Patents

Literature

151results about How to "Production Process Automation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

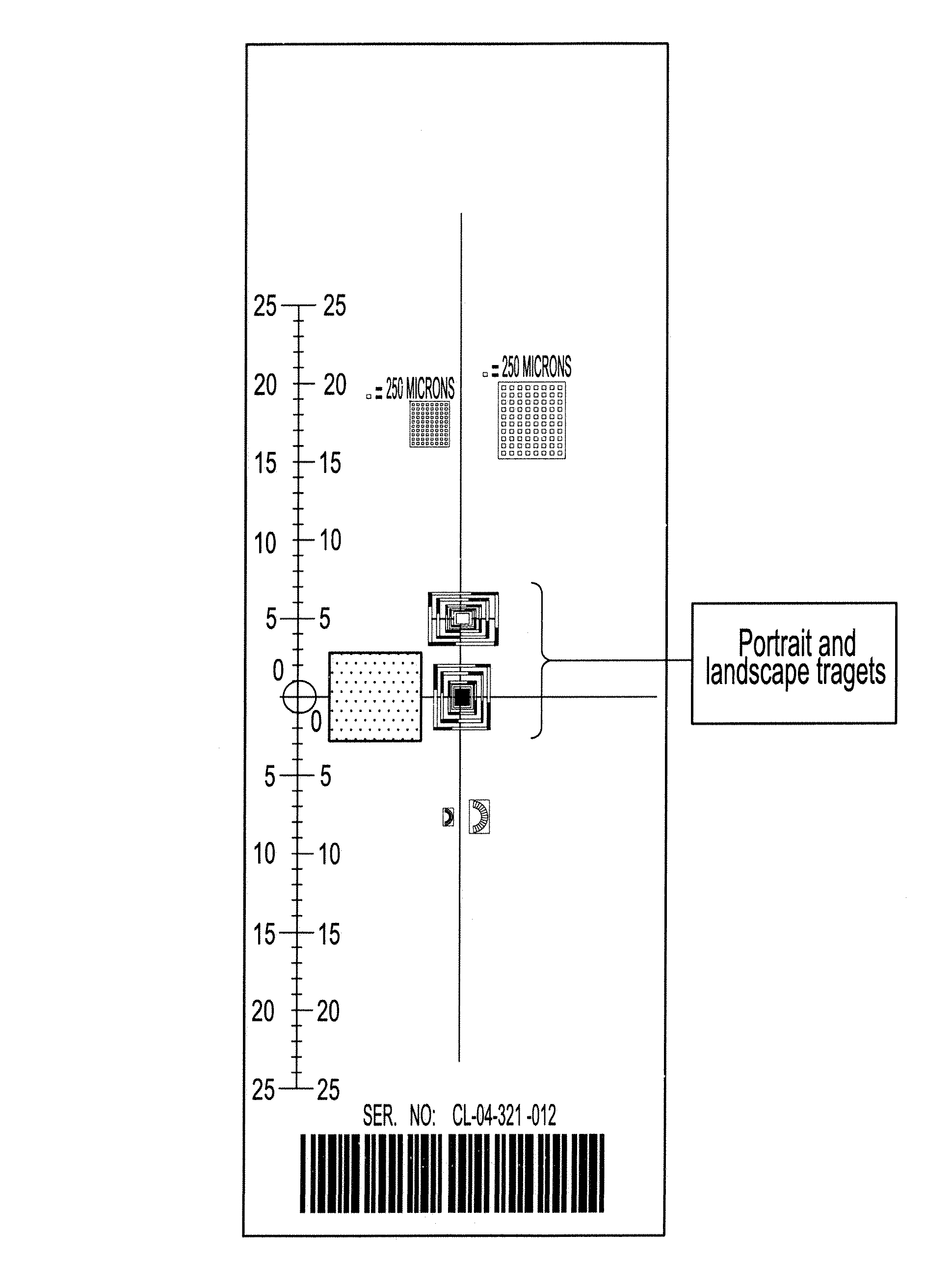

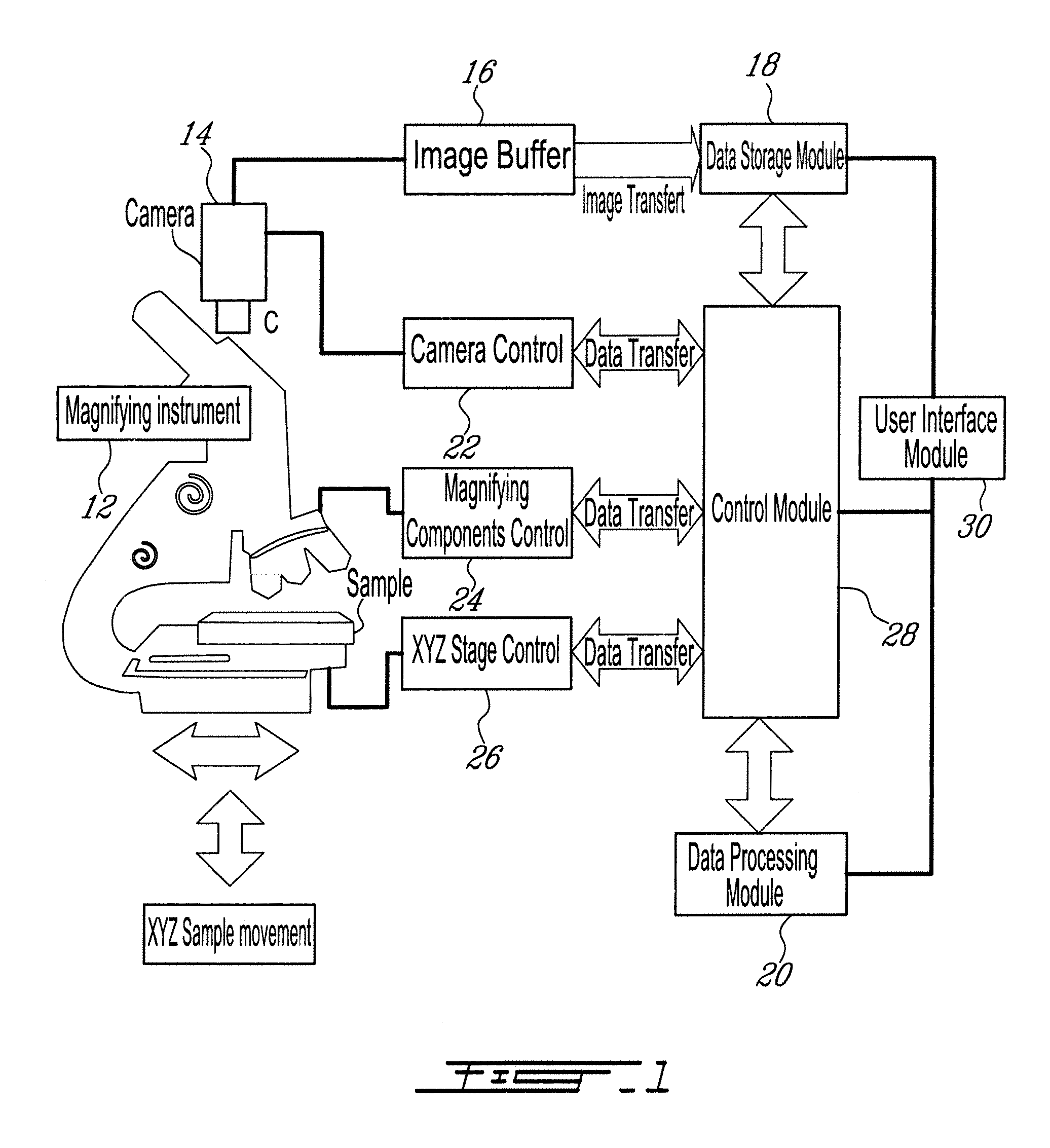

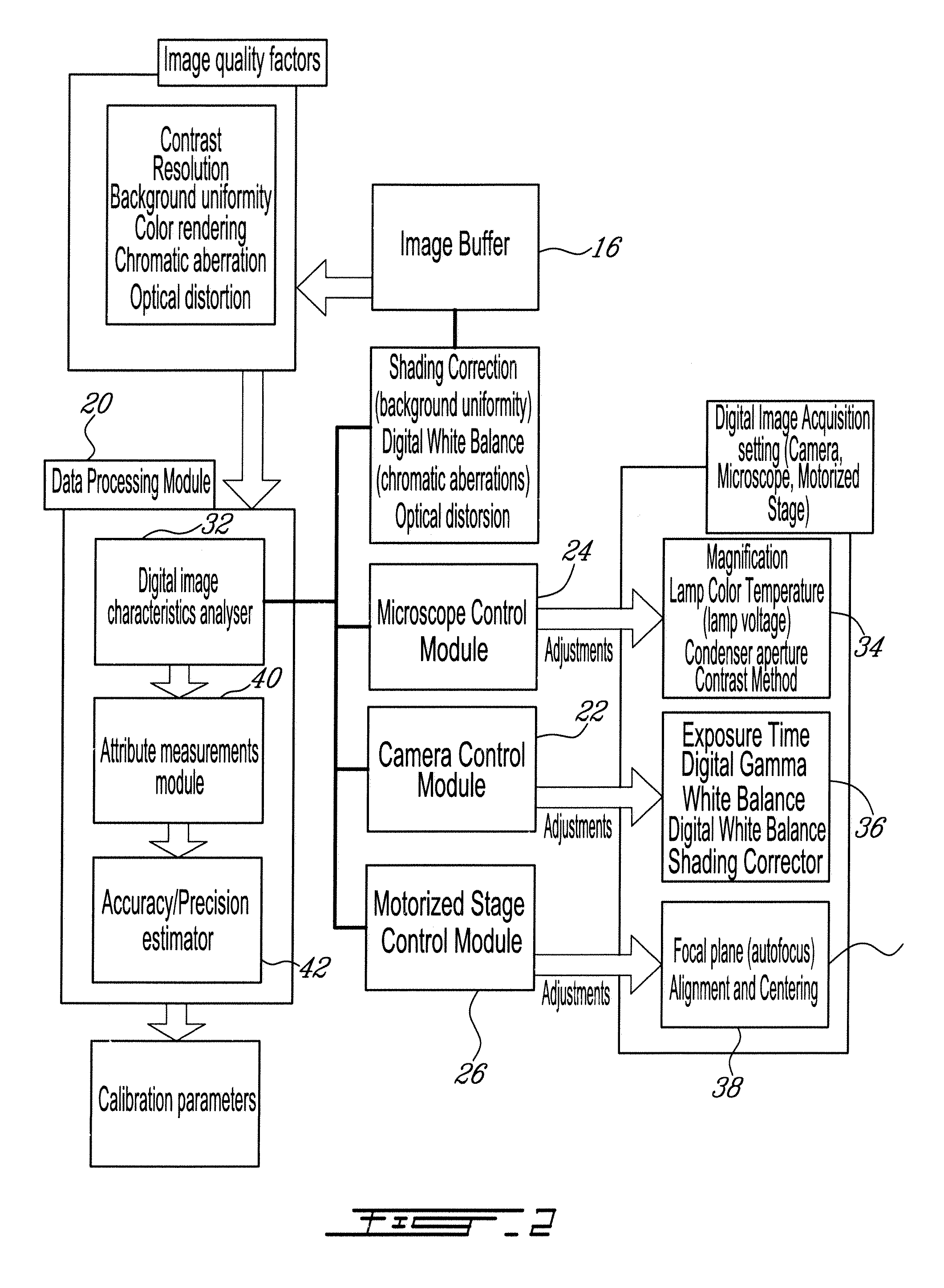

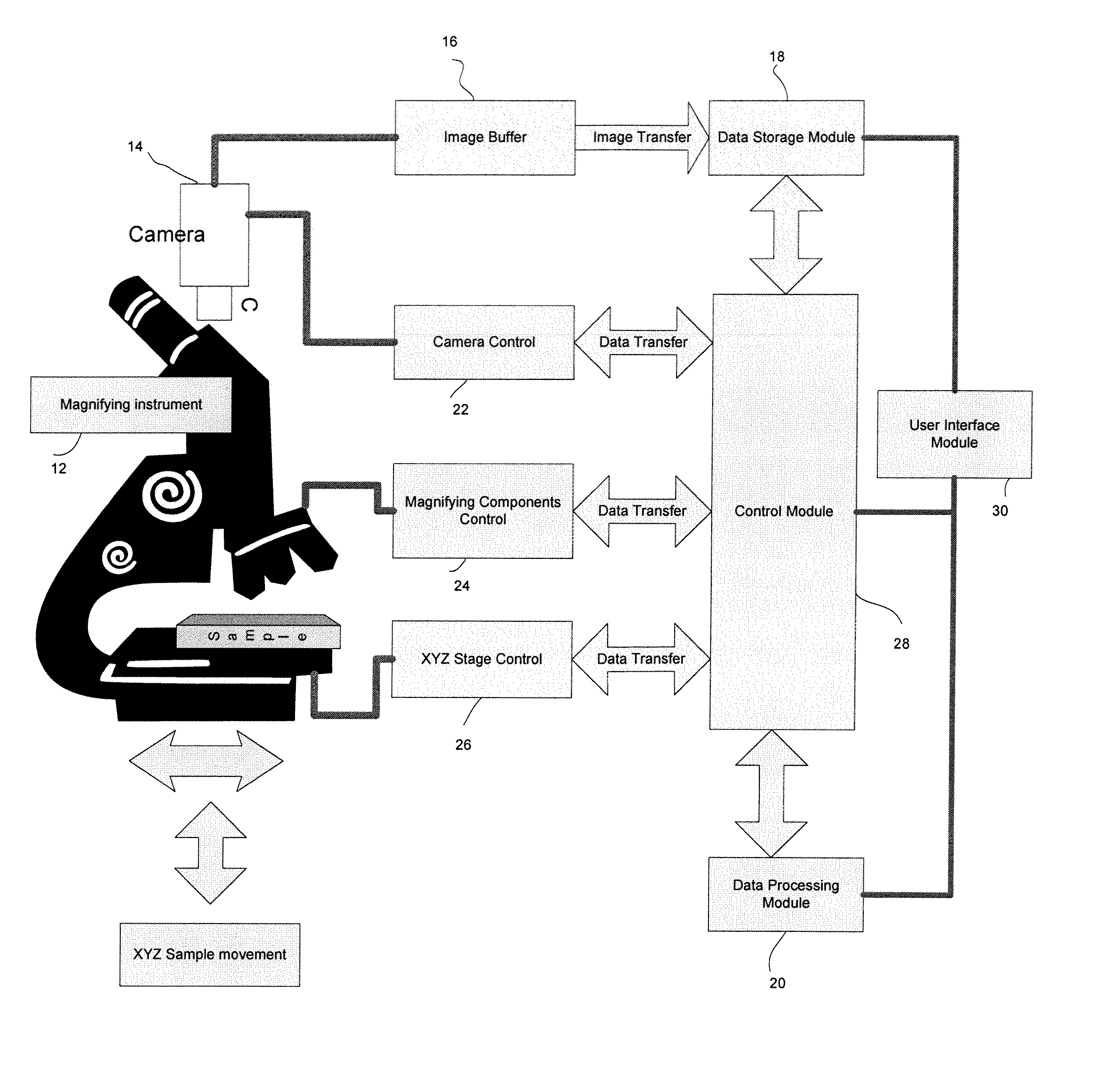

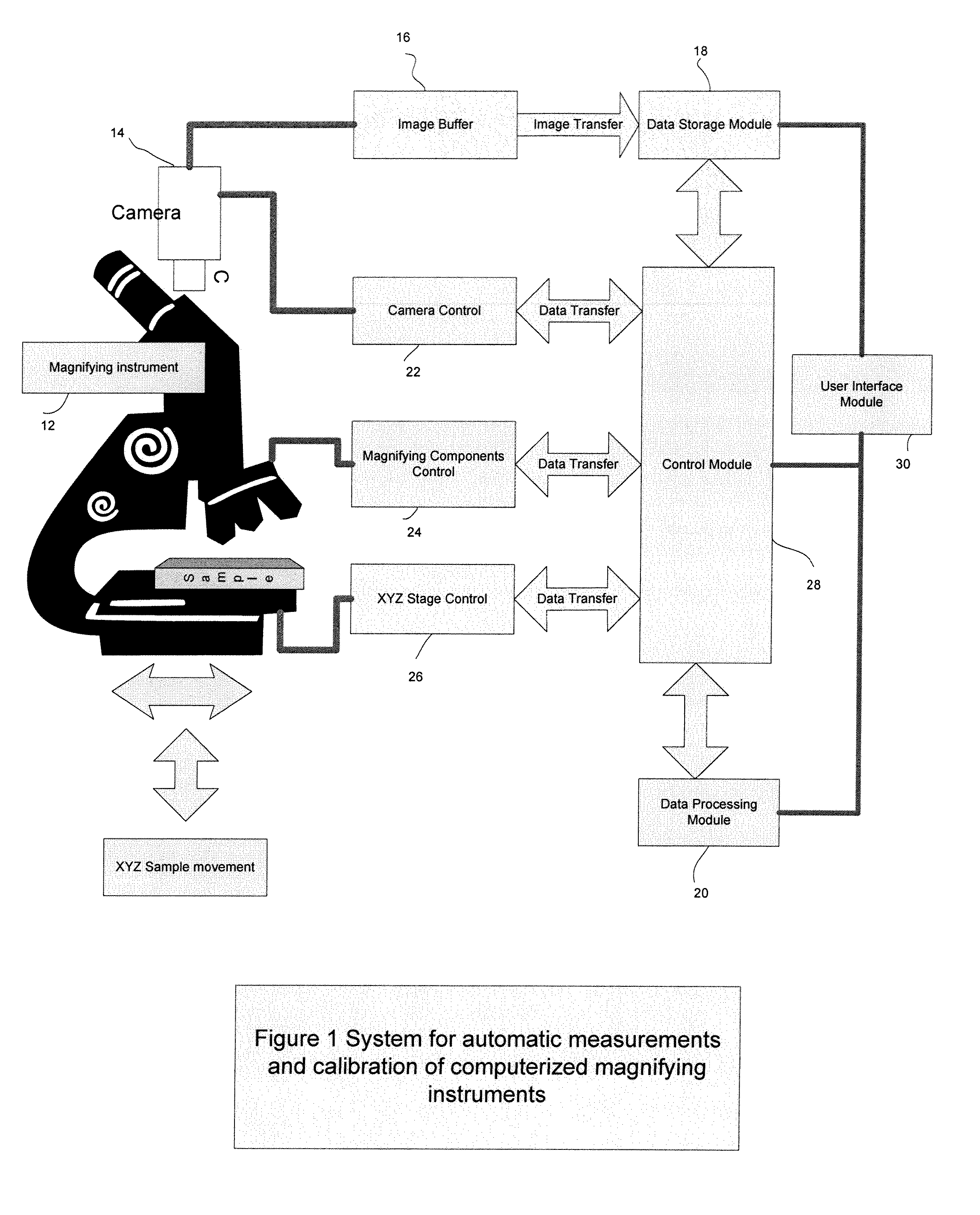

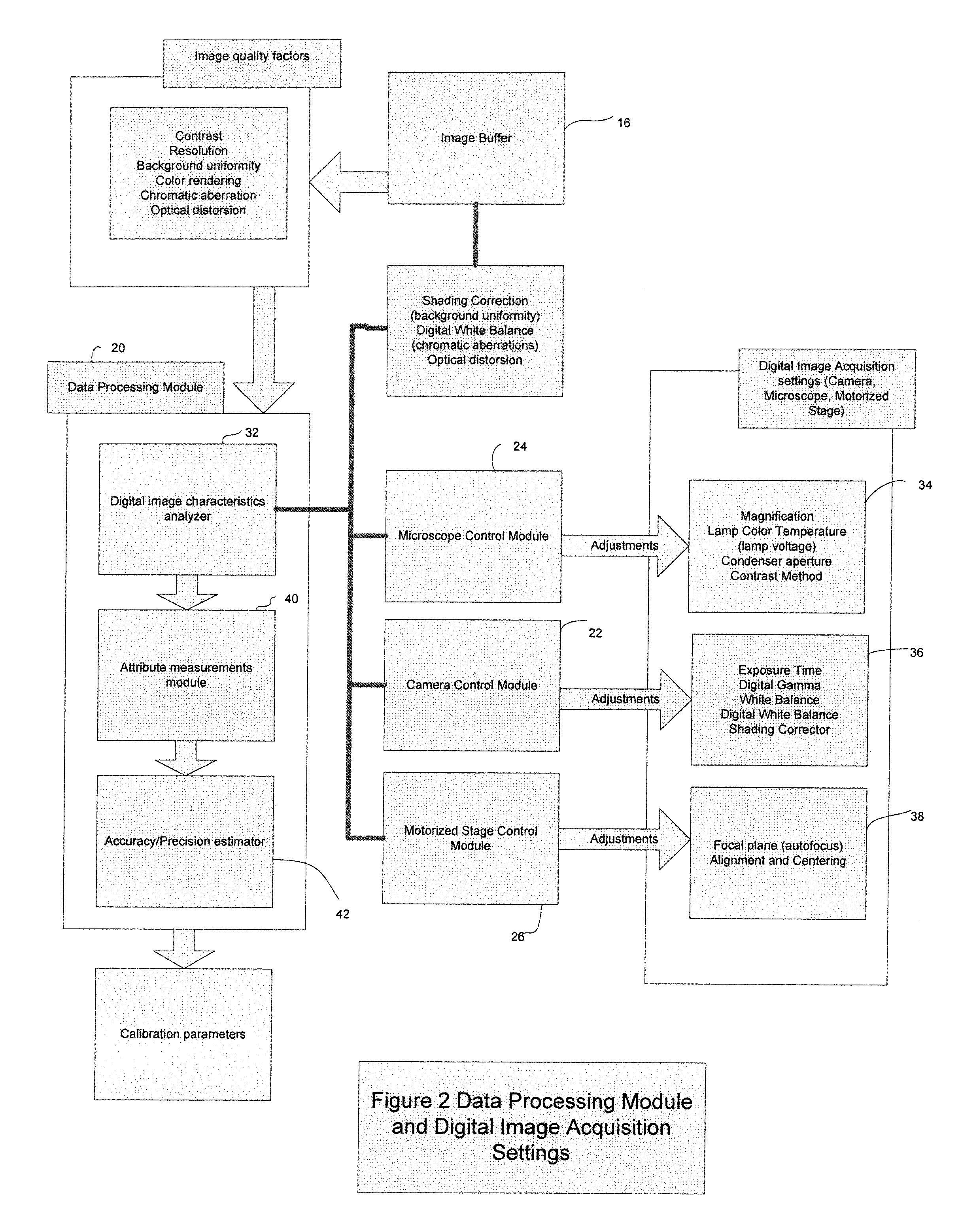

System and method for automatic measurements and calibration of computerized magnifying instruments

ActiveUS20070211243A1Not easy to make mistakesSimplify the calibration processImage enhancementPhotometry using reference valueIdentification deviceDigital image

The present invention relates to a system and method for automatic measurements and calibration of computerized magnifying instruments. More particularly, the method includes an automatic calibration aspect, which includes obtaining an optimized digital image of a reference object including at least one standardized landmark feature, and establishing calibration parameters based on one or more measured attributes of the landmark feature. The method further desribes a calibration aspect, which includes providing calibration parameters, obtaining a digital image including at least one known attribute, measuring the at least one known attribute and comparing the measured value with the known value. The method further includes an aspect of automatic measurement of an attribute of one or more object, which includes retrieving calibration parameters, acquiring a digital image and measuring the attribute. The system includes an object support, a reference object including one or more standardized landmark features, and an automatically readable identification means.

