Patents

Literature

303results about How to "Reliable grabbing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

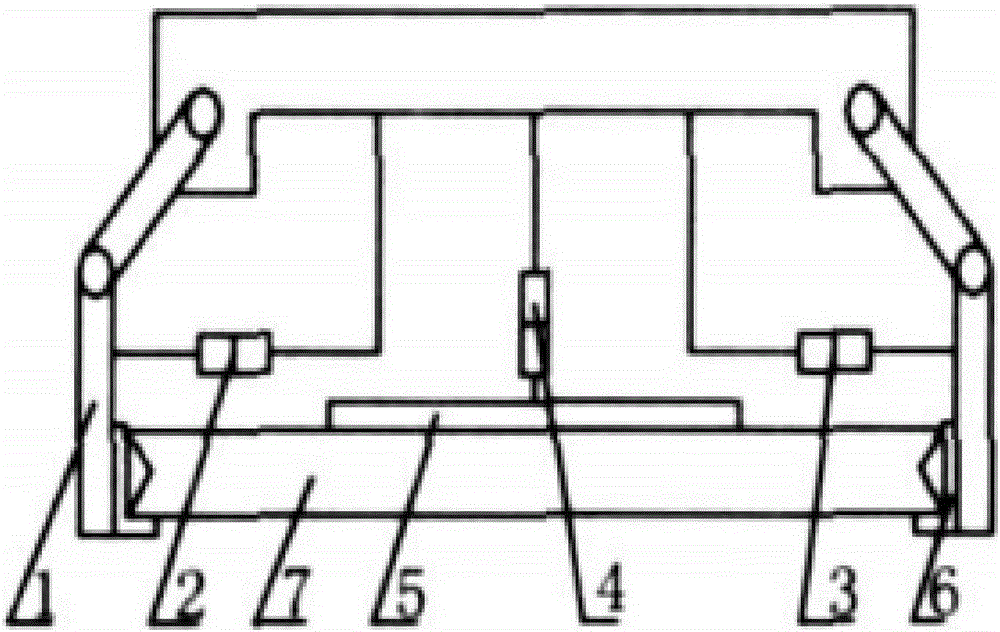

Defective goods automatic sorting method and equipment for high-speed automated production line

InactiveCN1806940AHigh-speed grabbing and sorting processingHigh-speed sorting processProgramme-controlled manipulatorGripping headsProduction lineRobotic arm

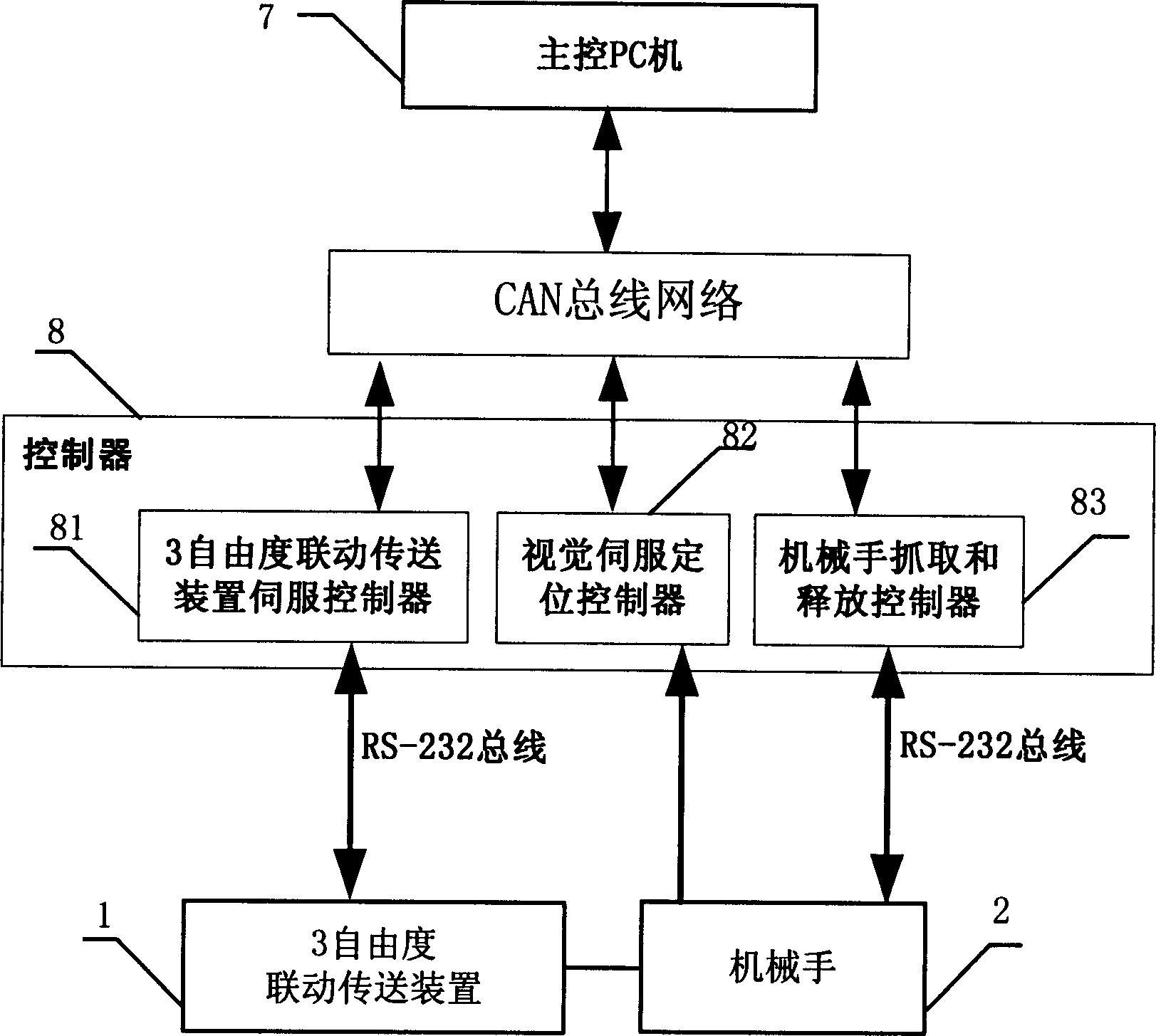

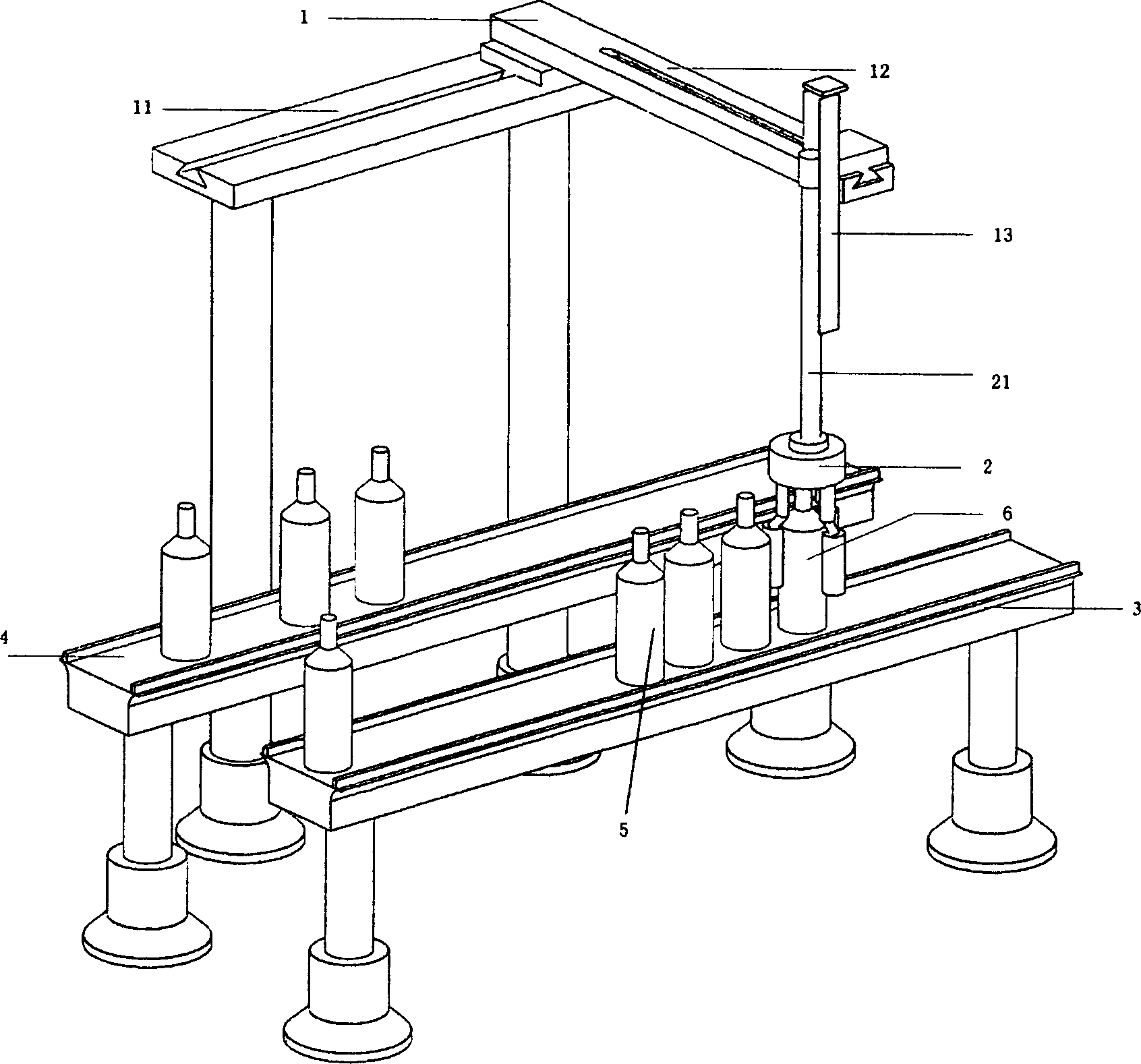

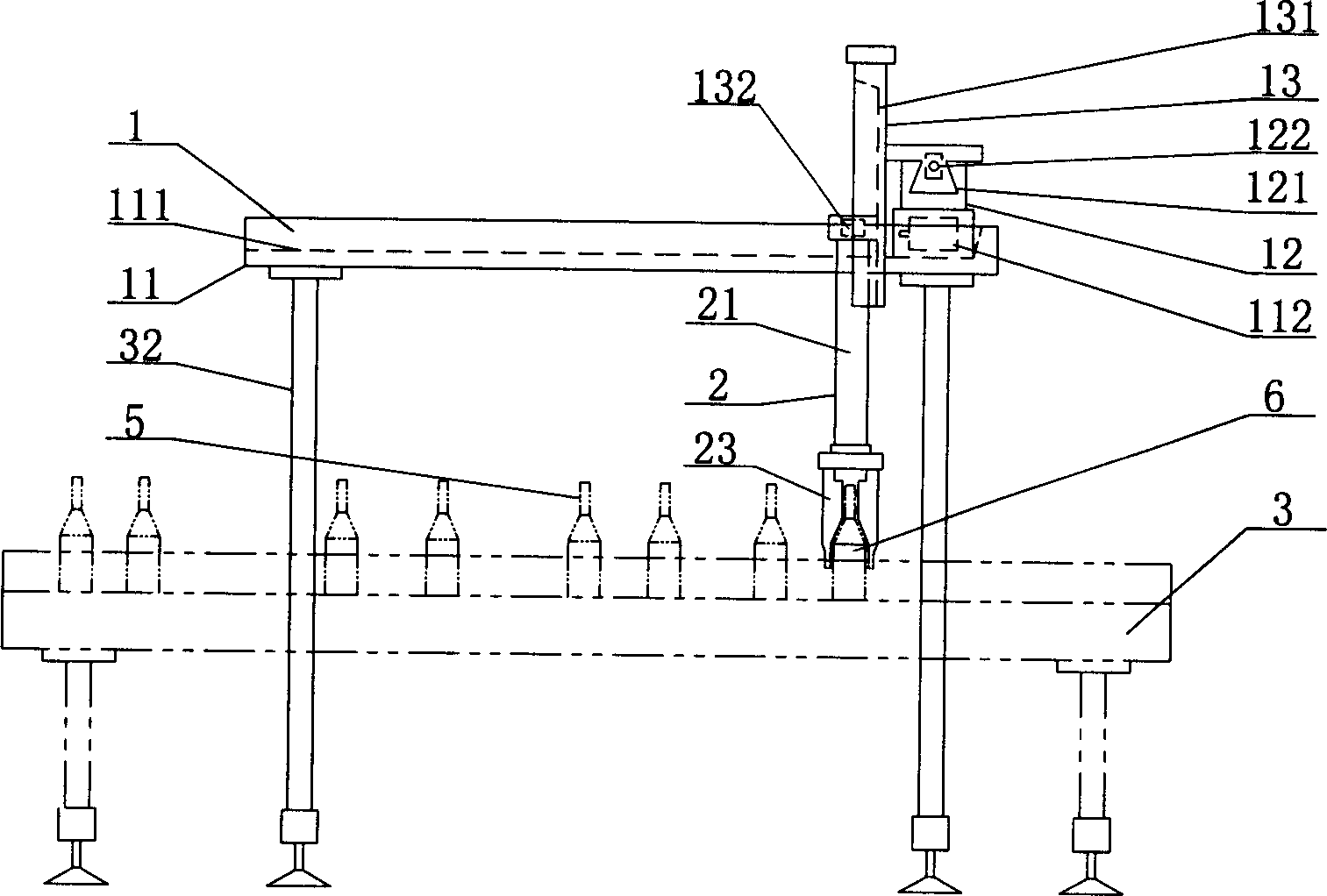

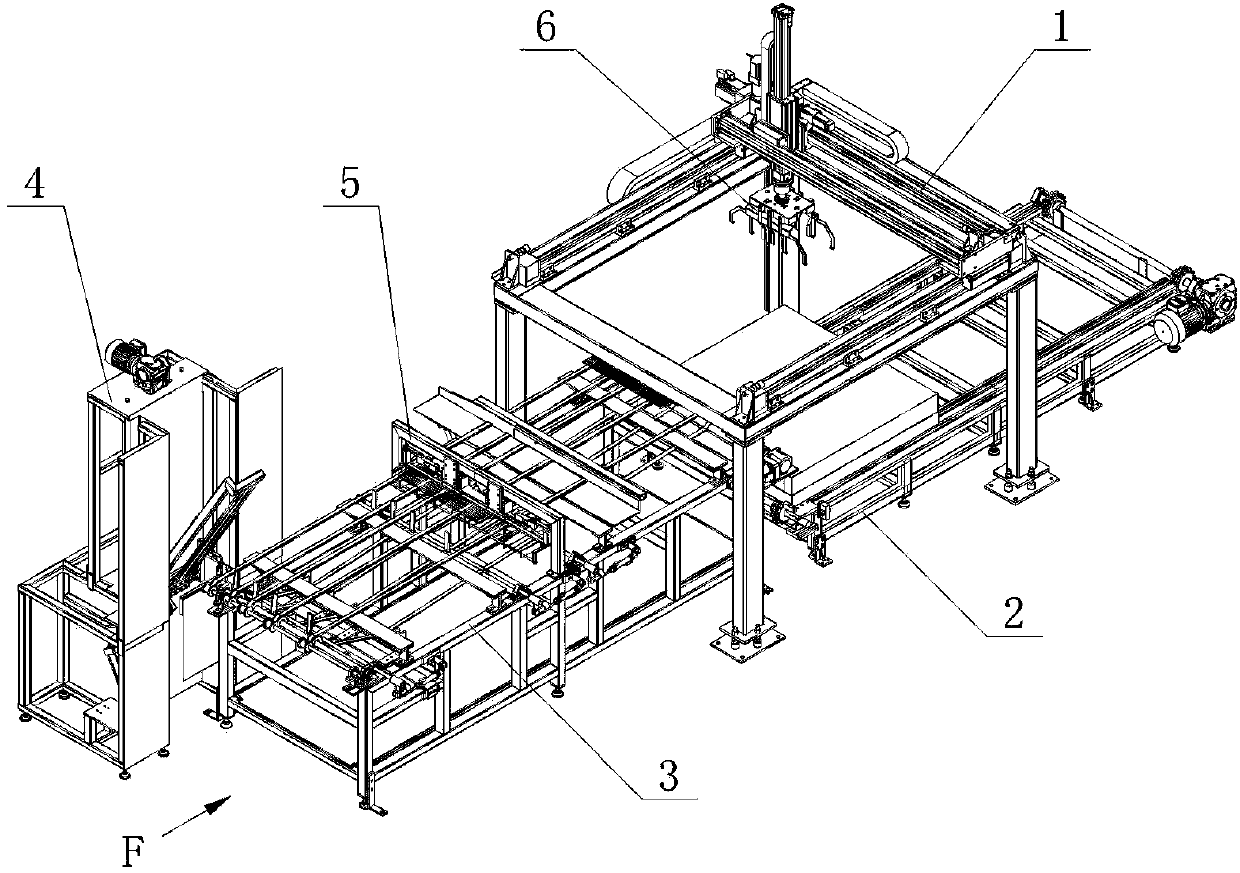

The invention relates the auto sorting faulty goods method on the high-speed automatic production line and unit. The method comprises the following steps: sorting faulty goods system receiving the sorting signal, starting the freedom degree linked conveying device 3, then positioning the mechanical arm connected with 3 on the faulty goods, the mechanical arm keeping the same speed with conveyer belt, gripping the faulty goods, lifting it and releasing it to appointed position. The unit comprises electrical control and mechanical part. The mechanical part comprises 3 and mechanical arm which comprises arm and hand. In the center of the mechanical hand there is camera, and the electrical control is connected with 3 and mechanical arm. The invention possesses high accuracy, low cost, good versatility, and no environmental pollution.

Owner:HUNAN UNIV

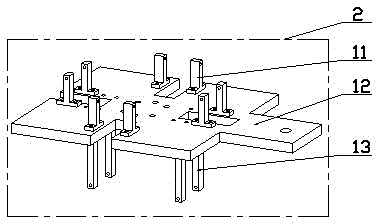

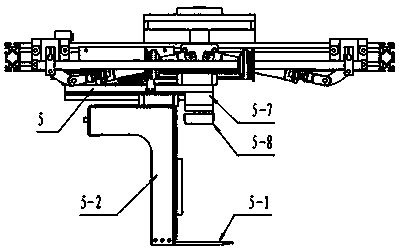

Lead-acid storage battery grid automatic conveying device

The invention discloses a lead-acid storage battery grid automatic conveying device which is arranged at the tail end of a grid production line. The automatic conveying device is provided with a main frame body, the main frame body is provided with a three-axis direction guide rail, a manipulator capable of moving in the direction of three axes and rotating in the Z axis direction is arranged through the guide rail, the manipulator is provided with a gripper adaptive to each grid and capable of being opened and closed, the gripper comprises a plurality of claw arms, and the lower end of each claw arm is of an L type. According to the automatic conveying device, the grids are conveyed through the adoption of a grabbing mode, the grids are conveyed away from a conveying table and then are stacked up in order, the manipulator grabs firmly and is suitable for the special structure and shape of each grid, and whole-course automation and intelligence of conveying can be achieved.

Owner:JIANGSU SANHUAN IND HLDG CO LTD

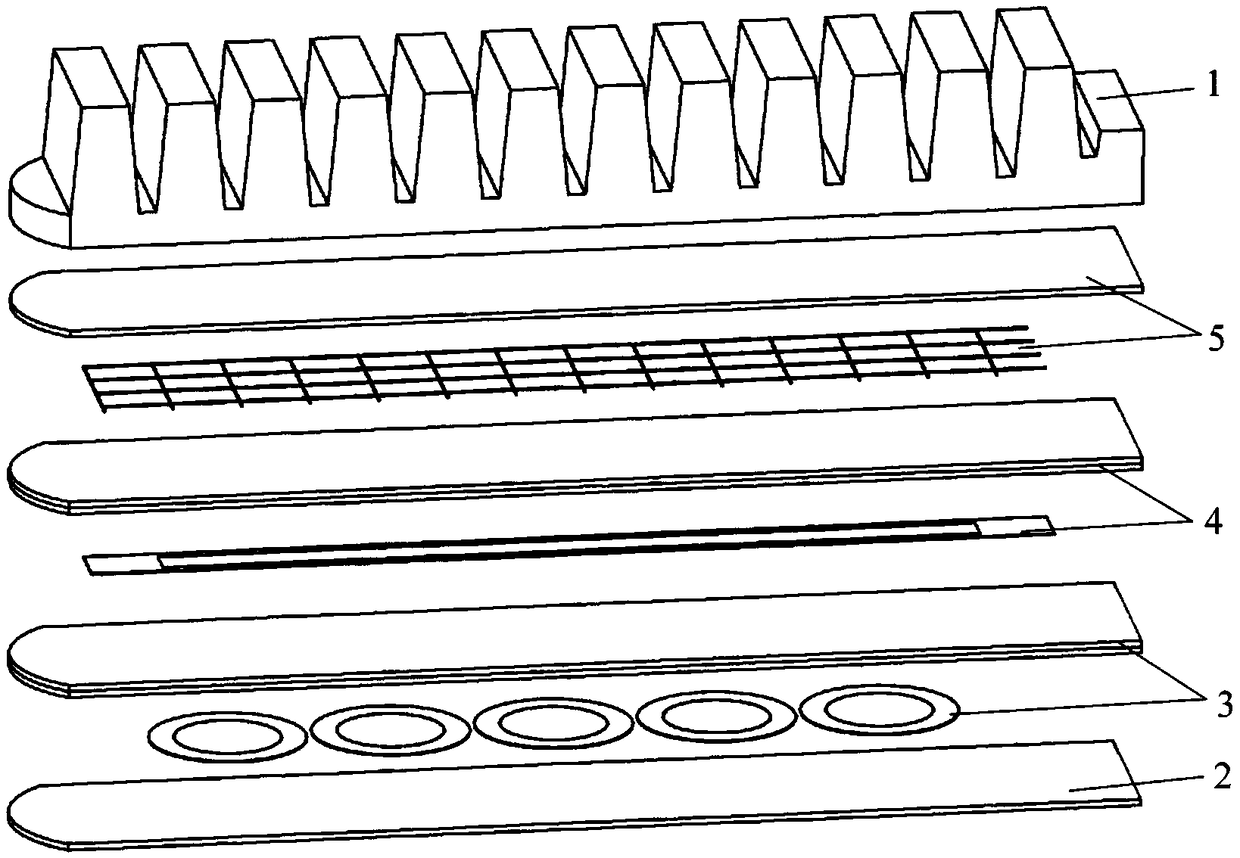

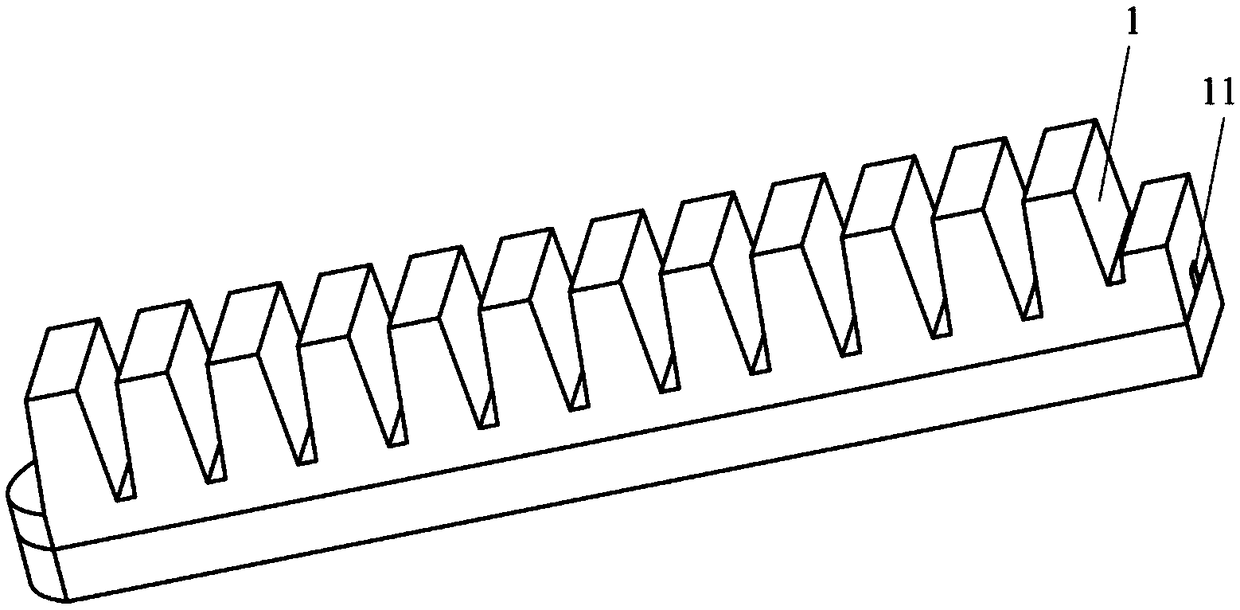

Pneumatic soft finger with tactile and shape perception function

The invention discloses a pneumatic soft finger with tactile force and a shape perception function. The upper portion of the pneumatic soft finger is an actuator, the lower portion of the pneumatic soft finger comprises a silicon substrate layer, a tactile force perception layer, a shape perception layer and an inextensible layer which are arranged sequentially from bottom to top, wherein the tactile force perception layer is internally provided with multiple film pressure sensors adhered to the top face of the silicon substrate layer and distributed in an array, the shape perception layer isinternally and horizontally provided with a slice-type bending sensor adhered to the top face of the tactile force perception layer in the length direction of the finger, the upper portion of the pneumatic soft finger is formed by one-time pouring with a mold, and the lower portion of the pneumatic soft finger is manufactured by layered pouring with the mold. The pneumatic soft finger with the tactile force and the shape perception function has the advantages that the distribution and size of the tactile force and deformation of the soft finger can be measured when the soft finger is in contact with an object, the pneumatic soft finger is used for object identification, sliding detection and the like, thereby achieving that the object is grabbed and operated more reliably.

Owner:TIANJIN UNIV

Pneumatic soft body gripper

InactiveCN109015724ASimple structureEasy to manufactureGripping headsPicking devicesCompressibilityEngineering

The invention provides a pneumatic soft body gripper. The pneumatic soft body gripper comprises pneumatic soft body drivers and a clamping device; the pneumatic soft body drivers are of hollow columnar structures with air cavities, the cross sections are semi-circular, the three pneumatic soft body drivers are evenly distributed according to the circumference to form the gripper, one end of each pneumatic soft body driver is fixed to the clamping device which is designed in an auxiliary manner, under the air pressure effect, the free end can generate bending action facing the round center direction, and the three pneumatic soft body drivers are in coordination to achieve gripping task. Compressibility of gas and elasticity of the soft body drivers enable the gripper to have the good characteristic of grabbing fragile items in a non-damage manner. Due to the clamping device designed in the auxiliary manner, a gas source is connected into the pneumatic soft body drivers, the soft body gripper is fixed to the tail end of a mechanical arm, the soft body gripper only needs to have two states of inflation and deflation to achieve grabbing and releasing of the items, and the pneumatic soft body gripper is simple in structure, high in self-adaptation capacity, simple in control, low in cost, high in generality and suitable for automation work of small fruit and vegetable picking, dailysmall object classified storage and the like.

