Patents

Literature

204 results about "Longitudinal strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Longitudinal strength is also called as global strength. Global strength pertains to assessing the strength of the entire ship when it is floating in still water or in waves. Local strength, on the other hand, is about assessing the strength of a localised structure,...

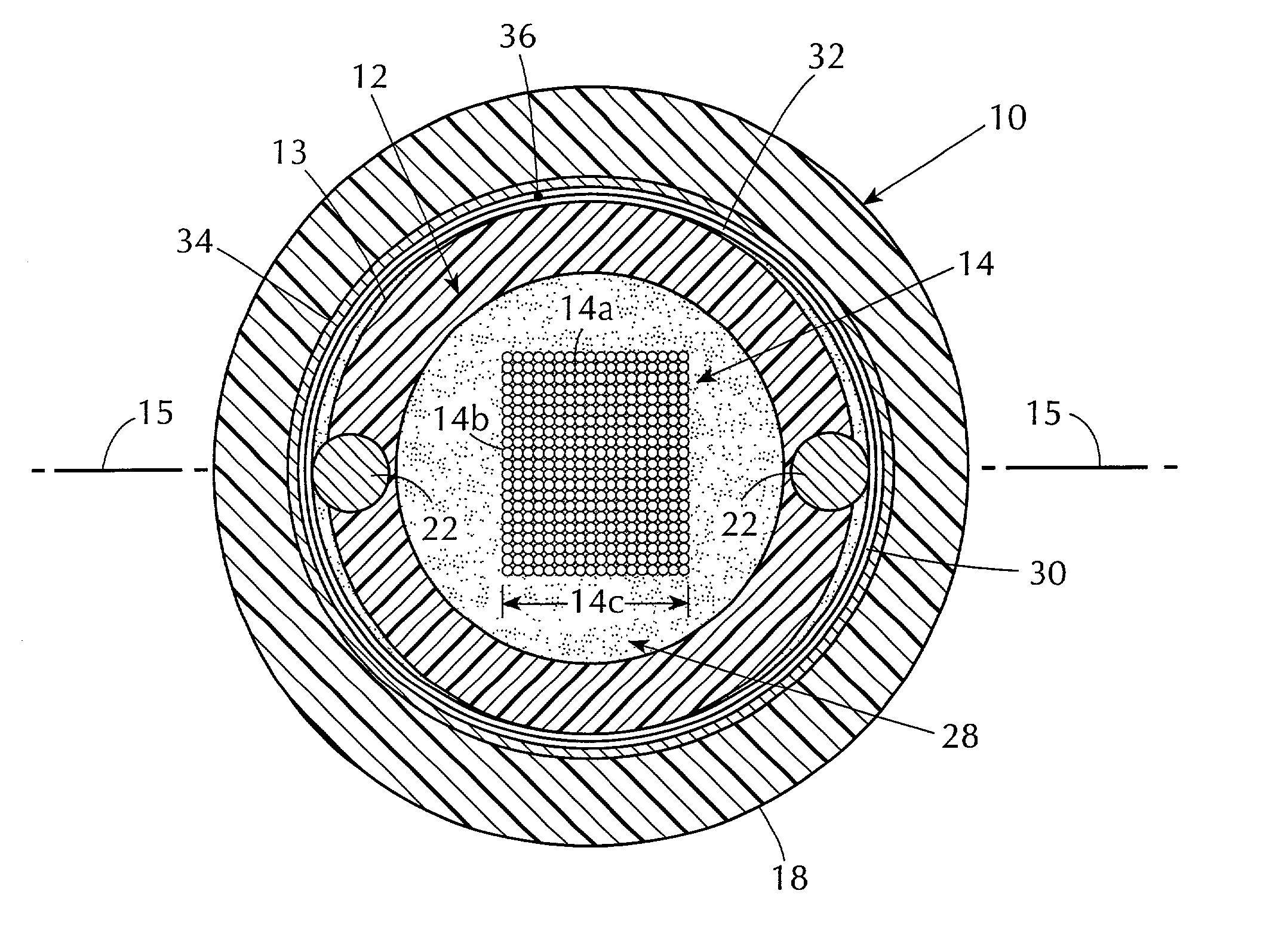

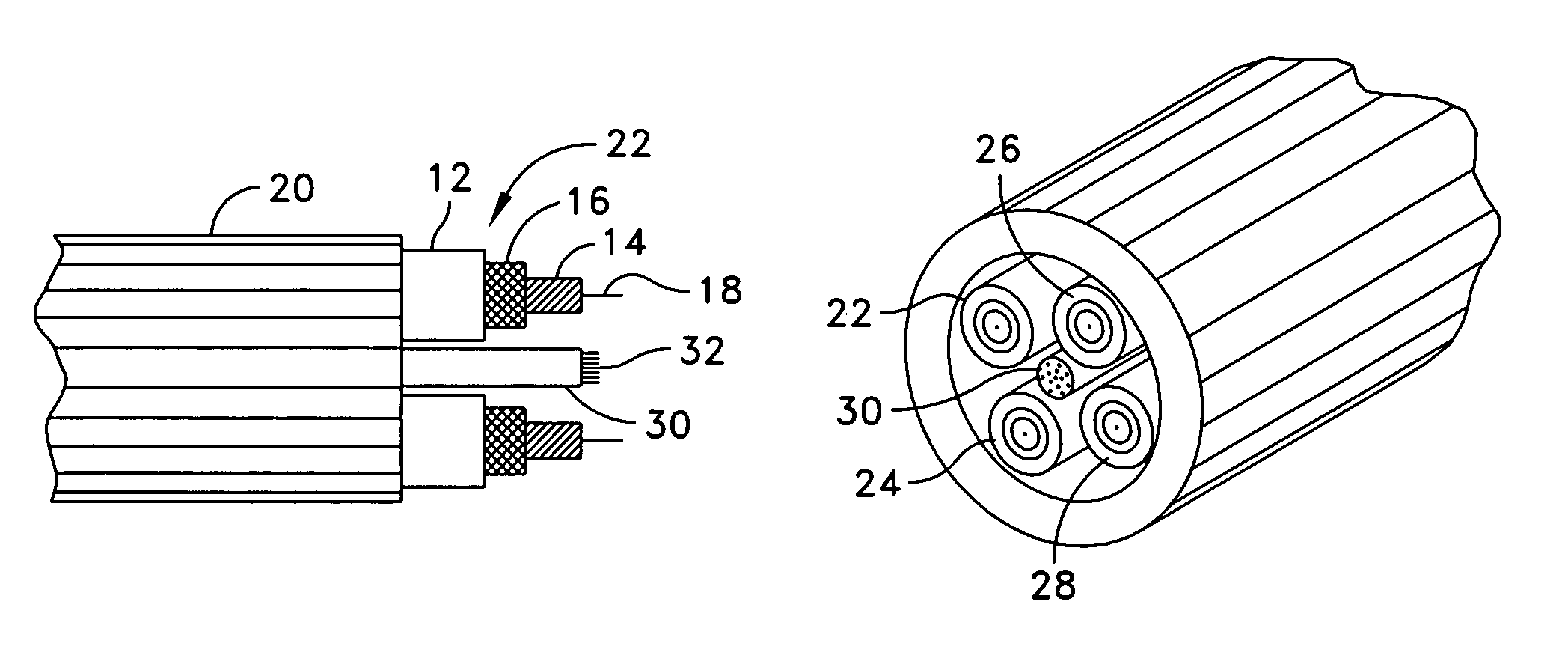

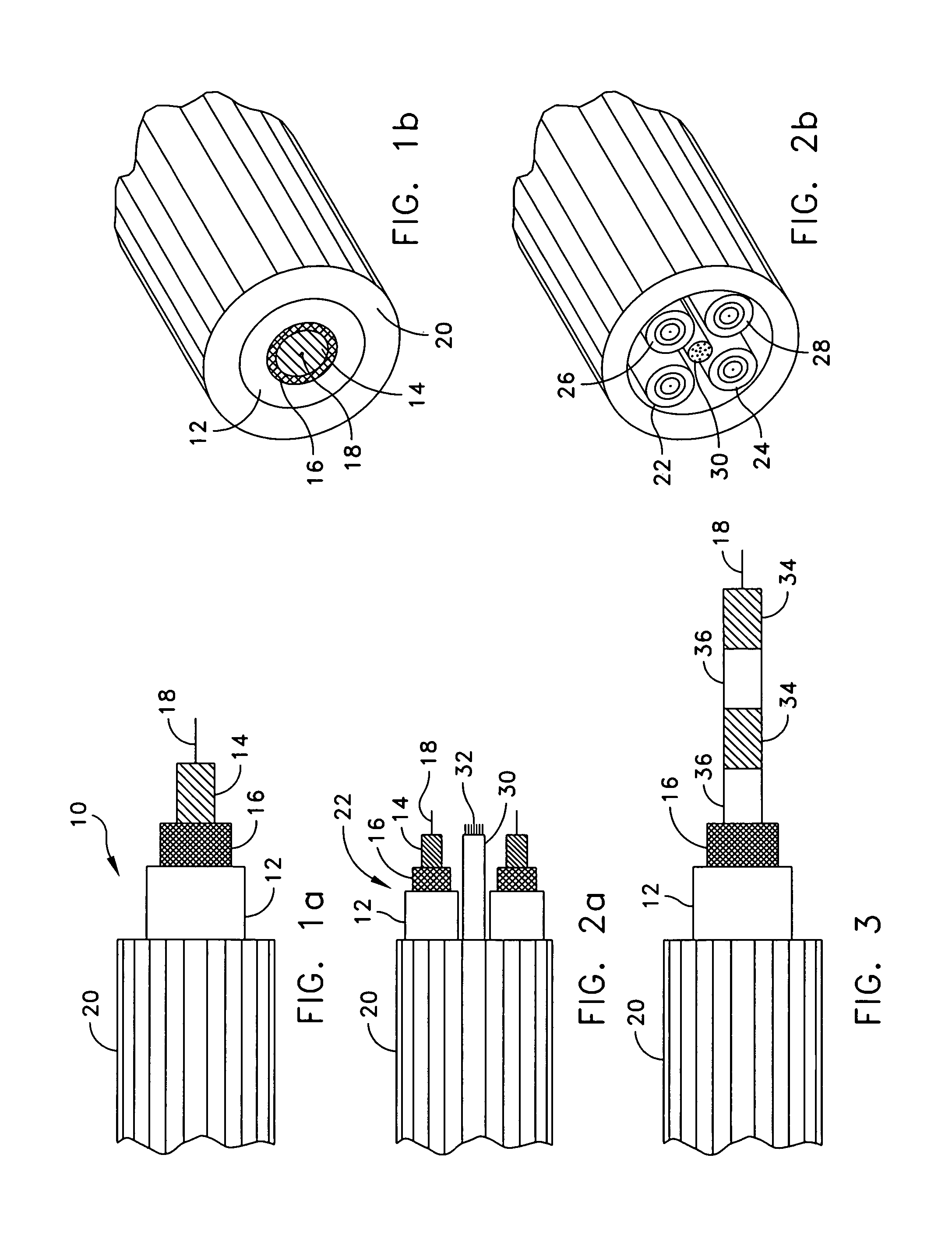

Optical fiber cable and core with a reinforced buffer tube having visible strength members and methods of manufacture thereof

InactiveUS20020126970A1Enhanced couplingPrevent longitudinal slippageFibre mechanical structuresEngineeringUltimate tensile strength

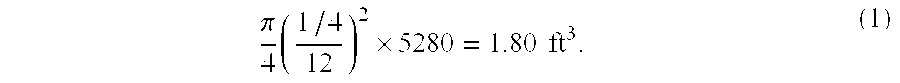

An optical fiber cable core includes a buffer tube containing at least one optical fiber and reinforced by at least two substantially radially incompressible longitudinal strength members, each strength member having surface portions radially outermost with respect to the tube axis which are at or protrude from the exterior surface of the buffer tube. If the strength members protrude from the exterior surface of the buffer tube, less than 50%, and preferably less than 20%, of the outer surface of the strength members protrudes from the exterior surface of the buffer tube. The positions of the strength members can be readily determined, can be visible and can be easily removed from the buffer tube prior to slitting the buffer tube to achieve midspan access. The core can include a buffer tube having an inner tubular portion, an outer tubular portion including the strength members, and a release agent between the tubular portions to enable easy separation of the tubular portions so that conventional slitting tools can be used to gain midspan access. Also, an optical fiber cable including the core and methods of manufacturing a reinforced buffer tube are disclosed.

