Patents

Literature

90results about How to "Strong mechanical connection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

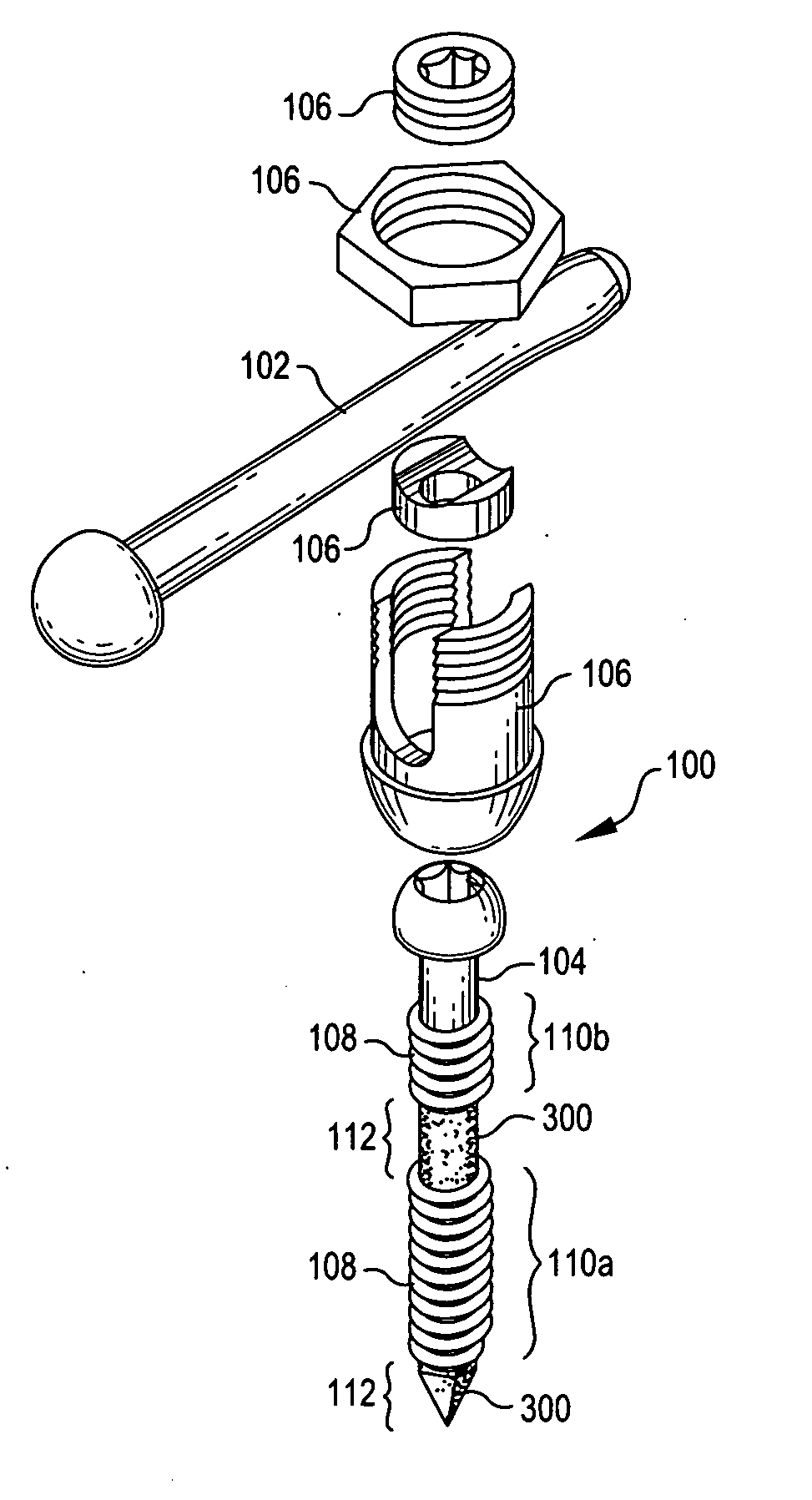

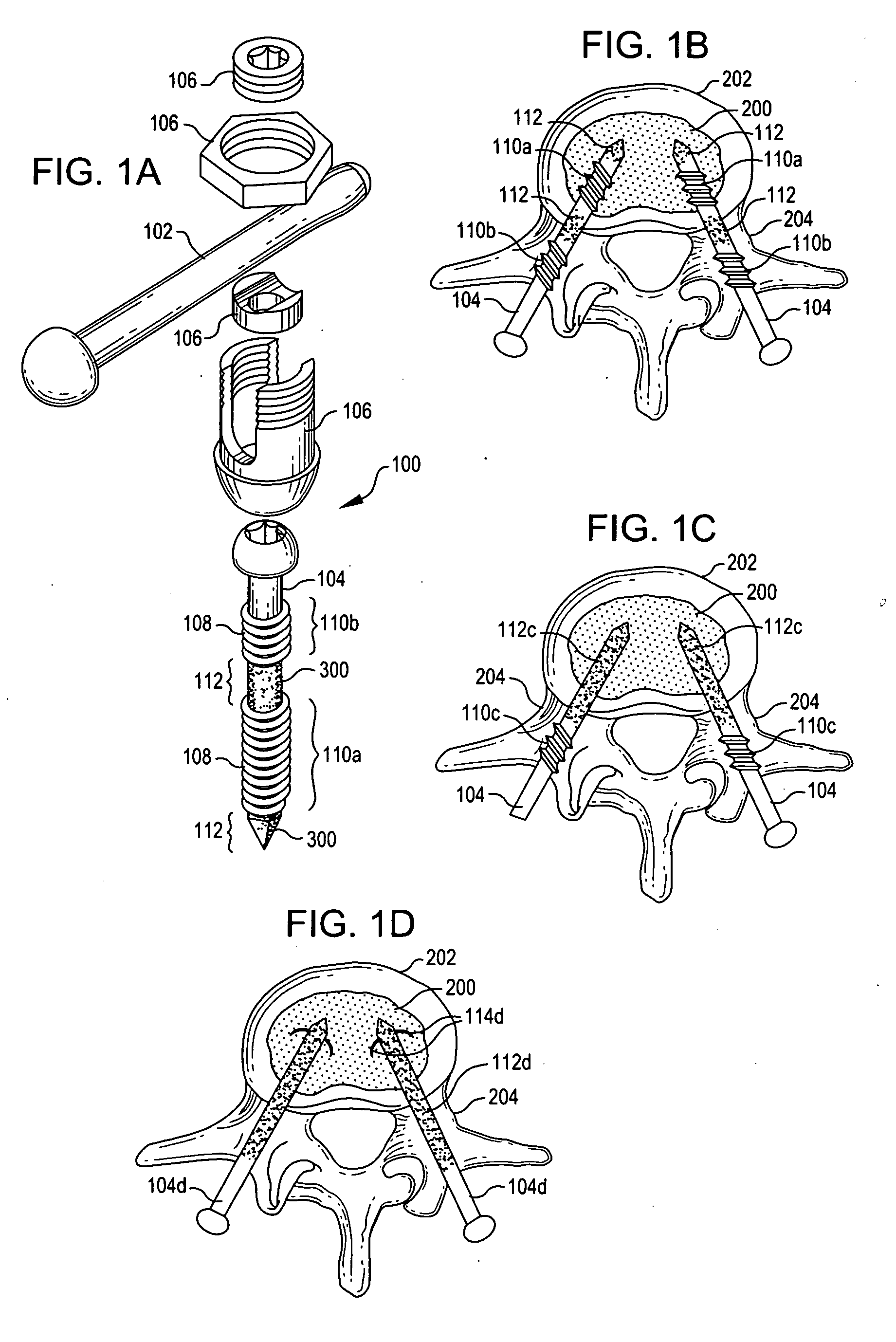

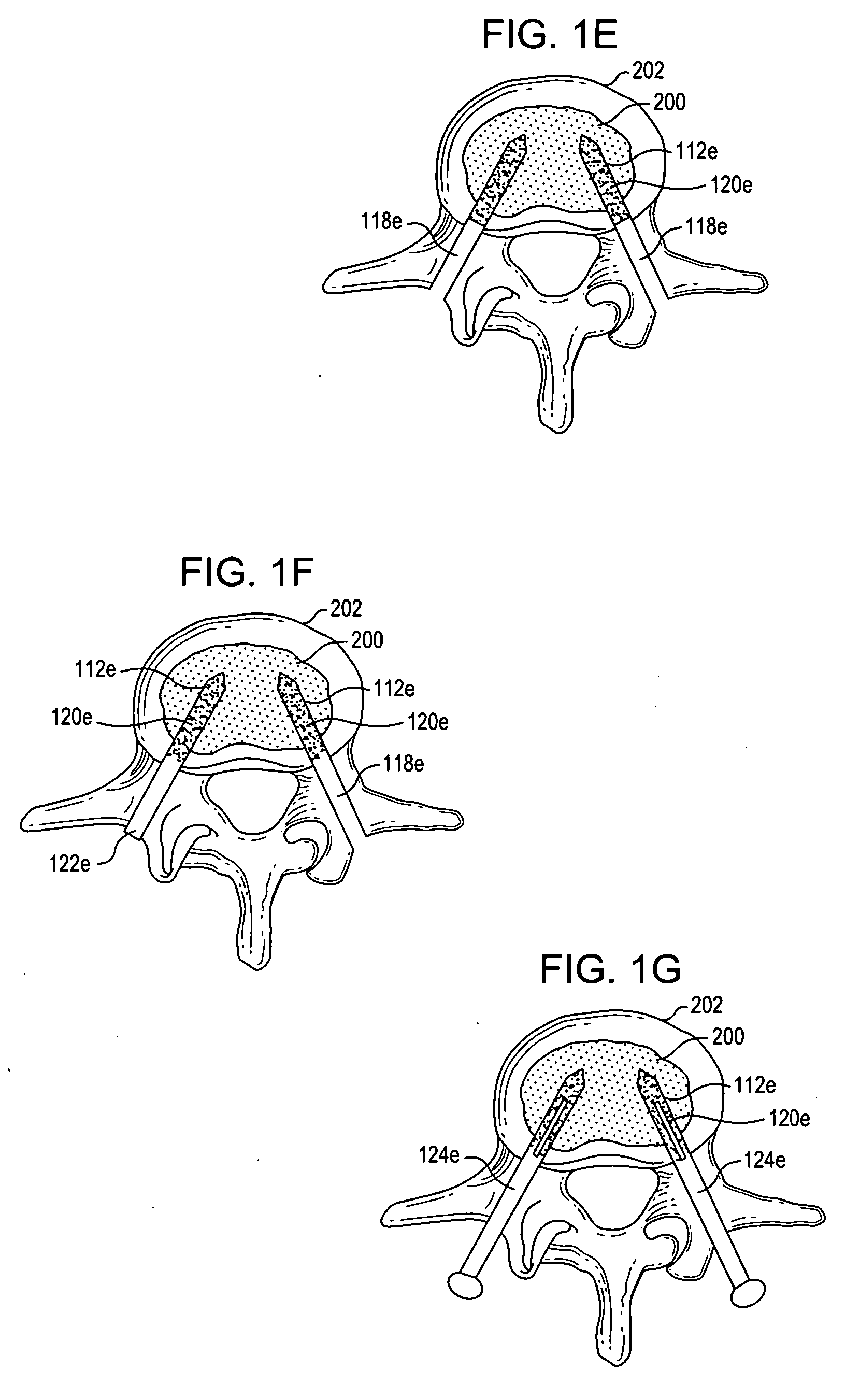

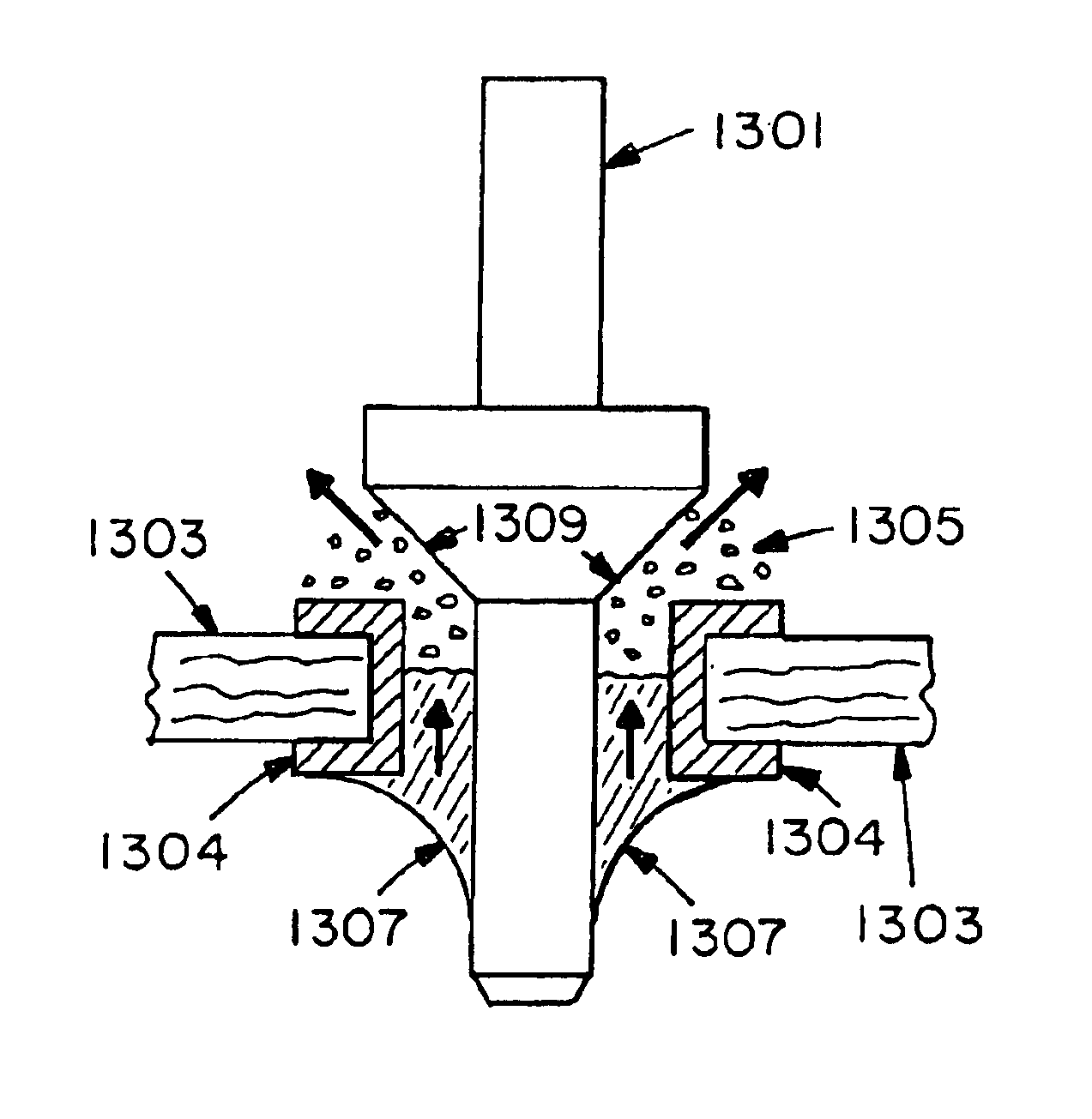

Methods and devices for improved bonding of devices to bone

InactiveUS20060079895A1Improve interface strengthSufficient supportSuture equipmentsInternal osteosythesisImplanted deviceSoft tissue

The present invention is directed to improving bonding between orthopedic devices, particularly vertebral devices, and bone. The present invention provides various methods and devices employing mechanical and bio-fixation modalities for such attachment. As provided herein, the initial mechanical attachment of a device to bone is sufficiently stable to ensure that the implanted device is relatively immobile (or alternatively microscopic motion is promoted), facilitating bone and soft tissue in-growth and the eventual bio-fixation of the device.

