Patents

Literature

187results about "Labelling non-rigid containers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

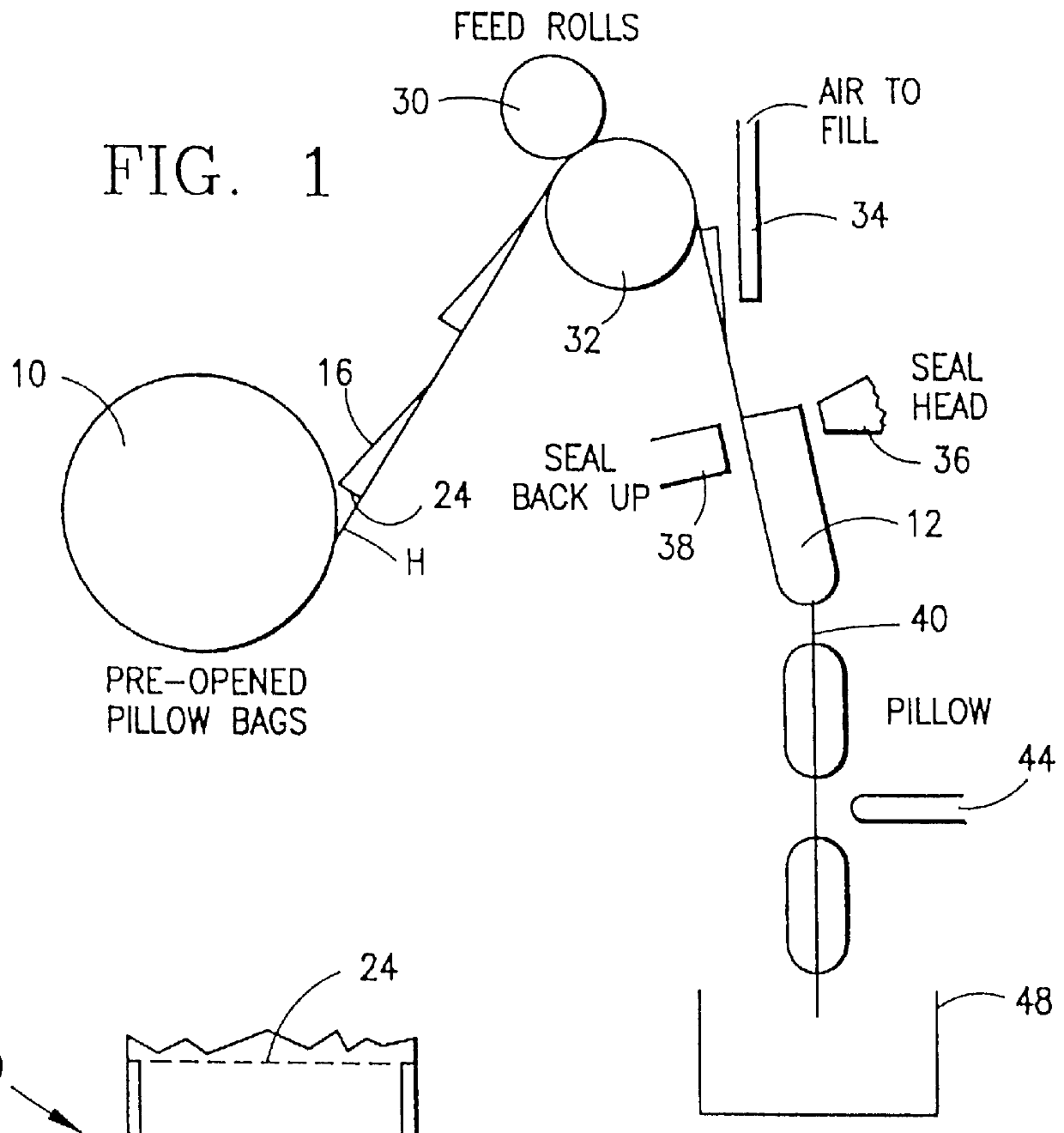

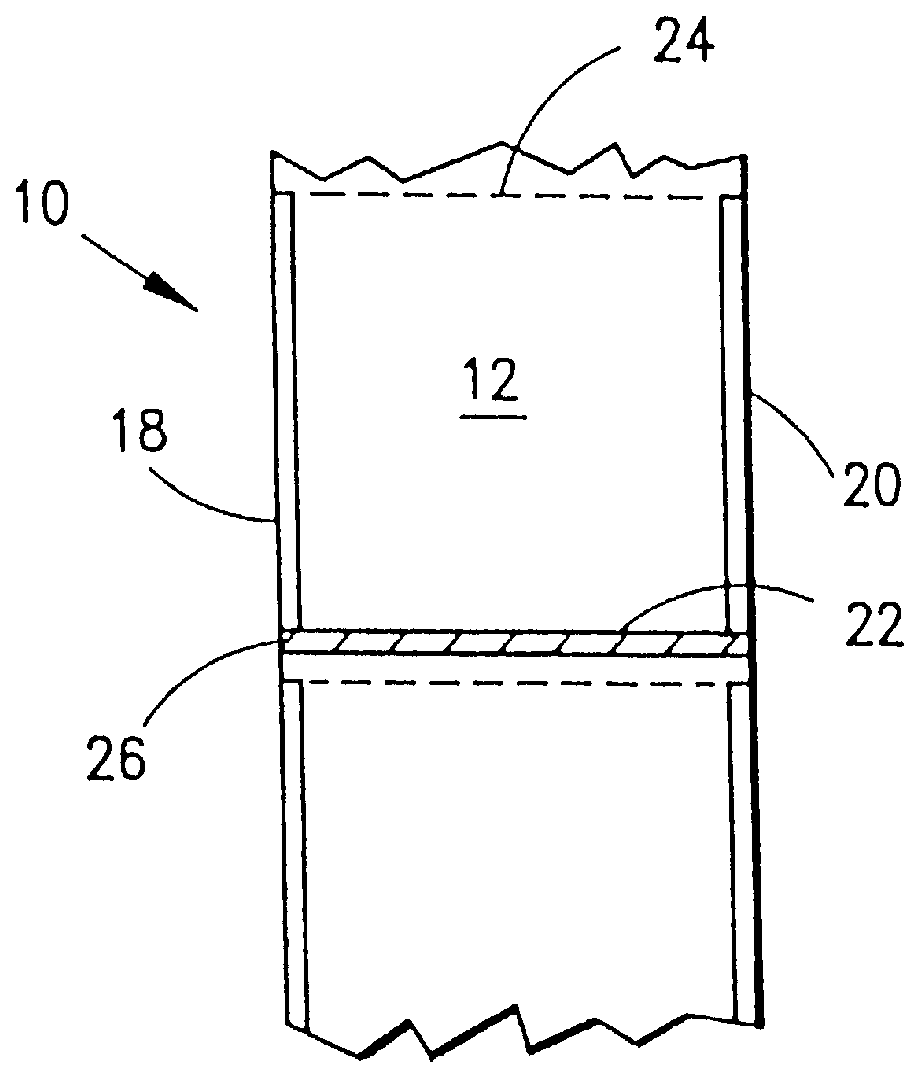

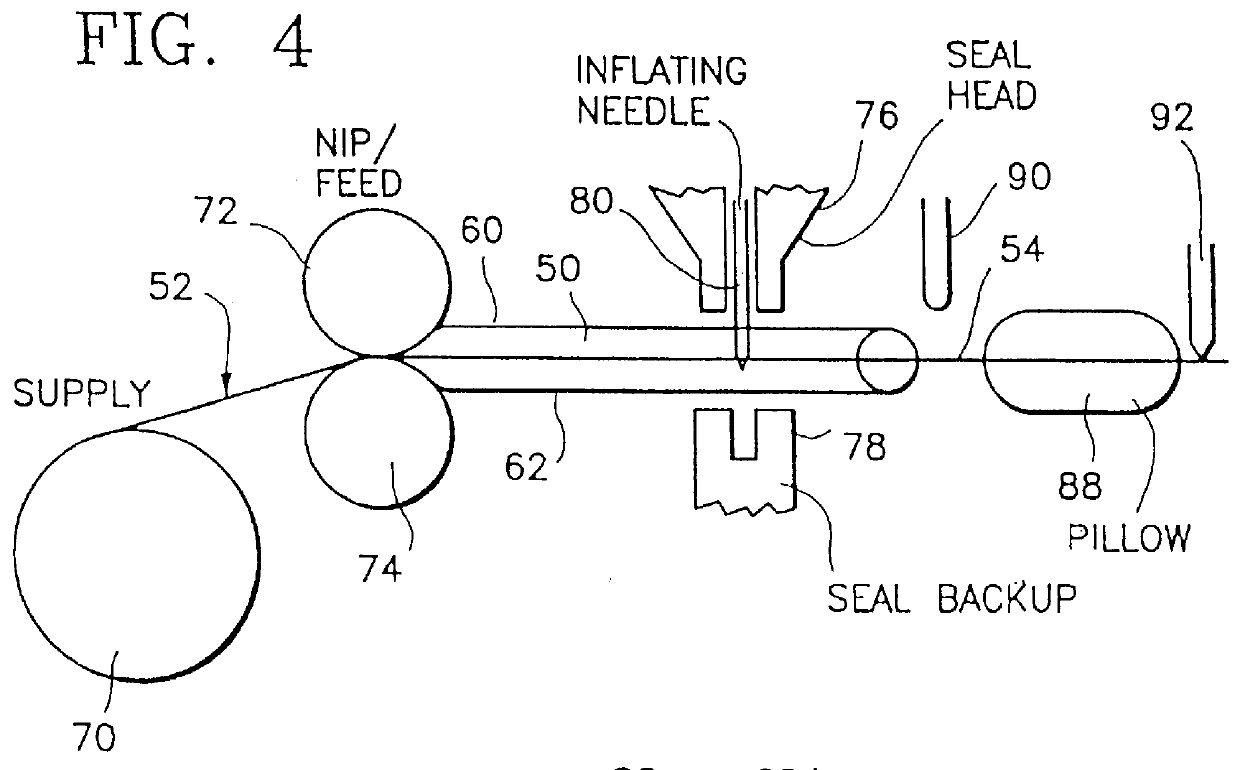

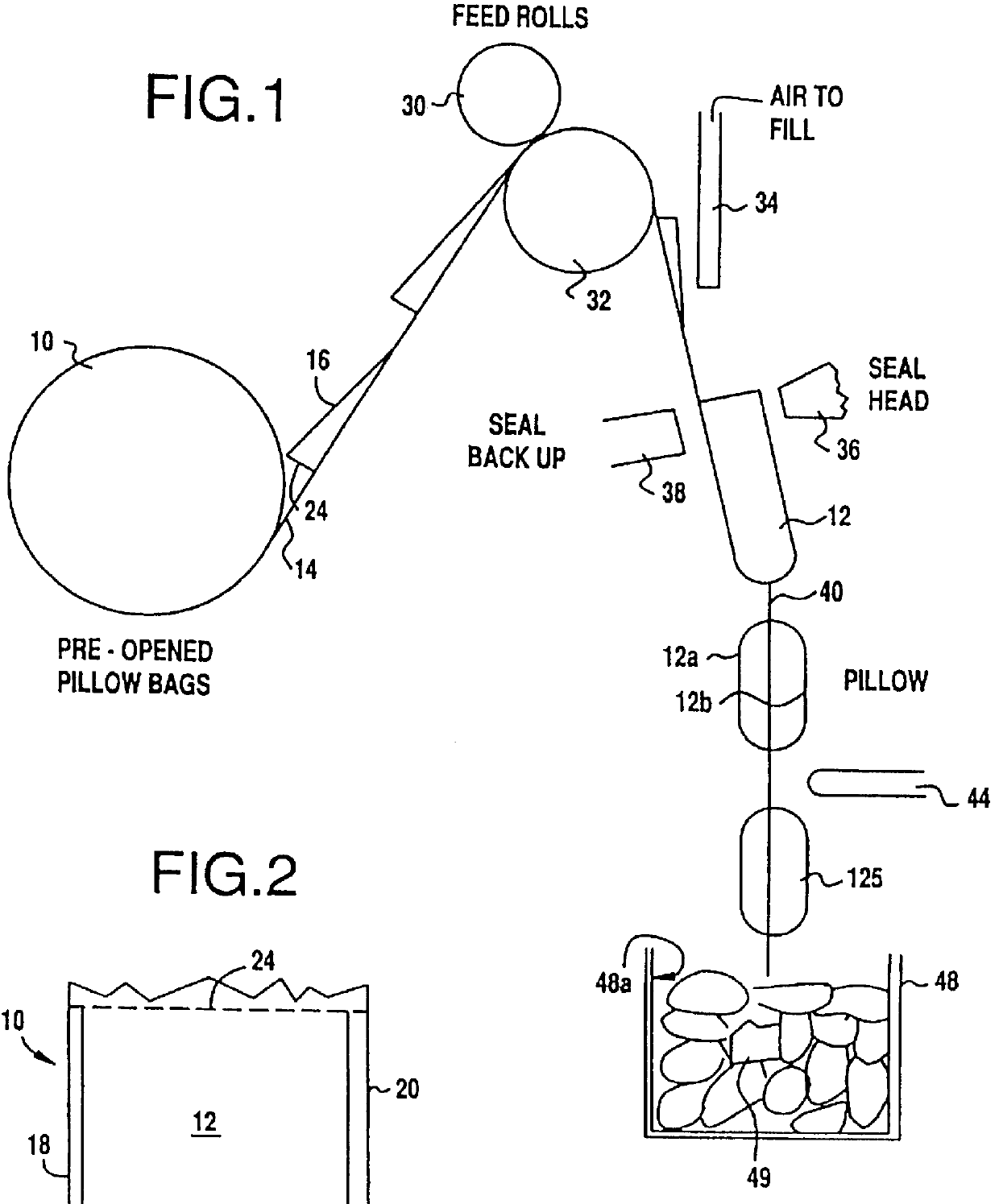

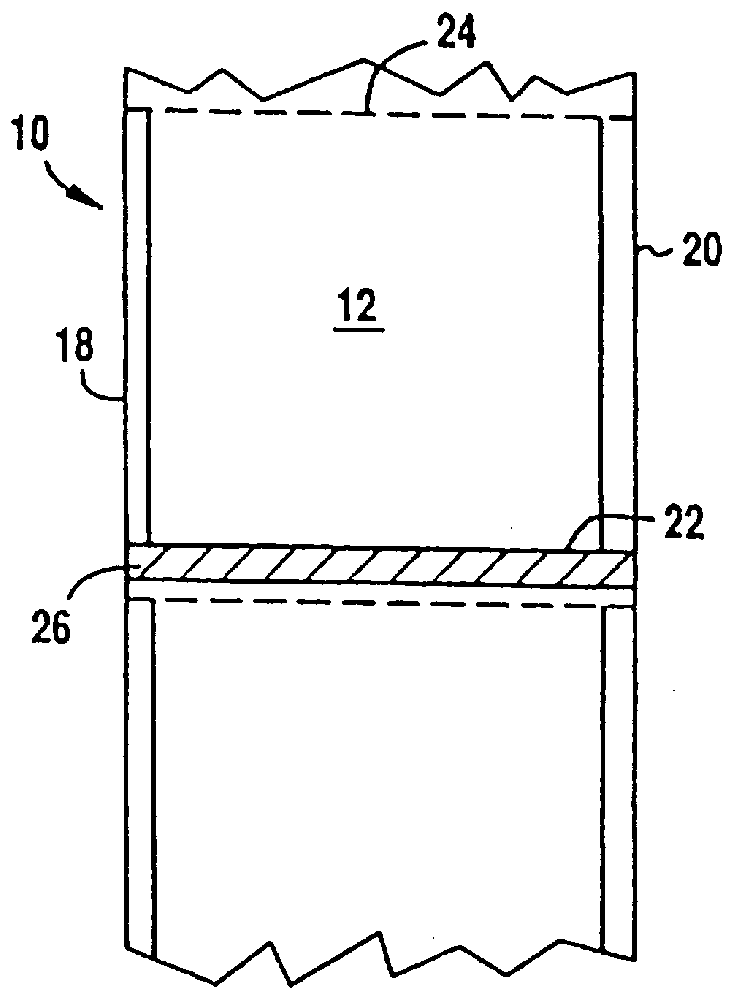

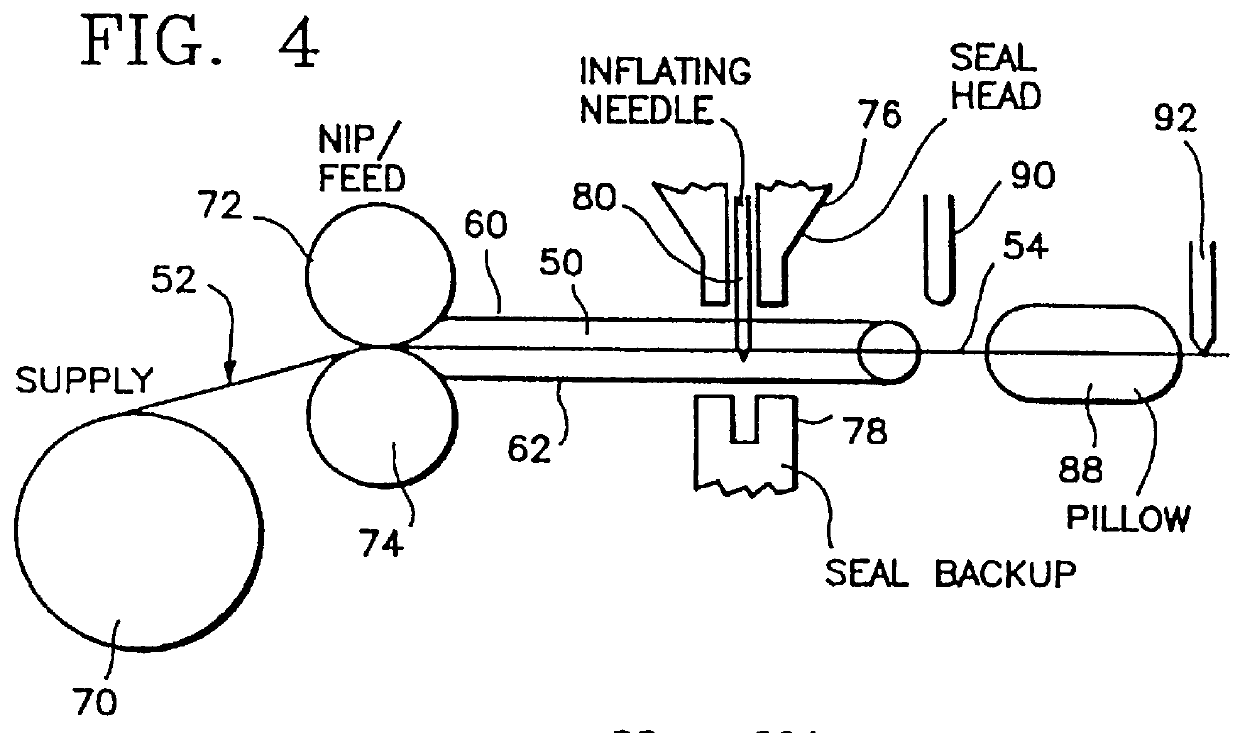

Method for producing inflated dunnage

InactiveUSRE36501E1Easy disposalEasy to reusePreventing unwanted cargo movementLabelling non-rigid containersDunnageCarton

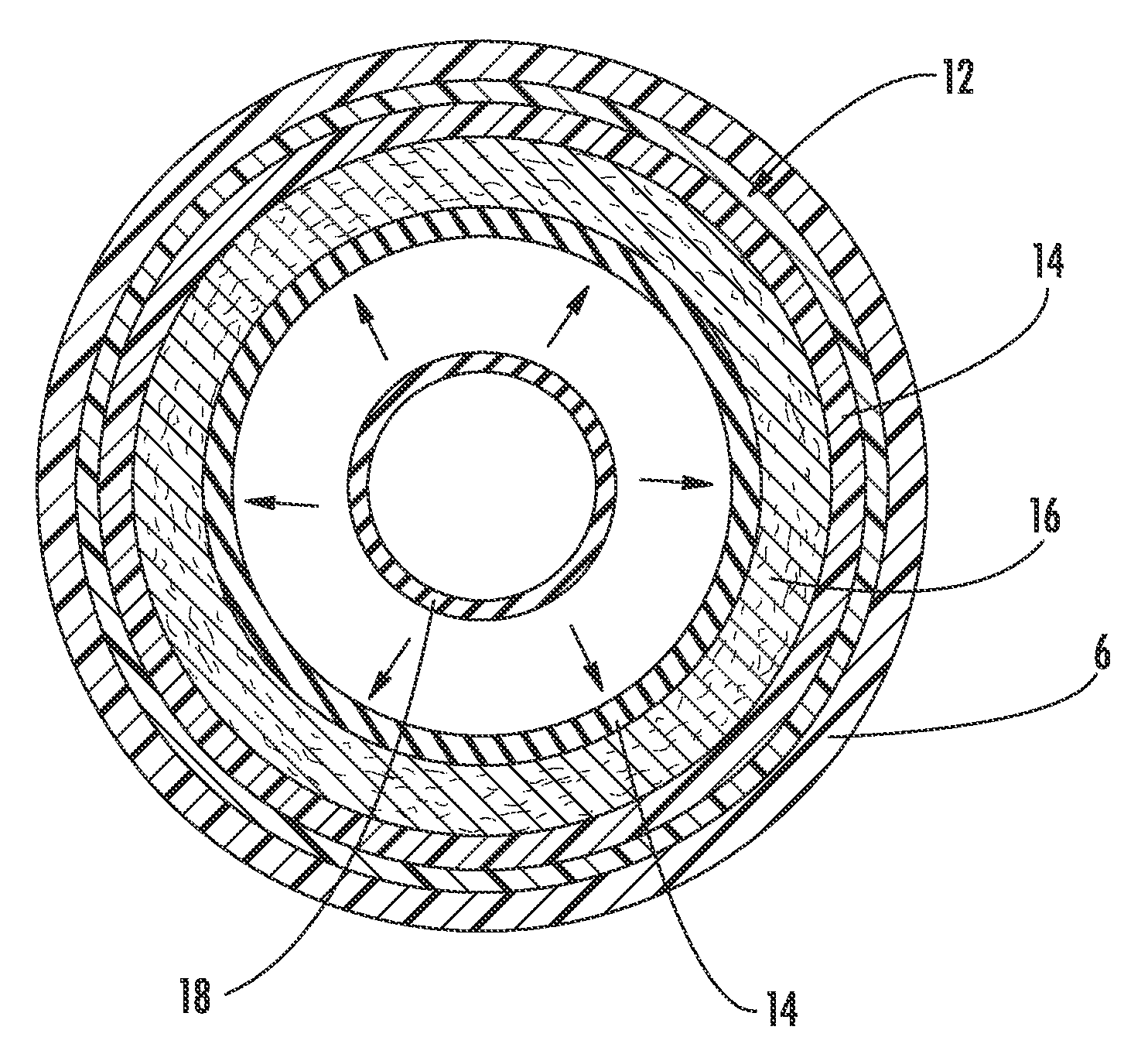

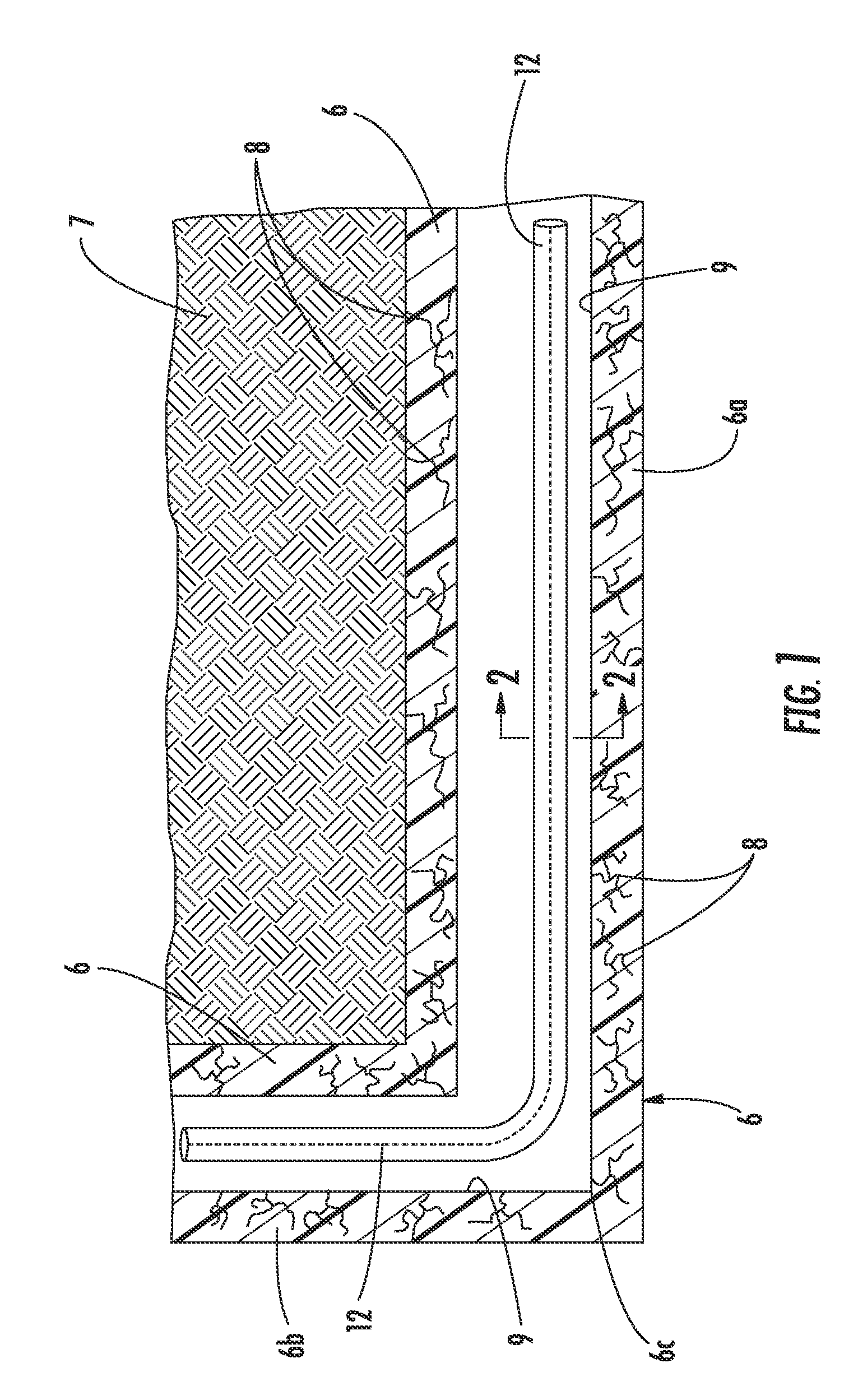

A method for producing inflated dunnage on the site of use, comprising providing, in rolled form, a plurality of preformed plastic bags, each of the bags comprising two plastic sheets in facing relationship and sealed along three edges with one edge remaining open. Air is blown toward each of the open edges in sequence, causing each bag to inflate, and the fourth edge of each inflated bag is sealed, the bag being empty except for the air. At least one sealed inflated bag is separated from the roll and placed in a carton to serve as dunnage. In an alternate embodiment, the stock material is provided in a continuous tubular form, and an air inflation needle is used to puncture a surface of the tube for inflation purposes.

Owner:AUTOMATED PACKAGING SYST

Inflated dunnage and method for its production

InactiveUSRE36759E1Reduce slippageEasy to prevent slippingPreventing unwanted cargo movementLabelling non-rigid containersDunnageCarton

A method for producing inflated dunnage on the site of use, comprising providing, in web form, a plurality of preformed plastic bags, each of the bags comprising two plastic sheets in facing relationship and sealed along three edges with one edge remaining open. Air is blown toward each of the open edges in sequence, causing each bag to inflate, and the open edge of each inflated bag is sealed, the bag being empty except for the air. A plurality of sealed inflated bags is separated from the web and placed in a carton to serve as dunnage. The bags have a slip resistant outer surface which causes the bags to interlock in the carton and better protect object therein from shock.

Owner:AUTOMATED PACKAGING SYST

Printing plastic containers with digital images

A method for printing digital images on plastic containers having curved surfaces, including providing a series of hollow plastic containers, moving the containers along a track past first and second digital printing locations, and printing first and second digital images on the curved container surfaces while maintaining the container being printed under internal pressure and while firmly holding the container being printed at spaced locations thereon.

Owner:PLASTIPAK PACKAGING

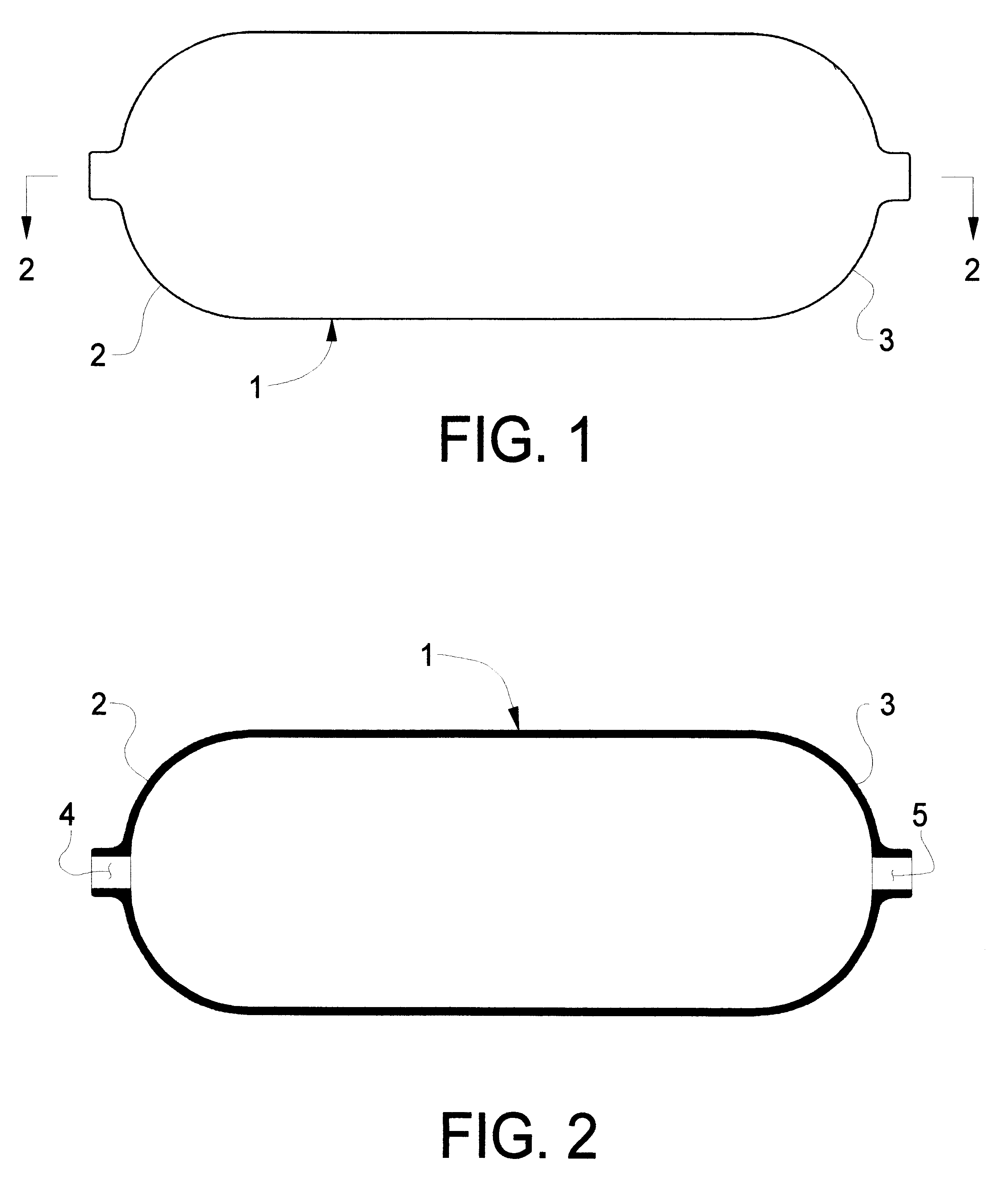

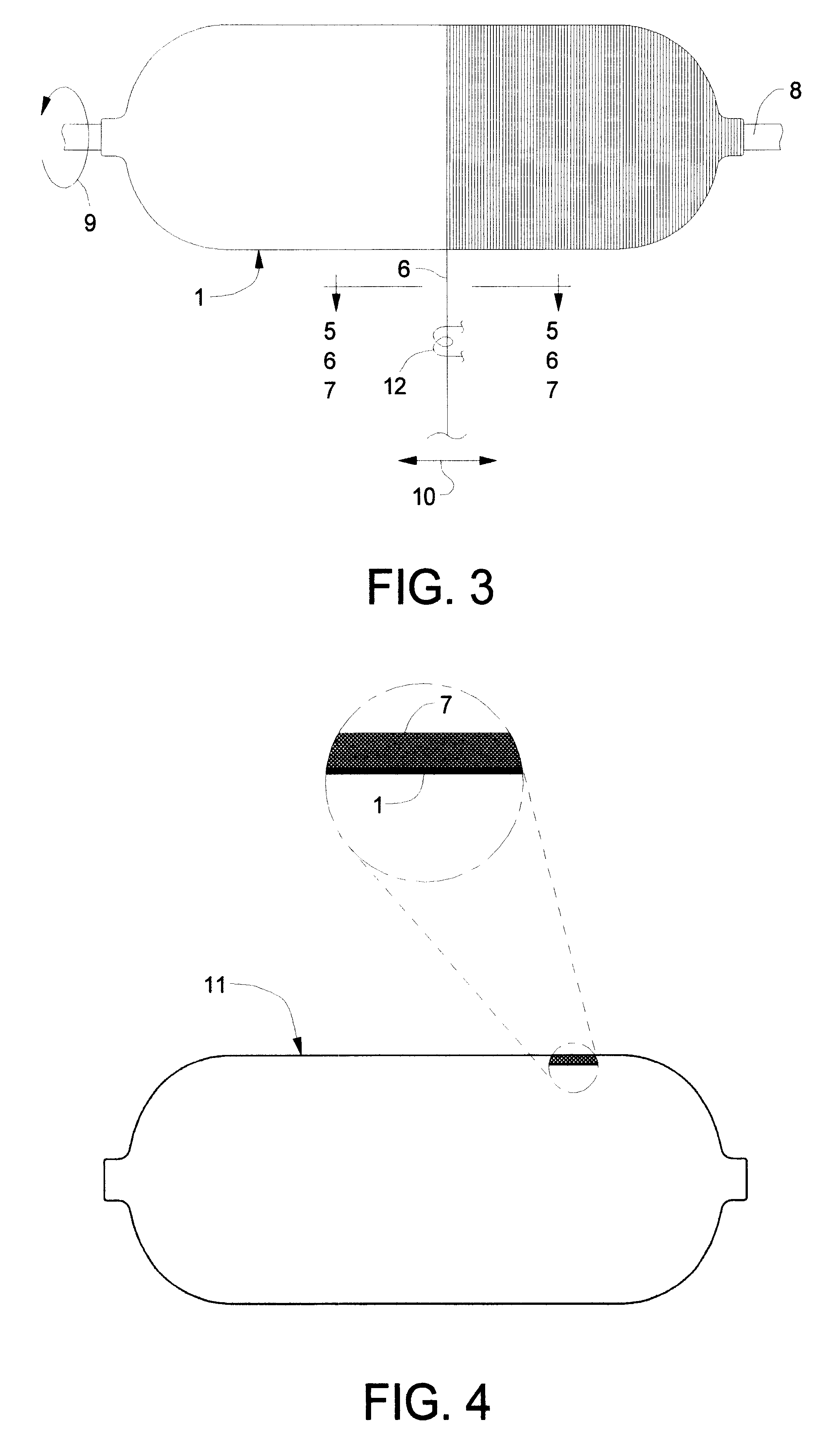

Method for fabricating composite pressure vessels and products fabricated by the method

InactiveUS6485668B1Speed up the processRatio is limitedLabelling non-rigid containersConfectioneryFiberSilicon rubber

A process, and the product thereof, for making a composite vessel having at least one closed end, the process including the steps of: fabricating a thermoplastic liner for the vessel; overlaying onto the liner a layer of commingled fiber and thermoplastic material to obtain a composite intermediate structure; pressing and heating the composite intermediate structure to effect at least partial consolidation in apparatus which includes upper and lower silicon rubber bags, the bags having dimensions such that, during operation, their facing peripheral regions abut to encompass the composite intermediate structure; then placing the composite intermediate structure in a mold; heating the composite intermediate structure in the mold while applying a force, such as internal gas pressure, tending to urge the composite intermediate structure against and into the shape of the interior walls of the mold until the thermoplastic liner and the overlaid layer fully consolidate; cooling the mold and composite vessel until the composite vessel is solidified; and removing the formed composite vessel from the mold. The commingled fiber and thermoplastic material may either be wound onto the liner or laid on the liner in the form of fabric woven from the fiber and threads of the thermoplastic material.

