An observation window installation structure

A technology of installation structure and observation window, applied in washing devices, textiles and papermaking, and other washing machines, etc., can solve problems such as lack of strength, and achieve the effect of strengthening overall strength, increasing stiffness, and improving space utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

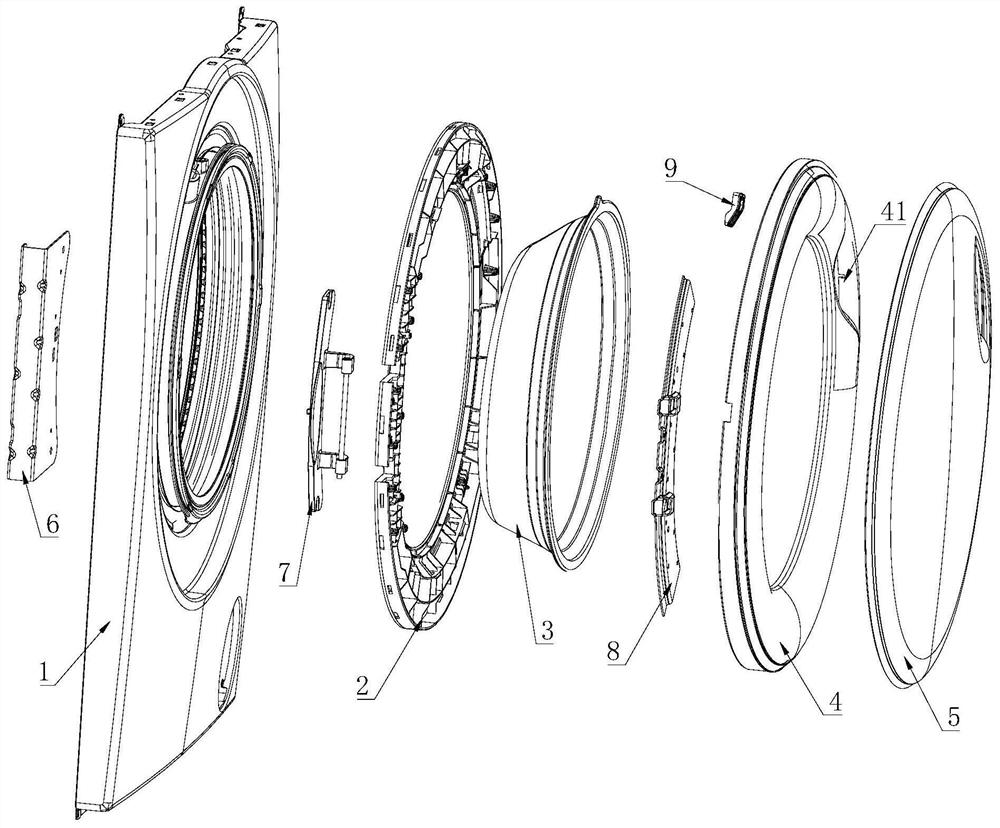

[0041] like figure 1 and Figure 4 As shown, the back side of the front plate 1 described in this embodiment is equipped with a first reinforcing plate 6 relative to the position of the hinge 7, which can effectively support the hinge 7 and can also strengthen the overall strength of the observation window; the inner frame 2 and A second reinforcing plate 8 is installed between the middle frame 4 and the corresponding position of the hinge 7, and the second reinforcing plate 8 is fixed on the inner frame 2, and the middle part of the inner frame 2 is installed with a glass basin 3, and the outer edge of the glass basin 3 is located on the inner frame 2. Between the inner frame 2 and the second reinforcing plate 8, the inner frame 2 and the second reinforcing plate 8 are fixed by connecting pieces such as bolts.

[0042] The first reinforcing plate 6 and the second reinforcing plate 8 are plate-shaped structures, the first reinforcing plate 6 and the hinge 7 are respectively f...

