Patents

Literature

47results about How to "Reduce sealing pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

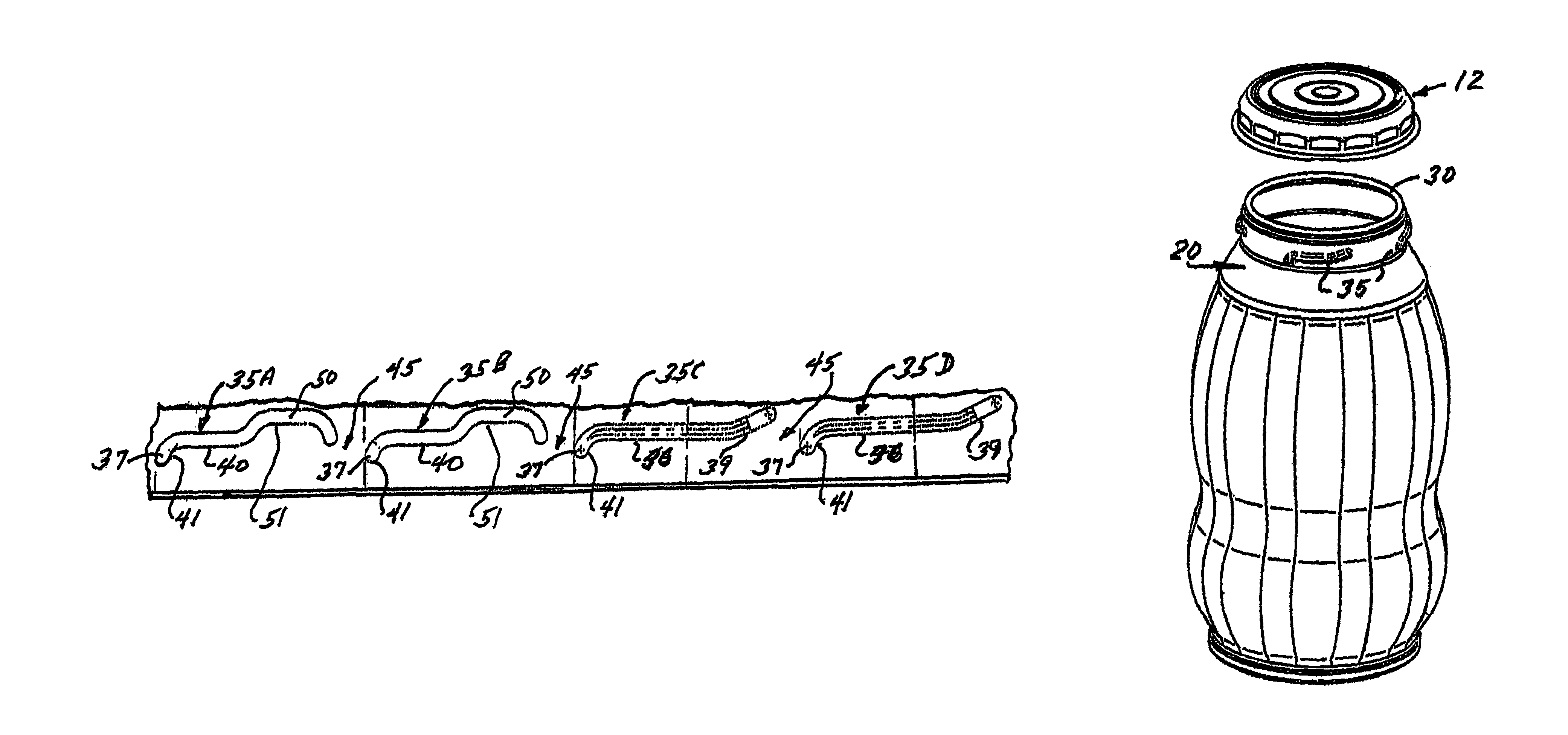

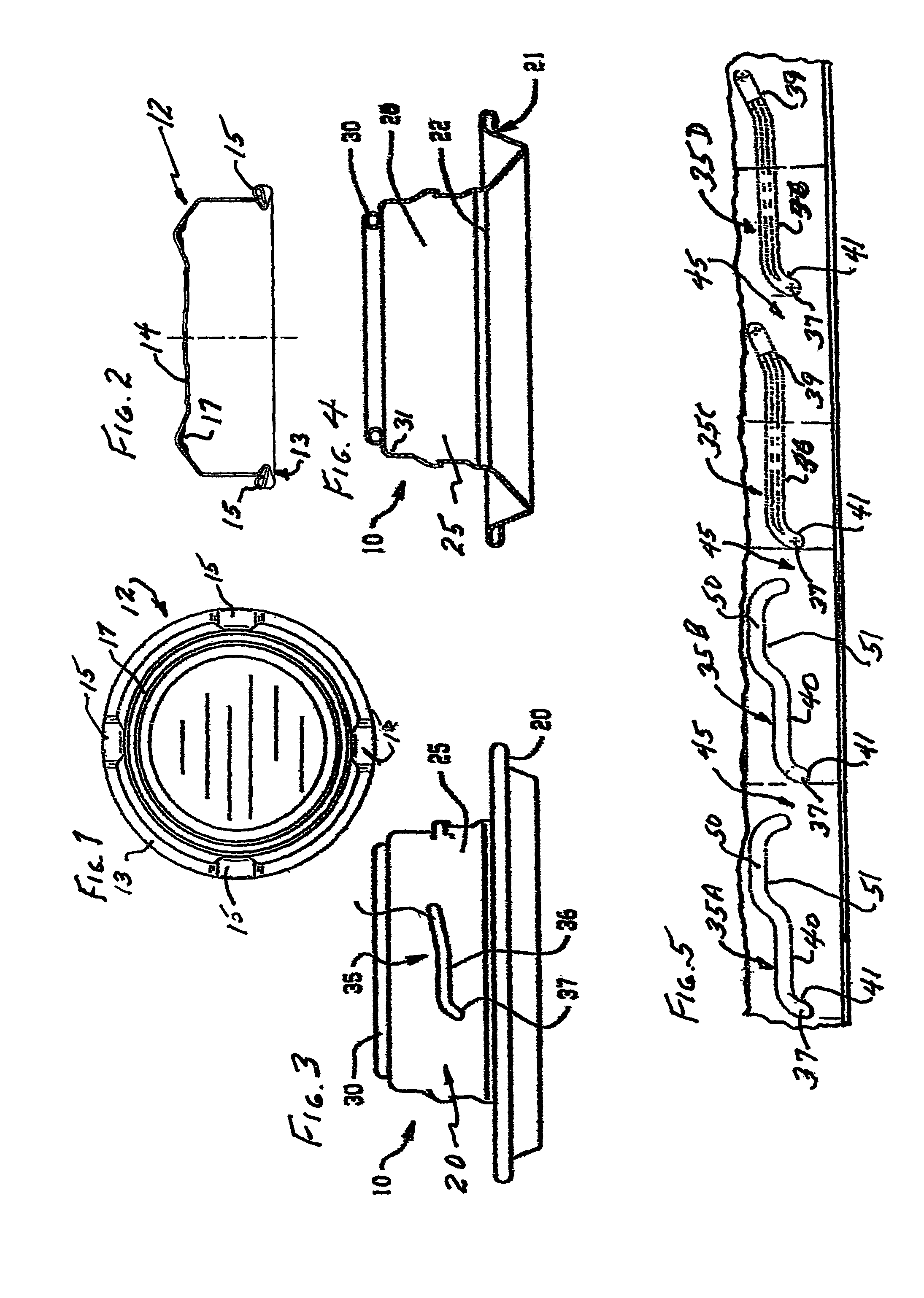

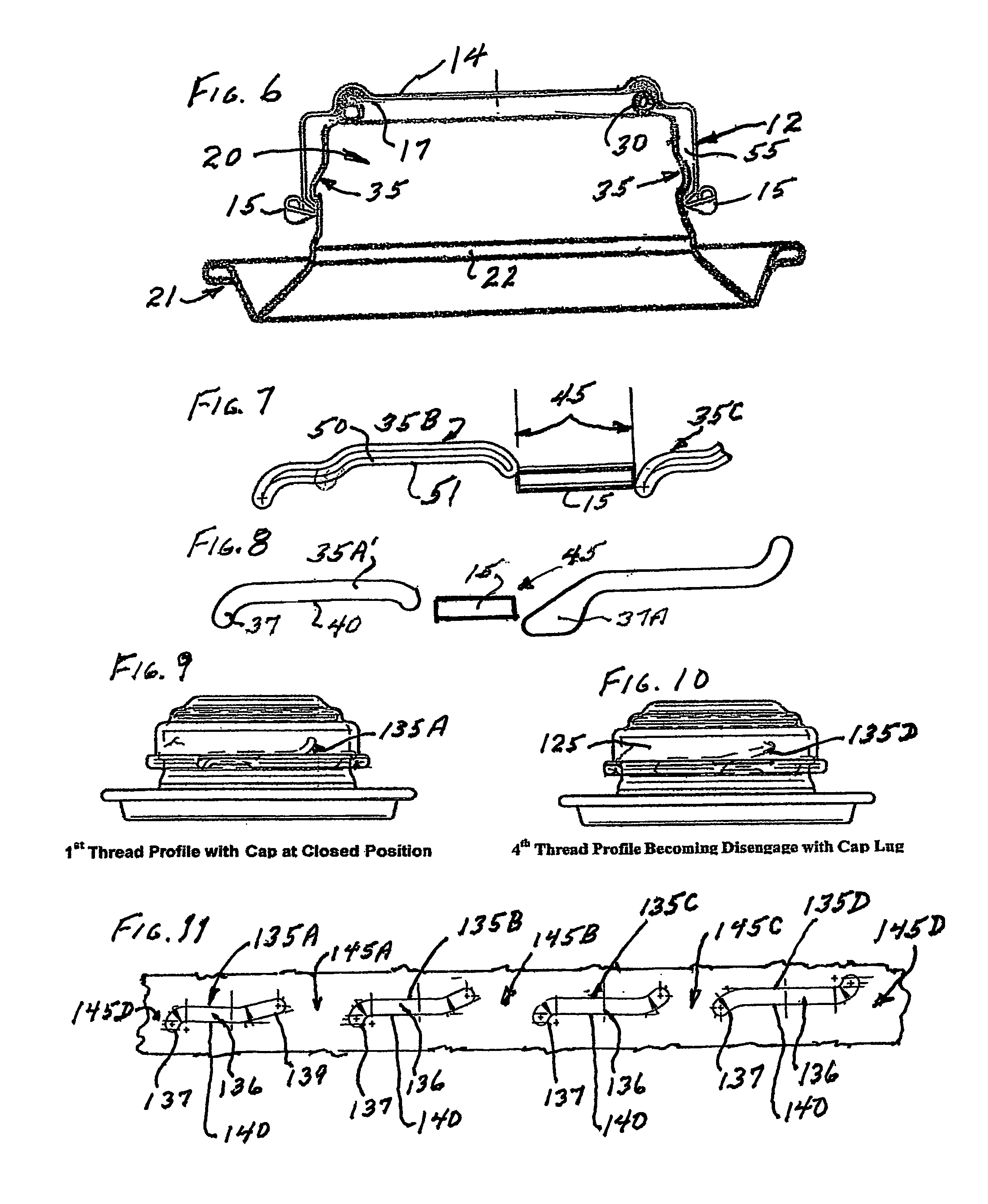

Container and removable closure cap with venting feature

A resealable can end is provided including a neck (10) and a cooperating cap member (12) which can be sealed onto and removed from the neck, and is capable of containing product under pressure or vacuum if desired. This end may be added, by convention seaming methods, such as roll seaming or by appropriate adhesive, to a container body, or may be formed integrally with container bodies. The venting feature of the end will achieve a controlled release of differential internal-to-ambient pressure upon initial opening of the cap, and may also provide resealed containment of partial contents retained in the container, although the contents will no longer be under pressure or vacuum, as the case may be. The end may be applied to, or incorporated in, containers made of various material, such as aluminum, coated steel, or selected plastics.

Owner:DAYTON SYST GRP

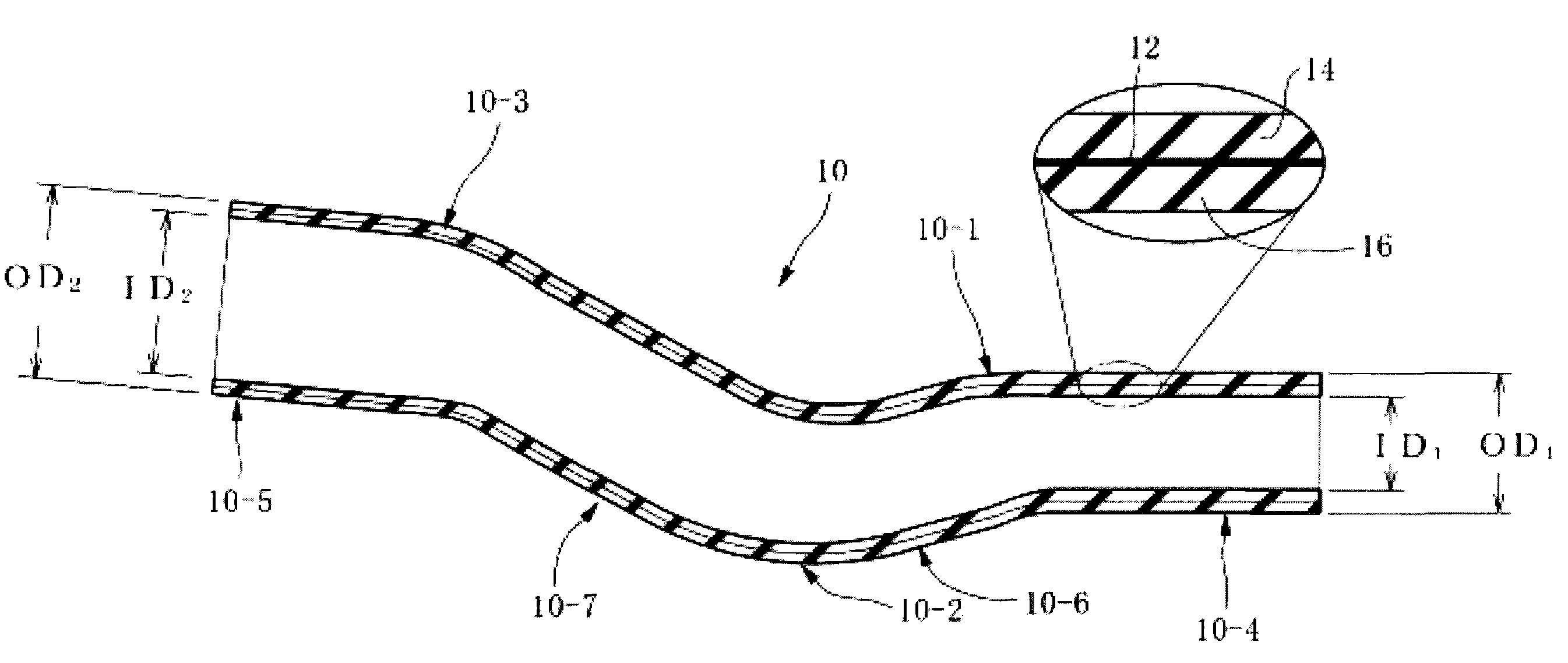

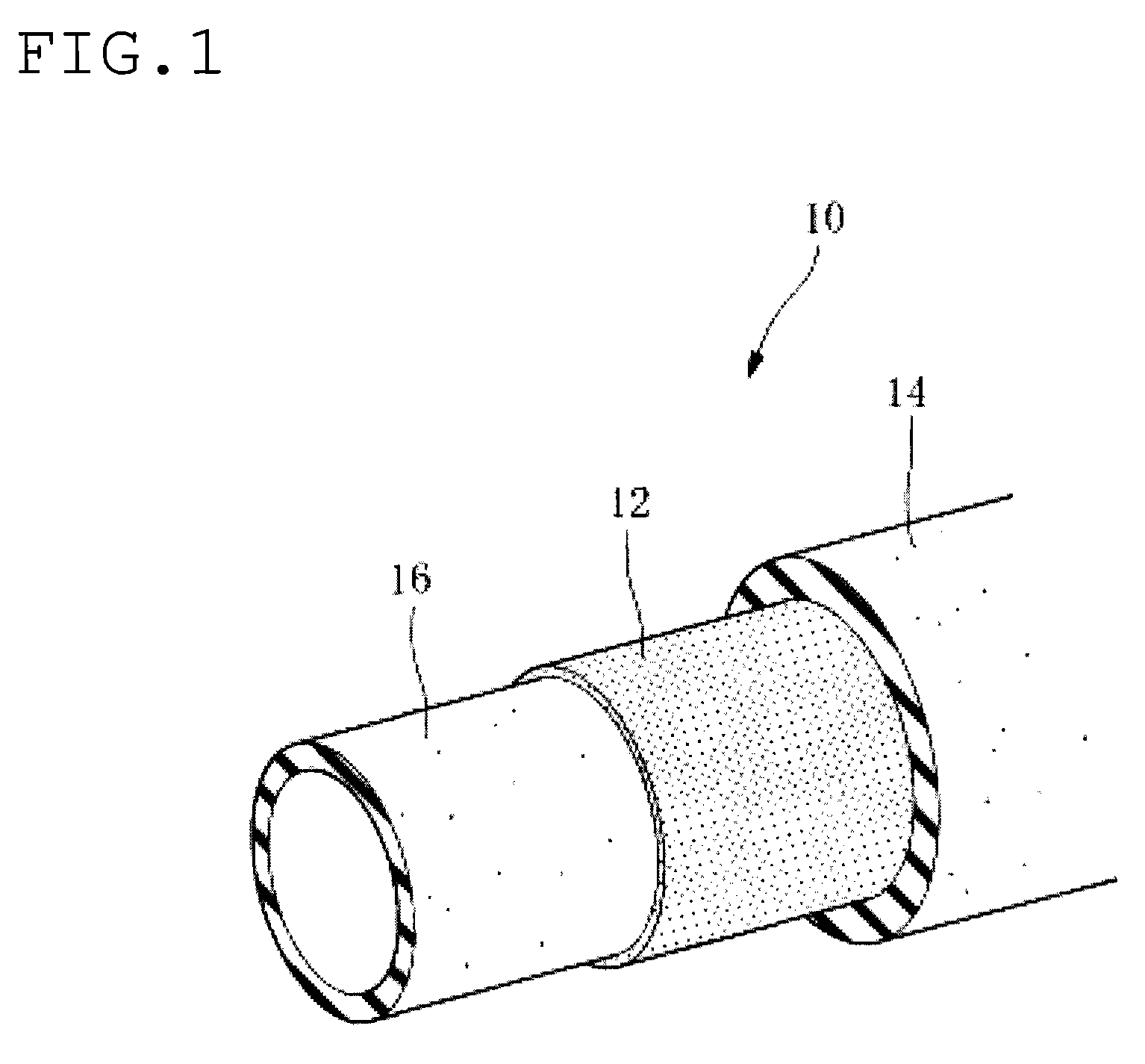

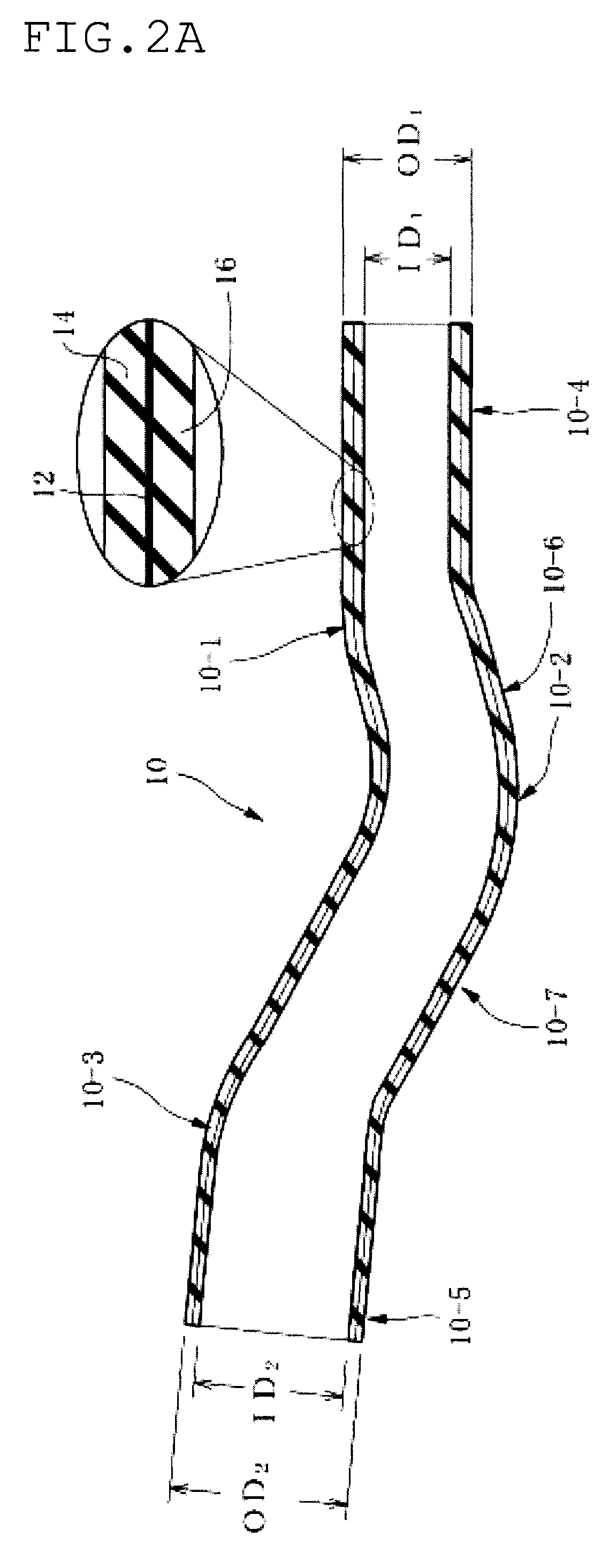

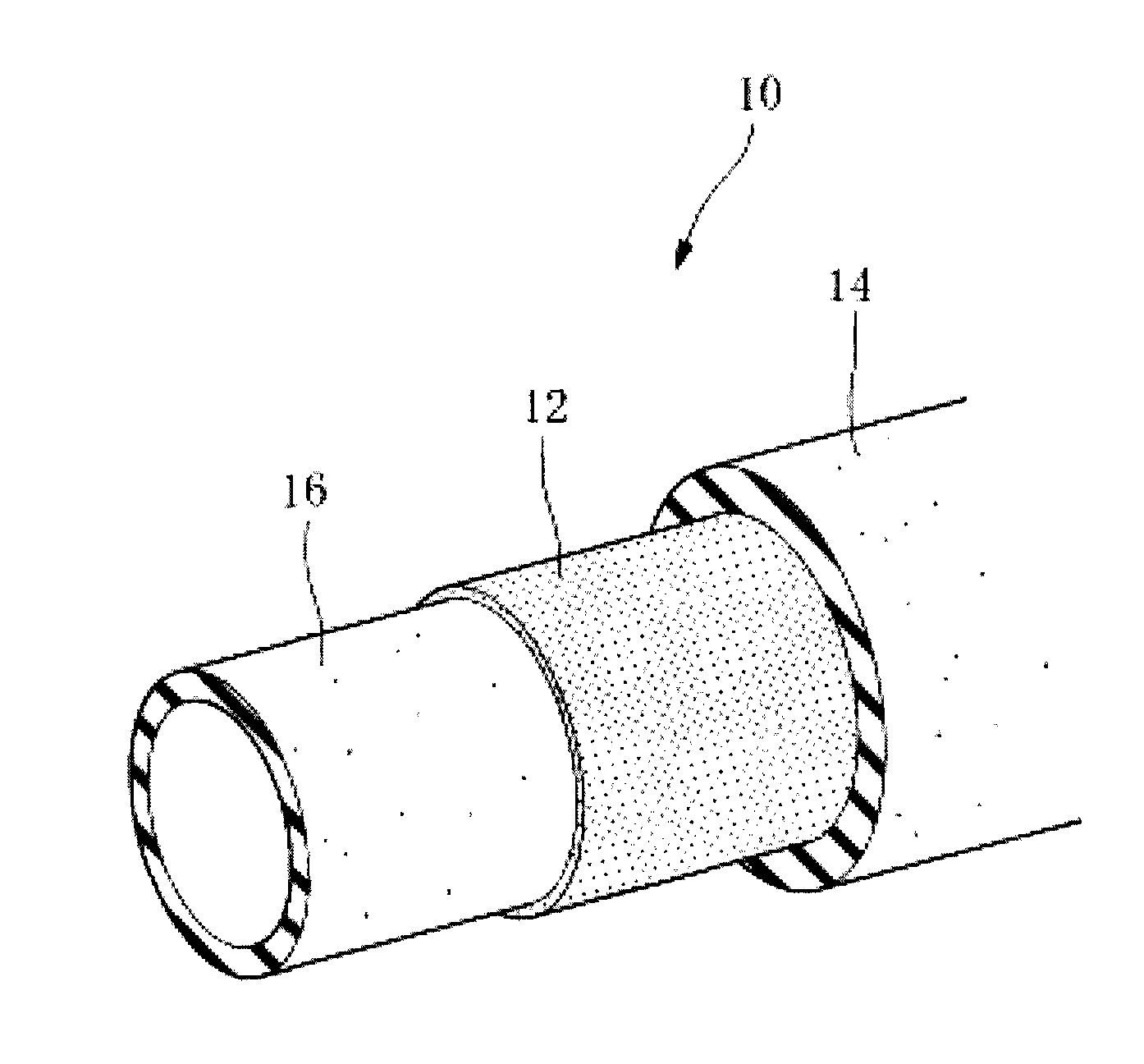

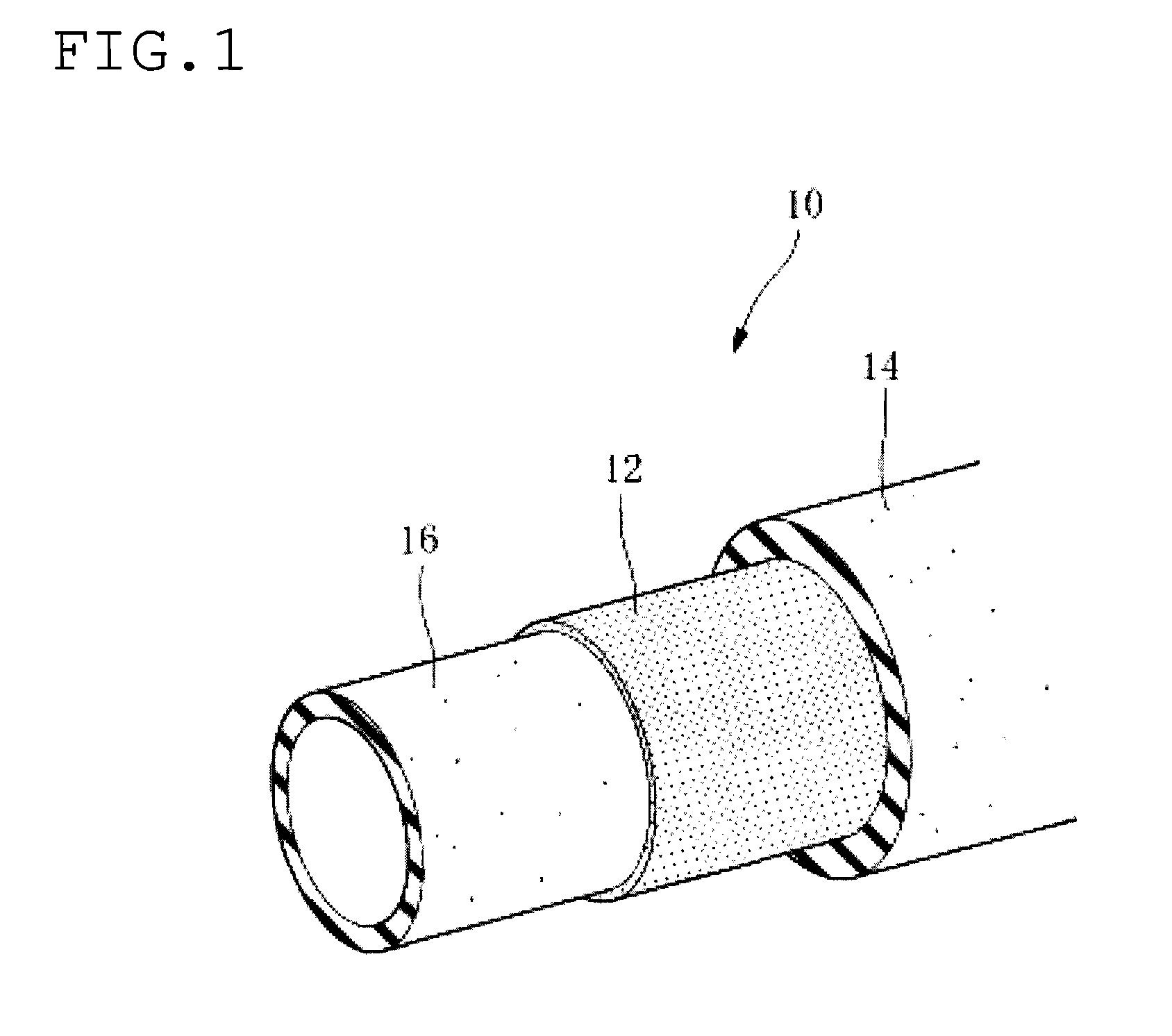

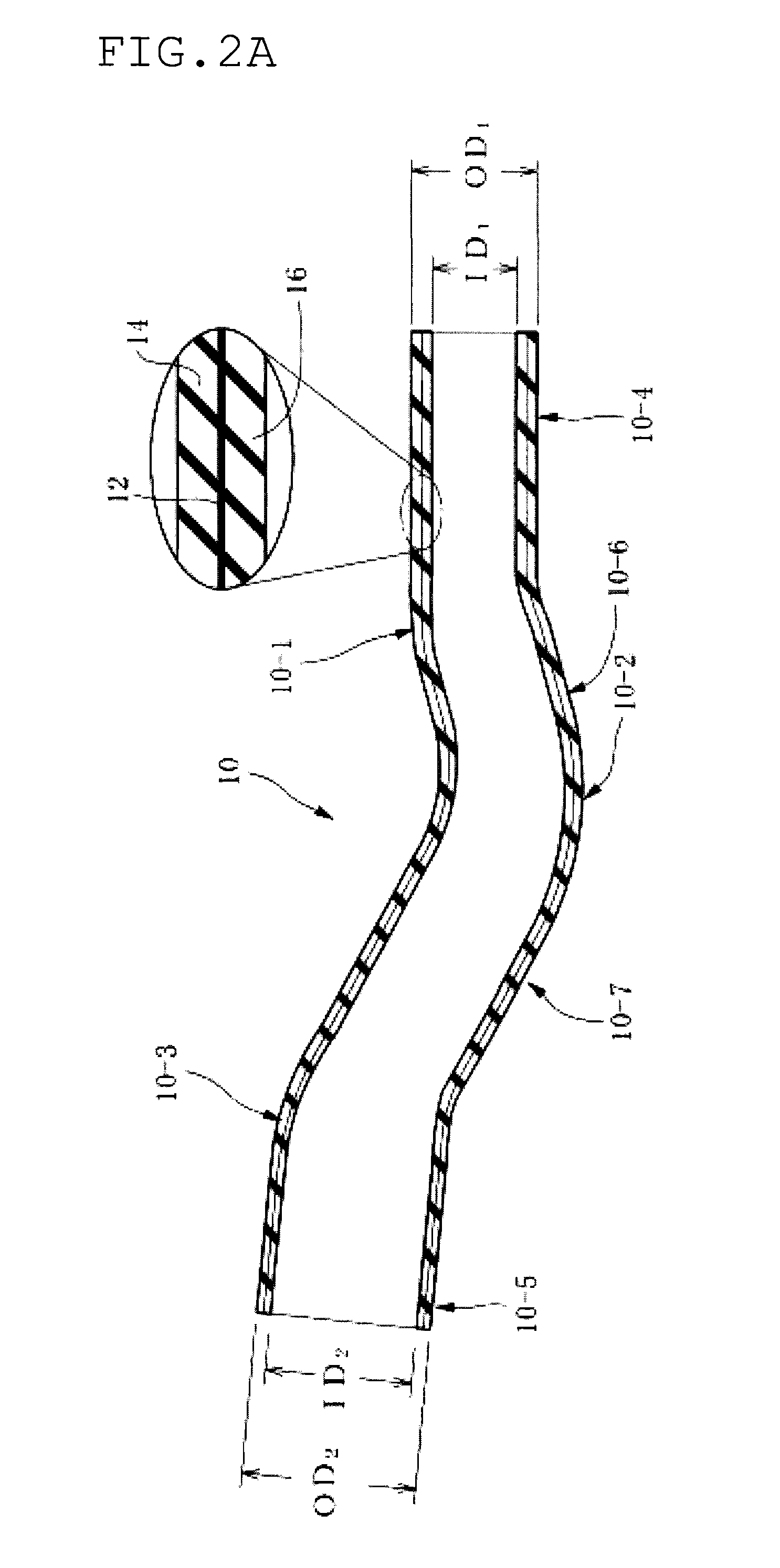

Resin composite fuel hose

ActiveUS7478653B2Easy to installReduce tightening forceSynthetic resin layered productsFlexible pipesSurface layerEngineering

A resin composite fuel hose of a multilayer construction includes a resin layer as a barrier layer having a fuel permeation resistance, an inner rubber layer as an inner surface layer laminated on an inner side of the resin layer and an outer rubber layer laminated on an outer side of the resin layer. The outer rubber layer has a rubber hardness degree equal to or greater than that of the inner rubber layer, and the inner rubber layer has a permanent elongation equal to or less than 90%.

