Force limiting adapter coupling wrench for assembling and disassembling bolt in aircraft engine rotor component deep cavity

A technology for aero-engines and internal bolts, which is applied to wrenches, manufacturing tools, wrenches, etc., can solve the problems of difficult loading and unloading of connecting bolts, and achieve the effects of easy loading and unloading, delivery stability, and avoiding excessive rotation angles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with embodiment.

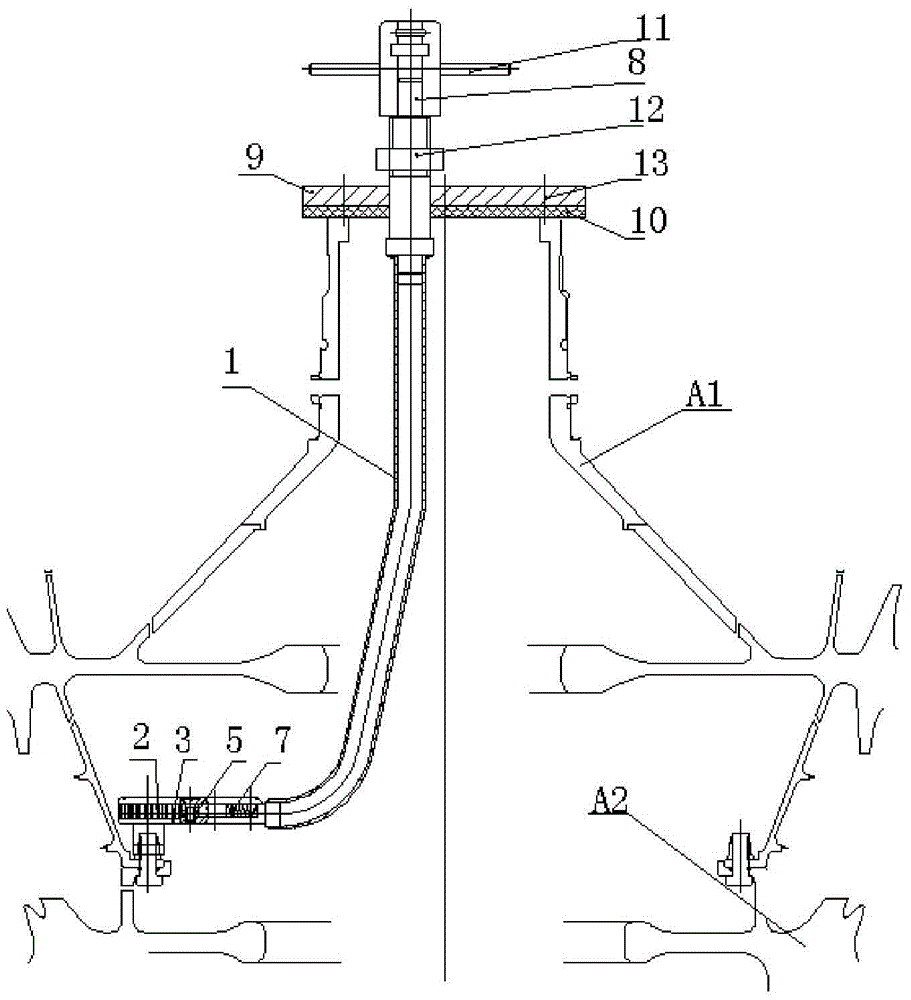

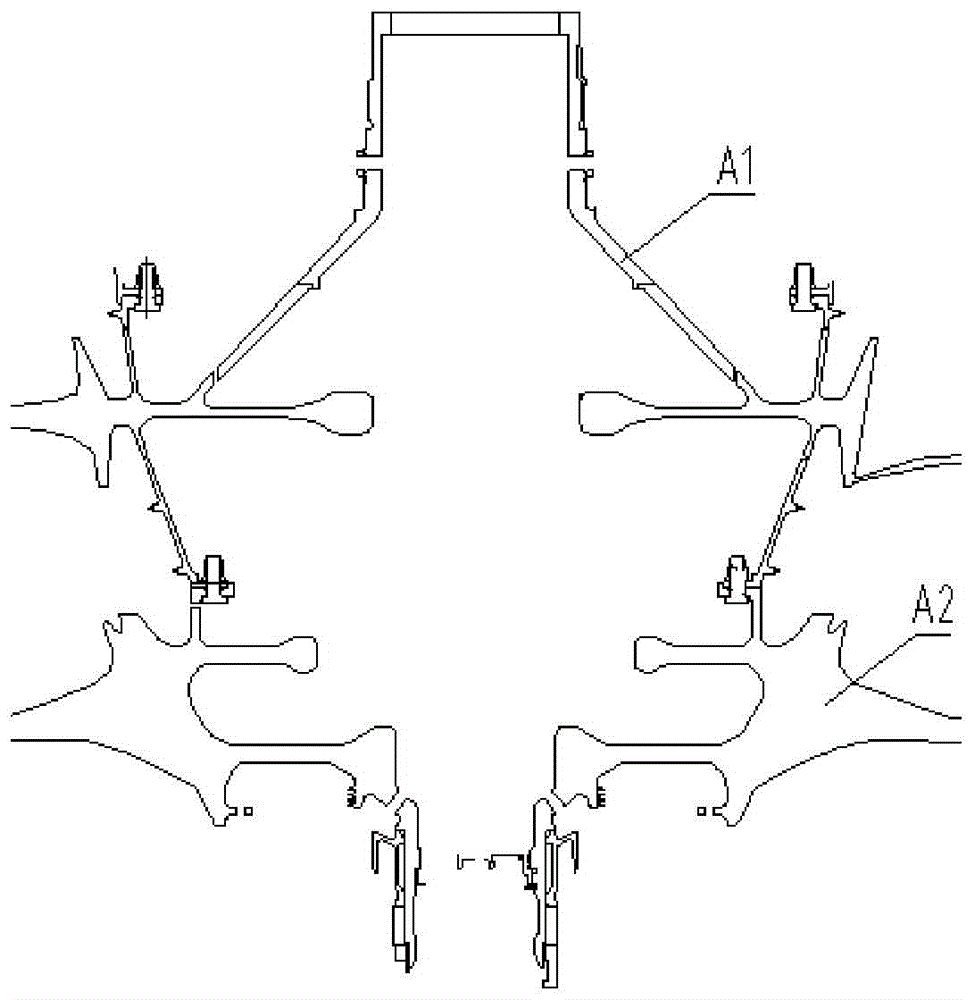

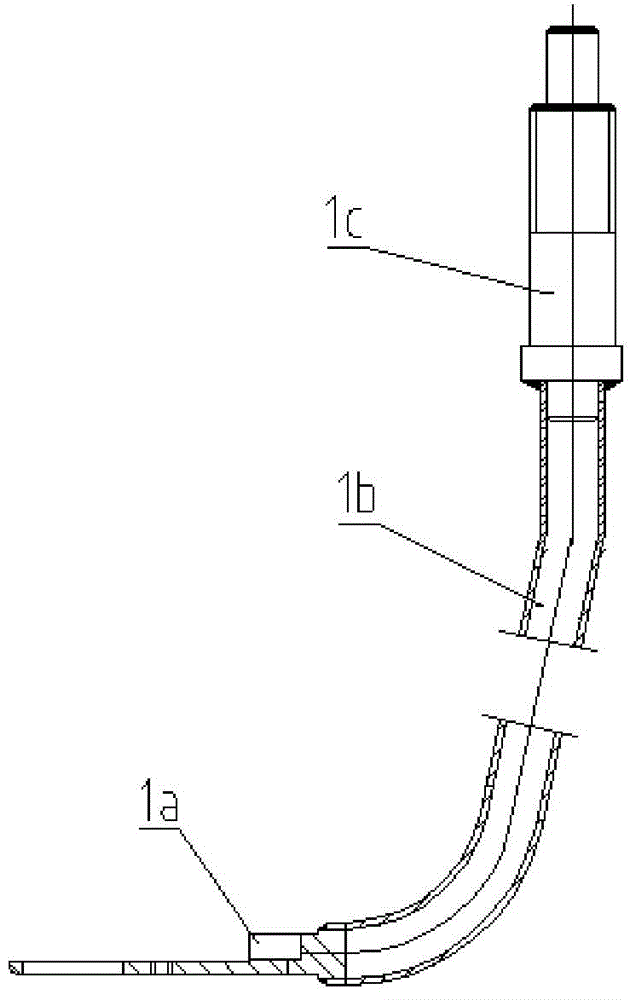

[0028] see figure 2 , the present invention includes: including a support plate 9 and a wrench body 1, the support plate 9 can be supported at the gourd mouth of the rotor blisk of an aero-engine, a spacer 10 is arranged under the support plate 9, and the support plate 9 and the spacer 10 pass screws 13 Fixedly connected together, the pad 10 and the supporting plate 9 are provided with corresponding arc holes, the angle of the arc holes of the supporting plate 9 and the pad 10 is 26°, and the wrench body 1 rotates 20 degrees each time in the arc hole. °, the ratchet 2 rotates 2 teeth, the wrench body 1 passes through the arc-shaped hole and can move along the arc-shaped hole; see image 3 The wrench body 1 includes a first adapter 1c, a steel pipe 1b, and a gear seat 1a that are integrally arranged. The first adapter 1c and the gear seat 1a are respectively located at both ends of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com