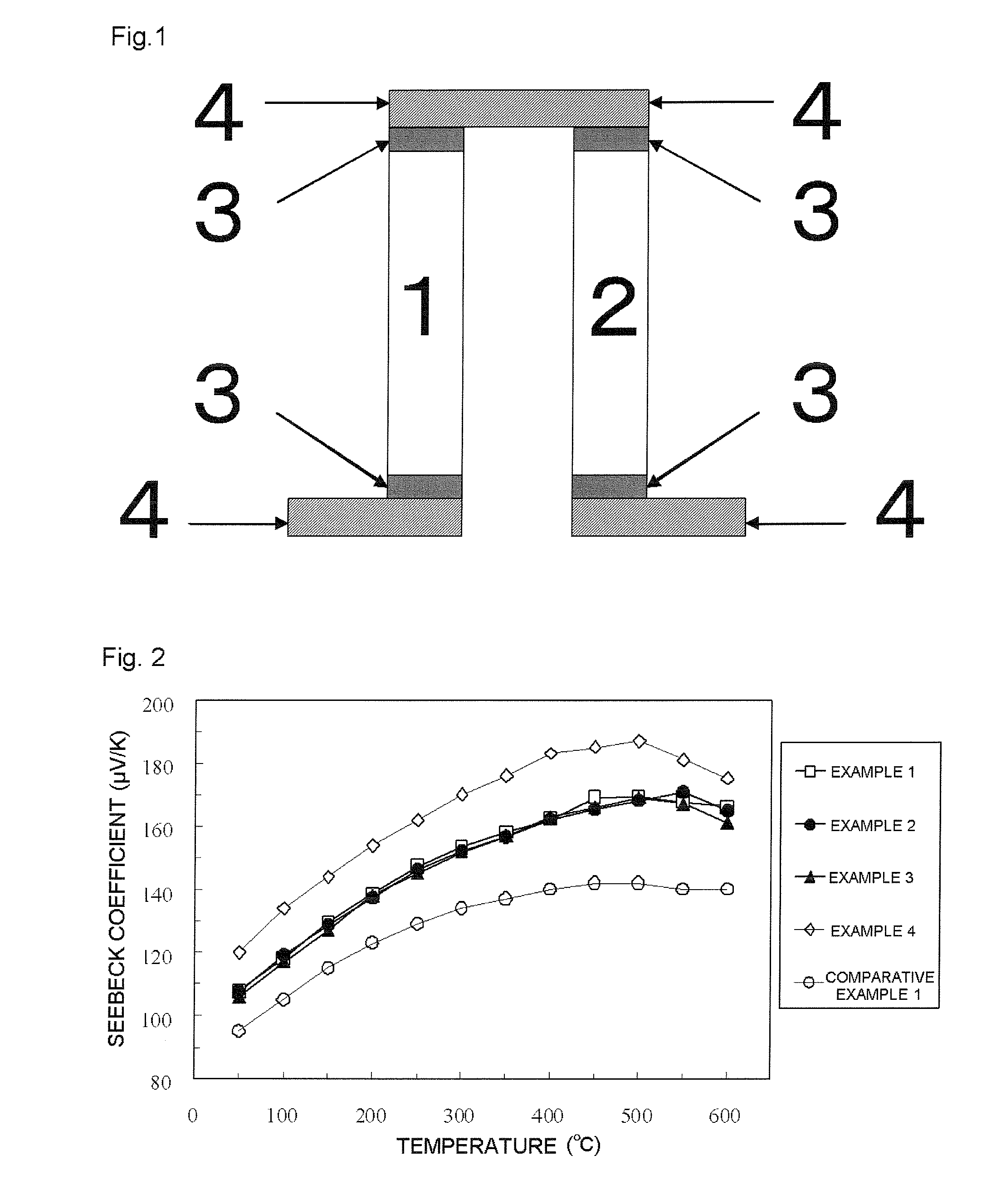

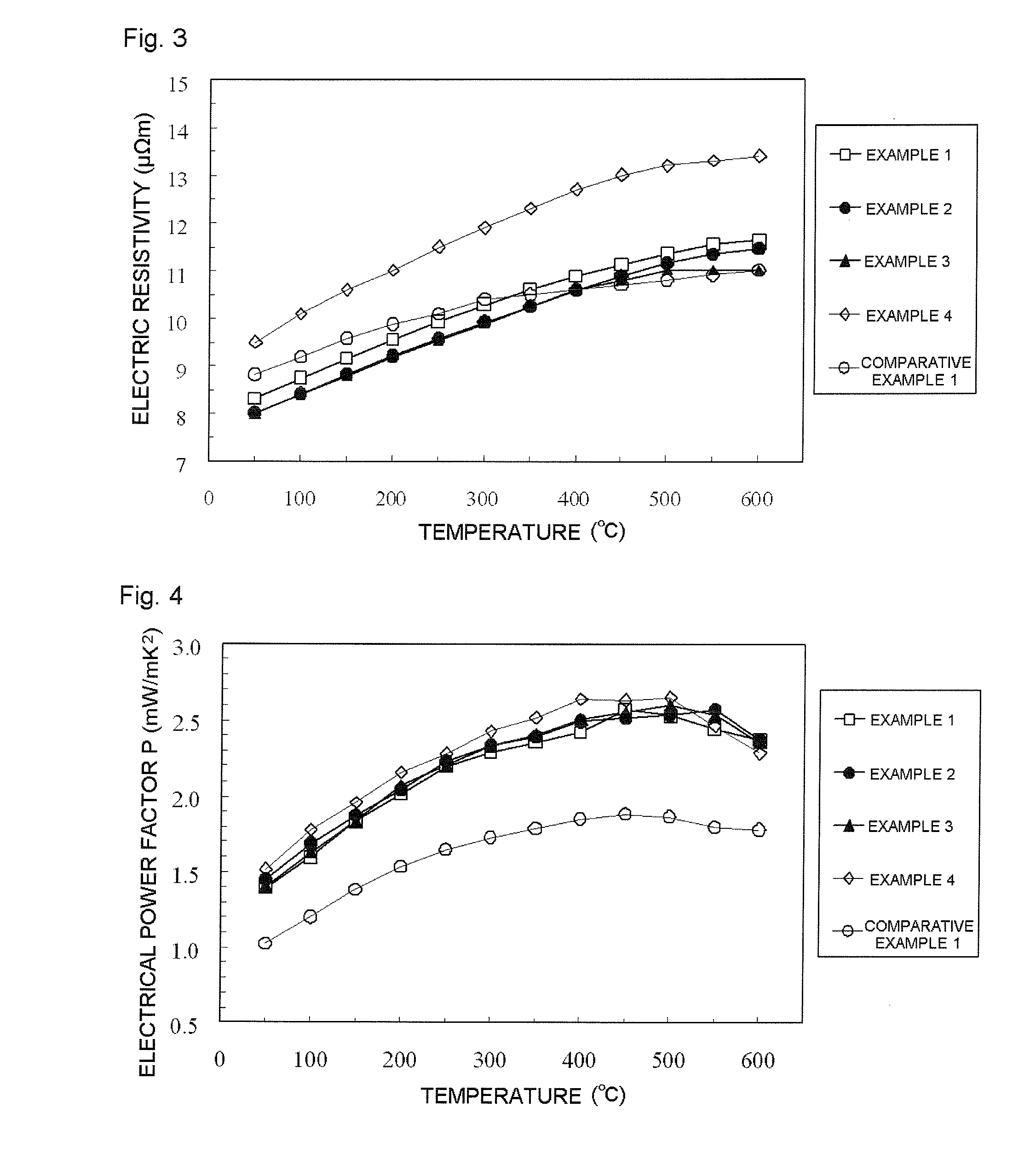

Thermoelectric conversion material, thermoelectric conversion element using the material, and electric power generation method and cooling method using the element

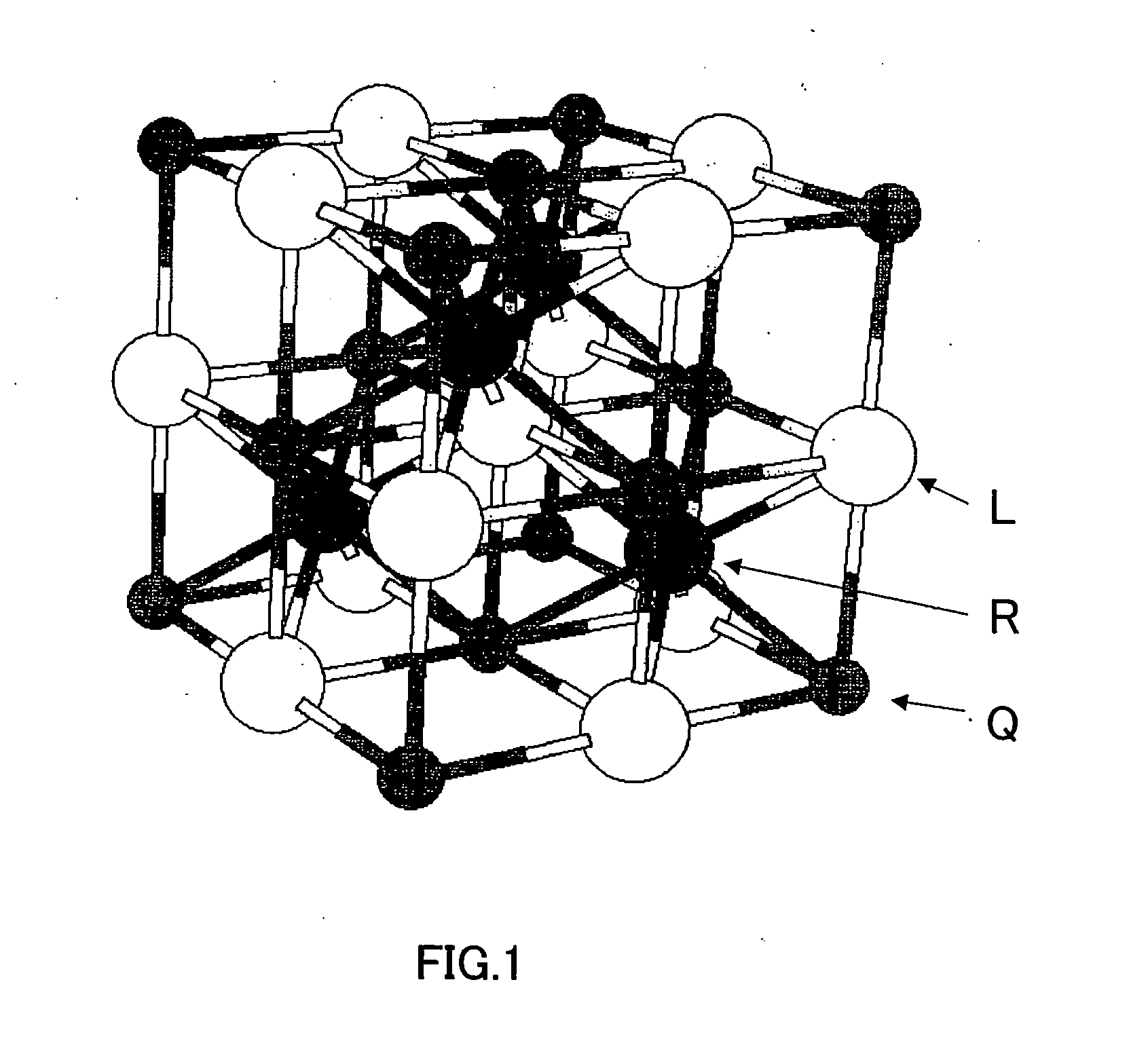

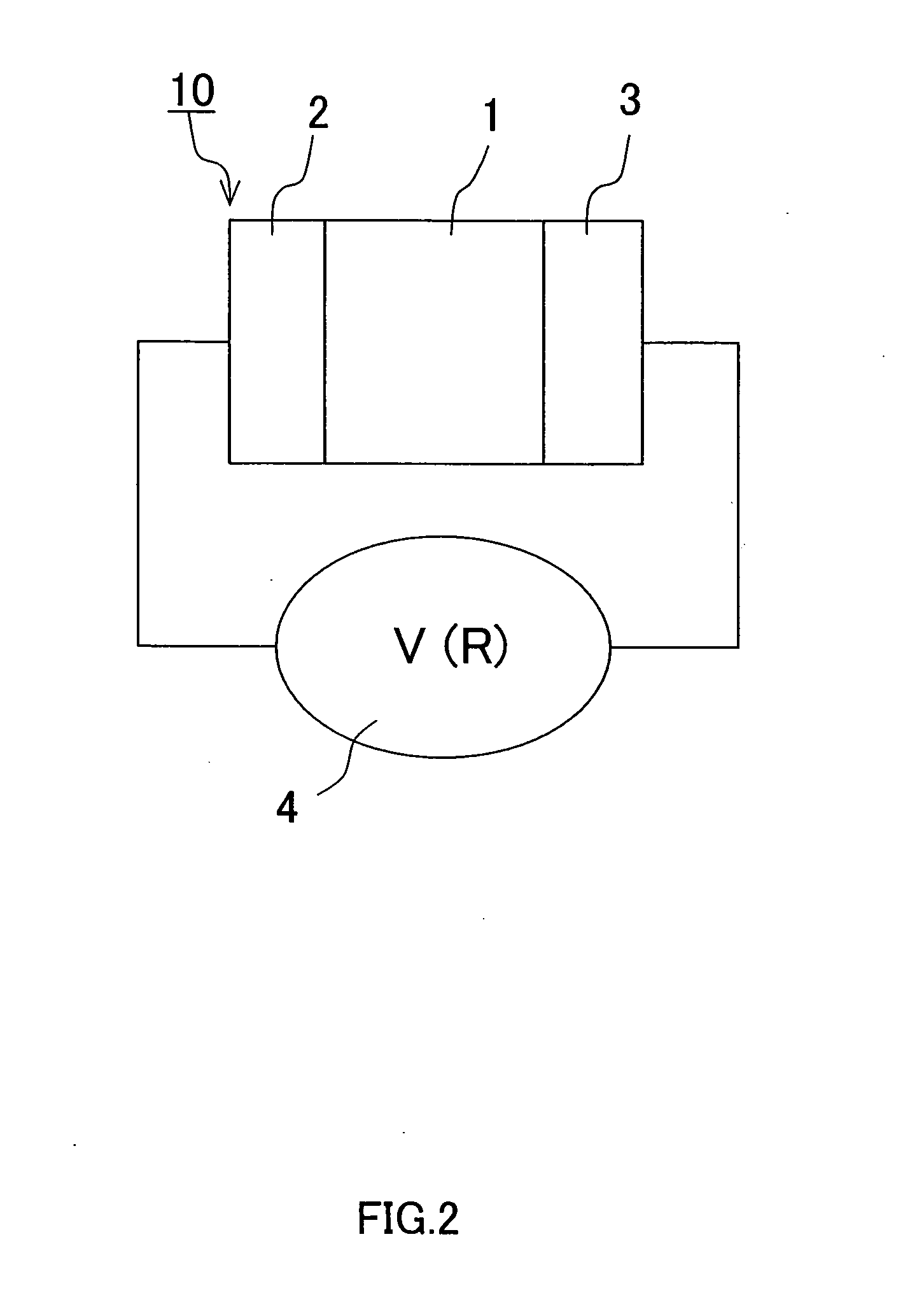

InactiveUS20040261833A1Improve featuresImprove thermoelectric performanceThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentIridiumIndium

The present invention provides a thermoelectric conversion material including a half-Heusler alloy represented by the formula QR(L1-pZp), where Q is at least one element selected from group 5 elements, R is at least one element selected from cobalt, rhodium and iridium, L is at least one element selected from tin and germanium, Z is at least one element selected from indium and antimony, p is a numerical value that is equal to or greater than 0 and less than 0.5. A preferable example of the half-Heusler alloy is NbCo(Sn1-pSbp). The thermoelectric conversion material according to the present invention is n-type, and therefore, it is desired that the material is combined with a p-type thermoelectric conversion material to make a thermoelectric conversion element.

Owner:PANASONIC CORP

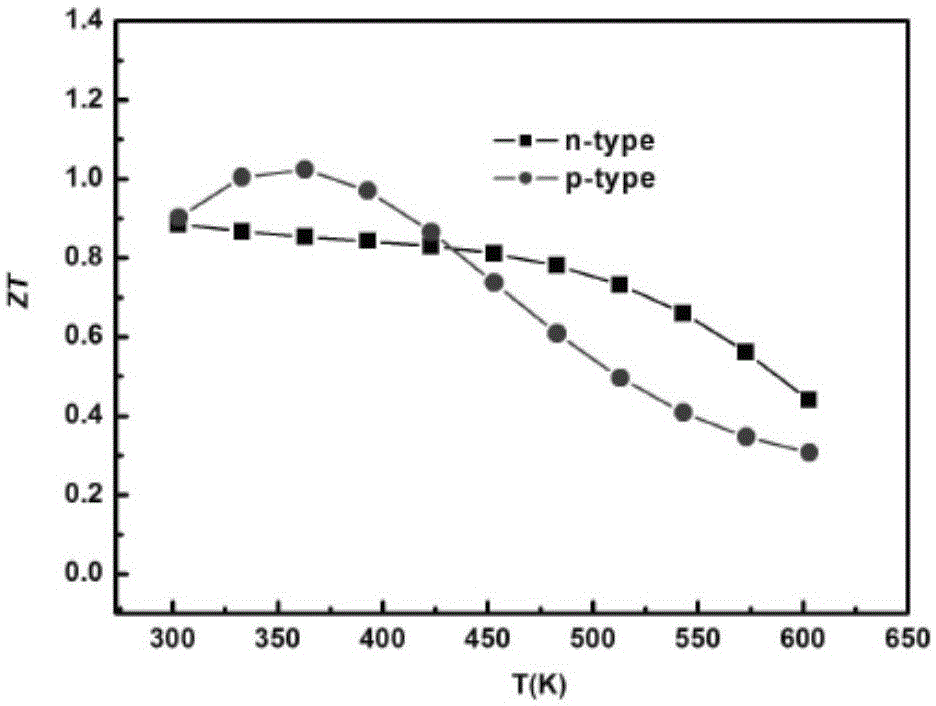

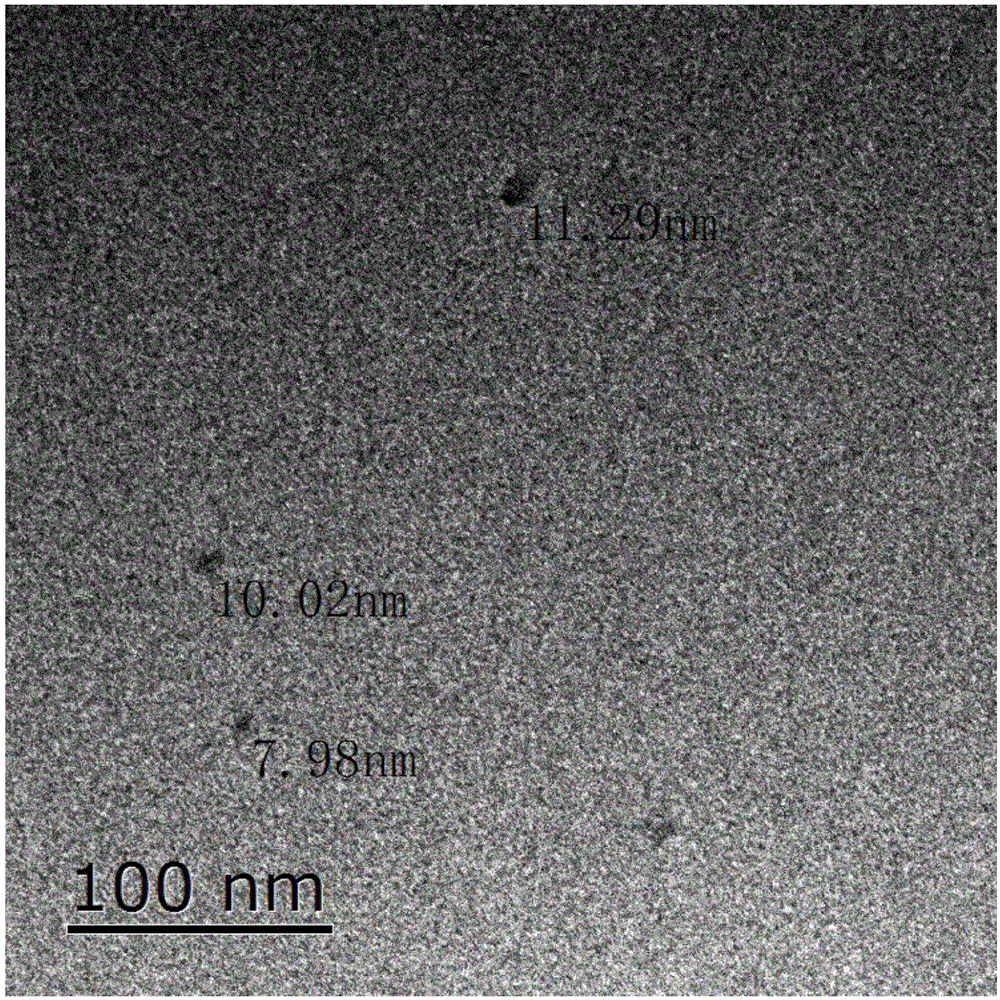

Nanophase doped bismuth telluride-based thermoelectric material and preparation method thereof

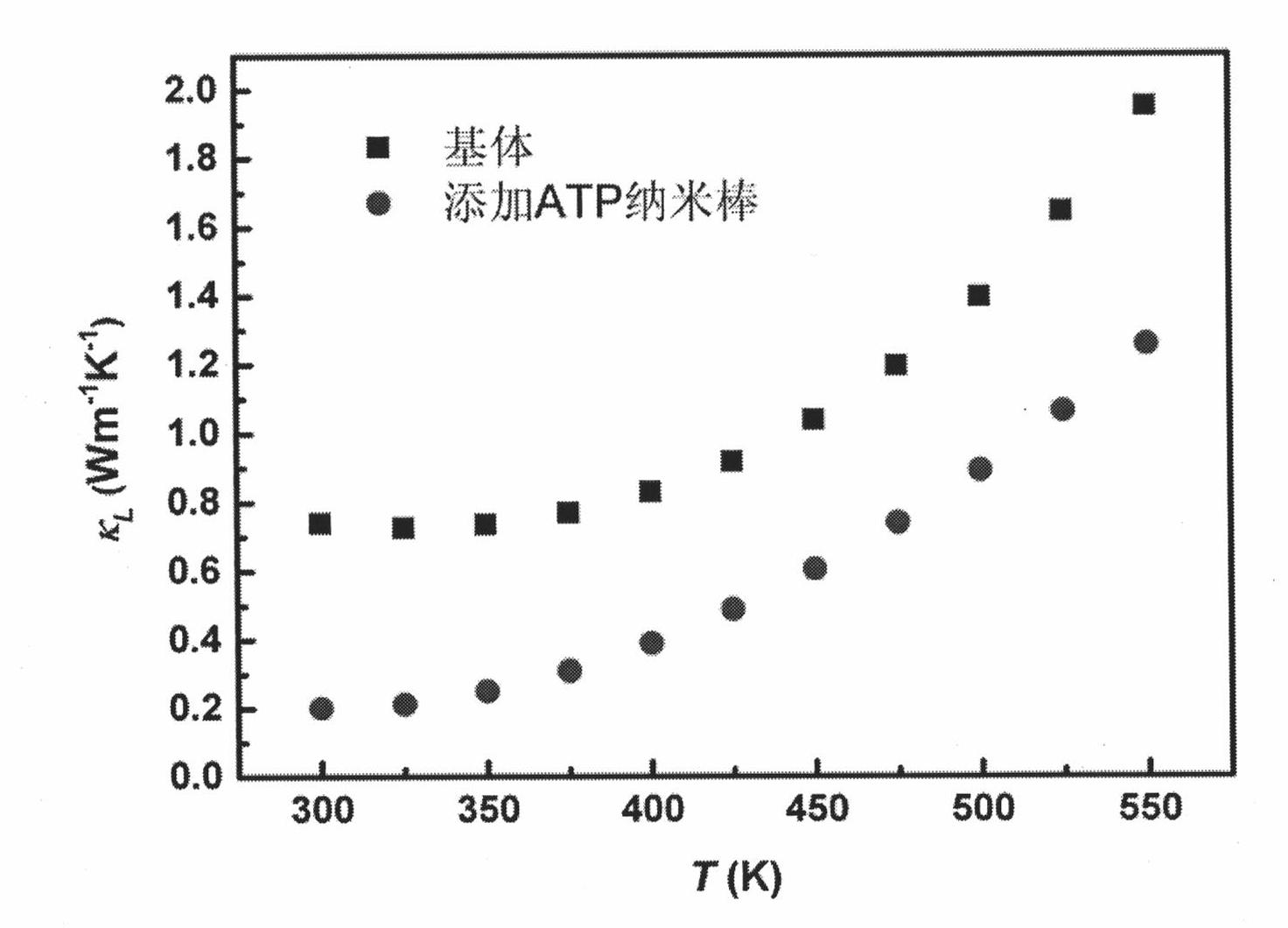

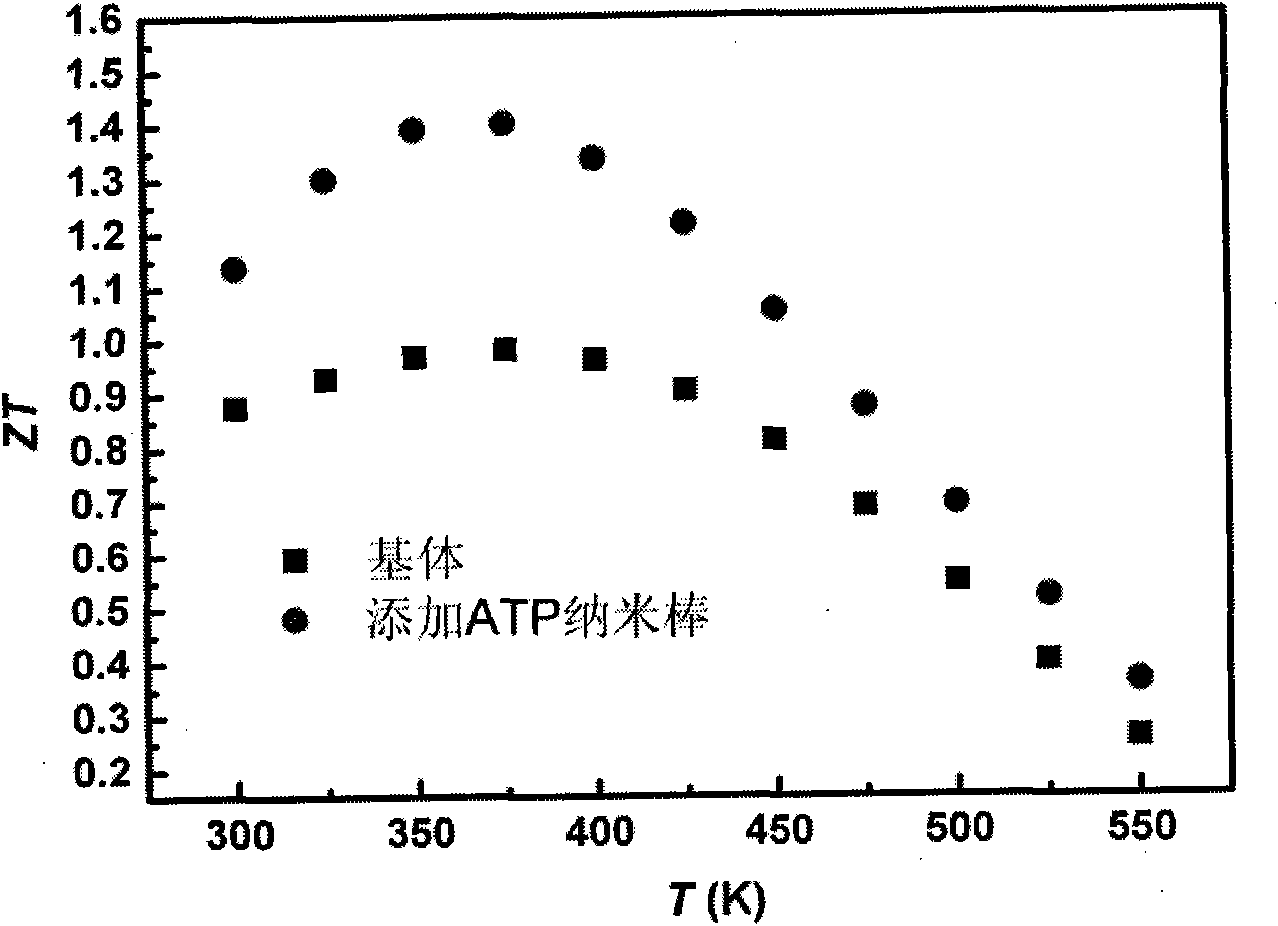

ActiveCN101994155ALower lattice thermal conductivityReduced lattice thermal conductivity κ