Owner:SUMITOMO RIKO CO LTD

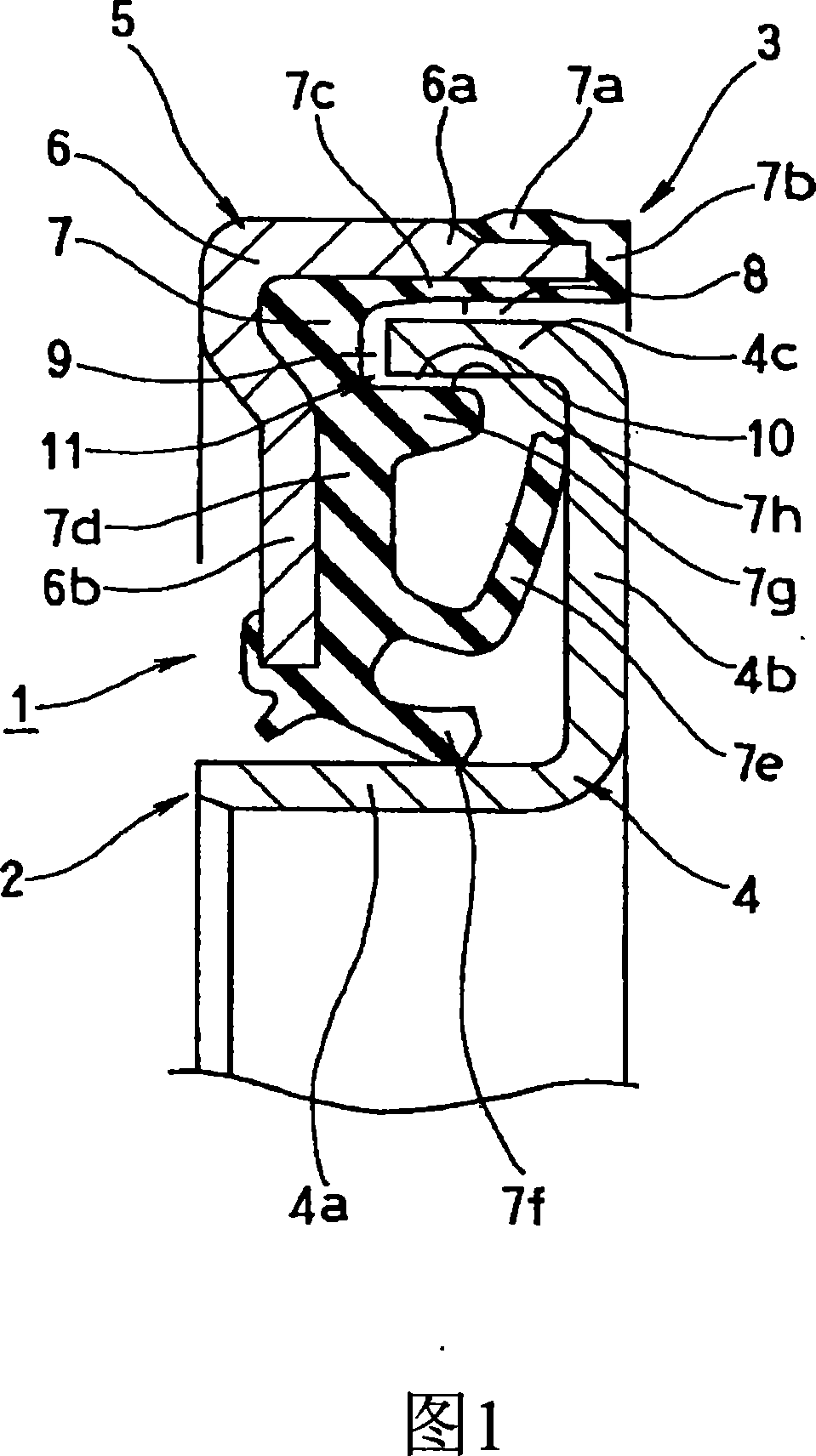

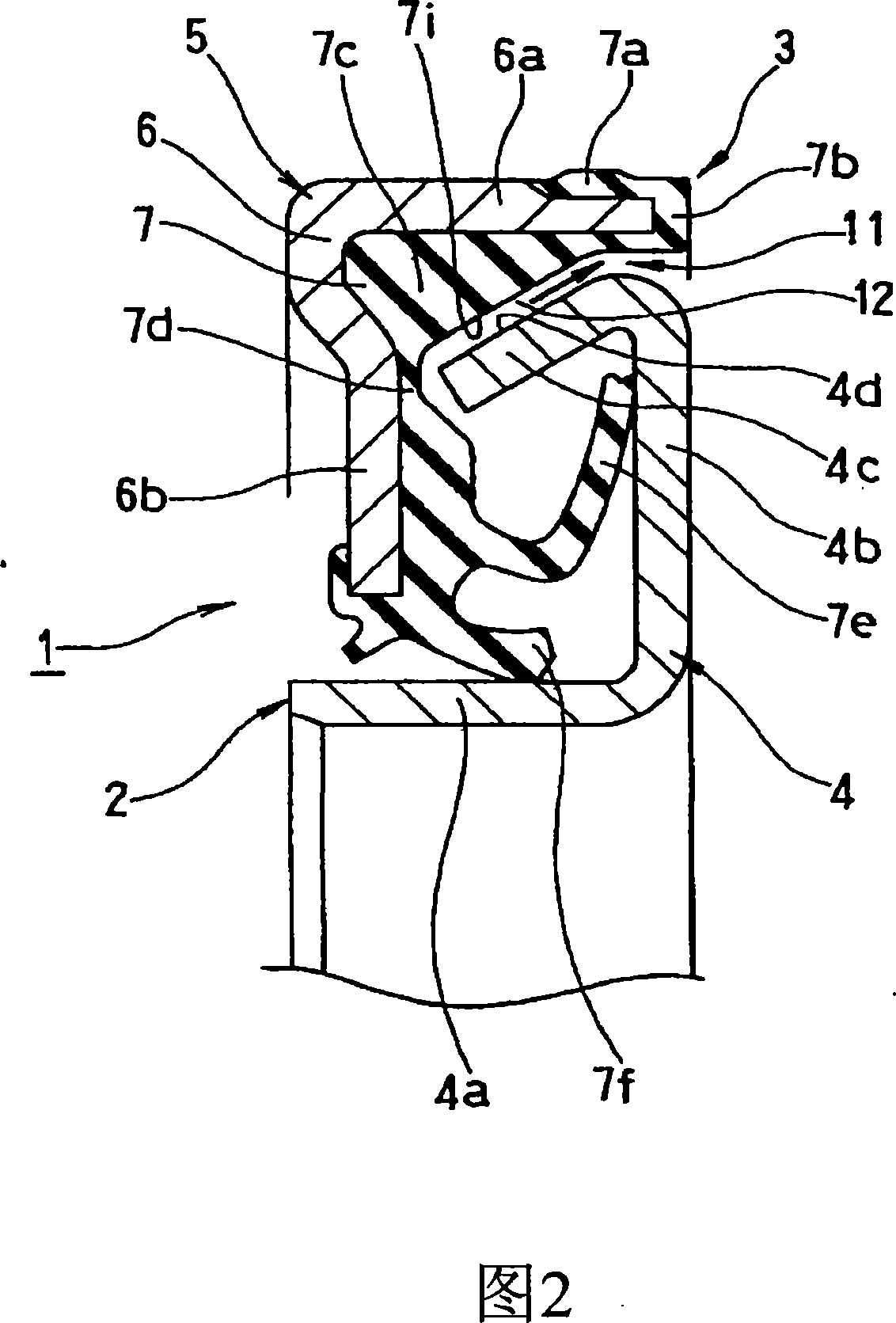

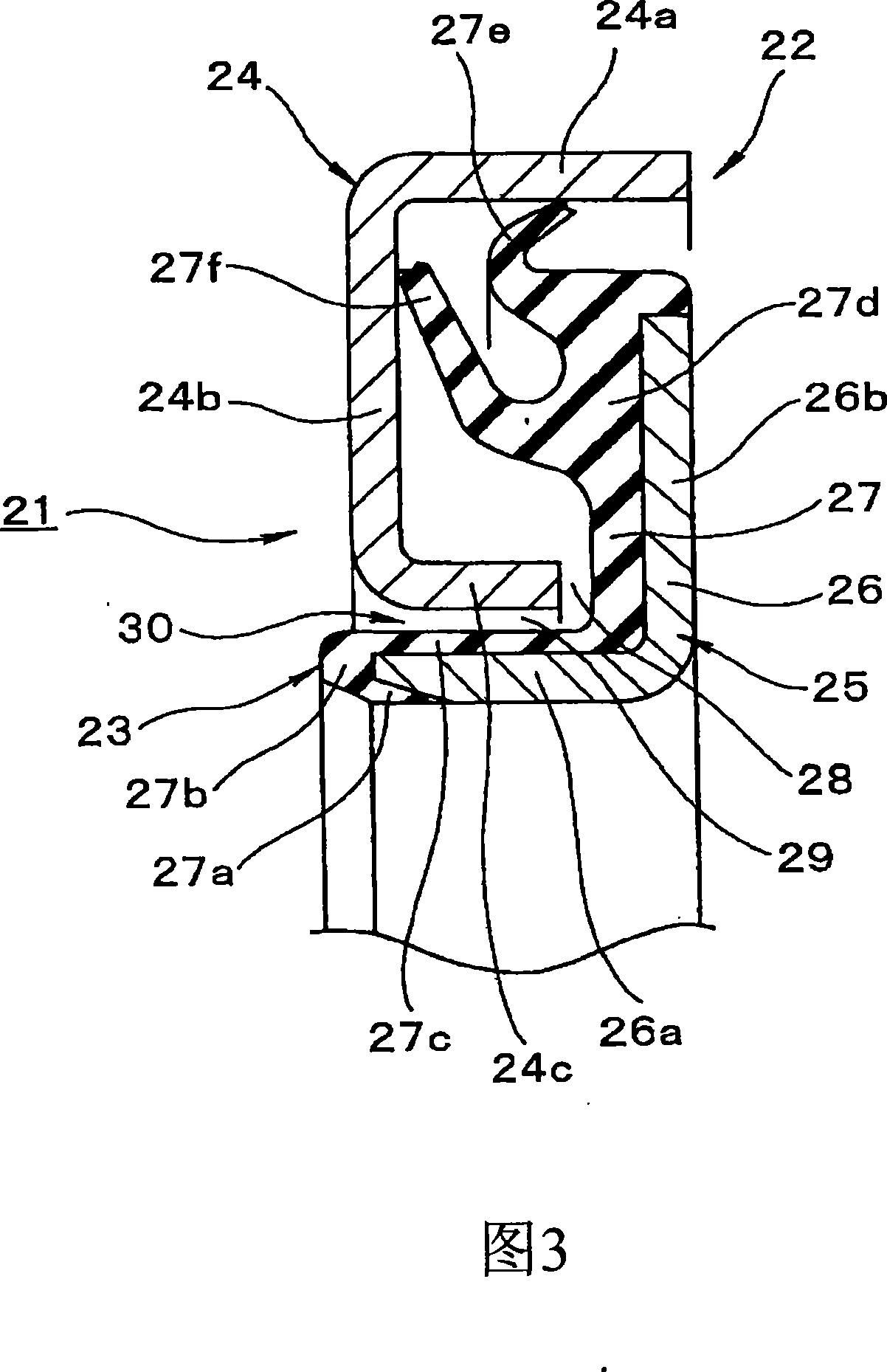

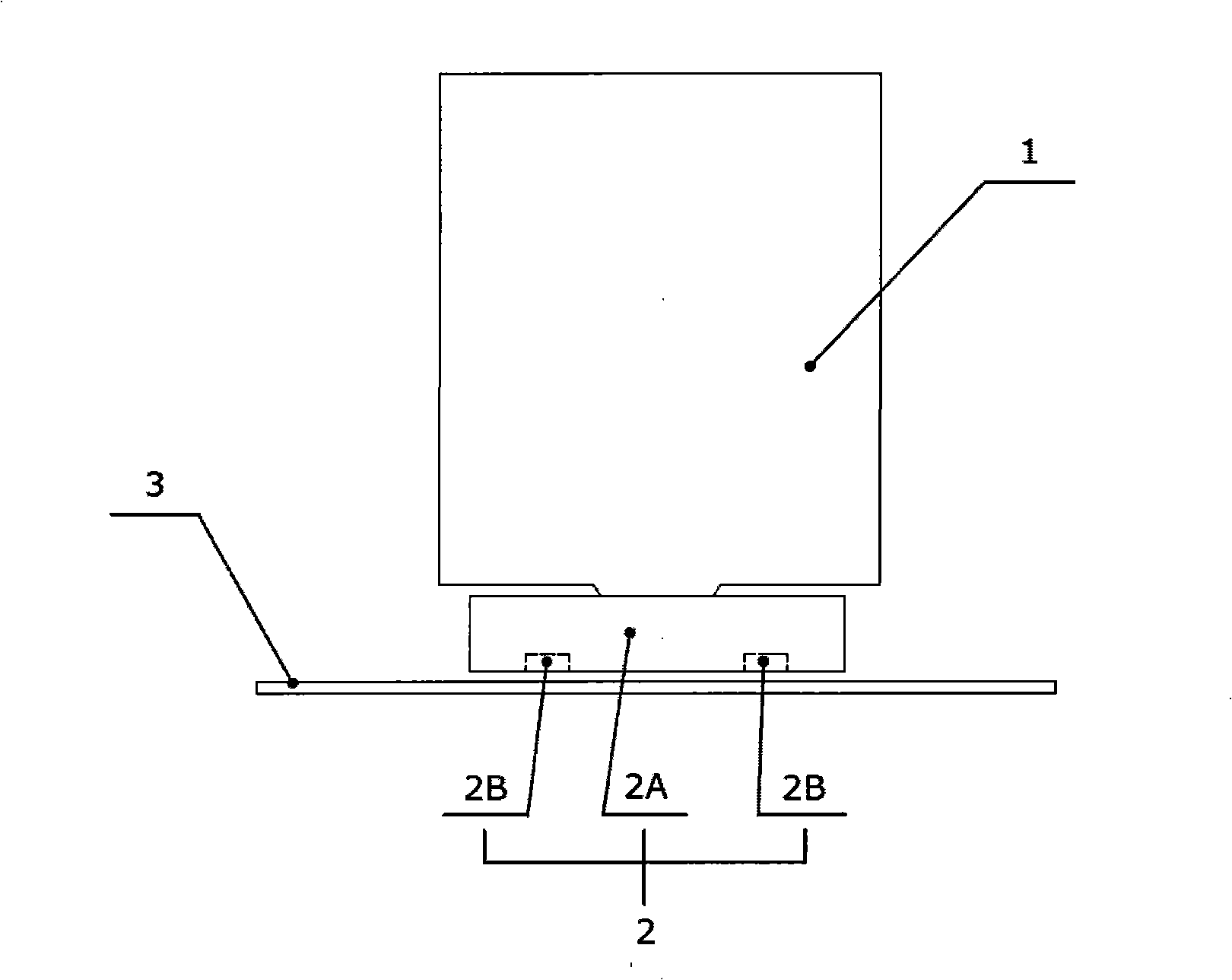

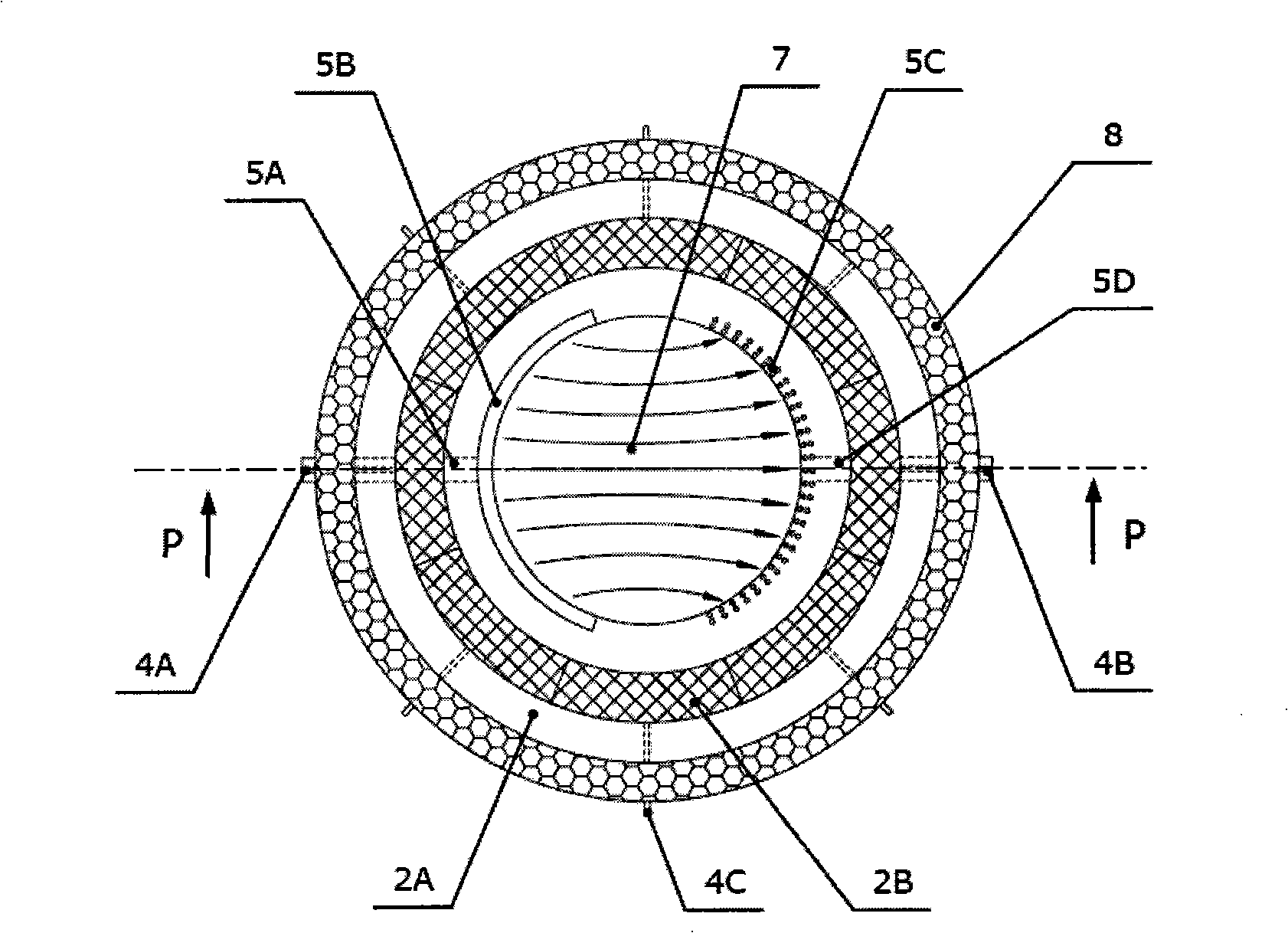

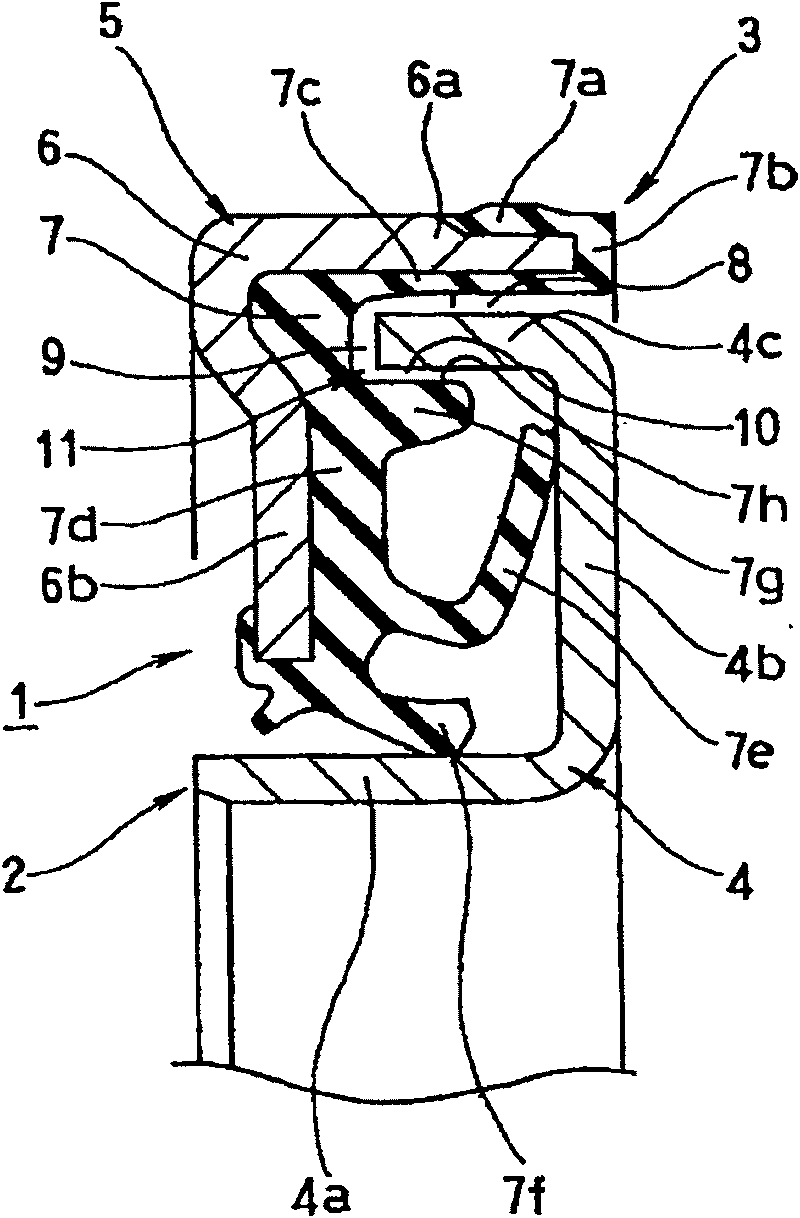

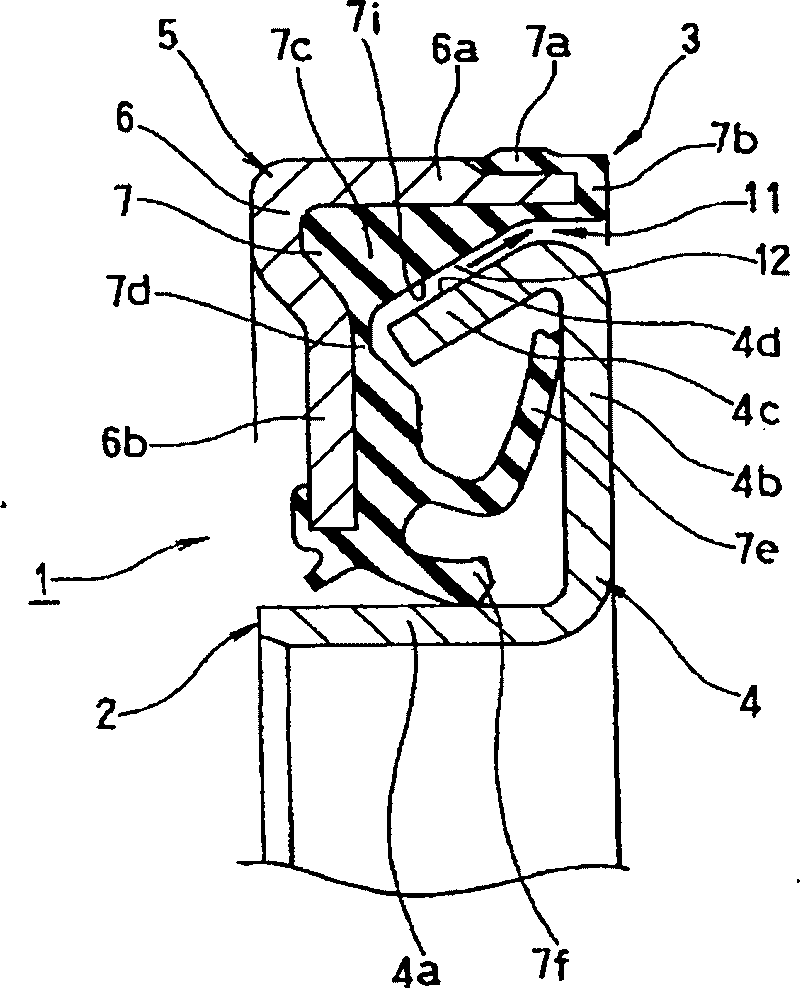

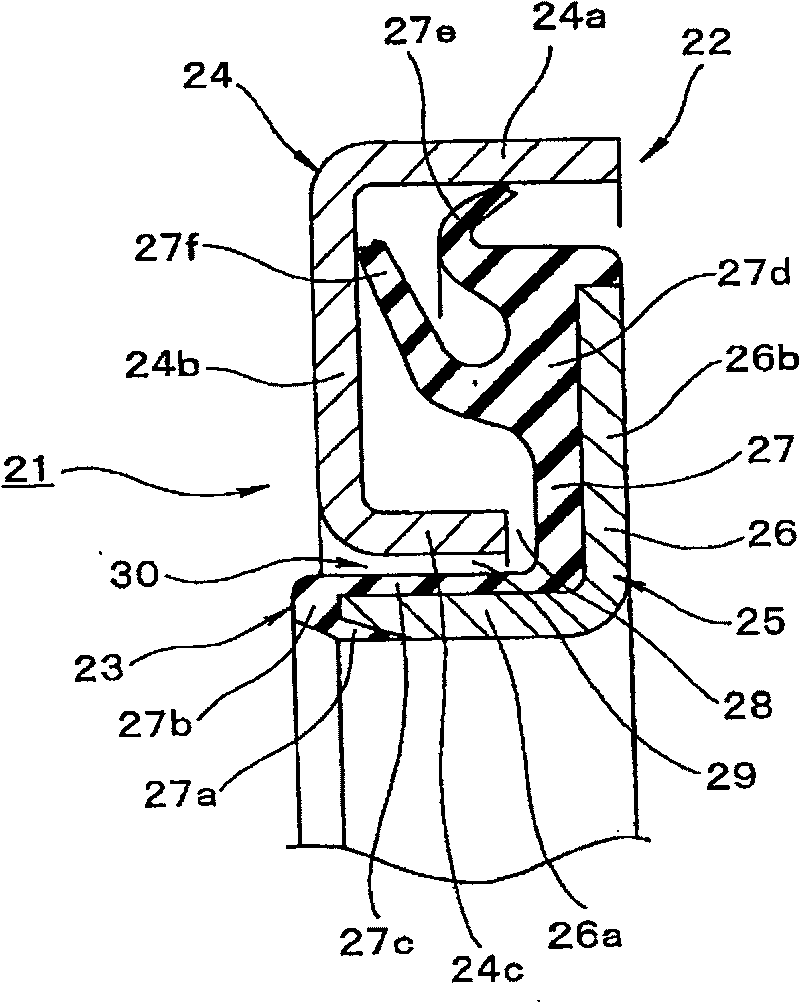

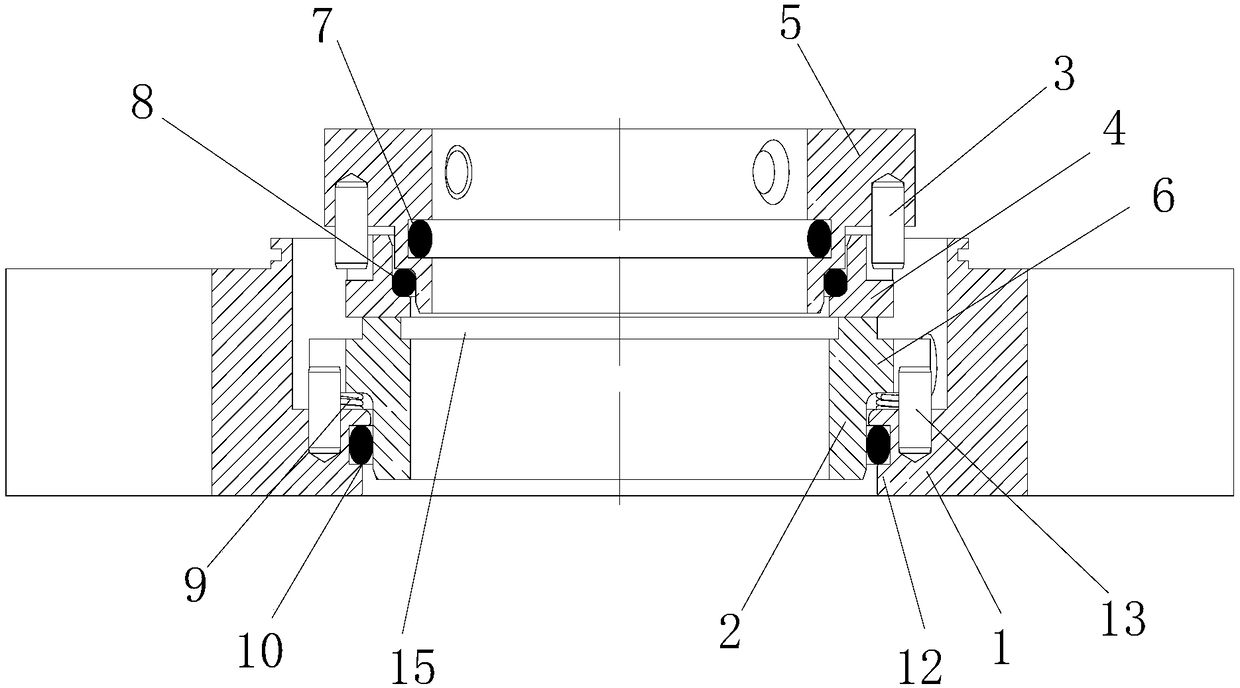

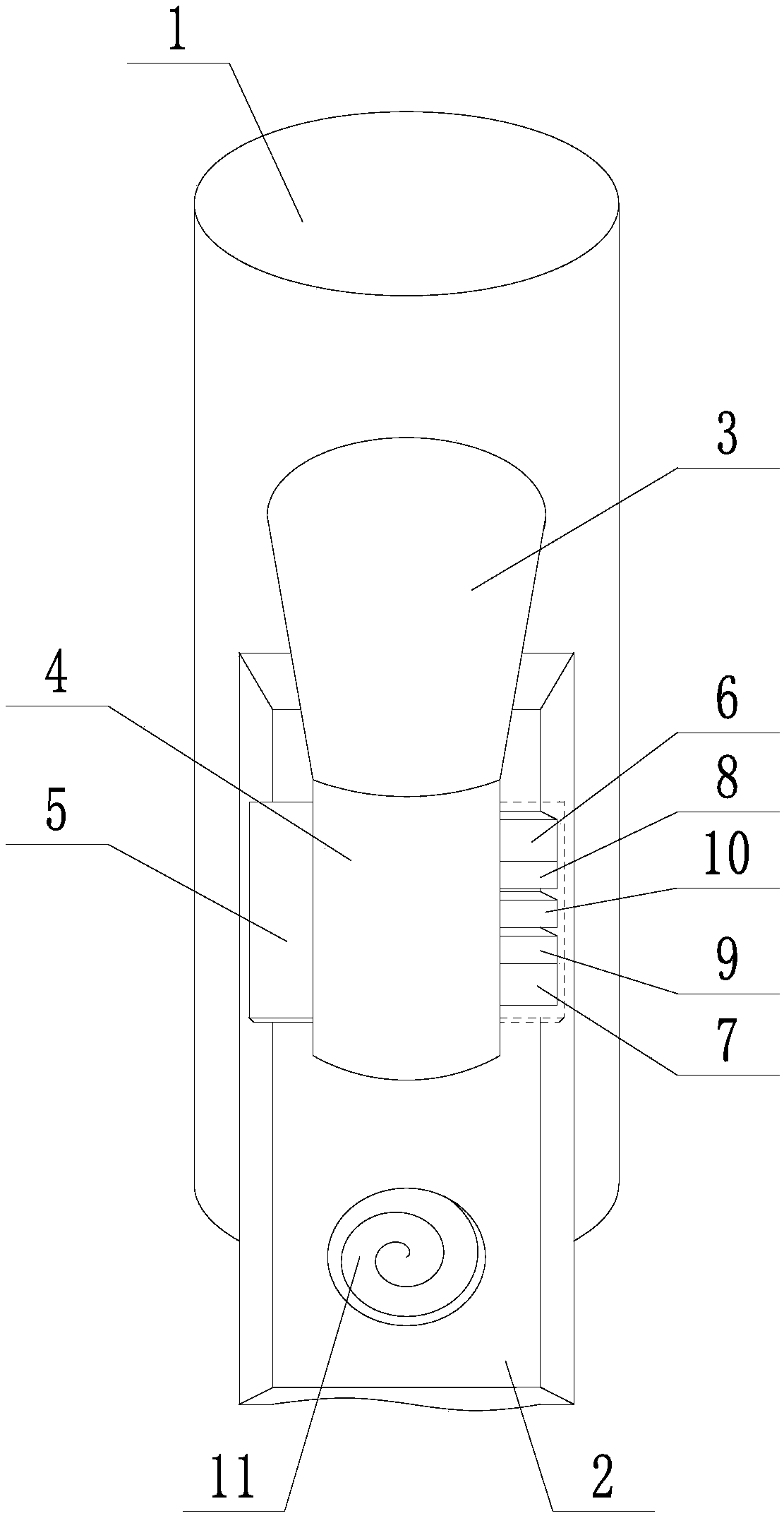

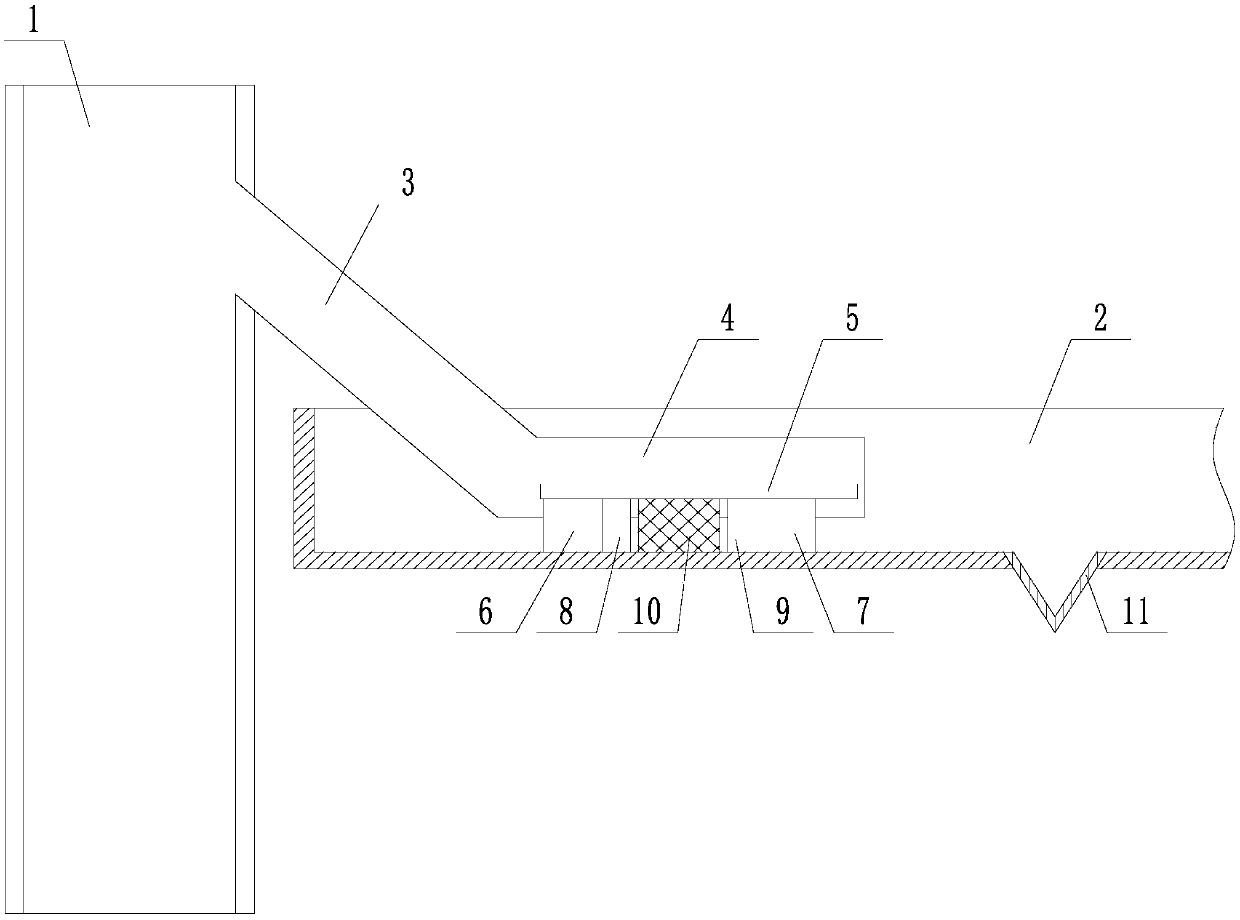

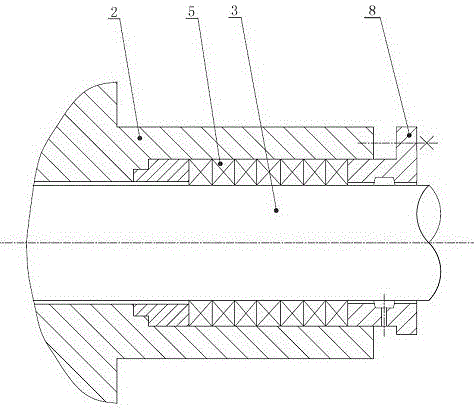

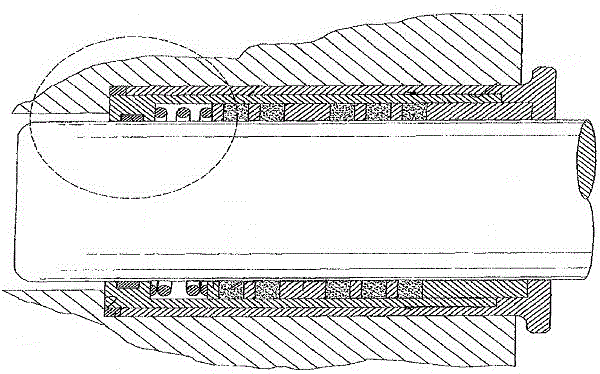

Sealing device

A sealing device (1) capable of further increasing sealing performance by a labyrinth to effectively suppress the entry of dust such as slurry, comprising an inner peripheral side sealing member (2) fitted to an inner peripheral side mounting member as one of two members rotating relative to each other and an outer peripheral side sealing member (3) fitted to the outer peripheral side mounting member as the other. An outer peripheral tube part (4c) is formed on the outer peripheral portion of the metal ring (4) of the inner peripheral side sealing member (2), and a series of long labyrinth spaces (8), (9), and (10) are formed between the outer peripheral surface of the outer peripheral tube part (4c) and the outer peripheral side sealing member (3), between the tip face of the outer peripheral tube part (4c) and the outer peripheral side sealing member (3), and between the inner peripheral surface of the outer peripheral tube part (4c) and the outer peripheral side sealing member (3).