Owner:PRYSMIAN COMM CABLES & SYST USA LLC

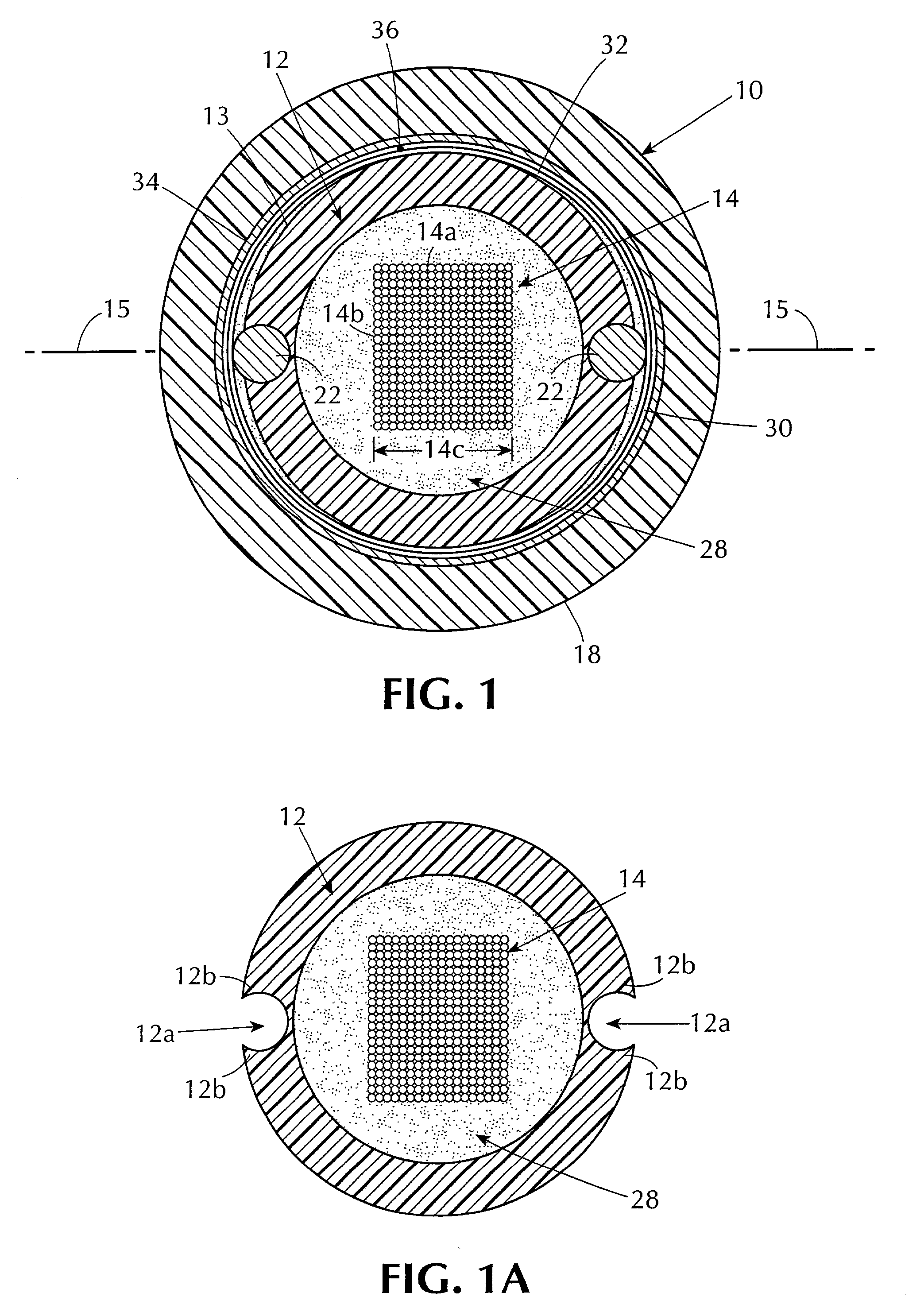

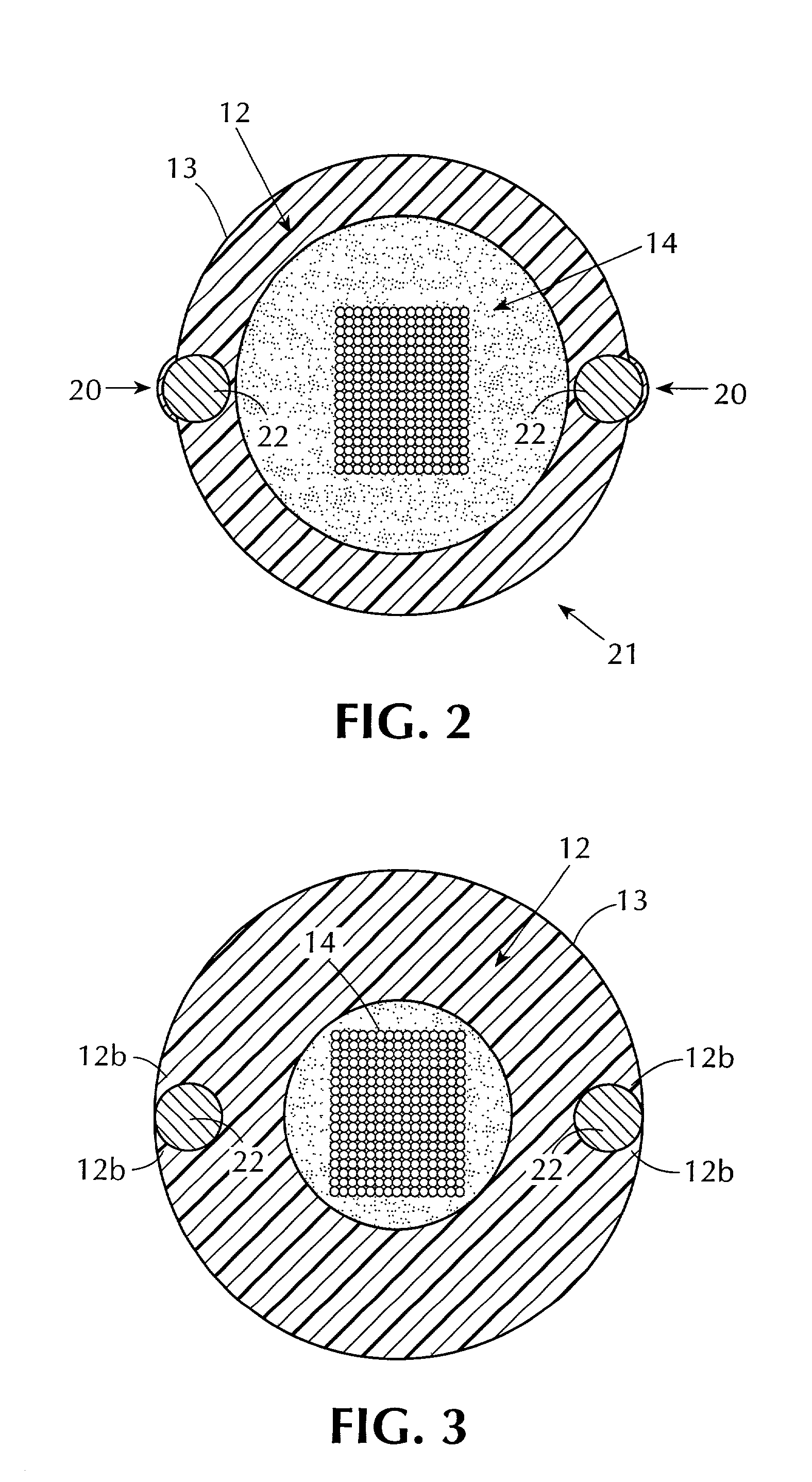

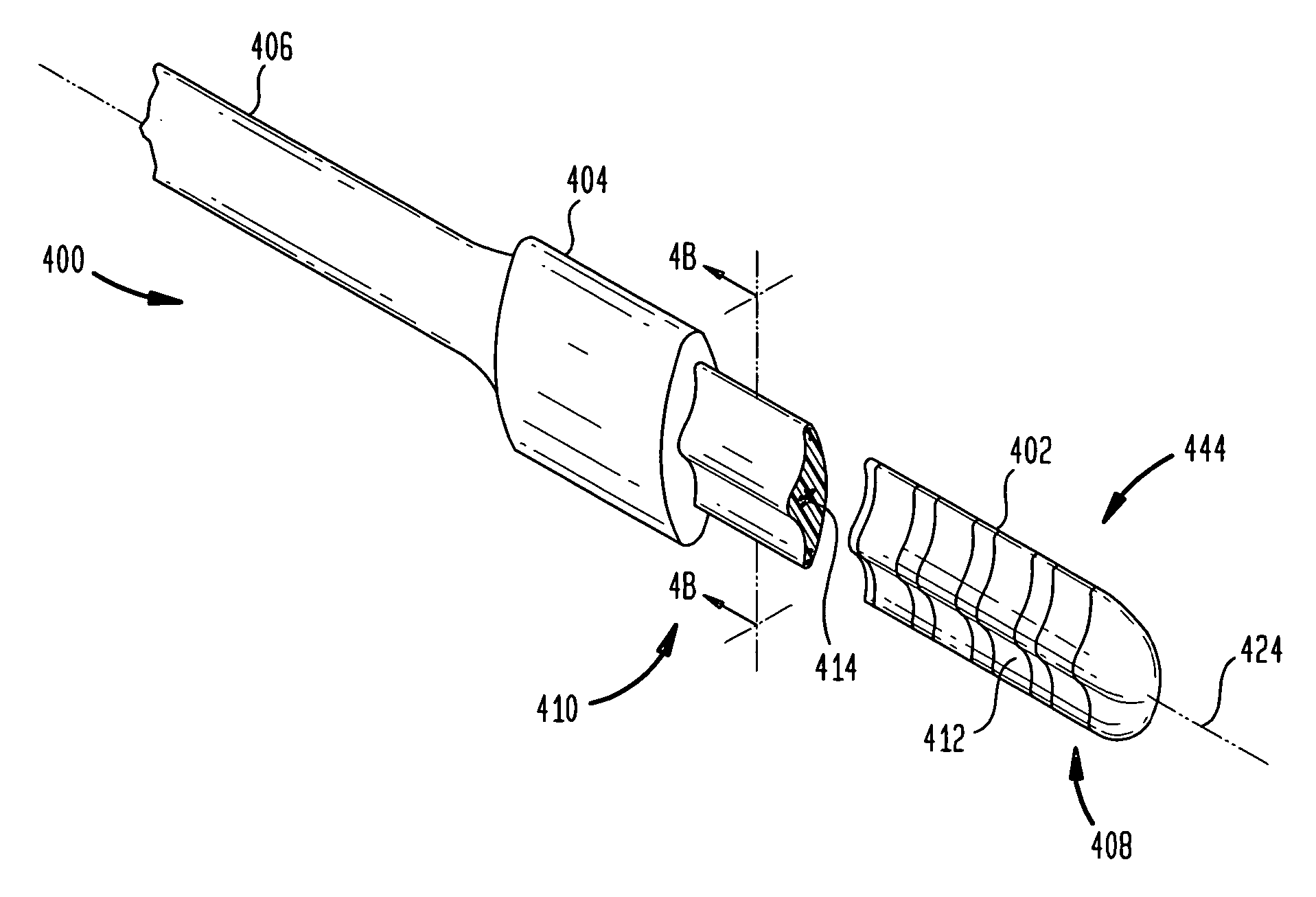

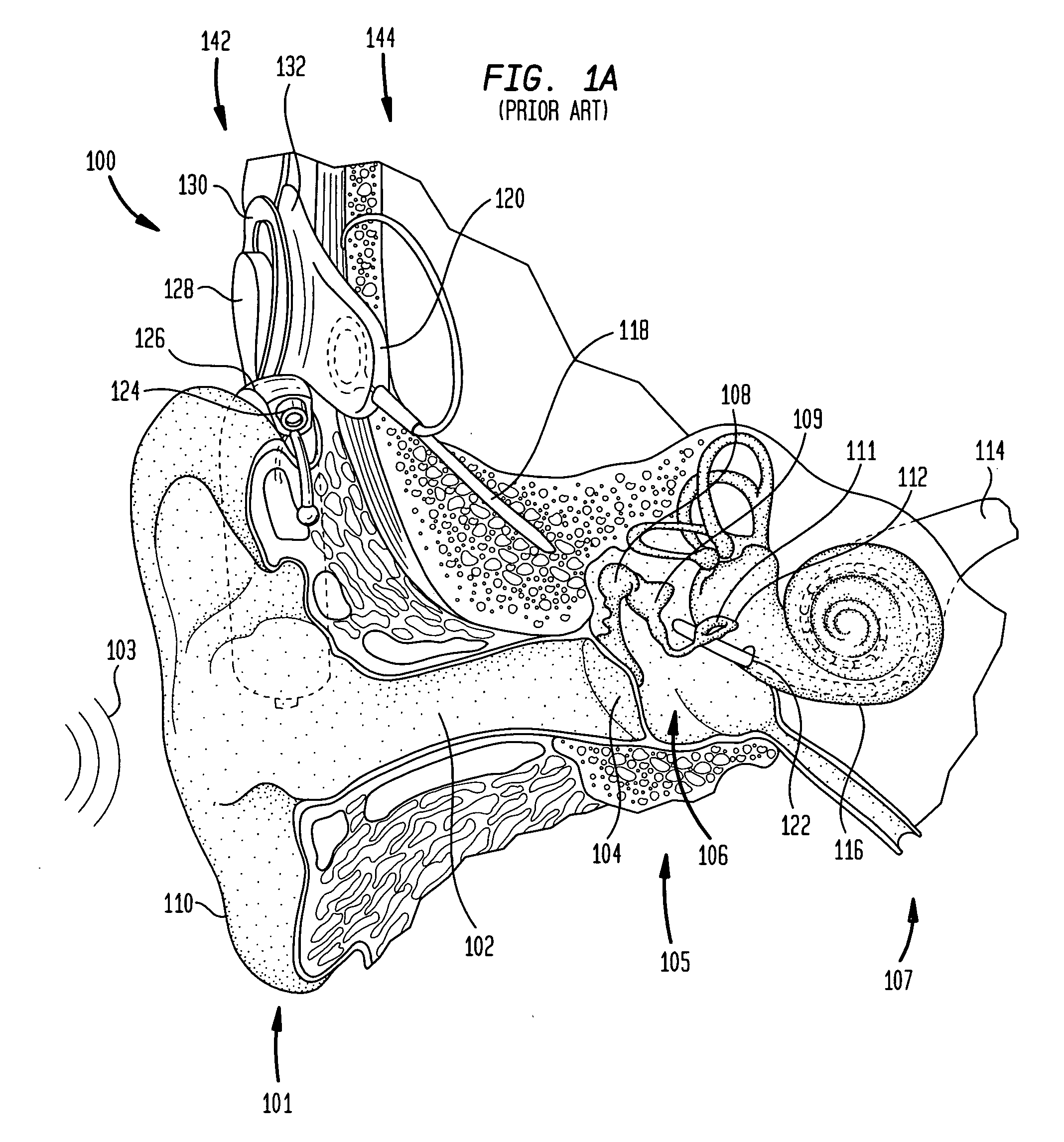

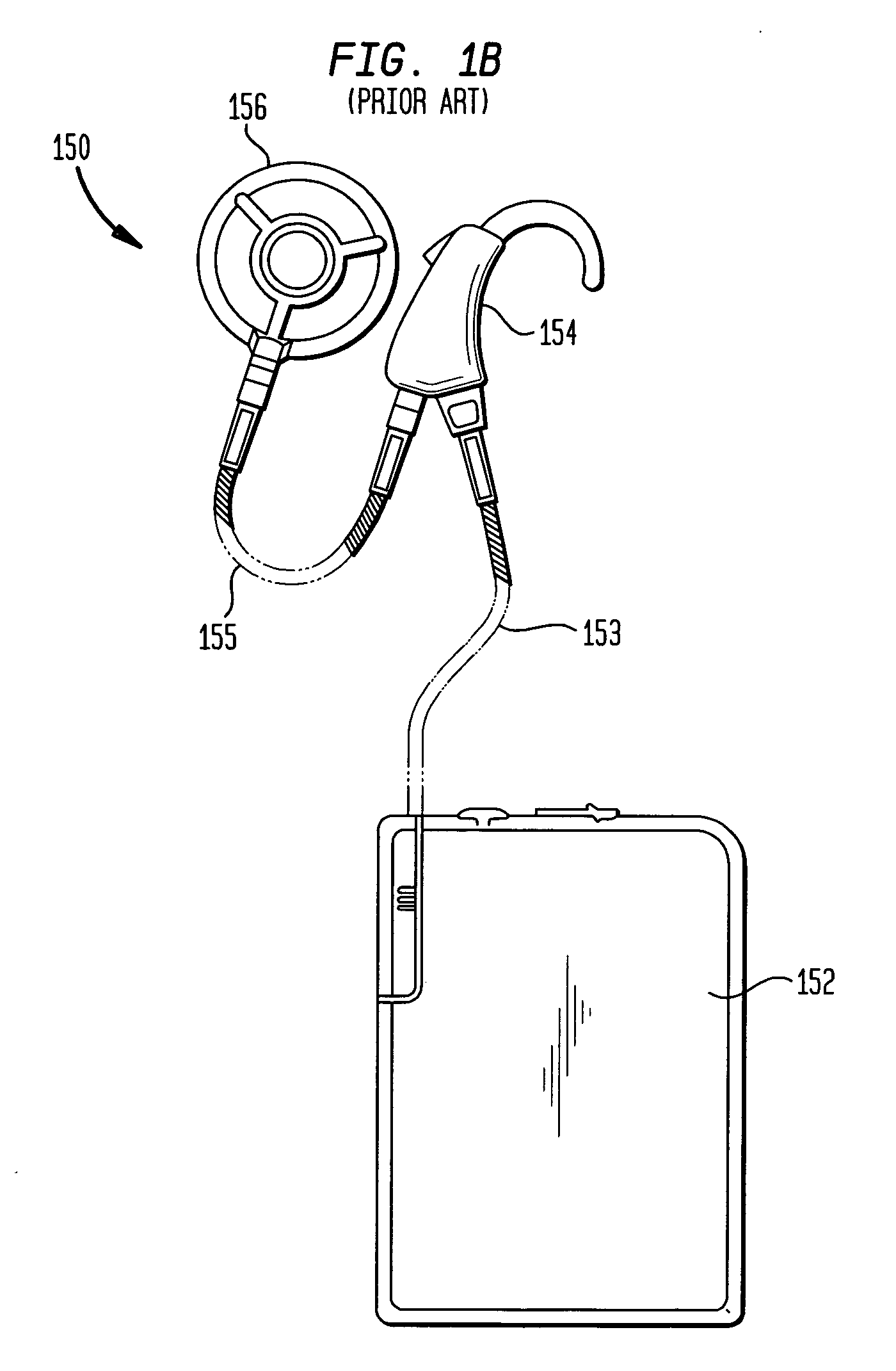

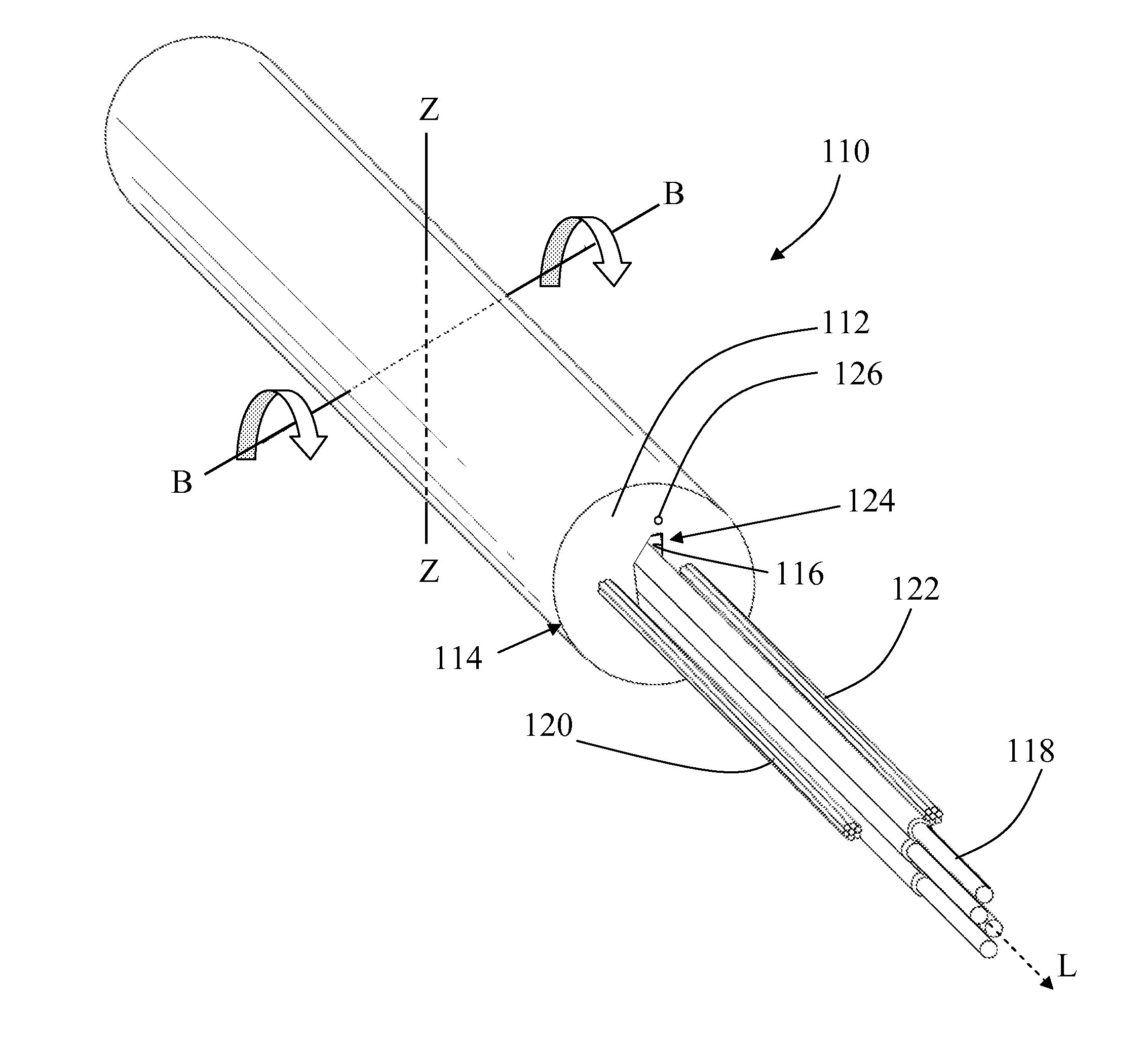

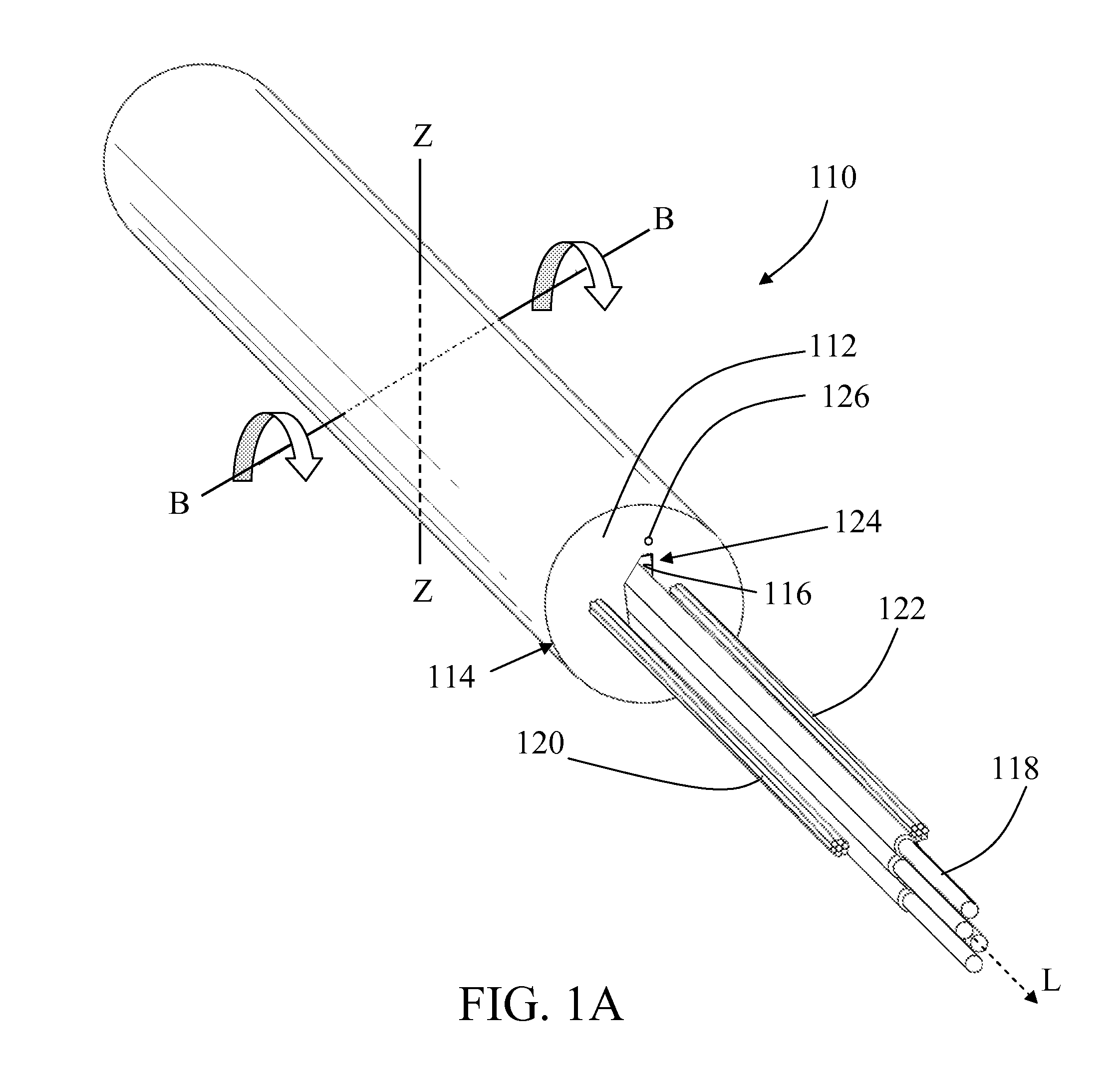

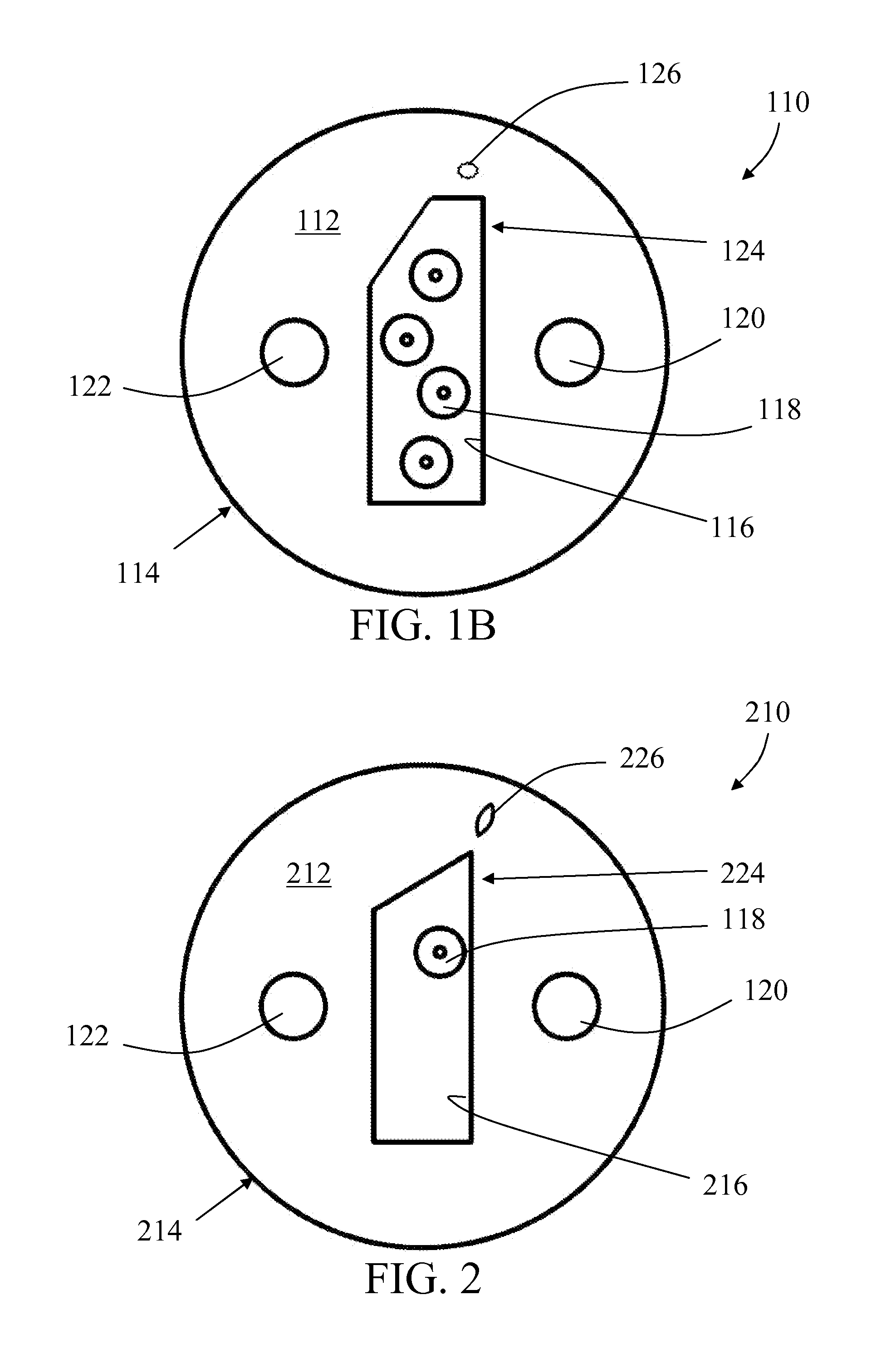

Cochlear endosteal electrode carrier member

InactiveUS20060079950A1Head electrodesDiagnostic recording/measuringMedial surfaceAnatomical structures

An elongate electrode carrier member for implantation in a location external to the cochlear canals to position at least one, and likely many, electrodes sufficiently proximate to the organ of Corti to effectively deliver stimulation signals to the auditory nerve fibers of the cochlear. Generally, the carrier member is dimensioned to be implanted in a crevice, channel or pocket formed between the spiral ligament and bony capsule of the cochlear. Embodiments of the carrier member preferably have a minimized volume to accommodate insertion into such a crevice. In addition, embodiments of the carrier member comprise an elongate bulbous central region having electrodes