Two Side Cut Reseal With Pressure Sensitive Adhesive and the Method for Making Same

a pressure sensitive adhesive and two-sided cutting technology, applied in the field of flexible bags, can solve the problems of complicated packaging manufacturing, high cost of interlocking strips, zippers or sliders, etc., and achieve the effect of preventing premature deterioration of quality and preventing damage to the contents within the bag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

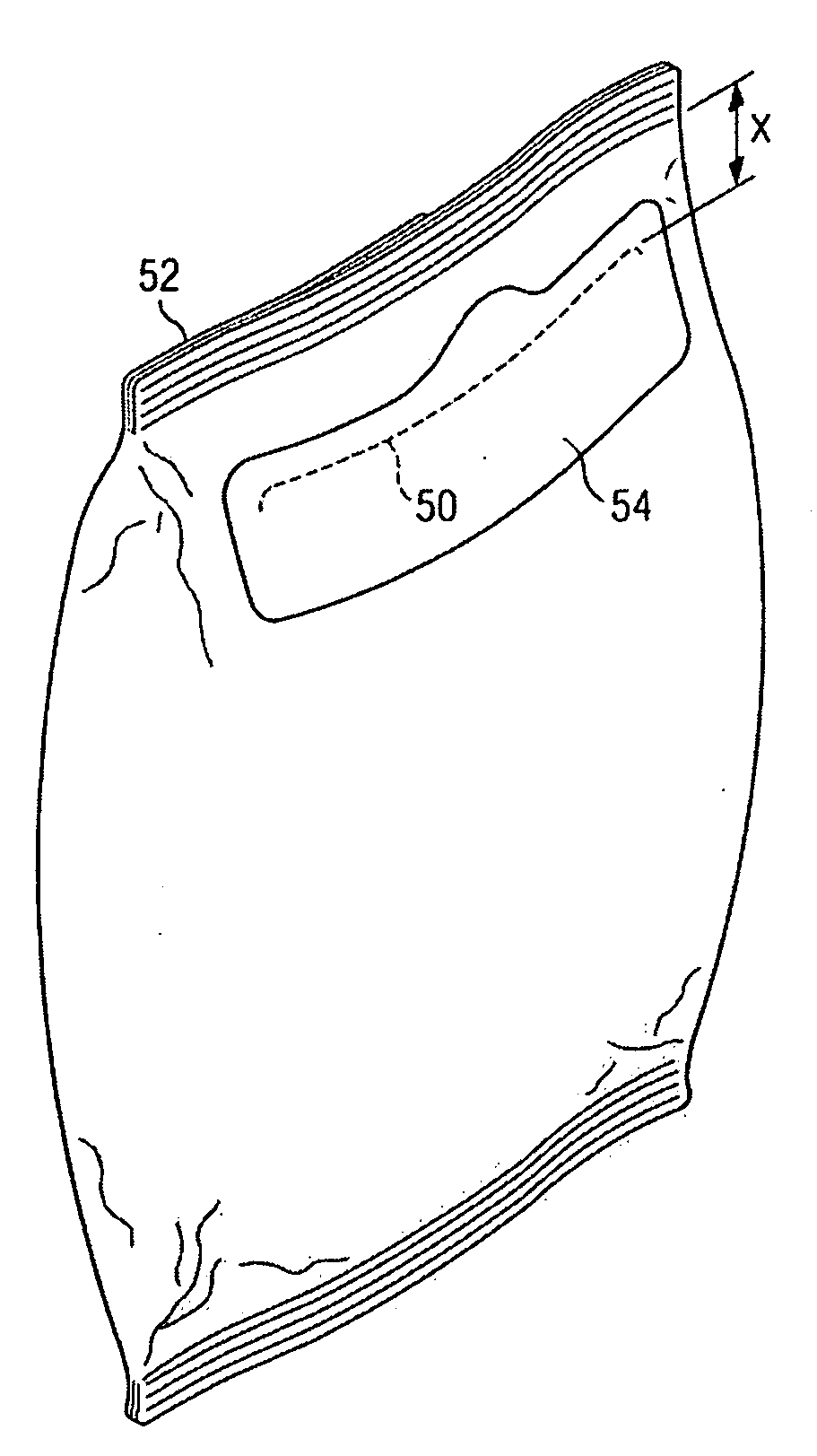

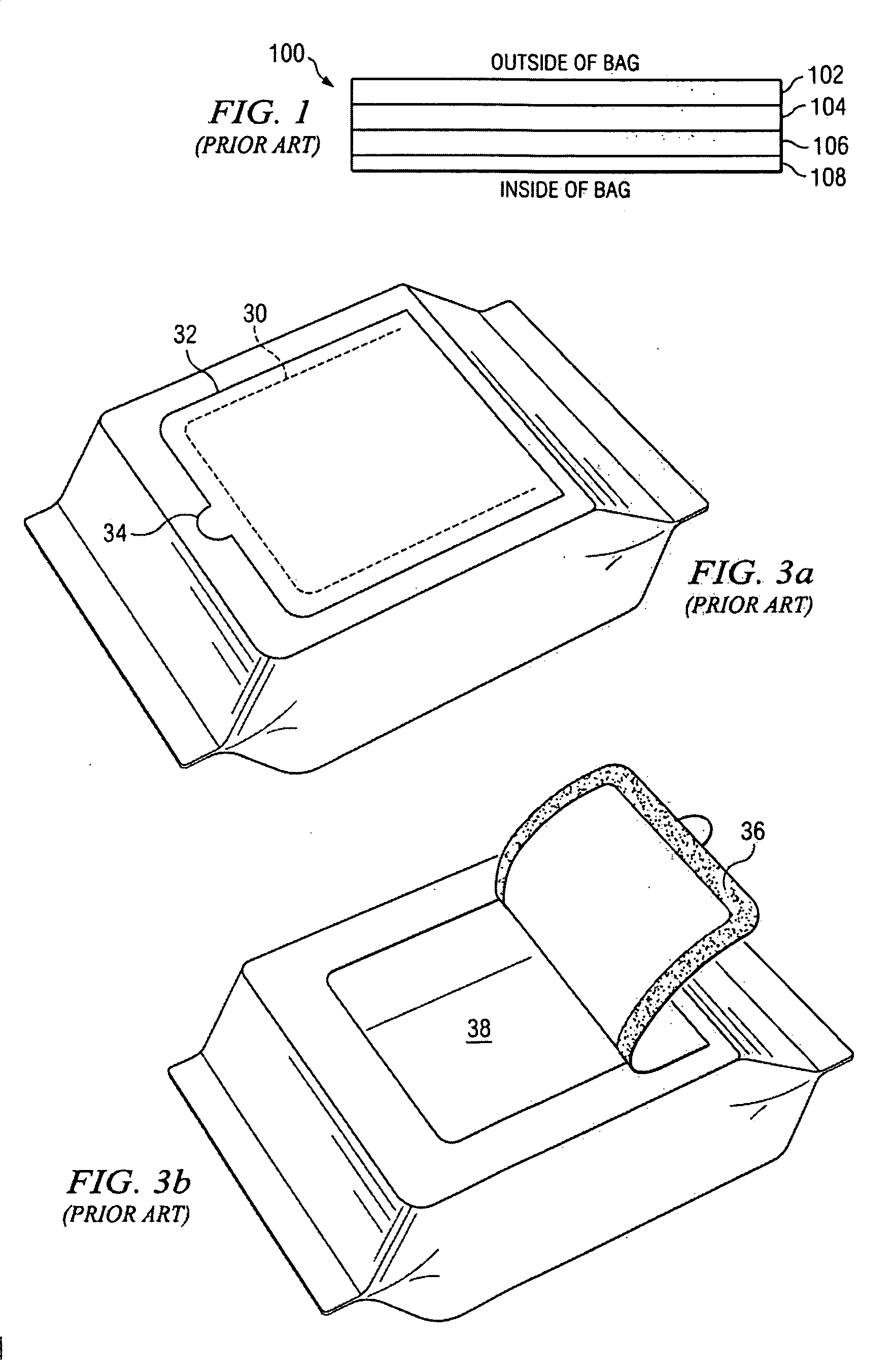