Owner:FACET SOLUTIONS

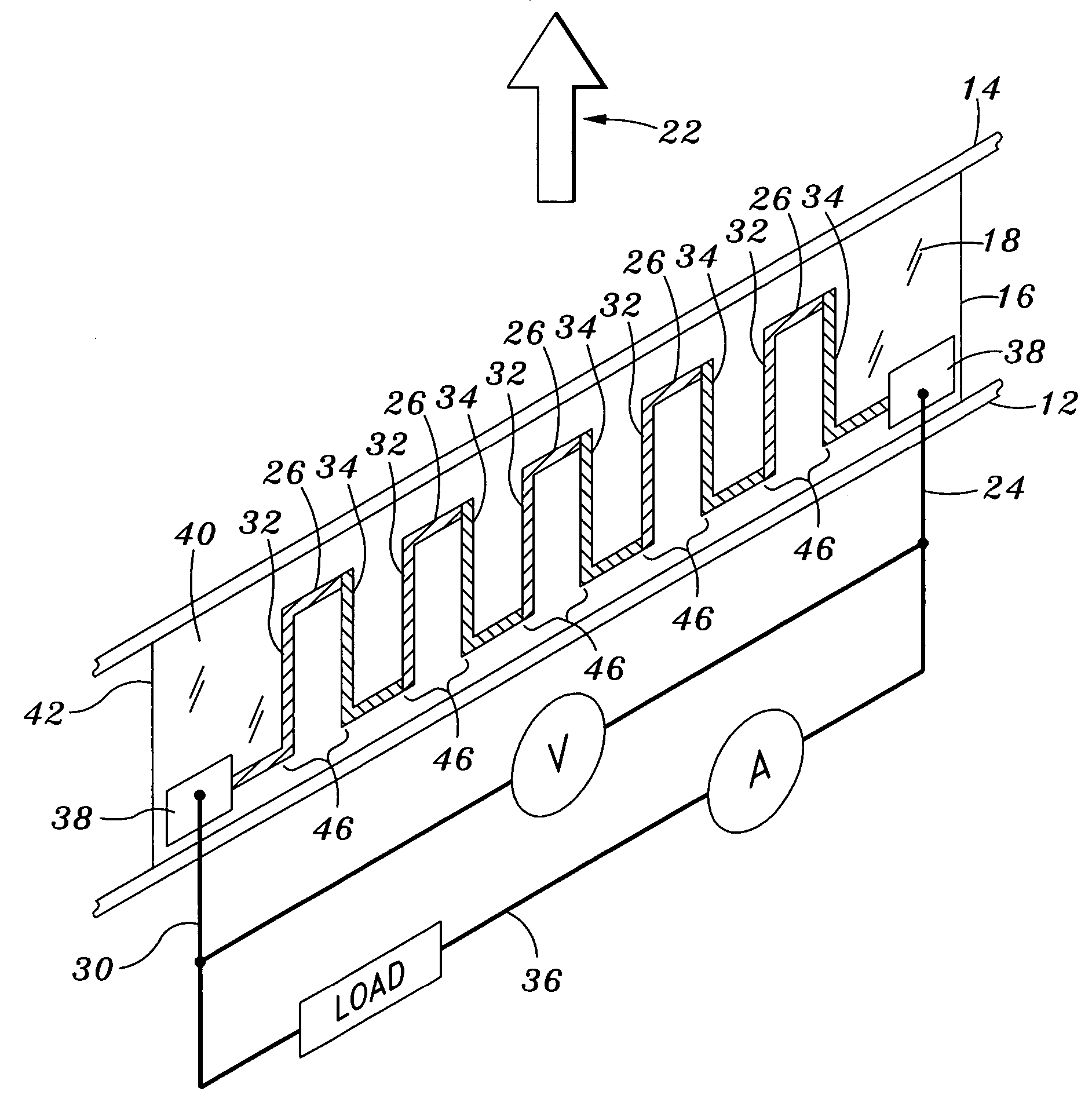

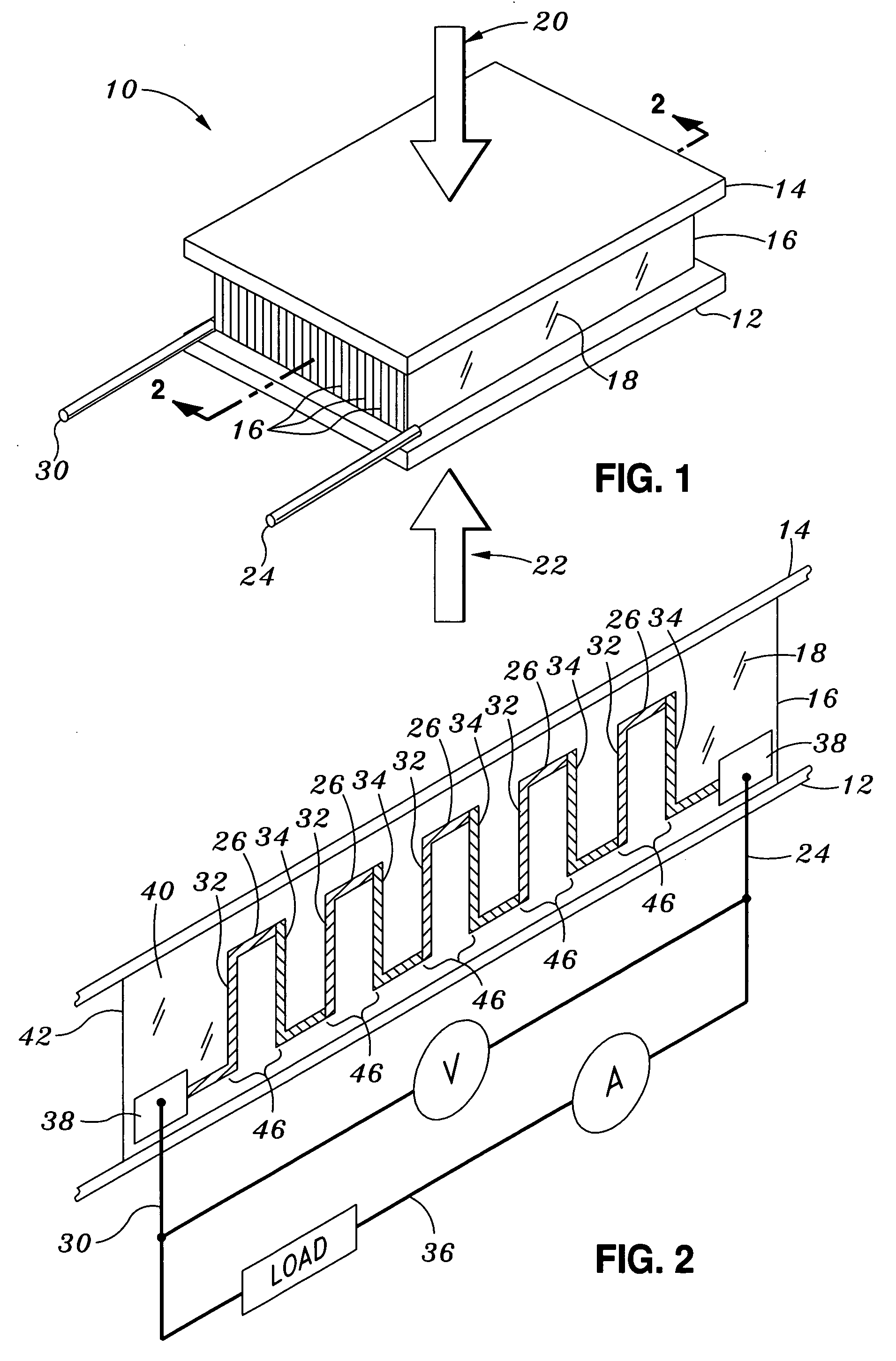

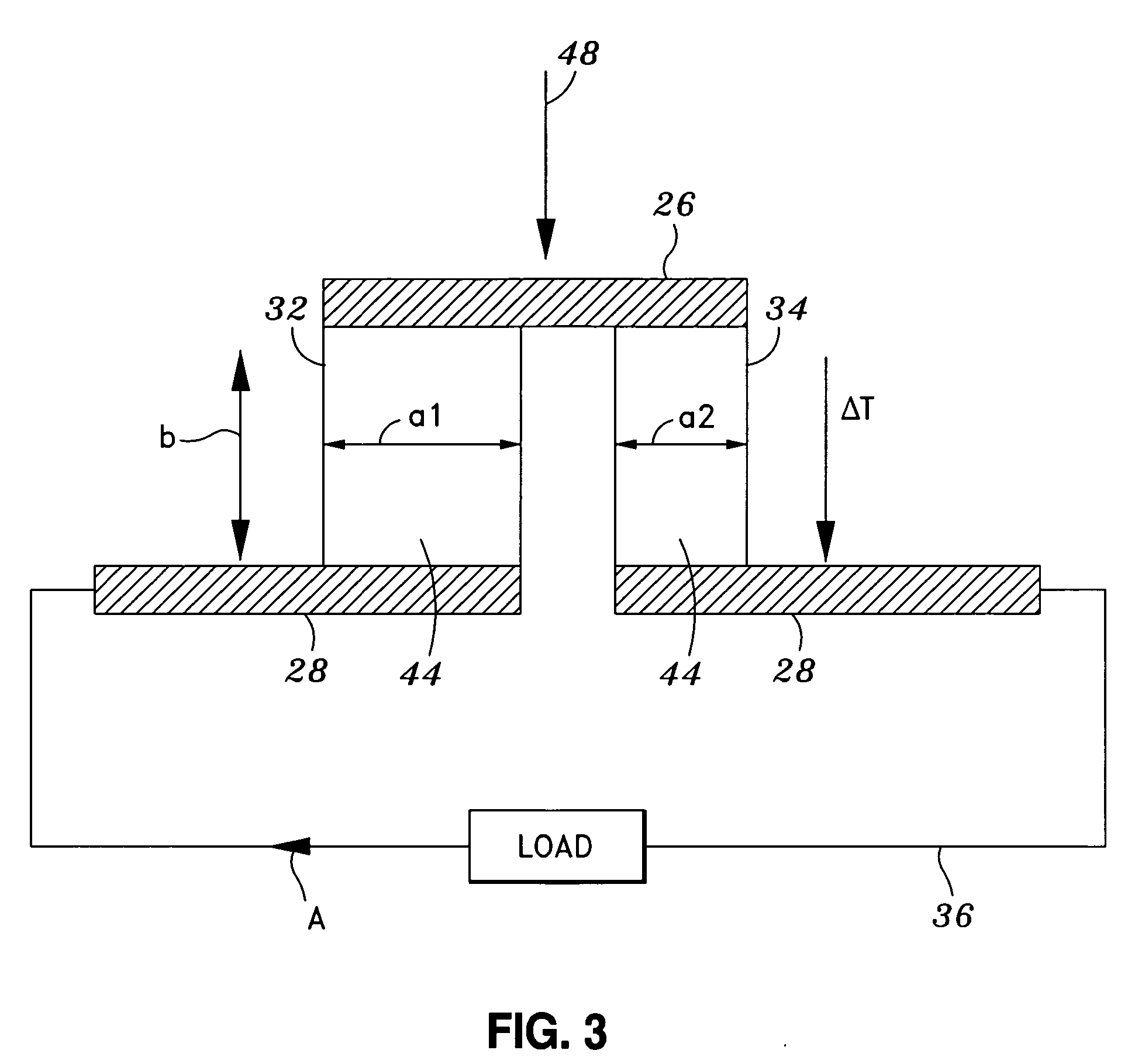

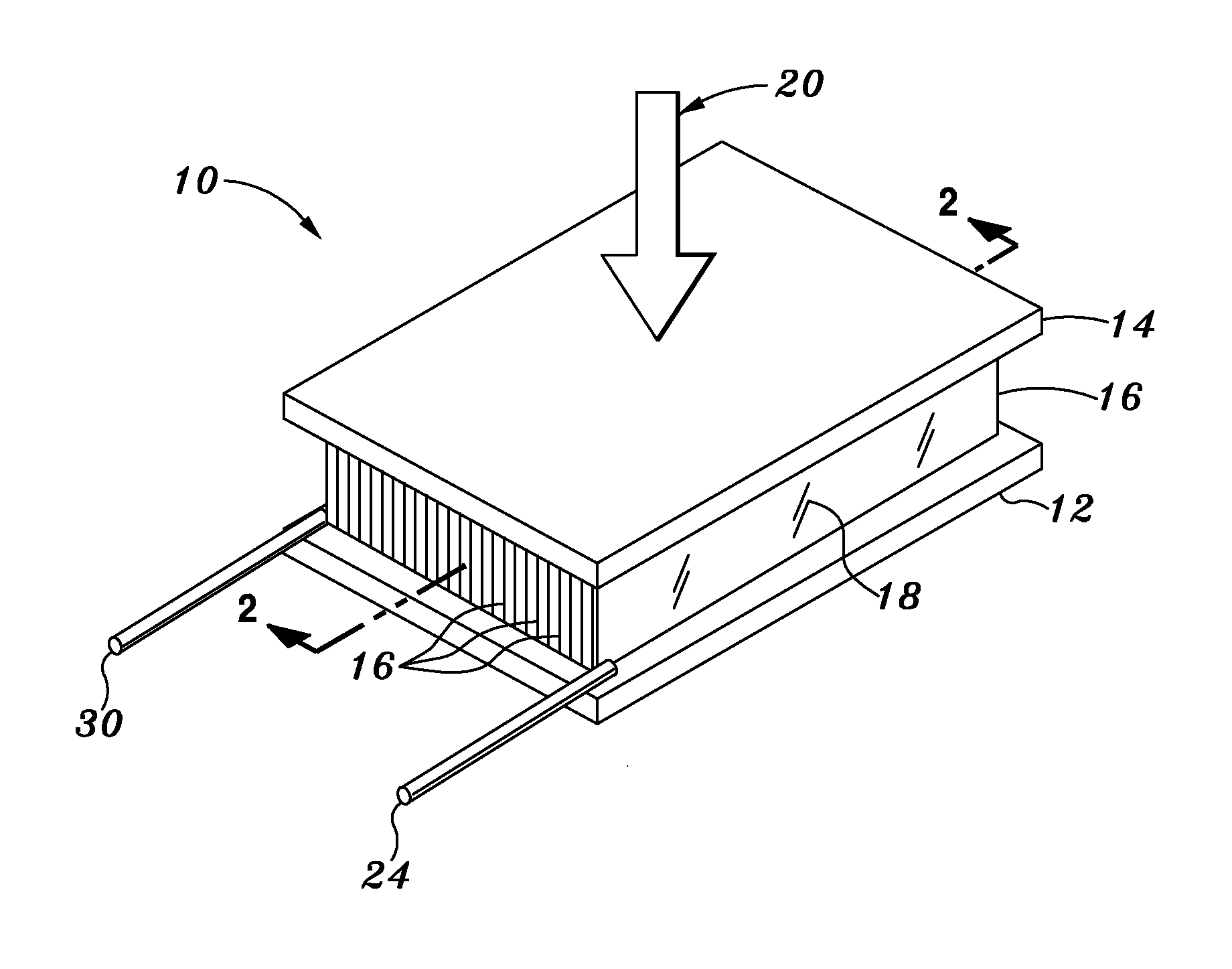

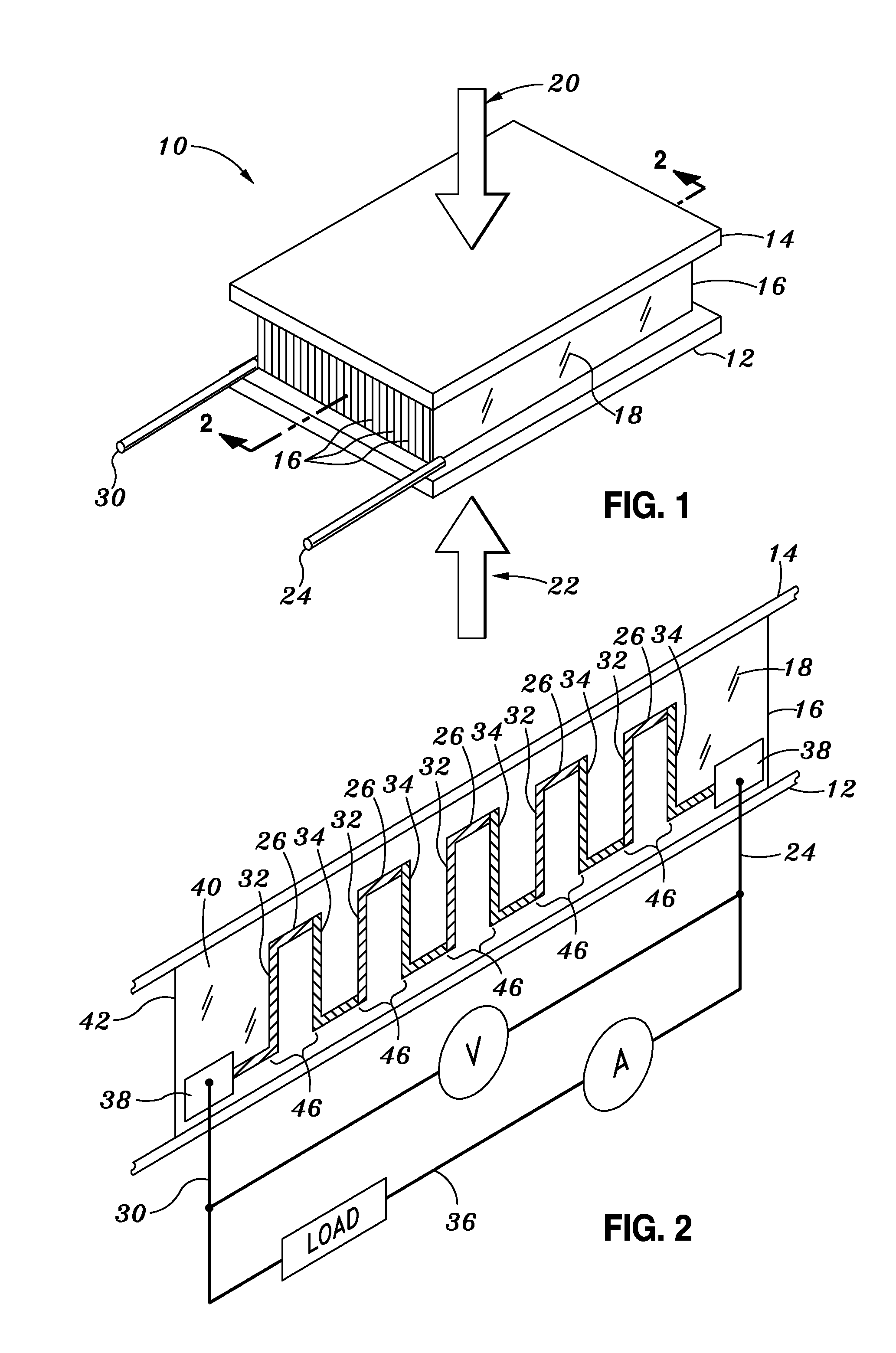

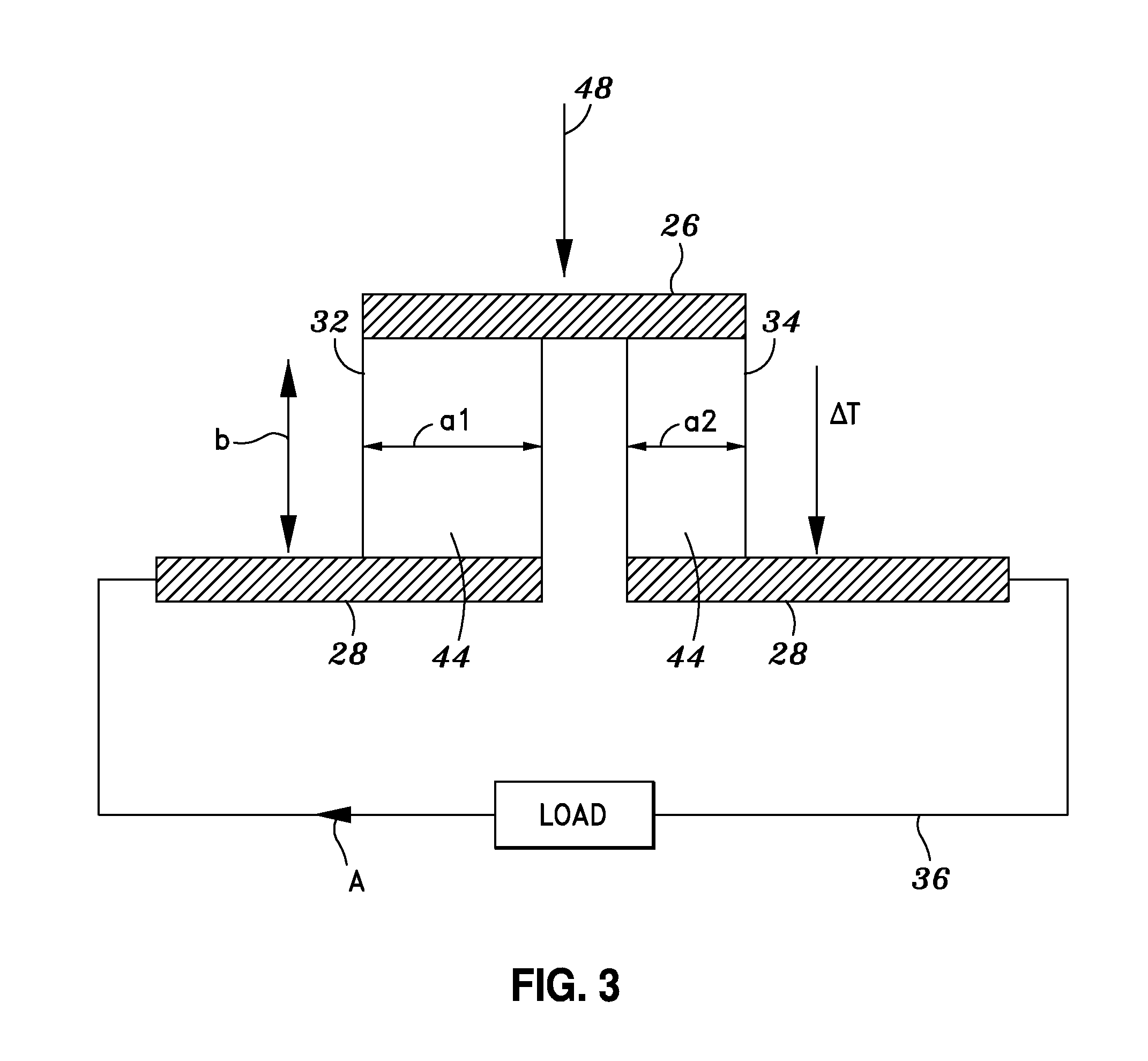

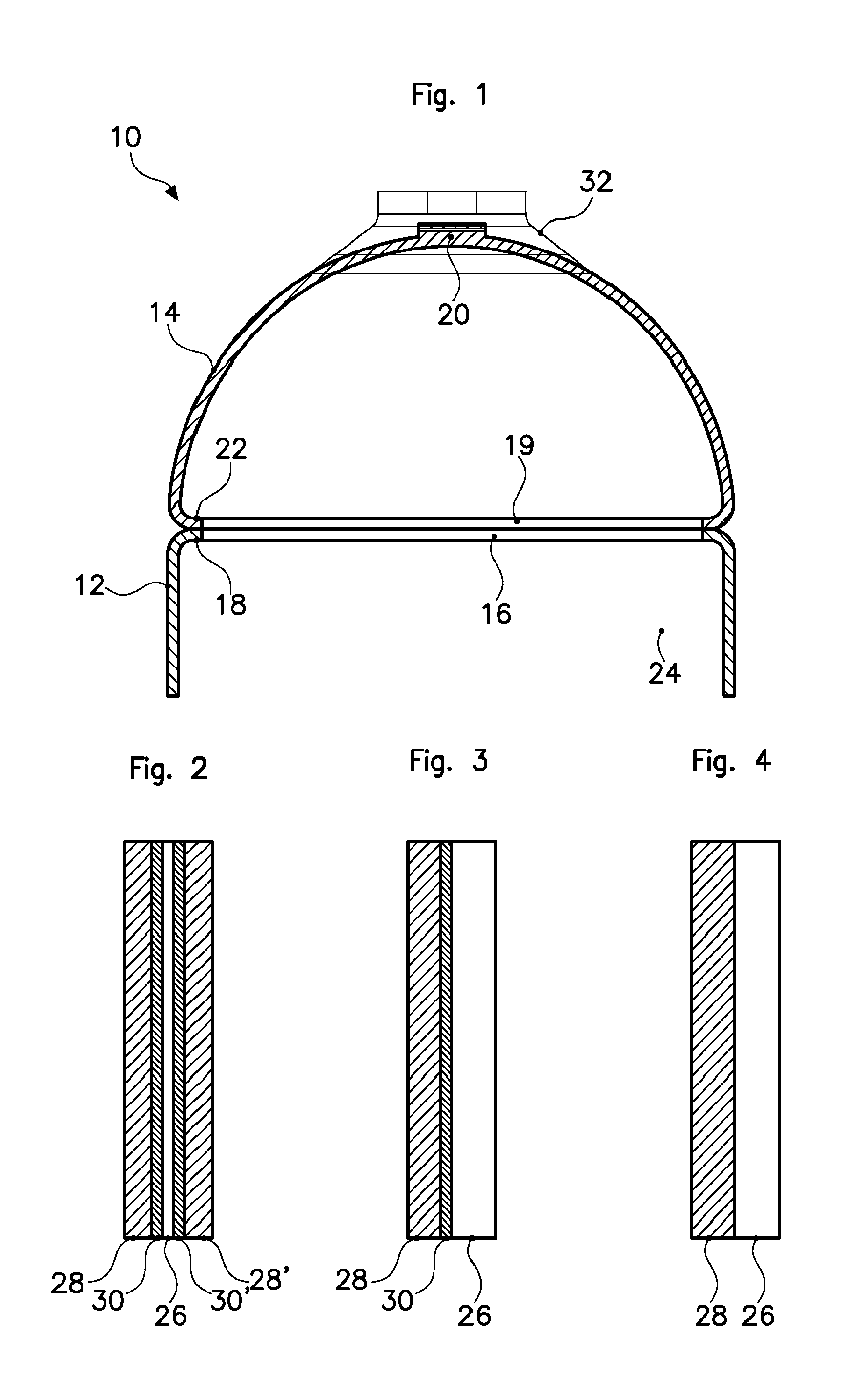

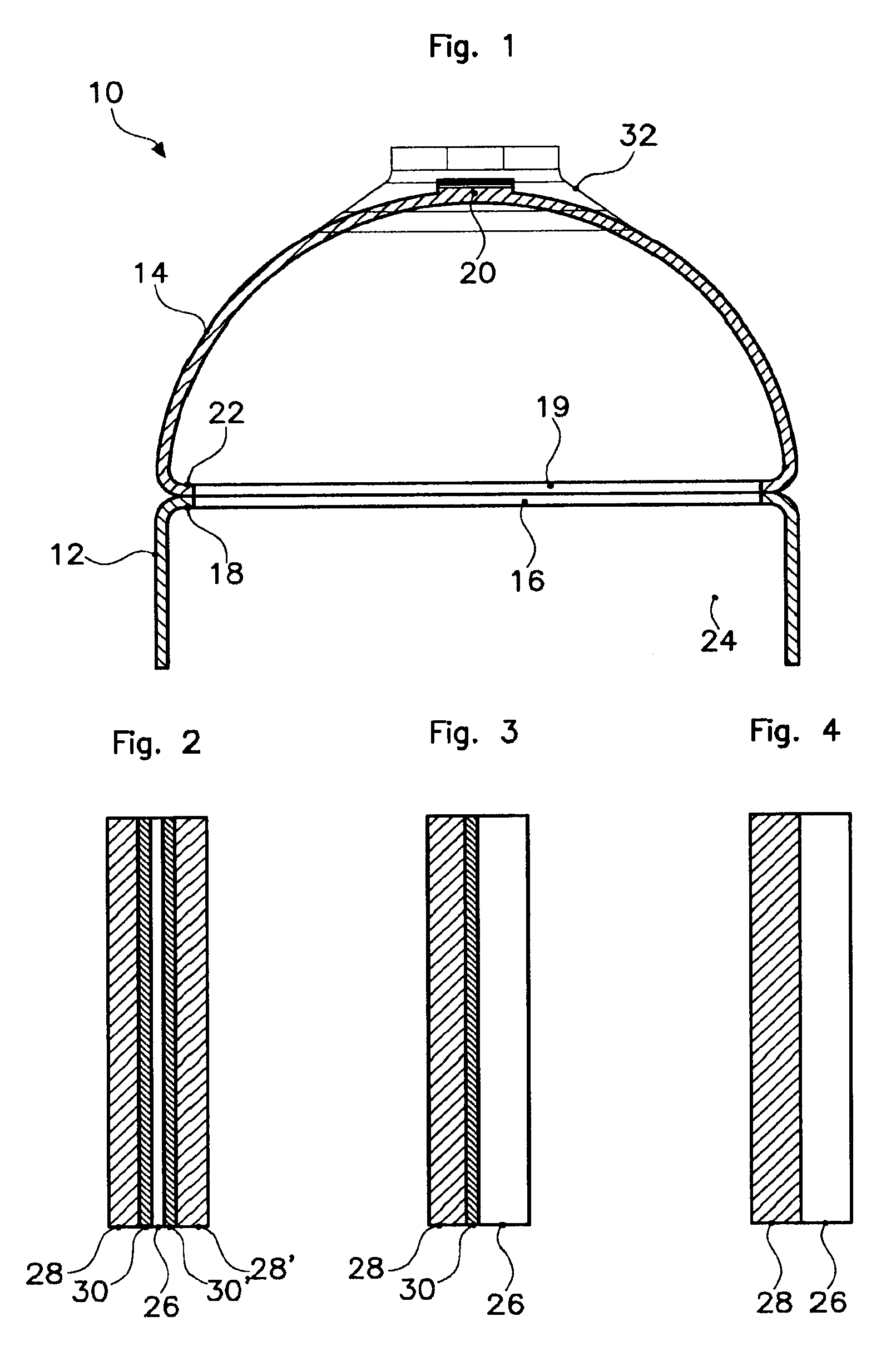

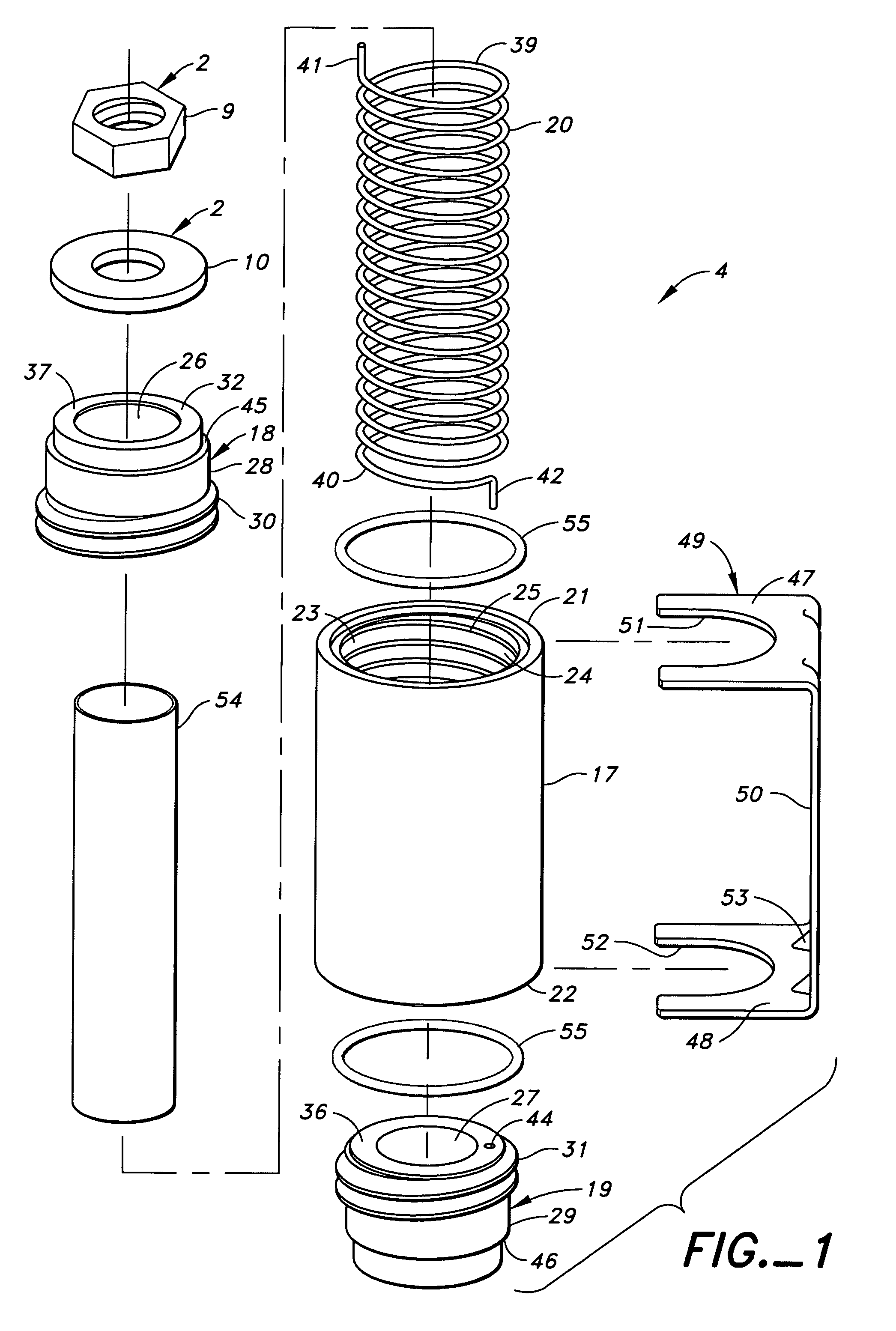

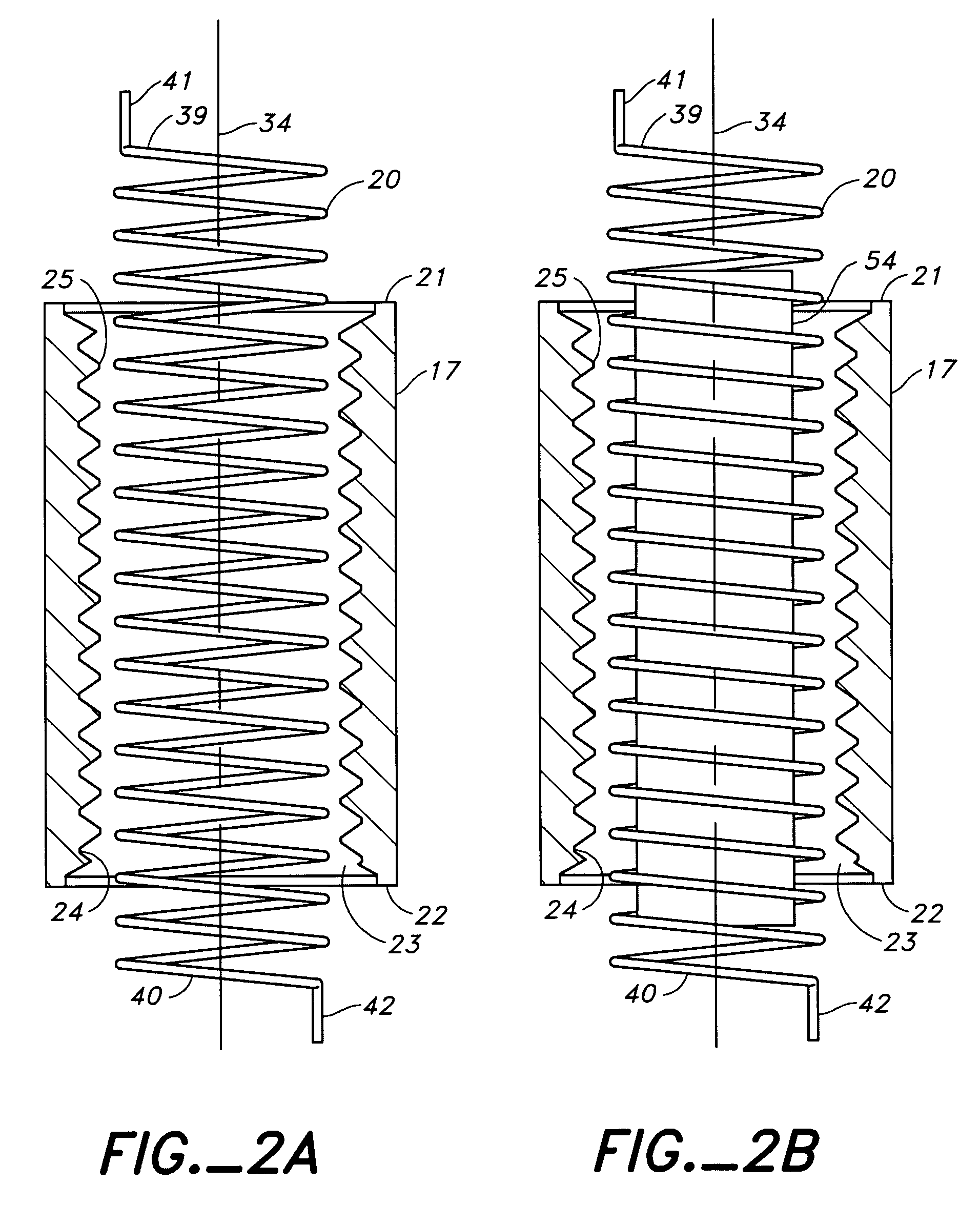

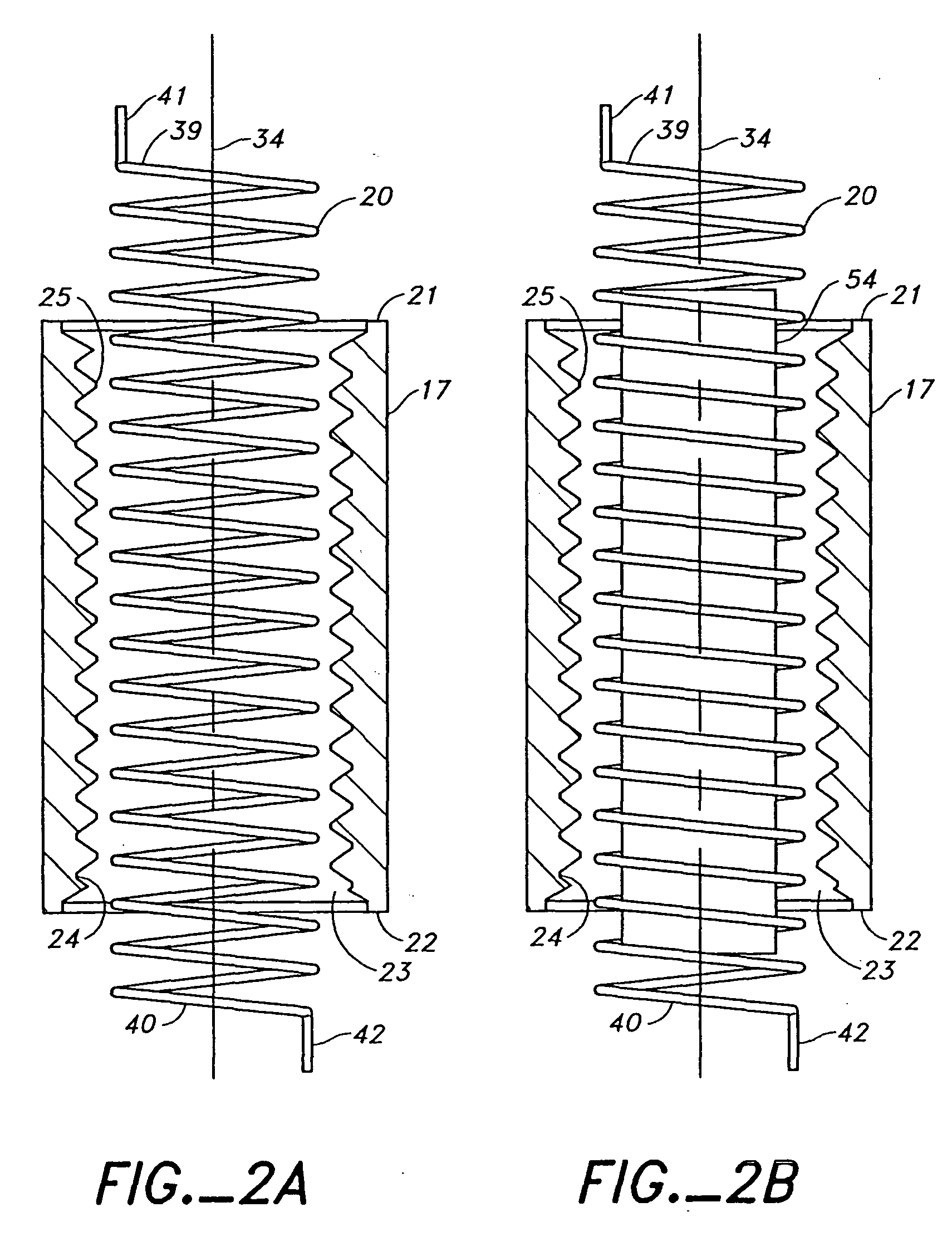

Low power thermoelectric generator

InactiveUS20060151021A1Improve thermoelectric performanceEnhance fabricationThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentBismuth tellurideEngineering

A thermoelectric generator has a top plate disposed in spaced relation above a bottom plate. A series of foil segments are electrically and mechanically connected end-to-end to generate a foil assembly that is spirally wound and in thermal contact with the bottom and top plates. Each foil segment comprises a substrate having a series of spaced alternating n-type and p-type thermoelectric legs disposed in parallel arrangement on the front substrate surface. Each of the n-type and p-type legs is formed of a bismuth telluride-based thermoelectric material having a thickness of about 10-100 microns, a width of about 10-100 microns and a length of about 100-500 microns. The alternating n-type and p-type thermoelectric legs are electrically connected in series and thermally connected in parallel such that a temperature differential between the bottom and top plates results in the generation of power.

Owner:DIGITAL ANGEL CORP

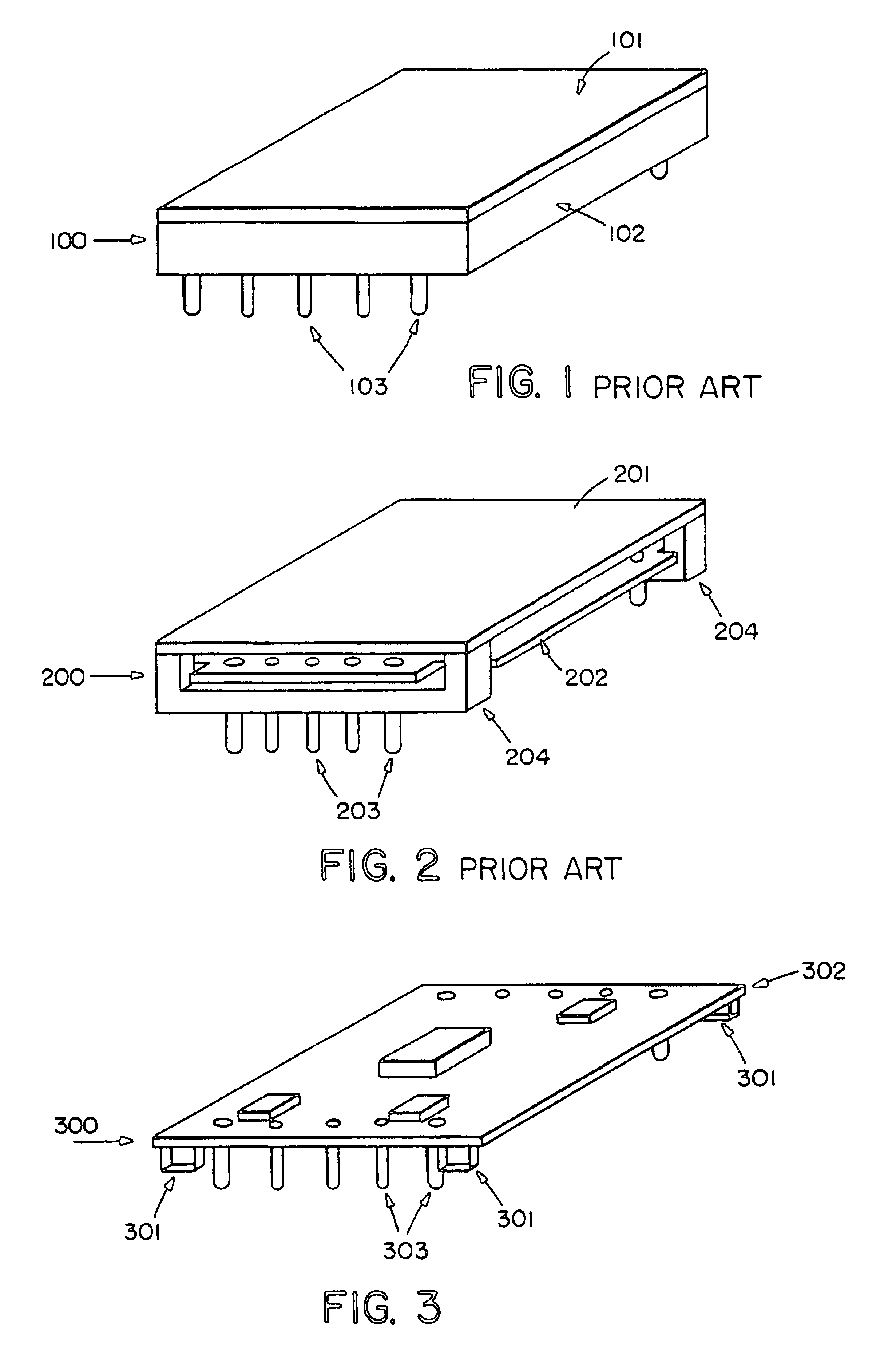

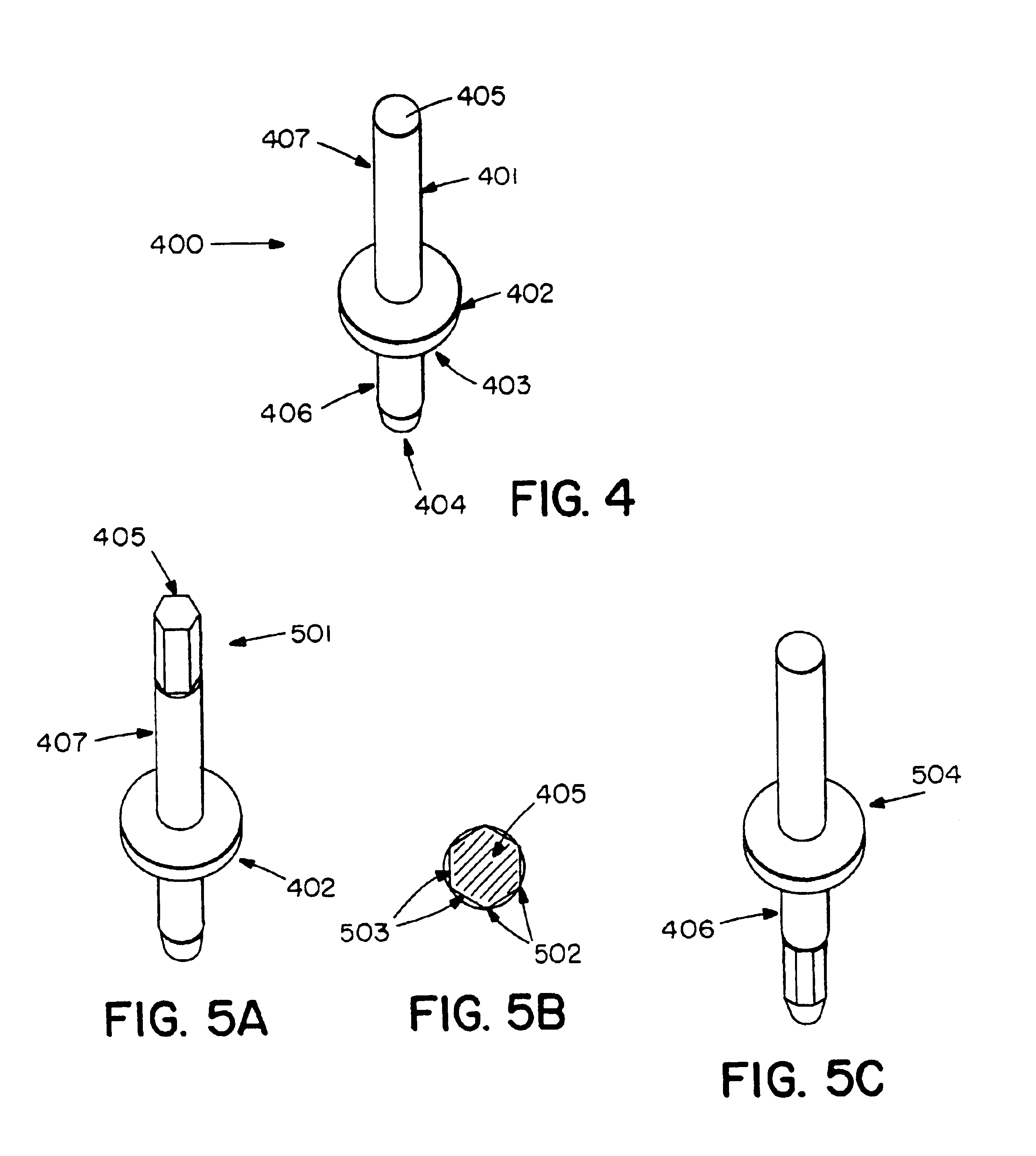

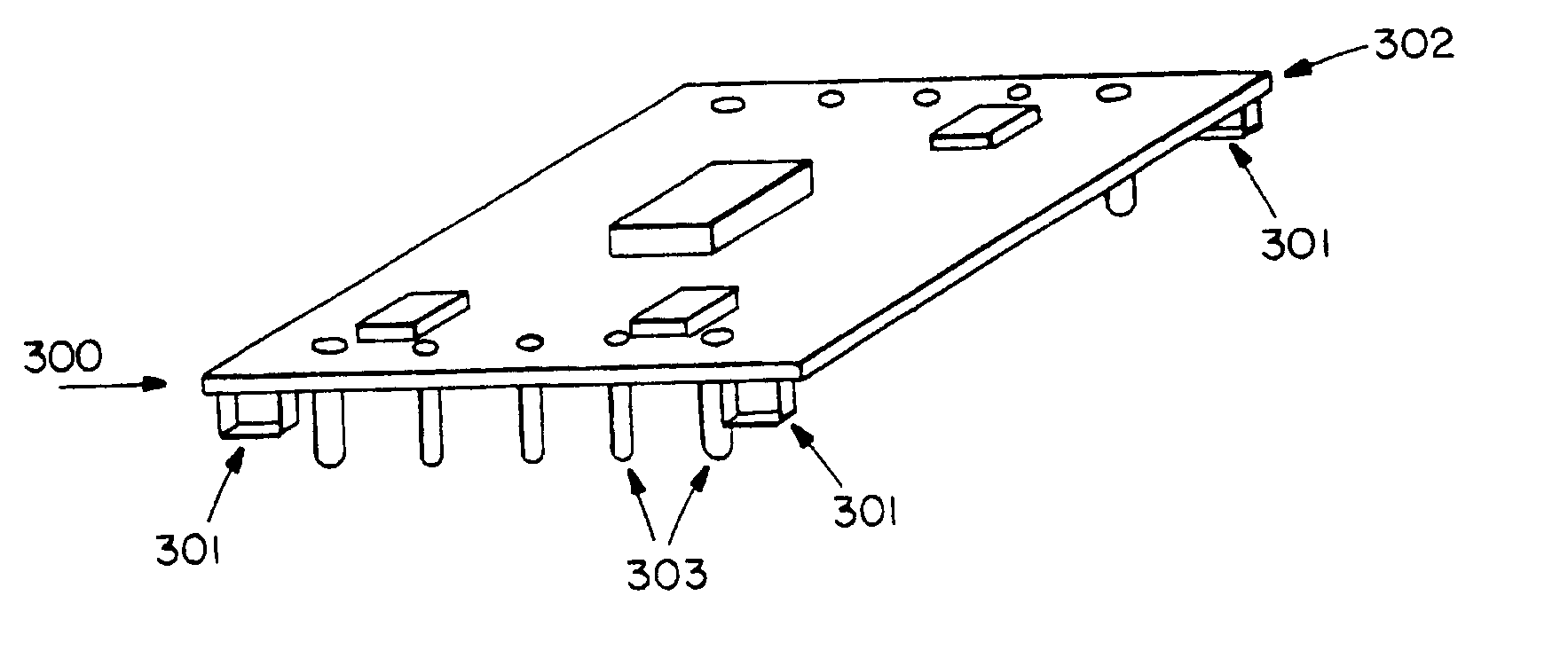

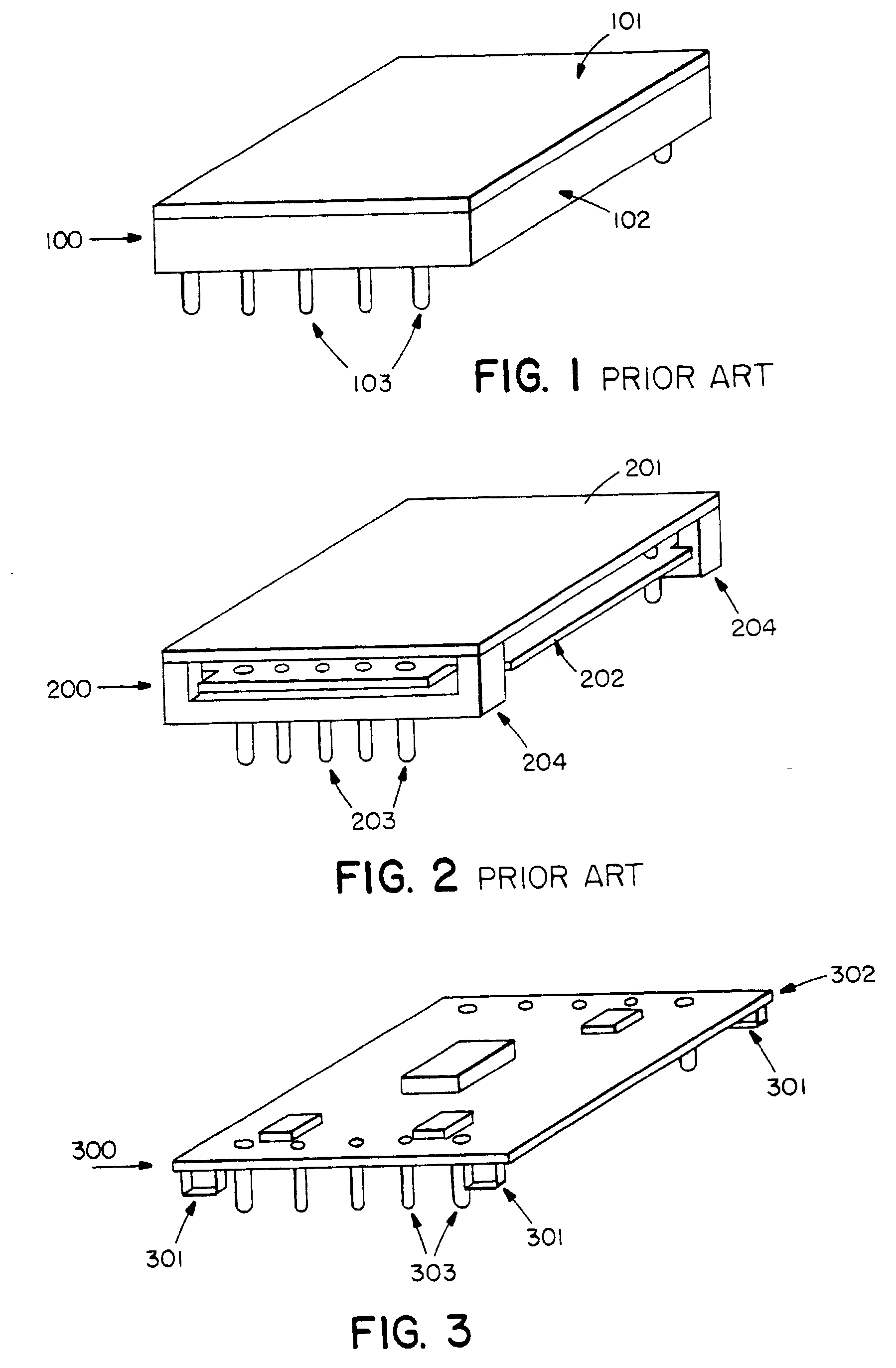

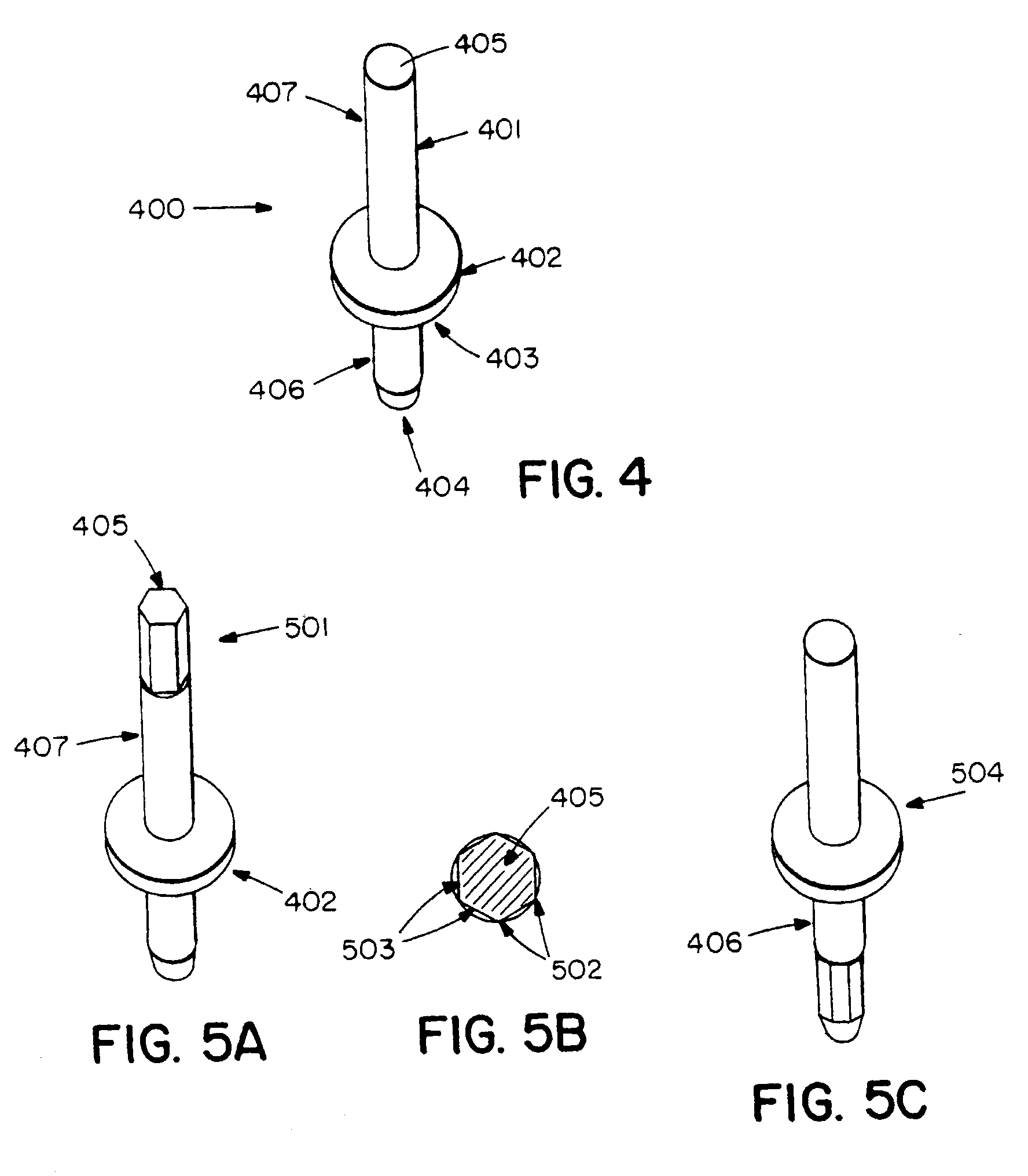

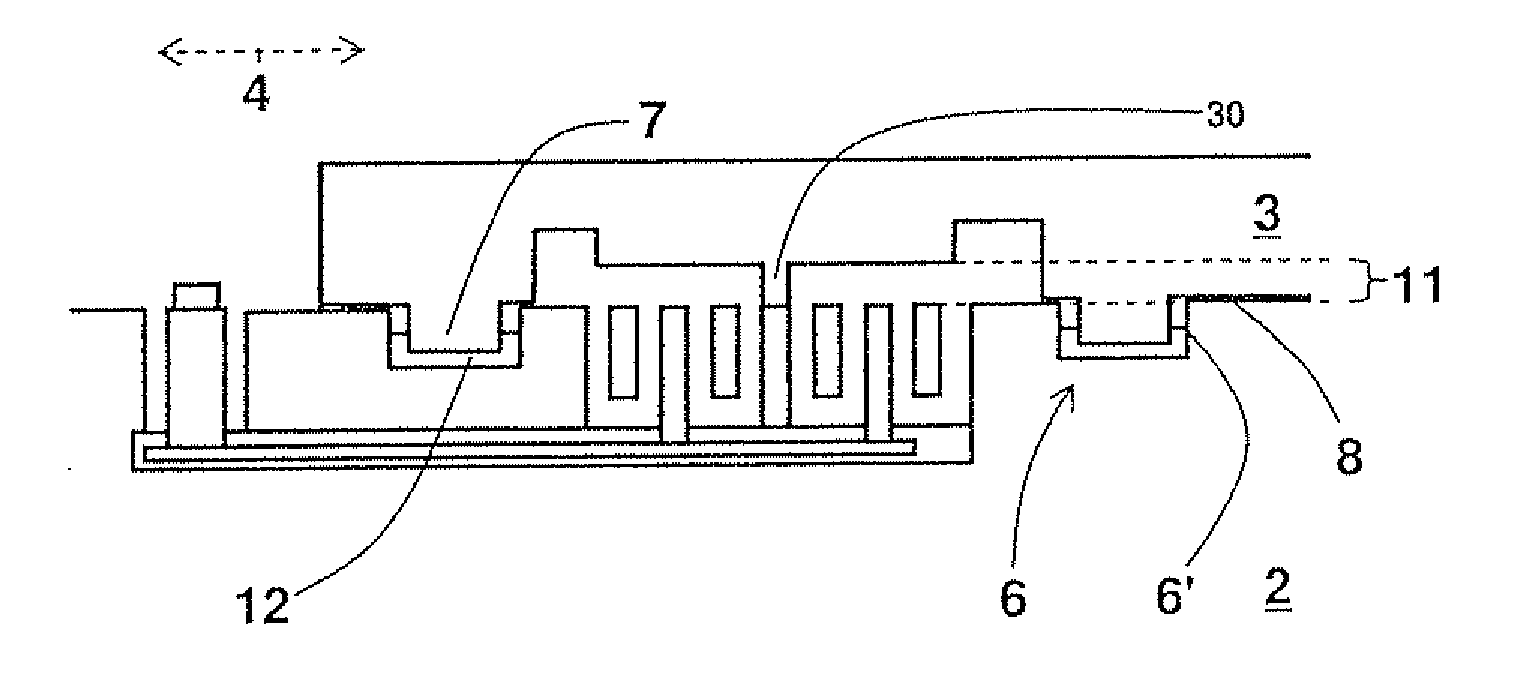

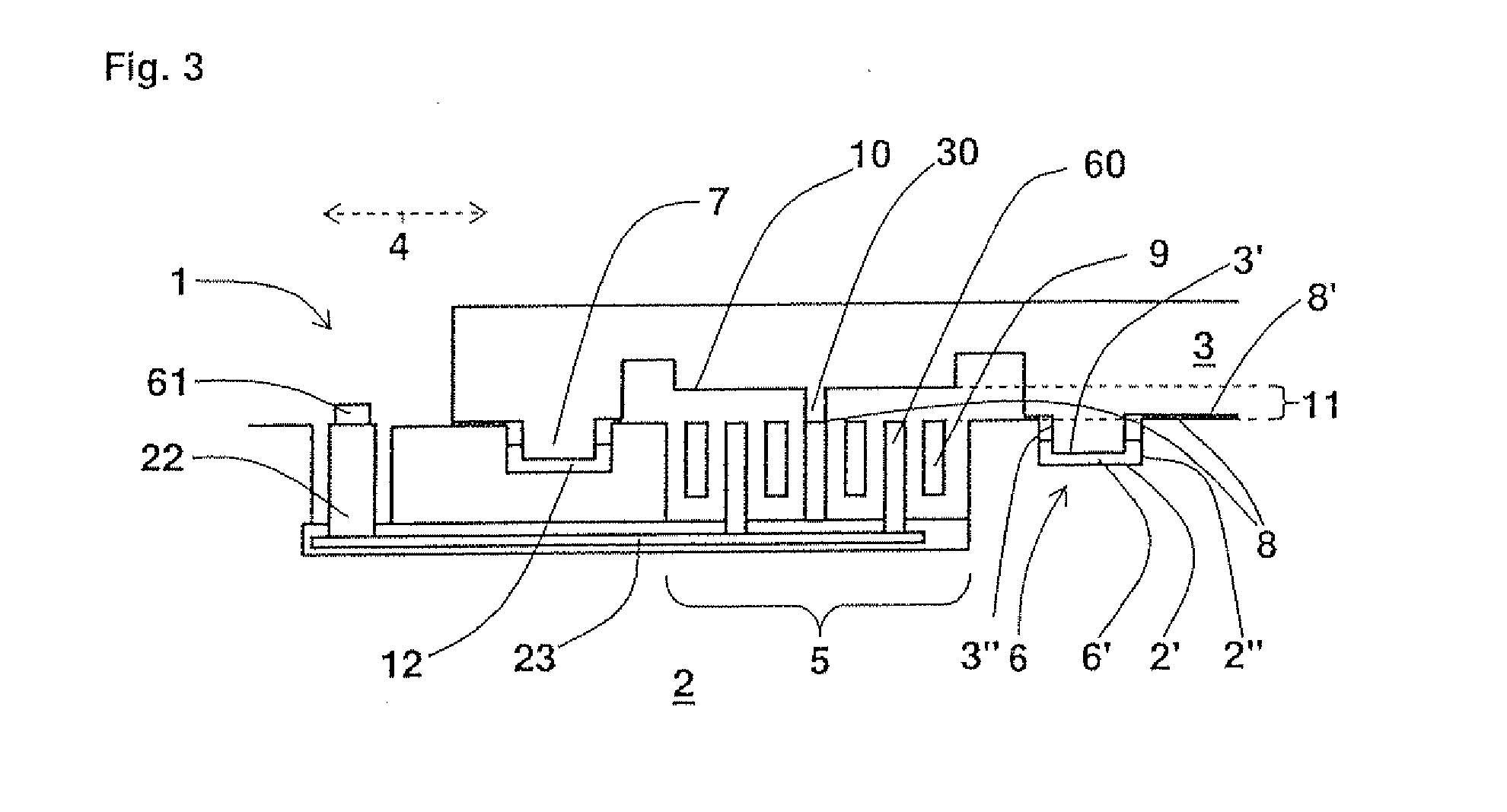

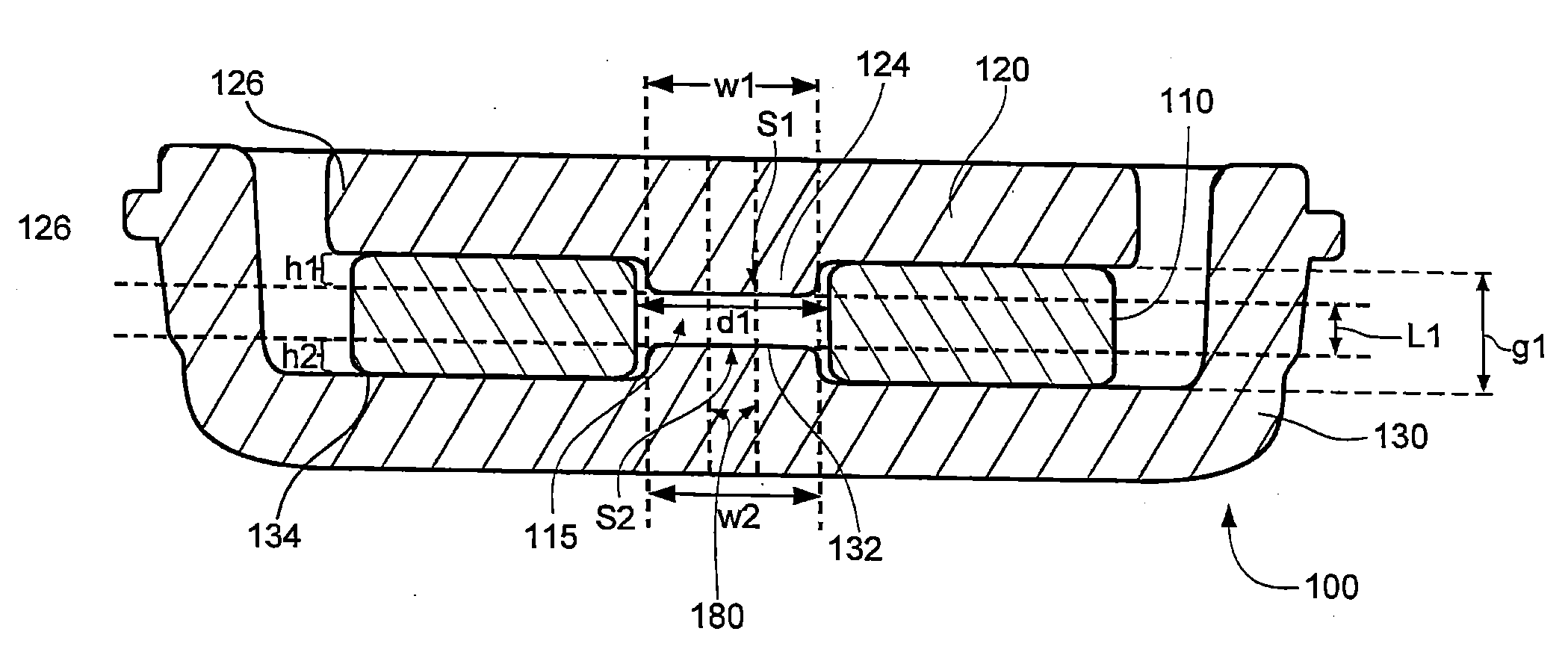

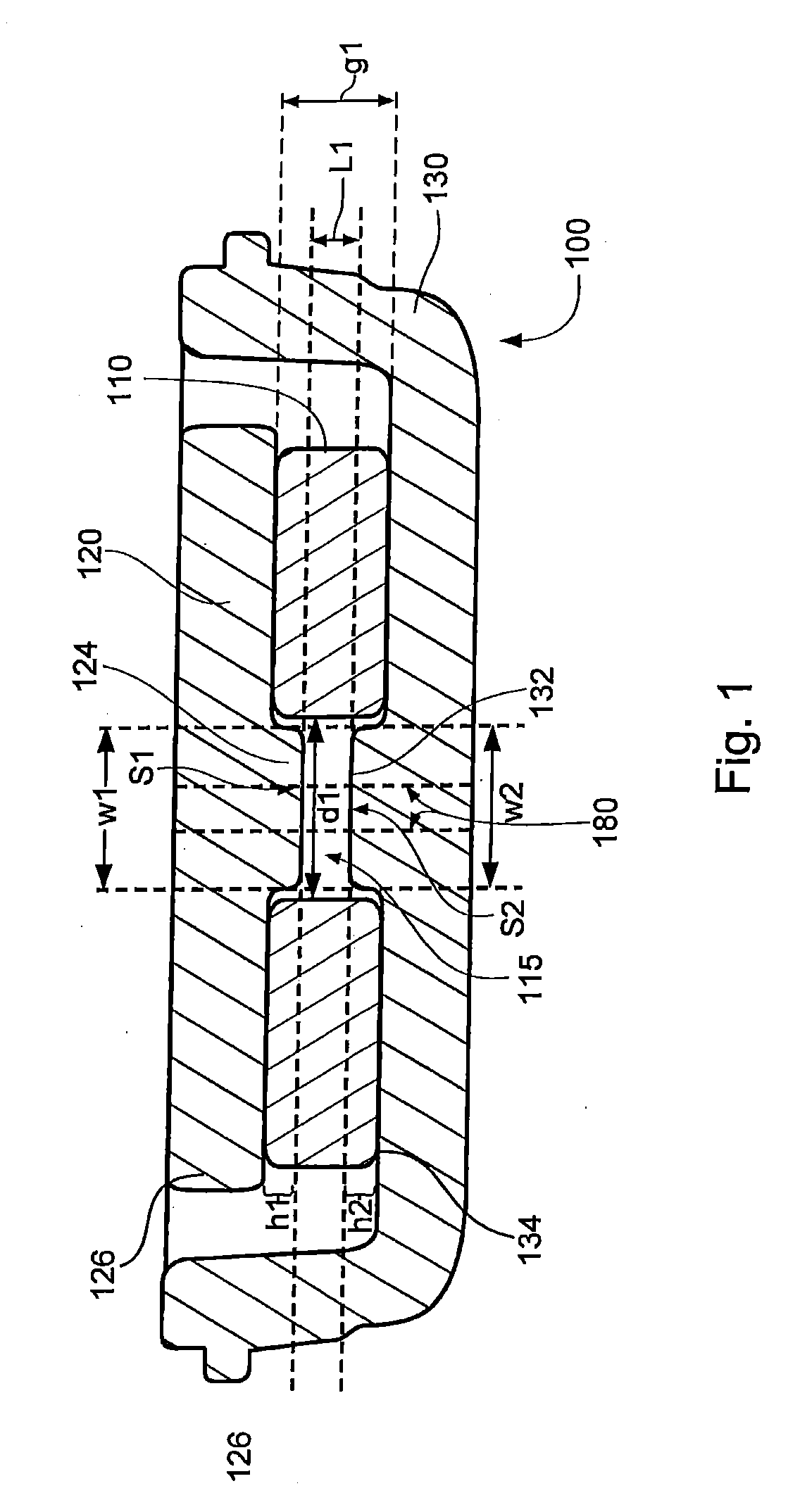

Flanged terminal pins for DC/DC converters

InactiveUS6896526B2Minimal interferenceStrengthen the mechanical connectionPrinted circuit assemblingElectrically conductive connectionsElectrical connectionEngineering

A dc / dc converter is mounted to a printed circuit board with rigid terminal pins which extend into a converter substrate to provide electrical connection to circuitry on the substrate. A terminal pin includes a flange which abuts the printed circuit board and spaces the converter substrate from the printed circuit board. Connection to the printed circuit board is made by solder provided between the flange and the circuit board.

