Patents

Literature

943 results about "Beam source" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

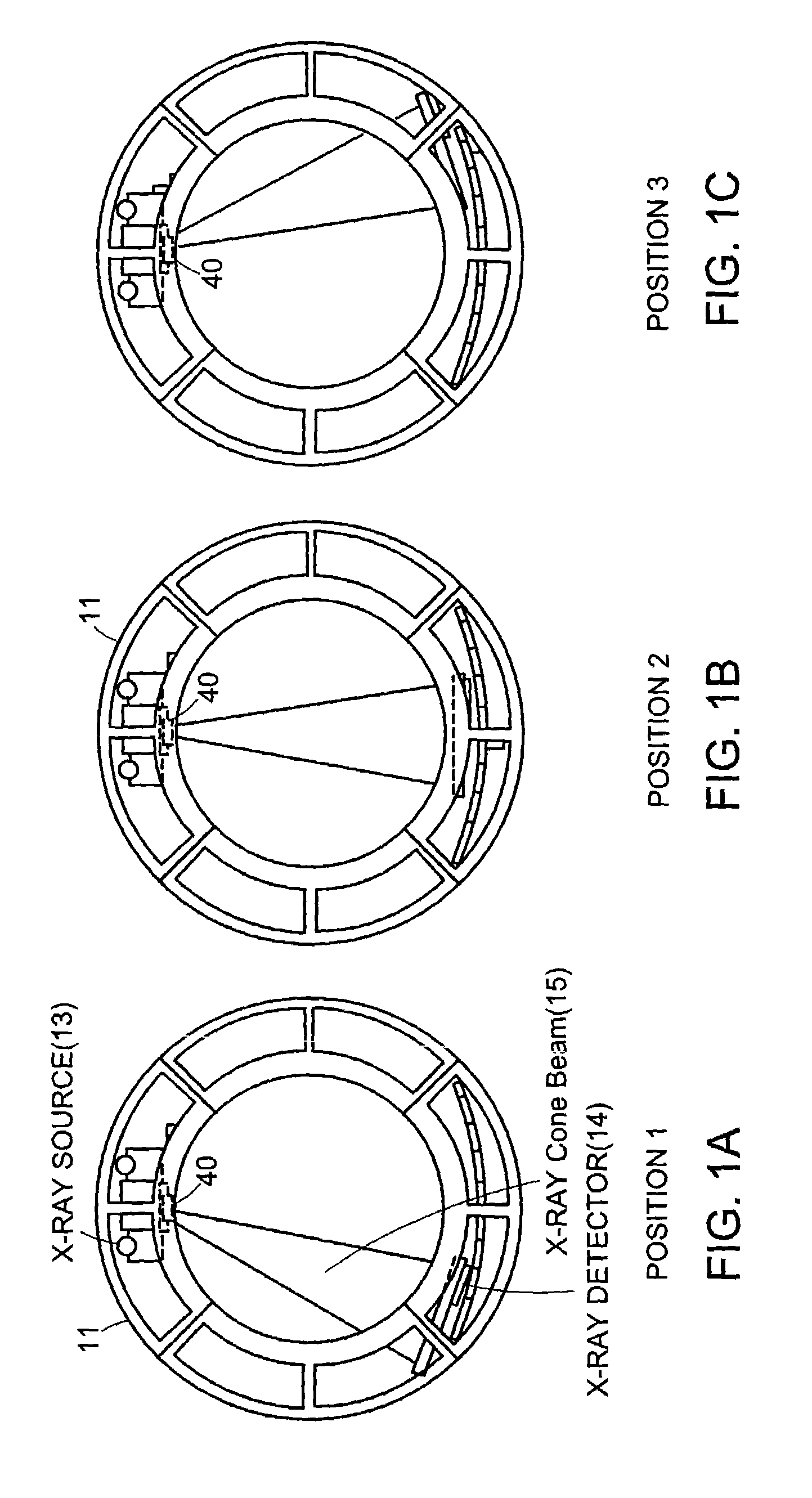

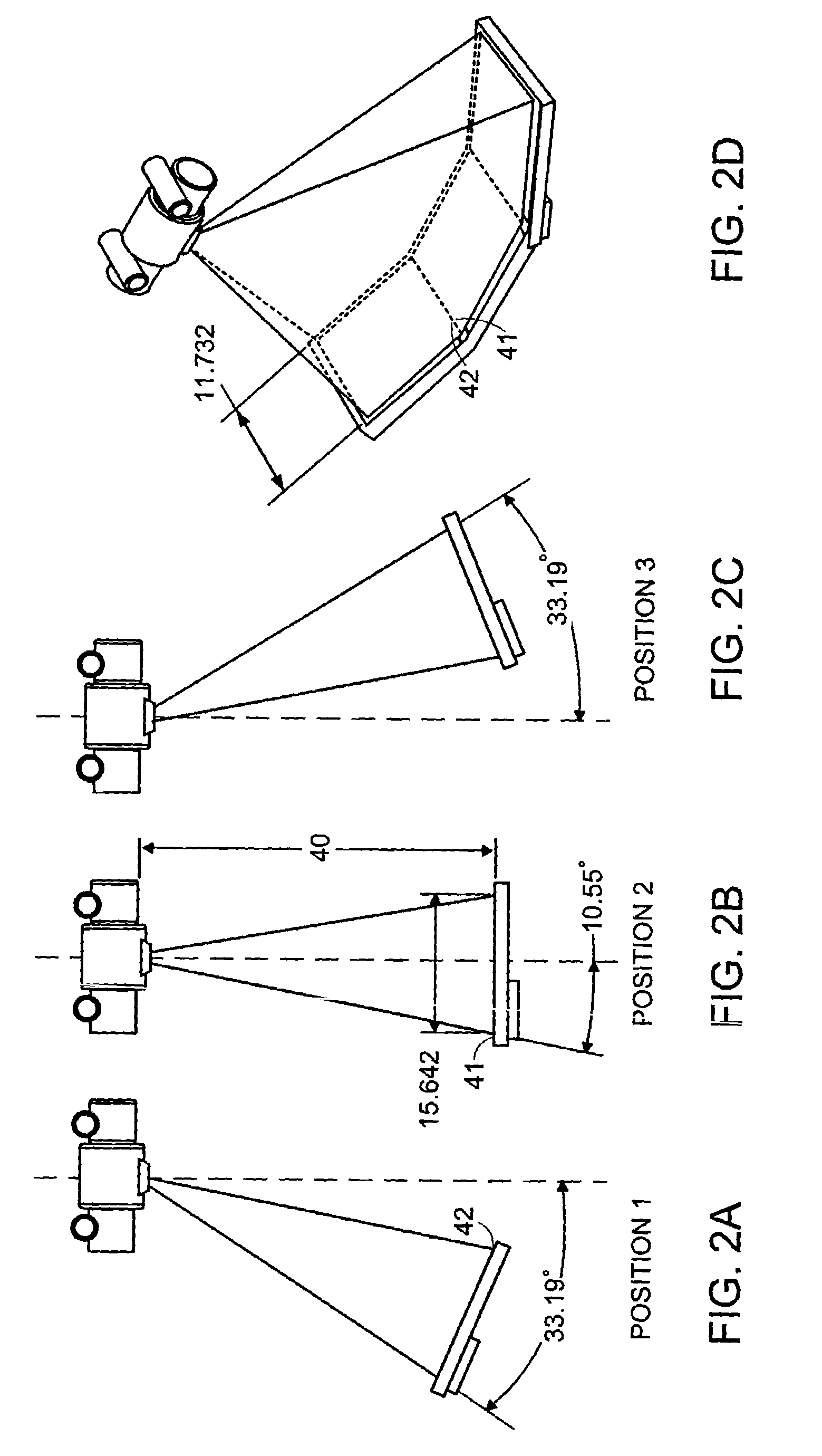

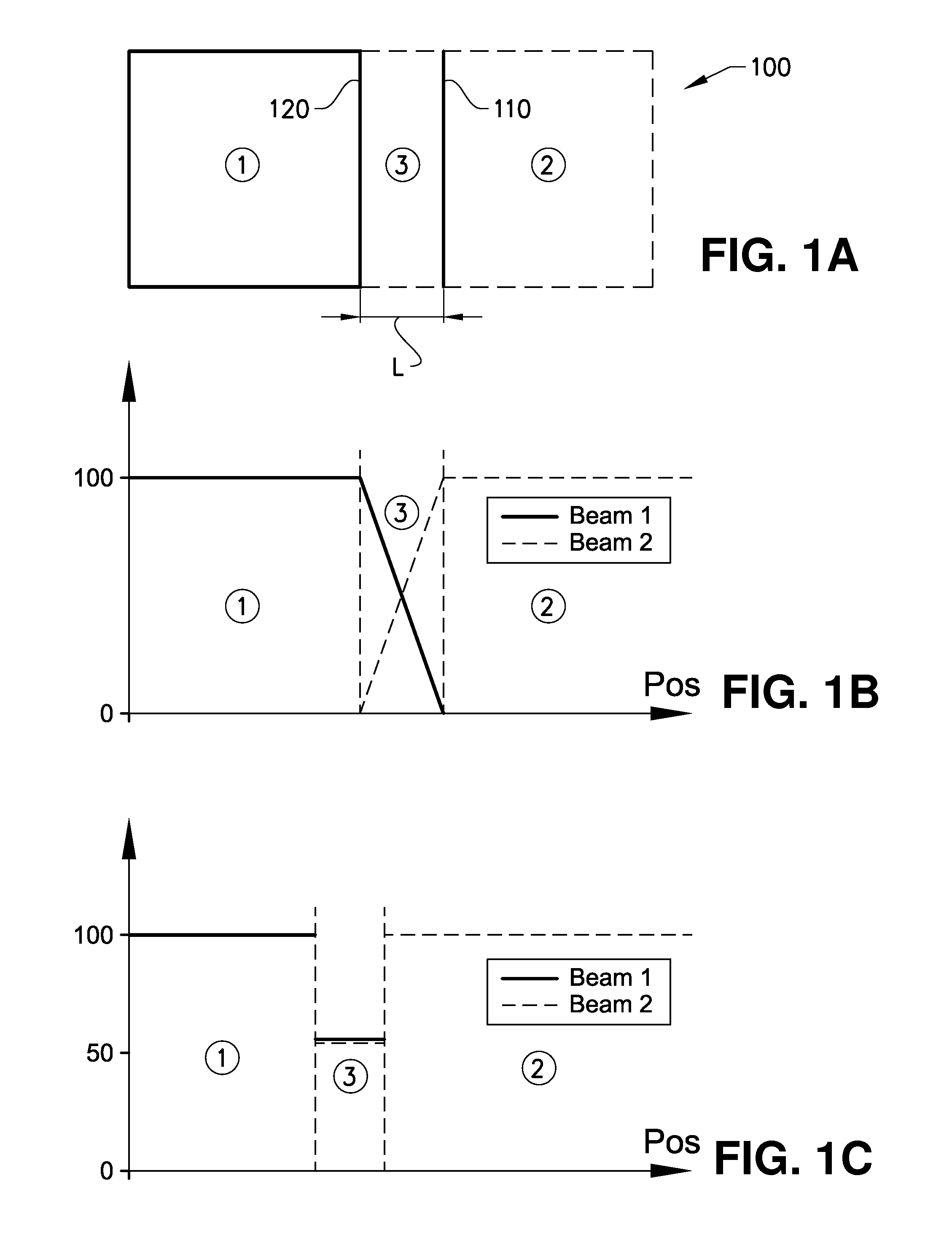

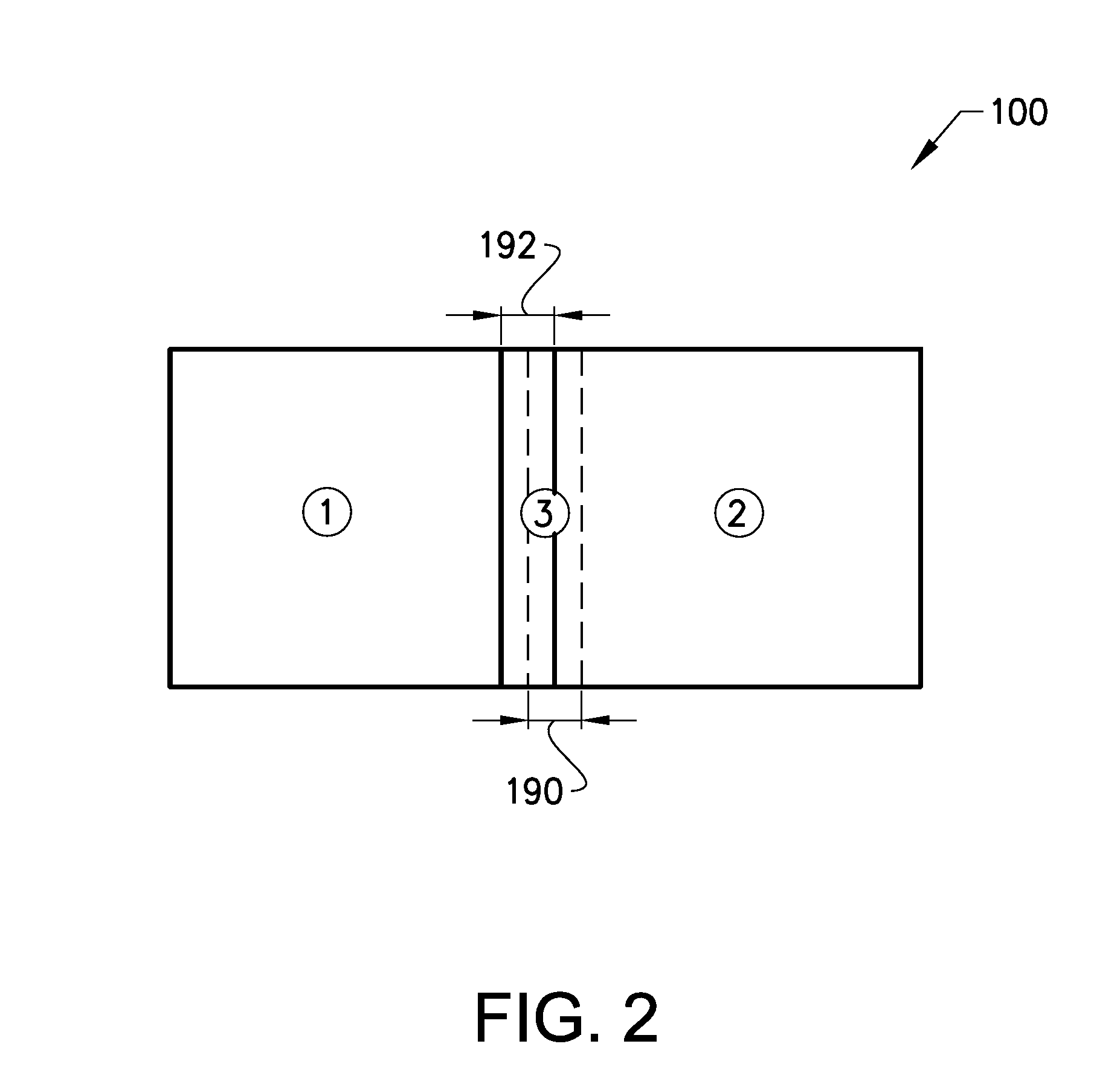

Systems and methods for imaging large field-of-view objects

InactiveUS7108421B2Quantity minimizationAvoiding corrupted and resulting artifacts in image reconstructionMaterial analysis using wave/particle radiationRadiation/particle handlingBeam sourceX-ray

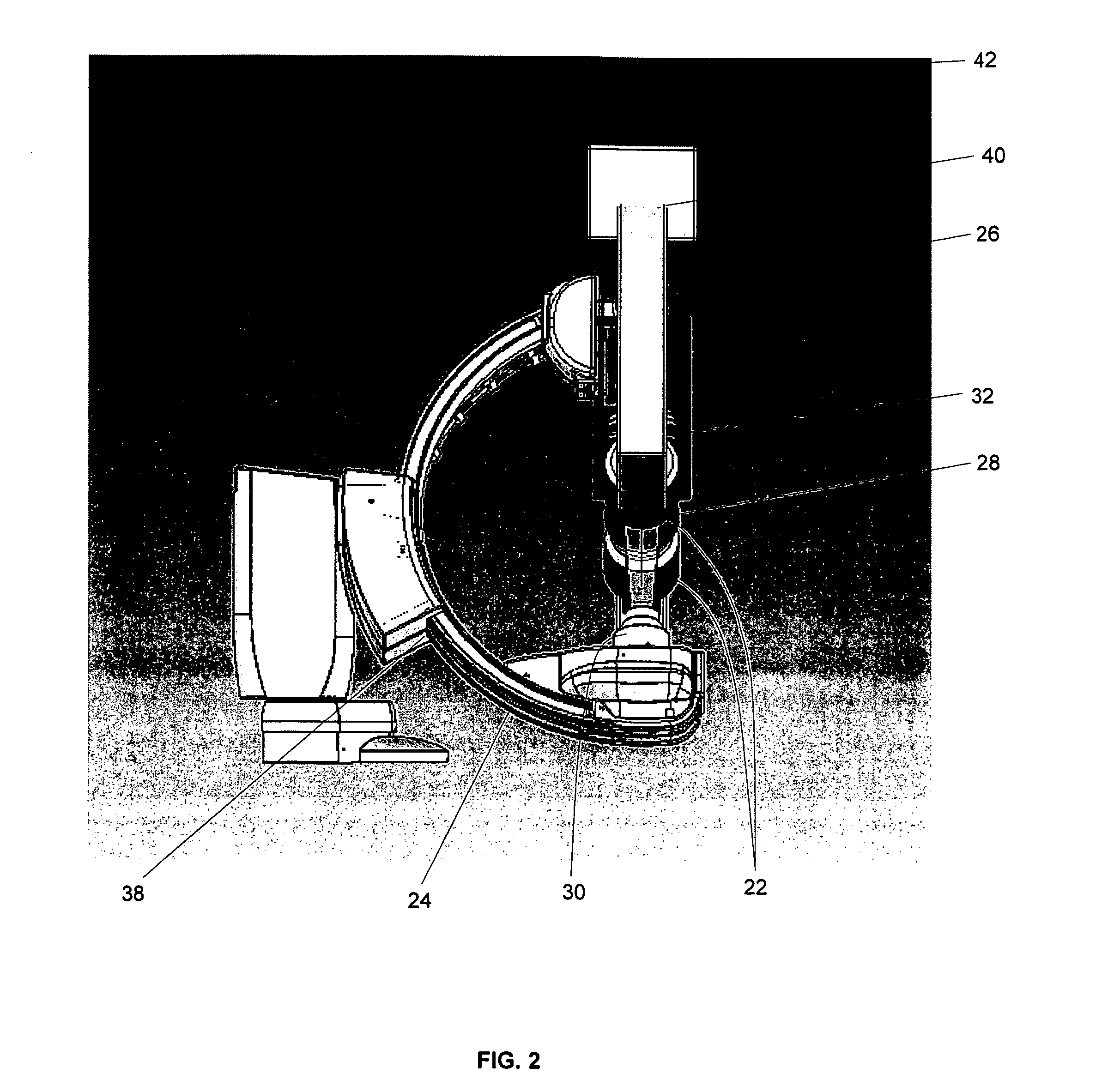

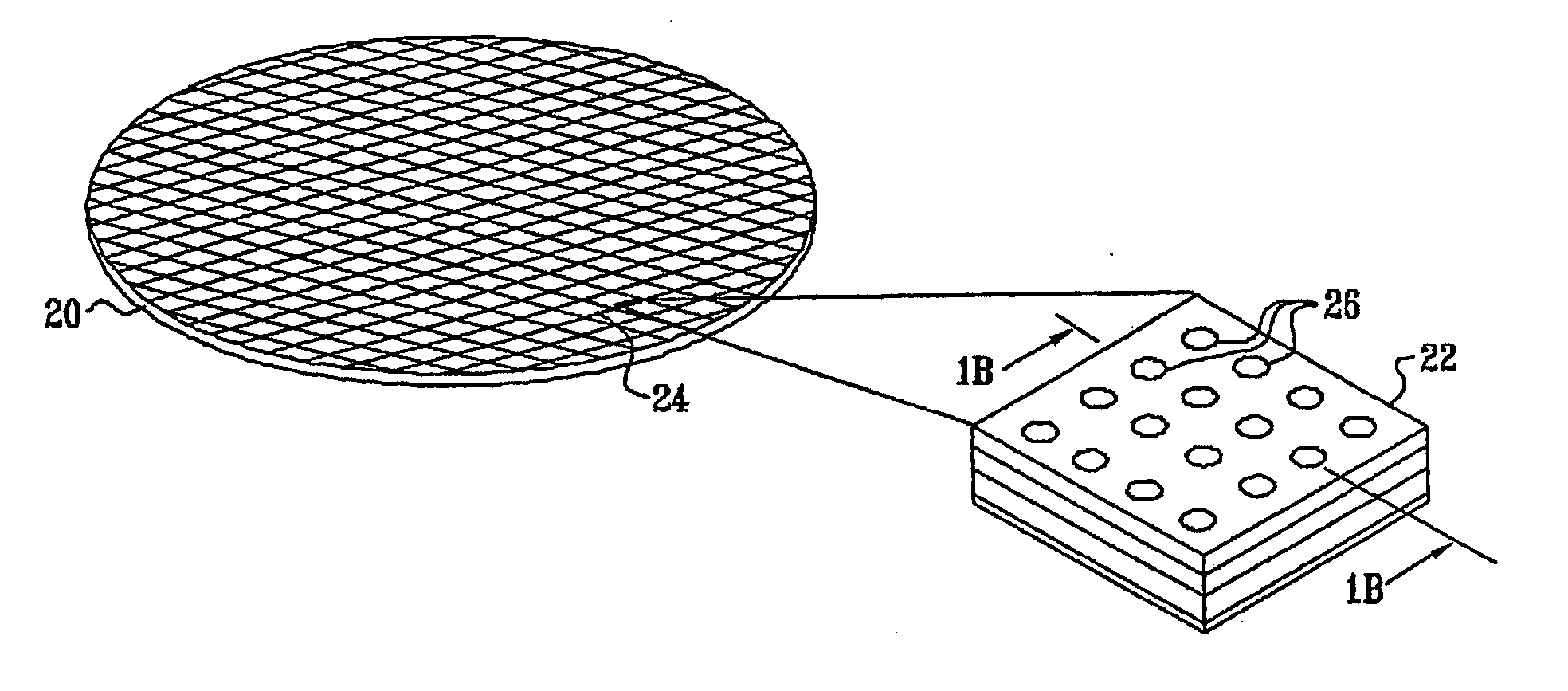

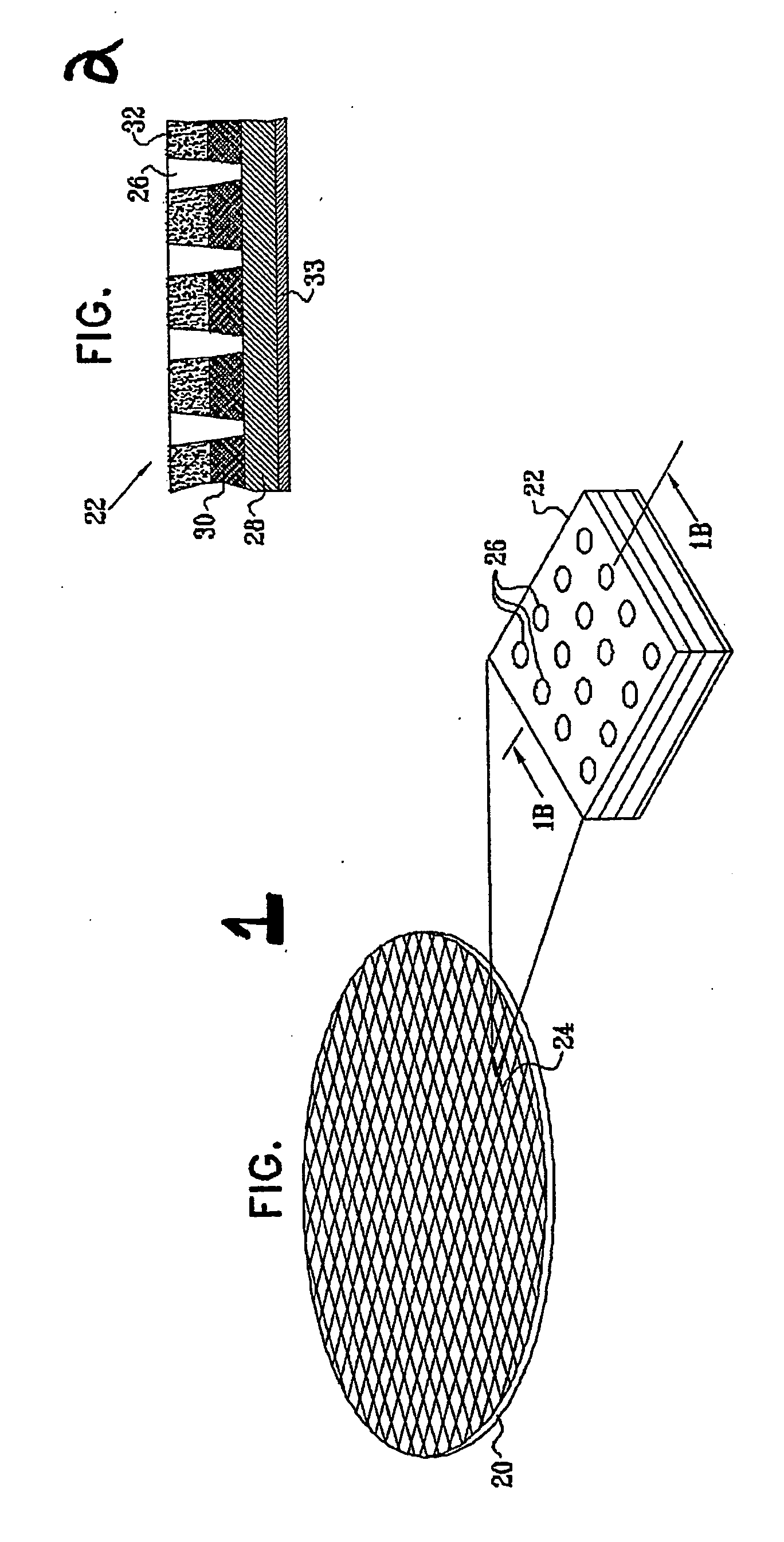

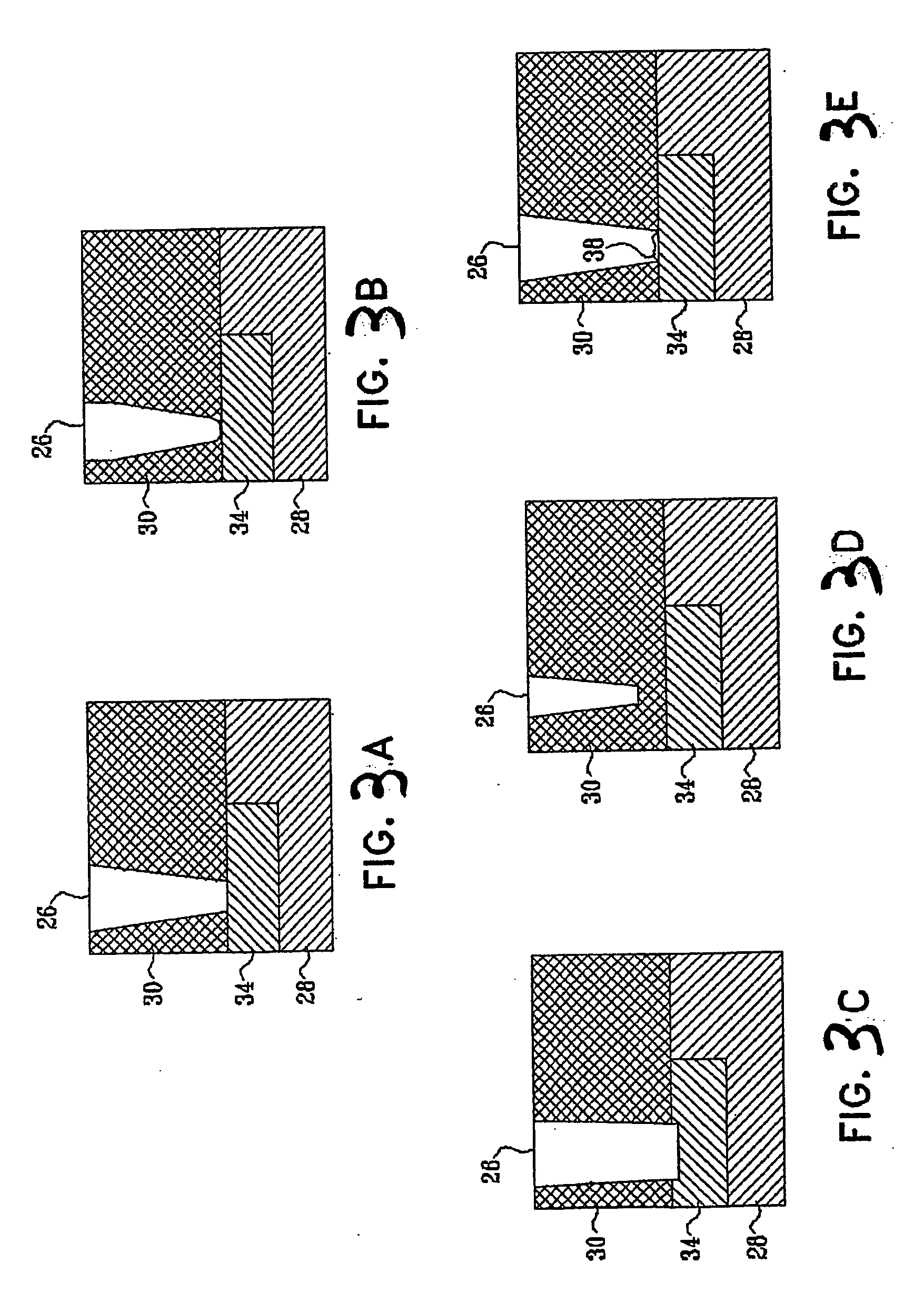

An imaging apparatus and related method comprising a source that projects a beam of radiation in a first trajectory; a detector located a distance from the source and positioned to receive the beam of radiation in the first trajectory; an imaging area between the source and the detector, the radiation beam from the source passing through a portion of the imaging area before it is received at the detector; a detector positioner that translates the detector to a second position in a first direction that is substantially normal to the first trajectory; and a beam positioner that alters the trajectory of the radiation beam to direct the beam onto the detector located at the second position. The radiation source can be an x-ray cone-beam source, and the detector can be a two-dimensional flat-panel detector array. The invention can be used to image objects larger than the field-of-view of the detector by translating the detector array to multiple positions, and obtaining images at each position, resulting in an effectively large field-of-view using only a single detector array having a relatively small size. A beam positioner permits the trajectory of the beam to follow the path of the translating detector, which permits safer and more efficient dose utilization, as generally only the region of the target object that is within the field-of-view of the detector at any given time will be exposed to potentially harmful radiation.

