Patents

Literature

421results about How to "Improve suitability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

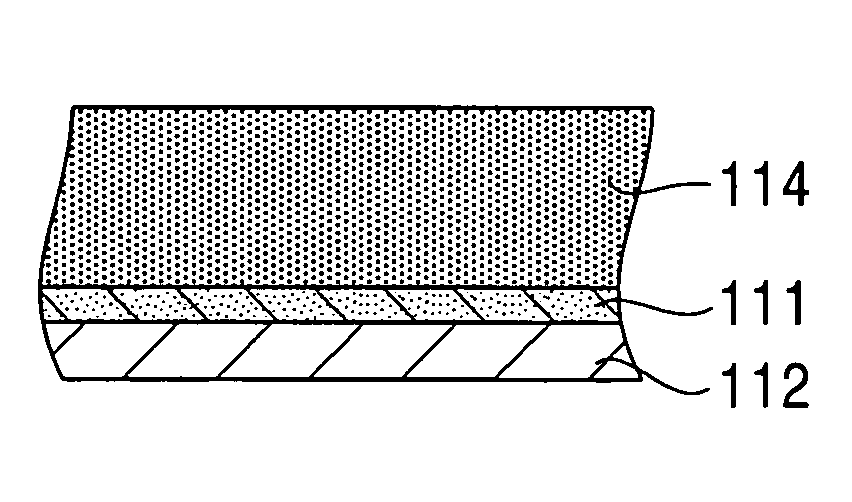

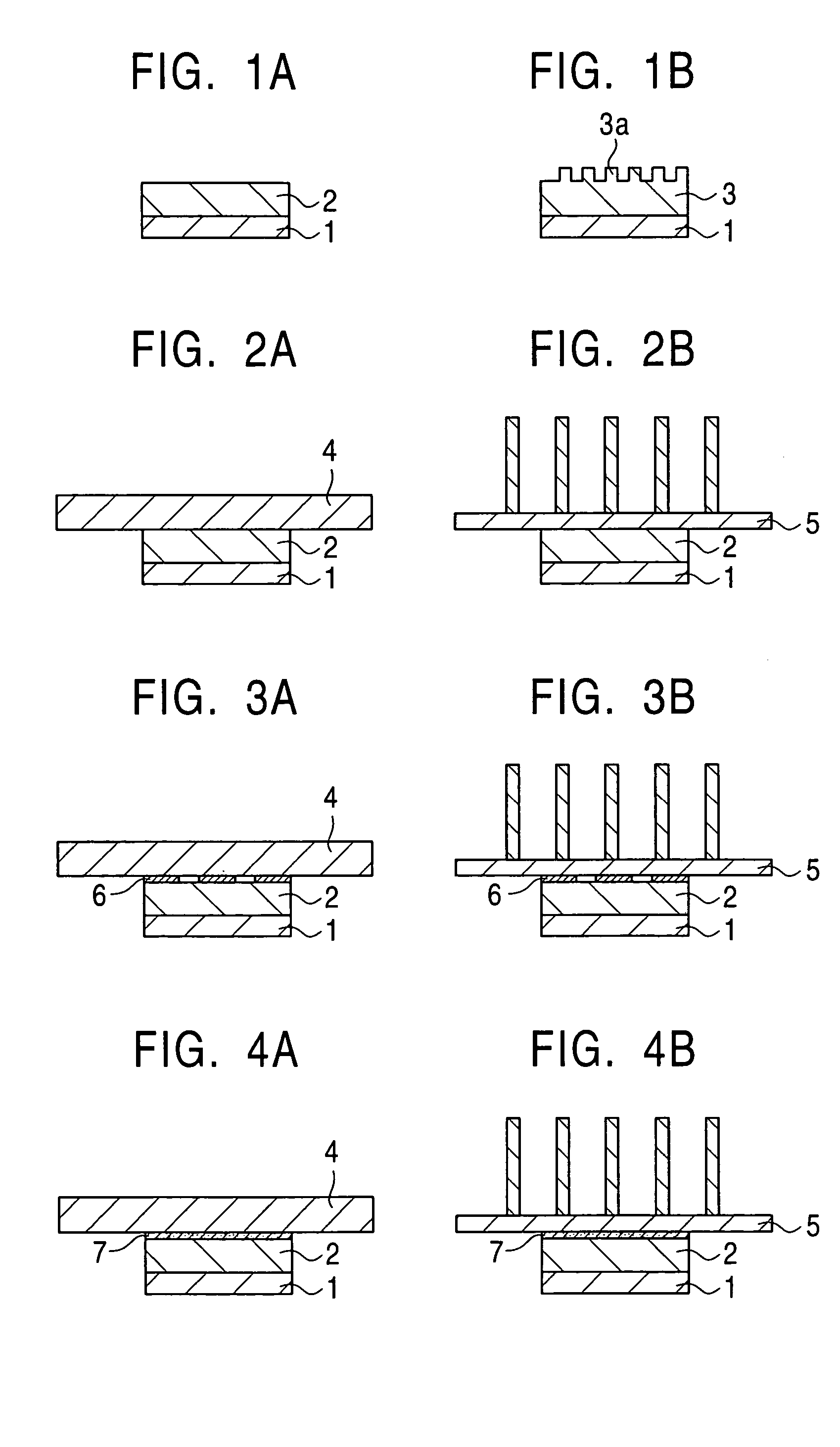

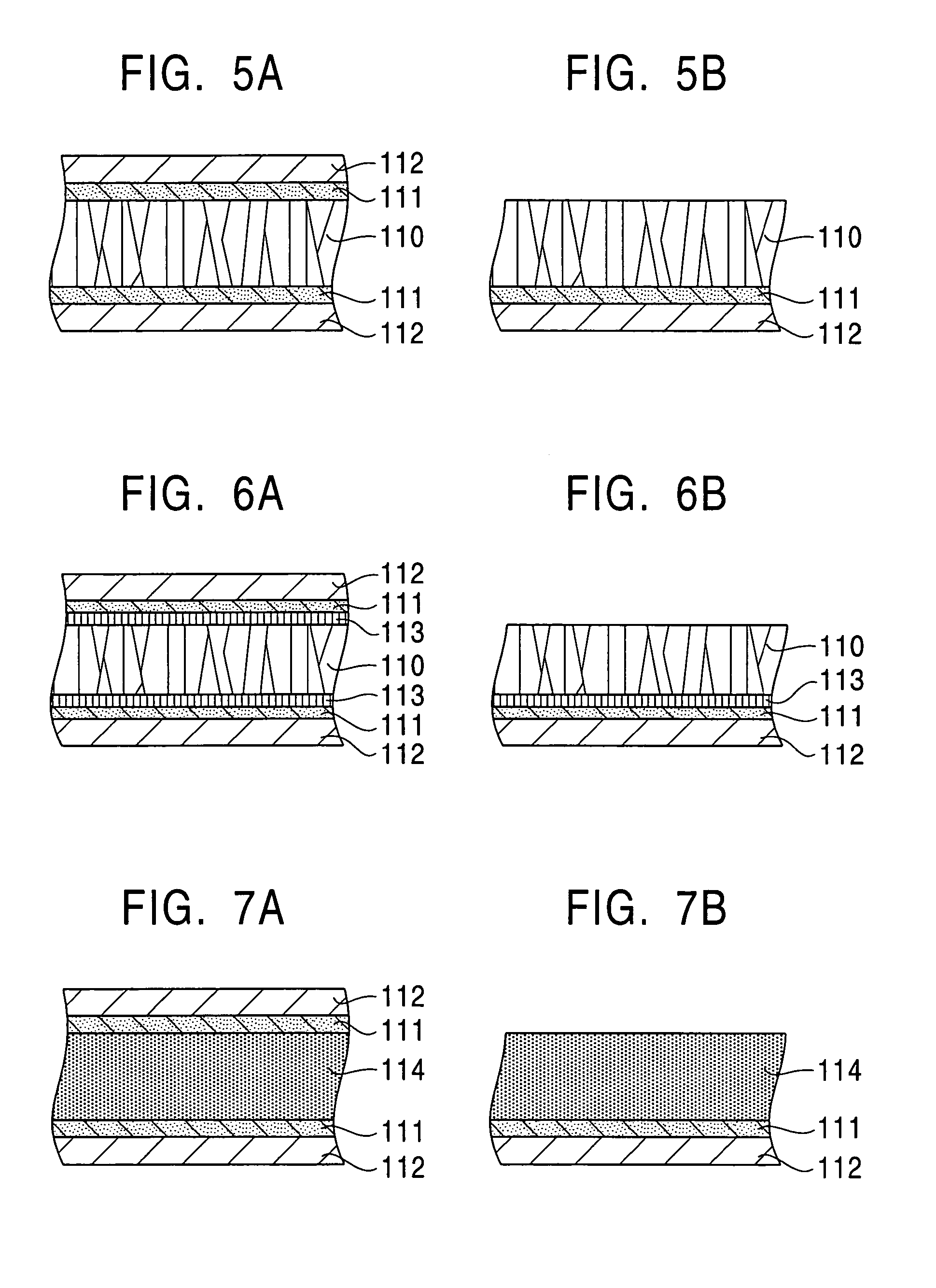

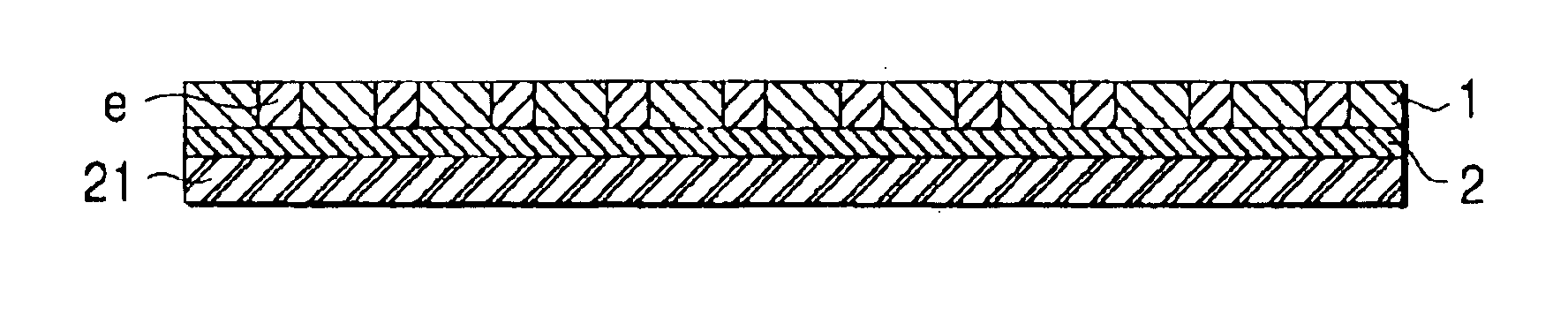

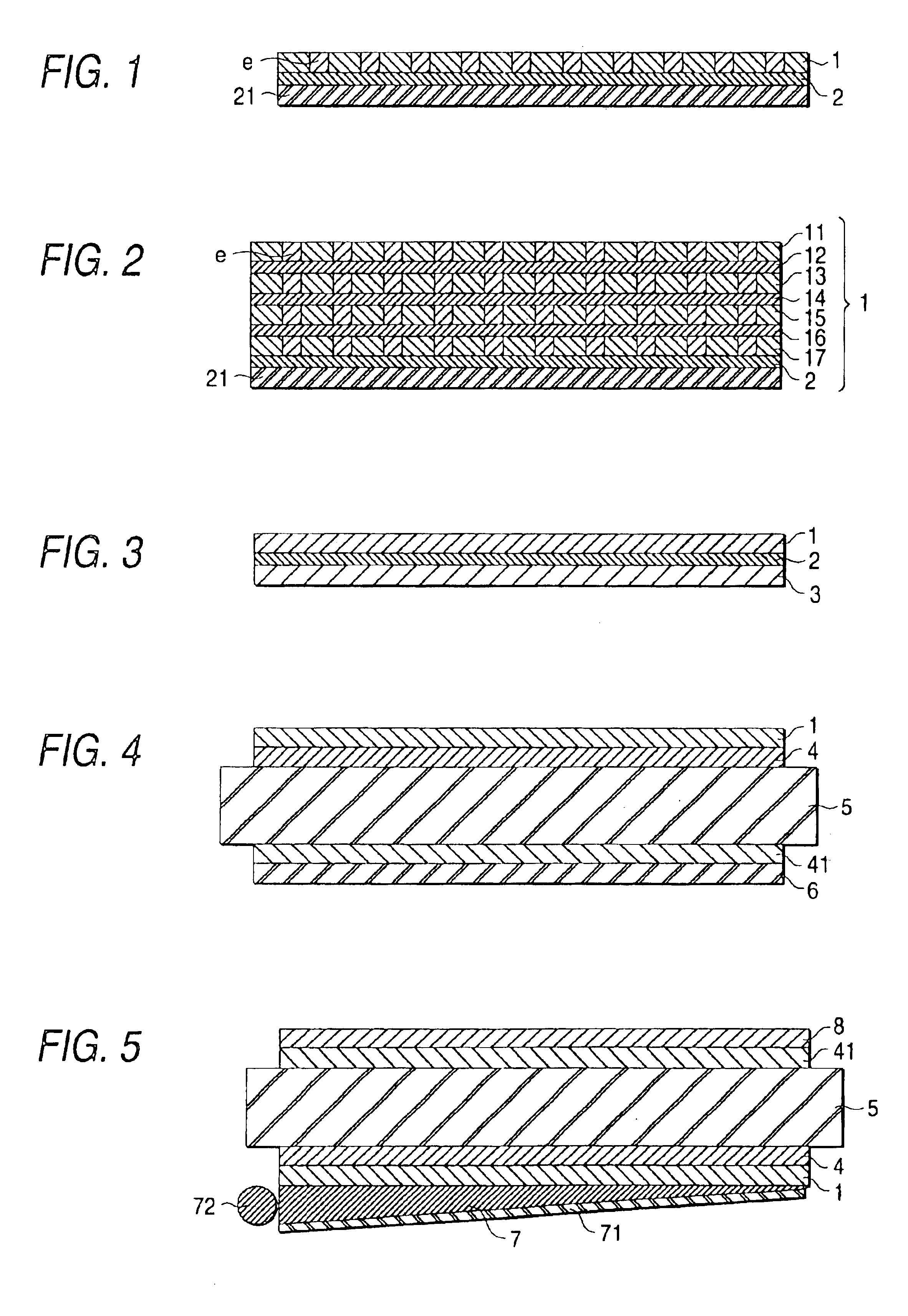

Heat spreader and semiconductor device and package using the same

InactiveUS7067903B2Improve thermal conductivityLarge thermal conductivitySemiconductor/solid-state device detailsSolid-state devicesPolymer adhesiveCeramic

A semiconductor device and package has a heat spreader directly disposed on the reverse surface of the semiconductor device. This heat spreader includes a diamond layer or a layer containing diamond and ceramics such as silicon carbide and aluminum nitride. The heat spreader is directly formed on a substrate for the semiconductor device. In particular, the heat spreader is composed of a diamond layer and one or two metal or ceramic members, which are bonded to the diamond layer with one or two polymer adhesive layers. This diamond layer has a fiber structure across the thickness or a microcrystalline structure. Cilia are formed on a surface of the diamond layer facing the one or two metal or ceramic members.

Owner:KOBE STEEL LTD

Packaging film or sheet

InactiveUS6416832B1Good formabilityExcellent gas barrier propertiesFlexible coversWrappersCopolymerPolymer chemistry

The invention provides a single-layer or multi-layer packaging film or sheet having at least one layer formed of a polyamide resin composition, wherein the layer formed of the polyamide resin composition is a layer (A) formed of a polyamide resin composition comprising a copolymer nylon (c) composed of an aliphatic nylon (co)polymer component (1) and an aromatic nylon (co)polymer component (2) in a proportion of at least 5 wt. %.

Owner:KUREHA KAGAKU KOGYO KK

Carbon black and process for producing the same

InactiveUS6358487B1High blacknessGood dispersionPigmenting treatmentAlkali metal halidesCarbon blackComposite material

A carbon black having an average particle size of at most 13 nm, Dmod of at most 80 nm, a D½ / Dmod ratio of at most 0.6 and at least pH 5.

Owner:MITSUBISHI CHEM CORP

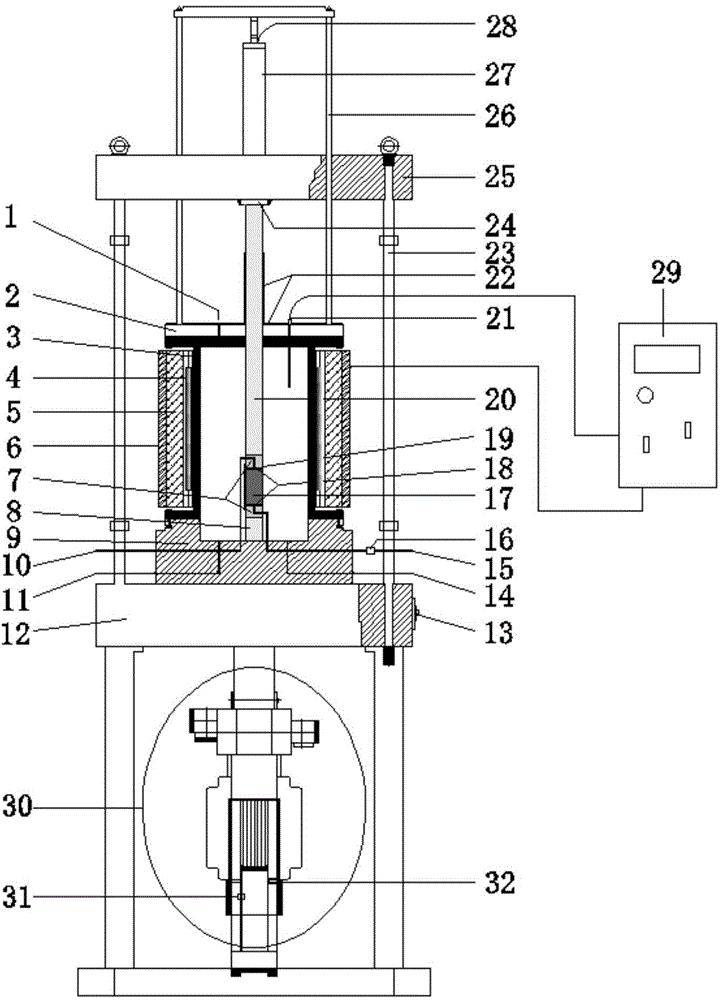

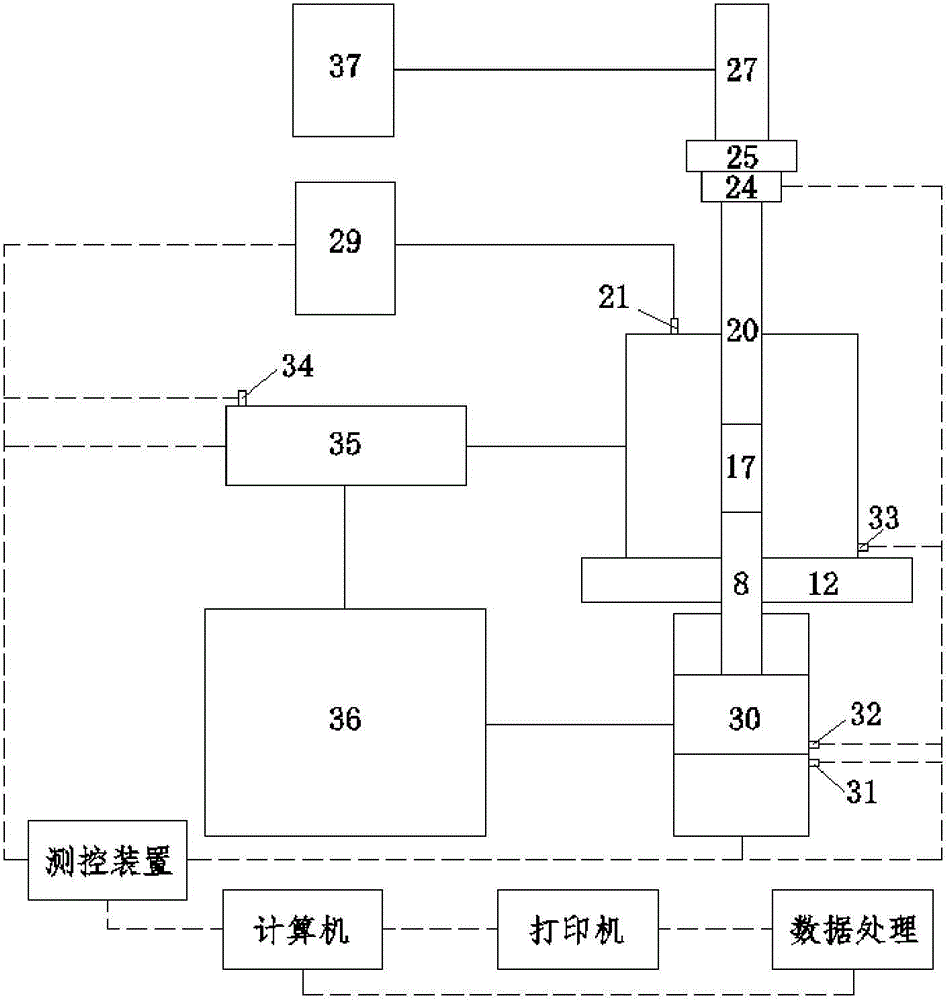

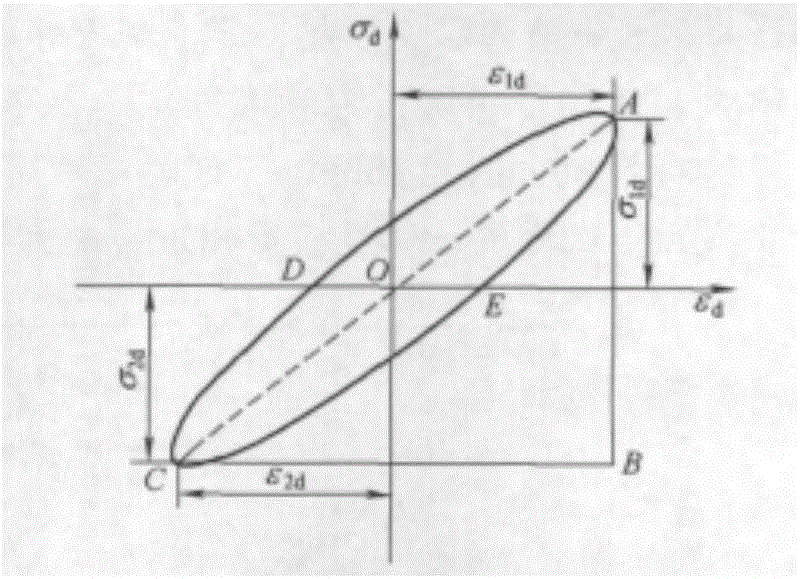

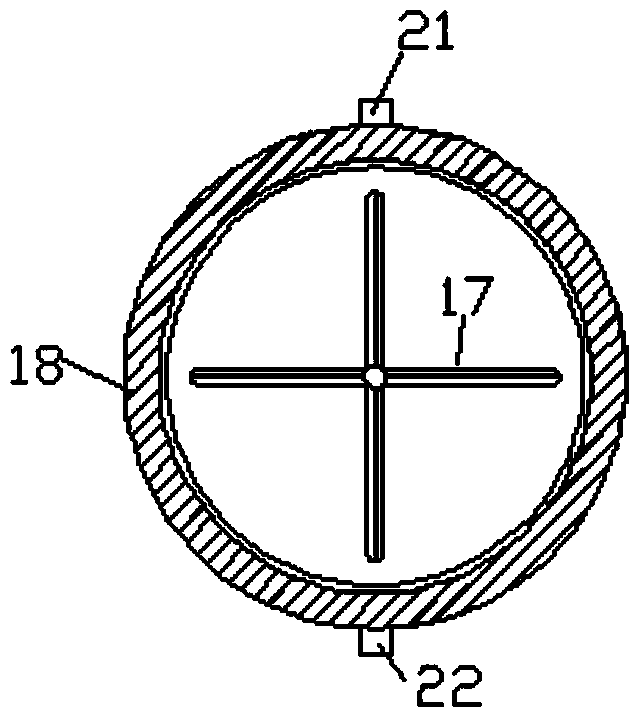

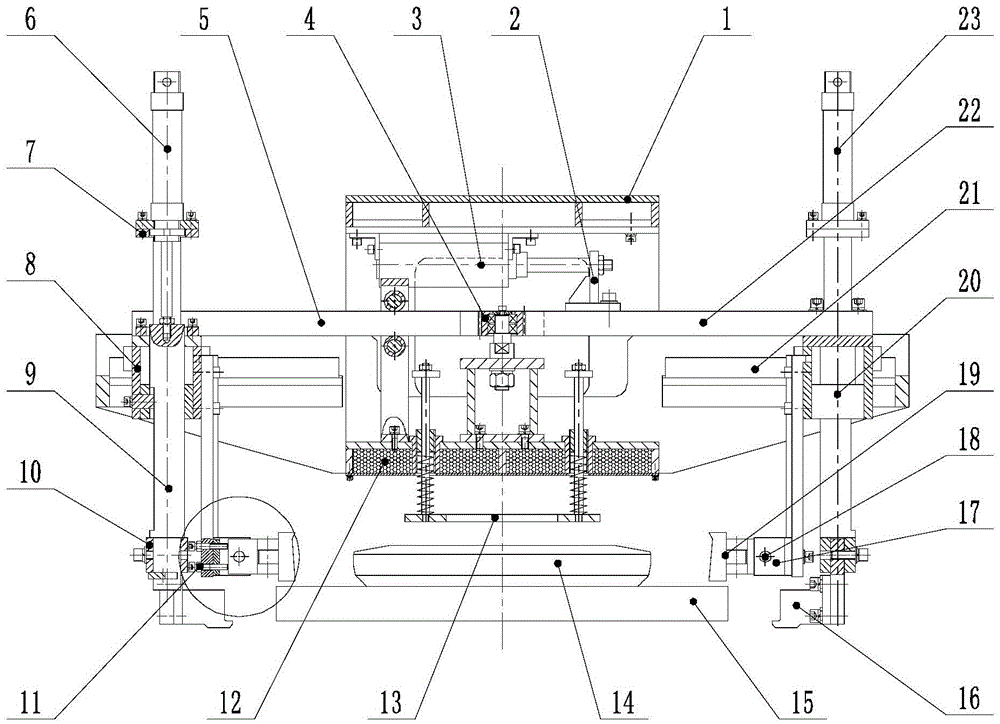

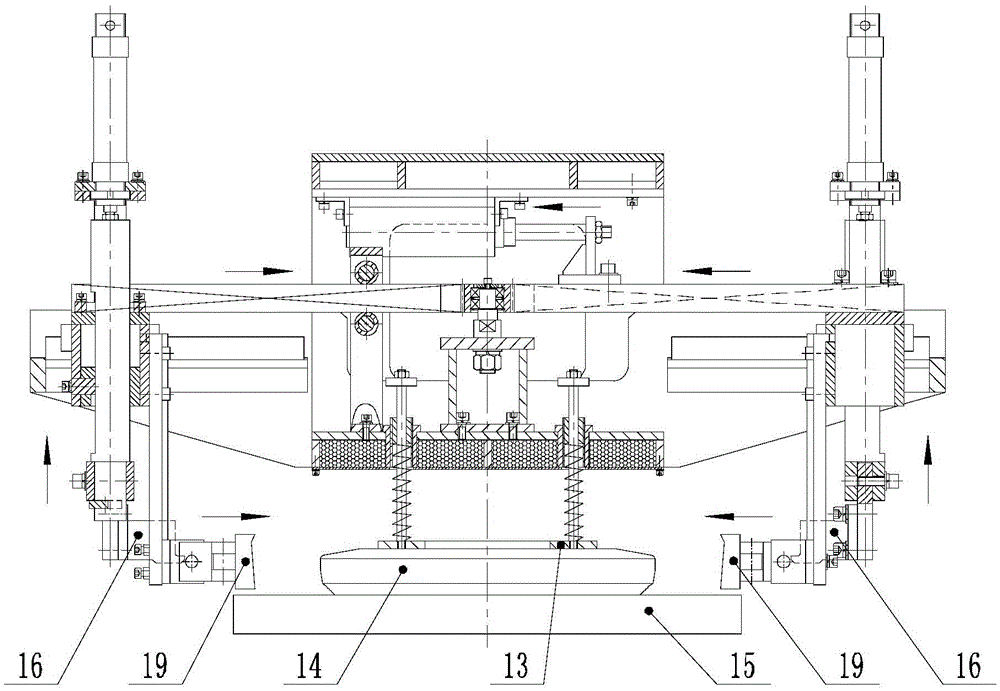

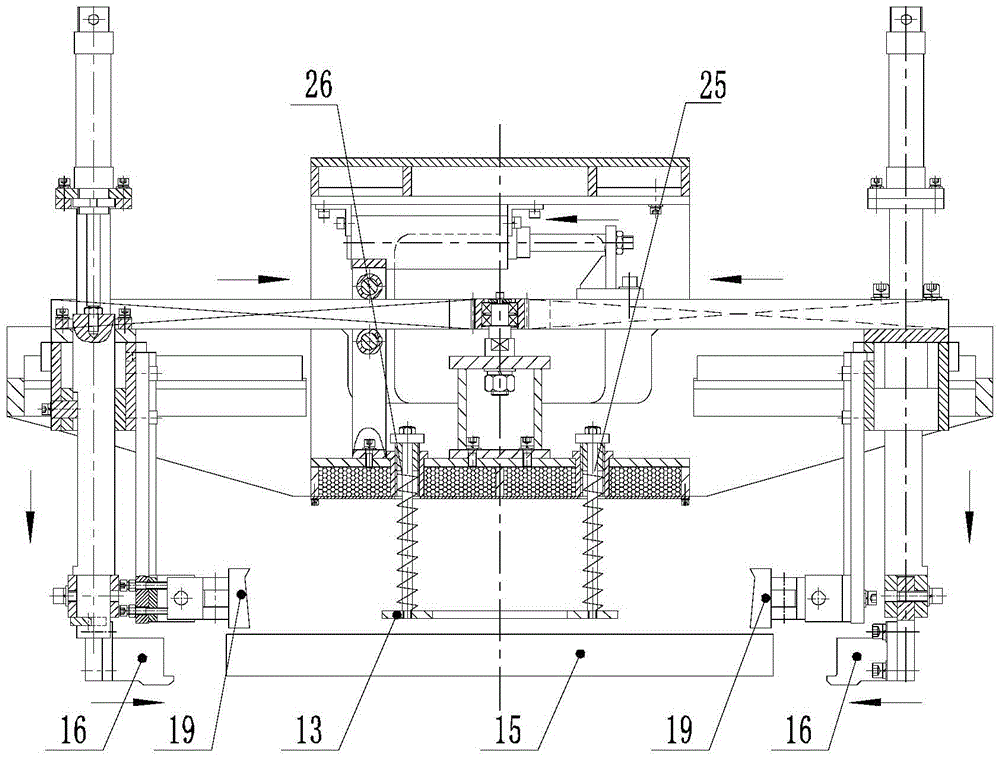

Rock-soil body temperature-control dynamic characteristic test system and test method

ActiveCN104596852AEasy loading and unloadingImprove suitabilityMaterial strength using tensile/compressive forcesStatic stressHeating temperature

The invention discloses a rock-soil body temperature-control dynamic characteristic test system and method, is characterized in that the system includes a dynamic triaxial pressure chamber and a temperature control device; the dynamic triaxial pressure chamber comprises a pressure chamber cylinder body, a piston rod and an upper dowel bar; a sample is arranged between the lower end of the upper dowel bar and the upper end of the piston rod; the dynamic triaxial pressure chamber also includes a pressure sensor, an axial displacement sensor, a deformation sensor, a confining pressure sensor, a lateral displacement sensor and a pore pressure sensor; the temperature control device includes a temperature sensor, a temperature controller and an arc plate type heater symmetrically coating the outer wall of the pressure chamber cylinder body. The temperature-control dynamic characteristic test method mainly includes installing the sample, setting the temperature control device, carrying out drainage consolidation of the sample, applying dynamic / static stress, and completing a temperature-control dynamic / static triaxial test, to determine the cumulative plastic strain, dynamic damping ratio, dynamic elastic modulus and other indexes of a rock-soil body under different temperatures. The system and the method have the advantages of uniform heating temperature, short heating time and low cost, and can accurately control the temperature in the pressure chamber.