disposed on the medial surface thereof, and elongate tapered side regions laterally extending from the central region. The side regions have rounded edges and are preferably flexible, while the carrier is configured to coil or turn toward the medial surface. This construction facilitates implantation of the carrier member: the carrier member has sufficient longitudinal strength to maintain its form and direction while being pushed into the surgically-formed crevice, and coils in a longitudinal plane to follow the contour of the cochlear, while the side regions serve to guide the direction of travel, flexing out of the lateral plane as necessary to avoid damaging anatomical structures. Once implanted, embodiments of the carrier member are urged to remain in its implanted position due to one or more of either the side regions extending into the corners of the crevice, and / or due to the curved lateral surface of the carrier member which approximates the curvature of the endosteum along the basal turn of the cochlea.

Owner:COCHLEAR LIMITED

Fully-degradable polylactic acid fiber melt-blowing nonwoven and preparation method thereof

InactiveCN101824708APromote degradationPromote growthMelt spinning methodsNon-woven fabricsVolumetric Mass DensityMelt blowing

The invention discloses fully-degradable polylactic acid fiber melt-blowing nonwoven and a preparation method thereof. The nonwoven is characterized in that polylactic acid slices are spinned at a melting temperature; and fiber filaments stretched by hot air is formed by self-adhesion and hot rolling, wherein, the even fineness of the nonwoven fiber filaments is 0.52-5mu m, the surface density is 5-50g / m2, the thickness is 0.1-0.9mm, the ratio of longitudinal strength to transverse strength is 0.9-1.2, and the filtering efficiency to bacteria is above 95%. The filtering efficiency of the melt-blowing nonwoven product of the invention to bacteria reaches up to 95% which is far higher than that of the existing similar products. The invention solves the problem of low and uneven longitudinal strength and transverse strength of the existing melt-blowing nonwoven. The invention lowers the melt-blowing die head temperature to 180-185 DEG C and brings optimal spinning effect. The technology of the invention is easy to operate and control, has favorable technical stability and can carry out industrial production.