Owner:ESSEF CORP +1

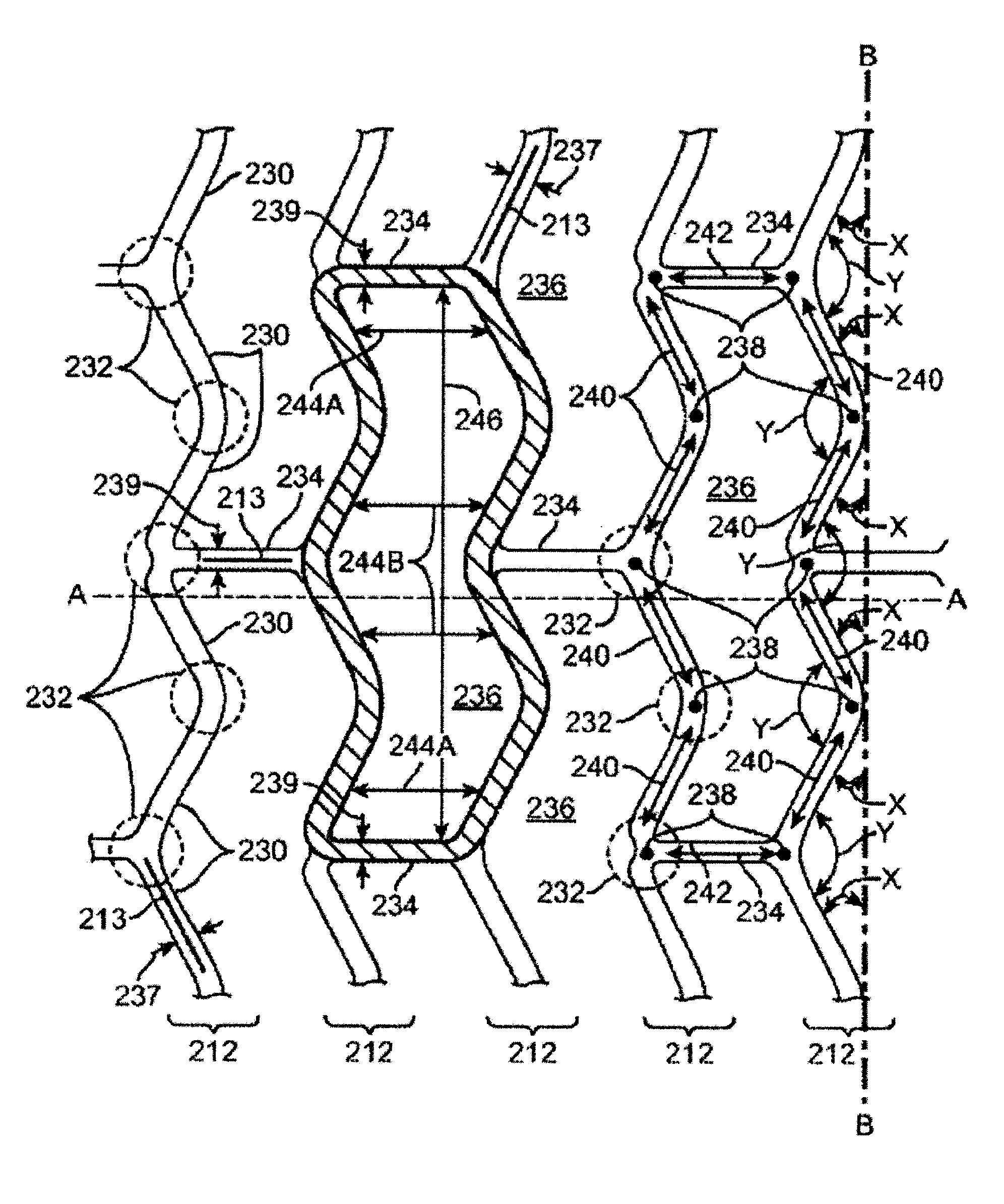

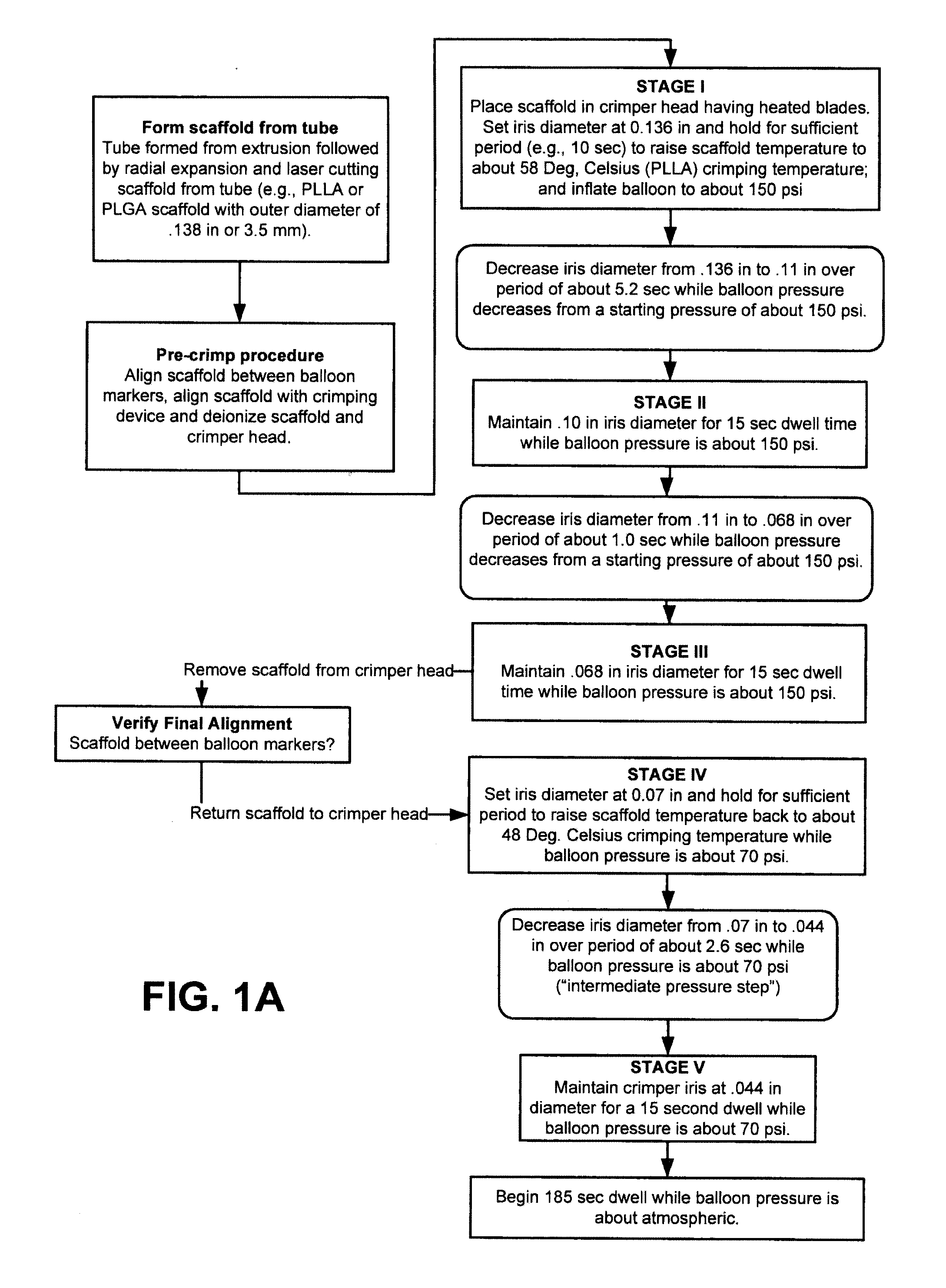

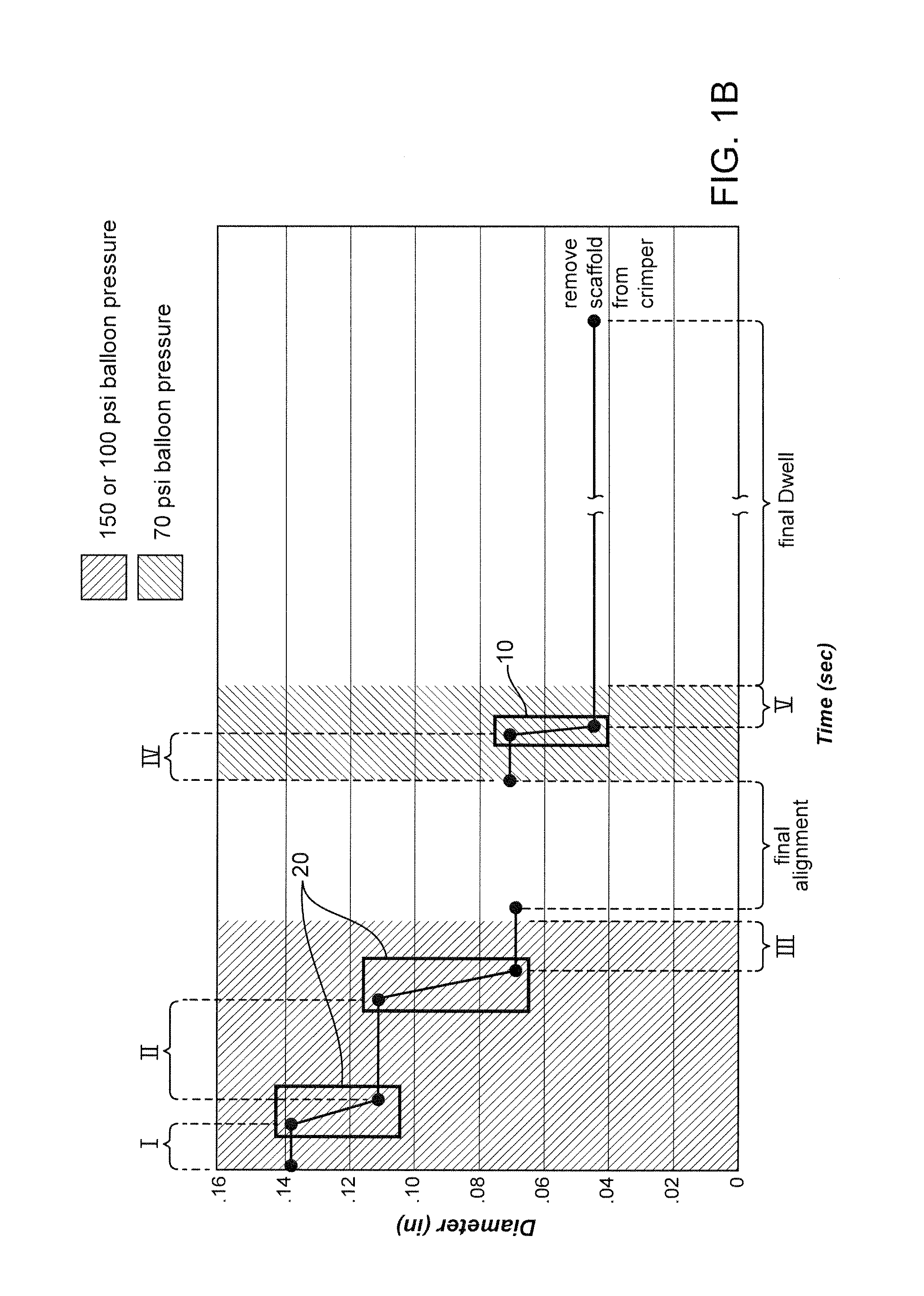

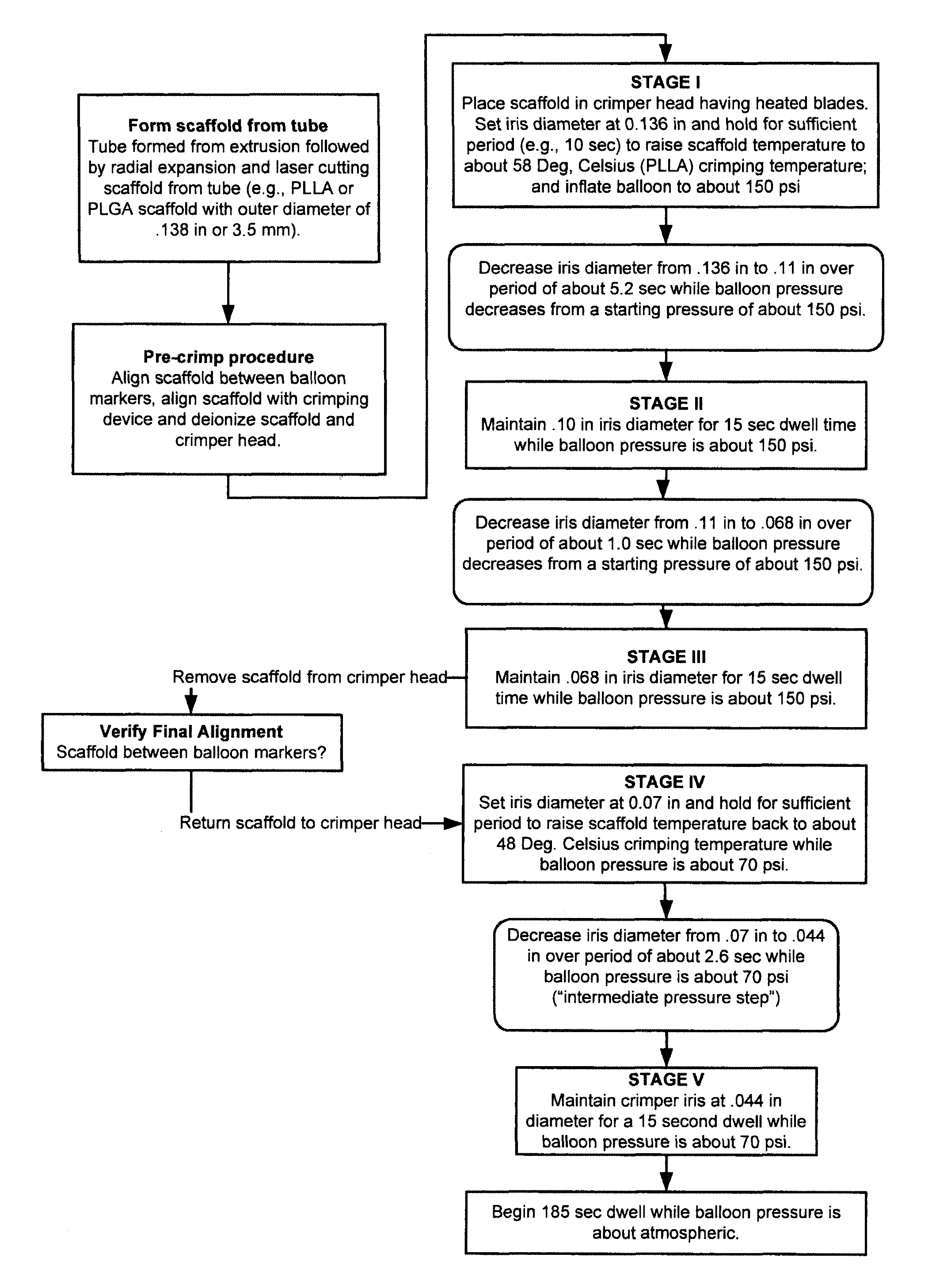

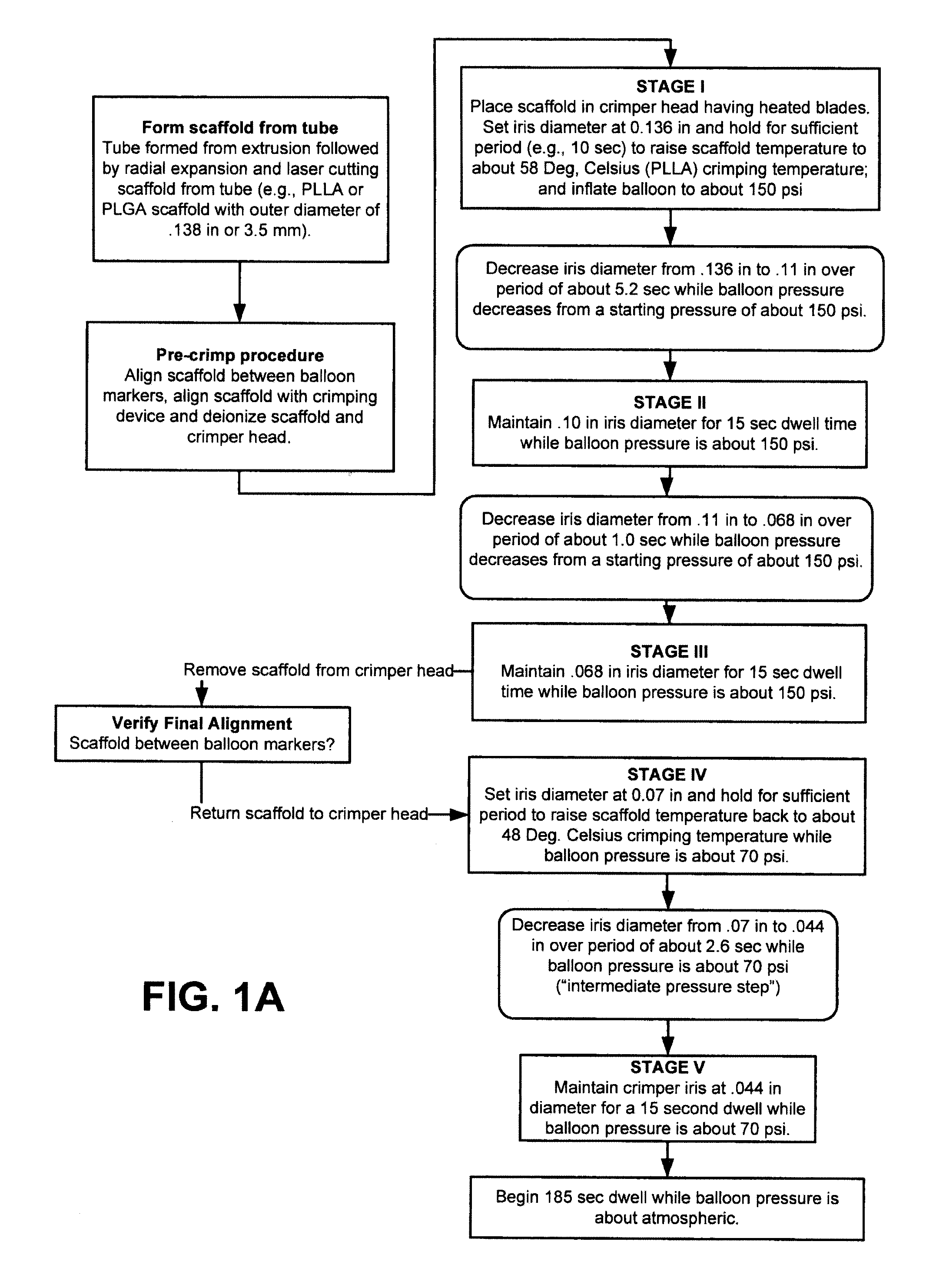

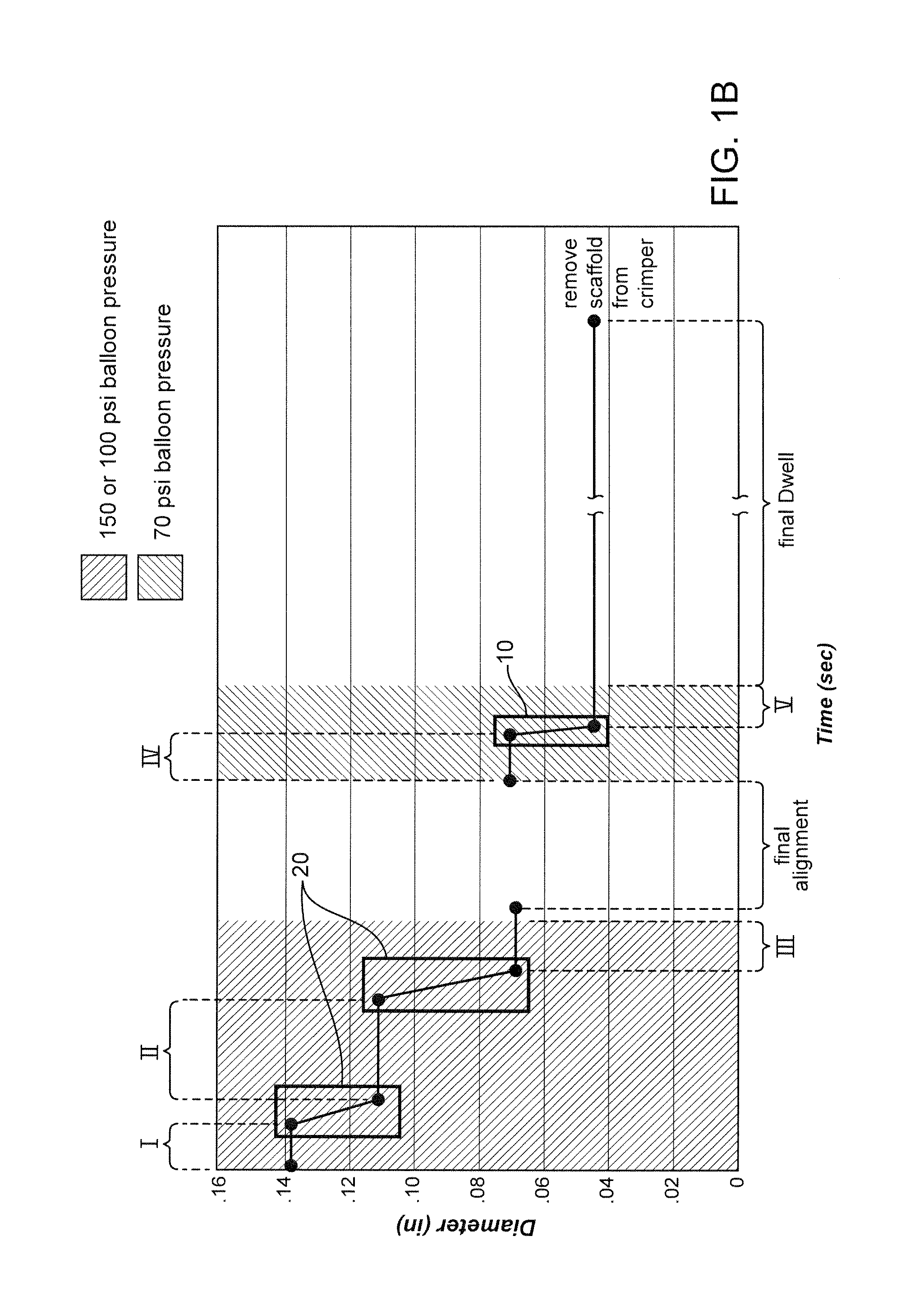

Methods for Crimping a Polymeric Scaffold to a Delivery Balloon and Achieving Stable Mechanical Properties in the Scaffold After Crimping

InactiveUS20120285609A1Reduce the overall diameterShorten the overall cycleStentsLabelling non-rigid containersVitrificationGlass transition

A medical device-includes a polymer scaffold crimped to a catheter having an expansion balloon. The scaffold is crimped to the balloon by a process that includes inflating the delivery balloon during a diameter reduction to improve scaffold retention. A crimping temperature is maintained at about the onset of glass transition of the polymer material to facilitate more rapid stabilization of mechanical properties in the scaffold following crimping.

Owner:ABBOTT CARDIOVASCULAR

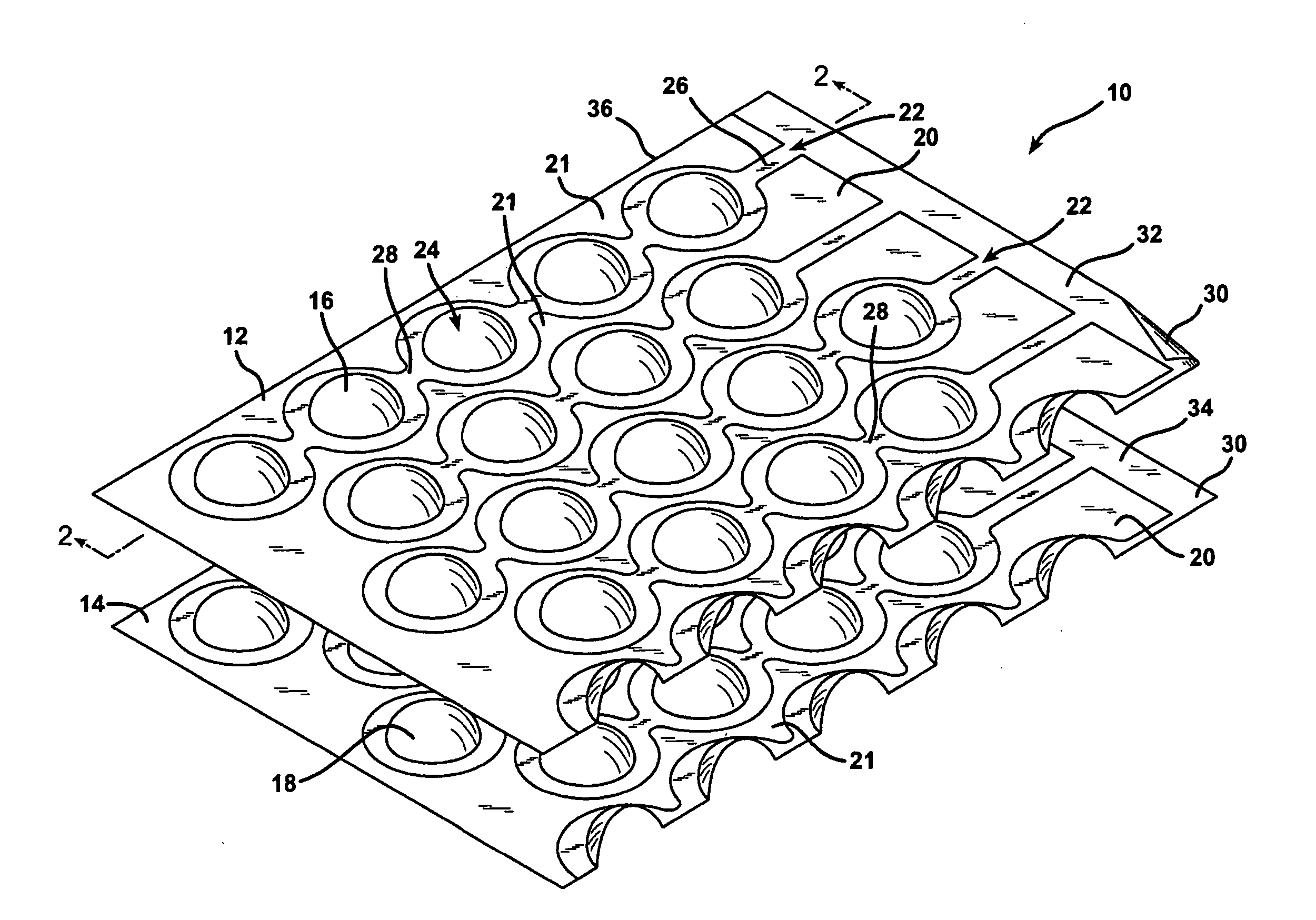

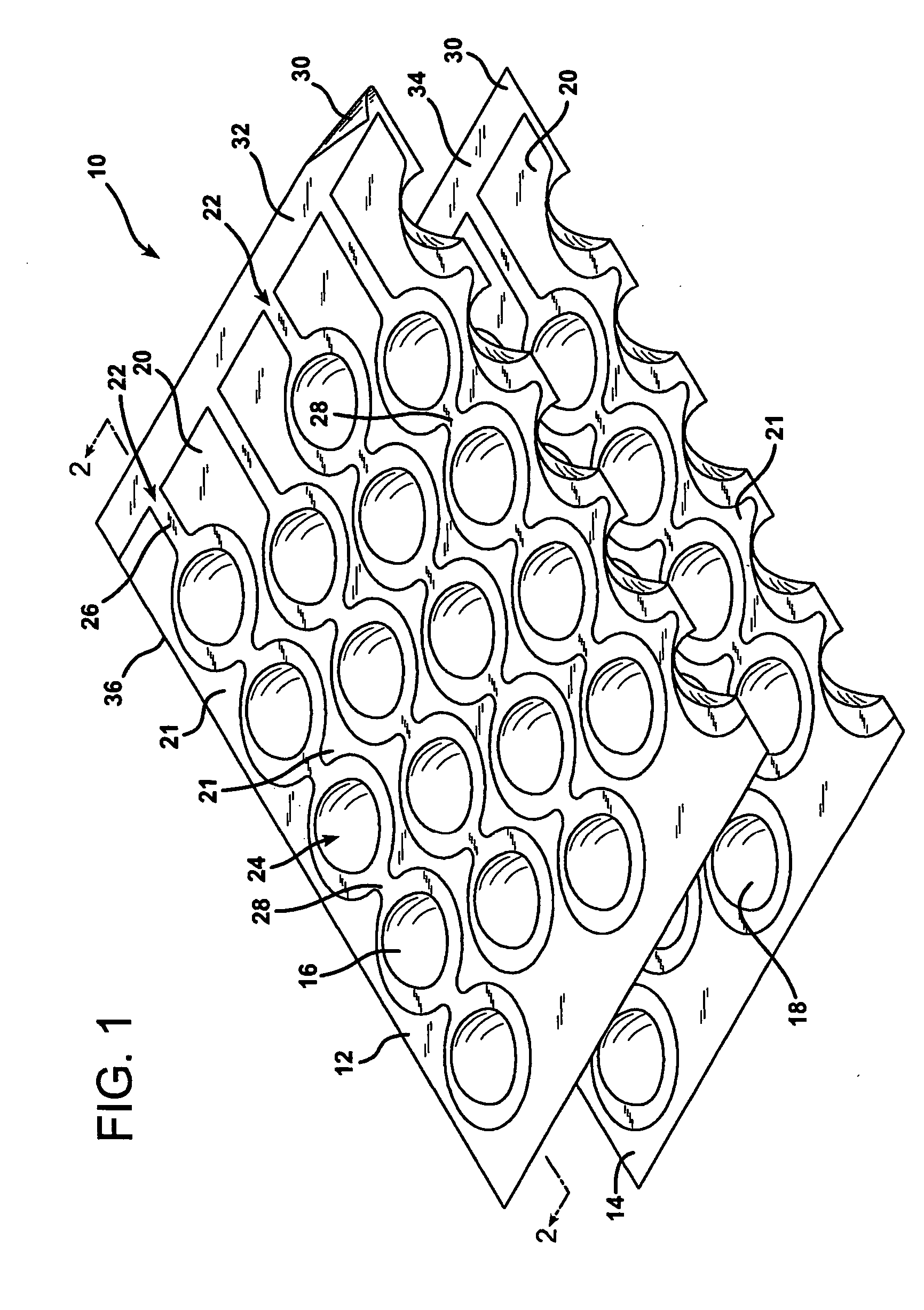

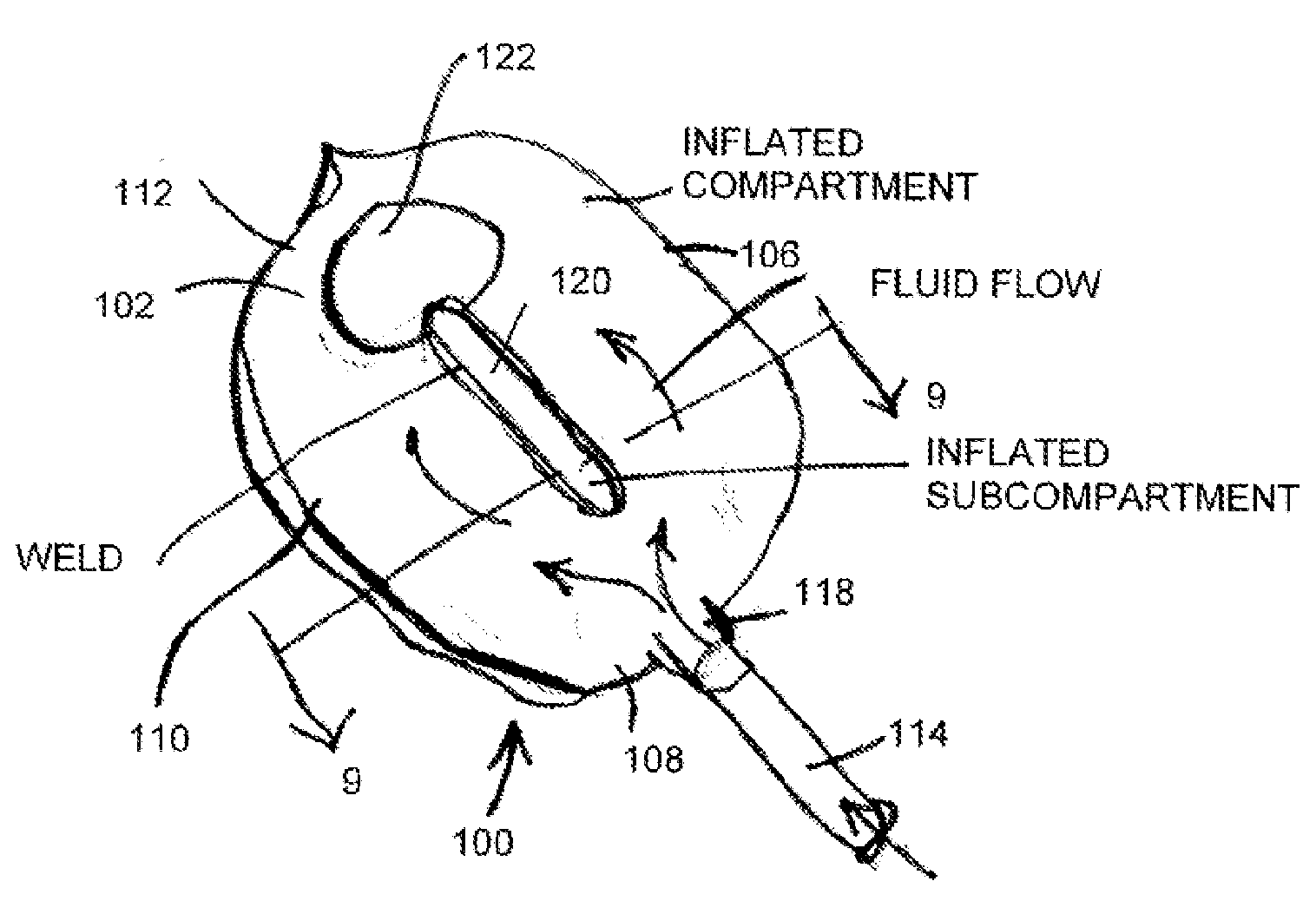

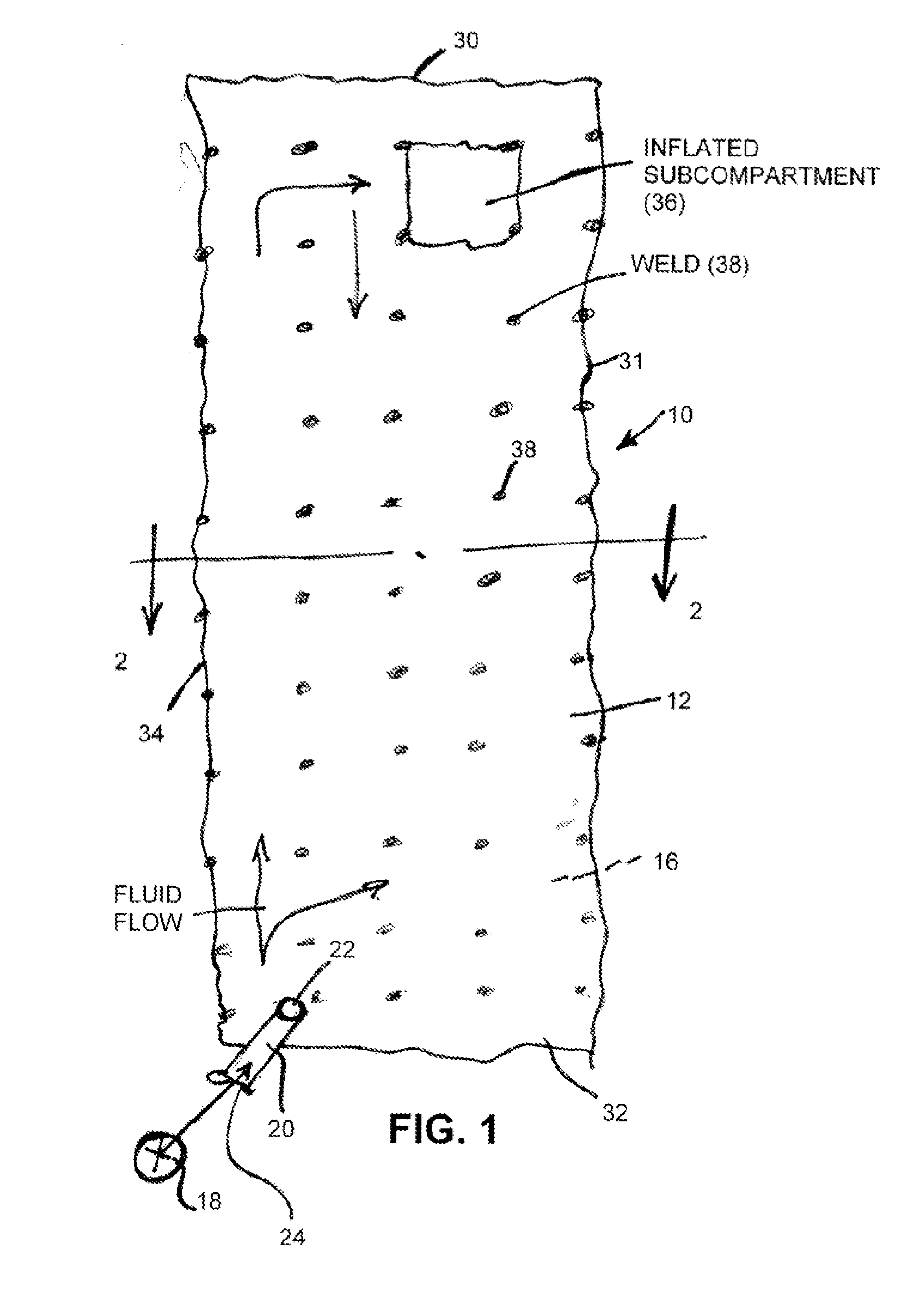

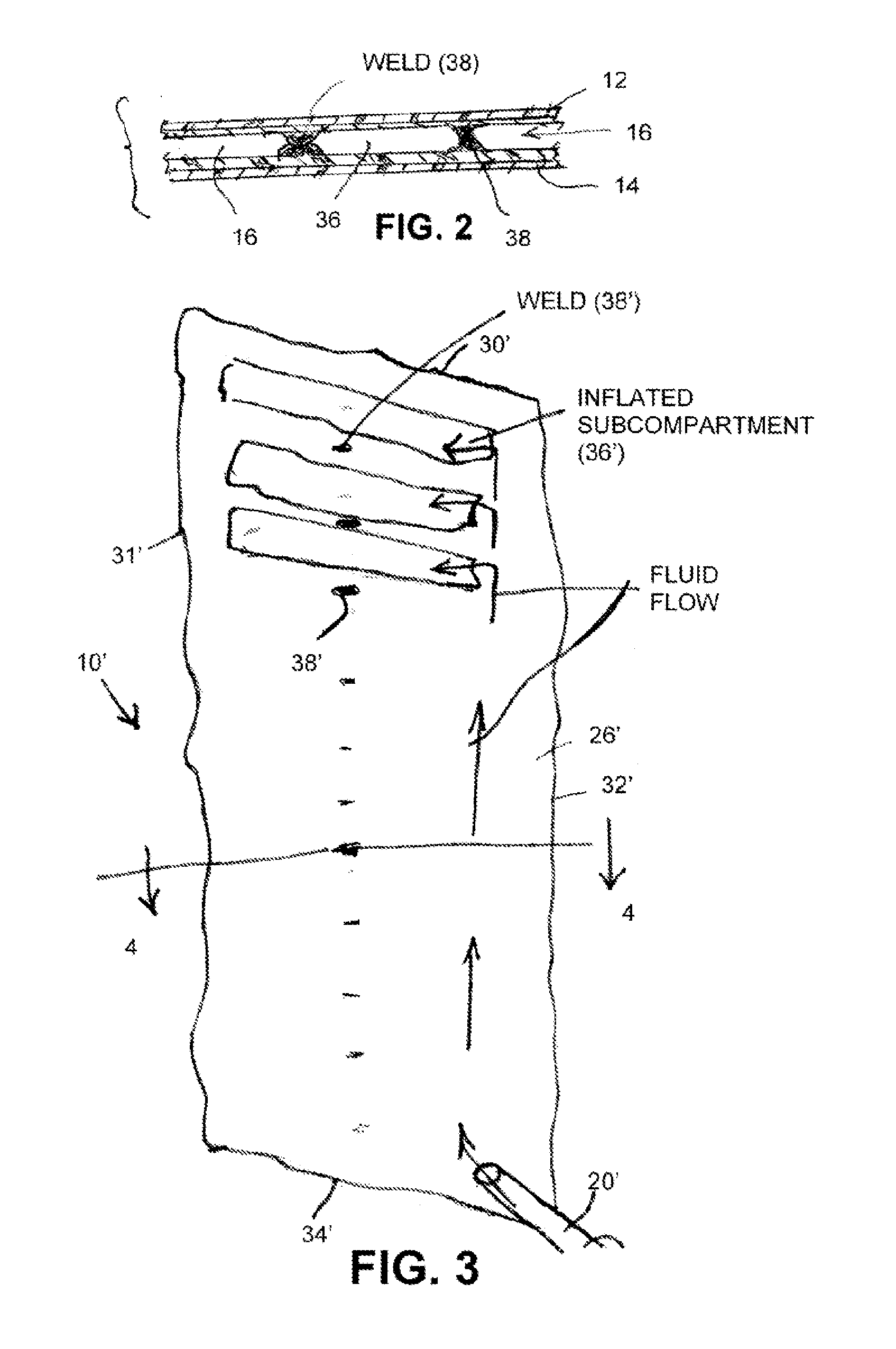

Formed inflatable cellular cushioning article and method of making same

InactiveUS20060210773A1Reduced lateral contractionCell height can be increasedLabelling non-rigid containersPaper/cardboard articlesCushioningHoneycomb like

An inflatable article has a first film bonded to a second film so as to provide between the first film and the second film a plurality of inflatable chambers, each of the inflatable chambers containing a plurality of cells. Each of the cells is connected to at least one adjacent cell by an inflatable connecting channel. The first film is bonded to the second film between adjacent inflatable chambers. The first film and the second film each have at least one formed region corresponding with a location of a cell, with the at least one formed region of the second film being nested into the at least one formed region of the first film. Also disclosed are processes of making the inflatable article.

