Patents

Literature

479results about How to "Large rotation angle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

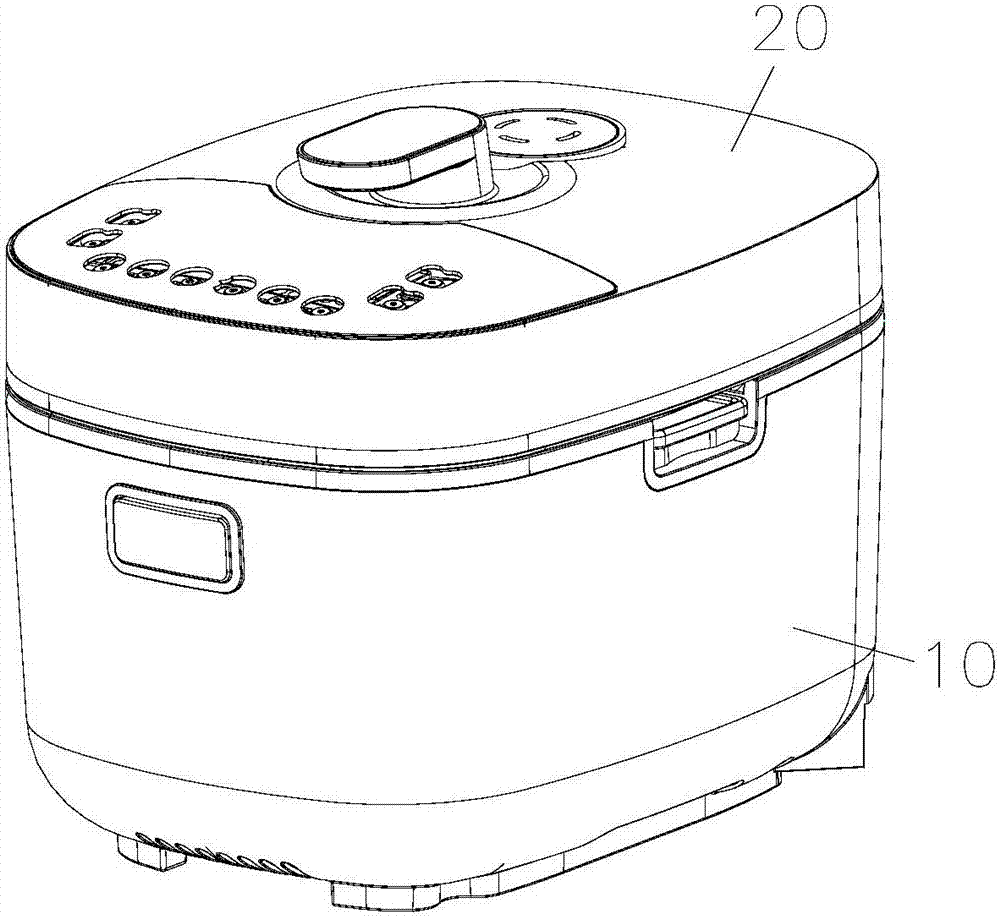

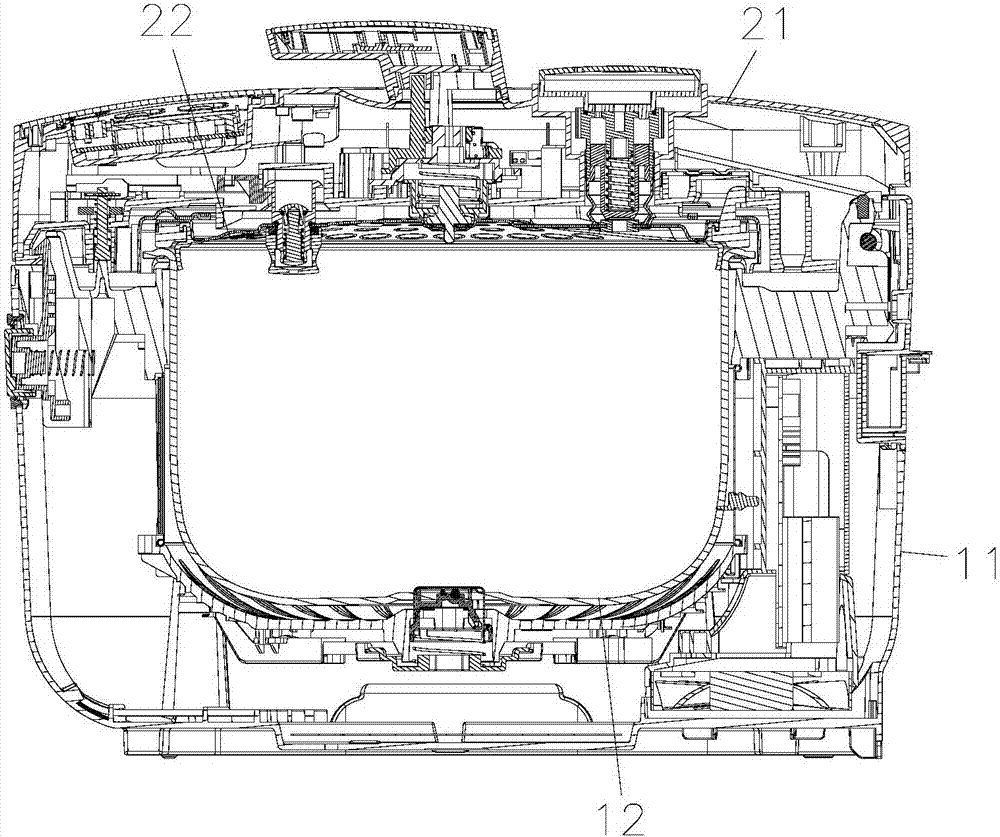

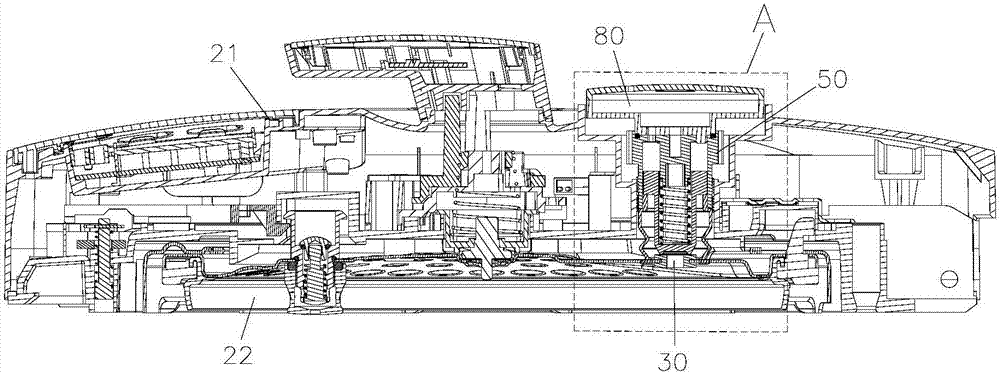

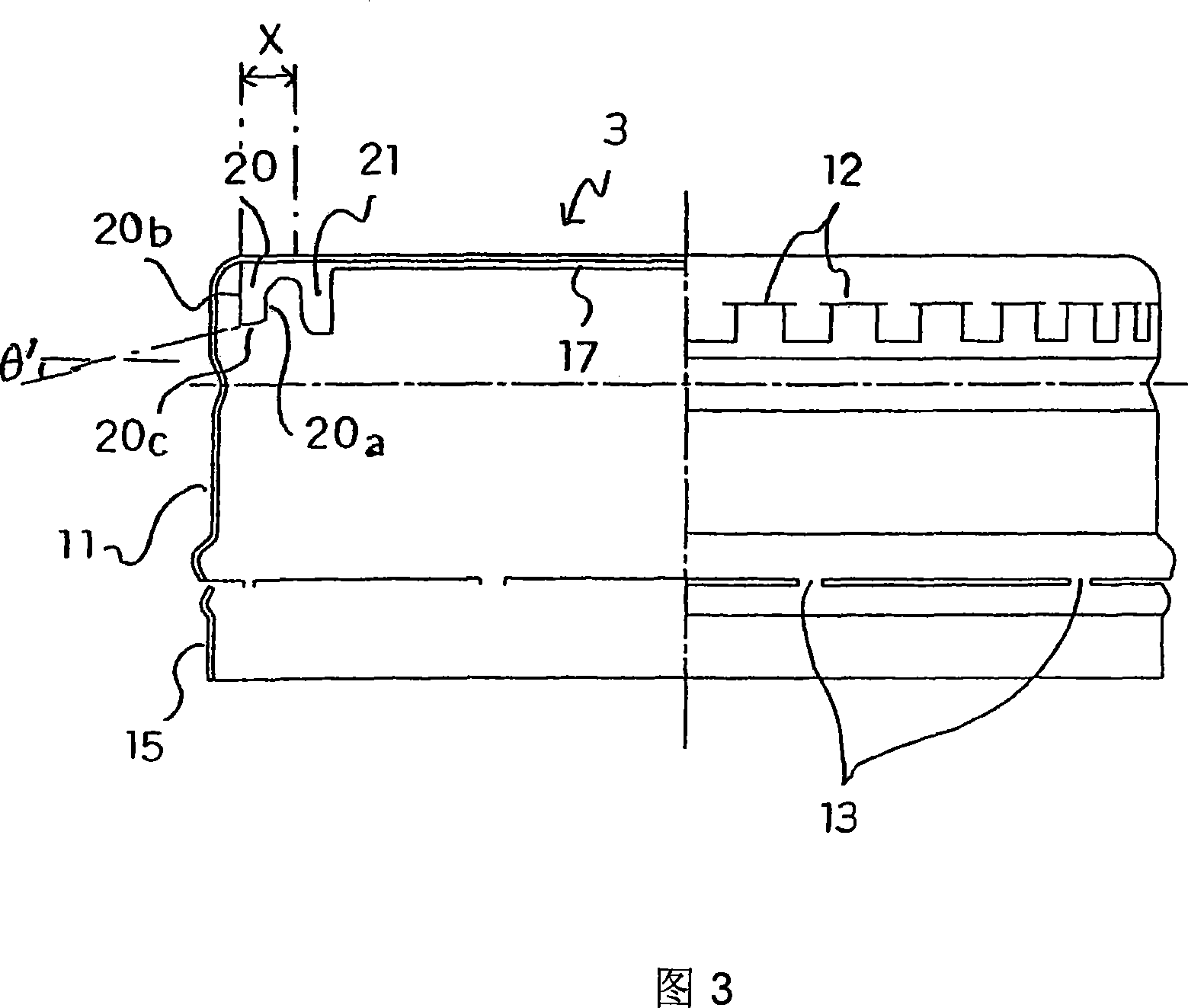

Electric pressure cooker

ActiveCN107019419ASmall linear motion distanceLarge rotation angleFood processingPressure-cookersEngineeringCooked food

The invention discloses an electric pressure cooker, which comprises a cooker body, a cooker cover and a driving mechanism, wherein the cooker body comprises an outer pot and an inner pot which is arranged in the outer pot, and the inner pot is used for accommodating cooked foods; the cooker cover is arranged on the cooker body and the cooker cover covers the inner pot in a sealing mode; an exhaust passage which communicates with the interior of the inner port and a pressure limiting valve which is in charge of controlling a ventilation state of the exhaust passage are arranged on the cooker cover; the driving mechanism comprises a power mechanism which is used for offering rotating motion of a rotating shaft and a threaded transmission mechanism which is used for converting rotation of the rotating shaft into vertical motion of the pressure limiting valve; and the threaded transmission mechanism comprises threaded pillars and threaded holes which are mutually matched. With the application of the technical scheme provided by the invention, a problem in the prior art that an electric pressure cooker, which cannot achieve continuous exhausting, is poor in cooking effect since foods cannot be kept turning continuously is solved.

Owner:ZHEJIANG SHAOXING SUPOR DOMESTIC ELECTRICAL APPLIANCE CO LTD

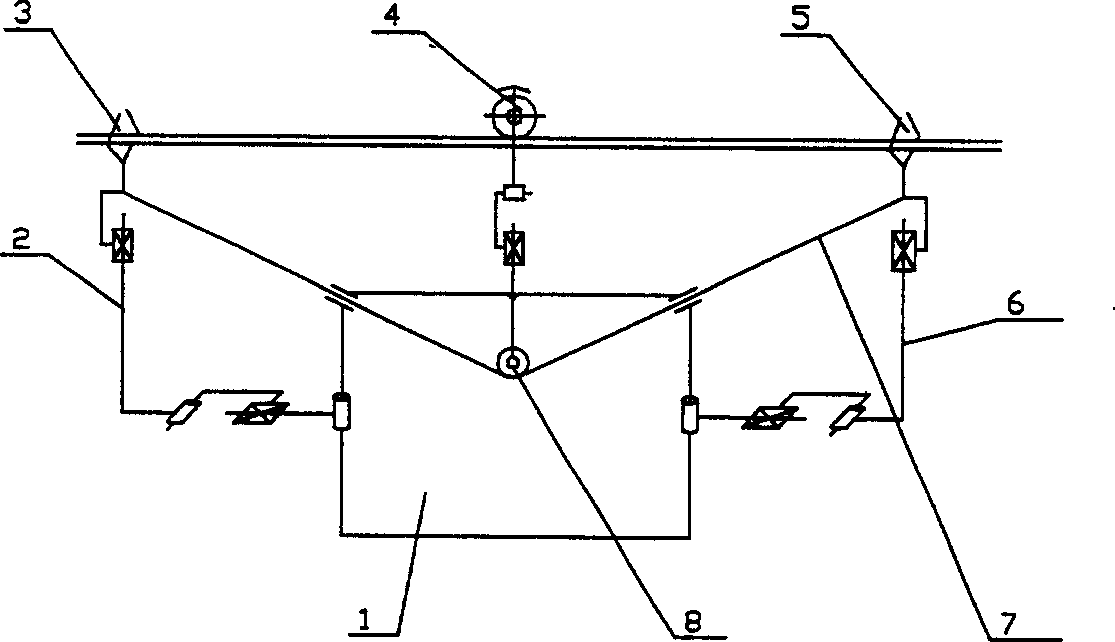

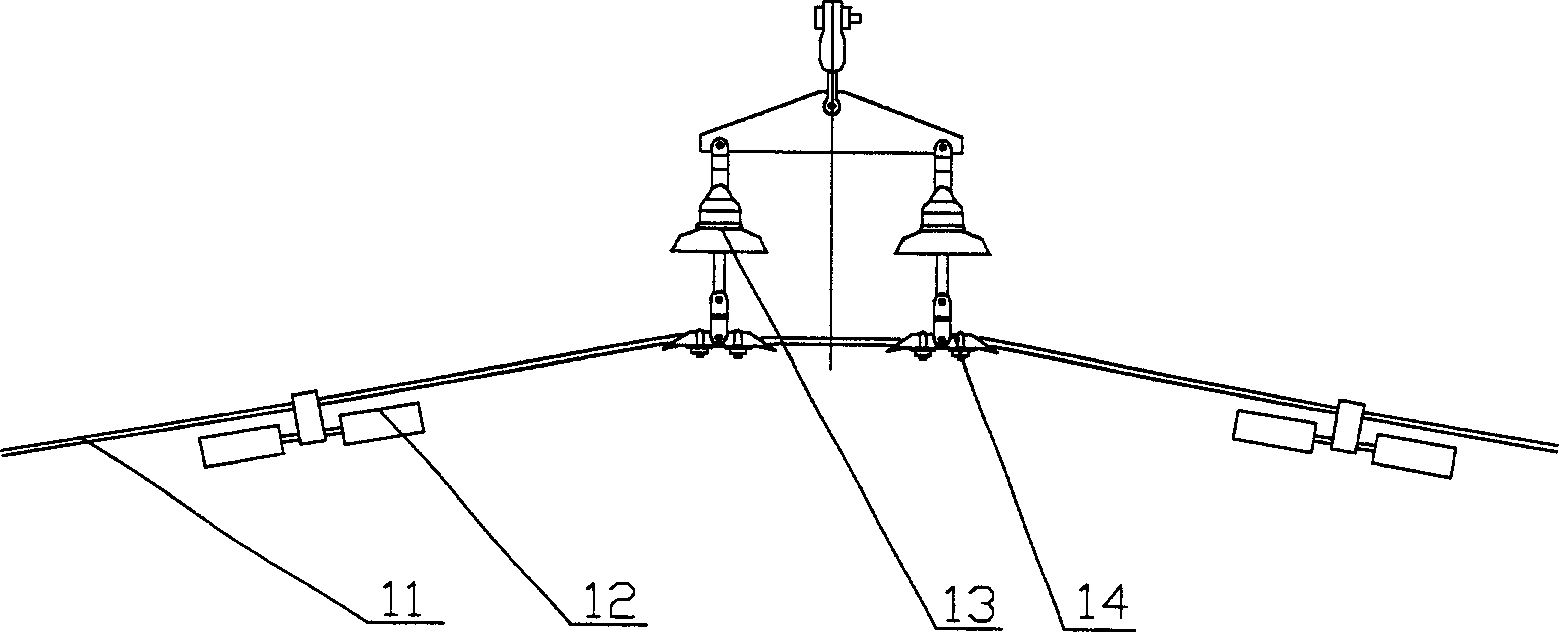

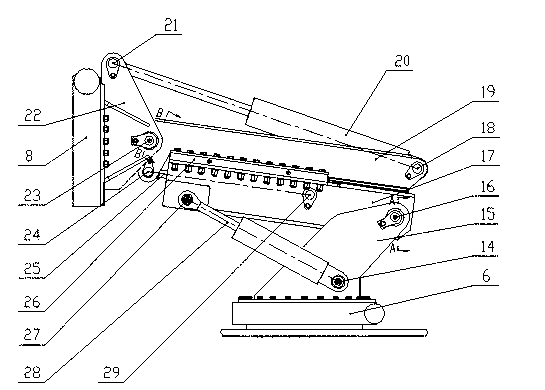

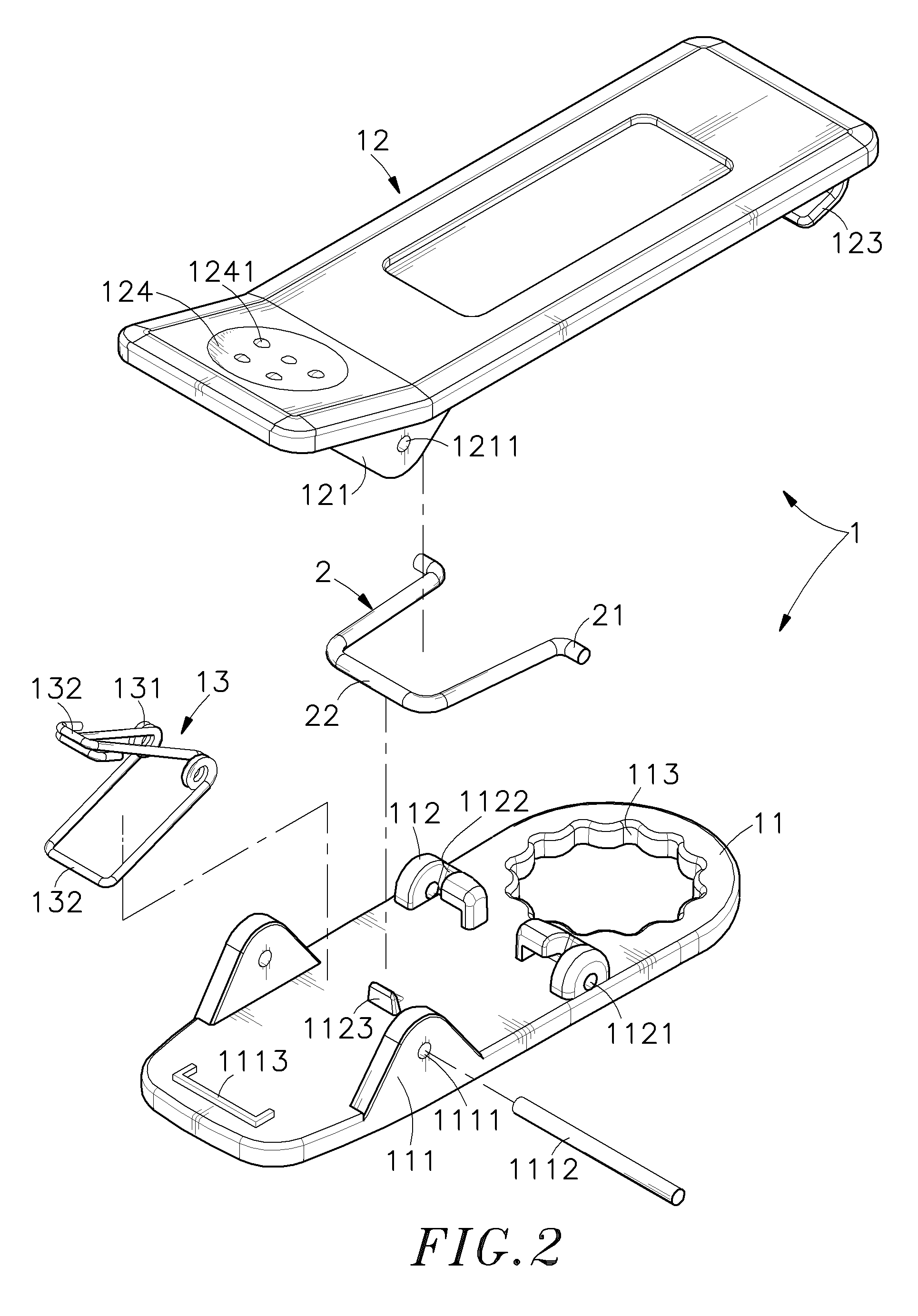

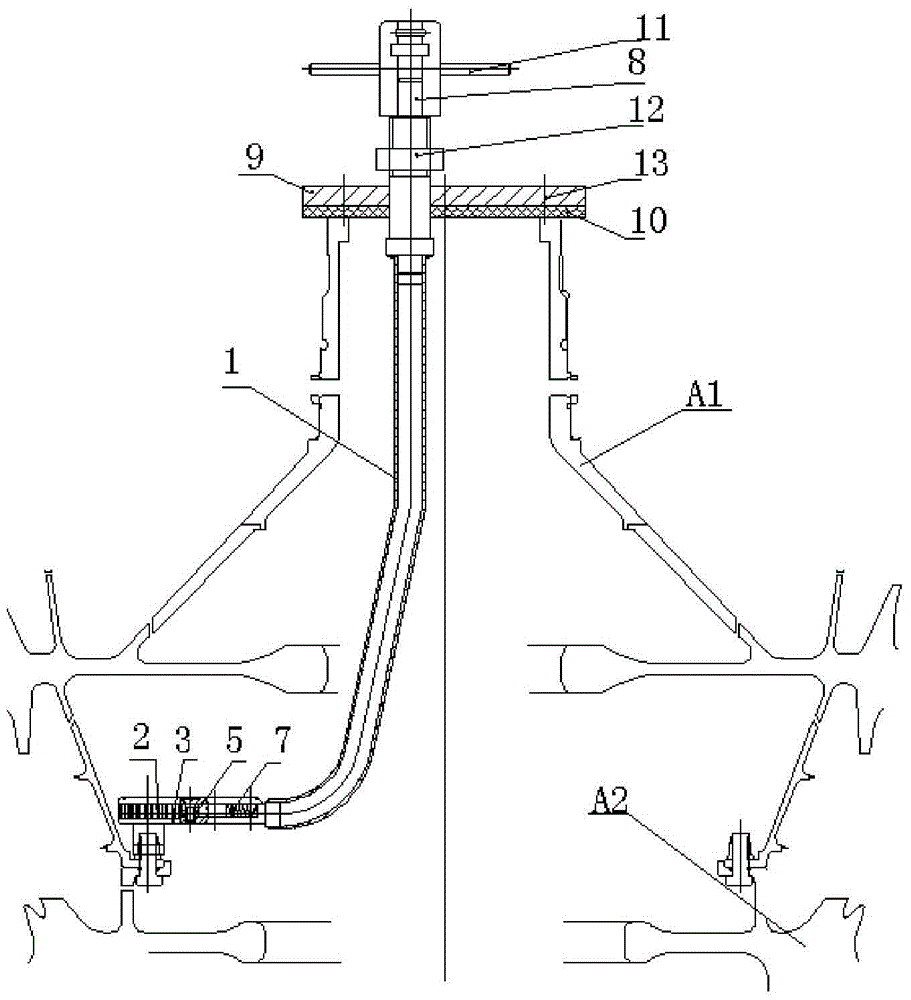

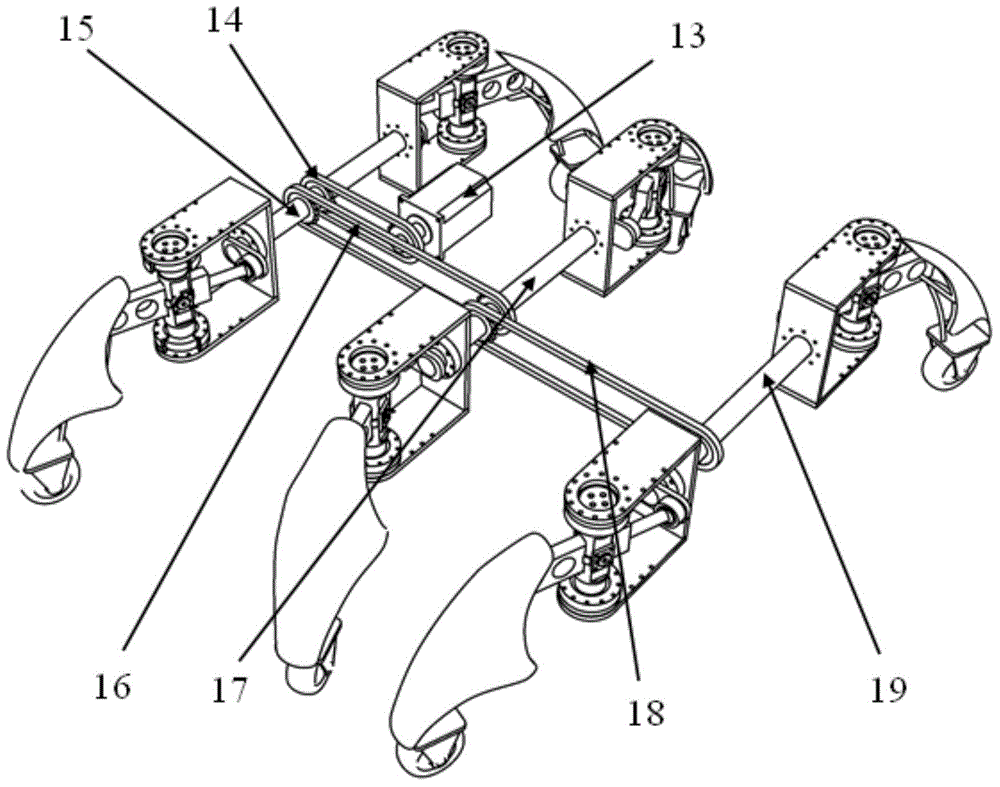

Super-voltage transmission line monitoring and detecting robot mechanism

InactiveCN1689769AEasy to walkConducive to overcoming obstaclesManipulatorMobile vehicleUltra high voltage

The present invention relates to movable robot mechanism, and is especially ultra high voltage power line polling robot mechanism. The polling robot mechanism consists of moving vehicle, back arm and front arm. The moving vehicle consists of vehicle body and walking wheel, the walking wheel is installed onto the vehicle body via horizontal rotation pair and moving pair and grasps the wire, and the vehicle body is connected via the rotation pair to the front arm and the back arm. The arm has hand claw in the end, the front arm and the back arm have the same structure, and each of the front arm and the back arm consists of two parts, upper arm and lower arm. The upper arm as one combined structure of link rod, ball lead screw and block is connected via horizontal rotation pair to the lower arm; and the lower arm is one great stroke telescopic mechanism. The present invention has great work space, light weight, low power consumption and powerful obstruction crossing capacity.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

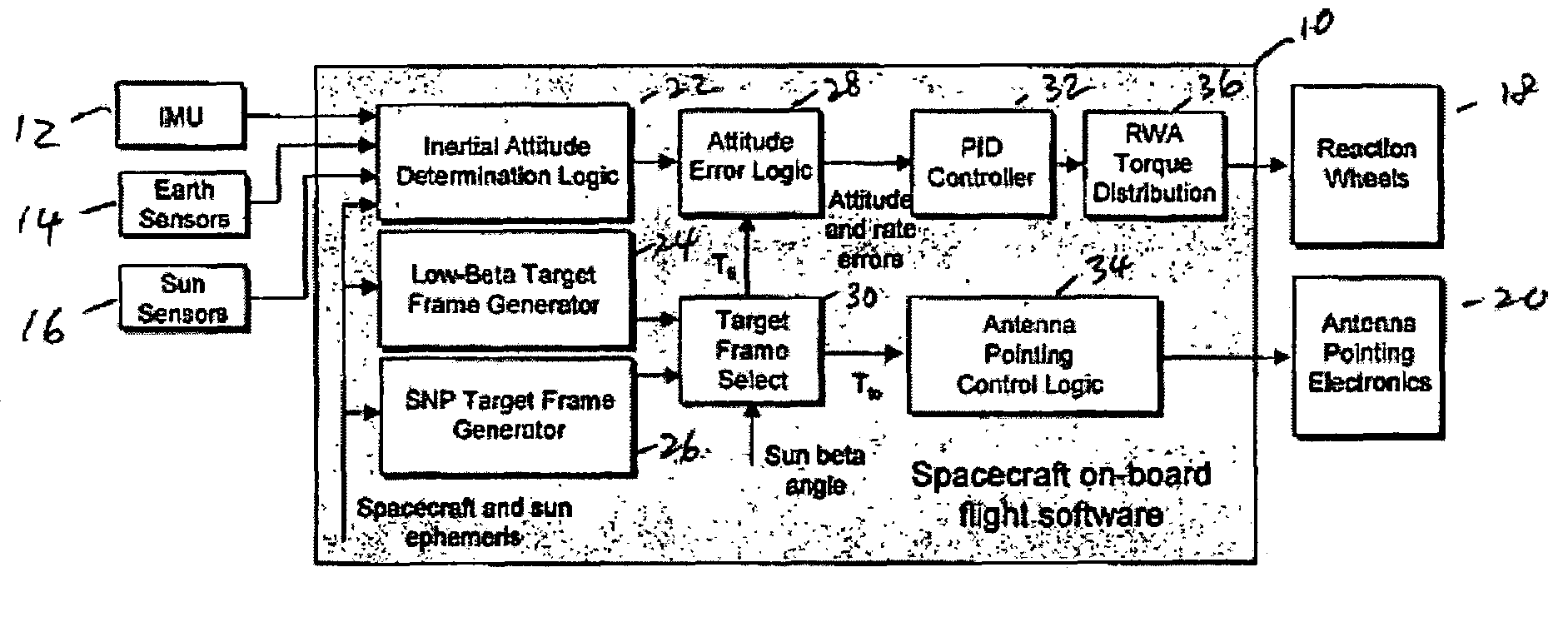

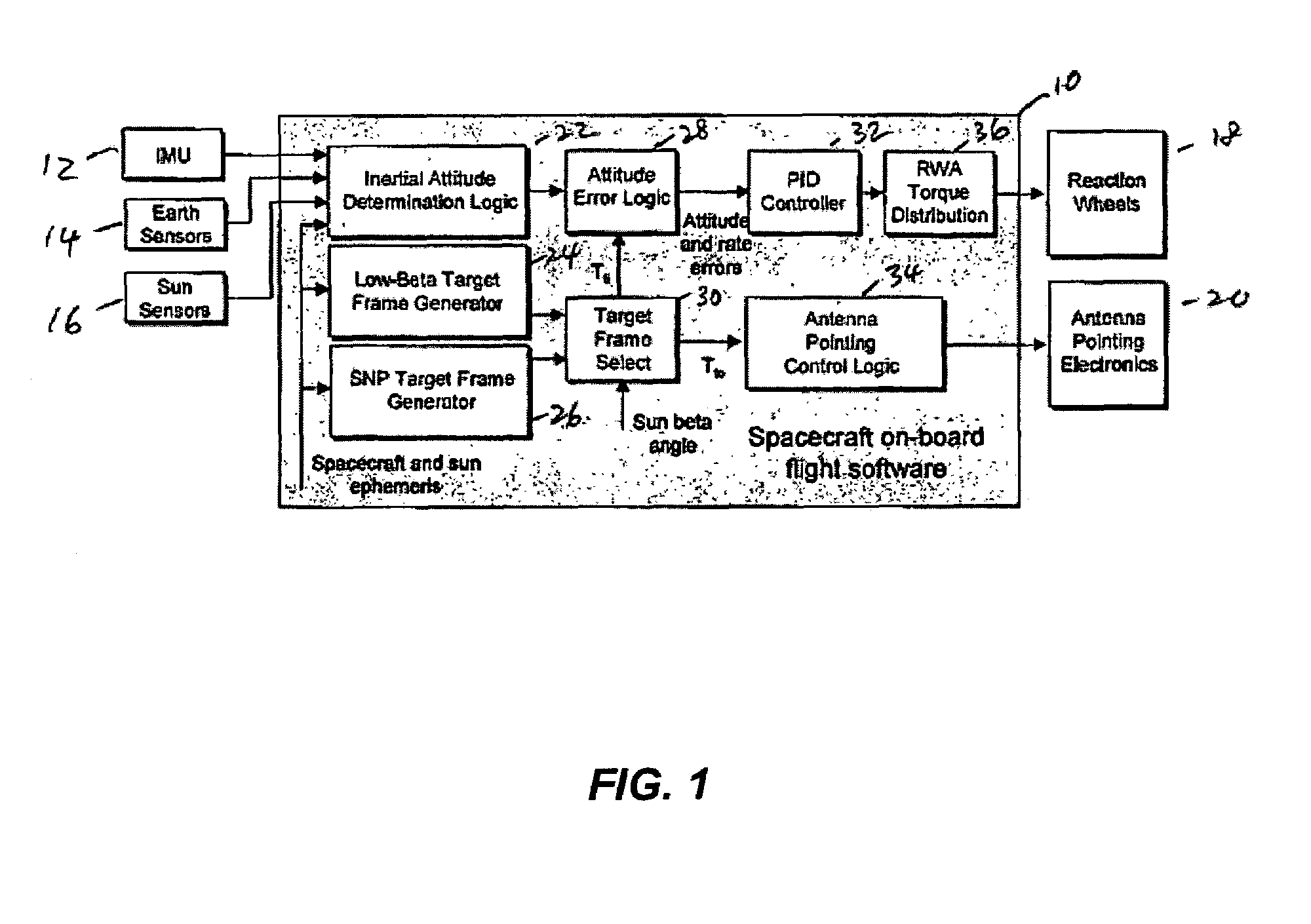

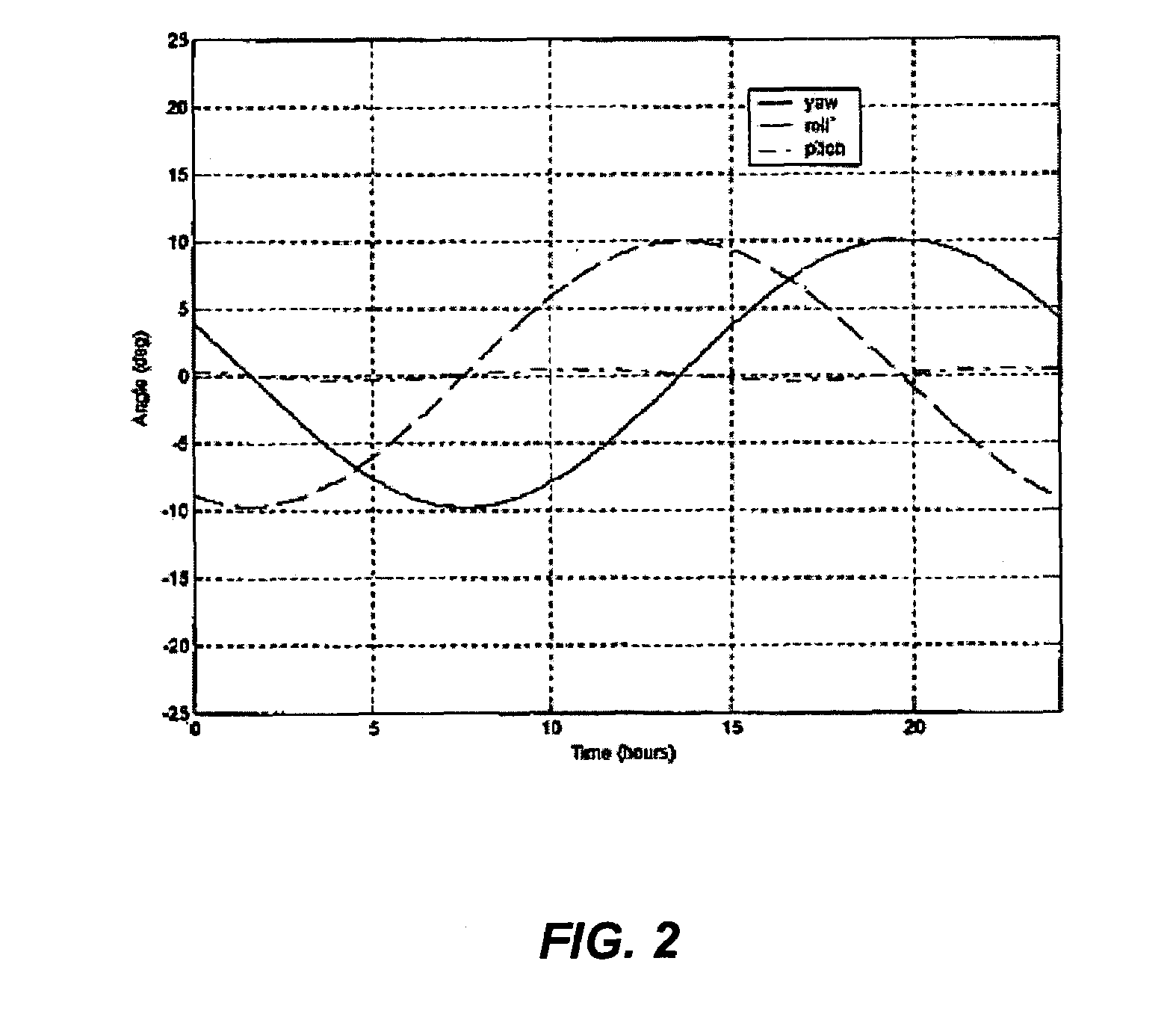

Attitude and antenna steering system for geosynchronous earth orbit (GEO) spacecraft

ActiveUS7357356B1High rateLarge rotation angleCosmonautic vehiclesRadio transmissionBeta angleGeosynchronous orbit

A system for providing attitude and antenna steering for a spacecraft is disclosed. The spacecraft has a number of reaction wheels and a number of antennas. The system includes control logic configured to: determine a beta angle, the beta angle being the angle between a sun vector and an orbit plane of the spacecraft, and alternately engage either a first mode or a second mode to provide attitude and antenna steering based on the beta angle.

