Patents

Literature

199results about How to "Large grabbing range" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

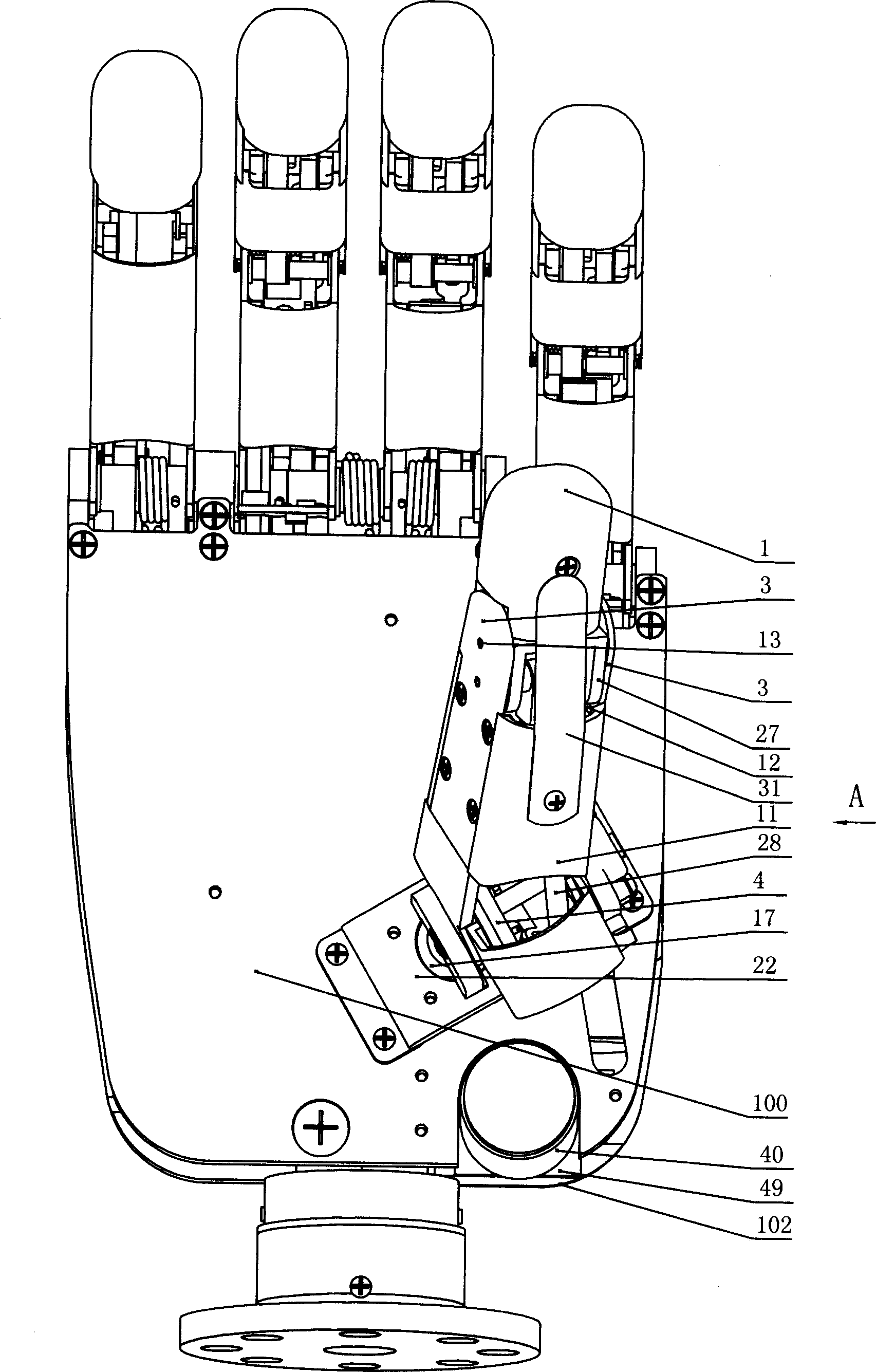

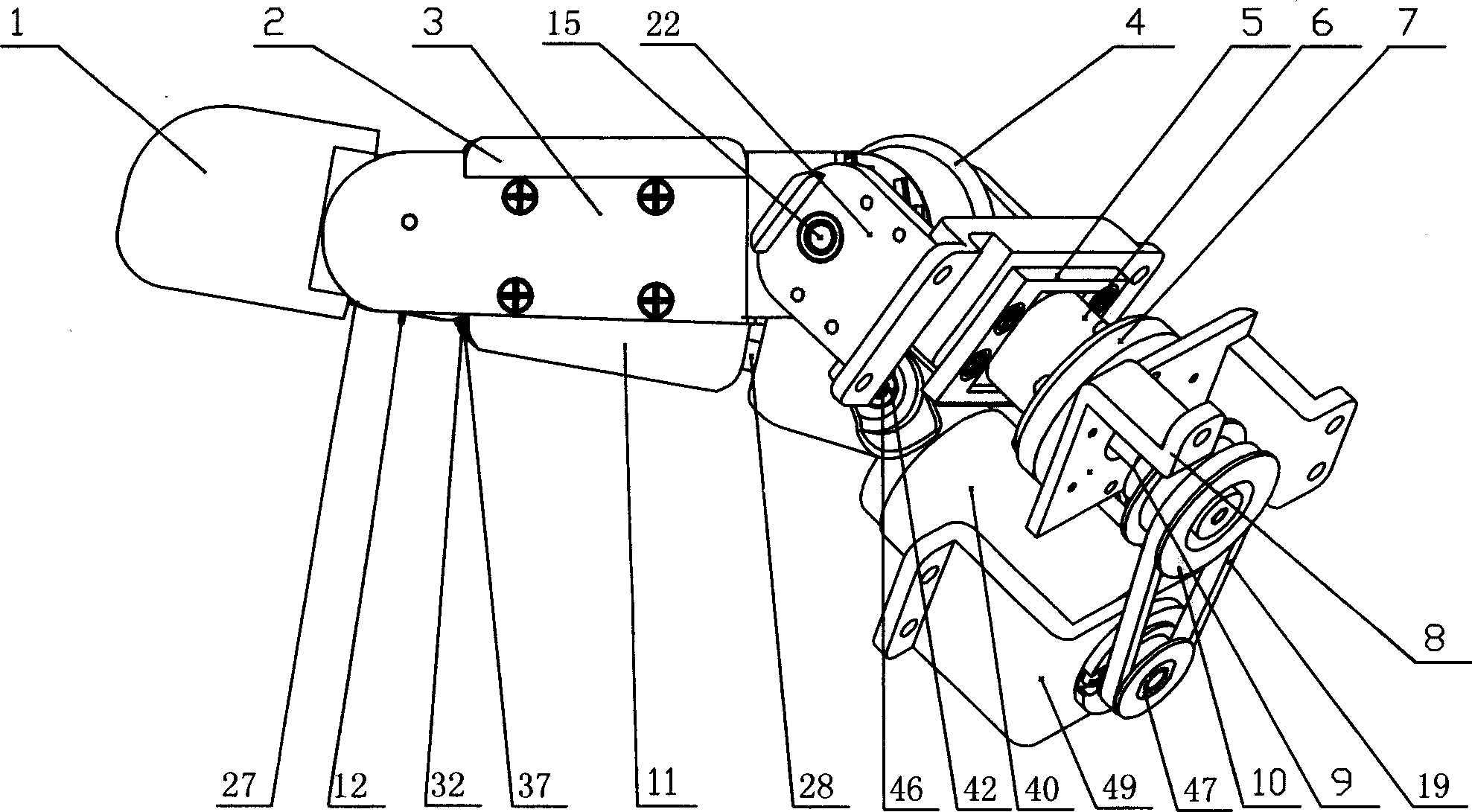

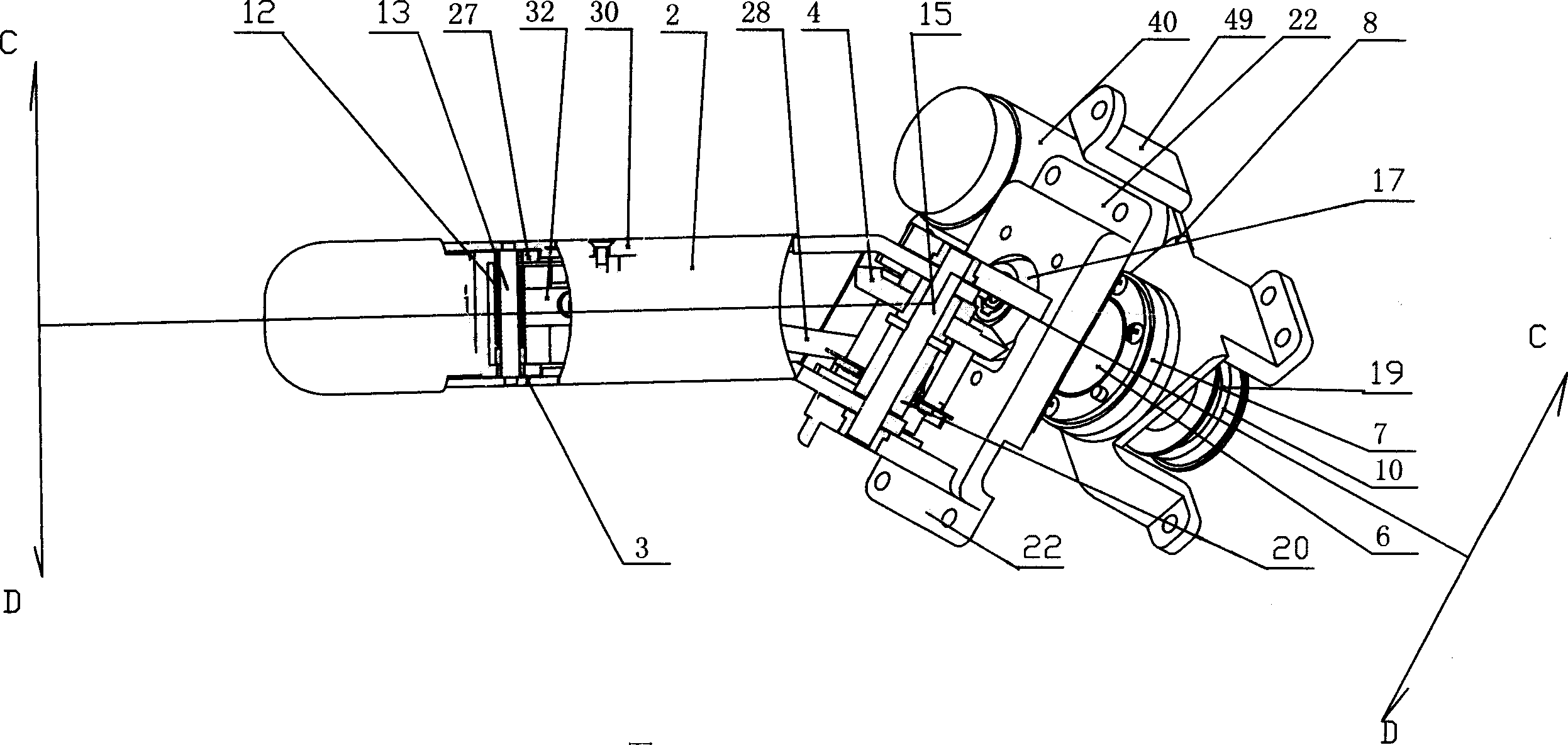

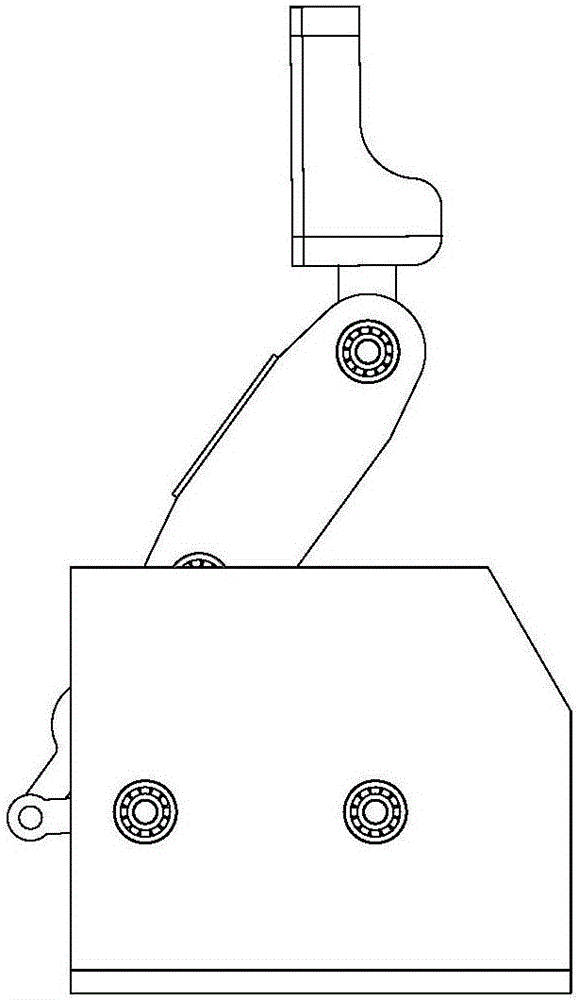

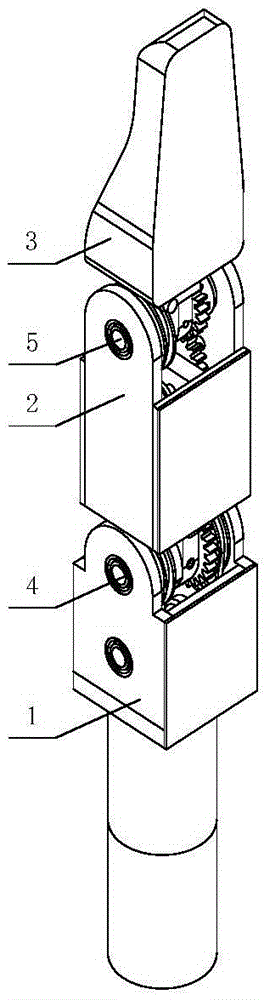

Thumb mechanism of underactuated self-adaptive hand prosthesis

The invention discloses a thumb device of little-driving self-adaptive artificial hand, which is characterized by the following: connecting one end of thumb finger-tip pin case (32) with the thumb finger-tip connecting rod pin shaft (37); fixing the thumb wheeled bearing (55) on the wave generator axle (54) under the thumb decelerator wheel (10); connecting the thumb decelerator wheel (10) with the wheeled pad (9) through the wheeled fixation pin (57); fixing the wave generator (52) of harmonic gear decelerator on the other end of the wave generator axle (54) of wheeled pad (9). The invention can display a 130 deg conical moving space in the moving course to realize the finger-pin little-driving movement, which is adaptive for the object shape to reach full-covering the object and stable grasping.

Owner:HARBIN INST OF TECH

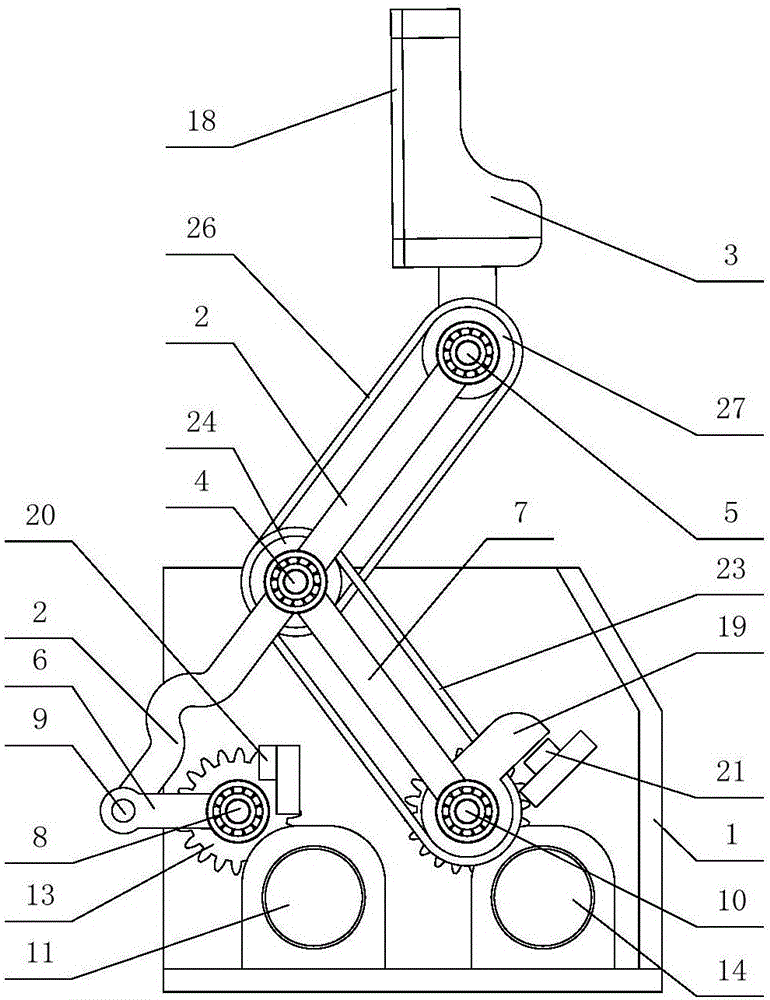

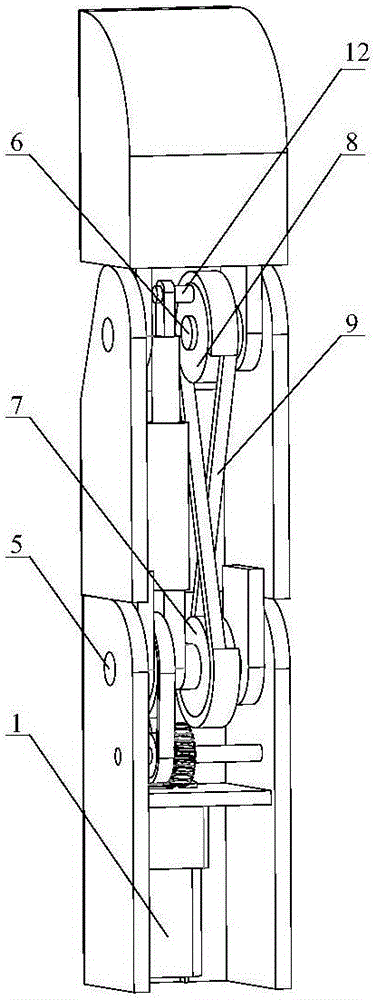

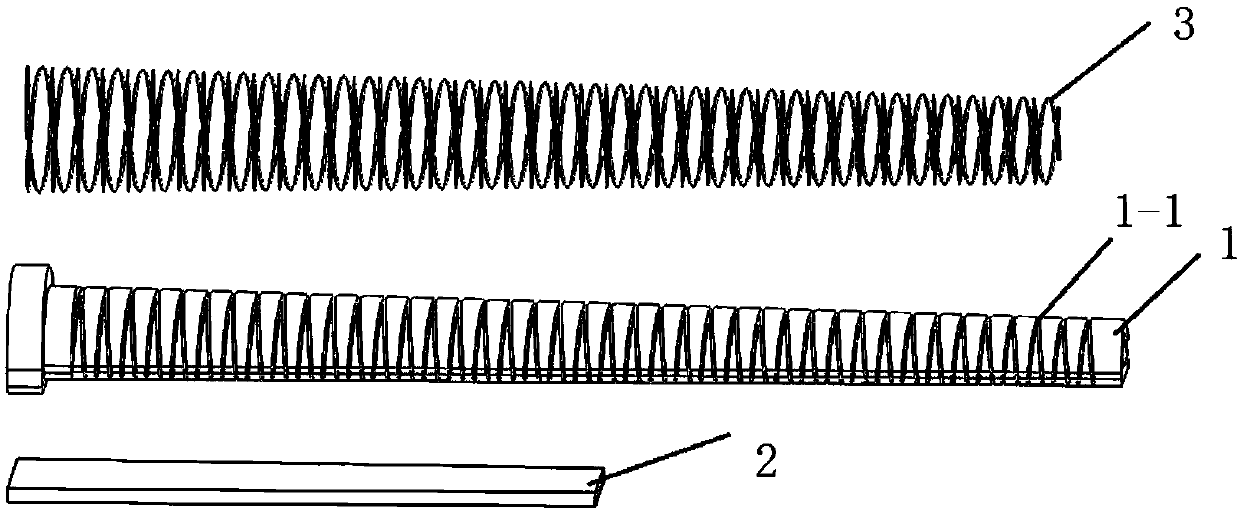

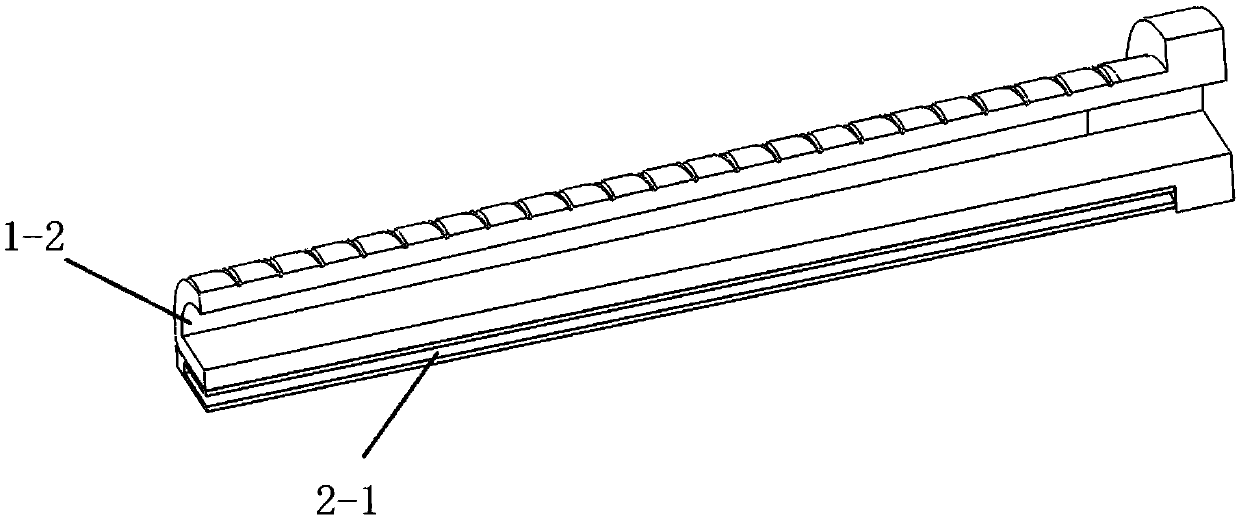

Connecting-rod gear-rack linear parallel clamping indirect self-adaptive robot finger device

The invention relates to a connecting-rod gear-rack linear parallel clamping indirect self-adaptive robot finger device, and belongs to the technical field of robot hands. The connecting-rod gear-rack linear parallel clamping indirect self-adaptive robot finger device comprises a base, two finger sections, two joint shafts, a gear rack, a plurality of gears, two driving wheels, a driving medium, a guiding rod, a spring piece and the like. The device achieves the function of linear parallel clamping and self-adaptive grabbing of fingers of a robot; a linear motion of a far joint shaft is achieved through a connecting mechanism, and a second finger section keeps a fixed posture relative to the base in a first grabbing phase by adopting the spring piece to be matched with a gear rack mechanism; when an object is in contact with a first finger section, the self-adaptive rotation of the second finger section around the far joint shaft is achieved through the gear rack mechanism; grabbing of objects with different shapes and sizes can be adapted; and the grabbing range is large, the grabbing is stable and reliable, the structure is simple, and the cost is low.

