Special baking oven and special movable material rack thereof for silicon material

A mobile, silicon material technology, applied in the direction of drying solid materials, drying, dryers, etc., can solve the problems of difficult discharge of water vapor, uneven heating of silicon materials, difficult control of oven temperature, etc., to achieve convenient loading and unloading and access, The effect of saving drying preparation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

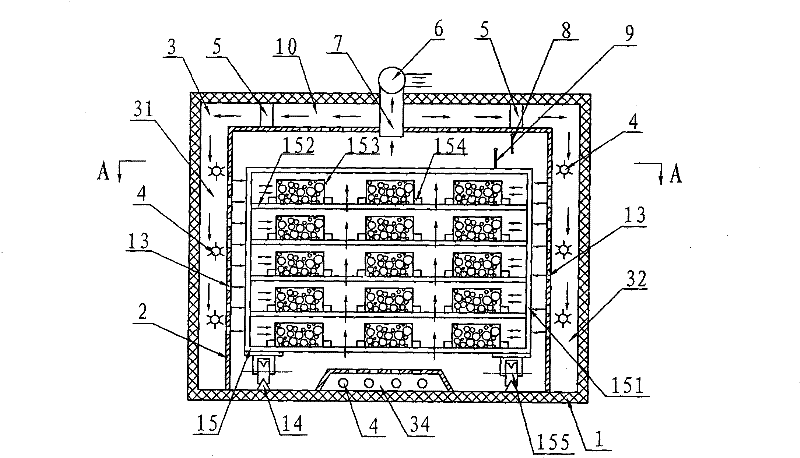

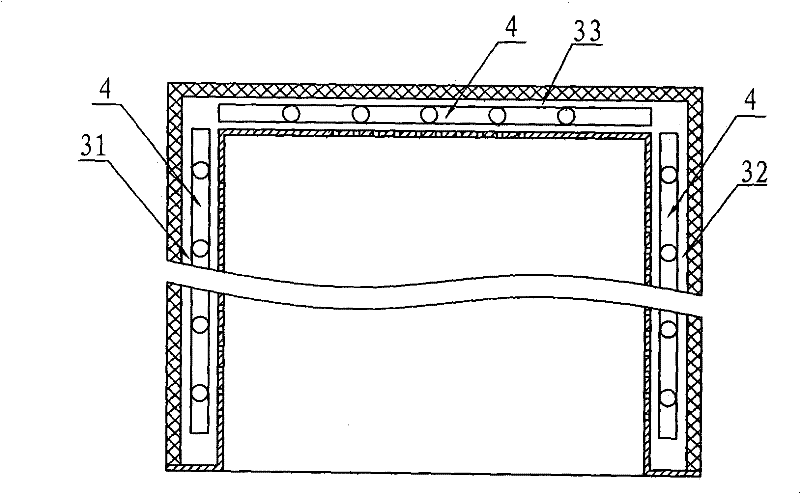

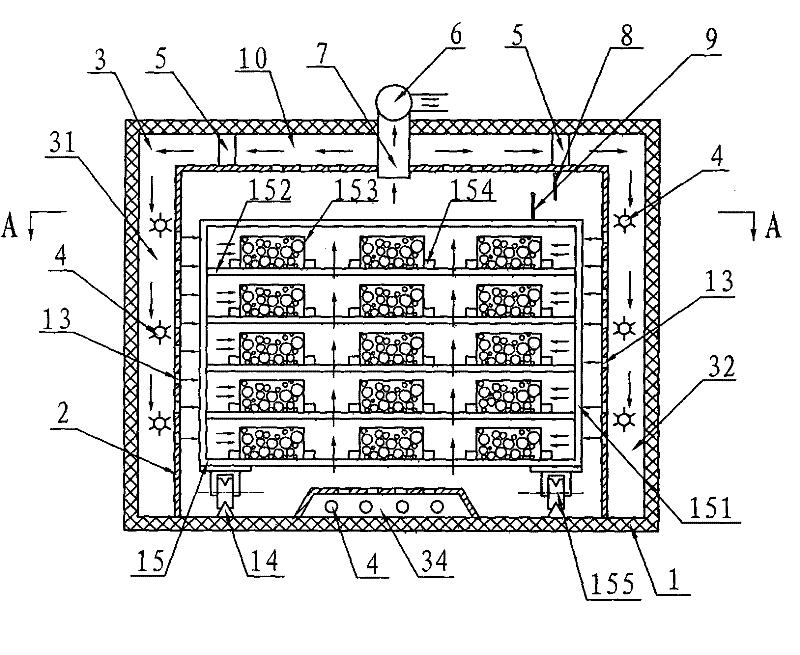

[0011] as attached figure 1 , figure 2 As shown, the special oven for silicon material of the present invention includes a thermal insulation shell 1, an inner tank 2, a heat passage 3, a heater 4, a circulation fan 5, a dehumidification fan 6, a dehumidification pipe 7, a humidity sensor 8 and a temperature The sensor 9 and the inner tank 2 are placed in the thermal insulation shell 1, and the top of the inner tank 2 is provided with a high-temperature gas chamber 10. The high-temperature gas cavity 10 is formed by the top of the inner tank 2 and the inner cavity top of the thermal insulation shell 1. The gas cavity 10 communicates with the inner cavity of the inner tank 2 through the vent hole 13; , the rear air passage 33 and the lower air passage 34, the left air passage 31, the right air passage 32, the rear air passage 33 and the lower air passage 34 are all provided with heaters 4, and all the heat passages 3 are connected to the inner tank through the air vent 13 Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com