Owner:SYNQOR

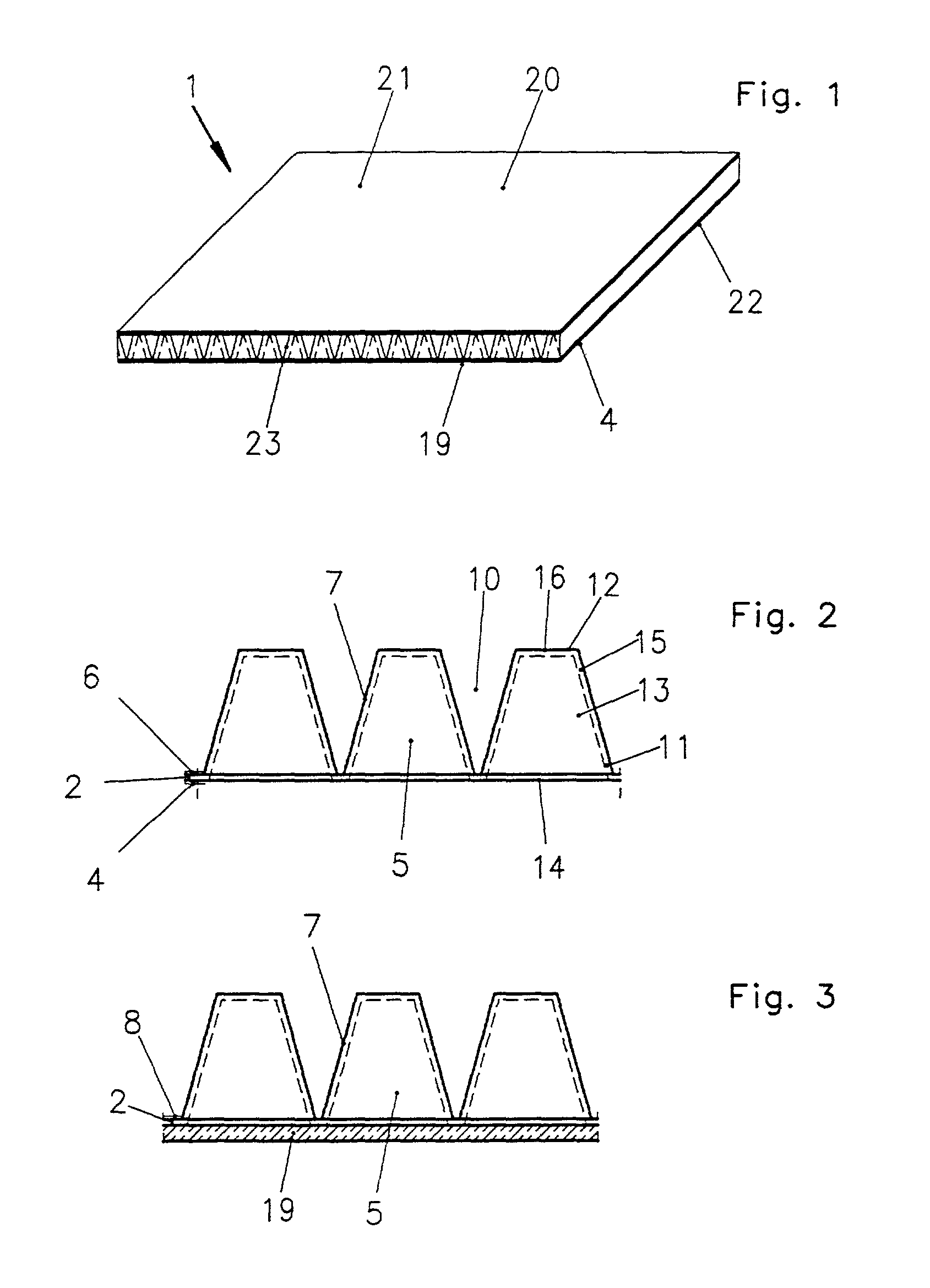

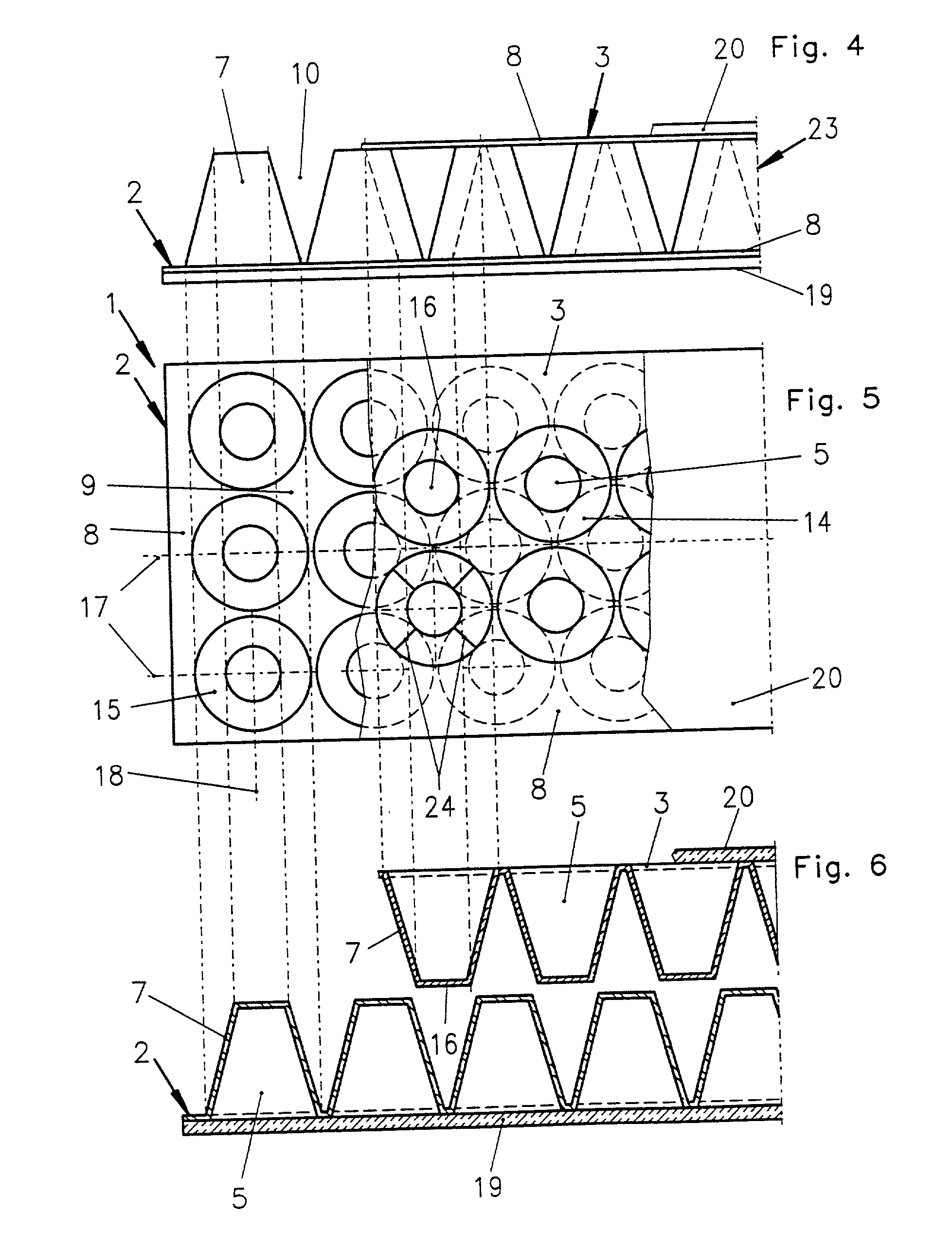

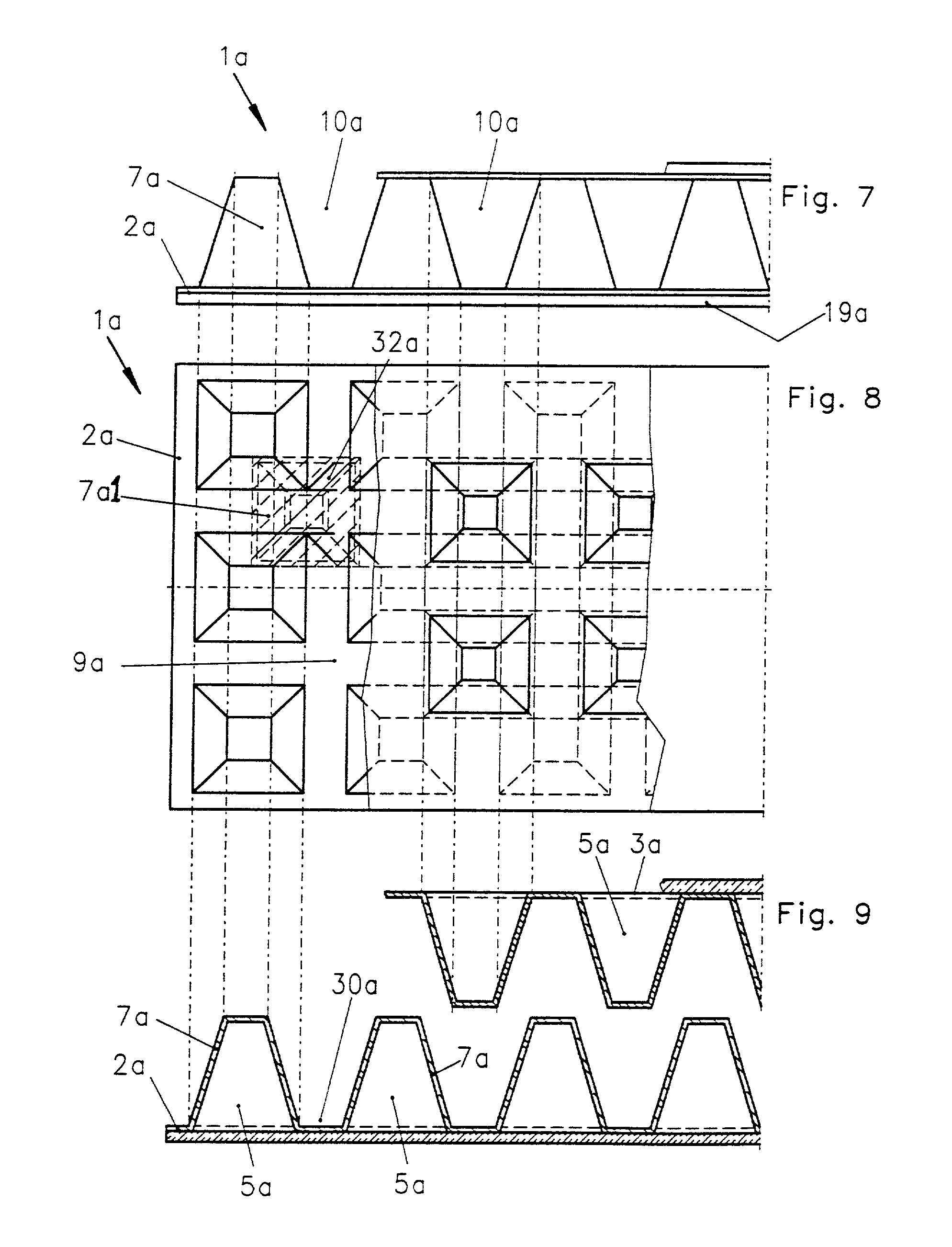

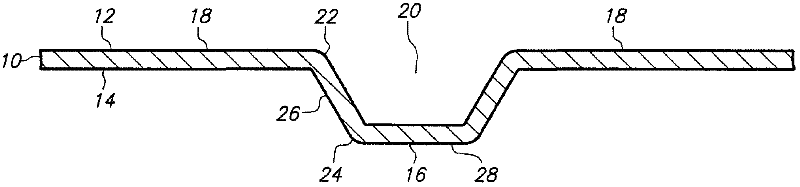

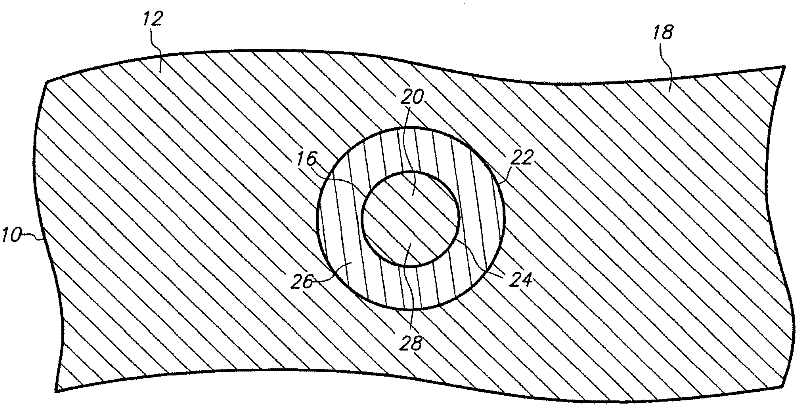

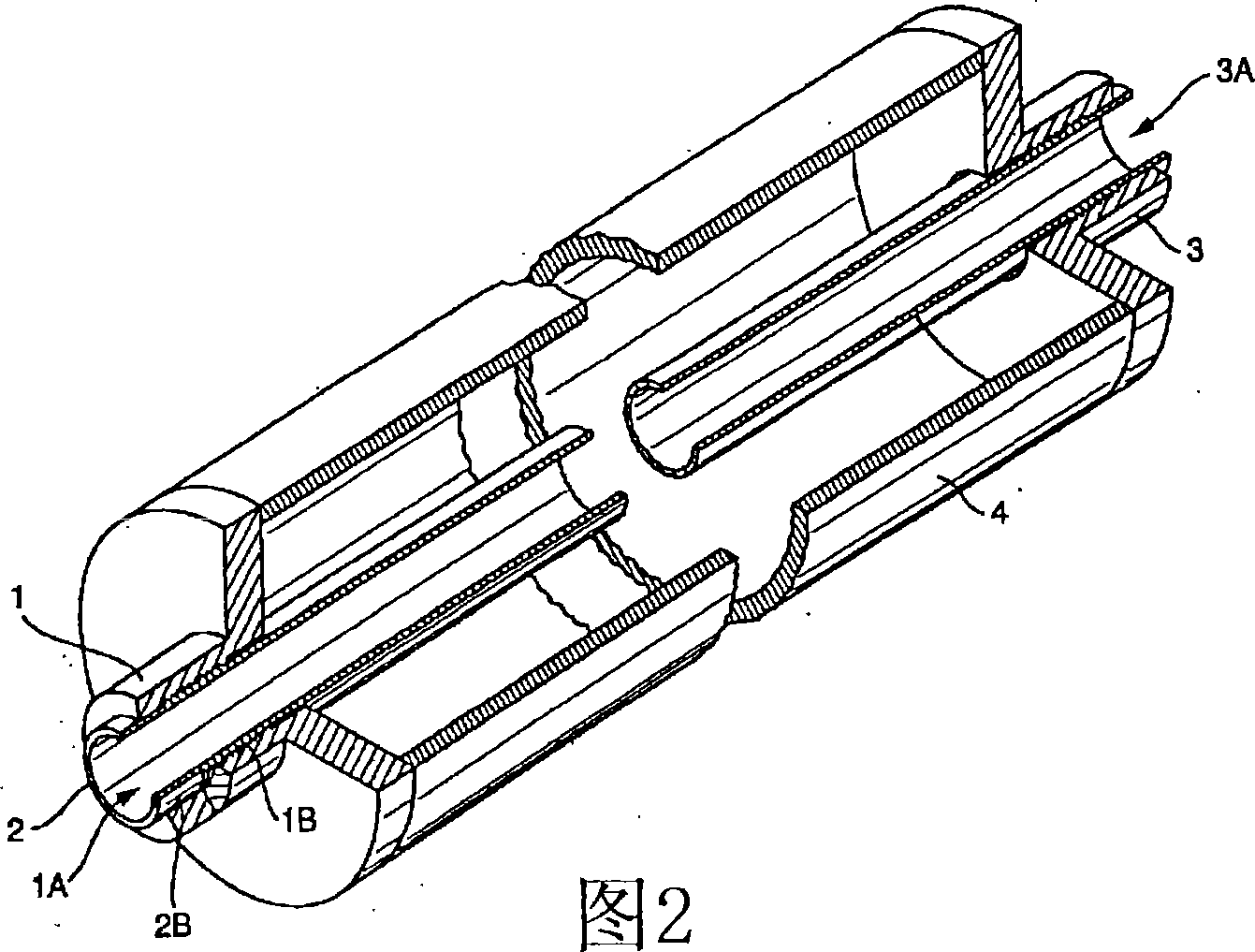

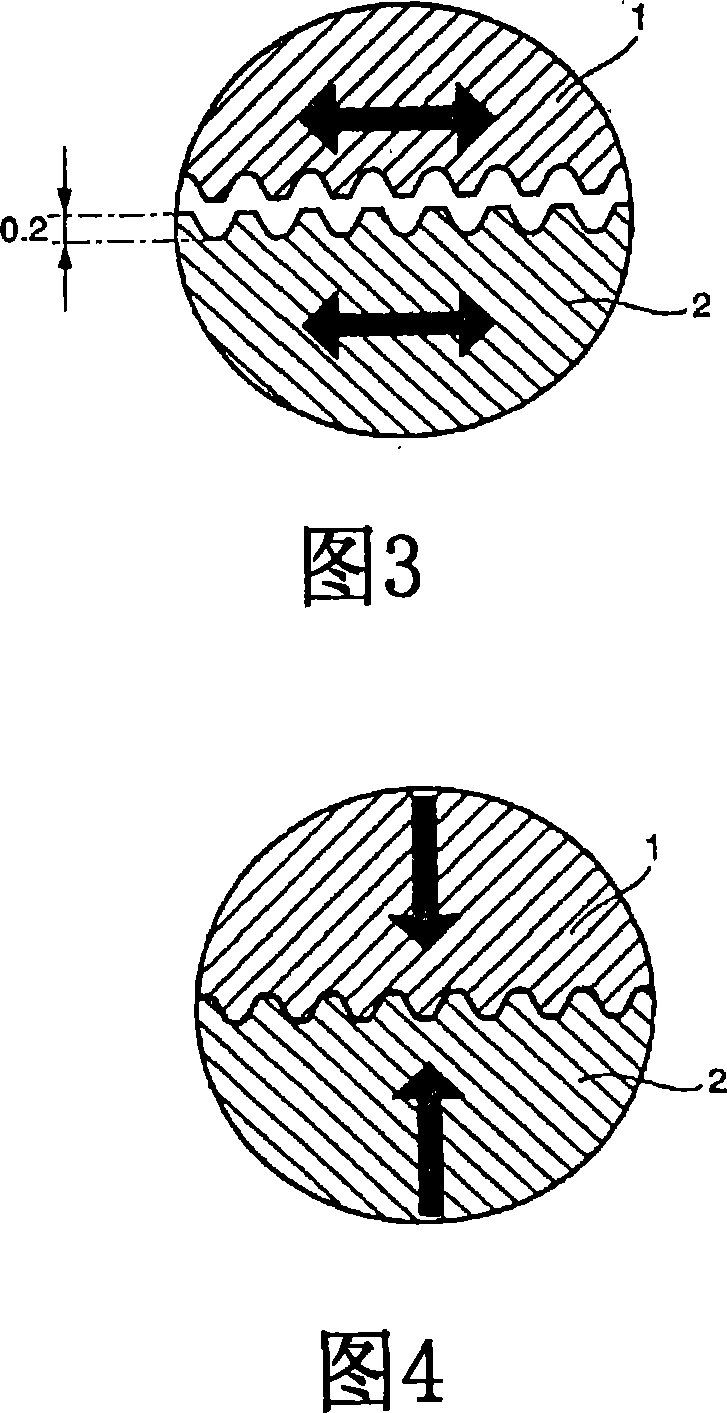

Strong lightweight panel element and apparatus for manufacturing the same

InactiveUS20010012812A1Increase strength and bending stiffnessStrong mechanical connectionBoxes/cartons making machineryBuilding componentsFilling materialsEngineering

A form-stable panel element, such as an automobile ceiling headliner, includes two layers of pyramid frustum-shaped cups that are intermeshed with each other, and two cover layers that close and seal hollow chambers in each of the cups. Each chamber is filled with a filler material that may be a loose mixed granulate of waste or recycled polymer. All of the layers are thermally fused and laminated integrally together. The panel element may be molded into a three-dimensional contour. The panel element is strong, lightweight, stiff against bending, incorporates waste or recycled materials, and provides good noise damping.

Owner:R S TECHN

Flanged terminal pins for DC/DC converters

InactiveUS7085146B2Minimal interferenceStrengthen the mechanical connectionPrinted circuit assemblingElectrically conductive connectionsTransverterElectrical connection

A dc / dc converter is mounted to a printed circuit board with rigid terminal pins which extend into a converter substrate to provide electrical connection to circuitry on the substrate. A terminal pin includes a flange which abuts the printed circuit board and spaces the converter substrate from the printed circuit board. Connection to the printed circuit board is made by solder provided between the flange and the circuit board.

Owner:SYNQOR

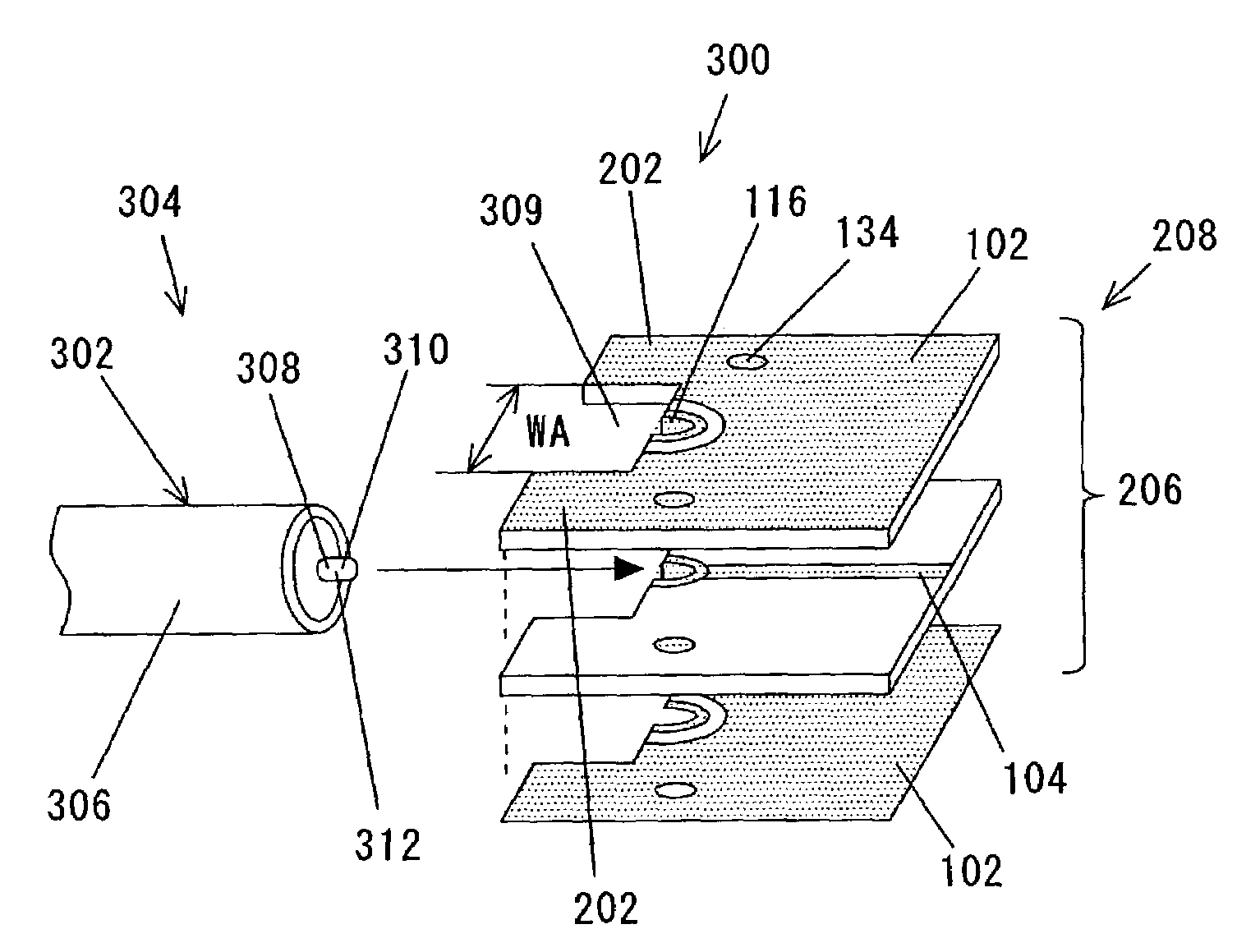

System for and method of interconnecting high-frequency transmission lines

InactiveUS6980068B2Strong mechanical connectionImproving Impedance MatchingMultiple-port networksSolid-state devicesImpedance matchingGround pattern

A cut via is formed in an end of a multilayer circuit board of the first transmission line, and a clearance is provided between the cut via and a ground pattern for achieving an impedance matching between the first and second transmission lines. The cut via of a first transmission line which may be a stripline or a microstrip line, and an electrode of the second transmission line are connected to each other, and ground patterns of the first and second transmission lines are connected to each other. The first and second transmission lines have respective signal lines positioned substantially coaxially with each other.