Owner:CLEMEX TECH

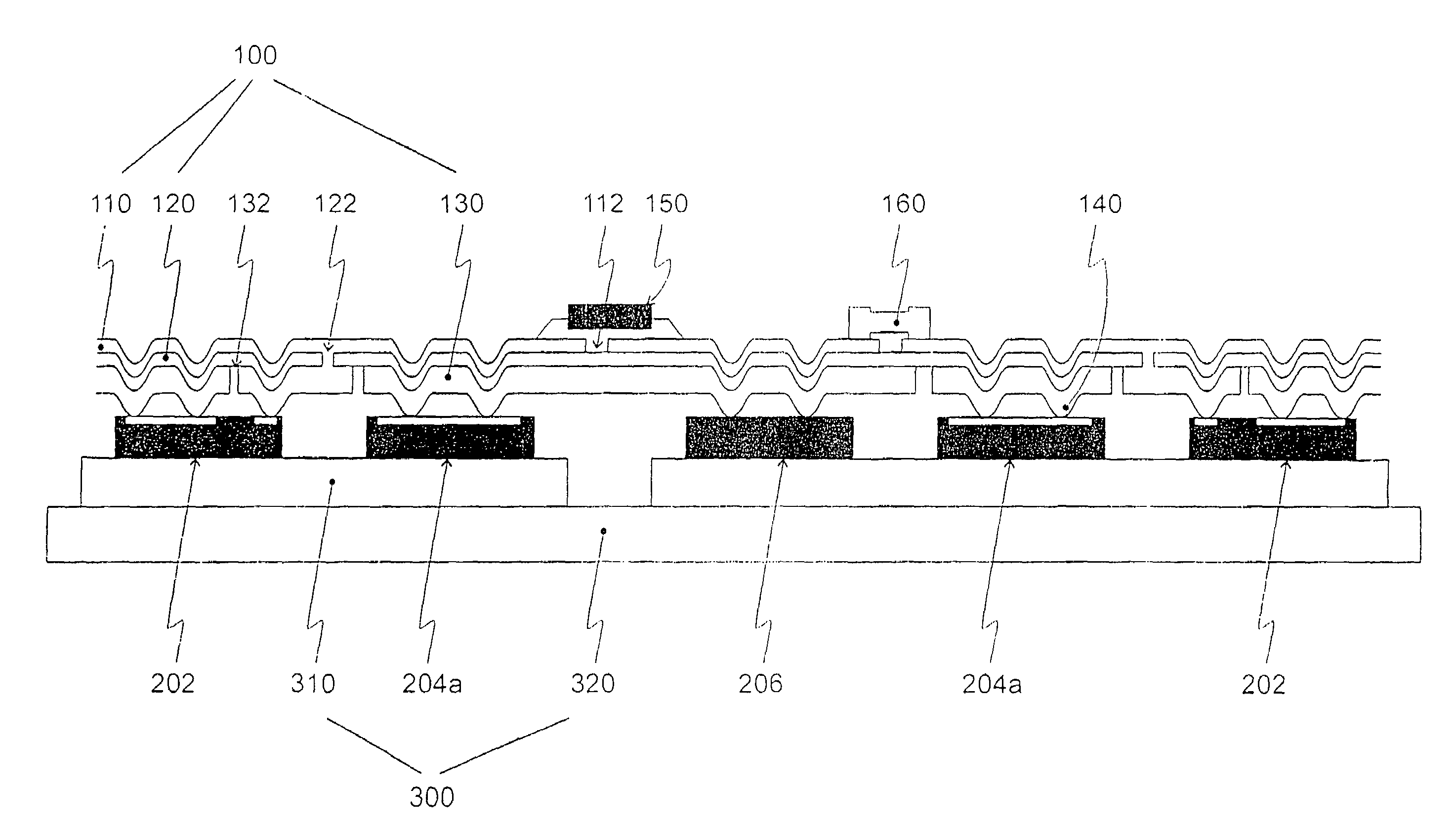

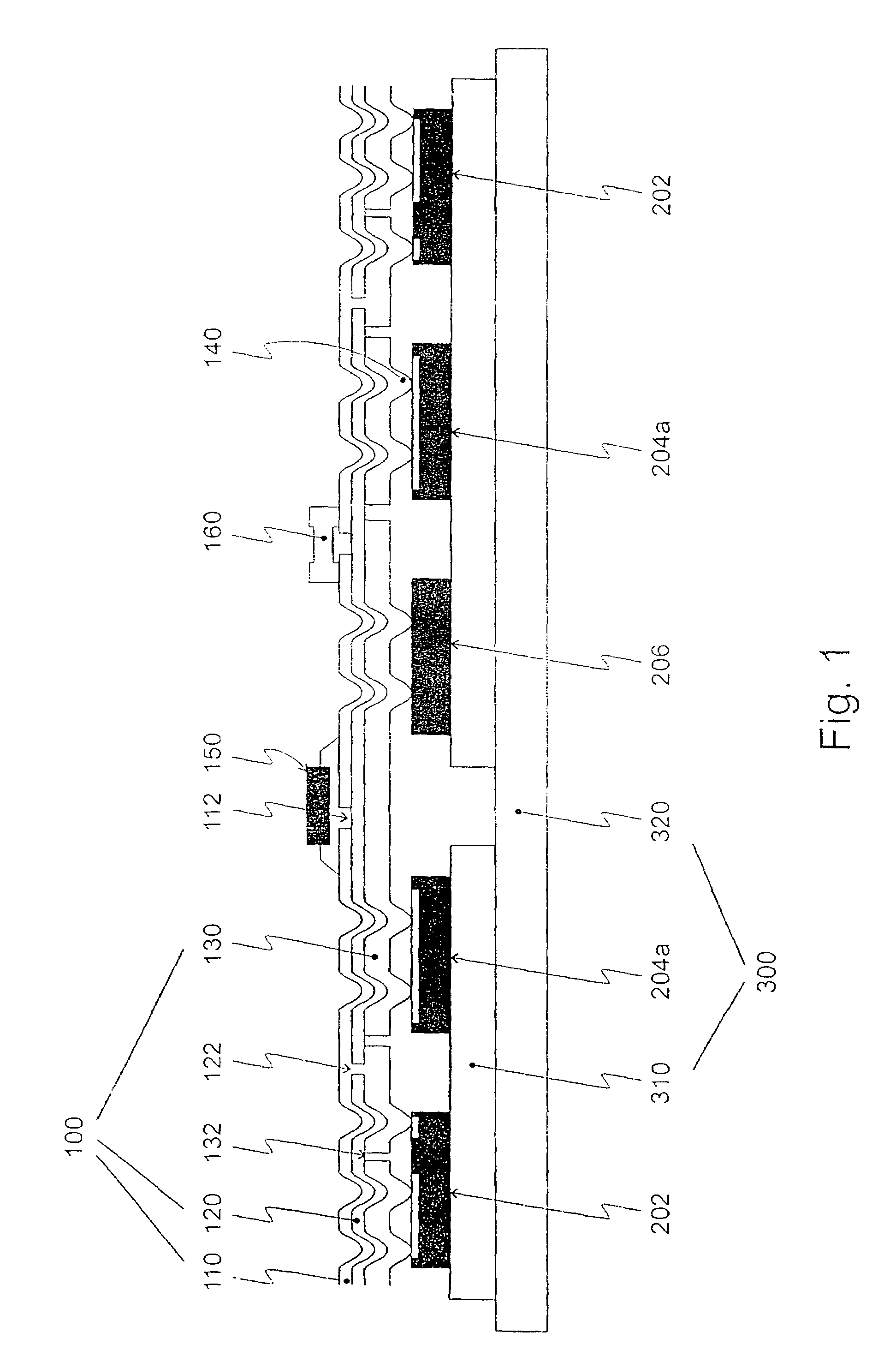

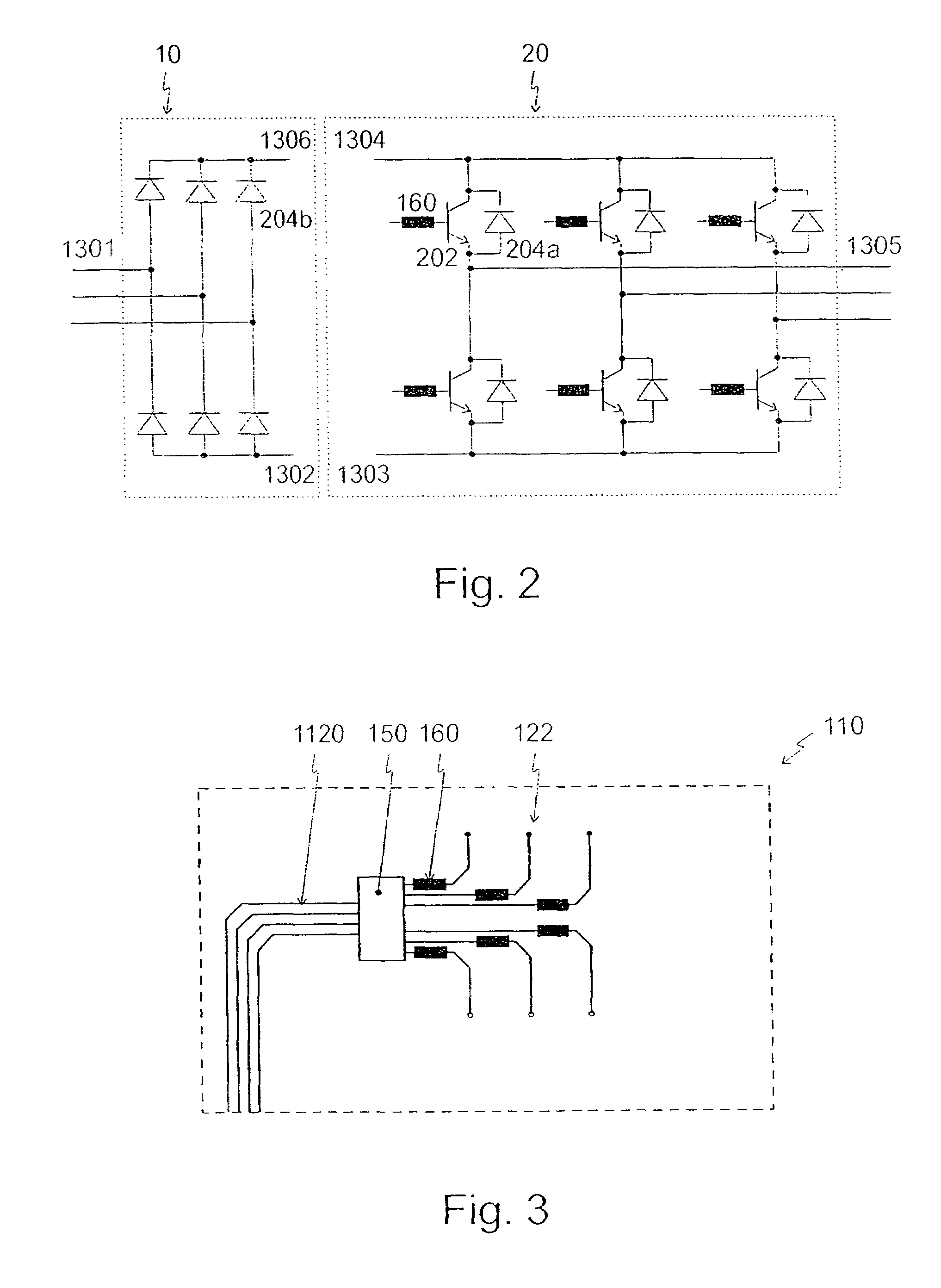

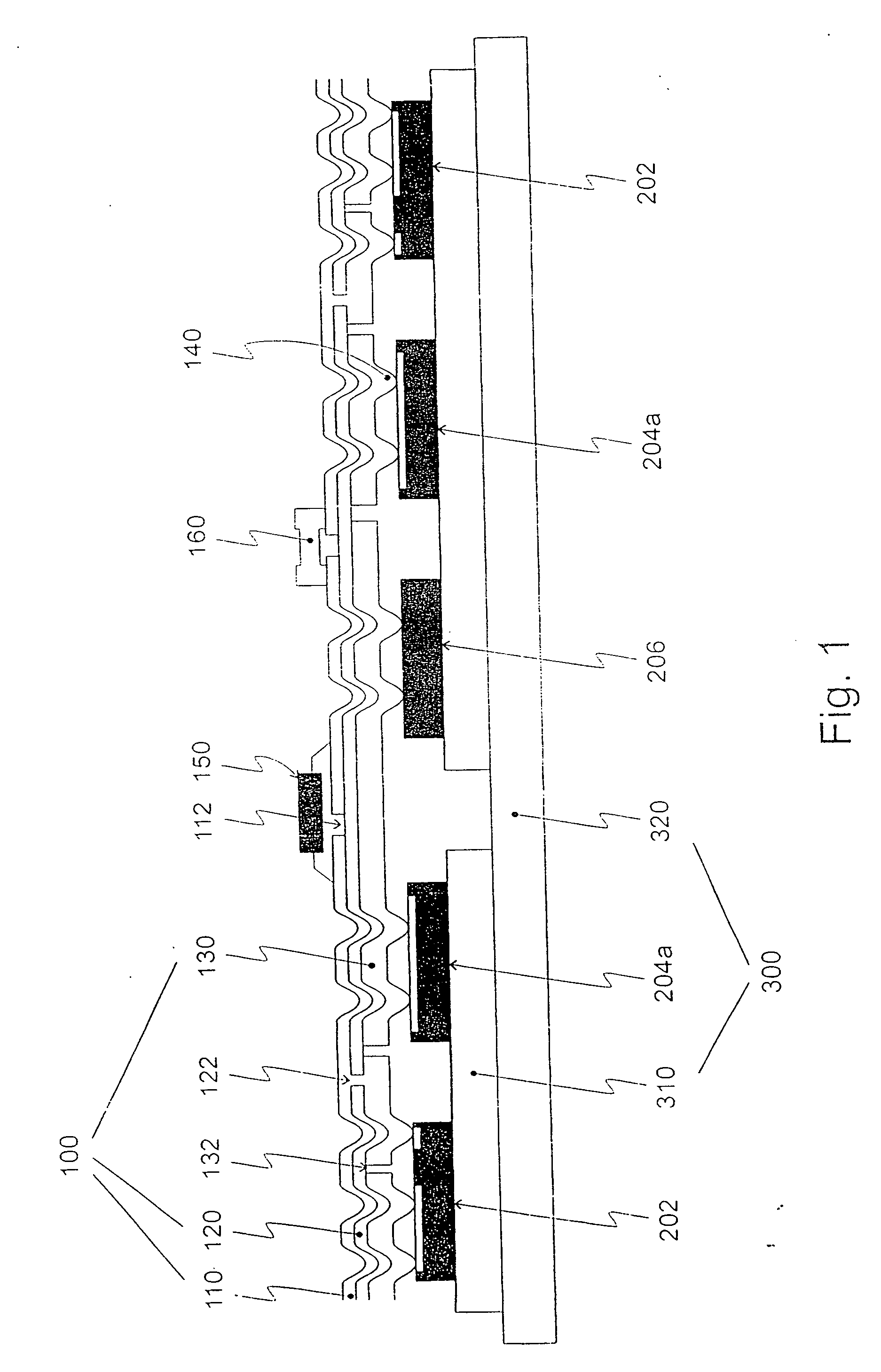

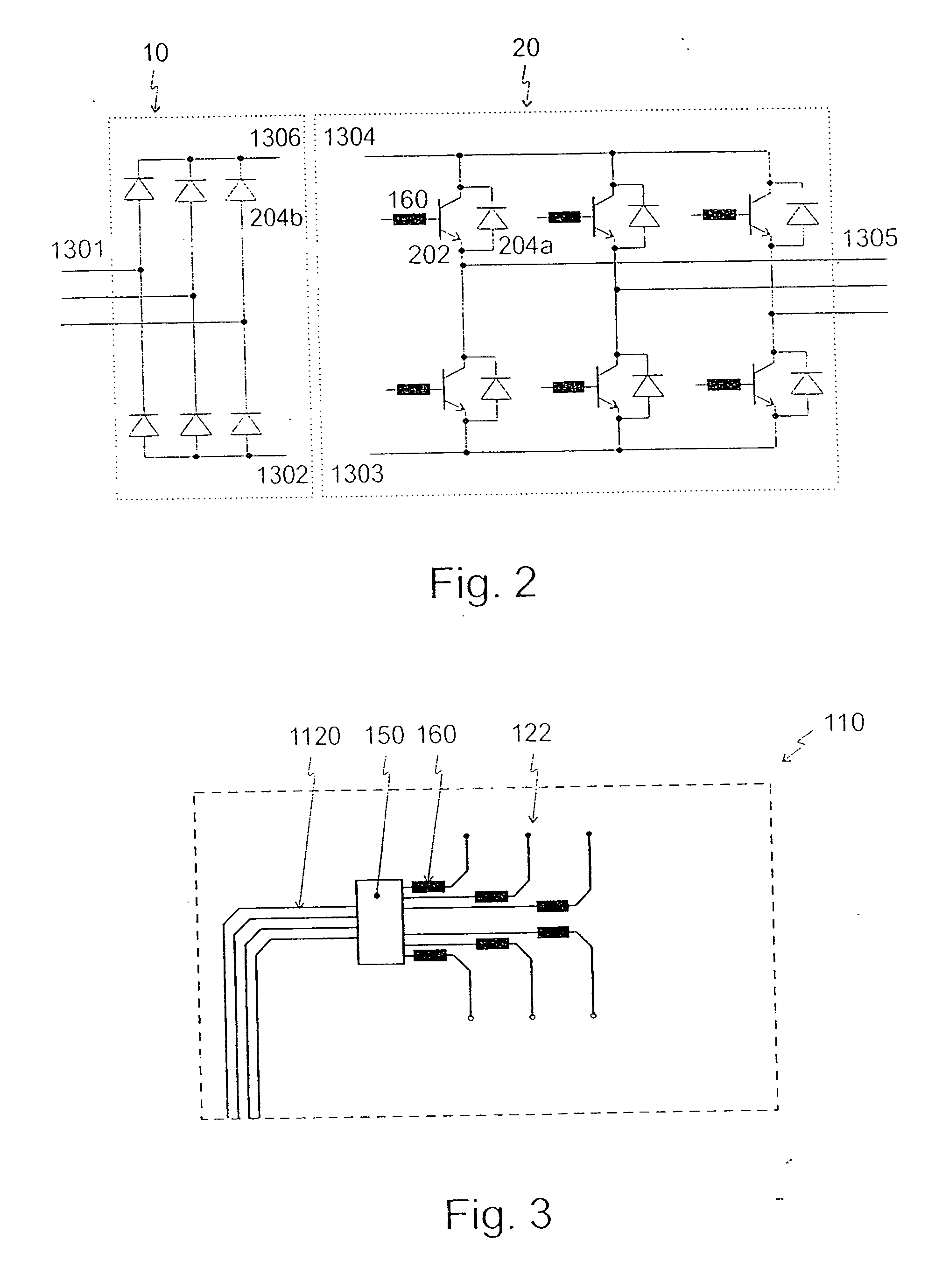

Power semiconductor module and method for producing it

InactiveUS7042074B2Reduce the numberProduction Process AutomationSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorUltrasonic welding

Owner:SEMIKRON ELECTRONICS GMBH & CO KG

PVC foaming architectural decoration material and preparation technique thereof

The invention relates to a PVC foaming construction decorative material and a preparation technique thereof. The preparation technique comprises the following steps: PVC plastics which are waste and are screened and ground, calcium carbonate, a stabilizer, an antioxidant, a lubricant, a foaming agent, a modifier, a foaming modifier, a dispersing agent, a colorant and the like are added into a high mixing machine according to the weight in sequence, mixed for 5 to 10 minutes, then placed into a low-temperature mixing machine for 5 to 10 minutes when being heated to be 120 to 125 DEG C; discharging is carried out when the temperature is 35 to 45 DEG C; the obtained materials are extruded by a parallel conical twin-screw extruder, molded, cooled in vacuum, pulled, film-stuck, cut and inspected and then the finished product of foaming plastic product is obtained. The invention is applicable to families, hotels, offices and entertainments, is the most ideal home decorative material with environment protection and is also the most practical home floor material.

