Torque motor direct-driven full immersion rotary table

A torque motor and direct drive technology, which is applied in the field of full-immersion liquid numerical control turntable, can solve the problems of complicated process technology and difficult manufacture of full-immersion turntable, and achieve good sealing effect, good power-in effect, and reliable static sealing structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

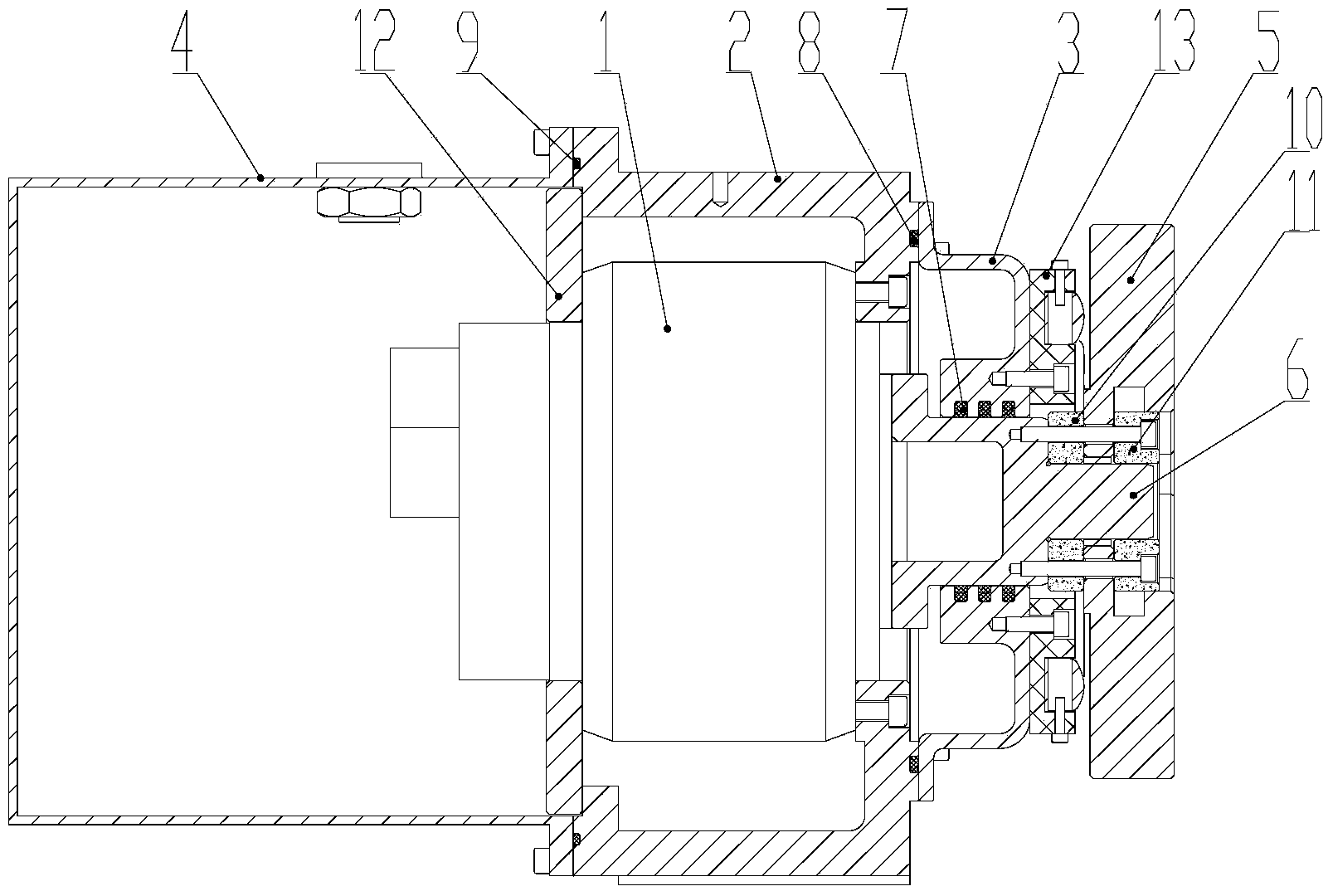

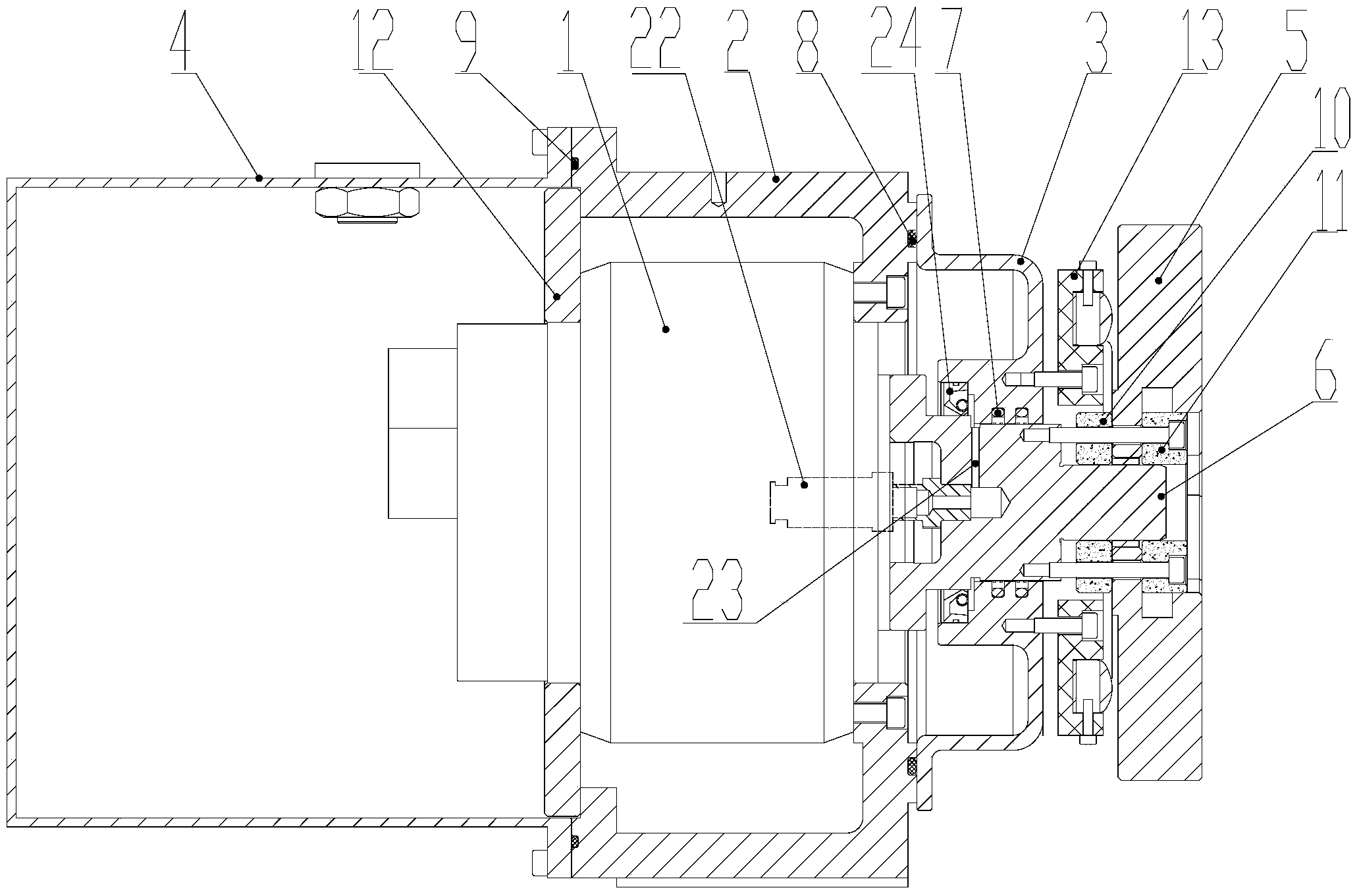