Owner:TSINGHUA UNIV

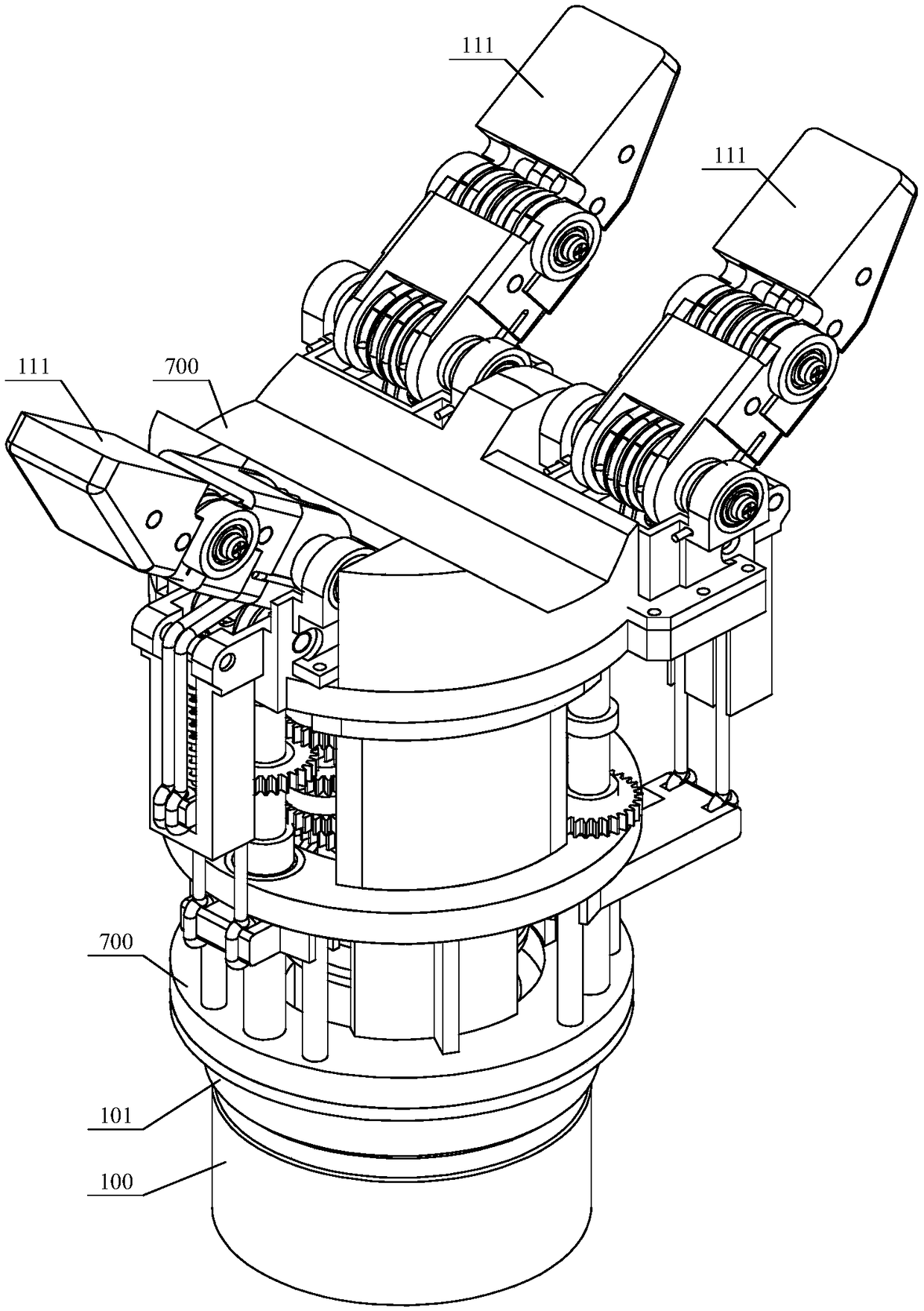

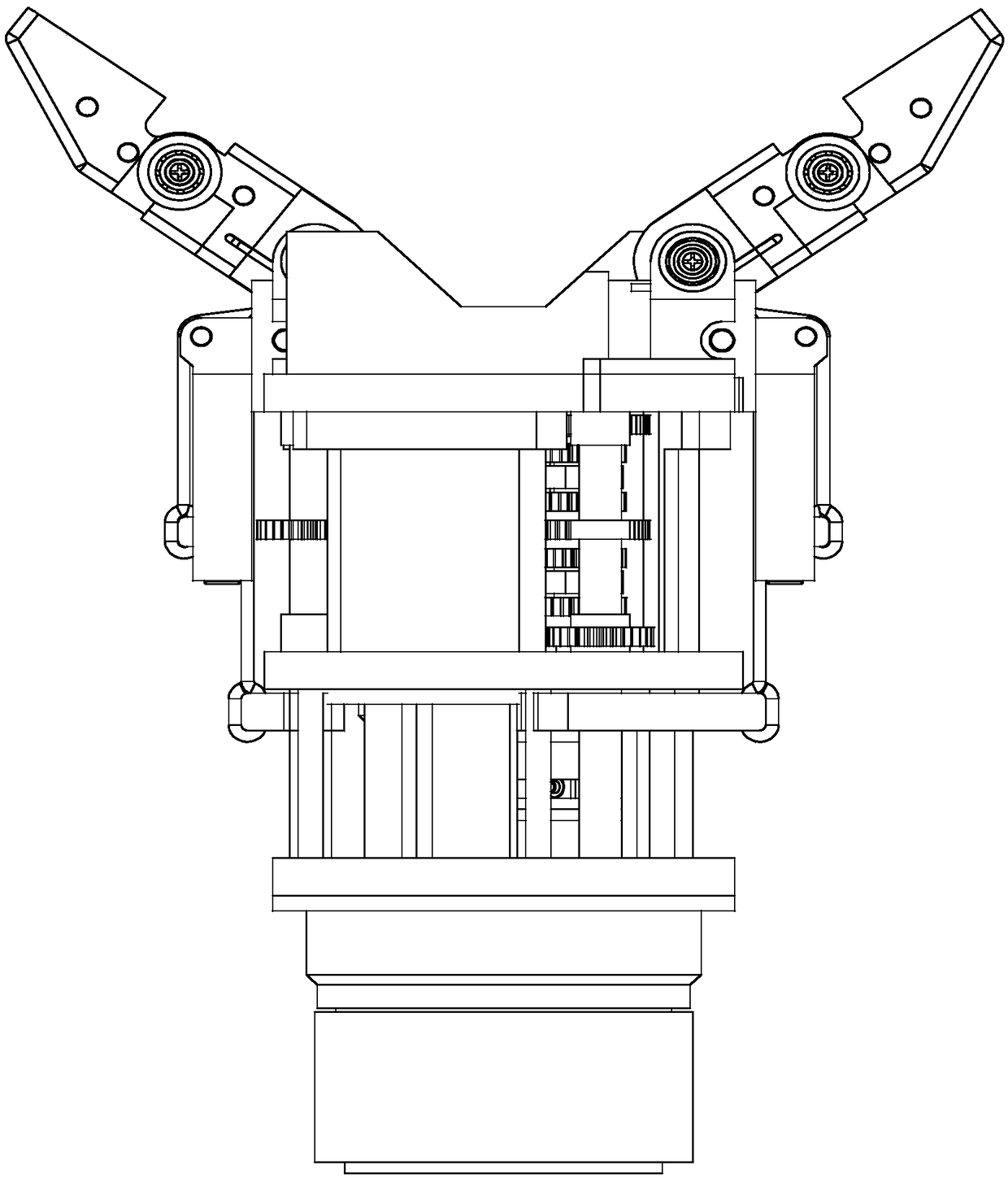

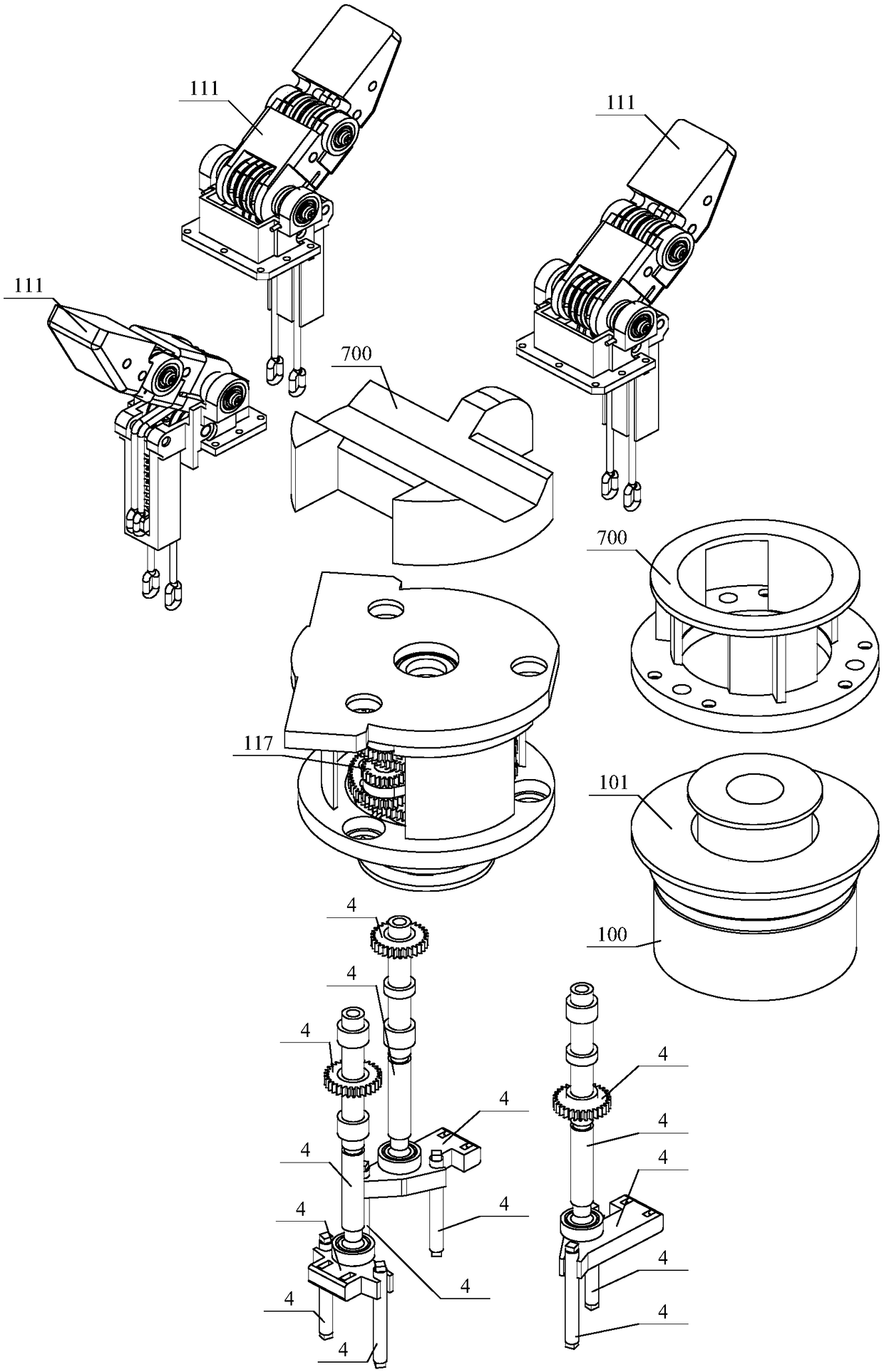

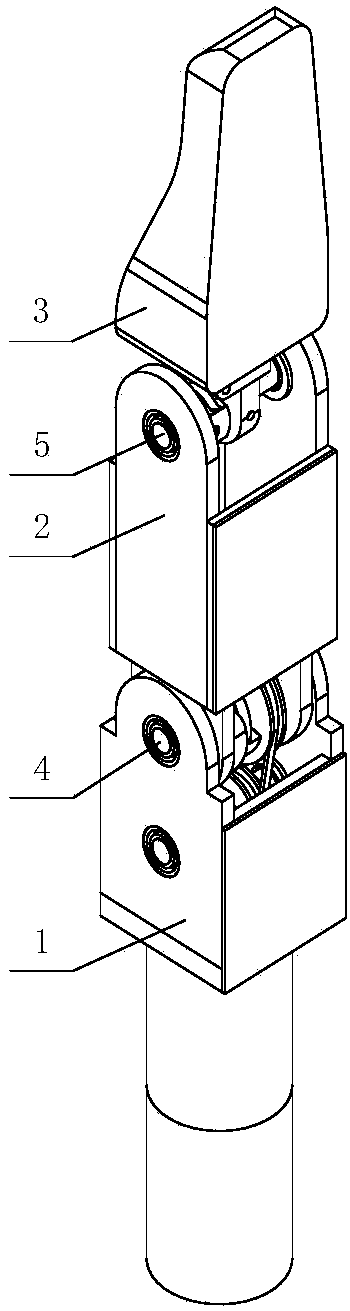

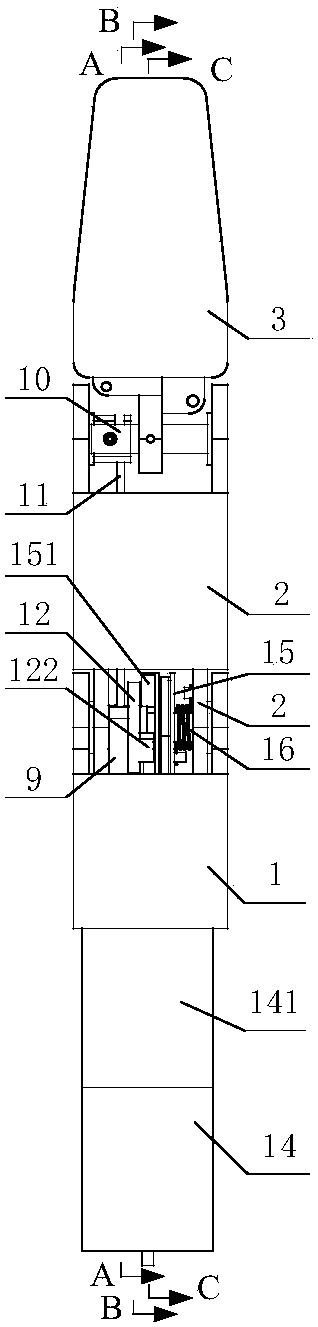

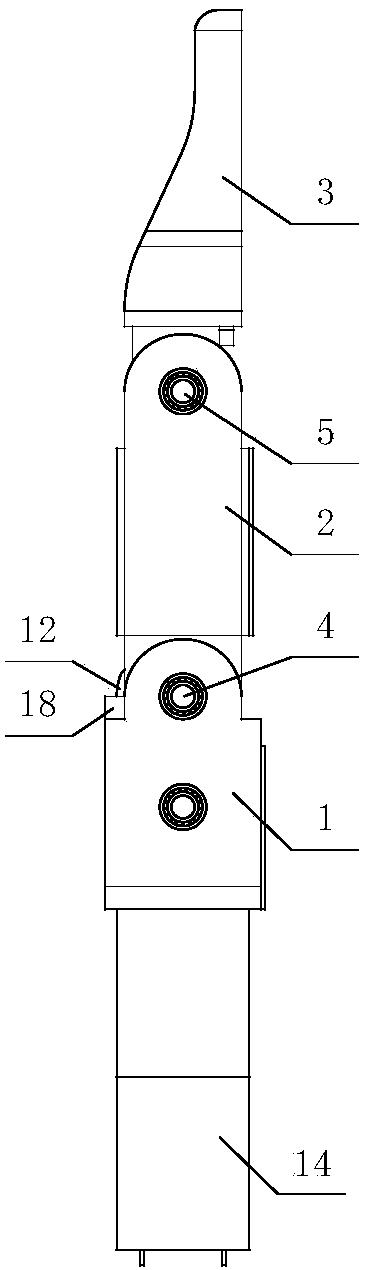

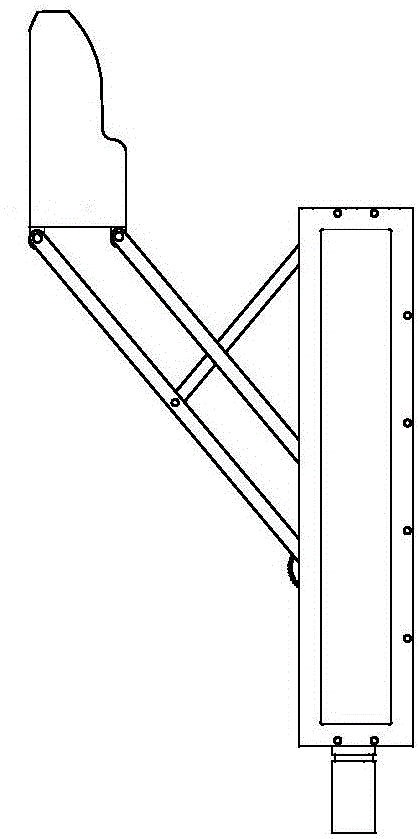

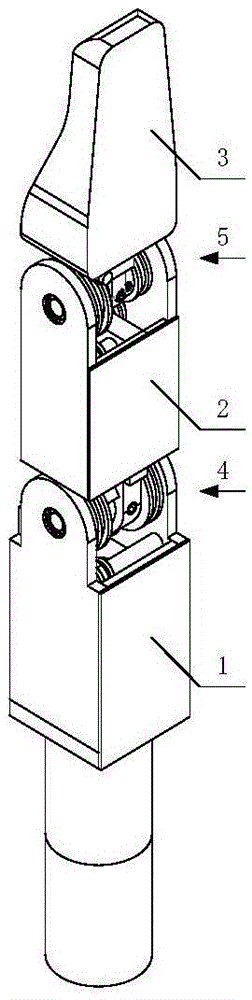

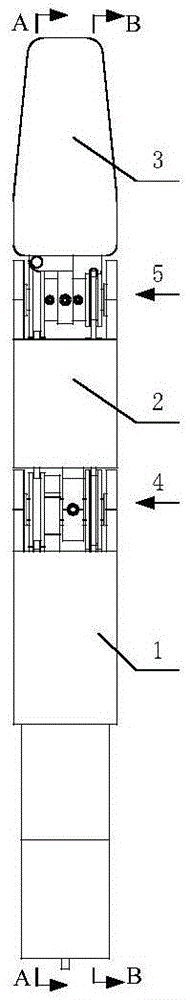

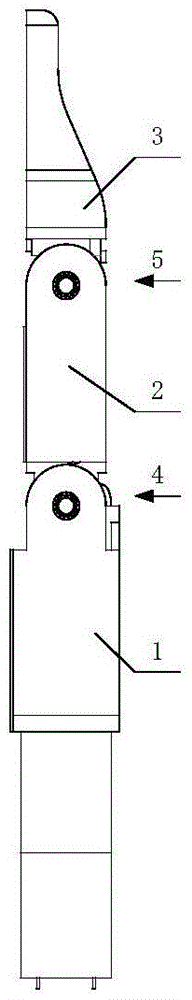

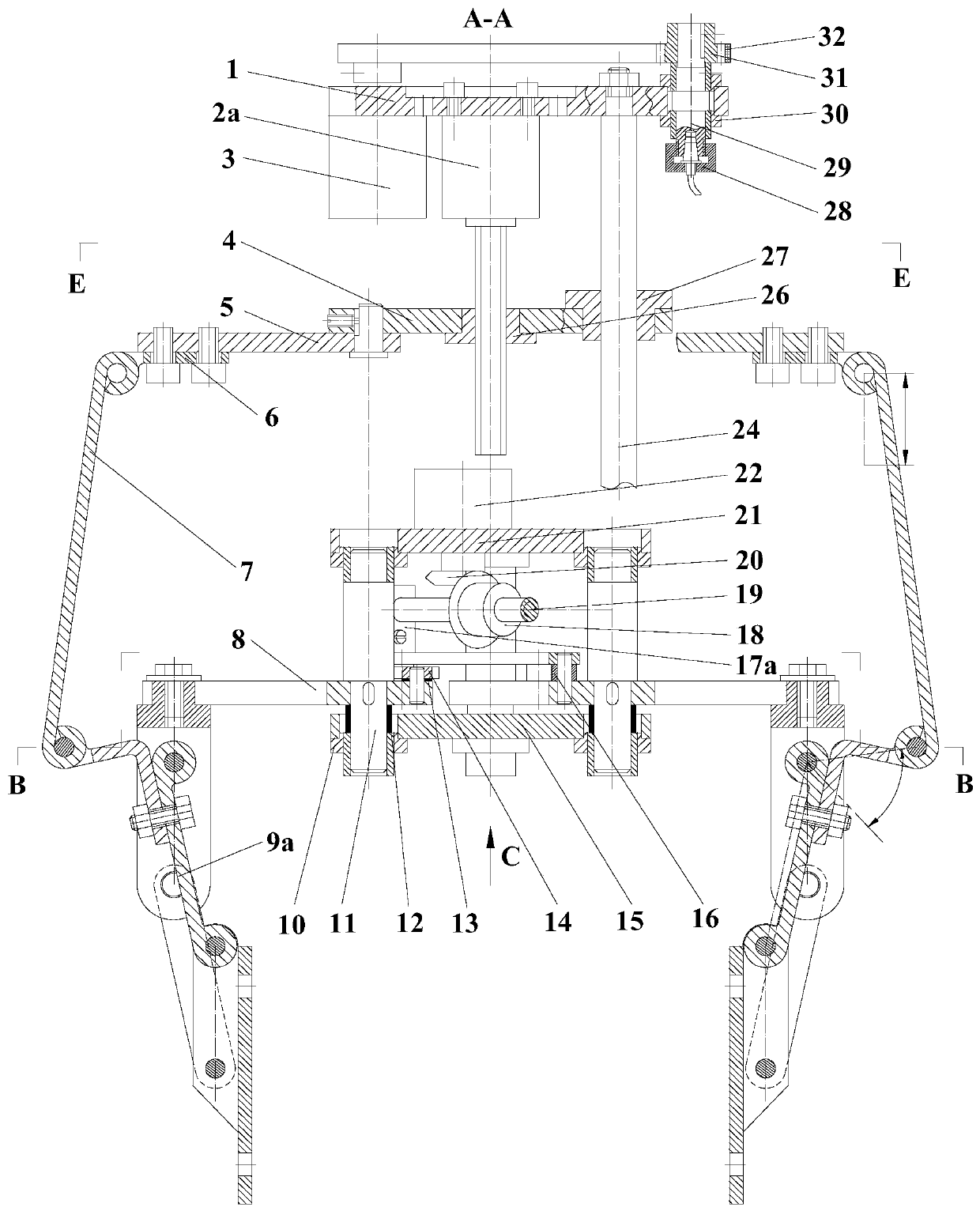

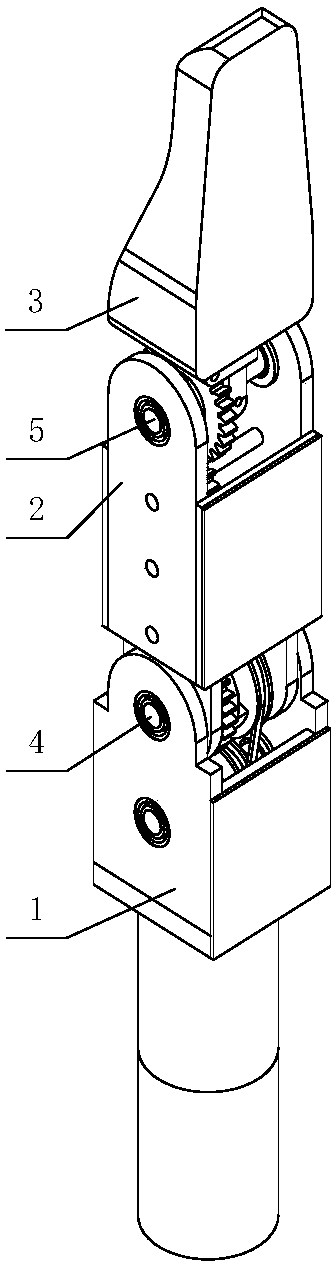

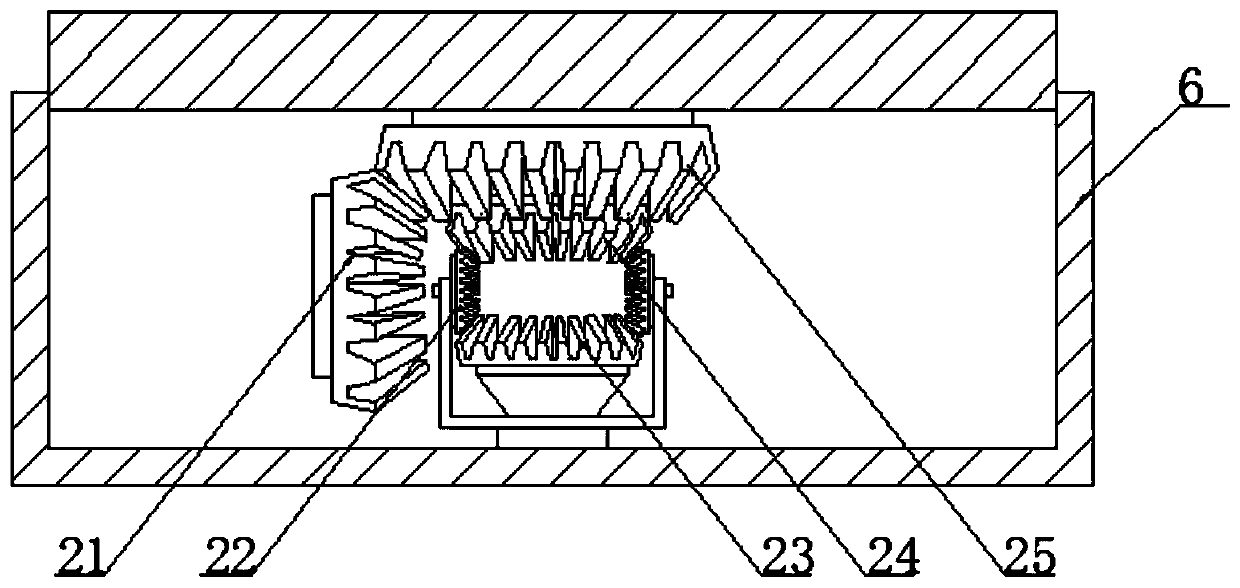

Self-adaptive underactuated robot clamping claw

ActiveCN108214534ARealize adaptive grip functionLarge grabbing rangeGripping headsUnderactuated robotsLinear motion

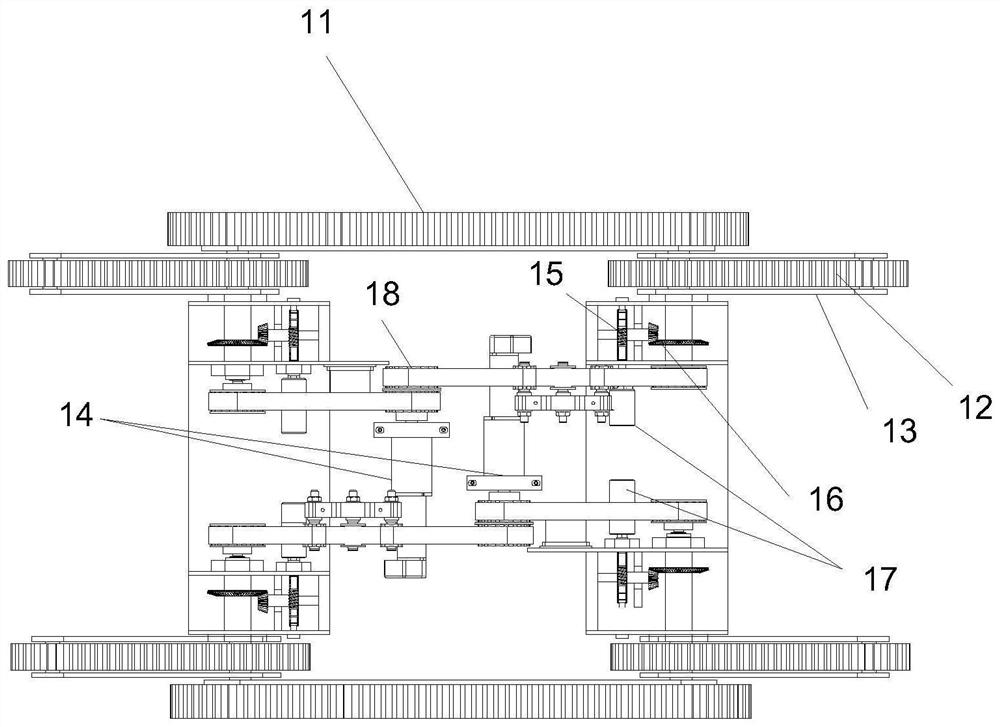

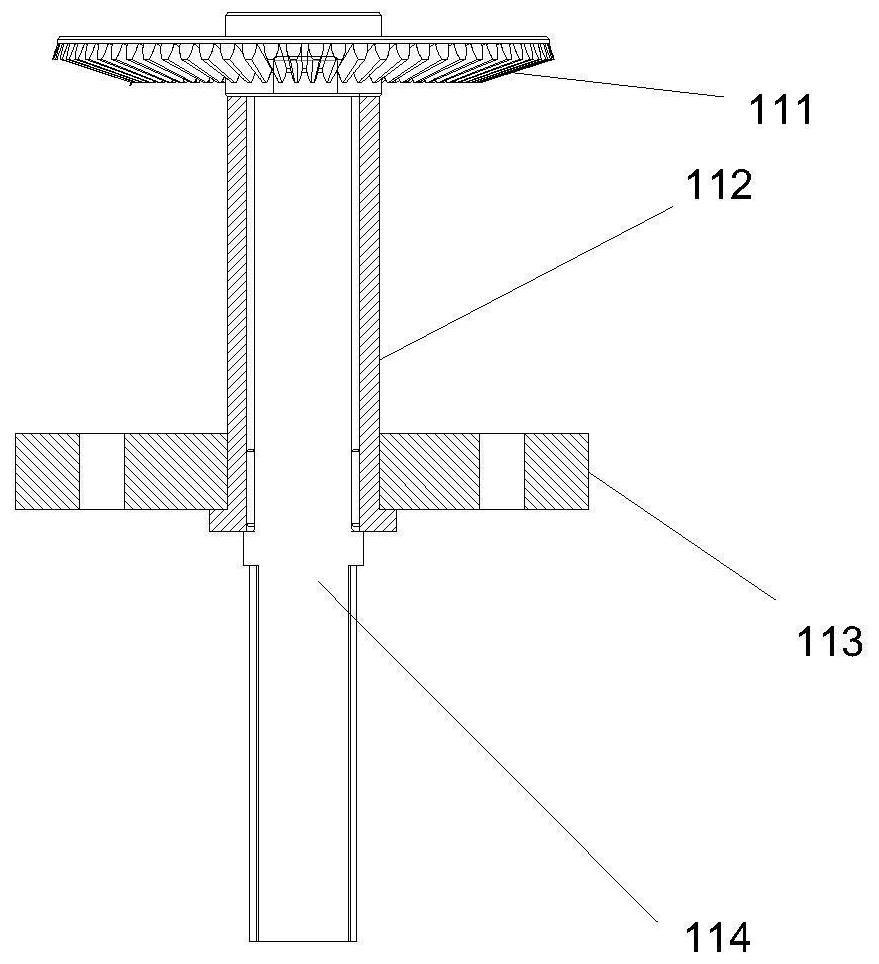

The invention discloses a self-adaptive underactuated robot clamping claw which comprises a clamping claw shell, a drive module and finger modules. The clamping claw shell comprises a front clamping claw shell body, a rear clamping claw shell body and a fixing flange, wherein the front clamping claw shell body and the rear clamping claw shell body are connected and are further in bolt connection with the fixing flange. The drive module is arranged in the clamping claw shell and comprises a drive motor, a power transmission device and drive rods. The drive motor is used for driving the drive rods to make synchronous linear motion and transmitting torque through the power transmission device. The finger modules comprise the first finger module and the second finger module which are each provided with a first finger section and a second finger section. Each first finger section and the corresponding second finger section are hinged to the corresponding drive rod through a self-adaptive connecting rod system and a parallel connecting rod system, and area driven to move through the drive rod. The self-adaptive underactuated robot clamping claw can grab objects in different shapes in different manners, is suitable for requirements of different occasions and high in clamping range and clamping force, and can grab the objects more conveniently.