Owner:胡大忠

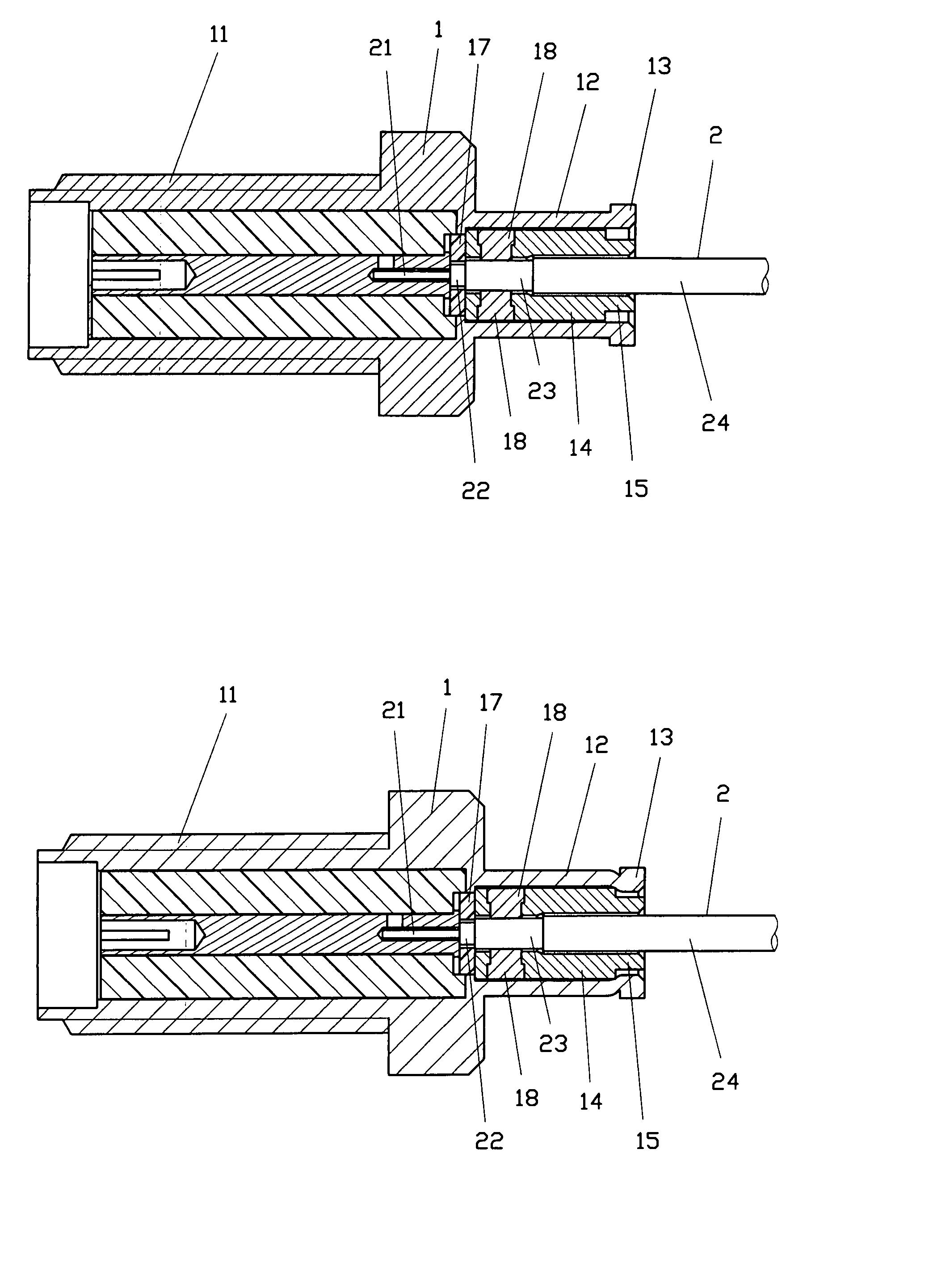

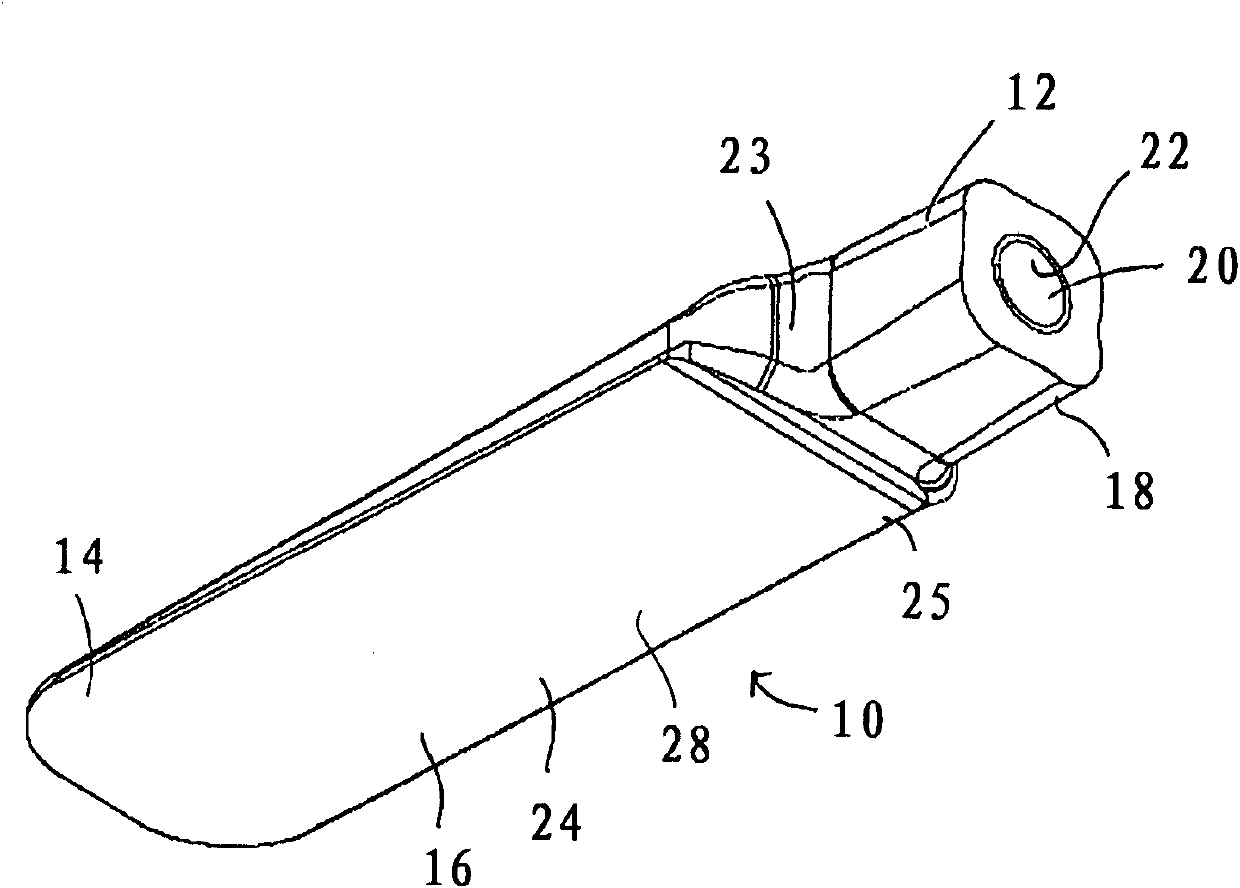

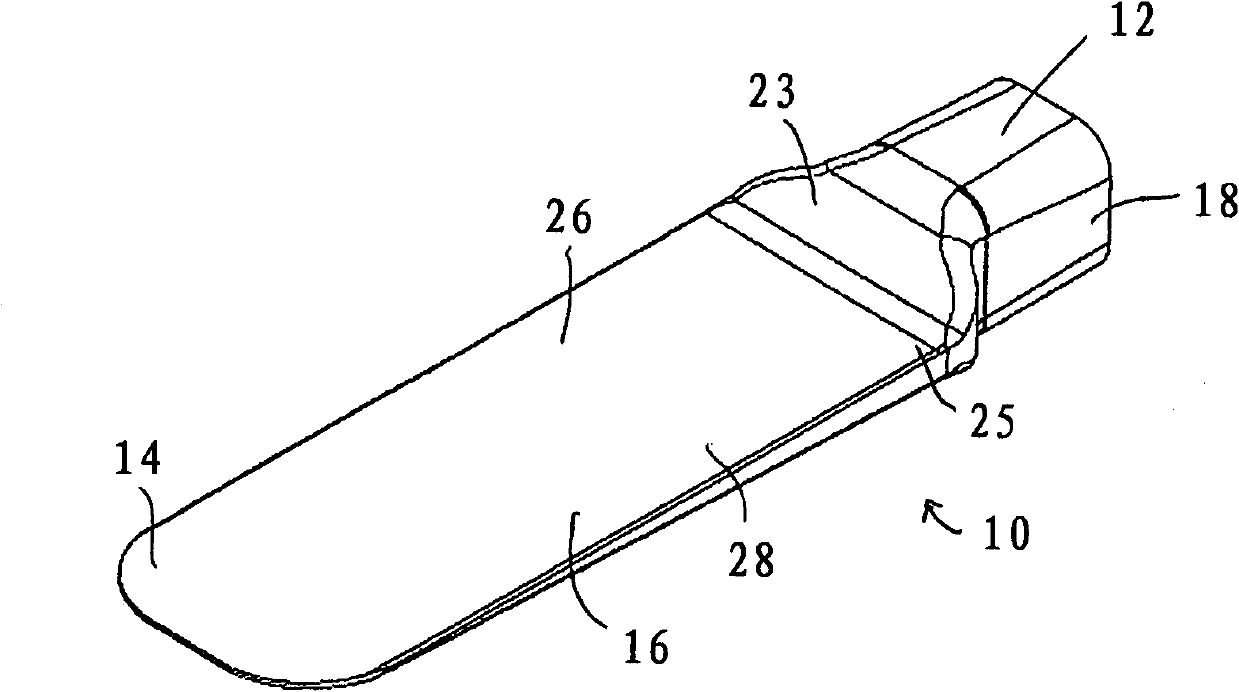

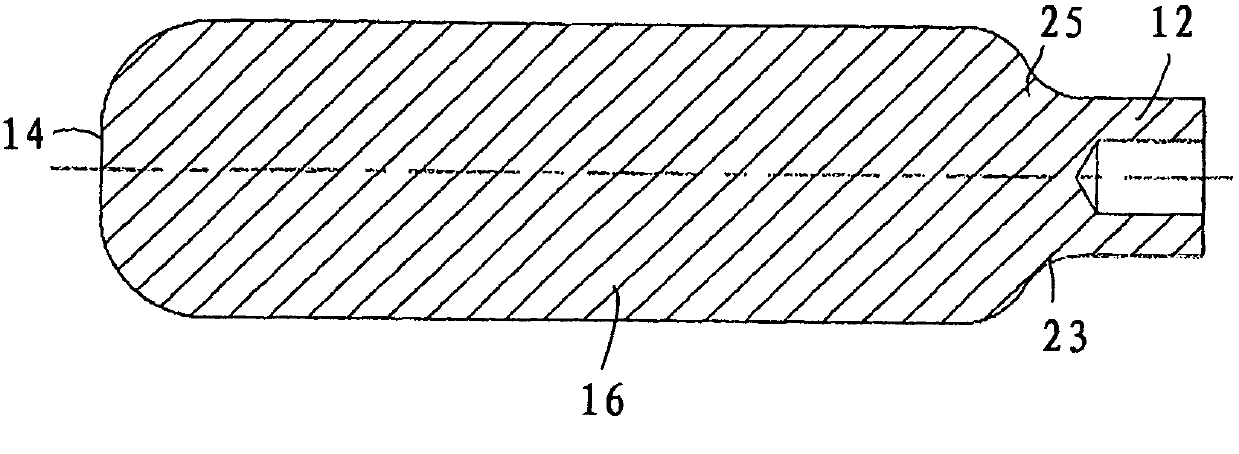

Coaxial connector structure

InactiveUS6929507B2Simple designProduction Process AutomationTwo pole connectionsCoupling device detailsEngineeringElectrical and Electronics engineering

A coaxial connector structure includes a connector and a signal wire. The connector has a threaded section at one end and a connecting section at the opposite end. The connecting section has an enlarged section with a metal sleeve therein. The sleeve is formed with a connecting end at one end and a pair of through holes across the sleeve. The through holes are filled with solder to secure and connect the signal wire with a metal layer to reinforce the strength of the connection between the signal wire and the metal layer.

Owner:HUANG LIANG PRECISION ENTERPRISE

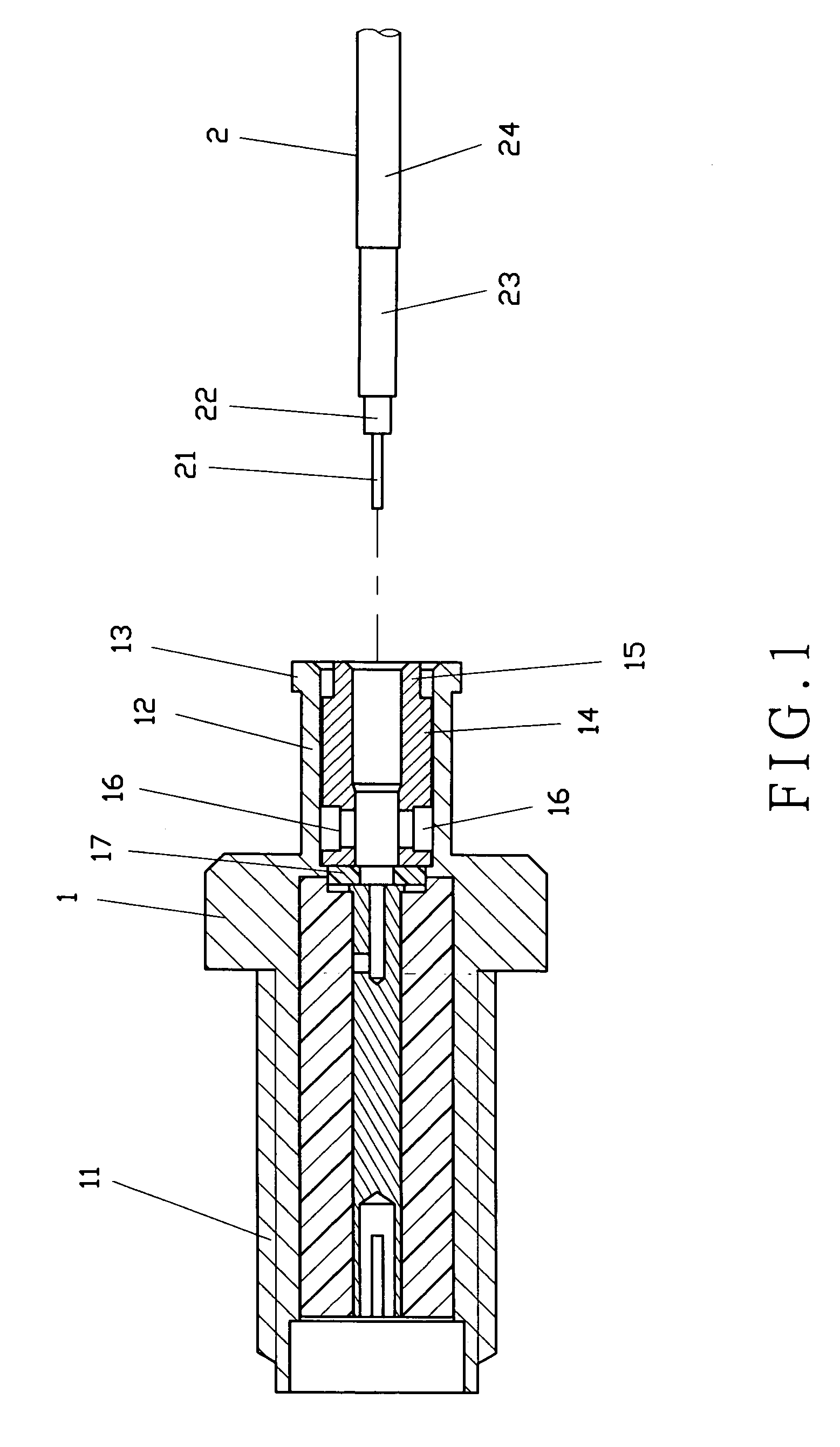

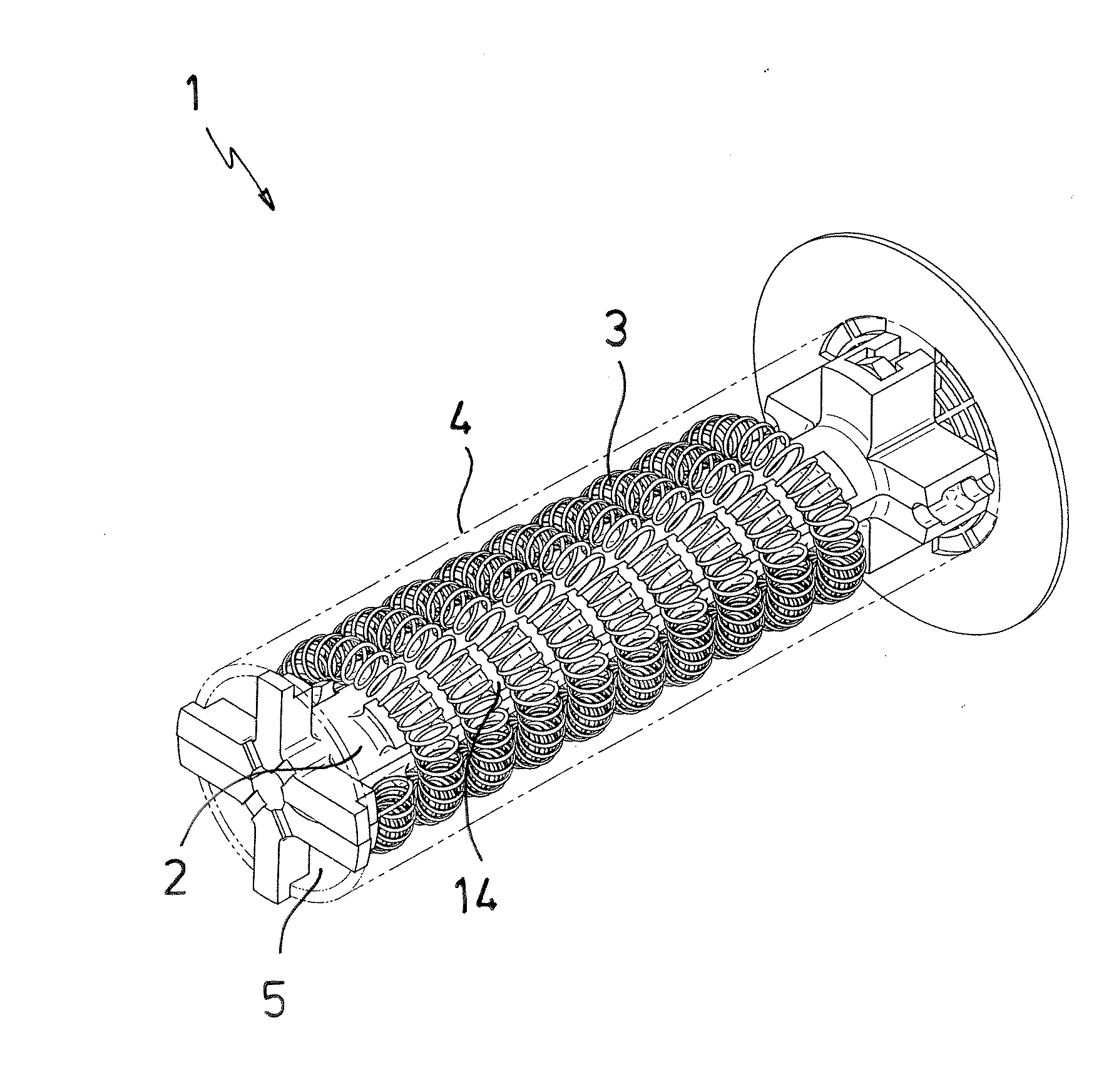

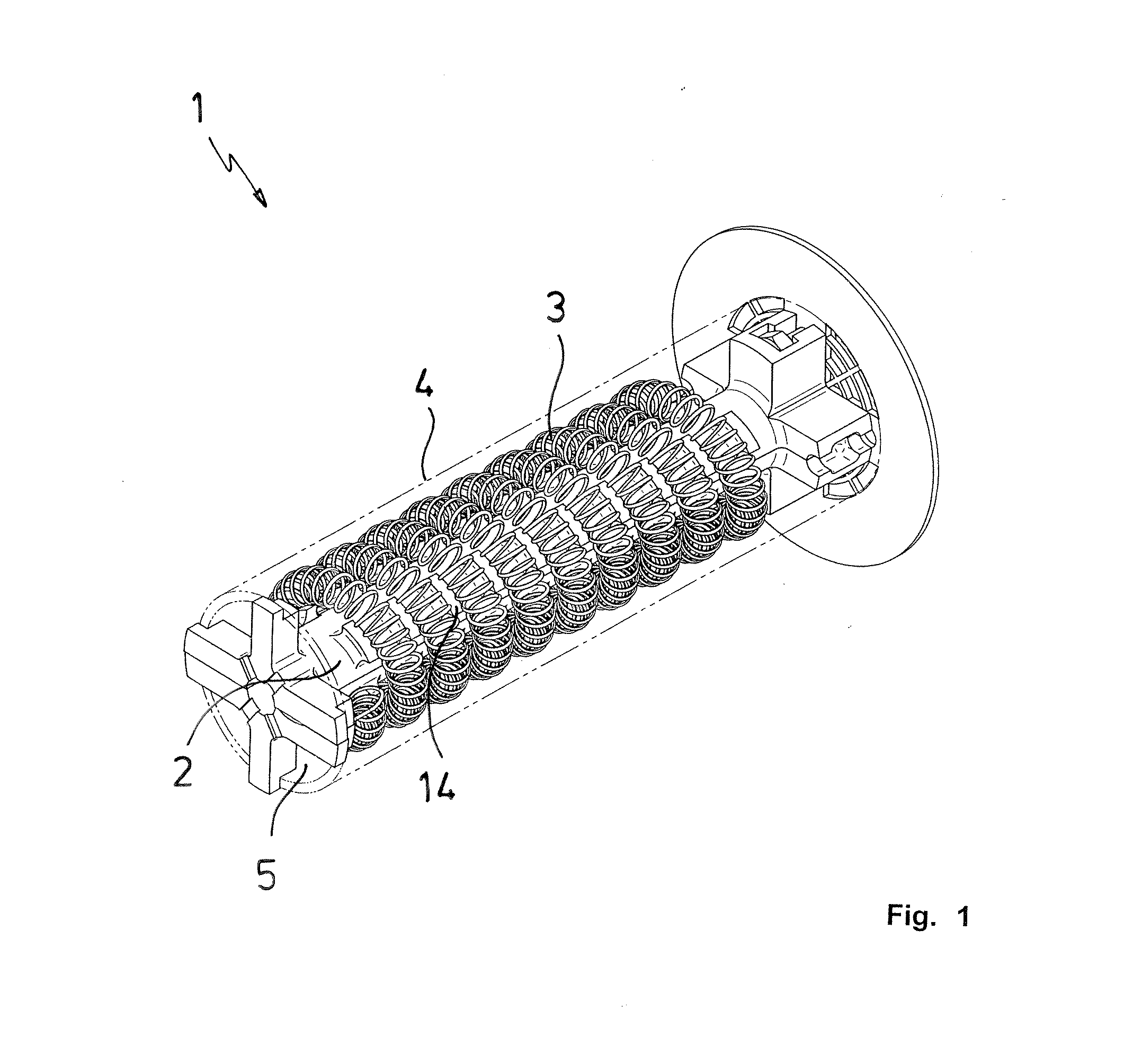

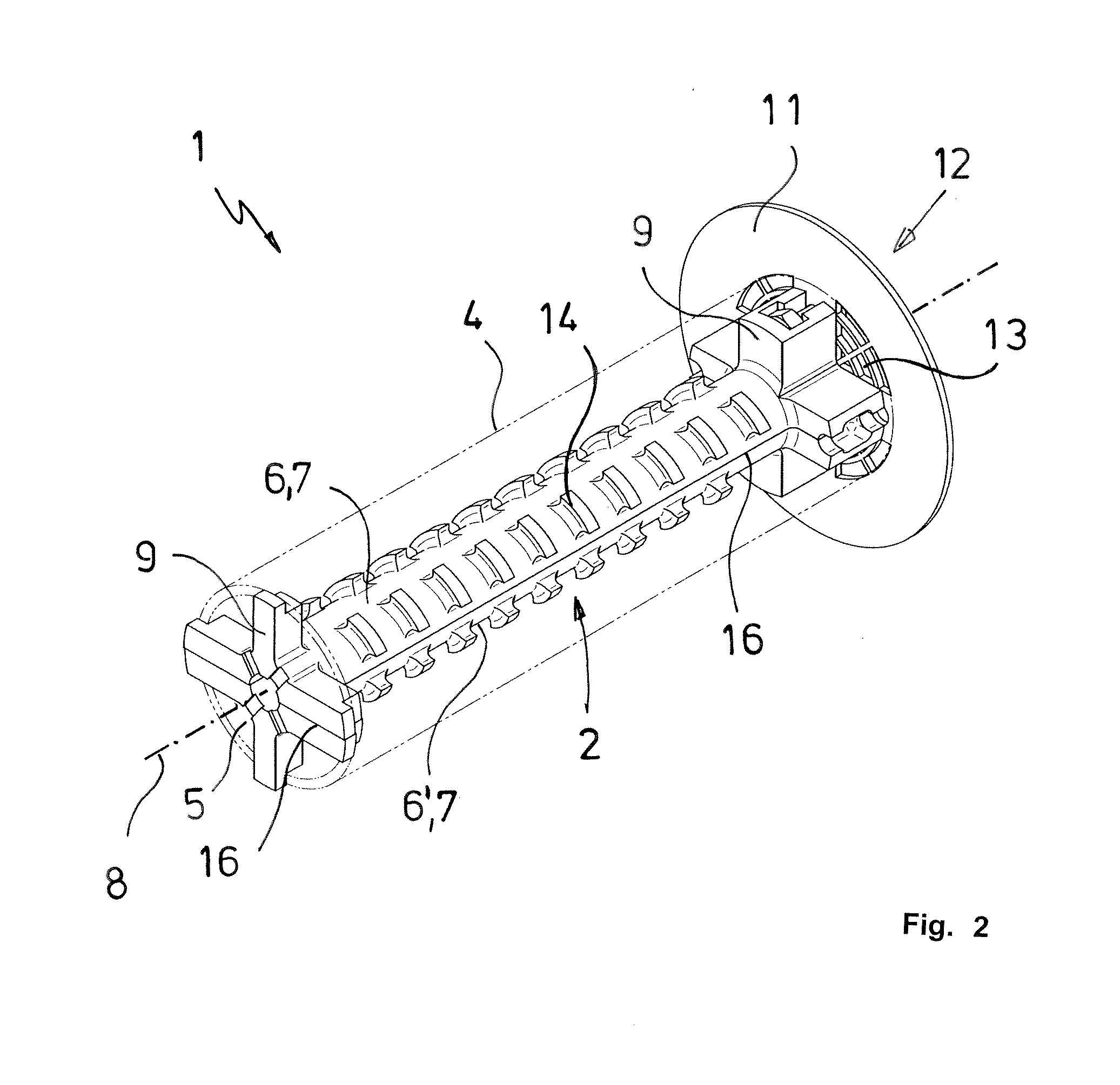

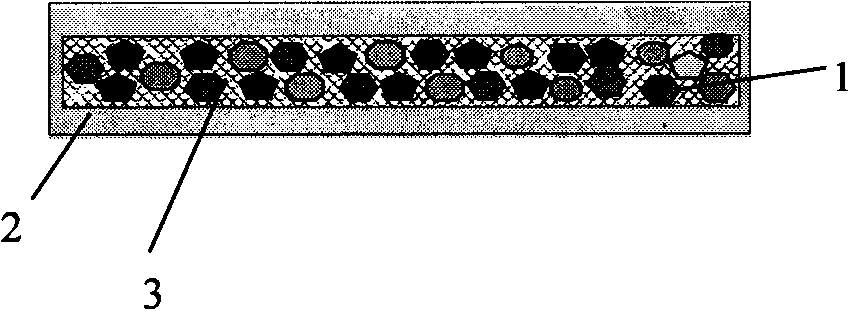

Electrical heating element

InactiveUS20110233191A1Easy constructionPrevent short-circuitingHeater elementsHeating element shapesElectricityHeating element

Electrical heating element 1, preferably for the ignition of biomass heating systems such as pellet stoves, with an elongated coil carrier 2 that is made of a thermally resistant, electrically insulating material and is designed to accept a heating wire coil, where the heating wire coil is held spiral-like on the outside the coil carrier 2 and is enclosed by a sleeve tube 4 also made of a thermally resistant material. The coil carrier 2 and the sleeve tube 4 delimit an air channel 5 through which the heating wire coil passes. According to the invention, the coil carrier 2 comprises at least two adjacent coil carrier shell parts 6, 6′ that extend symmetrically to the center axis 8 of the heating element 1 in the longitudinal direction of the coil carrier 2.

Owner:LEISTER TECHNOLOGIES

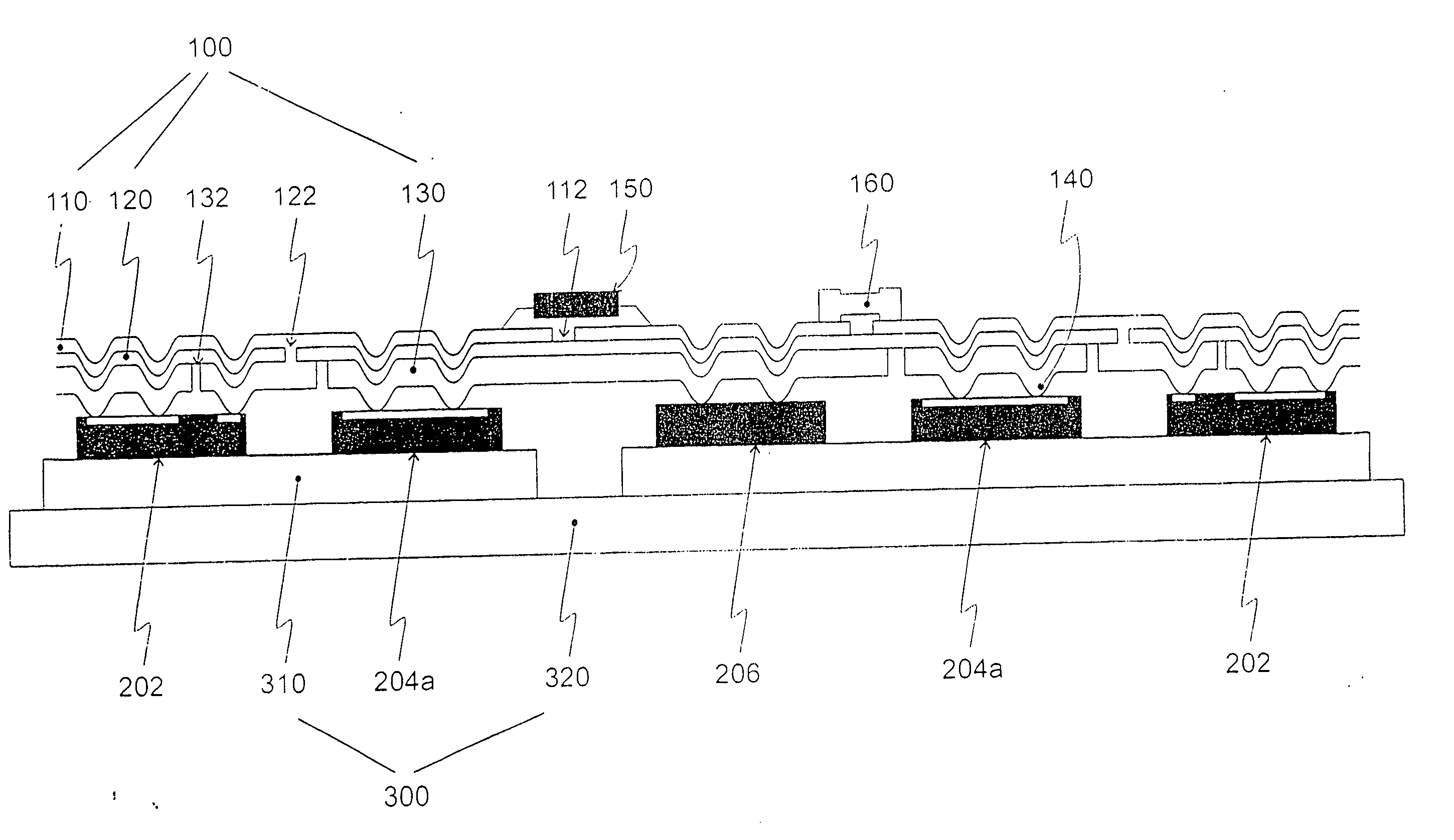

Power semiconductor module and method for producing it

InactiveUS20050127503A1Reduce the numberProduction Process AutomationSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorUltrasonic welding

A power semiconductor module and a method for producing it, wherein the module includes a substrate, with conductor tracks disposed on it to suit circuitry with which the module is used and with power semiconductor components disposed on the conductor tracks. Also disposed on the conductor tracks are spacer elements and a foil composite that includes two metal foil layers with an electrically insulating foil layer disposed between them. The foil composite has contact humps and plated-through holes. At least one of the metal foil layers is structured in a manner to suit the circuitry with which the module is used, and this foil composite is durably connected to the power semiconductor components and to the spacer elements, preferably by ultrasonic welding.