<sub>L</sub>Polycrystalline material growthBy zone-melting liquidsBismuth tellurideCarbon nanotube

The invention discloses a nanophase doped bismuth telluride-based thermoelectric material and a preparation method thereof. The bismuth telluride-based thermoelectric material is characterized in taking the bismuth telluride-based thermoelectric material containing a tellurium element, a bismuth element and a doped chemical element, as a matrix. The doped nanophase is a one-dimensional nanophase,and the weight of the one-dimensional nanophase accounts for 0.01-5 percent of the weight of the matrix. Attapulgite or a zinc oxide nanowire or a single-wall carbon nanotube or a multi-wall carbon nanotube is preferable to the one-dimensional nanophase. Compared with the prior art, in the bismuth telluride-based thermoelectric material, the lattice heat conductivity within the whole temperature zone range is reduced, thereby a ZT value is greatly improved and the thermoelectric performance of the bismuth telluride-based thermoelectric material is improved. The preparation method is simple and easy to implement, and compared with other methods of balling milling or liquid phase and the like, impurities are not easy to introduce in the preparation method so that the one-dimensional nanophase is evenly staggered and distributed in the matrix and the mechanical property of the material is effectively improved.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

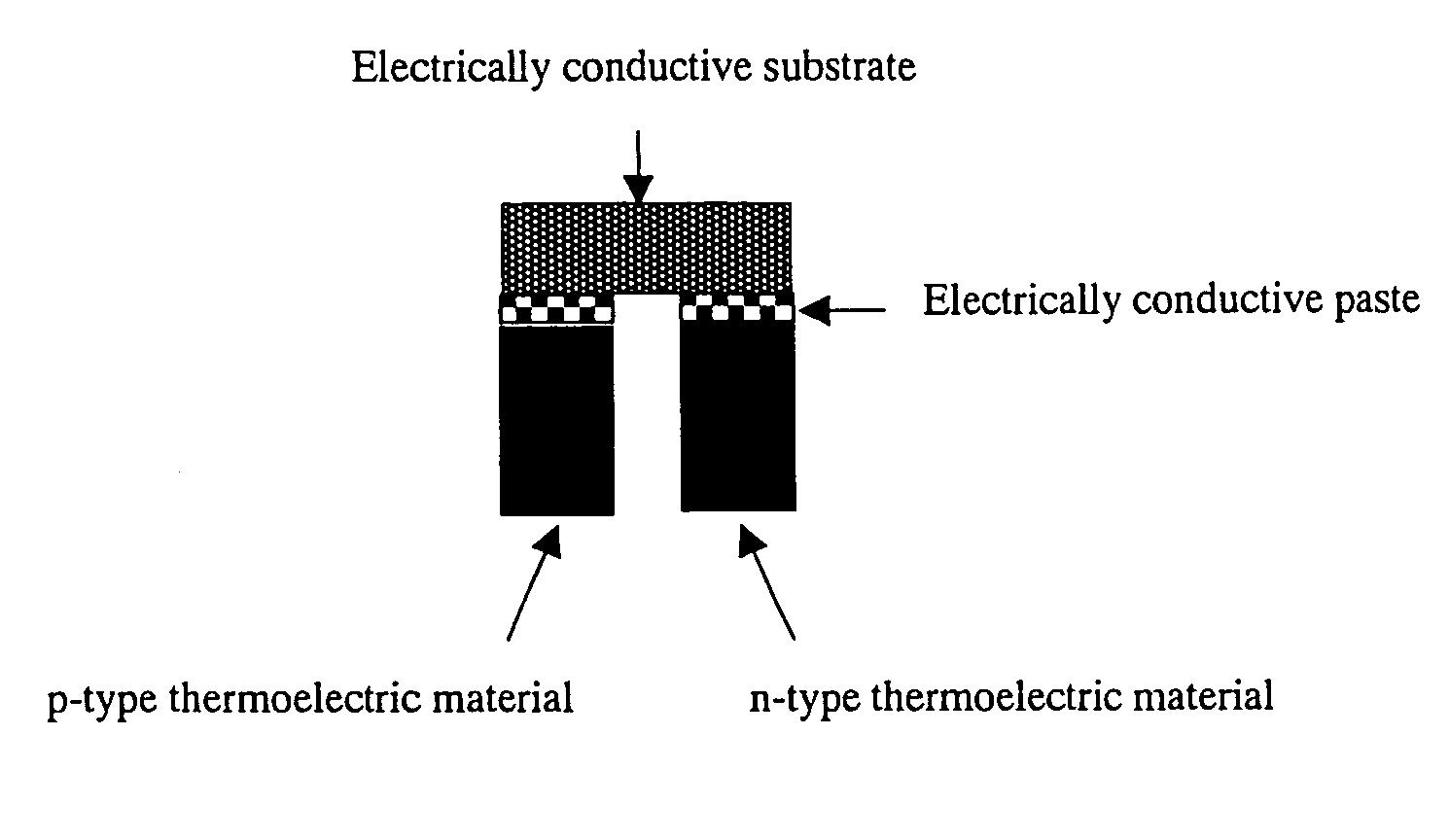

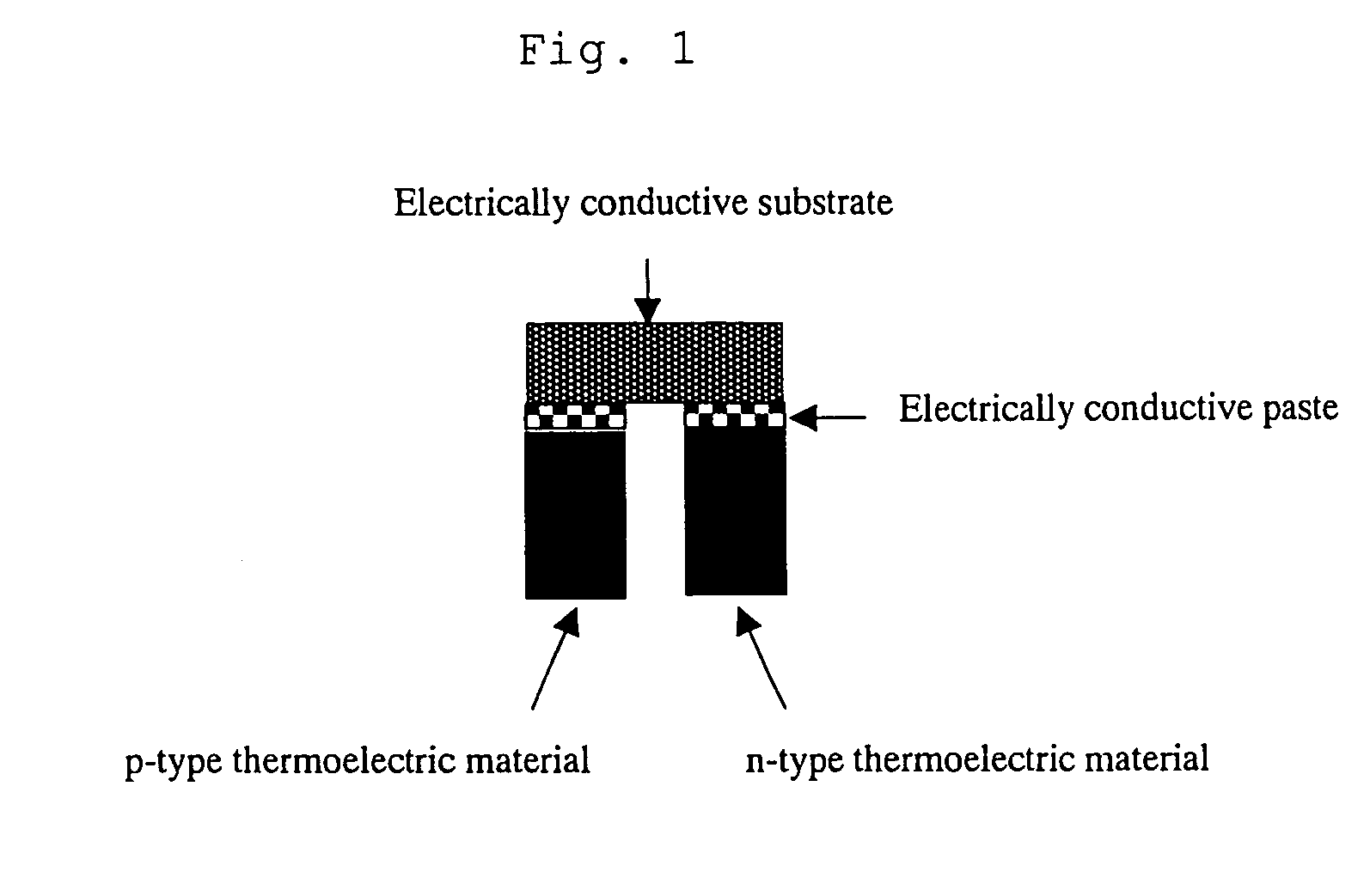

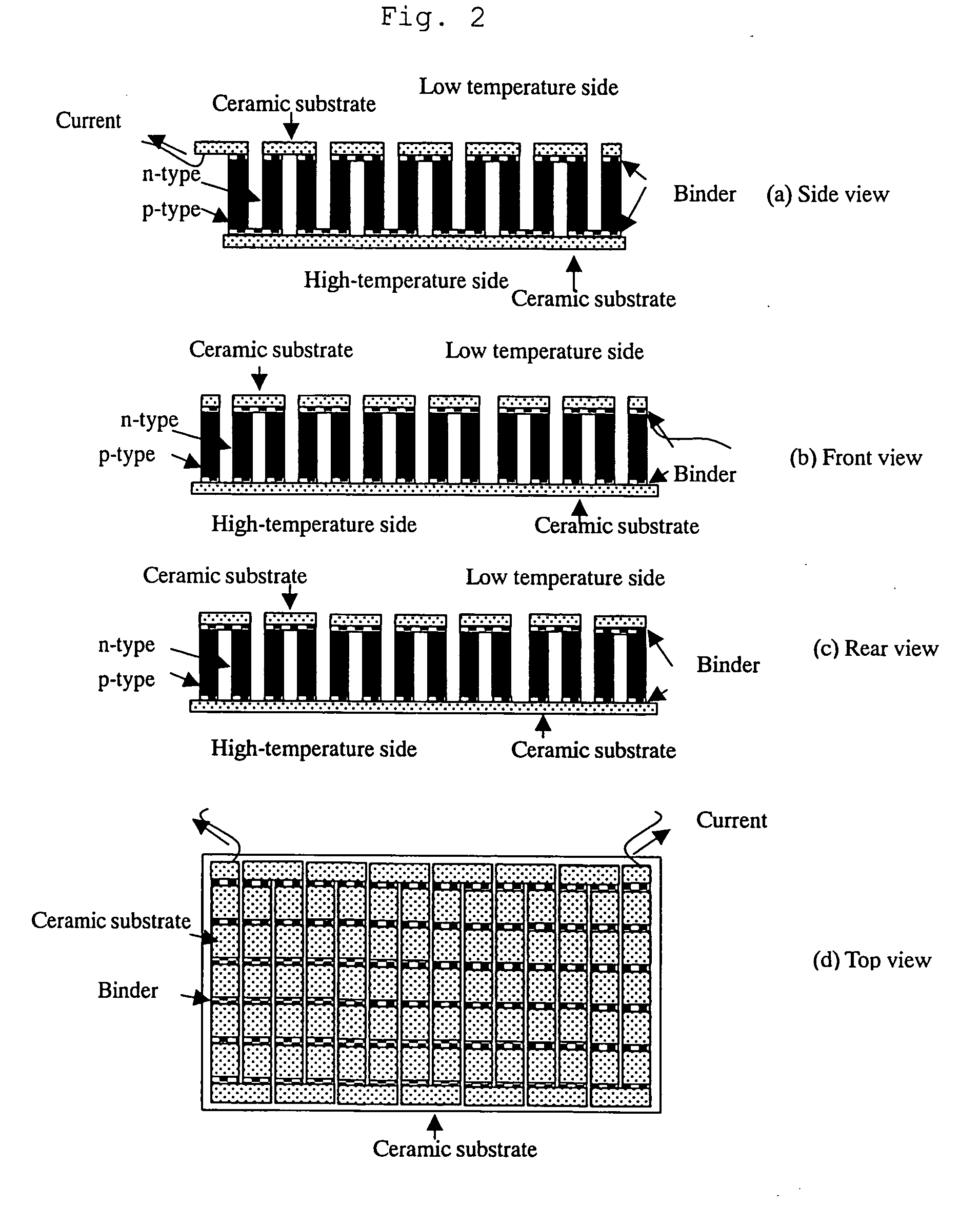

Conductive paste for connecting thermoelectric conversion material

InactiveUS20070125412A1Low electric resistanceHardly performance deteriorationThermoelectric device manufacture/treatmentOxide conductorsElectrically conductiveOxide

The present invention provides an electrically conductive paste for connecting thermoelectric materials, the paste comprising a specific powdery oxide and at least one powdery electrically conductive metal selected from the group consisting of gold, silver, platinum, and alloys containing at least one of these metals. By connecting a thermoelectric material to an electrically conductive substrate with the electrically conductive paste of the invention, a suitable electroconductivity is imparted to the connecting portion of the thermoelectric element. Further, the thermal expansion coefficient of the connecting portion can be made close to that of the thermoelectric material. Therefore, even when high-temperature power generation is repeated, separation at the connecting portion is prevented and a favorable thermoelectric performance can be maintained.

Owner:NAT INST OF ADVANCED IND SCI & TECH

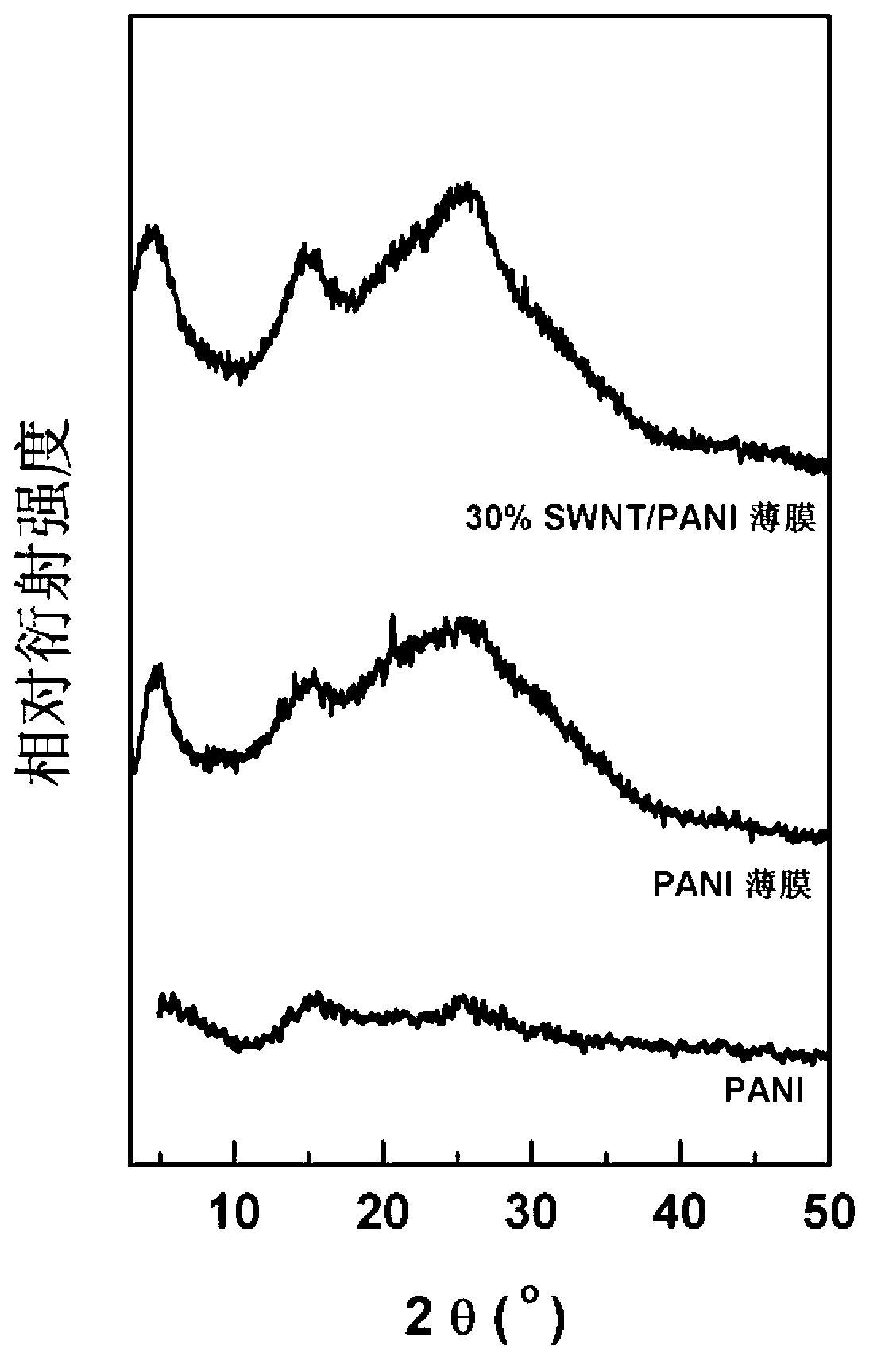

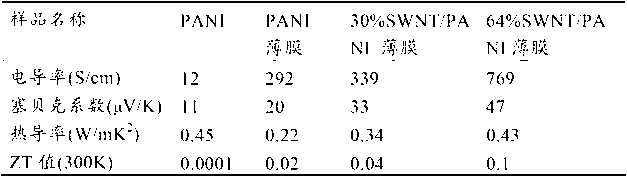

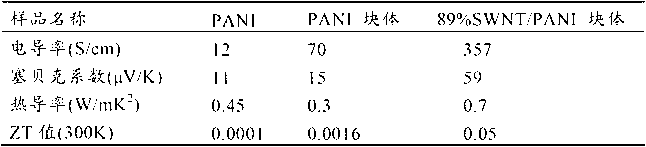

Method for obtaining high-performance polyaniline base thermoelectric materials

ActiveCN103137848AHigh degree of orderDefects to reduce π-π conjugation effectsThermoelectric device junction materialsThermoelectric materialsSolid reaction

The invention discloses a method for obtaining high-performance polyaniline base thermoelectric materials. The method comprises the following steps: (1) mixing polyaniline powder with ammonia water solution, carrying out stir, filter and drying, and obtaining eigen-state polyaniline, (2) mixing the polyaniline with sulfonic acid, carrying out grind, and obtaining polyaniline doped with the sulfonic acid, (3) dissolving the polyaniline doped with the sulfonic acid in phenol solvent, carrying out stirr, and obtaining polyaniline solution, and (4) adding nanocarbon materials in the polyaniline solution, carrying out stir in a full mode, removing the phenol solvent, and obtaining the high-performance polyaniline base thermoelectric materials. According to the method for obtaining the high-performance polyaniline base thermoelectric materials, the order degree of polyaniline molecular chain arrangement is firstly improved through interaction of the phenol solvent and polyaniline molecules, then through composition with the nano carbon composite materials, the order degree of the polyaniline molecular chain arrangement is further enhanced, and the high-performance polyaniline base thermoelectric materials are obtained. Therefore, ZT values of the polyaniline base thermoelectric materials and ZT values of block-shaped materials can be respectively improved by 0.5 and 0.05.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI +1