Owner:SHANGHAI JIAO TONG UNIV

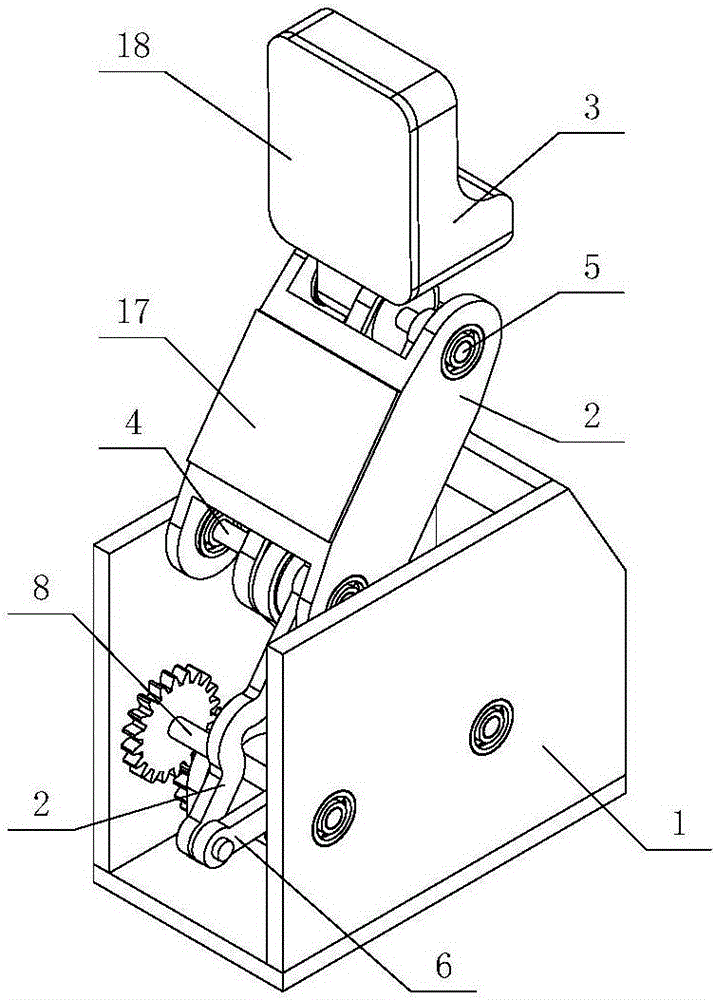

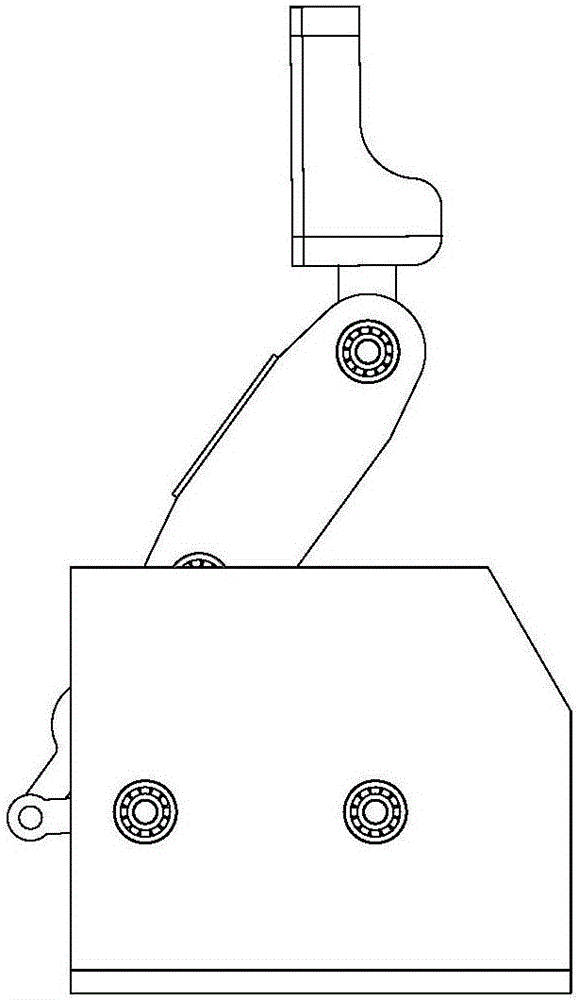

Intelligent transfer robot

ActiveCN103465263AEffective detection sizeEasy to classifyProgramme-controlled manipulatorGripping headsElectricityRollover

The invention discloses an intelligent transfer robot, which comprises a base, a rear cover shell, a mechanical arm, a swing arm movement mechanism, a rollover movement mechanism, a vertical movement mechanism, a horizontal movement mechanism, and a rotary movement mechanism. The rotary movement mechanism is connected with a rotary support driven by the rotary movement mechanism to rotate; a radio frequency reader and a mechanical paw are arranged on the rotary support; the radio frequency reader is electrically connected with a PLC (programmable logic controller); the mechanical paw comprises a paw base, a movement plate and a driving device driving the movement plate; teeth are arranged at two sides of the movement plate; the driving device is controlled by the PLC and is arranged on the rotary support; the paw base is connected with the rotary support through a connecting rod; rotary shafts are arranged on the positions, positioning at two sides of the movement plate, of the paw base; the rotary shafts are connected with paws and gears meshed with the teeth on the movement plate. Through adding the radio frequency reader, radio frequency identification tags on workpieces can be effectively identified, so that products can be conveniently classified; the intelligent transfer robot grabs the workpieces by the mechanical paw, so that the cost is low.

Owner:无锡智动力机器人有限公司

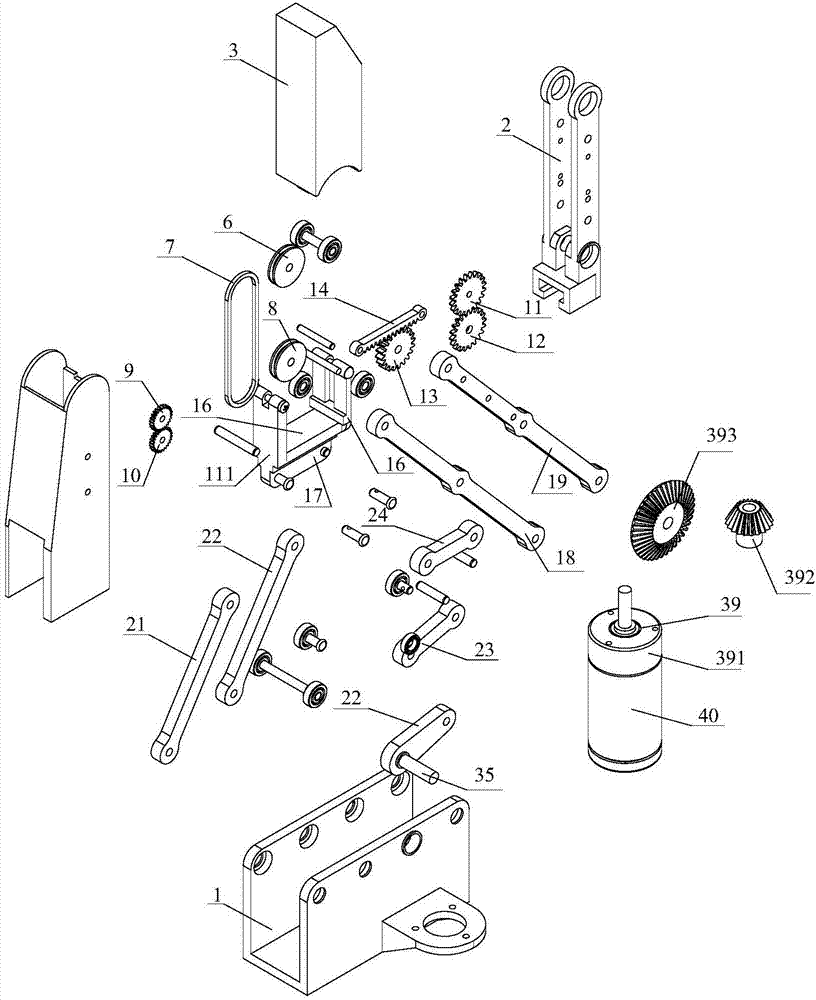

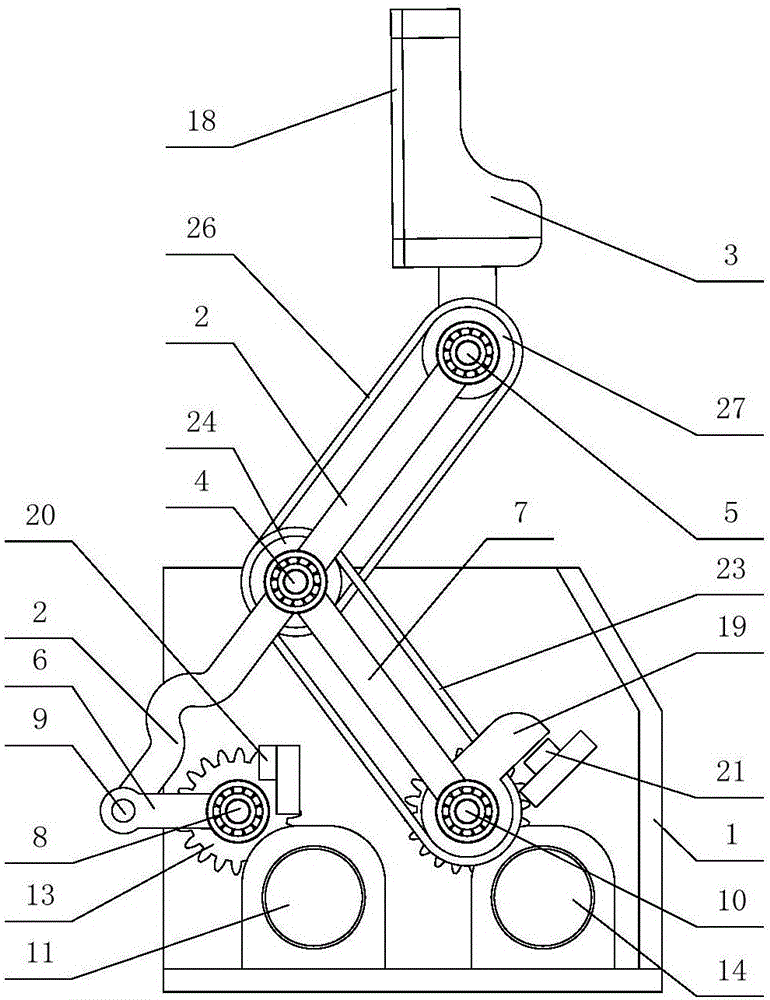

Connecting-rod gear-rack linear parallel clamping indirect self-adaptive robot finger device

The invention relates to a connecting-rod gear-rack linear parallel clamping indirect self-adaptive robot finger device, and belongs to the technical field of robot hands. The connecting-rod gear-rack linear parallel clamping indirect self-adaptive robot finger device comprises a base, two finger sections, two joint shafts, a gear rack, a plurality of gears, two driving wheels, a driving medium, a guiding rod, a spring piece and the like. The device achieves the function of linear parallel clamping and self-adaptive grabbing of fingers of a robot; a linear motion of a far joint shaft is achieved through a connecting mechanism, and a second finger section keeps a fixed posture relative to the base in a first grabbing phase by adopting the spring piece to be matched with a gear rack mechanism; when an object is in contact with a first finger section, the self-adaptive rotation of the second finger section around the far joint shaft is achieved through the gear rack mechanism; grabbing of objects with different shapes and sizes can be adapted; and the grabbing range is large, the grabbing is stable and reliable, the structure is simple, and the cost is low.

Owner:TSINGHUA UNIV

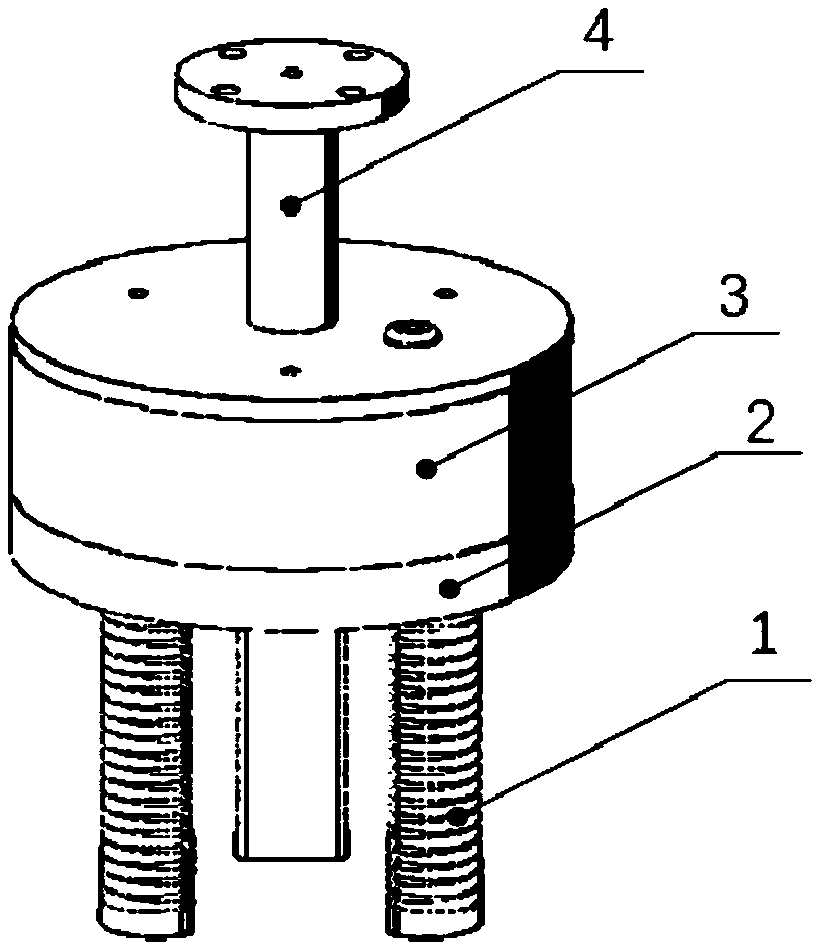

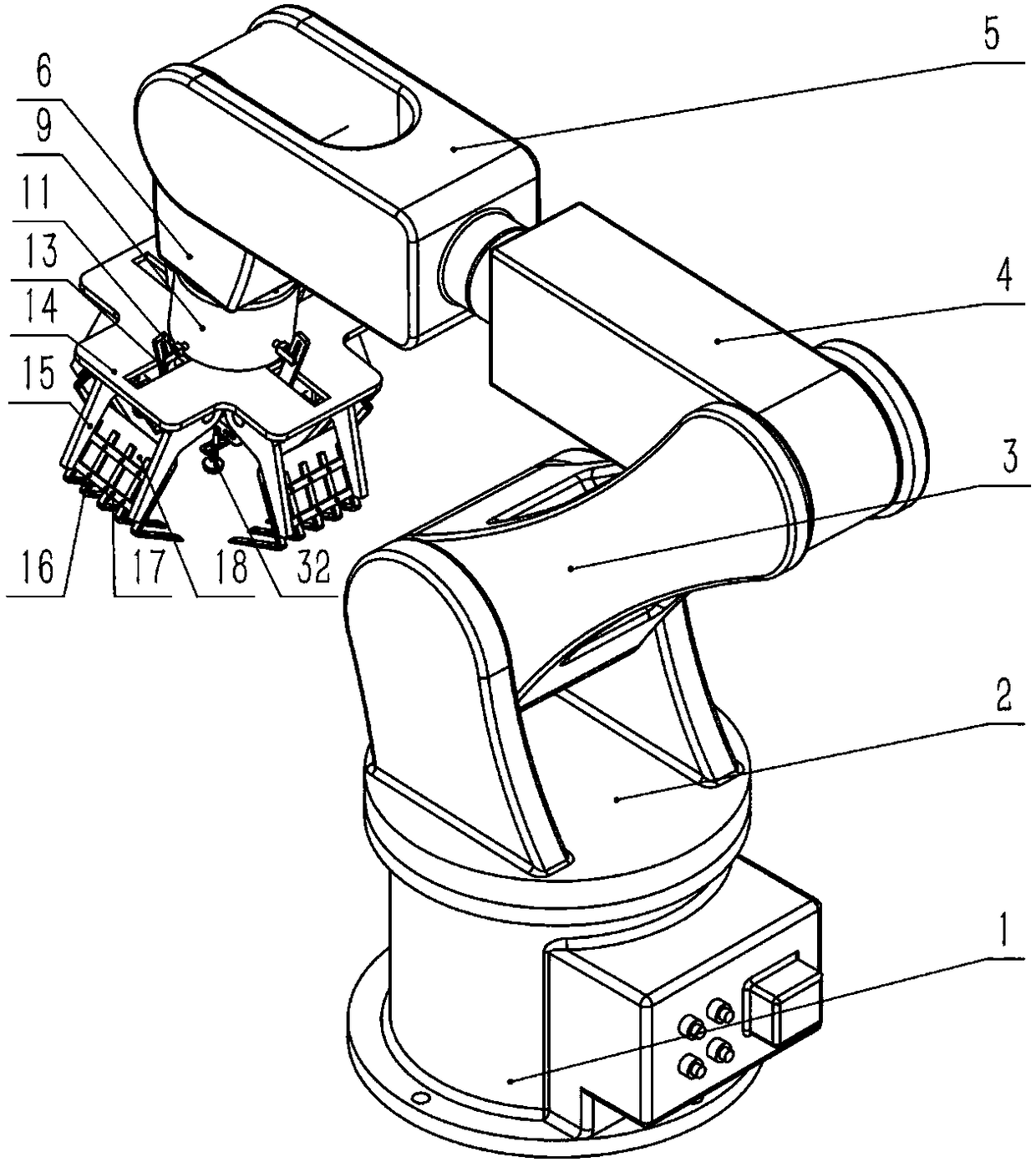

Synchronous control mechanical arm

ActiveCN108214535ASmall sizeReduce manufacturing costProgramme-controlled manipulatorGripping headsSynchronous controlElectric machinery

The invention discloses a synchronous control mechanical arm. The synchronous control mechanical arm comprises a base, a rotation table, a big arm, a first small arm, a second small arm, a wrist, anda mechanical gripping device. The base is positioned by four uniformly distributed bolt holes and fixedly installed on a workbench. The rotation table is installed on the base through bolts, and rotated around a central rotation shaft of the base. The big arm is connected with the front end of the rotation table through a joint. The first small arm is connected with the front end of the big arm through the joint. The second small arm is connected with the front end of the first small arm through the joint. The wrist is connected with the front end of the second small arm through the joint. Themechanical gripping device is fixedly installed at the front end of the wrist through the bolts. The synchronous control mechanical arm is simple in structure. The mechanical gripping device uses a motor to drive mutually vertically installed rotation cams to synchronously control four claws. Bag-packed articles and box-packed articles can be captured by the synchronous control mechanical arm instead of a person. The working strength of workers is reduced, and the working efficiency is greatly improved.

