Nonwoven pouch comprising heat sealable binder fiber

a non-woven, fiber-based technology, applied in the field of pouches, can solve the problems of affecting the biodegradability of the discarded pouch, the cost of applying conventional binders to the fibrous pouches, and the inability to meet the needs of packaging,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0076]The following non-limiting example describes how a nonwoven web and pouch can be made with monocomponent PLA fibers as the heat sealable binder fiber.

[0077]PLA and Rayon fibers are provided having 1.5 dtex, 40 mm length, 7 crimp / cm and 4 g / den tenacity. The fibers are blended in varying ratios by weight (PLA:Rayon). Each blended fiber is carded, which produces webs with parallel fiber orientation. The PLA and Rayon blended material is thermally bonded with heated calendar rolls with an embossed pattern to apply pressure at controlled areas of the fleece. Less than 30% of the fleece is point bonded.

[0078]The fabric is heat sealed. The heat seal is measured in the machine direction using a peel test. It is found that a higher percentage of PLA results in a stronger heat seal.

example 2

[0079]The following non-limiting example describes how a nonwoven web can be made with blended PLA fibers as the heat sealable binder fiber.

[0080]PLA:Viscose fibers are provided having 1.5 dtex, 40 mm length, 7 crimp / cm and 4 g / den tenacity. The fibers are blended in the following ratios by weight (PLA:Viscose): (a) 50:50; and (b) 60:40. The fleece fabric target weight is 30 gsm.

[0081]Each blended fiber is carded on a Erko Trüzschler Card machine.

[0082]Each blended fiber is hydroentangled with a machine having 1 pre-wetting nozzle and 4 bonding injectors (nozzles). The size of the nozzles change from 7-14 microns. Pressure is 15 bars for pre-wetting and 0-130 bars for bonding nozzles. The hydroentangling machine can include embossed drum surfaces and / or aperture drum surfaces. For fabrics with a basis weight of about 30 gsm, the line speed is 100 m / min. For fabrics with a basis weight of about 90 gsm, the line speed is 30 m / min.

[0083]The hydroentangled web then undergoes an ultrason...