Owner:RYOWA DENSHI

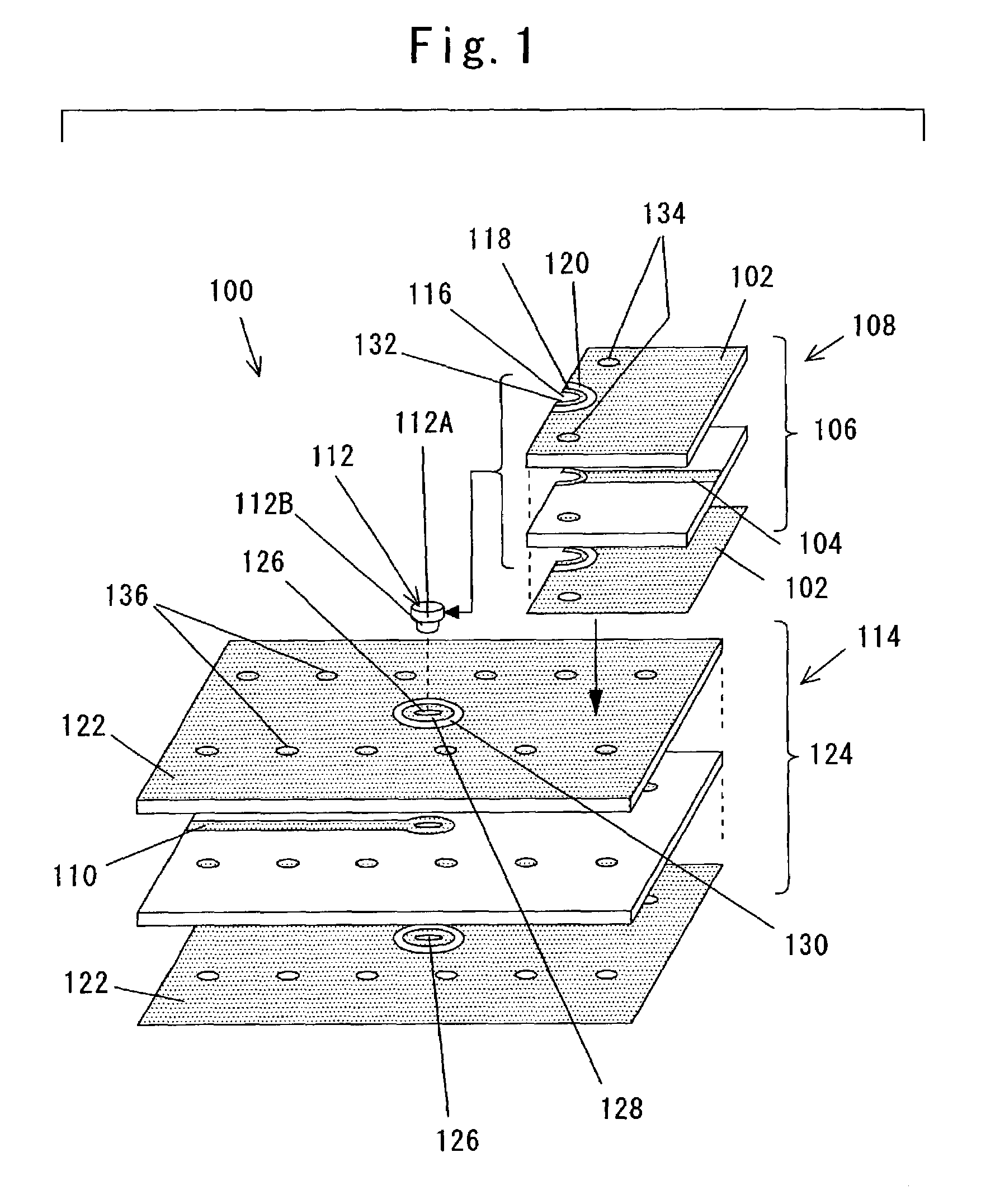

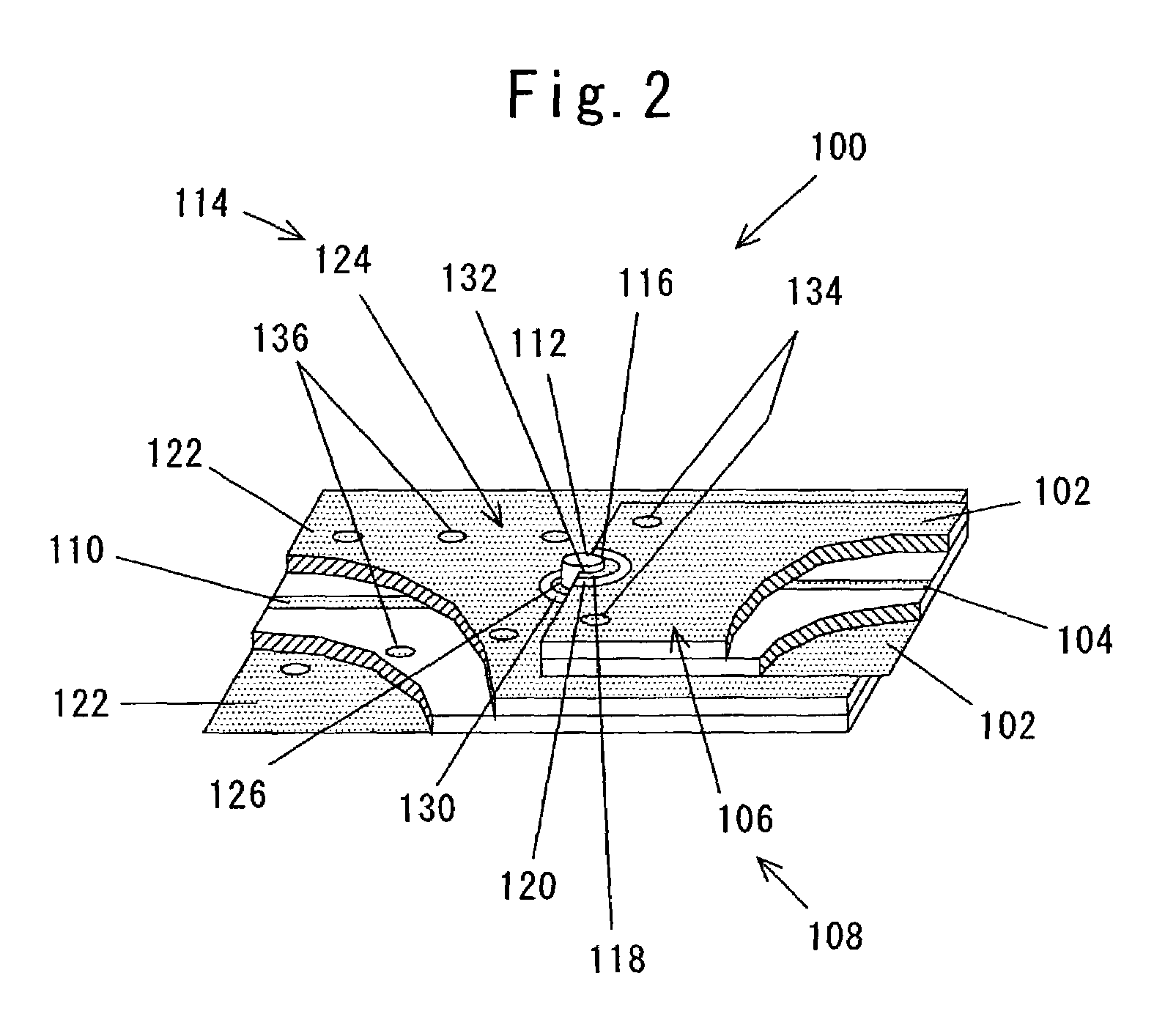

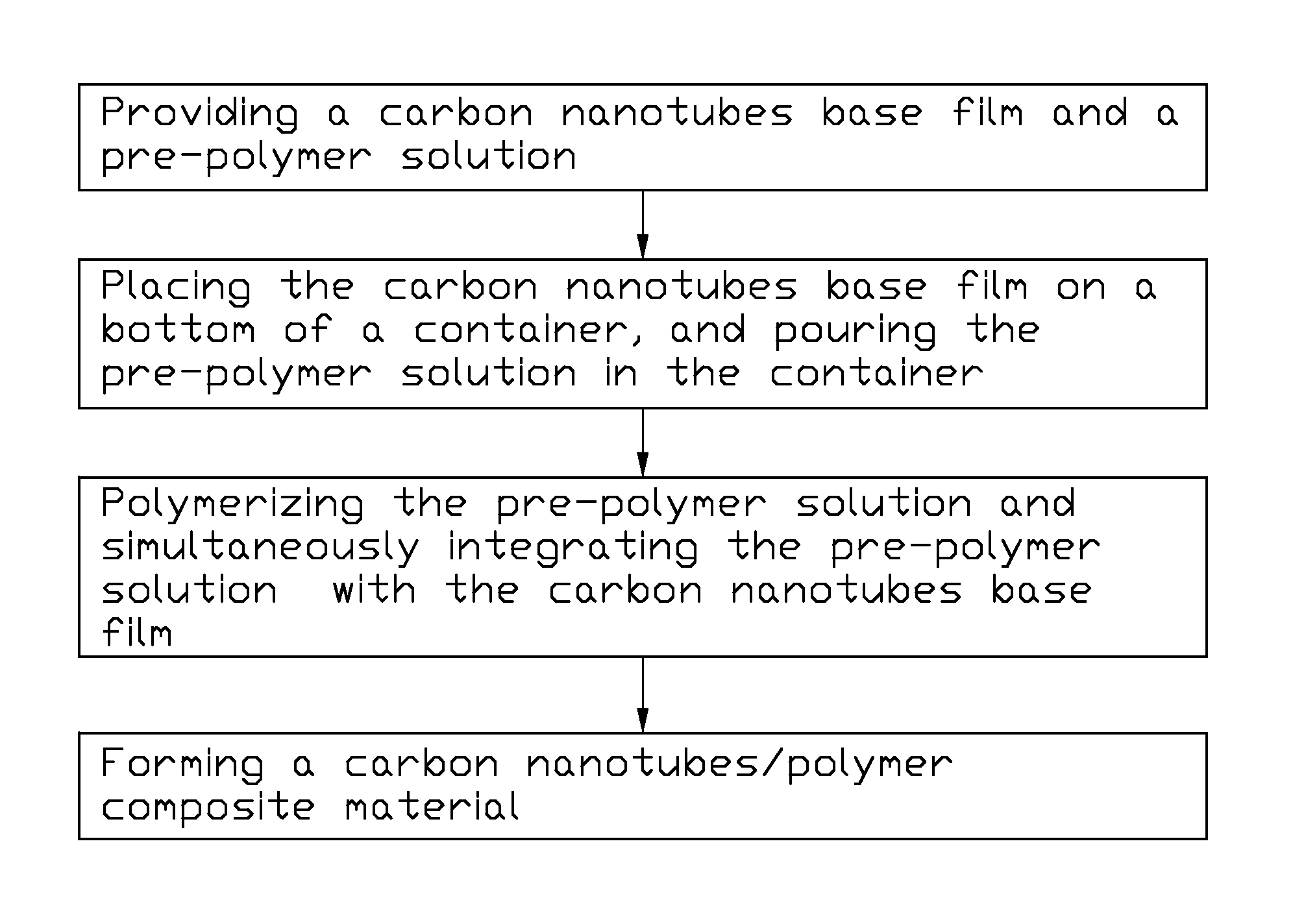

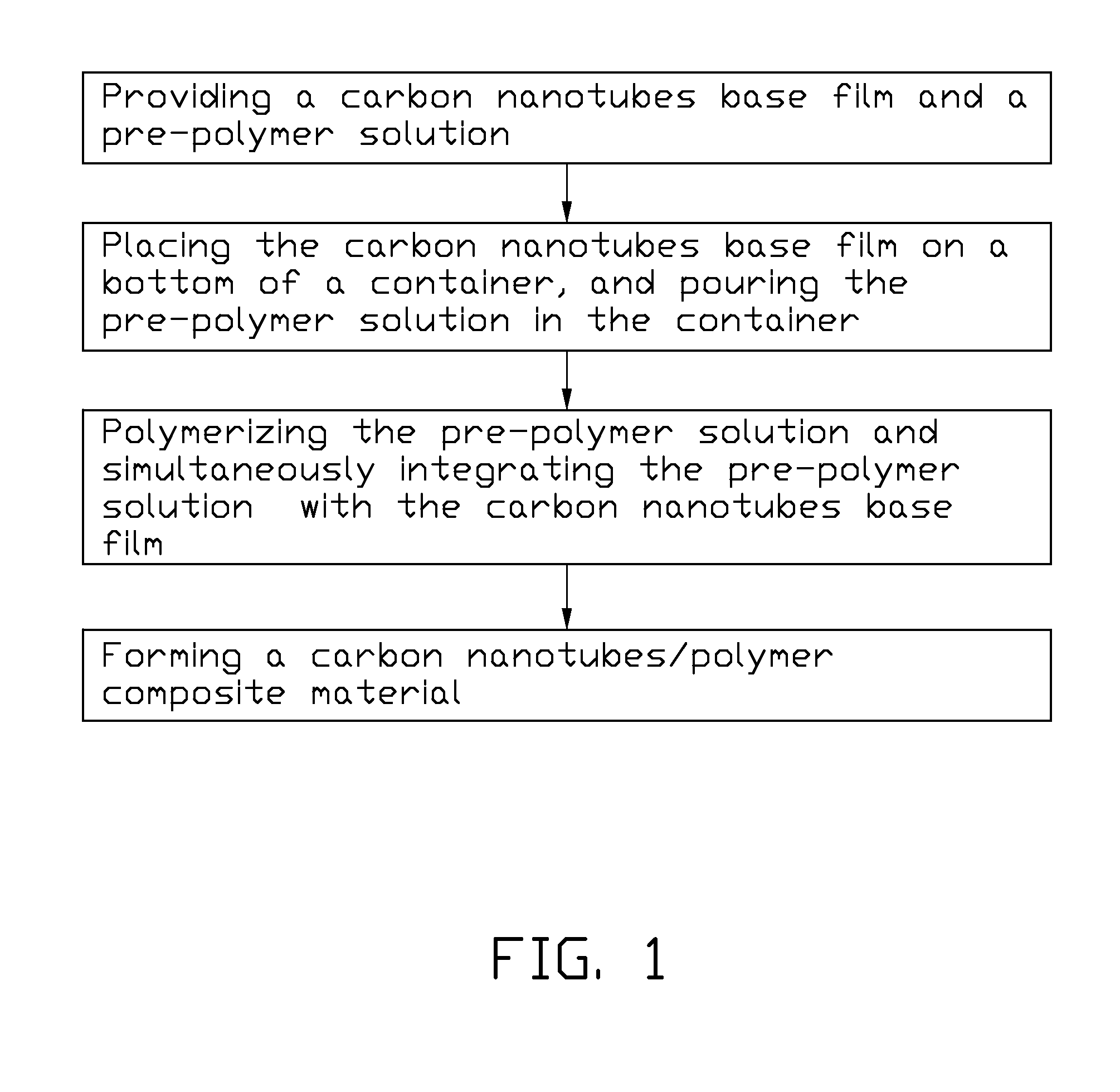

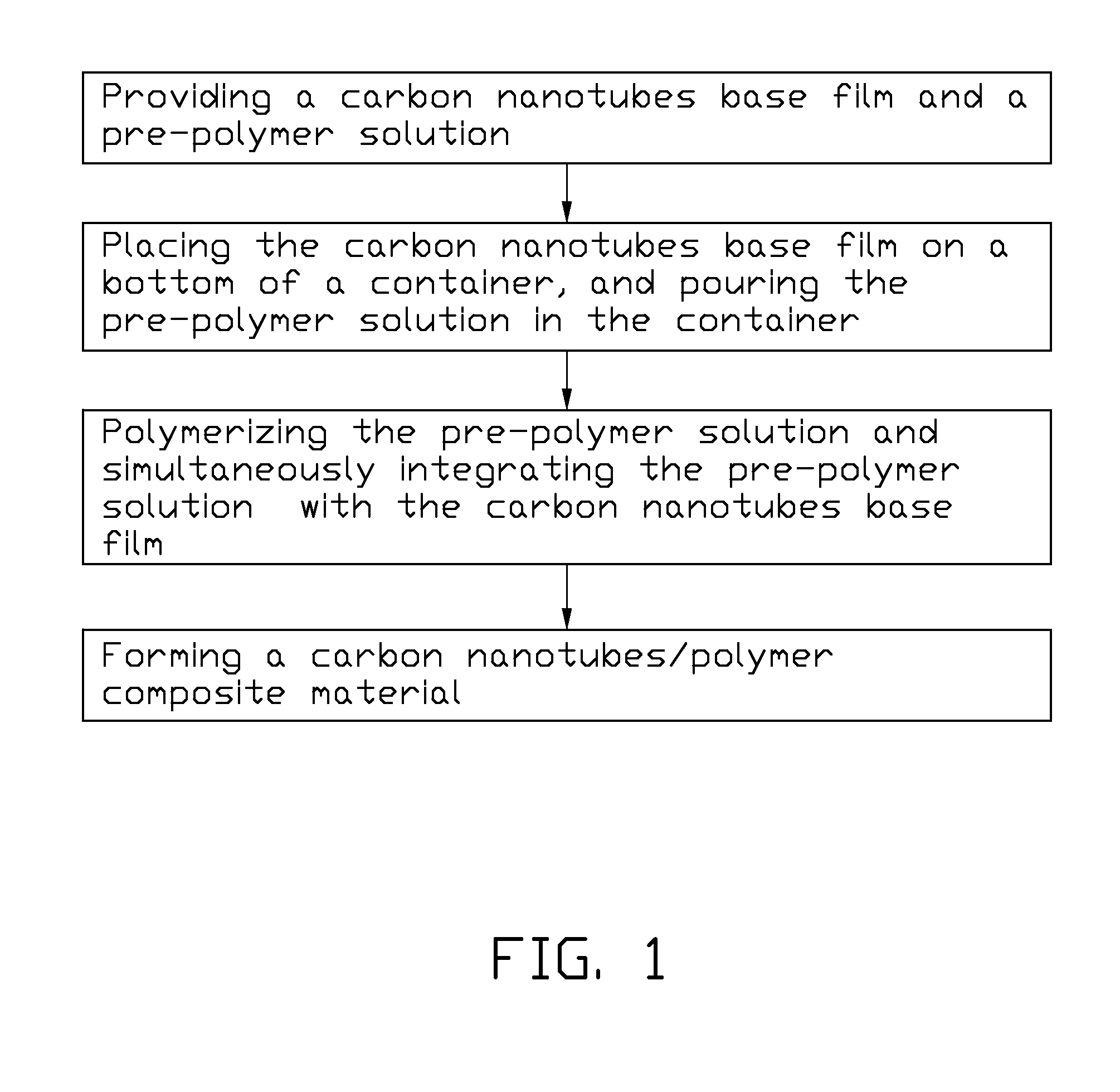

Method of preparing carbon nanotube/polymer composite material

ActiveUS7988896B2Improve conductivityStrong mechanical connectionMaterial nanotechnologyPretreated surfacesPolymer compositesPolymer solution

A method of preparing a carbon nanotube / polymer composite material is provided. The method includes (a) providing a carbon nanotube-based film and a pre-polymer solution; (b) placing the carbon nanotube-based film at a bottom of a container, and pouring the pre-polymer solution in the container; and (c) polymerizing the pre-polymer solution and simultaneously integrating the pre-polymer solution with the carbon nanotube-based film. As such, a carbon nanotube / polymer composite material, including the polymer-impregnated nanotube layer and an upper polymer layer, is obtained. A multi-layer composite can be produced by essentially repeating this process, using the upper polymer layer as the base layer for the formation of the next layer set thereon.

Owner:TSINGHUA UNIV +1

Low power thermoelectric generator

InactiveUS20090025771A1Improve conductivityStrong mechanical connectionThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentBismuth tellurideEngineering

A thermoelectric generator has a top plate disposed in spaced relation above a bottom plate. A series of foil segments are electrically and mechanically connected end-to-end to generate a foil assembly that is spirally wound and in thermal contact with the bottom and top plates. Each foil segment comprises a substrate having a series of spaced alternating n-type and p-type thermoelectric legs disposed in parallel arrangement on the front substrate surface. Each of the n-type and p-type legs is formed of a bismuth telluride-based thermoelectric material having a thickness of about 10-100 microns, a width of about 10-100 microns and a length of about 100-500 microns. The alternating n-type and p-type thermoelectric legs are electrically connected in series and thermally connected in parallel such that a temperature differential between the bottom and top plates results in the generation of power.

Owner:DIGITAL ANGEL CORP

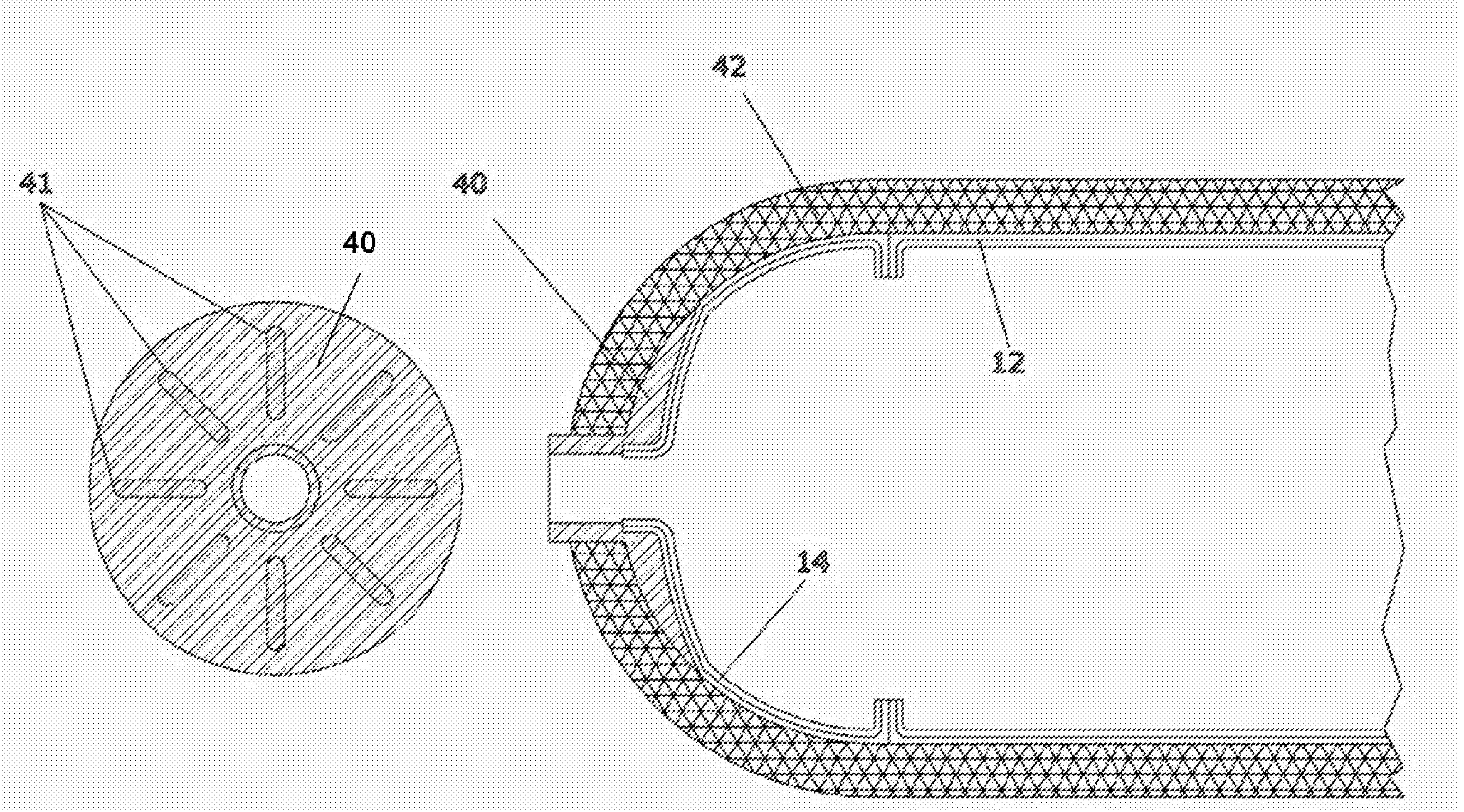

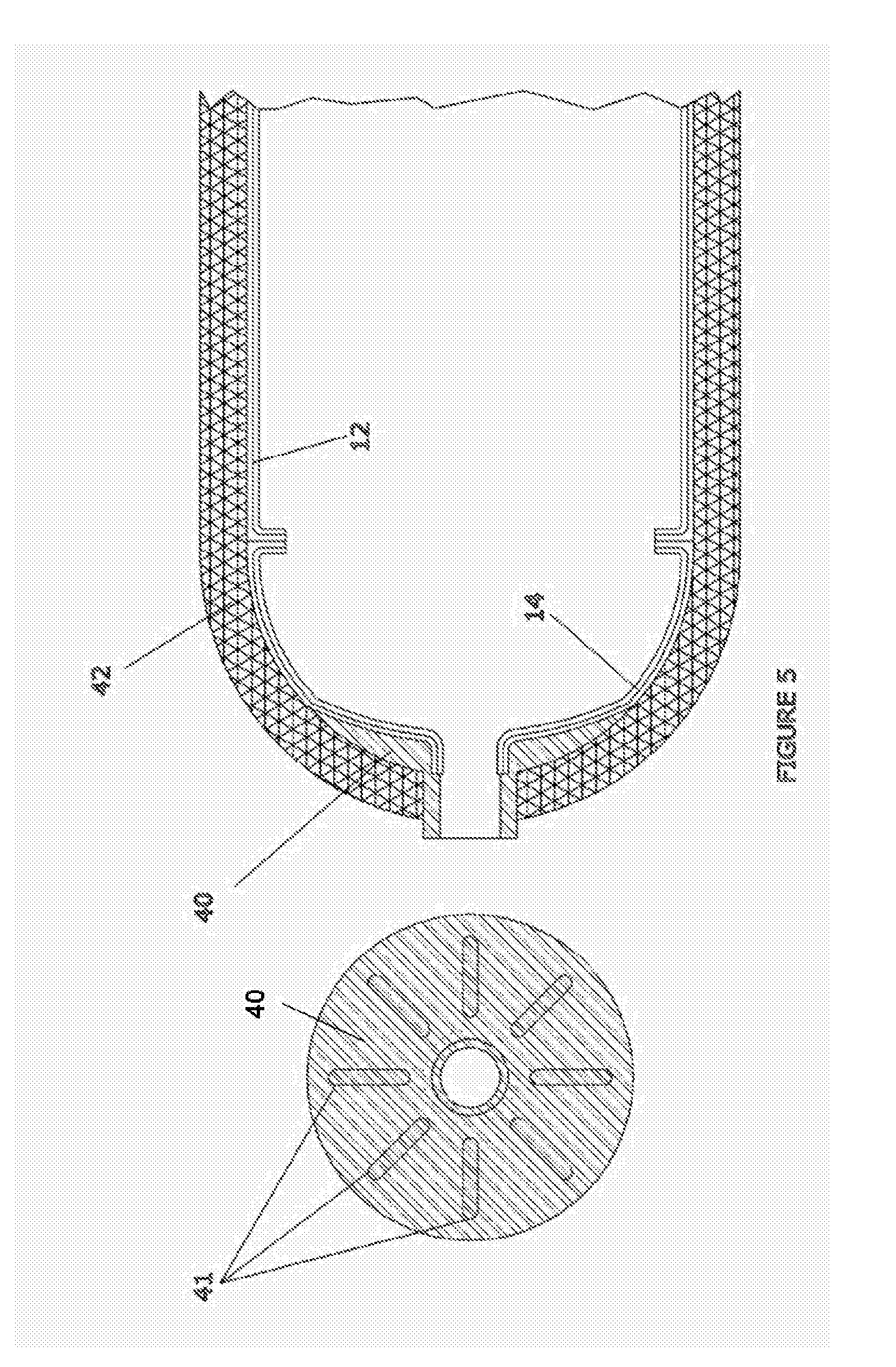

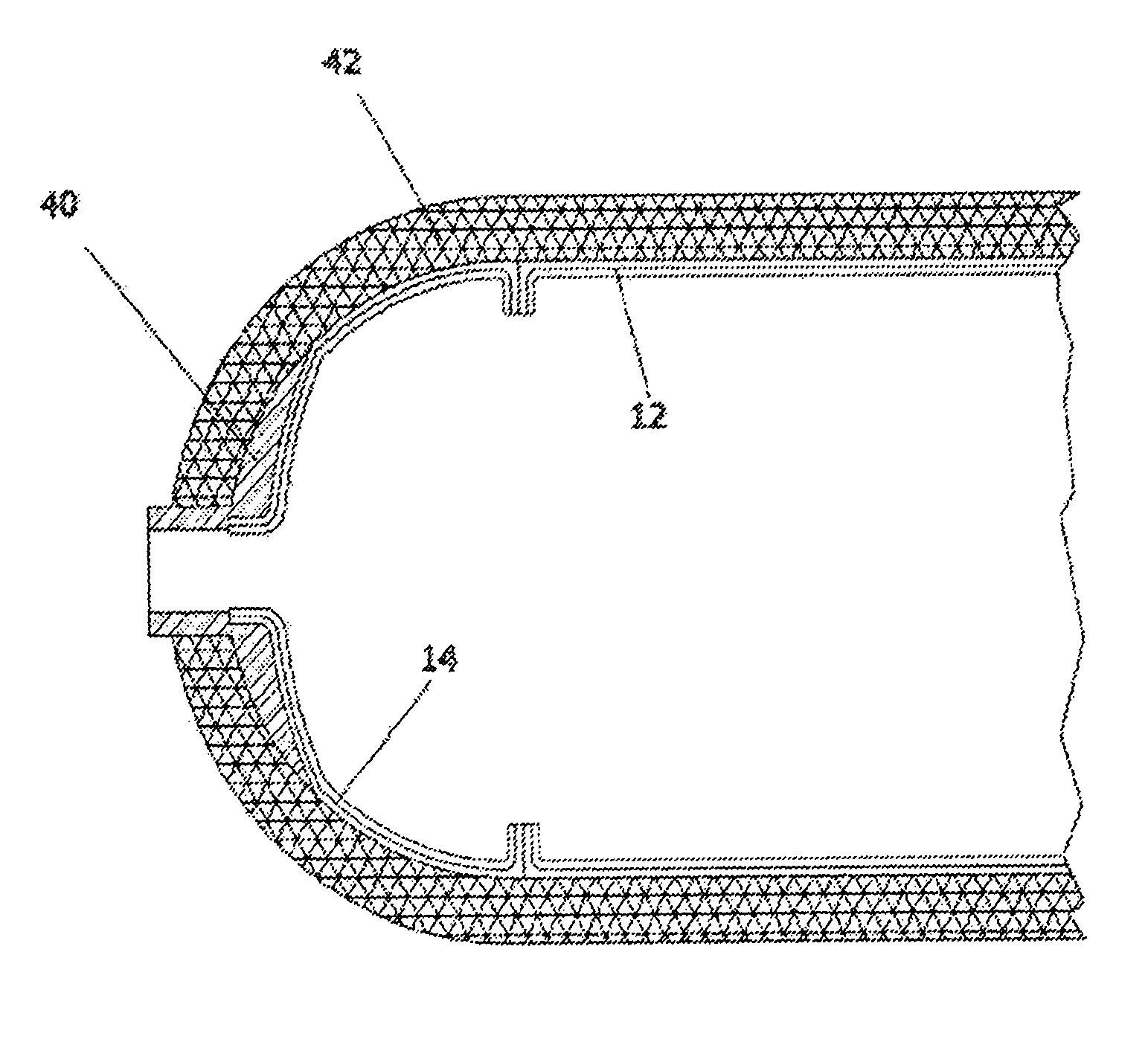

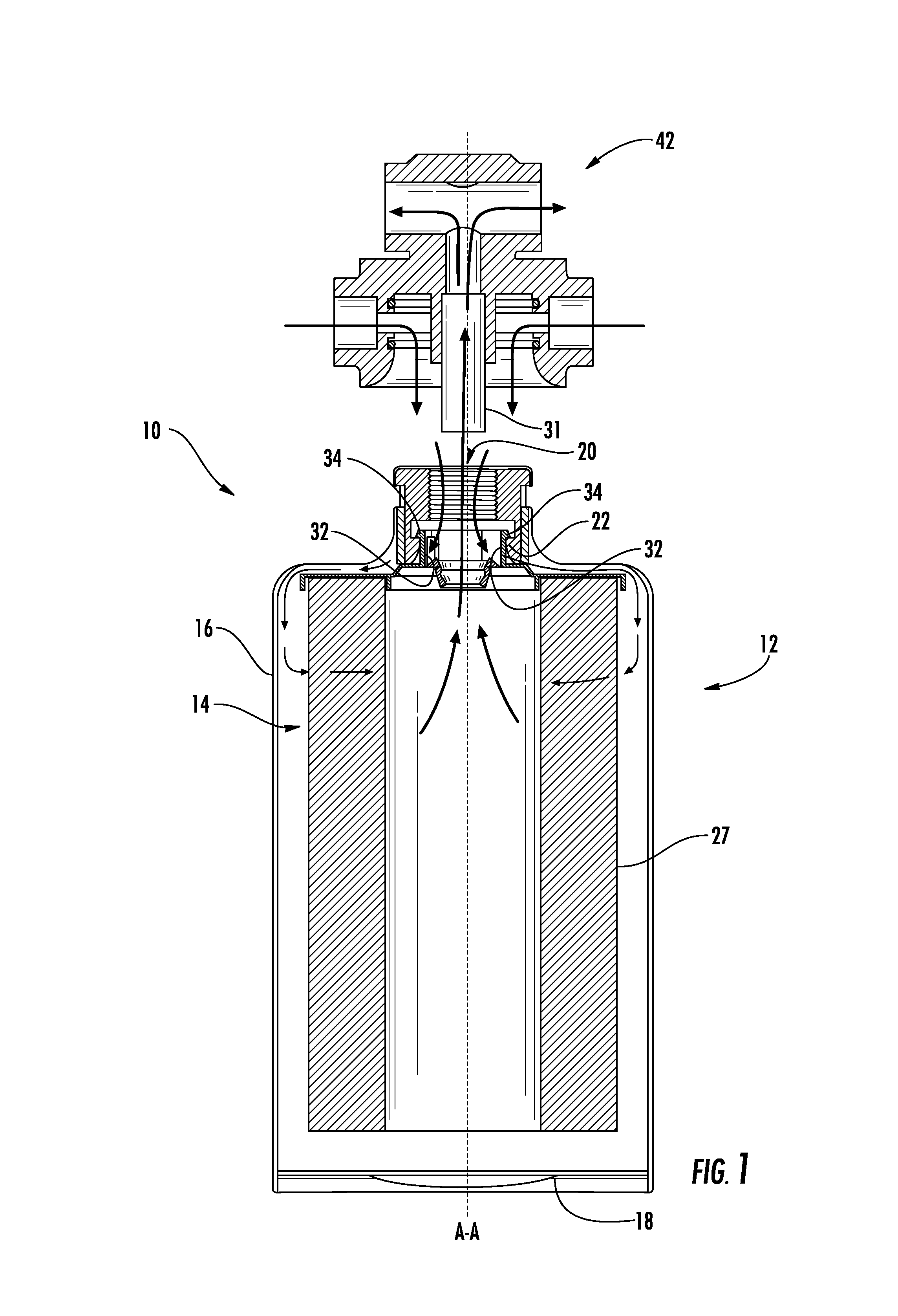

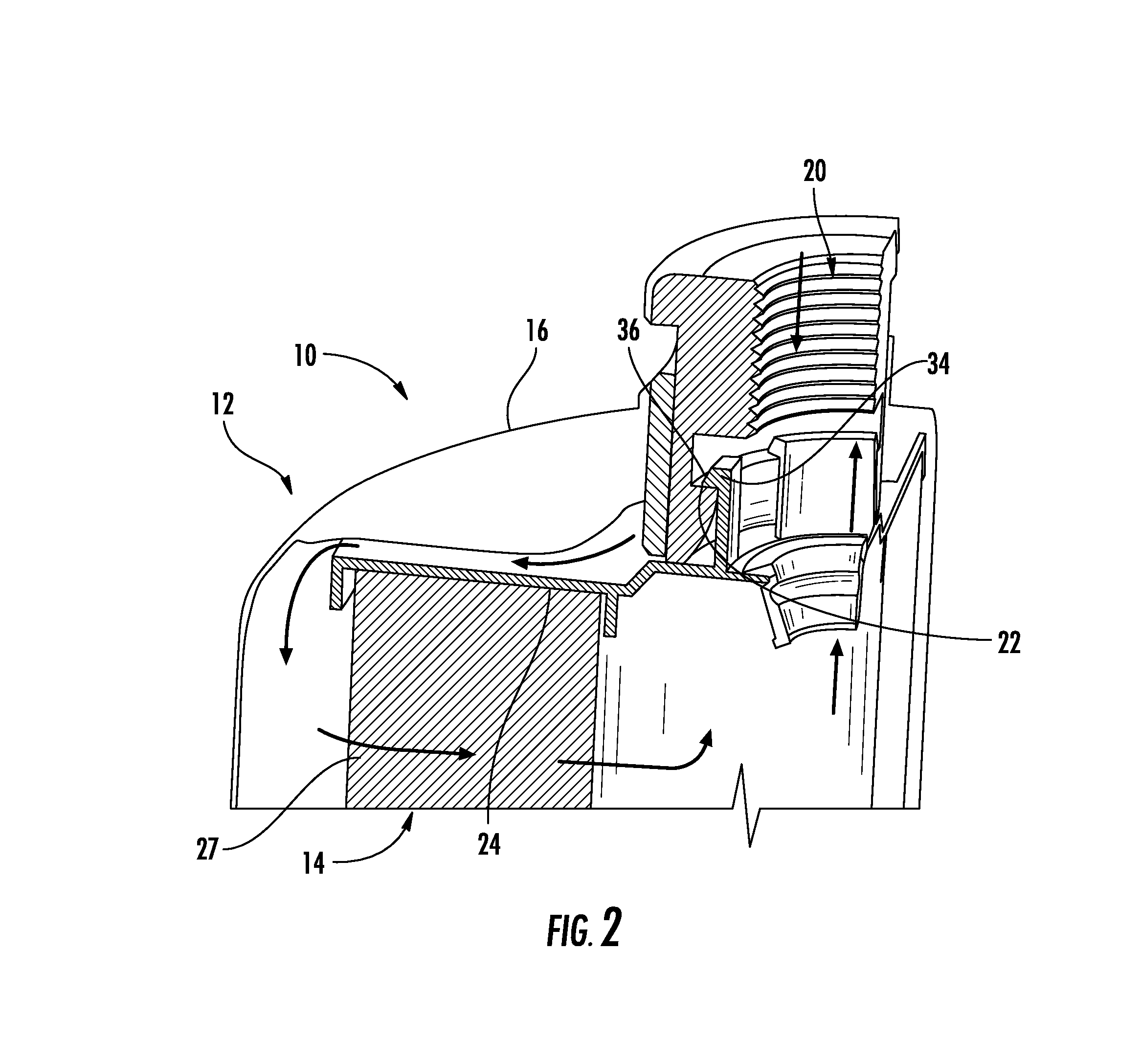

Method for Manufacturing an Inner Liner For a Storage Tank

ActiveUS20090263315A1Controlling the riskStrong mechanical connectionVessel mounting detailsVessel manufacturingEngineeringPolymer

A method for manufacturing a polymeric inner liner for a storage tank, particularly a hydrogen storage tank, comprising:providing a cylindrical body of polymer material, having a first open end and a first peripheral connection tab at the first open end, the cylindrical body comprising a structural layer and a barrier layer;providing a dome-shaped end cap of polymer material having a base with a cross-section essentially corresponding to a cross-section of the first open end of the cylindrical body and having a second peripheral connection tab at a peripheral end portion of such end cap;placing the end cap with its base onto the first open end of the cylindrical body and with the first and second peripheral tabs in contact with each other; andwelding both peripheral connection tabs together.A storage tank made using such liner. Use of such tank for storing hydrogen.

Owner:PLASTIC OMNIUM NEW ENERGIES FRANCE

Semiconductor chip assembly with post/base heat spreader and cavity over post

InactiveCN102456637AImprove cooling effectNot easy to delaminateSemiconductor/solid-state device detailsSolid-state devicesSignal routingElectrical conductor

The invention relates to a semiconductor chip assembly with a post / base heat spreader and a cavity over post. The semiconductor chip assembly at least includes a semiconductor device, the heat spreader, the substrate and an adhesive. The semiconductor device is electrically connected to the substrate and thermally connected to the heat spreader. The heat spreader at least includes a post and a base. The post extends upwardly from the base into an opening in the adhesive and an aperture in the substrate, and the base extends laterally from the post. The adhesive extends between the post and the substrate and between the base and the substrate. The assembly provides signal routing between a pad and a terminal.

Owner:BRIDGE SEMICON

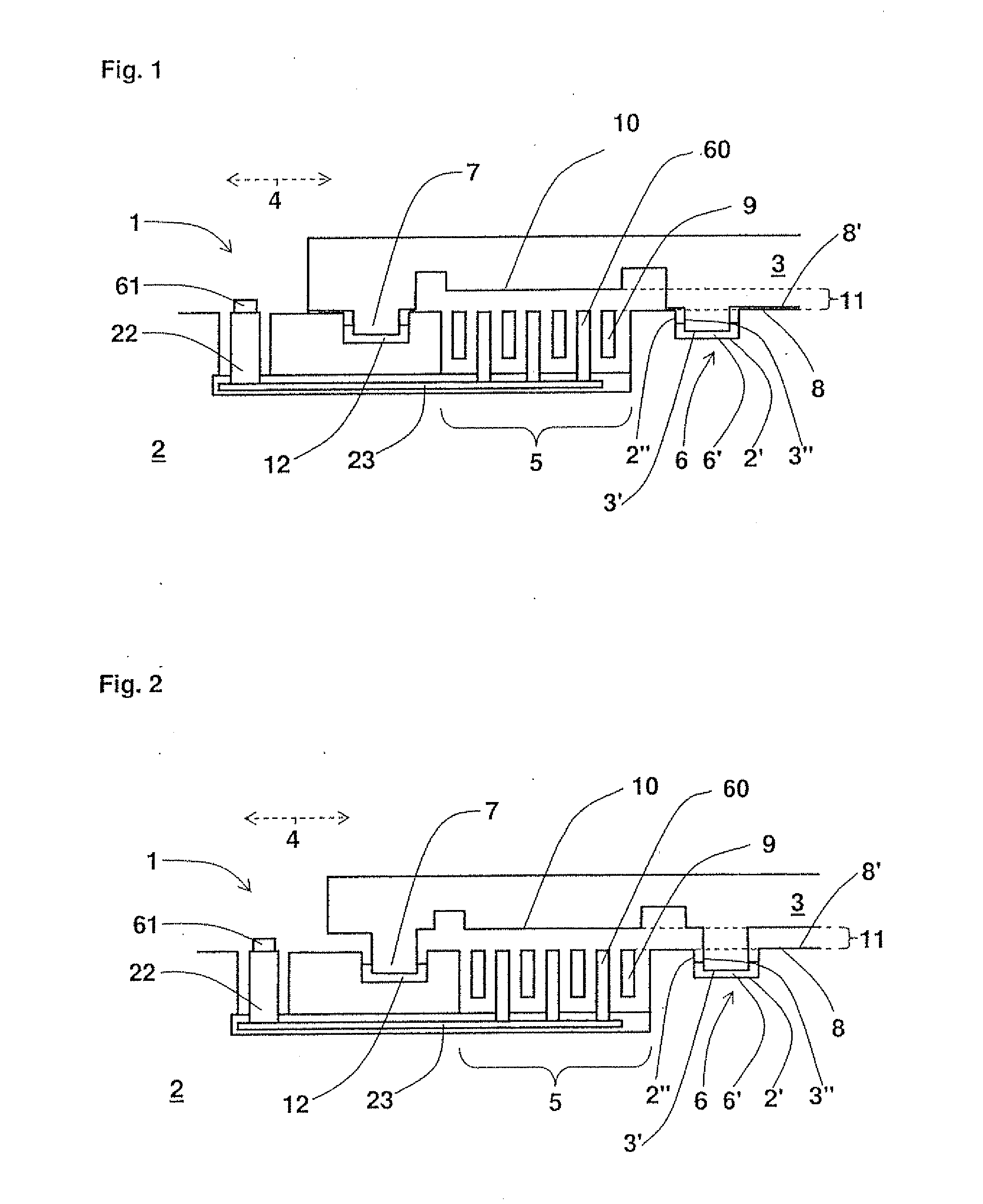

Micromechanical component and method for producing a micromechanical component

InactiveUS20090079037A1Strong mechanical connectionIncrease load capacityTransducer detailsFluid pressure measurement by electric/magnetic elementsRelative displacementWafering

A micromechanical component, in particular a micromechanical sensor, having a first wafer and a second wafer is provided, the first wafer having at least one structural element, and the second wafer having at least one mating structural element, and, in addition, the structural element and the mating structural element are designed in such a way that a relative displacement of the first wafer relative to the second wafer parallel to a main extension plane of the first wafer essentially leads to compressive loading or tensile loading between the structural element and the mating structural element.

Owner:ROBERT BOSCH GMBH

Method for manufacturing an inner liner for a storage tank

ActiveUS7918956B2Controlling the riskStrong mechanical connectionVessel mounting detailsVessel manufacturingPolymerStorage tank

A method for manufacturing a polymeric inner liner for a storage tank, particularly a hydrogen storage tank, comprising:providing a cylindrical body of polymer material, having a first open end and a first peripheral connection tab at the first open end, the cylindrical body comprising a structural layer and a barrier layer;providing a dome-shaped end cap of polymer material having a base with a cross-section essentially corresponding to a cross-section of the first open end of the cylindrical body and having a second peripheral connection tab at a peripheral end portion of such end cap;placing the end cap with its base onto the first open end of the cylindrical body and with the first and second peripheral tabs in contact with each other; andwelding both peripheral connection tabs together.A storage tank made using such liner. Use of such tank for storing hydrogen.