Owner:LOCKHEED MARTIN CORP

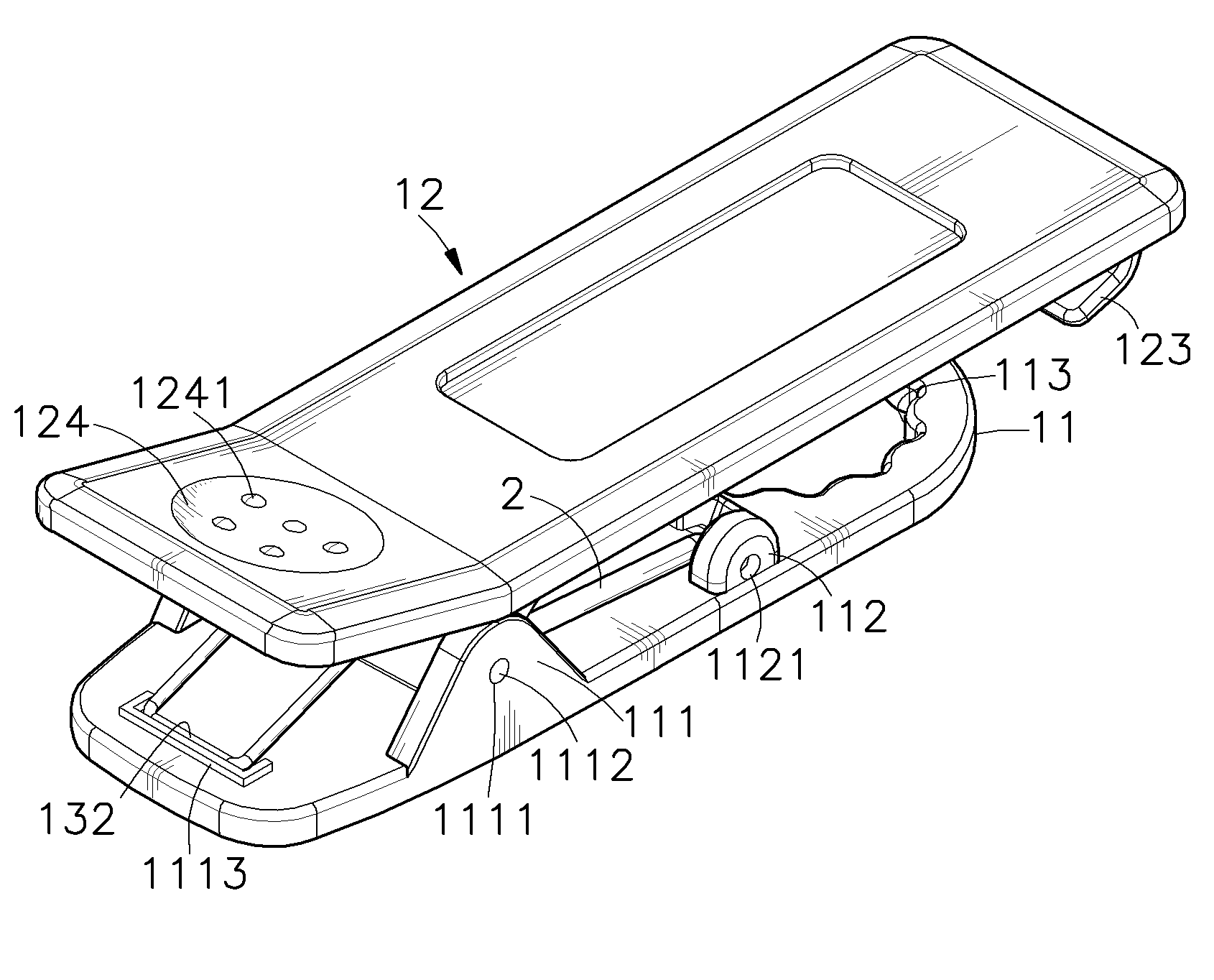

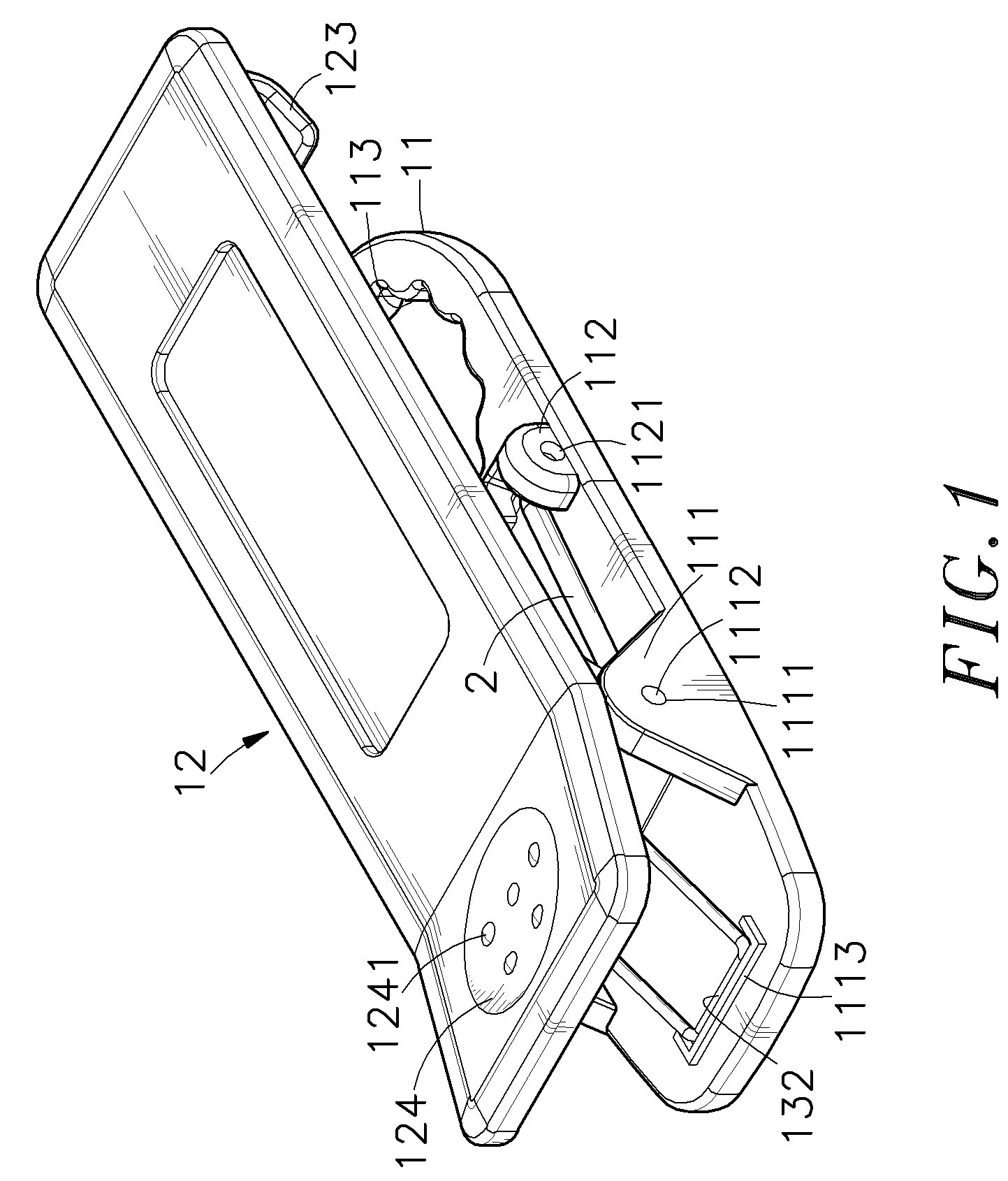

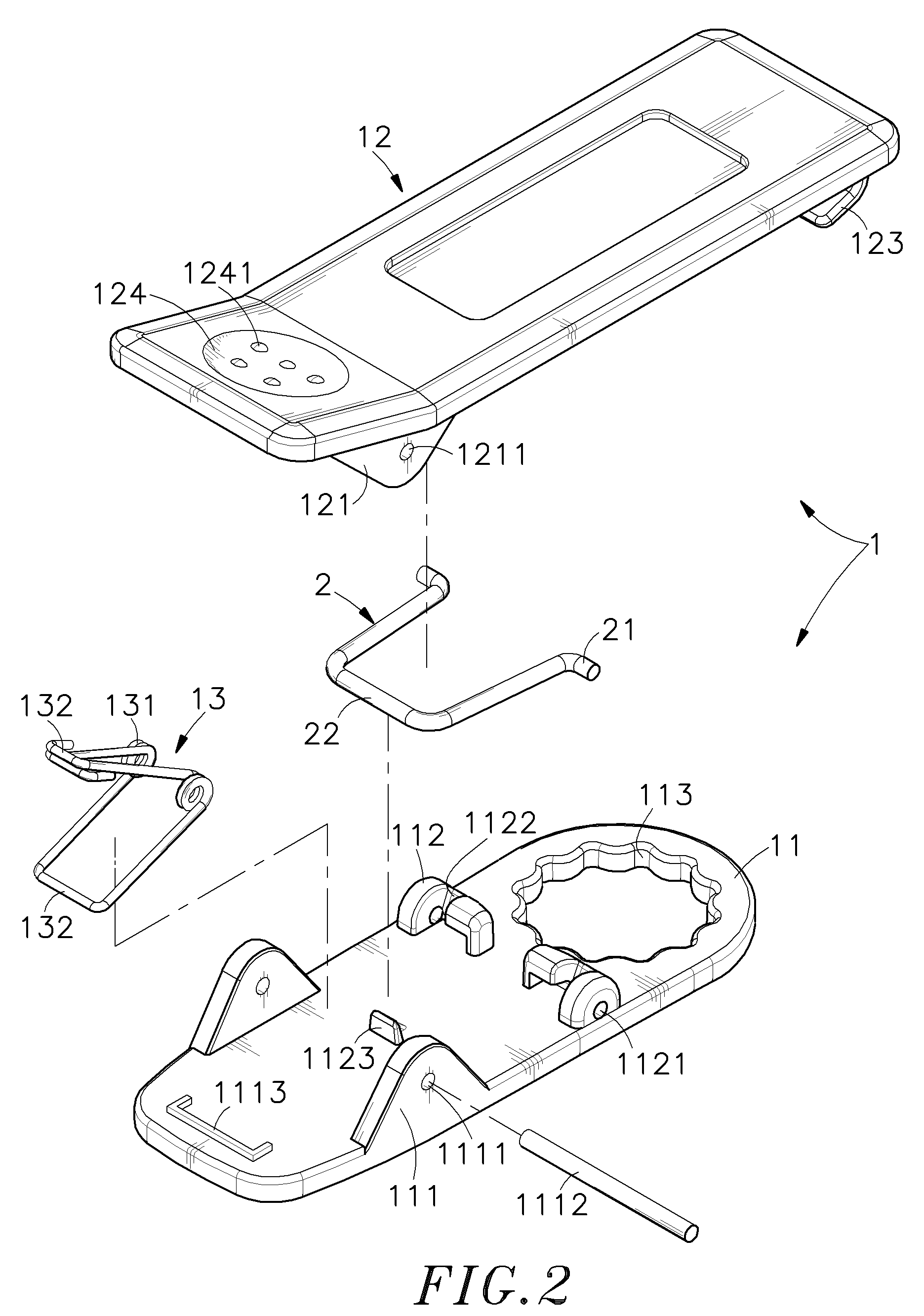

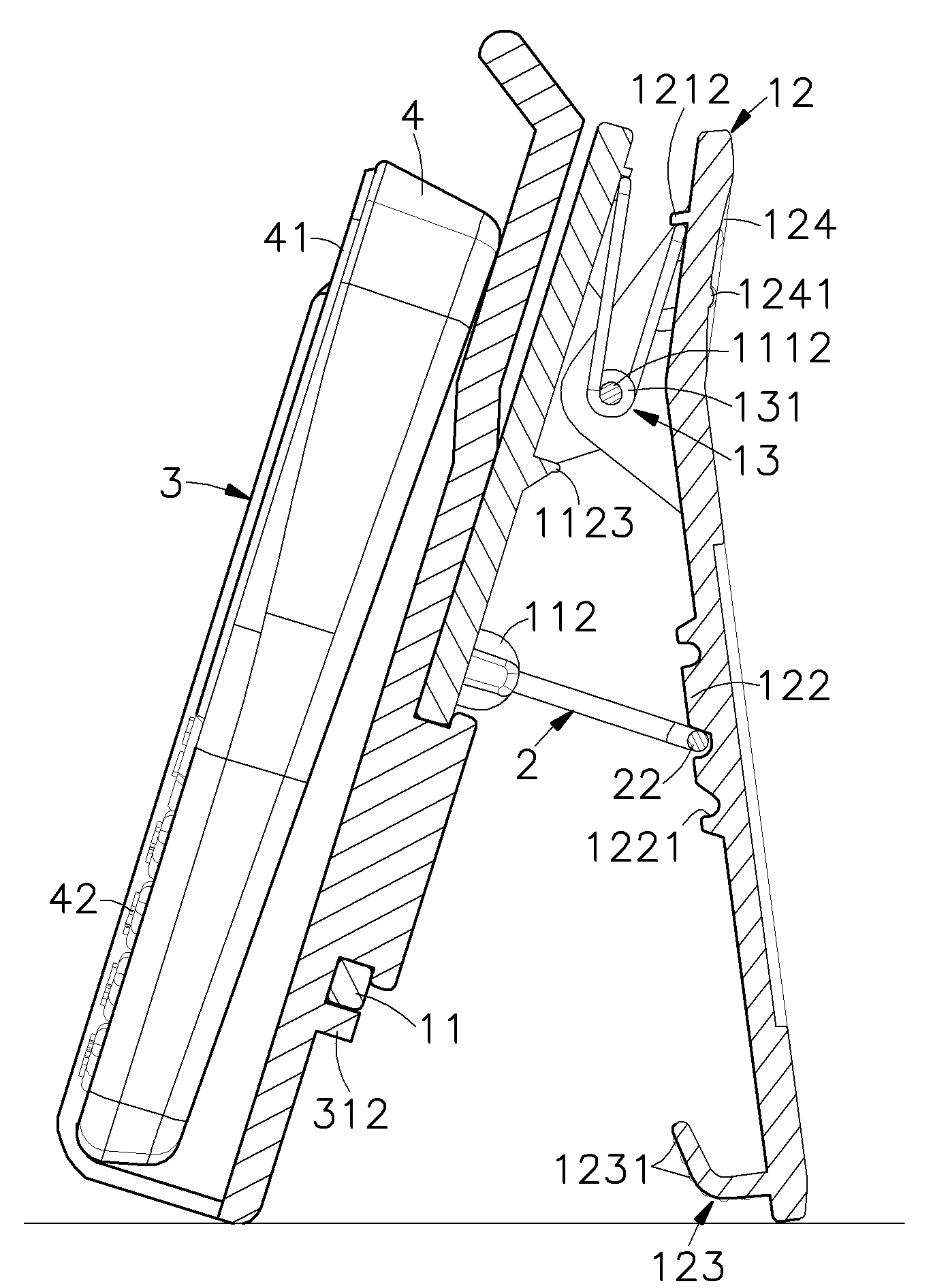

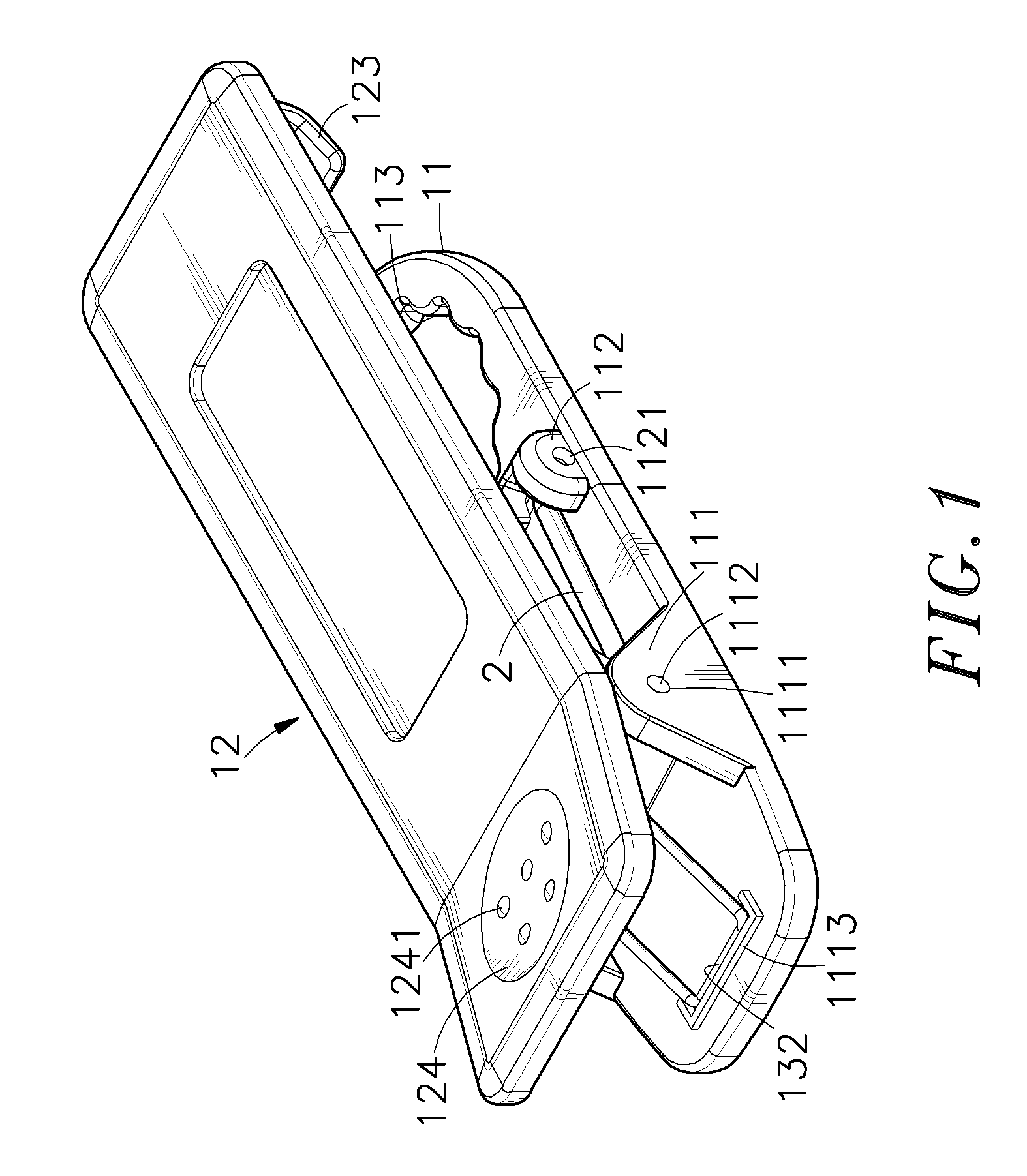

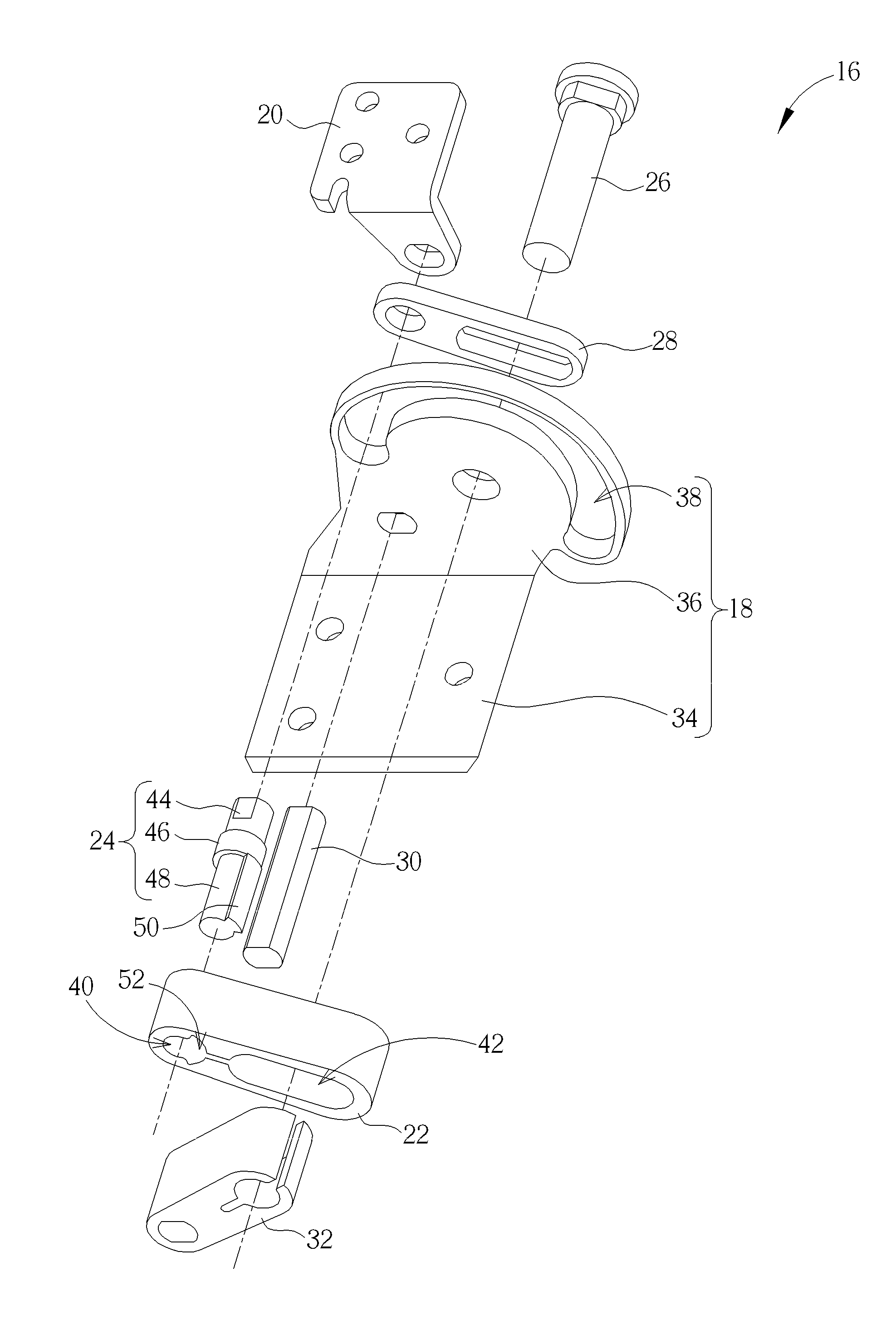

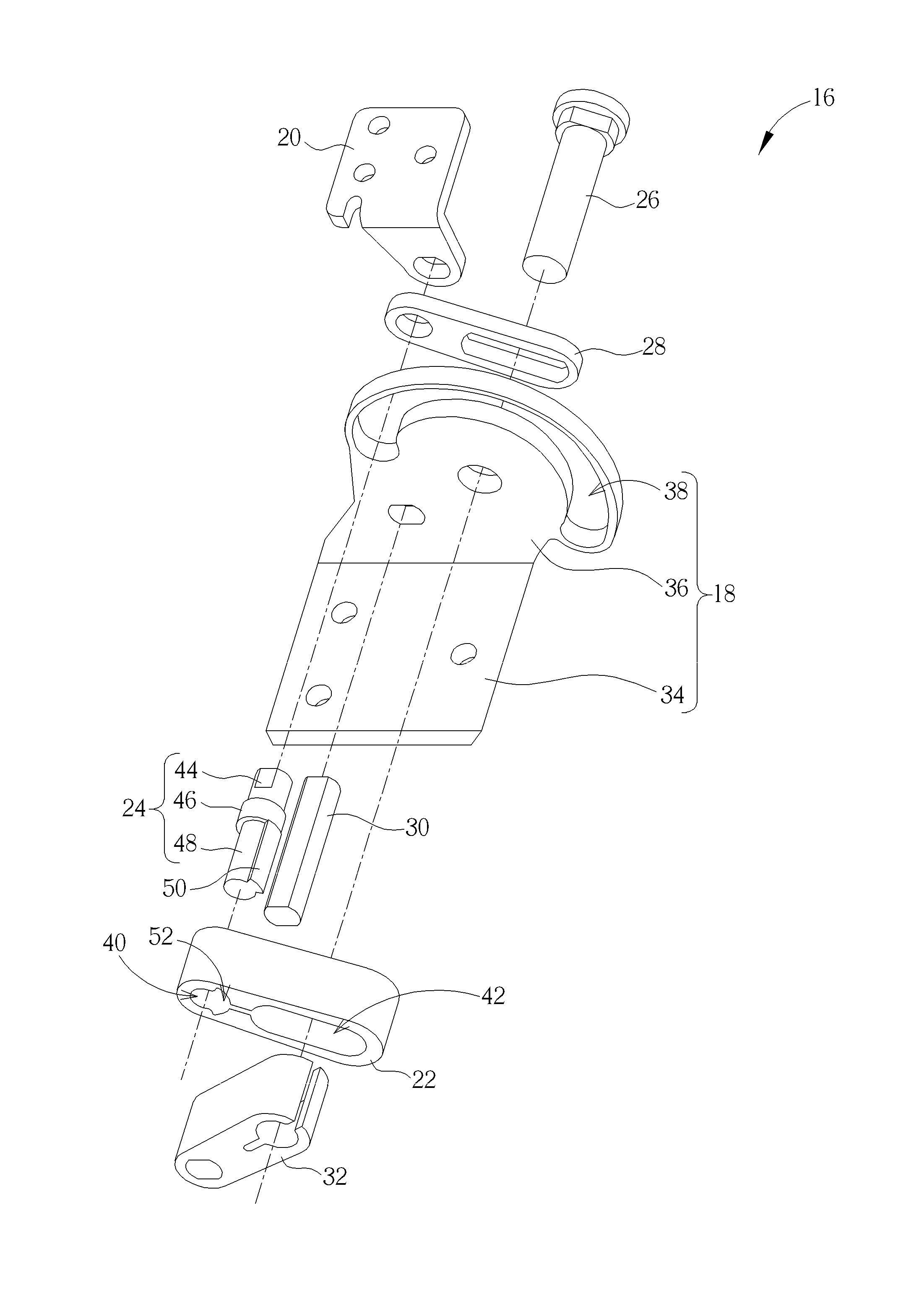

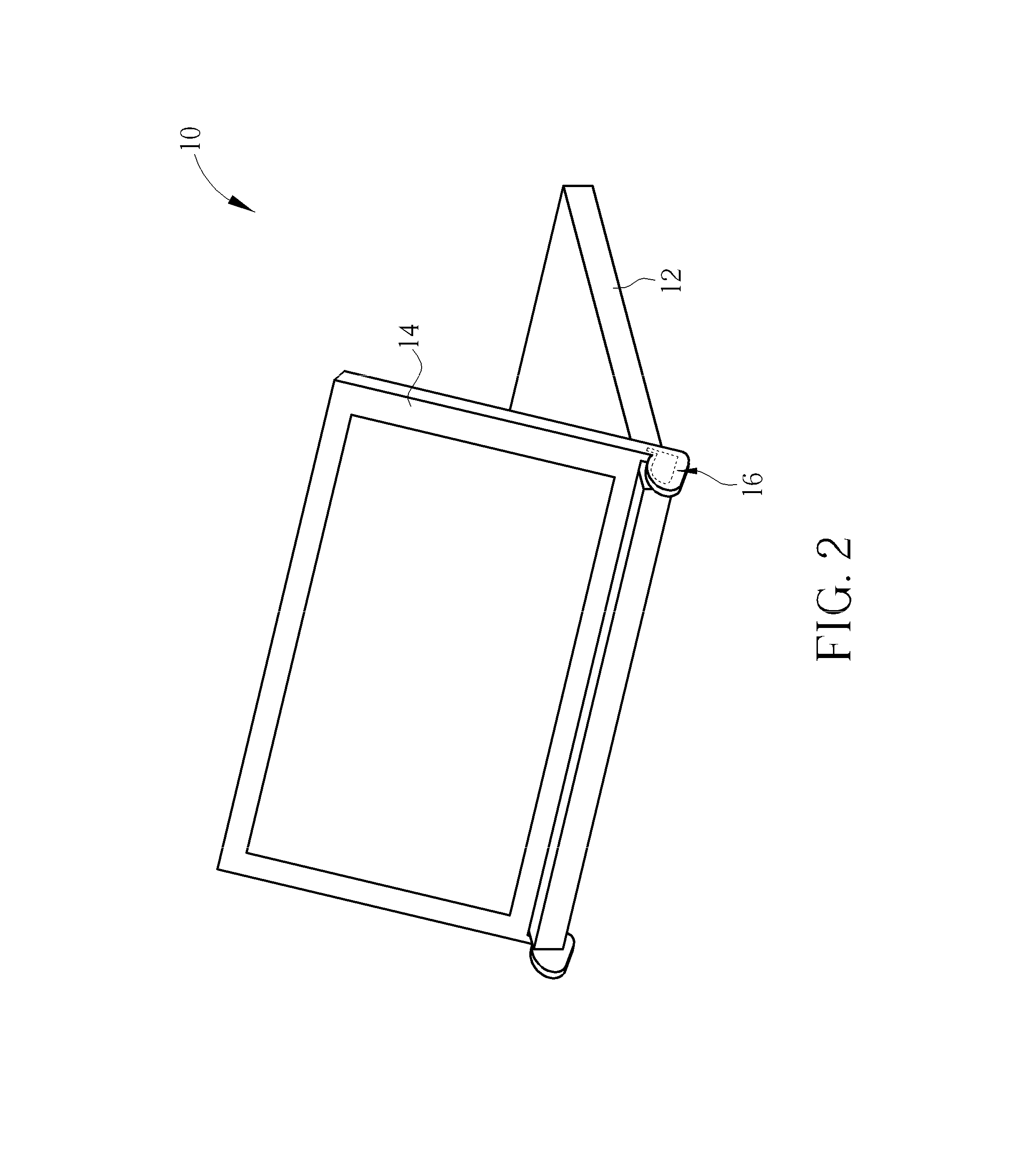

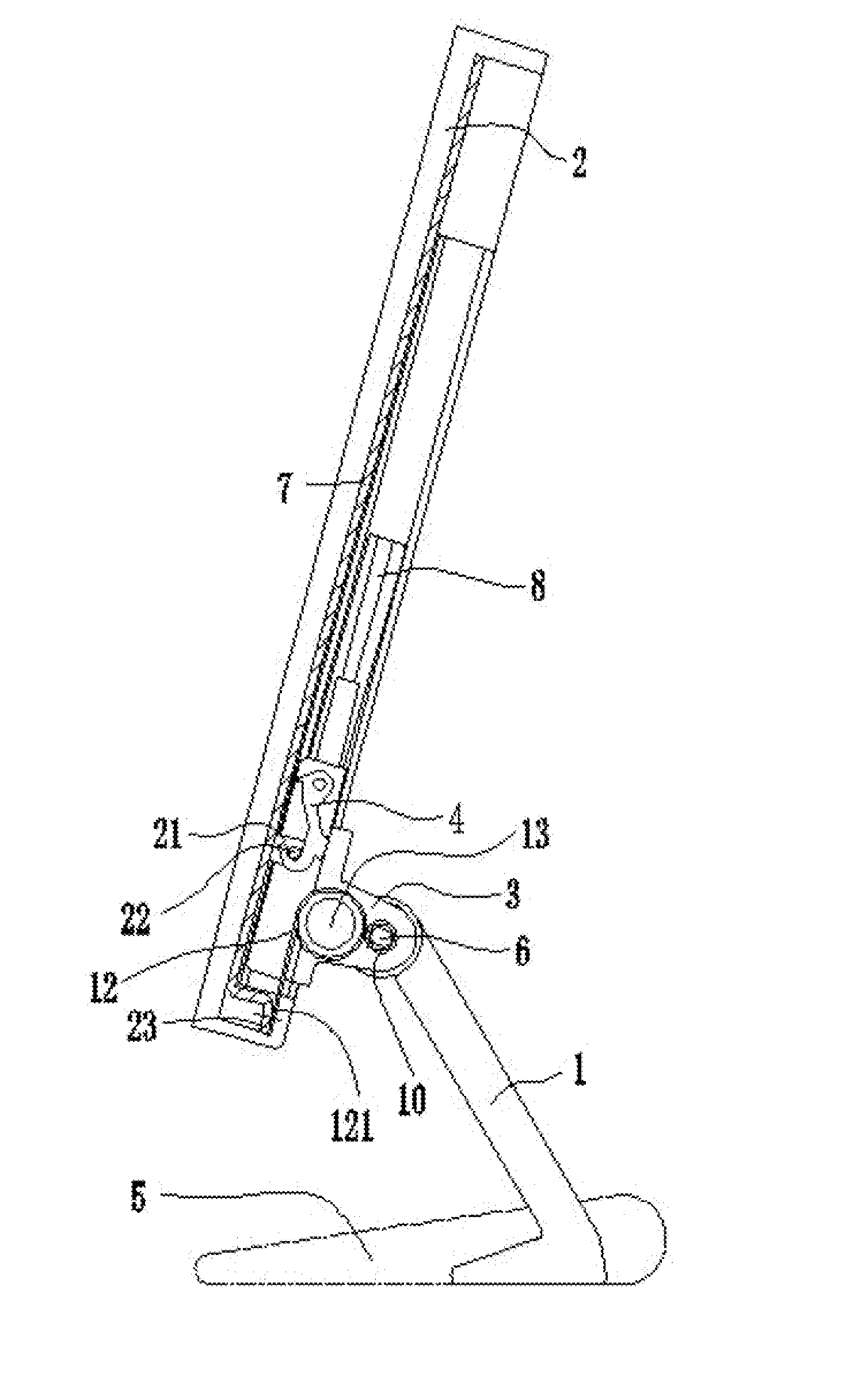

Adjustable stand

InactiveUS7513472B2Large rotation angleEasy to carryPicture framesDomestic mirrorsMechanical engineeringEngineering

An adjustable stand for carrying an electronic device and adjusting a position on a desk is provided to include a clamp and a supporting element. The clamp has a positioning element that comprises two axial portions each having a through hole, a clamping element that comprises an adjusting portion with a plurality of notches, and an elastic element positioned between the positioning element and the clamping element for restoring the position. The supporting element has two terminal rods that are axially fixed to the axial portions of the positioning element, and a supporting rod formed between the two terminal rods for lodging into one of the notches of the clamping element.