Owner:NANJING UNIV OF SCI & TECH

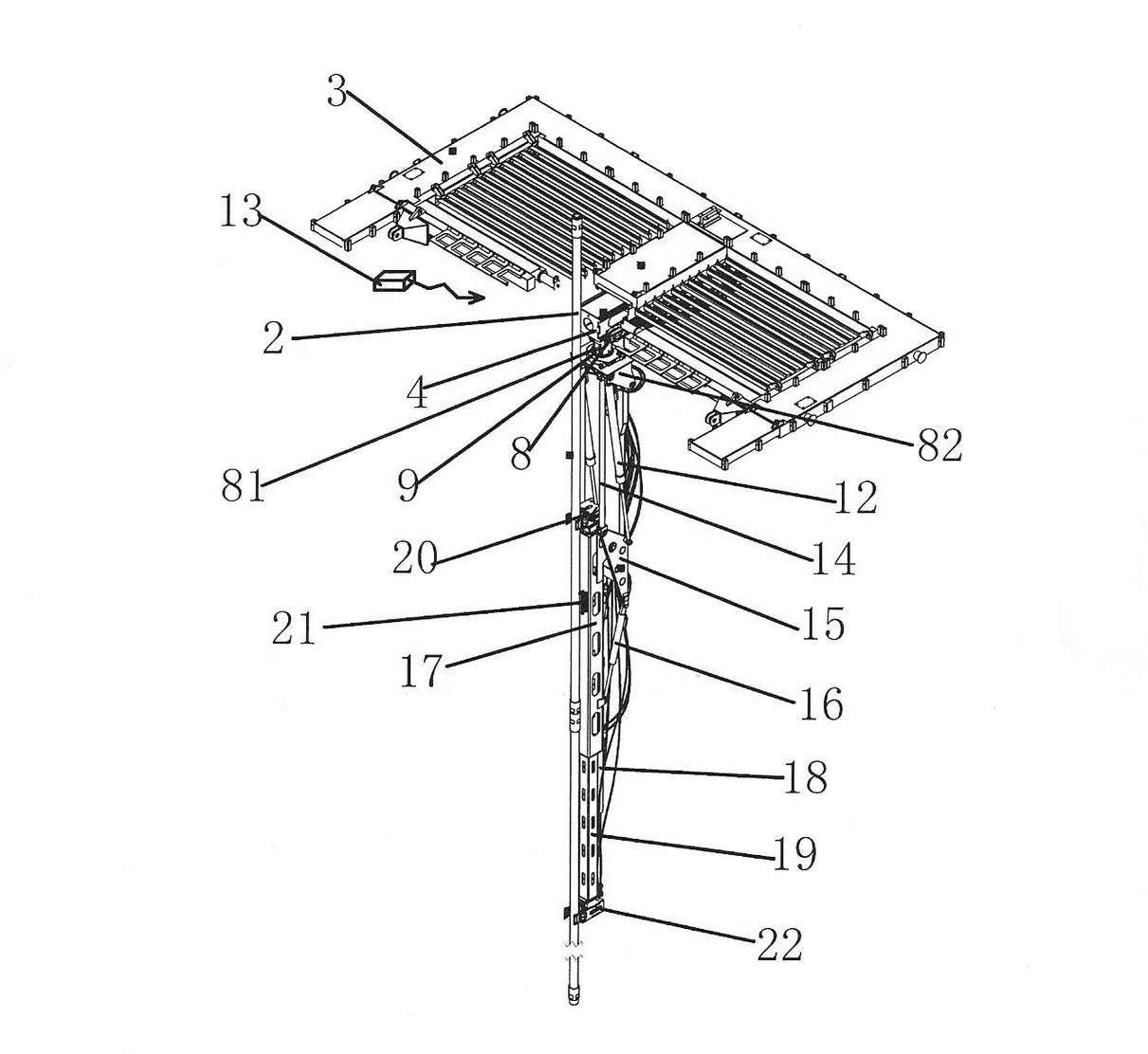

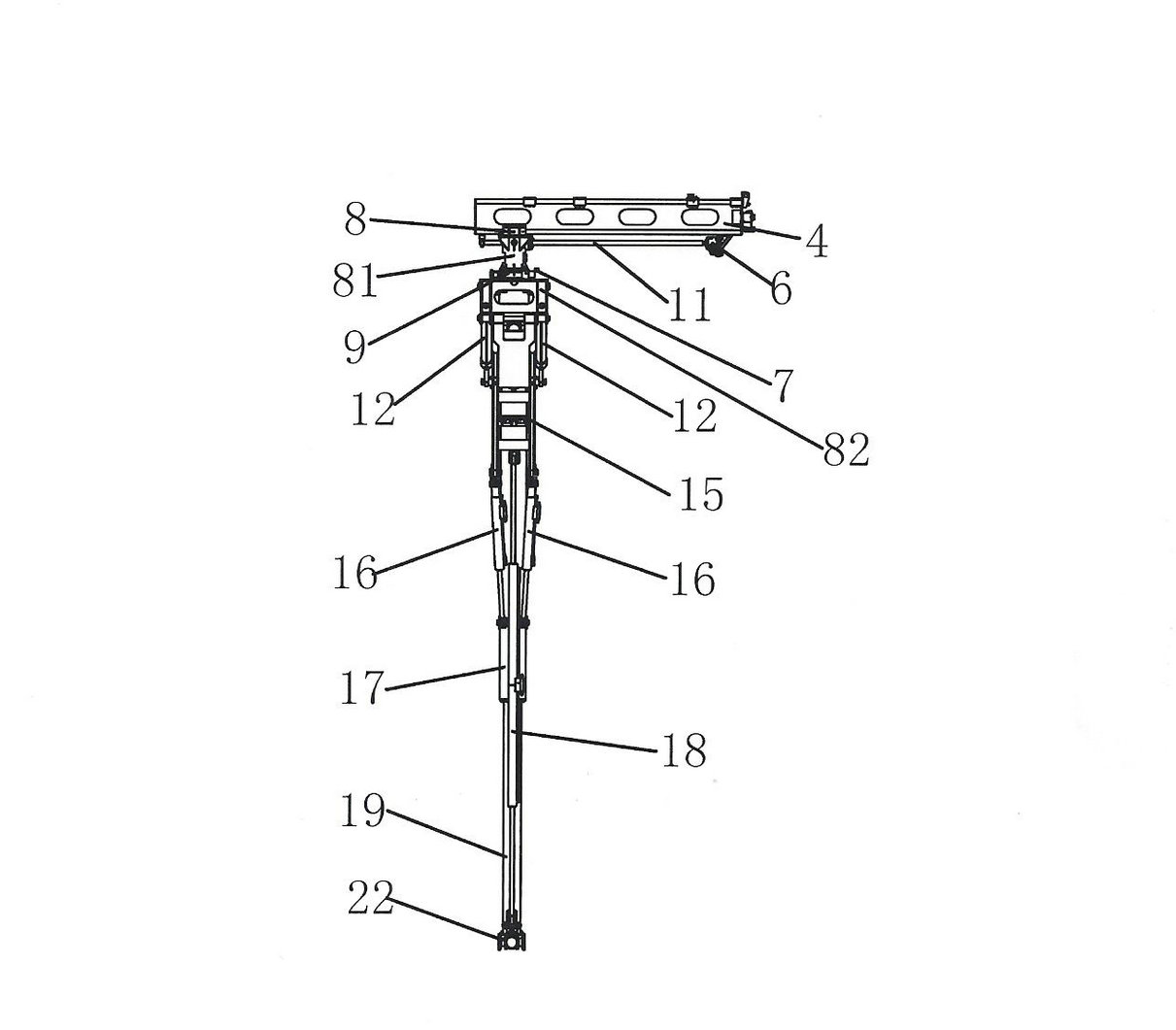

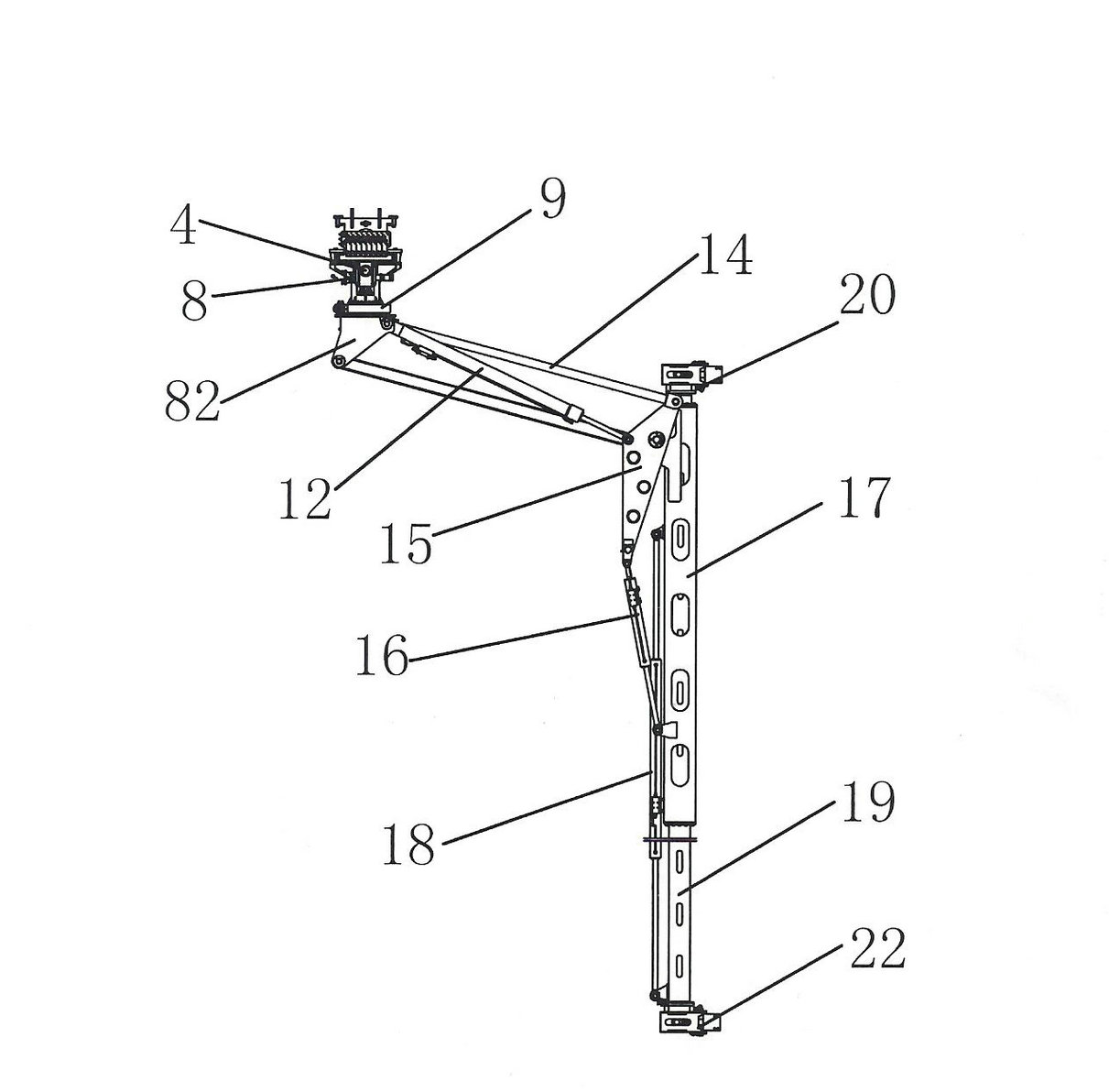

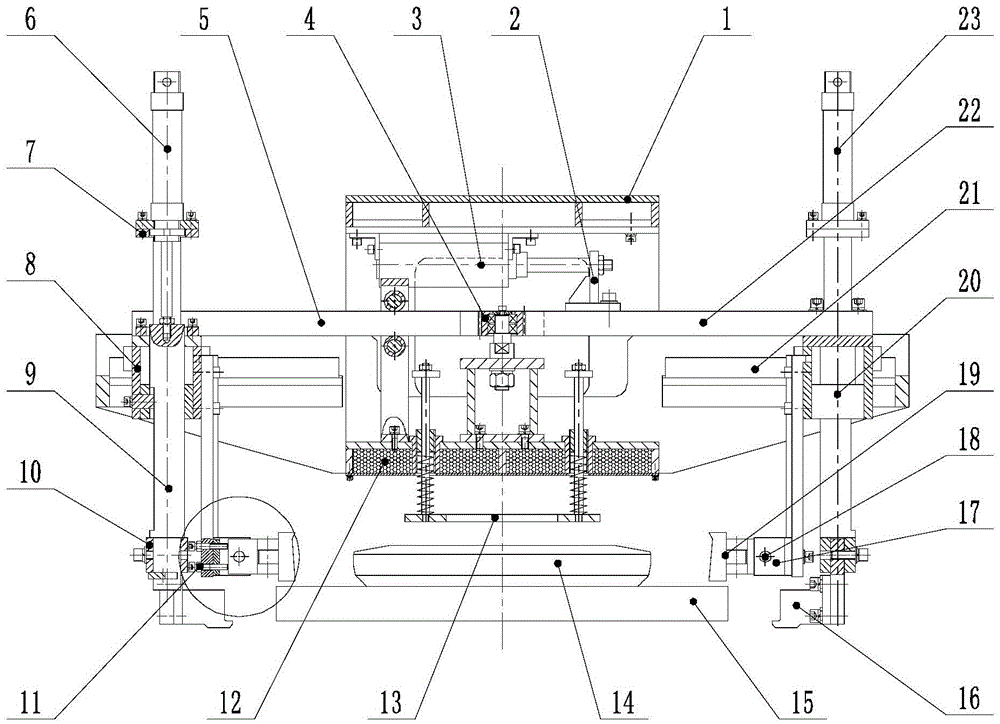

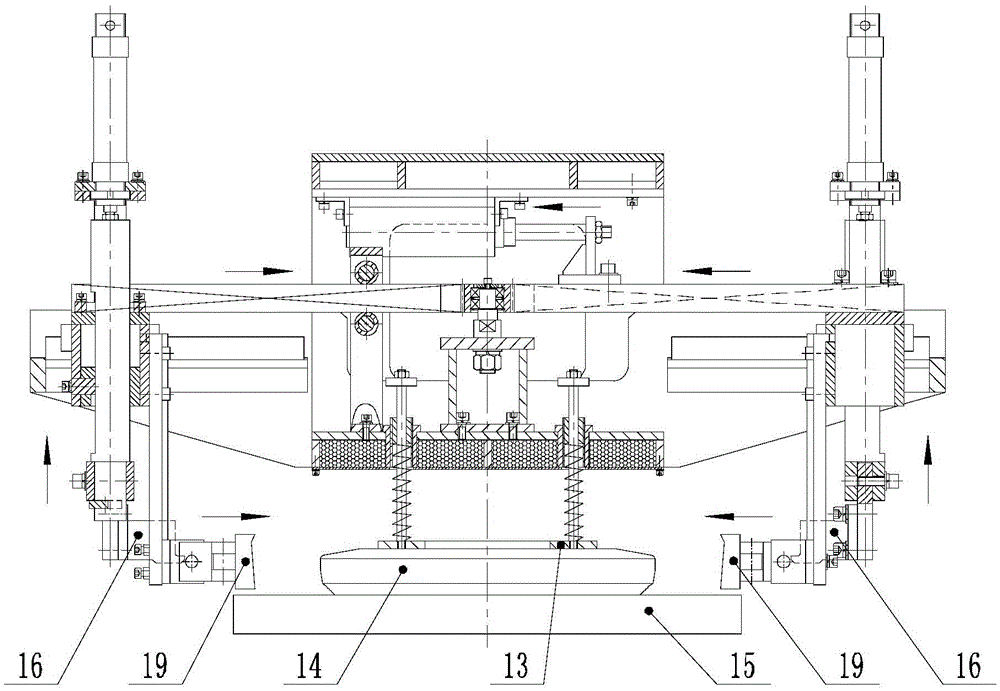

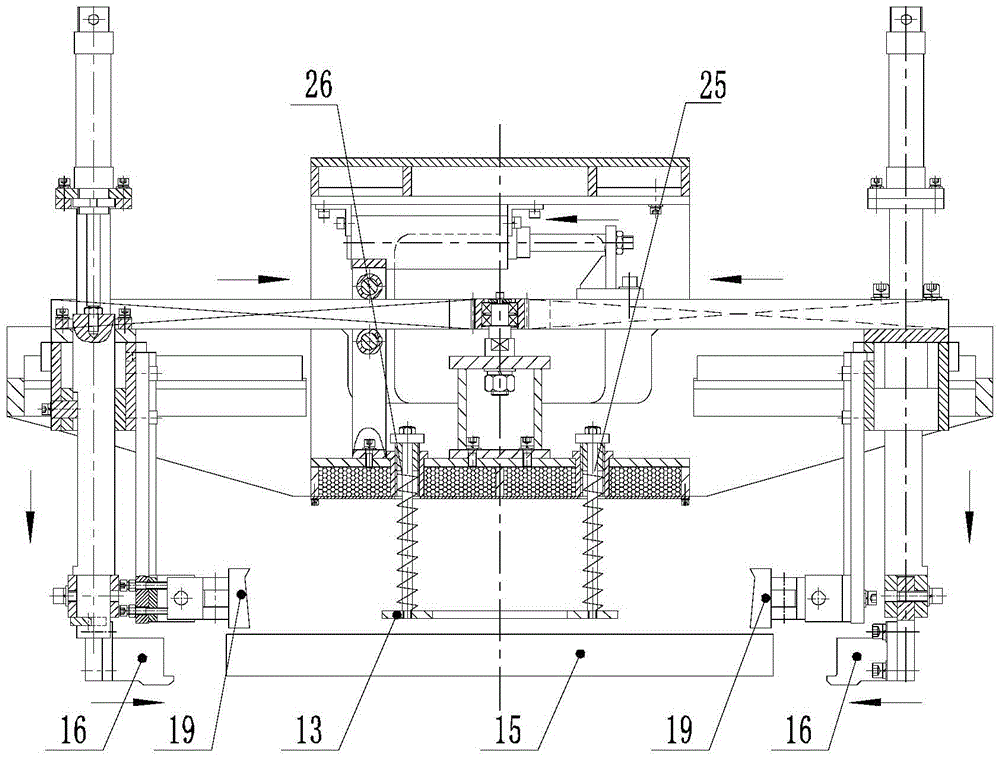

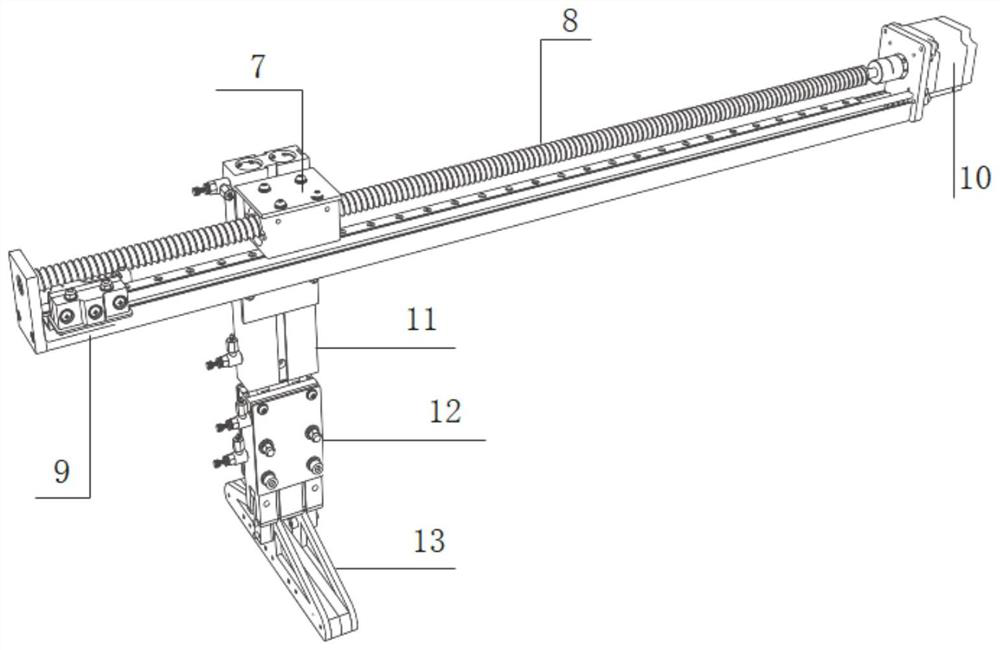

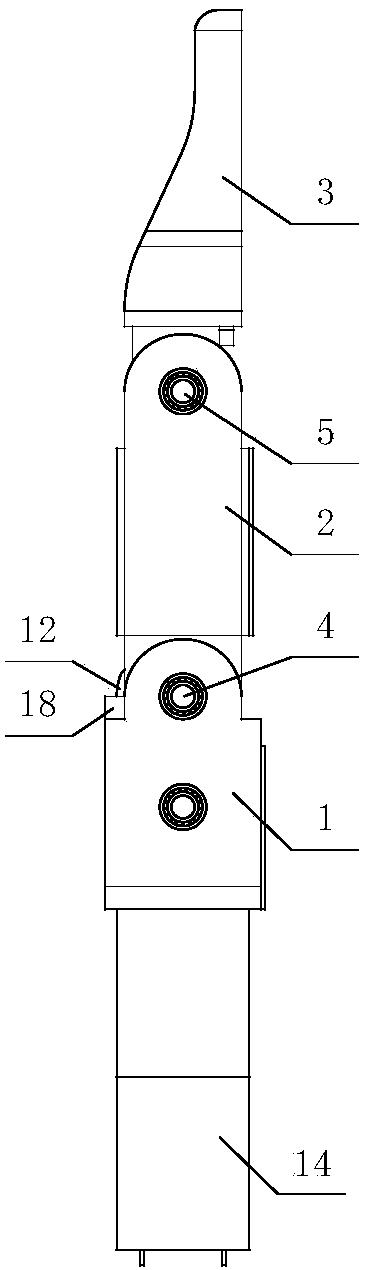

Hanging type adaptive automatic drill pipe string discharge device

InactiveCN102606092APrecise positioningReliable lockingDrilling rodsDrilling casingsProportional controlHydraulic circuit

The invention discloses a hanging type adaptive automatic drill pipe string discharge device, which consists of a pipe string discharger guide track, a hydraulic motor, a rotary encoder, a tackle, a worm gear and worm rotating device, a lead screw pair, an extension hydraulic cylinder, a movable arm, a triangular support, deviation rectifying hydraulic cylinders, masts, a lifting hydraulic cylinder, a mast inner guide rod, a manipulator, a double-axis horizontal inclination sensor and an electro-hydraulic proportional control system with a PID (proportion integration differentiation) adjusting function. The pipe string discharger guide track is fixed at the bottom of a tongue platform of a second-floor platform of a K-shaped derrick, a mounting foundation of the clamping manipulator is a double-layer lifting mast structure, and the external masts are mounted on the triangular support via universal joints and are driven by the two deviation rectifying hydraulic cylinders; the internal masts can slide along the external masts, when a parallelogram stretchable mechanism acts, the internal masts can be driven by the lifting hydraulic cylinder to move vertically, the lifting action of the internal masts can be synchronous to the stretching action, or the lifting action of the internal masts and the stretching action are carried out sequentially definitely, when a drilling rig is connected or disconnected, the internal masts are in a balancing and floating state, and the balancing and floating function is realized by a specific hydraulic loop and a control mode.

Owner:JILIN UNIV

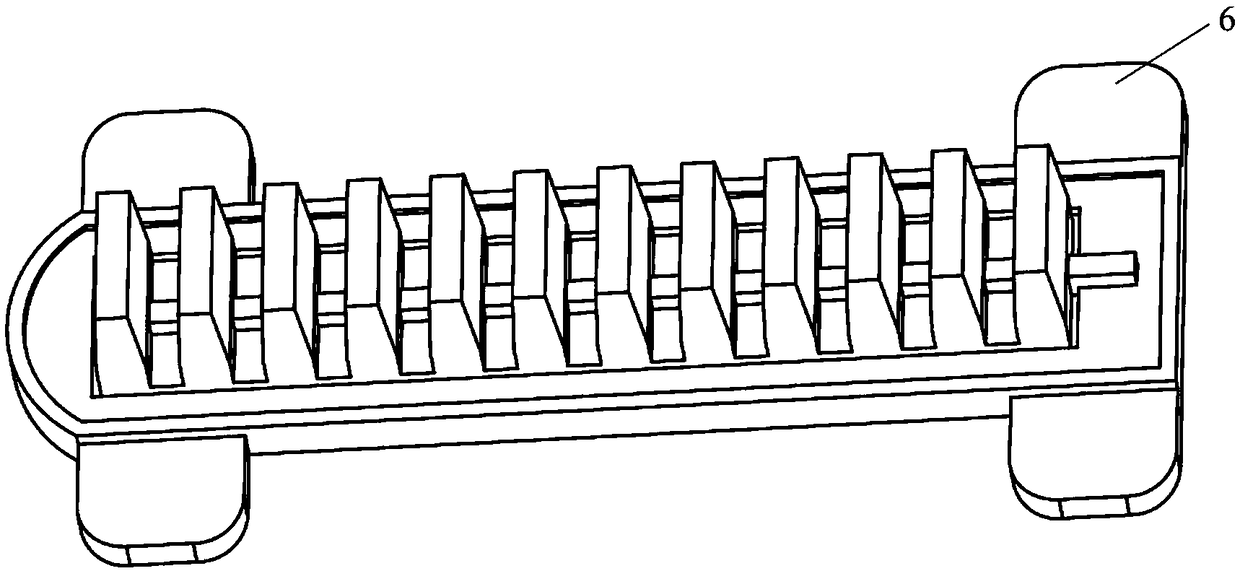

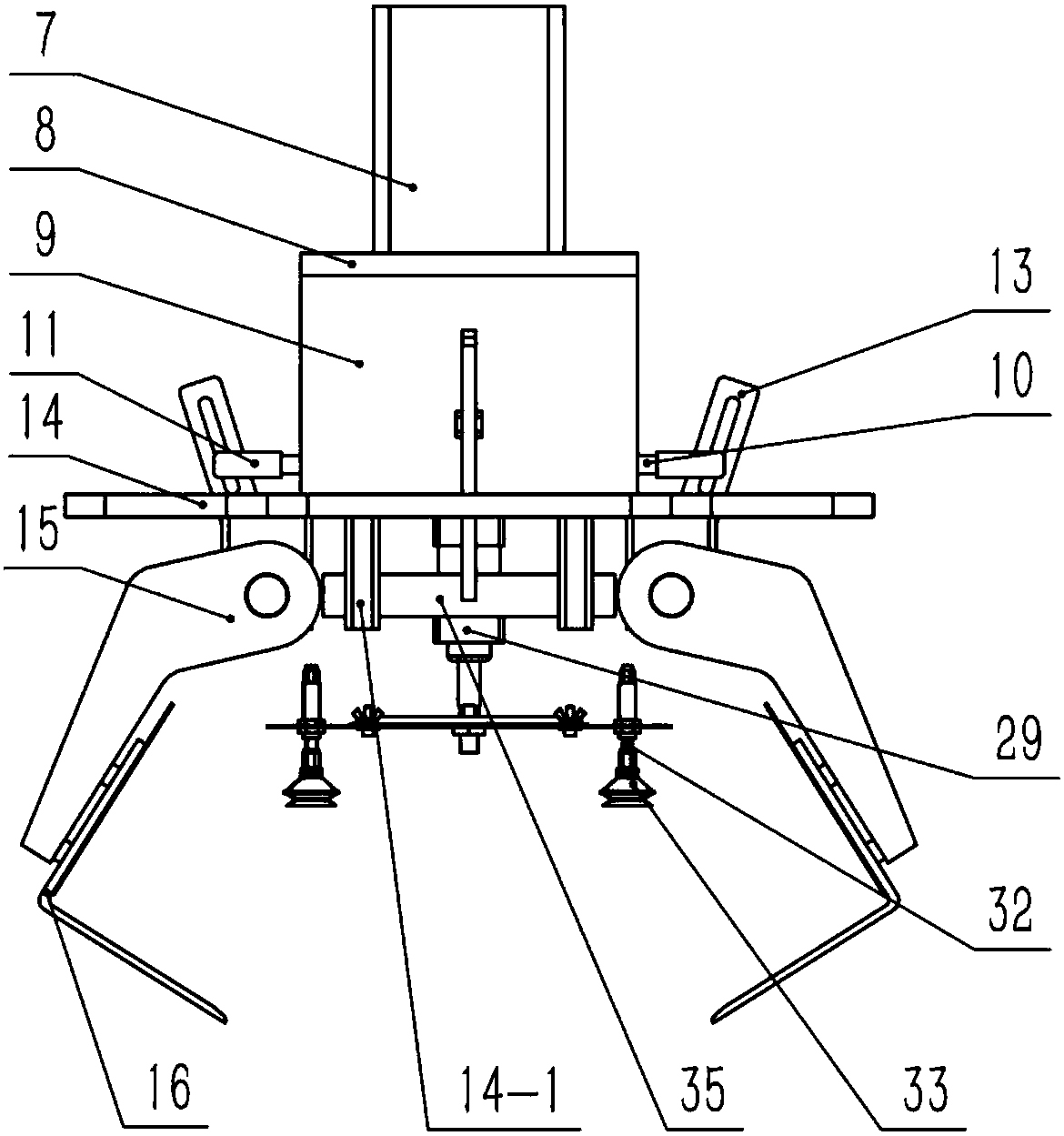

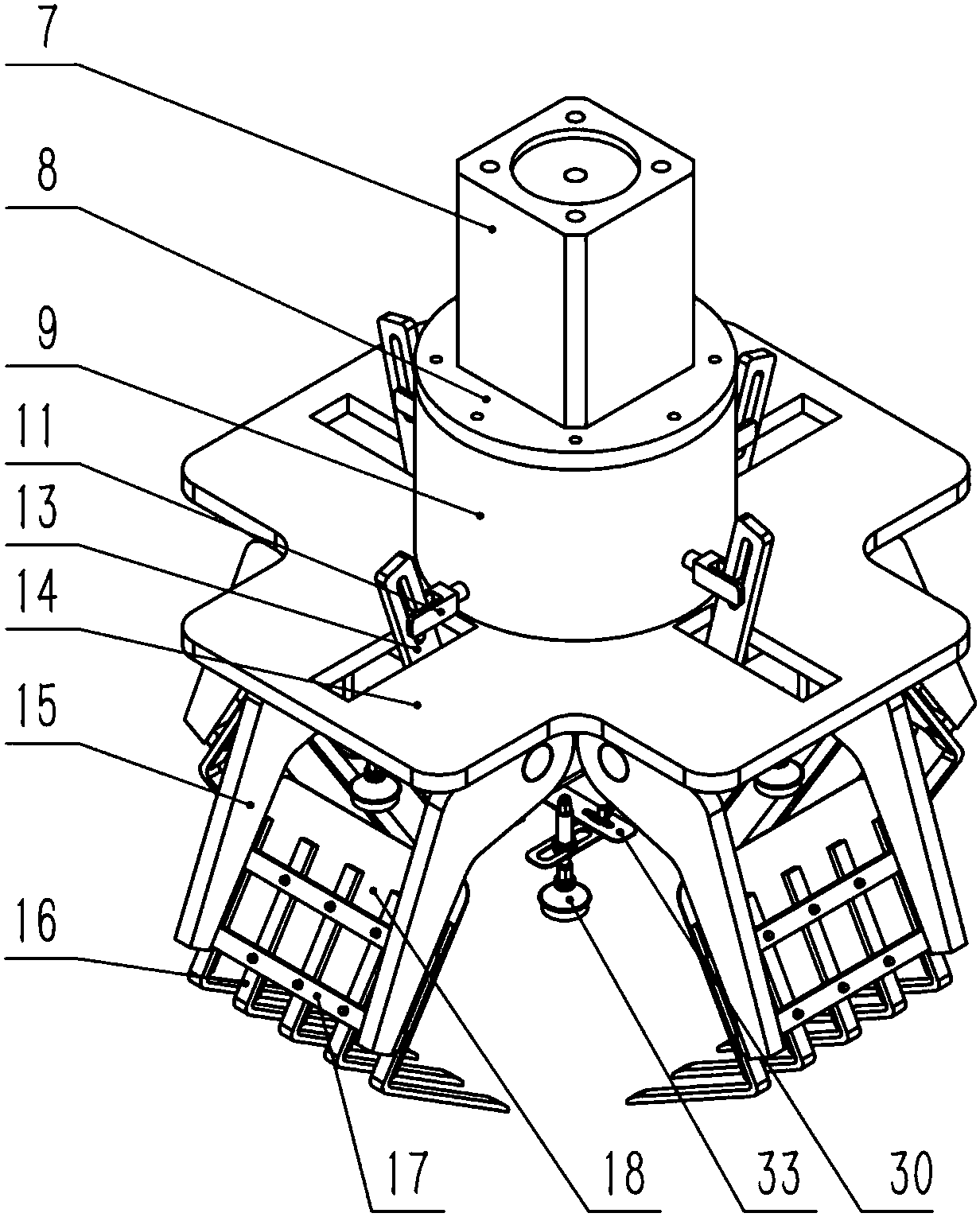

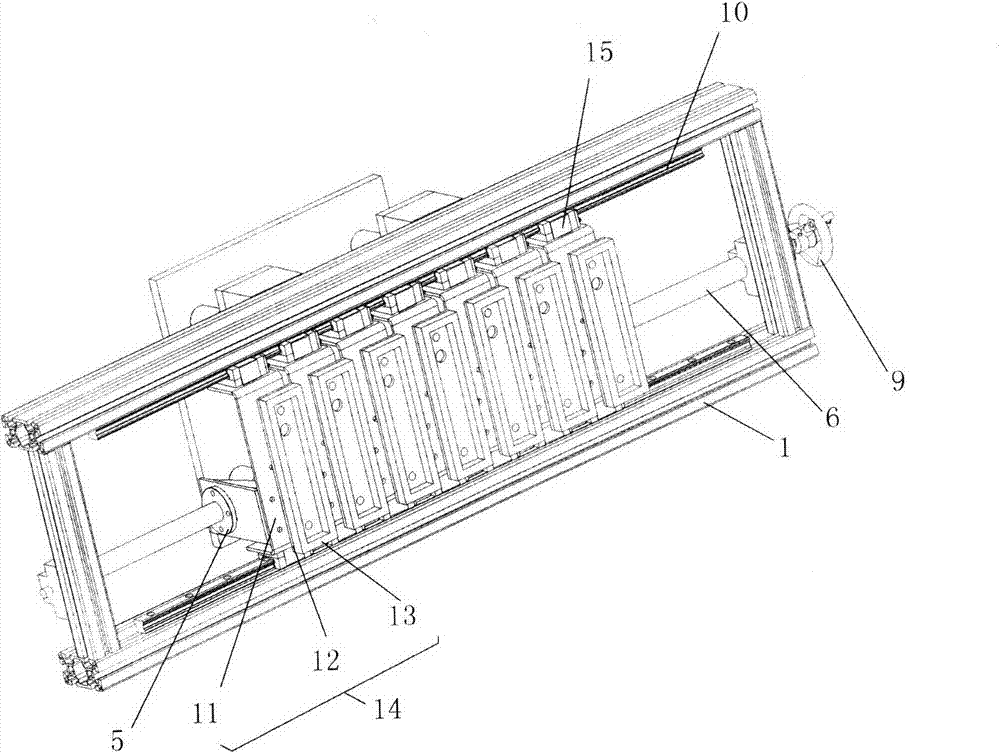

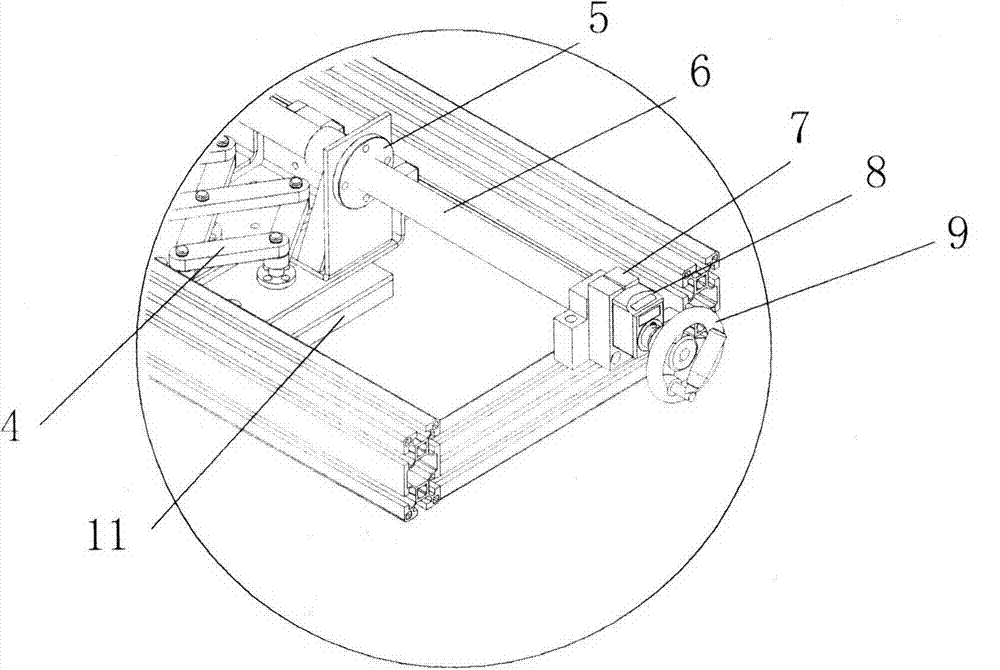

Robot sucker gripper

The invention provides a robot sucker gripper. The robot sucker gripper comprises an installing framework, a flange cover for connecting a mechanism arm is fixedly arranged above the installing framework, a guide rail is arranged on the installing framework, a plurality of sucker devices for gripping objects are arranged on the guide rail and can move along the guide rail, the plurality of sucker devices are hinged together through a link mechanism, a spacing adjustment device is further arranged on the sucker devices and comprises a screw rod and screw rod nuts, the screw rod is arranged on the installing framework and is parallel to the guide rail, two sides of the screw rod are matched with the screw rod nuts through inner and outer threads, and the screw rod nuts are connected with the sucker devices. According to the robot sucker gripper, intervals among the sucker devices are adjusted, the objects in different sizes can be gripped, and the robot sucker gripper has the advantages of being simple in structure, flexible in operation, and high in production efficiency.

