Patents

Literature

3963results about "Successive articles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

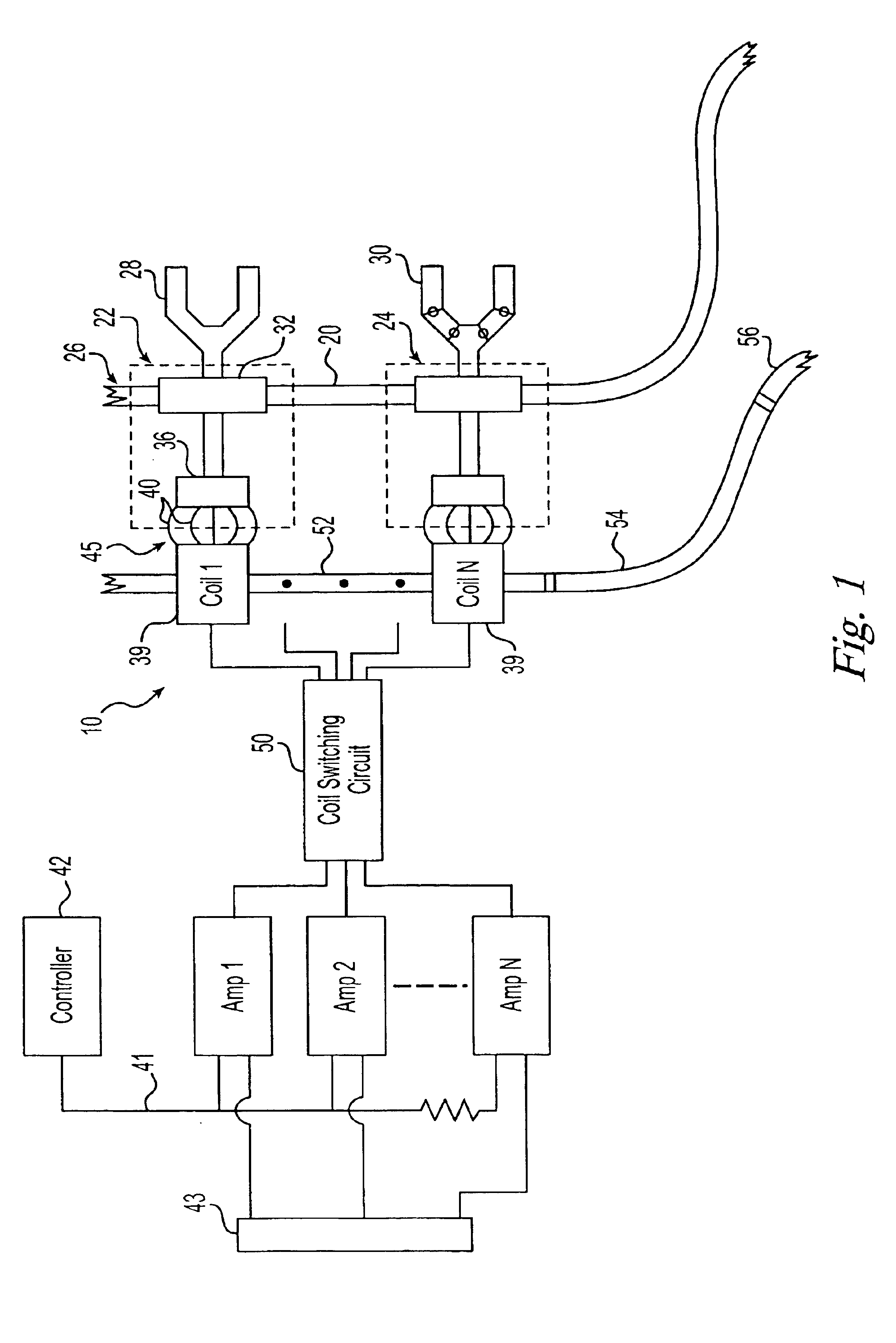

Position feedback system and method for use thereof

InactiveUS6625517B1Solid-state devicesSpecial data processing applicationsEngineeringVirtual sensors

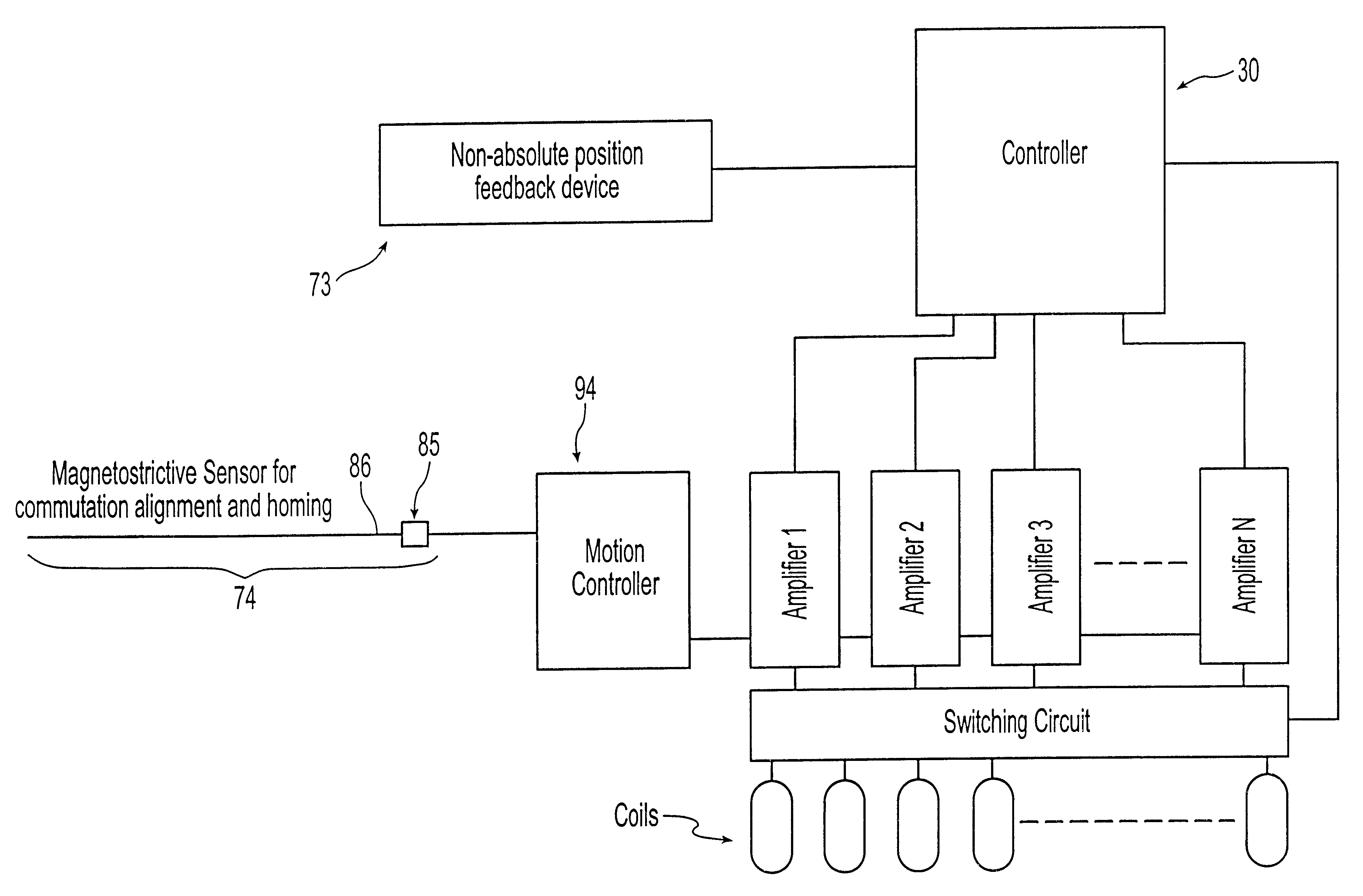

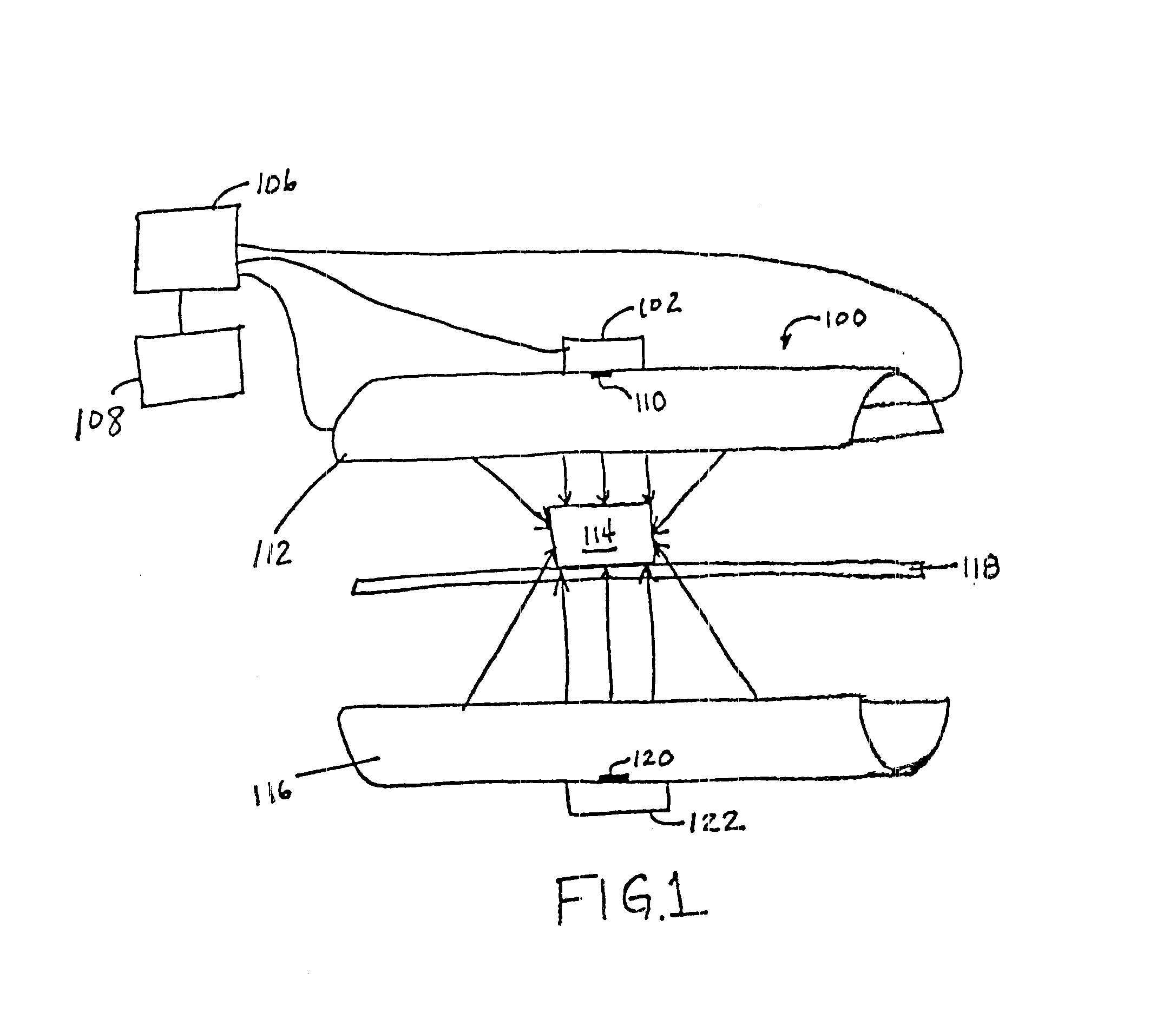

The present invention is directed to a machine with a position feedback system and a method for use thereof. The machine includes at least one movable element mounted for movement on a path and at least one programmable controller. The machine further includes at least two absolute or magnetostrictive sensors or the machine includes an absolute sensor and a non-absolute sensor. The programmable controller uses positional information from the sensors to determine the position of the movable elements on the path and control the movable elements. The method includes determining a known position for the movable elements, linking at least two magnetostrictive sensors into one virtual sensor, and / or performing commutation alignment for the movable elements. Determining the position and commutation alignment can occur when the movable elements are stationary or moving.

Owner:TETRA LAVAL HLDG & FINANCE SA

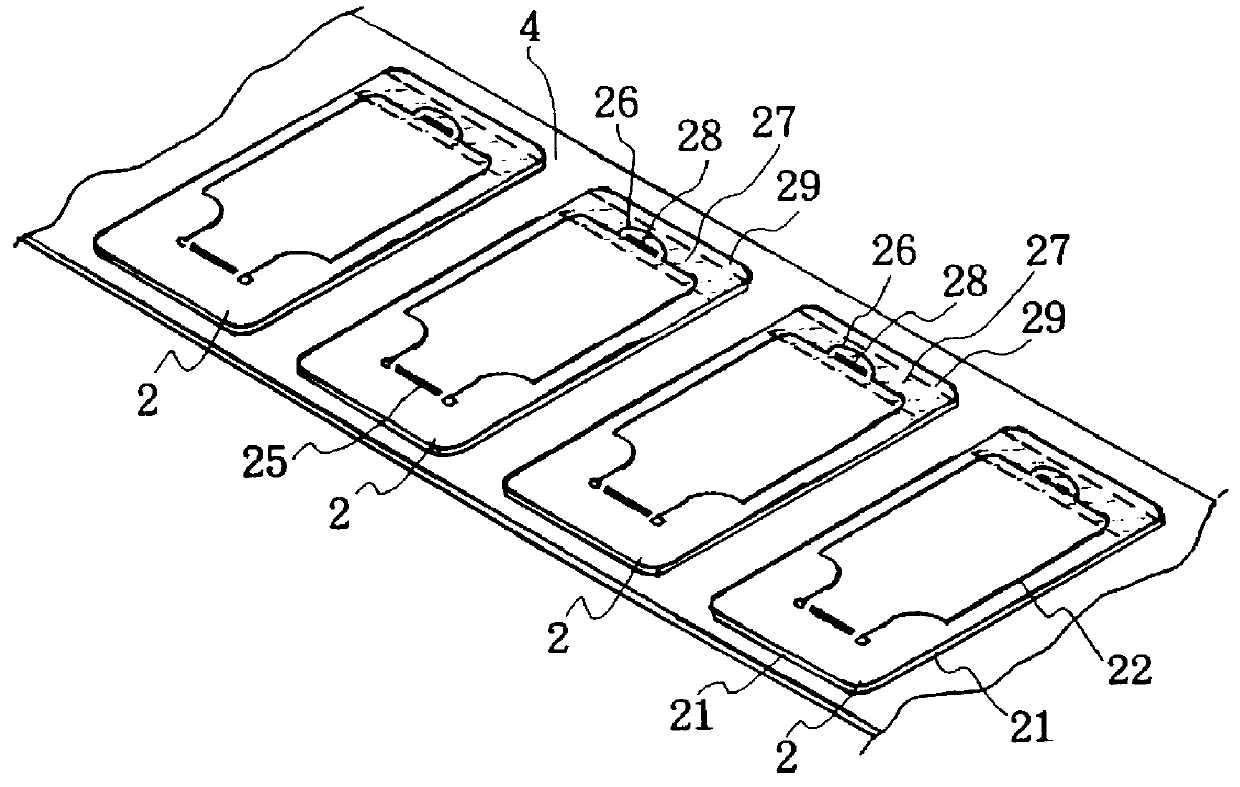

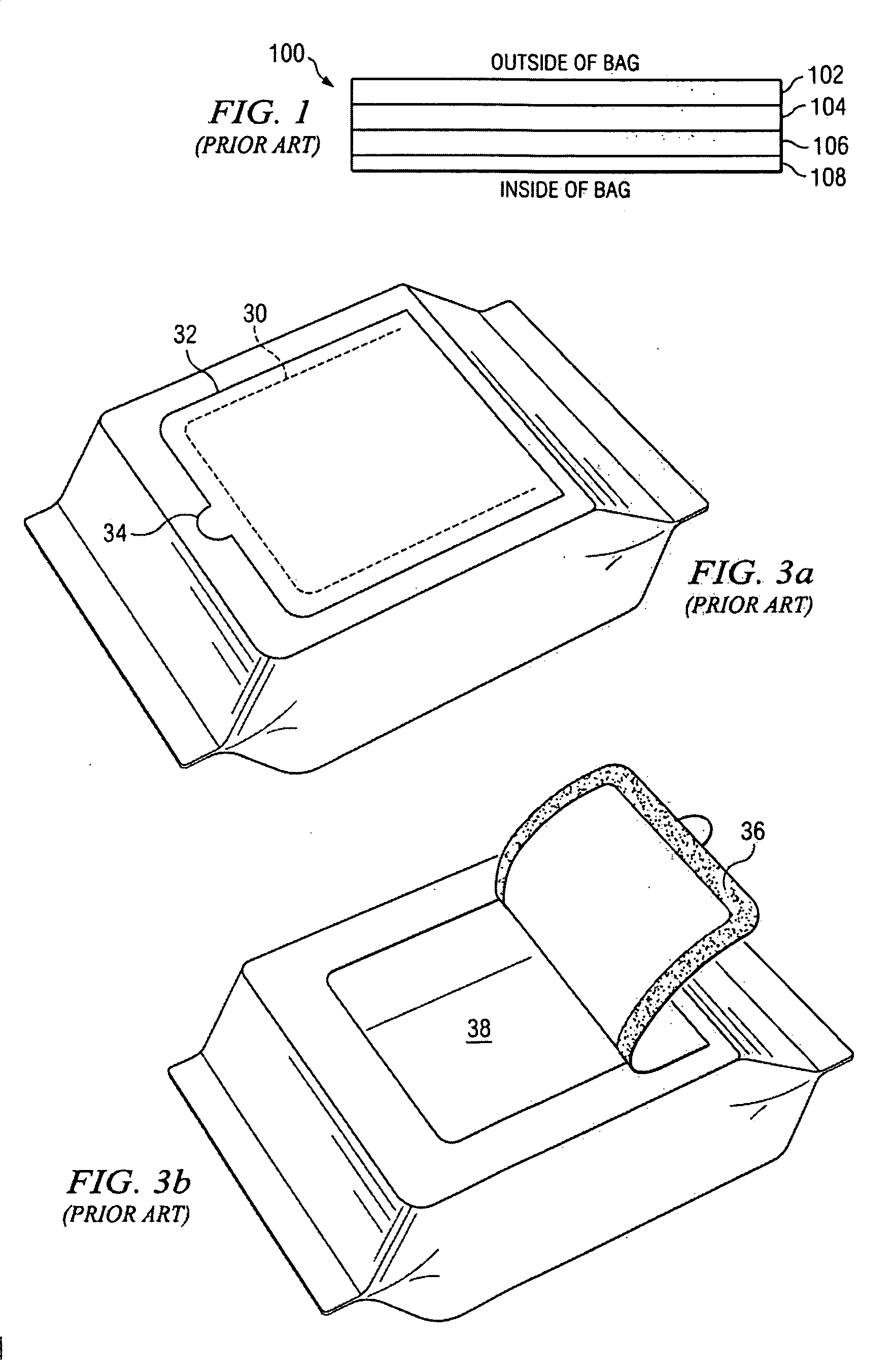

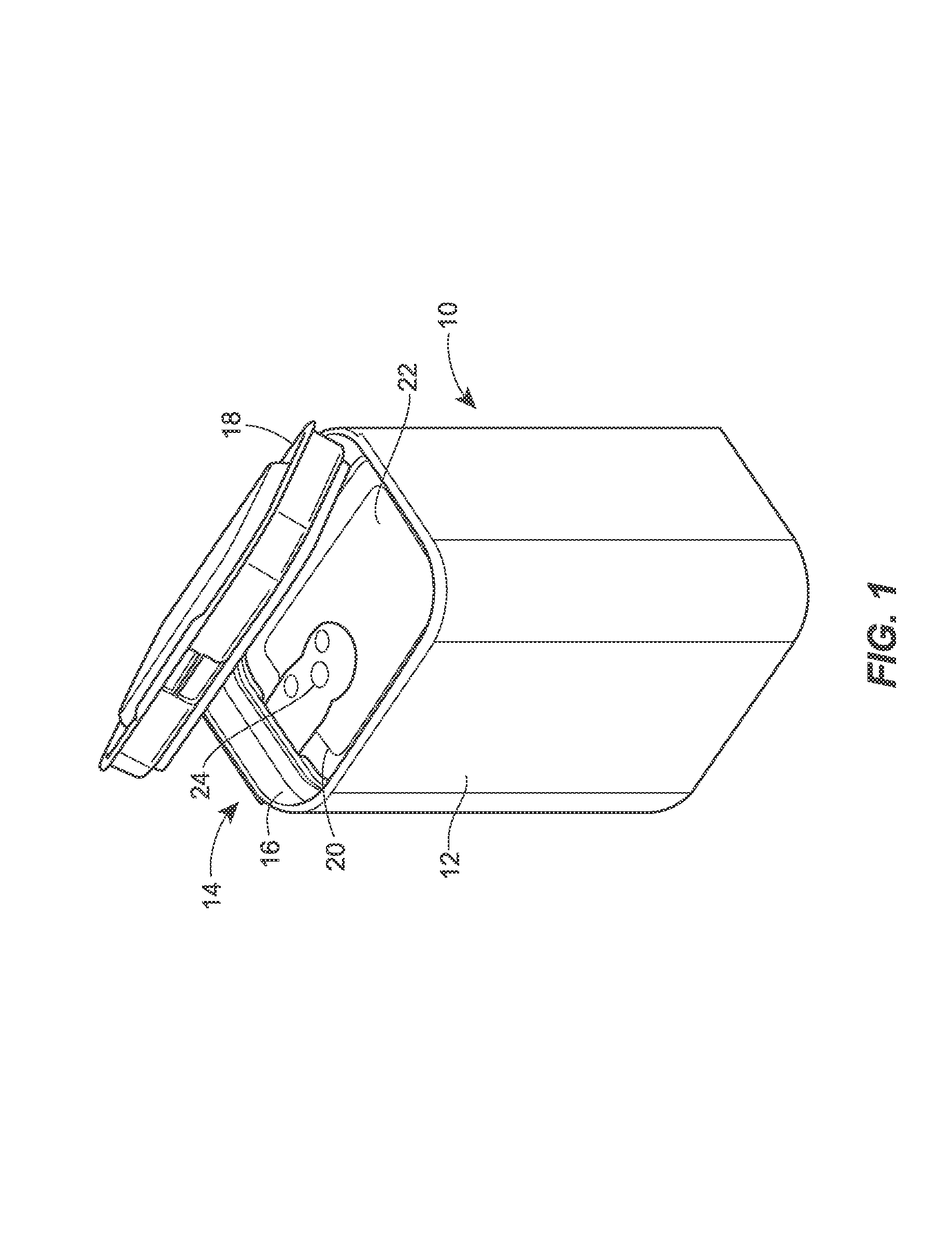

Resealable dispenser-container

InactiveUS6026953AWrapper folding/bending apparatusBathroom accessoriesEngineeringMechanical engineering

A resealable dispenser-container for containing wet tissues. A container, made of a flexible and impervious sheet, has at a top surface an opening for dispensing the wet tissues. A reinforcing sheet, larger than the dispensing opening and of a material harder than that forming the container, is attached to the top surface of the container and has an open looped cut line locating outside of the dispensing opening. The inside region of the open looped cut line is removable from the front end, opposite to the open portion of the open looped cut, toward the open portion so as to form a resealable flap. The reinforcing sheet has a crease locating at the open portion of the open looped cut and extending across the open portion so as to facilitate opening and closing of the flap.

Owner:NAKAMURA KENJI +1

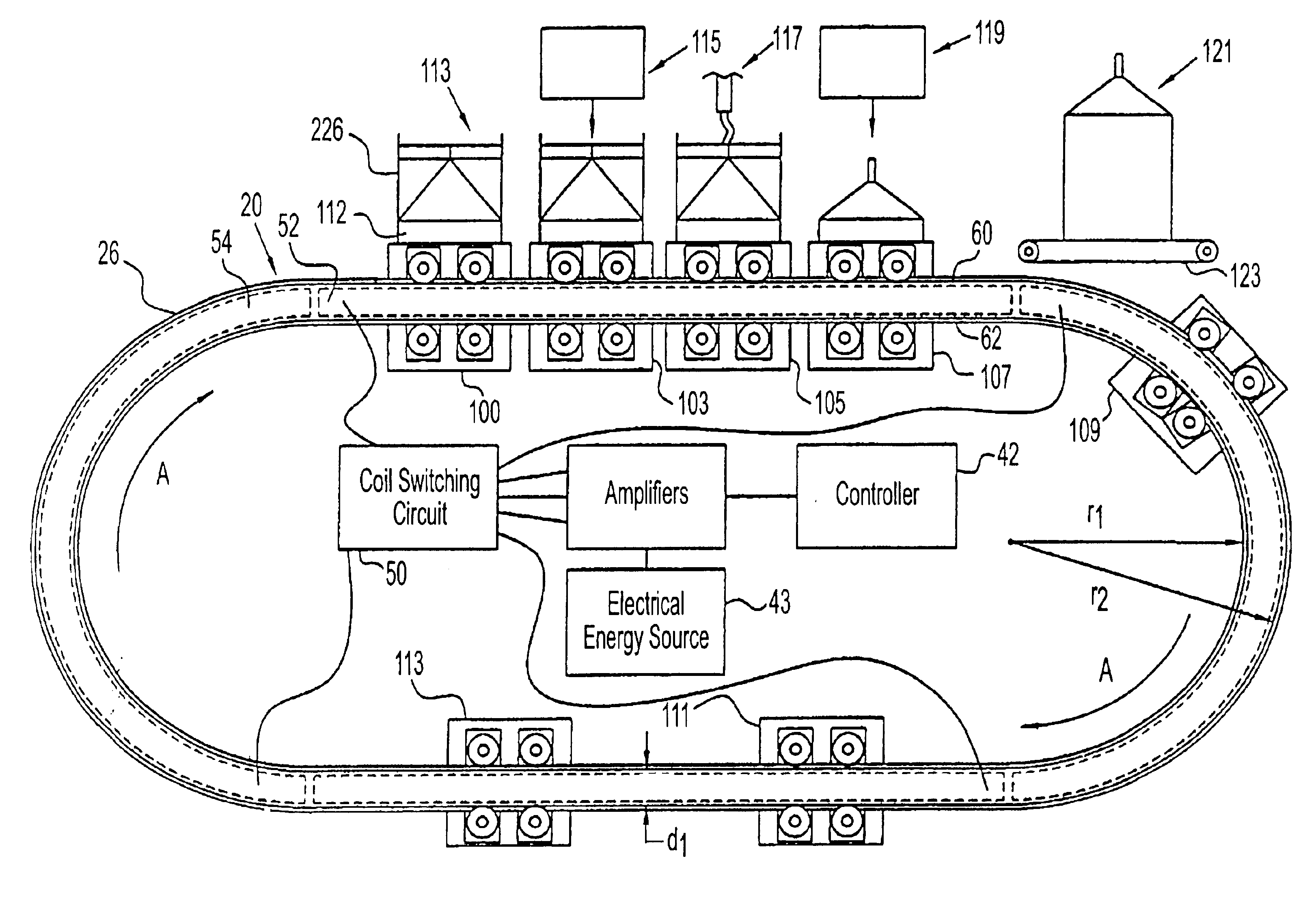

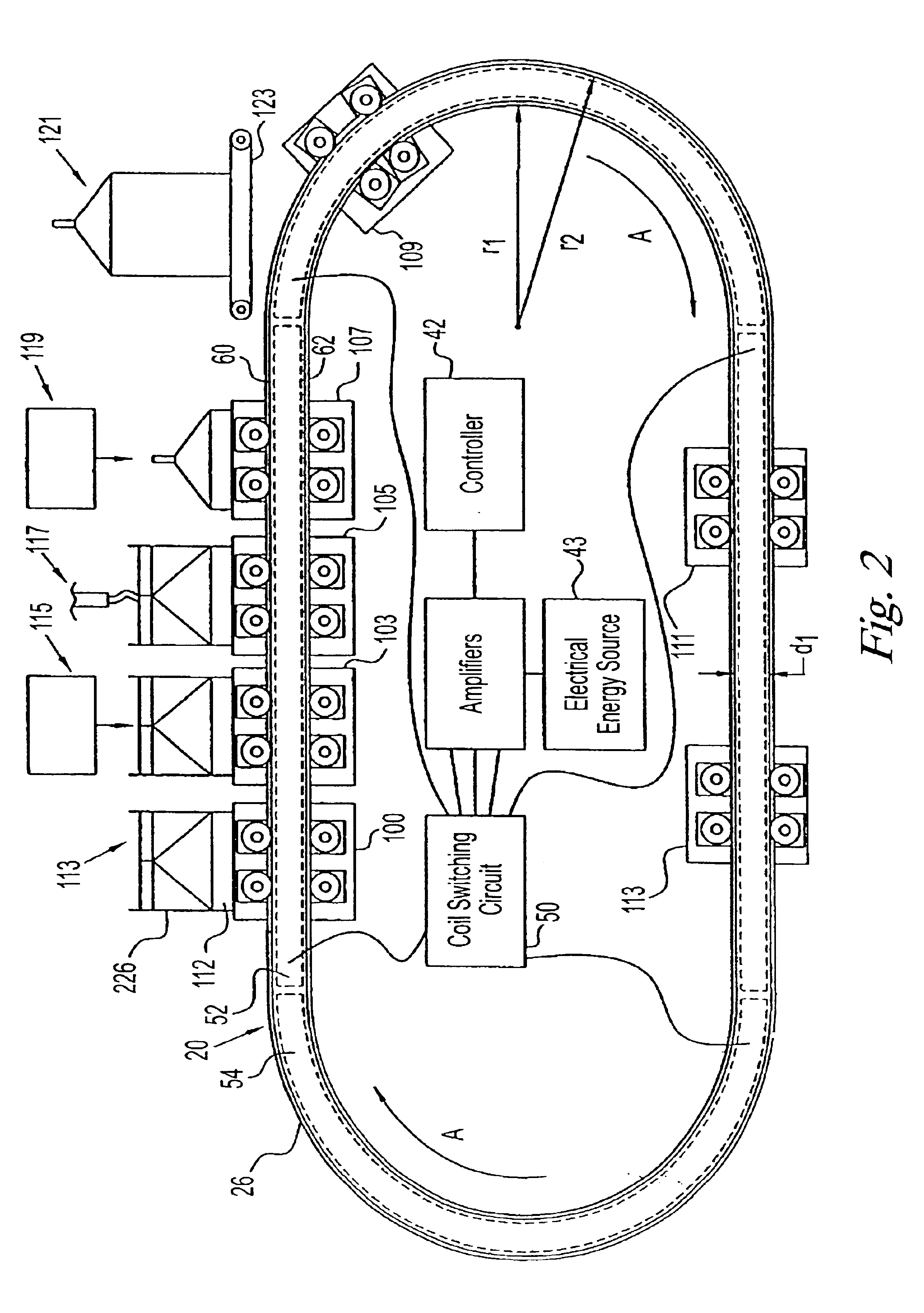

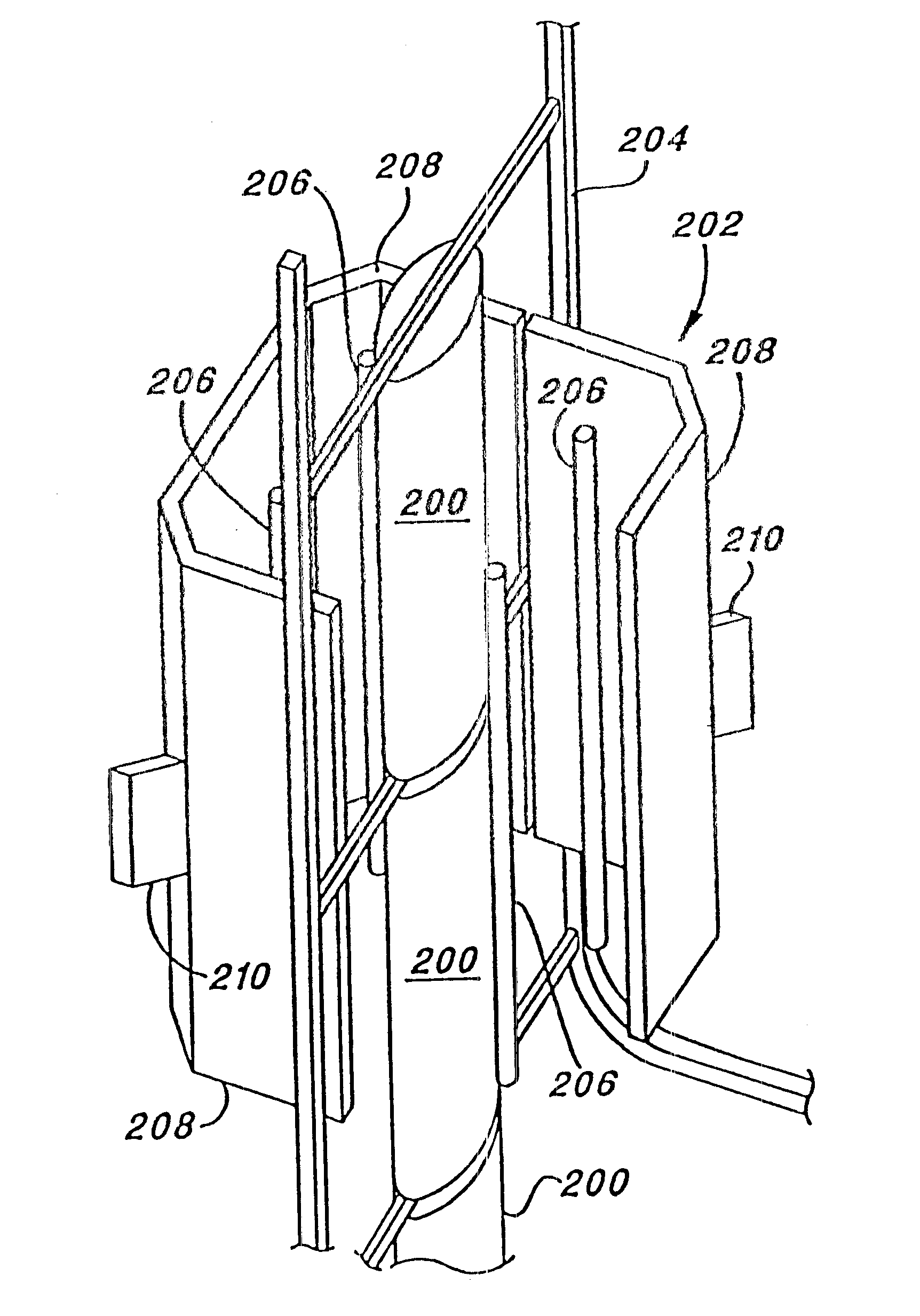

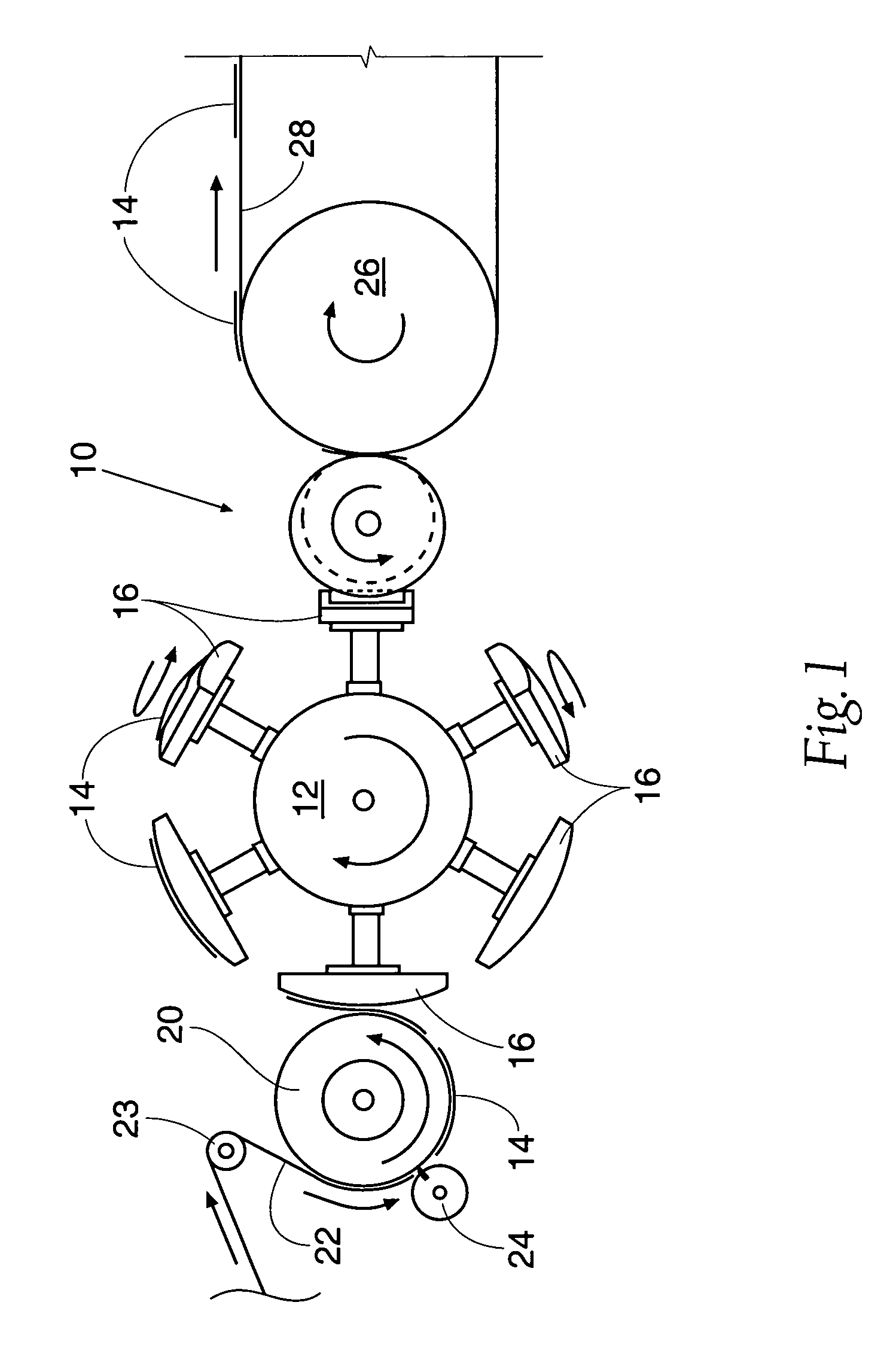

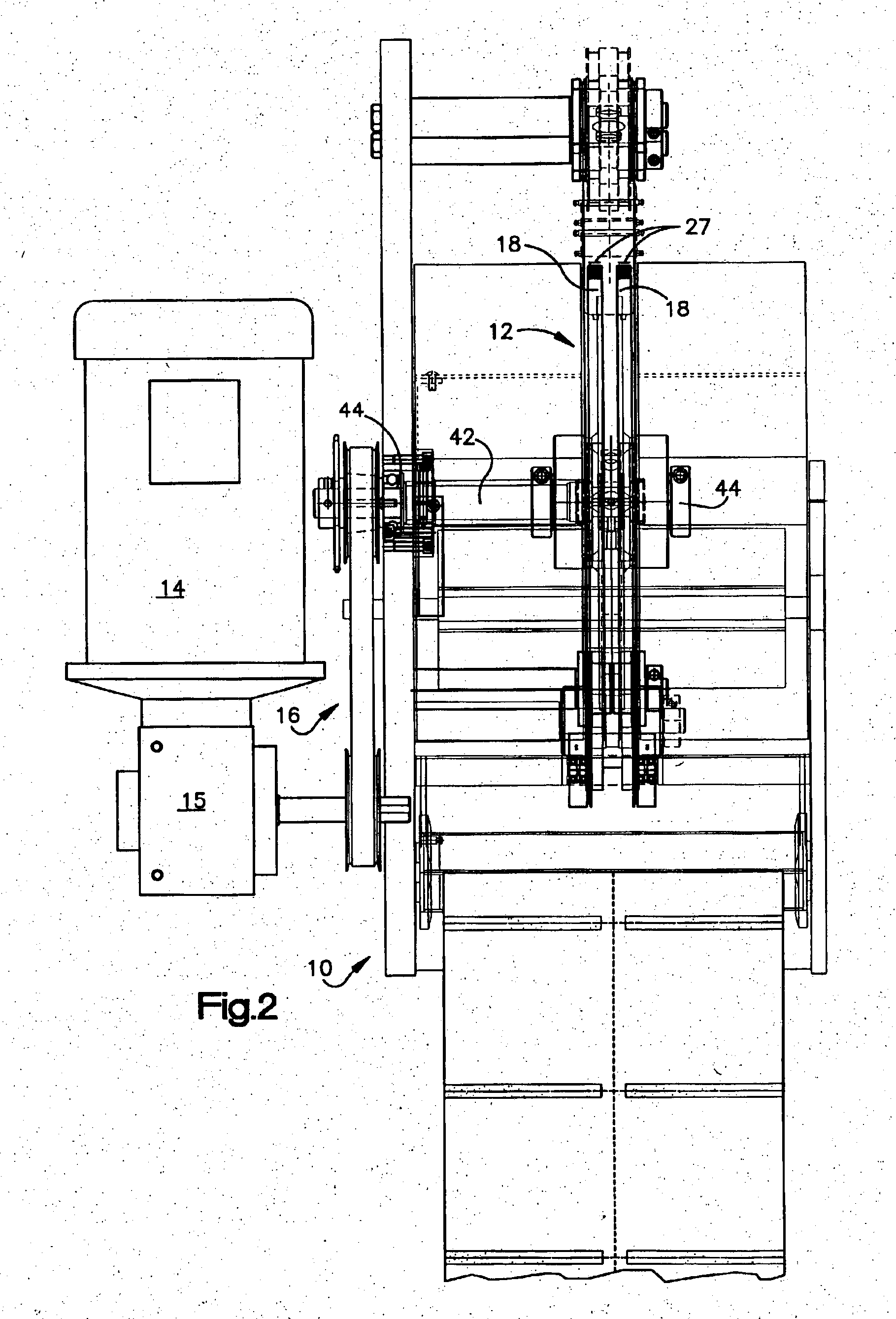

Variable motion system and method

InactiveUS6876896B1Motor/generator/converter stoppersDC motor speed/torque controlMotion parameterEngineering