Owner:YANG SHANG WEN

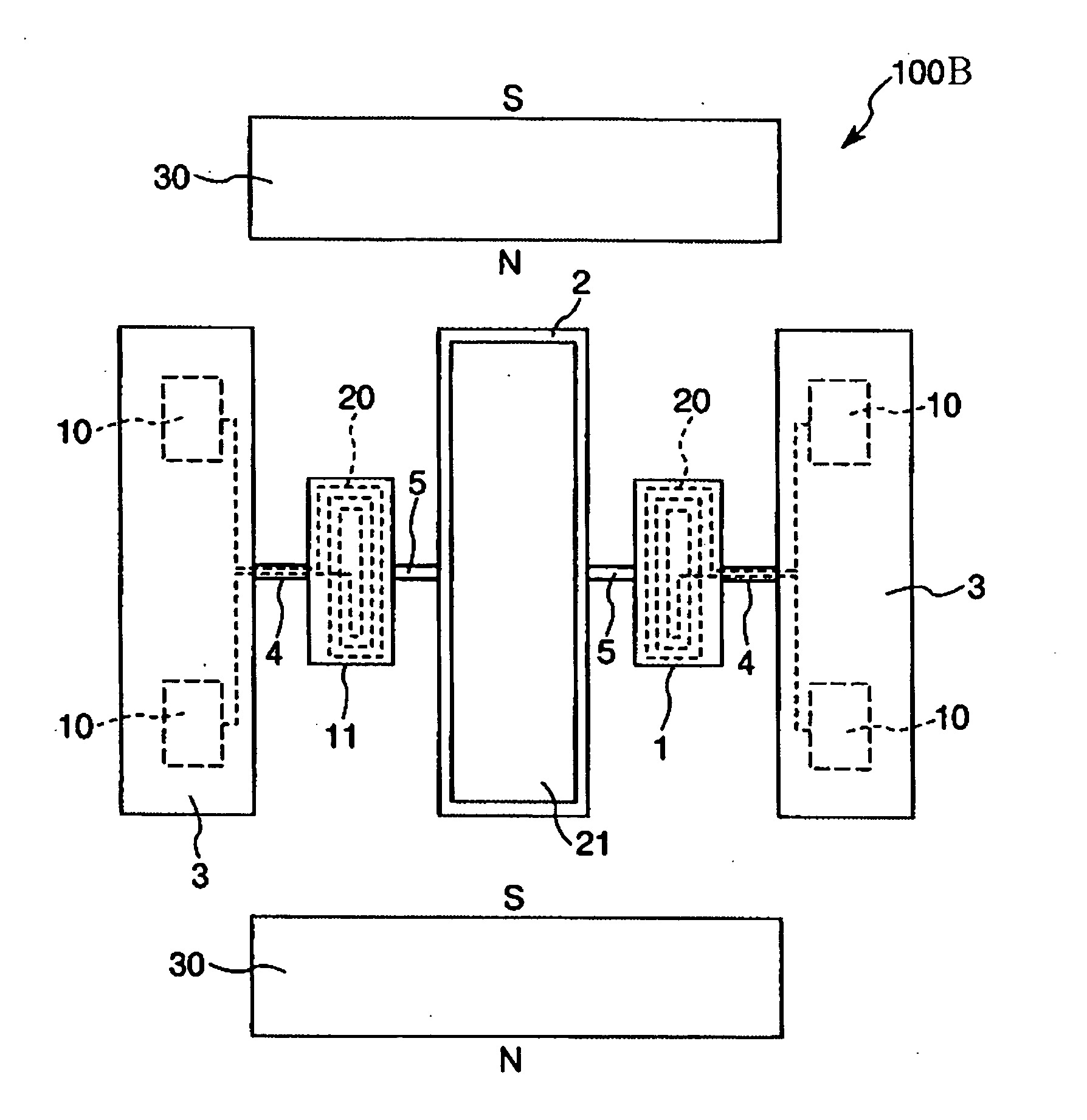

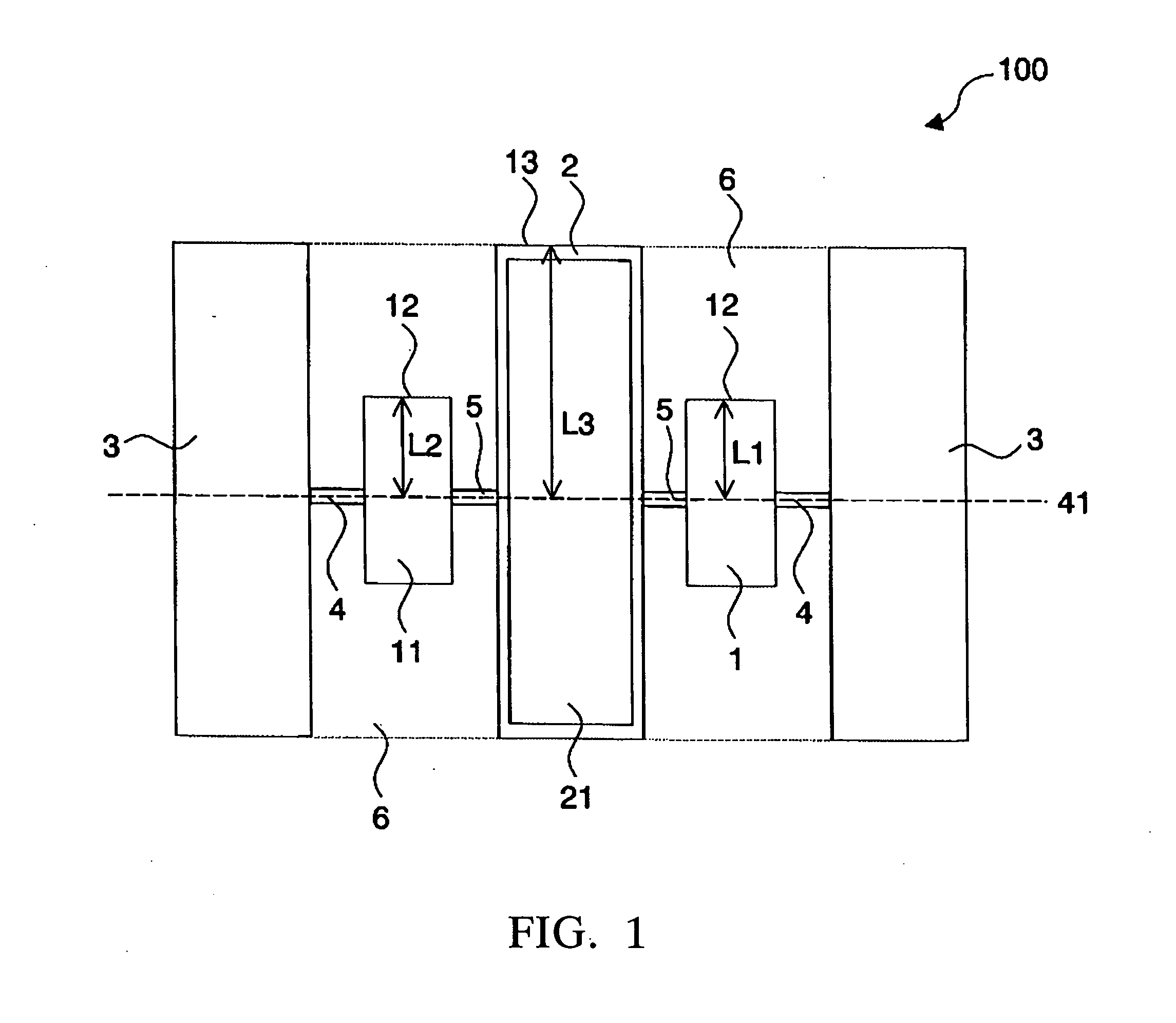

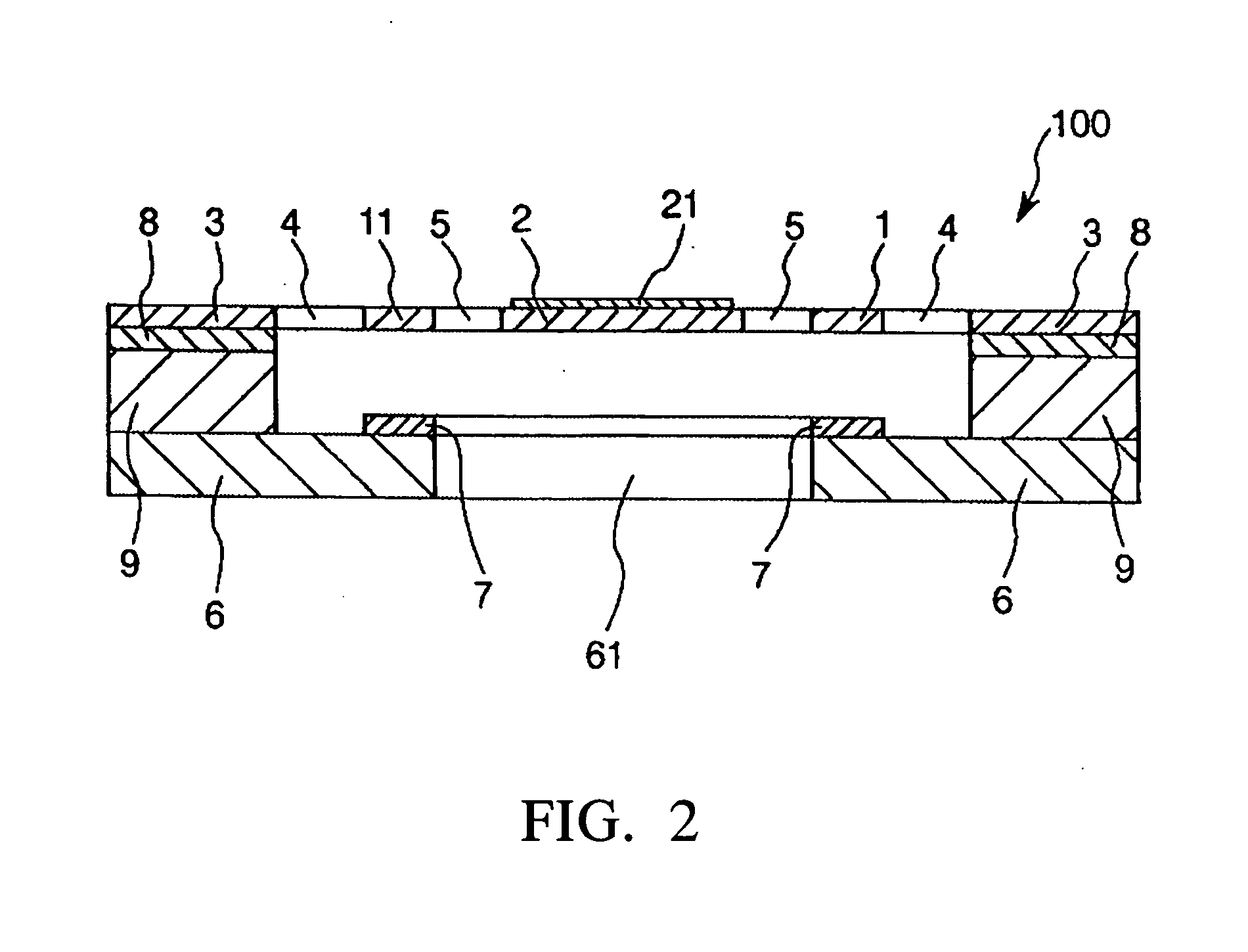

Actuator

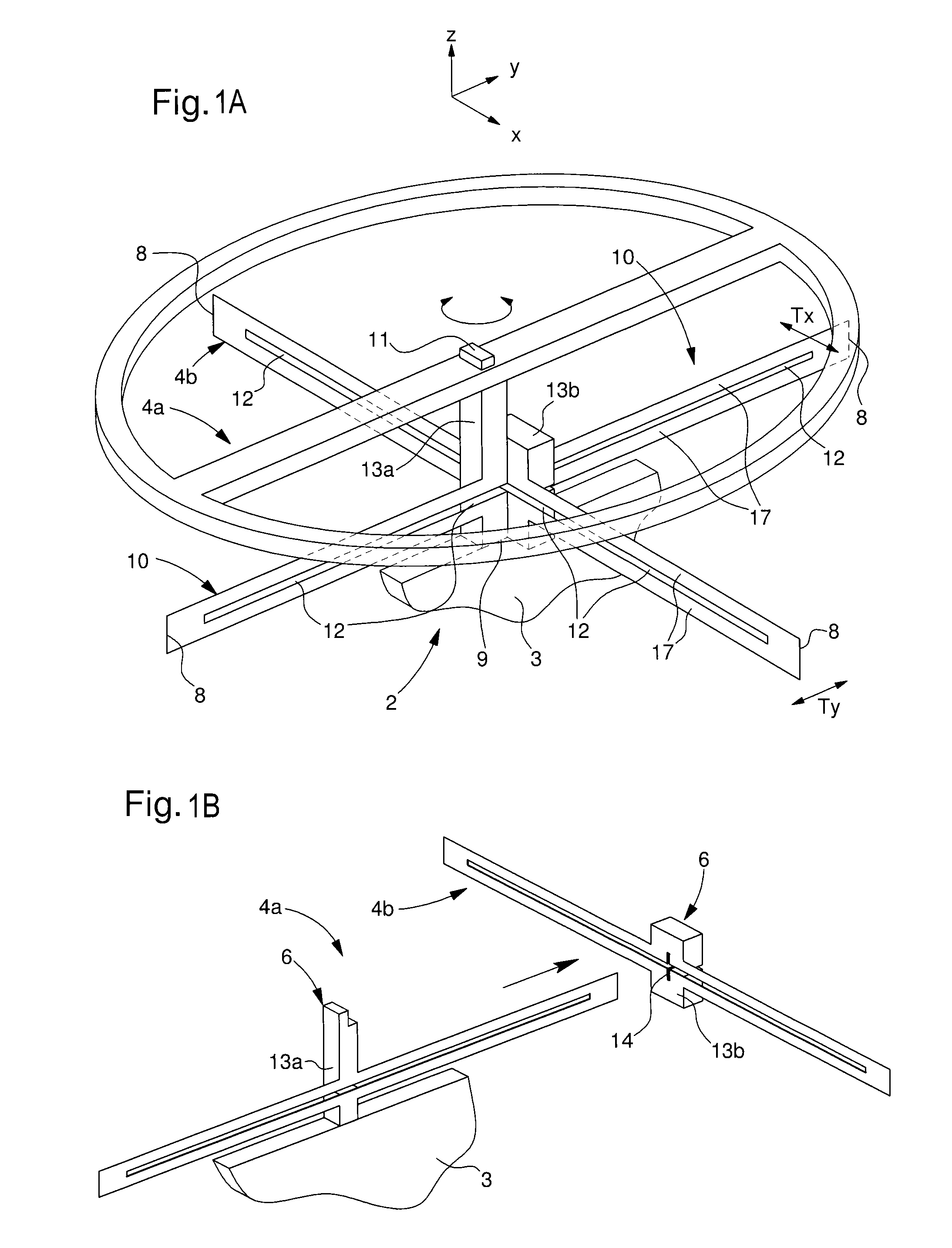

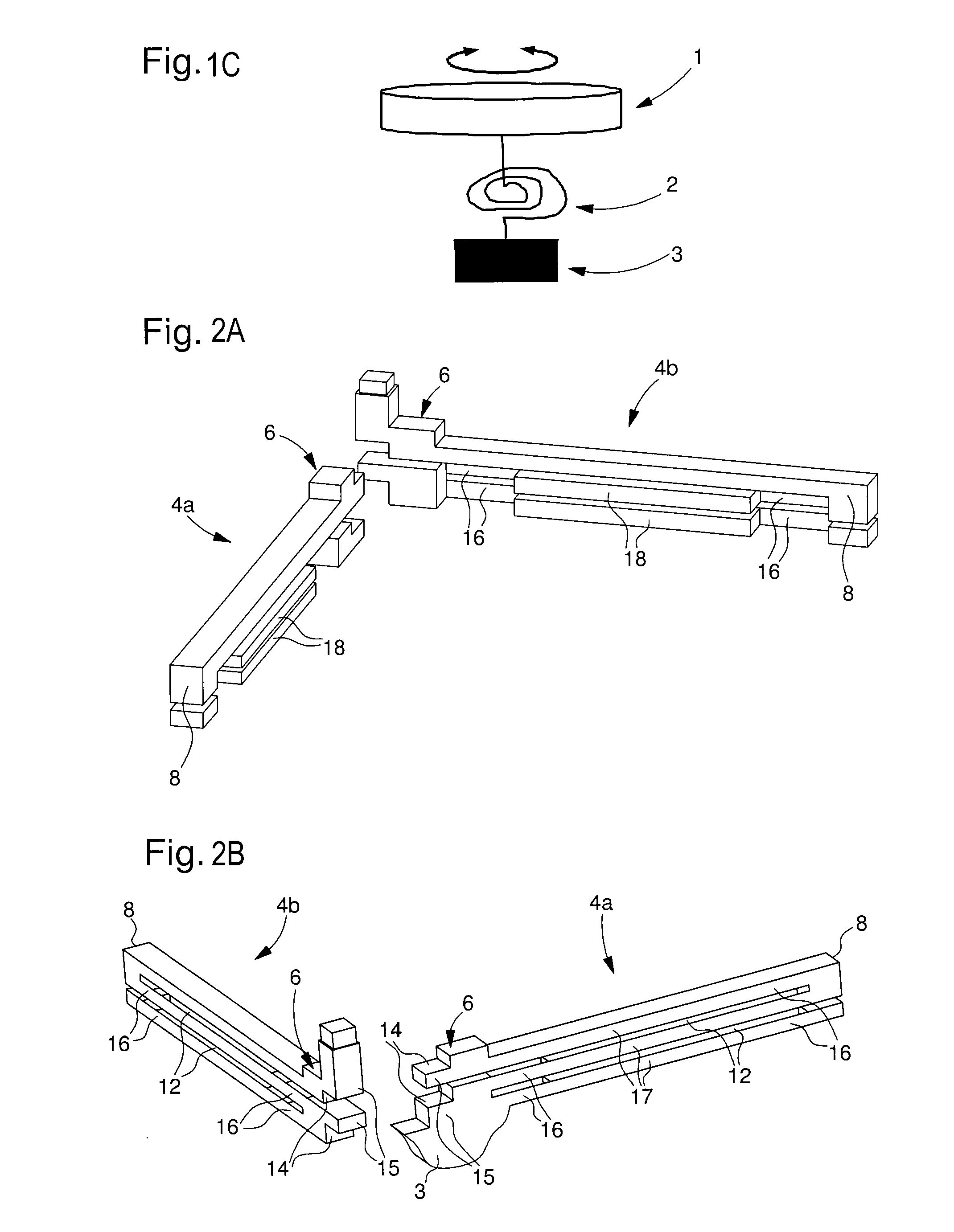

InactiveUS20050088715A1Large displacementLarge rotation angleElectric discharge tubesElectrostatic motorsResonanceLow voltage

An actuator of the type employing a two-degree-of-freedom vibration system includes a first mass portion, a second mass portion, a pair of supporting portions, as least a pair of first elastic connecting portions which connects the first mass portion to the supporting portion so that the first mass portion can rotate with respect to the supporting portion, and at least a pair of second elastic connecting portions which connects the second mass portion to the first mass portion so that the second mass portion can rotate with respect to the first mass portion. The first mass portion is driven by the application of an alternating voltage, causing the second mass portion to rotate, and the frequency of the alternating voltage is set so as to be substantially the same as a lower resonance frequency of resonance frequencies of the two-degree-of-freedom vibration system at which the first mass portion and the second mass portion resonate. This makes it possible to provide the actuator capable of operating at high speed and at low voltage and achieving a large rotation angle.

Owner:SEIKO EPSON CORP

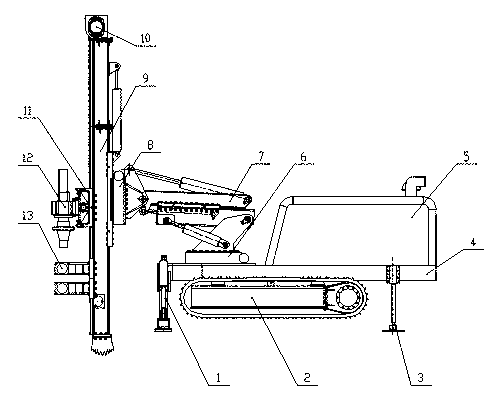

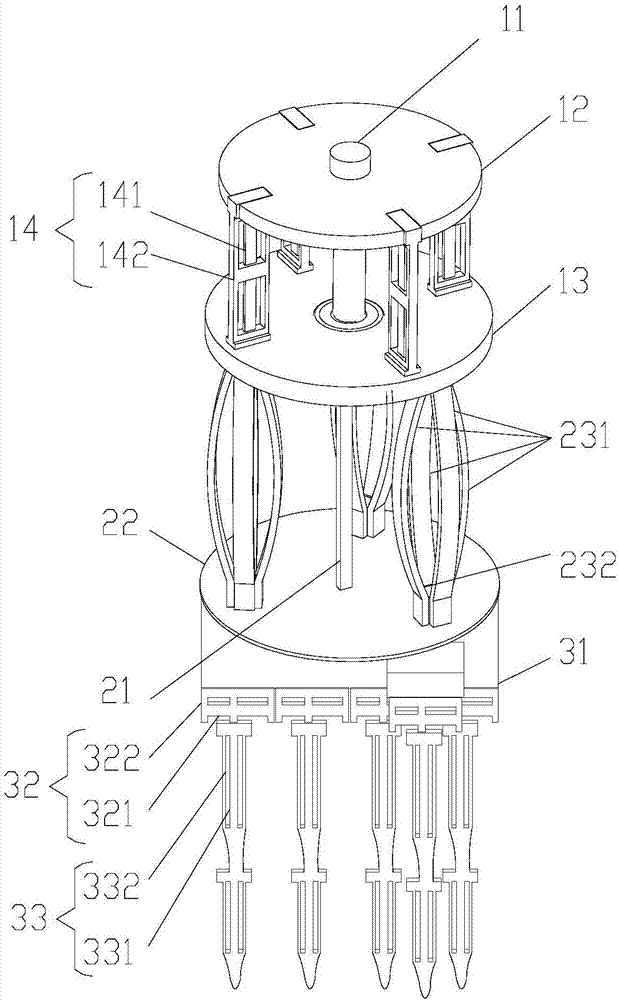

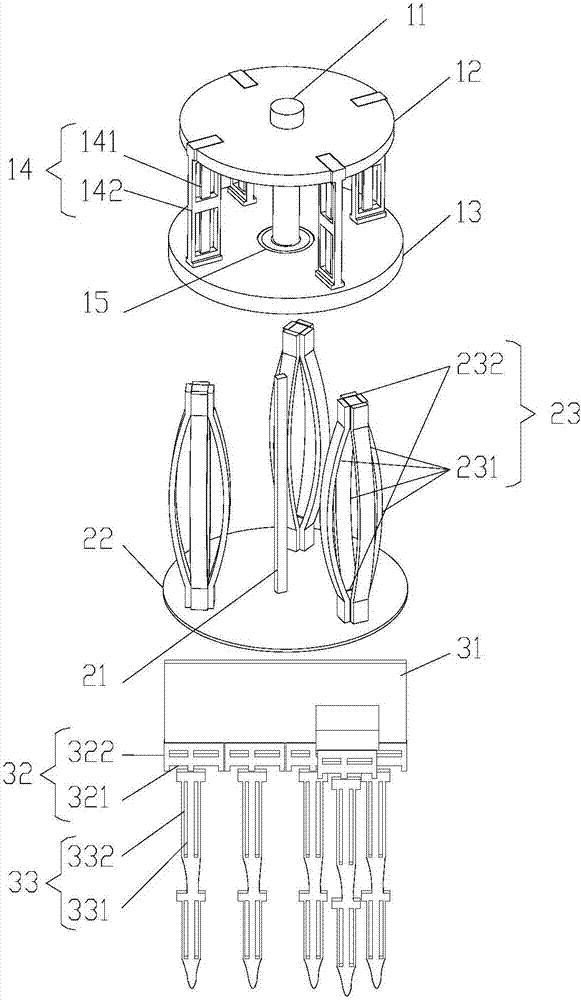

Multifunctional micropile drilling machine

The invention discloses a multifunctional micropile drilling machine, comprising a base plate, a platform which is fixed on the base plate, a covering element and an amplitude variation mechanism which are arranged on the platform, and a drilling and lifting device which is connected with the amplitude variation mechanism, wherein a hydraulic system and a main control system are arranged in the covering element; the amplitude variation mechanism comprises a turning pair A and a turning pair B; the turning pair A drives the amplitude variation mechanism and the drilling and lifting device to rotate relatively to the platform by + / - 90 degrees; and the turning pair B drives the drilling and lifting device to rotate relatively to the amplitude variation mechanism by 360 degrees. The turning pair A of the multifunctional micropile drilling machine does not turn along with the platform and just drives the amplitude variation mechanism and the drilling and lifting device to turn, so that the turning moment is reduced and turning becomes quite steady; the turning pairs employed also are lower than the turning pair employed to drive the whole platform in power so that the cost is saved; the turning pair B is capable of rotating by 360 degrees; and in contrast with the similar drilling machine employing an oil cylinder for rotation, the multifunctional micropile drilling machine has the advantages that the rotation angle is large and positioning of drilling is also quite accurate.

Owner:湖南优钻工程科技有限公司

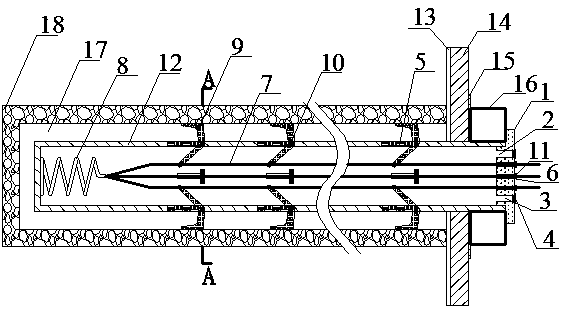

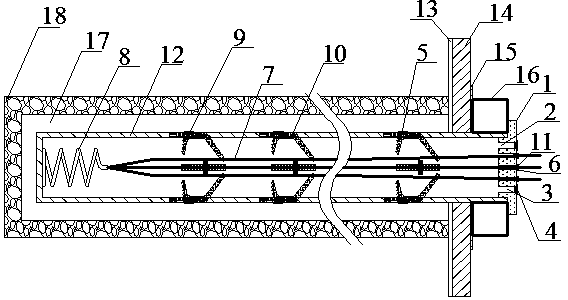

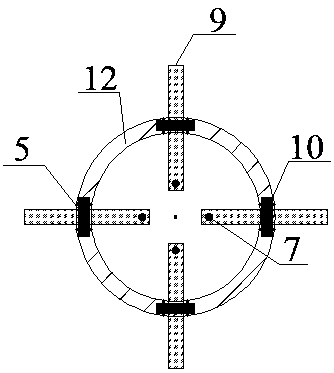

Novel anchoring grouting anchor rod and construction method thereof

ActiveCN108979692ASolve the anchorSolve the problem of insufficient groutingAnchoring boltsClimate change adaptationPre stressPre stressing

The invention discloses a novel anchoring grouting anchor rod and a construction method thereof. The novel anchoring grouting anchor rod is formed by a grouting system, an anchoring system and a fastening system. The grouting system comprises a cover, a vent hole, a grouting hole, a slurry plug, and overflow holes and various parts work together to ensure that slurry is full and tightly bonded. The anchoring system is formed by anchoring holes, a steel strand, a high-strength spring, an anchor claw, a rotating shaft and a steel strand clamp, initial anchoring force can be provided for the anchor rod, the anchor claw has barbs and rotates under the traction of the steel strand and closely attaches to a surrounding rock, and anchor removal is effectively prevented. The fastening system is formed by an anchor rod body, a slurry stop pad, a tray, a washer and a high-strength nut. After the slurry is solidified, the pre-stress can be provided for the grouting anchor to control the deformation of the surrounding rock. According to the invention, an anchor claw rotation design is employed, the anchor claw closely attaches to the surrounding rock, sufficient anchoring force is provided toprevent the anchor removal, and vent holes are set to ensure a pouring effect. The application defect of an existing grouting anchor is solved, and the novel anchoring grouting anchor rod and the construction method have the advantages of anchor removal prevention, high adaptability and good grouting effect.

Owner:SHANDONG UNIV OF SCI & TECH

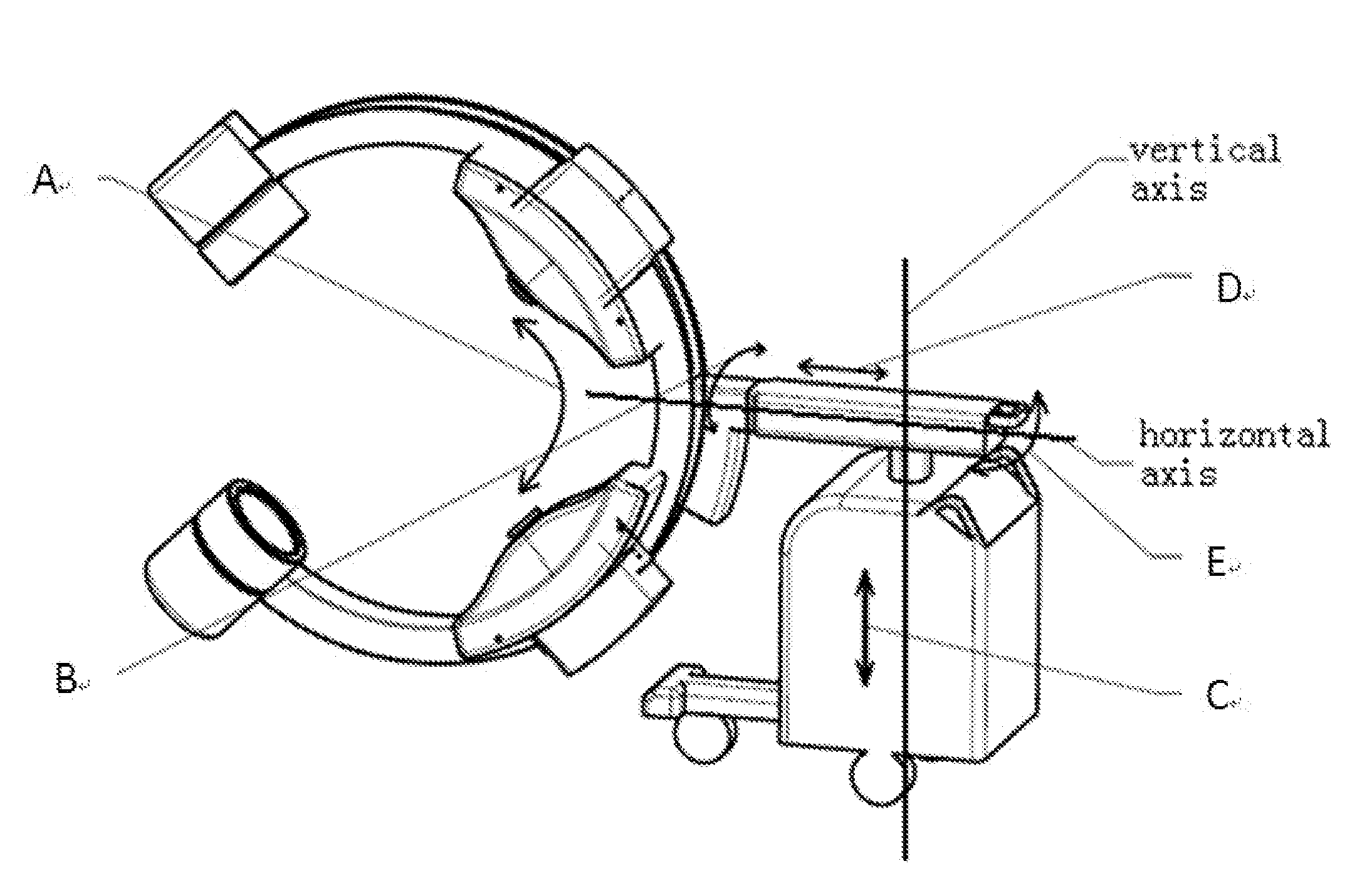

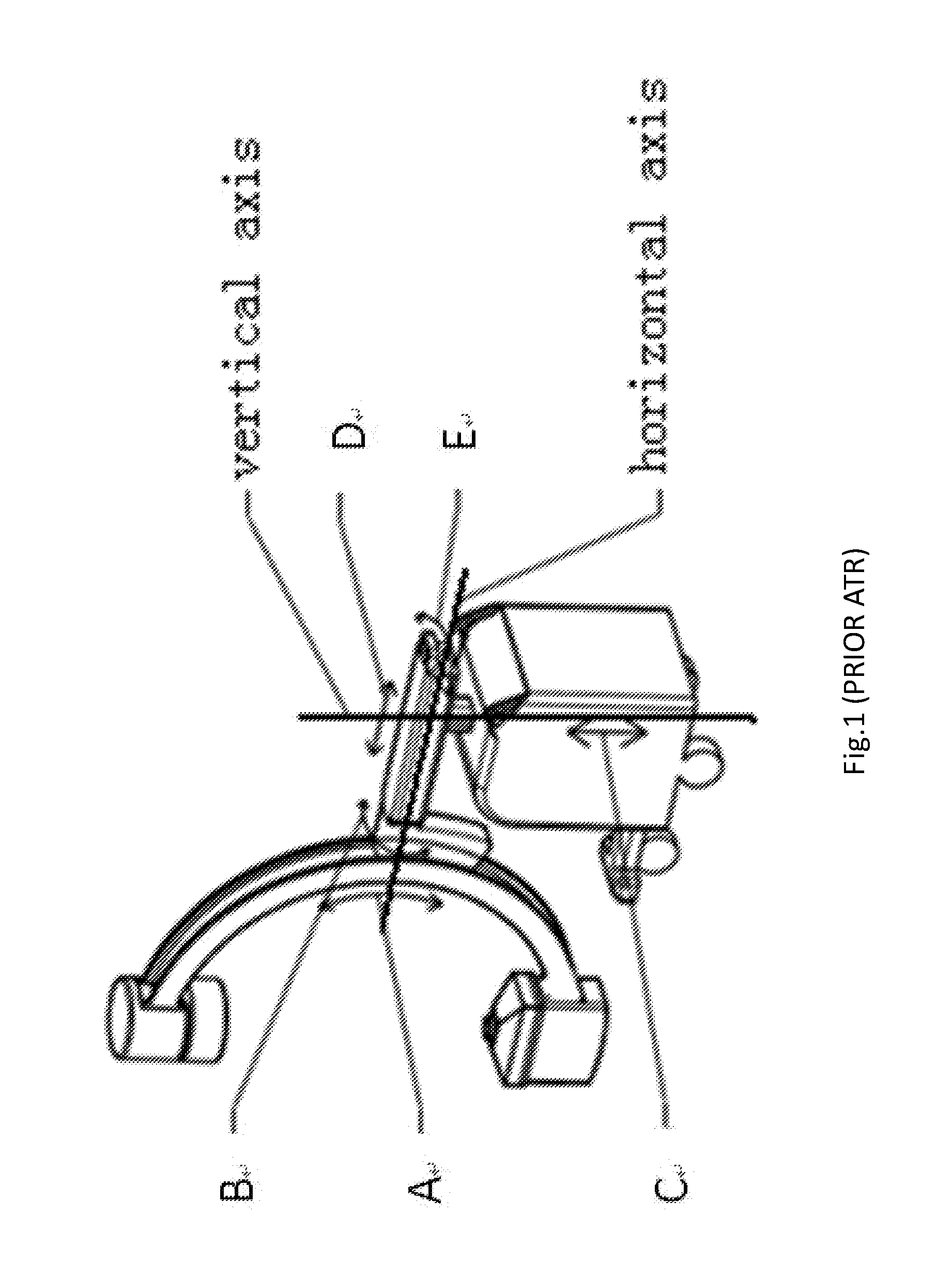

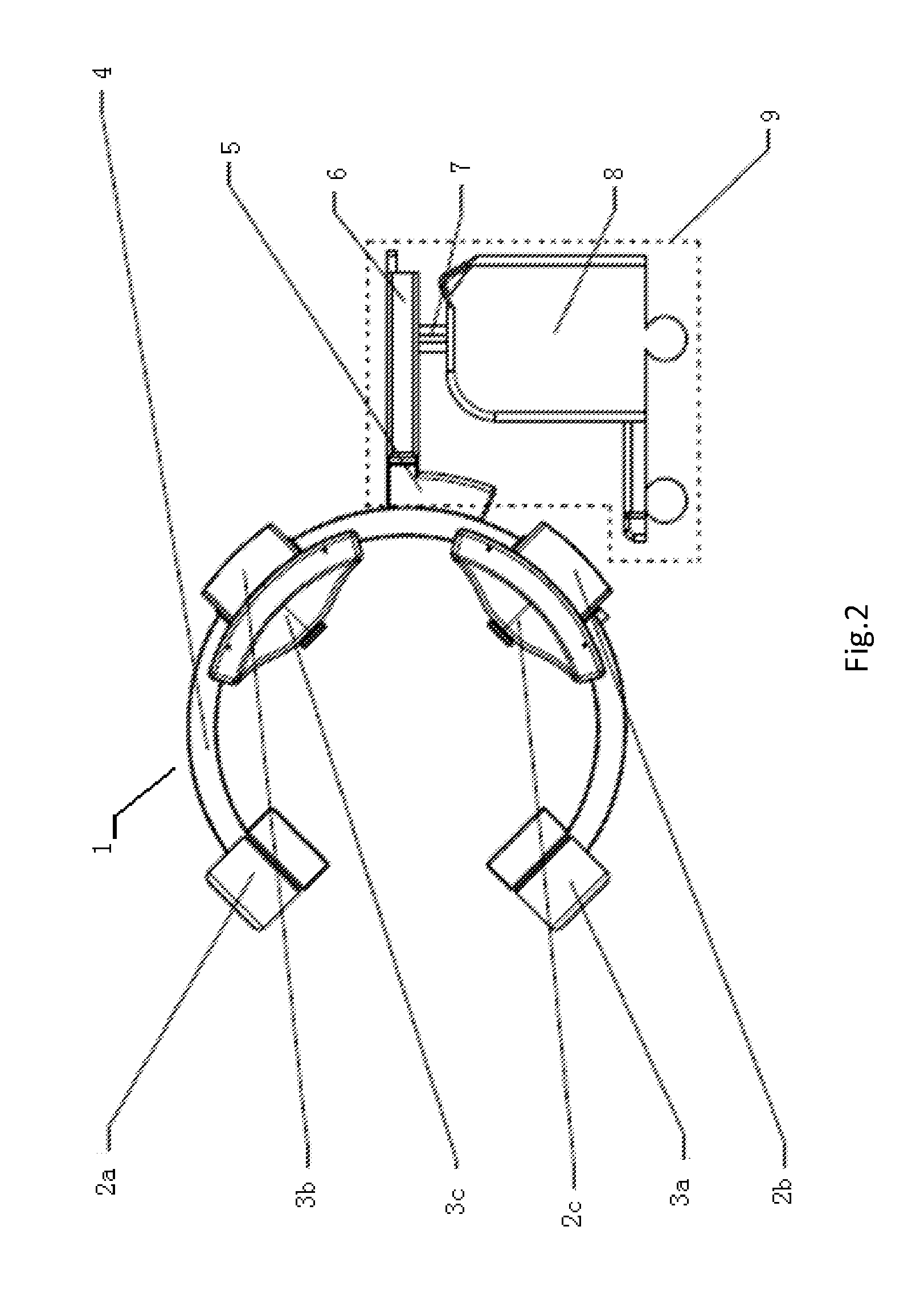

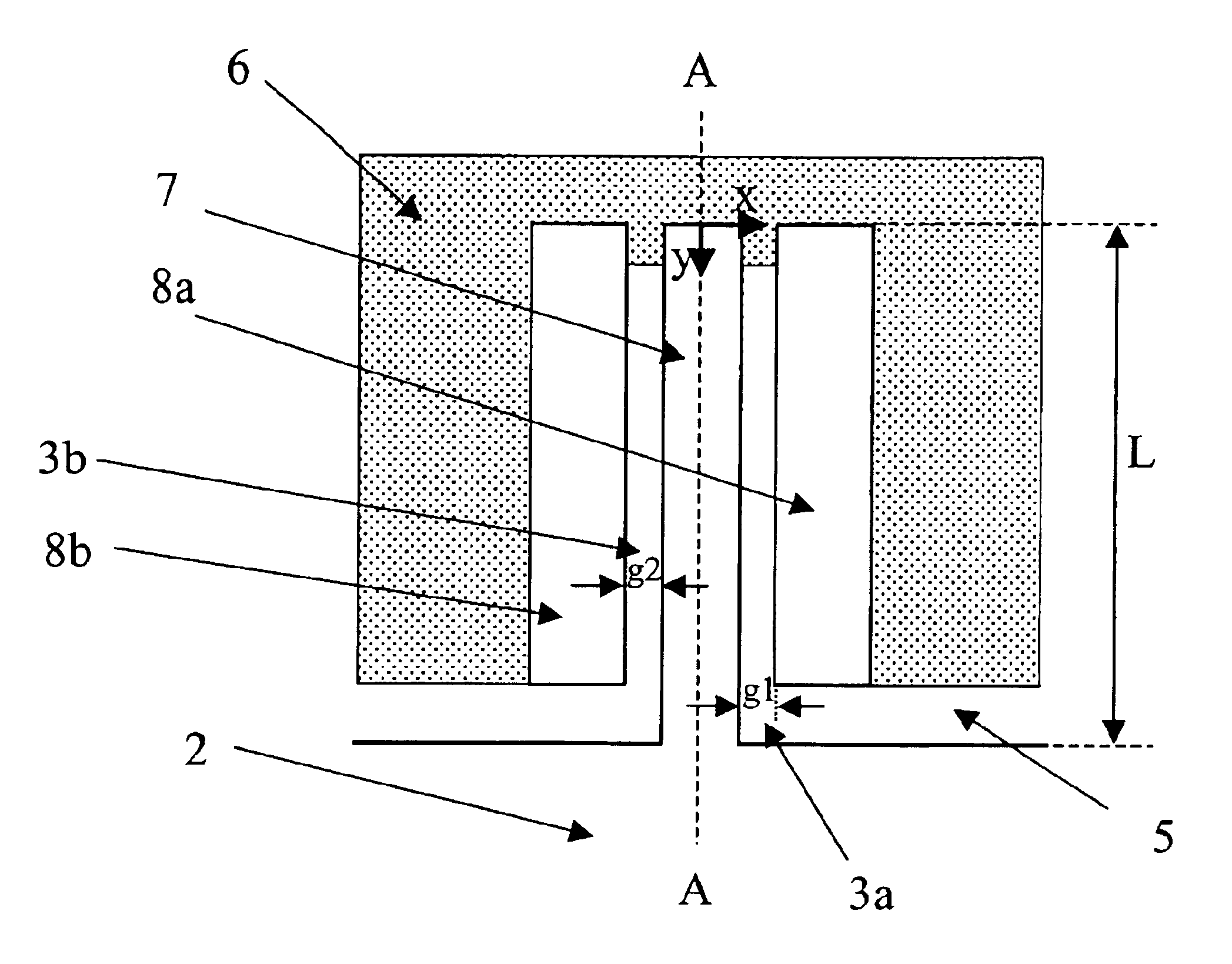

G-arm x-ray imaging apparatus

ActiveUS20150036799A1Great orbital rotation angleLarge rotation angleMaterial analysis by transmitting radiationRadiation diagnosticsPhysicsX ray image

An X-ray imaging apparatus is provided having advantages of both C-shaped, G-shaped, and ring-shaped arm configurations. The device consists of a gantry that supports X-ray imaging machinery. The gantry is formed to allow two bi-planar X-rays to be taken simultaneously or without movement of the equipment and / or patient. The gantry is adjustable to change angles of the X-ray imaging machinery. Further, in some embodiments, the X-ray receptor portion of the X-ray imaging machinery may be positioned on retractable and extendable arms, allowing the apparatus to have a larger access opening when not in operation, but to still provide bi-planar X-ray ability when in operation.