Owner:NINGBO UNIV

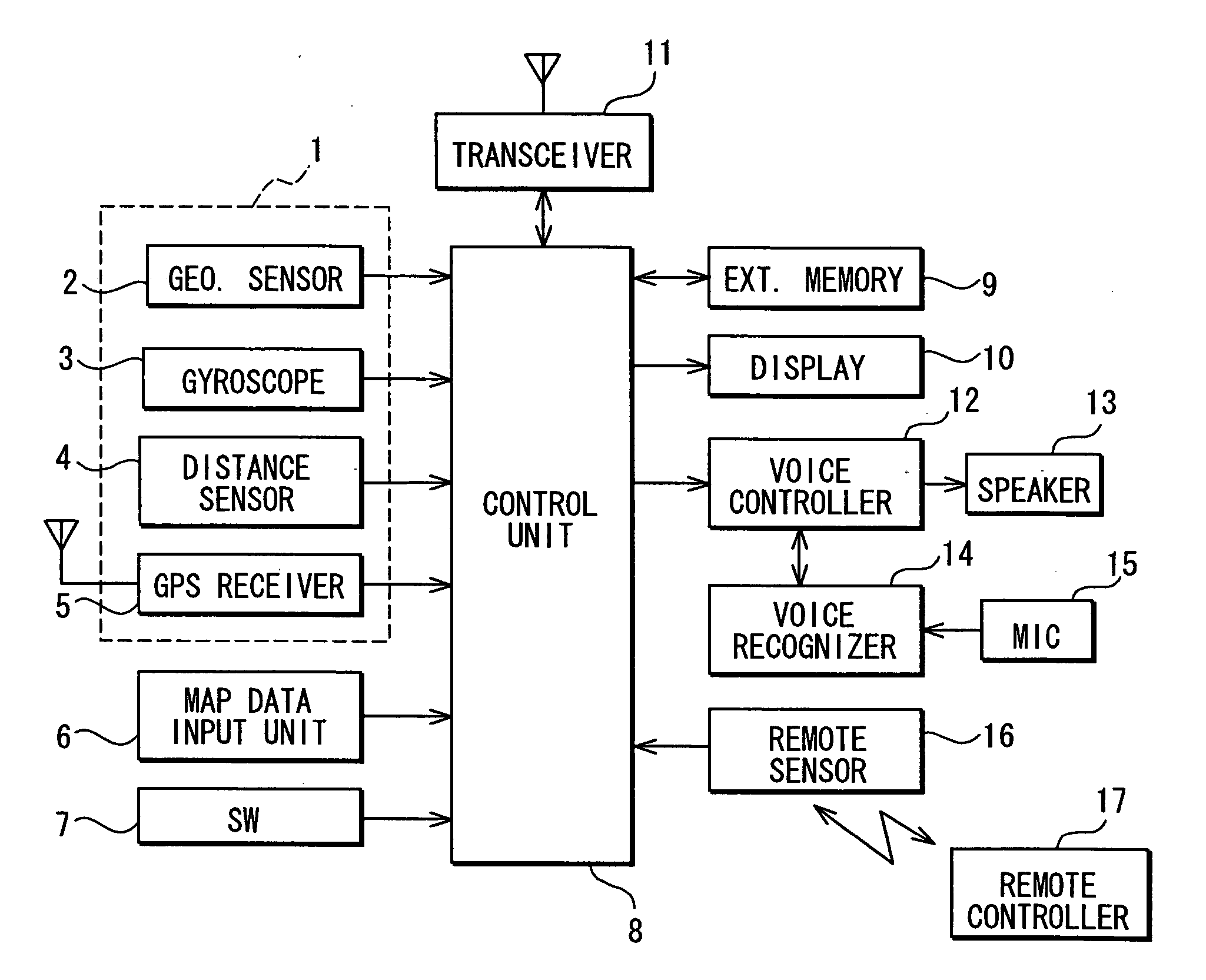

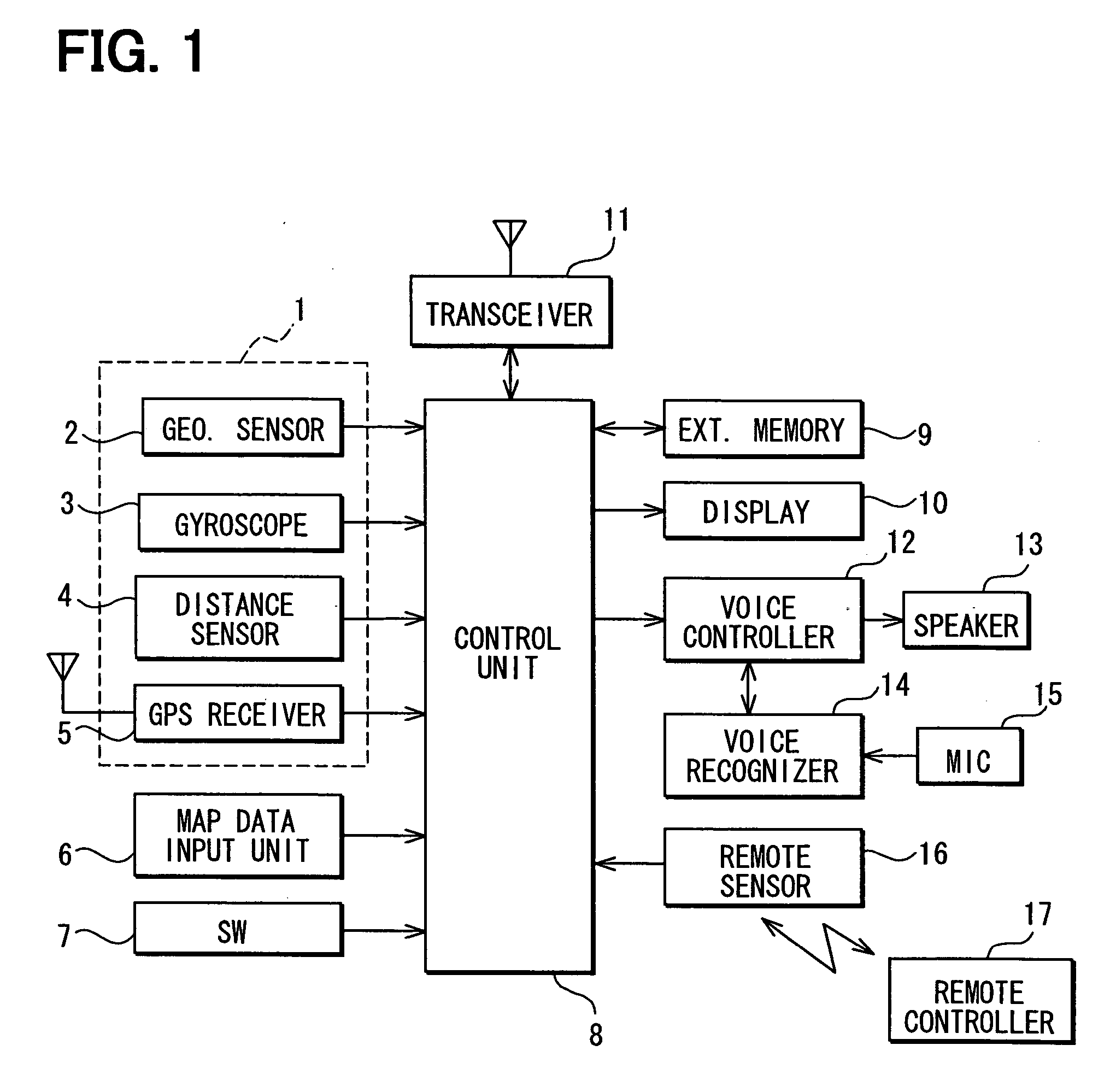

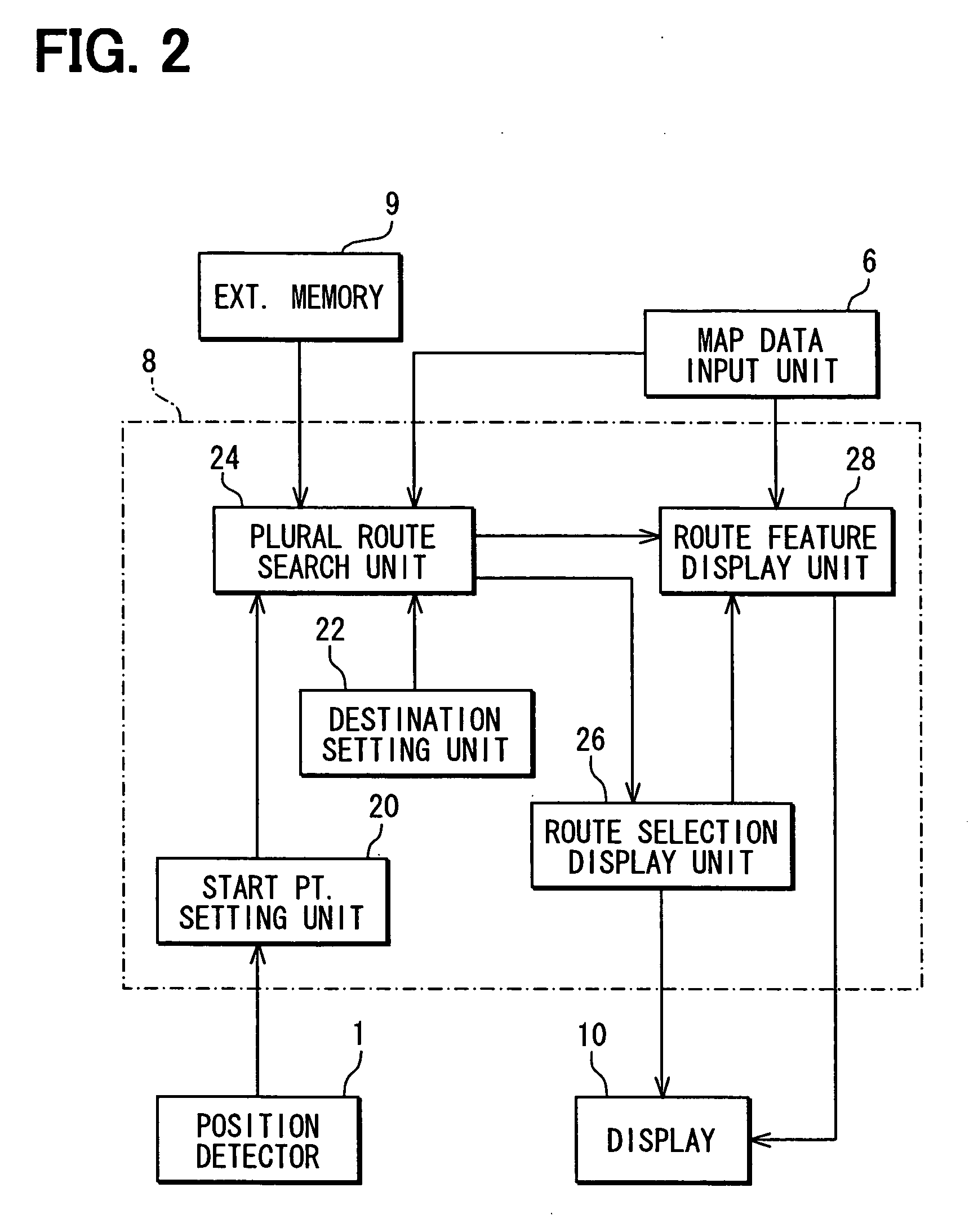

Navigation system

InactiveUS20070021905A1Increase the number ofStrong specificityInstruments for road network navigationData processing applicationsRoute searchNavigation system

A navigation system for providing a navigation route of a travel between a start point and an end point based on a route search by using a predetermined condition includes a display unit for displaying the navigation route and / or a navigation route candidate with a condition name associated thereto. The predetermined condition with the condition name associated thereto yields a plurality of navigation route candidates as a result of the route search.

Owner:DENSO CORP

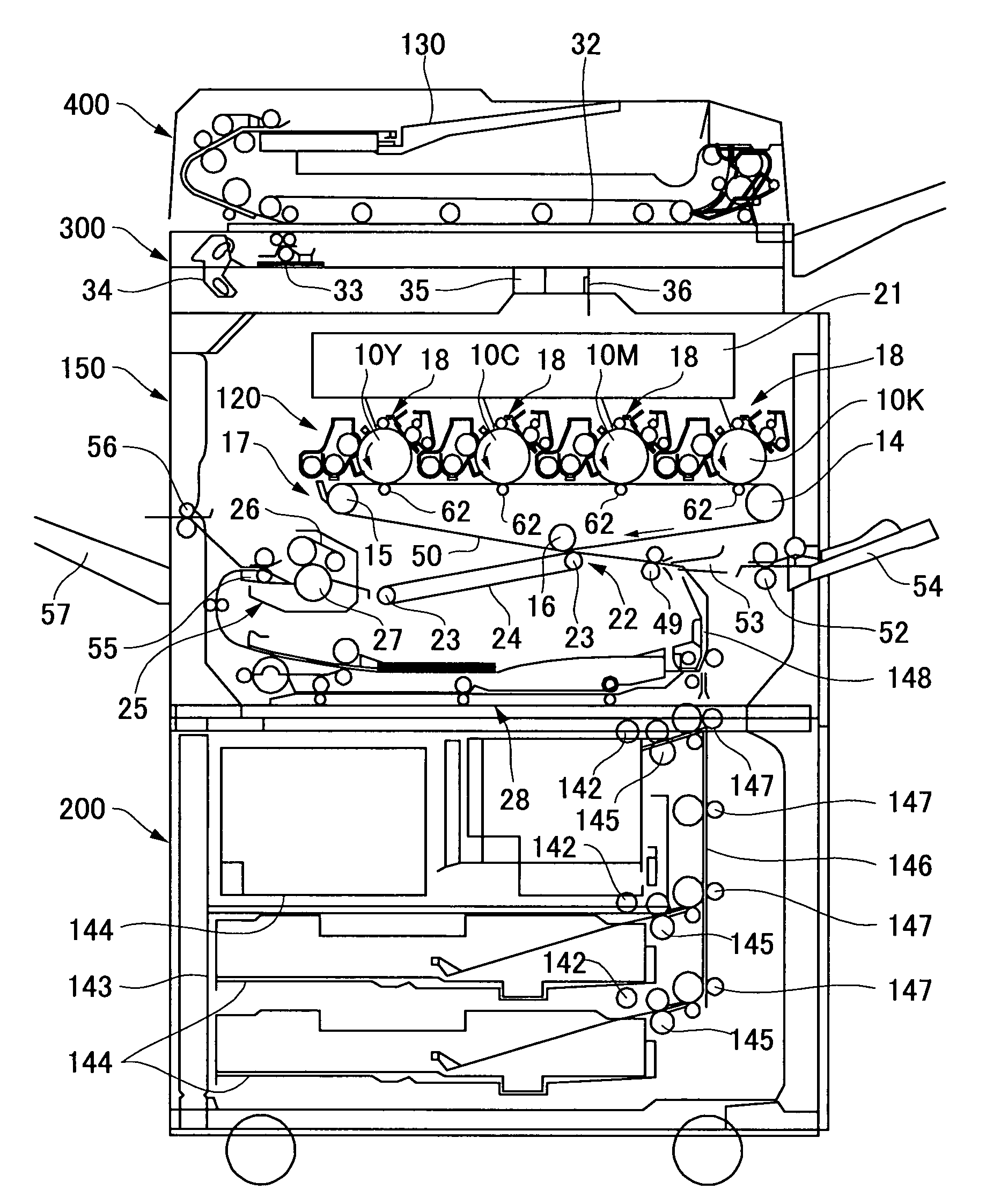

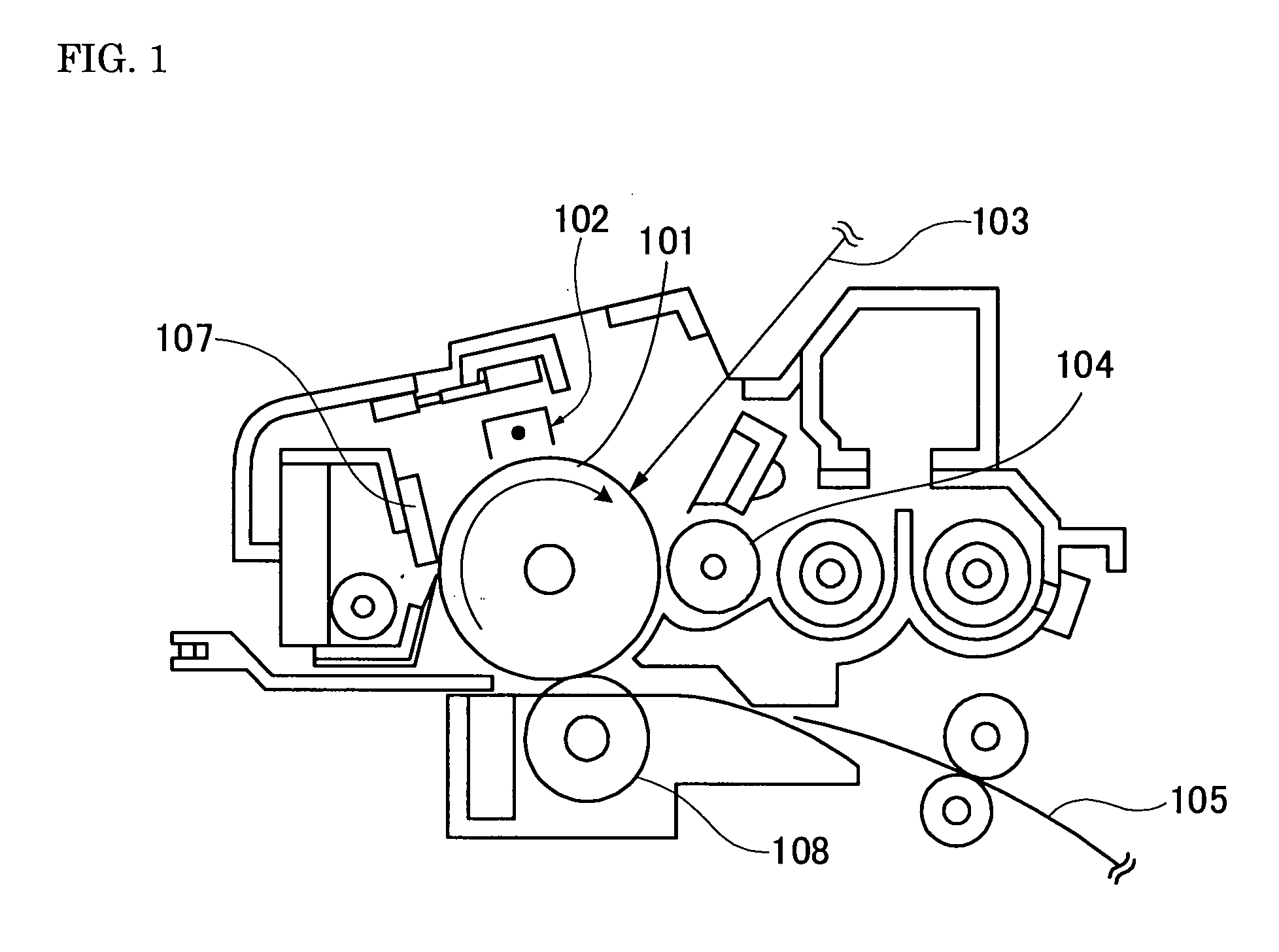

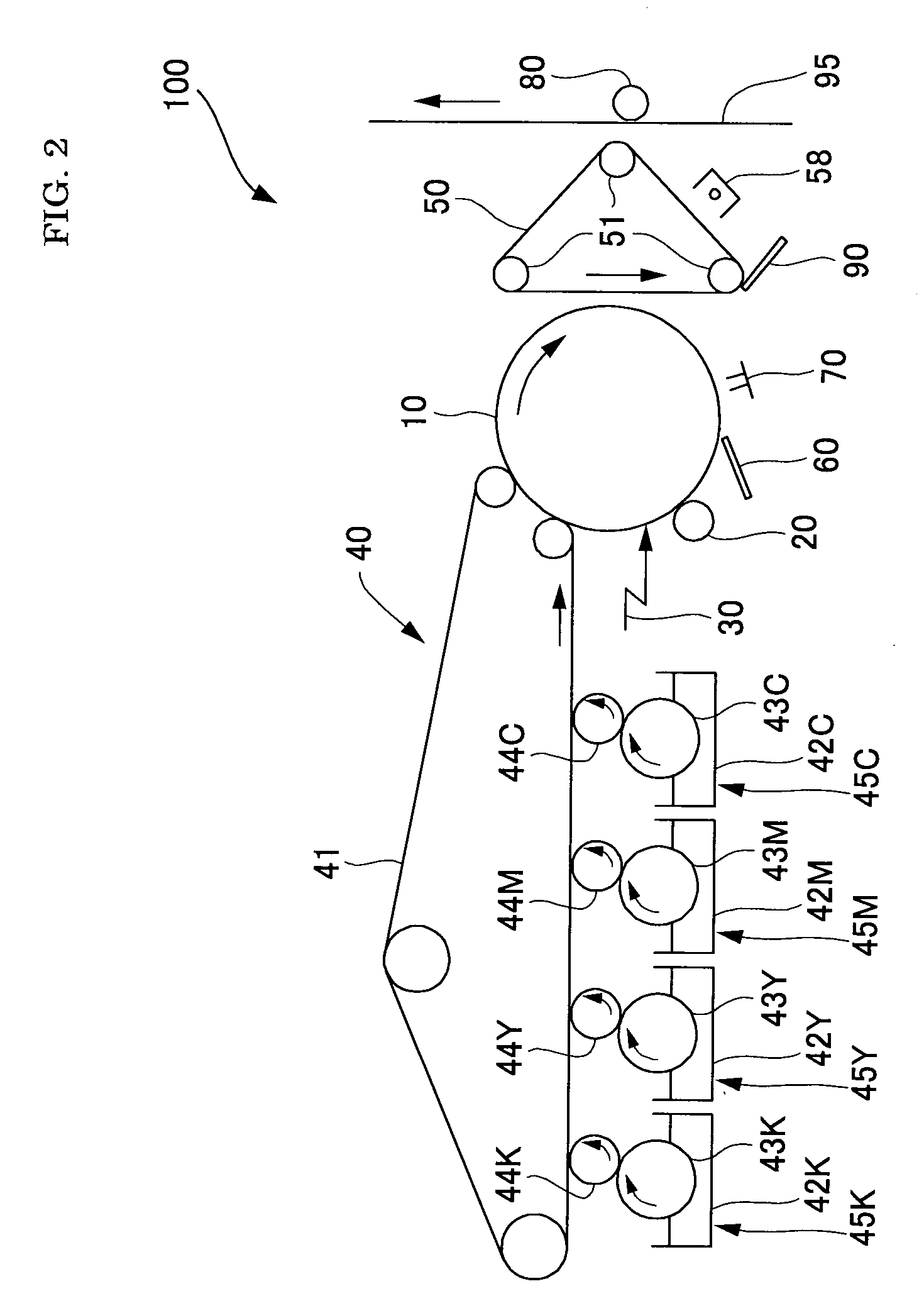

Toner, developer, toner container, process cartridge, image forming method, and image forming apparatus

InactiveUS20080131797A1Excellent offset resistanceImprove suitabilityDevelopersElectrographic processes using charge patternImage formationEngineering

To provide a toner that contains at least a binder resin, a colorant, a releasing agent and zeolite, the toner being manufactured through O / W type wet granulation and having an average circularity of 0.970 or greater, and a developer and image forming method using the toner.

Owner:RICOH KK

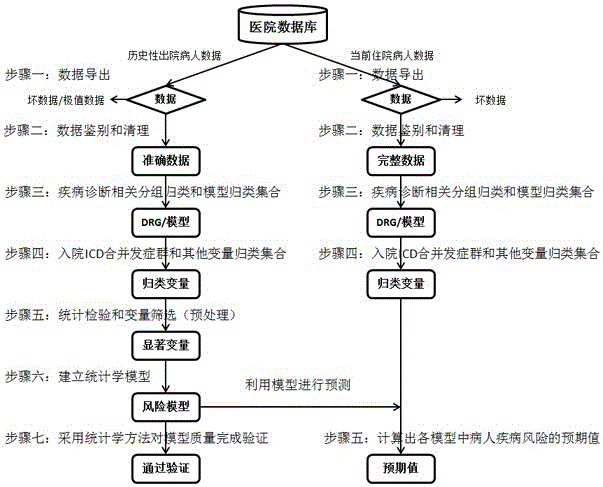

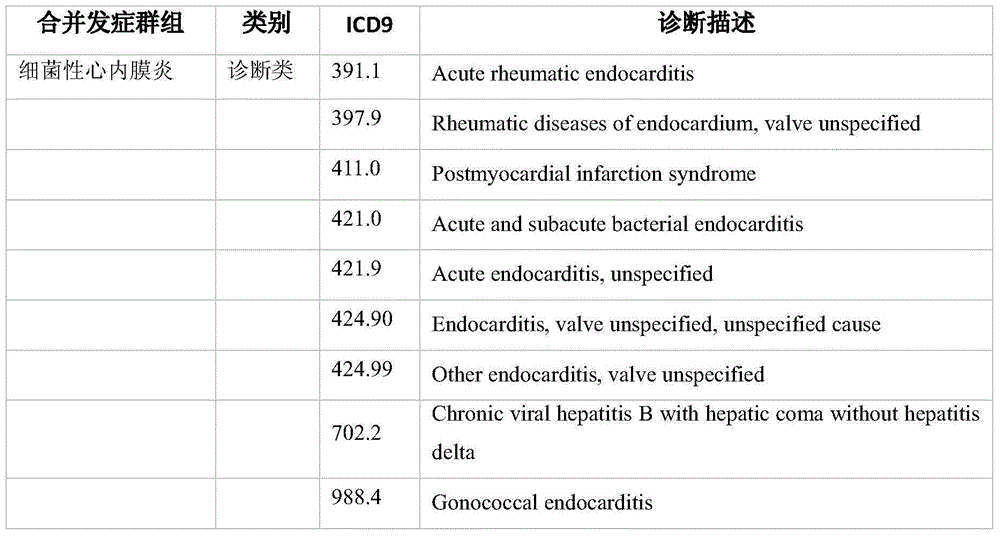

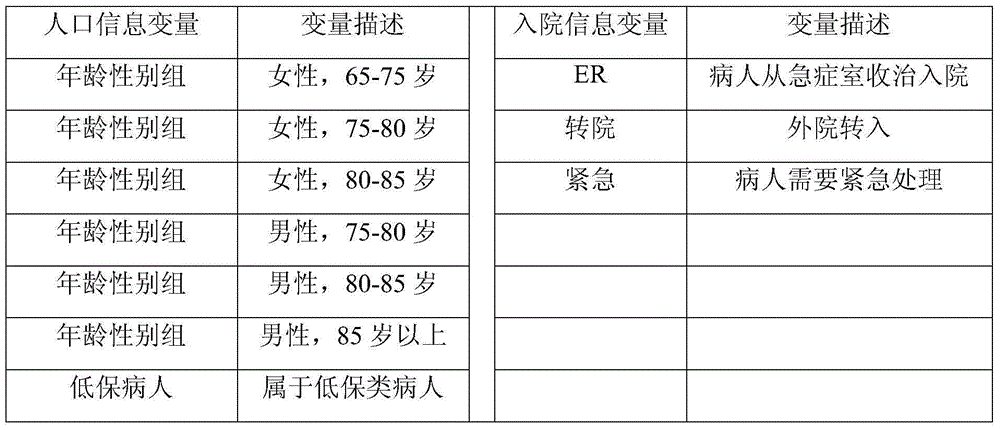

Inpatient medical management quality assessment method

InactiveCN105046406AImproving the level of medical quality managementImprove management levelResourcesMortality rateCvd risk

The invention discloses an inpatient medical management quality assessment method which screens historical data and builds models, including authenticating and clearing data, DRG(Diagnosis Related Group)and model classifying, classification and collection of ICD complication and other variables during hospital admission, the statistic tests and screening of hospital admission and complication variables, the building of statistic models and quality assessment. The method also screens current data and calculates a predicated value, including predicated value of risk when a patient is sent in hospital, to realize risk predictions on the mortality rate of each patient, the days spent in hospital and the medical cost in hospital as well. According to the invention, the method effectively converts medical data to find solutions so as to achieve the values of data based on the analysis of big data, the mathematic statistical method and machine learning method. The method also makes medical data comparable. The method not only performs assessment to medical quality among diseases but also realizes proper assessment to managements of treatment in a hospital between doctors, between different departments and between different patients.