Owner:NOK CORP

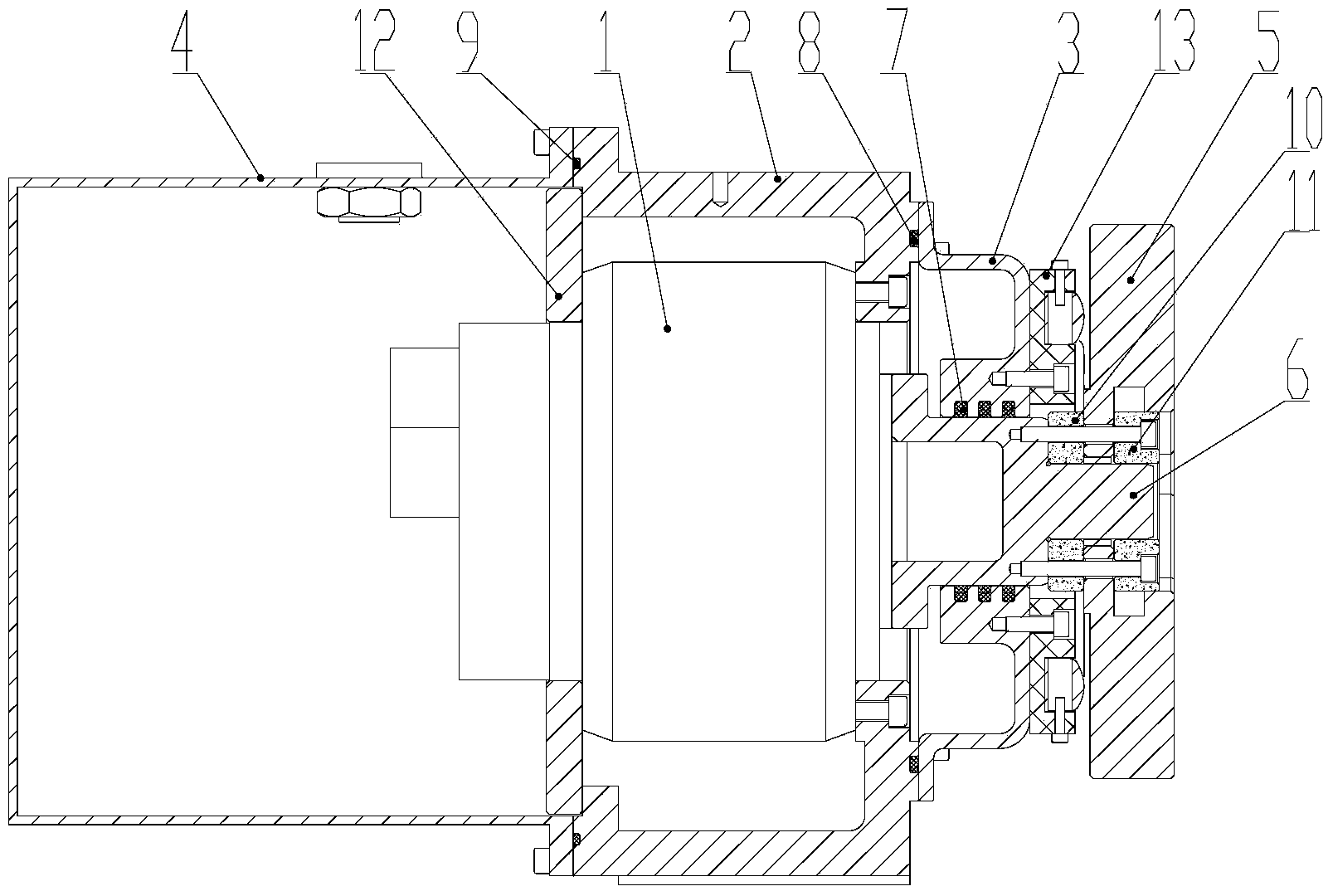

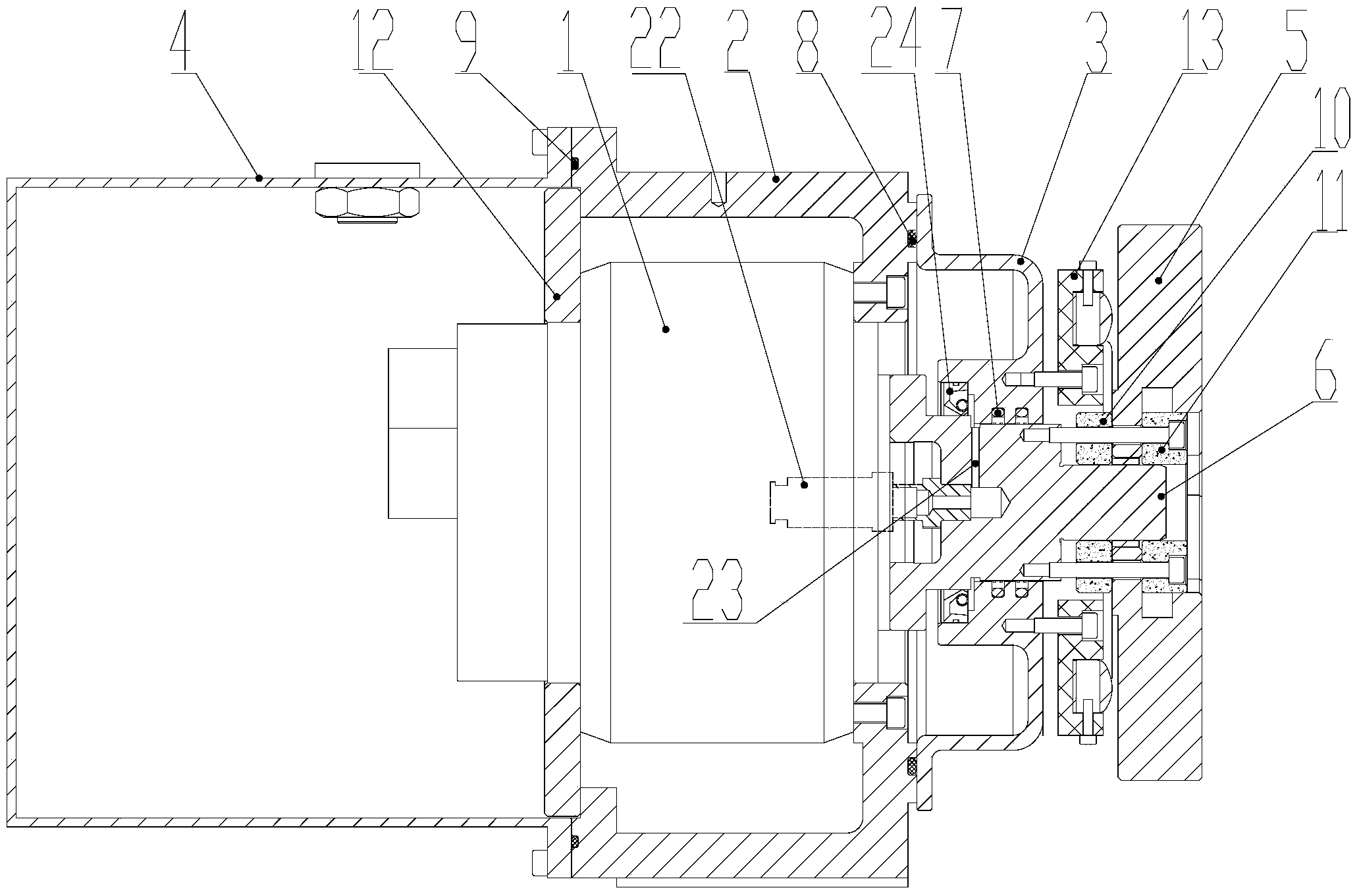

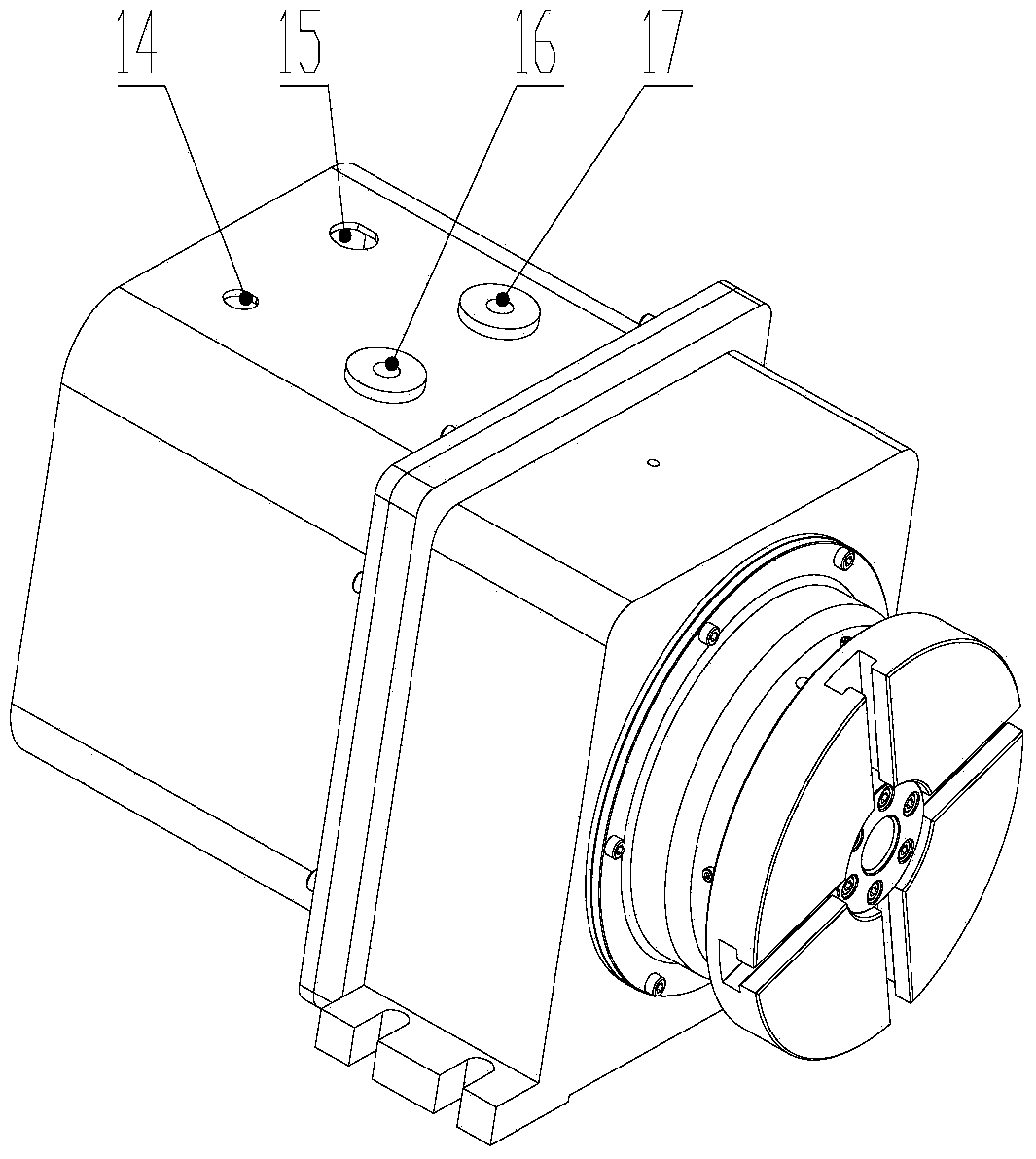

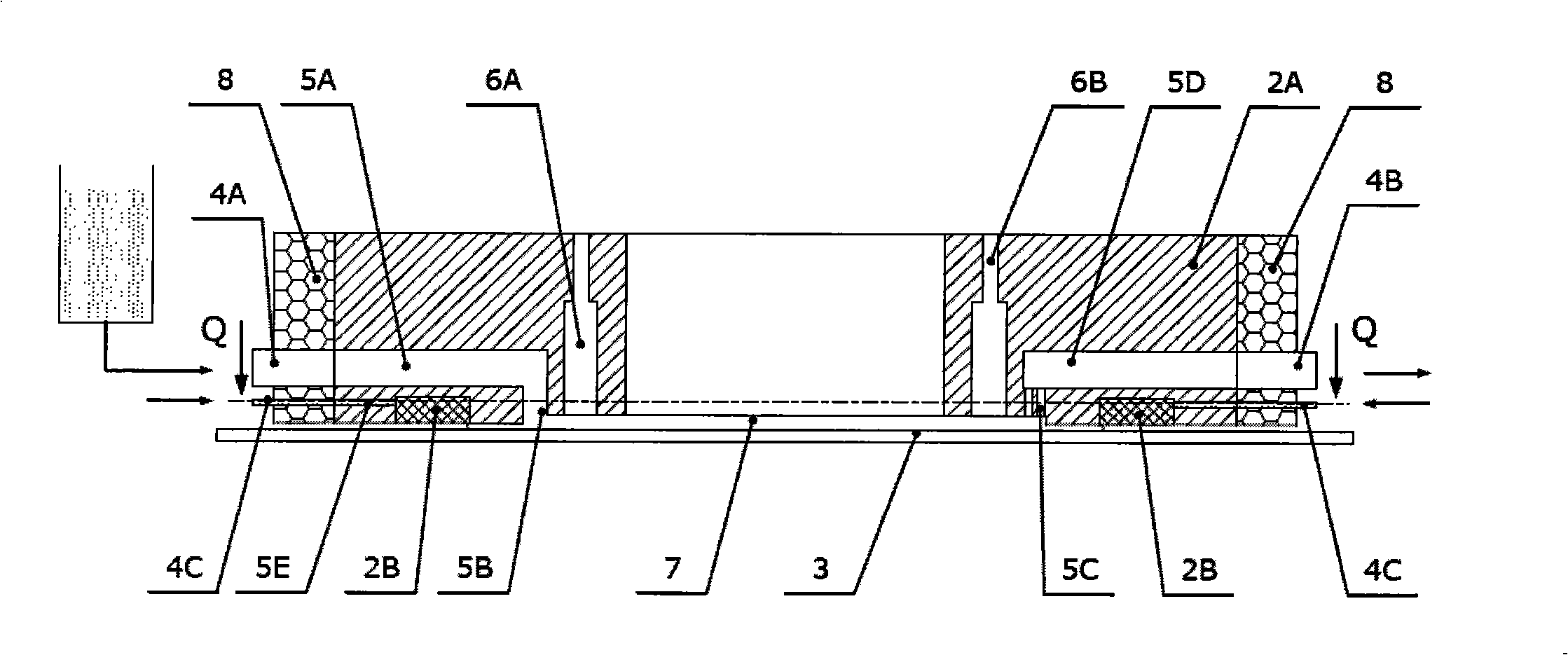

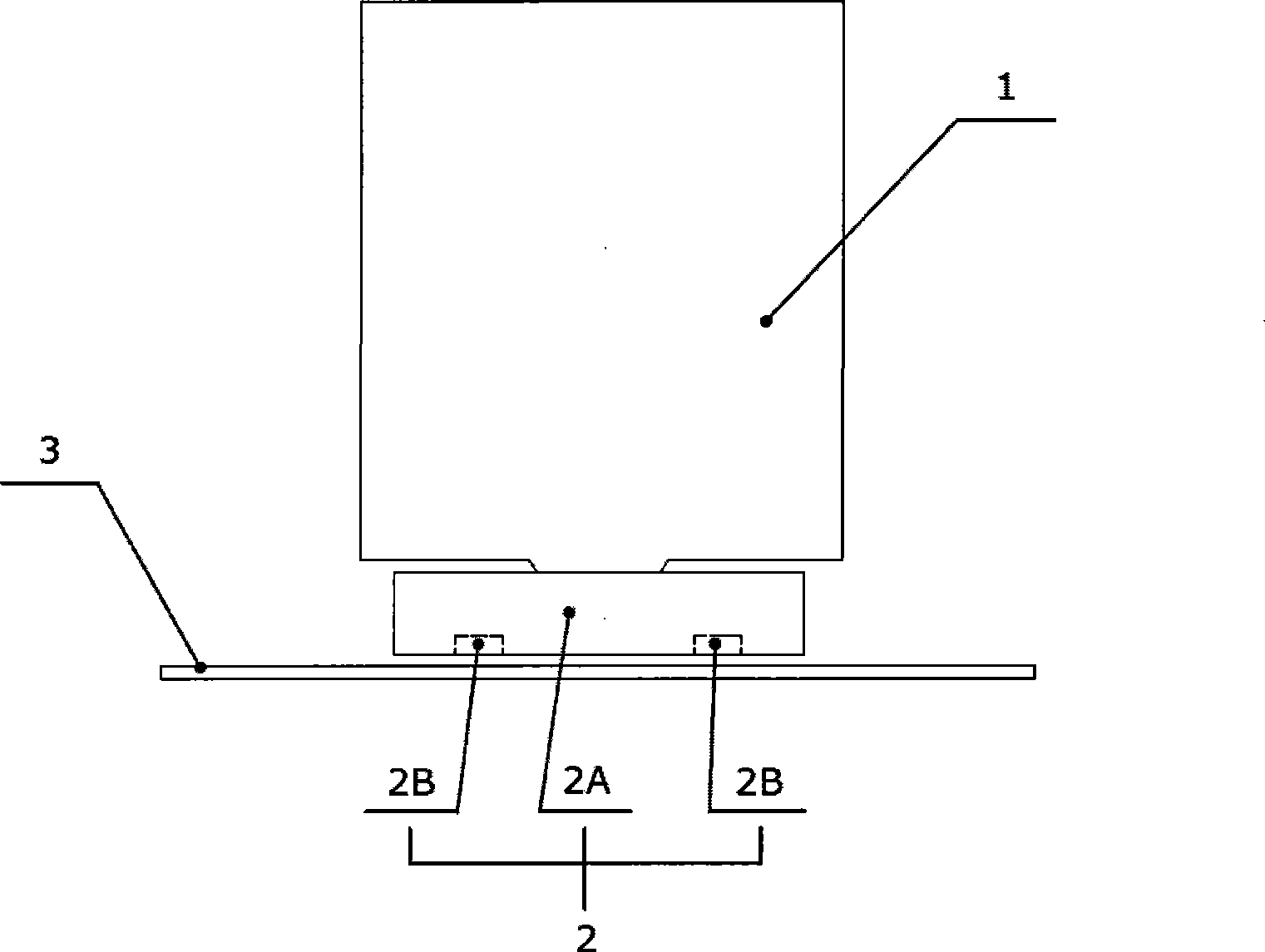

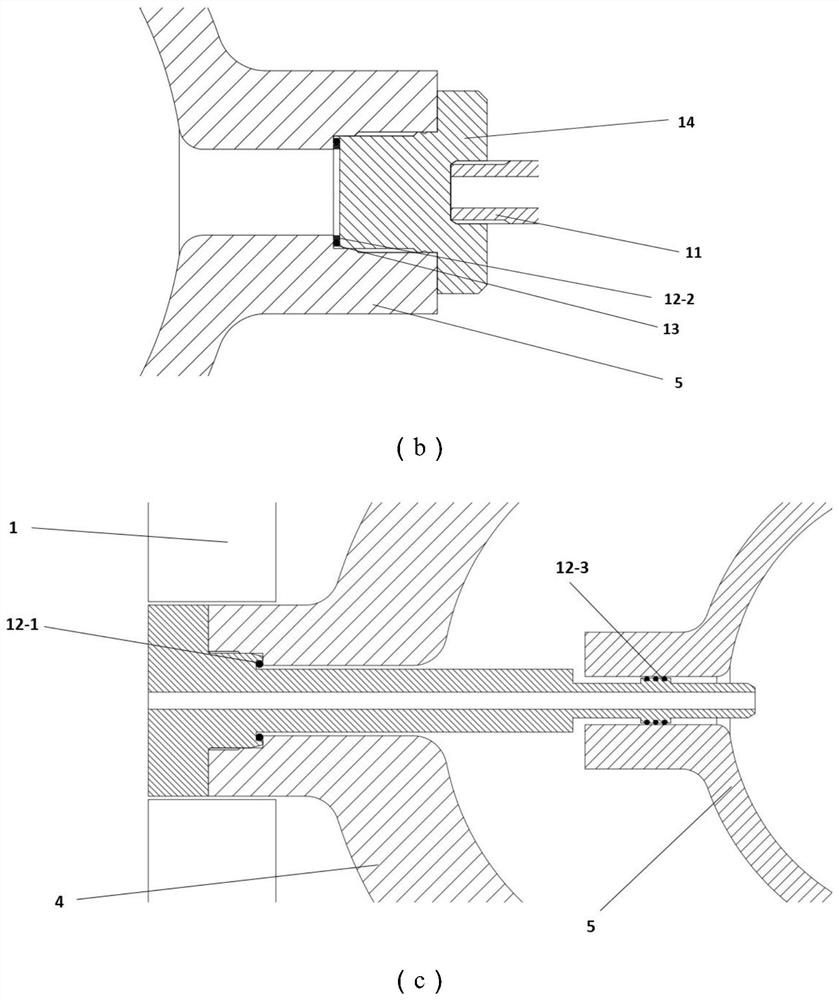

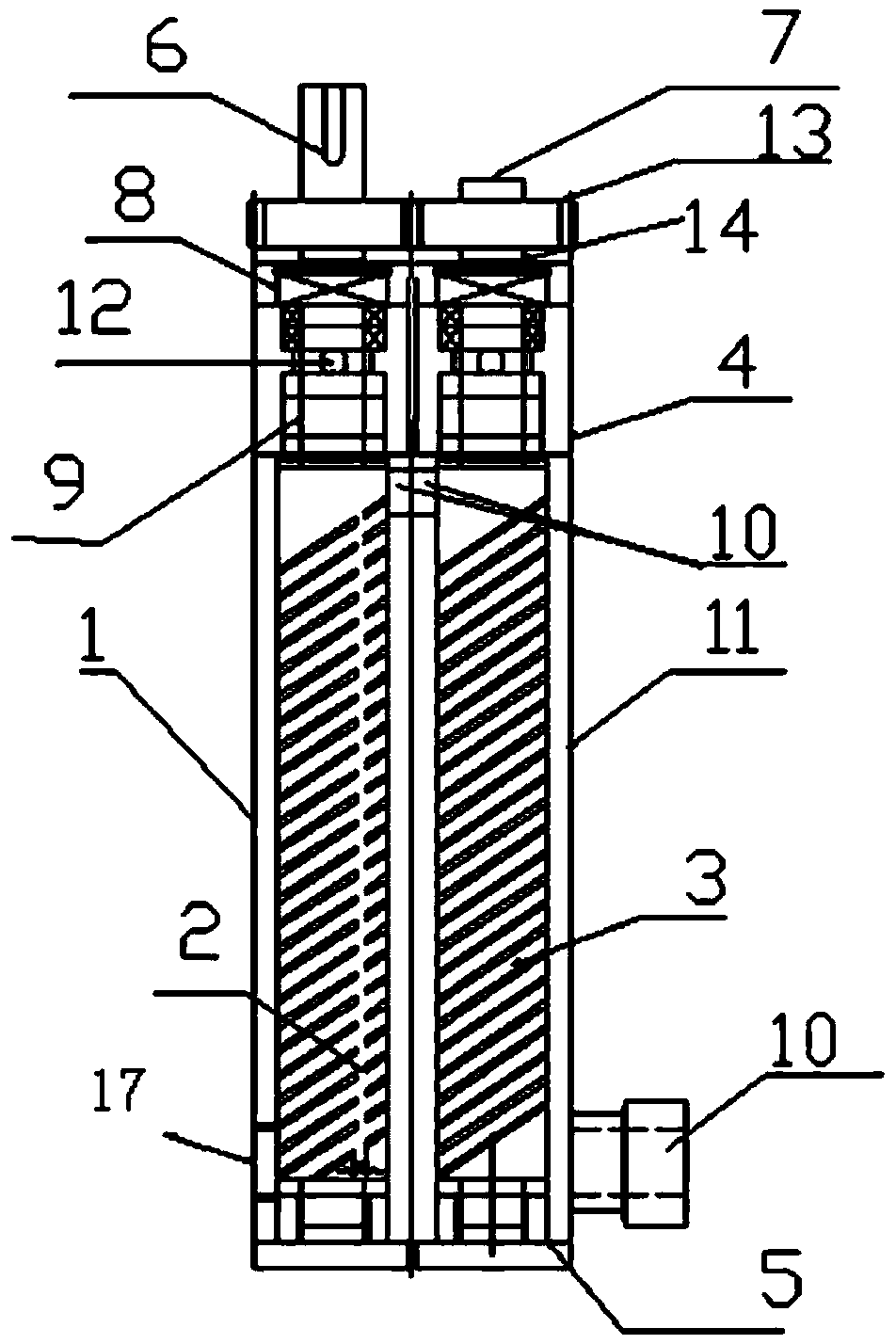

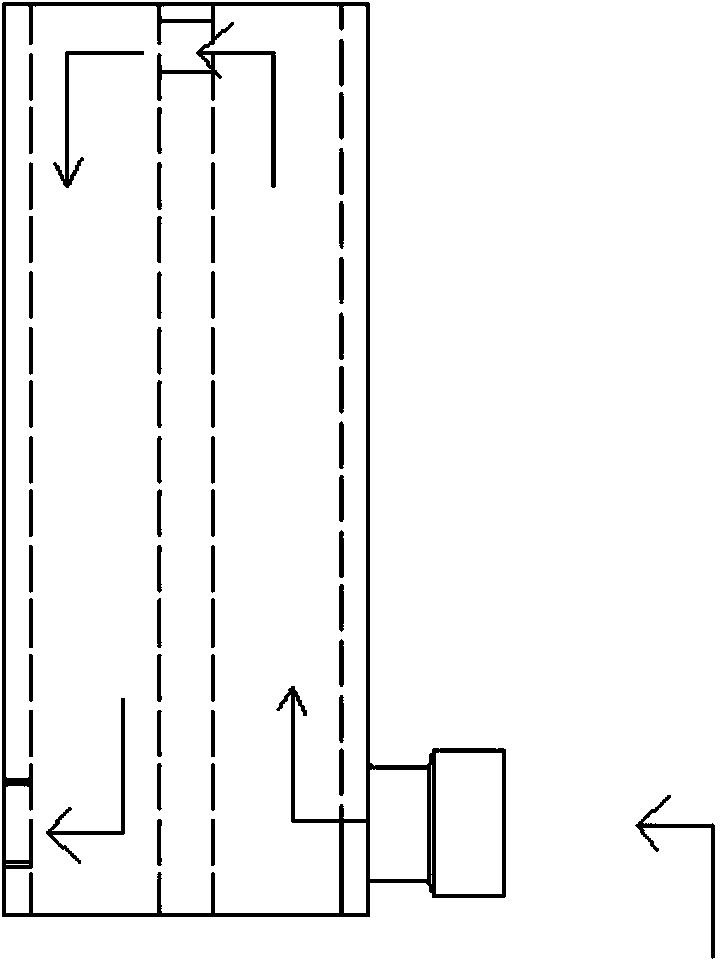

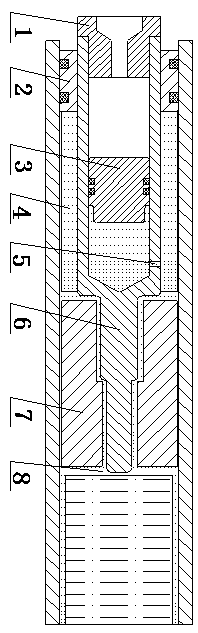

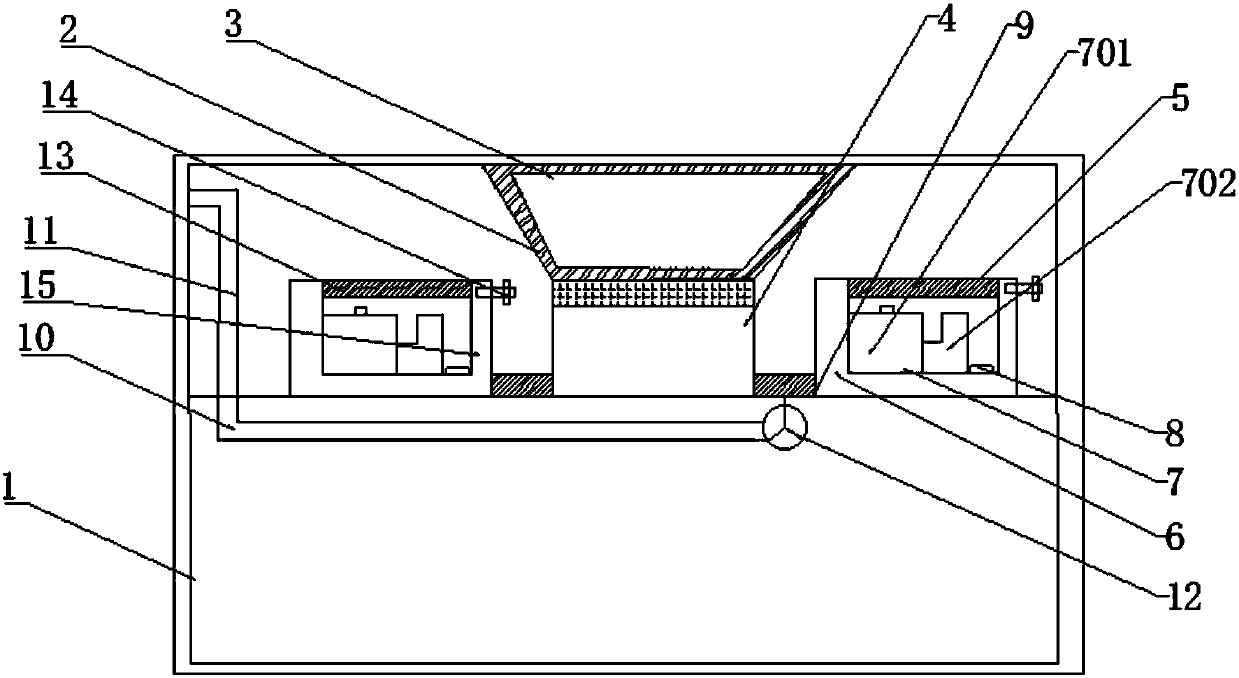

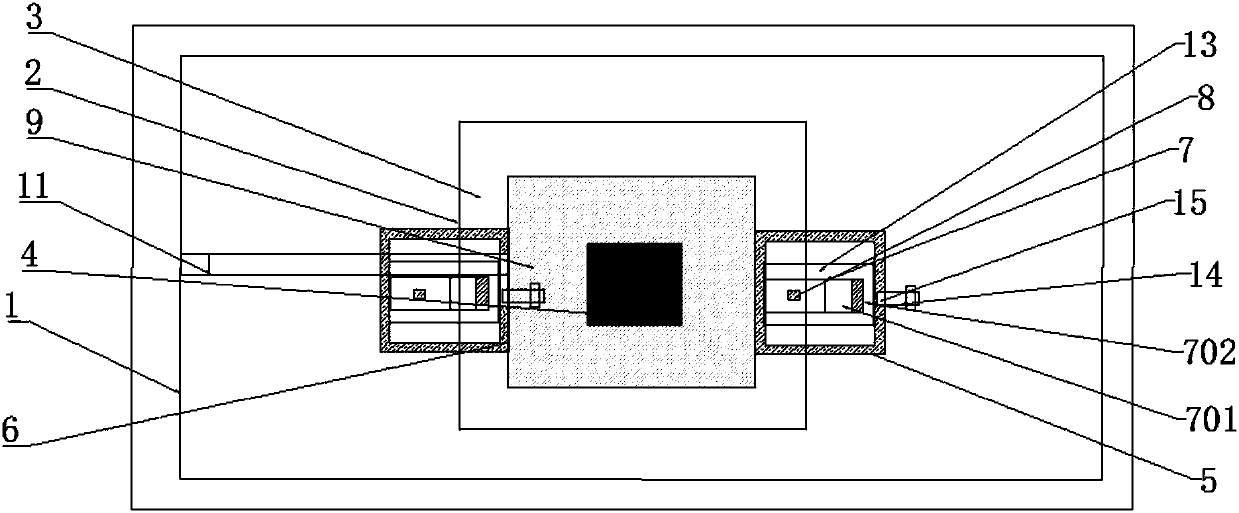

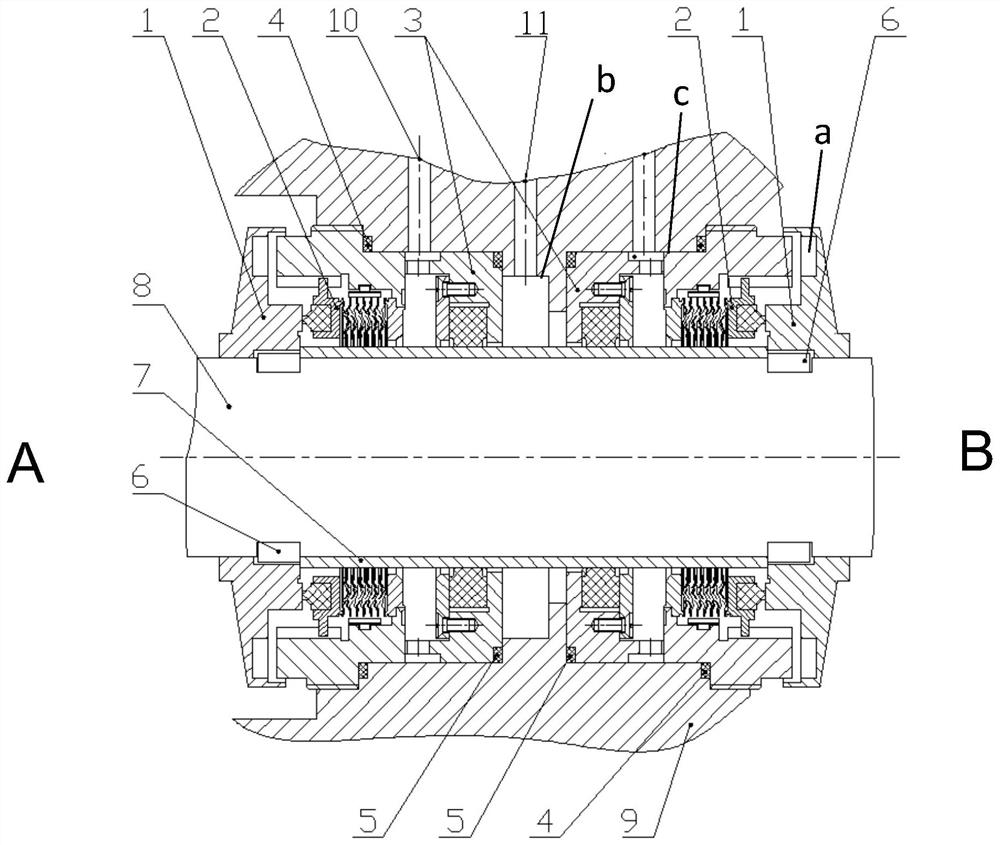

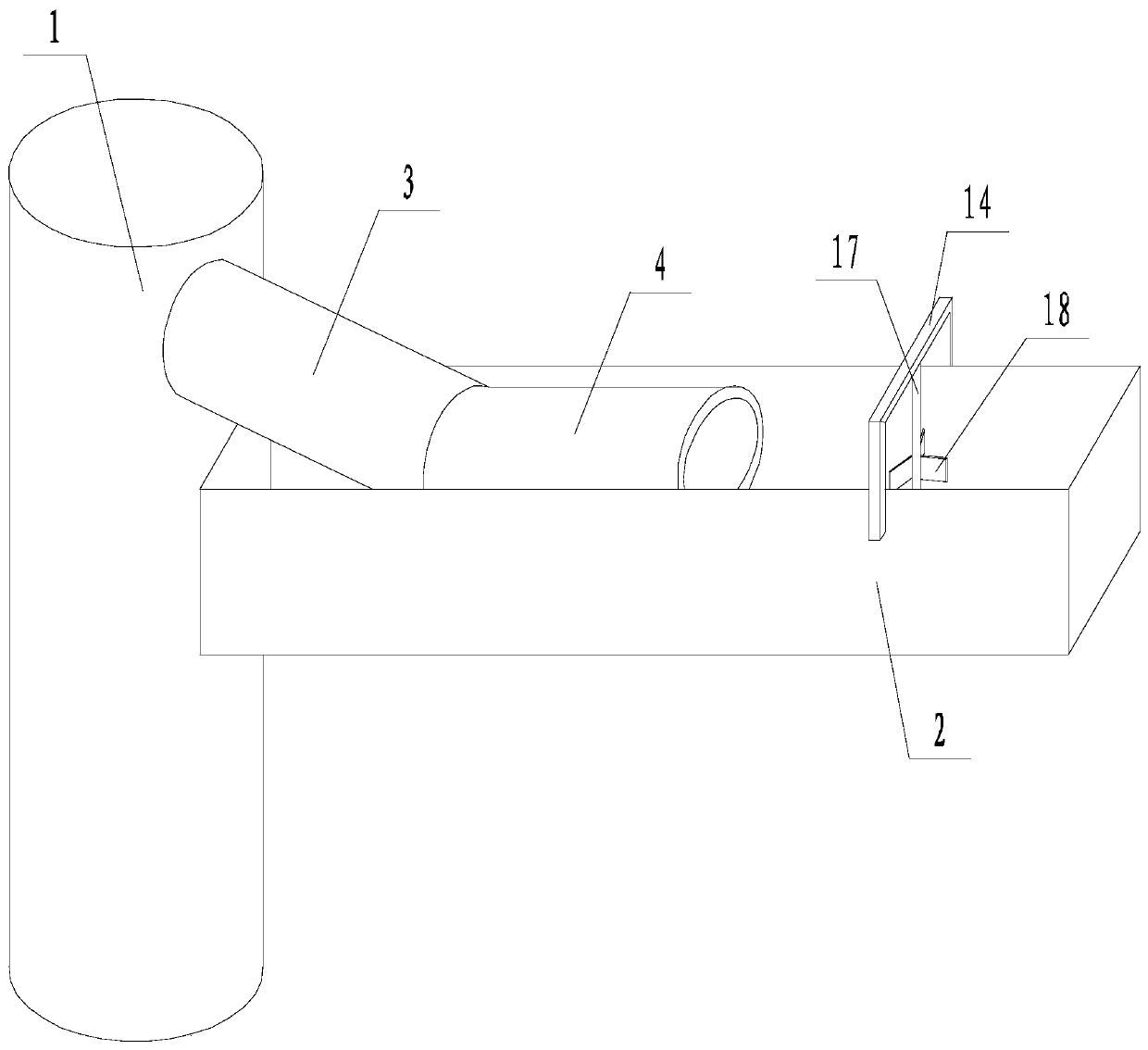

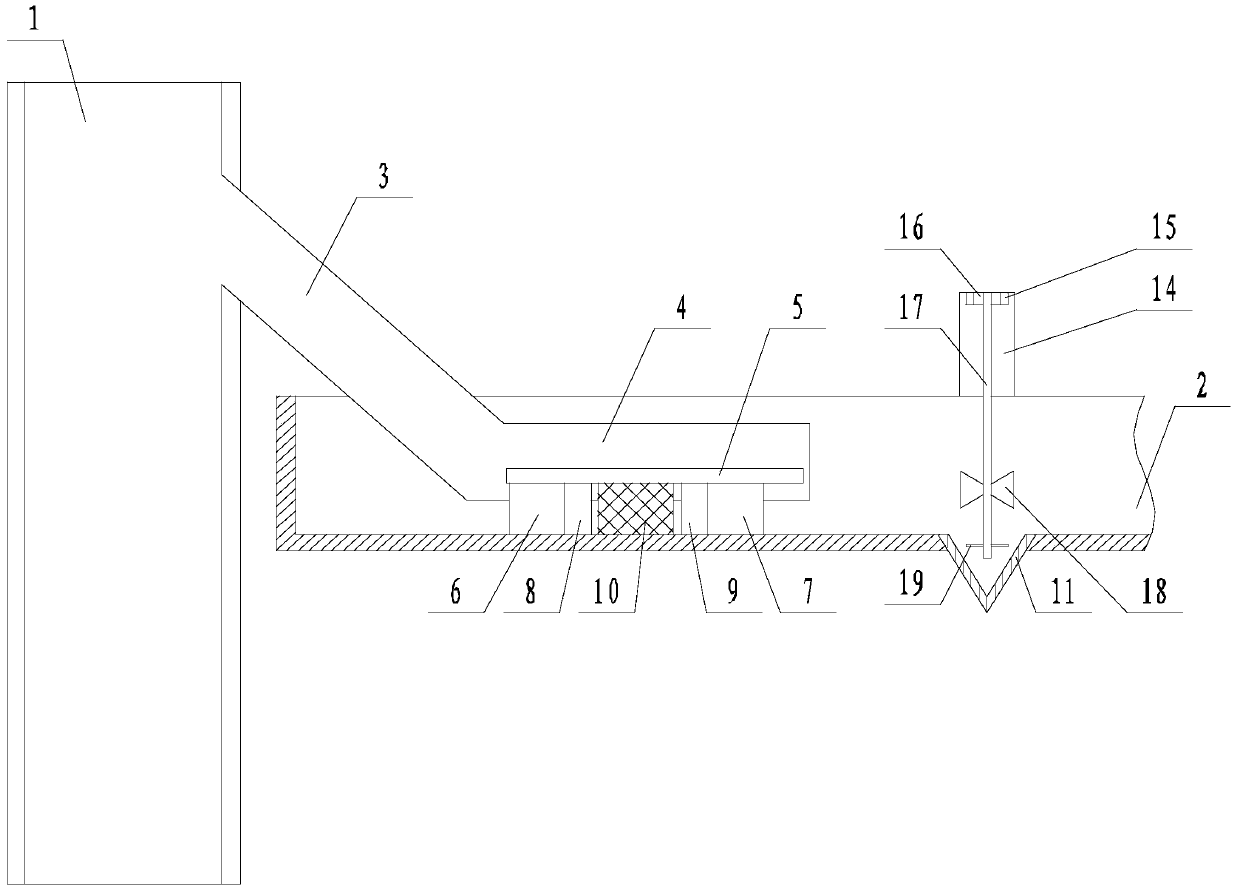

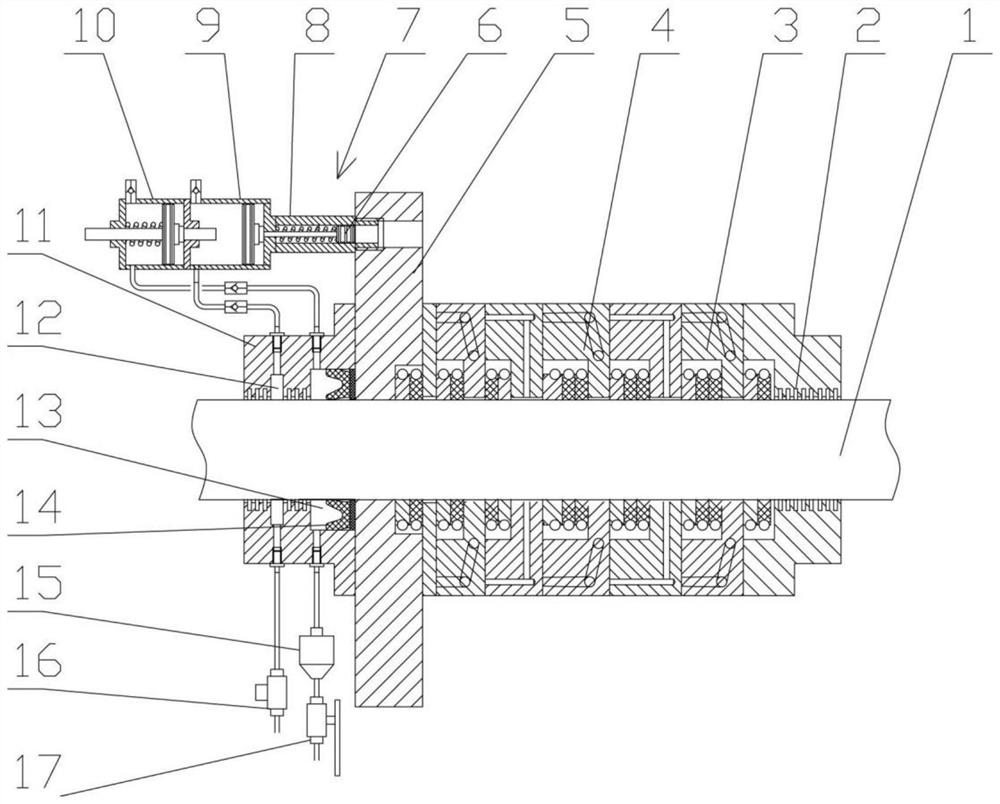

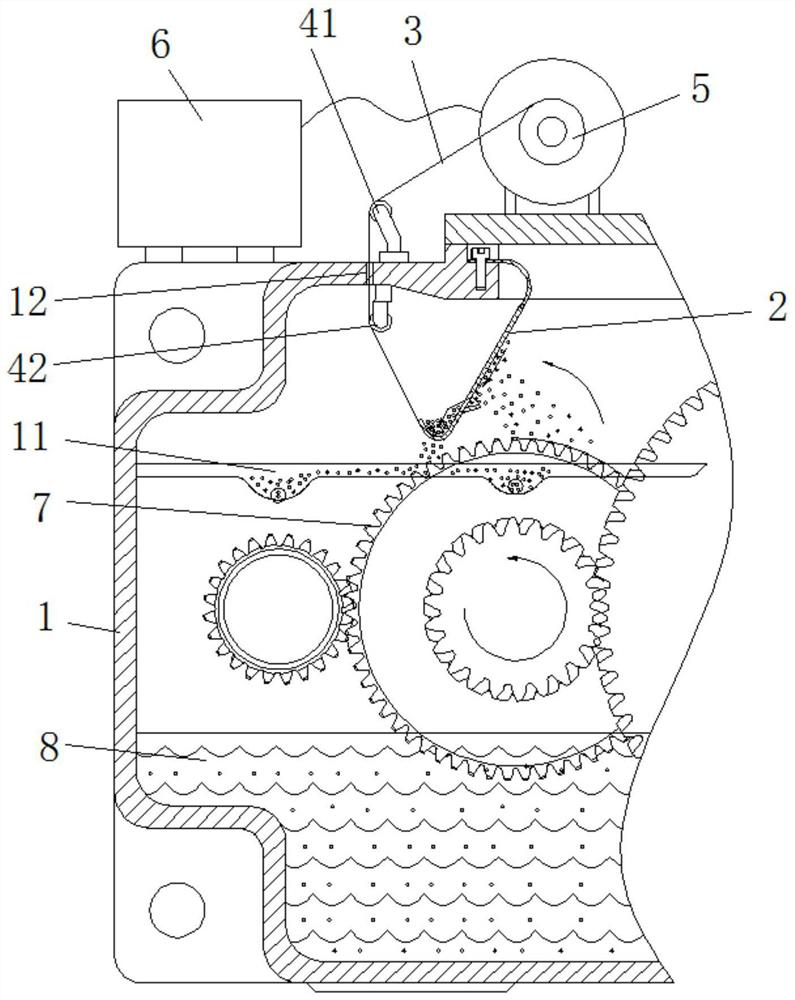

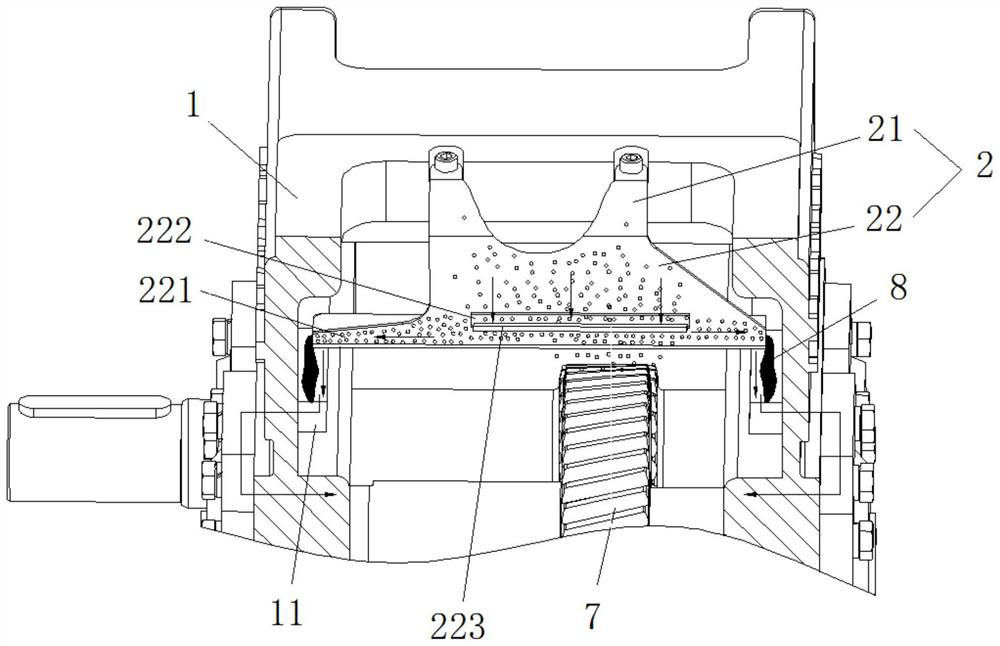

Torque motor direct-driven full immersion rotary table

ActiveCN104227163ASimple structureHigh indexing accuracyElectrical-based auxillary apparatusElectricityTorque motor

The invention provides a torque motor direct-driven full immersion rotary table comprising a supporting shell, the torque motor, an output rotary shaft and a worktable. The torque motor is fixed on the supporting shell and further sealed by a front hood and a rear hood. The output rotary shaft is directly fixed on the torque motor and penetrates the front hood in a sealed manner. The worktable is mounted on the output rotary shaft in an insulation manner. A powering structure is arranged between the worktable and a frame. By adopting the torque motor direct drive manner, the full immersion rotary table is simple in structure, small in size and high in indexing accuracy; a combined sealing manner includes pneumatic sealing, dynamic sealing, a drain-back passage and static sealing, allowing effective sealing performance; with the axial powering manner adopted, the powering system is convenient to mount to lead to good powering effect; with the two-point supporting manner adopted, the rotary table is good in bearing effect and stable in dynamic performance.