Owner:WHALE IMAGING INC

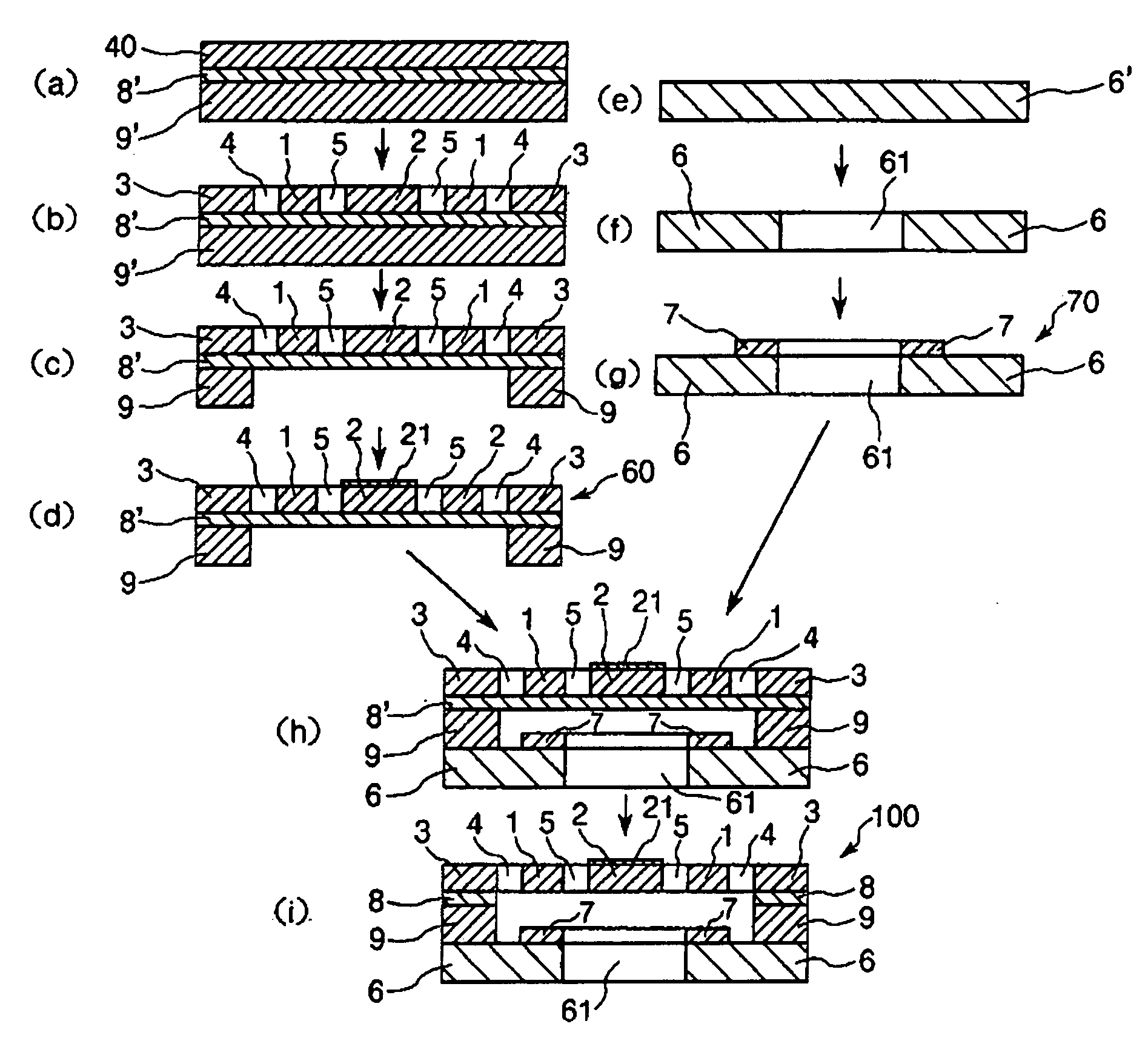

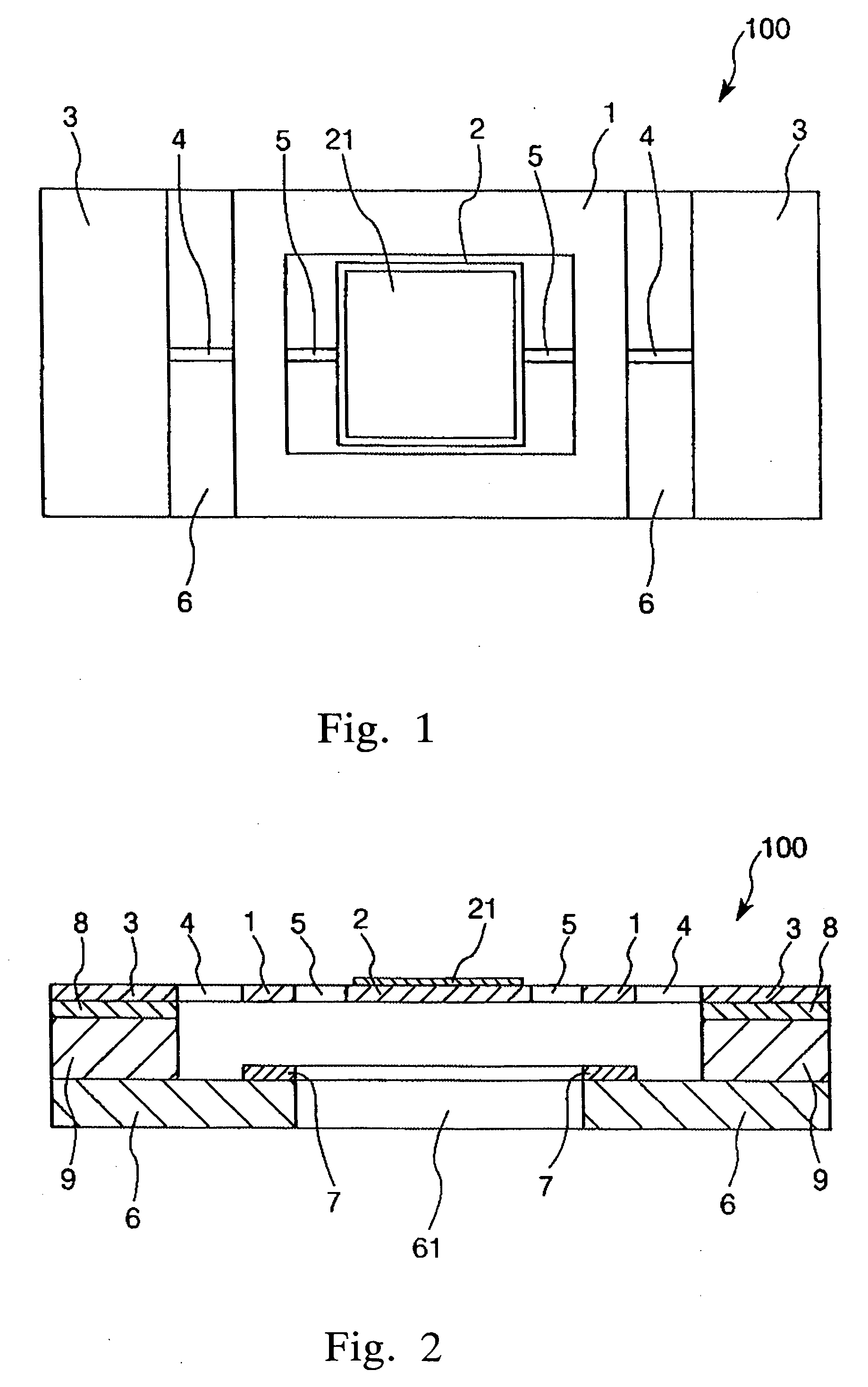

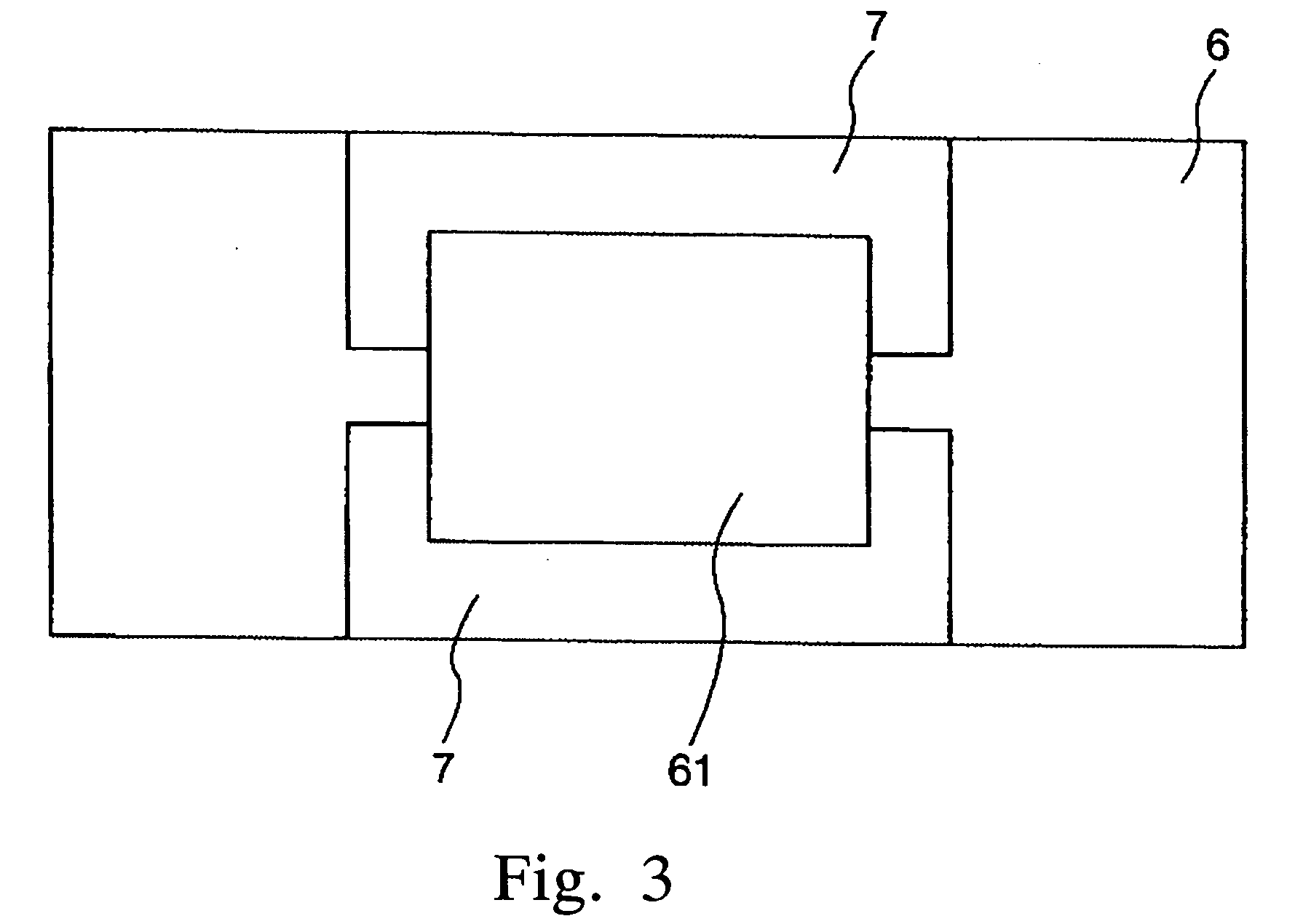

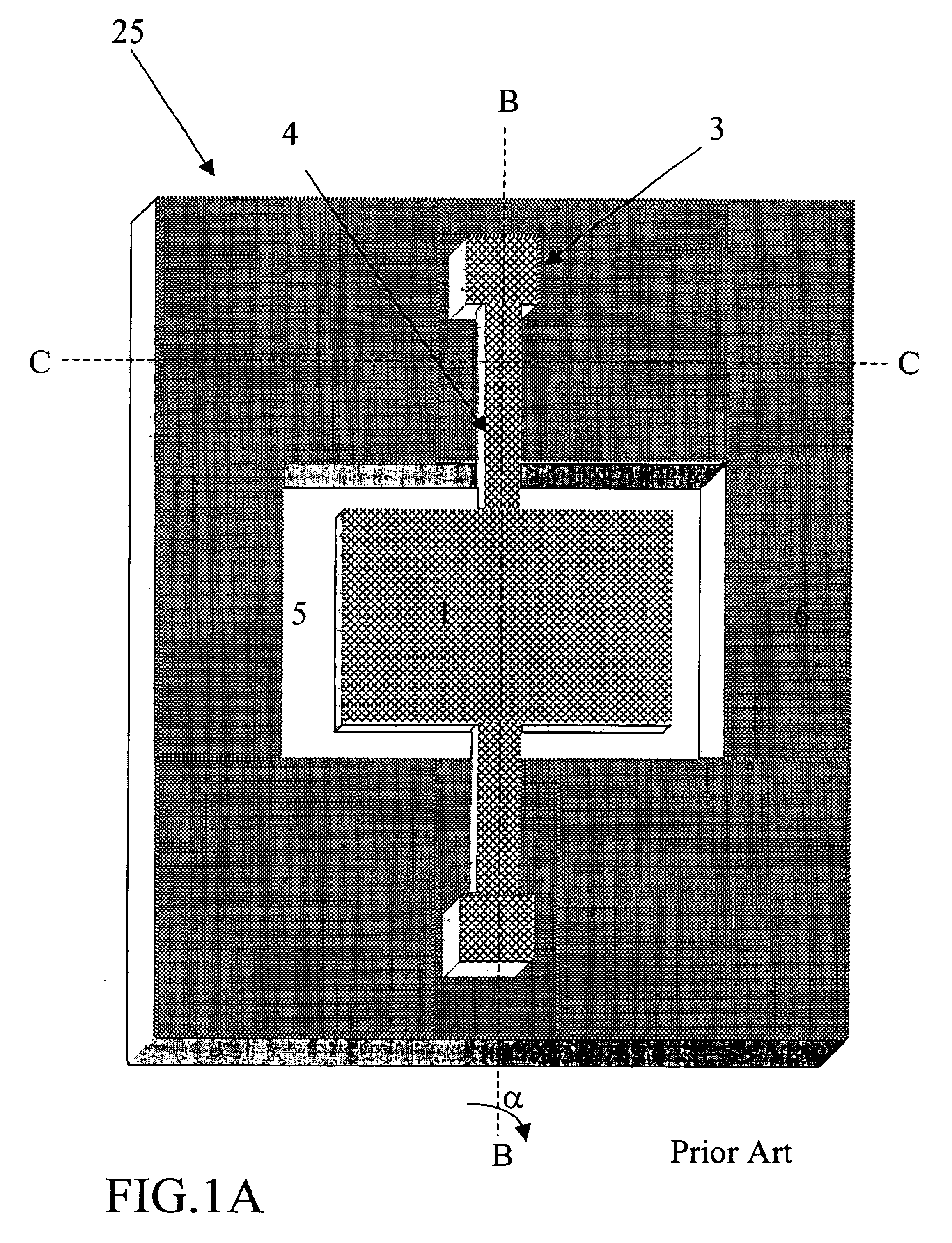

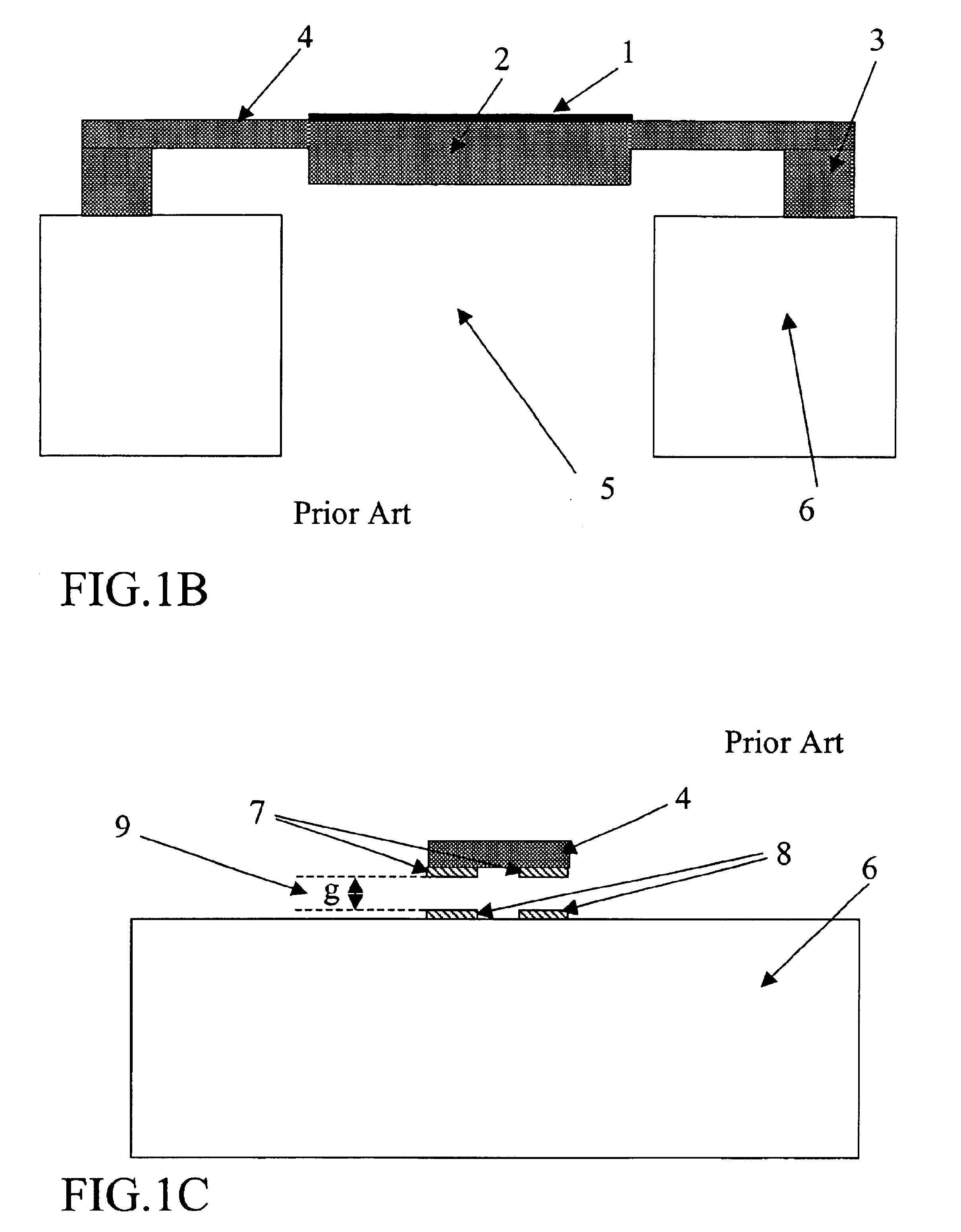

Micro-mechanical system employing electrostatic actuator and fabrication methods of same

InactiveUS6888662B2Raise the resonance frequencyLarge rotation angleAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsLayered structureElectrostatic actuator

A vertical electrostatic actuator is based on a layered structure consisting of two conducting or semiconducting layers separated by an insulating layer and / or layered structure consisting of p-type and n-type layers separated by a pn-junction. The number of conducting layers, p-type layers and / or n-type layers can be more than two as long as each two adjacent layers are separated by an insulating layer or a pn-junction. The mobile electrode of the actuator can be formed along a flexure in a micro-mechanical system. Two stationary electrodes are located on either side of the mobile electrode. The layered structure of the electrodes increases the torque on the flexure and thus improves the performance of the actuator. Fabrication methods for the electrostatic actuator and micro-mechanical systems employing the same are disclosed.

Owner:ABU AGEEL NAYEF M

Adjustable stand

InactiveUS20090014608A1Large rotation angleEasy to carryPicture framesDomestic mirrorsEngineeringDesk

An adjustable stand for carrying an electronic device and adjusting a position on a desk is provided to include a clamp and a supporting element. The clamp has a positioning element that comprises two axial portions each having a through hole, a clamping element that comprises an adjusting portion with a plurality of notches, and an elastic element positioned between the positioning element and the clamping element for restoring the position. The supporting element has two terminal rods that are axially fixed to the axial portions of the positioning element, and a supporting rod formed between the two terminal rods for lodging into one of the notches of the clamping element.

Owner:YANG SHANG WEN

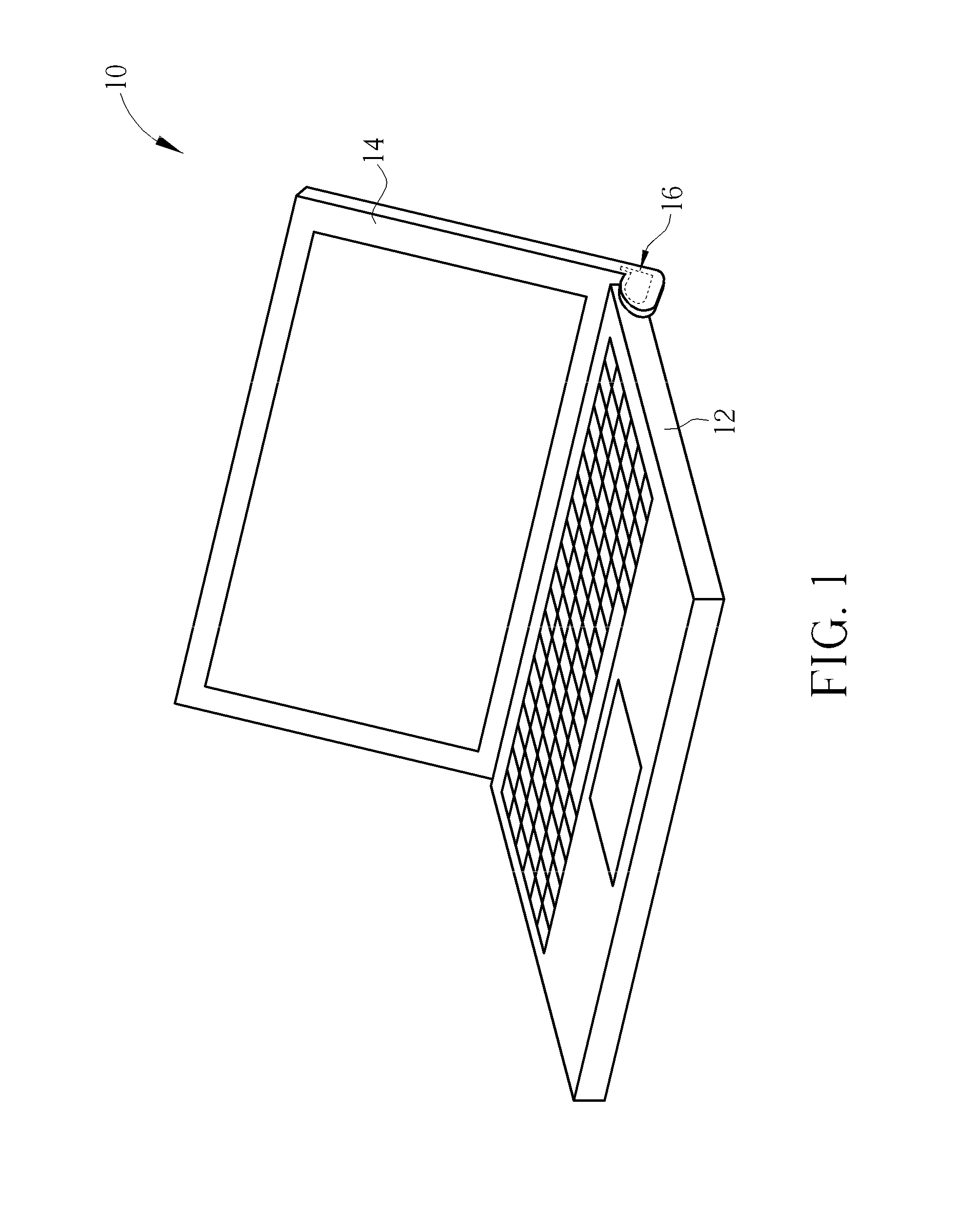

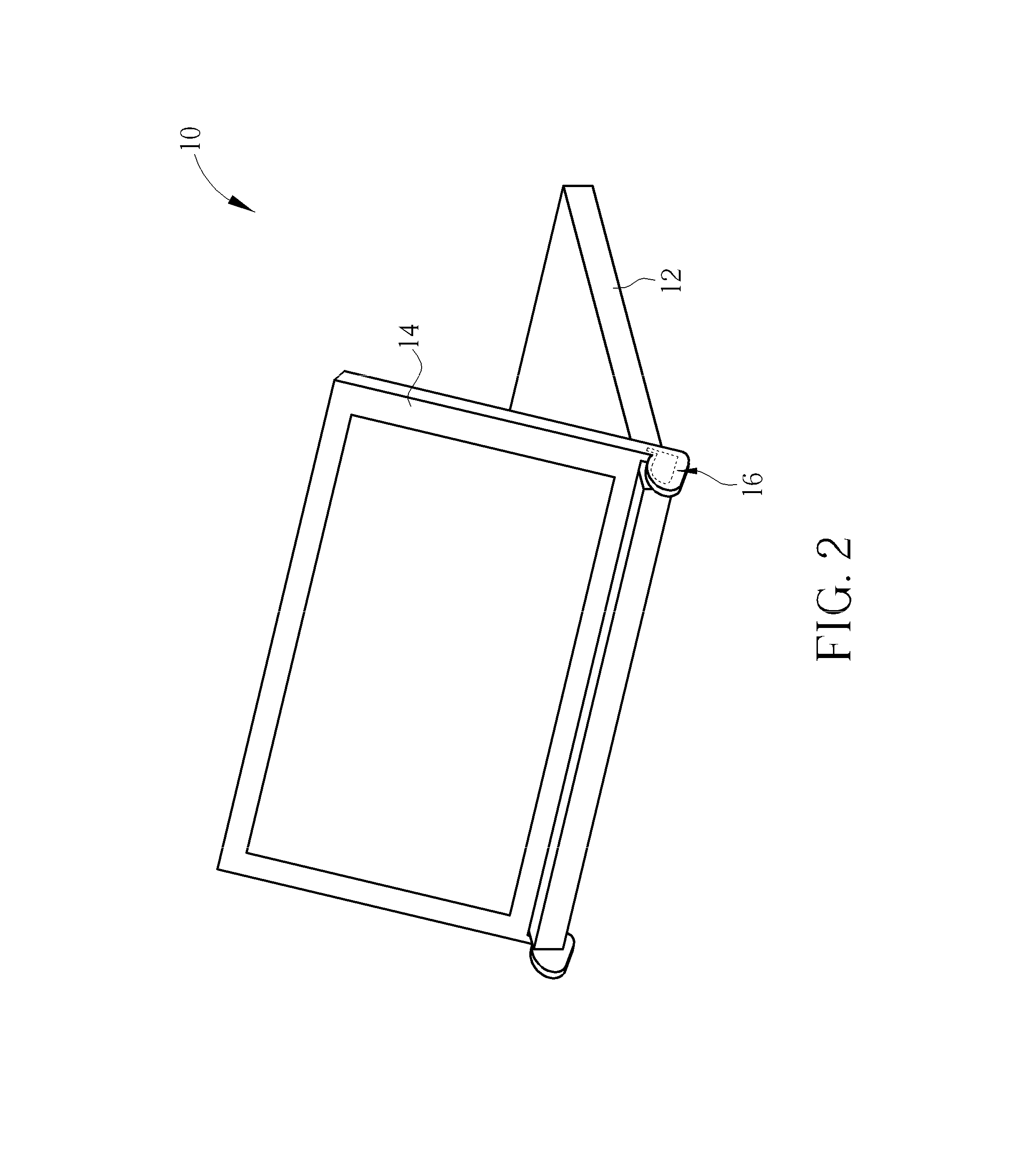

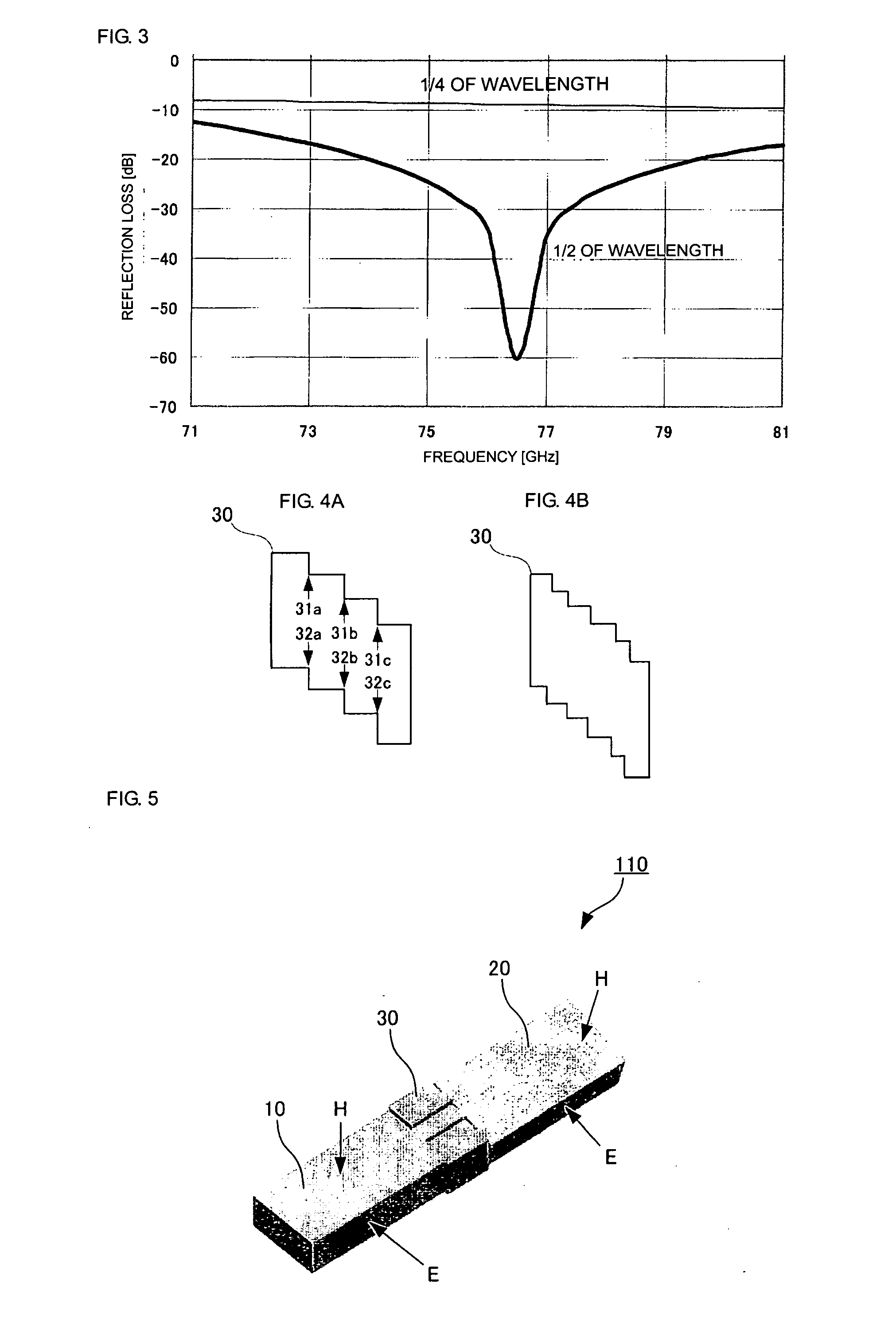

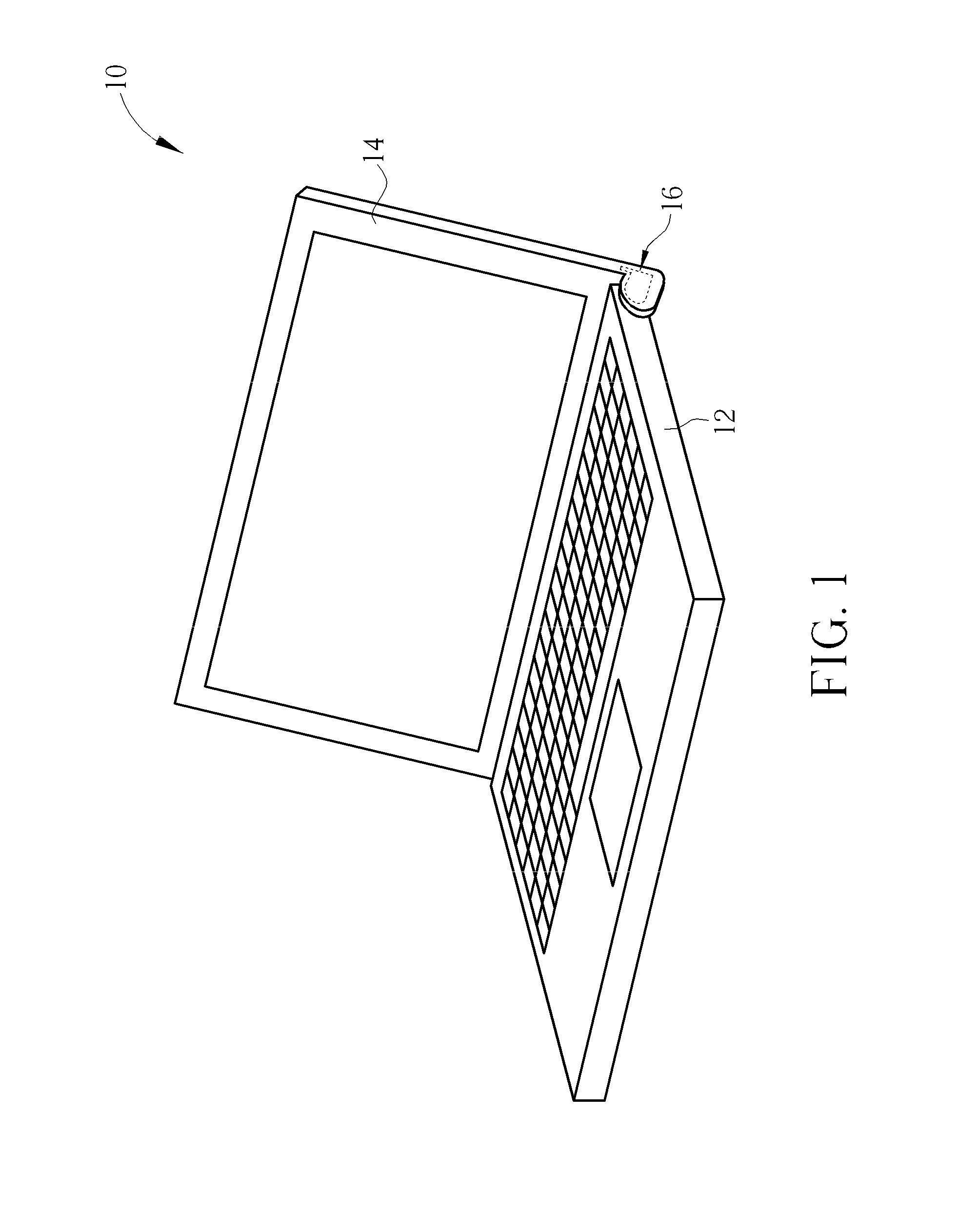

Rotary mechanism and related electronic device

ActiveUS20140168878A1Simple structureLarge rotation rangeDetails for portable computersHingesEngineeringElectric equipment