Owner:PLASTIC OMNIUM NEW ENERGIES FRANCE

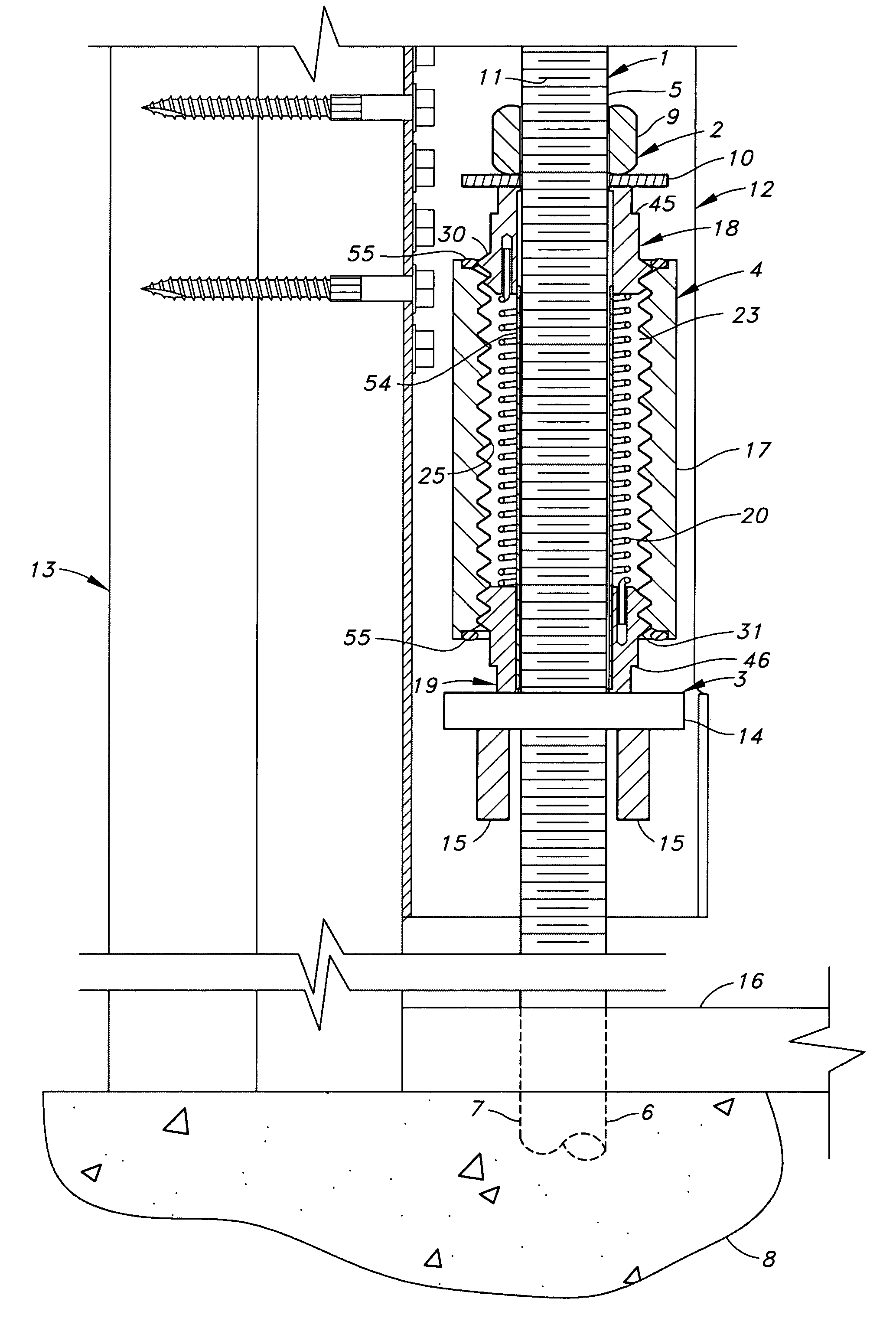

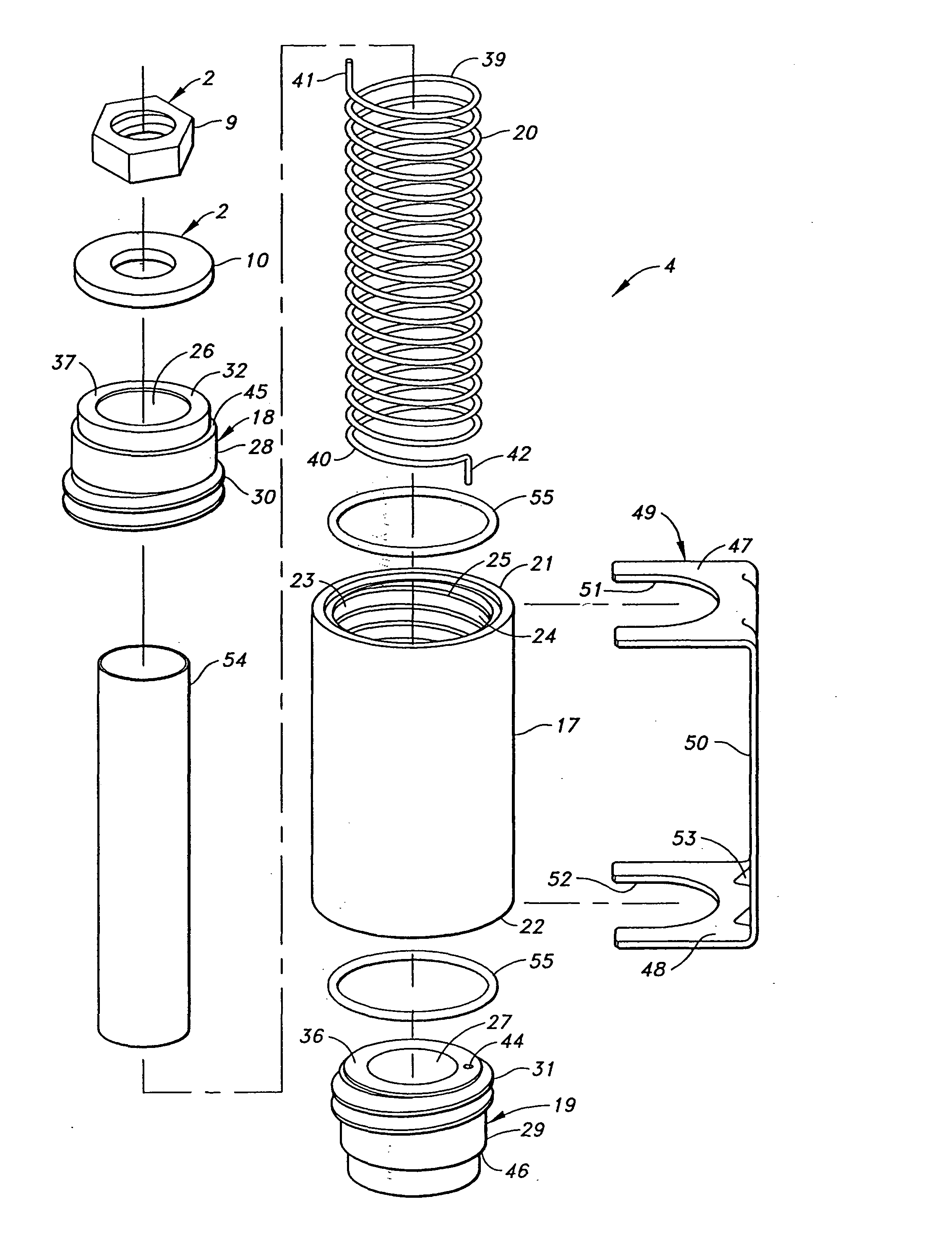

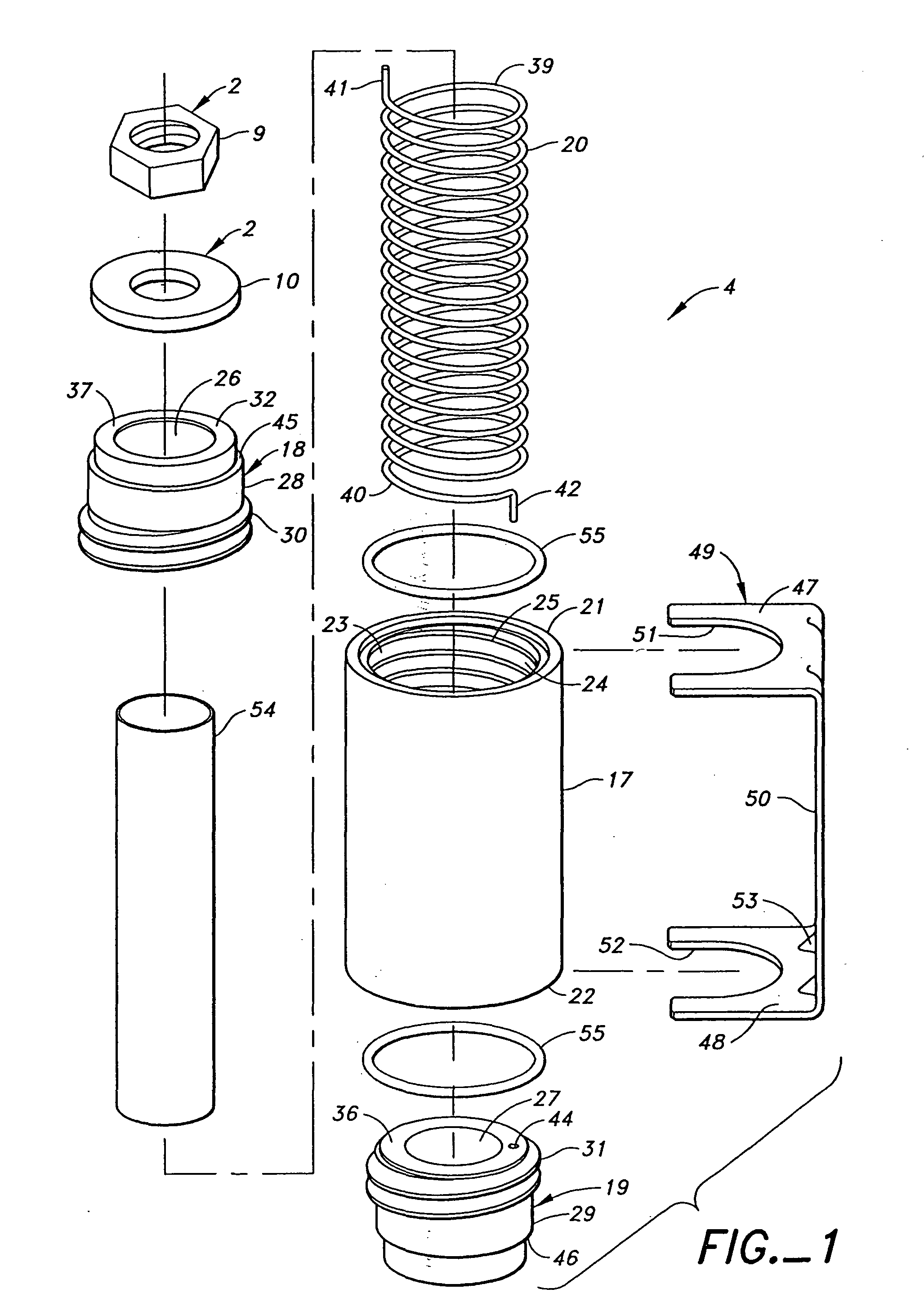

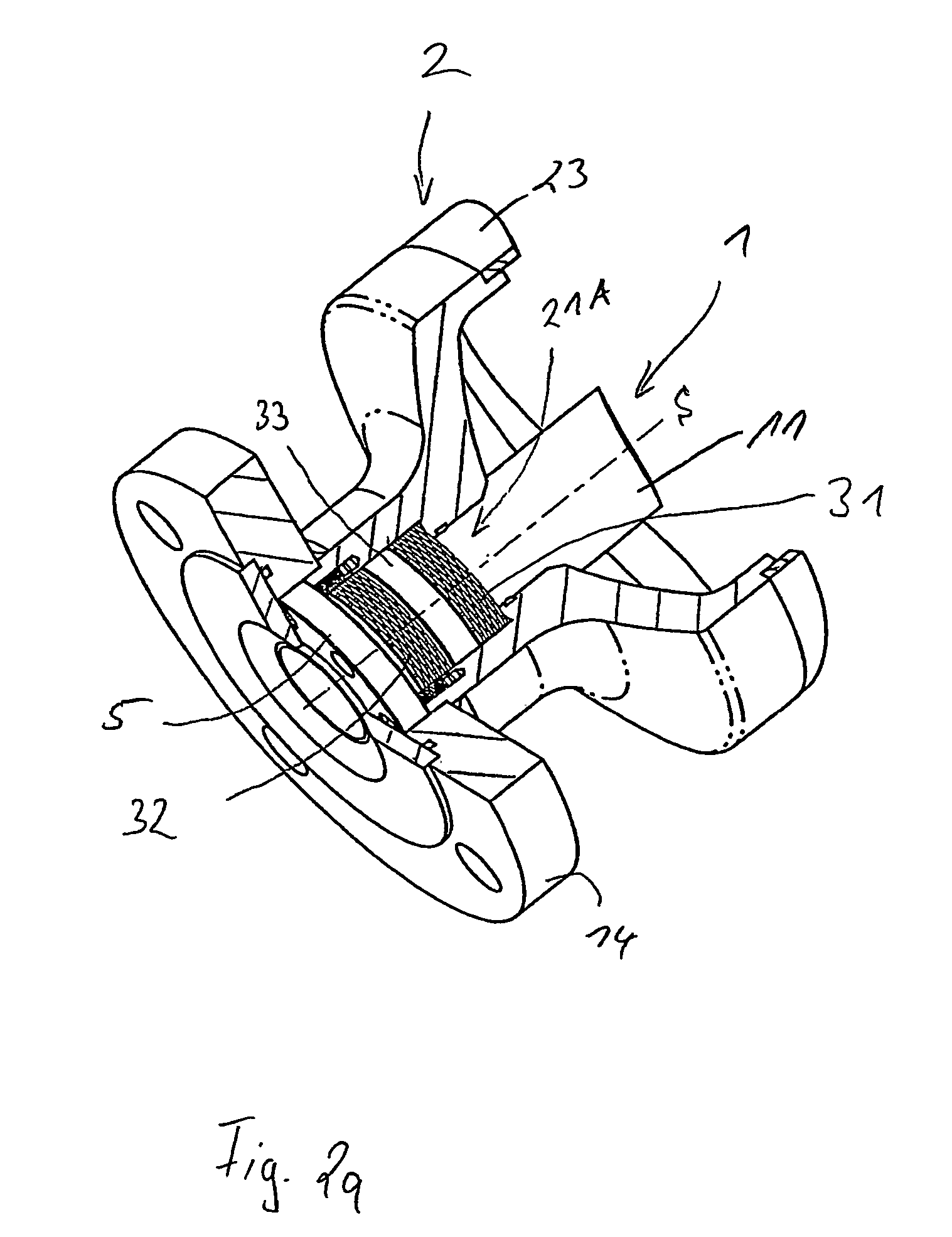

Automatic take-up device with internal spring

InactiveUS7509778B2Assure rigidityAssure tightnessLoad modified fastenersNutsEngineeringTension member

The present invention consists of a connection, having an anchored, elongated tension member, a fastening member attached to the elongated tension member, a resisting member that receives the elongated tension member and an expansion device that receives the elongated tension member there through and is compressively loaded between the fastening member and the resisting member by operation of the fastening member on the elongated tension member. The expansion device is formed with a sleeve. First and second bearing members are received in the central aperture of the surrounding sleeve and operatively connected to the surrounding sleeve. At least one of the bearing members is threadably connected to the sleeve. This bearing member can rotate in relation to the surrounding sleeve.

Owner:SIMPSON STRONG TIE

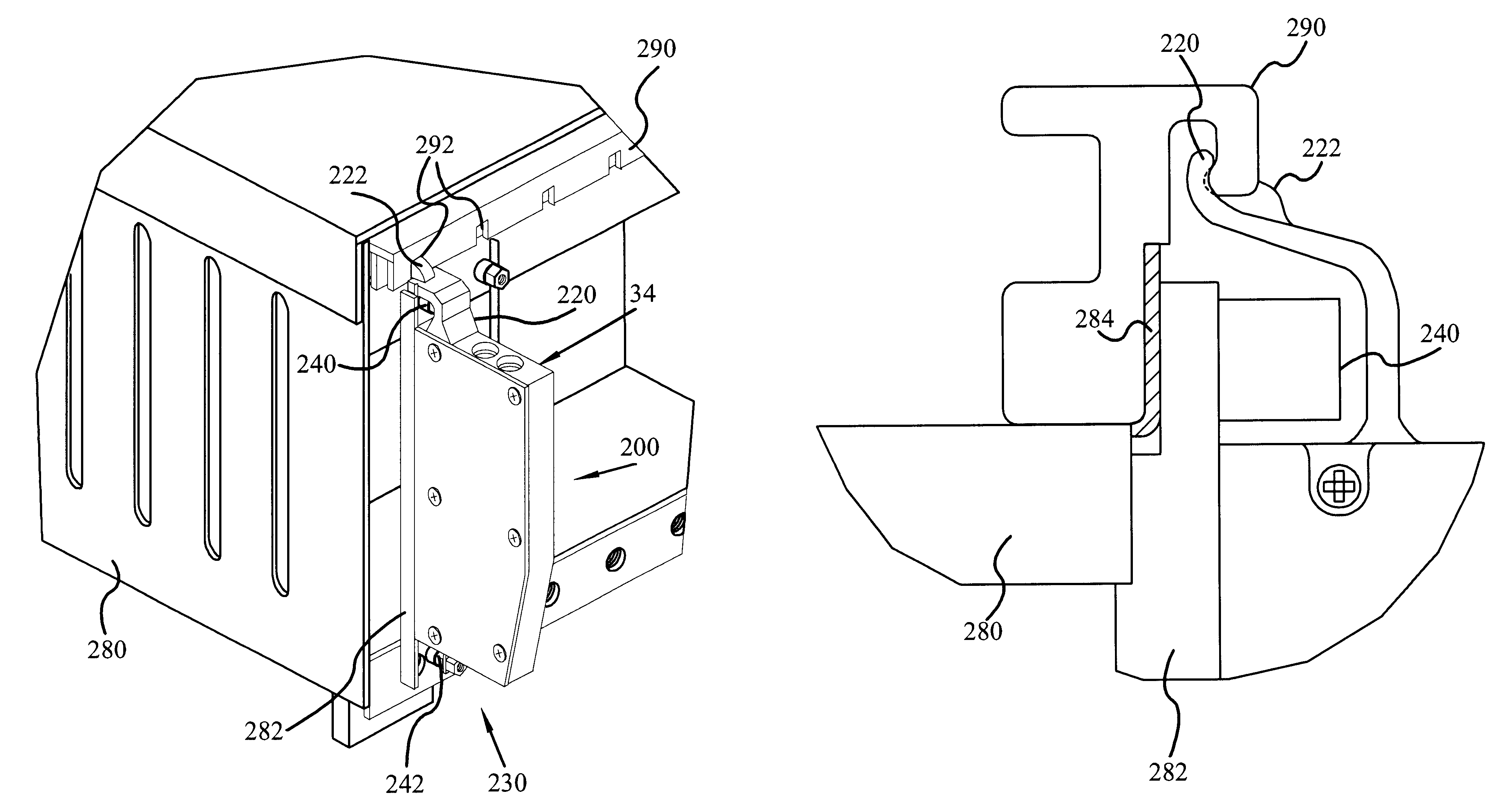

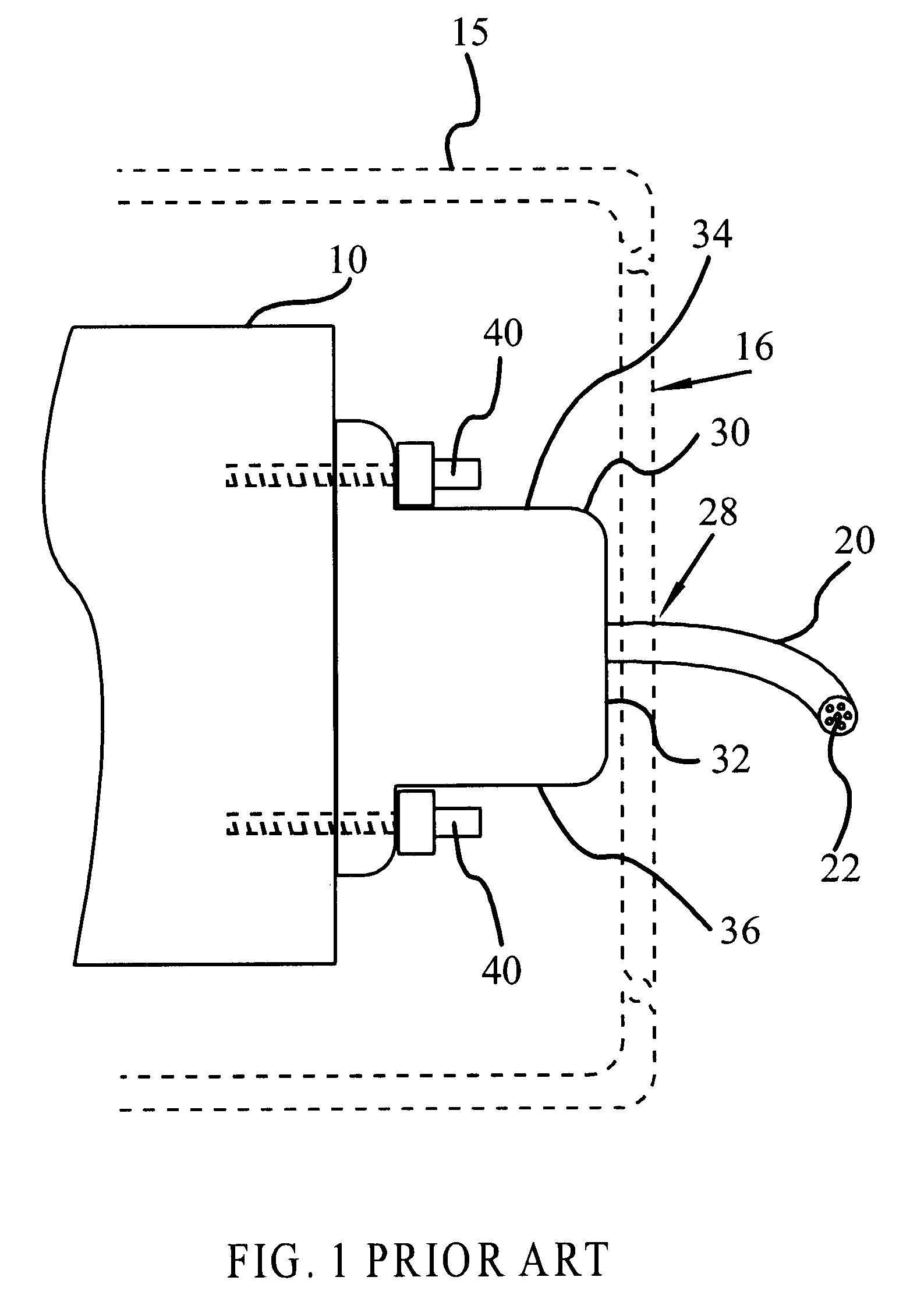

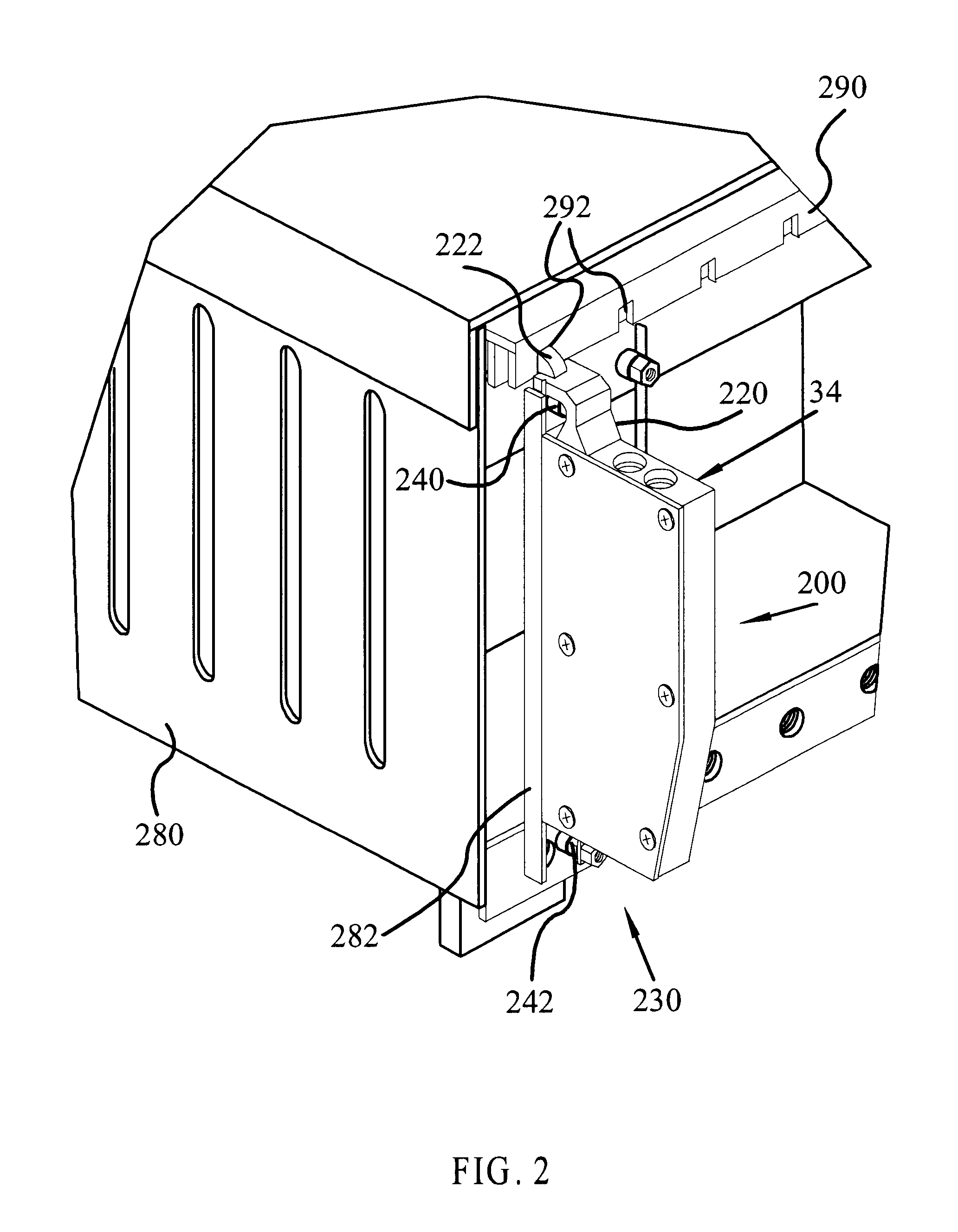

Apparatus and method for using a backshell

InactiveUS6561835B1Strong mechanical connectionCoupling device detailsSupport structure mountingCamElectrical connector

A backshell for forming an electrical connection with a cabinet, the backshell including at least one electrical connector, a deflection arm coupled to one end of the backshell for engaging a cam on a cabinet which holds a receiving connector, and a fastener on the opposite end of the backshell from the deflection arm. The deflection arm provides a clamping force when the fastener is fully engaged, and helps form a strong mechanical connection.

Owner:HONEYWELL INT INC

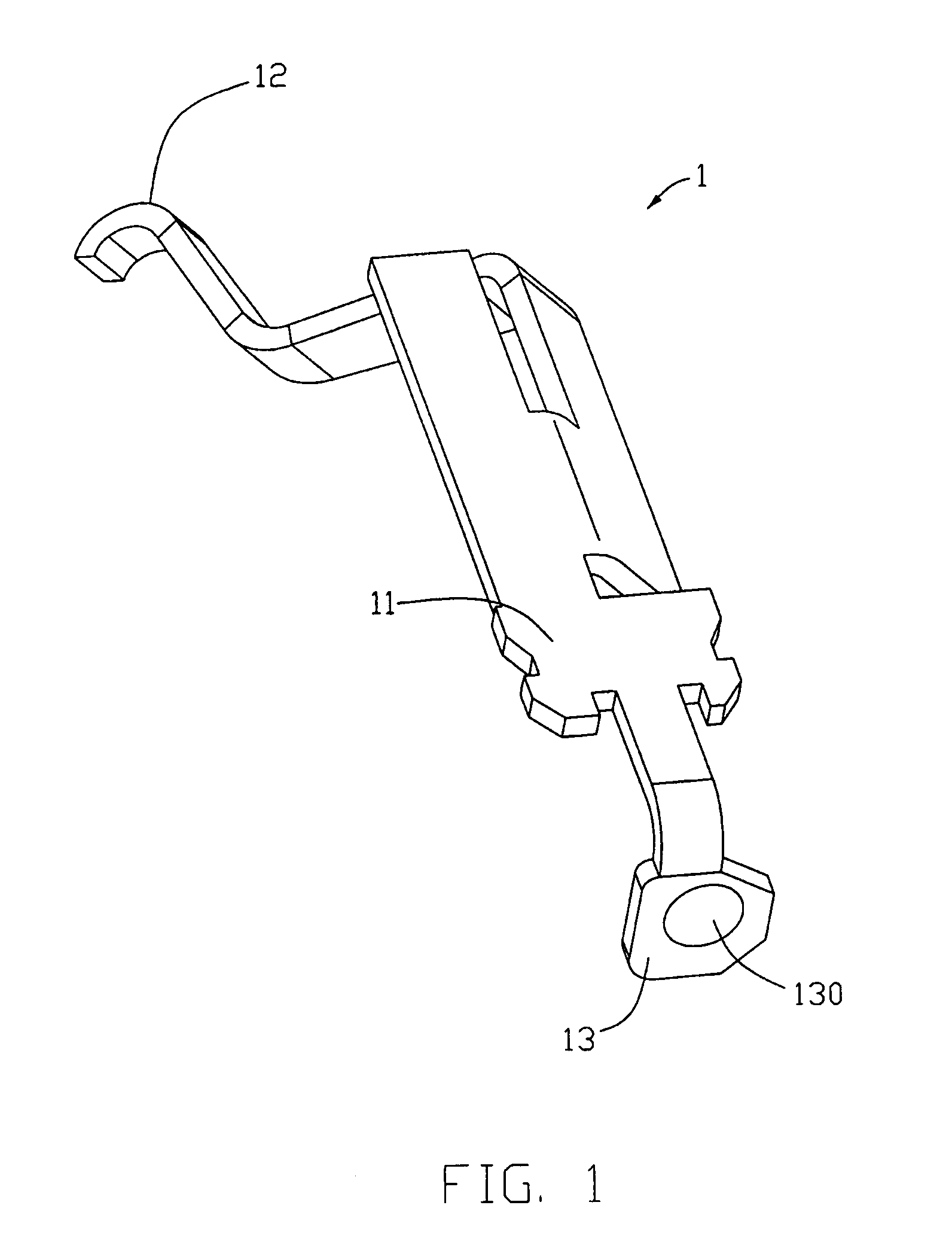

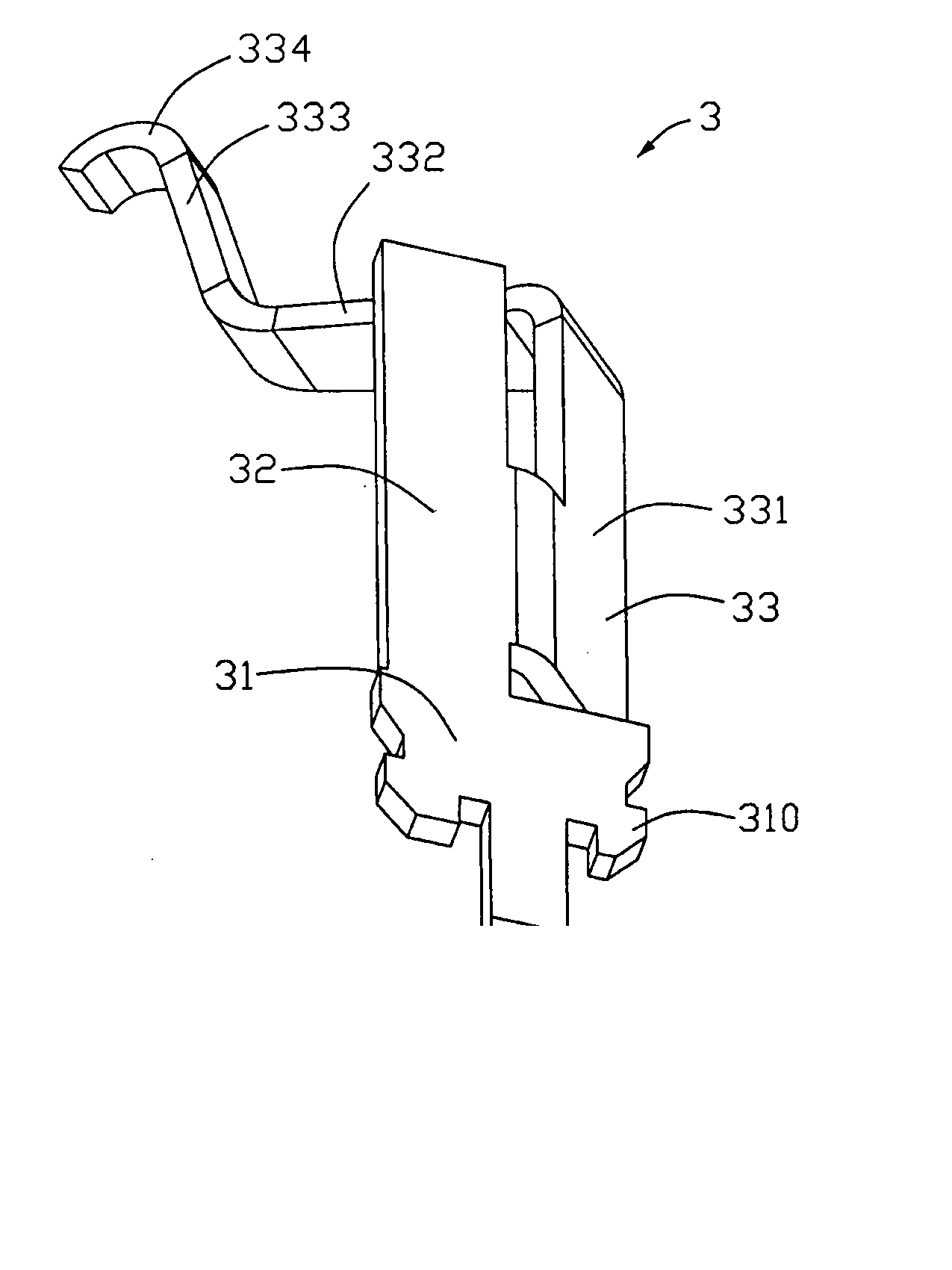

Electrical contact background of the invention

InactiveUS7534113B2Additional flawStrong mechanical connectionCoupling device detailsPrinted circuitsSolder ballEngineering

Owner:HON HAI PRECISION IND CO LTD

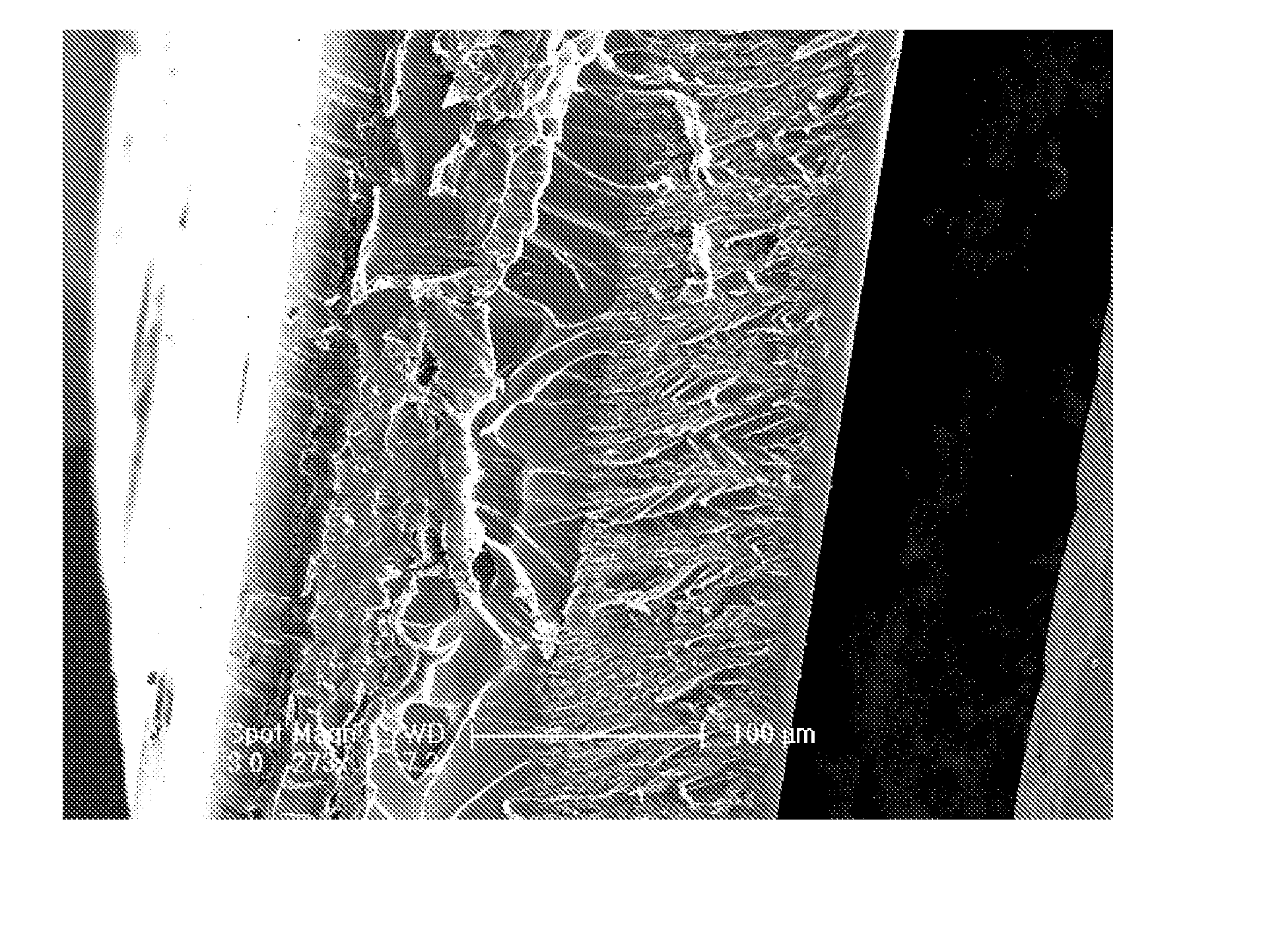

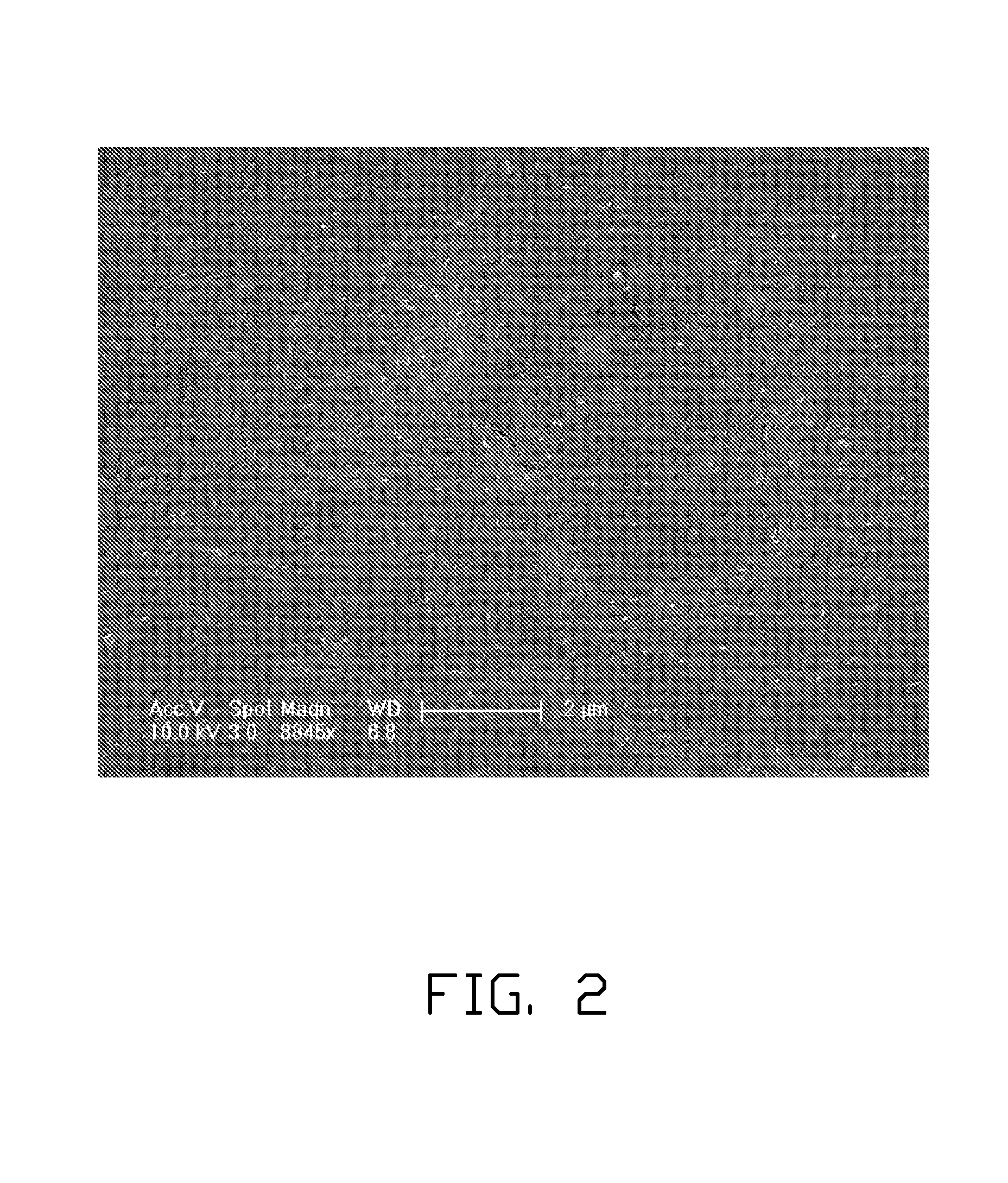

Method of preparing carbon nanotube/polymer composite material

ActiveUS20080145570A1Improve conductivityStrong mechanical connectionMaterial nanotechnologyPretreated surfacesPolymer solutionPolymer composites

A method of preparing a carbon nanotube / polymer composite material is provided. The method includes (a) providing a carbon nanotube-based film and a pre-polymer solution; (b) placing the carbon nanotube-based film at a bottom of a container, and pouring the pre-polymer solution in the container; and (c) polymerizing the pre-polymer solution and simultaneously integrating the pre-polymer solution with the carbon nanotube-based film. As such, a carbon nanotube / polymer composite material, including the polymer-impregnated nanotube layer and an upper polymer layer, is obtained. A multi-layer composite can be produced by essentially repeating this process, using the upper polymer layer as the base layer for the formation of the next layer set thereon.

Owner:TSINGHUA UNIV +1

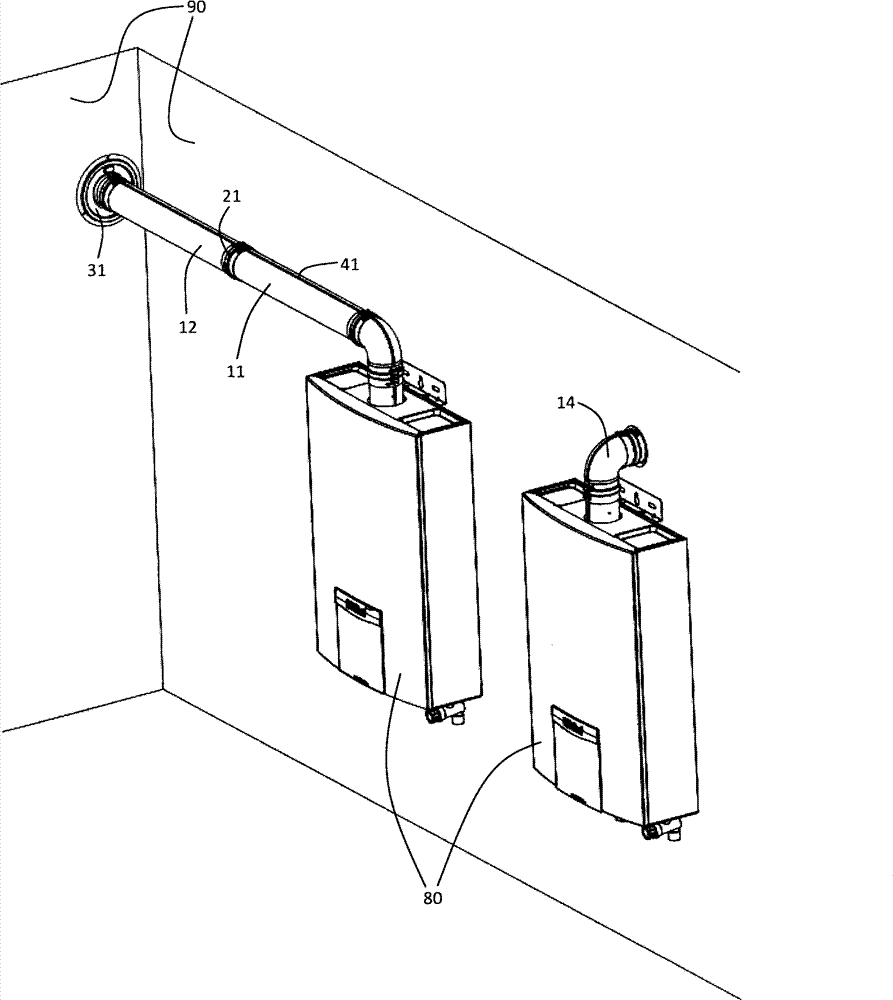

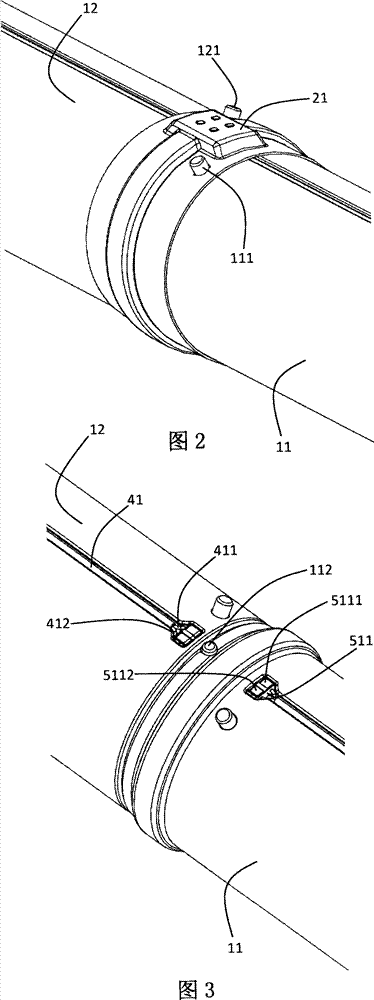

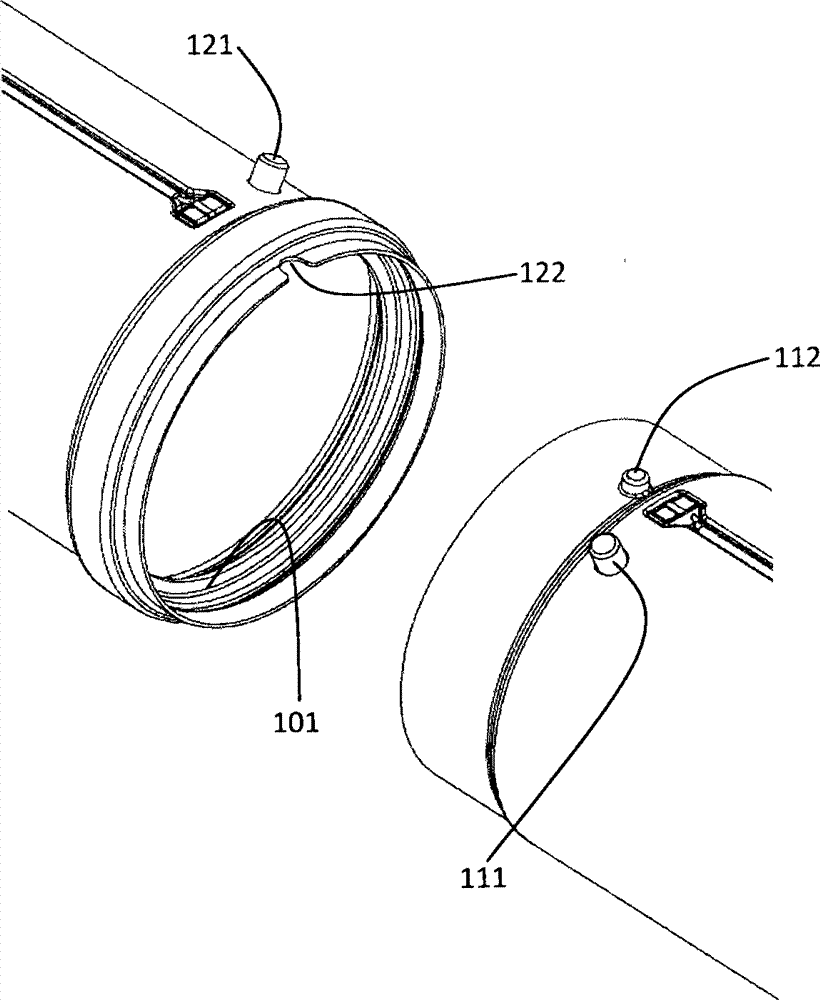

Smoke discharge pipe assembly for gas-fired equipment

ActiveCN104501191AStrong mechanical connectionReliable mechanical connectionChimneysControl circuitFuel gas

The invention provides a smoke discharge pipe assembly for gas-fired equipment. The smoke discharge pipe assembly at least comprises a first smoke discharge pipe and a second smoke discharge pipe, wherein a conductor is respectively arranged on the first smoke discharge pipe and the second smoke discharge pipe, the smoke discharge pipe assembly also comprises a pipe connecting mechanism, the pipe connecting mechanism is connected between the first smoke discharge pipe and the second smoke discharge pipe for realizing the fixed mechanical connection of the first and second smoke discharge pipes, and meanwhile, the elastic connection of conducting bodies of the first and second smoke discharge pipes is realized. Through the introduction of the pipe connection mechanism, the mechanical connection between the adjacent smoke discharge pipes becomes stable, firm and reliable, so that the displacement, staggering or disconnection condition is reduced. Even when the conditions occur, or the breaking of a circuit formed by connecting the conducting bodies of the smoke discharge pipes in series is caused when the installation is not carried out according to the specification, a control circuit of a gas water heater can detect the condition, and corresponding measures such as hot water operation stopping can be executed, so that the waste gas leakage can be further prevented.

