Device and method for producing and sealing packagings produced from at least one heat sealable packaging material strip

a technology of packaging material and device, which is applied in the direction of packaging, packaging by pressing/gasifying, transportation and packaging, etc., can solve the problems of limiting the amount of heat transfer and the application of sealing pressure,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

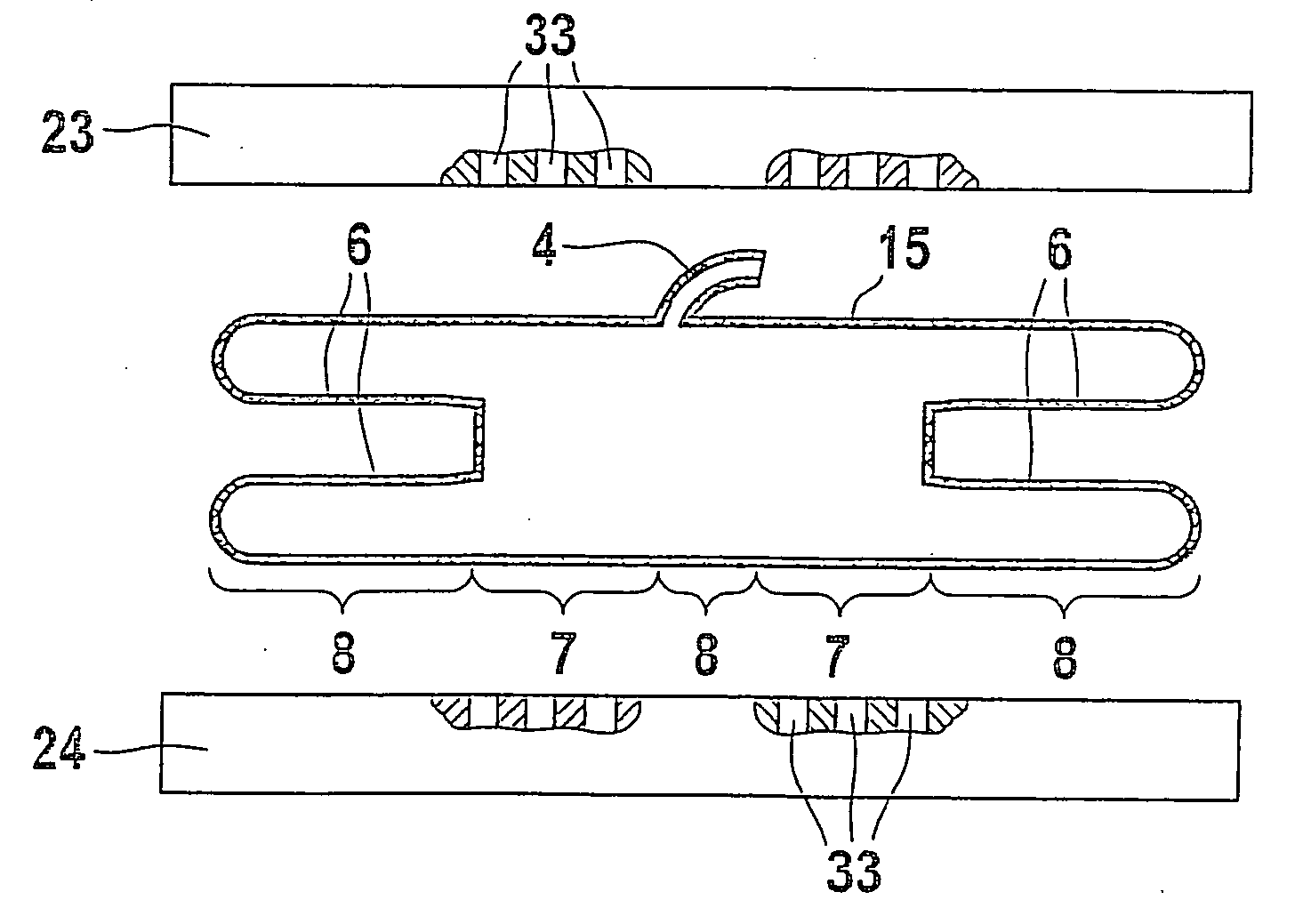

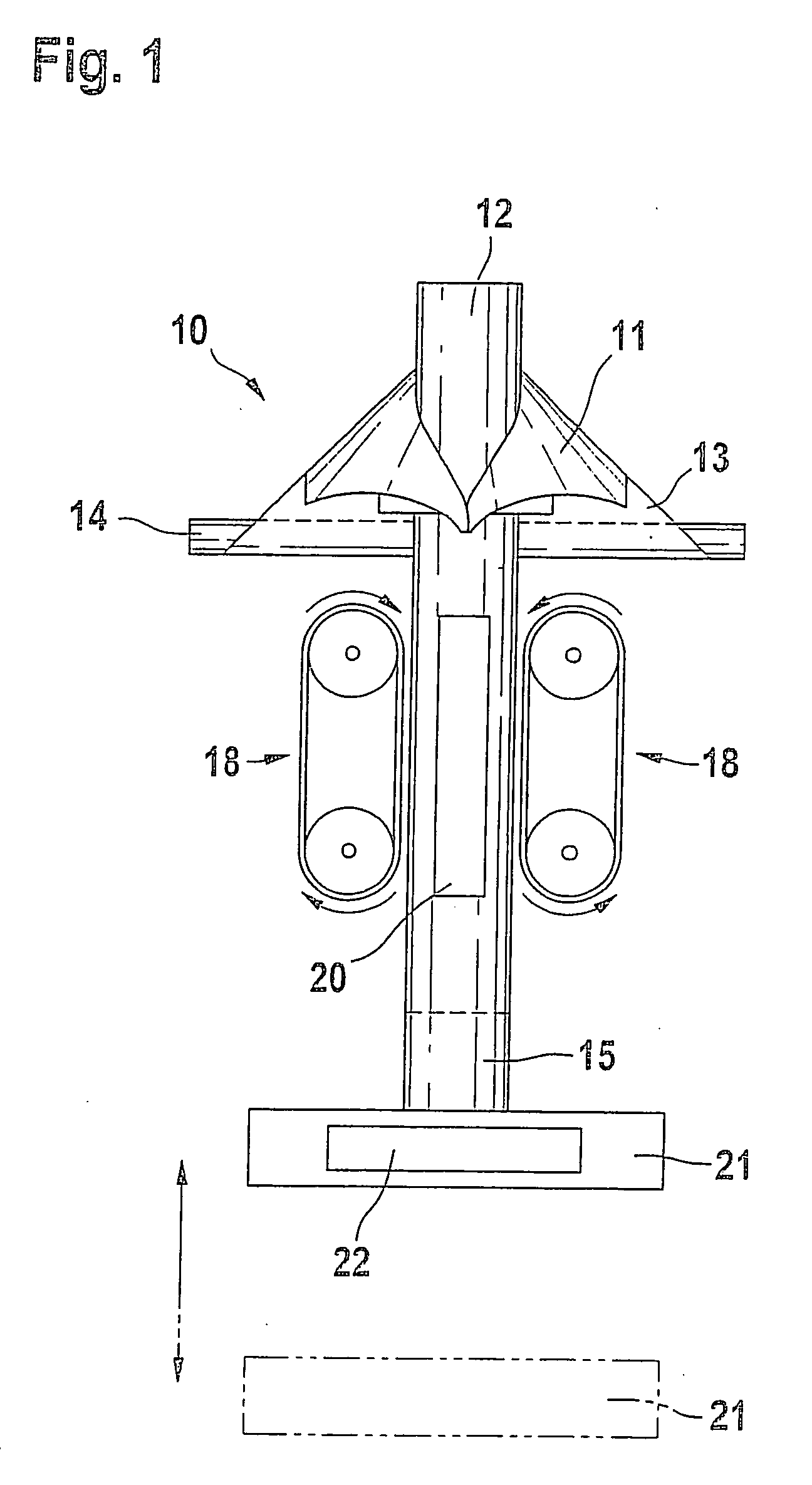

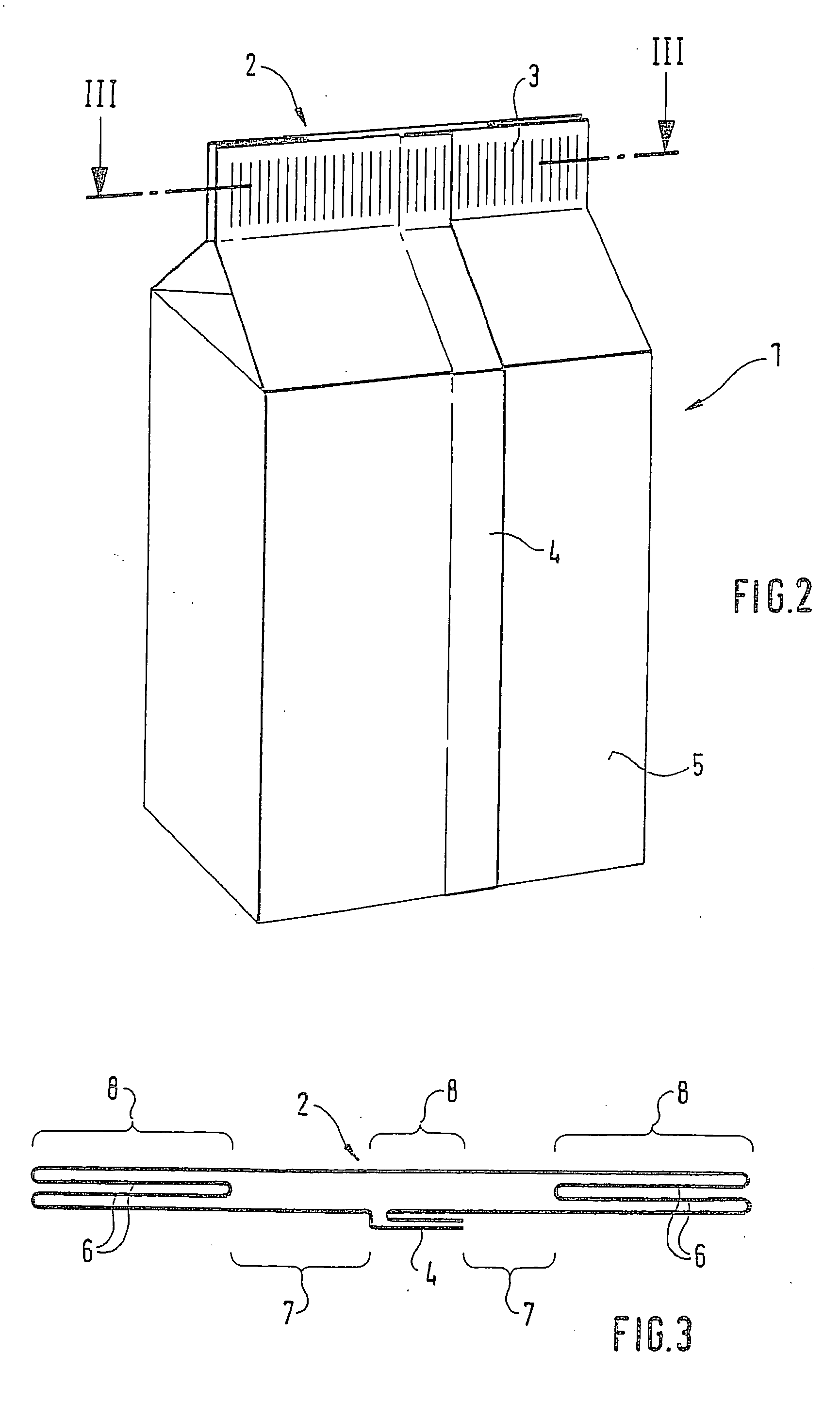

[0015] In FIG. 1, a tubular bag-making machine 10, known per se, is shown. The tubular bag-making machine 10 has a forming shoulder 11, which embraces a combined forming and filling tube 12. By means of the forming shoulder 11 and the forming and filling tube 12, a hot-sealable web of packaging material 13, which is drawn from a supply roll not shown and is delivered to the forming shoulder 11 via a feed roll 14, is shaped into a flexible tube 15.

[0016] Two vacuum prestretching belts 18, which serve to prestretch the flexible tube 15, are disposed facing one another on the forming and filling tube 12, below the forming shoulder 11. At the level of the vacuum prestretching belts 18, a longitudinal seam sealing device 20 is also disposed on the front side of the forming and filling tube 12; it welds the two peripheral regions of the web 13 of packaging material, placed one above the other by the forming shoulder 11, into a longitudinal sealing seam 4.

[0017] A raisable and lowerable tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexible | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| molding pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com