Patents

Literature

123results about How to "High indexing accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

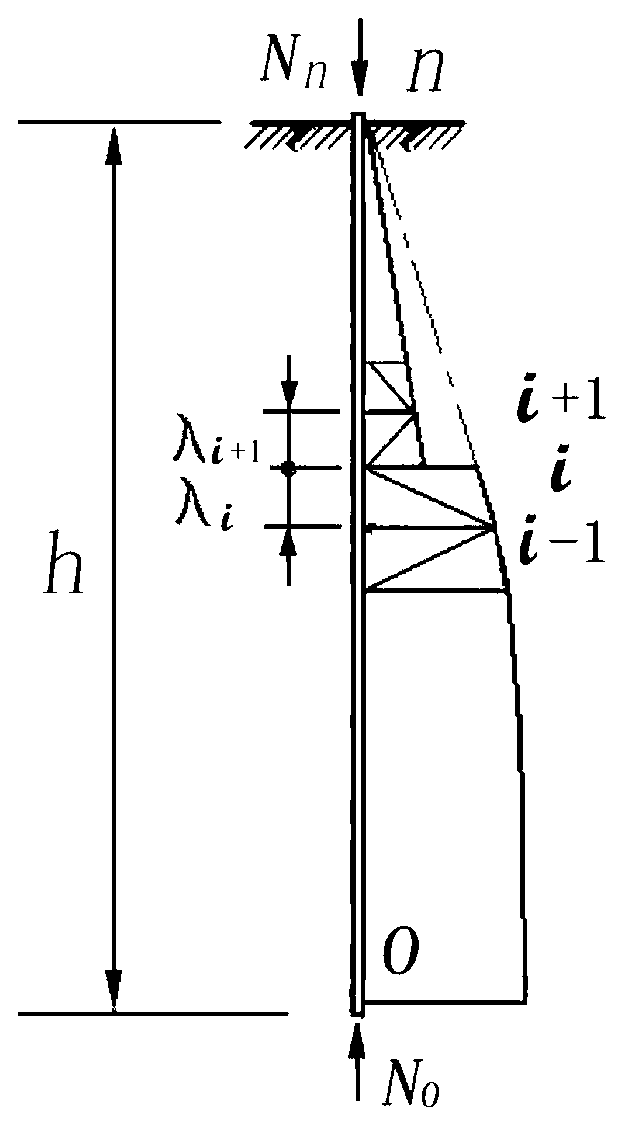

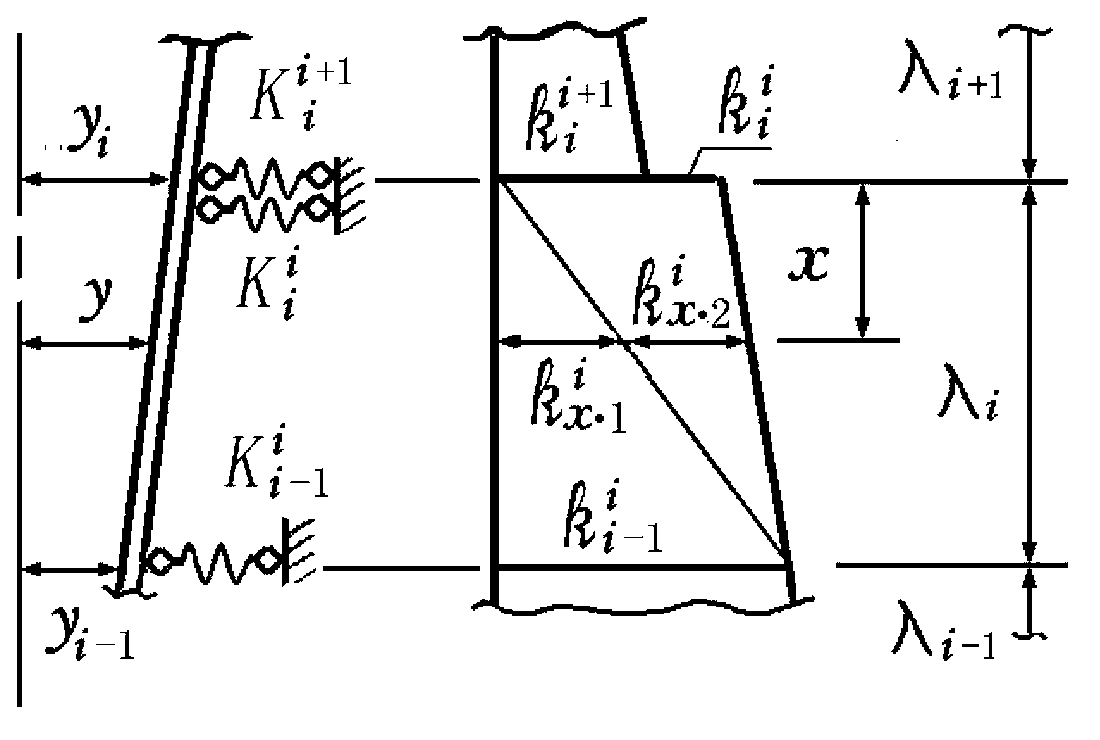

Foundation pile foundation model analyzing method and test device for same

InactiveCN103195112ASimplify the analysis processImprove calculation accuracyFoundation testingTurn angleTransmission matrix

The invention discloses a foundation pile foundation model analyzing method and a test device for the same. The method includes: building a dispersing spring support model of to-be-tested pile-earth related actions, building a to-be-tested pile inner force and deformation equation and transmission matrix, and a to-be-tested pile foundation reaction analyzing basic equation, building different founding reaction models and programming a corresponding computerizing program, arranging the foundation pile foundation test device in the field, measuring horizontal displacement and turning angle, on the ground, of the to-be-tested pile, and computerizing and analyzing according to the computerizing program to determine corresponding foundation reaction model parameters. The foundation pile foundation test device comprises a standard beam, a standard pile, a reaction pile and the to-be-tested pile which are disposed on the ground, a jack and a force sensor are connected between the reaction pile and the to-be-tested pile, and a angle measuring device and a displacement measuring device are disposed on the to-be-tested pile. By on-site pile testing, multiple hypothesis models can be built for the foundation pile foundation, related model parameters can be determined, and certain universality is achieved.

Owner:SICHUAN COLLEGE OF ARCHITECTURAL TECH

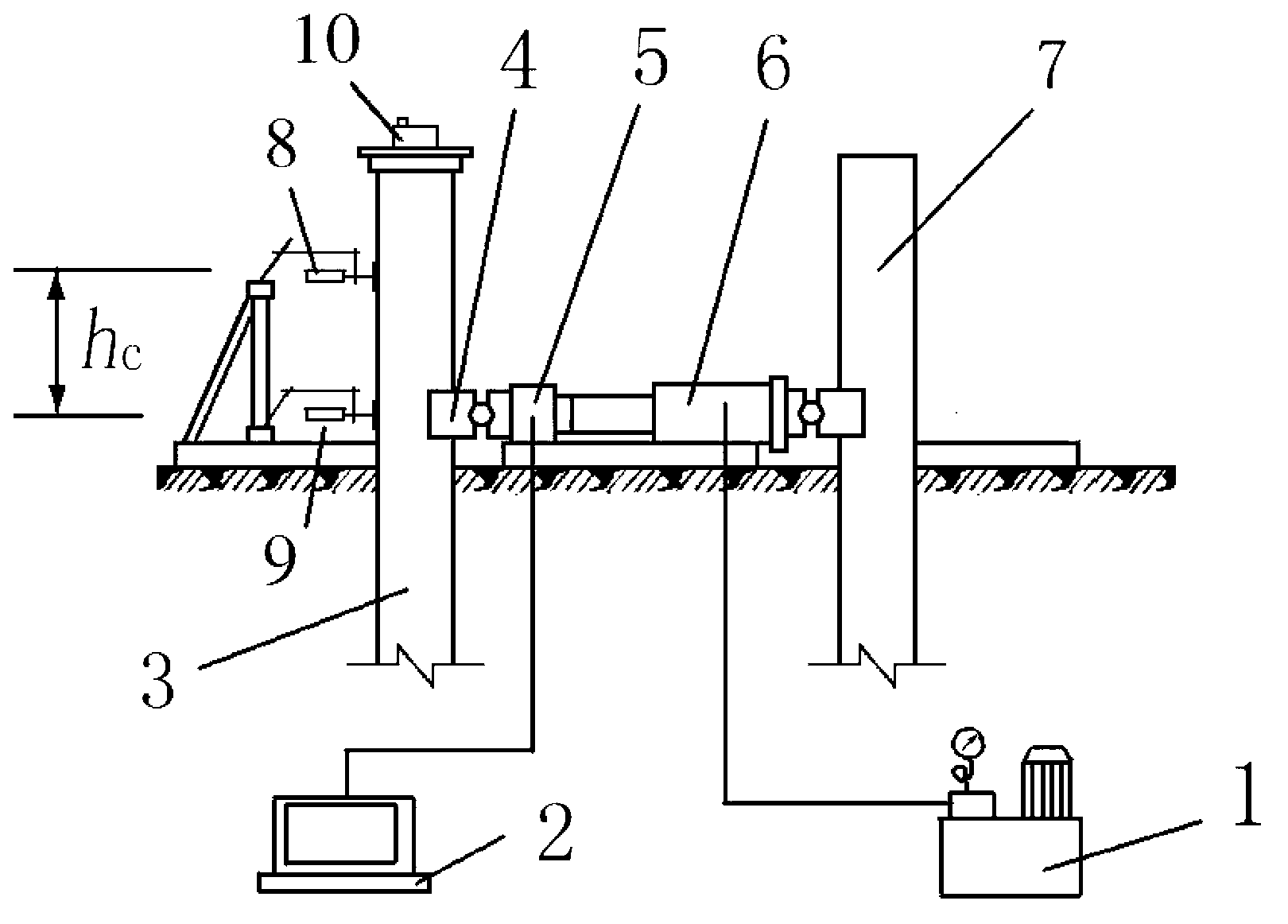

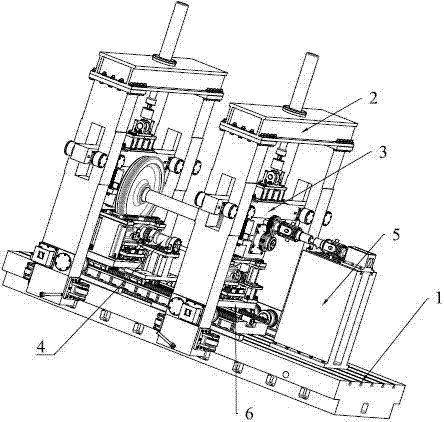

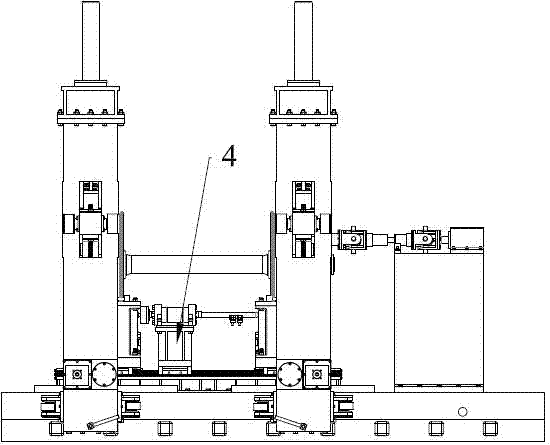

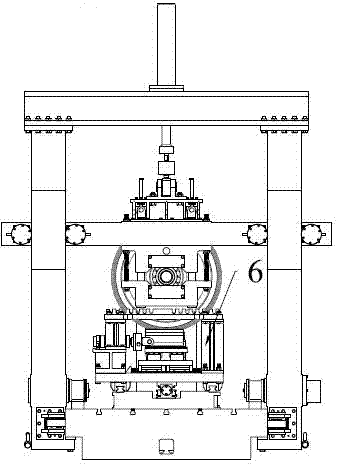

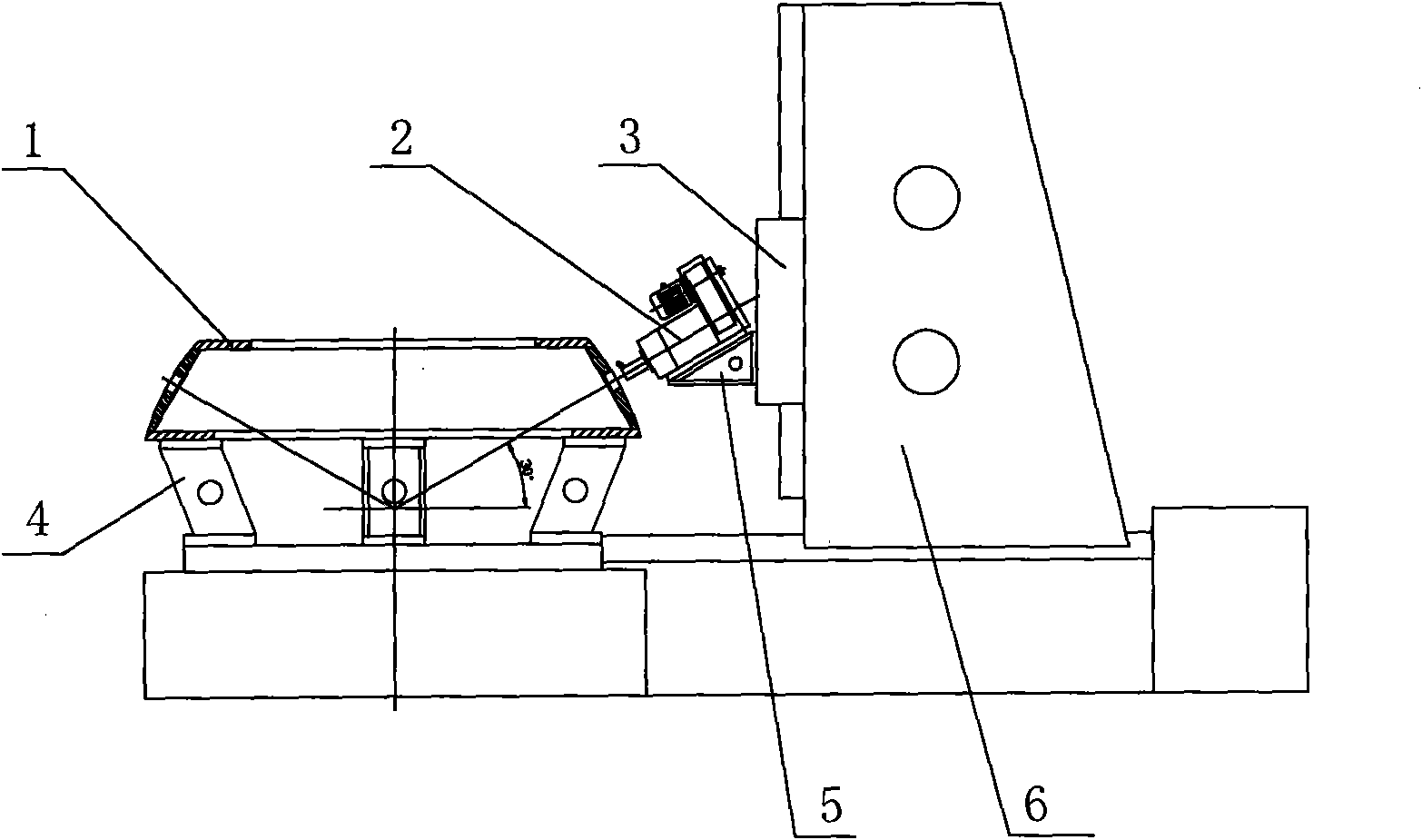

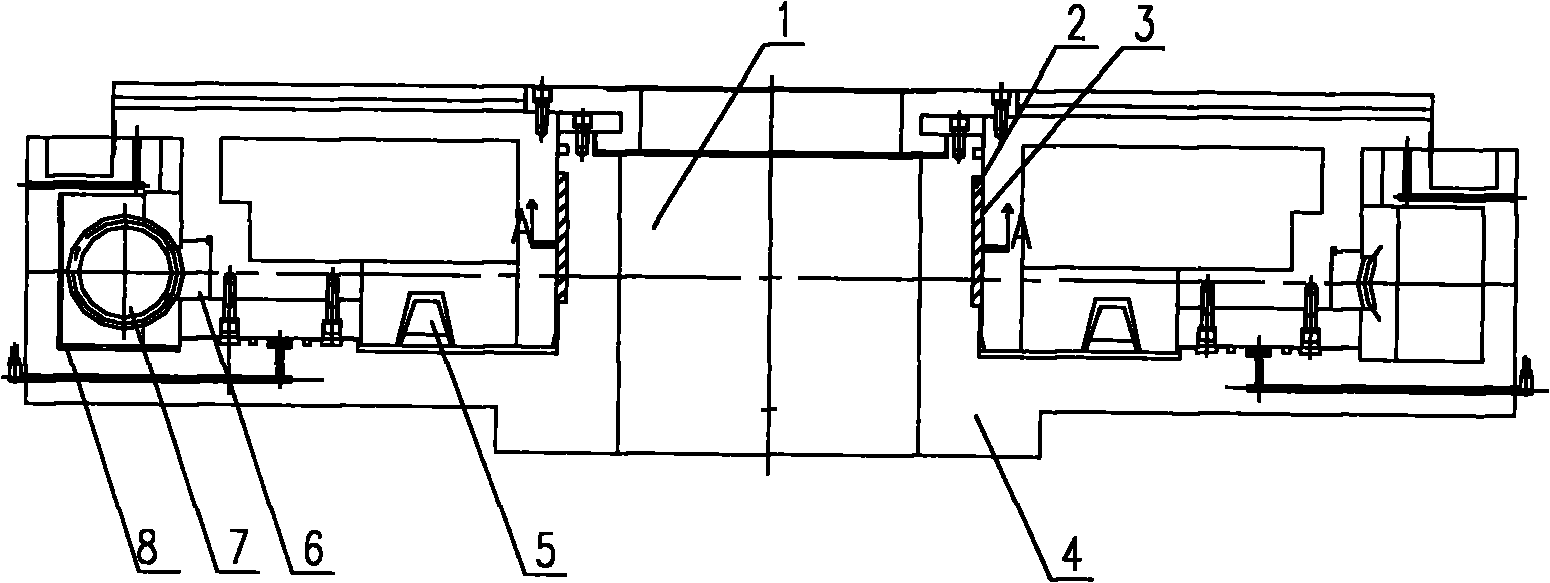

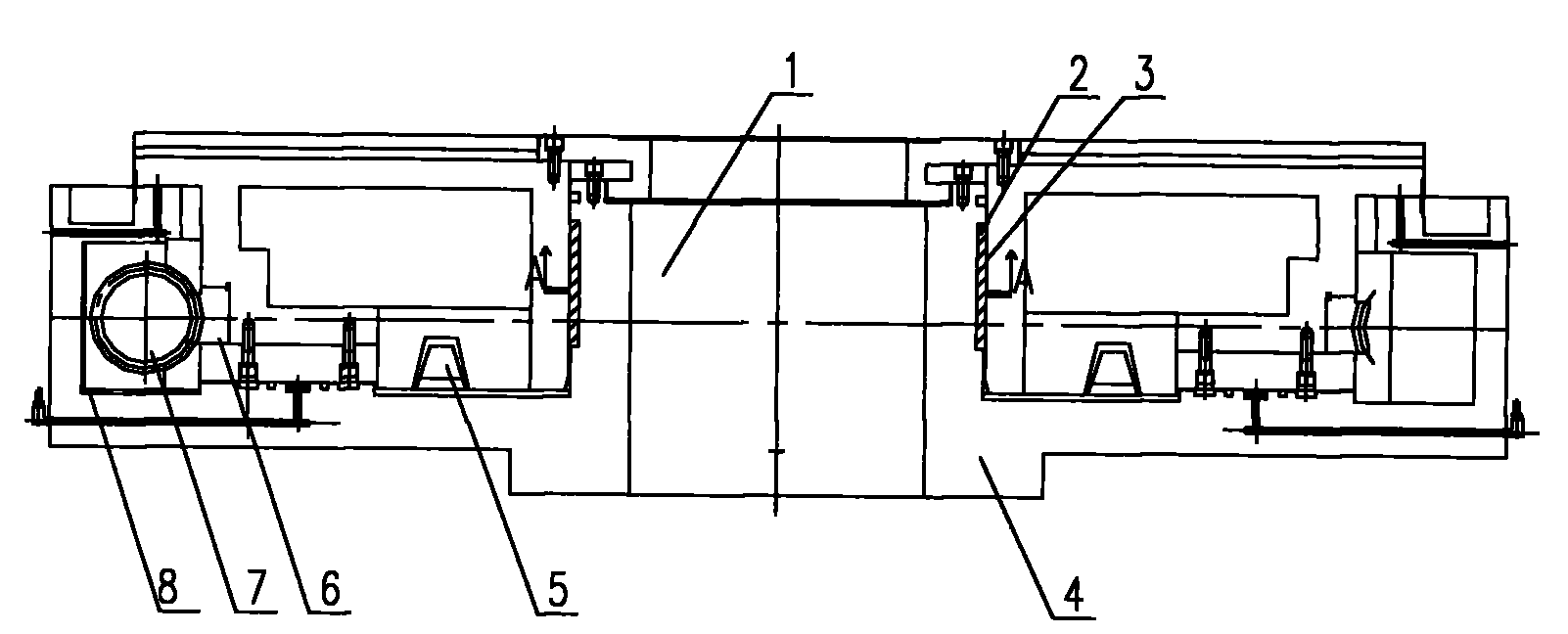

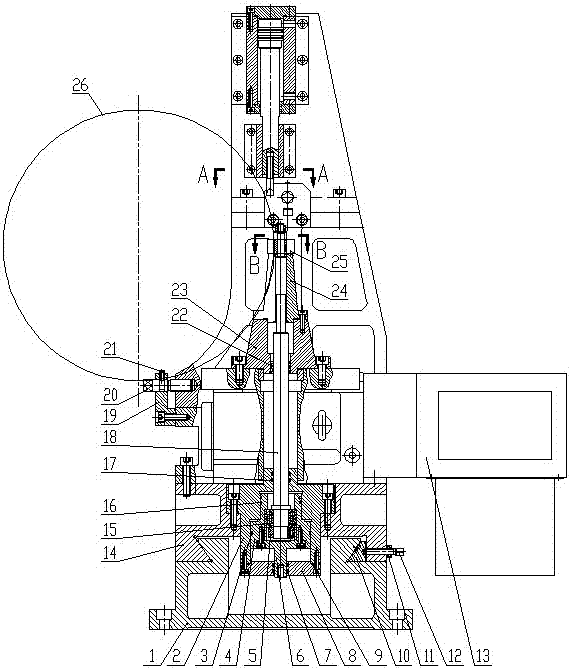

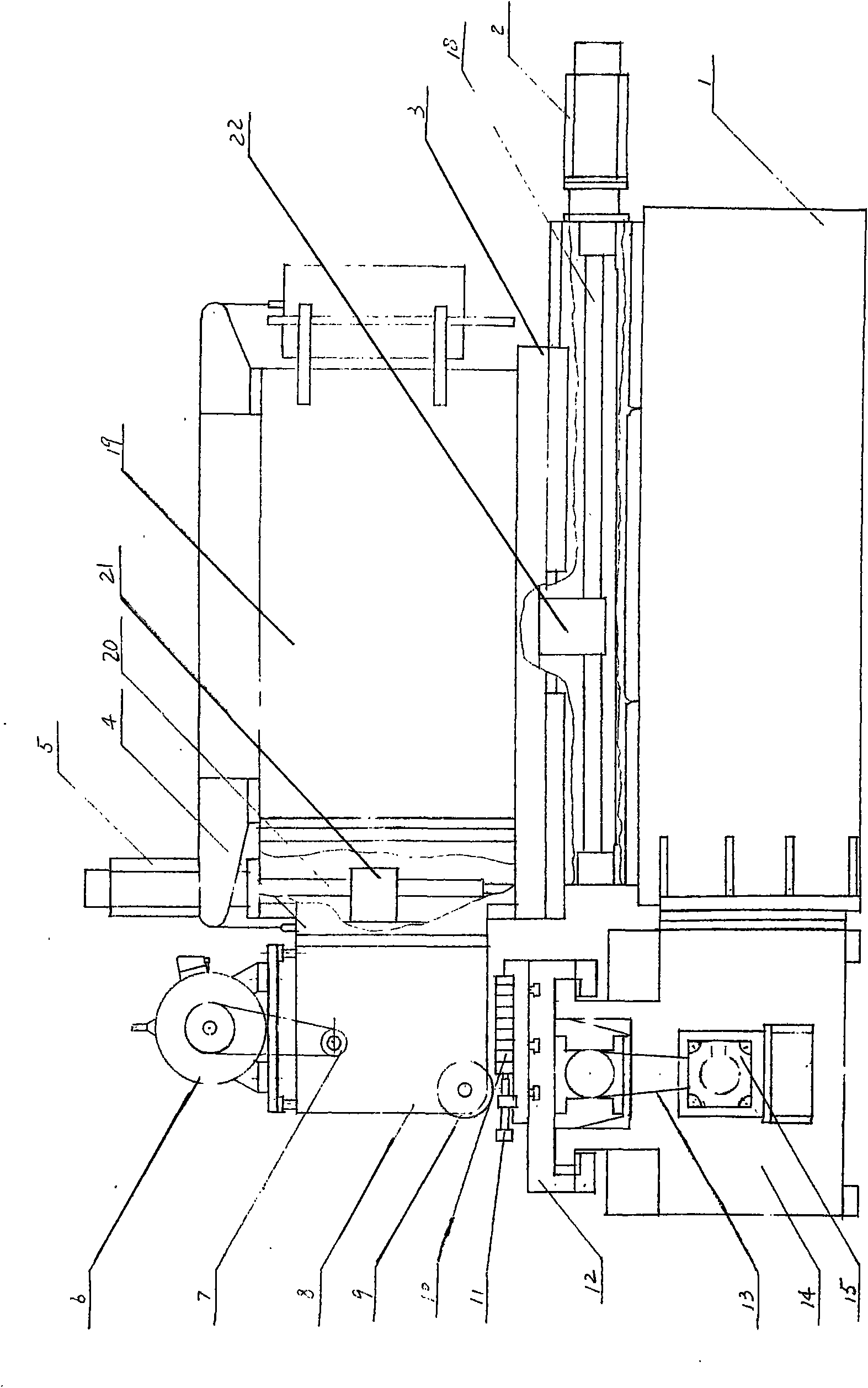

Force measurement wheel set calibration test stand

ActiveCN103759885AEasy to operateHigh precisionForce/torque/work measurement apparatus calibration/testingTransverse forceEngineering

A force measurement wheel set calibration test stand comprises a T-shaped stand base, portal systems and a transverse loading system. The force measurement wheel set calibration test stand is characterized in that perpendicular guide systems are installed on the portal systems and used for fixing a wheel set and achieving perpendicular loading; a bottom plate system is arranged at the position, below two portal top beams of the two portal systems, of the T-shaped stand base and used for adjusting track gauge, provides a platform for applying longitudinal force and transversely limiting the wheel set; a wheel set rotating indexing system is arranged at one end of the T-shaped stand base and used for achieving loading of any automatic rotating angle of the wheel set. According to the force measurement wheel set calibration test stand, perpendicular force and transverse force are independently loaded on the wheel set, and combined loading of loads in three directions can also be conducted on the wheel set; the force measurement wheel set calibration test stand has the wide track gauge calibration capacity, and meets the requirement for calibrating force measurement wheel sets of railway vehicles with the meter gauge, railway vehicles with the standard track gauge, railway vehicles with the wide gauge and other different railway vehicles; the force measurement wheel set calibration test stand has the capacity for adjusting lateral moving amount of wheel track contact points, and provides required perpendicular, transverse and longitudinal loads in a hydraulic loading mode.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