Owner:VAILLANT WUXI HEATING EQUIP

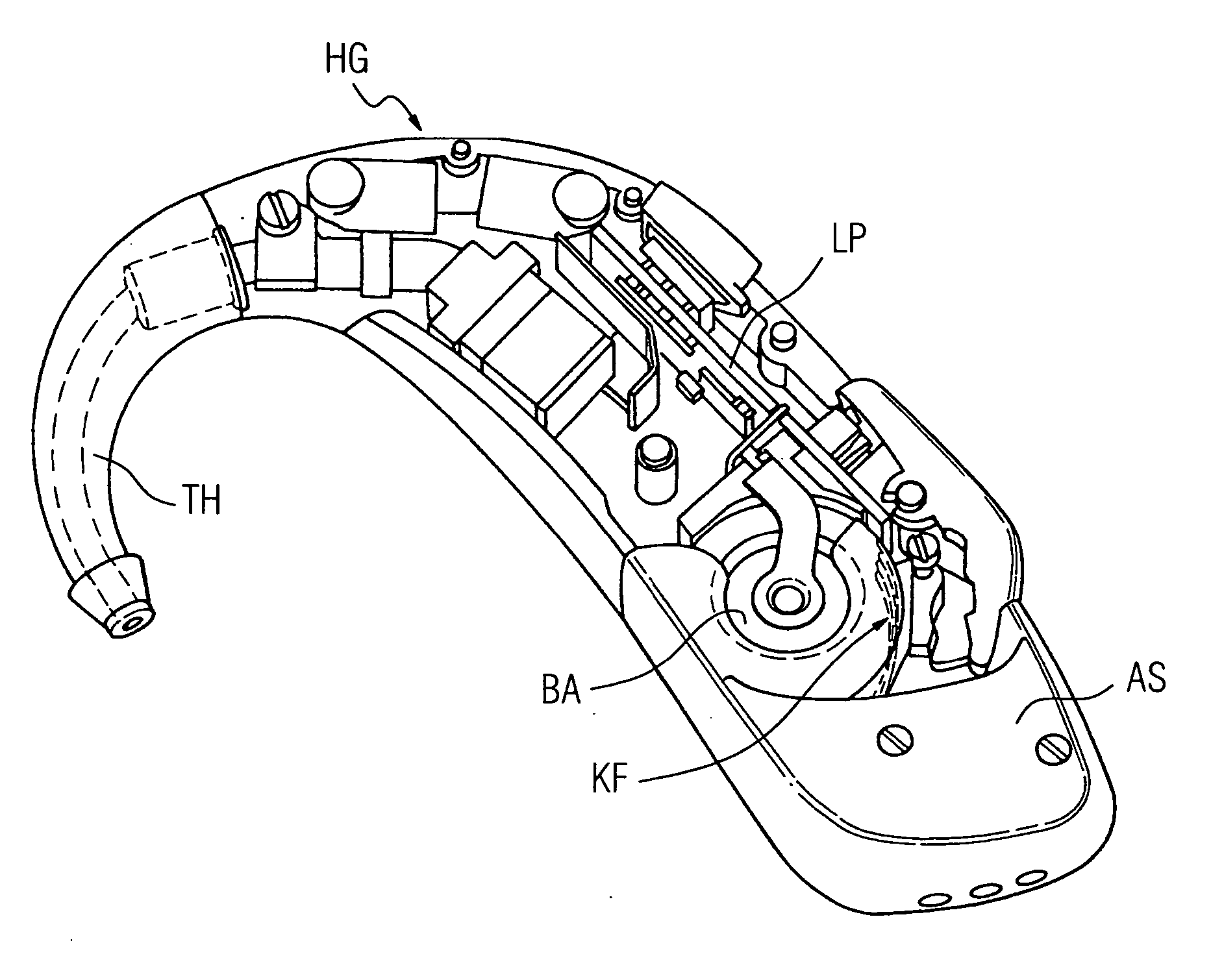

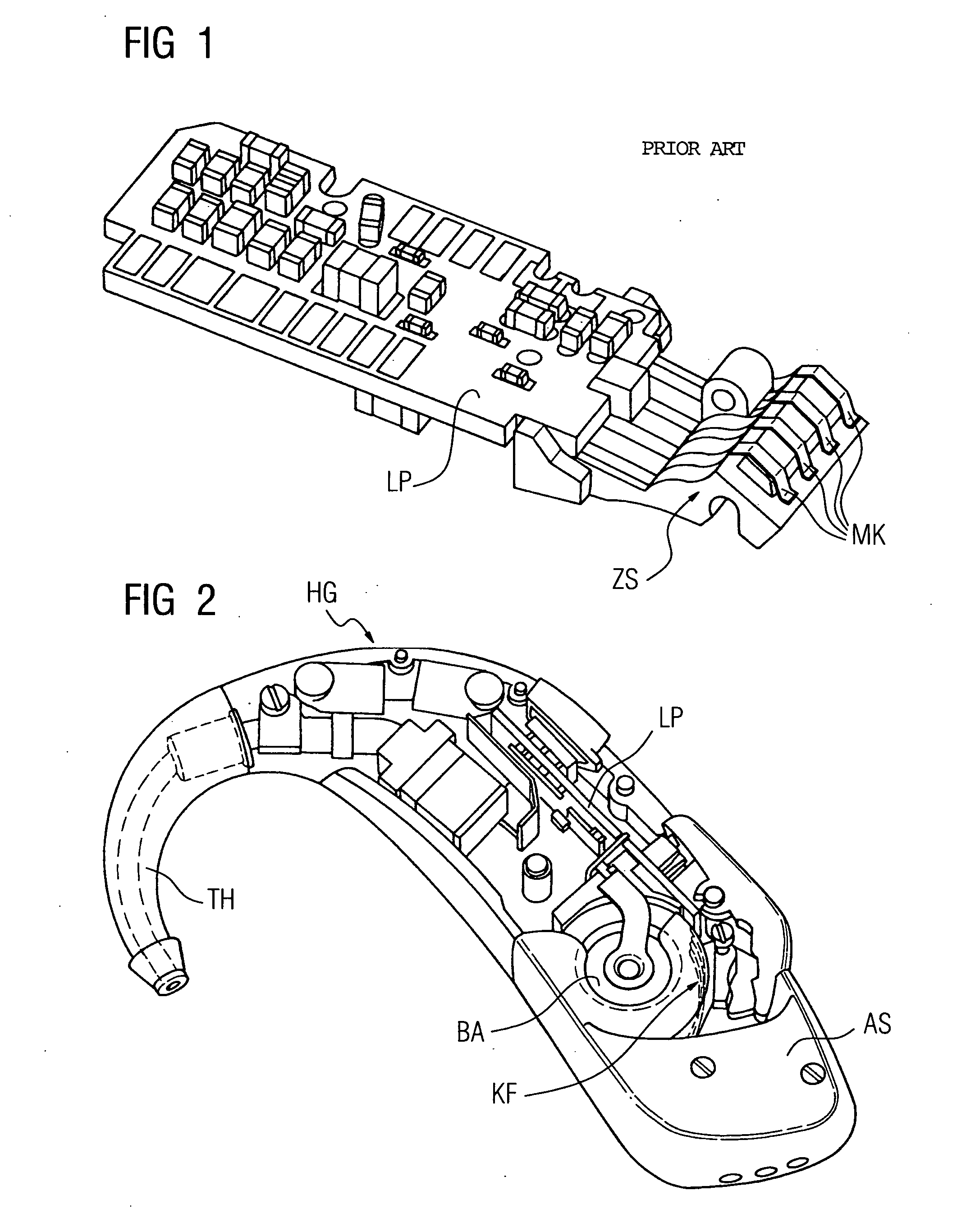

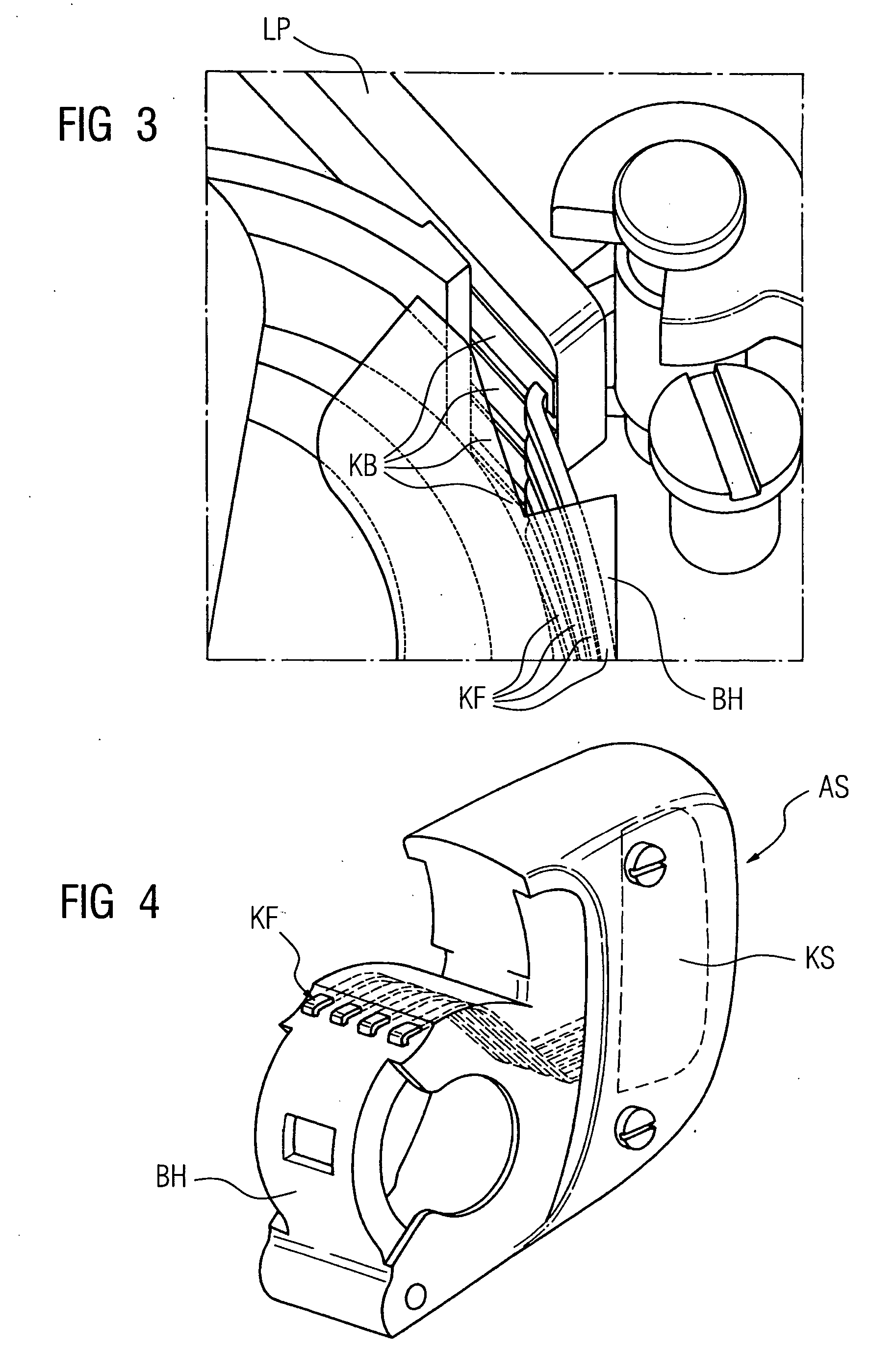

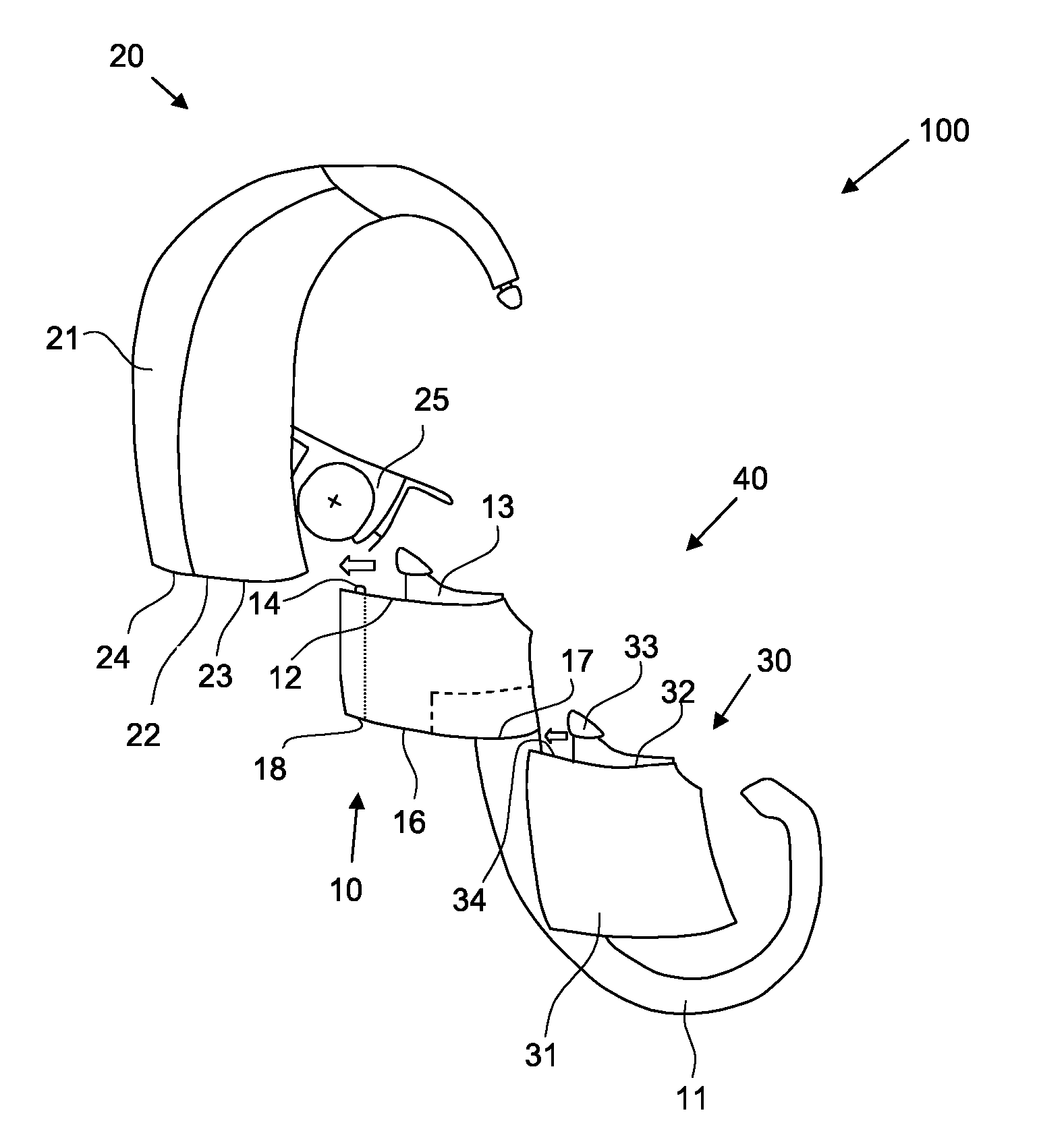

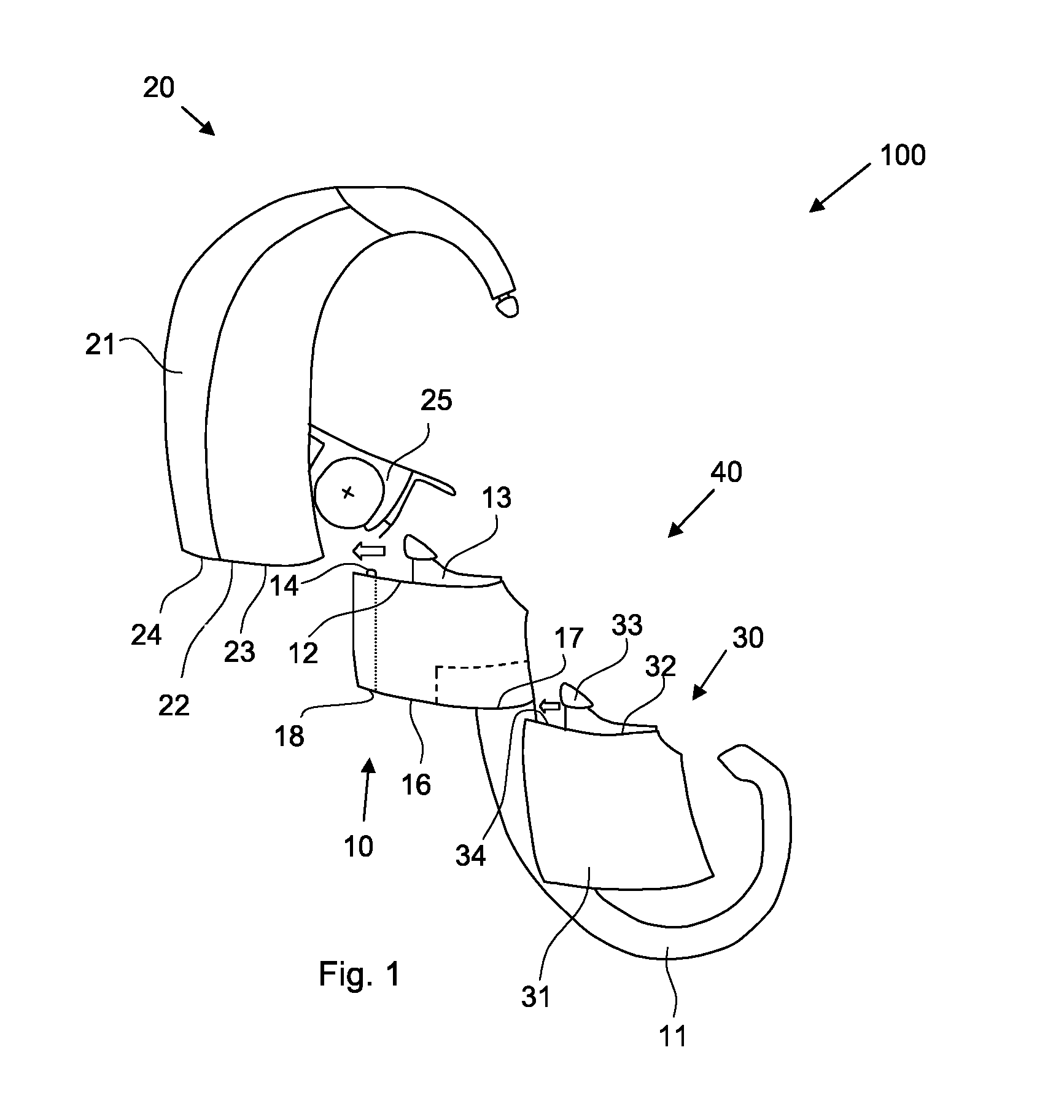

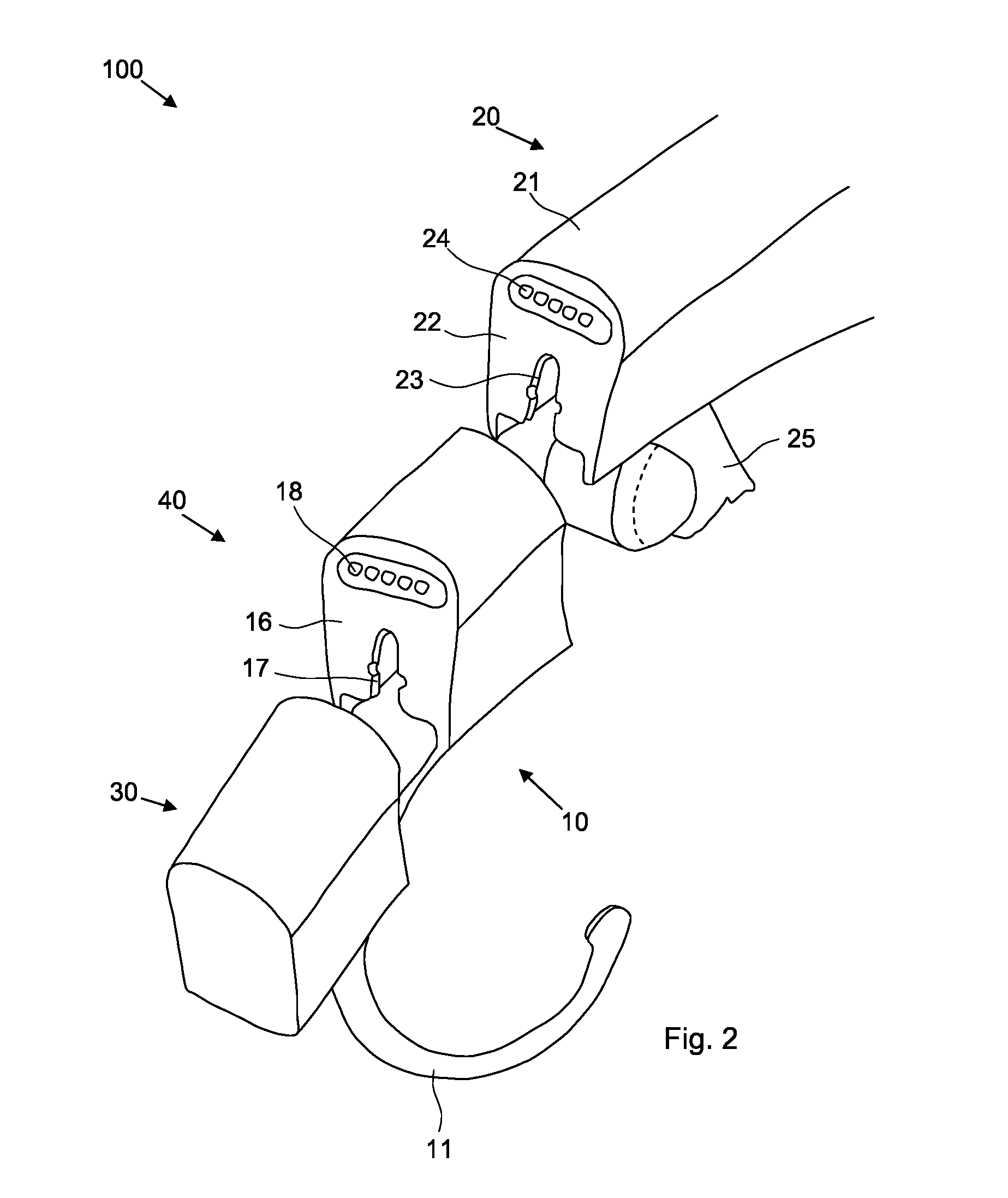

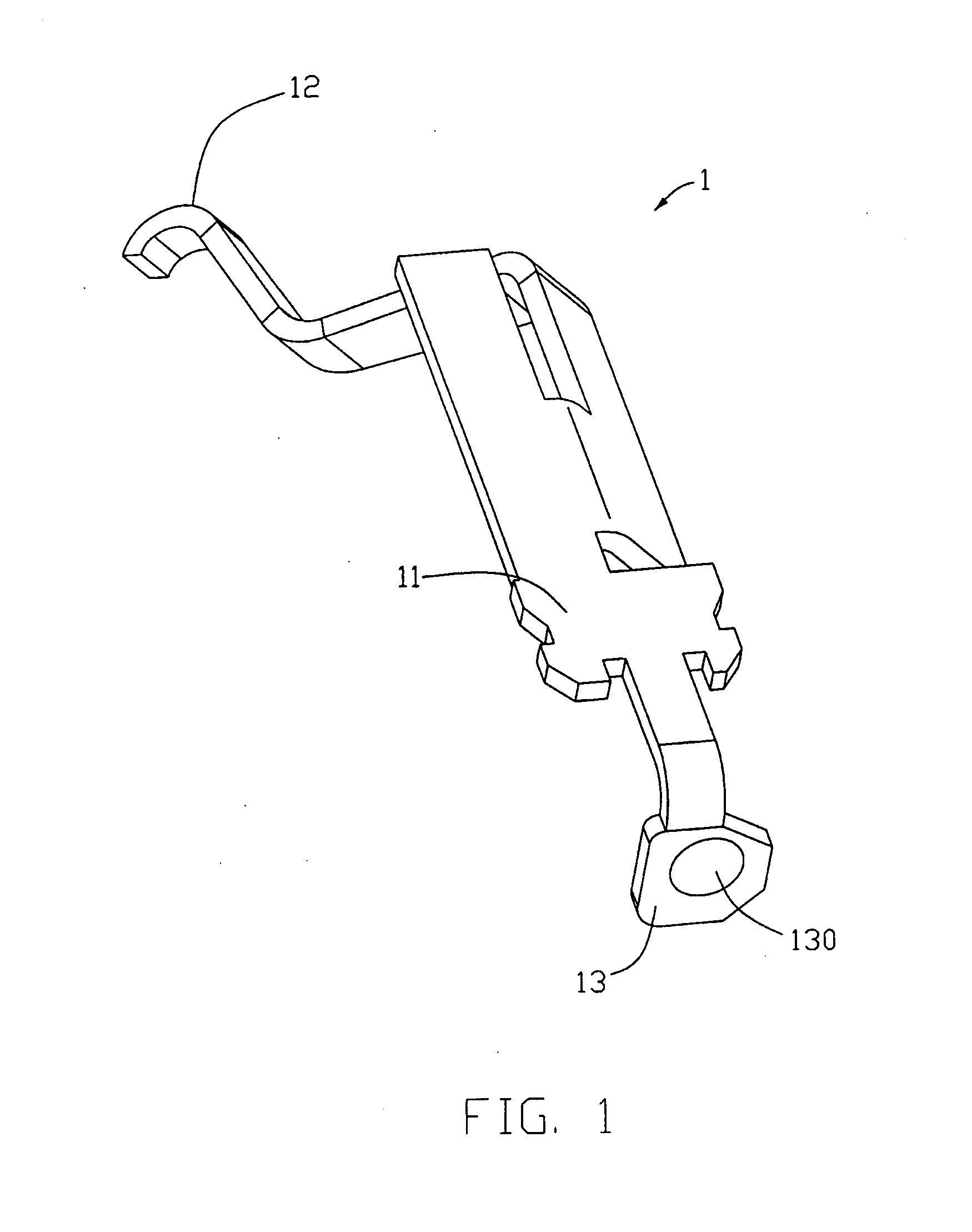

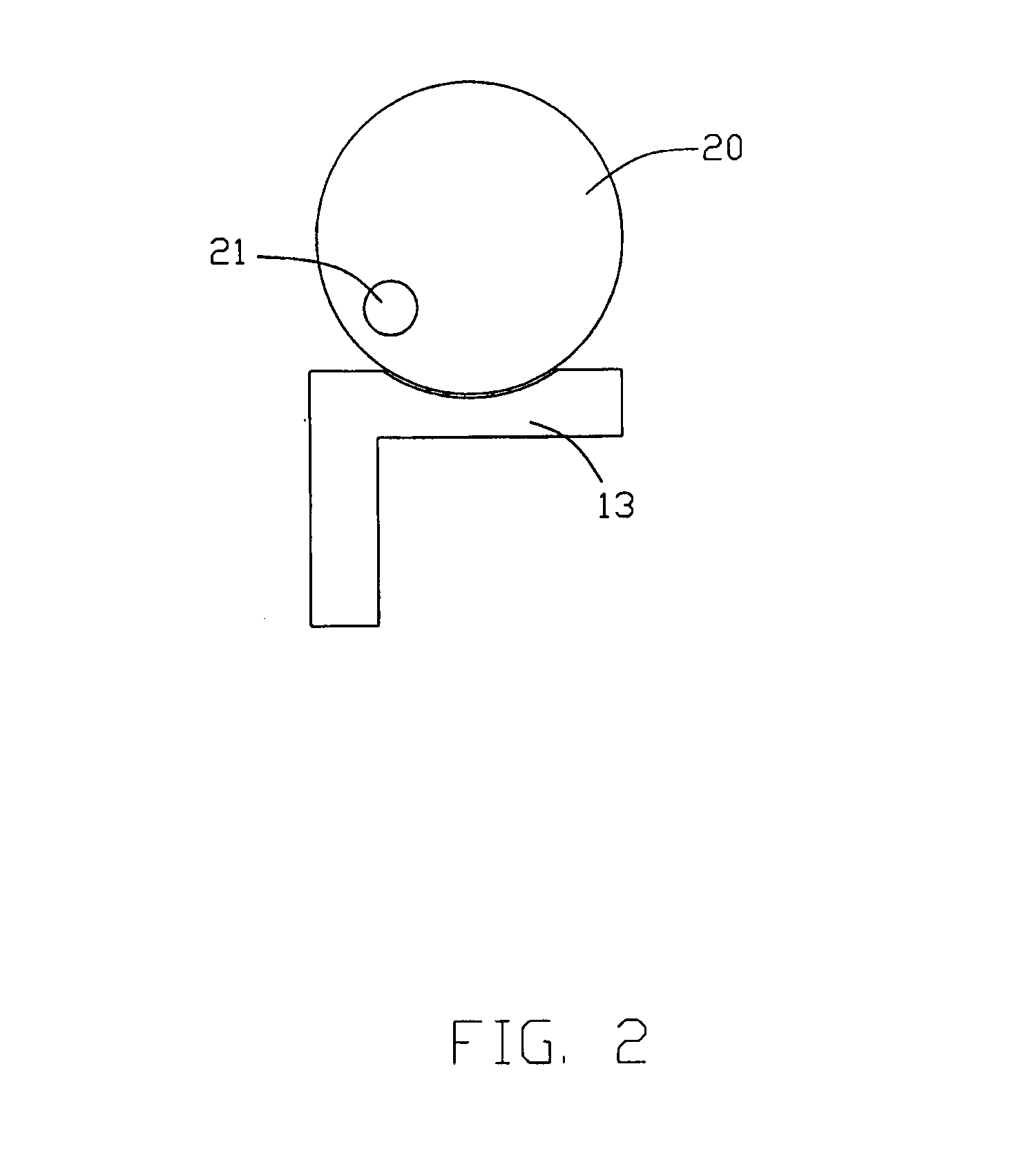

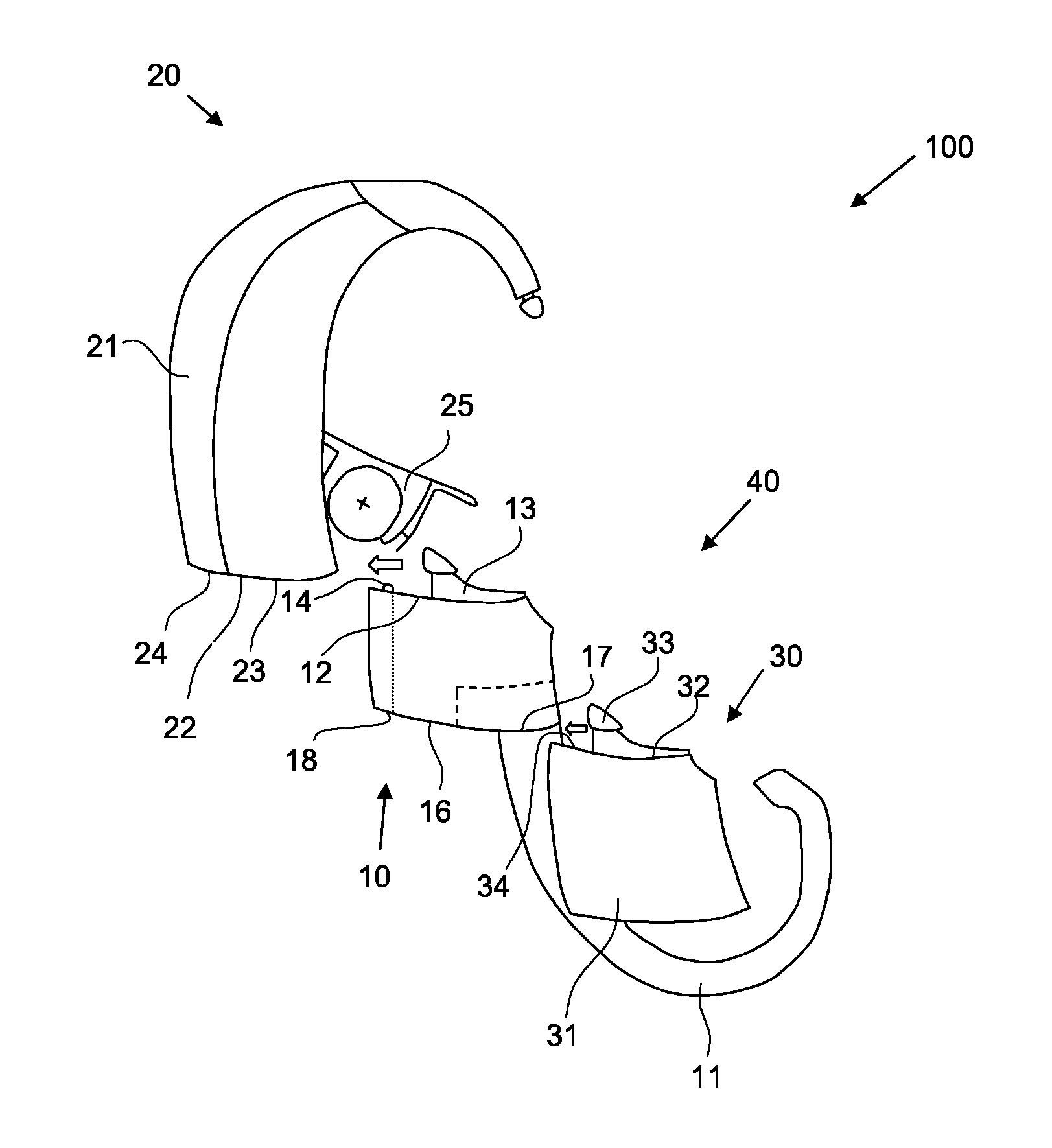

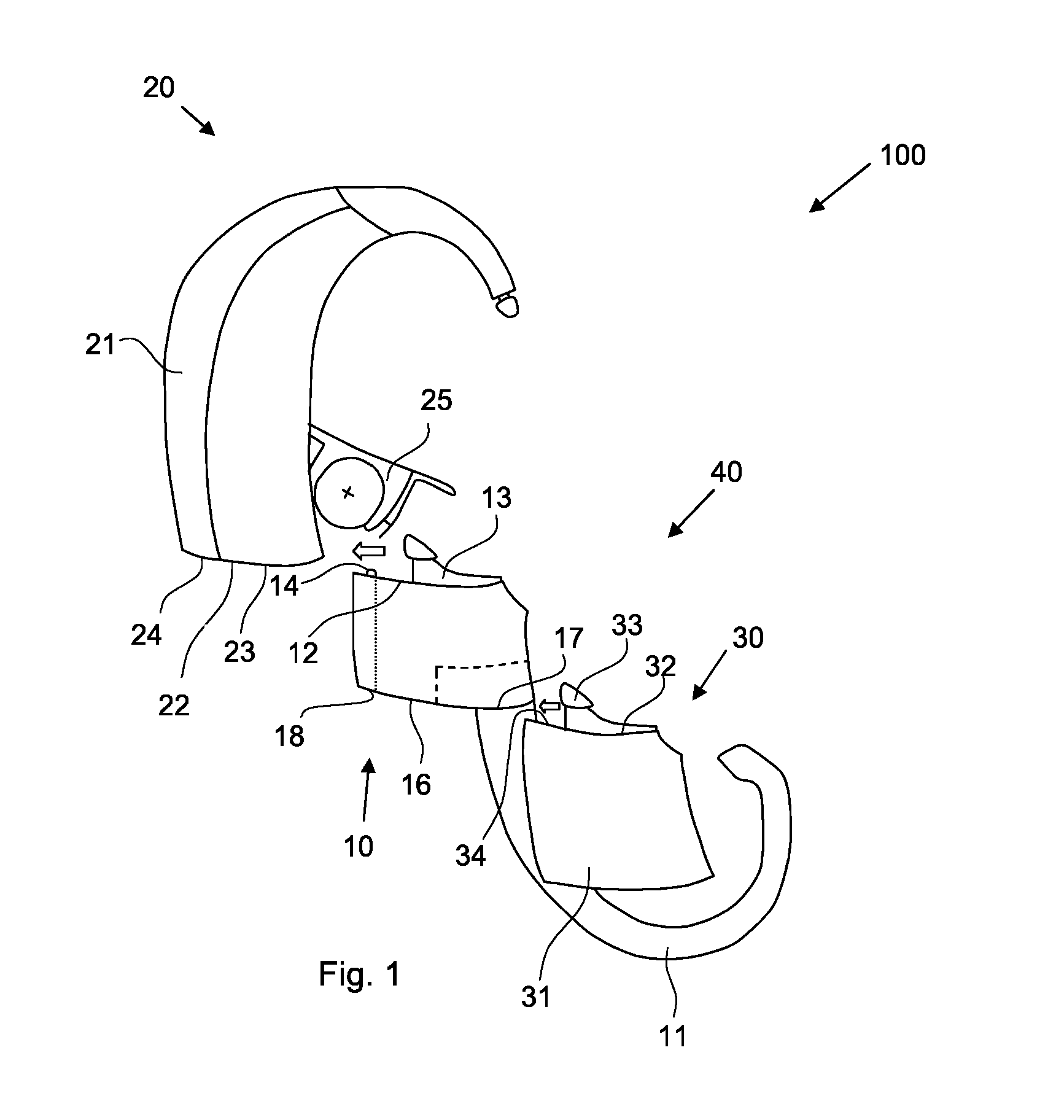

Audio shoe contact for a hearing device

ActiveUS20070047751A1Easy to assembleReduce susceptibility to interferenceHearing aids housingEngineeringHearing apparatus

A hearing device with an audio shoe is to be designed in a simpler and less interference-susceptible manner. To this end, provision is made for an audio shoe to comprise contact springs of such type that directly contact the circuit boards of a hearing device. A contact intermediate piece between the audio shoe and the circuit board of the hearing device can thus be dispensed with. Furthermore, contact problems caused by the intermediate piece can hereby be avoided and the assembly cost for the hearing device reduced.

Owner:SIVANTOS PTE LTD

Automatic take-up device with internal spring

InactiveUS20050034391A1Counteract shakingCounteract vibrationLoad modified fastenersNutsEngineeringTension member

The present invention consists of a connection, having an anchored, elongated tension member, a fastening member attached to the elongated tension member, a resisting member that receives the elongated tension member and an expansion device that receives the elongated tension member there through and is compressively loaded between the fastening member and the resisting member by operation of the fastening member on the elongated tension member. The expansion device is formed with a sleeve. First and second bearing members are received in the central aperture of the surrounding sleeve and operatively connected to the surrounding sleeve. At least one of the bearing members is threadably connected to the sleeve. This bearing member can rotate in relation to the surrounding sleeve. A torsion spring connects the first and second bearing members and is located within the surrounding sleeve. The torsion spring biases the first and second members in opposite rotational directions such that at least one of the bearing members is forced to rotate along the thread of the surrounding sleeve away from the other bearing member and out of the surrounding sleeve.