Owner:中科厚立信息技术(成都)有限公司

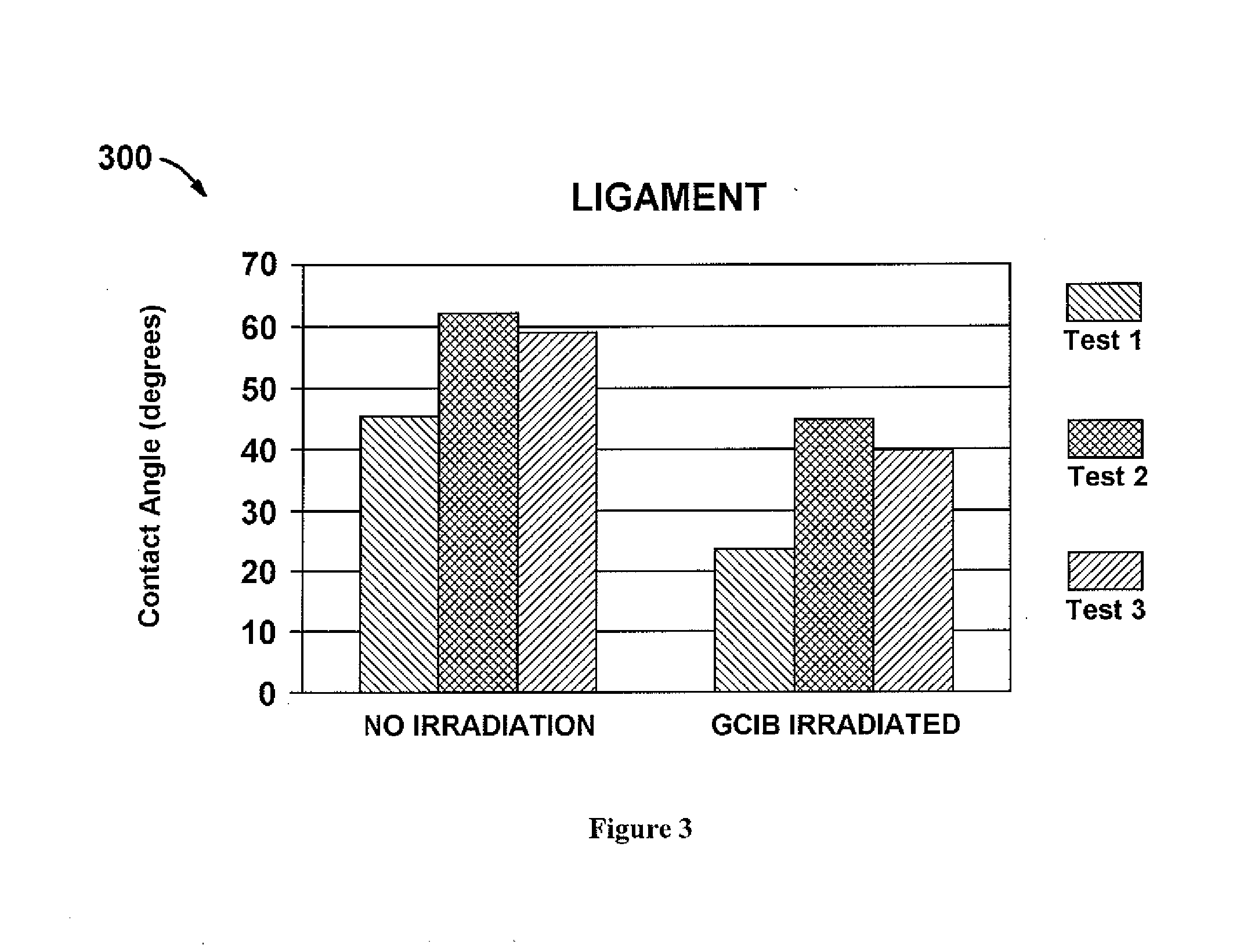

Method for modifying the wettability and/or other biocompatibility characteristics of a surface of a biological material by the application of gas cluster ion beam technology and biological materials made thereby

ActiveUS20100226958A1Improve adaptabilityPromoting cell attachmentBiocideSurgeryBiologyGas cluster ion beam

Owner:EXOGENESIS CORP

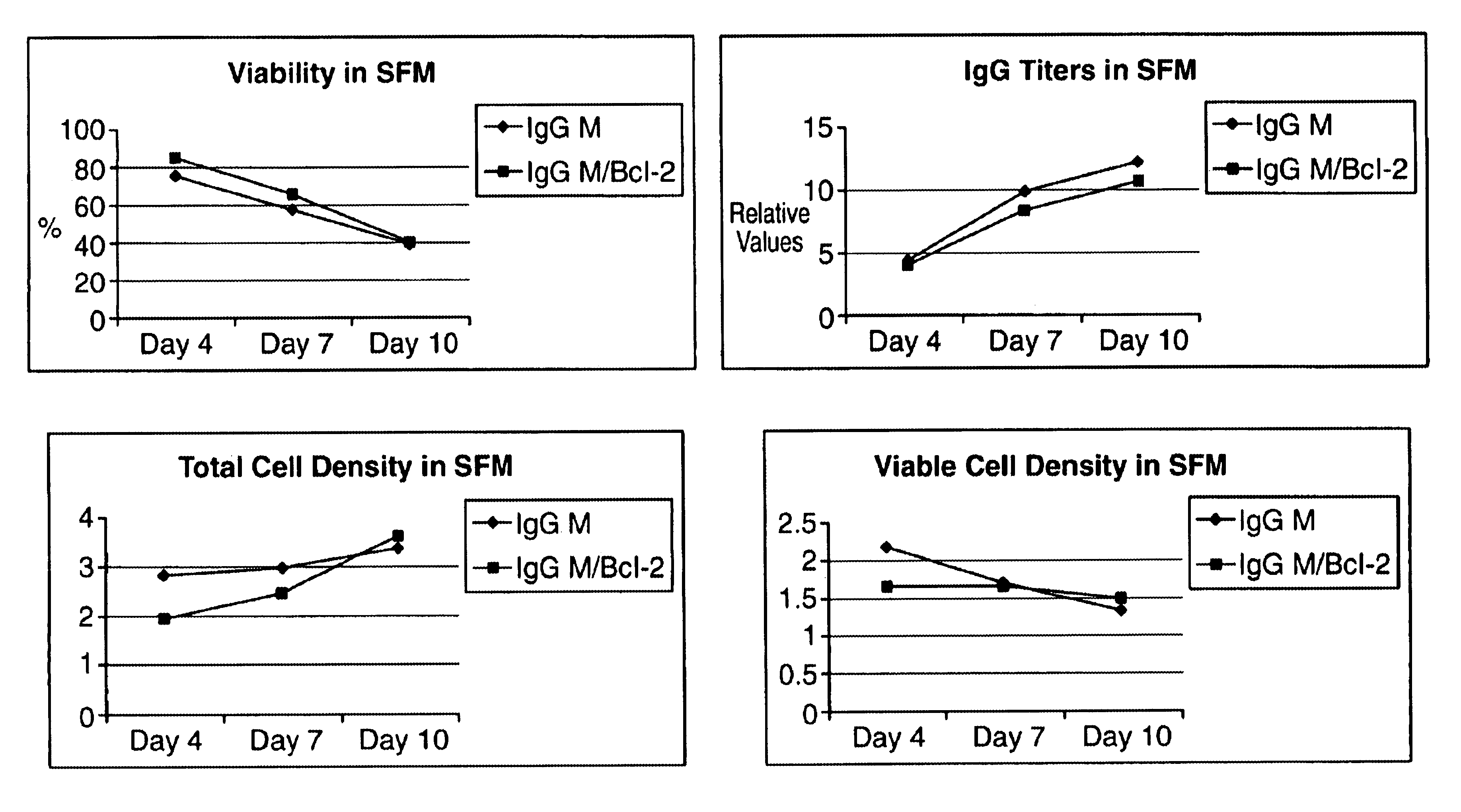

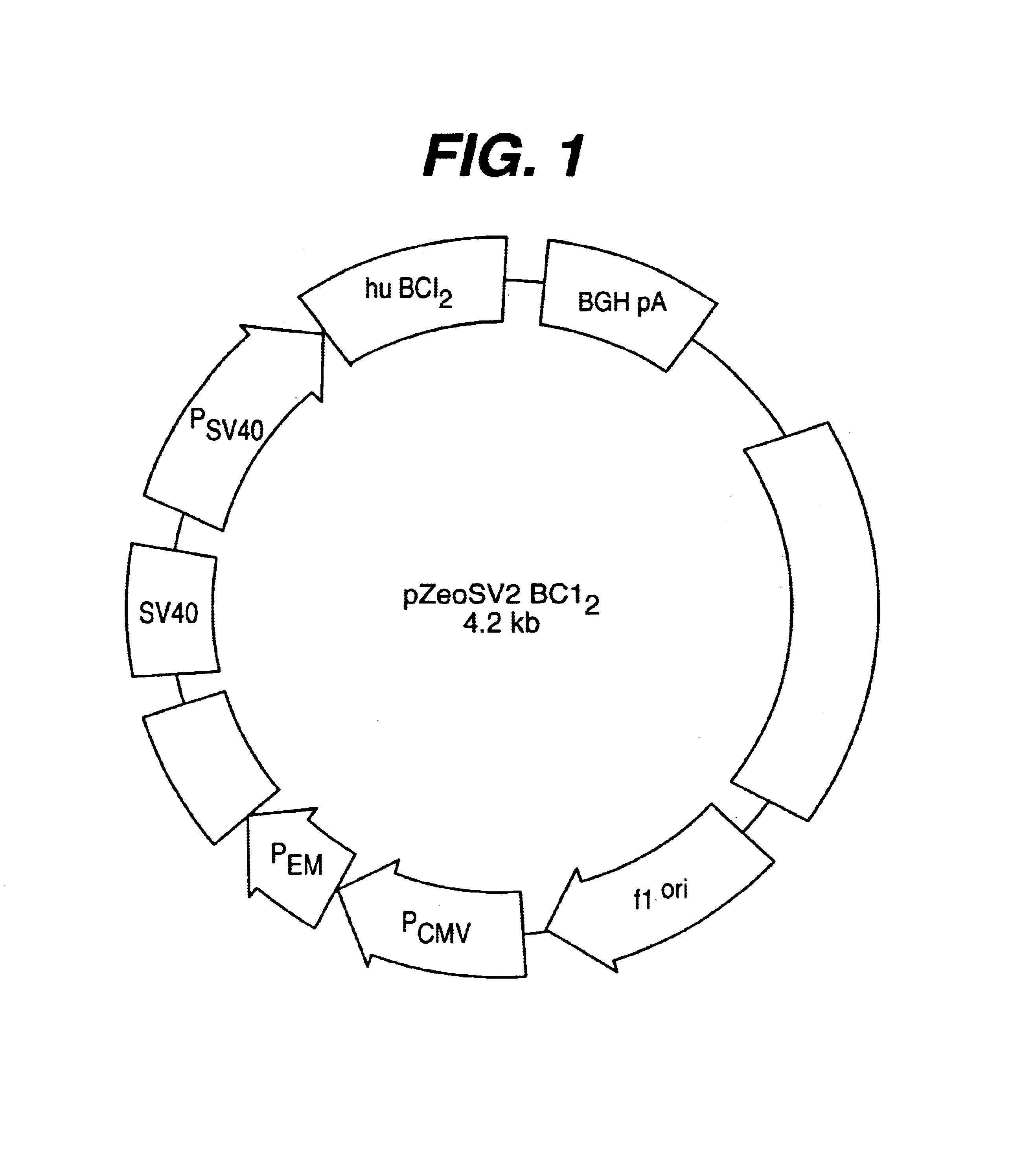

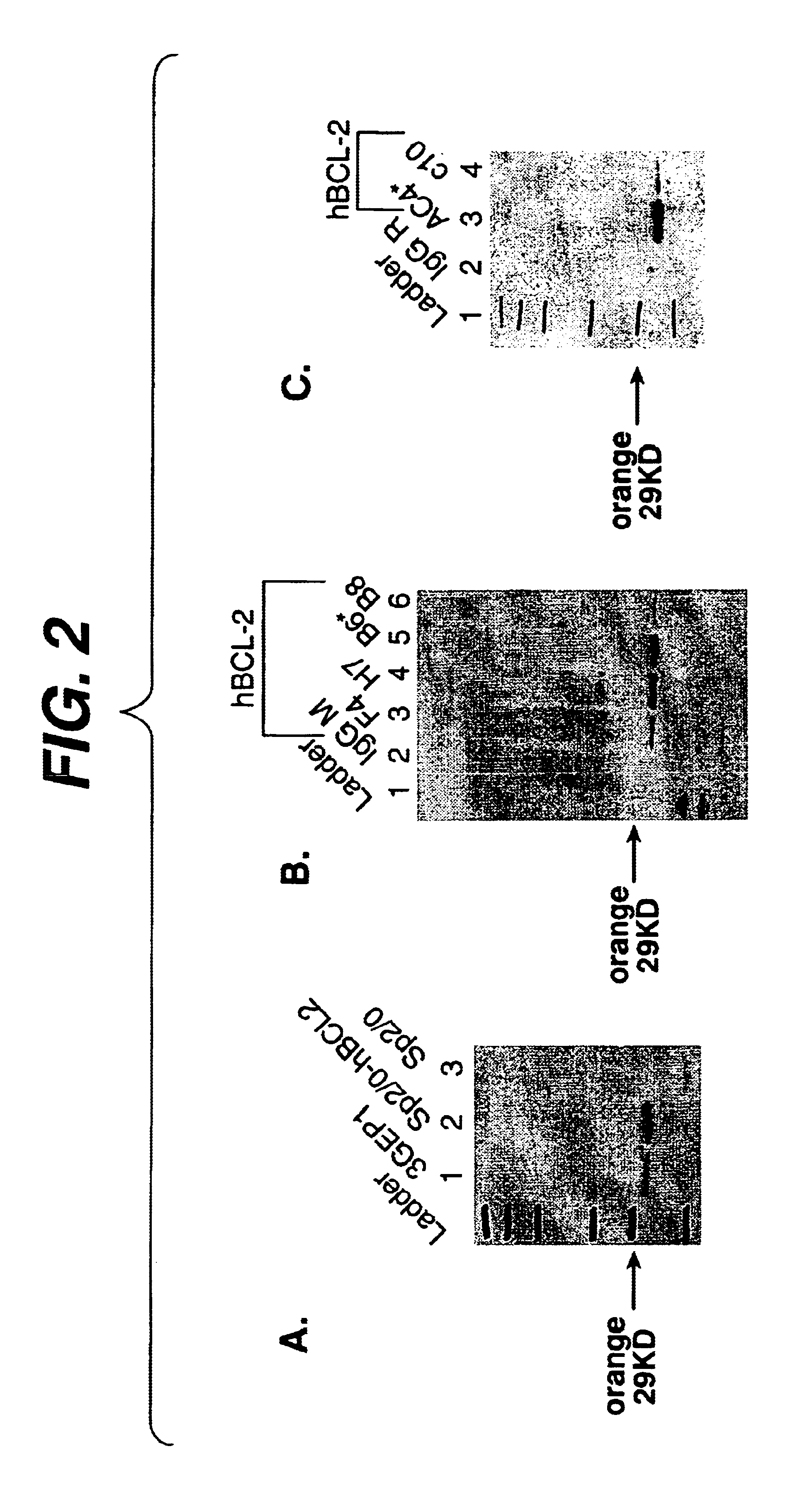

Methods and compositions for enhanced protein expression and/or growth of cultured cells using co-transcription of a Bcl2 encoding nucleic acid

InactiveUS6964199B2High yieldHigh expressionFluid pressure measurement using inductance variationAntibody ingredientsBiotechnologyCultured cell

Owner:CENTOCOR

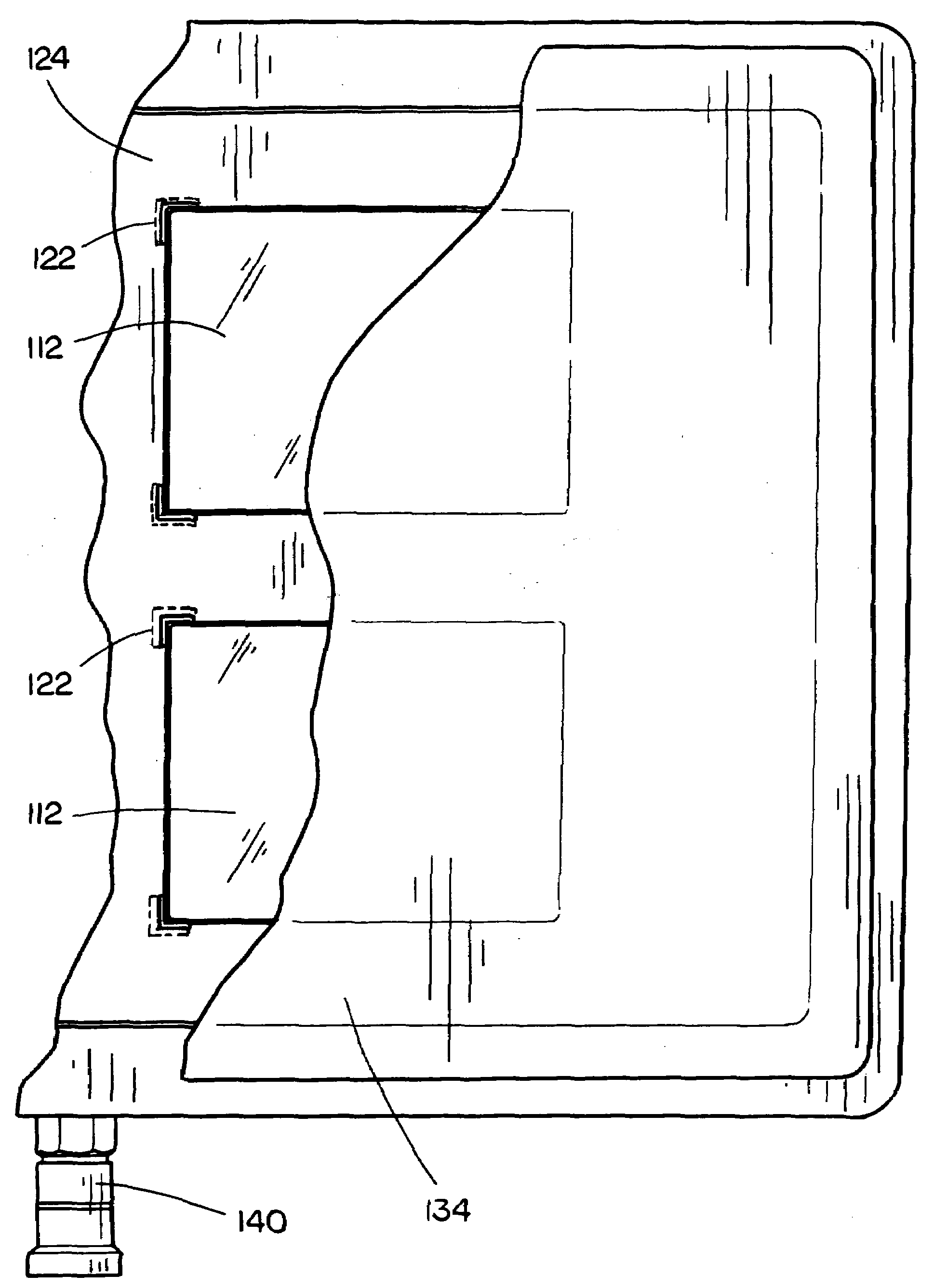

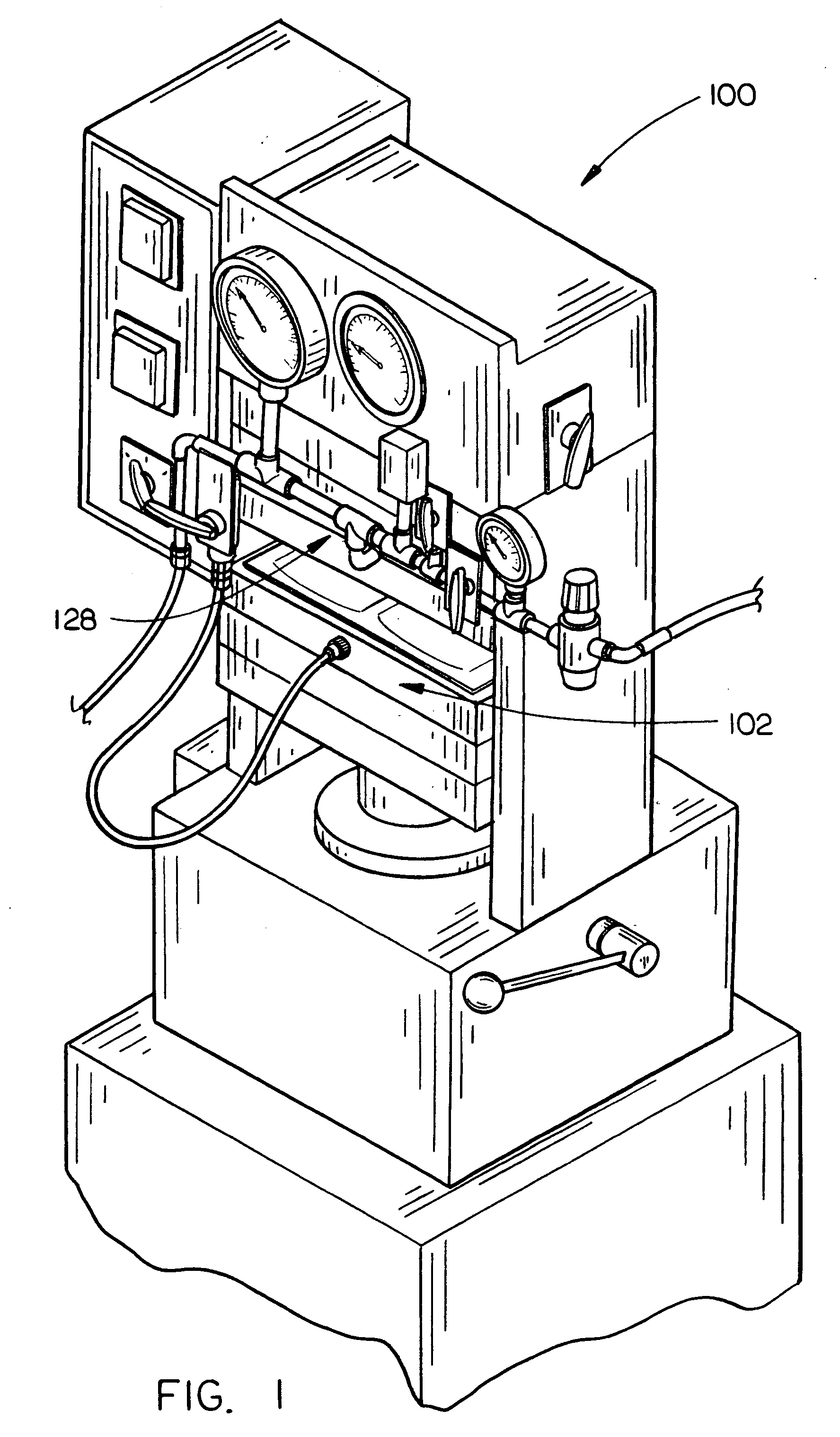

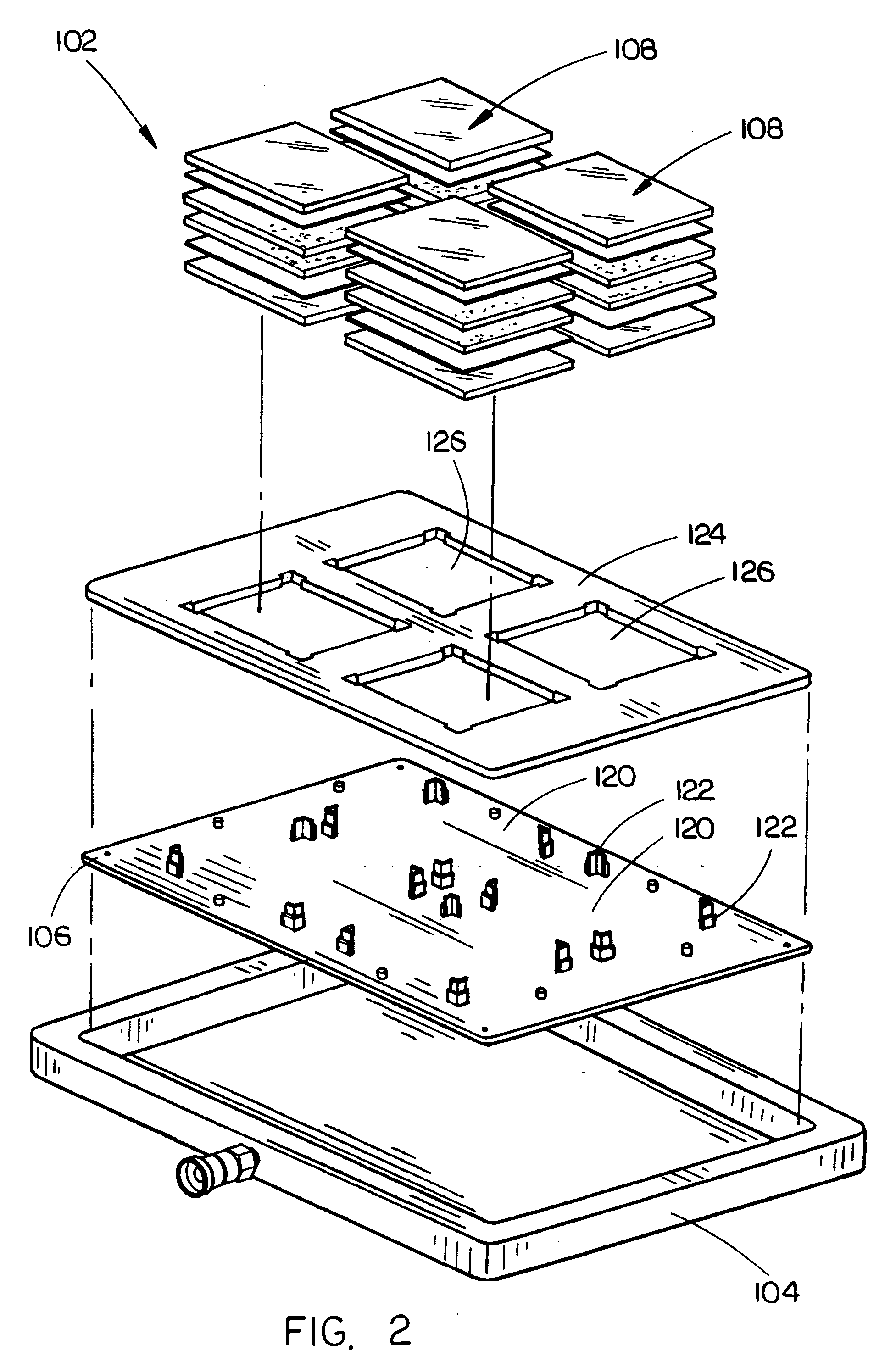

Planarization treatment of pressure sensitive adhesive for rigid-to-rigid substrate lamination

ActiveUS20090186218A1Improve suitabilitySynthetic resin layered productsLaminationBiomedical engineeringSupport surface

The present invention is a process for performing a planarization treatment of pressure-sensitive adhesive (PSA). The process includes positioning a first substrate onto a support surface of a planarization tool. The process further includes placing at least one layer of PSA onto the first substrate. The process further includes positioning a second substrate onto the layer(s) of PSA. The process further includes applying a pressure to the second substrate via a flexible membrane, said pressure being applied in a generally uniform, unidirectional and localized manner. Further, the applied pressure flattens the PSA between the first substrate and the second substrate for promoting suitability of the PSA for use in rigid-to-rigid lamination processes.