Owner:SEMIKRON ELECTRONICS GMBH & CO KG

Corn protein high F value oligopeptide production method

ActiveCN1733928AHigh degreasing rateHigh extraction rateFermentationProtein foodstuffs working-upSubstrate concentrationProtease

The preparation method for high-H-value oligopeptide from zein comprises, using corn powder as material, hypercritical CO2 liquid extracting to remove fat and smelly materials in said powder and extract zein; adding some water to the zein; taking extruding and modifying treatment at given temperature and pressure to increase its solubility; using two proleases for two-step enzymolysis to zein at given substrate concentration, enzyme concentration, pH value, and time condition; then, separating, purifying, drying, smashing and obtaining the product with F value more than 20.

Owner:吉林省长吉图开发建设现代农业投资有限公司

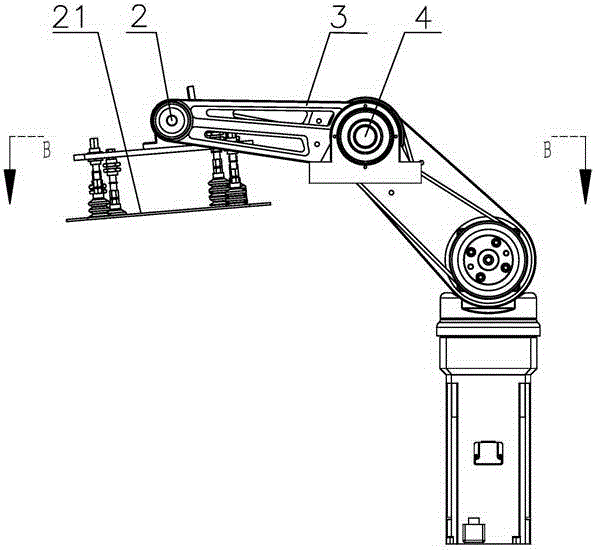

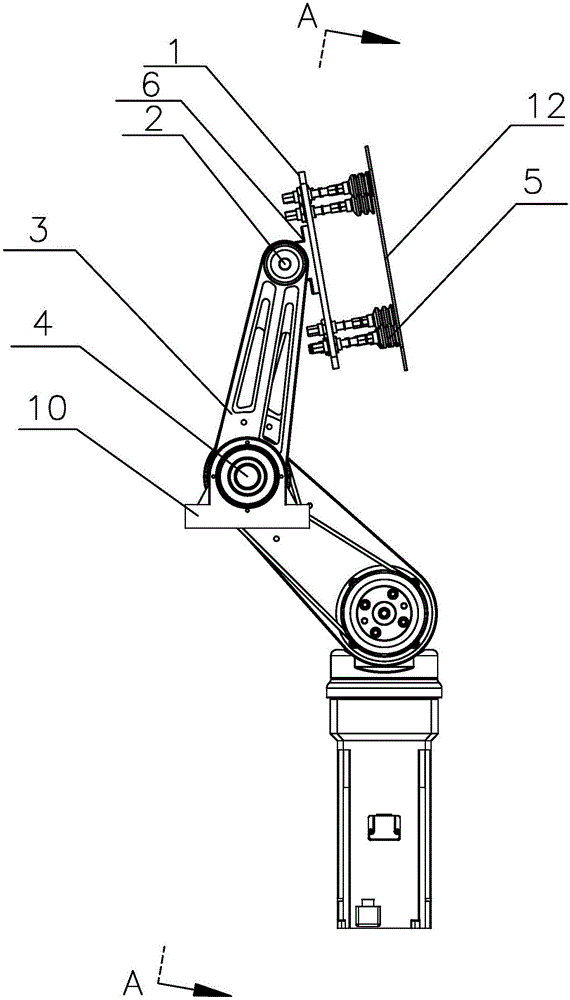

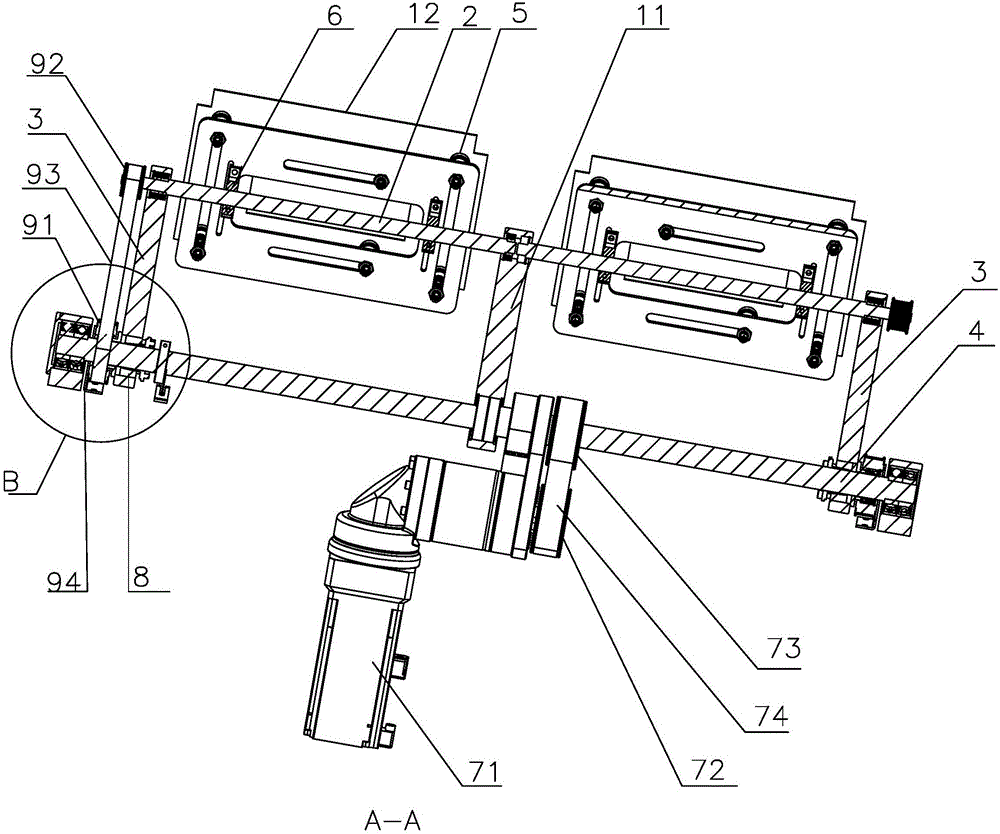

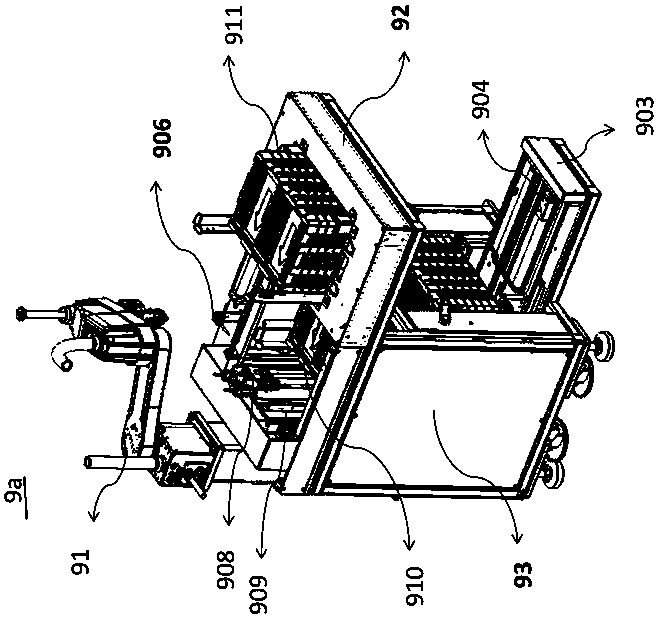

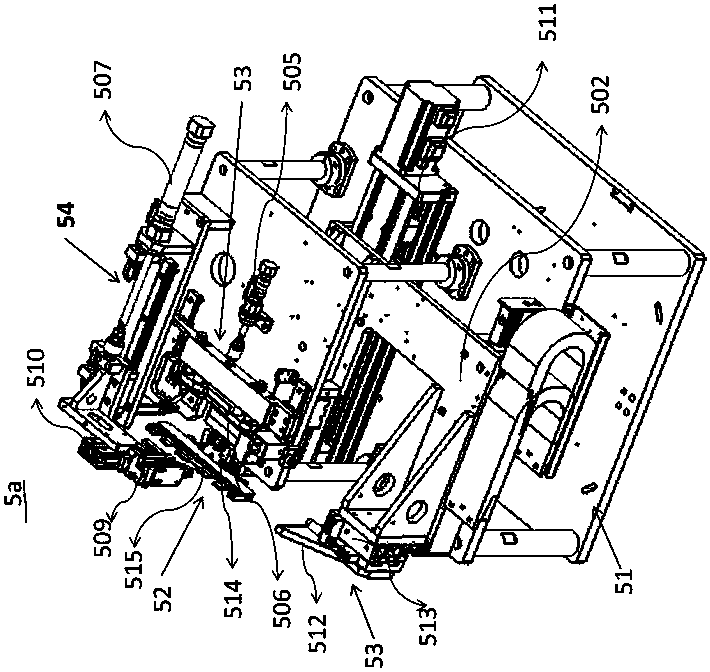

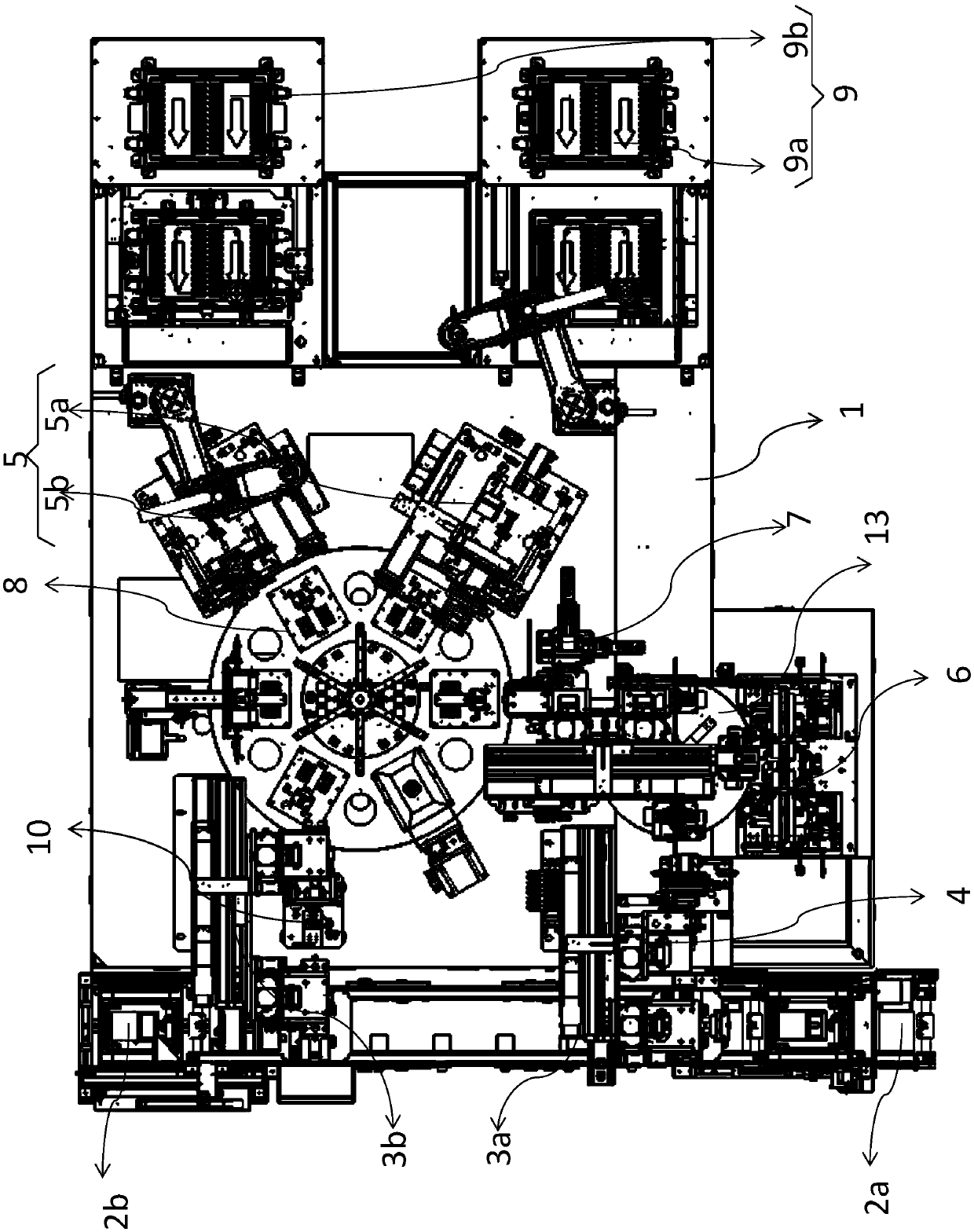

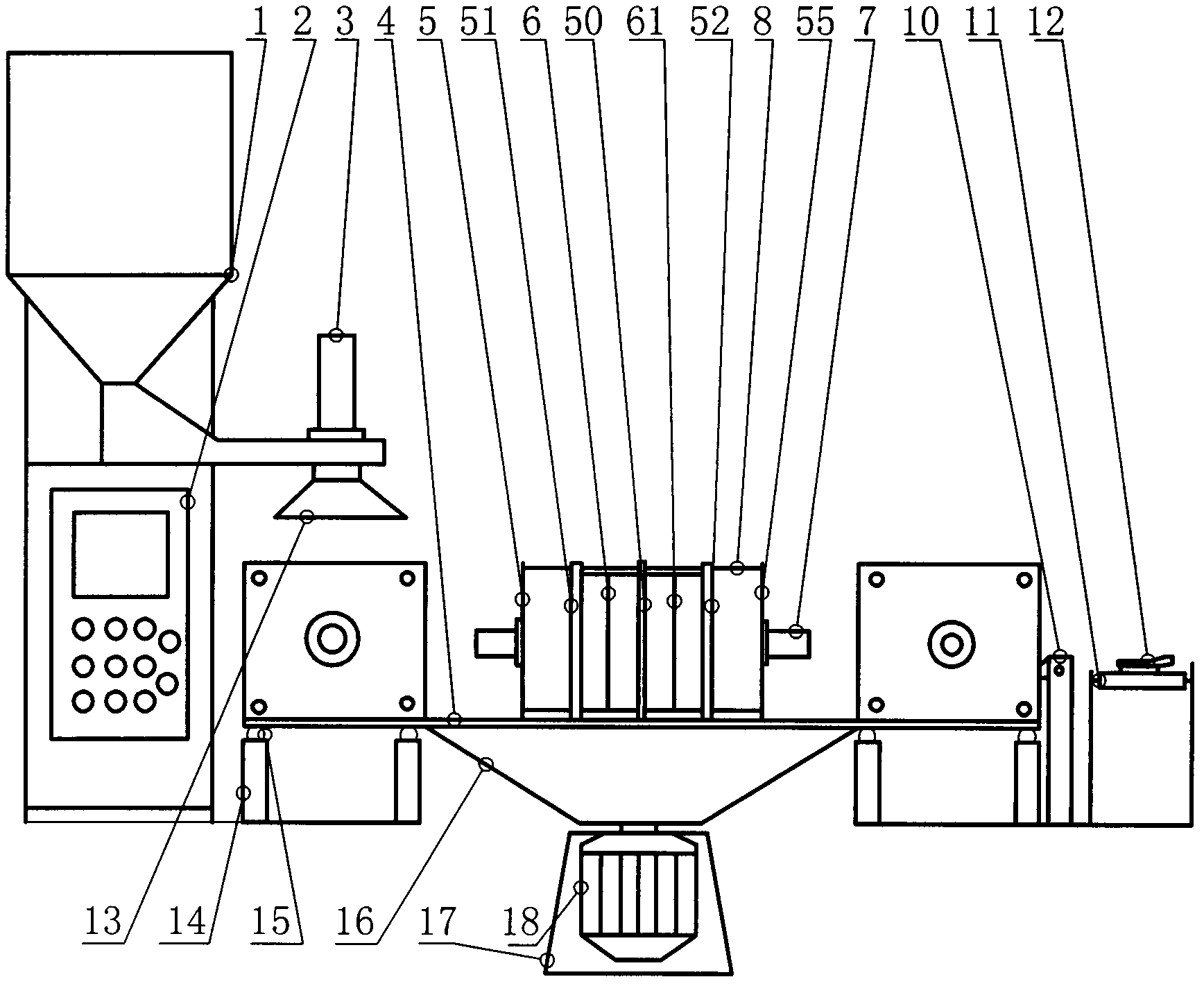

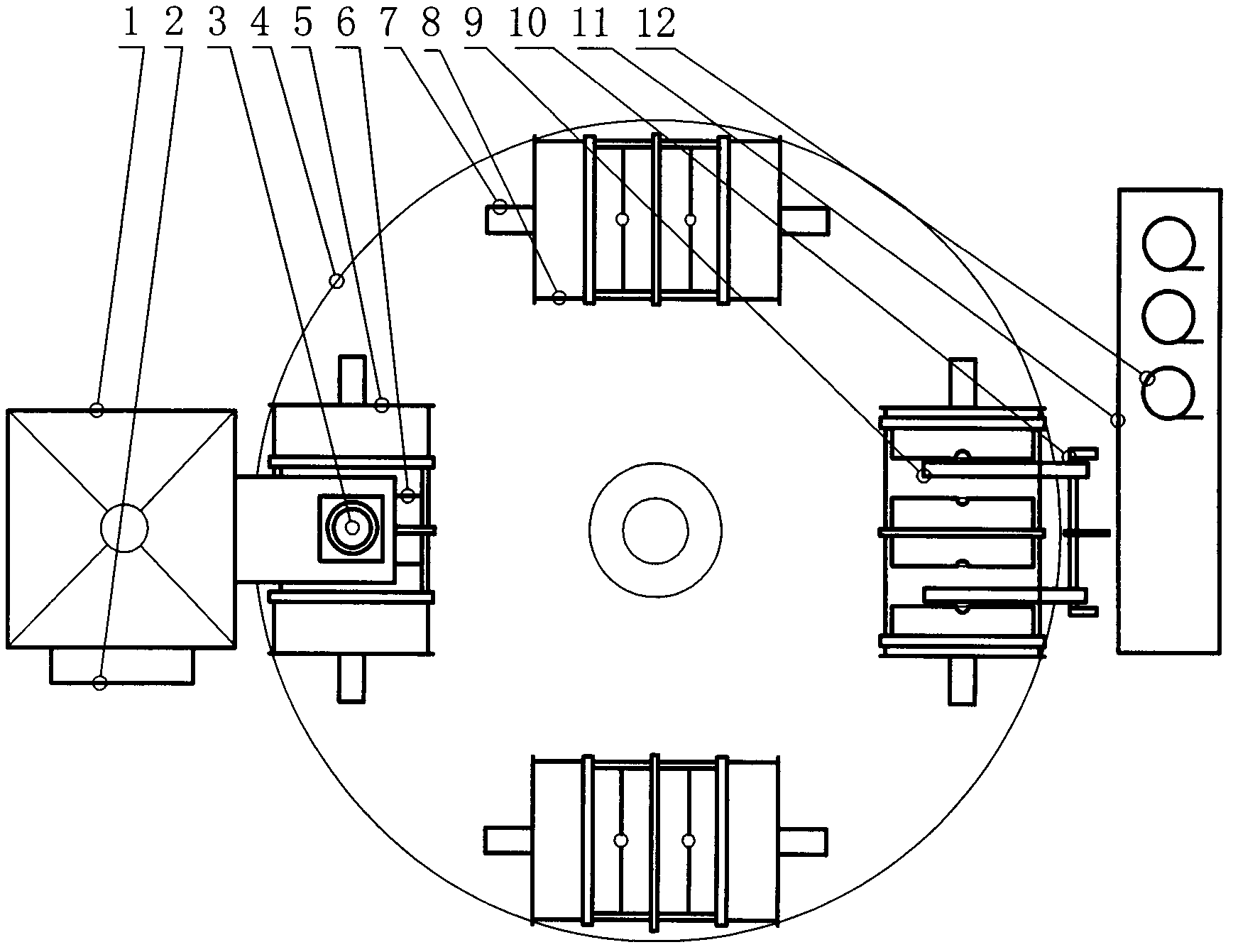

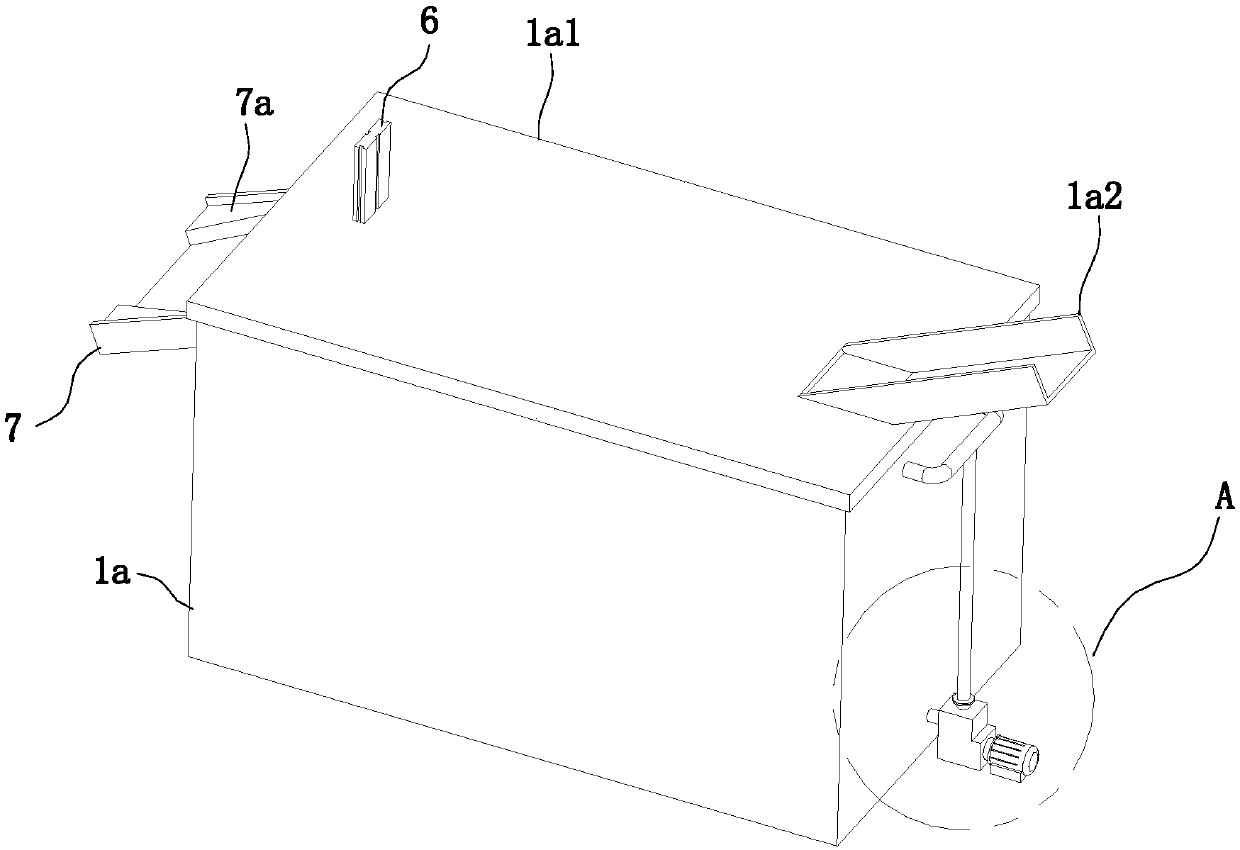

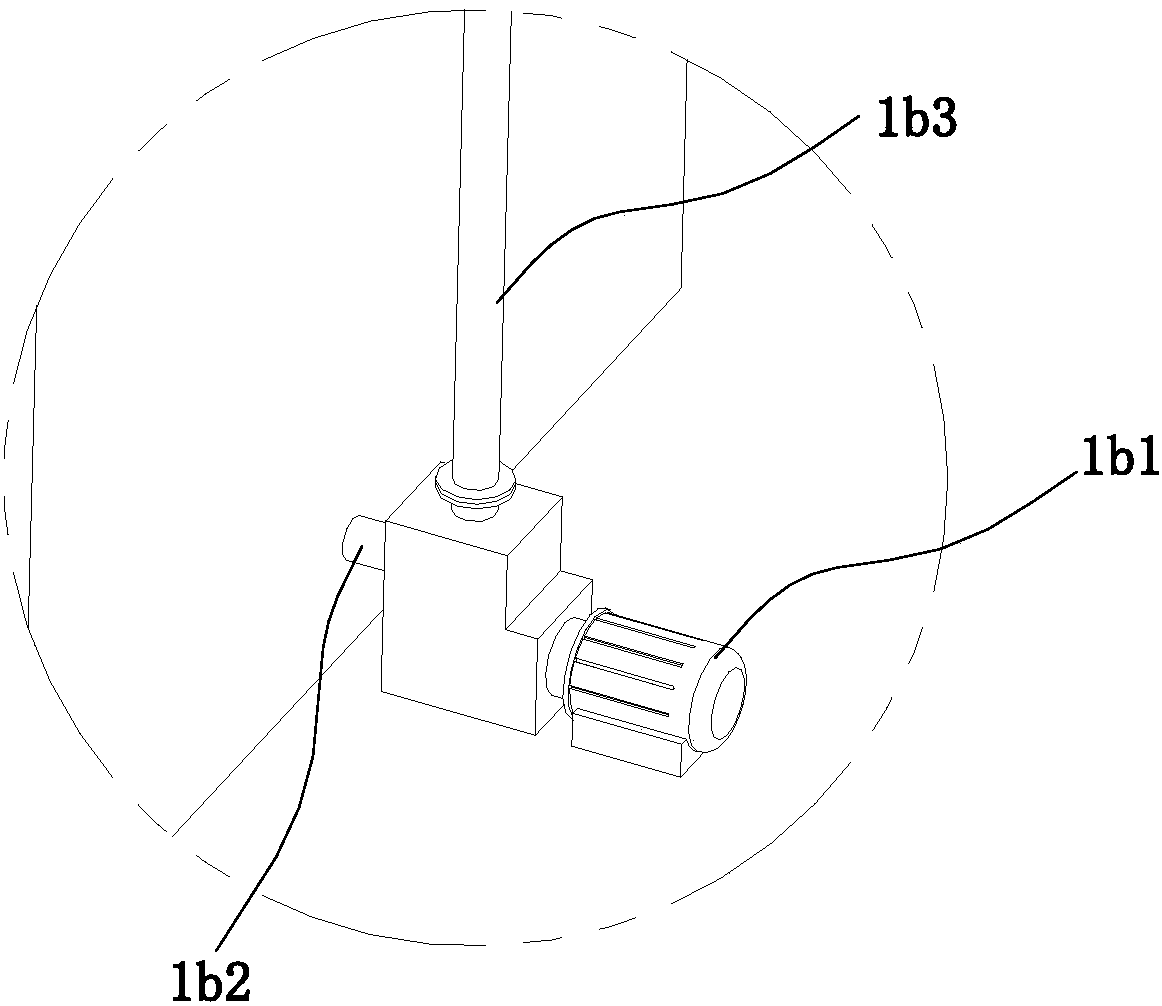

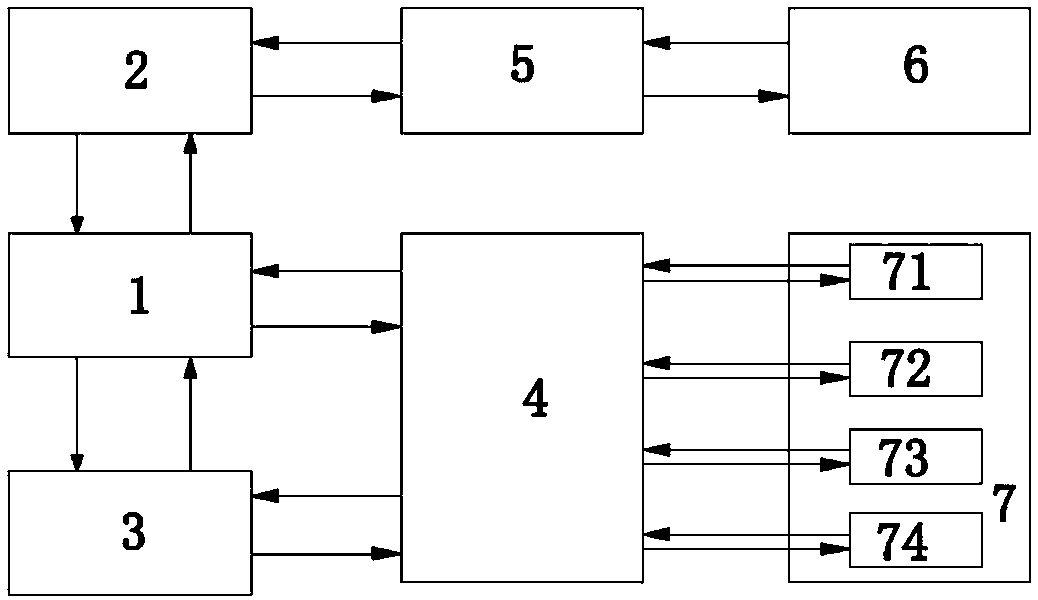

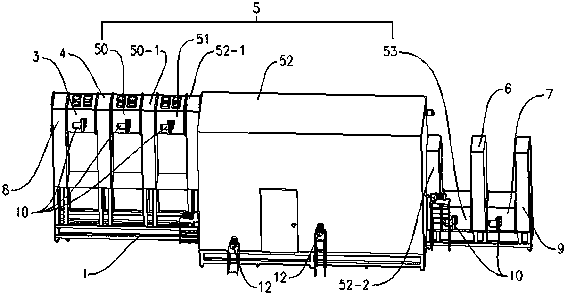

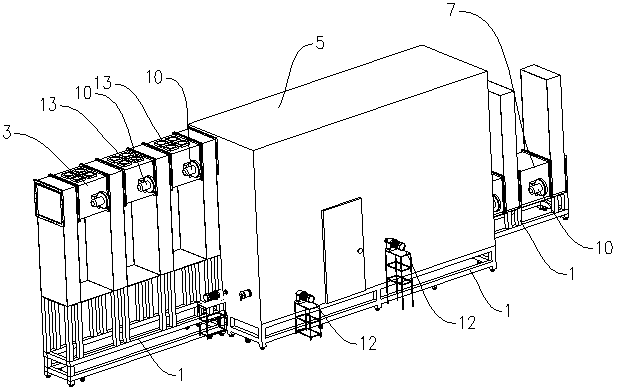

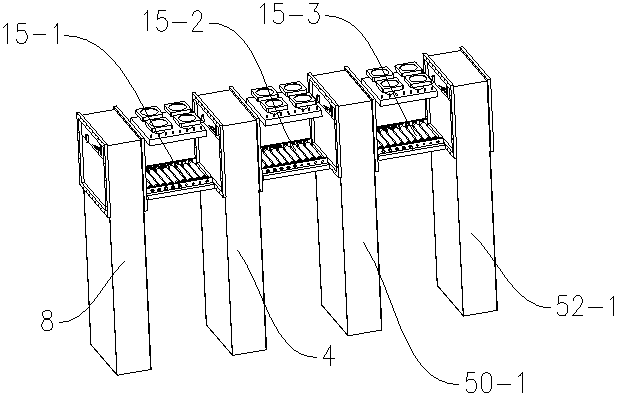

Battery cell holding rack mounting equipment

PendingCN107768725AReduce labor costsImprove job accuracyFinal product manufactureElectrolyte accumulators manufactureEngineeringLine structure

The invention relates to battery cell holding rack mounting equipment which comprises a feeding device, a gluing device, a rotating disc conveying device, a holding rack feeding device and a dischargedevice, wherein the feeding device, the gluing device, the rotating disc conveying device, the holding rack feeding device and the discharge device are mounted on a rack base according to a processing sequence to form a complete processing stream line. Due to adoption of an automatic line structure for loading and unloading materials, and a rotating disc multi-station conveying mechanism, the space can be relatively well utilized; the gluing mechanism, a detection mechanism, a holding rack pressing mechanism and the like are correspondingly arranged on the rotating disc multi-station conveying mechanism, then multi-station production is achieved, and relatively good automation of production is achieved; meanwhile, gluing and detection of electrode lug welding parts and mounting of a holding rack are achieved, full-automatic continuous product is achieved, the labor cost is reduced, high operation precision is achieved, different stations are compactly arranged and associated, the overall production efficiency and the equipment stability are improved, and automatic continuous line production is achieved.

Owner:海目星(江门)激光智能装备有限公司

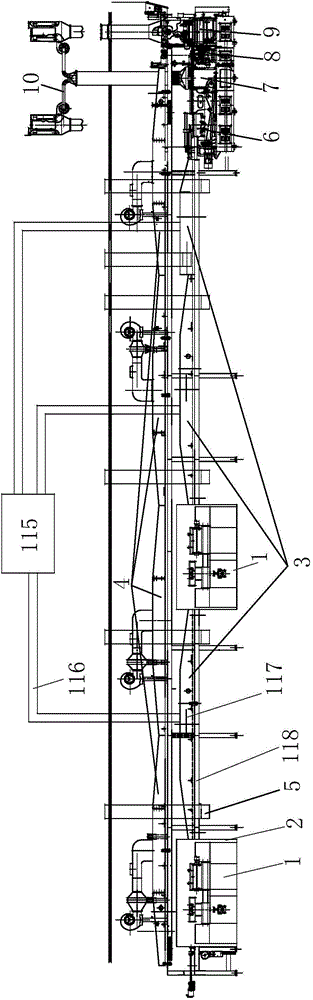

Fully-automatic enteric capsule production line

InactiveCN104546487AWon't emitProduction Process AutomationCapsule deliveryProduction lineVacuum pumping

The invention discloses a fully-automatic enteric capsule production line and belongs to the technical field of capsule production equipment. The fully-automatic enteric capsule production line comprises a platform machine, an automat, an oiling machine, a glue dipping machine, a waste material absorbing system, an upper baking channel, a lower baking channel and a main control system, wherein an air supply pipeline and an air returning pipeline are arranged on the lower baking channel at an interval; two coating machines are also arranged on the lower baking channel at an interval and are respectively arranged in separating spaces; the separating spaces are connected with a vacuum pumping device. The coating machines are arranged in the sealed separating spaces, and the vacuum pumping device absorbs volatile substances in coating liquid, so that the volatile substances are prevented from being dispersed into a workshop to cause explosion in case of open flame. A capsule produced by the fully-automatic enteric capsule production line satisfies enteric standards, the wall thickness of the capsule is uniform, and the quality of the capsule is good.

Owner:DANDONG JINWAN GRP

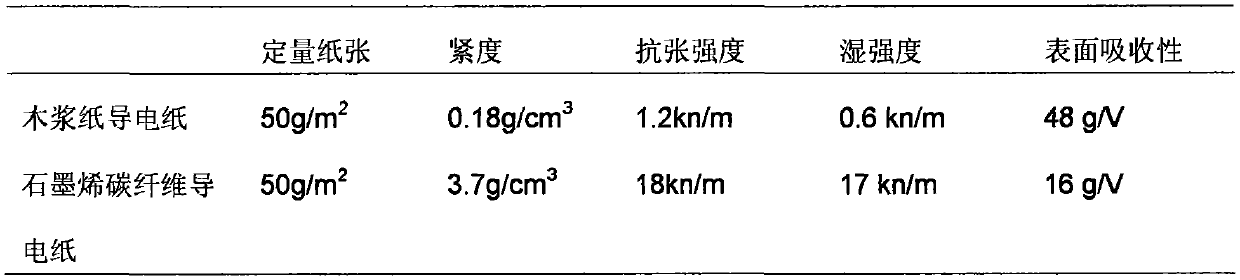

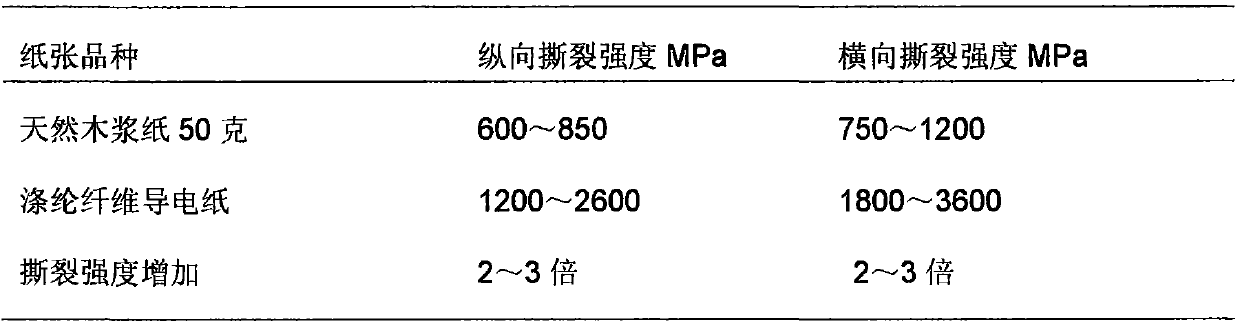

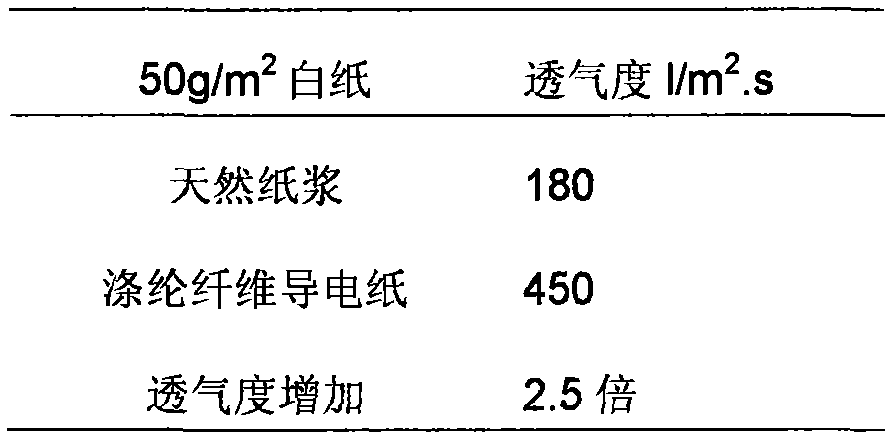

High-electrical-conductivity graphene carbon-fiber electrical-conductive paper and preparation method thereof

ActiveCN105369686AEvenly distributedUniform thicknessSpecial paperWater-repelling agents additionPolyesterFiber

The invention relates to a manufacturing technology of an electrical-conductive exothermic material, in particular to high-electrical-conductivity graphene carbon-fiber electrical-conductive paper and a preparation method thereof. The electrical-conductive paper comprises chopped carbon fibers, polyester super-short fibers, graphene powder and wood pulp fibers, and the high-electrical-conductivity graphene carbon-fiber electrical-conductive paper is obtained by conducting permeabilization treatment, defibering and dispersing, pulping treatment, mixing and papermaking on all the materials. According to the high-electrical-conductivity graphene carbon-fiber electrical-conductive paper and the preparation method thereof, the fibers are uniformly distributed, the thickness is uniform, the strength is high, water resistance is achieved, the air permeability is good, high electrical conductivity is achieved, the transition heat efficiency is high, the heat efficiency of the product is improved, the service life of the product is prolonged, and the electrical-conductive paper is a novel leap-upgrading and transformational breakthrough in the electrical exothermic material technology.

Owner:QINGDAO GRAPHENE CARBON NEW MATERIAL TECH CO LTD

Method for producing metal and diamond composite body

InactiveCN101480744AAvoiding problems with reduced sintering qualityQuality improvementSoldering apparatusMetal rolling arrangementsHardnessLarge deformation