Owner:SIMPSON STRONG TIE

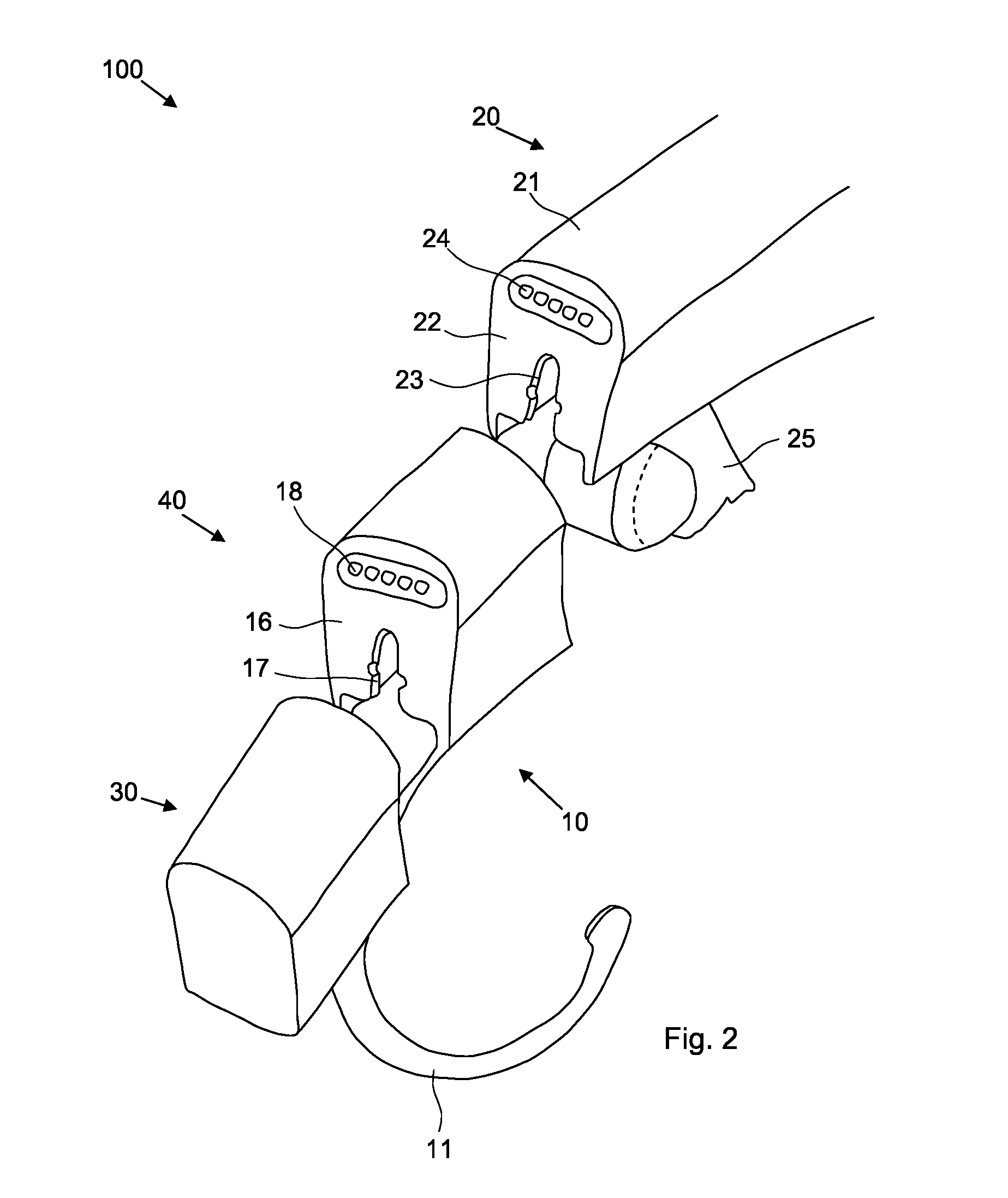

Hearing aid retainer accessory

ActiveUS20130294627A1High comfort in wearComfortable to wearHearing aids housingElectrical connectionHearing aid

A hearing aid retainer accessory is provided for use with a hearing aid having a housing with a longitudinal end face portion comprising a mechanical connection terminal and an electrical connection point. The hearing aid retainer accessory comprises a retainer element with a first end face portion having a first mechanical connection means configured to be engageable to a mechanical connection terminal of a longitudinal end face portion of a housing of a hearing aid.

Owner:OTICON

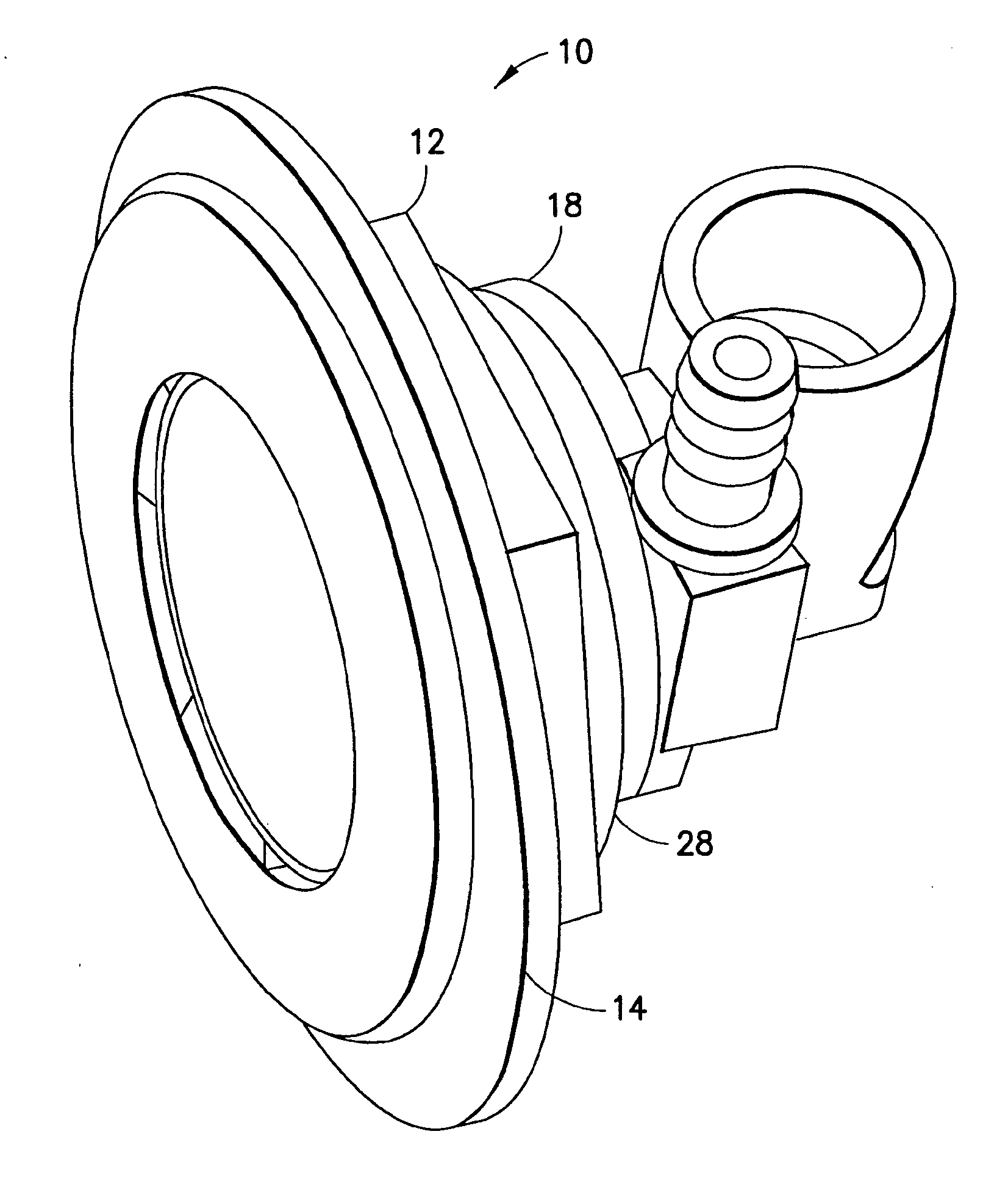

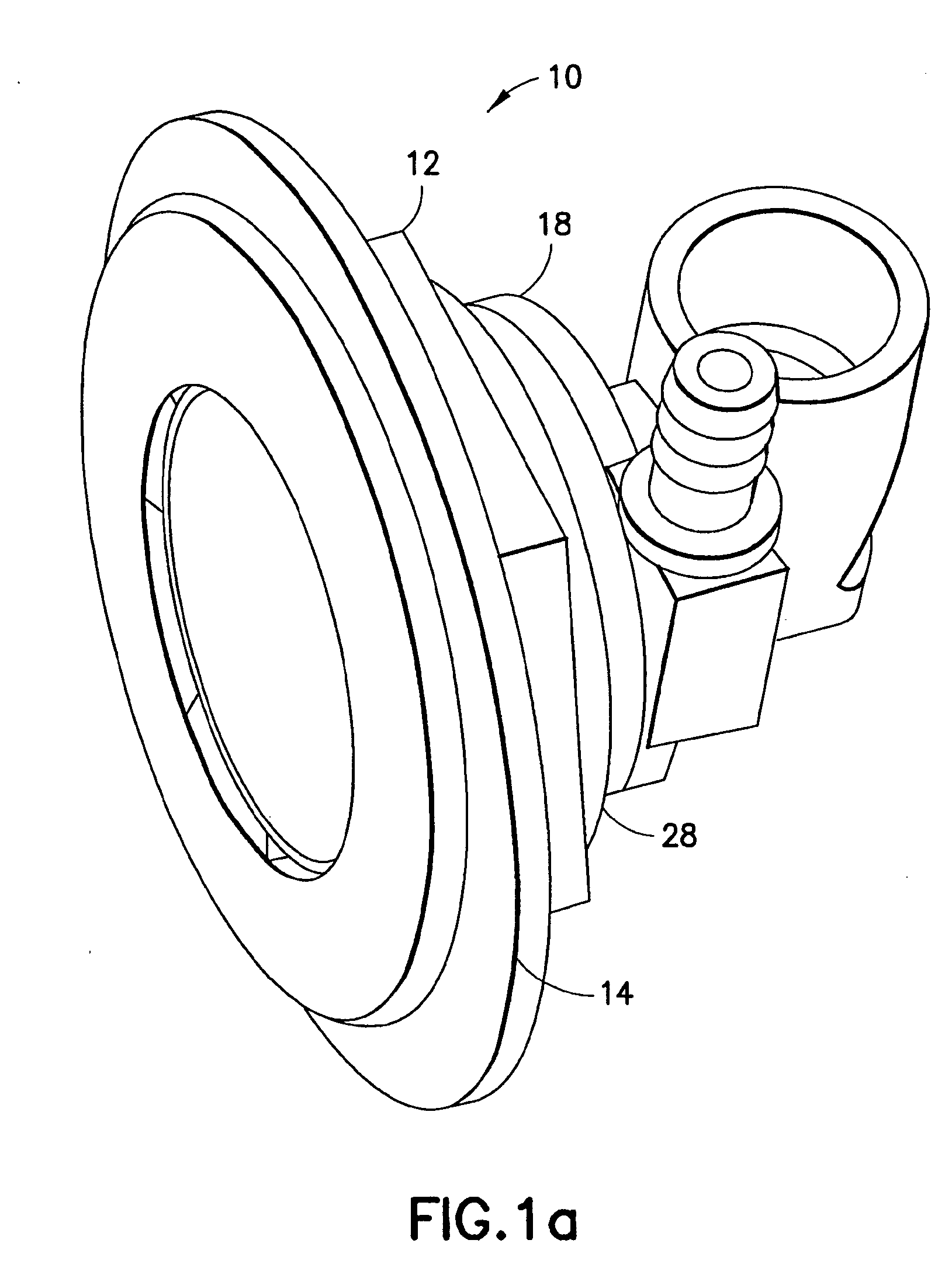

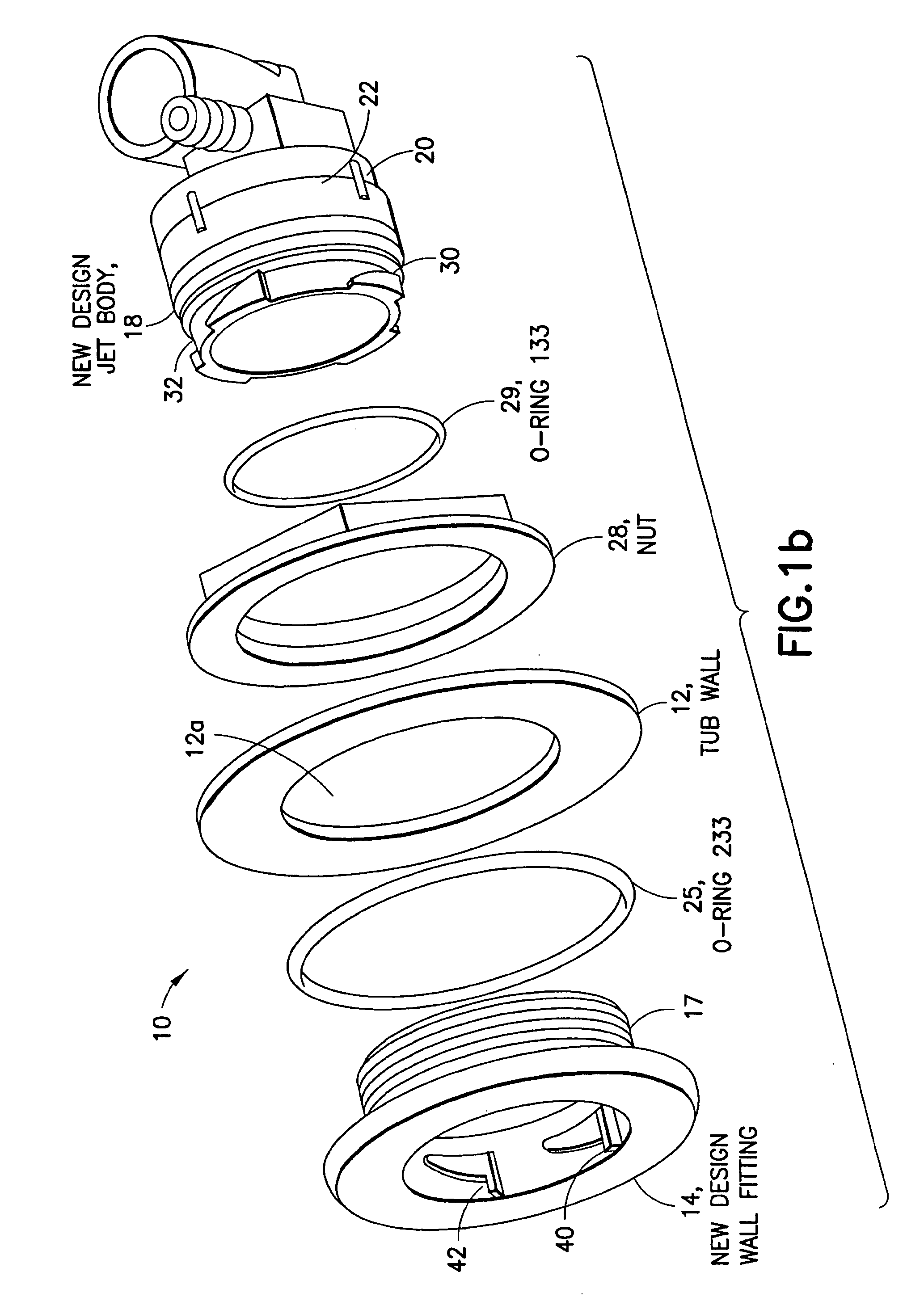

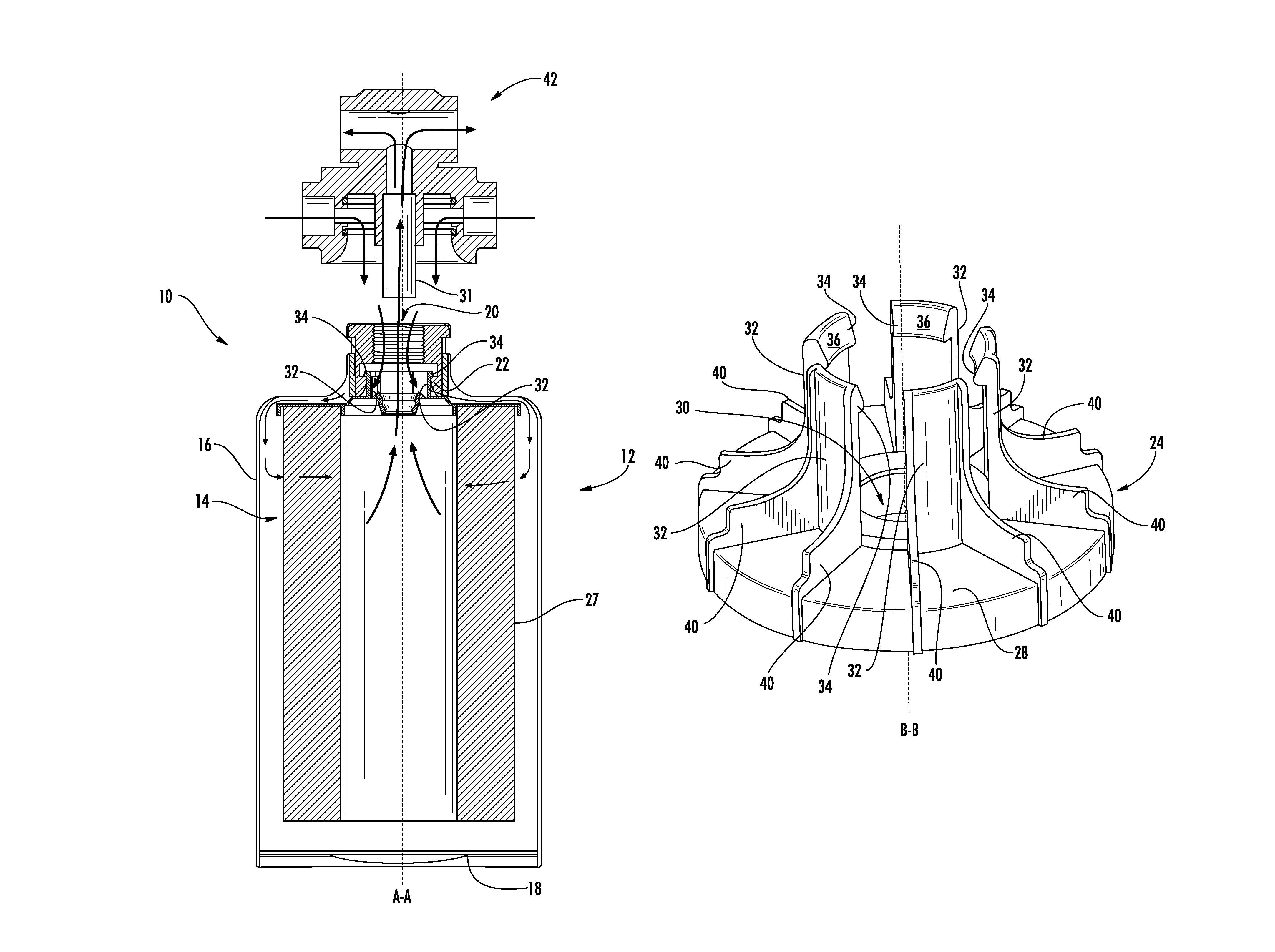

Flange fitting for bathtubs and spas

InactiveUS20070226893A1Enhanced water tight sealStrong mechanical connectionBathing devicesFlangeBathtub

A fitting arrangement is provided for coupling to a tub or spa wall featuring a wall fitting for inserting through a mounting opening in the tub or spa wall and having one or more corresponding rotational locking members; and a jet body having one or more rotational locking members for snapping onto one or more corresponding rotational locking members of the wall fitting as the jet body is advanced into the wall fitting to prevent the jet body and wall fitting from separating from one another.

Owner:BALBOA WATER GROUP

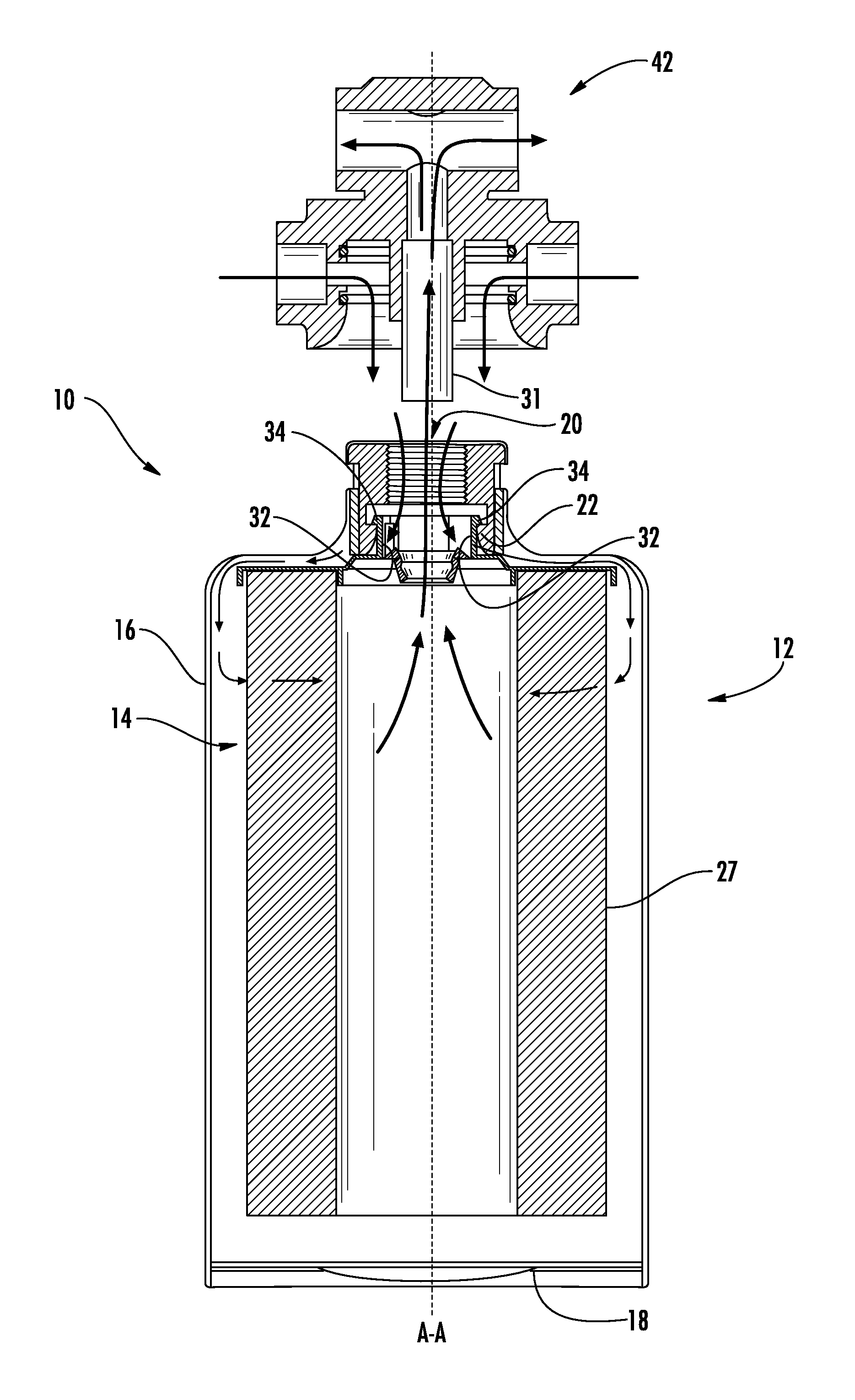

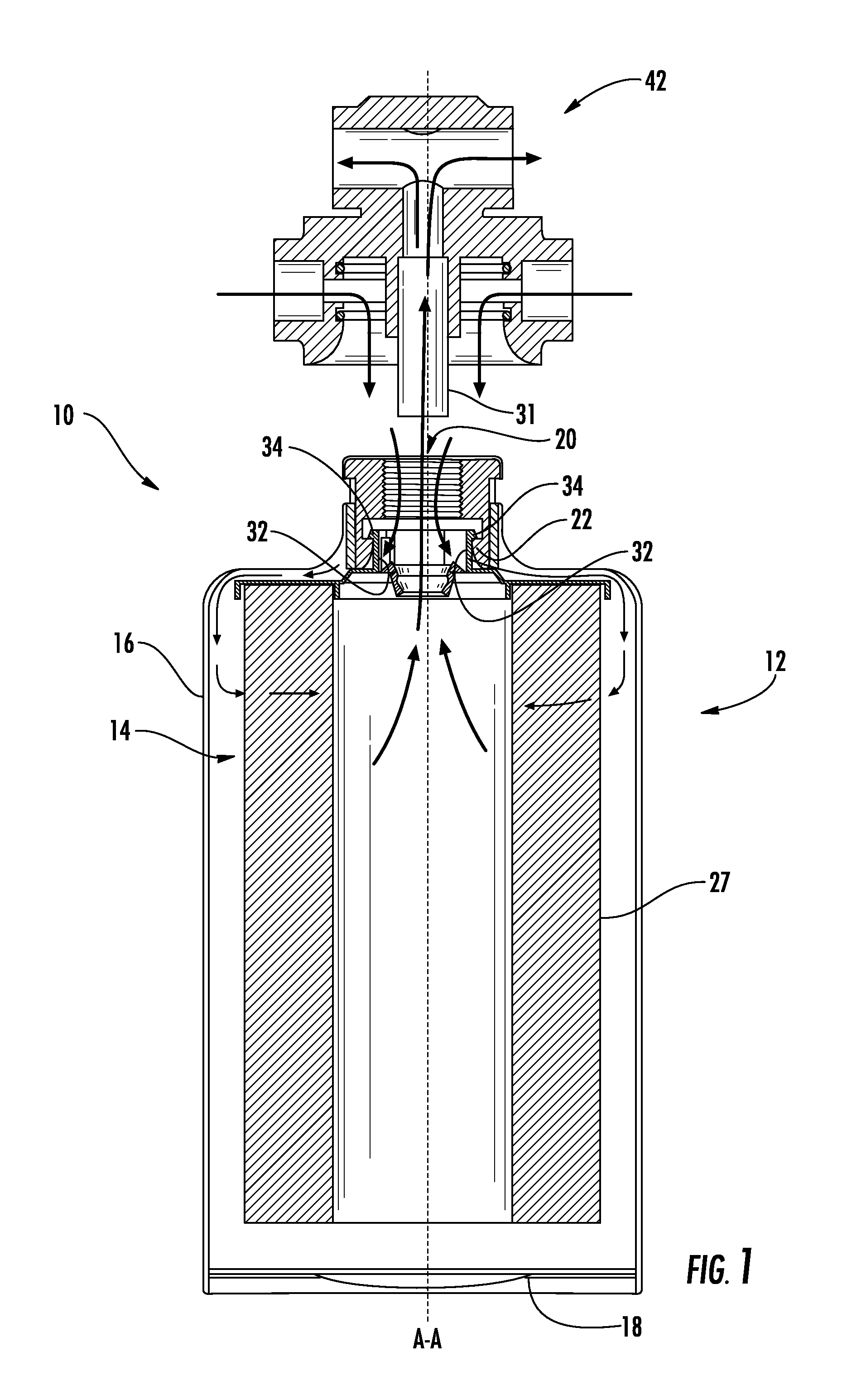

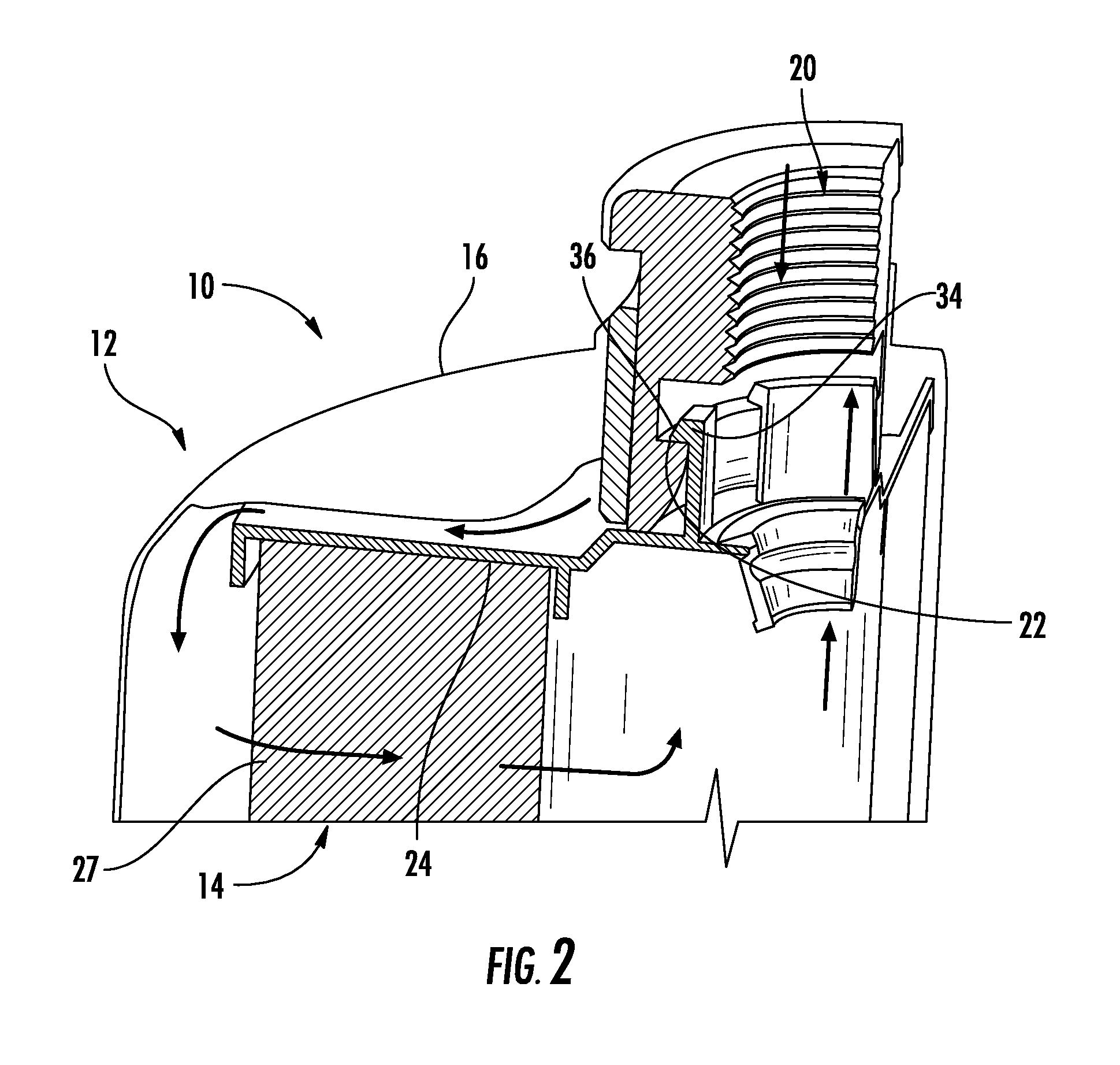

Filter cartridge assembly and method of manufacture thereof

ActiveUS9067156B2Shorten the timeReliable filtrationMembrane filtersCartridge filtersFilter mediaEngineering

A filter cartridge has a longitudinal axis. A cartridge housing has first and second shell portions. The first shell portion has a cartridge housing opening and an annular element retention lip which is disposed axially inward of the opening and coaxial with the longitudinal axis. The filter element has a first end cap, a second end cap, and a continuous ring of filter media disposed between the first and second end caps. The first end cap defines a fuel flow port which is coaxial with the longitudinal axis. A plurality of resilient element retention arms extend axially from the first end cap, and surround the fuel flow port. The arms terminate in retention barbs which are mateable with the annular lip. The resilient retention arms hold the retention barbs against the annular lip, suspending the filter element within the cartridge.

Owner:CLARCOR INC

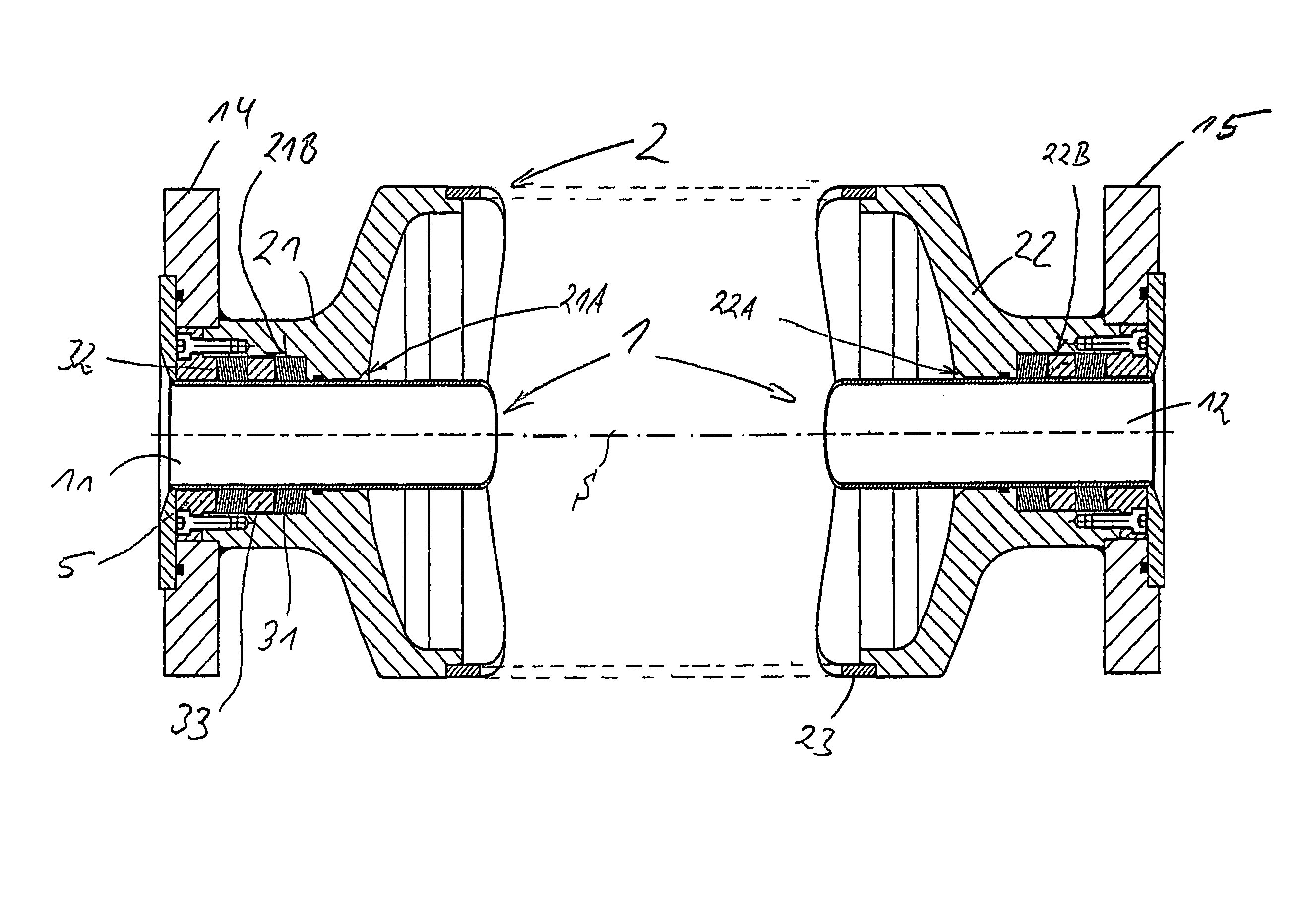

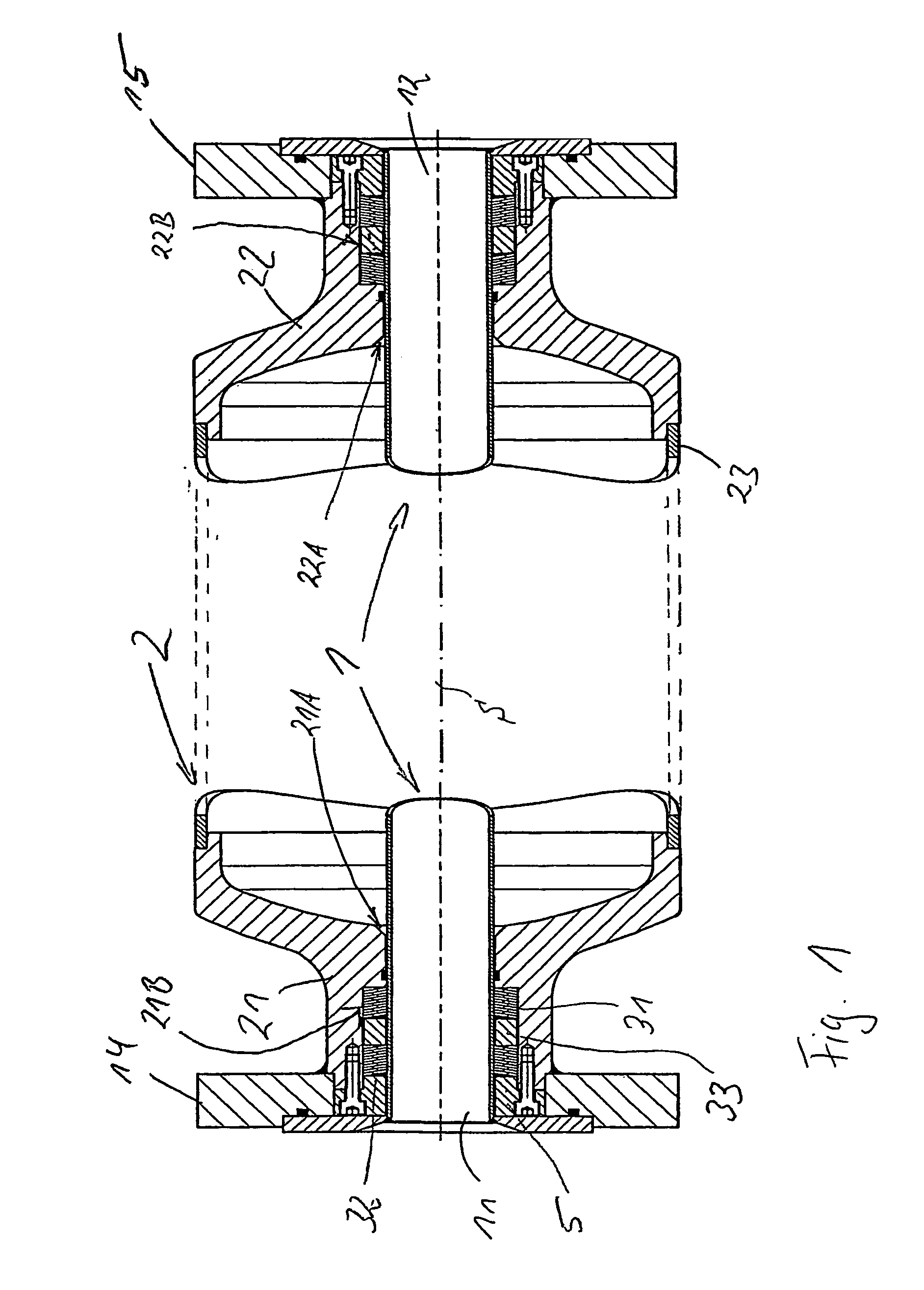

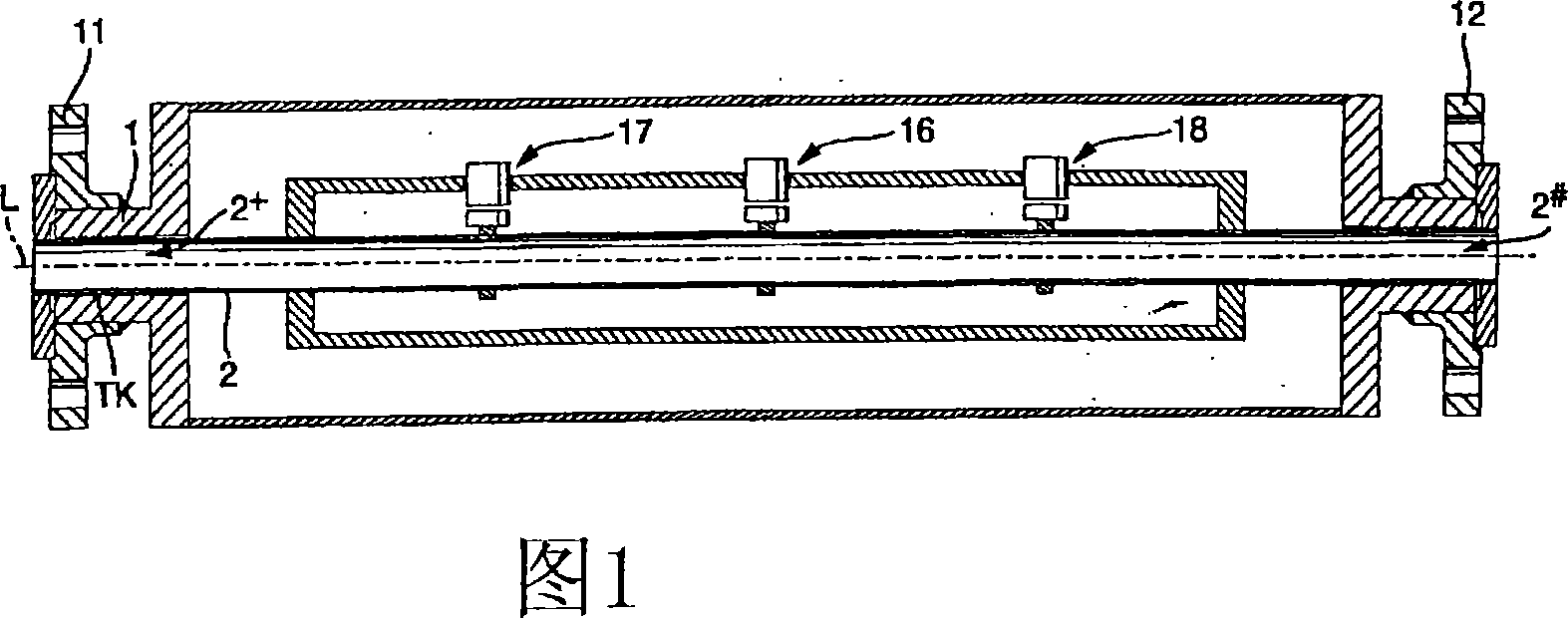

Vibration-type measurement pickup and its measuring tube

InactiveUS7509879B2Eliminate processingFirmly connectedDirect mass flowmetersSpecific gravity measurementTransducerEngineering

A measurement pickup, or transducer, includes at least one measuring tube for the conveying of a fluid. The measuring tube has an inlet end and an outlet end and vibrates at least at times. For enabling the fluid to be measured to flow through the measuring tube, the measuring tube communicates, via a first tube segment opening into the inlet end and via a second tube segment opening into the outlet end, with a pipeline connected therewith. For the oscillatable holding of the measuring tube, the measurement pickup further includes a support element having a first end piece containing a passageway for the securement of the first tube segment and having a second end piece containing a passageway for the securement of the second tube segment. Each of the two tube segments extends through its respective one of the two passageways and each of the two passageways has an inner diameter, which is greater than an outer diameter of its associated tube segment, so that an intermediate space is formed between each of the associated tube segments and end pieces. The measurement pickup further includes at least one, preferably metal, first spring element pushed onto one of the two tube segments. The spring element fills the intermediate space formed between tube segment and end piece at least partially, with the spring element being arranged in the intermediate space in such a manner that it contacts, at least sectionally, both its associated tube segment and also its associated end piece in such a manner that it is subjected, at least sectionally, to radially acting, deformation forces. As a result of elastic deformations accompanying such deformation forces, the spring element is held pressed against the associated tube segment and the associated end piece, whereby such tube segment is locked securely in the associated passageway.