Owner:ROCKWELL COLLINS INC

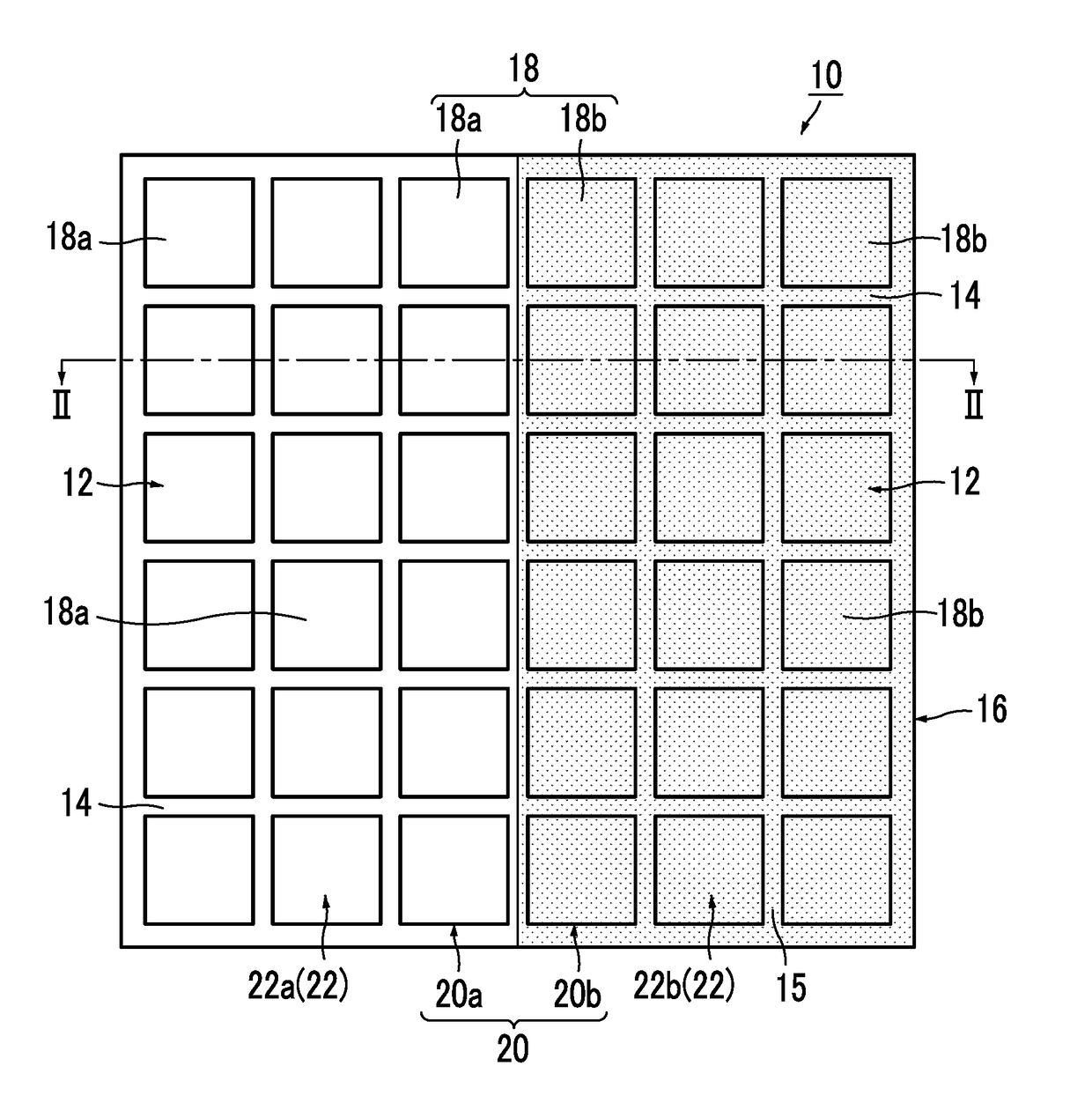

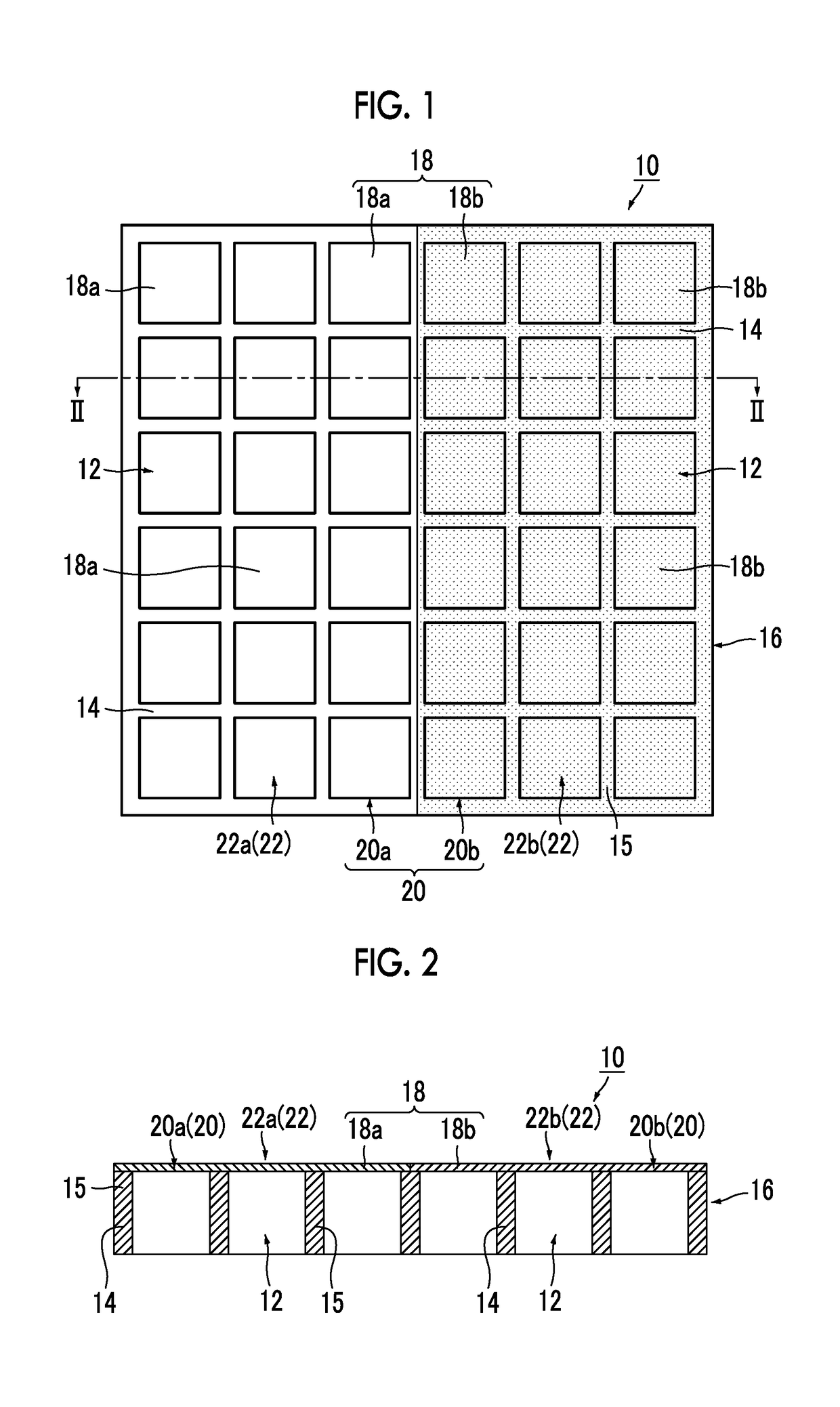

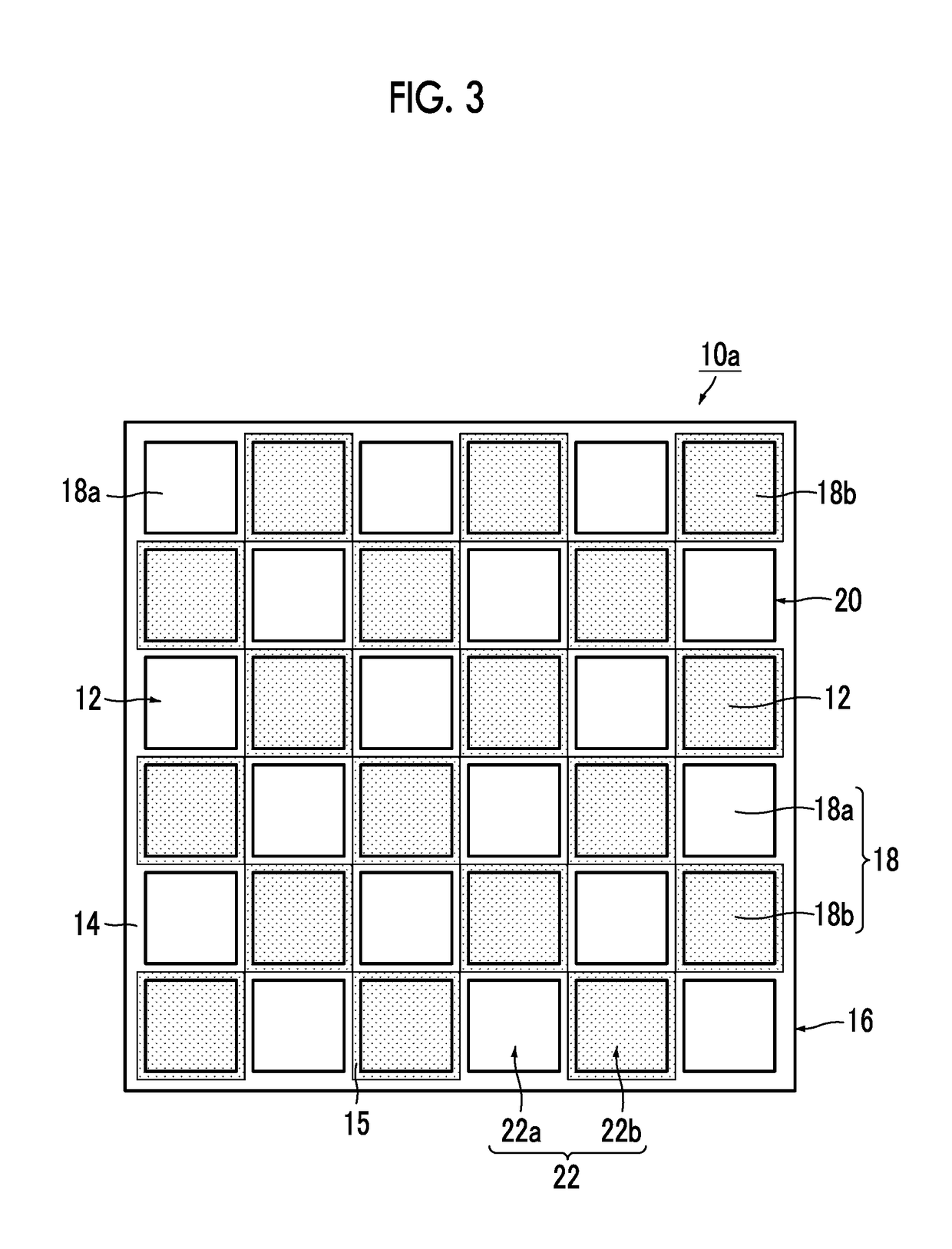

Soundproof structure and soundproof structure manufacturing method

ActiveUS20180051462A1Improve robustnessExcellent manufacturing suitabilitySound proofingSound producing devicesResonanceEngineering

A soundproof structure has a plurality of soundproof cells arranged in a two-dimensional manner. Each of the plurality of soundproof cells includes a frame formed of a frame member forming an opening and a film fixed to the frame. Two or more types of soundproof cells having different first resonance frequencies are present in the plurality of soundproof cells. A shielding peak frequency at which transmission loss is maximized is present within a range equal to or higher than a lowest frequency among first resonance frequencies of the soundproof cells and equal to or lower than a highest frequency among the first resonance frequencies of the soundproof cells.

Owner:FUJIFILM CORP

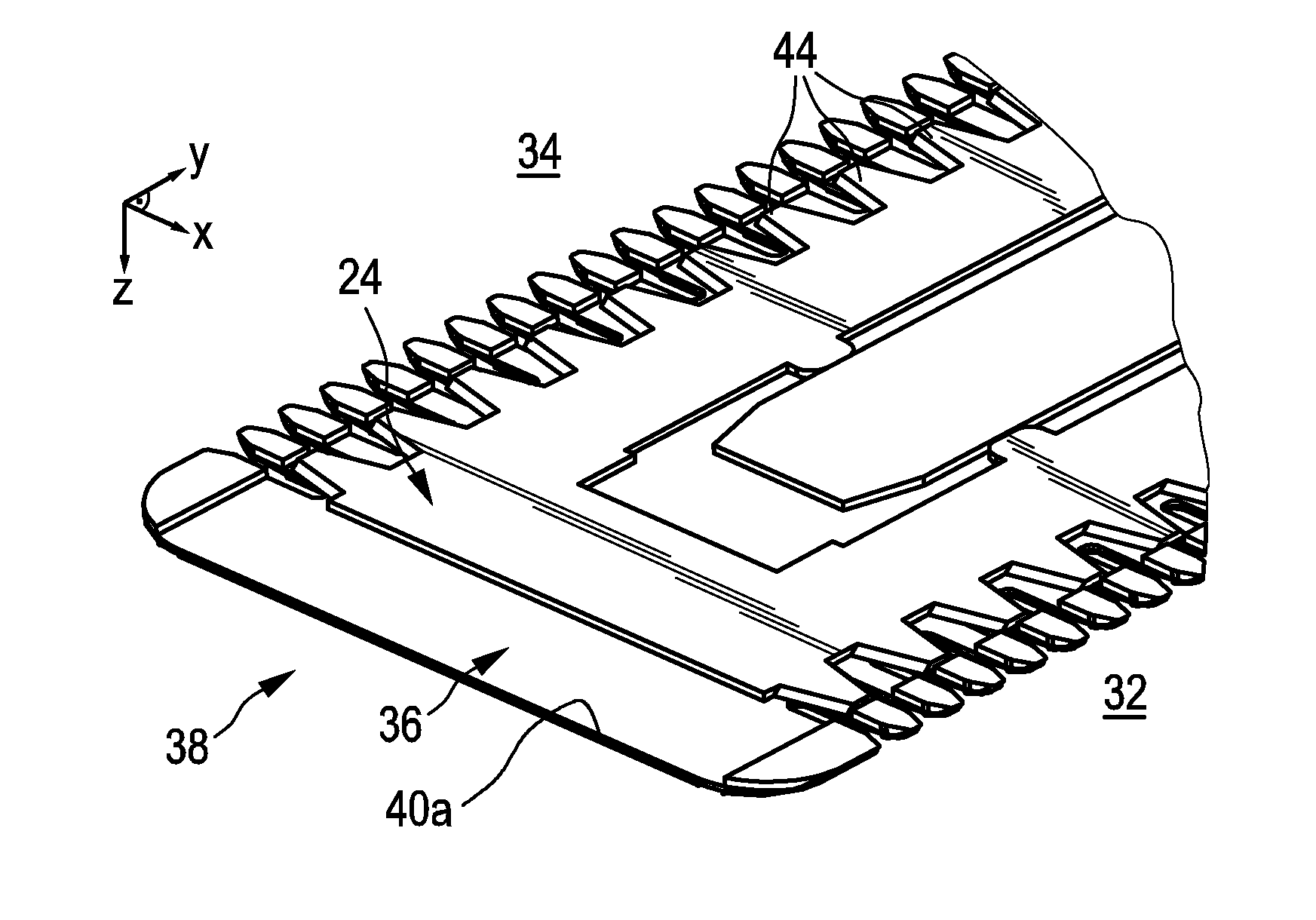

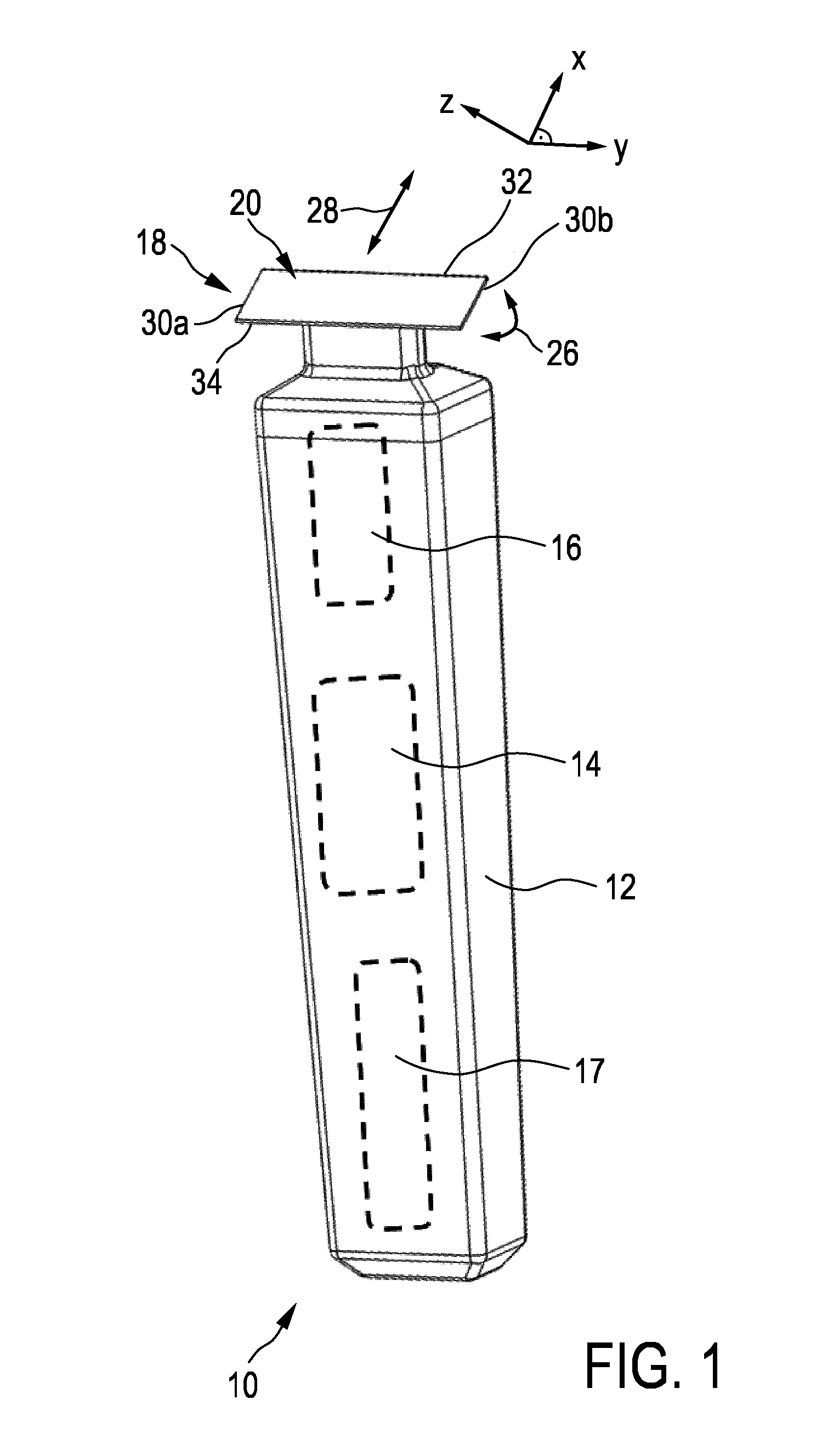

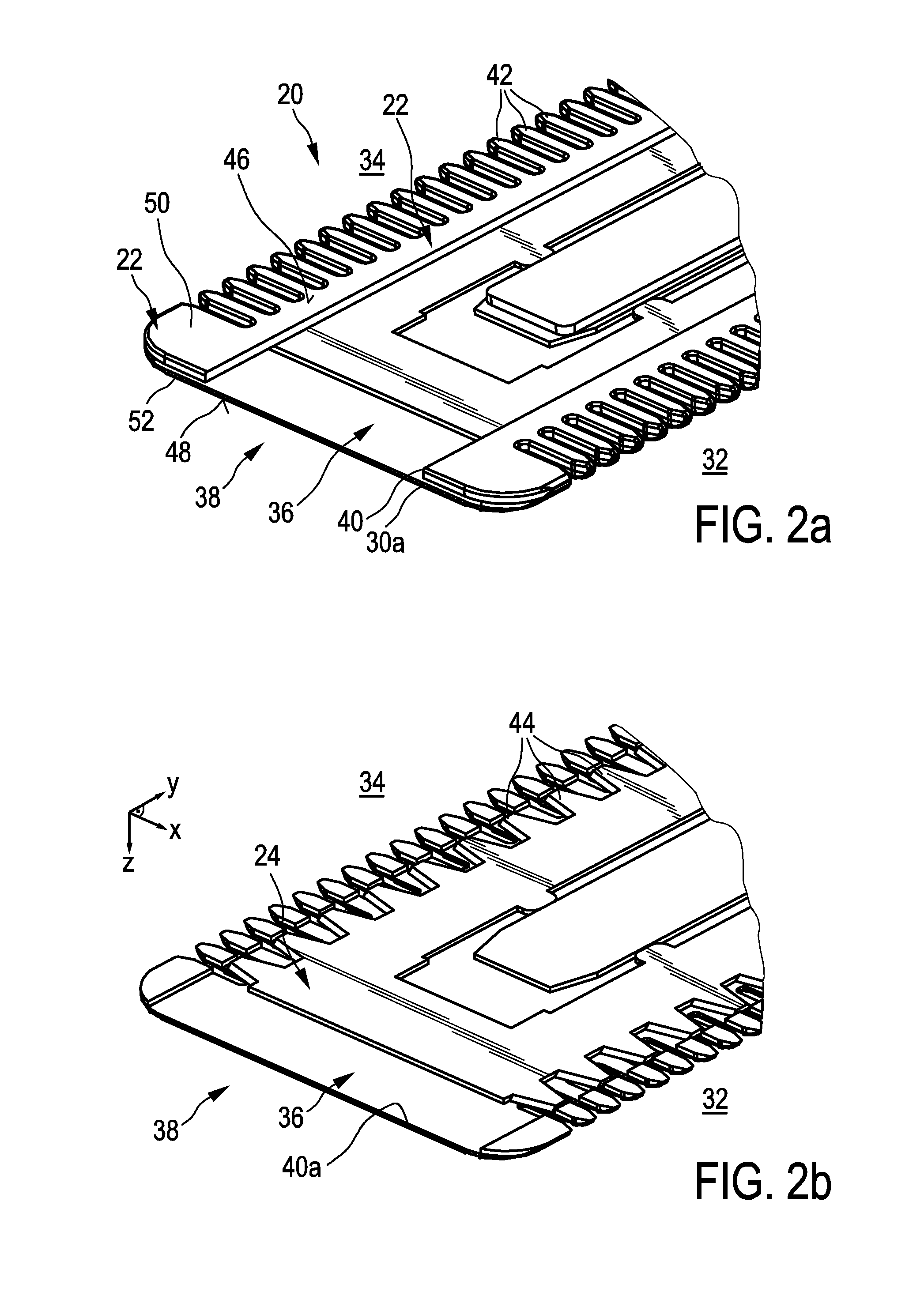

Hair cutting appliance and blade set

ActiveUS20160271814A1Increase contact areaImprove suitabilityMetal working apparatusSkin contactPlastic materials

The present invention relates to a hair cutting appliance (10) comprising a blade set (20), and to a blade set (20) of a hair cutting appliance (10). The blade set (20) is arranged to be moved through hair in an assumed moving direction (28) to cut hair. The blade set (20) comprises a stationary blade (22), a movable blade (24), and a lateral protecting element (56). The stationary blade (22) comprises at least one toothed cutting edge (32, 34), a lateral end (30), and a first surface (48) that is arranged, when in use for shaving purposes, as a skin-contacting surface. The movable blade (24) comprises a toothed cutting edge (32, 34). The stationary blade (22) and the movable blade (24) are arranged to be reciprocally moved with respect to each other in a cutting direction (Y) that is basically perpendicular to the assumed moving direction (28). The lateral protecting element (56) is associated with the lateral end (30), thereby defining a lateral end cap of the stationary blade (22), wherein the lateral protecting element (56) laterally shields a lateral edge (40) of the lateral end (30), such that, when in use, skin contact of the lateral edge (40) is prevented. The lateral protecting element (56) and the lateral end (30) cooperate so as to prevent hairs from being trapped there between. The stationary blade (22) and the movable blade (24) are at least partially made from steel, and the lateral protecting element (56) is made from plastic material. The blade set (20) configured to pivot or swivel with respect to a housing of the hair cutting appliance (10).