Owner:MEDTRONIC NAVIGATION

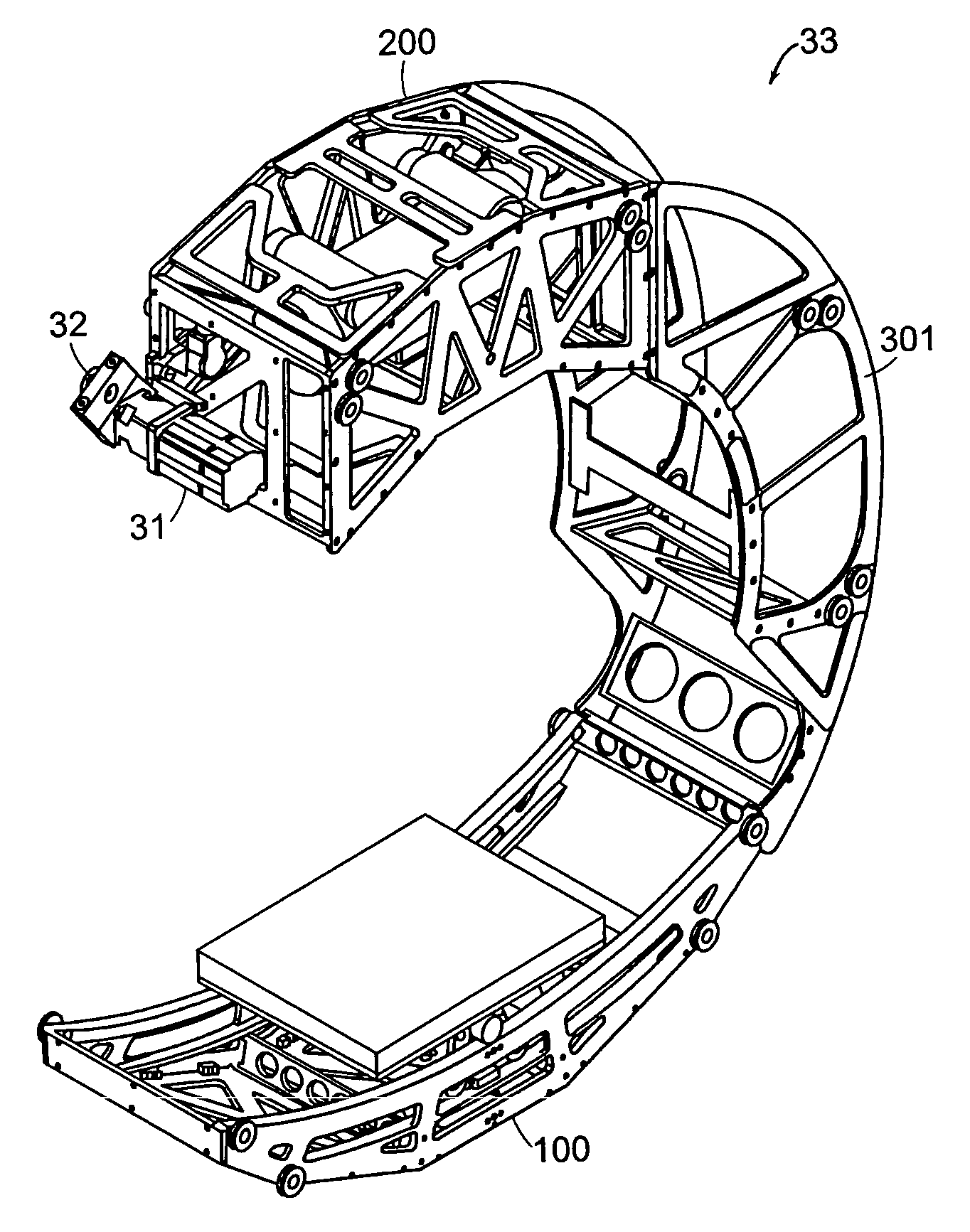

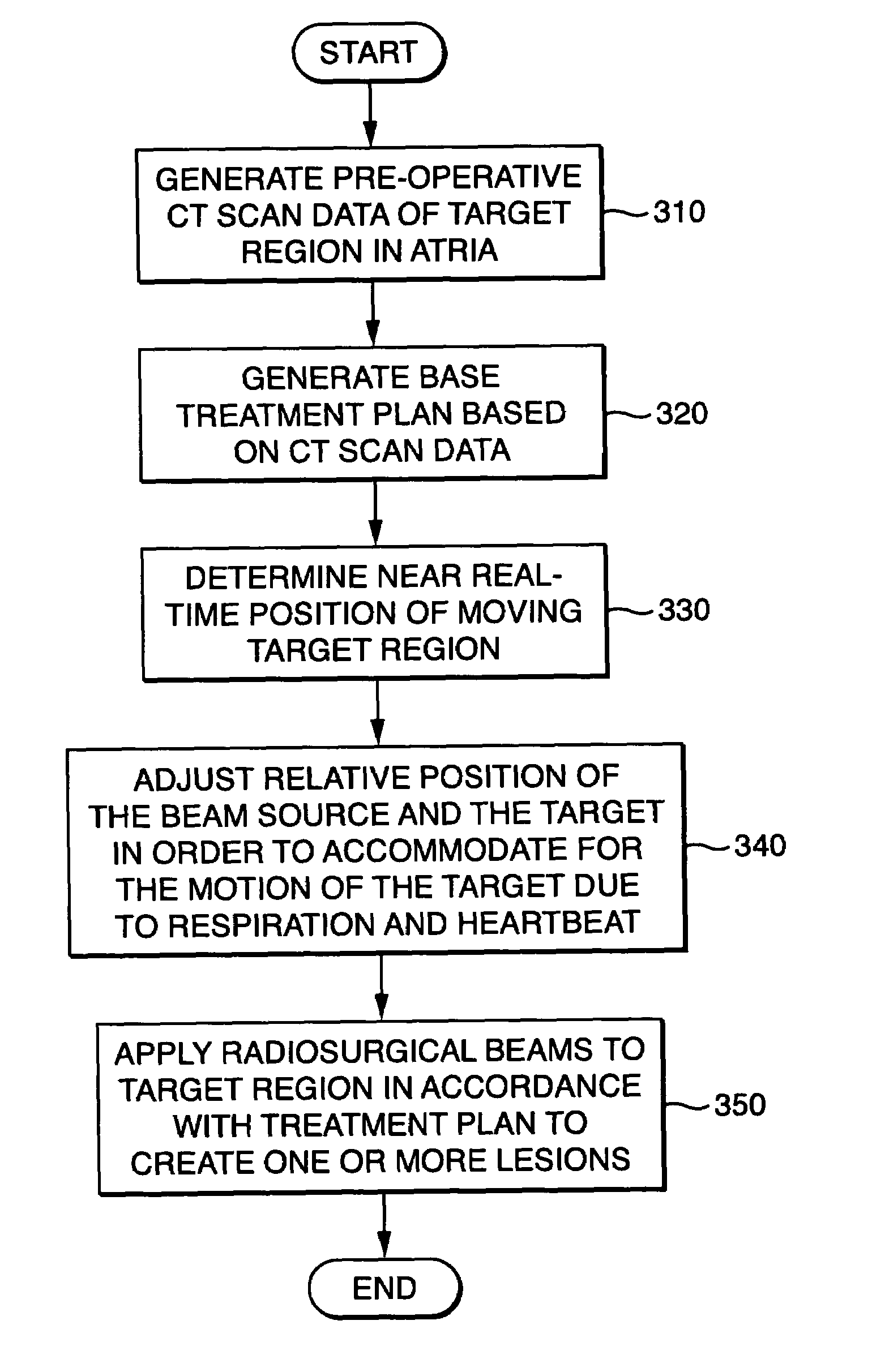

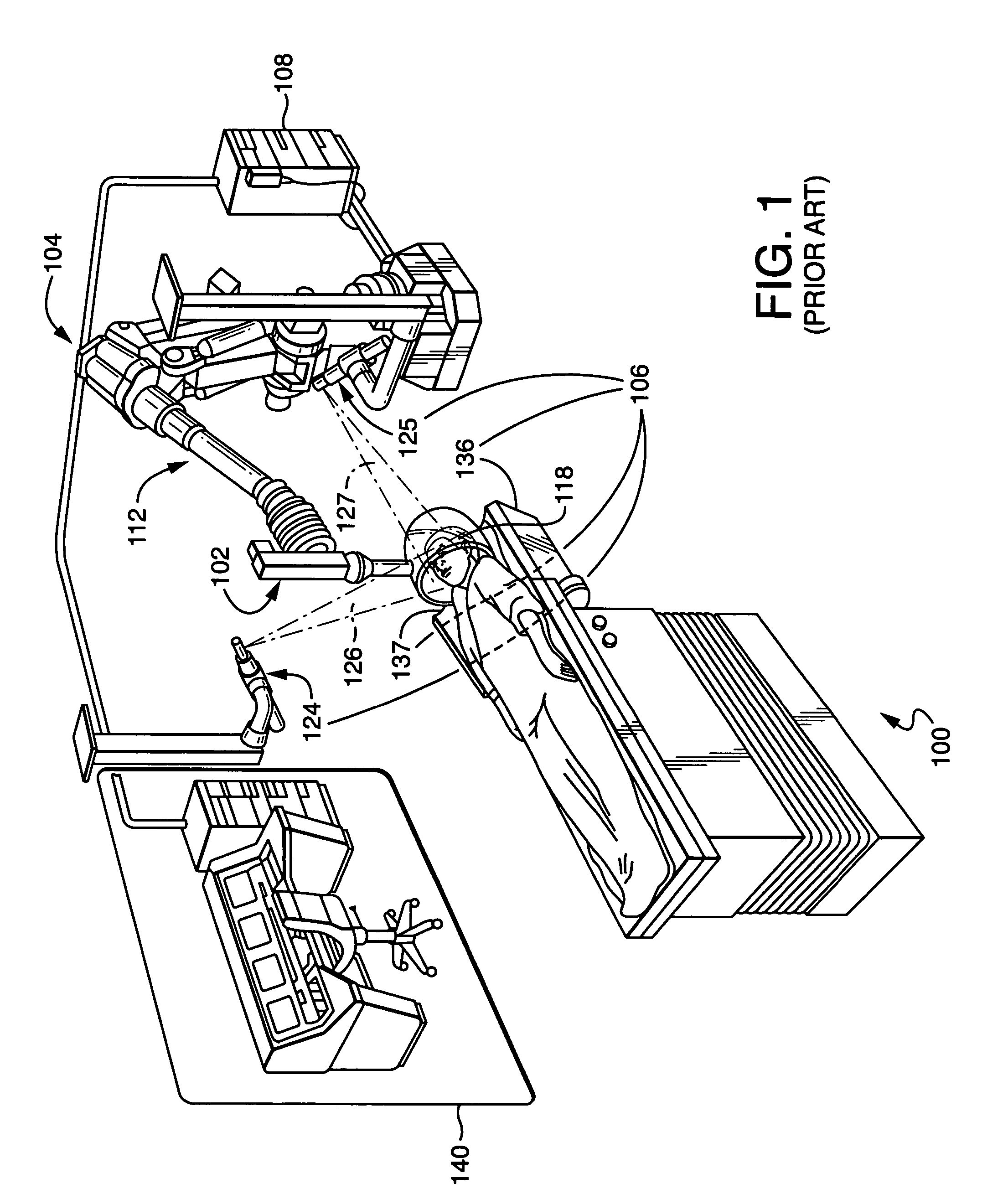

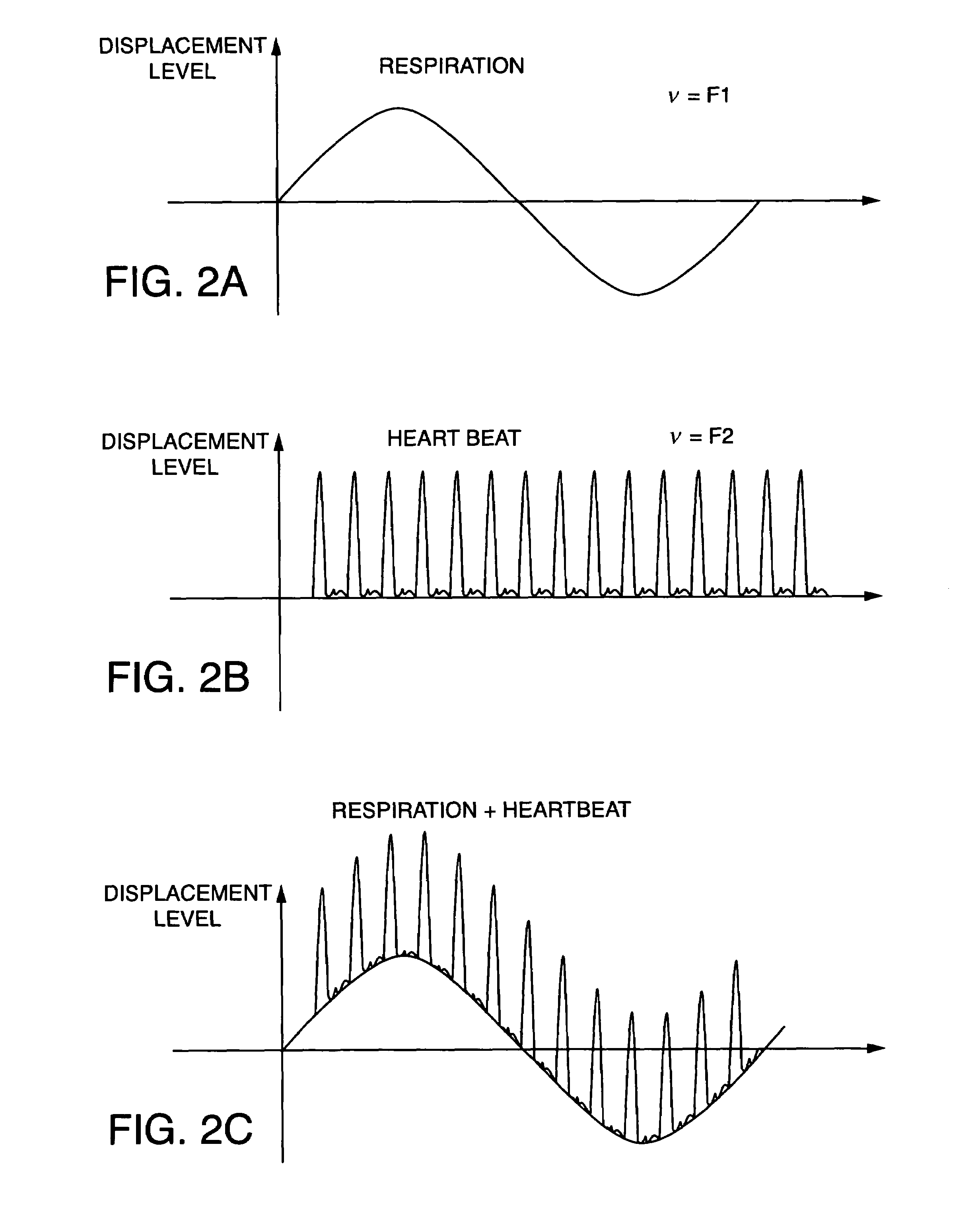

Apparatus and method for radiosurgery

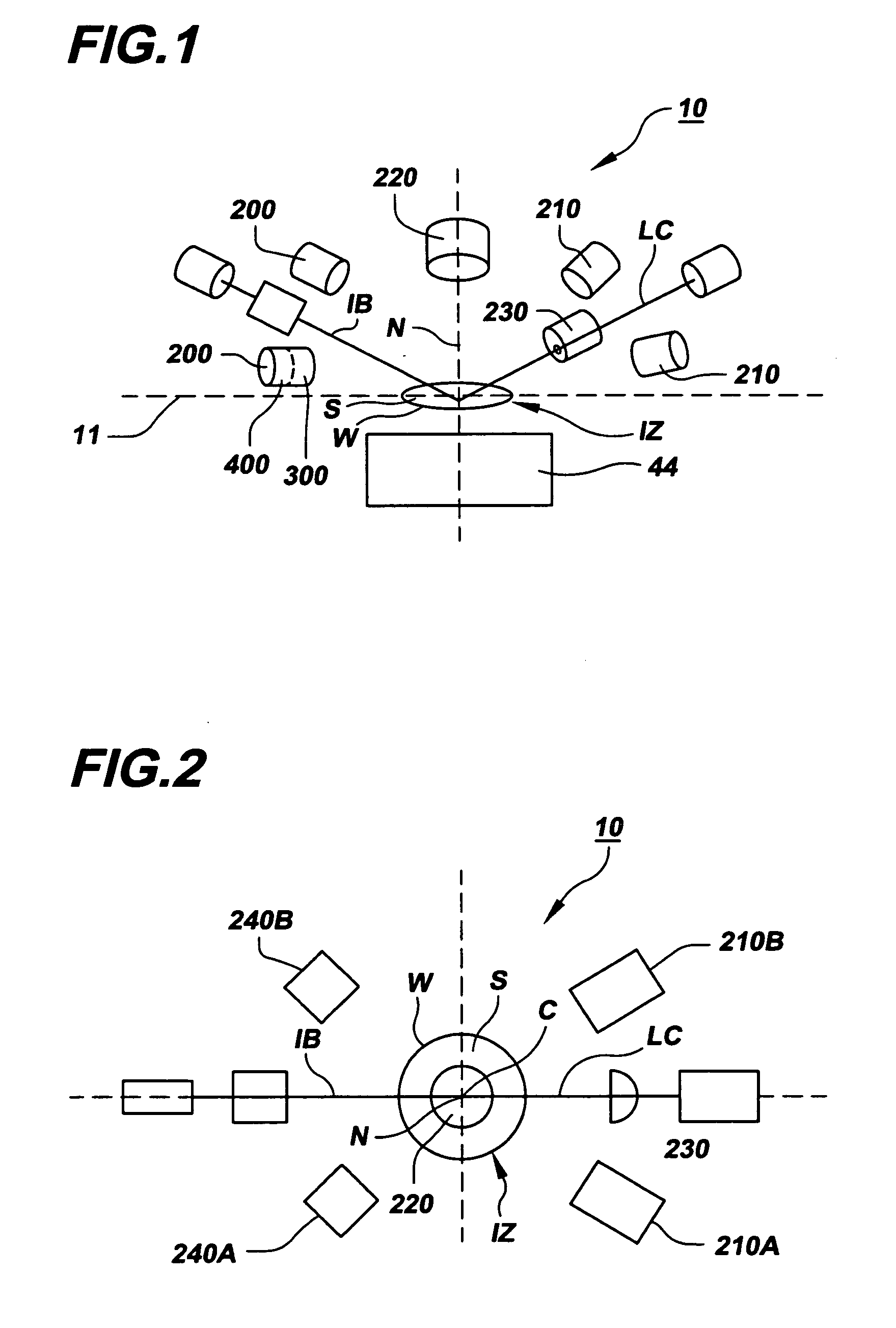

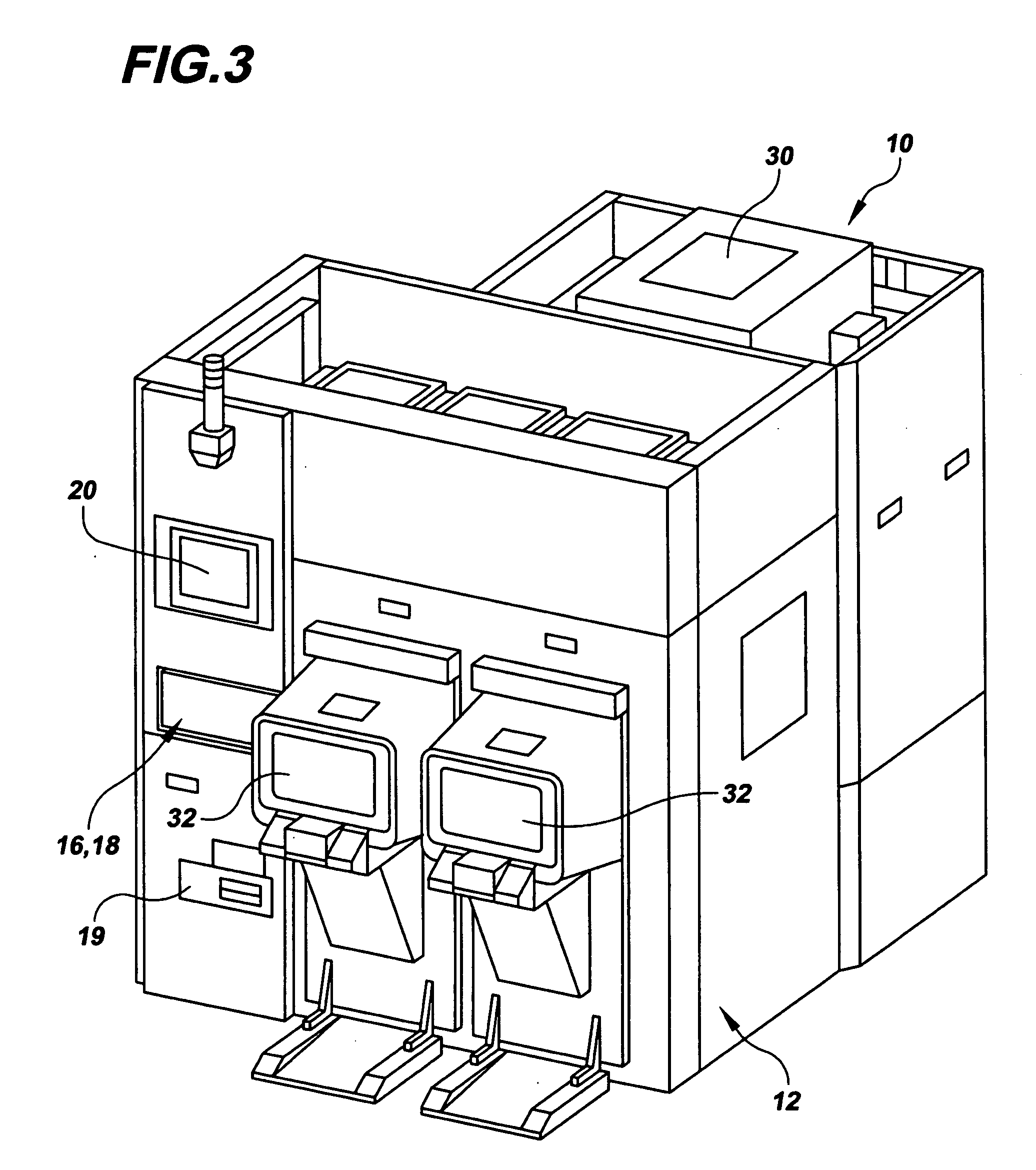

A method and system is presented for treating moving target regions in a patient's anatomy by creating radiosurgical lesions. The method includes determining a pulsating motion of a patient separately from a determining of a respiratory motion, and directing a radiosurgical beam, from a radiosurgical beam source, to a target in the patient based on the determining of the pulsating motion. Directing the radiosurgical beam to the target may include creating a lesion in the heart to inhibit atrial fibrillation. The method may further include determining the respiratory motion of the patient, and compensating for movement of the target, due to the respiratory motion and the pulsating motion of the patient, in the directing of the radiosurgical beam based on the determining of the respiratory motion and the determining of the pulsating motion.