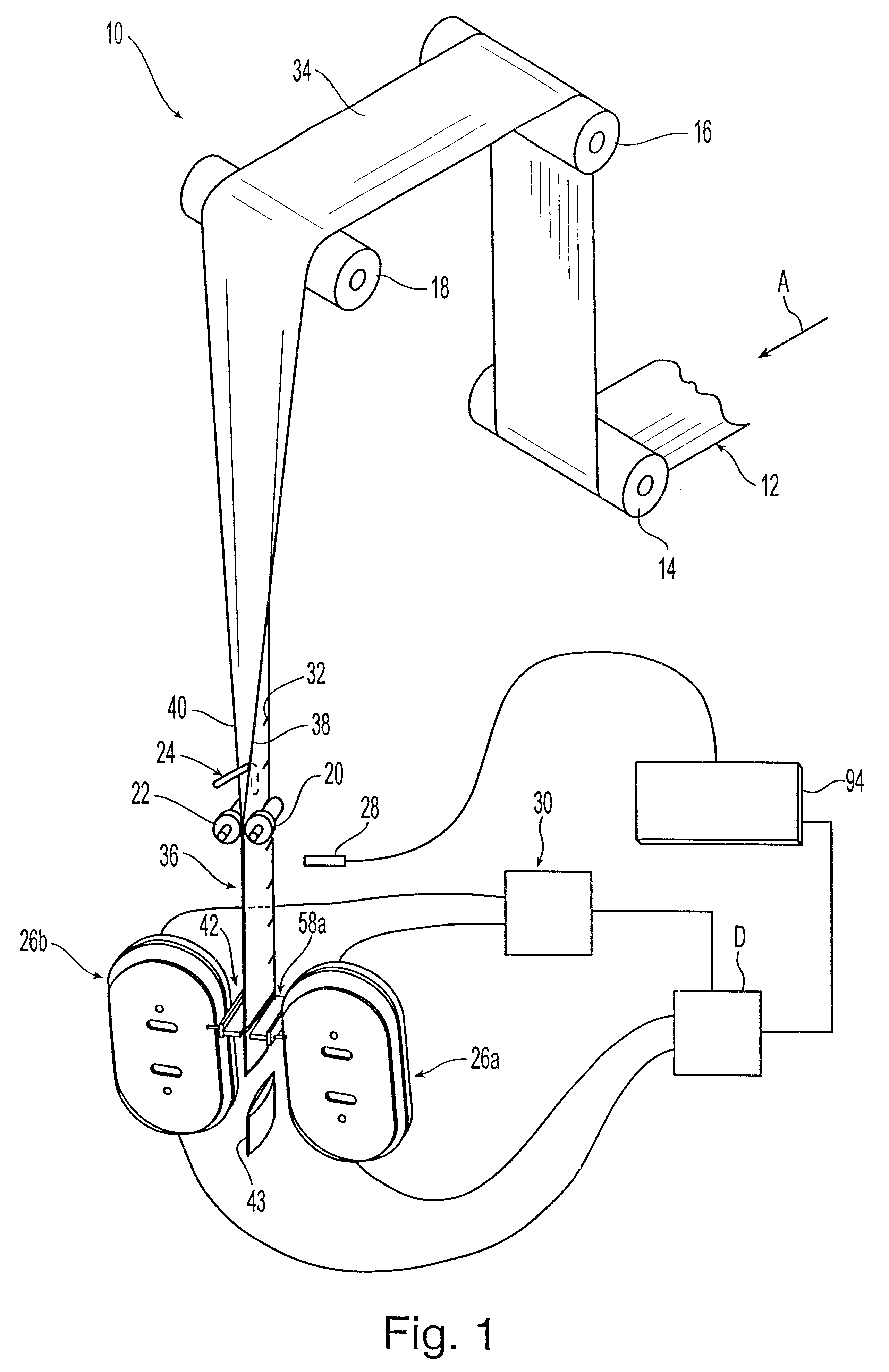

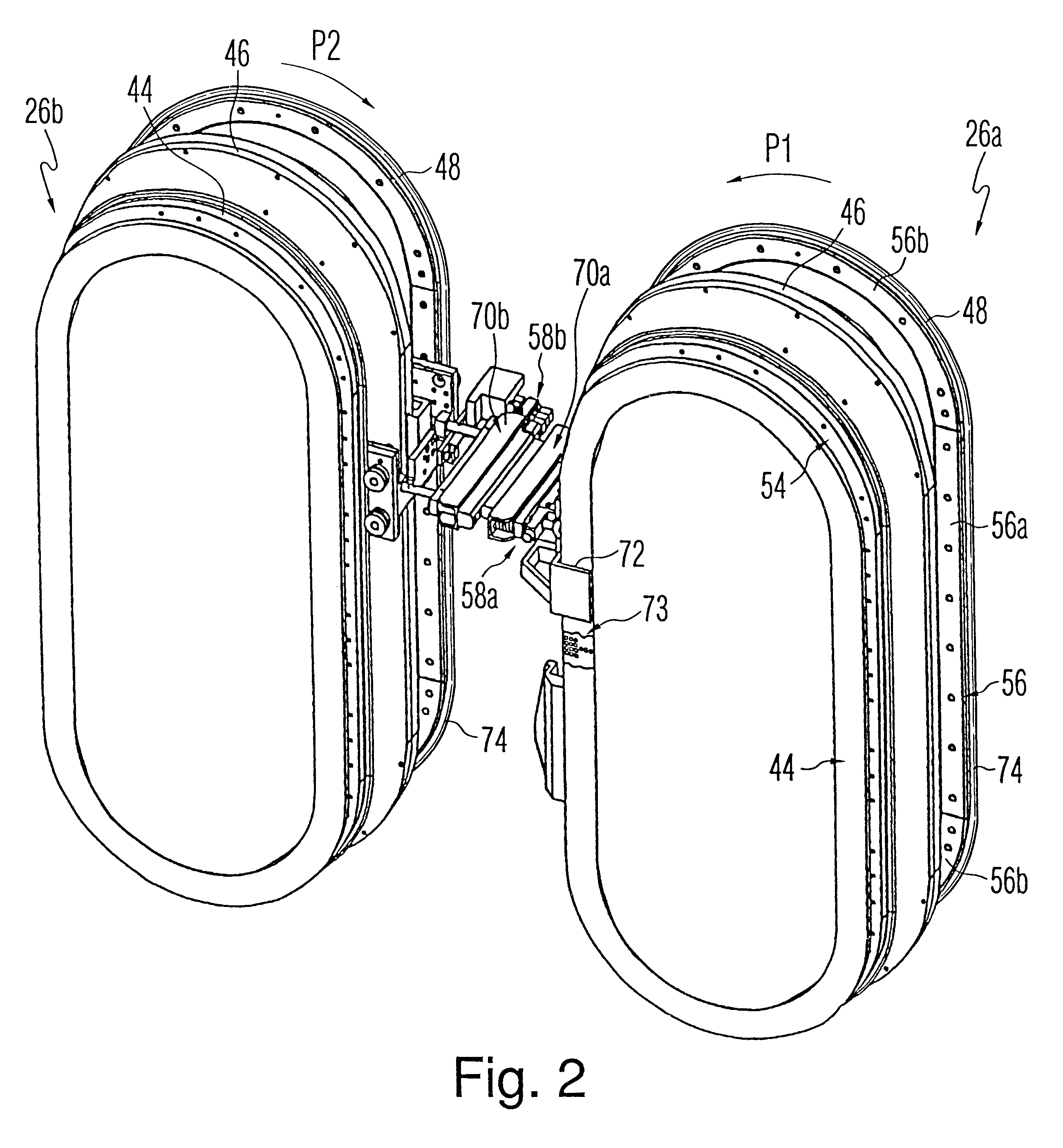

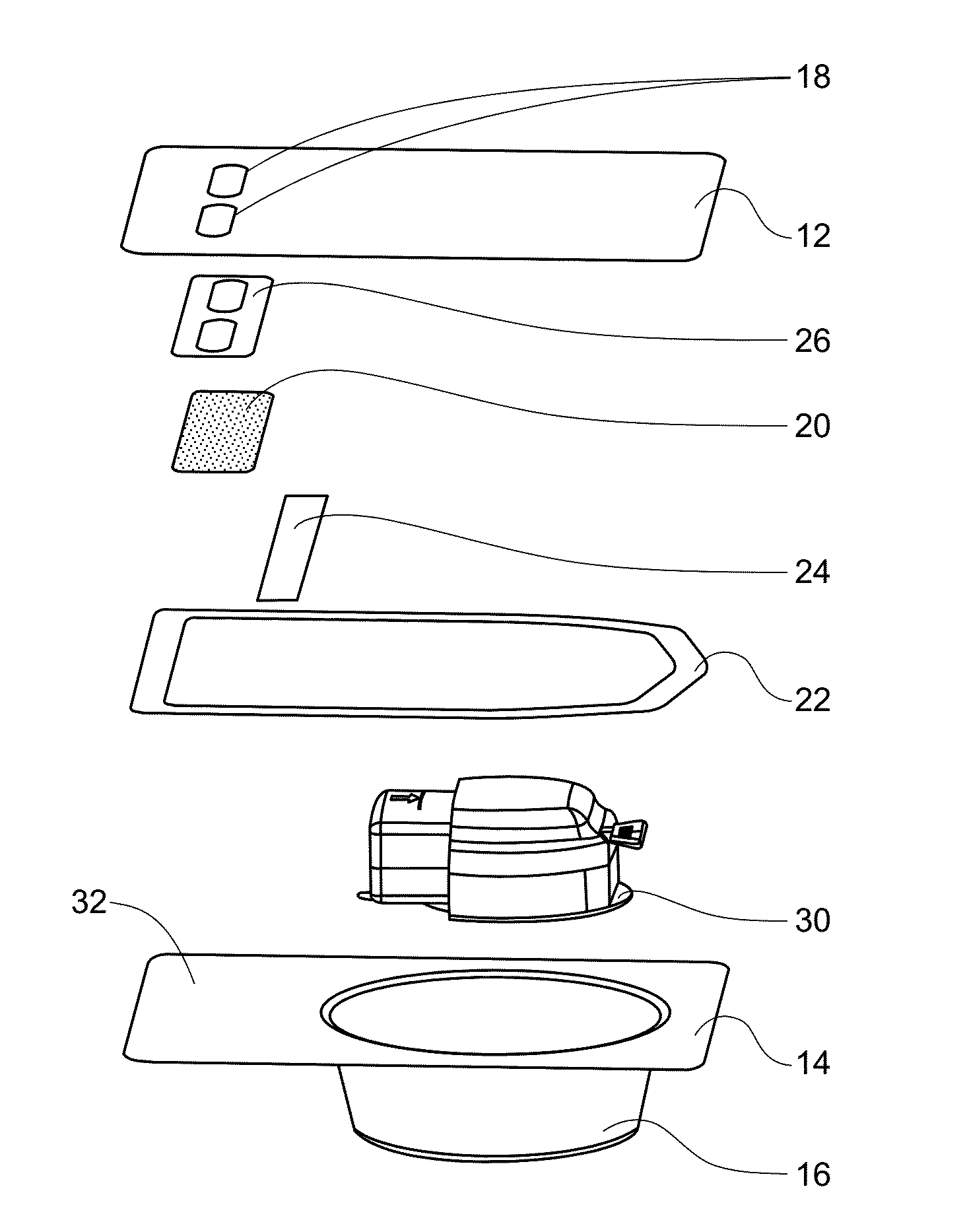

The invention relates to a system and a method for performing a manufacturing operation at a predetermined position relative to a first path. The system includes a plurality of first elements mounted for movement relative to the first path. The first elements have a plurality of motion parameters which are independently controllable. Active elements are operatively associated with reactive elements to produce relative movement between the first elements and the first path, with the active elements controlling the relative movement. A controller controls the activation of the active elements and a first tool is associated with each first element for performing at least part of the manufacturing operation. The system may also include at least one second element and a second path. The method includes the steps of mounting a plurality of first carriages for movement relative to a first path, operatively associating a plurality of active elements with at least one reactive element to produce relative movement between the first carriages and the path, associating a first tool with each first carriage for performing at least part of the manufacturing process, and controlling the activation of the active elements.

