Cover material covering nodularizer in graphite spheroidizing of cast iron

A technology of covering materials and nodulizers, applied in the field of covering materials of graphite nodulizers, can solve problems such as defective products, achieve the effect of reducing weight and improving workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] In the high-frequency melting furnace used for graphite crucible No. 15 (2.5L), with a total weight of 6000g, put pig iron and returned charge, recarburizer and inoculant and spherical shape (LCS4) in the processing bag for graphite spheroidization by the punching method The molten iron was obtained under the same conditions, and the composition of the nodular cast iron subjected to the spheroidizing reaction was analyzed and compared with the covering materials comprising various graphite nodularizing agents of the covering material of the present invention, and the results are shown in Table 1.

[0036] [Table 1]

[0037] (weight%)

[0038] Types of covering materials for graphite nodulizers

[0039] example)

Embodiment 2

[0041] In Example 1, the mechanical properties of the test bodies produced using the covering materials of various molten graphite nodulizers were compared, and are shown in Table 2 in comparison with the JIS standard which is ductile iron.

[0042] The results show that the ductile iron using the covering material of the present invention fully meets the specifications. [Table 2]

[0043]

Embodiment 3

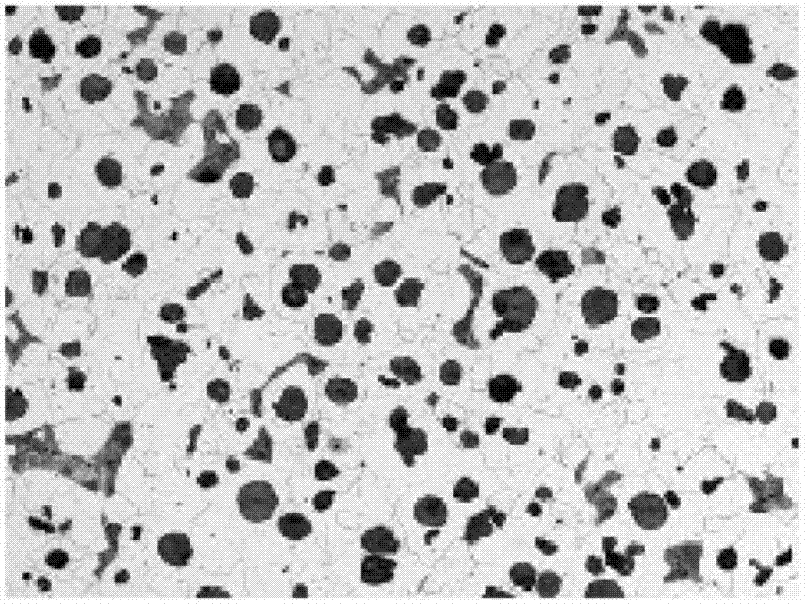

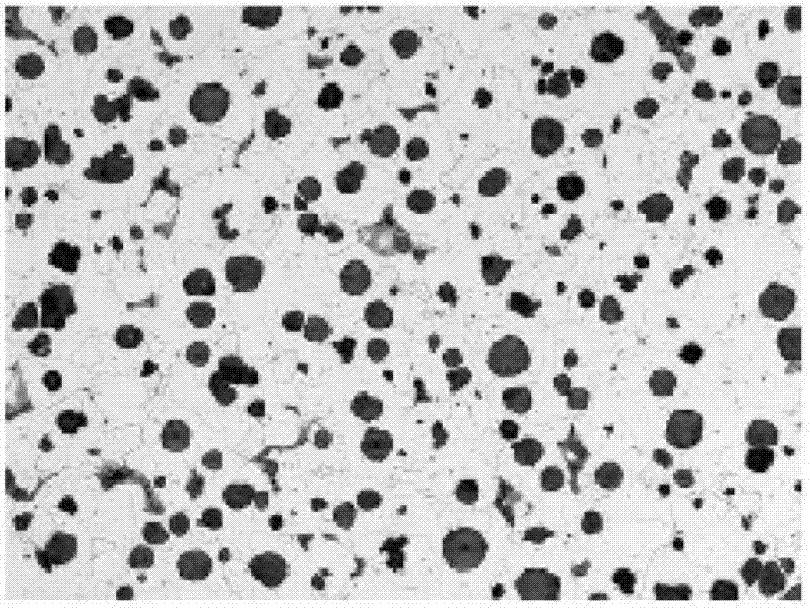

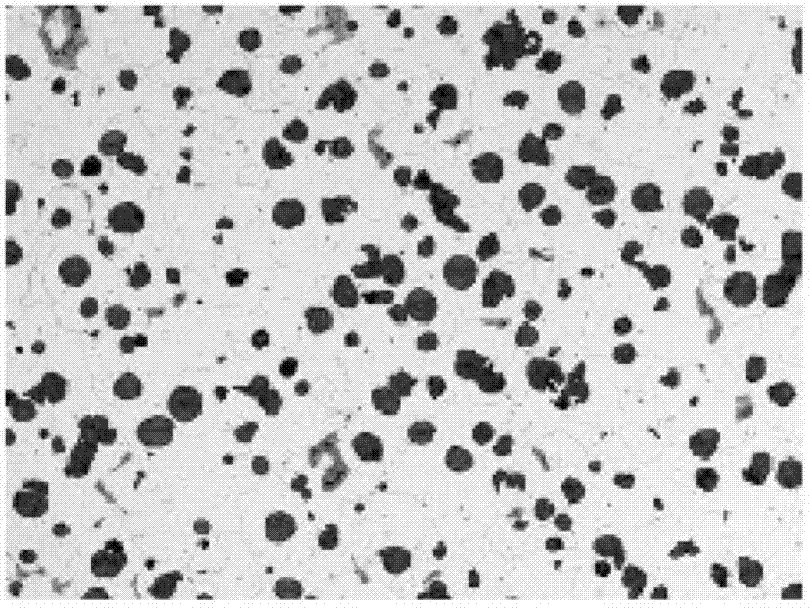

[0045] In embodiment 1, for the spheroidization rate that the cover material that uses melting multiple graphite spheroidizers to make, handle with 5% nitric alcohol solution corrosion solution, and in magnification 100 * 0.8 times and field of view (width) The comparison was carried out under 0.98mm, and the results are shown in Table 3.

[0046] [table 3]

[0047]

[0048] As mentioned above, the results of using the coating material of the present invention in the graphite spheroidization treatment of cast iron are shown in Tables 1 to 3, and the effect is equivalent to that of conventional stamping chips, and compared with stamping chips, It has the special effects of light weight and easy operation. In addition, it can also float on the liquid surface after melting to remove impurities, thereby reducing the amount of slag remover.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com