Owner:ACCURAY

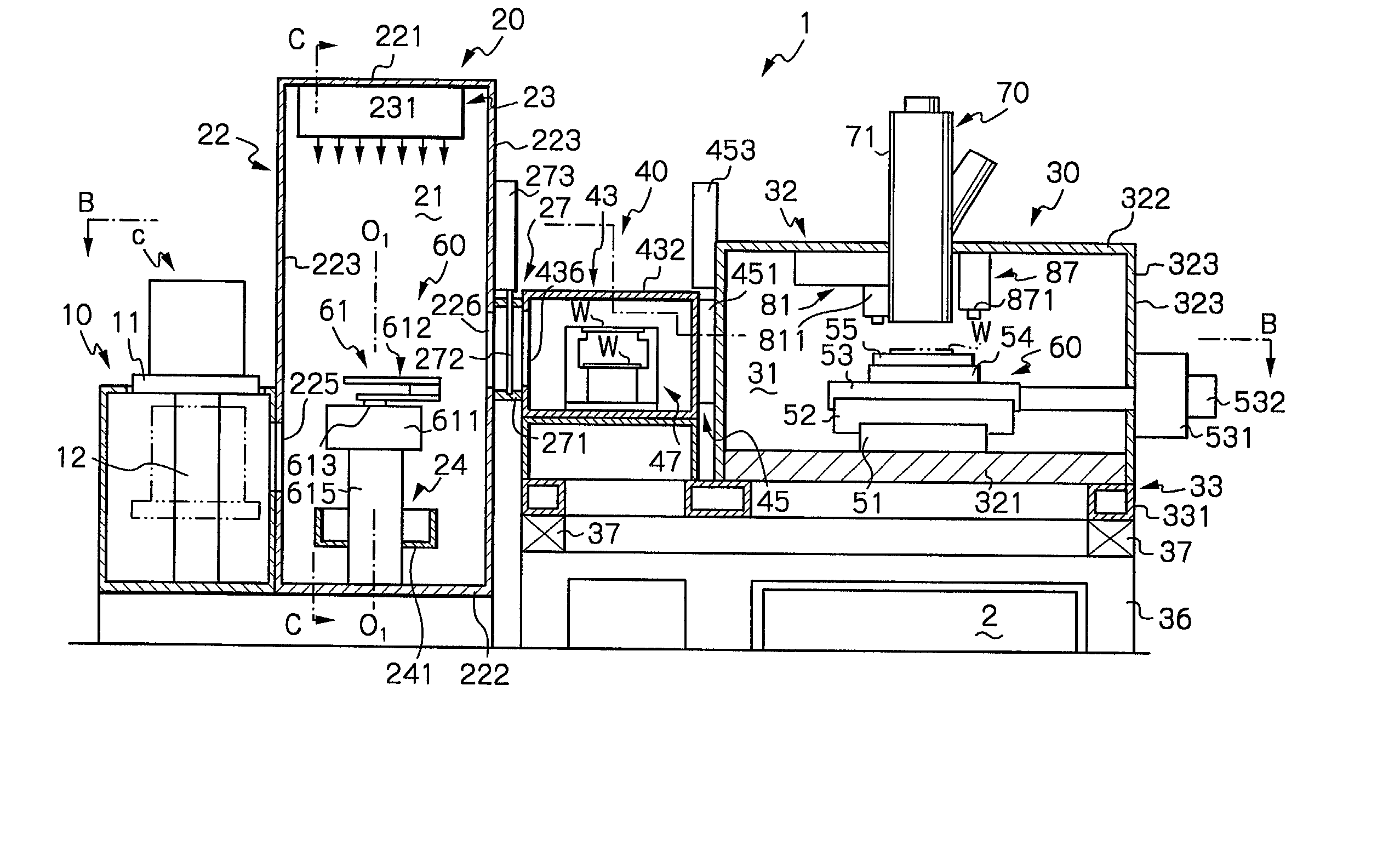

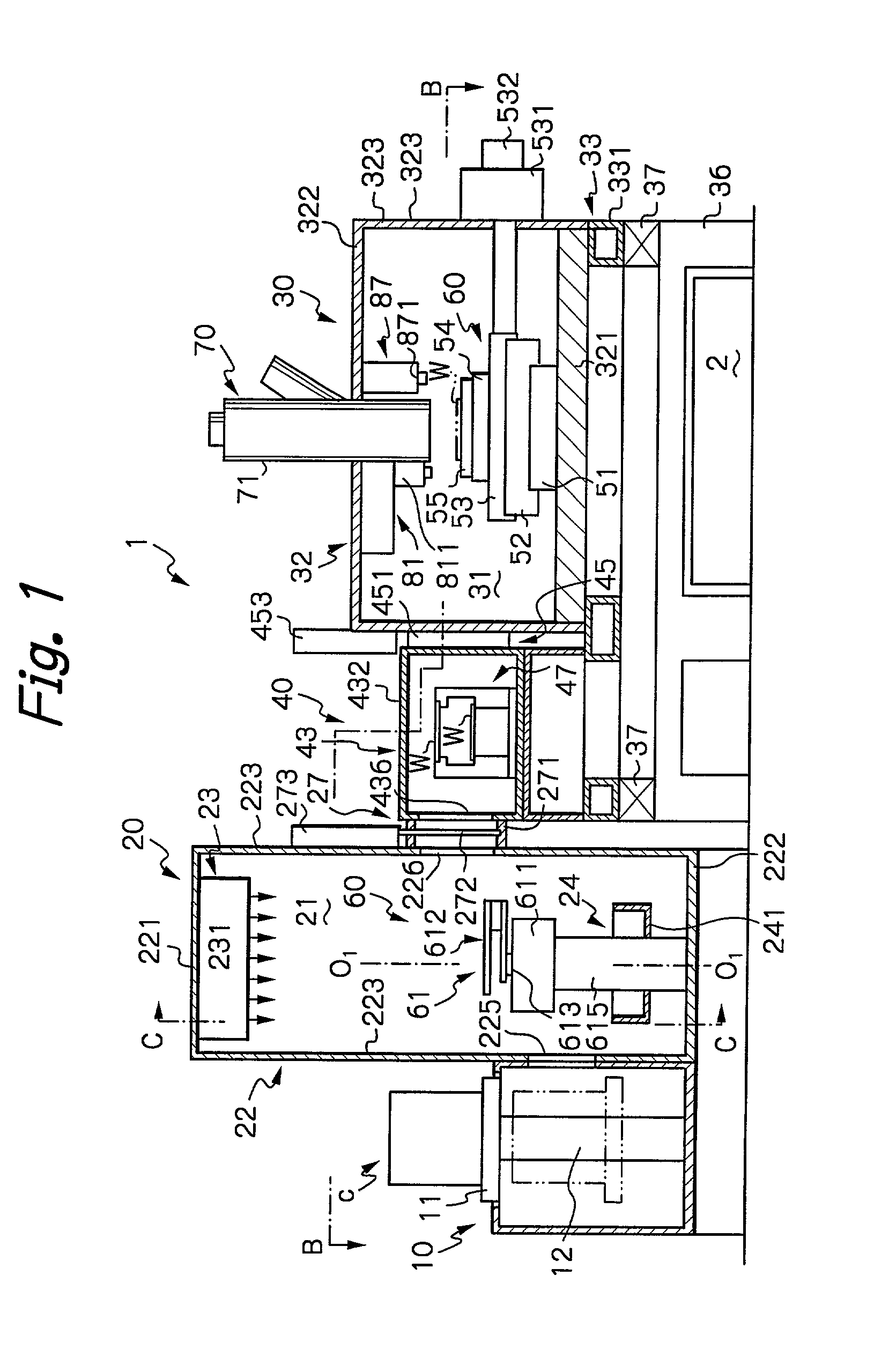

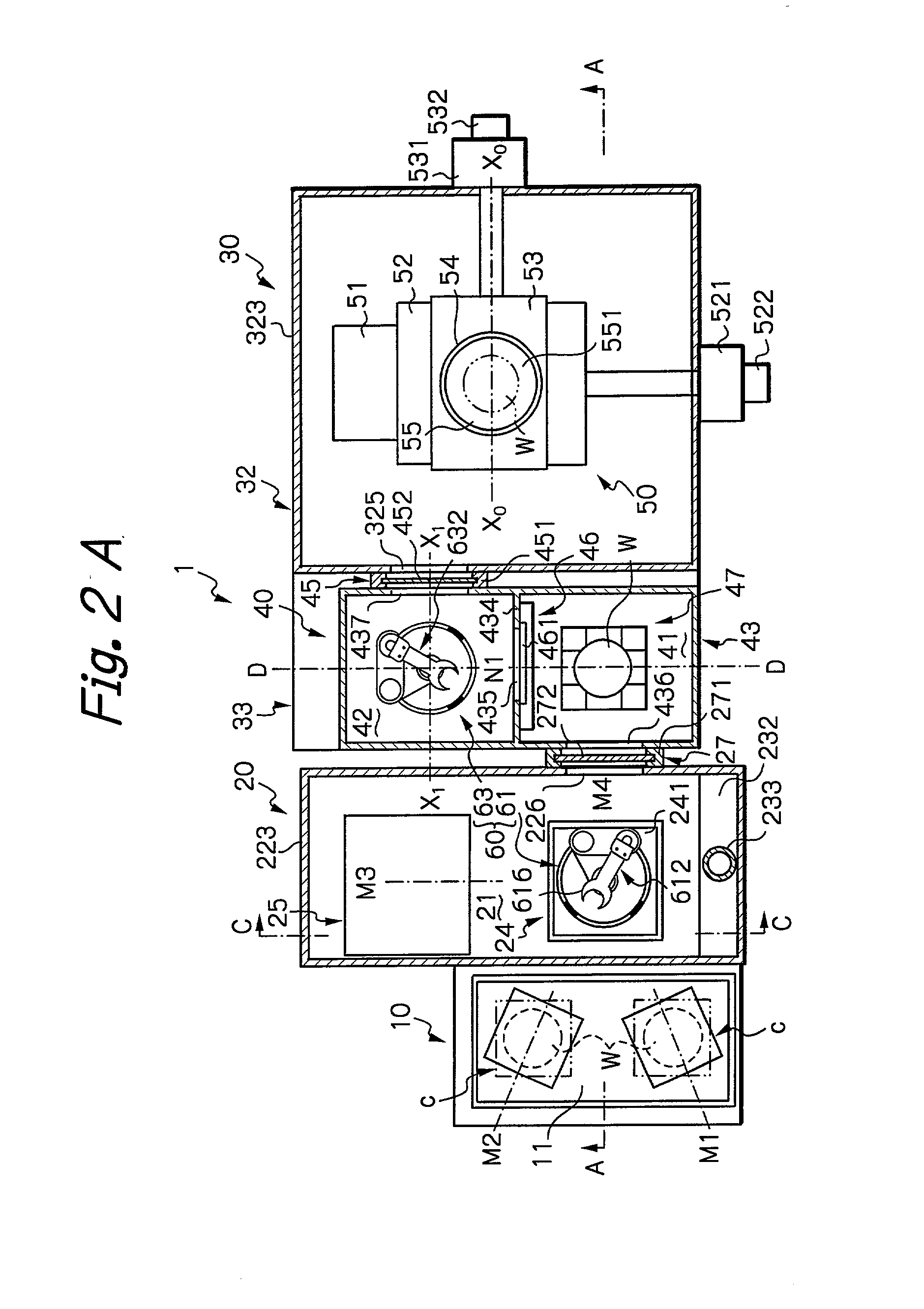

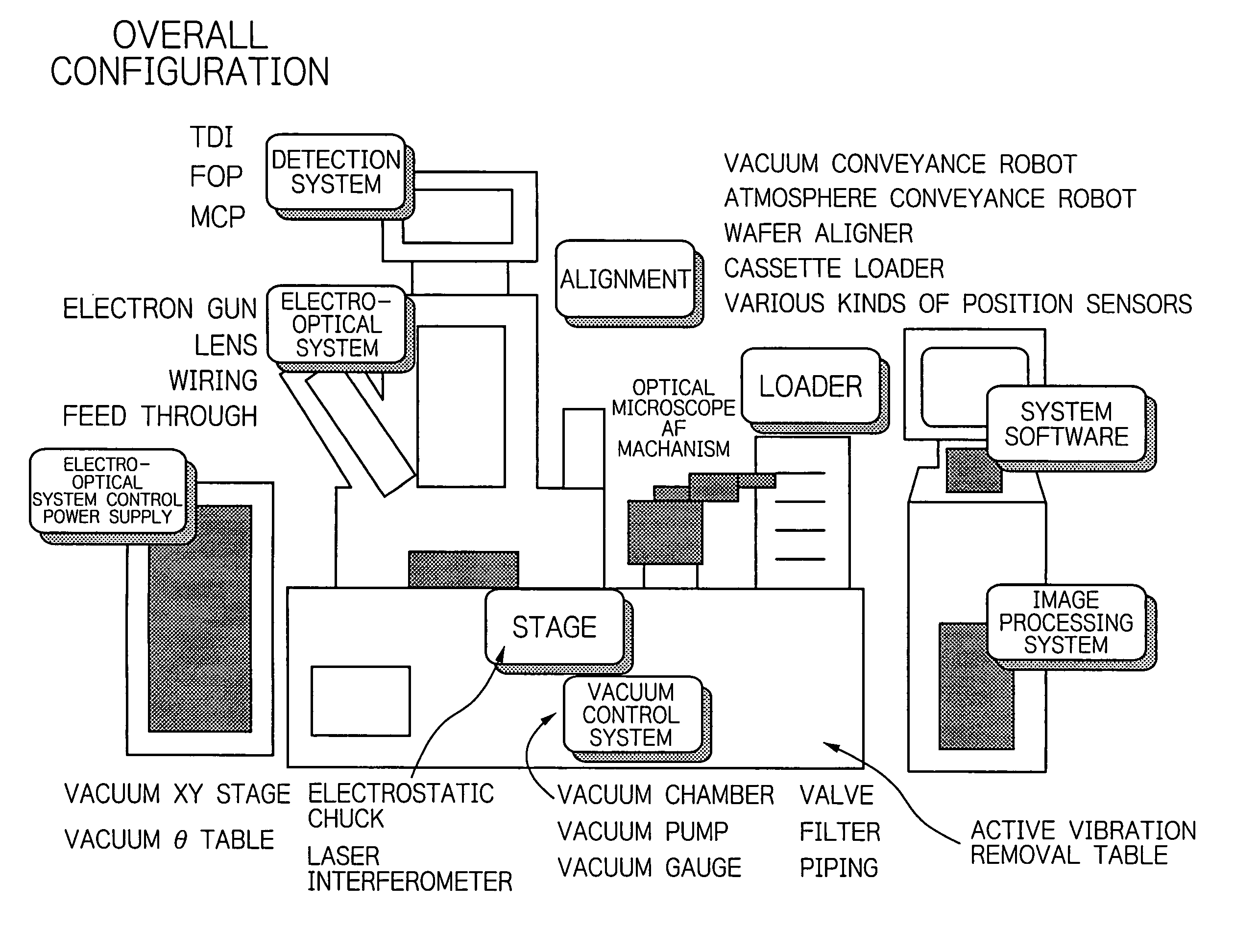

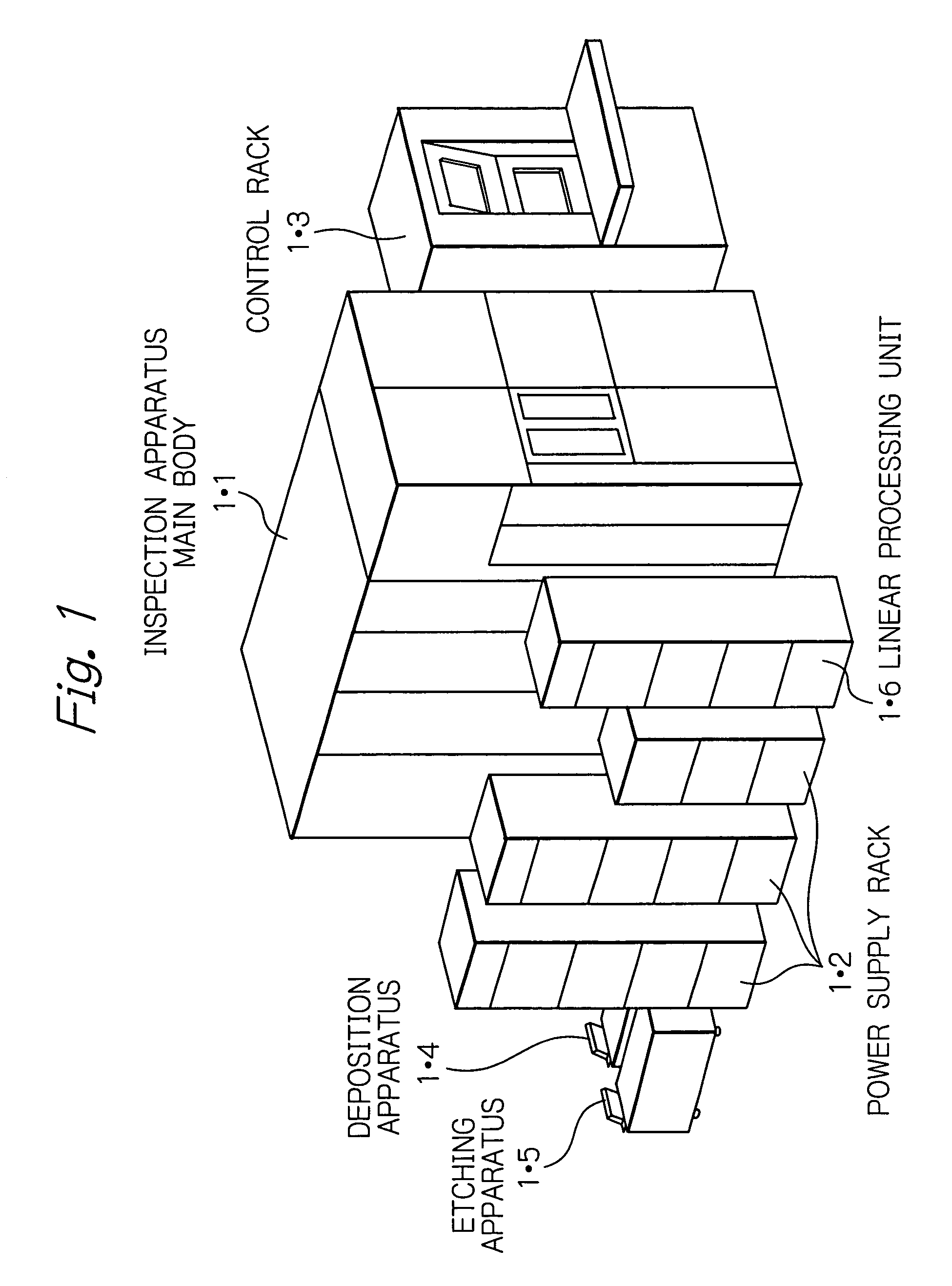

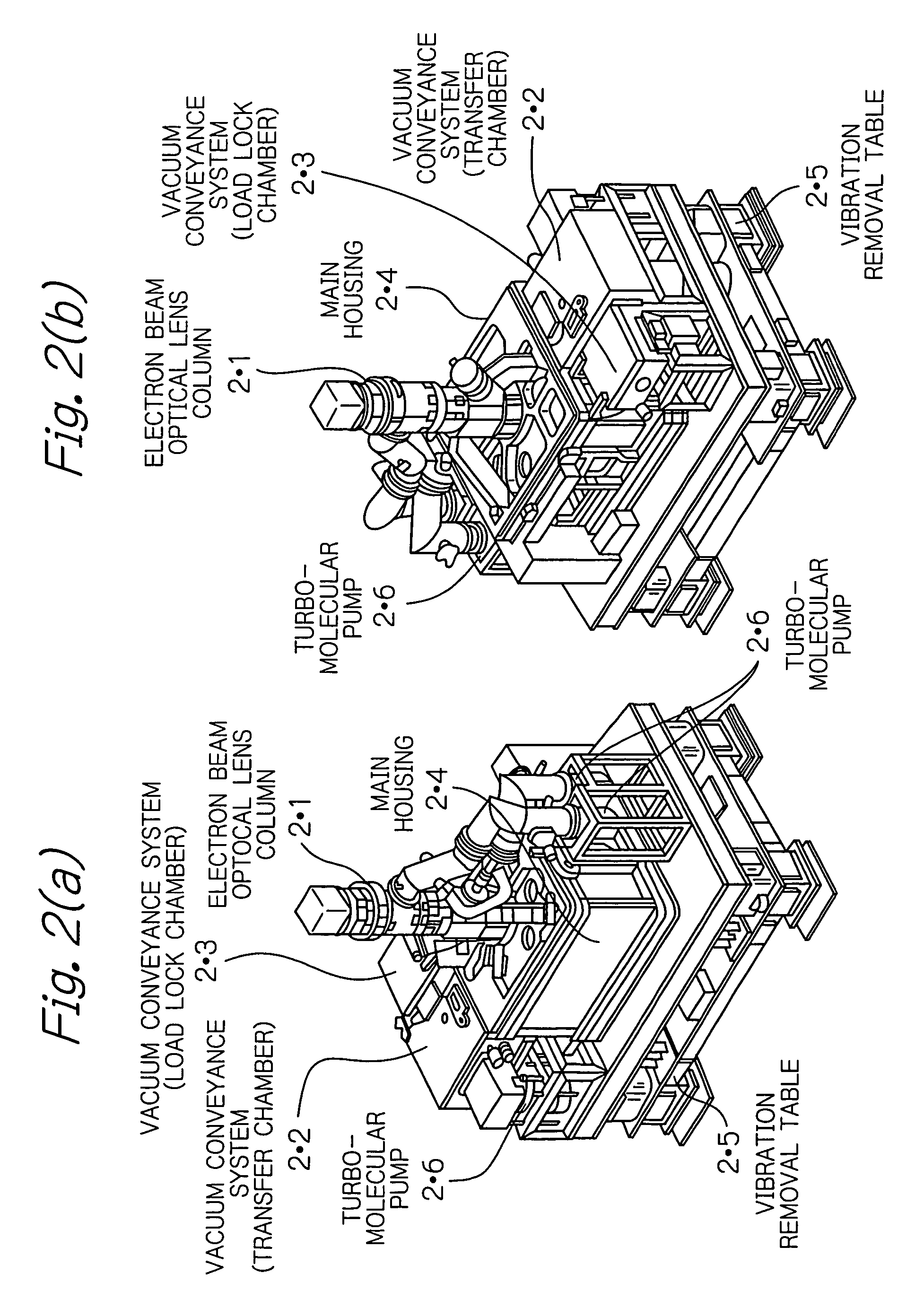

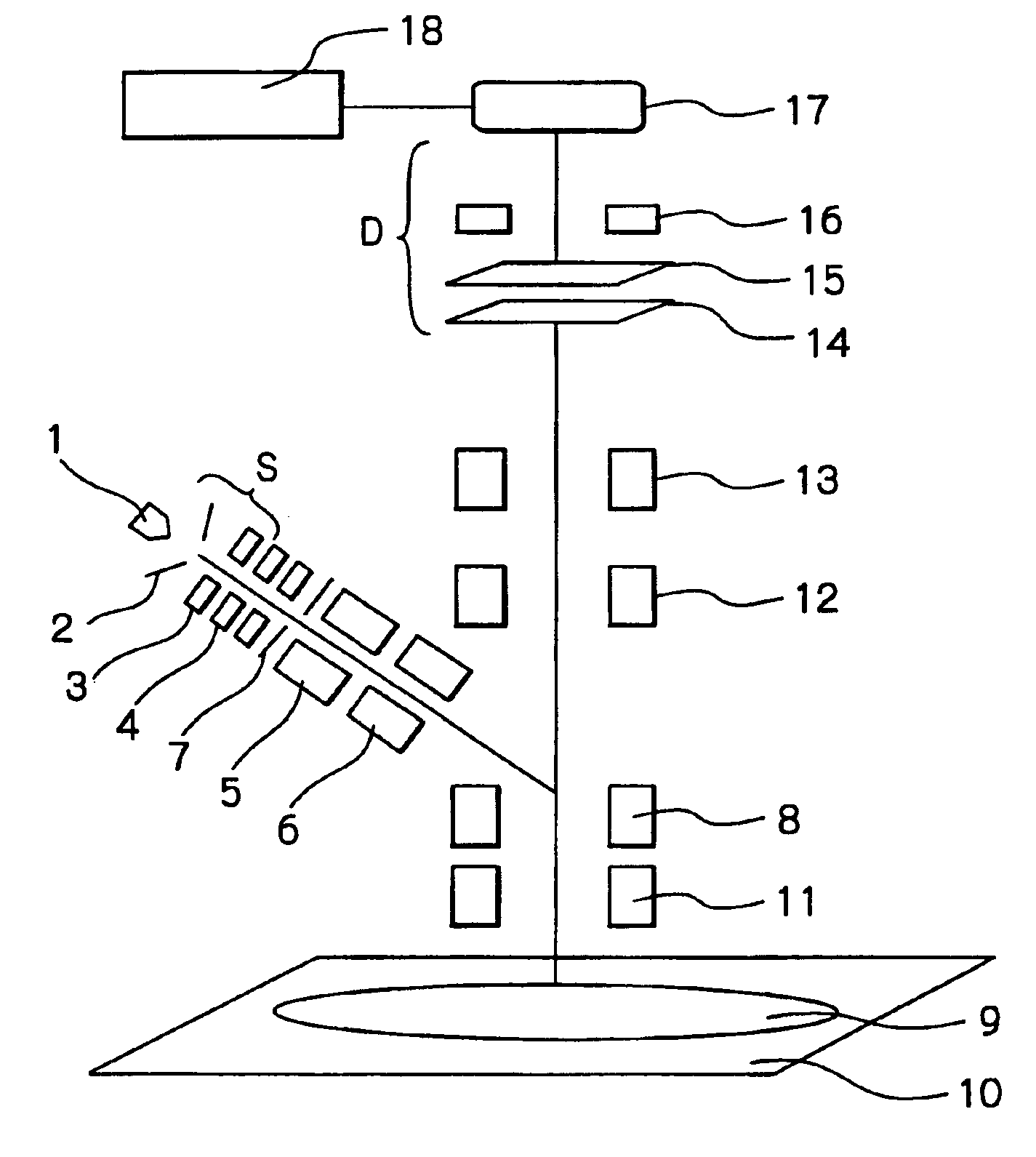

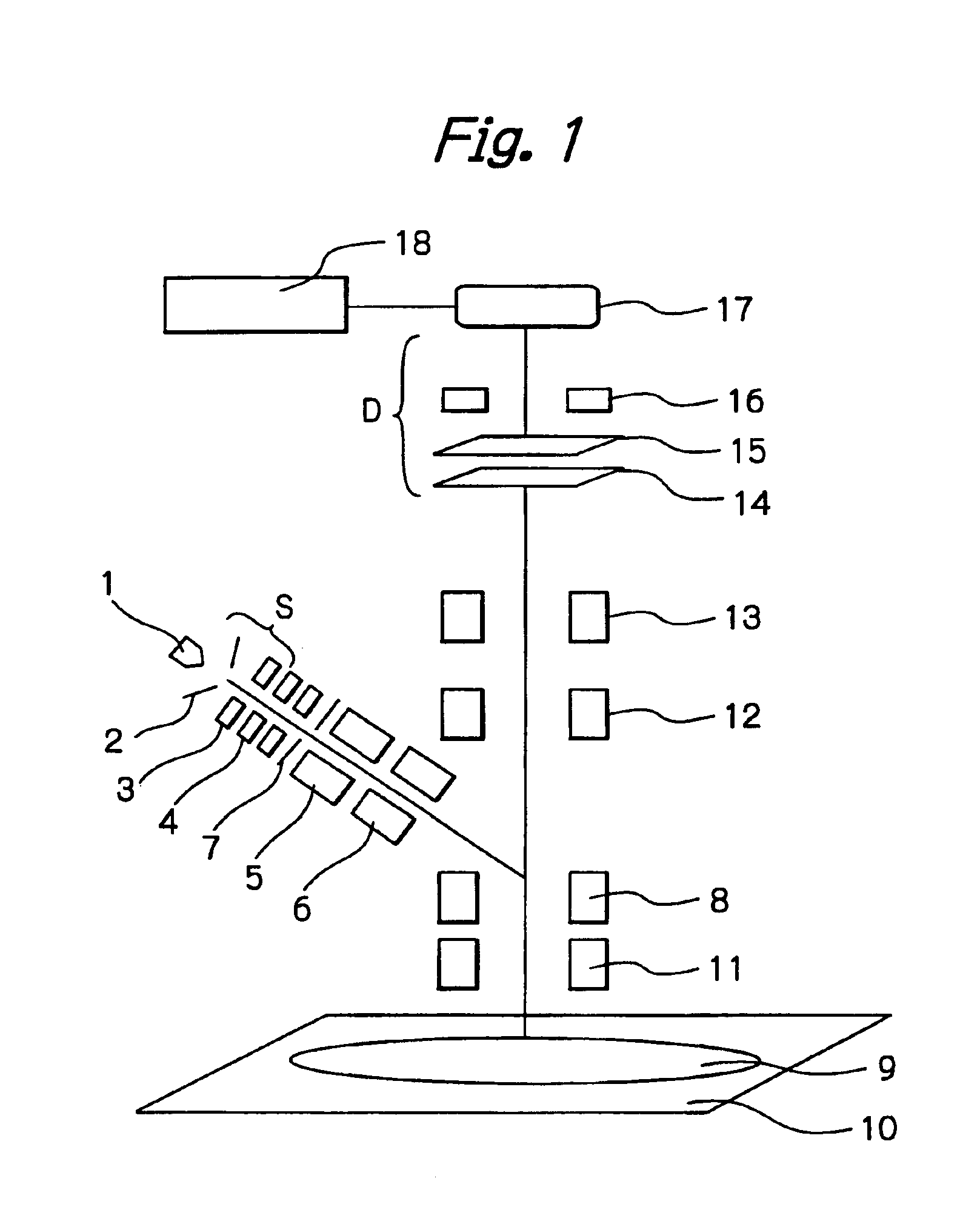

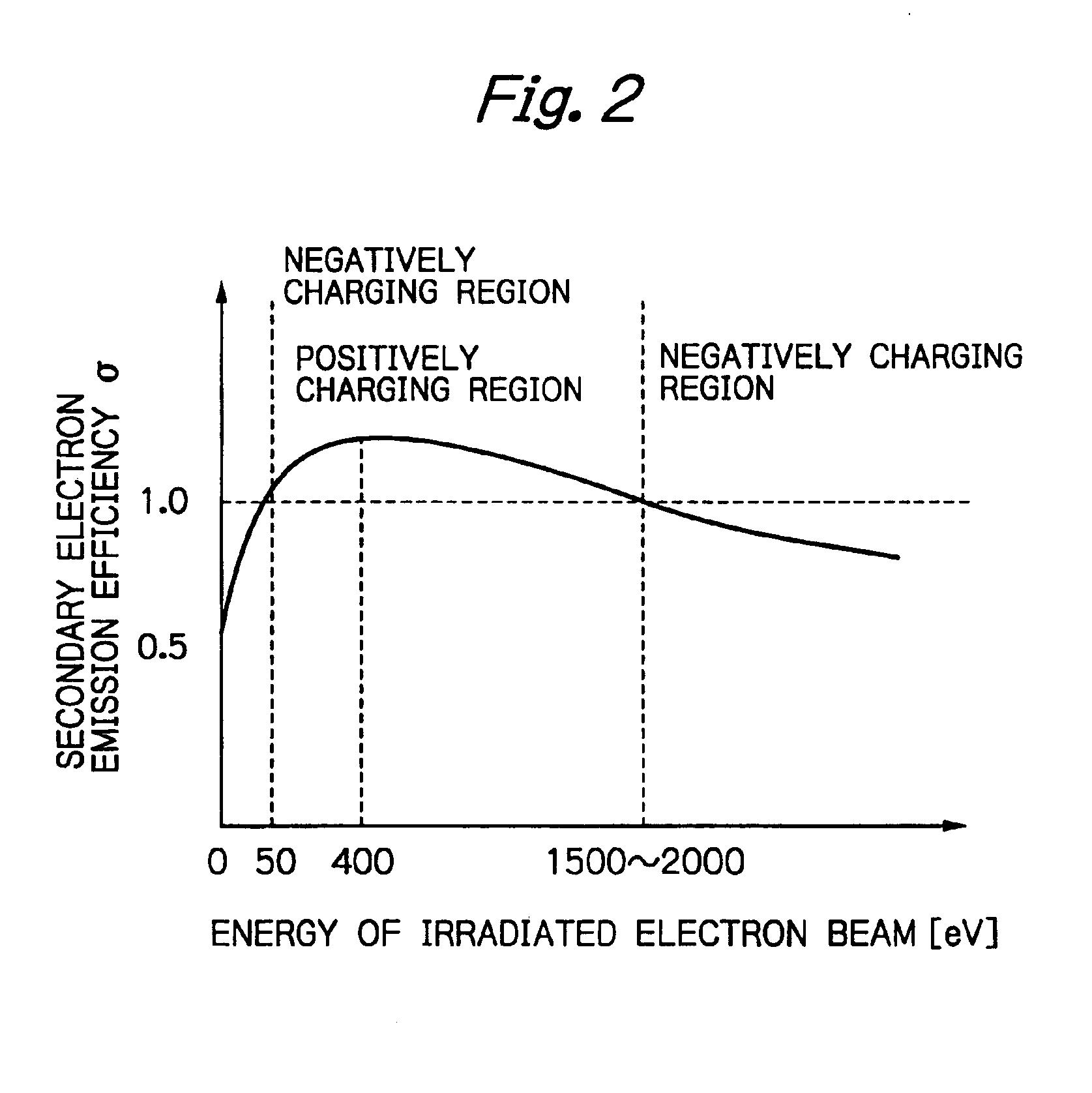

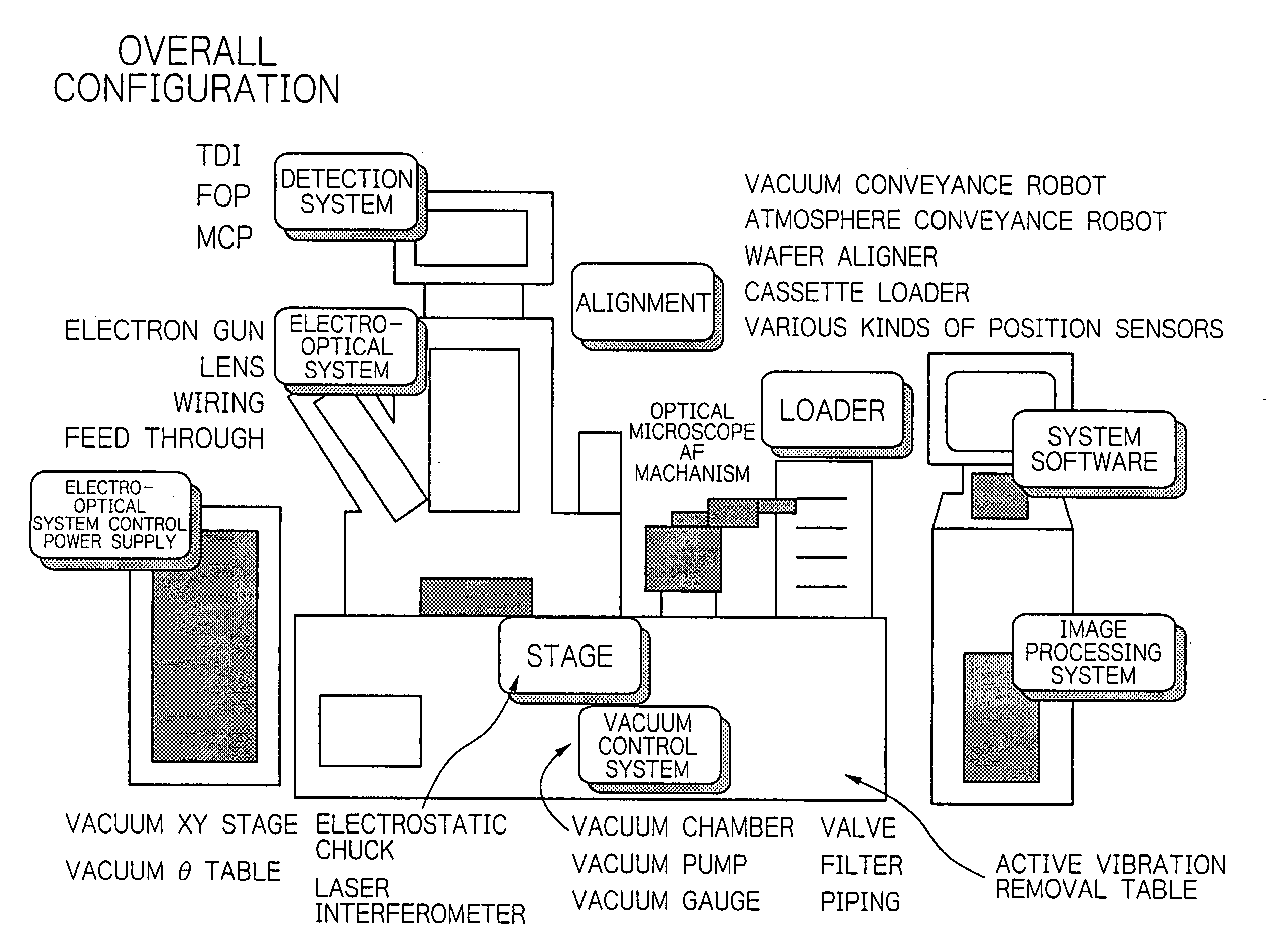

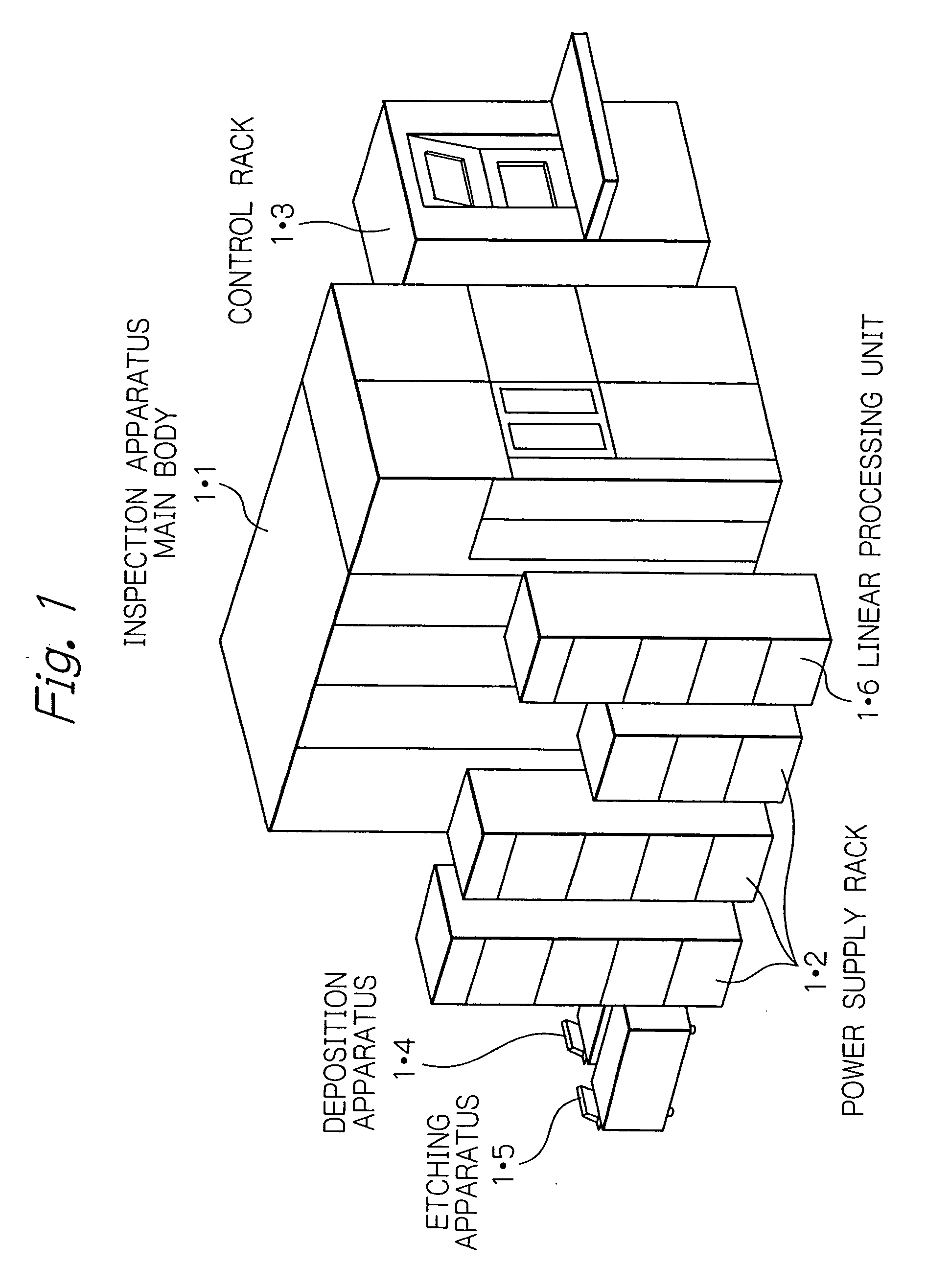

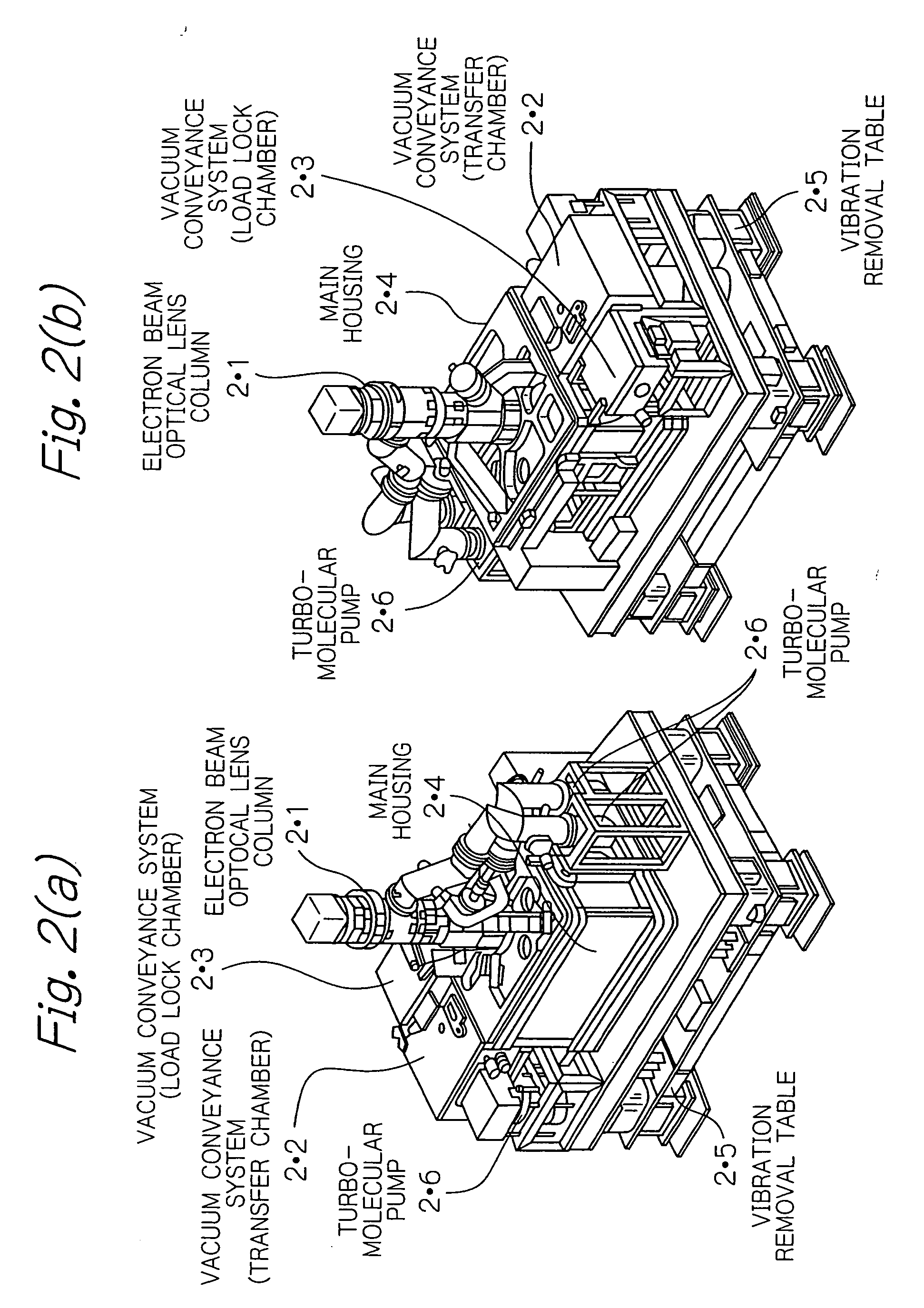

Inspection system by charged particle beam and method of manufacturing devices using the system

InactiveUS20020028399A1Efficiently and accurately inspecting objectAccurately inspect an objectMaterial analysis using wave/particle radiationElectrode and associated part arrangementsBeam sourceSecondary electrons

An inspection apparatus by an electron beam comprises: an electron-optical device 70 having an electron-optical system for irradiating the object with a primary electron beam from an electron beam source, and a detector for detecting the secondary electron image projected by the electron-optical system; a stage system 50 for holding and moving the object relative to the electron-optical system; a mini-environment chamber 20 for supplying a clean gas to the object to prevent dust from contacting to the object; a working chamber 31 for accommodating the stage device, the working chamber being controllable so as to have a vacuum atmosphere; at least two loading chambers 41, 42 disposed between the mini-environment chamber and the working chamber, adapted to be independently controllable so as to have a vacuum atmosphere; and a loader 60 for transferring the object to the stage system through the loading chambers.