Owner:TETRA LAVAL HLDG & FINANCE SA

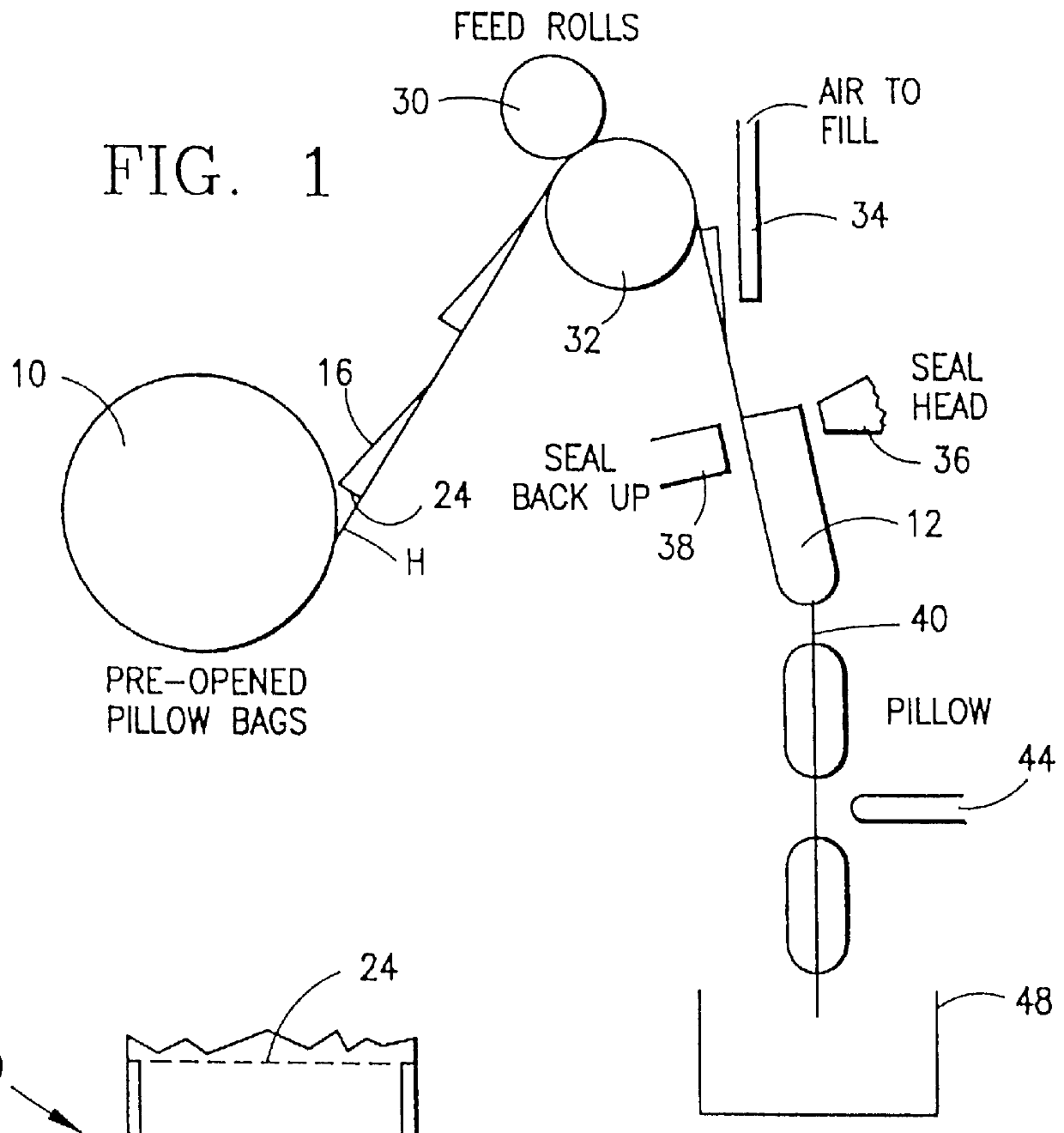

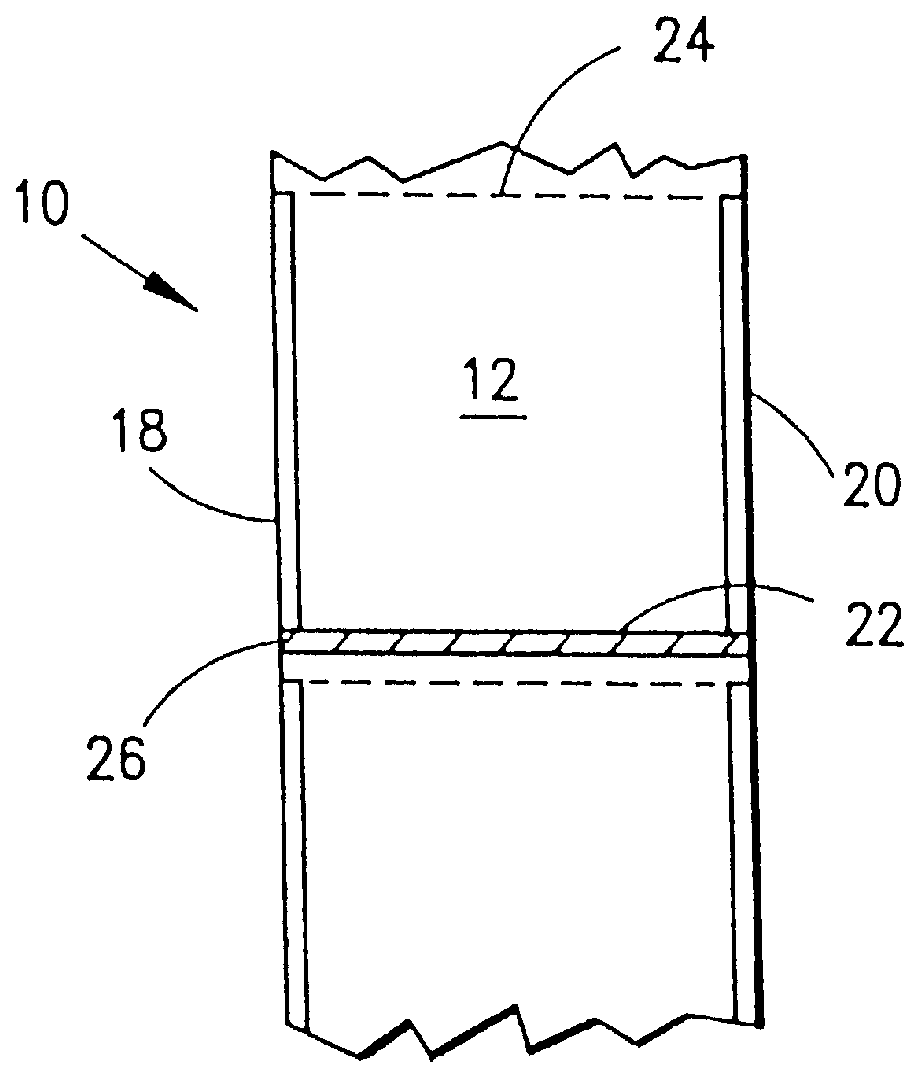

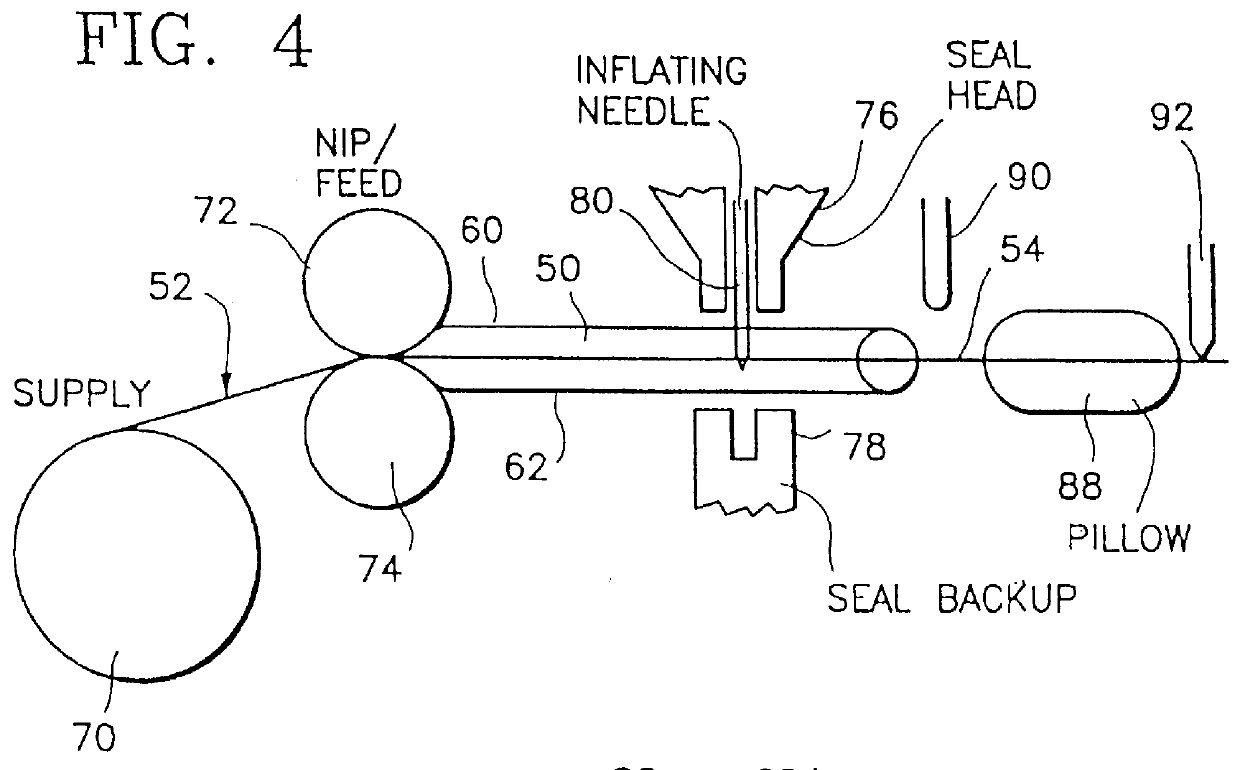

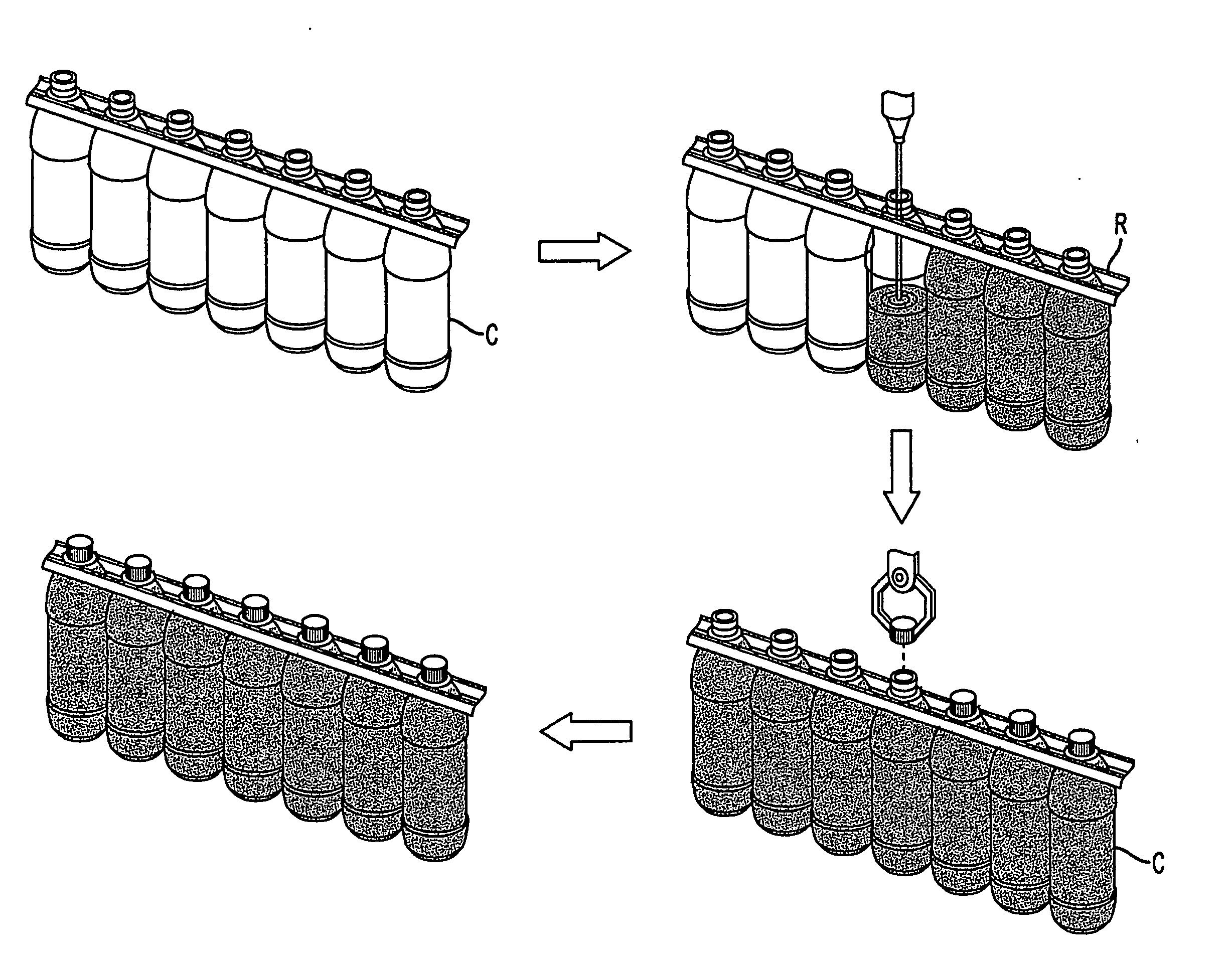

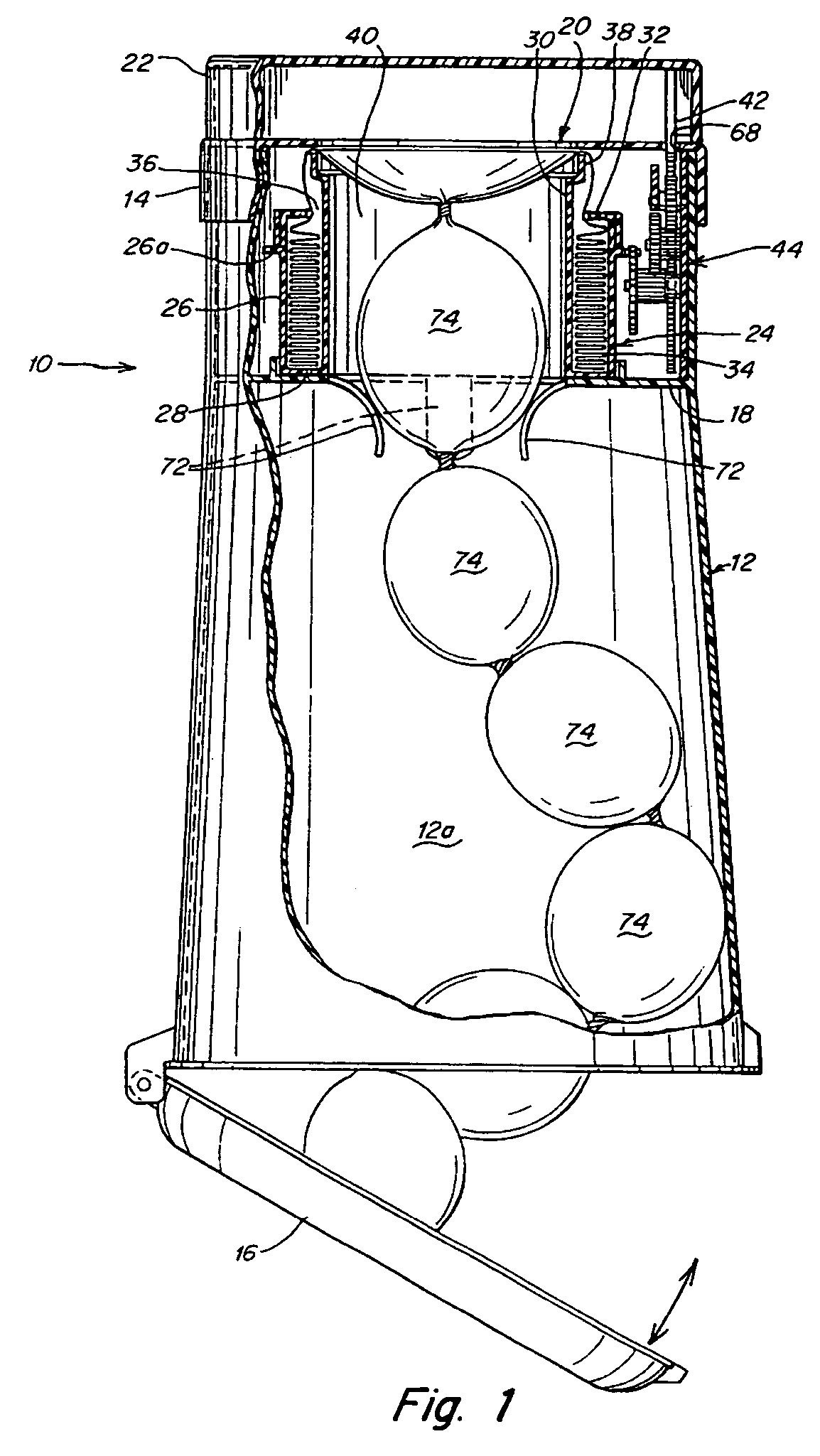

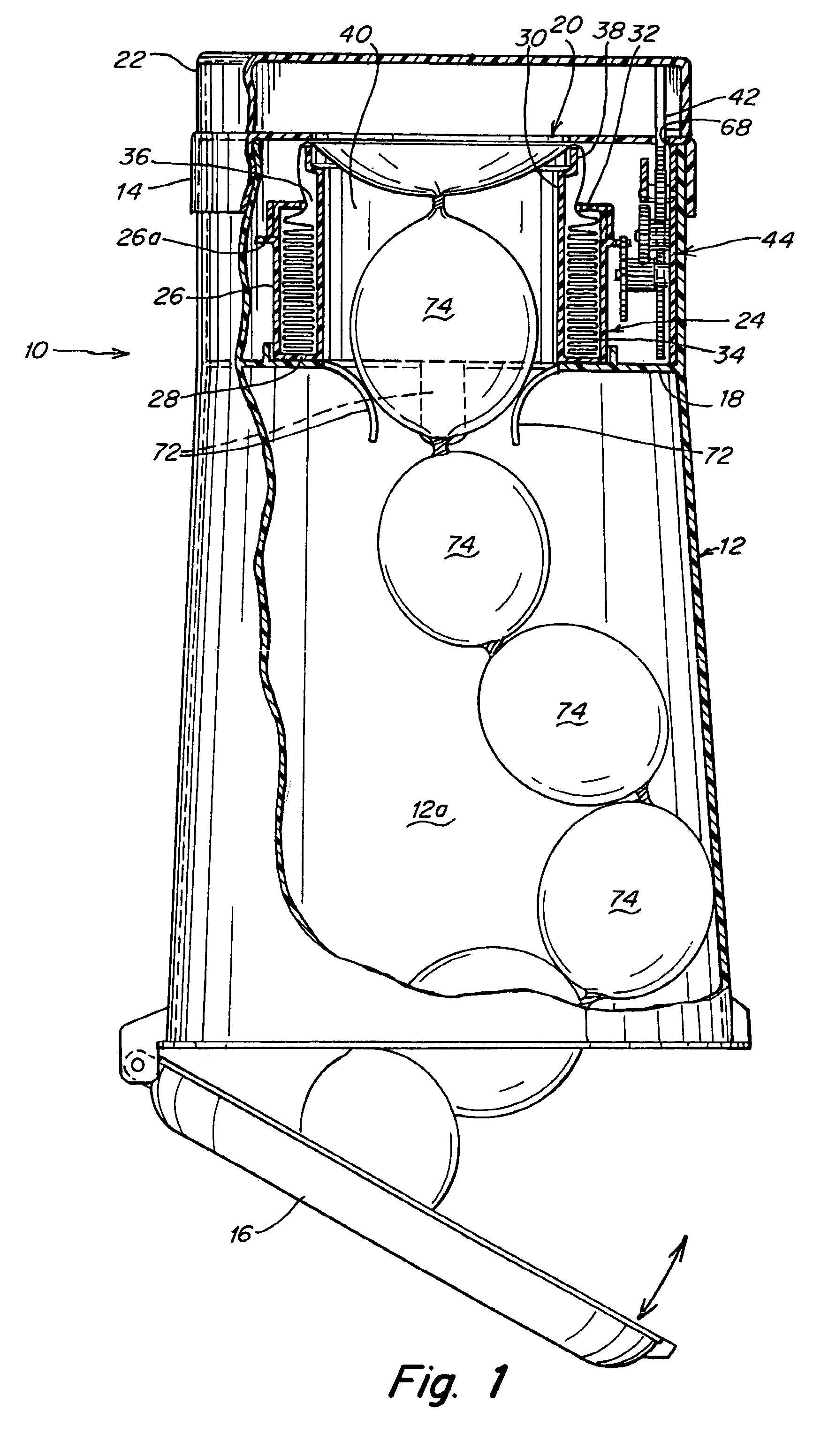

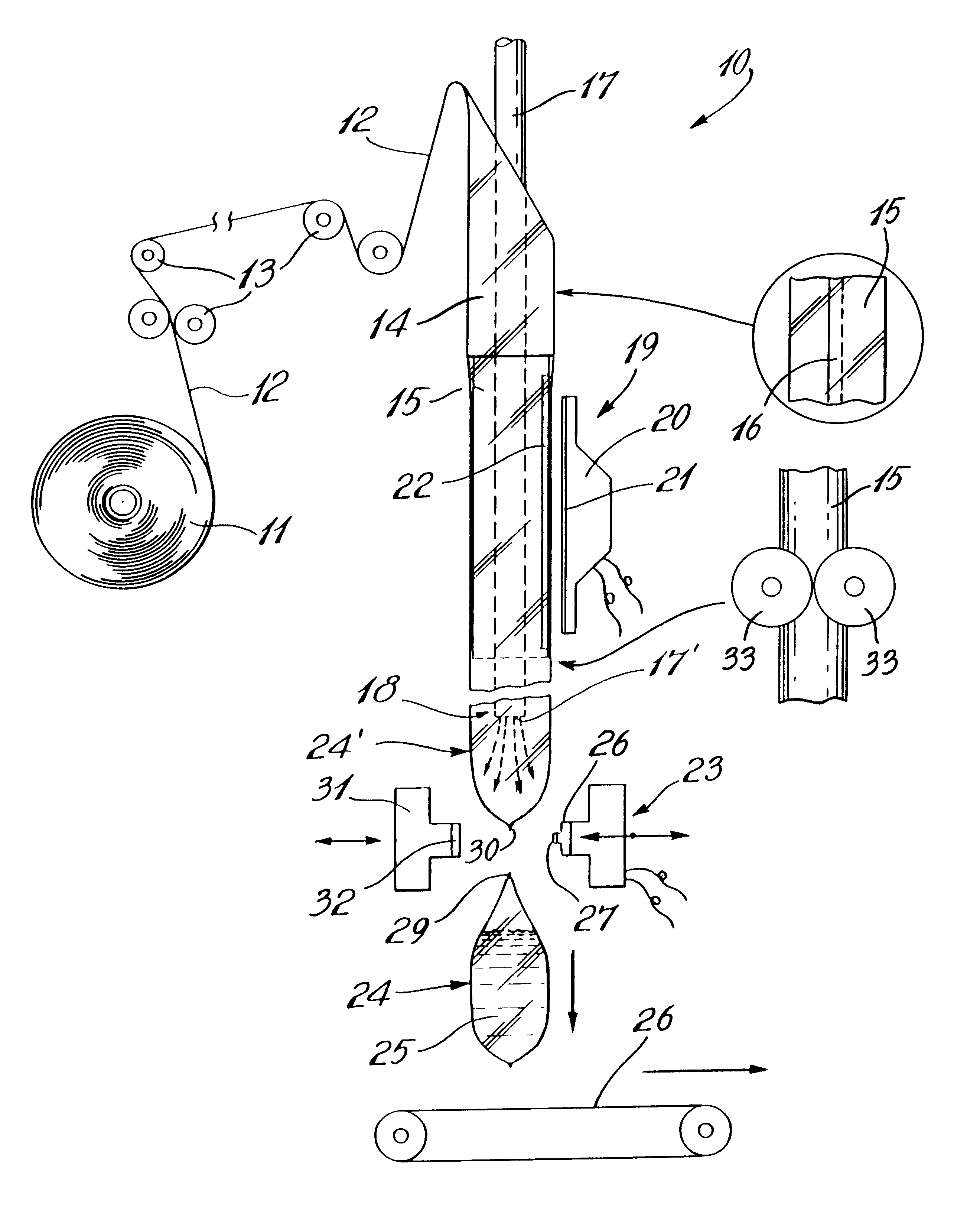

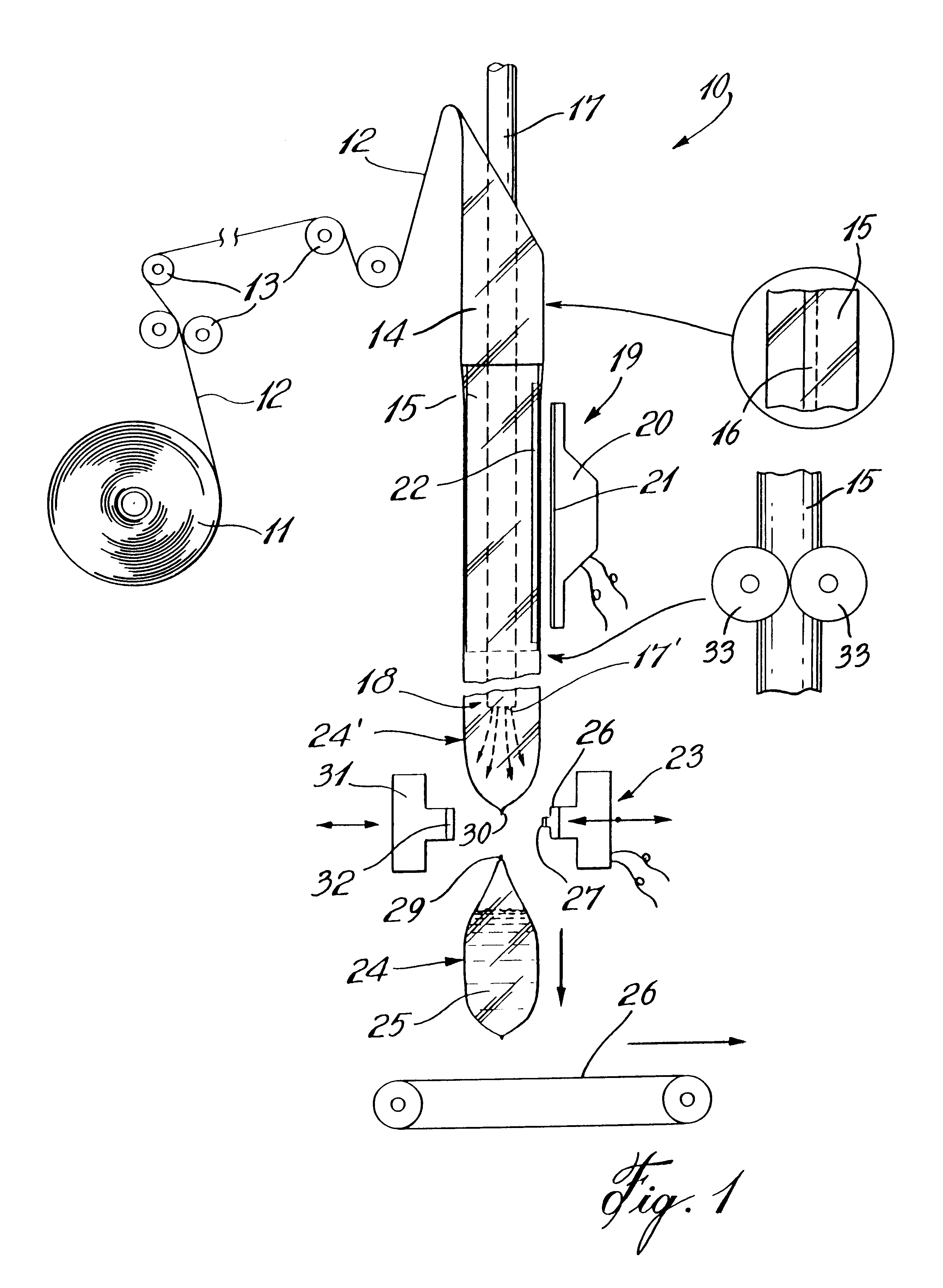

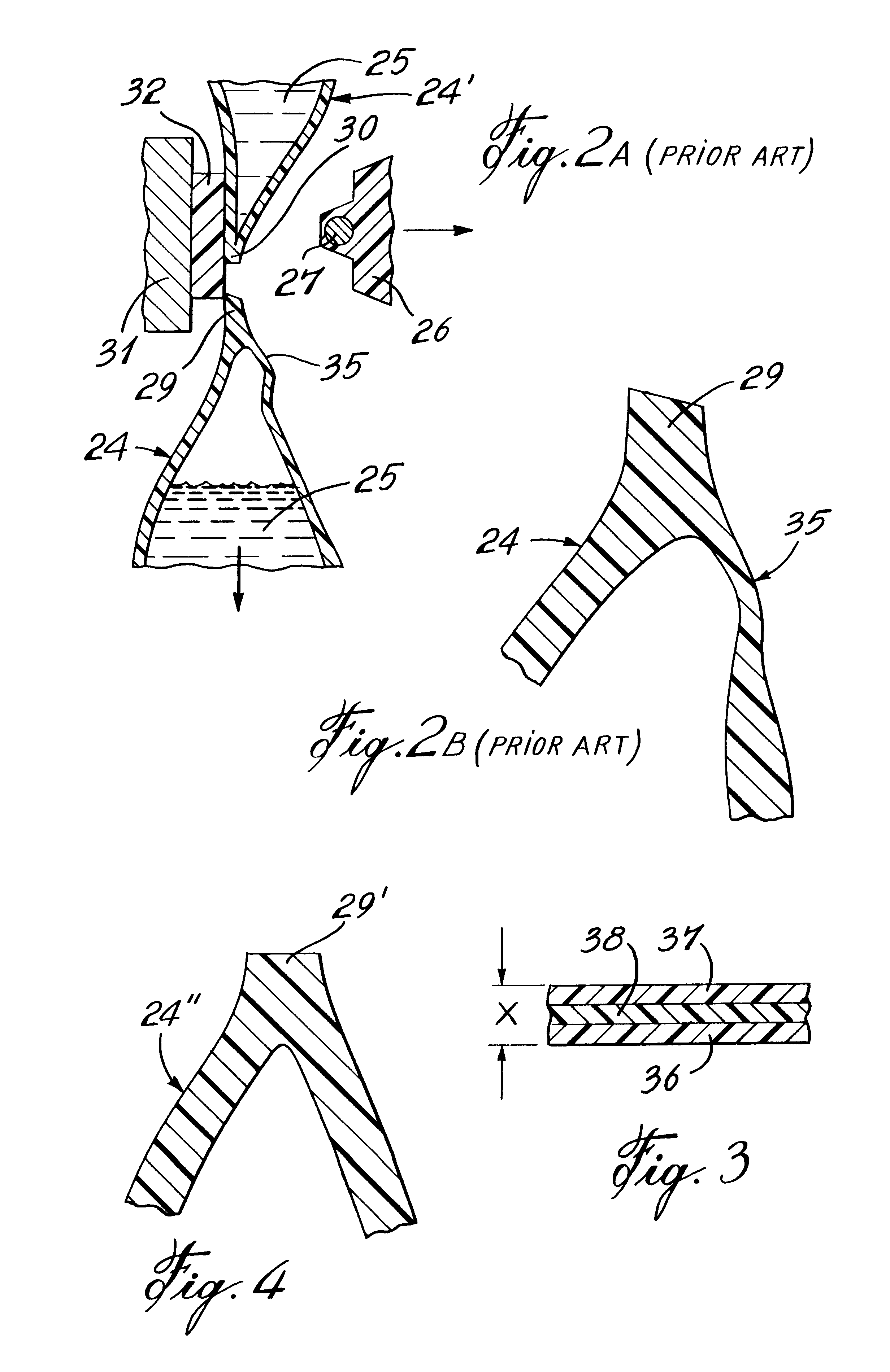

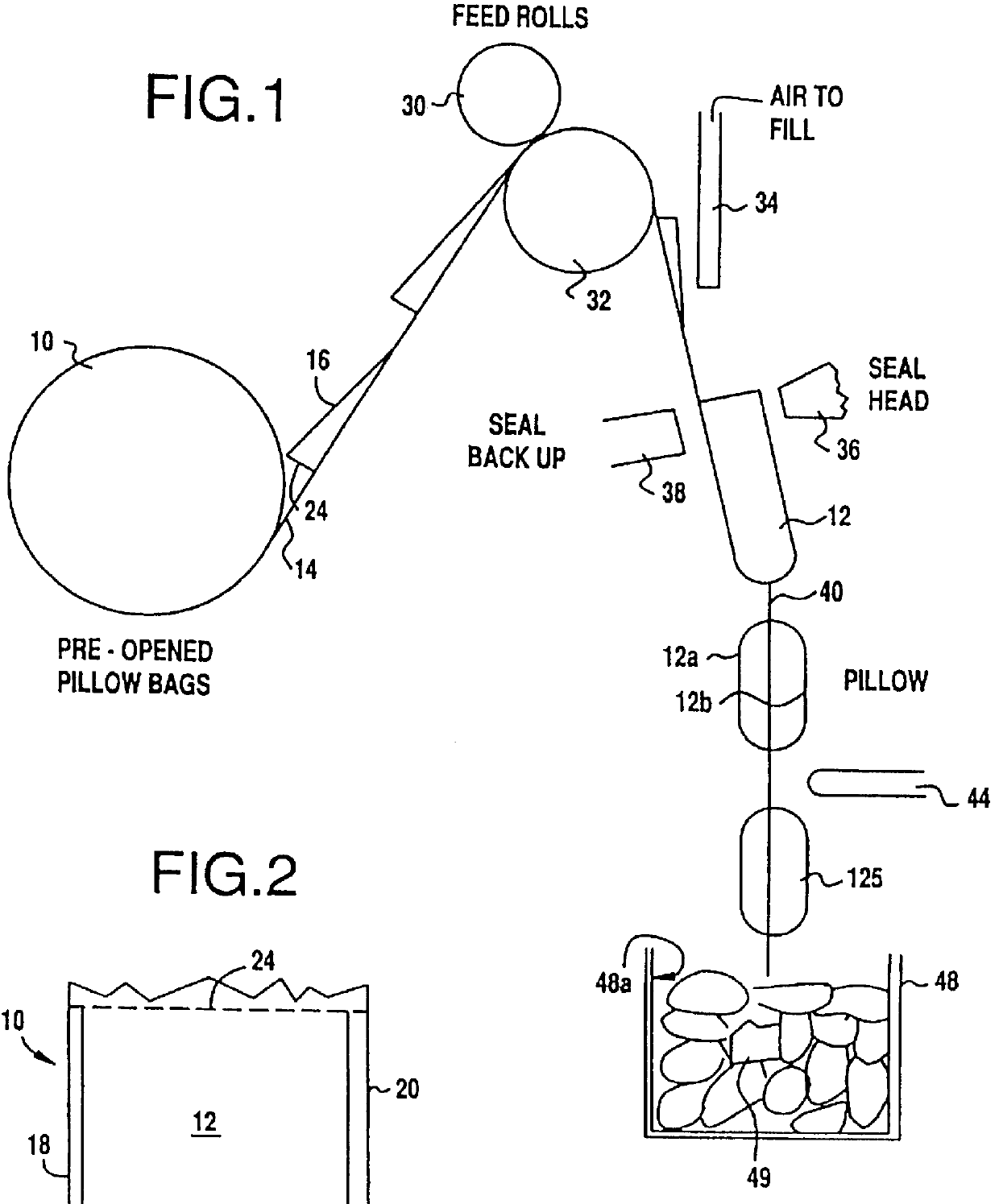

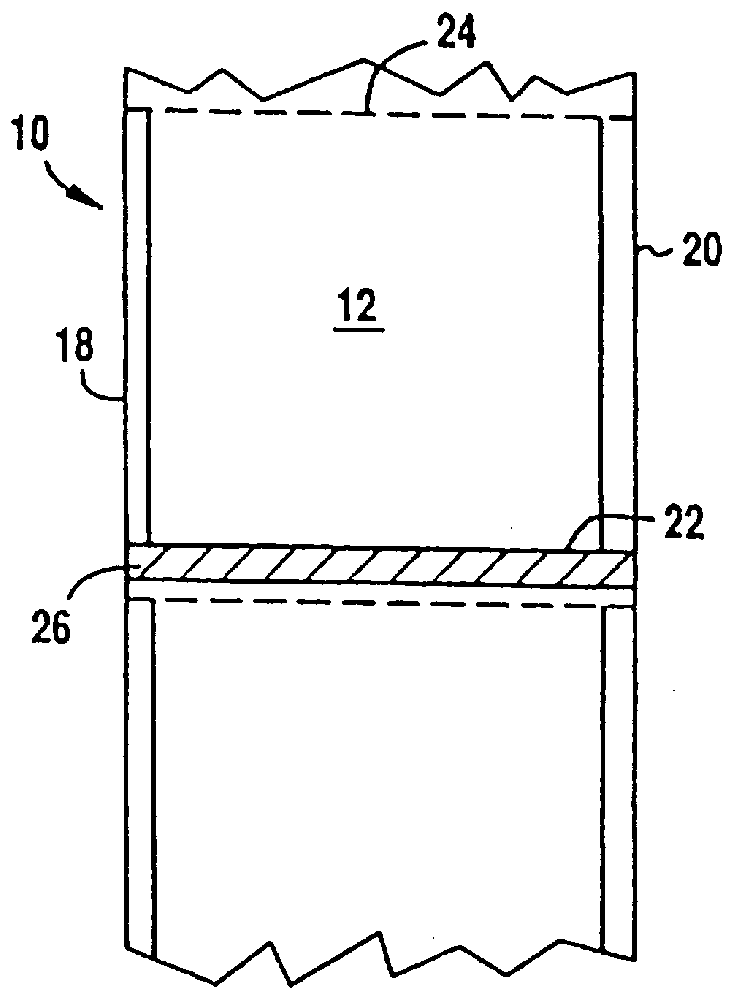

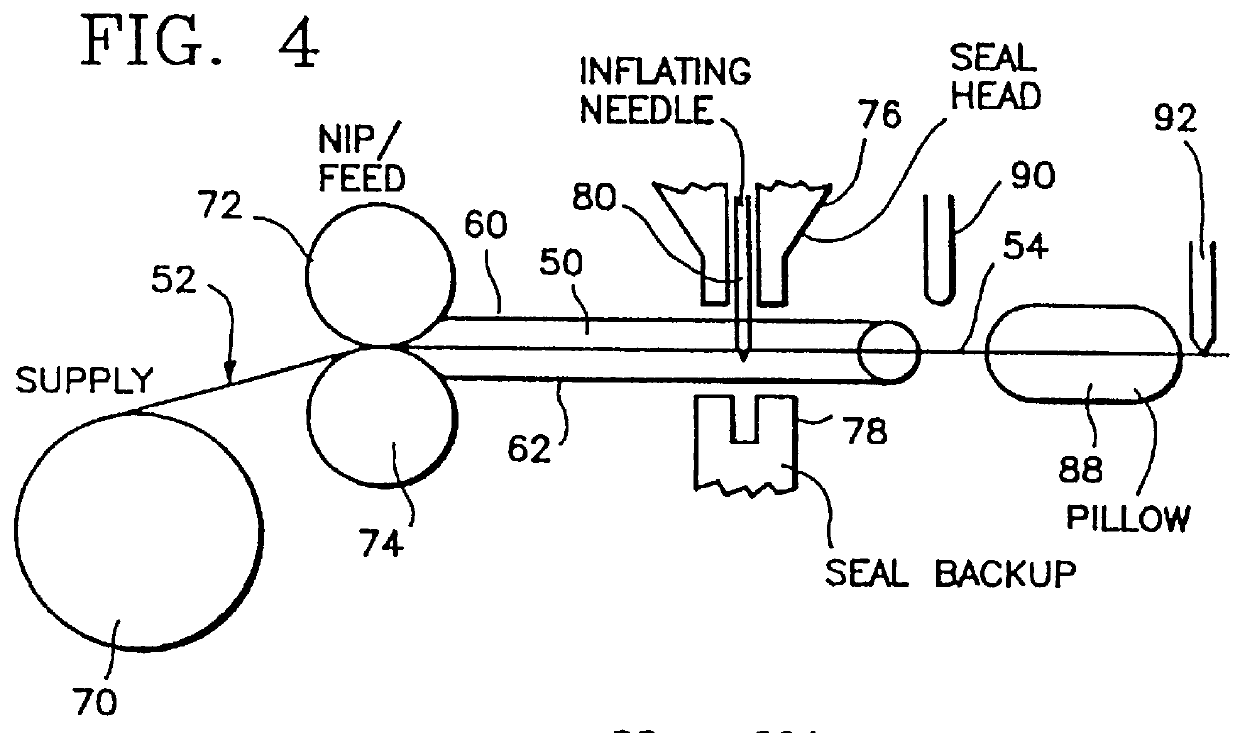

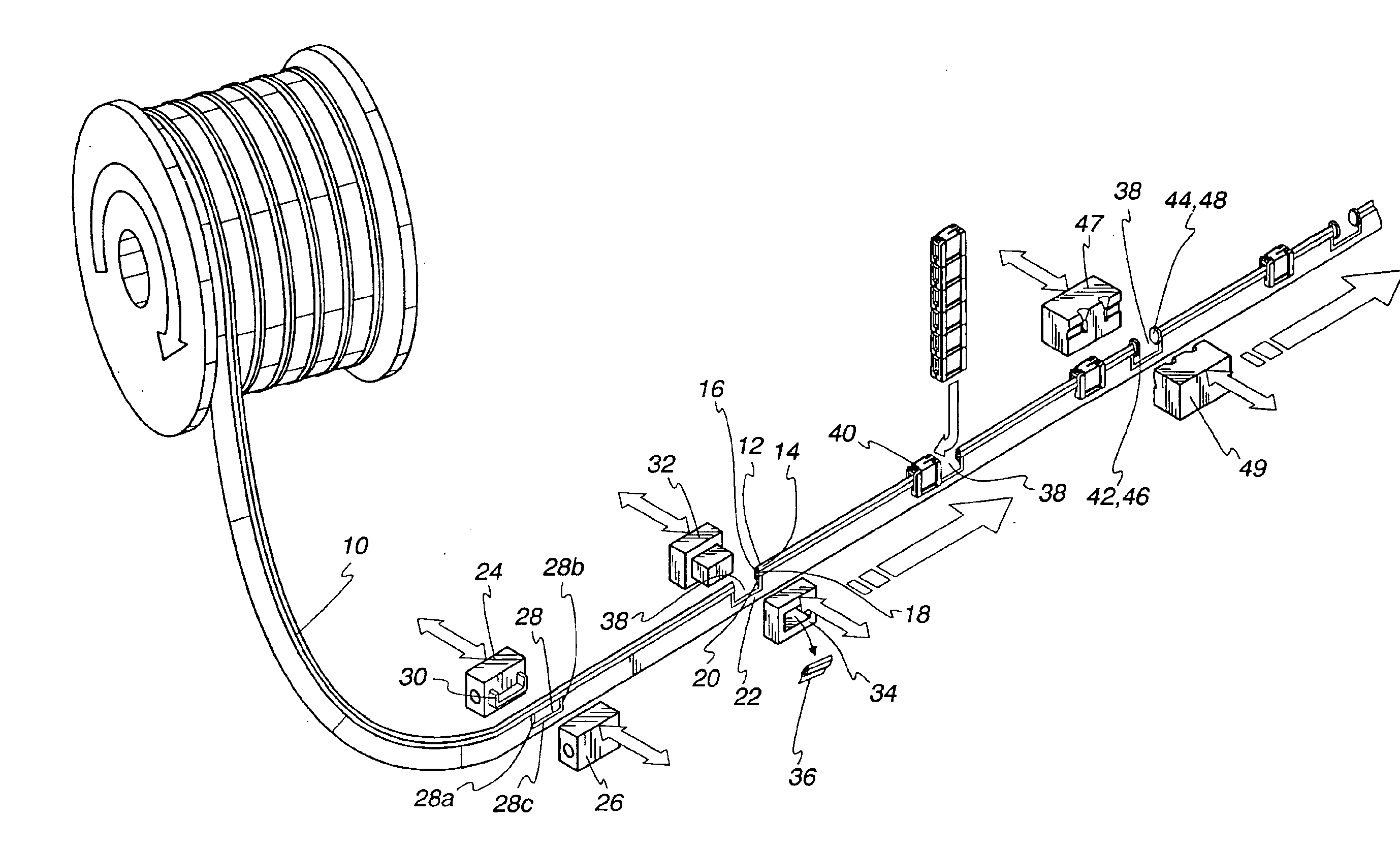

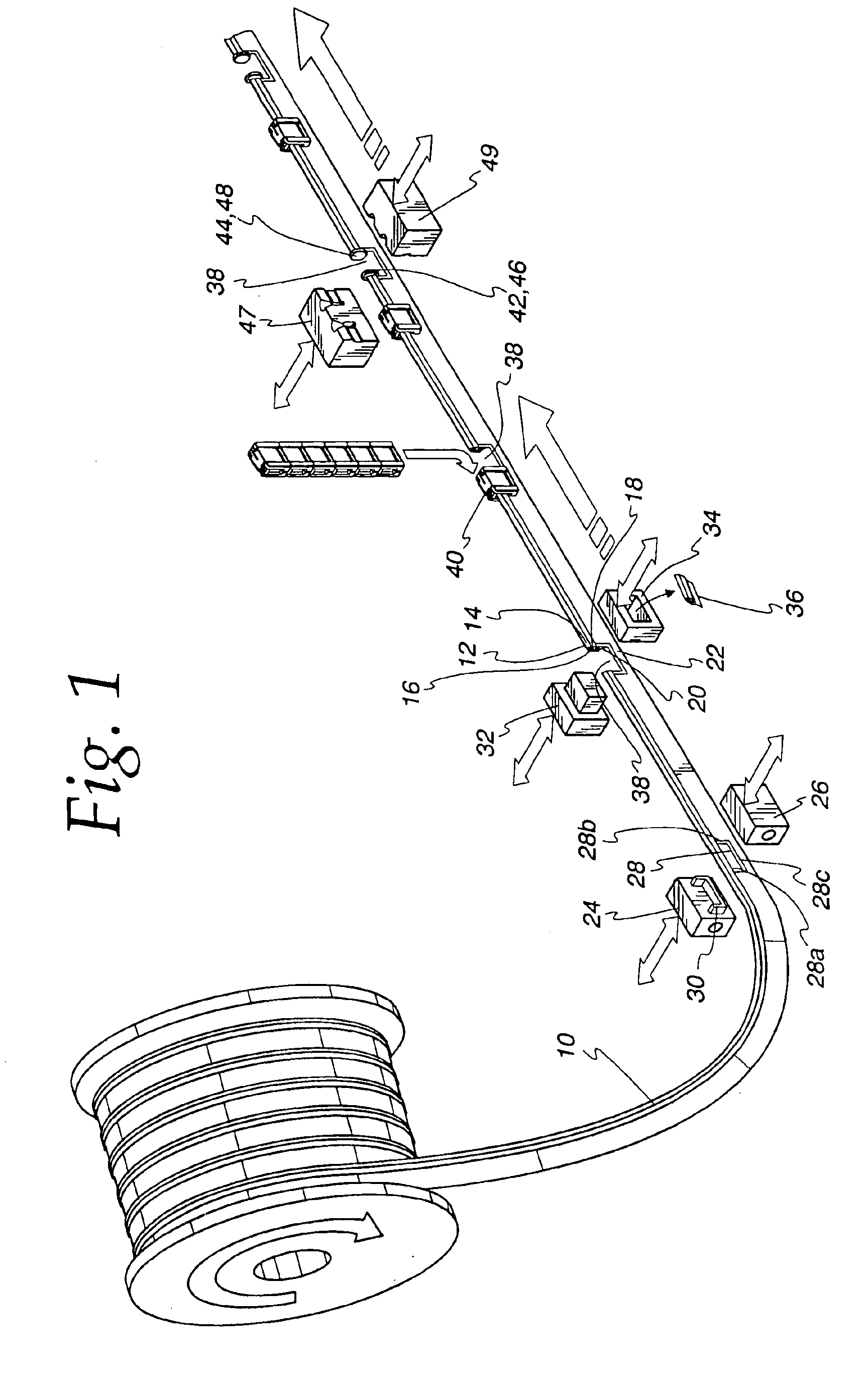

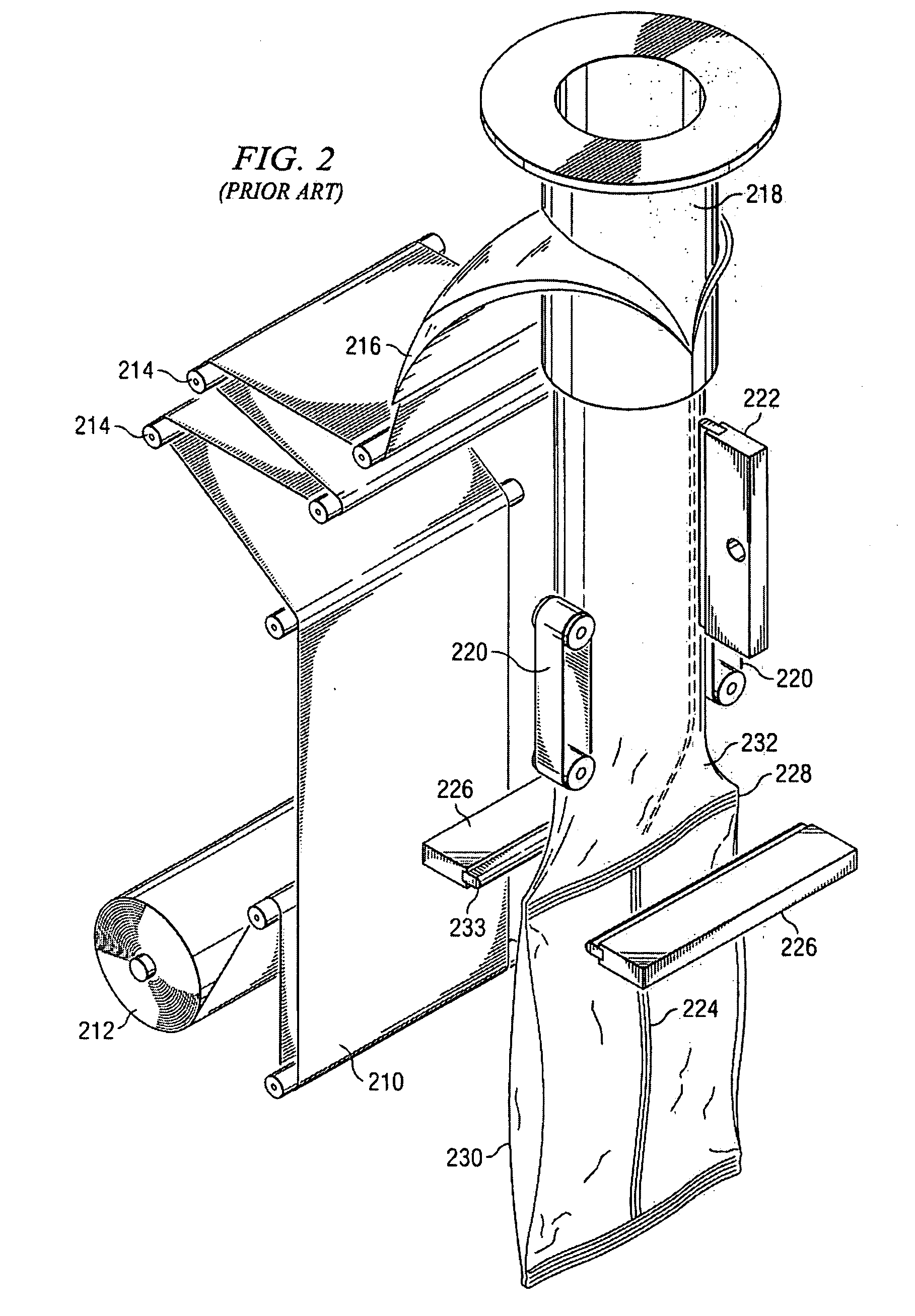

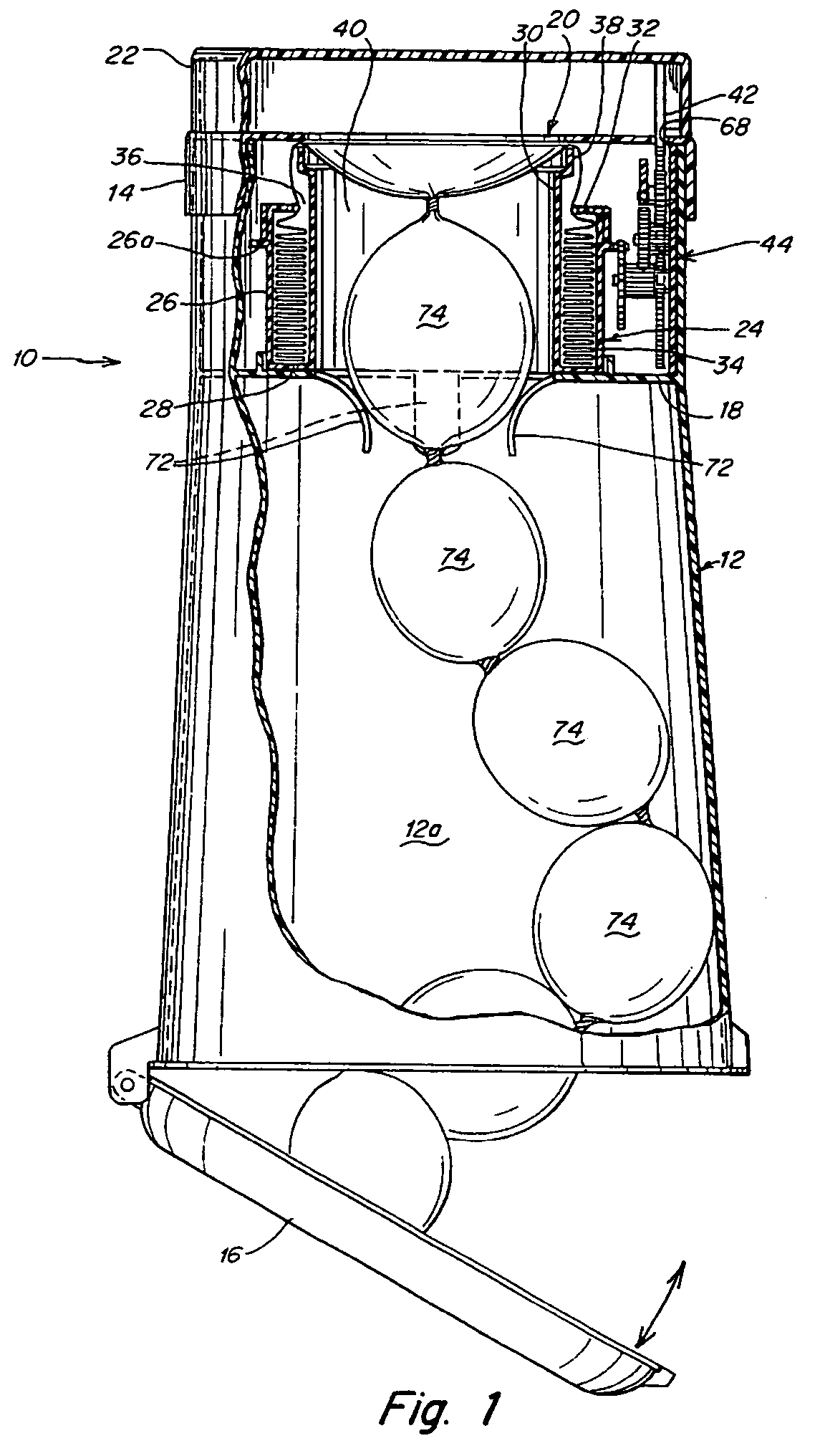

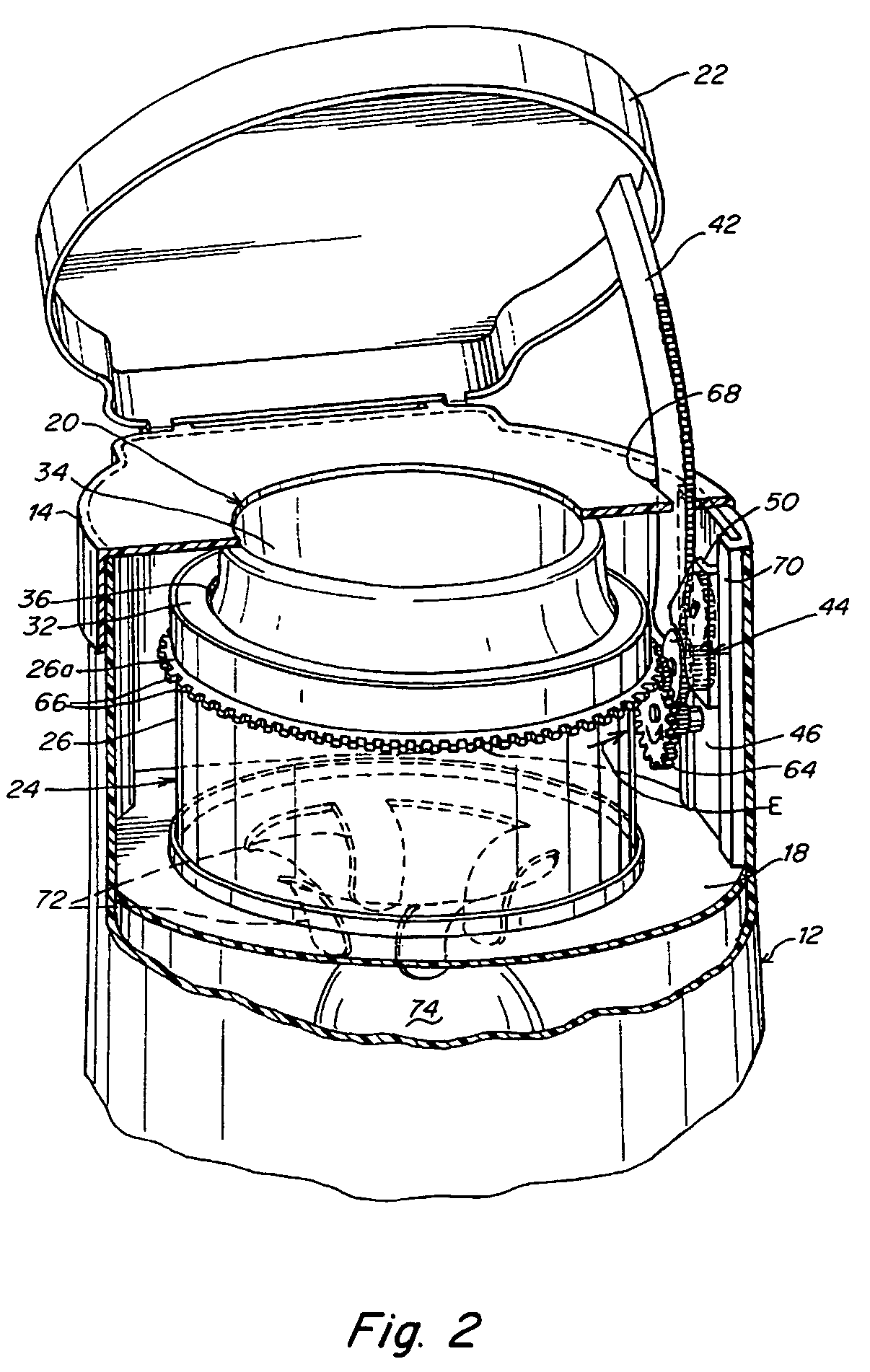

Method for producing inflated dunnage

InactiveUSRE36501E1Easy disposalEasy to reusePreventing unwanted cargo movementLabelling non-rigid containersDunnageCarton

A method for producing inflated dunnage on the site of use, comprising providing, in rolled form, a plurality of preformed plastic bags, each of the bags comprising two plastic sheets in facing relationship and sealed along three edges with one edge remaining open. Air is blown toward each of the open edges in sequence, causing each bag to inflate, and the fourth edge of each inflated bag is sealed, the bag being empty except for the air. At least one sealed inflated bag is separated from the roll and placed in a carton to serve as dunnage. In an alternate embodiment, the stock material is provided in a continuous tubular form, and an air inflation needle is used to puncture a surface of the tube for inflation purposes.

Owner:AUTOMATED PACKAGING SYST

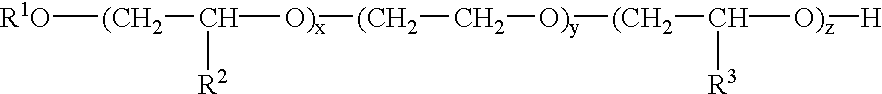

Detergent products, methods and manufacture

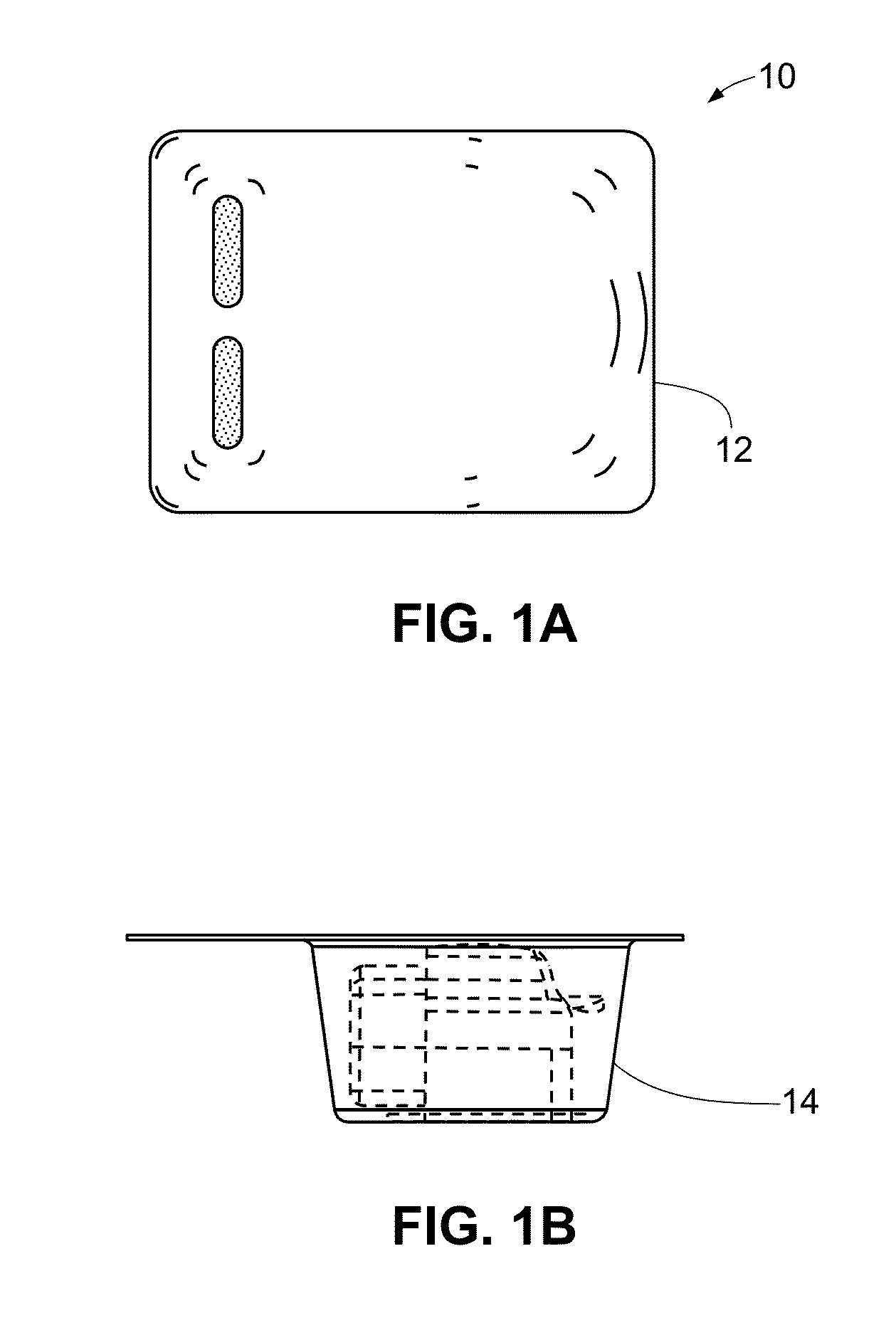

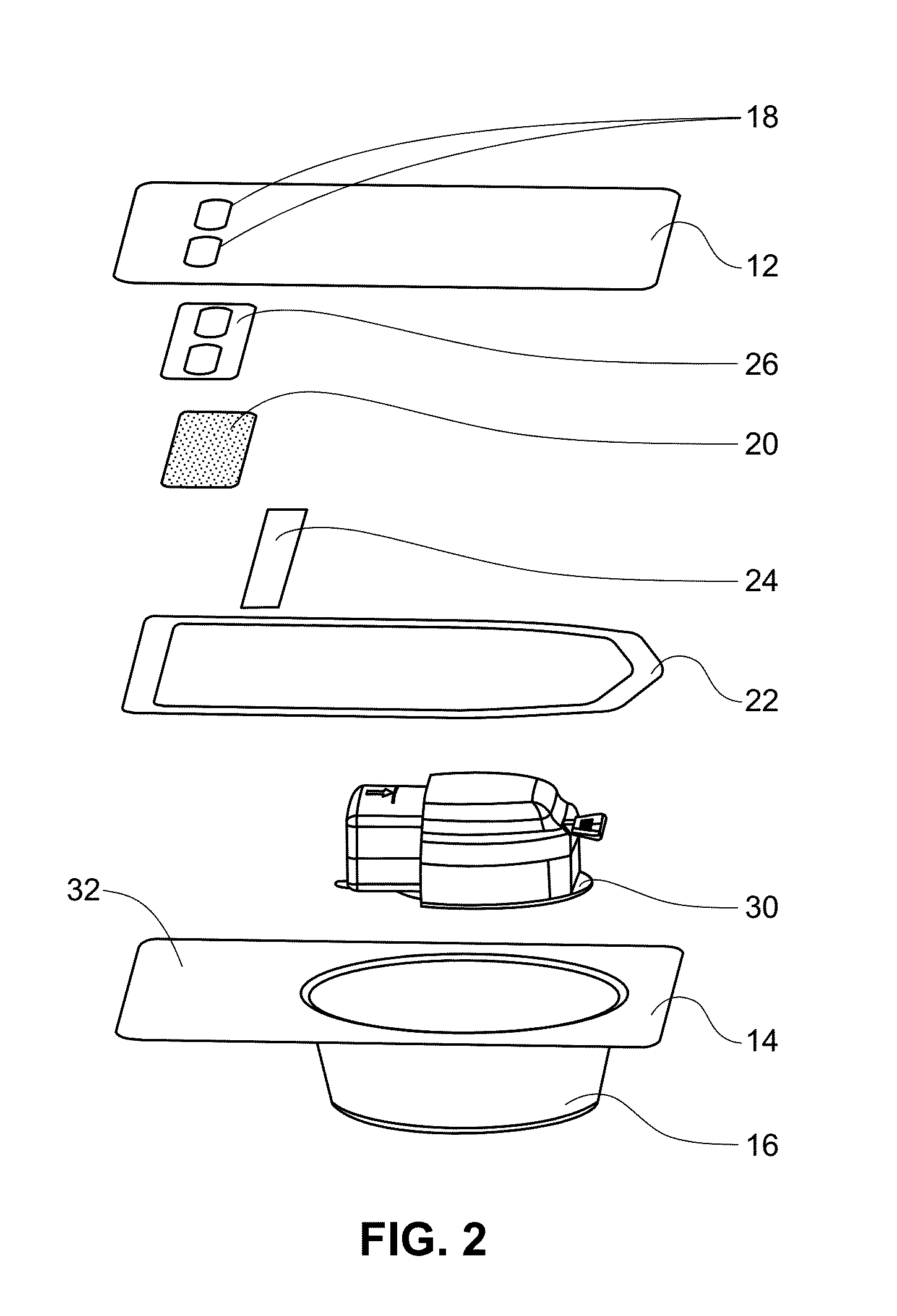

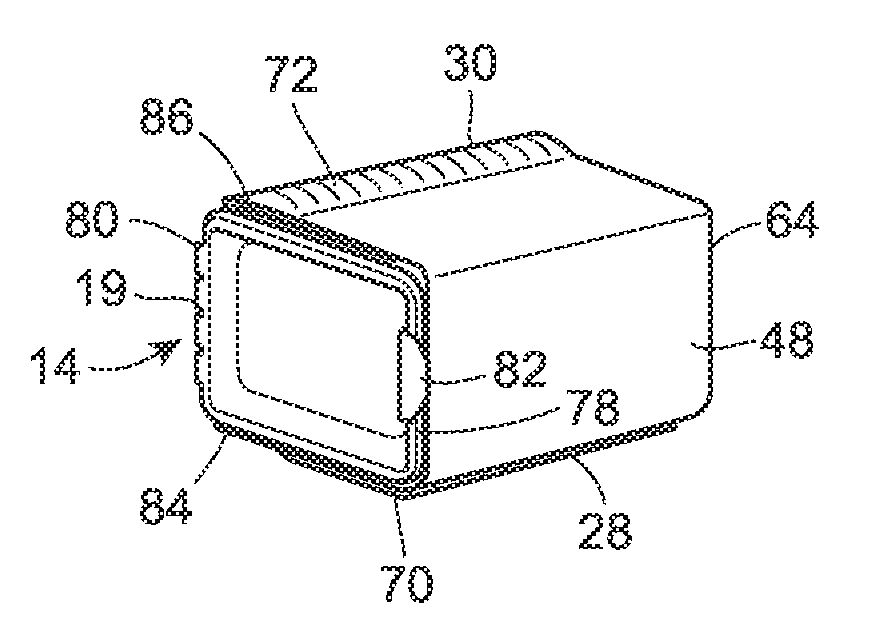

ActiveUS7125828B2Reduce areaReduce the possibilityFlexible coversNon-ionic surface-active compoundsWater solubleBiomedical engineering

A water-soluble pouch suitable for use in machine dishwashing and which comprises a plurality of compartments in generally superposed or superposable relationship, each containing one or more detergent active or auxiliary components, and wherein the pouch has a volume of from about 5 to about 70 ml and a longitudinal / transverse aspect ratio in the range from about 2:1 to about 1:8, preferably from about 1:1 to about 1:4. The water-soluble pouch allows for optimum delivery of dishwashing detergent. A process for the manufacture of multi-compartment pouches and a pack to contain the pouches are also disclosed.