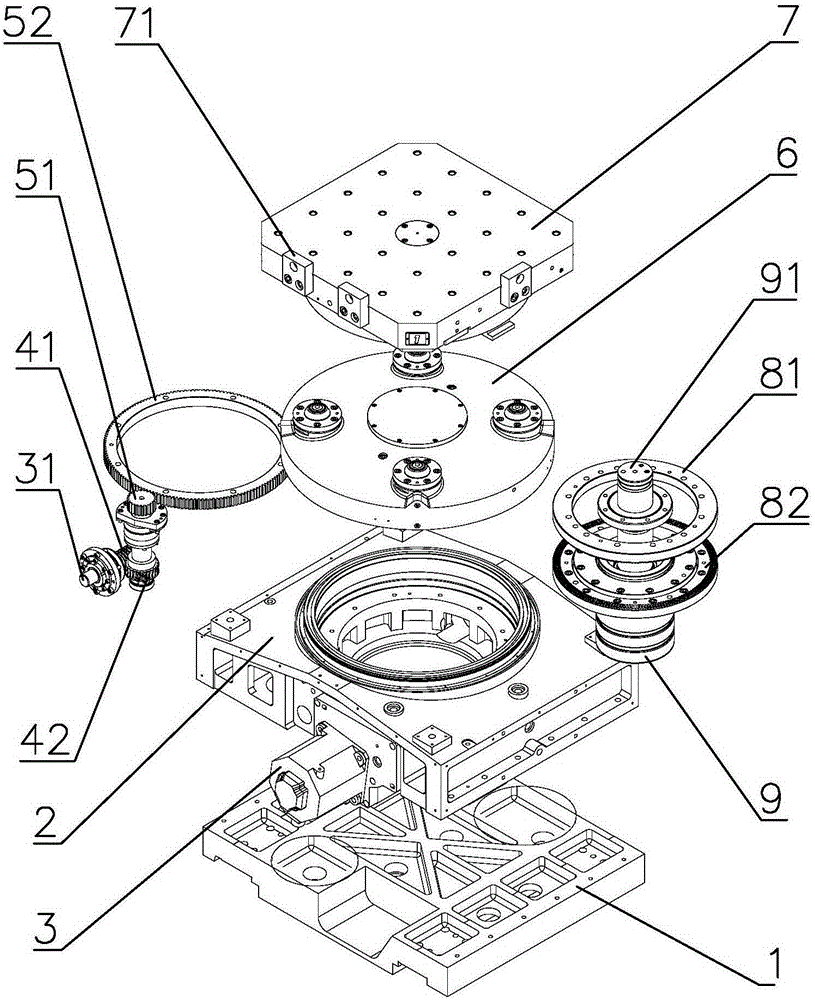

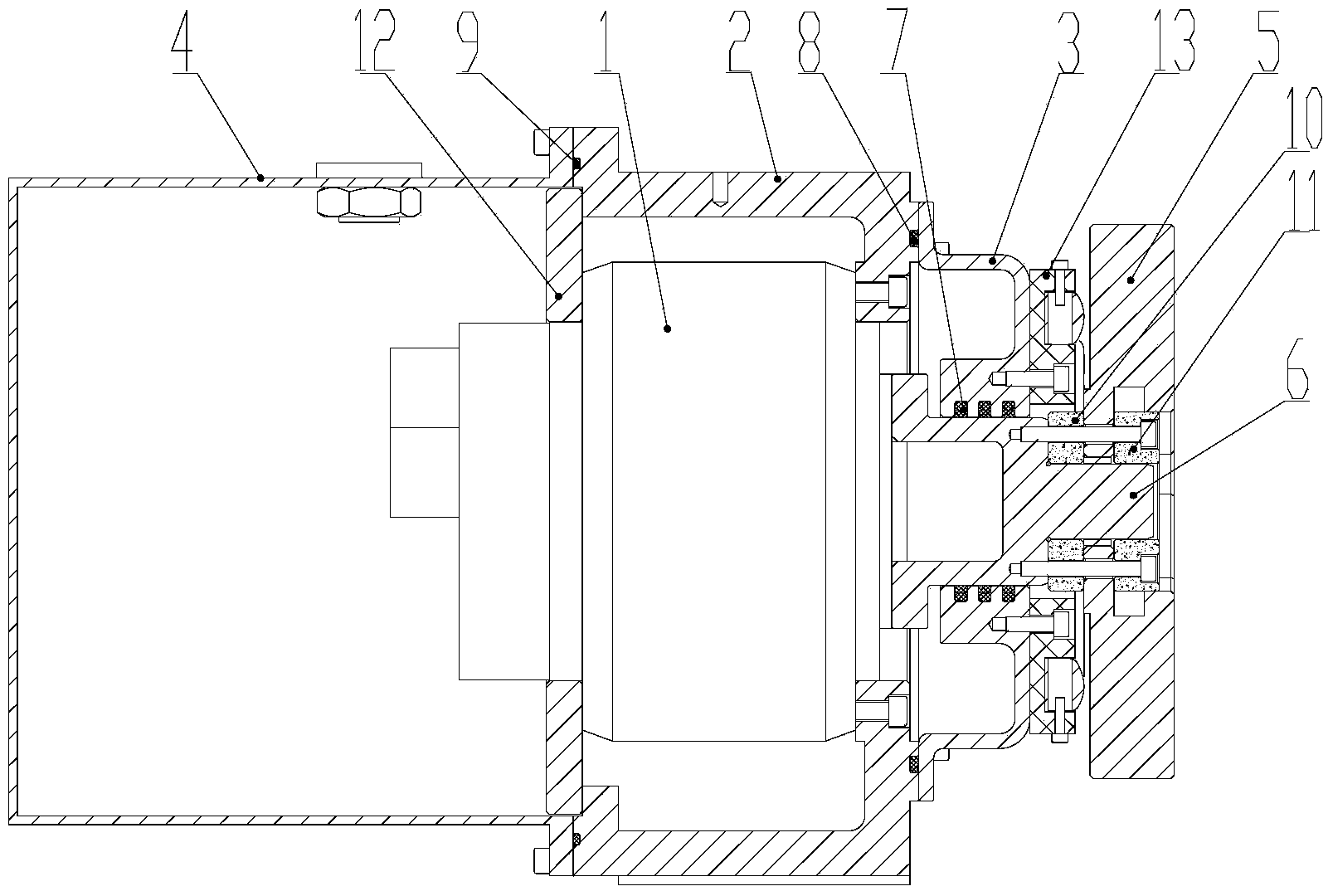

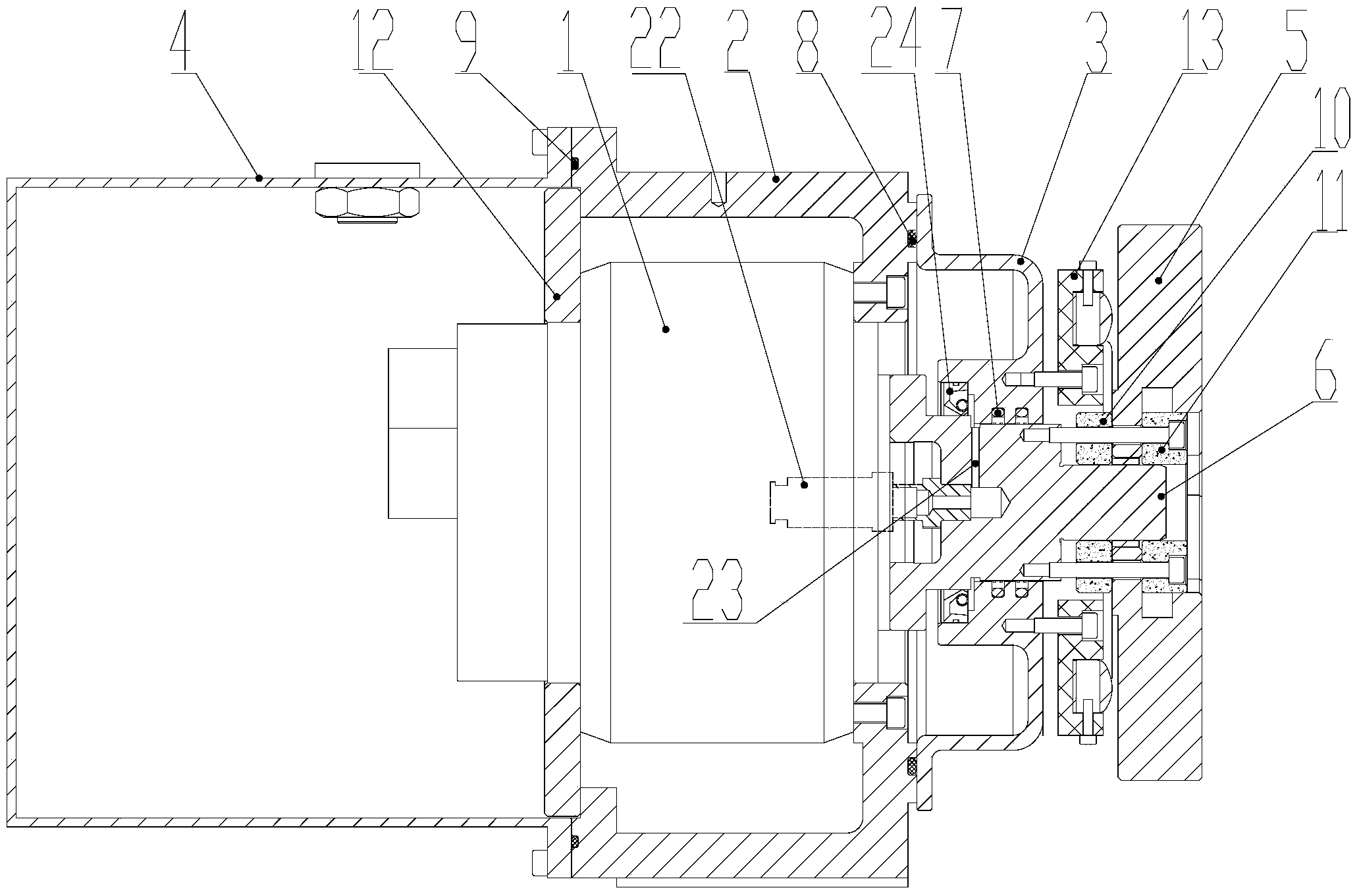

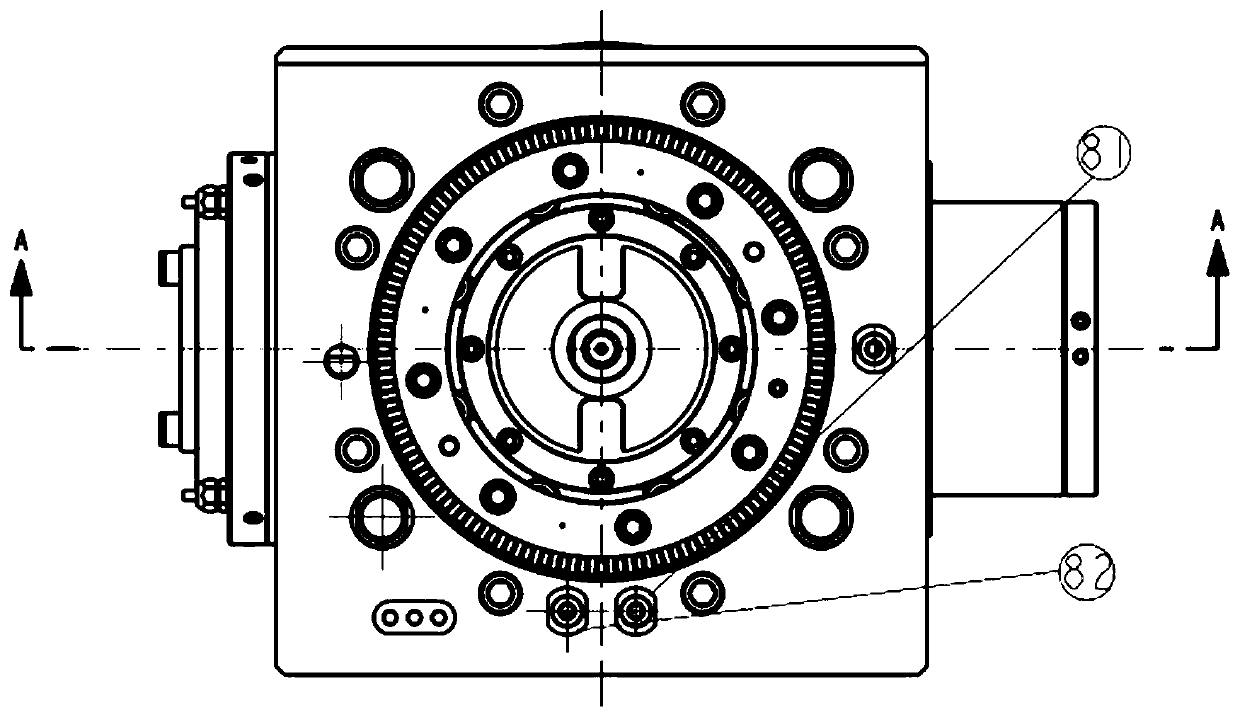

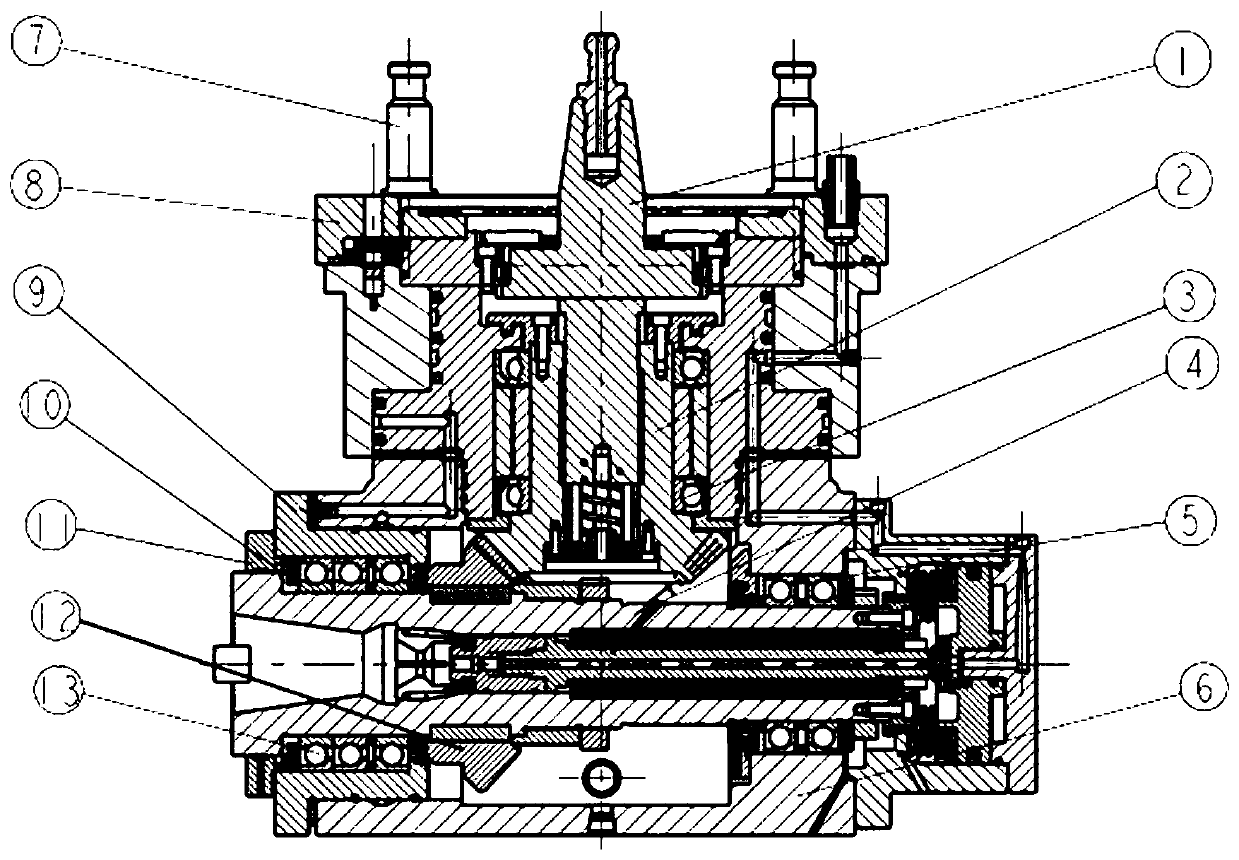

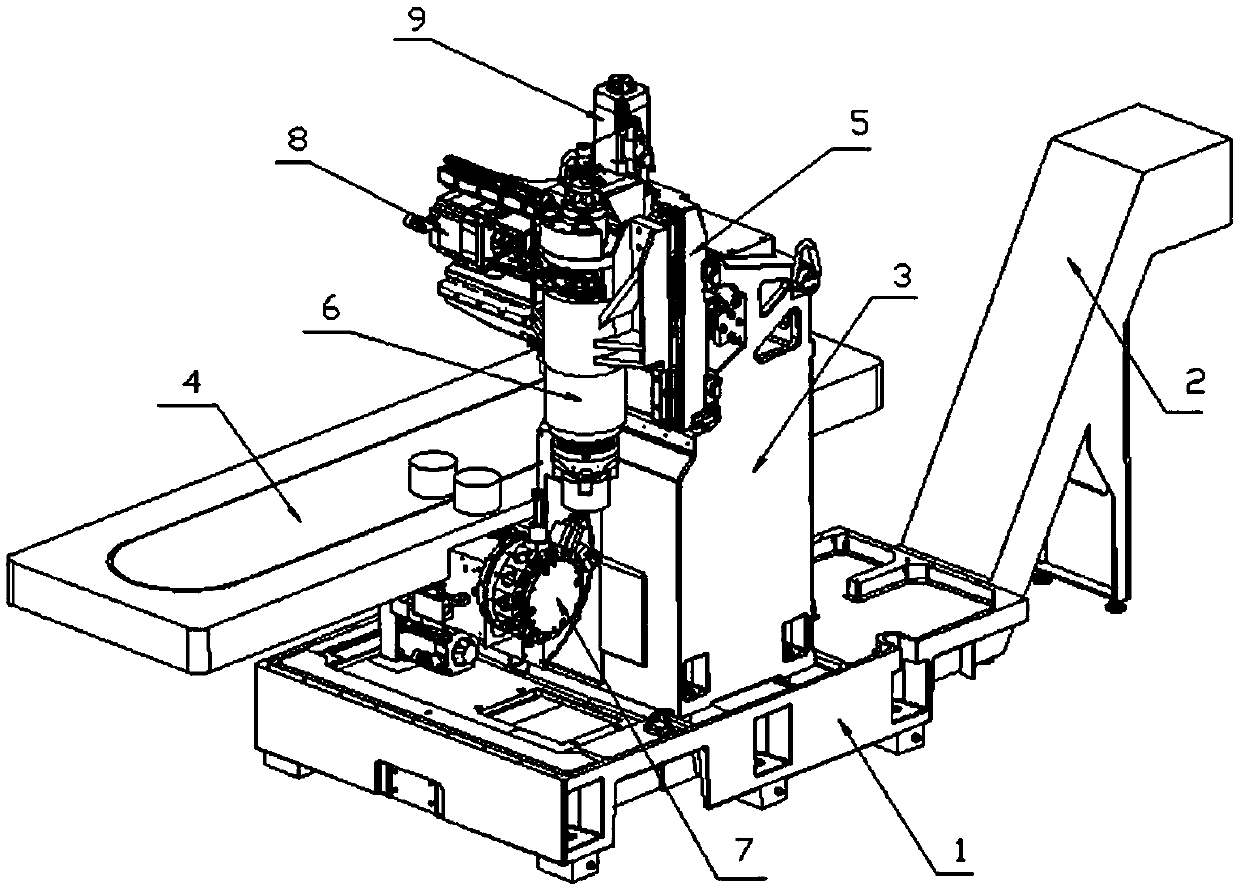

Numerical control rotation working table

InactiveCN105014480AImprove machining accuracyAvoid loss of precisionPrecision positioning equipmentNumerical controlTorque motor

A numerical control rotation working table comprises a machine body, a rotation shaft, a rotating encoder, a braking ring piece, a piston, a torque motor and a working rotating plate used for installing a workpiece. A cylinder is formed in the machine body. The rotation shaft is connected to the machine body in a pivoted mode. The rotating encoder is arranged on the machine body. The piston is movably arranged in the cylinder. The end, located on the outer side of the cylinder, of the piston forms an ejection end. The ejection rod is used for ejecting the braking ring piece and pressing the braking ring piece to the side wall of the machine body. According to the numerical control rotation working table, very high rotation accuracy and positioning accuracy can be output through direct drive of the torque motor and the cooperation with the high-precision encoder; in addition, linked machining and angle-fixed indexing machining can be achieved according to different machining requirements; in the linked machining process, stable machining can be conducted in the rotating process of the working rotating plate; and in the angle-fixed indexing machining process, by pressing the braking ring piece through the position and by means of the keeping torque of the torque motor, extremely high braking keeping torque can be generated so that the machining stability can be ensured.

Owner:GUANGZHOU HAOZHI ELECTROMECHANICAL

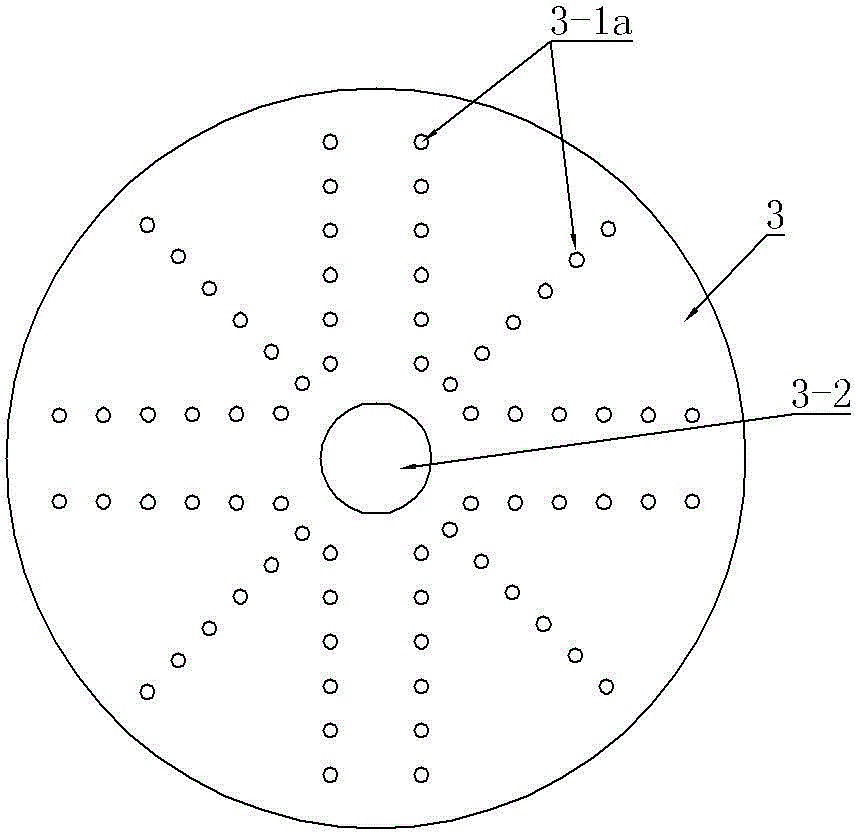

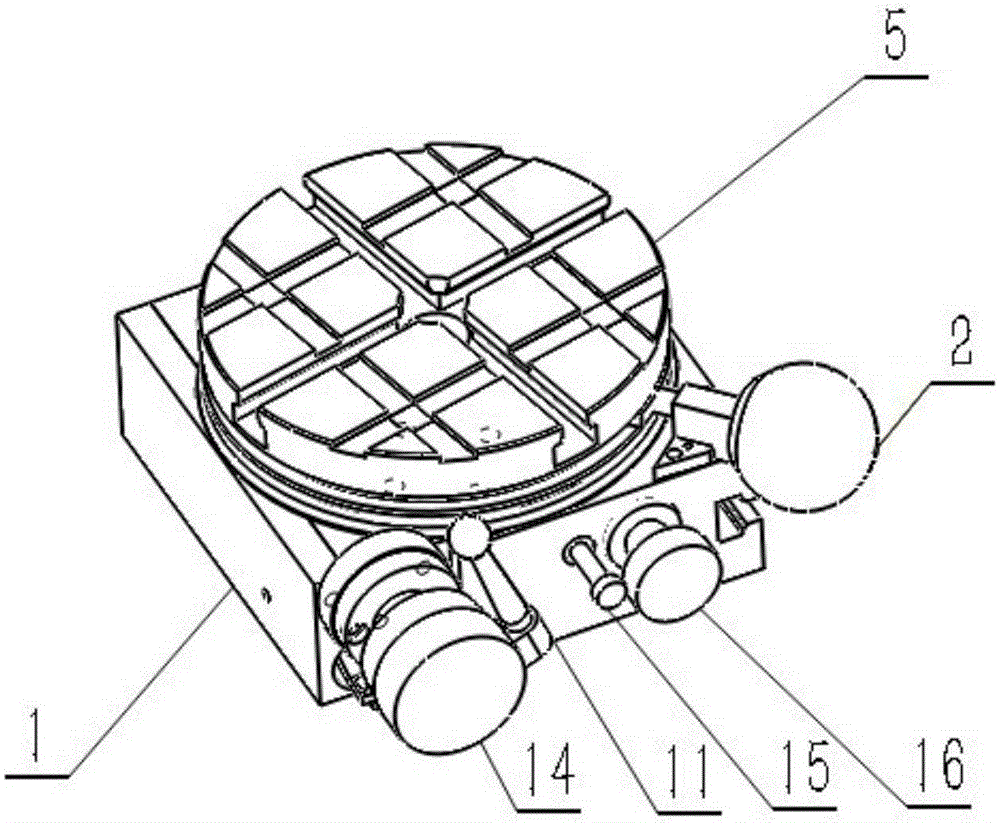

High-precision rotating dividing disc

ActiveCN104924152ASimple structureReduce transmission cumulative errorPrecision positioning equipmentComputer scienceRotating disc

The invention provides a high-precision rotating dividing disc. The high-precision rotating dividing disc can solve the problem that a conventional worm-gear-operated dividing device is complex in structure and large in dividing error, can be conveniently applicable to dividing operation of large parts, and improves the machining efficiency. The high-precision rotating dividing disc comprises a base, a dividing disc body, a rotating disc and dividing plug pins. Dividing grooves are formed in the dividing disc body, and the dividing plug pins are installed on the rotating disc. The dividing disc body is fixedly installed on the base, the rotating disc is installed on the base in a rotatable mode, and the dividing disc body and the rotating disc are arranged in a concentric mode, and are located and locked through the dividing plug pins. When the dividing disc body and the rotating disc are located and locked, the dividing plug pins are inserted into the dividing grooves of the dividing disc body. The rotating disc is supported on the base through a plane swing bearing.

Owner:HITACHI PUMP MFG WUXI +1

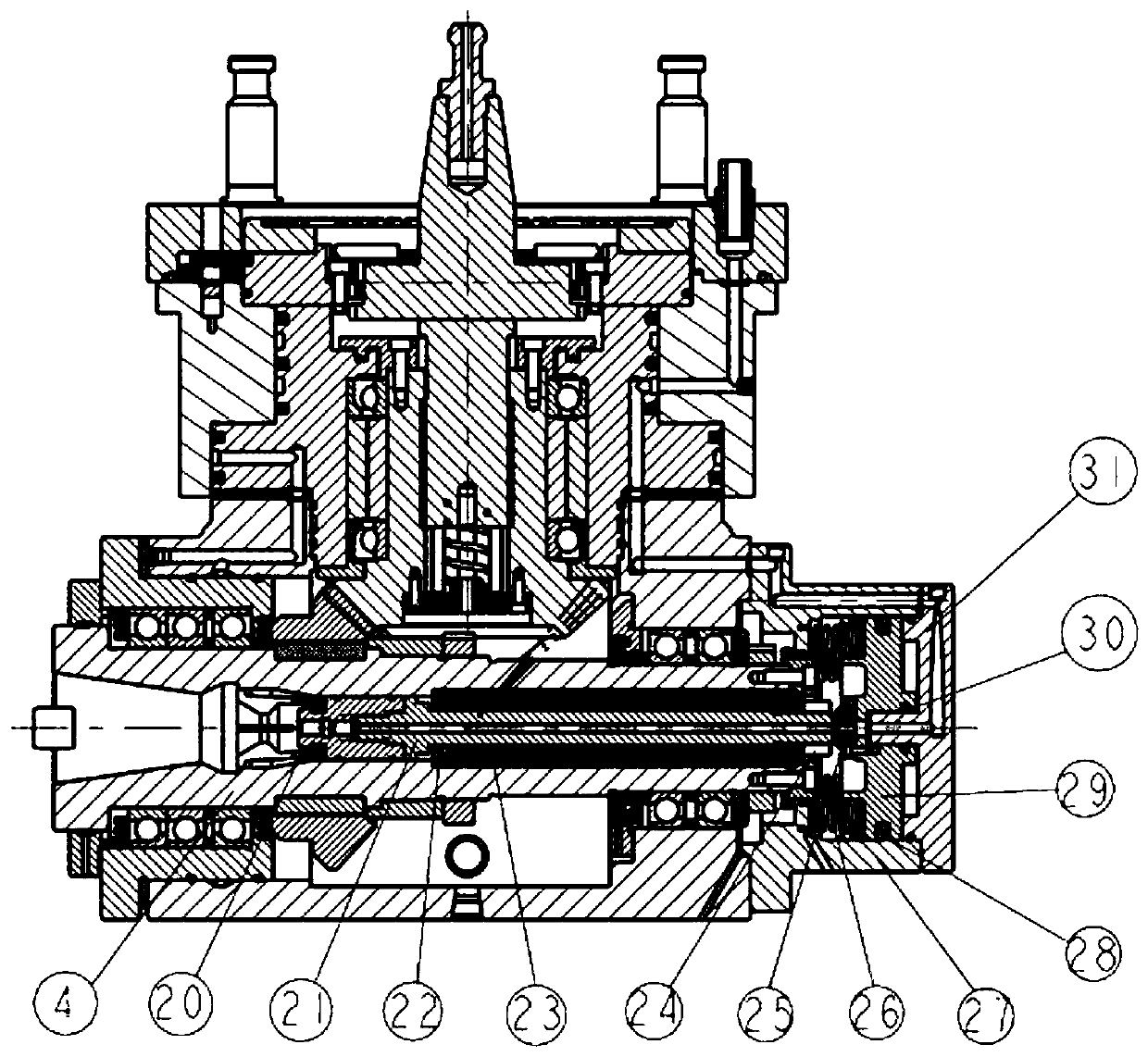

Numerical control rotary table

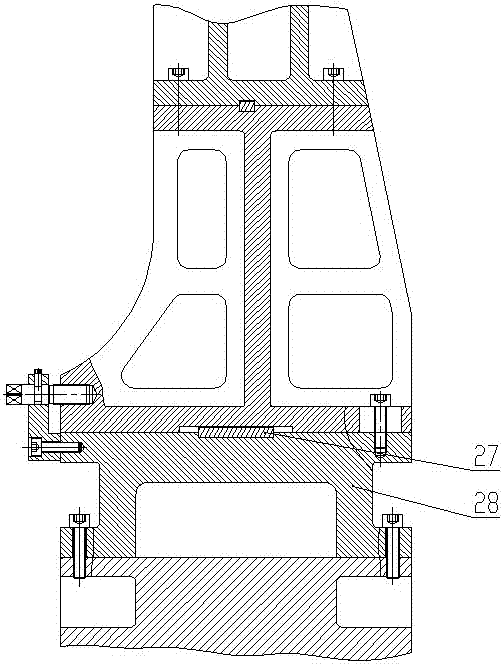

InactiveCN105171444APrecise positioningHigh indexing accuracyPrecision positioning equipmentLarge fixed membersHydraulic cylinderNumerical control

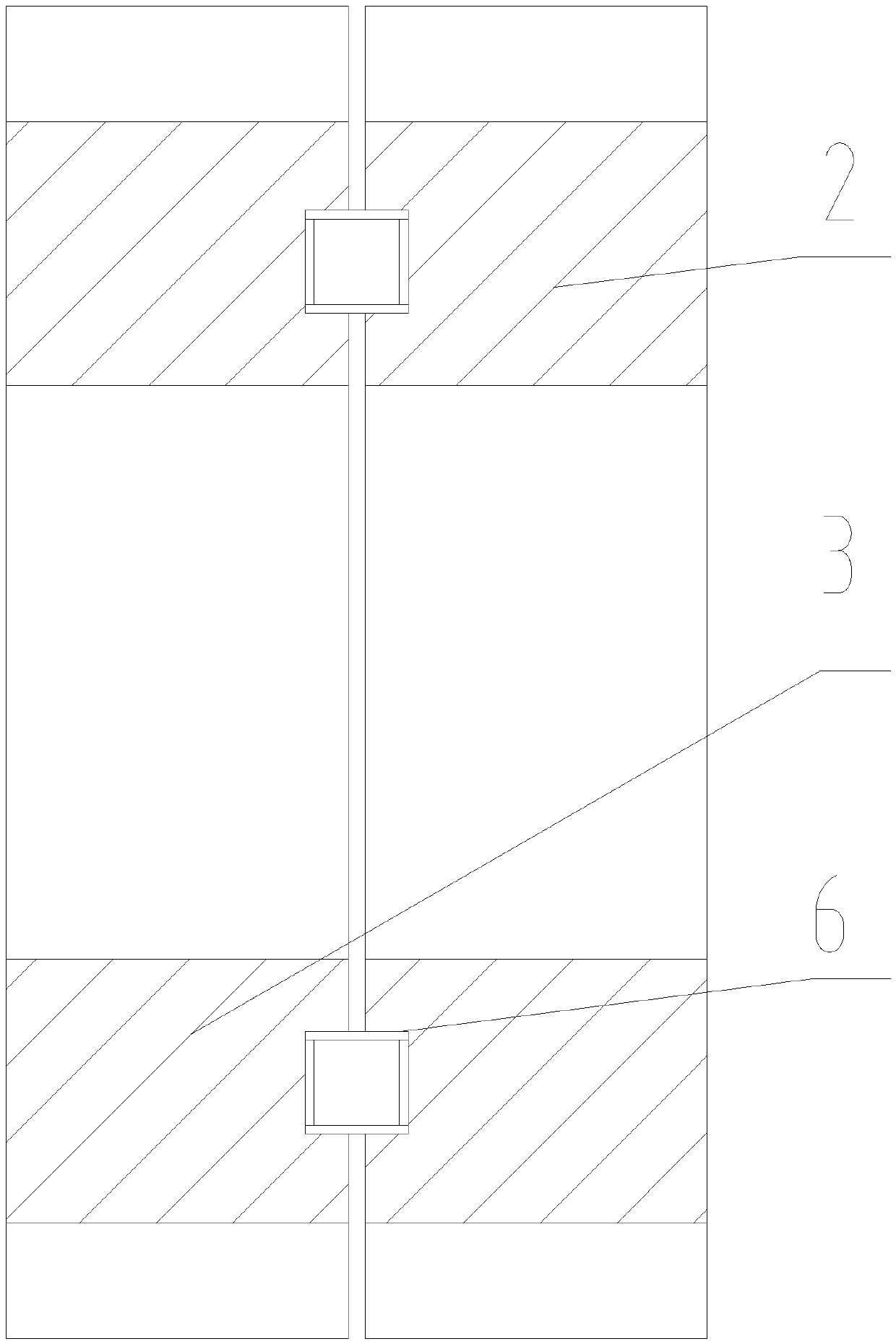

The invention discloses a numerical control rotary table. The numerical control rotary table comprises a connection plate arranged on a guide rail of a machine tool, a gear box is fixed on the connection plate, a motor is arranged on one side of the gear box, and an output shaft of the motor is in the horizontal direction and penetrates through a side wall of the gear box to enter an inner cavity of the gear box and to be connected with a worm gear and a worm; the output shaft drives the worm to rotate, the worm gear drives a reduction gear unit to rotate, the reduction gear unit comprises a driving gear and a driven gear, the axis of the drive gear is perpendicular to the horizontal surface, a working table supporting body is fixed at the upper end of the driven gear, and a working table is fixed above the working table supporting body; a locking mechanism is arranged in the middle of the driven gear in a penetration manner and comprises an upper hirth coupling fixed at the bottom end of the working table supporting body and a lower hirth coupling fixed on a hydraulic cylinder, and the working table supporting body can move up and down under pushing of a piston shaft of the hydraulic cylinder. The numerical control rotary table is high in precision and reliability.