The invention discloses a method for manufacturing a composite body of metal and diamond, comprising the following steps: diamond grits and metal powder bonds are arranged between two metal plates which can be copper plates or low-carbon steel plates, the metal plates are rolled to be in a flat pipe shape, braze welding and sealing are carried out on the round seaming part to manufacture a prefabricated piece, and multi-time cold rolling is carried out so that the thickness of the metal plates in a flat pipe shape is a little bigger than that of a particle and the metal plates in a flat pipe shape are sintered at the temperature ranging from 700-900 DEG C. The invention abandons a traditional powder metallurgy like method, instead, the capability feature that great difference exists between the rigidity of the diamond and the rigidity of the copper plate or the low-carbon plate is utilized, thereby the diamond embedded into a copper block or a low-carbon block in the rolling process and the combination of a little amount of metal powder bonds and high-speed flow deformation and large deformation rate which are unique in the rolling process enable the metal plates to be mutually welded so that the problem in the traditional method that the metal powder is prone to be oxidized to cause the sintering quality to be reduced is avoided. The invention is favorable for the mechanized and automated manufacturing and lowers the manufacturing cost.

Owner:YANSHAN UNIV

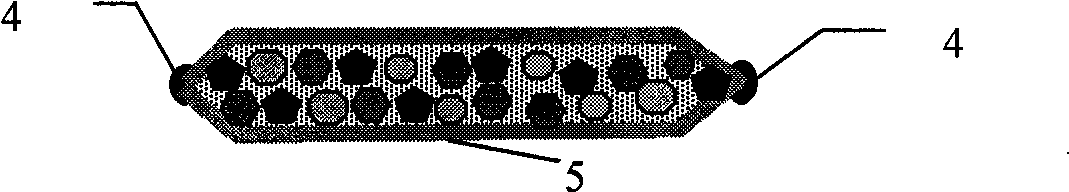

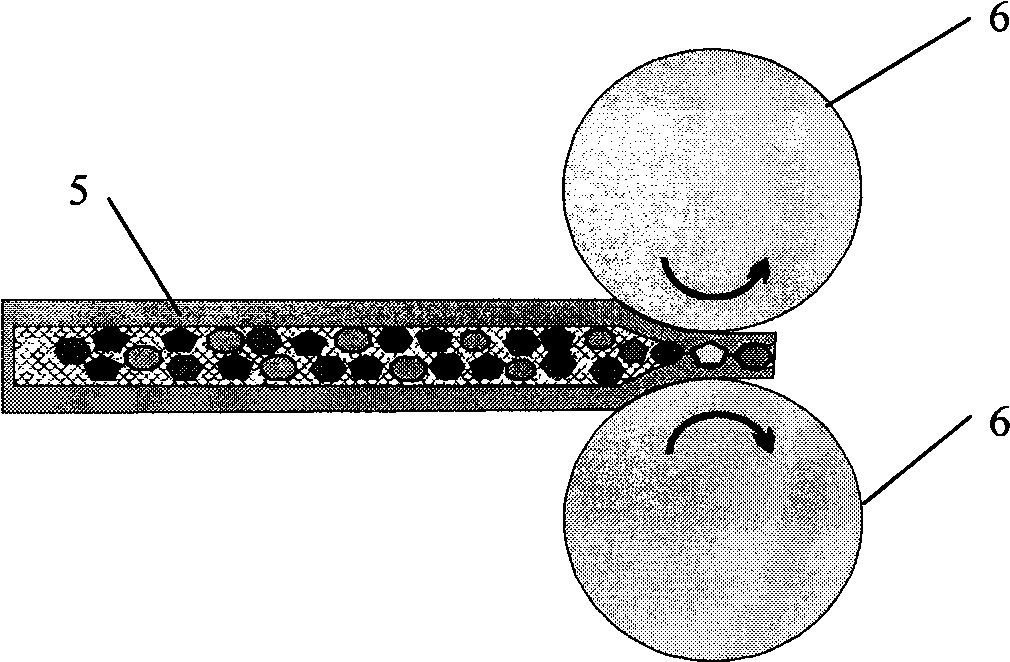

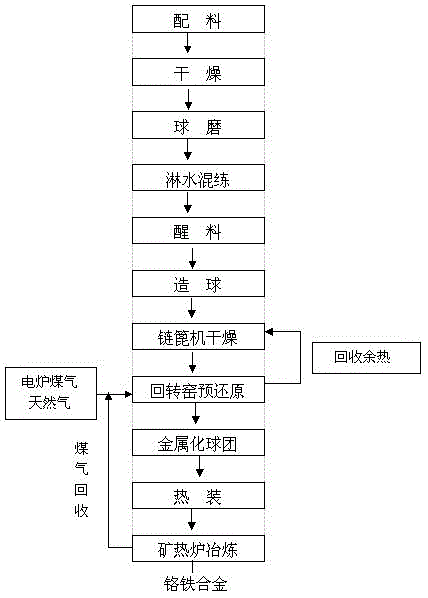

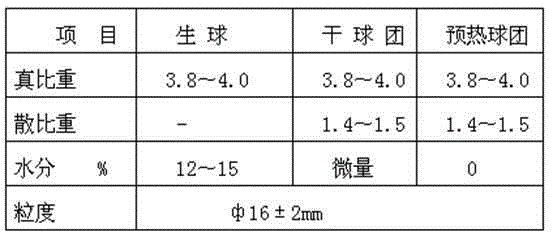

Method for producing ferrochrome

The invention discloses a method for producing ferrochrome and relates to chain grate-rotary kiln combined metalized pellet hot-filled methods for producing ferrochrome. The method is characterized in that a production process sequentially comprises the steps of proportioning materials, drying, carrying out ball milling, carrying out water-sprayed mulling, carrying out material waking, pelletizing, carrying out drying and preheating, carrying out rotary kiln pellet prereduction, carrying out hot filling and carrying out submerged-arc furnace smelting. According to the method disclosed by the invention, through material proportioning, ball milling and pelletizing, exhaust gas of a rotary kiln is used for drying and preheating in a chain grate, coal gas of a closed submerged-arc furnace and natural gas are used for heating, carbon in coke powder is used for reducing oxides of chromium and iron in chromite ore powder pellets, the comprehensive reduction rate of metal is controlled to reach 55-70%, the pellets are enabled to be metalized, and then, hot filling is used for carrying out transporting so as to supply high-carbon ferrochrome to submerged-arc furnace smelting. The method disclosed by the invention has the advantages that furnace conditions are effectively improved, the production process is stable in process, the reduction efficiency is high, the power consumption is low, the production cycle of the submerged-arc furnace is shortened, the consumption of the raw materials is low, the metal recovery rate is high, and the discharge of pollutants, such as dust and SO2, is low.

Owner:HEBEI TAIHANG FOUND MINERAL RESOURCES CO LTD

Insertion piece for wind turbine blade root

InactiveCN102022255AReduce weightLow raw material costFinal product manufactureMachines/enginesTurbine bladePulp and paper industry

The invention relates to an insertion piece for a wind turbine blade root. The insertion piece comprises a wedge-shaped part which is lengthwise and extends between the far end and the near end of the insertion piece, and the wedge-shaped part has two opposite main surfaces; and the thickness of the wedge-shaped part increases between the opposite main surfaces along the direction from the far end to the near end. The insertion piece also comprises a connecting part for assembling the insertion piece in a mounting piece, wherein the connecting part and the wedge-shaped part are connected into a whole, and the connecting part is positioned at the near end of the wedge-shaped part. By utilizing the insertion piece, the total weight of the assembled wind turbine blade and the cost of raw materials can be obviously reduced. The invention also discloses the wind turbine blade root comprising a plurality of the insertion pieces, and a manufacturing method of the wind turbine blade root.

Owner:GURIT TOOLING (TAICANG) CO LTD

Fully-automatic disk core shooter

The invention discloses a fully-automatic disk core shooter. The fully-automatic disk core shooter is characterized by comprising a core shooter mechanism, a mold hydraulic mechanism, a disk machine mechanism, a mechanical piece taking mechanism and a control mechanism, wherein the core shooter mechanism comprises a hopper, an air cylinder and a precoated sand injection device, which are arranged on the upper part of the core shooter; sand core molds are arranged below the precoated sand injection device and are arranged in the mold hydraulic mechanism; the mold hydraulic mechanism is arranged on a circular truncated cone of the core shooter mechanism; the mechanical piece taking mechanism is arranged beside a disk machine; a sand core output machine is arranged beside the mechanical piece taking mechanism; and the control mechanism of the mechanisms is arranged on one side of the core shooter by a control cabinet. The precoated sand injection device of the fully-automatic disk core shooter adopts a structure that two molds are shot at one time, the disk machine rotates and eight molds are supplied at one time, so that the utilization rate of the core shooter is fully improved; a piece is taken by piece taking arms, so that the safety of operation is improved; and a product is output by the sand core output machine, so that the fully-automatic disk core shooter is automatic in product manufacturing and low in cost.