Owner:豆丁乐园(南京)婴儿用品有限公司

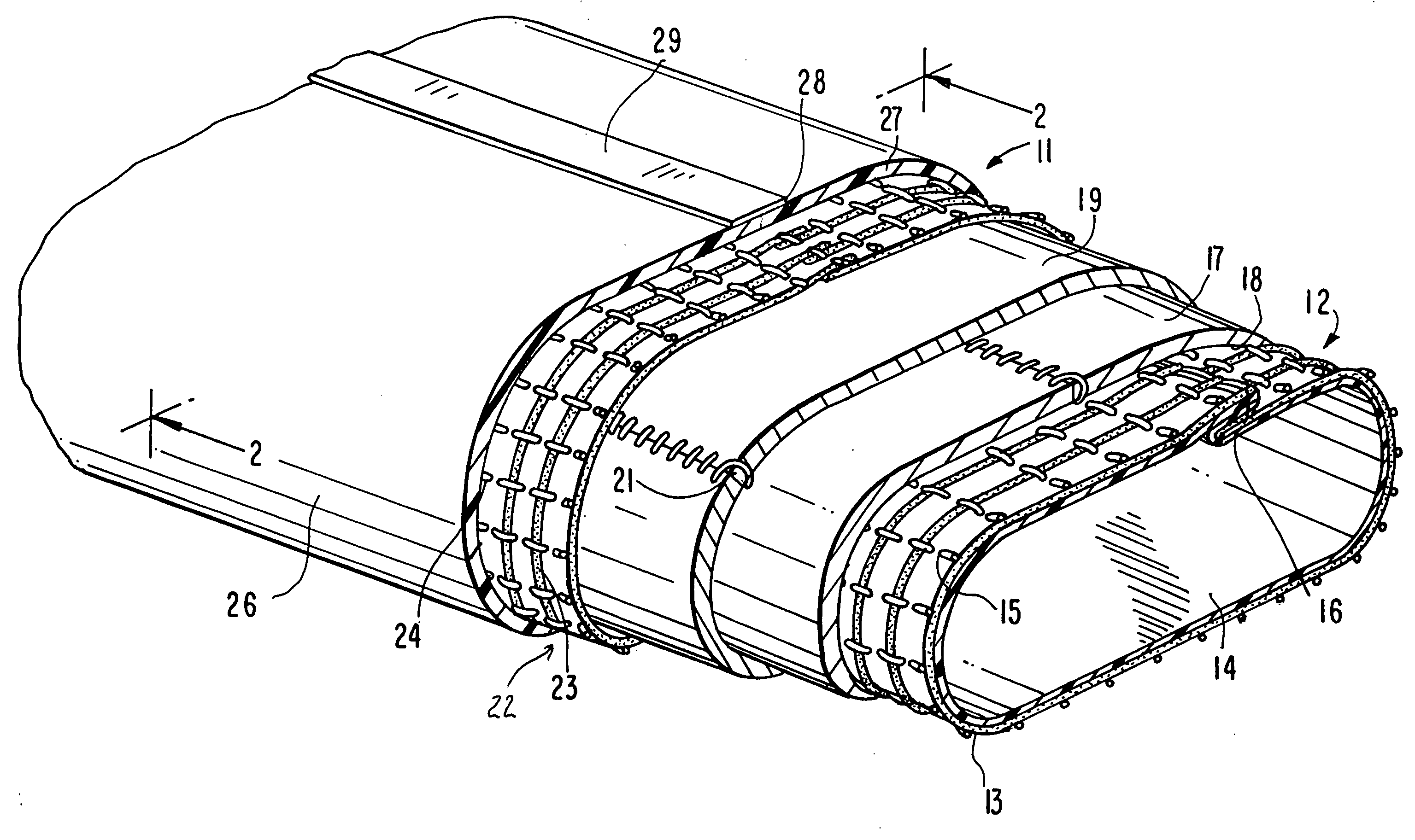

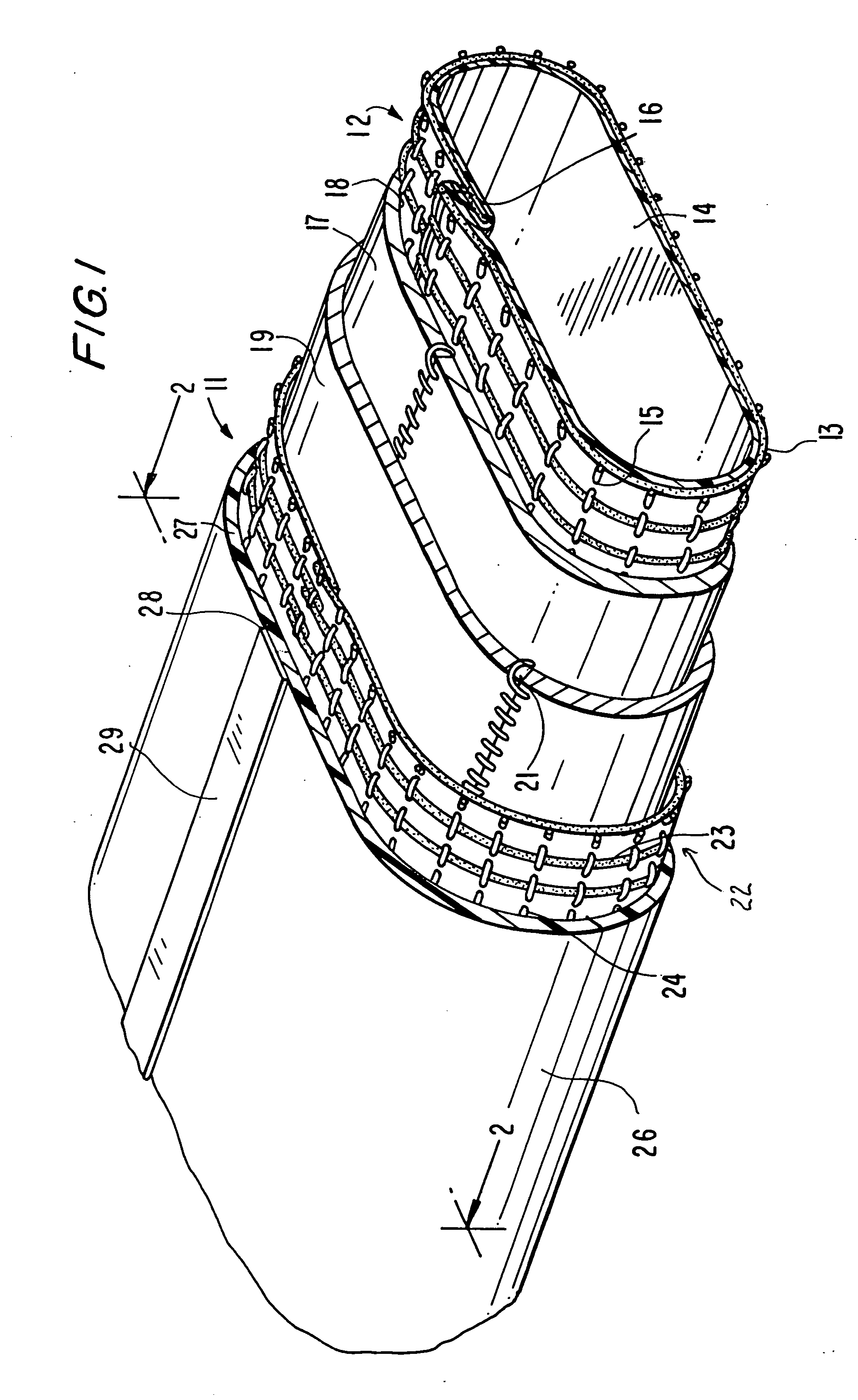

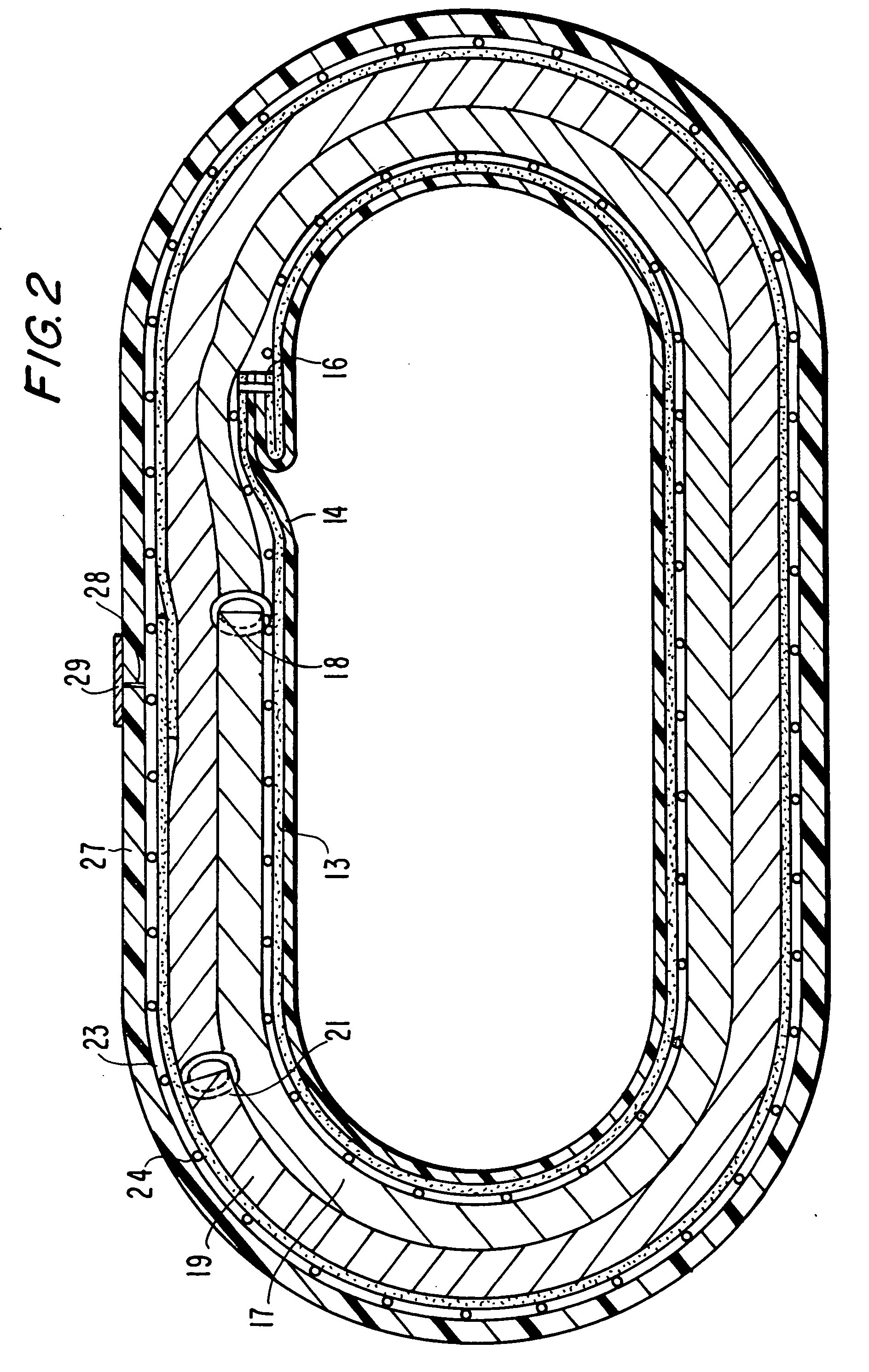

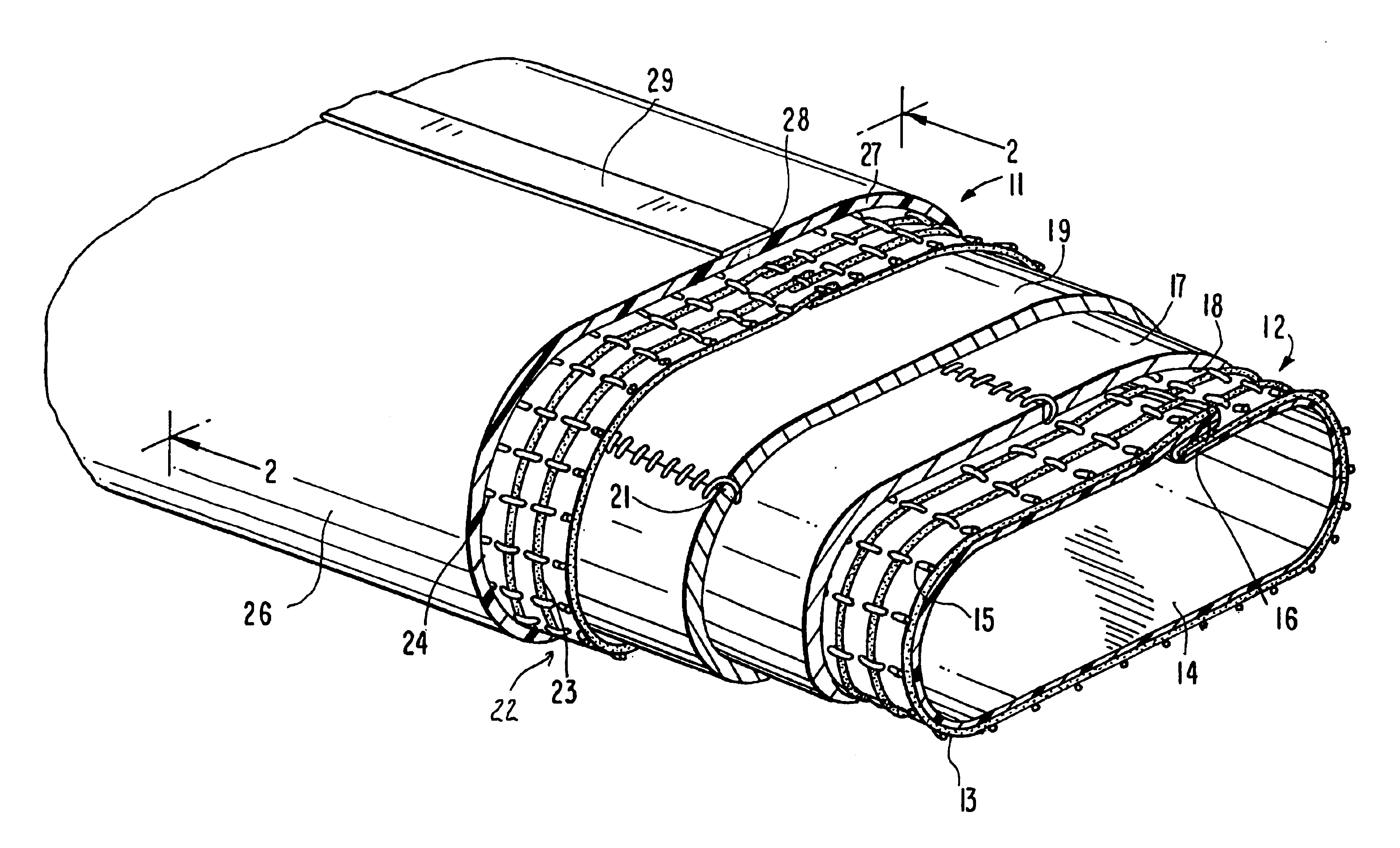

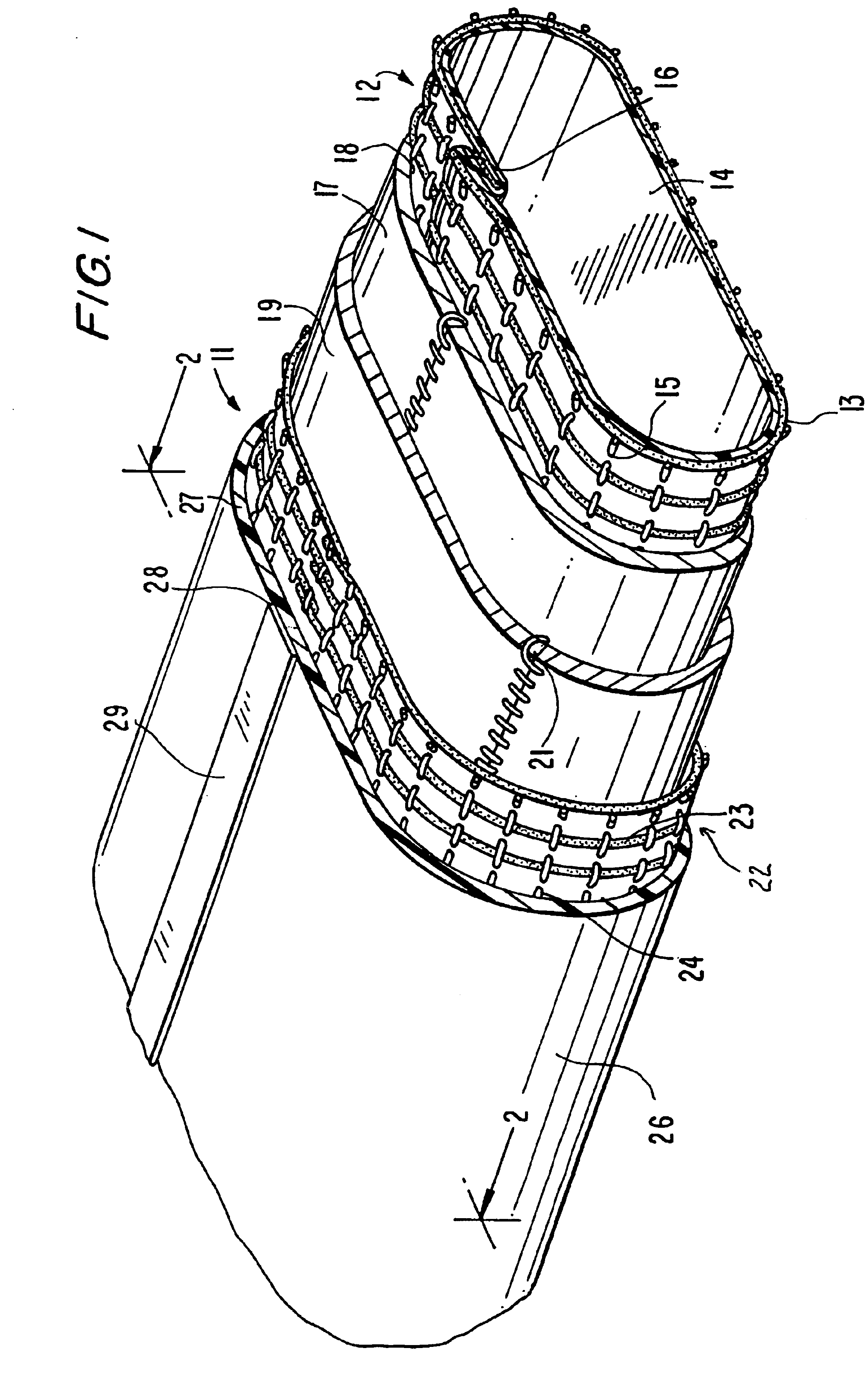

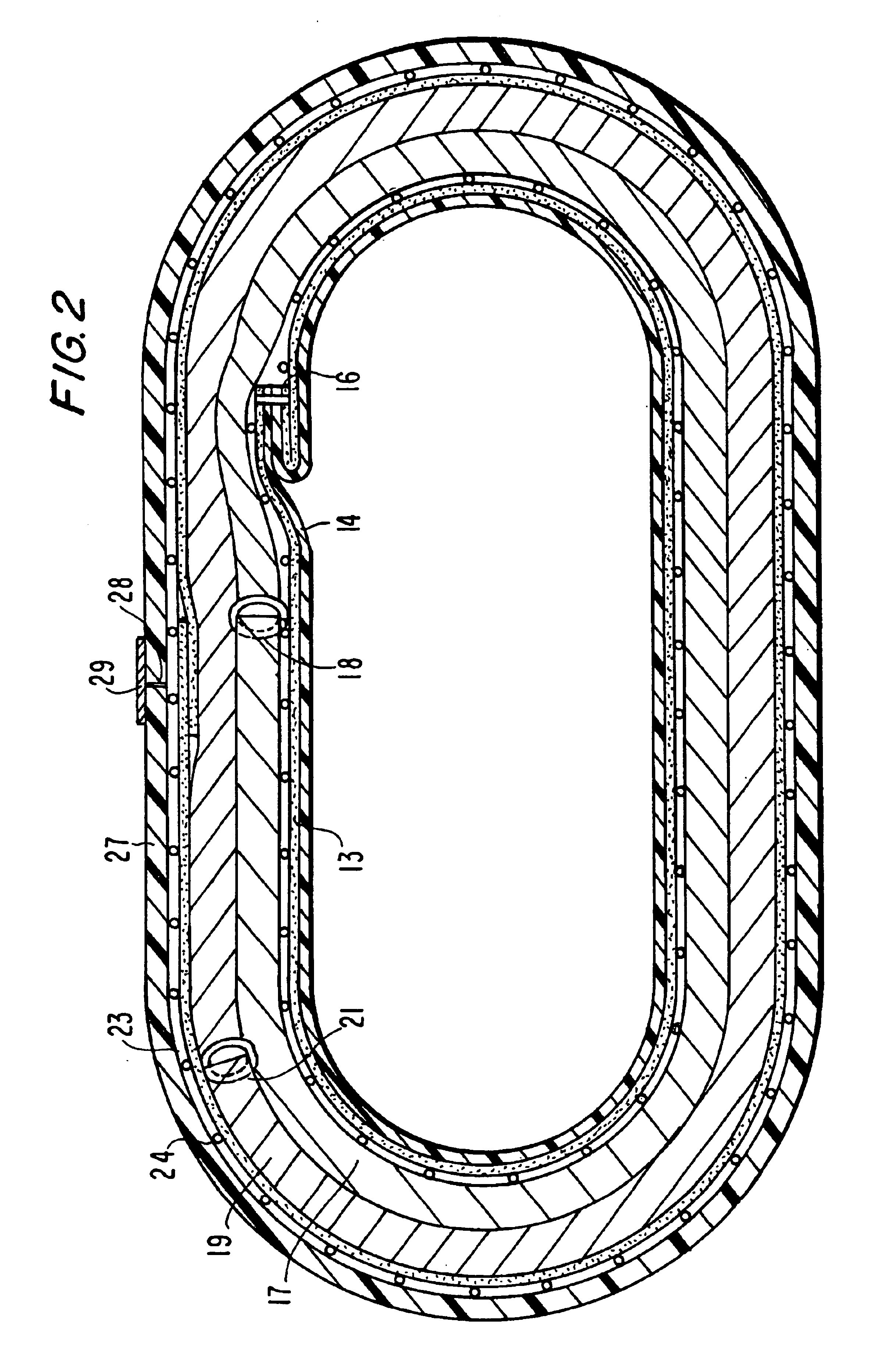

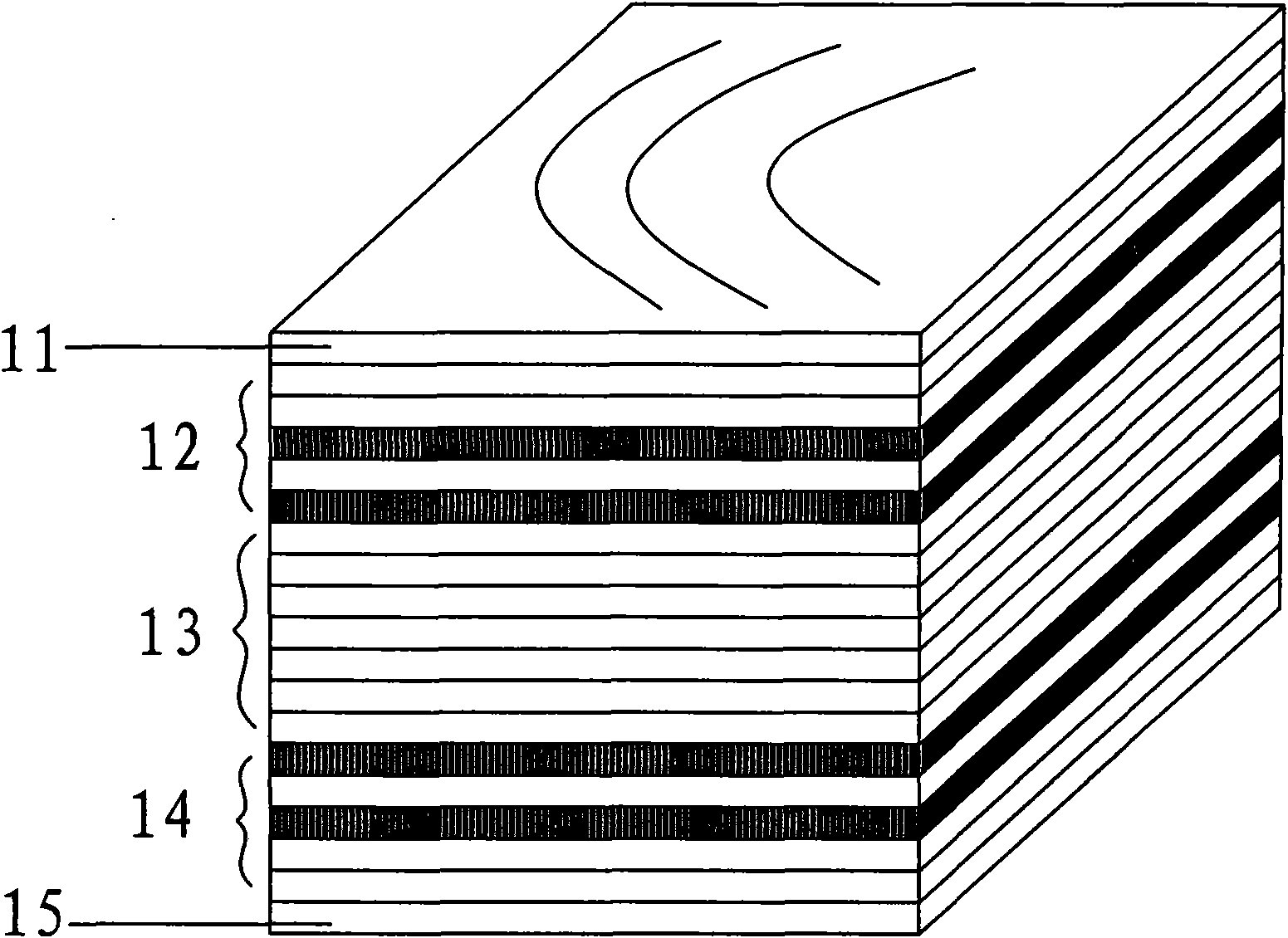

Fiber reinforced composite liner for lining an existing conduit and method of manufacture

InactiveUS6932116B2Increase stiffnessReduce thicknessUnderground chambersPipe elementsFiber bundleHigh intensity

A reinforced liner for cured in place pipe rehabilitation of an existing pipeline having a plurality of high-strength low-elongation fiber bundles disposed circumferentially around the tubular liner at both inner and outer surfaces of a resin absorbent layer of the liner is provided. The bundles of reinforcing fibers are continuous lengths of high modulus fibers laid circumferentially with the ability to stretch to accommodate variations in host pipe diameter. The ends of reinforcing fibers on the inner and outer reinforcing layers overlap so that the ends slide past each other as the liner is expanded prior to cure. The reinforcing fibers may be secured to a porous scrim to form an inner tubular reinforcing layer. An outer layer of bundles of reinforcing fiber are formed into a tube about the absorbent layer. An outer impermeable tubular layer is wrapped around the inner layers. The reinforcing layer may include longitudinal reinforcing fiber in either or both reinforcing layers to increase the longitudinal strength of the liner.