Owner:YANTAI TUOFU NUMERICAL CONTROL MACHINE TOOL

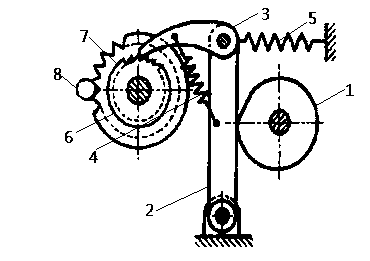

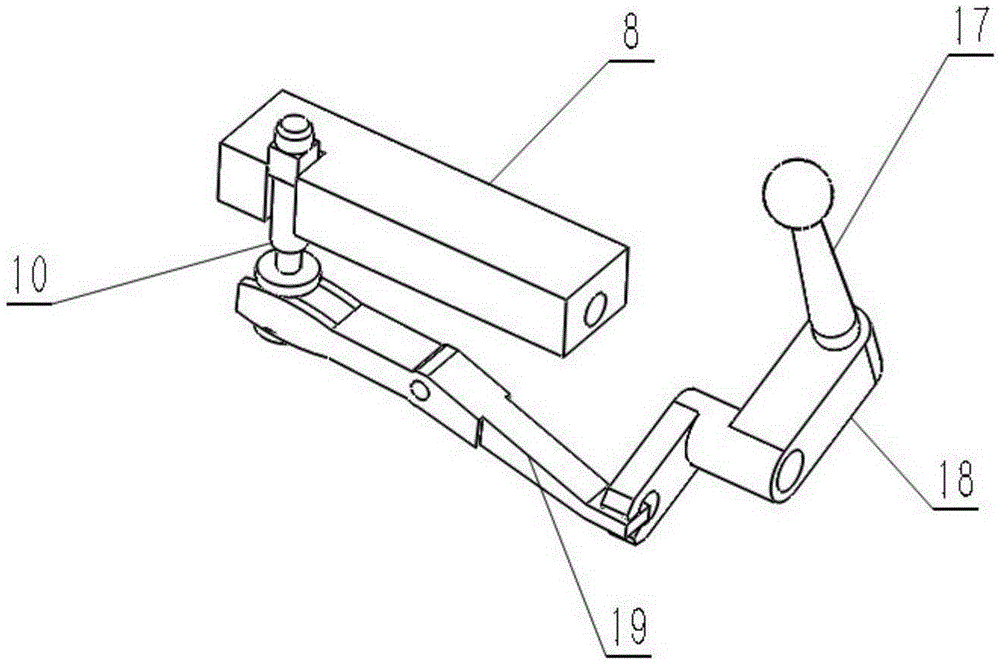

Indexing intermittent drive mechanism for intermittent feeding

The invention discloses an indexing intermittent drive mechanism for intermittent feeding. The indexing intermittent drive mechanism for intermittent feeding is used for solving the problems that an existing intermittent feeding drive mechanism is poor in stability, low in precision, and low in feeding accuracy. The indexing intermittent drive mechanism for intermittent feeding comprises a hinged cam capable of moving in the axial direction. The cam is provided with a conical surface, the flange of the cam abuts against a swinging rod, the lower end of the swinging rod is hinged, the upper end of the swinging rod is hinged to a pawl, a first tension spring is arranged between the end of the pawl and the swinging rod, a first ratchet wheel capable of being meshed with the end of the pawl is arranged at the end of the pawl, the first ratchet wheel is fixedly disposed on a rotating shaft, a second ratchet wheel parallel to the first ratchet wheel is arranged on the rotating shaft, and the flange of the second ratchet wheel abuts against the side of a push rod. The indexing intermittent drive mechanism for intermittent feeding is stable in drive and accurate in feeding.

Owner:重庆信奇建材机械制造有限公司

High-precision gear manufacturing method

The invention relates to a high-precision gear manufacturing method. By optimizing nitrogen process parameters and adopting a flexible positioning net, parts are nitrogenized in a free state, a sandblasting machining method is adopted in a subsequent process to uniform residual stress on the surface of a spoke plate, and by taking measures of using a self-adaptive gear grinding fixture, increasing a sandblasting process and the like, the problems that deformation occurs during gear machining and the precision cannot be guaranteed are solved. The method provided by the invention has the advantages that the stability of nitrogenization is guaranteed, the cutting precision is improved, the spoke plate is prevented from being deformed, the deformation during machining and nitrogenization is effectively controlled and the machining quality of the part is guaranteed.

Owner:HARBIN DONGAN ENGINE GRP

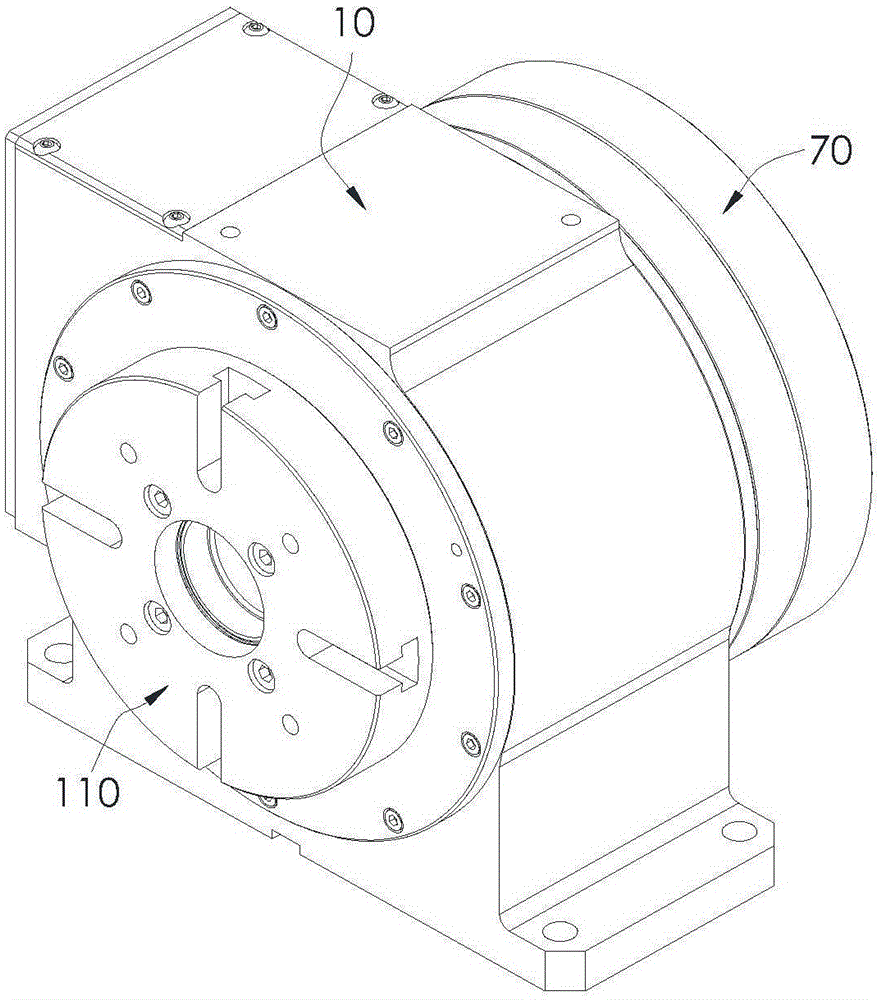

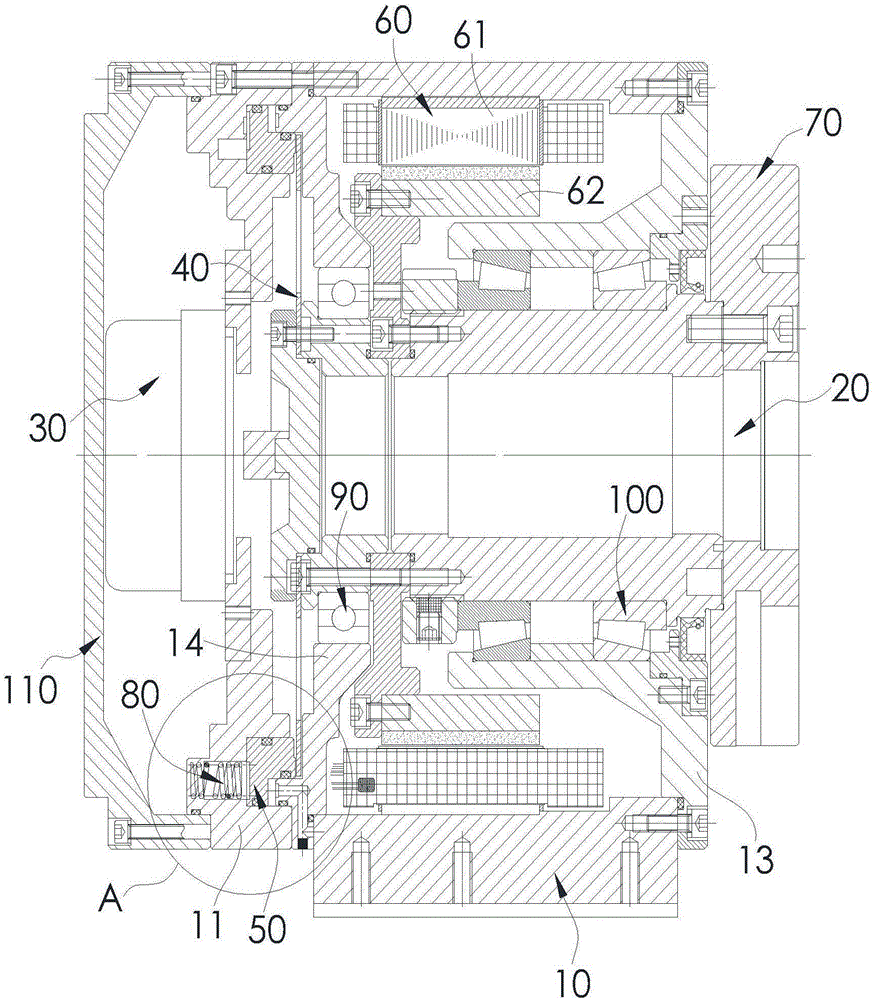

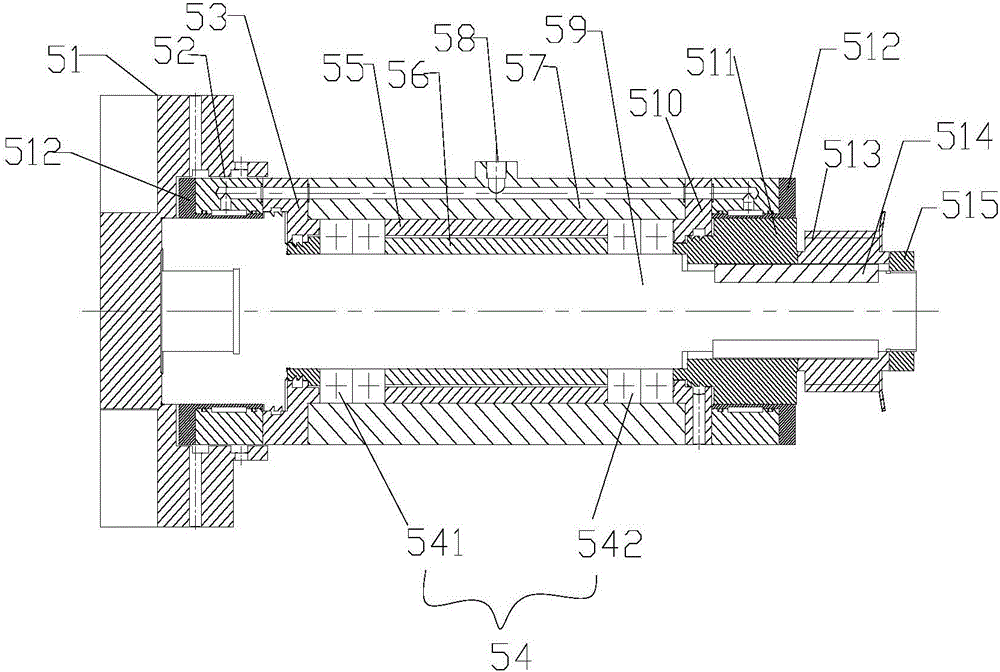

Torque motor direct-driven full immersion rotary table

ActiveCN104227163ASimple structureHigh indexing accuracyElectrical-based auxillary apparatusElectricityTorque motor

The invention provides a torque motor direct-driven full immersion rotary table comprising a supporting shell, the torque motor, an output rotary shaft and a worktable. The torque motor is fixed on the supporting shell and further sealed by a front hood and a rear hood. The output rotary shaft is directly fixed on the torque motor and penetrates the front hood in a sealed manner. The worktable is mounted on the output rotary shaft in an insulation manner. A powering structure is arranged between the worktable and a frame. By adopting the torque motor direct drive manner, the full immersion rotary table is simple in structure, small in size and high in indexing accuracy; a combined sealing manner includes pneumatic sealing, dynamic sealing, a drain-back passage and static sealing, allowing effective sealing performance; with the axial powering manner adopted, the powering system is convenient to mount to lead to good powering effect; with the two-point supporting manner adopted, the rotary table is good in bearing effect and stable in dynamic performance.

Owner:北京市电加工研究所有限公司 +1

Multifunctional servo driven glass press with gears

The invention discloses a multifunctional servo driven glass press with gears, which comprises a base, an upper bracing frame, a stamping apparatus, a die holder, a big disc, a moving mechanical arm, a cooling facility and a servo transmission device, the servo transmission device comprises a servo motor, a gear shifting box, a big gear and a small gear, a centrifuging device is arranged between the big gear and the small gear, a moving mechanical arm is arranged between the upper bracing frame and the big disc.

Owner:TAICANG HUANG FA JI MACHINERIES & MOLDS

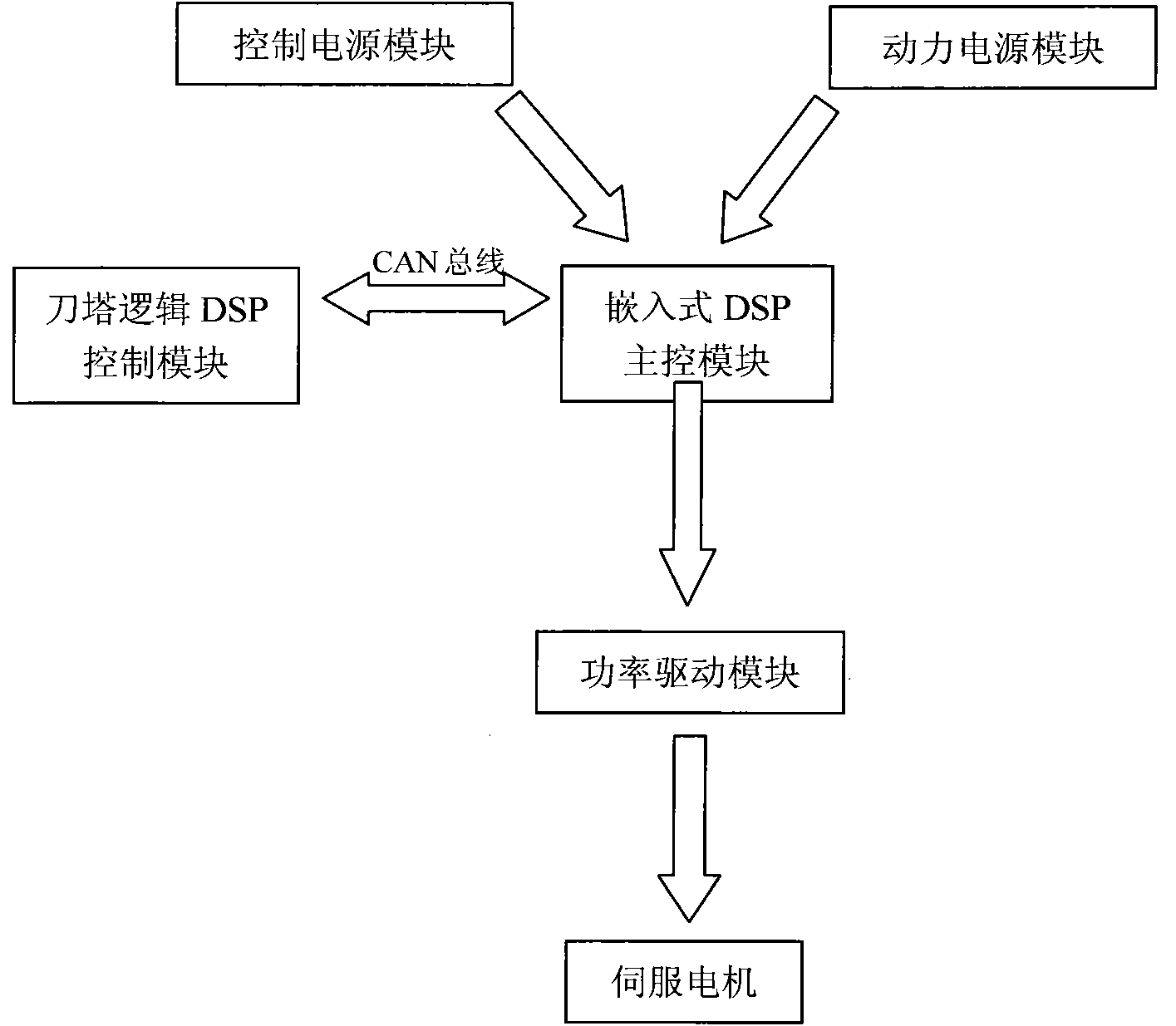

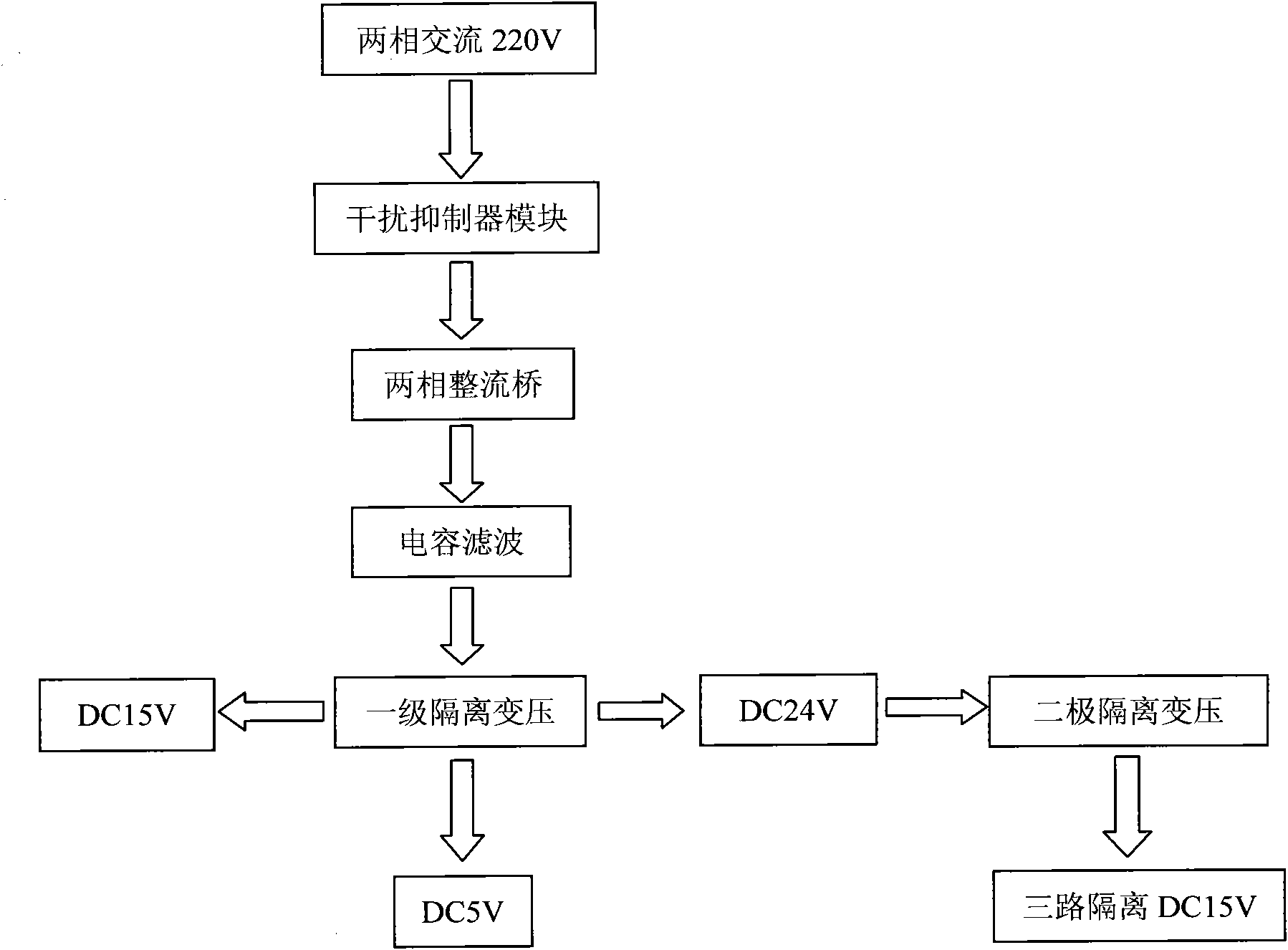

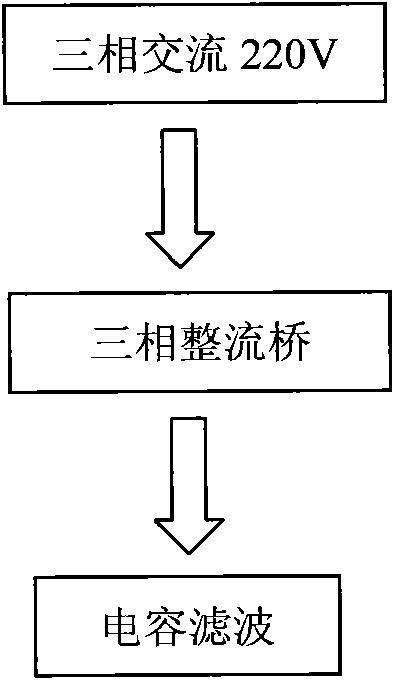

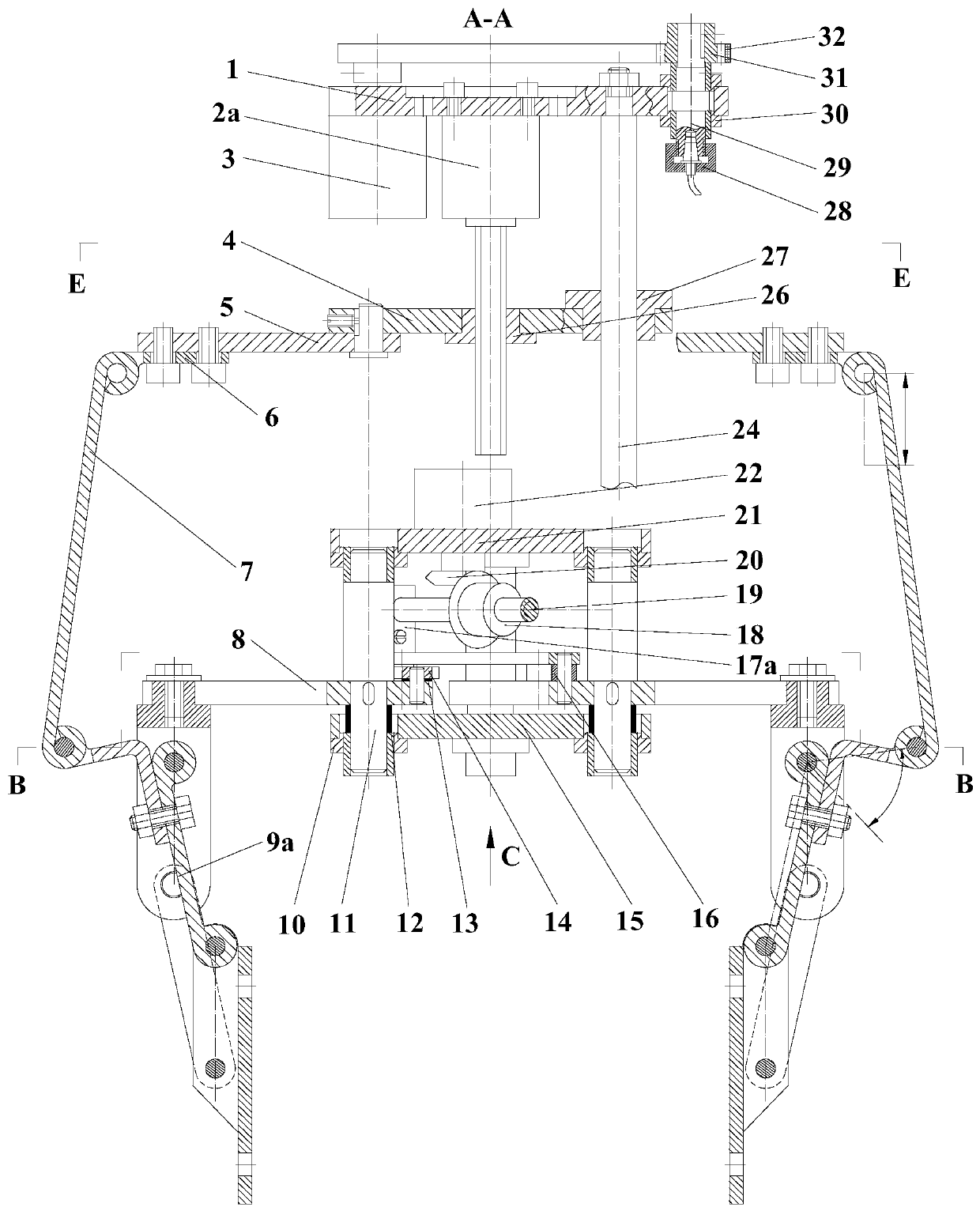

Control device for servo power turret

ActiveCN101846990AFast indexing speedReduce tool change timeNumerical controlMachine toolPush–pull output

The invention provides a control device for a servo power turret, which relates to a machine tool. A fully digital DSP processing chip, two central processing units (CPU), an embedded DSP main control module and a turret logical DSP control module are adopted by the device, wherein the embedded DSP main control module is a servo motor position control unit using TMS320LF2407 as a main processor, and the current, the position and the speed of a motor are controlled closely; the turret logical DSP control module is a user input / output management module using TMS320LF2406 as a co-processor; 74HC573 is used as a bus driving chip; and a push-pull output circuit of MOFET is adopted. The servo control turret has high transposition speed, can reduce the tool changing time of the turret, can improve the processing efficiency, the transposition precision and the tool changing accuracy of the machine tool, and can also improve the flexibility and the universality of control.

Owner:SHENYANG SHENGHUI MEASUREMENT & CONTROL TECH

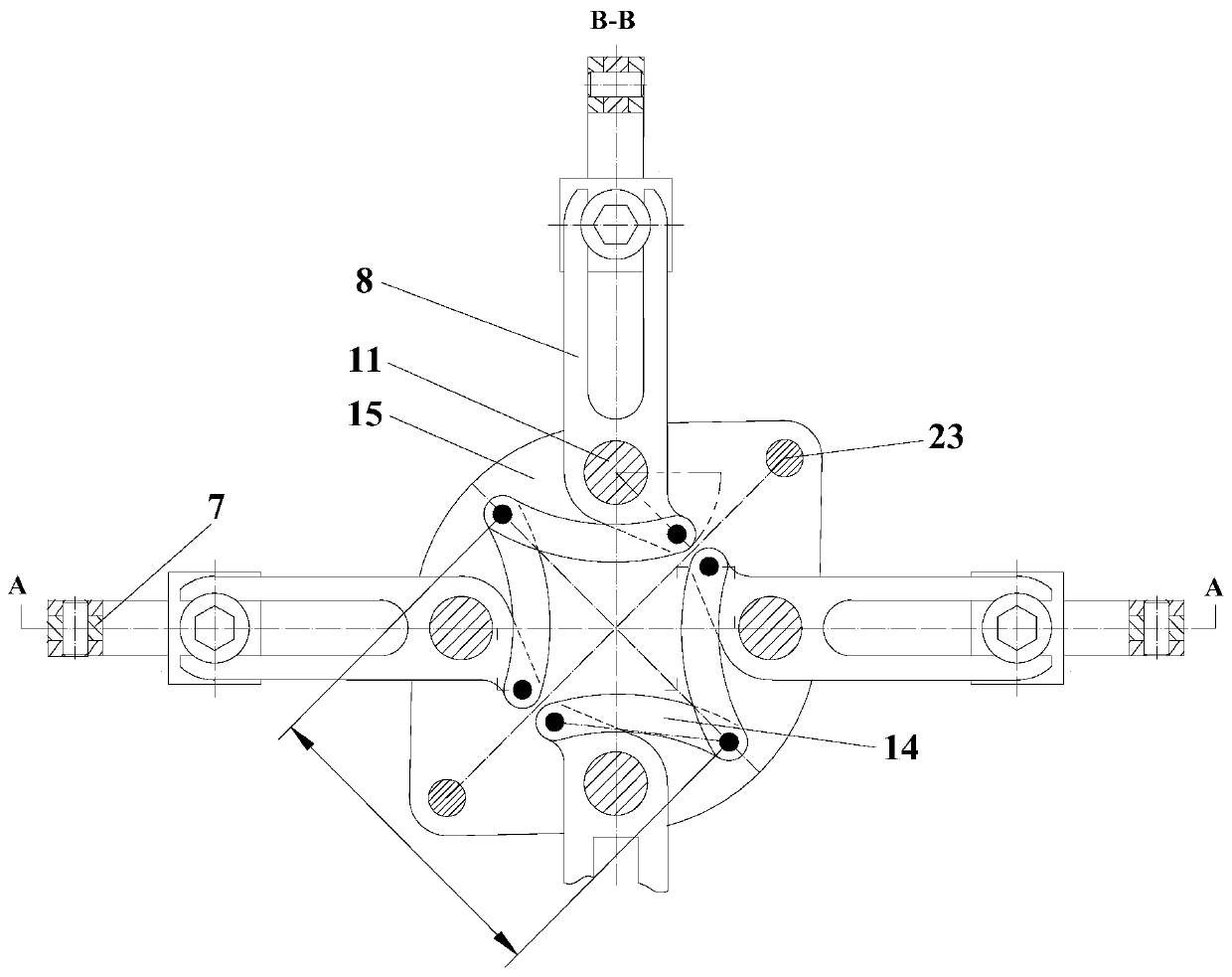

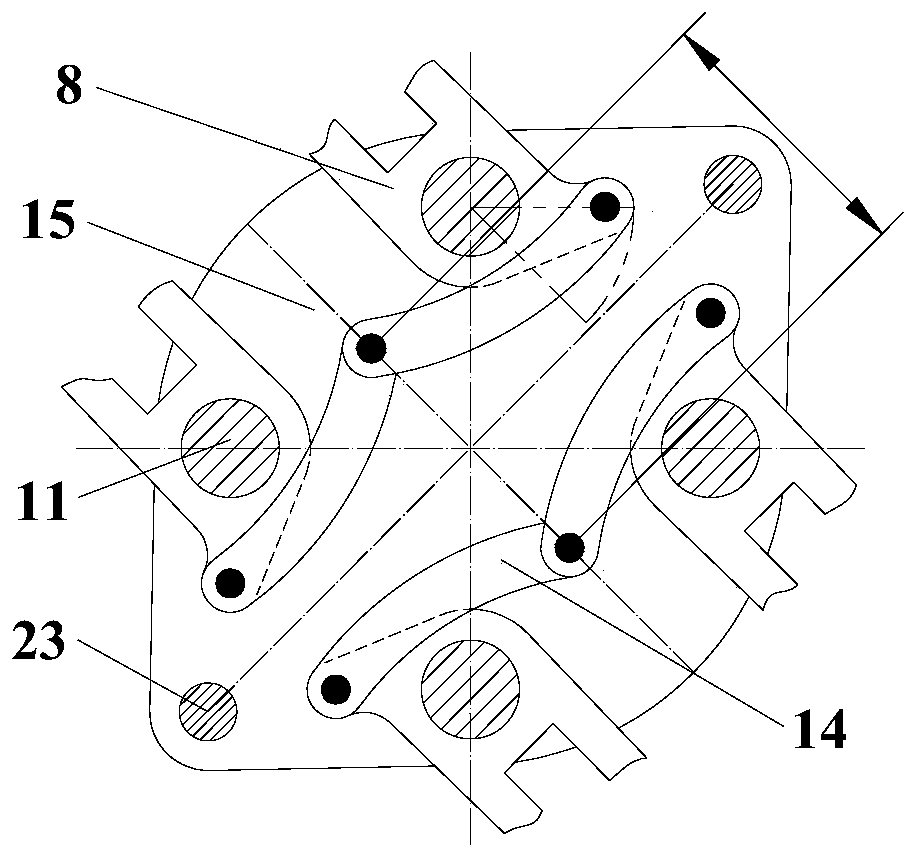

Pinching and flexible shaft drive drum tensioning belt wrapping grabbing composite mechanical hand and method

ActiveCN111409094AHas a binding effectImprove reliabilityGripping headsValve members for absorbing fluid energyLogistics managementRobot hand

The invention relates to a pinching and flexible shaft drive drum tensioning belt wrapping grabbing composite mechanical hand and a method, belongs to the field of robot and automation and suitable for the field of light industrial food and agricultural product sorting robots and packaging and logistics industry robots. The pinching and flexible shaft drive drum tensioning belt wrapping grabbing composite mechanical hand is composed of a palm part and four fingers of the same structure. The fingers have two kinds including horizontal moving clamping fingers and wrapping grabbing fingers. According to a finger root translocation function, the four fingers grab right circular cylinders, spheres and cubes, or under the drive of a motor, the left finger and the right finger conduct transposition by 45 degrees in the clockwise direction, the front finger and the rear finger conduct transposition by 45 degrees in the anticlockwise direction, and the four fingers grab horizontal cylinders andcuboids. According to a finger horizontal moving pinching function, due to the motor or a short-stroke air cylinder, the four fingers can rotate with the same finger root angle, and a parallelogram mechanism generates finger horizontal moving pinching. According to a wrapping grabbing function, the motor or a blade type rotating air cylinder drives a tooth-shaped belt, due to transmission of foursoft shafts, winding drums of braided fabric rubber belts are well tightened and loosened, and the four belts are used for grabbing objects.