Owner:EBARA CORP +1

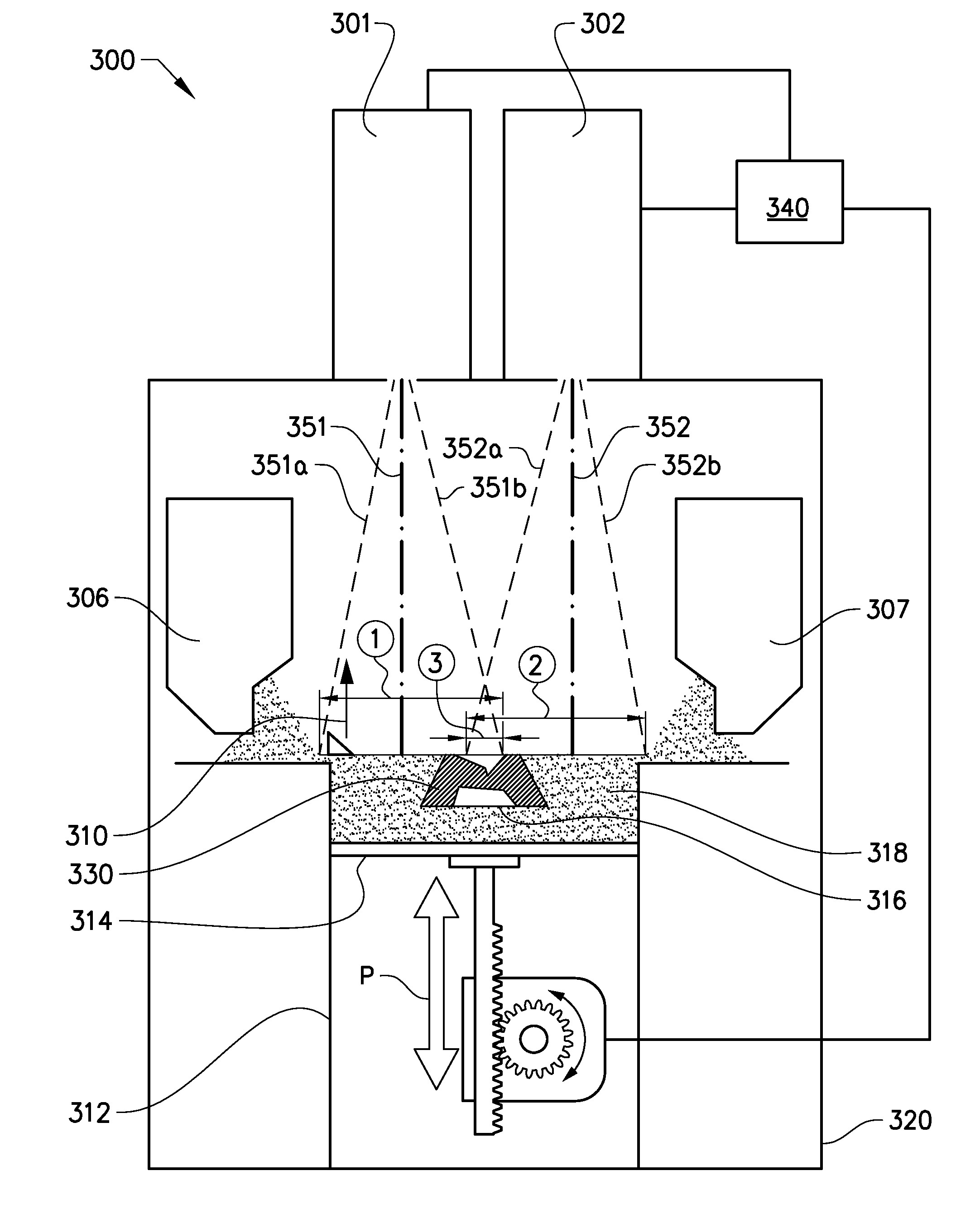

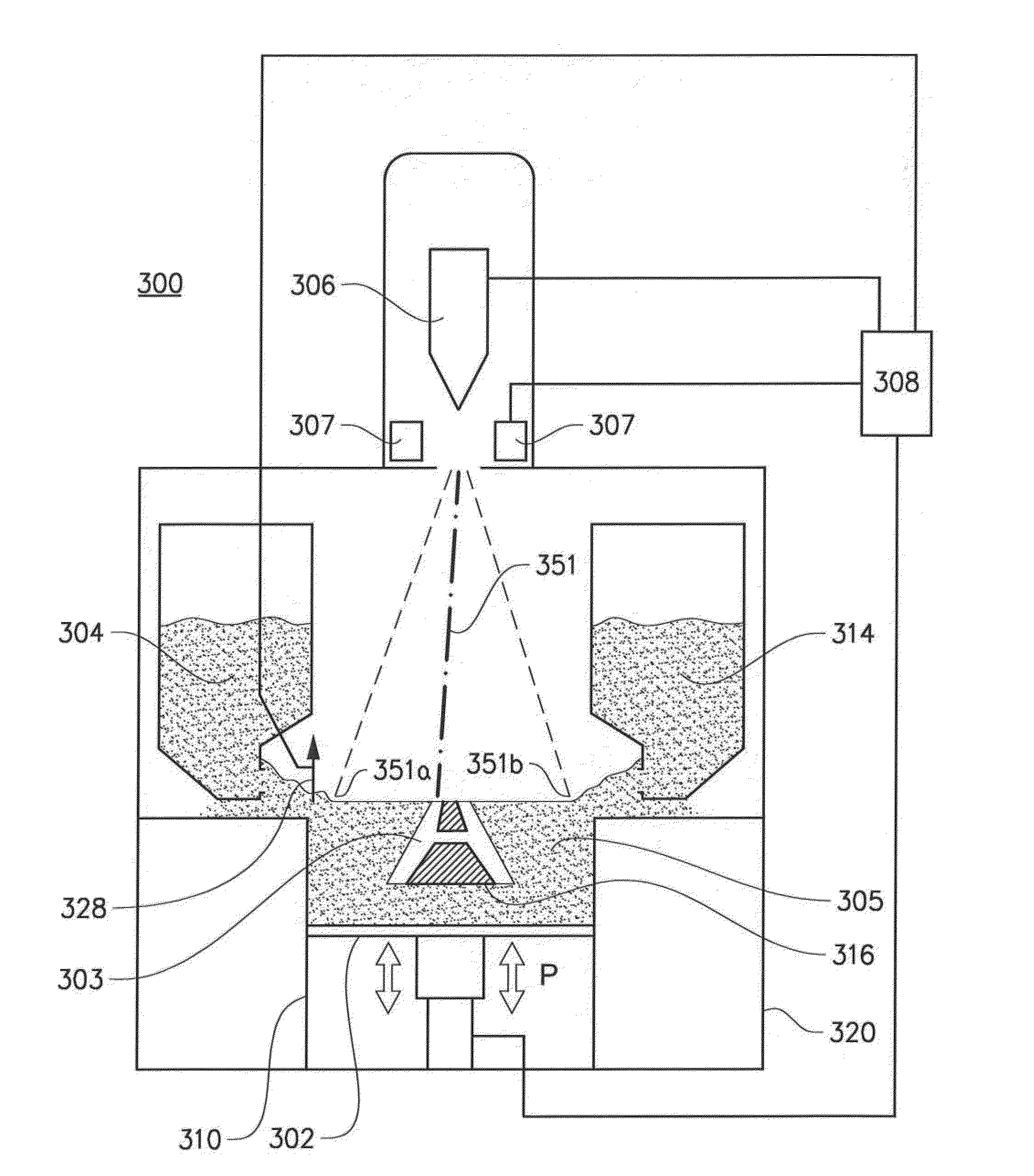

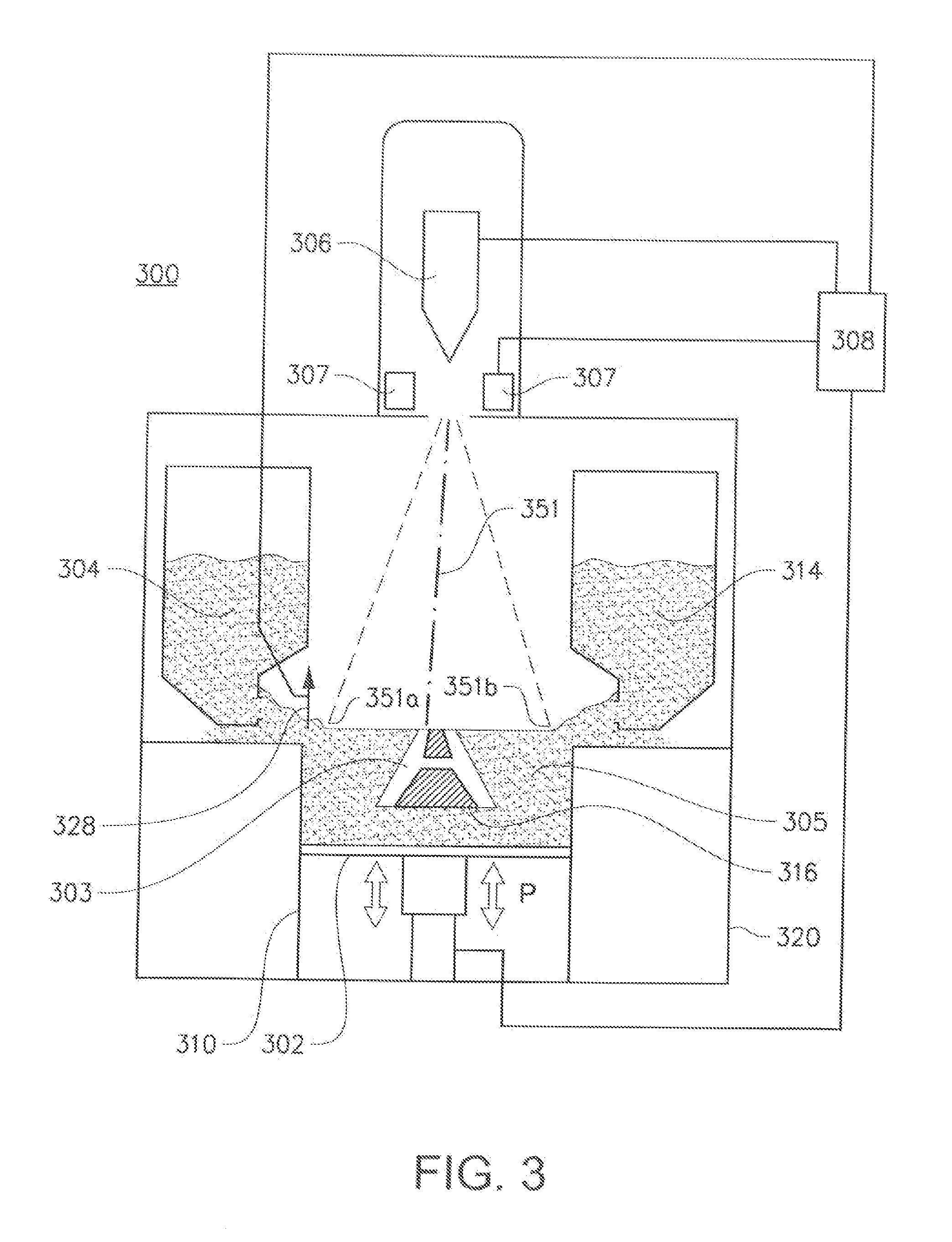

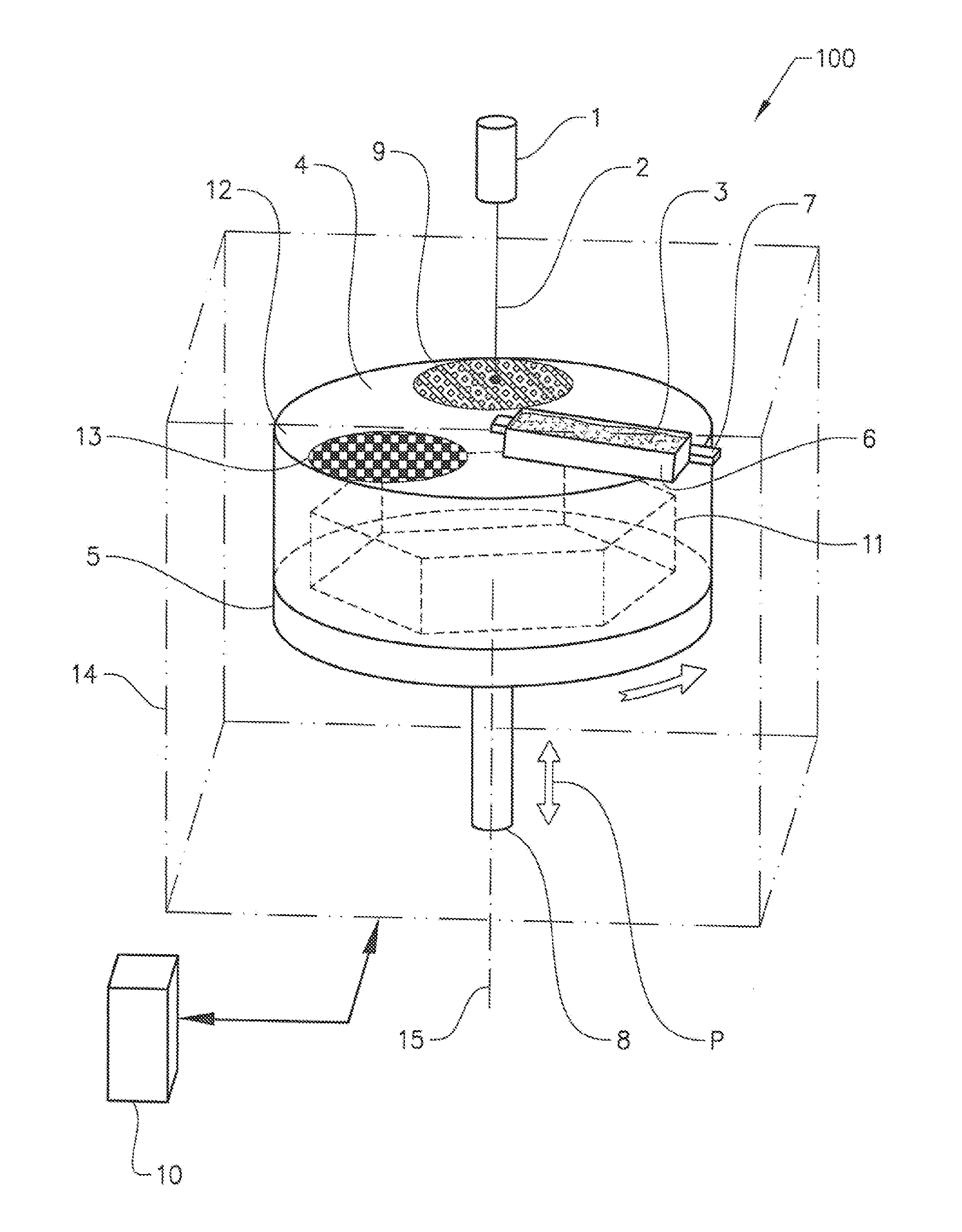

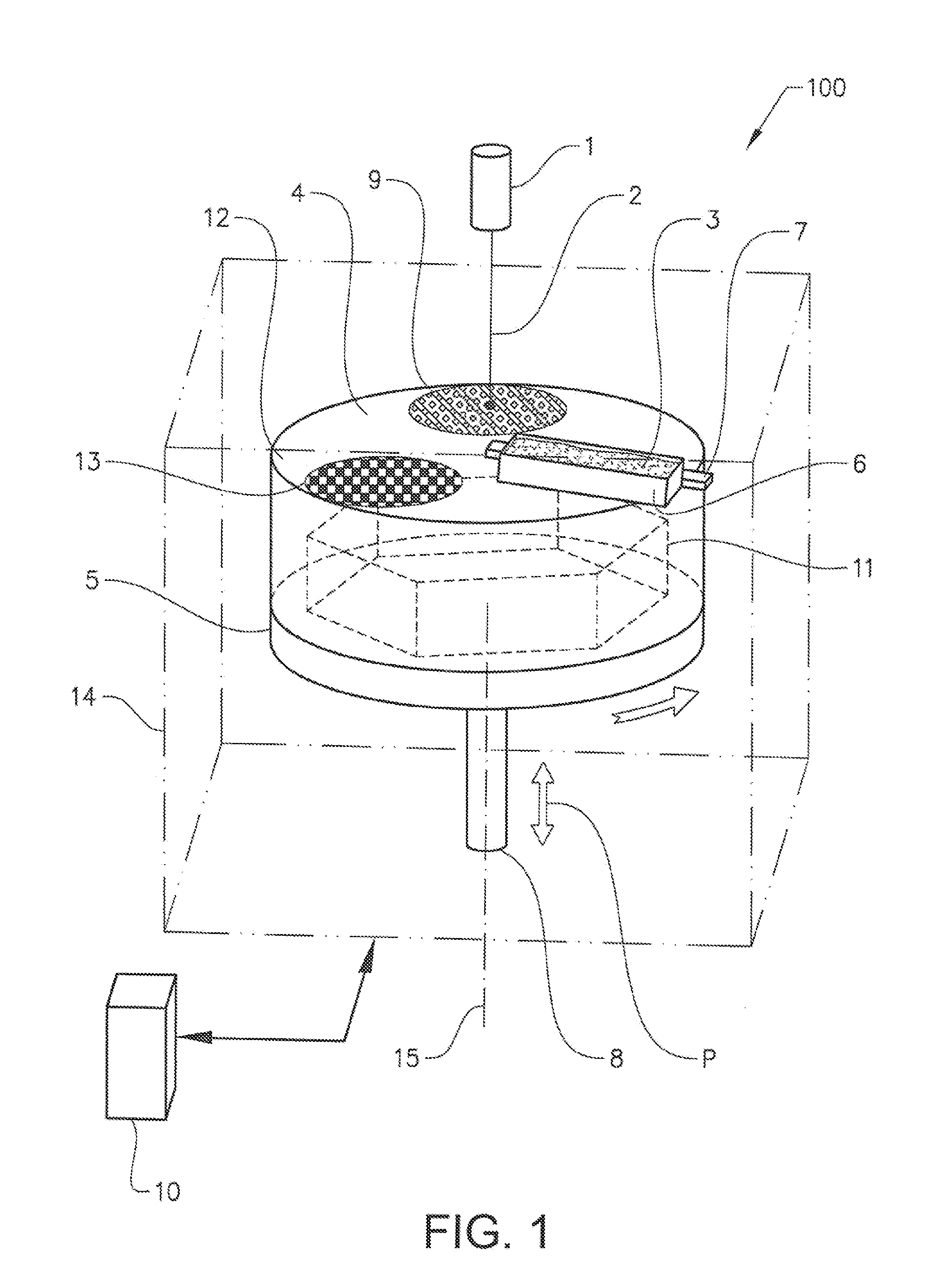

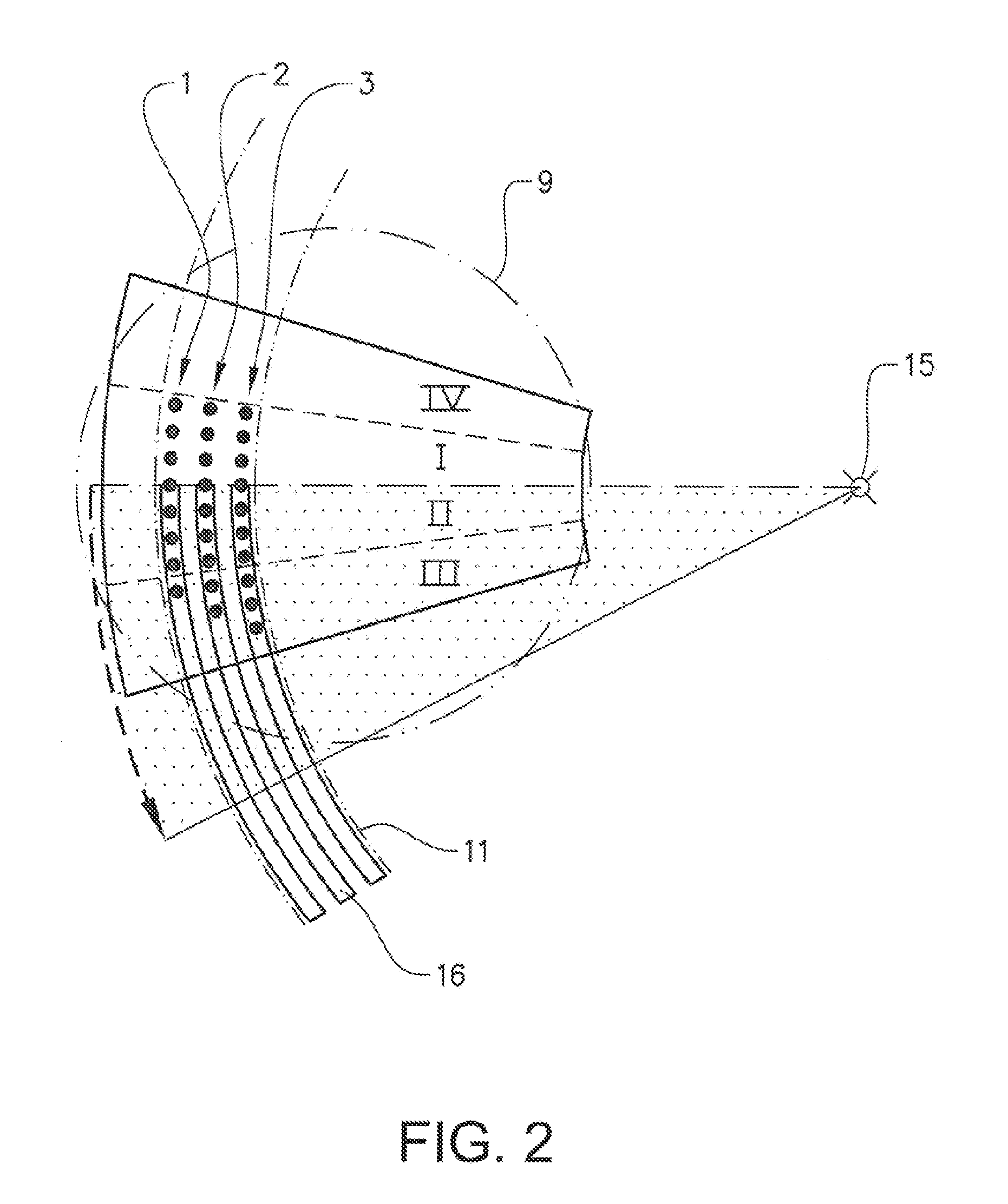

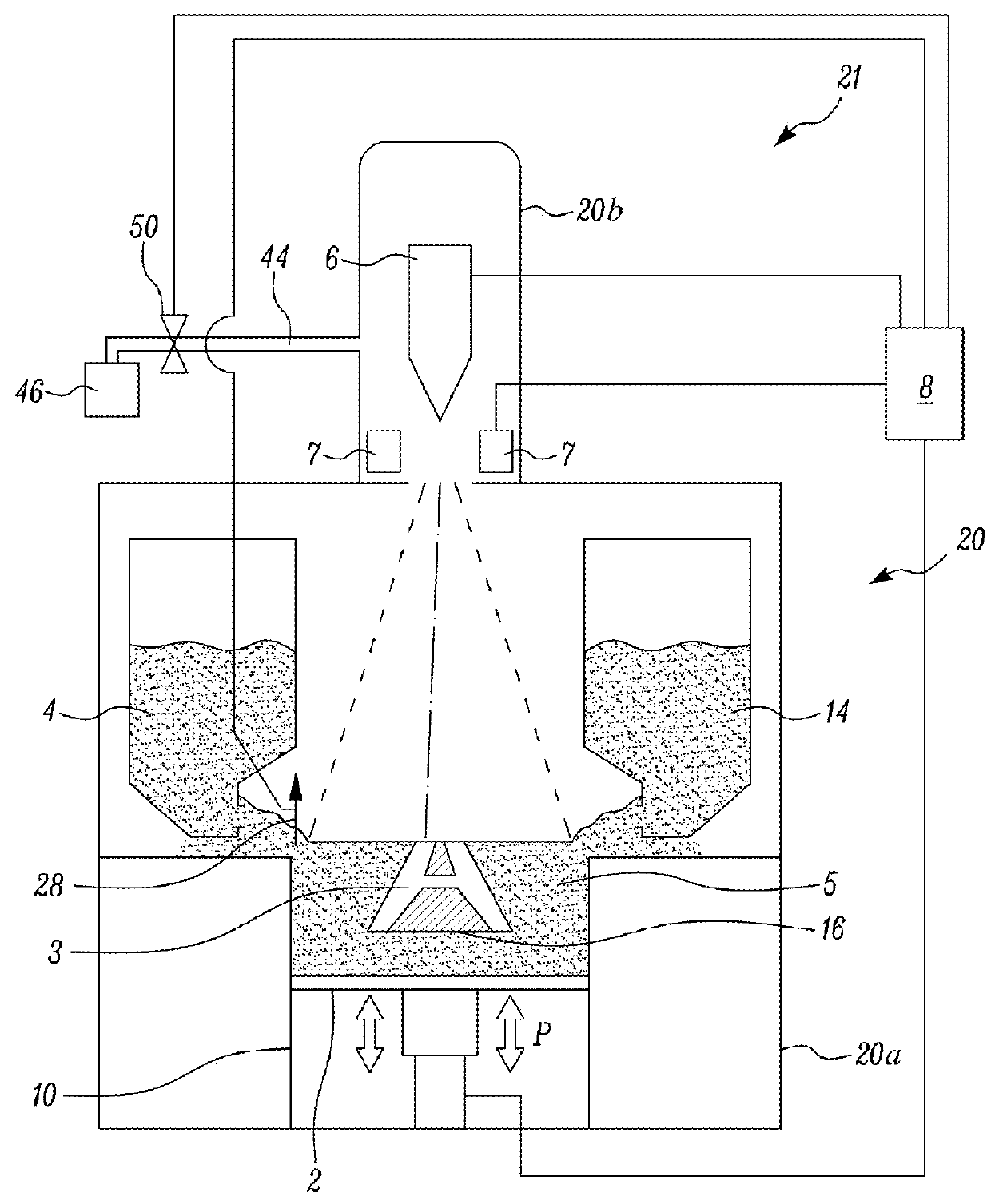

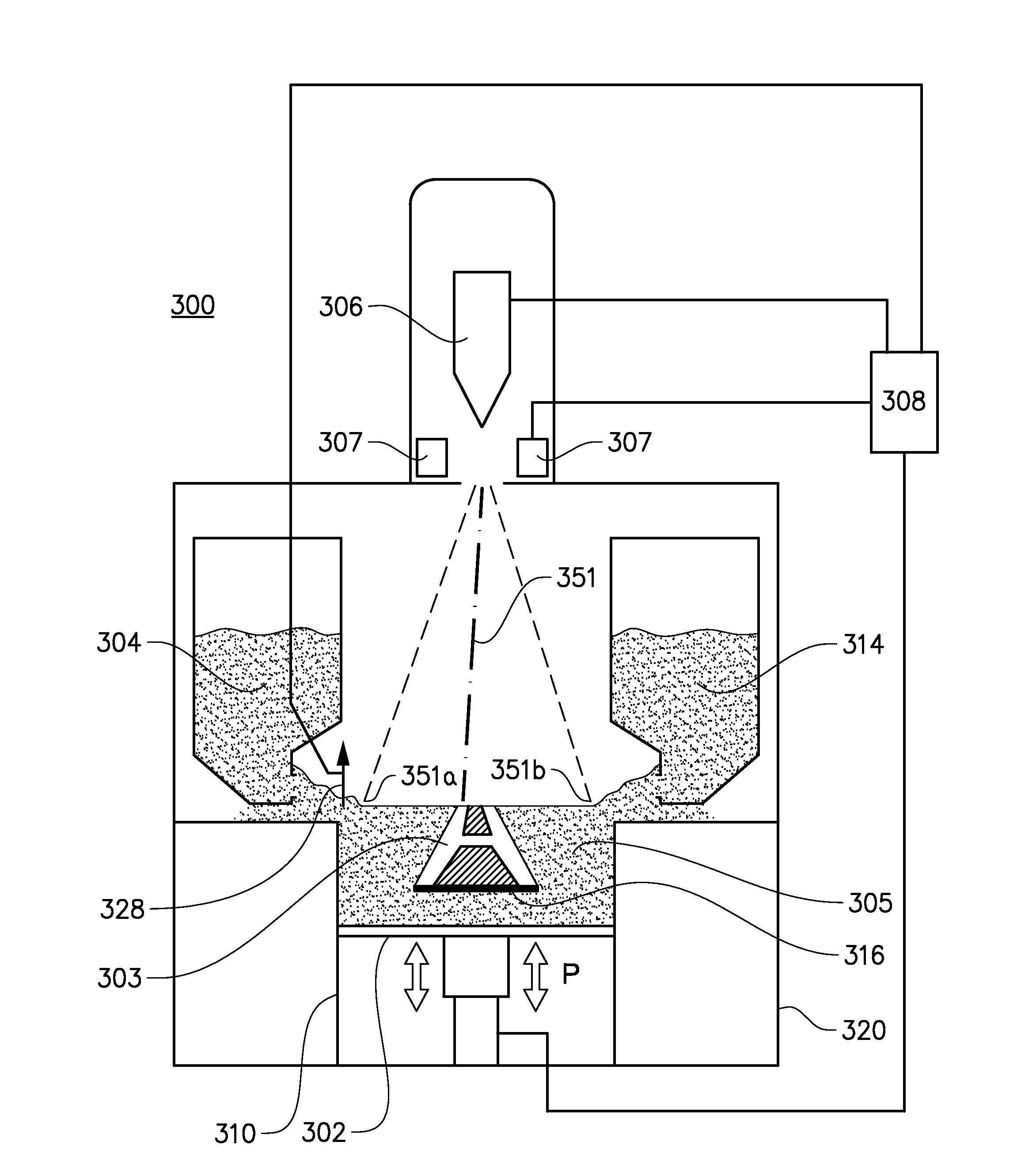

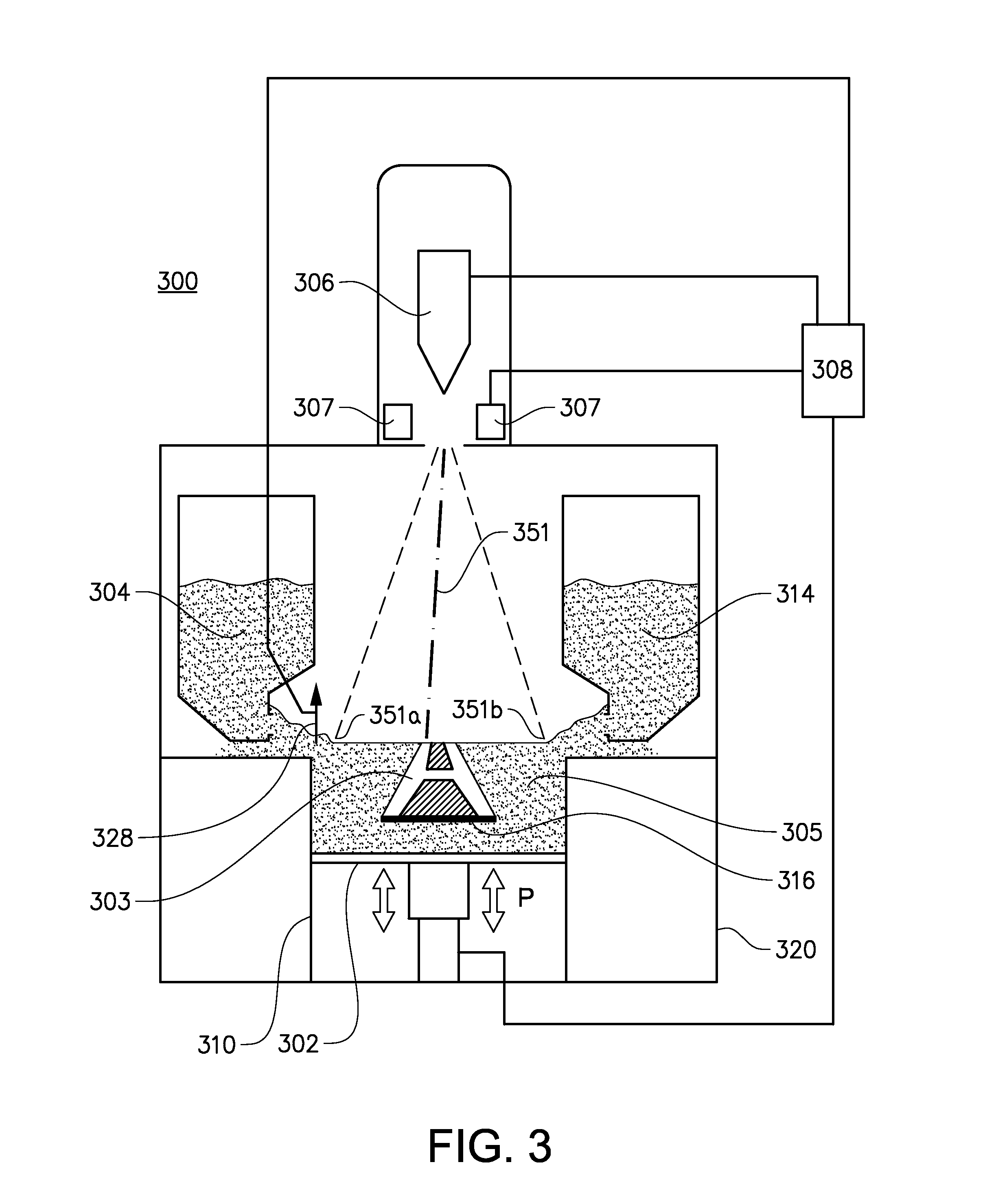

Method and apparatus for additive manufacturing

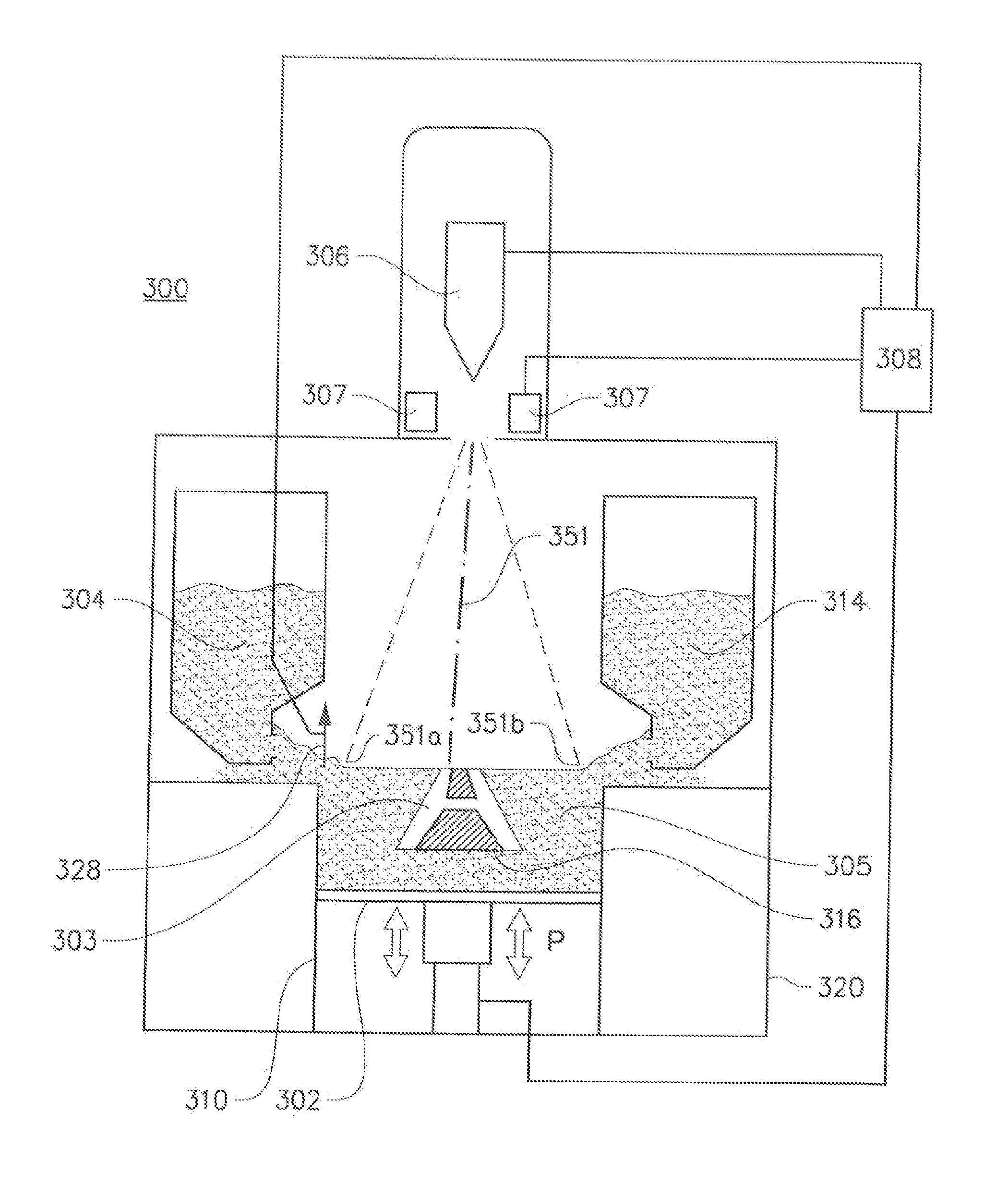

ActiveUS20140348691A1Large build volumeSacrificing qualityAdditive manufacturing apparatusAuxillary shaping apparatusBeam sourceEngineering

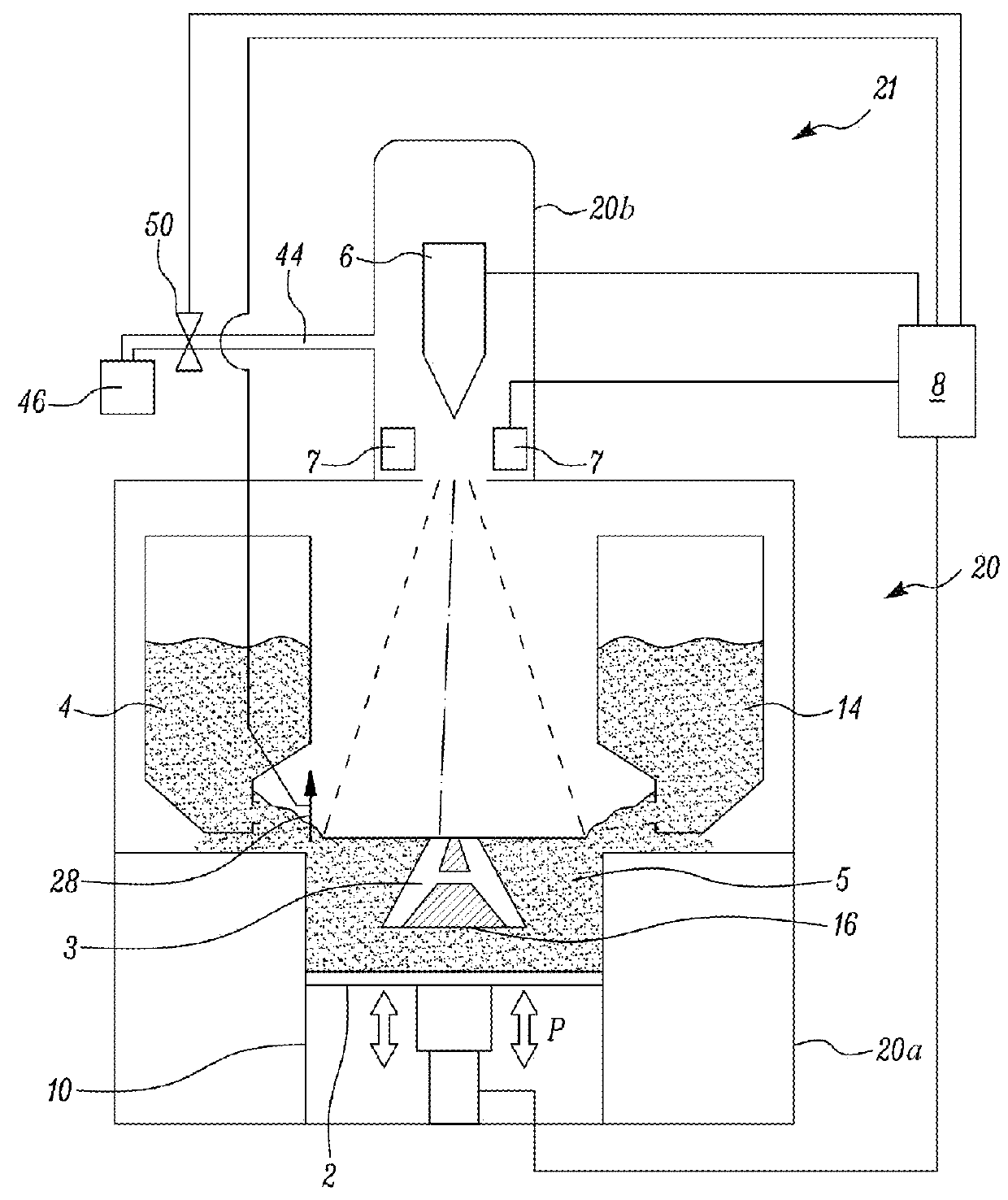

A method for forming a three-dimensional article through successive fusion of parts of a powder bed, which parts corresponds to successive cross sections of the three-dimensional article, said method comprising the steps of: providing a model of said three dimensional article, providing a first powder layer on a work table, directing a first energy beam from a first energy beam source over said work table causing said first powder layer to fuse in first selected locations according to said model to form a first cross section of said three-dimensional article, directing a second energy beam from a second energy beam source over said work table causing said first powder layer to fuse in second selected locations according to said model to form the first cross section of said three-dimensional article, wherein said first and second locations of said first powder layer are at least partially overlapping each other.

Owner:ARCAM AB

Testing apparatus using charged particles and device manufacturing method using the testing apparatus

ActiveUS7138629B2Material analysis using wave/particle radiationElectric discharge tubesIlluminanceBeam source

Owner:EBARA CORP

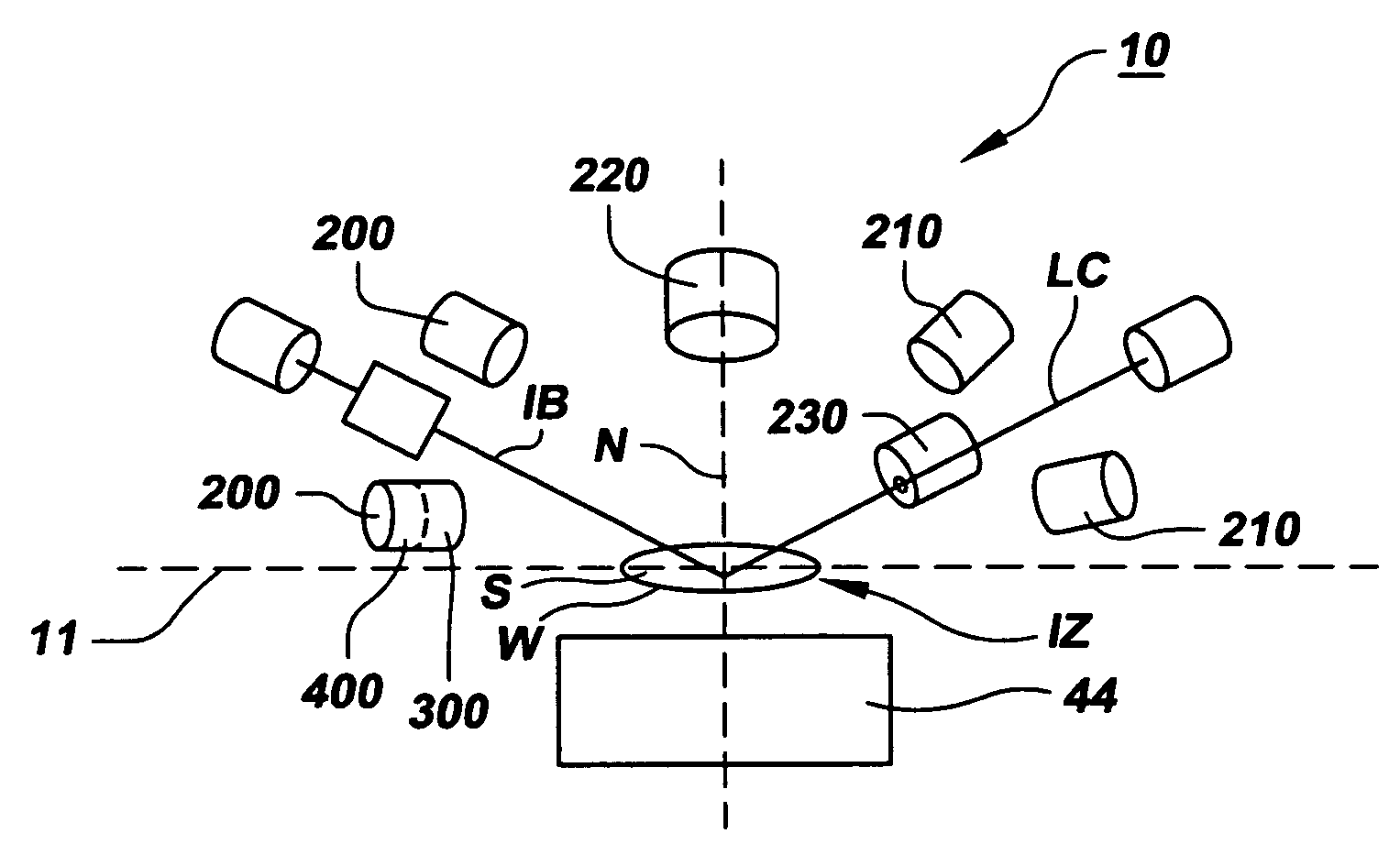

System and method for signal processing for a workpiece surface inspection system

ActiveUS20060181700A1High sensitivityImprove reliabilityImage enhancementImage analysisBeam sourceData acquisition

A surface inspection system, as well as related components and methods, are provided. The surface inspection system includes a beam source subsystem, a beam scanning subsystem, a workpiece movement subsystem, an optical collection and detection subsystem, and a processing subsystem. The signal processing subsystem comprises a series of data acquisition nodes, each dedicated to a collection detection module and a plurality of data reduction nodes, made available on a peer to peer basis to each data acquisition nodes. Improved methods for detecting signal in the presence of noise are also provided.

Owner:ADE CORPORATION

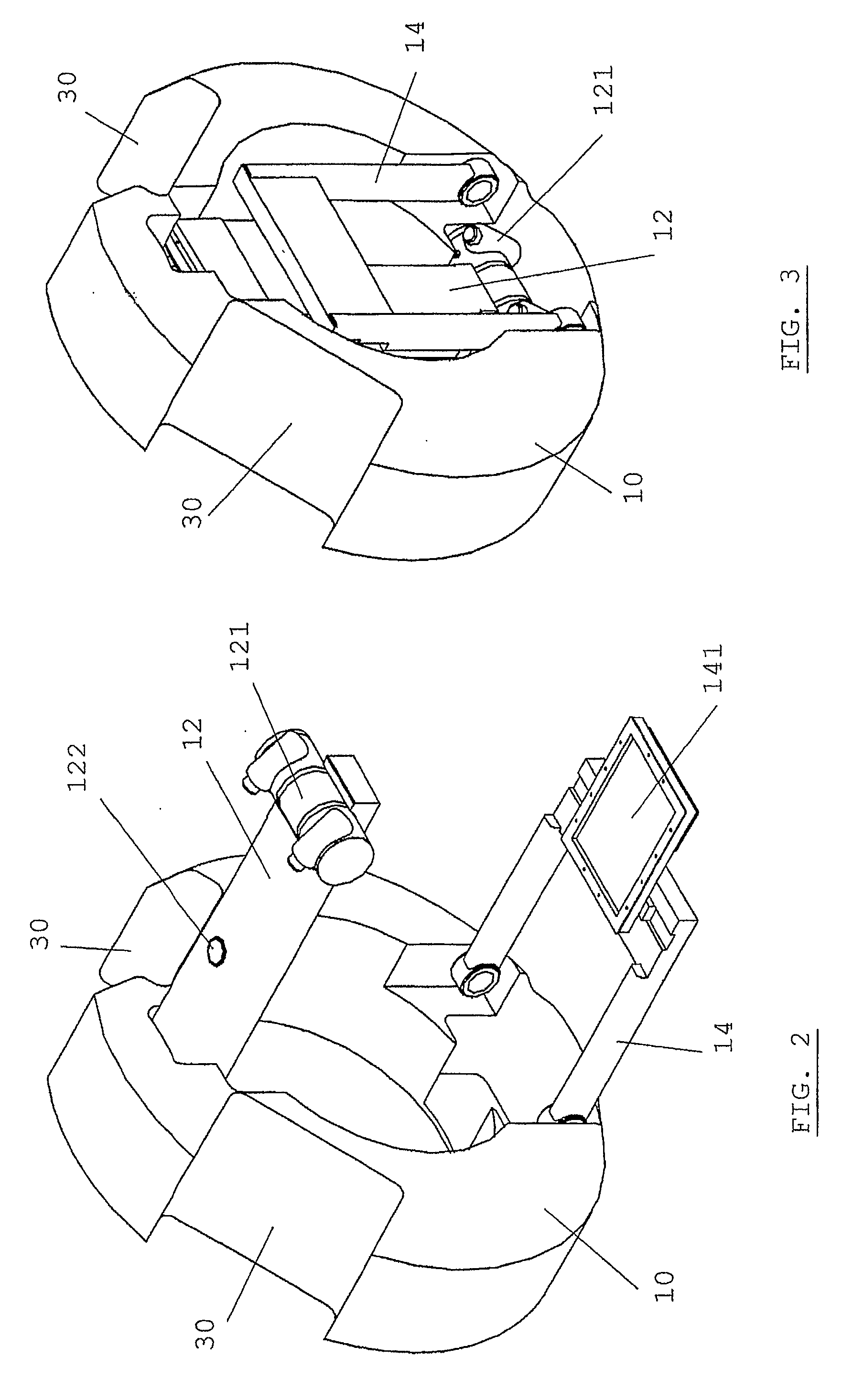

Patient positioning imaging device and method

InactiveUS20090304153A1Smooth foldingSmooth positioningMaterial analysis using wave/particle radiationRadiation/particle handlingRotational axisBeam source

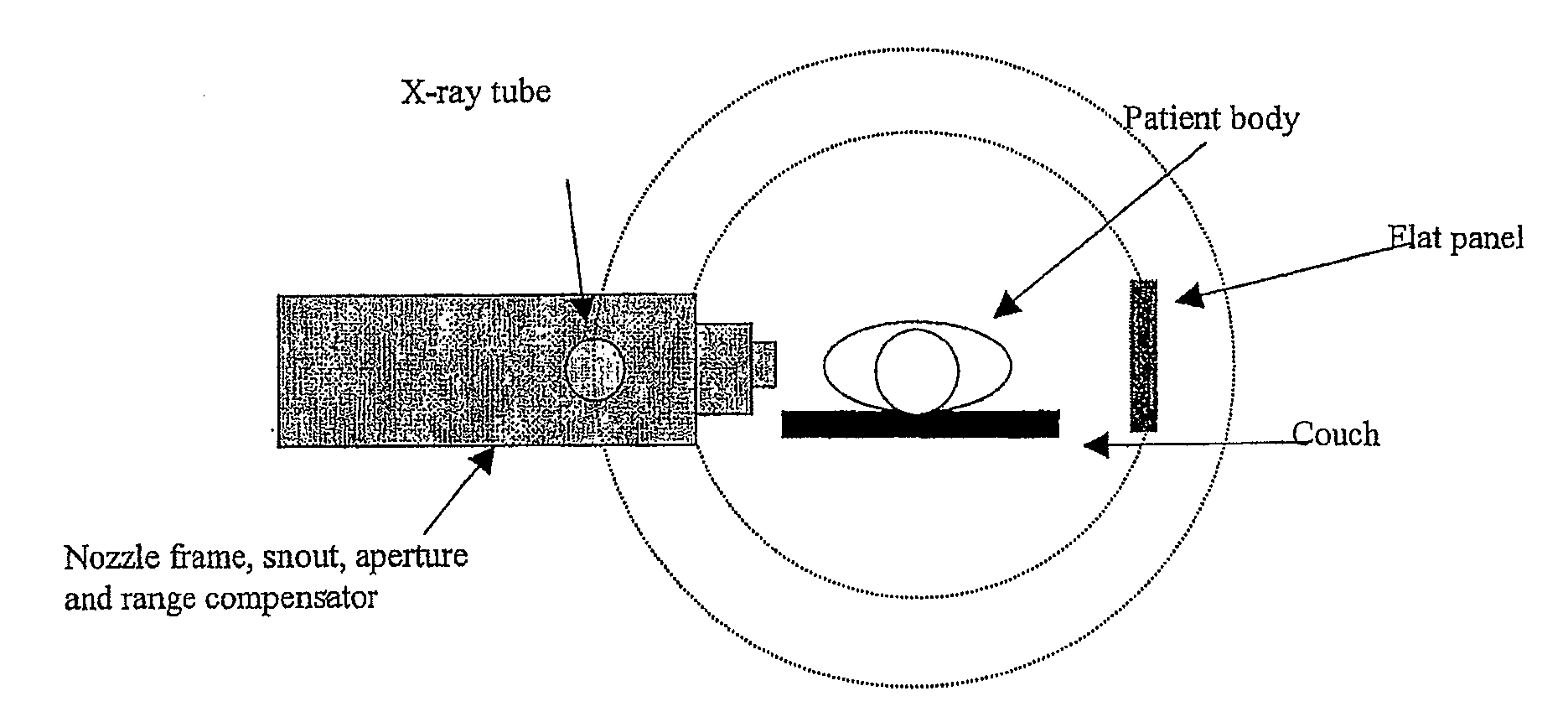

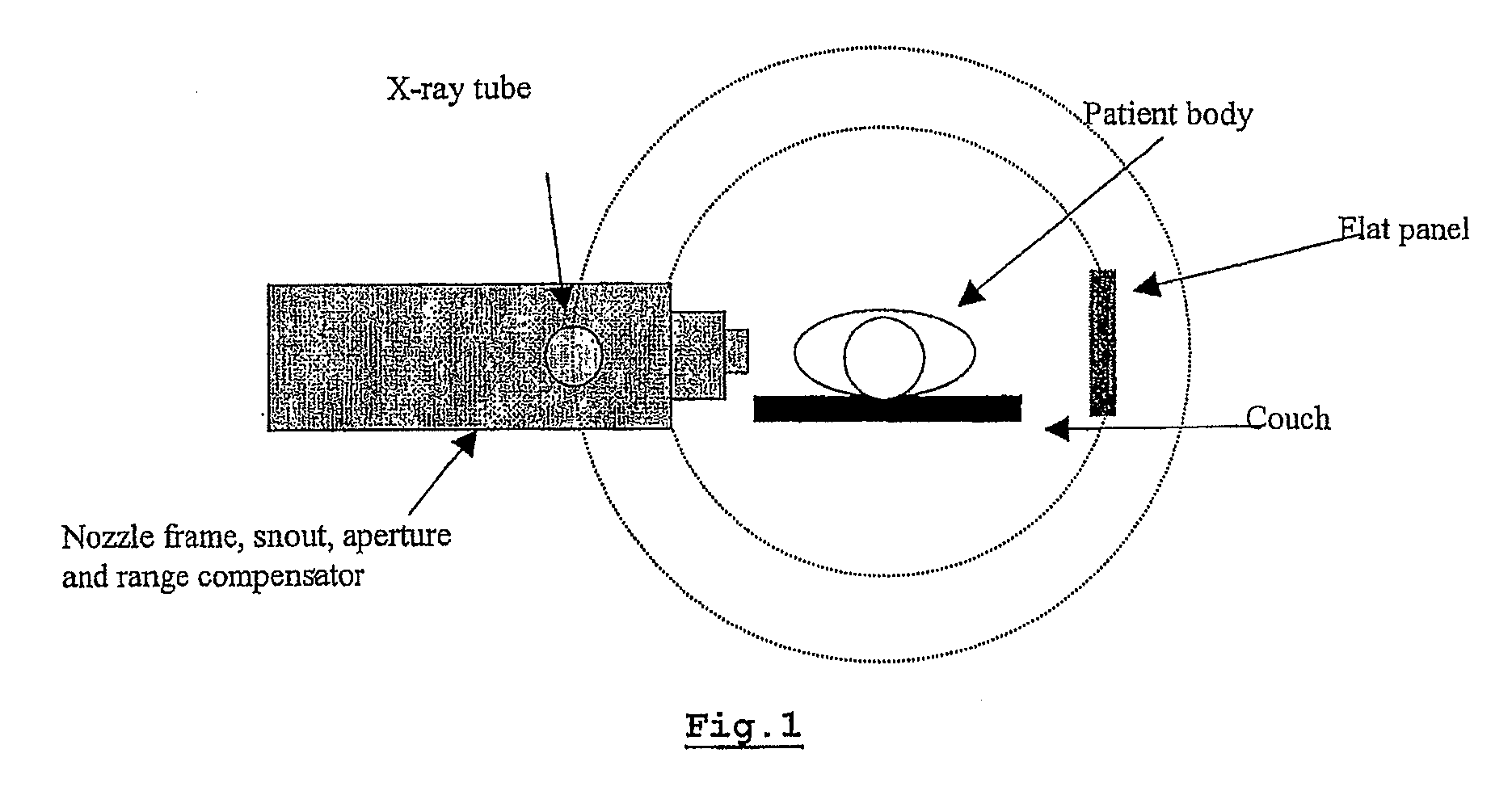

The present invention is related to a patient positioning imaging device for positioning a patient in a hadron therapy device provided with a rotatable gantry (20). The patient positioning imaging device comprises a rotatable structure (10) provided with an extensible arm or foldable pivoting arm (12) arranged for connecting an imaging beam source (121) and an extensible structure or foldable pivoting structure (14) arranged for carrying an imaging beam receiver (141). The rotatable structure (10) is arranged for taking CBCT shots of the patient while the patient is located in an offset position with respect to an isocentre of the hadron therapy device, said offset position being in the direction of a rotational axis of the rotatable gantry (20). The rotatable structure (10) is arranged for being rotated while the rotatable gantry (20) remains fixed, and while the extensible or pivoting arm (12) and the extensible or pivoting structure (14) are in extended or unfolded position.

Owner:ION BEAM APPL

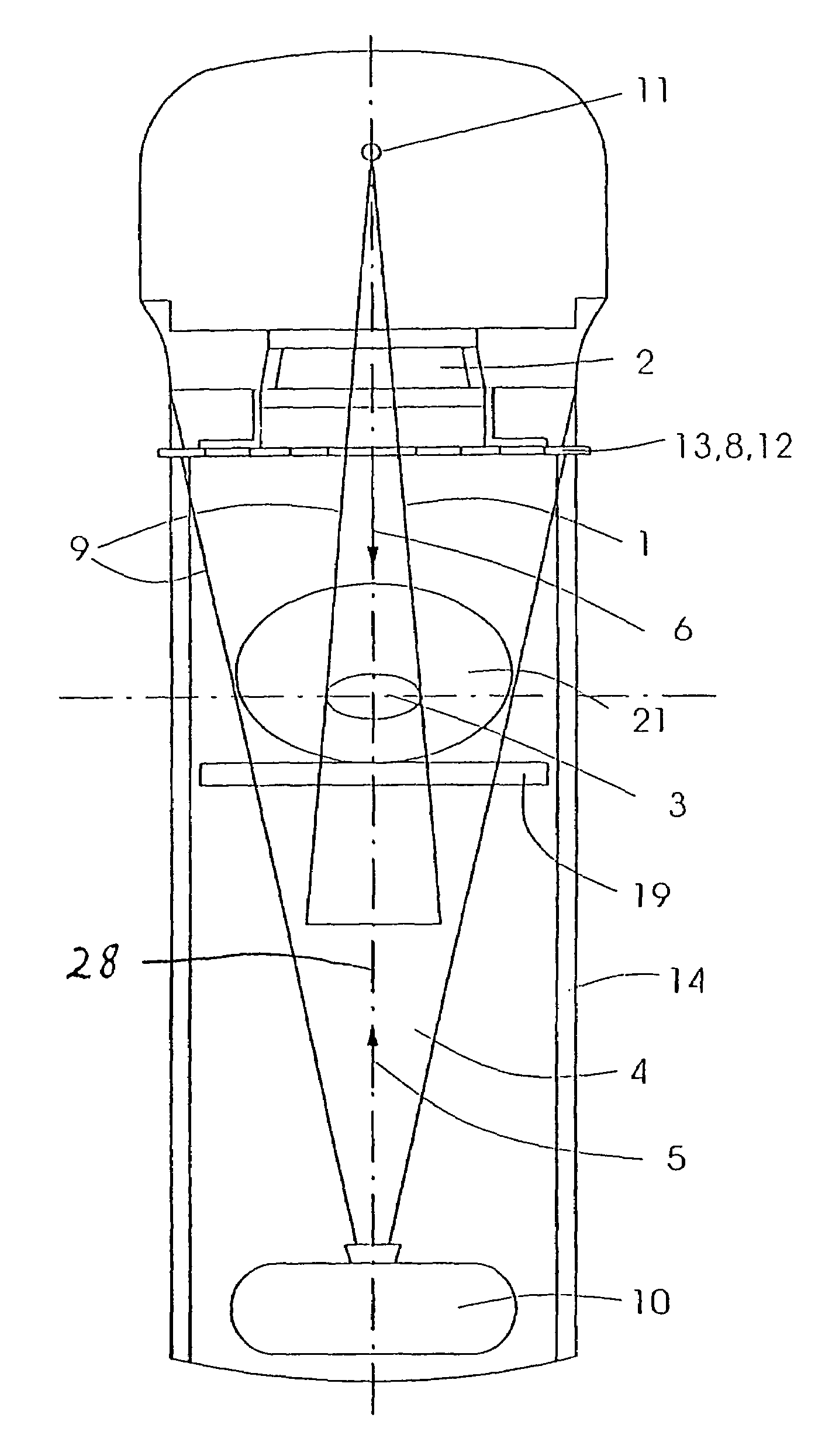

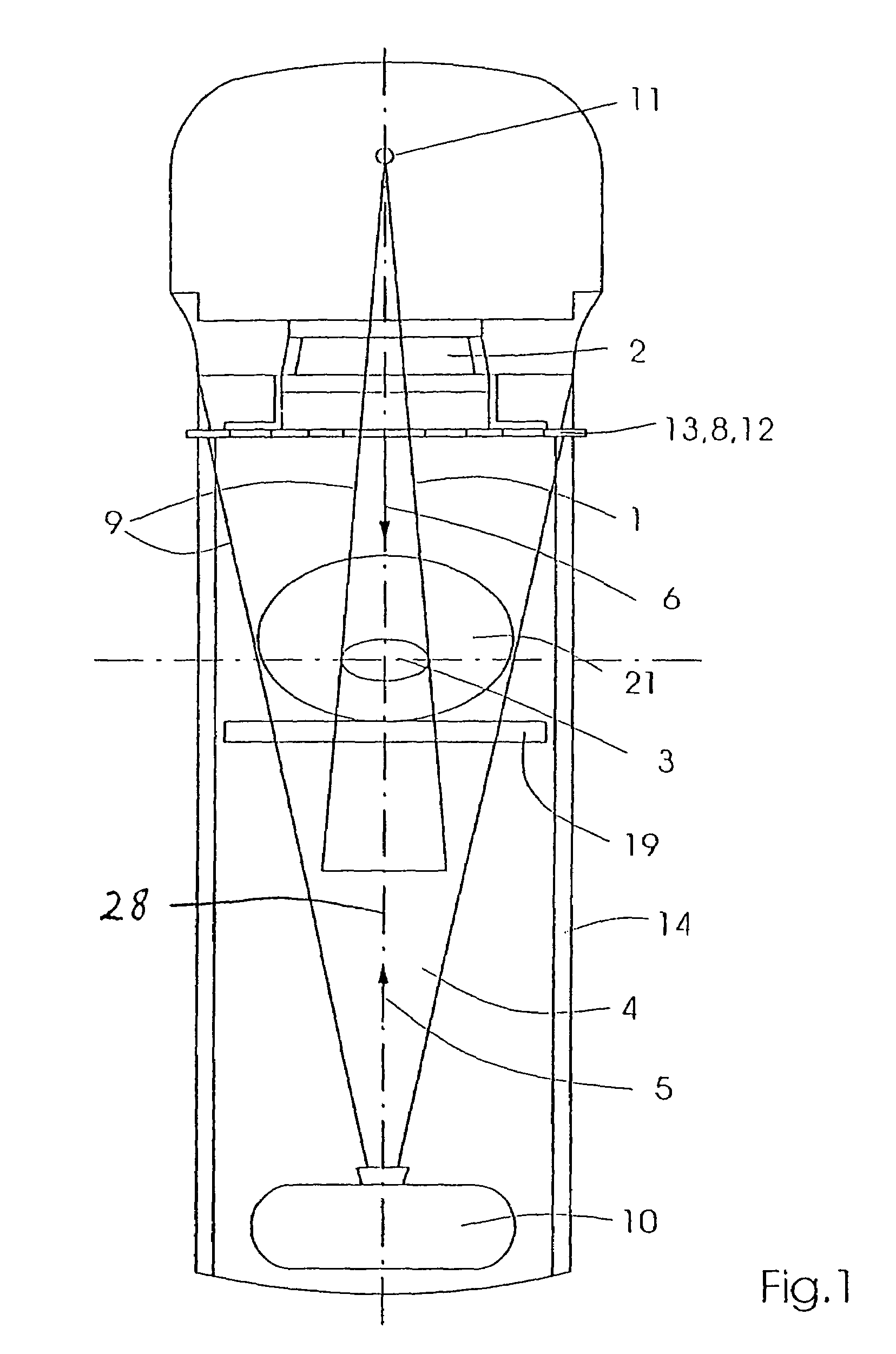

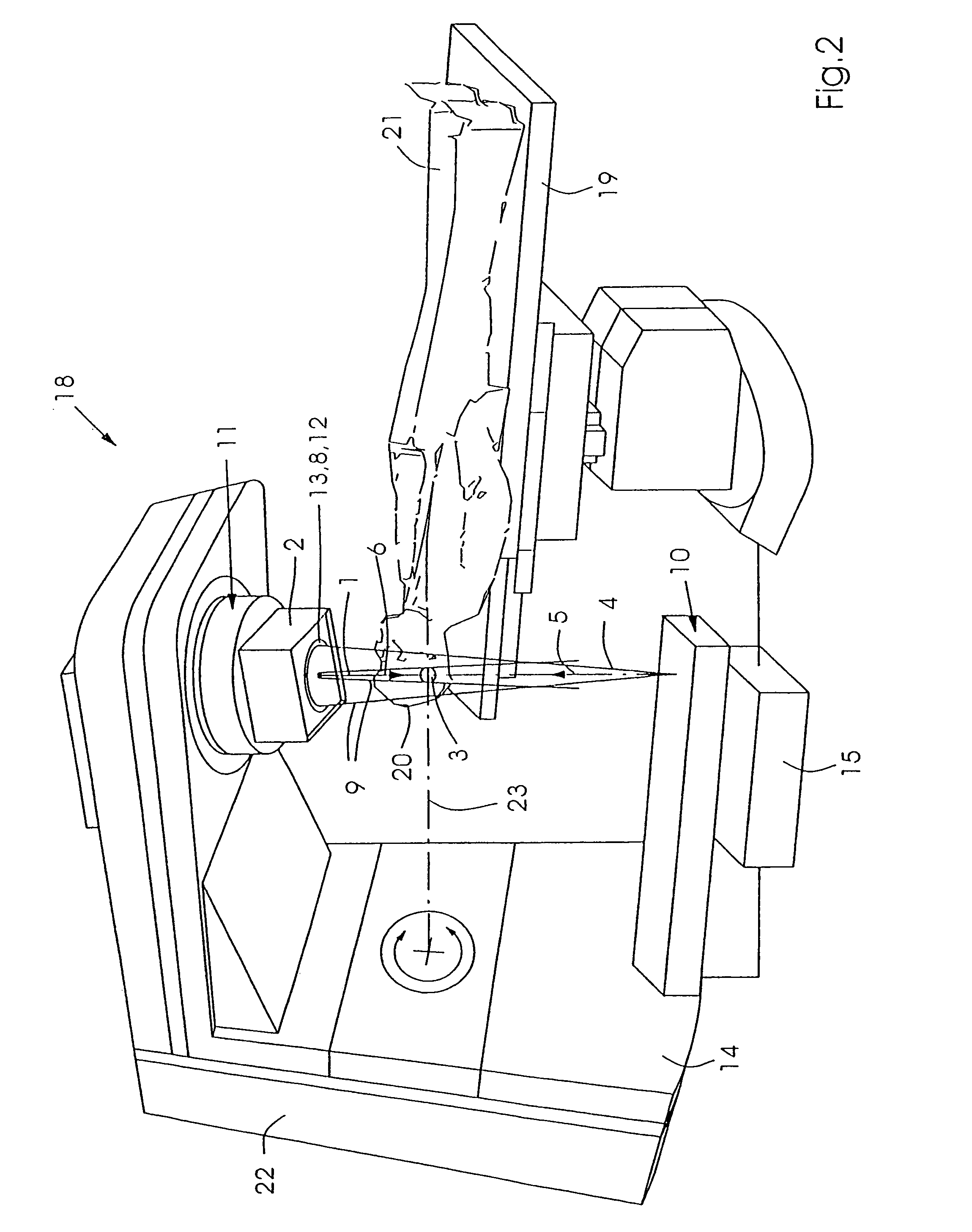

Device for performing and verifying a therapeutic treatment and corresponding computer program and control method

InactiveUS6993112B2Avoid radiationReduce in quantityIrradiation devicesX-ray/gamma-ray/particle-irradiation therapyBeam sourceTherapeutic treatment

The invention relates to a device for performing and verifying therapeutic radiation. An x-ray beam (4) is arranged across from a target volume (3) of the beam source (11) for the high-energy beam (1) in such a way that the beams (1, 4) run in essentially opposite directions (5, 6). The invention also relates to a computer program and a control method for operating said device. The inventive device makes it possible to exactly verify areas (16, 16′, 16″) that are subjected to different levels of radiation, the entire anatomy of the target volume (3), and the surroundings thereof in addition to the contour of the therapy beam (1). The x-ray beam (4) detects the anatomy and position of the patient (21) within the range of the target volume (3) before the high-energy beam (1) is applied and the shape of the applied high-energy beam (1) is then detected and areas (16, 16′, 16″) that are subjected to different levels of radiation as well as at least one partial segment of the target volume (3) during the emission breaks of the high-energy beam (1). The detected data is used for correcting the treatment plan.