Owner:KONINKLJIJKE PHILIPS NV

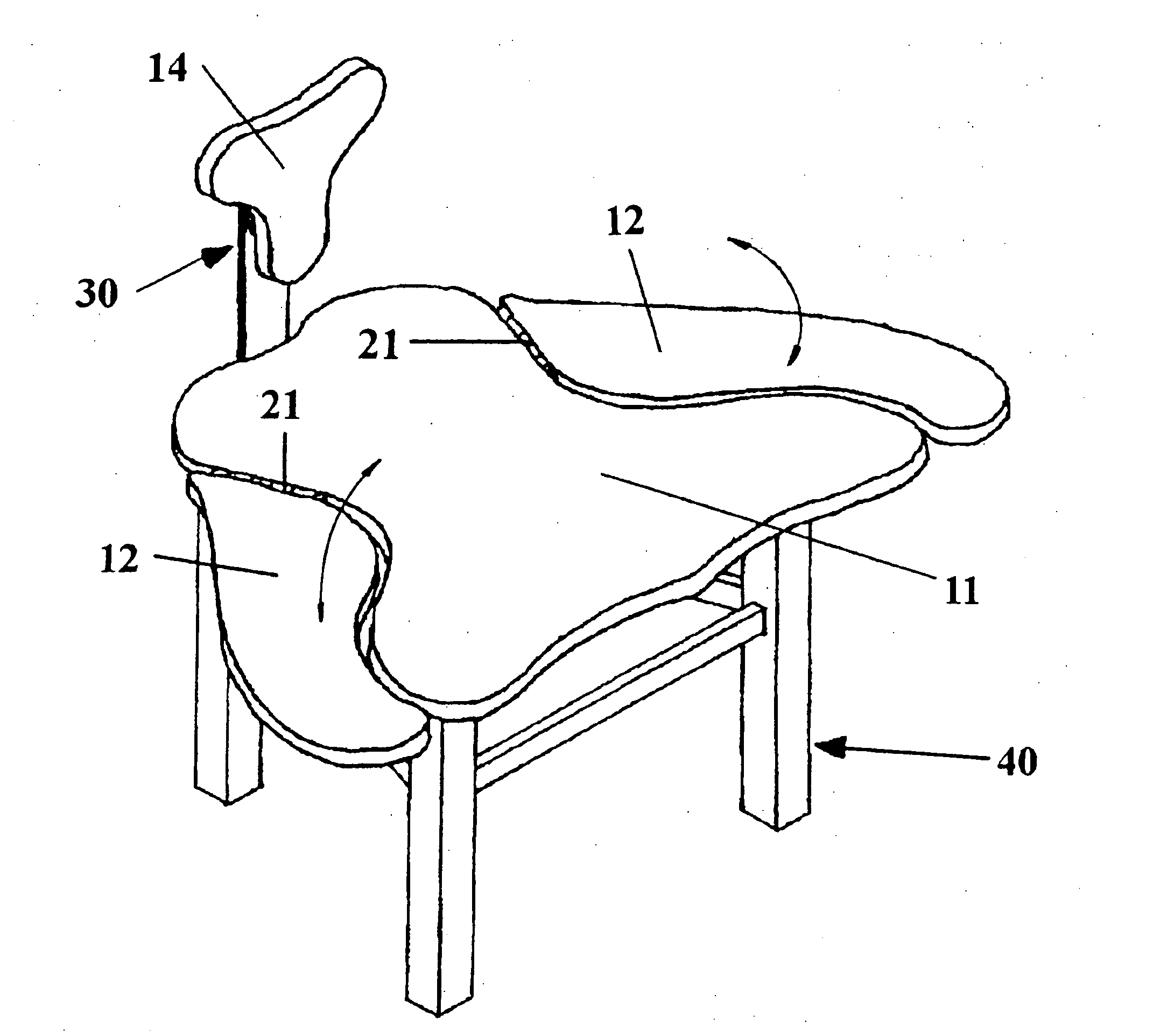

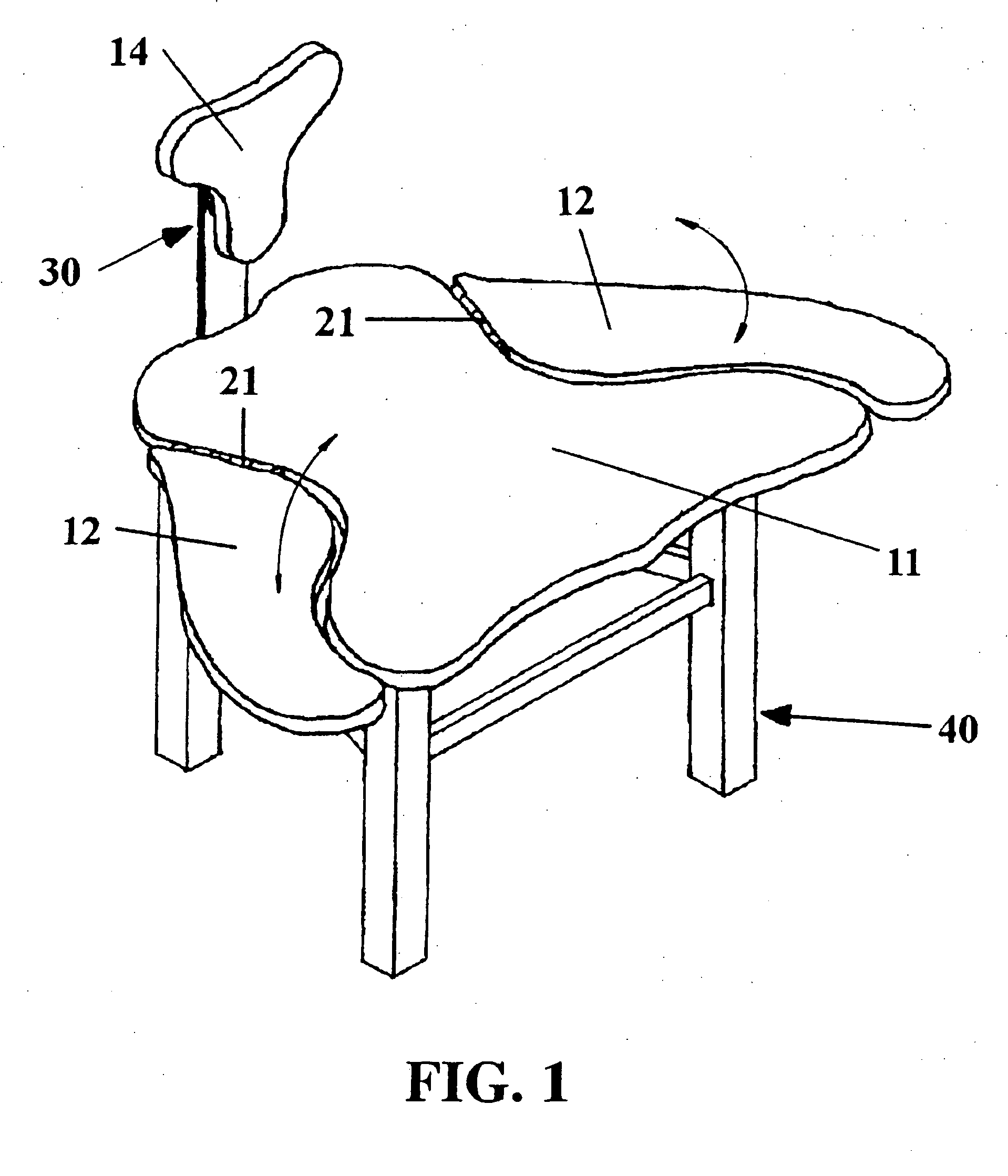

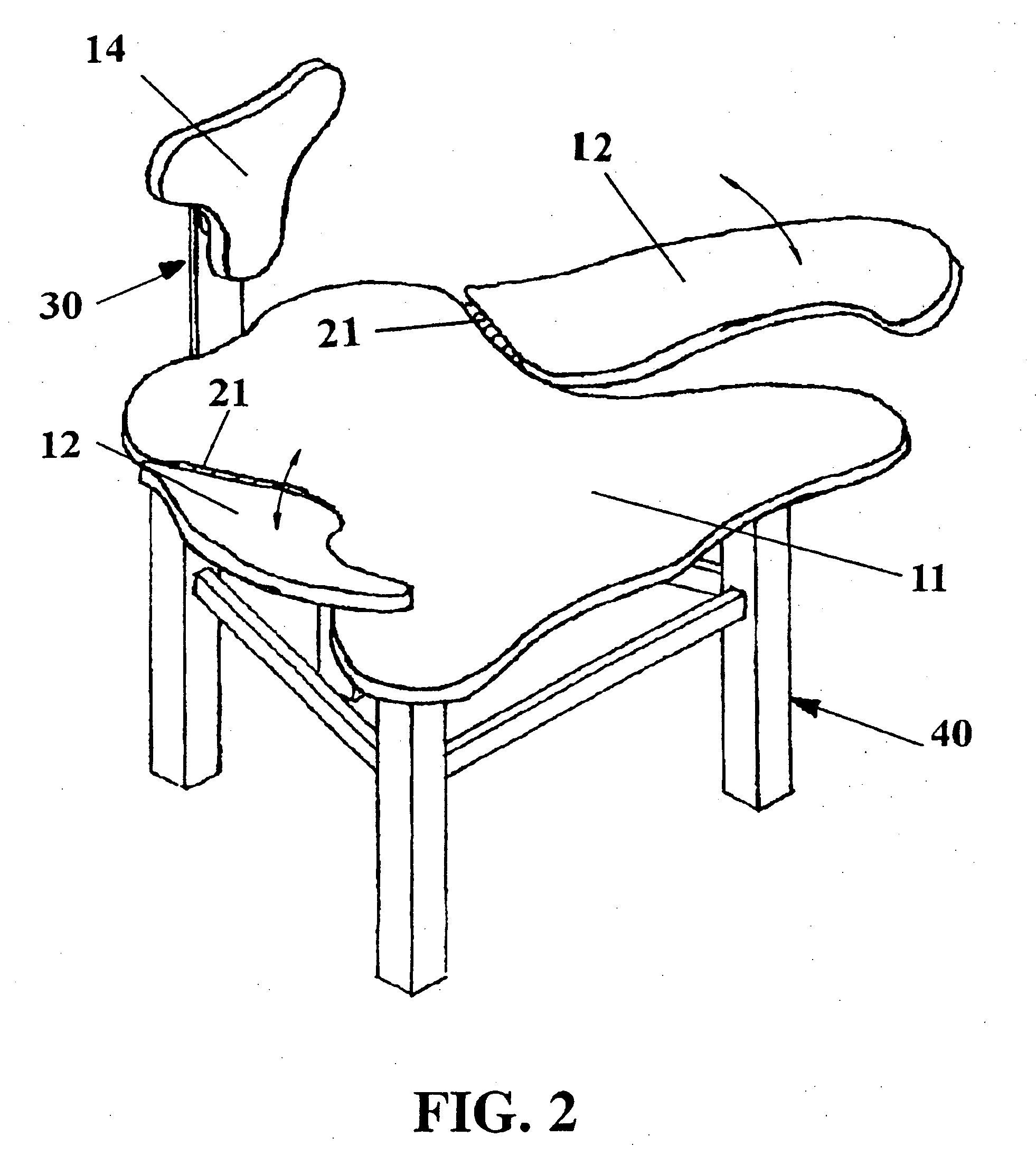

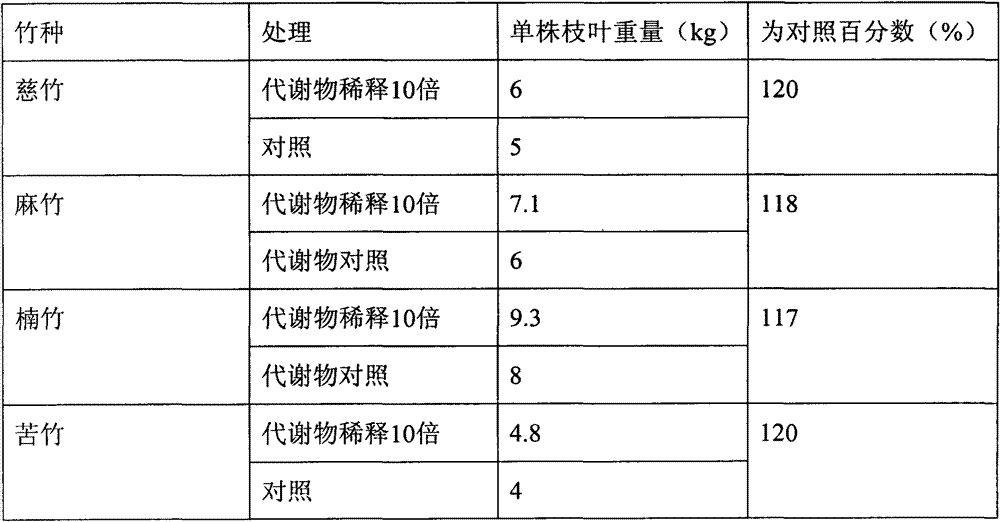

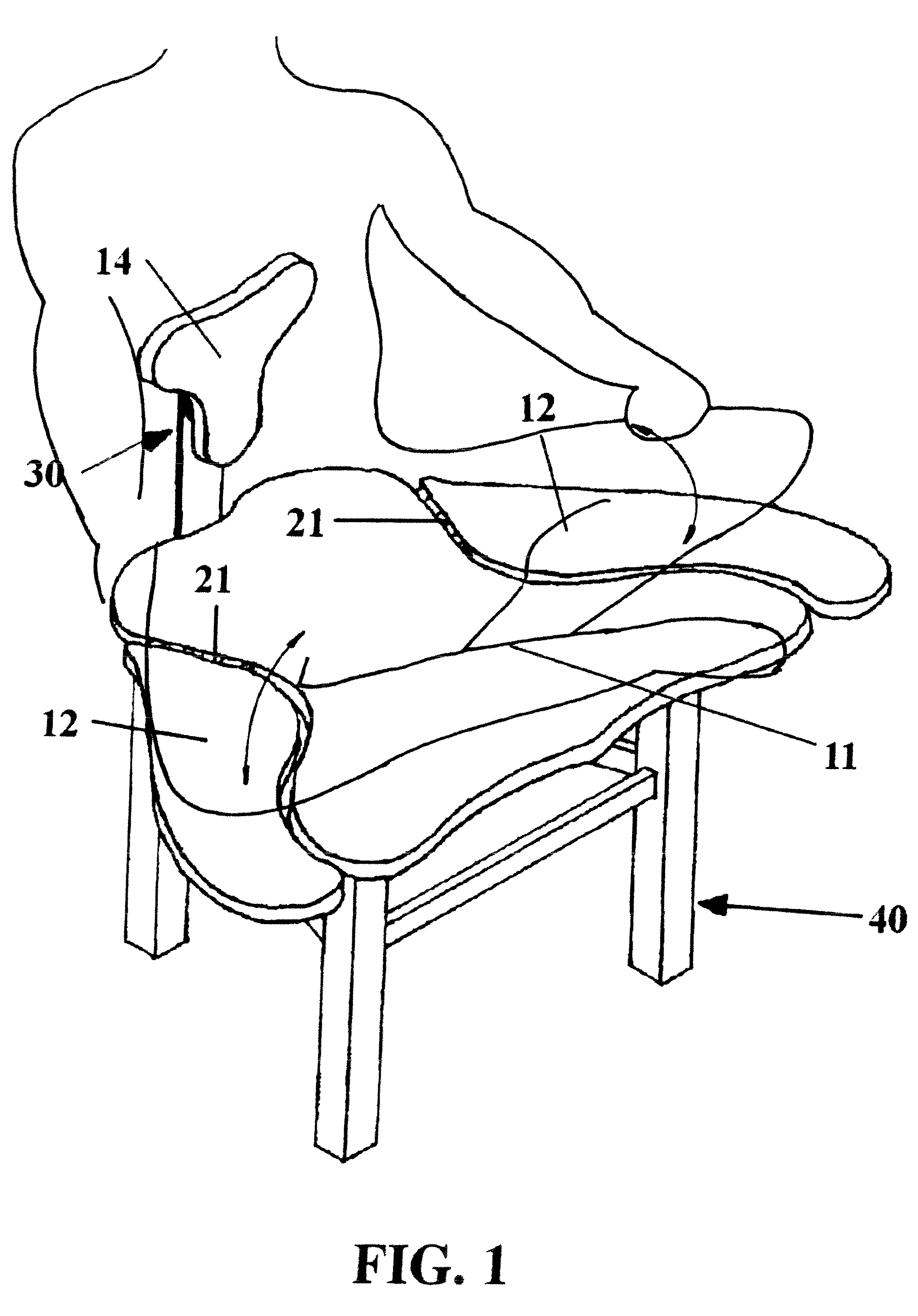

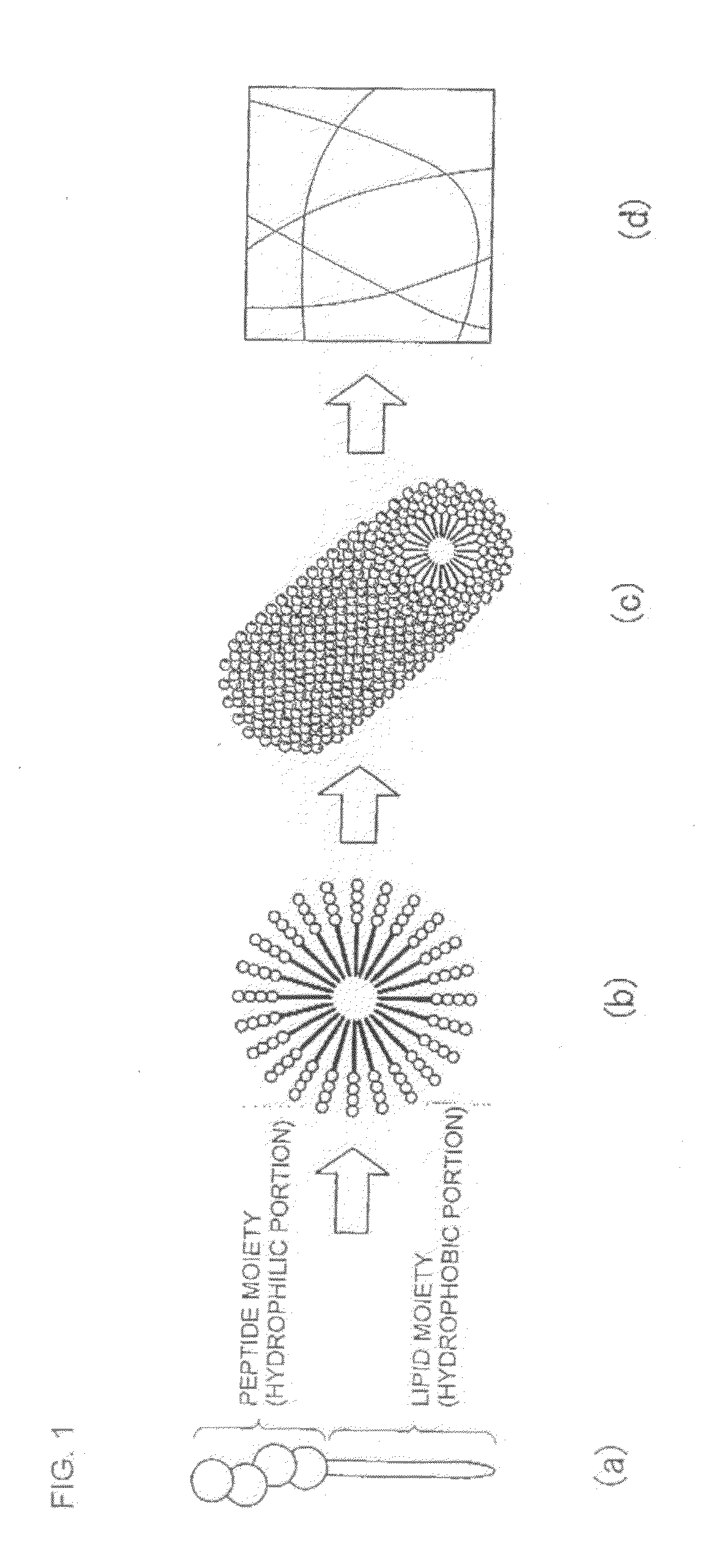

Adjustable cross-legged support seat

ActiveUS20070126271A1Improve suitabilityImprove versatilityOperating chairsDental chairsEngineeringBack support

Owner:BRODEUR CARL CHRISTOPHER

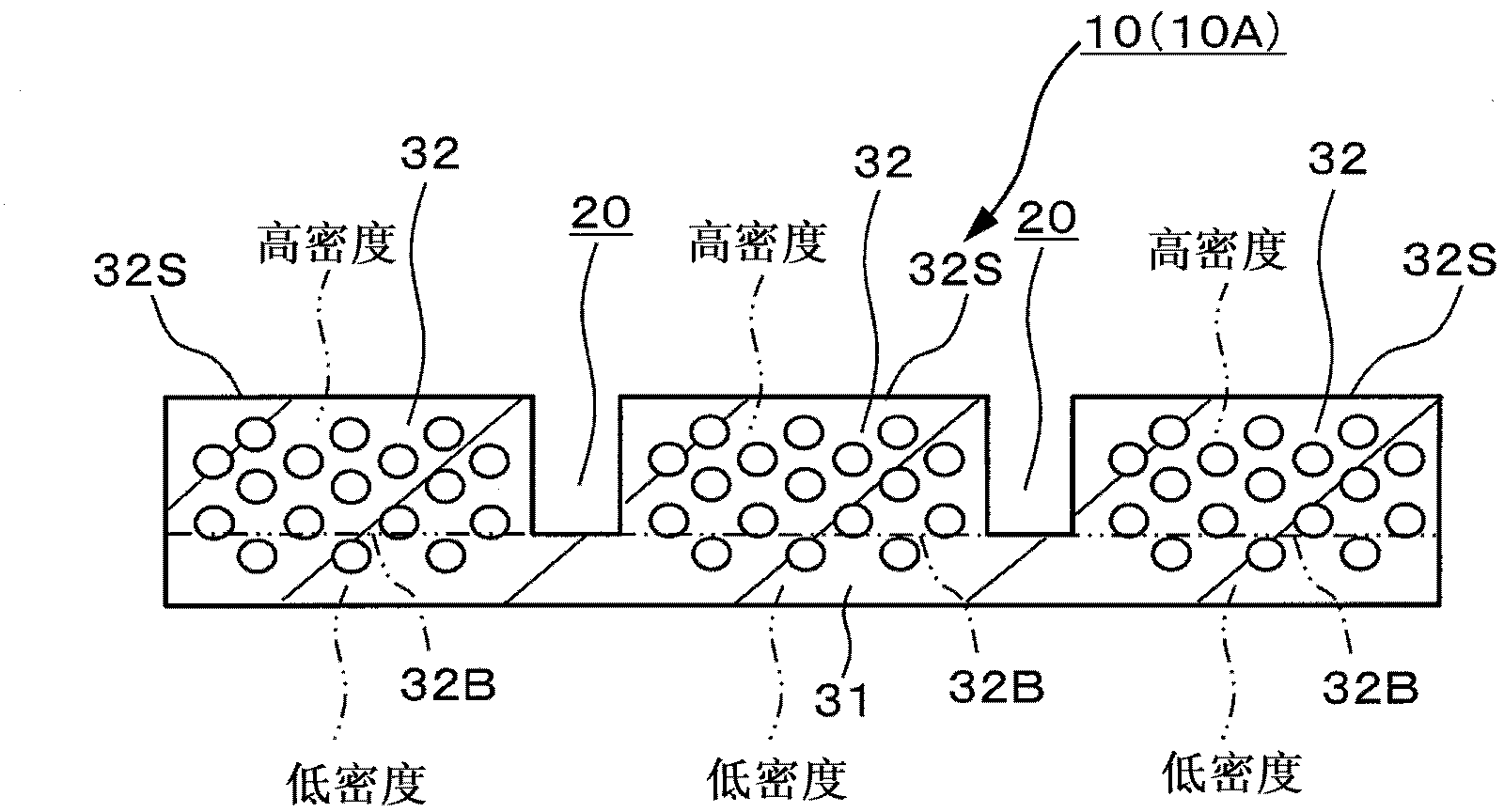

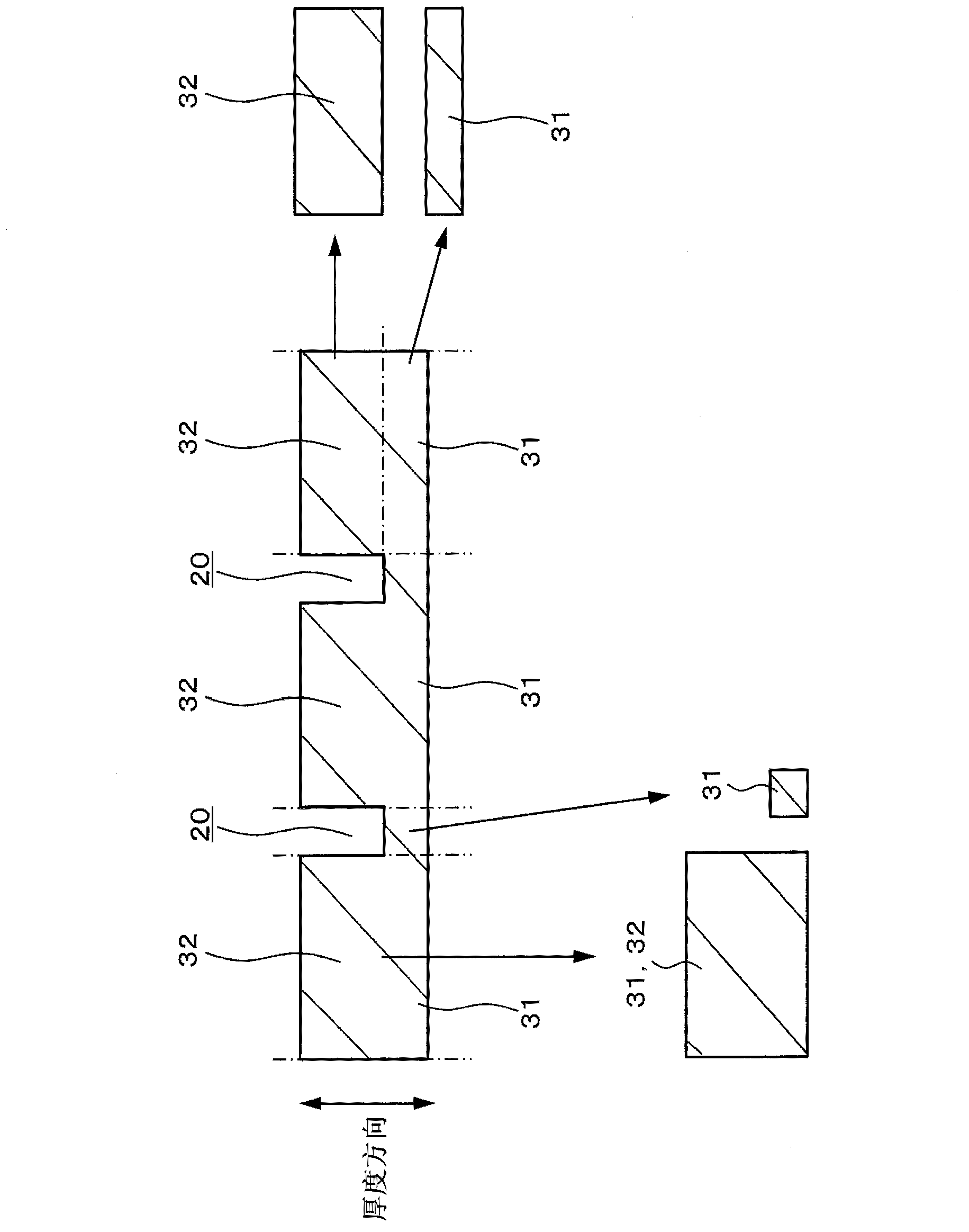

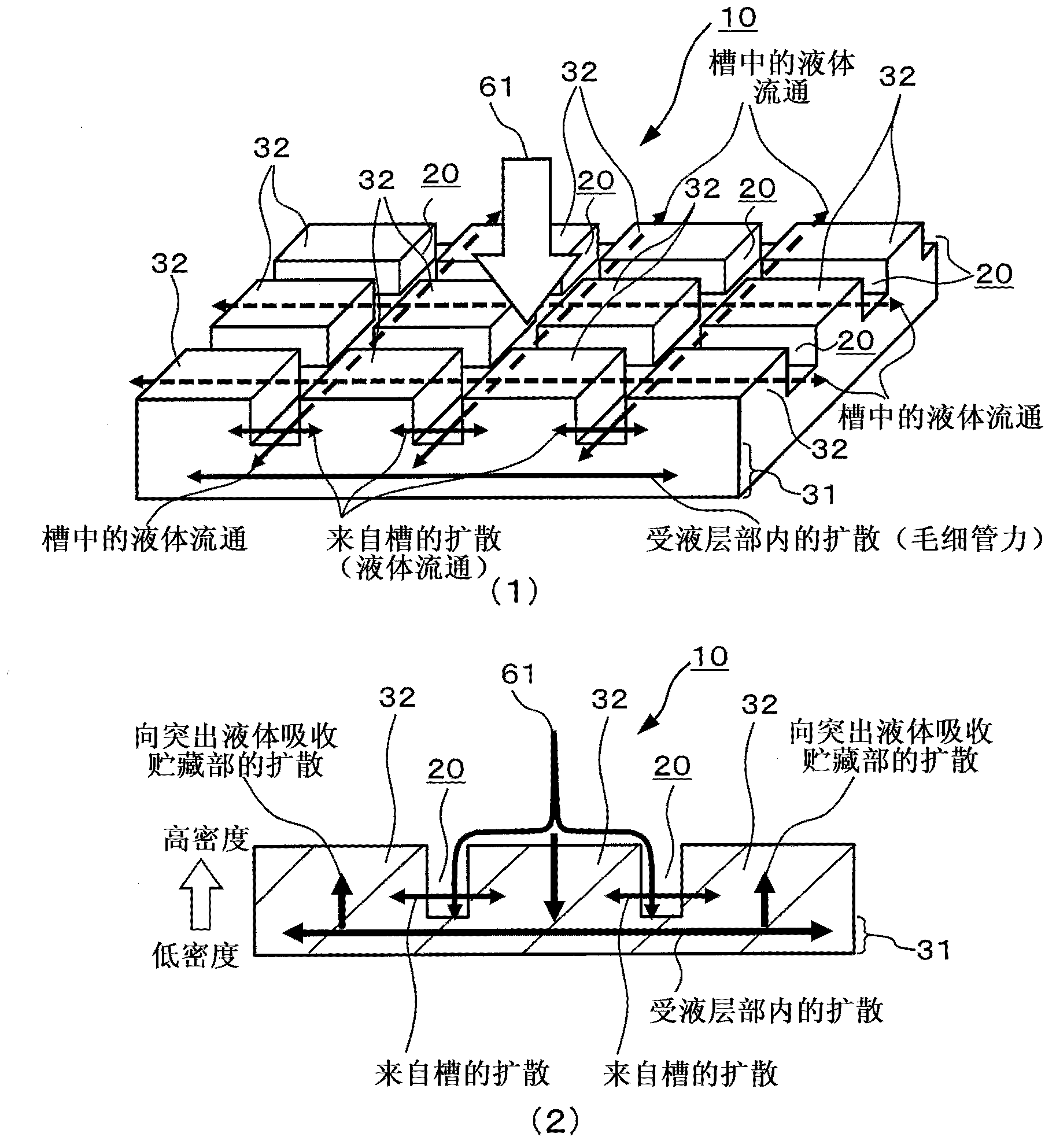

Absorbent and absorbent article

ActiveCN103260570AImproved liquid spreadingIncreased absorptionAbsorbent padsLiquid layerMechanical engineering

When the absorbent is segmented into three parts longitudinally, the absorbent has a middle first absorbing area, a second absorbing area that is the segment on one side of the first absorbing area, and a third absorbing area that is the segment on the other side of the first absorbing area. Each of the absorbing areas has a liquid-receiving layer that absorbs and diffuses liquid in the planar direction, and multiple protruding liquid absorbing and storing areas disposed on one surface of the liquid-receiving layer that are continuous with the liquid-receiving layer and absorb and store liquid, as well as having sunken groove-shaped crevices on one surface or at opposing positions on both surfaces, with the crevices being disposed between the protruding liquid absorbing and storing areas. The first crevices disposed in the first absorbing area are inside of the outer edges of the first absorbing area in plan view and are disposed in the longitudinal direction. The second and third crevices disposed respectively in the second and third absorbing areas are each disposed in a diagonal direction with respect to the longitudinal direction. The first and second crevices, and the first and third crevices are configured as crevices that are continuous with each other, or the first crevices are separated from the second crevices and the third crevices. The area ratio of the protruding liquid absorbing and storing areas is greater than that of the crevices. The liquid-receiving layer of the bottoms of the crevices is an absorbent of lower basis weight and density than the protruding liquid absorbing and storing areas.

Owner:KAO CORP

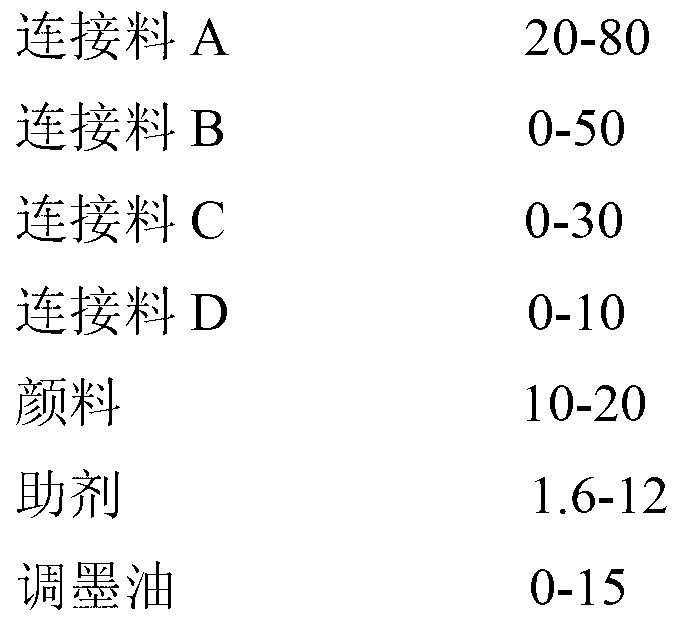

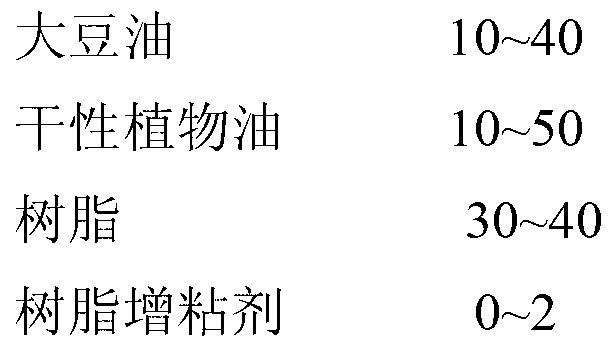

All vegetable oil high-speed planographic printing ink

The invention relates to all vegetable oil high-speed planographic printing ink. The all vegetable oil high-speed planographic printing ink comprises the following components in parts by weight: 20-80 parts of a binder A, 0-50 parts of a binder B, 0-30 parts of a binder C, 0-10 parts of a binder D, 10-20 parts of a pigment, 1.6-12 parts of an auxiliary and 0-15 parts of a vanish, wherein the binder A, the binder B, the binder C and the binder D are respectively composed of soybean oil, dry vegetable oil, resin and / or a resin tackifier. According to the all vegetable oil high-speed planographic printing ink, vegetable oil is used for substituting petroleum base mineral oil in the traditional printing ink, and no petroleum solvent is contained, so that the all vegetable oil high-speed planographic printing ink has excellent environmental protection property; and under middle and high speed printing conditions, the all vegetable oil high-speed planographic printing ink has the advantages of good suitability, high speed, stability on a printing machine and quick drying on a piece of paper and can meet the requirement of a printing company on an increasing printing speed as the modern printing machine is improved.

Owner:XINXIANG WENDE XIANGCHUAN PRINTING INK

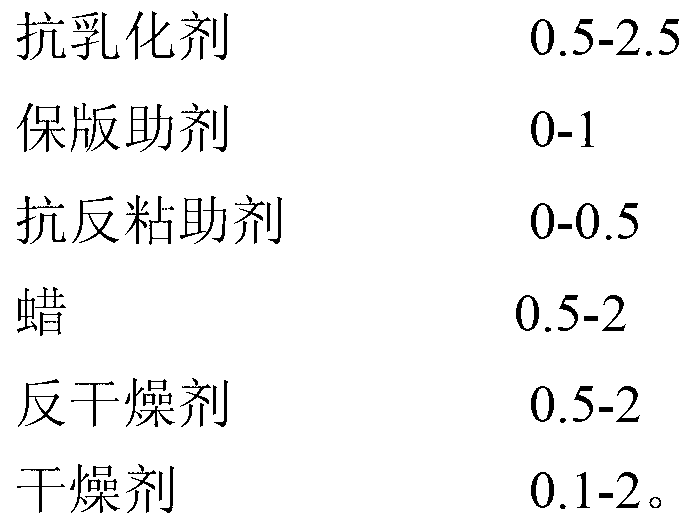

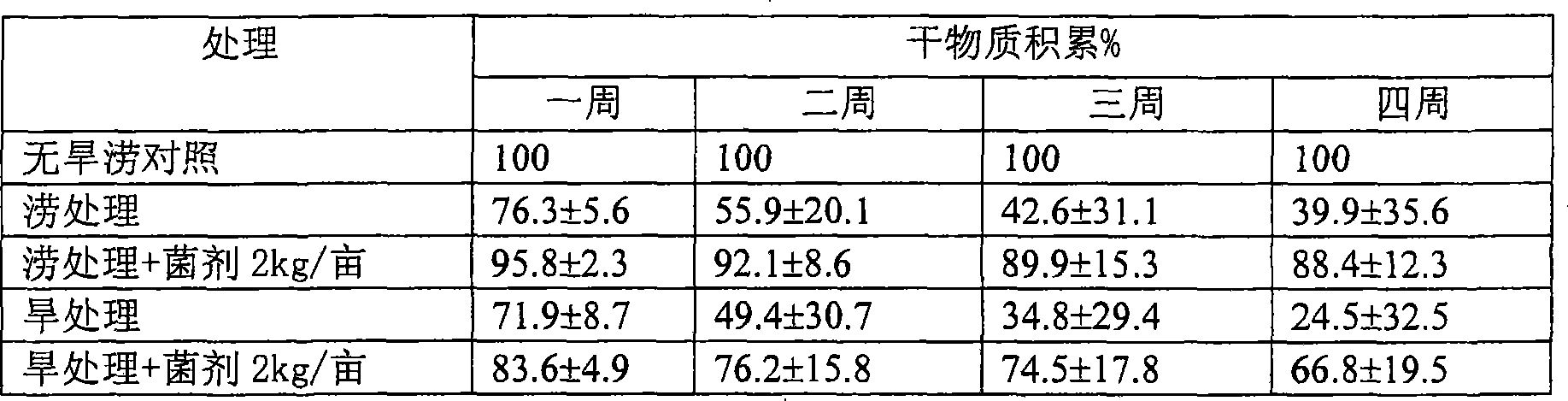

Bacillus velezensis ZJ20 strain and liquid preparations thereof

InactiveCN102703342AStrong stress resistanceImprove suitabilityBacteriaMicroorganism based processesMetaboliteHigh stress

The invention discloses a bacillus velezensis ZJ20 strain and liquid preparations thereof. The bacillus velezensis ZJ20 strain is preserved in China general microbiological culture collection center in Chaoyang district, Beijing, China under the number of CGMCC NO.5995 on April 13 2012. A microbial biocontrol agent, namely the novel bacillus velezensis ZJ20 strain, prepared by screening has endospores with high stress resistance and long shelf life, is highly environmentally adaptive and can be produced into commercial biological agents. Metabolites of the bacillus velezensis ZJ20 strain have high bactericidal power, have high colonization ability and fast speed on plants, and can occupy the surface of hybrid bamboo effectively to prevent dieback. Antibacterial protein (chitin with protein) produced by the strain is antibacterial, can promote growth of hybrid bamboo and various types of bamboo branches and leaves, and have a novel effect of recovering posterior production capacity.