Owner:JIANGNAN UNIV

Machine tool with spindle tool holder

ActiveCN105965040AReduce row toolShort tripFeeding apparatusLarge fixed membersMotor driveDrive motor

The invention discloses a machine tool with a spindle tool holder. The machine tool comprises a machine seat. An oblique lathe bed, an X-direction guide rail, an X-direction sliding plate, an X-direction motor, the spindle tool holder and a spindle tool holder drive motor are arranged on the machine seat. The X-direction motor drives the X-direction sliding plate to slide on the X-direction guide rail. The spindle tool holder drive motor drives the spindle tool holder to rotate. A workpiece spindle motor, a workpiece spindle transmission mechanism and a workpiece spindle are arranged on the portion, on the left side of the oblique lathe bed, of the machine seat. A tailstock sliding rail, a tailstock and a tailstock drive motor are arranged on the portion, on the right side of the oblique lathe bed, of the machine seat. The brand-new spindle tool holder is designed, row tools on the machine seat are reduced, the use rate of distributed tools of a cutterhead is increased, the stroke of the machine seat is reduced, and machining efficiency is improved.

Owner:GUANGZHOU WEIJIA MACHINE

Method for machining equated holes of large-sized rotating member by gear hobbing machine

InactiveCN101653839AReduce manufacturing costHigh indexing accuracyAttachable boring/drilling devicesHobbing

The invention relates to a method for machining equated holes of a large-sized rotating member by a gear hobbing machine. In the method, the gear hobbing machine is provided with a boring power head,the boring power head is utilized to machine the equated holes of the large-sized rotating member, and after centering and leveling, a position of a boring bar is centered on the spherical outside surface of the rotating member according to pitch circle scribing of the equated holes of the large-sized rotating member scribed by a vertical lathe so as to ensure that the axis of the boring bar is overlapped with the axes of the equated holes; and the boring power head performs rough machining and finishing on the equated holes. The method has the advantages of convenient operation, high machining accuracy and low manufacturing cost.

Owner:ANSTEEL HEAVY MACHINERY CO LTD

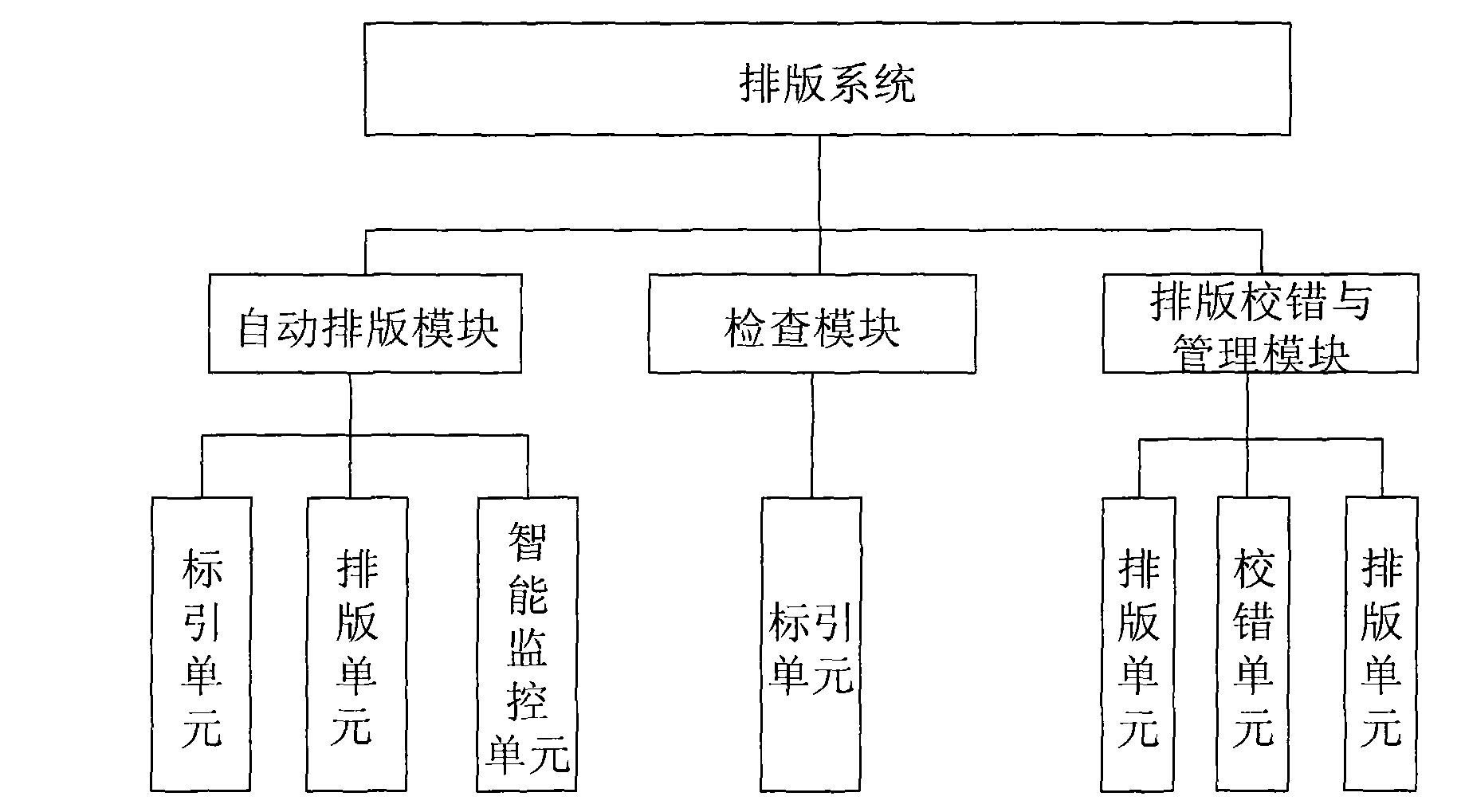

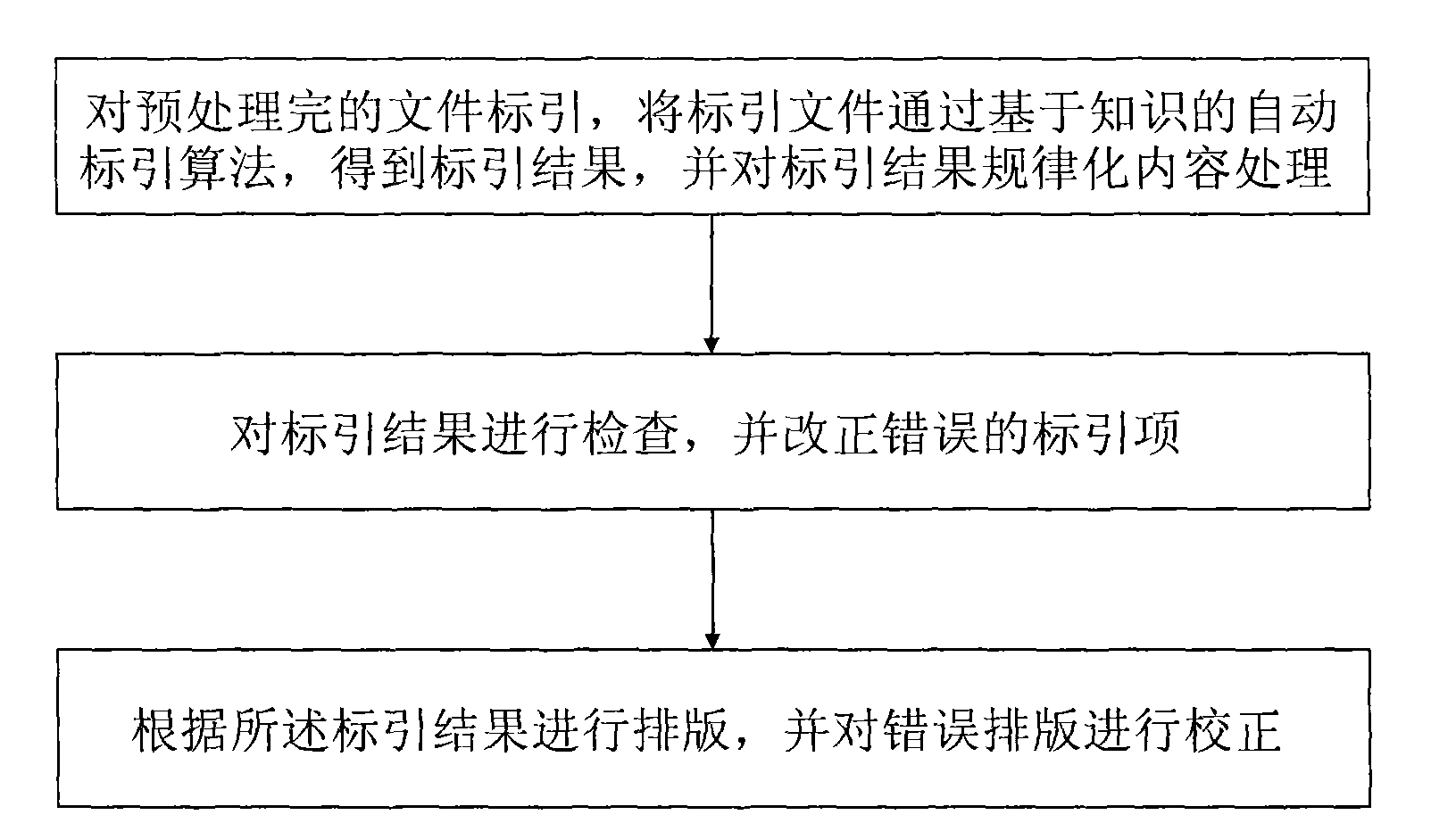

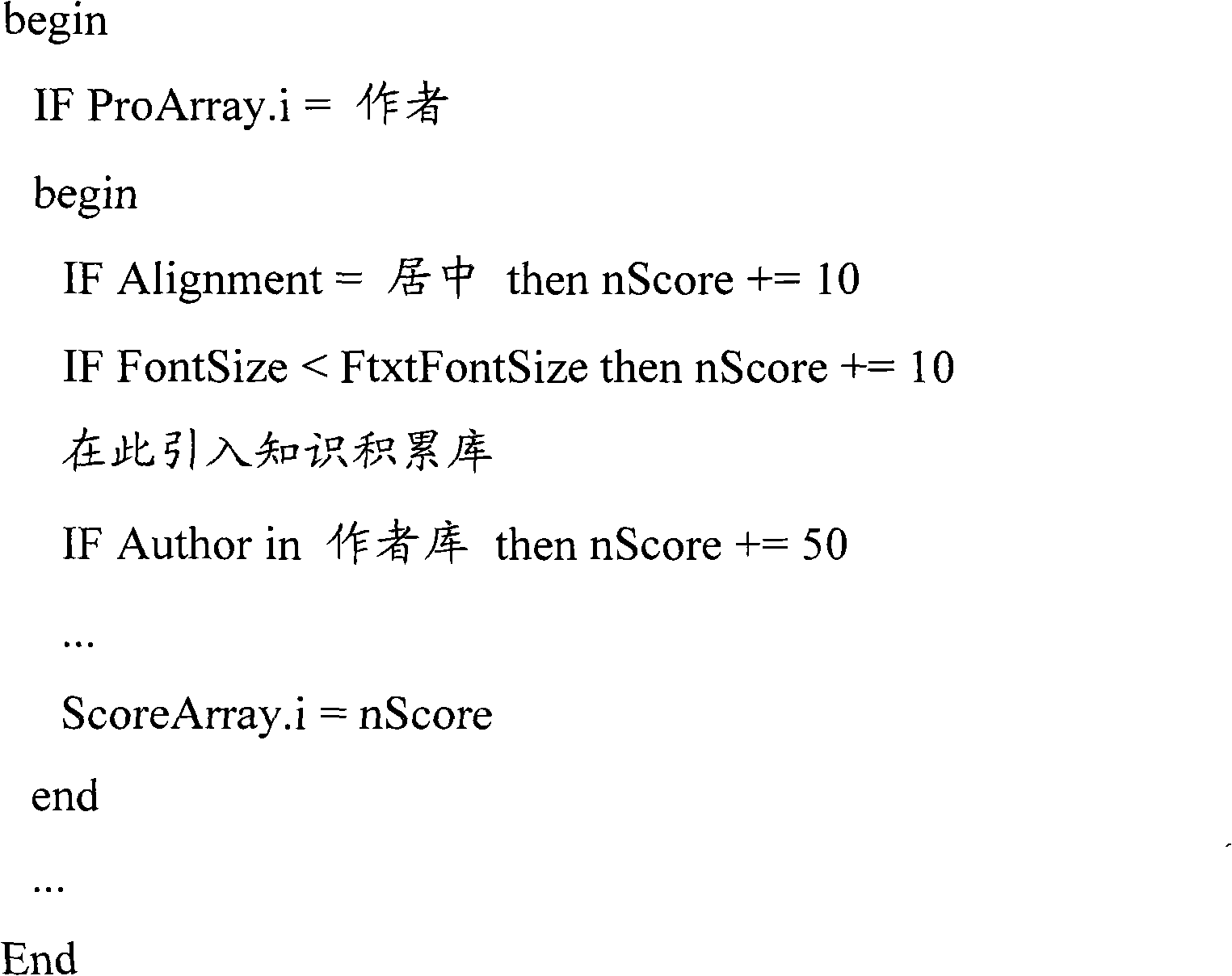

Rapid typesetting system and method

ActiveCN102841888ATypesetting speed is highHigh indexing accuracyNatural language data processingSpecial data processing applicationsAutomatic indexingData mining

The invention discloses a rapid typesetting system and a method. The system comprises: an automatic typesetting module, a check module and a typesetting error correction and management module, wherein the automatic typesetting module is used for indexing a pre-processed document, carrying out a knowledge-based automatic indexing algorithm for the indexed document so as to obtain an indexing result, and processing the indexing result for regulating contents; the check module is used for checking the indexing result and correcting wrong index terms; and the typesetting error correction and management module is used for typesetting according to the indexing result and correcting the wrong typesetting. The rapid typesetting system has the advantages of high typesetting speed, high quality and high indexing correct rate, wherein the correct rate for the main index terms is more than 95%, the correct rate for the secondary index terms is more than 90%, and the overall typesetting cost of an automatic typesetting system based on the automatic indexing algorithm is reduced by 30%.

Owner:《中国学术期刊(光盘版)》电子杂志社有限公司

Constant flow static pressure working table for gear shaping machine or gear milling machine

InactiveCN102029527ALess prone to wearReduce material requirementsLarge fixed membersGear-cutting machinesMechanical engineeringCentral spindle

The invention discloses a constant flow static pressure working table for a gear shaping machine or a gear milling machine. By constant flow static pressure technology, a static pressure cavity is formed on a central spindle, and lubricating oil is fed into the static pressure cavity by a constant pressure oil pump, so that an oil film is formed between the spindle of the working table and a pedestal to keep contact surfaces between the spindle and the pedestal in a constant pressure full-liquid lubricating state; therefore, the center of the working table is positioned well, a wear phenomenon is almost avoided during movement, and the rigidity and the accuracy of the working table are greatly improved and the life of the working table is greatly prolonged; and the pedestal is provided with a dual lead worm, and adjusting pads are arranged in both axial direction and radial direction of the worm, so the working table can work under a smaller backlash condition, and the dividing accuracy of a rotary working table can be improved.

Owner:WUHAN GEWEI MACHINERY

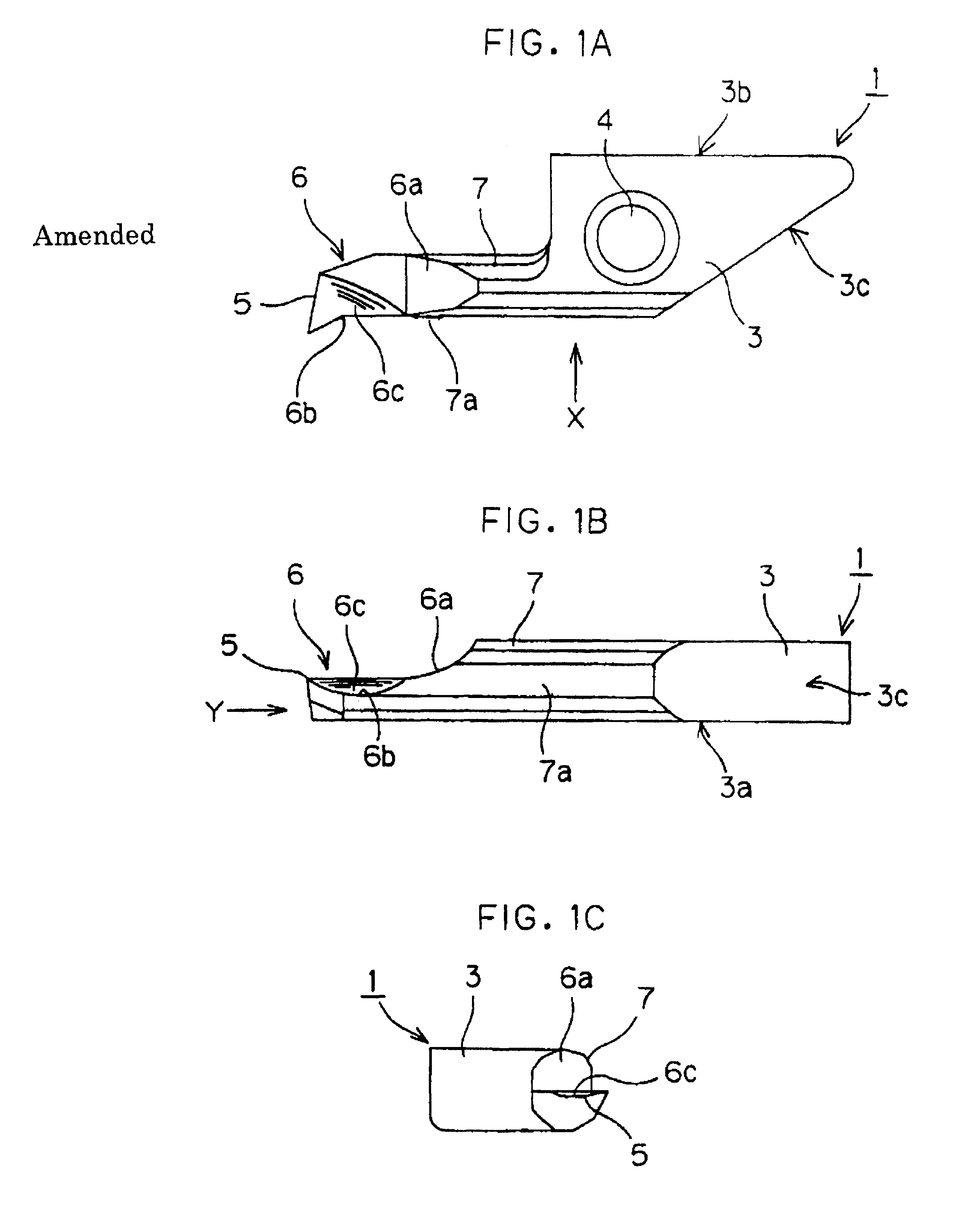

Indexable insert and cutting tool having indexable insert

InactiveUSRE41275E1Improve clamping effectHigh indexing accuracyTurning toolsBoring headsKnife bladesSmall hole

The indexable insert of the present invention has a cutting edge at the end of a stick-shaped portion projecting from a tool base. The base is shaped to ensure effective clamping, thereby avoiding chatter and backlash. A cutting edge and a rake face are provided at the end of the stick-shaped portion, which is also provided with a side relief face so that chips cut from the workpiece are smoothly carried away. The cutting edge extends sideways beyond the side relief face so that the insert can effectively cut the walls of small and deep holes.

Owner:POLY TEC PROD

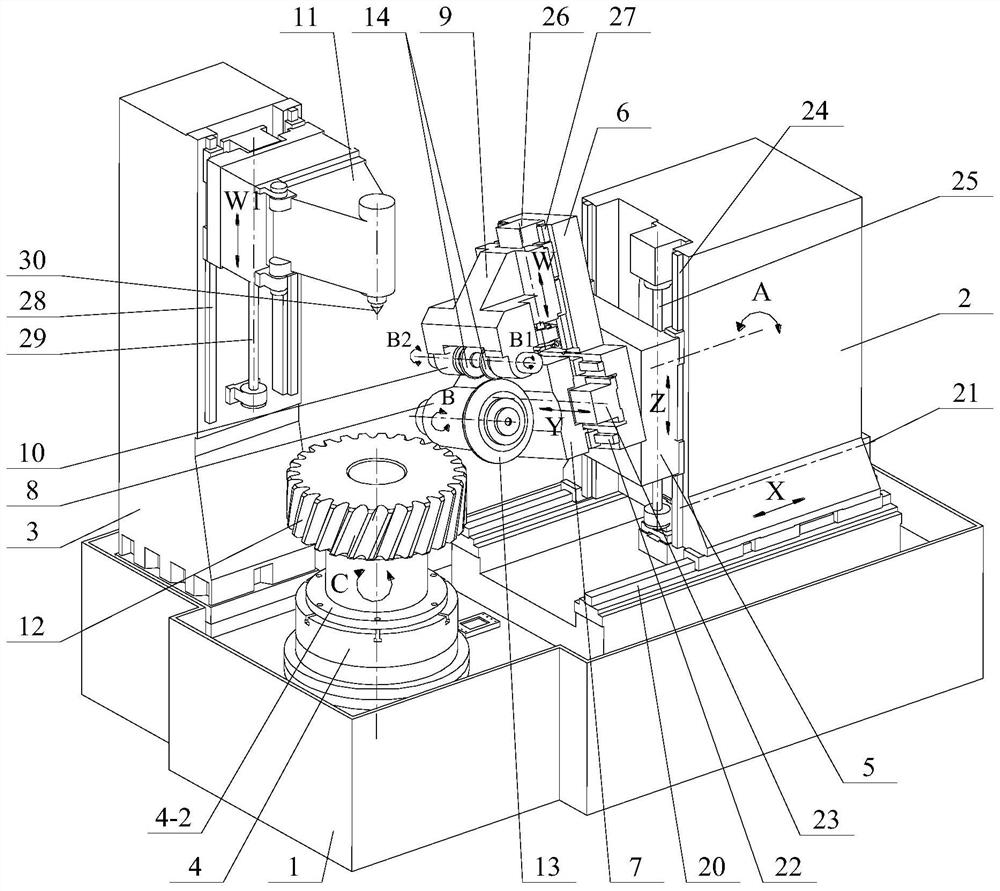

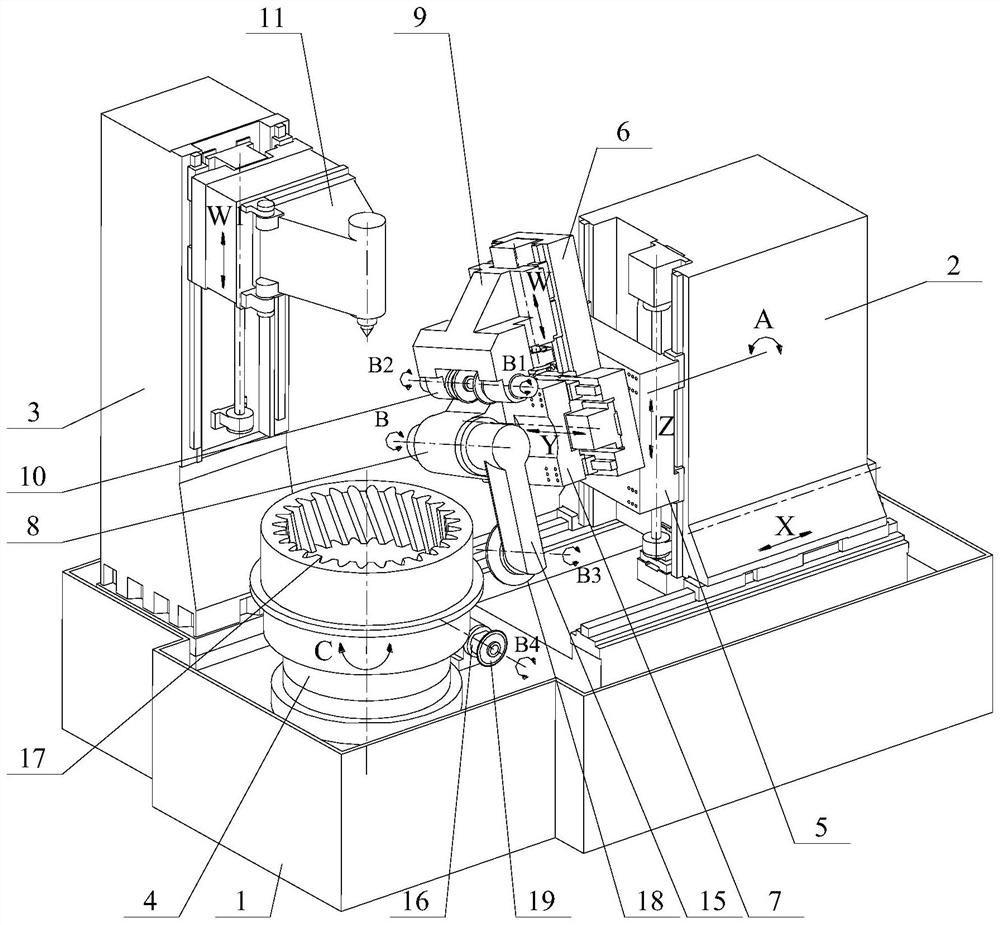

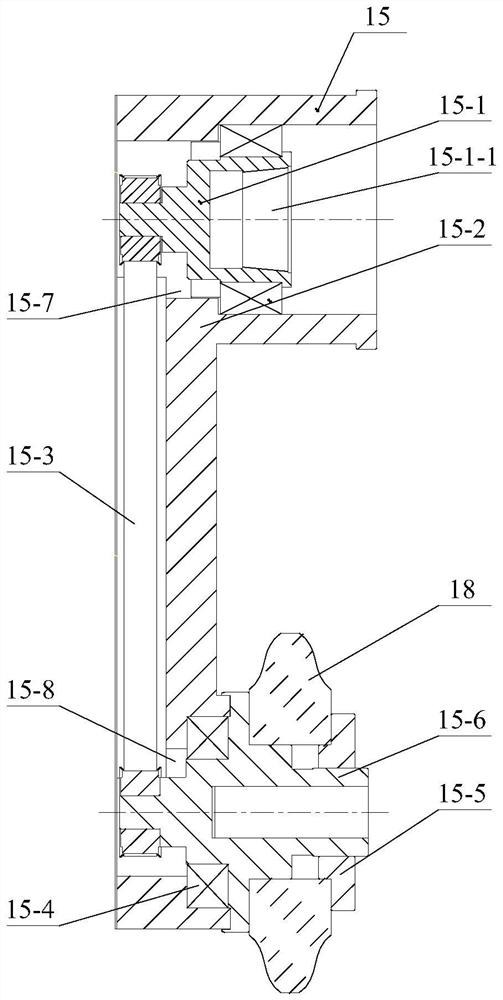

Formed grinding wheel gear grinding machine tool

ActiveCN114226868AReduce wearGood trimming accuracyAbrasive surface conditioning devicesLarge fixed membersGear grindingTeeth grinding

A Z-axis sliding table of the gear grinding machine tool is arranged on a stand column and can move along the Z axis relative to the stand column, an A-axis rotary table of the gear grinding machine tool is arranged on the Z-axis sliding table and can rotate around the A axis relative to the Z-axis sliding table, and a Y-axis sliding table of the gear grinding machine tool is arranged on the A-axis rotary table and can move along the Y axis relative to the A-axis rotary table. A W-axis sliding table is arranged on an A-axis rotary table and can move along a W axis relative to the A-axis rotary table; the grinding wheel spindle box is arranged on the Y-axis sliding table, and an outer tooth grinding wheel is detachably arranged on the grinding wheel spindle box. An outer tooth dressing spindle box is arranged on the W-axis sliding table, and an outer tooth dressing grinding wheel is arranged at the power output end of the outer tooth dressing spindle box; the Z axis is the grinding feeding direction, the X axis is the grinding feeding and retracting direction, the Y axis is the displacement direction of the grinding wheel spindle box along the axis of the grinding wheel spindle box, and the W axis is the direction in which the external tooth dressing grinding wheel is close to or far away from the external tooth grinding wheel in the radial direction of the external tooth grinding wheel. By applying the scheme, the machining precision and the grinding efficiency can be effectively improved.

Owner:HUNAN ZDCY (ZHONGDA CHUANG YUAN) CNC EQUIP CO LTD

Automatic right-angle milling head device

PendingCN110202203ARealize chip movementSimple structureLarge fixed membersMilling equipment detailsAutomatic indexingEngineering

The invention provides an automatic right-angle milling head device. The device comprises a transmission mechanism, an automatic broaching mechanism, an automatic indexing orientation mechanism and amulti-channel rotary pipeline mechanism. The device has the advantages of being simple in structure, reasonable in distribution, high in indexing precision, high in rotating speed and easy and convenient to maintain.