Owner:JIANGSU ZHONGKE YOUTE ROBOT TECH

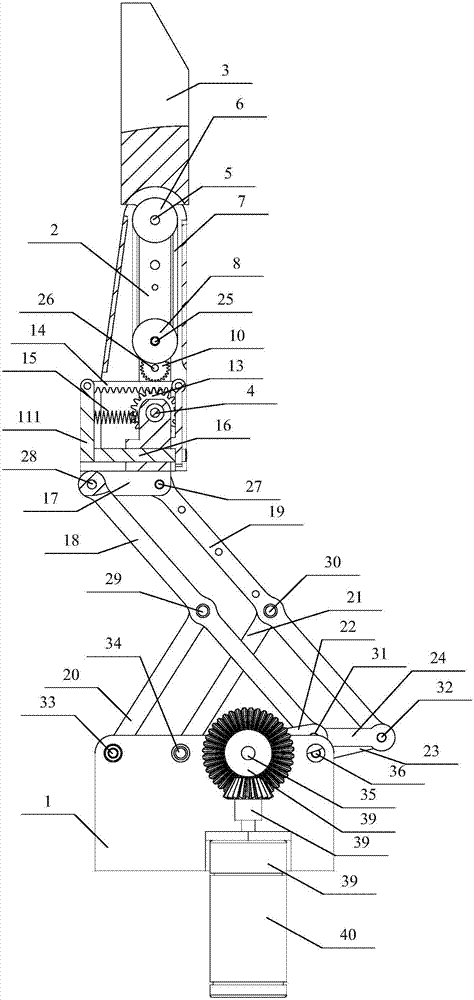

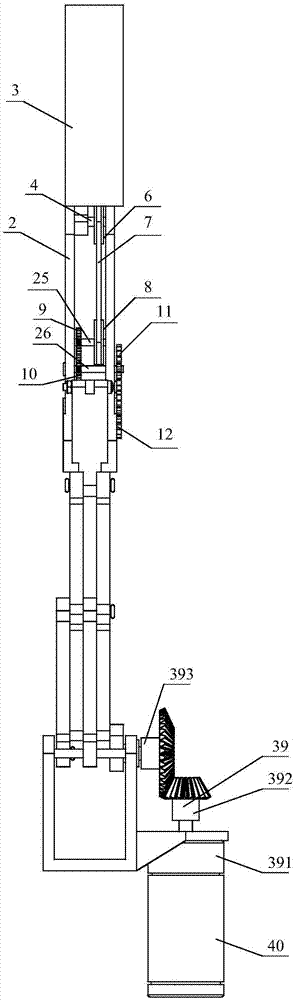

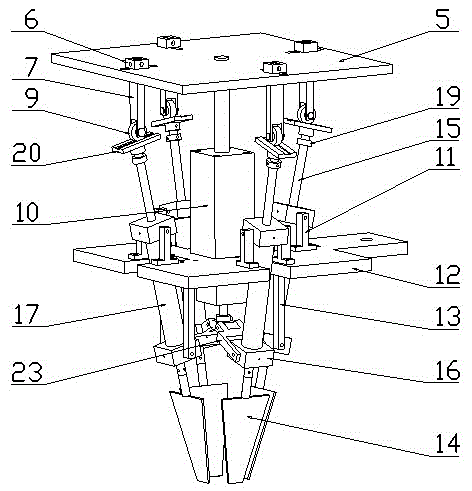

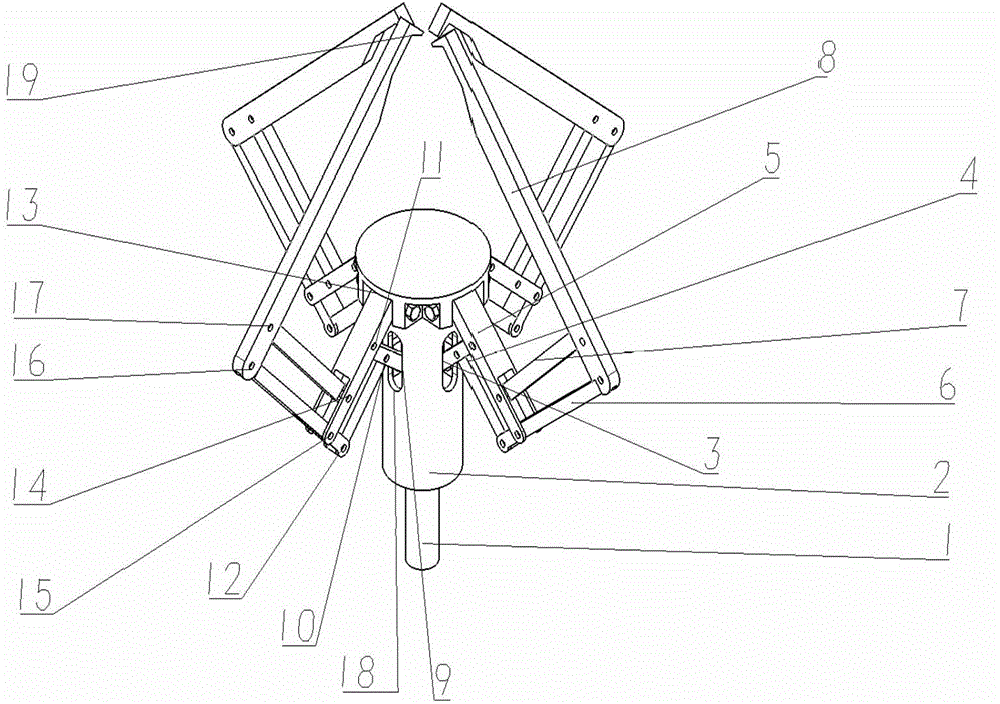

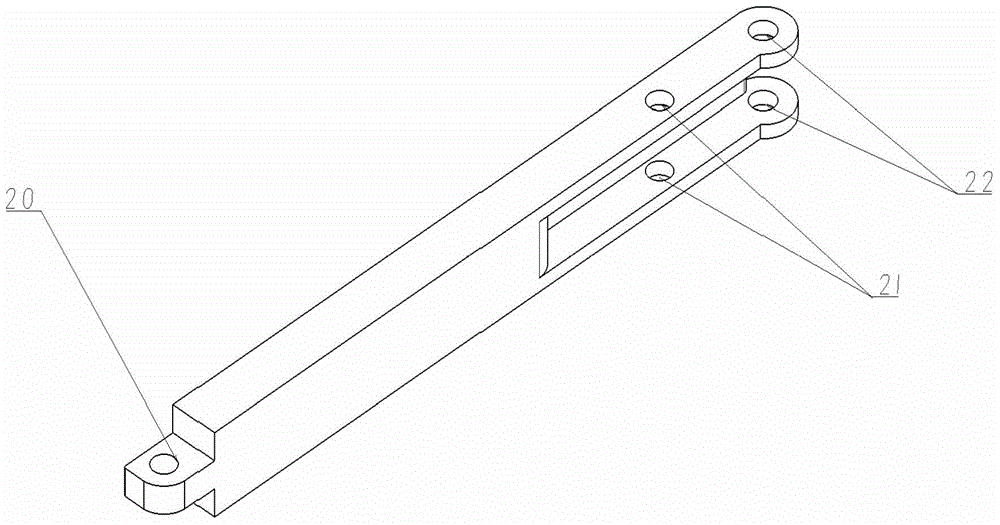

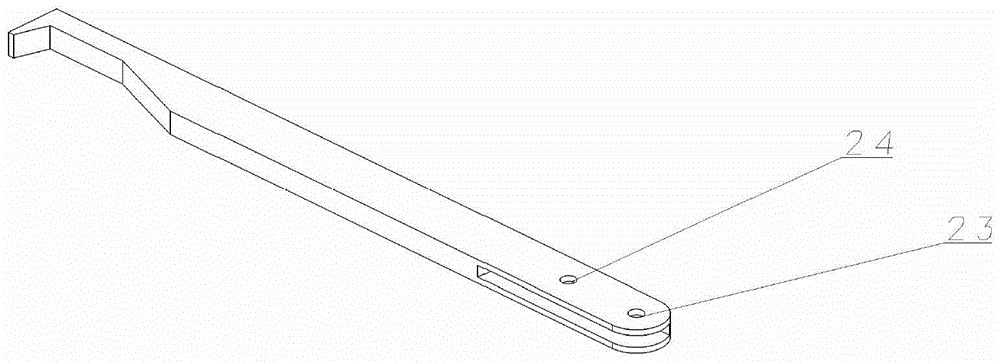

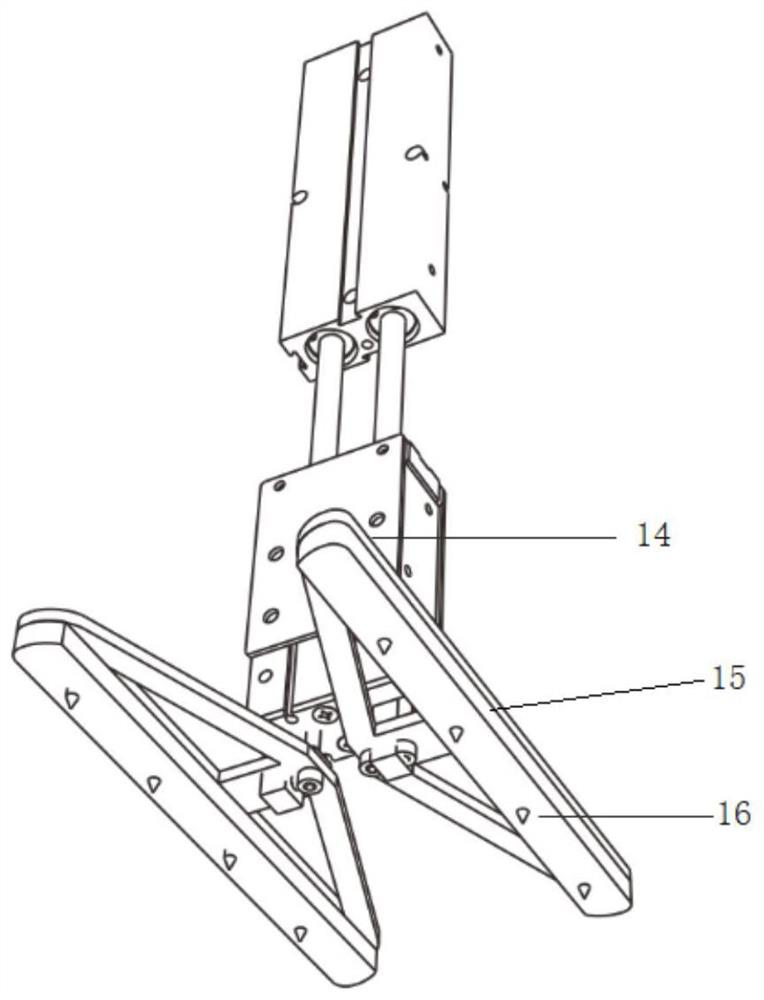

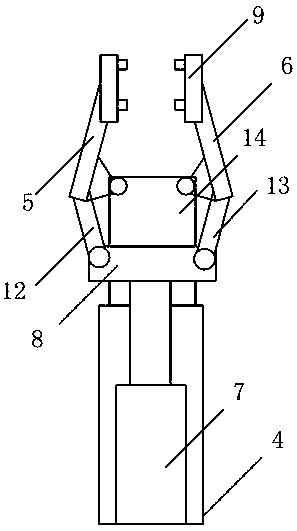

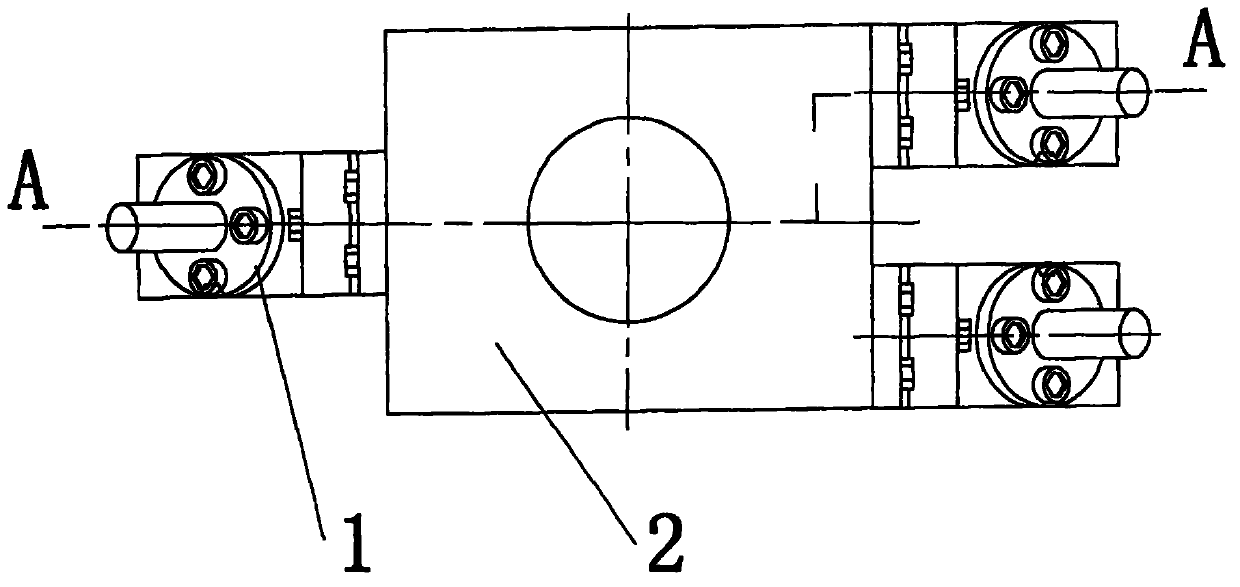

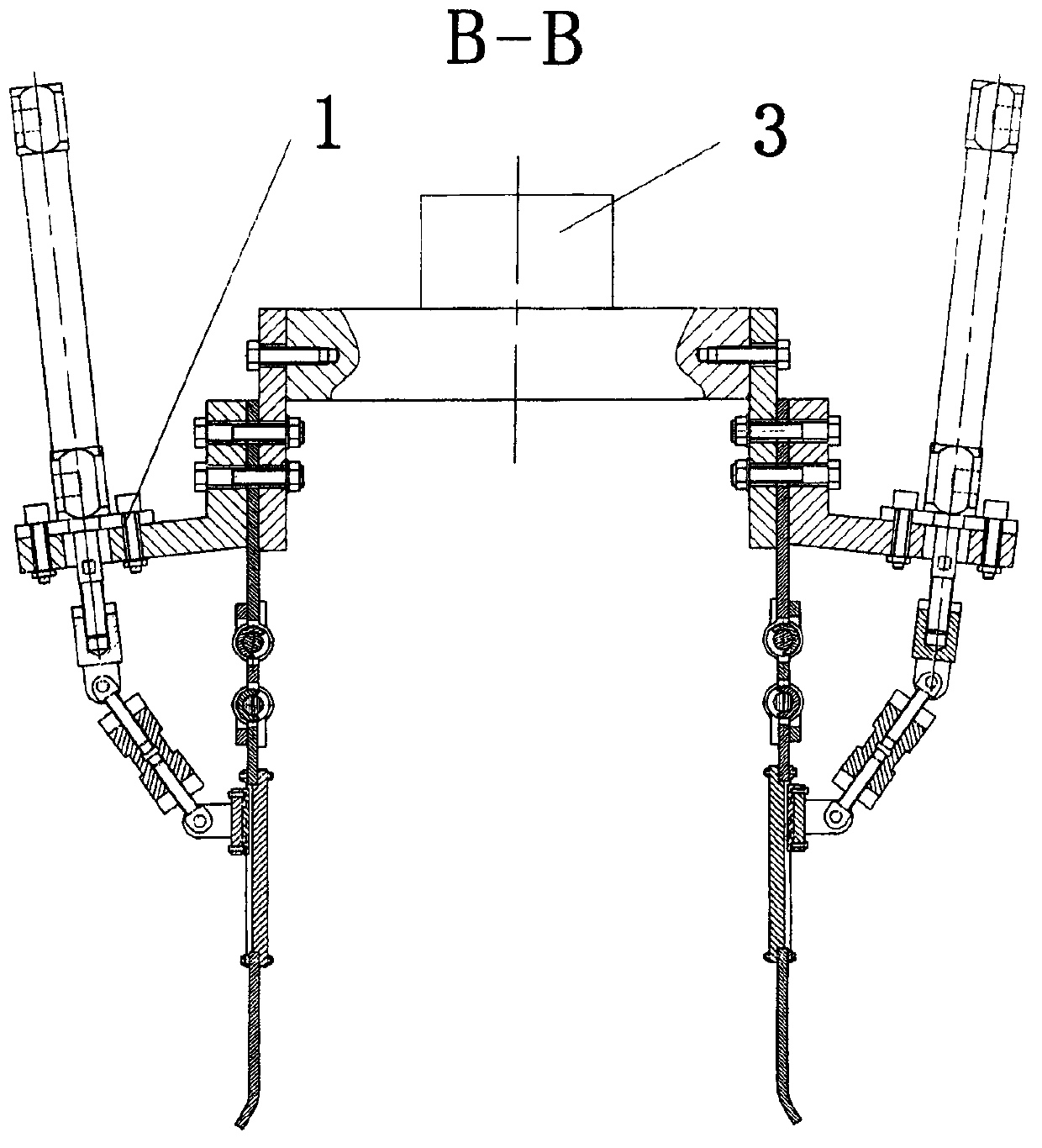

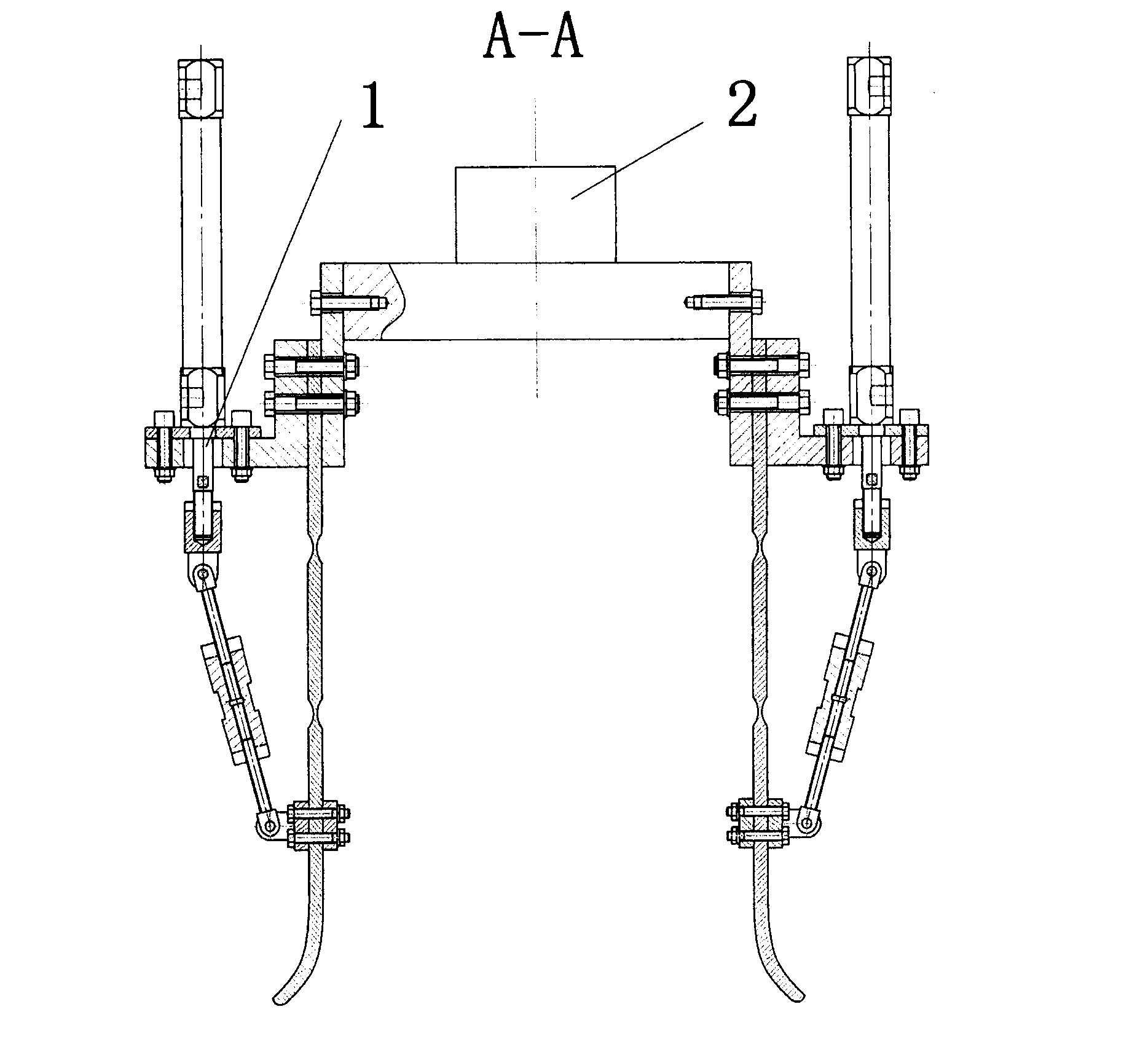

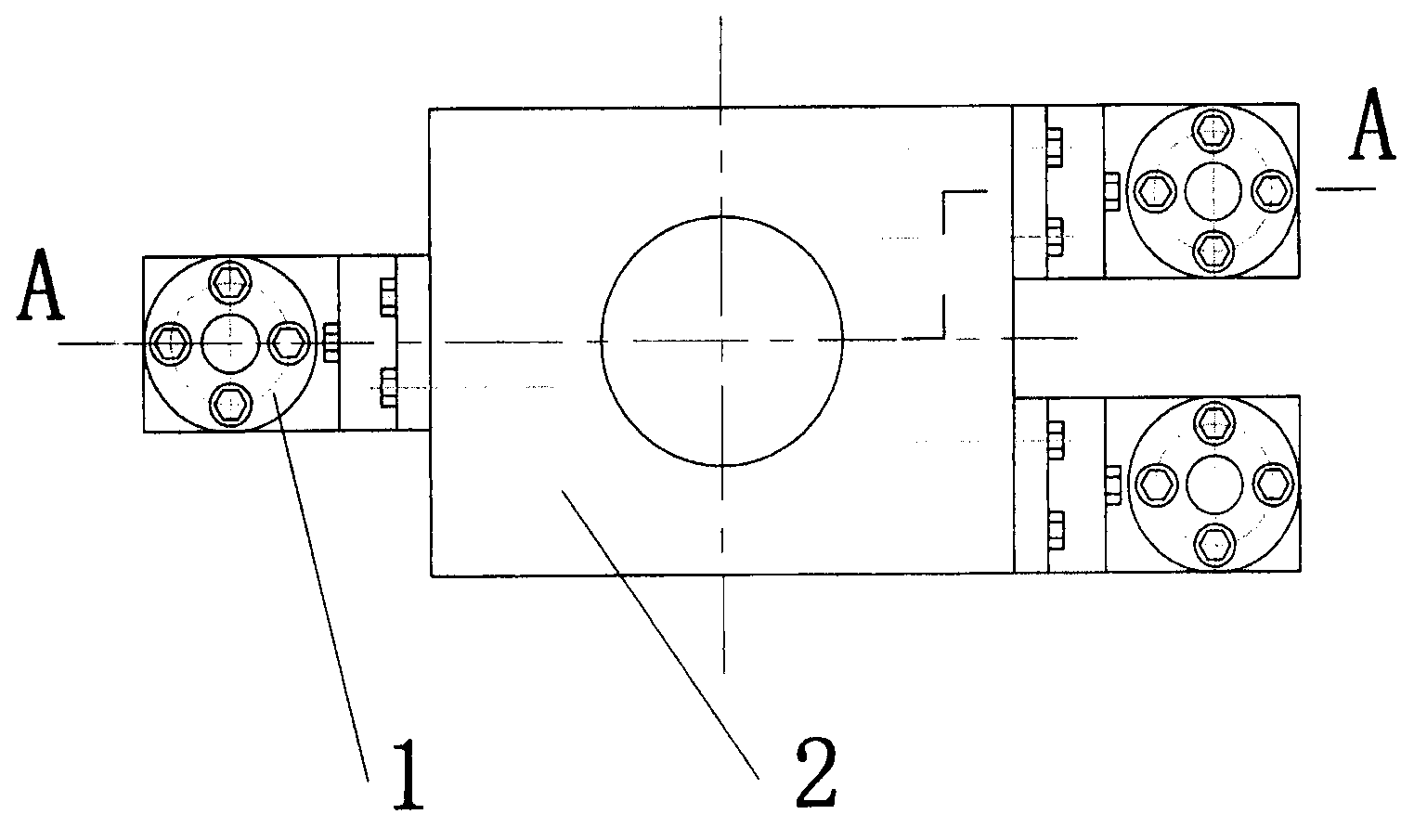

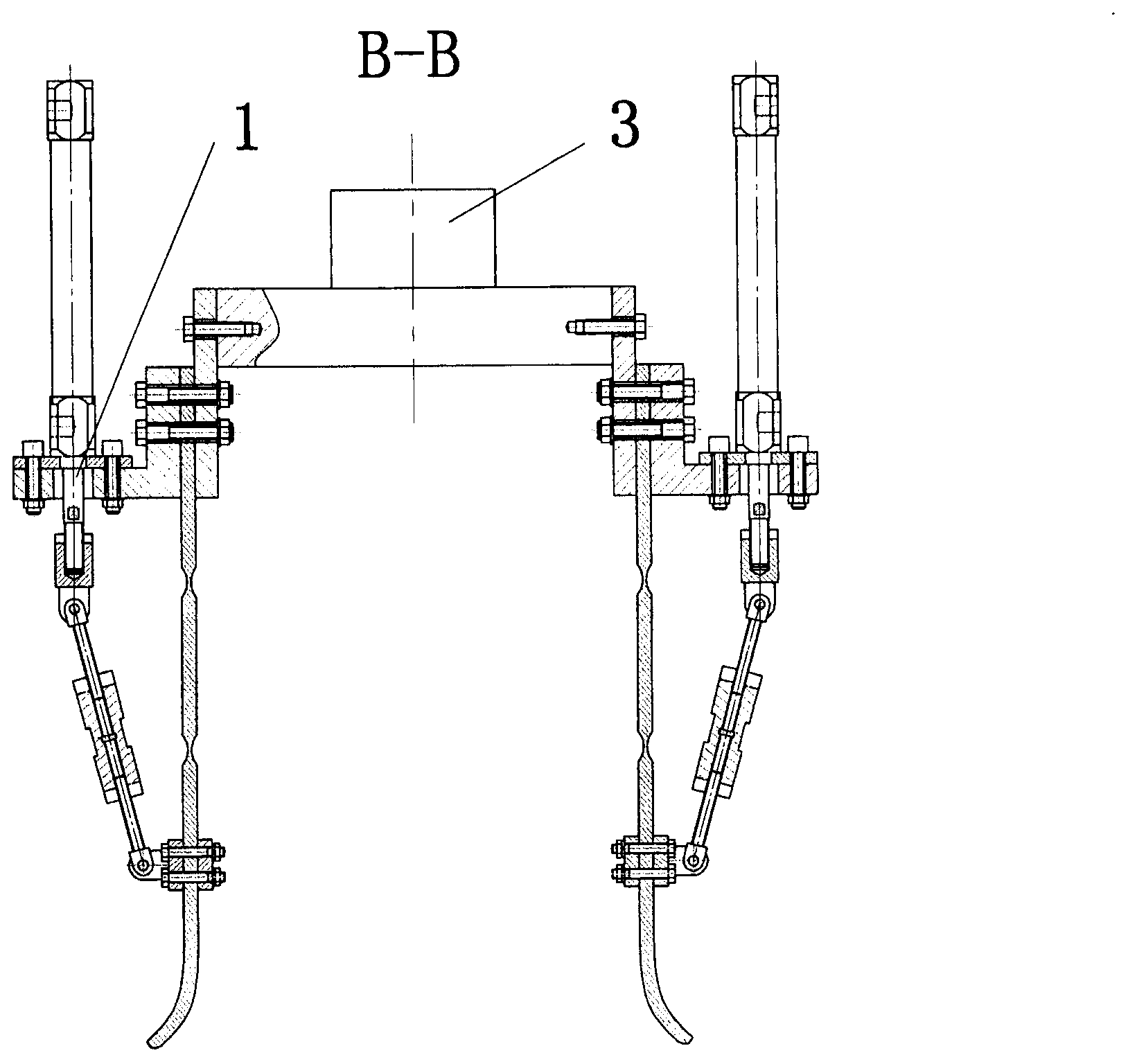

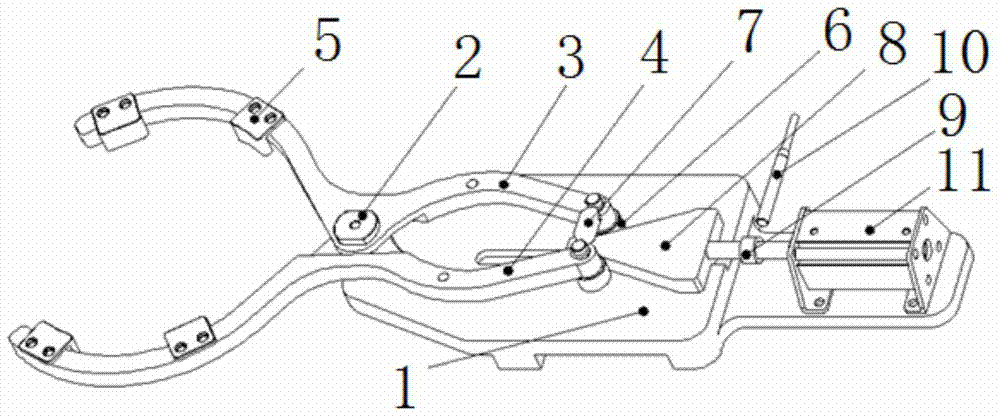

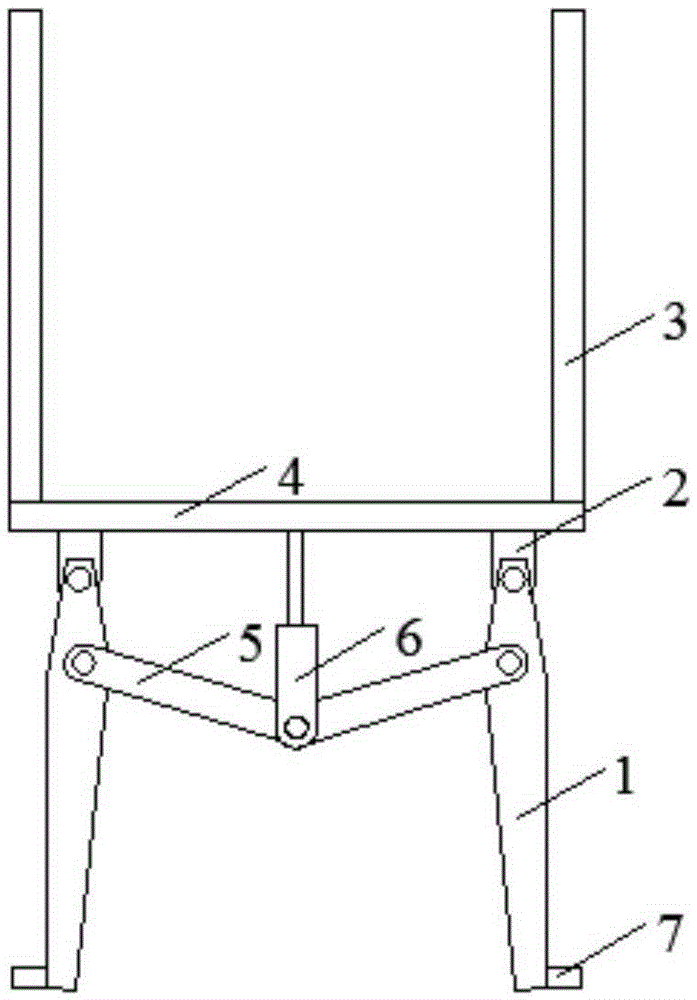

Inferior pot seedling removing and transplanting packaged type clamping end executor

ActiveCN104552327AImprove the success rate of culling and transplantingReliable grabbingGripping headsTransplantingThree degrees of freedomEngineering

The invention discloses an inferior pot seedling removing and transplanting packaged type clamping end executor, which comprises a force application plate, four bearing support fixing rings, four bearing supports, four fixed pins, four bearings, a seedling shovel pressing execution component pressing an air cylinder, an air cylinder fixing support component, a seedling shovel sliding execution component, and a clamping seedling shovel execution component, wherein the air cylinder fixing support component comprises four groups of upper conduit support seats, an air cylinder fixing and supporting plate and two groups of lower conduit support seats; the seedling shovel sliding execution component is formed by four seedling shovel rods with the same structures; the clamping seeding shovel execution component comprises a seedling shove clamping cylinder, an extending arm and two connecting supports; the four seedling shovel rods with the same structures are respectively arranged among the seedling shovel pressing execution component, the air cylinder fixing support component and the clamping seeding shovel execution component. A small hole of the air cylinder fixing and supporting plate is formed in a three degree of freedom mechanical arm of a transplanter. According to the inferior pot seedling removing and transplanting packaged type clamping end executor, the actions of inserting along a hole wall, packaging and clamping pot seedlings, and improving and releasing the pot seedlings are completed, so that the inferior pot seedlings can be reliably captured and effectively removed during the automatic transplanting operation, and the success rate of removing, transplanting, capturing the pot seedlings is improved.