Owner:北京市电加工研究所有限公司 +1

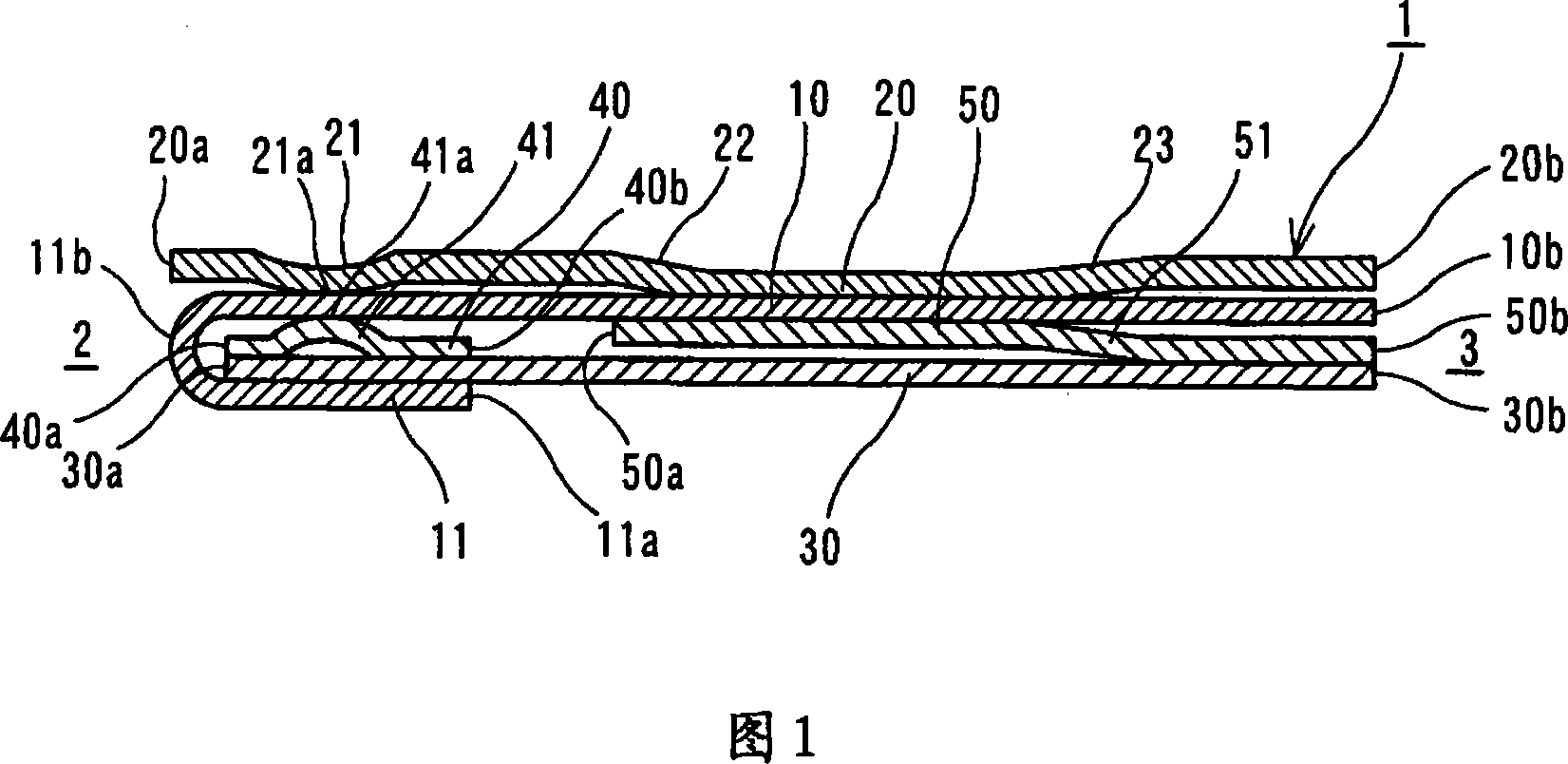

Resin Composite Fuel Hose

ActiveUS20070227607A1Easy to installReduce tightening forceSynthetic resin layered productsFlexible pipesSurface layerEngineering

A resin composite fuel hose of a multilayer construction includes a resin layer as a barrier layer having a fuel permeation resistance, an inner rubber layer as an inner surface layer laminated on an inner side of the resin layer and an outer rubber layer laminated on an outer side of the resin layer. The outer rubber layer has a rubber hardness degree equal to or greater than that of the inner rubber layer, and the inner rubber layer has a permanent elongation equal to or less than 90%.

Owner:SUMITOMO RIKO CO LTD

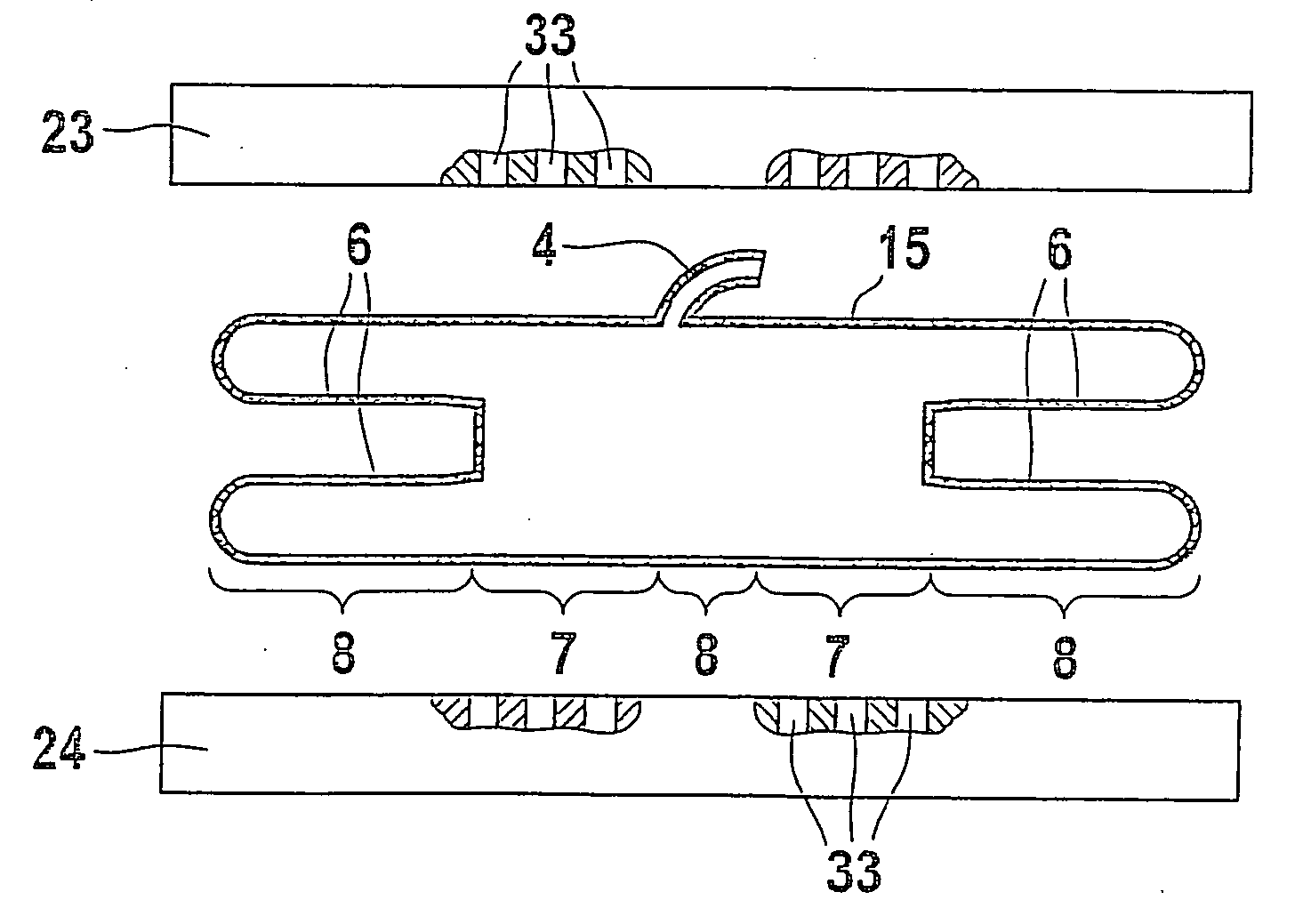

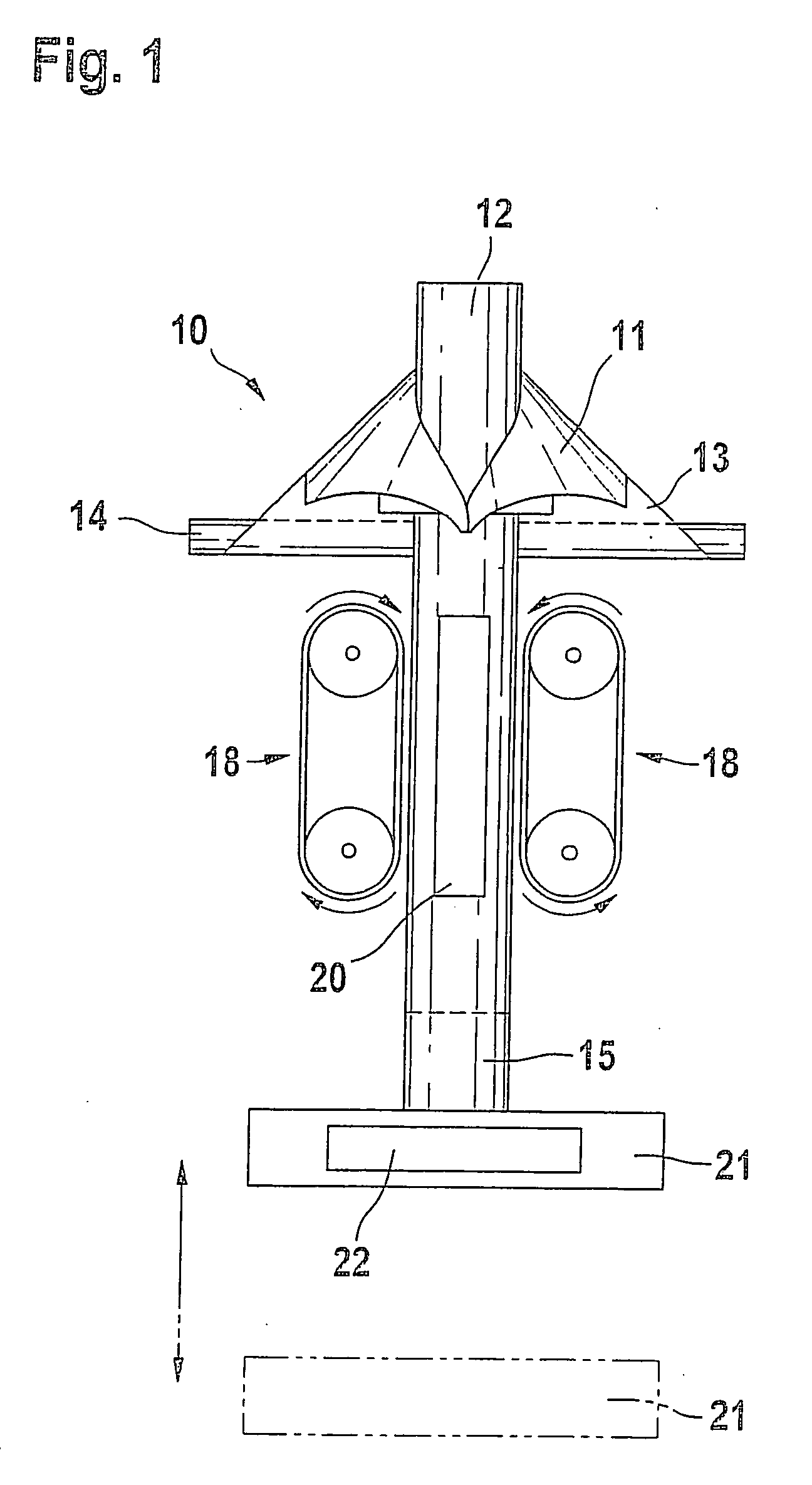

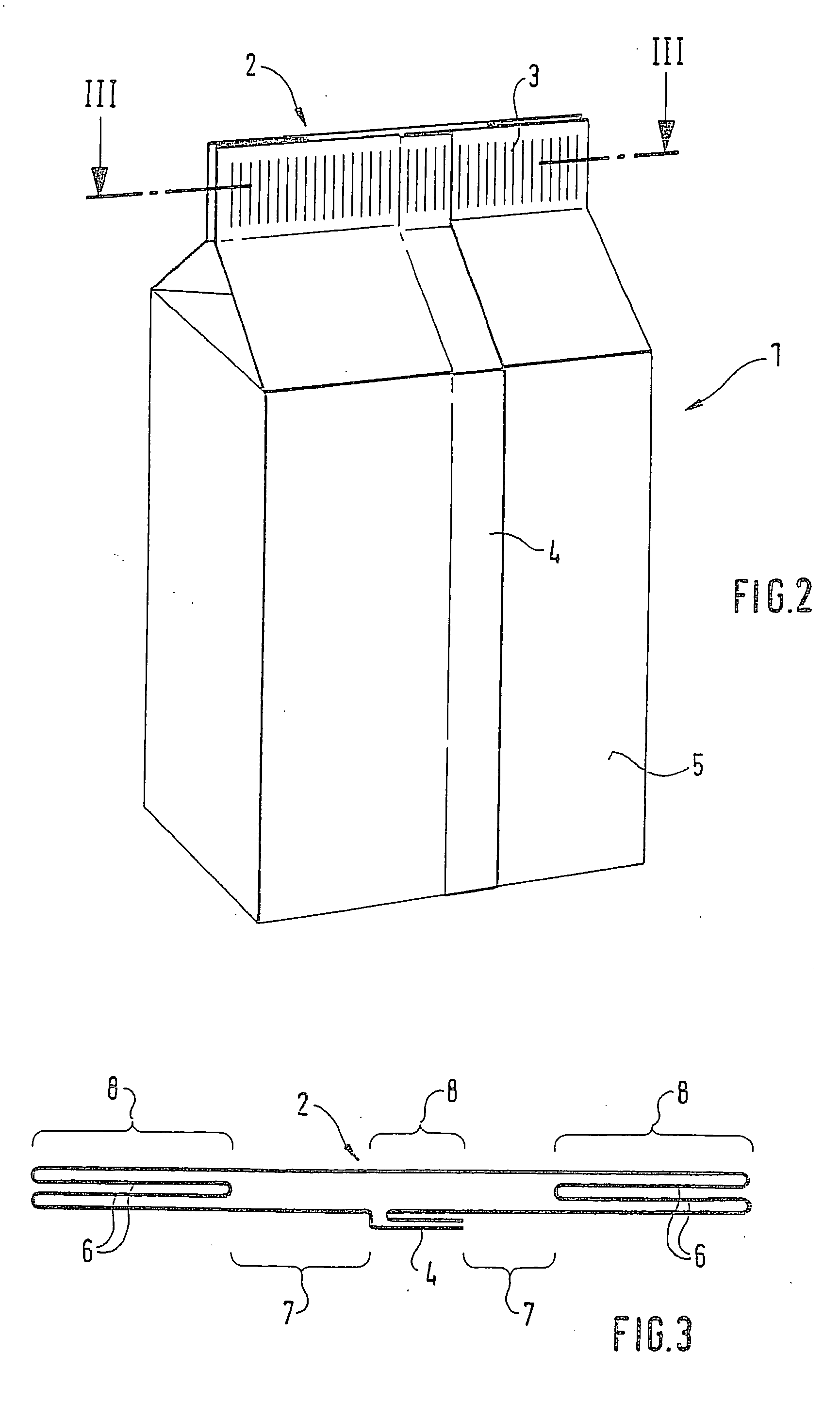

Device and method for producing and sealing packagings produced from at least one heat sealable packaging material strip

InactiveUS20040244338A1Adequate warming of packaging materialIncrease productionPackaging by pressurising/gasifyingWrapper twisting/gatheringMechanical engineeringPhysics

A tubular bag-making machine for forming a flexible tube from a hot-sealable web of packaging material sealed longitudinally by means of a longitudinal seam sealing device and transversely by means of a transverse seam sealing device to produce individual tubular bag packages. To improve the transverse sealing seams, bores which can be made to communicate in alternation with a negative-pressure source or an overpressure source are embodied in the sealing jaws of the transverse seam sealing device in regions having a reduced number of layers of packaging material to enable a good heat transfer and a higher sealing pressure in the region of changes in the number of layers of packaging material of the transverse sealing seams.