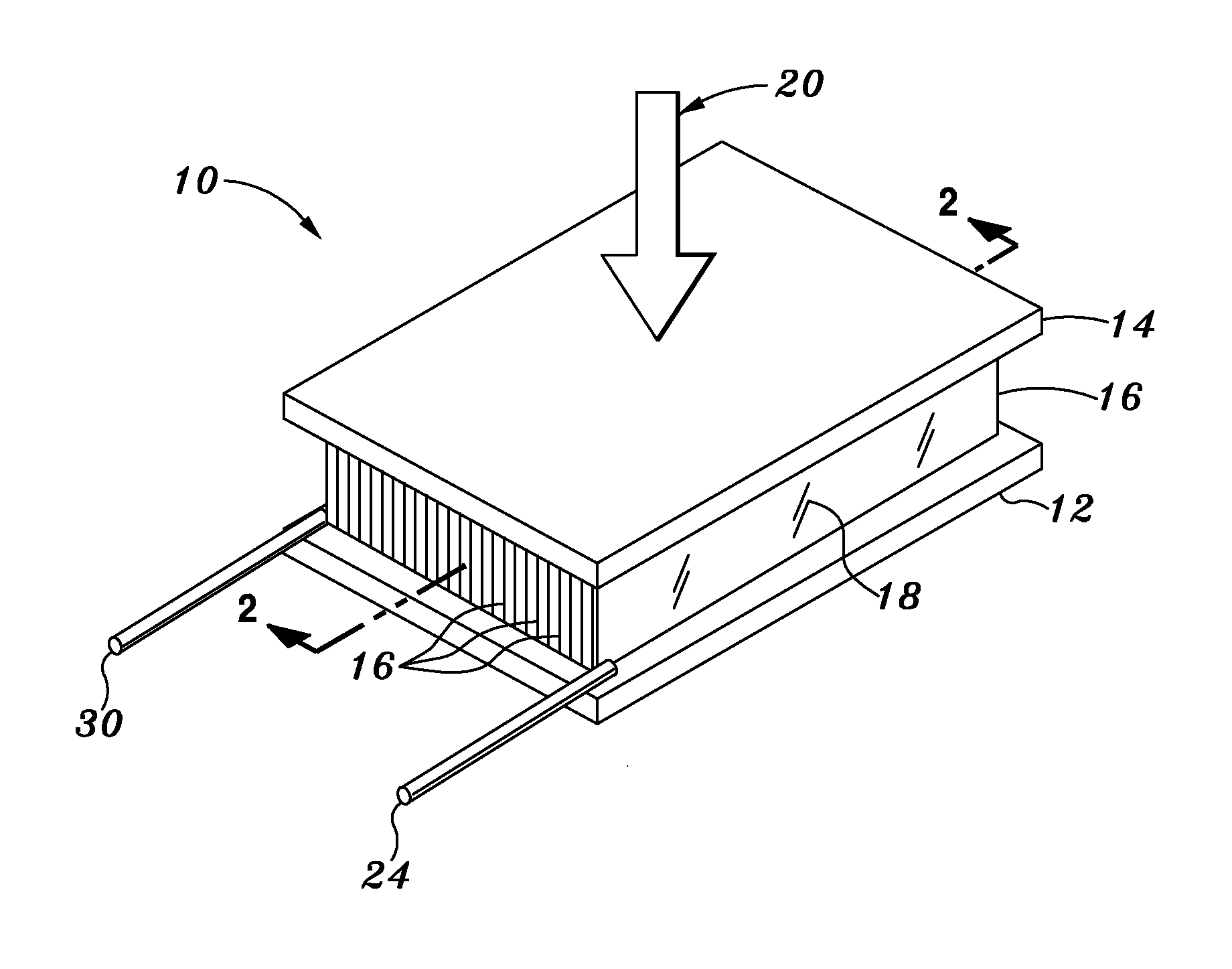

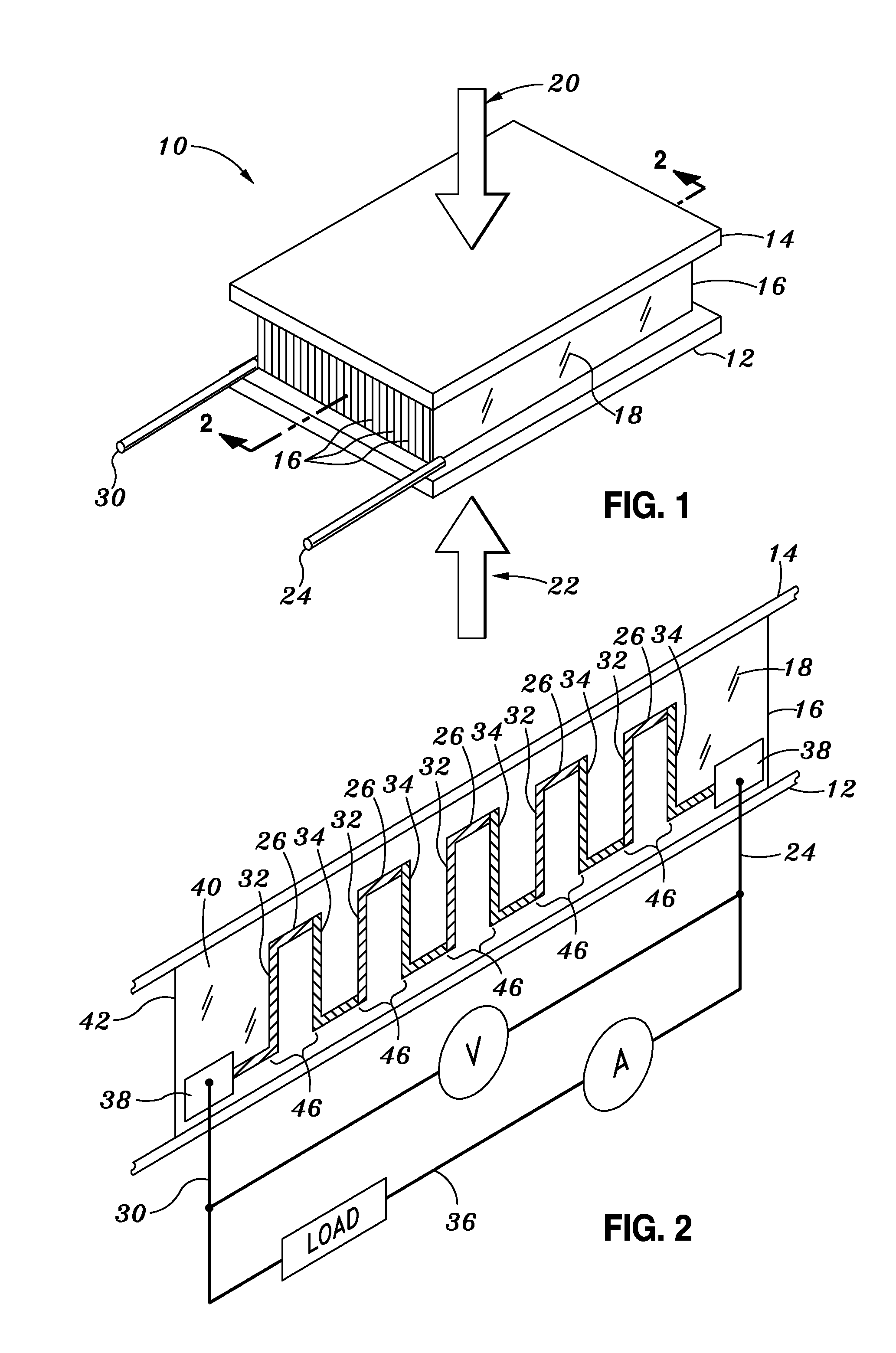

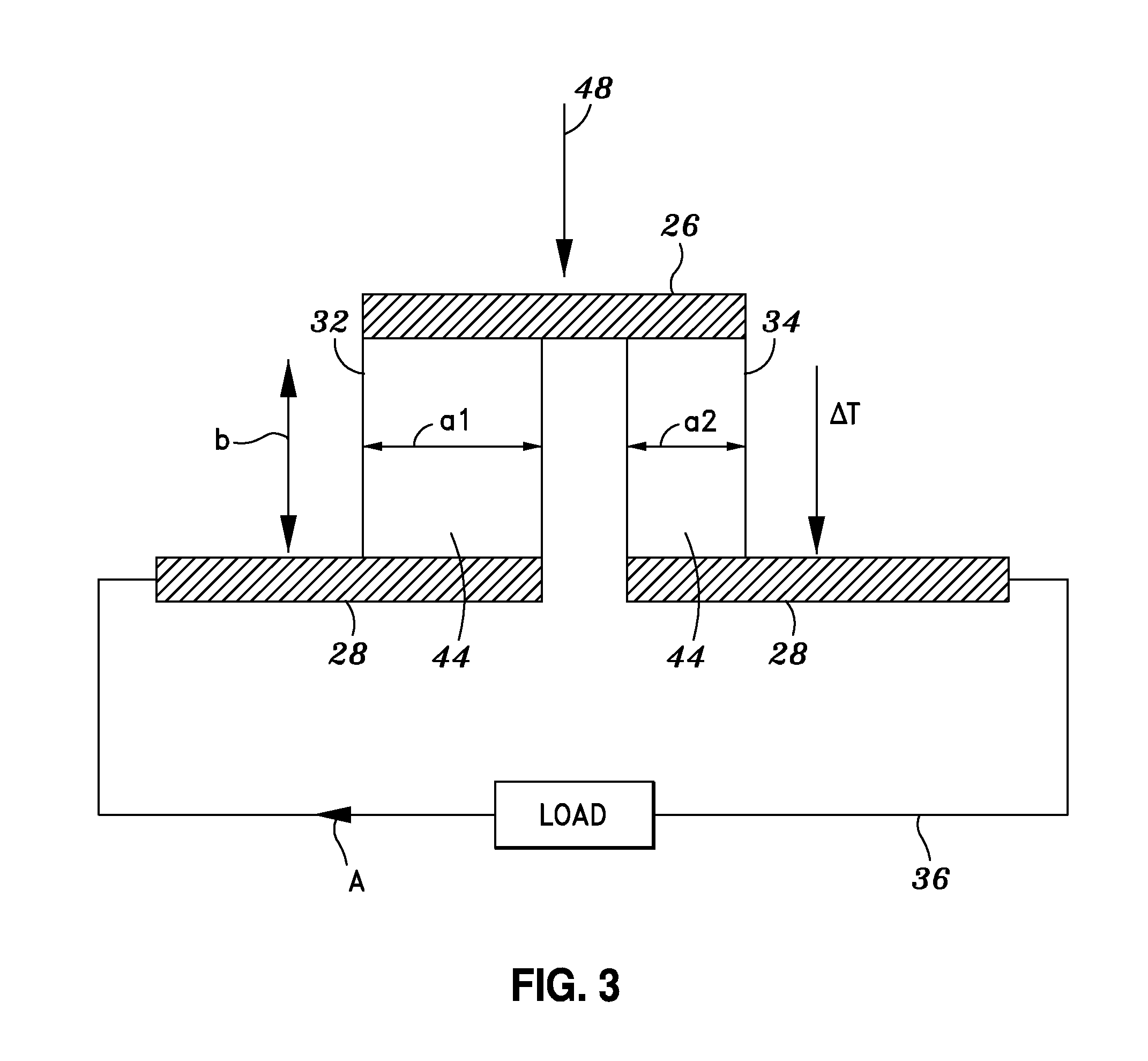

Low power thermoelectric generator

InactiveUS20090025771A1Improve conductivityStrong mechanical connectionThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentBismuth tellurideEngineering

A thermoelectric generator has a top plate disposed in spaced relation above a bottom plate. A series of foil segments are electrically and mechanically connected end-to-end to generate a foil assembly that is spirally wound and in thermal contact with the bottom and top plates. Each foil segment comprises a substrate having a series of spaced alternating n-type and p-type thermoelectric legs disposed in parallel arrangement on the front substrate surface. Each of the n-type and p-type legs is formed of a bismuth telluride-based thermoelectric material having a thickness of about 10-100 microns, a width of about 10-100 microns and a length of about 100-500 microns. The alternating n-type and p-type thermoelectric legs are electrically connected in series and thermally connected in parallel such that a temperature differential between the bottom and top plates results in the generation of power.

