Cup box grabbing mechanism and cup box grabbing method

A technology for grabbing mechanisms and cup boxes, which is applied in the direction of conveyor objects, object destacking, transportation and packaging, etc. It can solve problems such as complex mechanical structures, overturning, and increased power consumption, and achieve reliable grabbing of cup boxes and maintenance. The effect of convenience and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

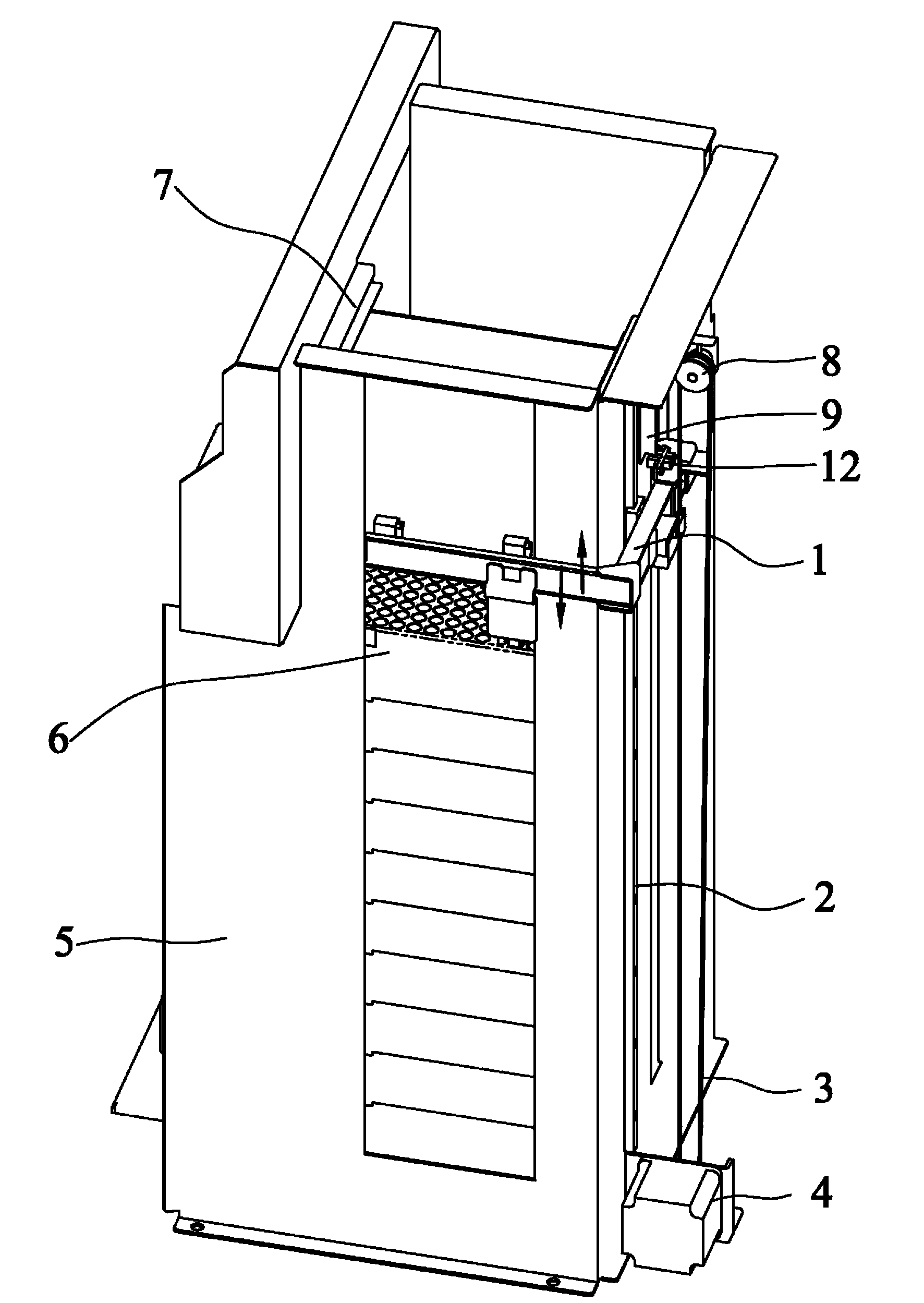

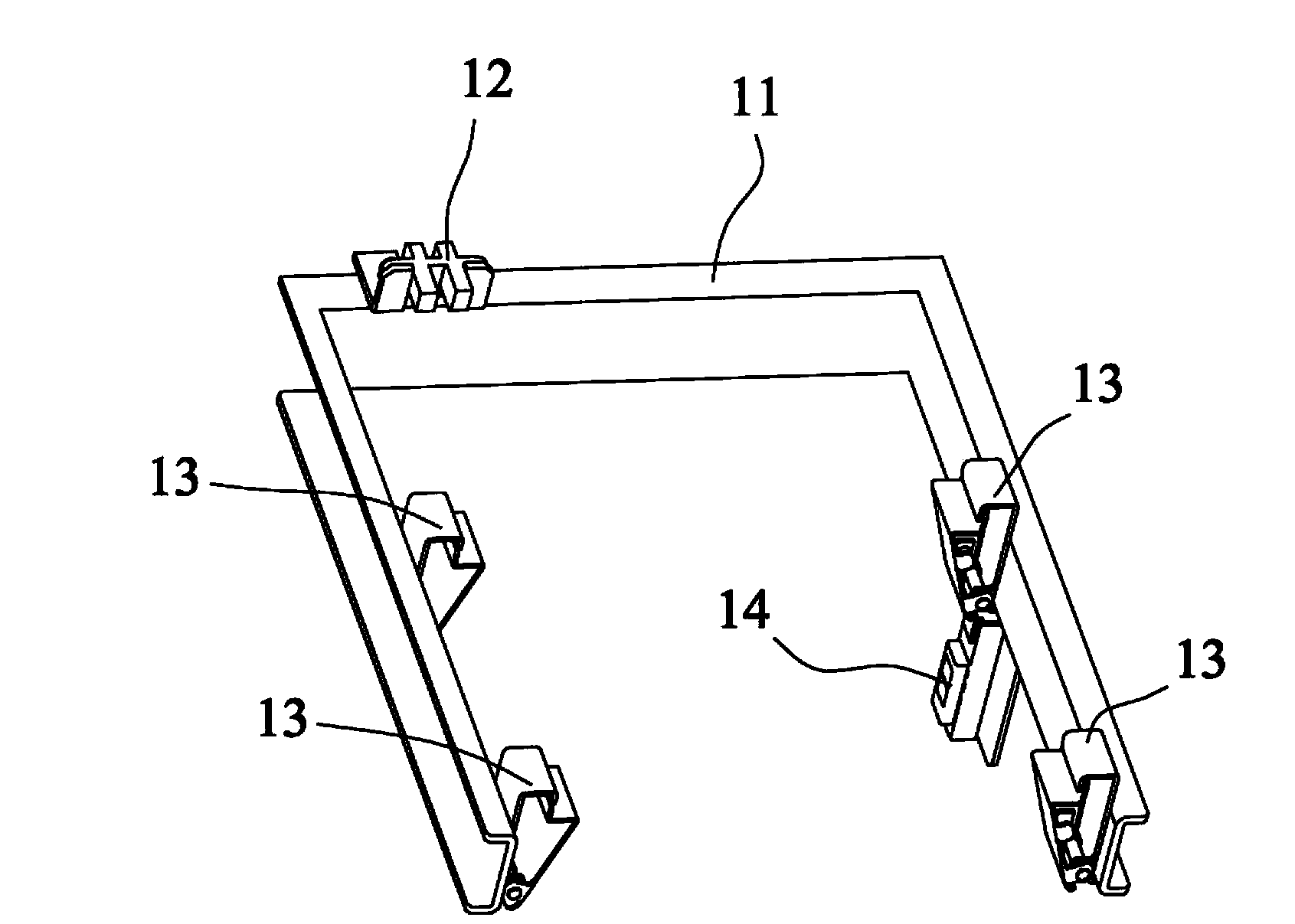

[0027] Such as figure 1 As shown, a cup box grabbing mechanism provided by the embodiment of the present invention includes a box body 5, a driving assembly and a grabbing assembly 1, and the driving assembly drives the grabbing assembly 1 to rise or fall vertically on the side of the box body 5. . A cup box 6 is stacked inside the box body 5 , and a code disc 9 is installed on the top of the box body 5 . The top of the code disc 9 is the waiting position 7 of the cup box 6 . The purpose of the cup box grabbing mechanism provided by the embodiment of the present invention is to enable the grabbing assembly 1 to grab a required number of cup boxes 6 from the cup box stacking area inside the box body 5, and transport and load them to the waiting position 7 superior.

[0028] Specifically, the drive assembly includes a motor 4 , a pulley 8 , a synchronous belt 3 connected between the motor 4 and the pulley 8 , a guide rail 2 extending in a vertical direction, and a slider insta...