Owner:SICHUAN AGRI UNIV

Adjustable cross-legged support seat

ActiveUS7628455B2Improve suitabilityImprove versatilityOperating chairsDental chairsEngineeringBack support

Owner:BRODEUR CARL CHRISTOPHER

Ethylene-vinyl alcohol resin composition, multilayer sheet, packaging material, and container

ActiveUS20150152256A1Superior in heat stretching propertyExcellent appearance characteristicsSynthetic resin layered productsDomestic containersEthyleneEthylene vinyl alcohol copolymer

The present invention provides a resin composition containing: (A) an ethylene-vinyl alcohol copolymer having an ethylene content of 20 mol % or more and 50 mol % or less; (B) an ethylene-vinyl alcohol copolymer having an ethylene content of 30 mol % or more and 60 mol % or less; and (C) an unsaturated aldehyde, a value obtained by subtracting the ethylene content of the ethylene-vinyl alcohol copolymer (A) from the ethylene content of the ethylene-vinyl alcohol copolymer (B) being 8 mol % or more, a mass ratio (A / B) of the ethylene-vinyl alcohol copolymer (A) to the ethylene-vinyl alcohol copolymer (B) being 60 / 40 or more and 95 / 5 or less, and the content of the unsaturated aldehyde (C) with respect to a resin content being 0.01 ppm or more and less than 100 ppm.

Owner:KURARAY CO LTD

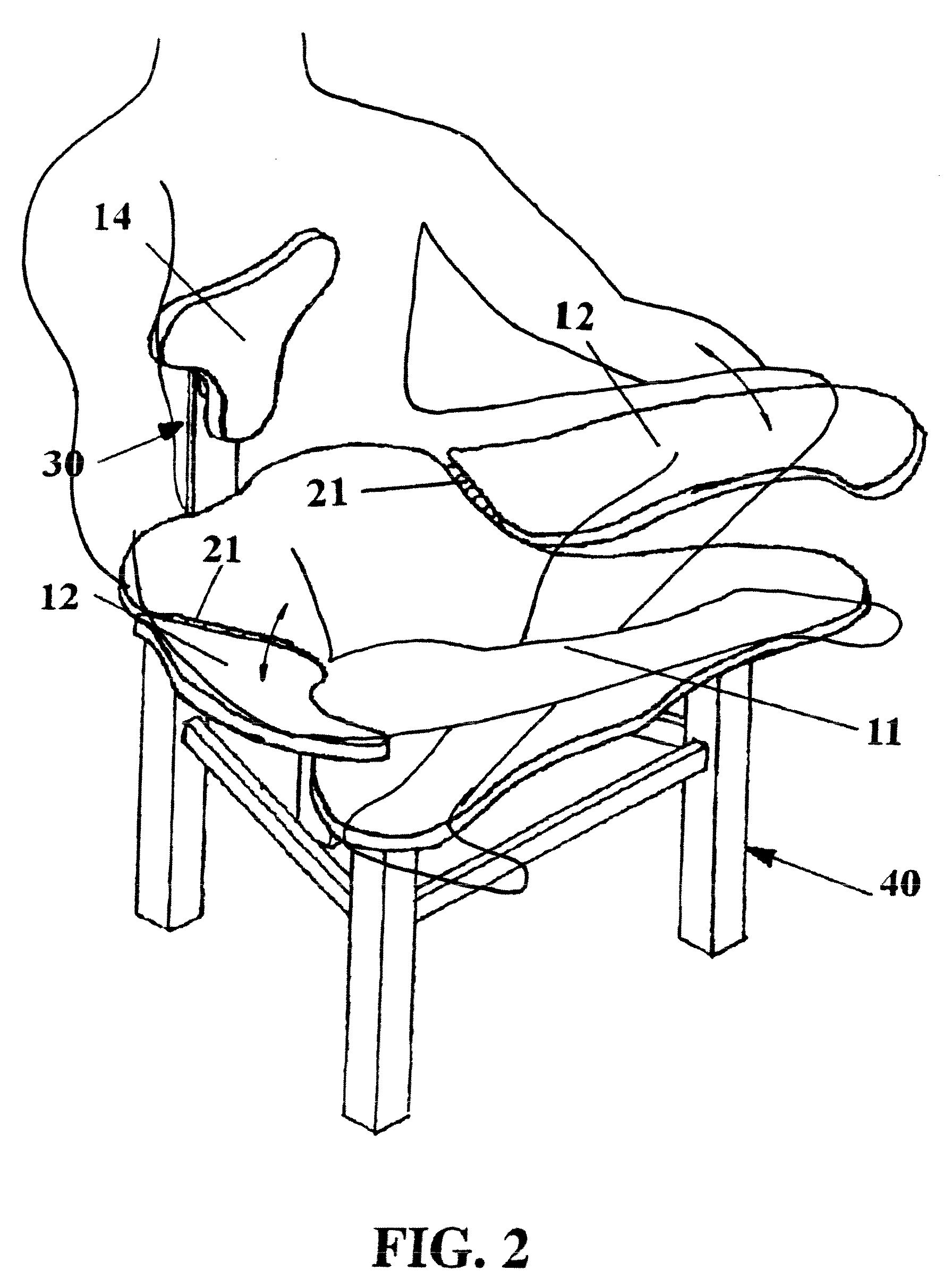

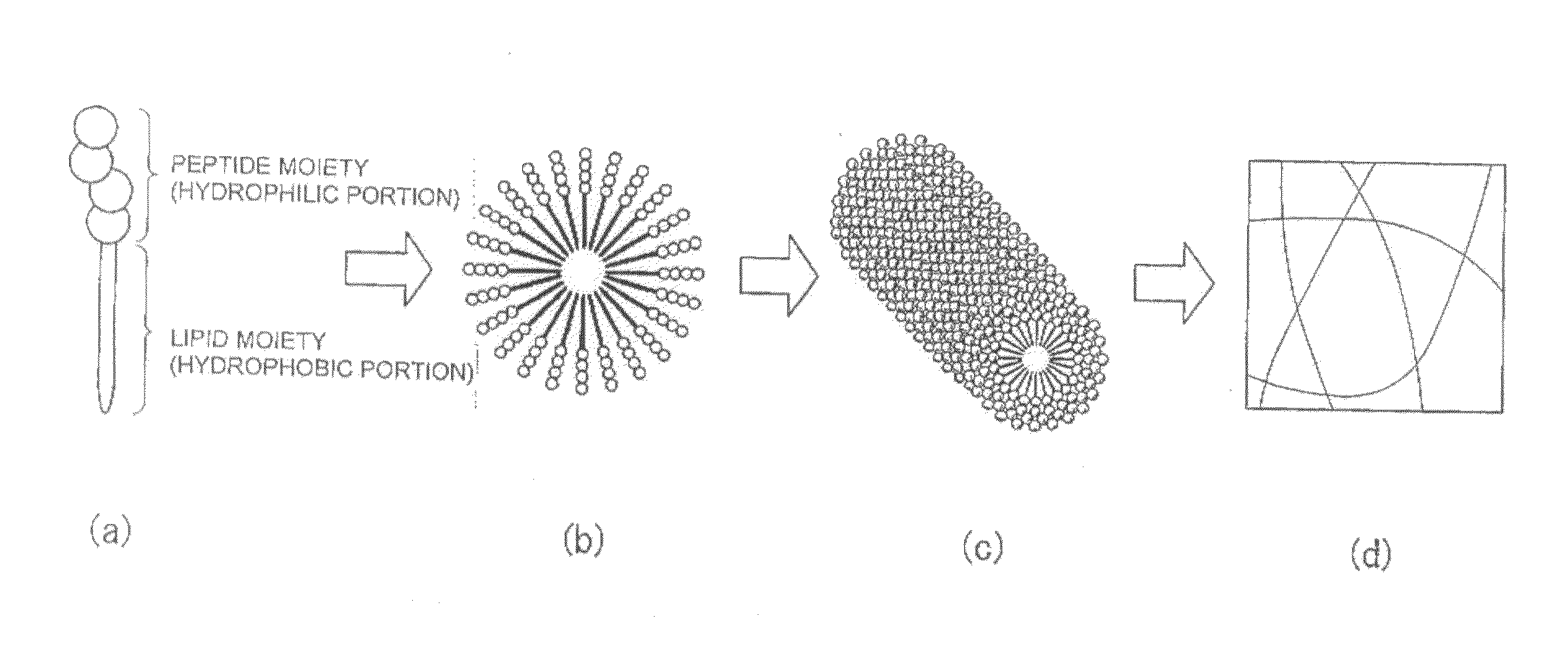

Novel lipid peptide and hydrogel

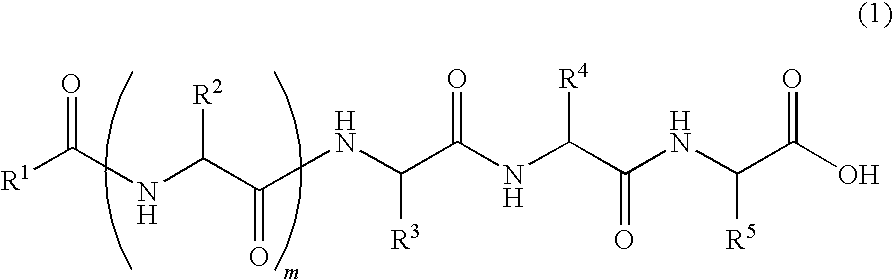

ActiveUS20100291210A1Reduce molecular weightImprove securityPowder deliveryTetrapeptide ingredientsLipid formationHydrogen atom

There is provided a lipid peptide that is capable of forming a hydrogel with an extremely small amount thereof over a liquid property range from acidic to alkaline, and a hydrogel having high environmental suitability, biocompatibility and biodegradability. A lipid peptide represented by Formula (1):(where R1 represents an aliphatic group having 9 to 23 carbon atoms; R2, R3, R4 and R5 independently represent a hydrogen atom, an alkyl group having 1 to 7 carbon atom(s) which optionally has a branched chain having 1 to 3 carbon atom(s), a phenylmethyl group, a phenylethyl group or a —(CH2)—X group, and at least one of R2, R3, R4 and R5 represents a —(CH2)n—X group;n represents the number of 1 to 4; X represents an amino group, a guanidine group, a —CONH2 group or a 5-membered ring, a 6-membered ring or a fused heterocyclic ring composed of a 5-membered ring and a 6-membered ring which optionally have 1 to 3 nitrogen atom(s); and in represents 1 or 2), and a hydrogel comprising the lipid peptide.

Owner:NISSAN CHEM IND LTD +1

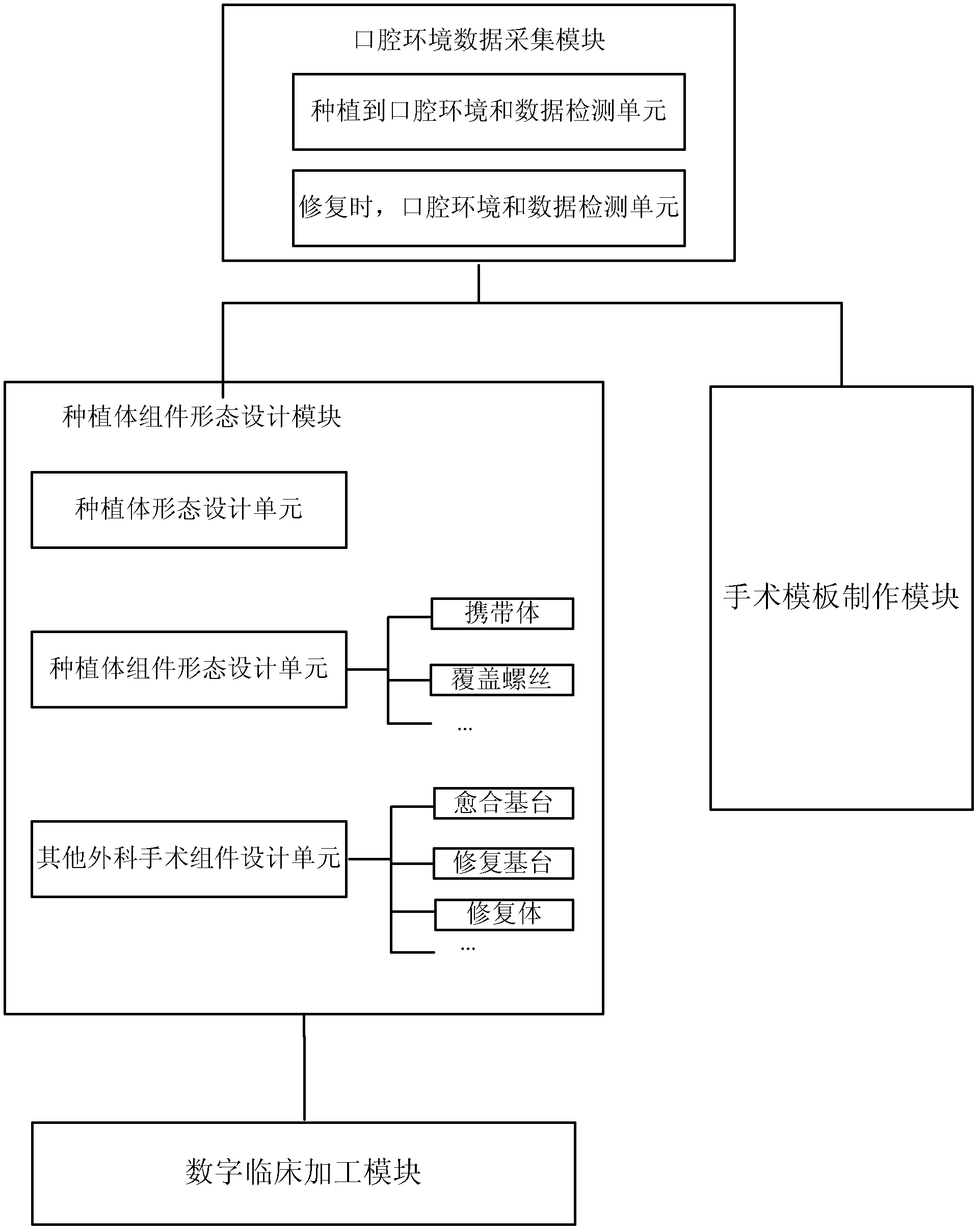

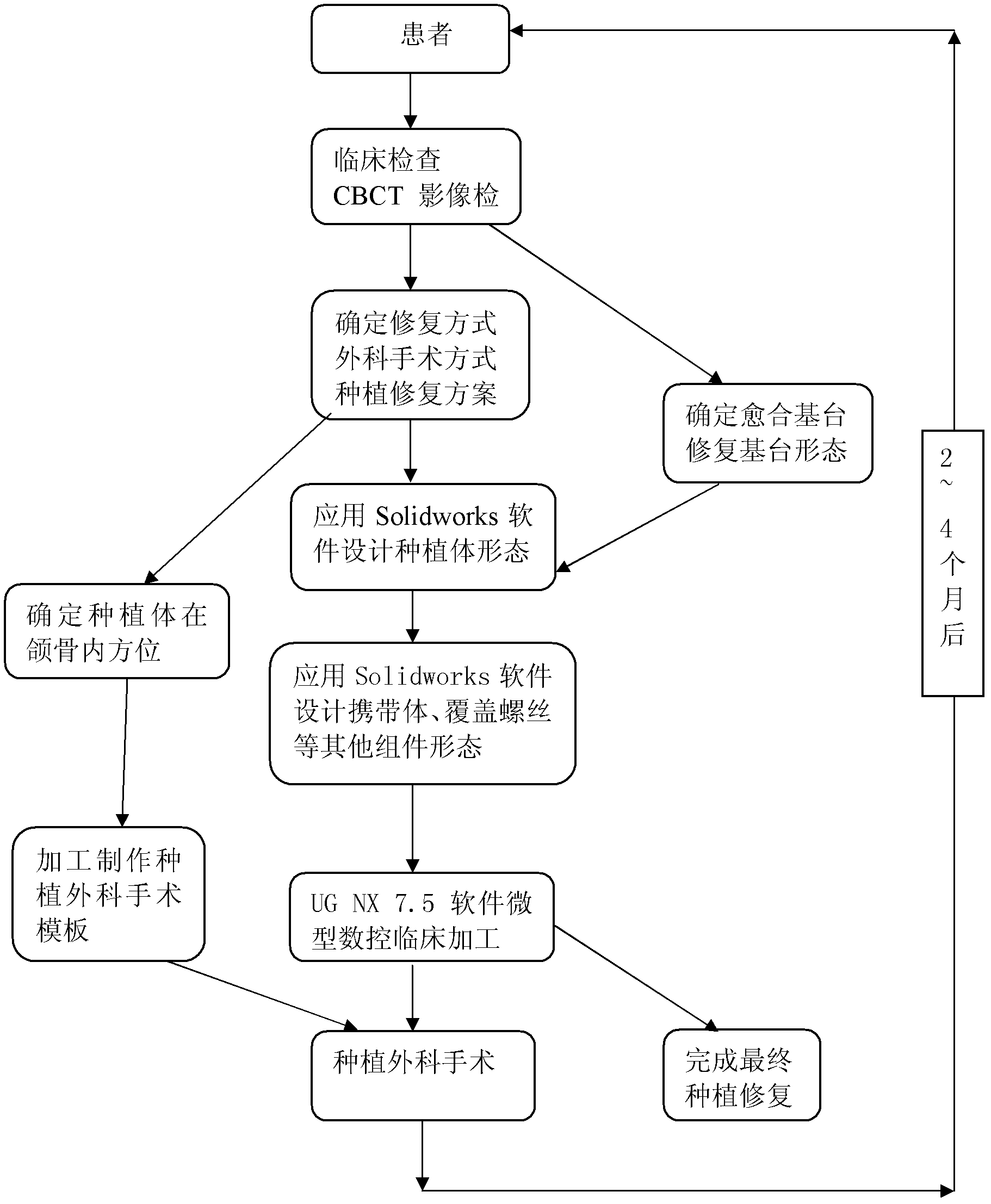

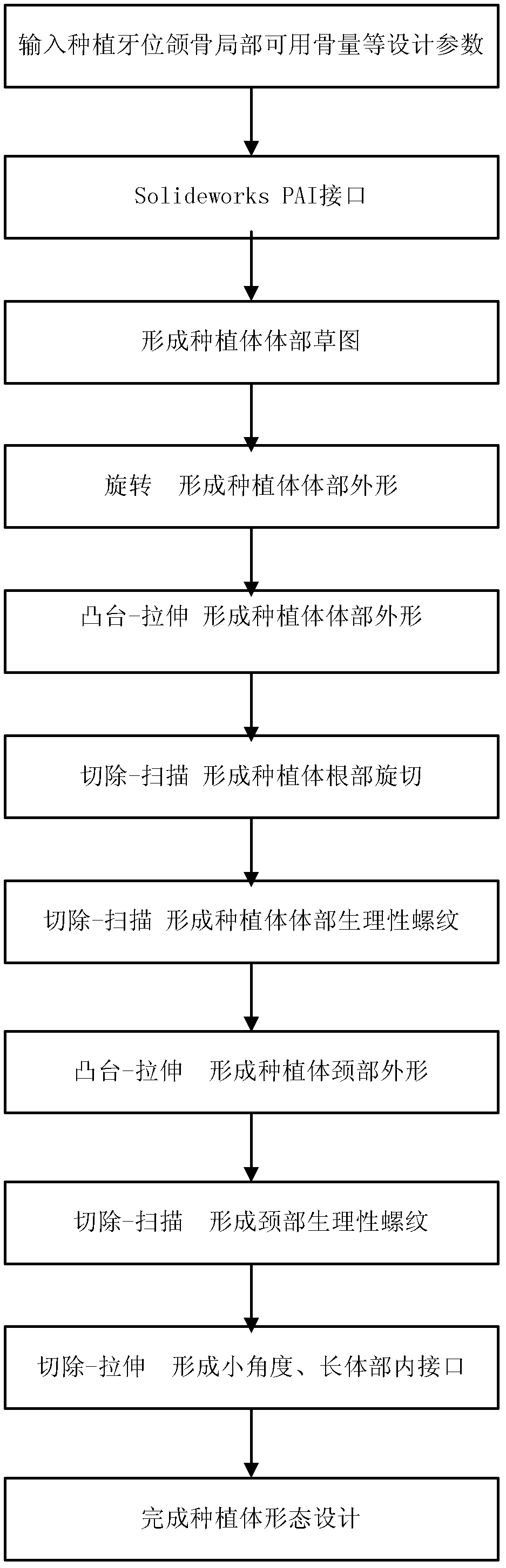

Digital processing system of personalized components in dental implantation and processing method thereof

The invention provides a digital processing system of personalized components in dental implantation and a processing method of the personalized components in dental implantation, belongs to the biomedical engineering field, and specificly relates to a personalized CAD / CAM (computer-aided design / computer-aided manufacturing) digital processing system of a dental implant, a carrier, a cover screw, a healing abutment, a restoration abutment and supporting tools. The system is characterized by comprising an oral environment data acquiring module, an implant component form design module, a digital clinical processing module and a surgical template manufacturing module. According to the digital processing system provided by the invention, the implant can be customized according to partial jaw condition of a patient so that the form of the implant can furthest meet clinical needs, compatibility of the implant to the patient as well as the success rate of the implant restoration can be improved, Meanwhile, the personalized digital processing system performs one-to-one design and processing, so that denture-implanting restoration hospitals do not need to store various implant systems and realize zero inventory, and the expenses and the waste of the product are reduced. The personalized components digital processing system provided by the invention is benefitial for popularizing and promoting denture implantation technology.

Owner:淄博昌国口腔种植技术研究院

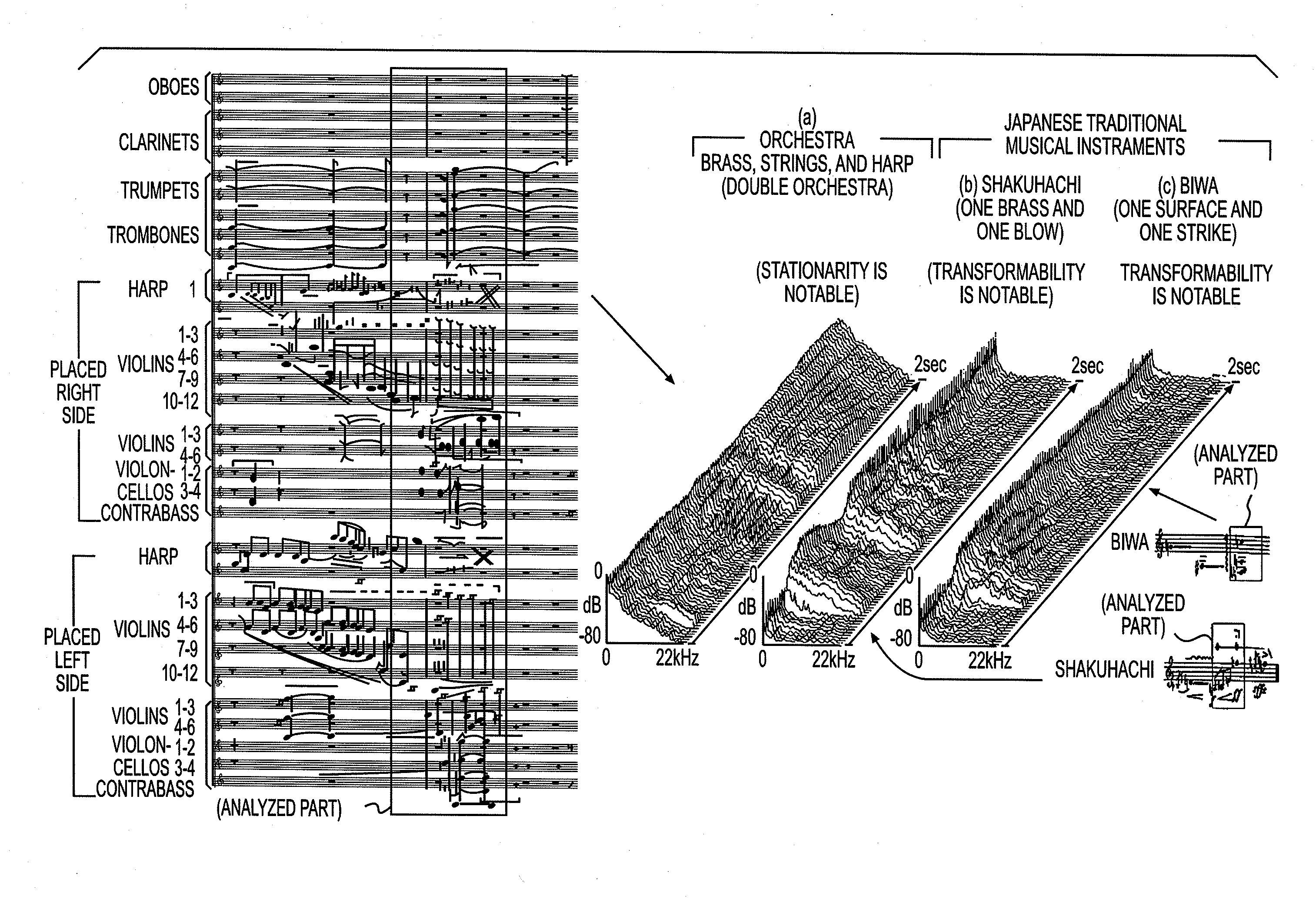

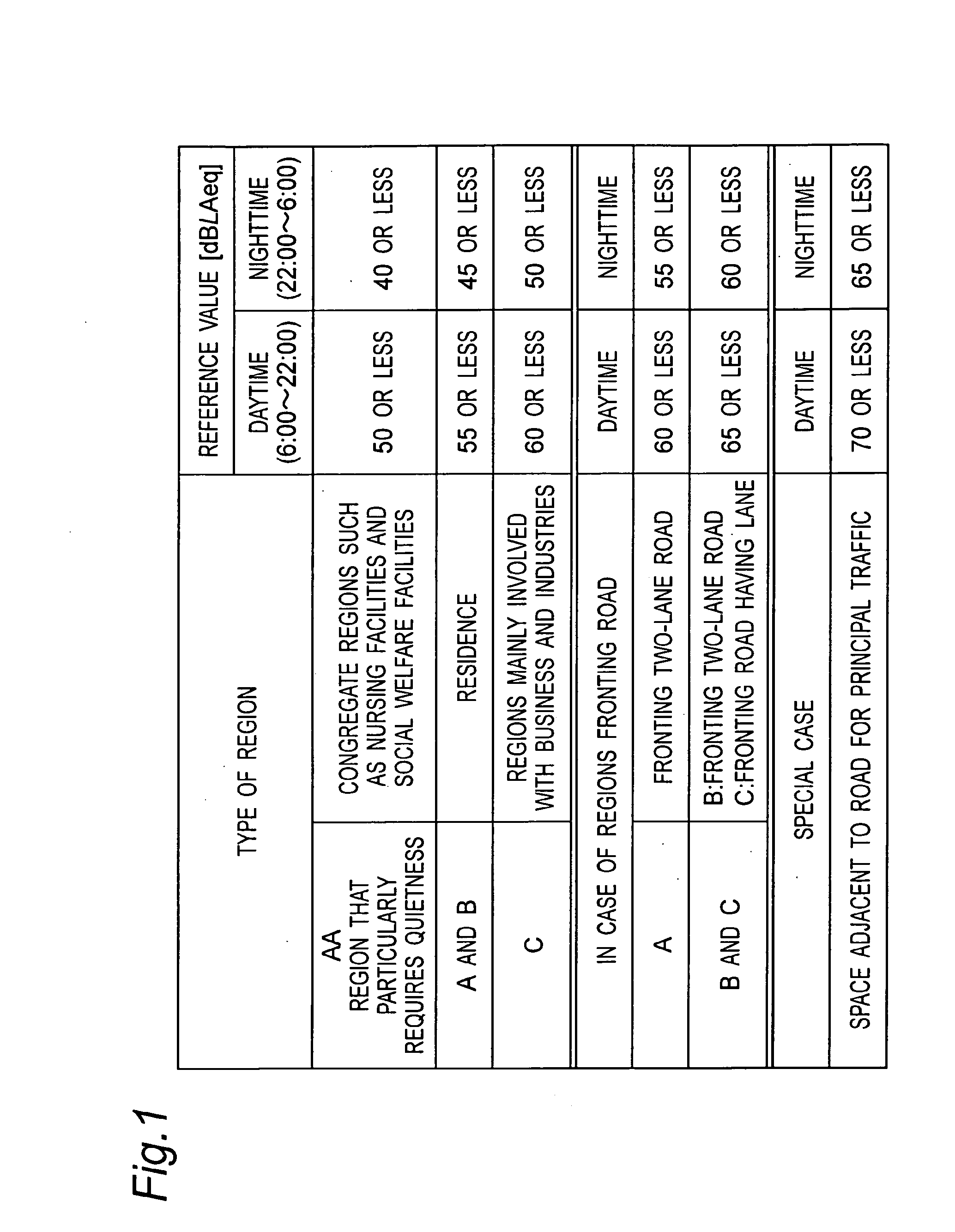

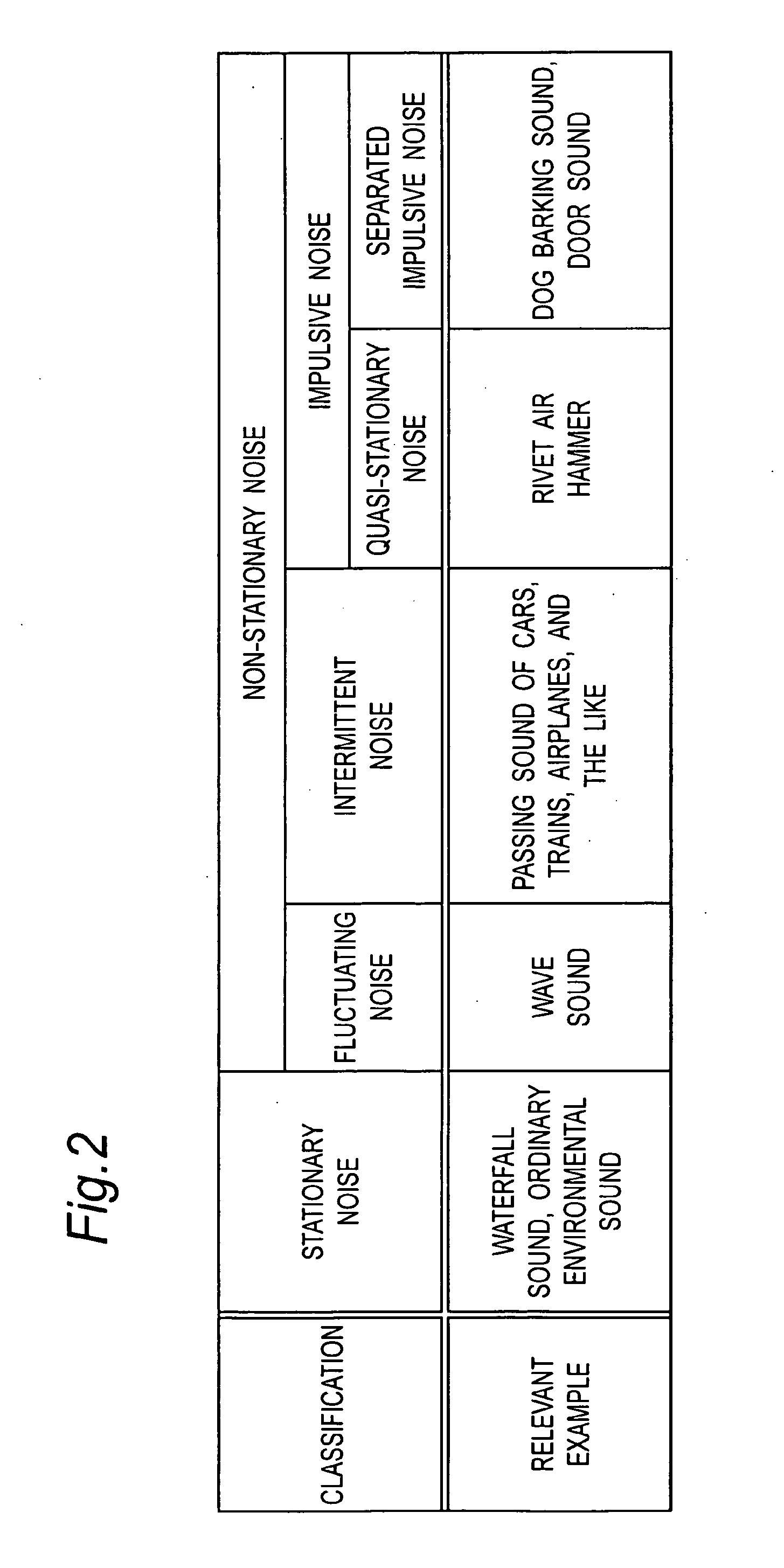

Method and apparatus for environmental setting and information for environmental setting

ActiveUS20100204540A1Eliminate human stressEnhance mental comfortElectrophonic musical instrumentsIsolation chambersDiseaseEnvironmental Setting

A space is set substantially in a tropical rain forest type environment to activate a human's essential brain region and realize an environment suitable for the human's brain by arranging a device for setting the tropical rain forest type environment based on characteristics of activating human's essential brain region responsive to tropical rain forest type environment information, in a space such as an urban space, a housing space or other living space. The tropical rain forest type environmental information has higher density and higher complexity than those of urban space type environmental information, and includes at least one of auditory information, visual information, and super perceptual information of aerial vibration. The tropical rain forest type environmental information is comfortable for the human with no excessive stress, and is environmental information for effecting prevention and treatment of diseases due to stress by realizing the environment comfortable for the human's brain.