Owner:DIGITAL ANGEL CORP

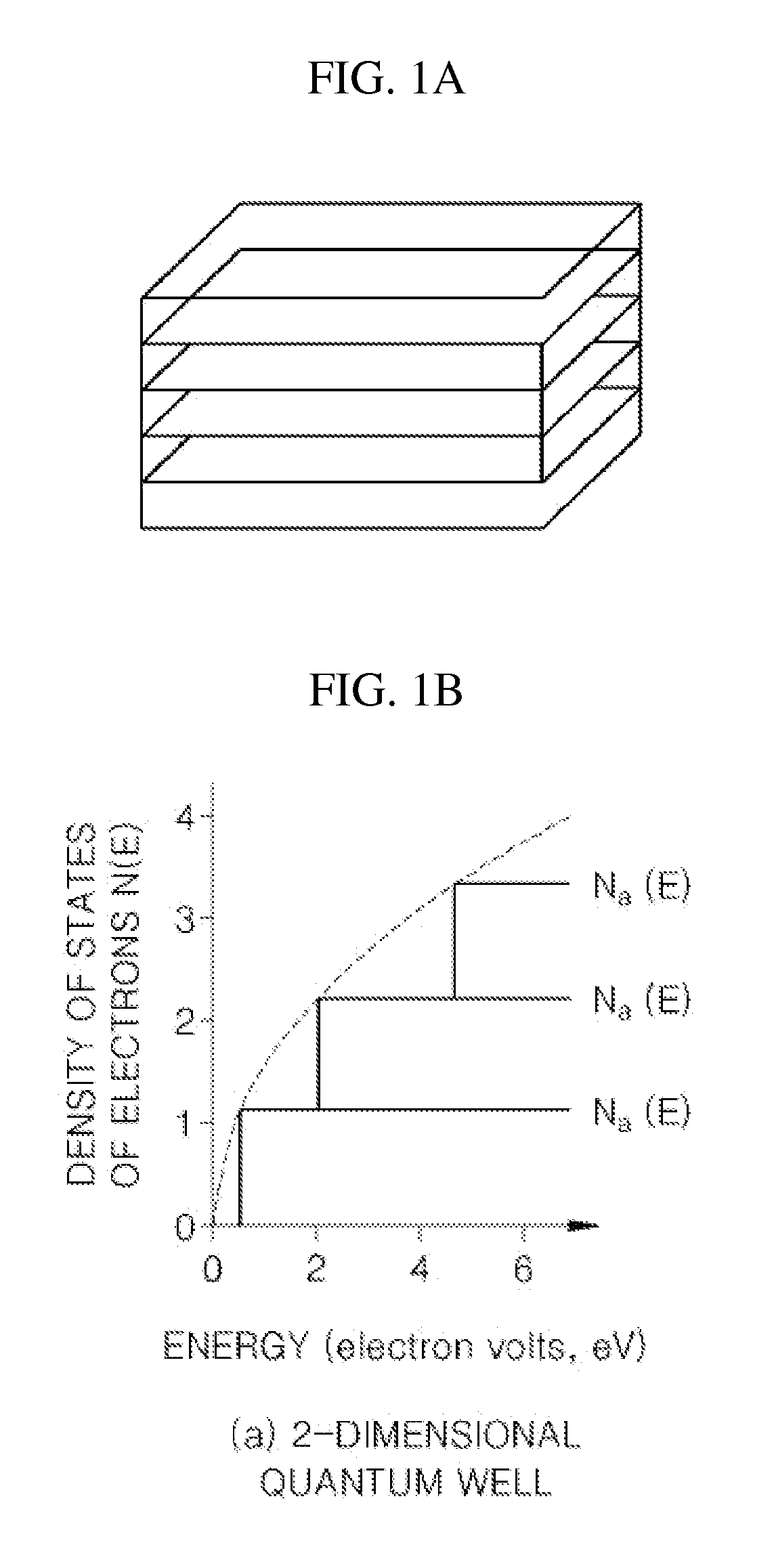

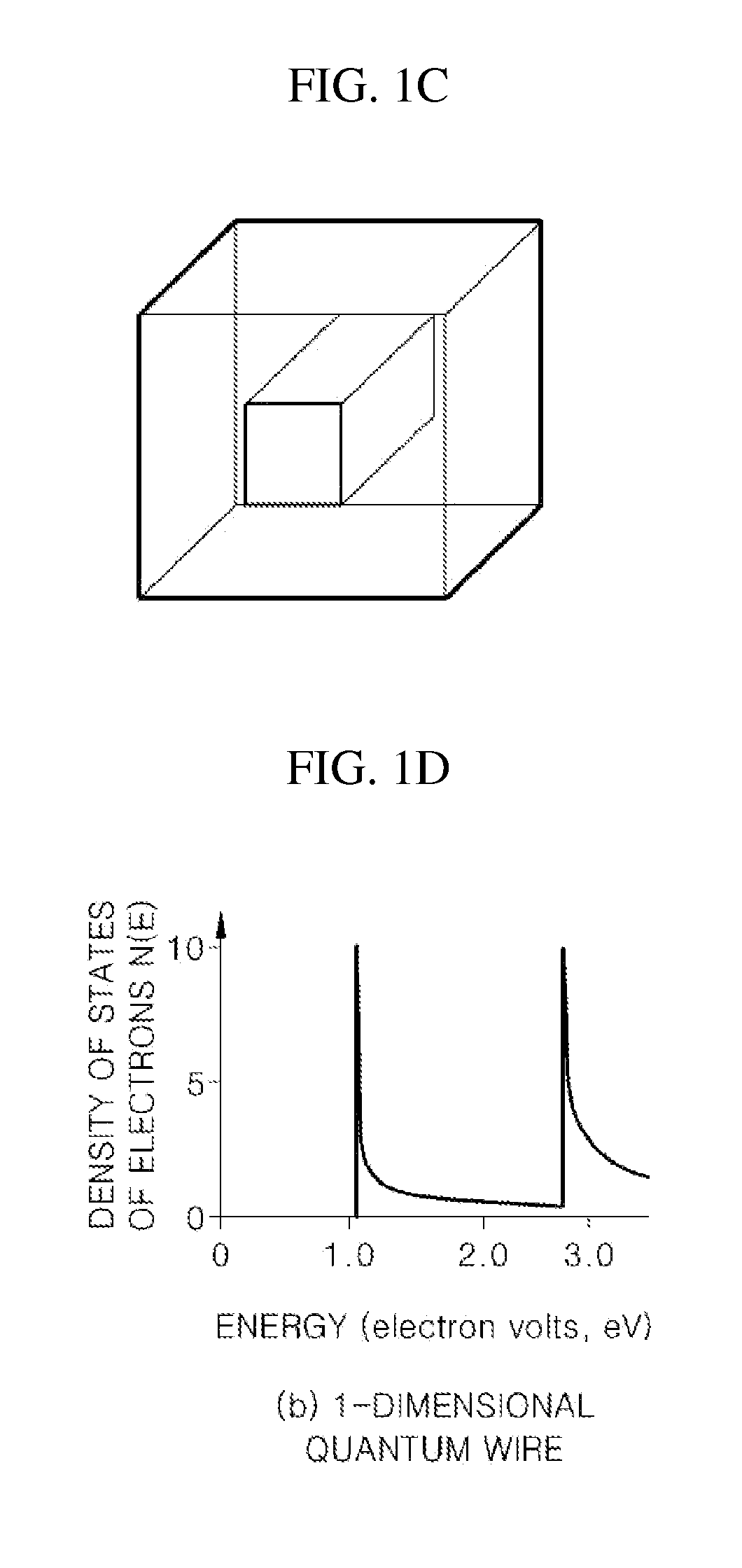

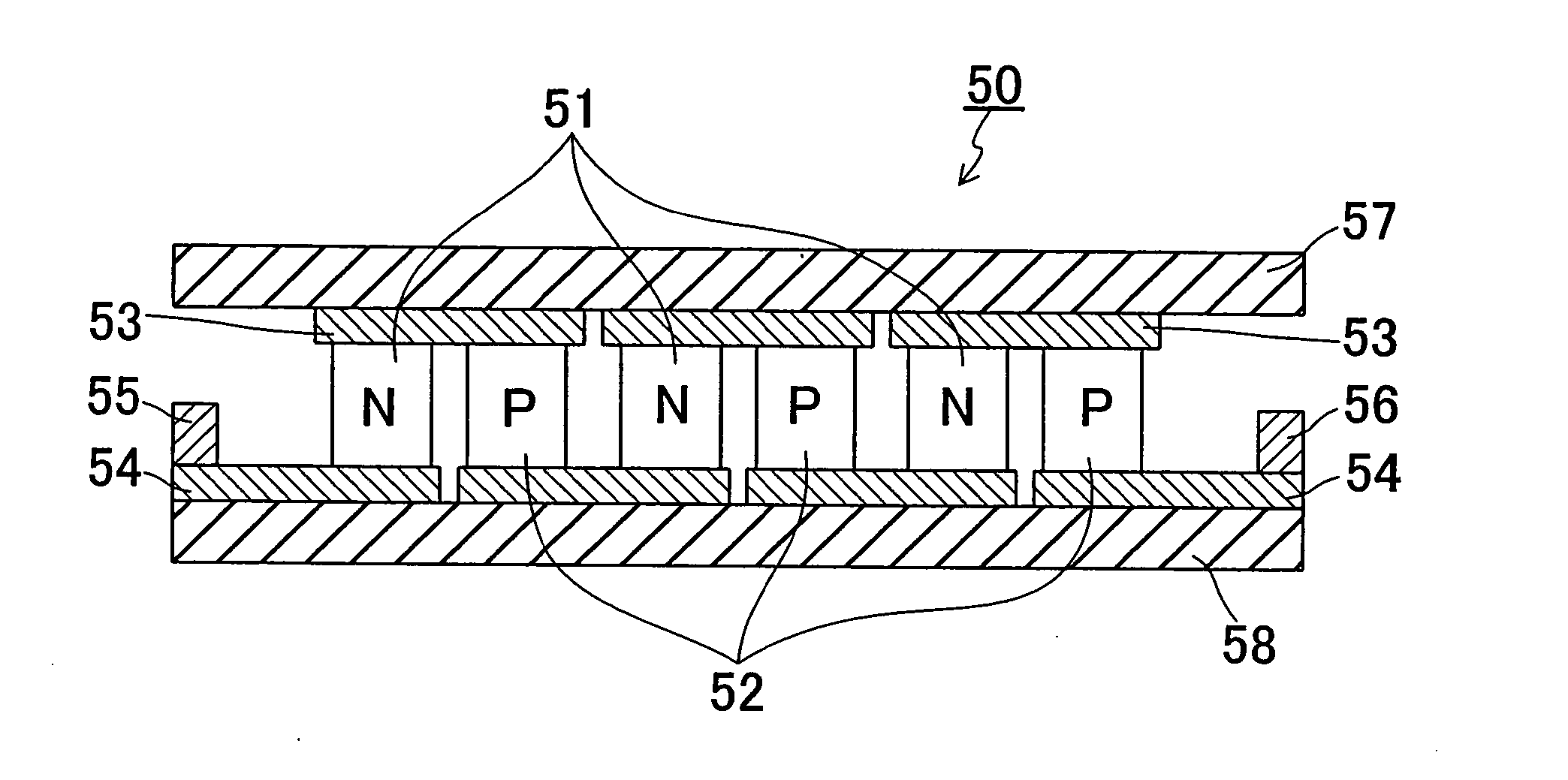

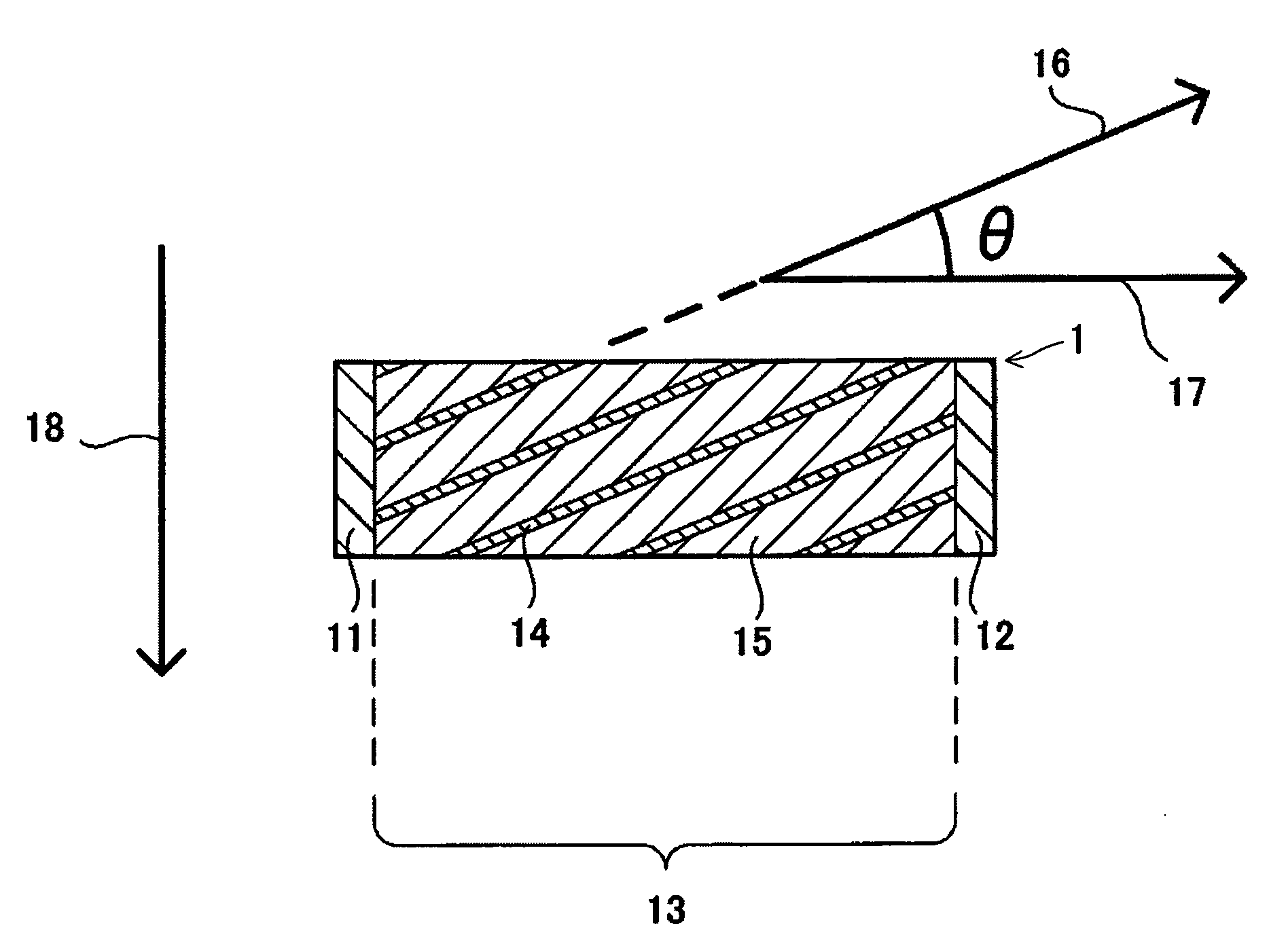

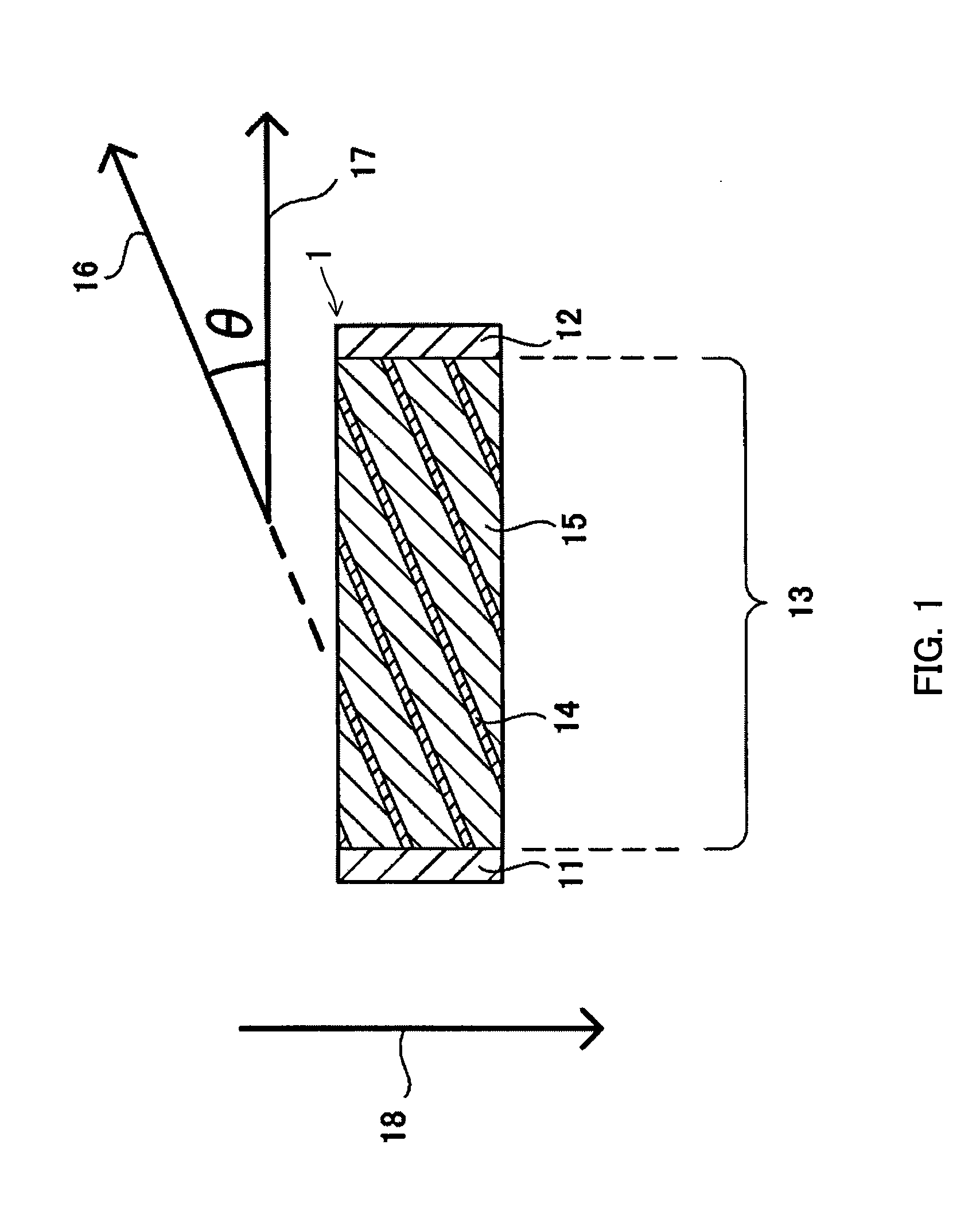

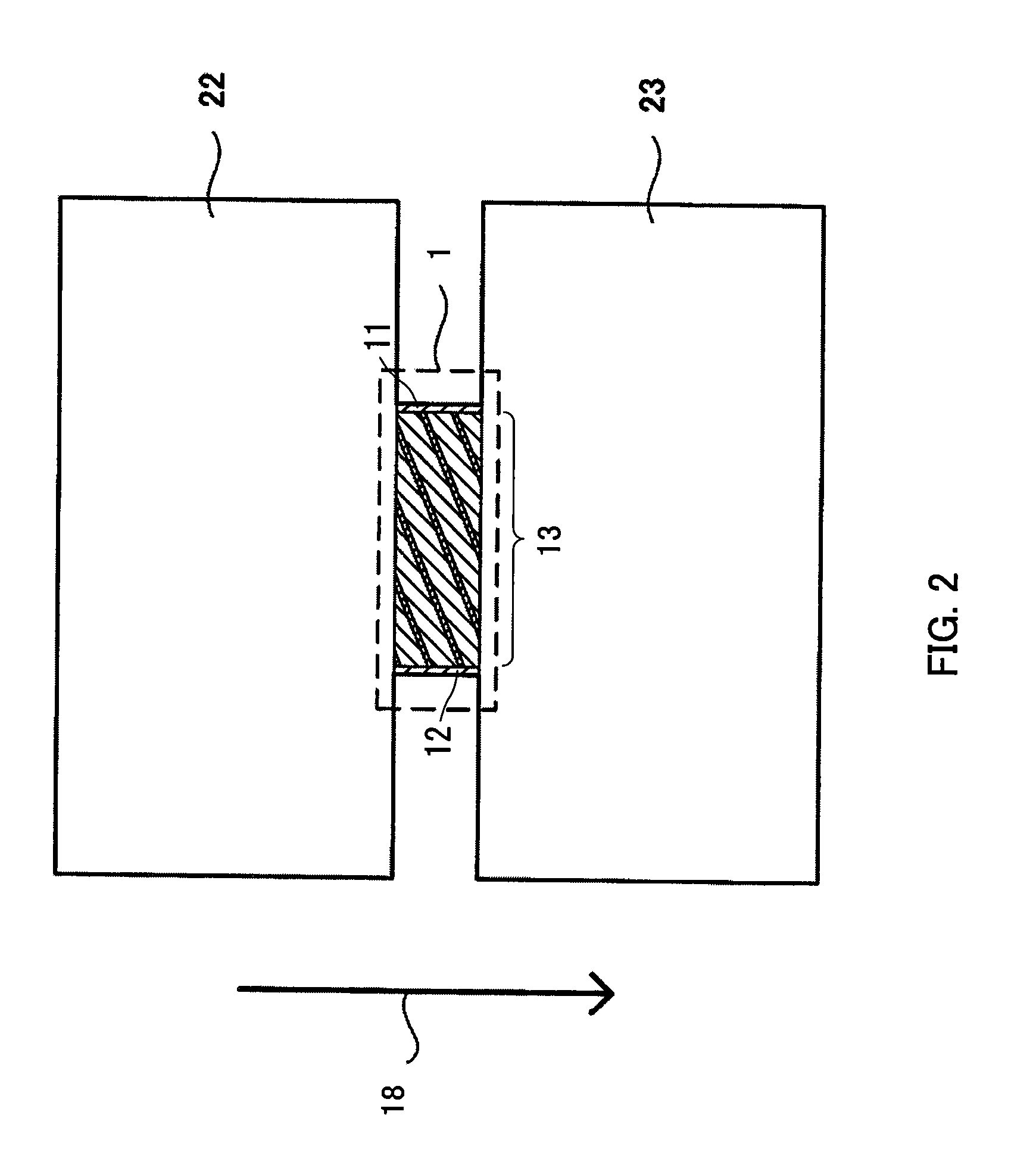

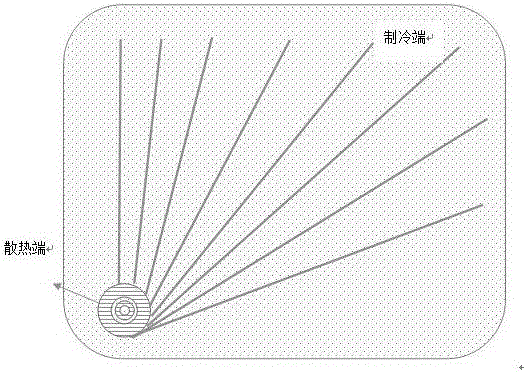

Power generation method using thermoelectric element, thermoelectric element and fabrication method thereof, and thermoelectric device

ActiveUS20080173343A1Improve energy conversion efficiencyImprove thermoelectric performanceThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentPotential differenceTemperature difference

The invention provides a power generation method using a thermoelectric element, a thermoelectric element, and a thermoelectric device that excel in thermoelectric performance and are applicable to a wider range of applications over conventional counterparts. The element includes a first electrode and a second electrode that are disposed to oppose each other, and a laminate interposed between the first and second electrodes and electrically connected to both of the electrodes. The laminate has a structure in which a Bi layer and a metal layer made of a metal other than Bi are alternately layered, and the Bi layer and the metal layer having layer surfaces that are slanted with respect to a direction in which the first and second electrodes oppose each other. The element generates a potential difference between the electrodes by a temperature difference created along a direction perpendicular to the opposing direction of the first and second electrodes in the element. The power generation method and the thermoelectric device use this element.

Owner:PANASONIC CORP

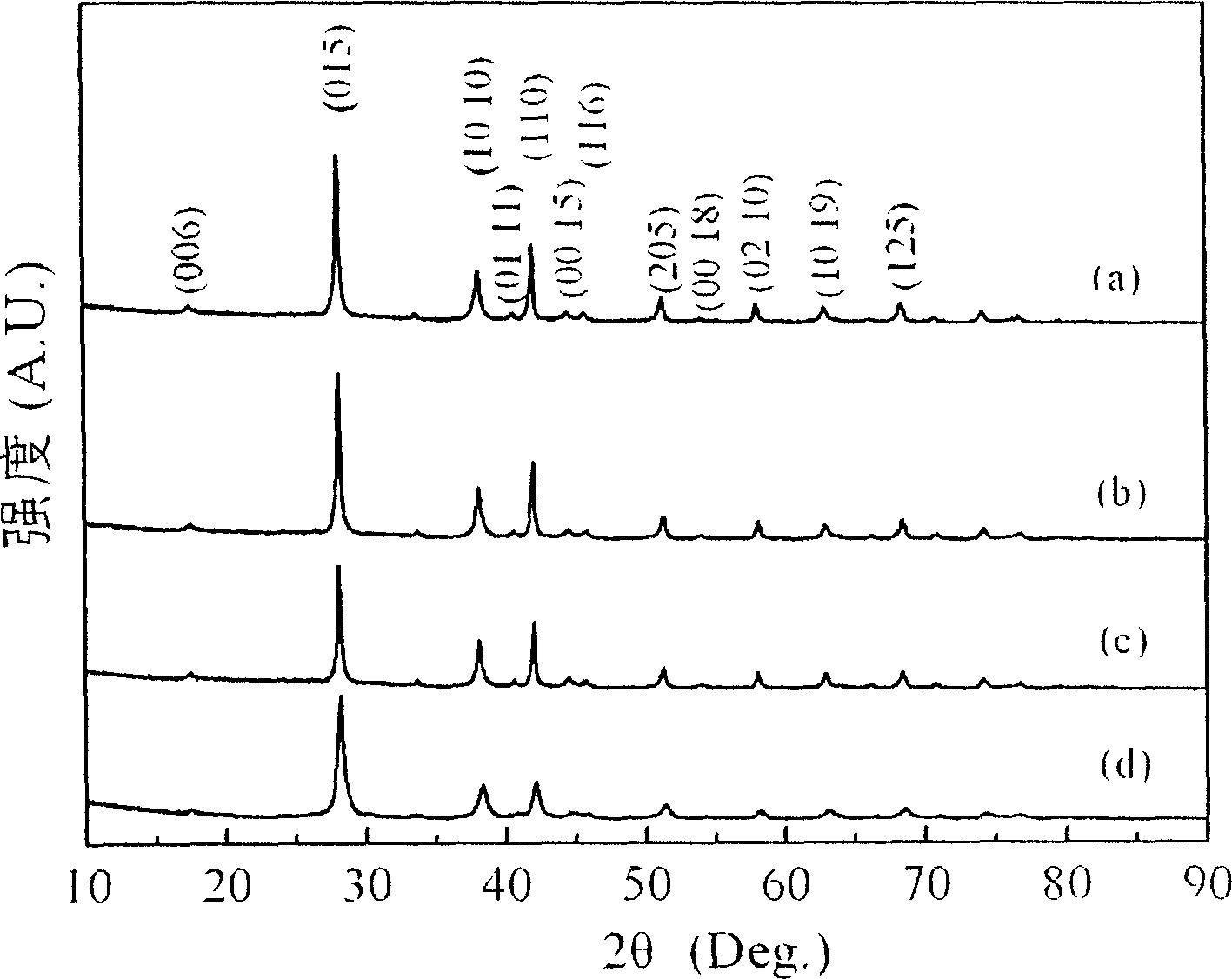

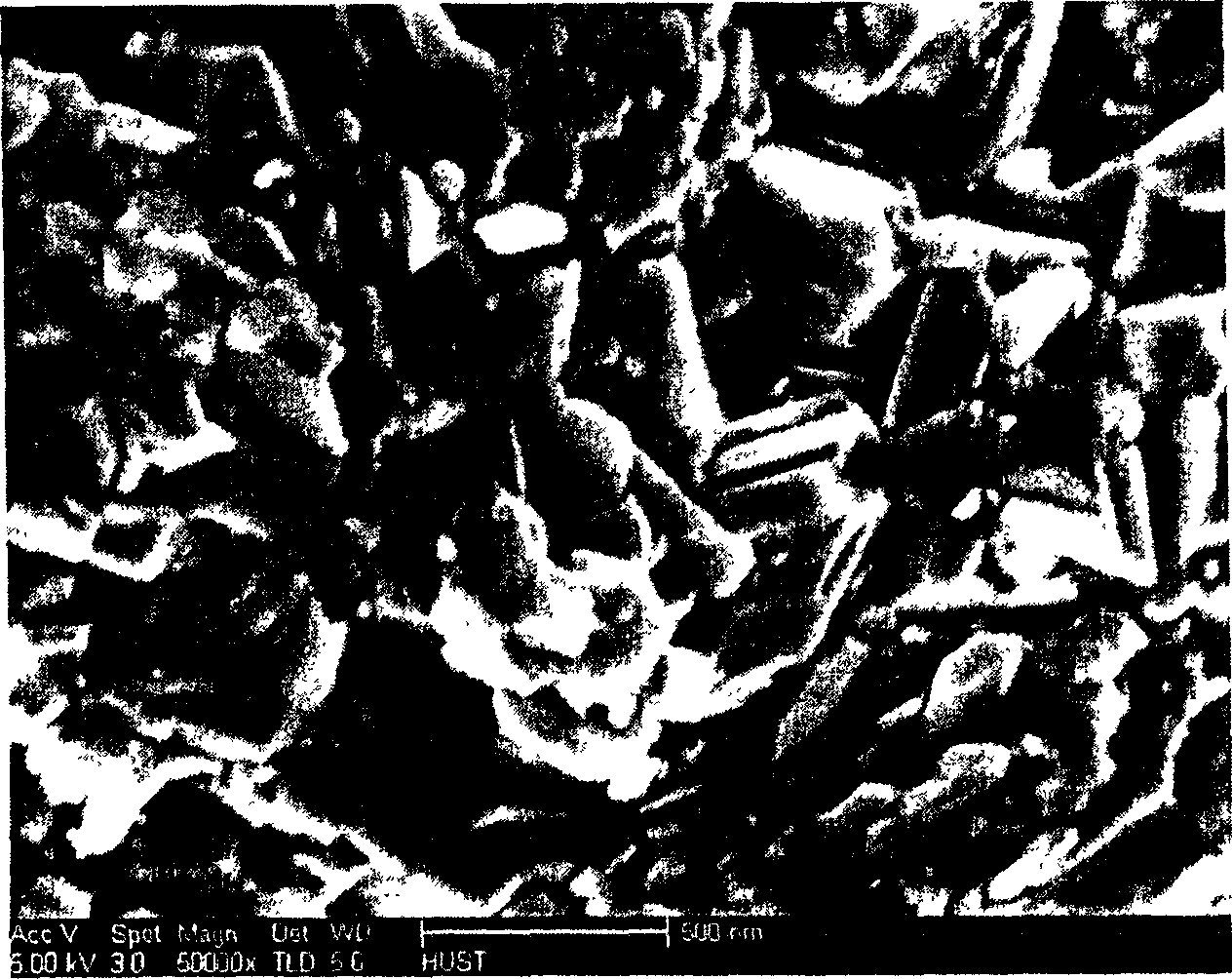

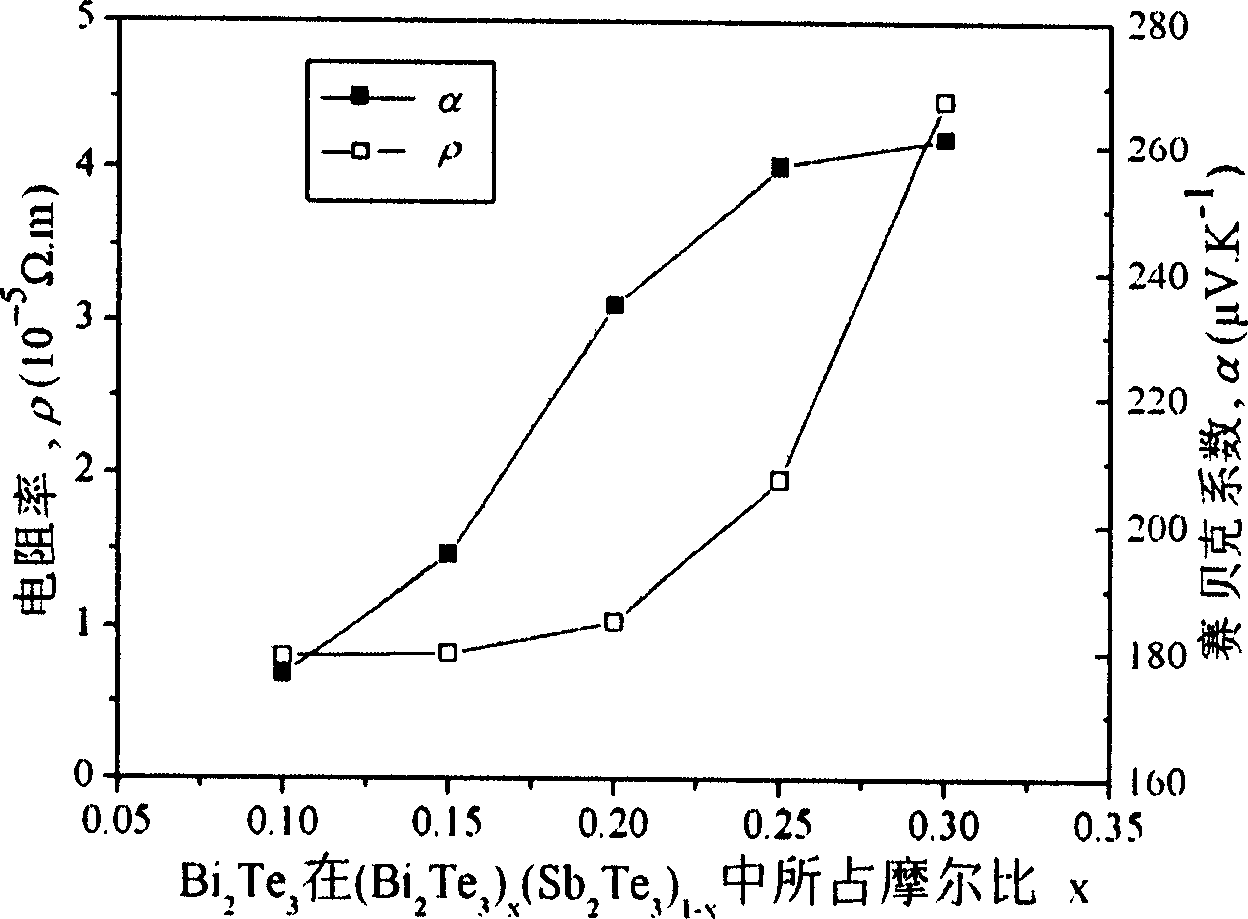

Method for preparing Bi-Sb-Te series thermoelectric material

InactiveCN1843667AUniform compositionSmall tissueThermoelectric device manufacture/treatmentThermoelectric materialsHigh energy

The invention provides a method for preparing thermoelectrical material in Bi-Sb-Te system, which comprises: preparing raw material powders in atom rate that Bi:Sb:Te=2x:2-2x:3, while 0.1<=x<=0.3; mixing and ball grinding it with high-energy to attain alloy powder, while the ball material mass percentage is 10:1-20:1, the rotational speed of ball grinding is 300-400r / min, the time of ball grinding is 8-12hours, and ball grinding uses inertia gas protection; activating said alloy powder with plasma to be sintered, while the temperature increase speed is 30-100Deg. C / min, the sintering temperature is 300-500Deg. C, the pressure when temperature increases is 15-25MPa, the pressure at constant temperature is 40-60MPa, and the time for constant temperature is 10-30mins; and the whole sintering process is process under the inertia gas protection or vacuum condition; the thermolelectrical valve at room temperature can reach 5.26*10-3 / K.

Owner:HUAZHONG UNIV OF SCI & TECH

BiSbTeSe-based thermoelectric material

InactiveCN105047808ALow thermal conductivityImprove thermoelectric performanceSelenium/tellurium compounds with other elementsThermoelectric device junction materialsThermoelectric materialsAlloy

The invention discloses a BiSbTeSe-based thermoelectric material. The formula of the BiSbTeSe-based thermoelectric material is Bi<m>Sb<n>Te<x>Se<y>M<z>, wherein m=0.4-0.6, n=1.4-1.6, x=2.7-2.9, y=0.075-0.3, z=0.02-0.15, and M is one or two kinds of elements selected from S, Si, P, Ge, Sn, Ce, Li, I, Br, Al, Cu, Ag, Yb, Tm, La, Gd and Dy. Steps such as powder mixing and alloy smelting are adopted to prepare the BiSbTeSe-based thermoelectric material. The BiSbTeSe-based thermoelectric material of the invention has the advantages of low thermal conductivity, excellent thermoelectric properties, extended application range and the like.

Owner:LEIZIG GUANGDONG THERMOELECTRIC TECH CO LTD

Fabrication of High Performance Densified Nanocrystalline Bulk Thermoelectric Materials Using High Pressure Sintering Technique

InactiveUS20100295202A1Low thermal conductivityIncrease valueMaterial nanotechnologyThermoelectric device manufacture/treatmentHigh densityAlloy

The present invention provides a method for the fabrication of high performance densified nanocrystalline bulk thermoelectric material, comprising: (1) preparing a thermoelectric alloy nanopowders by a ball milling process to achieve an average crystal size of 5-30 nm, and (2) preparing the nanocrystalline bulk thermoelectric material by high pressure sintering at a temperature of 0.25-0.8 Tm under a pressure of 0.8-6.0 GPa for 10-120 minutes, to achieve a relative density of 90-100% and an average grain size of 10-50 nm. The method is easy to operate and allows the production of a thermoelectric material with a ZT value higher than 2. In addition, the method can ensure both good thermoelectric properties and high density, and therefore have important applications for energy industry.

Owner:YANSHAN UNIV

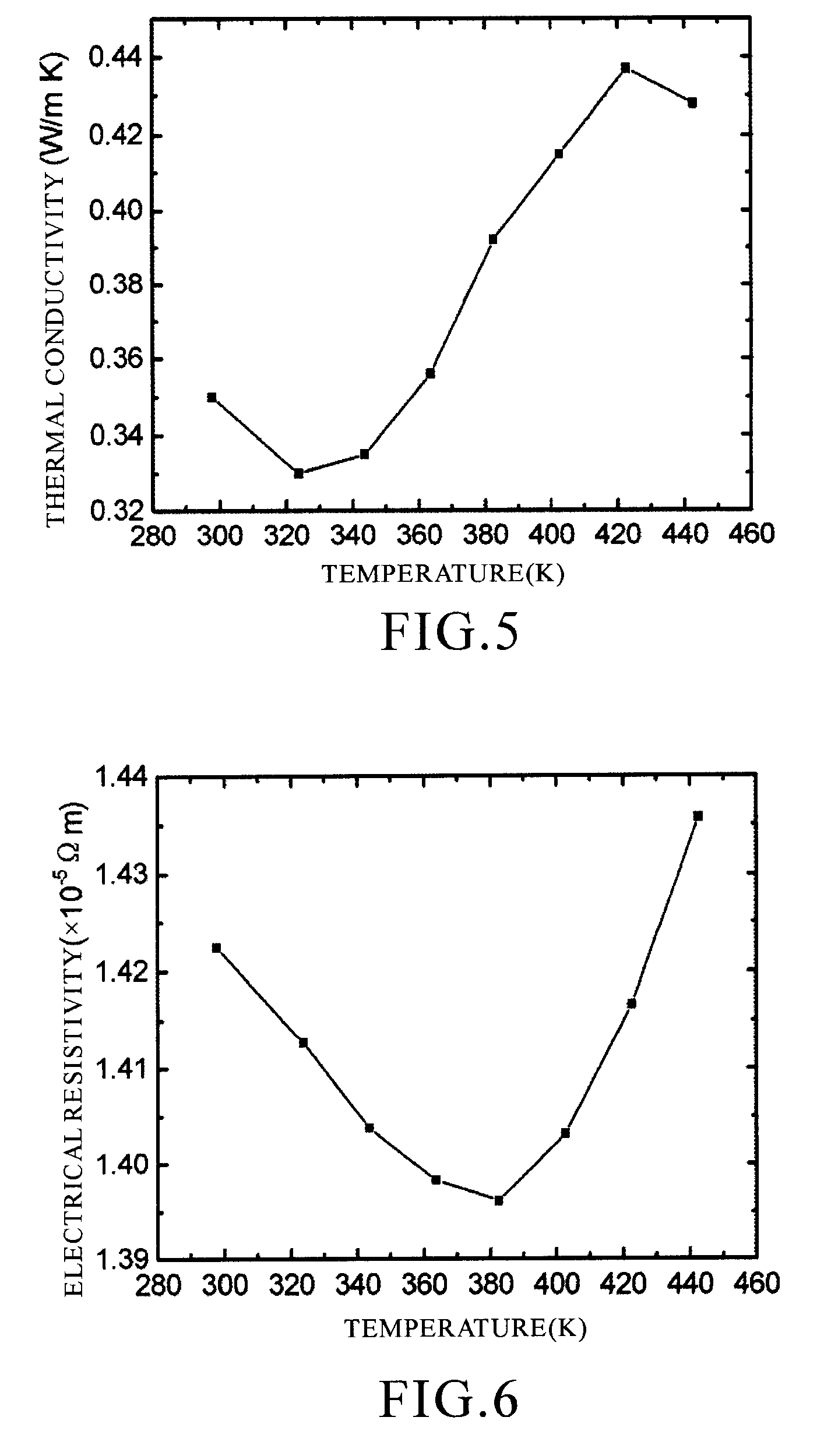

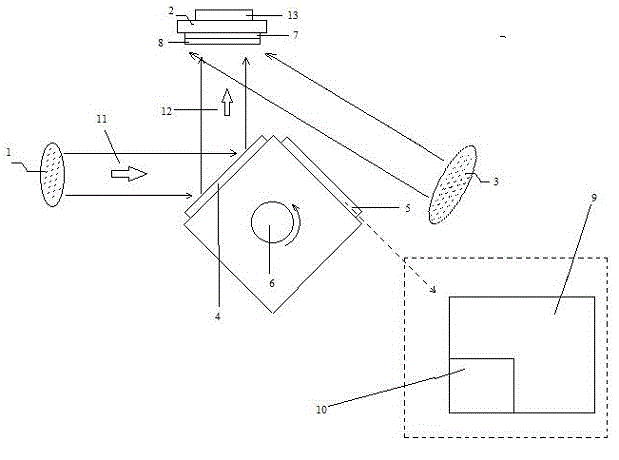

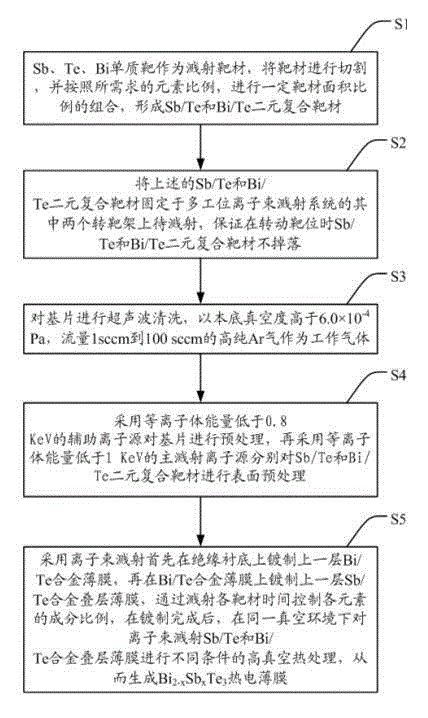

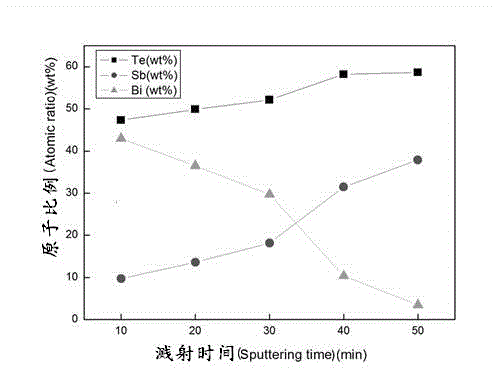

Method for preparing bismuth, antimony and telluride base thermoelectric film

ActiveCN103060750AHigh ion energyImprove qualityThermoelectric device manufacture/treatmentVacuum evaporation coatingRepeatabilityHot Temperature

The invention discloses a method for preparing a bismuth, antimony and telluride base thermoelectric film and particularly relates to a Bi[2-x]SbxTe3 base thermoelectric film. In the Bi[2-x]SbxTe3, x is not less than 0.1 and not more than 2.0. According to the method, the ion-beam sputtering depositing method is adopted, two binary complex targets which are Sb / Te and Bi / Te are used as sputtering target materials, the area proportions of the two target materials and the ion-beam sputtering parameters are controlled, and the high-temperature in situ heat treatment is carried out in the same vacuum environment to prepare the Bi[2-x]SbxTe3 thermoelectric film. The method has the advantages of simple process, good repeatability and high utilization rate of raw materials. Due to the adoption of the method, the high-precision controllable doping of elements of the Bi[2-x]SbxTe3 thermoelectric film can be realized, the structure of the Bi[2-x]SbxTe3 thermoelectric film can be optimized effectively, and the thermoelectric properties can be improved.