example 3

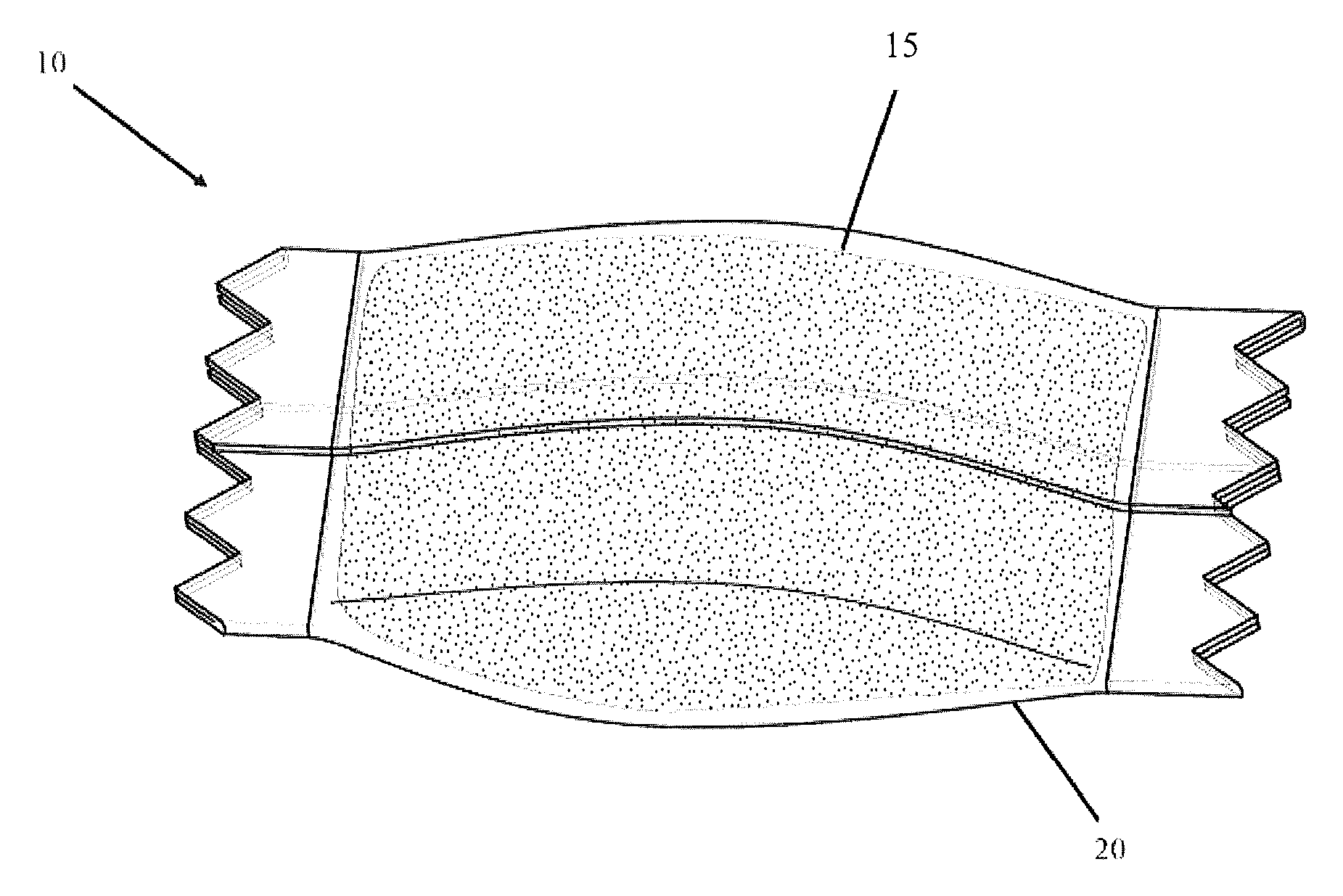

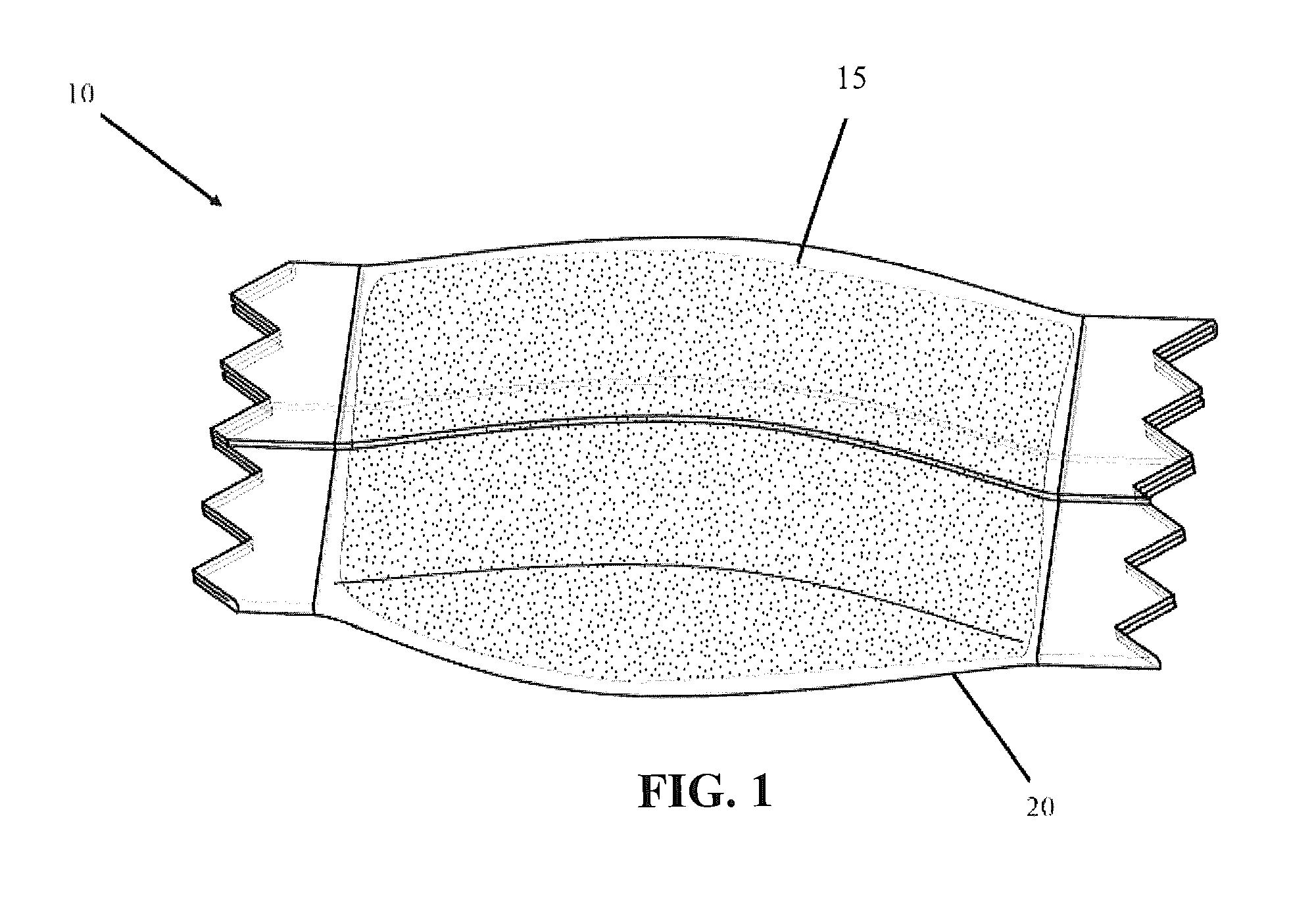

[0084]The following non-limiting example describes pouches formed from the hydroentangled web formed according to Example 2 above.

[0085]Rolls of the hydroentangled fabric made according to Example 2 above and measuring about 30-31 mm in width are provided. Pouches are formed from the nonwoven fabric on a Merz machine.

[0086]The pouches are able to be sealed appropriately. However, the nonwoven fabrics incorporating the PLA heat sealable binder encountered elongation and shrinkage problems. Accordingly, rolls of the nonwoven fabric measuring about 41 mm-45 mm in width are used to account for the fabric shrinkage. In addition, one or more surfaces of the pouching equipment that come in contact with the nonwoven material (e.g., rollers, cutting instruments, sealing devices, etc.) can be coated with Teflon to counteract any tackiness or stickiness that may be associated with certain embodiments of the nonwoven fabric of the invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com