Owner:ZHEJIANG RIFA PRECISION MACHINERY

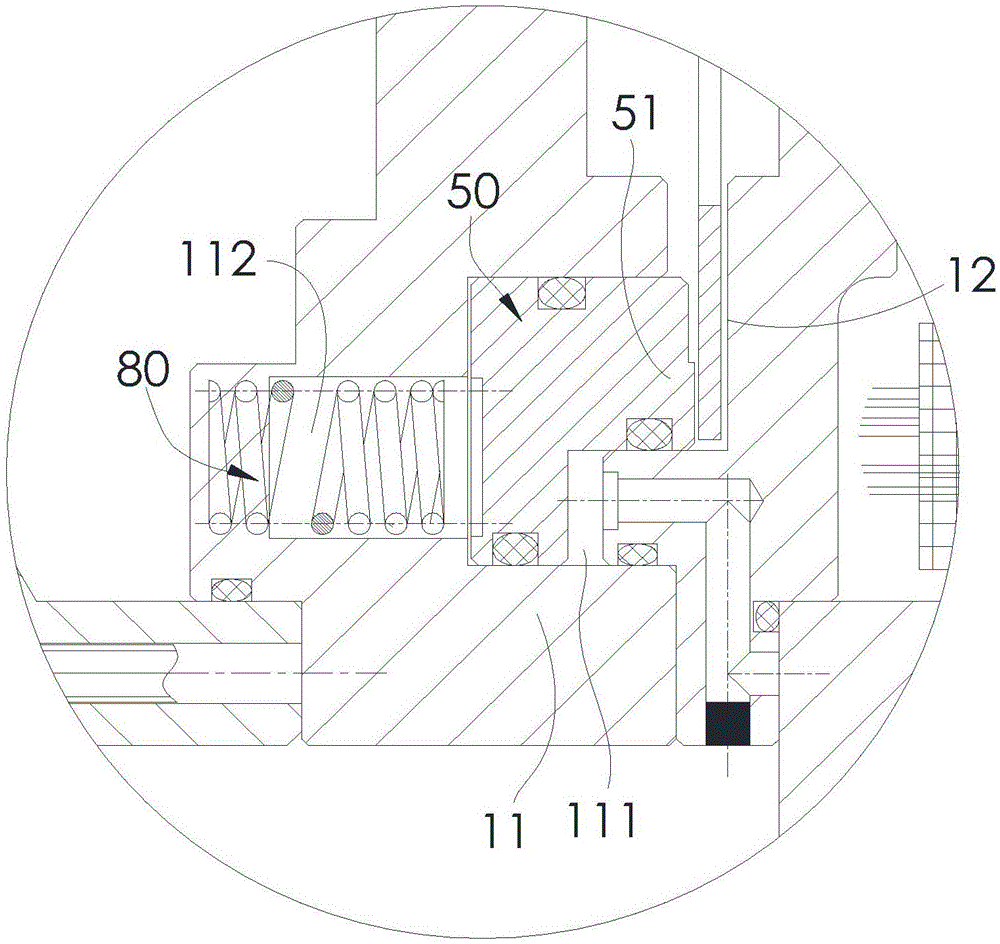

Rotor slot grinding fixture

ActiveCN106965088AReduce labor intensityHigh indexing accuracyGrinding machinesGrinding work supportsSet screwNumerical control

The invention provides a rotor slot grinding fixture which comprises a base; the base is fixedly provided with a sliding plate through tapered iron, a nut and a set screw, and the sliding plate is provided with a hydraulic clamping mechanism, a hydraulic positioning mechanism and a numerical control index plate; the hydraulic clamping mechanism comprises a clamping oil cylinder arranged in a sliding plate inner hole, the clamping oil cylinder is internally provided with a clamping piston, a clamping piston hole is internally provided with a pull rod through an angular contact ball bearing, the pull rod is provided with a lower fixture body through a lining, and the lower fixture body is fixedly connected with an upper fixture body through a screw; and the upper fixture body is arranged on the pull rod in a sleeved manner, a hole of the numerical control index plate is arranged on the clamping oil cylinder in a sleeved manner and fixed to the upper surface of the sliding plate, and the lower fixture body is fixed to the numerical control index plate. Indexing of the numerical control index plate is combined with hydraulic positioning and hydraulic clamping, so that the indexing precision, positioning precision and machining precision are greatly improved, production efficiency is improved, and labor intensity of workers is lowered.

Owner:荣成恒鑫动力科技股份有限公司

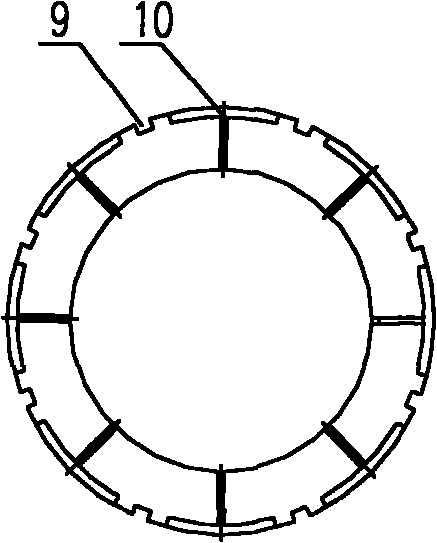

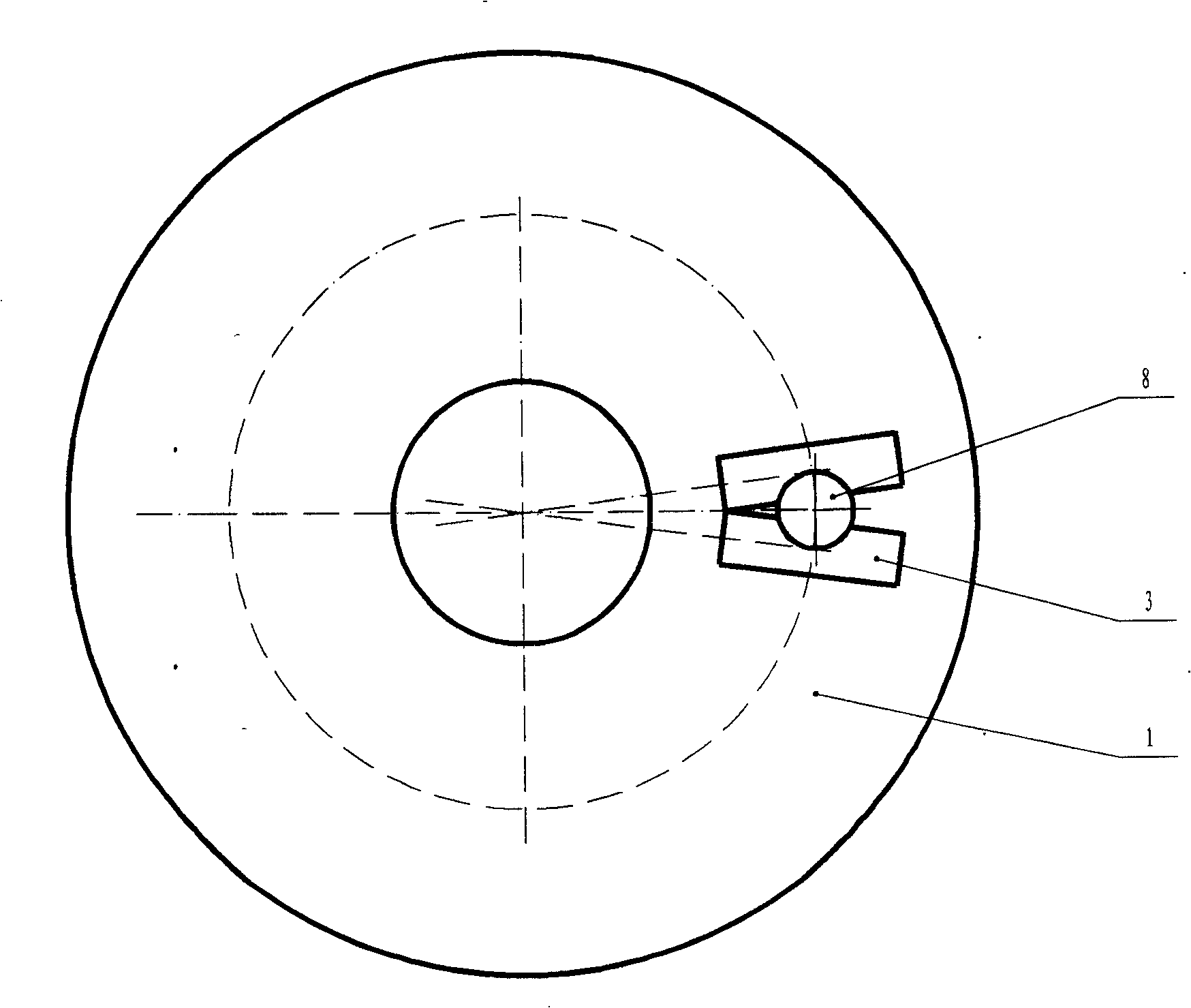

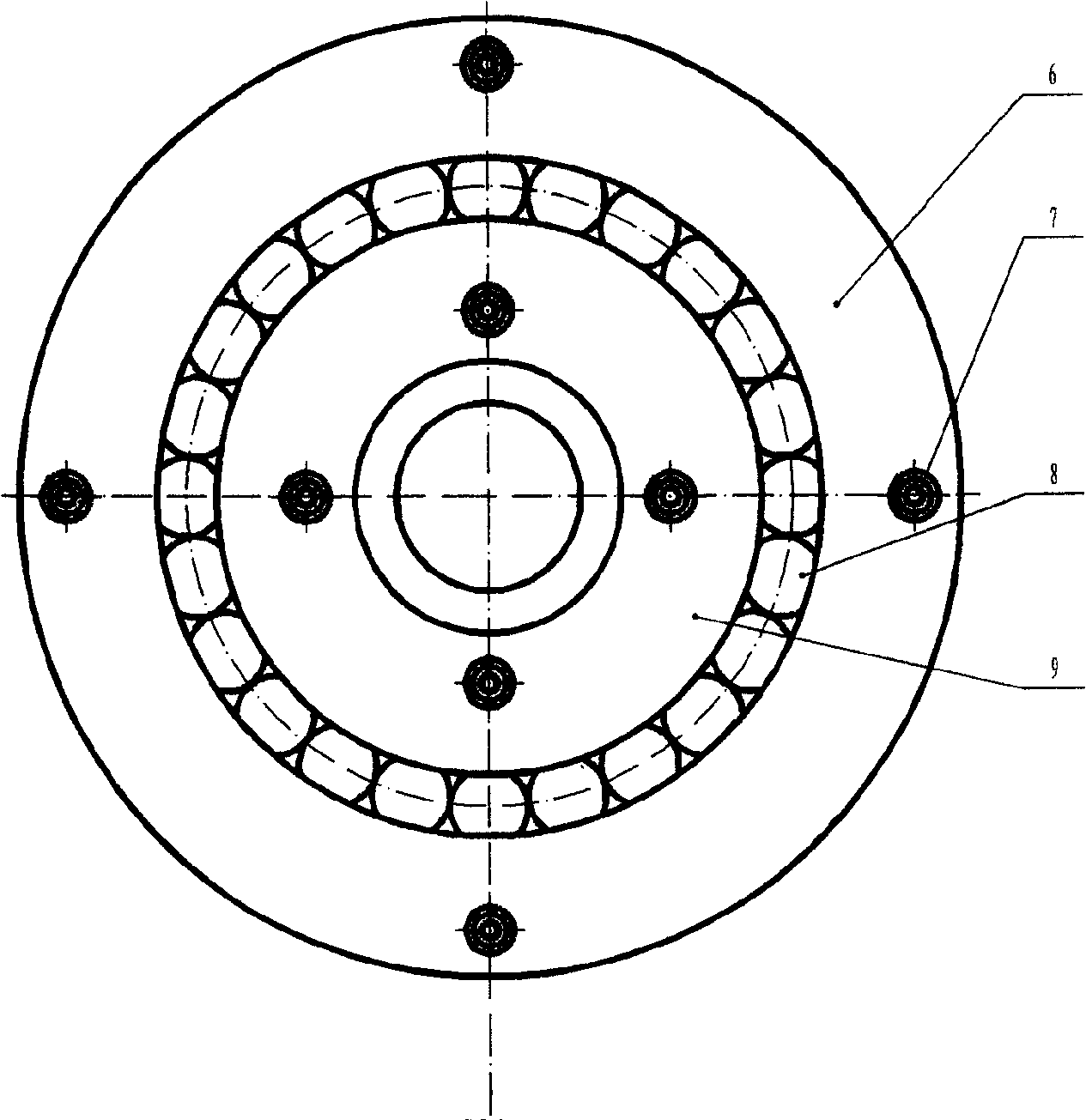

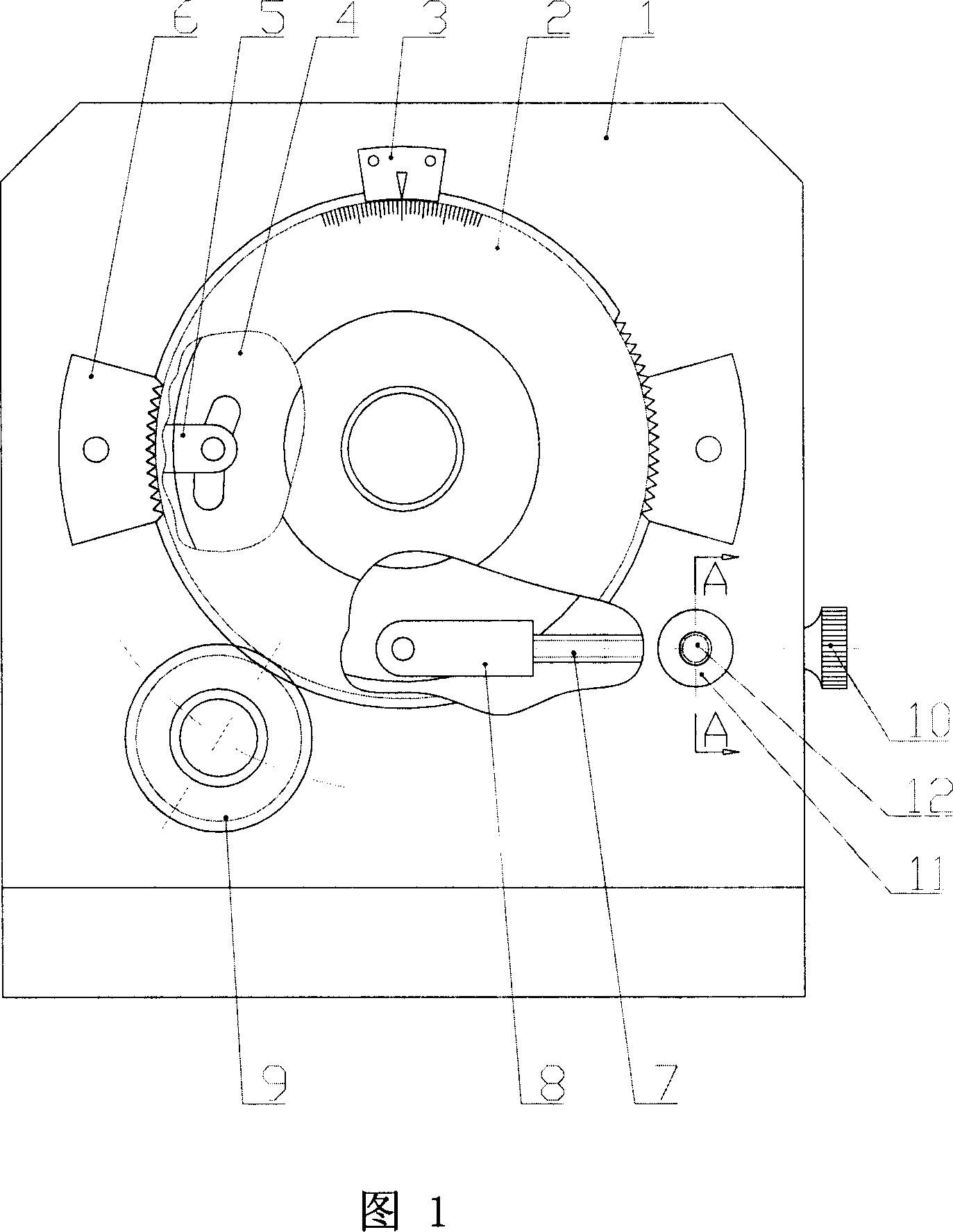

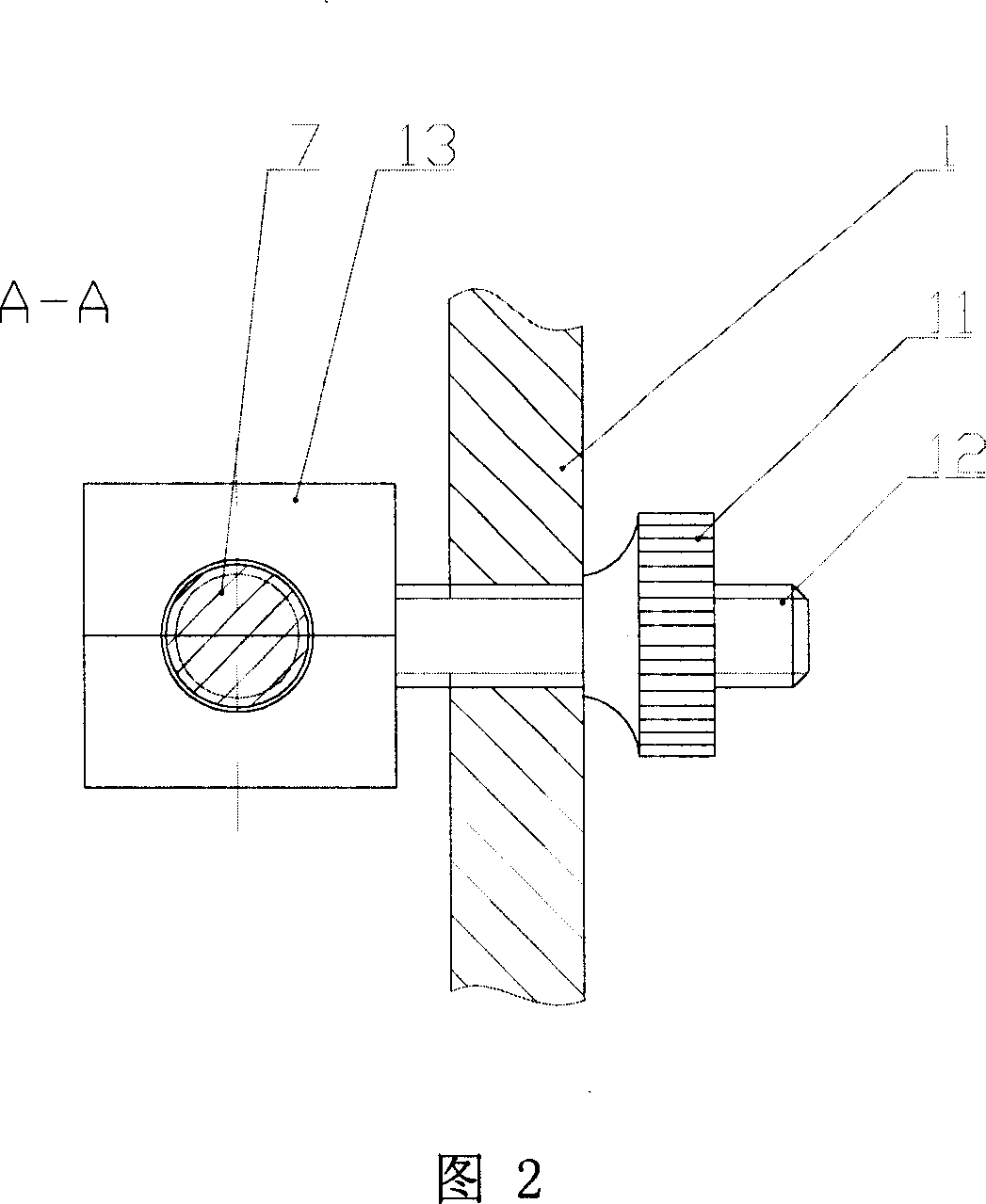

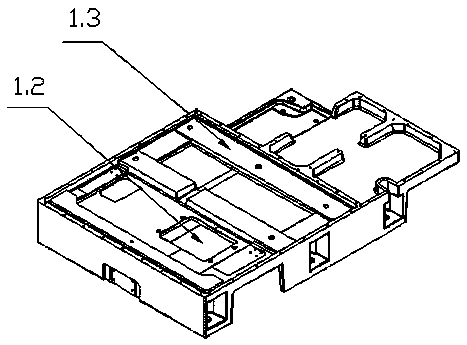

Steel ball roller indexing apparatus

InactiveCN101337331AHigh indexing accuracyWith self-centeringPrecision positioning equipmentMetallurgySteel ball

A self-centering steel ball and roller dividing device relates to a precision circular dividing and positioning device which is widely applied in various industrial fields. The dividing device adopts the technical proposal that in a pair of steel ball and roller dividing discs, a circle of steel balls of the same diameter are annularly distributed on an upper disc, a circle of rollers of the same diameter are annularly distributed and radially arranged on a lower disc, and one steel ball of the upper disc is in simultaneous contact with two rollers of the lower disc. Therefore, the steel ball and roller dividing disc can realize an equal division number or an integral multiple thereof which is determined by the number of steel balls in a circle. The dividing device has the characteristics of automatic centering and alignment. Therefore, the dividing device not only maintains the advantages of the known steel ball dividing disc, but also effectively reduces the requirement of the manufacture precision; furthermore, the dividing device has a self-centering function, and has the advantages of easy serialized and standardized design and manufacture, convenient installation and use, etc.

Owner:CHONGQING UNIV

Rigidity locating indexing disc

InactiveCN101032800AIncrease the number ofHigh indexing accuracyPrecision positioning equipmentLocking mechanismEngineering

The rigid locating index disc includes one indexing toothed disc, one eccentric locking disc, inner toothed parts and one bent plate. The rotating indexing toothed disc mounted on the bent plate and at least two inner toothed parts distributed around the indexing toothed disc are meshed via triangular teeth. The eccentric locking disc is connected coaxially with the indexing toothed disc, and has eccentric arced holes, to each of which one of the inner toothed parts is slip connected through one locking block. The present invention has the advantages of capacity of meshing the inner toothed parts to and separating them from the indexing toothed disc by means of the locking mechanism, capacity of regulating the angle of the indexing toothed disc in high precision, high meshing strength between the indexing toothed disc and the inner toothed parts and raised rigidity.

Owner:BEIJING LANXINTE TECH CO LTD

Bolt-type dividing device

ActiveCN105171523AHigh indexing accuracyIncrease productivityPrecision positioning equipmentEngineering

Owner:CHINA HANGFA GUIZHOU LIYANG AVIATION POWER CO LTD

Indexing mechanism

InactiveCN104354071AThe indexing operation process is clearThe indexing operation process is simplePrecision positioning equipmentGear-cutting machinesEngineeringSteel ball

The invention discloses an indexing mechanism. A guide sleeve is arranged on a vertical plate; the back part of a rotating shaft is supported in the guide sleeve through two bearings ; an indexing disc is fixedly arranged on the front part of the rotating shaft in a sleeving manner; three-jaw chuck mounting holes are uniformly distributed in the indexing disc along the circumferential direction; the outer circle surface of the indexing disc is provided with four indexing pits along the circumferential direction; a central angle between the first indexing pit and the second indexing pit is 45 degrees; a central angle between the first indexing pit and the third indexing pit and a central angle between the third indexing pit and the fourth indexing pit are 135 degrees; the back end of a connecting plate is perpendicularly fixed with the right end face of the vertical plate; a bolt spring locking pin with threads is arranged in a mounting hole in the front end part of the connecting plate; a steel ball of the bolt spring locking pin with the threads can be clamped in the indexing pits in the indexing disc. According to the indexing mechanism, a rotation angle can be known when the steel ball of the bolt spring locking pin with the threads is clamped in two different indexing pits successively, the rotation angle is an indexing angle of a workpiece, the whole indexing process is clear, simple and convenient, errors occur difficultly, and the indexing efficiency and accuracy are high.