Owner:SEALED AIR U S

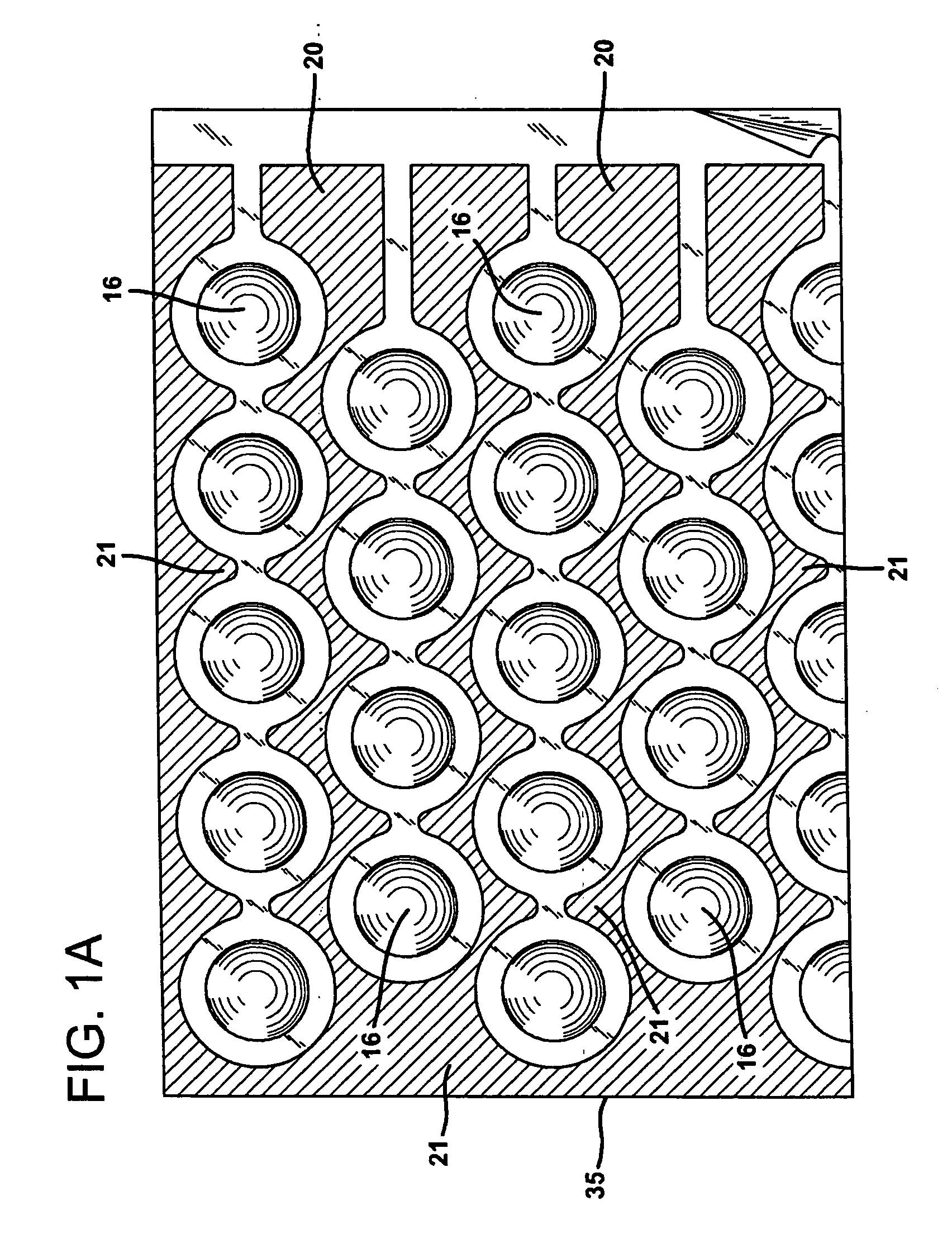

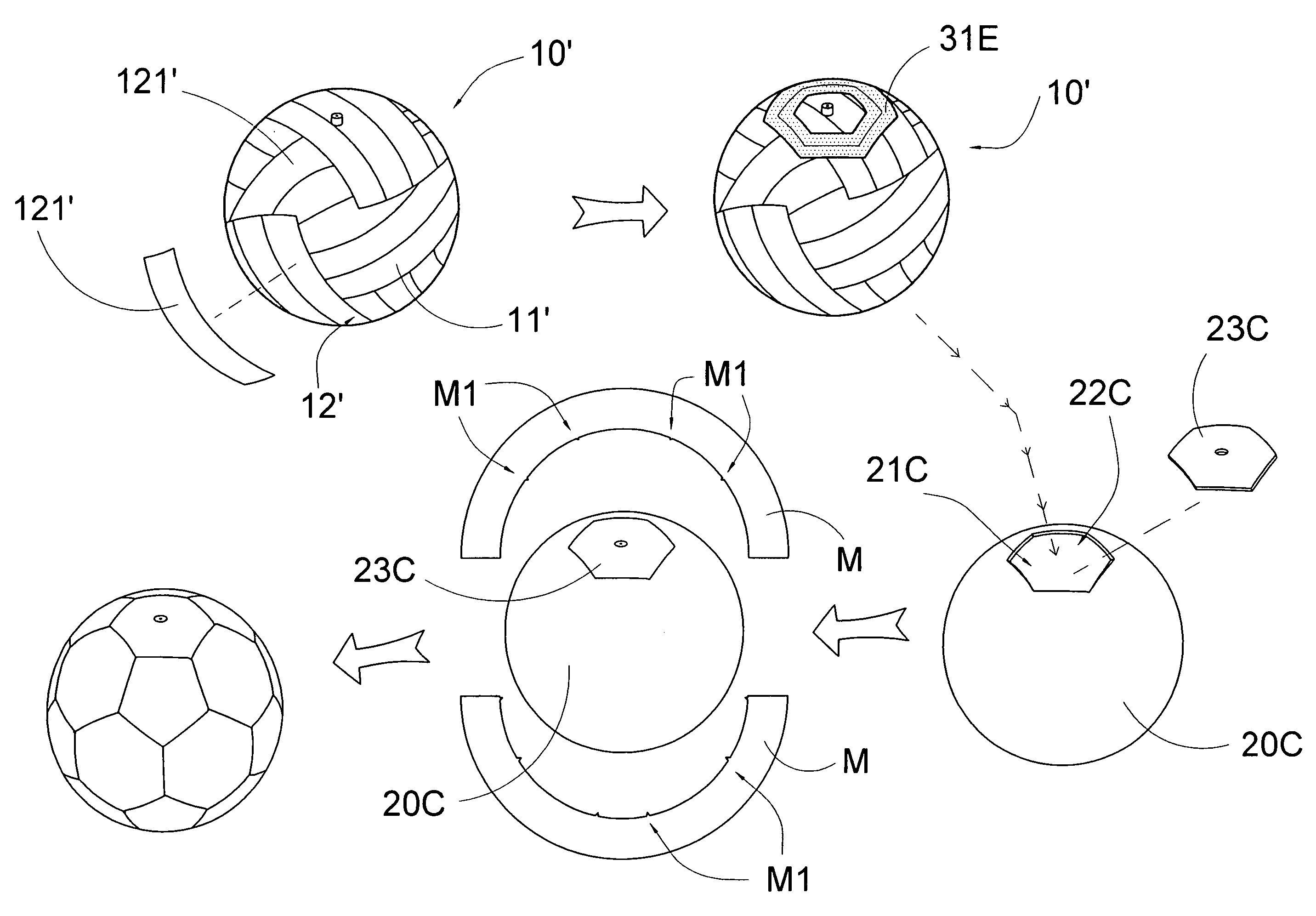

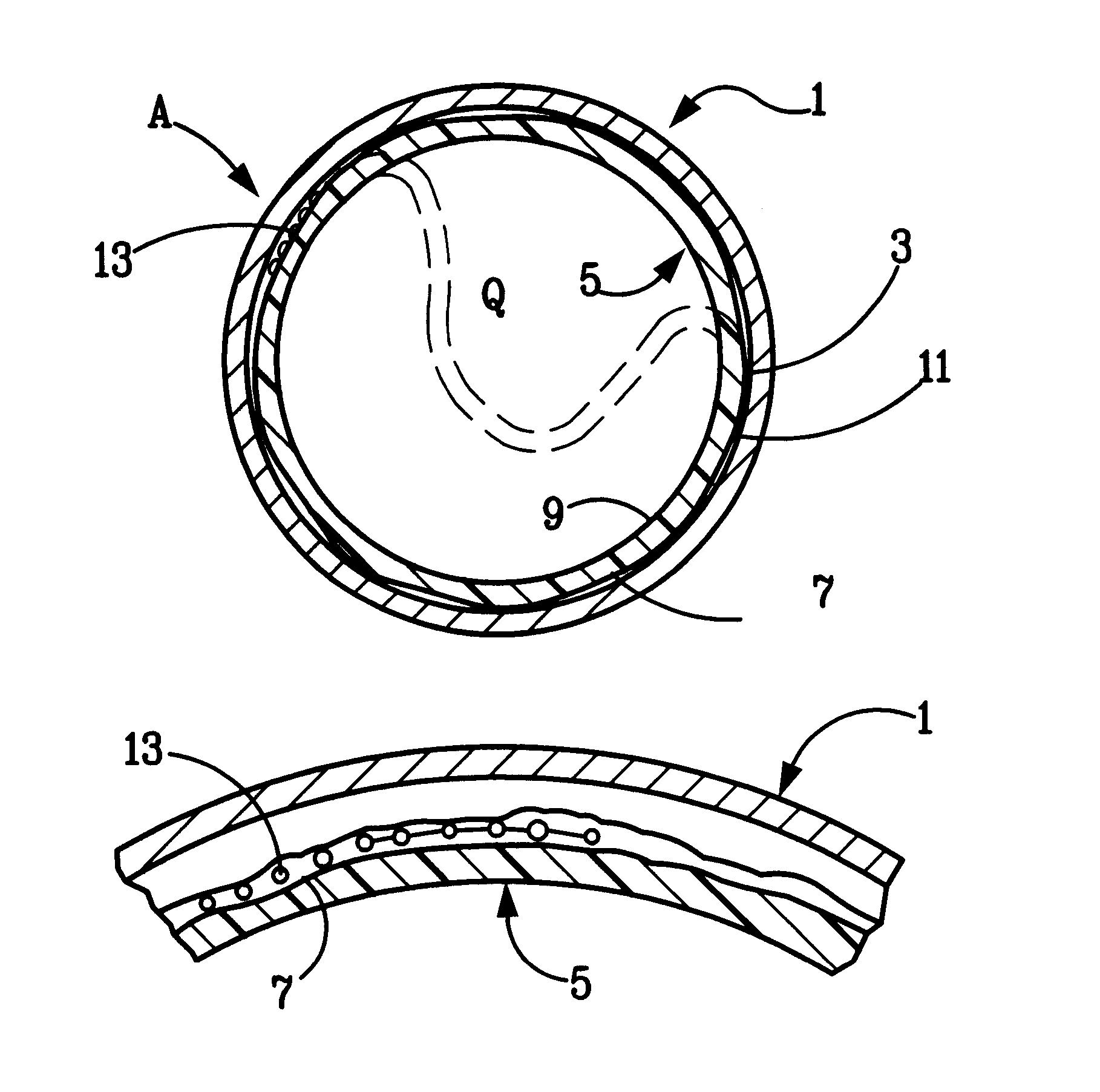

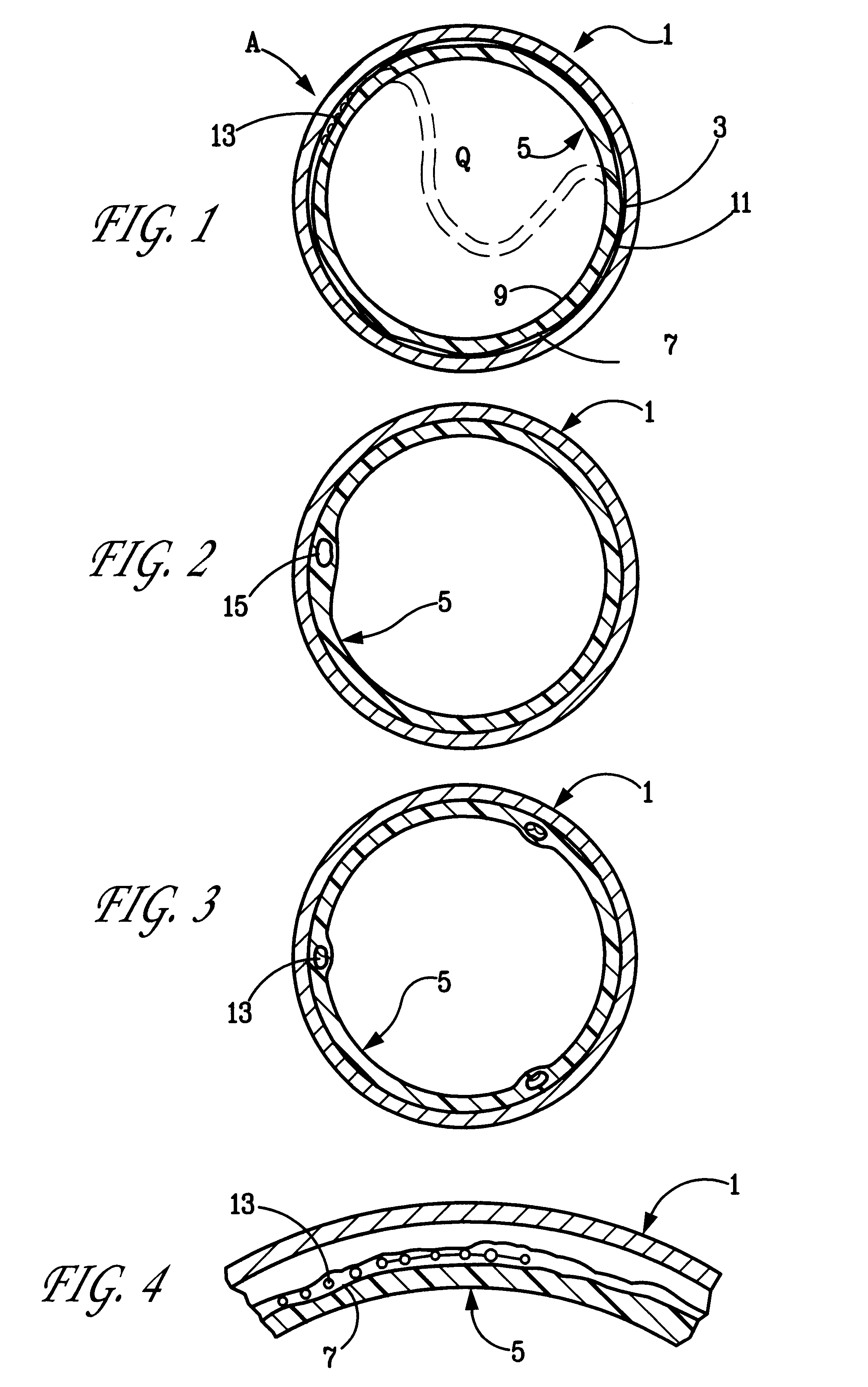

Stitchless seam arrangement of sportsball and manufacturing method thereof

InactiveUS20090325747A1Simplify final assembling operationReduce time-consuming manufacturing procedureLabelling non-rigid containersHollow inflatable ballsContour matchingCost effectiveness

A sportsball includes a ball carcass, an inflatable ball body received in a ball cavity of the ball carcass, and a stitchless seam arrangement which includes an elongated adhesive layer having a contour matching with a contour of an opening of the ball carcass, wherein after the ball body is disposed in the ball carcass, edge portions of the opening are adhered on an outer surface of the ball body via the adhesive layer, such that the opening is sealed to close the ball cavity for enclosing the ball body in the ball cavity of the ball carcass in a stitchless seam manner. Therefore, the manufacturing method of the sportsball excludes the traditional final assembling operation of hand stitching to reduce the time-consuming manufacturing procedure of the sportsball while being cost effective.

Owner:OU TSUNG MING

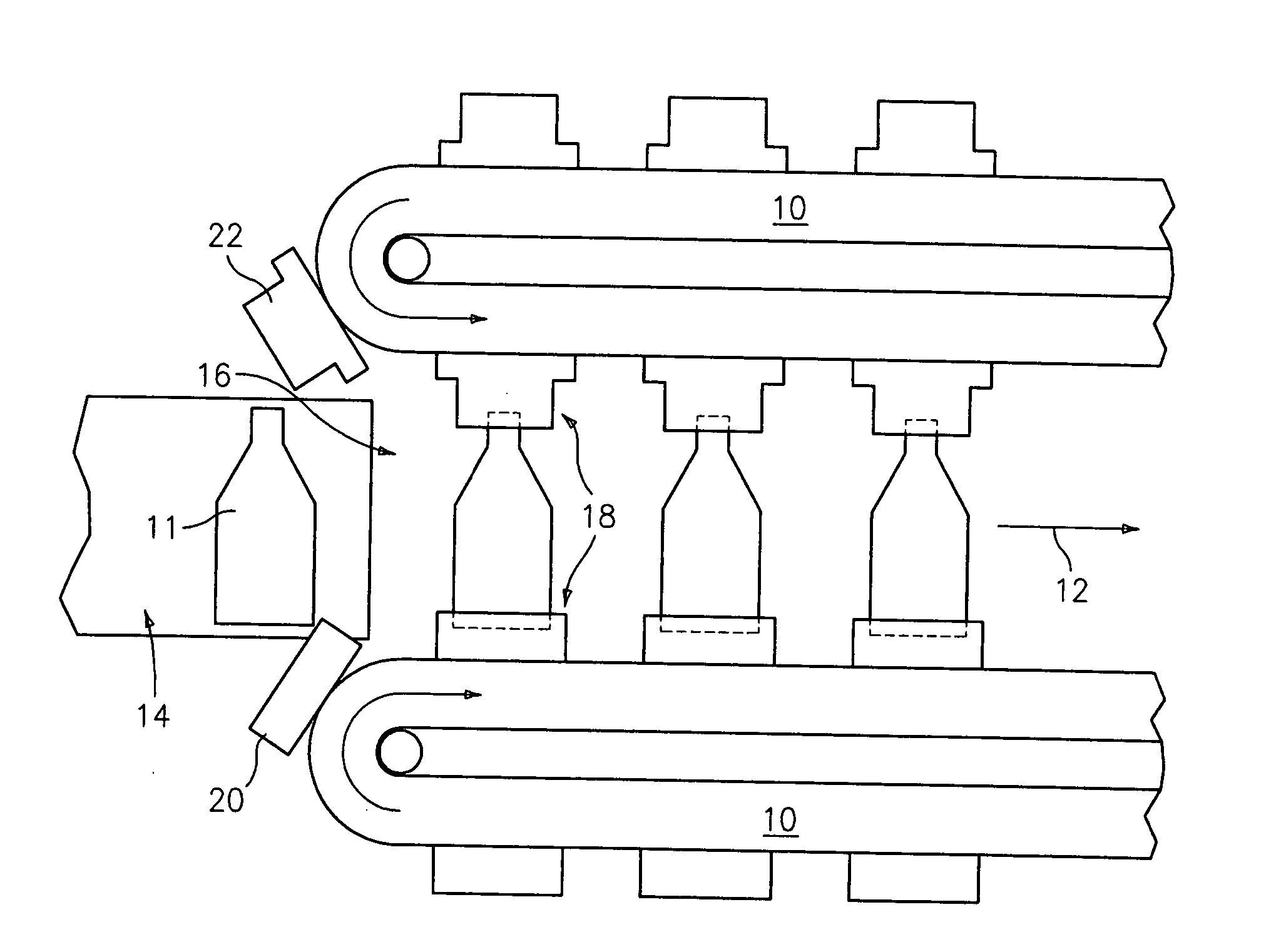

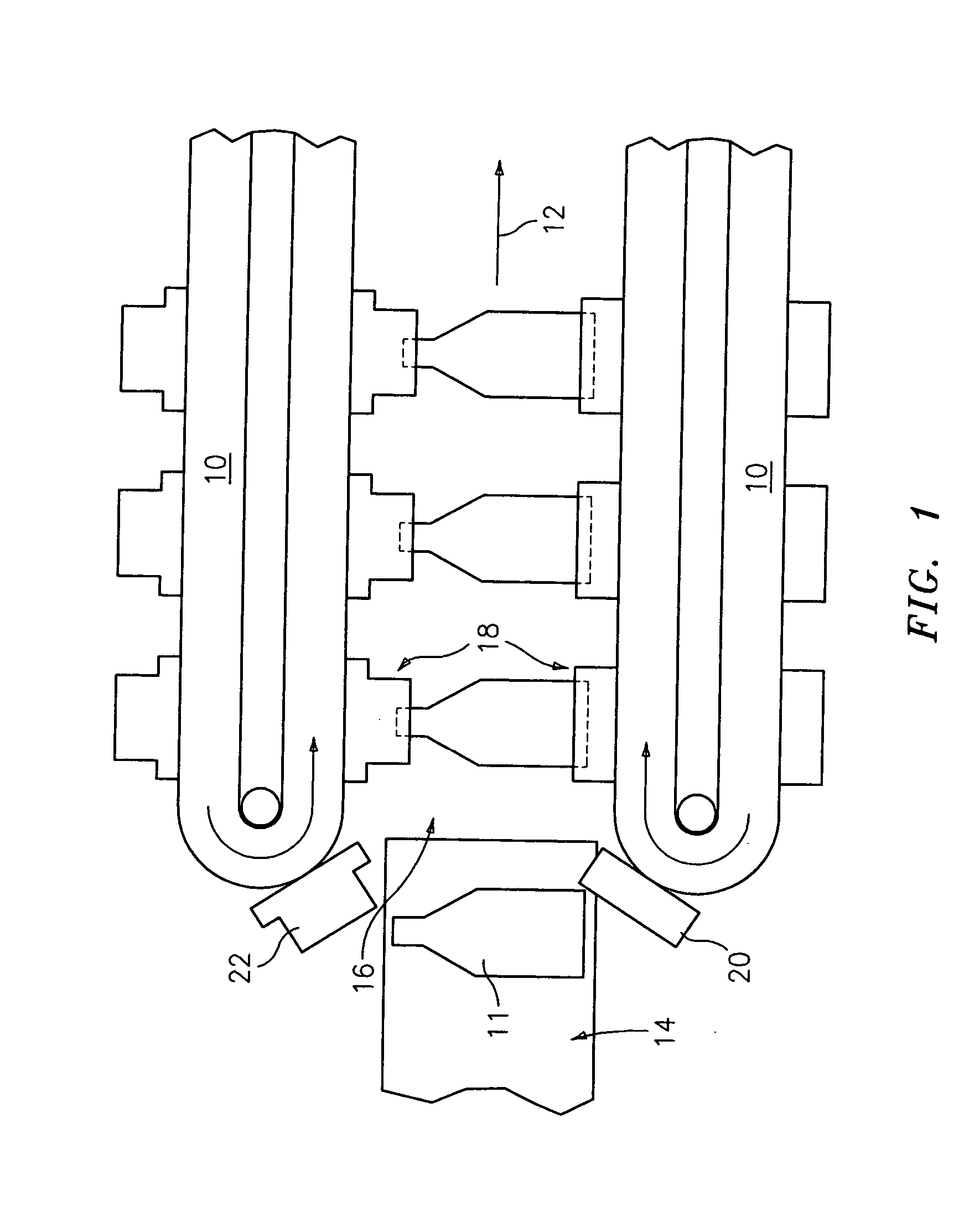

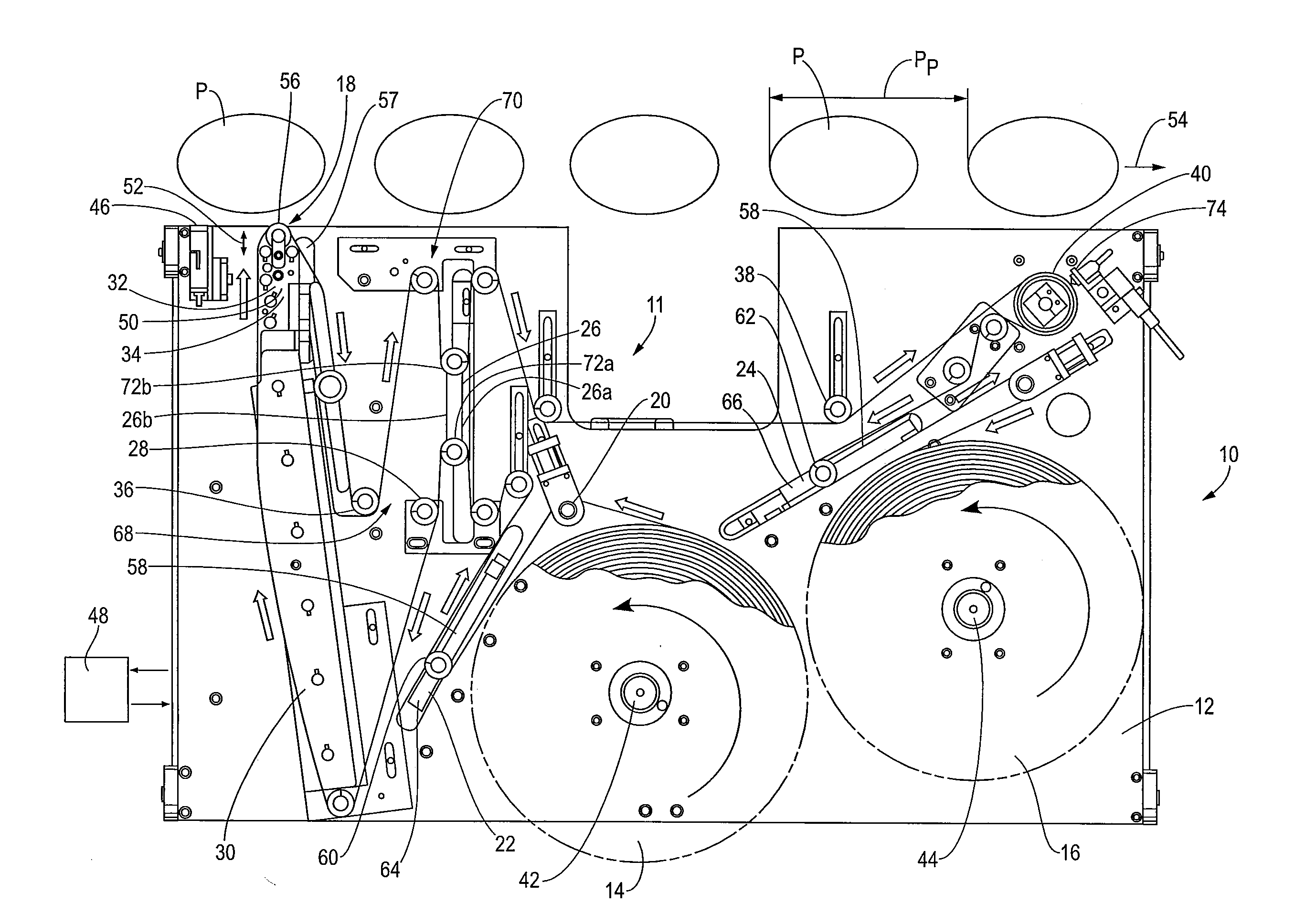

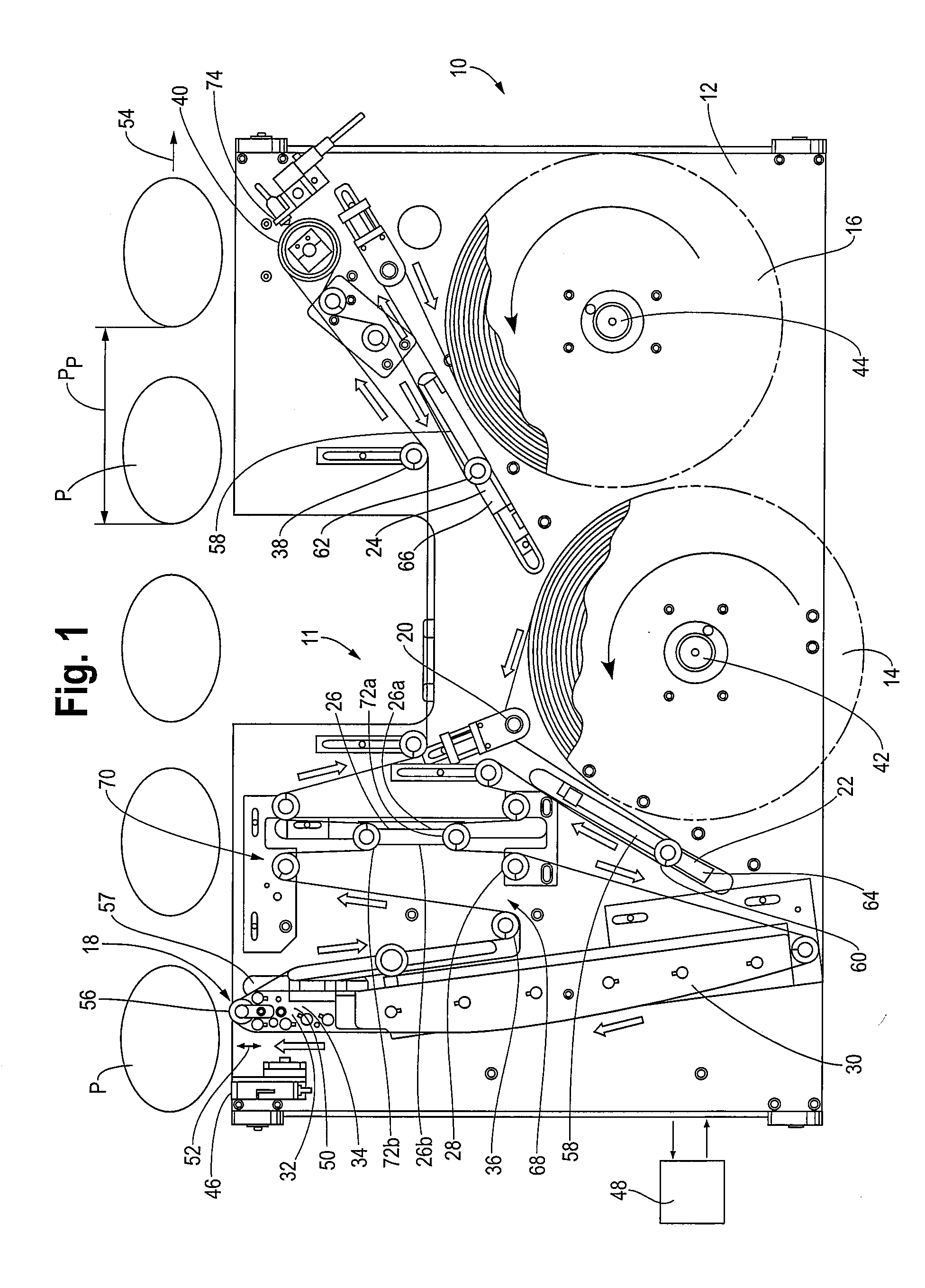

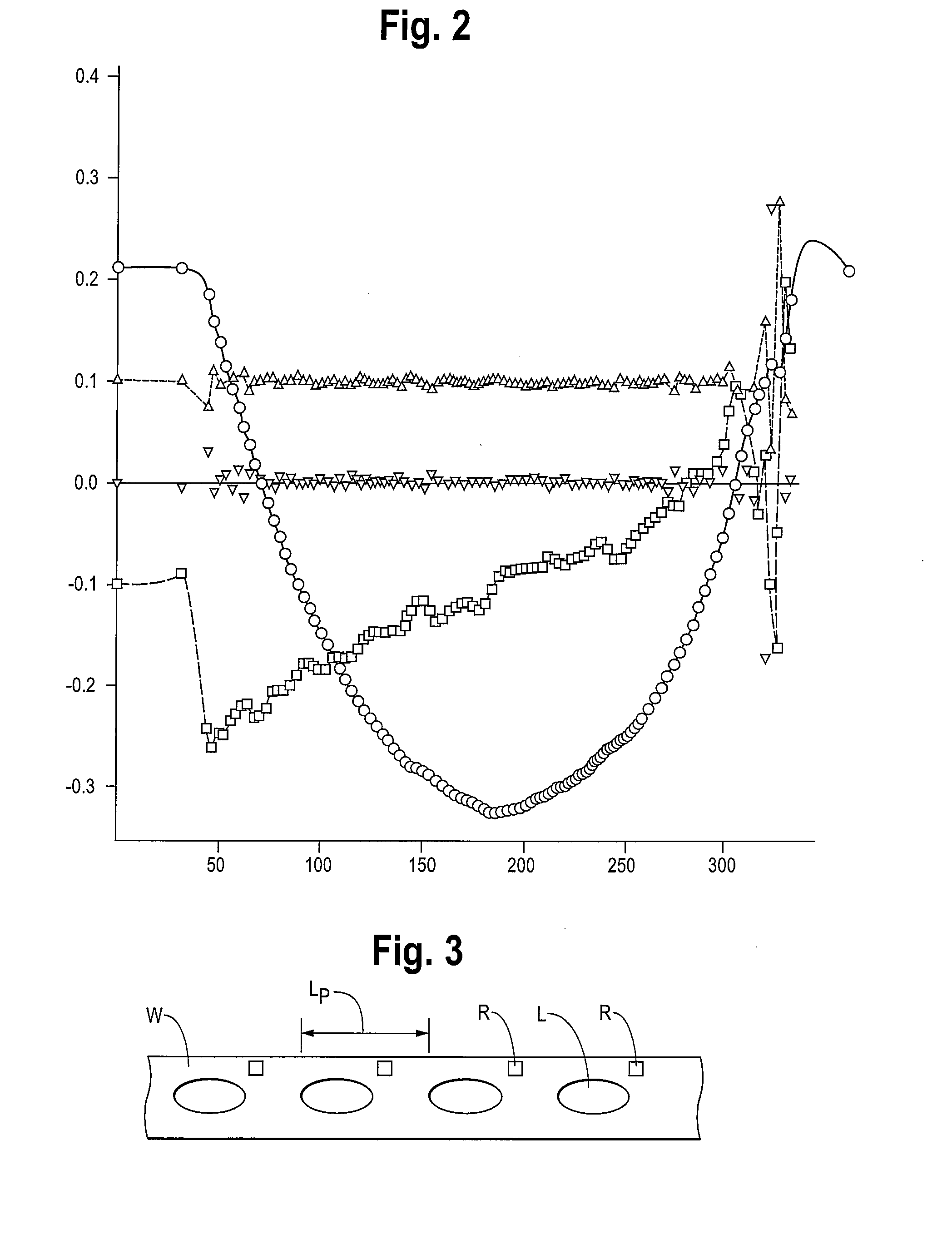

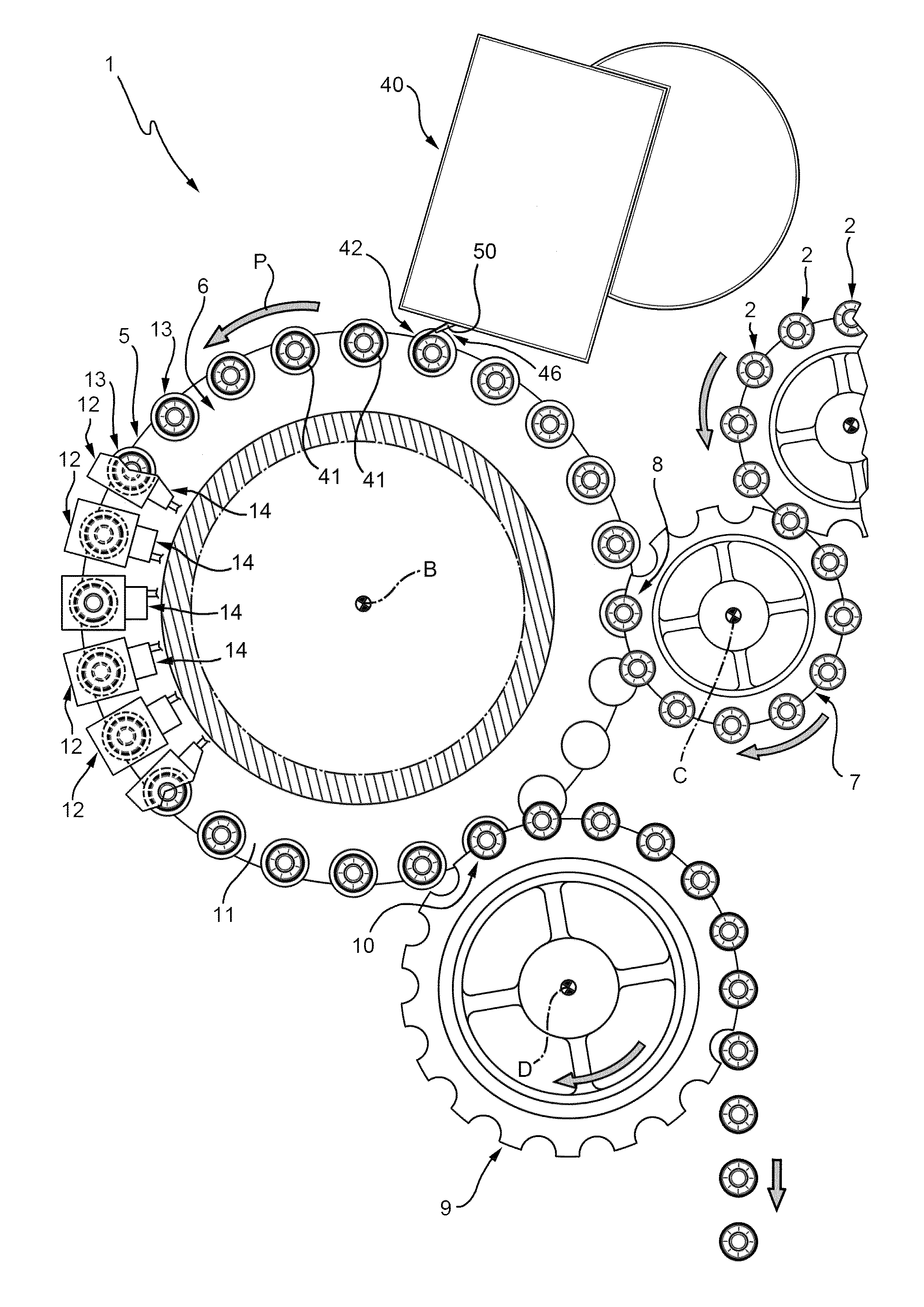

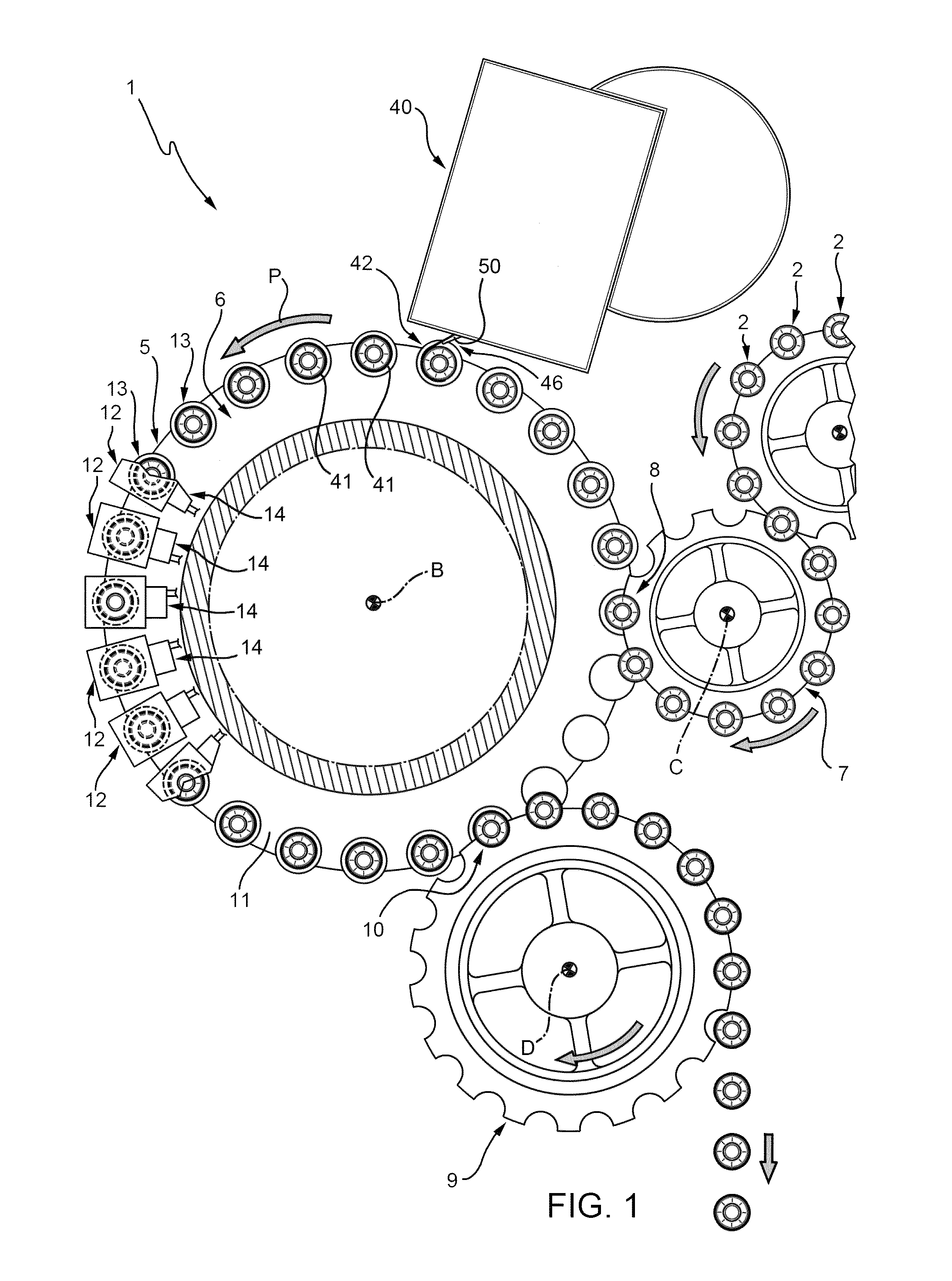

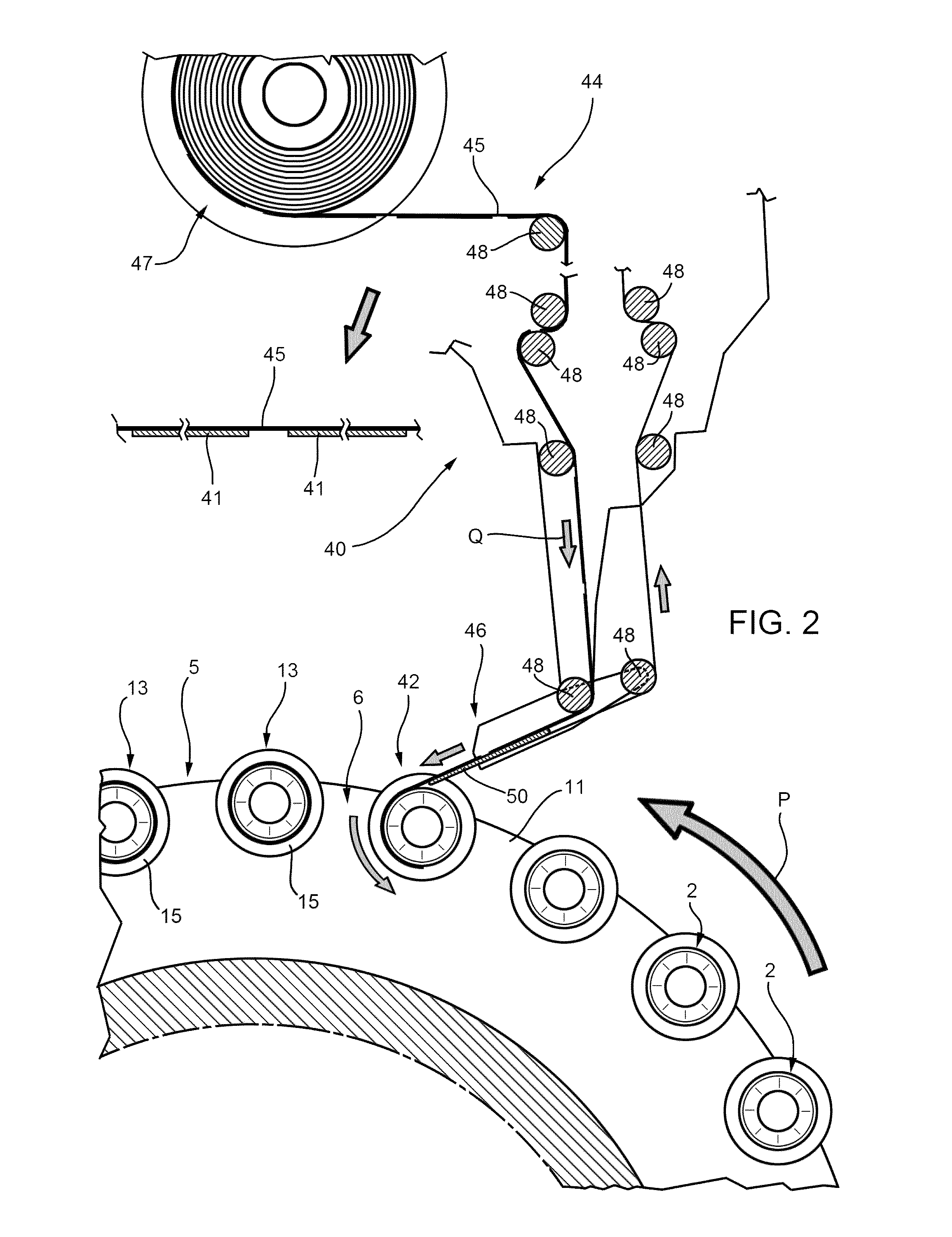

High speed decorating system

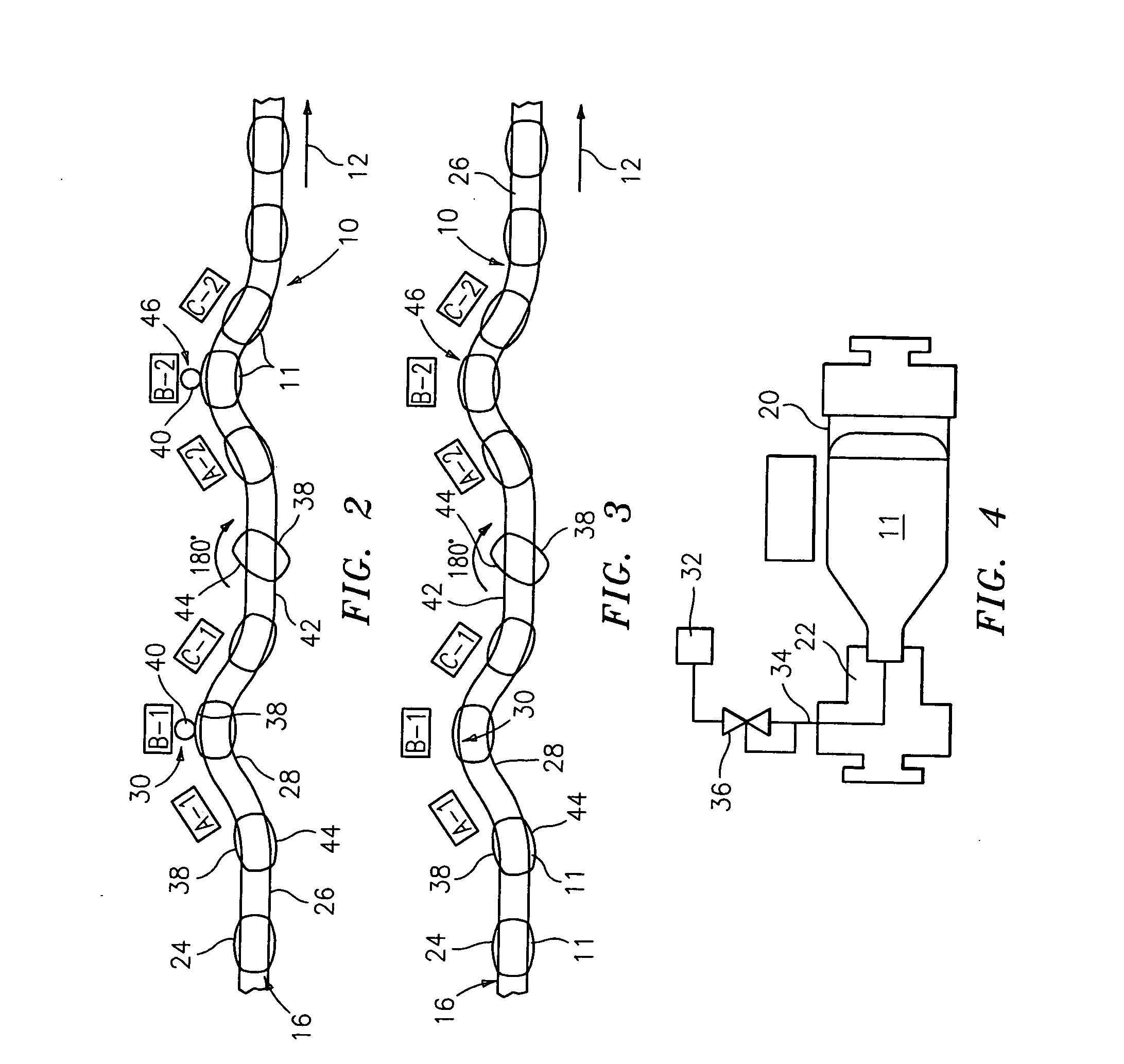

ActiveUS20070209753A1Increase speedAccurate transferLabelling non-rigid containersDecorative surface effectsEngineeringBottle

A label applicator system provides for high speed, accurate label transfer from a web to items moving on an item transport along a path relative to the system. The items, such as bottles, have a contoured surface. The applicator includes a supply reel for supplying labels on a web and a take-up for taking up the web after transfer of the label. A drive roller moves the web through the applicator system. The system includes a web positioning assembly and a movable label applicator head. A contour sensor senses the bottle contour and develops a profile for the head to follow to apply the labels to the bottles. The supply, take-up and the drive are operably engaged with one another to maintain a relatively constant tension in the web. The web positioning assembly is configured to advance and retract the web to accommodate a pitch difference between the bottles in the bottle transport and the labels on the web and to accommodate movement of the decorating head toward and away from the bottles in the bottle transport.

