Pinching and flexible shaft drive drum tensioning belt wrapping grabbing composite mechanical hand and method

A flexible shaft transmission and manipulator technology, applied in the field of composite manipulators, can solve the problems of small size adaptability, inability to envelop grasping, no shape adaptability, etc., and achieve the effects of good contact characteristics and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

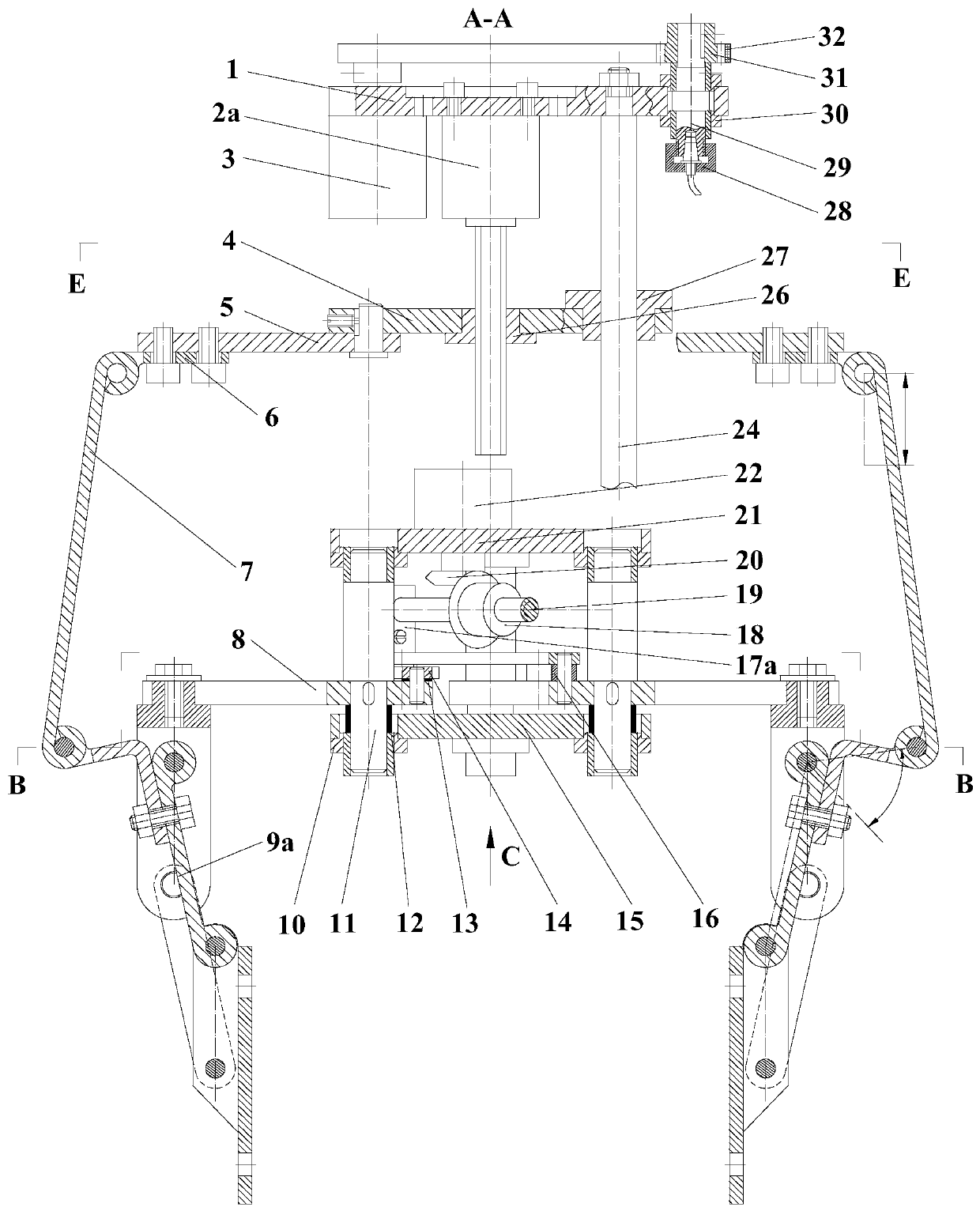

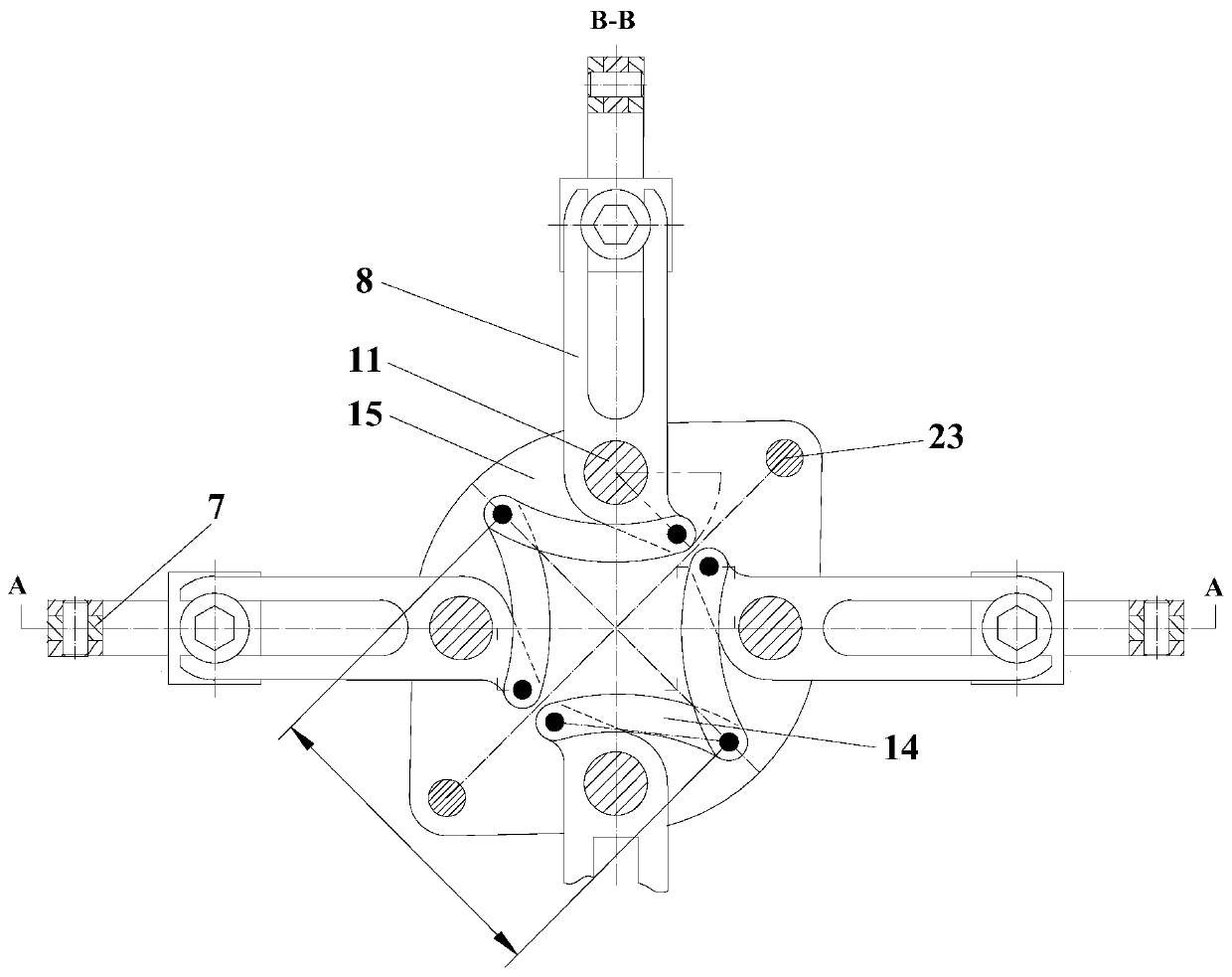

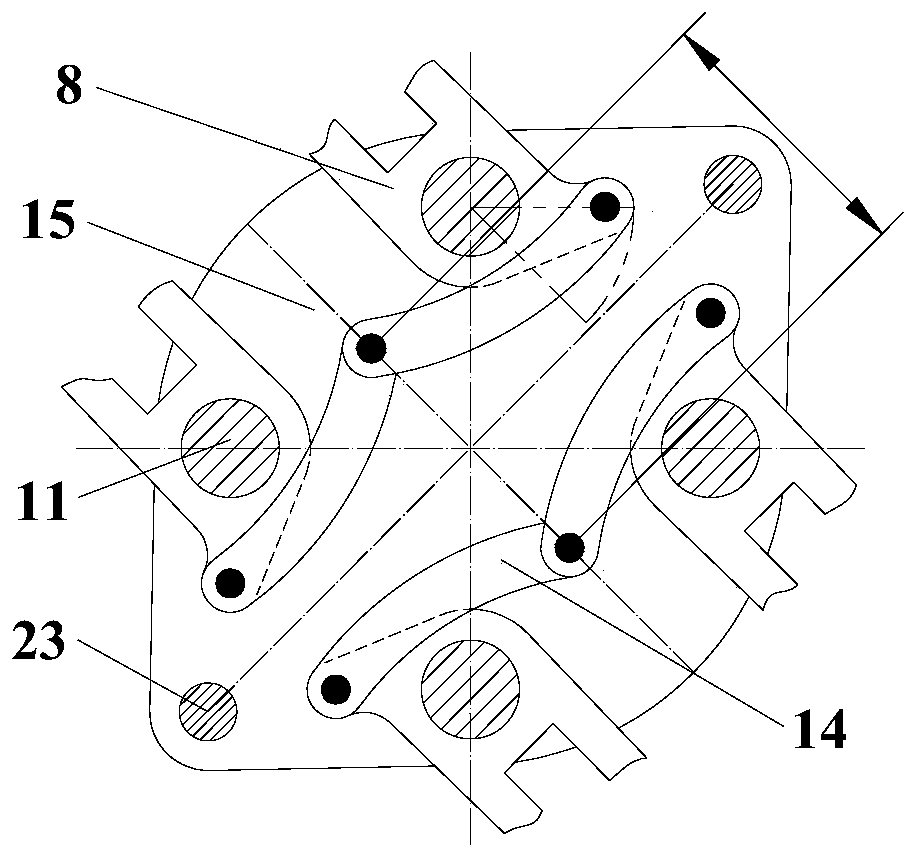

[0123] When adopting translational clamping finger 9a, the base of the finger is rotated and driven to select any one of clamping motor 2a or short-stroke cylinder 2b; the size of the contact force is determined by the size of the contact position and the driving force (torque), and the size of the contact