Owner:ZHEJIANG SCI-TECH UNIV

Electric push rod drive controlled flexible gripper with plate spring frameworks

ActiveCN103317521AGreat driving forceImprove gripProgramme-controlled manipulatorGripping headsEngineeringVolute spring

The invention relates to an electric push rod drive controlled flexible gripper with plate spring frameworks. The gripper comprises a palm and three flexible fingers, wherein one flexible finger 1 is installed in the left symcenter of a rectangular palm 2 and the other two flexible fingers 1 are respectively installed on the two sides of the right symcenter of the rectangular palm 2; the three flexible fingers 1 are respectively installed on three corresponding edges of a hexagonal palm 3; each flexible finger has the same structure and mainly comprises an electric push rod and a plate spring; the plate spring as a framework is divided into a deformation section and a gripping section; the lengths of the two sections can be adjusted relatively. The multi-finger gripper is applied to gripping fragile objects or special-shaped objects with shapes and sizes varying and belongs to the technical fields of applications of robots and mechatronics. The gripper is connected with a robot body and is especially suitable for the production and logistics places for gripping, sorting and packaging food, agricultural products and light industrial products.

Owner:兴化市聚鑫不锈钢有限公司

Novel multifunctional grabbing manipulator

The invention provides a novel multifunctional grabbing manipulator and belongs to the field of manipulators. The novel multifunctional grabbing manipulator comprises a main frame and a grabbing mechanism, the grabbing mechanism comprises a grabbing cylinder, a transmission component and grabbing fingers, and the grabbing cylinder is fixed to the main frame and is connected with the grabbing fingers through the transmission component; the transmission component comprises a left rack, a gear and a right rack, the gear is disposed between the left rack and the right rack, the gear meshes with the left rack and the right rack, and a piston rod end of the grabbing cylinder is fixedly connected with the left rack or the right rack; two groups of the grabbing fingers are provided and are connected with the left rack and the right rack, respectively. The novel multifunctional grabbing manipulator is reliable in structure, may perform grabbing flexibly, may grab high-temperature articles, and is simple to perform and high in automation level.

Owner:NINGXIA MACHINERY RES INST

Metamorphic type multifunctional mechanical gripper

The invention discloses a metamorphic type multifunctional mechanical gripper. A push rod is connected with a wrist through a movement pair. A first rod penetrates through a sliding groove, is connected with the push rod through a first fixed hinge, is connected with a second rod through a first movable hinge and is connected with a third rod through a second movable hinge. The second rod is connected with a fourth rod through a third movable hinge. The third rod is connected with the wrist through a second fixed hinge, is connected with a fifth rod through a fourth movable hinge and is connected with the fourth rod through a fifth movable hinge. The fourth rod is connected with a sixth rod through a sixth movable hinge. The fifth rod is connected with the sixth rod through a seventh movable hinge. The wrist is connected with an arm into a whole when installed on a manipulator or the arm of a robot, and four same fingers can be opened or closed at the same time through reciprocating linear movement of the push rod inside the wrist. The metamorphic type multifunctional mechanical gripper is made of light and high-strength materials, thereby being light and convenient and capable of achieving multidirectional and efficient working.

Owner:GUANGXI UNIV

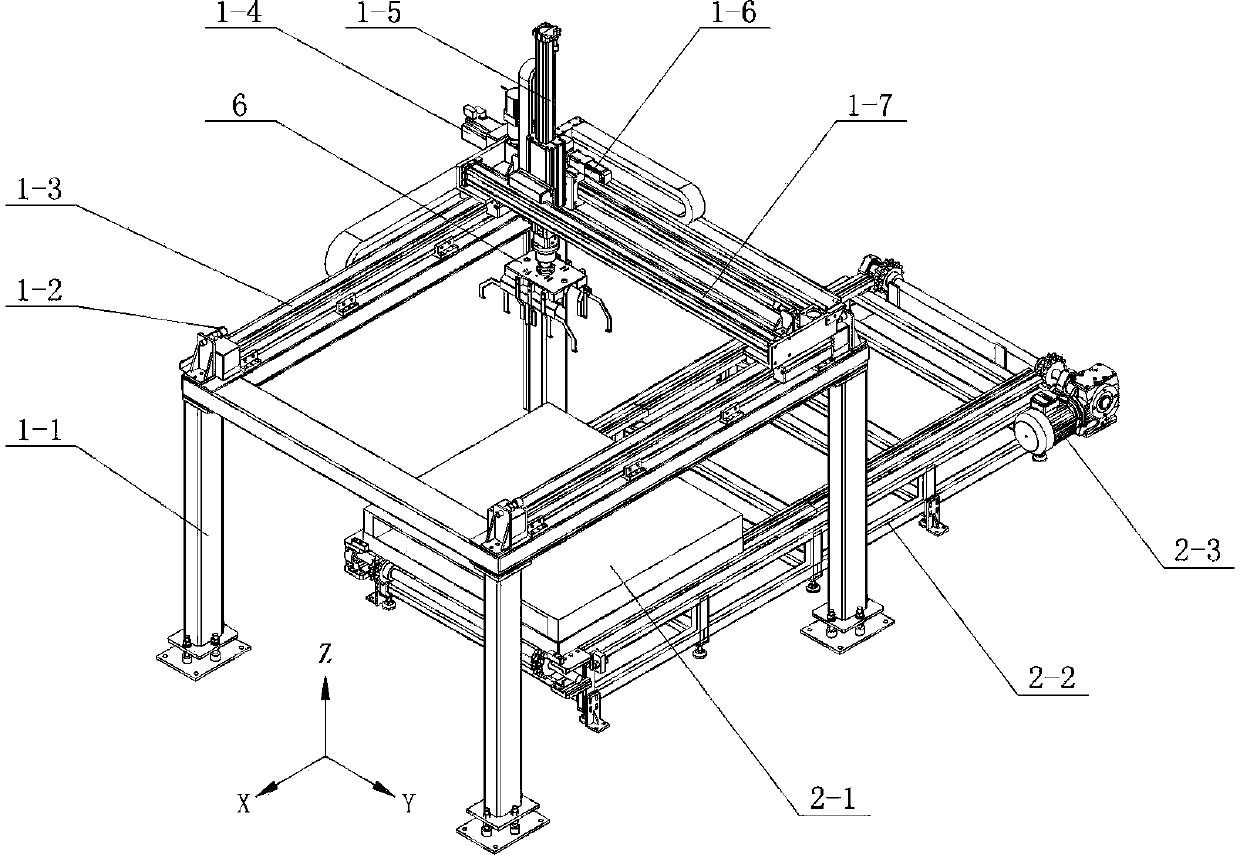

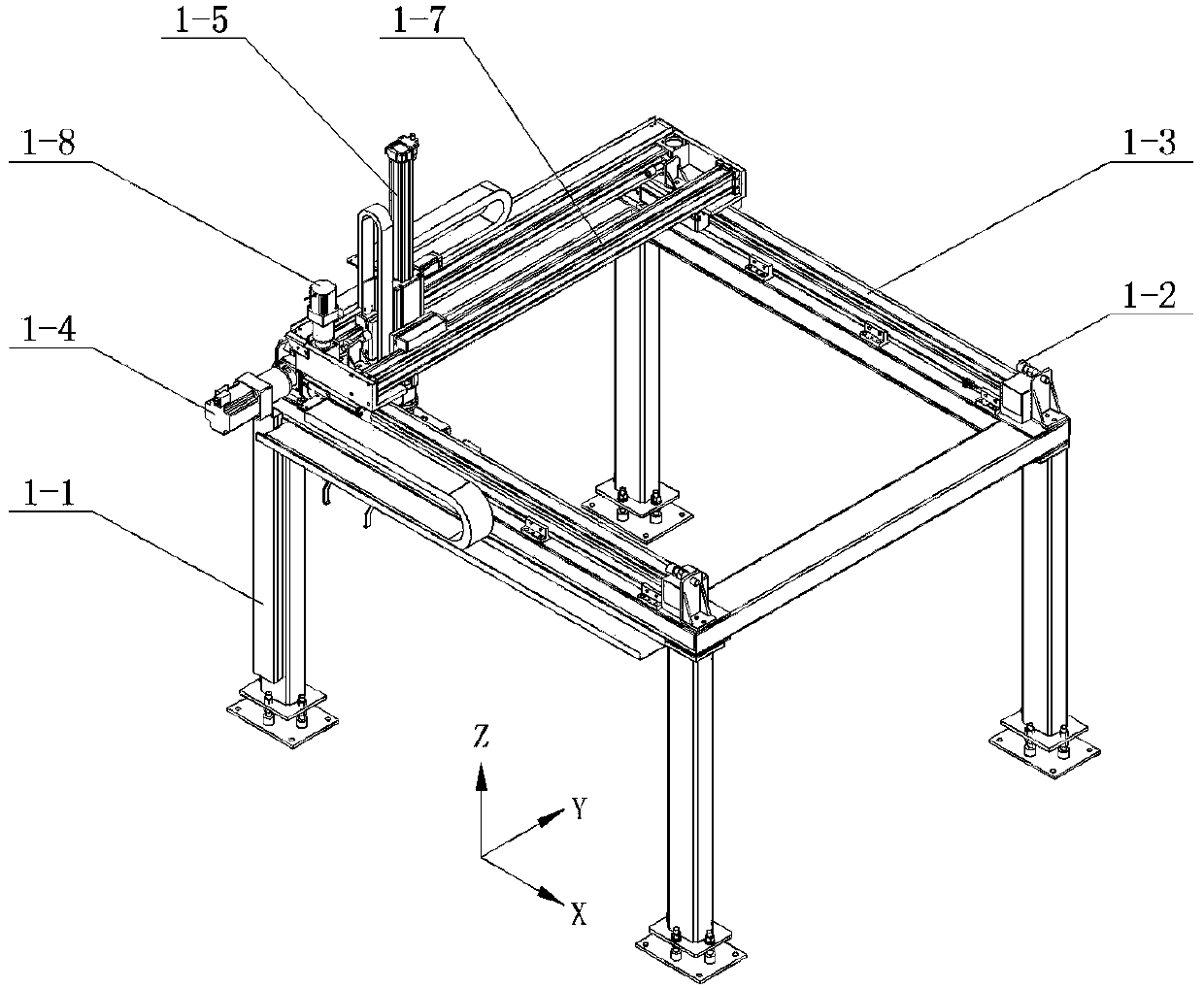

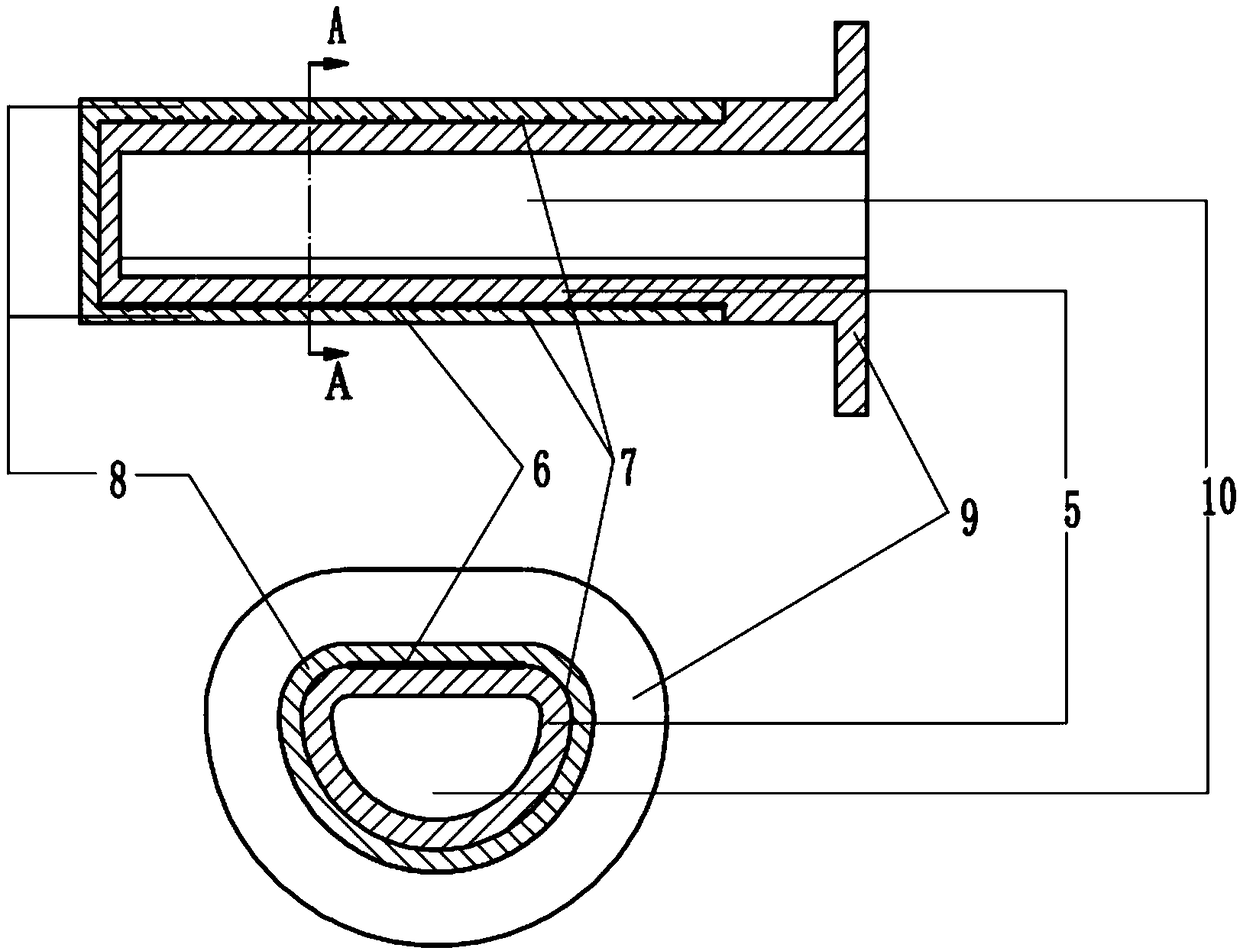

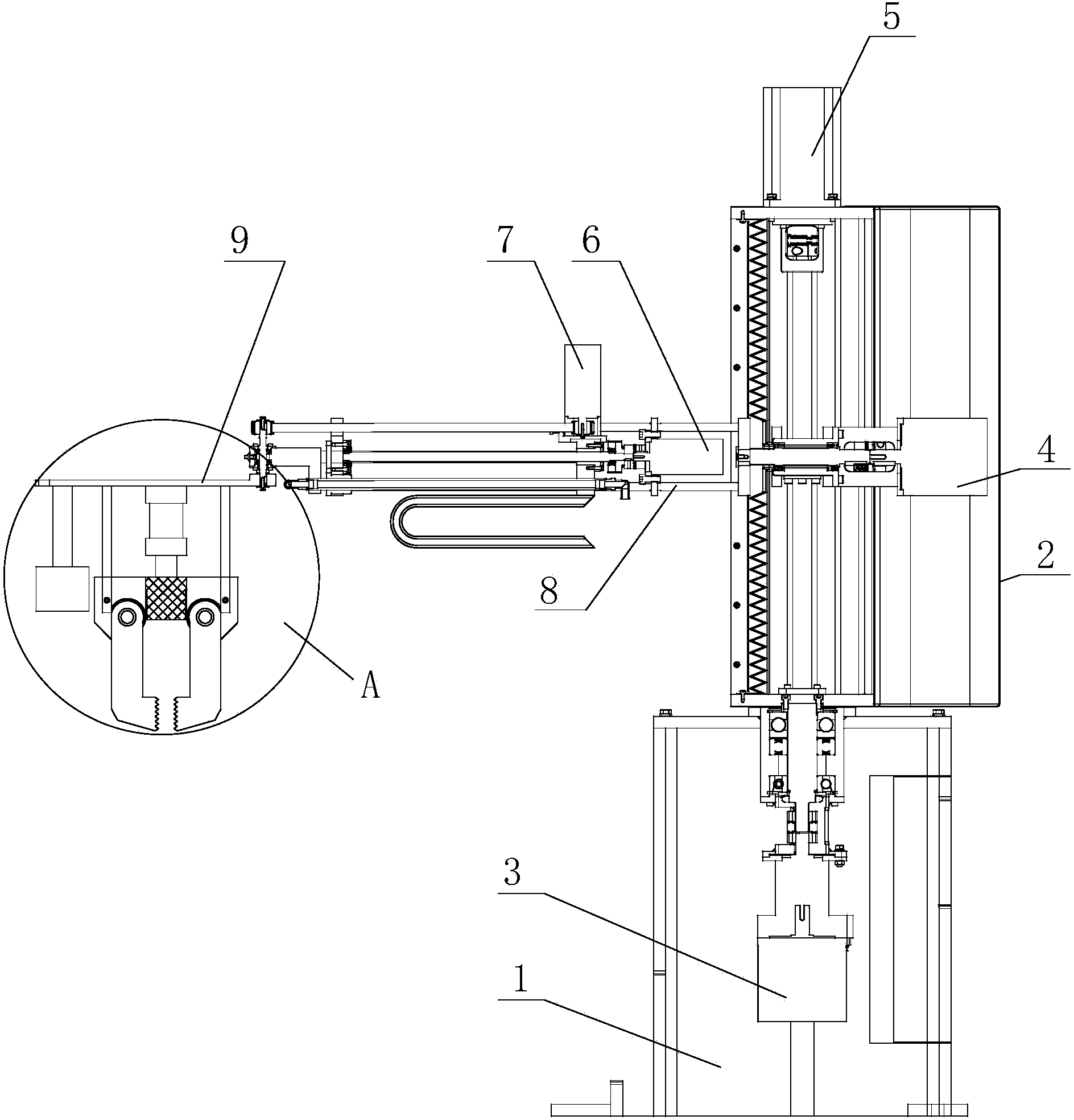

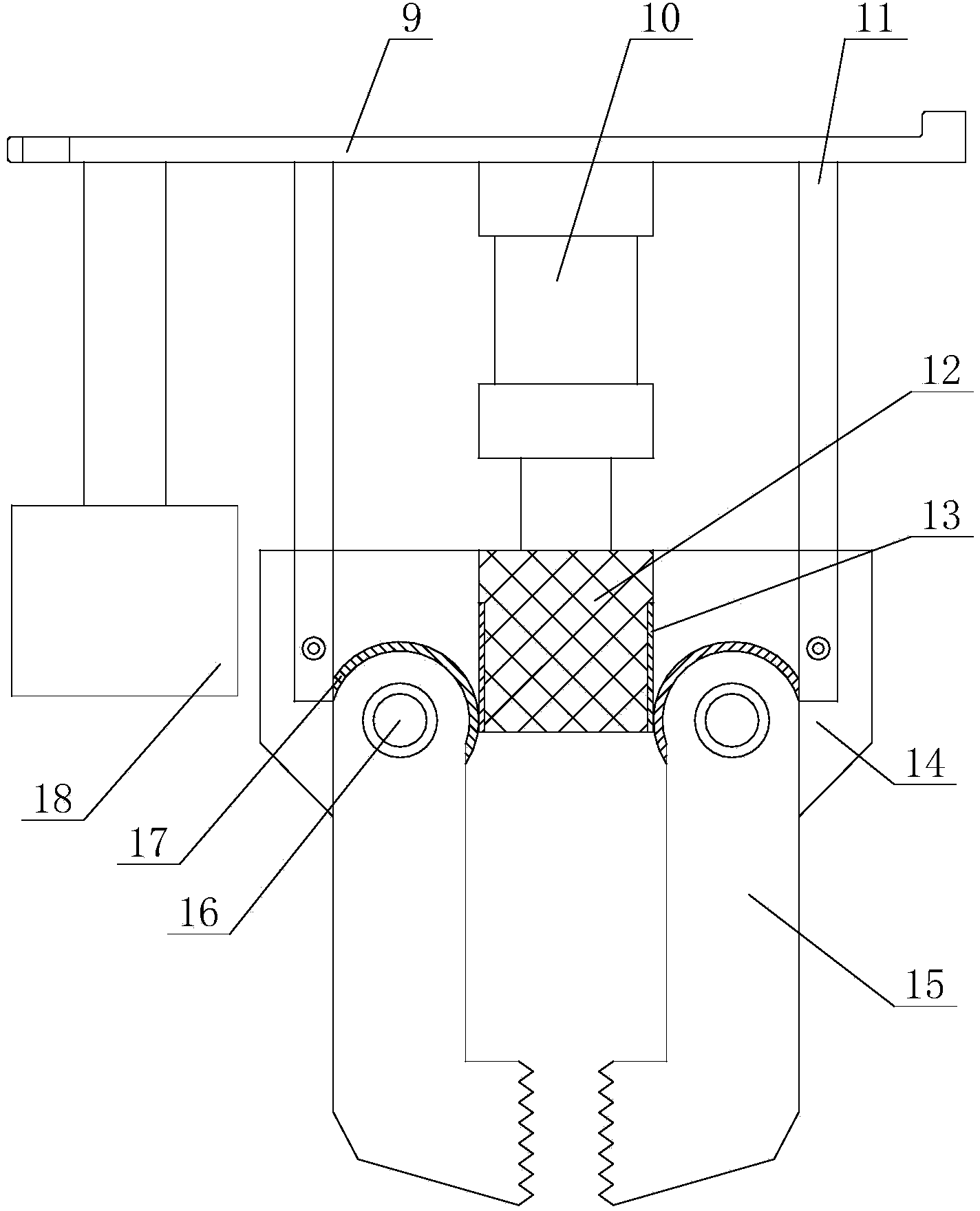

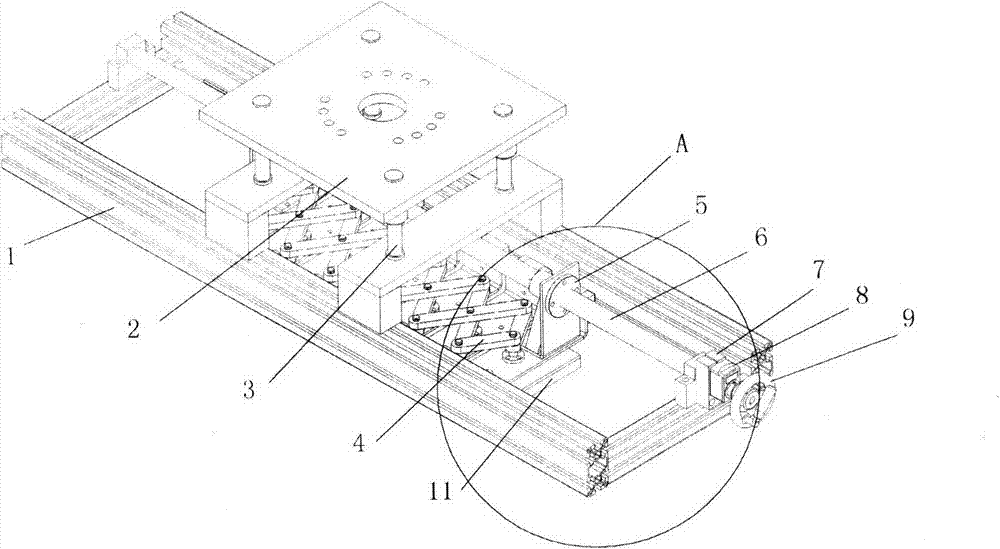

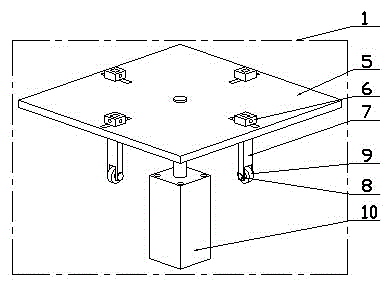

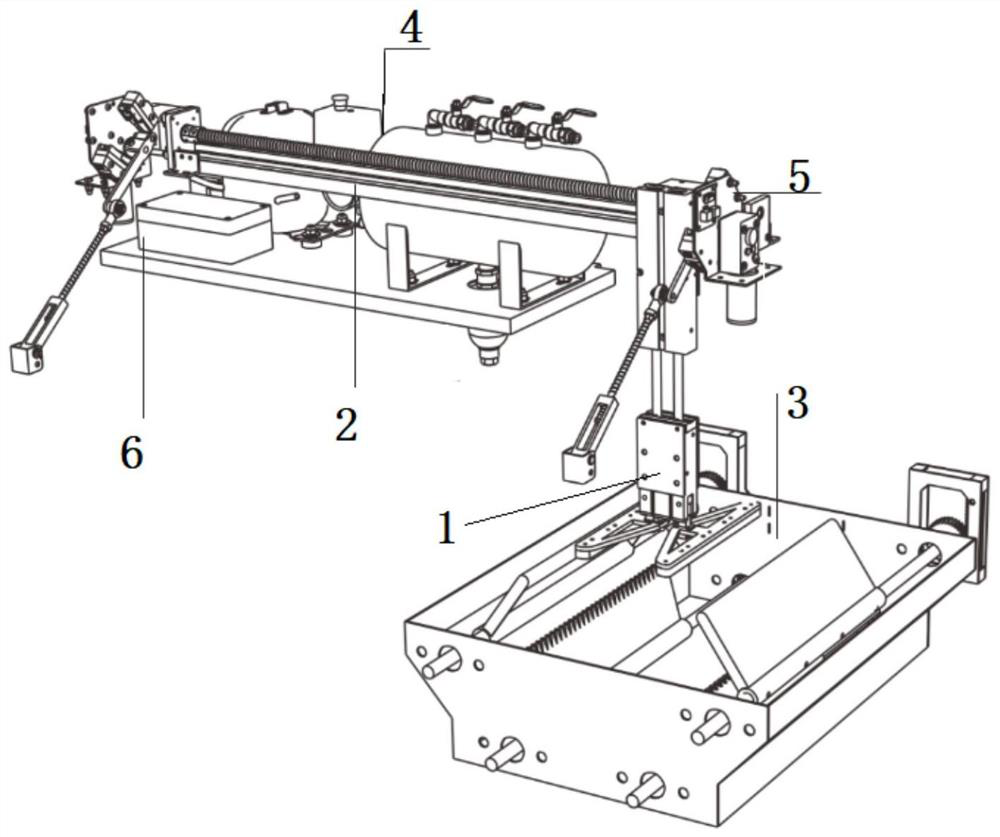

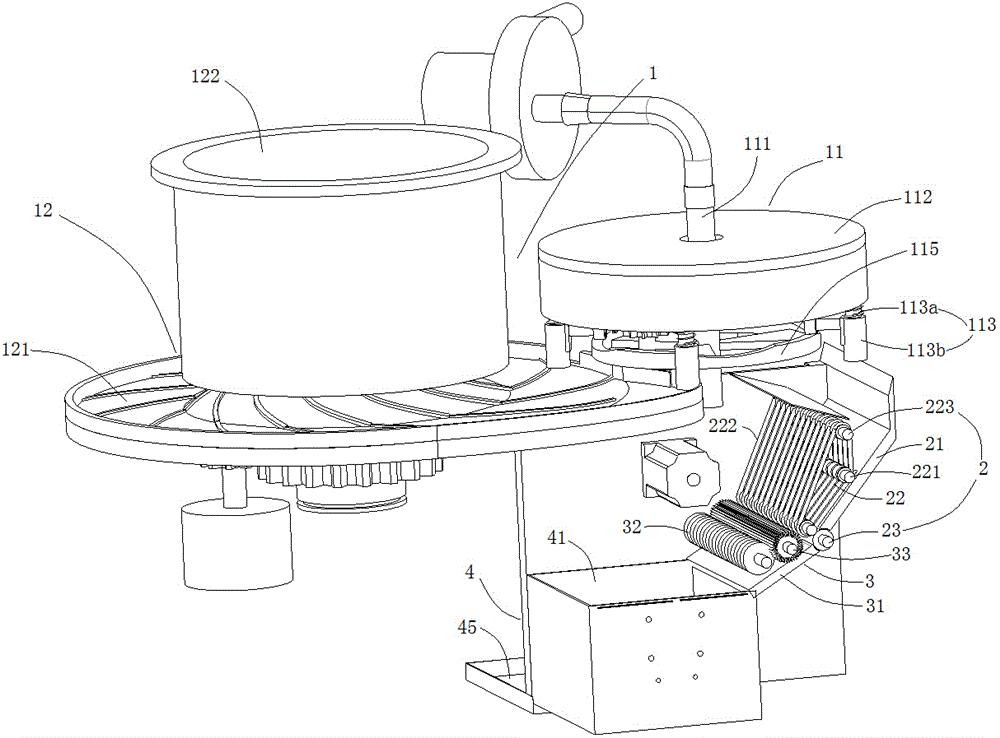

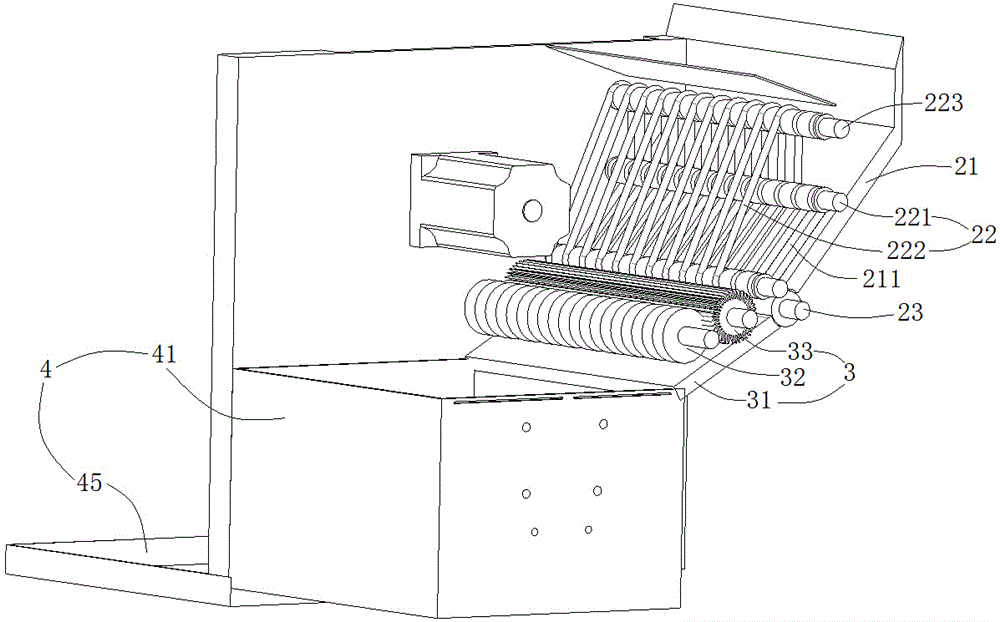

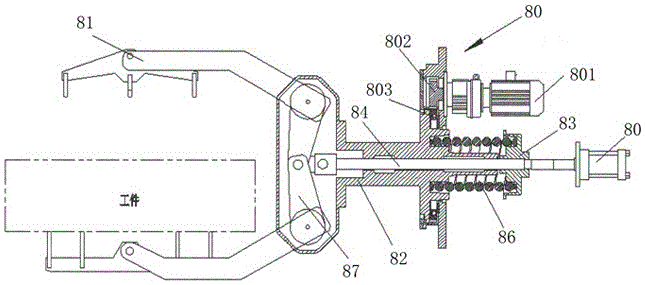

Bag breaking mechanism and automatic object and bag separation system

ActiveCN112124720ANo need to change delivery habitsEasy to grabGripping headsConveyor partsRobot handClassical mechanics

The invention provides a bag breaking mechanism and an automatic object and bag separation system. A garbage bag is grabbed to the position above the bag breaking mechanism through a movable mechanical arm, then the plastic garbage bag is scratched through the bag breaking mechanism, and reliable separation of garbage and the garbage bag is achieved. The automatic object and bag separation systemis characterized by comprising a mechanical arm unit, a horizontal moving unit, the bag breaking mechanism, a power unit and a control unit, the mechanical arm unit is used for grabbing the bag put into the bag breaking mechanism, the horizontal moving unit is used for driving the mechanical arm unit to horizontally move above the bag breaking mechanism, the bag breaking mechanism is used for tearing the bag after the mechanical arm unit grabs the bag, so that the object in the bag falls off, and the bag is separated from the object in the bag, the power unit provides power for the mechanicalarm unit, the horizontal moving unit and the bag breaking mechanism, and the control unit controls the mechanical arm unit, the horizontal moving unit, the bag breaking mechanism and the power unit tooperate.