Owner:DEUTES KREBSFORSCHUNGSZENT STIFTUNG DES OFFENTLICHEN RECHTS

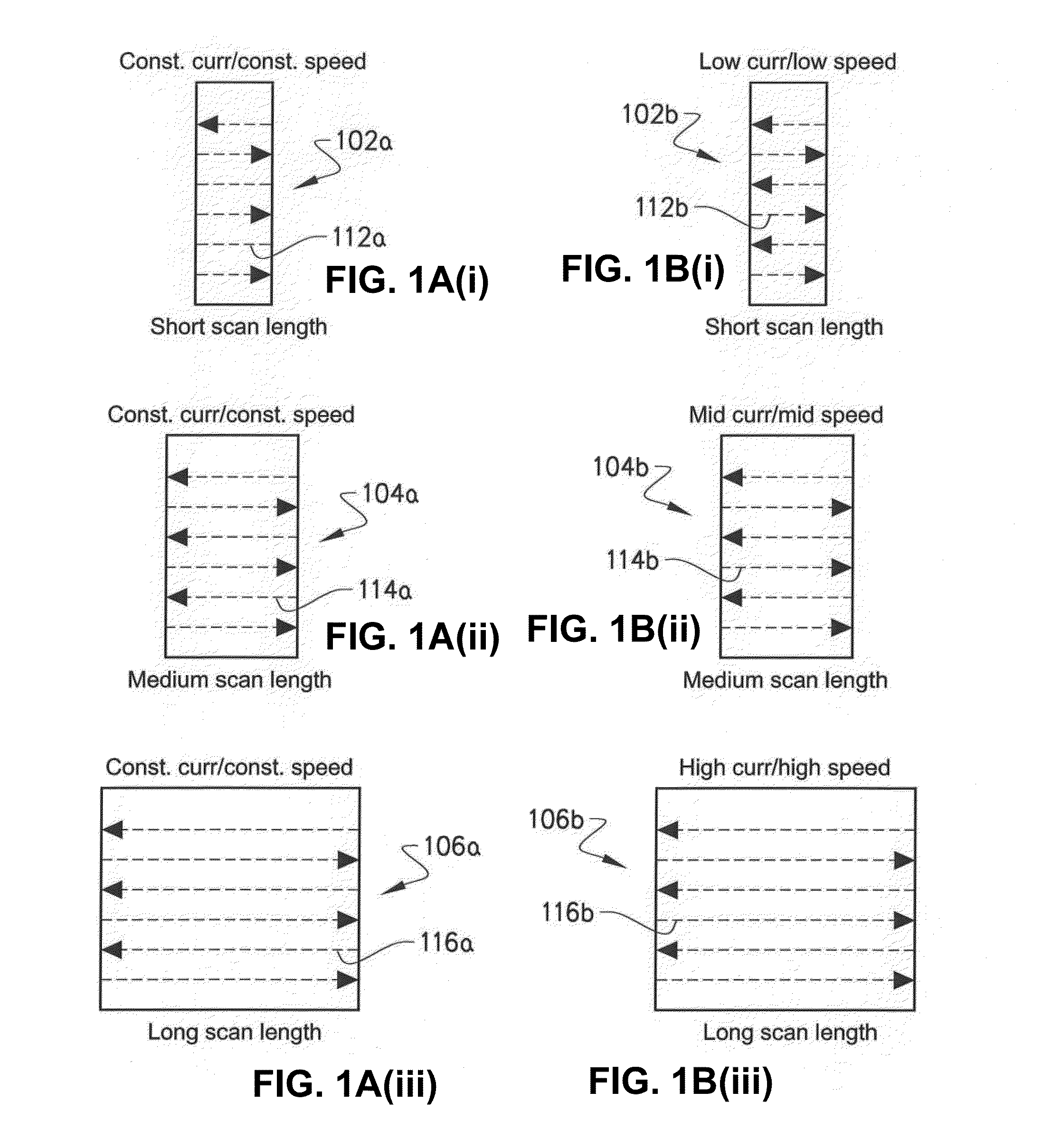

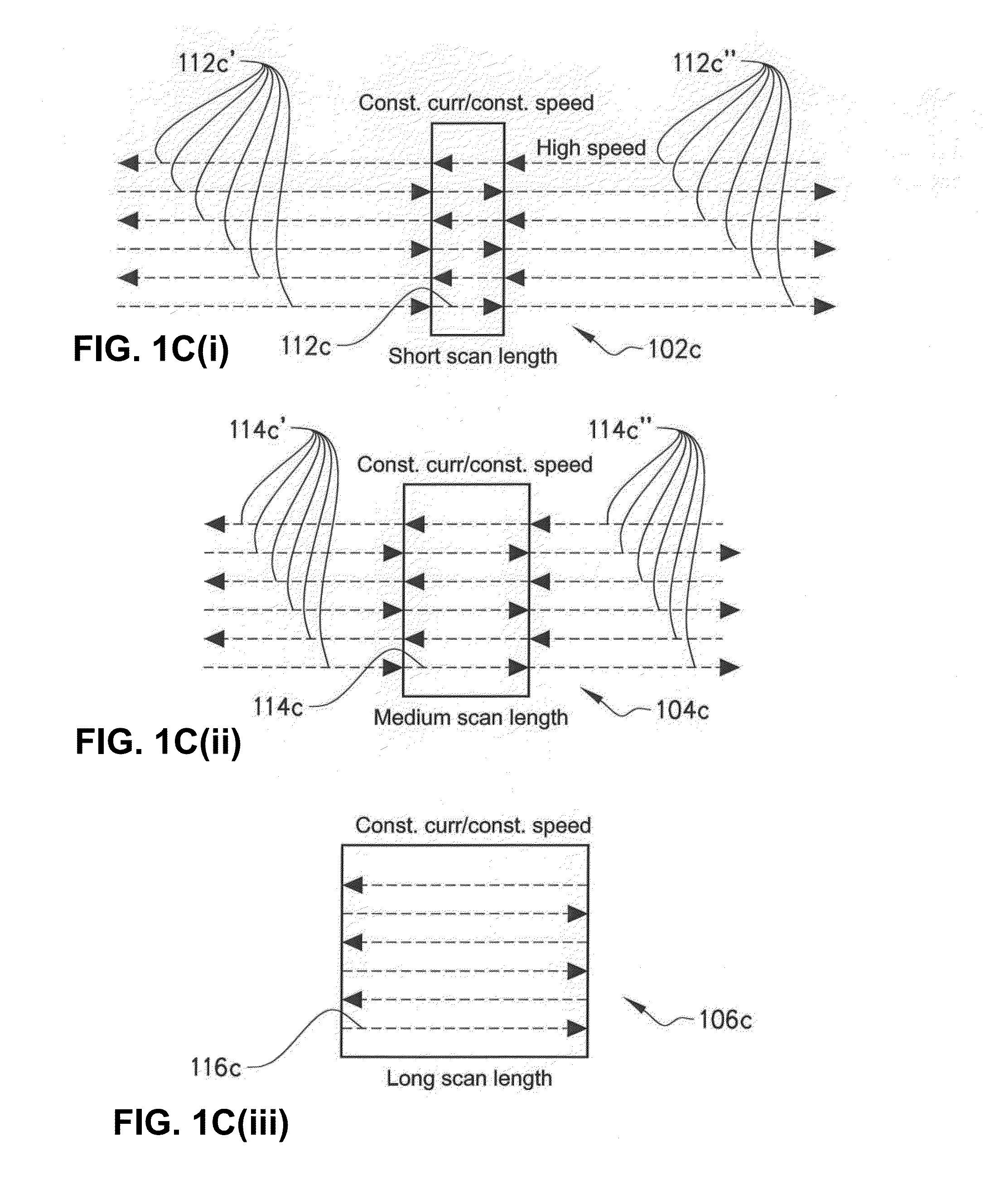

Method for additive manufacturing

ActiveUS20150174695A1Easy to controlImprove ductilityAdditive manufacturing apparatusIncreasing energy efficiencyScan lineBeam source

The invention relates to a method for forming a three-dimensional article through successive fusion of locations of a powder bed. The method comprising: providing a model of said three-dimensional article; applying a powder layer on a work table; determining a maximum scan length of an energy beam; directing said energy beam from a first energy beam source over said work table with constant energy causing said first powder layer to fuse in first selected locations according to said model to form a first cross section of said three-dimensional article, wherein locations with a shorter scan length than said maximum scan length is provided with a time sink before and / or after said scan line so that the time period between each two adjacent scan lines is constant throughout the manufacture of said three-dimensional article.

Owner:ARCAM AB

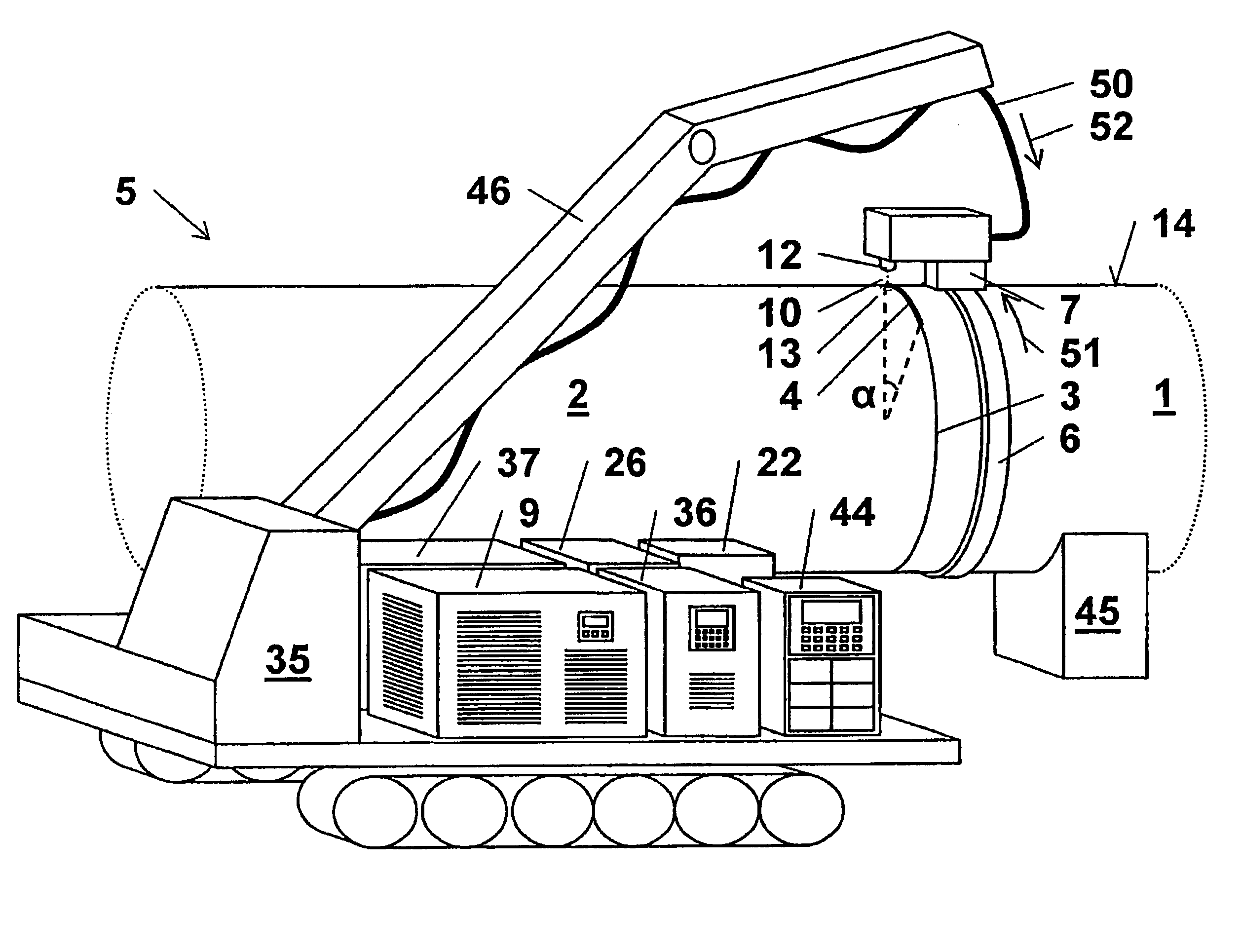

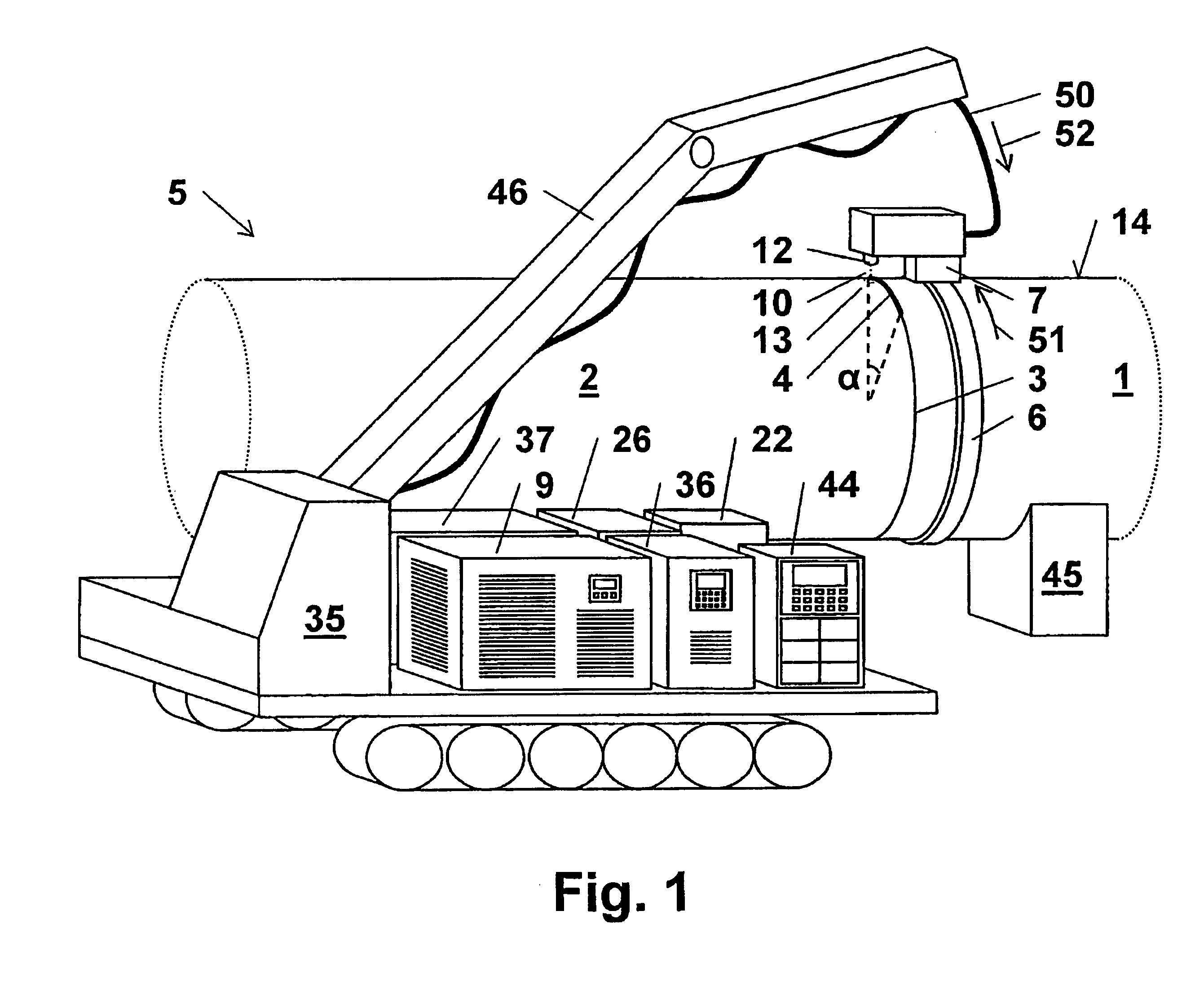

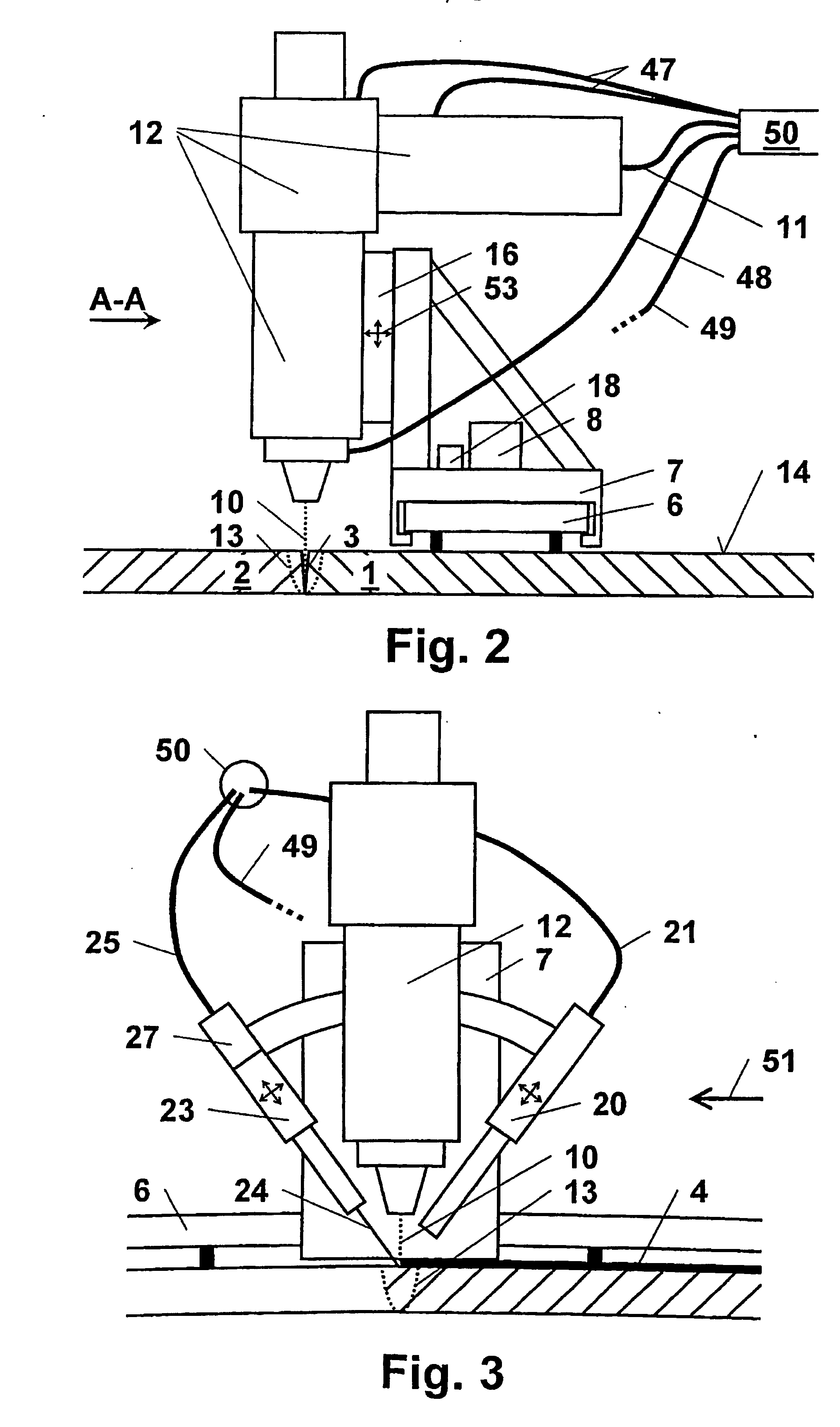

Orbital welding device for pipeline construction

InactiveUS20070119829A1Increase production speedArc welding apparatusLaser beam welding apparatusLight guideBeam source

The invention relates to an orbital welding device for mobile use in order to join a first pipe (1) and a second pipe end (2) along a circumferential joint (3) by at least one weld seam (4), particularly for producing a pipeline (5) to be placed on land. The inventive device includes a guide ring (6), which can be oriented toward the first pipe end (1) and the circumferential joint (3), and an orbital carriage (7) that can be motor-displaced along the guide ring (6) via an advancing device (8). On the orbital carriage (7), a laser welding head (12) for directing a laser beam (10) into a laser welding zone (13) is mounted in a manner that enables it to be oriented toward the circumferential joint (3) whereby enabling the production of the weld seam (4) along the circumferential joint (3) by displacing the orbital carriage (7). The laser beam (10) is produced by a high-power fiber laser beam source (9) located, in particular, on a mobile transport vehicle (35) while being situated at a distance from the orbital carriage (7), is guided by light guide (11) passing through a tube bundle (50) to the orbital carriage (7) and then supplied to the welding head (12). A significant advantage of the invention resides in the fact that the joining of two pipe ends by only one single welding process during a short period of time is made possible in the field with autonomous operation.

Owner:VIETZ

Method for additive manufacturing

ActiveUS20150088295A1Reduce and eliminate effectShorten production timeProgramme controlAdditive manufacturing apparatusBeam sourceScan line

A method for forming a three-dimensional article through successive fusion of parts of a powder bed, applying a first powder layer on a work table, directing a first energy beam from a first energy beam source over said work table causing said first powder layer to fuse in first selected locations according to a corresponding model to form a first cross section of said at least one three-dimensional article, where said first energy beam is fusing a first article with parallel scan lines in a first direction, fusing a second scan line in said first direction in said first layer in said first article within a predetermined time interval after fusing a first scan line in said first article, wherein at least one intermediate scan line is fused within said time interval at another predetermined position and where said first and second scan lines are adjacent to each other.

Owner:ARCAM AB

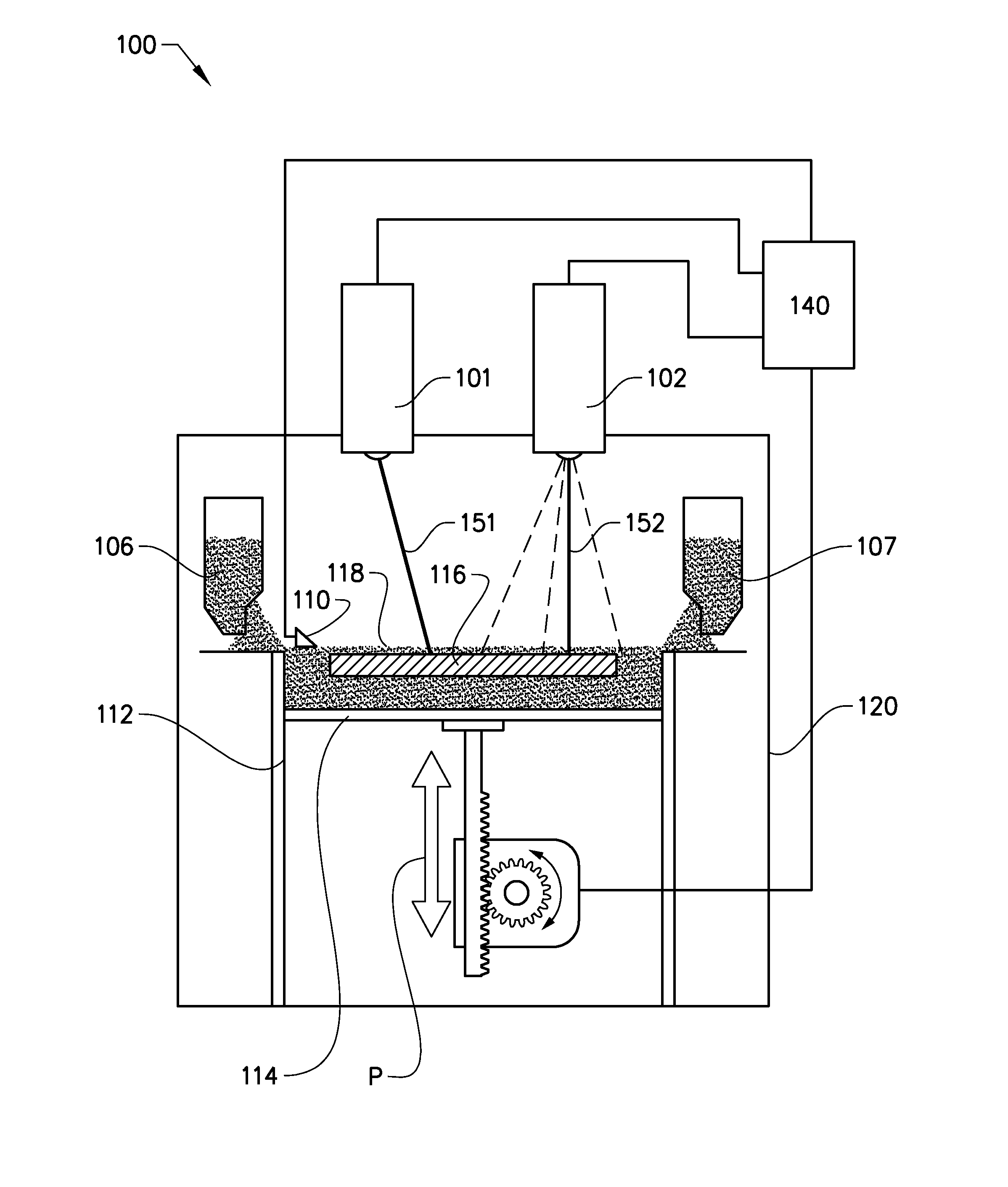

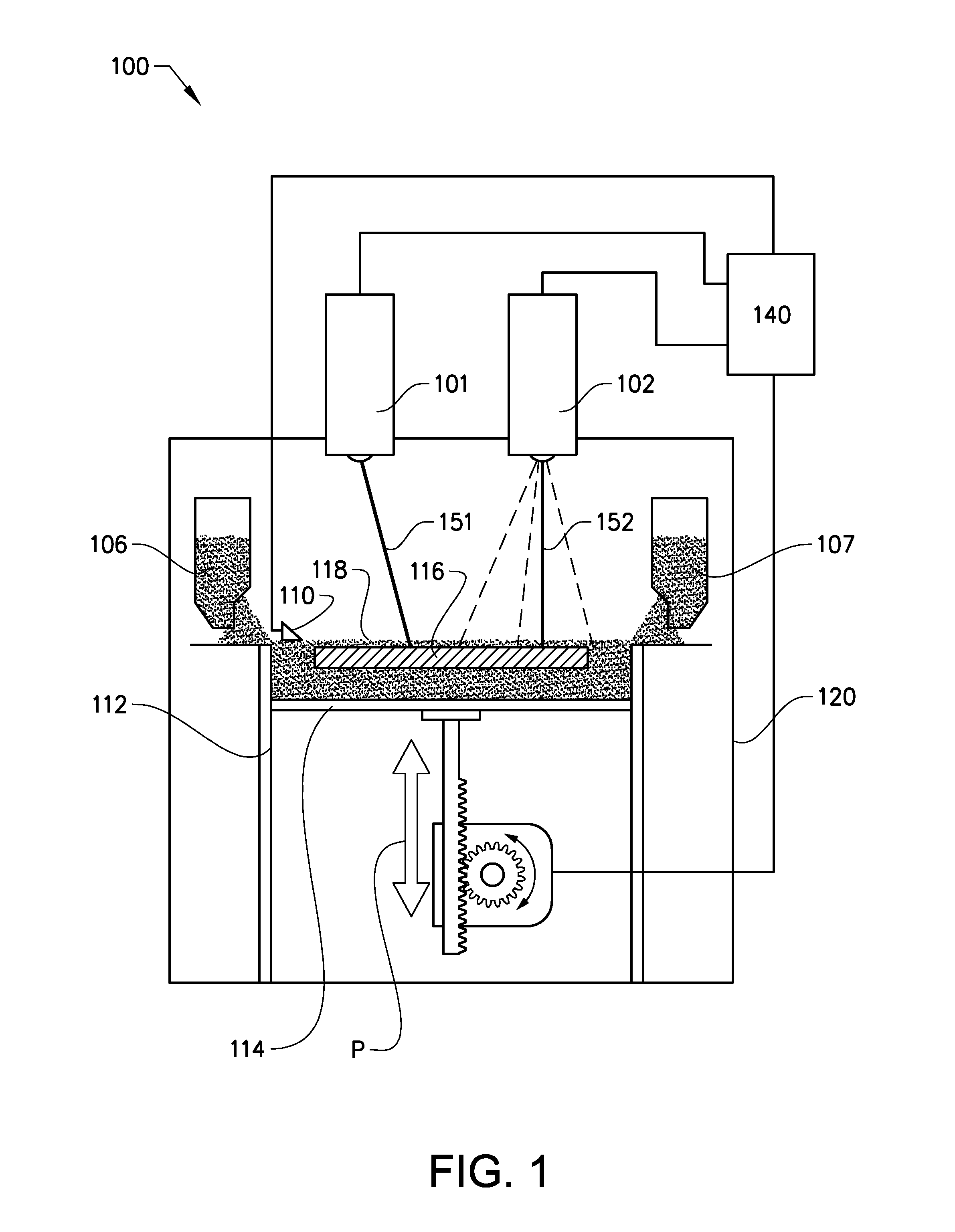

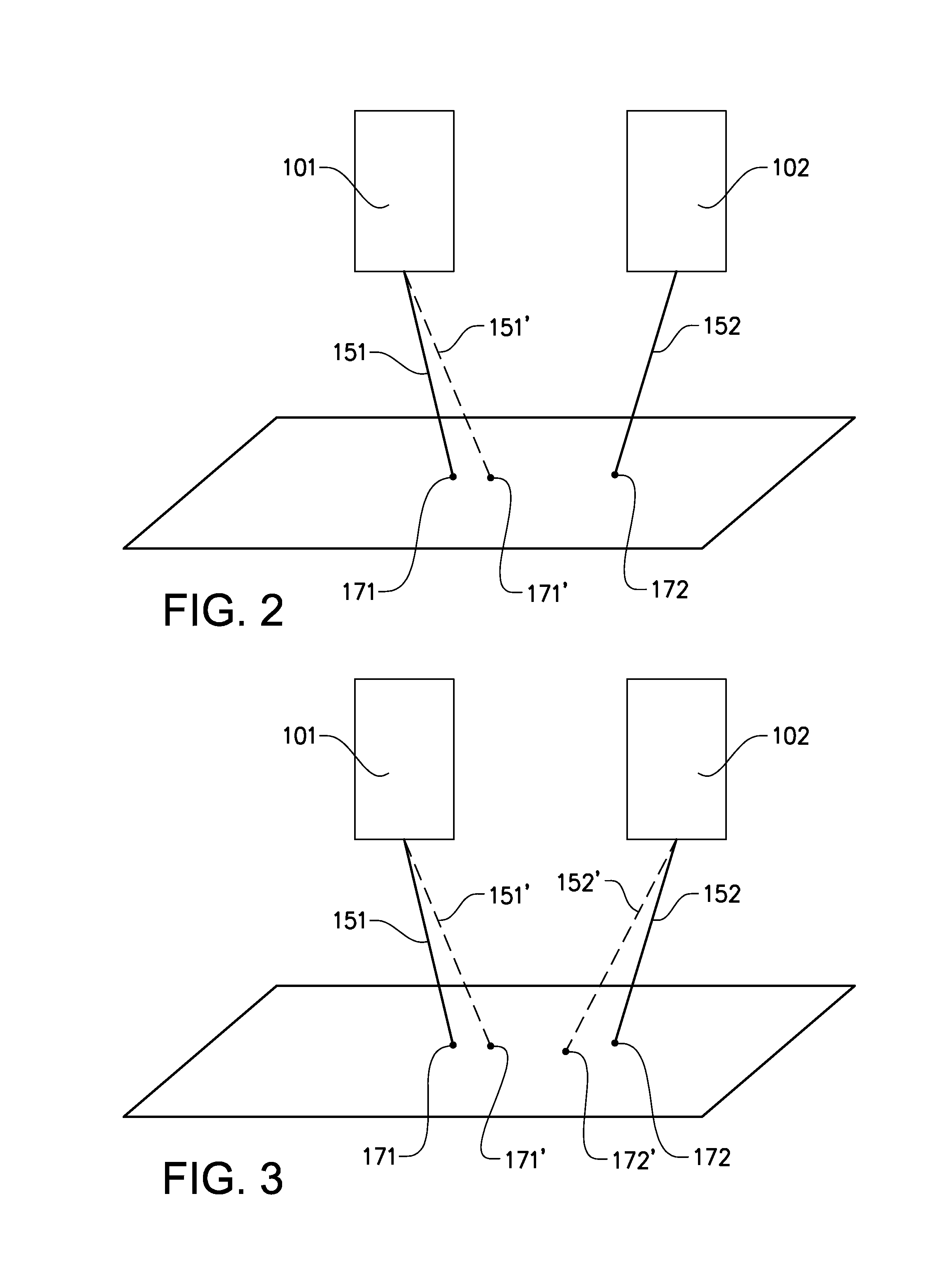

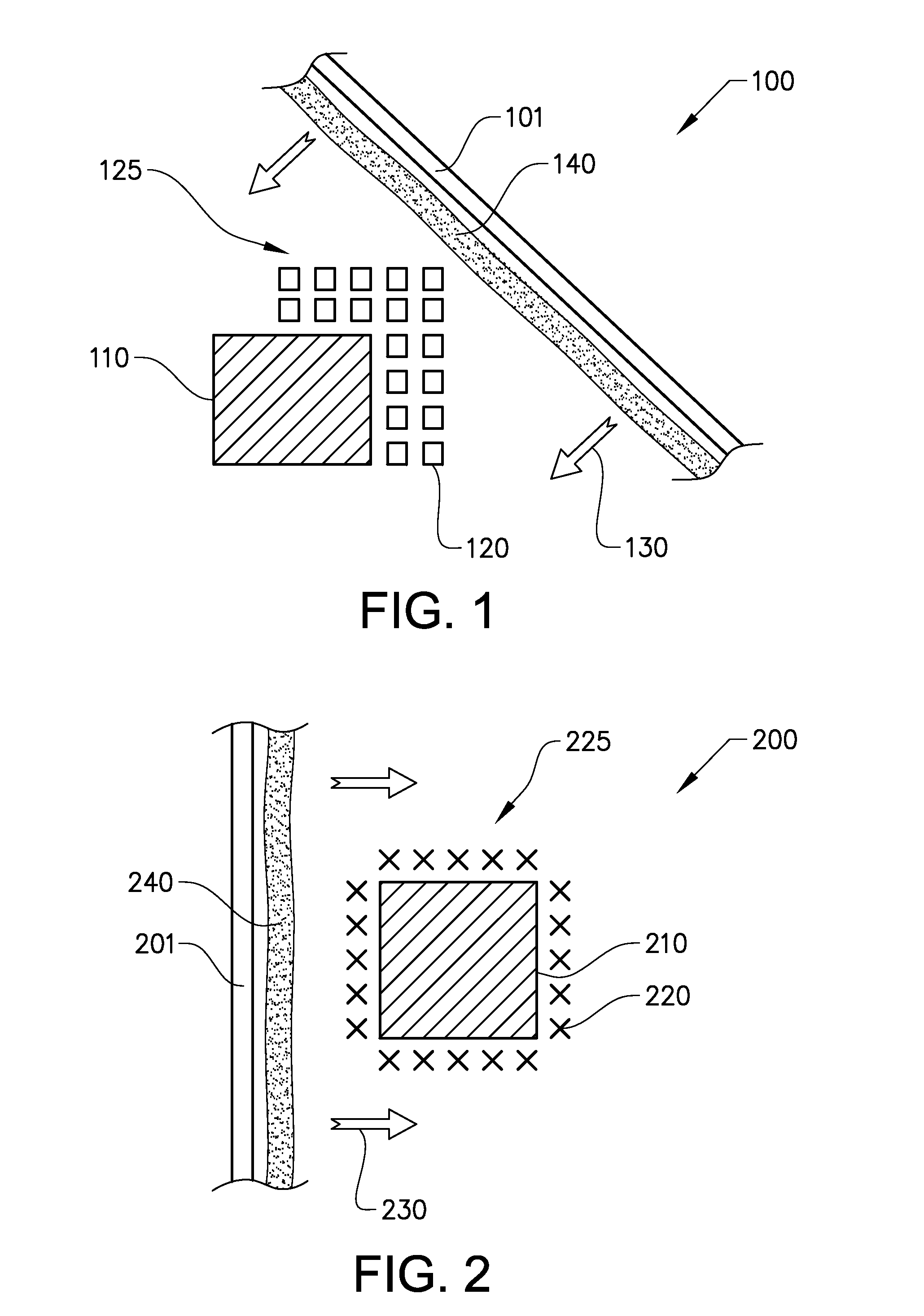

Method and apparatus for additive manufacturing

ActiveUS20150004045A1Promote resultsPrecise positioningAdditive manufacturing apparatusIncreasing energy efficiencyBeam sourceElectron

A method for forming a three-dimensional article comprising the steps of: applying a model of the three dimensional article, applying a first powder layer on a work table, directing a first electron beam from a first electron beam source over the work table causing the first powder layer to fuse in first selected locations according to the model to form a first cross section of the three-dimensional article, directing a second electron beam from a second electron beam source over the work table, registering at least one setting of the first electron beam source, registering at least one setting of the second electron beam source, correcting the position of the second electron beam depending on the at least one setting of the first electron beam source and the at least one setting of the second electron beam source.

Owner:ARCAM AB

Slicing method

InactiveUS20160167303A1Increase the lengthSynchronization is simpleManufacturing platforms/substratesArc welding apparatusRotational axisBeam source

A method for forming at least one three-dimensional article through successive fusion of parts of a powder bed, which parts correspond to successive portions of the three-dimensional article, said method comprising the steps of: providing at least one model of said three-dimensional article, wherein said model of said three-dimensional article is described in a 2-dimensional angular coordinate system; applying a powder layer on a support structure; directing at least one energy beam from at least one energy beam source over said powder layer causing said powder layer to fuse in first selected locations according to said model to form a first portion of said three-dimensional article, providing a first portion of said powder layer simultaneous as fusing a second portion of said powder layer, wherein said second portion of the powder layer is fused along a line perpendicular to a rotational axis of said support structure.

Owner:ARCAM AB

Method for additive manufacturing of three-dimensional articles

ActiveUS20150251249A1Line lengthAdditive manufacturing apparatusAuxillary shaping apparatusScan lineBeam source

A method for forming at least one three-dimensional article through successive fusion of parts of a powder bed, which parts correspond to successive cross sections of the three-dimensional article, the method comprising the steps of: providing a model of the at least one three-dimensional article; applying a first powder layer on a work table; directing a first energy beam from a first energy beam source over the work table causing the first powder layer to fuse in first selected locations according to corresponding models to form a first cross section of the three-dimensional article, where the first energy beam is fusing at least a first region of a first cross section with parallel scan lines in a first direction; varying a distance between two adjacent scan lines, which are used for fusing the powder layer, as a function of a mean length of the two adjacent scan lines.