Owner:无锡市蠡湖铸业有限公司

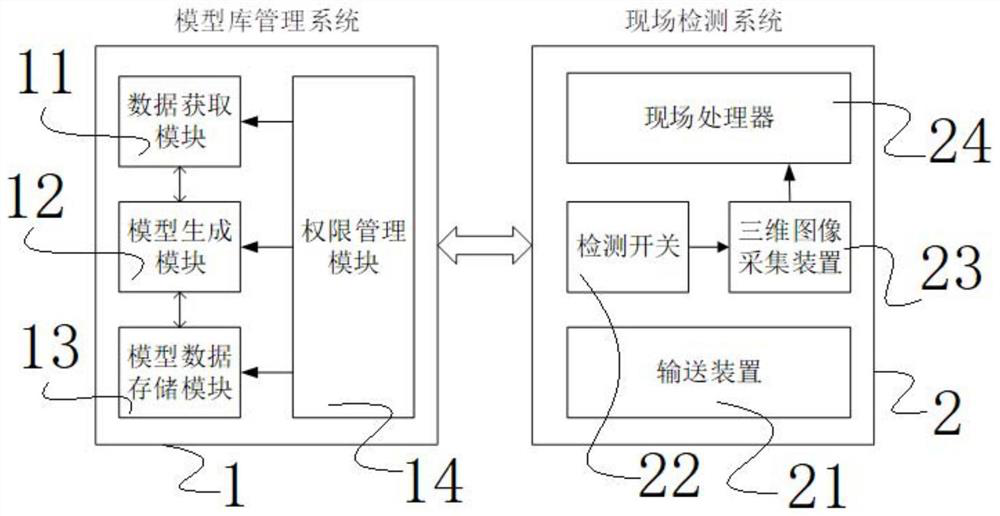

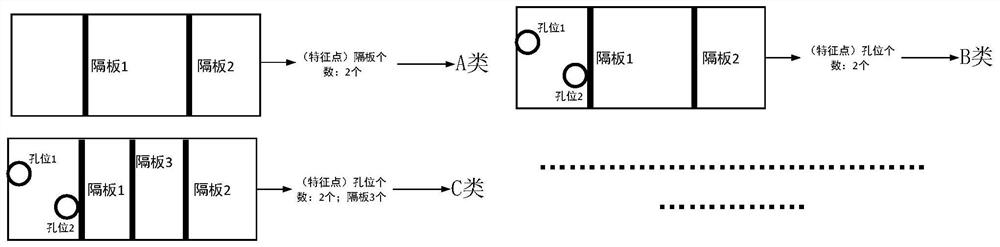

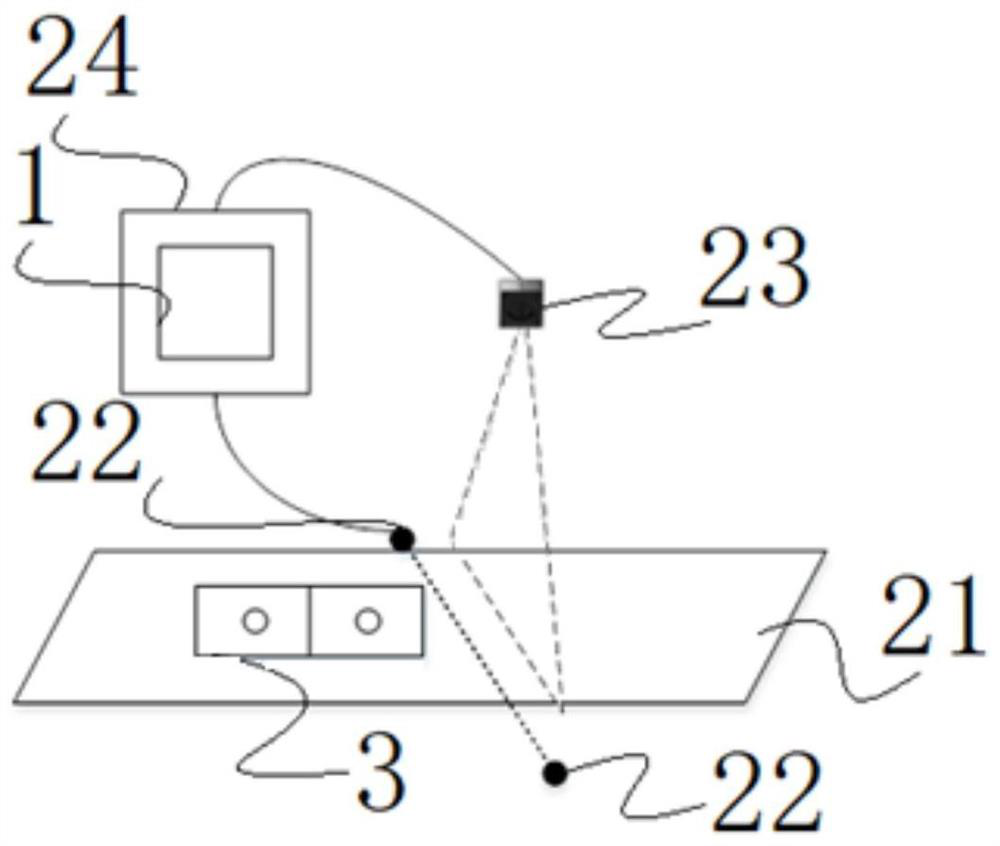

Building aluminum template automatic classification system and method based on three-dimensional imaging

PendingCN111651622ASimple methodEasy to operateStill image data indexingSpecial data processing applications3d imageProcess engineering

The invention discloses a building aluminum template automatic classification system and method based on three-dimensional imaging. The system comprises a model library management system for buildingaluminum template identification classification and model library construction and management system; and a field detection system which comprises a conveying device for conveying aluminum templates,a detection switch for detecting whether the aluminum templates are in place, a three-dimensional image acquisition device and a field processor, and the field processor is connected with the detection switch and the three-dimensional image acquisition device. The method is simple and easy to operate, high-speed, high-efficiency and non-contact automatic classification of the aluminum templates isachieved, automatic production is met, the problem of traditional manual classification verification of the aluminum templates is solved, the classification error recognition rate is improved, the labor intensity of workers is reduced, and the classification error rate is reduced; the category of the aluminum template can be detected on line in real time, and support is provided for links of production, storage, distribution, transportation, use, recovery and the like of the aluminum template.

Owner:YUNNAN KUNMING SHIPBUILDING DESIGN & RESEARCH INSTITUTE

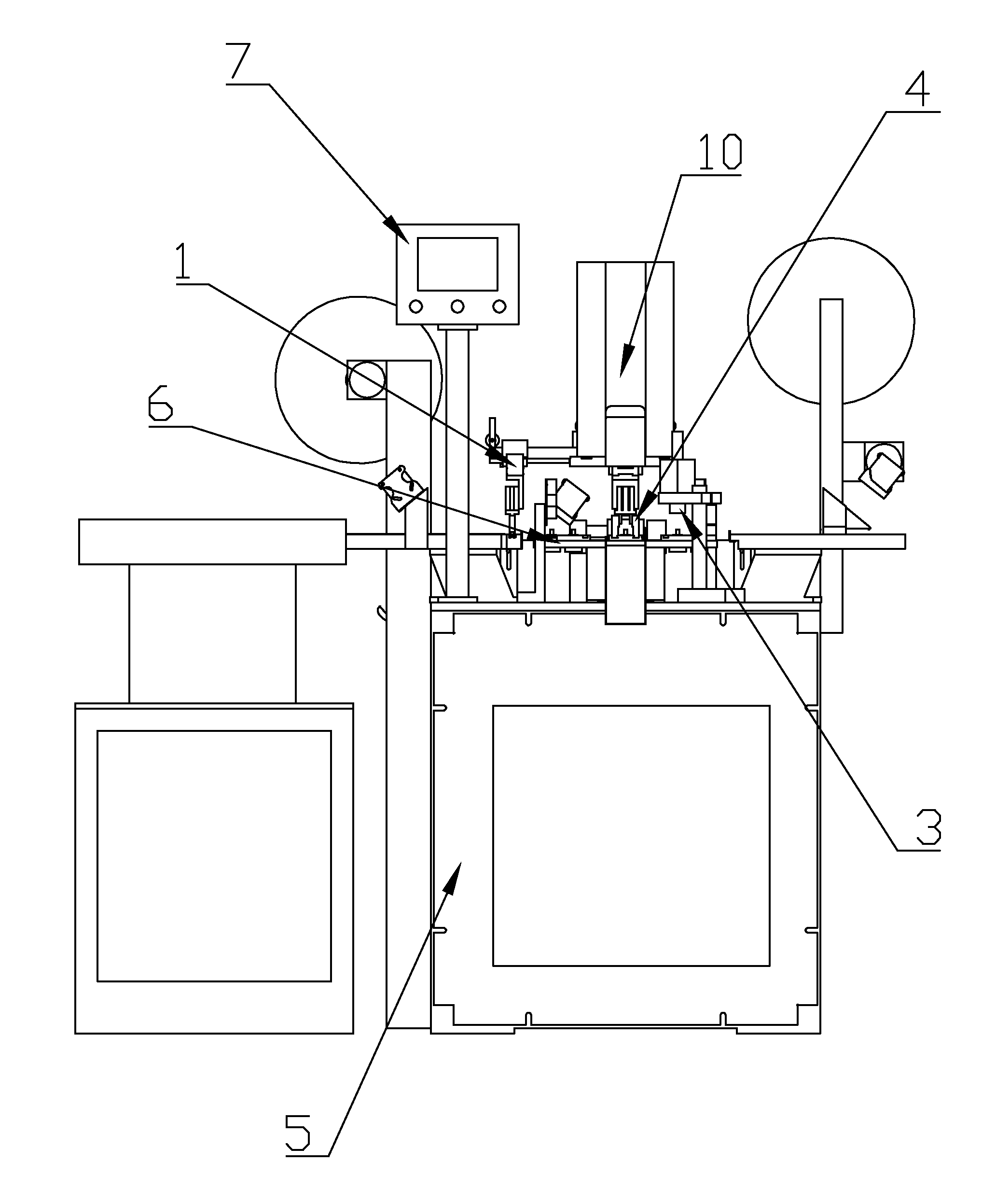

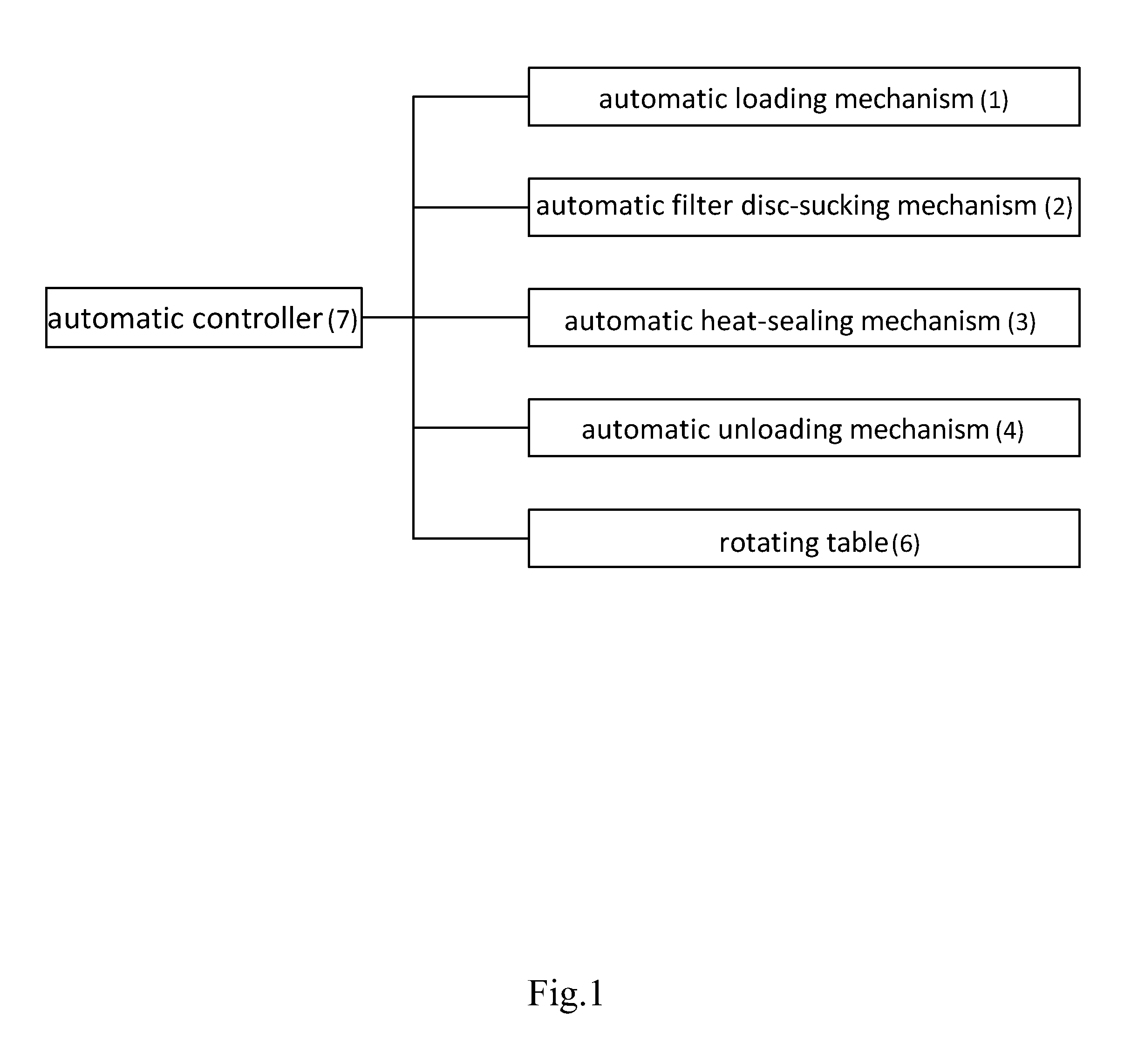

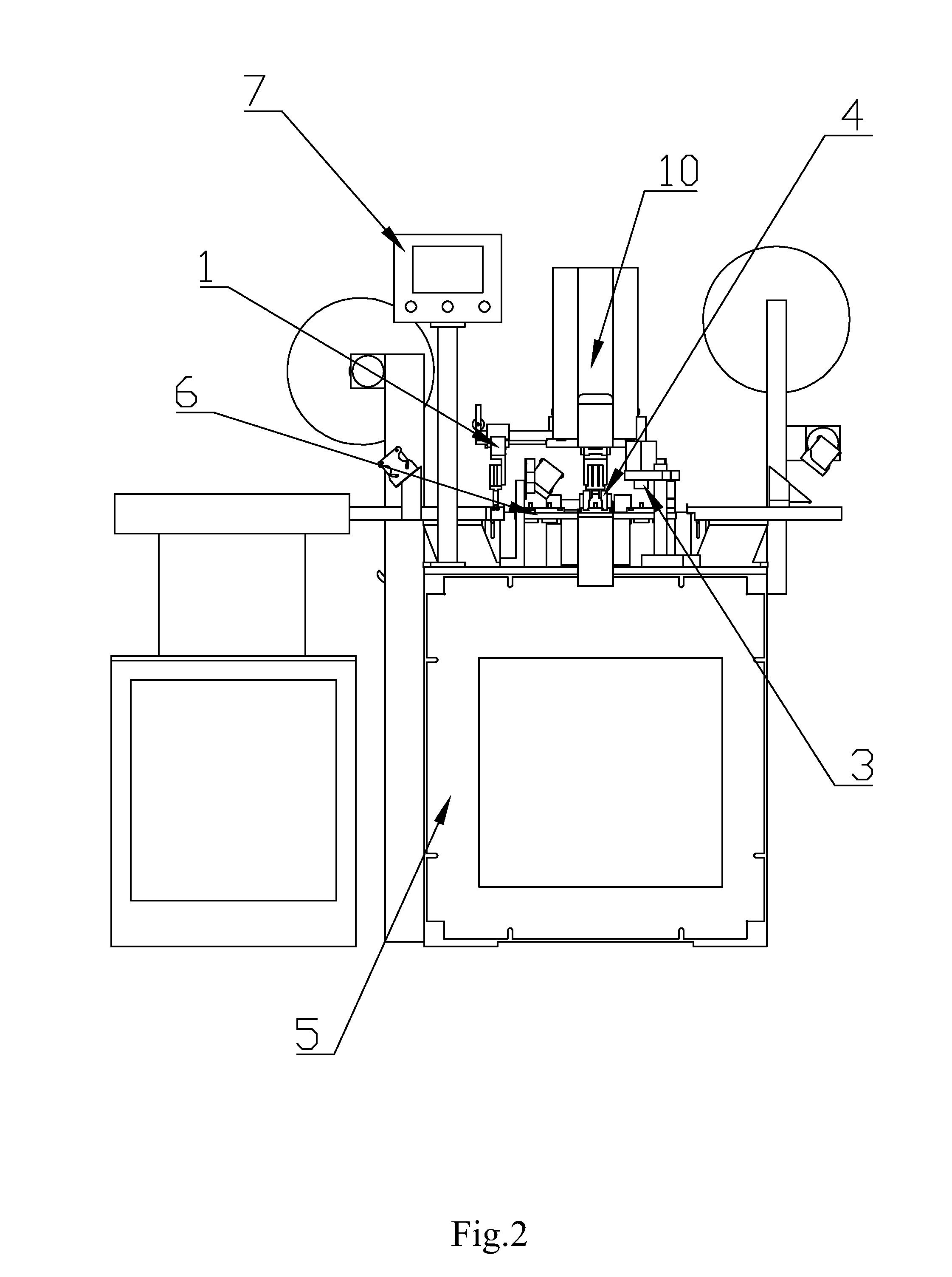

Assembly machine for venting cap of disposable cell culture flask

ActiveUS20130306241A1Improved yieldIncrease productionControlling laminationBiochemistry apparatusAutomatic controlAutomotive engineering

An assembly machine for venting cap of disposable cell culture flask includes a rack, and an automatic controller and a rotating table arranged on the rack. An automatic loading mechanism, an automatic filter disc-sucking mechanism, an automatic heat-sealing mechanism, and an automatic unloading mechanism are all arranged above the rotating table. The automatic controller is electrically connected with the rotating table, the automatic loading mechanism, the automatic filter disc-sucking mechanism, the automatic heat-sealing mechanism, and the automatic unloading mechanism. By way of the automatic loading mechanism, the automatic filter disc-sucking mechanism, the automatic heat-sealing mechanism, and the automatic unloading mechanism as well as the automatic controller adapted thereto, the assembly machine can realize the automatic loading of the venting cap of disposable cell culture flask, the automatic placing of the filter disc, and the automatic heat-sealing of the venting cap of disposable cell culture flask and the filter disc, so that the automatic production of the venting cap of disposable cell culture flask can be realized.

Owner:GUANGZHOU JET BIOFILTRATION CO LTD

Tomato crushing and beating machine

InactiveCN107772490AProduction Process AutomationJuice extractionFood treatmentEngineeringConveyor belt

The invention relates to the field of food production and in particular relates to a tomato crushing and beating machine. The tomato crushing and beating machine comprises a washing device, a crushingdevice, a conveyor belt and an air drying device, wherein the conveyor belt is located between the washing device and the crushing device and an input end of the conveyor belt is connected with the washing device; an output end of the conveyor belt is connected with the crushing device; the air drying device is erected on the conveyor belt and is used for carrying out air drying on tomatoes conveyed on the conveyor belt; the air drying device is provided with a drying assembly for independently drying the conveyor belt; in a working process, the tomatoes are put into the washing device and are washed; the washed tomatoes are conveyed into an acting region of the air drying device through the conveyor belt; after the air drying device is used for carrying out air drying on the tomatoes conveyed on the conveyor belt, the air-dried tomatoes are conveyed into the crushing device through the conveyor belt and the tomatoes are crushed and beaten through the crushing device. By adopting thetomato crushing and beating machine, automatic production of tomato sauce is realized, and the tomatoes are cut and pressurized through a cutter and a roller respectively so that the tomatoes are crushed into paste.

Owner:NINGBO KAMENG ELECTRICAL APPLIANCE

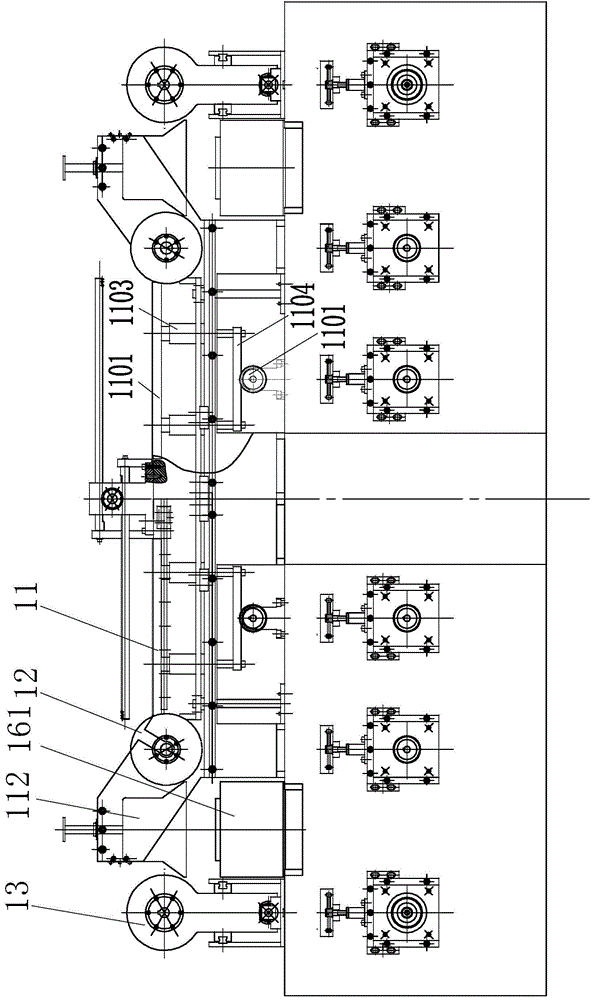

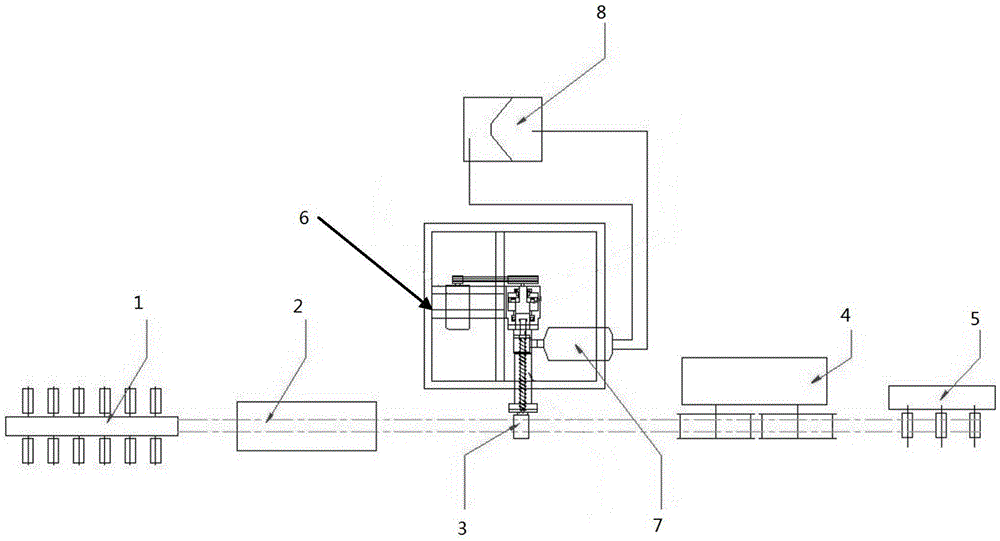

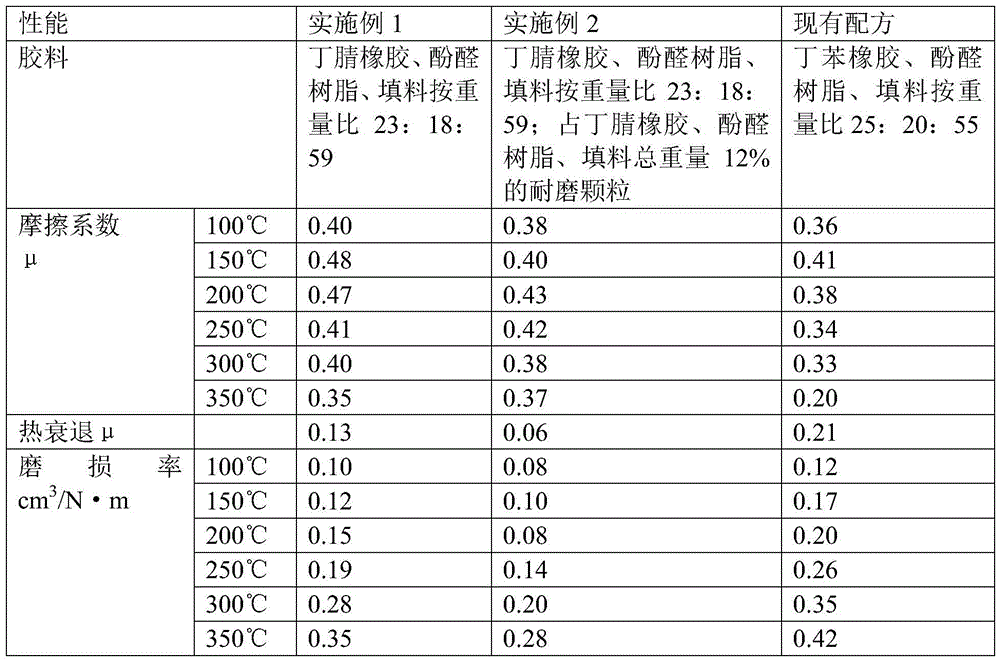

Method for preparing clutch facing blanks by adopting glue squeezing device

ActiveCN105538645AContinuous productionProduction Process AutomationCoatingsWinding machineFiber bundle

The invention relates to a preparation method for clutch facings, in particular to a method for preparing clutch facing blanks by adopting a glue squeezing device. According to the method, the surfaces of framework fiber bundles are continuously wrapped with glue through the glue squeezing device, and operations of glue squeezing, enveloping and winding are conducted synchronously. Specifically, the method includes the first step of mounting; the second step of glue squeezing and enveloping, i.e., glue is squeezed out in advance and placed into a glue particle storage box, the glue squeezing device is preheated to make the temperature of a squeezing head range from 75 DEG C to 95 DEG C, the temperature of a machine body range from 50 DEG C to 65 DEG C and the temperature of a screw range from 45 DEG C to 55 DEG C, then the glue is squeezed in advance, glue squeezing is stopped when the temperature of the glue to be squeezed out ranges from 75 DEG C to 85 DEG C, a pre-squeezing hole is blocked, a glue inlet of the squeezing head is opened, and the glue feeding speed is regulated and is made constant for production after the glue on the framework fiber bundles is uniform; and the third step of winding, i.e., the framework fiber bundles passing through the glue squeezing machine are wound synchronously through a winding machine, so that the clutch facing blanks are obtained.