Owner:CHONGQING LANDAI POWER TRANSMISSION MACHINERY

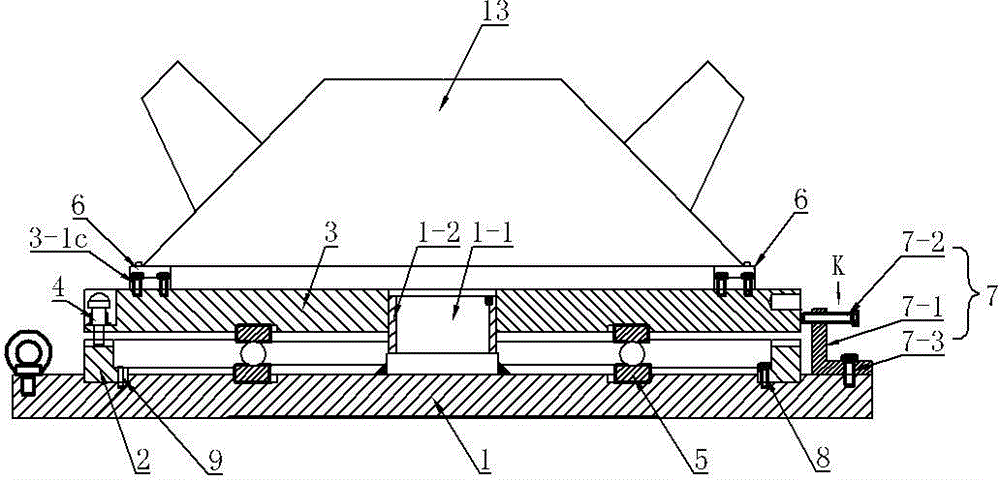

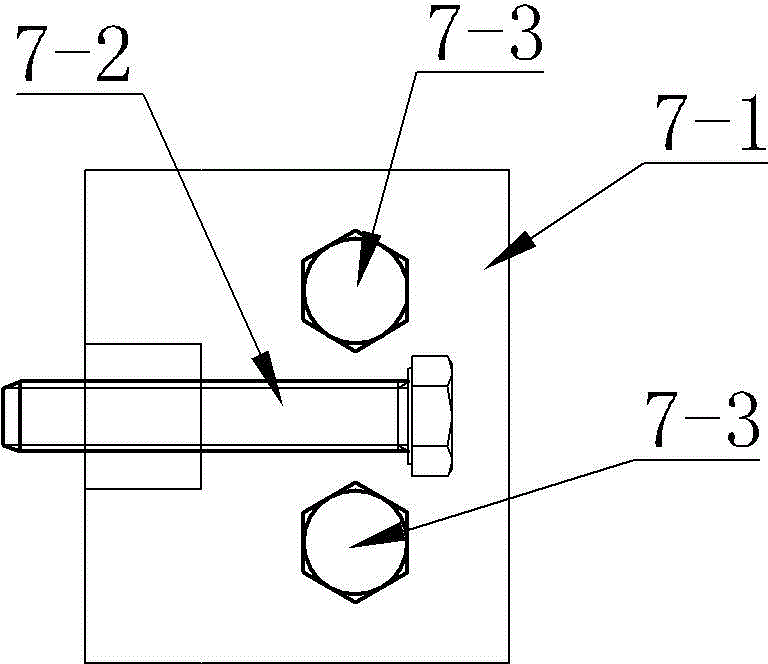

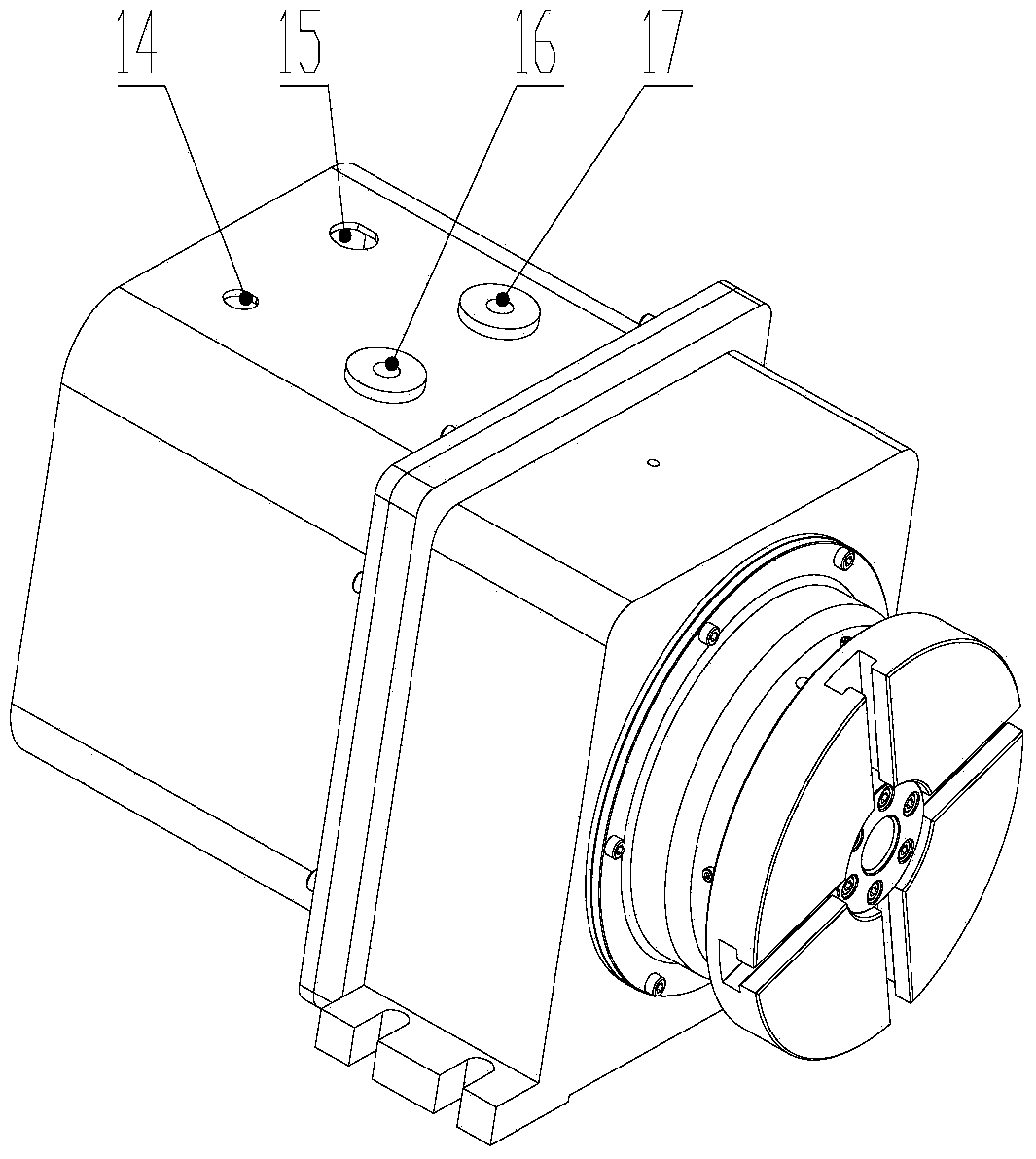

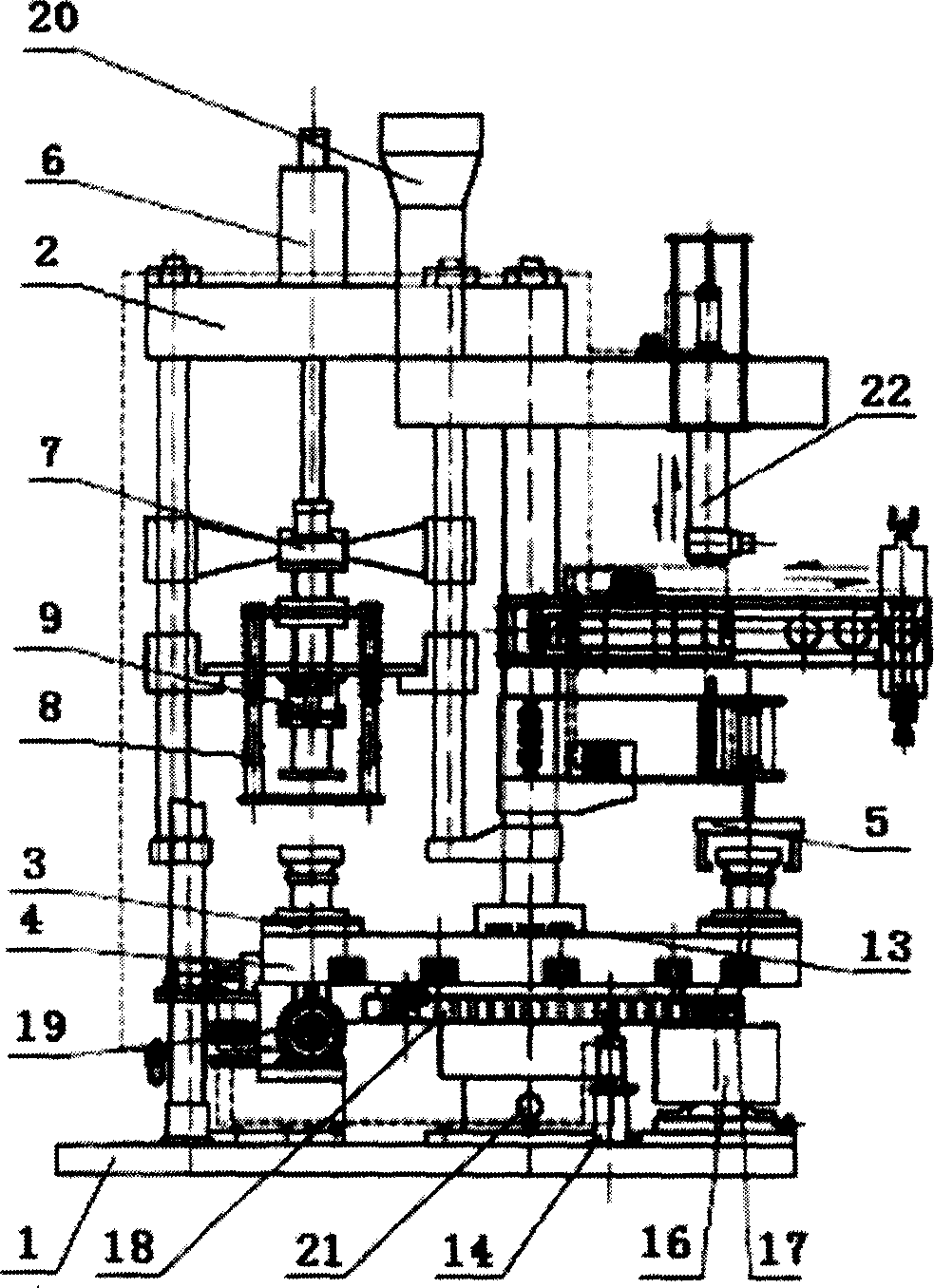

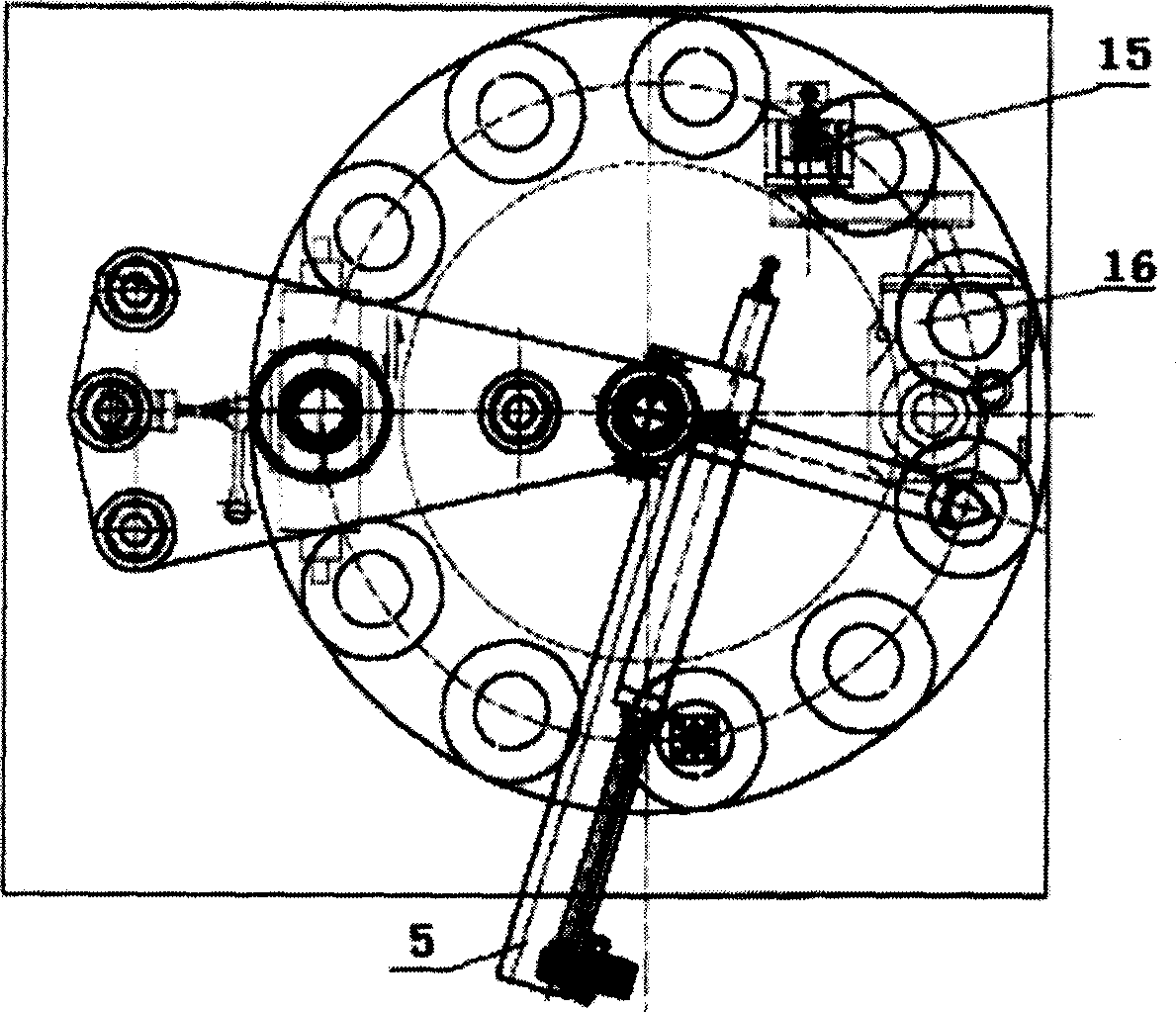

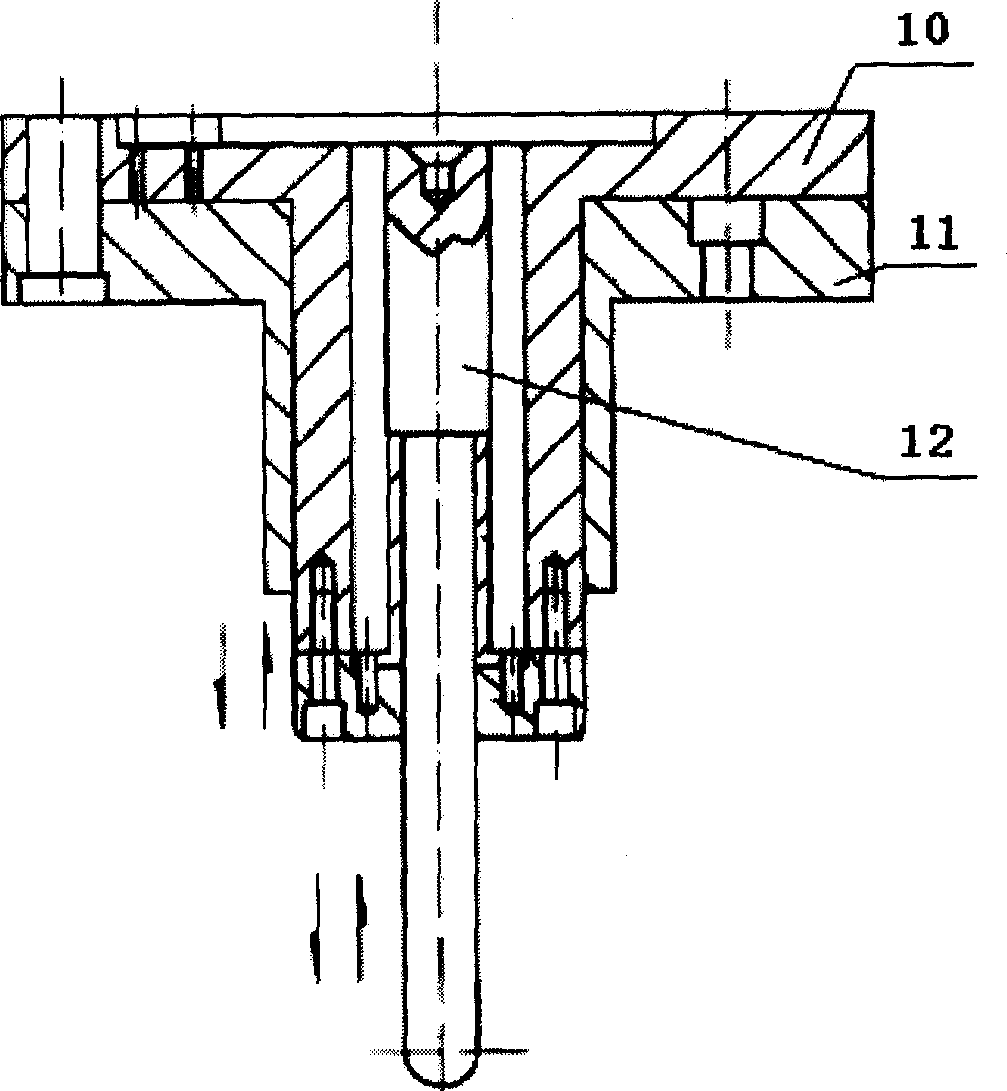

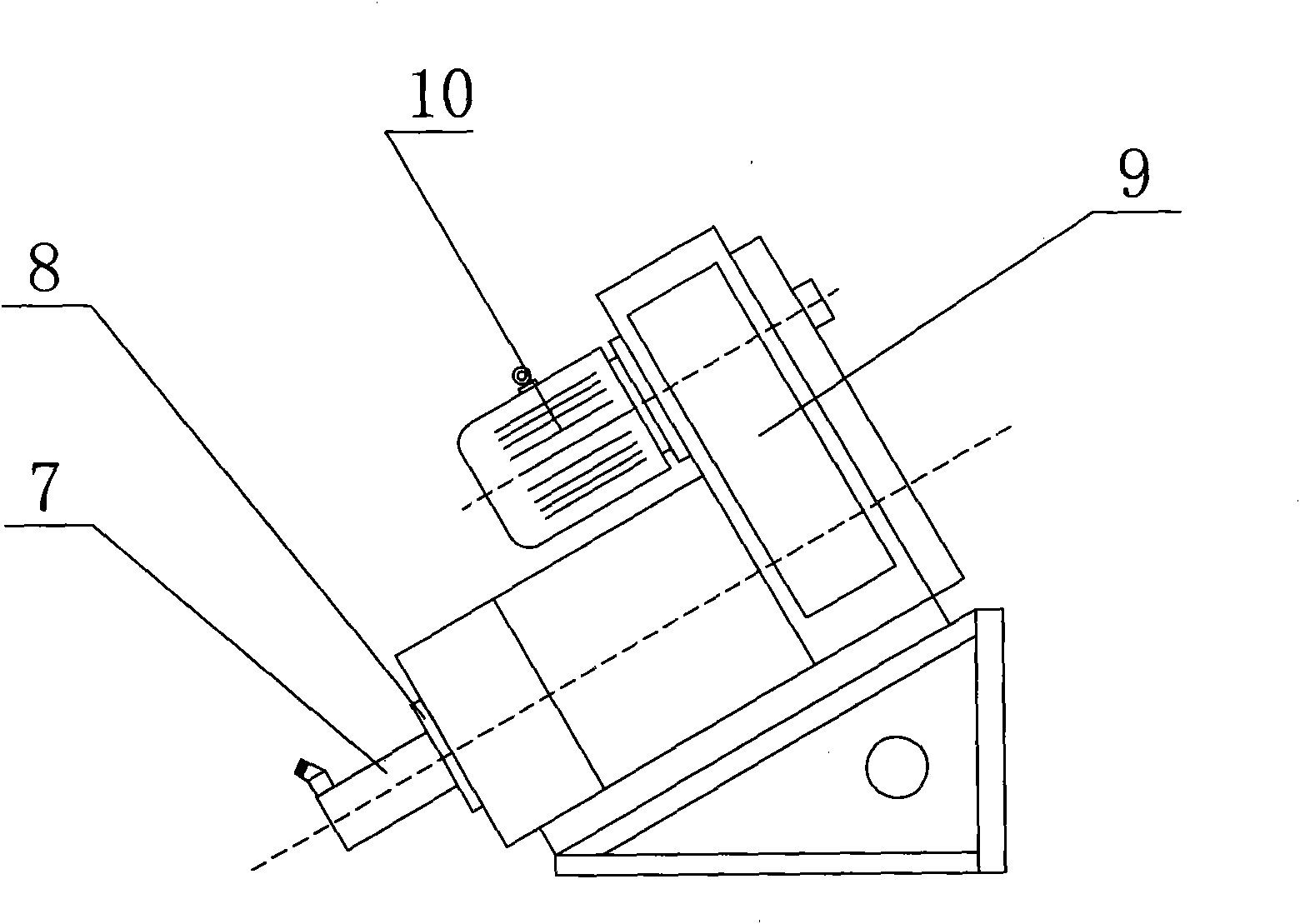

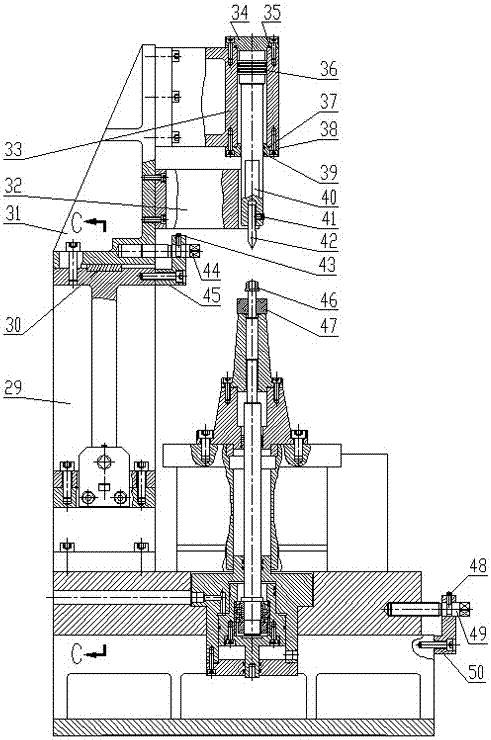

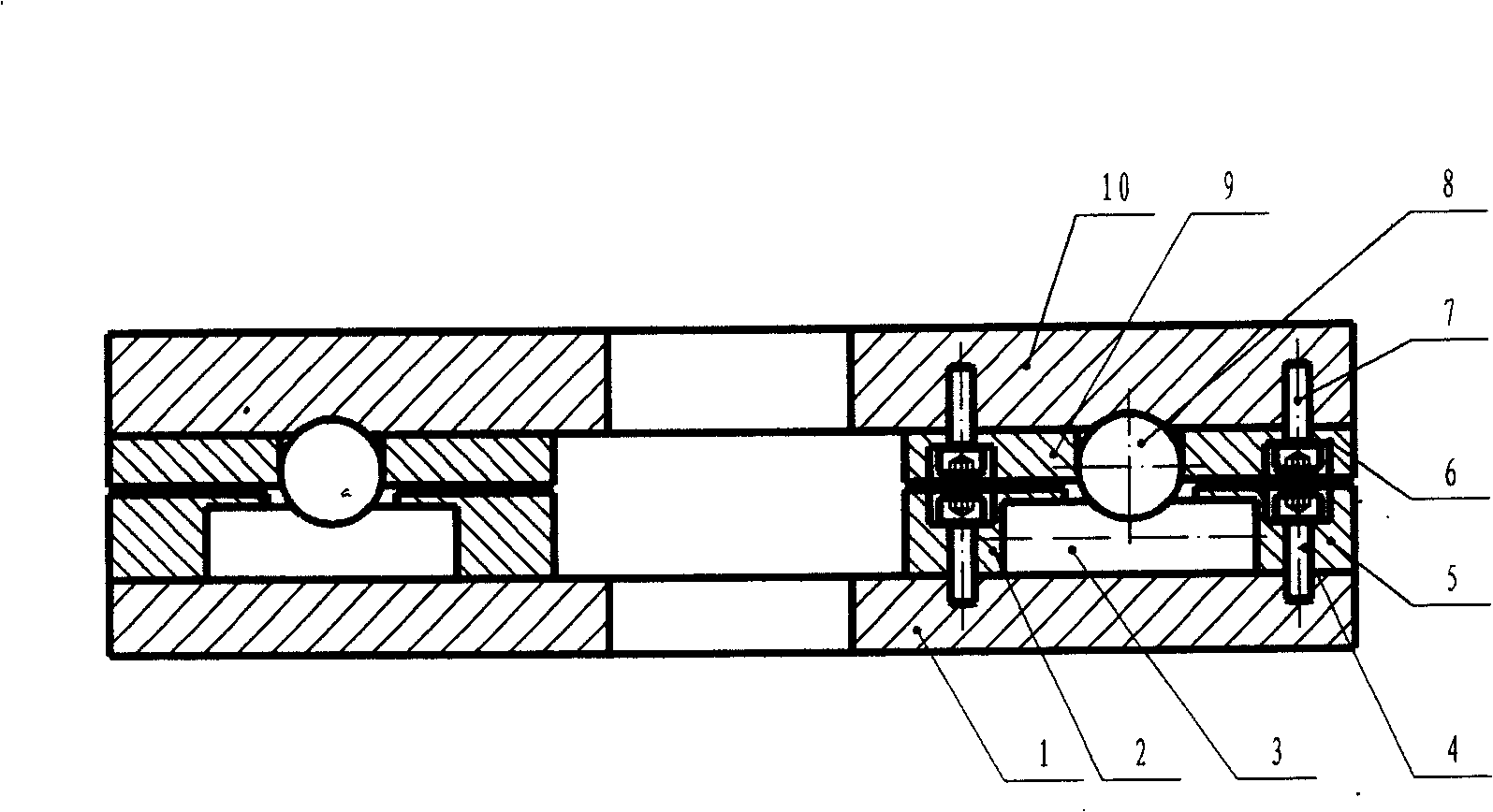

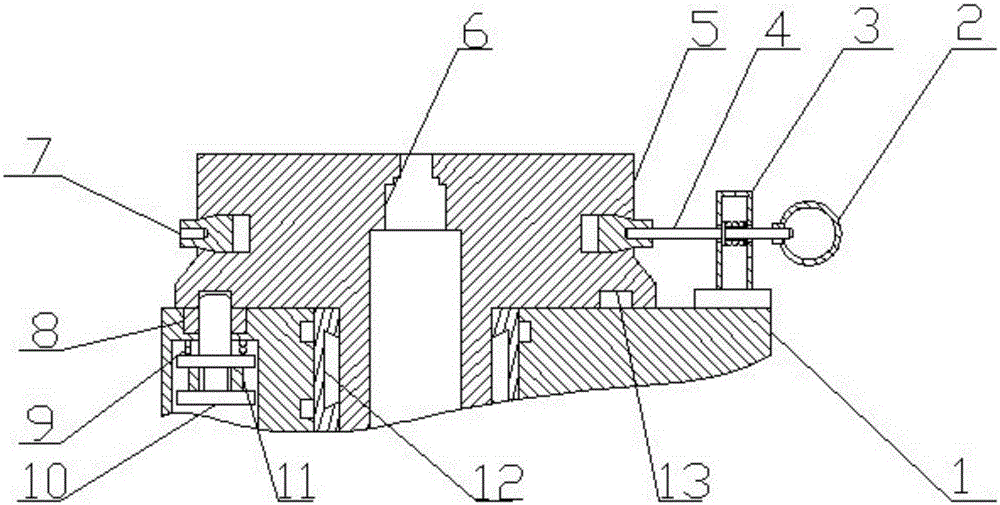

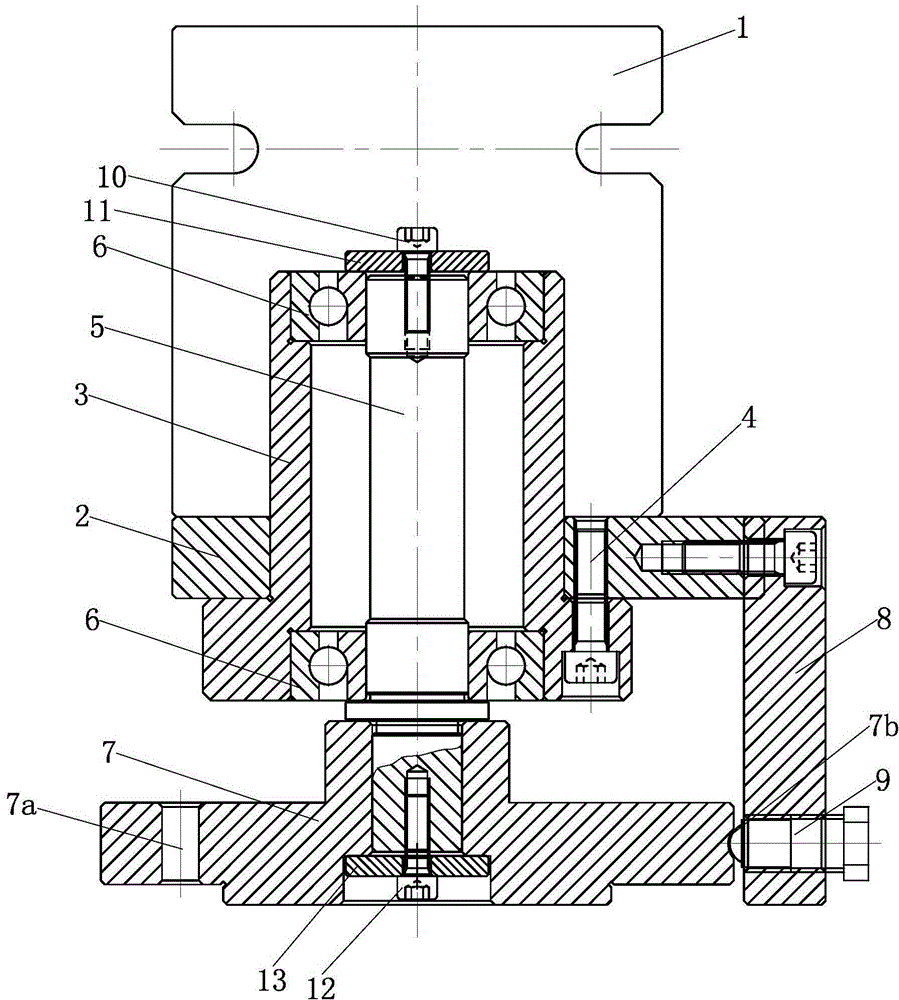

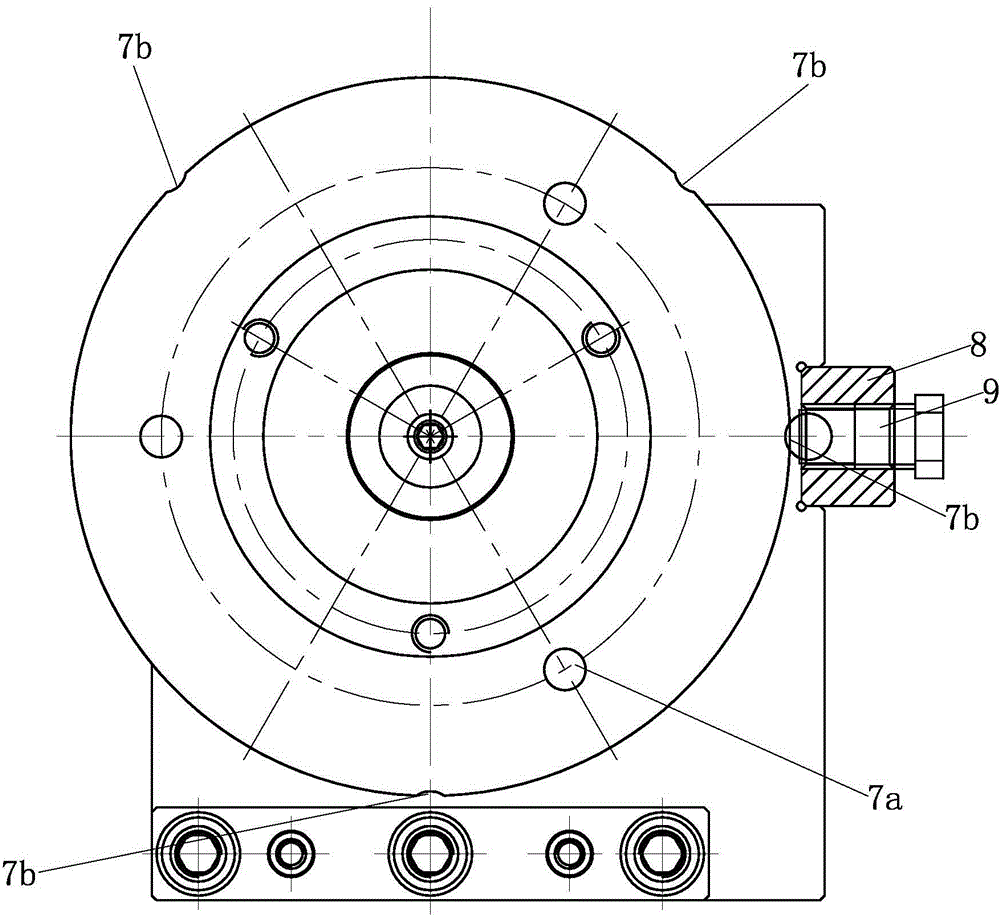

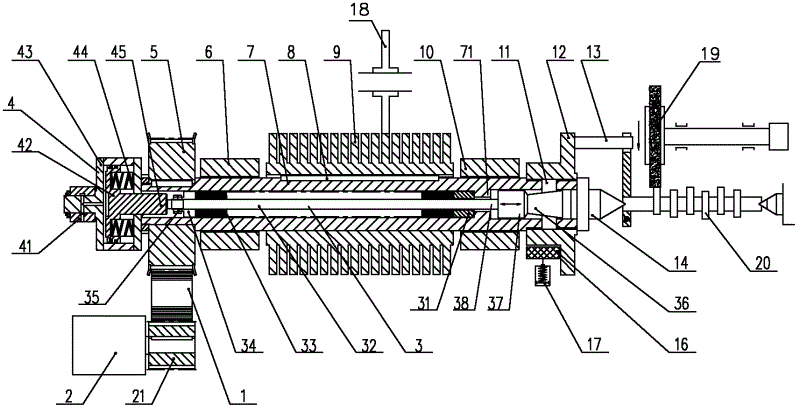

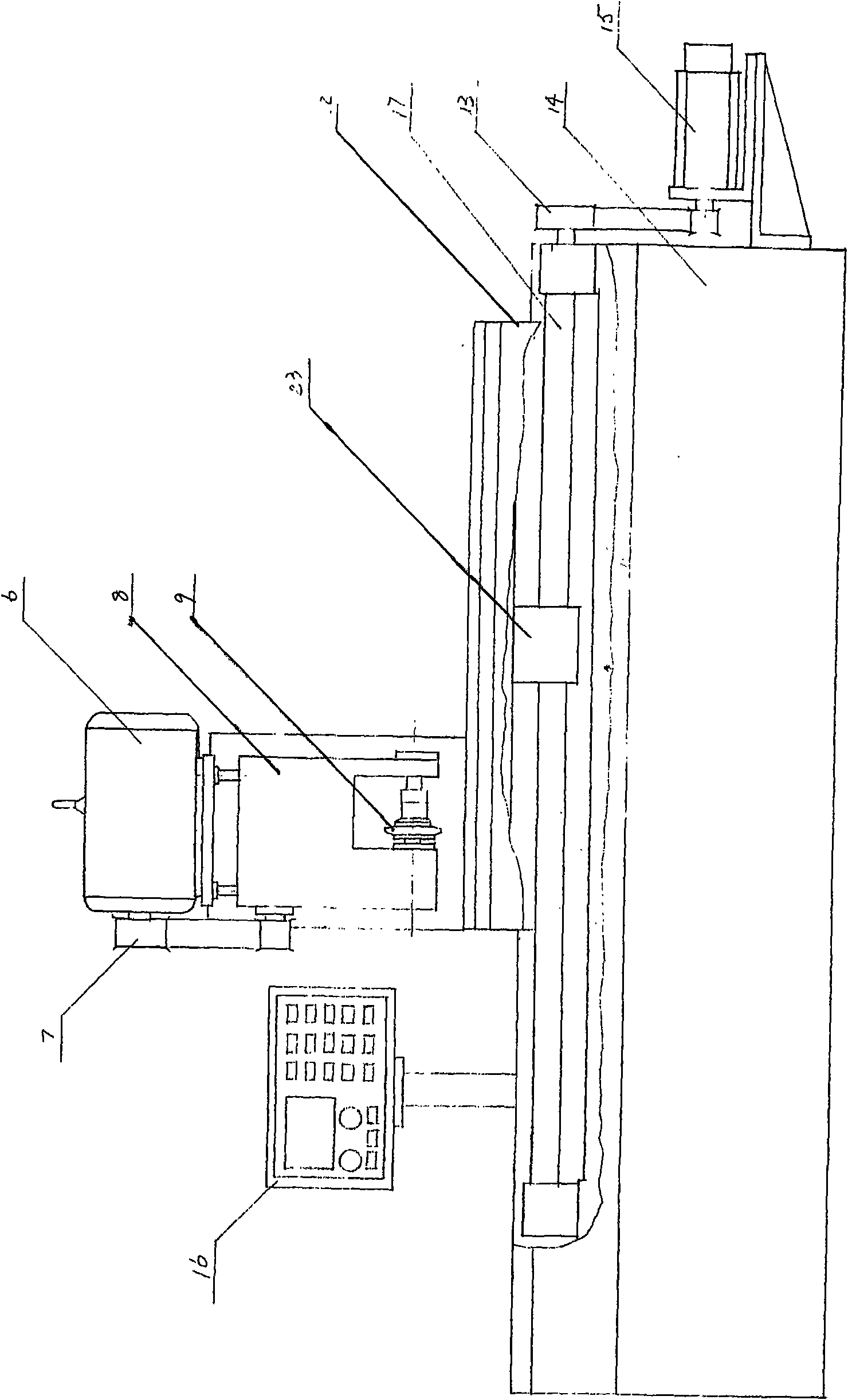

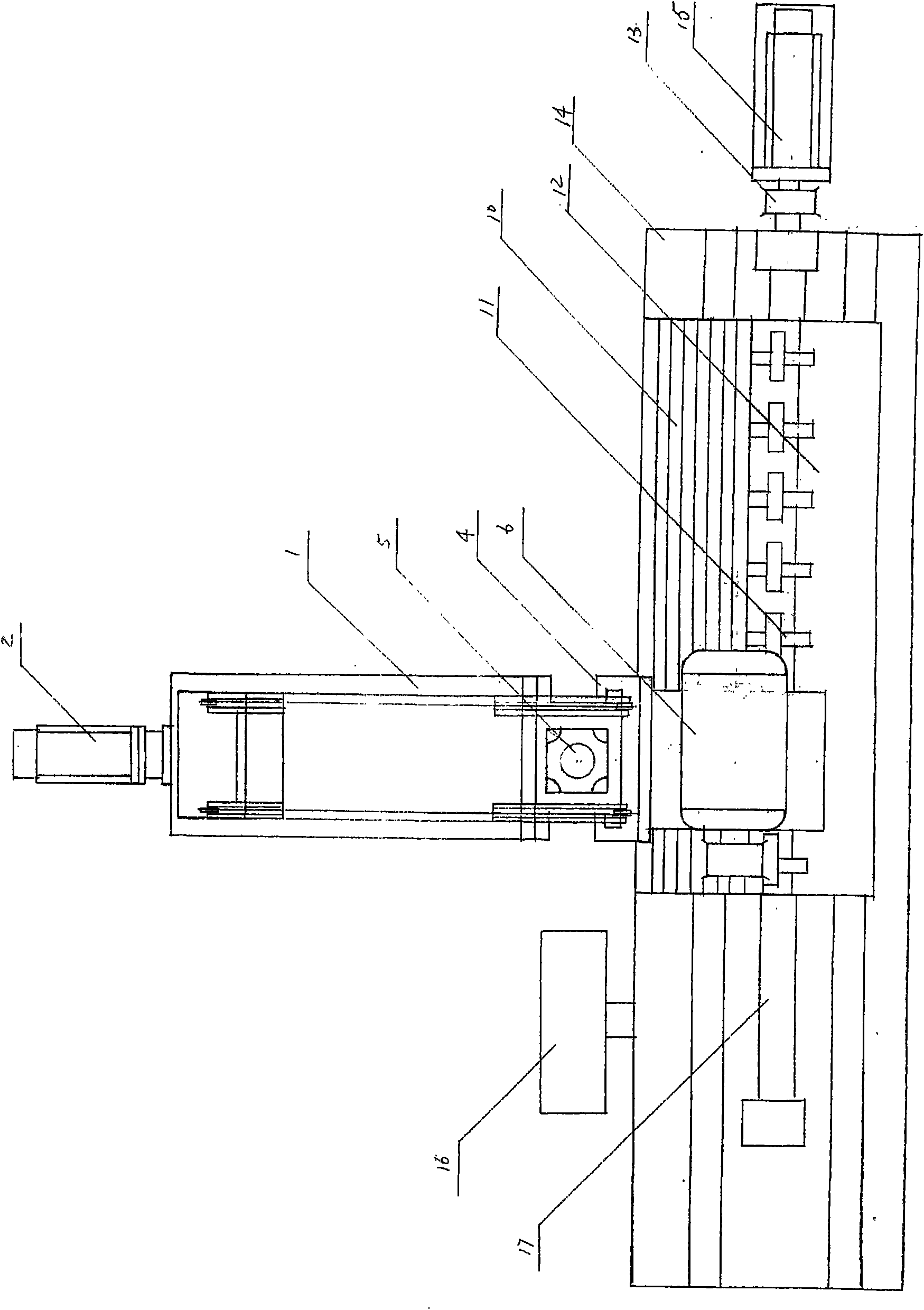

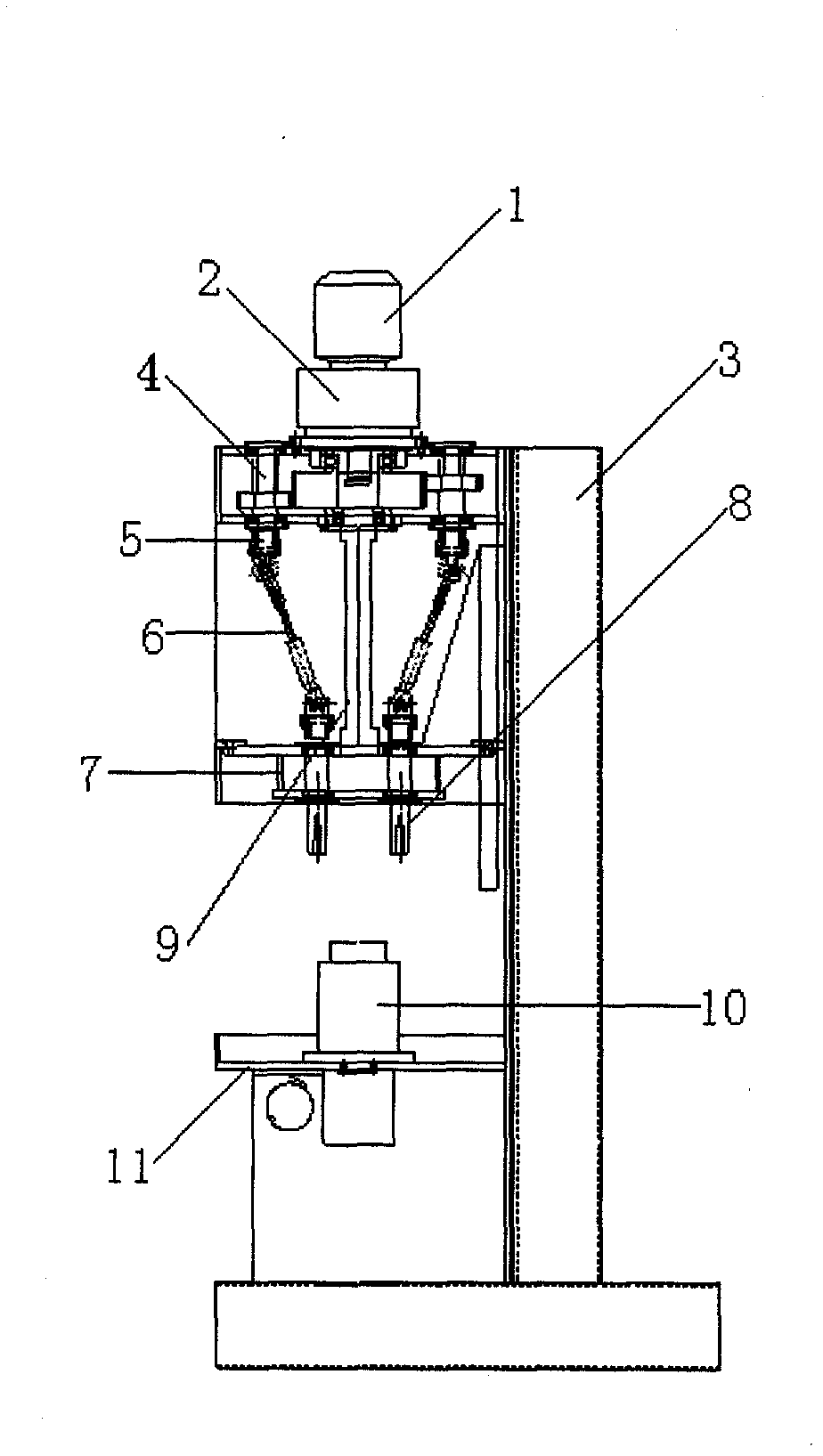

Stepless dividing device and camshaft grinder comprising same

The invention provides a stepless dividing device and a camshaft grinder comprising the same. The stepless dividing device comprises a servo motor (2), a hollow spindle (7) arranged between two bearing seats (6 and 10), a cam sample plate (9) fixedly connected onto the hollow spindle (7) and a dividing driving plate (12) movably sleeved on the head portion of the hollow spindle (7). The stepless dividing device is characterized in that a pulling tight set device for driving the hollow spindle (7) to be connected or disconnected with the dividing driving plate (12) is arranged in an inner hole of the hollow spindle (7), a pipe bending cylinder (4) for pushing the pulling tight set device (3) is sleeved on the tail portion of the hollow spindle (7), and a disc braking device for locking the dividing driving plate (12) is further arranged outside the dividing driving plate (12). The dividing driving plate (12) has the advantages of being simple in structure, easy to manufacture, capable of dividing at any angle, fast in dividing and high in accuracy.

Owner:黄俊豪 +1

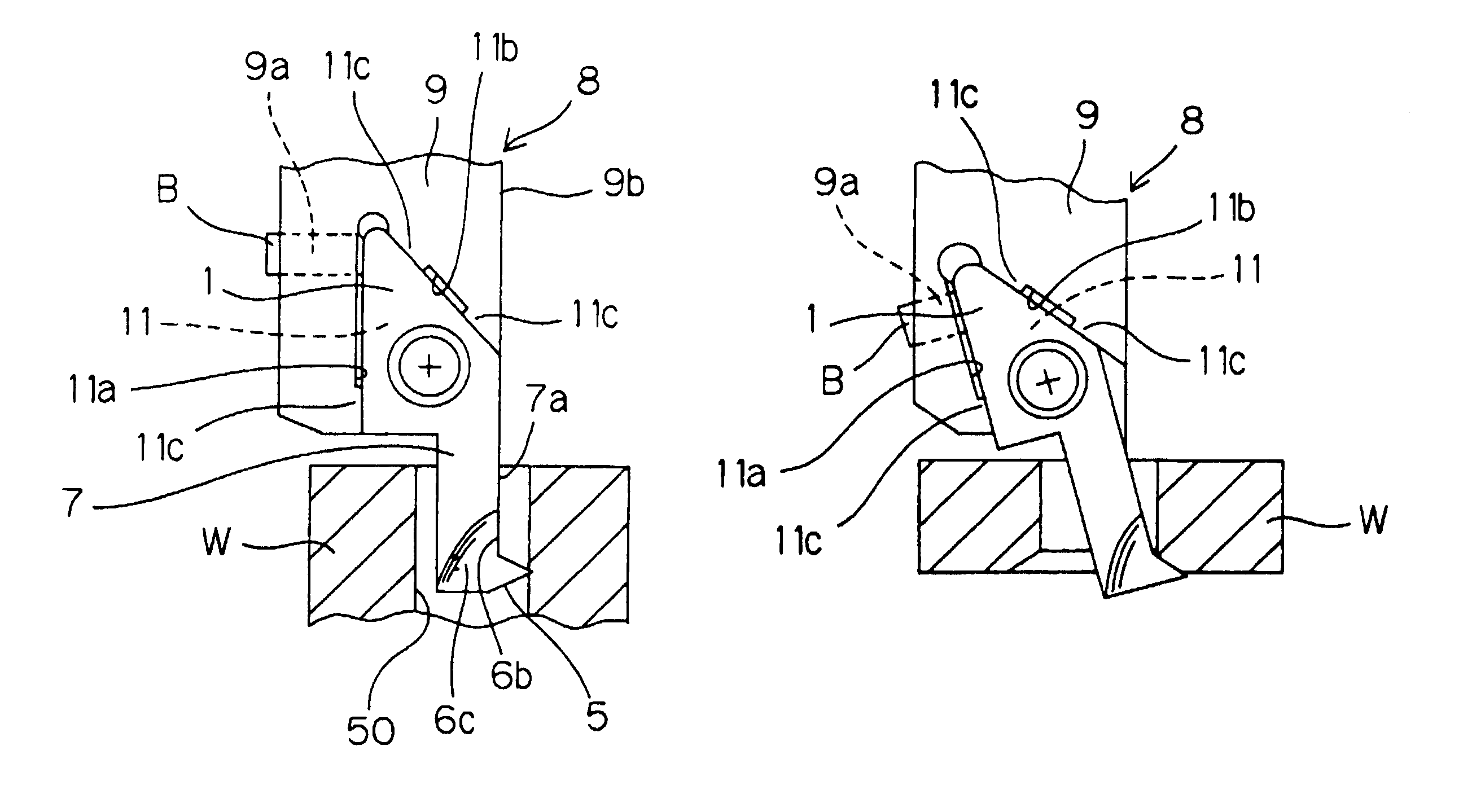

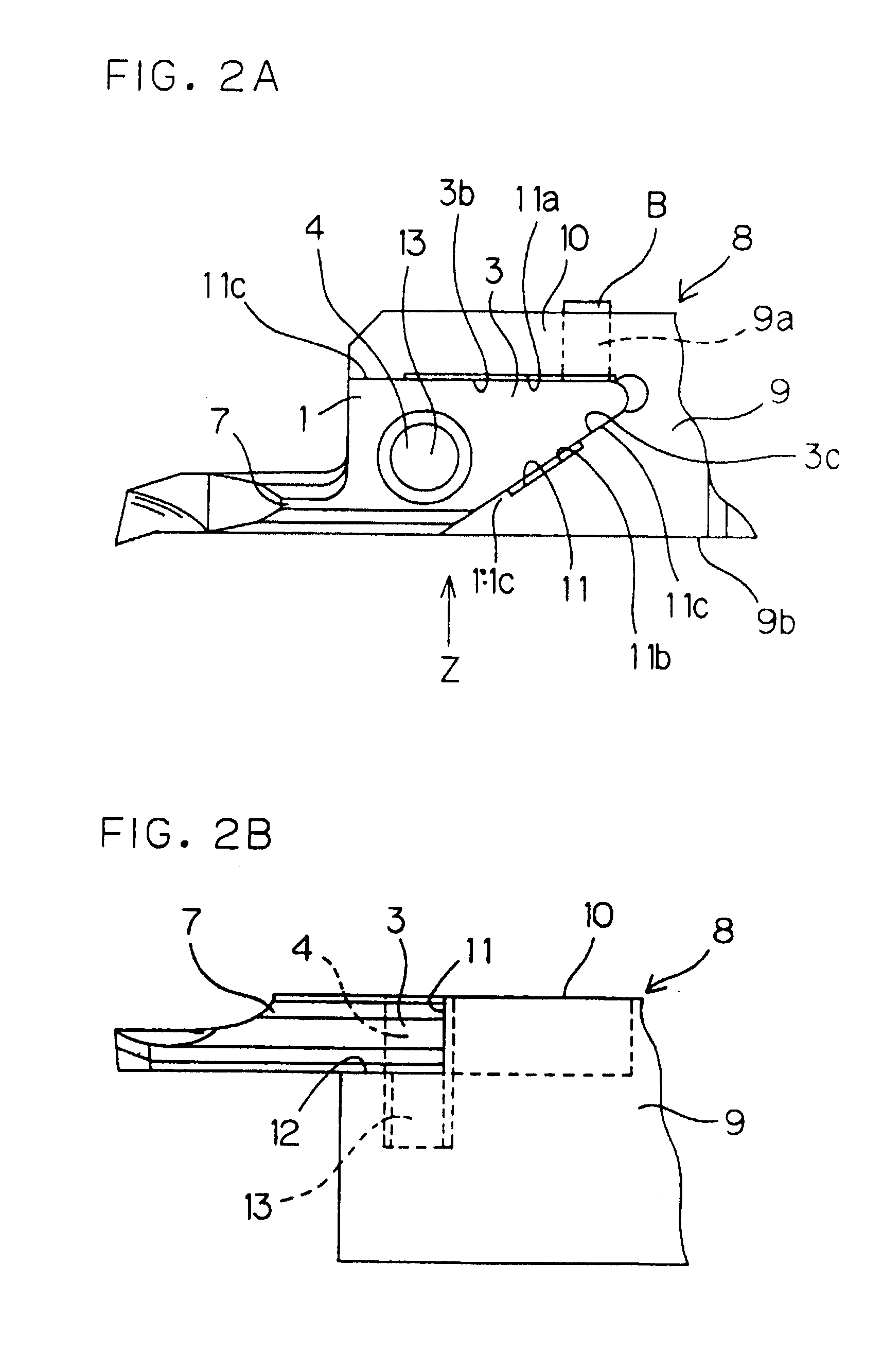

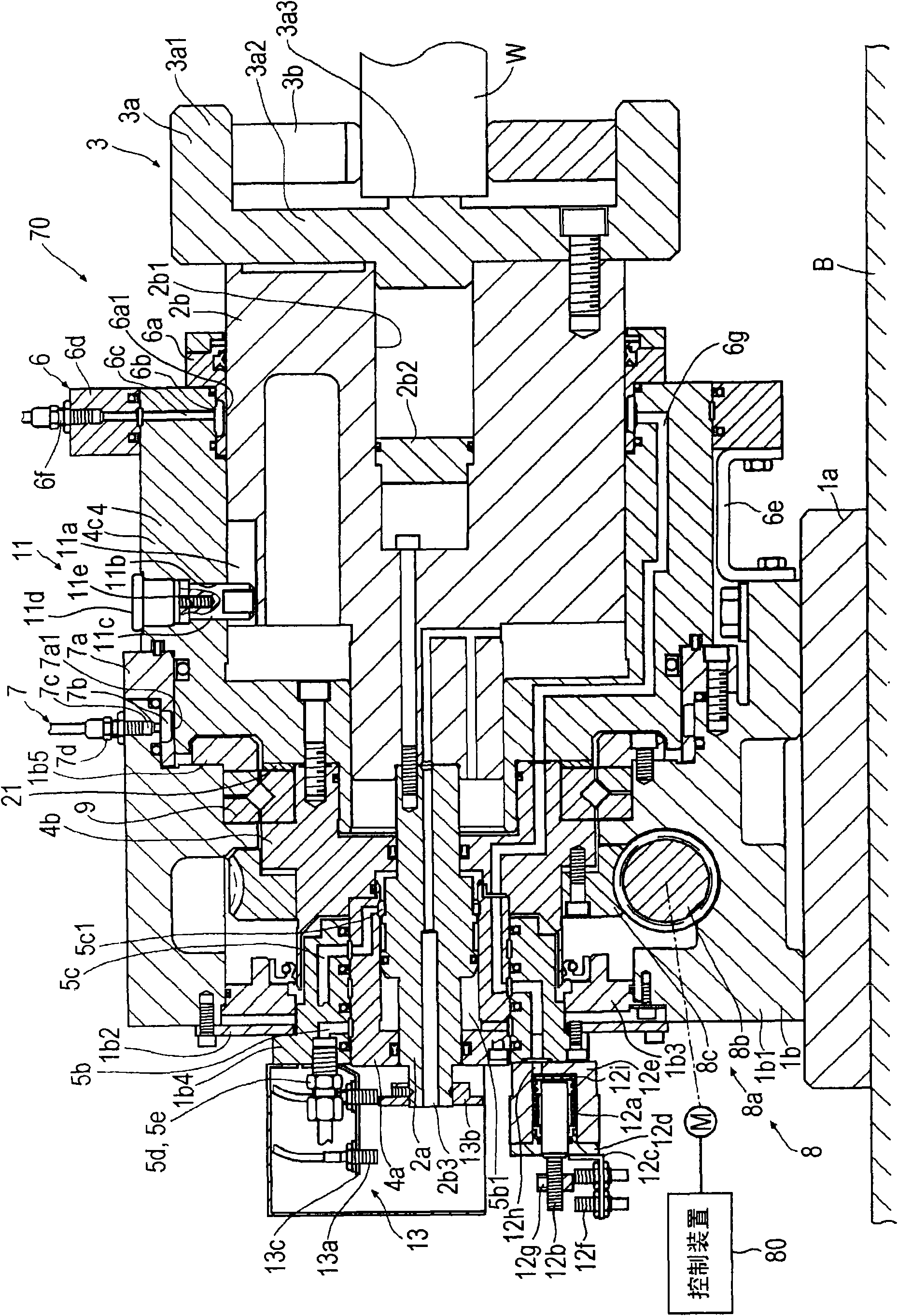

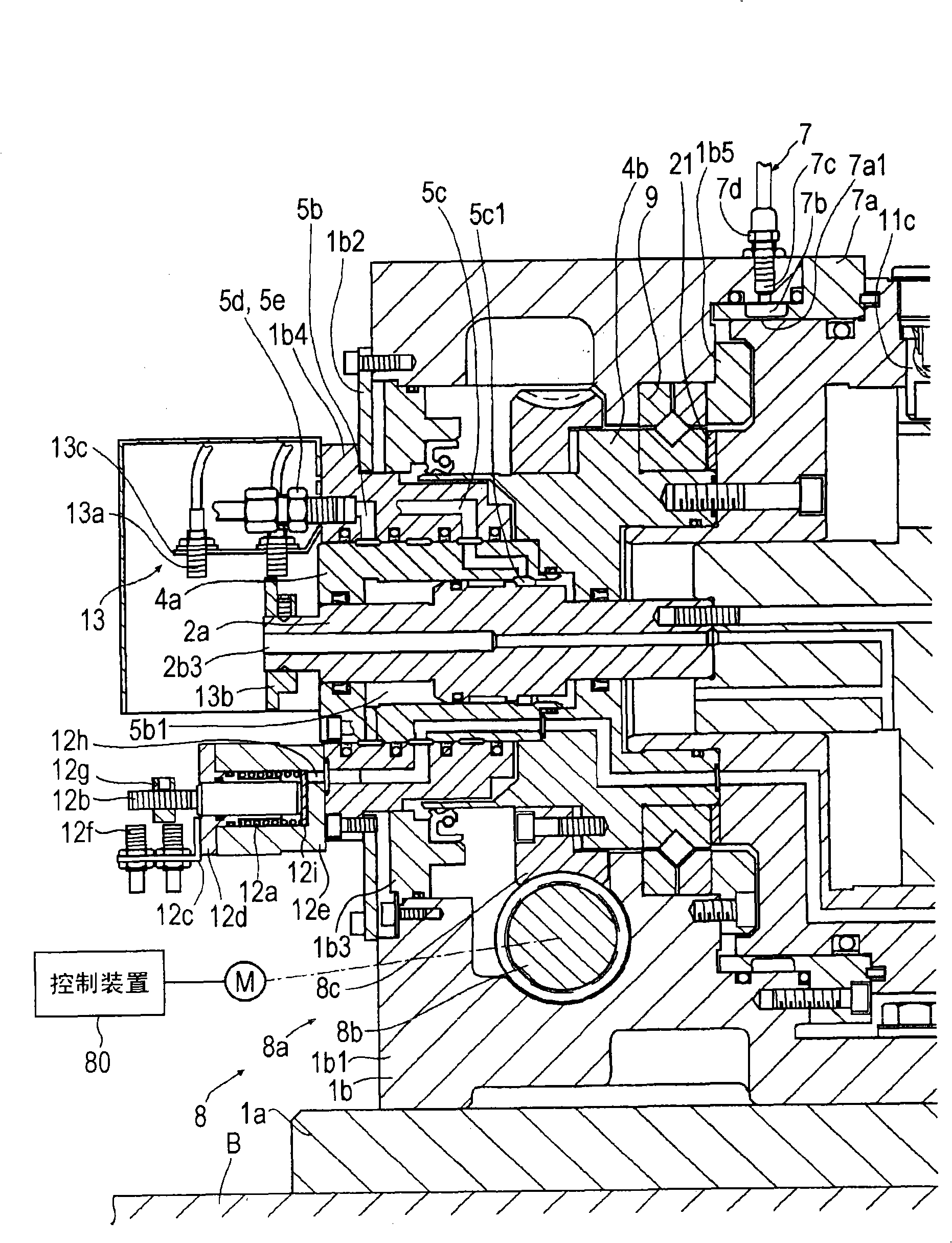

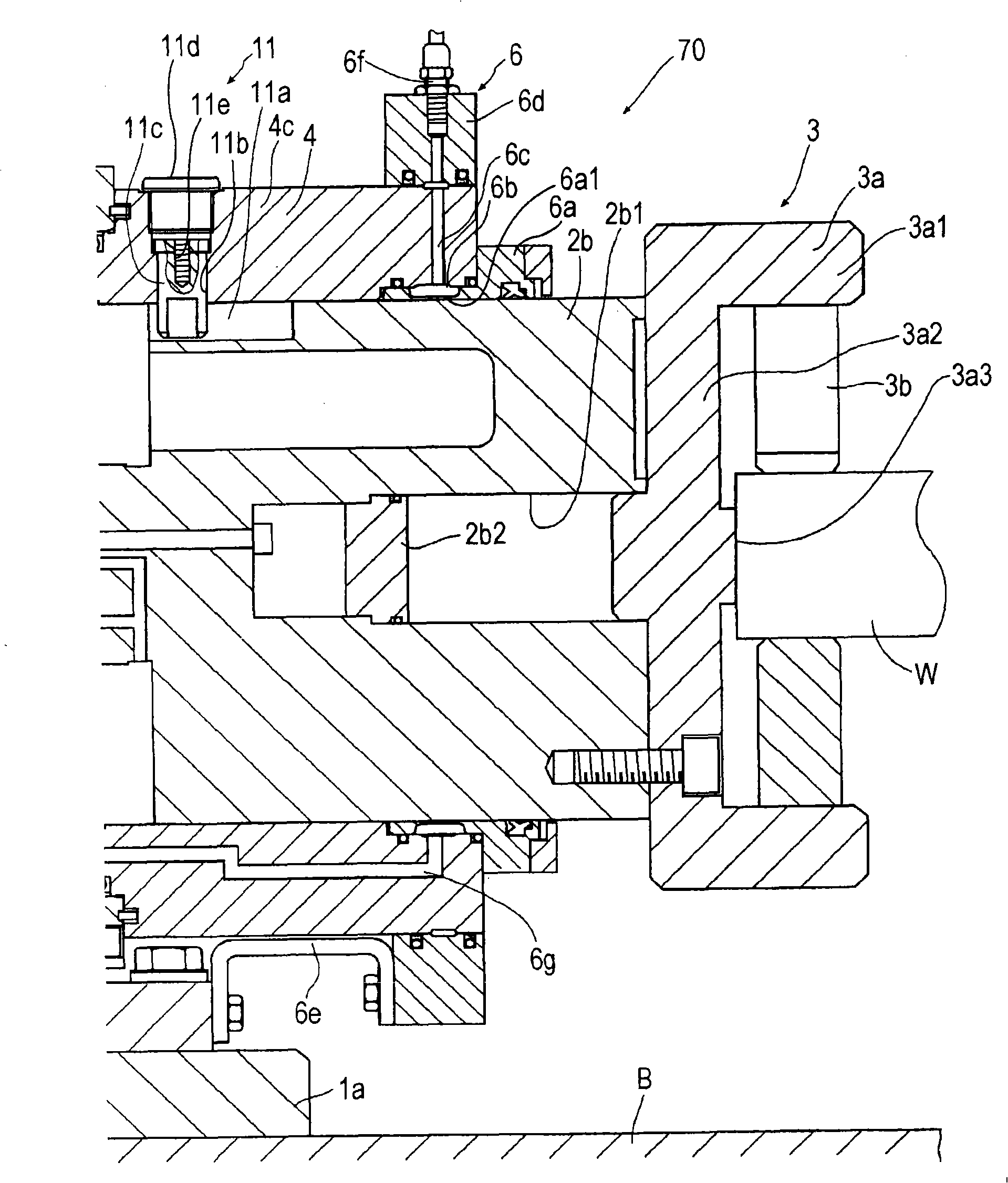

Workpiece support device and rotary indexer

ActiveCN101524816AHigh precisionSuppression of distortionPrecision positioning equipmentTailstocks/centresEngineeringMechanical engineering