Embodiment 2

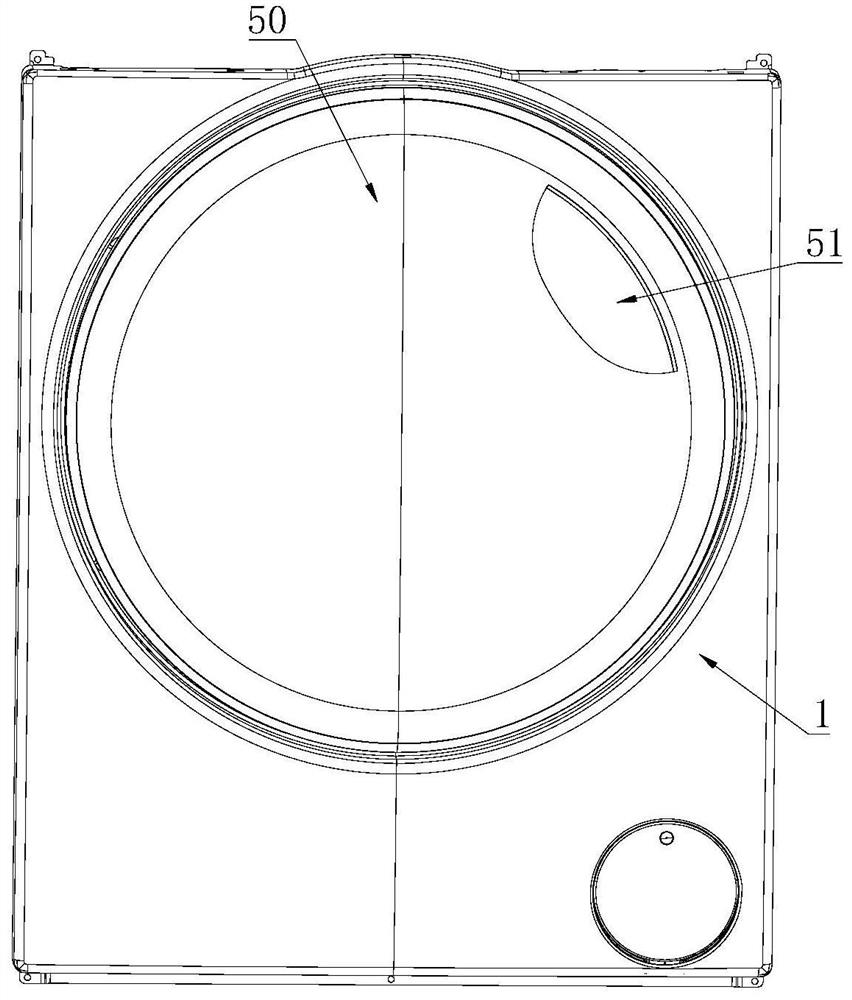

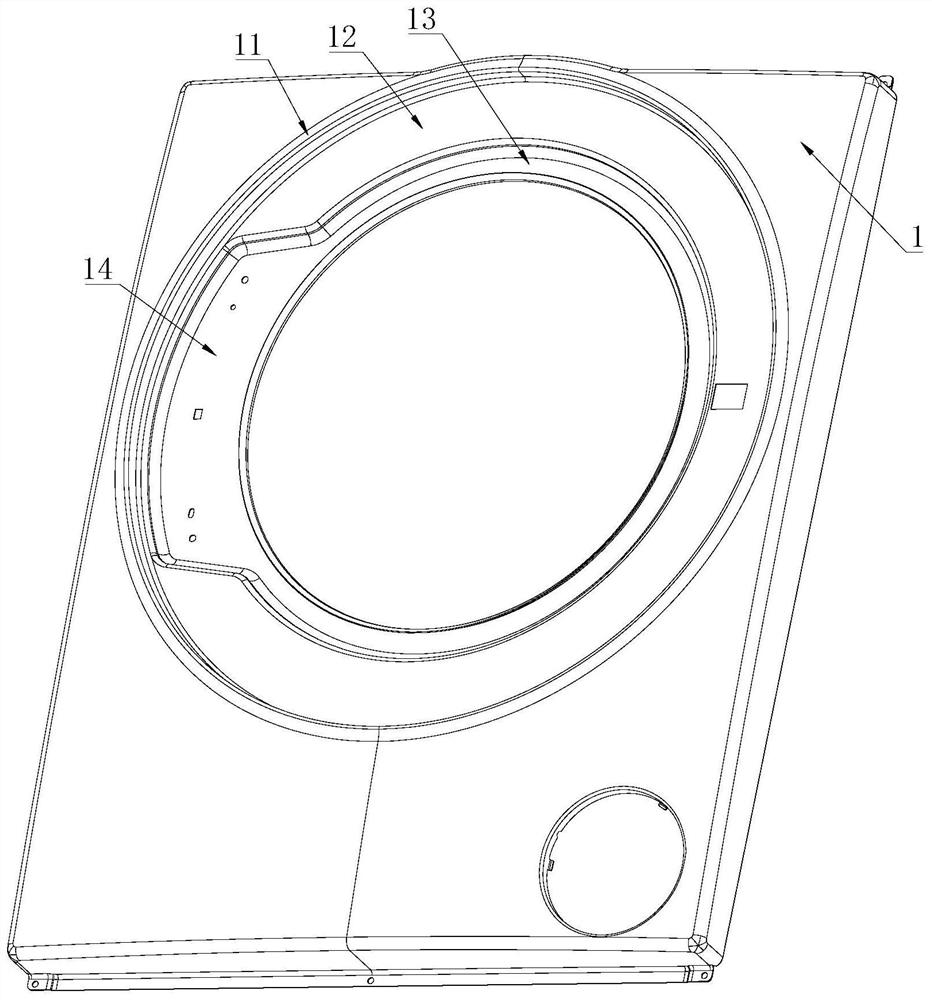

[0044] Figure 1 to Figure 3 As shown, the front plate 1 described in this embodiment is provided with an installation opening corresponding to the washing machine inlet, and the observation window is correspondingly installed in the installation opening. The circular groove 12 arranged on the outer periphery of the installation port, the inner frame 2 is installed inside the circular groove 12, and the outer periphery of the circular groove 12 is provided with a circle of outwardly protruding reinforcing ribs 11 to improve the rigidity of the front plate, so The reinforcing rib 11 protrudes from the surface of the front plate 1 toward the outer periphery of the circular groove 12 in an arc-shaped oblique upward direction, and the inclined surface is connected with the peripheral wall of the circular groove 12 in a smooth transition.

[0045]In this embodiment, the inner ring of the circular groove 12 is provided with an annular groove 13 that is recessed on the back of the fr...

Embodiment 3

[0048] See attached Figure 5 and Image 6 , the first reinforcing plate 6 described in this embodiment is detachably and fixedly installed on the back side of the front plate 1, which can enhance the rigidity of the front plate 1. The first reinforcement plate 6 forms an arc-shaped periphery on the side facing the installation port, and the side of the plate-shaped structure opposite to the arc-shaped periphery faces the same direction and is vertically bent twice to form a fixed part to improve stability. In particular, preferably, the first reinforcing plate 6 is a sheet metal part.

[0049] In this embodiment, the first reinforcing plate 6 includes a body 60 , a first bending surface 61 and a second bending surface 62 , the first bending surface 61 is parallel to the body 60 , and the two sides of the second bending surface 62 The side vertically connects the main body 60 and the first bending surface 61, and the connection between the first bending surface 61 and the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com