Owner:WISTRON CORP

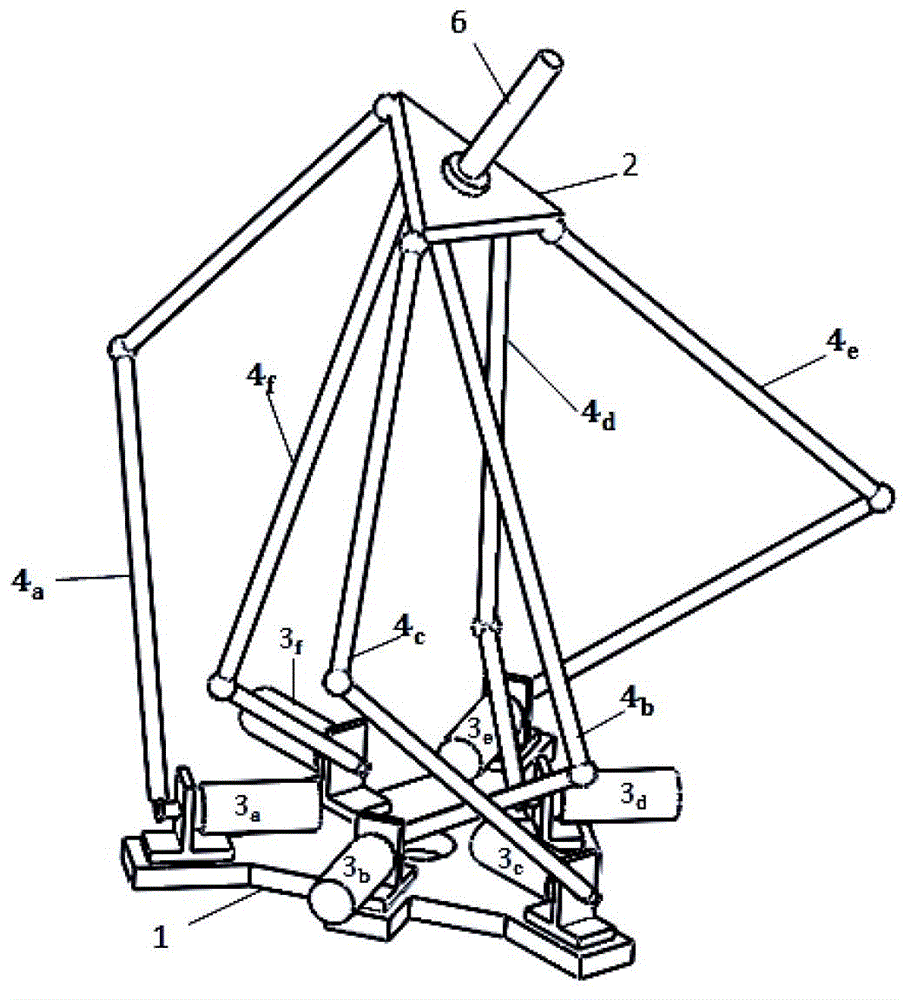

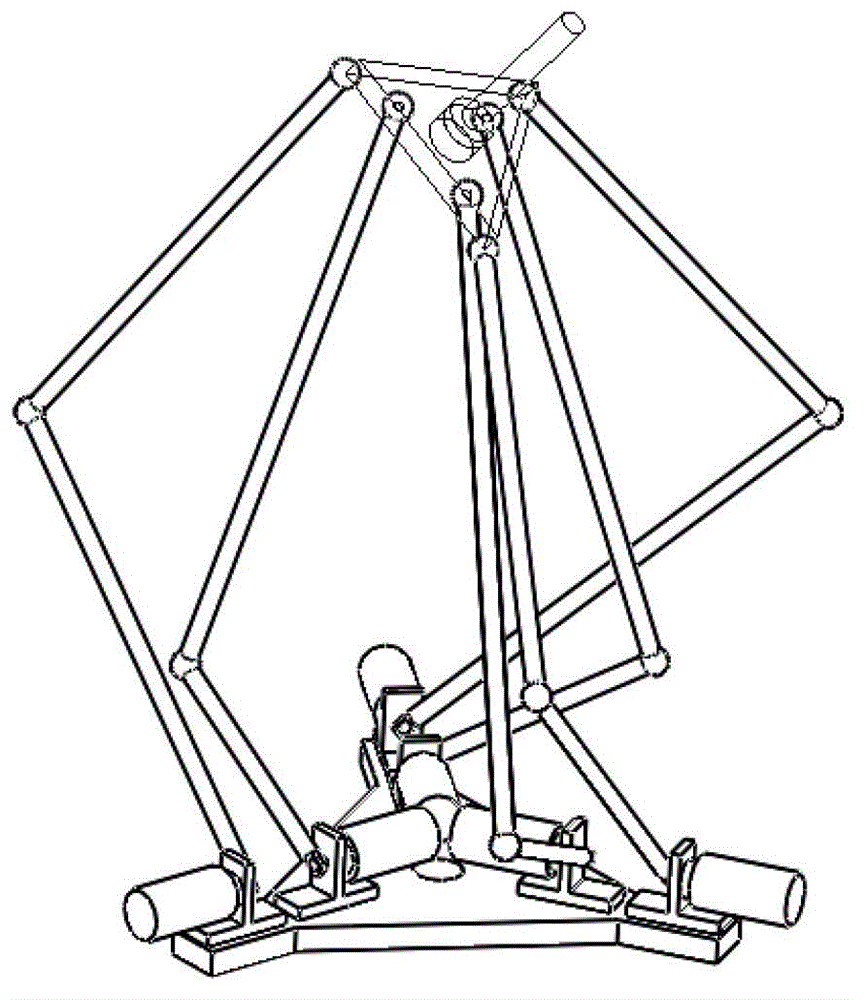

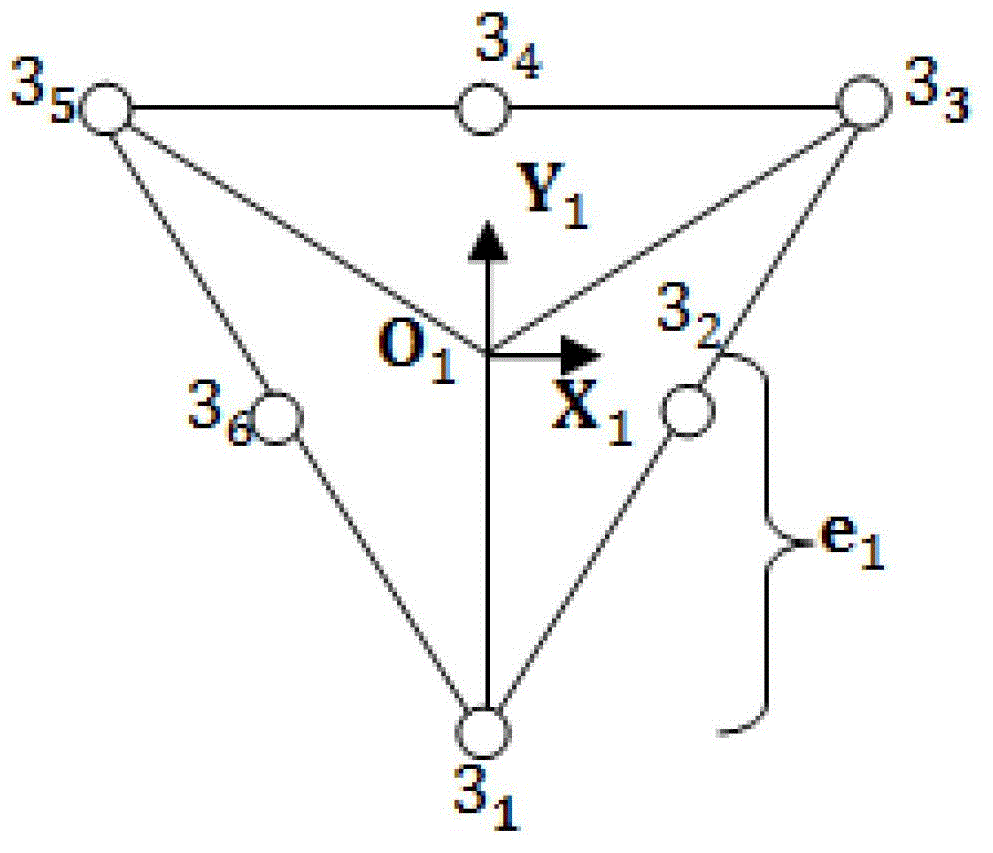

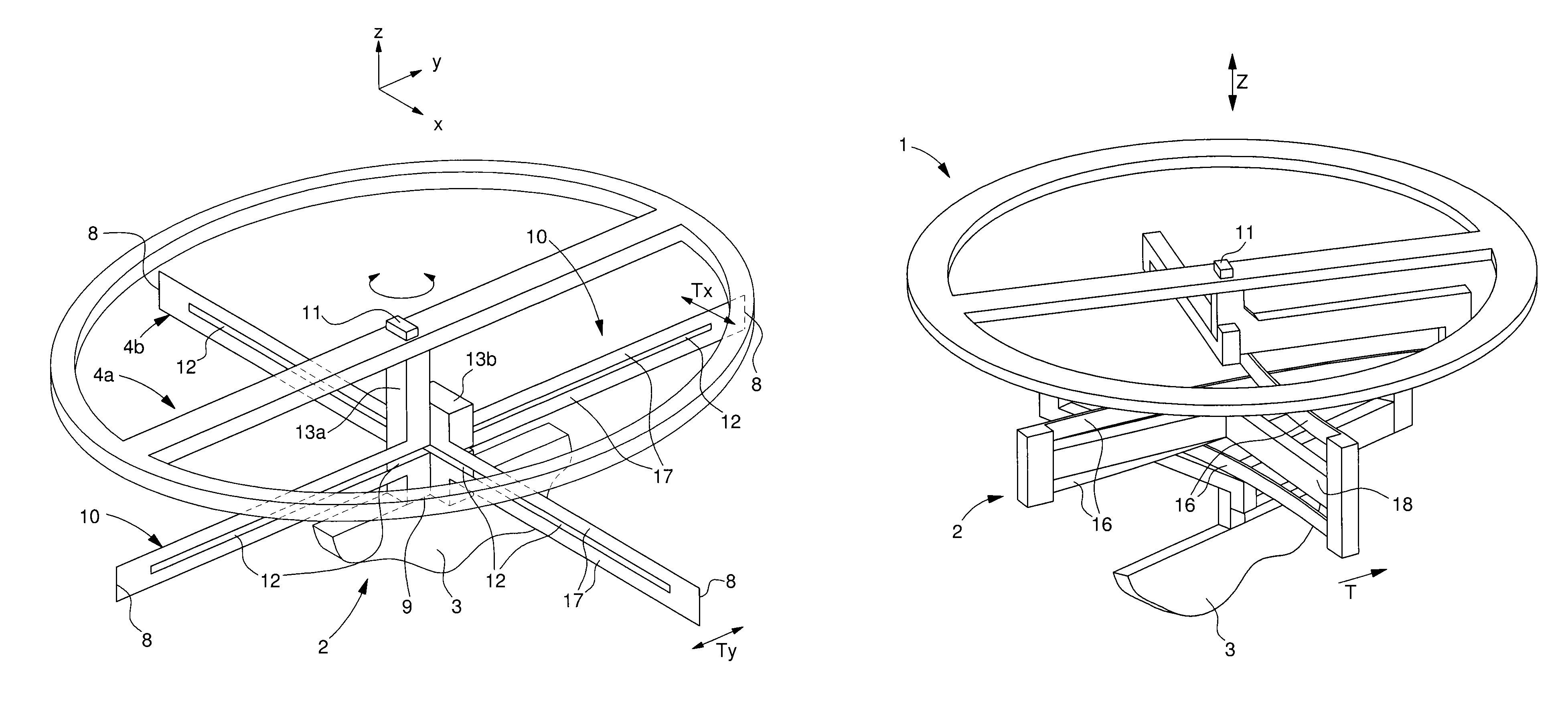

Six-degree of freedom parallel mechanism based on different radii

InactiveCN102717380ACompact distributionSave spaceProgramme-controlled manipulatorDegrees of freedomEngineering

The invention relates to a six-degree of freedom parallel mechanism based on different radii. The six-degree of freedom parallel mechanism comprises a static platform, a movable platform, six support frames, six upper spherical hinges, six lower spherical hinges, six direct-current motors, six branched chains and an operating rod, wherein the six support frames are fixedly connected with the static platform at the preset position; the six direct-current motors penetrate through holes in the support frames respectively and are connected with lower connecting rods of the six branched chains; upper connecting rods of the six branched chains are connected with the movable platform by the six upper spherical hinges; the upper and lower connecting rods of the six branched chains are connected with each other by the six lower spherical hinges; and the operating rod is connected with a through hole of the movable platform. According to the six-degree of freedom parallel mechanism, each branched chain can determine the spatial position of each spherical hinge on the movable platform, so that six degrees of freedom of motion of the platform can be realized by the six spherical hinges which are non-collinear; and three-dimensional force and three-dimensional moment are outputted on the movable platform, so that an interactive feeling that the three-dimensional force and the three-dimensional moment are the same as virtual force and virtual moment in virtual environment is provided for people. The six-degree of freedom parallel mechanism is force sense interactive equipment which is novel in configuration, simple in structure and high in performance.

Owner:BEIHANG UNIV

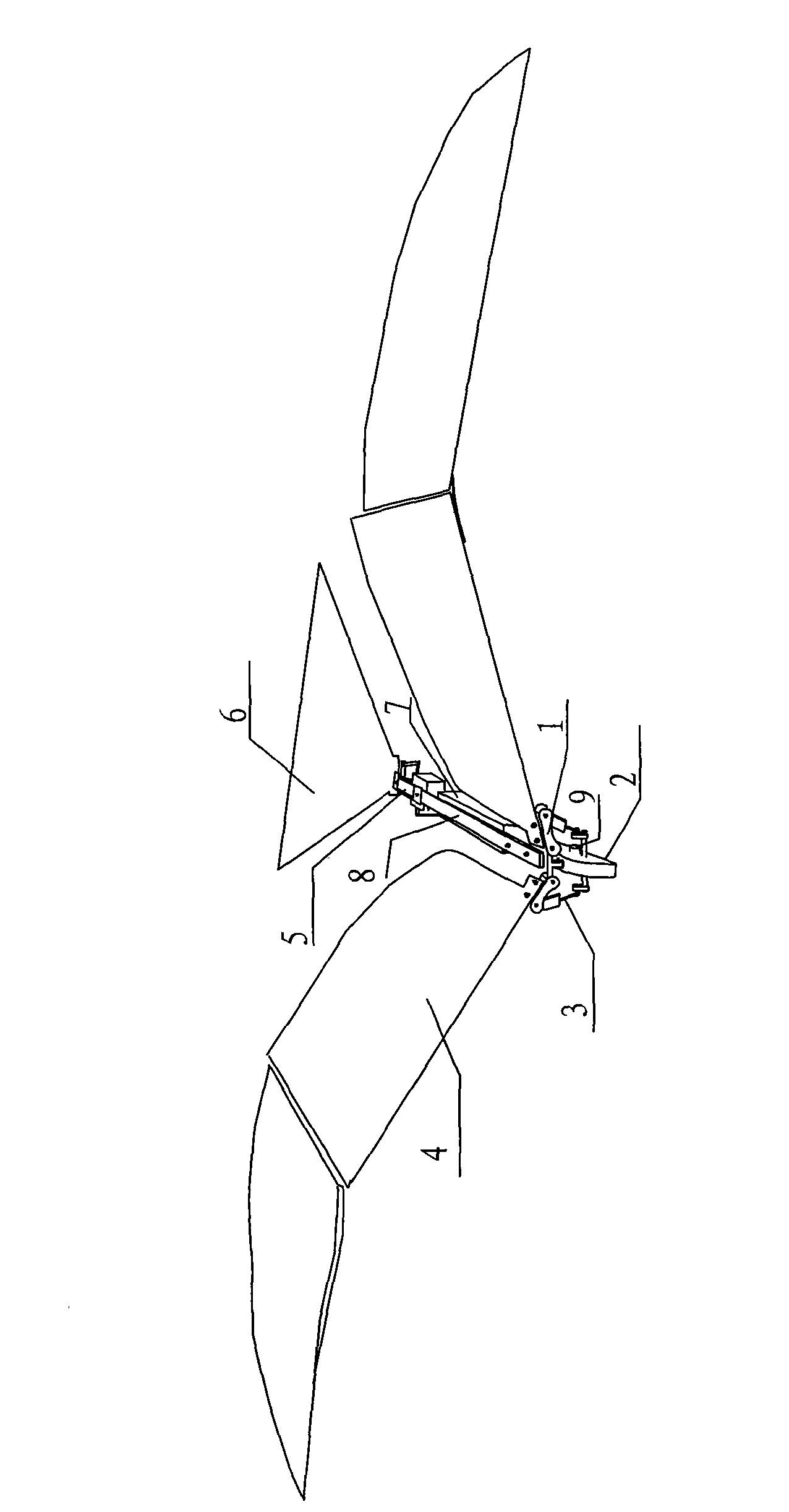

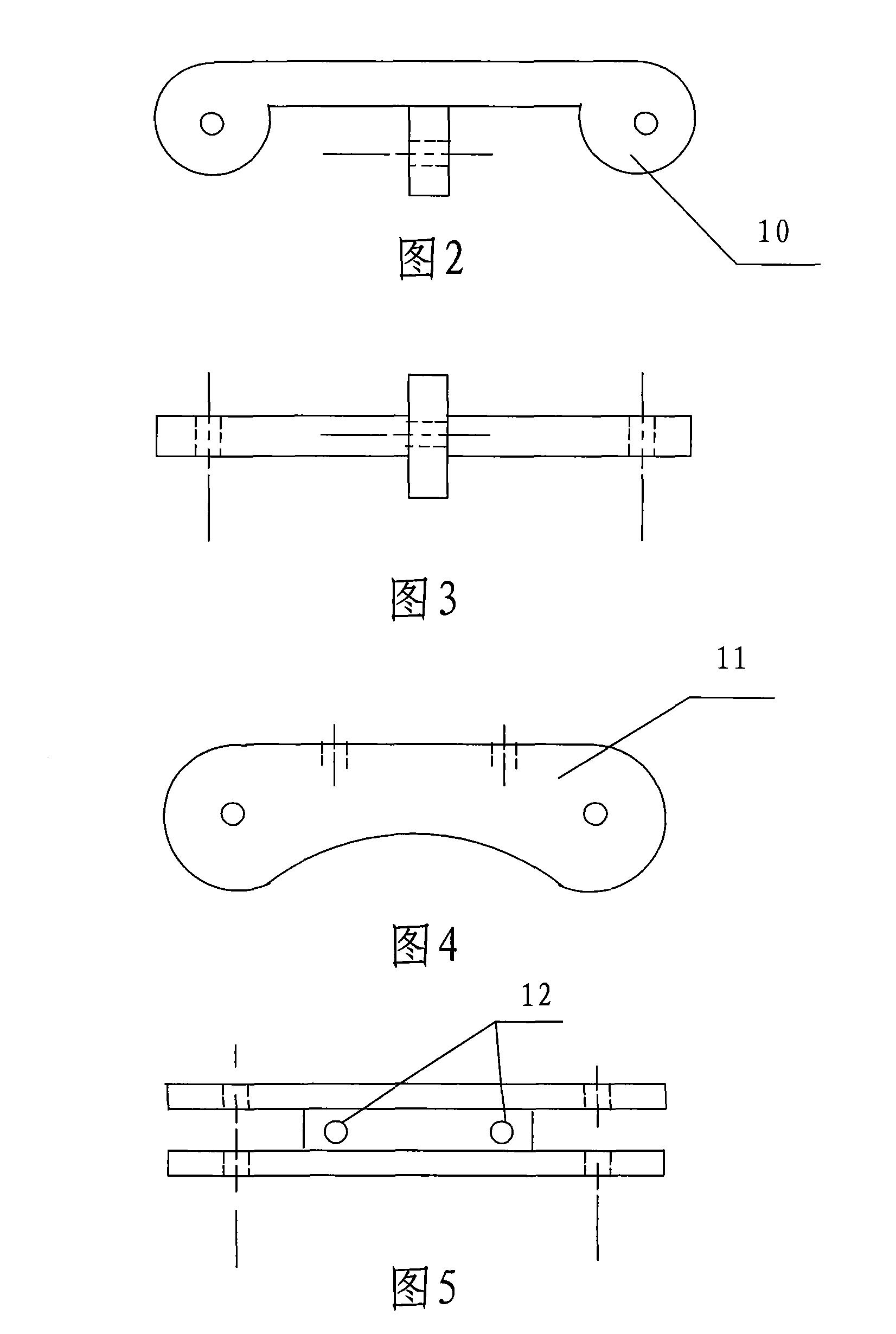

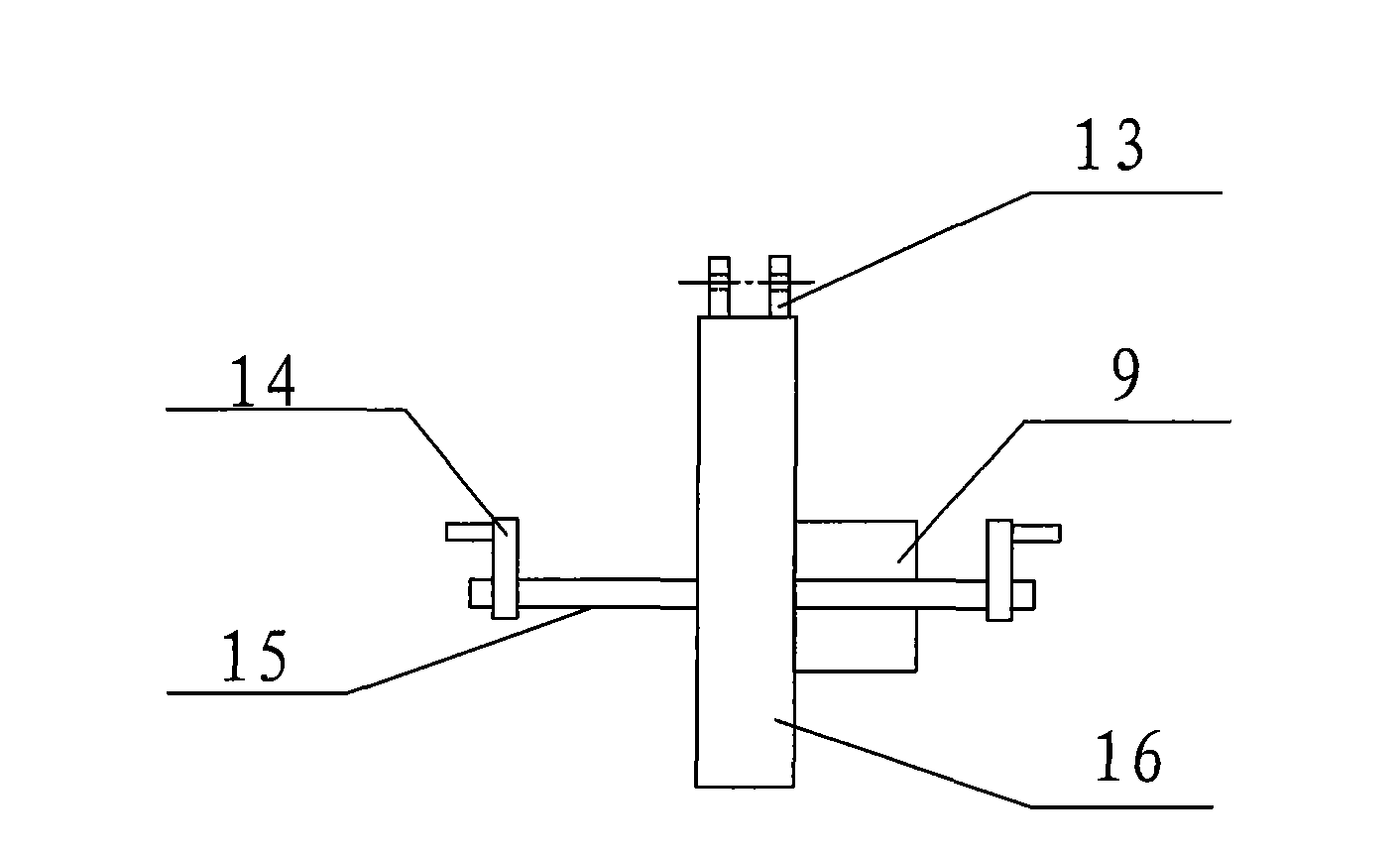

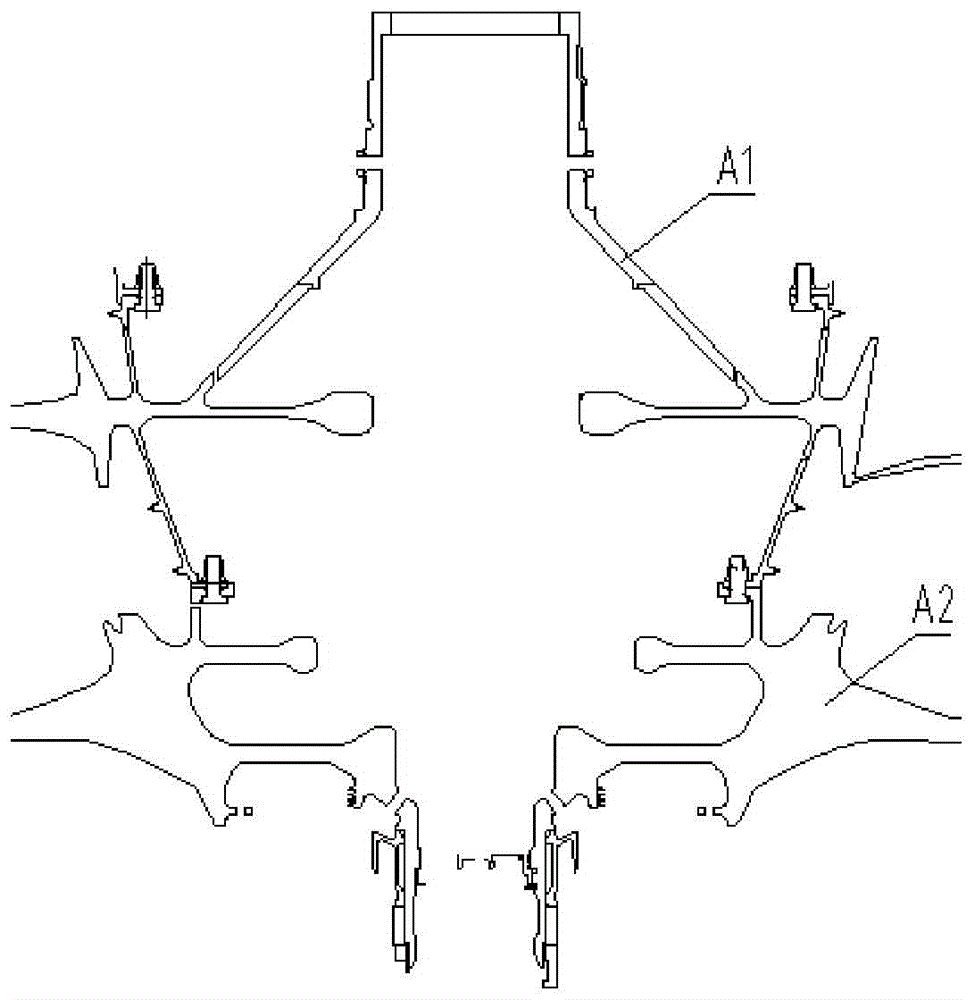

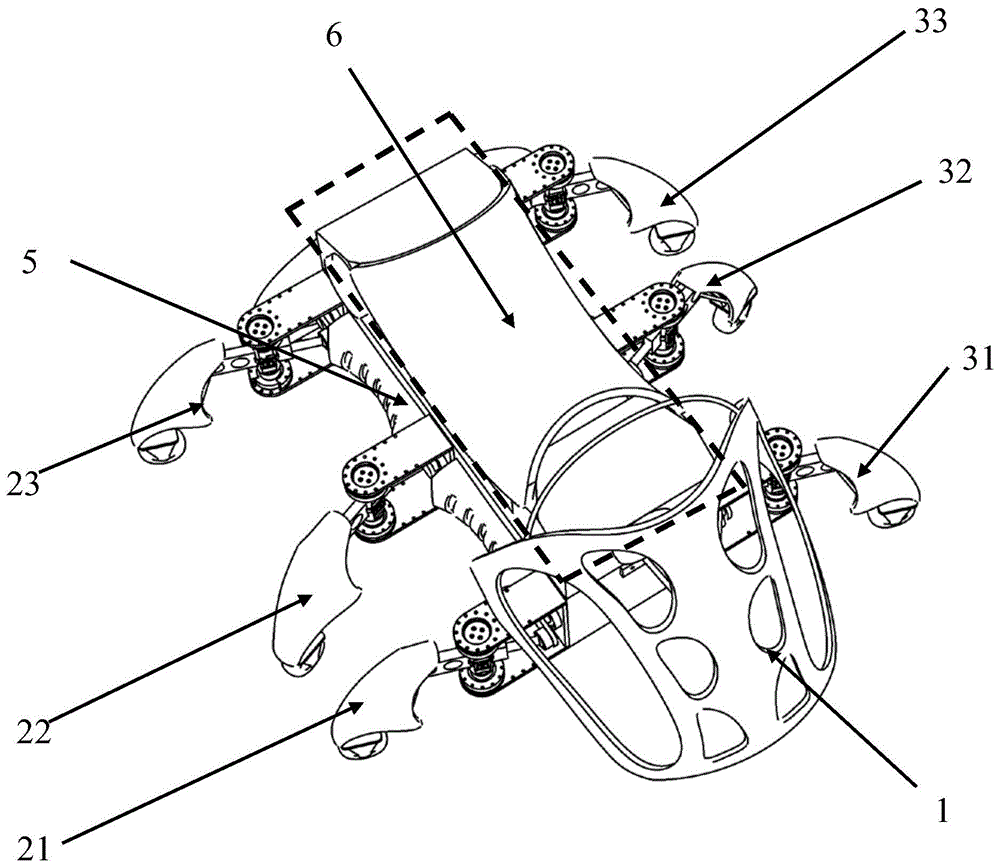

Bidirectional synchronous automatic turning flapping-wing aircraft

A bidirectional synchronous automatic turning flapping-wing aircraft belongs to the field of astronautic bionic aircraft device, comprising an airframe (8), a wing flapping mechanism (1), a bidirectional synchronous output deceleration mechanism (2), a connecting rod (3), an airfoil (4), an empennage control mechanism (5) and an empennage (6); the bidirectional synchronous automatic turning flapping-wing aircraft is characterized in that the wing flapping mechanism (1) comprises a crossed frame (10) and two wing roots (11); the crossed frame (10) is installed on the front end of the airframe (8) through a bearing; two wing roots (11) are respectively installed on two sides of the crossed frame (10); the airfoil (4) is connected with the wing root (11) through a wing bone; the bidirectional synchronous output deceleration mechanism (2) is connected with the wing root (11) through the connecting rod (3); the empennage control mechanism (5) is installed on the rear end of the airframe (8); the empennage (6) is connected with the empennage control mechanism (5). The airfoil is in spot connection with the airframe and performs the bidirectional synchronous automatic turning with high flying efficiency.

Owner:杨绍河

Metallic package

ActiveCN101148208ALarge rotation angleSeal Break PreventionCapsClosure capsEngineeringMechanical engineering

Owner:JAPAN CROWN CORK CO LTD

Rotating damper

ActiveUS7111712B2No damageLarge rotation angleLiquid resistance brakesSpringsCheck valveIndirect contact

An adequate rotation angle is ensured and any member is not damaged due to fluid resistance even with use of highly viscous fluid. A rotating shaft (2) is provided inside a casing (1) having first divider walls (5) provided on its inner periphery and in direct or indirect contact with the rotating shaft. Second divider walls (4) are provided on an outer periphery of the rotating shaft and in either direct or indirect contact with the casing. A flow passage (4a) is provided in the second divider wall for fluid communication between the pressure chambers. A check valve mechanism has curving portions (6a) moving on and along the periphery of the rotating shaft and valving portions (6b) each joining to the curving portion. The curving portion is supported between the rotating shaft and the first divider wall. The flow passage is opened / closed depending upon a direction of fluid flow.