Owner:THE PROCTER & GAMBLE COMPANY

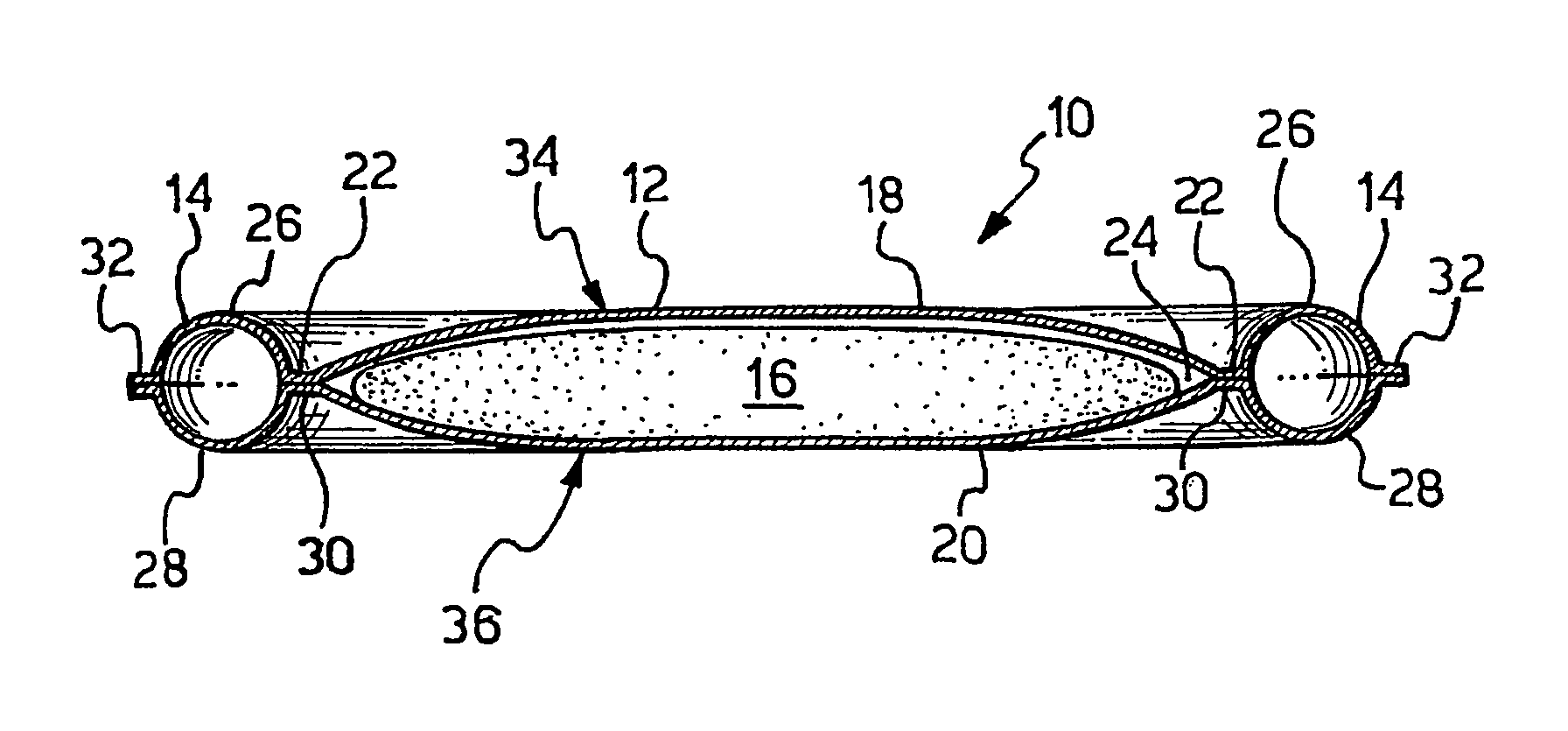

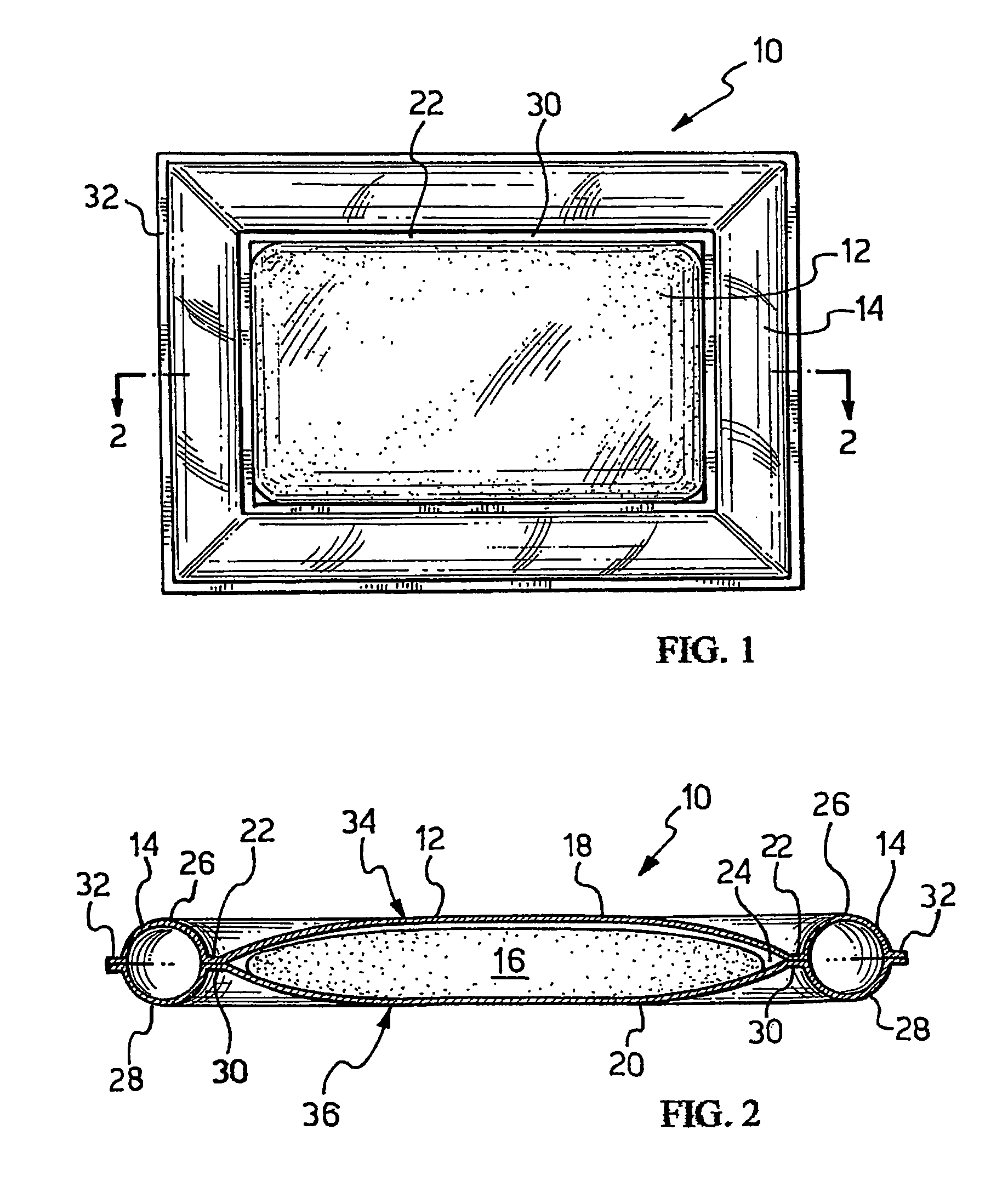

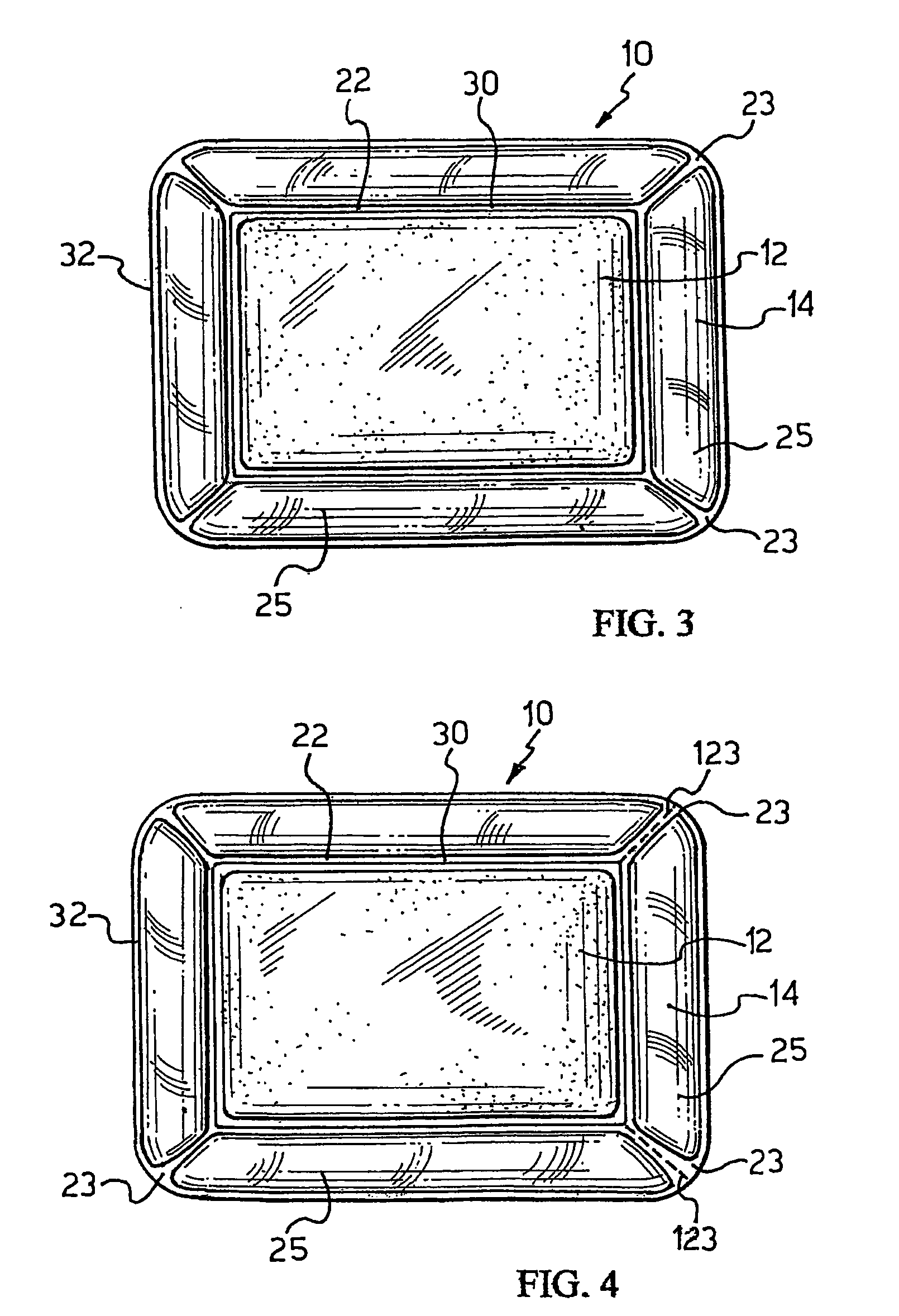

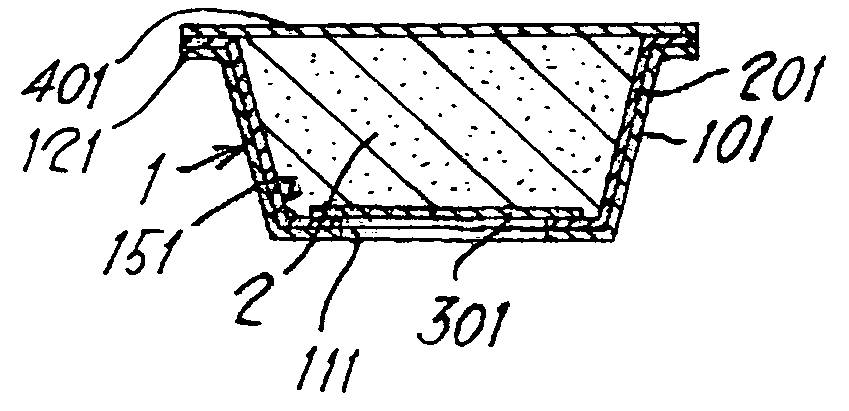

Package having an inflated frame

A package for containing a product such as meat. The package includes top and bottom opposing flexible chamber sheets. These sheets are sealed together in a selected chamber seal zone to define a watertight chamber portion that is capable of containing the product. A hollow frame circumscribes the chamber portion. The frame supports the chamber portion when the frame is inflated. The need for a rigid tray may be eliminated by the inventive package.

Owner:CRYOVAC ILLC

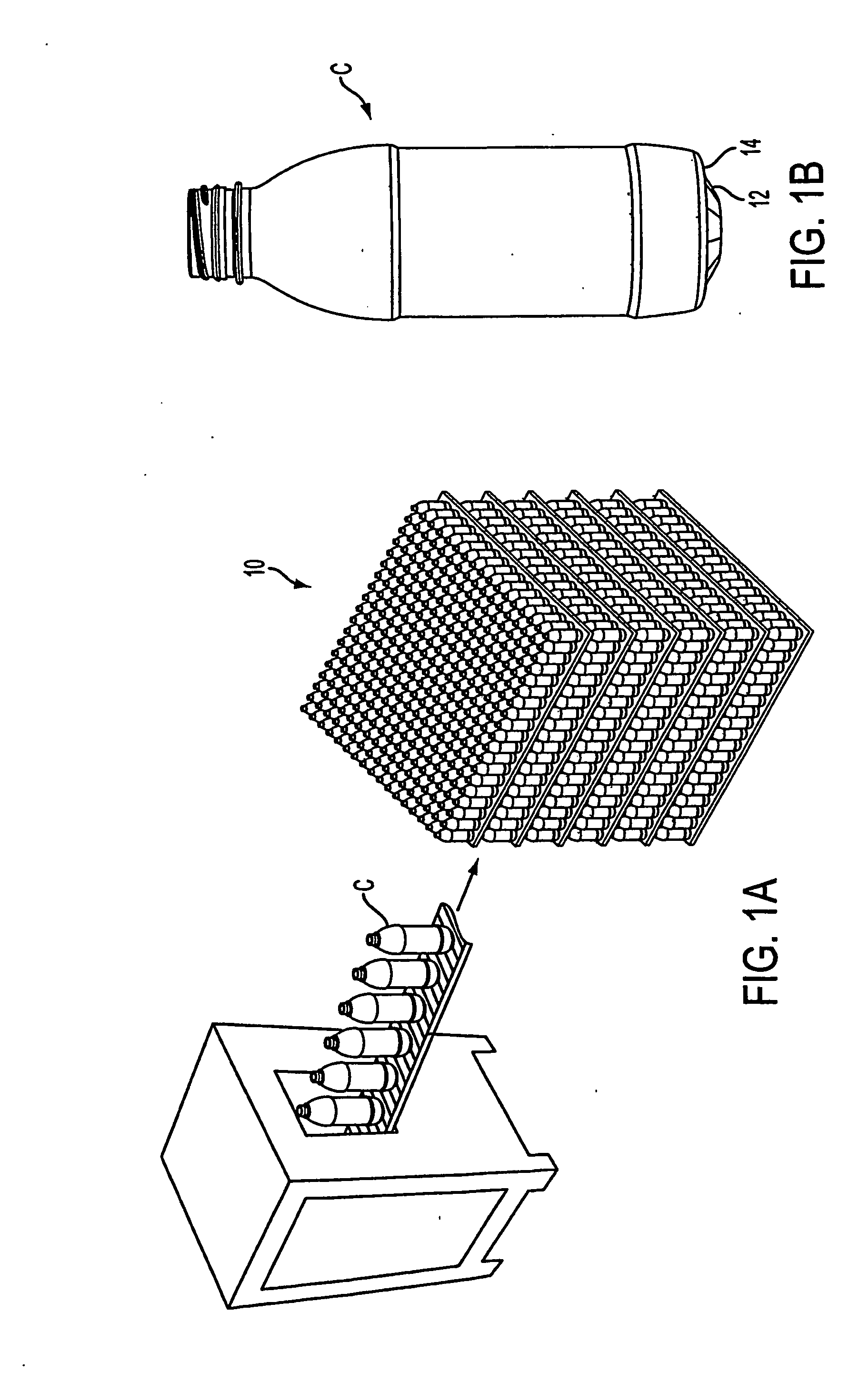

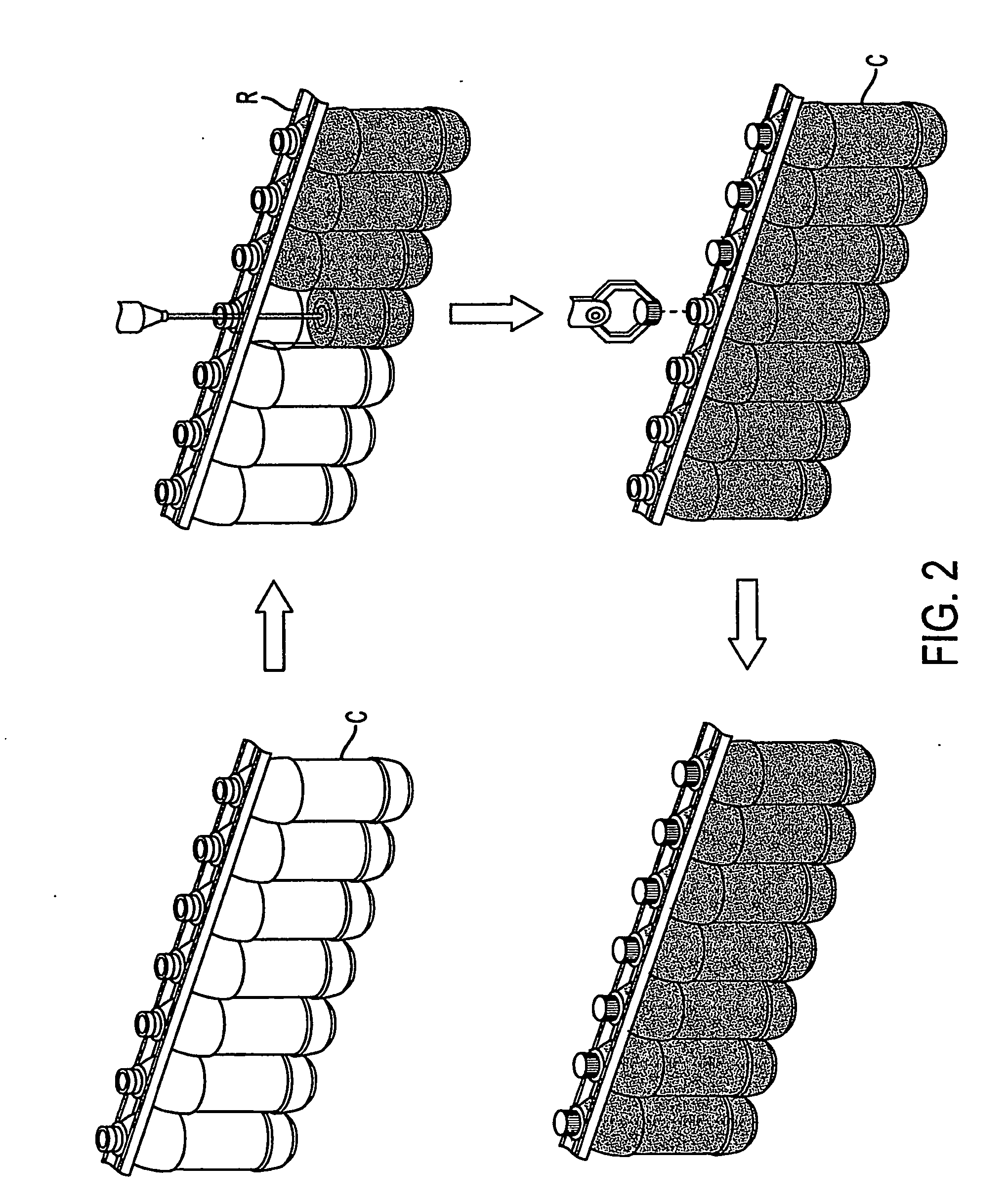

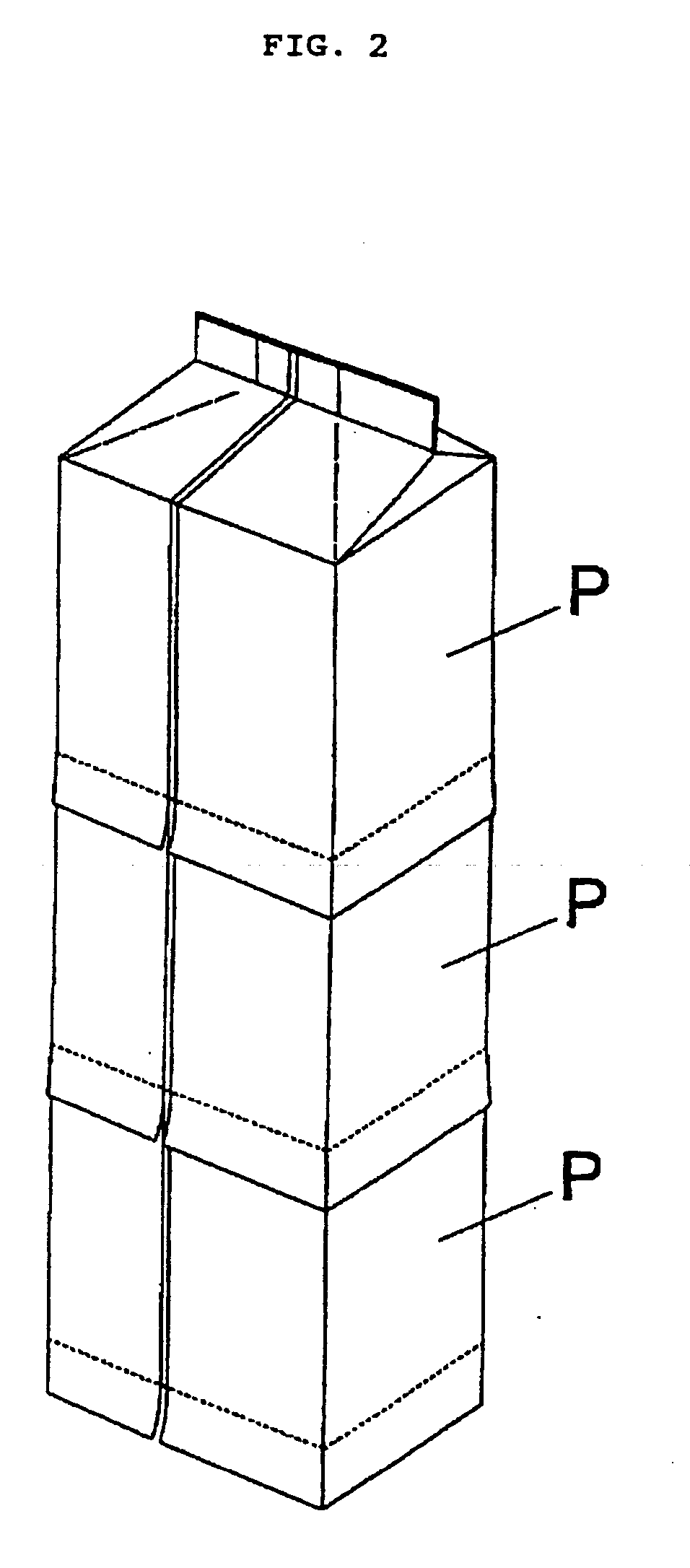

Container handling system

ActiveUS20070051073A1Smooth for label placementThorough removalCapsDecorative coversBlow moldingStructural geometry

A system for processing a simplified plastic container (C) that is to be filled with a hot product includes the step of blow-molding parison to form a container body, where the container body has a neck, a base, a side surface relatively free of structural geometry that surrounds an interior of the container body and, prior to being filled with the hot product, a projection (12) extending from the container body. After the container body is filled with a hot product in a production line, the neck of the filled container body is capped with a cap and then, the container body is cooled. During the cooling operation, the hot product is contracted so that the projection extending from the container can be pushed (P) into the container body like a traditional push-up so that the resultant, filled and cooled container body is relatively free of structural geometry.

Owner:CO2 PAC

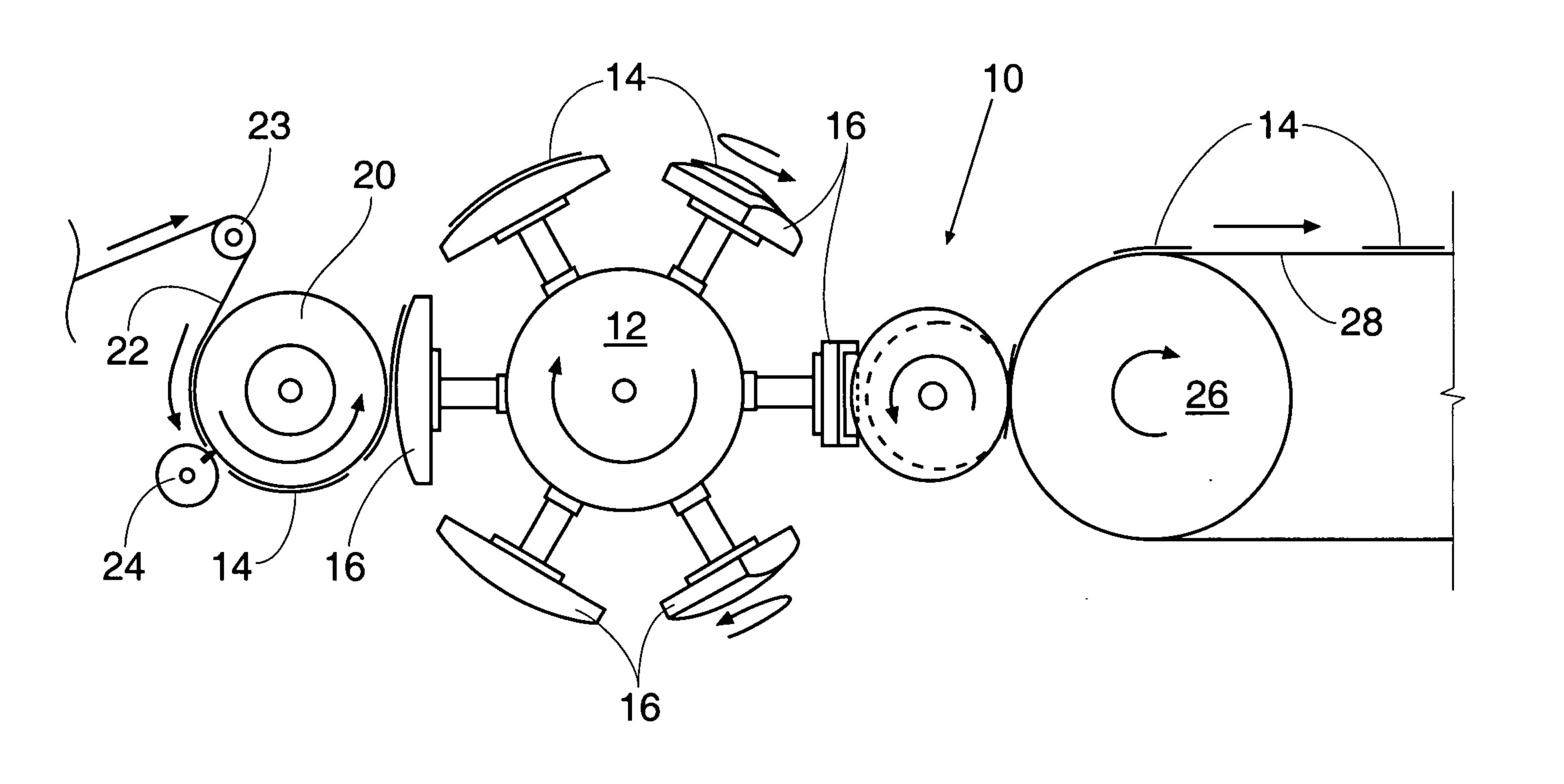

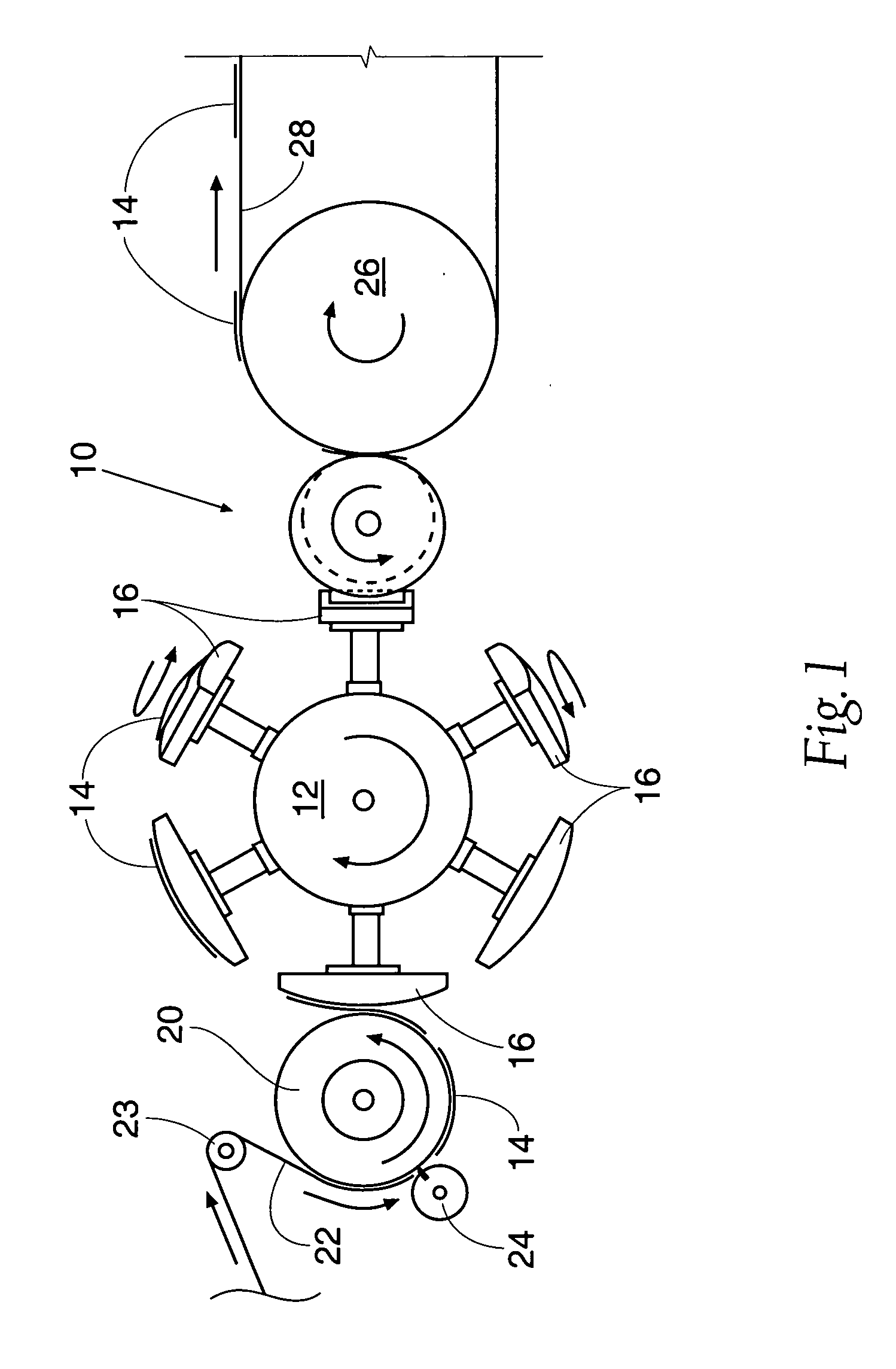

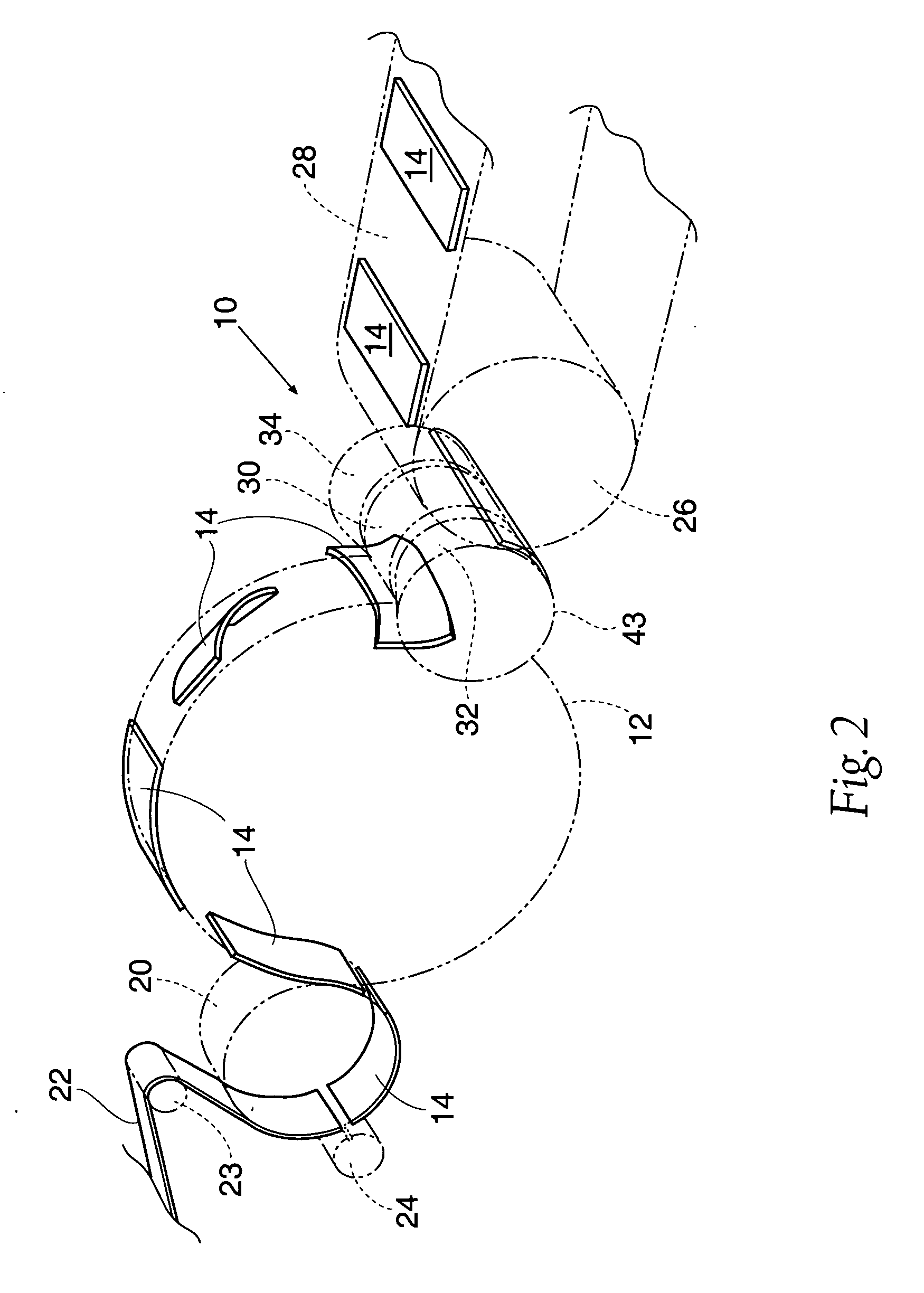

Article transfer and placement apparatus

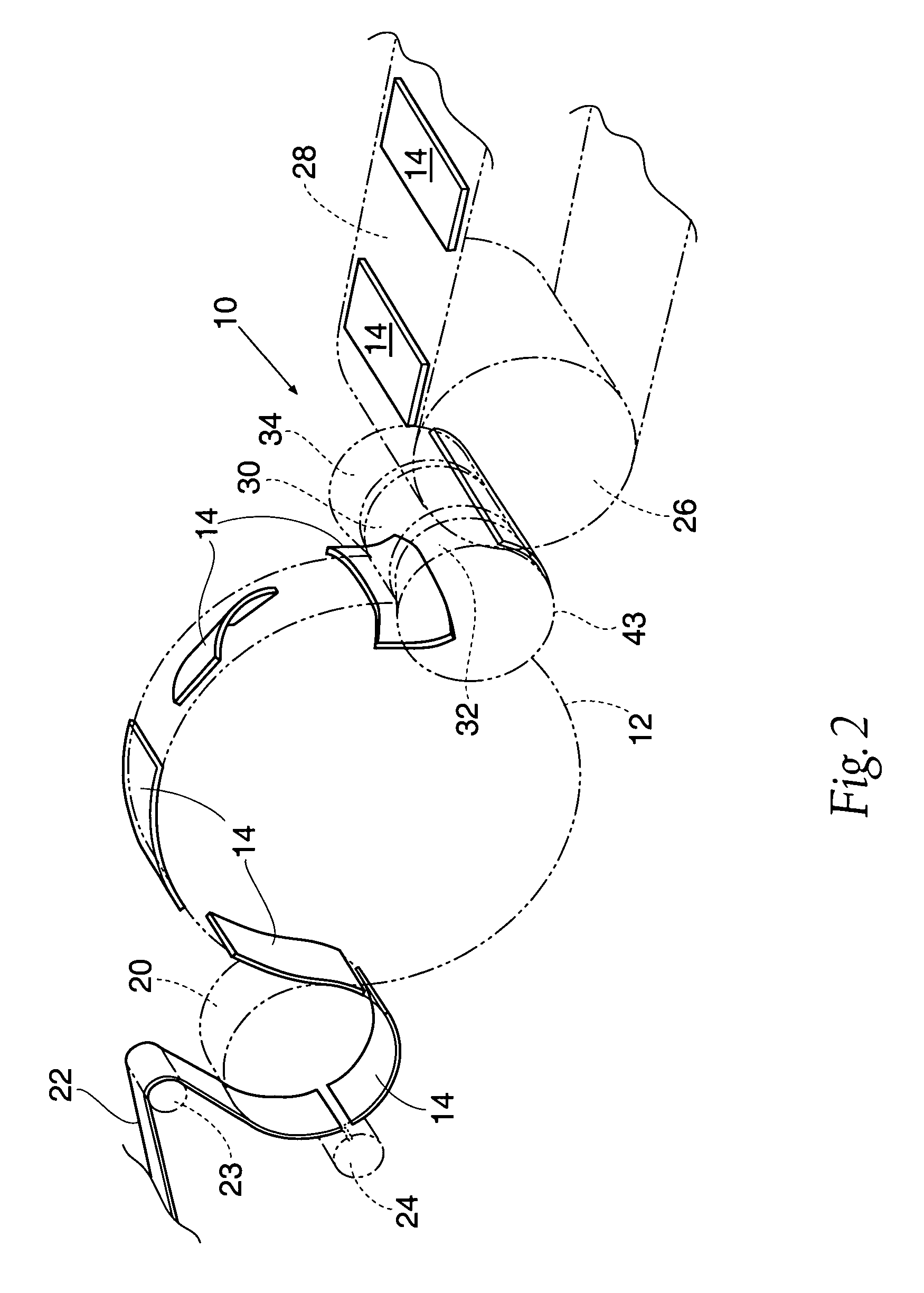

ActiveUS20070074953A1Reduce the amount requiredEasy transferAbsorbent padsArticle feedersEngineeringElectrical and Electronics engineering

An apparatus for transferring articles such as absorbent cores or disposable diaper chassis components from a rotary mechanism, such as a pad turner, to a linear mechanism, such as a conveyor, for further processing. The invention provides a device for picking an article from the outside of a toroidal surface, thence extending transversely under tension the article to be transferred so that at the point of deposition the article is held flat and at full length. Further, the invention allows for apparatus to match the velocity of both the first and second transfer points, even if these velocities are not the same. The device is of particular benefit where an article to be transferred is subject to internally biasing elastic forces.

