Manufacture method of wireless radio frequency identification mark

A technology for identifying tags and radio frequency. It is used in record carriers used in machines, semiconductor/solid-state device manufacturing, and instruments. It can solve problems such as low electrical accuracy, difficult radio frequency tag inventory, and antenna failure. Low water and electricity The effect of energy consumption, high product qualification rate and low equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The composition and other features of the present invention will become clearer after reading the following detailed description of the embodiments with accompanying drawings.

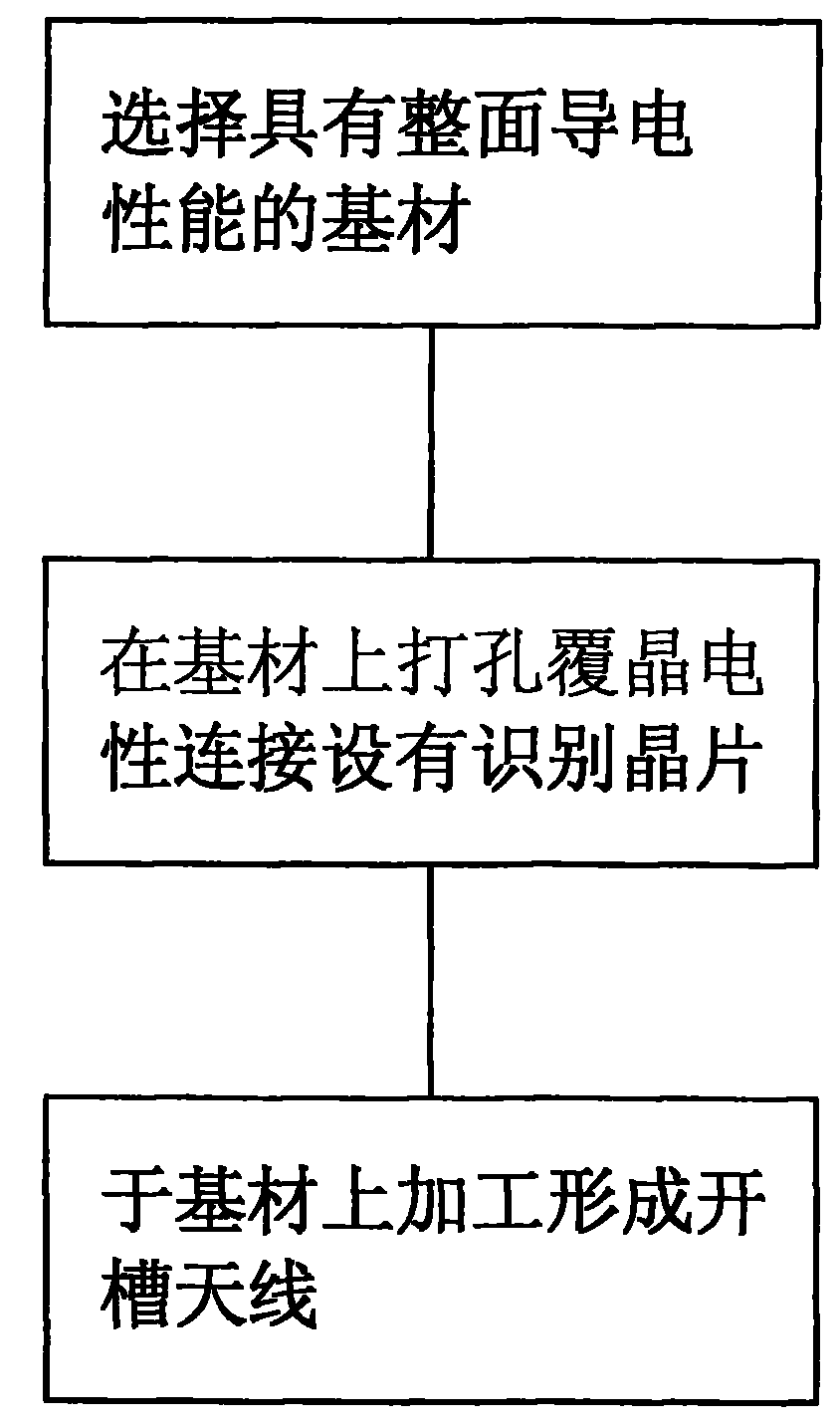

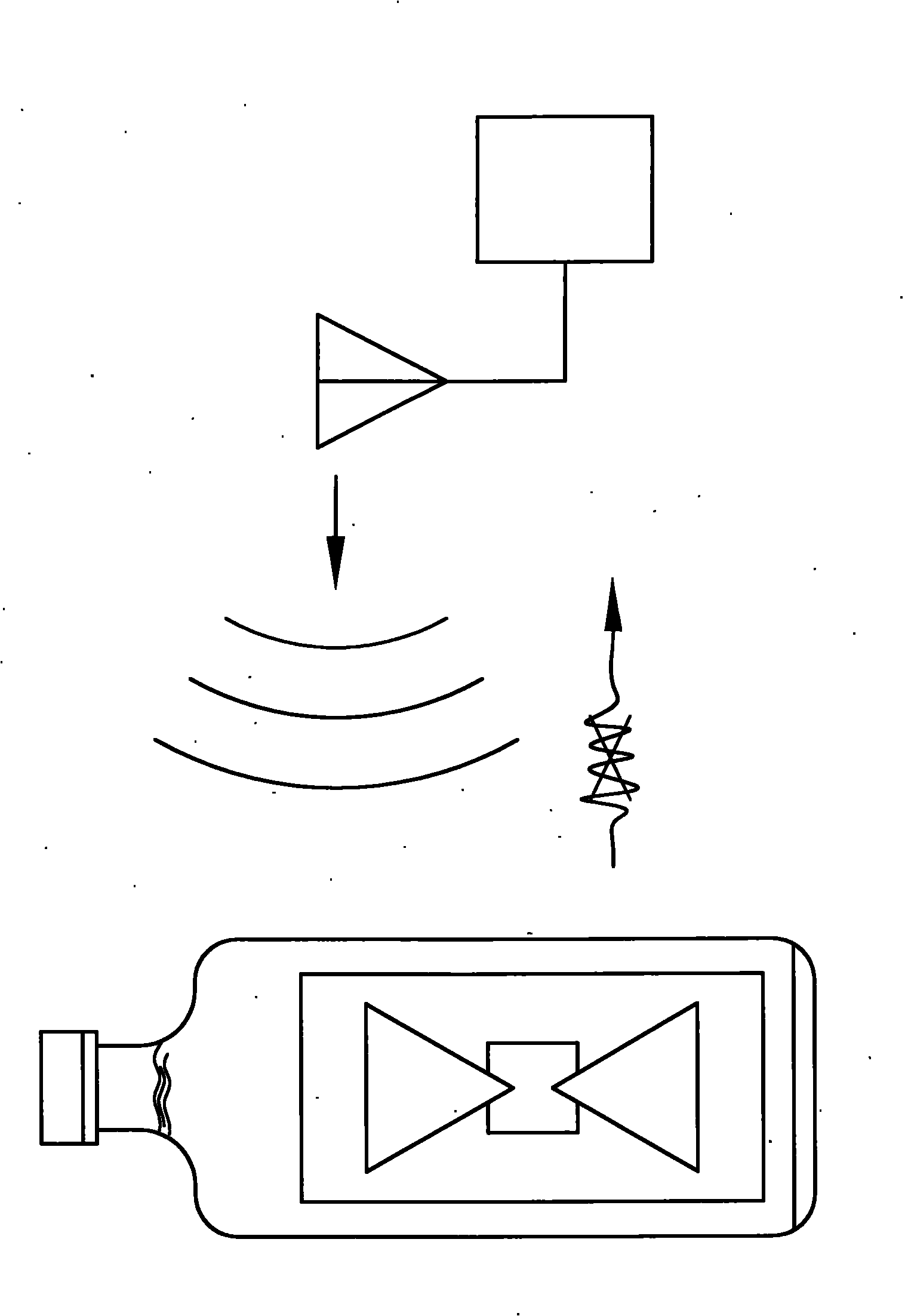

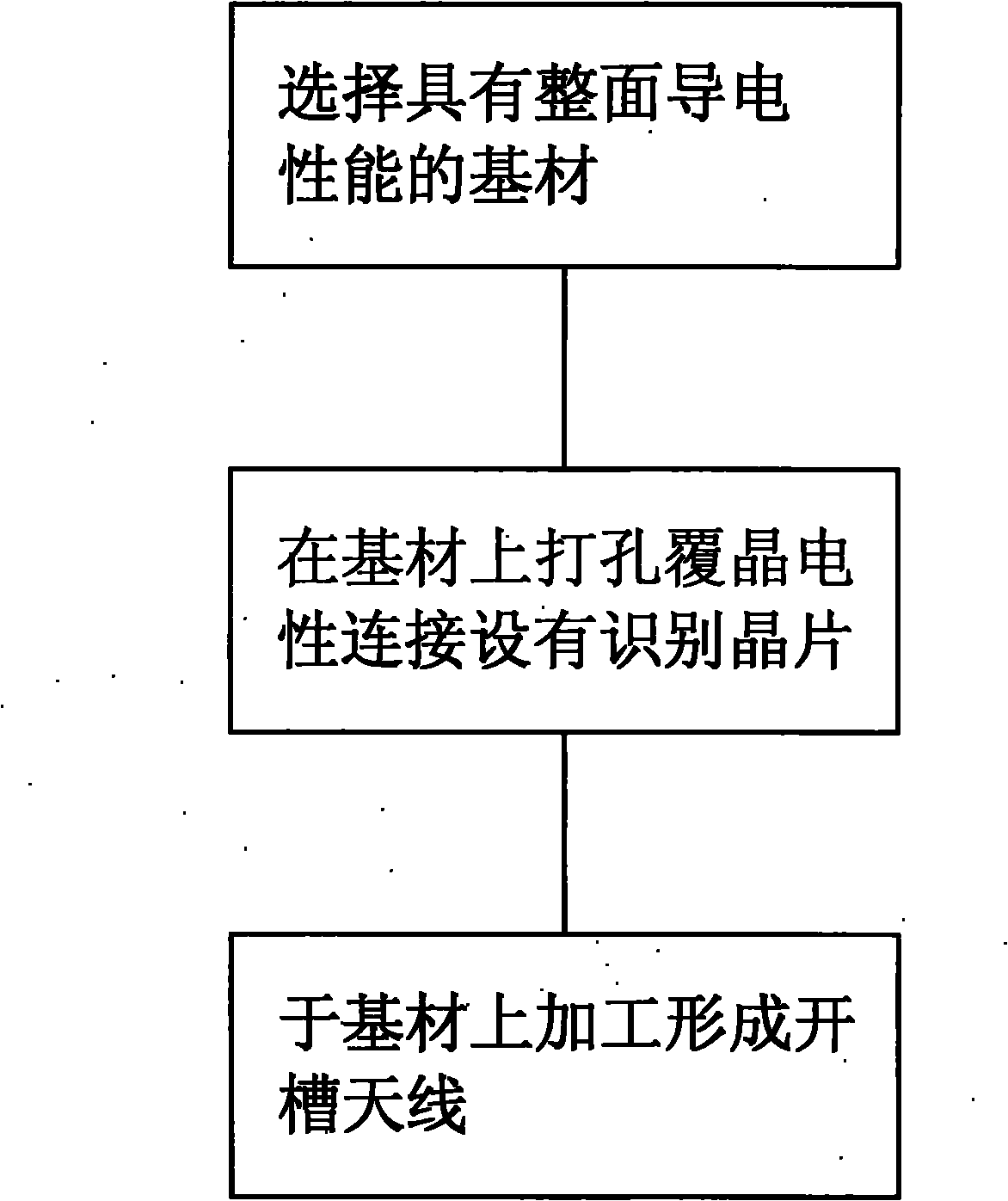

[0046] As shown in Figures 2 to 4, a method for making a radio frequency identification tag provided by the present invention mainly includes:

[0047] 1. Select a substrate 1 with continuous electrical conductivity across the entire surface;

[0048] 2. Drilling holes 11 on the base material 1 for flip-chip electrical connection with an identification chip 2, and;

[0049] 3. Processing and forming a slotted antenna 12 on the substrate 1;

[0050] Of course, in theory, the second step and the third step can also be reversed during processing, first forming the slotted antenna 12, and then setting the identification chip 2, the manufacturing method is exactly the same but the steps are different, so it will not be repeated in this article.

[0051] In this way, aluminum foil, tin foil, or cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com