Owner:万谦科技(北京)有限公司

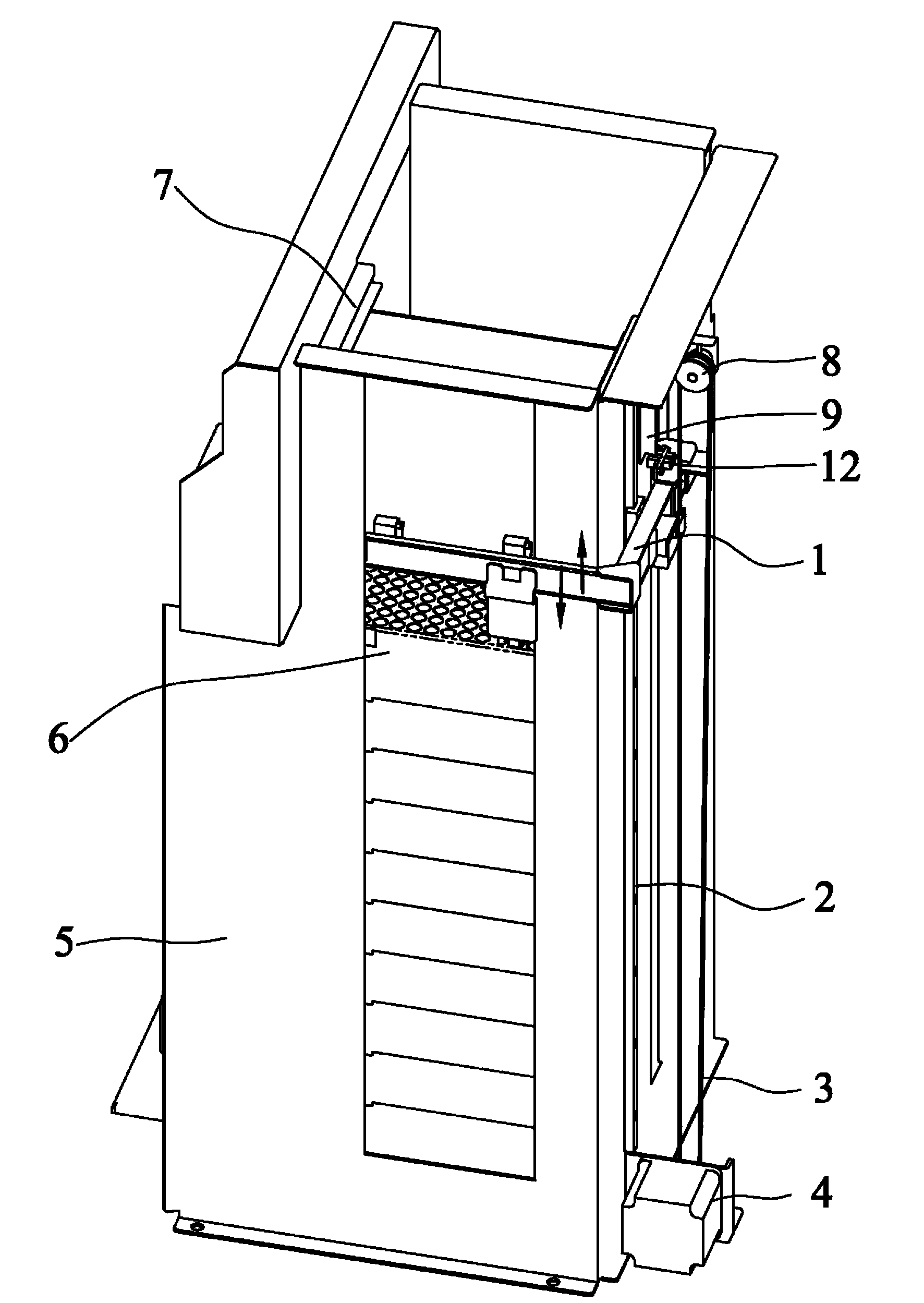

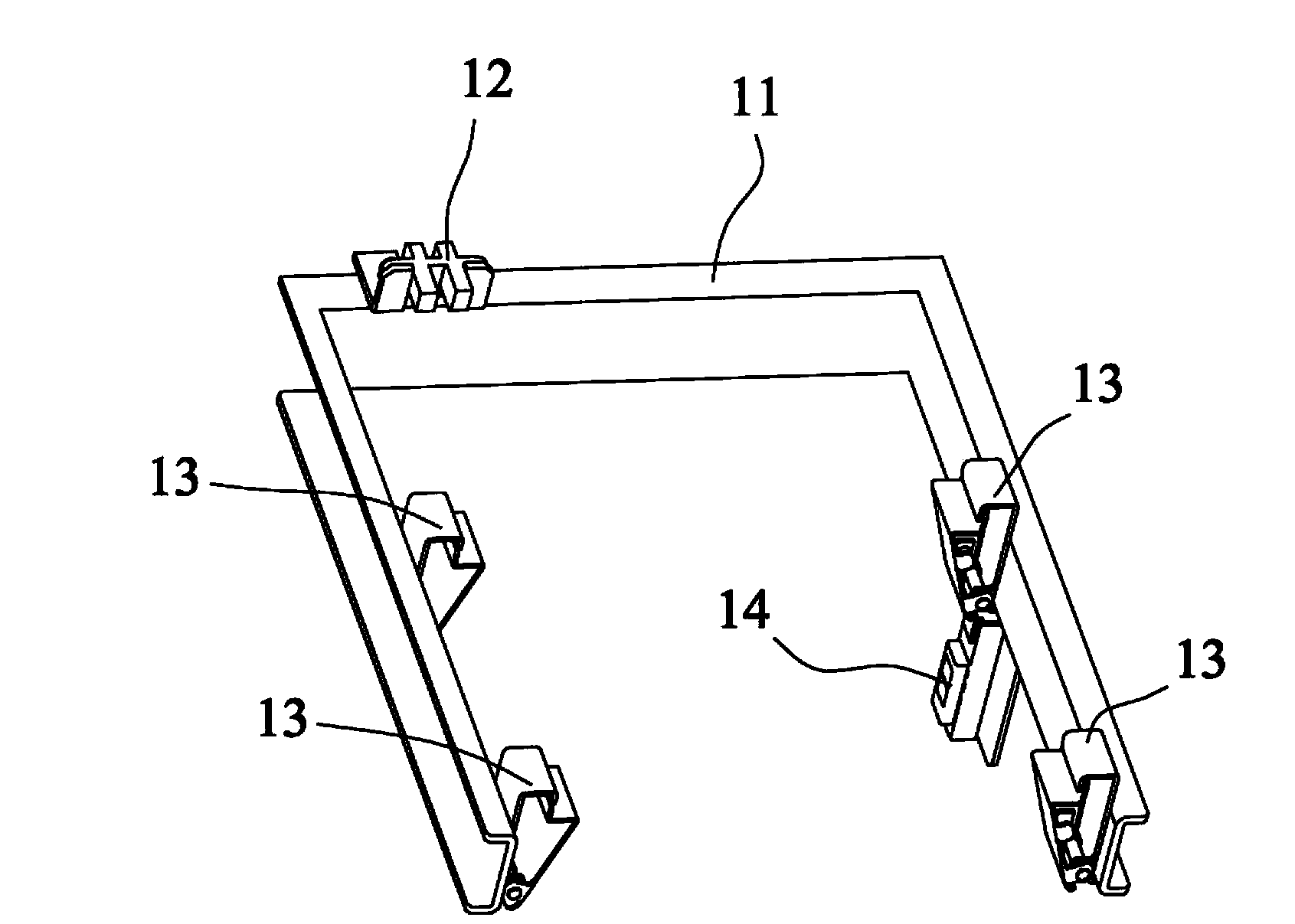

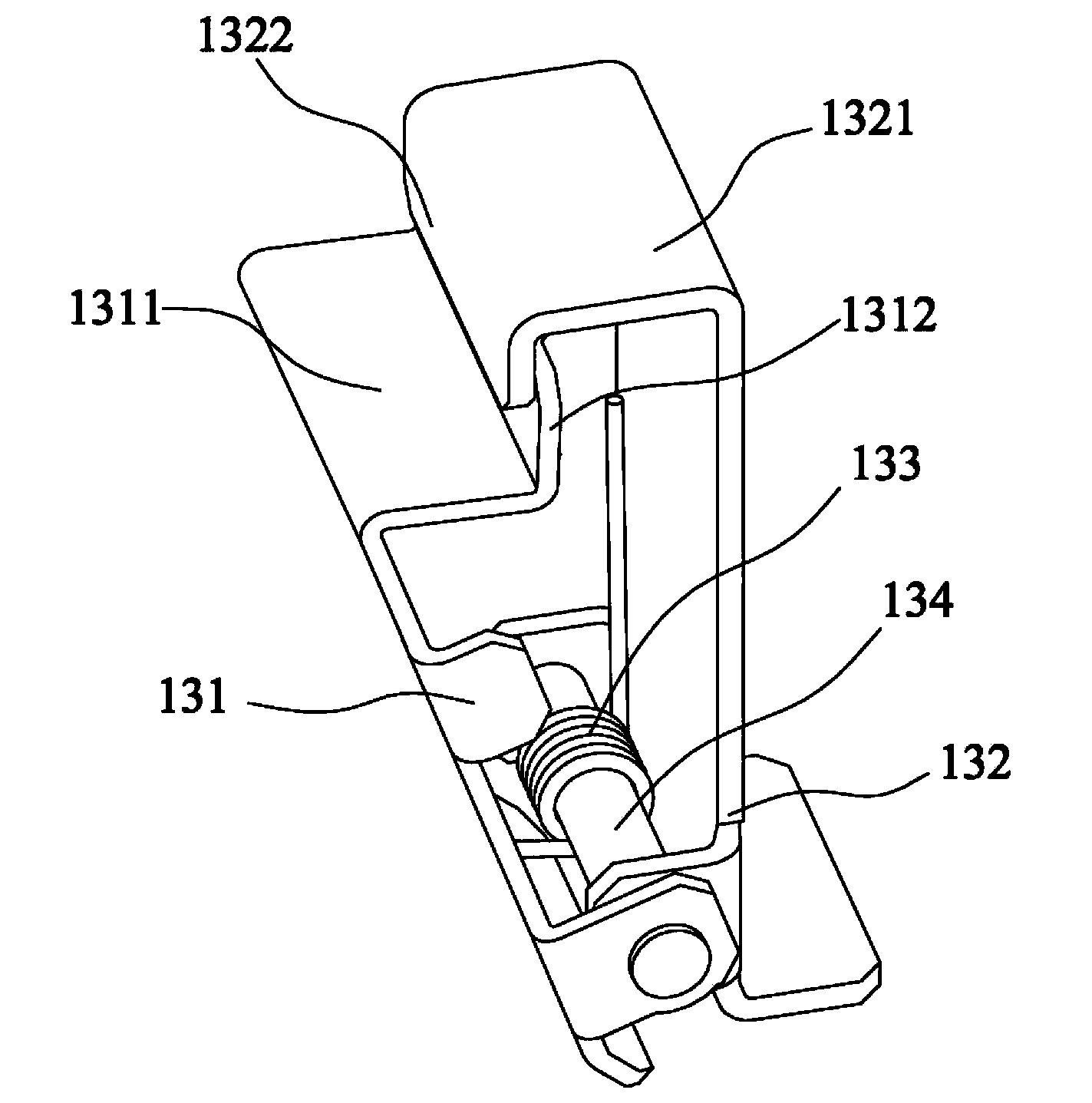

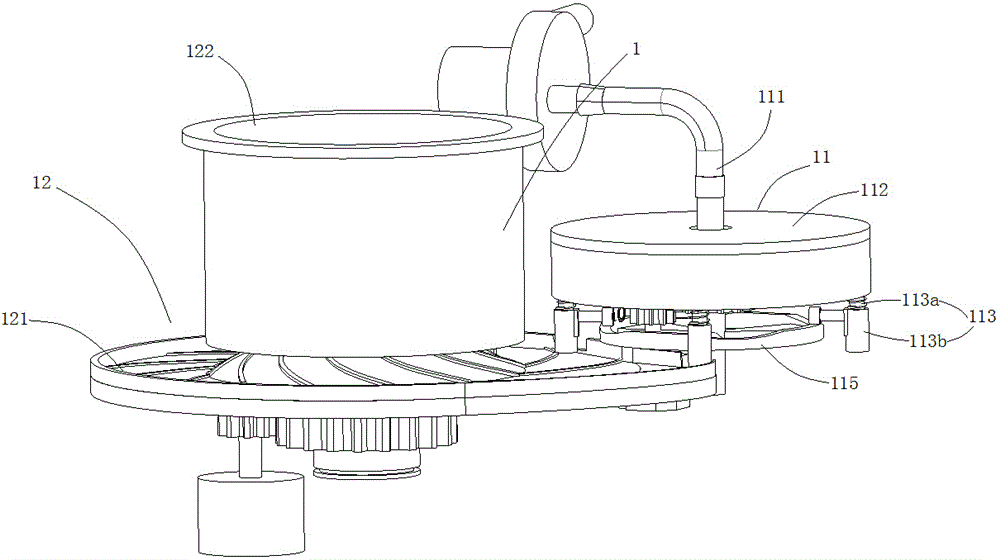

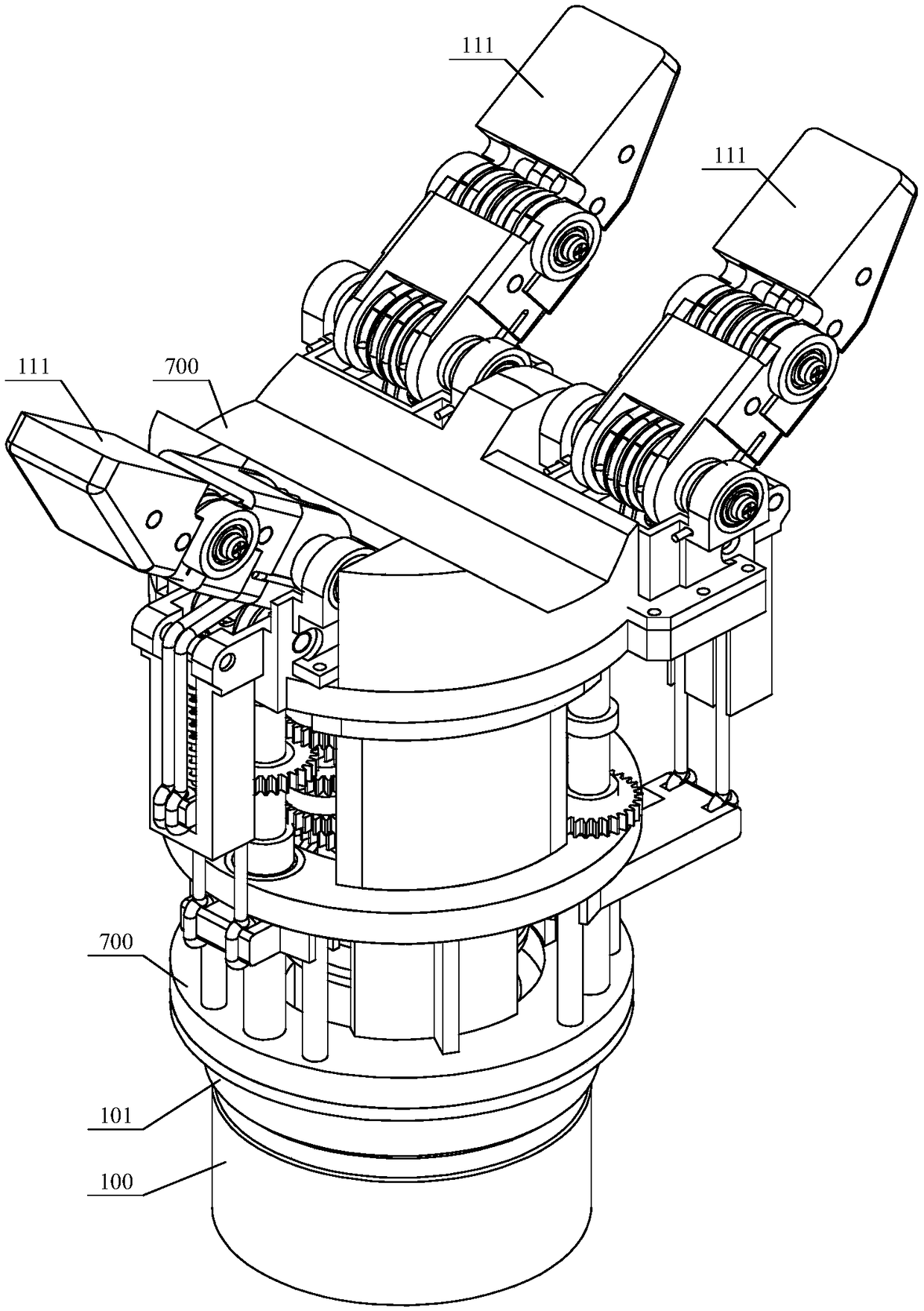

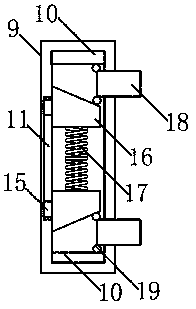

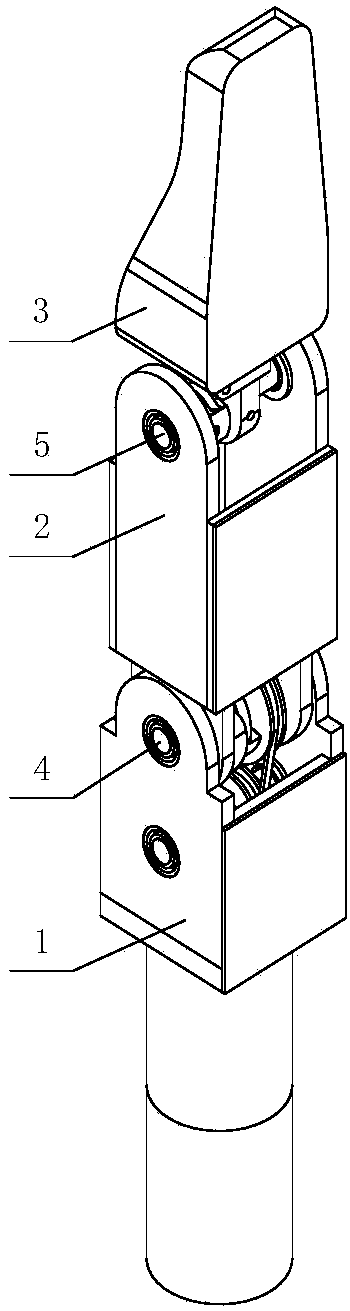

Cup box grabbing mechanism and cup box grabbing method

ActiveCN104108603AReliable grabbingRealize automatic deliveryDe-stacking articlesConveyor partsEngineeringMechanical engineering

Owner:SHENZHEN MINDRAY BIO MEDICAL ELECTRONICS CO LTD

Paper money friction flattening device

InactiveCN105600531ARelieve pressureReduce frictionArticle feedersArticle deliveryPulp and paper industryTotal thickness

The invention discloses a paper money friction flattening device. The paper money friction flattening device is characterized in that: the paper money friction flattening device comprises a loading mechanism, and a flattening mechanism, a shaping mechanism and a paper money collecting box, which are connected sequentially, wherein the flattening mechanism comprises a rectangular bottom plate which is arranged obliquely in a length direction, so that the paper money can slip long the upper surface of the bottom plate; a friction mechanism is arranged above the bottom plate, one side of the friction mechanism, close to the bottom plate, can move downwards in a length direction of the bottom plate, and a gap between the friction mechanism and the bottom plate is smaller than the total thickness of two paper moneys; a material inlet is formed between the upper end of the bottom plate and the friction mechanism and is arranged under a material outlet end of the loading mechanism. In general, the paper money friction flattening device has the advantages that the device can realize the grabbing, loading, automatic flattening and collection of the paper money, can grab the paper money reliably, has appropriate loading pace, high flattening speed, high efficiency and good reliability, is favor for reducing the labor intensity of workers, and can improve the working efficiency.

Owner:CHONGQING UNIV OF TECH

Tendon rope transmission coupling self-adaption three-finger differential motion robot hand paw device

The invention relates to a tendon rope transmission coupling self-adaption three-finger differential motion robot hand paw device, and belongs to the technical field of robots. The tendon rope transmission coupling self-adaption three-finger differential motion robot hand paw device comprises a hand paw base, three double tendon rope tandem type coupling self-adaption fingers, a hand paw transmission mechanism, a driver, a single-input three-output differential mechanism and the like. By means of the device, the robot finger coupling quick folding grabbing and self-adaption grabbing functionsand the overall hand paw self-adaption grabbing function are achieved. The device can drive all fingers to achieve quick coupling rotation to achieve self-adaption clamping of objects according to thedifferent shapes and positions of the objects, the remaining fingers / finger can be continuously driven to continuously move when any one or two of the fingers are blocked until the objects are stablyclamped, and the aim of self-adaption wrapping of the objects in different shapes and sizes through all fingers and the overall hand paw is achieved; the grabbing scope is large, and grabbing is stable and reliable; one driver is used for driving the three fingers; and the device has the high adaptability and large grabbing force and is stable and reliable to grab and suitable for various robots.

Owner:HARBIN INST OF TECH

Multifunctional storage battery stacking tongs

ActiveCN103662852ASolve manual palletizingSolve the paper backing problemGripping headsStacking articlesPaper basedEngineering

Owner:FENGFAN

Transferring mechanical gripper

Owner:XIAN ZHIDIAN INFORMATION TECH LTD

Self-locking boosting type flexible and smooth tail end gripper for serial connection loose hinge

ActiveCN104175325AKeep a safe gripSo as not to damageProgramme-controlled manipulatorGripping headsGrip forceSelf locking

The invention relates to a self-locking boosting type flexible and smooth tail end gripper for a serial connection loose hinge. The tail end gripper consists of a palm and three flexible fingers, wherein the palm is of two kinds of structures including a rectangular structure and a hexagonal structure, each flexible finger has the same structure and mainly consists of an inner guide air cylinder, a linear guide rail (which can also be a linear bearing) and the serial connection loose hinge, one torque spring is respectively arranged on a hinge mandrel of each serial connection loose hinge, the characteristic parameters and the pre-tightening angle of the torque springs are optimized and designed according to the characteristics of gripped objects, and the gripping force is generated through the driving of the air cylinder. The tail end gripper is applied to the gripping of fragile brittle objects or special-shape objects with variable shapes or sizes, belongs to the technical field of application of robots and mechatronics, is connected with a robot main body, and is particularly applicable to the fields of logistics and production such as gripping, sorting and packaging of food, farm products and light industrial products.

Owner:泰州市华驰不锈钢制品有限公司

Pneumatic serial-connection flexible hinge multi-finger paw of compliant mechanism

ActiveCN103213138AImprove versatilityReliable grabbingProgramme-controlled manipulatorGripping headsCompliant mechanismFinger structure

The invention relates to a pneumatic serial-connection flexible hinge multi-finger paw of a compliant mechanism. The multi-finger paw consists of a palm and three flexible fingers, and the palm has a rectangular structure and a hexagonal structure; the structure of each flexible finger is identical, and each flexible finger structure mainly consists of an internal guide air cylinder and a serial-connection flexible hinge; the multi-finger paw is driven by an air cylinder to produce a grasping force, the multi-finger paw is applied to a fragile object or used for grasping a specially-shaped object with a varied shape and varied size; and the flexible finger of the multi-finger paw is a compliant mechanism, and the serial-connection flexible hinge is a deformation element of the compliant mechanism. The pneumatic serial-connection flexible hinge multi-finger paw has the characteristics that: a good flexible degree of freedom and good buffering performance can be realized for an outer load, and the flexible adaptability is good. The pneumatic serial-connection flexible hinge multi-finger paw belongs to the technical field of the robot and mechatronics; and the pneumatic serial-connection flexible hinge multi-finger paw is connected with a robot main body and particularly suitable for the production and logistics field such as the grasping, sorting and packaging of food, agricultural products and light products.

Owner:泰州市华驰不锈钢制品有限公司

Mechanical arm

InactiveCN105128023ASmall sizeSynchronous slidingProgramme-controlled manipulatorGripping headsStructural balanceRobotic arm

The invention relates to a mechanical arm. The mechanical arm comprises a mechanical arm body and a mechanical claw located at the tail end of the mechanical arm body. The mechanical claw comprises an installing base. The installing base is provided with a mechanical arm clamping claw, a claw driving device used for driving the mechanical arm clamping claw to be closed and opened, and a connecting rod mechanism connected with the mechanical arm clamping claw and the claw driving device. The connecting rod mechanism comprises a sliding block structure driven by the claw driving device to move in a guiding manner in the front and back directions. The sliding block structure is connected with the output end of the claw driving device through a connecting arm. The connecting arm comprises a first connecting section fixedly connected with the output end of the claw driving device and a second connecting section fixedly connected with the sliding block structure. The second connecting section extends in the guiding moving direction of the sliding block structure, and the end, deviating from the first connecting section, of the second connecting section is located on the side, close to the claw driving device, of the first connecting section. The mechanical arm can be used for solving the technical problem that due to the fact that the size of a mechanical claw in the prior art is large, the structural balance of a whole mechanical arm is affected.

Owner:HENAN UNIV OF SCI & TECH

Manipulator used for griping high-temperature workpieces

The invention discloses a manipulator used for griping high-temperature workpieces. The manipulator comprises a first grip pawl and a second grip pawl which are opposite to each other and hinged through a rotating pin; the manipulator further comprises a manipulator mounting plate and a power cylinder, the rotating pin and the power cylinder are arranged on the manipulator mounting plate, and a driving block used for driving same ends of the first grip pawl and the second grip pawl to move oppositely is arranged on a piston rod of the power cylinder, and a cooling hole is arranged in the rotating pin. Only one rotating hinged point is arranged on the griping manipulator, so that the manipulator is simple in structure and low in cost, a manipulator joint is less prone to being jammed or loosened, the power cylinder is away from the front half section in distance, service life of the cylinder is prolonged, and the high-temperature workpieces can be gripped stably and reliably.