Owner:INA ACQUISITION

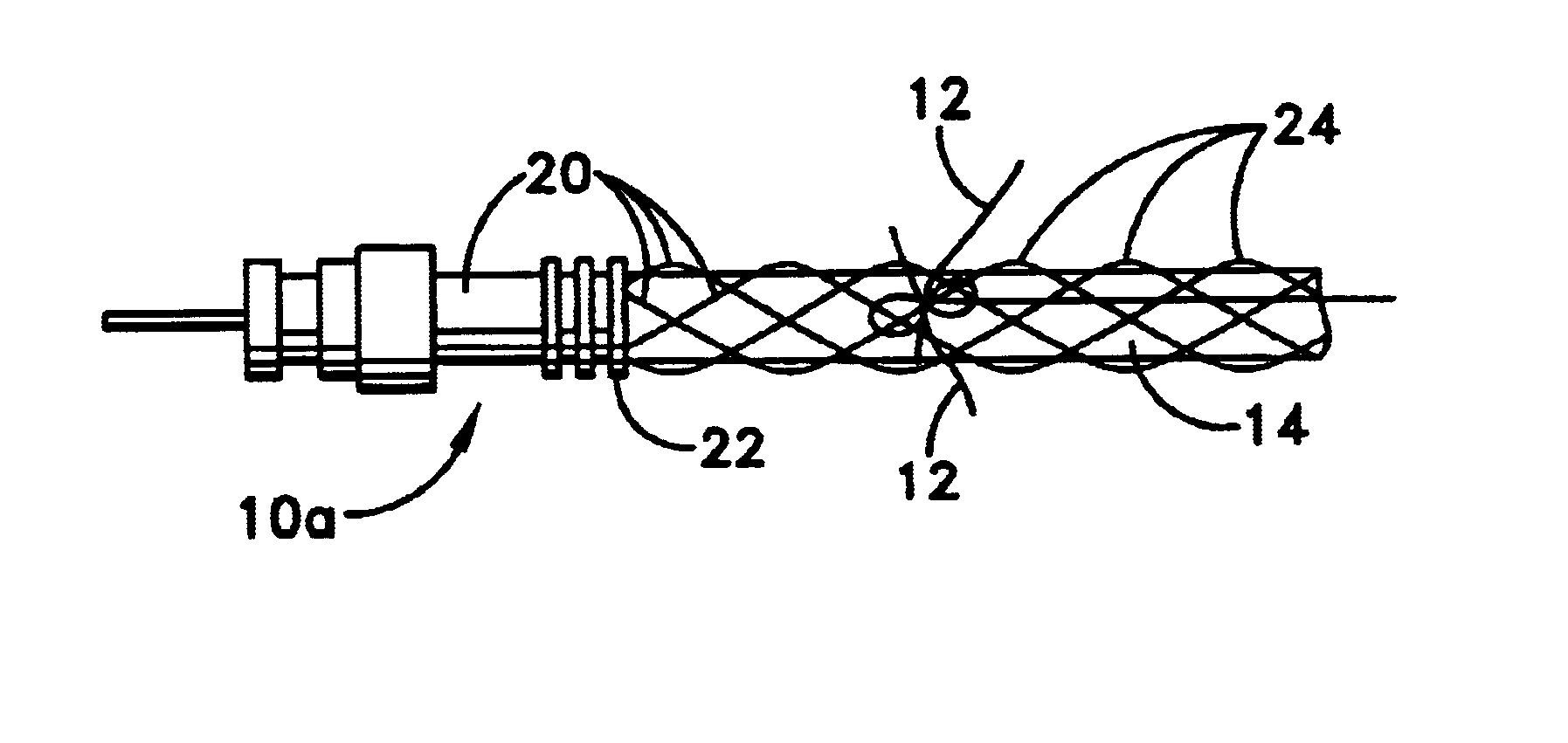

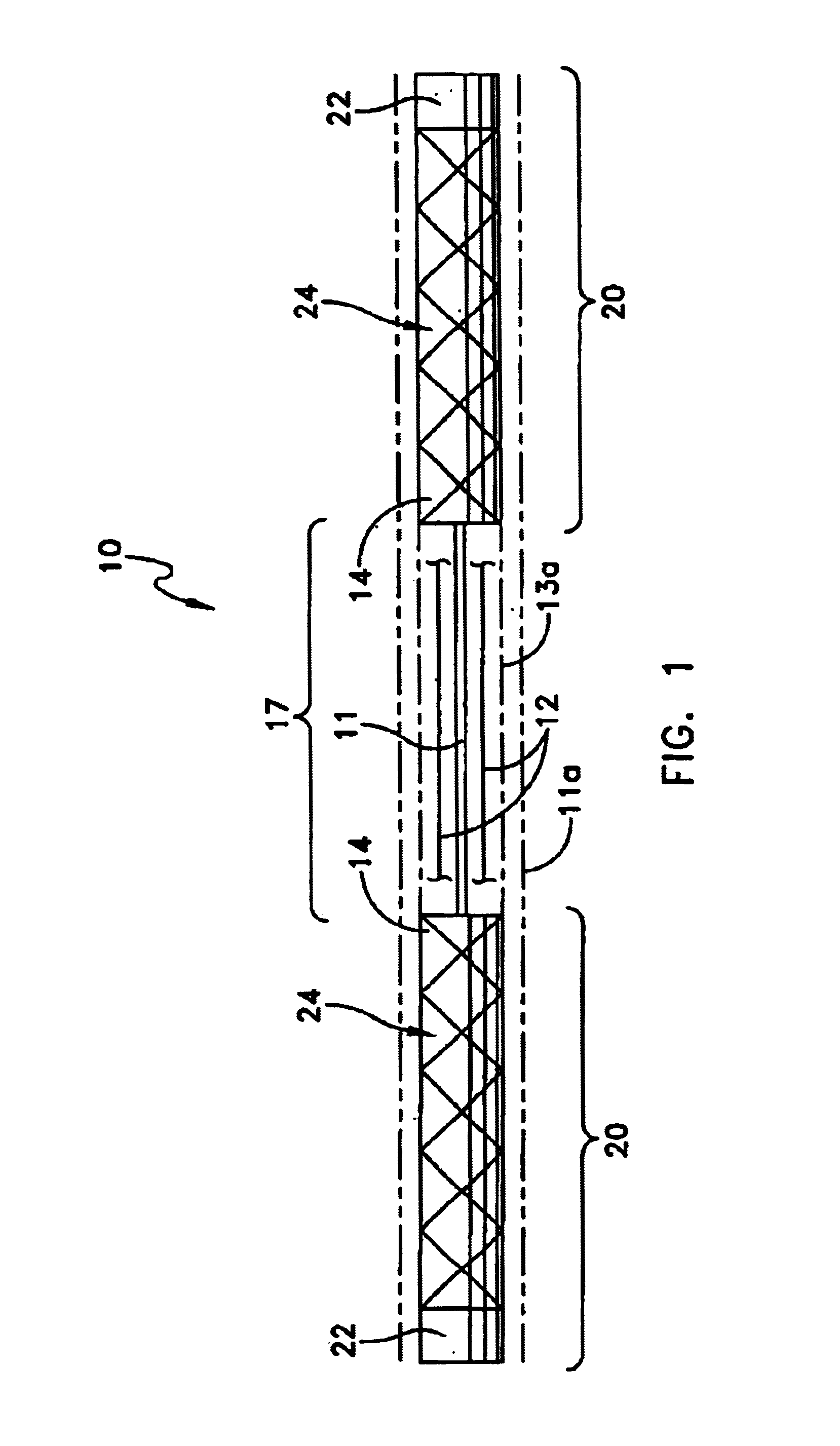

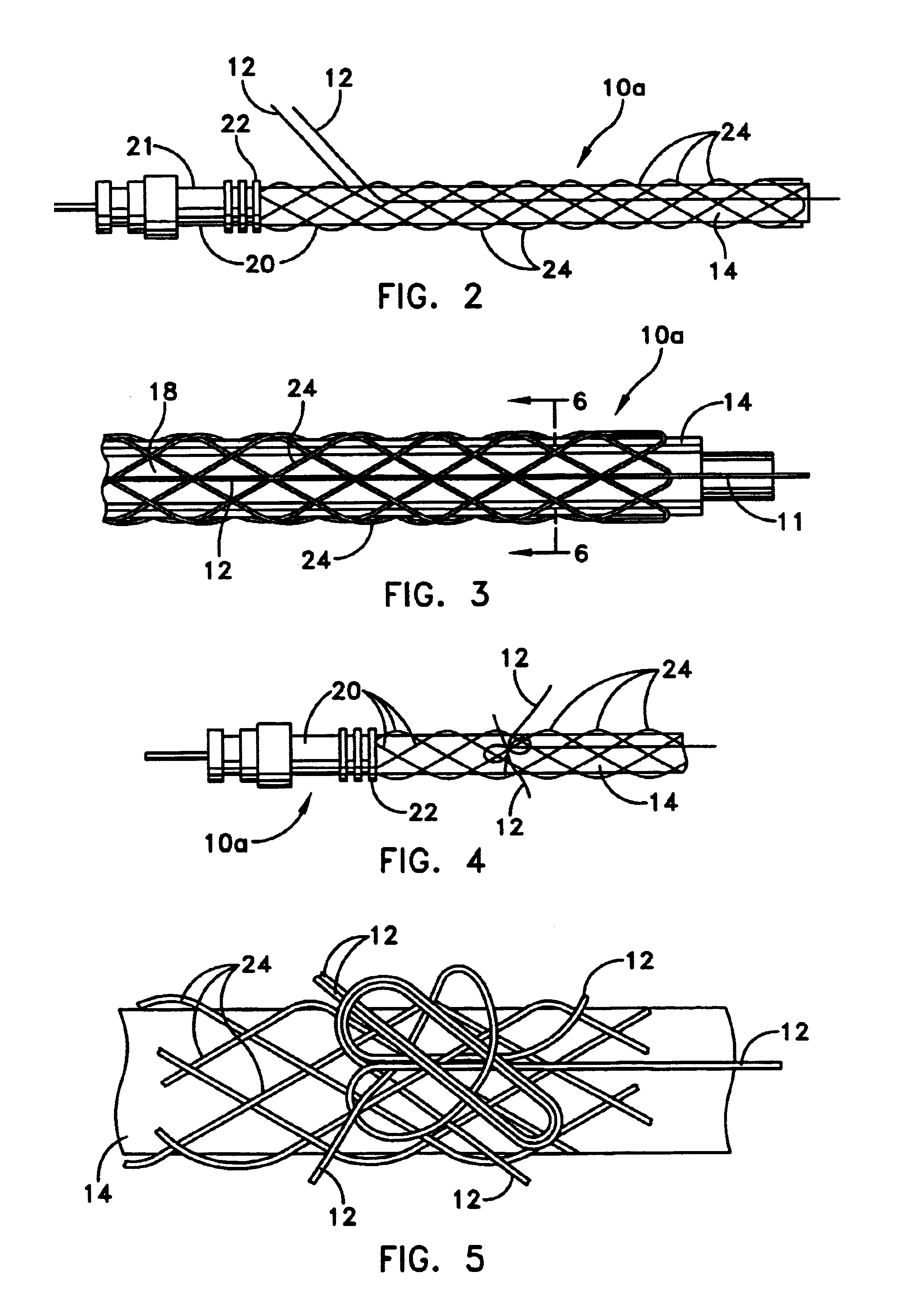

Strength strand construction for a longitudinal section of a cable

InactiveUS6992253B1Simple designHigh tensile strengthElectrically conductive connectionsAntenna adaptation in movable bodiesCoaxial cableCoaxial line

An assembly including a span of microwave signals flexible coaxial line, or other form energy transmission media, is provided with generally coextensive, non-metallic longitudinal strength strands to render greater tensile strength to the assembly. Marginal axial end sections of a coaxial cable span are potted in respective polyurethane grip foundation having longitudinal grooves. The grip foundations are inserted into an open-mesh-sleeve type cable-end grip device. The strength strands are seated in the grooves and interlaced in and out of the openings in the open-mesh-sleeves of the grip devices. Co-adjacent marginal end portions of the strength strands are bundled beyond the interlacing, and knotted to the open-mesh-sleeves of the grip devices. In forming the knots the bundled marginal end portions of the strength strands are entwined and bound together and with a pair of the crossing strands of the open-mesh-sleeve.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Fiber optic cable for very-short-distance networks

A fiber optic cable includes a polymeric jacket defining an outer periphery and a cavity interior thereto, an optical fiber positioned within the cavity, and first and second longitudinal strength elements fully embedded in the jacket on opposite sides of the cavity from one another, where the strength elements define a bend axis of the cable passing there through that is orthogonal to the length of the cable, and the bend axis and the length of the cavity define a preferential plane for bending. The cable resists bending about a third axis that is orthogonal to the length of the cable and the bend axis, where the third axis and the length of the cable define a non-preferential plane for bending. The difference in flexural rigidity between the preferential and non-preferential planes limits formation of spontaneous knots in a coil of the cable while providing flexibility for ease of handling.

Owner:CORNING OPTICAL COMM LLC

Fiber reinforced composite liner for lining an existing conduit and method of manufacture

InactiveUS20050028880A1Increase stiffnessReduce thicknessUnderground chambersPipe elementsFiber bundleFiber-reinforced composite

A reinforced liner for cured in place pipe rehabilitation of an existing pipeline having a plurality of high-strength low-elongation fiber bundles disposed circumferentially around the tubular liner at both inner and outer surfaces of a resin absorbent layer of the liner is provided. The bundles of reinforcing fibers are continuous lengths of high modulus fibers laid circumferentially with the ability to stretch to accommodate variations in host pipe diameter. The fibers on the inner surface are secured to a porous scrim to form an inner tubular reinforcing layer. A resin absorbent layer is formed into a tube about the inner layer. An outer layer of bundles of reinforcing fiber are formed into a tube about the absorbent layer. An outer impermeable tubular layer is wrapped around the inner layers. The reinforcing layer may include longitudinal reinforcing fiber in either or both reinforcing layers to increase the longitudinal strength of the liner.

