Fixing device for road reinforced concrete box culvert end formwork and its application method

A technology for reinforced concrete box culverts and end formwork, which is applied in the direction of road floors and buildings, and can solve the problems of inconvenient fixing of the end of reinforced concrete box culvert formwork, failure to meet construction requirements, economic losses, etc., and achieve good formwork fixation , Reduce engineering cost and construction period cost loss, and protect from damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

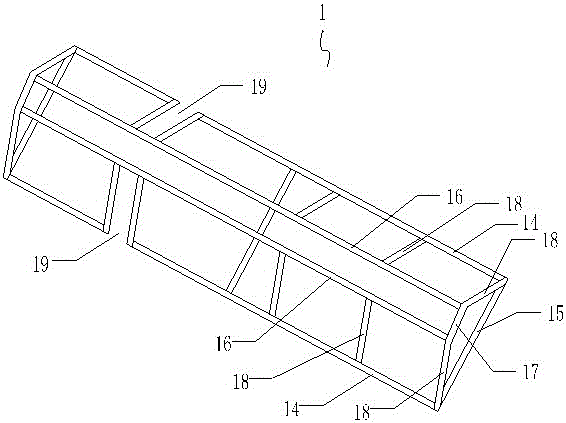

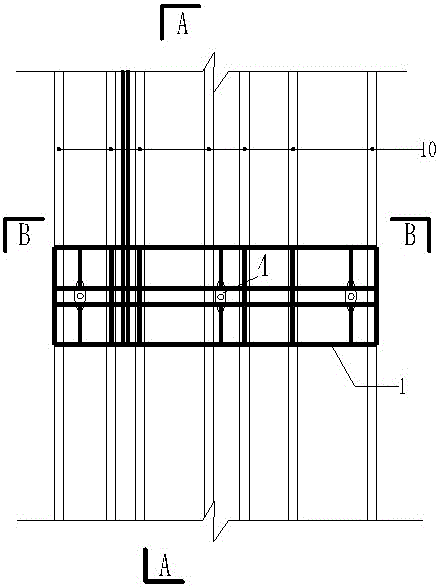

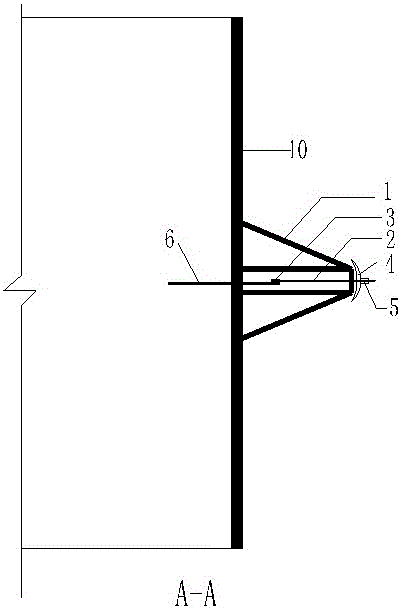

[0041] The fixing device for the formwork at the end of the road reinforced concrete box culvert of the present invention is arranged at the end of the box culvert, and the end of the box culvert is provided with a water stop, including a fixing frame 1, a steel bar connecting rod 6, and a pull screw 2. Features:

[0042] Described fixed frame 1 is that the cross section that steel bar makes is trapezoidal cage frame, and its lower longitudinal bar 14 is parallel with upper longitudinal bar 16, and lower cross bar 15 is parallel with upper cross bar 17; One end of cage frame is provided with gap 19, The width of the gap is 40mm, the upper longitudinal bar 16 is a complete steel bar, the lower longitudinal bar 14 is broken and divided into two, one end of the lower longitudinal bar at the disconnection is connected to one end of the diagonal brace 18, and the other end of the diagonal brace Connect with upper longitudinal bar 16; Described fixed frame 1 is made by the threaded ...

Embodiment 2

[0045] The using method of the fixing device for the end formwork of the reinforced concrete box culvert of the present invention is arranged on the end of the box culvert, and the end of the box culvert is provided with a water stopper, and is characterized in that it comprises the following steps:

[0046] a. When installing the box culvert bottom plate or side wall reinforcement, weld the reinforcement connecting rod 6 to the structural longitudinal reinforcement 7 in advance, and protrude 15cm from the outer side of the formwork; the structural transverse reinforcement is a threaded reinforcement with a diameter of 20mm.

[0047] b. Install template 9 and back frame 10;

[0048] c. Weld the threaded sleeve 3 on the end of the steel bar connecting rod;

[0049] d. Install the opposite pull screw 2, which is about to rotate one end of the opposite pull rod into the threaded sleeve 3; the opposite pull screw 2 is made of a 12mm diameter smooth round steel bar, and is 27cm lon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com