Owner:ILLINOIS TOOL WORKS INC

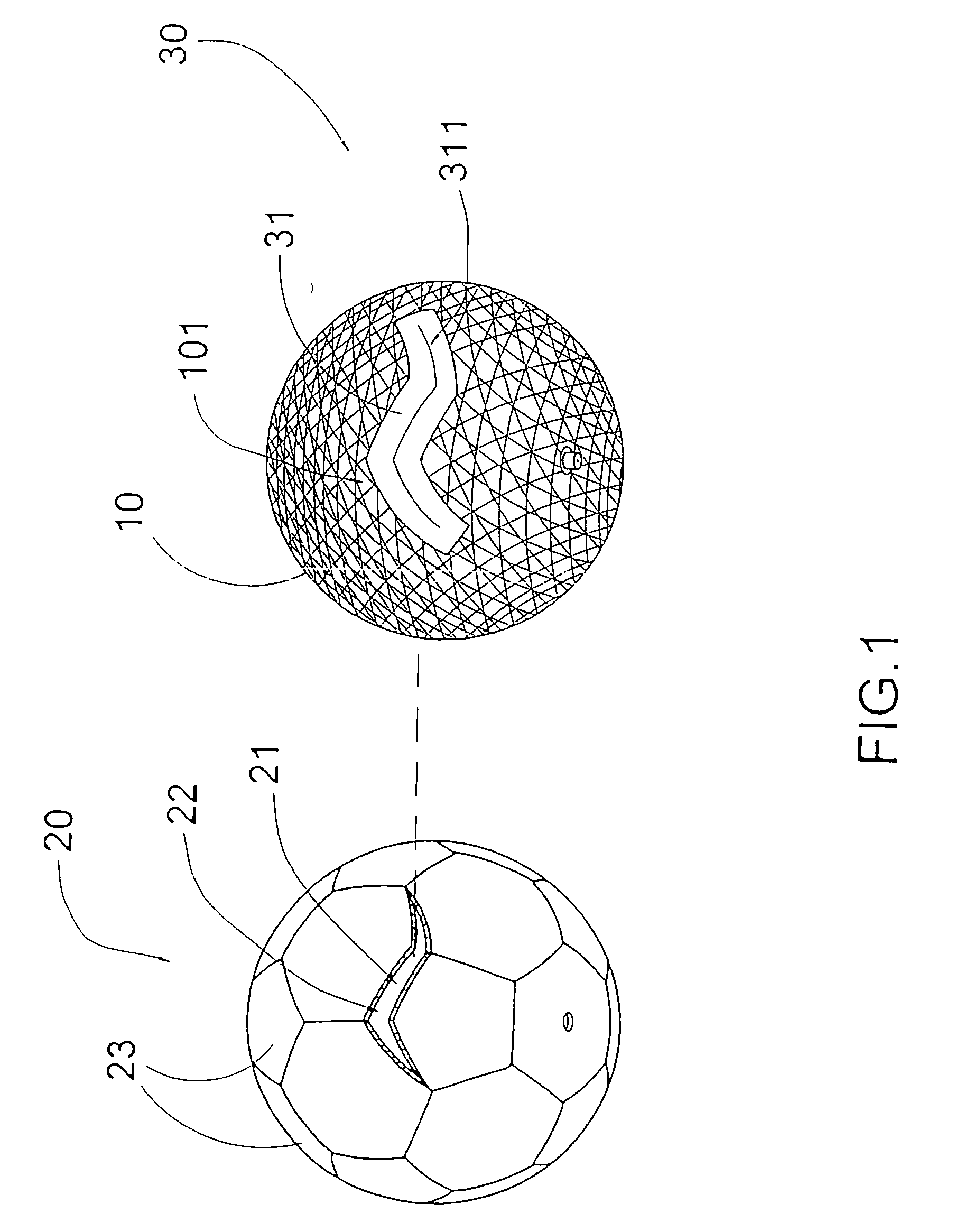

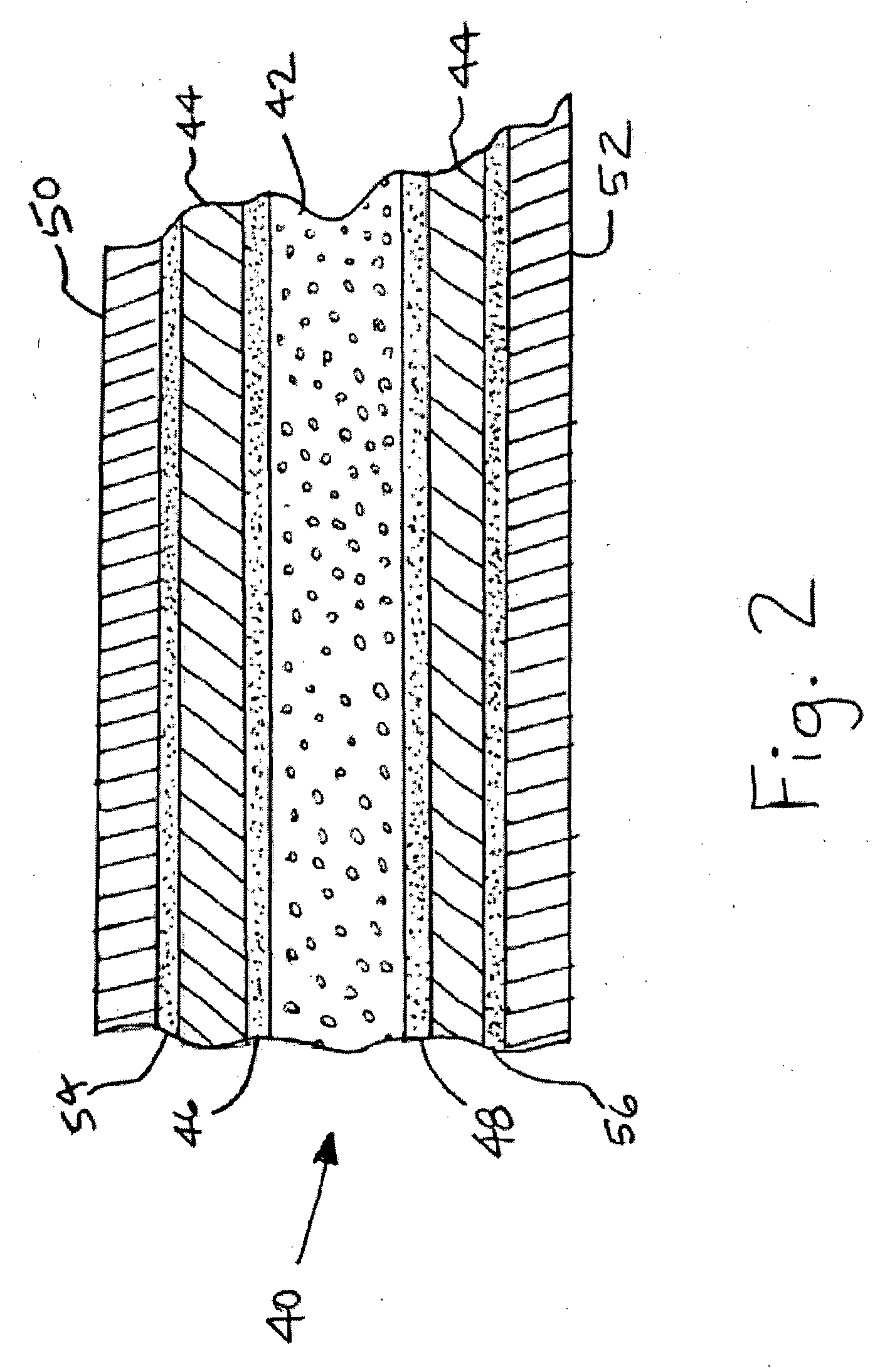

Method for fabricating rib-stiffened composite structures

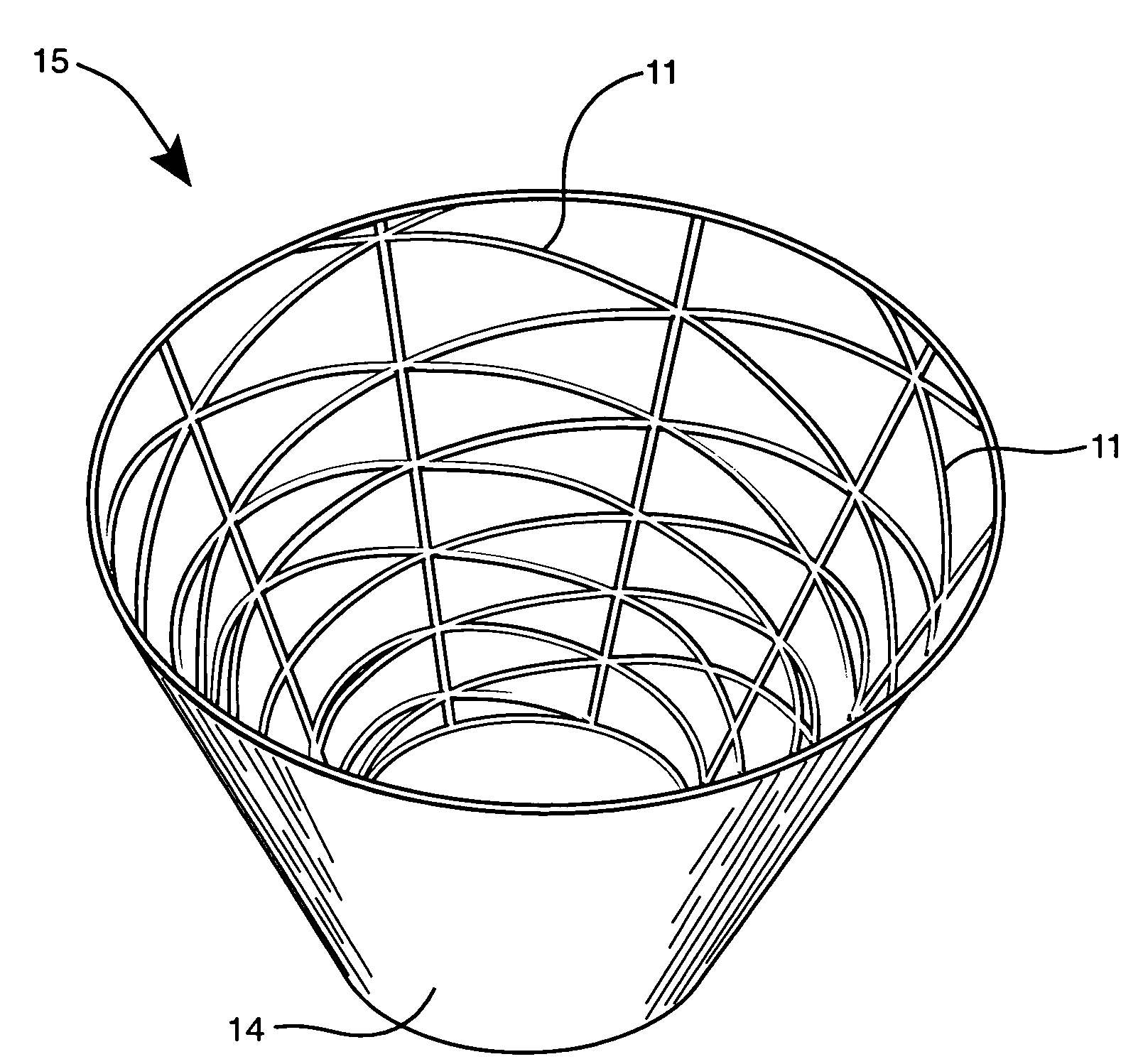

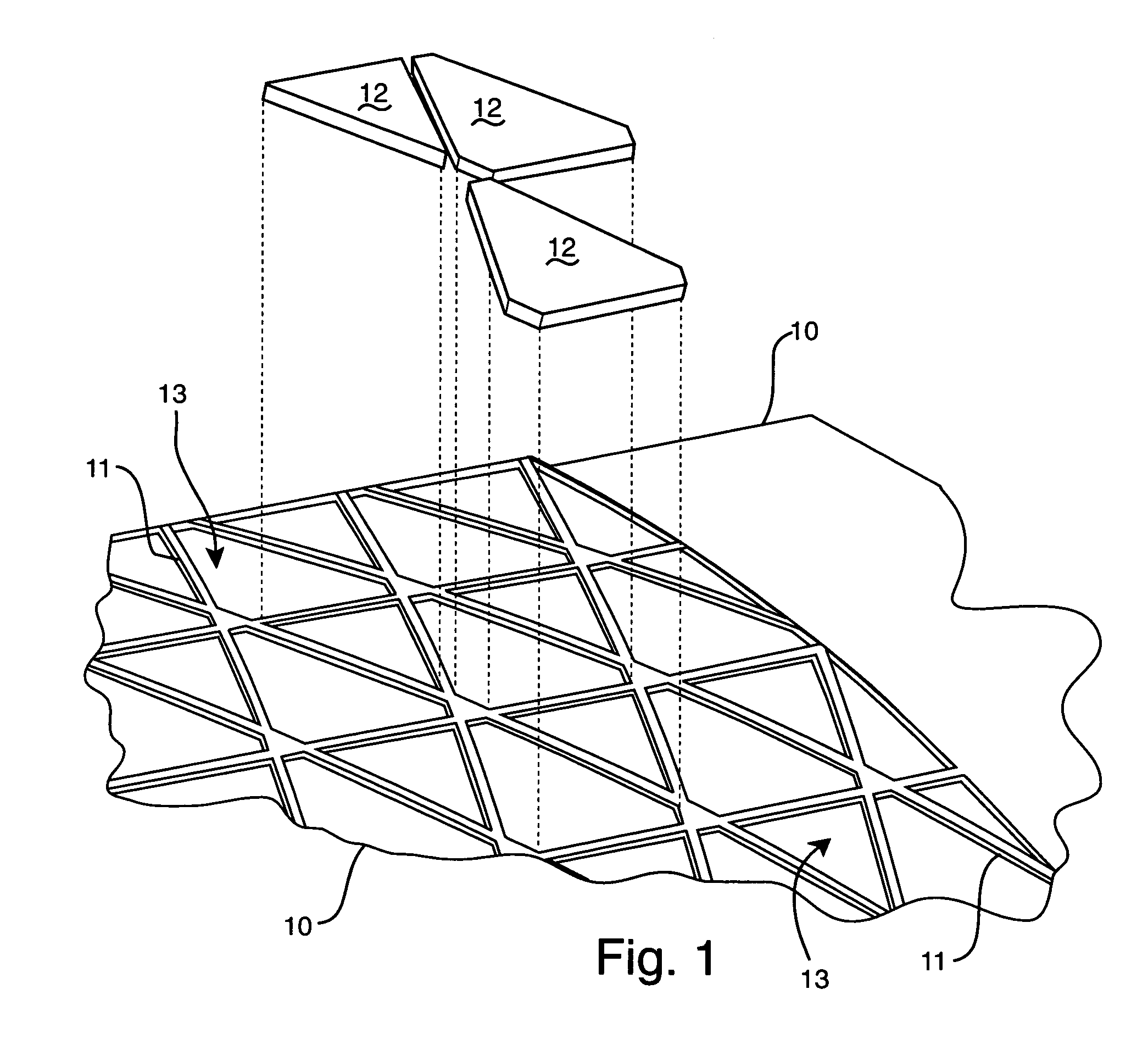

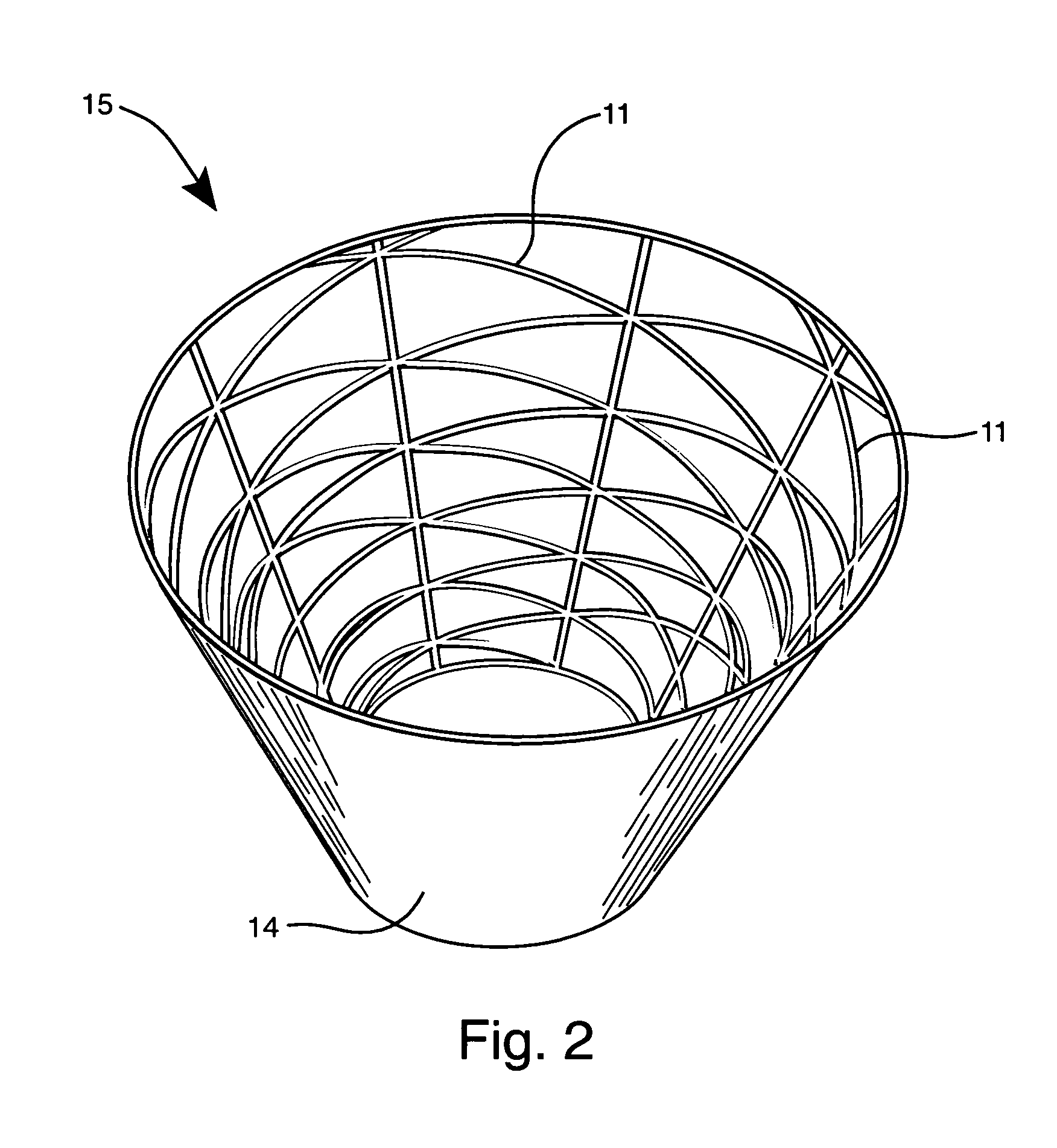

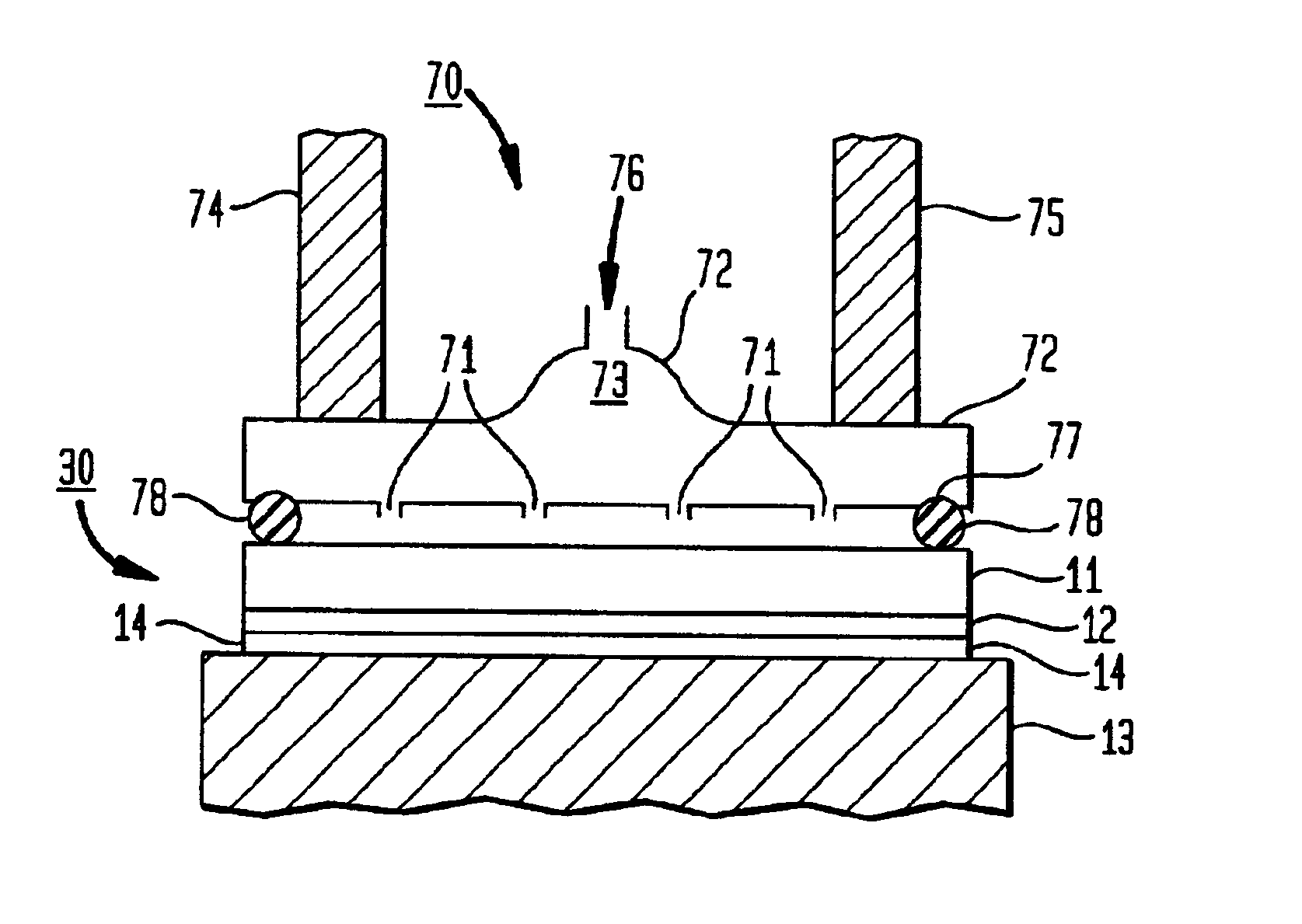

InactiveUS7479201B1Minimizing any differential in pressureLabelling non-rigid containersMouldsMesh gridComposite structure

A method for fabricating a grid-stiffened structure from fiber-reinforced composite materials. Ribs are formed on a smooth hard base tool. Expansion blocks are placed in the shallow cavities formed by the ribs and the base tool, and held in place by a synthetic elastomer-based adhesive while a skin is placed over the ribs, expansion blocks, and base tool. The assembly is then placed in a vacuum bag and autoclave cured. After cooling, the expansion blocks are removed and the formed structure is removed from the hard base tool. This abstract is provided to comply with the rules requiring an abstract, and is intended to allow a searcher or other reader to quickly ascertain the subject matter of the technical disclosure. It is submitted with the understanding that it will not be used to interpret or limit the scope or meaning of the claims.

Owner:THE UNITED STATES OF AMERICA AS REPRESETNED BY THE SEC OF THE AIR FORCE

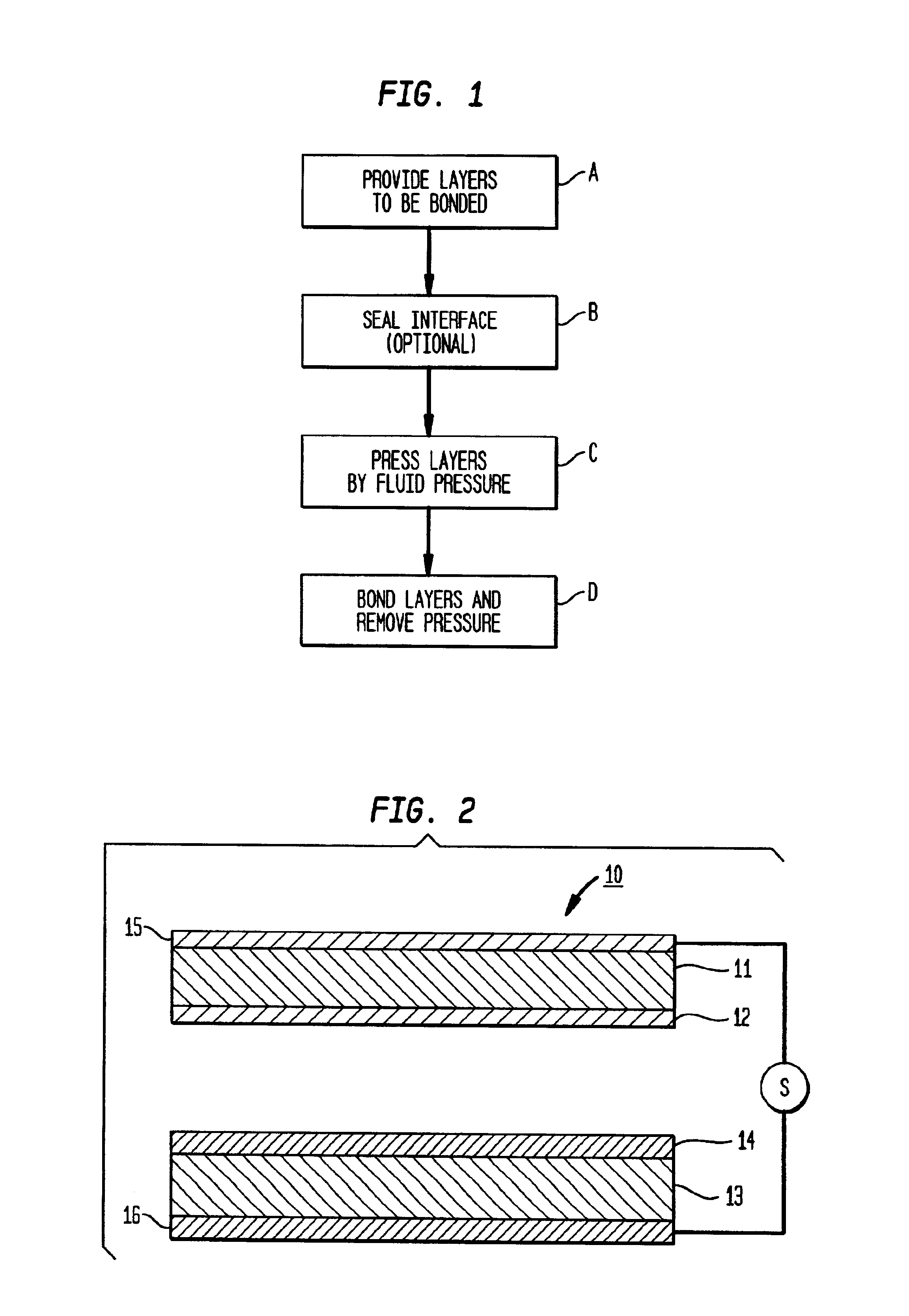

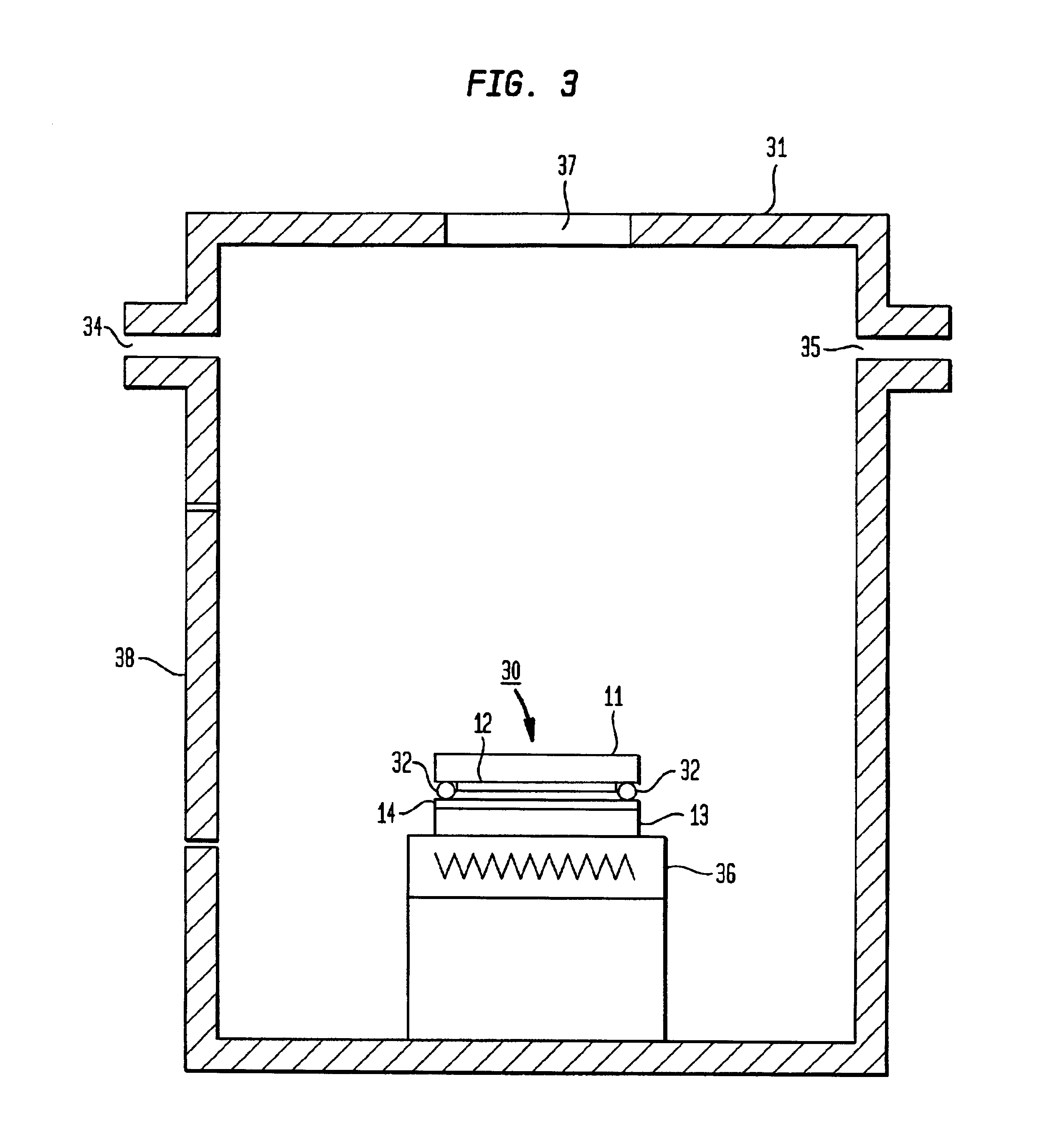

Fluid pressure bonding

InactiveUS6946360B2Reduce voidsImprove uniformityLabelling non-rigid containersNanoinformaticsImproved methodFluid pressure

An improved method of bonding involves using direct fluid pressure to press together the layers to be bonded. Advantageously one or more of the layers are sufficiently flexible to provide wide area contact under the fluid pressure. Fluid pressing can be accomplished by sealing an assembly of layers to be bonded and disposing the assembly in a pressurized chamber. It can also be accomplished by subjecting the assembly to jets of pressurized fluid. The result of this fluid pressing is reduction of voids and enhanced uniformity over an enlarged area.