Owner:ARCAM AB

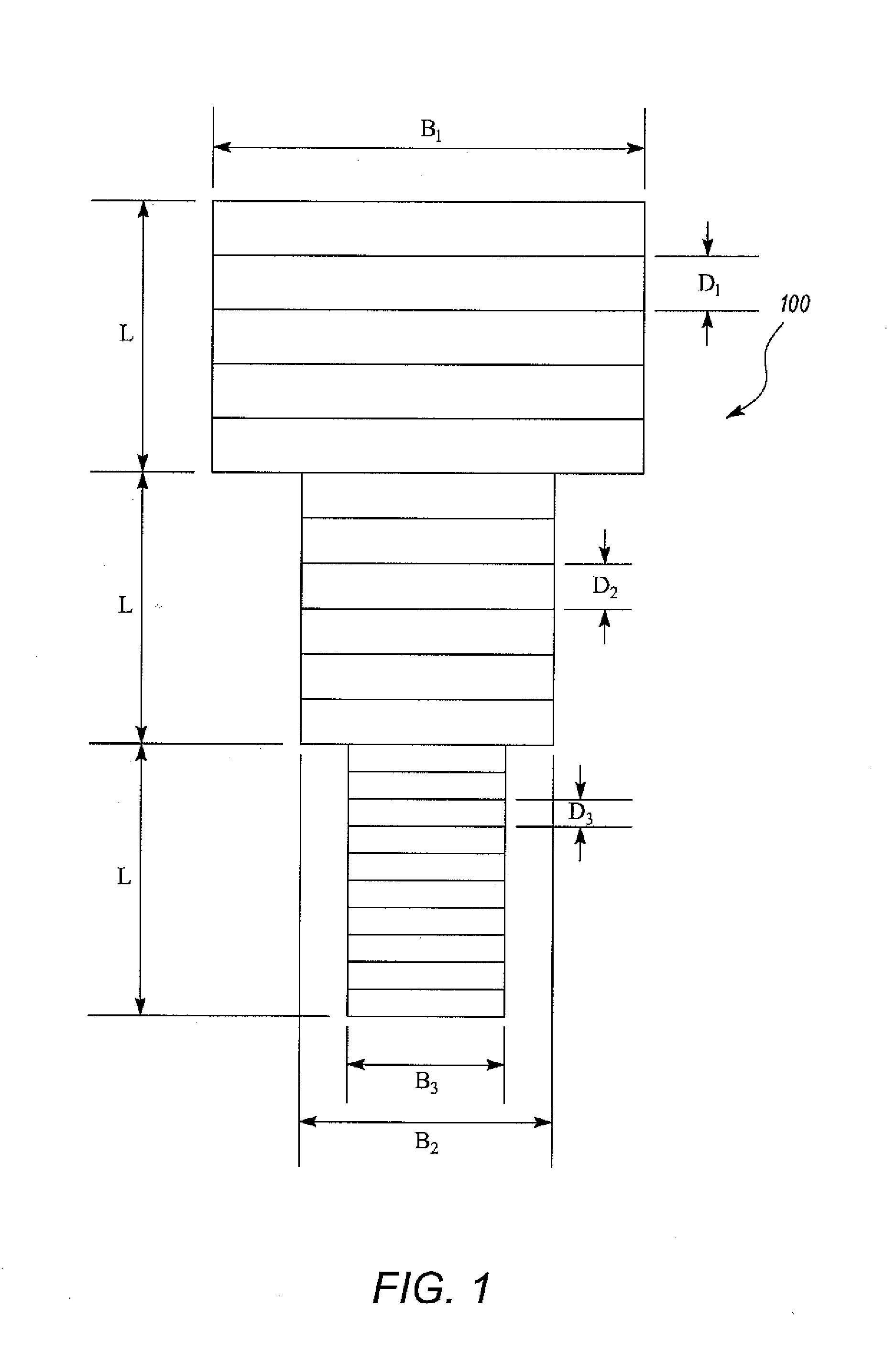

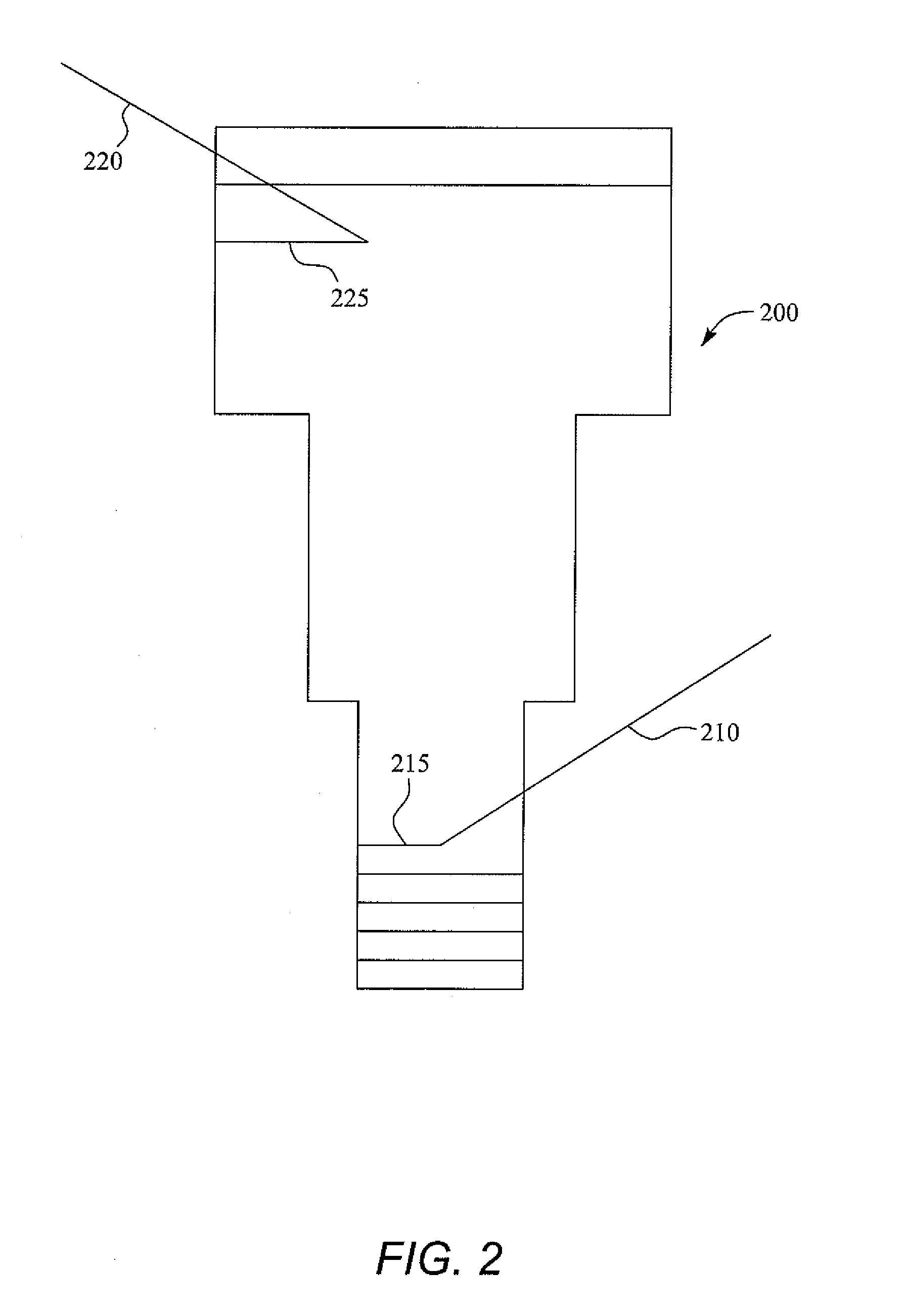

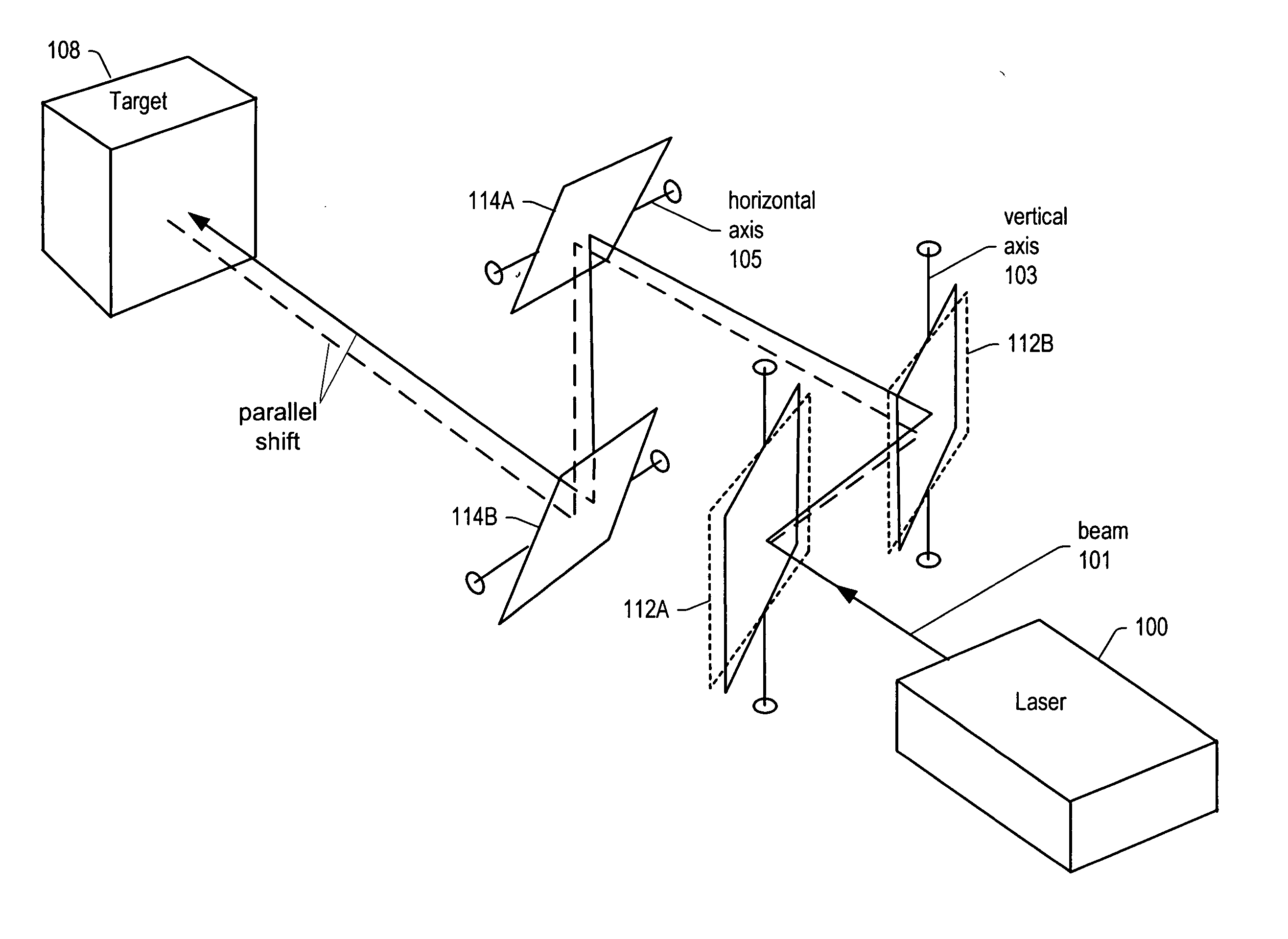

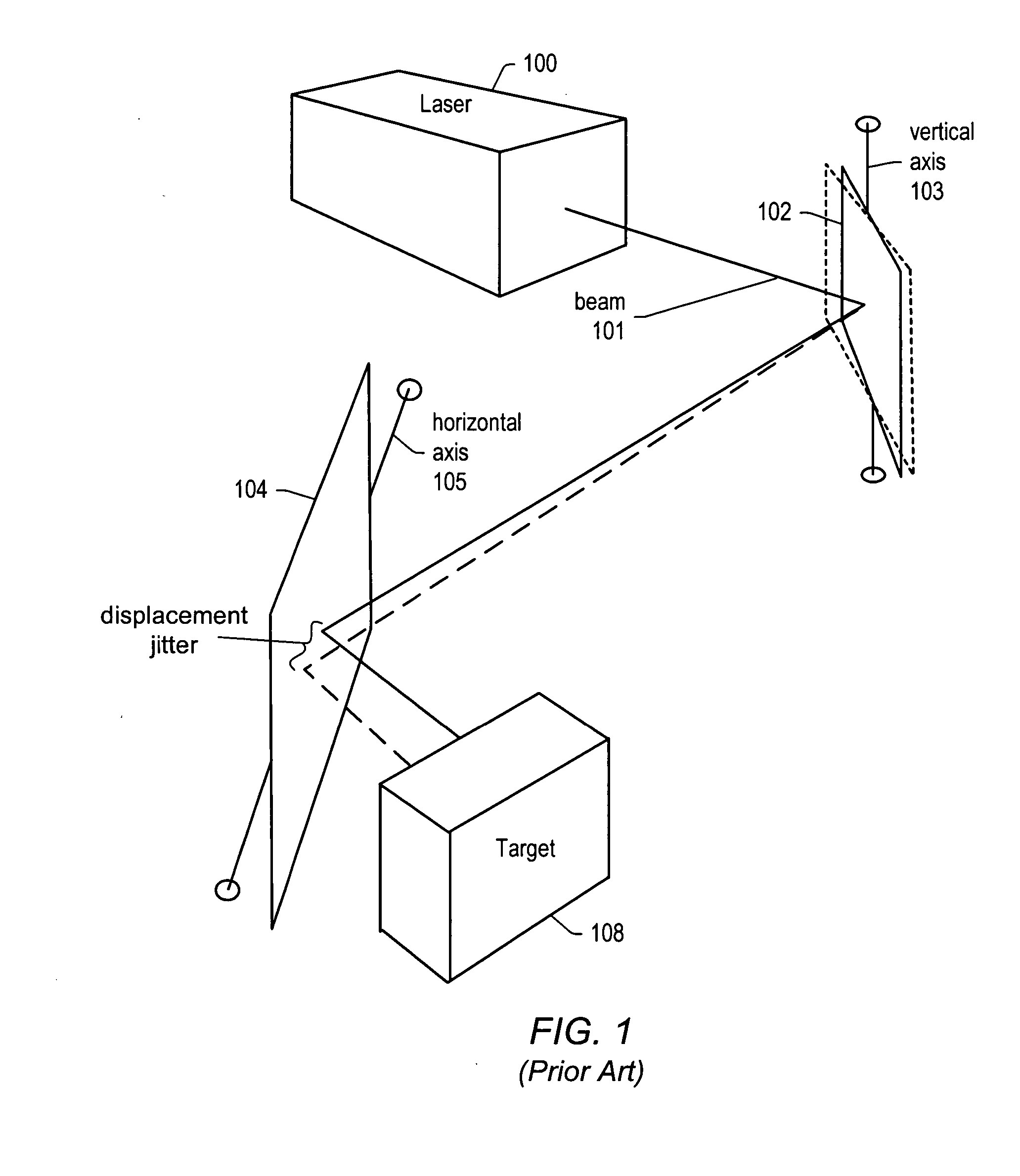

Parallel-beam scanning for surface patterning of materials

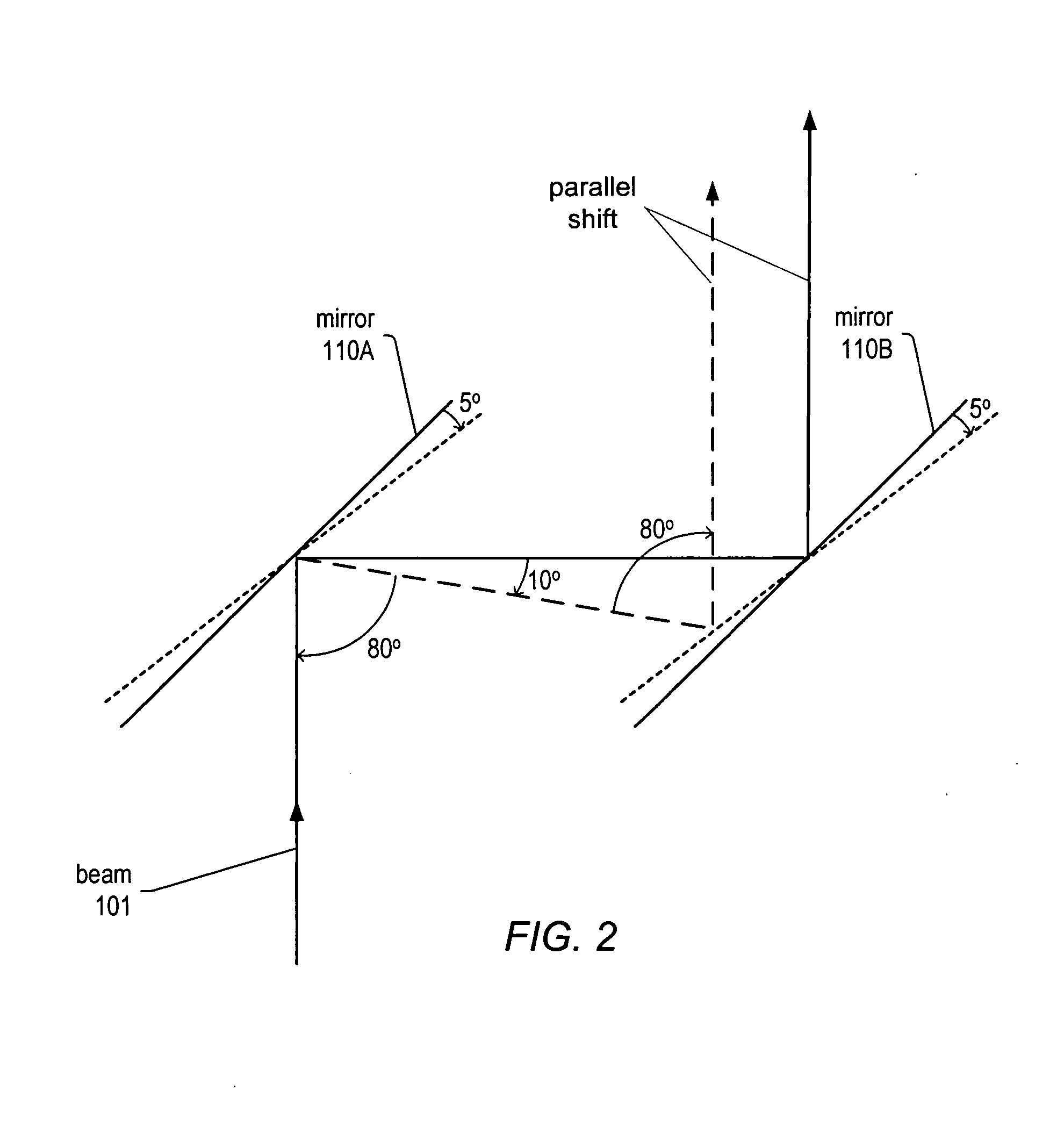

InactiveUS20060151449A1Semiconductor/solid-state device manufacturingWelding/soldering/cutting articlesBeam sourceLight beam

A system and method for parallel-beam scanning a surface. An energetic beam source emits an energetic collimated beam which is received by an optical device, comprising: one or more optical media, operable to receive the emitted beam, such as two pairs of coordinated mirrors or a right prism, and at least one actuator coupled to the one or more optical media, and operable to rotate each of the one or more optical media around a respective axis to perform a parallel displacement of the beam in a respective direction, wherein the respective direction, the beam, and the respective axis are mutually orthogonal. The optical device is operable to direct the beam to illuminate a sequence of specified regions of a surface.

Owner:SEMICUBE

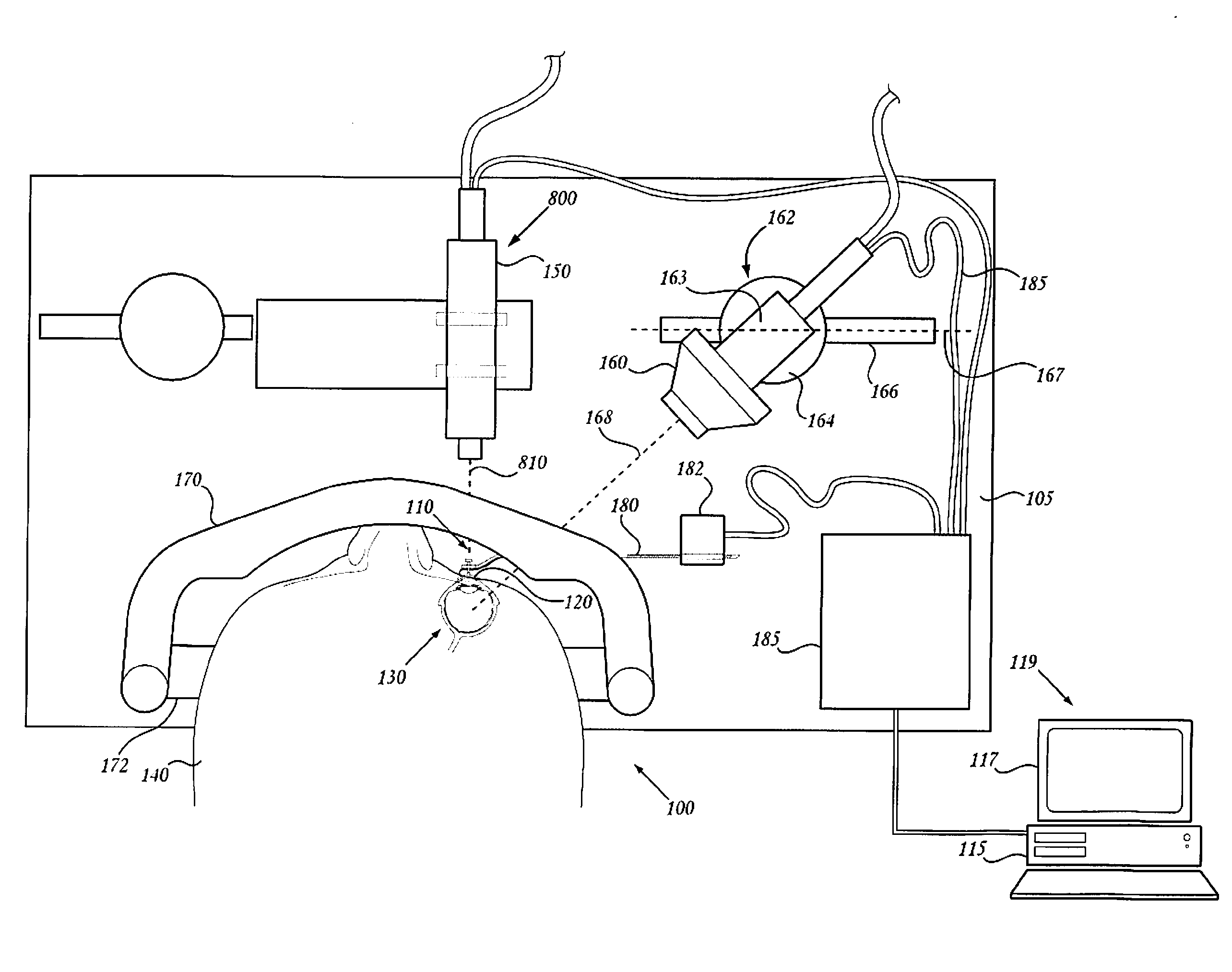

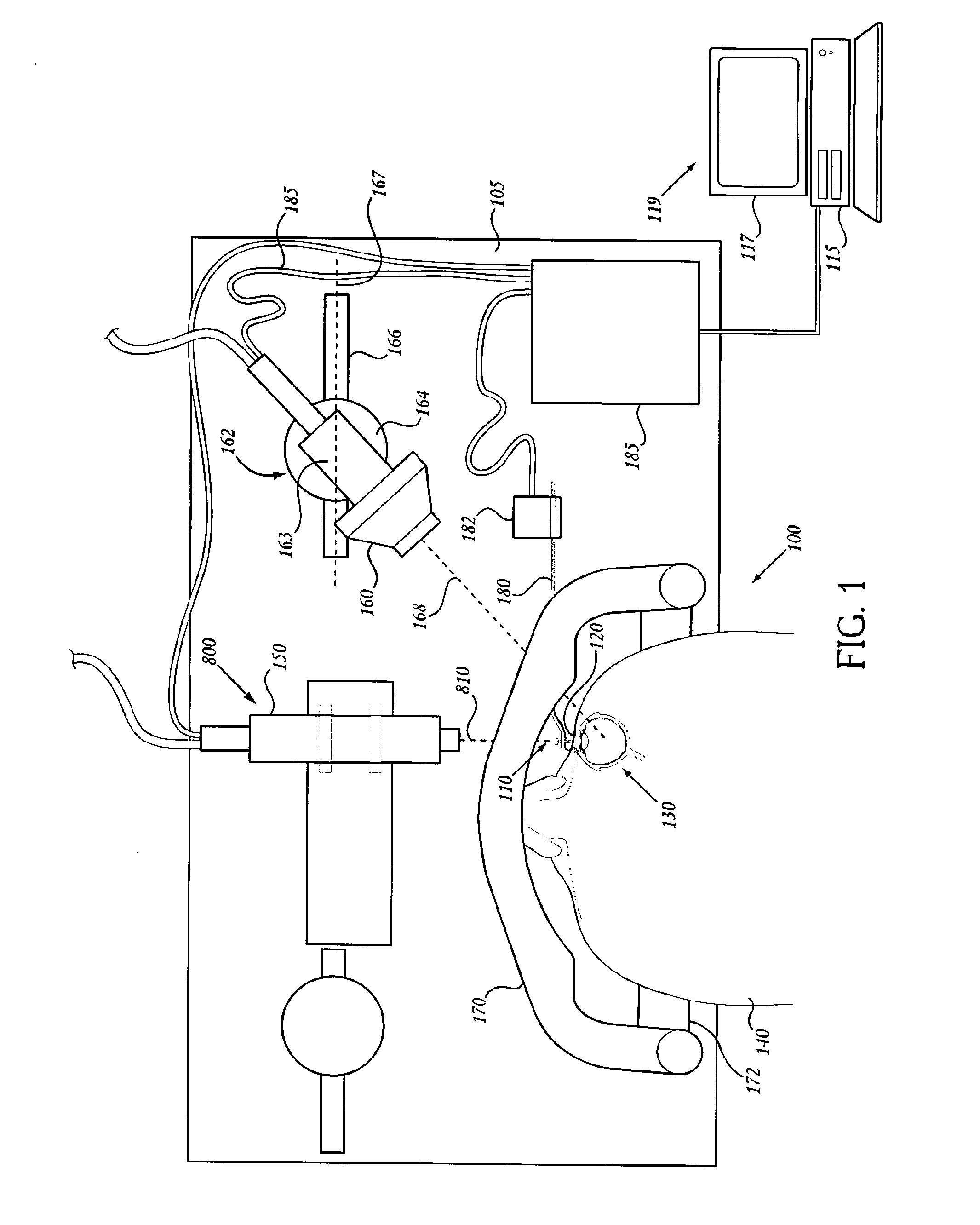

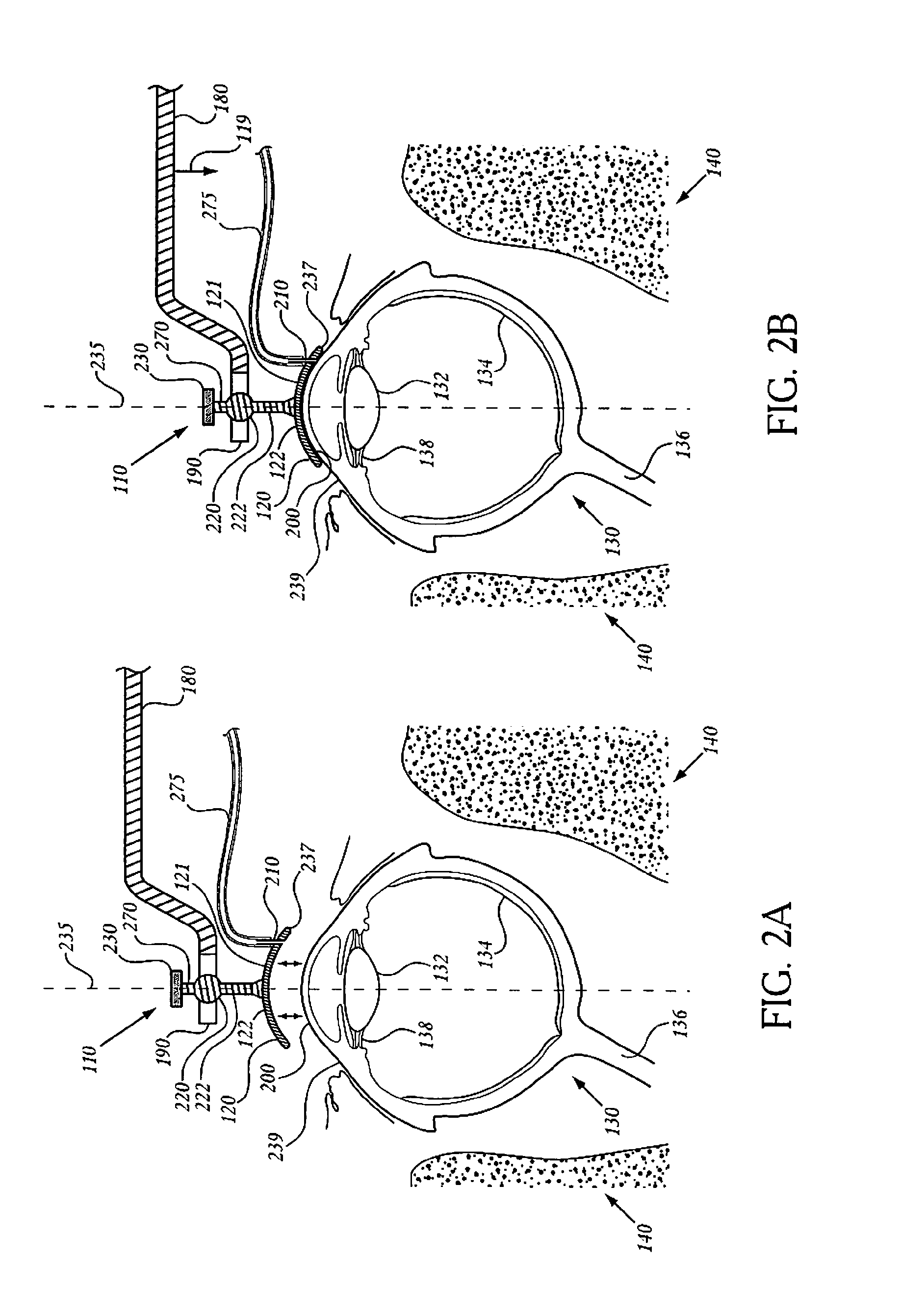

System and method for performing an ocular irradiation procedure

ActiveUS20090182310A1Stabilize position of eyeLaser surgerySurgical instrument detailsBeam sourceLight beam

A method and system for performing an ocular irradiation procedure on a patient's eye is disclosed. The system includes a head support for supporting the patient's head, an eye-contact device attachable to the front portion of the patient's eye, to stabilize the position of the eye; and a position detector for determining the position of the contact device in the external coordinate system. A source of a collimated electromagnetic radiation beam in the system is controlled by a beam-positioning assembly for positioning the beam source such that the beam, when activated, is aimed along a selected path at a selected coordinate in the external coordinate system corresponding to a selected target region in the patient's eye.

Owner:CARL ZEISS MEDITEC INC

Radiation process and apparatus

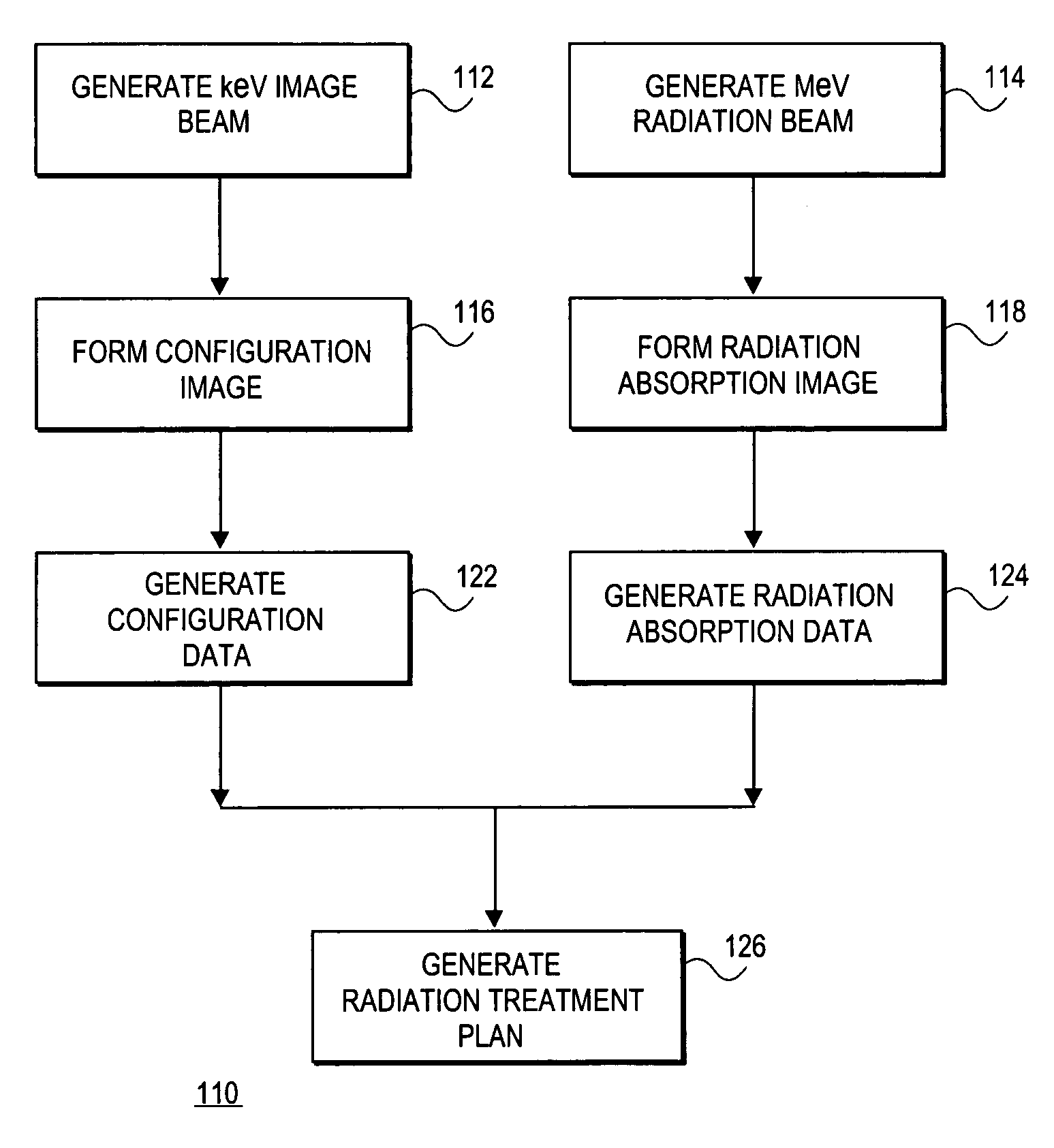

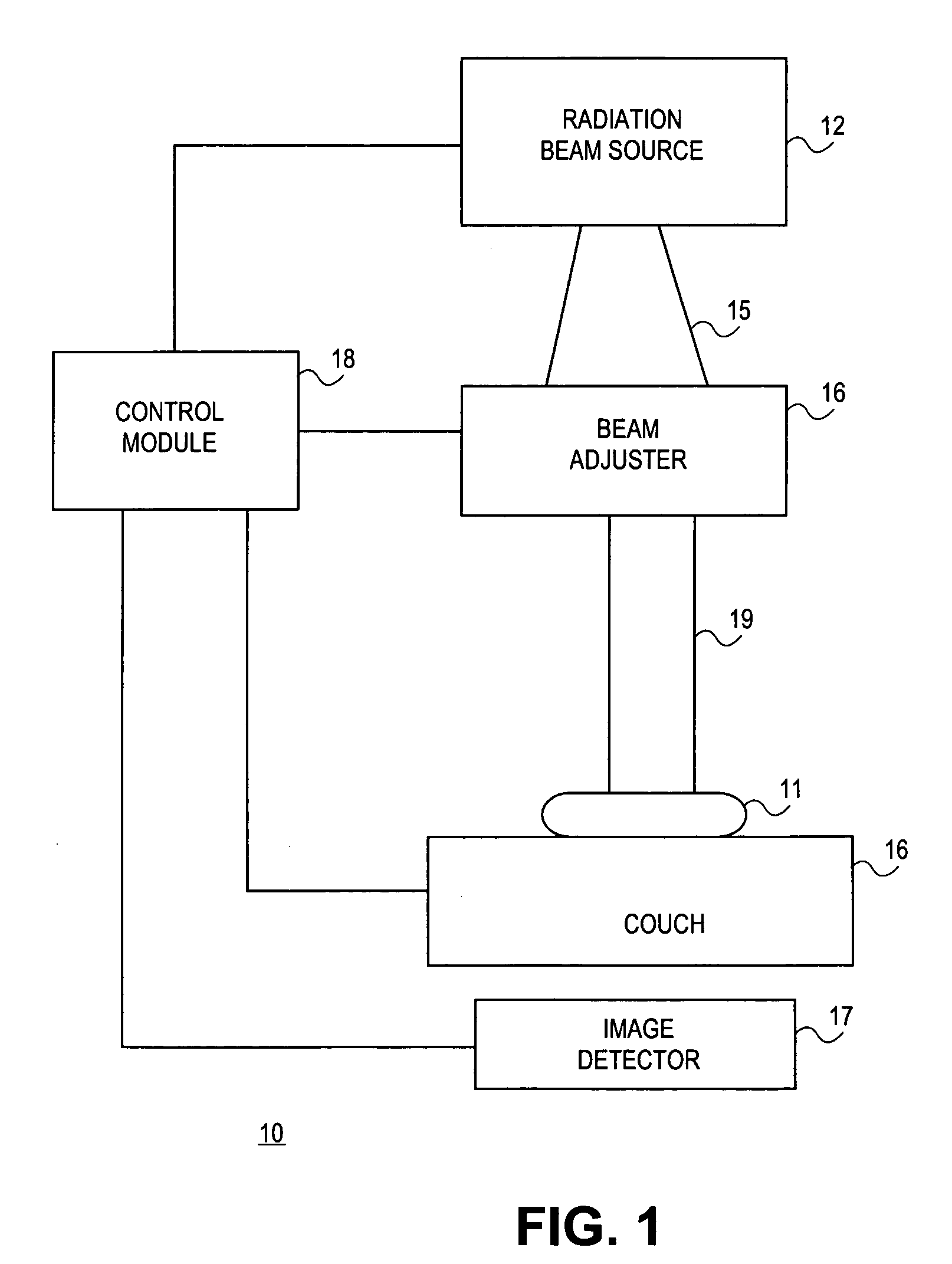

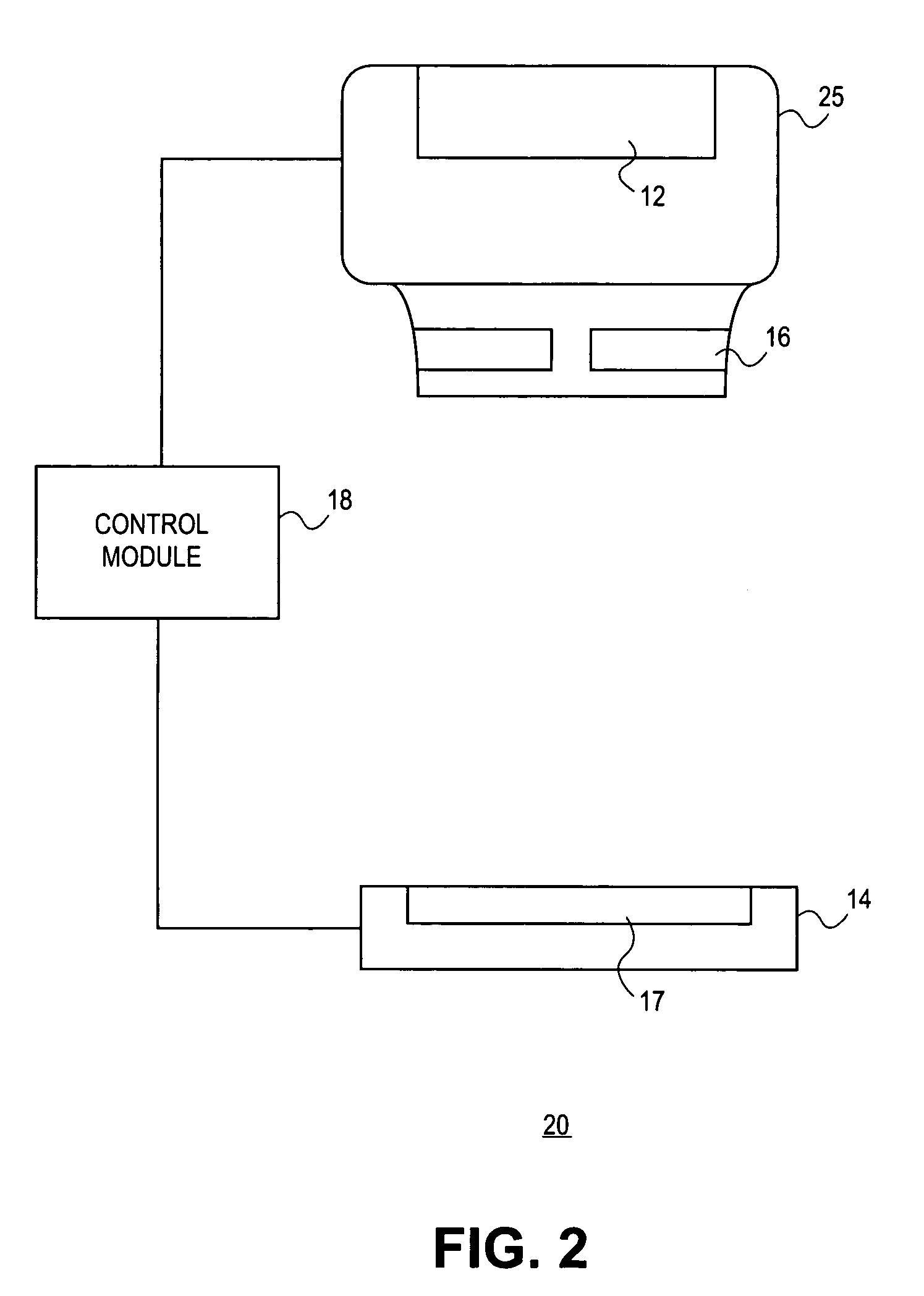

ActiveUS7289599B2Quality improvementMinimize radiation exposureCharacter and pattern recognitionX-ray/gamma-ray/particle-irradiation therapyBeam sourceLight beam

Owner:VARIAN MEDICAL SYSTEMS

Enhanced additive manufacturing

InactiveUS20160052079A1Shorten the timeSmall volumeAdditive manufacturing apparatusElectric discharge tubesBeam sourceVacuum level

Various embodiments of the present invention relate to a method for operating an additive manufacturing apparatus in which a three-dimensional article is formed. Said method comprising the steps of: providing a vacuum chamber having at least a first and a second section, wherein said first and second sections are openly connected to each other, providing a predetermined vacuum level inside said vacuum chamber, providing a layer of powder material on a work table in said first section of said vacuum chamber, directing an electron beam from said at least one electron beam source provided in said second section over said work table to fuse in first selected locations according to said model to form a first cross section of said three-dimensional article, purging said second section with a dry gas when said vacuum chamber is open for prohibiting ambient air into said second section.