Owner:CURT G JOA

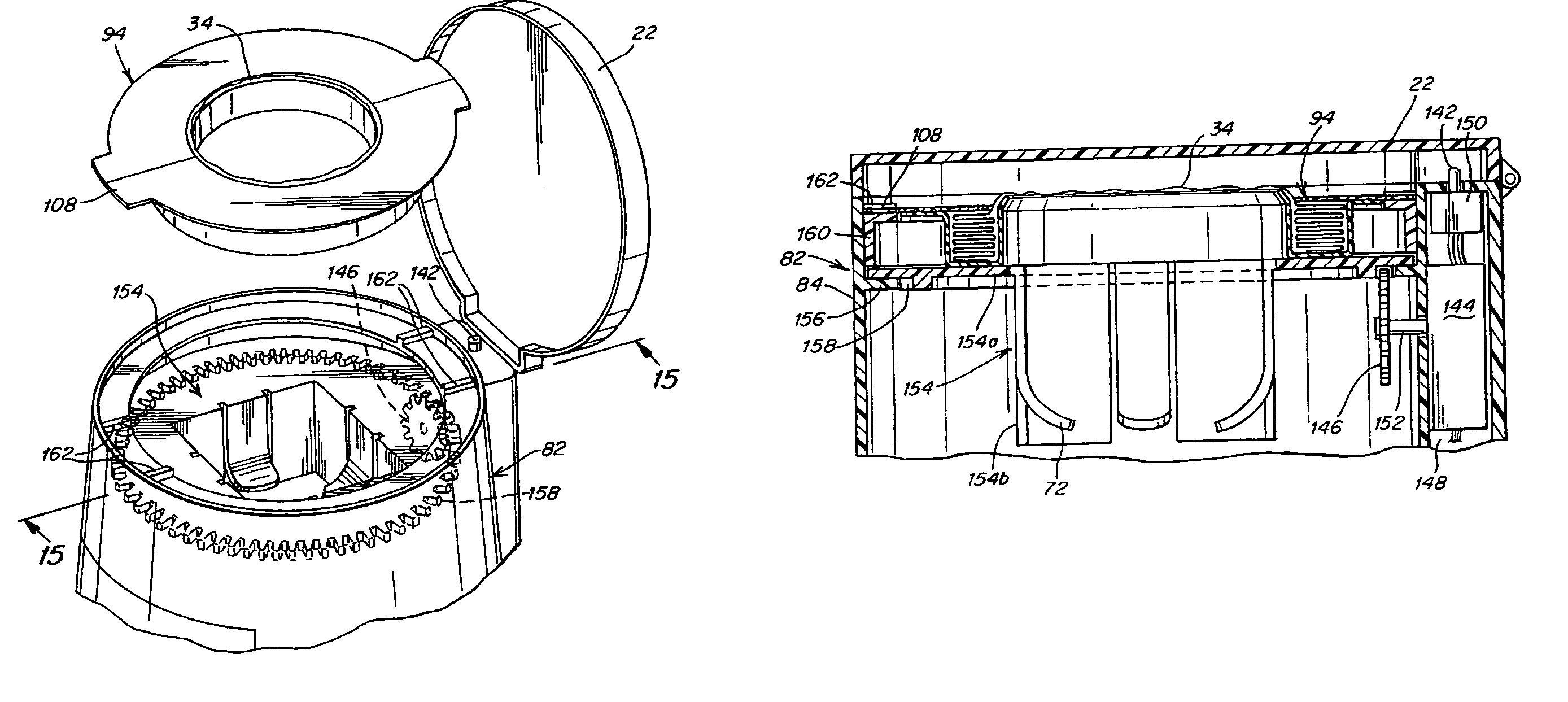

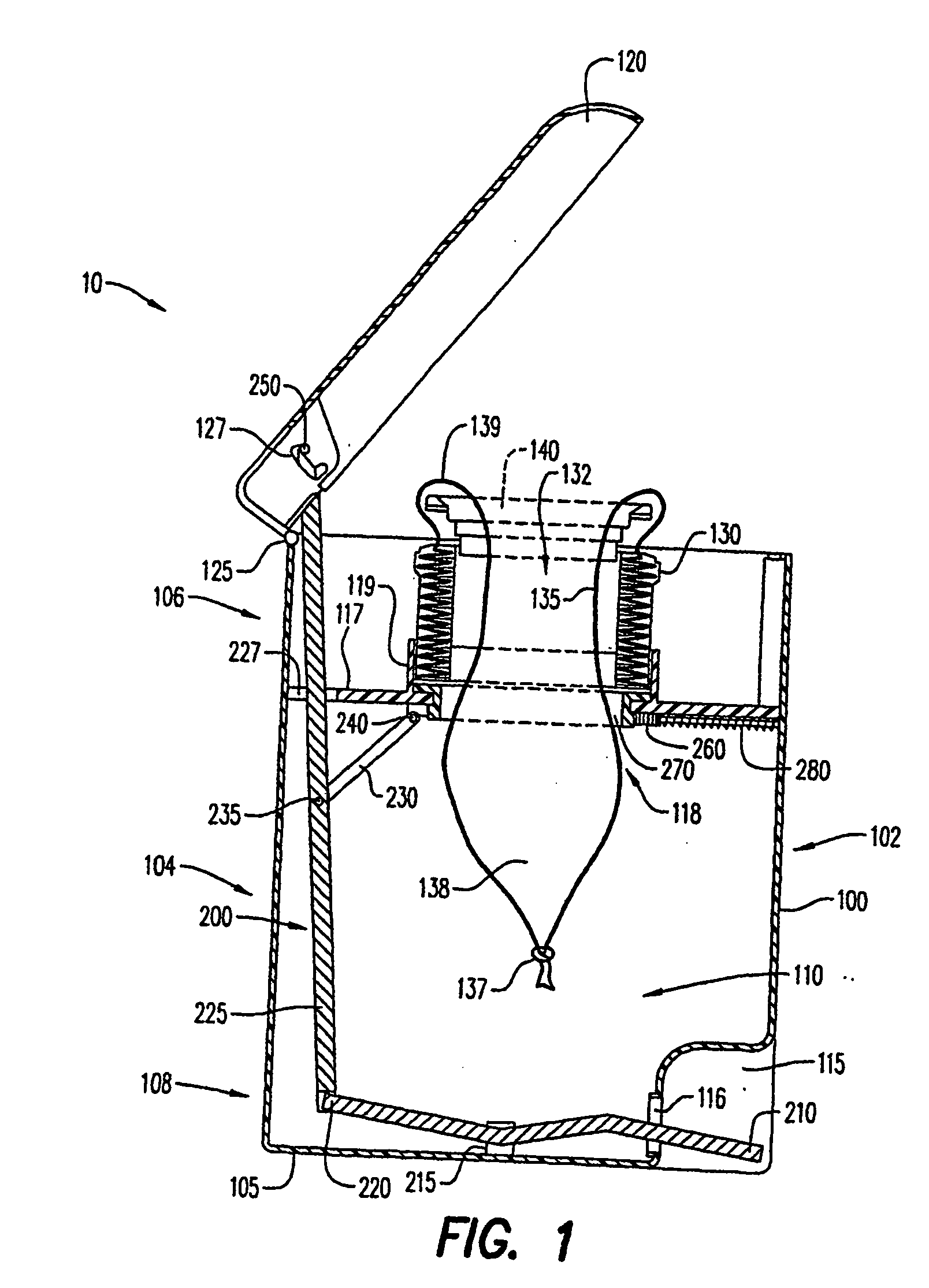

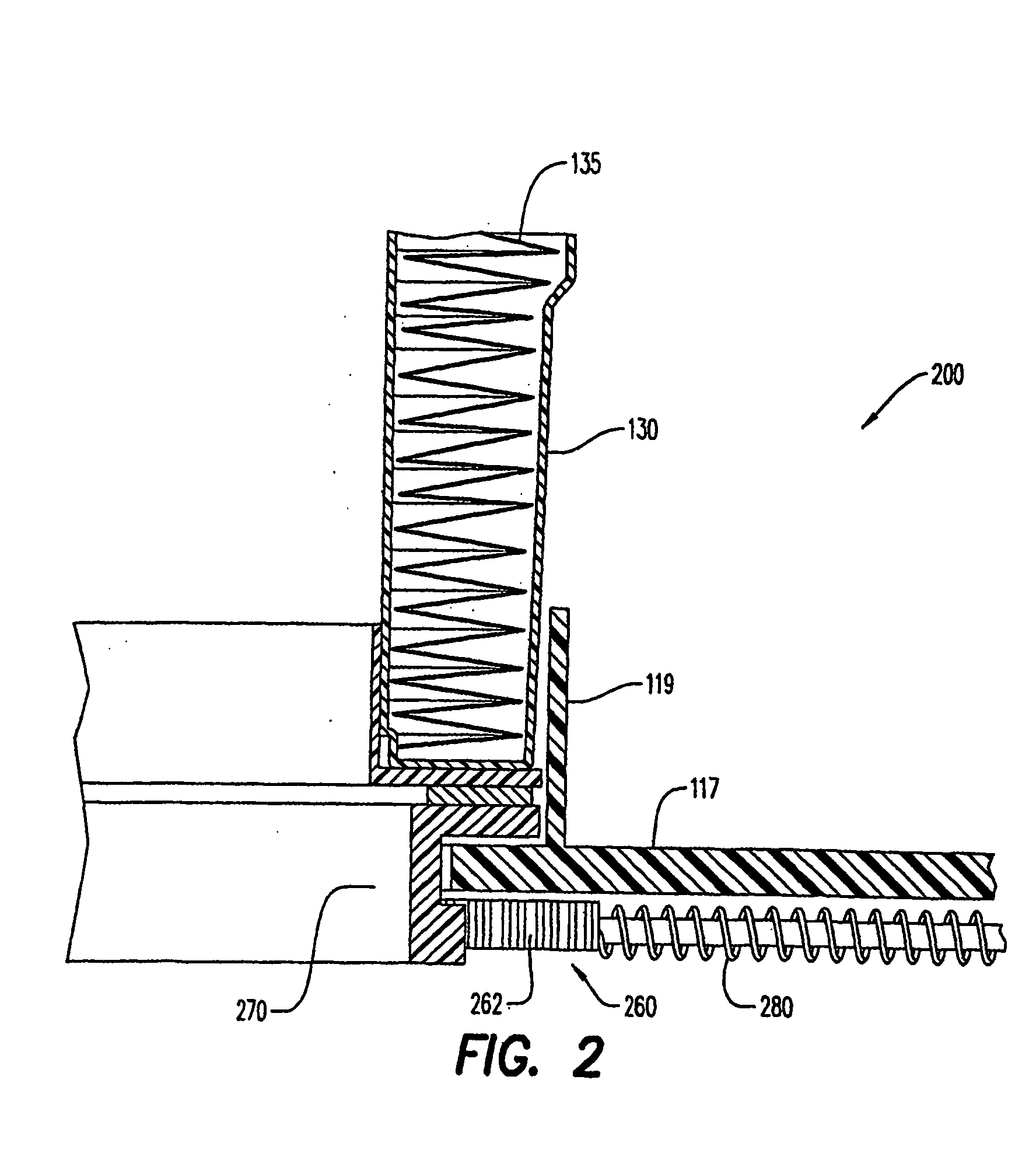

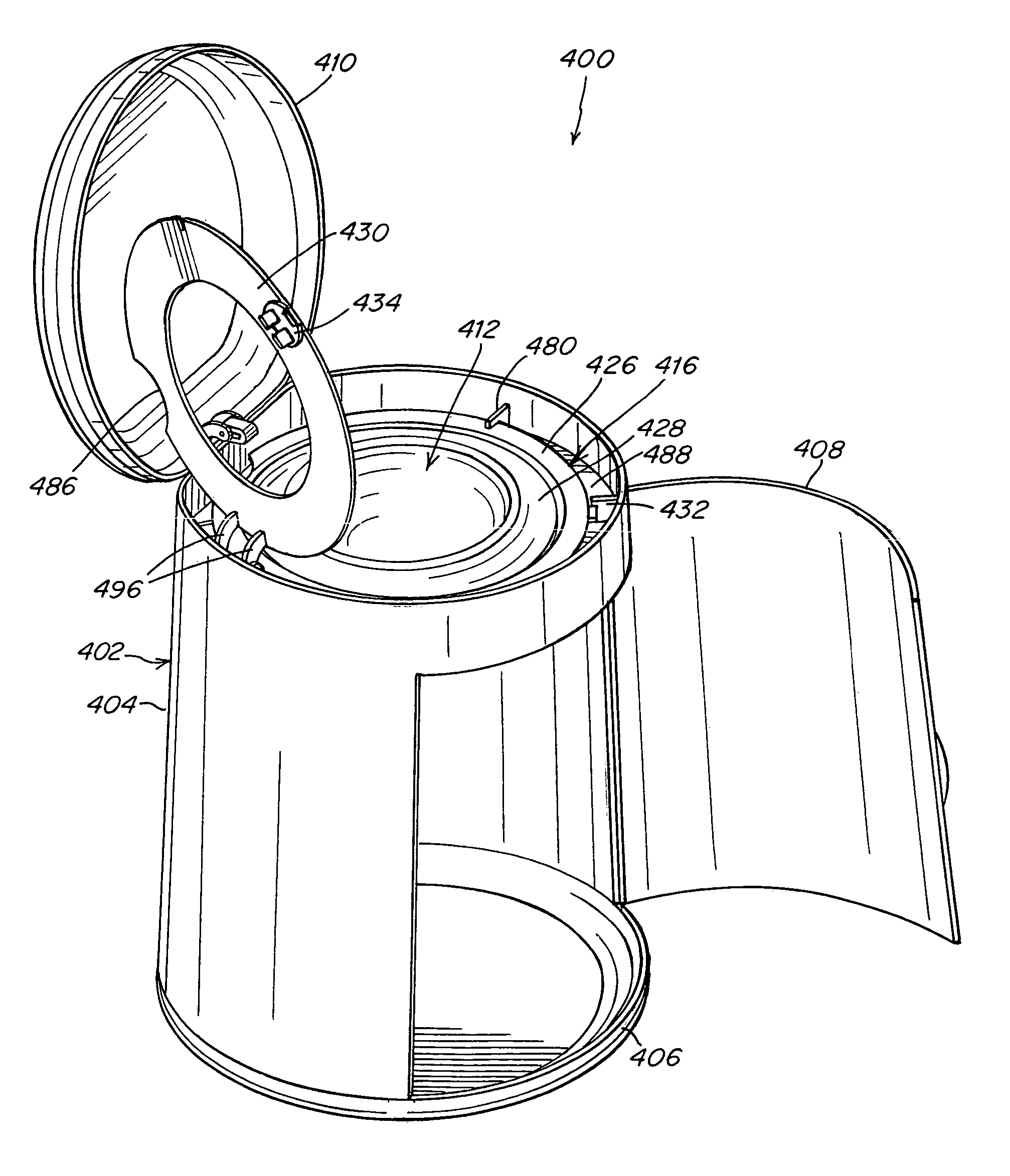

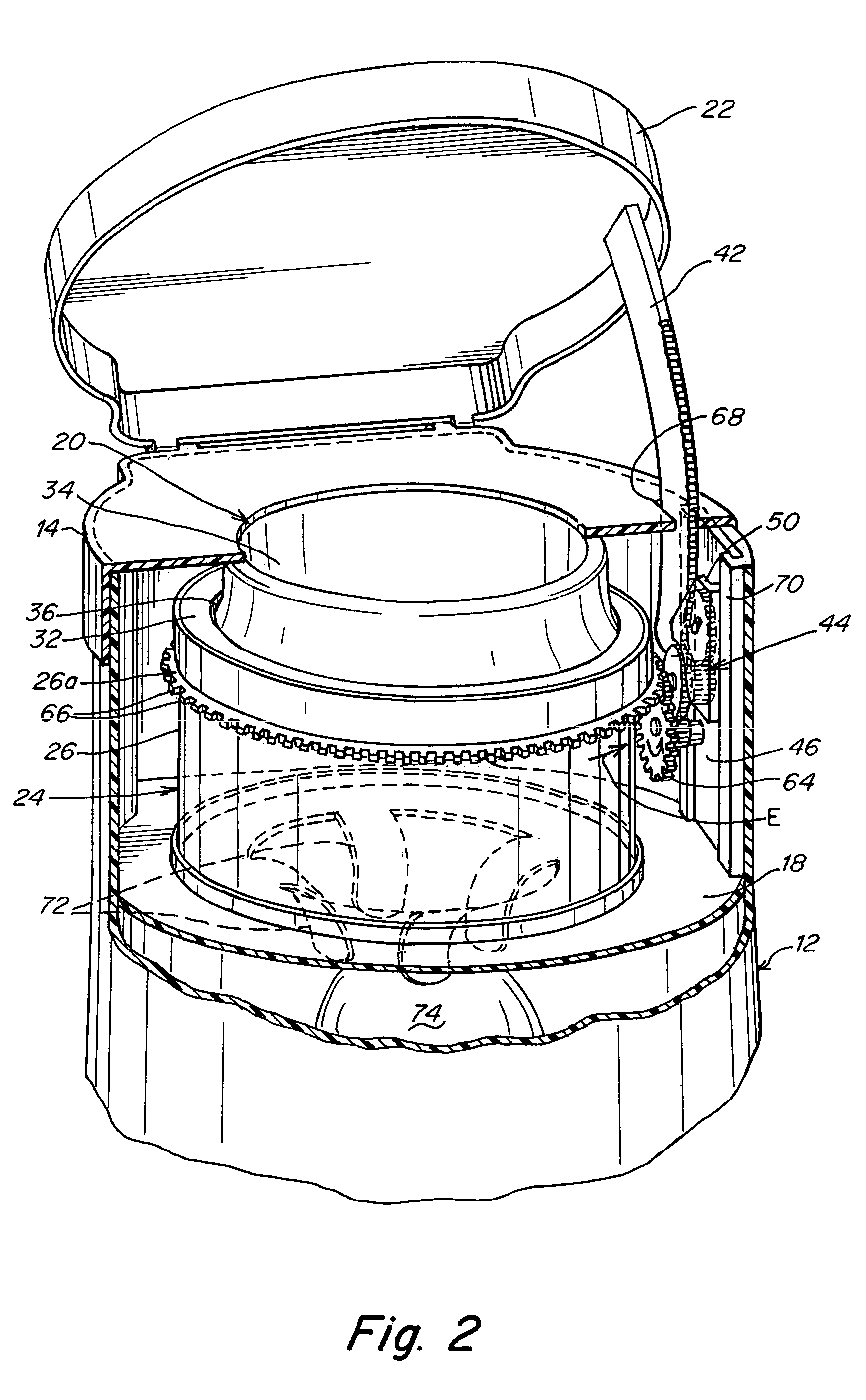

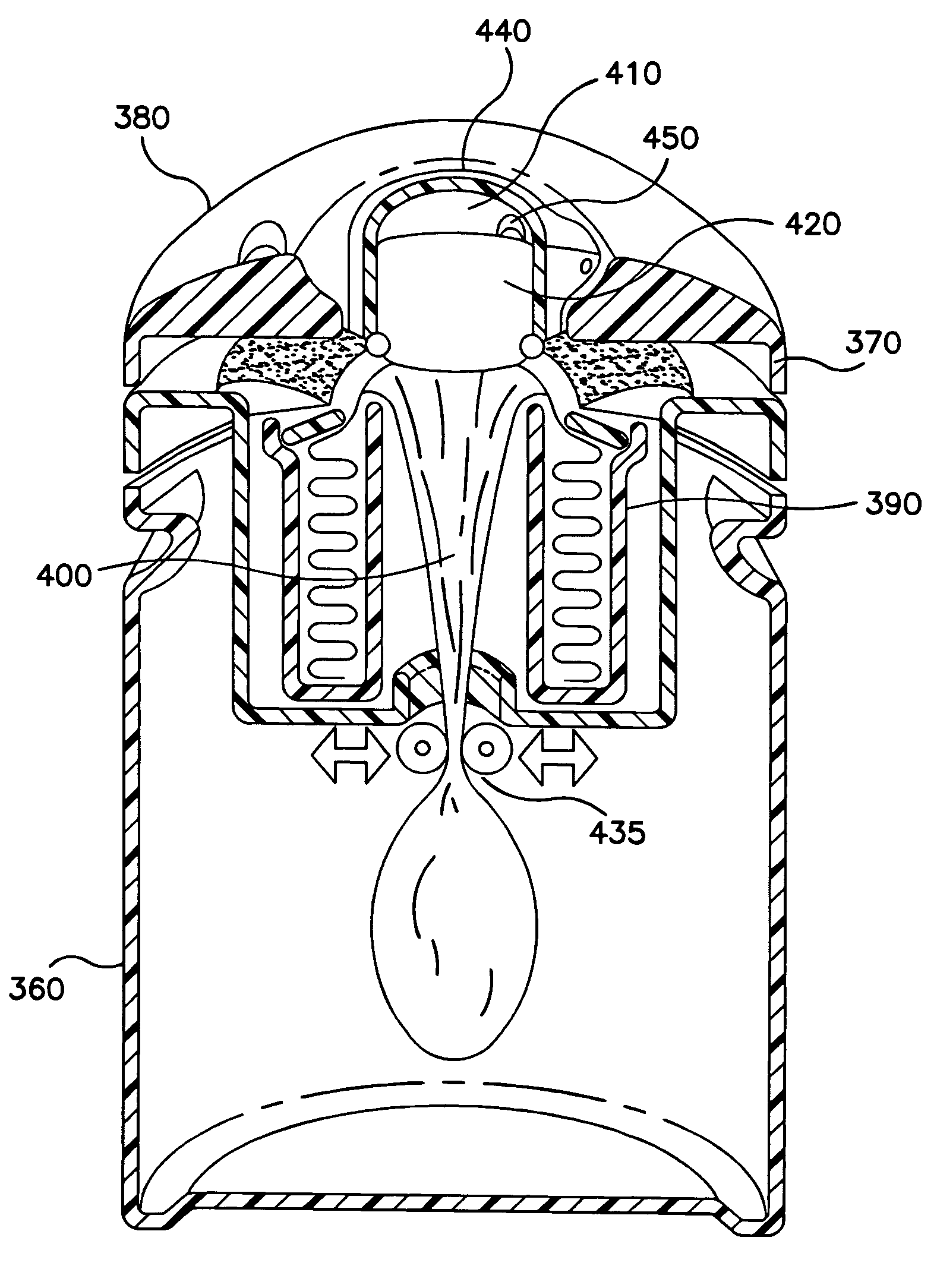

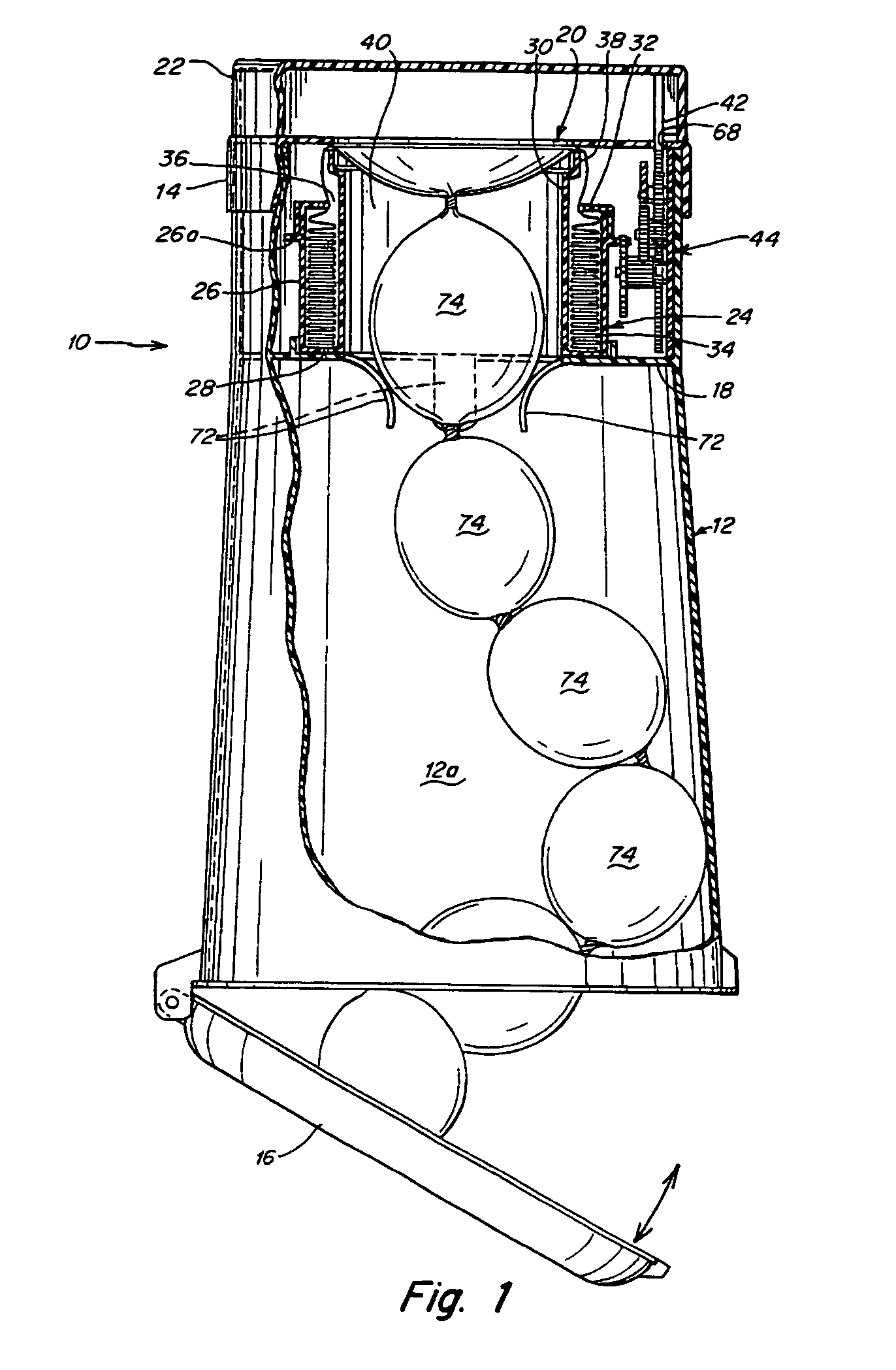

Waste disposal device including a sensing mechanism for delaying the rotation of a cartridge

InactiveUS7712285B2Effectively contains and prevents the release of odors from waste packagesEasy to disassembleContact operating partsLarge containersWaste materialWaste disposal

A waste disposal device including a sensing mechanism for delaying the rotation of a cartridge. The waste disposal device comprises a container defining a waste chamber for receiving encapsulated waste in a flexible tubing. The rotatable cartridge contains the flexible tubing. A lid is coupled to the device and is capable of moving between an open and closed position on the container. A rotation mechanism is operatively configured to engage the rotatable cartridge. A sensing mechanism is arranged to allow for delay in rotation of the cartridge until the lid assumes the closed position so that the waste is encapsulated in the flexible tubing after the closing of the lid, and after the subsequent twisting of the flexible tubing about the waste material caused by the rotation of the cartridge.

Owner:PLAYTEX PROD INC

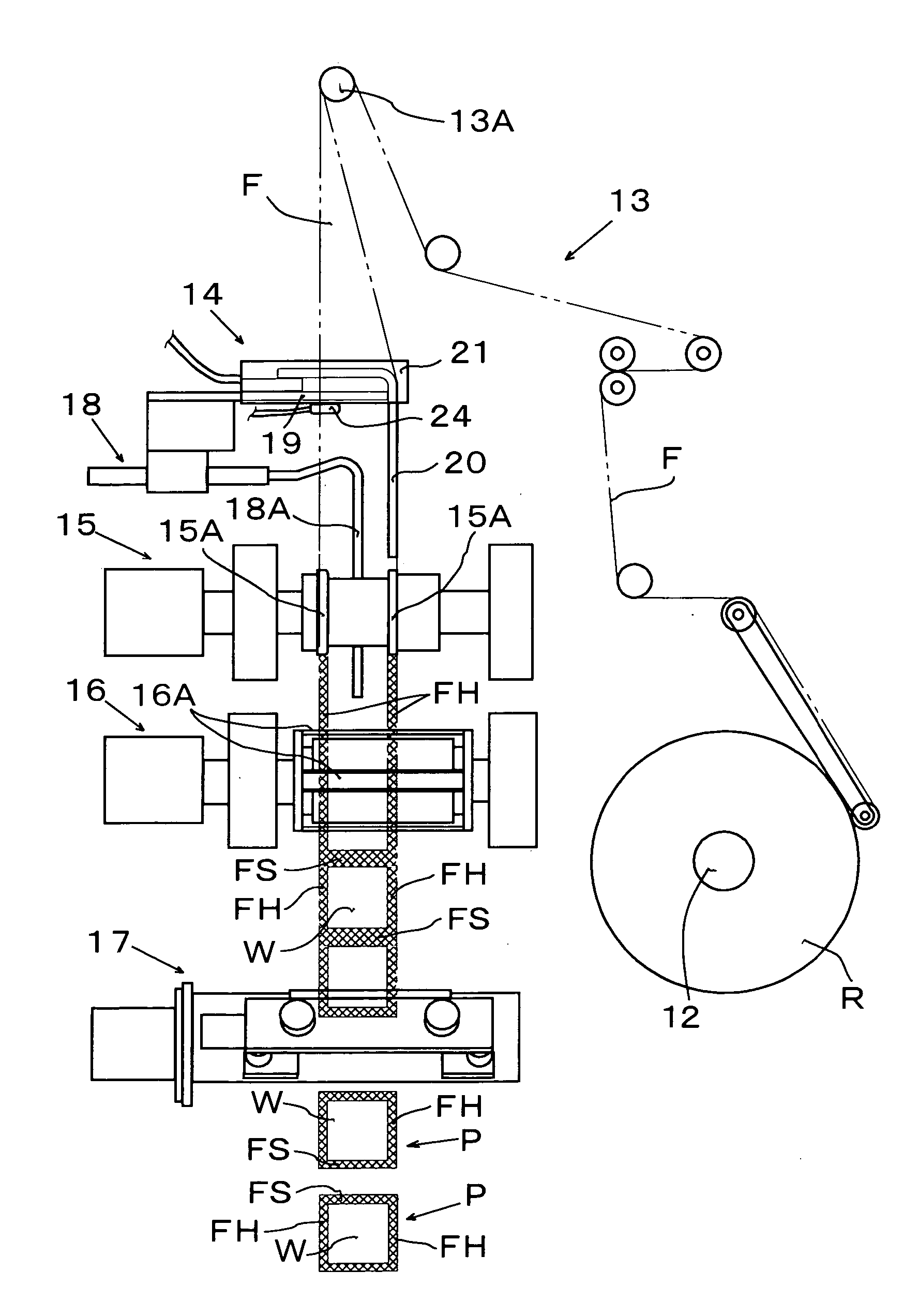

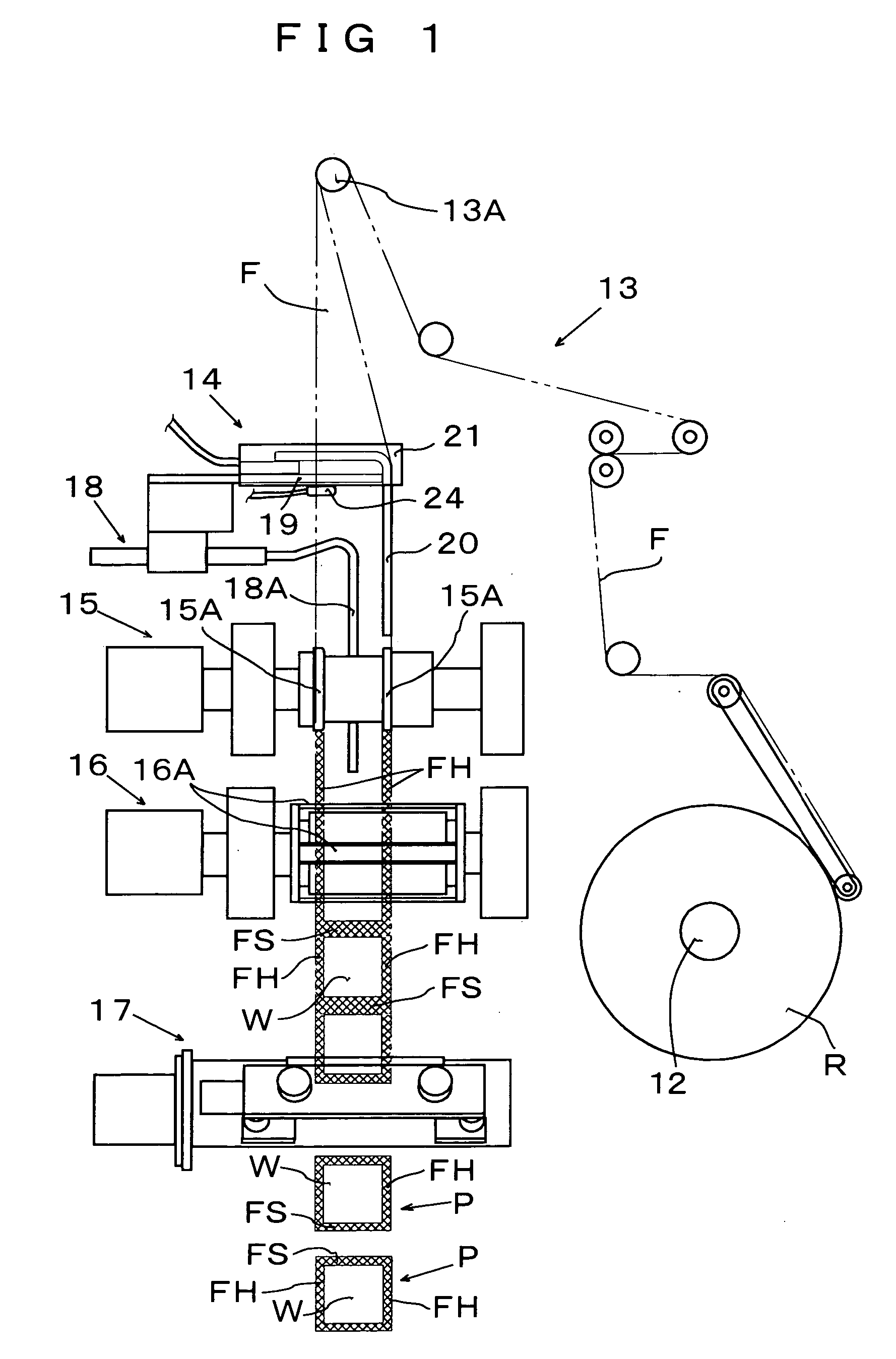

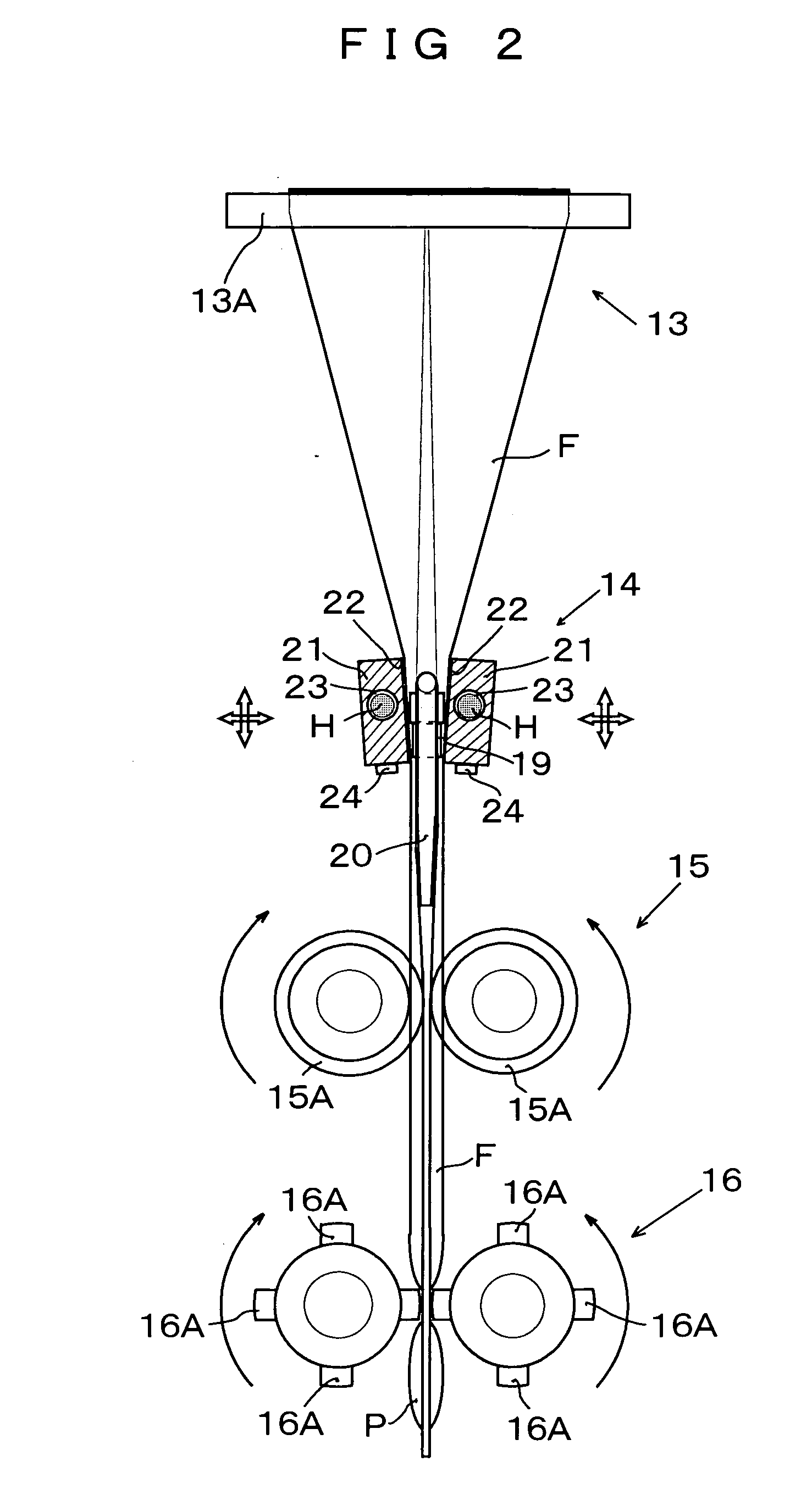

Filling and packaging machine

InactiveUS20060021300A1Melted excellentlyImperfect heat sealingWrappers shrinkagePaper-makingEngineeringSupport surface

A filling and packaging machine capable of supplementing the shortage of heat quality without lowering package speed when a film is heat-sealed while being pressurized by a vertical sealing mechanism, comprising a film folding mechanism having an inner surface guide member for guiding the film laterally, formed on the inner surface side of the film folded up into two parts, a pair of right and left pre-heating block members having tilted support surfaces or are support surfaces formed along the width-direction of the film on the outer surface side of the film through a specified interval from the inner surface guide member so that the interval on the upstream side of the film in feeding direction is larger than the interval on the downstream side, and heaters installed in the pre-heating block members.

Owner:NIPPON SEIKI CO LTD

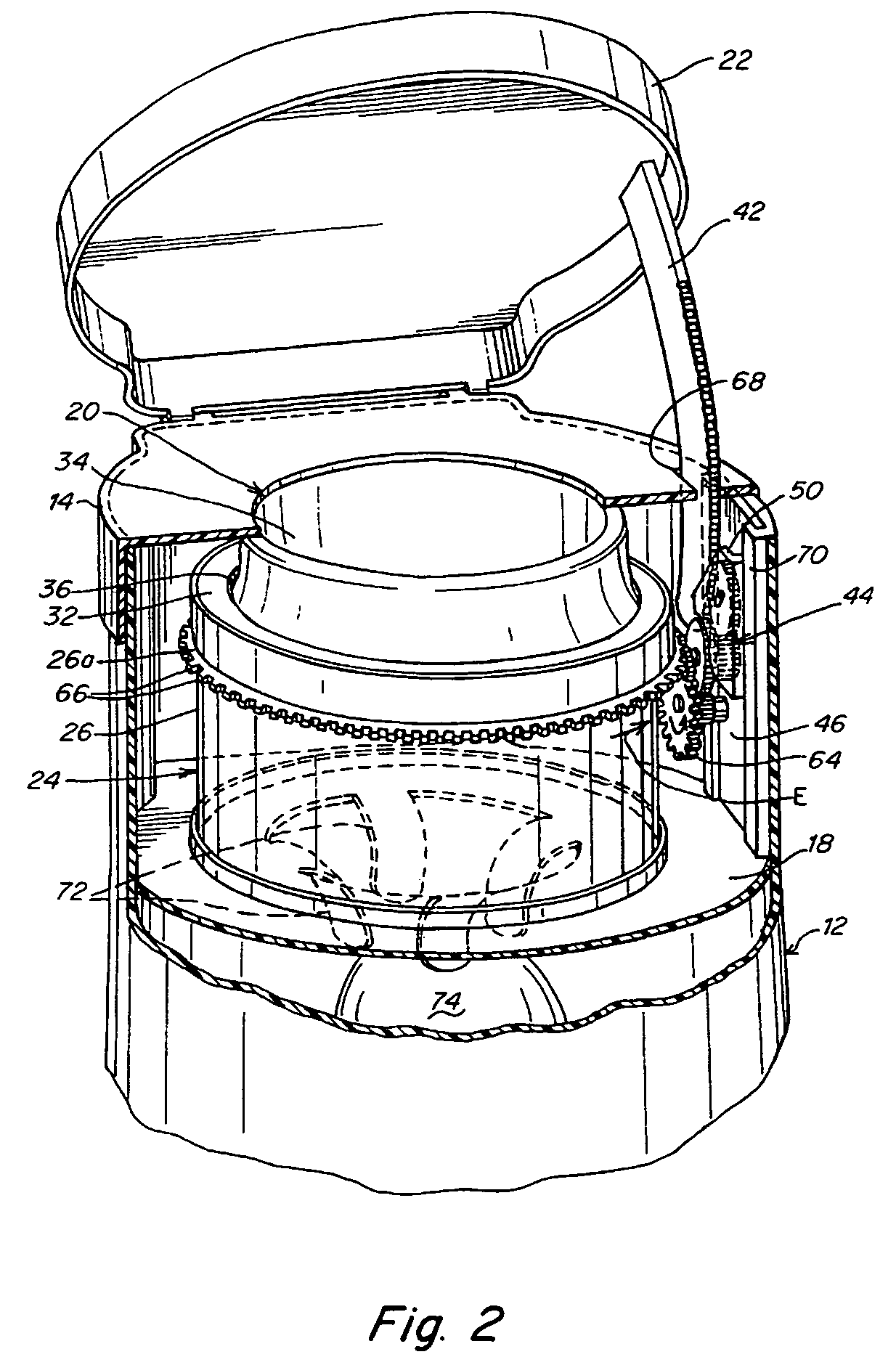

Waste storage device

InactiveUS20050044819A1Create efficientlySolve the lack of spaceRefuse receptaclesWrapper twisting/gatheringWaste disposalEngineering

The present invention discloses an automated sealing waste disposal apparatus using tubular material.