Owner:NANONEX

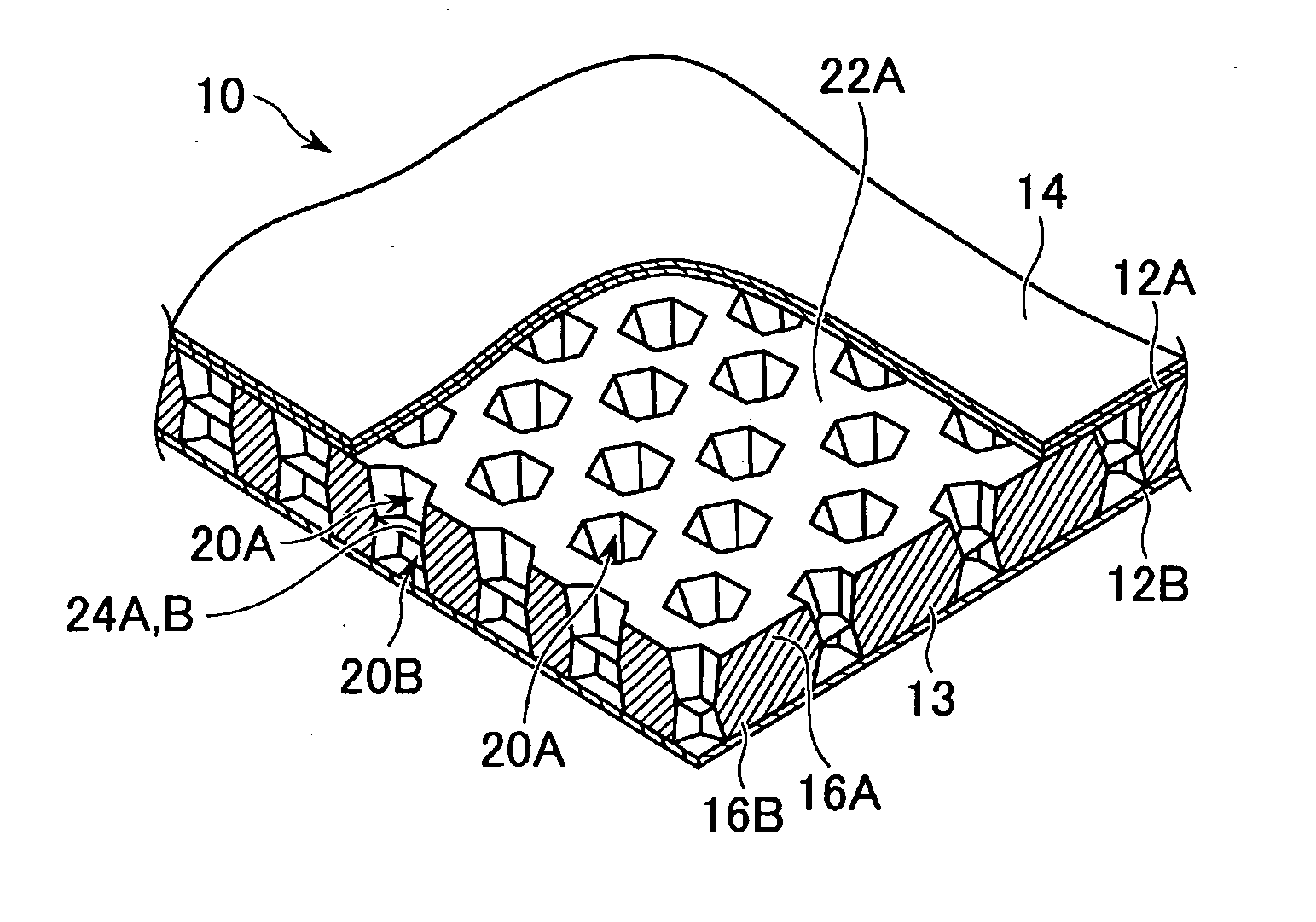

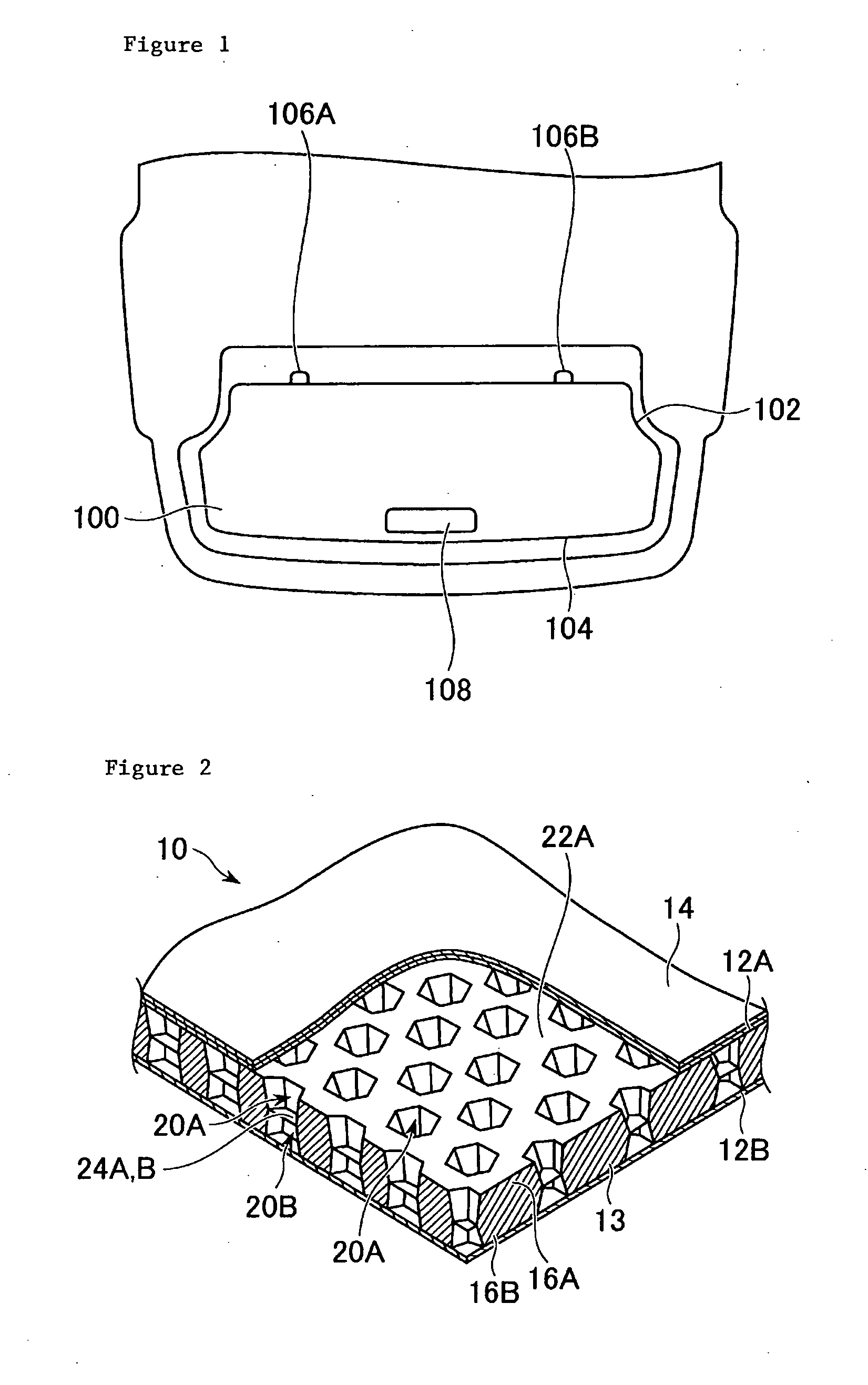

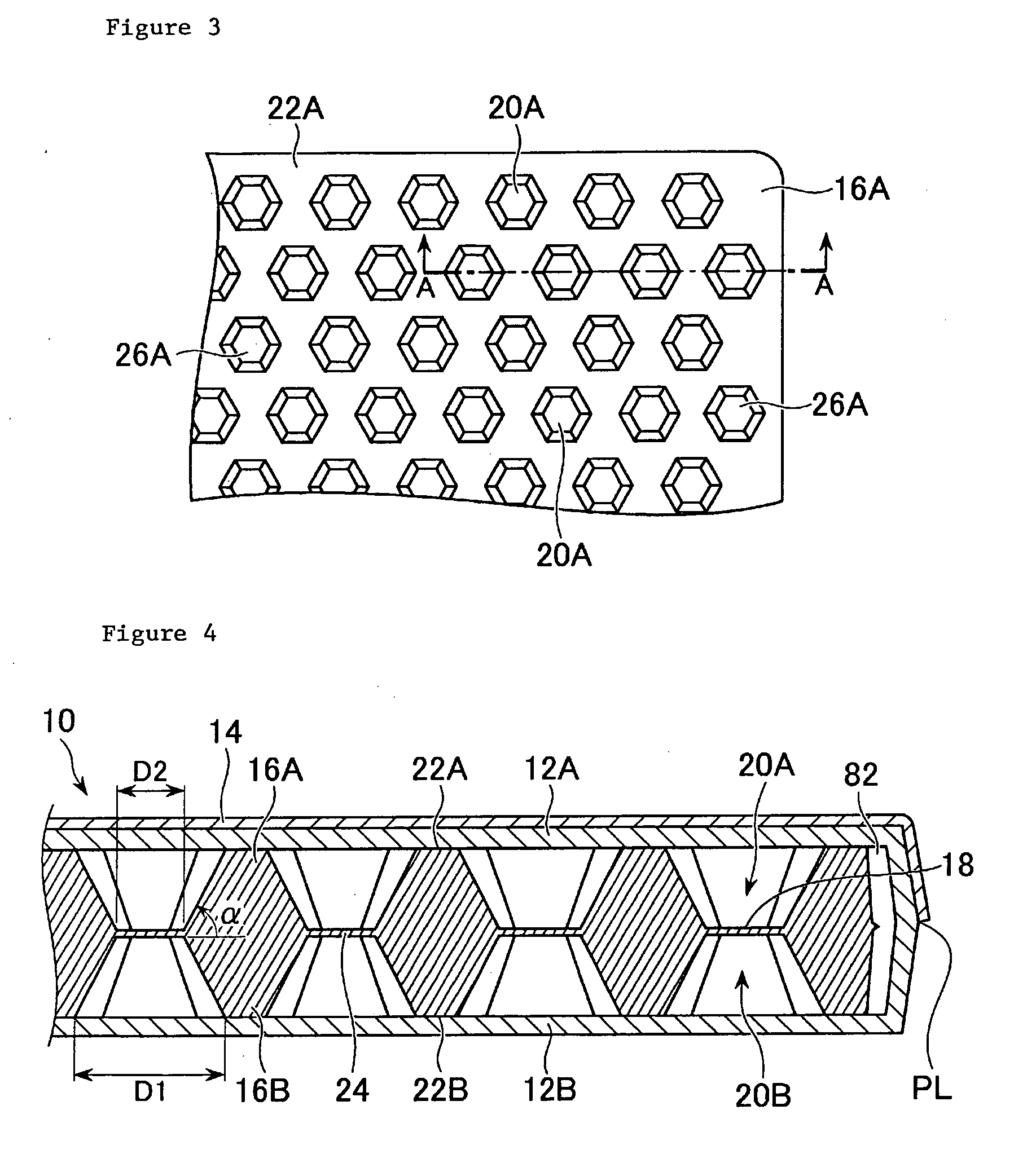

Core material for sandwich panel, method of molding core material for sandwich panel, sandwich panel, and method of molding sandwich panel

ActiveUS20110135862A1High strengthLabelling non-rigid containersLayered productsSandwich boardEngineering

An object of the present invention is to provide a core member for a sandwich panel and a method of forming the core member for the sandwich panel which are capable of attaining a desired profile, a desired pattern on its surface, and a desired inner structure in accordance with an application of the sandwich panel. According to an aspect of the invention, there is provided a thermoplastic resin core member interposed between two resin skin sheets comprising a closed hollow portion located to be inside of a desired position in accordance with an application of the sandwiched panel, and it is formed by clamping parison of a molten thermoplastic resin positioned to be between two split molds so as to exhibit a desired profile and / or a surface shape, two surfaces against each of which the molten parison is pressed to form an adhesive surface on which the corresponding resin skin sheet is formed.

Owner:KYORAKU CO LTD

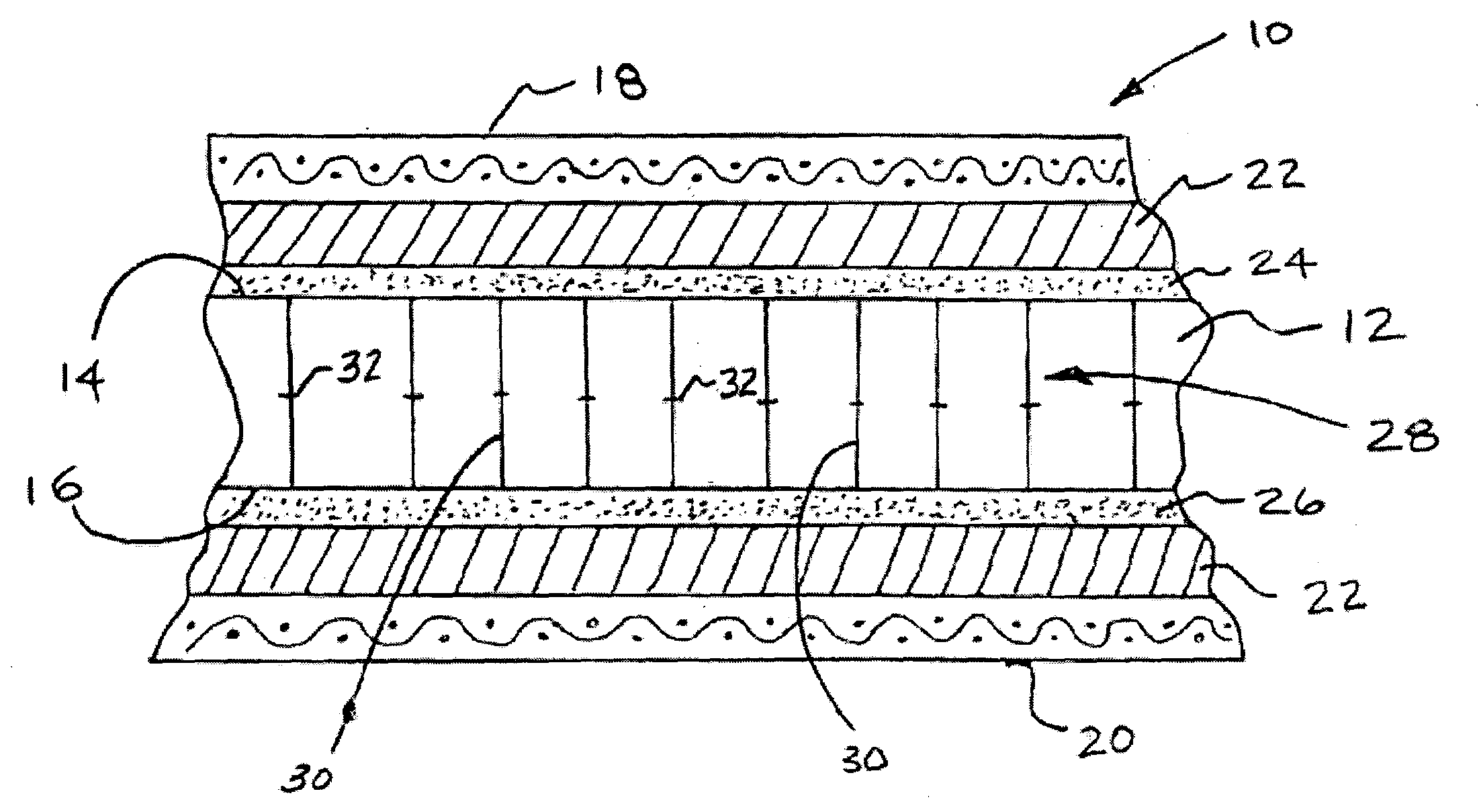

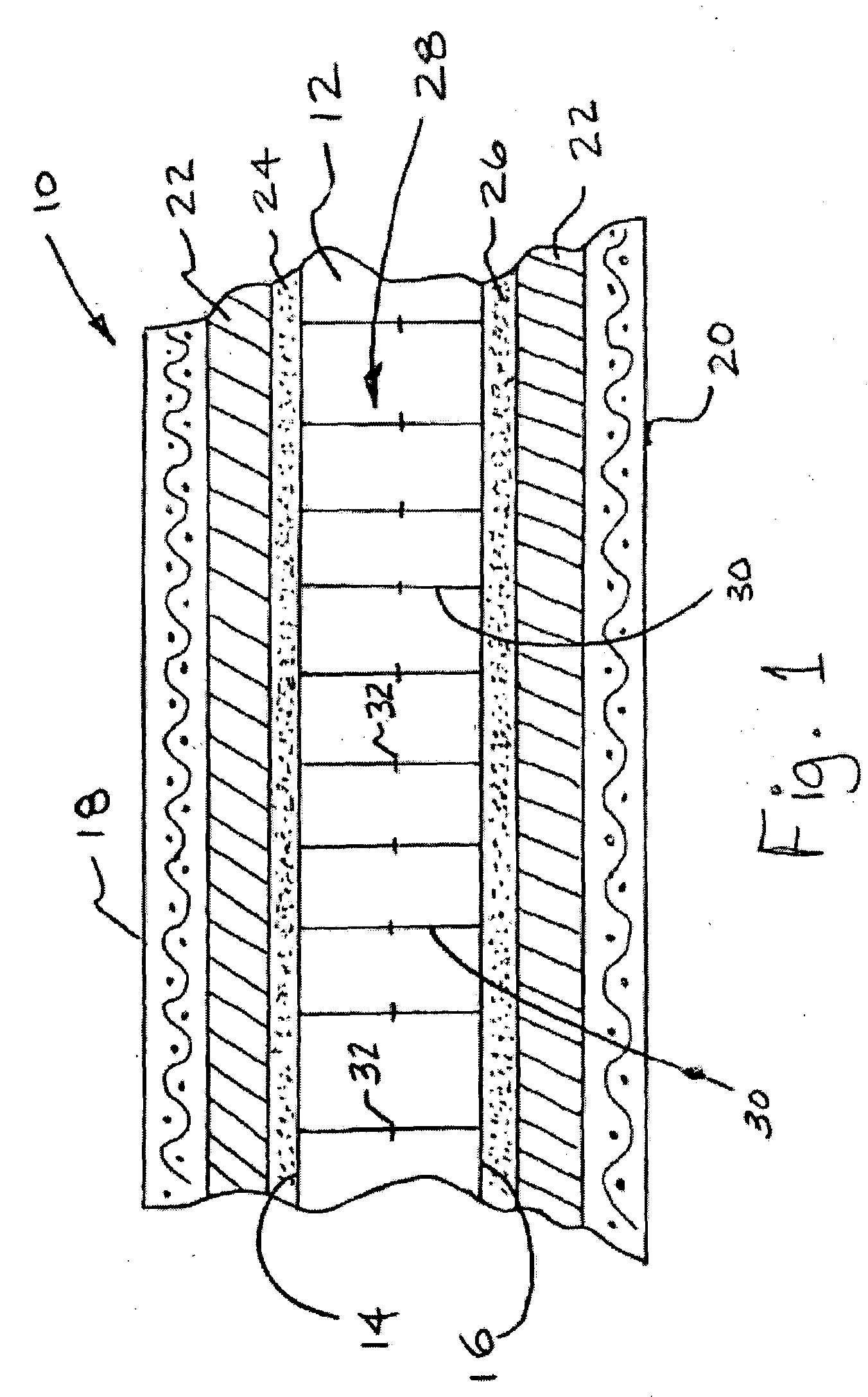

Sandwich panel with interior barrier

InactiveUS20050025929A1Reducing of other imperfectionReducing amount of void and other imperfectionLabelling non-rigid containersLaminationSurface finishCounter pressure

Composite sandwich panels that include a core having a permeable body that is sandwiched between two skins. An internal barrier is located between the skins and the core to provide an impermeable chamber surrounding the permeable core. The chamber is pressurized during formation of the panel to provide an interior counter pressure against the mold / press used to form the panel. The counter pressure applied by the chamber reduces the amount of voids in the skins and improves the surface finish of the skins. In addition, the impermeable material remains within the finished panel to provide an internal barrier surrounding the core.

Owner:HEXCEL

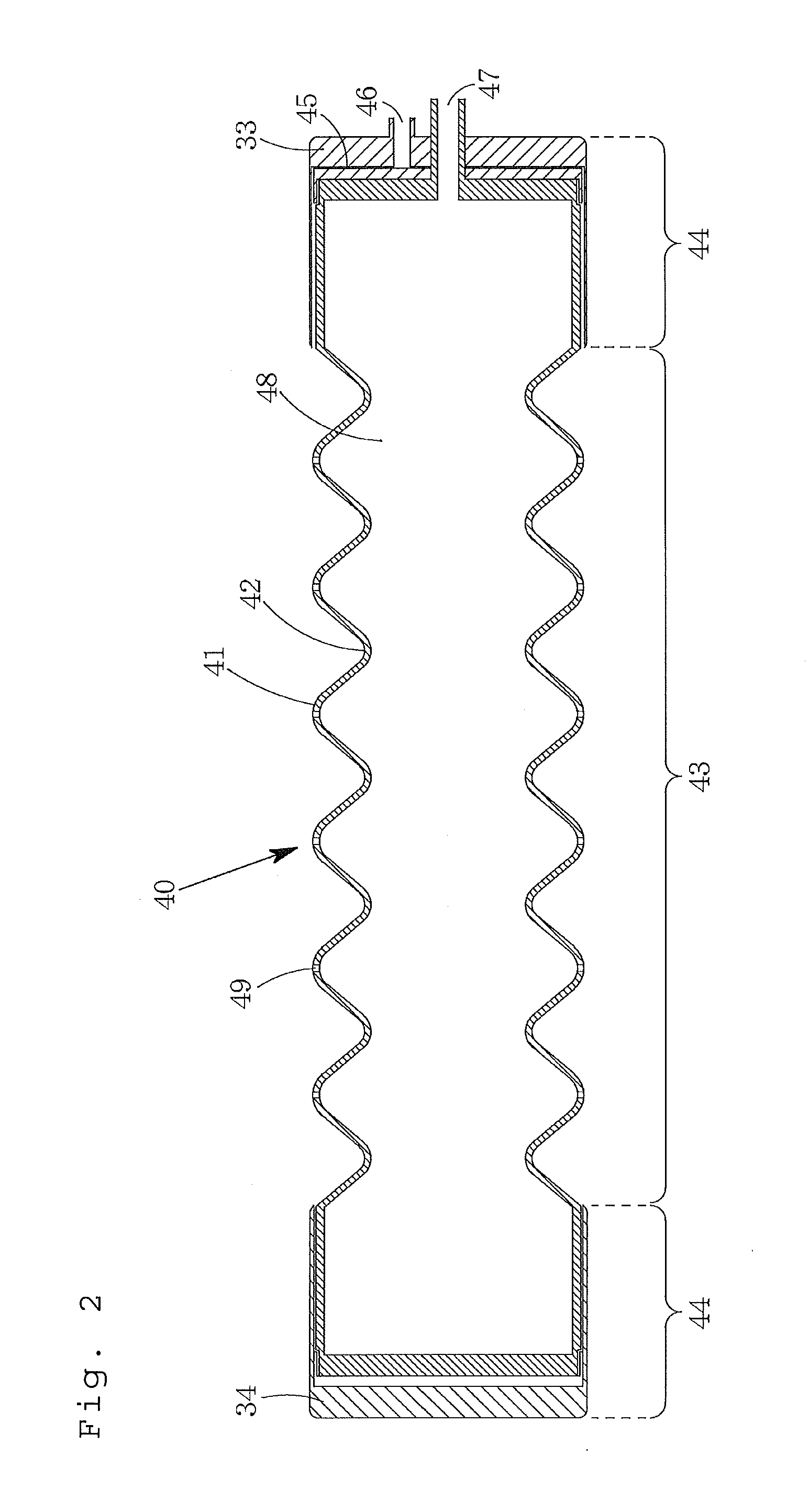

Method of making a medical balloon

ActiveUS20130261547A1Burst strength is maximizedMinimizes shrinkageLabelling non-rigid containersBalloon catheterBalloon catheterMelt temperature

A medical balloon for a balloon catheter is described. The balloon has at least a first layer made from a first material and a second layer made from a second material, said first and second layers being in overlying relationship with one another and being integral with one another; wherein the first layer has a softening or melting temperature which is higher than a softening or melting temperature of the second layer. A method of forming the medical balloon is also described, including locating a raw tubing in a mold; preheating and inflating the raw tubing so as to cause it to stretch; heating the raw tubing to soften or melt the second layer; setting the inflated raw tubing to form the medical balloon; and cooling the set balloon.

Owner:COOK MEDICAL TECH LLC

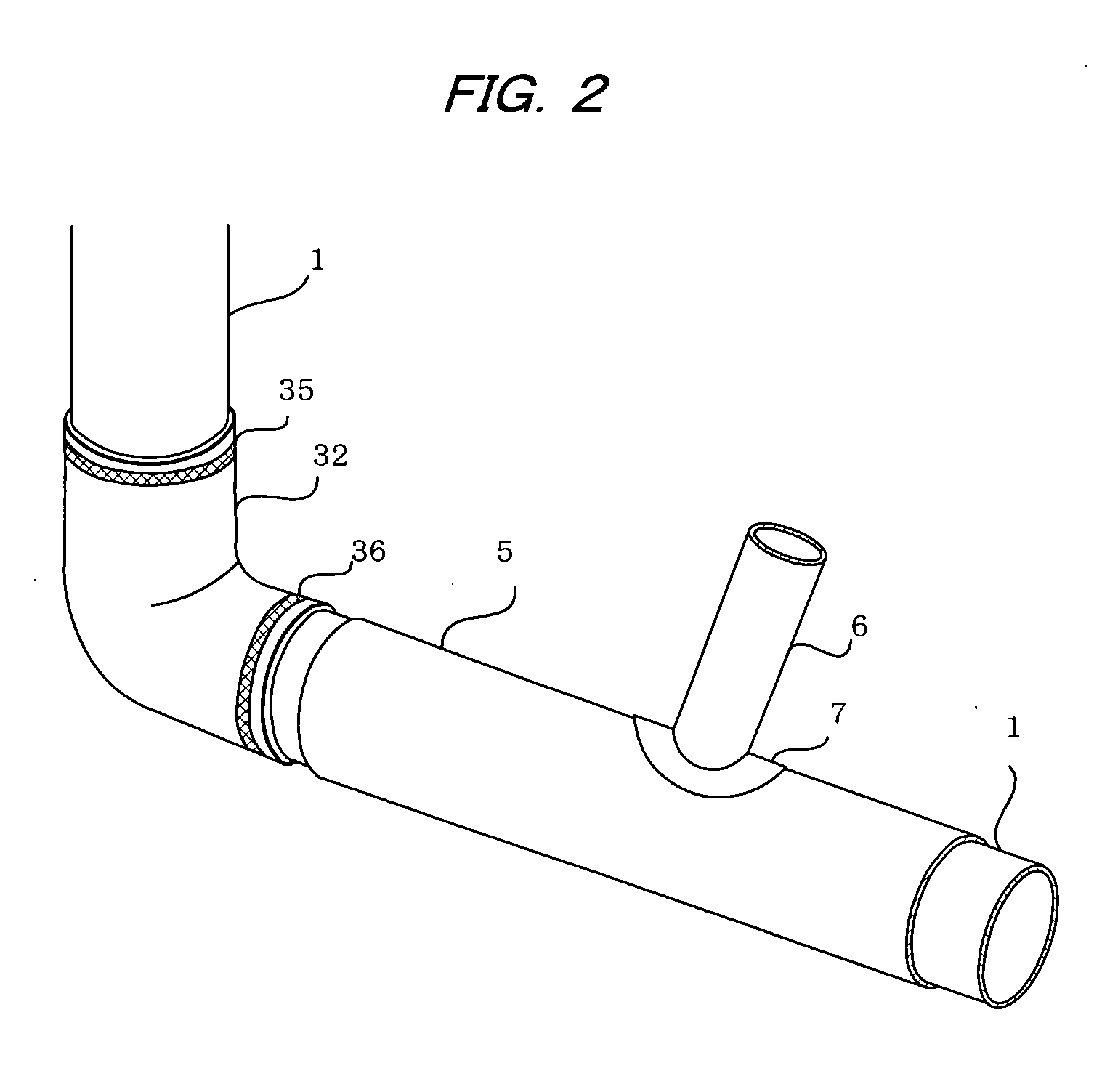

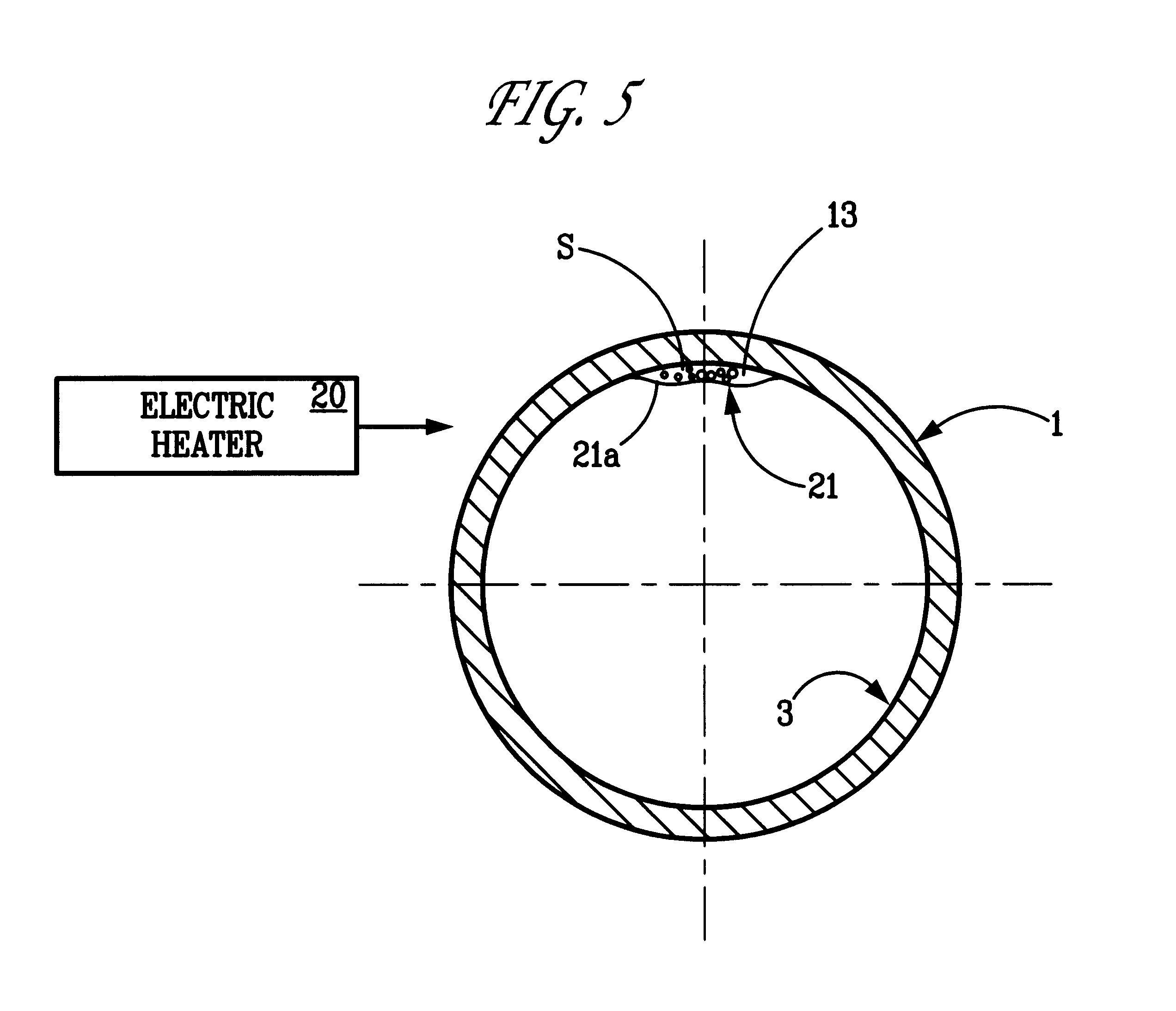

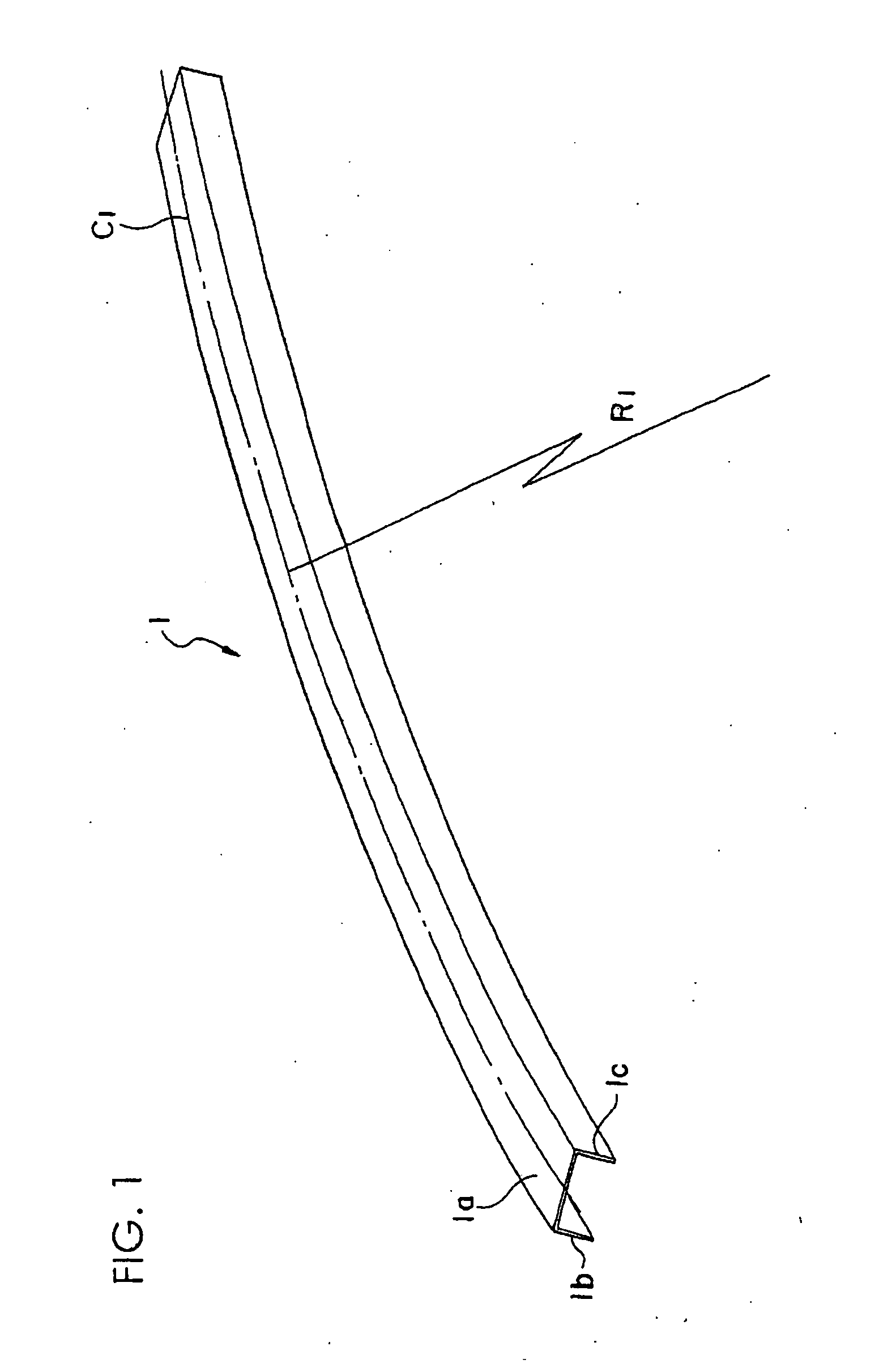

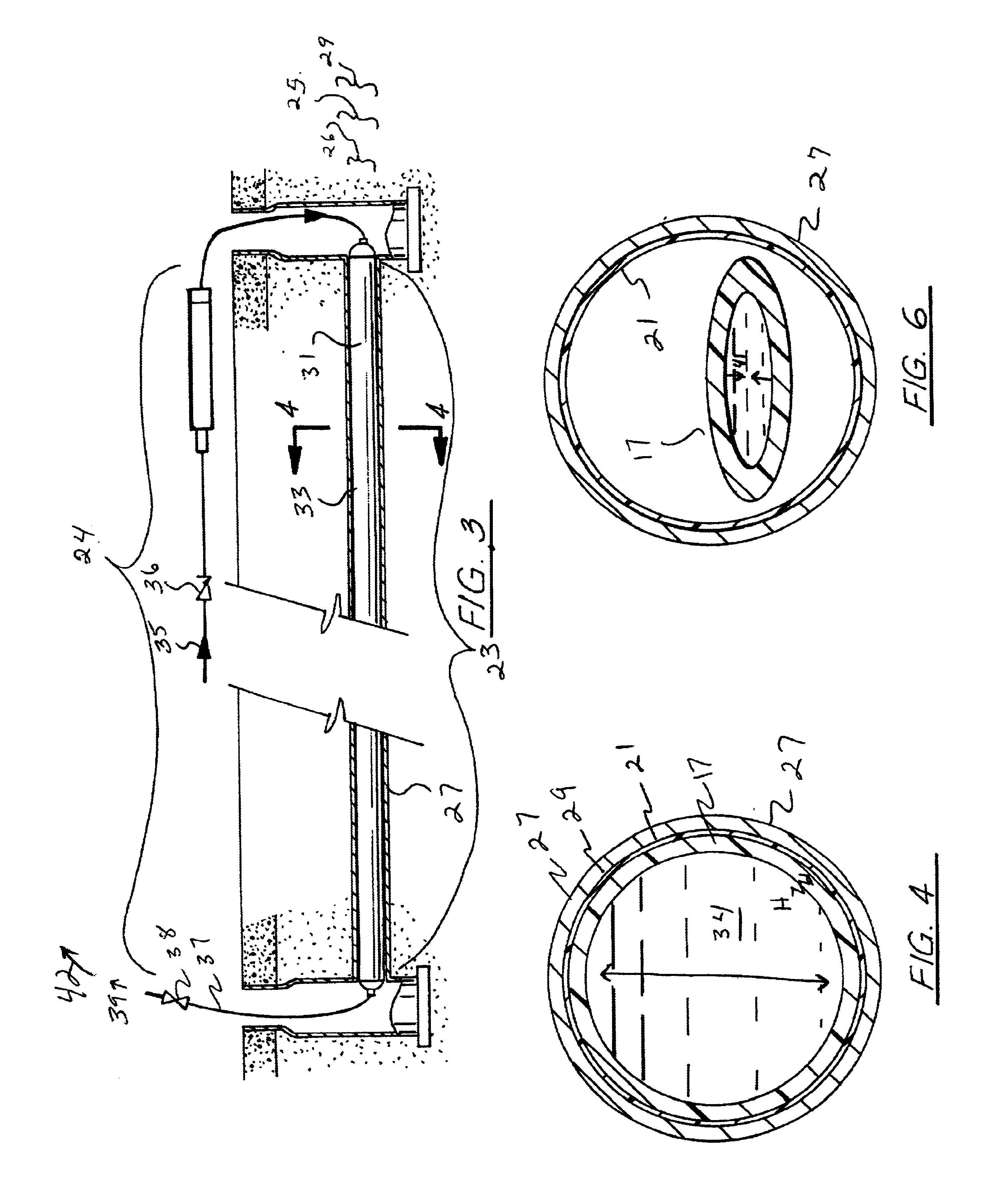

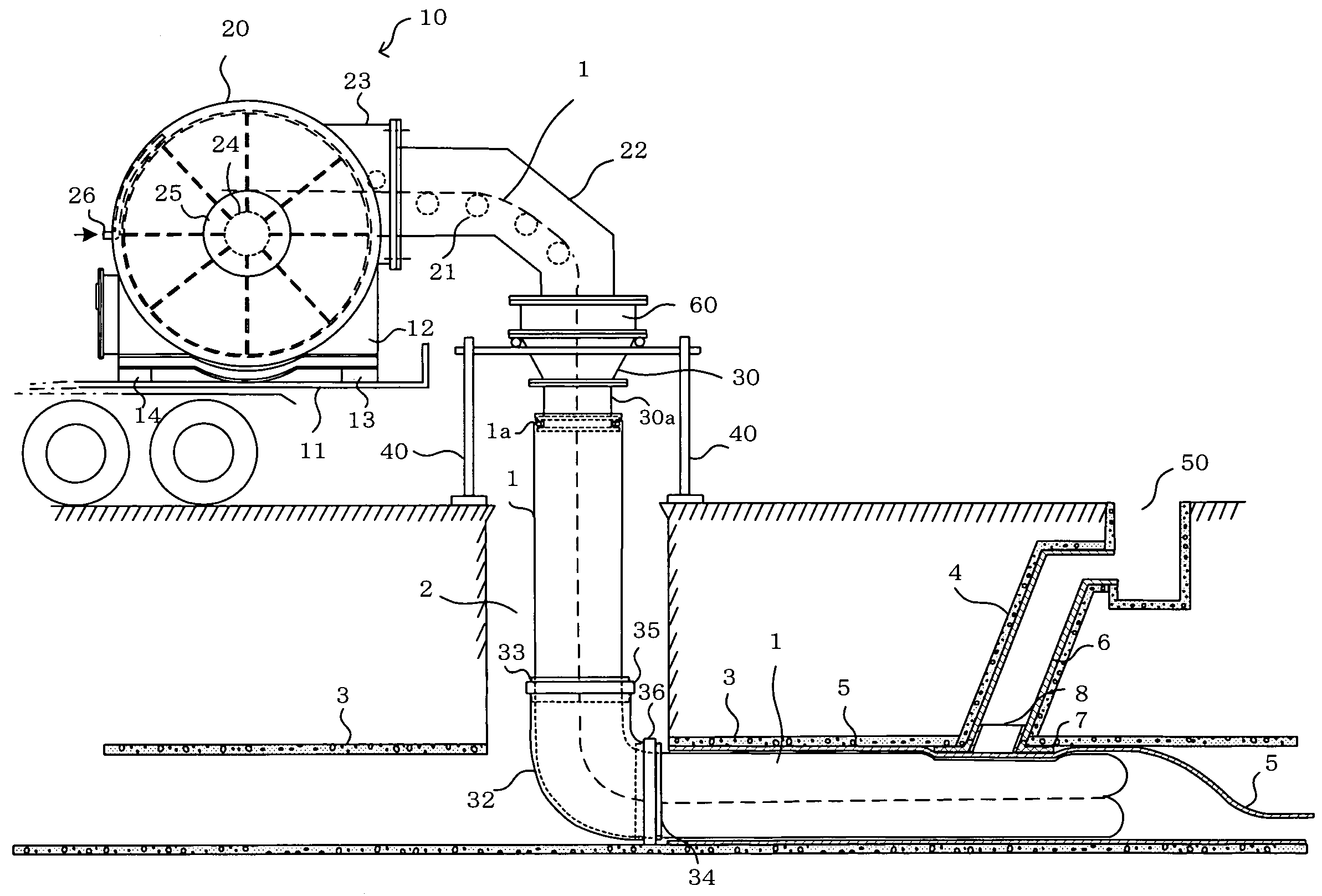

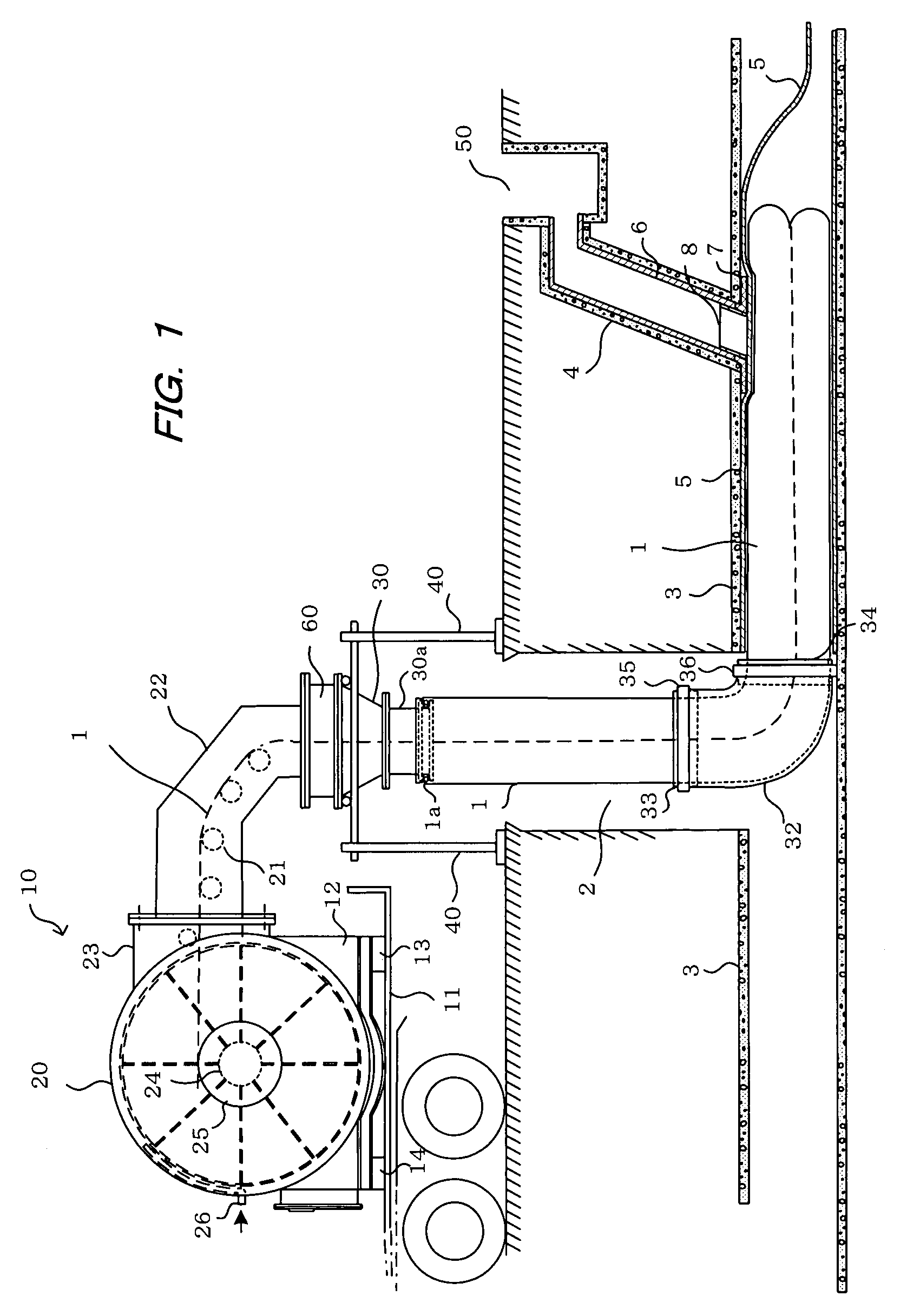

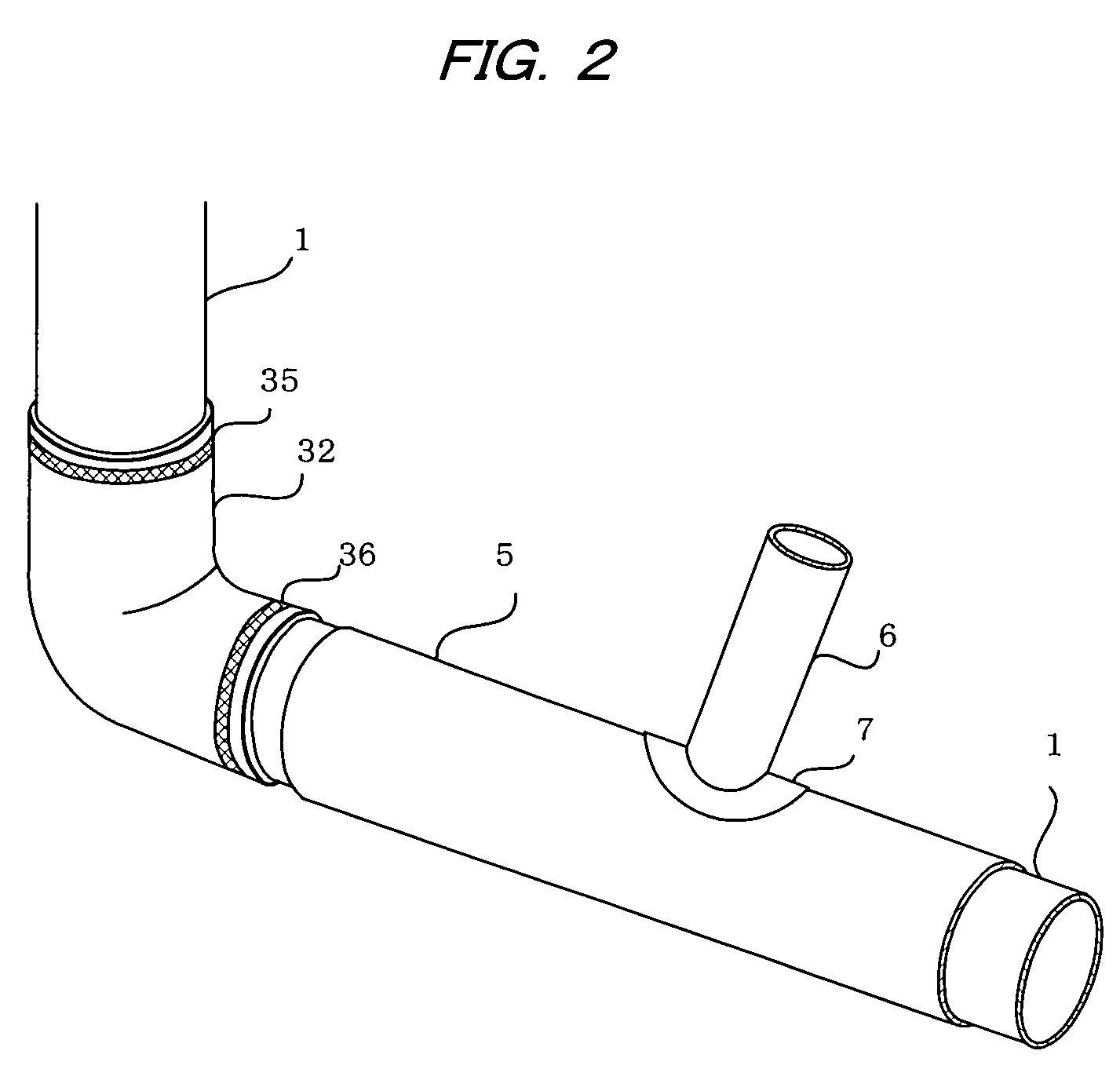

Pipe lining method

There is provided a pipe lining method wherein a lateral pipe lining material and a main pipe lining material are securely joined. After a lateral pipe has been lined, a start liner is applied to the main pipe and a main pipe lining material is then inserted. A heating wire for melting the start liner is mounted on a surface of a flange of the lateral pipe lining material during or after lining of the lateral pipe. While the main pipe is being lined, the heating wire is heated to melt the start liner existing between the flange of the lateral pipe lining material and the main pipe lining material. When the resin in the main pipe lining material is cured, the main pipe lining material and flange of the lateral pipe lining material are integrated. This allows the lateral pipe lining material and main pipe lining material to be reliably joined.

