Flexible packaging made from plastic

A plastic packaging and packaging technology, which is applied in packaging, transportation and packaging, paper/cardboard containers, etc., can solve problems such as poor rigidity, inconsistency, and difficulty in production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

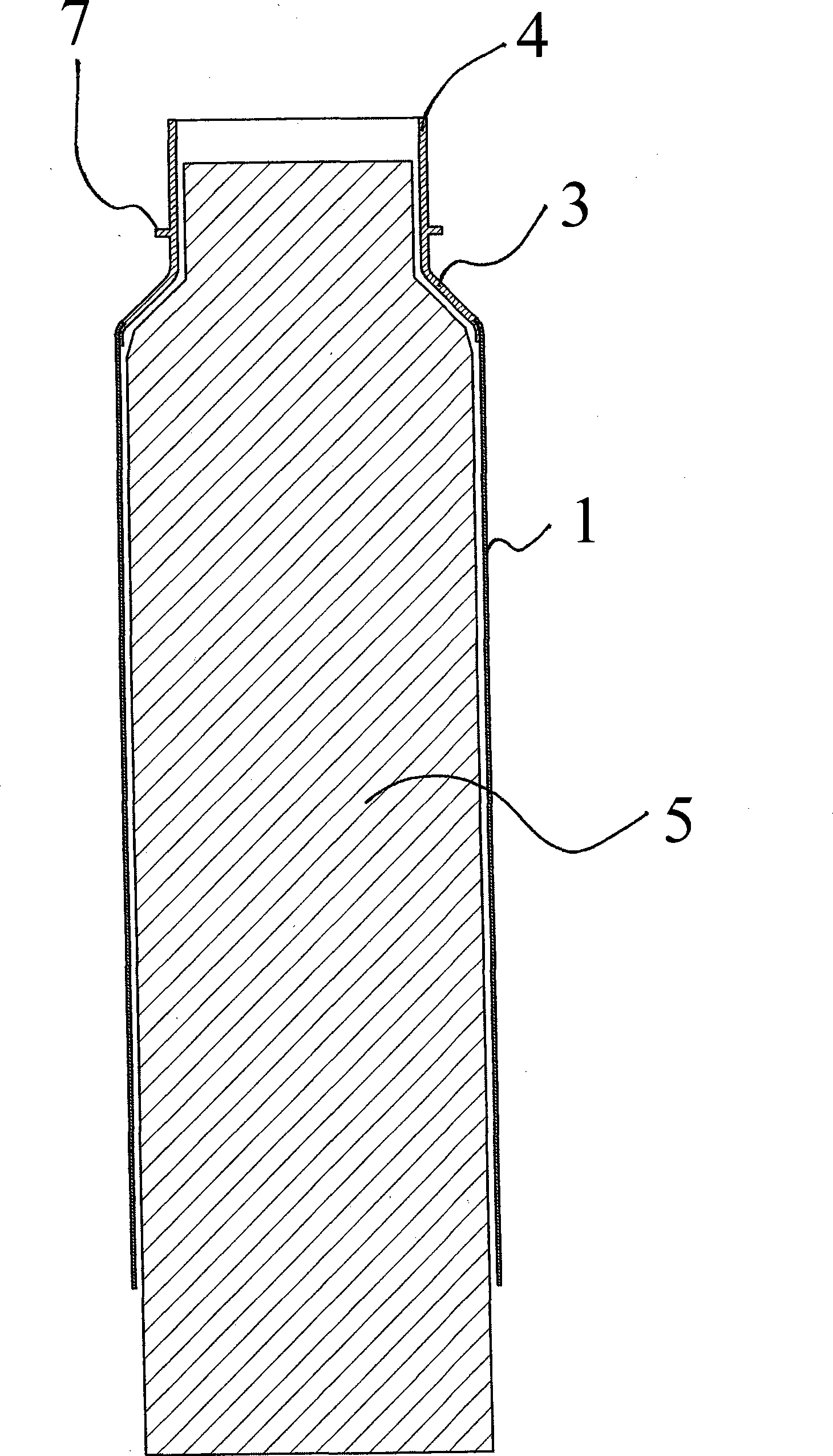

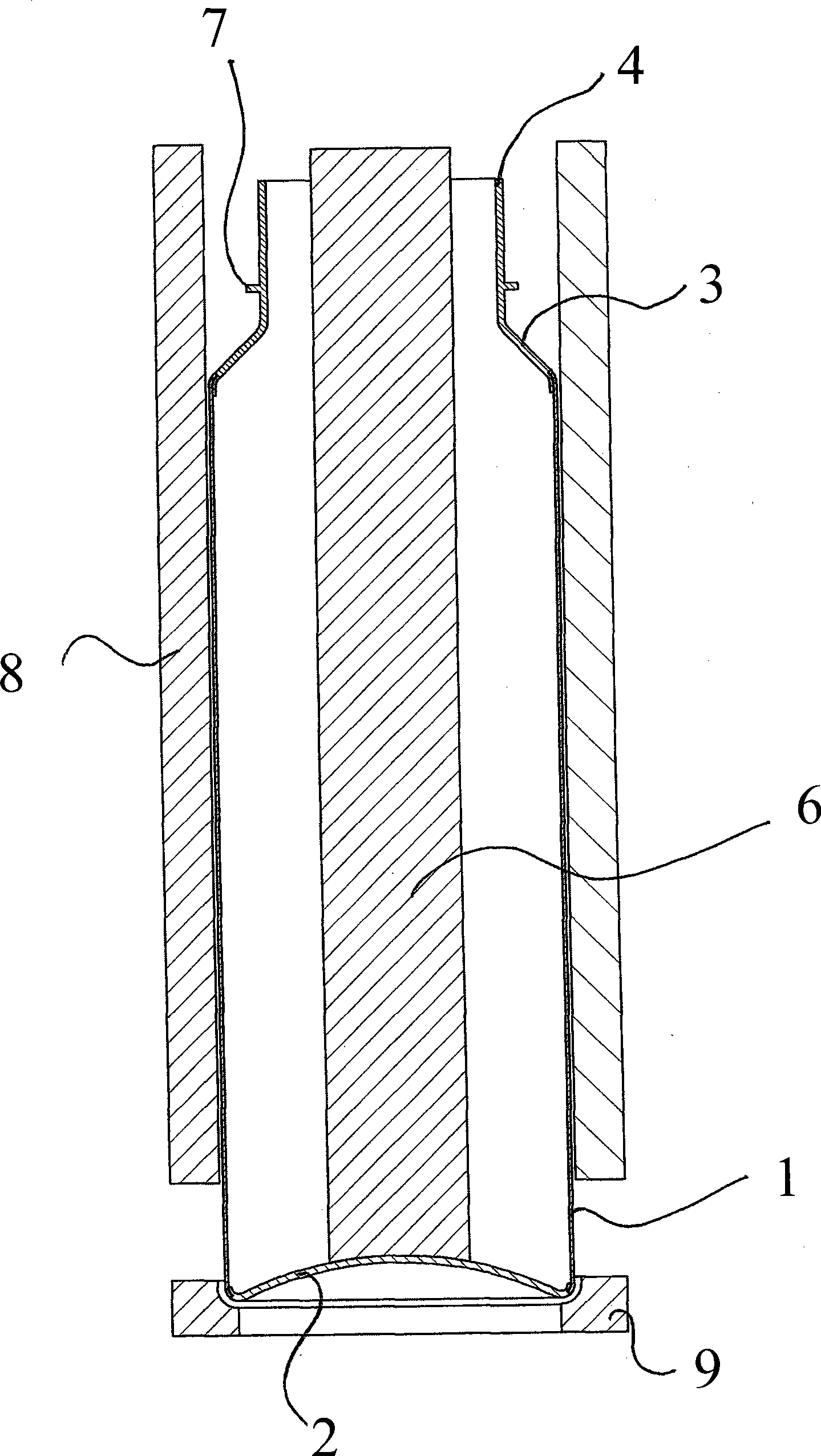

[0029] figure 1 and 2 The package shown in includes a side wall 1 constructed of wrapped laminate, a bottom 2 and a top 3, both of which are secured to the side wall 1 .

[0030] The top 3 is preferably rigid, while the bottom 2 is preferably made of semi-rigid plastic.

[0031] The neck 4 of the package is provided with a rigid flange 7 for handling when moving the tube around before or after assembly of its constituent elements.

[0032] In order to fix the top 3 to the side wall 1 ( figure 1 ), first bringing the mandrel 5 into contact with the two elements 1,3.

[0033] Similarly( figure 2 ), in order to fix the bottom 2 to the side wall 1, the mandrel 6 is first placed in contact with the center of the bottom 2.

[0034] The package is also secured by means of a support cylinder 8 and a support ring 9 .

[0035] It is extremely important to use mandrels 5, 6 inside the package when the top 3 and bottom 2 are welded to the side wall 1, for at least two reasons:

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com