Owner:CHOMIK RICHARD S +5

Waste disposal devices

InactiveUS7146785B2Effectively contains and prevents the release of odors from waste packagesReduce decreaseRefuse receptaclesWrappingWaste treatment

Owner:MUNCHKIN INC

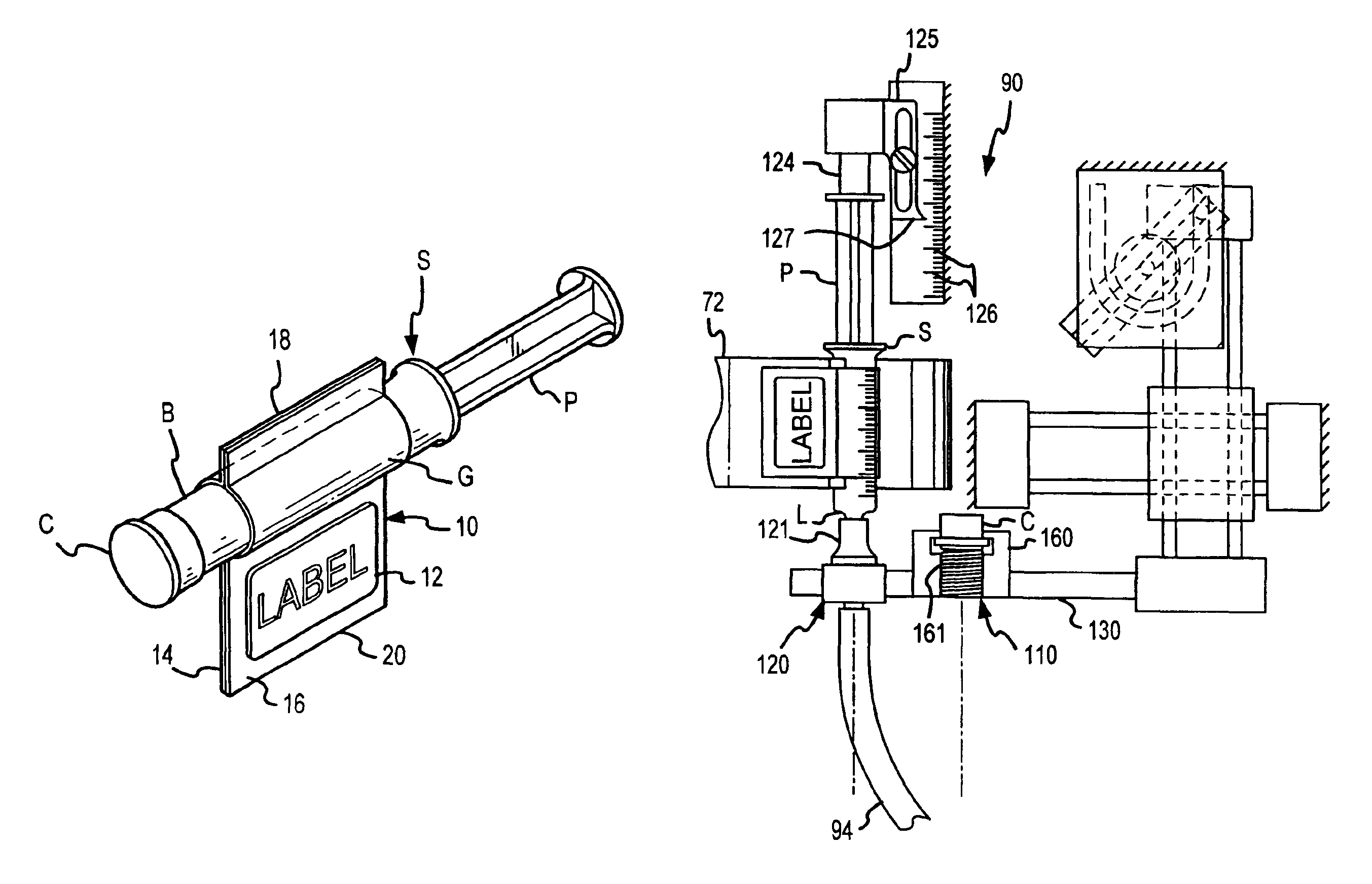

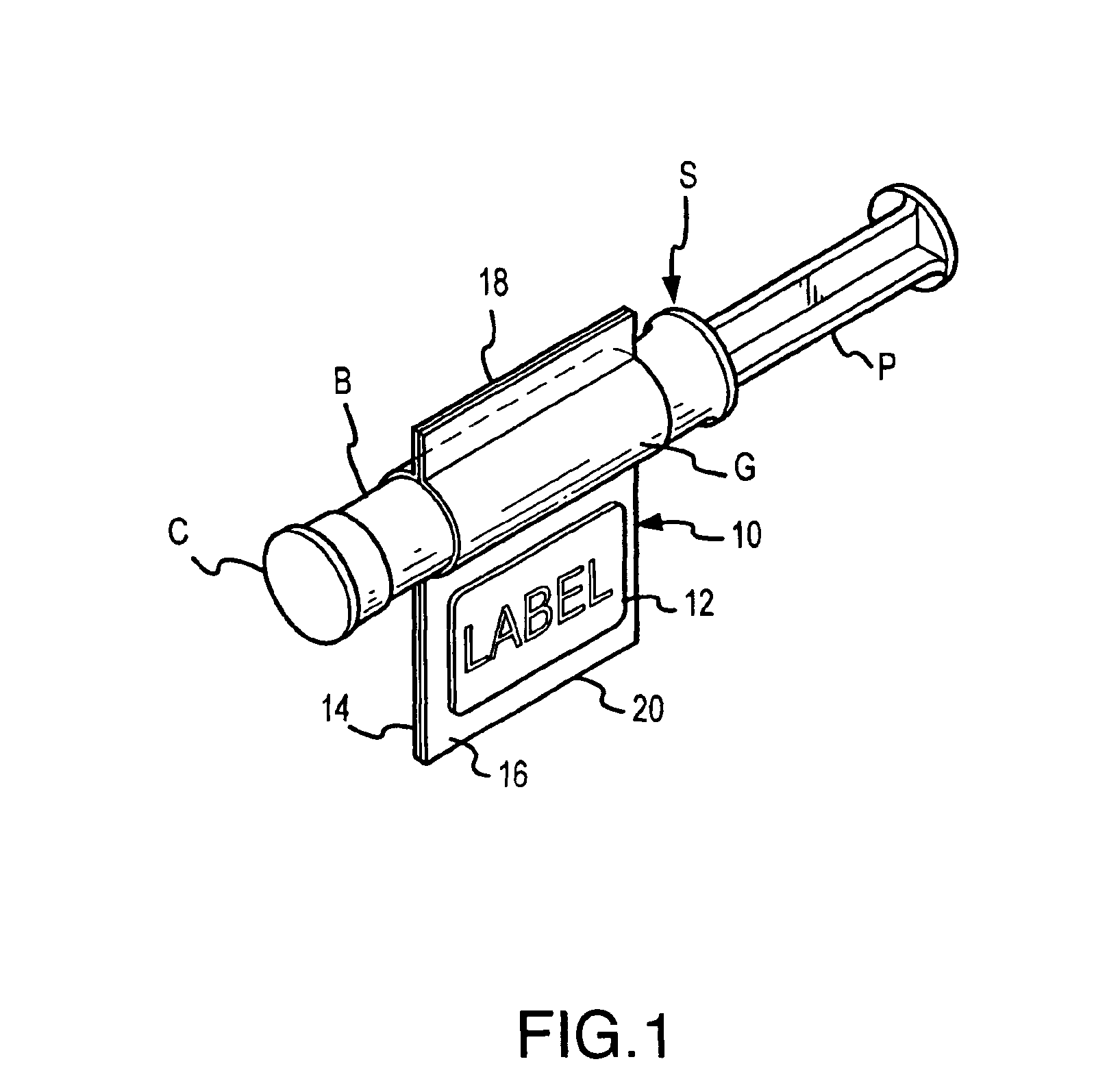

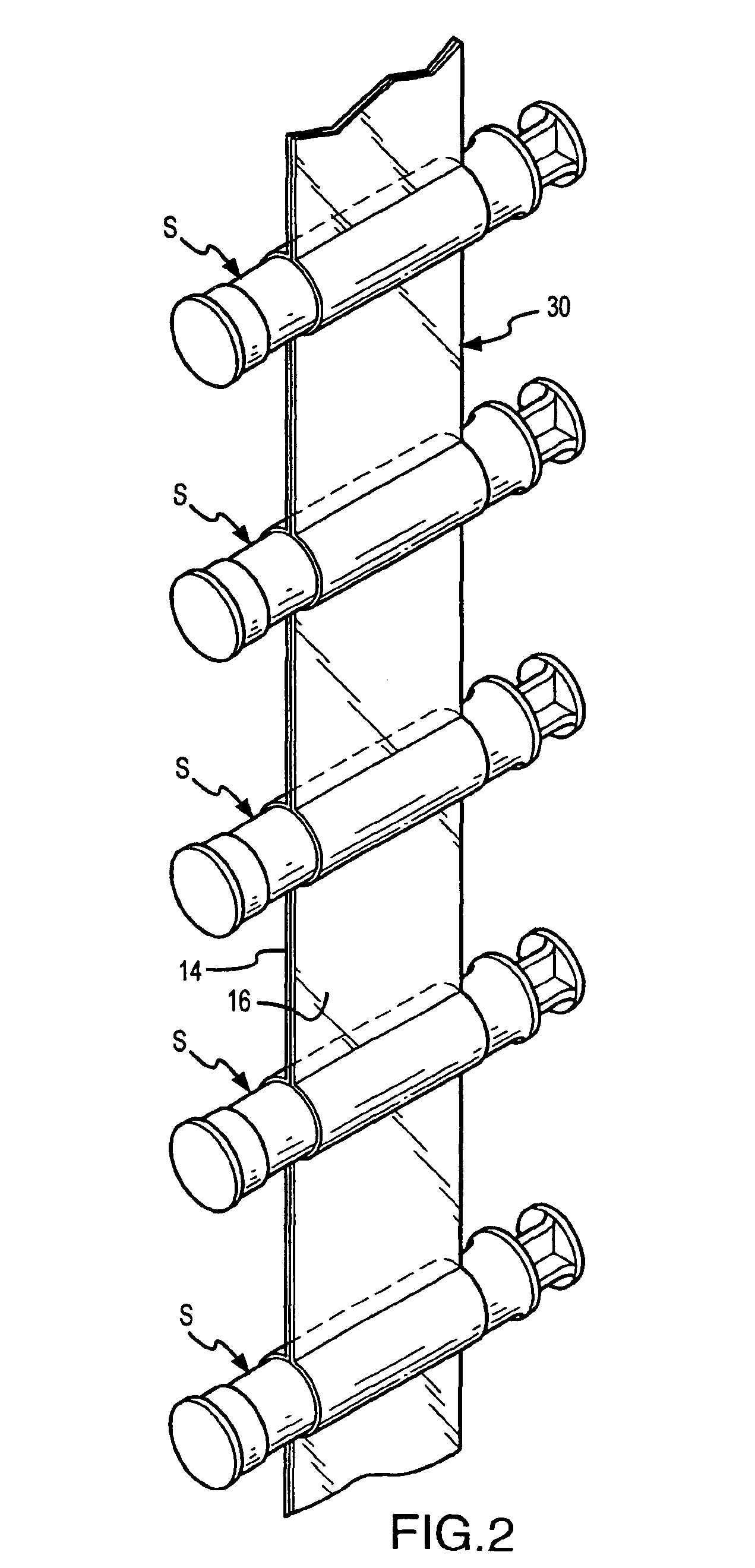

Method for filling and capping syringes

InactiveUS6976349B2Facilitates maintenance of sterilityImproved syringe fillingCapsAmpoule syringesManual handlingBiomedical engineering

An inventive method, system and apparatus are provided for syringe handling, and more particularly, for syringe labeling, filling and capping operations. To facilitate syringe handling, an inventive apparatus includes a plurality of syringe bodies interconnected in a predetermined orientation by a belt. Such belt may be of pliable construction and may define a predetermined spacing in between adjacent ones of the syringe bodies, such predetermined spacing corresponding with a distance between holders provided in a handling apparatus. The syringe handling apparatus may provide for the placement of contents-related information on belt segments between adjacent syringe bodies and for separating the belt segments, wherein a flap is left interconnected to each syringe body. The syringe handling apparatus may alternatively or also provide for automated filling of the syringe bodies wherein cap removal, filling and cap replacement operations are completed free from manual handling.

Owner:BAXTER ENGLEWOOD

Precharged ground coffee capsule, method for its production and apparatus for implementing said method

Taught herein are a precharged ground coffee capsule comprising a polygonal cross-section container body made of a liquid-impermeable material, the container body having an open end and a large axial opening formed in a bottom wall of the container body, two walls made of a liquid-permeable material being arranged on the open end and at the bottom wall respectively, the liquid-impermeable material comprising a metallic material support layer and a thermoplastic material layer, the thermoplastic material layer facing the interior of the container body, the permeable walls being coupled to the container body through the thermoplastic material layer, an outwardly projecting radial flange being provided at the open end of the container body; a method for producing the capsule; and an apparatus for implementing the method.

Owner:REATI MARCO

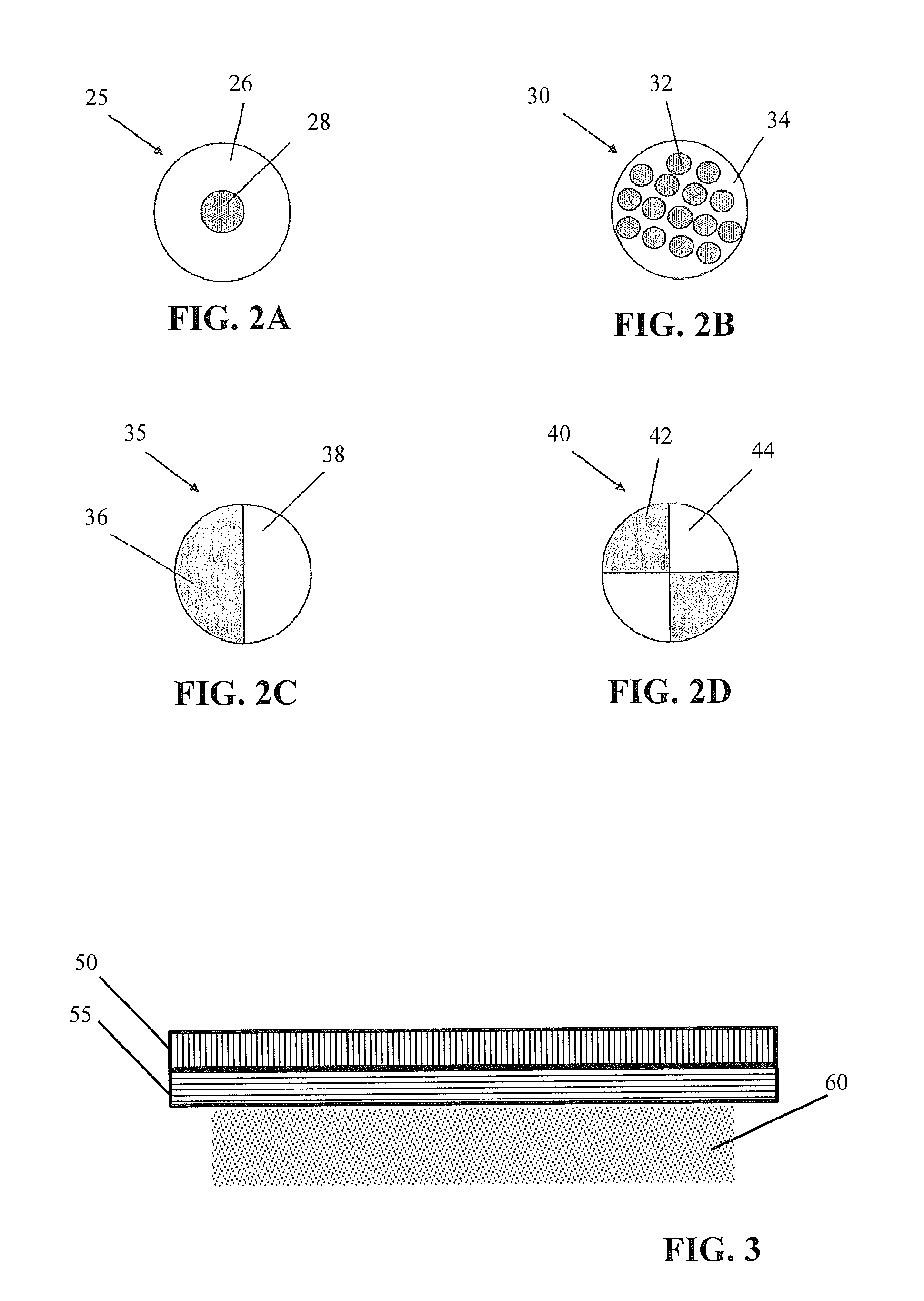

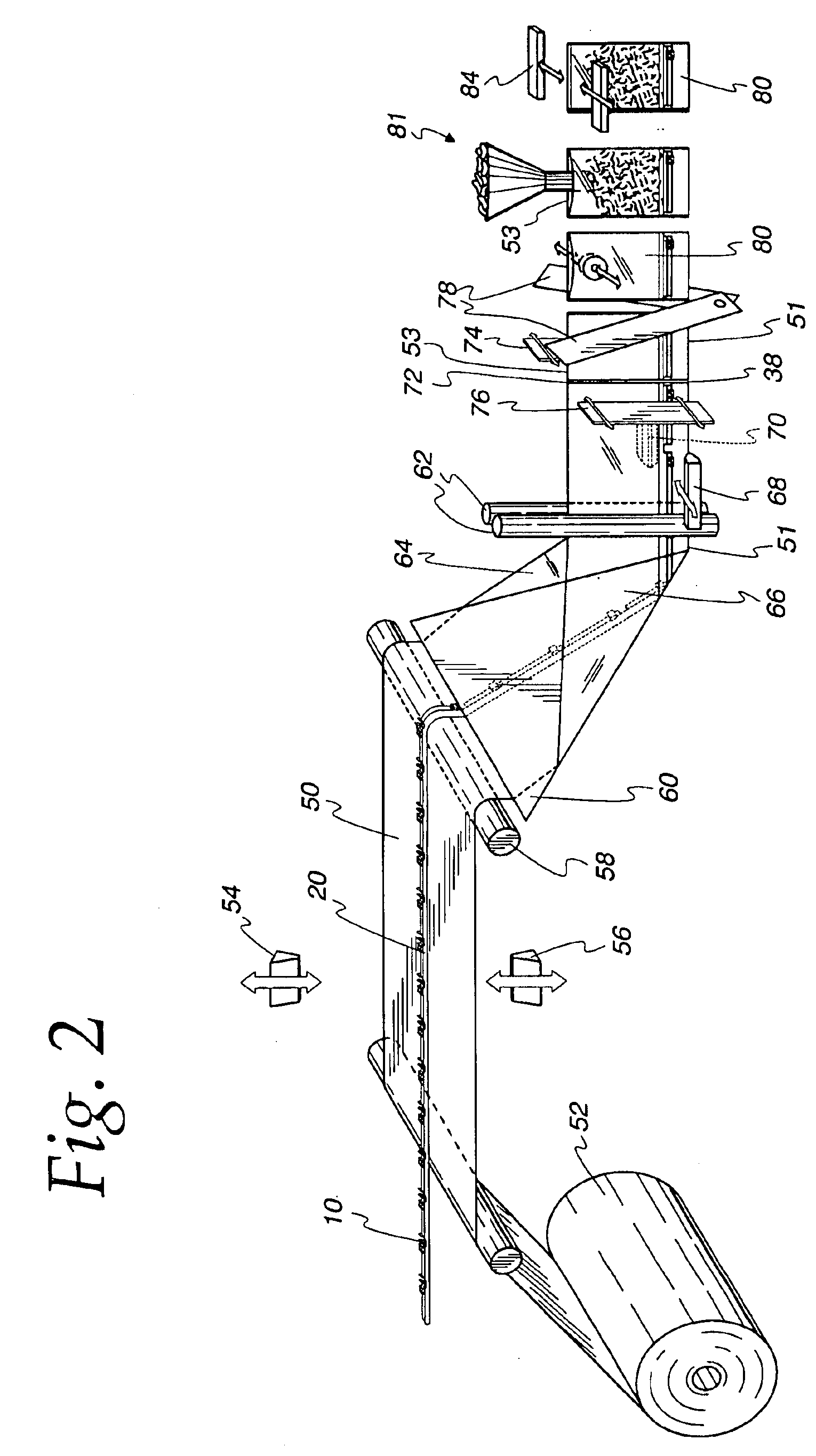

High-speed pouch forming, sealing and filling machine, method of operation, and multi-layer film therefore

InactiveUS6237308B1Improve methodImprove throughputSynthetic resin layered productsWrapper twisting/gatheringPuncture resistanceEngineering

The multi-layer film structure having an inner sealing layer which comprises metallocene resin, a core which includes polypropylene copolymer and an outer layer and wherein the multi-layer film structure has a thickness within a range between about 50 and 70 microns (2.0-2.75 mil). By utilizing this thin film with specific properties the sealers may be operated at lower temperatures thereby resulting in an energy saving and they produce seals having improved seal strength of 30% to 50% as compared with known prior mono-layer polyethylene film. The seal initiation temperature is reduced by 10° C. to 15° C. and the film exhibits an improved machine direction tensile strength of 25% to 40% and an improvement of 30% to 50% in puncture resistance as compared with a 76 microns (3 mil) mono-layer polyethylene film. This results in a reduction in the sealing cycle time and an increase in the throughput of the machine. This results in a liquid pouch having a substantial improvement in drop test performance, puncture resistance and seal strength. The machine accomplishes better seals with less energy, requires less downtime for roll changes and maintenance and increase throughput.

Owner:GLOPAK INC

Inflated dunnage and method for its production

InactiveUSRE36759E1Reduce slippageEasy to prevent slippingPreventing unwanted cargo movementLabelling non-rigid containersDunnageCarton

A method for producing inflated dunnage on the site of use, comprising providing, in web form, a plurality of preformed plastic bags, each of the bags comprising two plastic sheets in facing relationship and sealed along three edges with one edge remaining open. Air is blown toward each of the open edges in sequence, causing each bag to inflate, and the open edge of each inflated bag is sealed, the bag being empty except for the air. A plurality of sealed inflated bags is separated from the web and placed in a carton to serve as dunnage. The bags have a slip resistant outer surface which causes the bags to interlock in the carton and better protect object therein from shock.

Owner:AUTOMATED PACKAGING SYST

Ice measuring and dispensing apparatus

ActiveUS7421834B1Contracting/expanding measuring chambersLighting and heating apparatusHorizontal axisEngineering

An ice measuring and dispensing apparatus includes a rotating drum rotatable about a horizontal axis. The rotating drum has a plurality of chambers, and an ice supply hopper has a delivery opening for delivering ice into the plurality of chambers. A discharge tube to dispense ice from the plurality of chambers is also provided. The delivery opening of the supply hopper is larger than an opening of each of the chambers.

Owner:HAMER FISCHBEIN LLC

Nonwoven pouch comprising heat sealable binder fiber

Owner:R J REYNOLDS TOBACCO COMPANY

Parametric control in pulsed light sterilization

InactiveUS6566659B1Material analysis using wave/particle radiationElectric discharge tubesControl systemFlash light

An approach for sterilizing microorganisms at a target object employs a flashlamp system including means for generating pulses of light, and for deactivating microorganisms within the target object by illuminating the target object with the pulses of light having been generated; a photo-sensitive detector positioned so as to receive a portion of each of the pulses of light as a measure of an amount of light illuminating the target object, for generating an output signal in response thereto; and a control system, coupled to the flashlamp system and the photo-sensitive detector, for determining, in response to the output signal, whether the pulses of light are sufficient to effect a prescribed level of deactivation of microorganisms at the target object. In accordance with this approach sterilizing microorganisms involves steps of generating a pulse of light; deactivating microorganisms at the target object by directing the pulse of light having been generated at the target object; receiving a portion of the pulse of light as a measure of an amount of the pulse of light illuminating the target object; generating an output signal in response to the receiving of the portion of the pulse of light; and determining, in response to the generating of the output signal, whether the pulse of light is sufficient to effect a prescribed level of deactivation of microorganisms at the target object.

Owner:TESLA INC +1

Method and apparatus for making reclosable plastic bags using a pre-applied slider-operated fastener

InactiveUS6871473B1Not adversely impactEasy to modifyEnvelopes/bags making machineryWire articlesThin membraneEngineering

A method and apparatus for making reclosable plastic bags is provided. In the method and apparatus, a fastener is attached to a moving flat web of plastic film, preferably in the direction of web movement and near the center of the web. A plurality of sliders are mounted to the fastener either before or after the fastener is attached to the flat web, but prior to conveying the web to a FFS machine. The flat web, with the slider-operated fastener already attached thereto, is then conveyed to a vertical or horizontal FFS machine where the flat web is formed into bags, and the bags are successively filled and sealed.

Owner:REYNOLDS PRESTO PRODS

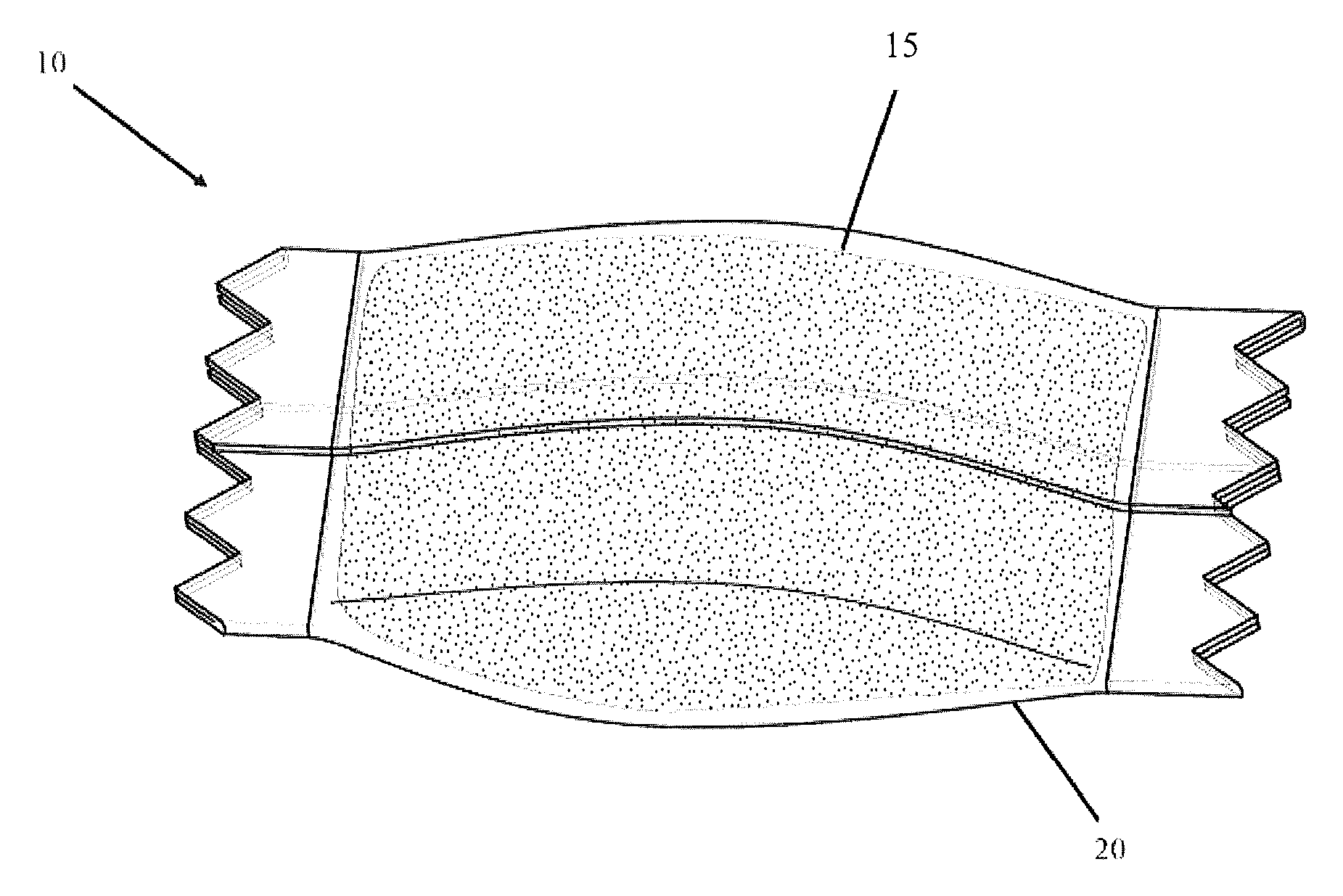

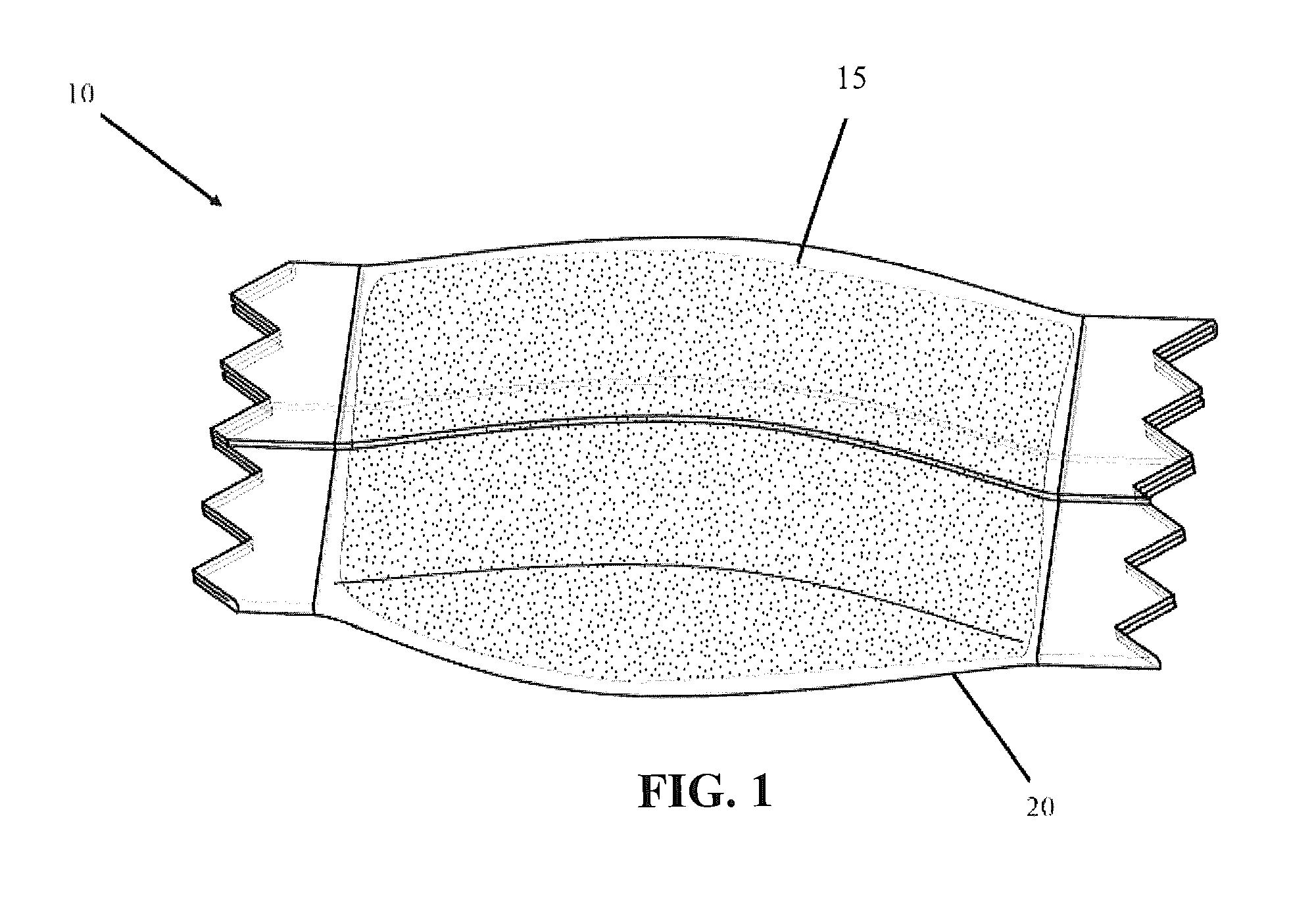

Two Side Cut Reseal With Pressure Sensitive Adhesive and the Method for Making Same

InactiveUS20100111453A1Prevent premature deterioration of qualityAvoid damageCapsDecorative coversSheet filmHermetic packaging

Two side cut reseal with pressure sensitive adhesive. A flexible package having a reseal integrated within the opposite layers of its film is constructed using existing vertical form fill and seal packaging machines. The invention involves a single sheet of flexible packaging film web having at least three layers. In a preferred embodiment, the reseal is comprised of two offsetting score lines on interior and exterior sides of the film and spaced apart by 0.5 to 1 inch. The scoring creates lines of weakness, which define an opening in the package. Upon opening, a pressure sensitive adhesive layer, which is pattern applied in between the offsetting score lines, is exposed from an interior side of the film. The adhesive releasably adheres the inner and outer layers of the film back together once separated by a consumer.