Owner:SHONAN GOSEI JUSHI SEISAKUSHO KK

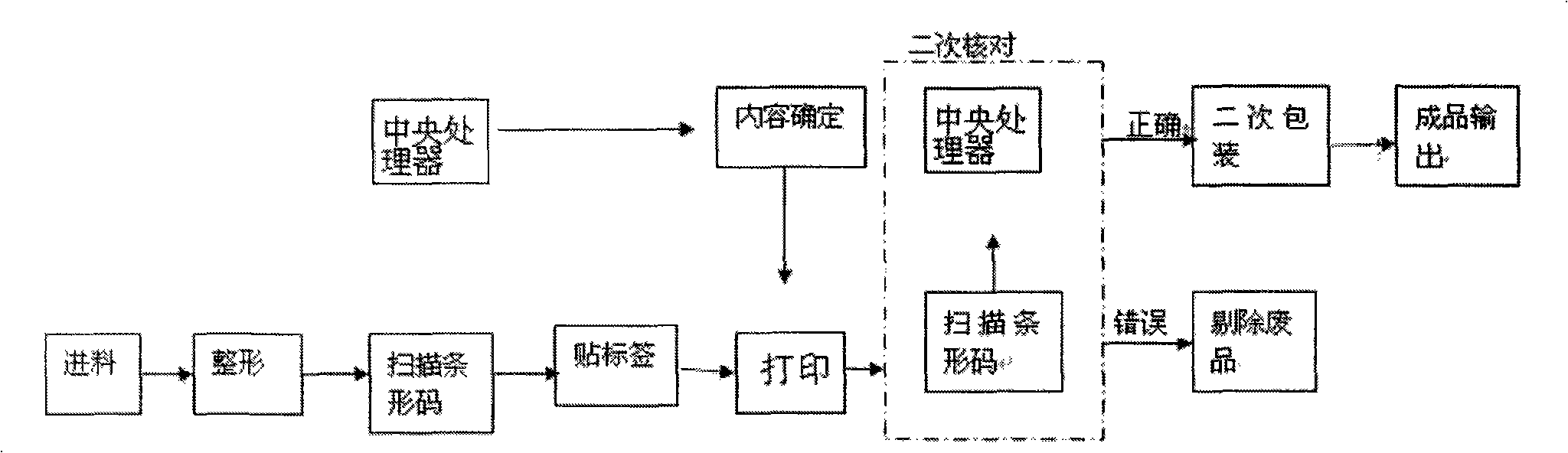

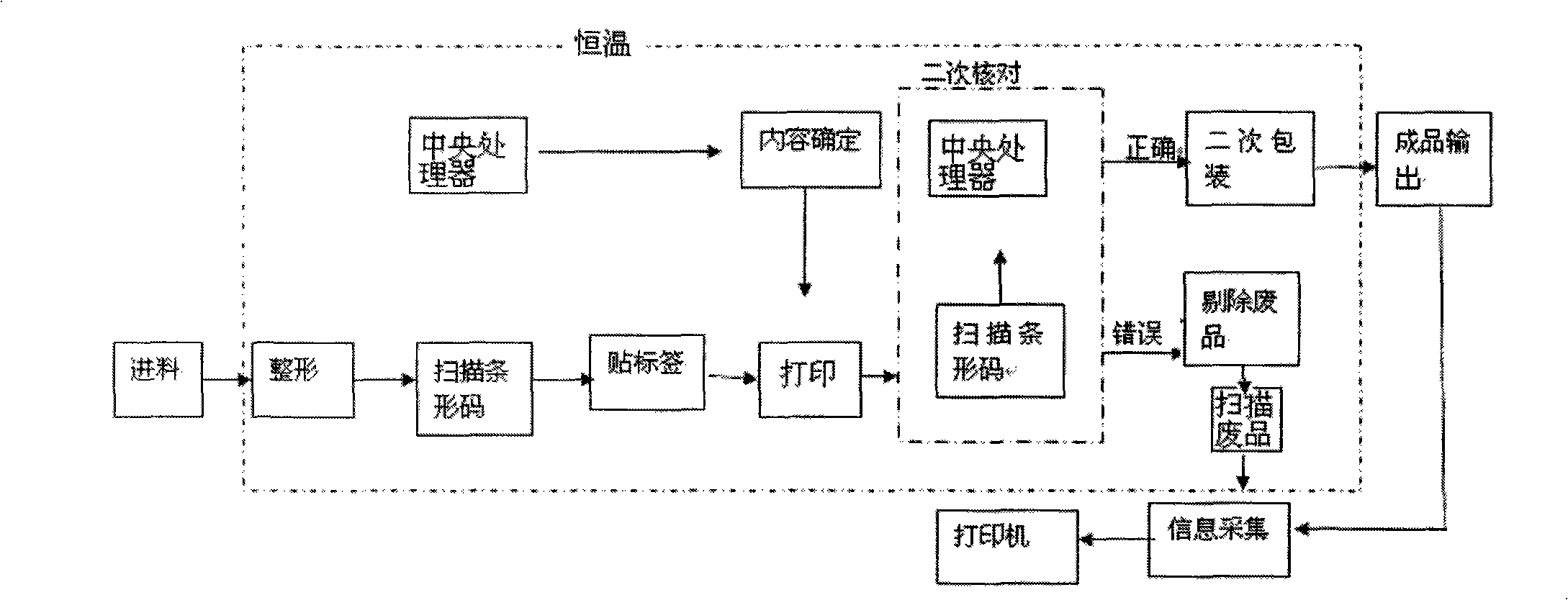

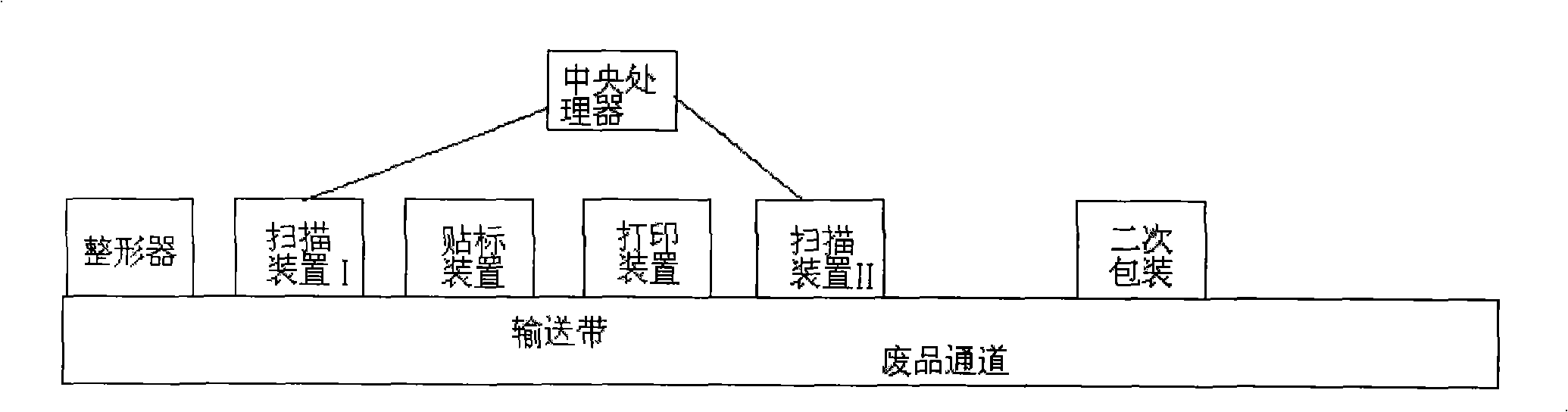

Full-automatic intelligentized blood bar code safety recognition sorting and checking package method and system

ActiveCN101342955ARealize intelligent identificationProduction Process AutomationLabelling non-rigid containersPackaging automatic controlWhole blood productBlood product

The invention discloses a fully automatic intelligentized blood bar code safety identification, partial checking and packing method and a system thereof. A blood bag is first reshaped and then is scanned; the scanning information is sent to a central processor; after that, the blood bag is labeled and printed and then is scanned again; the central processor checks the bar code of the blood bag again, the blood bags with right information will enter a secondary packing device and the blood bags with wrong information will be sent to a waster passage. The invention realizes intelligentized identification, automatic labeling, automatic classification and packing of blood products and is safe, standard, scientific and reasonable, and the production can be quicker, more accurate and automatic; the invention ensures the quality of the product and eliminates the defects of low efficiency and wrong labels caused in manual processing.

Owner:ZHENGZHOU FEILONG MEDICAL EQUIP CO LTD

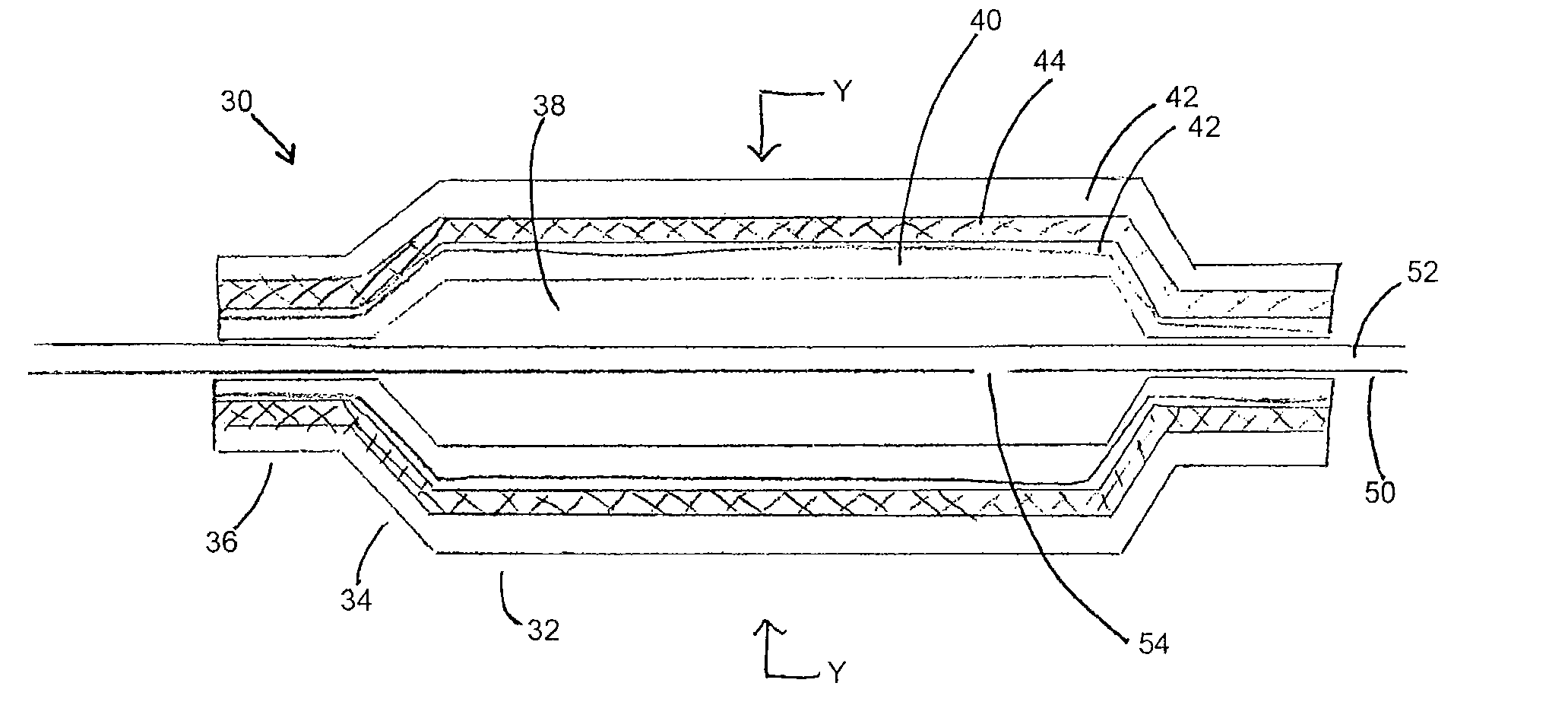

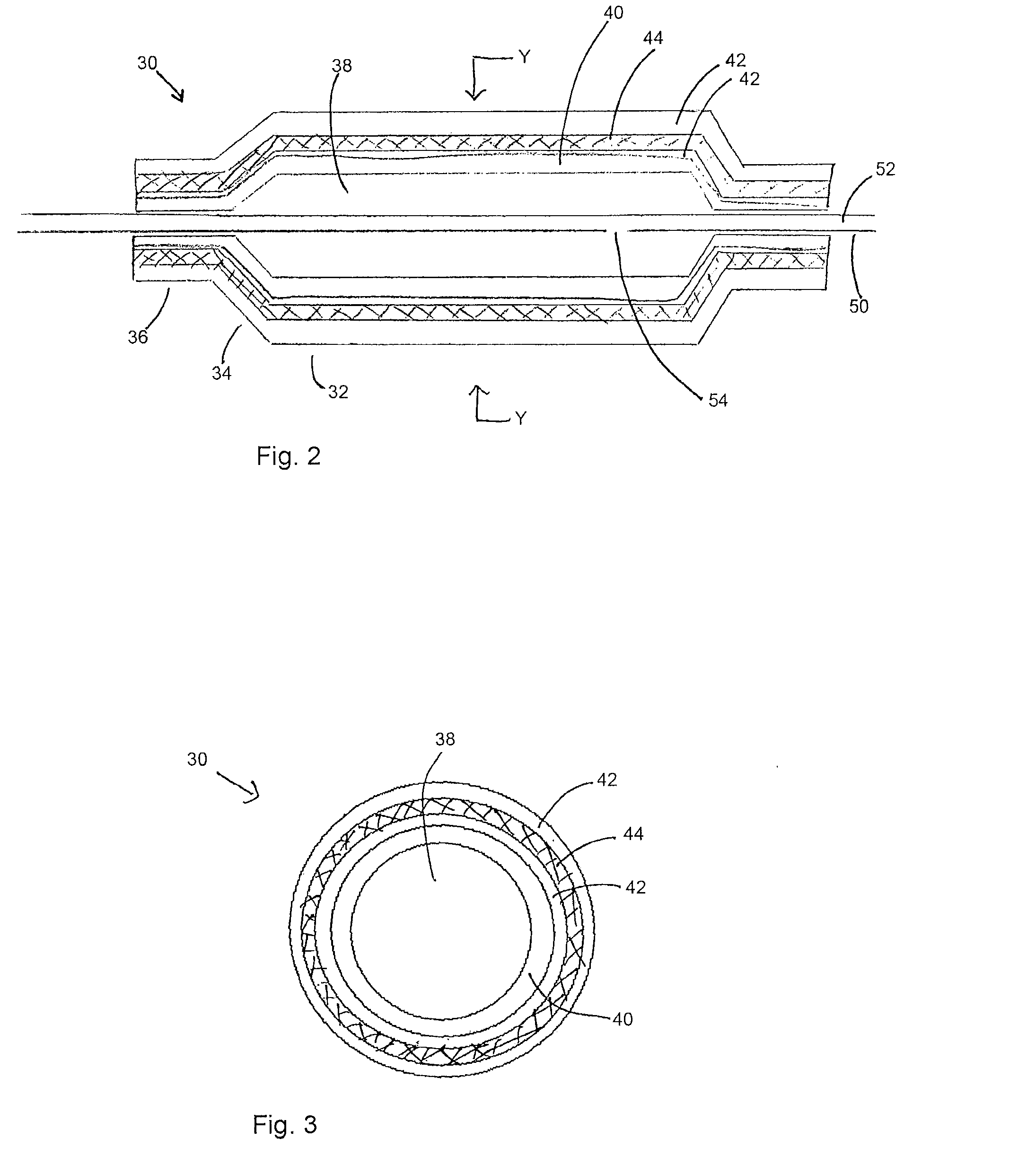

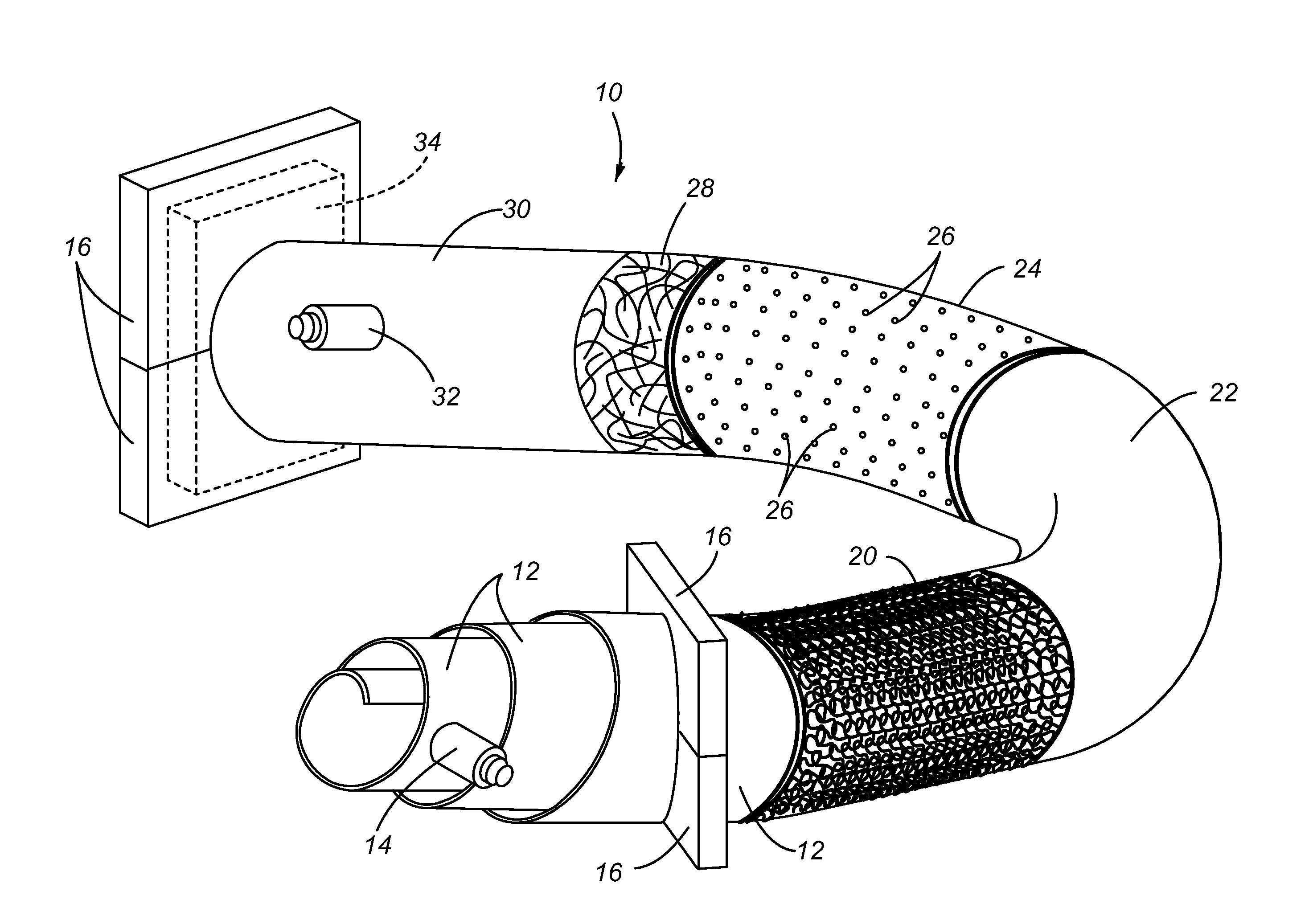

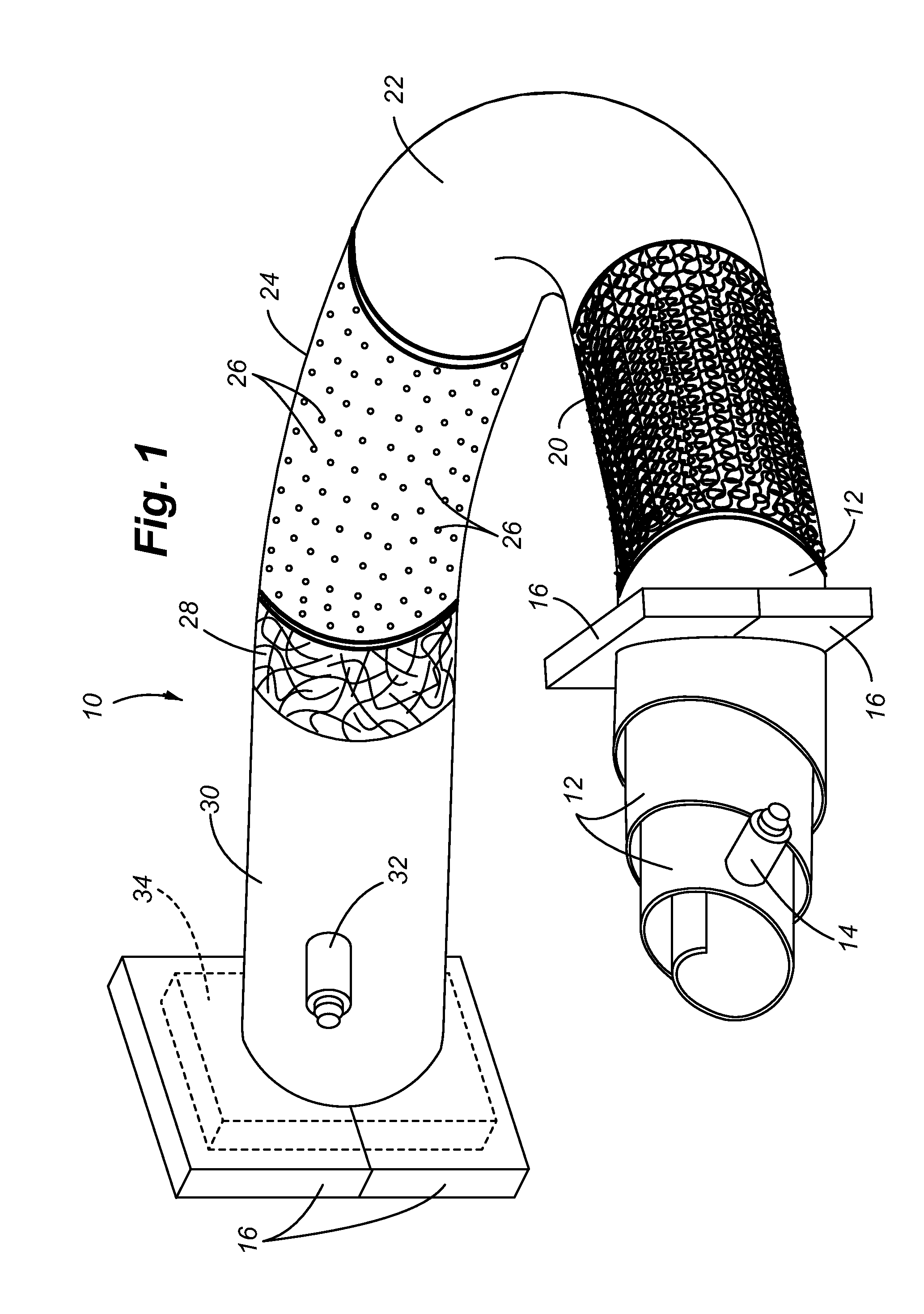

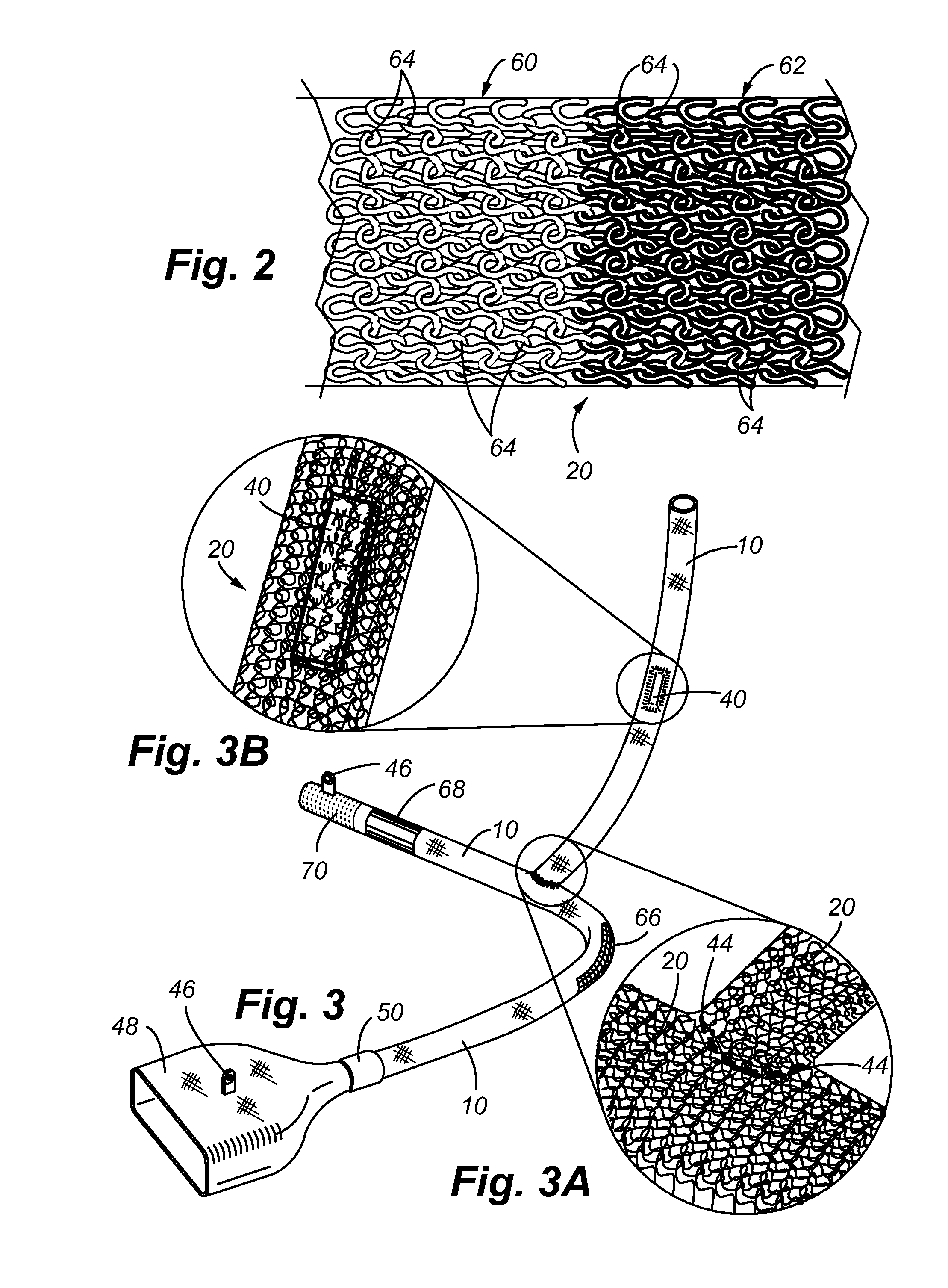

Composite tube for fluid delivery system

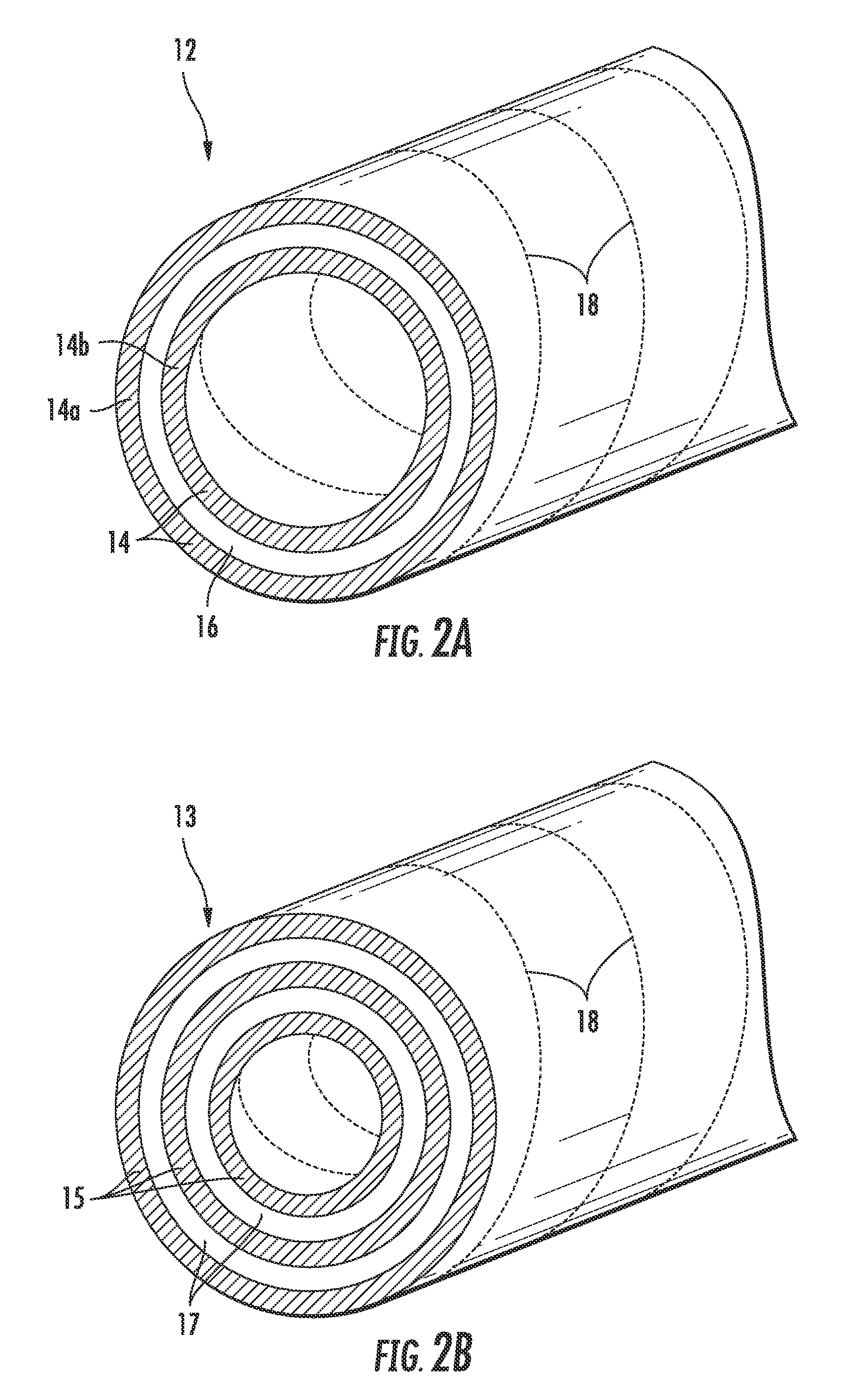

ActiveUS20120168012A1Avoids laminated seamAvoid layeringLabelling non-rigid containersPipe elementsFiberCarbon fibers

The composite tube comprises a tubular arrangement of knitted fiber characterized by a plurality of interlocking loops. Selected knitted patterns provide desired density or spacing between fibers. Selected fibers may include materials such as Kevlar®, carbon fiber, and combinations thereof. The tubular knitted pattern allows for variable electrical, mechanical and geometrical options. A matrix material is applied over the knitted fiber pattern and is allowed to cure. The matrix material may include a combination of resin and epoxy constituents. The matrix material may be applied by a vacuum bag molding process. Electrical and mechanical properties can also be controlled by selecting desired resin and epoxy constituents. The flexible knitted reinforcing layer allows use of an inflatable bladder to hold the reinforcing layer in the desired shape, thereby facilitating tube constructions of varying shapes and diameters. Continuous application of the matrix material avoids overlapping seams that are prone to delamination.

Owner:EATON INTELLIGENT POWER LIMITED

Method of laying data cables and the like in underground pipes and pipe-cable combinations

InactiveUS6572306B2Ensure protectionLabelling non-rigid containersUnderground chambersSewageEngineering

One or more electric and / or data transmitting cables are confined in an elongated strip-shaped body containing a hardenable resin or the like, and the body is placed against a portion of the internal surface of an underground sewage, water or other pipe. An expandible tubular liner is thereupon introduced into the pipe and is expanded to press the body against the pipe. The body is caused to set, by conveying a hot fluid through the liner and / or by electrically heating the cable or cables, and to adhere to the internal surface of the pipe. The liner can remain in the pipe and can be bonded to the strip-shaped body and / or to the remaining portion of the internal surface of the pipe. Alternatively, the liner is caused to collapse and is withdrawn from the pipe once the strip-shaped body is bonded to the internal surface of the pipe.