Owner:ROBERT BOSCH GMBH

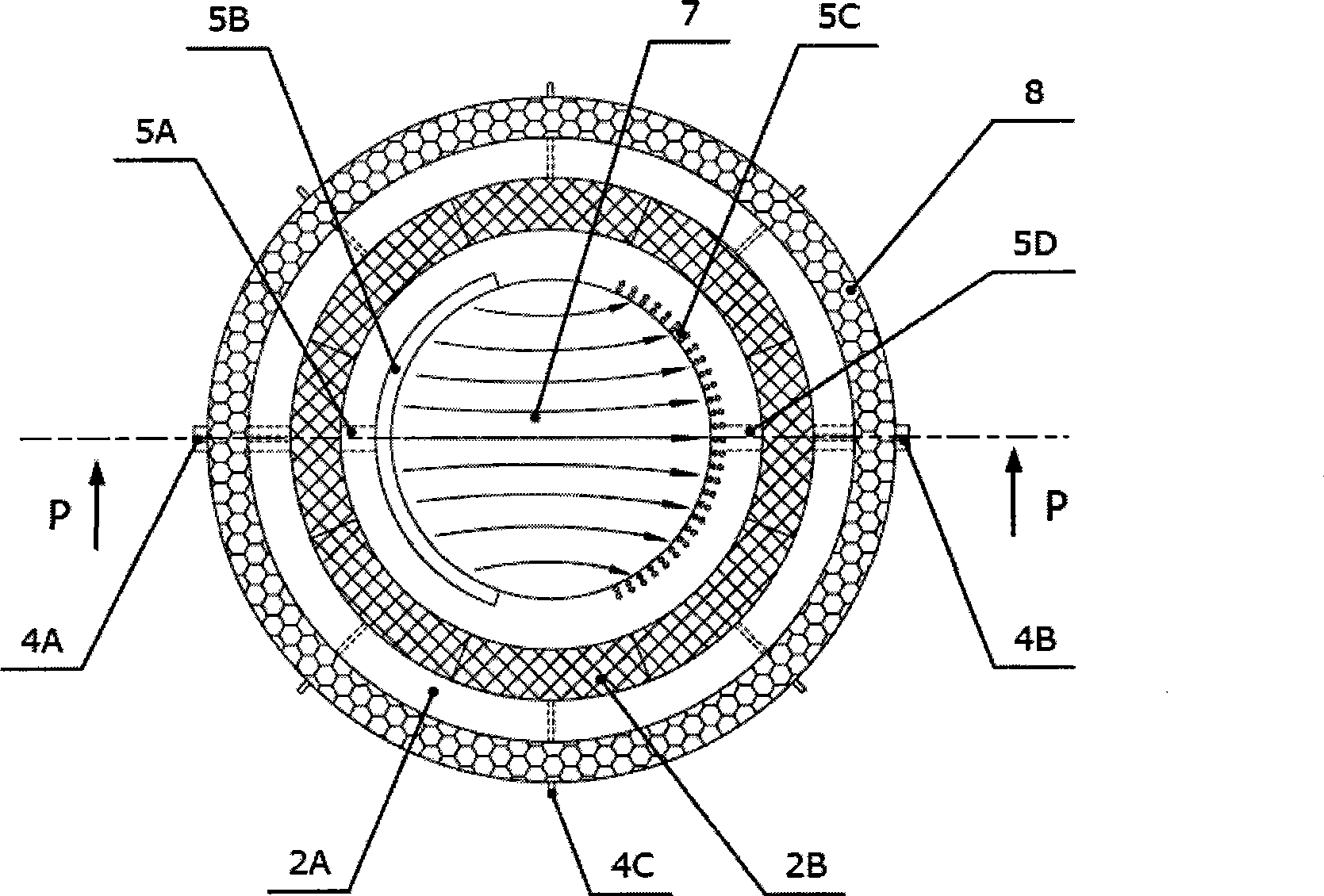

Immersion self-adapting seal control device used for photo-etching machine

InactiveCN101403861APrevent flow field fluctuationsAvoid interferencePhotomechanical exposure apparatusMicrolithography exposure apparatusLithographic artistEngineering

The invention discloses an immersion self-adaptive sealing control device used in a lithography machine. The immersion self-adaptive sealing control device is arranged between a projection lens set and a substrate, and consists of a sealing element and a self-adaptive sealing member. When liquid forms the impact on the self-adaptive sealing member due to traction of the substrate, the device can absorb the impact formed by the high-speed moving liquid and converts the impact into power enhancing sealing; on the contrary, when the substrate draws the liquid away from the self-adaptive sealing member, the liquid prestored inside the device follows to enter a slit flow field to avoid gas bubble entrainment owing to the loss of the liquid at the boundary, meanwhile, the reduction of the liquid prestored inside the device reduces the sealing power of the self-adaptive sealing member, and the leaked liquid flows back to the inside of the slit flow field along with the substrate due to the reduction of obstruction. The liquid transmission mode of the immersion self-adaptive sealing control device adopts negative pressure recovery and free flow of a fluid injection end, which avoids the flow field fluctuation caused by the in-coordination between the injected fluid and the recovery pressure.

Owner:ZHEJIANG UNIV

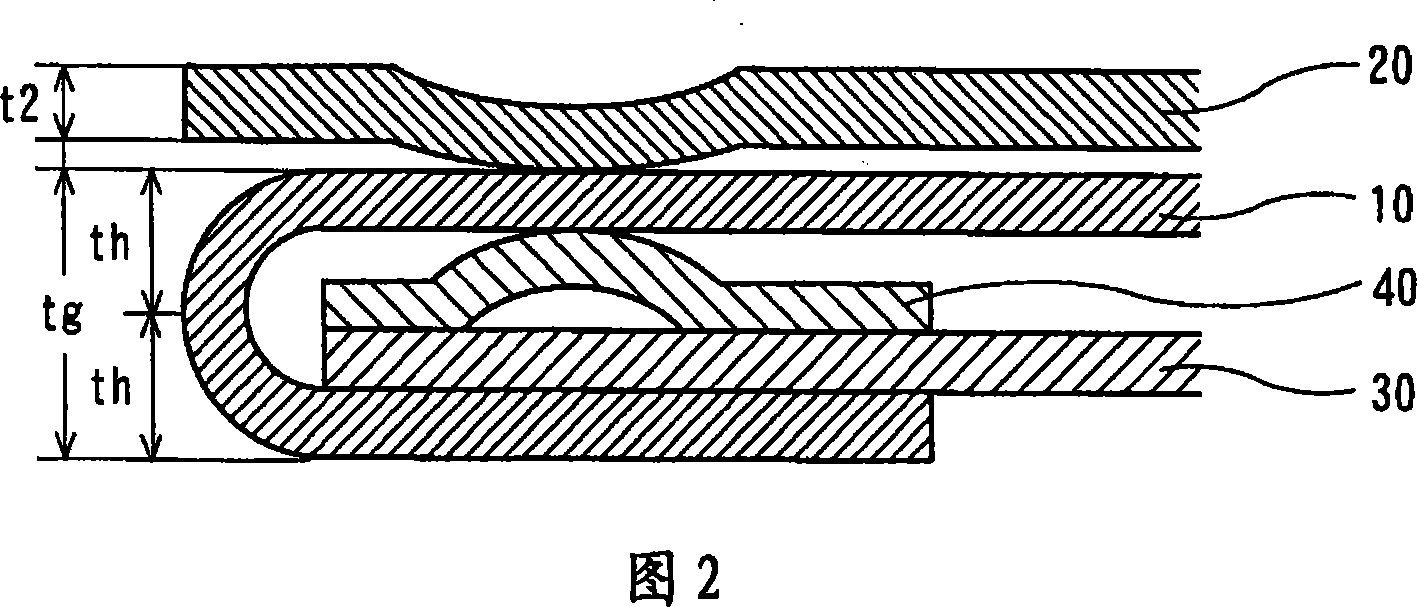

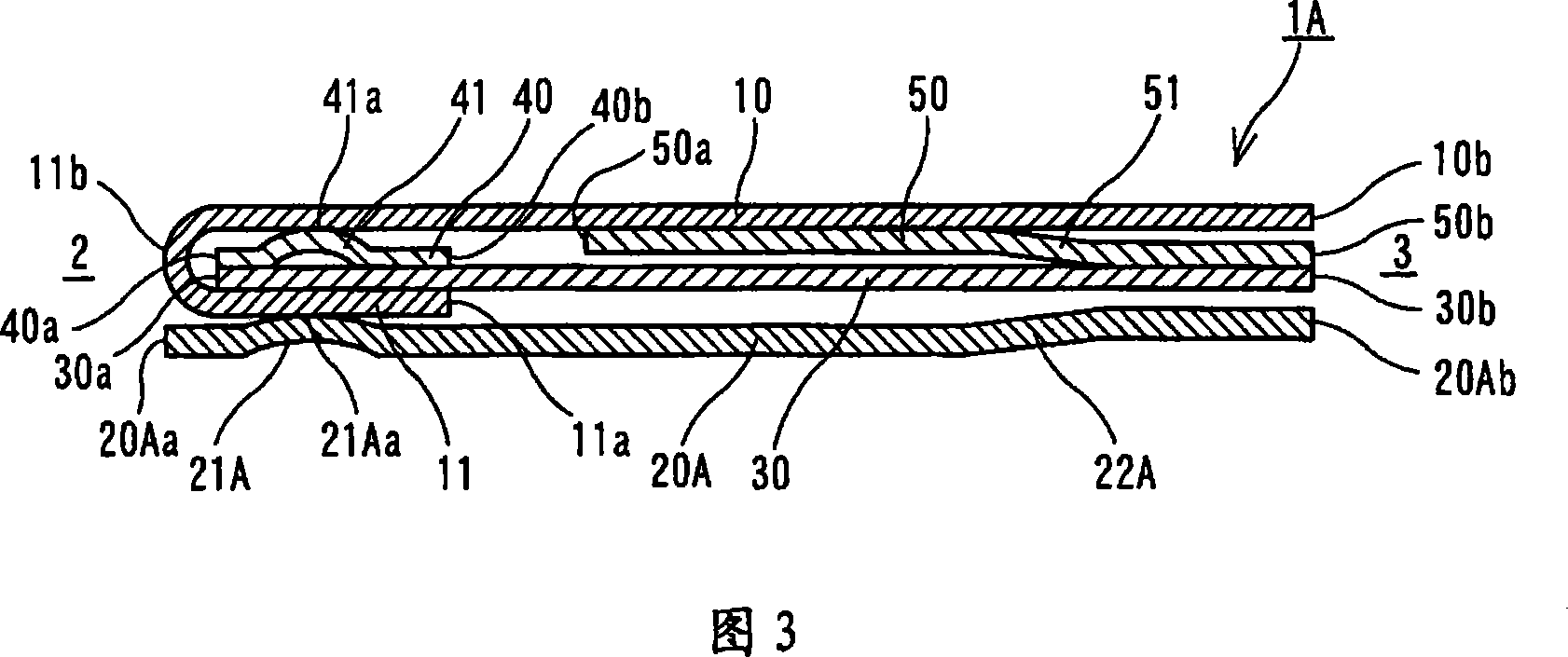

Cylinder head gasket

InactiveCN101074730AAvoid deformationAdequate airtightnessEngine sealsSealing arrangements for enginesCylinder headEngineering

The invention provide a cylinder head gasket having sufficient sealing performance around a cylinder bore hole while suppressing the deformation of a cylinder bore of an engine. The cylinder head gasket 1 comprises: a first metal structural plate 10 having a folded back portion 11 and formed around the cylinder bore hole 2; and full beads 21 formed opposite to each other on a second metal structural plate 20 and a third metal structural plate 30, respectively, holding the first metal structural plate 10 therebetween with their protrusions on the sides of the first metal structural plate 10, the full beads 21 which have protruded portions 21a arranged on the inner periphery side of an end 11a of the folded back portion 11. At least one or more sub plates 40, 50 are inserted and arranged inside the folded back portion 11. Thicknesses t2 of the second metal structural plate 20 and the third metal structural plate 30 around the cylinder bore hole 2 are respectively smaller than a half th of a thickness tg of the folded back portion 11.

Owner:TOYOTA JIDOSHA KK +1

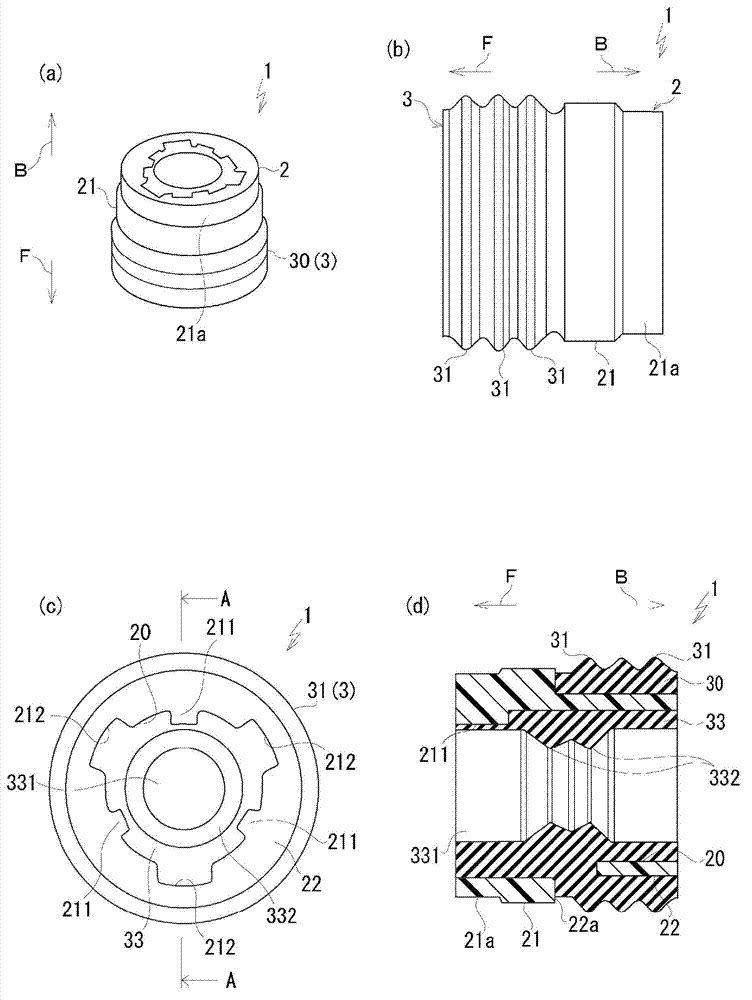

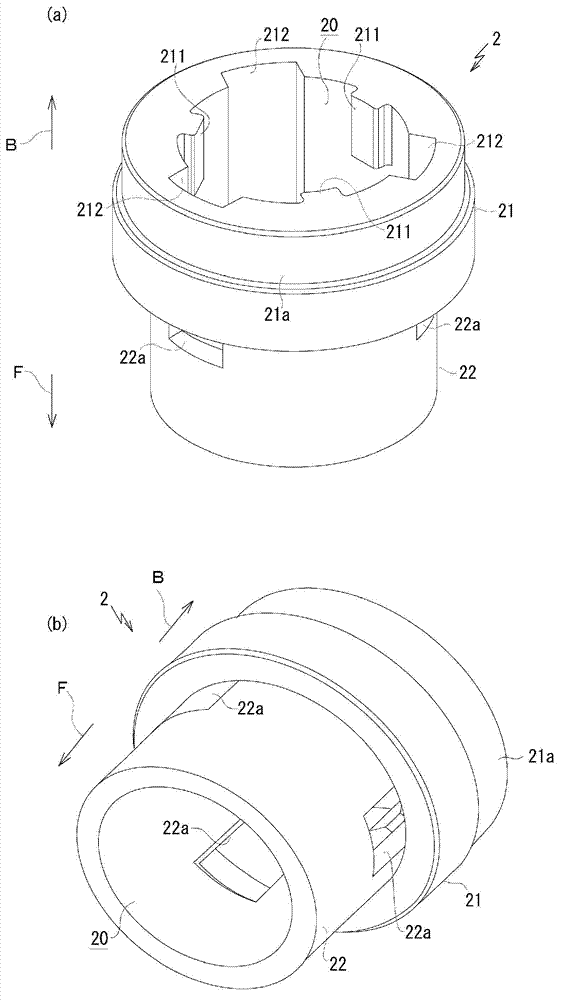

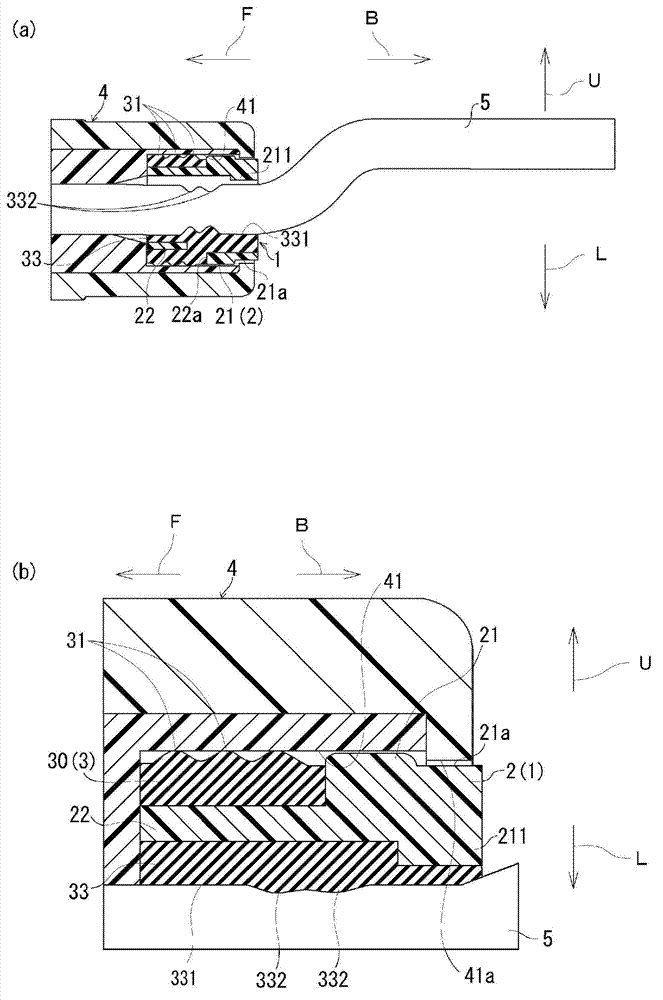

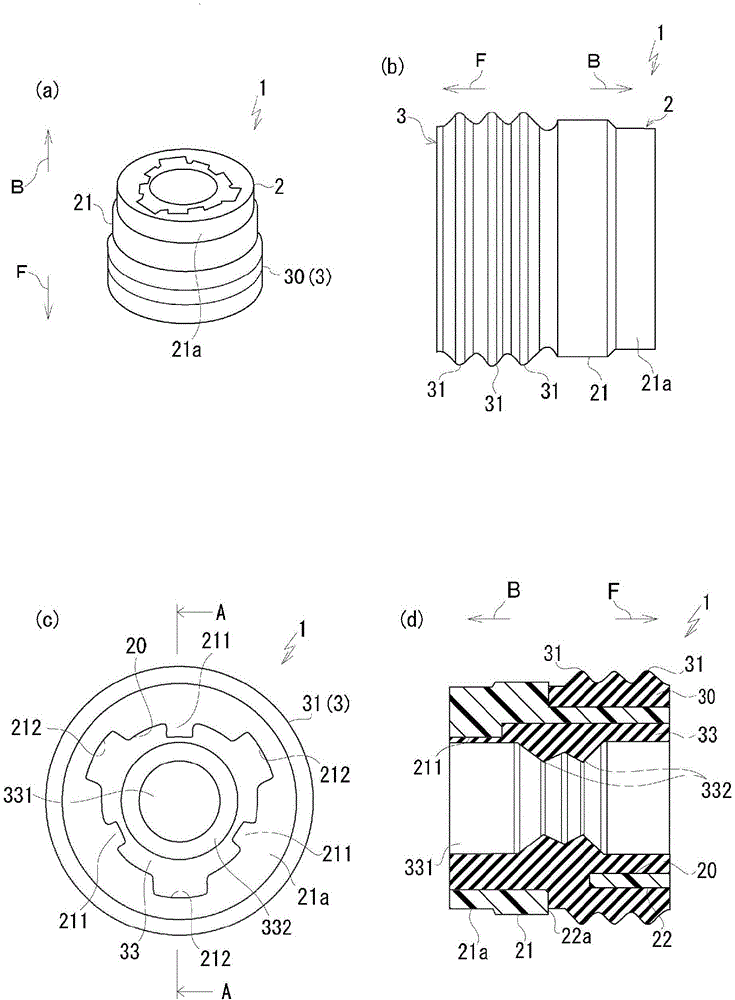

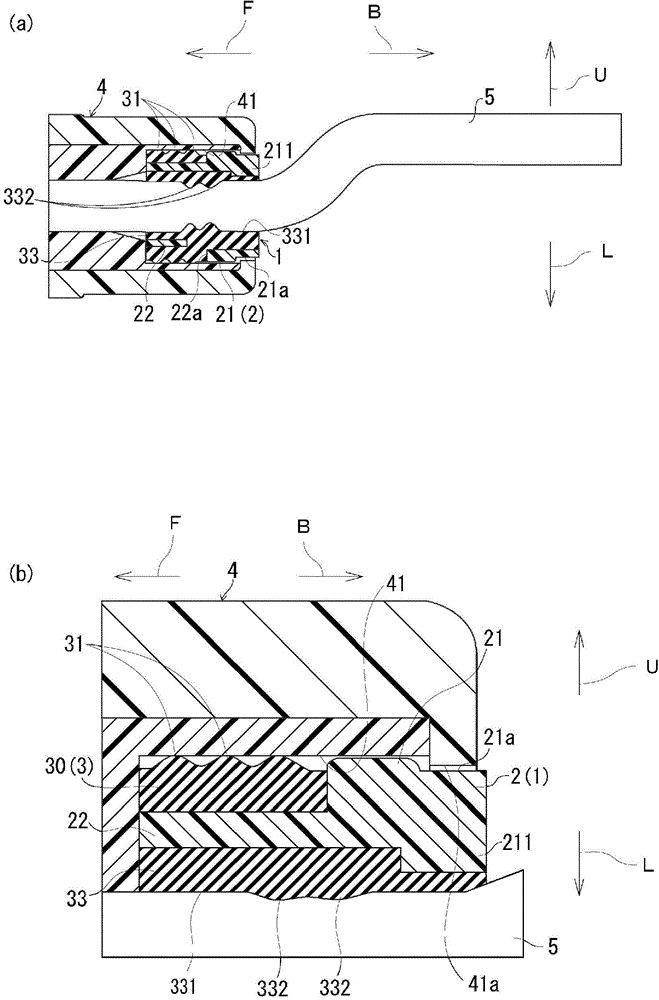

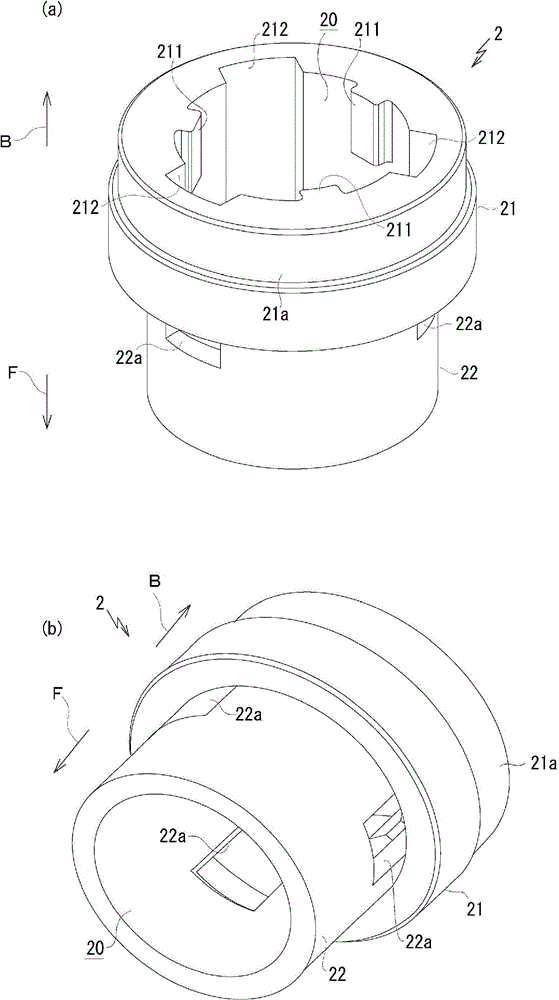

Waterproof plug

ActiveCN102823077AReduce movementReduce sealing pressureCouplings bases/casesElectrical apparatus casings/cabinets/drawersEngineeringMechanical engineering

Owner:YAZAKI CORP

Immersion self-adapting seal control device used for photo-etching machine

InactiveCN101403861BAvoid interferenceImproved flow field stabilityPhotomechanical exposure apparatusMicrolithography exposure apparatusLithographic artistEngineering

The invention discloses an immersion self-adaptive sealing control device used in a lithography machine. The immersion self-adaptive sealing control device is arranged between a projection lens set and a substrate, and consists of a sealing element and a self-adaptive sealing member. When liquid forms the impact on the self-adaptive sealing member due to traction of the substrate, the device can absorb the impact formed by the high-speed moving liquid and converts the impact into power enhancing sealing; on the contrary, when the substrate draws the liquid away from the self-adaptive sealing member, the liquid prestored inside the device follows to enter a slit flow field to avoid gas bubble entrainment owing to the loss of the liquid at the boundary, meanwhile, the reduction of the liquid prestored inside the device reduces the sealing power of the self-adaptive sealing member, and the leaked liquid flows back to the inside of the slit flow field along with the substrate due to the reduction of obstruction. The liquid transmission mode of the immersion self-adaptive sealing control device adopts negative pressure recovery and free flow of a fluid injection end, which avoids the flow field fluctuation caused by the in-coordination between the injected fluid and the recovery pressure.

Owner:ZHEJIANG UNIV

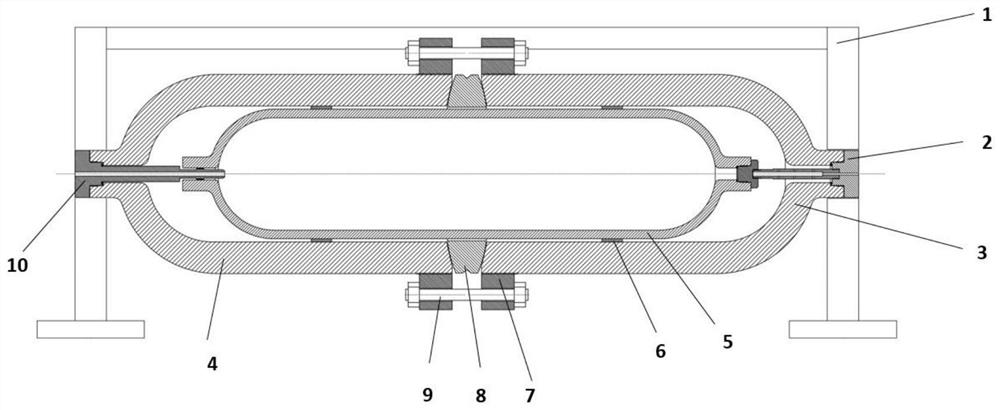

Anti-fatigue high-pressure hydrogen storage container for hydrogen refueling station

ActiveCN112212205AHardenability is easy to guaranteeHigh manufacturing reliabilityVessel mounting detailsEngine sealsHigh pressure hydrogenWeld seam

The invention discloses an anti-fatigue high-pressure hydrogen storage container for a hydrogen refueling station. The container adopts a non-welding double-layer cylinder structure, an inner container is a large-volume seamless gas cylinder, an outer container is a two-section combined large-volume seamless gas cylinder, the inner container is connected through a flange, and the inner container is supported in the outer container through a gasket and gas inlet / outlet pipes at two ends of the container. During use, the inner container is filled with high-pressure hydrogen, and the outer container is filled with high-pressure nitrogen serving as balance gas. The stress level of the inner container is adjusted by balancing the gas pressure, and the crack propagation driving force of the inner container is reduced. The inner container can be made of austenitic stainless steel with good hydrogen compatibility, and the outer container can be made of high-strength steel to bear the high-pressure nitrogen. According to the anti-fatigue high-pressure hydrogen storage container for the hydrogen refueling station, the problem of hydrogen embrittlement of a current single-layer hydrogen storage container material is effectively solved, and the defects that an existing multi-layer high-pressure hydrogen storage device is complex in manufacturing process, multiple and dense in weld joint, large in welding quality control difficulty, long in production period and high in cost are overcome.

Owner:EAST CHINA UNIV OF SCI & TECH

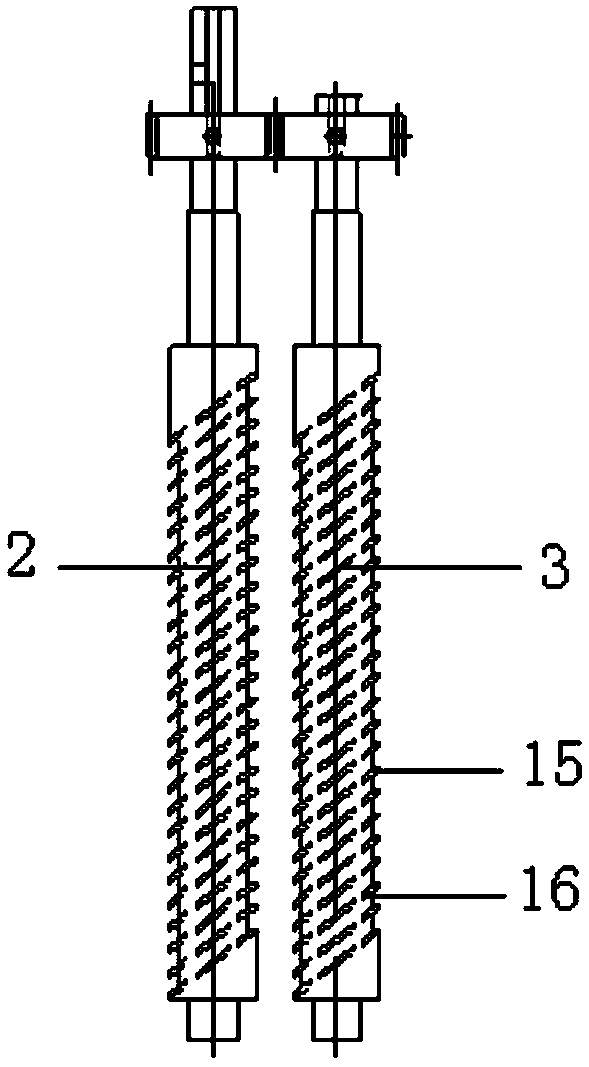

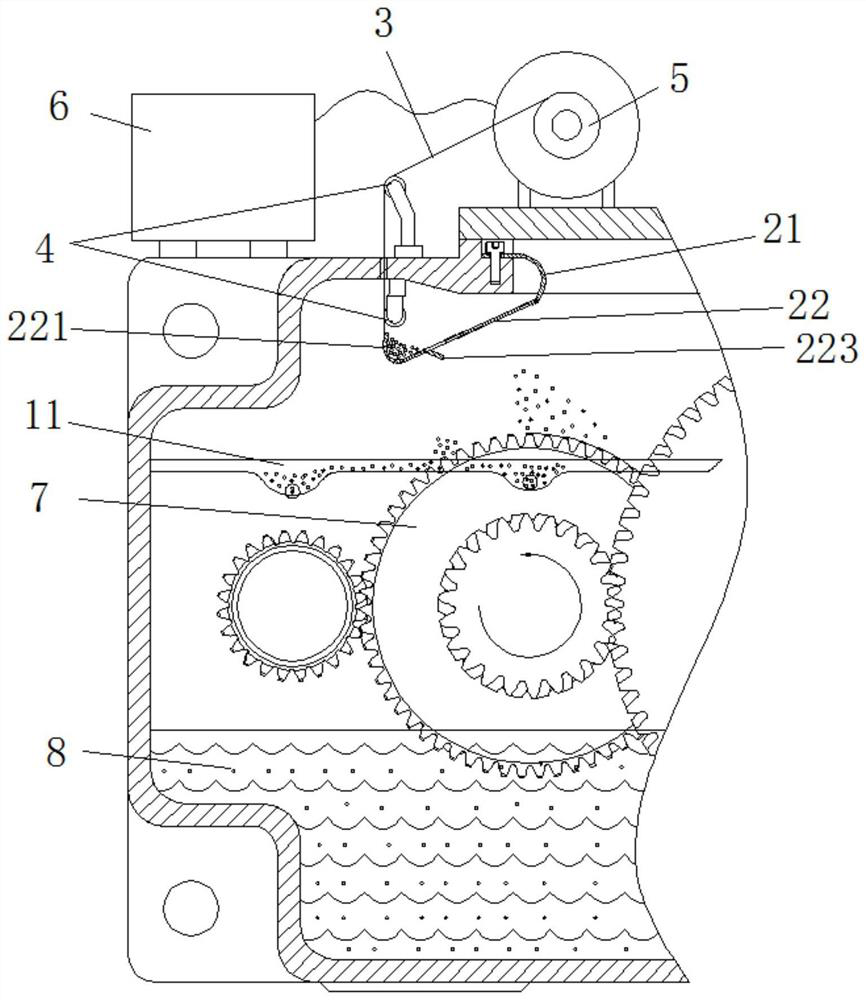

Glue mixing accelerator

ActiveCN104069764AIncrease flow rateStir wellRotary stirring mixersMixing liquids with solidsEngineeringMechanical engineering

The invention relates to the technical field of glue mixing devices, and provides a glue mixing accelerator. The glue mixing accelerator comprises two cavity bodies arranged side by side, namely a first cavity body and a second cavity body; the first cavity body and the second cavity body are internally provided with a first screw-type glue mixing bar and a second screw-type glue mixing bar respectively; one of the first screw-type glue mixing bar and the second screw-type glue mixing bar is directly driven to rotate by a driving device, and the other one is transmitted to rotate by a transmission device. An original passive glue mixing mode of the glue mixing accelerator is changed into an active glue mixing mode, and the static glue mixing is changed into the active glue mixing; glue with a component A and glue with a component B in the cavity bodies are rotated and stirred in an acceleration manner by driving the two screw-type glue mixing bars to rotate, and can be stirred uniformly, and the flowing velocity of the glue is increased; the glue discharge flow is increased, so that the glue sealing efficiency is improved.