Owner:SHENZHEN DH ROBOTICS TECH CO LTD

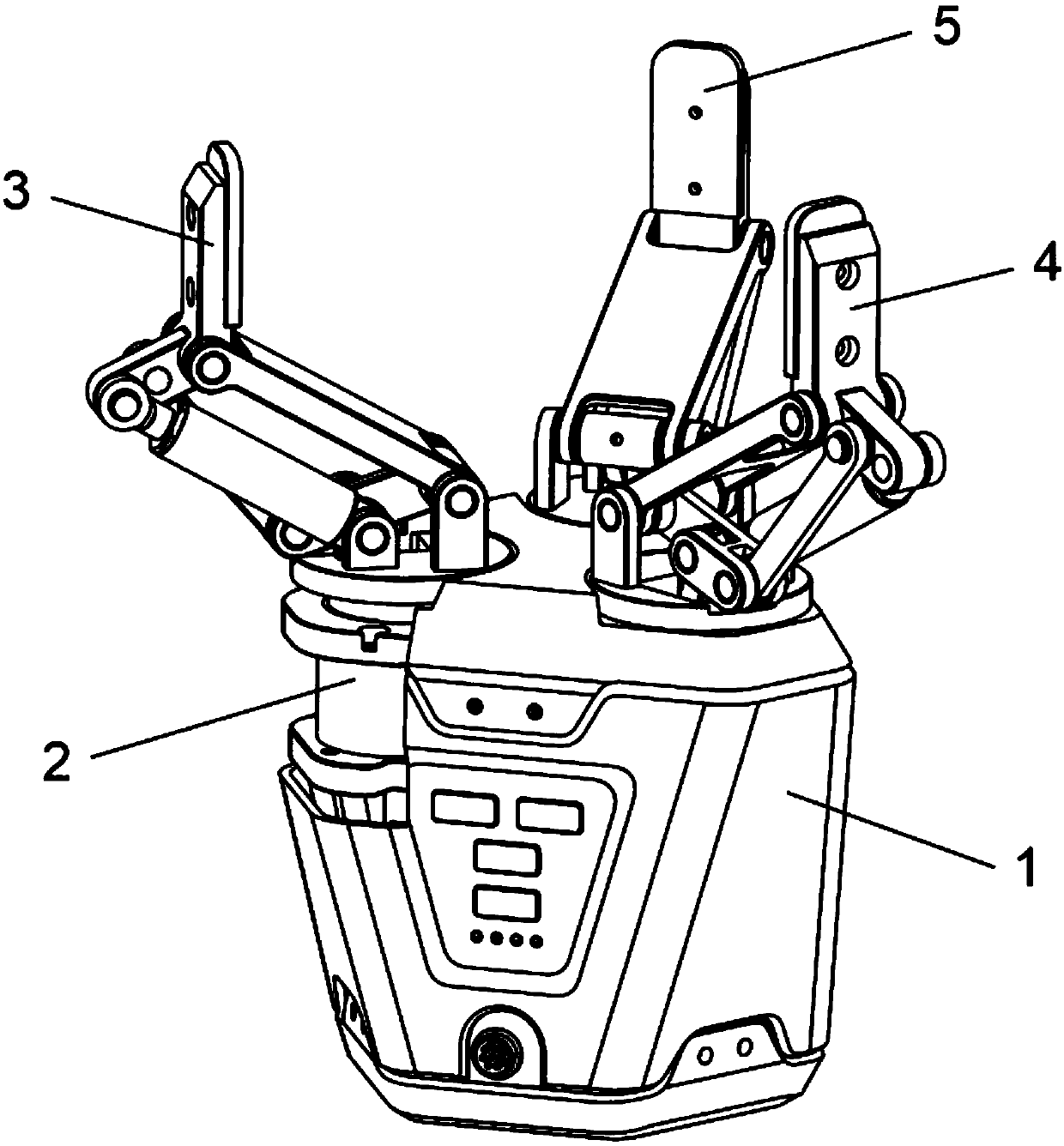

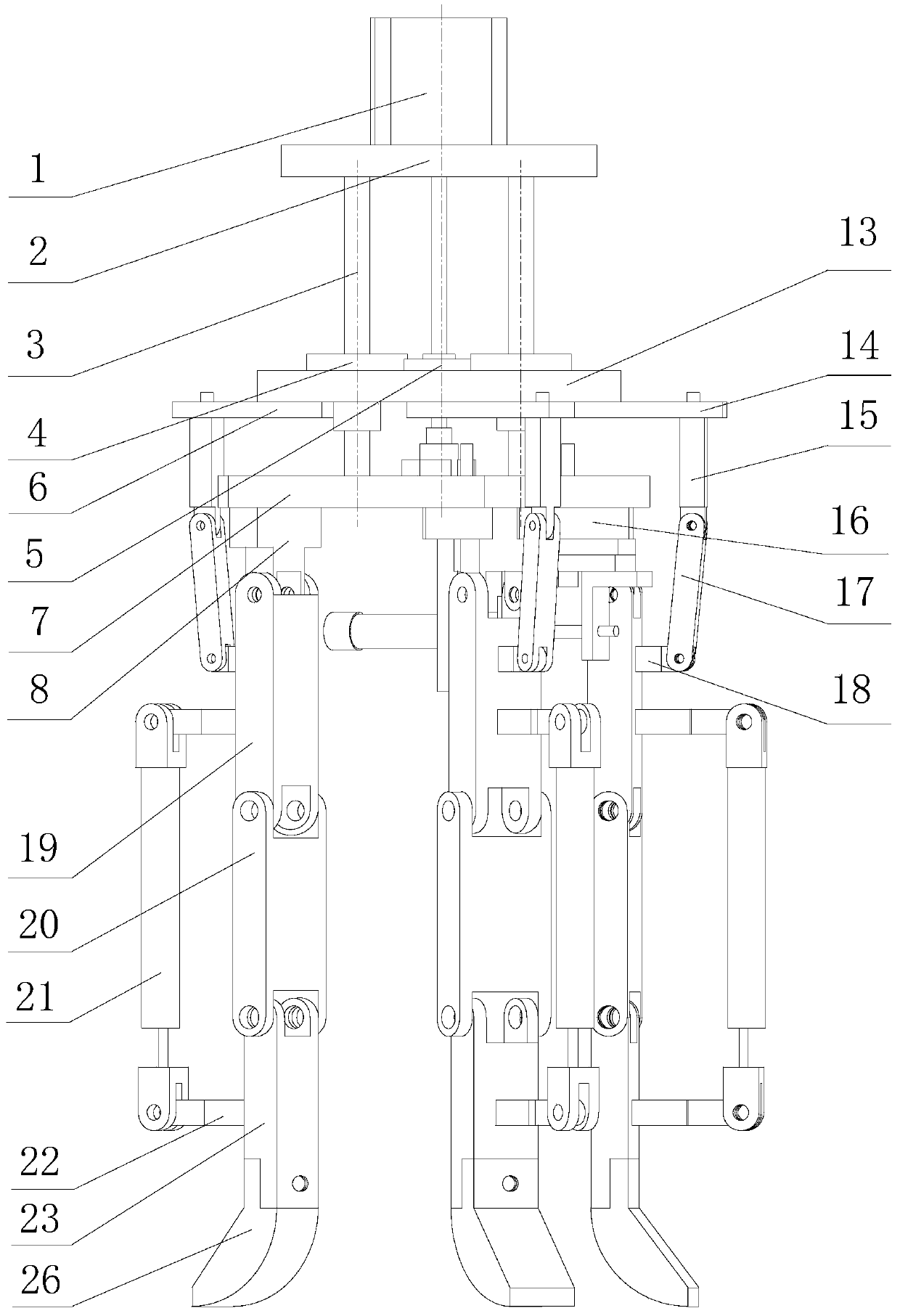

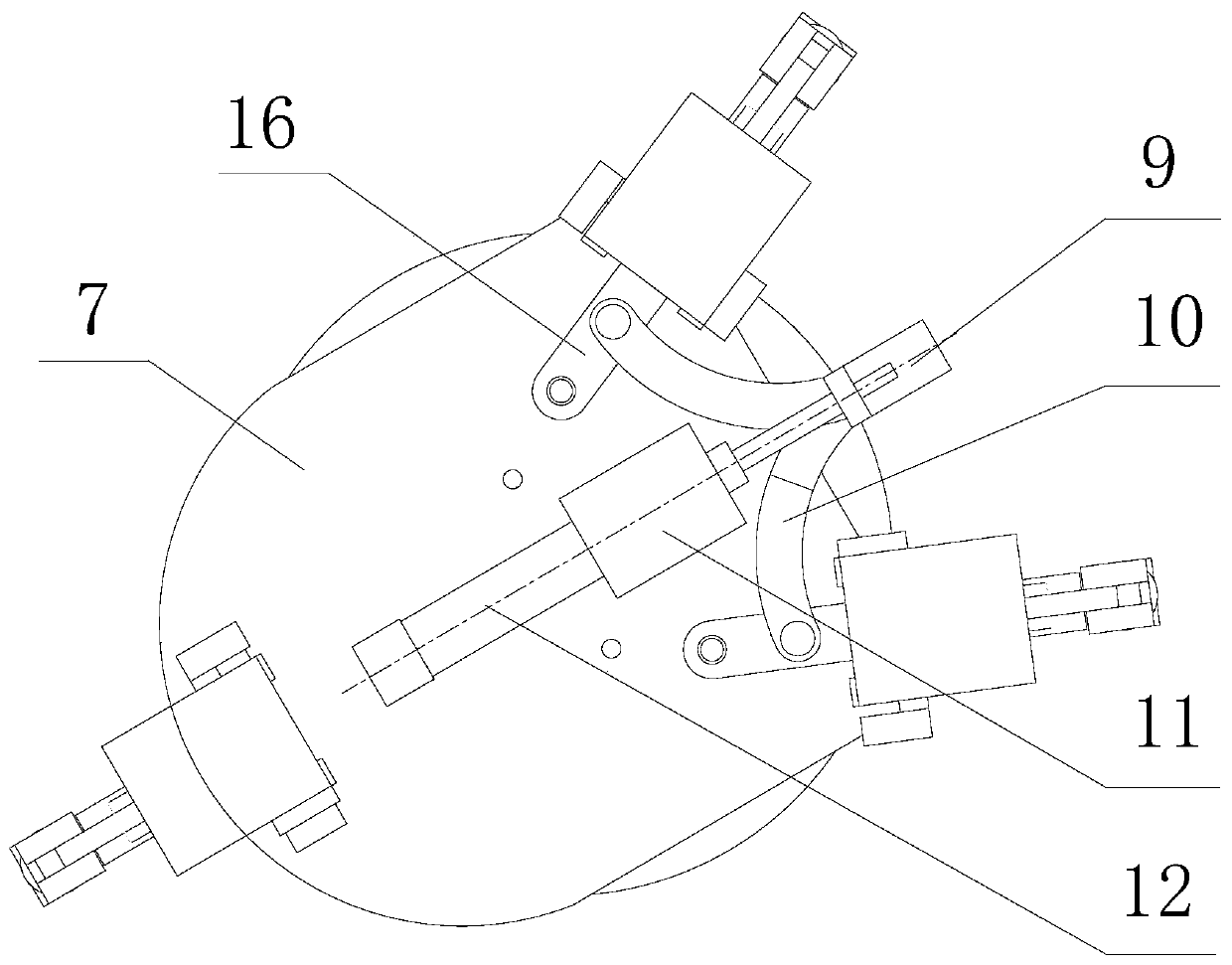

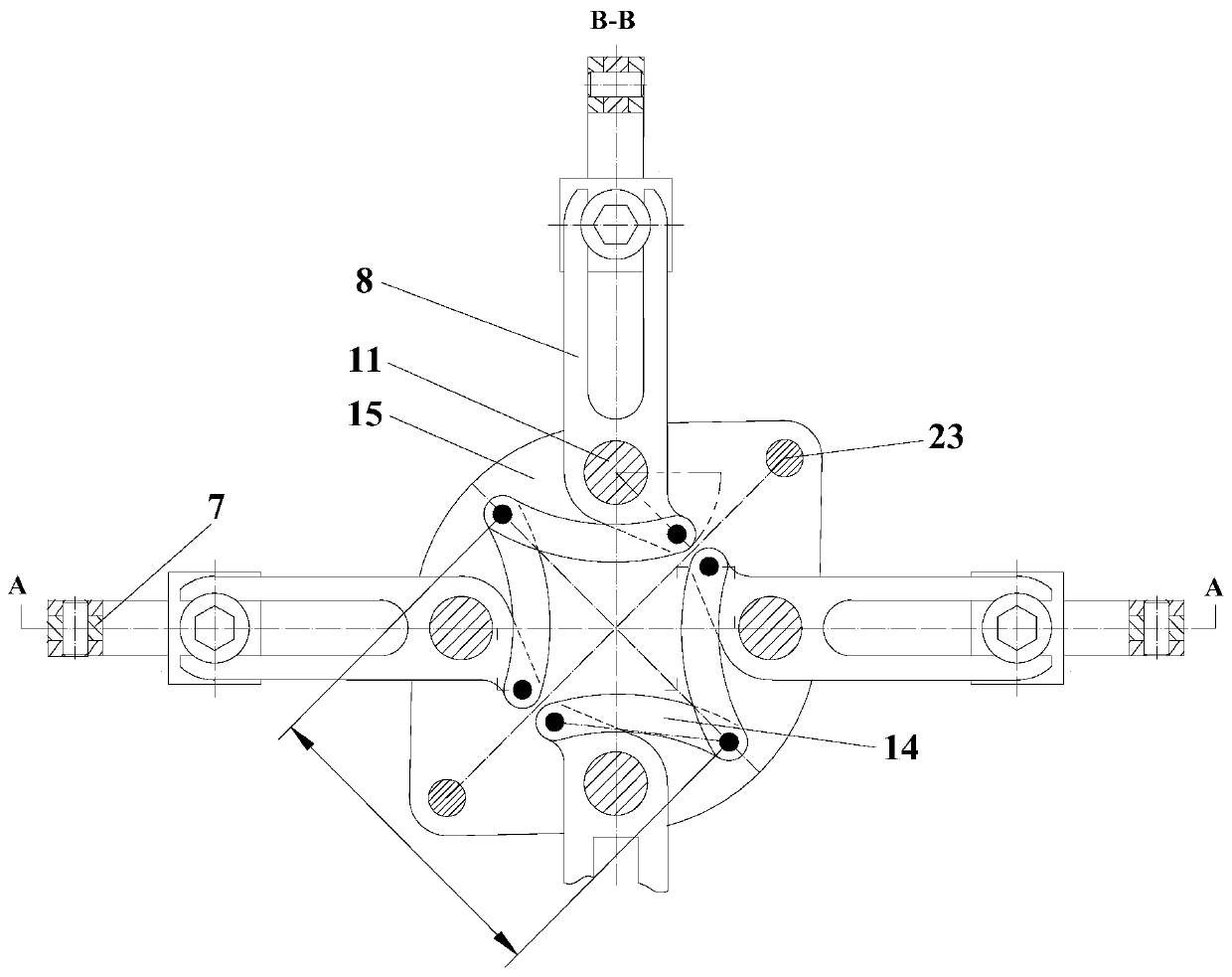

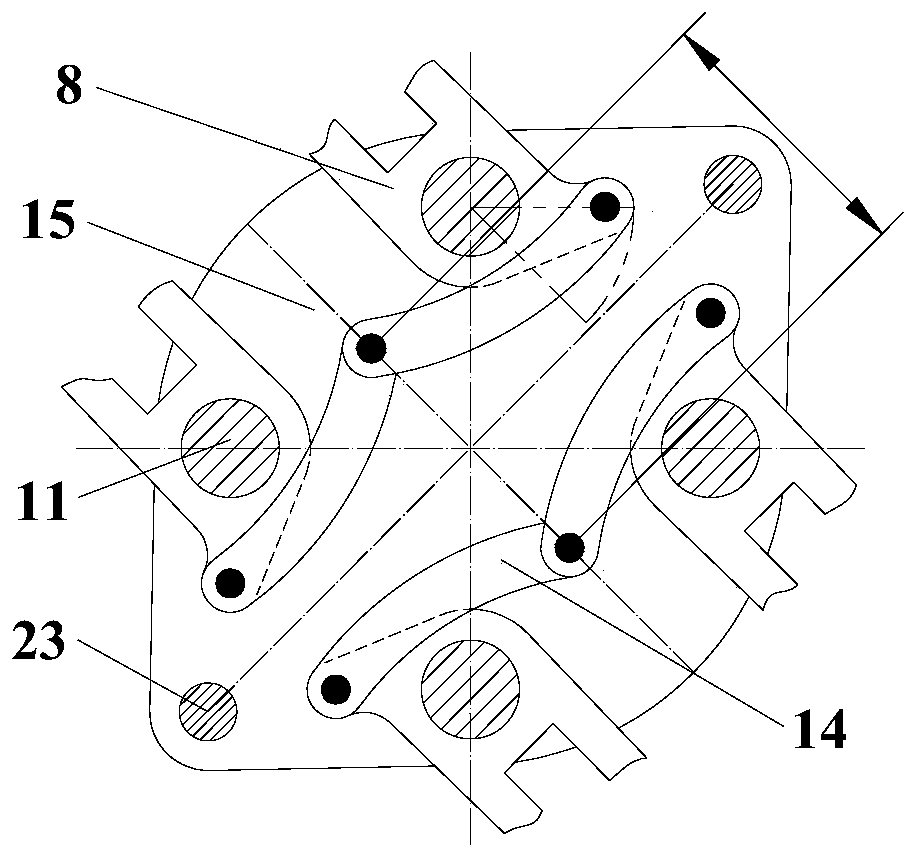

Self-adaptive under-actuated turning three-finger robot clamping jaw

The invention belongs to the field of robot clamping jaws, and specifically relates to a self-adaptive under-actuated turning three-finger robot clamping jaw. The clamping jaw comprises a clamping jawshell, a drive module, a first finger module, a second finger module and a third finger module, wherein the drive module is installed in the clamping jaw shell and comprises a first drive motor, a second drive motor, a first power transmission system, a second power transmission system and three drive rods, the three finger modules are distributed circumferentially and are distributed at three sides of the top of the clamping jaw shell, each finger module comprises a finger base, a first finger section and a second finger section, the first drive motor drives the three finger modules to finish a grasp action through the first power transmission system, the second drive motor drives the second finger module and the third finger module to rotate along respective axis through the second power transmission system so as to acquire corresponding gestures of different finger modules. The clamping jaw can grasp a target object adaptively, has a large stroke, grasps stably, and has a graspingand self-locking function.

Owner:SHENZHEN DH ROBOTICS TECH CO LTD

Self-adaption robot finger device of composite flexible drive flat clamp

InactiveCN105643647ALarge grabbing rangeIncrease in sizeJointsGripping headsUnderactuationDrive wheel

The invention discloses a self-adaption robot finger device of a composite flexible drive flat clamp, and belongs to the technical field of robot hands. The self-adaption robot finger device comprises a base, two finger segments, two joint shafts, a driver, two flexible drive parts, four drive wheels, a protruding block shifting disc, two spring parts, a limiting protruding block and the like. The device utilizes the driver, a closed-loop flexible part drive mechanism, an opened-loop flexible part drive mechanism, the two spring parts, the protruding block shifting disc, the limiting protruding block and the like to comprehensively achieve functions of parallel clamping and self-adaption grabbing; according to the difference of shapes and positions of target objects, the second finger segment can be moved horizontally to nip and hold the objects or can be expanded outwards for supporting, and the first finger segment and the second finger segment can be sequentially rotated to wrap the objects in different shapes and with different sizes; and the device is large in grabbing range; the underactuation manner is adopted, the driver is used for driving two joints, and a complex sensing and control system is not needed; and the device is compact in structure, small in size, low in manufacturing and maintaining cost and suitable for the robot hands.

Owner:TSINGHUA UNIV

Parallel connection type parallel-clamping and self-adapting robot finger device with flexible part and connection rods

The invention belongs to the technical field of robot hands and discloses a parallel connection type parallel-clamping and self-adapting robot finger device with a flexible part and connection rods. The device comprises a base, two finger sections, two joint shafts, a driver, the flexible drive part, two drive wheels, the multiple connection rods, a protrusion block drive plate, a spring part and a limiting protrusion block. The device realizes the parallel clamping and self-adapting grabbing functions through the comprehensive effect of the driver, a closed loop flexible part drive mechanism, a parallel four connection rod drive mechanism, the spring part, the protrusion block drive plate and the limiting protrusion block; according to the different shapes and positions of target objects, the second finger section can be horizontally moved for pinching the objects or extending outwards for supporting the objects, and the first finger section and the second finger section can be sequentially rotated for enveloping the objects of different shapes and sizes; the grabbing range is wide; by adopting the under-drive mode, one driver is used for driving two joints, and complicated sensing and control systems are not needed. In addition, the device is compact in structure, small in size, low in manufacturing and maintaining cost and suitable for the robot hands.

Owner:TSINGHUA UNIV

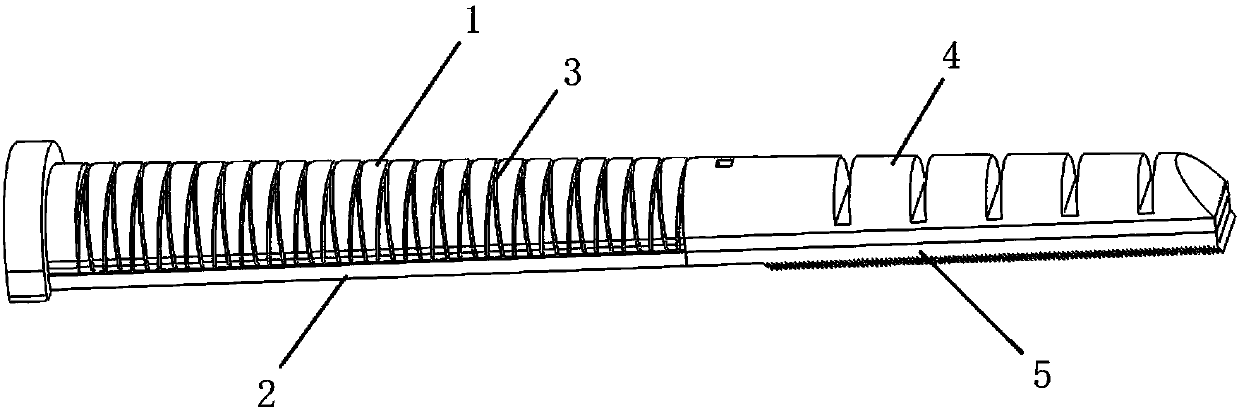

Soft finger capable of realizing segmented bending by utilizing giant electrorheological fluid

PendingCN112045694AAchieving Segmented BendingLarge grabbing rangeGripping headsEngineeringMechanical engineering

The invention belongs to the related technical field of soft robots, and discloses a soft finger capable of realizing segmented bending by utilizing giant electrorheological fluid. The soft finger comprises a corrugated pipe, a restraint layer and a plurality of variable stiffness layers; the corrugated pipe forms a first side surface; the restraint layer is arranged on the first side surface; theplurality of variable stiffness layers are arranged on the restraint layer at intervals in the length direction of the corrugated pipe; each of the variable stiffness layers comprises an insulating cavity body, and a positive electrode plate, a negative electrode plate and a giant electrorheological fluid layer which are accommodated in the insulating cavity body; the insulating cavity is filledwith the giant electrorheological fluid layer, the rigidity of the giant electrorheological fluid layer is changed by applying an electric field to the giant electrorheological fluid layer, then the stiffness of the corresponding variable stiffness layer is adjusted, and adjustment of the stiffness of the soft finger is achieved. The stiffness change of each knuckle is realized by controlling theon-off of an external electric field of each knuckle variable stiffness layer of the soft finger, so that various different configurations of the finger are realized, and the soft finger is suitable for various different application scenes.

Owner:HUAZHONG UNIV OF SCI & TECH

Tendon rope transmission coupling self-adaption three-finger differential motion robot hand paw device

The invention relates to a tendon rope transmission coupling self-adaption three-finger differential motion robot hand paw device, and belongs to the technical field of robots. The tendon rope transmission coupling self-adaption three-finger differential motion robot hand paw device comprises a hand paw base, three double tendon rope tandem type coupling self-adaption fingers, a hand paw transmission mechanism, a driver, a single-input three-output differential mechanism and the like. By means of the device, the robot finger coupling quick folding grabbing and self-adaption grabbing functionsand the overall hand paw self-adaption grabbing function are achieved. The device can drive all fingers to achieve quick coupling rotation to achieve self-adaption clamping of objects according to thedifferent shapes and positions of the objects, the remaining fingers / finger can be continuously driven to continuously move when any one or two of the fingers are blocked until the objects are stablyclamped, and the aim of self-adaption wrapping of the objects in different shapes and sizes through all fingers and the overall hand paw is achieved; the grabbing scope is large, and grabbing is stable and reliable; one driver is used for driving the three fingers; and the device has the high adaptability and large grabbing force and is stable and reliable to grab and suitable for various robots.