Owner:SHENZHEN UNIV

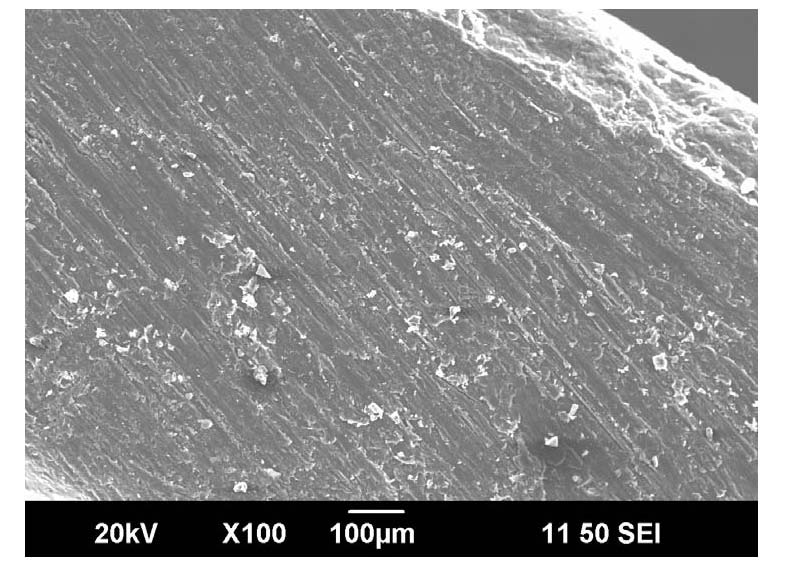

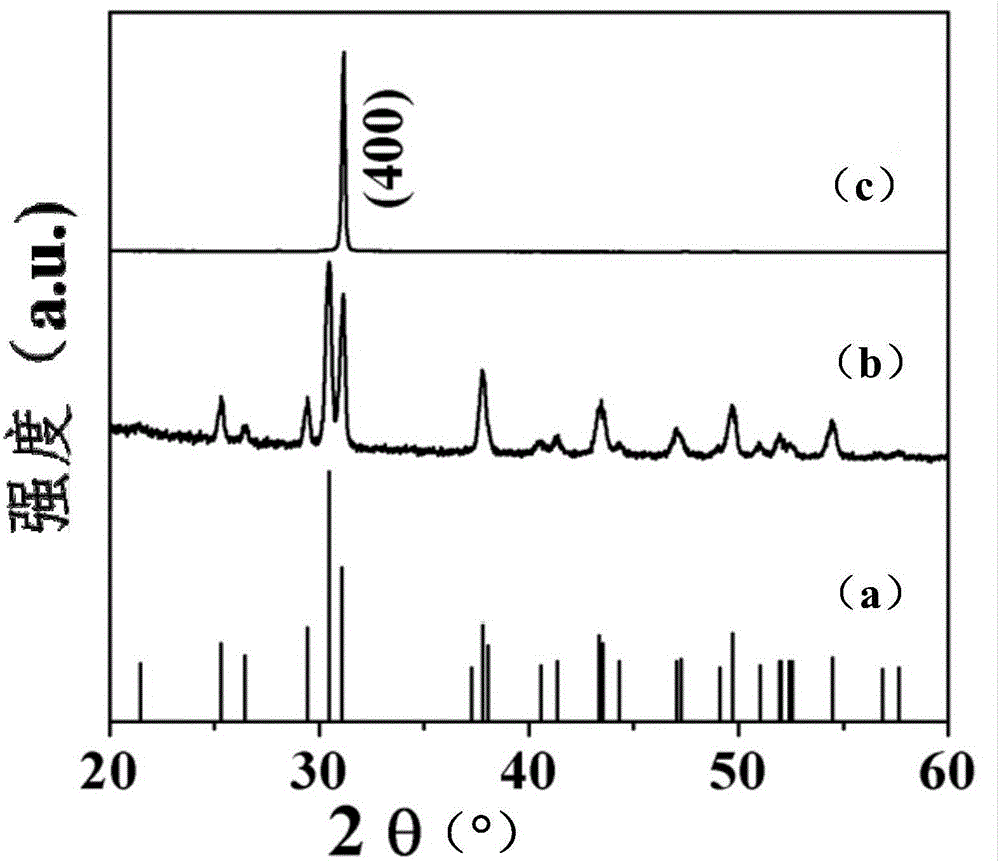

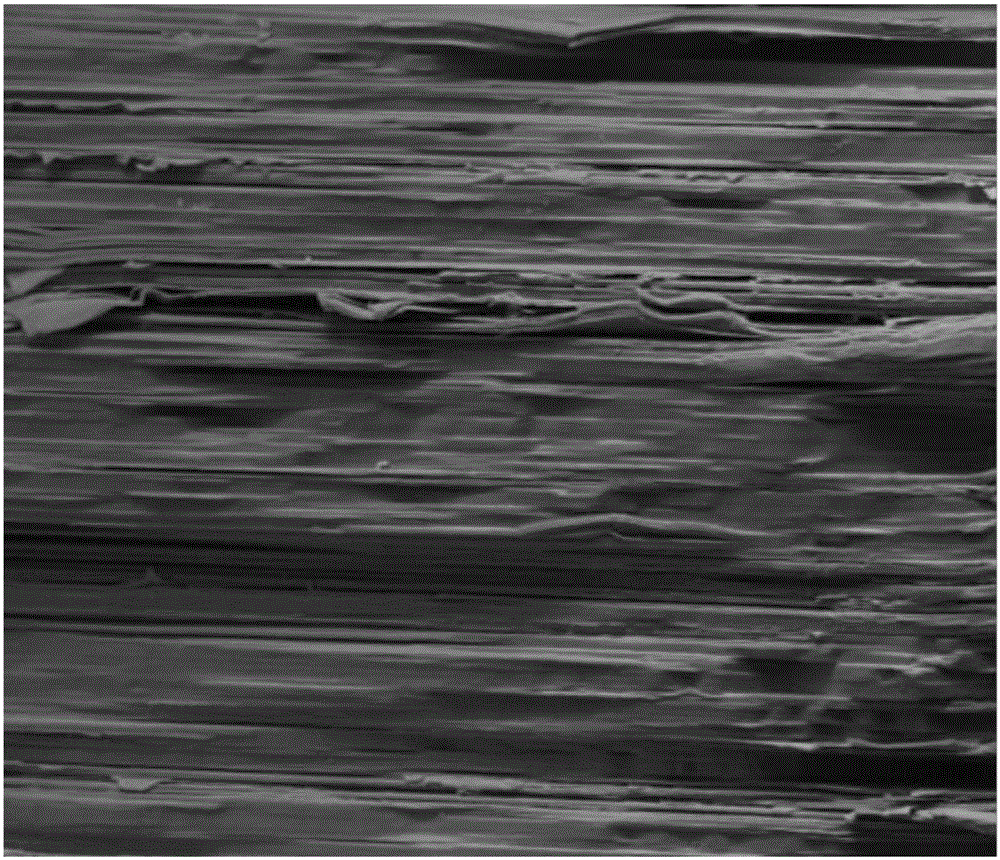

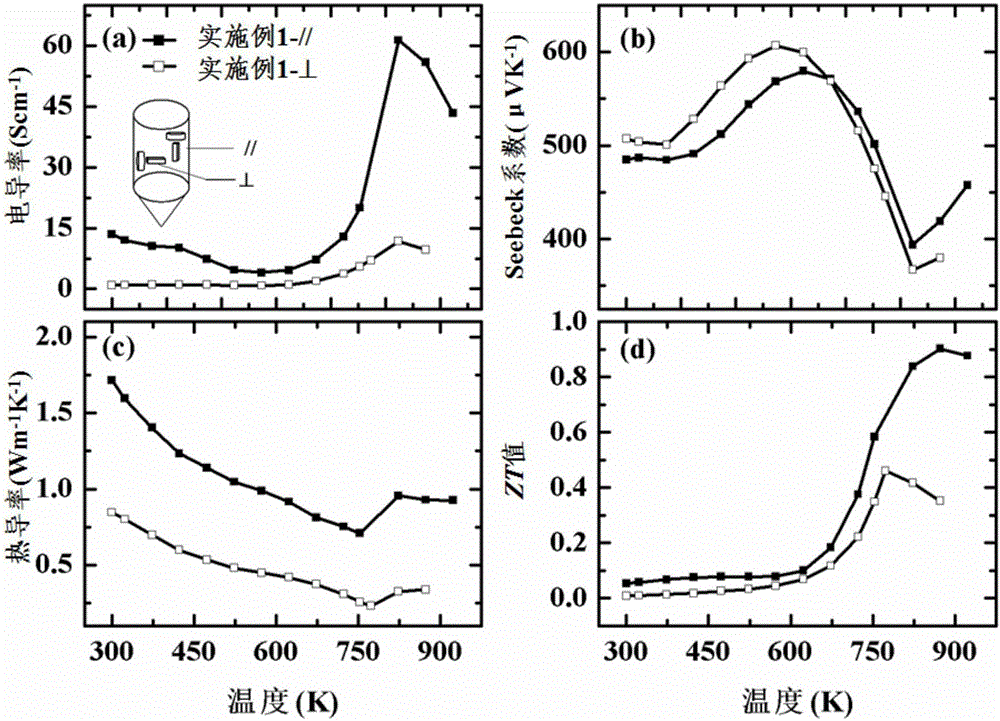

Sleeve forging and pressing preparation method of bismuth-telluride-base thermoelectric material

The invention relates to a sleeve forging and pressing preparation method of a bismuth-telluride-base thermoelectric material, which comprises the following steps: (1) material preparation: smelting raw materials to obtain a bismuth telluride base block material, pulverizing, grinding and screening to obtain powder; (2) sleeve filling: filling the powder into an aluminum sleeve, putting the aluminum sleeve in a cold-press die, and compacting the powder with a pressing machine to obtain a block blank; (3) presintering: heating to 300-580 DEG C, and keeping the temperature for 3 minutes to 1 hour; (4) forging and pressing: forging the bismuth telluride base block alloy thermoelectric material with the aluminum sleeve under the forging and pressing pressure of 20-900MPa until the die cavity is fully filled, and maintaining or not maintaining the pressure; and (5) sleeve removal: removing the aluminum sleeve to obtain the required bismuth telluride base block thermoelectric material. The invention has the following advantages: 1) the required equipment is simple; 2) the preparation technique is simple and practical; 3) the technique of sheathing an aluminum sleeve outside the sample is adopted to effectively avoid sample cracking which can possibly occur in the forging process; and 4) the prepared sample has high thermoelectric properties and favorable actual effect.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