Owner:天津南玻节能玻璃有限公司

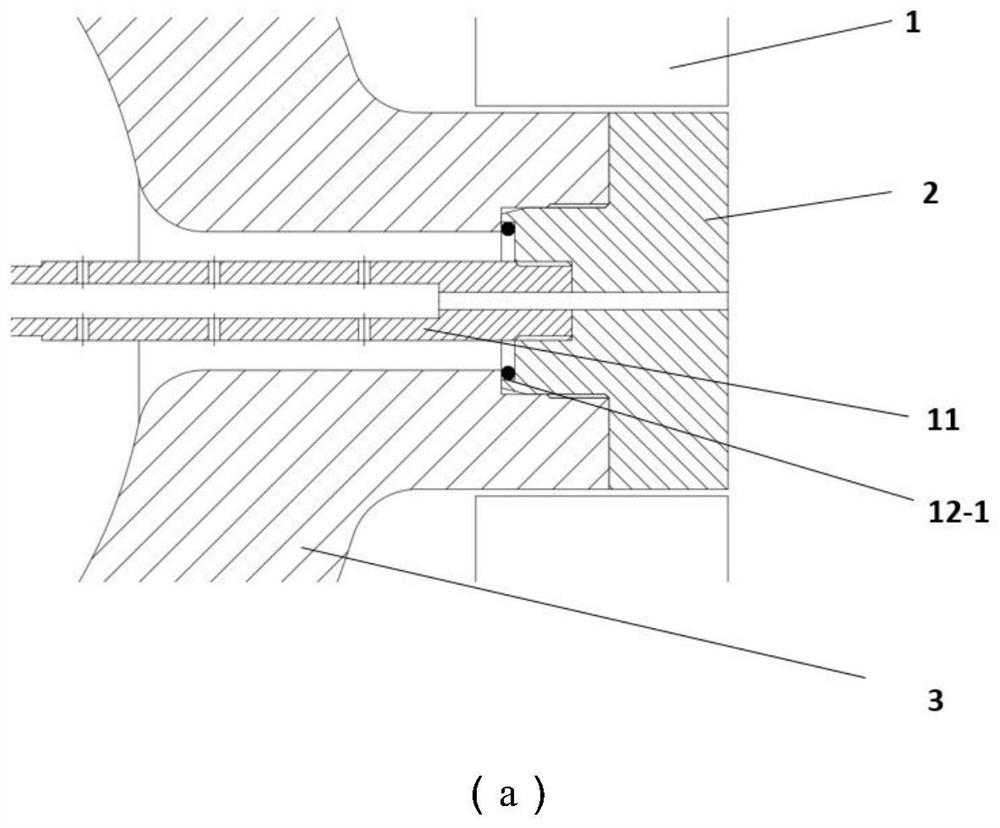

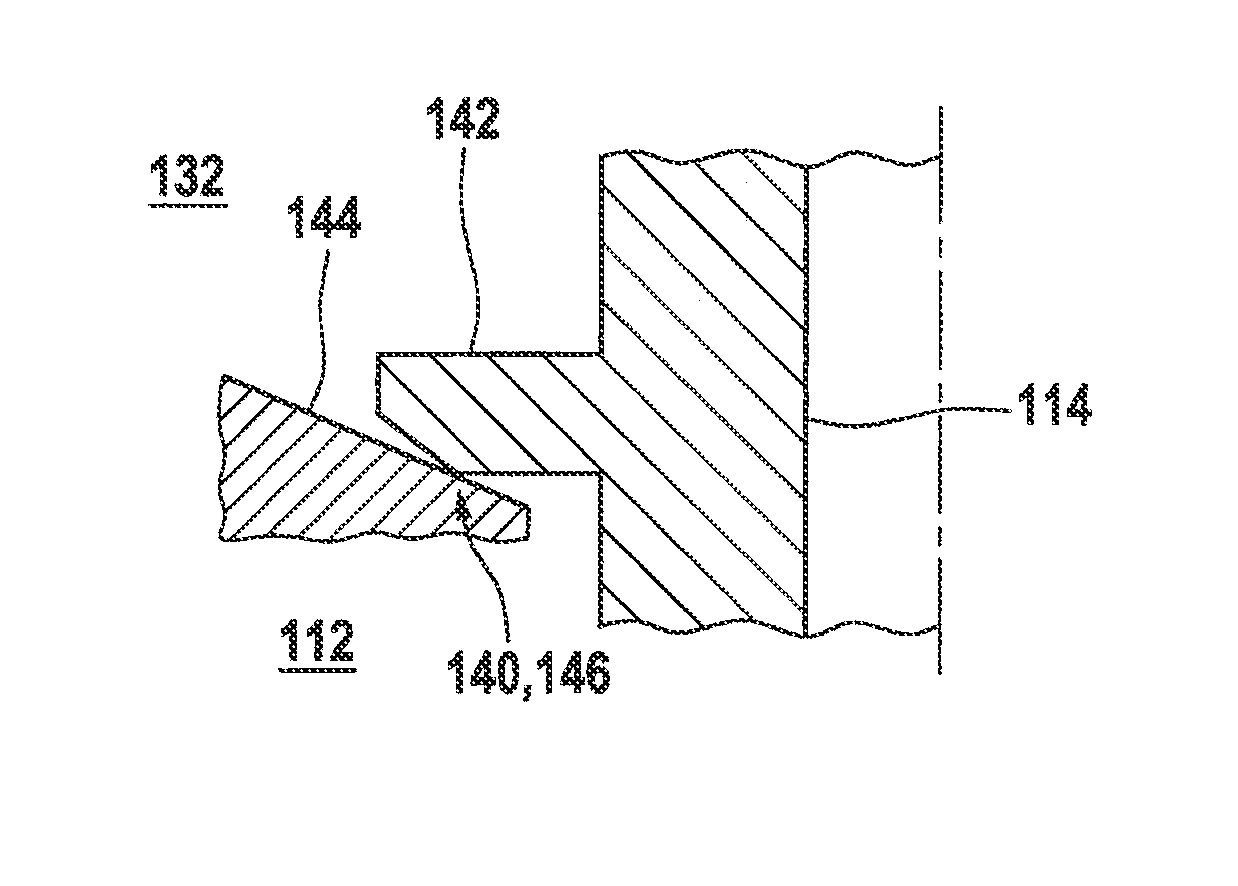

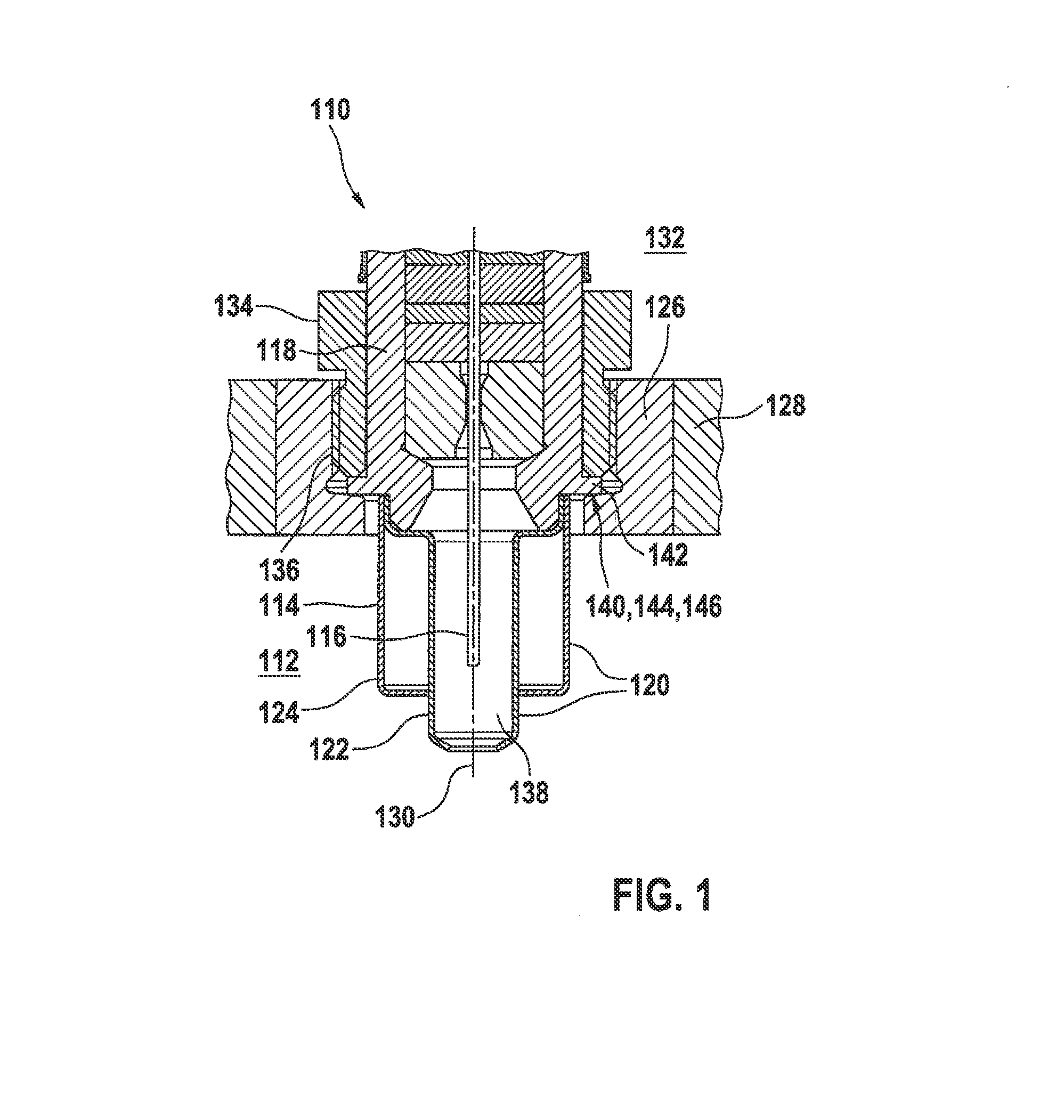

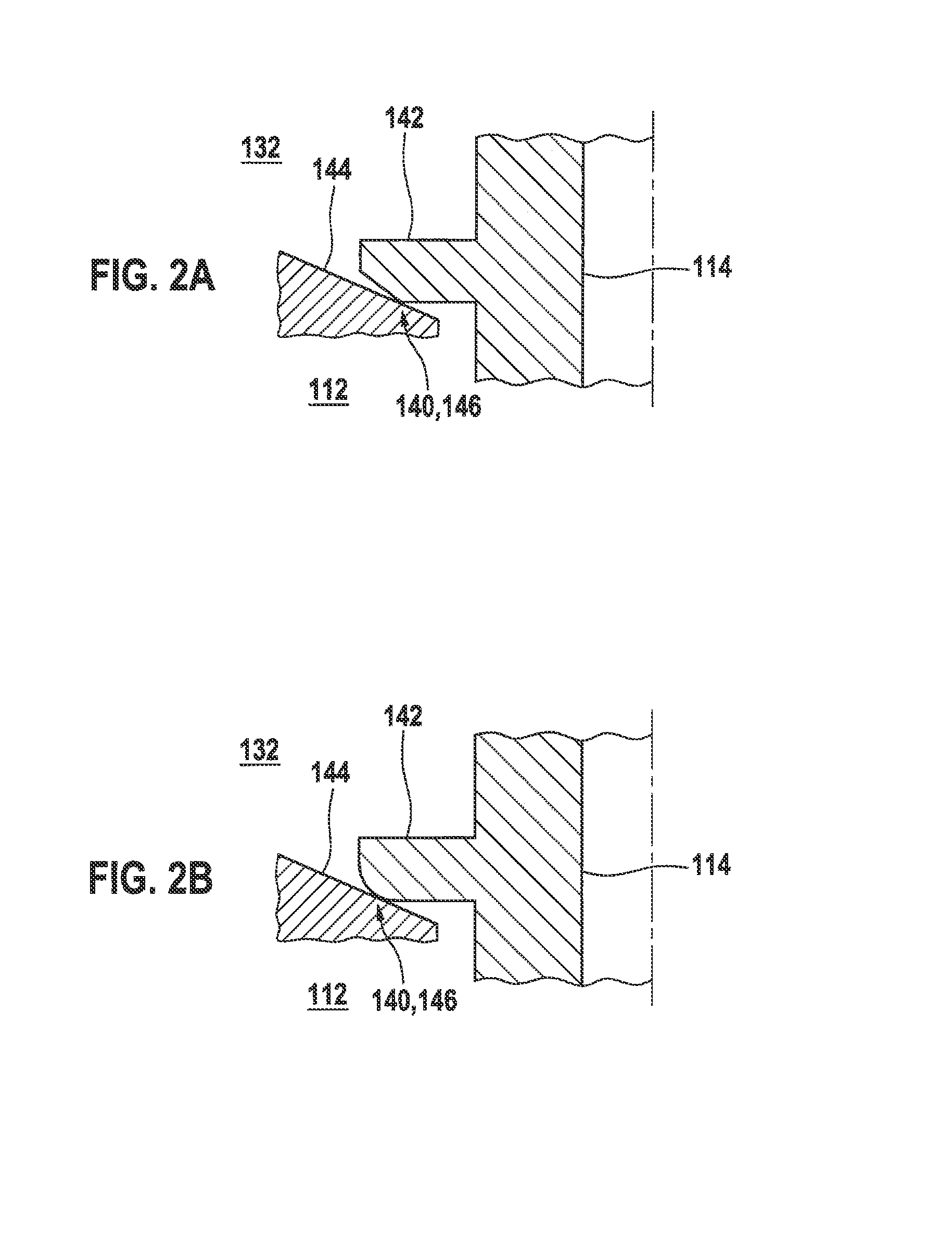

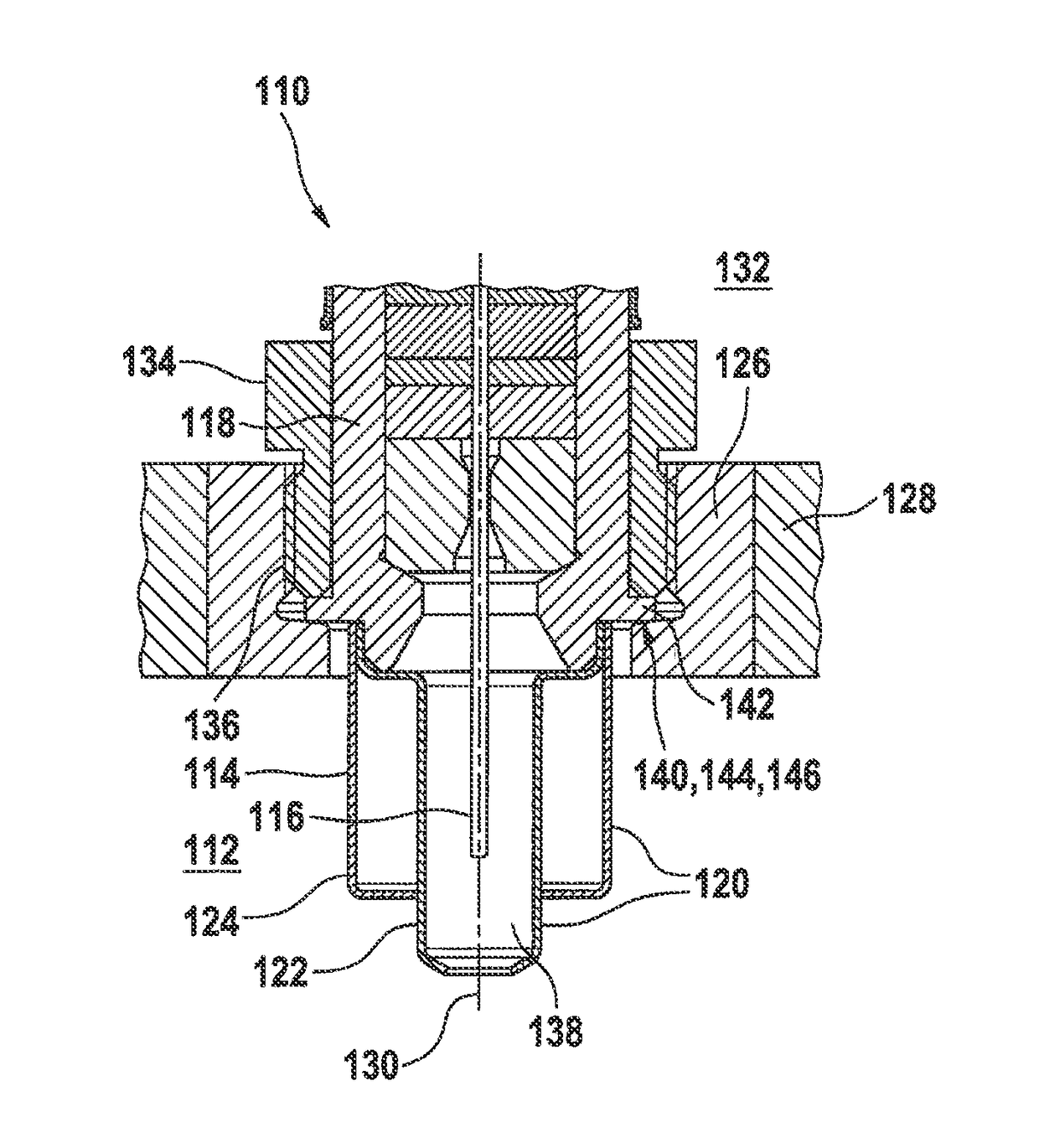

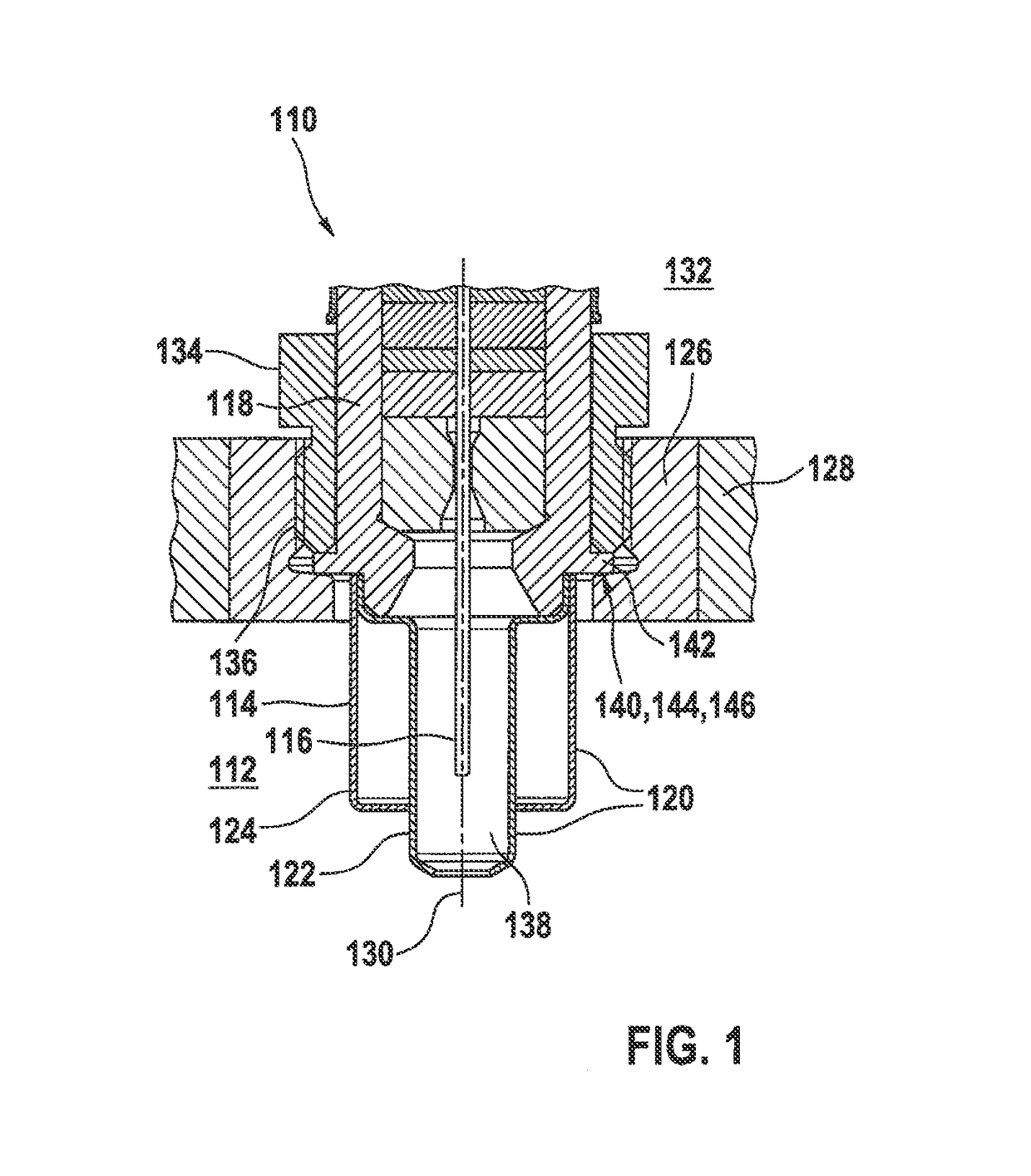

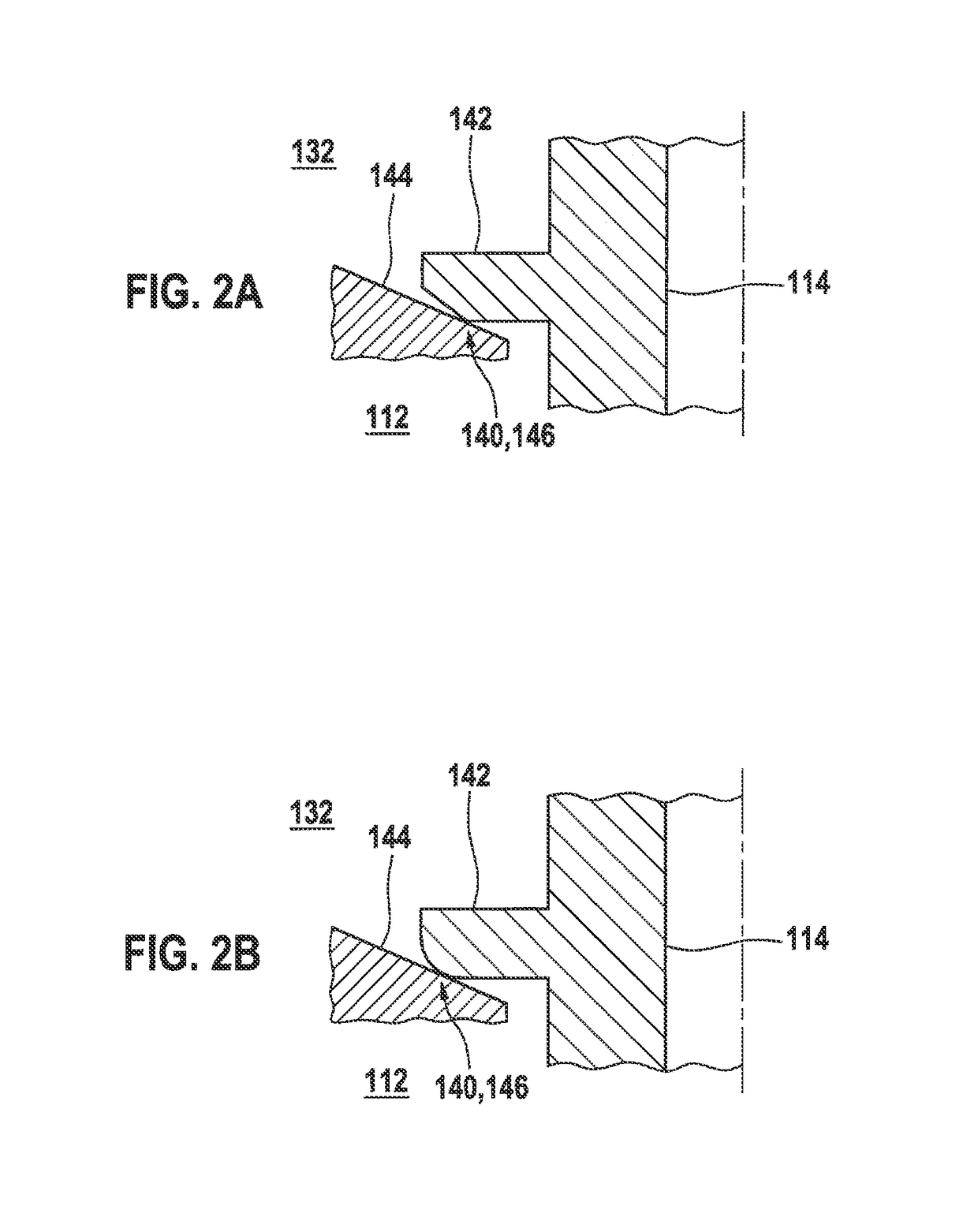

Special seal geometry for exhaust gas sensors for producing high leak tightness with respect to the measurement chamber

ActiveUS20160025222A1Eliminate disadvantagesReduce sealing pressureInternal-combustion engine testingEngine sealsEngineeringSensor system

A sensor system, for sensing at least one property of a measured gas in a measured-gas space, includes a probe for sensing the property of the measured gas. The probe has at least one sensor element and at least one housing surrounding the sensor element. The housing is configured so that the sensor element in the housing is capable of being impinged upon with the measured gas. The sensor system also includes a receiving element connectable to a wall of the measured-gas space. The probe is introducible along an insertion axis into the receiving element and securable in the receiving element. The probe is capable of being sealed off from the measured-gas space by at least one seal. The seal encompasses at least one linear seal.