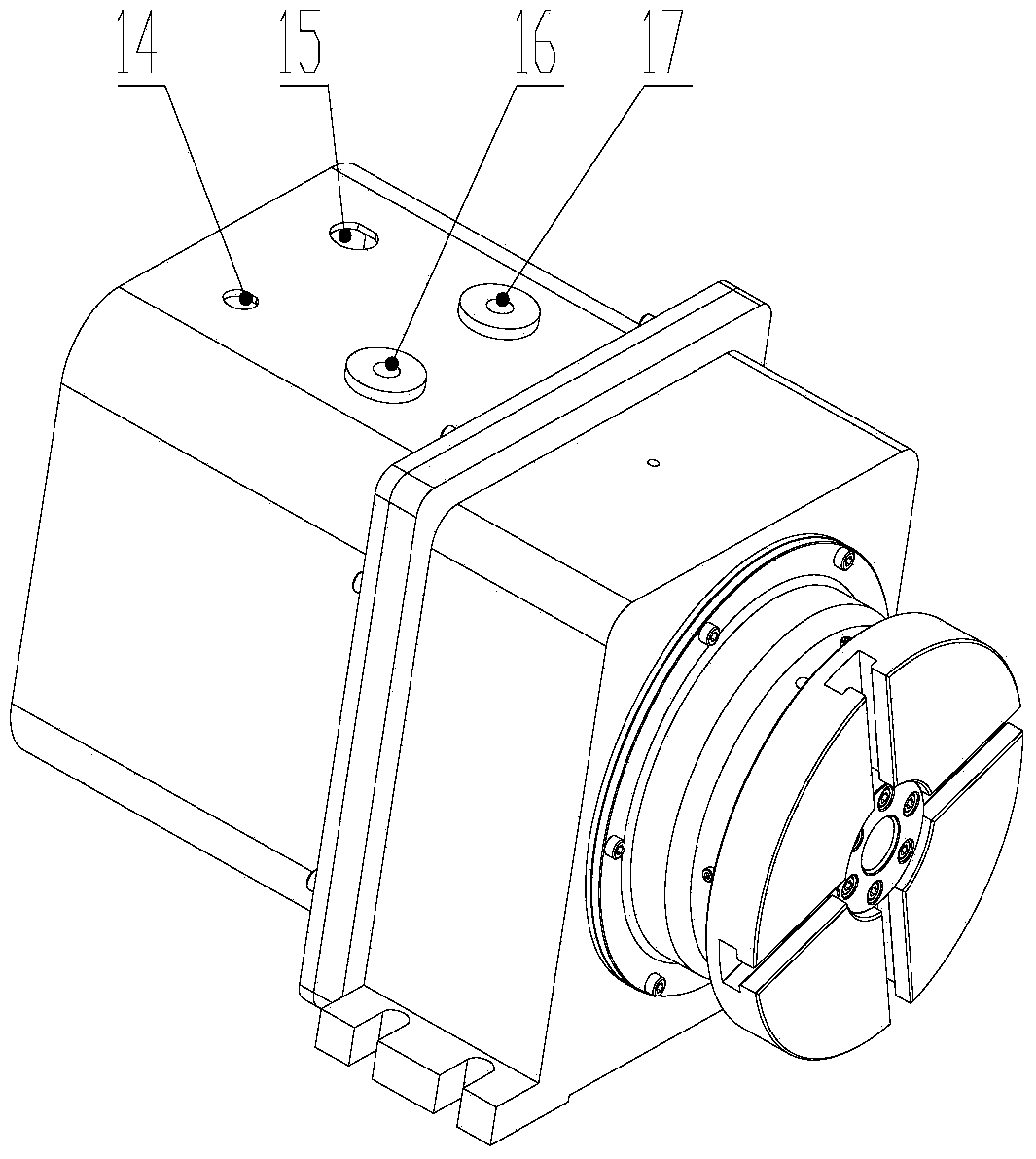

[0037] Such as figure 1 and image 3 As shown, the torque motor direct drive type full immersion turntable provided by the present invention mainly includes: torque motor 1, support shell 2, front protective cover 3, rear protective cover 4, workbench 5, output shaft 6, rotating grid Ring 7, O-ring I8, O-ring II9, insulating pad I10, insulating pad II11, support plate 12, power supply system 13, air intake adapter 16, oil return adapter 17.

[0038] The supporting shell 2, the front protective cover 3 and the rear protective cover 4 mainly constitute the frame, the torque motor 1 is fixed on the supporting shell 2, and is sealed by the front protective cover 3 and the rear protective cover 4 of the turntable, and the output shaft 6 is directly fixedly installed on the torque motor shaft, the output rotating shaft 6 passes through the front protective cover 3 in a sealed manner, the worktable 5 is installed on the output rotating shaft 6 in an insulated manner, and an electric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com