Owner:TOK BEARING CO LTD

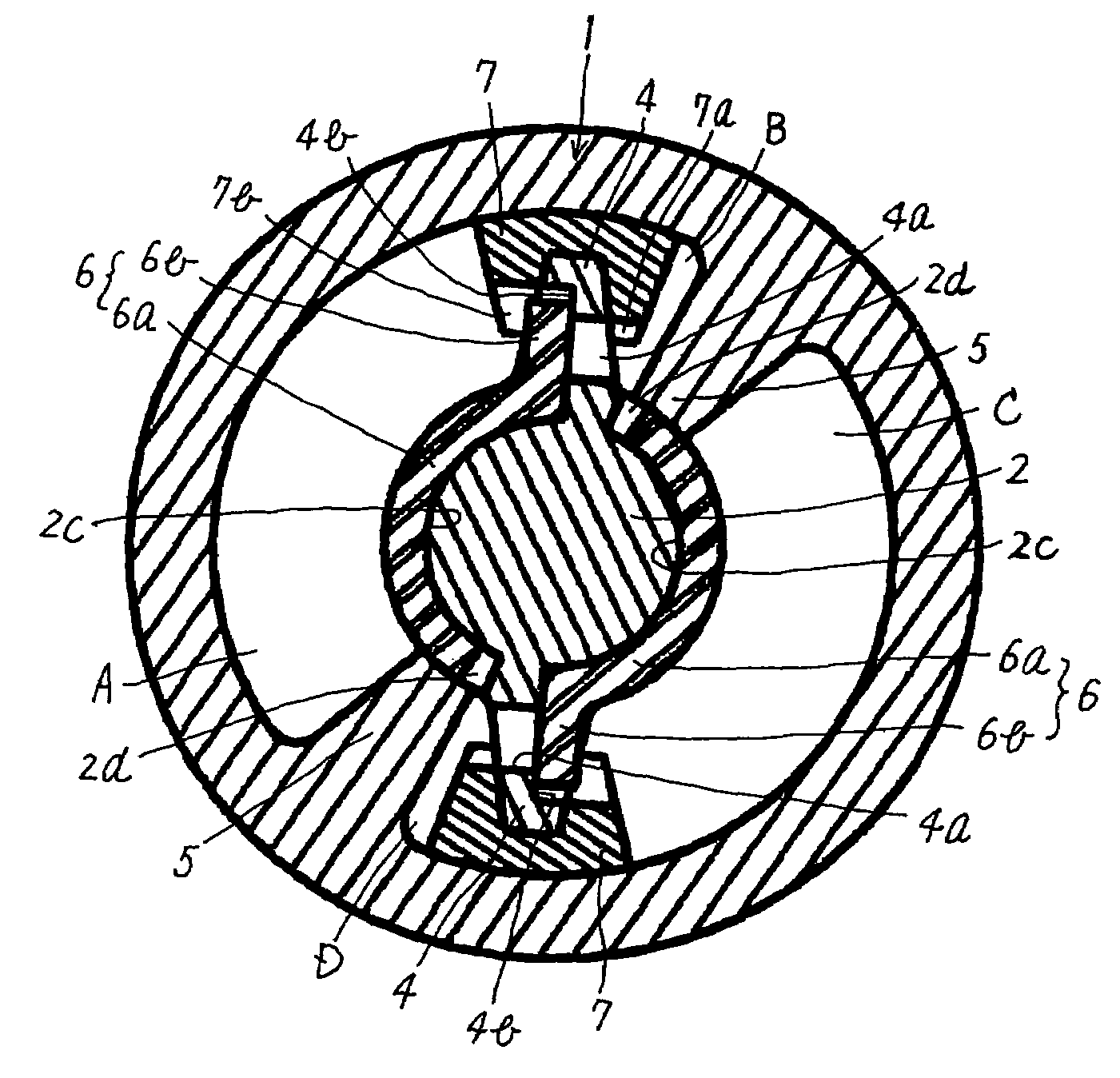

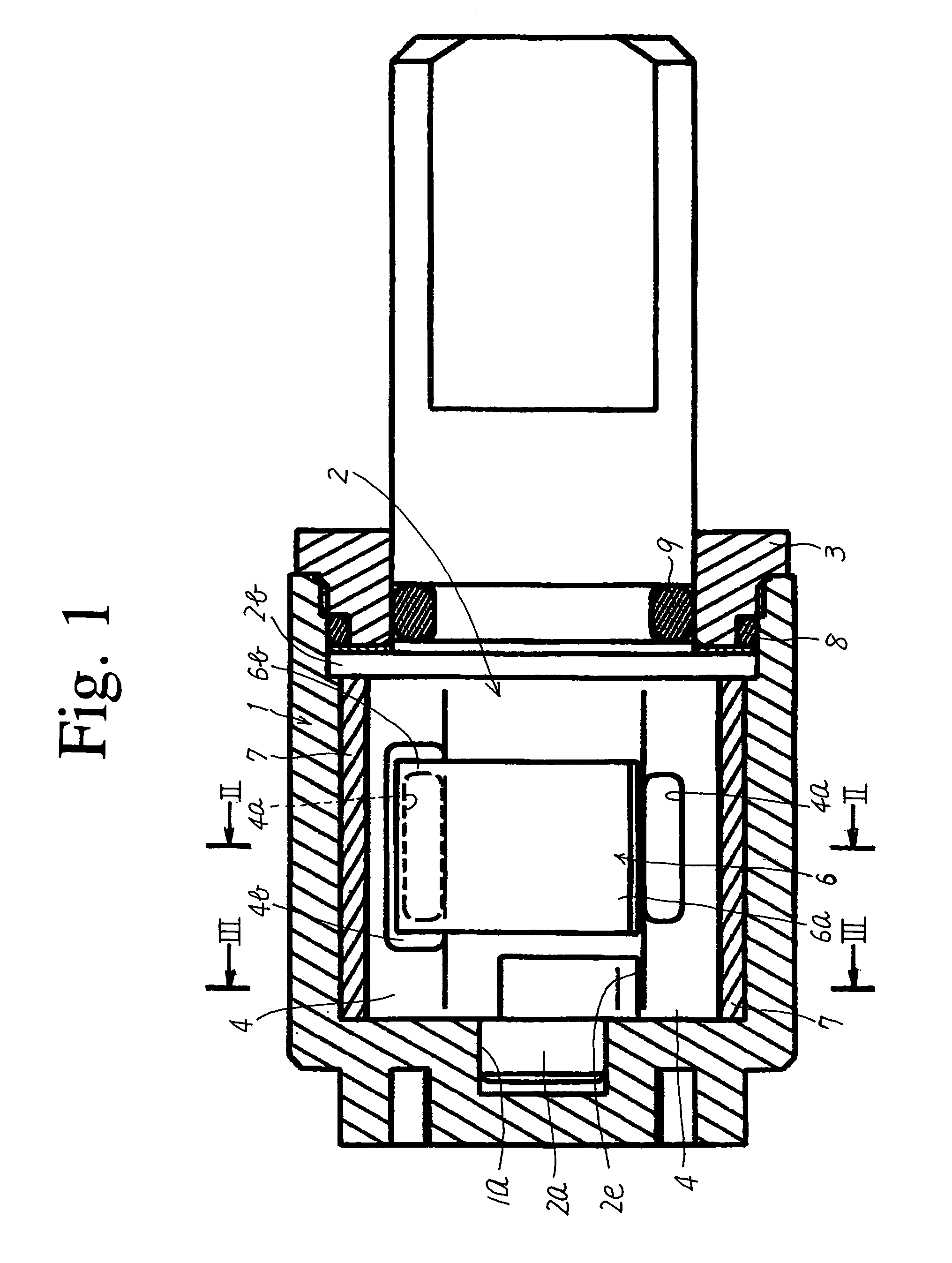

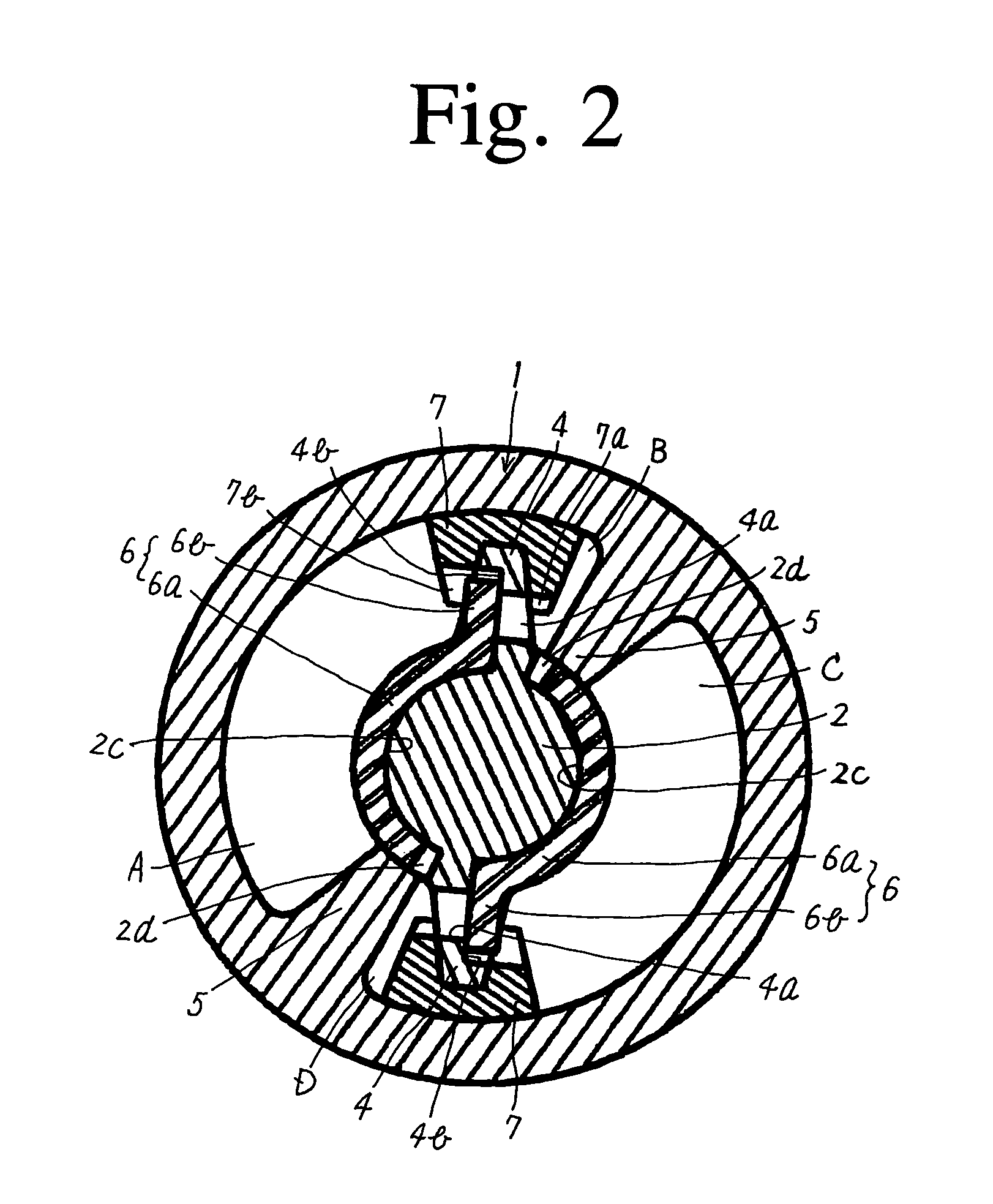

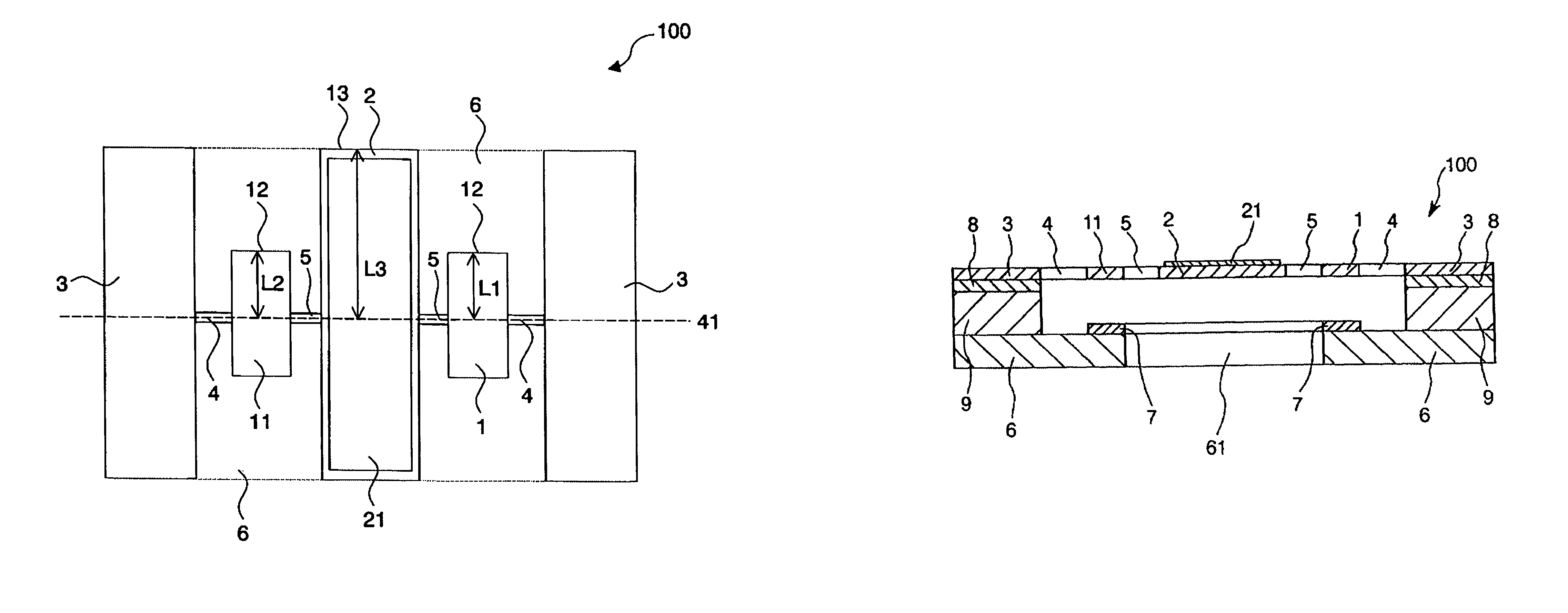

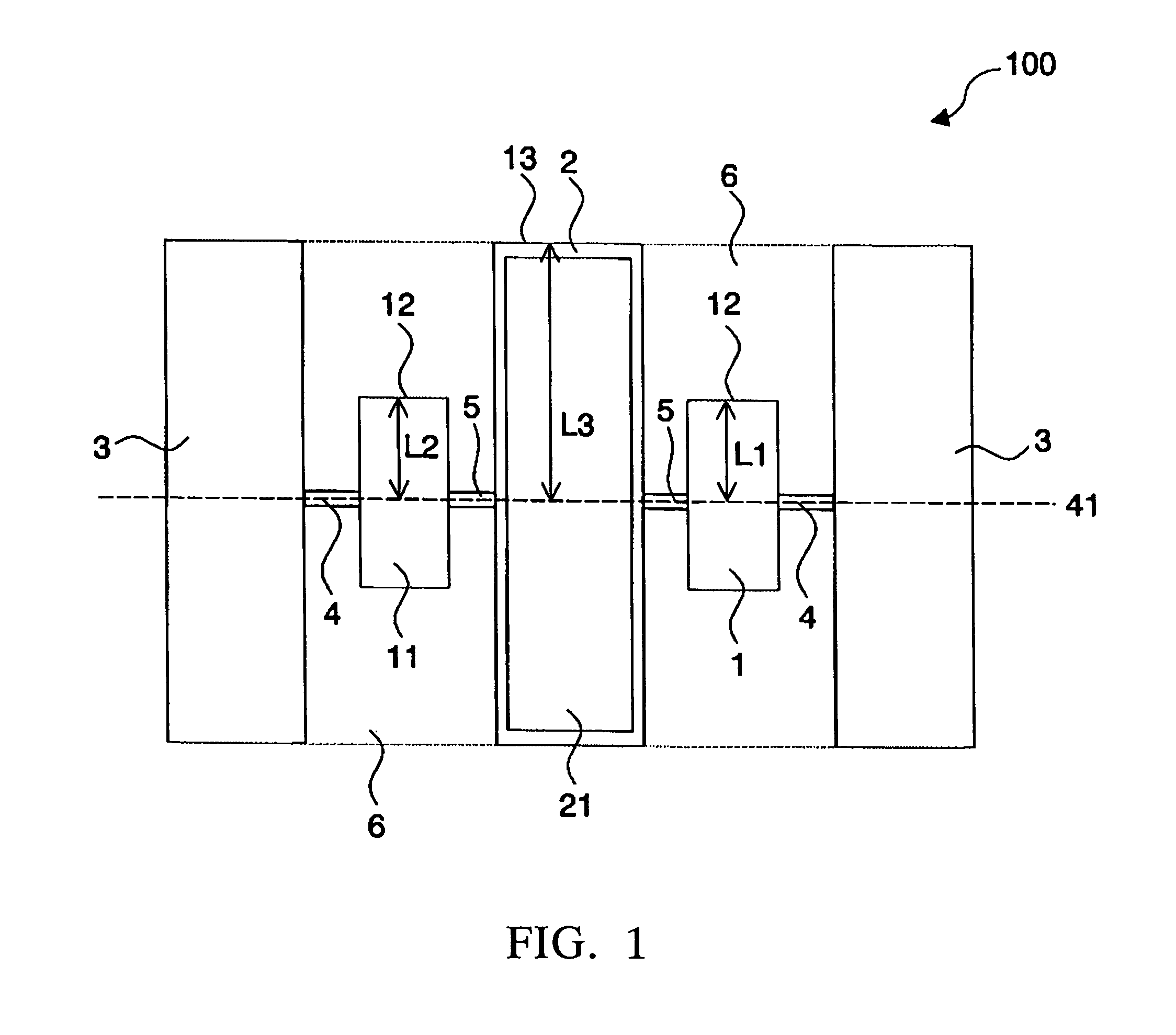

Actuator

InactiveUS7095156B2Large displacementLarge rotation angleElectrographic process apparatusDynamo-electric machinesEngineeringActuator

An actuator 100 of the type employing a two-degree-of-freedom vibration system includes: a pair of first mass portions 1, 11; a second mass portion 2 provided between the pair of first mass portions 1, 11; a pair of supporting portions 3, 3 for supporting the pair of first mass portions 1, 11 and the second mass portion 2; at least a pair of first elastic connecting portions 4, 4 which respectively connect the first mass portions 1, 11 to the supporting portions 3, 3 so that each of the first mass portions 1, 11 can rotate with respect to the supporting portions 3, 3; and at least a pair of second elastic connecting portions 5, 5 which respectively connect the second mass portion 2 to the first mass portions 1, 11 so that the second mass portion 2 can rotate with respect to the first mass portions 1, 11. Each of the first mass portions 1, 11 is driven by the application of an alternating voltage, causing the second mass portion 2 to rotate.

Owner:SEIKO EPSON CORP

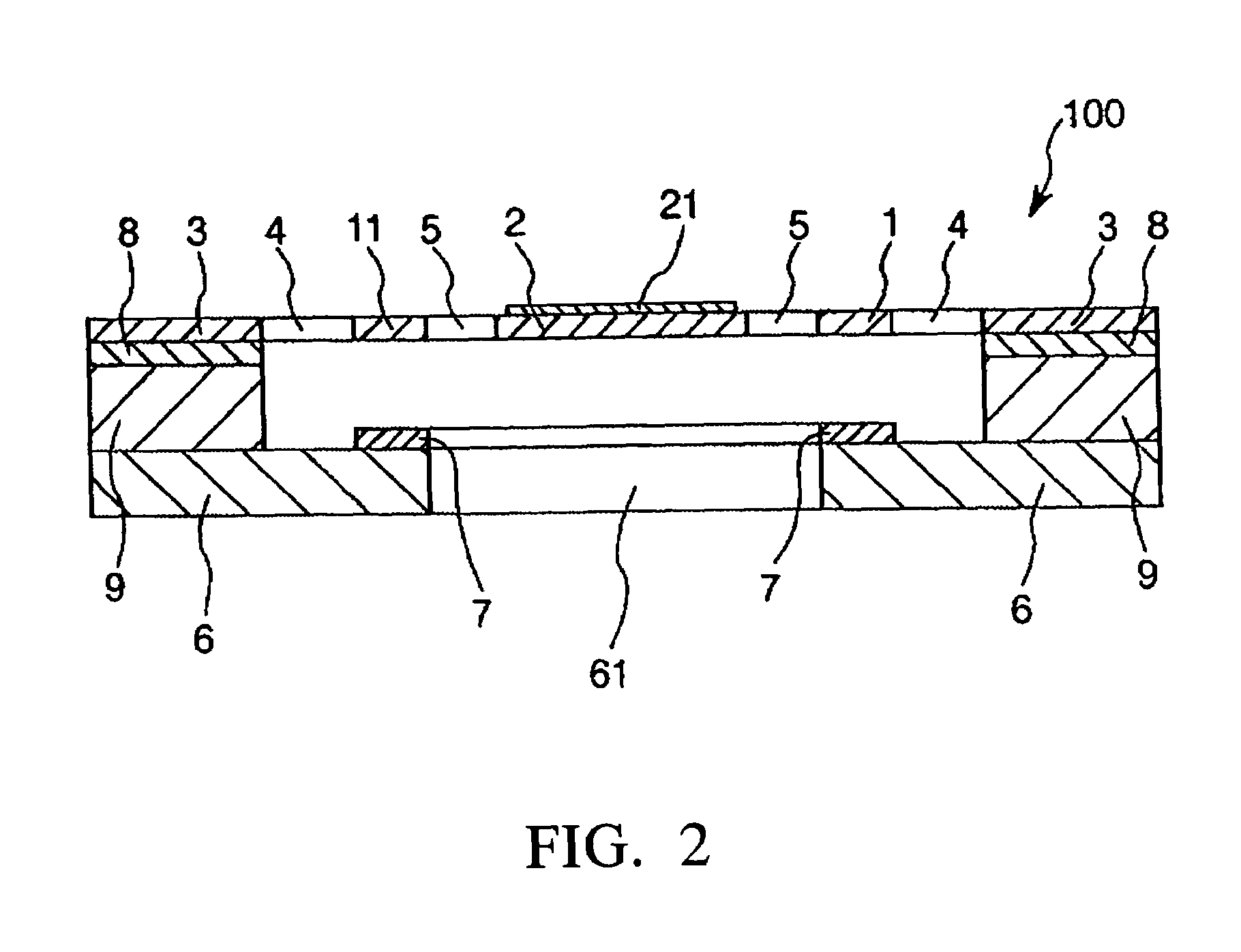

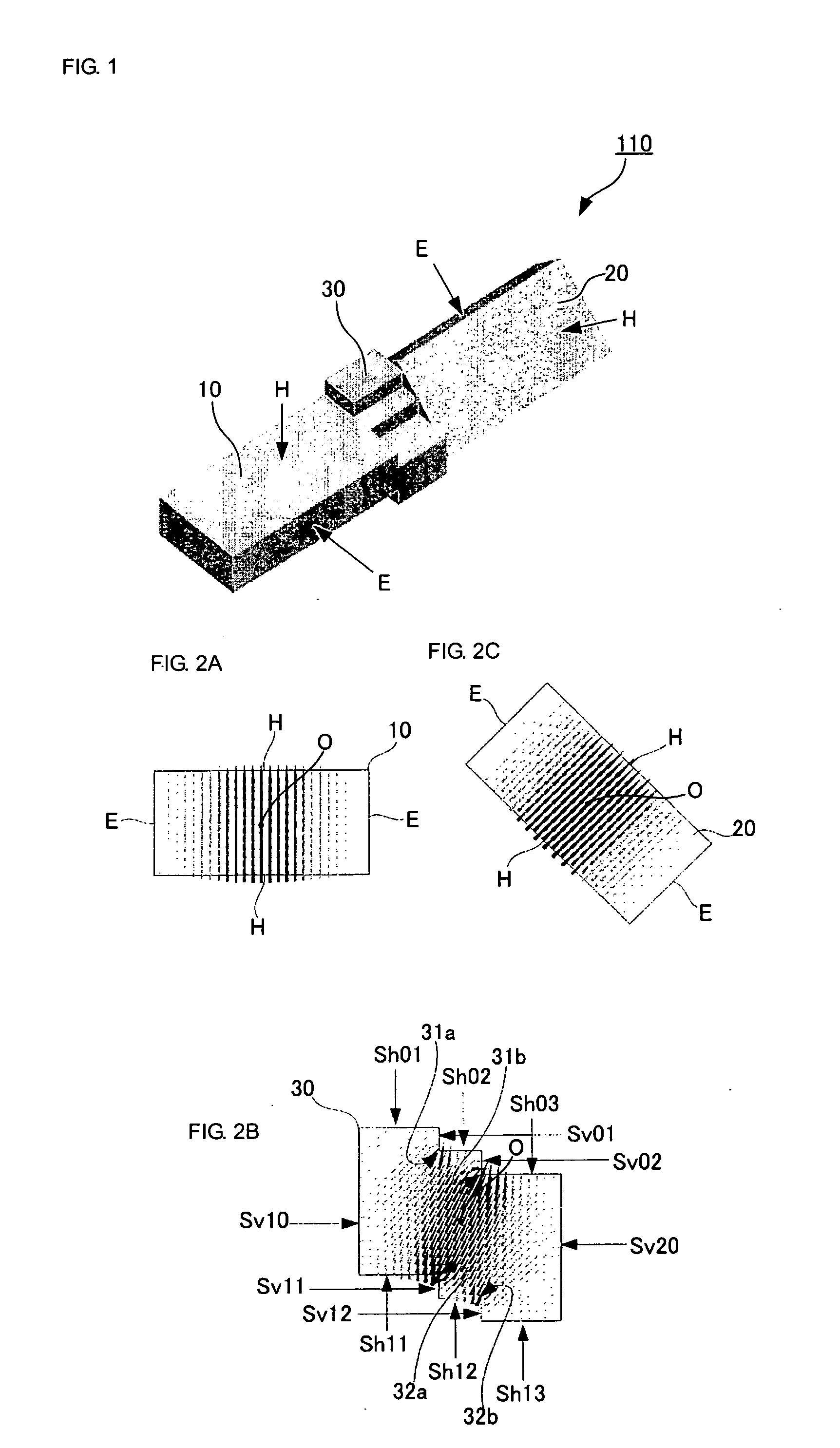

Twist waveguide and radio device

InactiveUS20060097816A1Wide frequency rangeCost reductionWaveguide type devicesAntennasElectric fieldWaveguide

H plane and E plane of a second rectangular waveguide element are inclined at an angle of 45° with respect to H plane and E plane of a first rectangular waveguide element. A connection element disposed between the first and second rectangular waveguide elements has an inner periphery that surrounds a central axis extending in a direction of electromagnetic-wave propagation. The inner periphery includes surfaces parallel to H plane and E plane of the first rectangular propagation path element, and these surfaces form a staircase such that abutting sections between the surfaces parallel to H plane and the surfaces parallel to E plane constitute projections. The staircase is inclined in a direction corresponding to a direction in which H plane of the second rectangular propagation path element is inclined. Accordingly, an electric field is concentrated in the projections of the connection element (30), and a plane of polarization of an electromagnetic wave propagating through the connection element is rotated from a plane of polarization in the first rectangular waveguide element towards a plane of polarization in the second rectangular waveguide element.

Owner:MURATA MFG CO LTD

Rotary mechanism and related electronic device

ActiveUS9189032B2Simple structureLarge rotation rangeDetails for portable computersMulti-purpose toolsEngineeringElectric equipment

Owner:WISTRON CORP

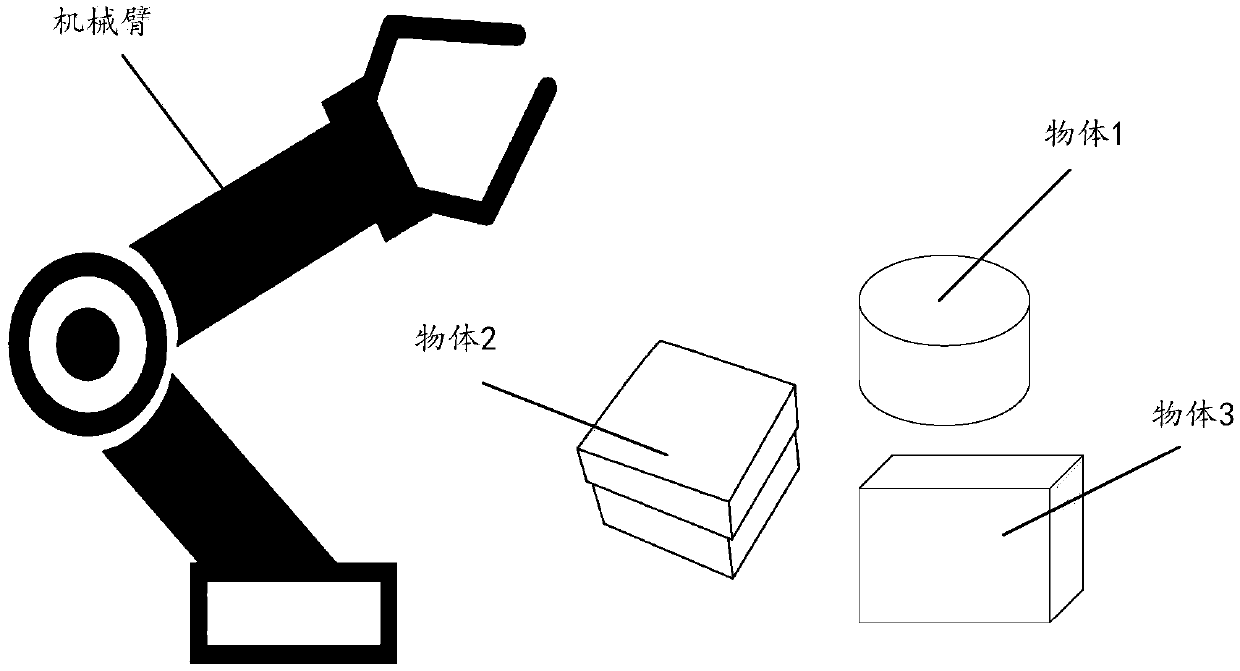

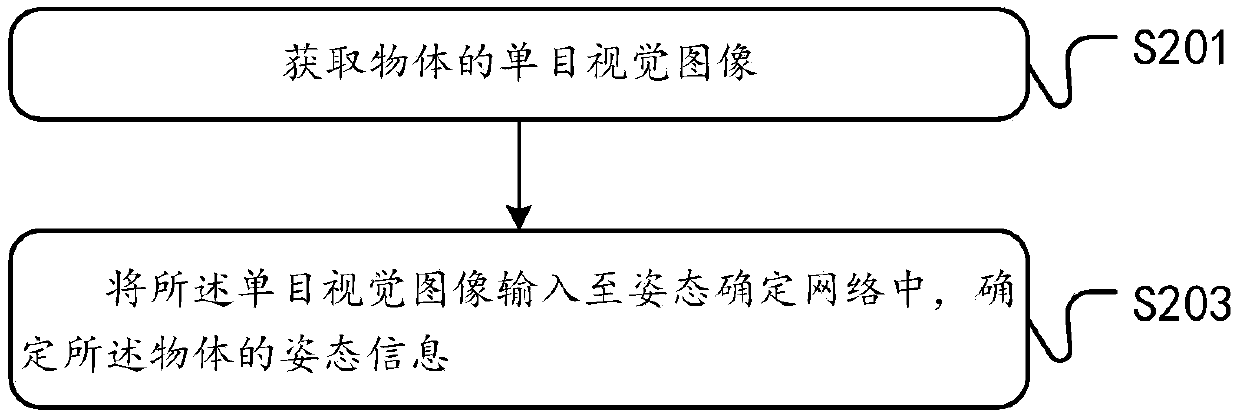

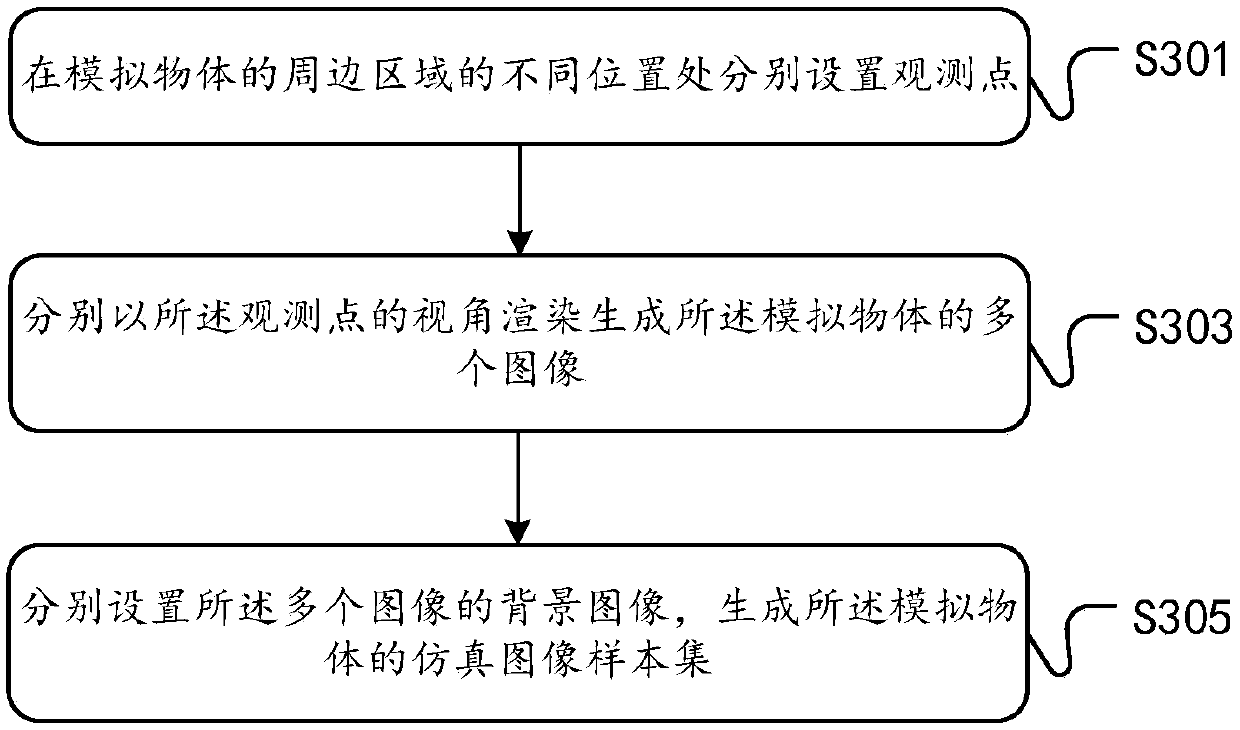

MetObject attitude determination method and devicehod and device for determining object posture, electronic equipment and computer medium

InactiveCN109615655ALower acquisition costsImprove accuracyImage enhancementImage analysisVisual perceptionMonocular vision

The invention relates to an object attitude determination method and device, electronic equipment and a computer medium. The method comprises the steps of obtaining a monocular vision image of an object; inputting the monocular vision image into an attitude determination network, and determining attitude information of the object; W; wherein the attitude determination network is obtained by training a simulation image sample set and a real image sample set. By utilizing the method provided by the embodiment of the invention, the cost of obtaining the sample data can be reduced on the basis ofensuring the high accuracy of the attitude determination network.

Owner:SHENZHEN SENSETIME TECH CO LTD

Actuator

InactiveUS20050116551A1Large displacementLarge rotation angleElectrographic process apparatusDynamo-electric machinesTwo degrees of freedomEngineering

An actuator 100 of the type employing a two-degree-of-freedom vibration system includes: a pair of first mass portions 1, 11; a second mass portion 2 provided between the pair of first mass portions 1, 11; a pair of supporting portions 3, 3 for supporting the pair of first mass portions 1, 11 and the second mass portion 2; at least a pair of first elastic connecting portions 4, 4 which respectively connect the first mass portions 1, 11 to the supporting portions 3, 3 so that each of the first mass portions 1, 11 can rotate with respect to the supporting portions 3, 3; and at least a pair of second elastic connecting portions 5, 5 which respectively connect the second mass portion 2 to the first mass portions 1, 11 so that the second mass portion 2 can rotate with respect to the first mass portions 1, 11. Each of the first mass portions 1, 11 is driven by the application of an alternating voltage, causing the second mass portion 2 to rotate.