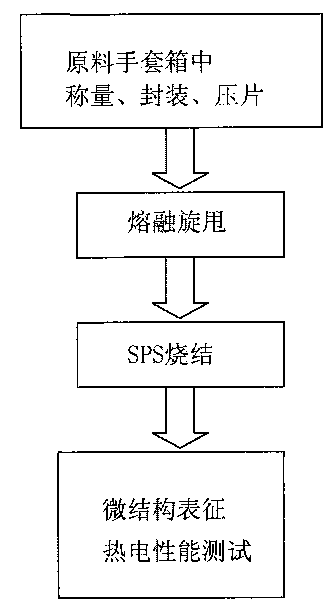

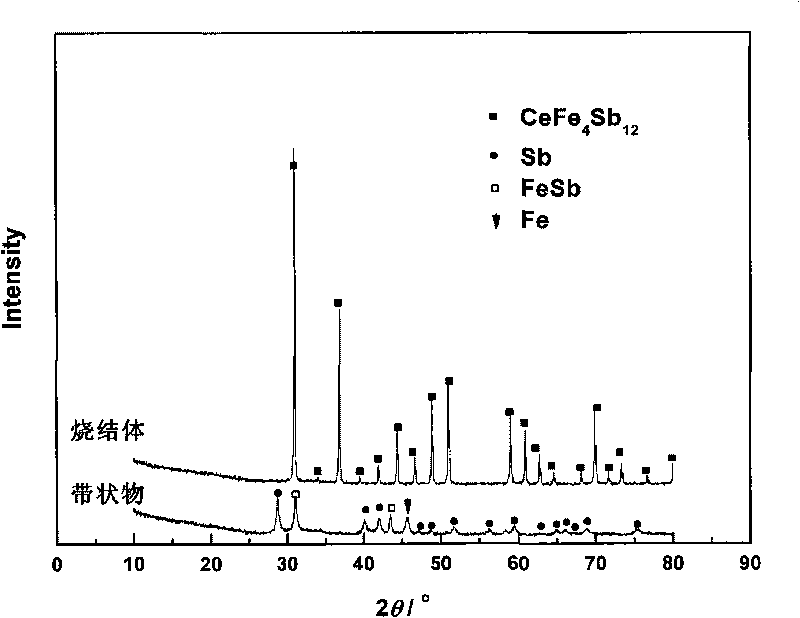

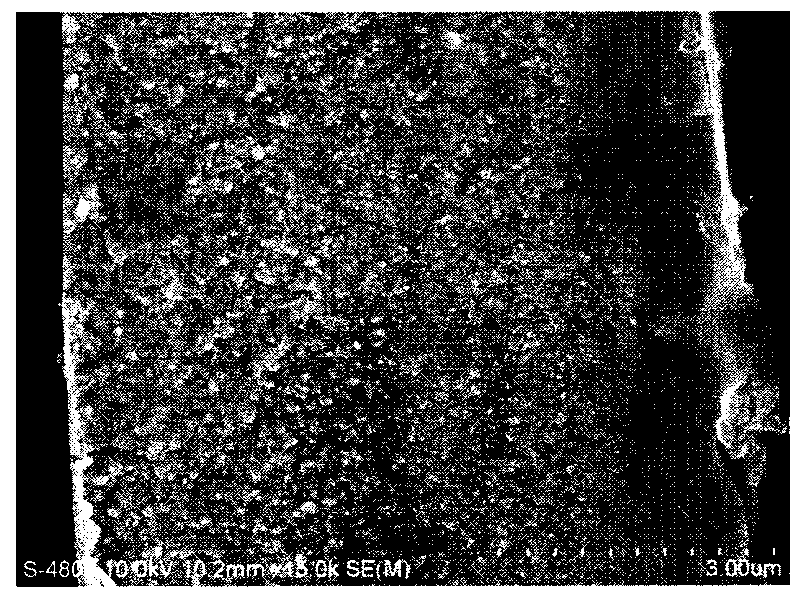

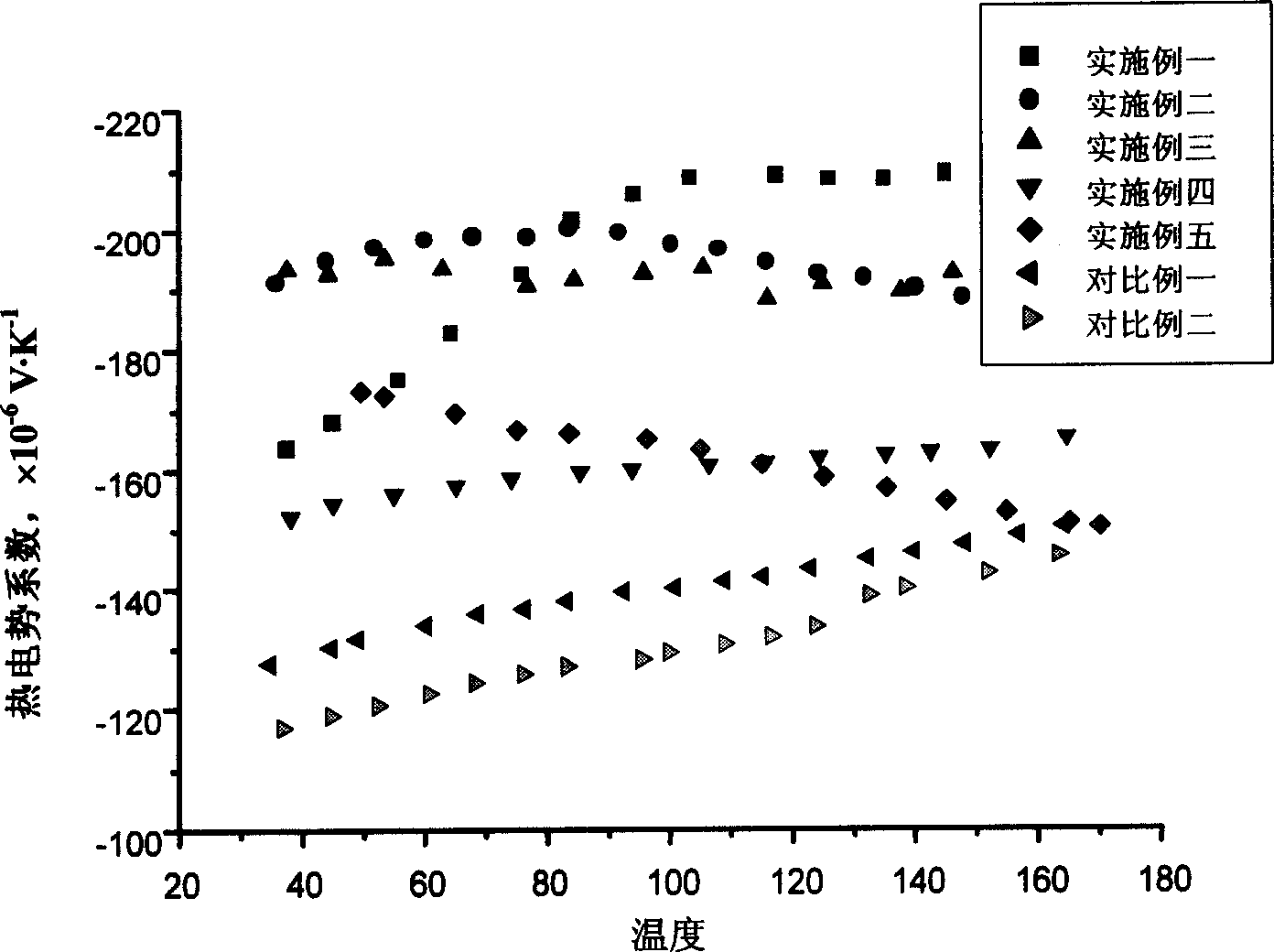

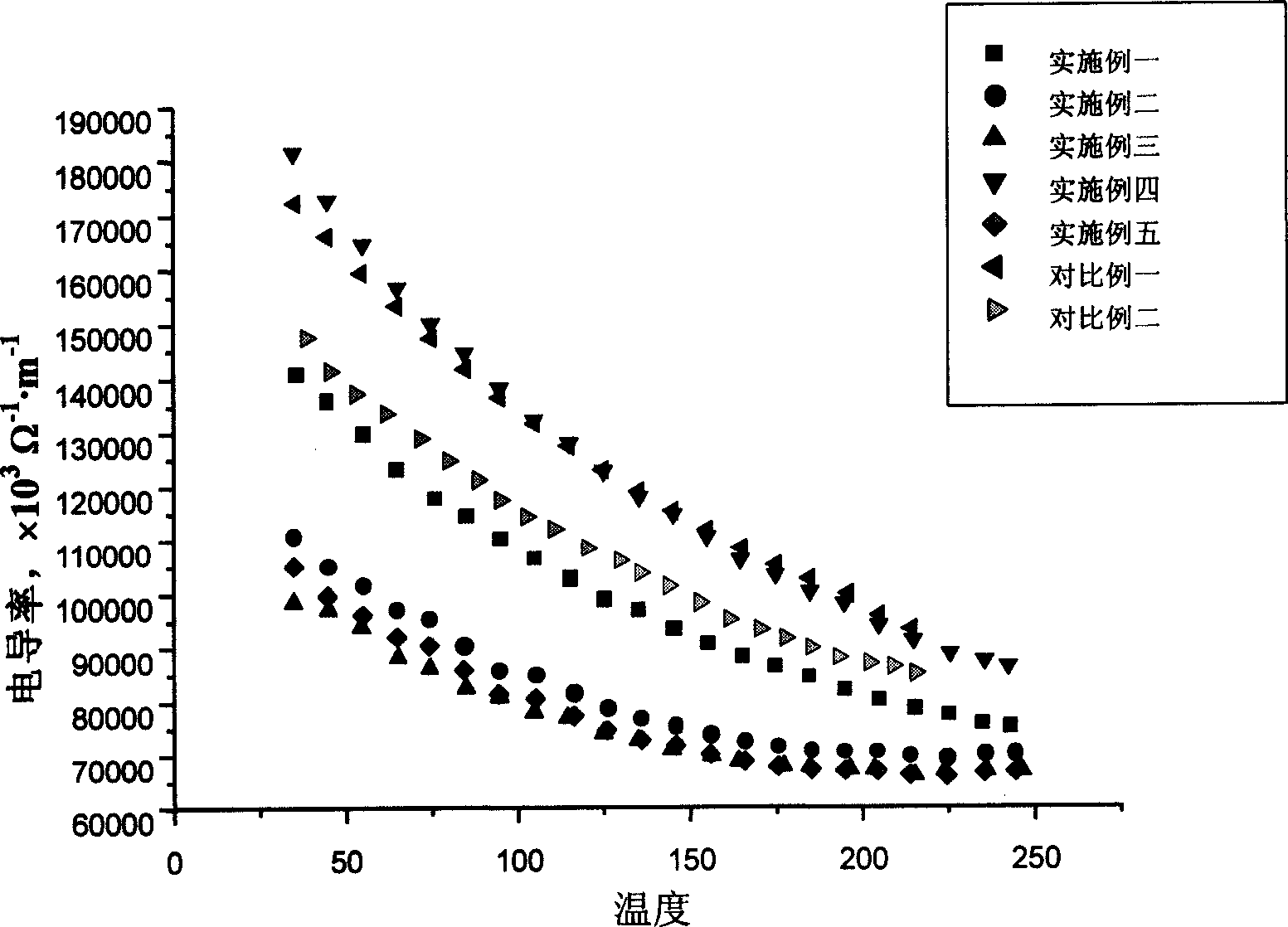

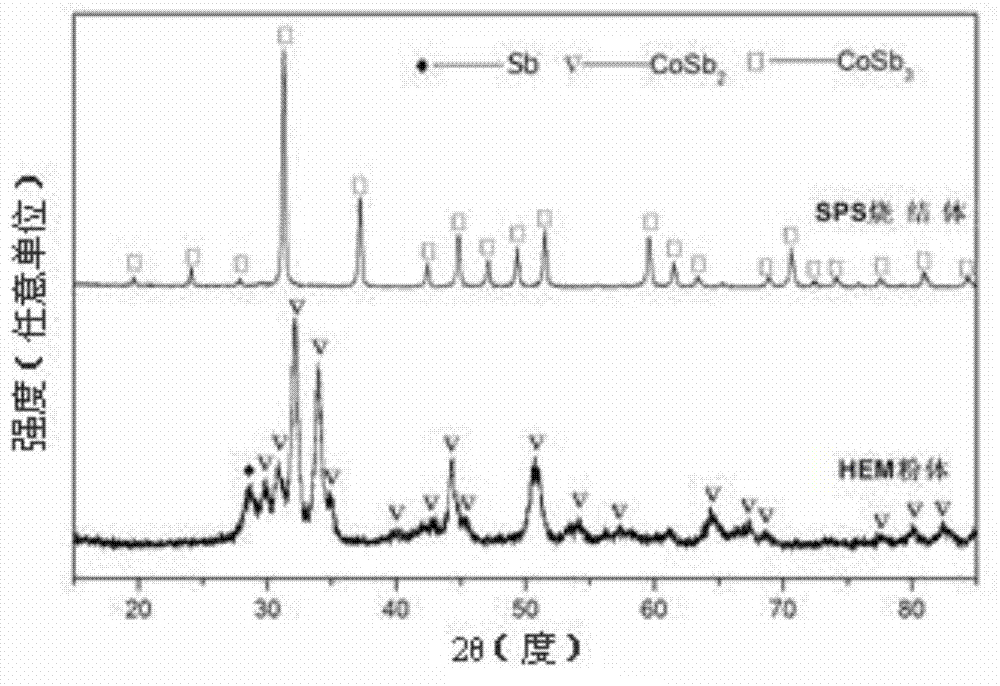

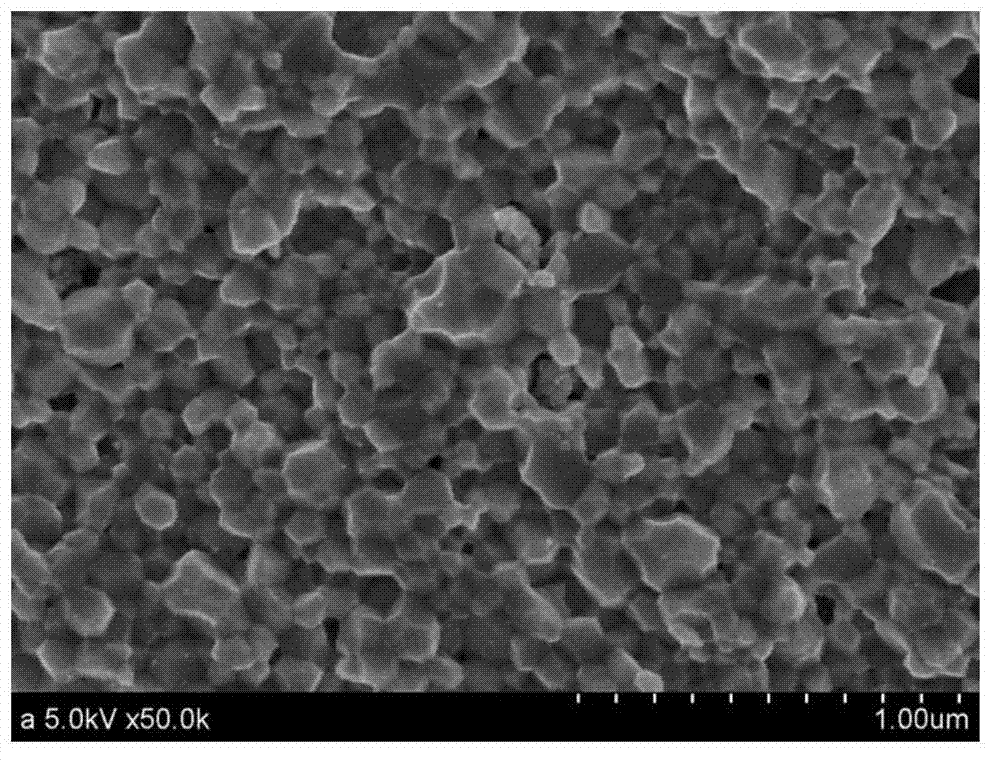

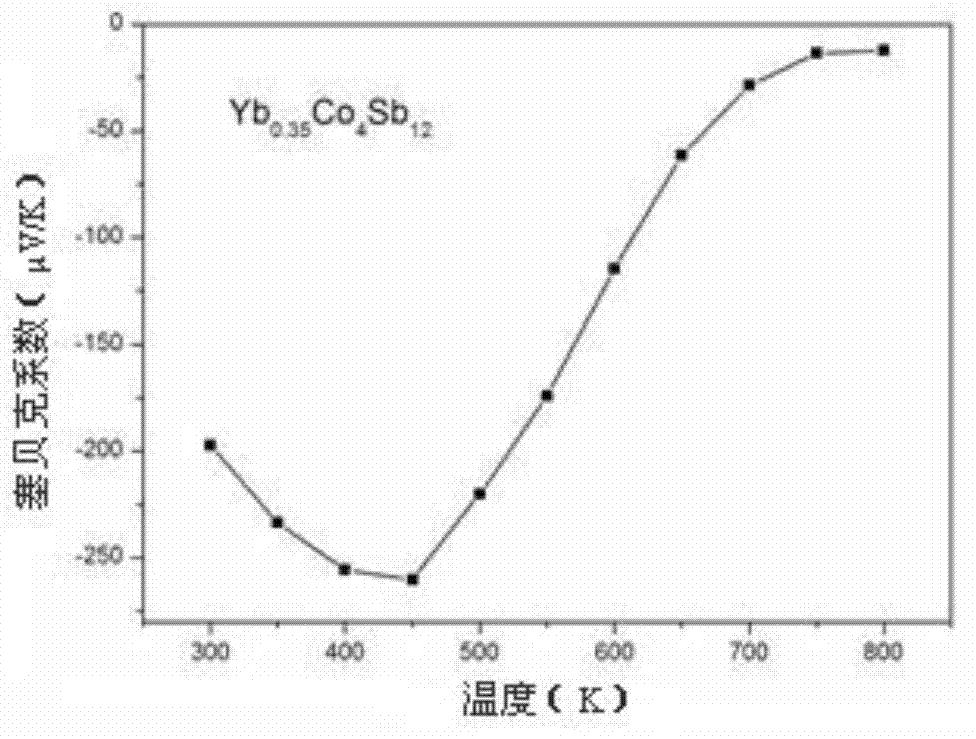

Method for preparing p-type filling type skutterudite compound thermoelectric material

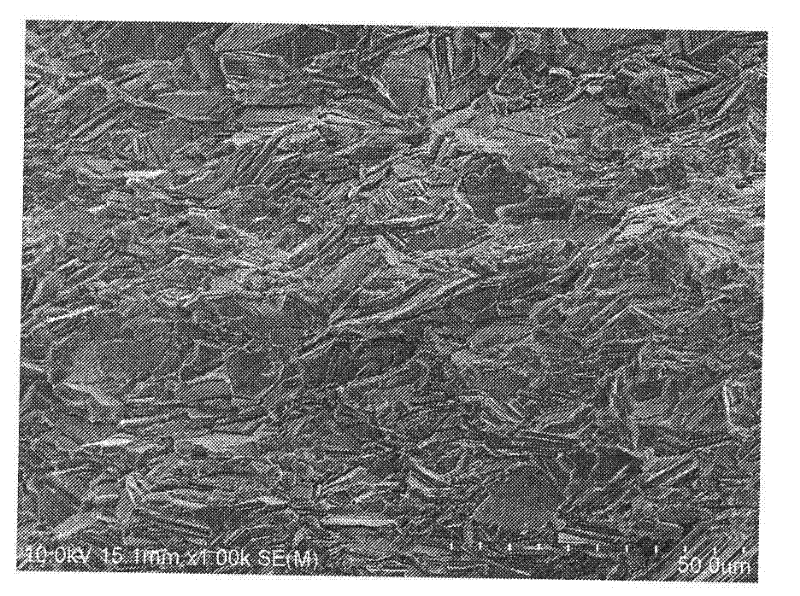

InactiveCN101693962AOmit premeltingPrevent deviationThermoelectric device junction materialsSkutteruditeArgon atmosphere

The invention belongs to the field of new energy materials, and particularly relates to a method for preparing filling type skutterudite thermoelectric compound. A method for preparing the p-type filling type skutterudite compound thermoelectric material comprises the following steps: firstly, taking high-purity granule type M, Fe, Co and Sb as starting reaction materials, weighing reaction raw materials in an Ar gas glove box according to the chemical formula MFe4-xCoxSb12+y, wherein 0<=x<=3, 0<=y<=1.0, mixing the high purity granule type M, Fe, Co and Sb, then, pressing into columnar blocks under the pressure of 300 to 400MPa, secondly, melting columnar blocks, swinging melted welding flux in argon atmosphere, obtaining belt-shaped products, thirdly, sintering in vacuum through a discharge plasma sintering method after coarsely grinding and pressing the belt-shaped products tightly, and obtaining single-phase compact p-type filling type skutterudite compound thermoelectric material. The method for preparing p-type filling type skutterudite compound thermoelectric material has the characteristics of simple technique, short reaction time, low energy consumption, excellent repeatability, and the like.

Owner:WUHAN UNIV OF TECH

Bi2Te3 based nano composite thermoelectric materials

InactiveCN1546369AUnique carrier transport propertiesIncrease thermoelectric potential coefficientBinary selenium/tellurium compoundsNanometreCharge carrier

The invention discloses a high-performance Bi2Te3 based nano composite thermoelectric material which is prepared by adding Bi2Te3 based nanostructured powder into Bi2Te3 based thermoelectric material powder through compression agglomeration recombination. The thermoelectric property of the prepared Bi2Te3 based nano composite thermoelectric material is superior to that of the Bi2Te3 based thermoelectric material with non-recombination nanostructured powder as base.

Owner:ZHEJIANG UNIV

Graphene compounded with stibine cobalt base skutterudite thermoelectric material and preparation method of material

ActiveCN102931335AReduce the temperatureShorten the timeThermoelectric device manufacture/treatmentThermoelectric device junction materialsRare-earth elementAlkaline earth metal

The invention relates to a graphene compounded with stibine cobalt base skutterudite thermoelectric material and a preparation method of the graphene compounded with stibine cobalt base skutterudite thermoelectric material. The chemical general expression of the material is MxCo 4 Sb 12 / graphene, wherein x is greater than or equal to 0 and less than or equal to 1, M is one of a rare earth element, alkali earth metal, alkali metal, Ga and Tl, and the content of the graphite olefine is less than 3%. The preparation method comprises the following steps of: (1) weighing M, cobalt and antimony, then mixing with a carbon nanometer pipe, and carrying out ball milling under inert gas shielding; and (2) placing the obtained substances in a graphite jig, and carrying out discharge plasma sintering under the inert gas shielding, thus obtaining the graphene compounded with stibine cobalt base skutterudite thermoelectric material. The graphene compounded with stibine cobalt base skutterudite thermoelectric material and the preparation method of the graphene compounded with stibine cobalt base skutterudite thermoelectric material have the advantages of simple preparation technology, short preparation time, easiness in control, good repeatability, low cost and good industrialization prospect; and the obtained material has a good pyroelectricity property.

Owner:JIANGSU CNANO TECHNOLOGY CO LTD

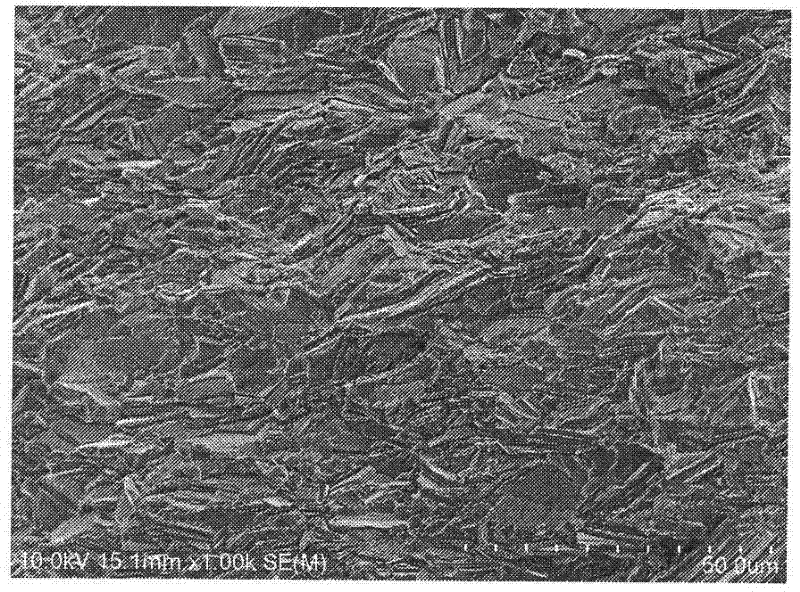

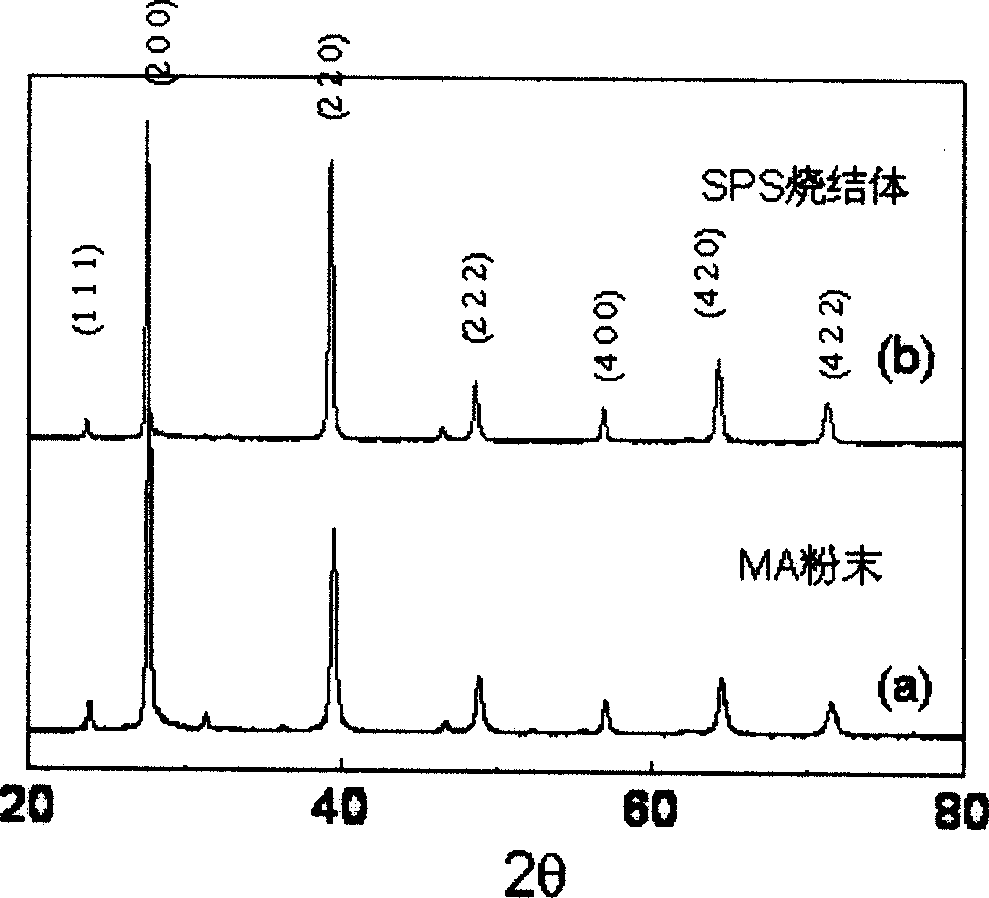

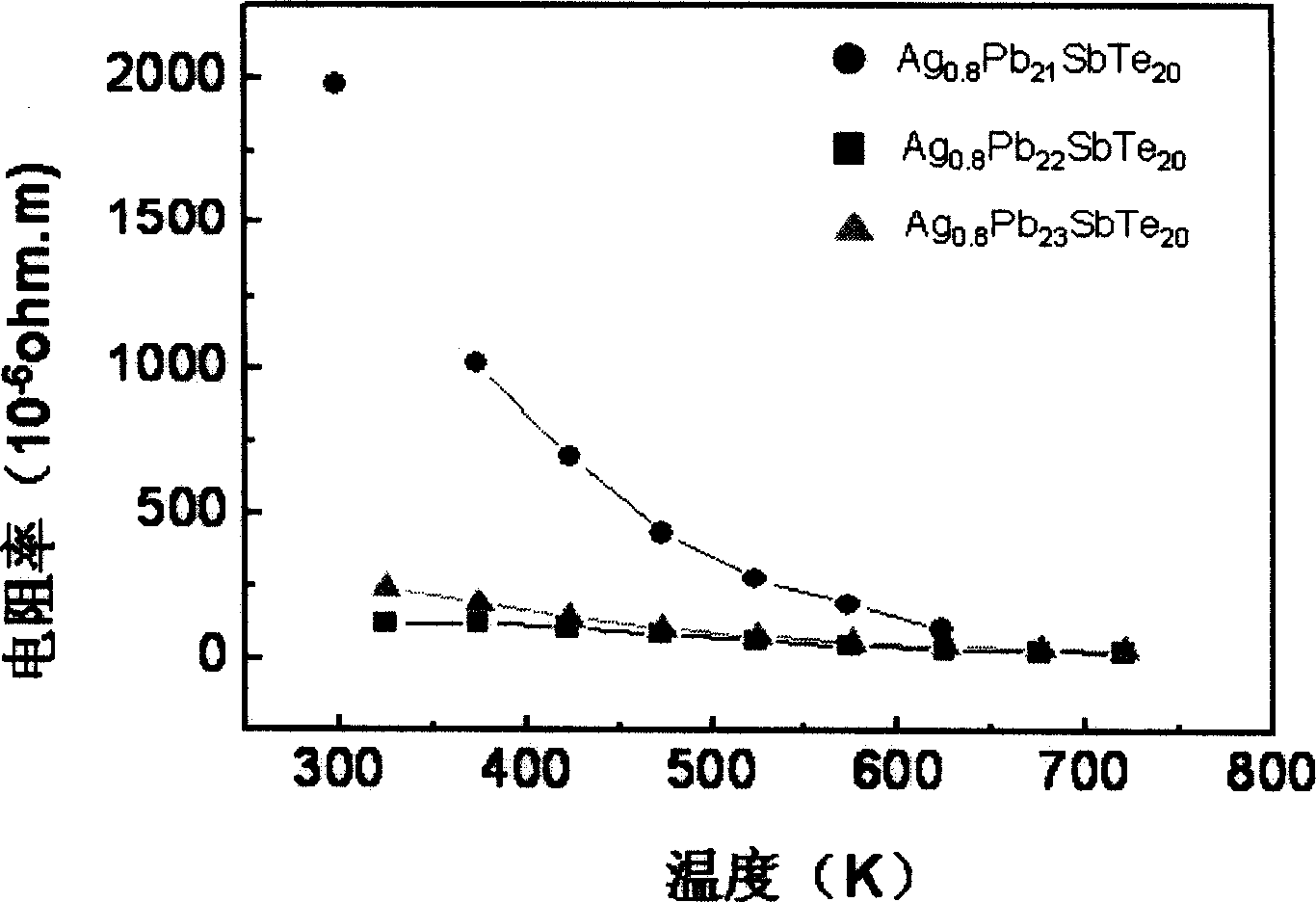

Ag-Pb-Sb-Te thermoelectric materials and preparation process thereof

ActiveCN1755961AFine grainImprove thermoelectric performanceThermoelectric device manufacture/treatmentThermoelectric device junction materialsNew energySemiconductor

The invention discloses new energy resource material and its preparing technique, relating to a Ag-Pb-Sb-Te thermoelectric material of thermoelectric semi-conductor compound with high thermoelectric effect and the relative preparing method. The invention utilizes the mechanical alloying (MA) combined with discharge plasma sinter (SPS) to prepare the PbTe high-performance thermoelectric material, which can be displayed as Ag1-XPb18+YSbTe20, wherein, the x is the amount of deviated Ag amount and y is amount that the raw material powder over the measurement rate of Pb. Compared to traditional powder metallurgy technology, the inventive MA+SPS process has the advantages of short process, high efficiency, lower energy consumption, and application to the industrial mass production and the attained thermoelectric material has better thermoelectric performance while the non-dimensional merit ZT of thermoelectric material of Ag1-XPb18+YSbTe20 prepared by MA and SPS can reach 1.37 in the temperature of 450 Deg. C.