Owner:芜湖陀曼精机科技有限公司

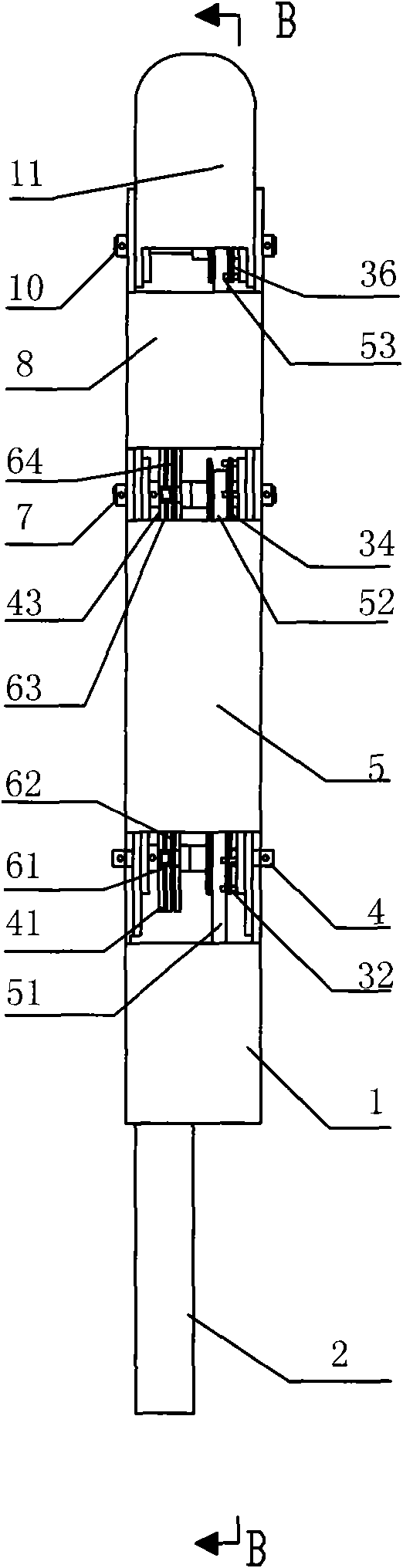

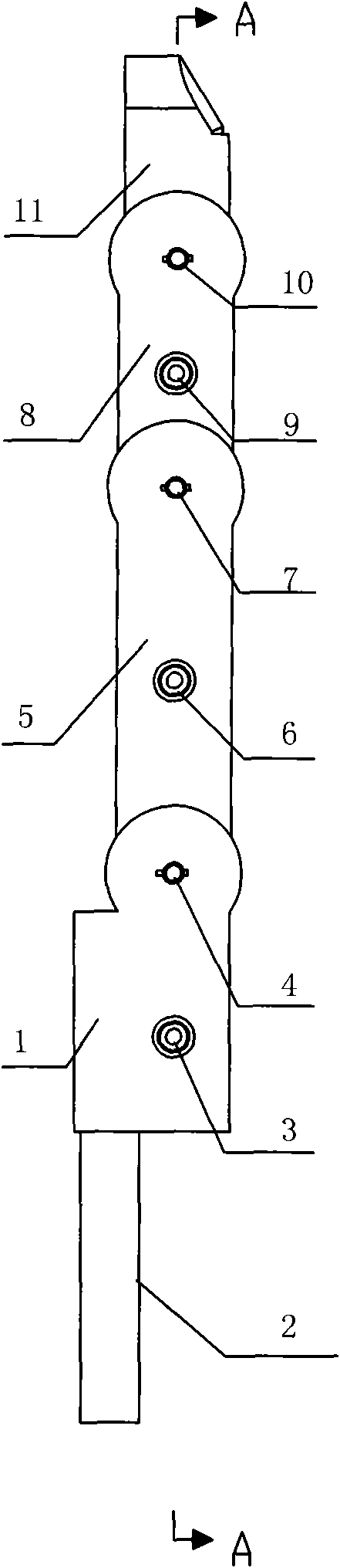

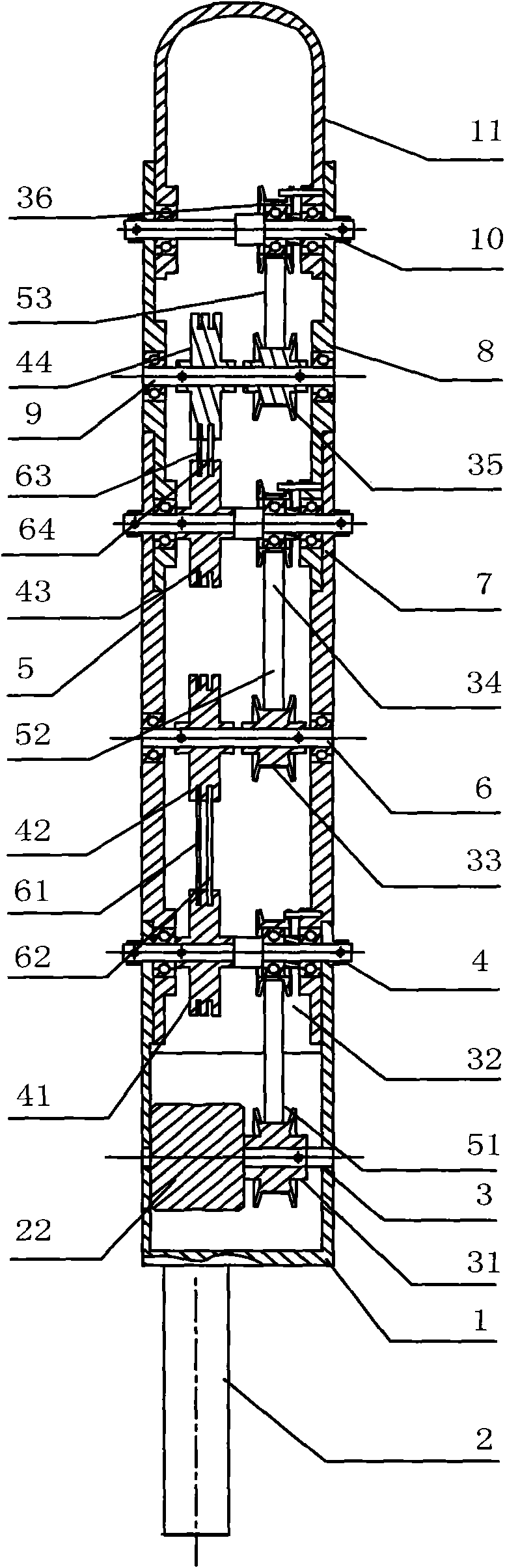

Finger device of coupling three-joint robot

InactiveCN101633170ANo transmission backlash problemSimple structureGripping headsCouplingElectric machinery

The invention relates to a finger device of a coupling three-joint robot, belonging to the technical field of human simulation robots. The finger device comprises a pedestal, an electric motor, a near joint shaft, a first finger section, a middle joint shaft, a second finger section, an end finger section, two transition shafts, two sets of 8-shaped wheel type transmission mechanisms, two sets of parallel wheel type transmission mechanisms and the like. The device utilizes the electric motor, the two sets of 8-shaped wheel type transmission mechanisms, the parallel wheel type transmission mechanisms and the like to comprehensively achieve the special effect that fingers are bent to grasp an object by a three-joint coupling mode. The device has no transmission gap problem and can realize long distance transmission. The invention has simple structure, stable and reliable grasping, low cost, convenient installation and maintenance, small size, light weight and easy control. Moreover, the appearance and the grasping motion of the finger device are similar to those of hands, and therefore, the invention is especially suitable for serving as the fingers of the hands of the human simulation robots.

Owner:WUXI RES INST OF APPLIED TECH TSINGHUA UNIV +1

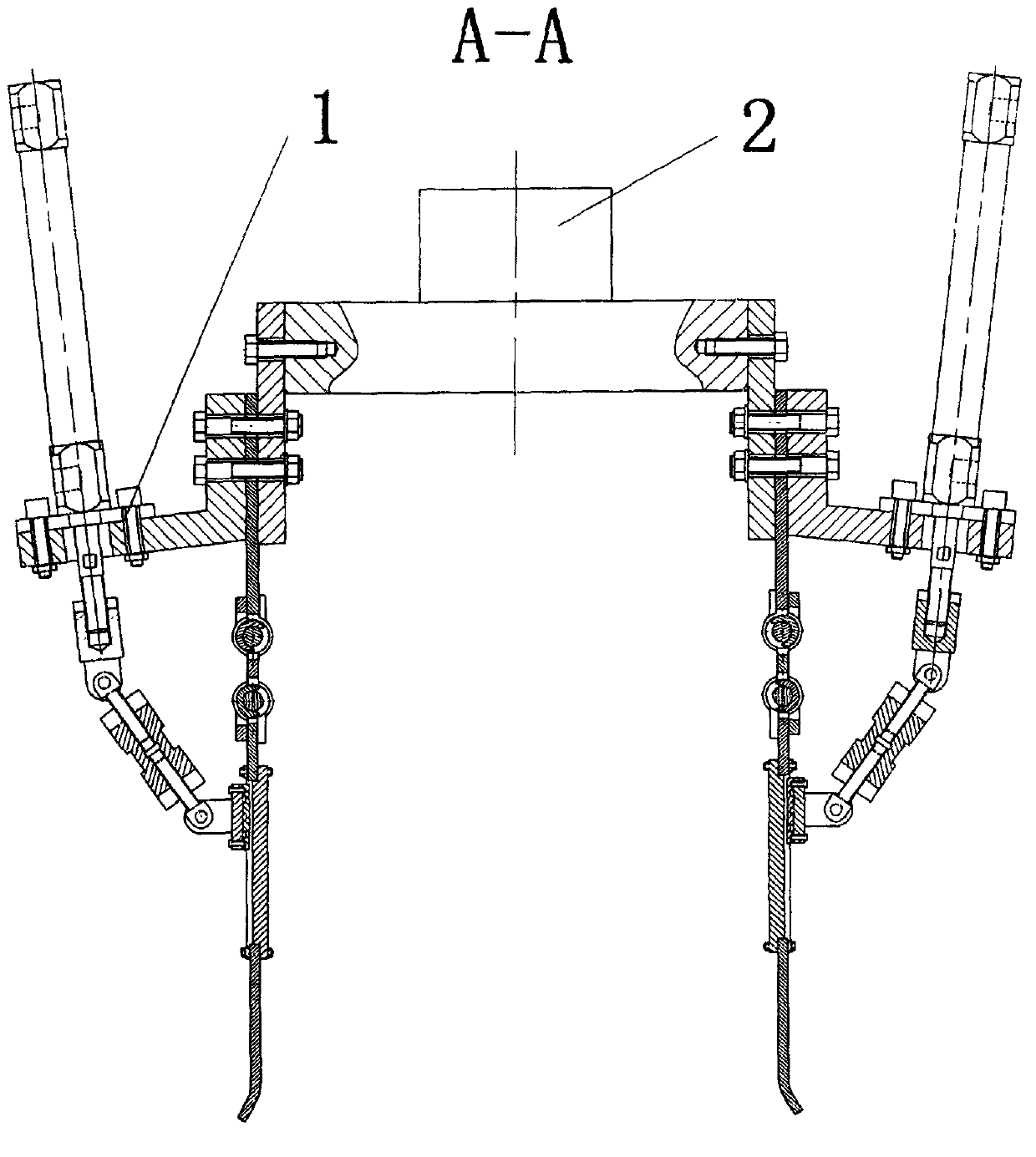

Gripper jaws for transporting steel plate

InactiveCN105270994ANot easy to shakeNot easy to damageLoad-engaging elementsHydraulic cylinderEngineering

The invention discloses a gripper jaws for transporting a steel plate. The gripper jaws are installed on the two sides respectively and connected with respective connection rods through hinges, and the connection rods are also connected with a rack through hinges; in this way, the connection rods can rotationally move relative to the gripper jaws and the rack. The tail ends of hydraulic telescopic cylinders are connected with the rack through bolts, and the other ends of the hydraulic telescopic cylinders are connected with the corresponding gripper jaws respectively. The gripper jaws are controlled to open and close by controlling the telescopic lengths of the hydraulic cylinders. The long edges of L-shaped plates abut against the gripper jaws, and the short edges of the L-shaped plates are on the same plane with the bottom ends of the gripper jaws. The L-shaped plates are fixed on the gripper jaws through bolts, and in this way, the bottom edge of the steel plate abuts against the short edges of the L-shaped plates to prevent the steel plate from sliding down. The steel plate is not liable to shaking in the transporting and loading process, so that the transporting process is more stable. Meanwhile, the area of a gripper plate is large, so that damage to the steel plate is avoided.

Owner:WUXI QINGYANG MACHINERY MFG

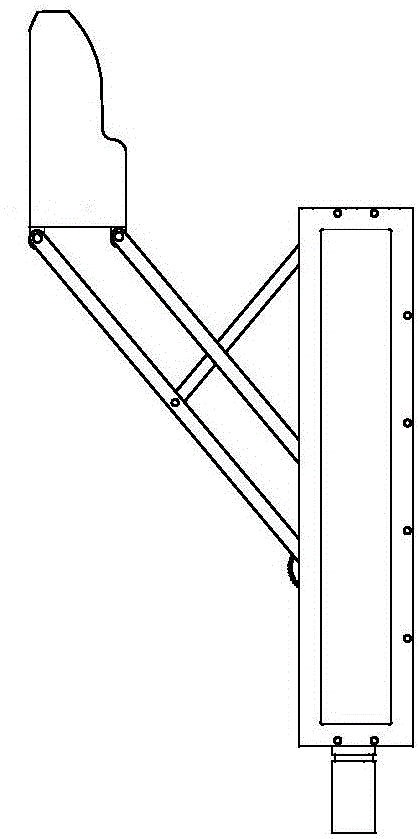

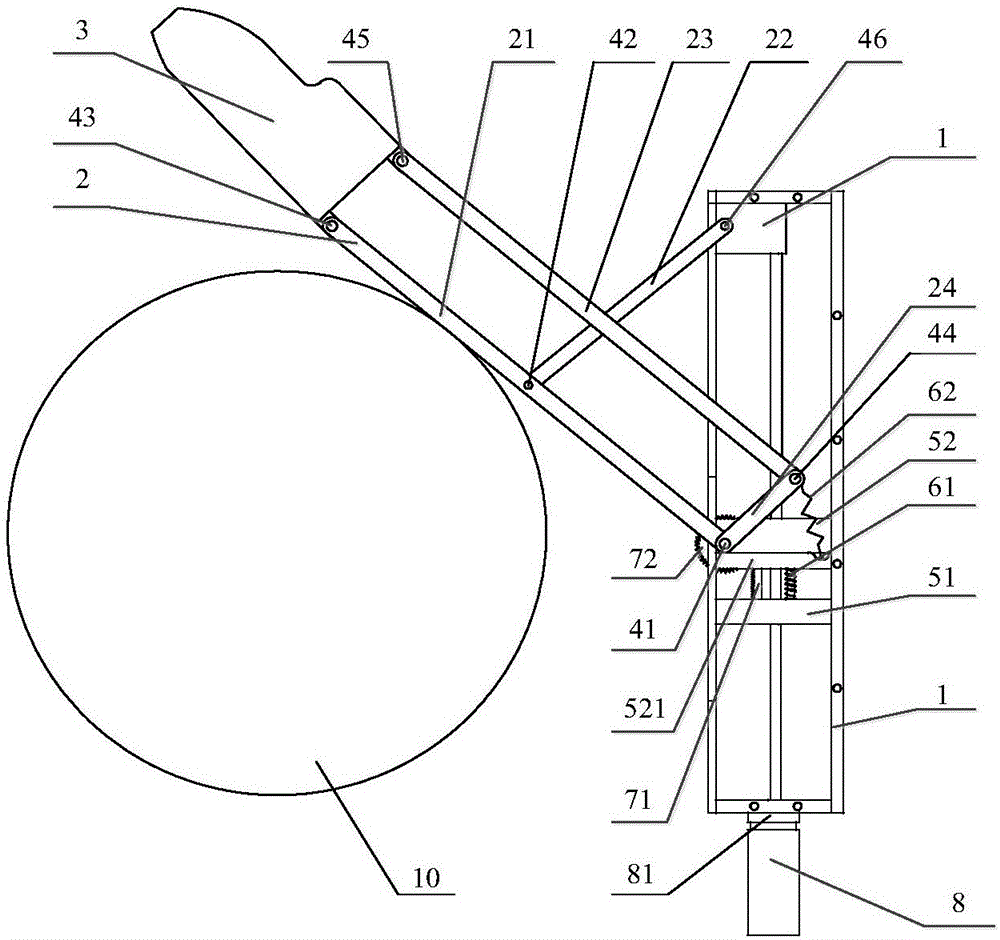

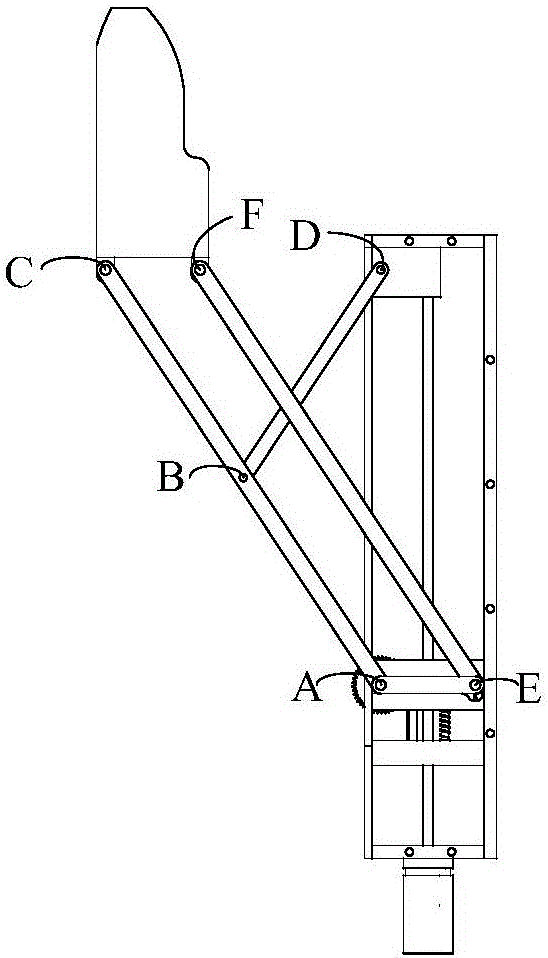

Tire grabbing device

Owner:ANHUI SNELL MACHINERY MFG

Four-link flat clip adaptive robot finger device

The invention relates to a finger device of a four-linkage parallel clamping and adaptive robot, which belongs to the technical field of robot hands. The finger device comprises a base, a first finger section, a second finger section, a proximal joint axis, a distal joint axis, a driver, a first connecting rod, a second connecting rod, a third connecting rod, a first rod shaft, a second rod shaft, a bulge driving disk, a thumb wheel, a transmission mechanism, a first spring part, a second spring part and a limiting bulge. According to the device, the finger functions of parallel clamping and adaptive grabbing are comprehensively realized, the second finger section can horizontally move to pinch an object or extend to take the object, or the first finger section and the second finger section are rotated in sequence, so as to adaptively envelop objects of different shapes and sizes; the grabbing range is wide, and the grabbing is stable and reliable; two joints are driven only by one driver, and a complex sensing and control system is not needed; the finger device has the advantages of simple structure, small size, light weight and low processing, assembly and maintenance cost and is suitable for the robot hands.

Owner:TSINGHUA UNIV

Herringbone connecting rod, rack and sliding block linear parallel clamping self-adaption finger device

The invention provides a herringbone connecting rod, rack and sliding block linear parallel clamping self-adaption finger device and belongs to the technical field of robot hands. The herringbone connecting rod, rack and sliding block linear parallel clamping self-adaption finger device comprises a base, two finger segments, a driver, a plurality of connecting rods, two sliding blocks, two spring parts, a gear, a rack and the like. According to the herringbone connecting rod, rack and sliding block linear parallel clamping self-adaption finger device, a robot finger linear parallel clamping and self-adaption grabbing function is achieved; the second finger segment can be linearly and parallelly moved to clamp an object and also can be automatically rotated to make contact with the object after the first finger segment make contact with the object, and the purpose that objects with different shapes and sizes are wrapped in a self-adaption mode is achieved; the grabbing range is large, and grabbing is stable and reliable; the two finger segments are driven by one driver; and the herringbone connecting rod, rack and sliding block linear parallel clamping self-adaption finger device is simple in structure, small in size, light in weight and low in machining cost, assembling cost and maintenance cost.

Owner:TSINGHUA UNIV

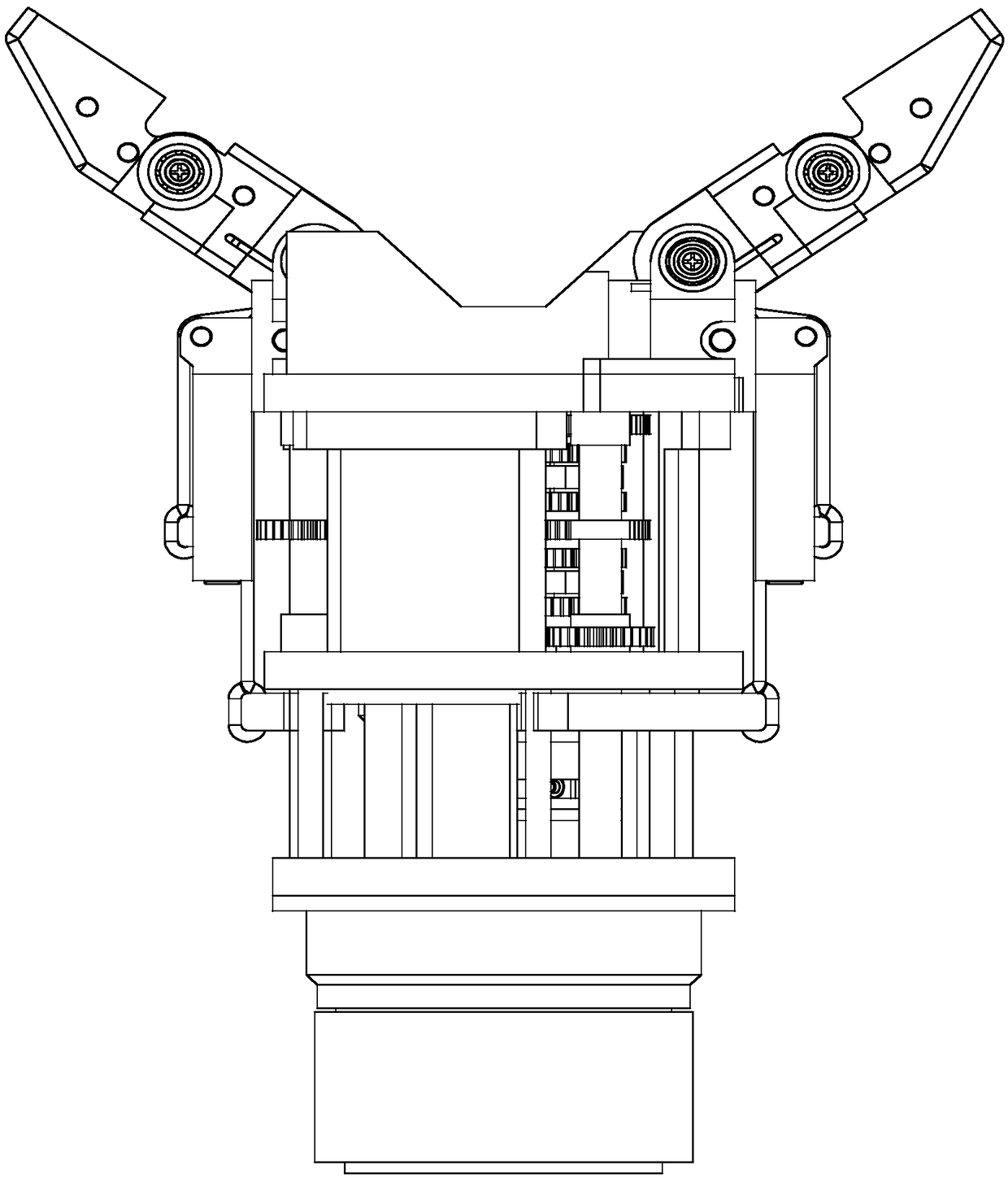

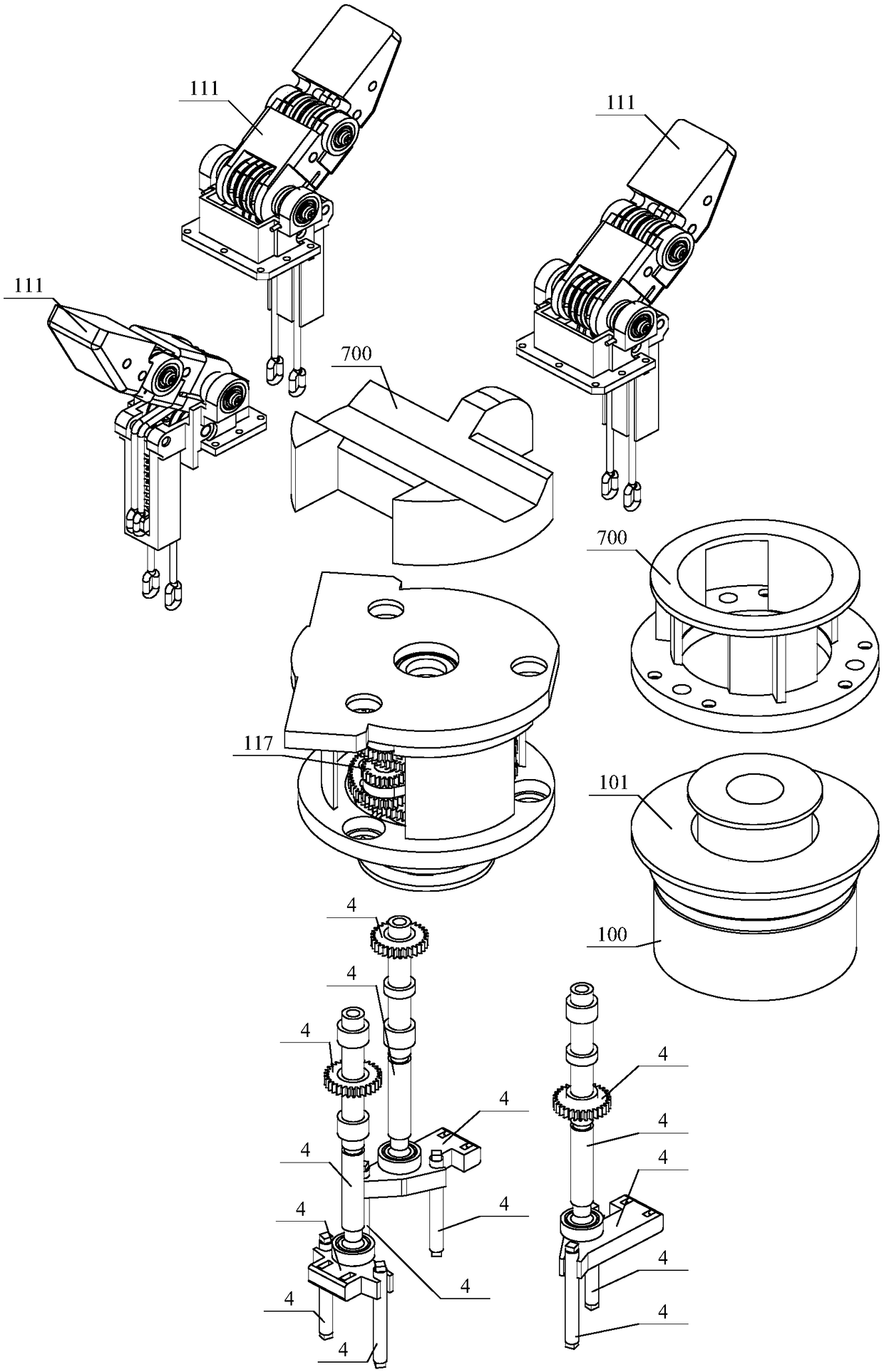

Connection rod belt wheel linear flat clamping sensing self-adaptive robot finger device

ActiveCN106078781ALarge grabbing rangeReliable grabbingProgramme-controlled manipulatorGripping headsRobot fingerSelf adaptive

The invention provides a connection rod belt wheel linear flat clamping sensing self-adaptive robot finger device and belongs to the technical field of robot hands. The device comprises a base, two finger sections, two joint shafts, two drivers, multiple connection rods, multiple stages of belt wheel transmission mechanisms, a protruding block driving plate, multiple sensors and a control module with a built-in control program. By means of the device, the linear parallel clamping and self-adaptive grasping functions of a robot finger are achieved, and particularly, sheet parts on a worktable can be well clamped. A four-bar mechanism is adopted so that the far joint shaft can move linearly, and the second finger section can horizontal move due to cooperation of belt wheels and the four-bar mechanism. The self-adaptive grasping function can be achieve by means of the sensors, the control module and the built-in control program, and the finger device can adapt to grasping of objects in different shapes and sizes. The grasping range is large, and grasping is stable and reliable. Two joints are driven by the two drivers. The finger device is simple in structure, small in size, low in weight and low in machining, assembly and maintenance cost.