Owner:HARBIN INST OF TECH

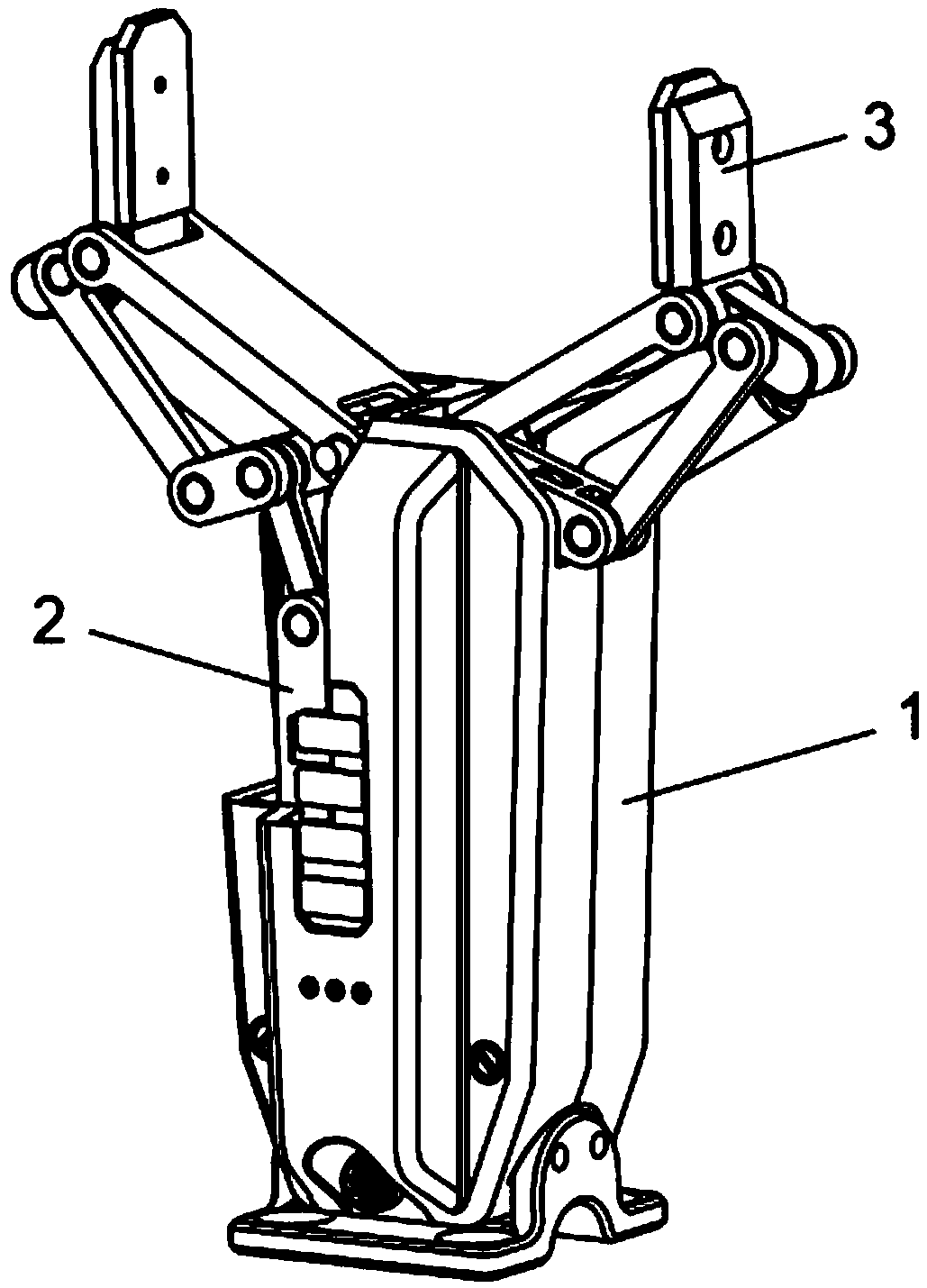

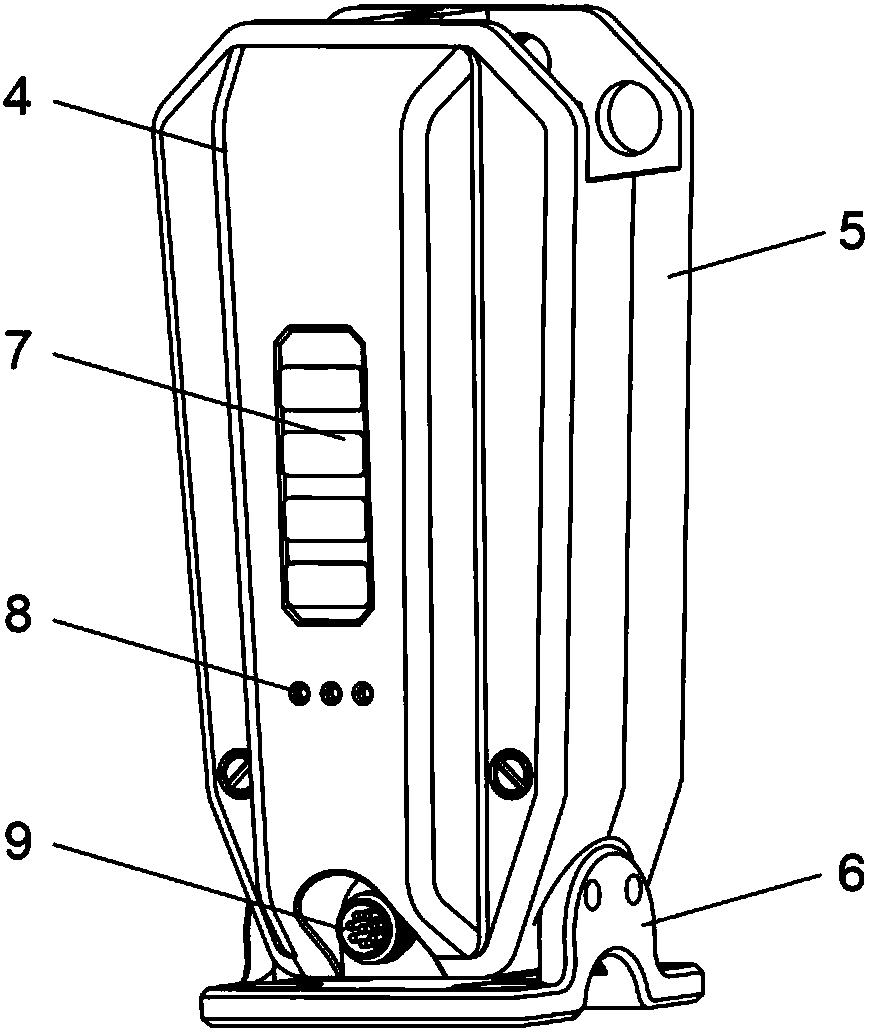

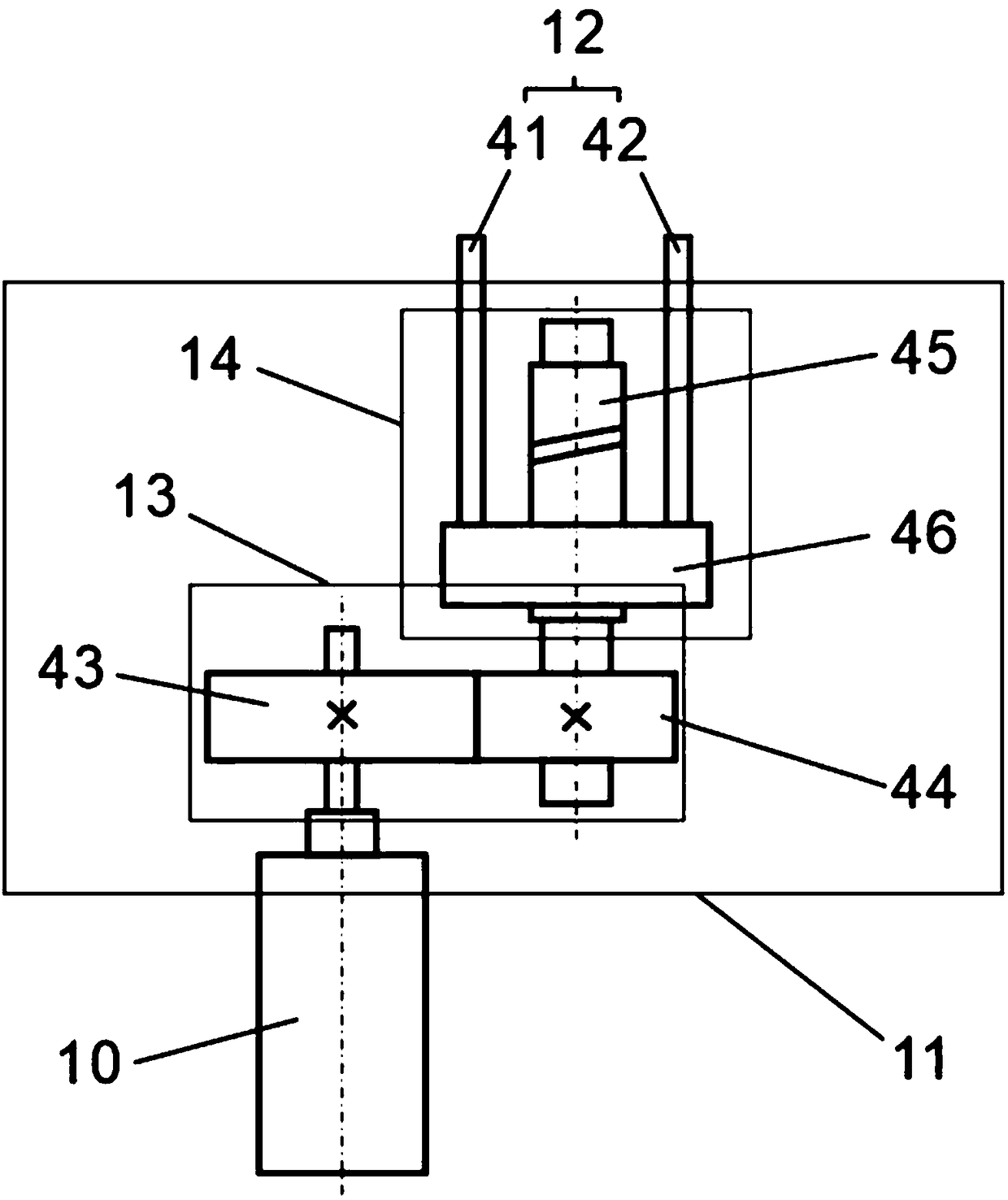

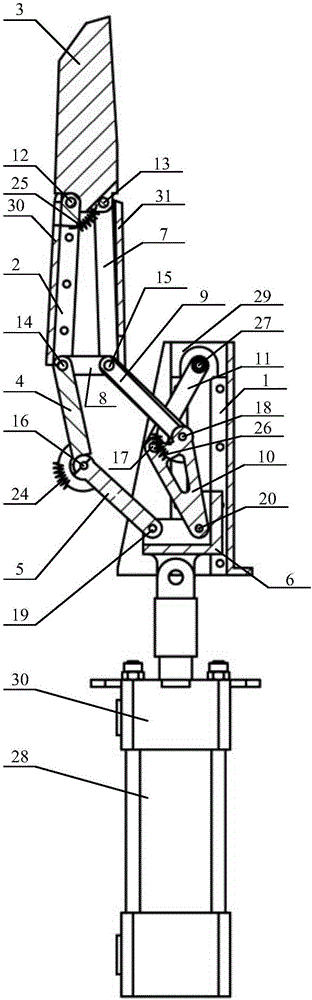

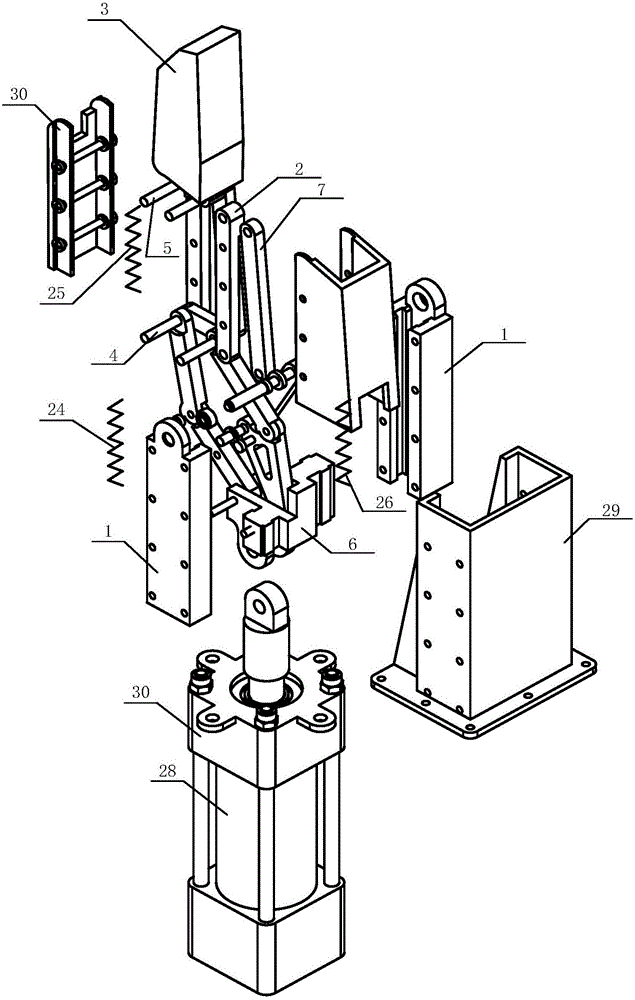

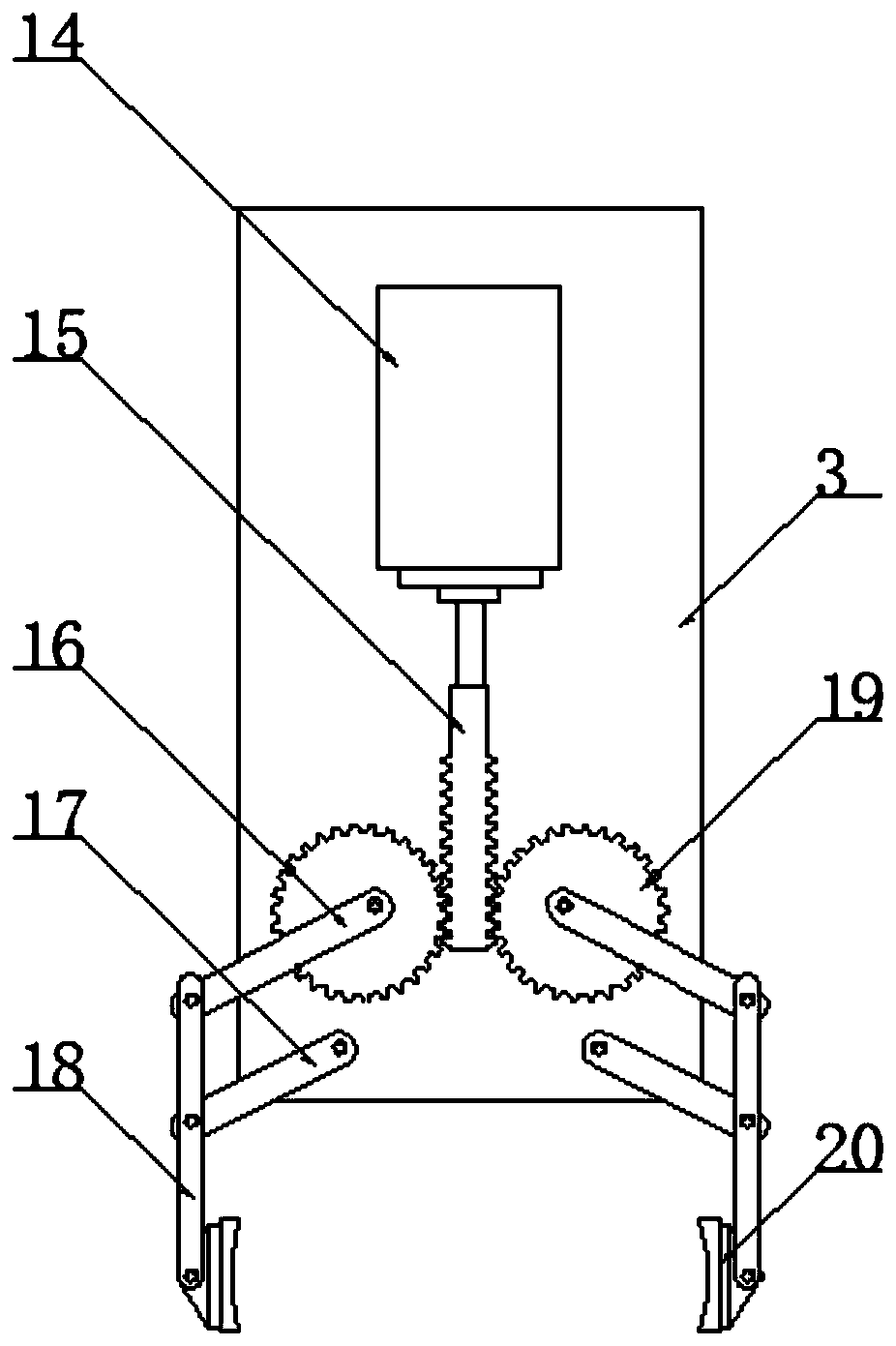

Pneumatic finger clamping and finger root rotation electric finger root rotatable flexible manipulator

ActiveCN109910039APneumatic clamping fast responseAdjustable grasping attitudeGripping headsHorizontal axisEngineering

The invention relates to a pneumatic finger clamping and finger root rotation electric finger root rotatable flexible manipulator. The manipulator comprises a fixed plate. A lead screw shaft motor ismounted on the upper surface of the fixed plate. The lower surface of the fixed plate is connected with a bottom plate through guide rods. The portions, located between the bottom plate and the fixedplate, of the guide rods are sleeved with a moving plate. A lead screw nut fixed into the moving plate is screwed on a lead screw shaft of the lead screw shaft motor. The manipulator further comprisesa fixed finger and two rotary fingers, and the fixed finger and the rotary fingers are of the same structure. The fixed finger is connected to a push rod fixing plate on one side of the bottom surface of the moving plate and rotates along the horizontal axis parallel to the axes of two torsion springs. The rotary fingers are connected to a rotary push rod fixing plate on the other side of the bottom surface of the moving plate and rotate along the vertical axis perpendicular to the different surface of the horizontal axis at equal angular displacement in the opposite direction. The pneumaticfinger clamping and finger root rotation electric finger root rotatable flexible manipulator is suitable for vertically and horizontally grabbing objects in various types of complex shapes, wide in grabbing range, high in rotation precision and high in response speed.

Owner:JIANGNAN UNIV

Closed loop parallel-clamping and self-adapting robot finger device with connection rods and flexible part

The invention belongs to the technical field of robot hands and discloses a closed loop parallel-clamping and self-adapting robot finger device with connection rods and a flexible part. The device comprises a base, two finger sections, two joint shafts, a driver, three drive rods, two drive wheels, the flexible drive part, a protrusion block drive plate, a spring part and a limiting protrusion block. The device realizes the parallel-clamping and self-adapting grabbing functions through the comprehensive effect of the driver, connection rod drive mechanisms, a closed loop flexible part drive mechanism, the spring part, the protrusion block drive plate and the limiting protrusion block; according to the different shapes and positions of target objects, the second finger section can be horizontally moved for pinching the objects or extending outwards for supporting the objects, and the first finger section and the second finger section can be sequentially rotated for enveloping the objects of different shapes and sizes; the grabbing range is wide; by adopting the under-drive mode, one driver is used for driving two joints, and complicated sensing and control systems are not needed. In addition, the device is compact in structure, small in size, low in manufacturing and maintaining cost and suitable for the robot hands.

Owner:TSINGHUA UNIV

Parallel-opening-closing self-adaptive robot finger device with double annular flexible parts

The invention provides a parallel-opening-closing self-adaptive robot finger device with double annular flexible parts, and belongs to the technical field of robot hands. The finger device comprises a base, two finger sections, two knuckle shafts, an actuator, two sets of flexible part wheel train transmission mechanisms, a convex block pushing disc, a spring, a limiting convex block and the like. According to the finger device, parallel-opening-closing pinching and self-adaptive envelope-grabbing functions are achieved through combination of the single actuator, the two sets of flexible part wheel train transmission mechanisms with the reasonably set transmission ratio, the spring, the convex block pushing disc, the limiting convex block, the finger sections movably connected in a sleeving mode and the like; an object can be pinched by horizontally moving the second finger section, and the first finger section and the second finger section also can be sequentially rotated to envelope objects in different shapes and sizes. The master-slave driving mode through the two sets of flexible part wheel train transmission mechanisms is adopted by the finger device, the grabbing range is large, and dead moving zones are avoided; meanwhile, the under-actuated mode is adopted, two knuckles are driven by only one actuator, and complex sensing and control systems are not needed; the finger device is compact in structure, small in size, low in manufacturing and maintaining cost and suitable for a robot hand.

Owner:TSINGHUA UNIV

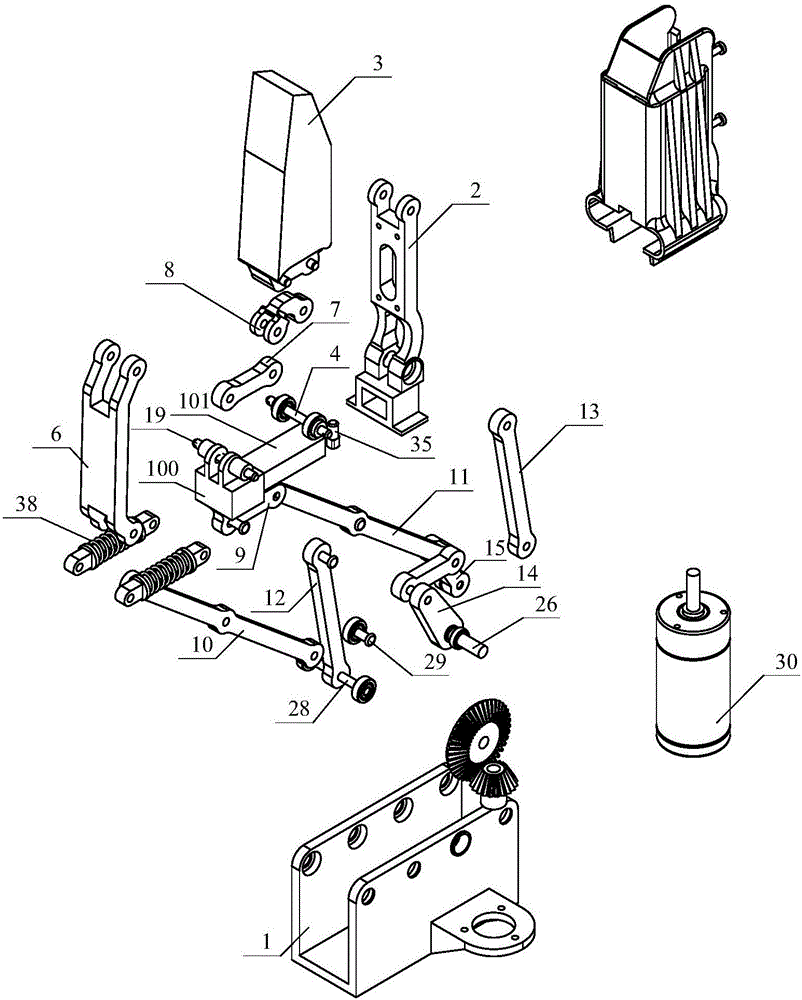

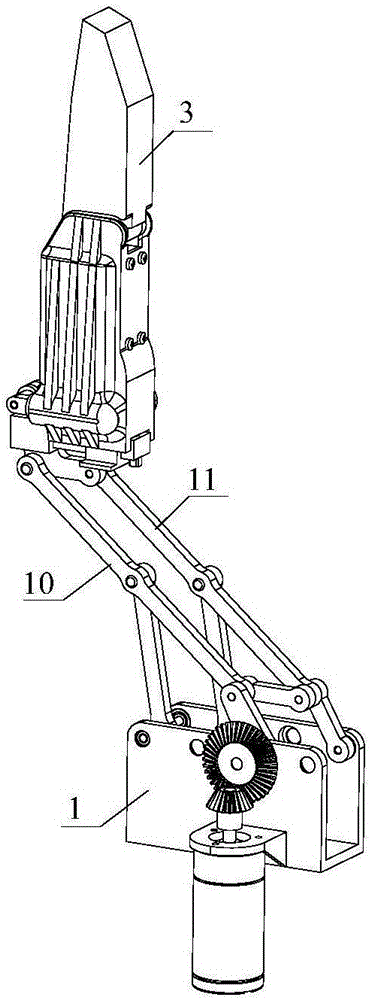

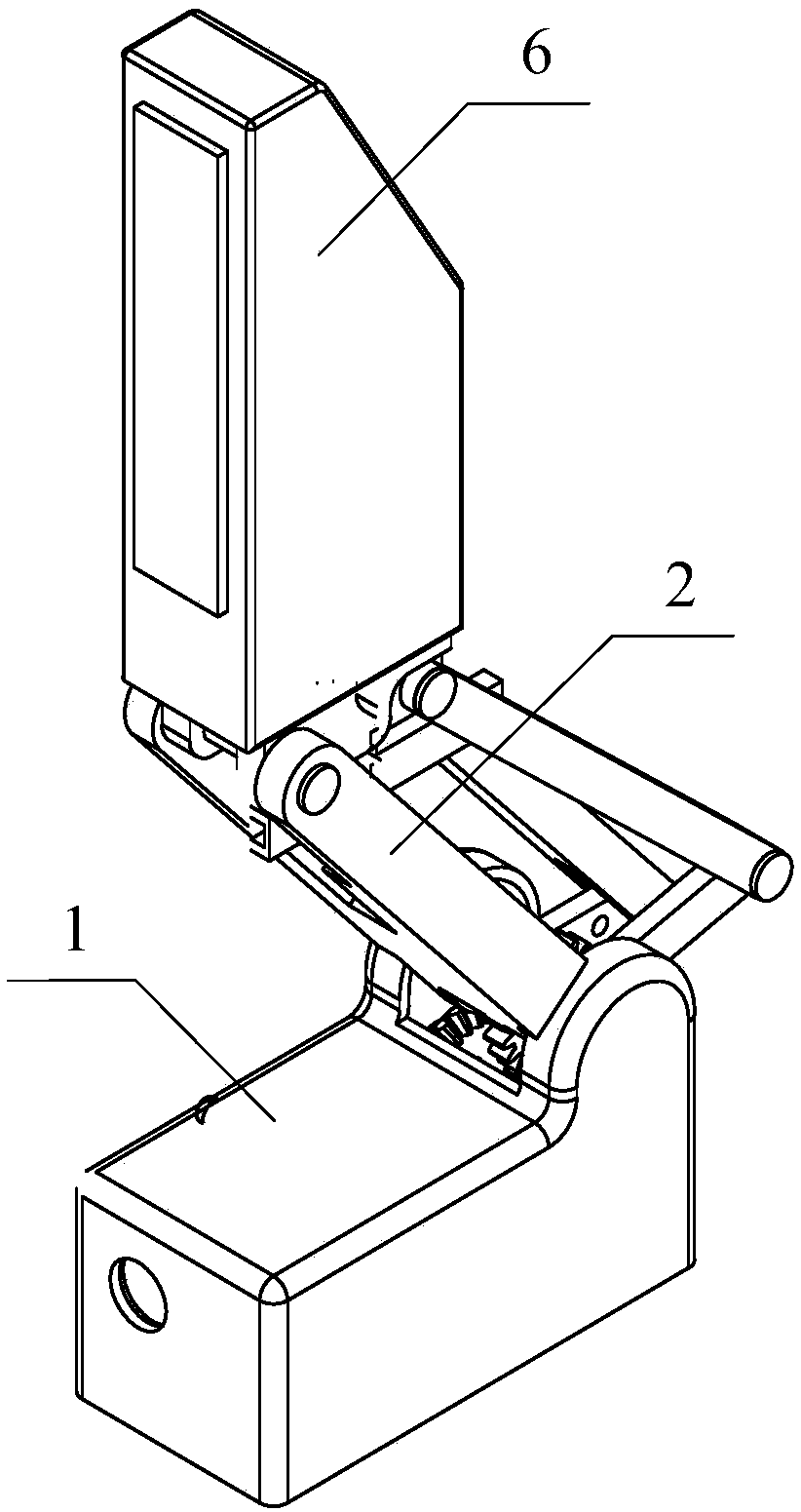

Four-link flat clip adaptive robot finger device

The invention relates to a finger device of a four-linkage parallel clamping and adaptive robot, which belongs to the technical field of robot hands. The finger device comprises a base, a first finger section, a second finger section, a proximal joint axis, a distal joint axis, a driver, a first connecting rod, a second connecting rod, a third connecting rod, a first rod shaft, a second rod shaft, a bulge driving disk, a thumb wheel, a transmission mechanism, a first spring part, a second spring part and a limiting bulge. According to the device, the finger functions of parallel clamping and adaptive grabbing are comprehensively realized, the second finger section can horizontally move to pinch an object or extend to take the object, or the first finger section and the second finger section are rotated in sequence, so as to adaptively envelop objects of different shapes and sizes; the grabbing range is wide, and the grabbing is stable and reliable; two joints are driven only by one driver, and a complex sensing and control system is not needed; the finger device has the advantages of simple structure, small size, light weight and low processing, assembly and maintenance cost and is suitable for the robot hands.

Owner:TSINGHUA UNIV

Herringbone connecting rod, rack and sliding block linear parallel clamping self-adaption finger device

The invention provides a herringbone connecting rod, rack and sliding block linear parallel clamping self-adaption finger device and belongs to the technical field of robot hands. The herringbone connecting rod, rack and sliding block linear parallel clamping self-adaption finger device comprises a base, two finger segments, a driver, a plurality of connecting rods, two sliding blocks, two spring parts, a gear, a rack and the like. According to the herringbone connecting rod, rack and sliding block linear parallel clamping self-adaption finger device, a robot finger linear parallel clamping and self-adaption grabbing function is achieved; the second finger segment can be linearly and parallelly moved to clamp an object and also can be automatically rotated to make contact with the object after the first finger segment make contact with the object, and the purpose that objects with different shapes and sizes are wrapped in a self-adaption mode is achieved; the grabbing range is large, and grabbing is stable and reliable; the two finger segments are driven by one driver; and the herringbone connecting rod, rack and sliding block linear parallel clamping self-adaption finger device is simple in structure, small in size, light in weight and low in machining cost, assembling cost and maintenance cost.

Owner:TSINGHUA UNIV

Connection rod belt wheel linear flat clamping sensing self-adaptive robot finger device

ActiveCN106078781ALarge grabbing rangeReliable grabbingProgramme-controlled manipulatorGripping headsRobot fingerSelf adaptive

The invention provides a connection rod belt wheel linear flat clamping sensing self-adaptive robot finger device and belongs to the technical field of robot hands. The device comprises a base, two finger sections, two joint shafts, two drivers, multiple connection rods, multiple stages of belt wheel transmission mechanisms, a protruding block driving plate, multiple sensors and a control module with a built-in control program. By means of the device, the linear parallel clamping and self-adaptive grasping functions of a robot finger are achieved, and particularly, sheet parts on a worktable can be well clamped. A four-bar mechanism is adopted so that the far joint shaft can move linearly, and the second finger section can horizontal move due to cooperation of belt wheels and the four-bar mechanism. The self-adaptive grasping function can be achieve by means of the sensors, the control module and the built-in control program, and the finger device can adapt to grasping of objects in different shapes and sizes. The grasping range is large, and grasping is stable and reliable. Two joints are driven by the two drivers. The finger device is simple in structure, small in size, low in weight and low in machining, assembly and maintenance cost.