position It is related to the size and contact state of the object to be grasped, and is established (consisting of a push plate 4, a bar-shaped index plate 5, a flat-mounted double-ear seat 6, a push rod 7, a fork-shaped index plate 8, and a translation clamping finger 9a ) mechanical equations of the connecting rod system, control parameters such as the angular displacement and output torque of the clamping motor 2a, the displacement and the driving force of the short-stroke cylinder 2b can be obtained according to these mathematical models, and the control method: ① select the clamping motor 2a, and The contact force is controlled by the output torque of the clamping motor...

Embodiment 2

[0125] When wrapping and grabbing finger 9b is used, the pinching method of adjustable nail tip 9b7 is the same as the control method of the aforementioned translation gripping finger 9a; the wrapping and grabbing method is used to grab spheres, horizontally place cylinders, and ellipsoids , Irregular objects made of curved surfaces, and objects with complex contact forces (such as peaches, soft-packed goods), the adjustable nail tip 9b7 has a waist-shaped groove, which can be retracted for installation or directly removed when needed;

[0126] The clamping motor 2a and the winding motor 3b can be controlled in forward and reverse directions and precise control of angular displacement, but the response speed is not as good as that of pneumatic components; while the vane-type rotary cylinder 3a can be controlled in forward and reverse directions, which cannot realize precise control of angular displacement and has a short stroke Cylinder 2b can be controlled by reciprocating mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com