Owner:PRUSAK MARTIN

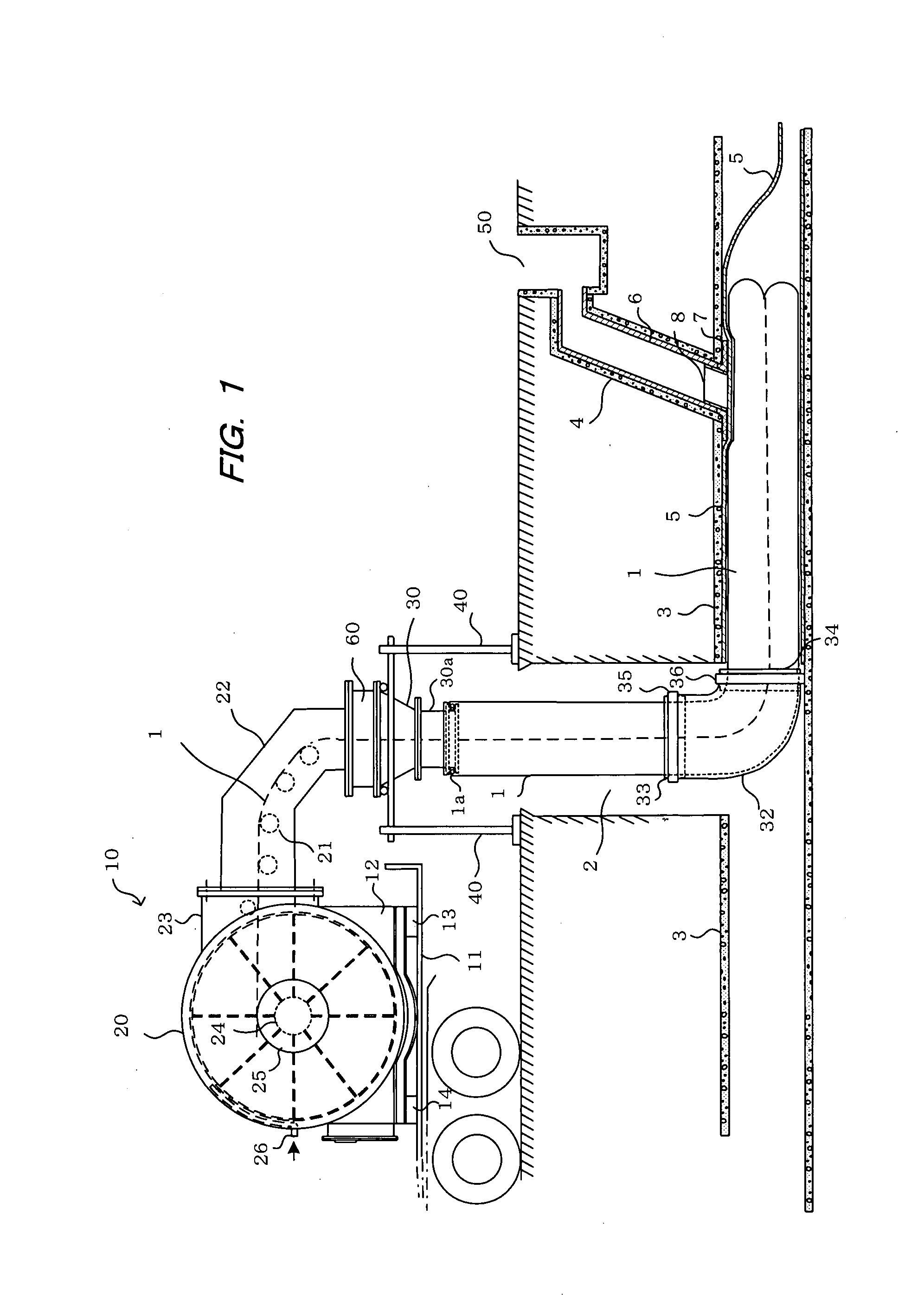

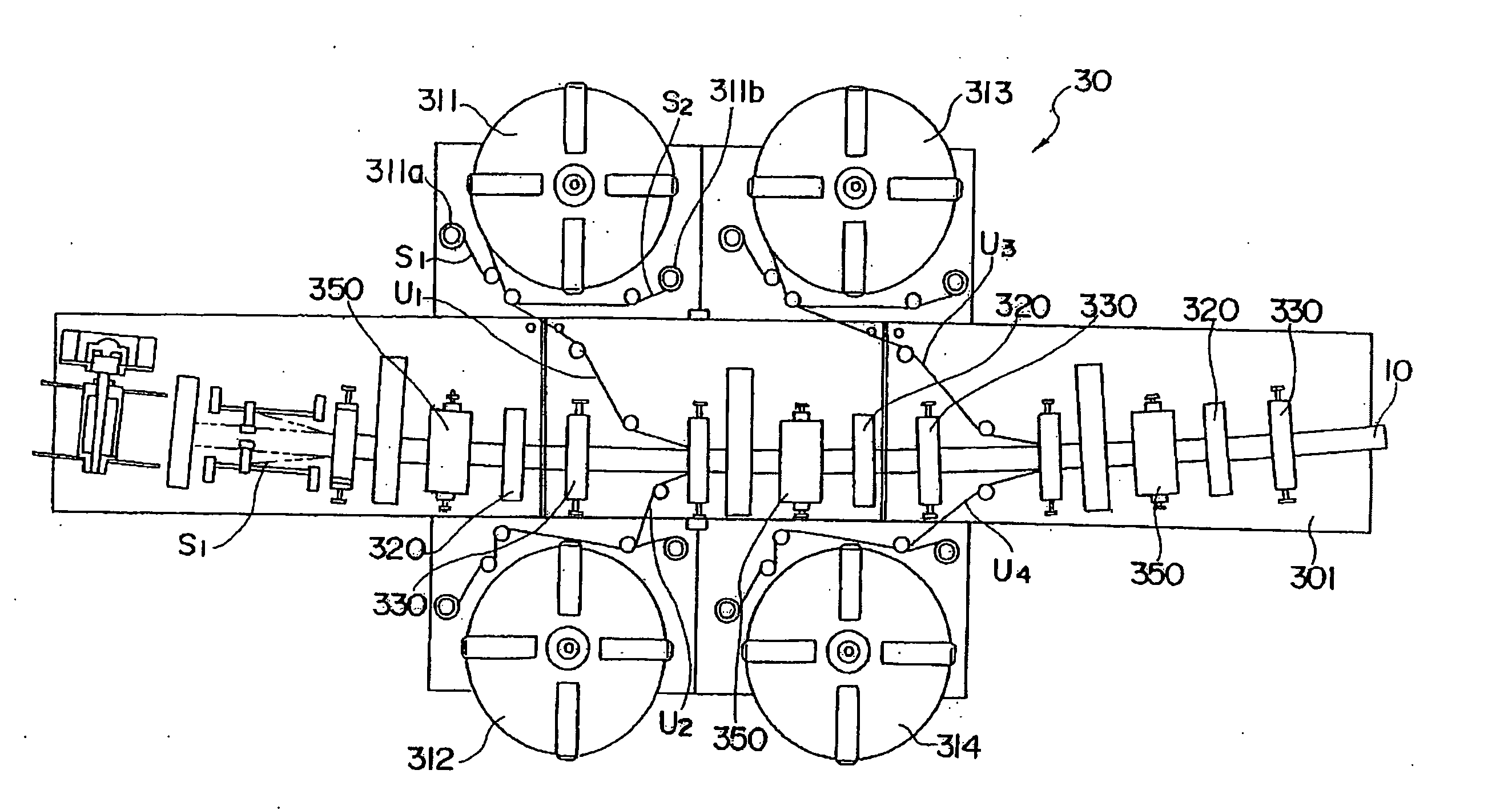

Method and apparatus for continuous molding of fiber reinforced plastic member with curvature

ActiveUS20060083806A1Avoid loadHigh strengthLabelling non-rigid containersConfectioneryShell moldingEngineering

In a continuous molding apparatus equipped with a long core 10 having a curvature disposed on a plane, a release film supplied from a lower release film feeder 20 is sent onto the core 10, and prepreg sheets supplied from a prepreg sheet feeder 30 are laminated thereon and preformed. A release film supplied from a release film feeder 40 is disposed on top of the laminated body, before the body is sent into a hot press 50. A puller 60 moves the laminated body without loading tension thereto. The laminated body enters a postcure device 70 in which thermosetting of the material is completed.

Owner:JAMCO

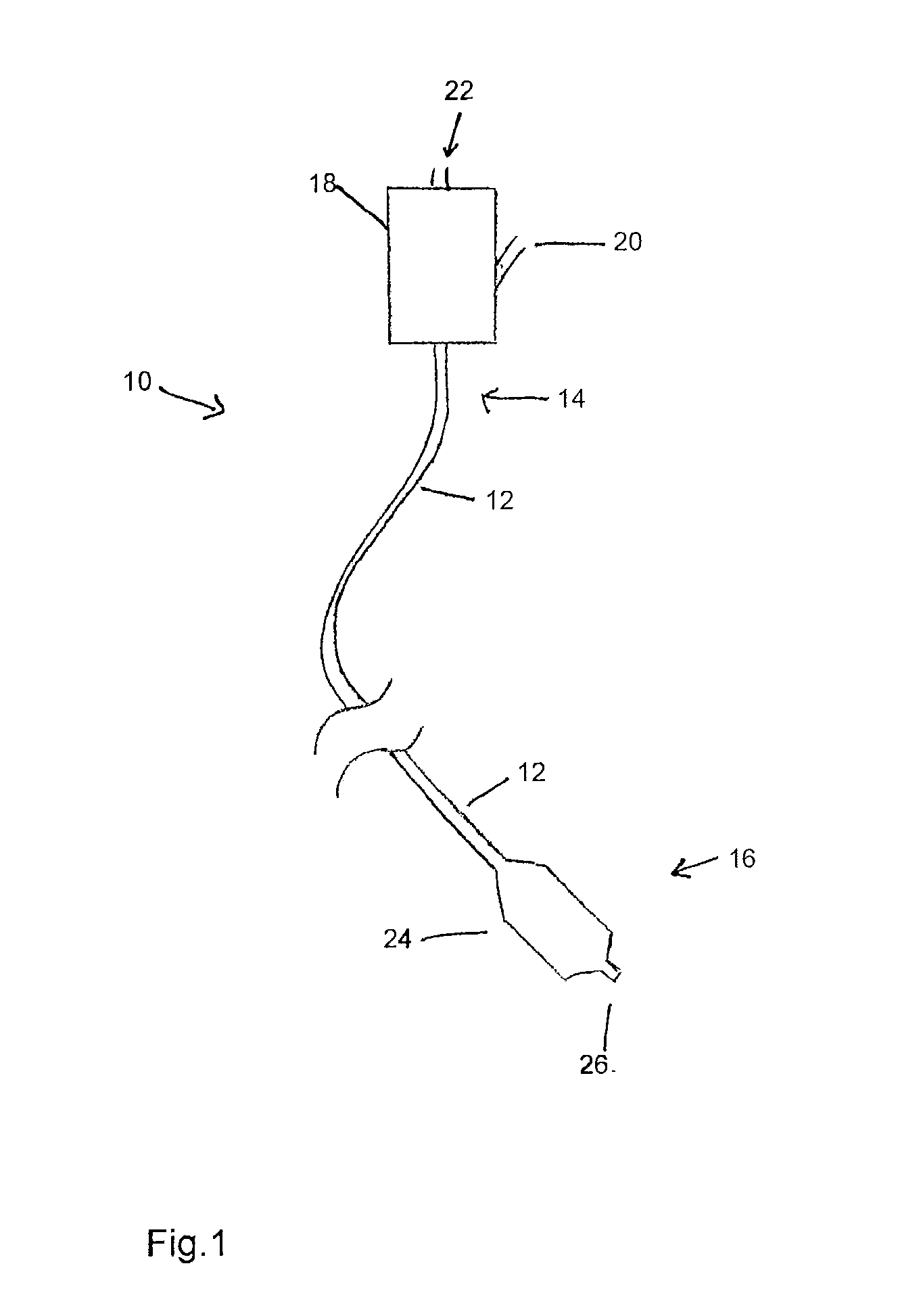

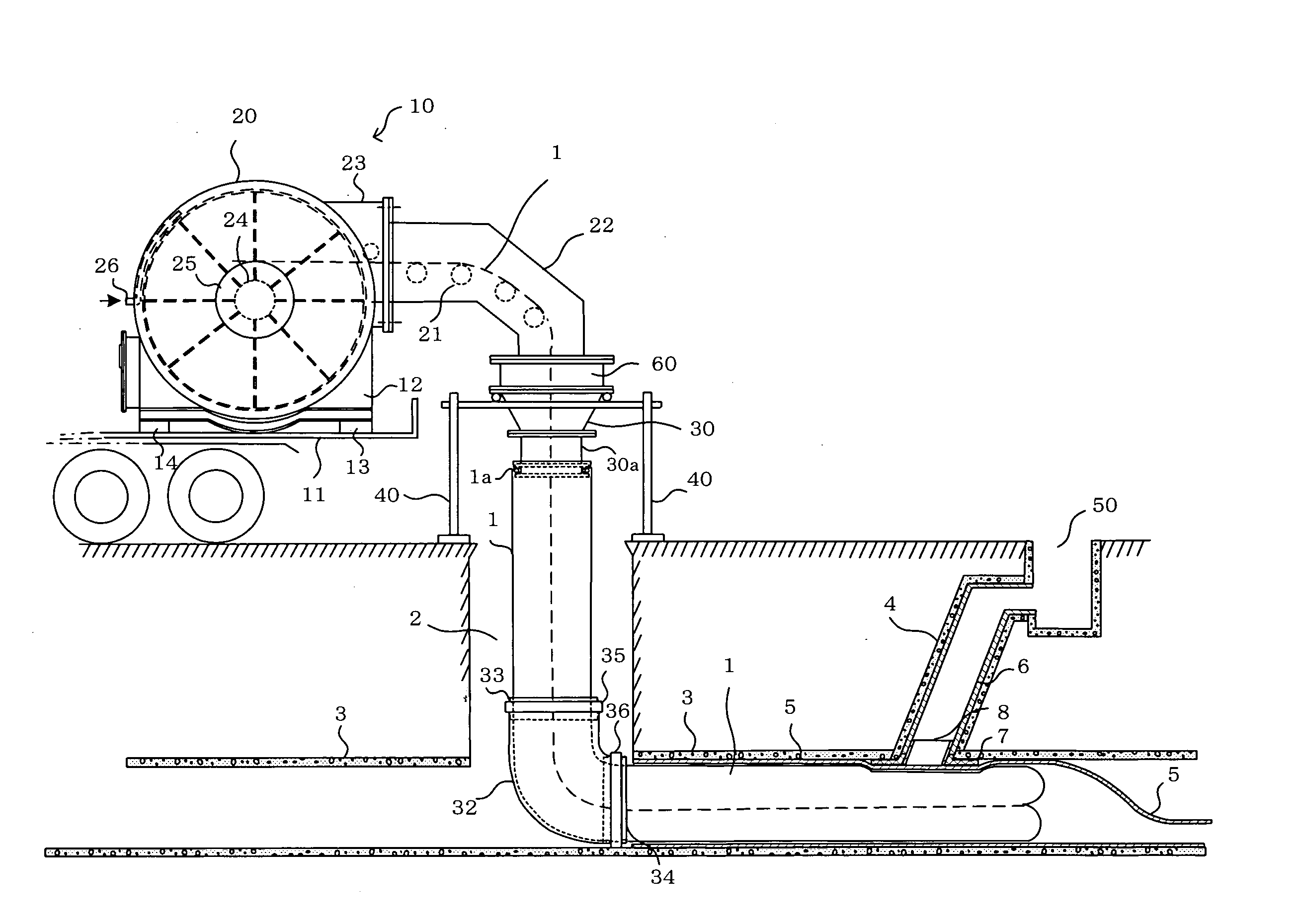

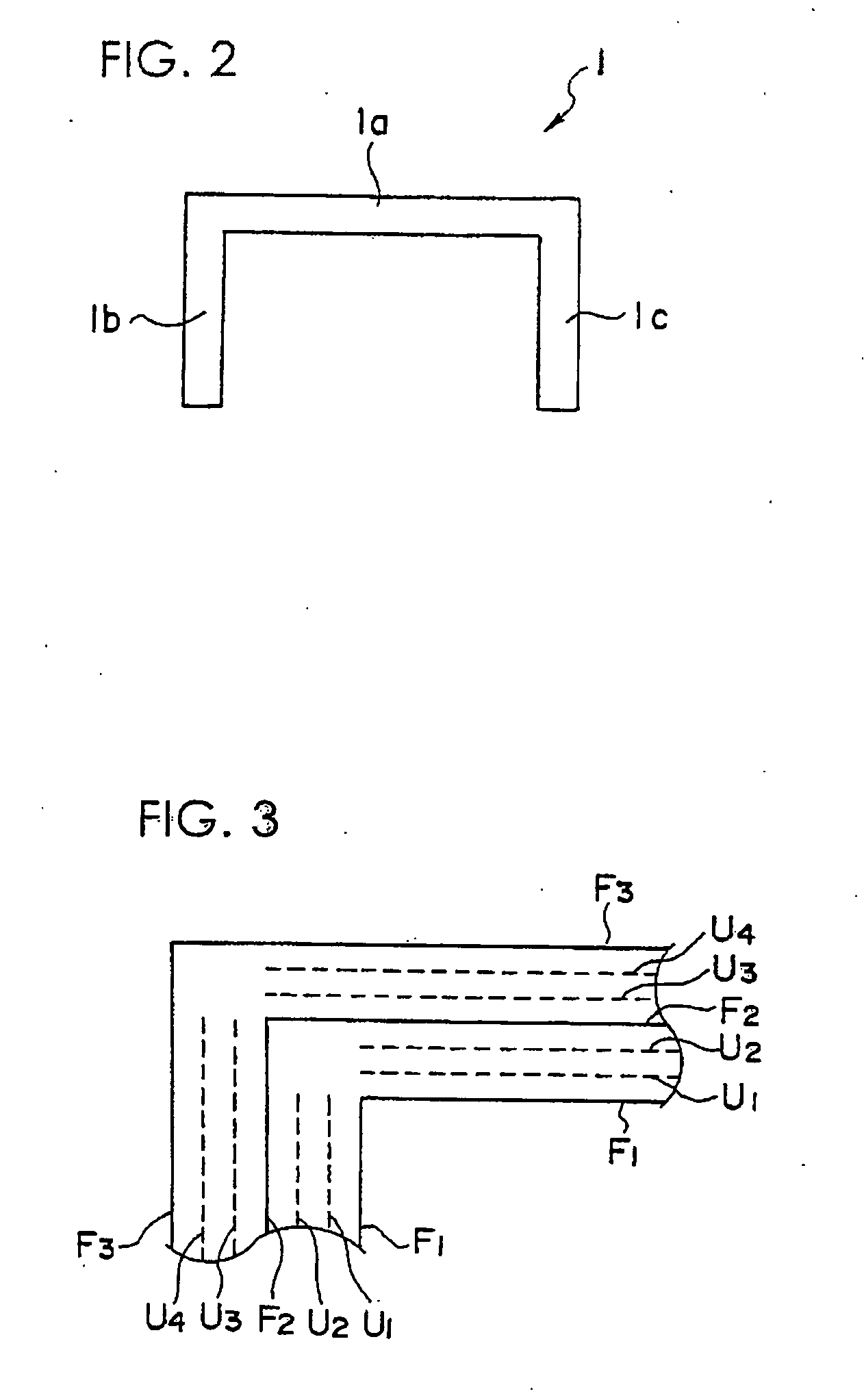

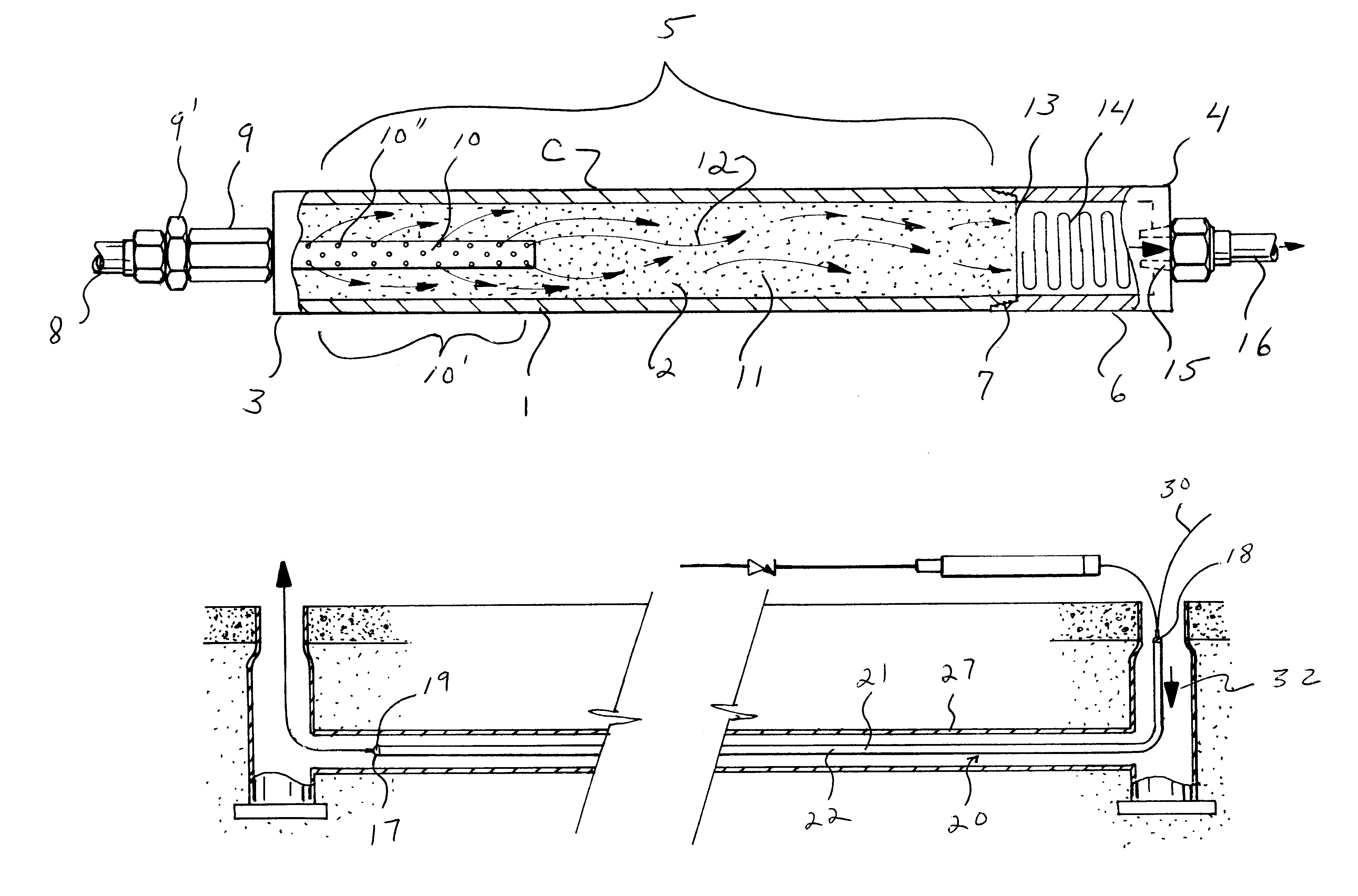

System for providing heated fluid utilizing exothermic chemical reaction for curing resin in pipe liner/repair process

InactiveUS6652690B1Quick implementationCost effectiveExothermal chemical reaction heat productionLabelling non-rigid containersChemical reactionAqueous solution

A "chemical heater" in the form of a cartridge containing an exothermic agent such as sodium hydroxide (caustic) soda, or the like, which, when infused into water, releases heat in the form of an exothermic reaction. In the preferred embodiment of the invention, a cartridge is provided which contains the exothermic material. Water or the like is then directed through said cartridge so that the exothermic material dissolves, providing a solution of water infused with the exothermic material. The solution is heated by virtue of the exothermic reaction, said solution passing out of the cartridge and into a bladder located in a pipe, filling same. Situated about the bladder is a patch or sleeve of material including heat cured resin, which is urged to line the pipe by virtue of the bladder inflating, while simultaneously heated to cure same by virtue of the heated solution. Upon curing of the resin, the bladder is deflated and the fluid drained or otherwise disposed of, with the cured resin sleeve or patch remaining in place lining the pipe. The bladder may then be removed. An alternative design of the invention teaches a bladder configured to receive the exothermic material, allowing the bladder to inflate and provide an exothermically heated solution to heat the bladder simultaneously.

Owner:ROVIRA DWAYNE

Multi-layer film welded articulated balloon

Owner:ANGIODYNAMICS INC +1

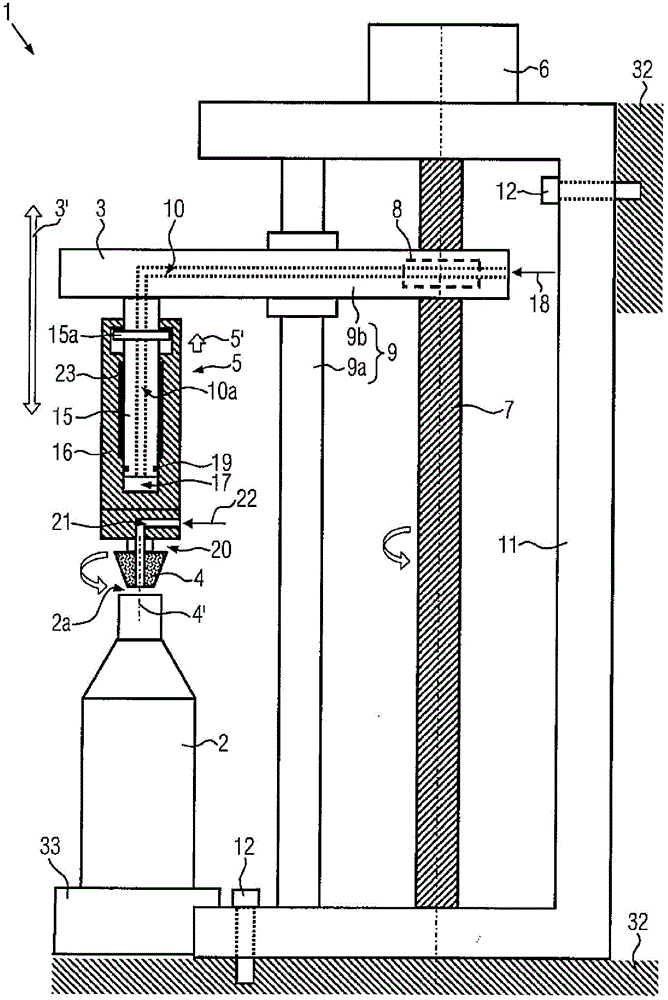

Clamping unit for containers on container handling machines

ActiveCN104417086AMove preciselyRealize lifting actionLabelling non-rigid containersTypewritersEngineeringMechanical engineering

A clamping unit for containers at container treatment machines where, apart from a vertically movable lifting arm with a centering support for clamping a container from above, a motor for driving the lifting arm and a pneumatic spring against the resistance of which the centering support is mounted at the lifting arm so as to be movable to the top are provided. The lifting arms may be set to a desired vertical position independently of the movement or the rotational position of an associated rotary machine, and a clamping force of the centering supports may be easily and flexibly adjusted by applying a suited pressure to the pneumatic spring.

Owner:KRONES AG

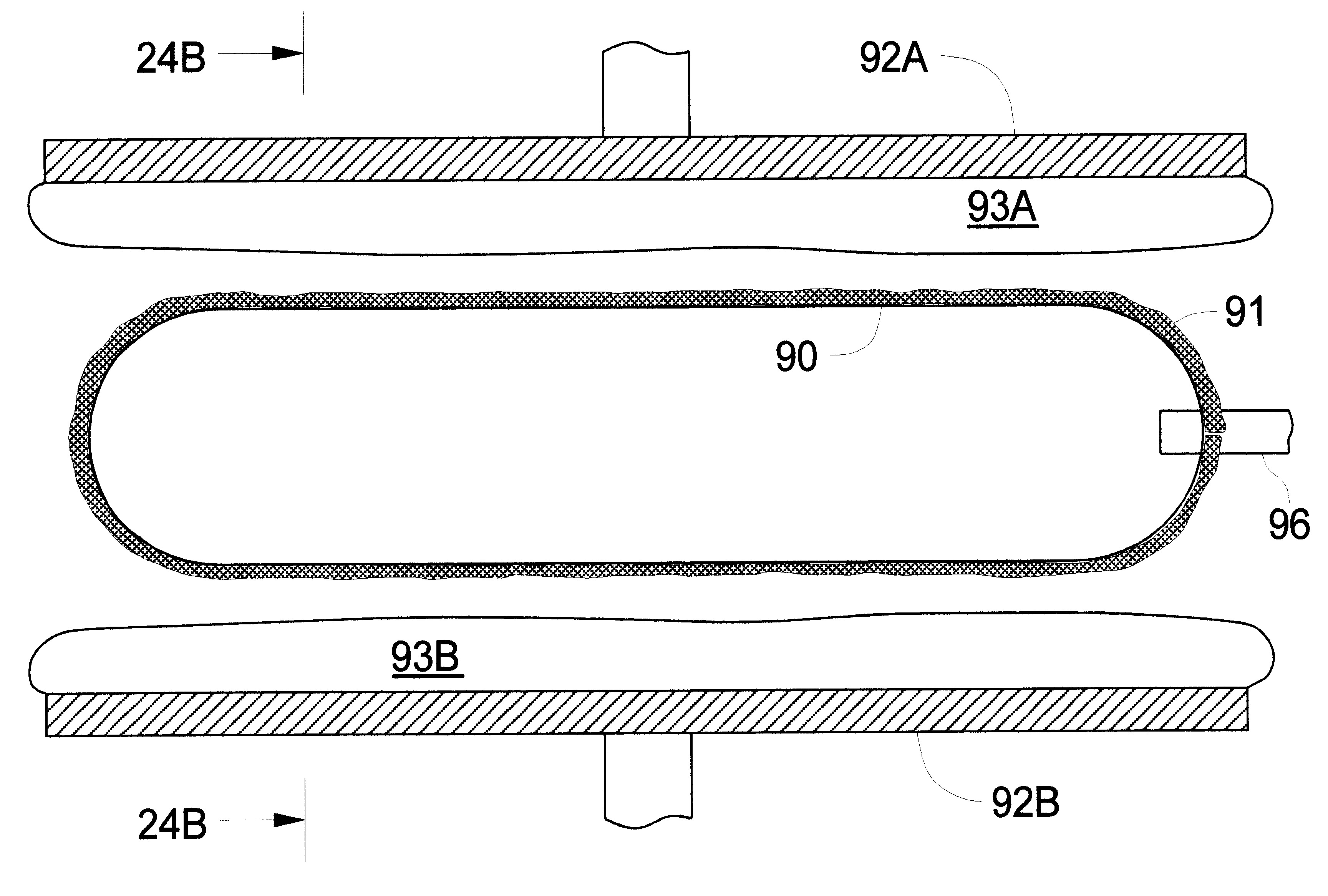

Inflatable dorn

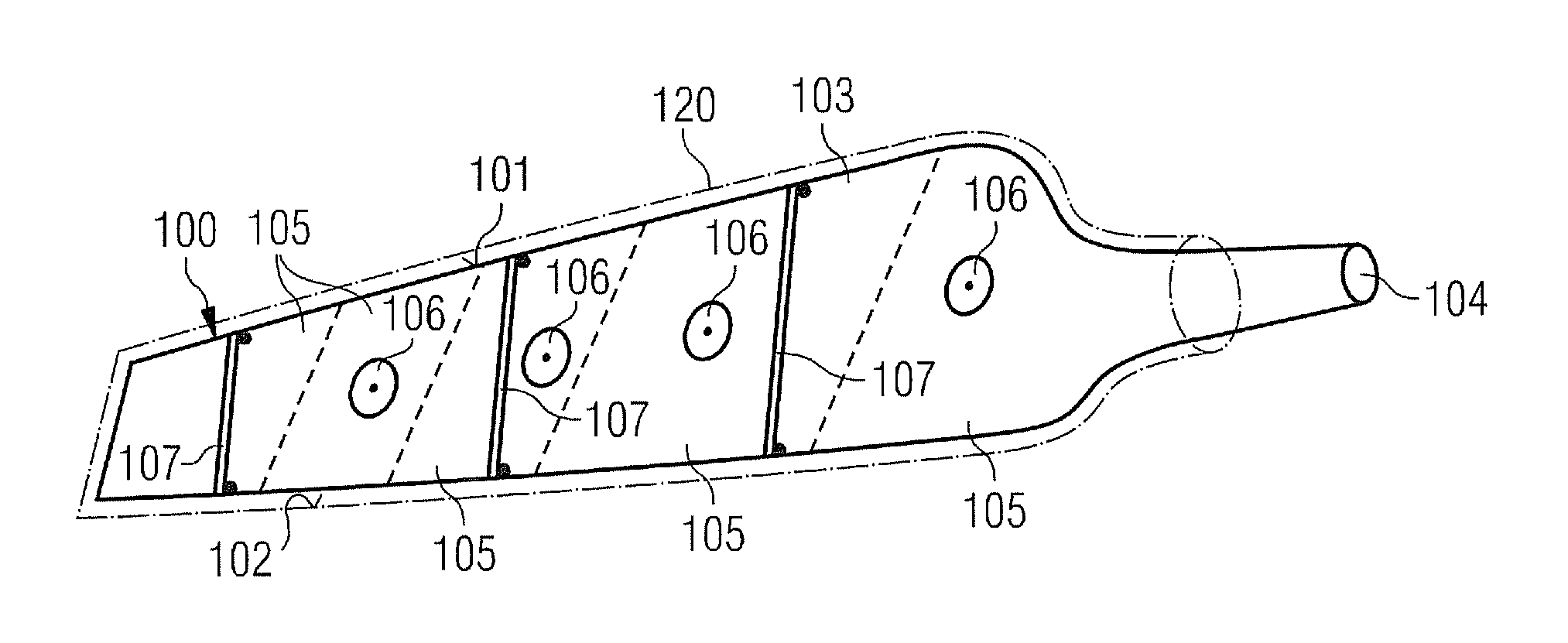

ActiveUS8919754B2Easy to handleEfficient preparation methodLabelling non-rigid containersFinal product manufactureFiber-reinforced compositeTurbine

A mandrel for producing a fiber-reinforced composite part, in particular a blade for a wind turbine is disclosed. The mandrel includes an expandable body with an outer surface onto which a fiber material of the fiber-reinforced composite part is layable out. The expandable body is expandable in an expanded state, wherein in the expanded state the outer surface forms an interior shape of the fiber-reinforced composite part to be produced. Moreover, the expandable body is collapsible in a collapsed state.