Owner:SEIKO EPSON CORP

A positioning and adjusting device of display

InactiveUS20150382491A1Easy to watchProtection from damagePicture framesCasings/cabinets/drawers detailsDisplay deviceEngineering

Owner:YE MAOQING

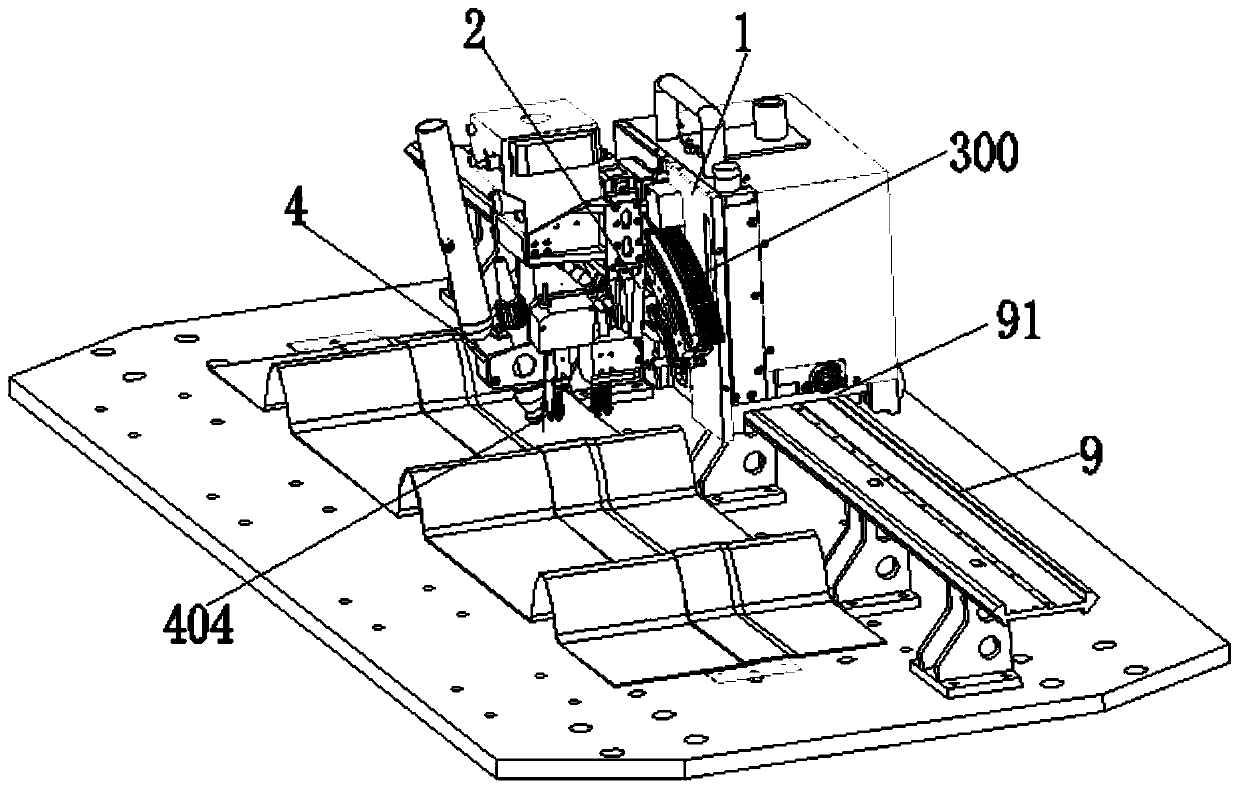

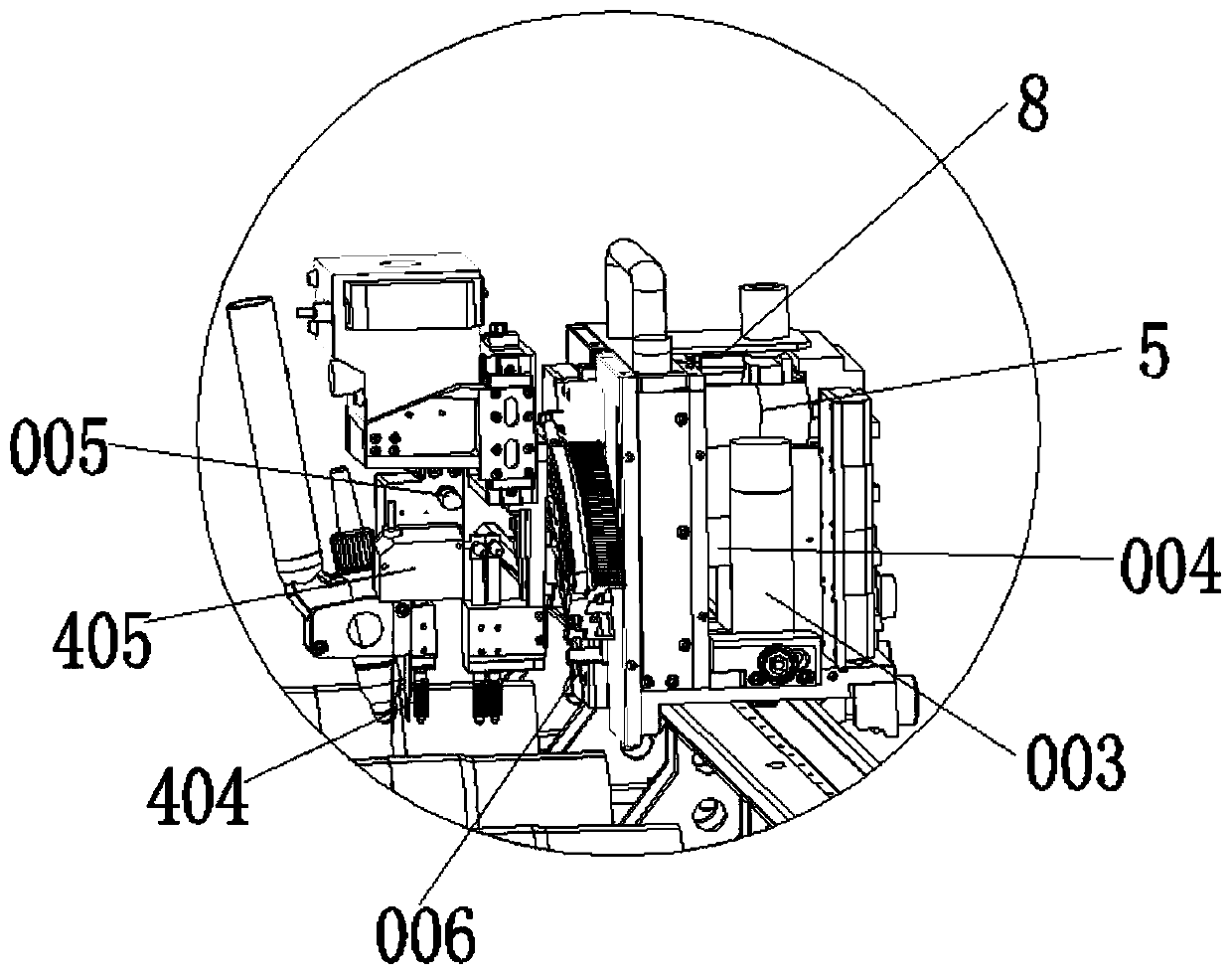

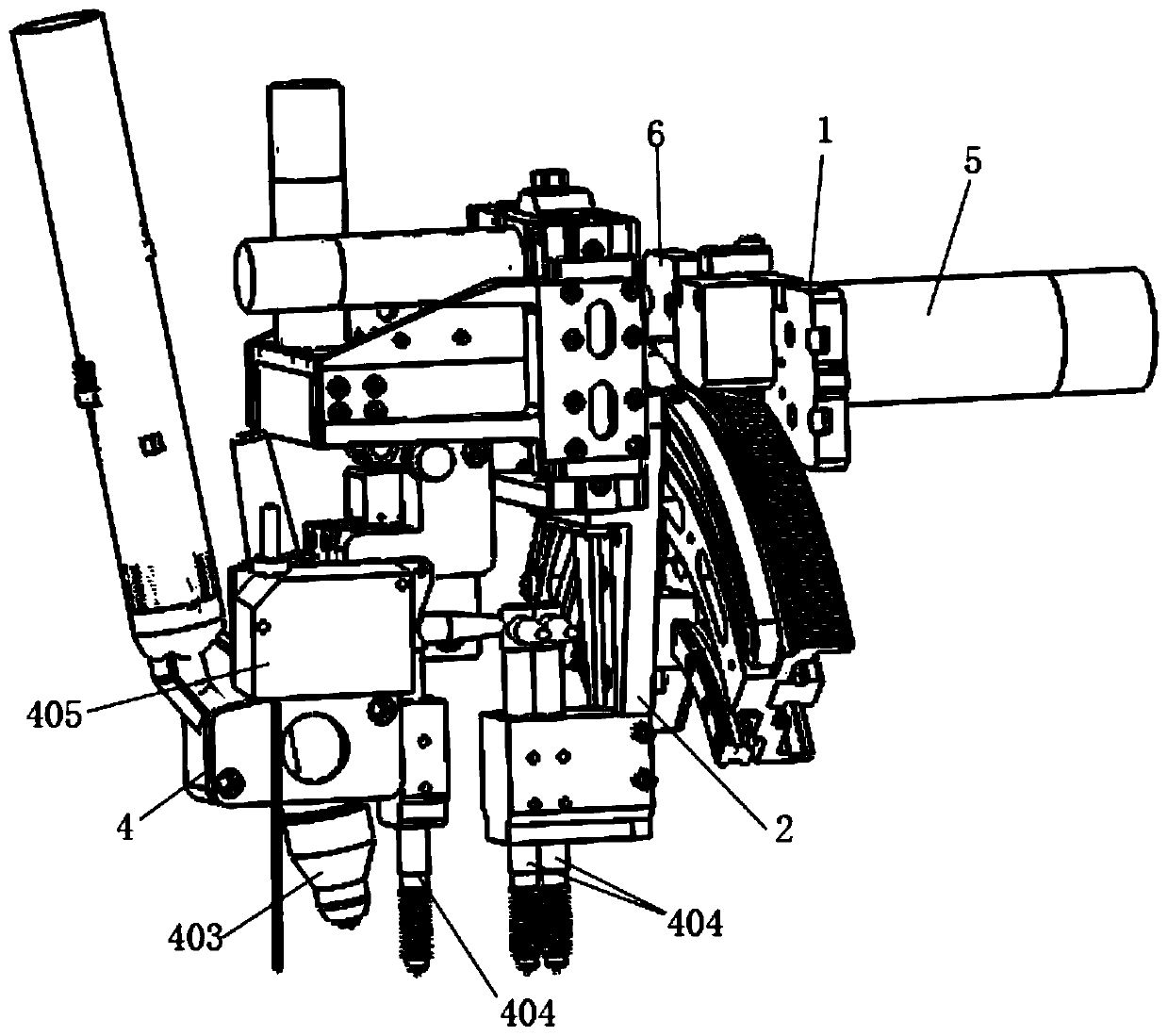

Plasma welding robot

PendingCN110722259ALarge rotation angleGuaranteed stabilityPlasma welding apparatusAutomotive engineeringWeld bead

The invention discloses a plasma welding robot. The plasma welding robot comprises rails, a welding car and a plasma power supply; the car is provided with a drive walking mechanism and a bracket thereof, welding gun angle and position adjusting mechanisms and a welding gun bracket; the walking mechanism controls motions in an X-axle rail direction and a Y-axle rail perpendicular direction; the angle adjusting mechanism is provided with an angle sensor for realizing the angle rotating adjustment of a R-axle welding gun; the welding gun position adjusting mechanism provides the position adjustment in Z-axle front and back directions and AVC-axle welding gun firepower line directions; a laser tracking sensor controls the position adjustment of ZX-axle laser points deviated from welding linesfront and back; three contact sensors are arranged on the car; two are used for judging curved surface positions to control the car to walk and to adjust the angle of the welding gun; and one is usedfor measuring local deformation of plates to realize automatic arc height adjustment. The plasma welding robot adopts quickly installed guide rails to realize automatic welding of all-position stainless steel corrugated plate joints through control of a six-axle linkage robot and a welding line laser automatic tracking system by a PLC.

Owner:ZHEJIANG JINHUA JUNENG ELECTRONICS TECH

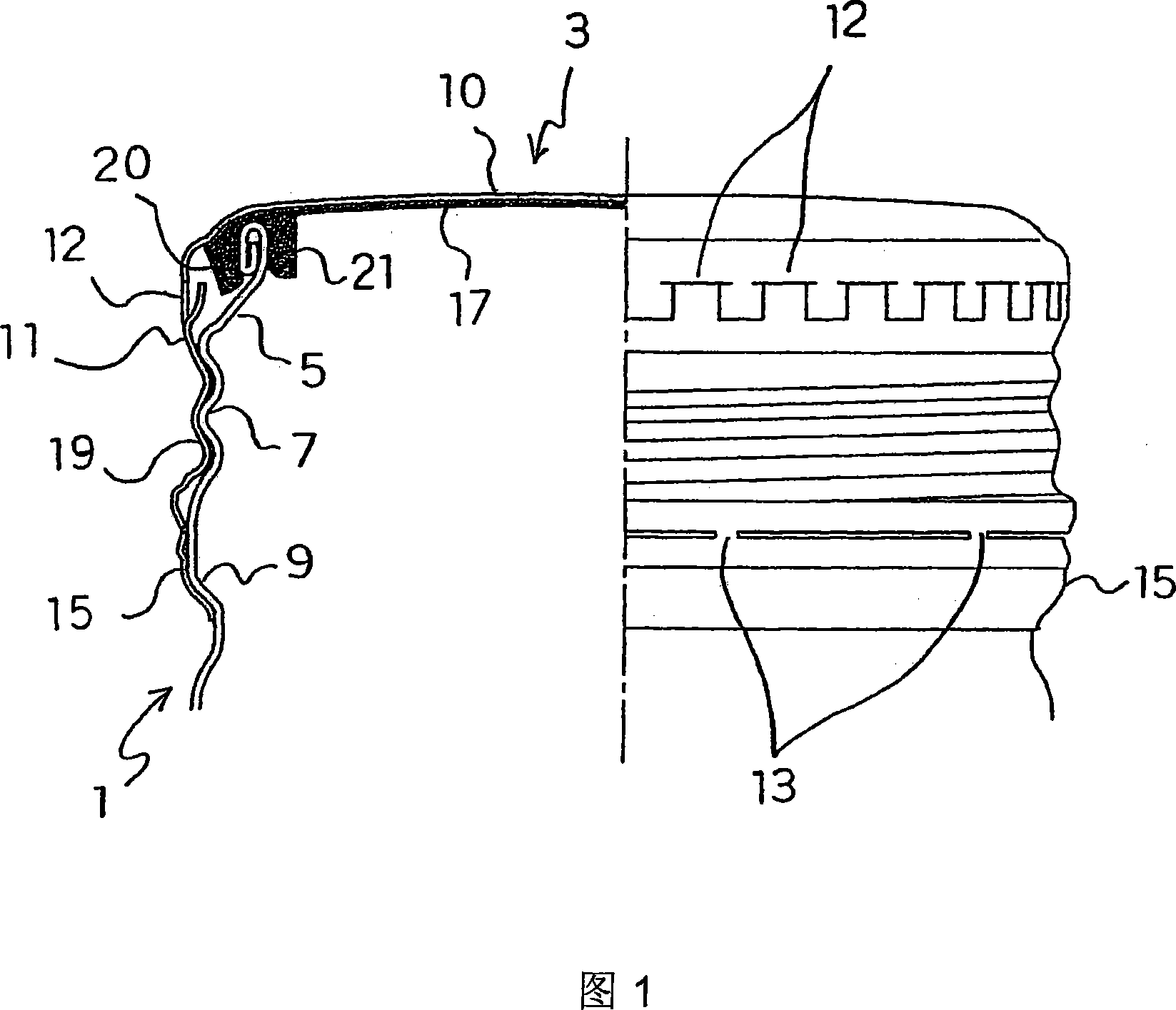

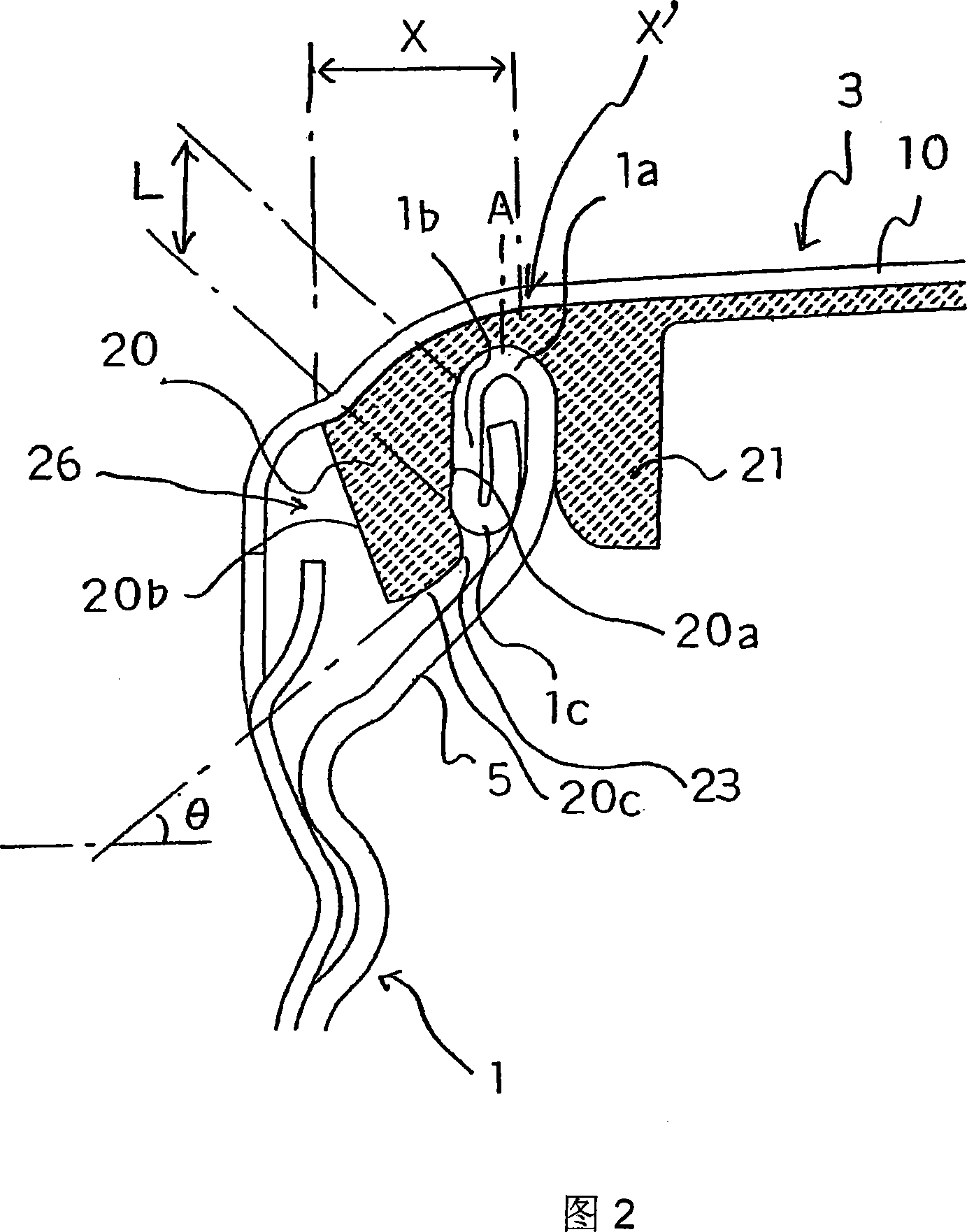

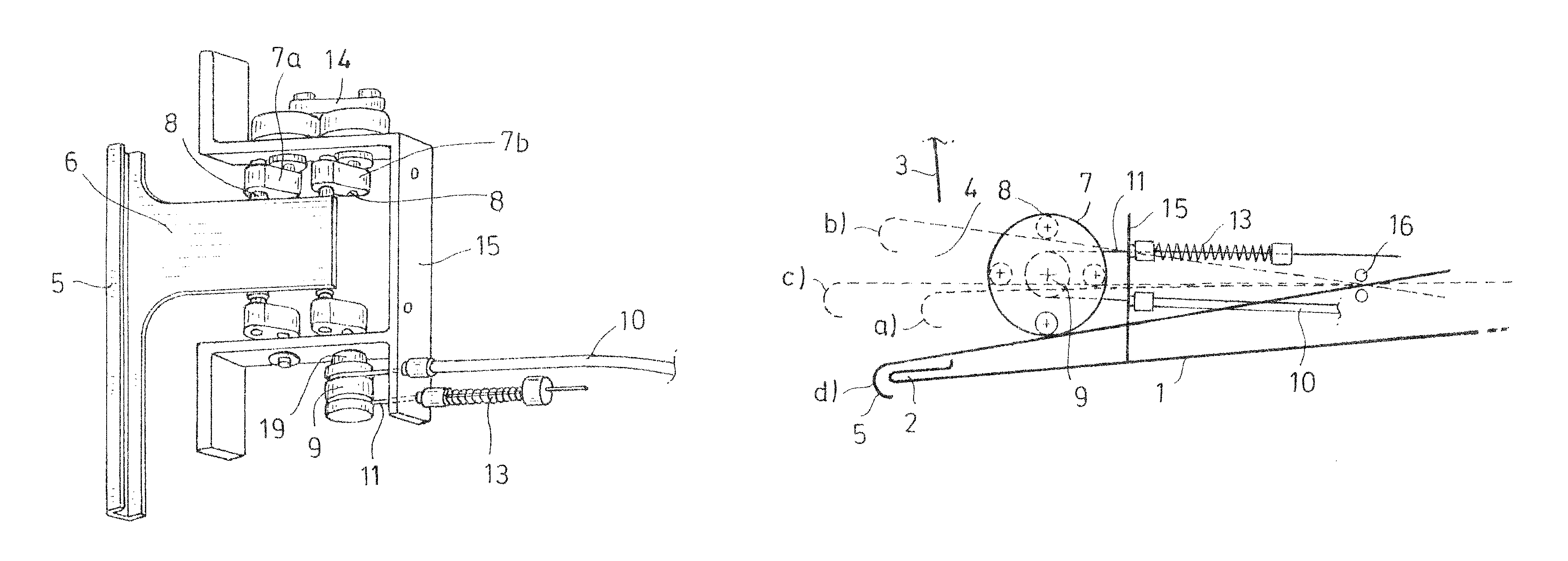

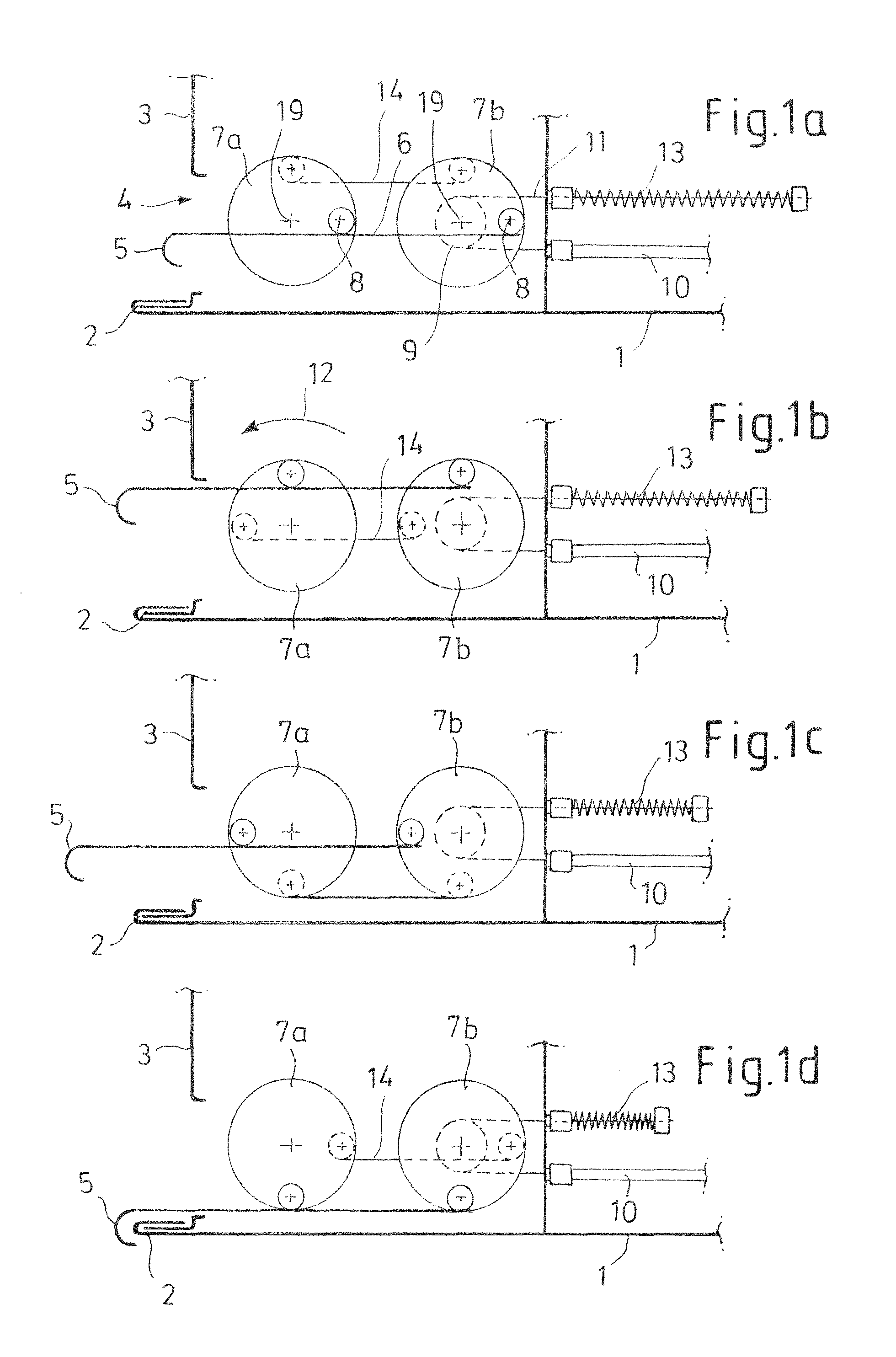

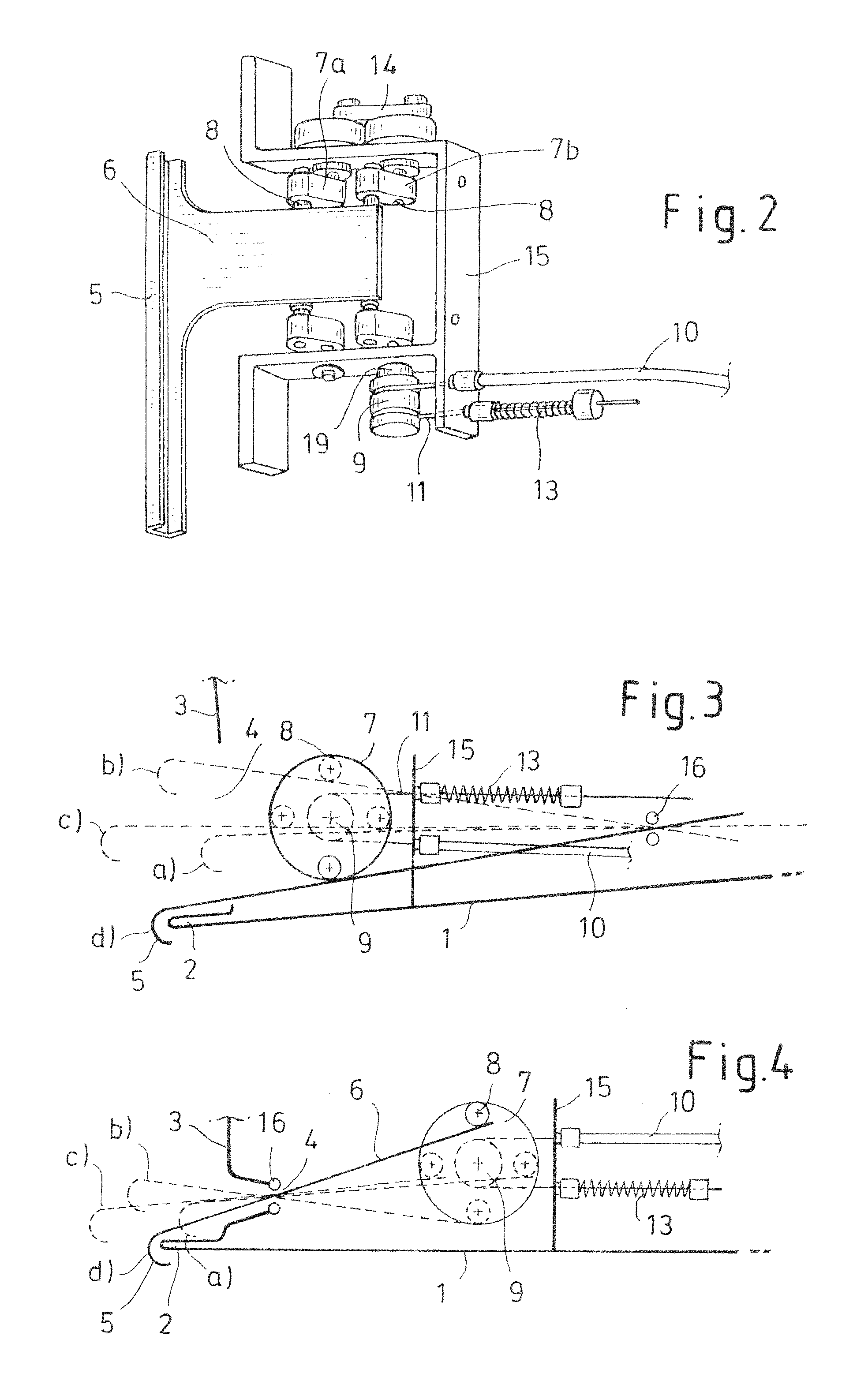

Door edge protection device

A door edge protection device for a motor vehicle door which comprises a door edge protection member guided movably with respect to the door at at least two points lying one behind the other in a longitudinal direction of the door. The door edge protection member is driven via an eccentric lever mounted rotatably in the door.

Owner:FORD GLOBAL TECH LLC

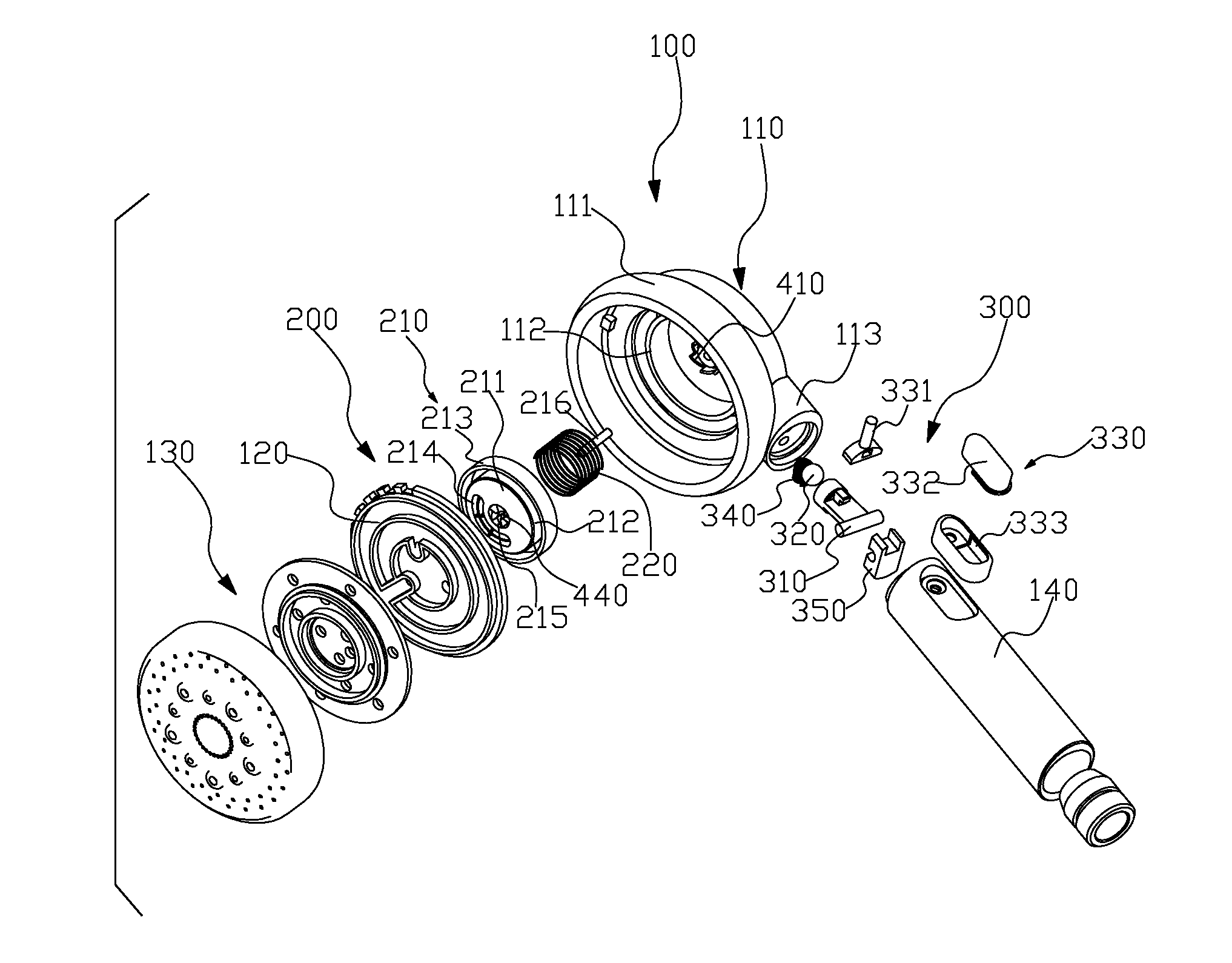

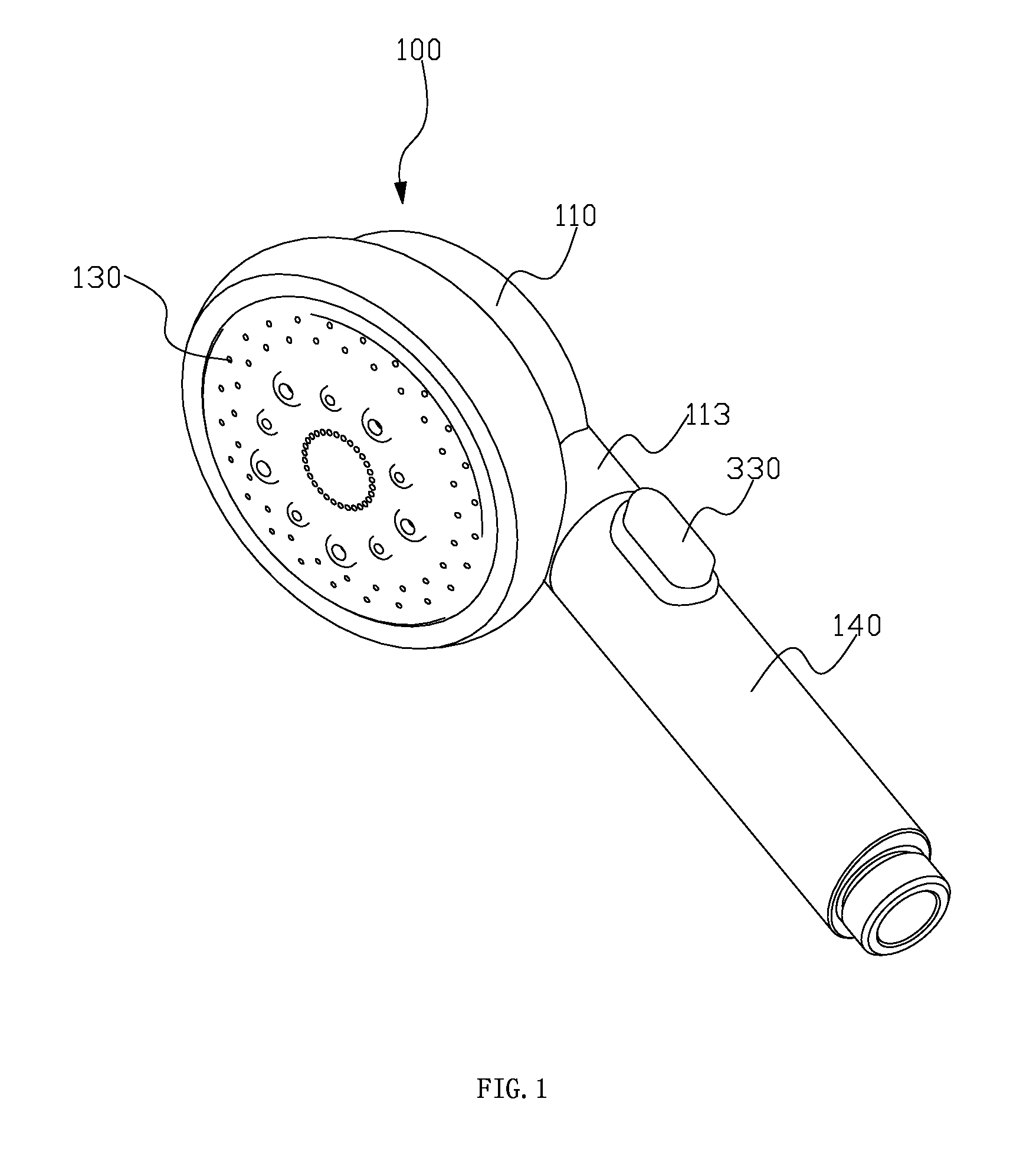

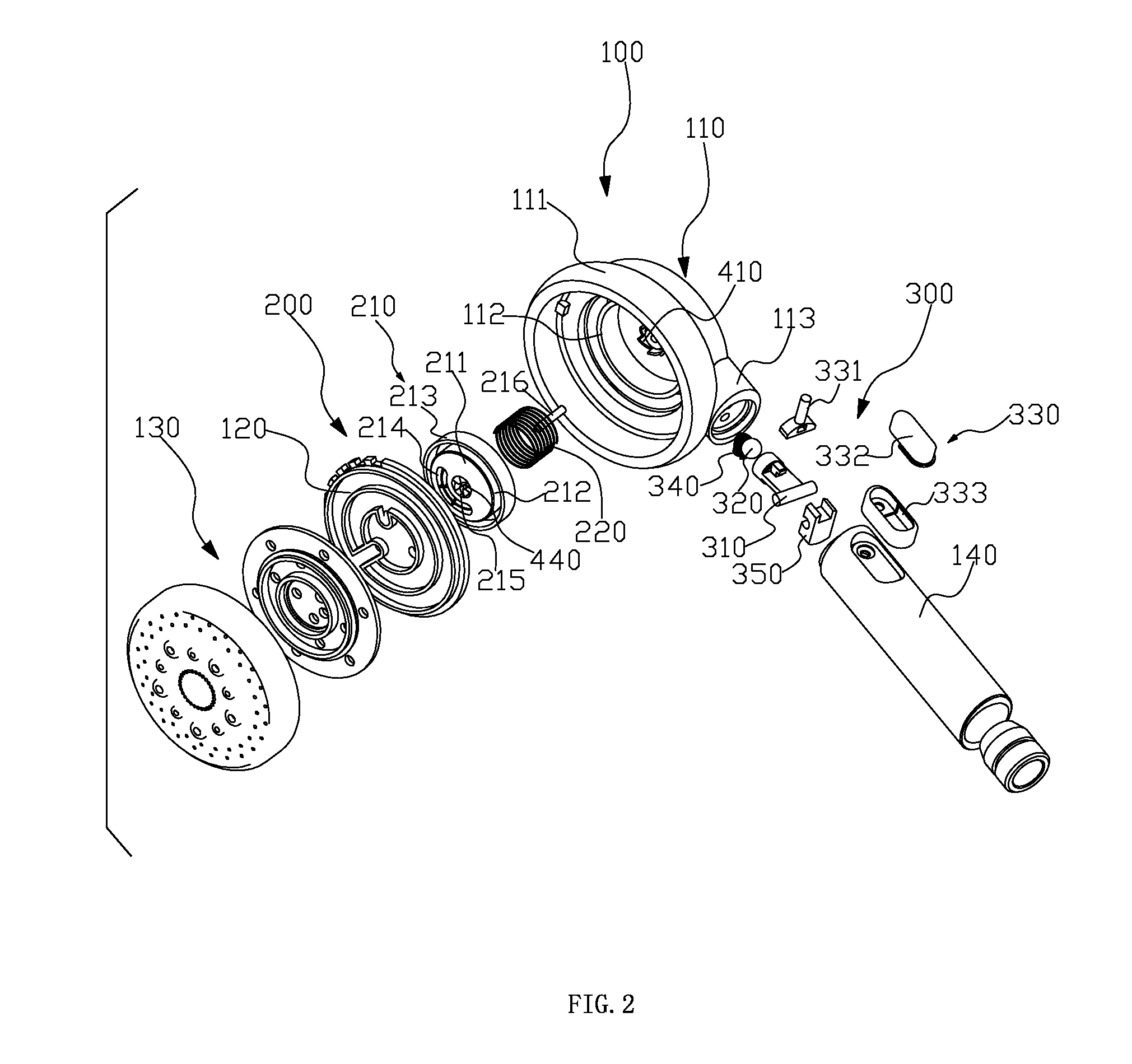

Outlet switch device and an outlet switch method

ActiveUS20120312403A1Large rotation angleThe process is convenient and fastPlug valvesDiaphragm valvesMechanical engineeringMechanics

Owner:XIAMEN SOLEX HIGH TECH IND CO LTD

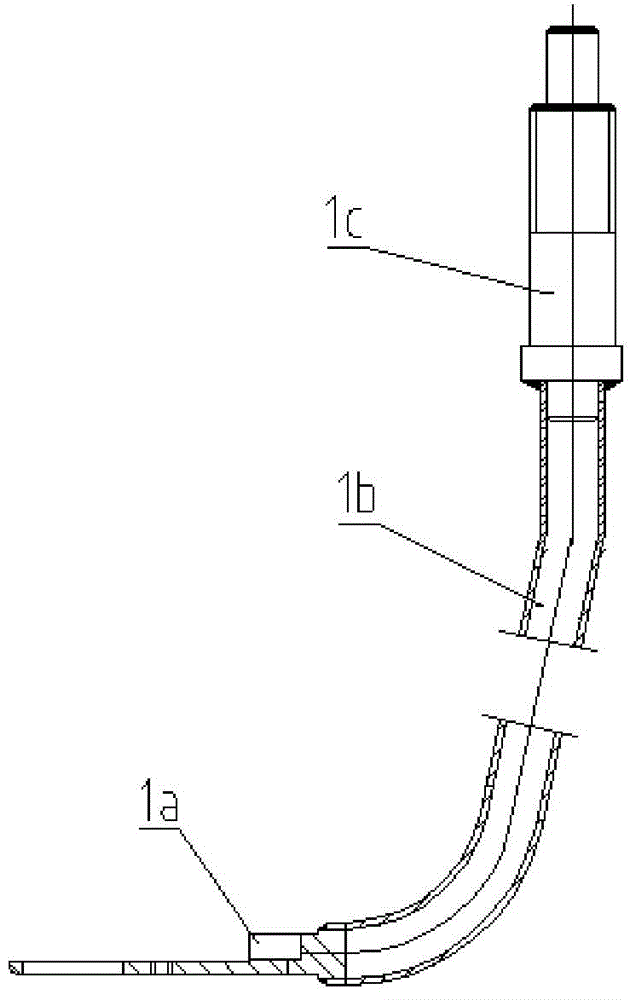

Force limiting adapter coupling wrench for assembling and disassembling bolt in aircraft engine rotor component deep cavity

ActiveCN104476462AEasy loading and unloadingAvoid excessive rotation anglesSpannersWrenchesSteel tubeWrench

The invention discloses a force limiting adapter coupling wrench for assembling and disassembling a bolt in an aircraft engine rotor component deep cavity, and aims to realize assembly and disassembly operation in an aircraft engine gourd-shaped deep cavity and solve the problem of difficulty in assembly and disassembly of the bolt between integral turbine wheels of an engine. According to the adopted technical scheme, the wrench comprises a supporting plate and a wrench body, wherein the supporting plate can be supported against a gourd-shaped opening of an aircraft engine rotor blade disk and is provided with a cambered hole; the wrench body passes through the cambered hole, can move along the cambered hole and comprises a first adapter, a steel pipe and a gear seat which are integrated; the steel pipe is curved; the end face of the first adapter is guaranteed to be perpendicular to the end face of the gear seat; the first adapter is connected with a second adapter; the second adapter is connected with a force limiting wrench capable of screwing the entire device; the gear seat is provided with a ratchet wheel mechanism; the ratchet wheel mechanism comprises a ratchet wheel and a pawl matched with the ratchet wheel; the ratchet wheel is provided with a counterbore; the size of the counterbore is the same as the size of a nut matched with the bolt of the blade disk.