Owner:FRITO LAY NORTH AMERICA INC

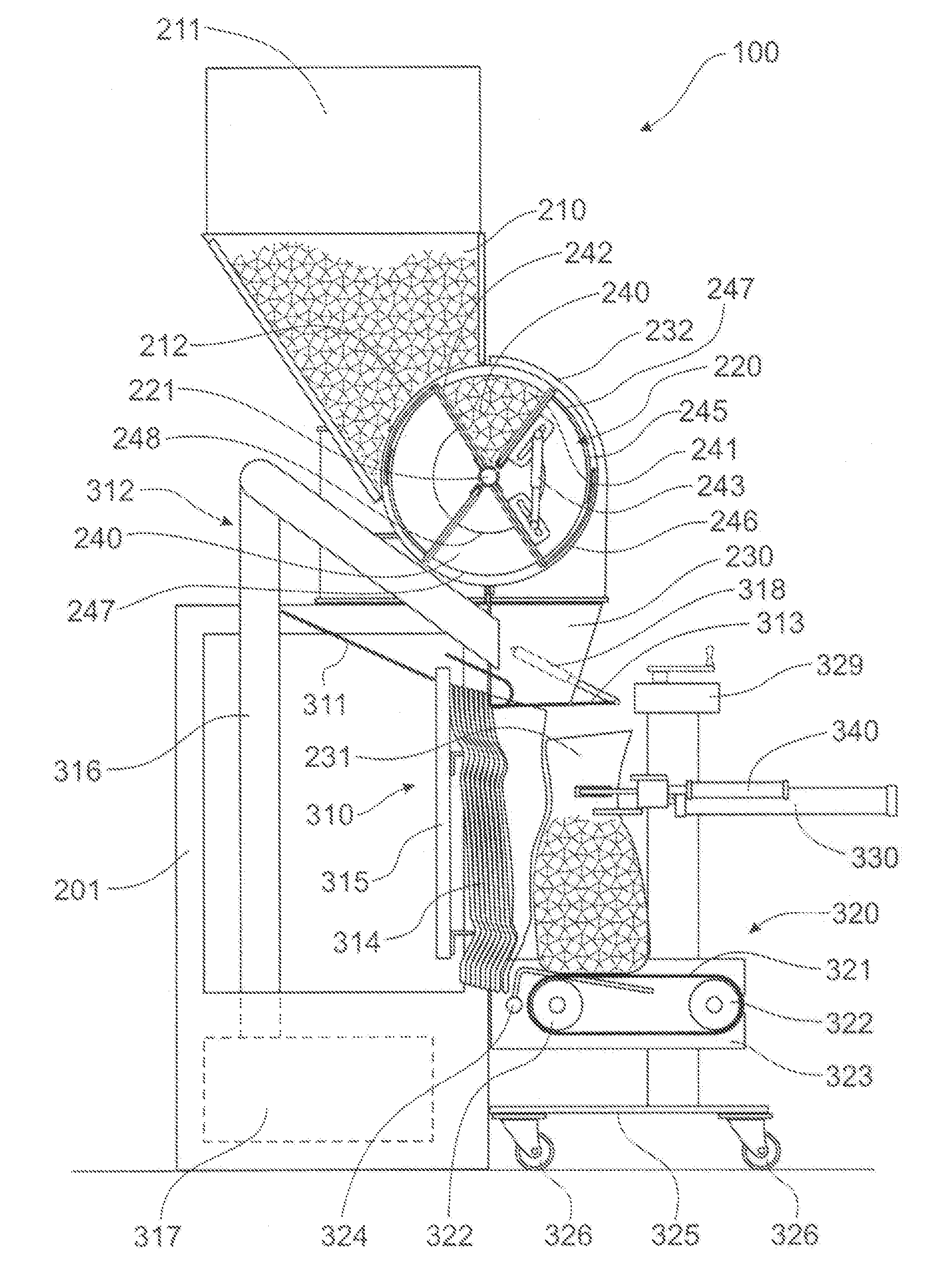

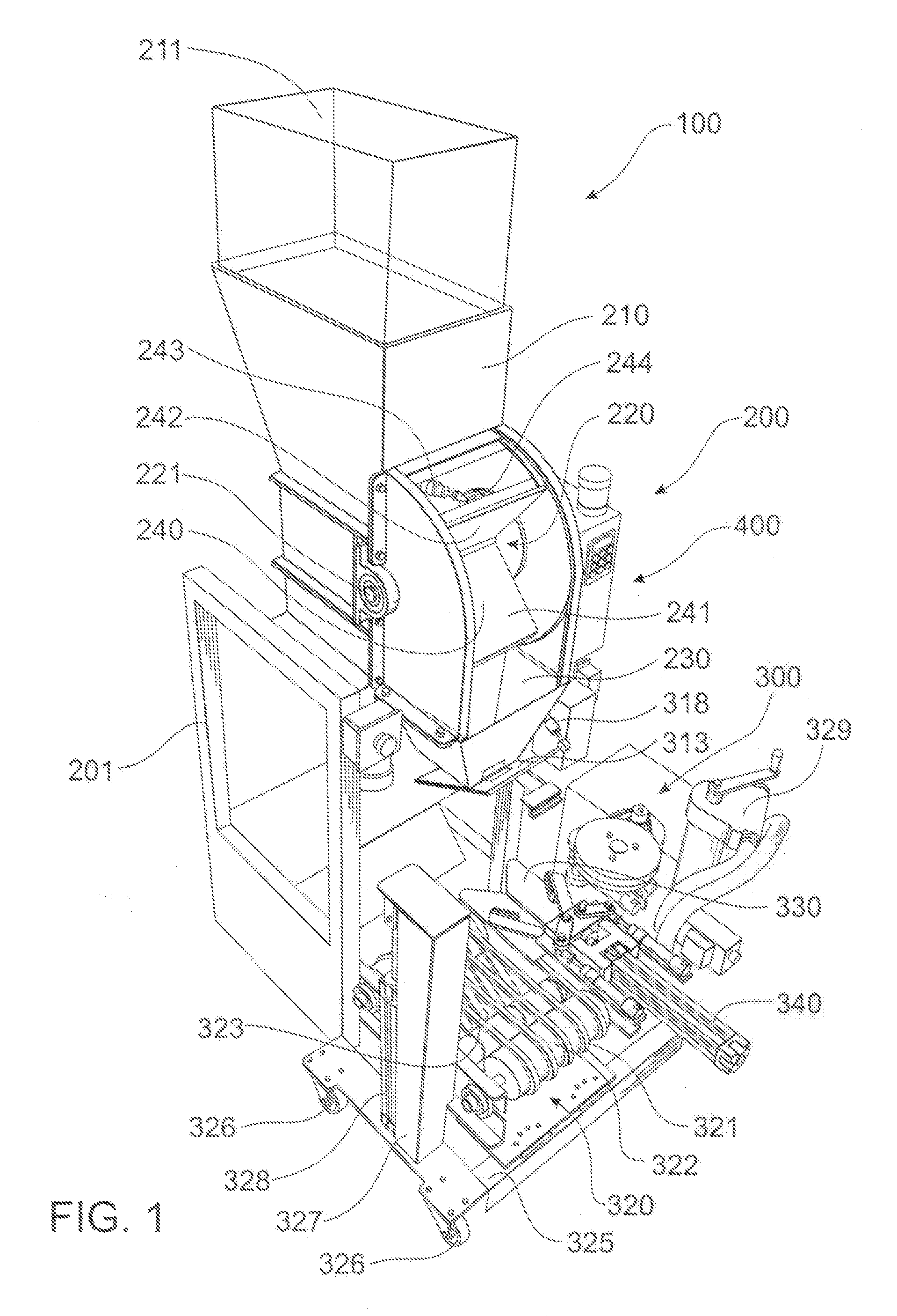

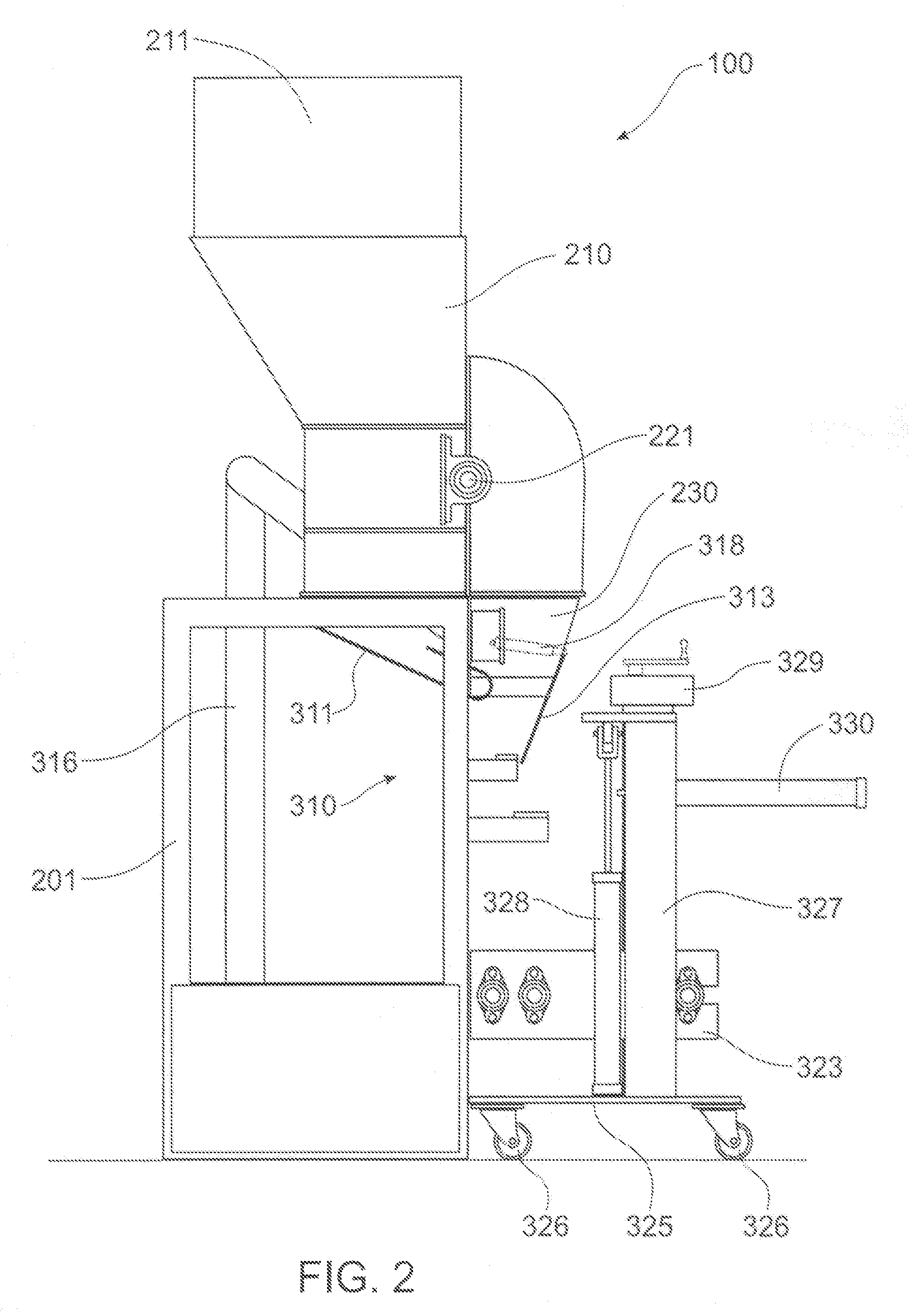

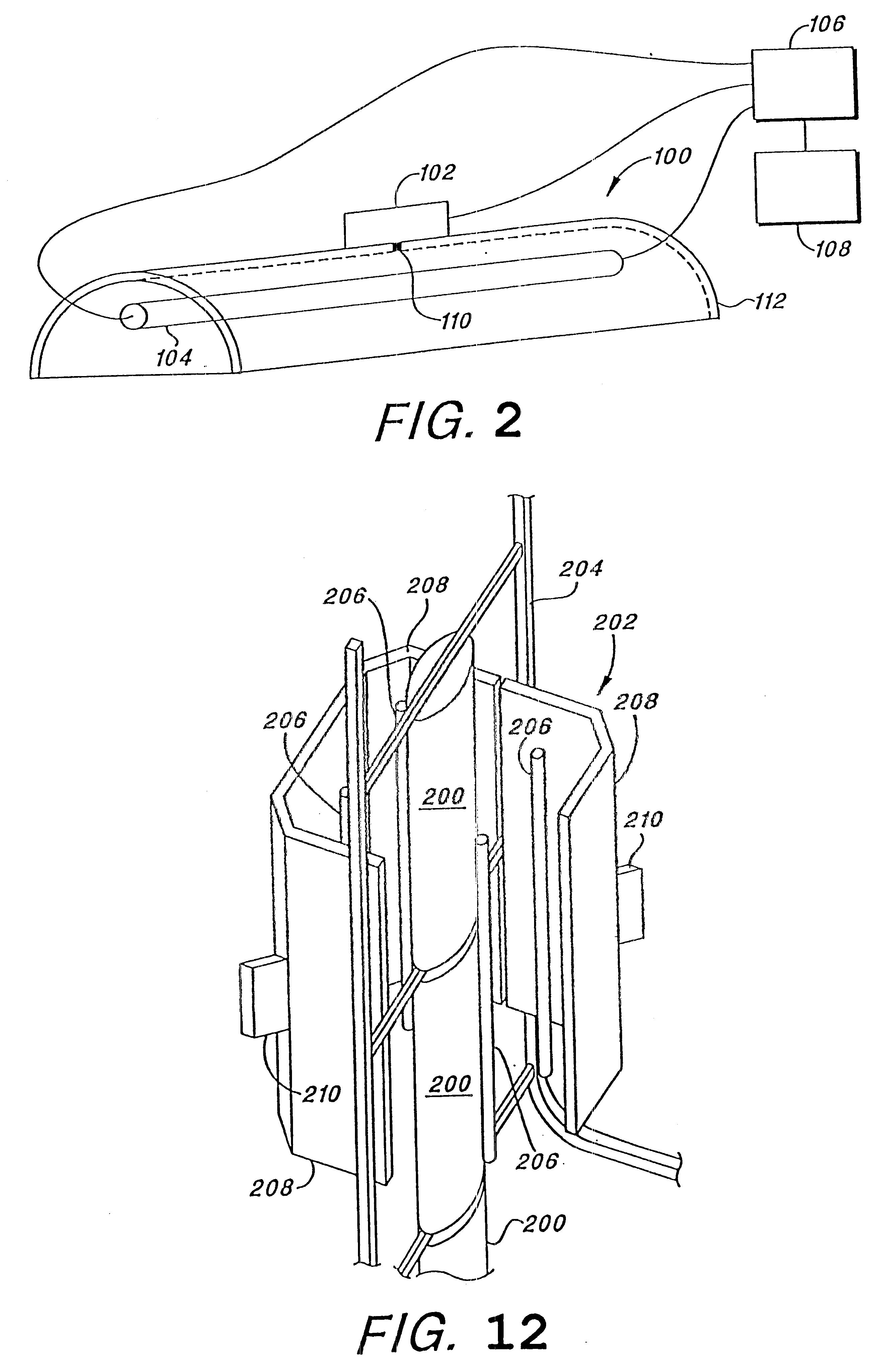

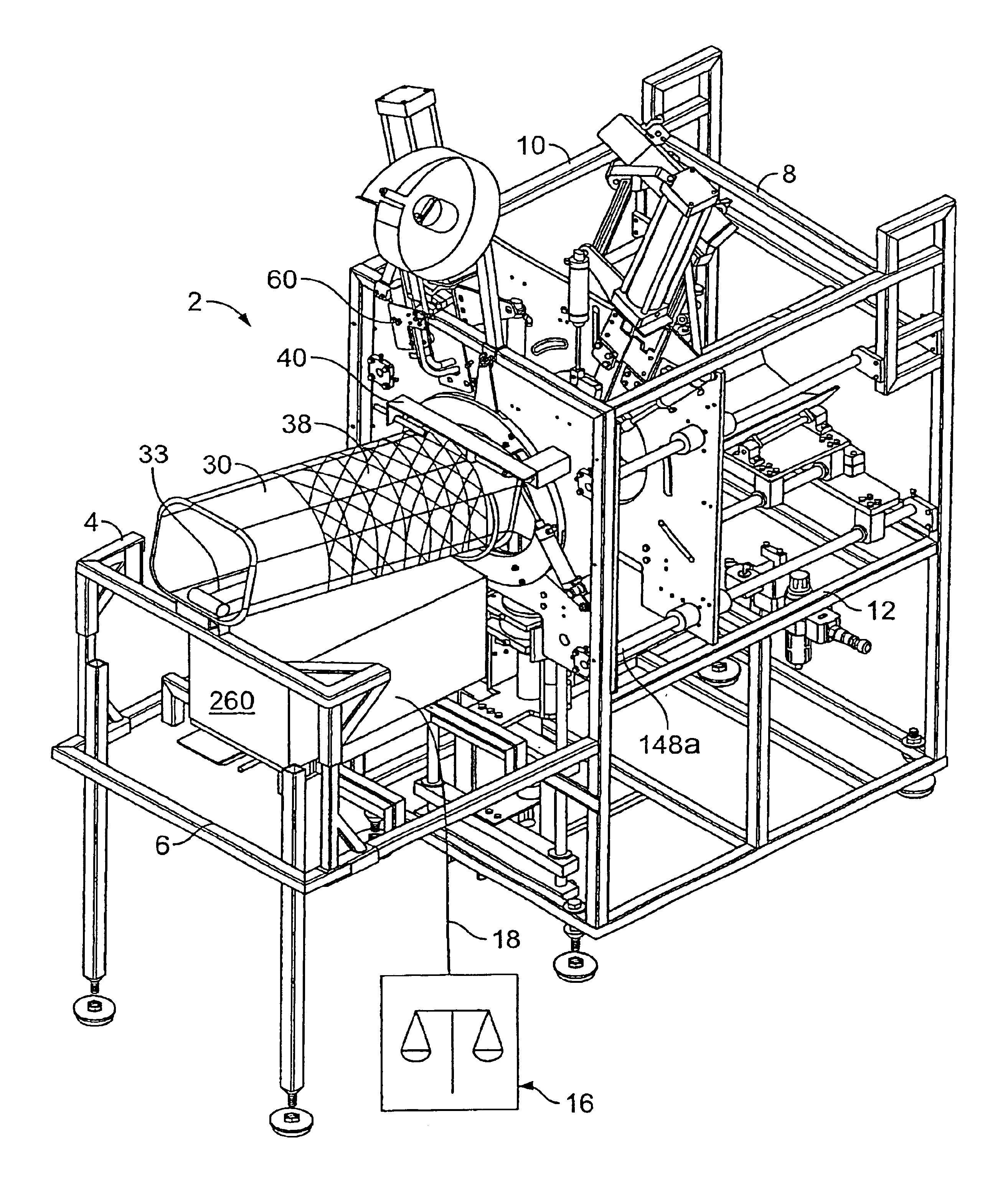

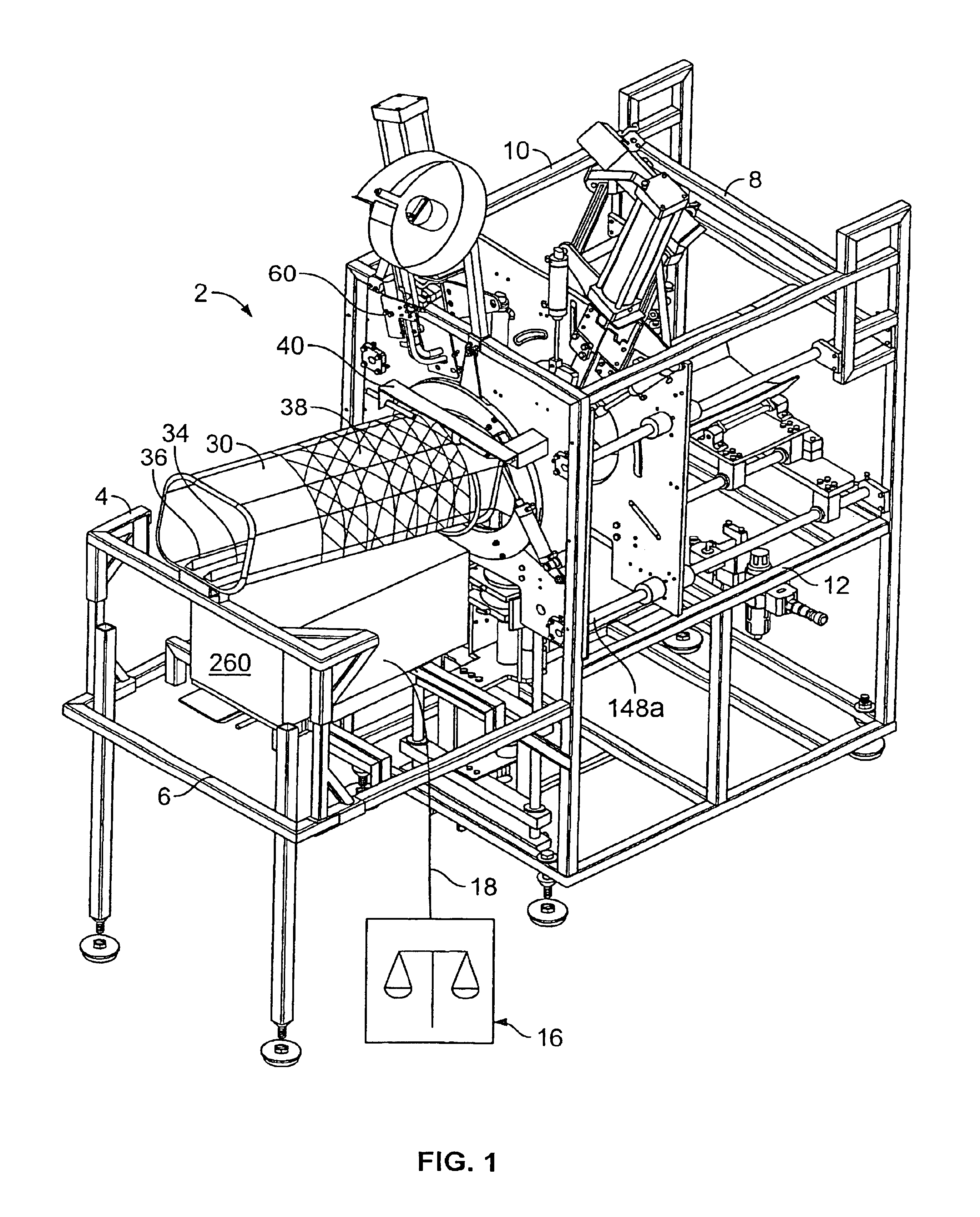

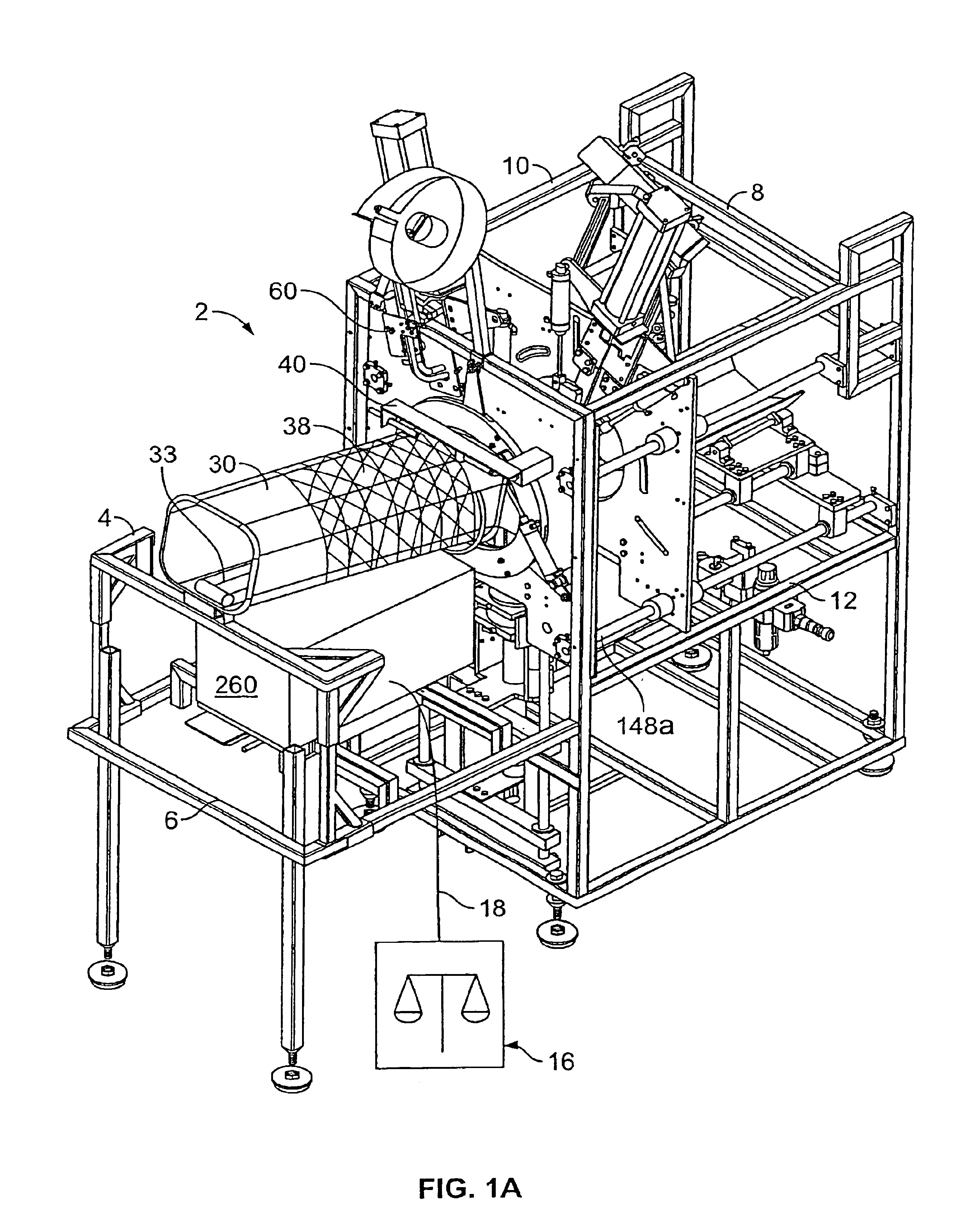

Apparatus for enclosing material in a net

InactiveUS6883297B2Uniform appearanceLighten the taskAffixing tagsSkinless sausage makingEngineeringMechanical engineering

An apparatus and method of enclosing material in a net and supplying a handle for ease of carrying the netted material, comprising clippers, irises, and a handle maker. A conveyor carries the material to a pair of irises. The irises gather the netting around the material, the first clipper cuts and closes the netting, and the handle maker forms a loop out of the severed netting. The second clipper attaches the loop back to the netting to form a handle. A scale can be used to weigh the material and a printer can create a label, with the weight or whatever other information is desired, for attachment to the netting.

Owner:POLY CLIP SYST

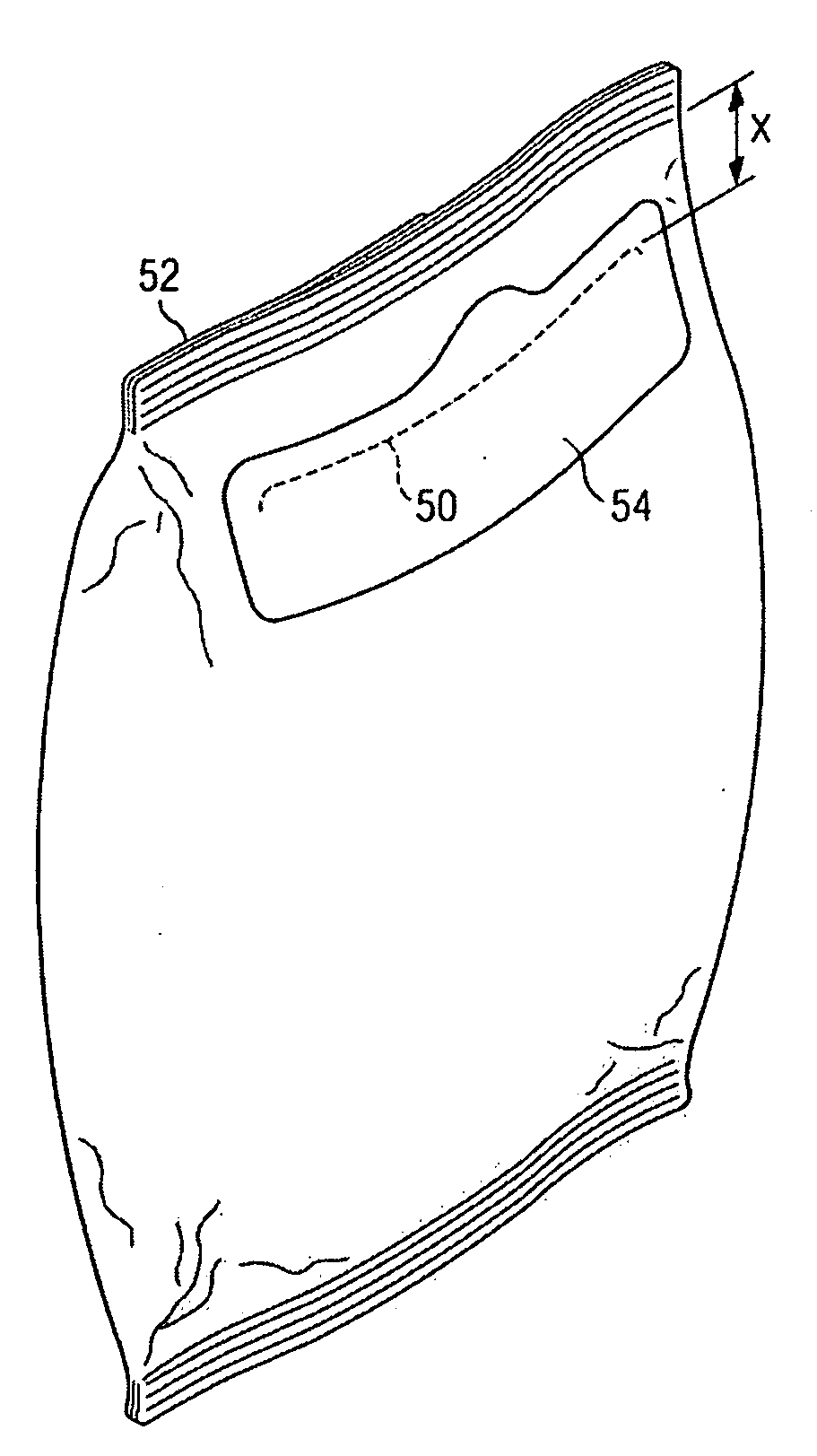

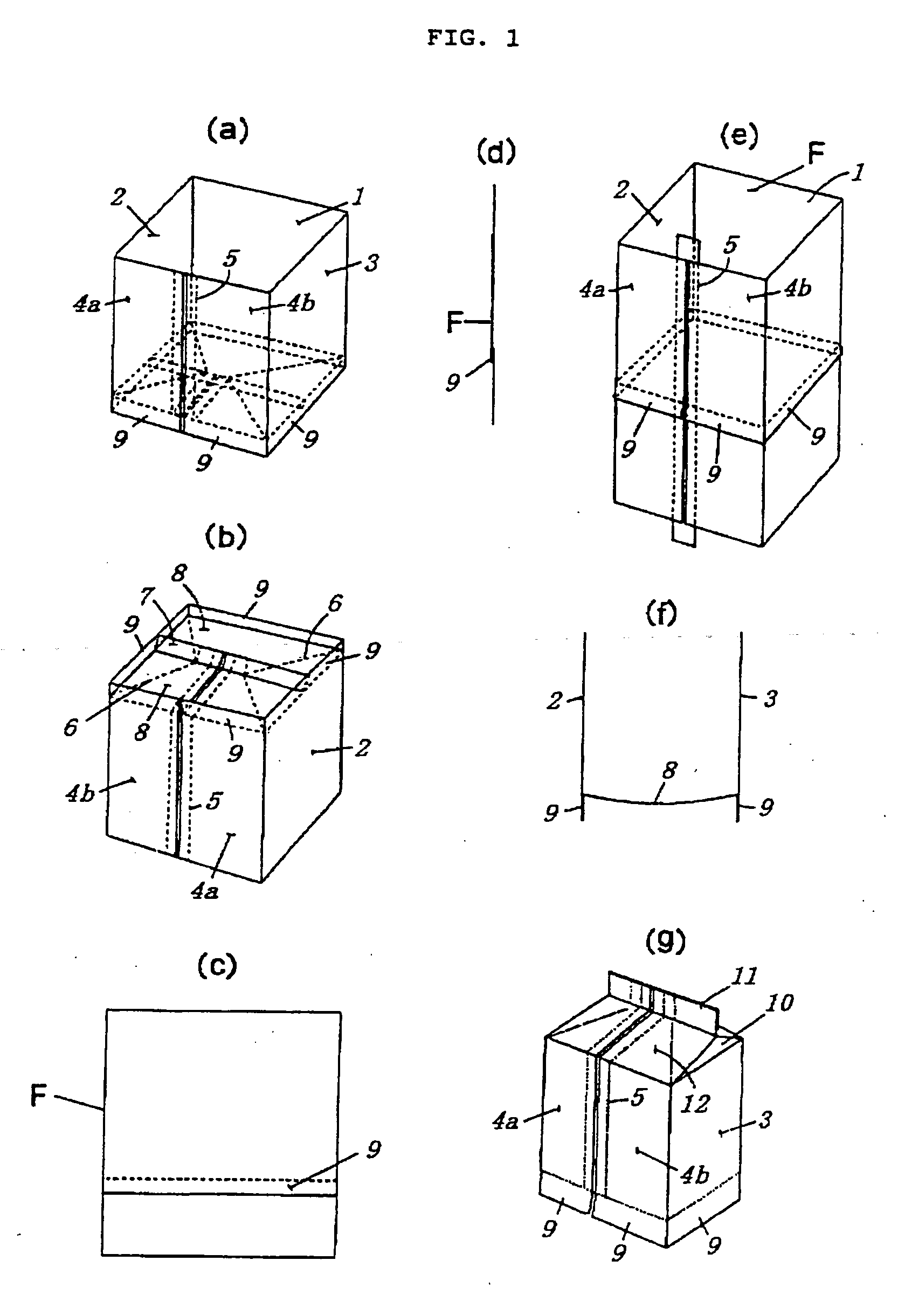

Self-standing packaging bag, packaging body, web roll, and manufacturing method therefor

InactiveUS20050069230A1Quality improvementStably stand upEnvelopes/bags making machineryBag making operationsEngineeringPack material

A stand-up packaging pouch manufactured in three-dimensional form or flattened form and provided with at least front face portion and rear face portion sides formed from packaging material having a pleat which is formed by folding a part of the packaging material in a three-fold strip form and adhering the inner faces of this folded part is constituted such that when the pouch is opened out into three dimensions, the pleat, formed in the same plane as the peripheral face portion, is positioned at a substantial right angle to a bottom face portion, thereby concealing the bottom face portion.

Owner:CHOKOKU PLAST CORP

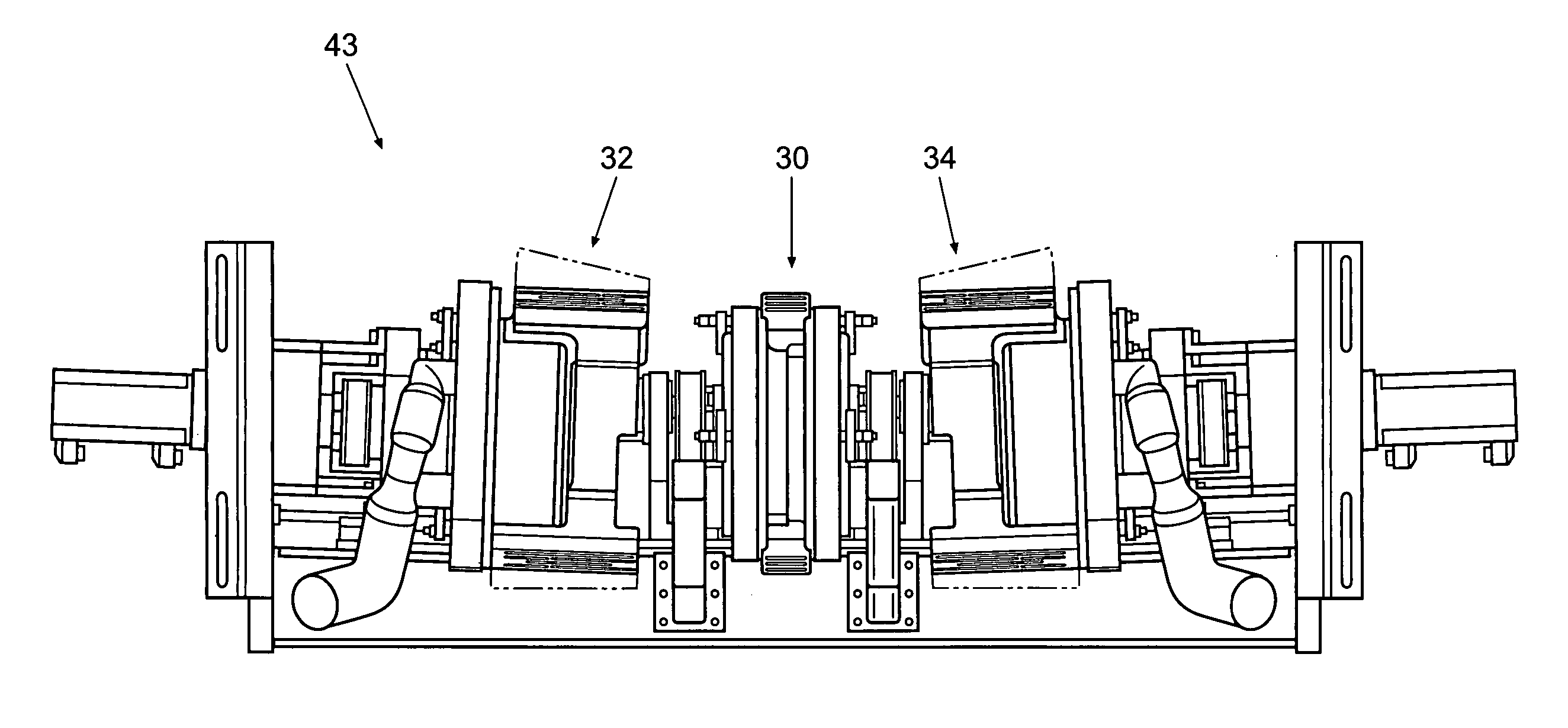

Article transfer and placement apparatus

An apparatus for transferring articles such as absorbent cores or disposable diaper chassis components from a rotary mechanism, such as a pad turner, to a linear mechanism, such as a conveyor, for further processing. The invention provides a device for picking an article from the outside of a toroidal surface, thence extending transversely under tension the article to be transferred so that at the point of deposition the article is held flat and at full length. Further, the invention allows for apparatus to match the velocity of both the first and second transfer points, even if these velocities are not the same. The device is of particular benefit where an article to be transferred is subject to internally biasing elastic forces.

Owner:CURT G JOA

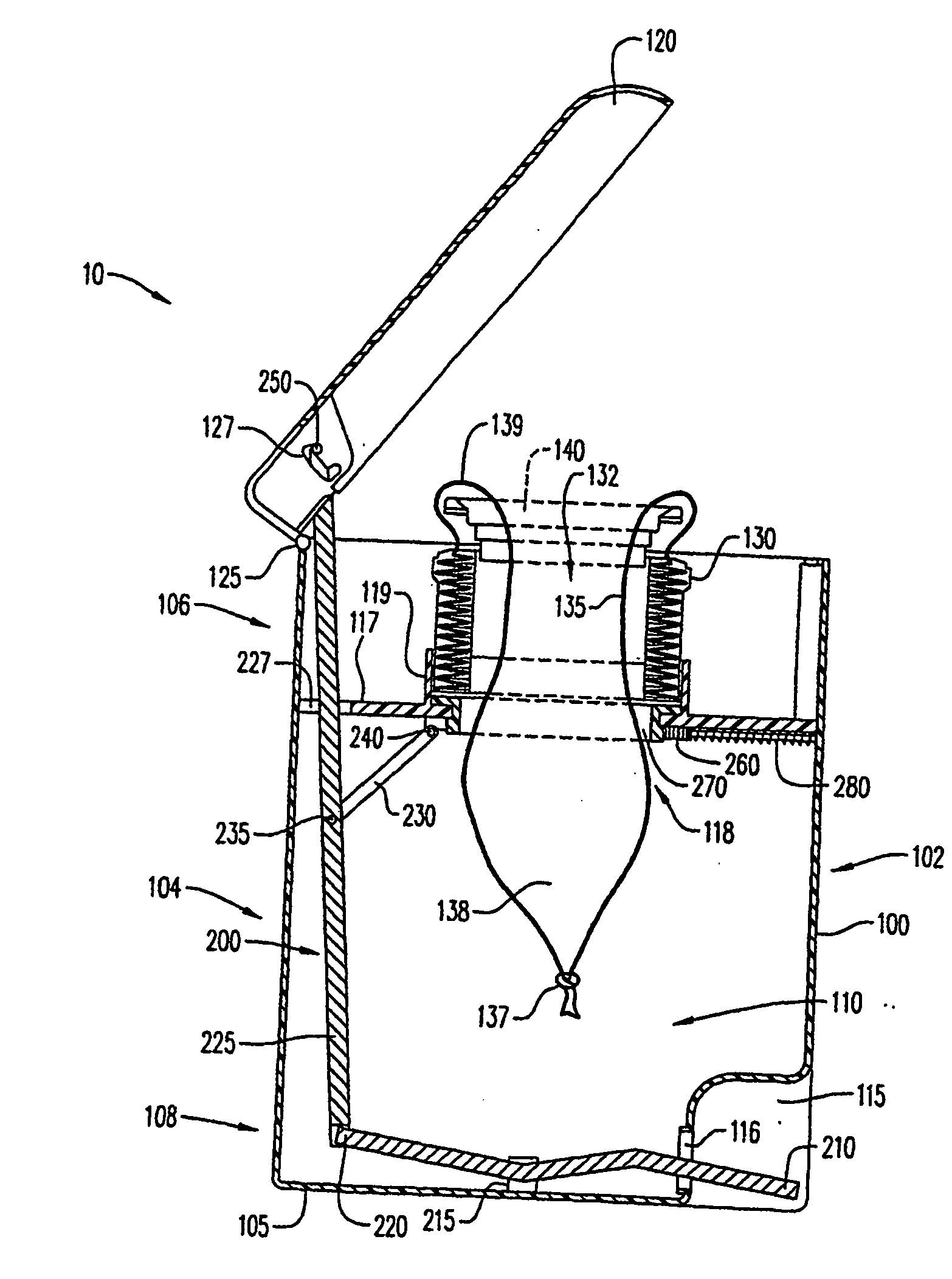

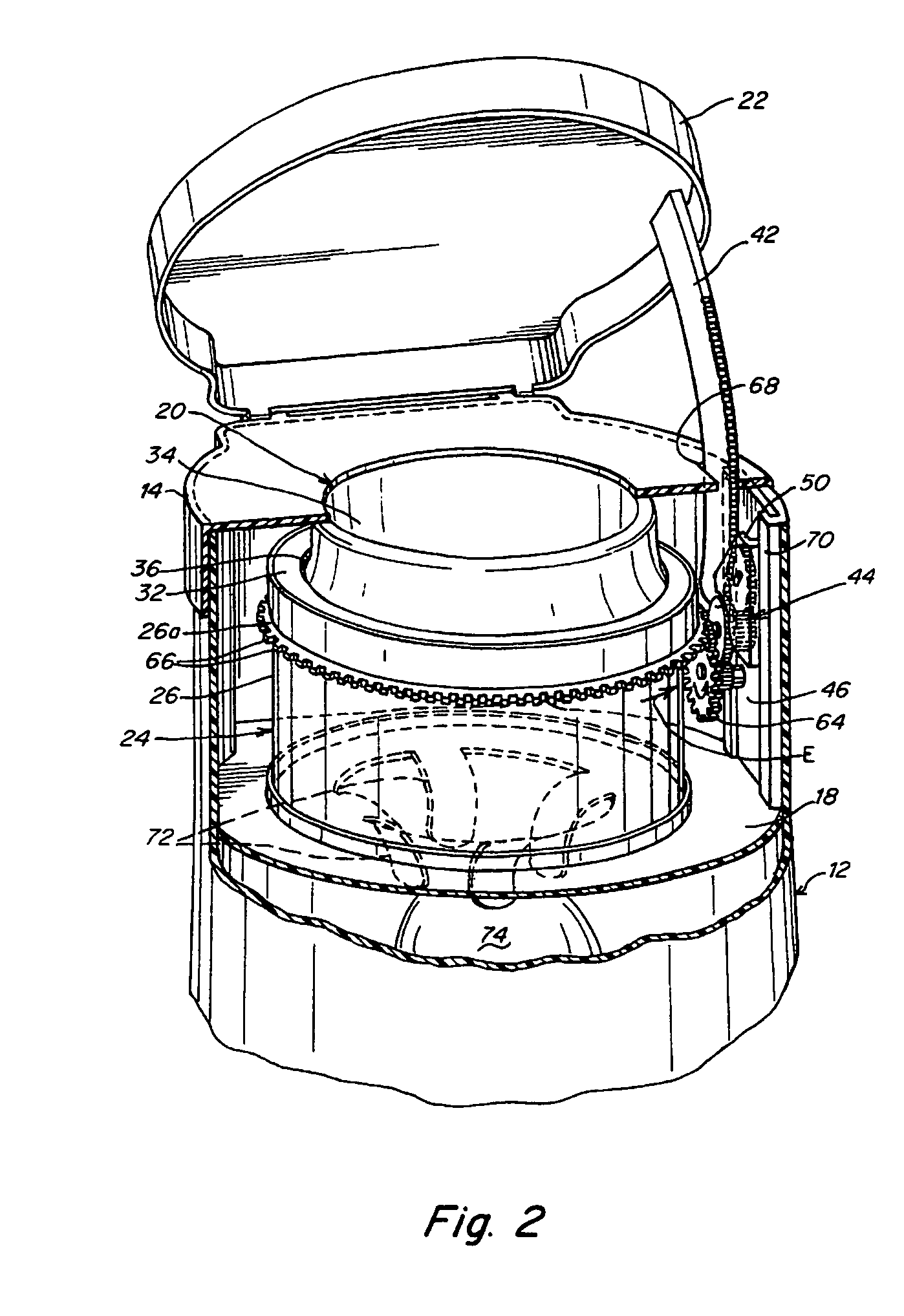

Waste disposal device including a film cutting and sealing device

InactiveUS7316100B2Effectively contains and prevents the release of odors from waste packagesEasy to disassembleWrapper folding/bending apparatusRefuse receptaclesThin membraneBiological activation

An integrated cutting system for a waste disposal device comprising a waste storage receptacle and a film cutting and sealing device. A cartridge containing a continuous length of film is positioned over the receptacle. The integrated cutting system further includes an activation mechanism operatively configured to alternatively engage a cutting device or a film sealing device capable of twistably sealing the film of the cartridge when the film is dispensed from the cartridge. A selection mechanism is arranged to control the activation mechanism to either engage the cutting device while deactivating the film sealing device, or to engage the film sealing device while deactivating the cutting device. The cutting device comprises a blade positioned to sever the film from the cartridge.