The invention discloses a workpiece support device, which aims at providing a workpiece support device for enhancing the processing precision of a workpiece one end of which is connected with the rotating shaft of a rotation driving device. A workpiece support device (70) includes a coupling member (3) that couples a second end of a workpiece (W); a support shaft (2), the coupling member (3) provided at a first end of the support shaft (2); a frame (1) that supports the support shaft (2) axially movably and rotatably; a force generating device (5) that applies a force in an axial direction tothe support shaft (2); and an axial clamping device (6) including a single pressing member (6a1) extending along the entire periphery of the support shaft (2) or a plurality of pressing members (6a1)equally arranged in a circumferential direction of the support shaft (2), the pressing member (6a1) generating a force in a radial direction while the force generating device (5) is activated, the axial clamping device (6) fixing the support shaft (2) to the frame (1) in the axial direction by the force.

Owner:TSUDAKOMA KOGYO KK

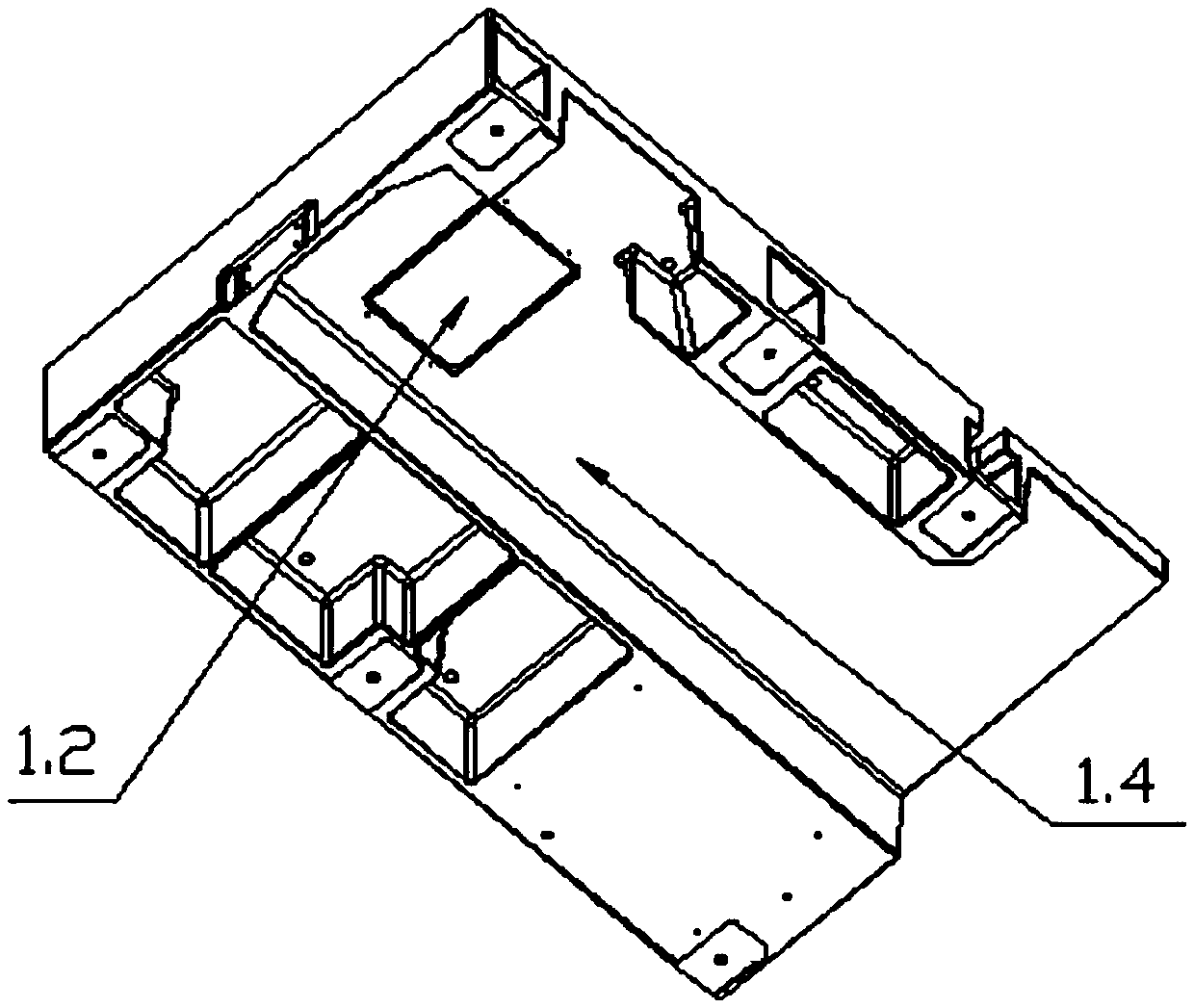

Numerical control rack gear milling machine

InactiveCN101524775AHigh indexing accuracyReduce labor intensityGear-cutting machinesNumerical controlBall screwEngineering

The invention relates to a numerical control rack gear milling machine. A Z-direction tool body (1) and an X-direction tool body (14) are spliced into a T shape, and a large X-direction dragging plate (12) is movably arranged above the X-direction tool body (14). An X-direction roll ball screw rod (17) is arranged in the X-direction tool body (14), and an X-direction servo motor (15) is arranged on the right side of the X-direction tool body (14). An X-direction synchronous rack belt wheel (13) is connected between the X-direction servo motor (15) and the X-direction roll ball screw rod (17), and an X-direction roll ball screw rod nut (23) is fixedly arranged on the large X-direction dragging plate (12), and the X-direction roll ball screw rod nut (23) can move left and right on the X-direction roll ball screw rod (17). A press screw nail (11) is arranged above the large X-direction dragging plate (12), and parts such as a Z-direction dragging plate (3), a small Y-direction dragging plate (4), and the like are arranged in the mode similar to that of the parts in the X direction. A numerical control system (16) is fixedly arranged on the tool body (14). Compared with the prior rack machine, the numerical control rack gear milling machine obviously improves the indexing accuracy, has the advantages of automatic cutting, automatic indexing and low labor intensity, and greatly saves the labor cost.