Owner:SIEMENS GAMESA RENEWABLE ENERGY AS

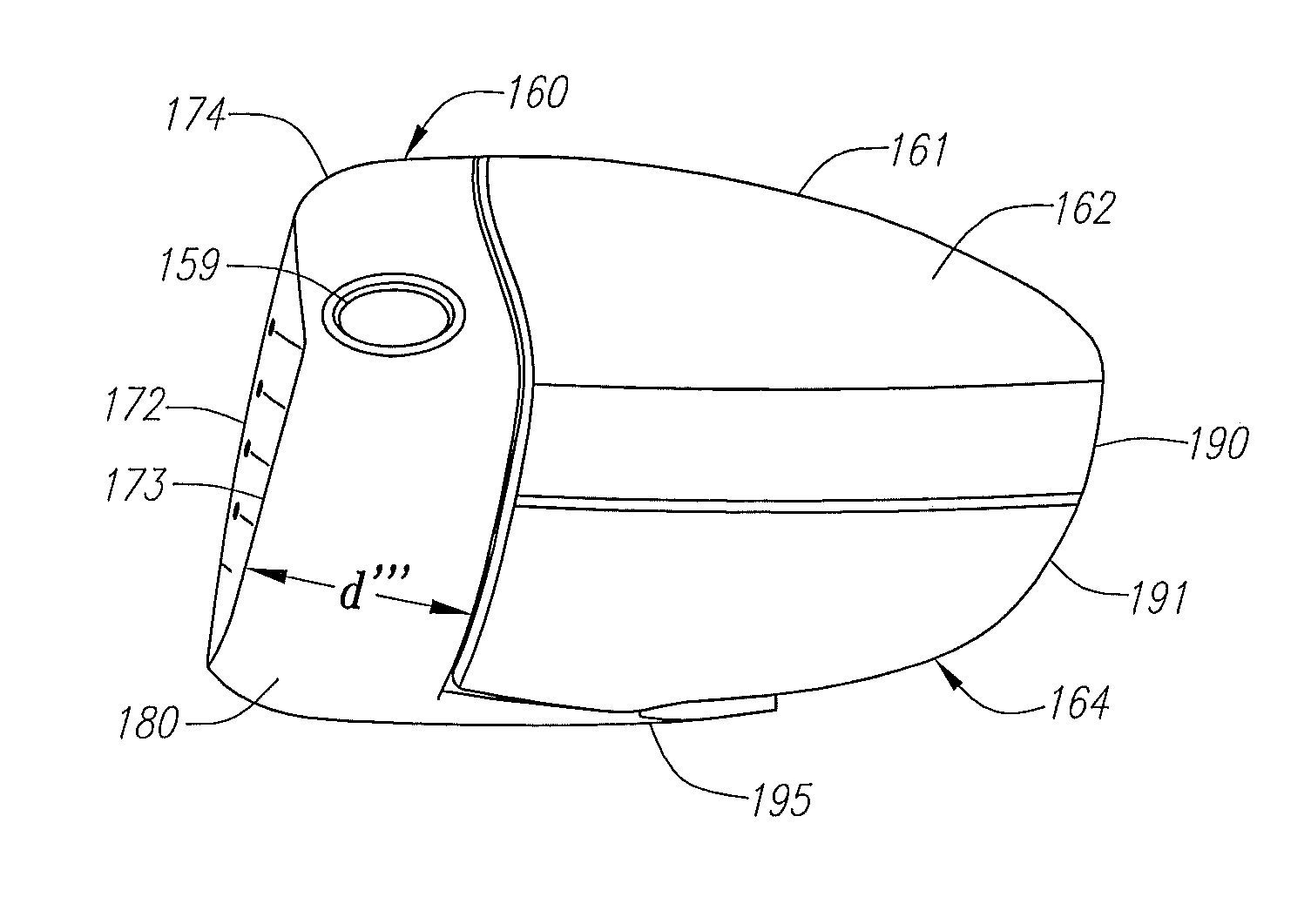

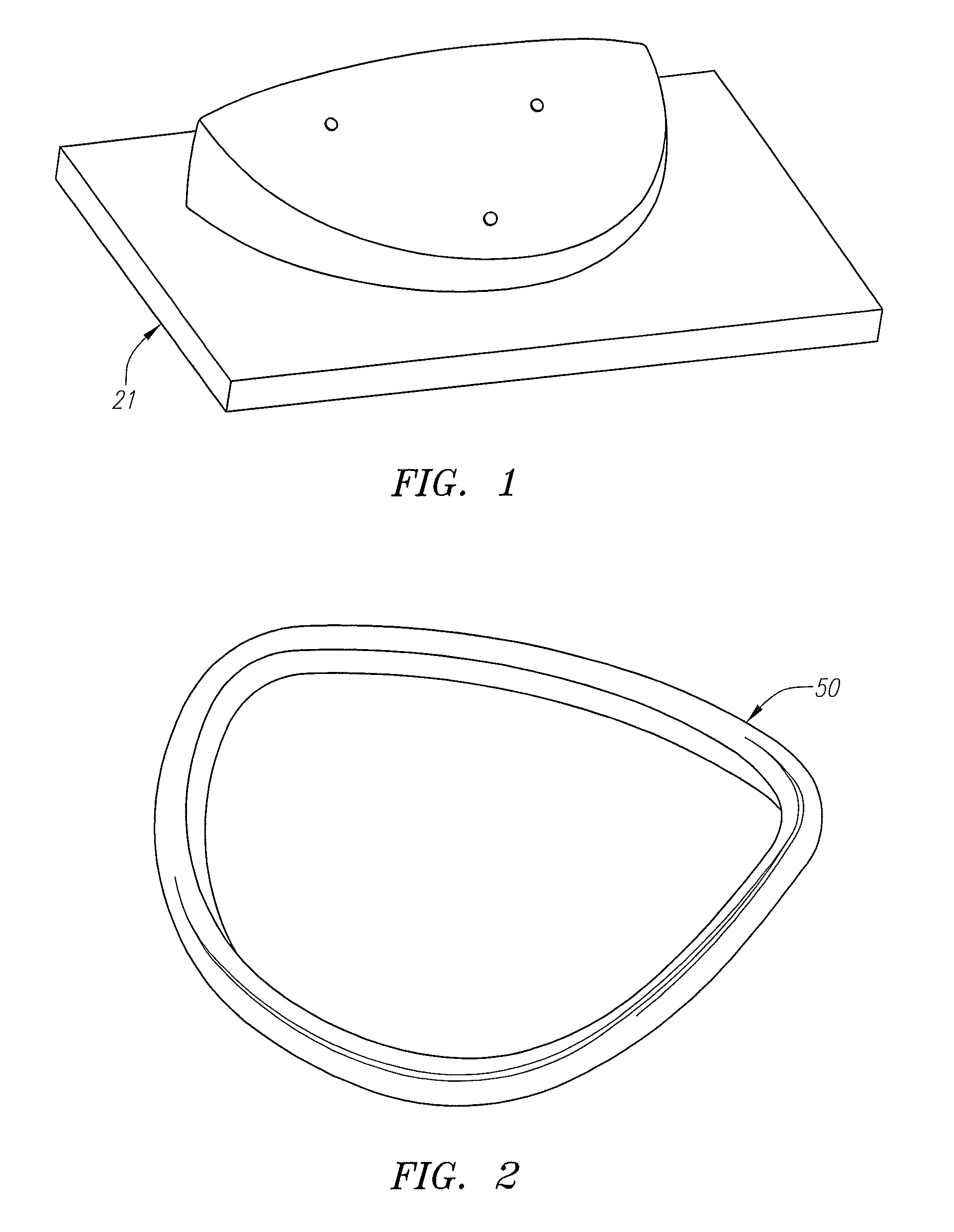

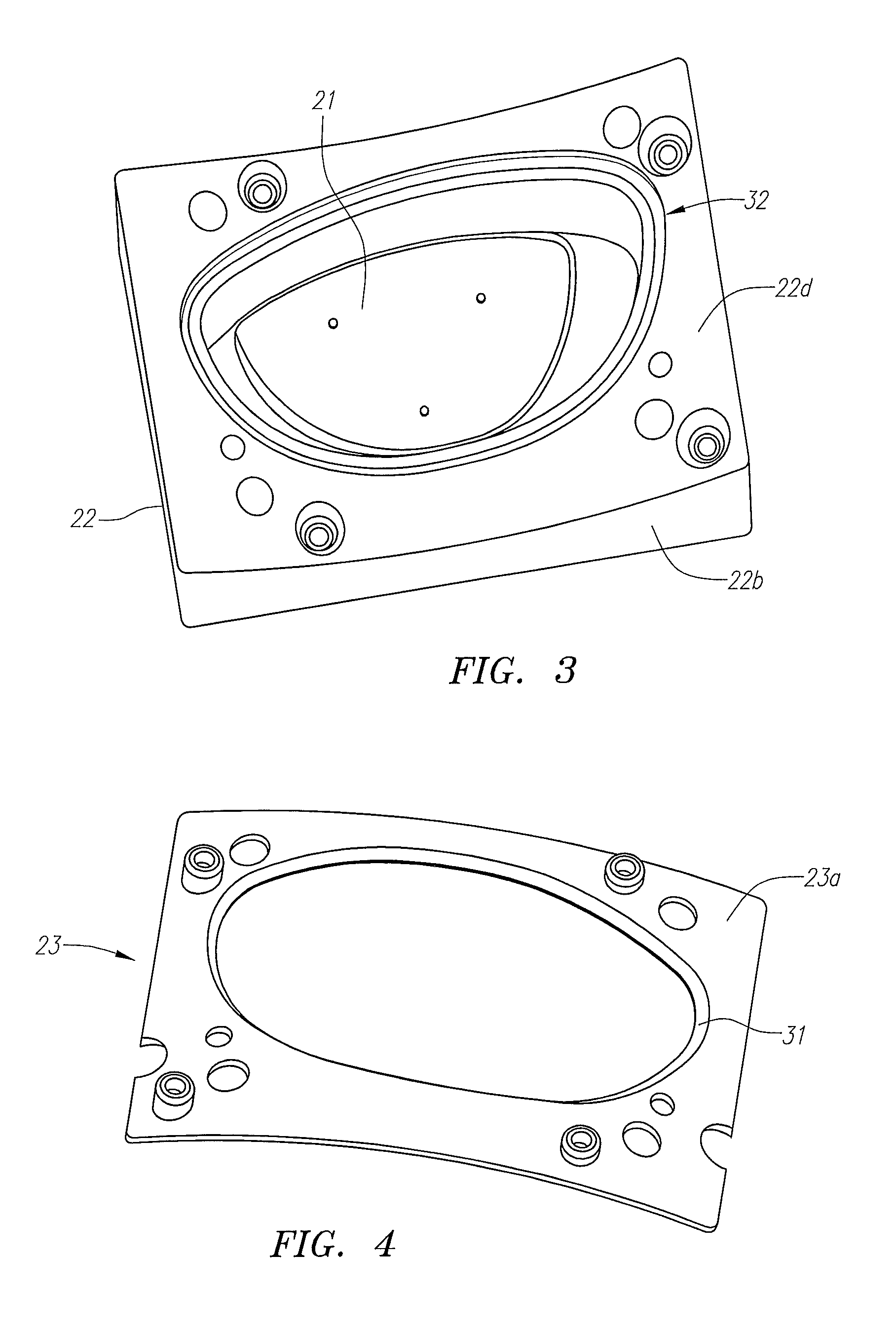

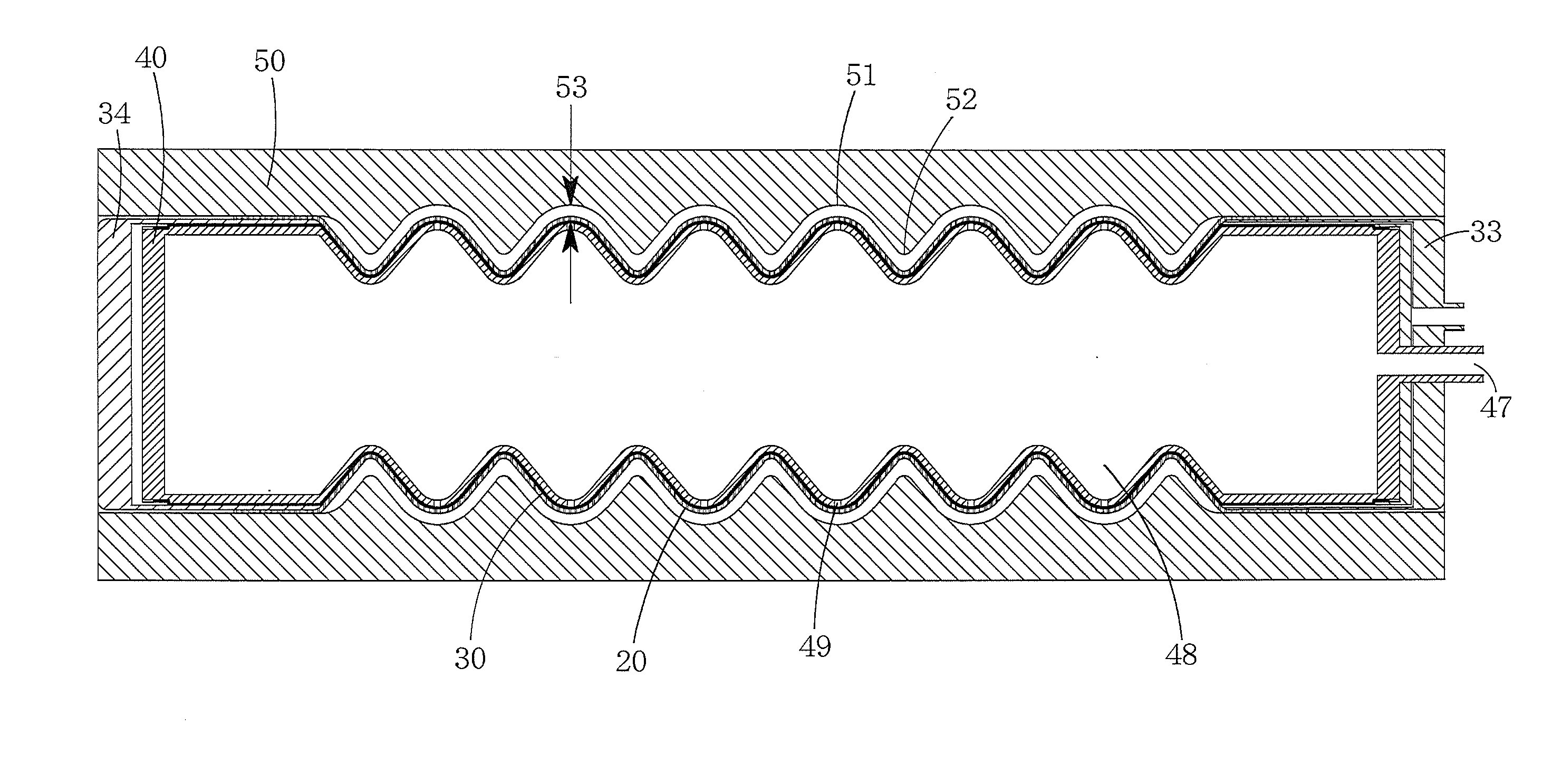

Apparatus and method for manufacturing a multiple material golf club head

Owner:TOPGOLF CALLAWAY BRANDS CORP

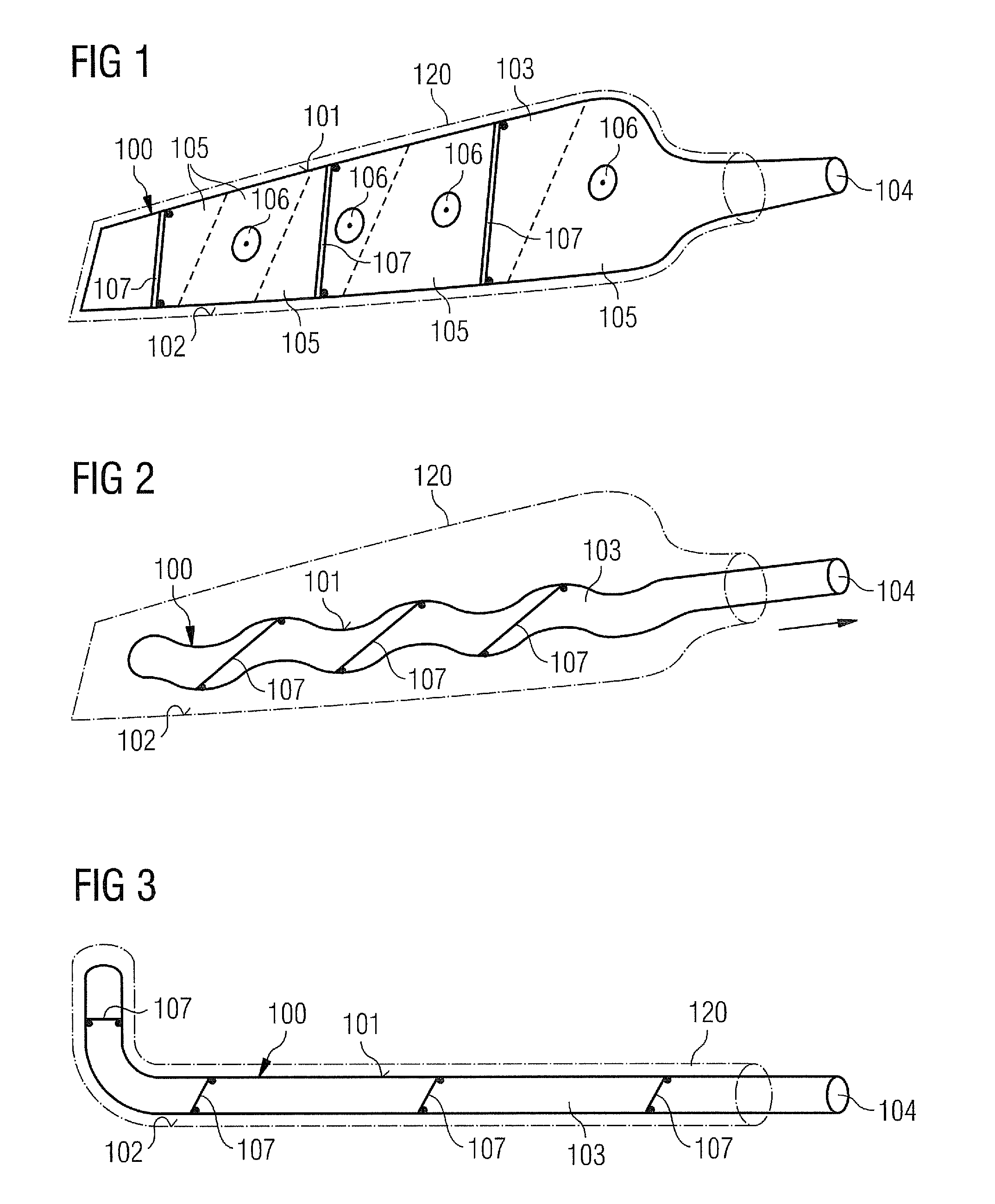

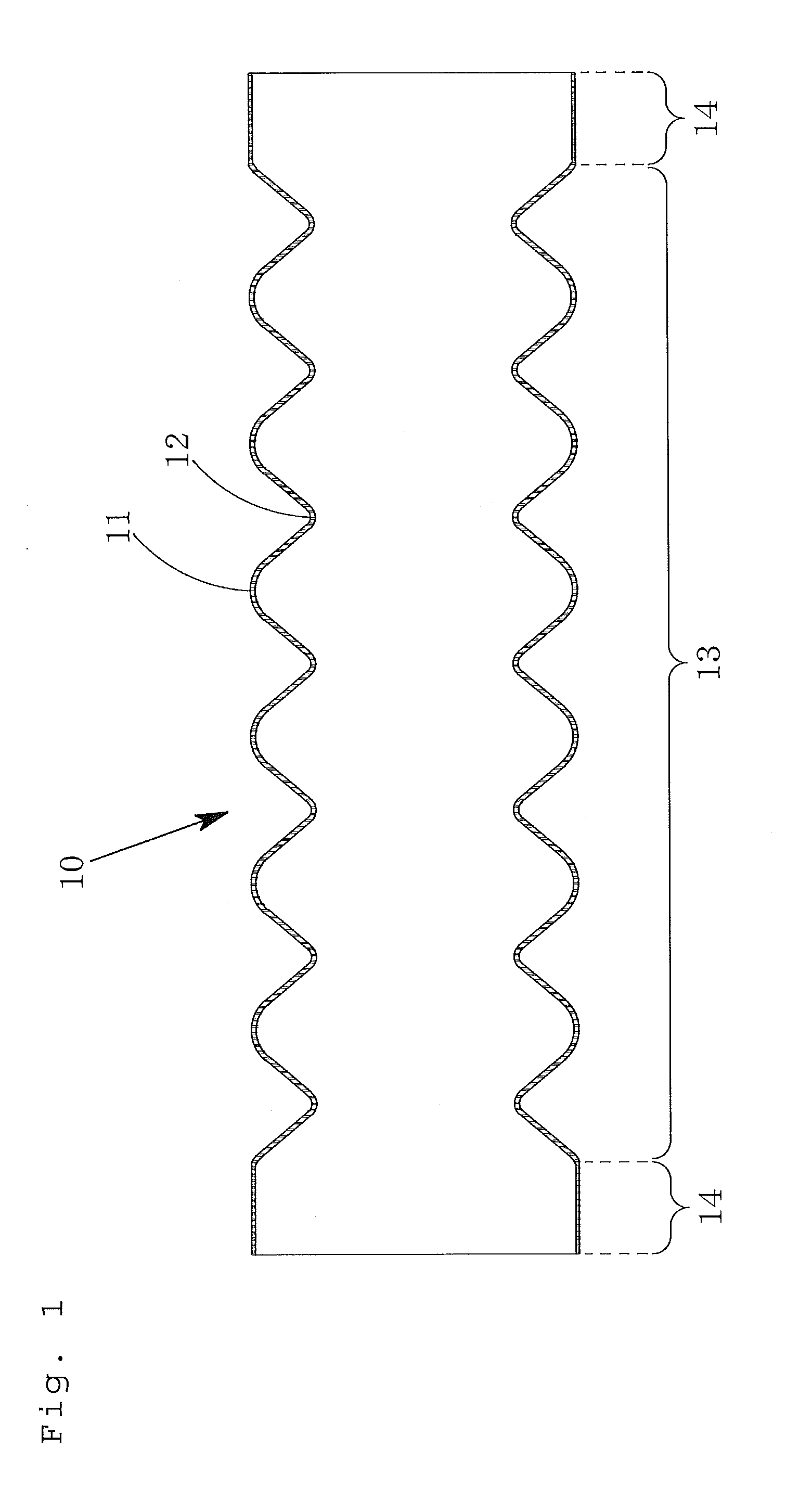

Method for manufacturing reinforced rubber hose

InactiveUS20100294421A1Reduce manufacturing costImprove productivityLabelling non-rigid containersInternal combustion piston enginesEngineeringAirbag

An inner mold having, on the outer surface thereof, corrugations matching the shape of the bellows, and an outer mold having, on the inner surface thereof, corrugations matching the shape of the bellows, are used. An airbag that is previously and at least partially formed into a bellows shape is placed on an outer side of the inner mold so as to cover at least a corrugated part with the airbag. A cylindrical preform comprising unvulcanized rubber and a reinforcement material is placed on the outer side of the airbag. An outer mold is placed on the outer side of the preform. A pressurized fluid is supplied between the inner mold and the airbag so as to inflate the airbag. The preform is vulcanized under heating while being pressed against an inner surface of the outer mold, whereby a reinforced rubber hose is manufactured.

Owner:MARUGO RUBBER IND

Methods for crimping a polymeric scaffold to a delivery balloon and achieving stable mechanical properties in the scaffold after crimping

InactiveUS8752265B2Reduce the overall diameterShorten the overall cycleStentsLabelling non-rigid containersMedicineCatheter

A medical device-includes a polymer scaffold crimped to a catheter having an expansion balloon. The scaffold is crimped to the balloon by a process that includes inflating the delivery balloon during a diameter reduction to improve scaffold retention. A crimping temperature is maintained at about the onset of glass transition of the polymer material to facilitate more rapid stabilization of mechanical properties in the scaffold following crimping.

Owner:ABBOTT CARDIOVASCULAR

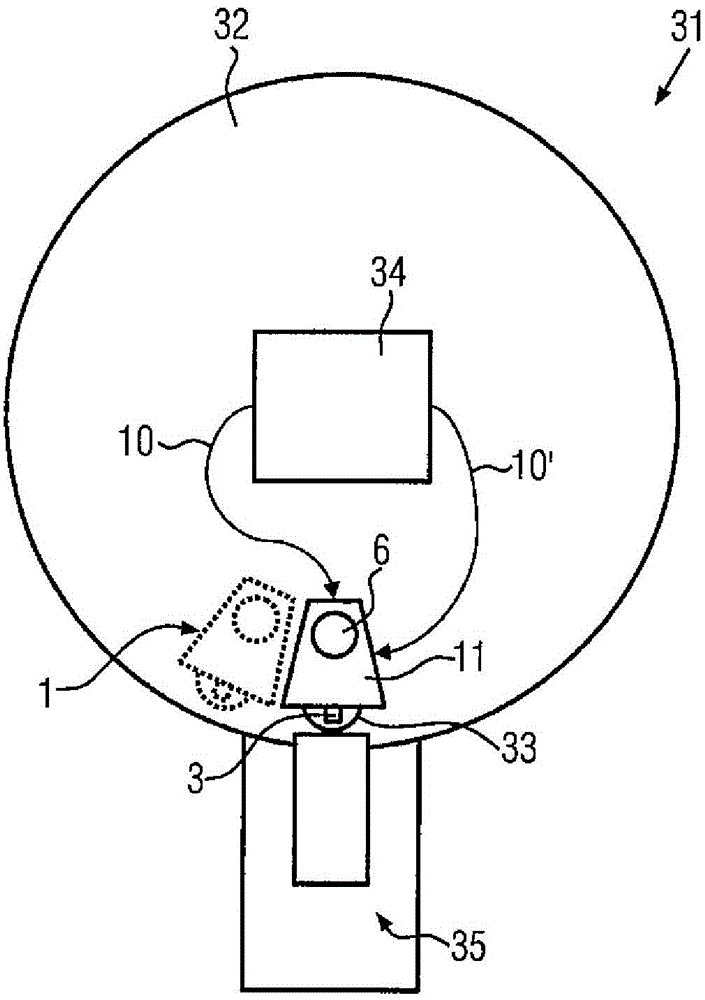

A machine and a method for filling containers

ActiveUS20160194189A1Cheap and easy to implementLabelling non-rigid containersFilling using counterpressureEngineeringActuator

A machine for filling a container having a longitudinal axis is disclosed. The machine comprises a conveying device, and at least one handling unit moved by the conveying device along a path. The at least one handling unit comprises a support device configured to receive and retain the container, and at least one filling device configured to feed a pourable product into the container as the at least one handling unit travels along the path. The machine further comprises an actuator configured to rotate the container about the longitudinal axis while the container is filled with the pourable product by the at least one filling device.

Owner:SIDEL SPA

Method and composition for lining a pipe

ActiveUS20090229696A1Effectively seal all crack and faultHigh strengthLabelling non-rigid containersCovering/liningsFiberCarbon fibers

A pipe lining composition and a method for installing the pipe lining composition into a pipeline requiring repair is provided. The lining composition is a layered lining composite formed of alternating plies of felt and carbon fiber strand reinforcing such that layers of carbon fiber reinforcing strands are trapped between layers of felt. Once the composite is laid up the composite is preferably stitched to provide stability and to maintain the layers relative to one another and then formed into a tube. In accordance with the method, the lining tube is then sequentially filled resins of increasing viscosity as it is drawn through rollers in a manner that fully wets out the carbon fiber before it is placed into the pipe to be lined.

Owner:WARREN ENVIRONMENTAL & COATING LLC

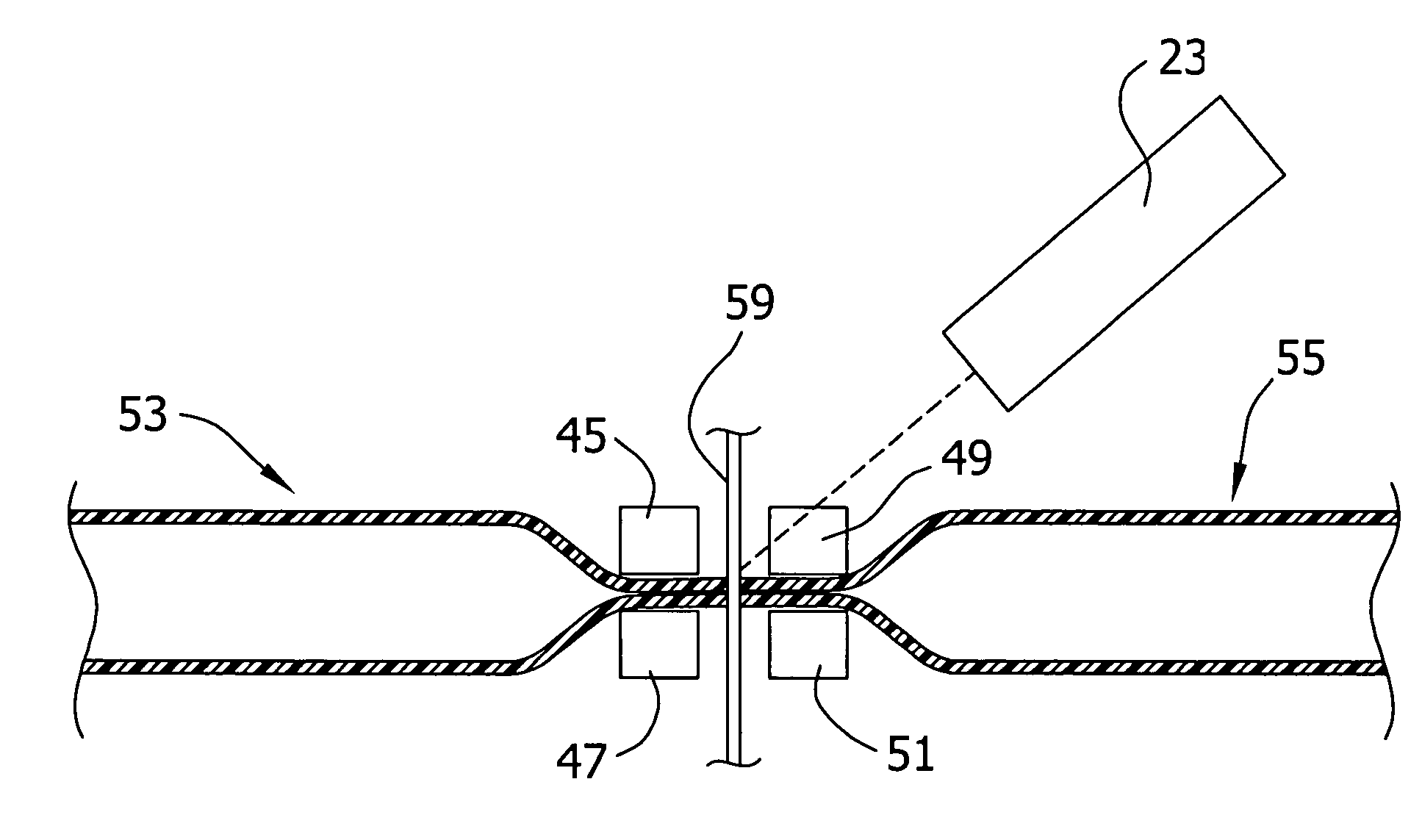

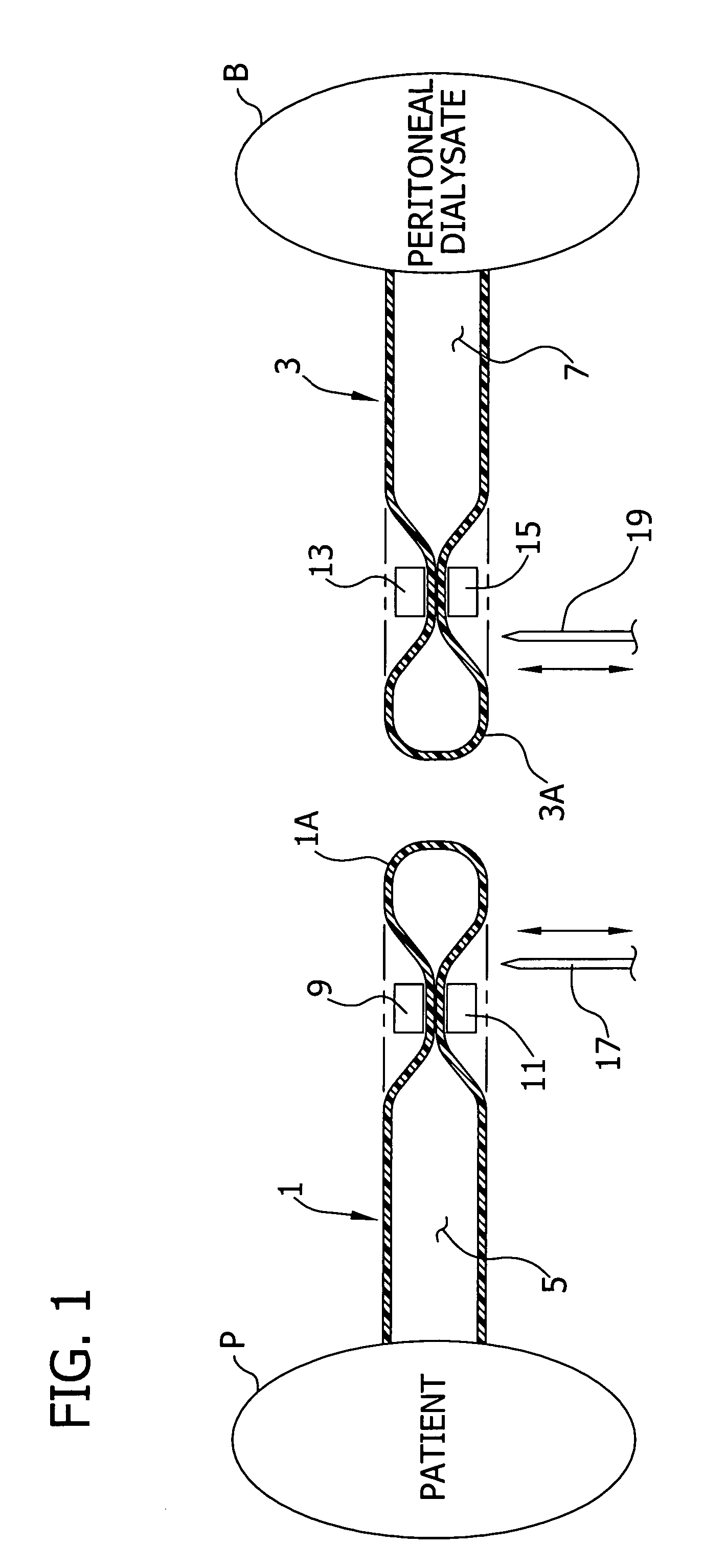

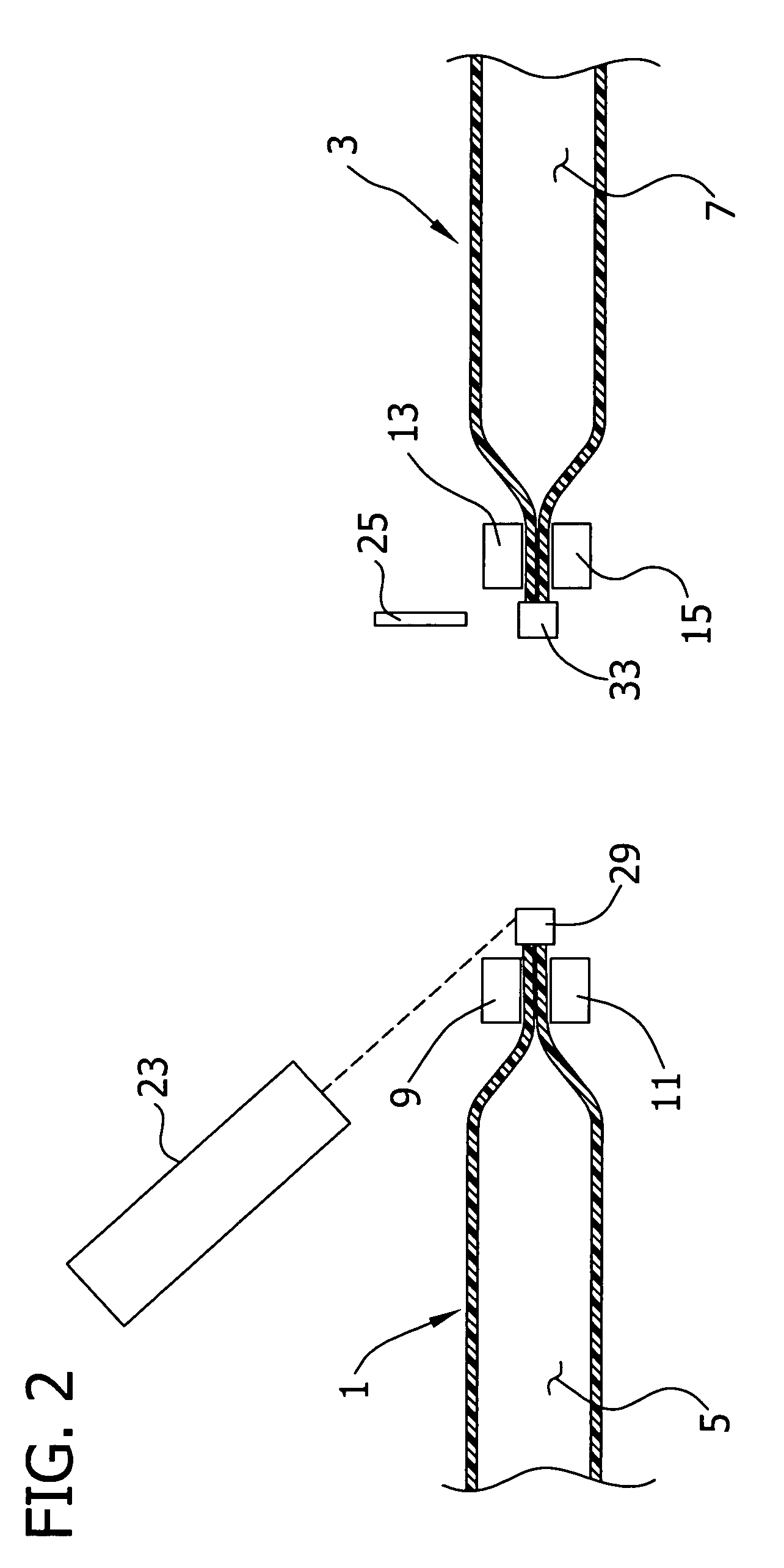

Method for sterile connection of tubing

A method for sterile connection of tubing includes welding the tubing sections together using an efficient laser. The ends of the tubing sections are brought together prior to the initiation of welding, facilitating isolation of interior passage of the tubing sections. The method can be carried out by an apparatus which is relatively inexpensive and compact.

Owner:BAXTER INT INC

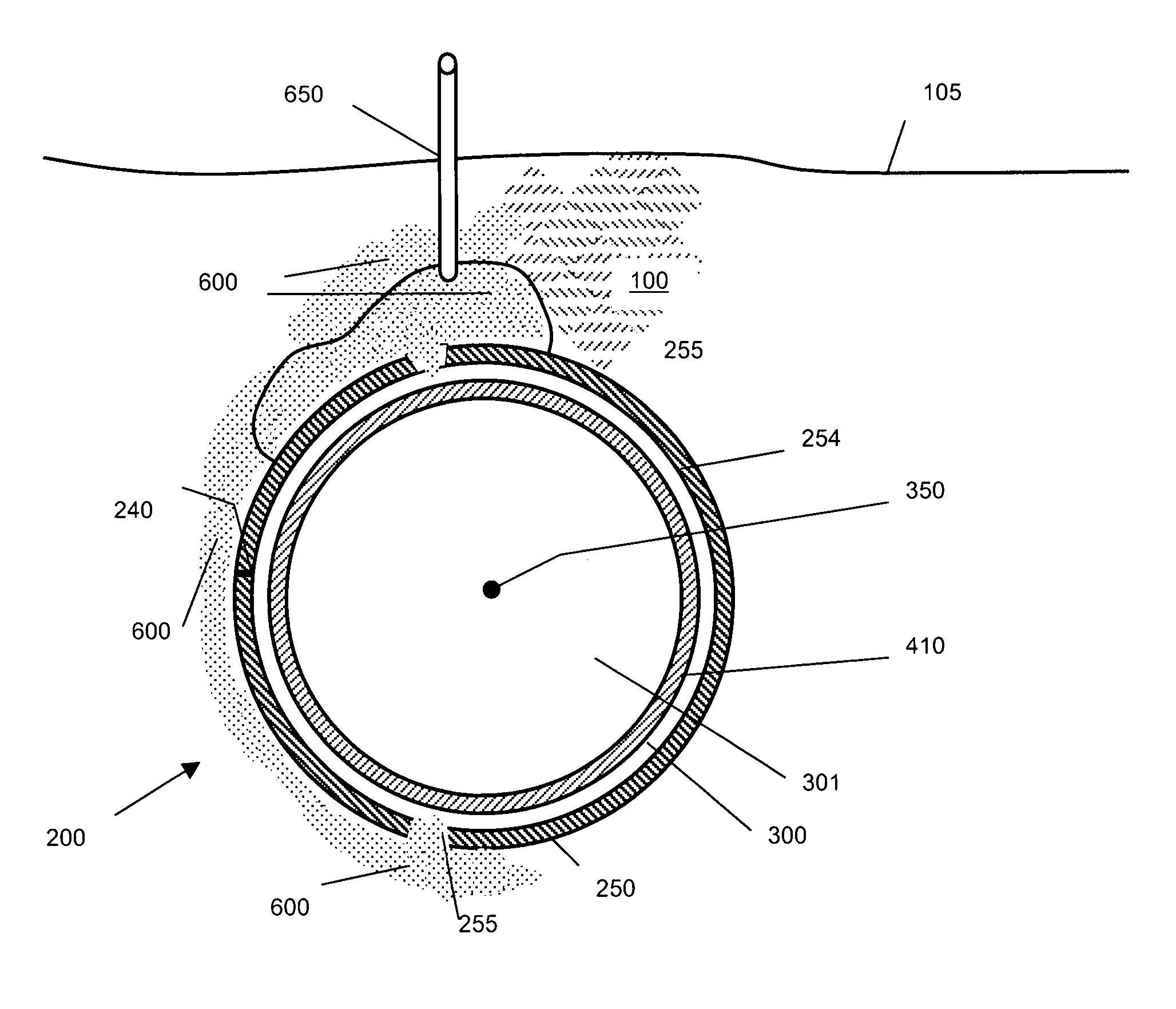

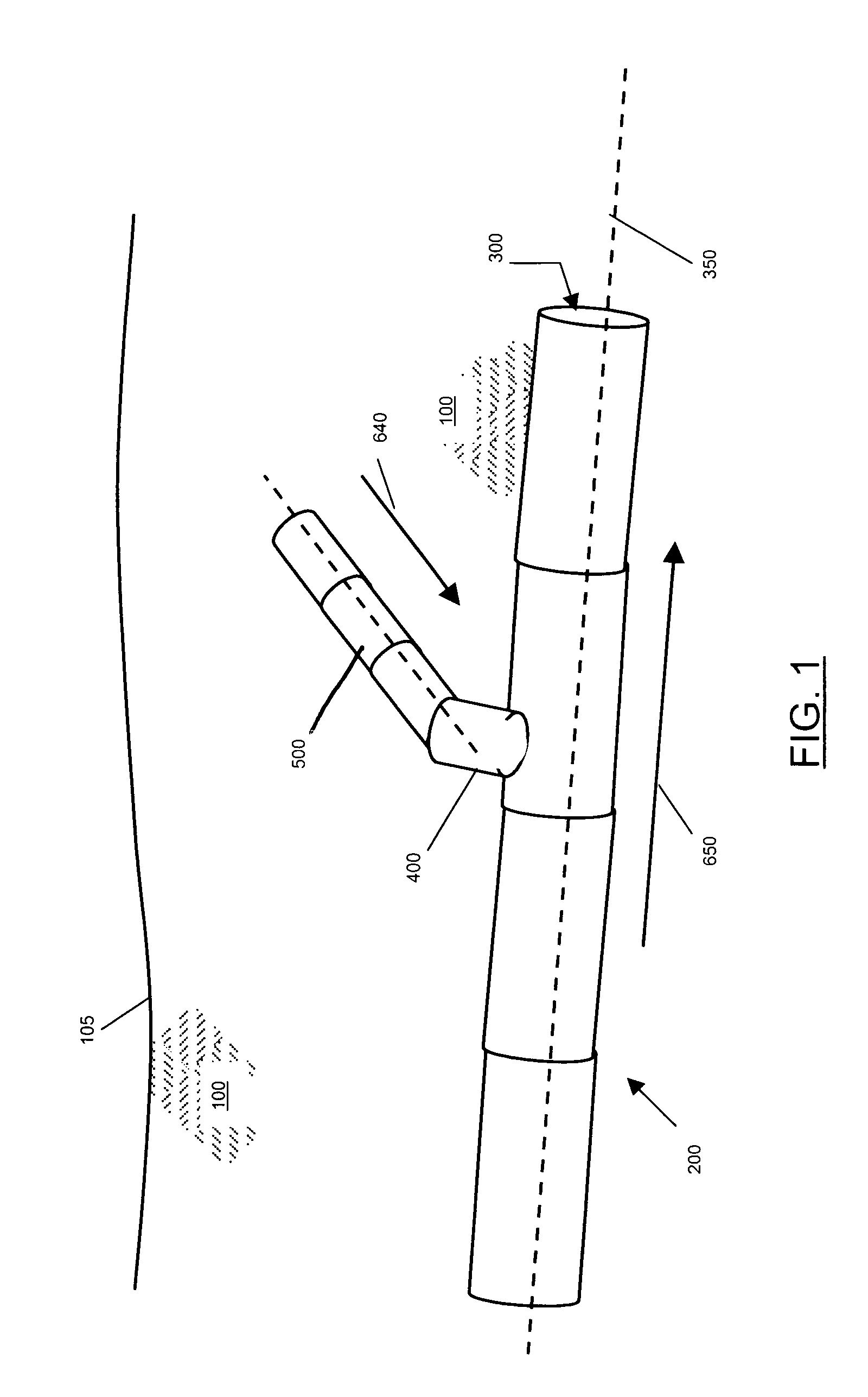

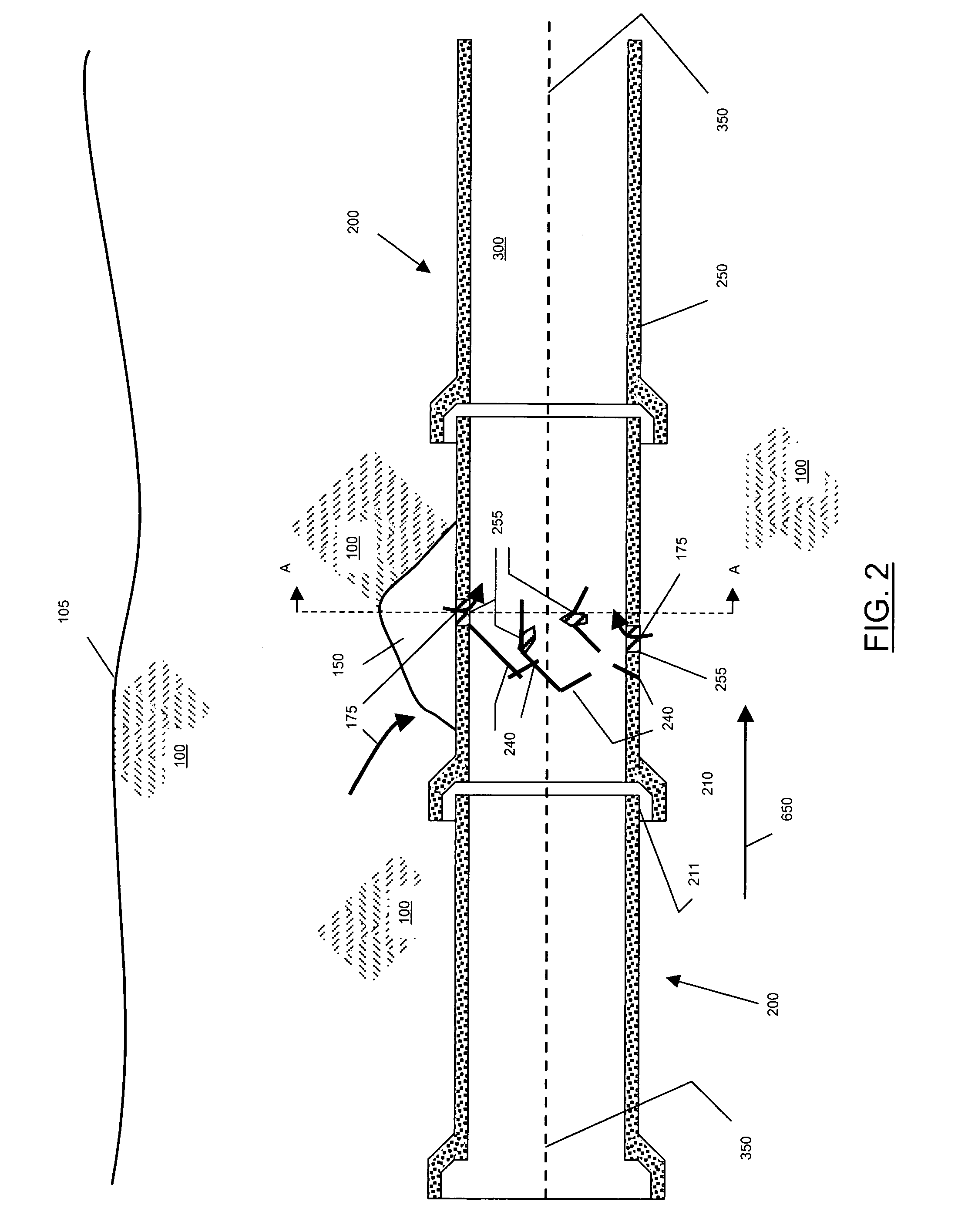

Apparatus and method for the repair and stabilization of underground pipes

InactiveUS7135087B2Prevent penetrationSimple methodPipe laying and repairLabelling non-rigid containersGroundwaterConductor pipe

Owner:EMS USA HLDG I

Pipe lining method

There is provided a pipe lining method wherein a lateral pipe lining material and a main pipe lining material are securely joined. After a lateral pipe has been lined, a start liner is applied to the main pipe and a main pipe lining material is then inserted. A heating wire for melting the start liner is mounted on a surface of a flange of the lateral pipe lining material during or after lining of the lateral pipe. While the main pipe is being lined, the heating wire is heated to melt the start liner existing between the flange of the lateral pipe lining material and the main pipe lining material. When the resin in the main pipe lining material is cured, the main pipe lining material and flange of the lateral pipe lining material are integrated. This allows the lateral pipe lining material and main pipe lining material to be reliably joined.

Owner:SHONAN GOSEI JUSHI SEISAKUSHO KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com