Owner:TSINGHUA UNIV +1

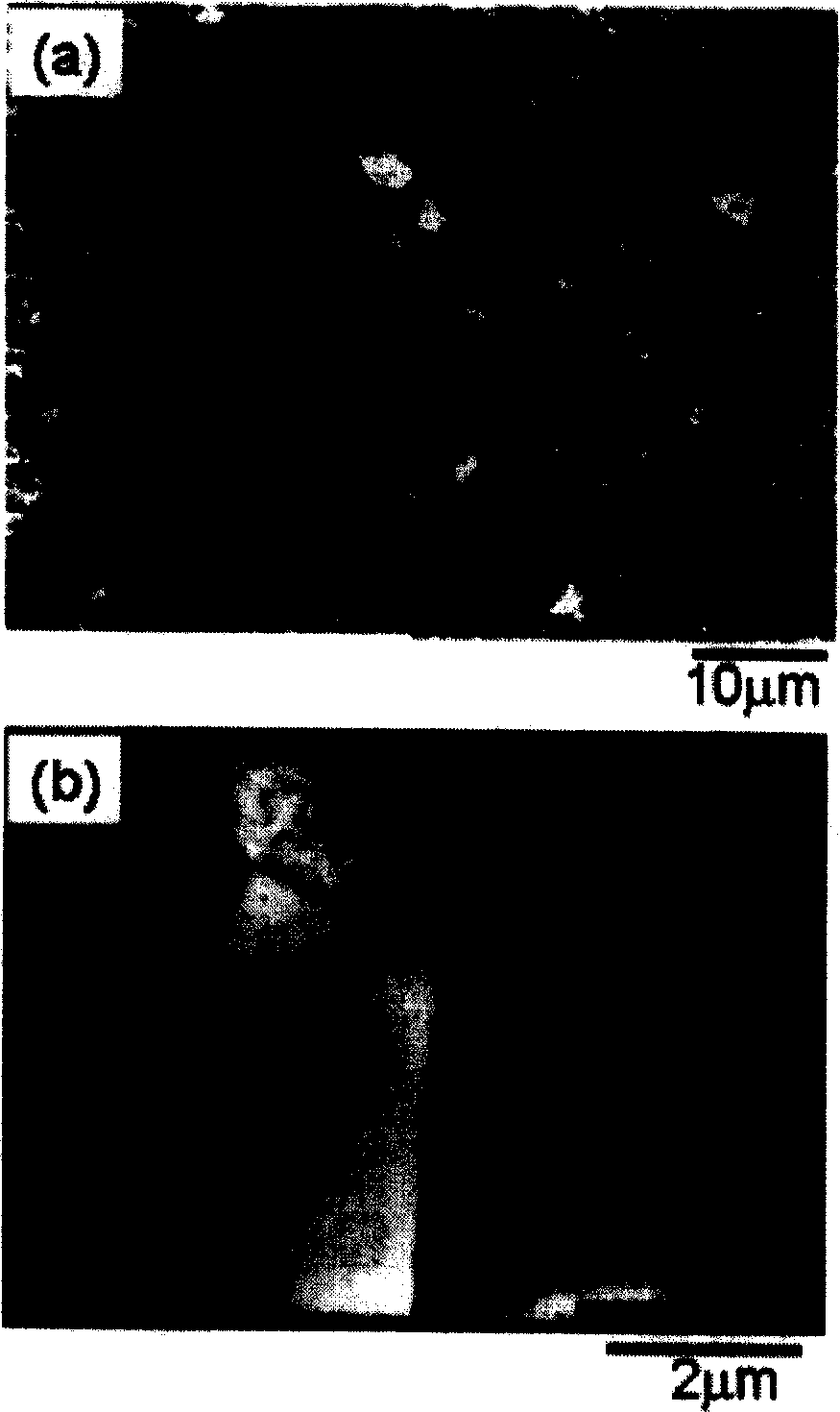

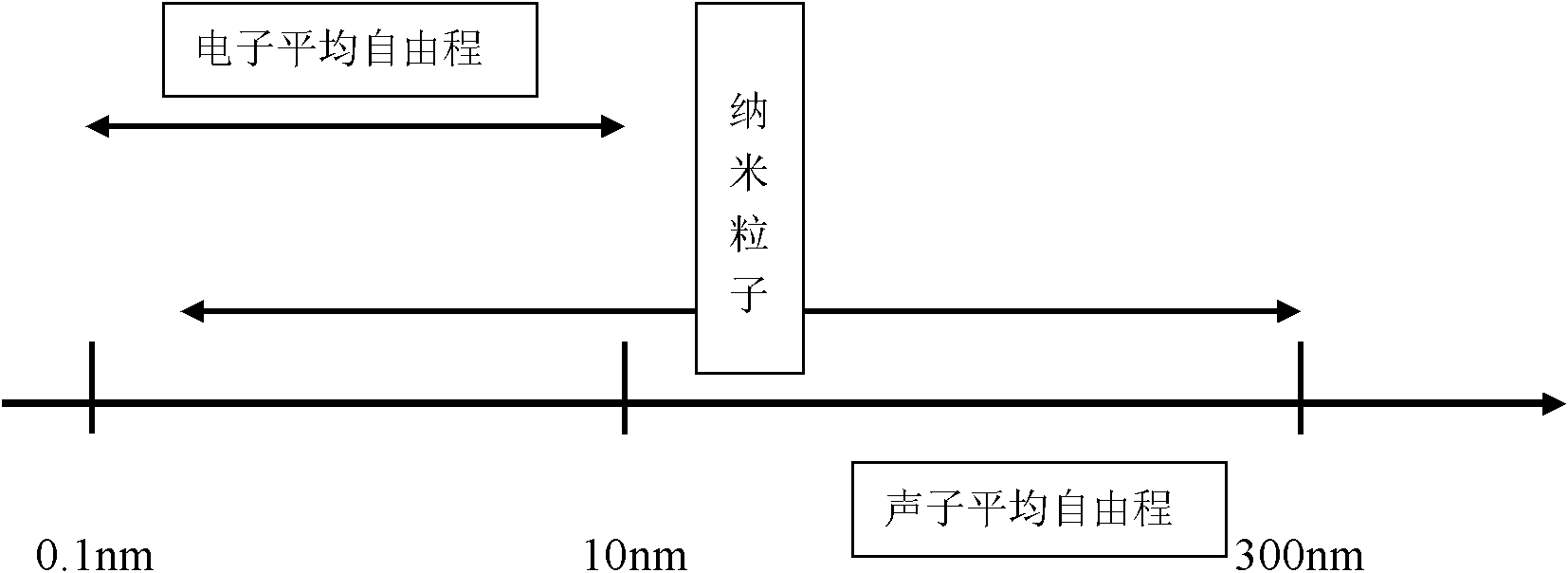

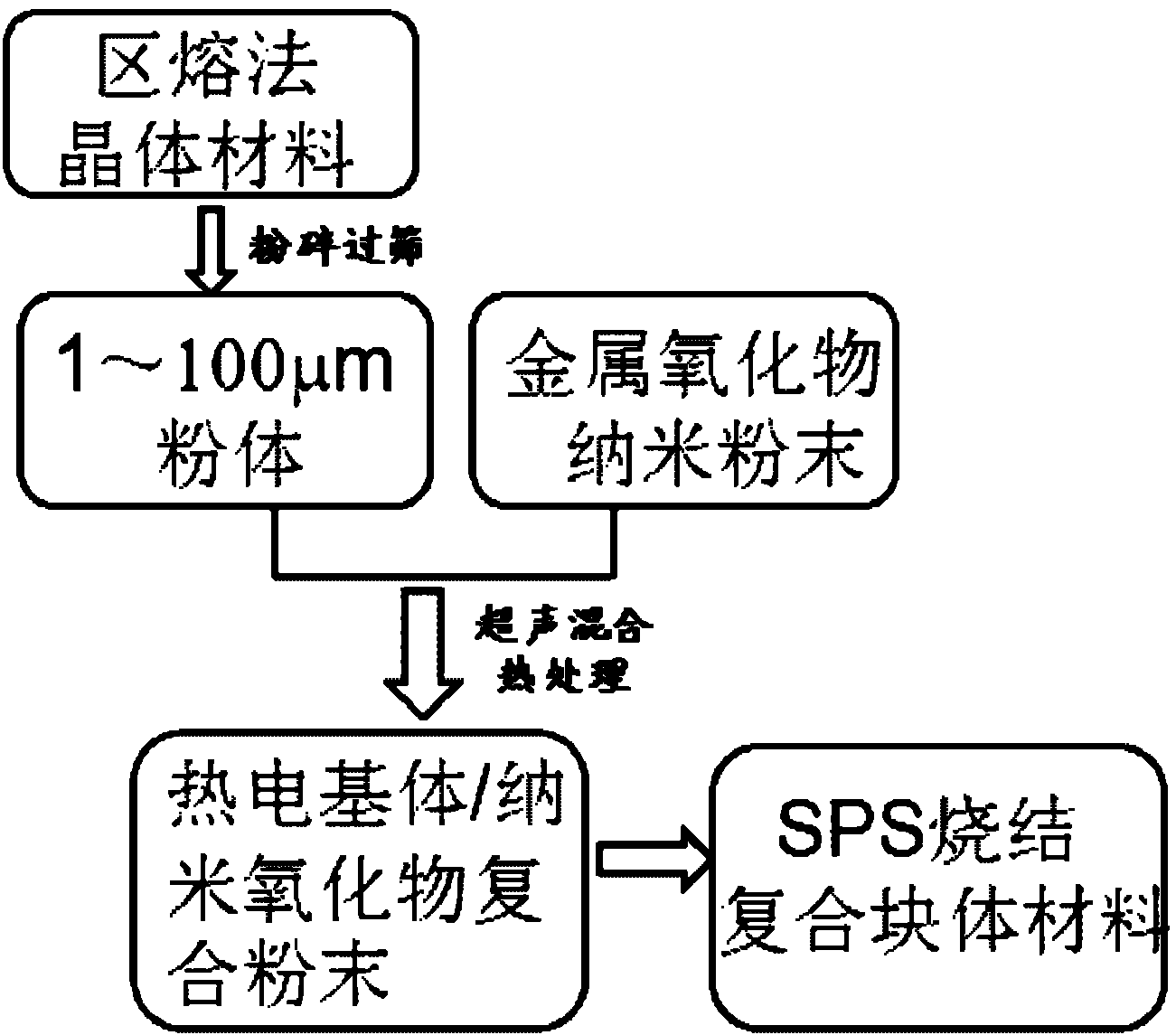

High-performance thermoelectric composite material and preparation method thereof

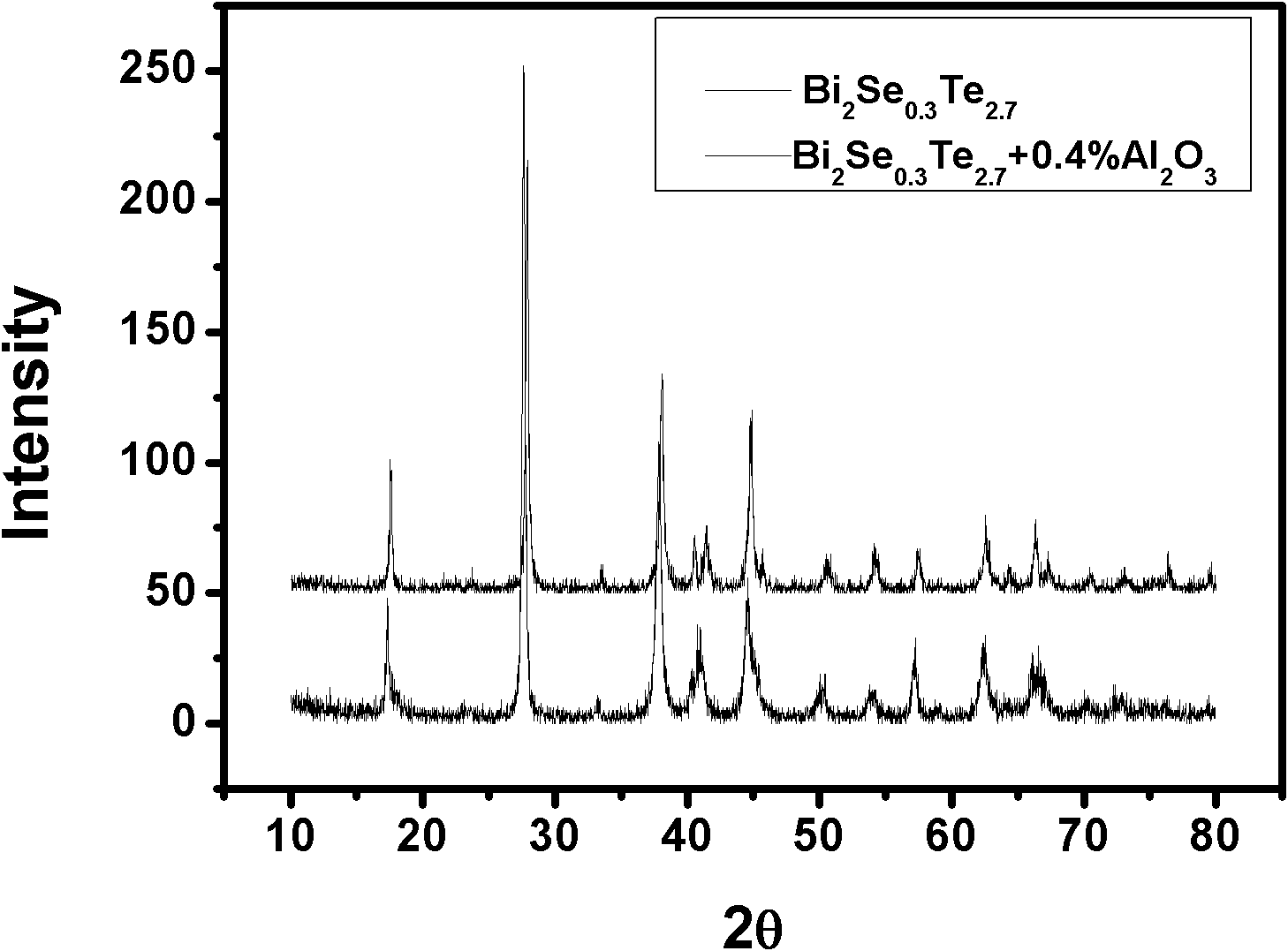

ActiveCN102339946AImprove Seeback coefficientLow thermal conductivityThermoelectric device manufacture/treatmentThermoelectric device junction materialsBismuth tellurideLattice thermal conductivity

The invention relates to a high-performance thermoelectric composite material and a preparation method thereof, belonging to the field of thermoelectric materials. The composite material consists of two phases. A first phase is n-type Bi2Te3-Bi2Se3 or p-type Bi2Te3-Sb2Te3, and a second phase is nanometer powder of a metallic oxide. The nanometer powder of the metallic oxide accounts for 0.05-10% in terms of the total weight of the thermoelectric composite material. According to the preparation method provided by the invention, the n-type Bi2Te3-Bi2Se3 or p-type Bi2Te3-Sb2Te3 powder is ultrasonically mixed with the nanometer oxide, and discharge plasma sintering is carried out on the mixture to obtain a dense block material. Compared with the bismuth-telluride-based thermoelectric base material, under the condition that the electric conductivity of the thermoelectric base material is maintained to be unchanged basically in the invention, the high-performance thermoelectric composite material, provided by the invention, achieves the advantages of obviously reduced lattice heat conductivity and increased Seeback coefficient, and therefore the thermoelectric performance of the material can be greatly improved.

Owner:中科西卡思(苏州)科技发展有限公司

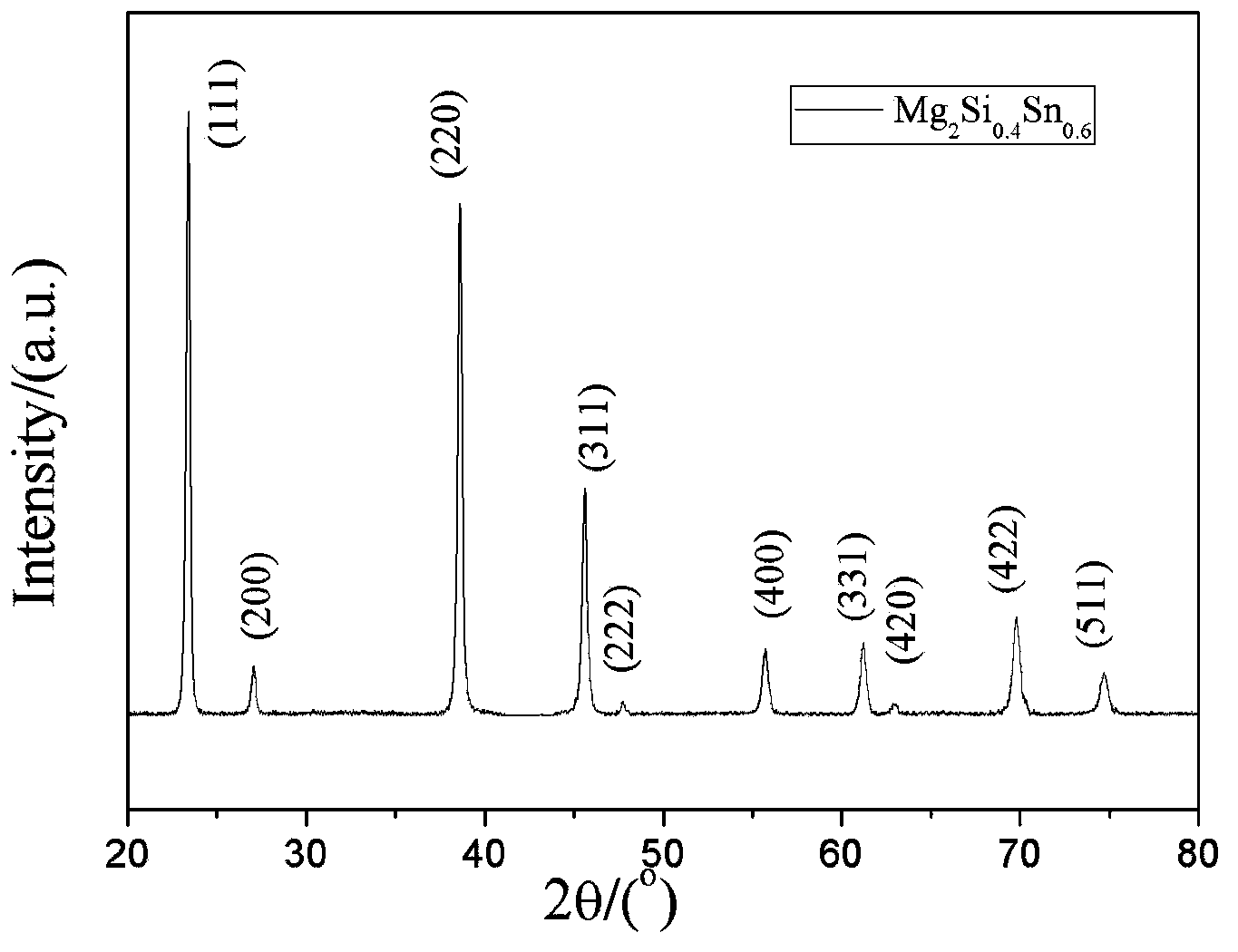

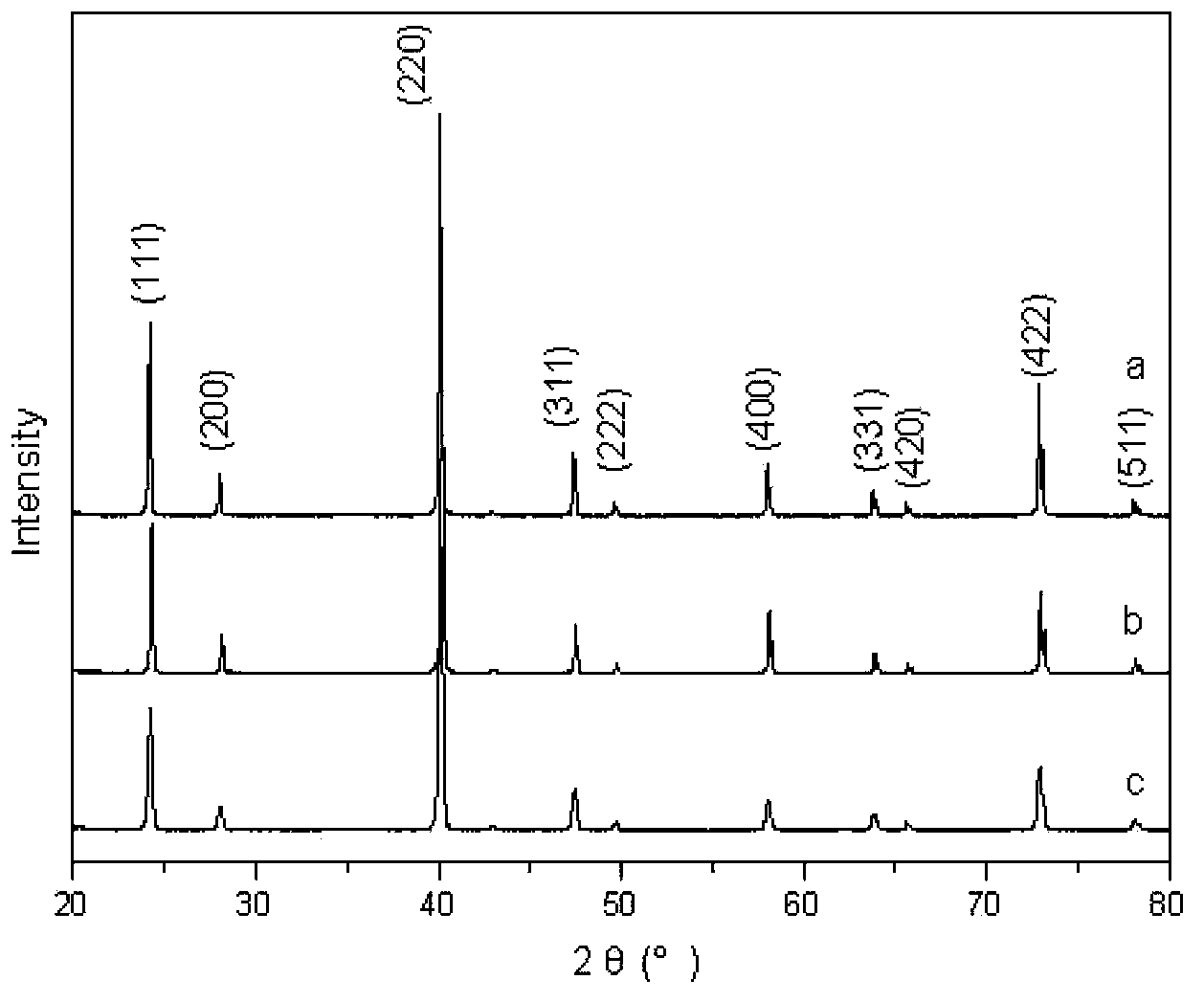

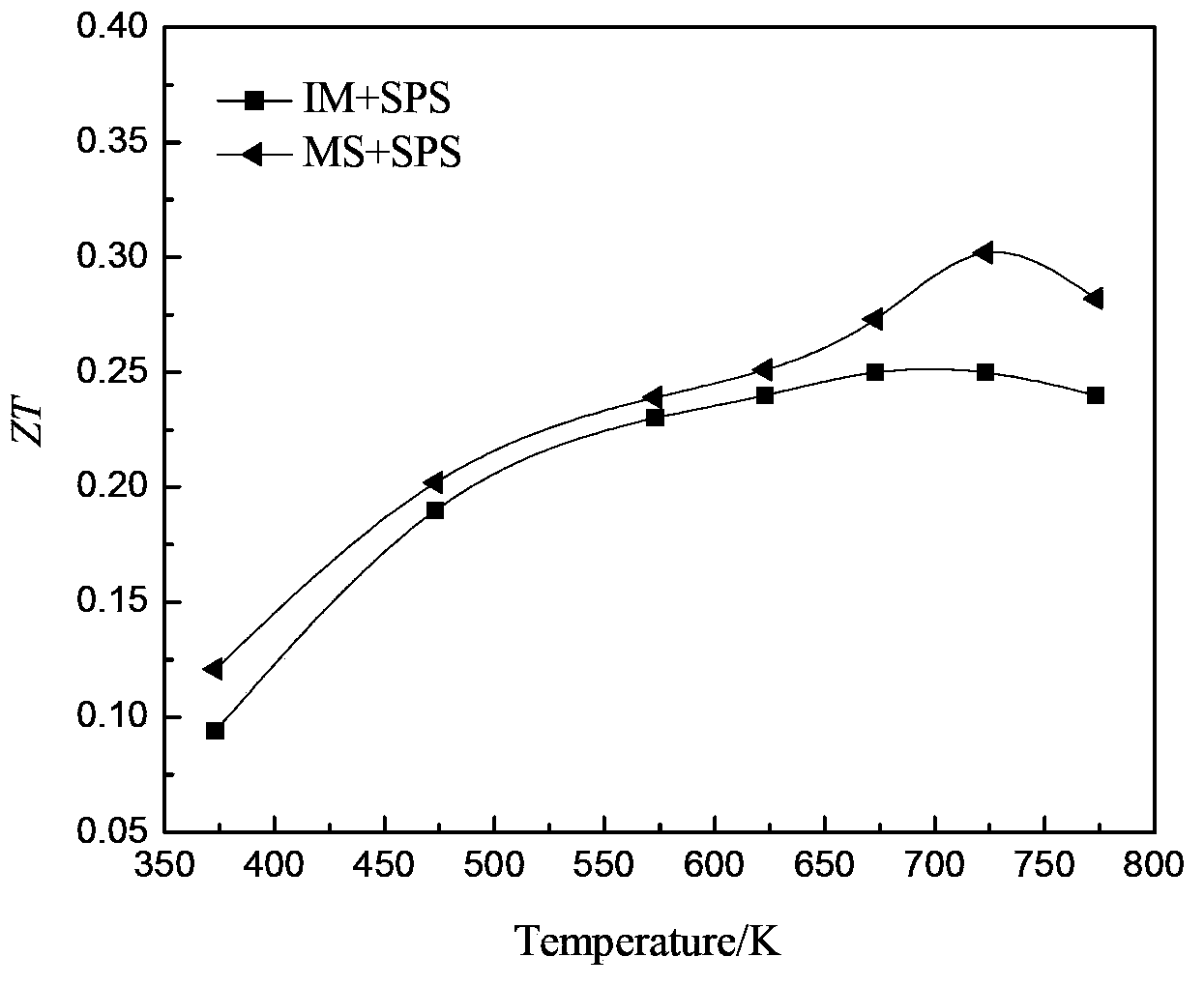

Nanocomposite structure Mg2Si-based thermoelectric material and preparation method thereof

InactiveCN103700759APrevent oxidationPrevent volatilizationThermoelectric device manufacture/treatmentThermoelectric device junction materialsThermoelectric materialsMolten state

The invention relates to a nanocomposite structure Mg2Si-based thermoelectric material and a preparation method thereof, and belongs to the technical field of preparation of semiconductor thermoelectric materials. The preparation method comprises the following steps: taking Mg, Si and Sn elementary substance materials according to a stoichiometric ratio and performing high-frequency induction smelting to form cast ingot; crushing the smelted cast ingots, filling into a quartz glass tube with a lower open end, vertically placing into an induction smelting coil, vacuumizing a cavity of a rapid quenching furnace, filling protective gas, performing induction smelting to enable the block to reach a molten state, spraying the melt to a copper rod, throwing out to form belt materials, and collecting the belt materials; placing the belt materials into a glove box under the argon protective atmosphere, grinding into powder, and performing spark plasma sintering into blocks. The preparation method is simple and feasible; the process flow is short; oxidation of Mg can be effectively inhibited; process parameters are easy to control. An amorphous / nanocrystalline composite structure exists in a sample, the grain size is obviously refined, the grain size distribution is controllable, scattering of electrons and phonons is increased, the Seebeck coefficient is greatly increased, and the thermoelectric property of the material is improved.