Owner:ENDRESS HAUSER FLOWTEC AG

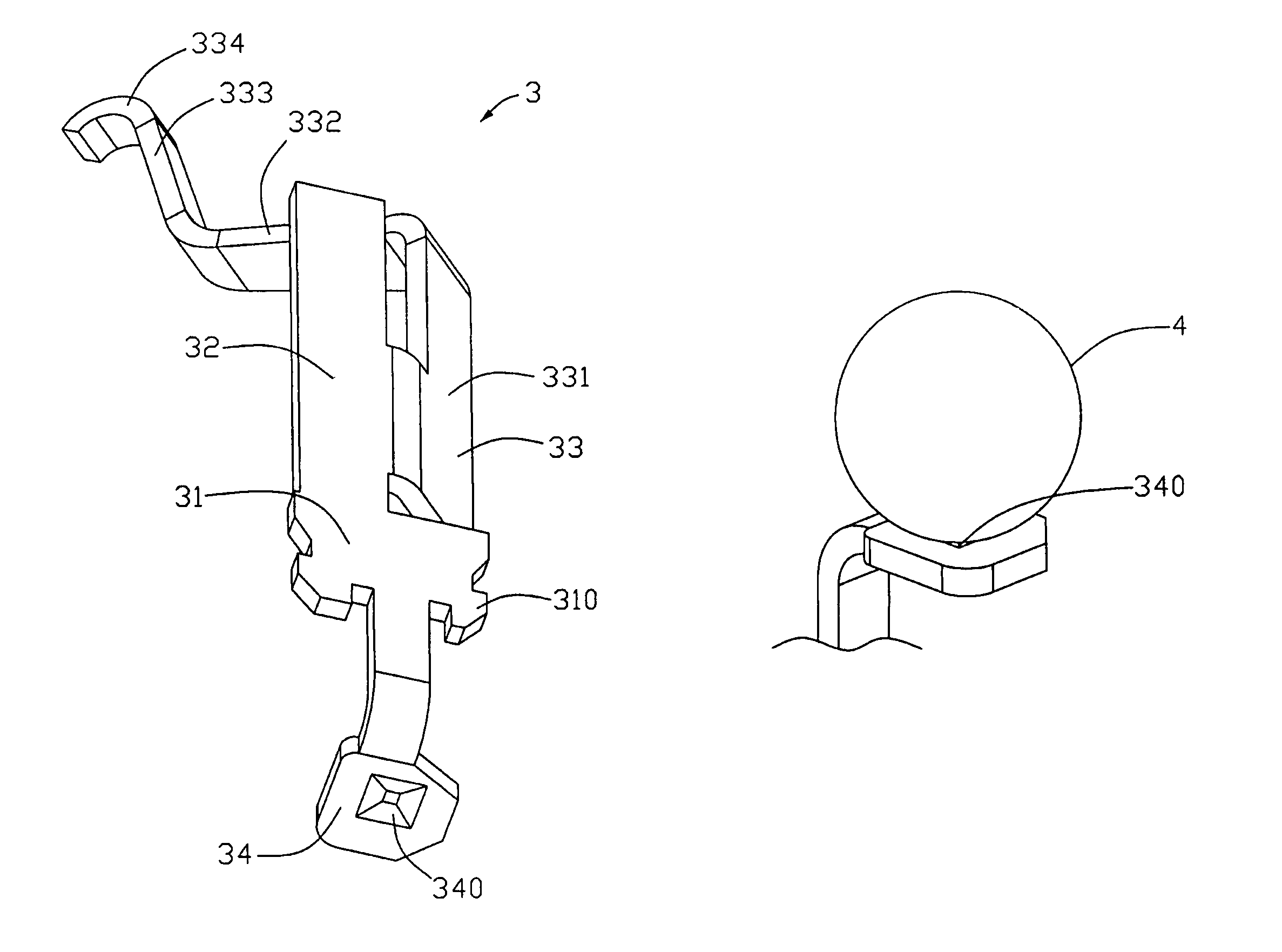

Electrical contact background of the invention

InactiveUS20080124957A1Additional flawStrong mechanical connectionCoupling device detailsPrinted circuitsSolder ballEngineering

A conduct (3) includes a retention portion (31), a contacting portion (334) extending upwardly from the retention portion (3), a tail portion (34) formed on a distal end of the retention portion. The tail portion (34) has a relatively larger bottom surface vertical to the major surface of the base defining a multilateral-shaped recess (340) adapted to engage a solder member, e.g. solder ball, thereby establishing electrical engagement between the contact and the PCB.

Owner:HON HAI PRECISION IND CO LTD

Composite system, method for producing said system and sensor comprising a composite system of this type

ActiveCN101072983ANot subject to deformationStrong mechanical connectionVolume meteringNon-disconnectible pipe-jointsClassical mechanicsStructural engineering

To improve reliability with respect to fixing of a compression element and its drive motor into a casing, in a hermetic compressor. Since a shape of a welding hole 20 is conical, weld surely reaches a projection part 17 and prevents defects such as stay of the weld on a surface of a case.

Owner:ENDRESS HAUSER FLOWTEC AG

Filter Cartridge Assembly and Method of Manufacture Thereof

ActiveUS20130206680A1Shorten the timeReliable filtrationMembrane filtersCartridge filtersFilter mediaEngineering

A filter cartridge has a longitudinal axis. A cartridge housing has first and second shell portions. The first shell portion has a cartridge housing opening and an annular element retention lip which is disposed axially inward of the opening and coaxial with the longitudinal axis. The filter element has a first end cap, a second end cap, and a continuous ring of filter media disposed between the first and second end caps. The first end cap defines a fuel flow port which is coaxial with the longitudinal axis. A plurality of resilient element retention arms extend axially from the first end cap, and surround the fuel flow port. The arms terminate in retention barbs which are mateable with the annular lip. The resilient retention arms hold the retention barbs against the annular lip, suspending the filter element within the cartridge.

Owner:CLARCOR INC

Hearing aid retainer accessory

ActiveUS8848958B2Good adhesionStrong mechanical connectionBehind the ear hearing aidsHearing aids housingElectrical connectionEngineering

A hearing aid retainer accessory is provided for use with a hearing aid having a housing with a longitudinal end face portion comprising a mechanical connection terminal and an electrical connection point. The hearing aid retainer accessory comprises a retainer element with a first end face portion having a first mechanical connection means configured to be engageable to a mechanical connection terminal of a longitudinal end face portion of a housing of a hearing aid.

Owner:OTICON

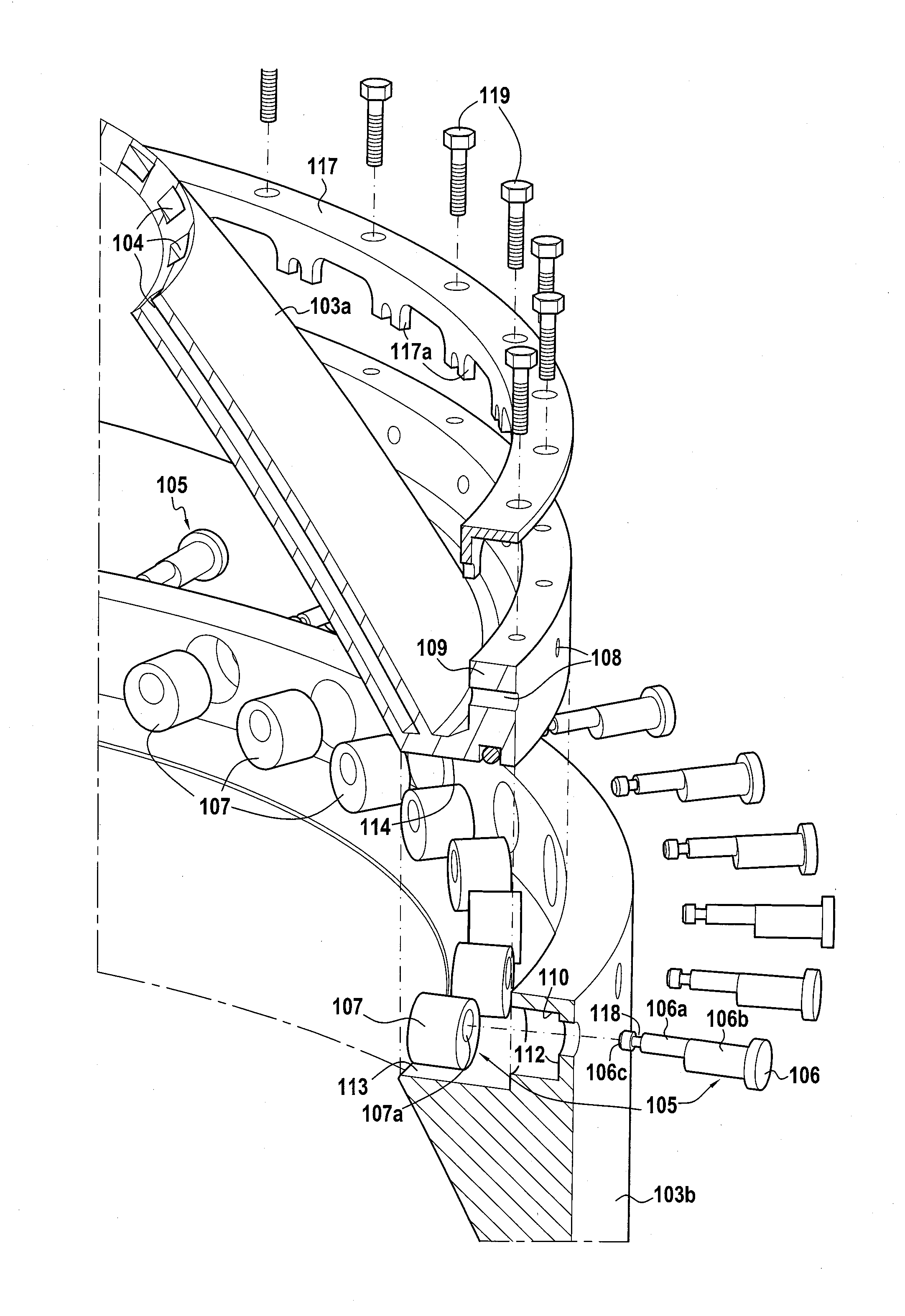

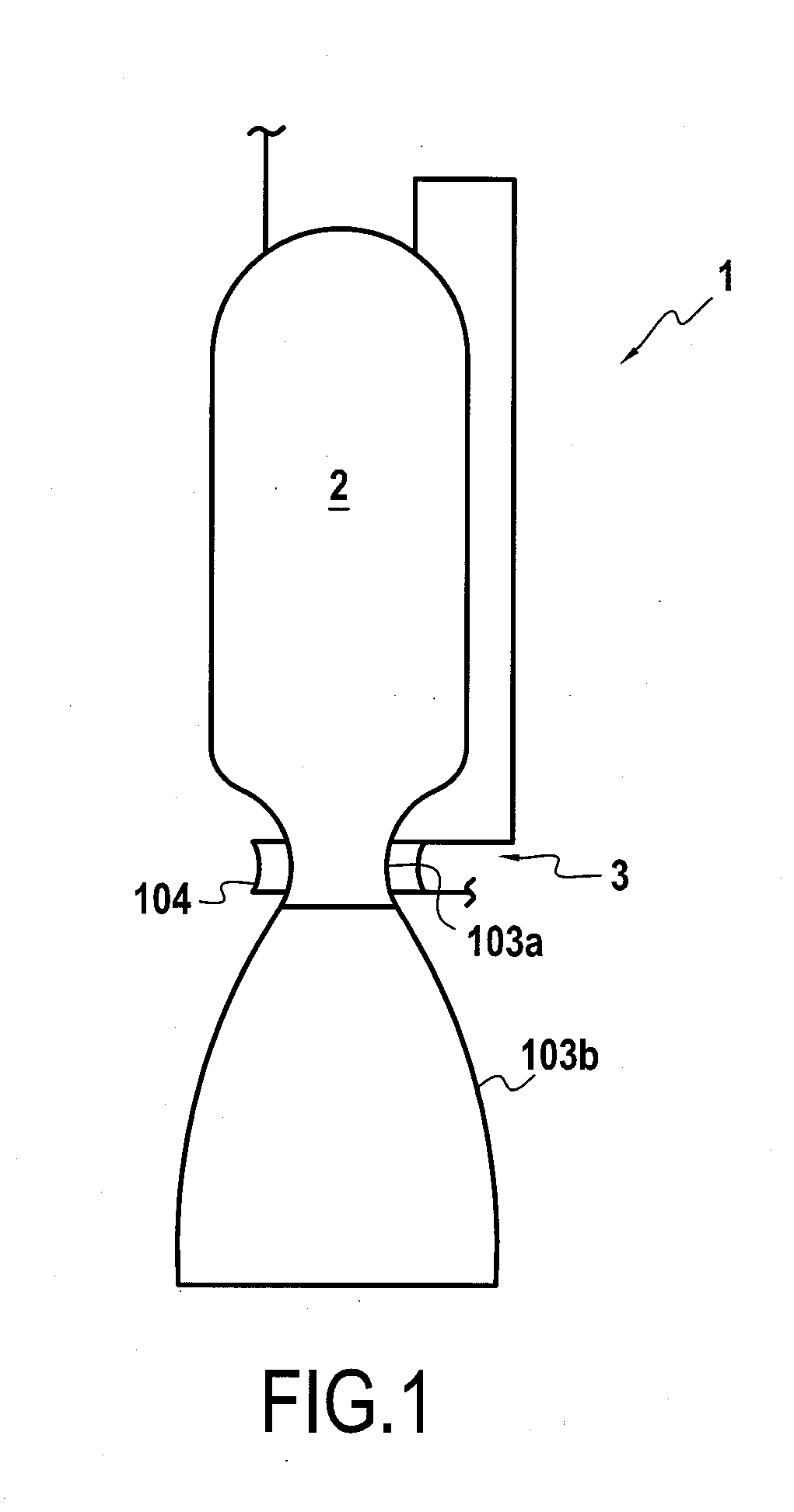

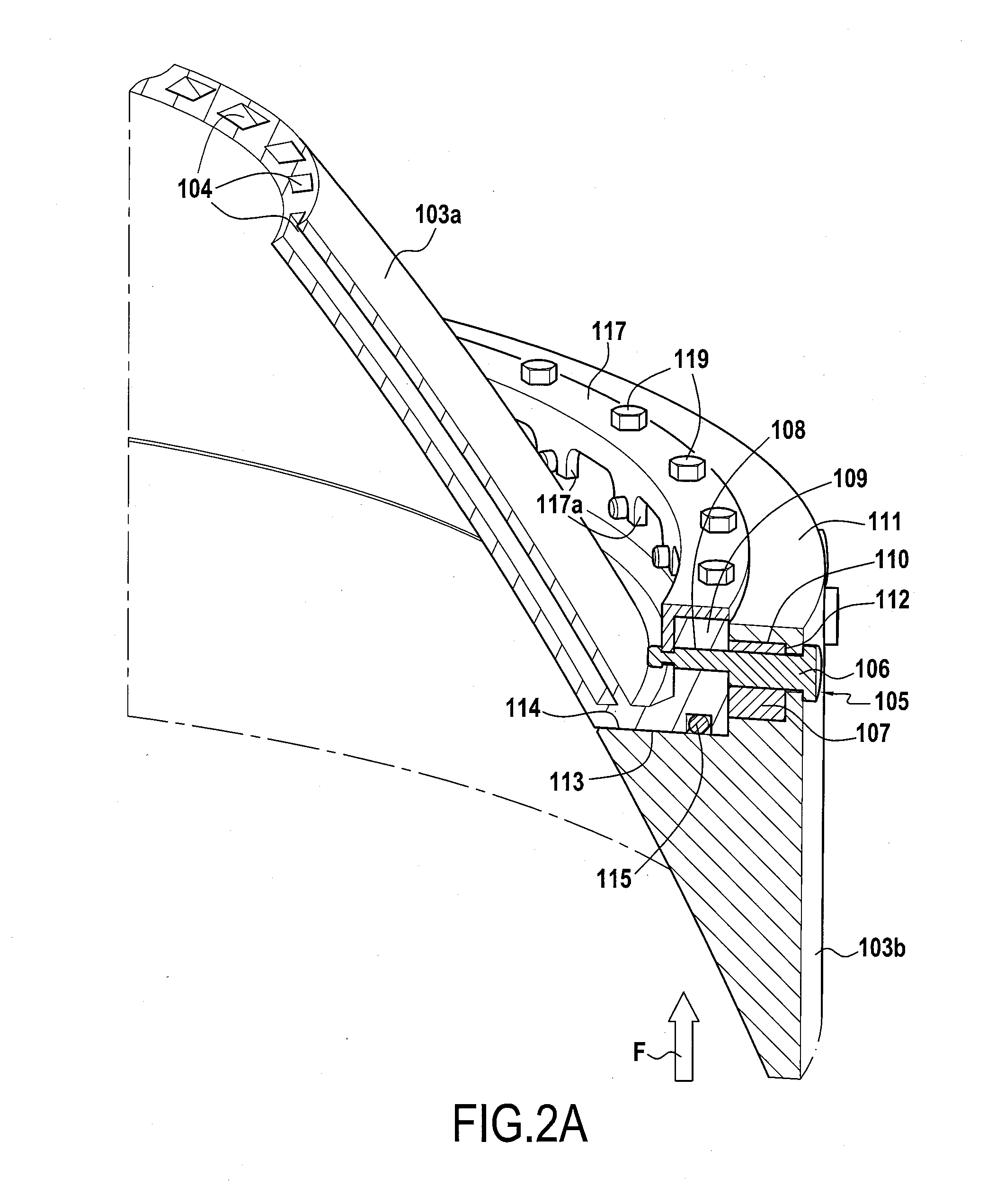

Device for connecting two segments of a propelling nozzle

InactiveUS20160169155A1Reliable mechanical connectionAvoid large gradientEngine manufactureEngine fuctionsEngineeringPropelling nozzle

The invention relates to the field of propulsion nozzles, and in particular to a device (105) for connecting together first and second segments (103a, 103b) of a propulsion nozzle that are made of thermally dissimilar materials. The device (105) comprises at least one pin (106) and an eccentric bushing (107). The pin (106) presents both a first axisymmetric surface (106a) that is to be housed in a radial orifice (108) of the first nozzle segment (103a) and also a second axisymmetric surface (106b) that is eccentric relative to said first axisymmetric surface (106a).

Owner:ARIANEGRP SAS

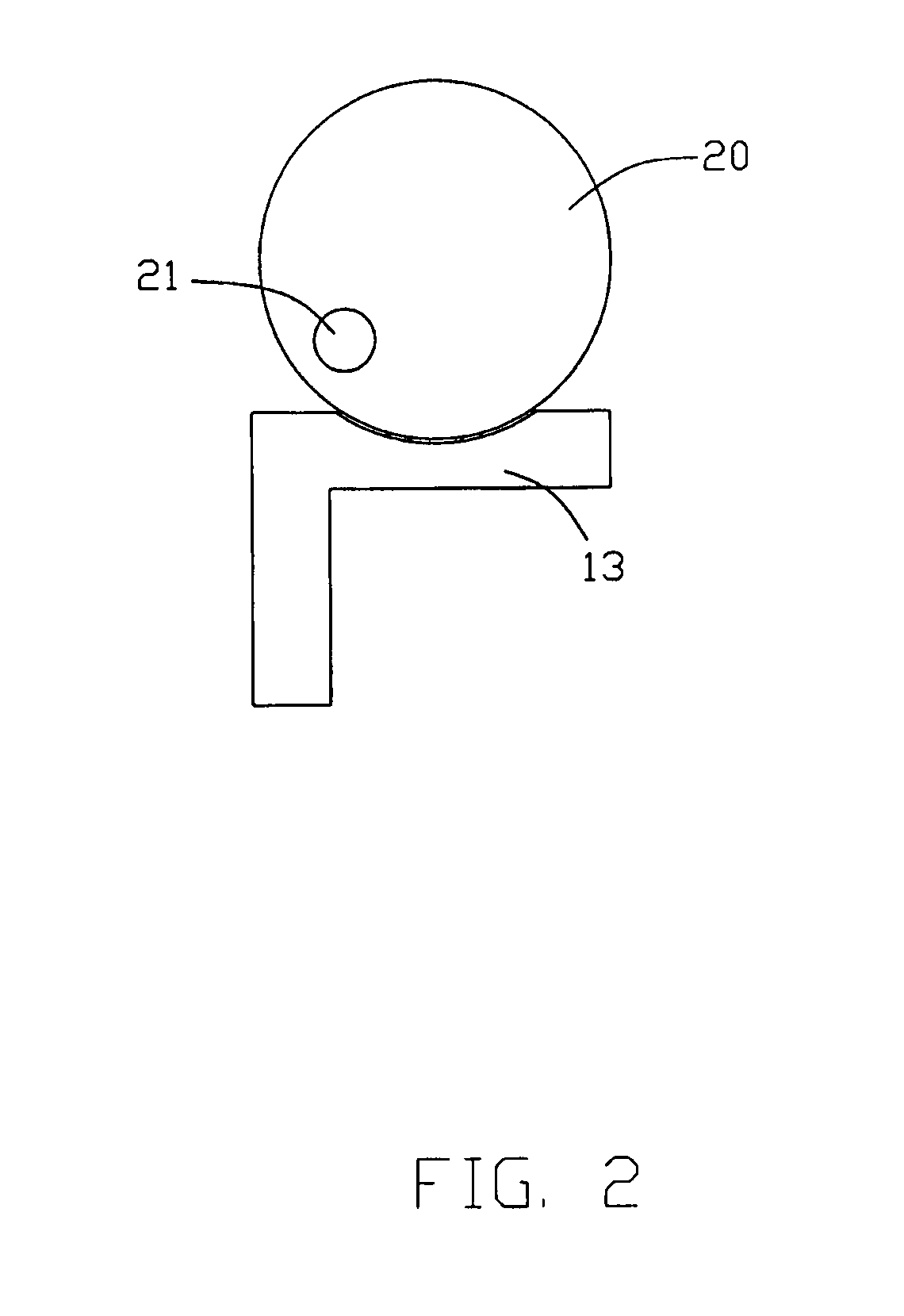

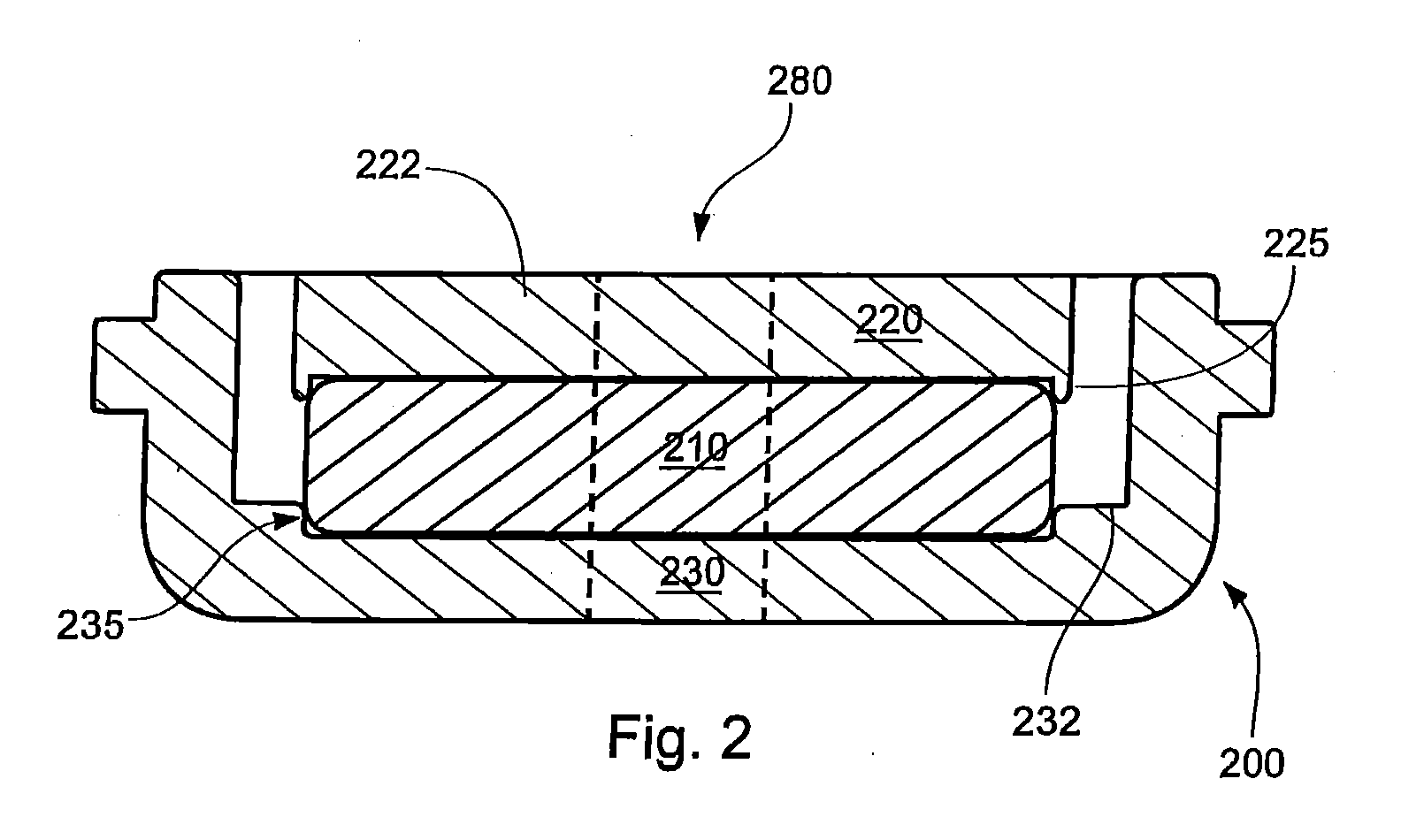

Loudspeaker having an interlocking magnet structure

A magnet structure for use with a loudspeaker has an interlocking mechanism. The magnet structure can include a magnet, a shell pot and at least one core cap. The shell pot can contain the magnet in its hollow interior. The magnet can be a single magnet or double magnets. The core cap has two surfaces. For a single magnet, one surface of the core cap faces the magnet. For double magnets, the core cap can be vertically disposed between the two magnets. The magnet, the core cap and the shell pot can interlock with one another such that a position of the magnet relative to the core cap and the shell pot can be rigidly preserved. The magnet can be configured to be, for example, overlapped, inserted, staked and / or engaged with at least one of the shell pot or the core cap.

Owner:HARMAN INT IND INC +1

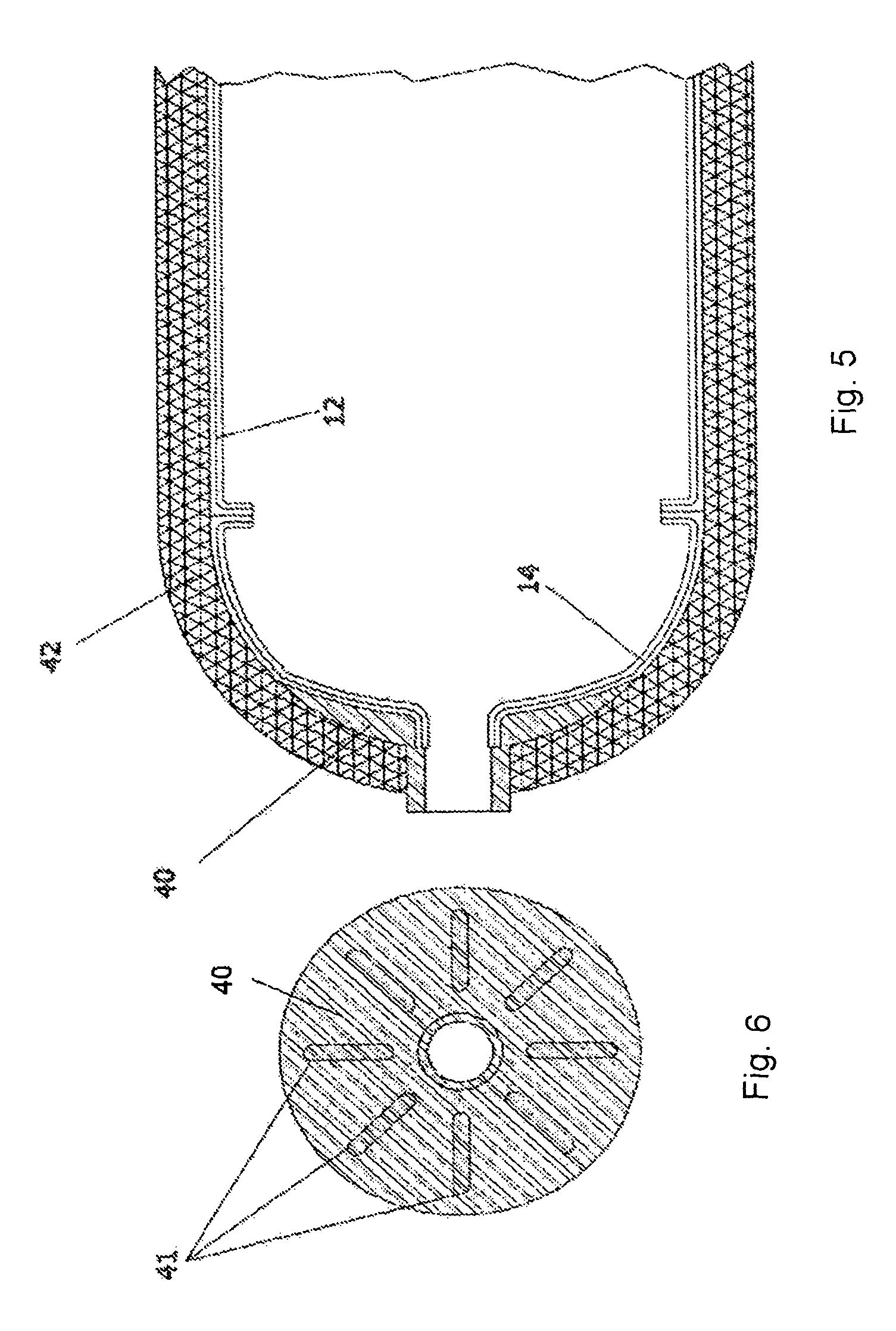

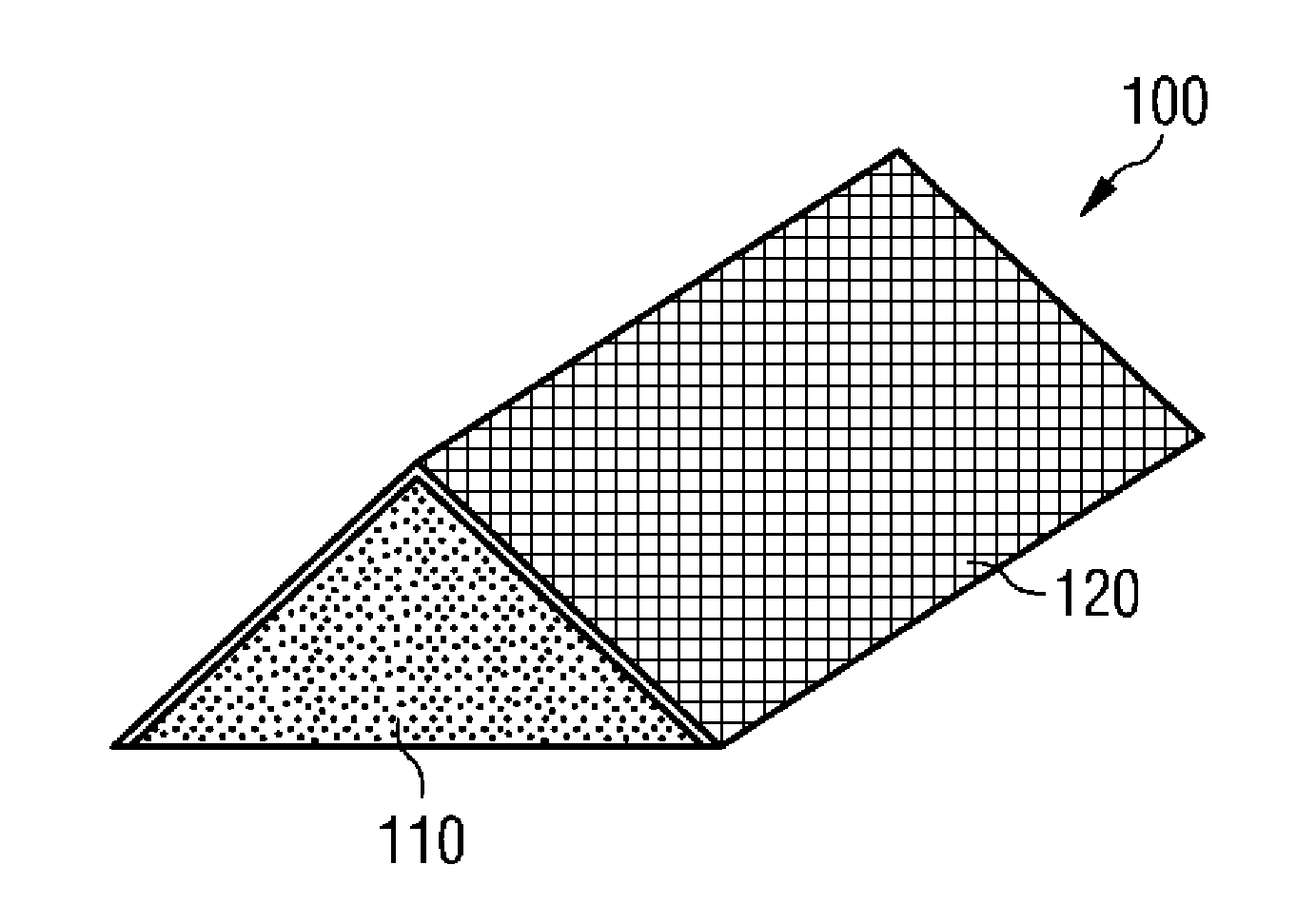

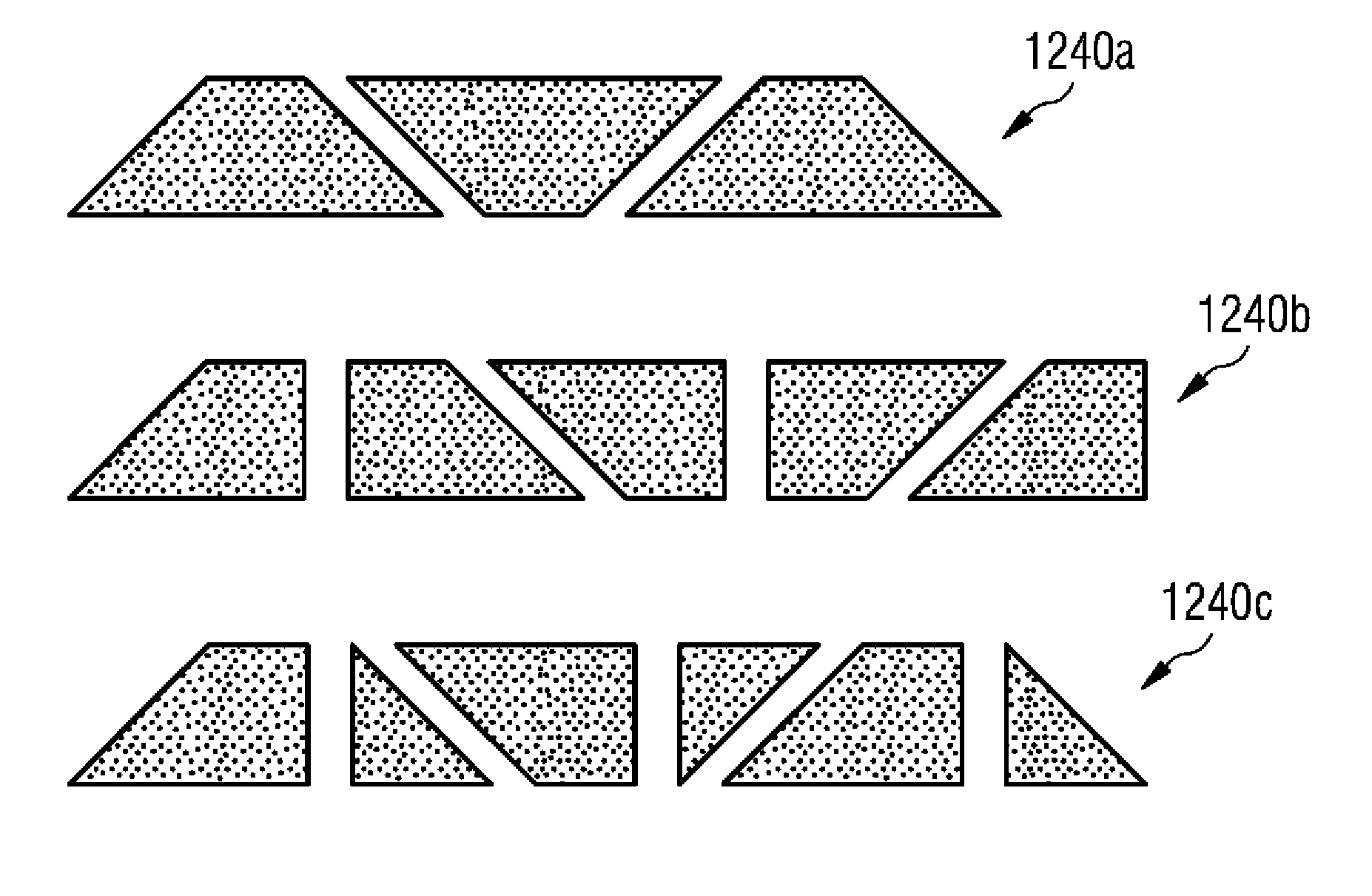

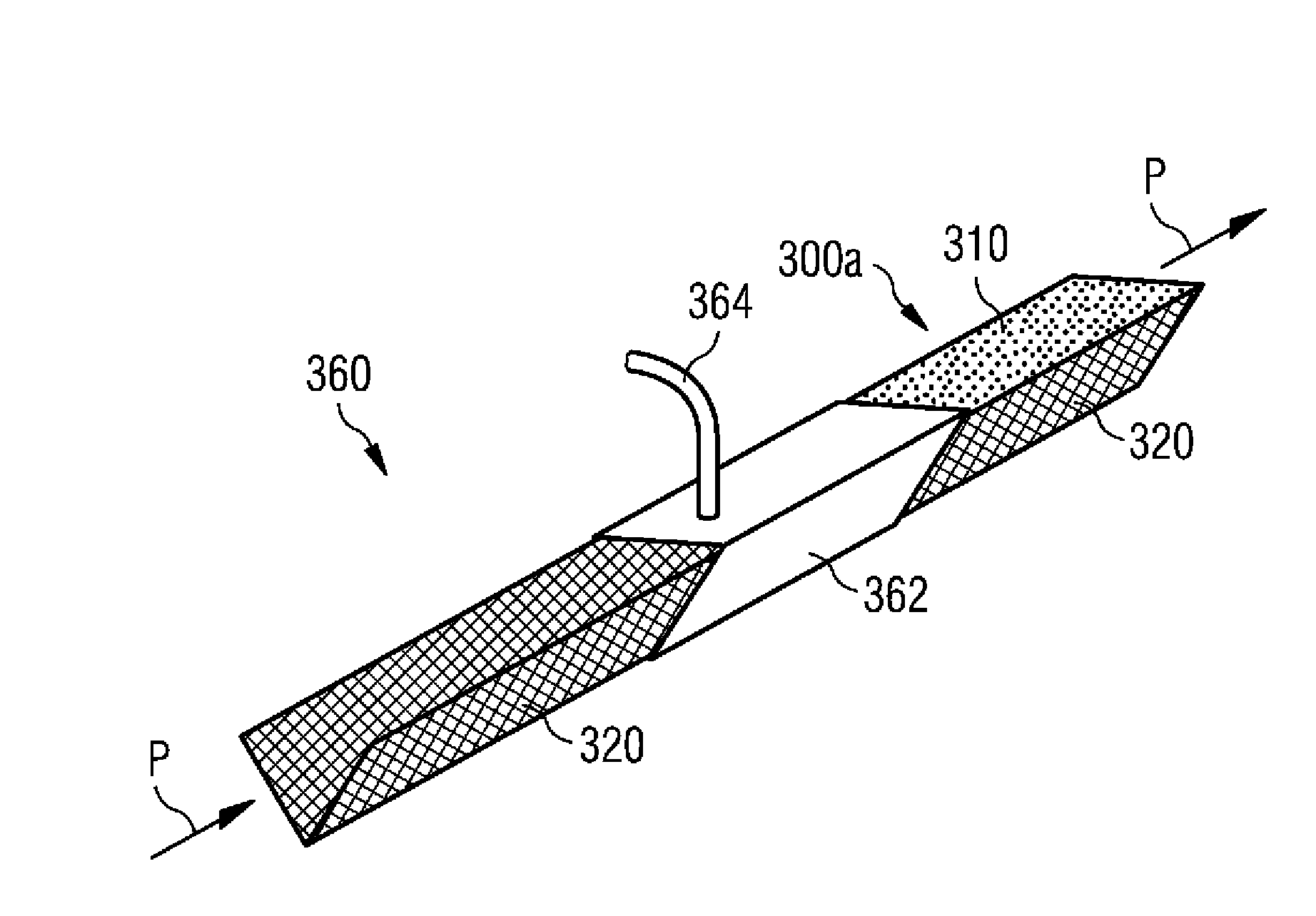

Formation of a core structure of a wind turbine rotor blade by using a plurality of basic core components

InactiveCN103052791AImprove mechanical stabilityStrong mechanical connectionEngine manufactureFinal product manufactureCore componentEngineering

It is described a basic core component (240, 740, 840, 940, 1040, 1140, 1240a-c) for forming, together with at least one another basic core component, a core structure of a rotor blade of a wind turbine. The basic core component comprises a precasted base element (110, 210, 310, 710, 810, 910, 1010, 1110) being made from a foam material (468, 568, 668), and a resin receiving layer (120, 220, 320, 420, 520, 620, 720, 820, 920, 1020, 1120), which is adhered to at least one surface of the precasted base element. When, during a casting procedure, the resin receiving layer adjoins the surface of another basic core component, the resin receiving layer is adapted to receive resin such that, after hardening the received resin, the basic core element and the another basic core element are mechanically connected with each other. It is further described a structural support assembly comprising at least one of such a basic core component and at least one further basic core component. Further, it is described a wind turbine rotor blade, which comprises a core structure comprising at least one of such a structural support assembly. Furthermore, a method for manufacturing such a basic core component is described.

Owner:SIEMENS AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com