Embodiment 2

[0037] The embodiment of the present invention also provides a method for grabbing a cup box using the cup box grabbing mechanism described in Embodiment 1, which needs to meet the following basic conditions:

[0038] First, the bottom width of each cup box 6 stacked in the box body 5 needs to be greater than the top width, and all cup boxes 6 need to be stacked;

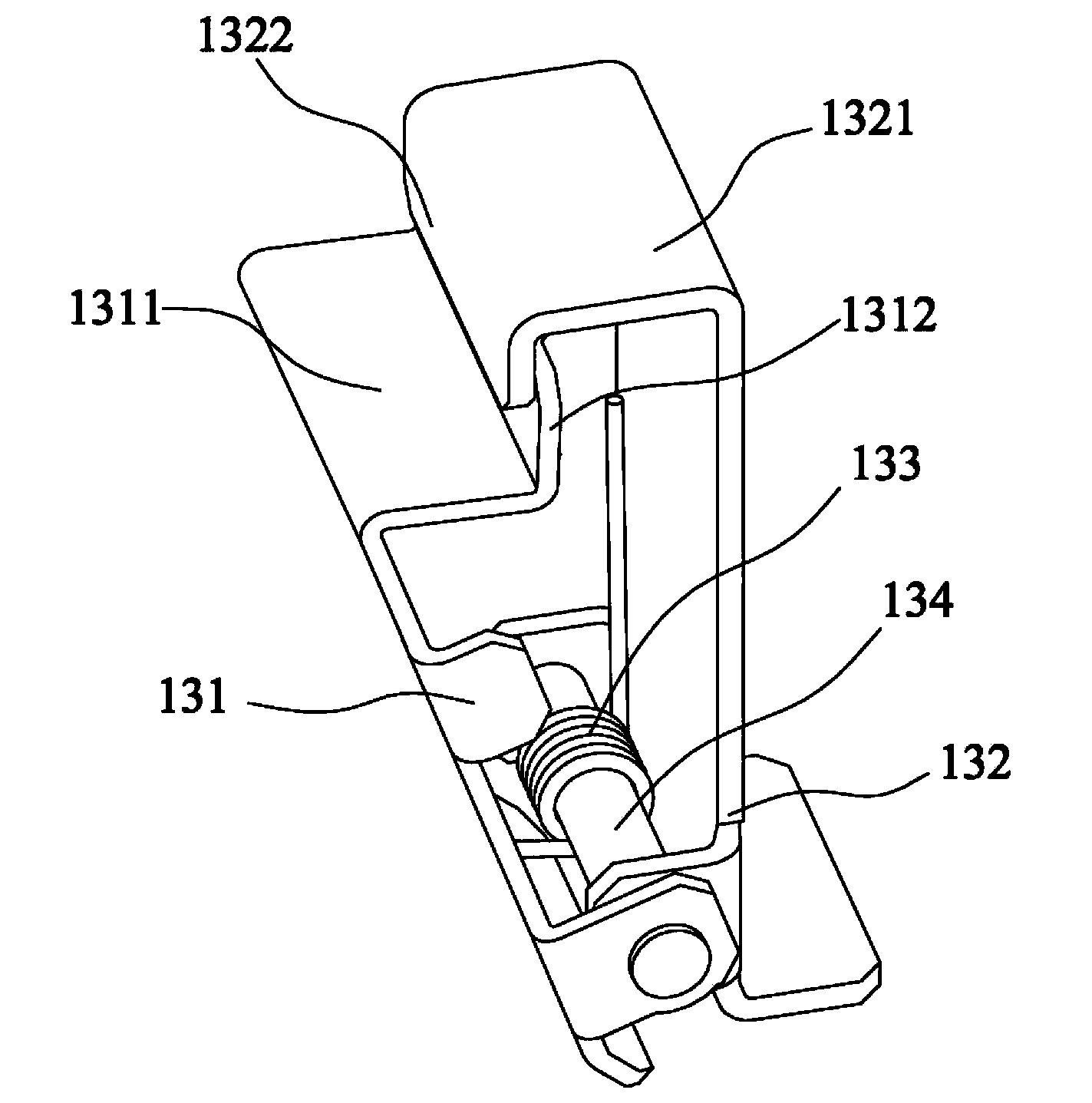

[0039] Secondly, when the rotating plate 131 on the finger 13 is at the maximum deflection stroke, the minimum distance L1 between the two fingers 13 is less than the width L2 of the cup box bottom; The minimum distance L3 between them is greater than or equal to the bottom width L2 of the cup box.

[0040] Described method specifically comprises the following steps:

[0041] S1. The grabbing assembly 1 descends vertically on the box body 5. When the reflective optocoupler 14 detects the cup box 6 at the highest place in the stacking area of the cup box, grab the cup box 6 according to the required quantity and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com