Owner:BEIJING UNIV OF TECH

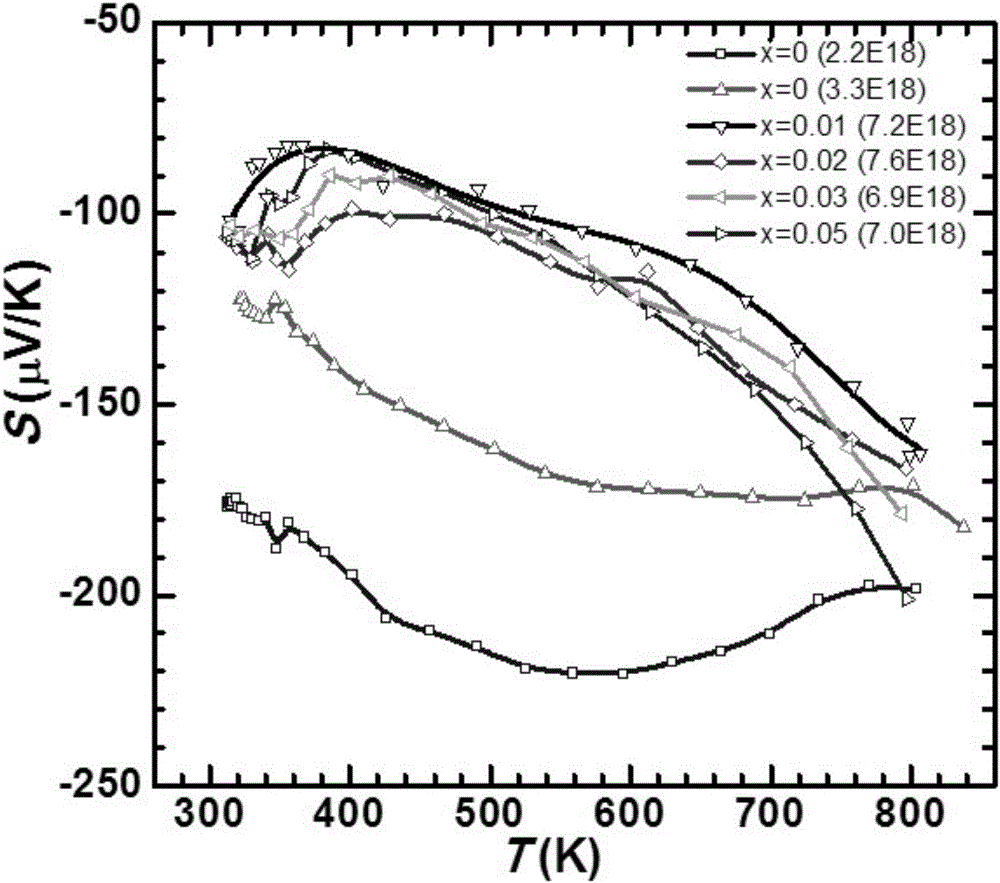

Medium and low temperature p-type multi element pyroelectric alloy possessing high thermoelectric figure of merit (ZT)

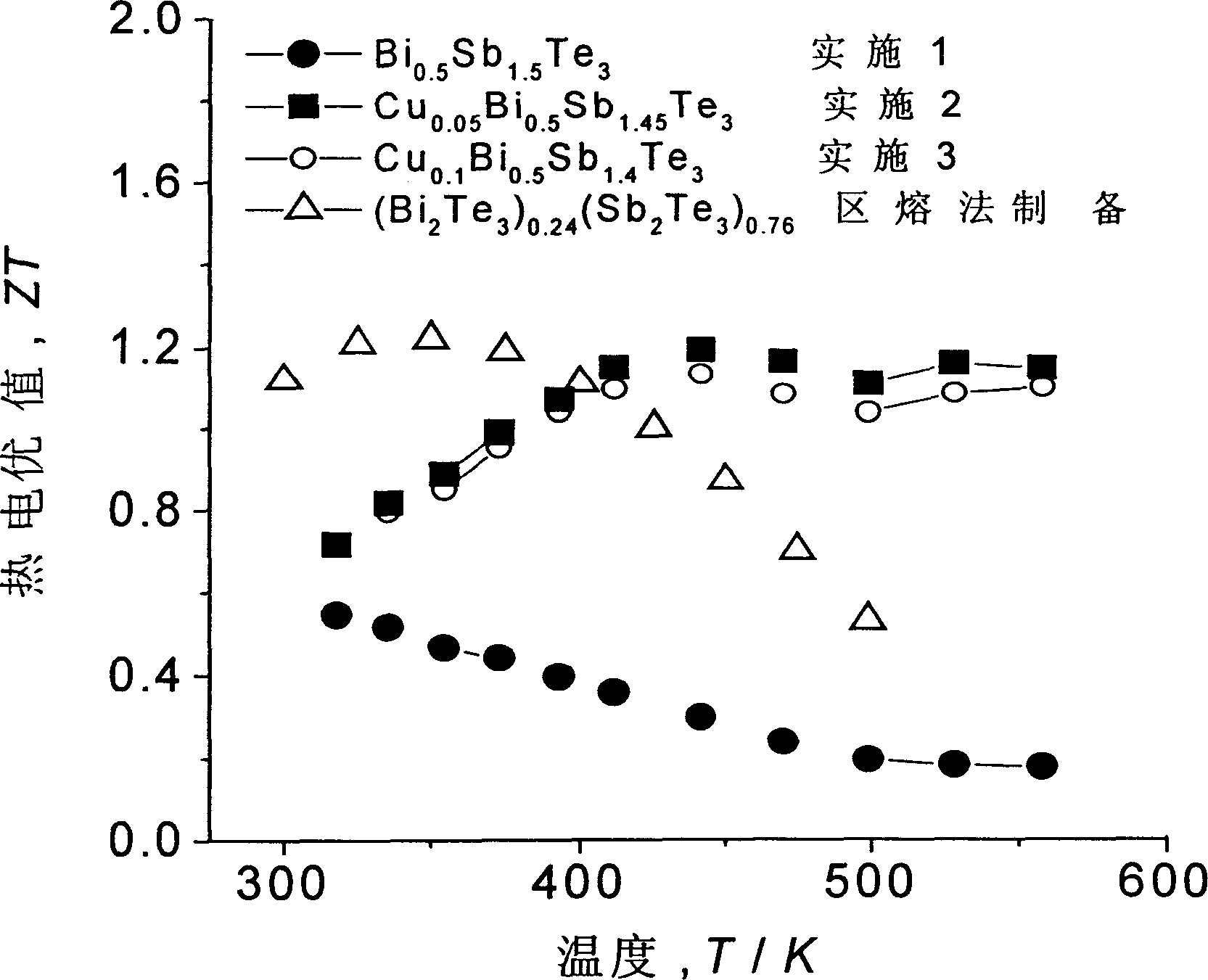

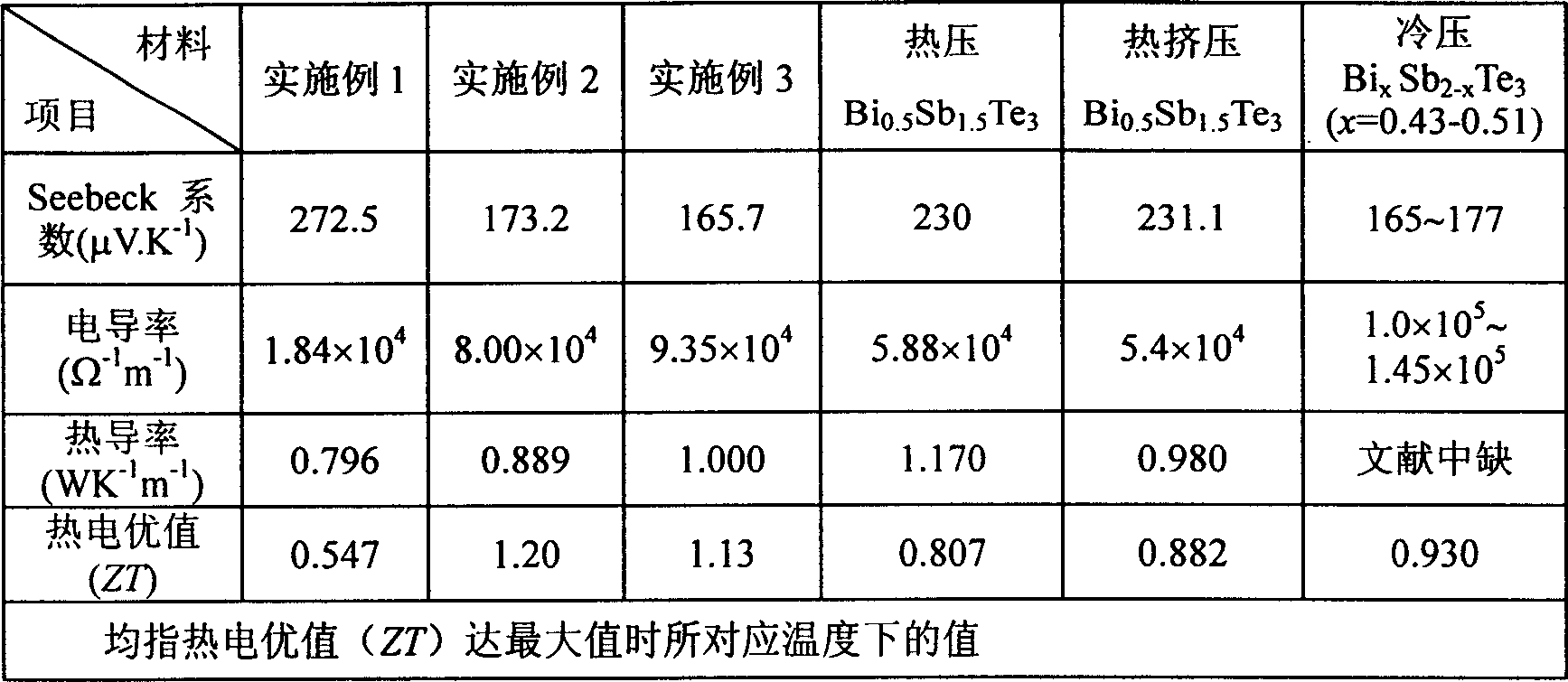

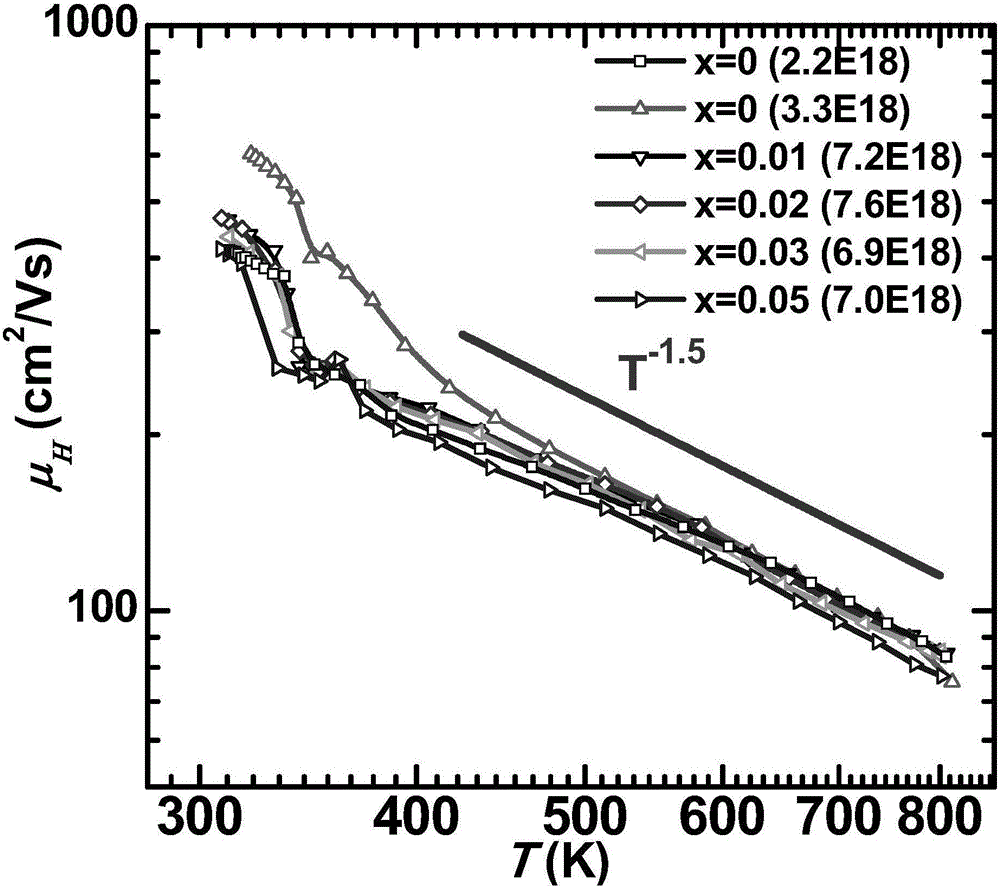

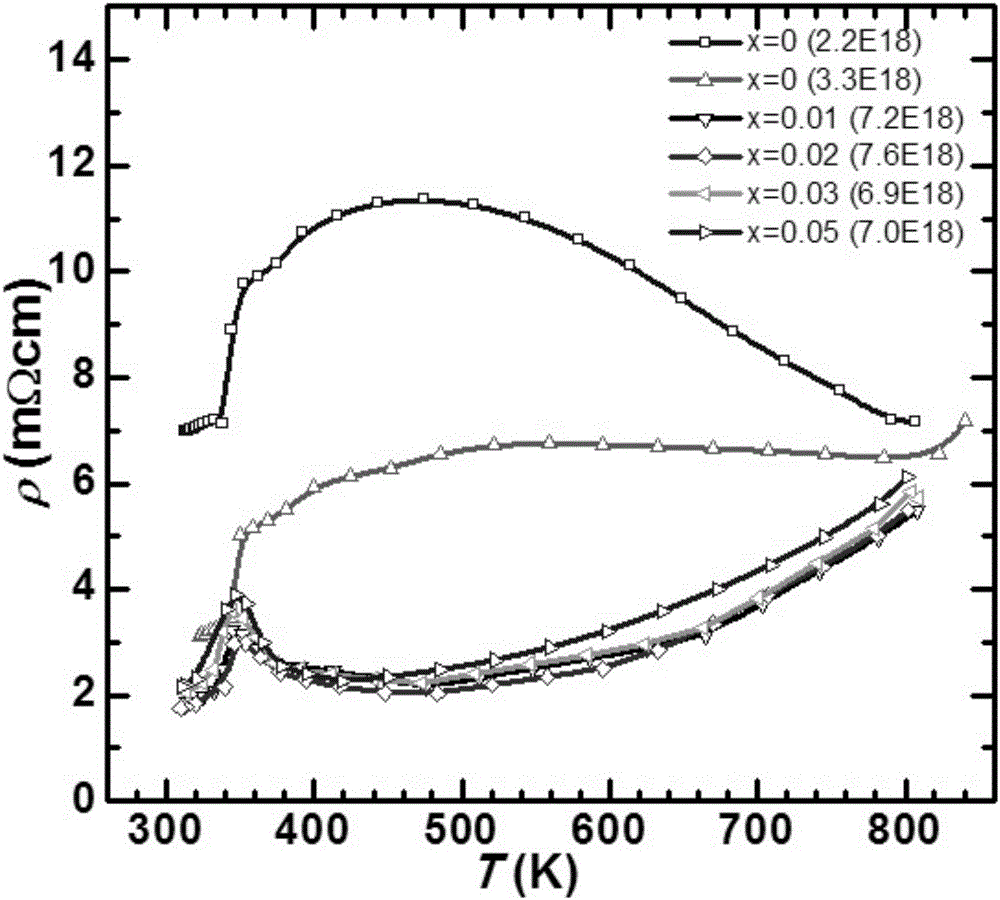

A medium-and low-temp multi-element P-type thermoelectric alloy with high ZT value is a CuxBi0.5 Sb1-xTe3 alloy. Its thermoelectric property is improved through designing the components of the basic Bi-Te material and discharge plasma spark sintering. It features that part of Sb is replaced by Cu. Its advantages are high reliability and thermoelectric properties, long service life and no pollution and noise.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

Argyrodite thermoelectric material and preparation method thereof

InactiveCN106098923AImprove thermoelectric performanceLow thermoelectric performanceThermoelectric device manufacture/treatmentThermoelectric device junction materialsArgyroditeSlow cooling

The invention relates to an argyrodite thermoelectric material, the chemical formula of which is Ag8Sn(1-x)NbxSe6, x=0-0.05. The preparation method of the argyrodite thermoelectric material is characterized by, with simple substances being raw materials, carrying out material blending according to stoichiometric ratio of the chemical formula; after vacuum packaging, melting reaction quenching and thermal treatment quenching, grinding ingots into powders; and carrying out vacuum high-temperature hot-pressure sintering, and after slow cooling, obtaining a block material, which is the argyrodite thermoelectric material. Compared with the prior art, the high-performance thermoelectric material, which is low in heat conduction and high in thermoelectric performance, is prepared, and the method for preparing the thermoelectric material, which is high in density, high in mechanical strength and high in thermoelectric performance, is explored; the thermoelectric material has very low lattice thermal conductivity (0.2-0.4 W / m.K) in a whole-temperature range; when the temperature is 900 K, thermoelectric peak of the thermoelectric material reaches 1.2; when the temperature is 300-850 K, the average thermoelectric figure of merit zTave of the thermoelectric material is infinity-0.8; and the argyrodite thermoelectric material is a potential thermoelectric material.

Owner:TONGJI UNIV

Graphene quantum dot/carbon nanotube/PEDOT:PSS composite film and preparation method thereof

The invention discloses a graphene quantum dot / carbon nanotube / PEDOT:PSS composite film and a preparation method thereof. The preparation method includes blending graphene quantum dots and carbon nanotubes in water sufficiently to form a graphene quantum dot / carbon nanotube hybrid, and dispersing the hybrid to an electroconductive polymer PEDOT:PSS to form the graphene quantum dot / carbon nanotube / PEDOT:PSS composite film. The graphene quantum dot / carbon nanotube / PEDOT:PSS composite film and the preparation method thereof have the advantages that both the graphene quantum dots and the carbon nanotubes structurally comprise large delocalized pi-bonds, a graphene quantum dot layer is modified on the wall of each of the carbon nanotubes through pi-pi conjugation, and accordingly excellent water solubility is achieved; the graphene quantum dot / carbon nanotube hybrid is evenly dispersed into a PEDOT:PSS water solution through uniform dispersity of the graphene quantum dots and the PEDOT:PSS in water, and the graphene quantum dots, the carbon nanotubes and PEDOT:PSS are combined together uniformly and effectively with the aid of pi-pi interaction between the graphene quantum dots and PEDOT, so that the graphene quantum dot / carbon nanotube / PEDOT:PSS composite film is formed. The graphene quantum dot / carbon nanotube / PEDOT:PSS composite film is excellent in electroconductivity, high in Seebeck coefficient and low in heat conduction coefficient.

Owner:TIANJIN RES INST FOR ADVANCED EQUIP TSINGHUA UNIV

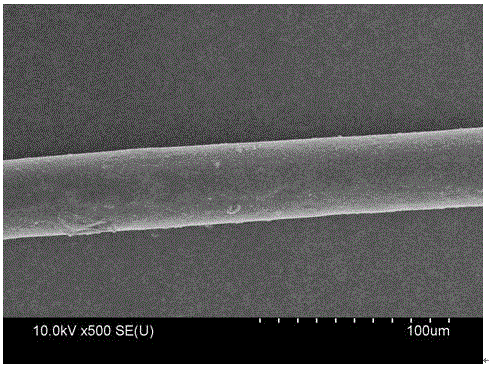

Polymer sheath-core composite fiber with thermoelectric effect as well as preparation method and application thereof

ActiveCN106637489ARealize the cooling effectRealize functionFilament/thread formingConjugated synthetic polymer artificial filamentsFiberPolyethylene terephthalate glycol

The invention discloses a polymer sheath-core composite fiber with a thermoelectric effect as well as a preparation method and application thereof. The polymer sheath-core composite fiber is composed of a polymer sheath layer and a thermoelectric master batch material core layer, wherein the mass ratio of the sheath layer to the core layer ranges from (2 to 1) to (1 to 2); the polymer sheath layer is prepared from one of polypropylene, polyamide 6, polyamide 66 and polyethylene terephthalate resin; the thermoelectric master batch material core layer is composed of ternary components including carbon nanotubes / graphene, bismuth telluride and resin. According to the polymer sheath-core composite fiber disclosed by the invention, the graphene, the bismuth telluride and the macromolecule resin are used as raw materials, and are subjected to methods including melting and commixing, solid-phase force shearing and the like, so that uniform dispersion of a graphene and bismuth telluride compound phase is realized in one step. After thermoelectric master batches are prepared, a melting compounded spinning technology is adopted to prepare a sheath-core composite thermoelectric fiber material. The fiber material has an important application prospect in the field of thermoelectric conversion. The polymer sheath-core composite fiber can be made into a thermoelectric refrigerating device which is arranged in a fabric and clothes; the temperature can be adjusted and the temperature is comfortable and adjustable.

Owner:TIANJIN POLYTECHNIC UNIV

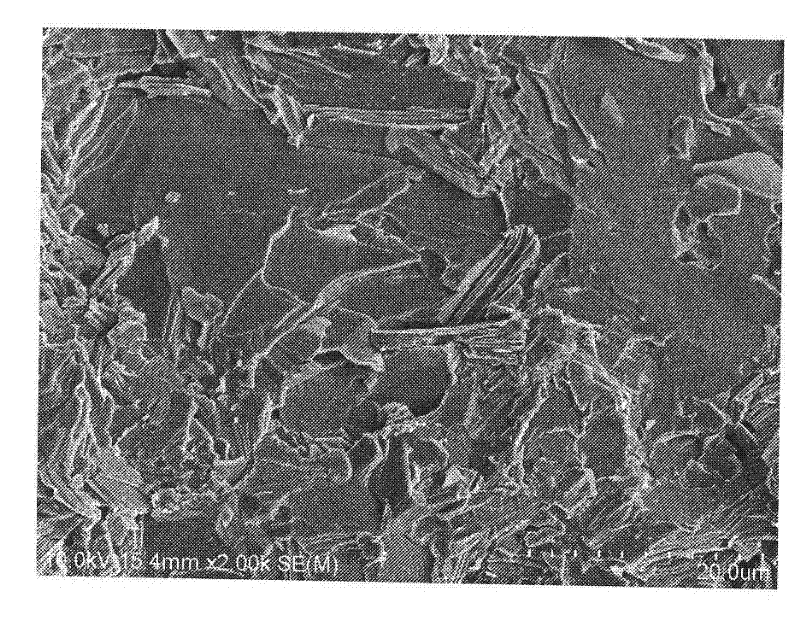

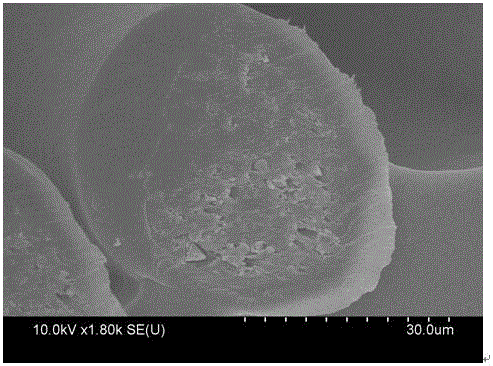

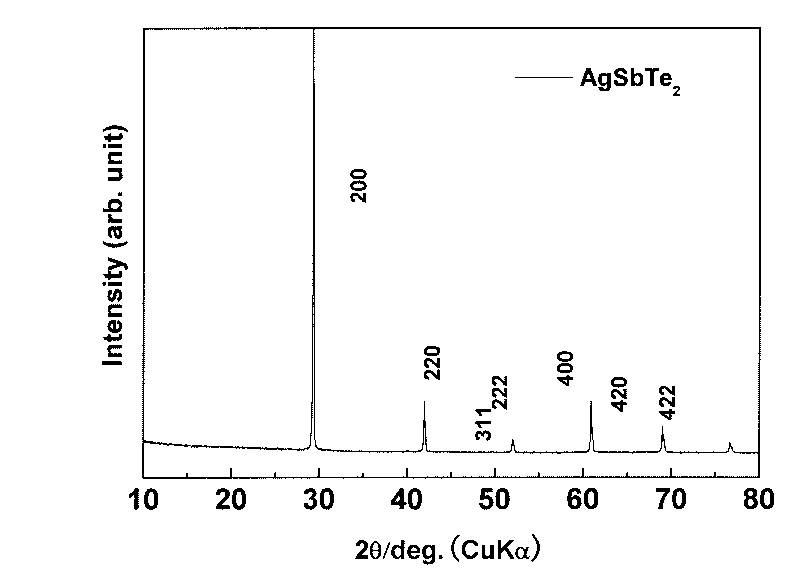

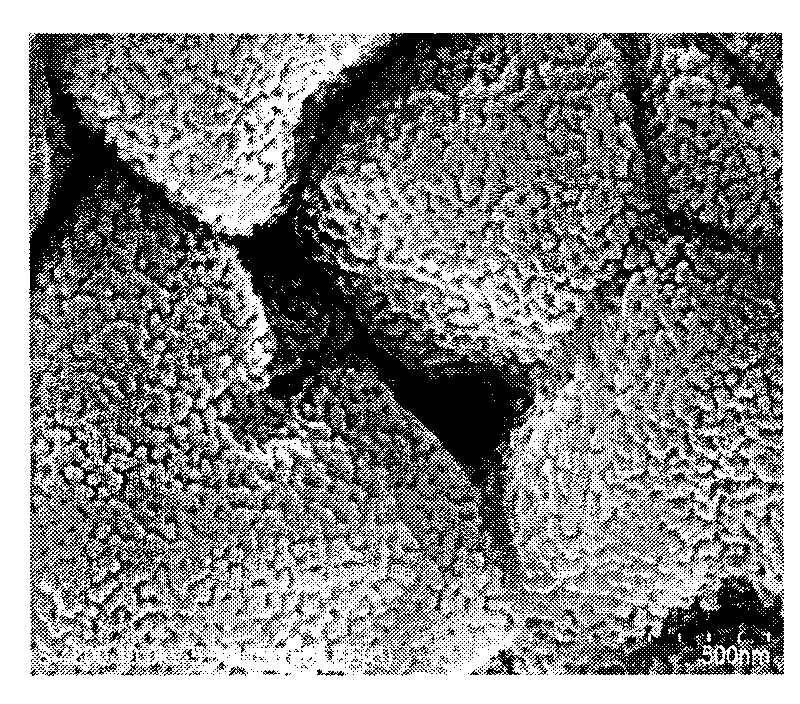

Method for preparing AgSbTe2 thermoelectric material by combining fusant rotatable swinging and spark plasma sintering

The invention relates to a method for preparing a thermoelectric compound. The method for preparing a AgSbTe2 thermoelectric material by combining fusant rotatable swinging and discharge plasma sintering is characterized by comprising the following steps of: (1) mixing; weighing thread-shaped Ag, block-shaped Te and granular Sb as initial raw materials according to a chemical formula AgSbTe2+x, wherein x is equal to 0-0.08; (2) preparing mother alloy; mixing the thread-shaped Ag, the block-shaped Te and the granular Sb, placing the mixture into a smelting furnace, heating to 700 DEG C, smelting for 8-10 hours, cooling to 550 DEG C and then quenching in supersaturated saline water to obtain the mother alloy; (3) grinding and tabletting the mother alloy, placing the mother alloy into an induction heating furnace to melt to form a fusant and then rotatably swinging the fusant to obtain a band-shaped product having an amorphous / nanocrystal composite structure; and (4) grinding the band-shaped product having an amorphous / nanocrystal composite structure and carrying out spark plasma sintering to obtain the AgSbTe2 thermoelectric material. The method has short preparation period, low cost, pure phase, simple and easy control of process, safety and no pollution.

Owner:武汉经开科创运营有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com