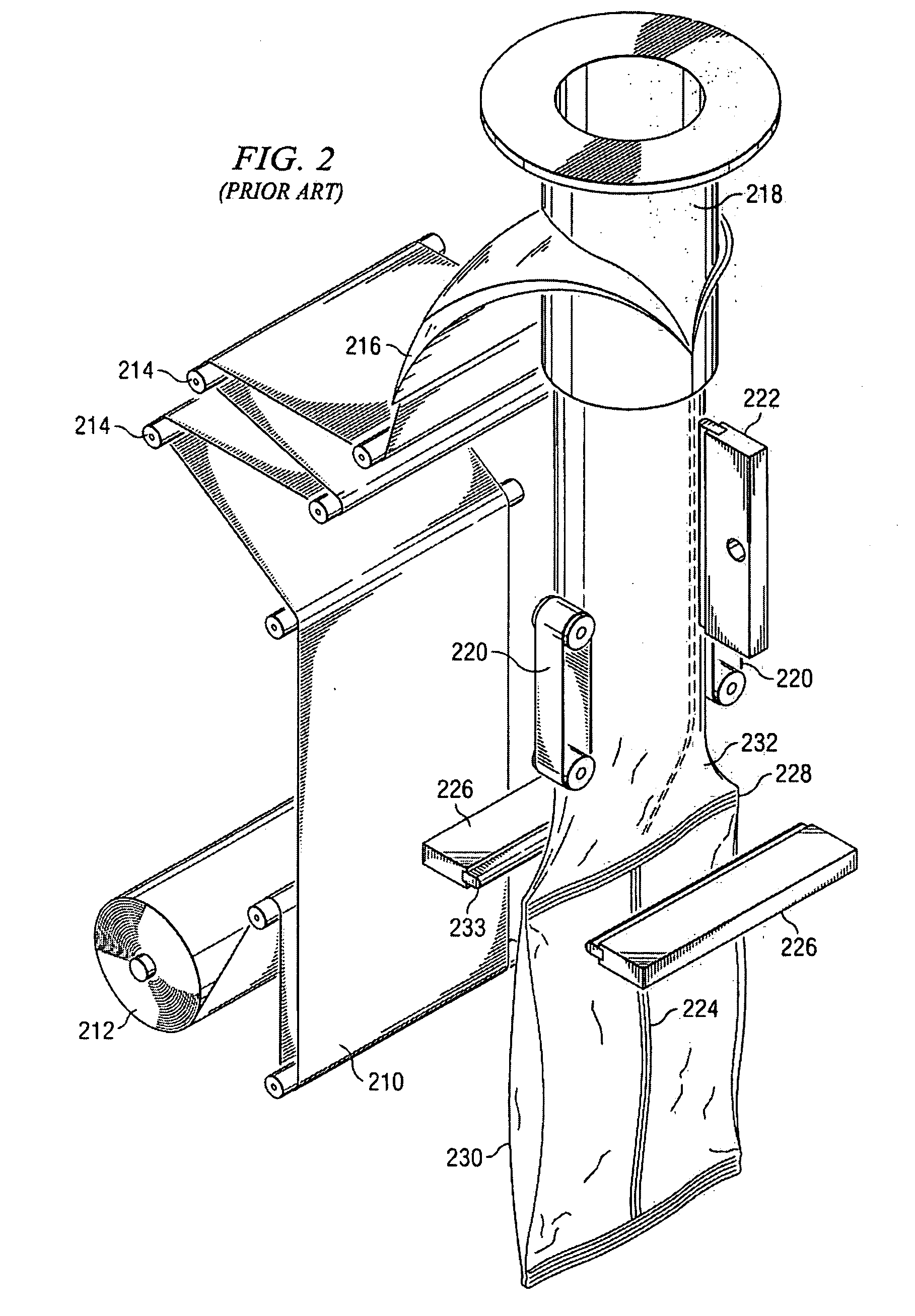

[0028]FIGS. 5 and 6 depict two embodiments of the package of the present invention, which may be closed after being opened (ie, resealed) to preserve moisture sensitive food products, including but not limited to snack chips. The packages are made using a vertical form, fill, and seal machine and a flexible packaging film having at least three layers. In a preferred embodiment, an adhesive layer is pattern applied in between outer and inner film layers, preferably a pressure sensitive adhesive is placed in between an outer and inner score line and forms a bond in between the outer and inner film layers when pressure is applied across the top portion of the resulting package. As described above, and as seen in FIG. 2, in a vertical form, fill, and seal machine, a length of plastic film is formed into a vertical tube around a product delivery cylinder. The vertical tube is vertically sealed along its length to form a back seal and is transversely sealed to form top and bottom seals de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com