Owner:ACTION RES

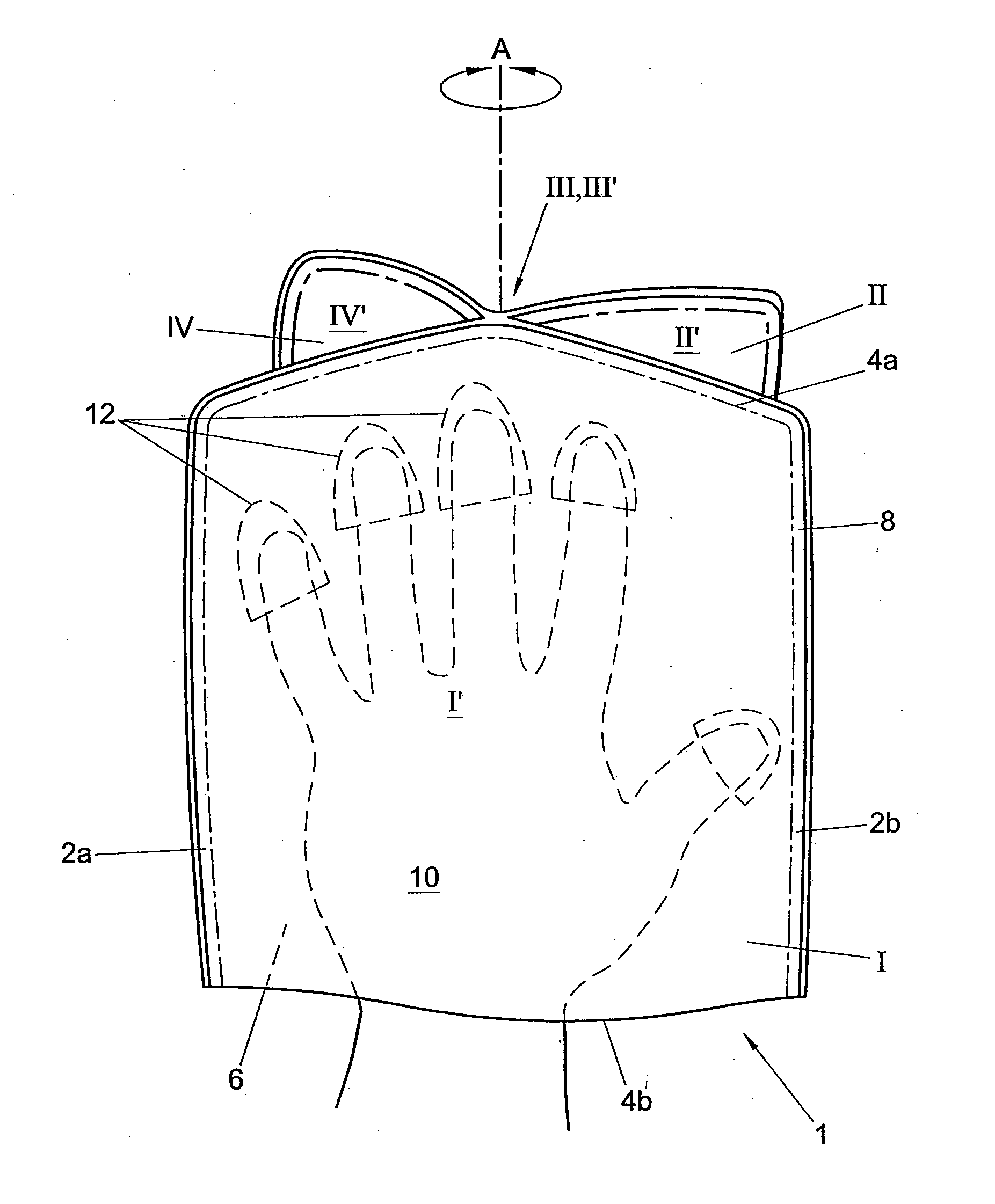

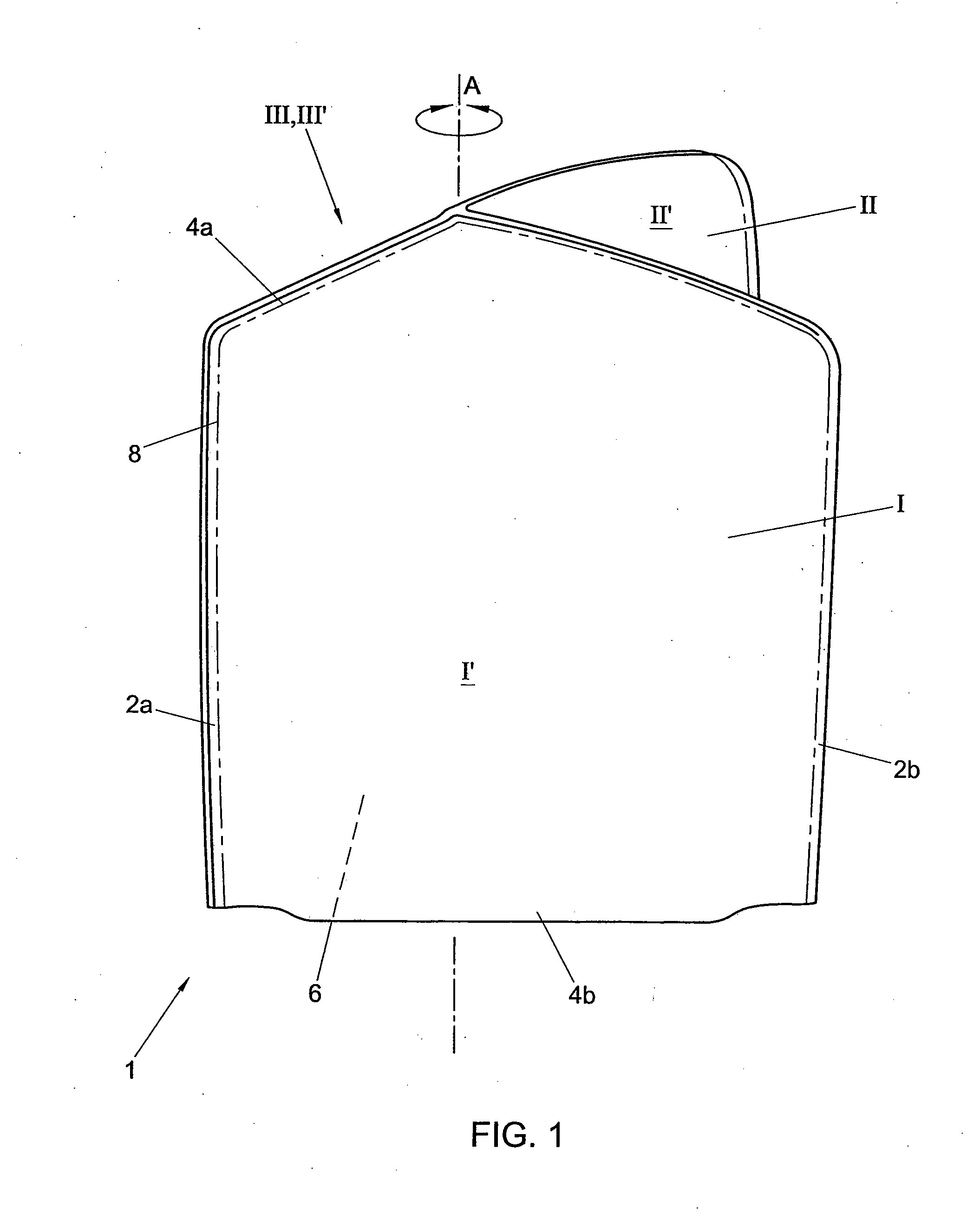

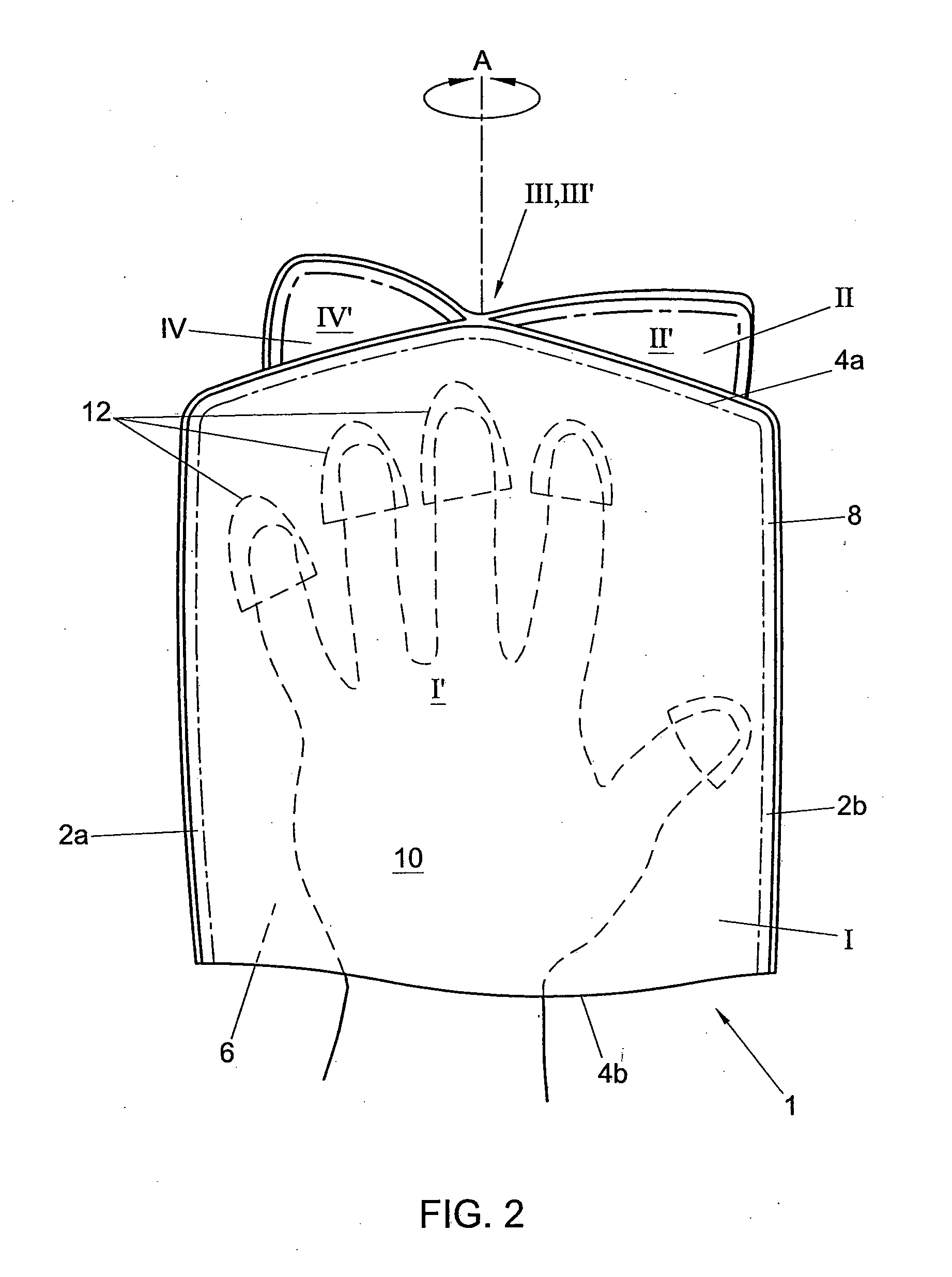

Multi-sided washcloth

InactiveUS20100192318A1Improve efficiencyConvenience to workBoard cleaning devicesCarpet cleanersEngineeringBiomedical engineering

Owner:SCA HYGIENE PRODUCTS ASSEN BV

Light diffusing plate, optical element, and liquid-crystal display

InactiveUS6850295B1Easy to produceImprove stabilityStatic indicating devicesDiffusing elementsTransmittanceRefractive index

A light diffusing plate is formed of a birefringent film containing dispersed therein minute regions differing from the birefringent film in birefringent characteristics. The minute regions are formed of a thermoplastic liquid-crystal polymer. The difference in refractive index between the birefringent film and the minute regions in a direction perpendicular to the axis direction in which a linearly polarized light has a maximum transmittance, Δn1, is 0.03 or larger and that in said axis direction, Δn2, is not larger than 80% of the Δn1. An optical element is formed of a multilayer structure of the above light diffusing plate and at least either of a polarizing plate and a phase plate. A liquid-crystal display is formed of a liquid-crystal cell and, disposed on one or each side thereof, either the above light diffusing plate or the above optical element.

Owner:NITTO DENKO CORP

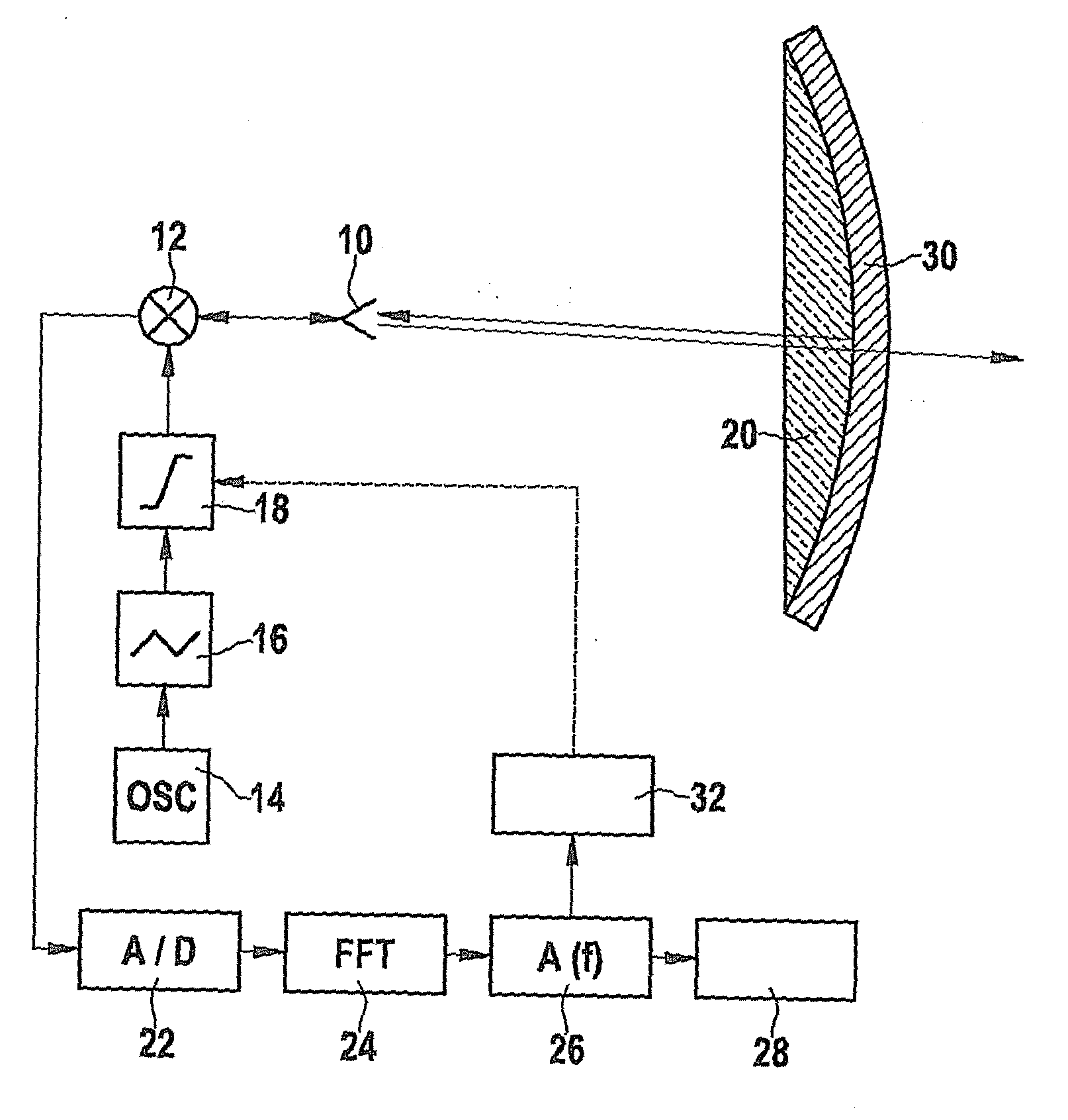

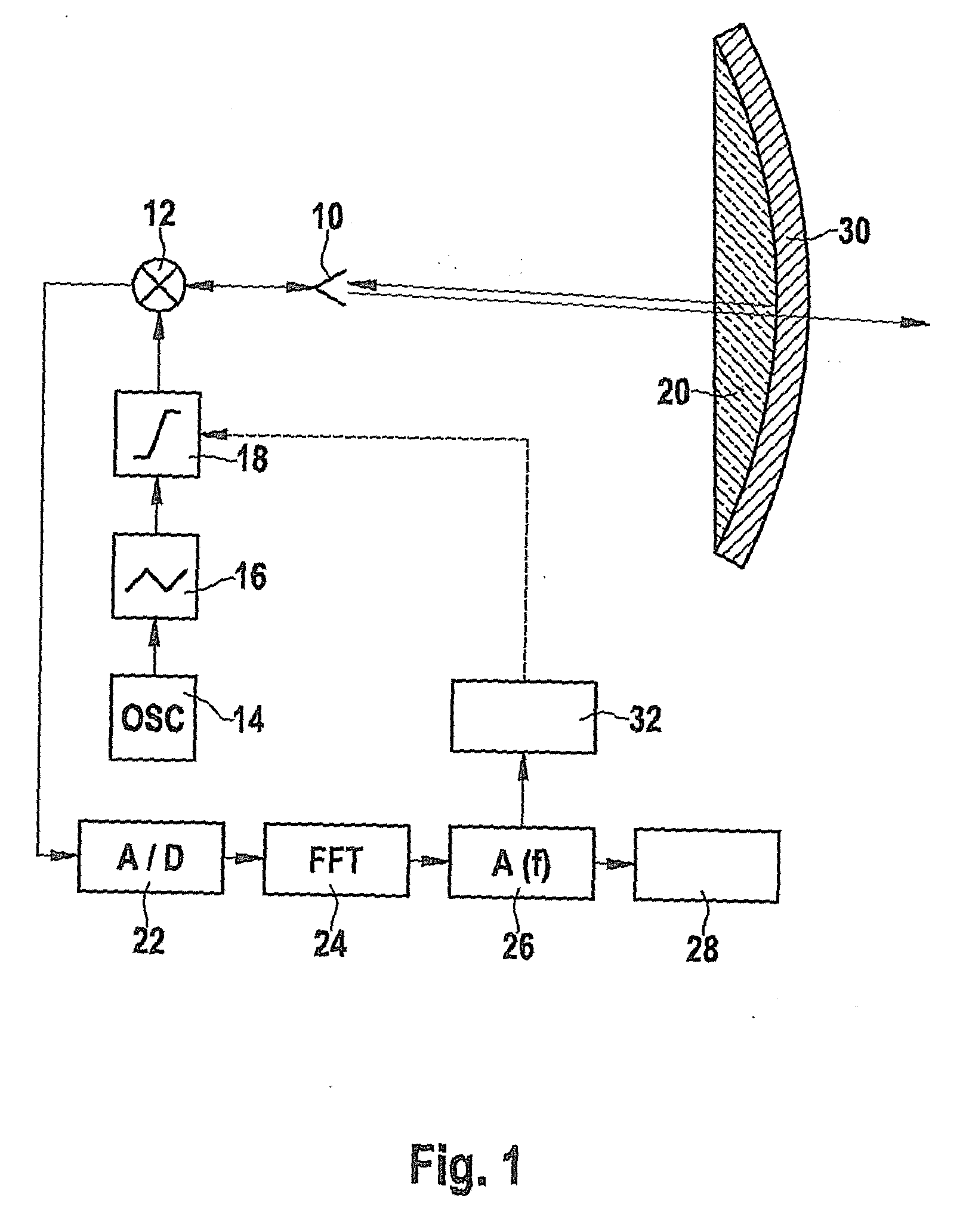

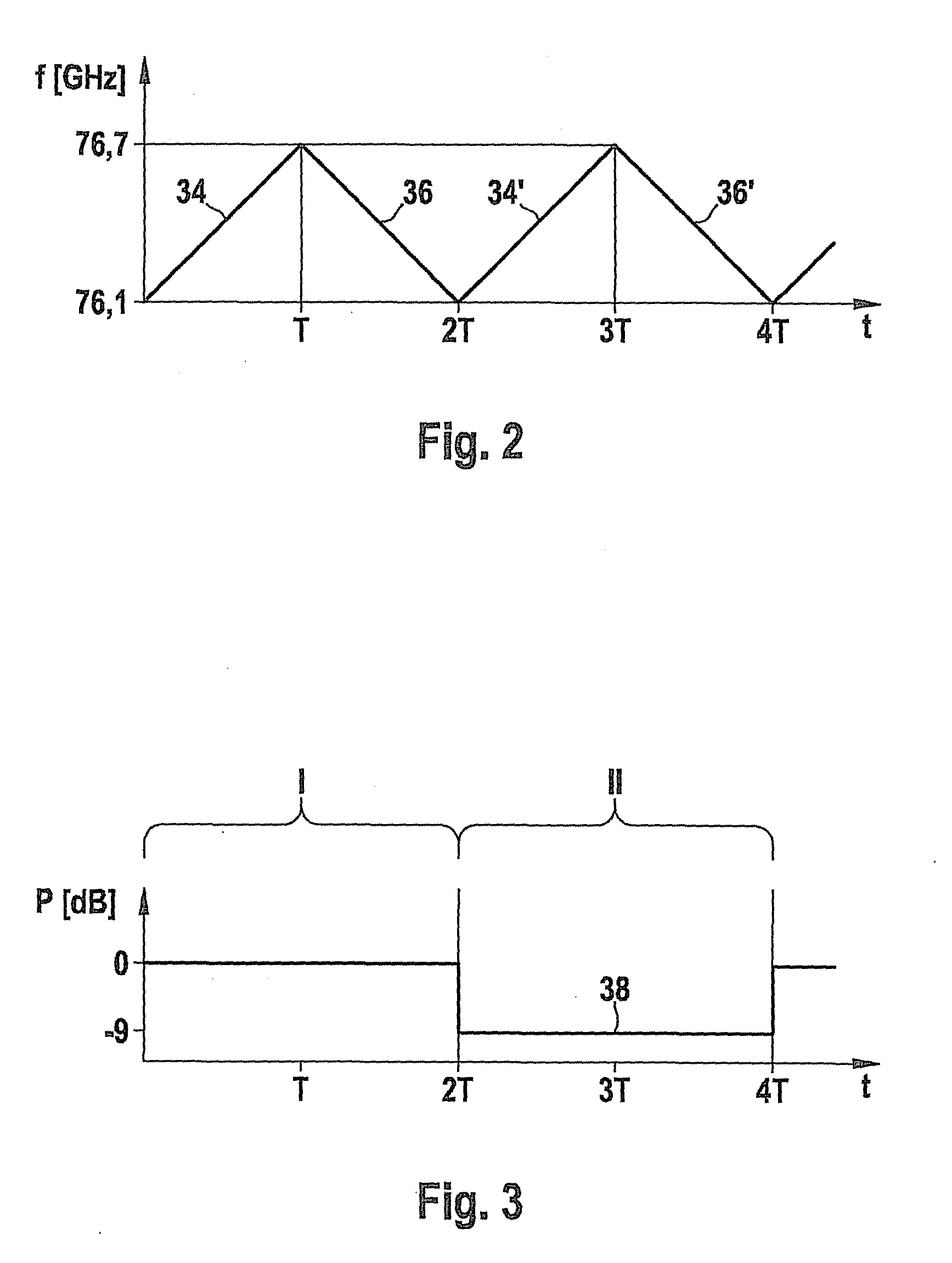

Method for detecting loss of sensitivity of an fmcw radar locating device by diffuse sources of loss

ActiveUS20120032838A1Improve robustnessImprove suitabilityRadio wave reradiation/reflectionRadarVIT signals

A method for the detection of sensitivity losses of an FMCW radar locating device due to diffuse sources of loss, in which the radar locating device emits a transmit signal whose frequency is periodically modulated in successive modulation ramps, and at least one power characteristic of at least one frequency portion of a signal received by the radar locating device is evaluated, wherein the power of the transmit signal is varied cyclically, in each case after the completion of a modulation ramp, and the sensitivity losses are determined on the basis of differences in the power characteristics of signals received during successive modulation ramps having identical modulation.