Owner:广州市轻工职业学校

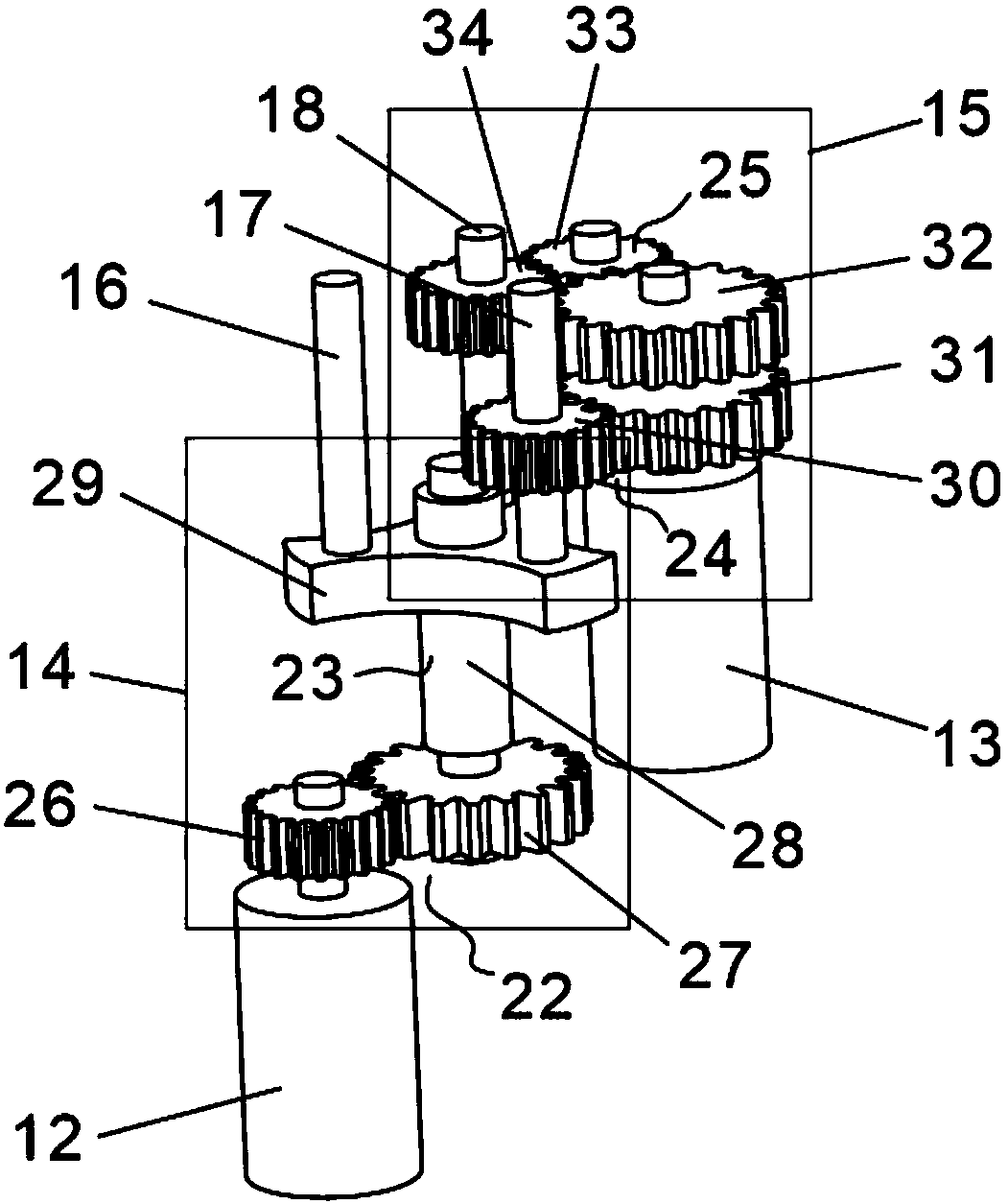

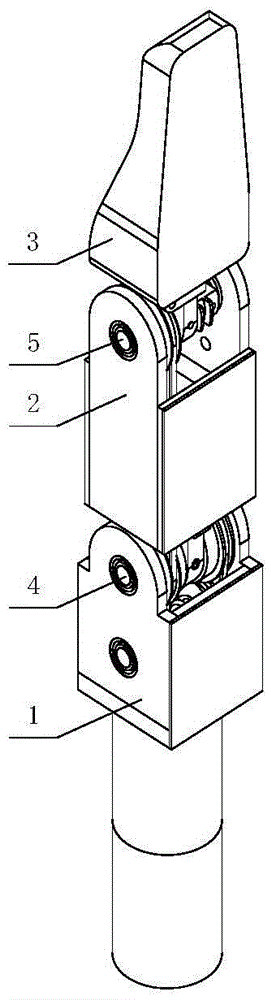

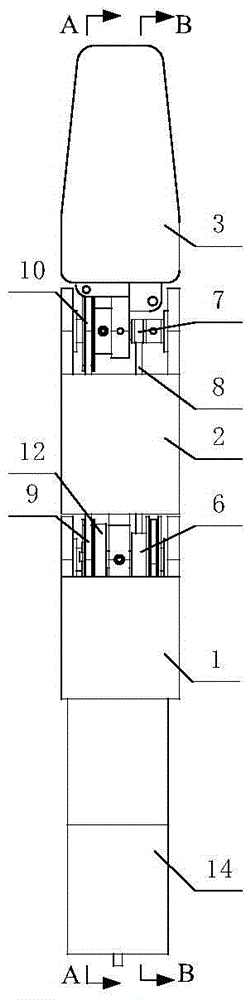

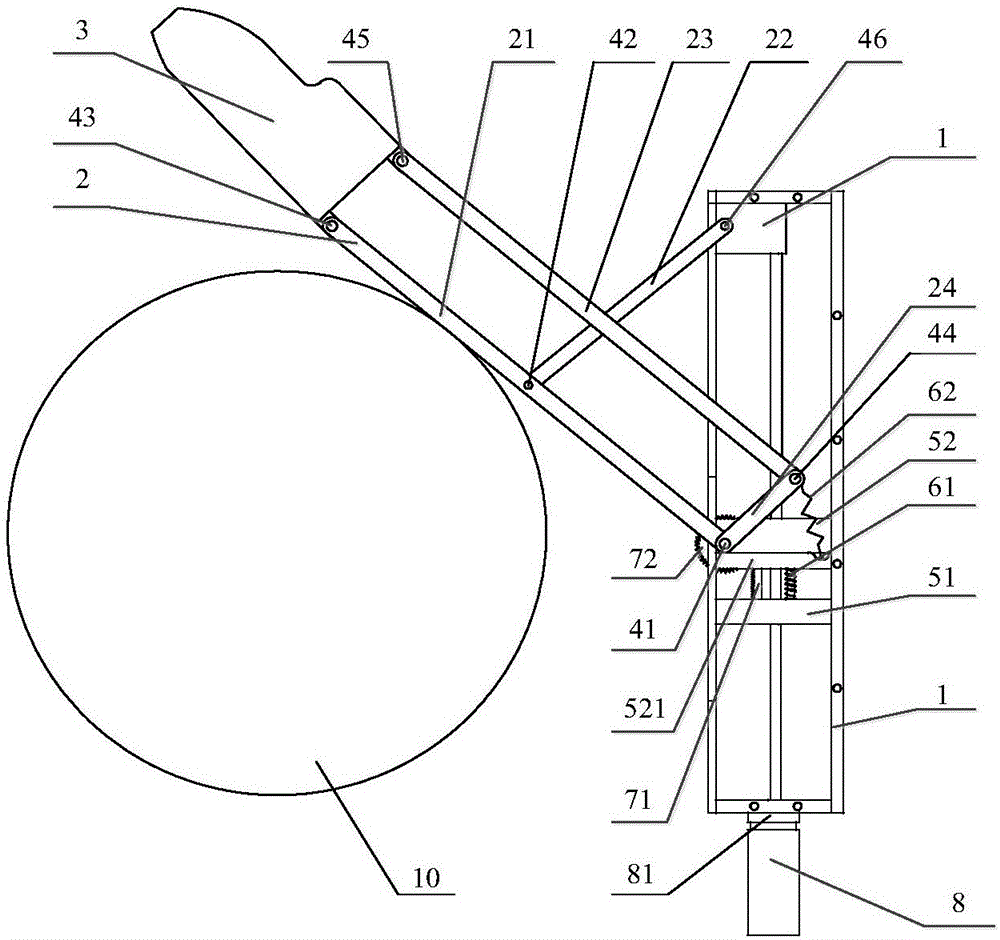

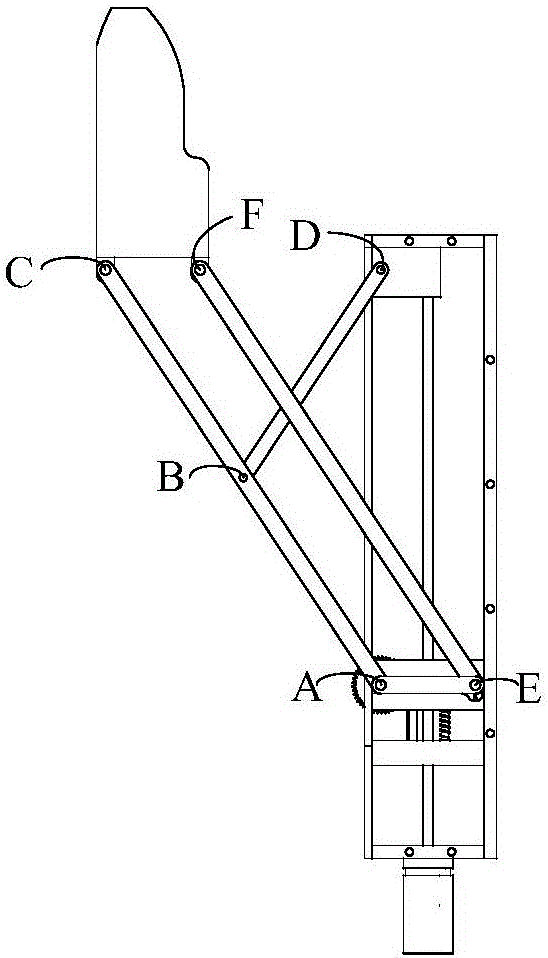

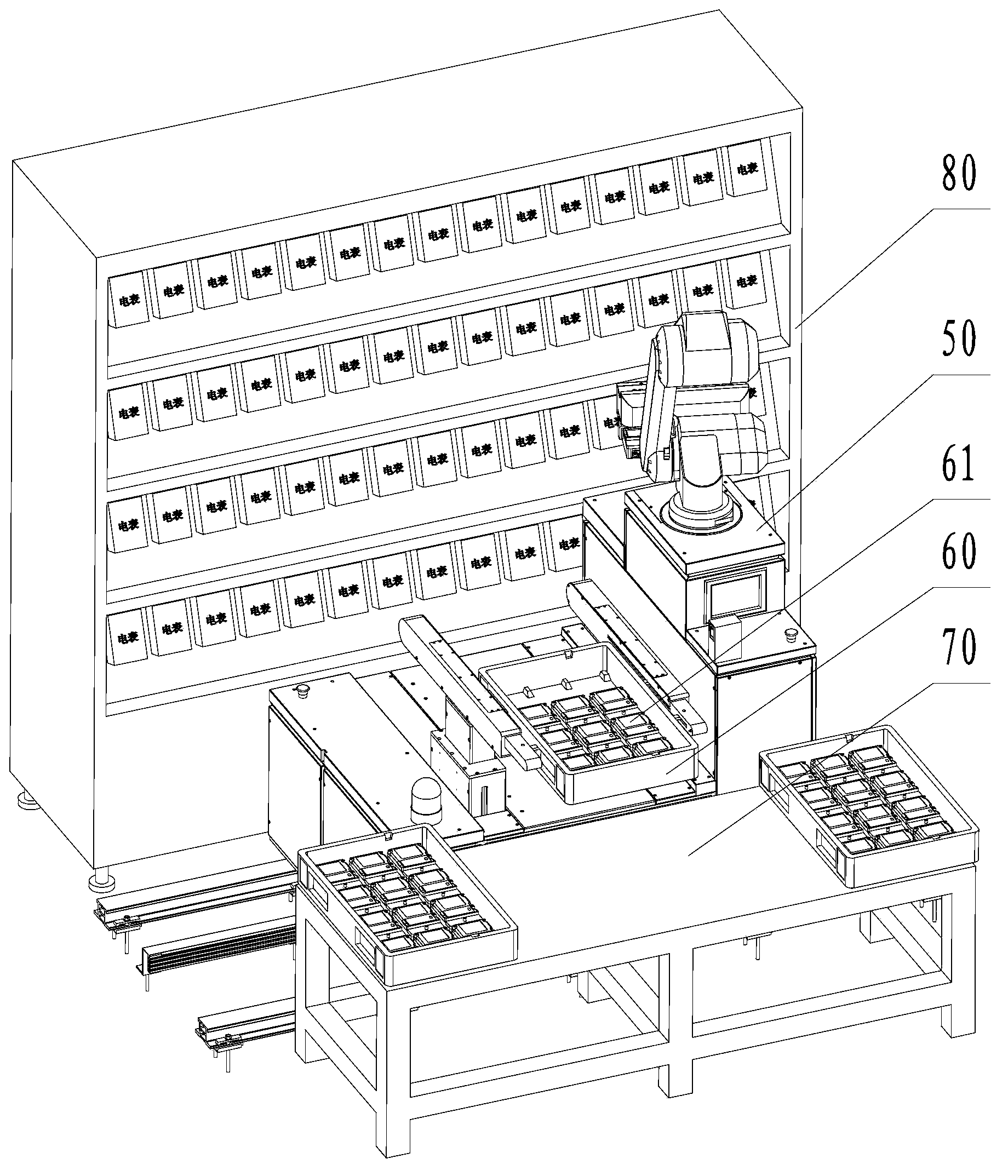

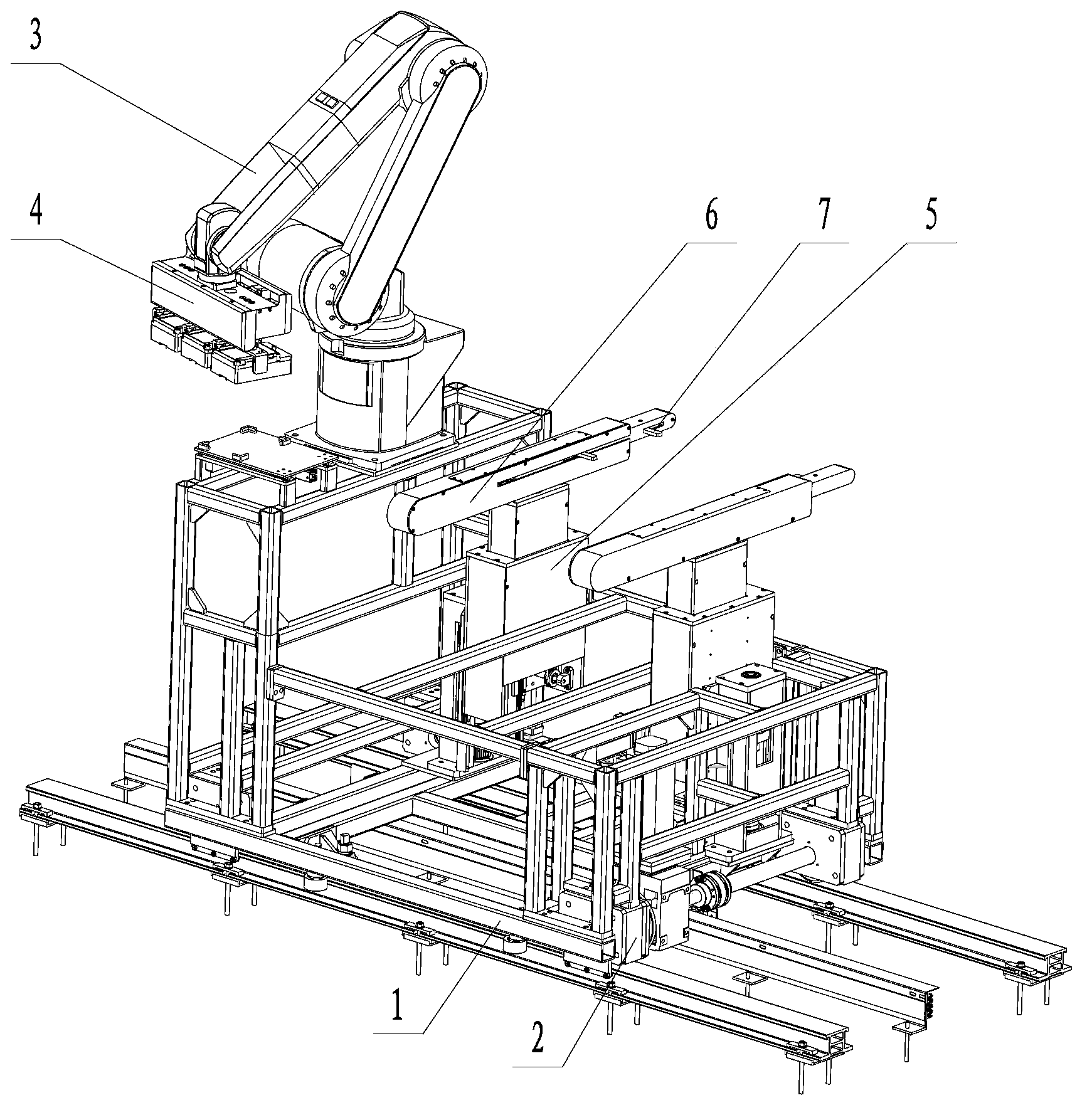

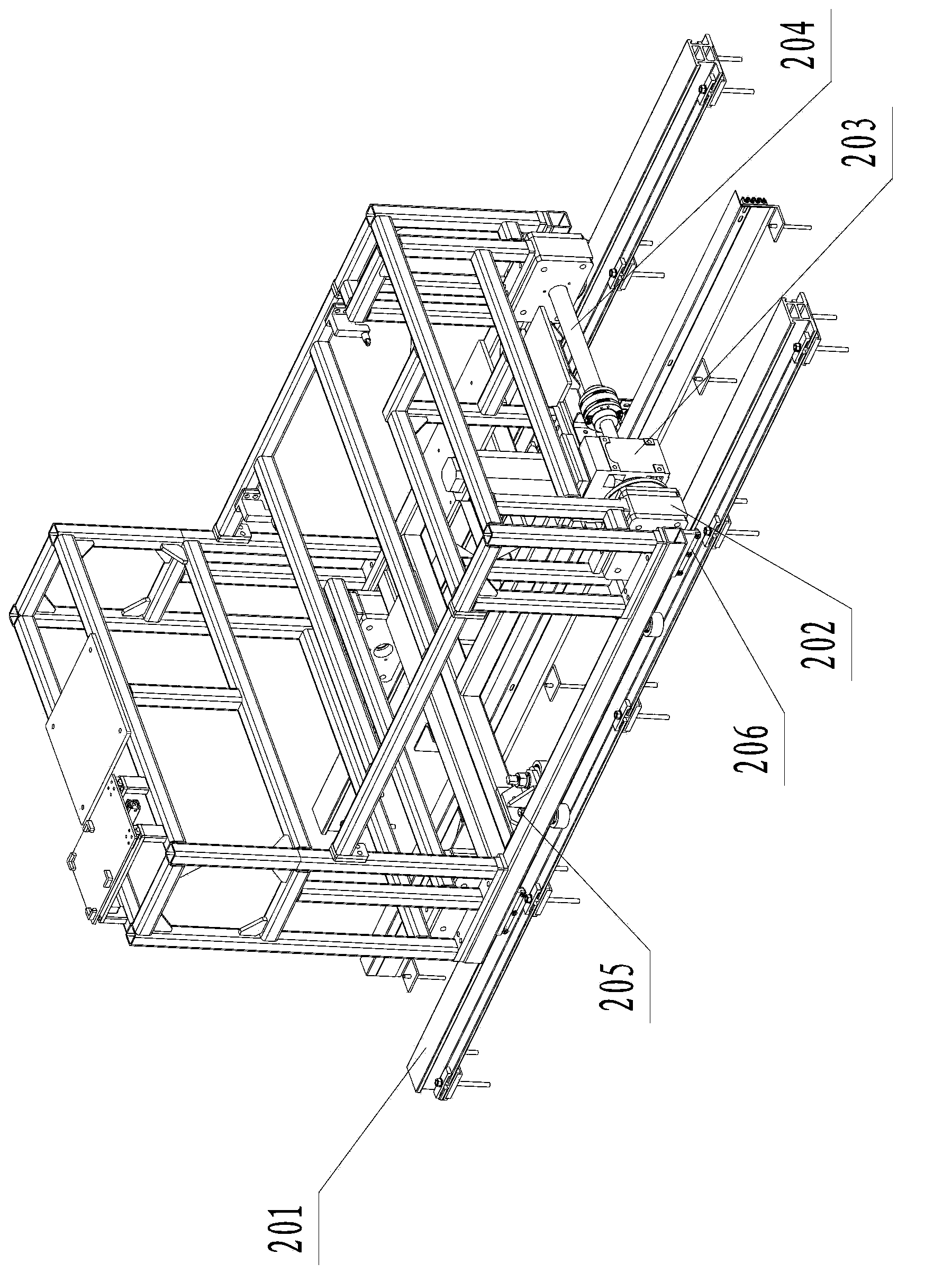

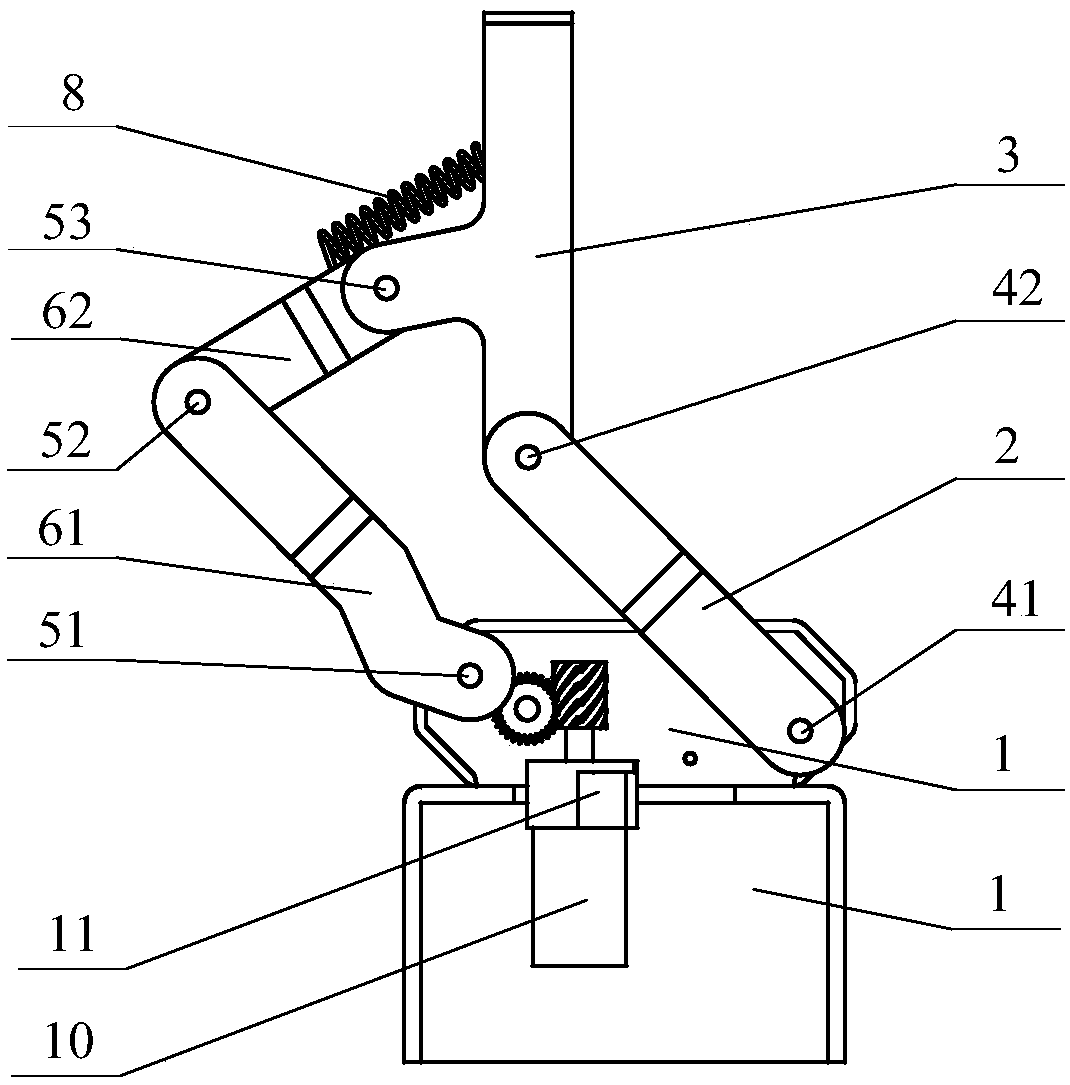

Feeding and discharging device of intelligent mobile robot

InactiveCN103878758ALarge grabbing rangeAutomate operationGripping headsReciprocating motionEngineering

The invention relates to transporting and arranging device of cargoes to be precisely positioned, in particular to a feeding and discharging device of an intelligent mobile robot. The feeding and discharging device comprises a frame, a moving mechanism, a multi-axis motion robot, a grabbing mechanism, a fork lifting mechanism, a fork mechanism and a clamping mechanism. The frame is arranged on rails and is driven to reciprocate on the same via the moving mechanism mounted on the frame. The multi-axis motion robot and the fork lifting mechanism are respectively mounted on the frame, the output end of the multi-axis motion robot is connected with the grabbing mechanism, the fork lifting mechanism drives the fork mechanism to lift, the fork mechanism with a clamping mechanism hidden inside extends out of two sides of a meter box on a wire side rack, and the clamping mechanism extends out of the meter box arranged on the frame. By the feeding and discharging device of the intelligent mobile robot, automatic operation in detecting an electric energy meter is realized, detection reliability and production efficiency are improved, and labor resources are saved. Besides, the feeding and discharging device is high in arrangement position accuracy, wide in application range and applicable to various working places.

Owner:SHENYANG SIASUN ROBOT & AUTOMATION

Open-chain flexible component parallel clamping type adaptive robot finger device

InactiveCN105619440ALarge grabbing rangeNo motion dead zoneJointsGripping headsRobot fingerSacroiliac joint

An open-chain flexible component parallel clamping type adaptive robot finger device belongs to the technical field of robot hands. The open-chain flexible component parallel clamping type adaptive robot finger device comprises a chassis, two finger sections, two joint shafts, a driver, two flexible components, four driving wheels with reasonably arranged radii, a lug dial, two spring components and a limit lug. The device comprehensively realizes parallel clamping and universal grabbing functions. According to different target object shapes and positions, the second finger sections can move in parallel so as to pinch objects, and the first finger sections and the second finger sections can also be sequentially rotated so as to envelop objects in different shapes and sizes. Due to the adoption of a master-slave driving mode with two sets of driving wheel systems, the device is large in grabbing range and free of movement dead zones; and at the same time, due to the adoption of an underactuation mode, two joints are driven by utilizing one driver, and complicated sensing and control systems are not required. The device is compact in structure, small in size, low in manufacture and maintenance costs and suitable for robot hands.

Owner:TSINGHUA UNIV

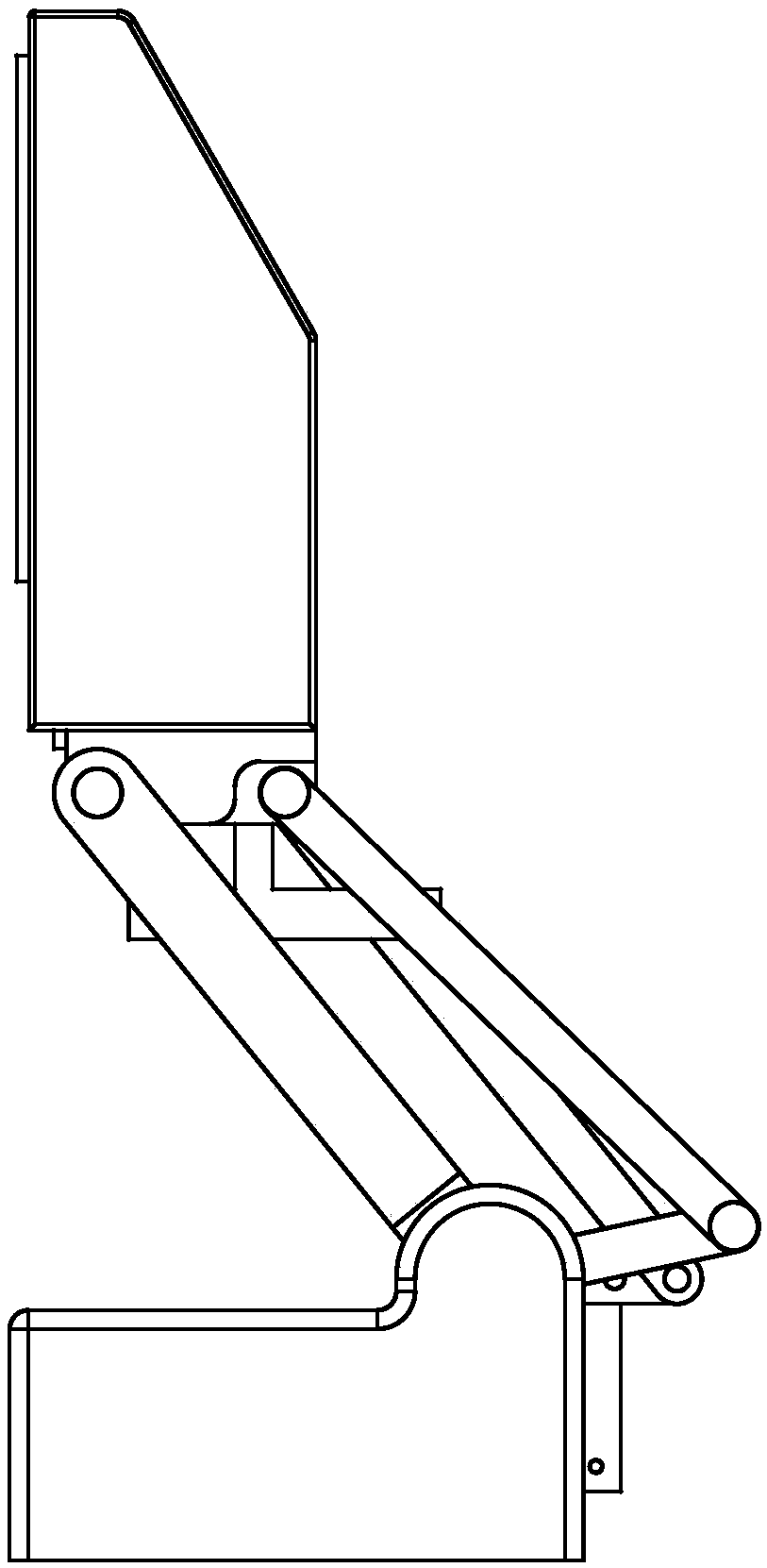

Toggle slide bar adaptive robot finger device

The invention relates to a toggle slide bar adaptive robot finger device, belonging to the technical field of robot hands. The device comprises a base, two finger sections, two joint axes, a guide rod, a plurality of connecting rods, a spring part, a plurality of shafts, and the like. The device realizes the functions of straight line parallel clamping and adaptive grabbing of robot fingers; the linear motion of the far joint axis is realized by adopting a link mechanism which meets certain conditions; the spring part is matched with a crank-slider mechanism, so that the second finger section keeps in a posture of being fixed relative to the base in a first grabbing stage; the crank-slider mechanism is adopted, so that the second finger section makes adaptive rotation around the far joint axis when an object is in contact with the first finger section; the device can adapt to the grabbing for objects with different shapes and sizes; the device is large in grabbing range, stable and reliable in grabbing, simple in structure and low in cost.