Owner:浙江科马摩擦材料股份有限公司

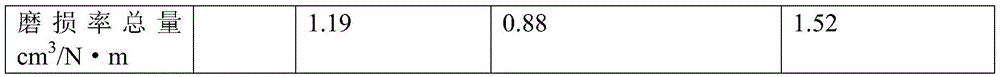

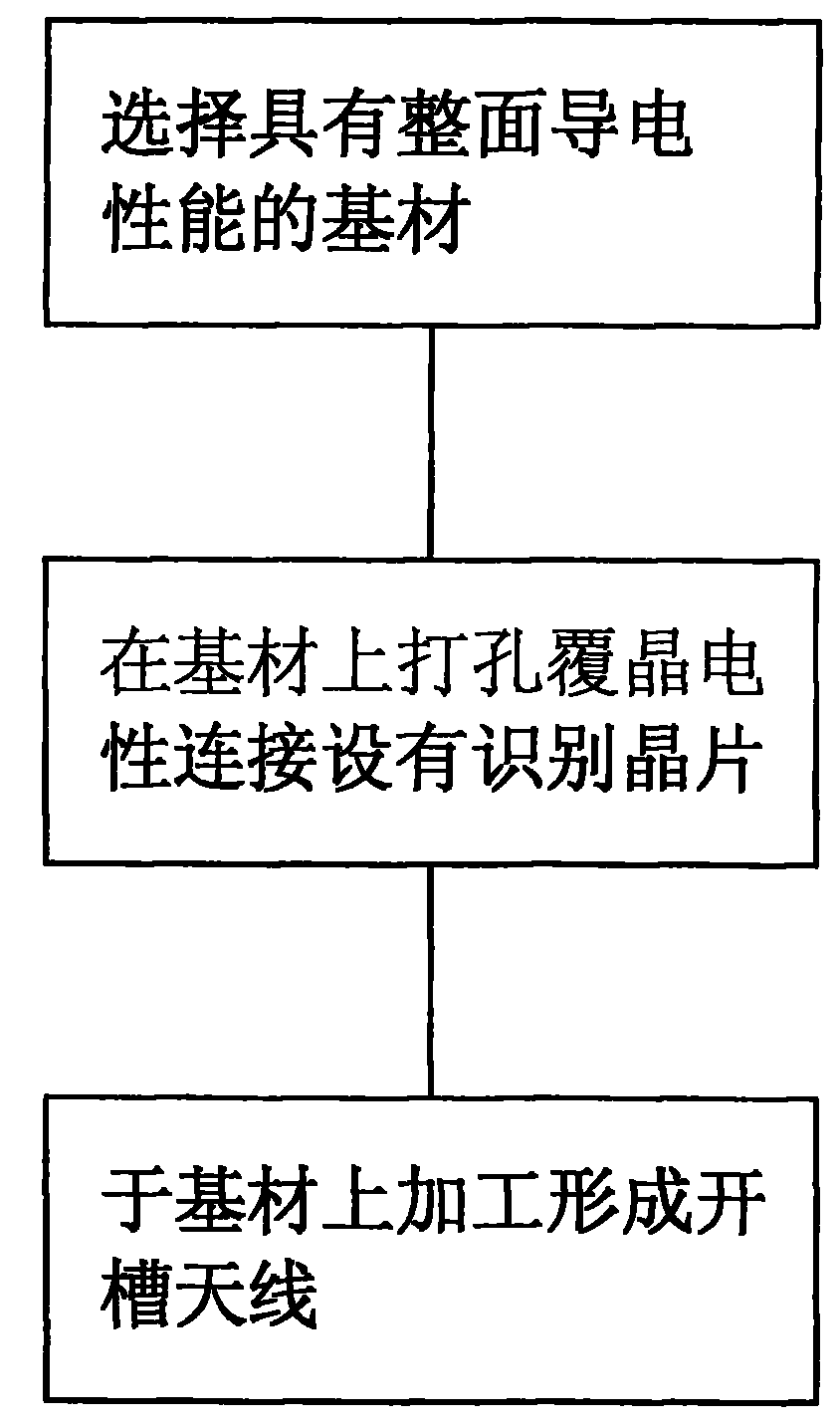

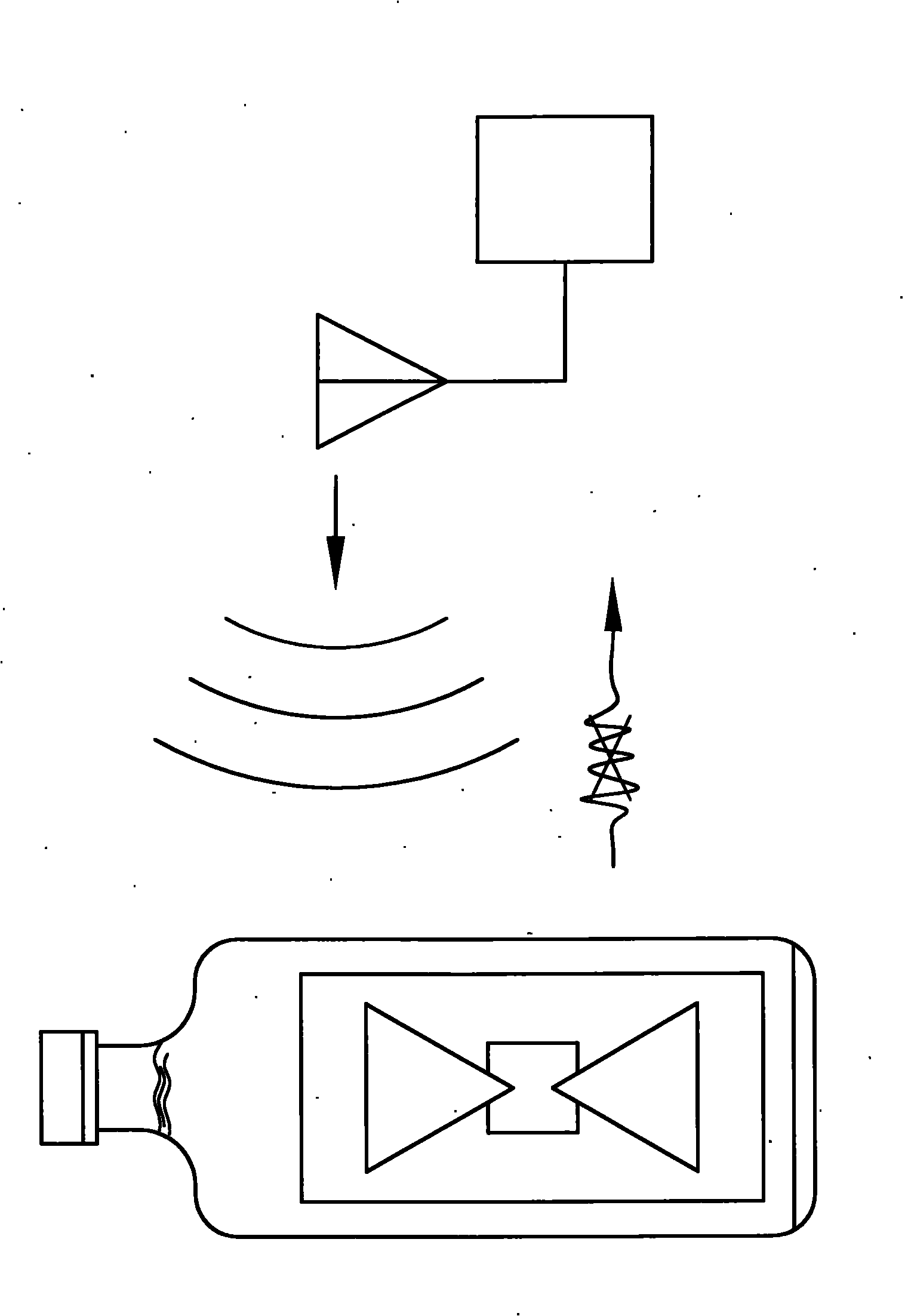

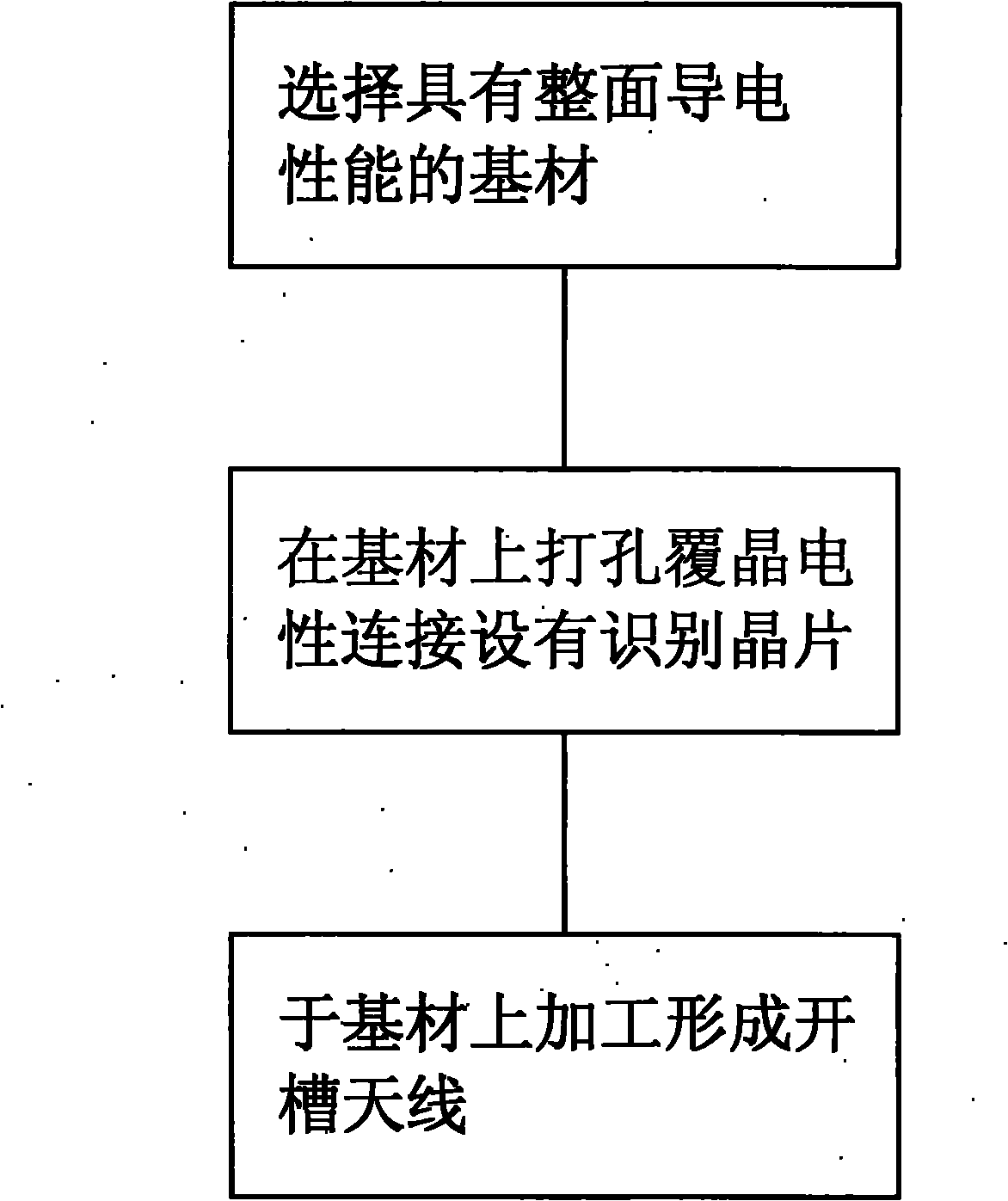

Manufacture method of wireless radio frequency identification mark

ActiveCN101814156ALow costEasy to getSolid-state devicesSemiconductor/solid-state device manufacturingElectricityRetrievability

The invention relates to a manufacture method of a wireless radio frequency identification mark, which mainly comprises the following steps: 1. selecting base materials with the whole surface continuous conductive performance; 2. drilling holes on the base materials, covering crystals on the base materials, and electrically connecting and installing identification wafers on the base materials; and 3. processing and forming groove antennas on the base materials. Thereby, the manufacture cost of the wireless radio frequency identification mark is greatly reduced, and the invention has the advantages of electricity saving, energy saving, no pollution, retrievability, obvious and high grain of the antennas, strong reflectivity and high conductivity. In addition, the shielding effect of the whole surface conductive performance of the base materials is good, and the electric performance influence on the radio frequency identification mark by objects and environment can be obviously reduced, so the invention is more applicable to the radio frequency identification mark of the objects such as metal objects, water-containing conductors and the like.

Owner:ELKA INT

Ginseng high-quality dietary fiber and production method thereof

The invention relates to ginseng high-quality dietary fiber and a production method thereof. The invention belongs to health food processing technology. According to the invention, after ginsenoside and ginseng polysaccharide are extracted by using an organic solvent technology, obtained ginseng residue is further subject to a supercritical extraction-elution one-step method, such that precipitation and impurity removing are carried out; the ginseng residue is subject to a wet high-temperature high-pressure shearing functionalizing treatment, such that the high-quality ginseng dietary fiber is prepared. Macro-molecular insoluble components such as lignin and cellulose are degraded, such that high-quality dietary fiber with good swelling property, good water binding capacity and good lipoid absorbability is produced. According to the invention, residue obtained after ginsenoside and ginseng polysaccharide solvent extraction processes is processed into an eatable substance. Physical property and processing performance of ginseng fiber are improved; and biological activity of ginseng fiber is enhanced. The reaction conditions are mild. During a preparation process, denaturation and pollution do not occur to the raw material, such that utilization efficiency of ginseng resource is improved.

Owner:JILIN WEIYIKANG BIOLOGICAL SCI & TECH

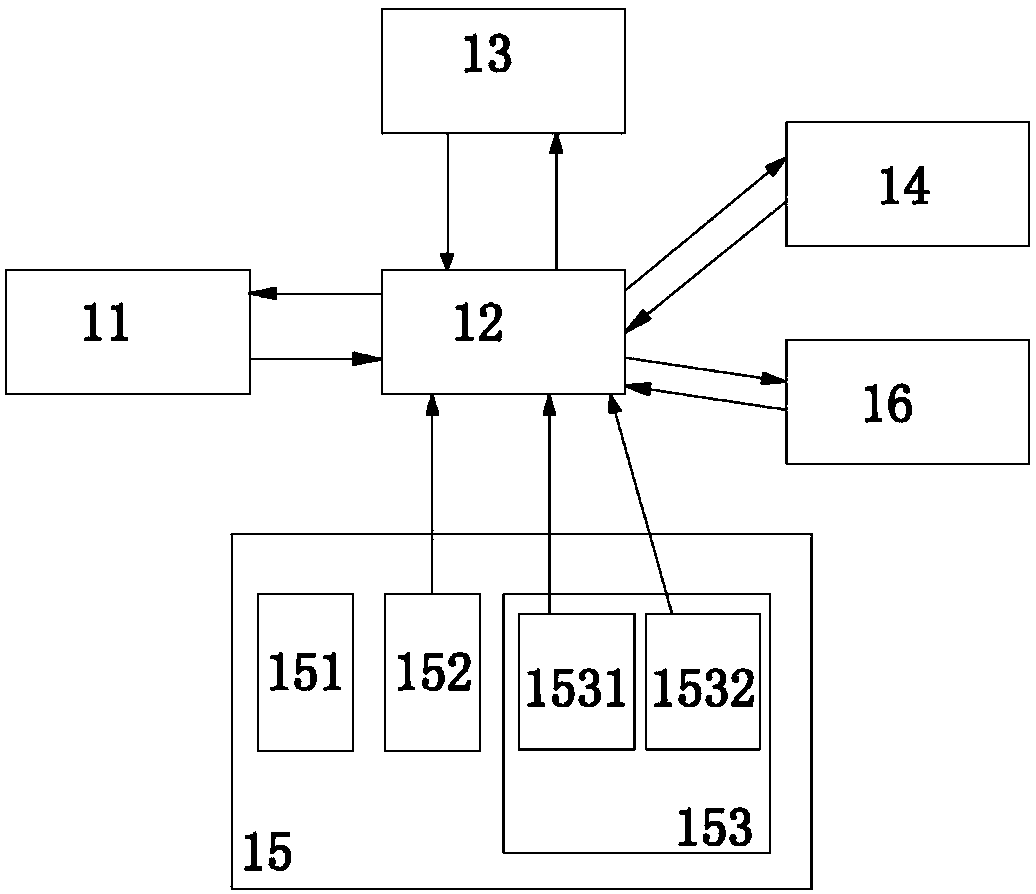

Intelligent manufacture platform of customized plate furniture

InactiveCN108170100ASatisfy personalizationProduction Process AutomationProgramme controlComputer controlNumerical controlPersonalization

The invention relates to an intelligent manufacture platform of customized plate furniture, and belongs to the technical field of intelligent manufacturing. The platform comprises a central processingmodule, a cloud server, a production server, a main control computer of production, an ordering terminal, a furniture design terminal and a controller of processing numerical control equipment; the central processing module is in signal connection with the cloud server, the production server and the main control computer of production via a network communication module; the production server is in signal connection with the main control computer of production; the cloud server is in signal connection with the ordering terminal via the network communication module; the ordering terminal is incommunication connection with the furniture design terminal; and the processing numerical control equipment is in signal connection with the main control computer of production. The platform has the advantages that customized and automatic production of customized furniture can be met, the production efficiency is improved effectively, automatic seamless connection from customized design to production can be realized, and growing customized requirements of people can be satisfied.

Owner:SUZHOU ODIHUA ELECTRONIC CO LTD

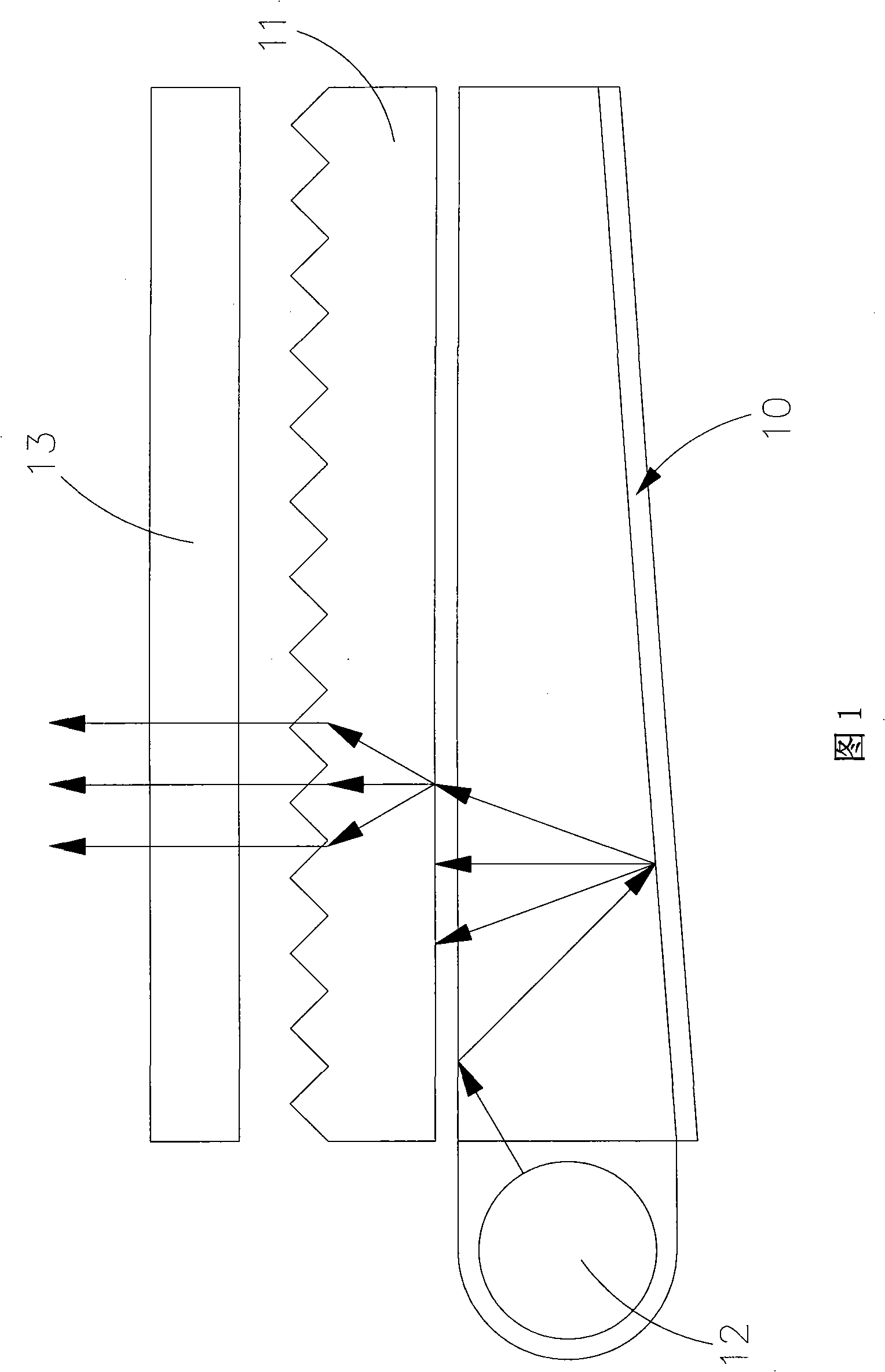

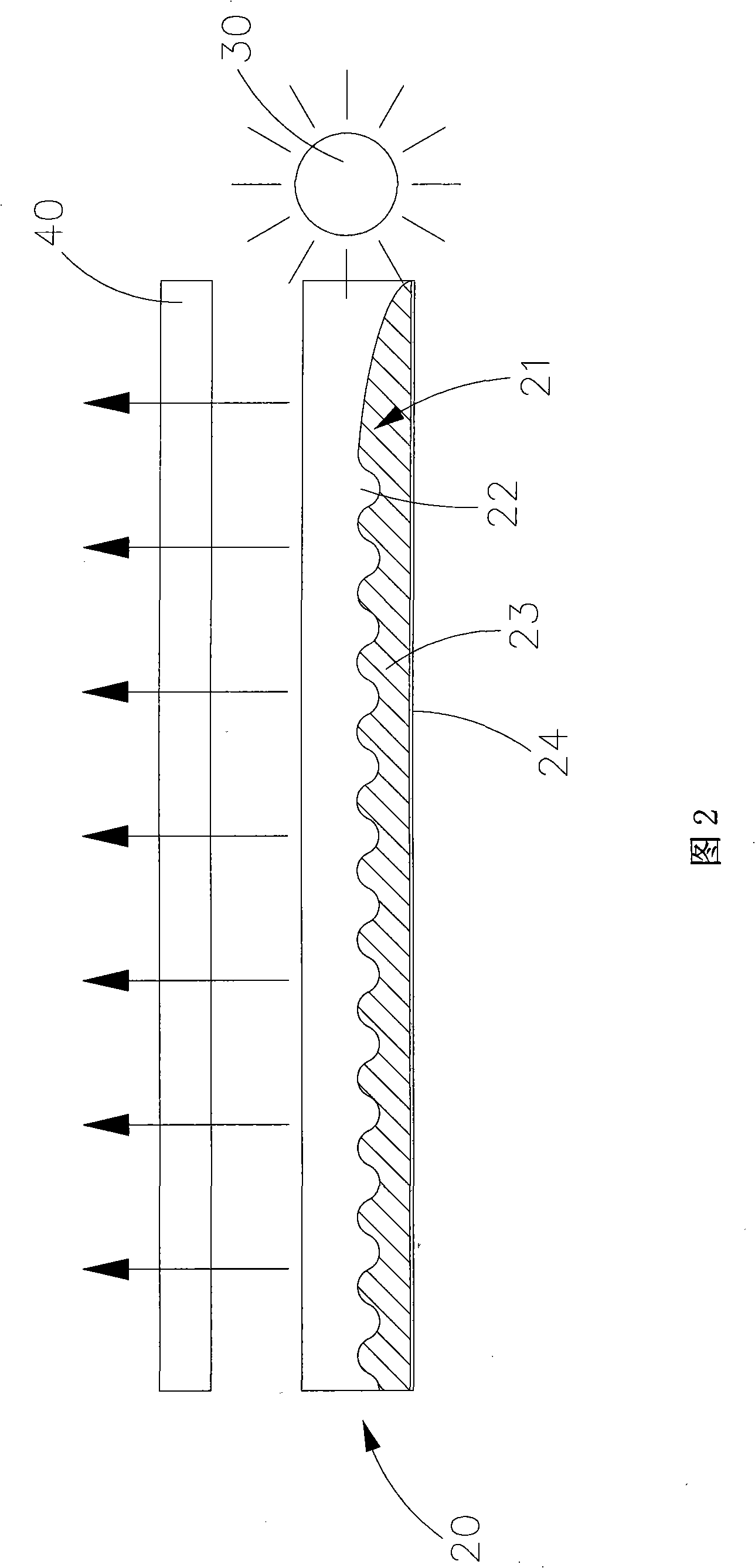

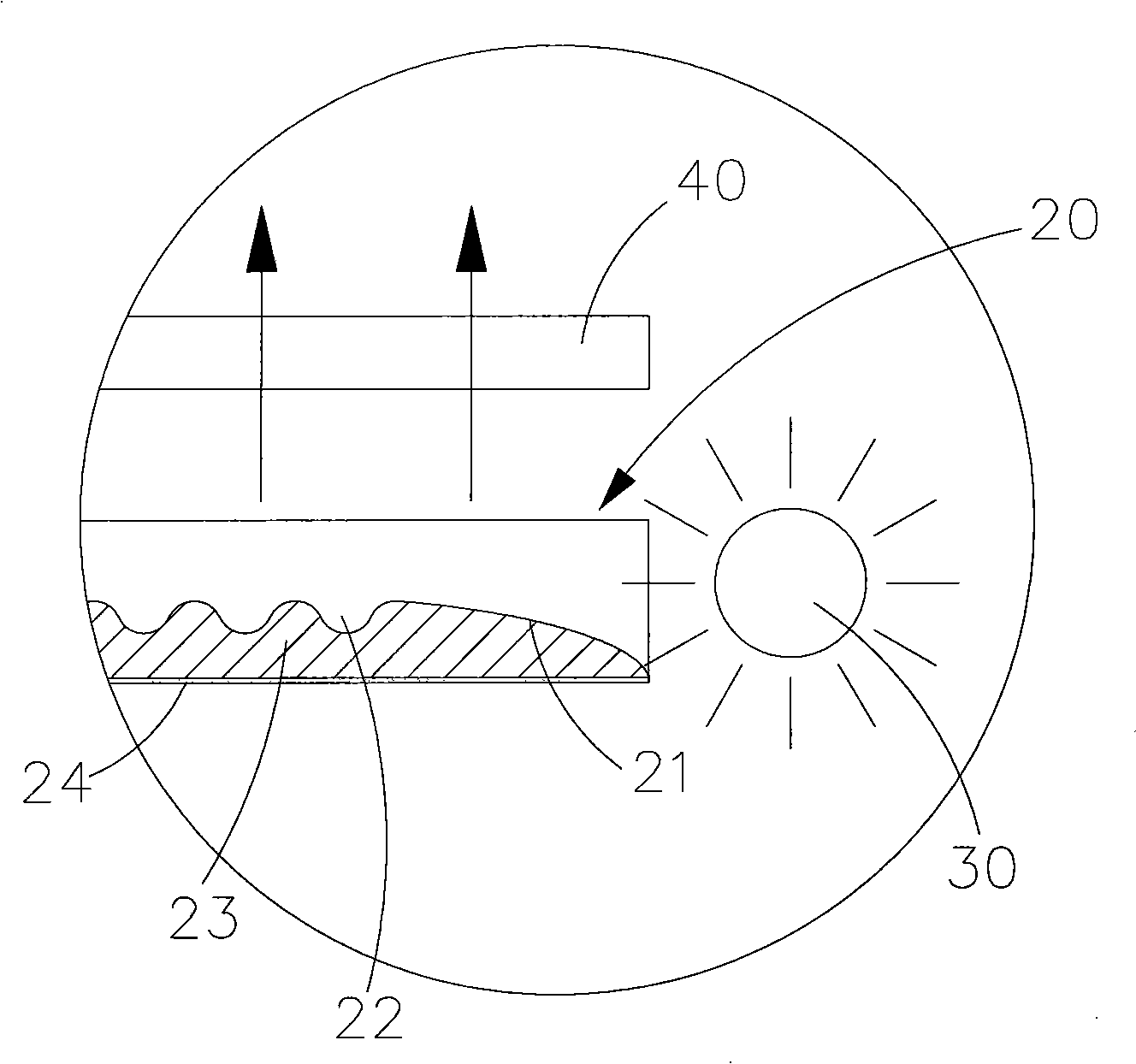

Thin type backlight module

PendingCN101334551ASimplify the production lineReduced number of assembly componentsNon-linear opticsOptical elementsDiffusionOptoelectronics