Owner:ARCAM AB

Enhanced electron beam generation

InactiveUS20160052056A1Easy dischargeHigh manufacturing stabilityAdditive manufacturing apparatusElectric discharge tubesBeam sourceVacuum chamber

A method for forming a three dimensional article through successively depositing individual layers of powder material that are fused together with an electron beam from an electron beam sources so as to form the article. Providing a model of said three-dimensional article; a vacuum chamber having at least a first and a second section, powder material that are fused together is provided in said first section, at least one electron beam source is provided in said second section, wherein said first and second sections are openly connected to each other. Directing an electron beam from said at least one electron beam source over said work table to fuse in first selected locations according to said model to form a first cross section of said three-dimensional article while supplying a gas to said second section of said vacuum chamber.

Owner:ARCAM AB

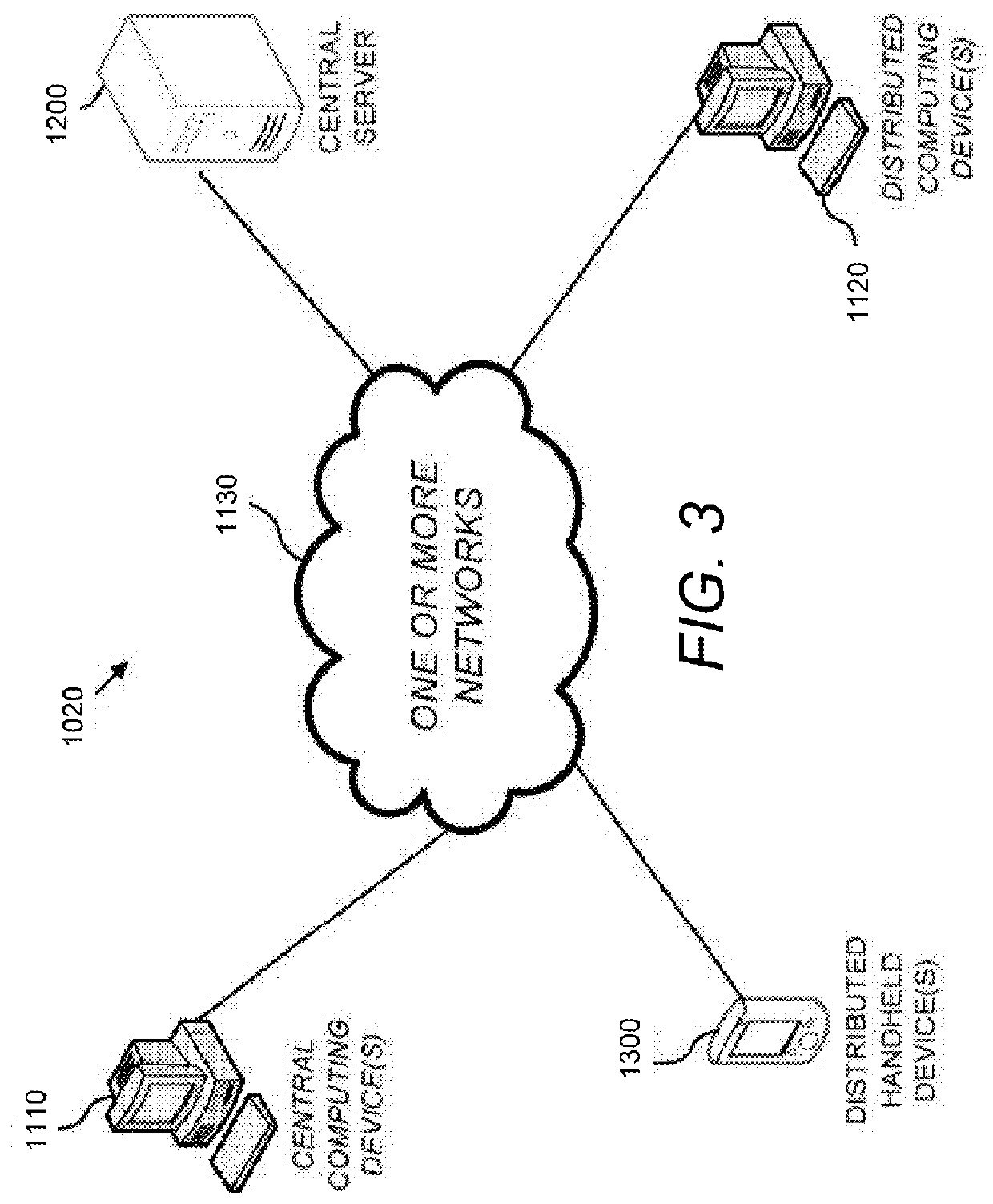

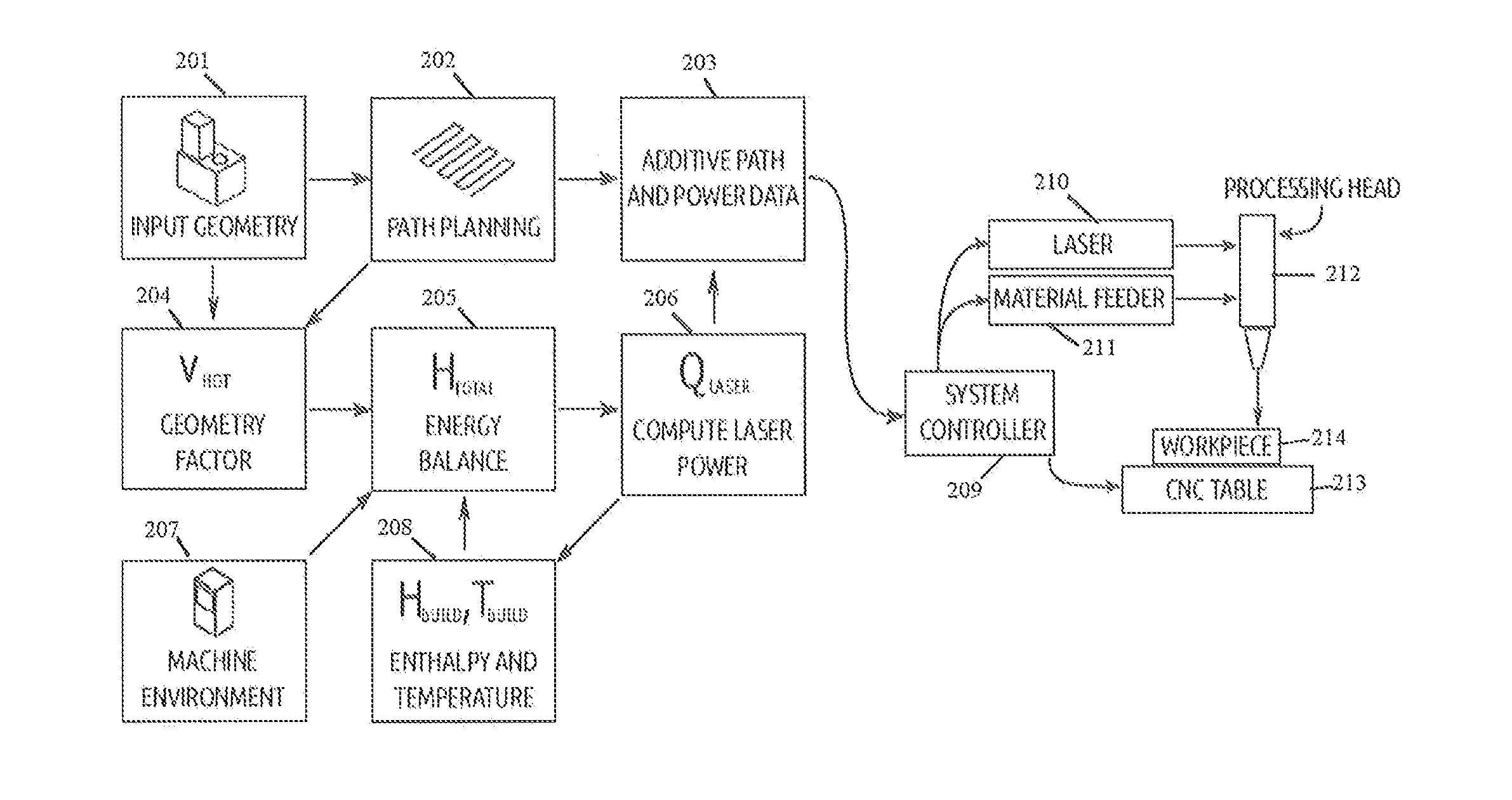

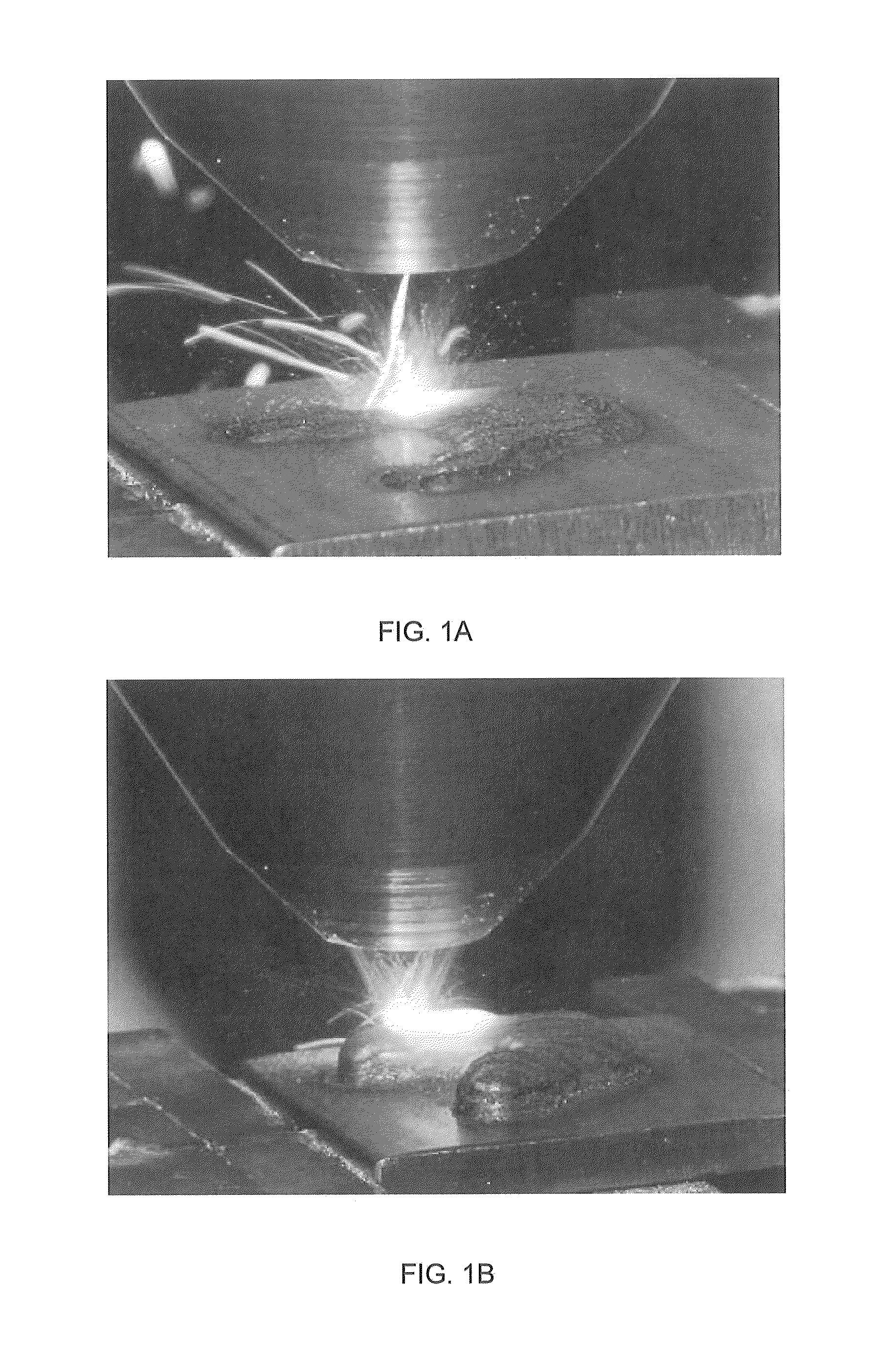

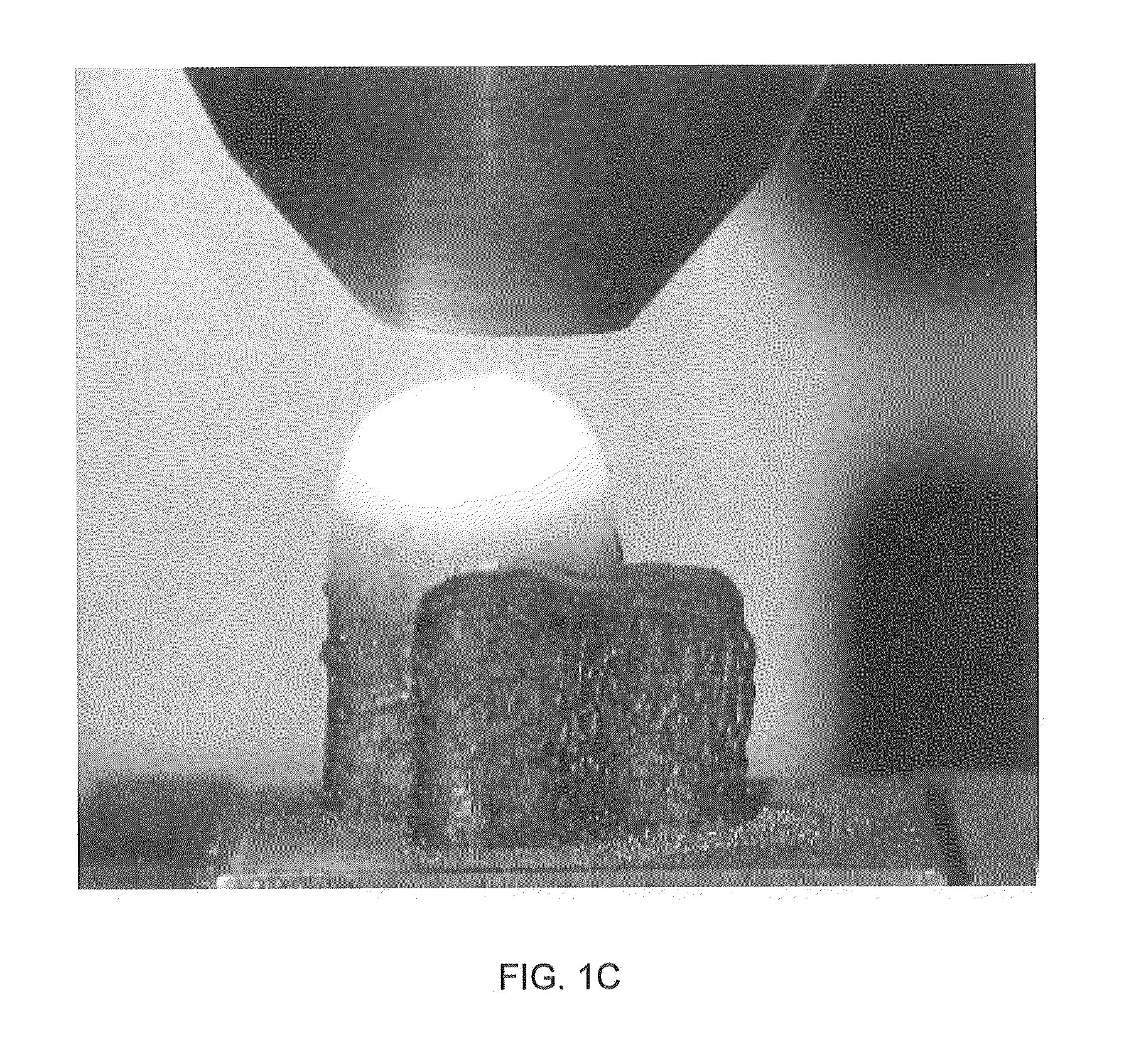

System and Method for Determining Beam Power Level Along an Additive Deposition Path

ActiveUS20160059352A1High frequencyImprove numerical stabilityAdditive manufacturing apparatusArc welding apparatusBeam sourceEnergy balanced

A power schedule calculation method utilizes an idealized geometry to predict laser power levels on an additive path during laser deposition. The method calculates beam power for any point along the path traveled to form a build having a geometry. Each point along the path has associated with it an idealized geometry comprising a melt pool, hot zone and bulk portion. The method comprises creating a geometric description representing the geometry of the build during the process, creating a path description representing the path of the beam source through space during the process, calculating the idealized geometry for the point on the path based upon the geometric description and path description, calculating an energy balance at the melt pool for the point on the path, calculating total energy needed at the point on the path and calculating optimum beam source power. In the calculations, build temperature is based upon a calculation of hot zone temperature derived from the idealized geometry.

Owner:PROD INNOVATION & ENG L L C

Electron beam apparatus and device manufacturing method using same

InactiveUS6909092B2Reduce image distortionLess aberrationThermometer detailsBeam/ray focussing/reflecting arrangementsElectron sourceImaging processing

A defect inspecting apparatus is provided for generating a less distorted test image to reliably observe a surface of a sample for detecting defects thereon. The defect detecting apparatus comprises a primary electron beam source for irradiating a sample, electrostatic lenses for focusing secondary electrons emitted from the surface of the sample irradiated with the primary electron beam, a detector for detecting the secondary electrons, and an image processing unit for processing a signal from the detector. Further, a second electron source may be provided for emitting an electron beam irradiated to the sample, wherein the sample may be irradiated with the electron beam from the second electron source before it is irradiated with the primary electron beam from the first electron source for observing the sample. A device manufacturing method is also provided for inspecting devices under processing with high throughput using the defect detecting apparatus.

Owner:EBARA CORP

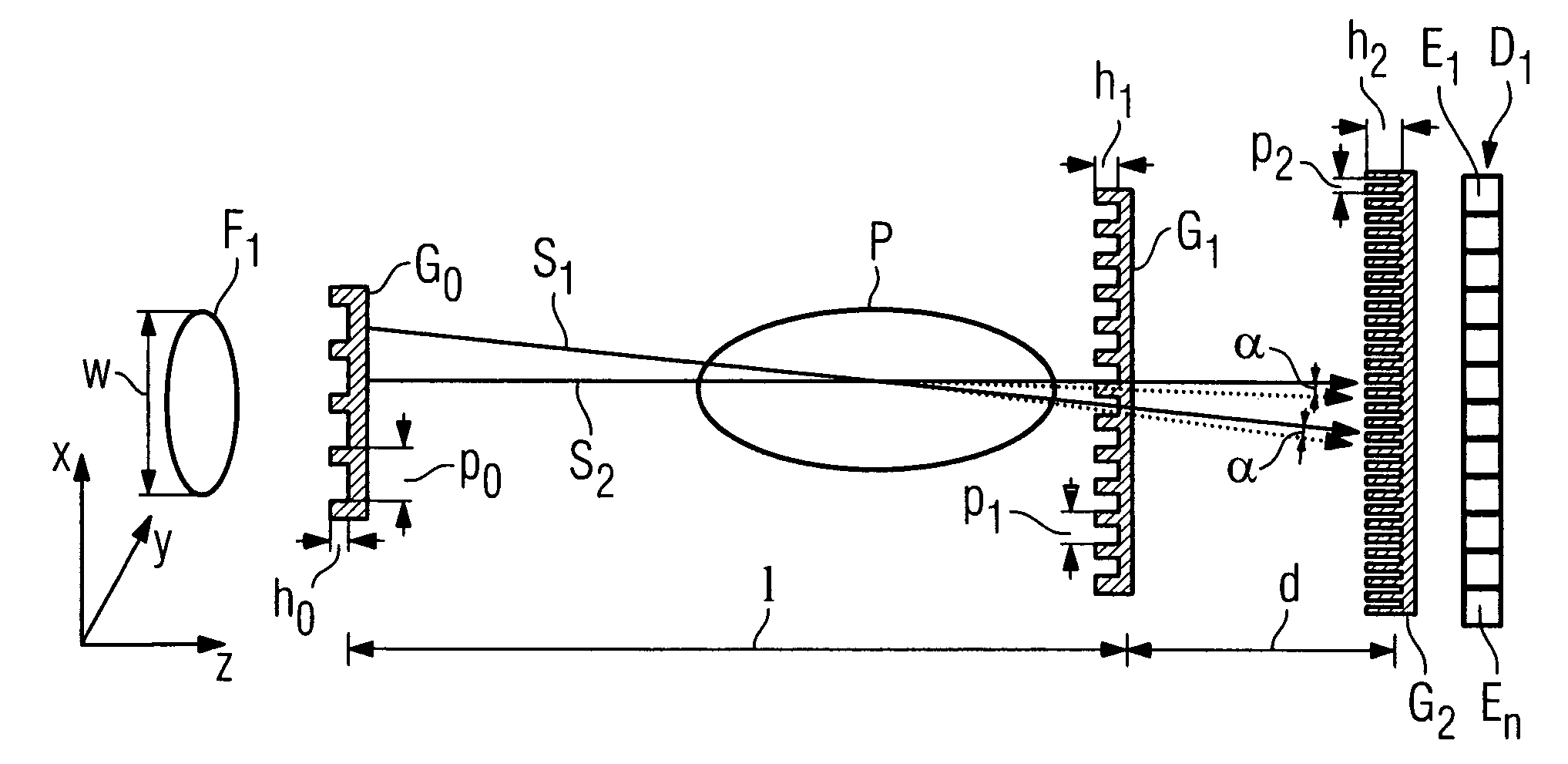

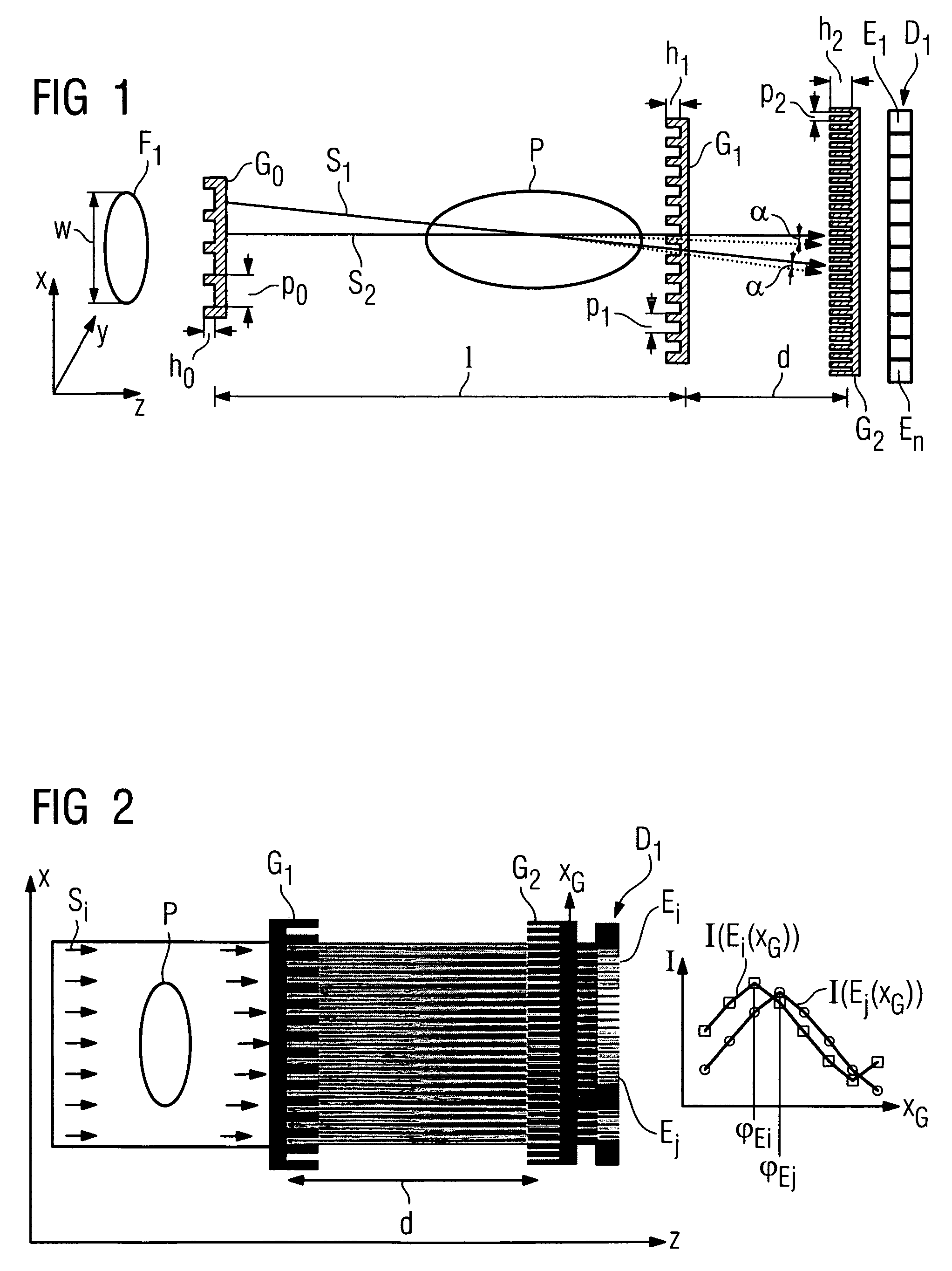

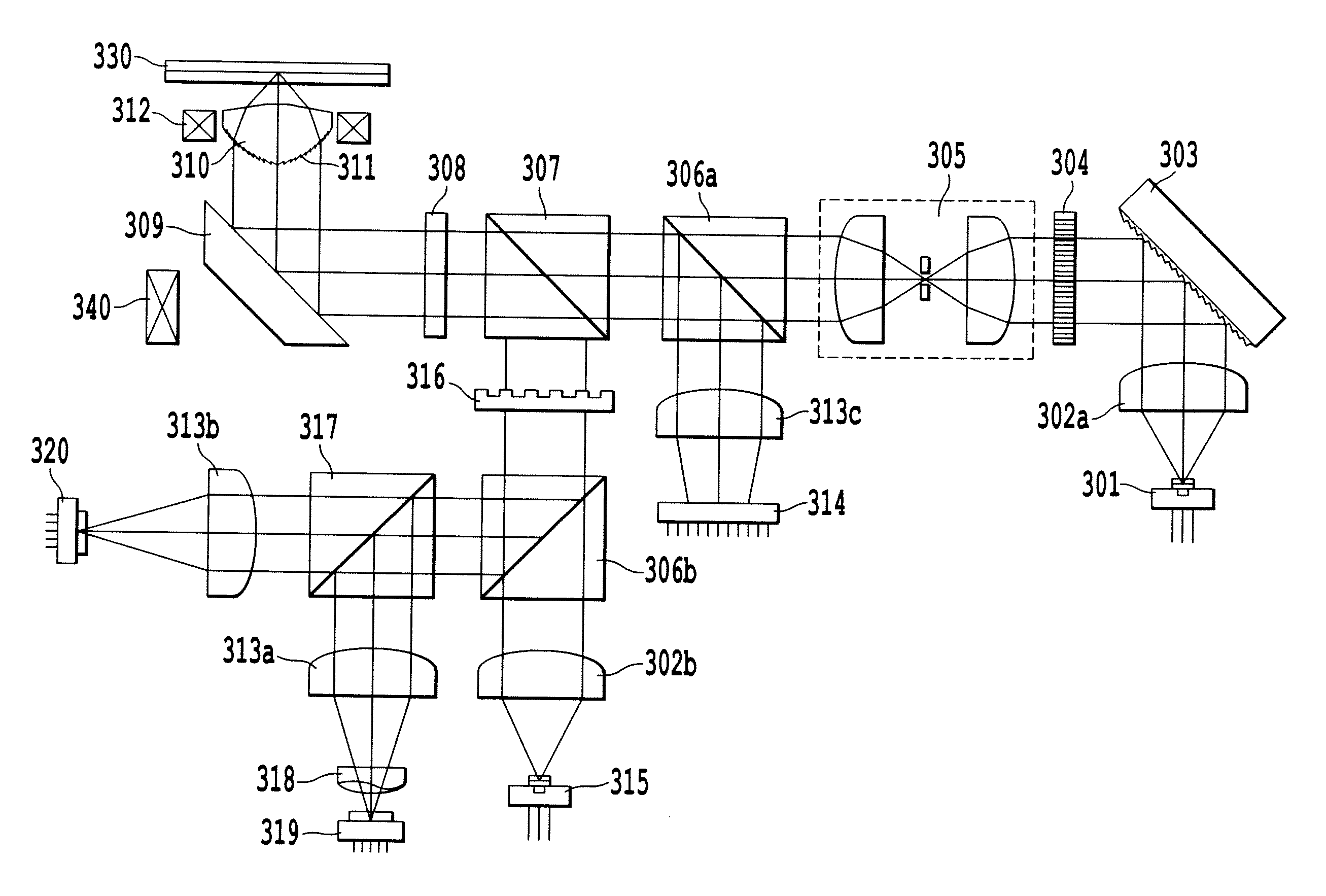

Focus/detector system of an x-ray apparatus for generating phase contrast recordings

InactiveUS7492871B2Improve stabilitySimple structureImaging devicesMaterial analysis using wave/particle radiationPhase gratingBeam source

A focus / detector system of an X-ray apparatus and a method for generating projective or tomographic phase contrast recordings, are disclosed. In an embodiment of the system, the system includes a beam source equipped with a focus and a focus-side source grating, arranged in the beam path and generates a field of ray-wise coherent X-rays, a grating / detector arrangement having a phase grating and grating lines arranged parallel to the source grating for generating an interference pattern, and a detector having a multiplicity of detector elements arranged flat for measuring the position-dependent radiation intensity behind the phase grating. Finally, the detector elements are formed by a multiplicity of elongate scintillation strips, which are aligned parallel to the grating lines of the phase grating and have a small period, whose integer multiple corresponds to the average large period of the interference pattern which is formed by the phase grating.

Owner:SIEMENS HEALTHCARE GMBH +1

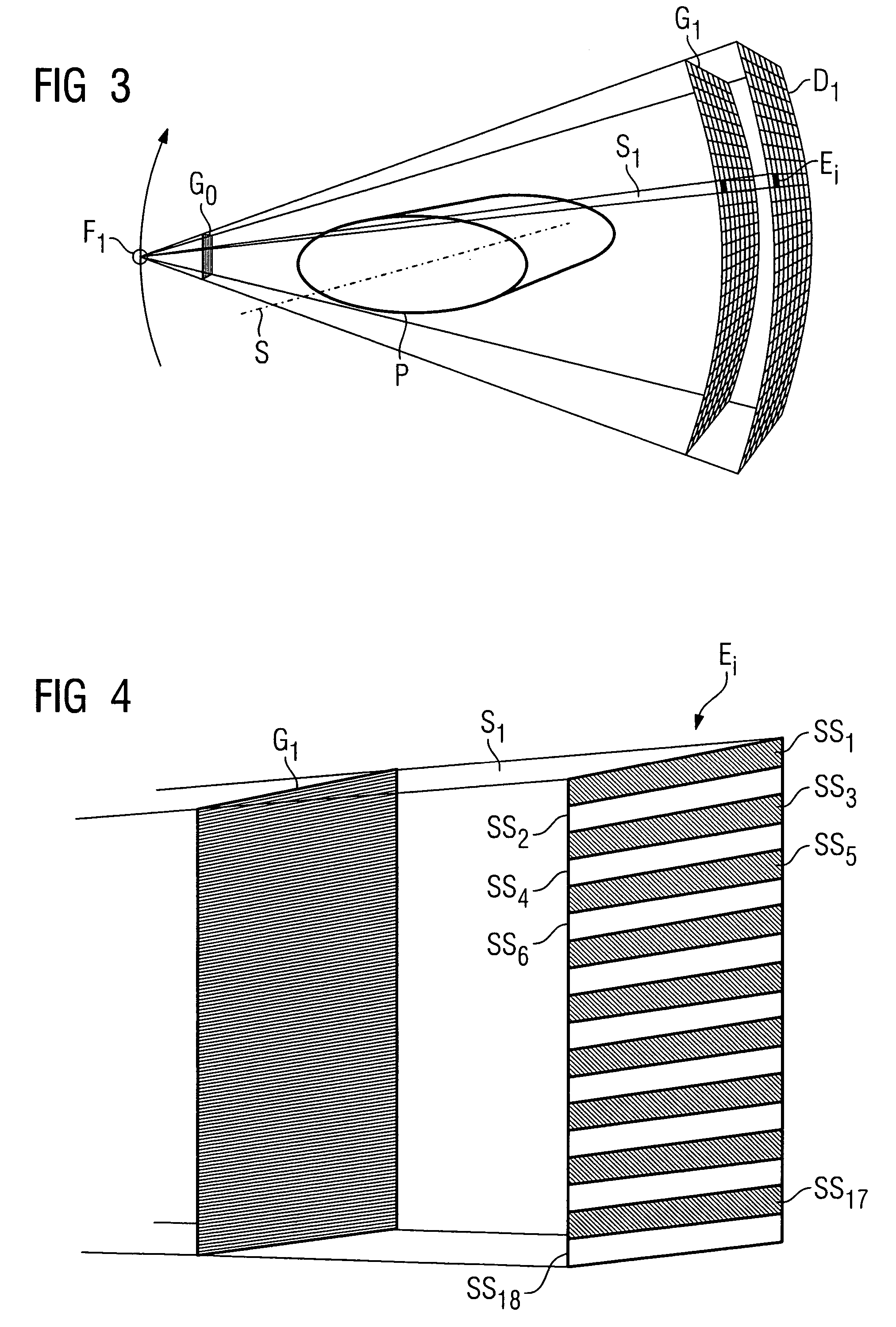

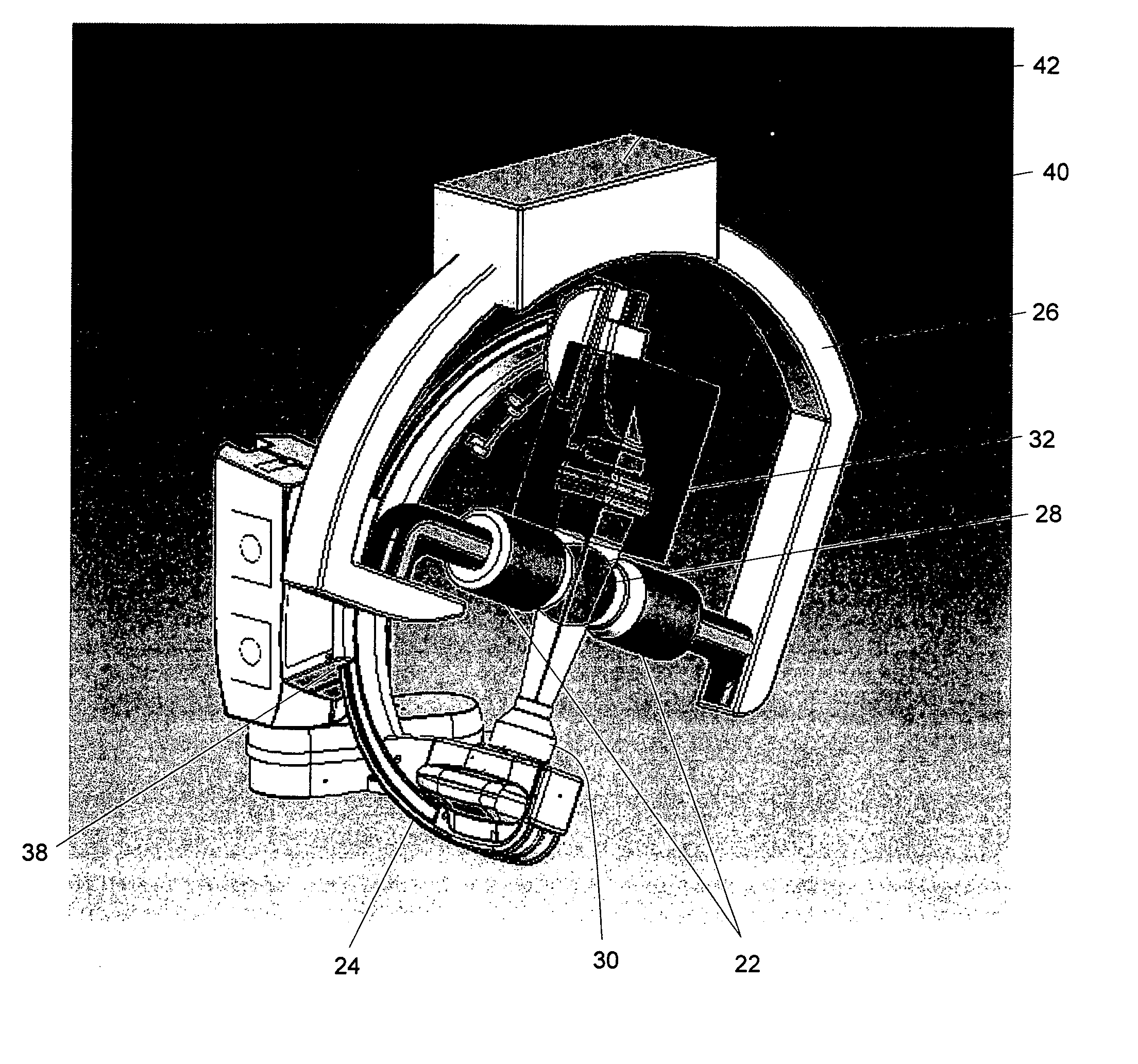

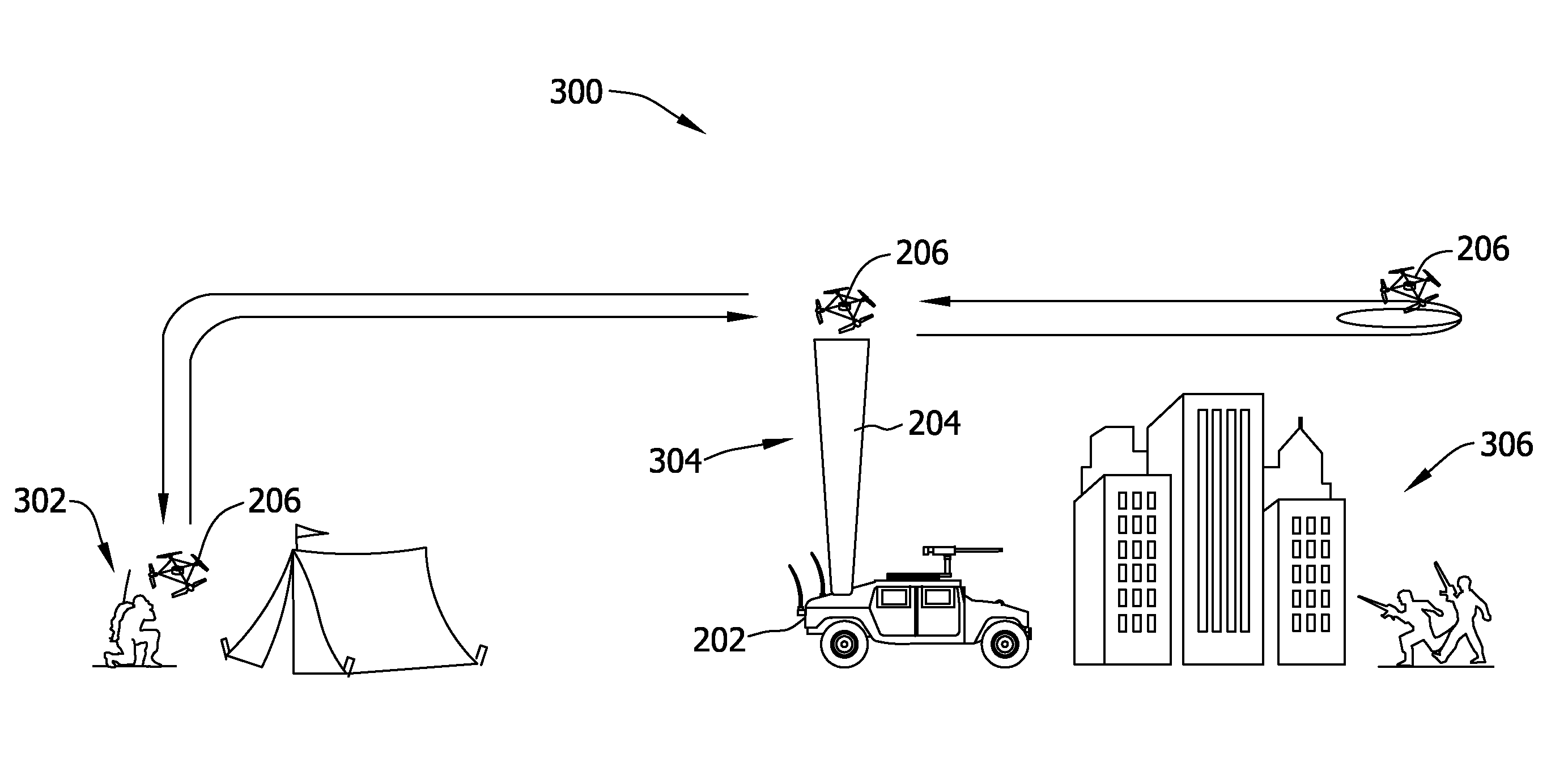

Magnetic navigation and imaging system

InactiveUS20070038064A1Improves flexibility and accessibilityMove quicklyUltrasonic/sonic/infrasonic diagnosticsElectrotherapyBeam sourceLight beam

A system for imaging and magnetically navigating a medical device within an operating region in a subject's body is provided that comprises a first C-arm and a second C-arm. The system comprises an imaging beam source and an imaging beam receiver mounted on the first C-arm that are positioned to be disposed on opposite sides of the operating region to image the operating region. Some embodiments comprise a pair of magnetic pods, which are movably mounted on either the first or second C-arm. Some embodiments comprise magnetic pods that are movable between an imaging position and a navigating position in which the pods are disposed on opposite sides of the operating region in the same plane as at least one imaging beam source. The magnetic navigation units may apply a navigating magnetic field of at least 0.08 T in any direction to the operating region. In some embodiments of the invention, the second C-arm is movable between an imaging position in which the imaging beam source and imaging beam receiver on the second C-arm is positioned so that the imaging beam sources and receivers are in the same plane.