Owner:TSINGHUA UNIV

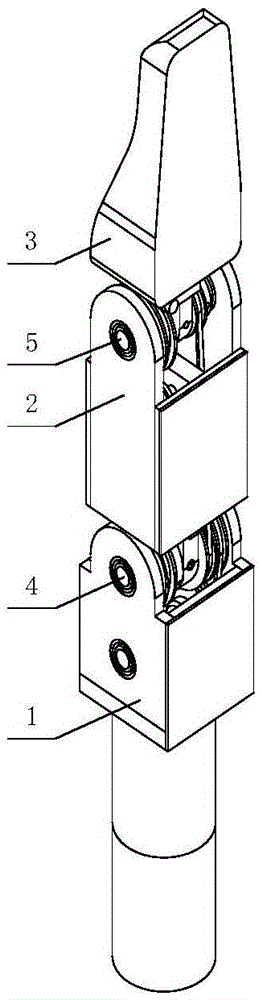

Double-toggle-joint, connecting rod, linear and parallel clamping and self-adapting type finger device of robot hand

The invention provides a double-toggle-joint, connecting rod, linear and parallel clamping and self-adapting type finger device of a robot hand, and belongs to the technical field of robot hands. The double-toggle-joint, connecting rod, linear and parallel clamping and self-adapting type finger device of the robot hand comprises a rack, two finger sections, two housings, two joint shafts, a motor, a plurality of connecting rods, three spring parts, a guide rail and a slide block. With the adoption of the device, fingers of the robot hand can linearly parallelly clamp and adaptively grab, in particularly can clamp a thin-wall workpiece. According to the double-toggle-joint, connecting rod, linear and parallel clamping and self-adapting type finger device of the robot hand, a crank block mechanism meeting a certain condition is utilized to achieve the linear movement of a remote joint shaft and a near joint shaft; a four-connecting-rod mechanism and the spring parts are used in match to remain the second finger section relative to the first finger section at the same location, thus achieving parallel movement; a six-connecting-rod mechanism and the spring parts are used in match to achieve the self-adaptive grabbing function, so as to adapt to grab articles with different shape and size. Therefore, the grabbing range is large, and the grabbing stability and reliability can be ensured; one motor can be used for driving the two finger sections. The device is simple in structure, and low in cost of processing, assembling and repairing.