Owner:AECC AVIATION POWER CO LTD

Multi-degree-of-freedom simple mechanical arm based on artificial muscle (IPMC) driving

ActiveCN107253188ASimple structureFlexible operationProgramme-controlled manipulatorRobotic armEngineering

The invention belongs to the technical of robots and particularly relates to a multi-degree-of-freedom simple mechanical arm based on artificial muscle (IPMC) driving. The multi-degree-of-freedom simple mechanical arm comprises a rotating part, an extending-retracting part and a grabbing part. The rotating part comprises a fixed shaft, a fixed disc, a rotating disc and rotating driving units. IPMC rotating assemblies in the rotating driving unit provide power for rotating driving of the arm. The extending-retracting part comprises a connecting shaft, a supporting disc and extending-retracting driving units. IPMC extending-retracting assemblies in the extending-retracting driving unit provide power for extending-retracting driving of the arm. The grabbing part comprises a palm plate, finger mechanisms and a thumb mechanism. IPMC rotating assemblies and IPMC bending assemblies of the finger mechanisms and the thumb mechanism provide power for rotating driving and bending driving of fingers correspondingly. The multi-degree-of-freedom simple mechanical arm has the beneficial effects that the IPMC-driven arm can make actions of rotating, extending-retracting, grabbing and the like of the arm, and has characteristics of simple structure, flexible operation, less energy consumption, low weight and the like.

Owner:CHANGZHOU UNIV

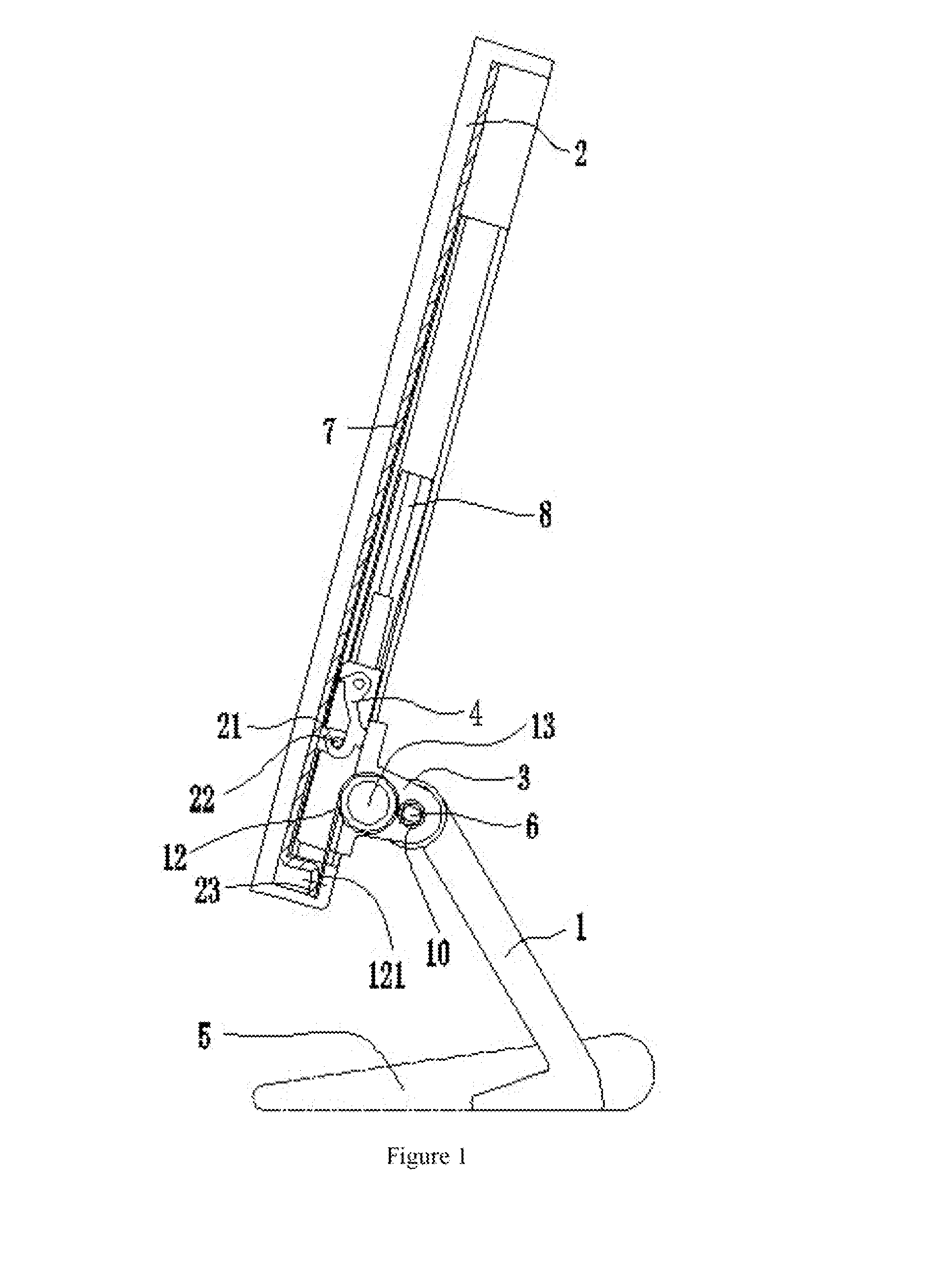

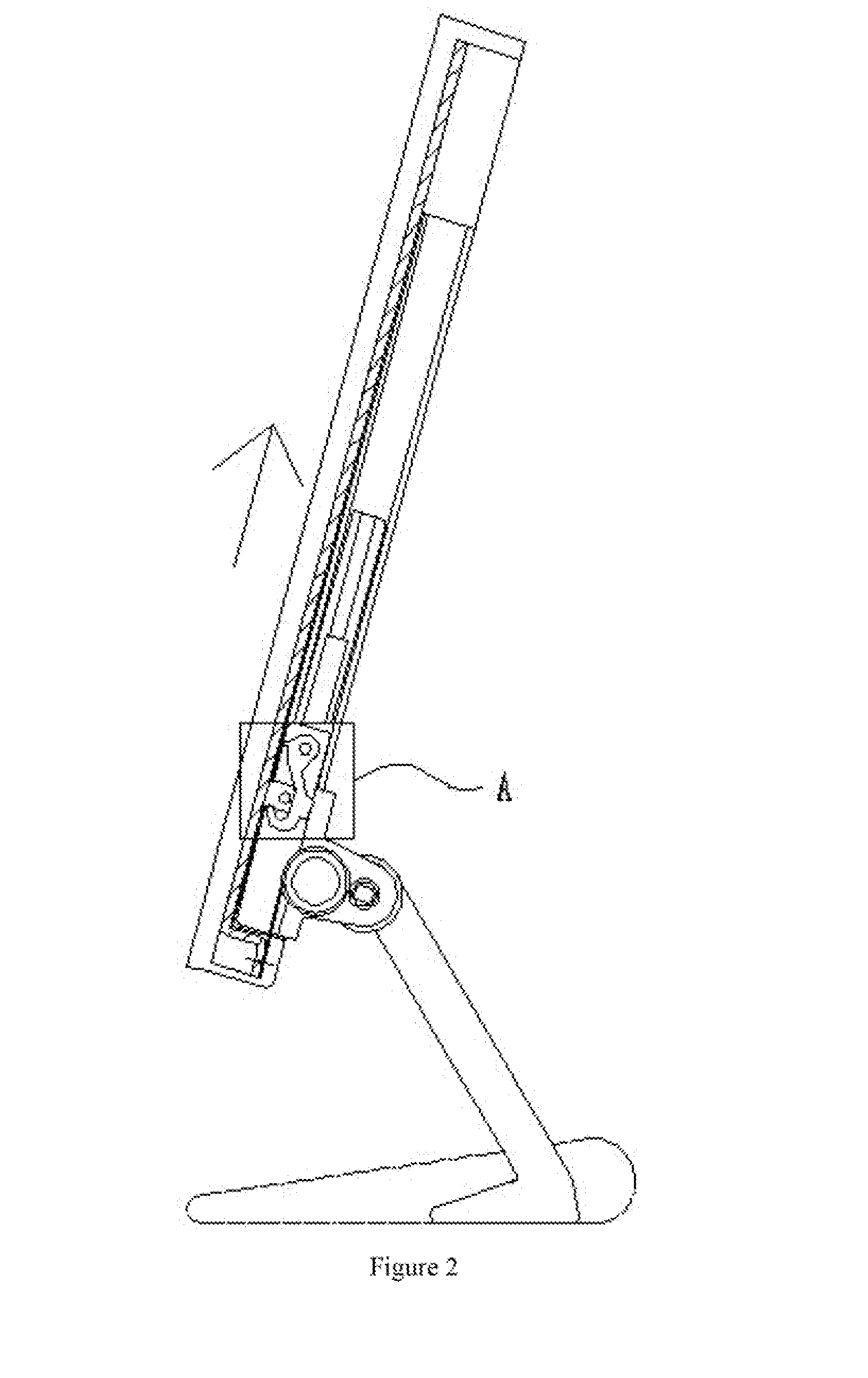

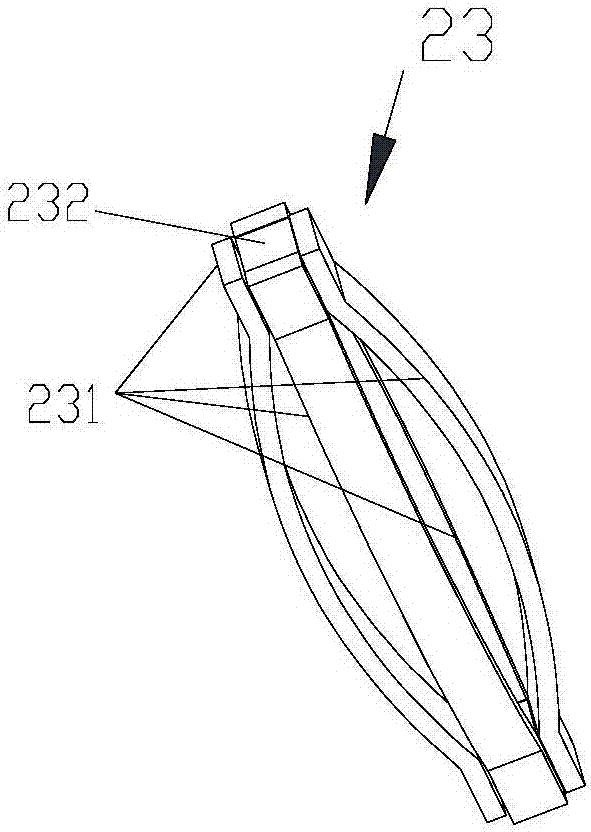

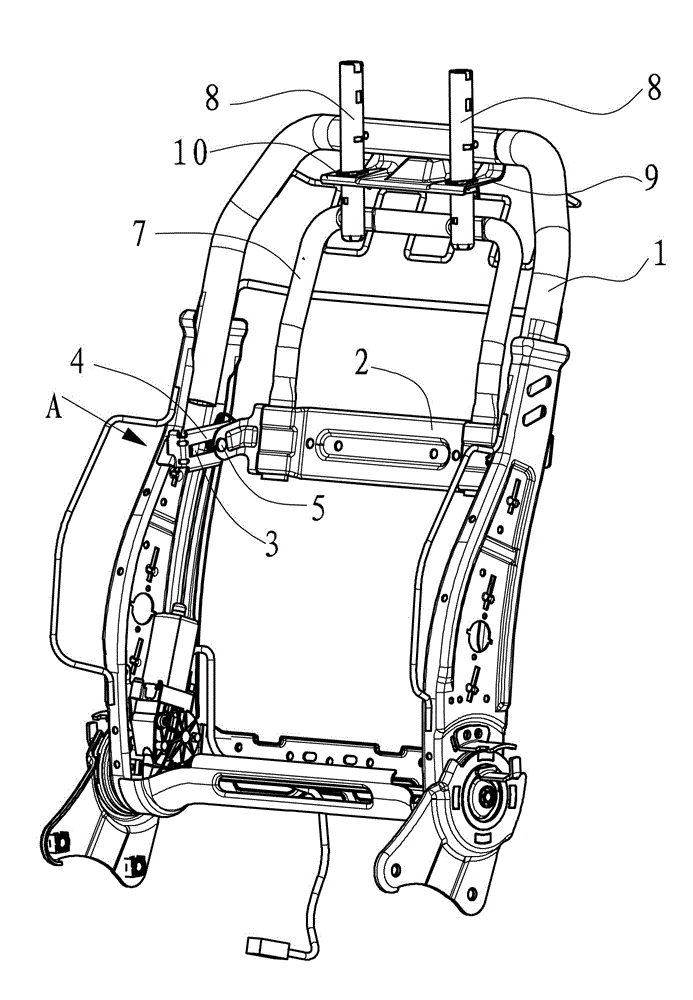

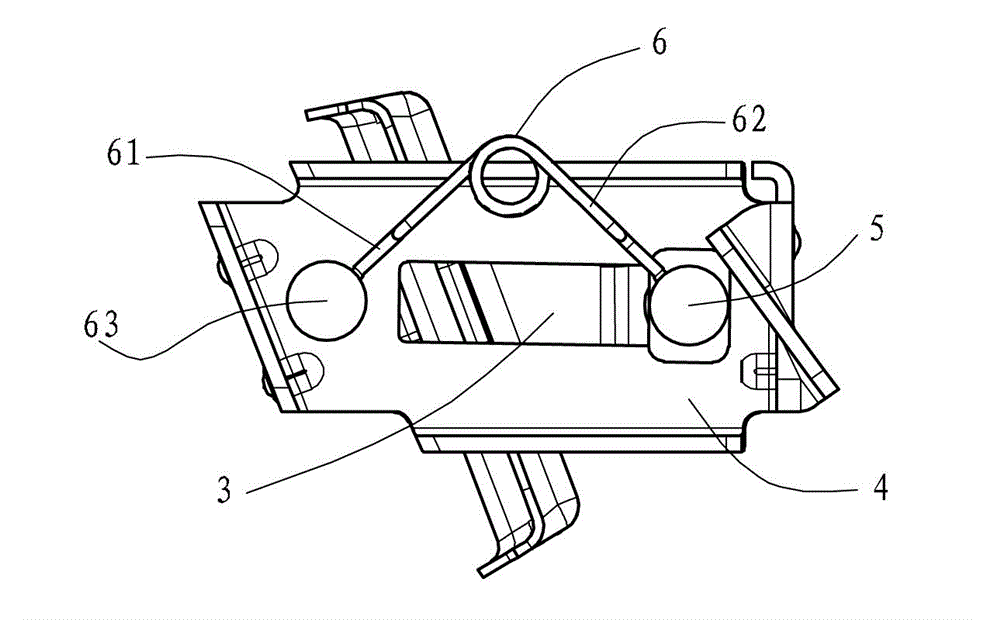

Active headrest device for automobile seat

The invention relates to an active headrest device for an automobile seat. The active headrest device for the automobile seat comprises a backrest framework (1), a triggering plate (2) arranged on the backrest framework (1), and a bracket structure fixedly connected with the triggering plate (2) for supporting a headrest. The backrest framework (1) is fixedly provided with a guide plate (4) with a through groove (3). The triggering plate (2) is in sliding connection on the guide plate (4) through a sliding part in slide match with the through groove (3). An elastic device for providing an elastic restoring force to the triggering plate (2) is arranged between the guide plate (4) and the sliding part. The direction of the elastic restoring force provided by the elastic device to the triggering plate (2) and the sliding direction of the sliding part are on a same straight line. With the adoption of the technical scheme provided by the invention, the direction of the elastic restoring force provided by the elastic device to the triggering plate and the sliding direction of the sliding part are on a same straight line so that the triggering plate triggered can restore rapidly.

Owner:GREAT WALL MOTOR CO LTD

Flexible timepiece guidance

ActiveUS9323222B2Compact and economical to manufactureEasy to useEscapementsFrequency stabilisation mechanismEngineeringMechanical engineering

A device for elastic guidance in rotation for a timepiece mechanism allowing rotation of one element relative to another element about an axis of rotation Z defining an axial direction, including construction blades, each construction blade includes an assembly fixing part including a body and a functional part extending from the body as far as one end, the assembly fixing part and the functional part being separated by at least one slot in at least two extensions which are elastically connected and extend in a radial direction transverse to the axial direction, and anchorage zones which are disposed at opposite axial ends of the flexible guidance device, and configured to be fixed to the elements.

Owner:NIVAROX FAR

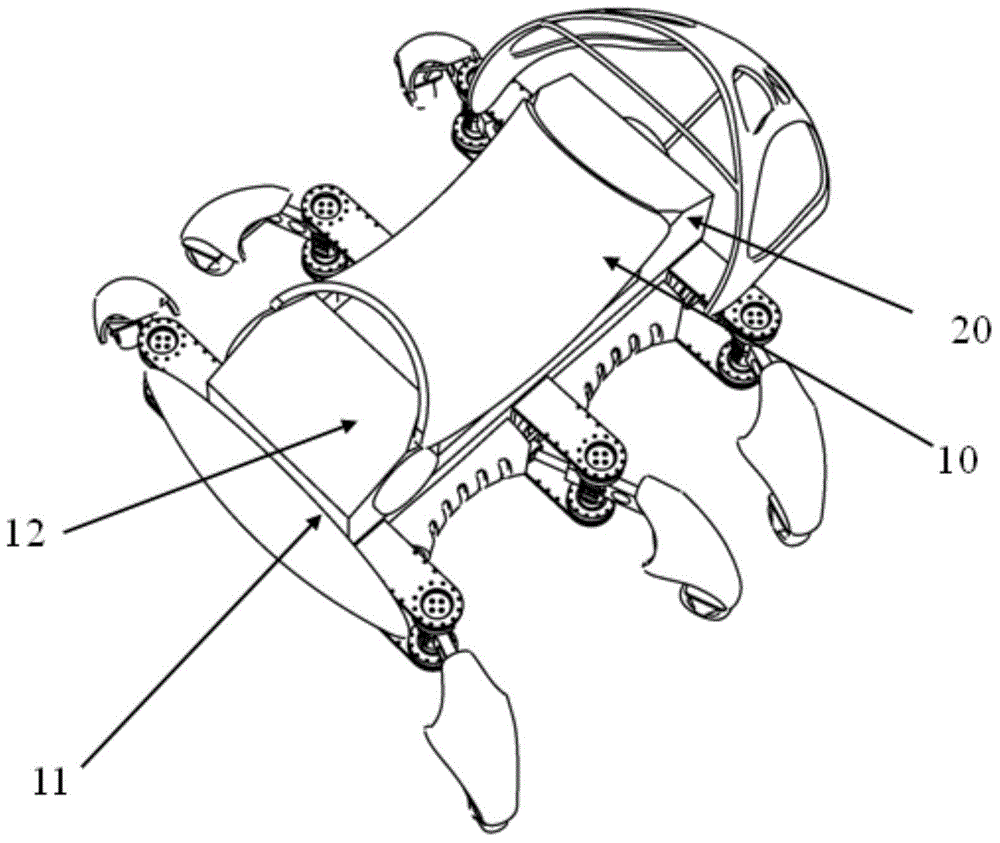

Hexapod robot

The invention discloses a hexapod robot. The robot comprises a head part, a body, a driving device, a transmission system and six mechanical legs. The hexapod robot is characterized in that the six mechanical legs are reversely and symmetrically mounted on both sides of the long edge of the body, and adopt the completely same structures; the driving device and the transmission system are arrayed at the inner part of the body; the driving device performs driving through a servo motor, and the transmission system performs transmission through sprocket chains; three output rods are also arranged at the inner part of the body, and the two mechanical legs are reversely and symmetrically mounted on both sides of each output rod; the six mechanical legs are divided into three groups, and the three groups of output rods are connected in a transmission manner by adopting the sprocket chains; the servo motor of the driving device designed at the inner part of the body simultaneously drives the six mechanical legs to move.

Owner:SHAANXI JIULI ROBOT MFG

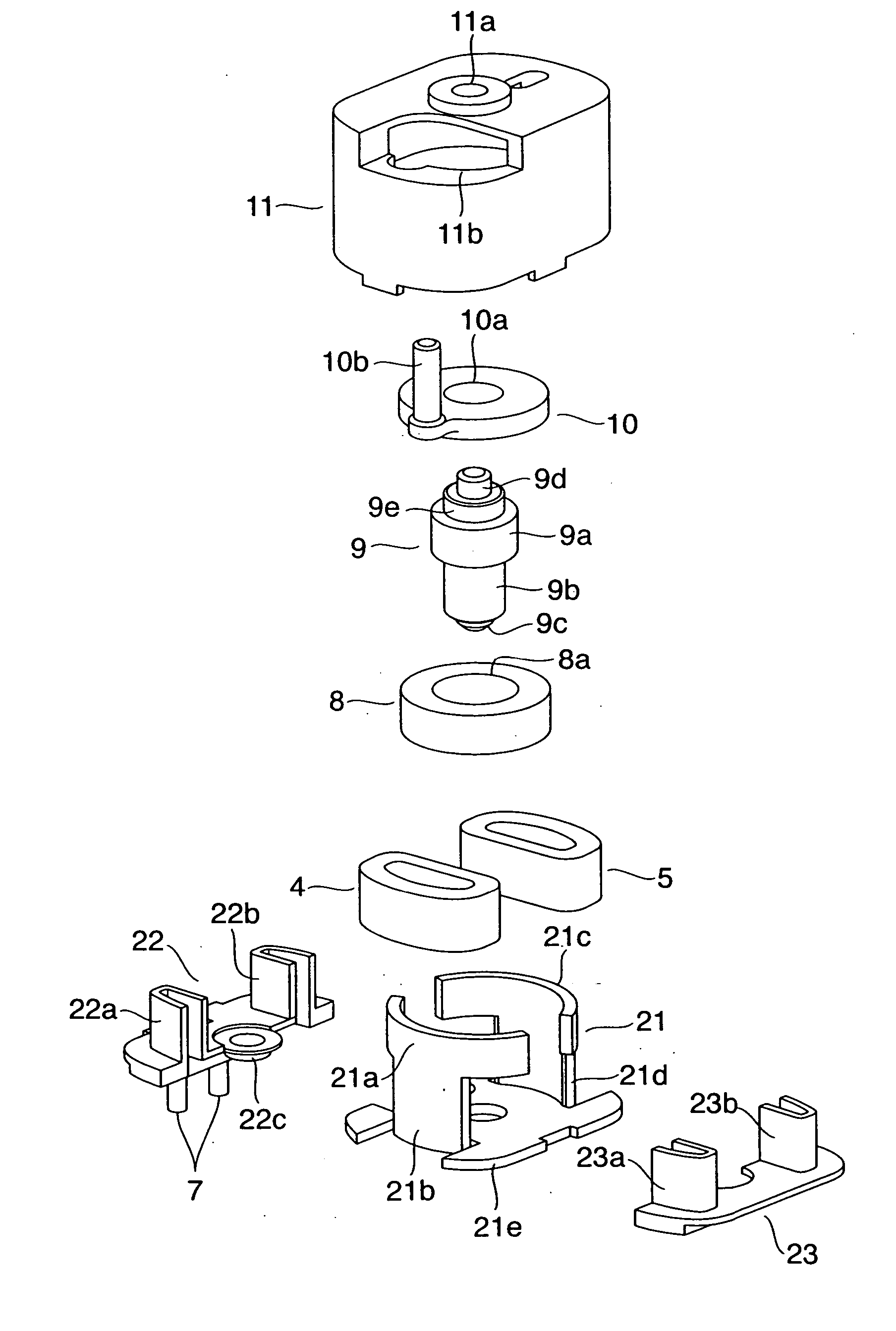

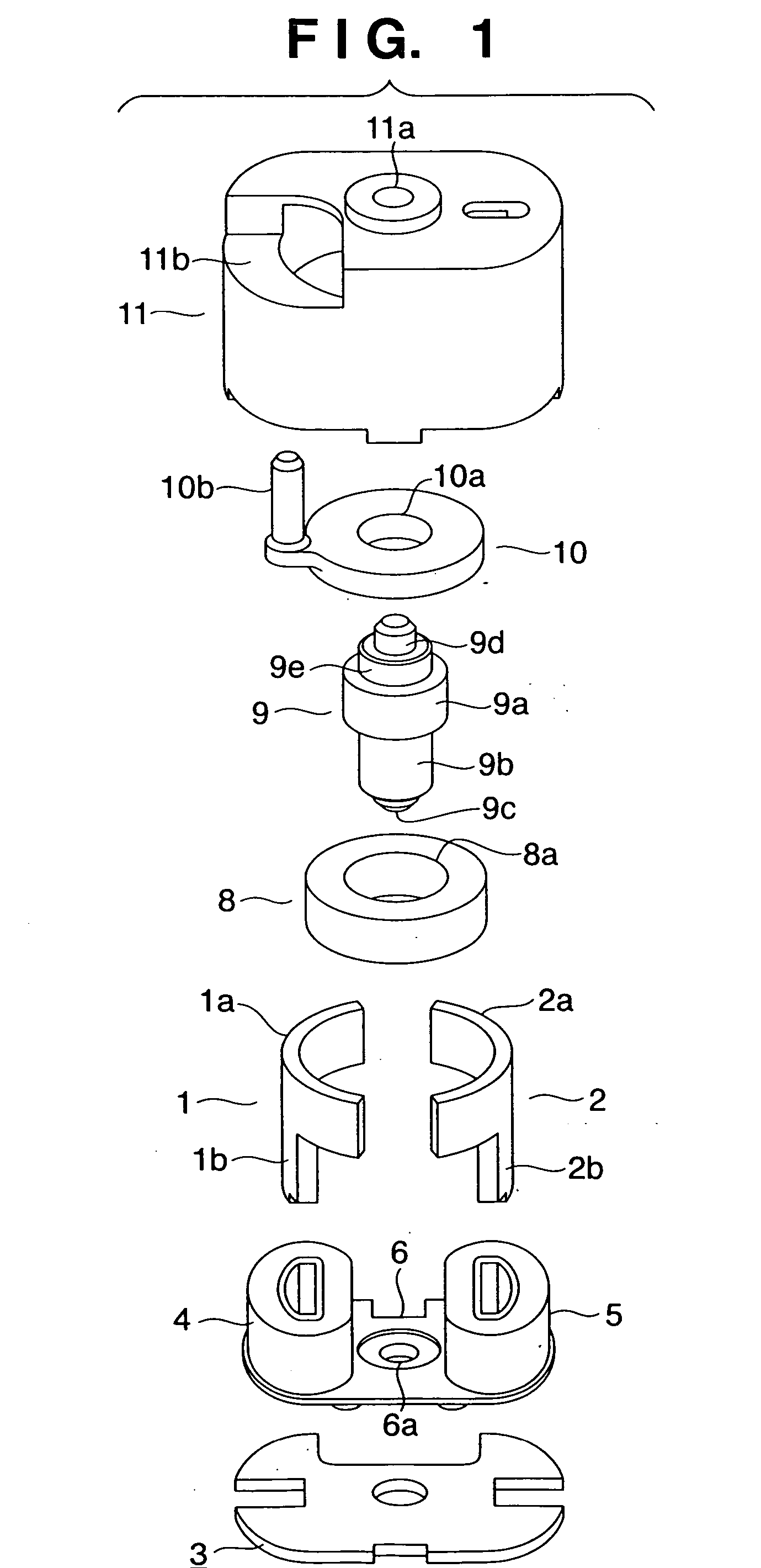

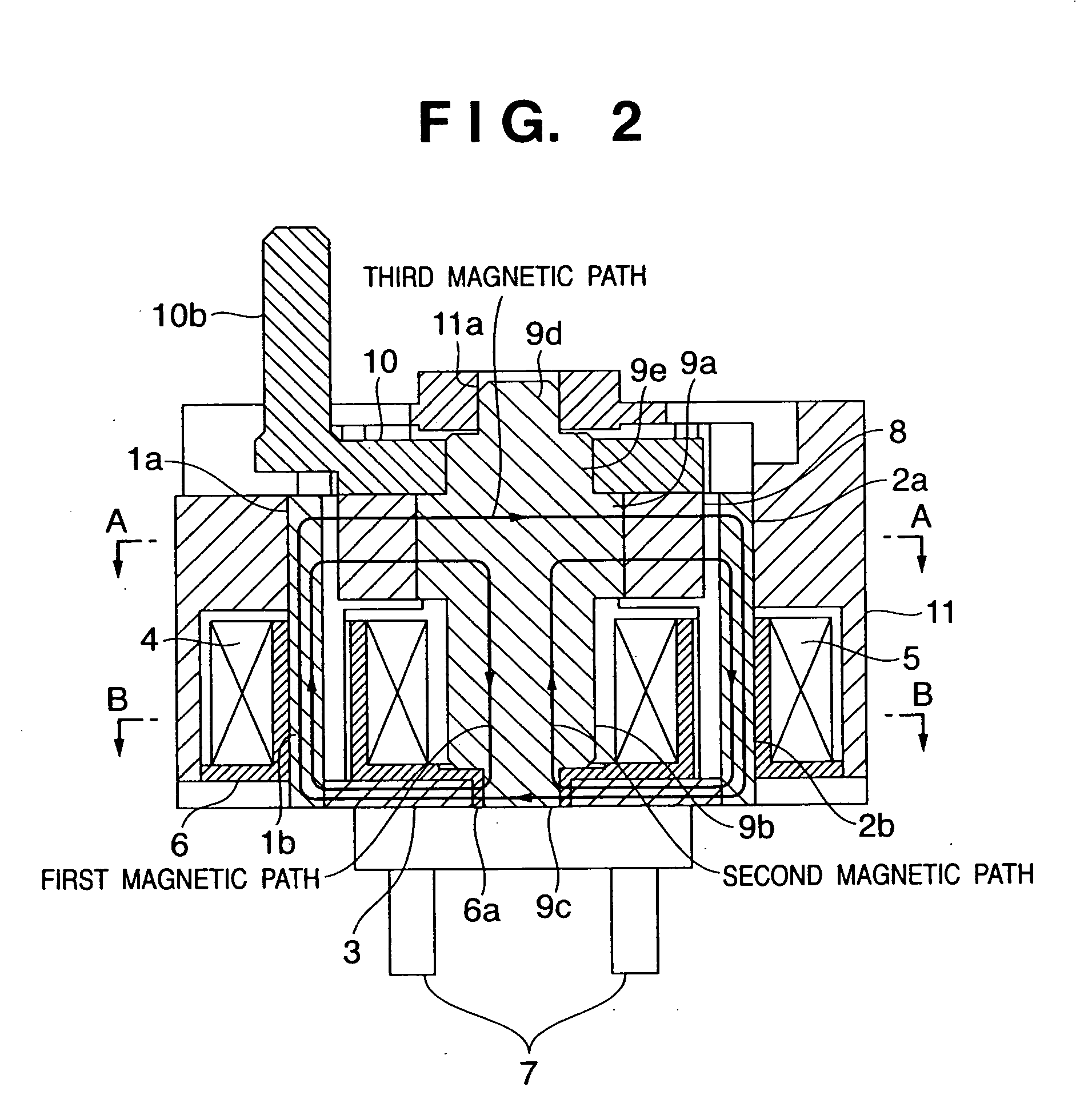

Driving apparatus and light amount adjustment apparatus

InactiveUS20060006968A1DownsizingIncrease productionMagnetic circuit stationary partsMaster clocksMagnetic polesCoil insertion

The invention provides a driving apparatus comprising: a magnet that is magnetized to at least two poles in a circumferential direction and fixed to a rotor axis formed with a soft magnetic material; first and second coils arranged in the same direction as the magnet with respect to the magnet-axis direction and arranged adjacent to an end surface of the magnet in the magnet-axis direction; the first magnetic pole portion excited by energizing the first coil; the second magnetic pole portion excited to a pole opposite to the first magnetic pole portion by energizing the second coil; and a yoke portion formed with a soft magnetic material for supporting the first and second magnetic pole portions. The first magnetic pole portion includes a first coil insertion portion that is inserted to an internal diameter portion of the first coil, and a first magnet facing portion that is arranged to face a magnetized outer circumferential portion of the magnet with a predetermined gap at a predetermined angle. The second magnetic pole portion includes a second coil insertion portion that is inserted to an internal diameter portion of the second coil, and a second magnet facing portion that is arranged to face a magnetized outer circumferential portion of the magnet with a predetermined gap at a predetermined angle.

Owner:CANON KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com