Owner:ANGELCARE USA LLC

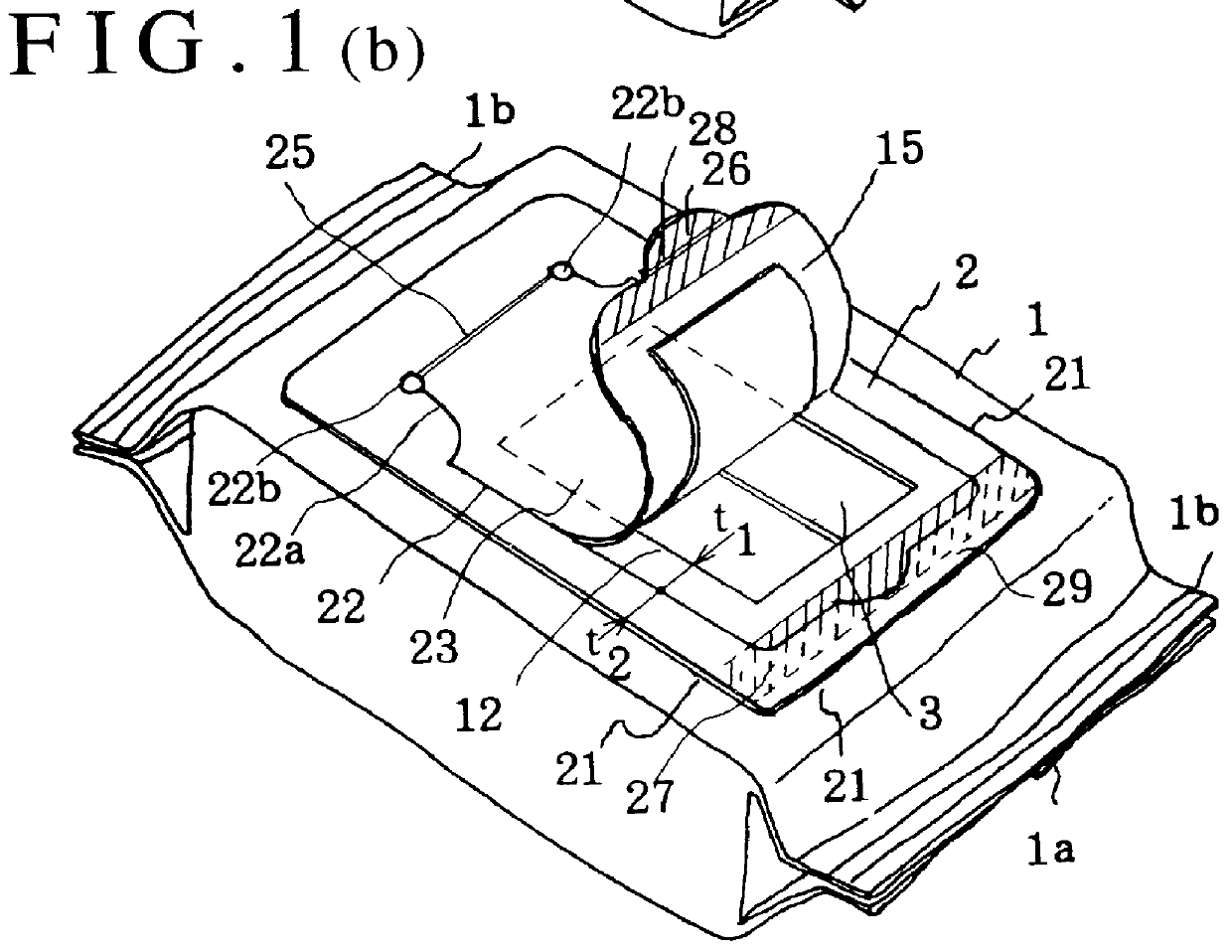

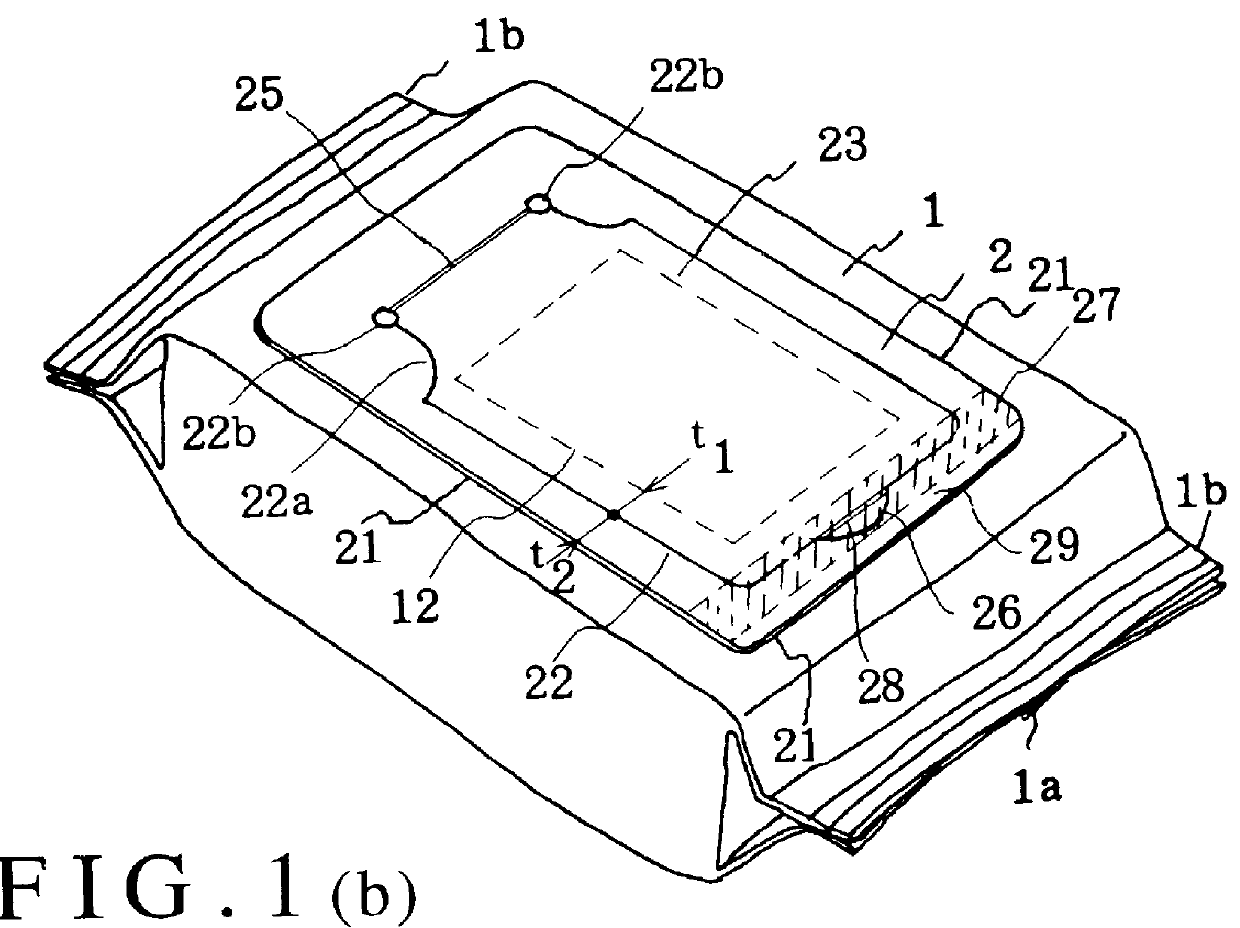

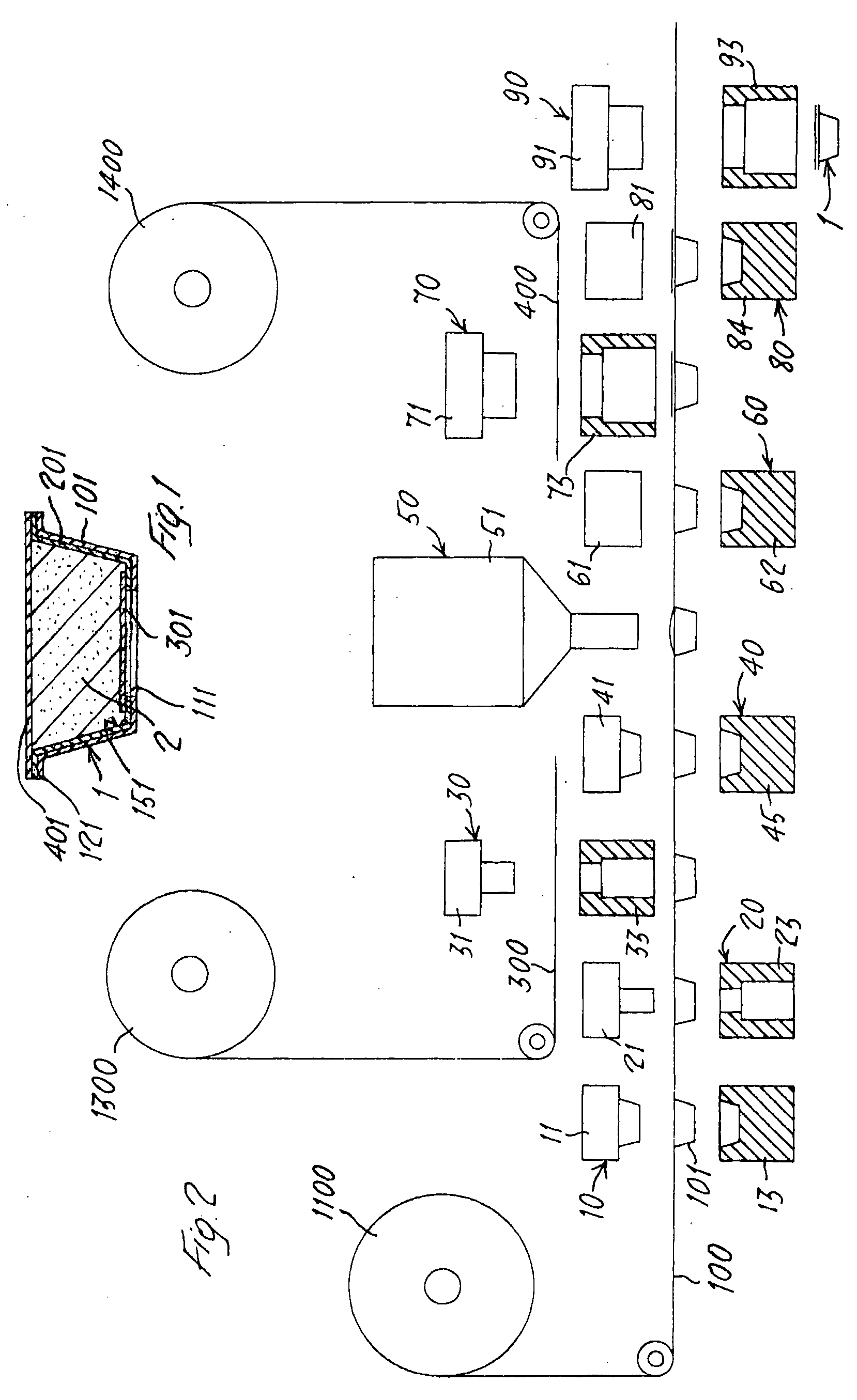

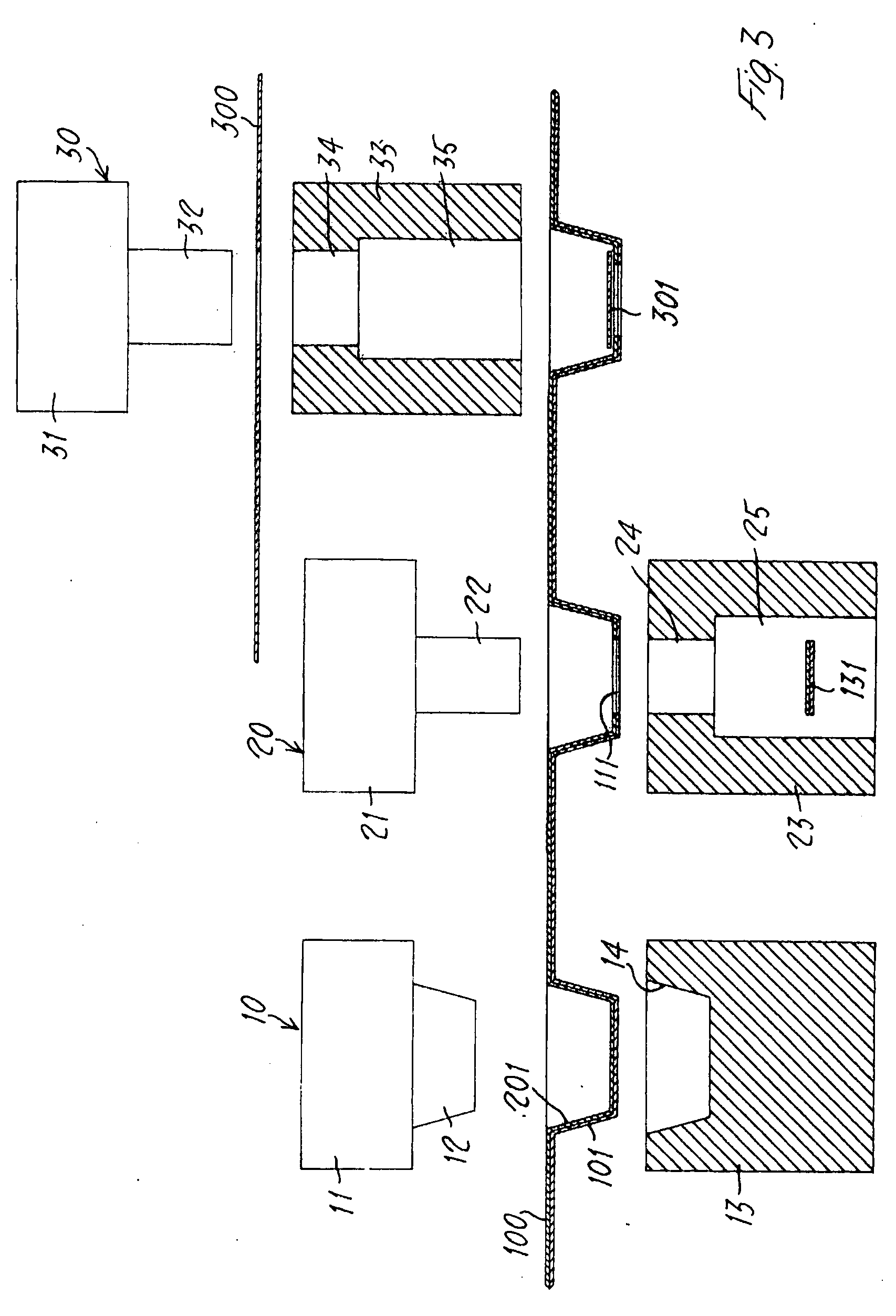

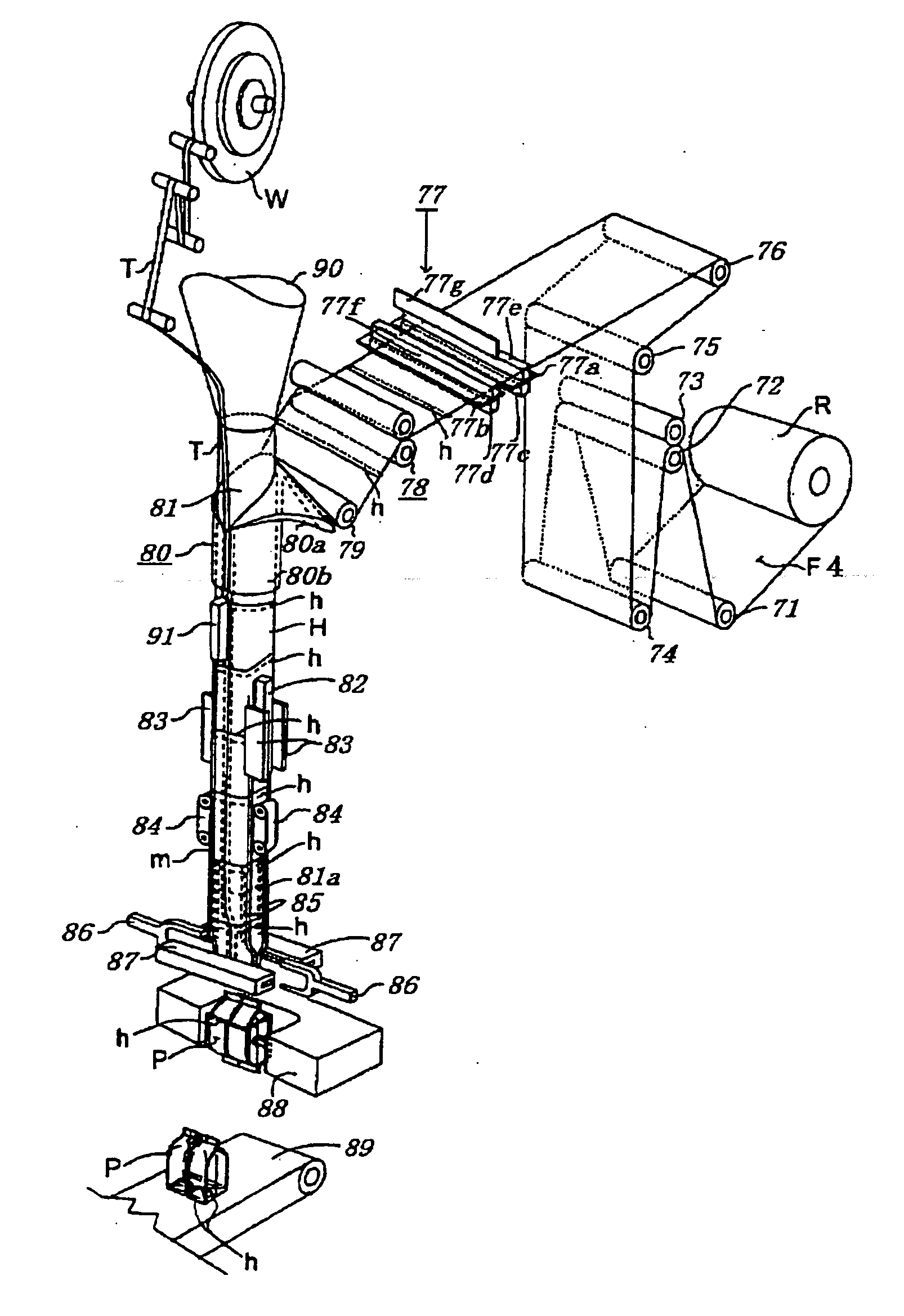

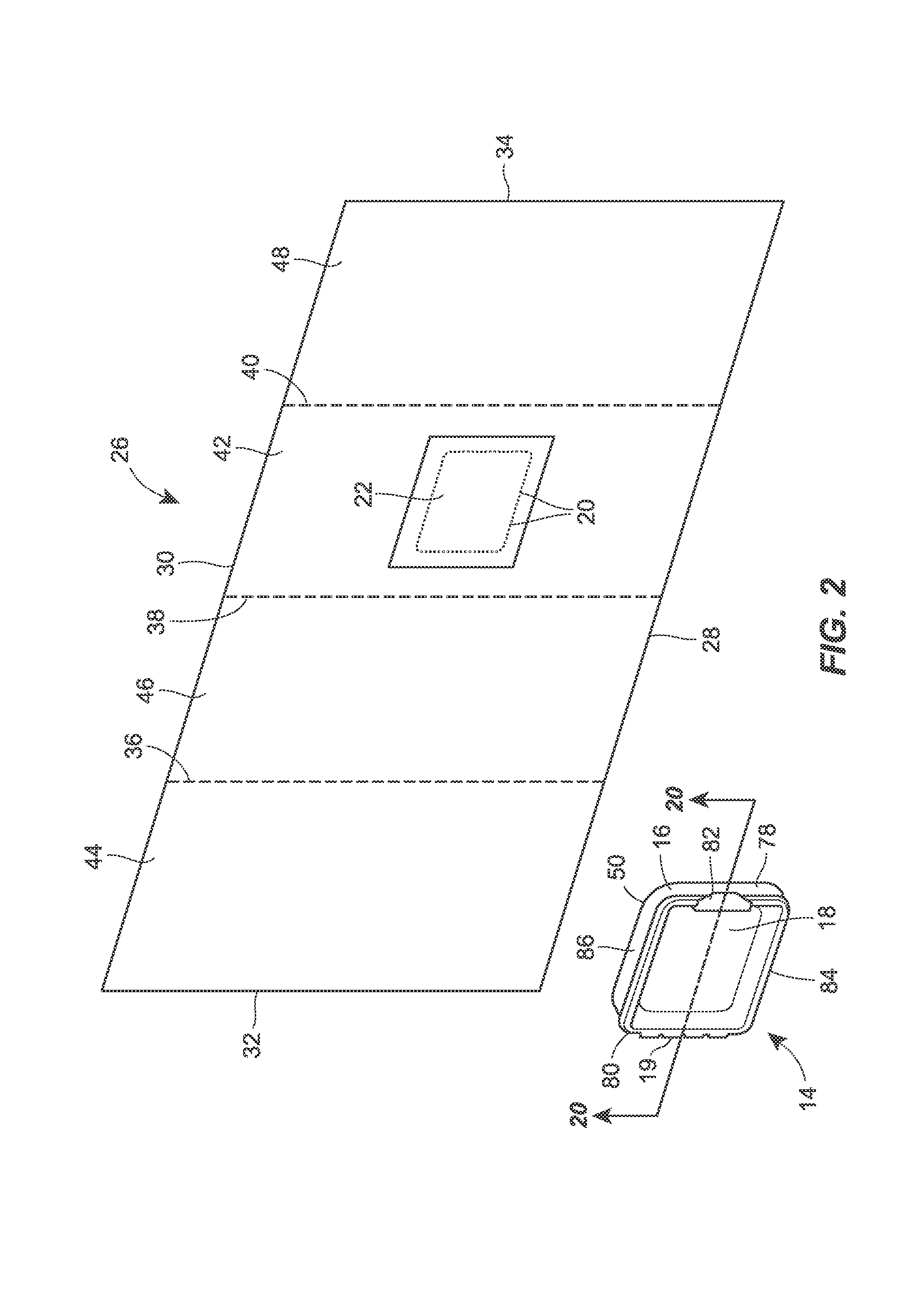

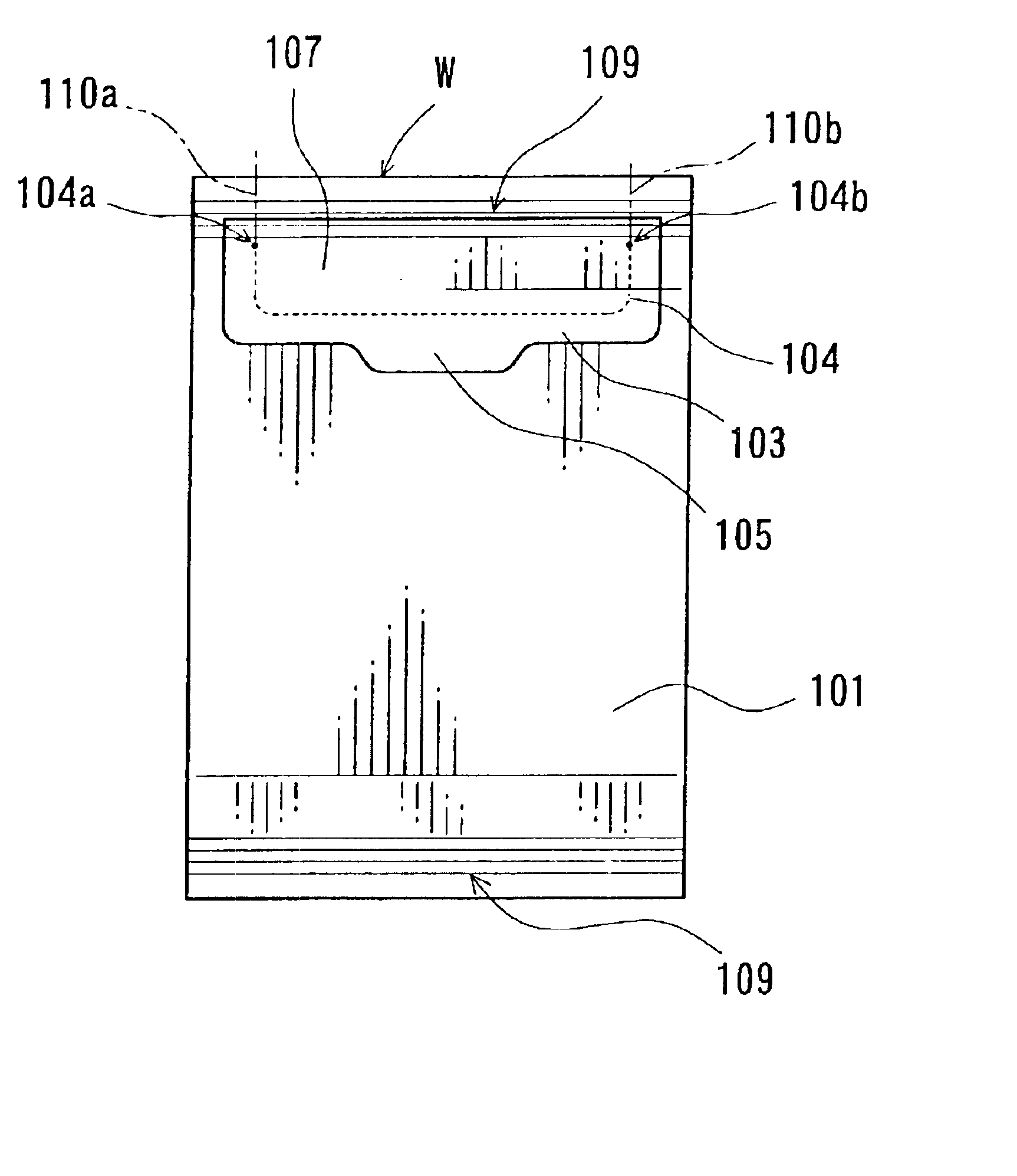

Form-fill sealing machines, resealable flexible packages and methods of manufacturing resealable flexible packages

InactiveUS6865860B2Hinders its propagationReliable stopWrapping material feeding apparatusBagsHermetic packagingEngineering

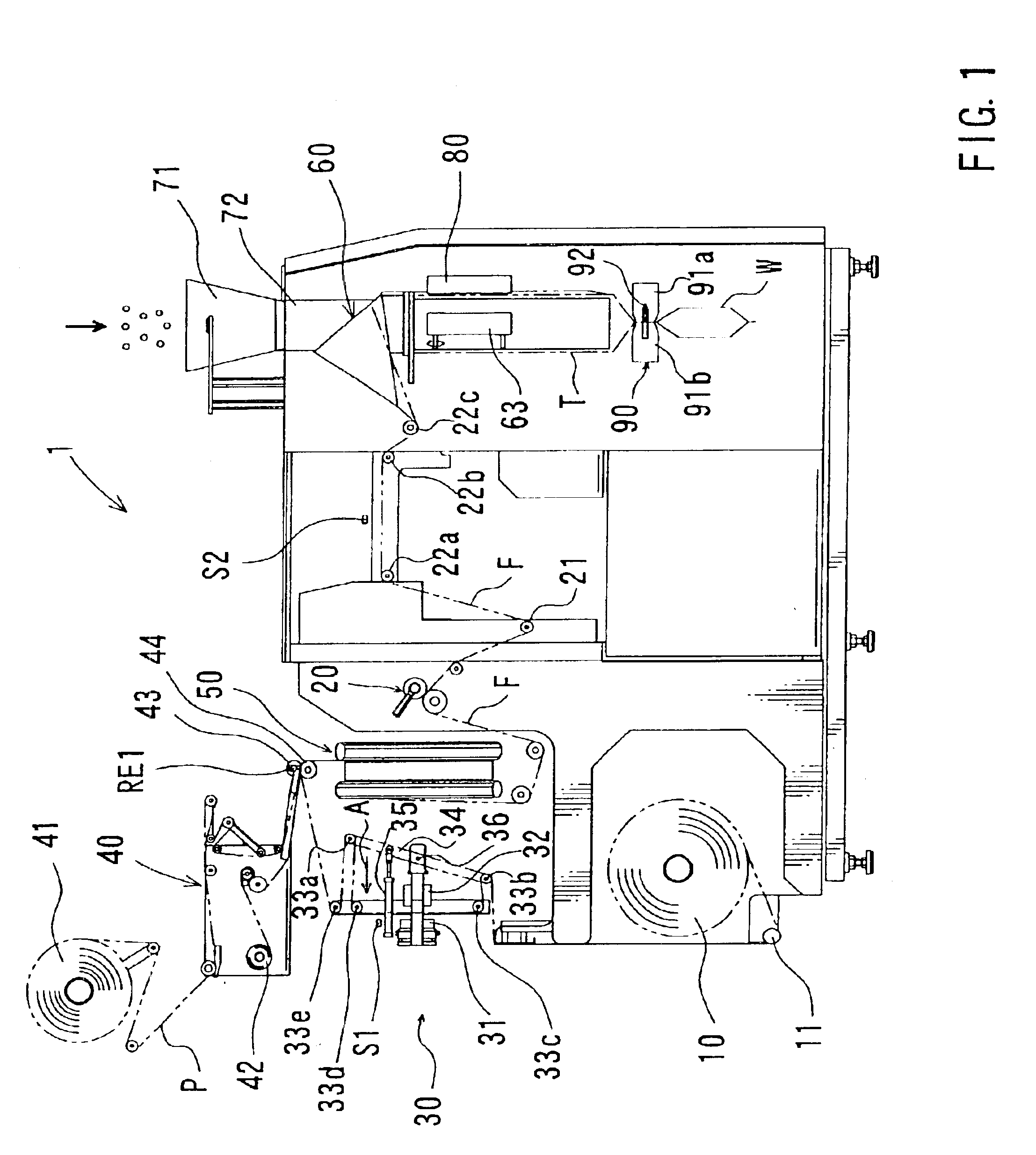

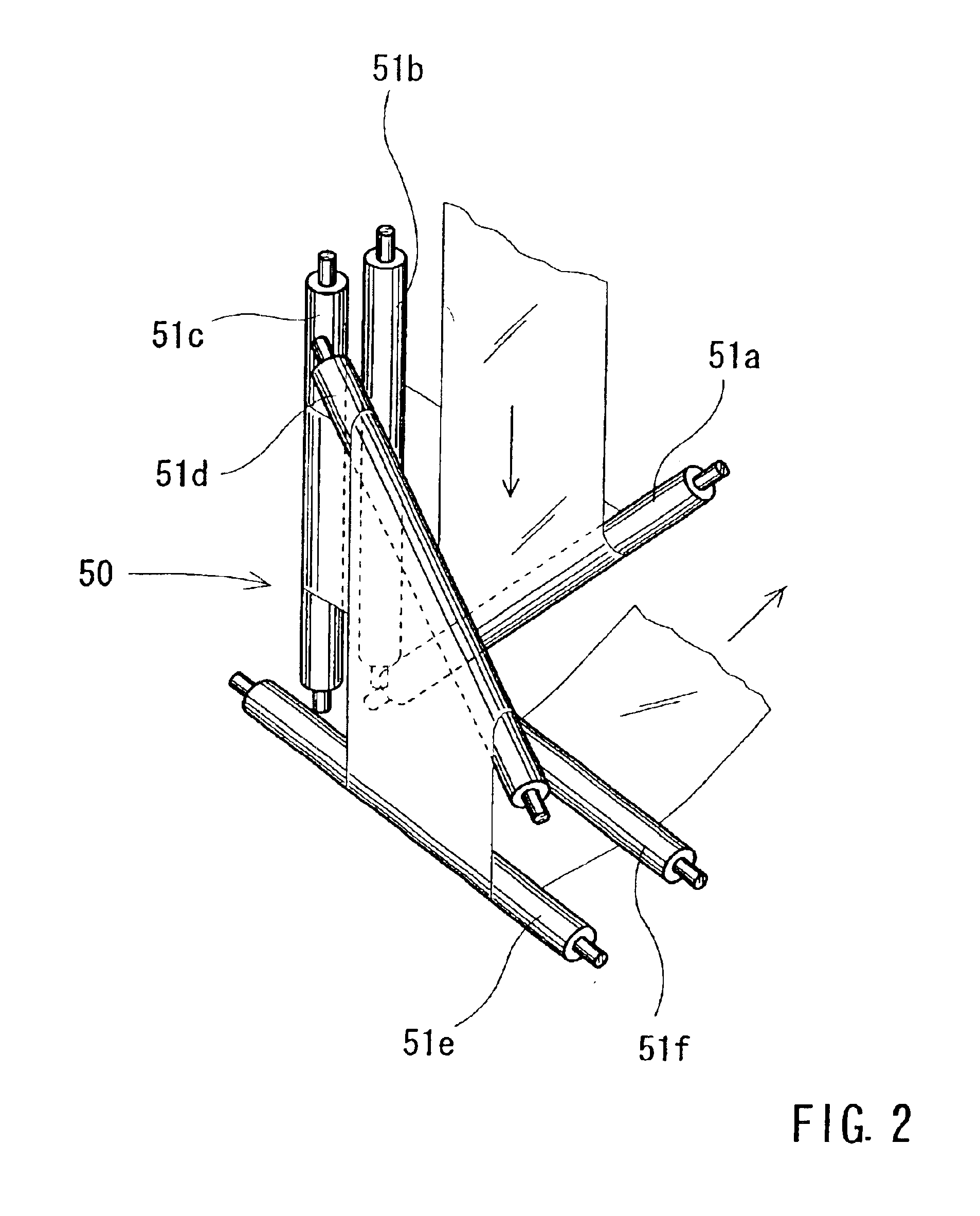

A form-fill sealing machine (1) for manufacturing resealable packages (W) includes a tearable line forming device (30) that serves to form tearable lines (104) in a film (F). A labeling device (40) serves to stick re-stickable labels (103) onto the film in positions to cover respective tearable lines. A tube forming device (60) serves to form the film into a tubular film (T). A first sealing device (80) serves to seal lapped edges of the tubular film so as to form a lengthwise sealed portion (111). A second sealing device (90) serves to seal the tubular film in a crosswise direction, so that crosswise sealed portions (109) are formed on the tubular film. Each tearable line is positioned between two adjacent crosswise sealed portions and adjacent to one of two adjacent crosswise sealed portions.

Owner:FUJI KIKAI KK

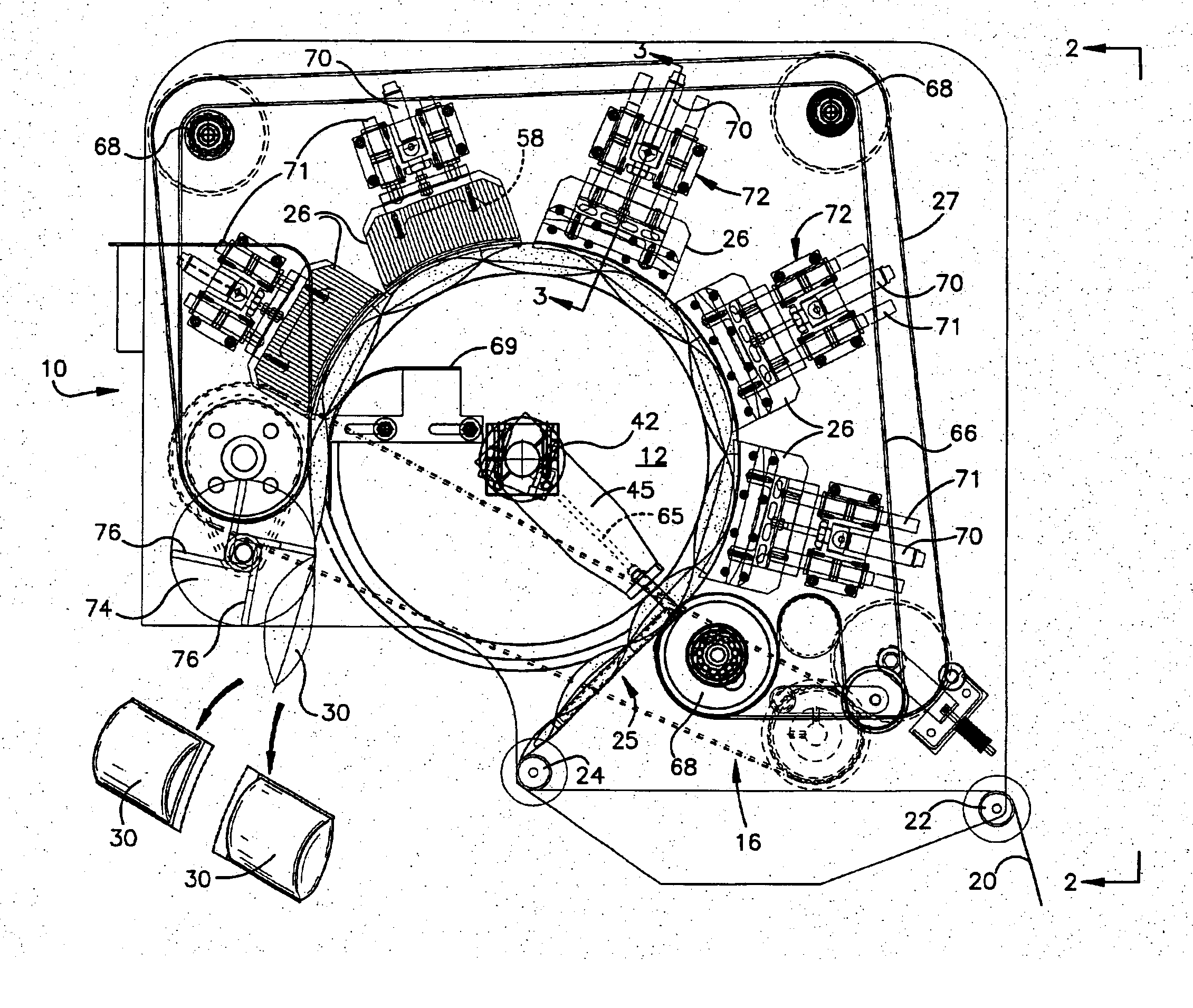

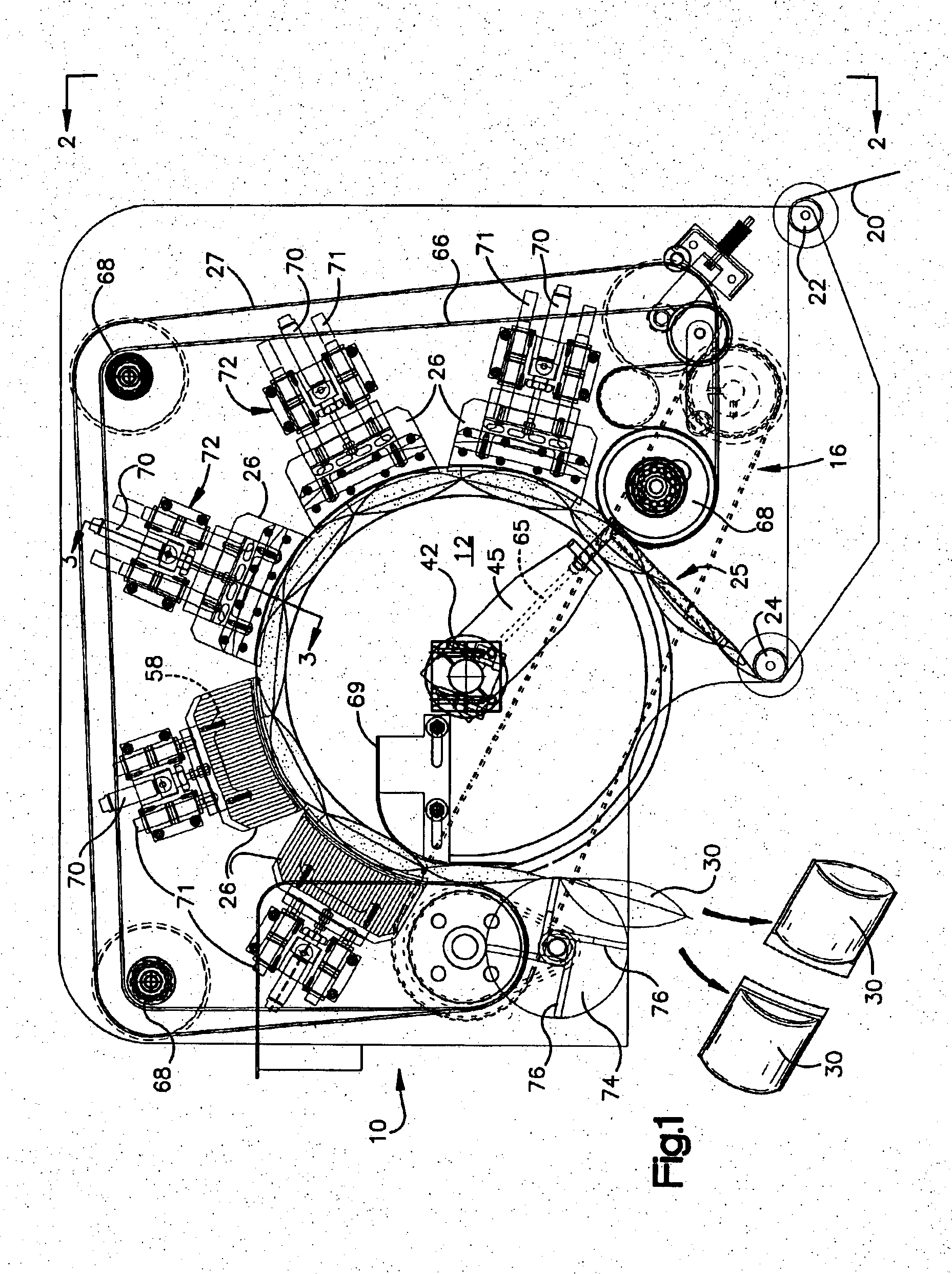

Fluid filled unit formation machine and process

A machine for the manufacture of inflated plastic dunnage and other fluid filled units is disclosed. In a disclosed and pictured dunnage embodiment, the machine includes a hollow shaft rotatably mounted on a frame. In the preferred embodiment the shaft is solid. With either embodiment a drive is operably connected to the shaft for causing the shaft to rotate about its axis and a drum mounted on the shaft to rotate with the shaft. The drum is in the form of a pair of closely spaced discs having perimetral, cylindrically contoured sealing surfaces for support and, in cooperation with driven metal belts, transport of a web being formed into dunnage units. Sets of heating and cooling shoes having spaced arcuate surfaces are complementally positioned adjacent the drum surfaces with the cooling shoes downstream from the heating shoes in the direction of dunnage formation rotation. A nozzle is mounted generally tangentially of the drum at a location midway between the discs. Each of the cooling shoes includes an air expansion chamber communicating through a shoe inlet when in use with a supply of air under pressure. In the hollow shaft embodiment one cooling shoe chamber has an outlet in communication with the nozzle via the shaft.

Owner:AUTOMATED PACKAGING SYST

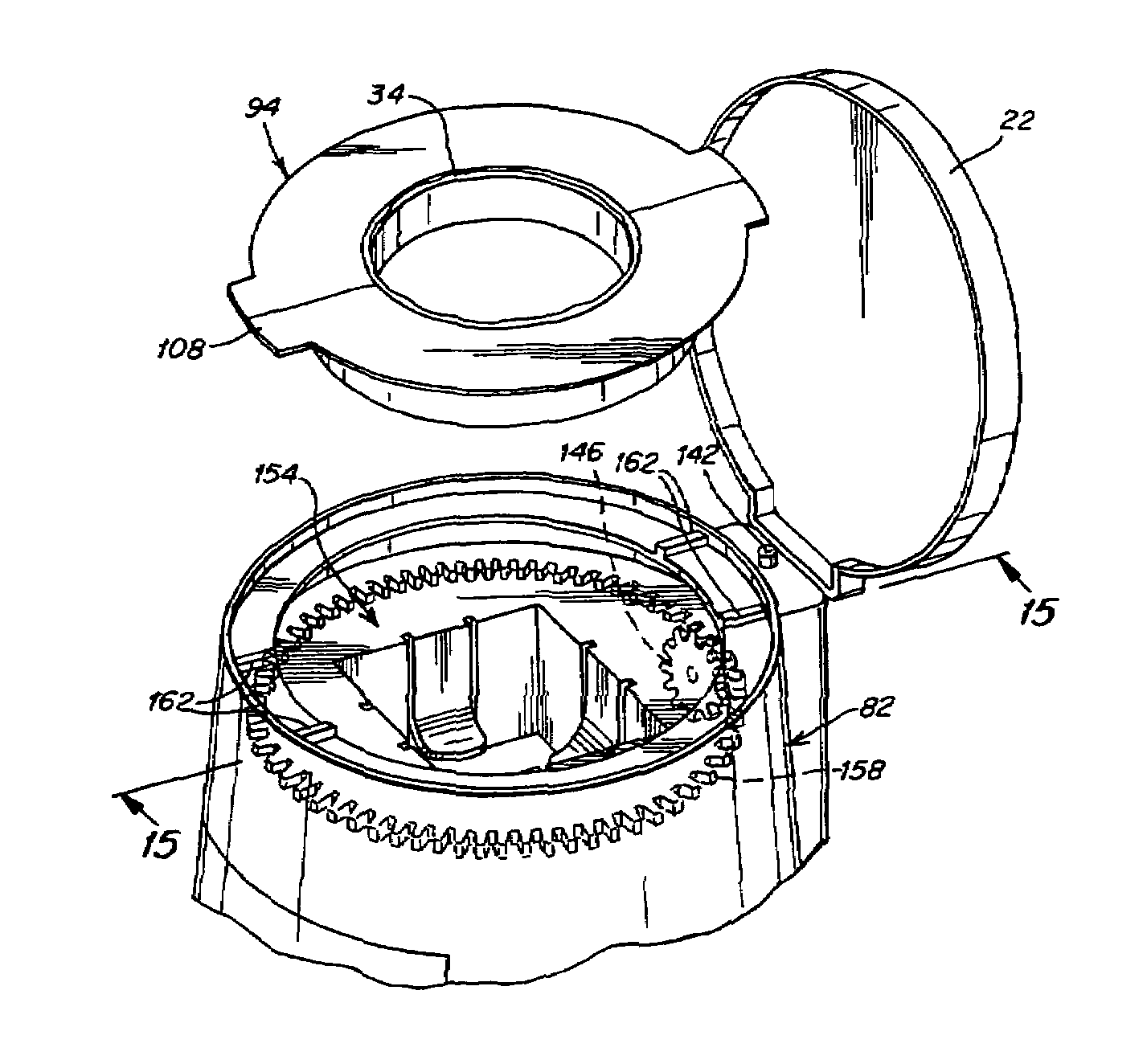

Waste disposal device including a rotatable geared rim to operate a cartridge

InactiveUS7434377B2Effectively contains and prevents release of odorEasy to disassembleRefuse receptaclesSolid materialFlangeWaste disposal

A waste disposal device has a rotatable geared rim to operate a cartridge. The device comprises a rotation mechanism. A flange supports a rotatable geared rim. The support flange is operatively configured to be driven by the rotation mechanism. The cartridge is also operatively configured to engage the geared rim so as to be capable of rotating with the support flange upon actuation of the rotation mechanism.

Owner:ANGELCARE USA LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com