Owner:ROBERT BOSCH GMBH

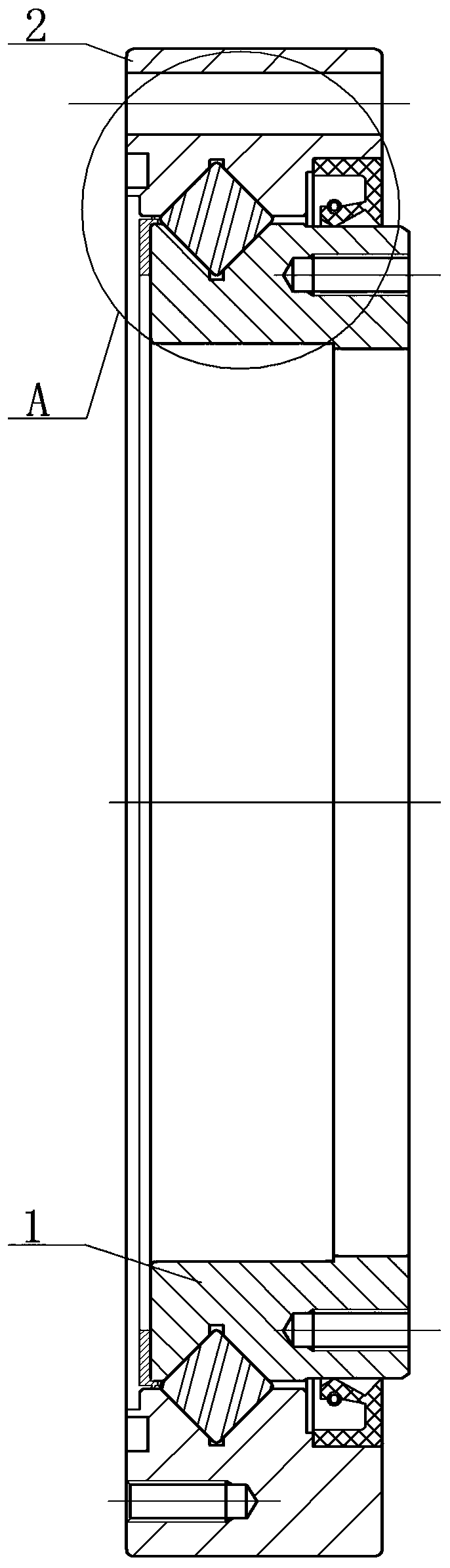

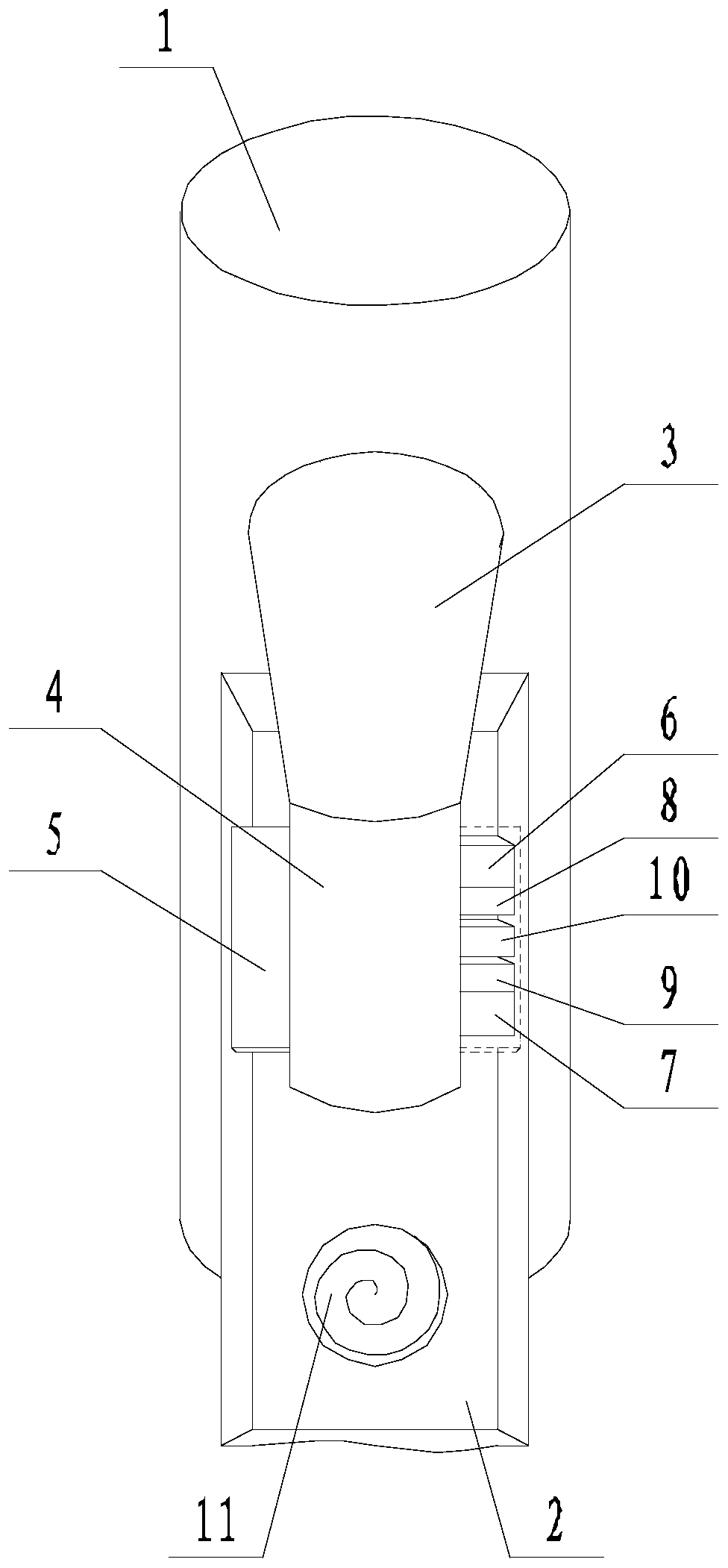

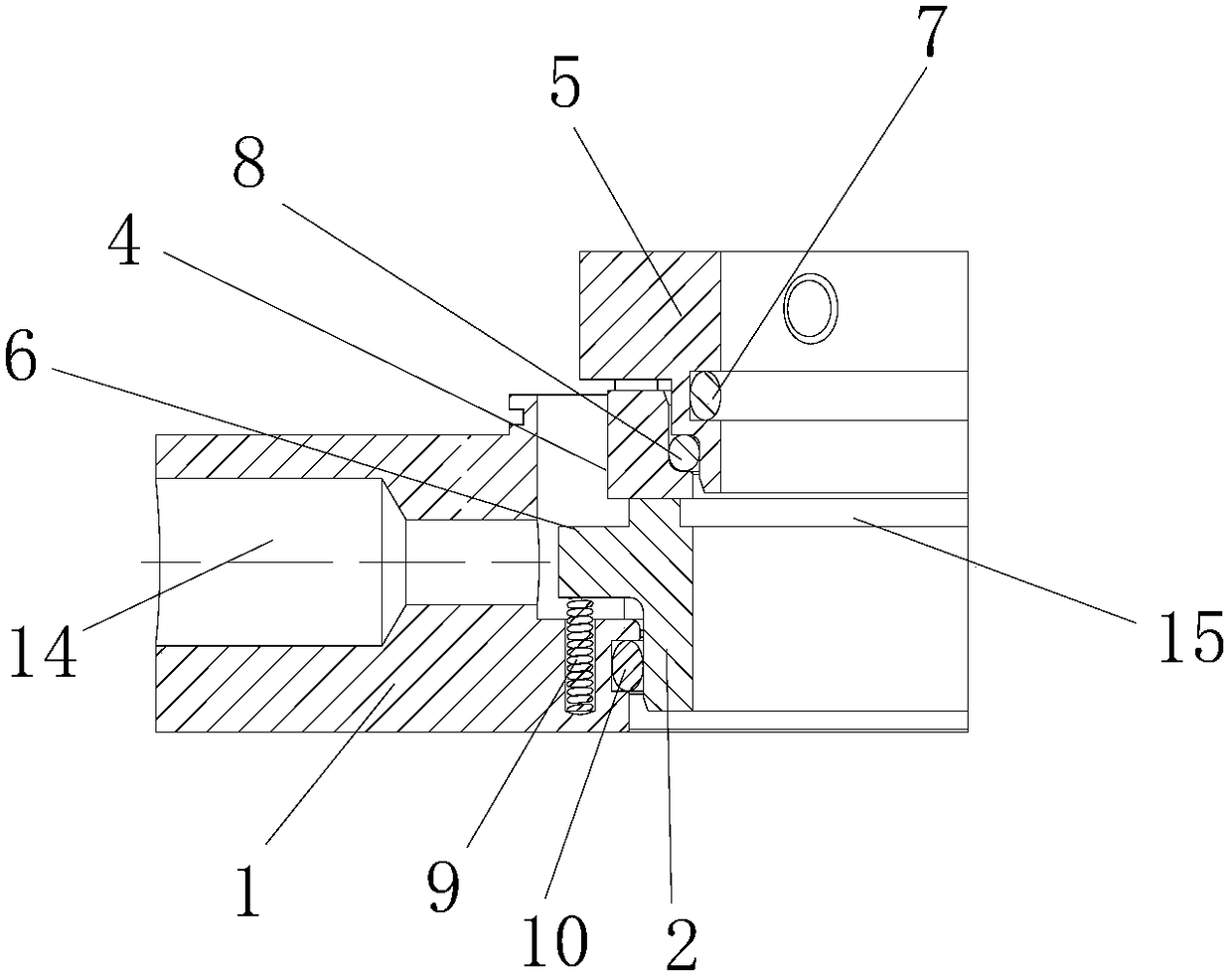

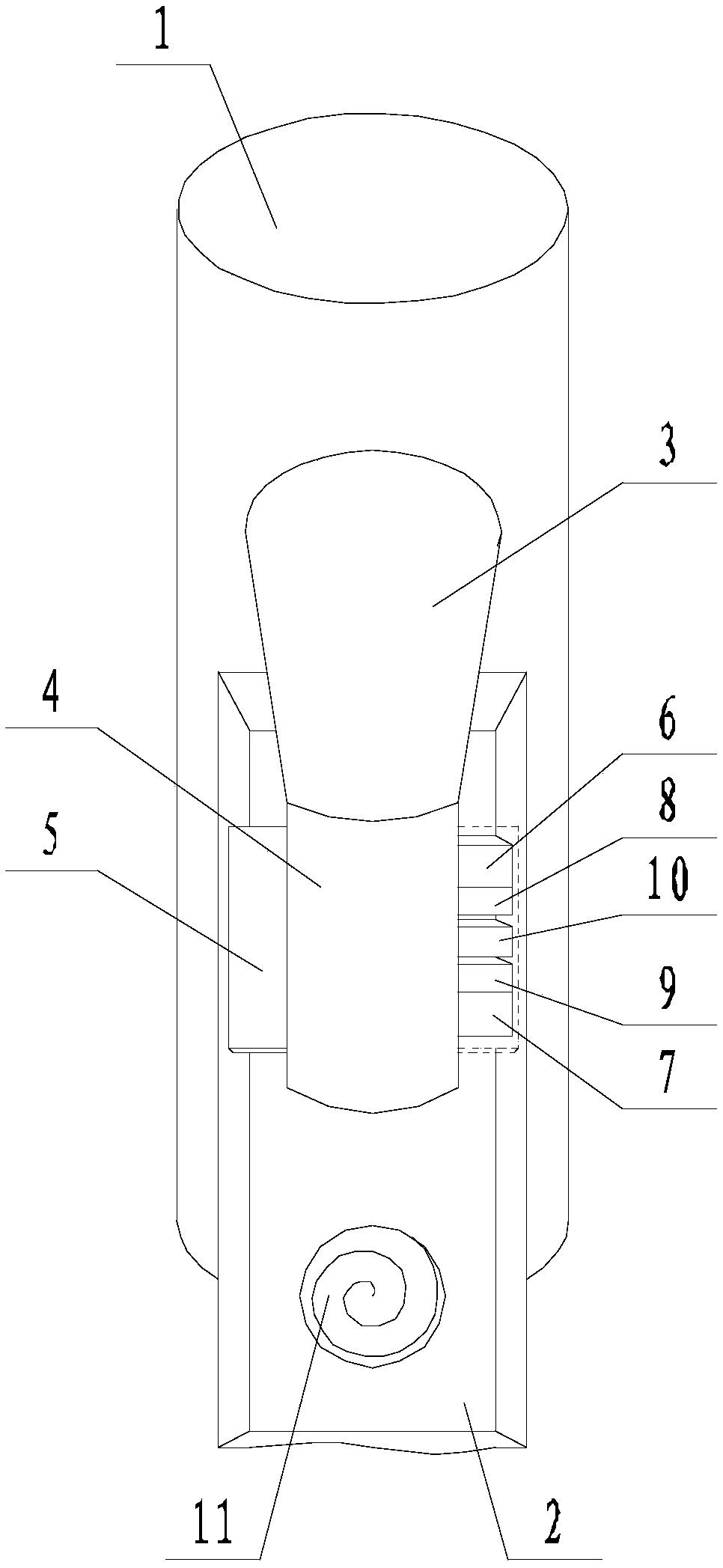

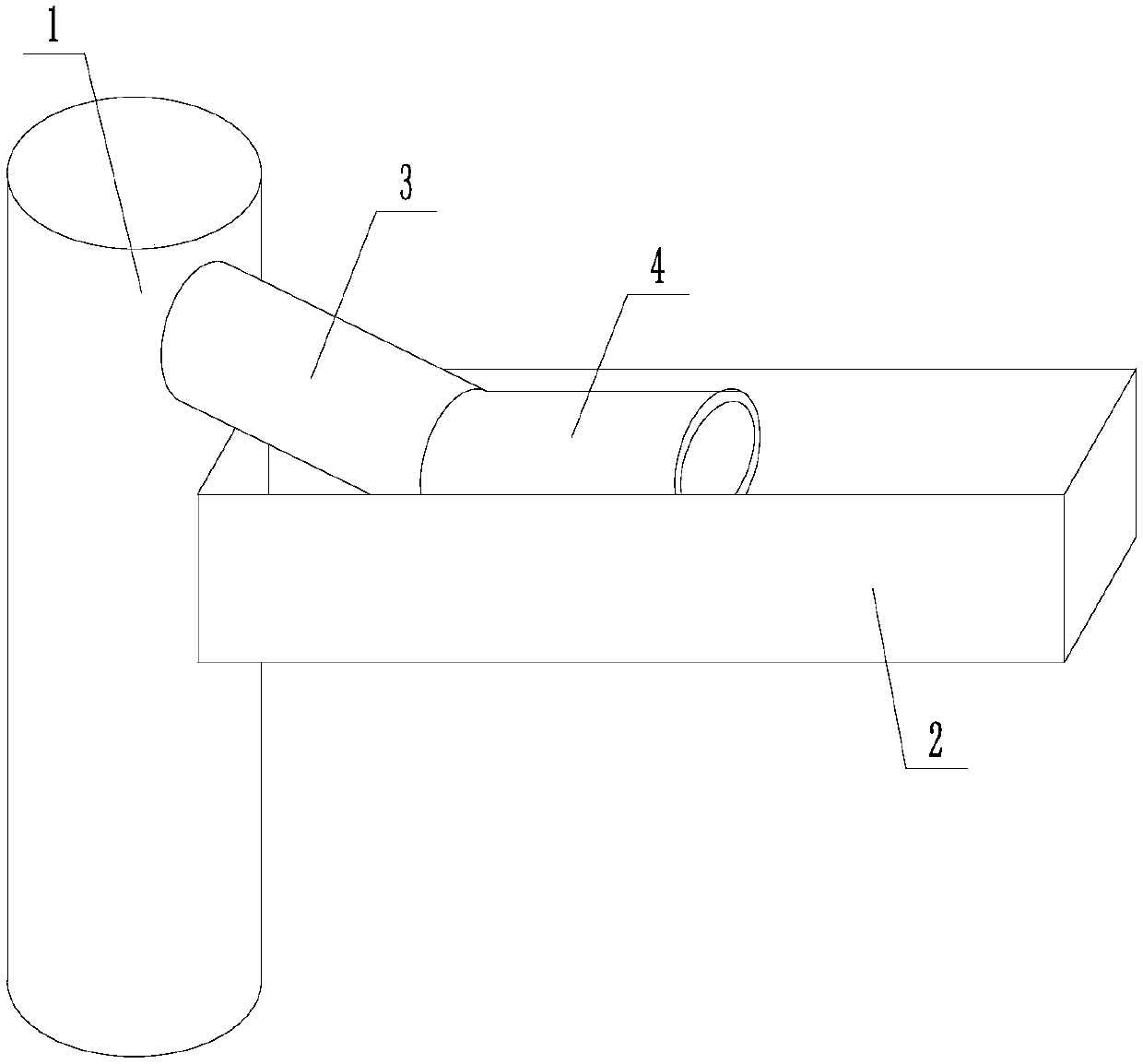

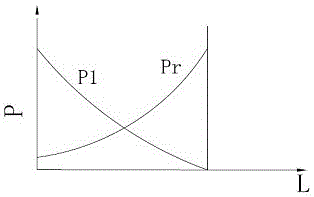

High pressure self-compensation mechanism of water injection well pulse generator

PendingCN109372496AIncrease in sizeReduce sealing pressureSurveySeries compensationSelf compensation

The invention discloses a high pressure self-compensation mechanism of a water injection well pulse generator. The high pressure self-compensation mechanism comprises a cavity, a middle body and a sealing and plugging body, wherein the cavity is a sealed oil cavity; the middle body is a hollow driving main shaft; the sealing and plugging body is a floating piston; a sealed oil cavity is formed inthe cavity of the sealed oil cavity; a piston cavity is formed in the center of the hollow driving main shaft; a floating piston is arranged in the piston cavity; a pressure self-compensation passageis formed in the radial direction of the hollow driving main shaft; one end of the pressure self-compensation passage communicates with the piston cavity; the other end of the pressure self-compensation passage communicates with the sealed oil cavity; and the diameter of the pressure self-compensation passage is smaller than the diameter of the piston cavity. The high pressure self-compensation mechanism has the advantages that in the work process of a driving system, pressure compensation is performed in a self-adaptive way through the volume of a hydraulic oil cavity; the one-way pressure bearing stress state of a sealing element is improved; the impact force of environment fluid is balanced; meanwhile, components such as inside bearings can be lubricated; and the work reliability of thepulse generator is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Special seal geometry for exhaust gas sensors for producing high leak tightness with respect to the measurement chamber

ActiveUS10024432B2Eliminate disadvantagesReduce sealing pressureInternal-combustion engine testingEngine sealsExhaust fumesEngineering

A sensor system, for sensing at least one property of a measured gas in a measured-gas space, includes a probe for sensing the property of the measured gas. The probe has at least one sensor element and at least one housing surrounding the sensor element. The housing is configured so that the sensor element in the housing is capable of being impinged upon with the measured gas. The sensor system also includes a receiving element connectable to a wall of the measured-gas space. The probe is introducible along an insertion axis into the receiving element and securable in the receiving element. The probe is capable of being sealed off from the measured-gas space by at least one seal. The seal encompasses at least one linear seal.

Owner:ROBERT BOSCH GMBH

Ball mill packing and sealing device

InactiveCN107899680AGood thermal stabilityStrong wear resistanceGrain treatmentsBall millEngineering

The invention discloses a ball mill packing and sealing device. The ball mill packing and sealing device comprises a machine box, a packing device is installed at the position, close to the upper portion, of the interior of the machine box, and the packing device comprises a feeding hopper and a feeding barrel. The feeding hopper is located at the opening position of the machine box, and the section of the feeding hopper is in a trapezoidal shape. The feeding barrel is a cylindrical barrel and embedded in the discharging opening position of the bottom of the feeding hopper in a sleeving mode.The interior of the machine box is further provided with a sealing device. The sealing device comprises a sealing seat. The sealing seat is connected with the outer surface of the feeding barrel in asleeving mode. A magnetic sealing assembly is connected with the tail end of a through hole of the sealing seat in a sleeving mode. The magnetic sealing assembly faces the tail end of the feeding barrel directly and is used for achieving bottom sealing of the feeding barrel. A circular-annular O-shaped ring is arranged at the connection of the magnetic sealing assembly and the sealing seat in a padded mode. A blowing-removing device is further installed on the lower portion of the interior of the machine box. The blowing-removing device is installed on the right side edge of an outlet of the feeding barrel. The ball mill packing and sealing device is good in sealing performance and is not prone to being worn, dust can also be effectively prevented from entering, the service life is prolonged, and the maintenance cost of equipment is reduced.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

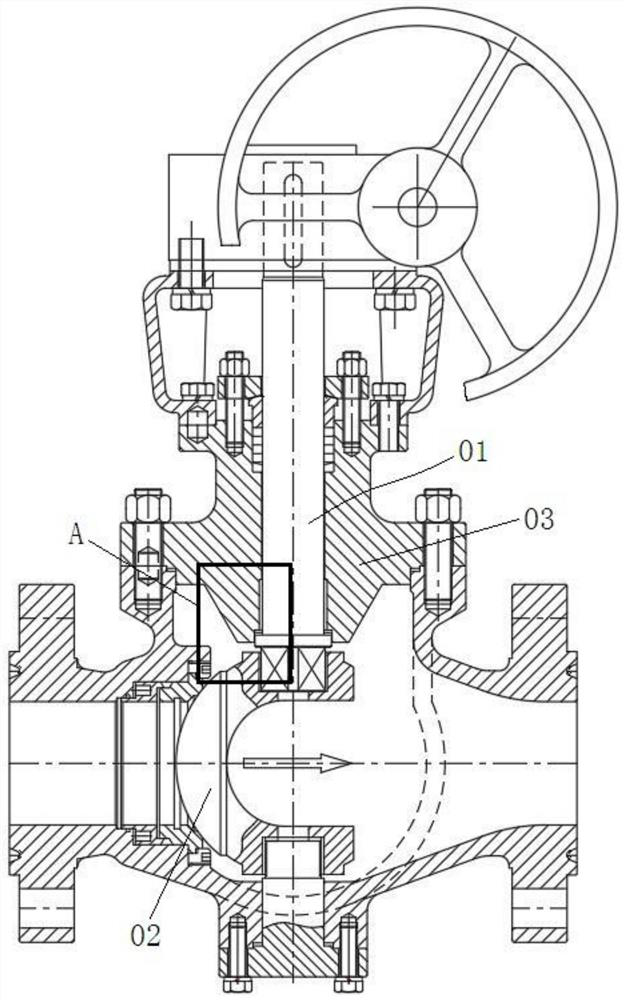

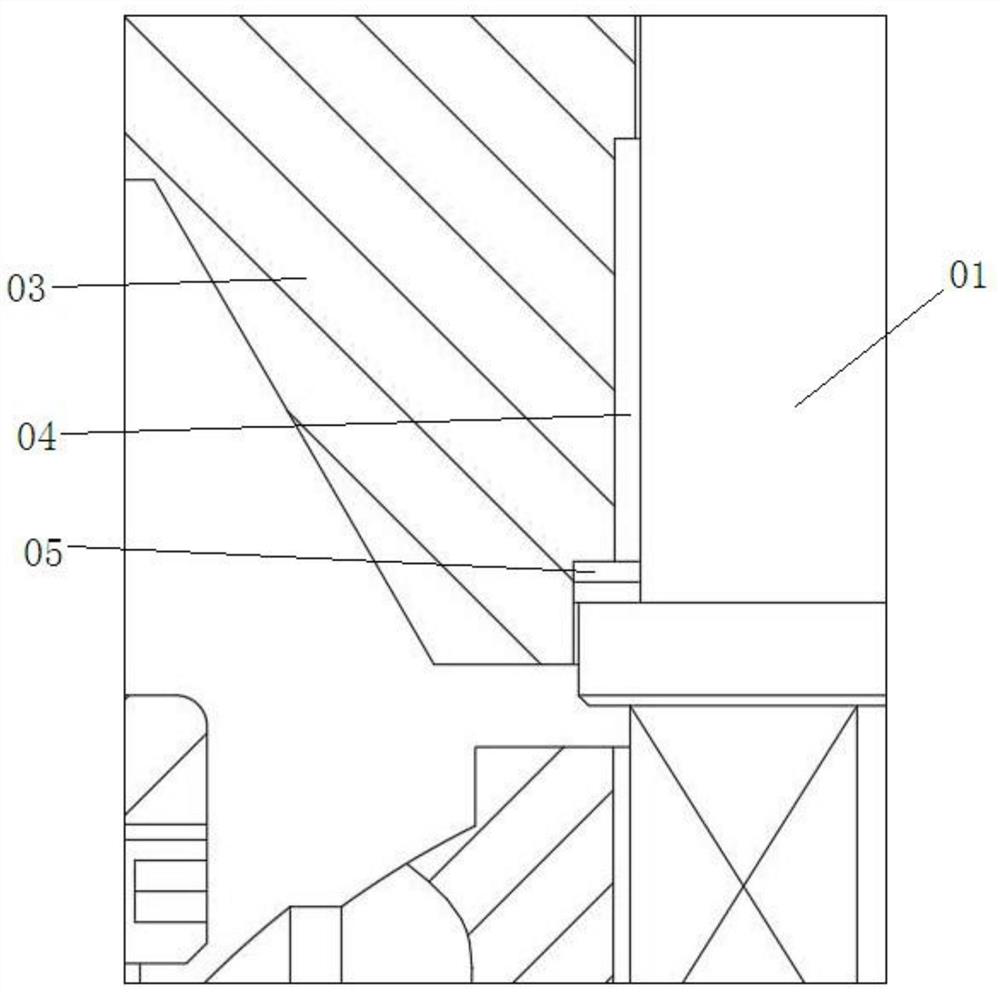

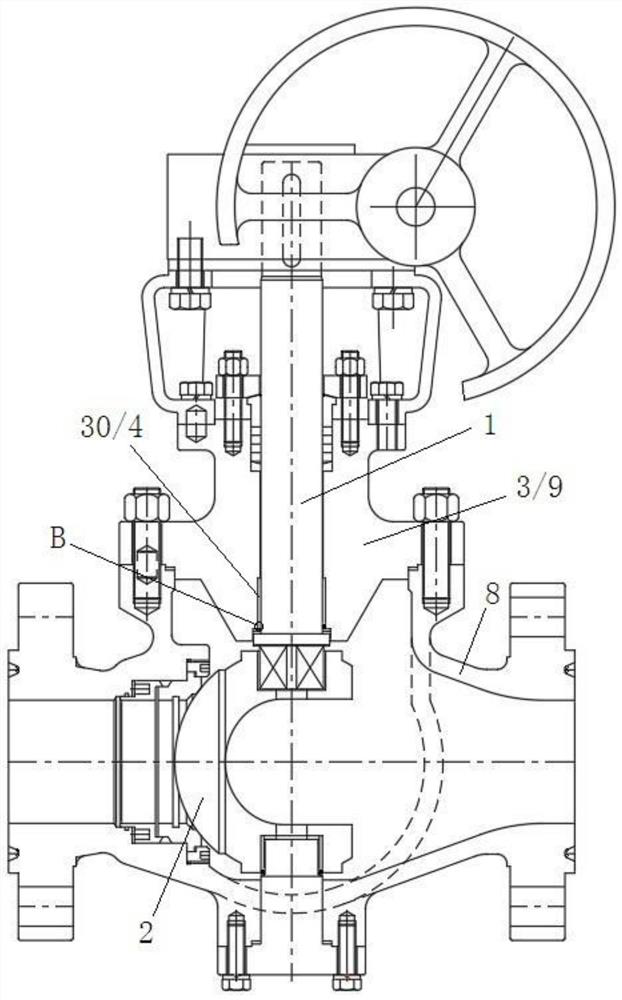

Valve rod sealing structure and eccentric semi-ball valve

PendingCN112664673AClose contactIncrease the areaSpindle sealingsPlug valvesEngineeringFriction force

The invention provides a valve rod sealing structure and a ball valve. The valve rod sealing structure comprises a lubricating bearing, an elastic sealing piece, an abutting piece and a fixing piece. The lubricating bearing is used for reducing rotating friction force. The elastic sealing piece is arranged on a valve rod in a sleeving mode with an inverted-U-shaped opening facing outwards under the action of the fixing piece and the abutting piece. The two side walls of the elastic sealing piece are in close contact with the outer wall of the valve rod and the inner wall of a supporting structure correspondingly. After external fluid enters the position from a gap between the valve rod and the supporting structure, the pressure of the fluid presses the middle of the elastic sealing piece, the two side walls of the elastic sealing piece are extruded to be in close contact with the outer wall of the valve rod and the inner wall of the supporting structure correspondingly, and thus the sealing effect is achieved. According to the valve rod sealing structure, most of medium particles can be prevented from entering the position between the valve rod and the supporting structure, thus the valve rod does not rub with the medium particles when rotating, and abrasion is small.

Owner:SHANDONG AFA FLOW CONTROL

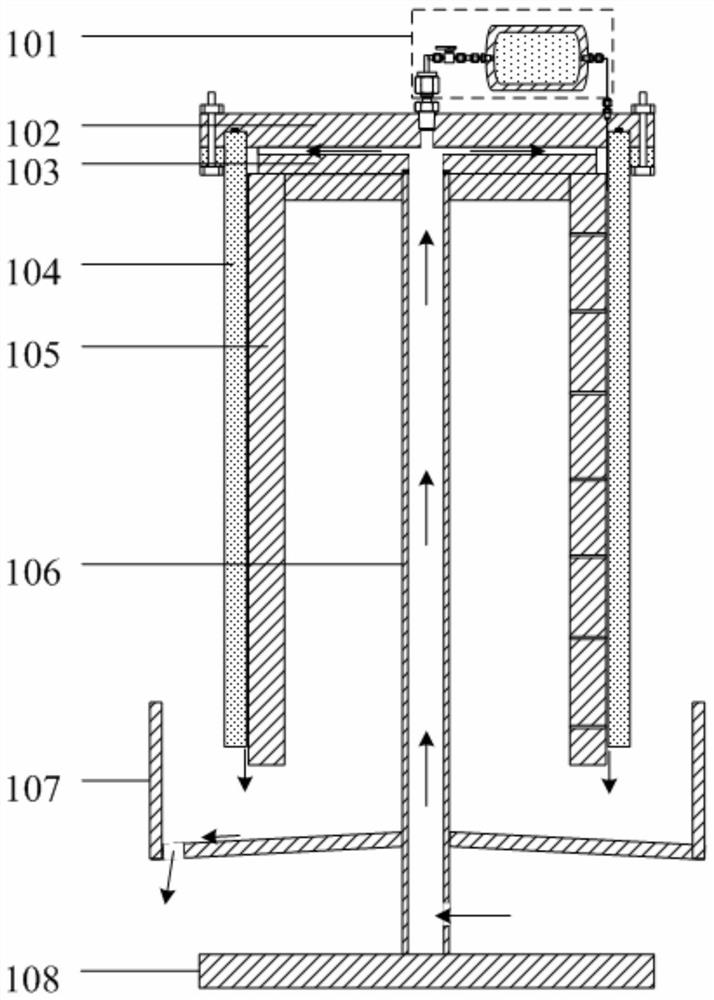

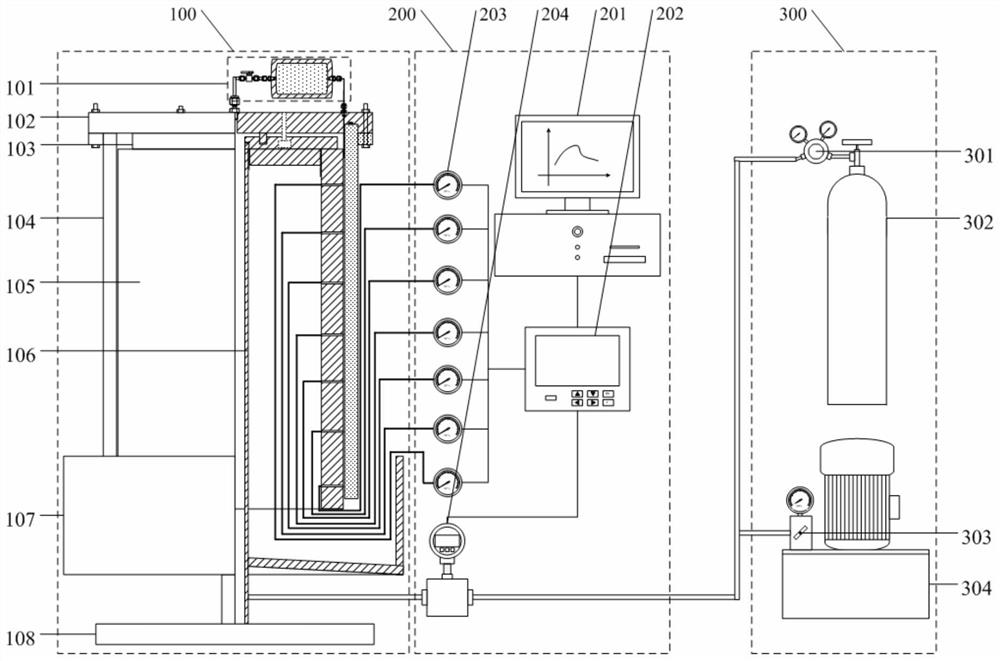

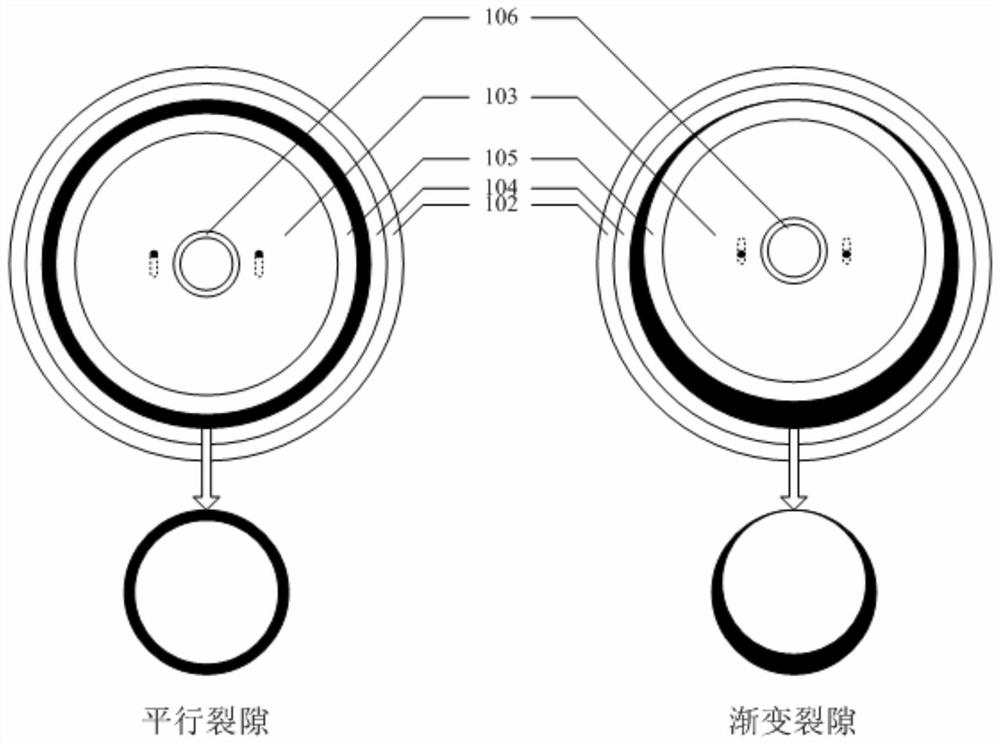

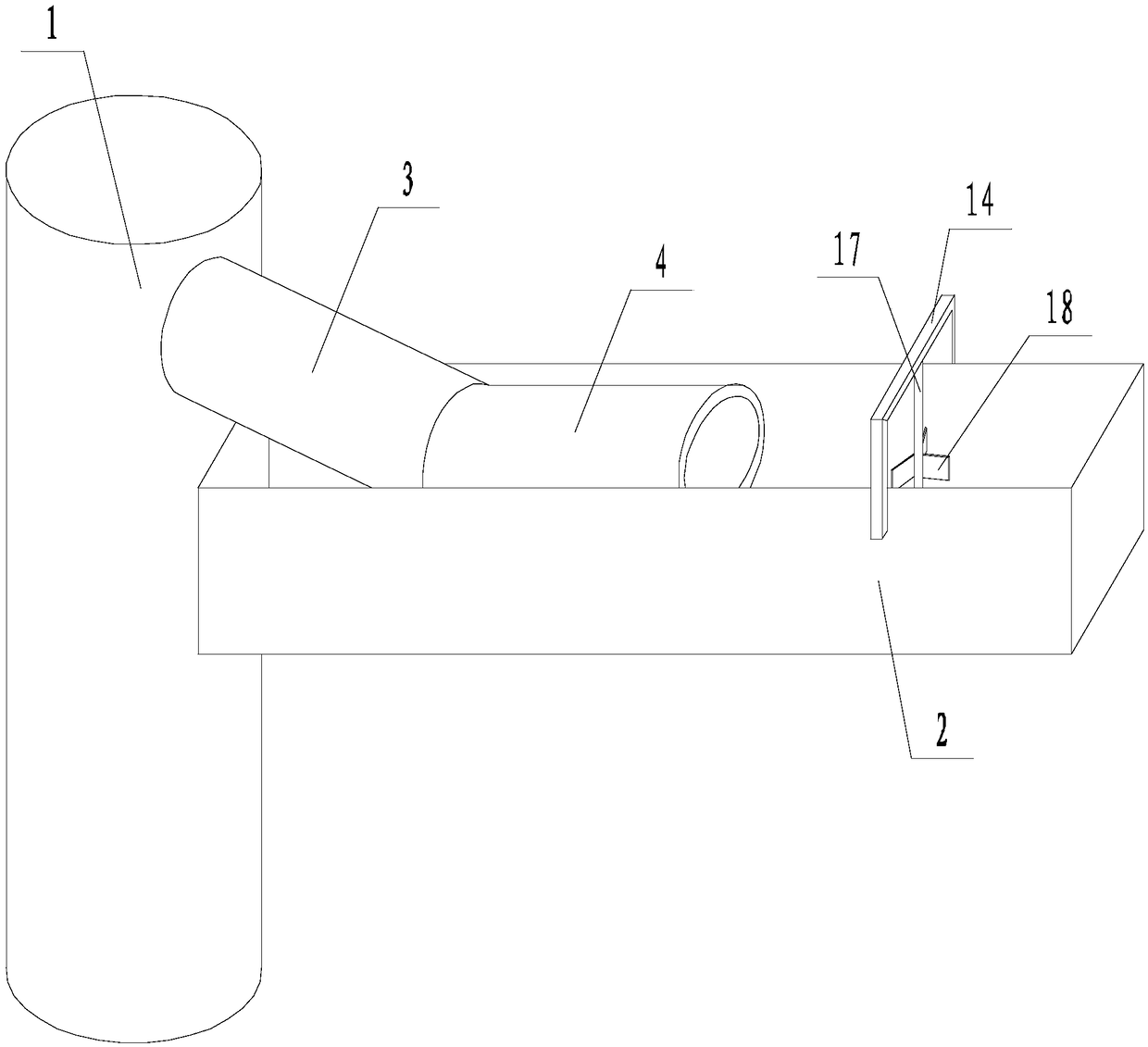

Multifunctional visual cylindrical surface crack permeation device and use method thereof

ActiveCN113340785AReduce the sealing force areaHigh osmotic pressure differencePermeability/surface area analysisFlow transducerParallel plate

The invention relates to the technical field of geotechnical engineering, in particular to a multifunctional visual cylindrical surface crack permeation device which comprises a cylindrical surface crack permeameter, an acquisition and analysis unit and a gas-liquid supply unit, wherein the cylindrical surface crack permeameter comprises an inner cylinder and a transparent outer cylinder, a cylindrical space between the outer cylinder and the inner cylinder is a cylindrical surface crack, and the cylindrical surface crack is used for simulating a rock mass crack; a plurality of pressure sensors are arranged in the inner cylinder in the height direction; the position of the inner cylinder can be adjusted relative to the outer cylinder; when the inner cylinder and the outer cylinder are coaxial, the cylindrical surface cracks are parallel plate cracks; when the inner cylinder and the outer cylinder are not coaxial, the cylindrical surface crack is a crack with gradually changed gap width; the gas-liquid supply unit can inject fluid into the cylindrical surface crack, transmits pressure data in the cylindrical surface crack through the pressure sensor, transmits flow velocity data when the fluid is input through the flow sensor, and performs state adjustment according to data processing. Therefore, seepage conditions under different crack conditions are simulated, the structure is simple, the osmotic pressure difference is high, and the deformation is small.

Owner:LUDONG UNIVERSITY

Sealing device

InactiveCN101189461BPrevent intrusionImprove sealingEngine sealsBearing componentsSlurryMechanical engineering

A sealing device (1) capable of further increasing sealing performance by a labyrinth to effectively suppress the entry of dust such as slurry, comprising an inner peripheral side sealing member (2) fitted to an inner peripheral side mounting member as one of two members rotating relative to each other and an outer peripheral side sealing member (3) fitted to the outer peripheral side mounting member as the other. An outer peripheral tube part (4c) is formed on the outer peripheral portion of the metal ring (4) of the inner peripheral side sealing member (2), and a series of long labyrinth spaces (8), (9), and (10) are formed between the outer peripheral surface of the outer peripheral tube part (4c) and the outer peripheral side sealing member (3), between the tip face of the outer peripheral tube part (4c) and the outer peripheral side sealing member (3), and between the inner peripheral surface of the outer peripheral tube part (4c) and the outer peripheral side sealing member (3).