The invention discloses a thin back light module, comprising at least a light guiding plate, at least a light source and a display panel; the surface of the light guiding plate is provided with a concavo-convex light guiding diffusion structure; furthermore, the concavo-convex light guiding diffusion structure is covered by a reflection metal layer; the exposed surface of the reflection metal layer is covered by an anti-oxidant film; therefore, the concavo-convex light guiding diffusion structure of the light guiding plate is matched with the reflection metal layer so as to guide the light source to diffuse and refract towards the display panel; furthermore, the thickness of the existing back light module design is effectively reduced.

Owner:柳广德

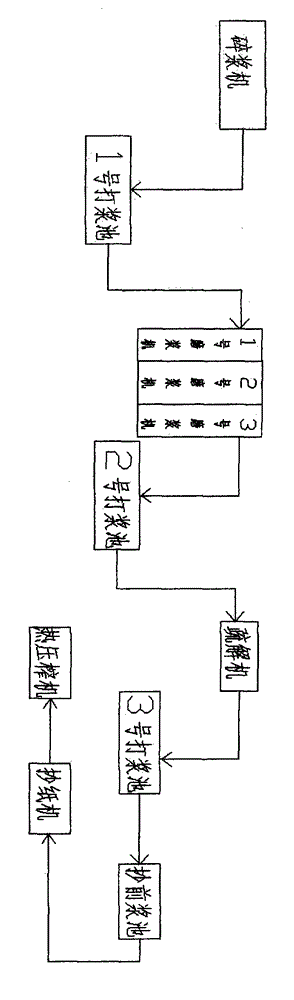

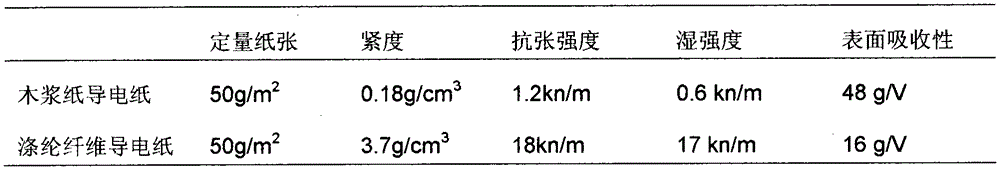

Polyester fiber conductive paper and preparation method thereof

InactiveCN104831584AUniform thicknessUniform heating temperatureSpecial paperPaper/cardboardChemistryElectric heating

The invention discloses polyester fiber conductive paper and a preparation method thereof. The polyester fiber conductive paper disclosed by the invention comprises short carbon fiber, polyester ultra-short fiber, low-melting-point ultra-short fiber and wool pulp fiber. The preparation method comprises the following steps: firstly manufacturing conductive paper; and then carrying out hot press processing treatment. The polyester fiber conductive paper disclosed by the invention not only maintains the advantages of wood pulp conductive paper in a paper technology, that is, uniform thickness, uniform distribution of carbon fiber and uniform heating temperature, but also remedies the defects that the wood pulp conductive paper is low in strength, low in water resistance and airtight and cannot be recovered as the damp powder is attenuated, so that the automatic production process of electric heating products is satisfied, the condition that the conductive layer is easy to break and layer in the processes of producing and using the products is overcome, the failure rate and power attenuation of a conductive paper material in the using process are eliminated, and the quality of the electric heating products is greatly improved and the service life of the electric heating products is prolonged. The polyester fiber conductive paper is a leap and upgrade and transformative innovation breakthrough in the technology of the electric heating material.

Owner:QINGDAO GRAPHENE CARBON NEW MATERIAL TECH CO LTD

Method for preparing Kaoline colloid

InactiveCN1579725AReduce consumption costReduce labor costsCatalyst carriersClay processing apparatusKaolin clayColloid

The invention discloses a kaolin colloid preparation method which including following steps: (1)Kaolin is transferred to preparation locale by container, than is inputted into the kaolin store jar; (2)Machine crash the kaolin in the store jar until the average diameter less than 150mum; (3) The kaolin powder after crashing is transferred to the next step by screw transport; (4) Blend the necessary liquid material for kaolin colloid and the kaolin powder, and prepare the kaolin colloid. This method can reach the continuum and automation of the preparation procession, and decrease the material consume and labor cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

Full-automatic continuous vacuum drying system

PendingCN107764023ASave human effortIncrease productivityDrying solid materials without heatDrying gas arrangementsMaterial transferMultiple use

The invention is suitable for the technical field of drying devices, and discloses a full-automatic continuous vacuum drying system. The system comprises a machine frame, a drying bin set, an electric device and an electric control system, wherein the drying bin set, the electric device and the electric control system are arranged on the machine frame, and the electric control system is used forcontrolling the electrical device; the drying bin set comprises a feeding transition bin, a vacuum drying bin set and a discharging transition bin; the ends, connected with the outside atmosphere, ofthe feeding transition bin and the discharging transition bin are correspondingly provided with a feeding sealing door and a discharging sealing door; and the feeding transition bin, the vacuum dryingbin set and the discharging transition bin are correspondingly provided with pipelines to be connected with a vacuum pump and an inflator pump at outside, and a material conveying mechanism is arranged in each bin and is used for continuously conveying materials. According to the device, the problems that in an existing drying process of products such as a battery, a capacitor and other products, vacuum degree is low, energy loss is large, occupied manpower resources are large and production cost is high, meanwhile, the drying production process of the products is discontinuous instead of continuous production, and efficiency of the drying production process is low are solved.

Owner:林福兴

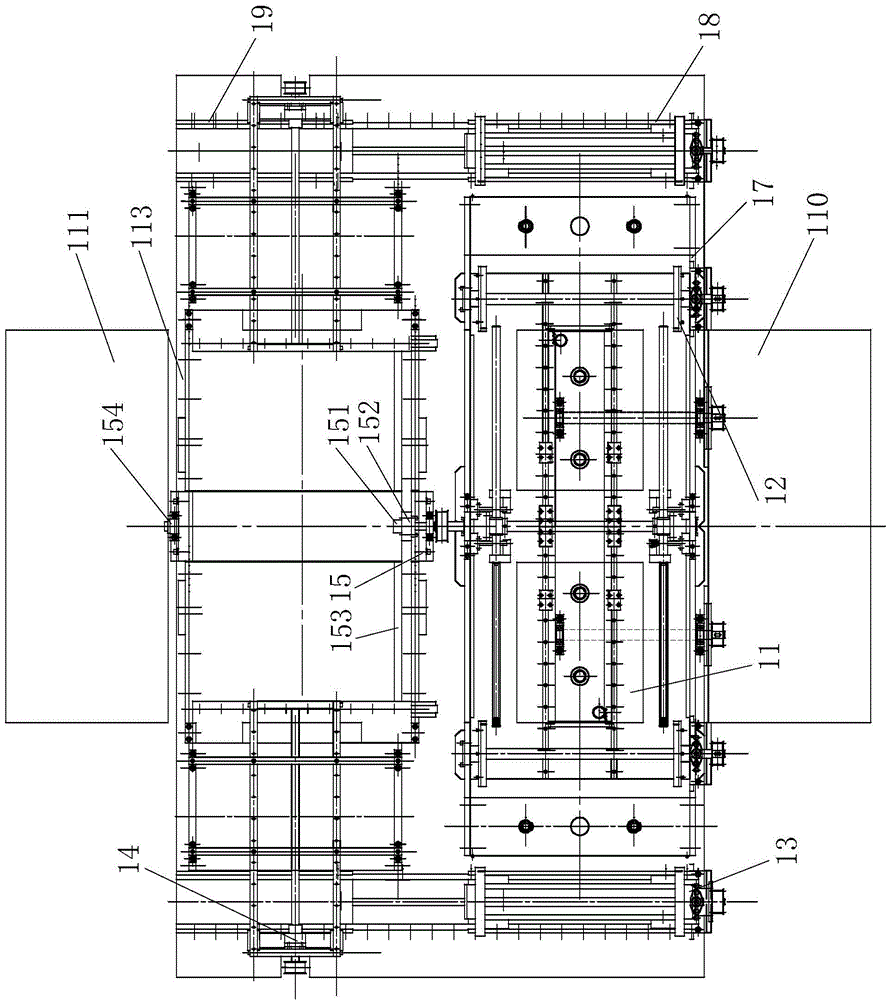

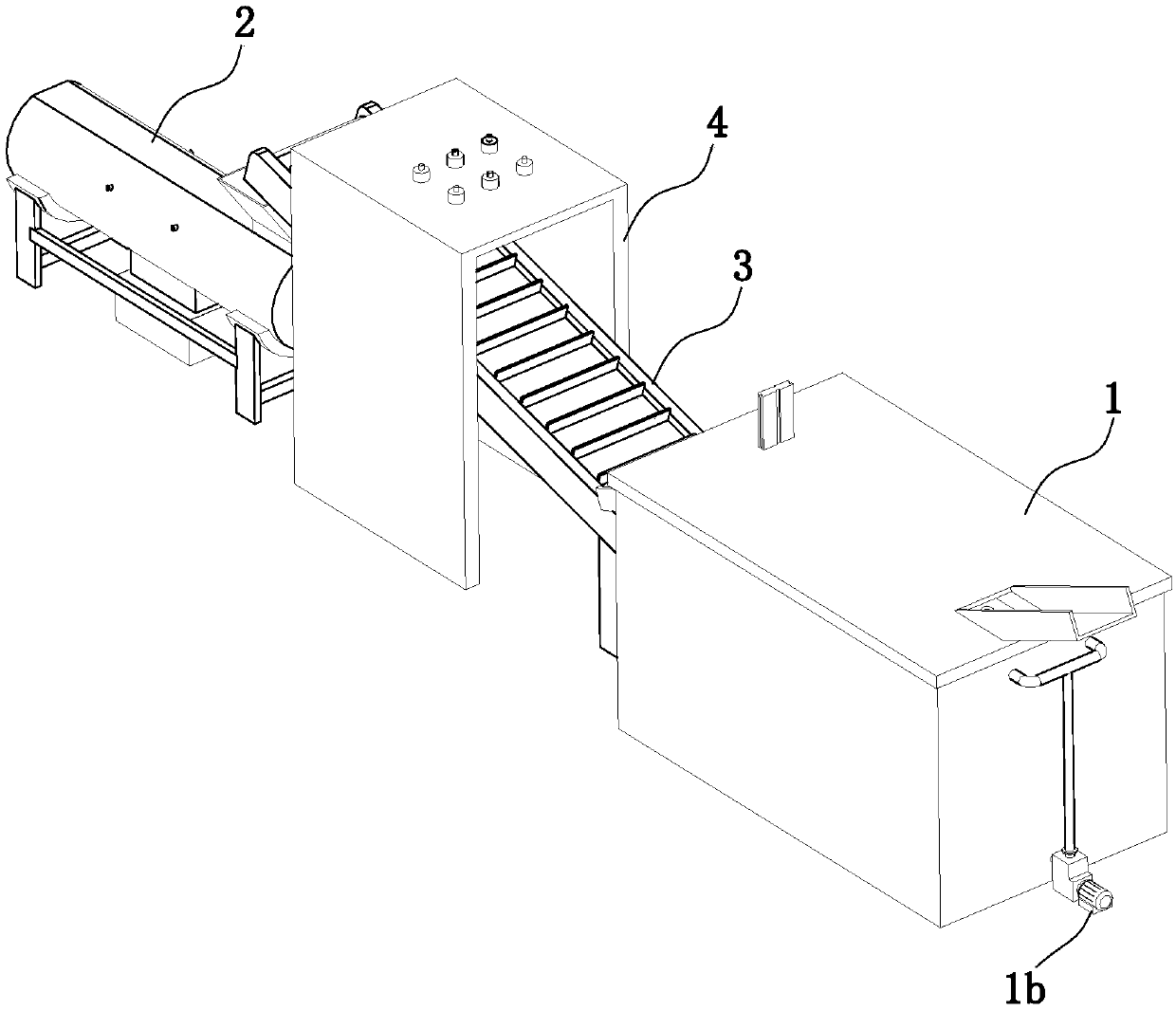

Automatic leaching, synthesizing and sub-packaging method of technetium [99mTc] labeled drug

ActiveCN113353306AProduction Process AutomationEnsure production safetyGroup 5/15 element organic compoundsRadioactive preparation carriersBiochemical engineeringPharmaceutical drug

The invention discloses an automatic leaching, synthesizing and sub-packaging method of a technetium [99mTc] labeled drug. The method comprises the following steps: providing an automatic synthesis module; connecting an inlet of a molybdenum-technetium generator to a leacheate bottle, and connecting an outlet of the molybdenum-technetium generator to a sixth valve; connecting an injector to an eighth valve through a pipeline; connecting a reaction bottle to a third valve and a seventh valve through pipelines, connecting a diluent bottle to a tenth valve through a pipeline, and connecting a packaging container to a fourth valve through a product tube; through cooperation of an injector, a molybdenum technetium generator, a leacheate bottle, a reaction bottle, a diluent, a packaging container and an automatic synthesis module, automatic leaching, synthesis and split charging of technetium [99mTc] labeled drugs are achieved. According to the method, repeatable and stable automatic production of technetium [99mTc] labeled drugs can be met, the GMP production specification is met, and radiation suffered by workers can be reduced to the maximum extent.

Owner:JIANGSU HUAYI TECH

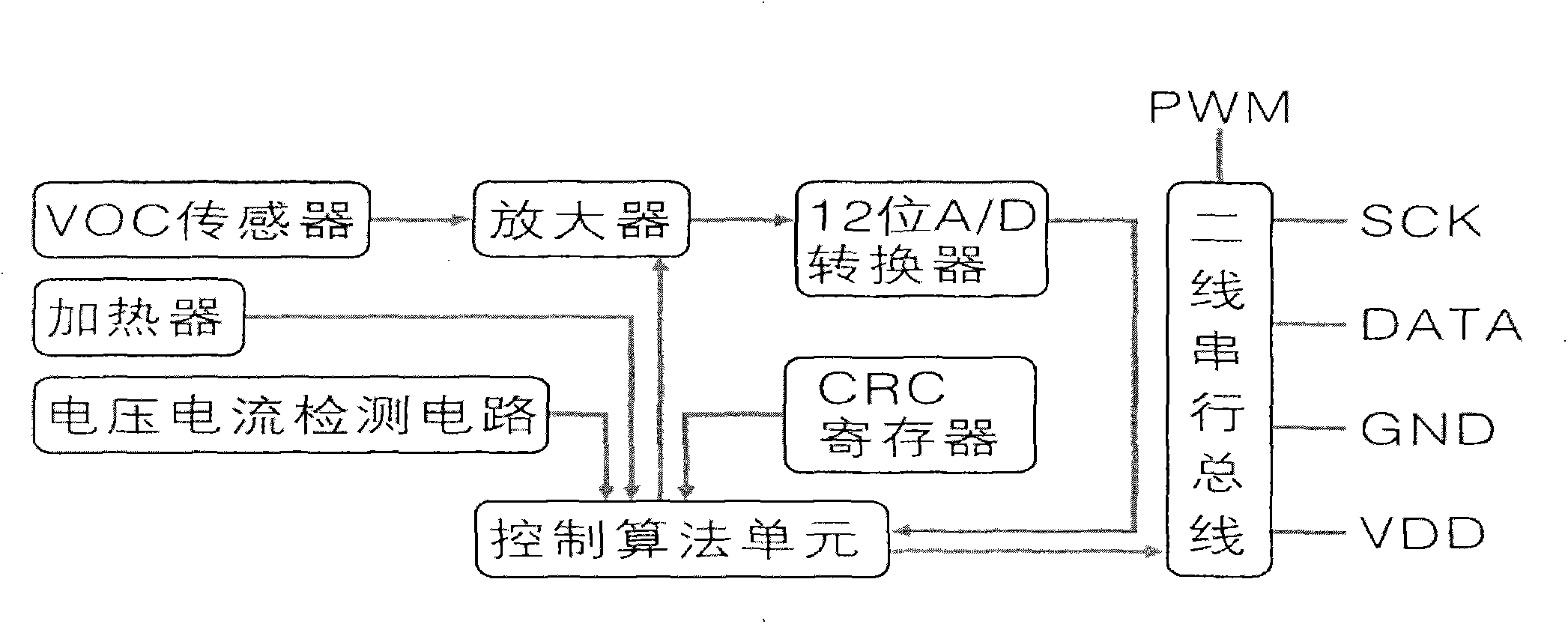

Device for measuring air pollution

InactiveCN103353471ASimple designThe preparation process is matureMaterial resistanceManufacturing technologyEngineering

The invention provides a device for measuring air pollution, which comprises an air quality VOC sensor module, an amplifying module, an A / D transverter module, a heater module, a control algorithm unit module and a two-wire serial bus module; the air quality VOC sensor module, the amplifying module and the A / D transverter module are electrically connected with the control algorithm unit module; the heater module is electrically connected with the control algorithm unit module; the control algorithm unit module is electrically connected with the amplifying module and the two-wire serial bus module separately. The device provided by the invention has the advantages that the equivalent calculation of the density of CO2 can be realized through a semiconductor sensor. The method is mature in manufacturing technology, facilitates miniaturize integrated circuit design, is large in batch, can be manufactured automatically, and is low in cost.

Owner:张伟

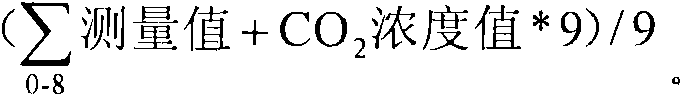

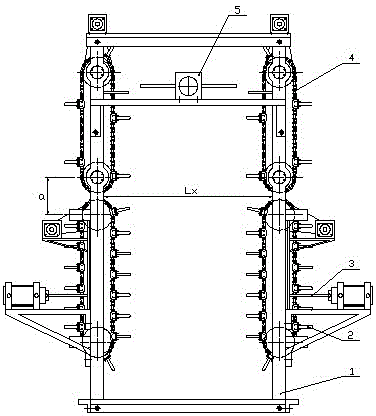

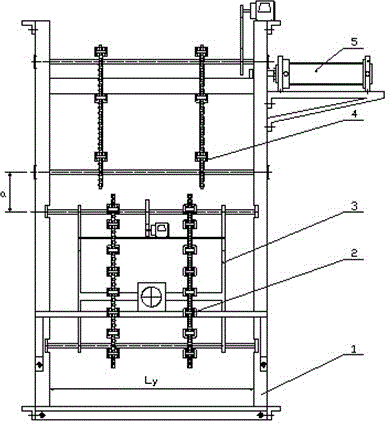

Automatic lifting and separating device for floor panels

InactiveCN104444086ASimple structureEasy to processConveyorsDe-stacking articlesDrive shaftPosition control

The invention relates to an automatic lifting and separating device for floor panels. The automatic lifting and separating device for floor panels adopts the technical scheme that first lifting devices (2) are symmetrically mounted on the left and the right sides of the lower part of a base frame (1); the upper ends of two position control devices (3) are movably connected with first lifting driving shafts (28) of the corresponding two first lifting devices (2), and the lower ends of the two position control devices (3) are movably connected with first lifting driven shafts (27) of the corresponding two first lifting devices (2); second lifting devices (4) are symmetrically mounted on the left and the right sides of the upper part of the base frame (1); a pull-off device (5) is mounted on the front side of the upper part of the base frame (1); the center distance a between first lifting driving chain wheels (23) of the first lifting devices (2) and second lifting driven chain wheels (36) of the second lifting devices (4) in a profile projection is equal to (0.7 to 0.8) (Lx-L0), wherein Lx is the distance between the inner sides of two horizontally adjacent uprights (8), and L0 is the length of a floor panel. The automatic lifting and separating device for floor panels has the characteristics of simple structure, low cost, high efficiency and high work reliability, and can meet the requirement of modern automatic production.

Owner:WUHAN UNIV OF SCI & TECH

System and method for automatic measurements and calibration of computerized magnifying instruments

ActiveUS8401269B2Reduce eliminateReduce the numberImage enhancementPhotometry using reference valuePattern recognitionDigital image

The present invention relates to a system and method for automatic measurements and calibration of computerized magnifying instruments. More particularly, the method includes an automatic calibration aspect, which includes obtaining an optimized digital image of a reference object including at least one standardized landmark feature, and establishing calibration parameters based on one or more measured attributes of the landmark feature. The method further describes a calibration aspect, which includes providing calibration parameters, obtaining a digital image including at least one known attribute, measuring the at least one known attribute and comparing the measured value with the known value. The method further includes an aspect of automatic measurement of an attribute of one or more object, which includes retrieving calibration parameters, acquiring a digital image and measuring the attribute. The system includes an object support, a reference object including one or more standardized landmark features, and an automatically readable identification means.

Owner:CLEMEX TECH

Rotary suction assembly

InactiveCN106184942AProduction Process AutomationIncrease productivityPackagingArticle feedersDrive shaftPaperboard

The invention relates to the technical field of packaging devices, in particular to a rotary suction assembly. The rotary suction assembly comprises sucking disc plates, a rotating shaft, swinging arms and a driving shaft, wherein sucking discs are fixedly mounted on one sides of the sucking disc plates; fixed brackets are arranged on the other sides of the sucking disc plates; the fixed brackets are fixedly mounted on the rotating shaft in a sleeving manner; one ends of the swinging arms are mounted on the rotating shaft in a sleeving manner; the other ends of the swinging arms are mounted on the driving shaft in a sleeving manner; swinging mechanisms which can enable one ends of the swinging arms to perform circumferential swinging around the axis of the driving shaft are mounted at the other ends of the swinging arms; a synchronous belt transmission mechanism which can drive the rotating shaft to rotate is connected on the rotating shaft; and the swinging mechanisms and the synchronous belt transmission mechanism synchronously move. According to the rotary suction assembly, the rotating shaft can rotate on the own axis while the swinging arms swing, so that a vertically placed paperboard is taken to a low place from a high place; and the paperboard is overturned to be horizontally placed, the automatic production is achieved, and the production efficiency is improved.

Owner:常州节卡智能装备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Automatic leaching, synthesizing and sub-packaging method of technetium [99mTc] labeled drug Automatic leaching, synthesizing and sub-packaging method of technetium [99mTc] labeled drug](https://images-eureka.patsnap.com/patent_img/f8a65ec4-54ff-4878-85ad-3663ae5d90c5/HDA0003104461180000011.png)