Owner:ROBERT BOSCH GMBH

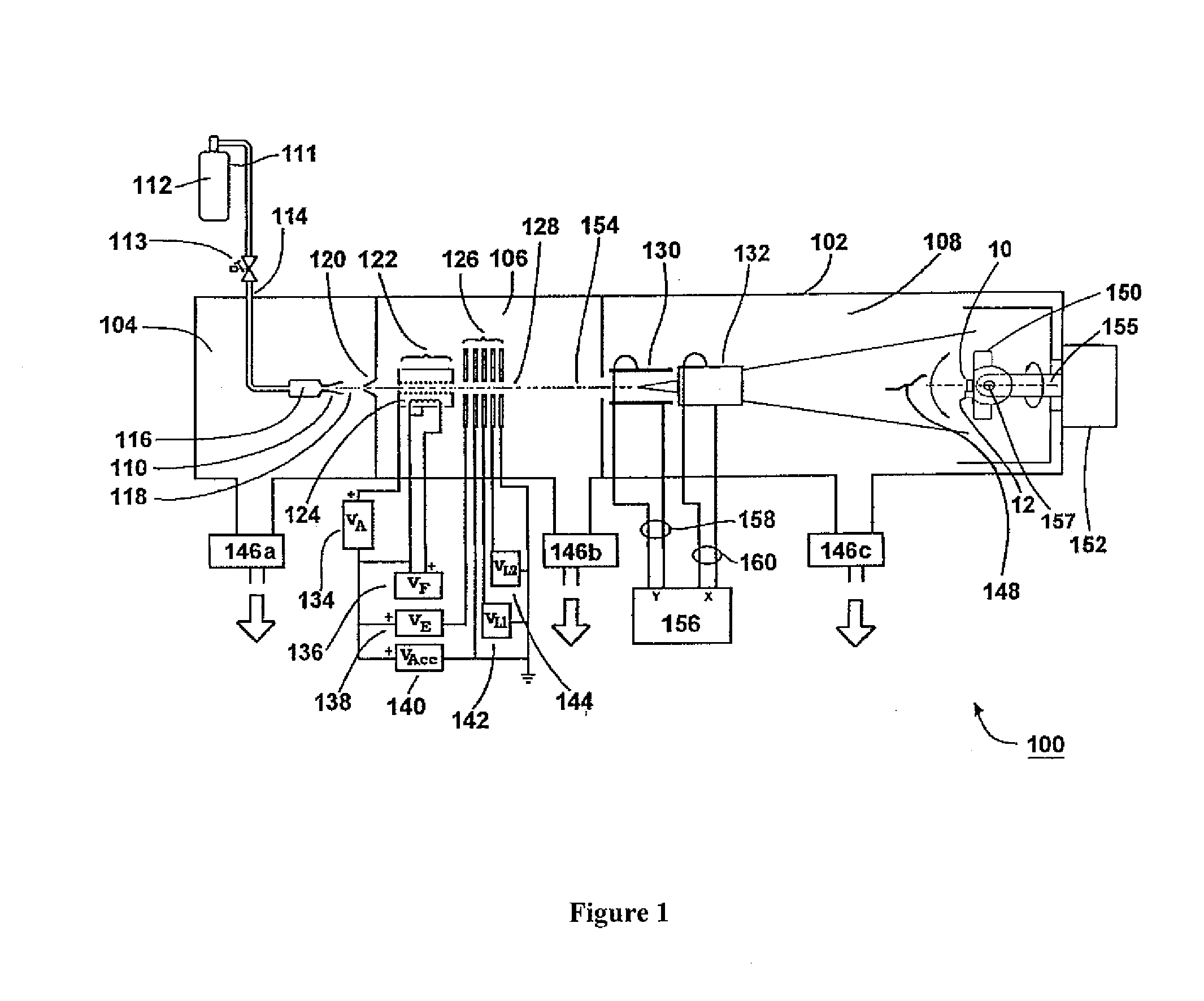

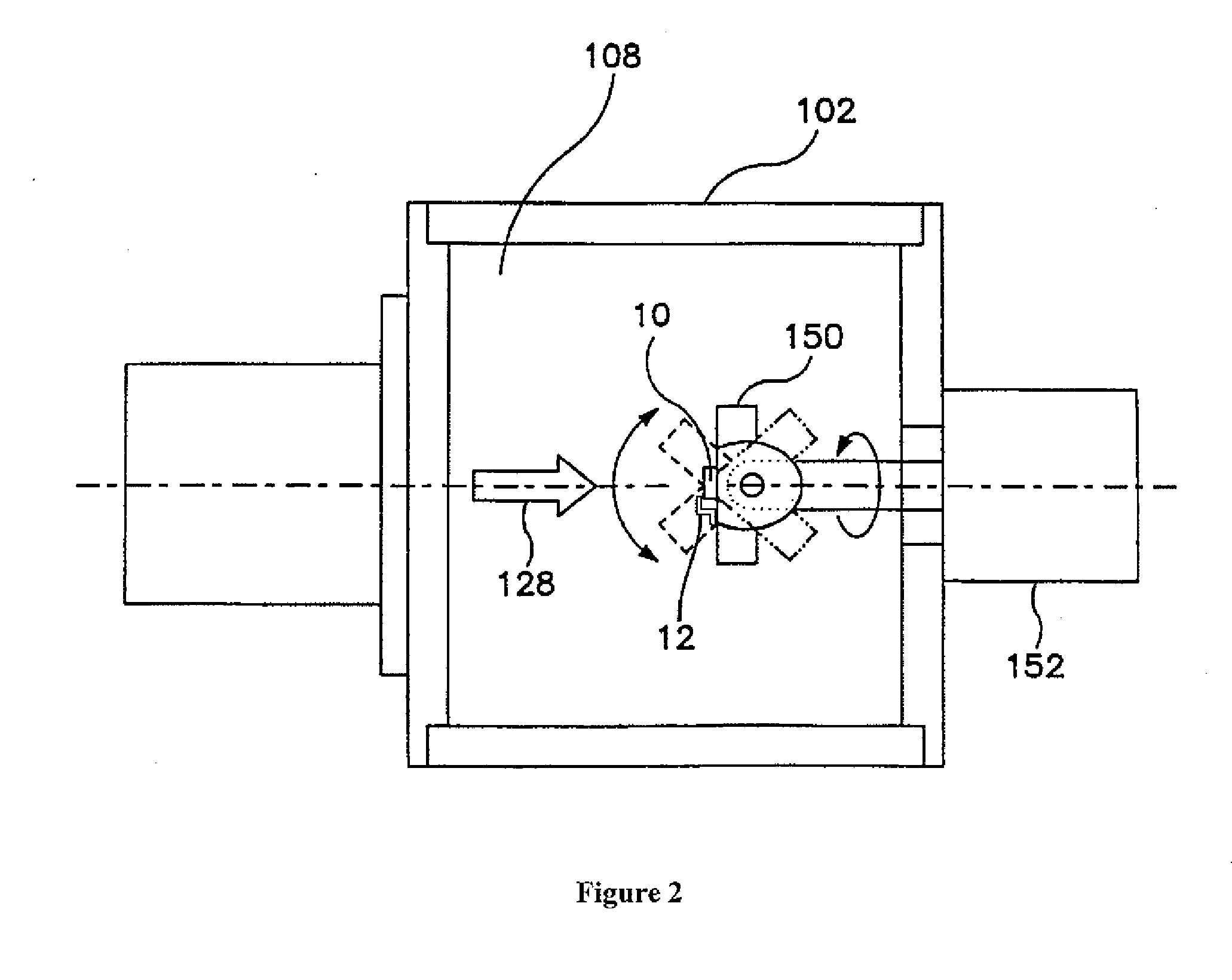

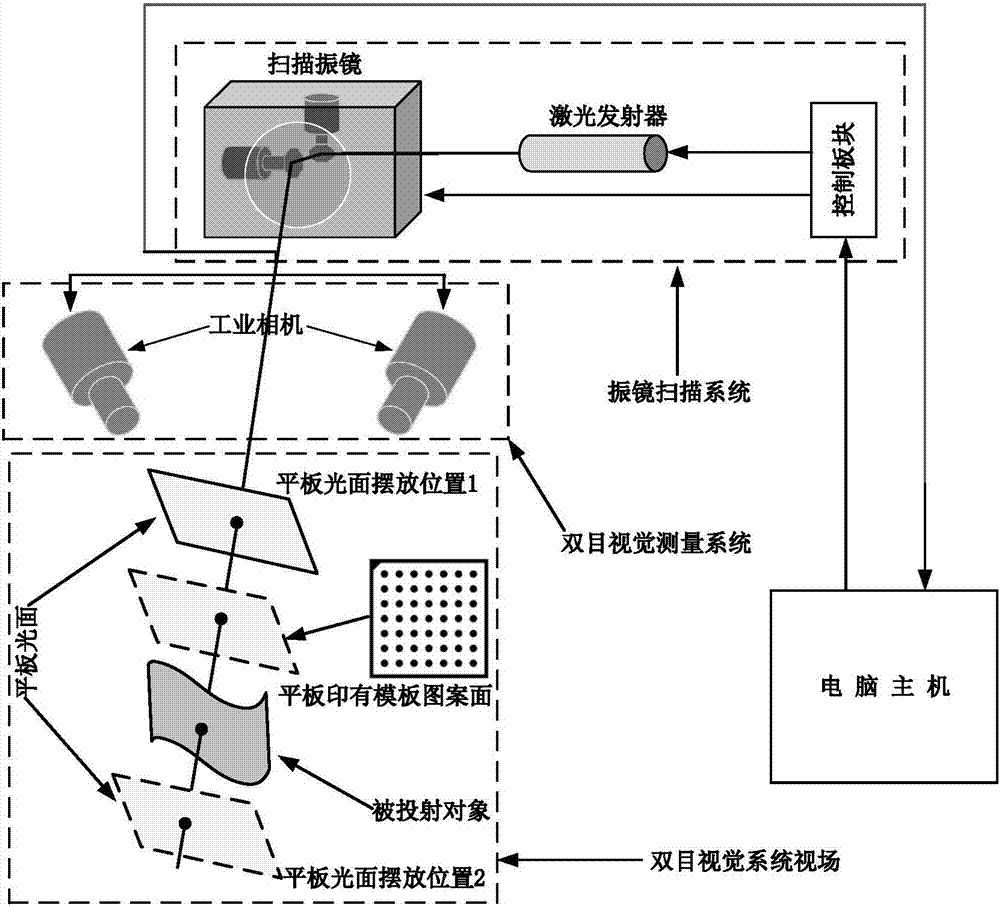

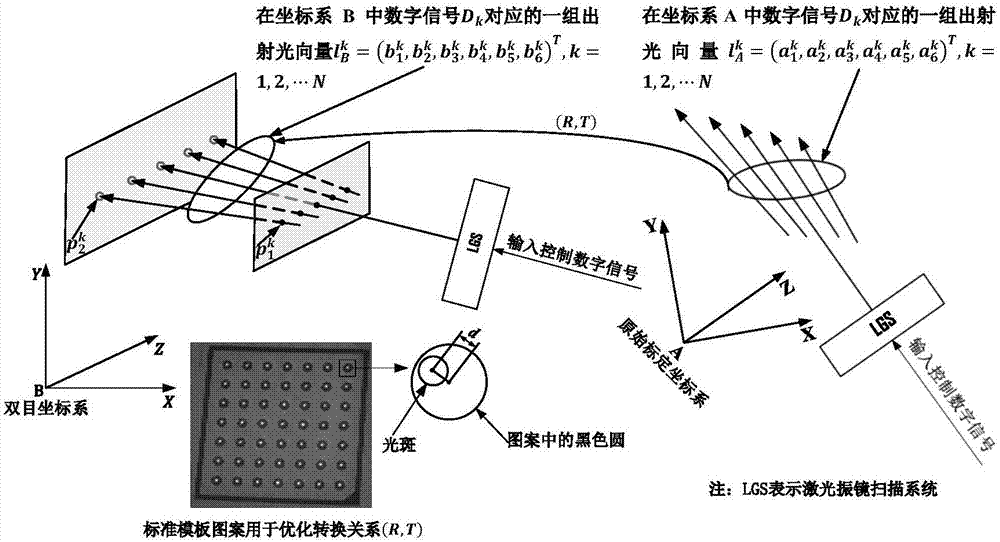

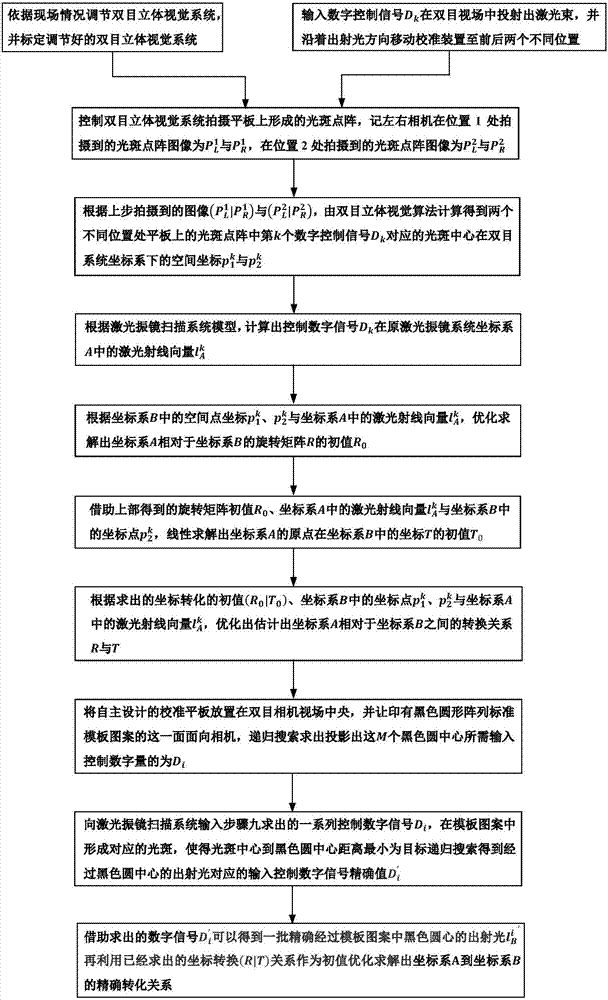

Flexible-layout vision-assisted laser galvanometer scanning system and on-site calibration method thereof

ActiveCN107449374AImprove suitabilityImprove efficiencyImage enhancementImage analysisGalvanometerEngineering

The invention provides a flexible-layout vision-assisted laser galvanometer scanning system and an on-site calibration method thereof. The system comprises a laser galvanometer scanning system, a visual positioning device and a calibration device. The calibration device is a piece of calibration flat plate, wherein one surface of the calibration flat plate is an interval-known black circular array standard template pattern, and the other surface is a smooth plane suitable for laser spot imaging. The calibration method enables the calibration result of the laser galvanometer scanning system to be also suitable to a field binocular system coordinate system through coordinate transformation relation of coordinate systems of the calibration results of the binocular stereo vision system coordinate system and an original galvanometer scanning system, thereby realizing on-site calibration of the laser galvanometer scanning system; the calibration method is simple to operate, short in consumed time, high in calibration precision and high in stability; and the calibration method can greatly improve field use flexibility and operability of the vision-assisted laser galvanometer scanning system.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

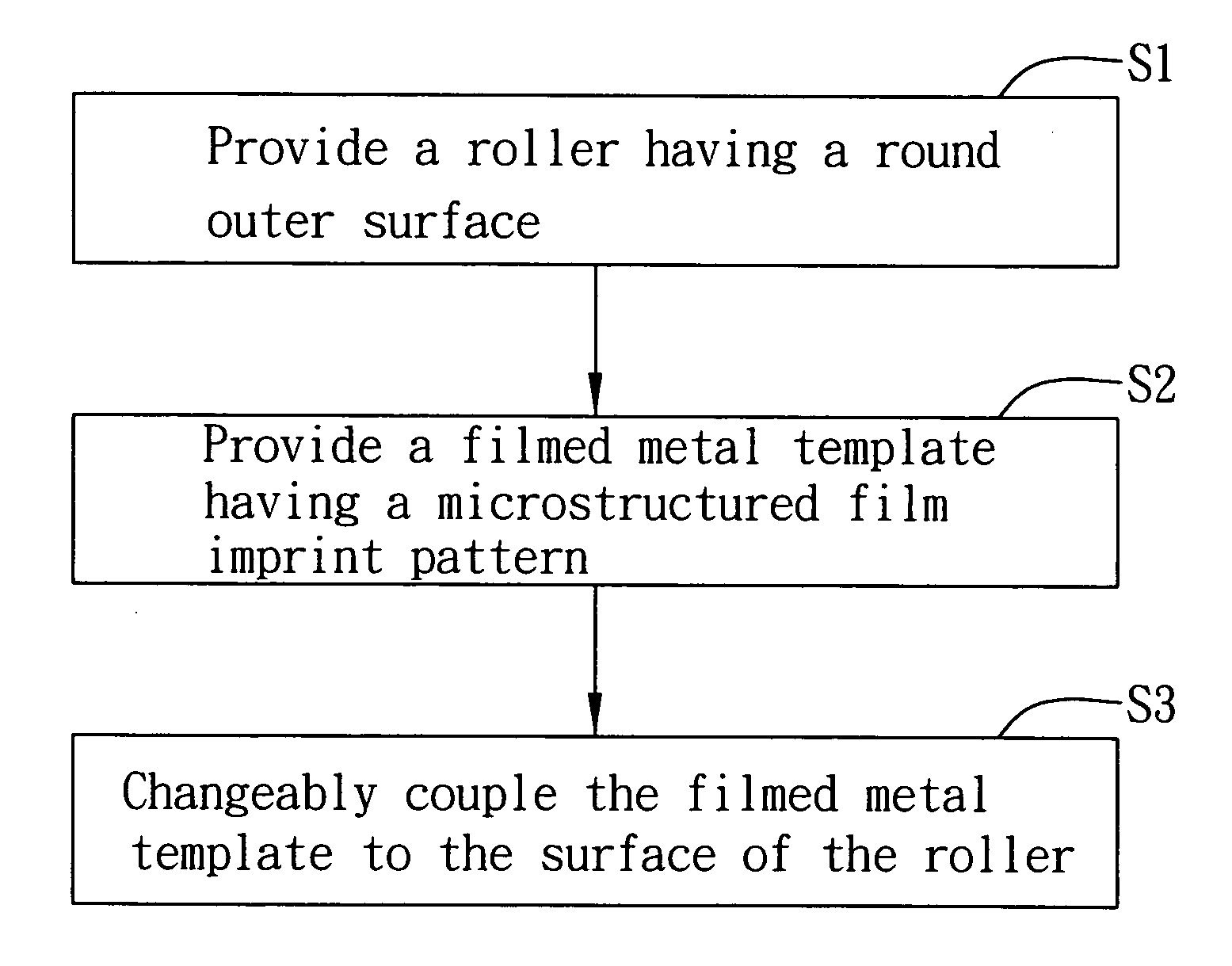

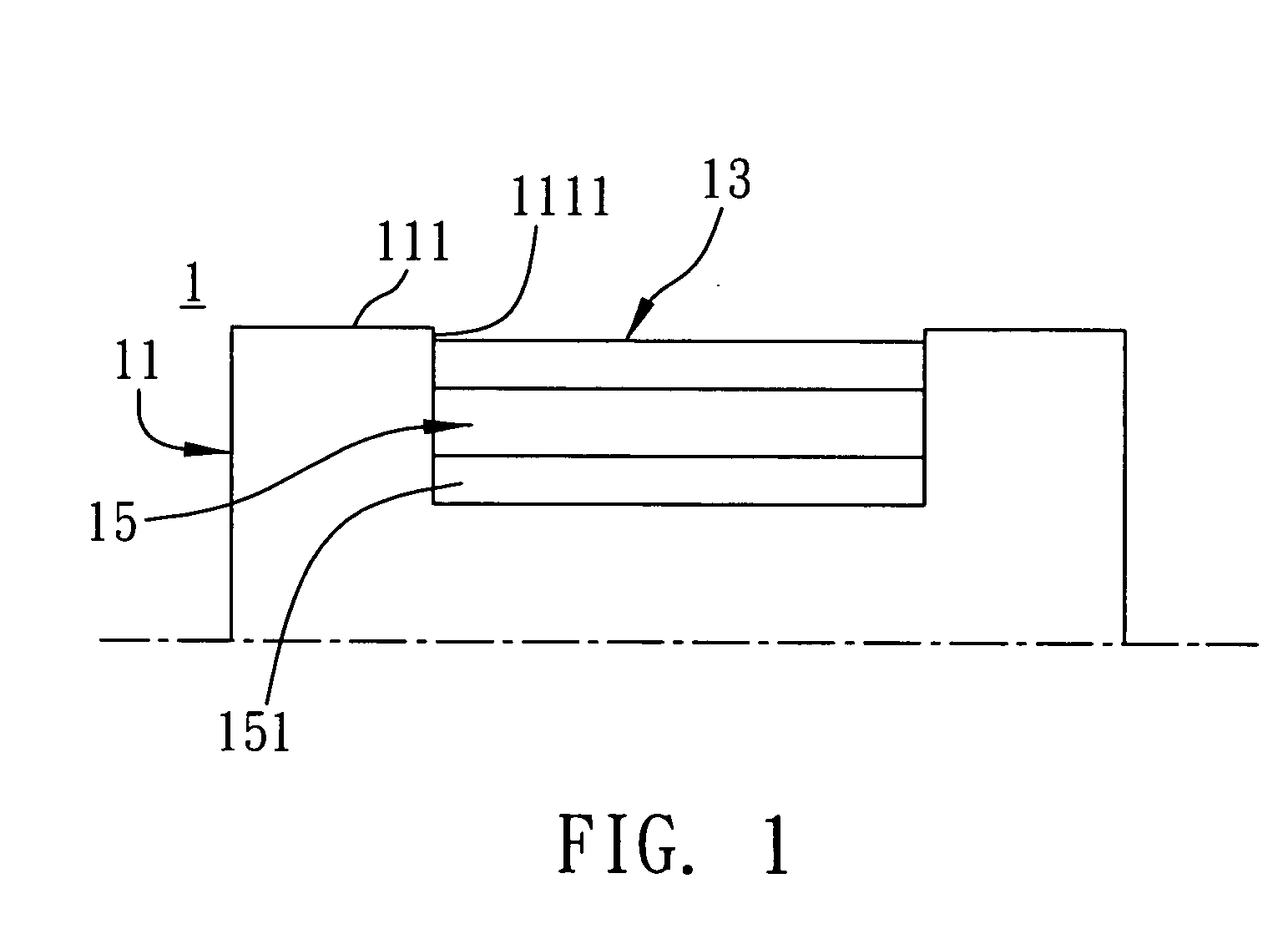

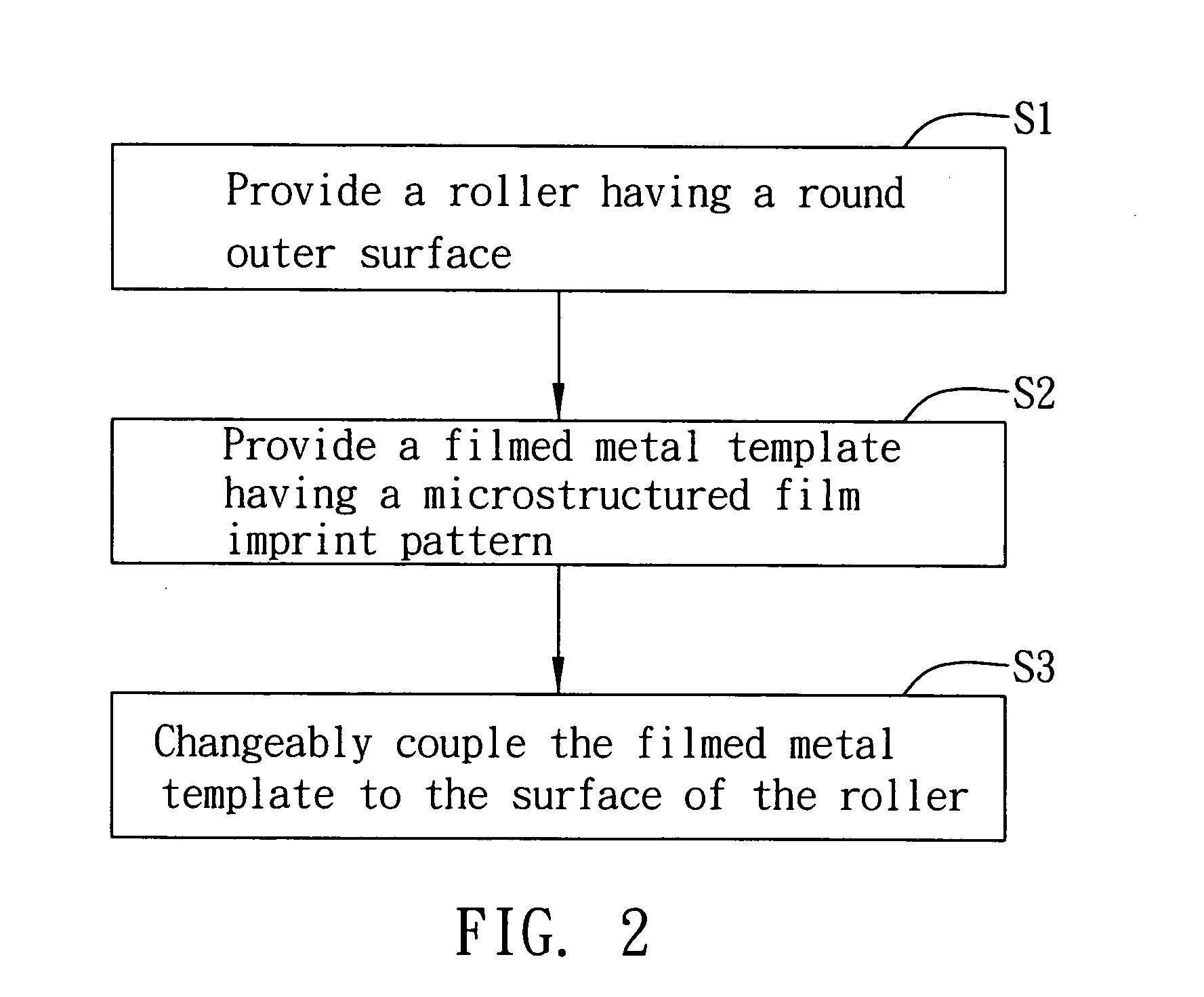

Rolling mold for microstructured film imprinting

InactiveUS20070271791A1High hardnessSolution to short lifeNanoinformaticsMetal-working apparatusMaterials science

A rolling mold for microstructured film imprinting includes a roller and a filmed metal template. The roller has a round outer surface. The filmed metal template is disposed with a microstructured film imprint pattern and changeably coupled to the roller by magnetic force or vacuum suction. Rolling of the roller allows the microstructured film imprint pattern to form a microstructured film, thus solving the drawbacks of the prior art.

Owner:IND TECH RES INST

Biological preparation containing plant growth promoting bacteria, as well as preparation and use thereof

InactiveCN101497542APromote growthImprove stress resistanceOrganic fertilisersGrowth plantBiotechnology

The invention provides a plant growth-promoting bacterium, a biological agent containing the plant growth-promoting bacterium and a method for preparing the bacterium and the biological agent. The biological agent contains a composite carrier material and a bacterial liquid, wherein the composite carrier material comprises an organic matter, humic acid, a decomposed organic matter, a complex displacer and an embedding material; the bacterial liquid is a solution which contains the plant growth-promoting bacterium and comprises UW3 and UW4 with a proportion of bacteria number being 1-2:2-1; and the composite carrier material and the bacterial liquid lead the bacteria number of the plant growth-promoting bacterium to reach at least 0.1 billion / per gram composite carrier material so as to obtain the biological agent. The biological agent used in agricultural production can promote plant growth, improve yield, and improve manurial effect and anti-adversity capability of the plant.

Owner:黄晓东

Chicken feed additive

InactiveCN105394430AImprove disease resistanceImprove meat qualityFood processingAnimal feeding stuffBiotechnologyBroiler chick

The invention provides a chicken feed additive free of antibiotics and hormones. By utilizing pure natural Chinese herbal medicine plants, broiler chickens can resist diseases and be kept healthy. Besides, the natural sour, sweet, bitter and hot tastes of these plant product additives cater to feeding hobbies of the broiler chickens, and the adaptability and utilization rate of feed can be improved. The chicken feed additive comprises, by weight parts, 1800-2500 parts of tangerine peel, 1200-2000 parts of herba houttuyniae, 1500-2000 parts of herba andrographitis, 1500-2000 parts of folium isatidis, 2000-2500 parts of folium artemisiae argyi, 2000-2500 parts of pine needle, 1000-1500 parts of radix isatidis, 1000-1500 parts of radix sophorae flavescentis, 1000-2000 parts of purslane, 800-1000 parts of dandelion, 500-800 parts of astragalus, 500-1000 parts of radix glycyrrhizae, 500-1000 parts of folium perillae, 500-1000 parts of garlic, 500-800 parts of cinnamon, 250-500 parts of clove, 300-400 parts of ginger, 250-300 parts of anise and 200-250 parts of pepper.

Owner:罗熙凤

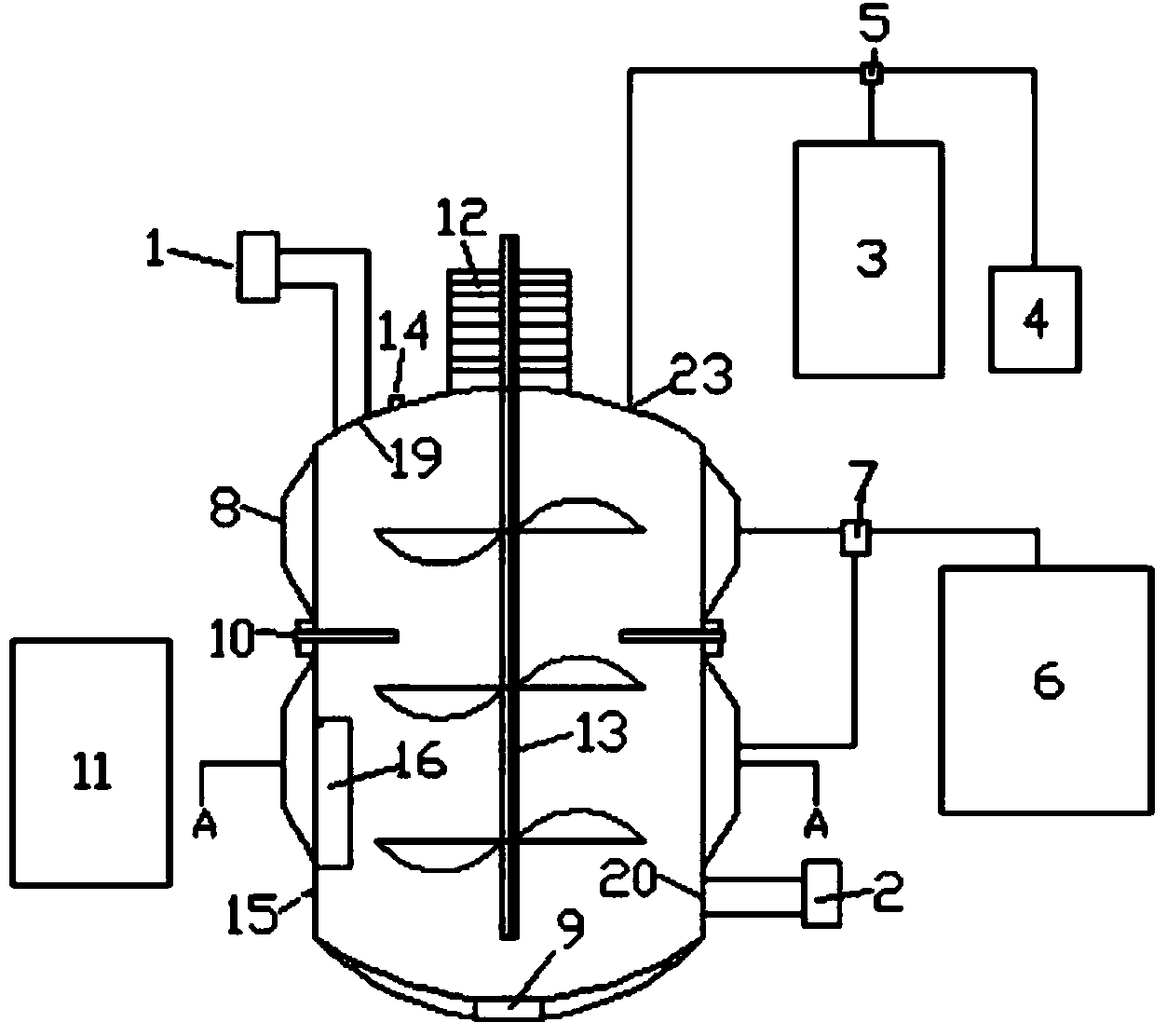

Acid producing fermentation tank for treating kitchen wastes and producing carbon source

InactiveCN103834560AImprove suitabilityLow costBioreactor/fermenter combinationsBiological substance pretreatmentsAgricultural engineeringCarbon source

The invention discloses an acid producing fermentation tank for treating kitchen wastes and producing a carbon source. A feed port and a vent hole are formed in the upper part of a fermentation tank main body; a temperature probe, a pH probe, a DO probe, a sampling port, a sight glass port and a sight glass lamp are arranged on the lateral surface of the fermentation tank; a rotating main shaft is arranged on the axis of the fermentation tank main body, agitating vanes are arranged on the main shaft, the top of the rotating main shaft is connected with a speed change motor, the feed port is connected with a feed pipeline, a discharge port is formed in the lower part of the lateral surface of the tank body and connected with a discharge pipeline, and a pH adjusting port is formed in the top of the acid producing fermentation tank and connected with an acid tank and an alkali tank through a pH adjusting valve. The acid producing fermentation tank has the functions of temperature control, pH control, agitating speed control, ultrasonic enhanced treatment and the like, can realize automatic feed and discharge of the kitchen wastes, and has a pH value pre-adjusting function; by adopting the acid producing fermentation tank, the pH value fluctuation of fermentation liquid is smaller than 0.1.

Owner:TSINGHUA UNIV

Novel multifunctional grabbing manipulator

The invention provides a novel multifunctional grabbing manipulator and belongs to the field of manipulators. The novel multifunctional grabbing manipulator comprises a main frame and a grabbing mechanism, the grabbing mechanism comprises a grabbing cylinder, a transmission component and grabbing fingers, and the grabbing cylinder is fixed to the main frame and is connected with the grabbing fingers through the transmission component; the transmission component comprises a left rack, a gear and a right rack, the gear is disposed between the left rack and the right rack, the gear meshes with the left rack and the right rack, and a piston rod end of the grabbing cylinder is fixedly connected with the left rack or the right rack; two groups of the grabbing fingers are provided and are connected with the left rack and the right rack, respectively. The novel multifunctional grabbing manipulator is reliable in structure, may perform grabbing flexibly, may grab high-temperature articles, and is simple to perform and high in automation level.

Owner:NINGXIA MACHINERY RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com