Owner:徐国金

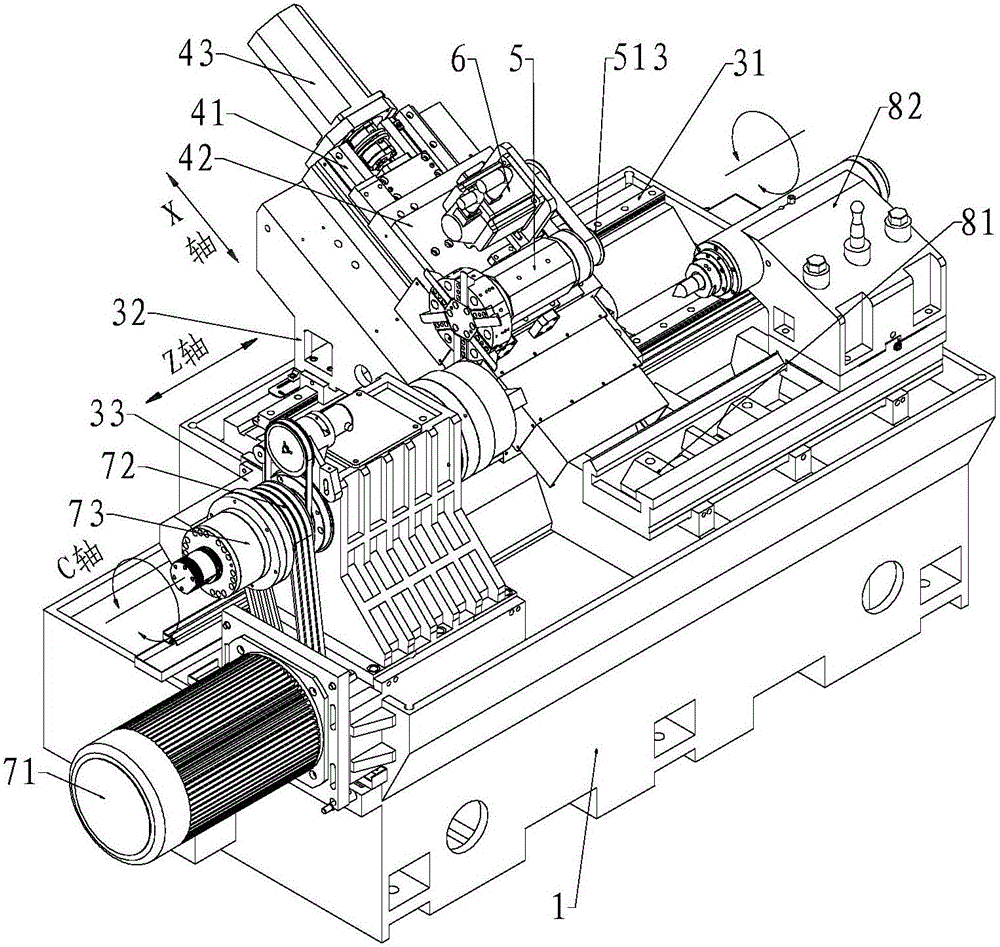

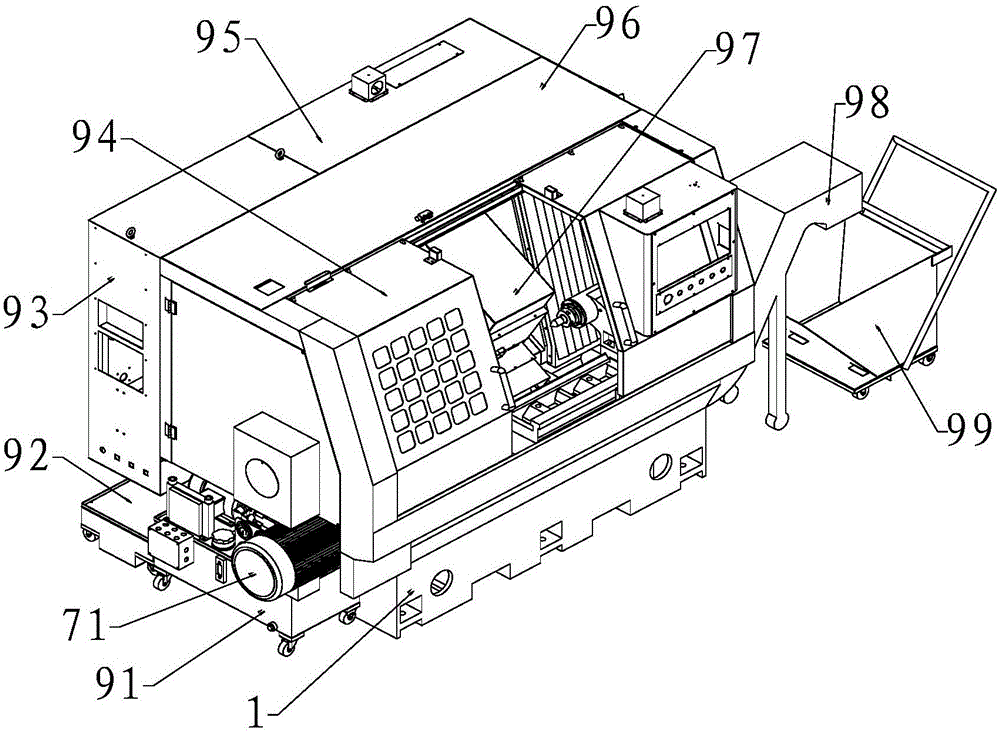

Turing center with inverted spindle

ActiveCN105500105ASmall footprintReduce the numberLarge fixed membersMetal working apparatusEngineeringSlide plate

The invention relates to a turning center with an inverted spindle. The turning center comprises a base plate, a rear chip cleaner, a C-shaped machine tool, a feeding device, a slide plate and a cutter holder, wherein the base plate is fixed on a foundation, the rear chip cleaner longitudinally penetrates the bottom of the base plate in a front-back direction, the C-shaped machine tool is connected to the upper end face of the base plate, the feeding device is biased on one side and longitudinally penetrates the machine tool in a front-back direction, the slide plate is arranged on one side of the machine tool, the slide plate is connected with the machine tool through a linear guide rail, a spindle box is arranged on one side of the slide plate, the slide plate is connected with the spindle box through the linear guide rail, the cutter holder is mounted in front of the lower side of the machine tool and located below the feeding device, an X-axis drive system is mounted behind the slide plate, and a Z-axis drive system is mounted in front of the slide plate. The turning center has the advantages that the turning center is compact in structure, machine tool floor space can be reduced favorably, and the automation level of the machine tool is increased.

Owner:希斯机床(沈阳)有限责任公司

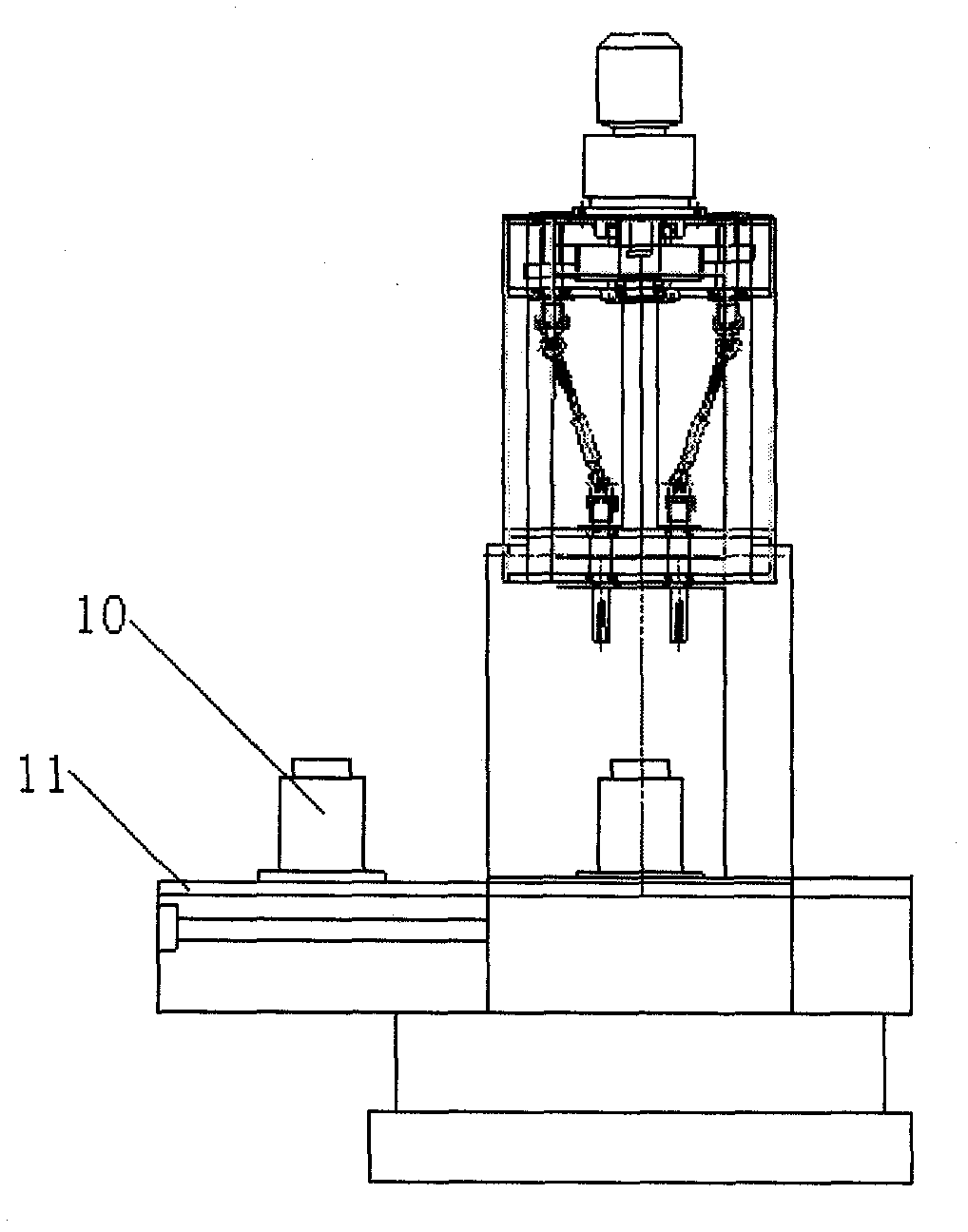

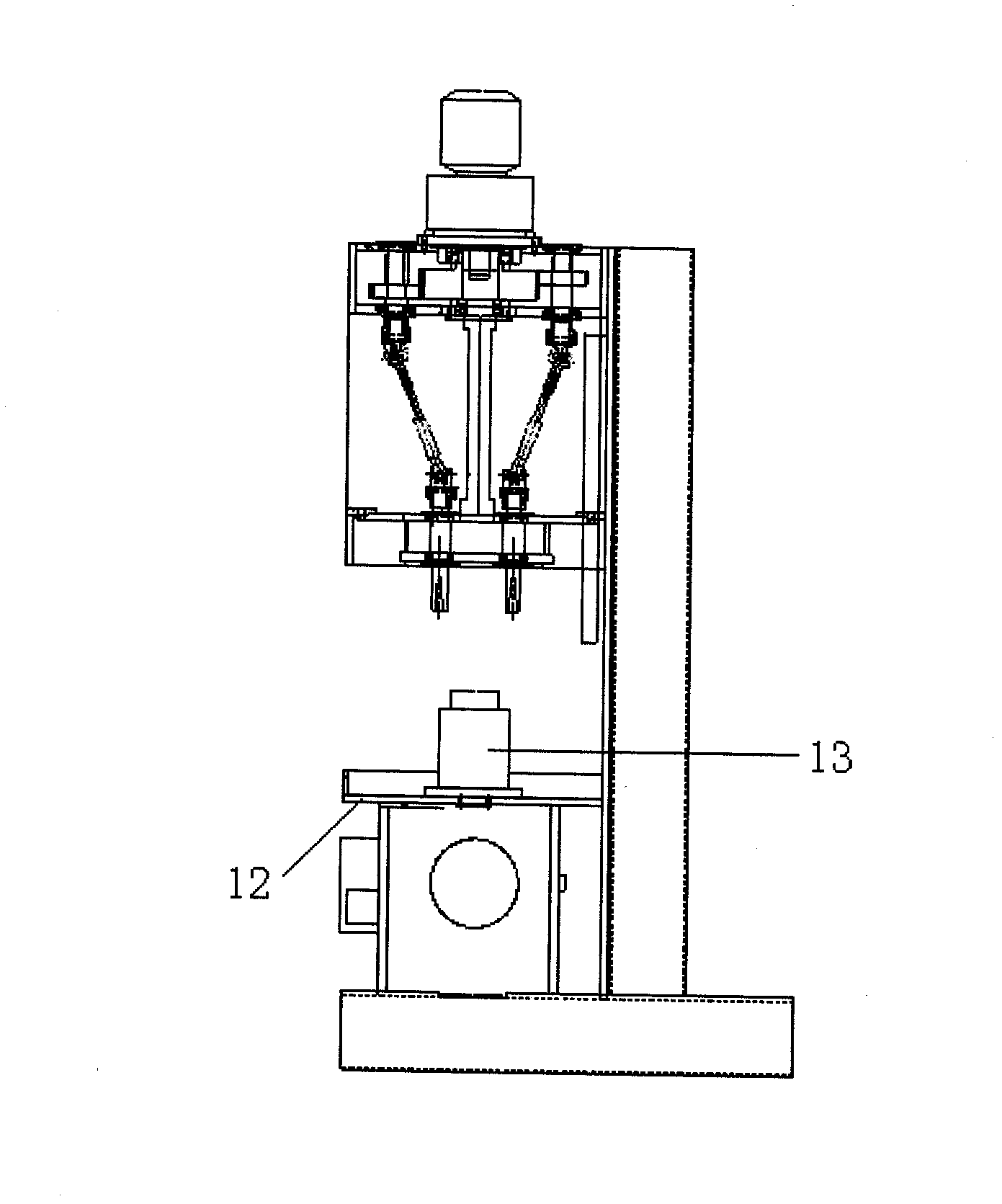

Multifacet drill boring device and machining method utilizing same

InactiveCN102847973AHigh indexing accuracyShorten processing timeBoring/drilling componentsBoring/drilling machinesEngineeringDrill bit

The invention relates to a multifacet drill boring device and a machining method utilizing the same. A boring mechanism is arranged above a worktable and comprises a driving mechanism and a plurality of power output shafts driven by the driving mechanism. Each power output shaft is connected with a drill pipe through a transmission mechanism, and the drill pipe is connected with a bit or screw tap. A workpiece is placed on a workpiece clamp on the worktable, the bits or screw taps are mounted on the drill pipes according to machining requirements, the driving mechanism is then started to drive the drill pipes to rotate simultaneously, and thus the workpiece is bored.

Owner:蒋振

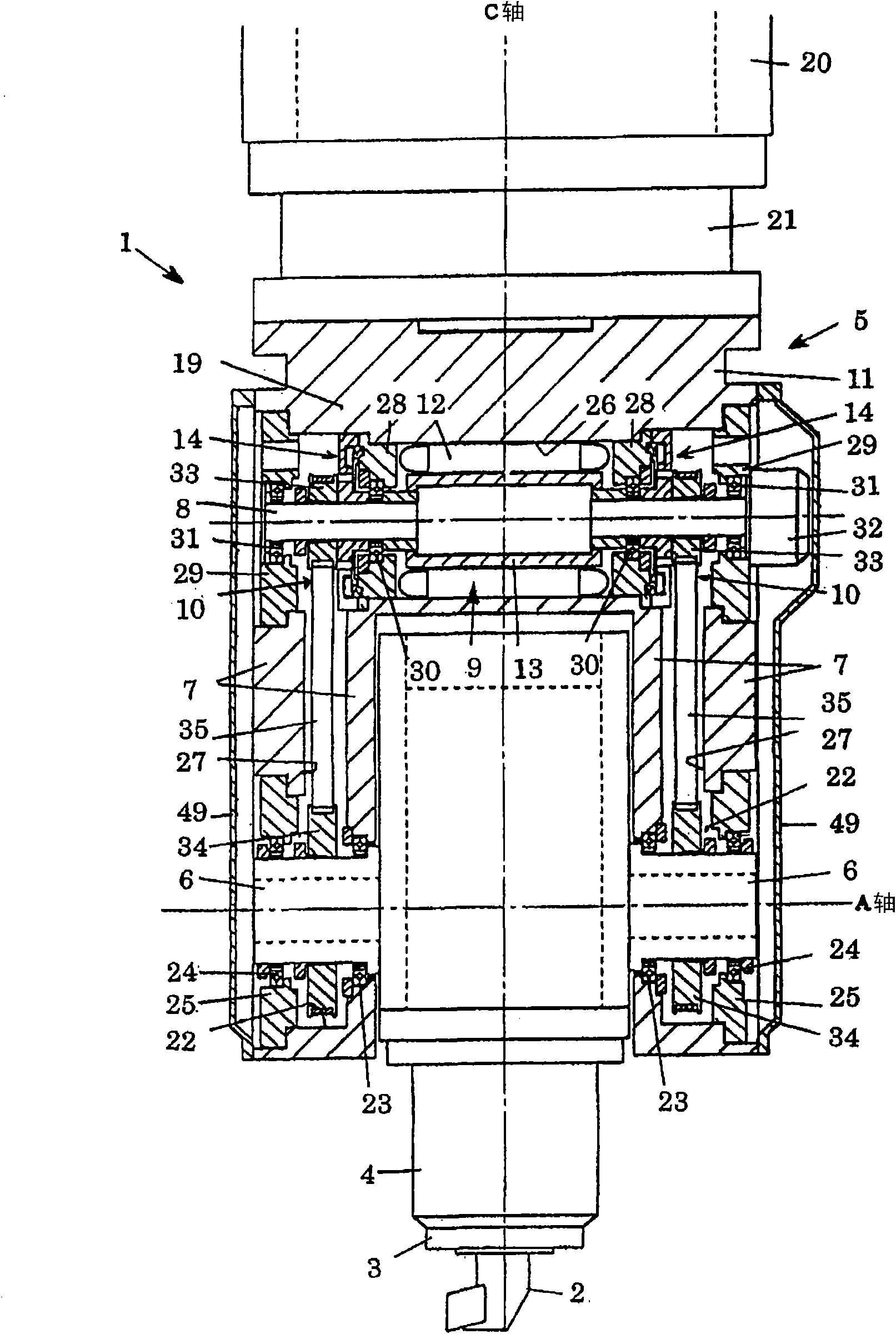

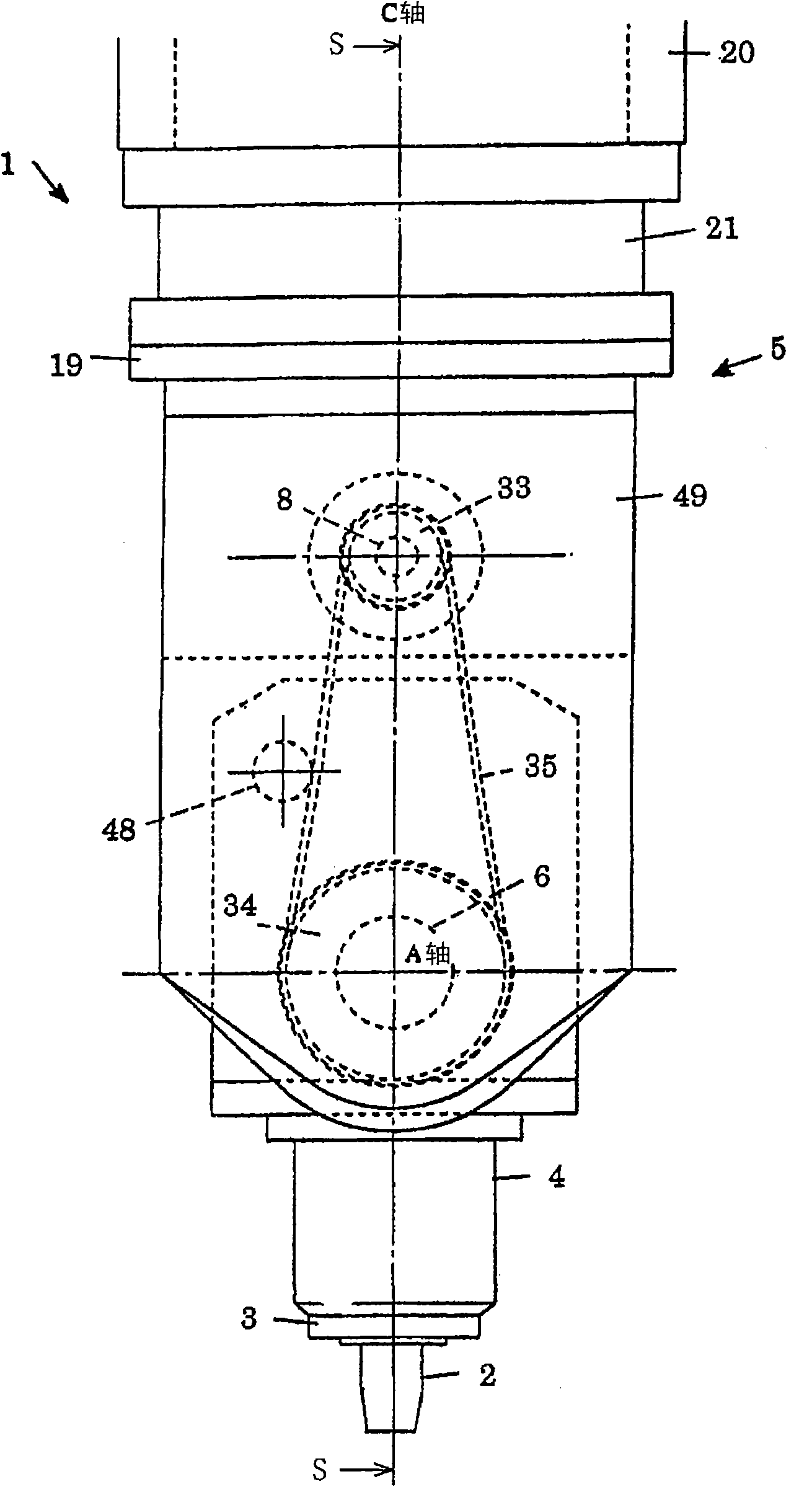

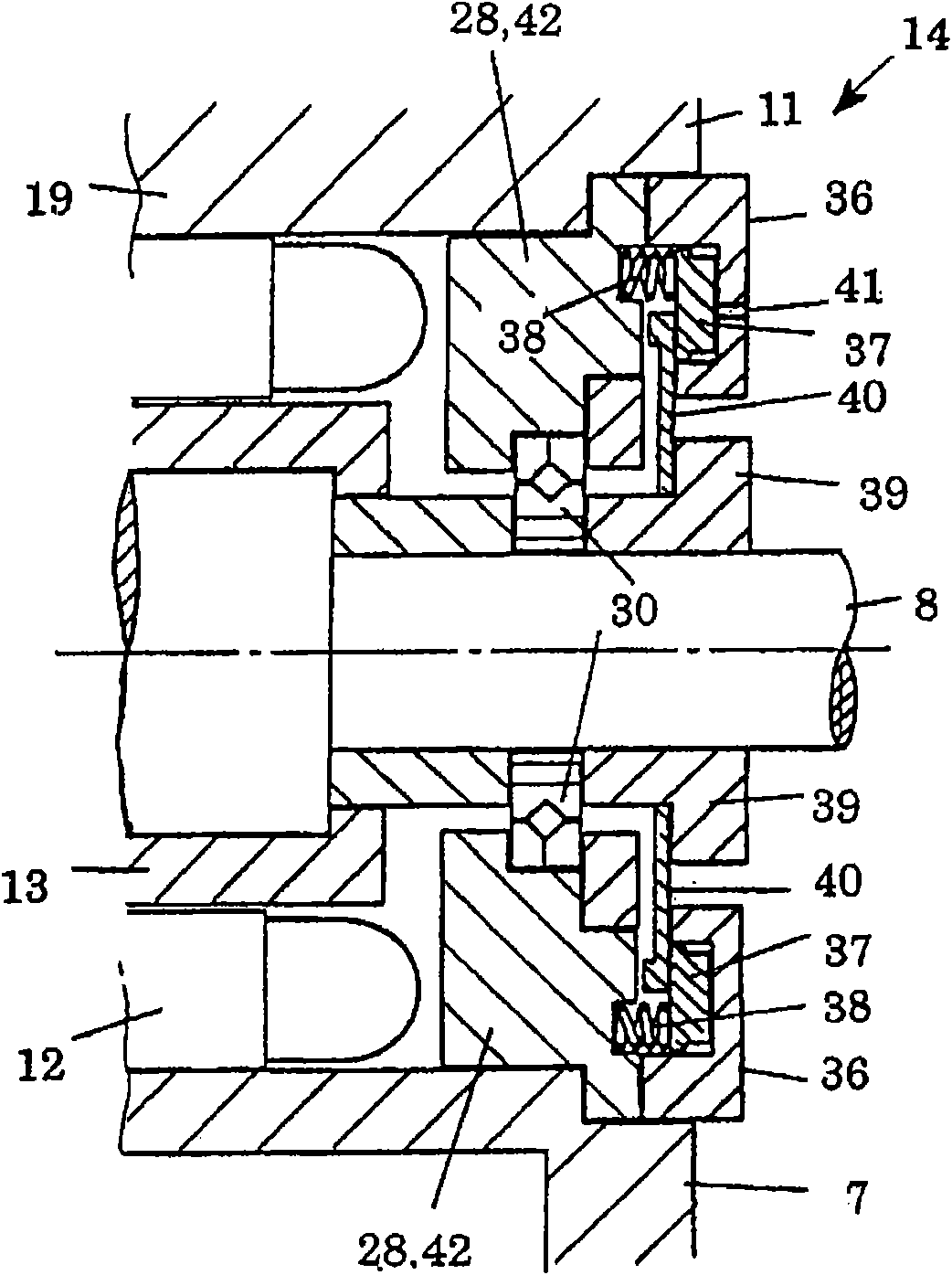

Machine tool spindle head

InactiveCN101801593AImprove machining accuracyHigh indexing accuracyPrecision positioning equipmentMachine tool componentsDrive shaftEngineering

A machine tool spindle head which is constructed in compact size and in which a motor can be controlled easier than in conventional devices. The spindle head (1) includes a spindle unit (4) for rotationally driving a spindle (3) on the head of which a tool (2) is installed, and also includes a fork-shaped support head (5) having a pair of fork arms (7) respectively rotatably supporting a pair of support shafts (6) for supporting the spindle unit (4). The spindle head (1) further has a drive shaft (8) rotatably supported in the support head (5) and extending parallel to the direction of the axis of the support shafts (6), a drive motor (9) for rotationally driving the drive shaft (8), and a pair of drive transmission mechanisms (10) each interconnecting each of opposite ends of the drive shaft (8) and each of the support shafts (6) and transmitting rotation of the drive motor (9) to the support shafts (6).

Owner:杉山明 +1

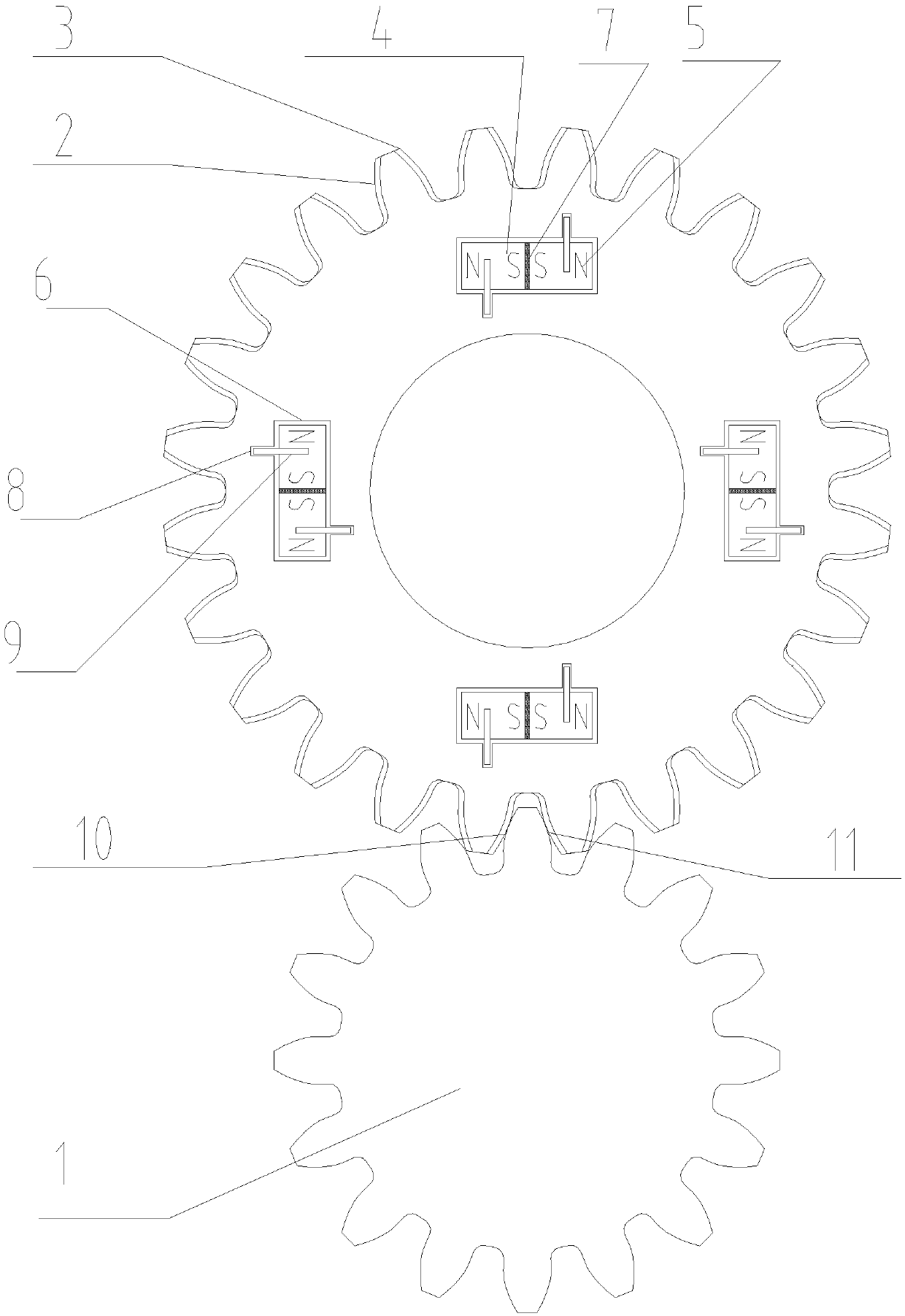

Magnetic gear transmission pair

InactiveCN107893842AFast transmissionEliminate backlashPortable liftingGearing detailsMachine buildingEngineering

The invention discloses a magnetic gear transmission pair and relates to the field of mechanical manufacturing. The magnetic gear transmission pair is composed of a gear A, a gear B1, a gear B2, a gear B1 magnet and a gear B2 magnet; the gear B1 and the gear B2 are coaxial, are the same in diameter, and are the same in tooth number; the gear B1 and the gear B2 are attached together; the gear A isengaged with the gear B1 and the gear B2; torque is input by the gear A, and is transmitted to the gear B1 and the gear B2 through teeth to be output; a plurality of magnets are installed in the gearB1 and the gear B2; and the gear B1 magnet and the gear B2 magnet are installed in a homopolar and opposite manner. The magnetic gear transmission pair has the beneficial effects that due to the homepolar repulsion principle of the magnets and by means of the magnetic force effects, the gear B1 and the gear B2 are made to rotate in opposite directions, and make contact with the two sides of the tooth part of the gear A on engagement points at the same time, and therefore gear backlash is eliminated, and the gear transmission and indexing precision is improved.

Owner:蚌埠市行星工程机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com