Owner:TSINGHUA UNIV

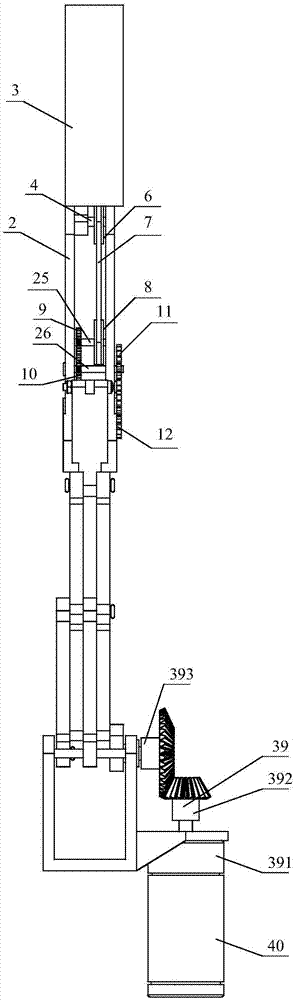

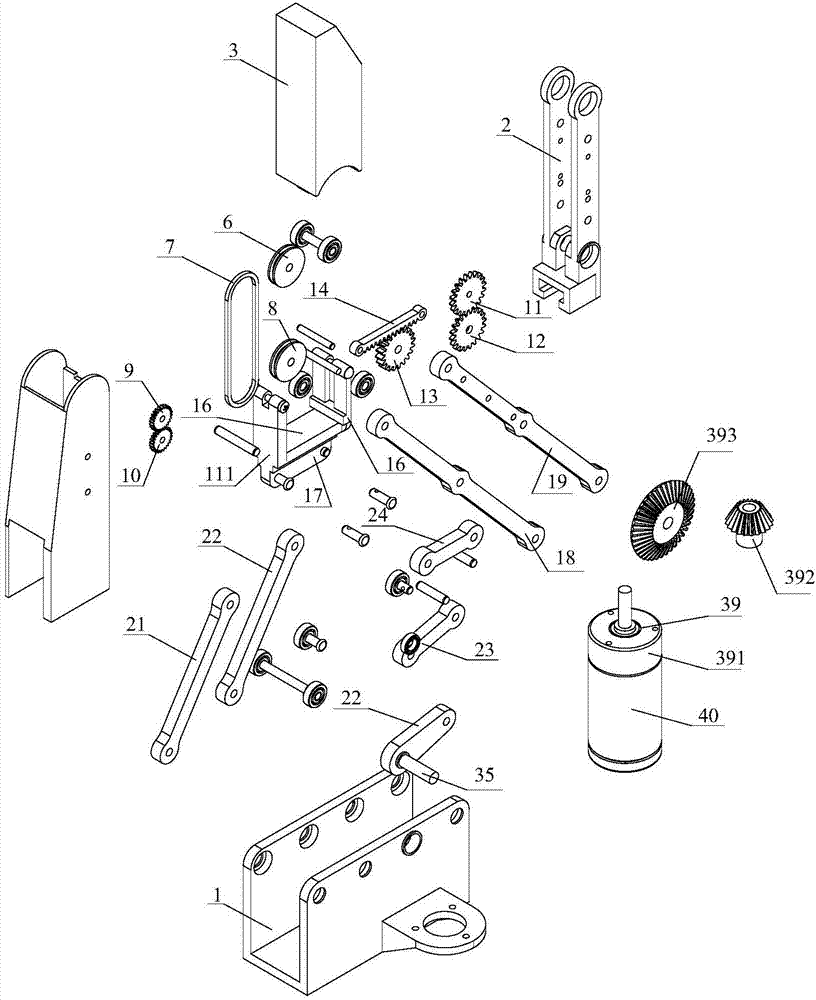

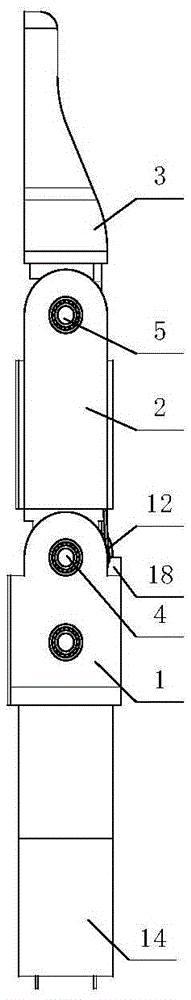

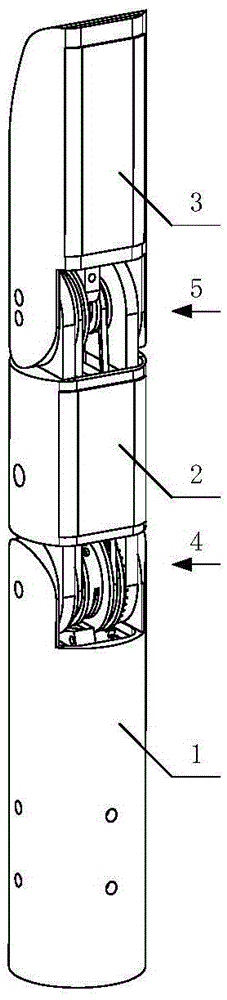

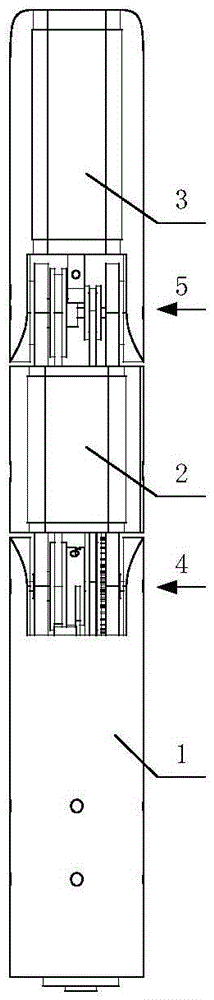

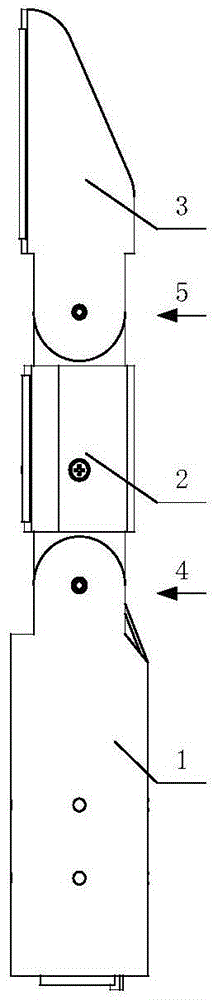

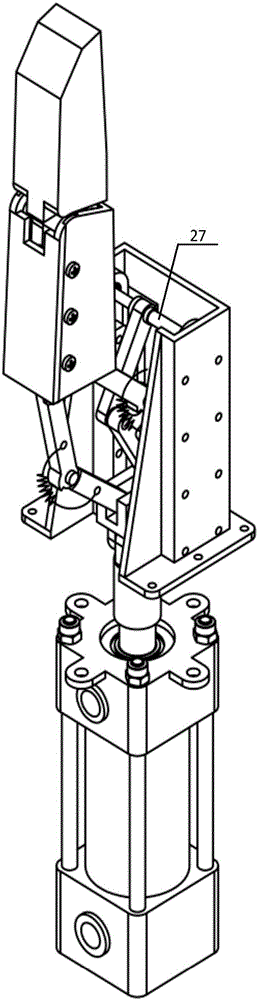

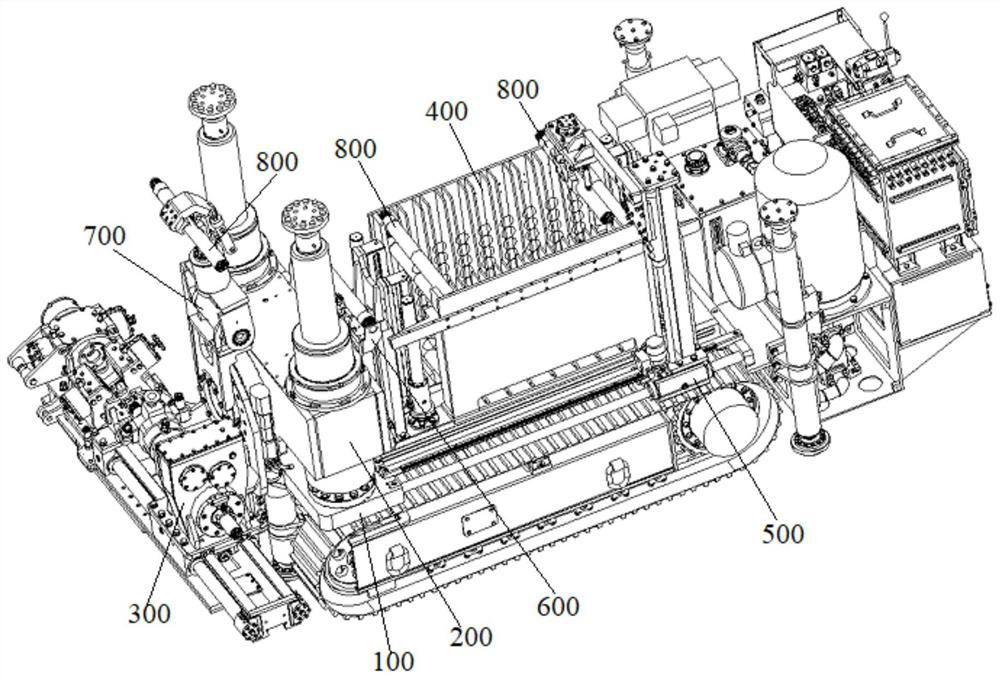

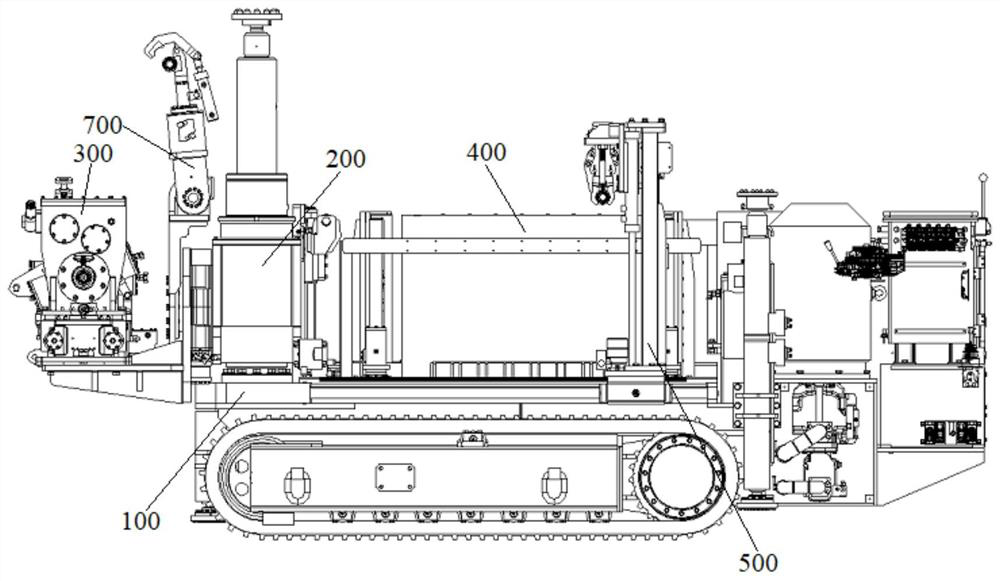

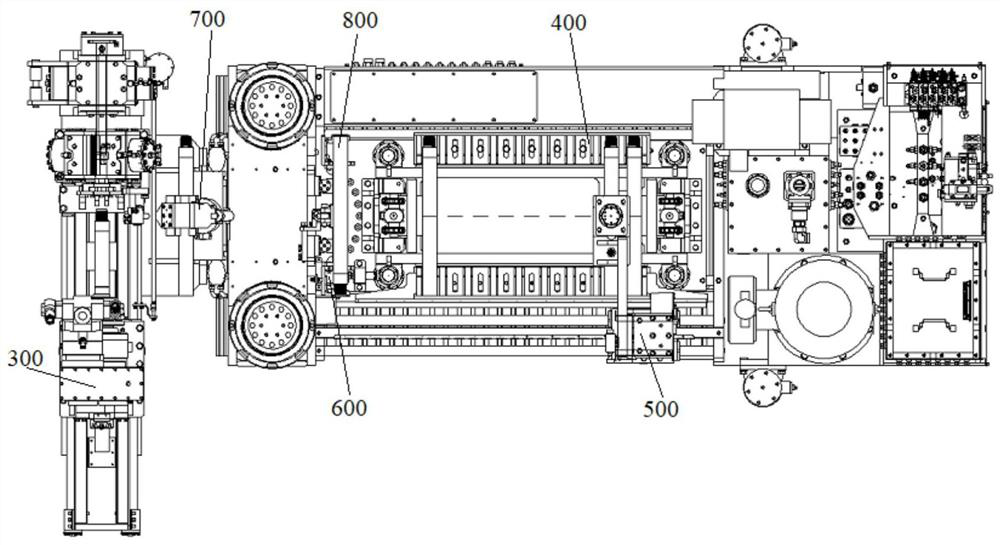

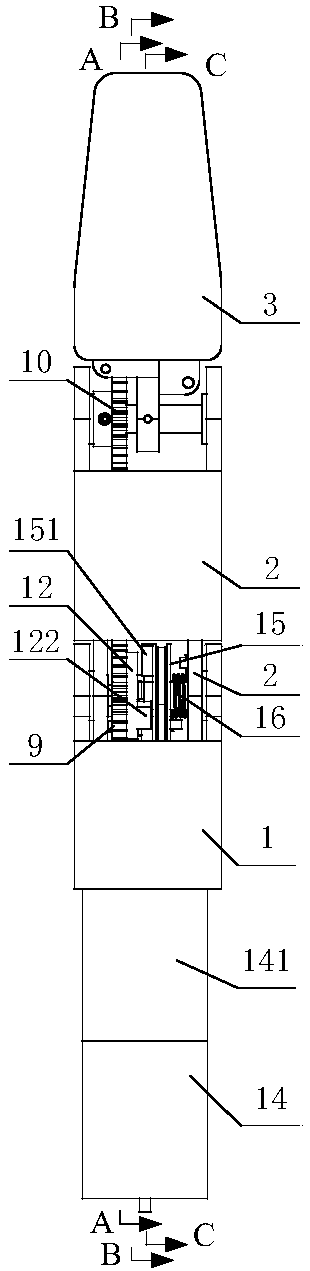

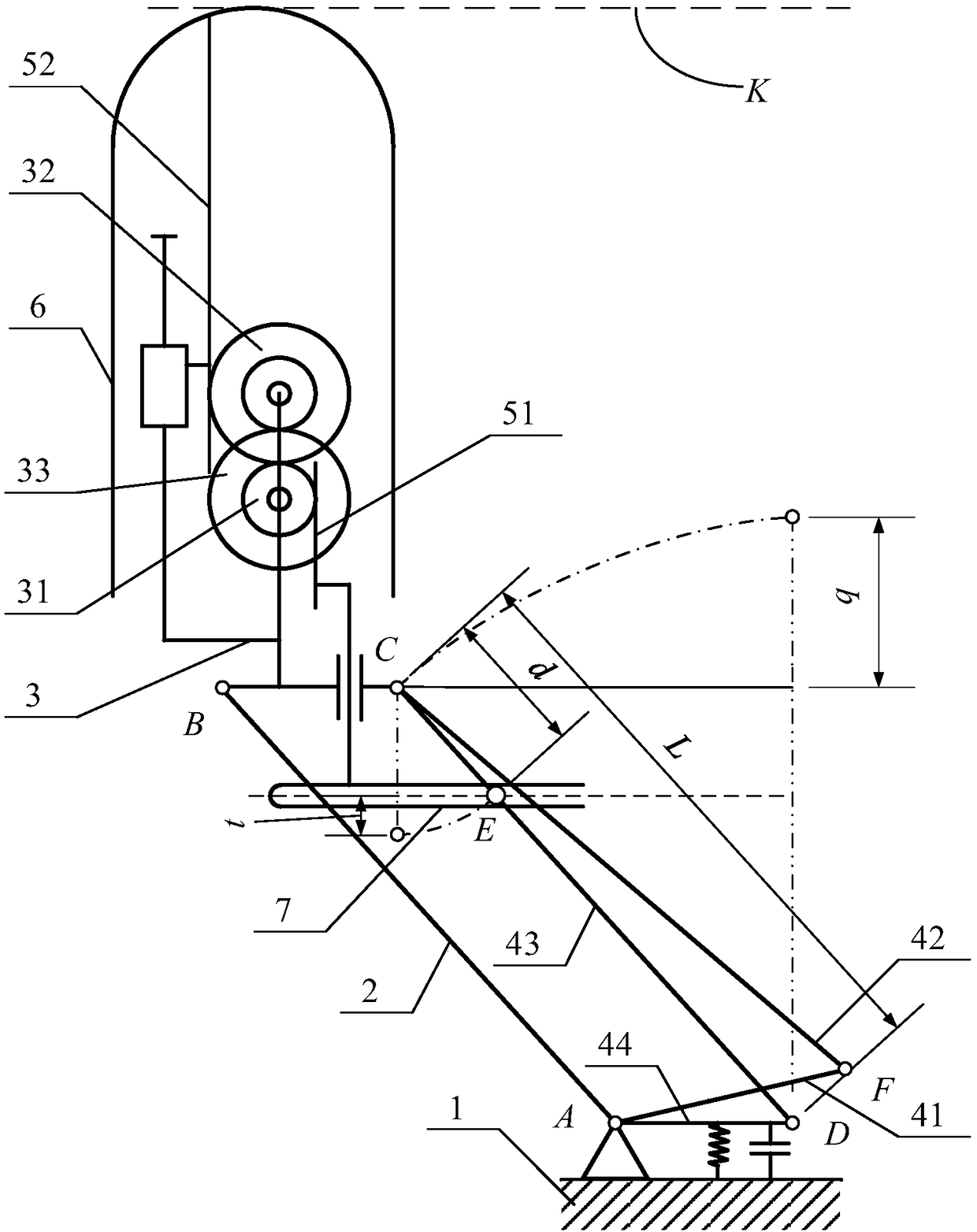

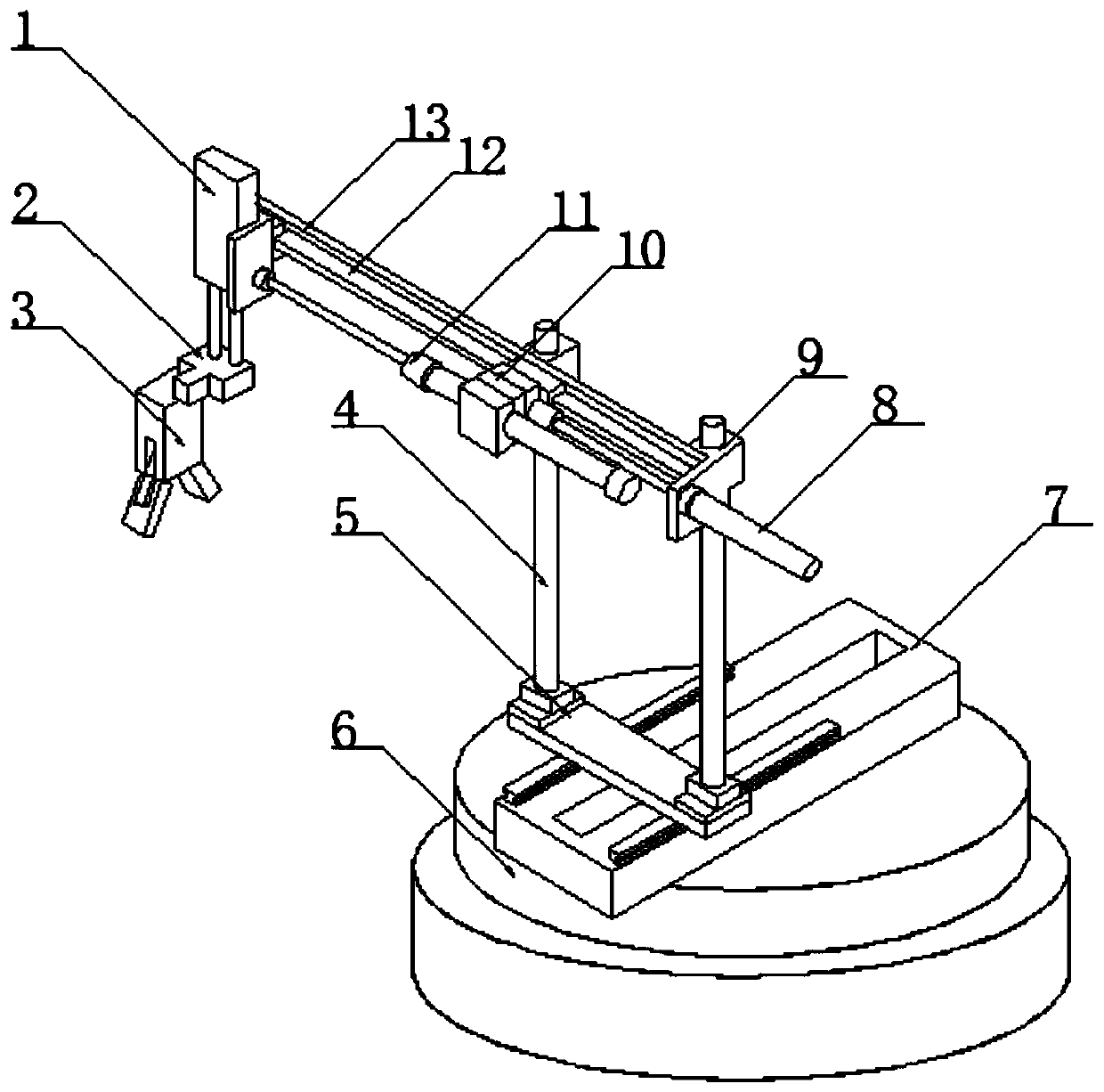

Automatic rod adding drilling machine

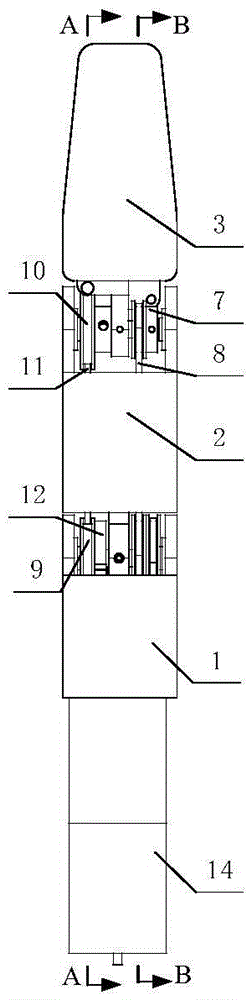

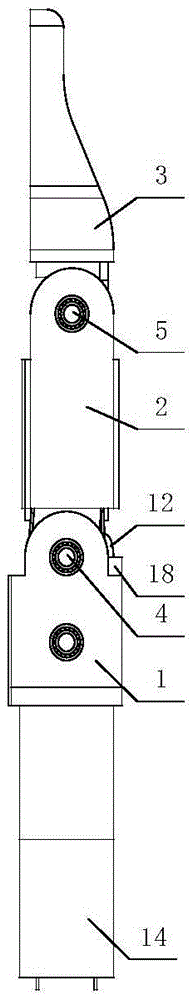

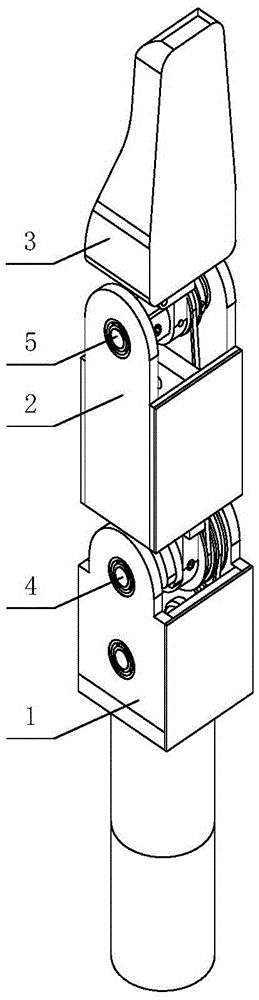

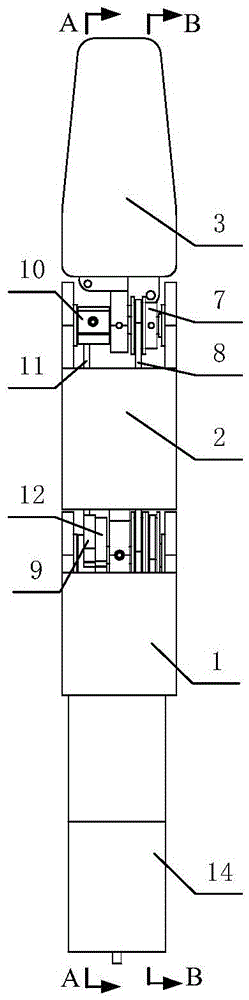

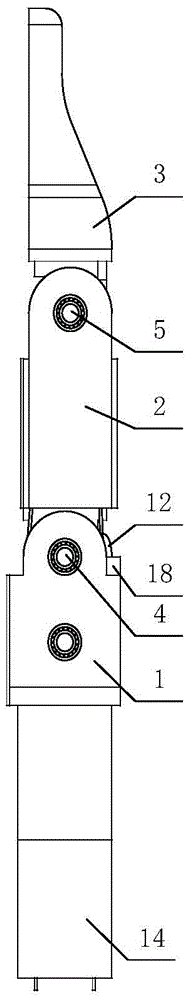

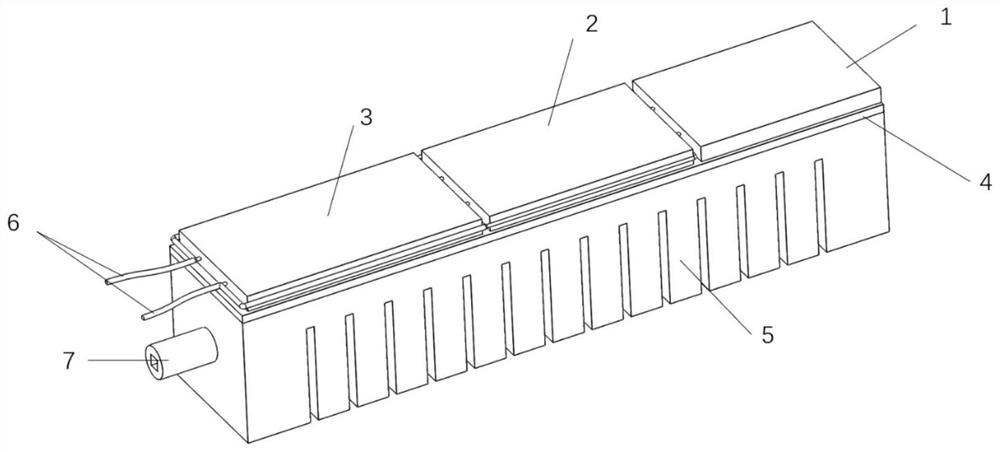

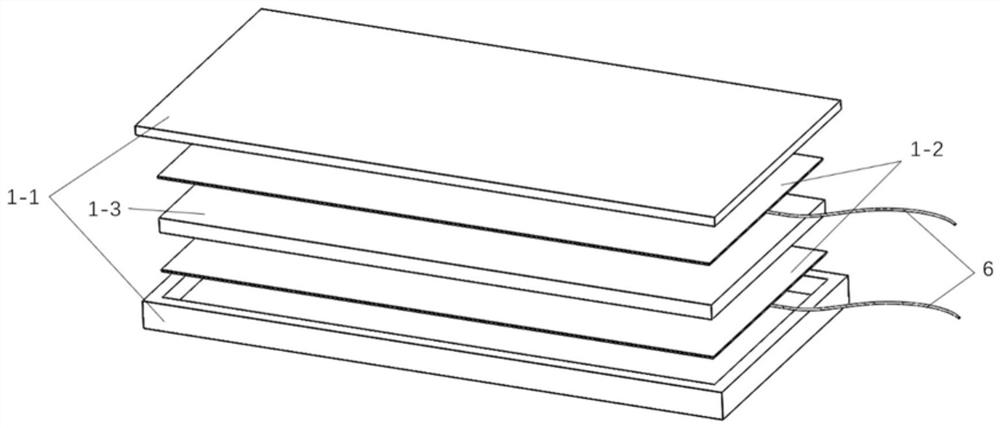

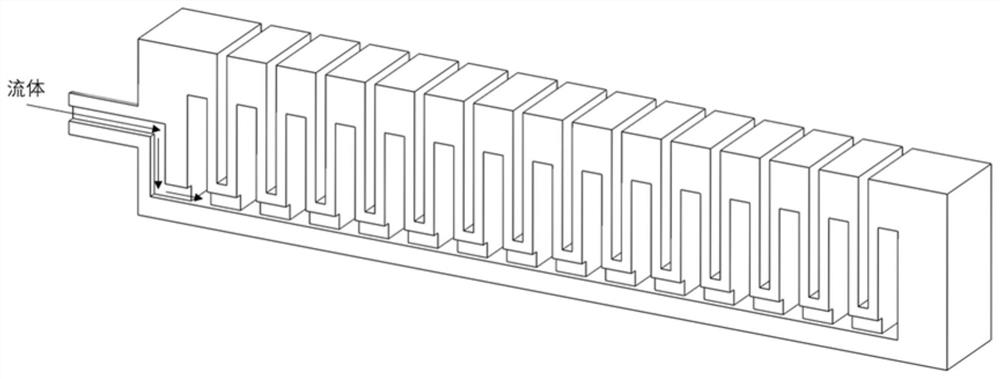

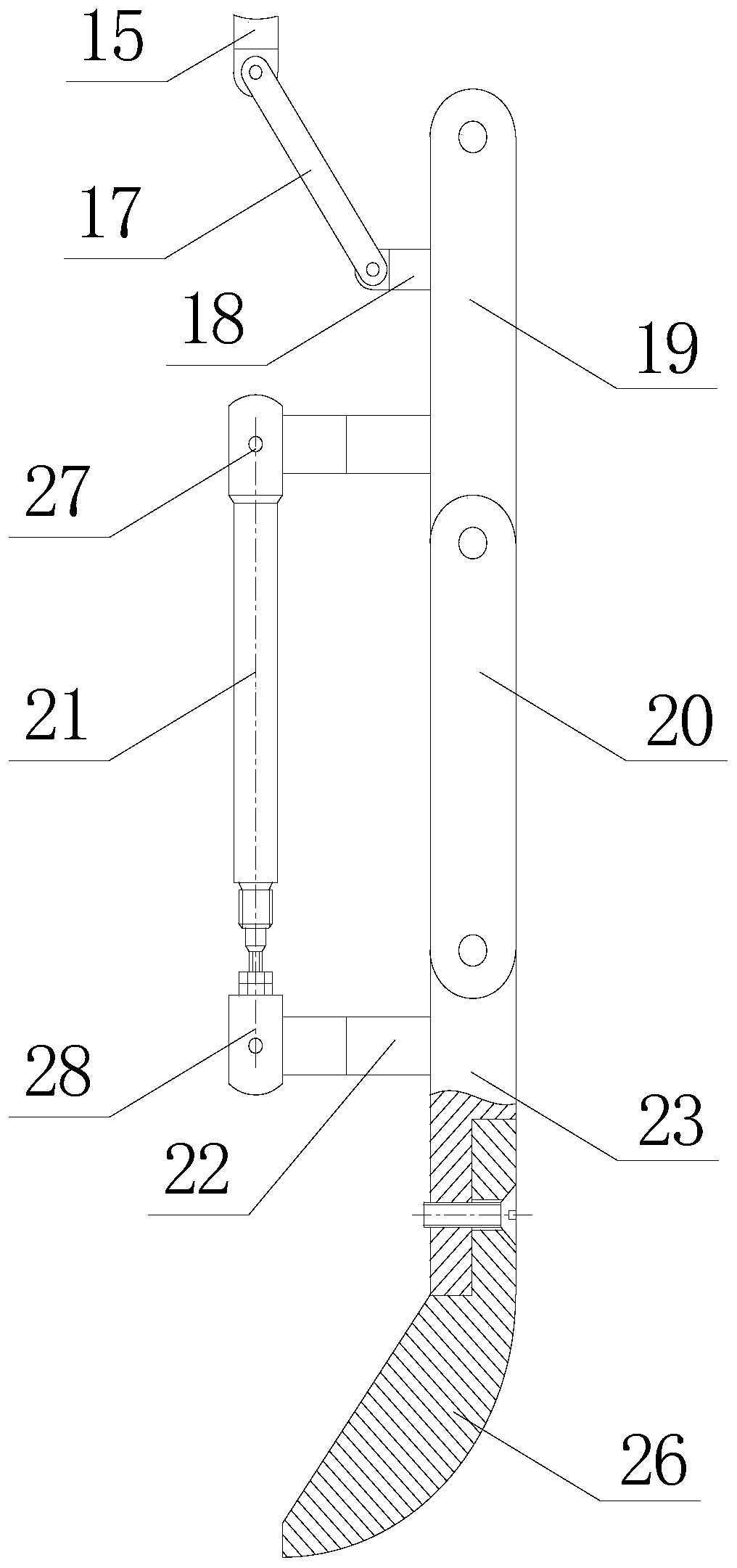

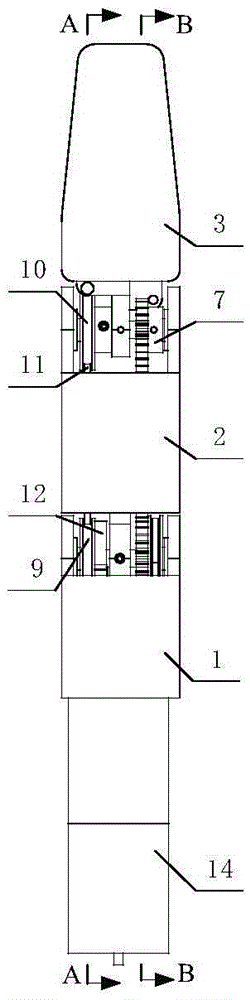

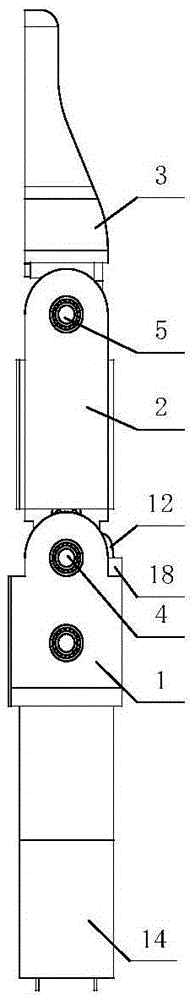

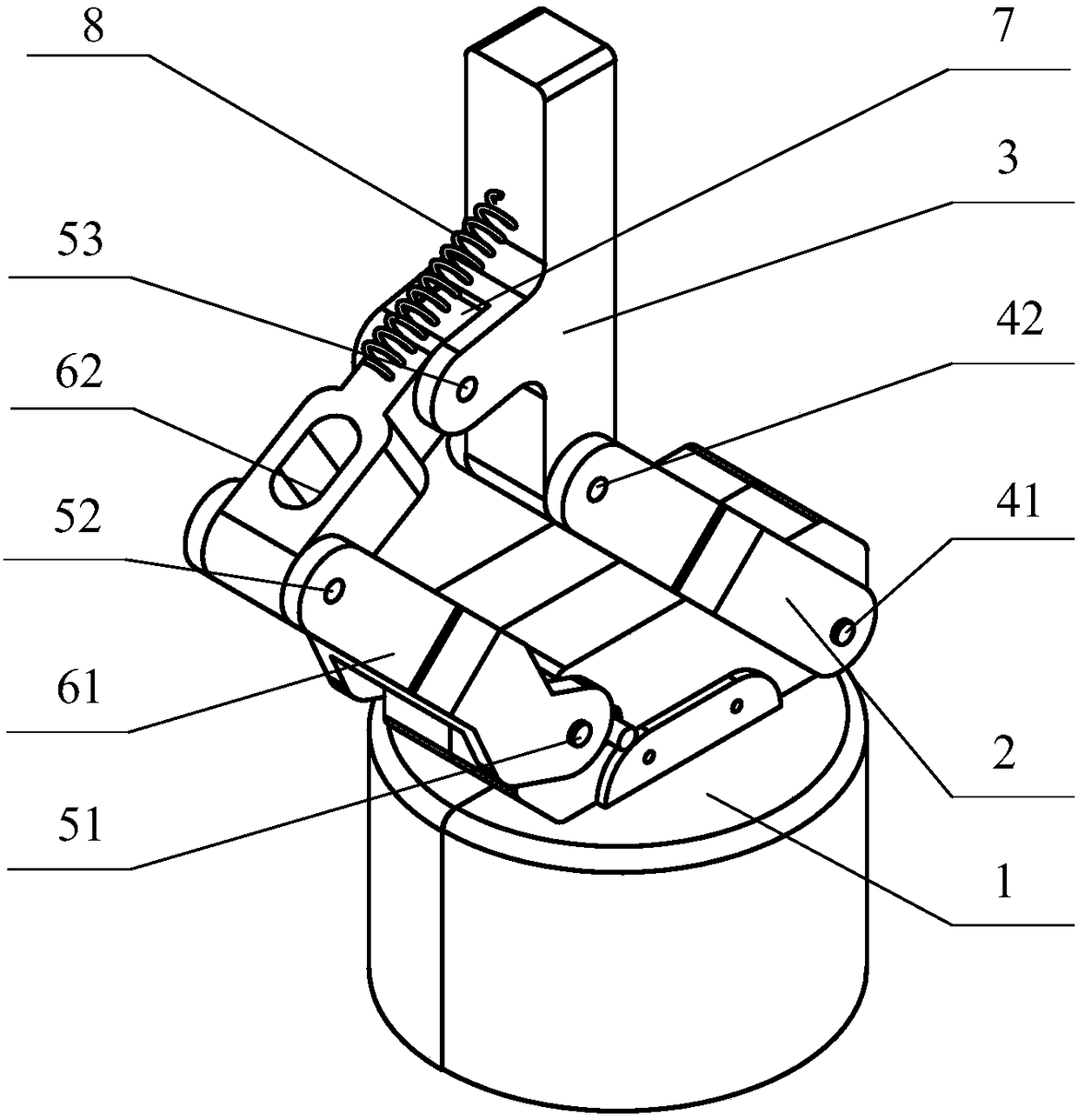

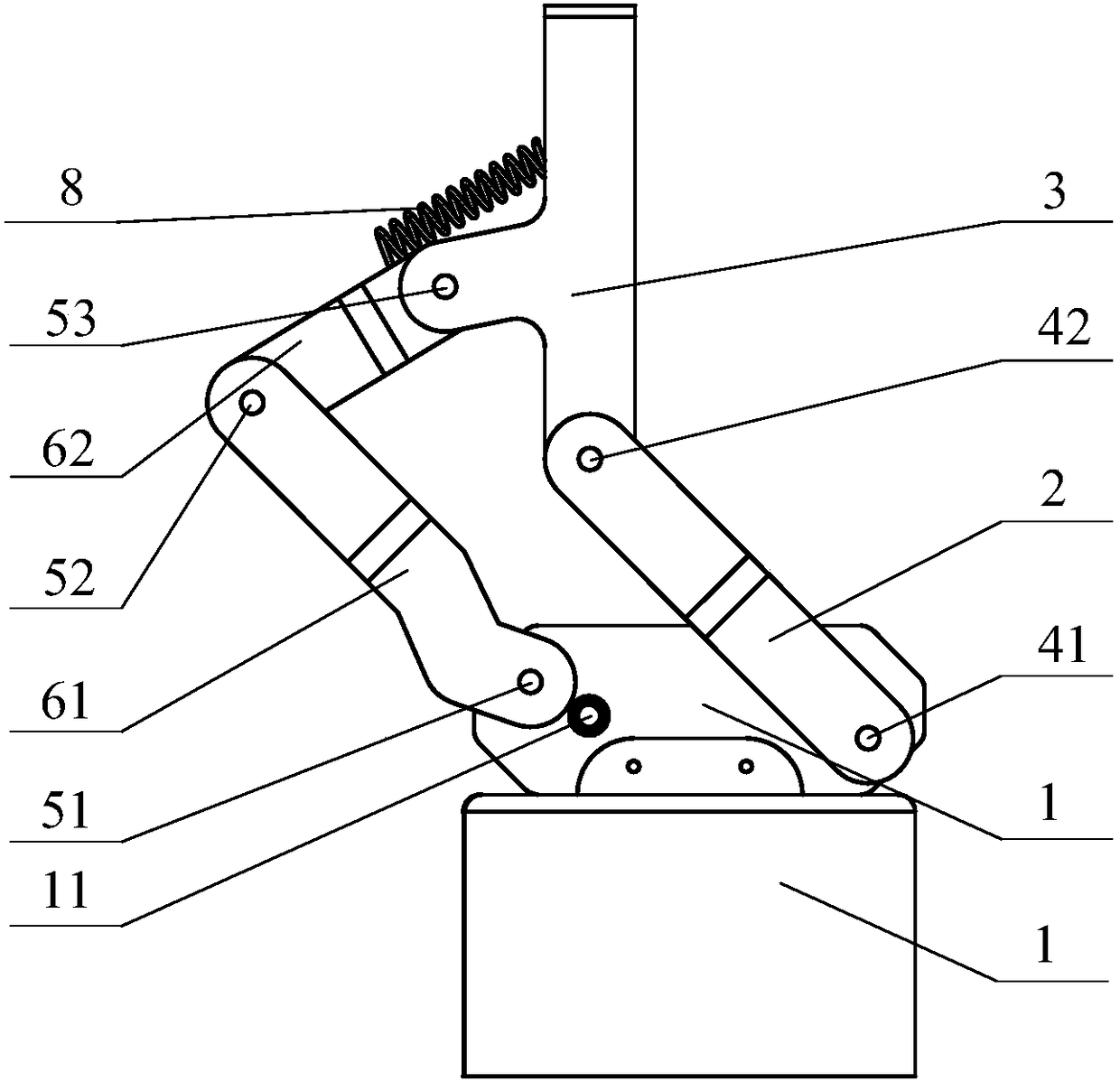

PendingCN112814565AImprove loading and unloading efficiencyImprove work efficiencyDrilling rodsDerricks/mastsMachineIndustrial engineering

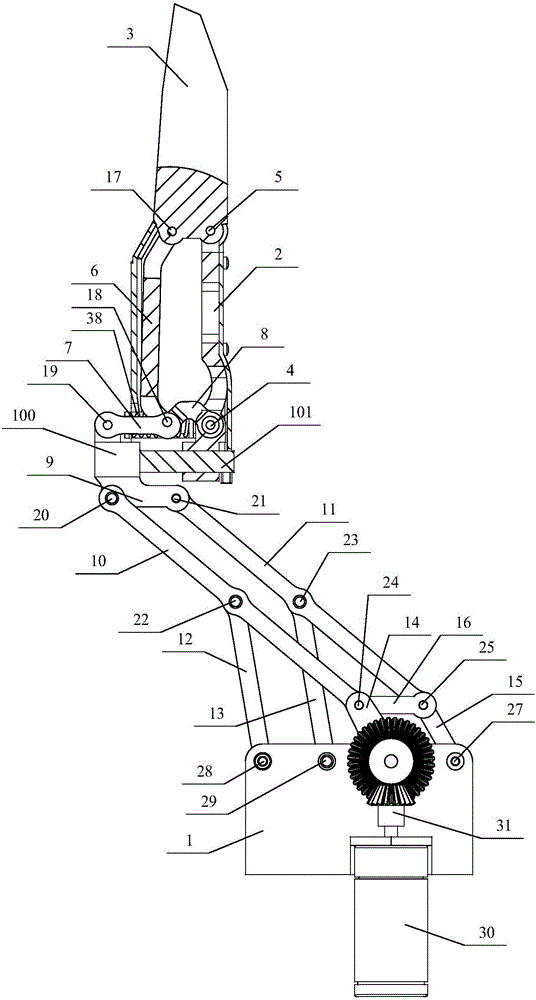

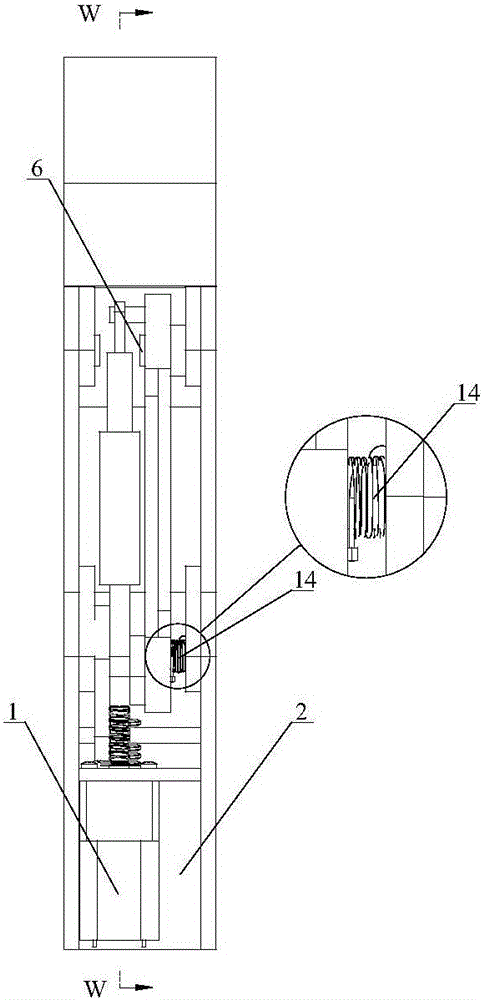

The invention discloses an automatic rod adding drilling machine. The automatic rod adding drilling machine comprises a chassis installed on a crawler, a lifting supporting assembly connected to the chassis, a drilling machine main machine installed on the lifting supporting assembly, a large-capacity drill rod box used for containing a plurality of rows of drill rods, a transfer bracket used for temporarily storing the drill rods, a first mechanical arm used for transferring the drill rods between the large-capacity drill rod box and the transfer bracket, and a second mechanical arm used for transferring the drill rods between the transfer bracket and the drilling machine main machine, wherein the lifting supporting assembly is used for adjusting the drilling height and the drilling pitch angle of the drilling machine main machine; and the large-capacity drill rod box, the transfer bracket, the first mechanical arm and the second mechanical arm are all installed on the chassis, and one of the large-capacity drill rod box and the first mechanical arm can ascend and descend in the height direction of the chassis. The first mechanical arm and the second mechanical arm transfer the drill rods between the large-capacity drill rod box and the transfer bracket and between the transfer bracket and the drilling machine main machine respectively, the stroke of each mechanical arm is reduced, and the drill rod loading and unloading efficiency and the working efficiency of the drilling machine are effectively improved.

Owner:CHONGQING PINGSHAN MINING ELECTROMECHANICAL EQUIP

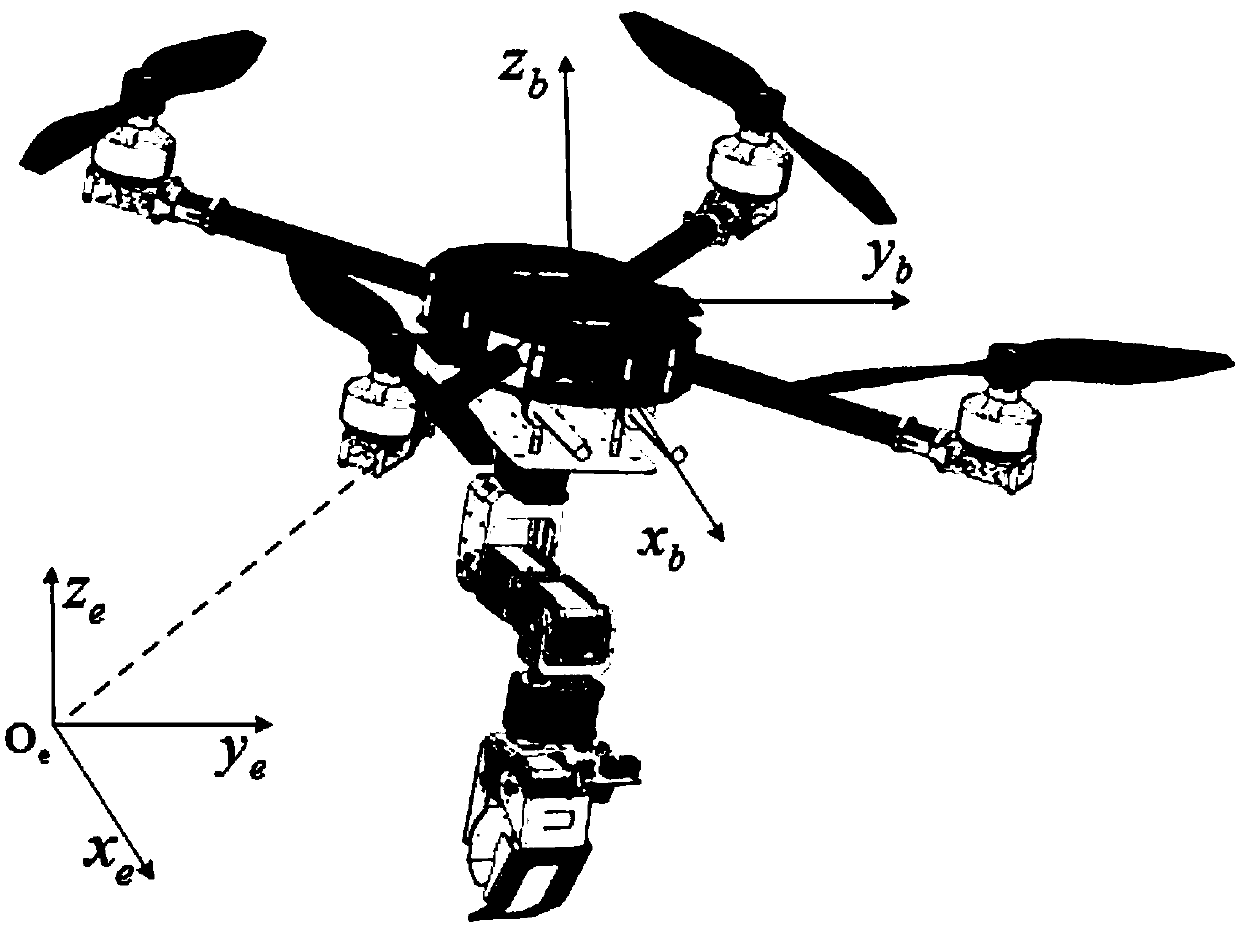

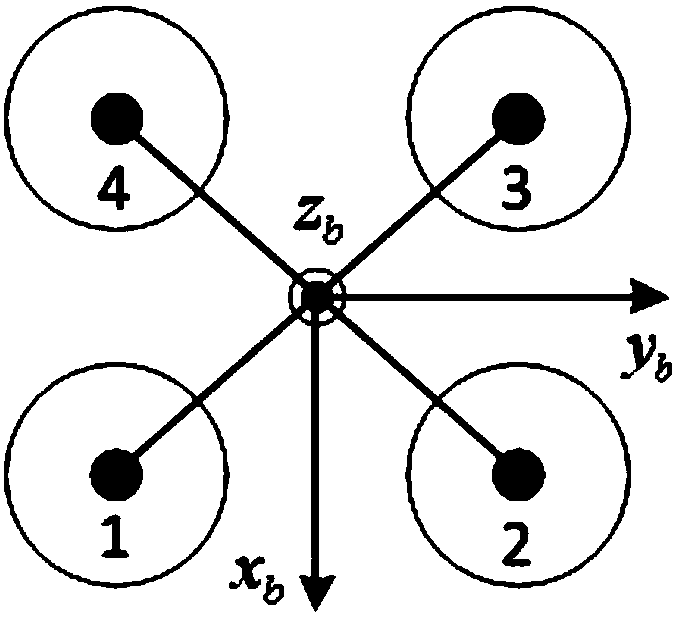

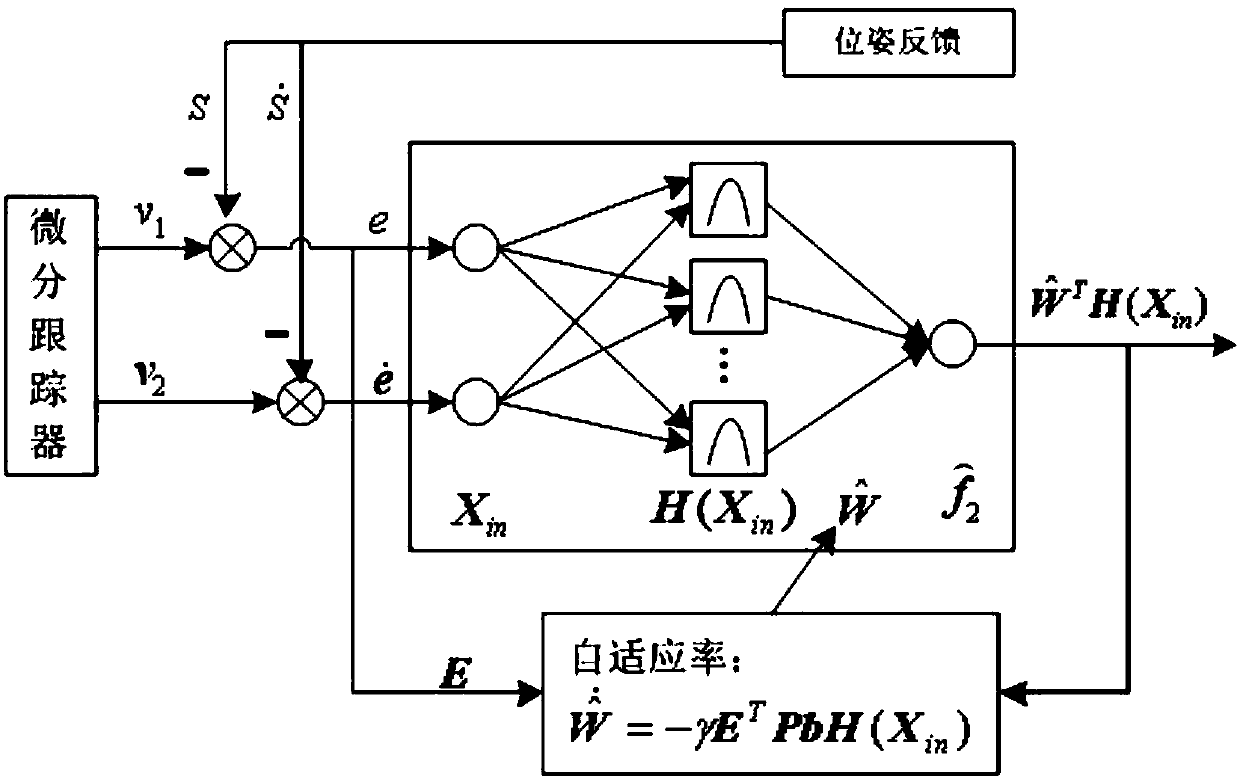

Self-adaptive RBFNNs noise-measurement active-disturbance-rejection control method for rotor wing flight manipulator

ActiveCN108398885ACompensate for interferenceImprove gripAdaptive controlControl signalAttitude control

The invention discloses a self-adaptive RBFNNs noise-measurement active-disturbance-rejection control method for a rotor wing flight manipulator. The method comprises the following steps that the rotor wing flight manipulator is subjected to stress analysis, and a Newton-Eulerian method is used for establishing a dynamics model of the rotor wing flight manipulator; a height controller and a levelcontroller based on RBFNNs\ADRC are designed; according to the dynamics model and the actual flight conditions of the rotor wing flight manipulator, the output of the level controller is converted into an expected attitude angle; an attitude controller based on RBFNNs\ADRC is designed; according to a flight mode of the rotor wing flight manipulator, control signals are converted into all rotor wing rotation speed values. According to the method, self-adaptive RBFNNs are utilized for estimating inner and outer disturbance of all channels of the flight manipulator and conducting real-time compensation, on this basis, the attitude controller based on RBFNNs\ADRC is designed, the disturbance of the movement of the manipulator to a flight platform can be effectively compensated for, and the rotor wing flight manipulator in the flight process can stably grip.