Owner:STEREOTAXIS

High current electron beam inspection

ActiveUS20070057687A1Electric discharge tubesIndividual semiconductor device testingBeam sourceHigh current

A method and apparatus for wafer inspection. The apparatus is capable of testing a sample having a first layer that is at least partly conductive and a second, dielectric layer formed over the first layer, following production of contact openings in the second layer, the apparatus includes: (i) an electron beam source adapted to direct a high current beam of charged particles to simultaneously irradiate a large number of contact openings at multiple locations distributed over an area of the sample; (ii) a current measuring device adapted to measure a specimen current flowing through the first layer in response to irradiation of the large number of contact openings at the multiple locations; and (iii) a controller adapted to provide an indication of the at least defective hole in response to the measurement.

Owner:APPL MATERIALS ISRAEL LTD

Aberration-correcting dark-field electron microscopy

ActiveUS20110192976A1Thermometer detailsMaterial analysis using wave/particle radiationBeam sourceLight beam

A transmission electron microscope includes an electron beam source to generate an electron beam. Beam optics are provided to converge the electron beam. An aberration corrector corrects the electron beam for at least a spherical aberration. A specimen holder is provided to hold a specimen in the path of the electron beam. A detector is used to detect the electron beam transmitted through the specimen. The transmission electron microscope operates in a dark-field mode in which a zero beam of the electron beam is not detected. The microscope may also be capable of operating in an incoherent illumination mode.

Owner:MOCHII VOXA

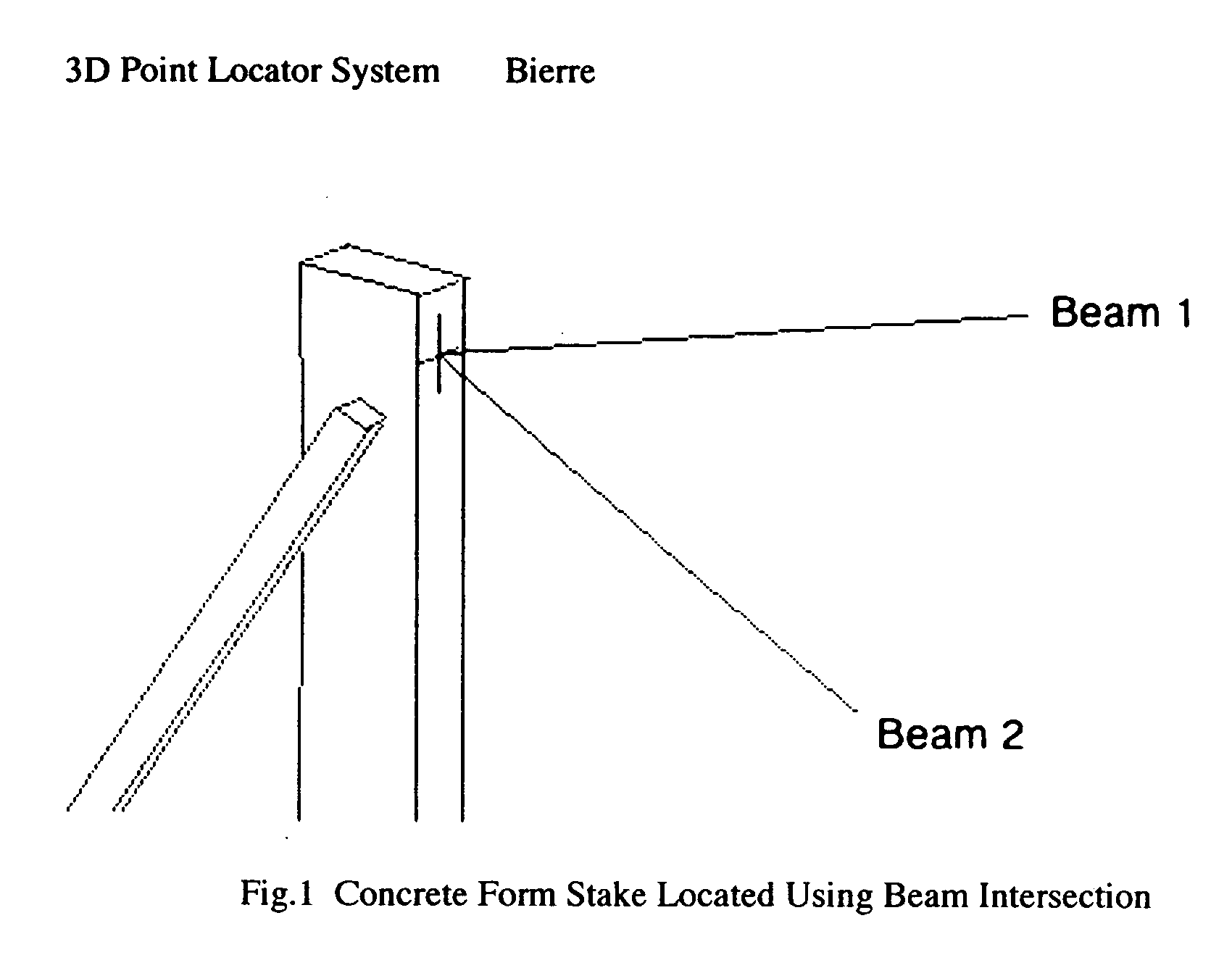

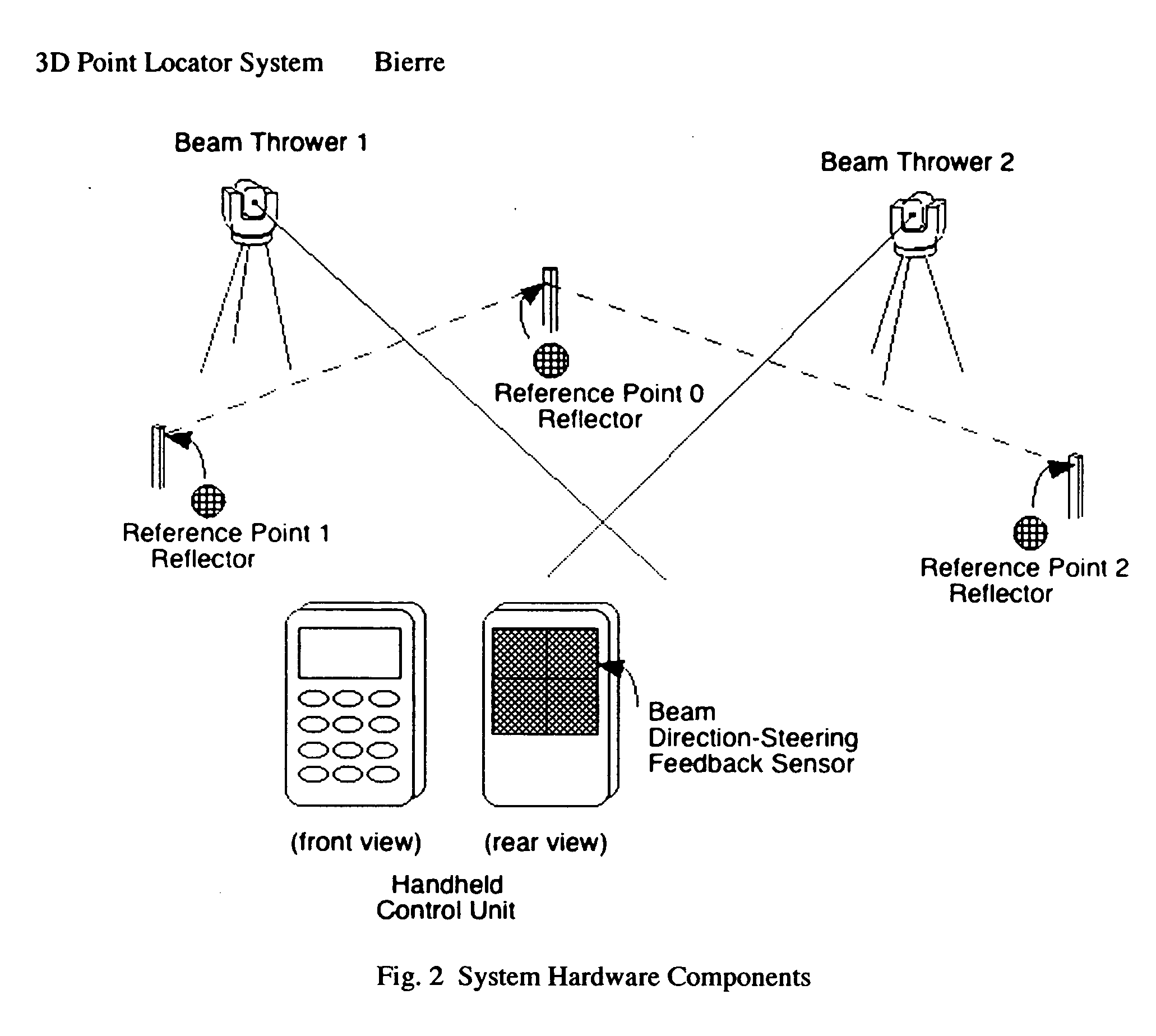

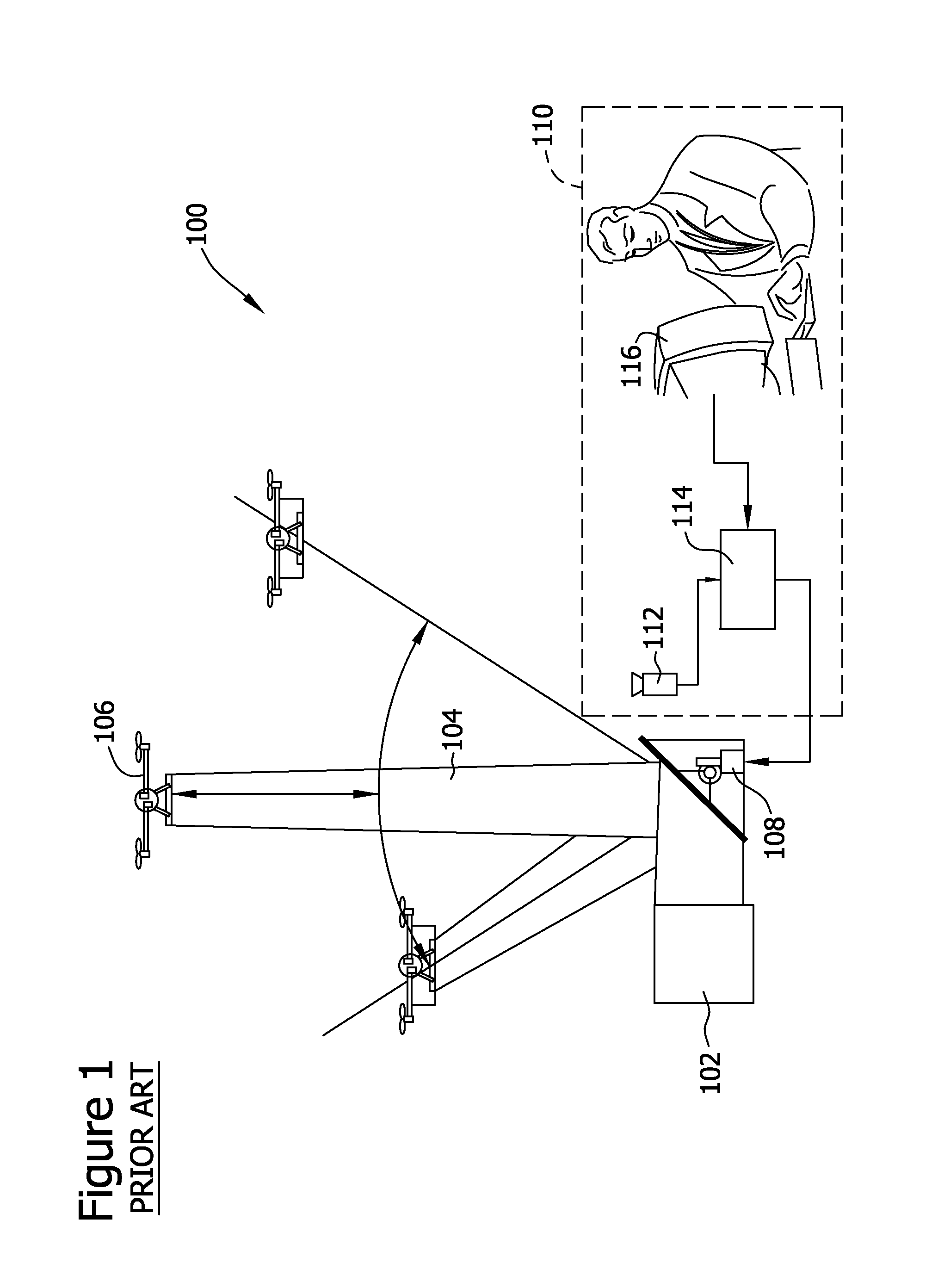

3D point locator system

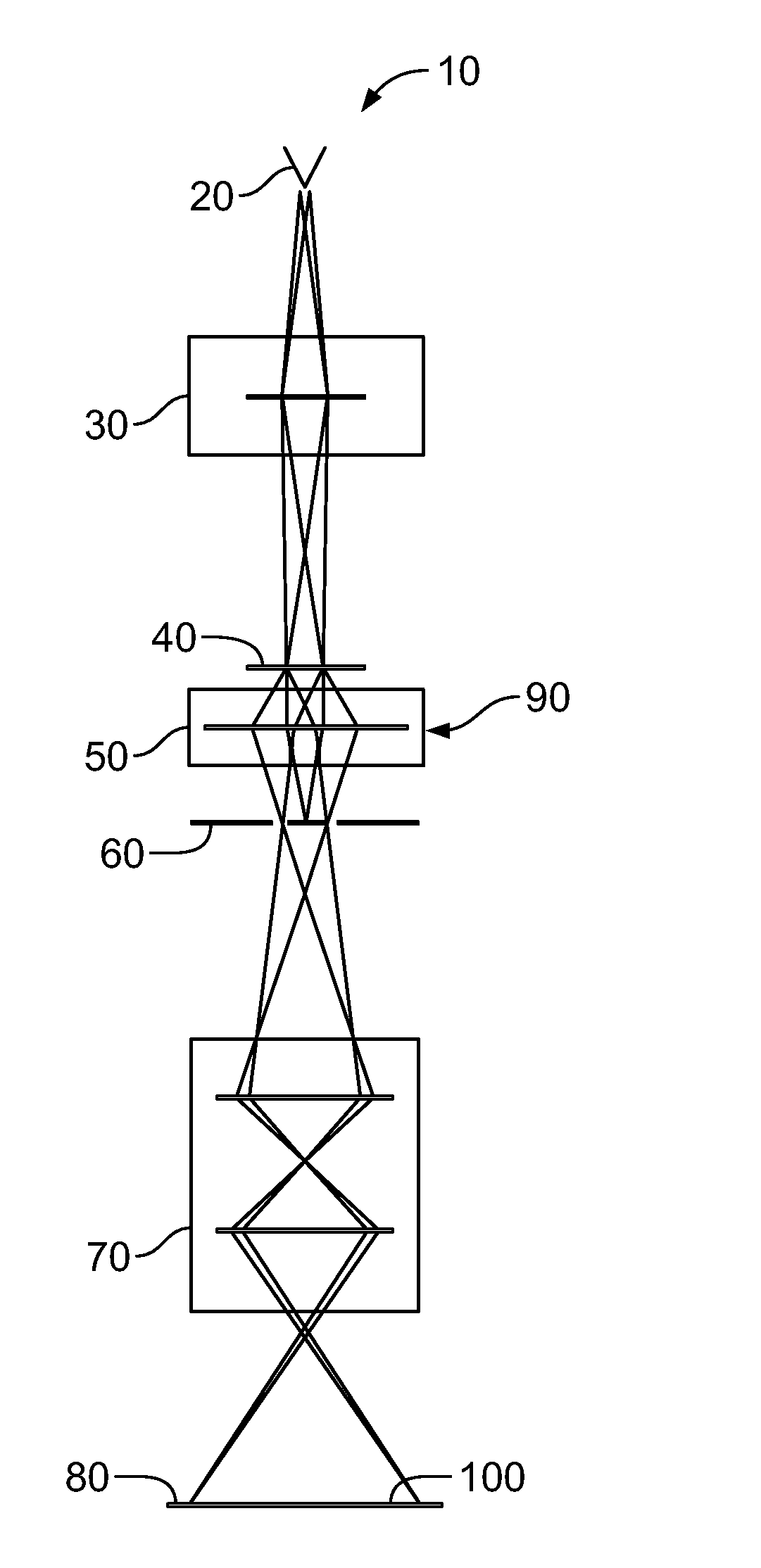

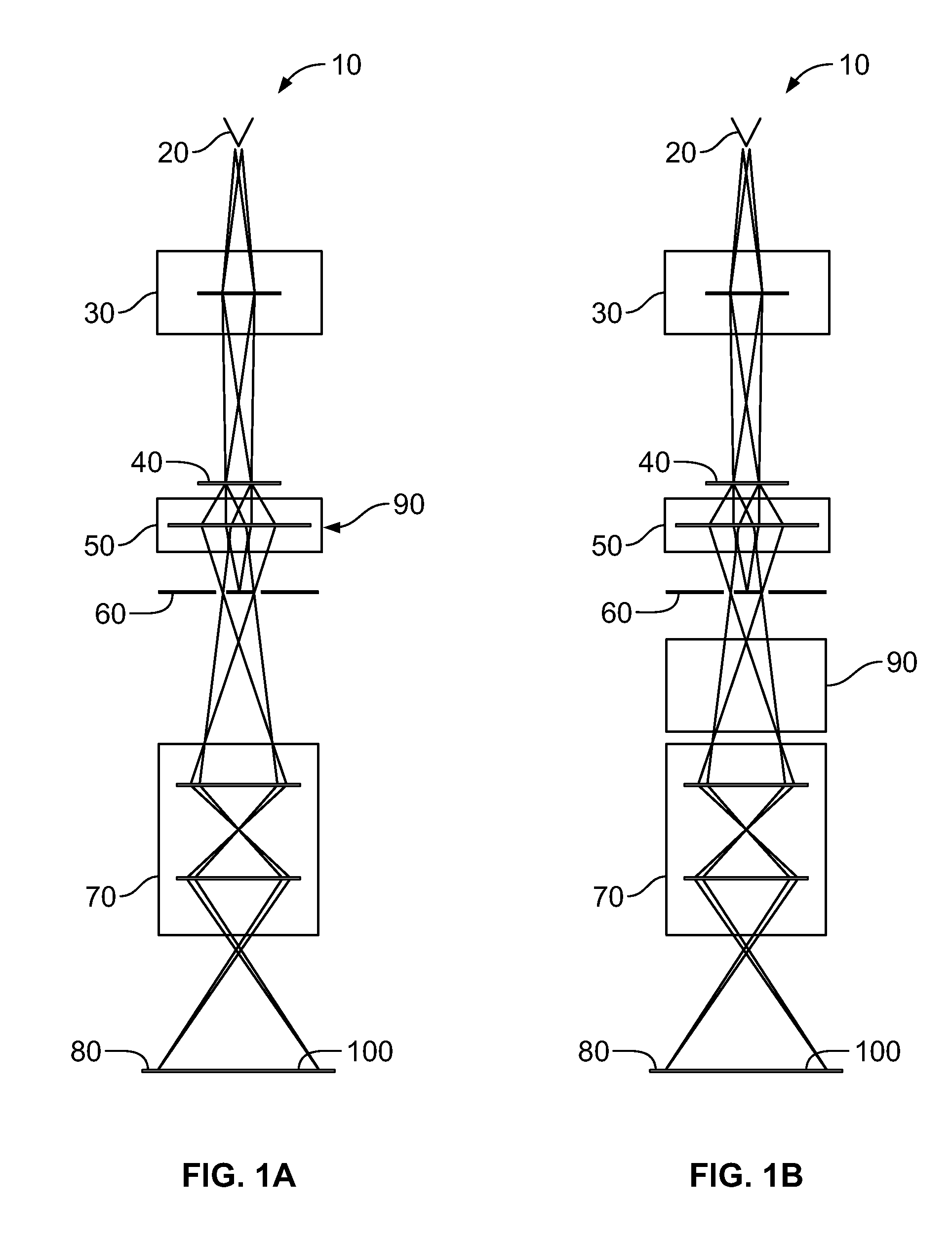

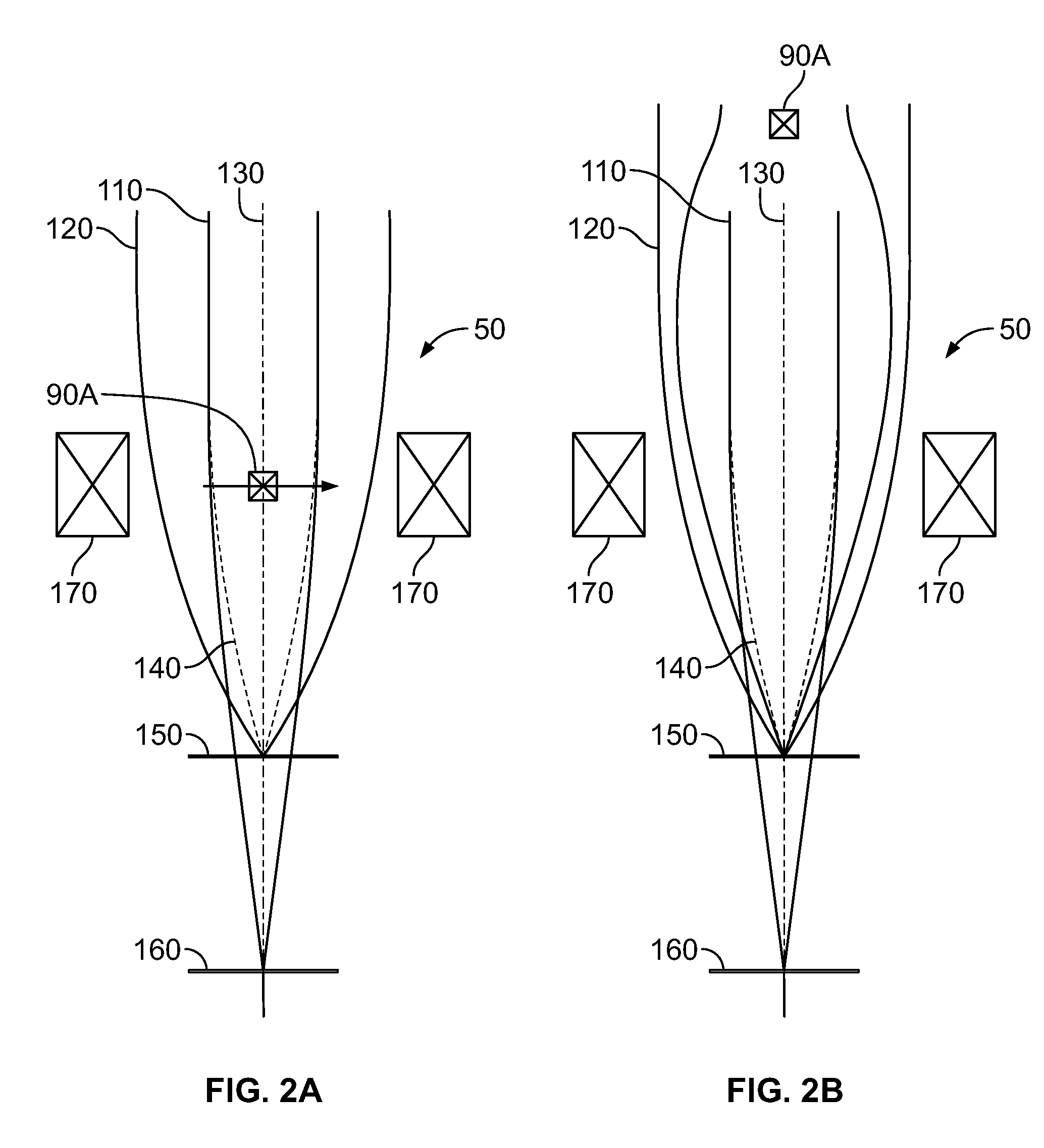

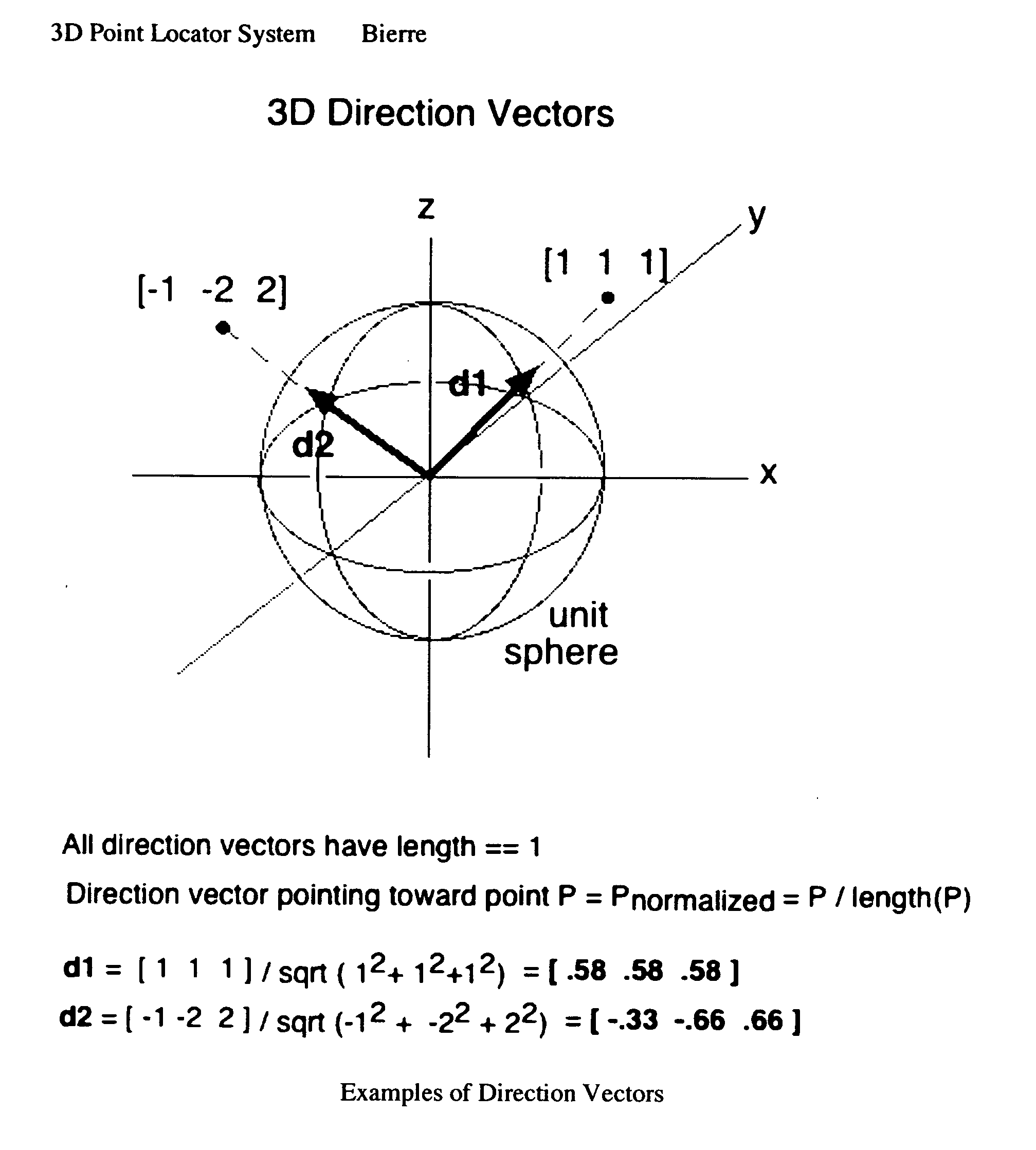

InactiveUS20050102063A1DistanceReduce distanceComputer controlSimulator controlOperational systemSurvey instrument

An automated system and method of geometric 3D point location. The invention teaches a system design for translating a CAD model into real spatial locations at a construction site, interior environment, or other workspace. Specified points are materialized by intersecting two visible pencil light beams there, each beam under the control of its own robotic ray-steering beam source. Practicability requires each beam source to know its precise location and rotational orientation in the CAD-based coordinate system. As an enabling sub-invention, therefore, an automated system and method for self-location and self-orientation of a polar-angle-sensing device is specified, based on its observation of three (3) known reference points. Two such devices, under the control of a handheld unit downloaded with the CAD model or pointlist, are sufficient to orchestrate the arbitrary point location of the invention, by the following method: Three CAD-specified reference points are optically defined by emplacing a spot retroreflector at each. The user then situates the two beam source devices at unspecified locations and orientations. The user then trains each beam source on each reference point, enabling the beam source to compute its location and orientation, using the algorithm of the sub-invention. The user then may select a CAD-specified design point using the handheld controller, and in response, the handheld instructs the two beam sources to radiate toward the currently selected point P. Each beam source independently transforms P into a direction vector from self, applies a 3×3 matrix rotator that corrects for its arbitrary rotational orientation, and instructs its robotics to assume the resultant beam direction. In consummation of the inventive thread, the pair of light beams form an intersection at the specified point P, giving the worker visual cues to precisely position materials there. This design posits significant ease-of-use advantages over construction point location using a single-beam total station. The invention locates the point effortlessly and with dispatch compared to the total station method of iterative manual search maneuvering a prism into place. Speed enables building features on top of point location, such as metered plumb and edge traversal, and graphical point selection. The invention eliminates the need for a receiving device to occupy space at the specified point, leaving it free to be occupied by building materials. The invention's beam intersection creates a pattern of instantaneous visual feedback signifying correct emplacement of such building materials. Unlike surveying instruments, the invention's freedom to situate its two ray-steering devices at arbitrary locations and orientations, and its reliance instead on the staking of 3 reference points, eliminates the need for specialized surveying skill to set up and operate the system, widening access to builders, engineers, and craftspeople.

Owner:BIERRE PIERRE

Method for improved powder layer quality in additive manufacturing

InactiveUS20160129501A1Improve homogeneityMaximize powder layer thickness homogeneityAdditive manufacturing apparatusIncreasing energy efficiencyBeam sourceEngineering

Various embodiments of the present invention relate to a method for forming at a three-dimensional article through successively depositing individual layers of powder material that are fused together with at least one energy beam so as to form the article, said method comprising the steps of generating a model of said three-dimensional article; applying a first powder layer on a work table; directing said at least one energy beam from at least one energy beam source over said work table causing said first powder layer to fuse in first selected locations according to said model to form a first cross section of said three-dimensional article; introducing a predetermined pattern laterally separated from said first cross section for reducing thickness variations in a powder layer provided on top of said first cross section.

Owner:ARCAM AB

Testing apparatus using charged particles and device manufacturing method using the testing apparatus

InactiveUS20060169900A1Material analysis using wave/particle radiationElectric discharge tubesIlluminanceBeam source

A system for further enhancing speed, i.e. improving throughput in a SEM-type inspection apparatus is provided. An inspection apparatus for inspecting a surface of a substrate produces a crossover from electrons emitted from an electron beam source 25•1, then forms an image under a desired magnification in the direction of a sample W to produce a crossover. When the crossover is passed, electrons as noises are removed from the crossover with an aperture, an adjustment is made so that the crossover becomes a parallel electron beam to irradiate the substrate in a desired sectional form. The electron beam is produced such that the unevenness of illuminance is 10% or less. Electrons emitted from the sample W are detected by a detector 25•11.

Owner:EBARA CORP

Optical disc recording apparatus, controlling method of the same, and optical disc

InactiveUS20070201338A1Improve signal-to-noise ratioOptical beam sourcesRecord information storageSignal-to-noise ratio (imaging)Beam source

An optical disk recording apparatus and method utilize a recording beam source, a spatial light modulator that modulates a recording radiation beam into an information beam carrying information and a reference beam, a focusing unit that focuses the information beam and the reference beam onto an information recording layer, an image sensing device that detects intensity distribution of the information beam, and a control unit. The control unit controls the spatial light modulator on the basis of the intensity distribution detected by the image sensing device. An optical disk recording apparatus, and a control method thereof, thereby has a high signal-to-noise ratio.

Owner:KK TOSHIBA

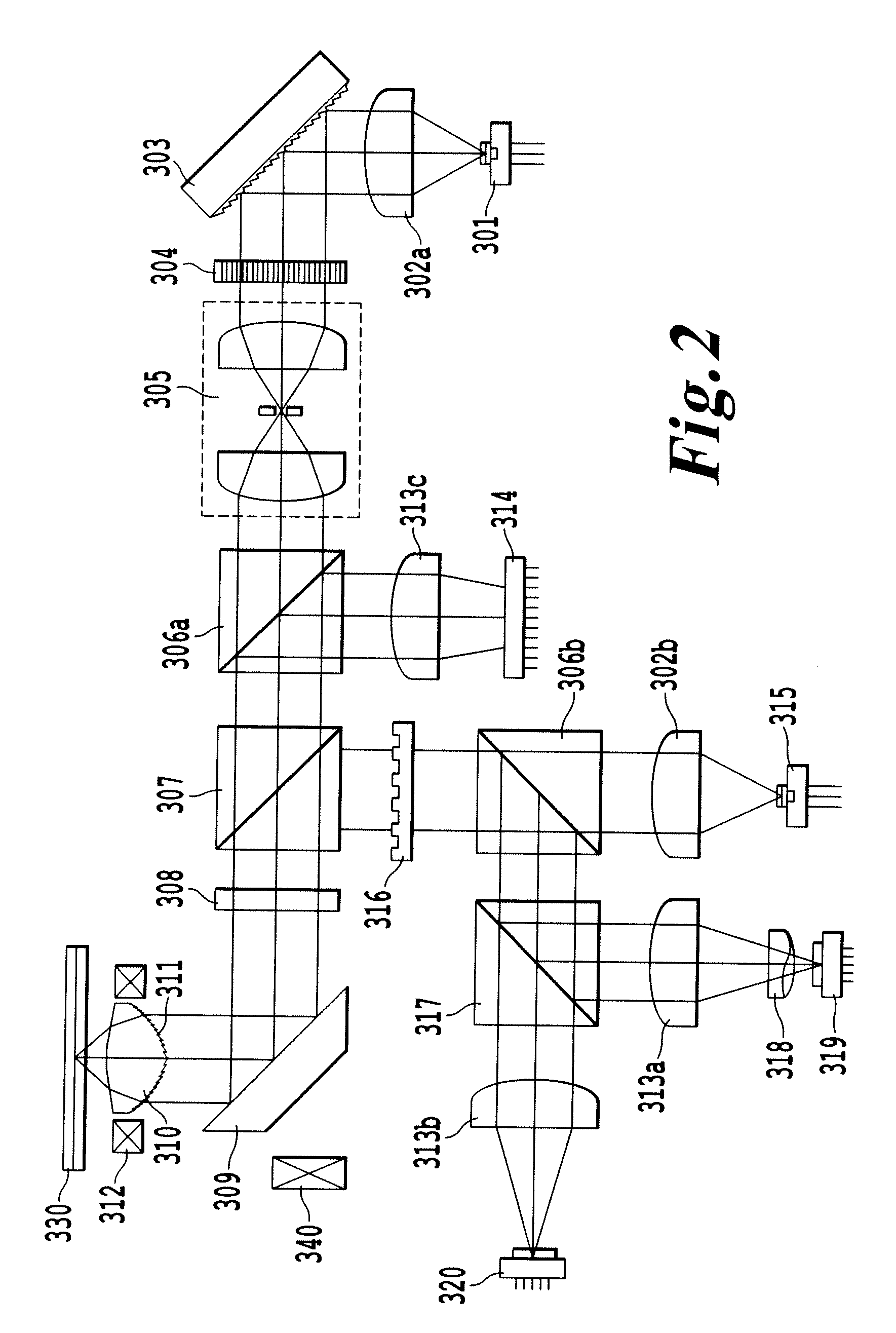

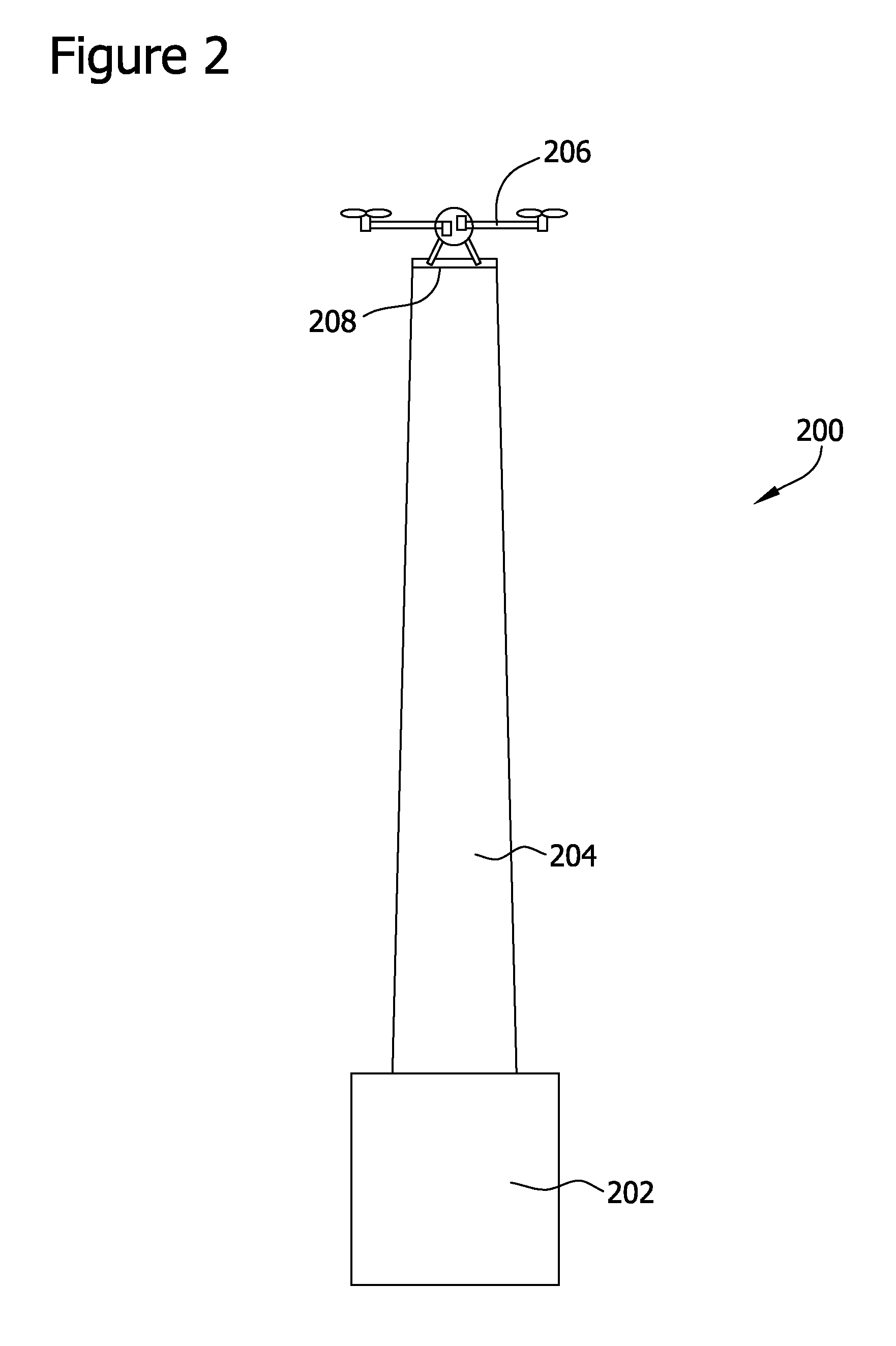

Unmanned vehicle and system

ActiveUS20120150364A1Unmanned aerial vehiclesDigital data processing detailsBeam sourceMarine engineering

An unmanned vehicle is provided. The unmanned vehicle includes a navigation system configured to navigate the unmanned vehicle relative to a beam of energy emitted from a beam source, a power receiver configured to receive energy from the beam, and an energy storage system configured to store received energy for use in selectively powering the unmanned vehicle.

Owner:THE BOEING CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com