Acid producing fermentation tank for treating kitchen wastes and producing carbon source

A technology for acid-producing fermentation and kitchen waste, applied in specific-purpose bioreactor/fermenter, bioreactor/fermenter combination, biomass post-processing, etc. environment and high cost, to achieve the effect of high suitability, low cost and improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

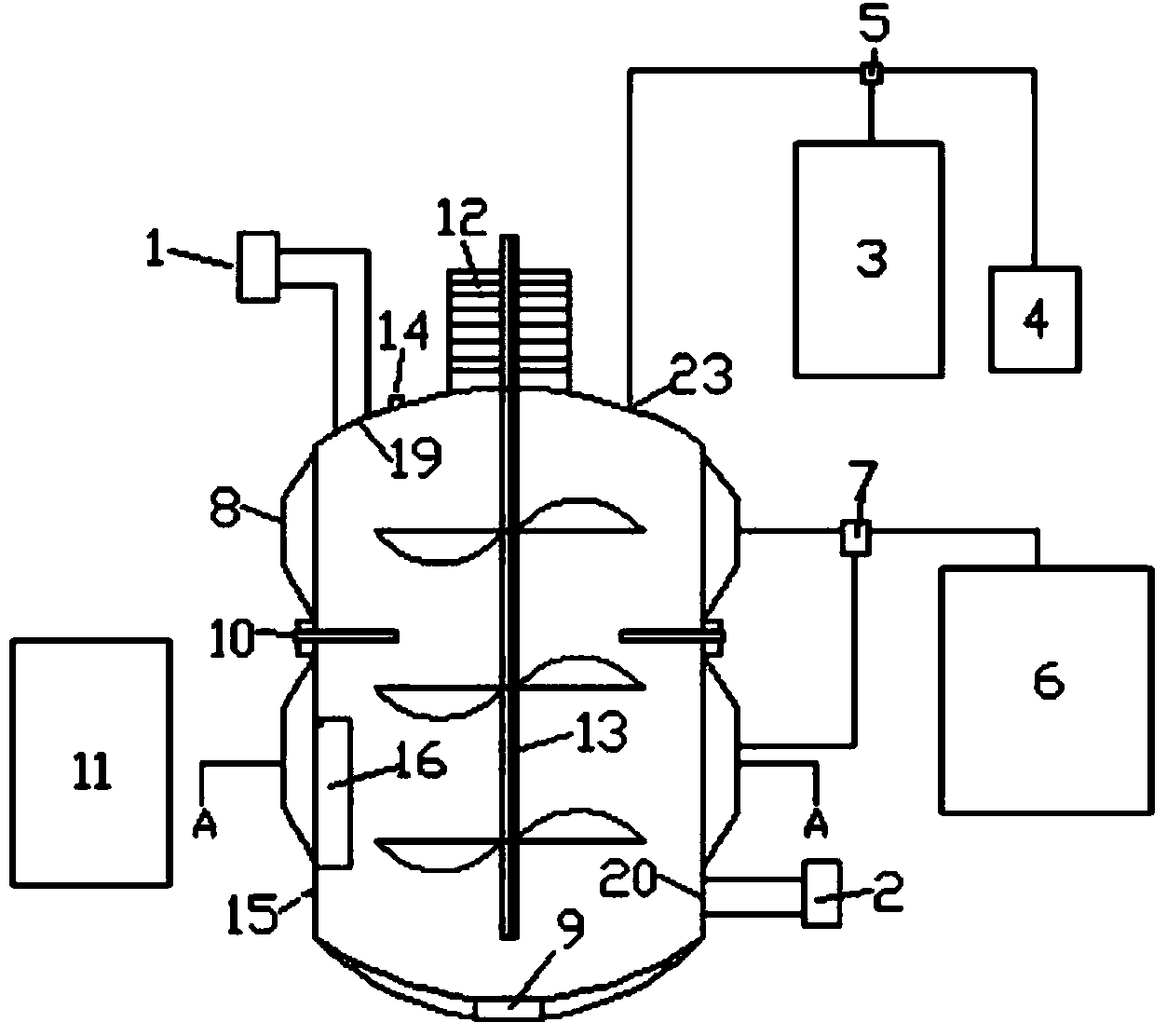

[0025] Embodiment 1 (sequential batch type)

[0026] The solid content rate of raw food waste is 15%, the concentration of organic acid in the supernatant of food waste before fermentation is 625mg / L, the COD content is 71g / L, and the operating condition of the acid-producing fermentation tank is set at 35.0°C. The pH is 6.0, the stirring speed is 125rpm, the ultrasonic pulse generator is turned off, and the acid-producing fermentation tank is operated for 4 days. The concentration reached 34g / L, and ethanol reached 4g / L.

Embodiment 2

[0027] Embodiment two (sequencing batch type)

[0028] The solid content rate of raw food waste is 15%, the concentration of organic acid in the supernatant of food waste before fermentation is 665mg / L, the COD content is 74g / L, and the operating condition of the acid-producing fermentation tank is set at 35.0°C. The pH is 6.0, the stirring speed is 125rpm, the ultrasonic pulse generator generates 20kHz ultrasonic waves, and the pulse is once every 5min. The acid-producing fermentation tank is operated for 4 days. The concentration of organic acid in the garbage supernatant reached 41g / L, and the concentration of ethanol reached 6g / L.

Embodiment 3

[0029] Embodiment three (continuous)

[0030] The solid content rate of the raw food waste is 15%, the organic acid concentration in the supernatant of the food waste before fermentation is 671mg / L, and the COD content is 73g / L. The acid-producing fermentation tank is set to operate at a temperature of 35.0°C. The pH is 6.0, the stirring speed is 125rpm, the ultrasonic pulse generator generates 20kHz ultrasonic waves, and the pulse is once every 15min. The hydraulic retention time is 4 days, and the continuous operation is 30 days. ℃, the concentration of organic acid in the supernatant of food waste is maintained at about 28g / L, and the concentration of ethanol is about 4g / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com