Owner:NOK CORP

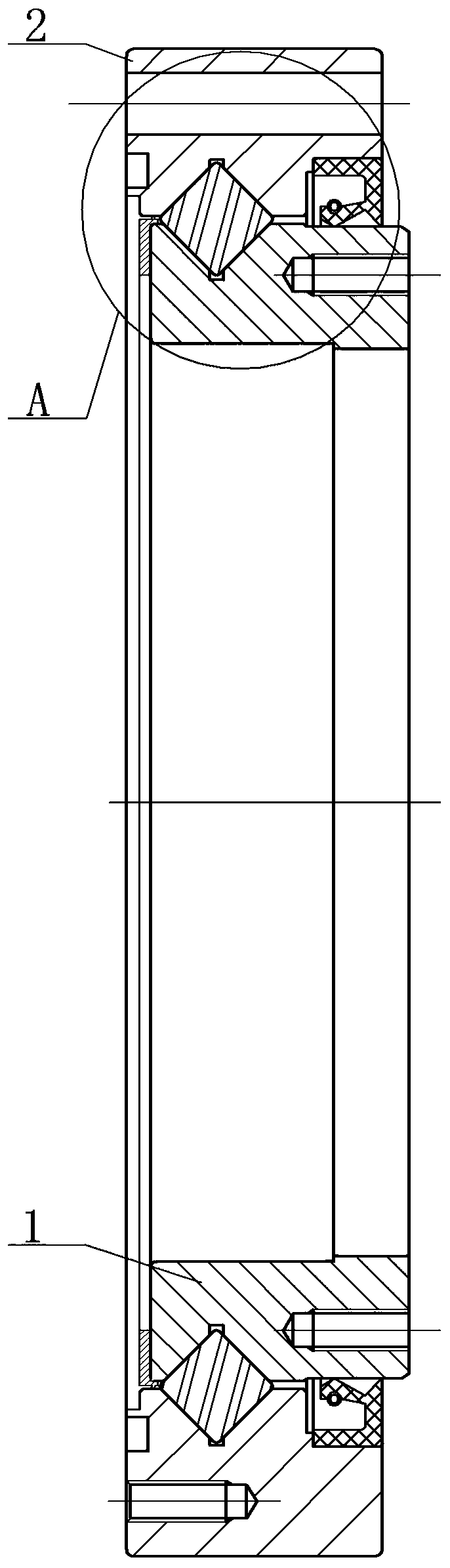

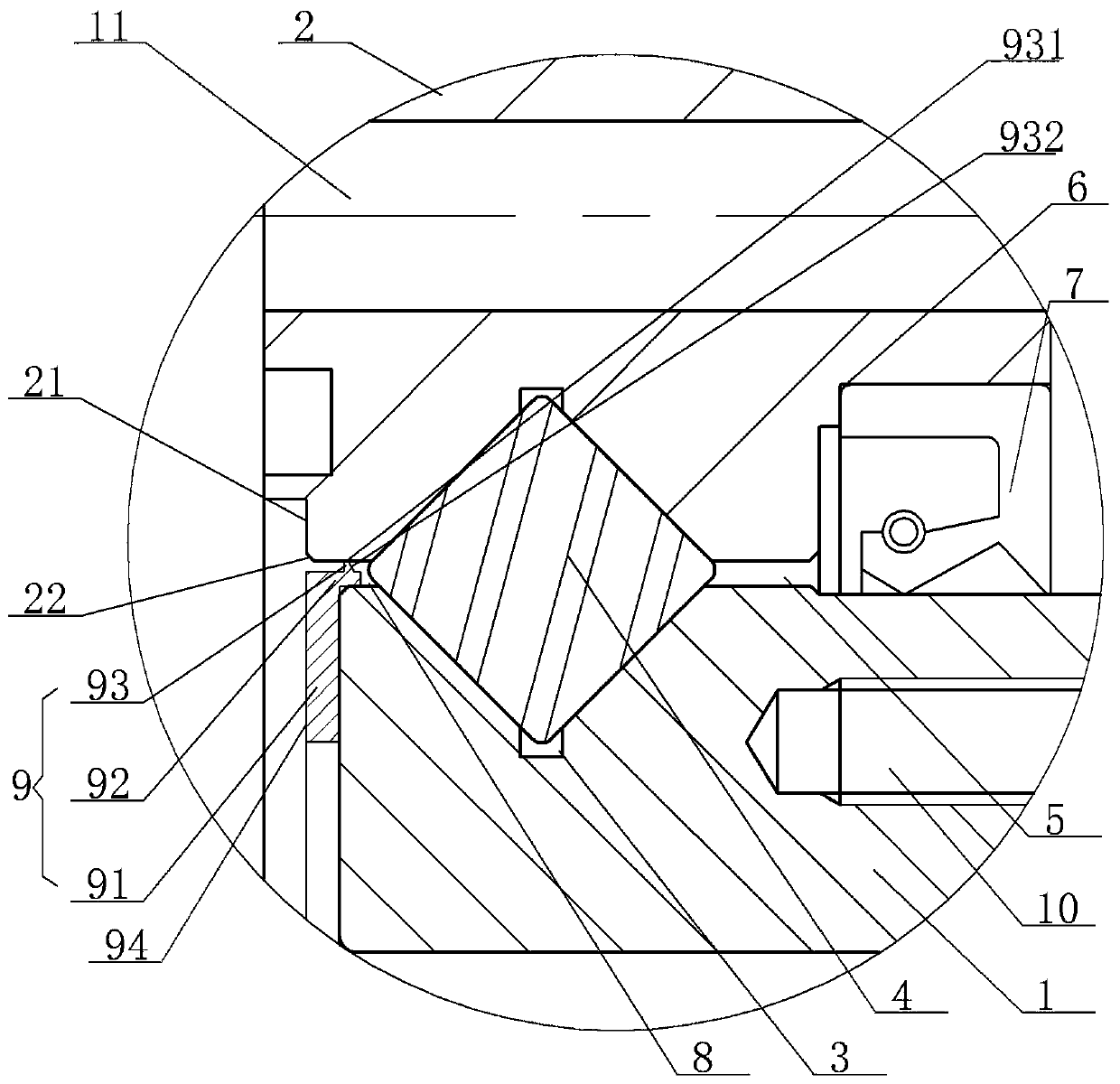

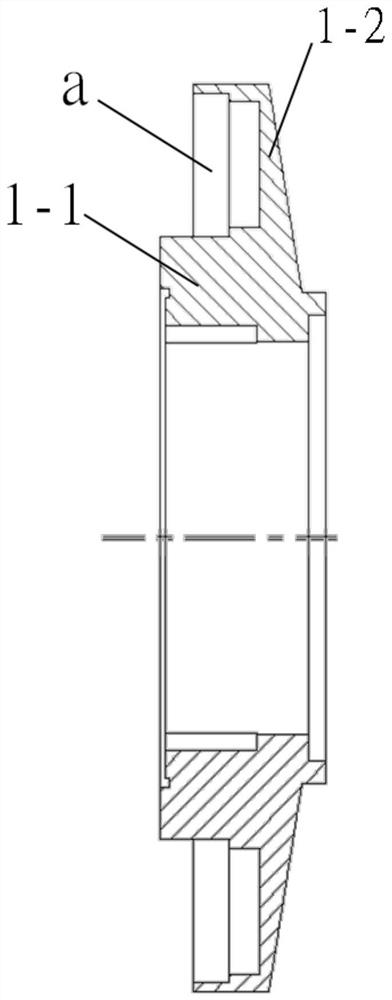

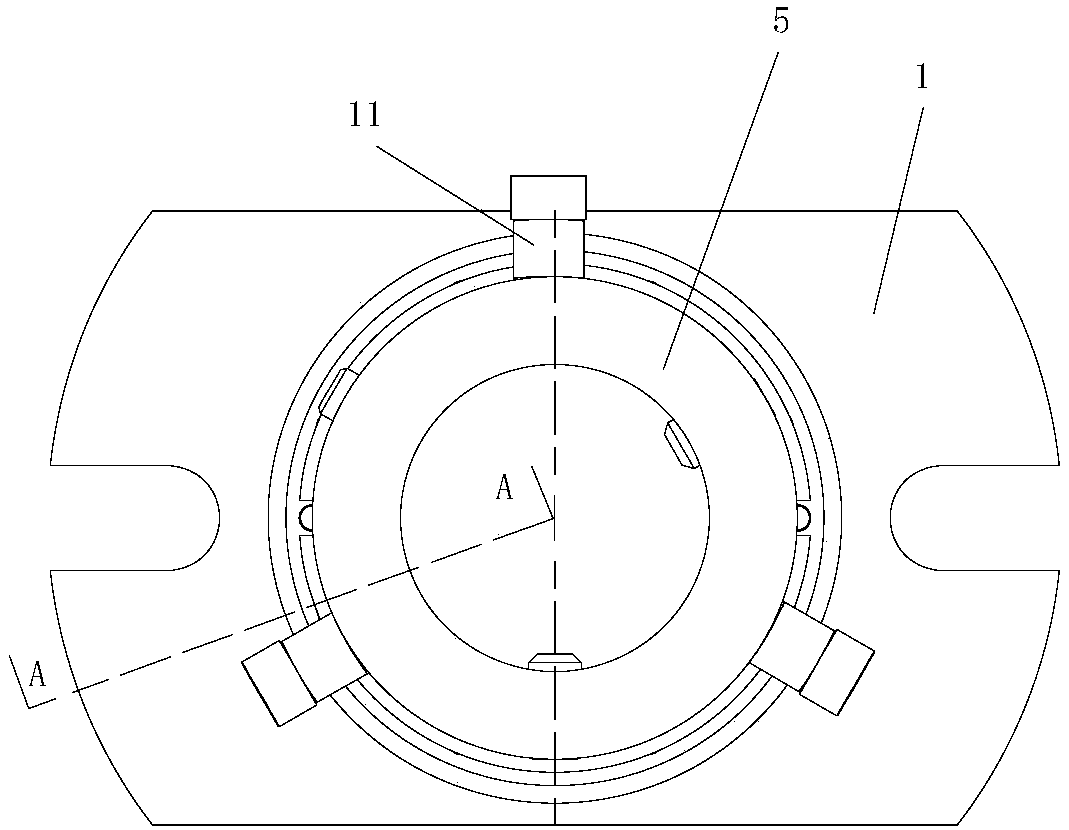

Criss-crossed roller bearing with novel sealing structure

PendingCN110030279AReduce the probability of oil spillsReduce sealing pressureBearing componentsEngineeringMechanical engineering

The invention provides a criss-crossed roller bearing with a novel sealing structure. The sealing pressure of a framework oil seal is reduced, the oil leakage rate of the bearing is reduced, and criss-crossed rollers are ensured to be lubricated sufficiently. The criss-crossed roller bearing with the novel sealing structure comprises a bearing inner ring and a bearing outer ring, wherein roller installation ring slots are formed in the corresponding thickness positions between an outer ring surface of the bearing inner ring and an inner ring surface of the bearing outer ring; the correspondingrollers are arranged in corresponding roller slots of the roller installation ring slots through a criss-crossed form; a framework oil seal installation seam allowance is arranged at the outer end ofan outer-end connecting ring slot gap in the thickness direction after the bearing inner ring and the bearing outer ring are assembled; a framework oil seal is arranged on the framework oil seal installation seam allowance and blocks lubricating oil at the corresponding end surface; a sealing element blocks the tail end of an inner-end connecting ring slot gap in the thickness direction of the bearing inner ring and the bearing outer ring, and concretely comprises a connecting ring, a transition flanging ring and an outer convex seal ring; and the first end surface of the connecting ring andthe inner end surface of the bearing inner ring are fixedly arranged in a fitting way.

Owner:SUZHOU LEADERDRIVE HARMONIC WAVE TRANSMISSION TECH CO LTD

Symmetrical low-temperature-resistant combined type sealing device

PendingCN113124163AExtended temperature rangeSealed and compactEngine sealsWorking environmentProcess engineering

The invention relates to combined type sealing devices, in particular to a symmetrical low-temperature-resistant combined type sealing device. The invention aims to solve the technical problems of limited sealing performance and reliability, poor environmental adaptability and poor repeatability due to the adoption of end face sealing in an existing dynamic sealing structure. According to the symmetrical low-temperature-resistant combined type sealing device, the end face seal of a liquid seal wheel, the inner end face of the liquid seal wheel and a static ring seal assembly and the floating ring seal are connected in series, the end face seal of the liquid seal wheel and the static ring seal assembly serve as the main seal, the floating ring seal serves as the auxiliary seal, trace leakage media can be discharged through each leakage channel, and the device has the advantages of being compact in sealing structure, high in sealing capacity, high in reliability, large in environment temperature tolerance range, capable of tolerating the low temperature of liquid oxygen, good in repeatability and suitable for high-pressure working environments.

Owner:XIAN AEROSPACE PROPULSION INST

Waterproof plug

ActiveCN102823077BReduce movementReduce sealing pressureCouplings bases/casesElectrical apparatus casings/cabinets/drawersEngineeringElectric wire

Owner:YAZAKI CORP

Anti-blocking and anti-corrosion structure for the junction of the flare tube and the return tank

ActiveCN109113668BSolve problems prone to corrosion phenomenaReduce corrosion rateFlushingEngineeringElectrochemical corrosion

The invention discloses an anti-blocking and anti-corrosion structure for the junction of a horn pipe and a backflow groove. The electrically communicating whole is composed of a parallel guiding pipe, an inclined guiding pipe and the horn pipe and does not make contact with the backflow groove, and an electrochemical corrosion passage between the horn pipe and the backflow groove is directly cutoff; a ceramic mounting plate, a first ceramic cushion block, a first rubber sealing pad, a bearing frame, a second rubber sealing pad and a second ceramic cushion block are matched to conduct mounting bearing, sealed protection and automatic reinforcing, thus the problem that in the prior art, the junction of the horn pipe and the backflow groove are extremely prone to corrosion is solved, and the purposes of decreasing the corrosion rate of the junction of the horn pipe and the backflow groove and decreasing the maintenance and replacement frequency are achieved; and meanwhile, the anti-blocking and anti-corrosion structure is high in stability, can be self-sealed, and can significantly lower the blocking risk of the backflow groove.

Owner:MIANYANG FEIYUAN TECH CO LTD

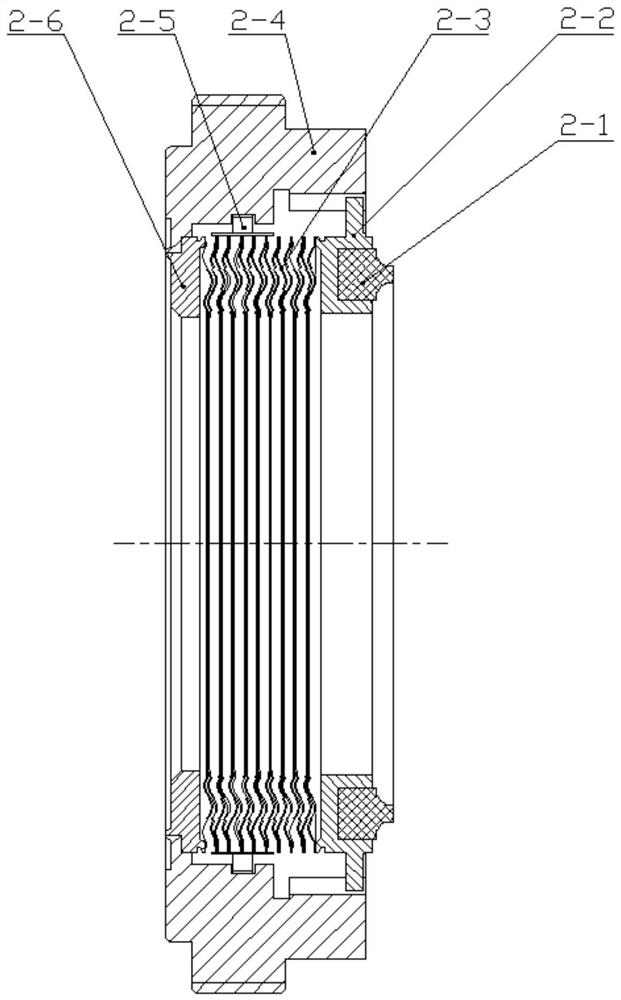

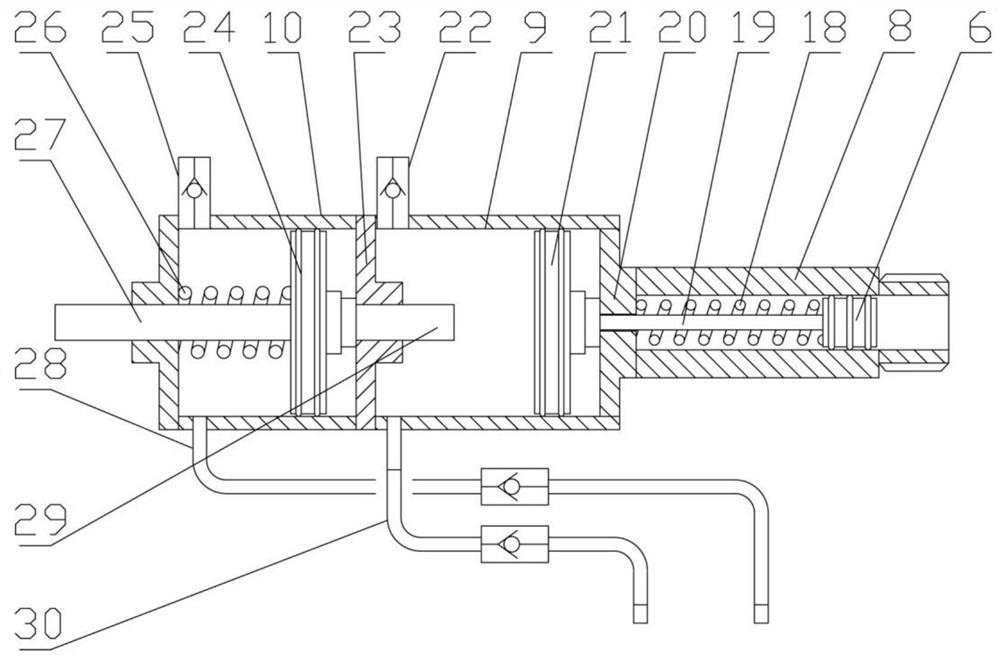

An ultra-short cartridge mechanical seal and its working method

The invention relates to a ultrashort packing machine seal and a working method thereof. The ultrashort packing machine seal comprises a static ring, a movable ring, a clamping ring and a flange; a convex edge is peripherally arranged on the outer wall of the static ring; the lower side of the convex edge of the static ring is tightly matched with the inner wall of the flange; multiple dowel pins are arranged between the convex edge and the flange; a spring is arranged between the lower end surface of the convex edge of the static ring and the flange for providing compensation power to the static ring; the upper end surface of the static ring is tightly matched with the lower end surface of the movable ring; the clamping ring is fixedly connected with the movable ring; the outer wall of the clamping ring is tightly matched with the inner wall of the movable ring; a groove is peripherally formed in the inner wall of the clamping ring, so that a first O-shaped sealing ring between the clamping ring and a rotating shaft to be sealed is arranged in the groove to achieve a better sealing effect; the clamping ring is directly contacted with the rotating shaft to prevent use of a shaft sleeve; the static ring is arranged in the flange; and the end surface of the flange is matched with the static ring to prevent use of a static ring mounting base and a movable ring mounting base, so that the structure is simple, and the axial length of the machine seal is effectively shortened.

Owner:ZHENJIANG OUSA IND SEAL CO LTD

A packing sealing mechanism for a reciprocating compressor

ActiveCN113007355BReduce sealing pressureExtended seal lifeEngine sealsPositive displacement pump componentsEngineeringStructural engineering

A stuffing sealing mechanism of a reciprocating compressor includes a stuffing sealing ring and a decompression ring, and a first labyrinth sealing ring is arranged at one end of the decompression ring. A second labyrinth seal ring is provided at one end of the packing seal ring, a slot is provided inside the second labyrinth seal ring, an air intake sleeve is communicated with the cylinder body of the compressor, and the first booster sleeve is communicated with one end of the air intake sleeve. The inner diameter of the first pressurized sleeve is larger than the inner diameter of the intake sleeve, a first partition is provided between the intake sleeve and the pressurized sleeve, a first piston is provided in the intake sleeve, and a second piston is provided in the first pressurized sleeve , the first piston and the second piston are connected through the first plug rod, and there is a first spring outside the first plug rod. One end communicates with the slot through the first air pipe, and the first one-way valve communicates with the first pressurized sleeve and the first air pipe. The invention can automatically adjust the seal according to the working conditions of the compressor, reduce the pressure of the packing seal, and prolong the service life of the packing seal.

Owner:湛江科技学院

Anti-blocking and anti-corrosion structure for junction of horn pipe and backflow groove

ActiveCN109113668ASolve problems prone to corrosion phenomenaReduce corrosion rateFlushingElectricityEngineering

The invention discloses an anti-blocking and anti-corrosion structure for the junction of a horn pipe and a backflow groove. The electrically communicating whole is composed of a parallel guiding pipe, an inclined guiding pipe and the horn pipe and does not make contact with the backflow groove, and an electrochemical corrosion passage between the horn pipe and the backflow groove is directly cutoff; a ceramic mounting plate, a first ceramic cushion block, a first rubber sealing pad, a bearing frame, a second rubber sealing pad and a second ceramic cushion block are matched to conduct mounting bearing, sealed protection and automatic reinforcing, thus the problem that in the prior art, the junction of the horn pipe and the backflow groove are extremely prone to corrosion is solved, and the purposes of decreasing the corrosion rate of the junction of the horn pipe and the backflow groove and decreasing the maintenance and replacement frequency are achieved; and meanwhile, the anti-blocking and anti-corrosion structure is high in stability, can be self-sealed, and can significantly lower the blocking risk of the backflow groove.

Owner:MIANYANG FEIYUAN TECH CO LTD

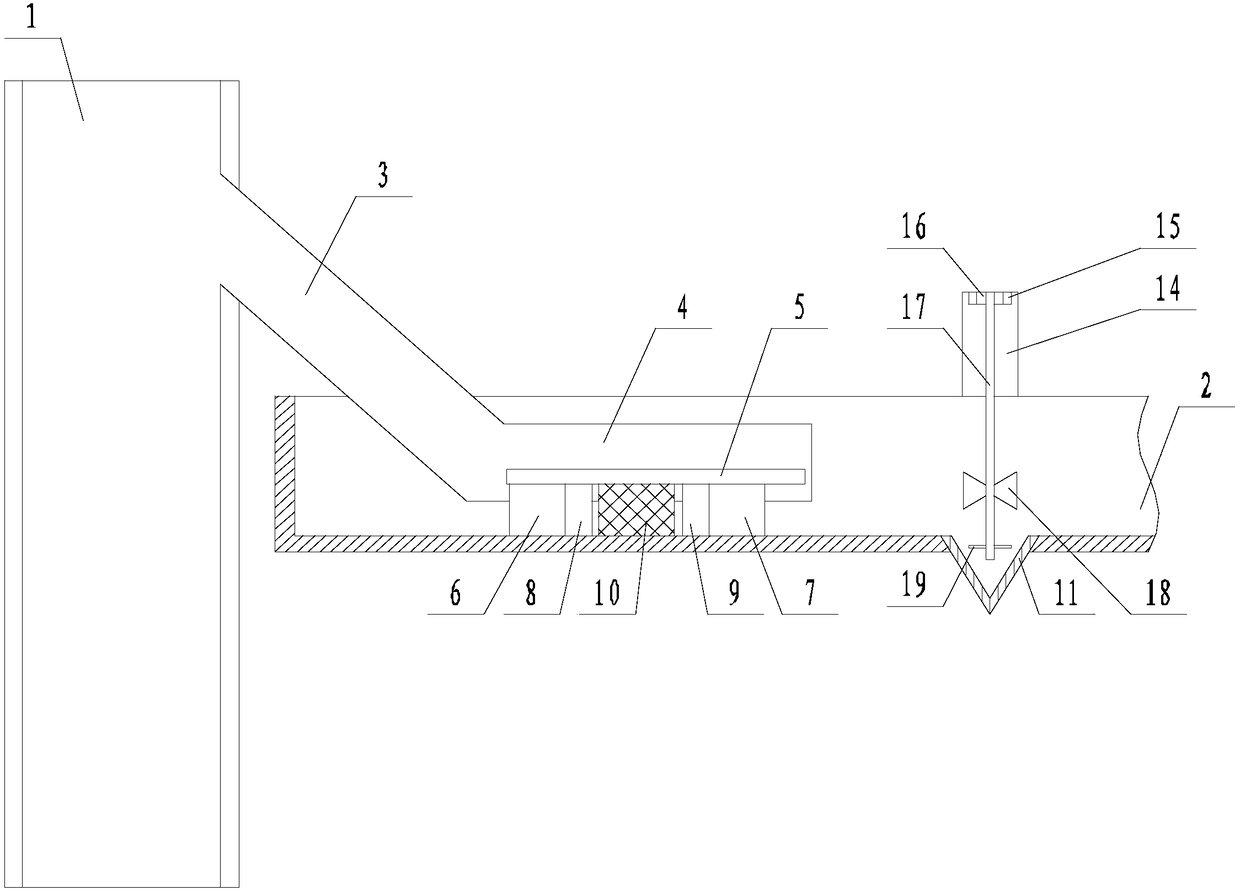

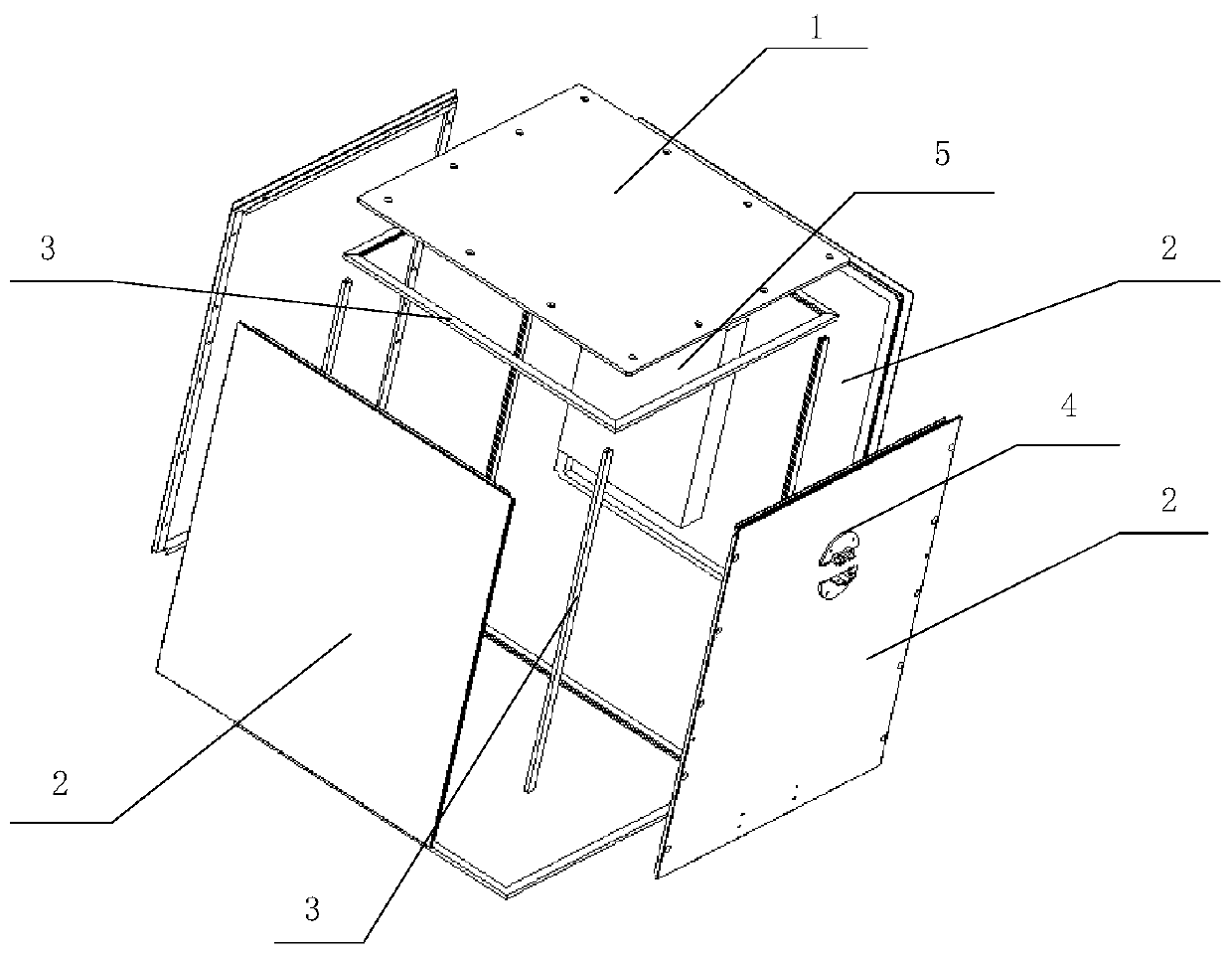

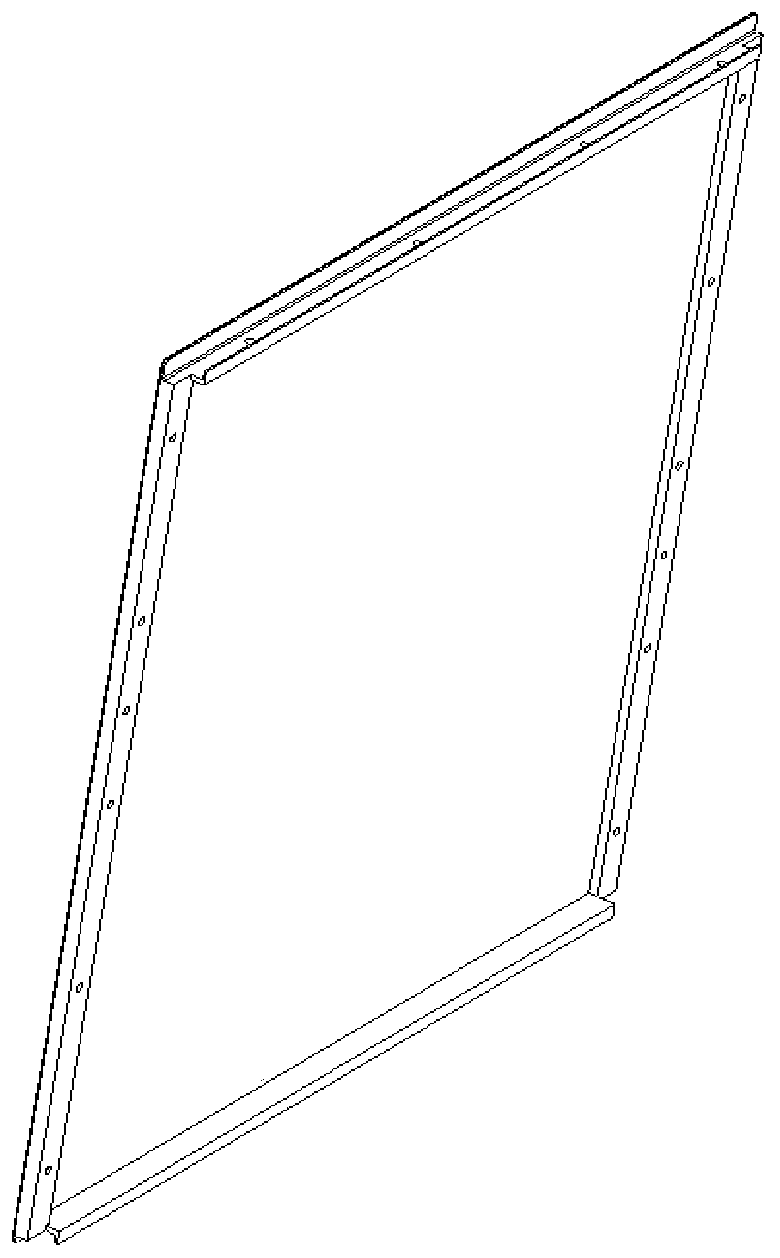

A sealed and noise-reducing structure that can be repaired quickly in orbit

InactiveCN109323077BReduce error accumulationReduced precision requirementsEngine sealsPipesEngineeringNoise reduction

The invention relates to a sealing noise reduction structure capable of being rapidly maintained on an orbit. The sealing noise reduction structure comprises a box body, a top cover and a sealing structure. The box body is a cube with an opening in the top wall, and the interior of the box body is used for containing equipment to be subjected to sound insulation and noise reduction. A counter groove is formed in the end face, facing the top wall, of the side wall of the box body. The sealing structure is an elastic component with a U-shaped cross section. The sealing structure is matched withthe counter groove in the side wall of the box body, and the sealing structure is placed in the counter groove in the side wall of the box body. The U-shaped opening of the sealing structure faces theside, with high inside and outside pressure, of the box body. The top cover is fixedly connected with the counter groove, with the sealing structure arranged, in the box body through a fastener. According to the sealing noise reduction structure, the noise of the equipment inside the box body can be reduced to 60 dB, and the sealing air leakage amount is not more than 1L / min. The sealing noise reduction structure has the functions of being good in bearing performance, good in sealing performance, capable of reducing noise, rapid in maintenance and convenient to disassemble and assemble, and normal work of astronauts on the rail can be guaranteed.

Owner:BEIJING SATELLITE MFG FACTORY

Anticorrosion structure of return outlet of trumpet tube

ActiveCN109098680ASolve problems prone to corrosion phenomenaReduce corrosion rateCorrosion preventionPipe protection against corrosion/incrustationWhole bodyEngineering

The invention discloses an anticorrosion structure of a return outlet of the trumpet tube. A parallel guide tube, an inclined guide tube and the trumpet tube form an electric communication whole body,the whole body is not in contact with a backflow groove, a channel for electrochemical corrosion between the trumpet tube and the backflow groove is cut off directly, by cooperation of a ceramic mounting plate, a first ceramic cushion block, a first rubber sealing pad, a carrying frame, a second rubber sealing pad and a second ceramic cushion block, mounting carrying, sealing protection and automatic reinforcing are carried out, the problem that a position where a trumpet tube is connected with a backflow groove in the prior art is corroded quite easily is solved, and purposes of relieving the corrosion rate of the position where the trumpet tube is connected with the backflow groove and reducing the maintaining and changing frequency are achieved.

Owner:MIANYANG FEIYUAN TECH CO LTD

Packing shaft seal structure for high pressure reciprocating pump

The invention discloses a packing shaft seal structure for a high-pressure reciprocation pump. The packing shaft seal structure for the high-pressure reciprocation pump comprises a shaft seal box connected on a pump body and a plunger arranged in the shaft seal box, a pressurizing piston type packing shaft seal assembly is arranged between the shaft seal box and the plunger, and a counter pull type packing shaft seal assembly is arranged inside and outside the shaft seal box. According to the packing shaft seal structure for the high-pressure reciprocation pump, the two kinds of internal pressure type packing shaft seal assemblies are used in a series connection mode, the distribution of the sealing radial force on the plunger by a packing ring is made to be identical the distribution of pressure of pumped media, the sealing radial force on the plunger by the packing ring is adjusted automatically along with the change of the pressure of the media inside the shaft seal box, dropped pressure occurring caused by abrasion of the packing ring can be compensated automatically, the defect that the sealing radial force on the plunger by the packing ring is just opposite to the pressure of the media in distribution in an existing external pressure type packing shaft seal structure is overcome, excessively fast abrasion of the outside packing ring and the plunger is avoided, and the reliability of the shaft seal is improved. The packing shaft seal structure is especially suitable for shaft seals of high-pressure or ultrahigh-pressure reciprocation pumps or the sealing of high-pressure or ultrahigh-pressure valves and valve rods.

Owner:CHINA CHENGDA ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com