Linear vibration table for prefabricated concrete components and concrete vibration compaction method

A technology of linear vibration and prefabricated components, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of easy quality problems of concrete components, low vibration compaction efficiency, uneven vibration distribution, etc., to improve efficiency and quality, and compact structure , the effect of reducing vibration and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

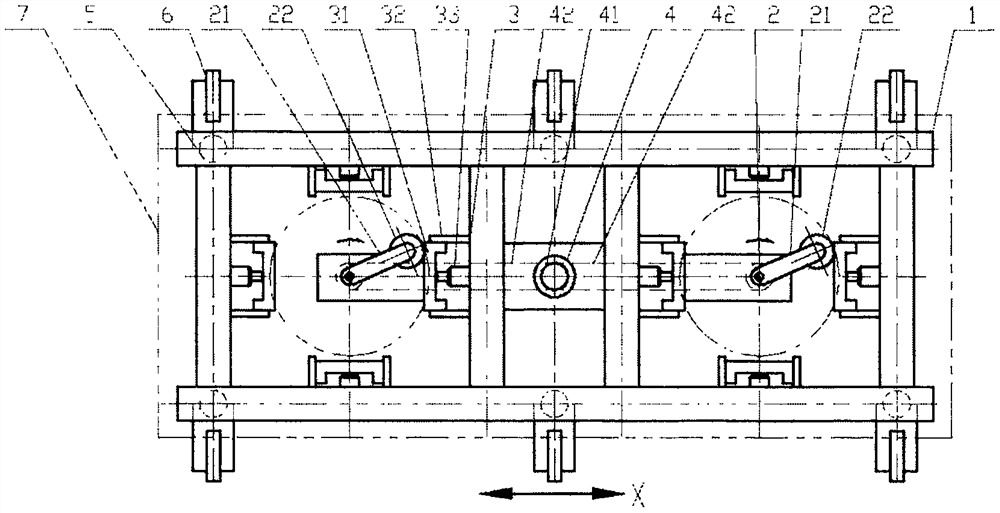

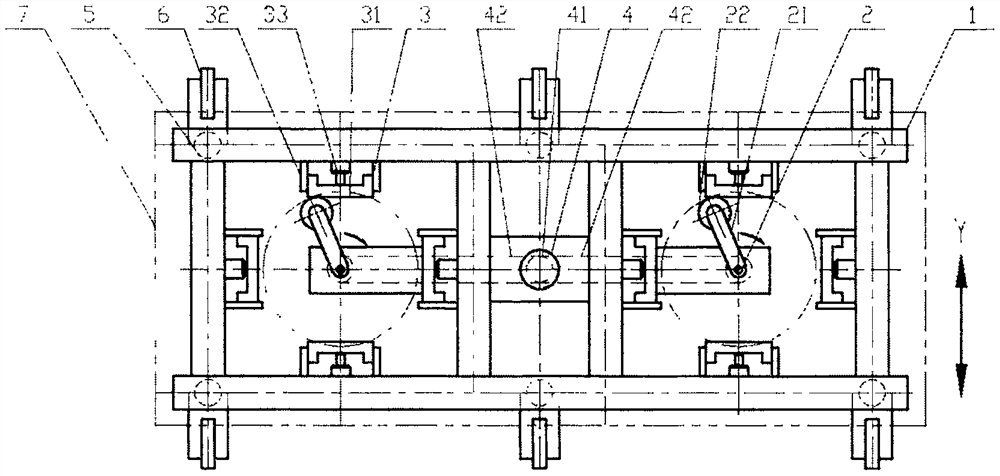

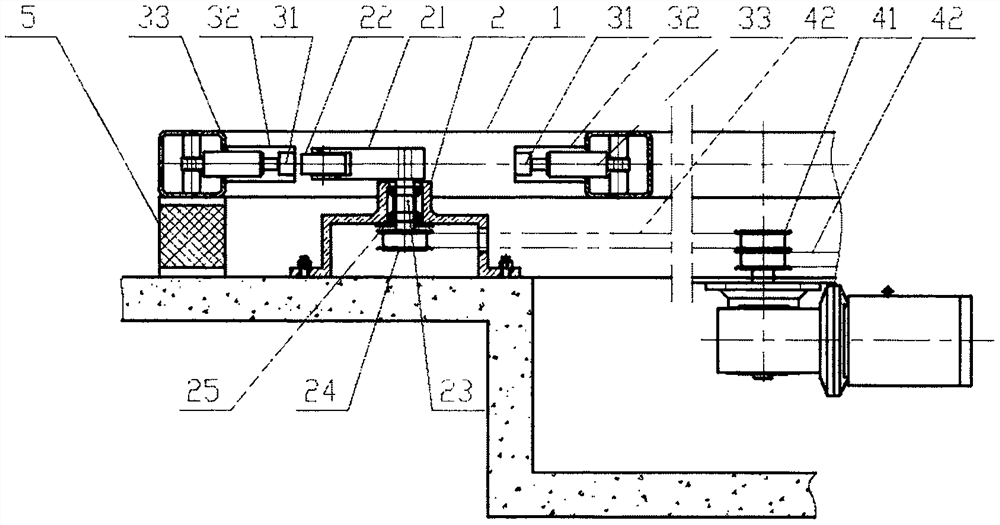

[0035] see Figure 1-3 , the linear vibrating table for prefabricated concrete components may include:

[0036] Chassis 1;

[0037] The position limiting device 3 is arranged on the underframe 1 and its position relative to the center of rotation of the corresponding following rotary arm 21 is adjustable;

[0038] a support, which is provided with two or more swivel arms 21, the two or more swivel arms 21 are installed at the same phase angle and separated by a predetermined distance; and

[0039] The drive system 4 is used to drive the two or more rotating arms 21 to rotate synchronously and in phase around their respective centers of rotation;

[0040] Wherein, the limiting device 3 is provided correspondingly to the two or more rotating arms 21 , and the two or more rotating arms 21 press their corresponding limiting devices 3 to generate linear vibration during rotation.

[0041] It can be understood that the underframe 1 and the support of the present invention can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com