Polyester fiber conductive paper and preparation method thereof

A polyester fiber, conductive paper technology, applied in special paper, synthetic cellulose/non-cellulose material pulp/paper, fiber raw material processing, etc. Layer and other problems, to eliminate the failure rate and power attenuation, improve quality and service life, overcome the effects of easy cracking and delamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments.

[0032] A polyester fiber conductive paper of the present invention and a preparation method thereof are described in detail below.

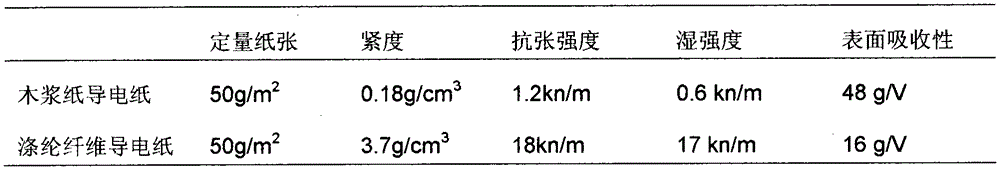

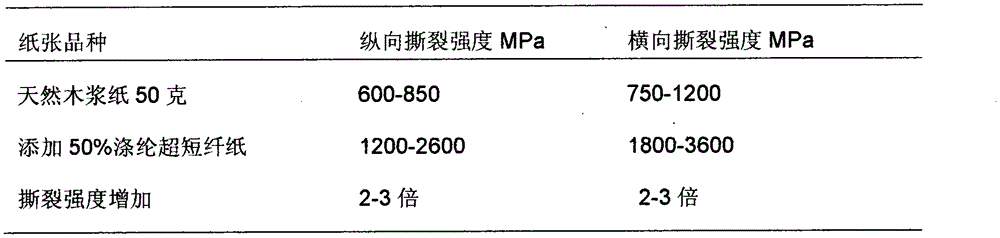

[0033] A polyester fiber conductive paper of the present invention, the conductive paper includes 3%-15% of chopped carbon fiber, 50%-60% of polyester ultra-short fiber, 3%-5% of low melting point ultra-short fiber, and 20%-5% of wood pulp fiber 30%. Among them, the length of chopped carbon fiber is 6-10mm; the melting point of low-melting ultra-short fiber is 130-150°C, the length is 6-10mm, and the thickness is 0.8-2 mm; the length of polyester ultra-short fiber is 6-10mm, and the thickness is 0.8-2 1.6 tanks; wood pulp fiber is natural color wood pulp of chemical fiber.

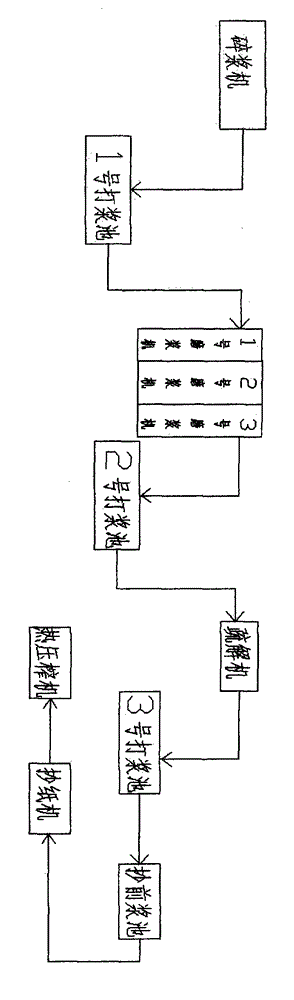

[0034] figure 1 For the schematic flow chart of the present i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com