Owner:HUNAN UNIV

Self-adaptive robot finger device with function of parallel clamping realized by gear transmission and flexible member transmission

The invention discloses a self-adaptive robot finger device with a function of parallel clamping realized by gear transmission and flexible member transmission, and belongs to the technical field of robot hands. The self-adaptive robot finger device comprises a base, two finger sections, two joint shafts, a driver, a flexible transmission member, a transmission wheel, a gear, a lug shifting disc, two springs, a limit lug and the like. The device realizes functions of parallel clamping and self-adaptive grabbing by virtue of the integration of the driver, a flexible member transmission mechanism, a gear transmission mechanism, the two springs, the lug shifting disc, the limit lug and the like, and according to the difference of the shapes and the positions of target objects, the second finger section can be translated to grip or support outwards the objects, and the first finger section and the second finger section can also be sequentially rotated to envelope the objects with different shapes and sizes; the device has a large grabbing range; two joints are driven by virtue of one driver in an under-drive manner, without the need of complex sensing and control systems; and the device is compact in structure, small in size, low in manufacturing and maintenance costs, and suitable for a robot hand.

Owner:TSINGHUA UNIV

Five connecting rod parallel clamping self-adaption robot fingers device

The invention discloses a five connecting rod parallel clamping self-adaption robot fingers device, and belongs to the technical field of robot hand. The five connecting rod parallel clamping self-adaption robot fingers device comprises a base seat, two finger segments, two joint shafts, a motor, a transmission mechanism, two connecting rods, a spring part and a limiting convex block. According tothe five connecting rod parallel clamping self-adaption robot finger device, the functions of parallel clamping and self-adaption grasping of two joint robot fingers are realized. According to the difference of the shape and position of an object, a second finger segment is moved in parallel to hold the object and is splayed to support the object, and a first finger segment and the second fingersegment are rotated in sequence to envelop the objects of different shapes and sizes. The five connecting rod parallel clamping self-adaption robot fingers device is large in capture range. The underactuated manner is adopted, and a motor is used to drive two joints without the need for using complex sensing and control system. The five connecting rod parallel clamping self-adaption robot fingersdevice is simple in structure, small in volume, low in manufacture and maintenance cost, and suitable for the robot hand.

Owner:TSINGHUA UNIV

Pinching and flexible shaft drive drum tensioning belt wrapping grabbing composite mechanical hand and method

ActiveCN111409094AHas a binding effectImprove reliabilityGripping headsValve members for absorbing fluid energyLogistics managementRobot hand

The invention relates to a pinching and flexible shaft drive drum tensioning belt wrapping grabbing composite mechanical hand and a method, belongs to the field of robot and automation and suitable for the field of light industrial food and agricultural product sorting robots and packaging and logistics industry robots. The pinching and flexible shaft drive drum tensioning belt wrapping grabbing composite mechanical hand is composed of a palm part and four fingers of the same structure. The fingers have two kinds including horizontal moving clamping fingers and wrapping grabbing fingers. According to a finger root translocation function, the four fingers grab right circular cylinders, spheres and cubes, or under the drive of a motor, the left finger and the right finger conduct transposition by 45 degrees in the clockwise direction, the front finger and the rear finger conduct transposition by 45 degrees in the anticlockwise direction, and the four fingers grab horizontal cylinders andcuboids. According to a finger horizontal moving pinching function, due to the motor or a short-stroke air cylinder, the four fingers can rotate with the same finger root angle, and a parallelogram mechanism generates finger horizontal moving pinching. According to a wrapping grabbing function, the motor or a blade type rotating air cylinder drives a tooth-shaped belt, due to transmission of foursoft shafts, winding drums of braided fabric rubber belts are well tightened and loosened, and the four belts are used for grabbing objects.

Owner:JIANGNAN UNIV

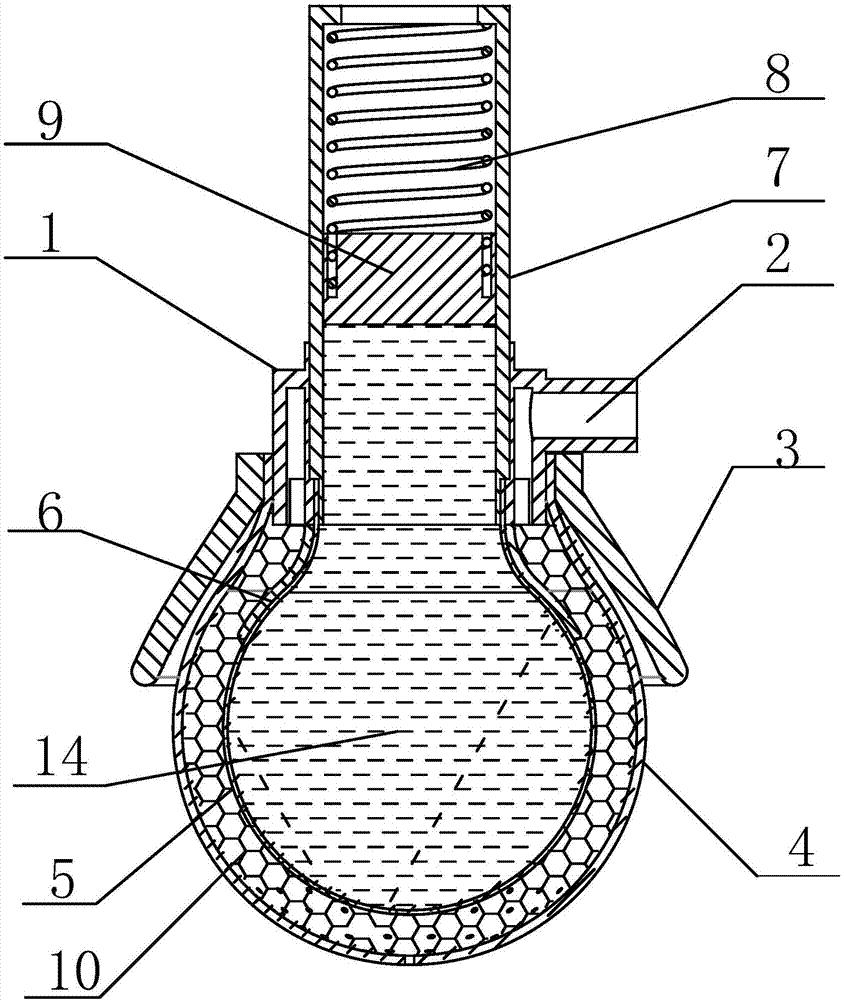

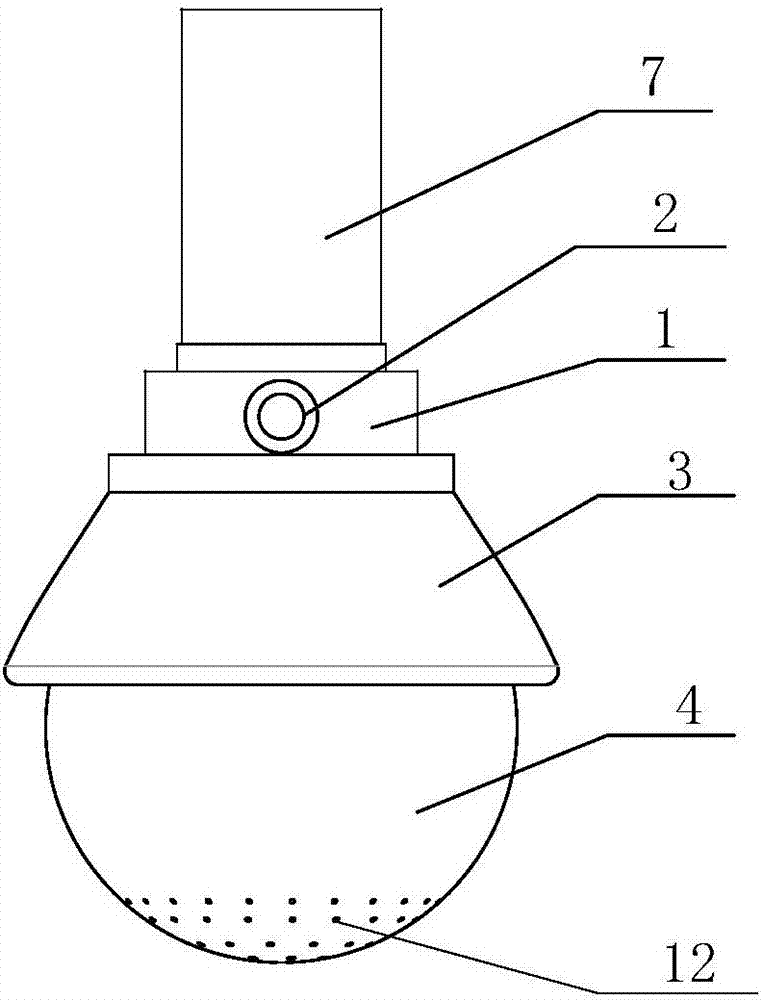

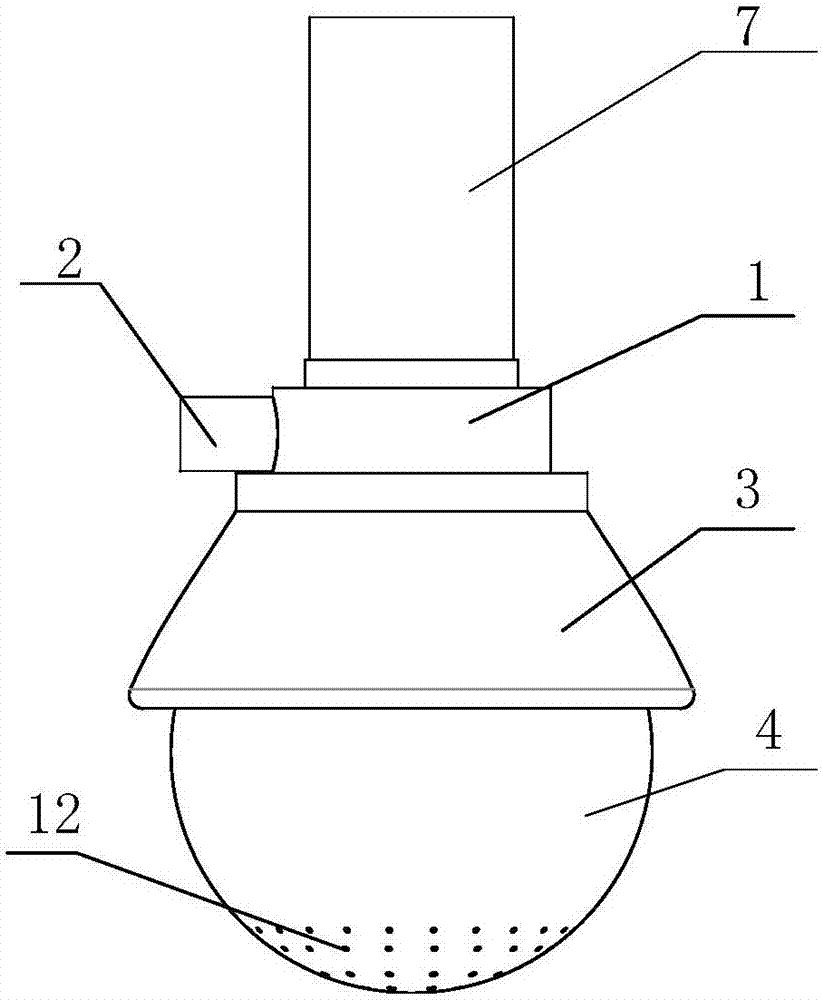

Porous double-layered fluid self-adaptive robot hand device

PendingCN107457797AGet Multidimensional Adaptive EffectsImprove grip stabilityGripping headsRobot handSimulation

The invention relates to a porous double-layered fluid self-adaptive robot hand device and belongs to the technical field of robot hands. The porous double-layered fluid self-adaptive robot hand device comprises a substrate, an air inlet, an external bowl-shaped supporting piece, an internal bowl-shaped supporting piece, a first flexible film, a second flexible film, a piston cylinder assembly and the like. A multi-dimensional self-adaptive active grasping function is comprehensively achieved by means of positive and negative pressures provided by an air source, the piston cylinder assembly, small holes in the first flexible film, a porous flexible material, the internal bowl-shaped supporting piece, the external bowl-shaped supporting piece, a fluid and the like, so that objects of different shapes and dimensions can be self-adaptively grasped. The porous double-layered fluid self-adaptive robot hand device can be adaptive to the object in multiple directions to obtain the multi-dimensional self-adaptive effect, and is high in grasping stability. By combining the advantages of the spherical self-adaptive hand and a sucking disc, the porous double-layered fluid self-adaptive robot hand device provided by the invention not only can be adaptive to grasp an object with a counteractive surface, but also can be adaptive to grasp an object without the counteractive surface, and is large in grasping range and high in grasping weight; and the porous double-layered fluid self-adaptive robot hand device is simple in structure, low in cost and easy to control.

Owner:清研(洛阳)先进制造产业研究院

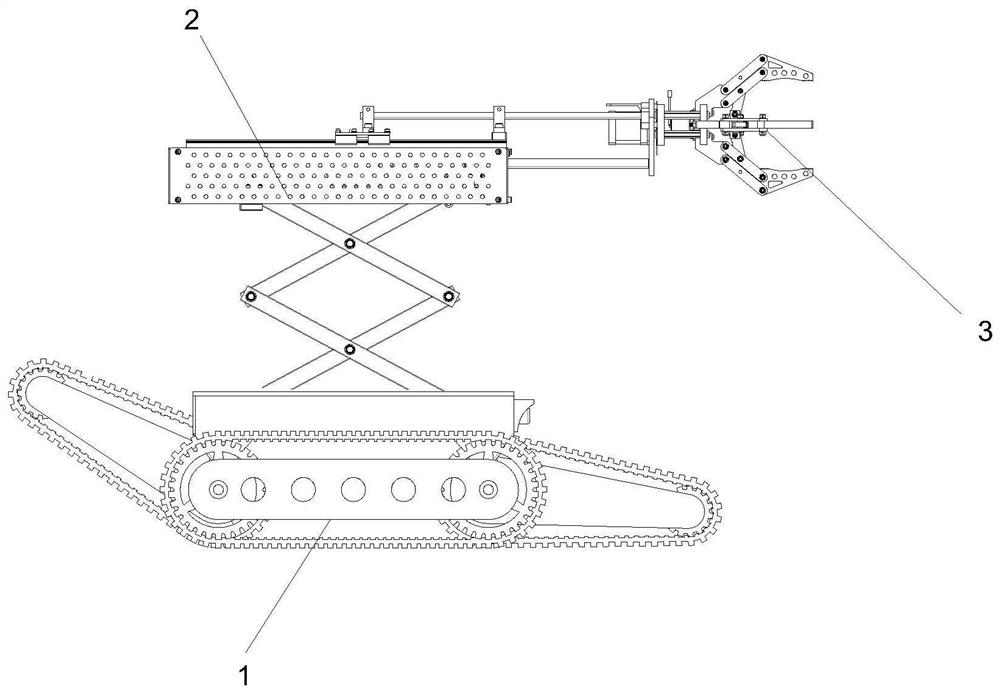

Crawler-type transfer robot

PendingCN112959295AWith travel efficiencyCapable of surmounting obstaclesProgramme-controlled manipulatorGripping headsVehicle frameLegged robot

The invention discloses a crawler-type transfer robot which comprises an obstacle crossing type crawler chassis, a telescopic lifting device arranged on the obstacle crossing type crawler chassis and a transfer claw arranged on the telescopic lifting device. The obstacle crossing type crawler chassis comprises a vehicle frame, two crawler devices arranged on the two sides of the vehicle frame respectively and a driving system arranged on the vehicle frame and used for driving the crawler devices to operate. Each crawler device comprises a walking crawler mechanism and two obstacle crossing crawler mechanisms arranged on the front side and the rear side of the walking crawler mechanism. The driving system comprises a walking driving mechanism used for driving walking crawler wheels to rotate and an obstacle crossing driving mechanism used for driving a whole crawler mounting frame of each obstacle crossing crawler mechanism to rotate. The robot has the advancing efficiency of a crawler-type robot and the obstacle crossing ability of a legged robot at the same time; and meanwhile, a carrying claw of the carrying robot is arranged on the telescopic lifting device, so that the grabbing range of the carrying claw is greatly enlarged, and the flexibility of carrying operation of the robot is improved.

Owner:CHONGQING AEROSPACE POLYTECHNIC COLLEGE

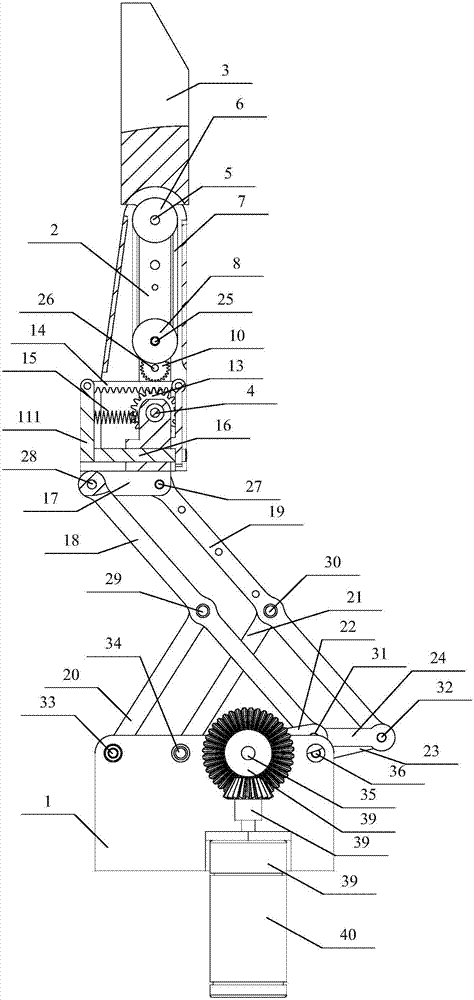

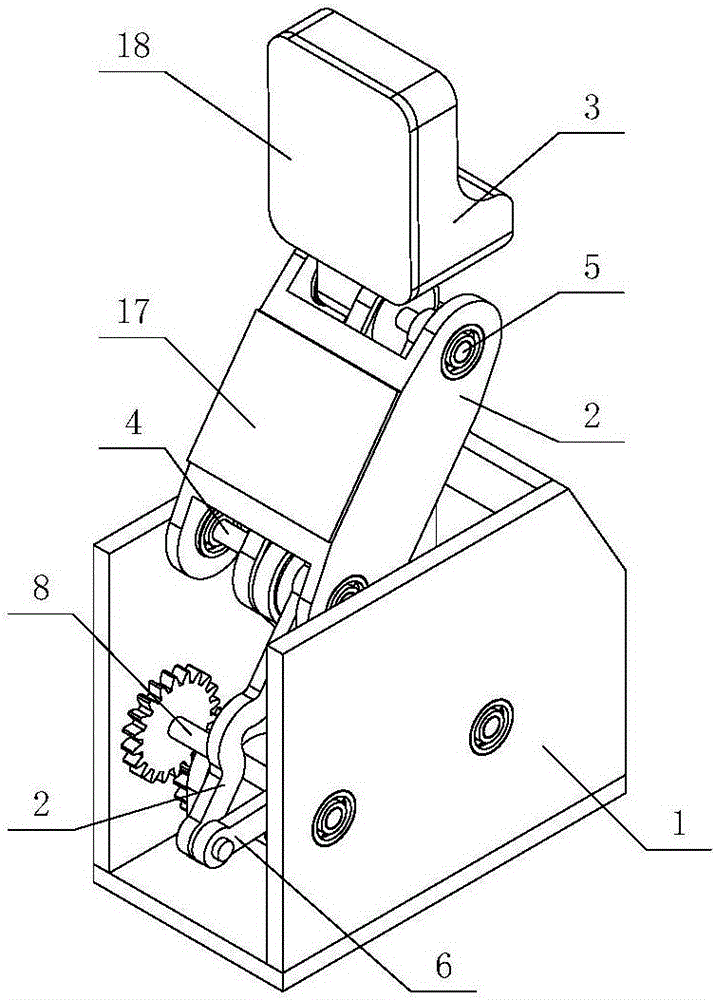

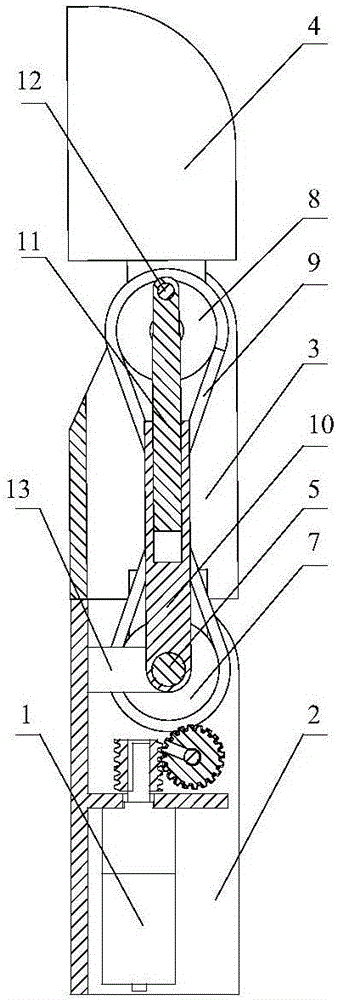

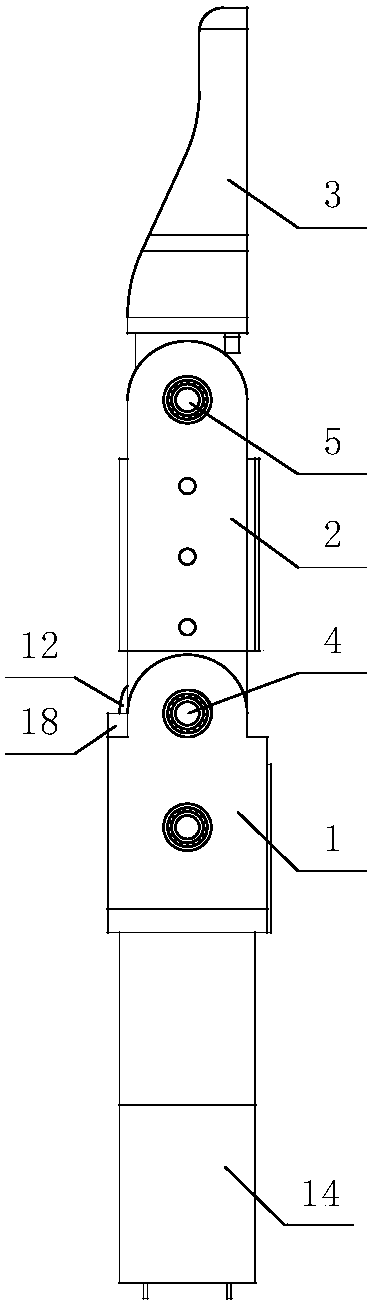

Rod-wheel combined type coupling self-adapting under-actuated robot finger device

The invention discloses a rod-wheel combined type coupling self-adapting under-actuated robot finger device, and belongs to the technical field of robot fingers. The rod-wheel combined type coupling self-adapting under-actuated robot finger device comprises a pedestal, a driver, two finger sections, two joint shafts, two transmission wheels, a transmission part, two connecting rods, a rotary shaft, a pulling block and a spring part. According to the device, the function of gripping an object in a coupling self-adapting manner is realized by combining the double transmission wheels, the 8-shaped transmission part, the swinging double connecting rods which are in sliding inlay, a sleeved and mobile middle finger section, the spring part and the like; the device can imitate a gripping mode of a hand during gripping as follows: the first finger section and the second finger section can simultaneously rotate, the rotation speed of the far joint is greater than that of the near joint, the object is gripped in a self-adapting enveloping manner, and the self-adaption to the shape and the dimension of the gripped object are achieved; the gripping range is great, the two finger sections are uniform in stress, the gripping is stable; and meanwhile, the rod-wheel combined type coupling self-adapting under-actuated robot finger device has an anthropopathic appearance, has flexibility and a compact structure, so that the driving of two joints is realized by only needing one spring part and only using one driver.

Owner:TSINGHUA UNIV

Free-travel contact gear flat clip adaptive robot finger device

Owner:TSINGHUA UNIV

Rack cosine extension linear flat clamping self-adaption finger device

The invention discloses a rack cosine extension linear flat clamping self-adaption finger device, and belongs to the technical field of robot hands. The device comprises a base, two finger sections, two joint shafts, a driver, multiple connecting rods, a transmission mechanism, a spring piece and the like. The device realizes the functions of robot finger linear parallel clamping and self-adaptiongrabbing. The device can keep the gesture of a second finger section to linearly and flatly move the second finger section to clamp objects according to different shapes and positions of the objects;after a first finger section is contacted with the objects, the second finger section is automatically rotated to contact with the objects to achieve the purpose of self-adaption enveloping of the objects with different shapes and sizes; the grabbing range is wide; the grabbing is stable and reliable; one driver is used for driving two finger sections; and the device is simple in structure, low in manufacturing, assembly and maintenance cost and suitable for robot hands.

Owner:TSINGHUA UNIV

Double-joint variable-cross-section soft-body hand with wedged transverse-pattern structure

InactiveCN110497439AIncrease stiffnessIncrease frictionGripping headsEngineeringAtmospheric pressure

The invention discloses a double-joint variable-cross-section soft-body hand with a wedged transverse-pattern structure. The double-joint variable-cross-section soft-body hand structurally comprises abracket and three soft-body fingers fixed on the bracket. The soft-body hand has the characteristics of being low in mass, easy to control, low in price, easy to manufacture and the like, can clamp complex fragile objects, and has high flexibility, safety and adaptability; and compared with other existing soft-body fingers, the soft-body fingers of the soft-body hand have the advantages of beinggreater in bending and higher in responding speed under a same atmospheric pressure due to variable-cross-section cavities, and similar to the human finger profile.

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com