Owner:广州市轻工职业学校

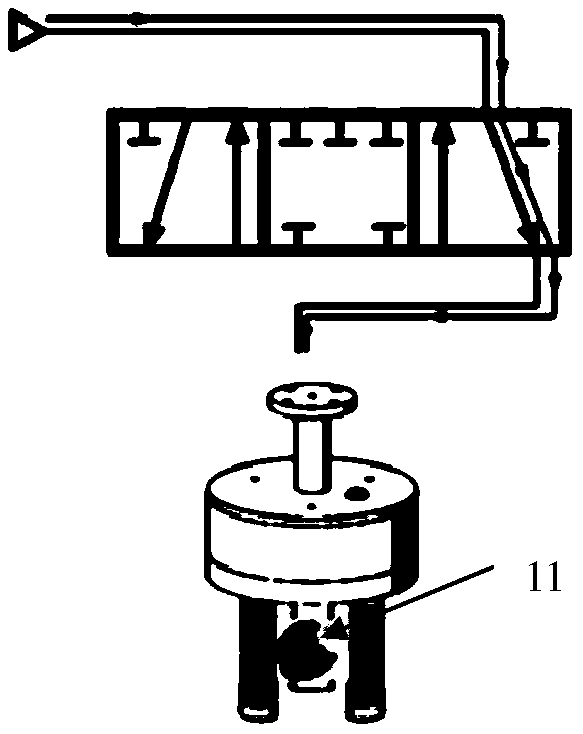

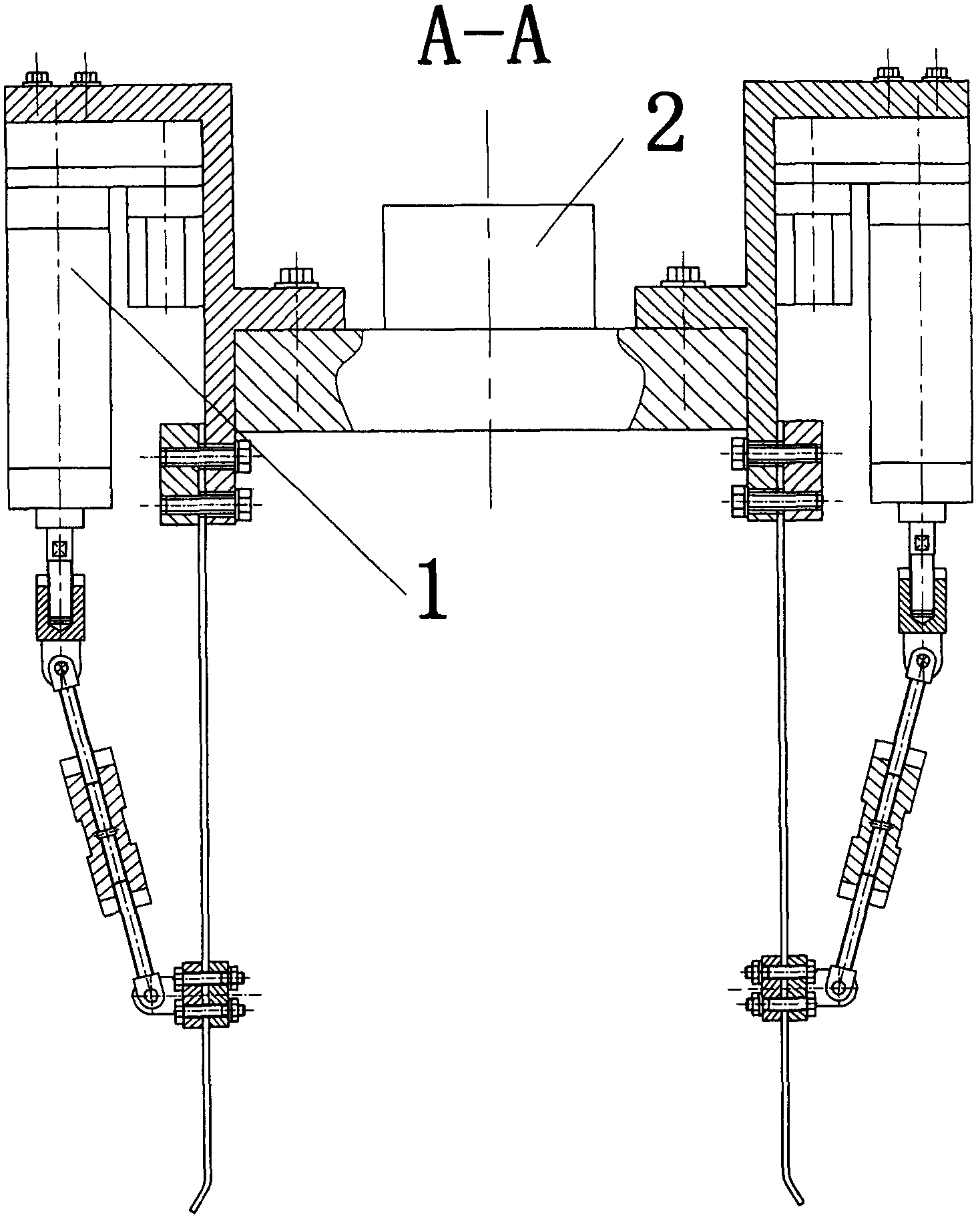

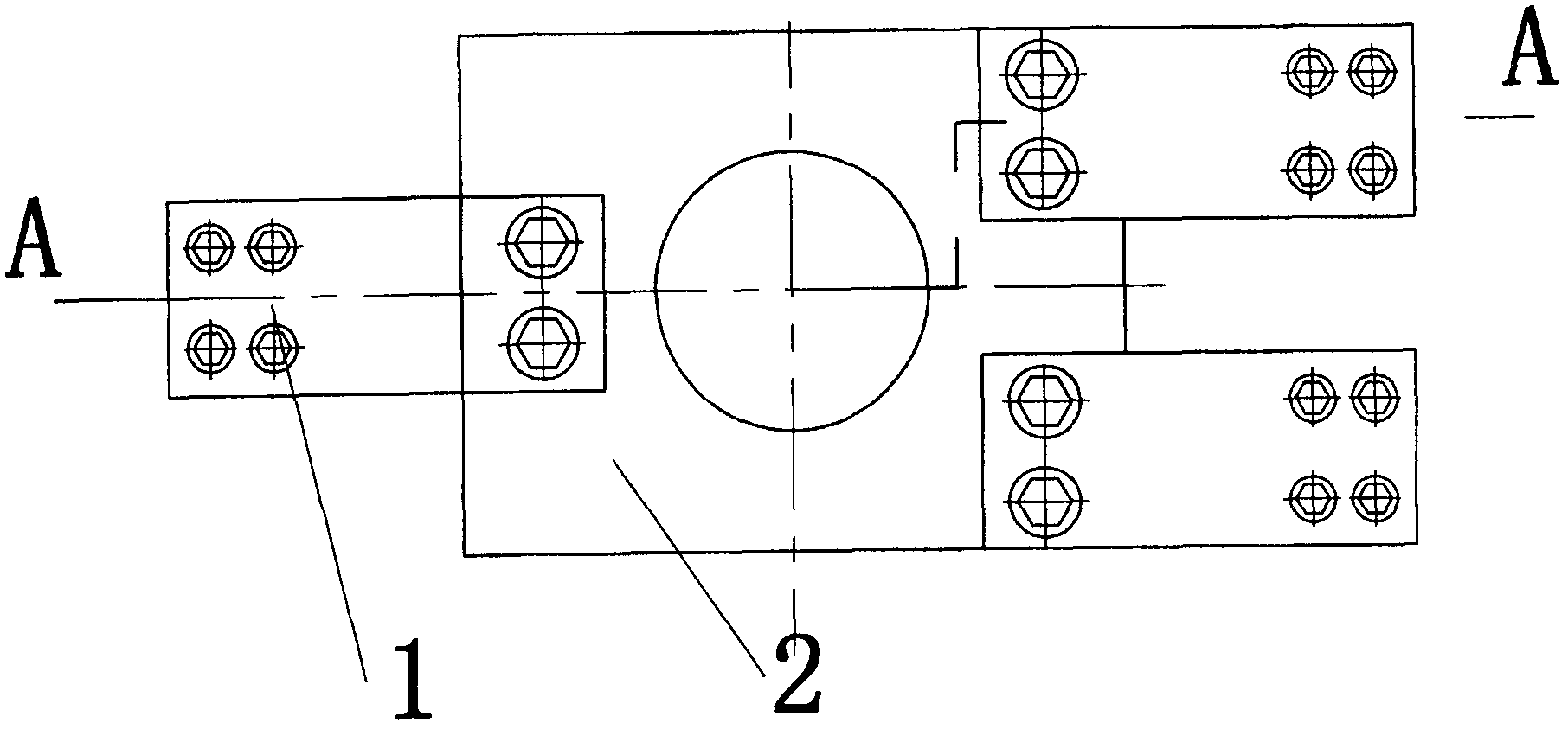

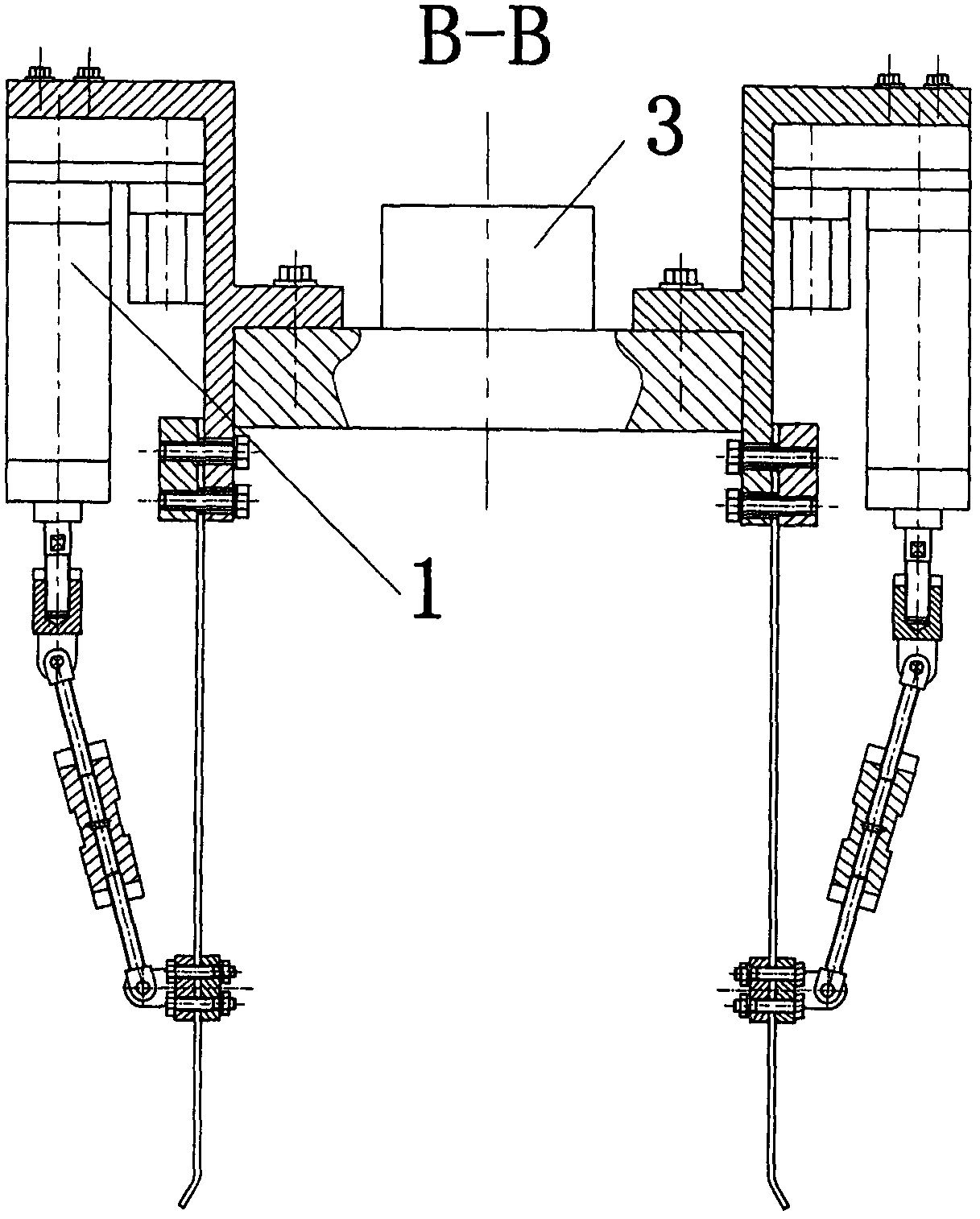

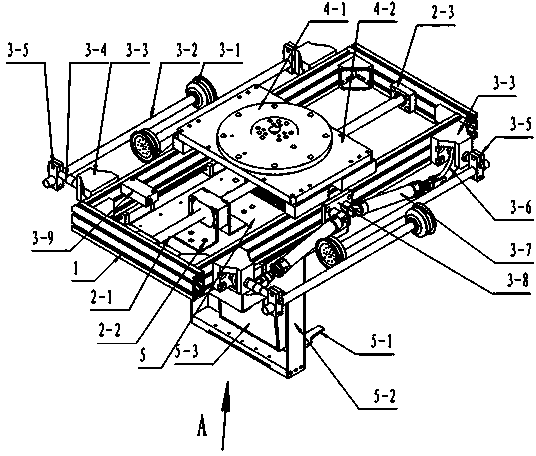

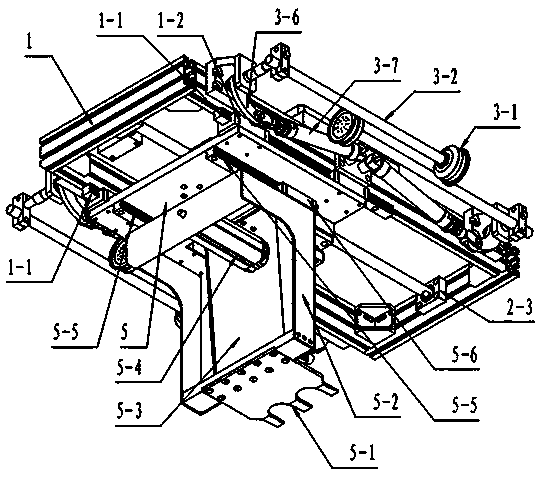

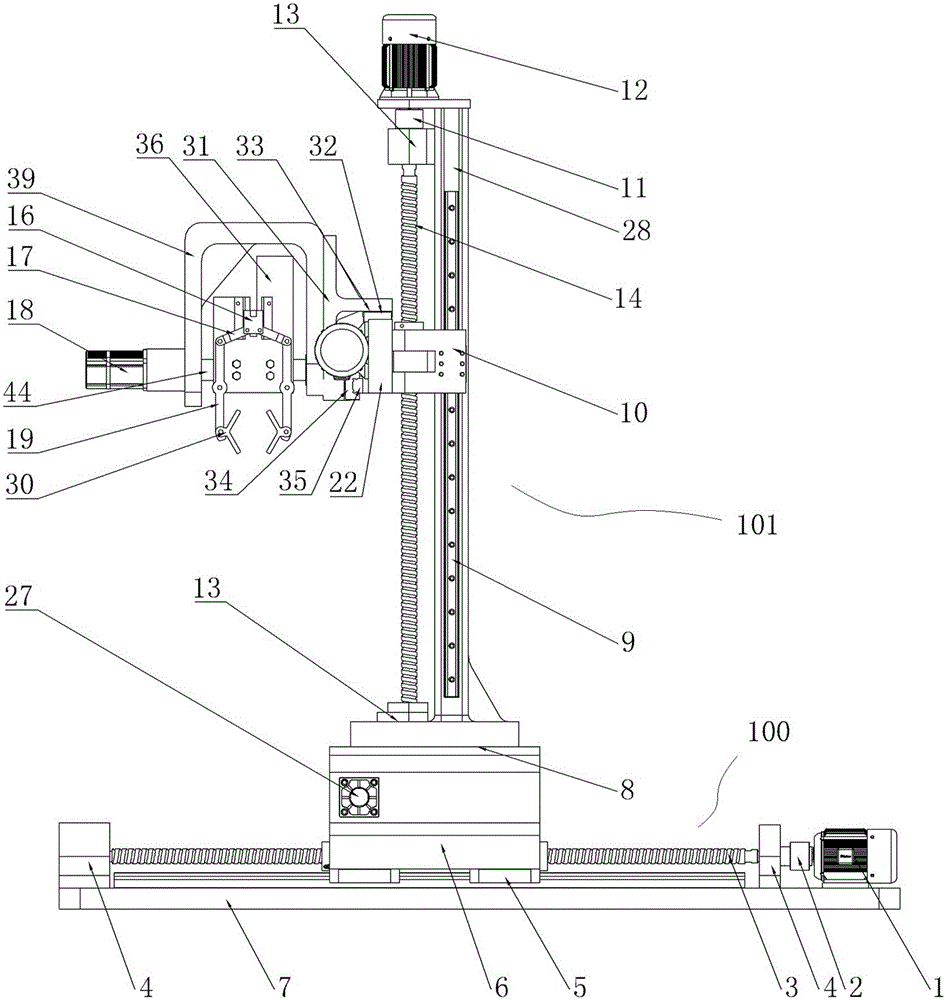

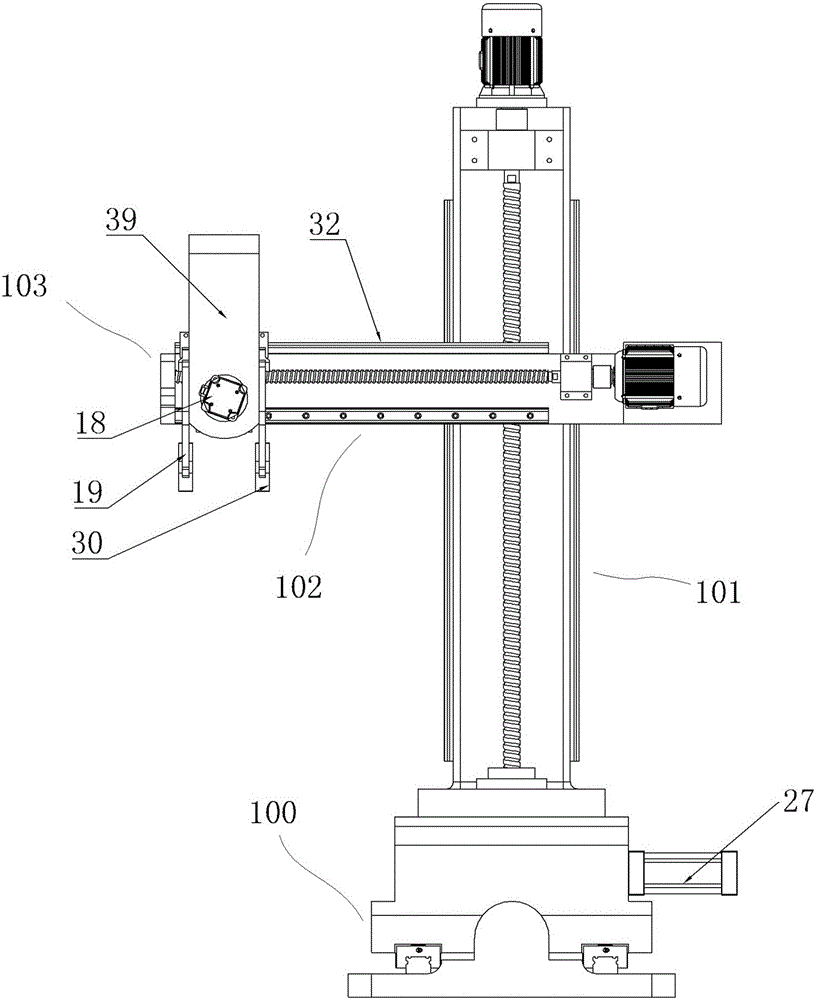

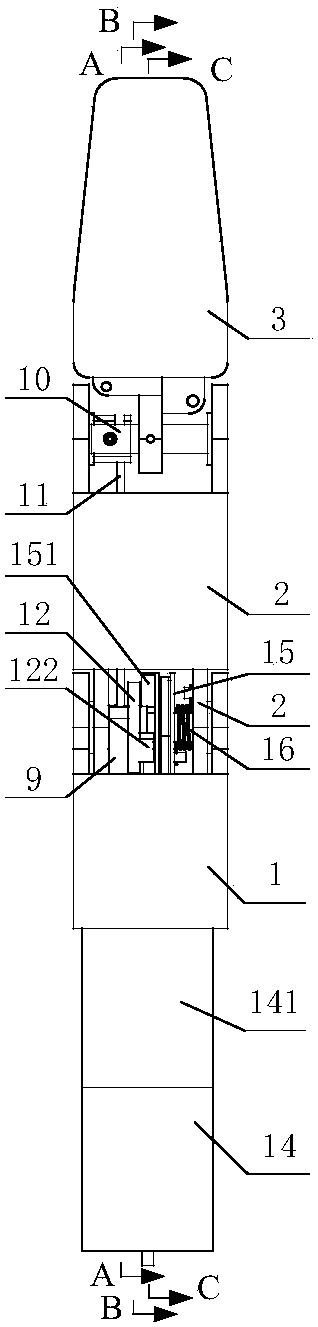

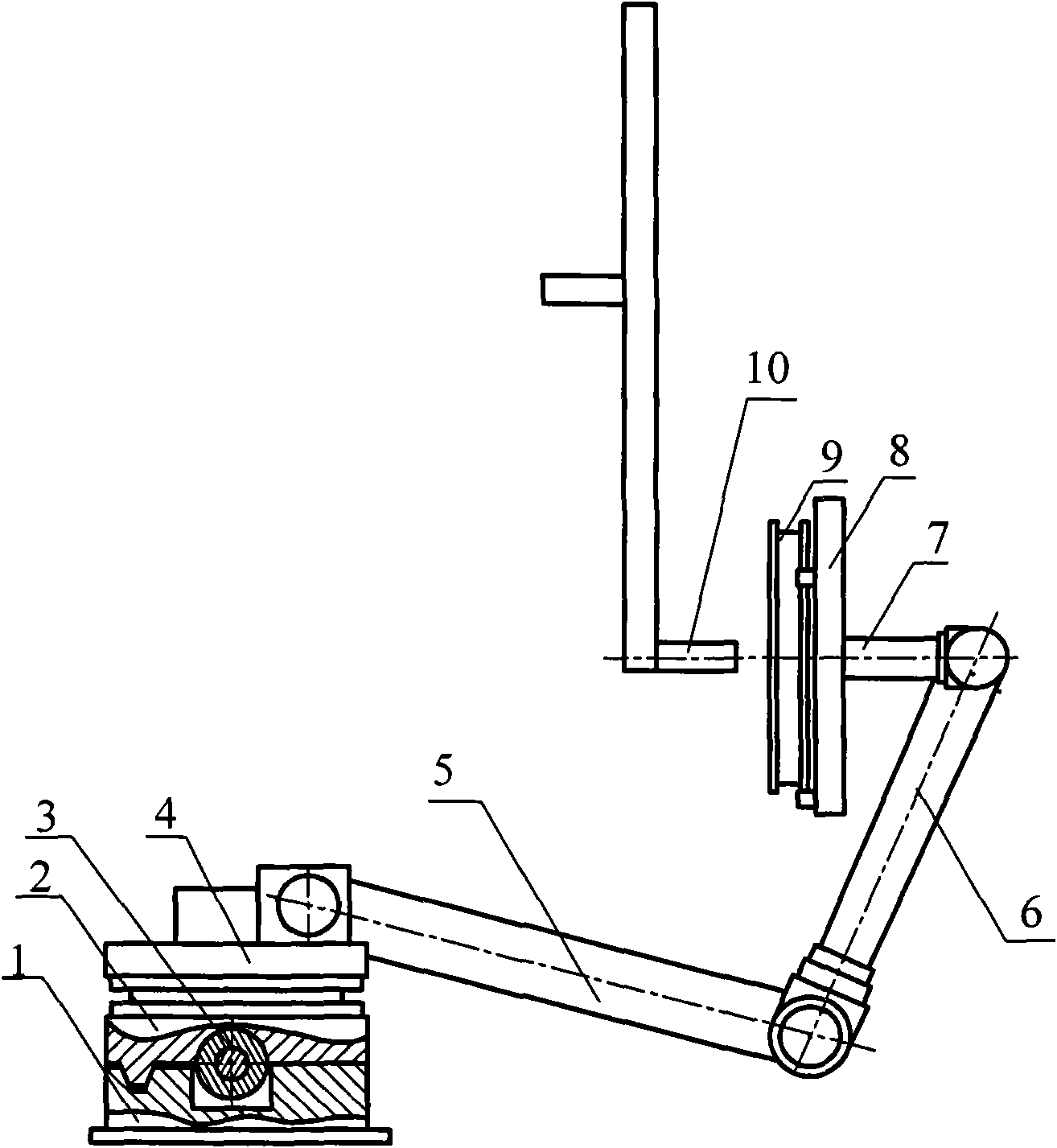

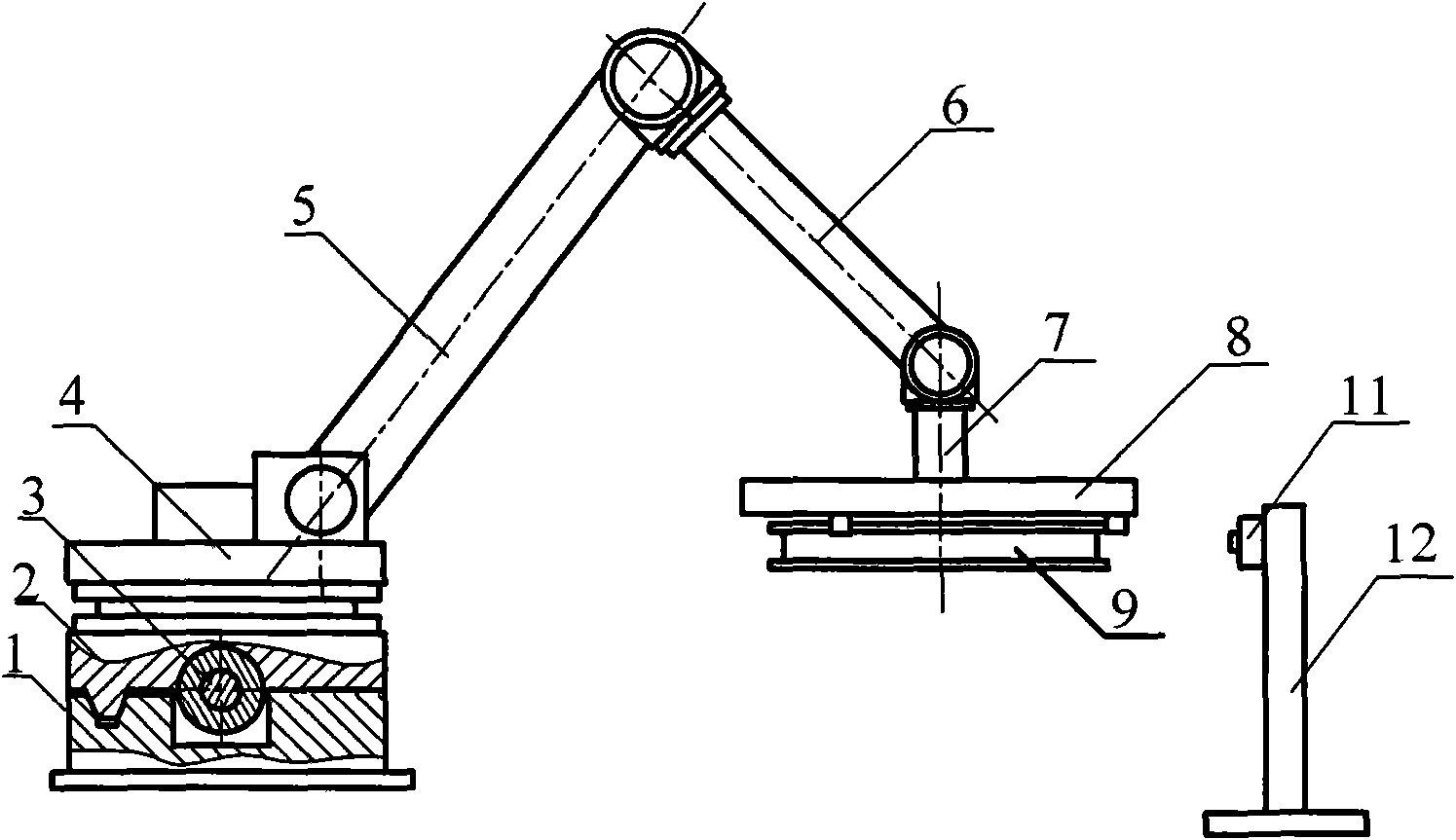

Robot for assembling and disassembling automobile wheel on braced chain coating line

InactiveCN102179809AQuick loading and unloadingReliable grabbingProgramme-controlled manipulatorEngineeringBall screw

The invention discloses a robot for assembling and disassembling an automobile wheel on a braced chain coating line. A movable seat and a member on the upper part of the movable seat are driven to move through a ball screw assembly along the movement direction of a braced chain; the movable seat and the member on the upper part of the movable seat can be kept travelling at the same speed as the braced chain to suspend the automobile wheel; a waist part is rotated relative to the movable seat; a lower arm is swung relative to the waist part; an upper arm is swung relative to the lower arm; a wrist part is rotated and swung relative to the upper arm so as to ensure the spatial position of the automobile wheel; a wheel clamp holder on the wrist part is used for grasping or releasing the automobile wheel pneumatically; and an industrial camera is fixed on a camera bracket and is used for searching the position of a valve hole of the automobile wheel to position the automobile wheel. By the robot for assembling and disassembling the automobile wheel on the braced chain coating line, the automobile wheel can be quickly grasped, the position of the valve hole of the automobile wheel can be found by rotating the wrist part, the automobile wheel is suspended on a braced chain suspension rod, and the valve hole of the automobile wheel can be positioned on the suspended top; and the equipment makes the grasp reliable, the assembly and disassembly quick and the position accurate.

Owner:UNIV OF JINAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com