Composite system, method for producing said system and sensor comprising a composite system of this type

A technology for measuring transmitters and composite systems, which is applied in the field of composite systems and can solve problems such as falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

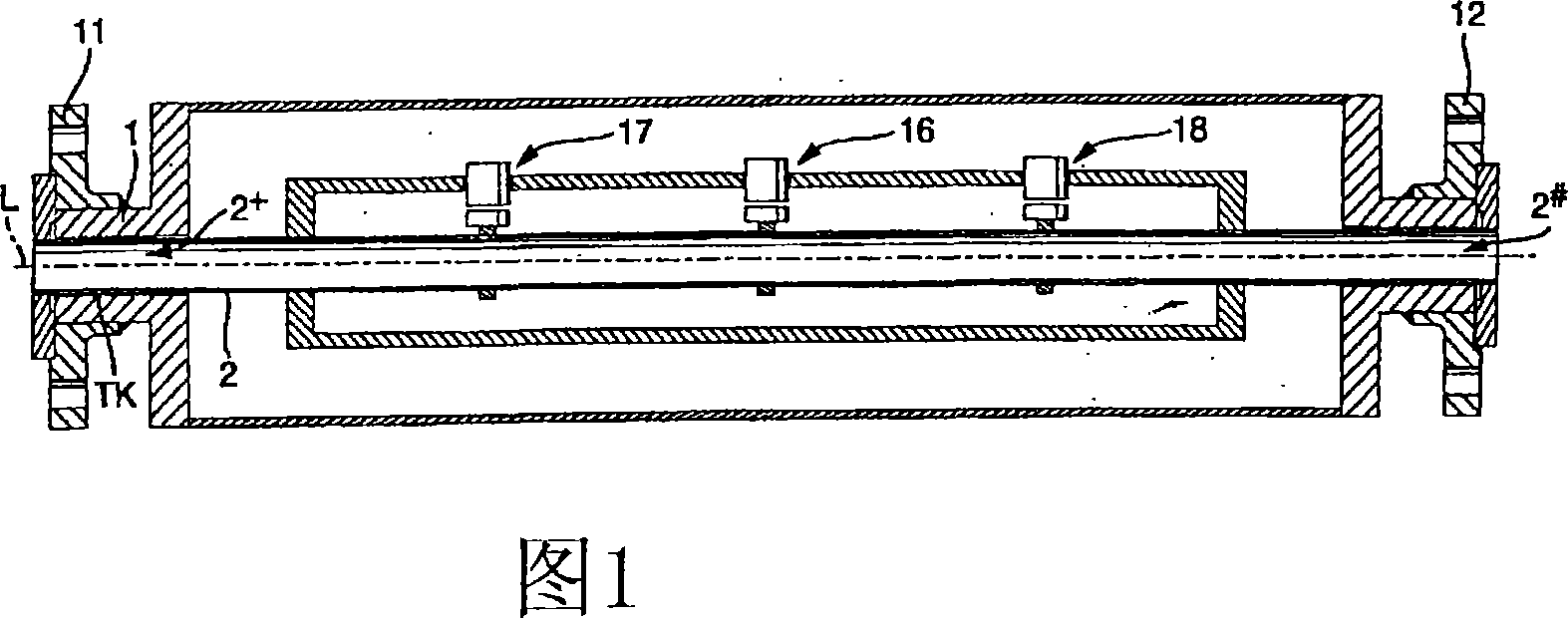

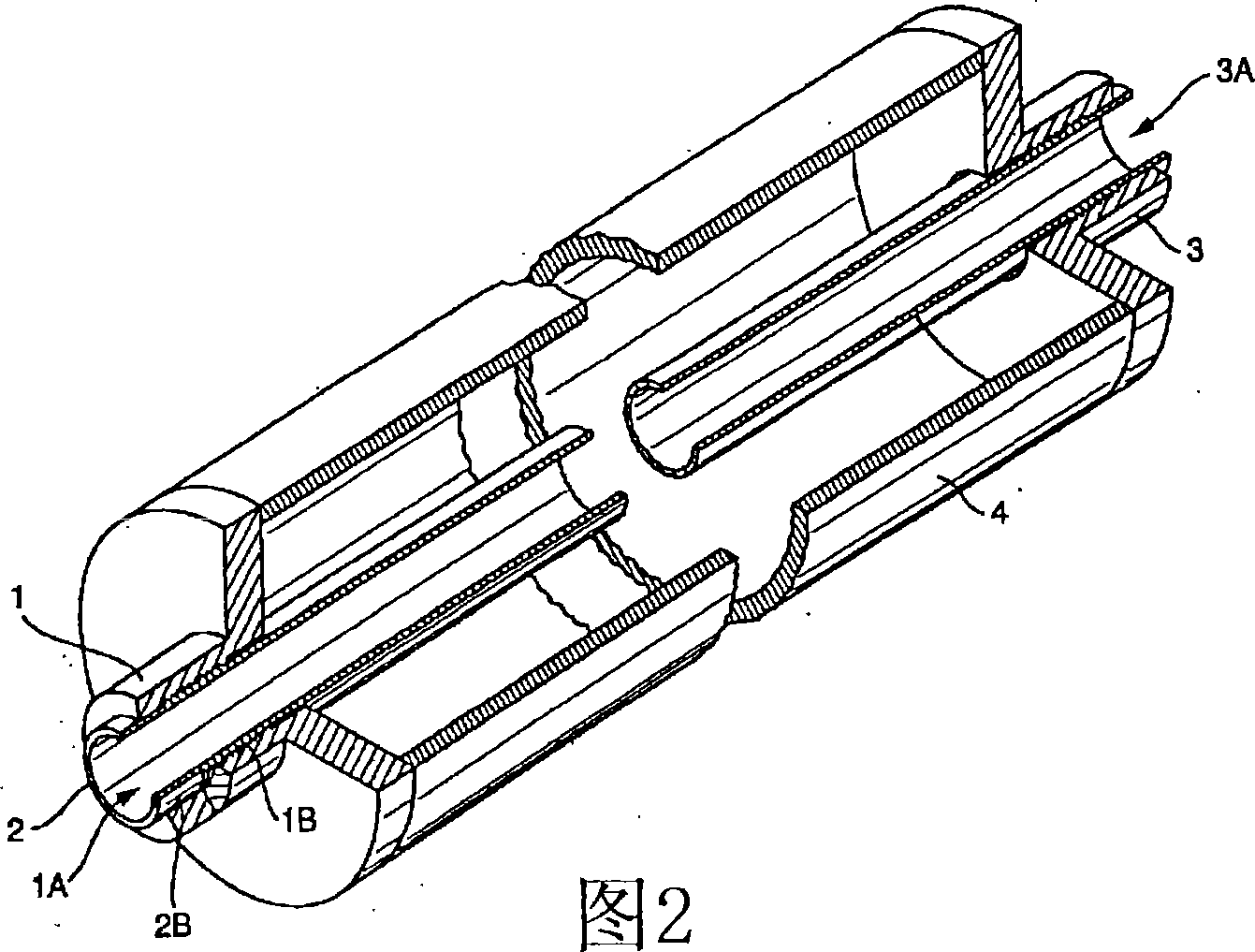

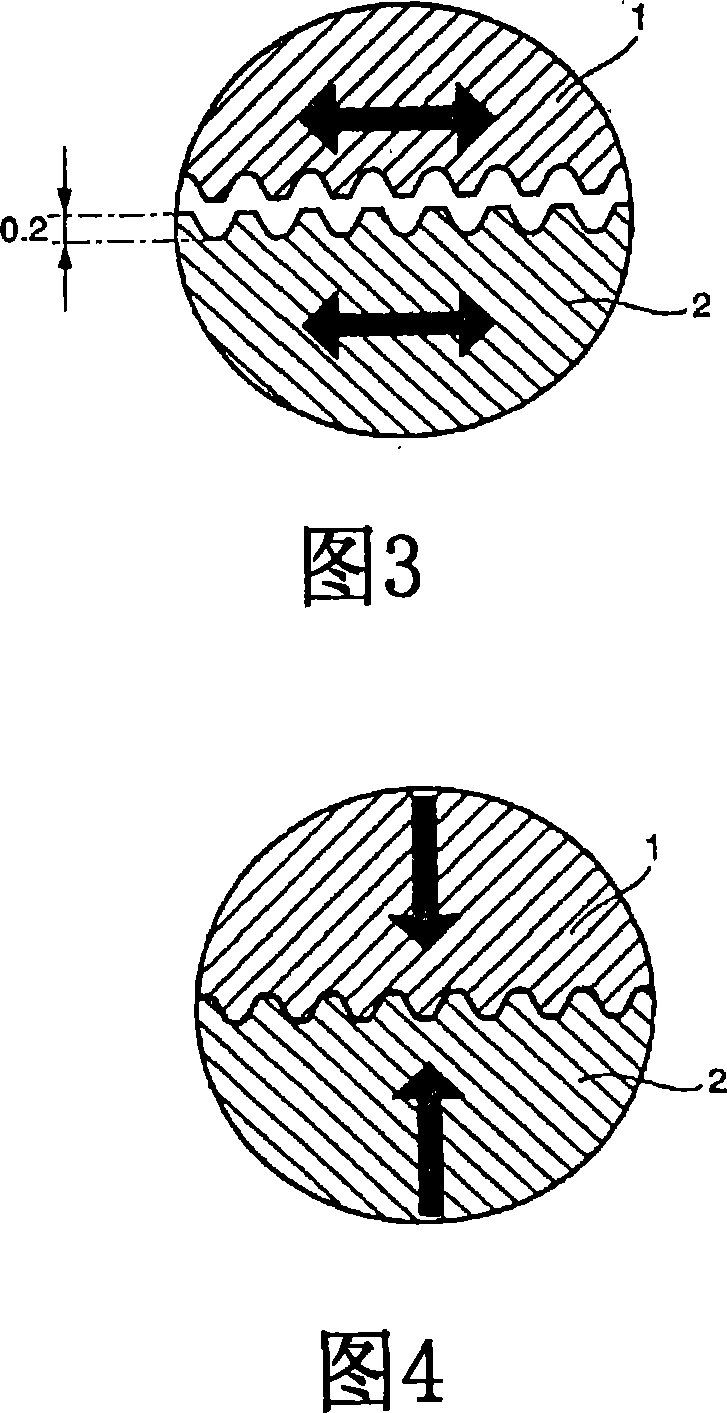

[0111] FIG. 1 shows in particular an embodiment of a bimetallic composite system formed from a first part 1 and a second part 2 , wherein the second part extends at least partially through the first part along an imaginary longitudinal axis L of the composite system. As can be seen from FIG. 1, the second part 2 here has an at least partially curved outer surface, in particular configured as a cylinder, which touches the inner surface of the first part 1 flush so that the first part has at least Sectionally at least partially enclosing the second component, creating a composite system of first and second active surfaces 1B, 2B. In order to increase the fatigue strength of the composite system, in particular to increase the pull-out strength of its second part 2 from the first part 1, the composite system effective surfaces 1B, 2B formed by the surfaces of the two parts, in particular in direct contact, are formed in such a way that The two parts 1 , 2 have partial contours TK ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com