Robot sucker gripper

A technology of robots and suction cups, applied in the direction of manipulators, chucks, manufacturing tools, etc., can solve the problems of easily damaged objects and low efficiency of grabbing and palletizing, and achieve high production efficiency, firm gripping objects, and flexible operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

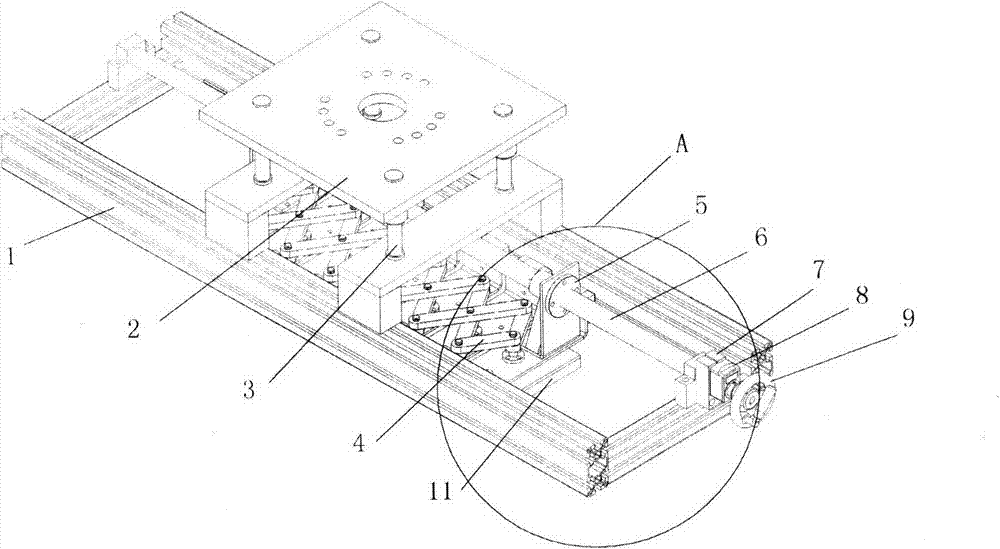

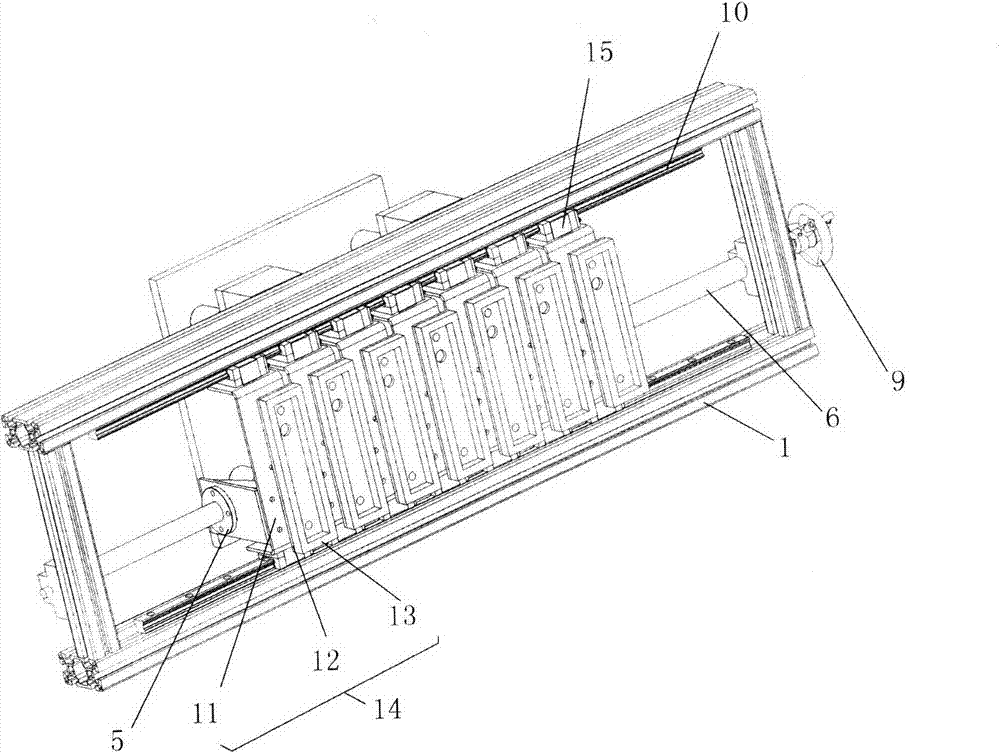

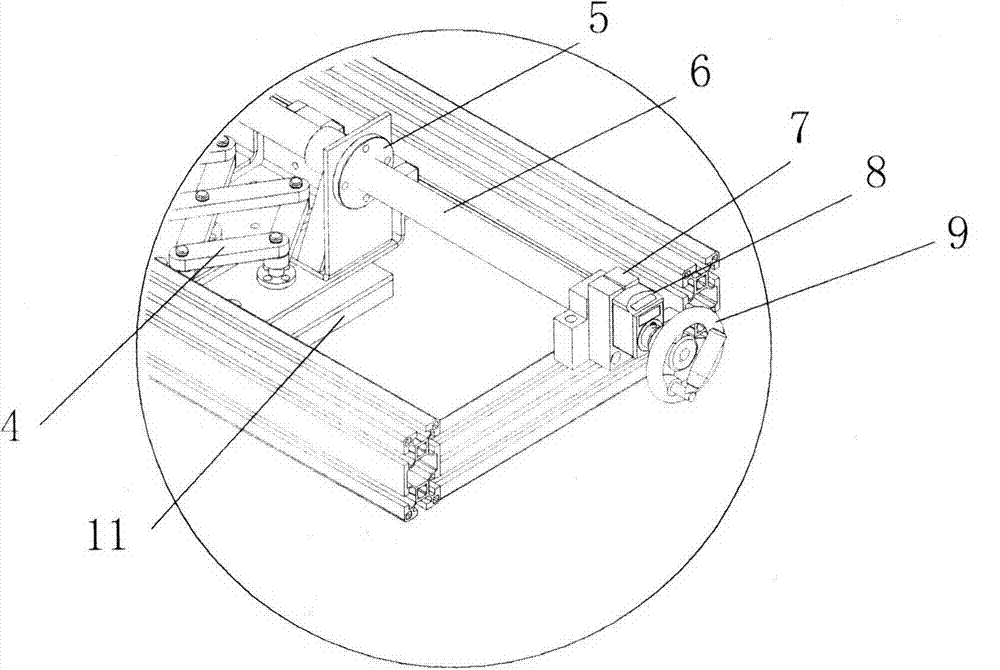

[0022] Such as figure 1 As shown, a suction cup gripper of a robot of the present invention includes an installation frame 1, and a flange cover 2 for connecting a mechanical arm is fixed above the installation frame 1, and is characterized in that: the installation frame is provided with a guide rail 10, the guide rail 10 is provided with a plurality of sucker devices 14 that can move along the guide rails and are used to grab objects. The plurality of sucker devices 14 are hinged together through the linkage mechanism 4. The sucker device 14 is also provided with a spacing adjustment device. The device includes a lead screw 6, a lead screw nut 5 and a rotating handle 9, the lead screw 6 is arranged on the installation frame 1 and arranged parallel to the guide rail 10, and the lead screw nut 5 is arranged on both sides of the lead screw 6 through internal and external threads. Lead screw nut 5 is connected with described sucker device 14; Described sucker device 14, comprise...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com