Owner:INA ACQUISITION

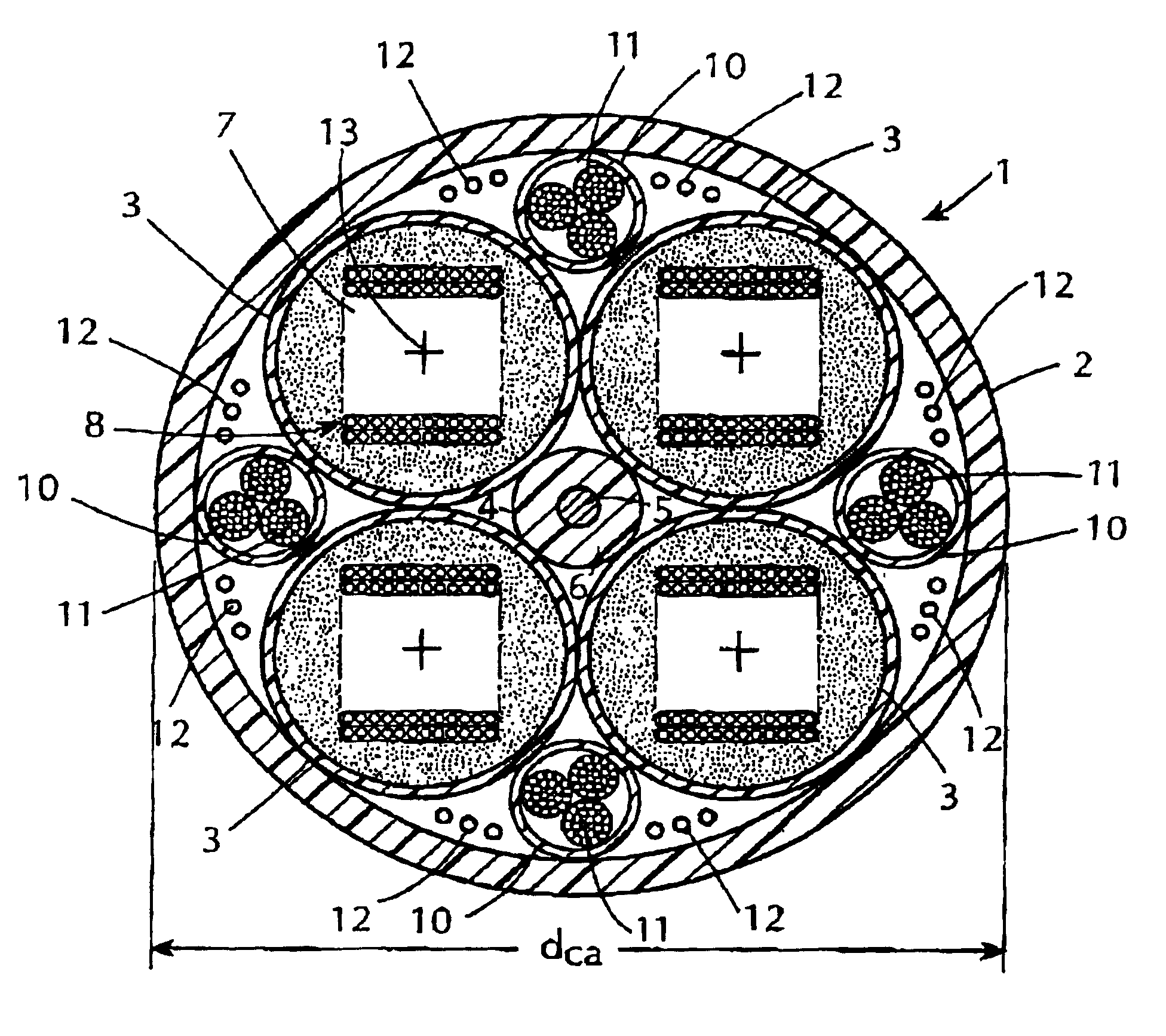

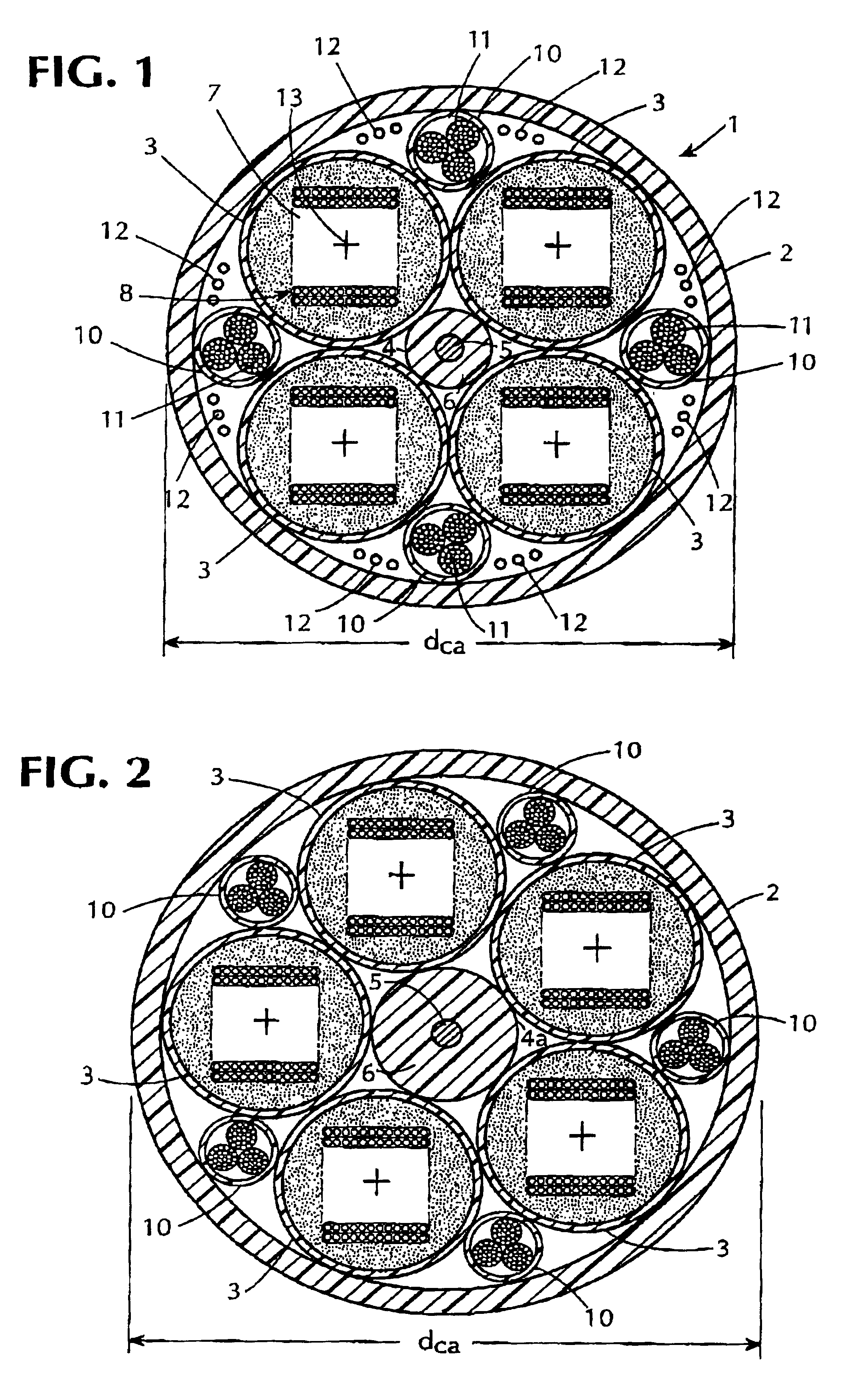

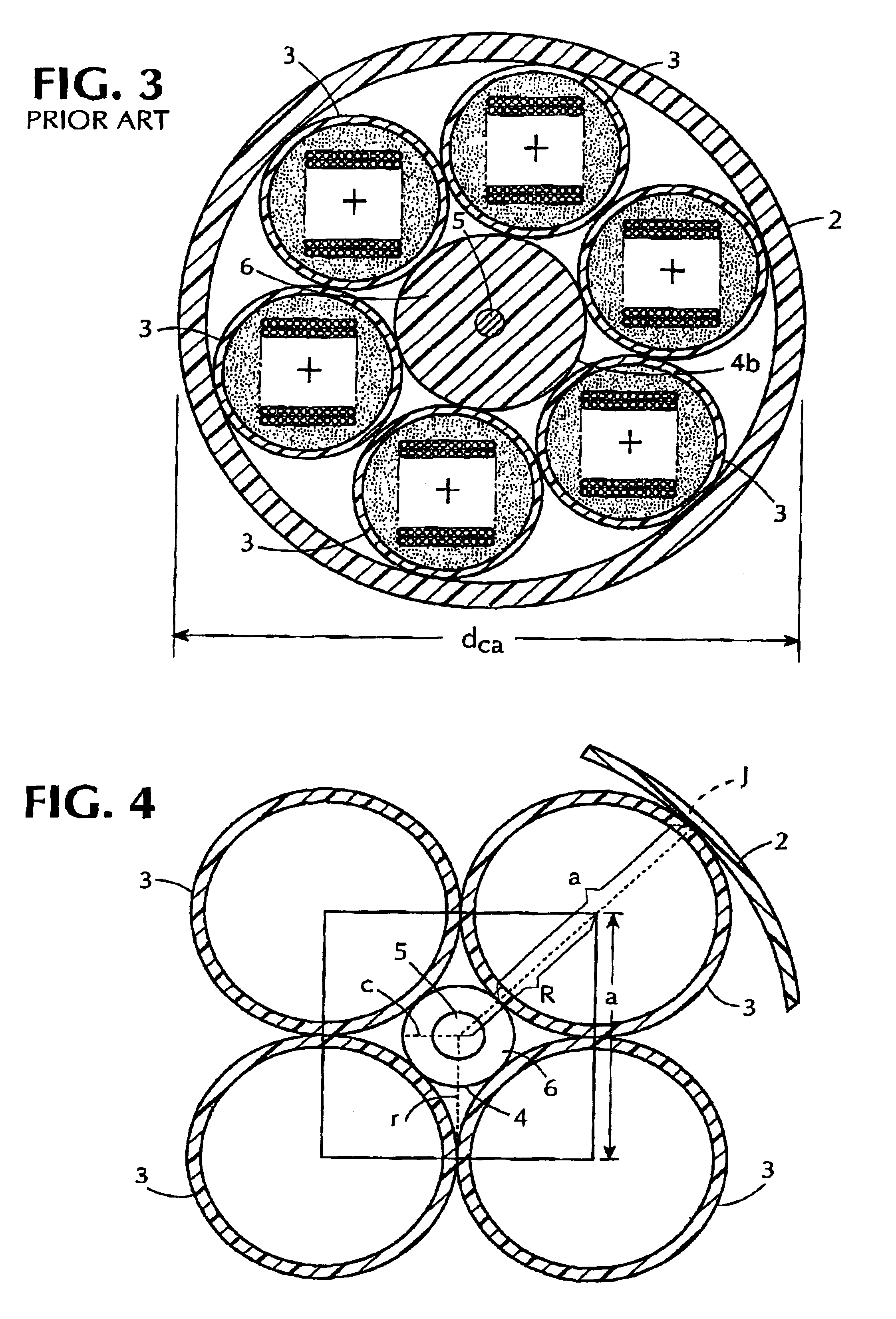

High fiber count optical fiber cable with buffer tubes around central strength member

InactiveUS6870995B2Increase the number ofReduce the overall diameterFibre mechanical structuresFiberFill factor

Optical fiber cable with a central strength member structure and with four or five buffer tubes each loosely receiving optical fiber ribbons in a stack and is disposed around and contacting the strength member. The optical fiber count is in excess of 1000 and the fill factor is not greater than 85% in a two inch duct. Each buffer tube contacts adjacent buffer tubes, and the buffer tubes are encircled by a jacket. Optionally, spaces bounded by pairs of buffer tubes and the jacket have optical fibers therein and can also include flexible longitudinal strength members and / or water blocking filaments. Preferably, the strength member structure and / or the buffer tubes are encircled by a water blocking tape. The optical fiber ribbons in the stacks can include different numbers of fibers, and hence, can have different width.

Owner:PRYSMIAN COMM CABLES & SYST USA LLC

Fiber reinforced composite liner for lining an existing conduit and method of manufacture

InactiveUS6923217B2Increase stiffnessReduce thicknessUnderground chambersPipe elementsFiber bundleHigh intensity

A reinforced liner for cured in place pipe rehabilitation of an existing pipeline having a plurality of high-strength low-elongation fiber bundles disposed circumferentially around the tubular liner at both inner and outer surfaces of a resin absorbent layer of the liner is provided. The bundles of reinforcing fibers are continuous lengths of high modulus fibers laid circumferentially with the ability to stretch to accommodate variations in host pipe diameter. The fibers on the inner surface are secured to a porous scrim to form an inner tubular reinforcing layer. A resin absorbent layer is formed into a tube about the inner layer. An outer layer of bundles of reinforcing fiber are formed into a tube about the absorbent layer. An outer impermeable tubular layer is wrapped around the inner layers. The reinforcing layer may include longitudinal reinforcing fiber in either or both reinforcing layers to increase the longitudinal strength of the liner.

Owner:INA ACQUISITION

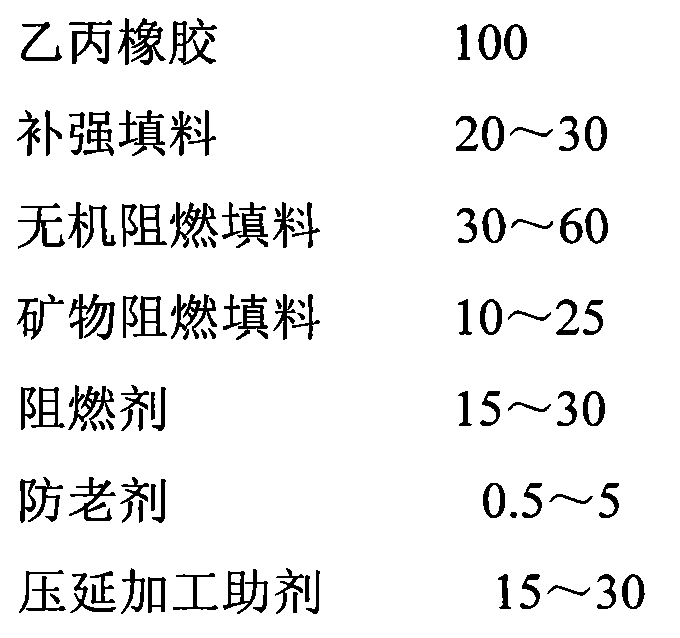

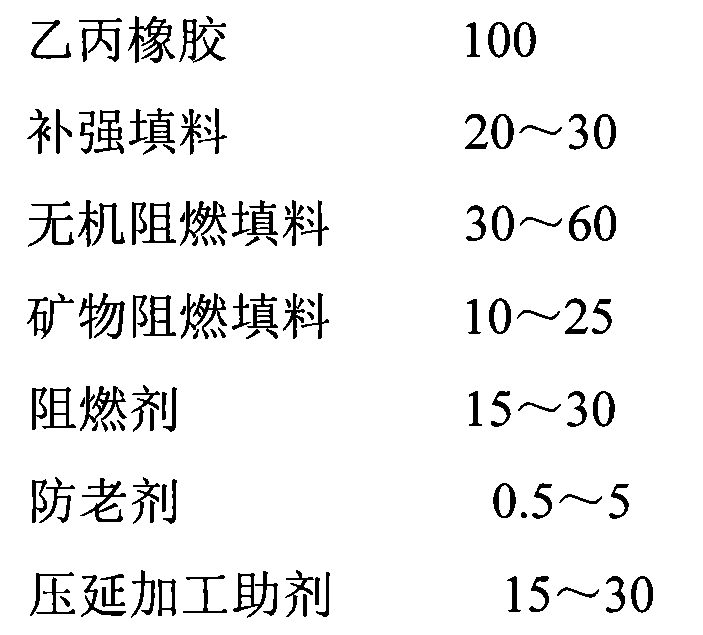

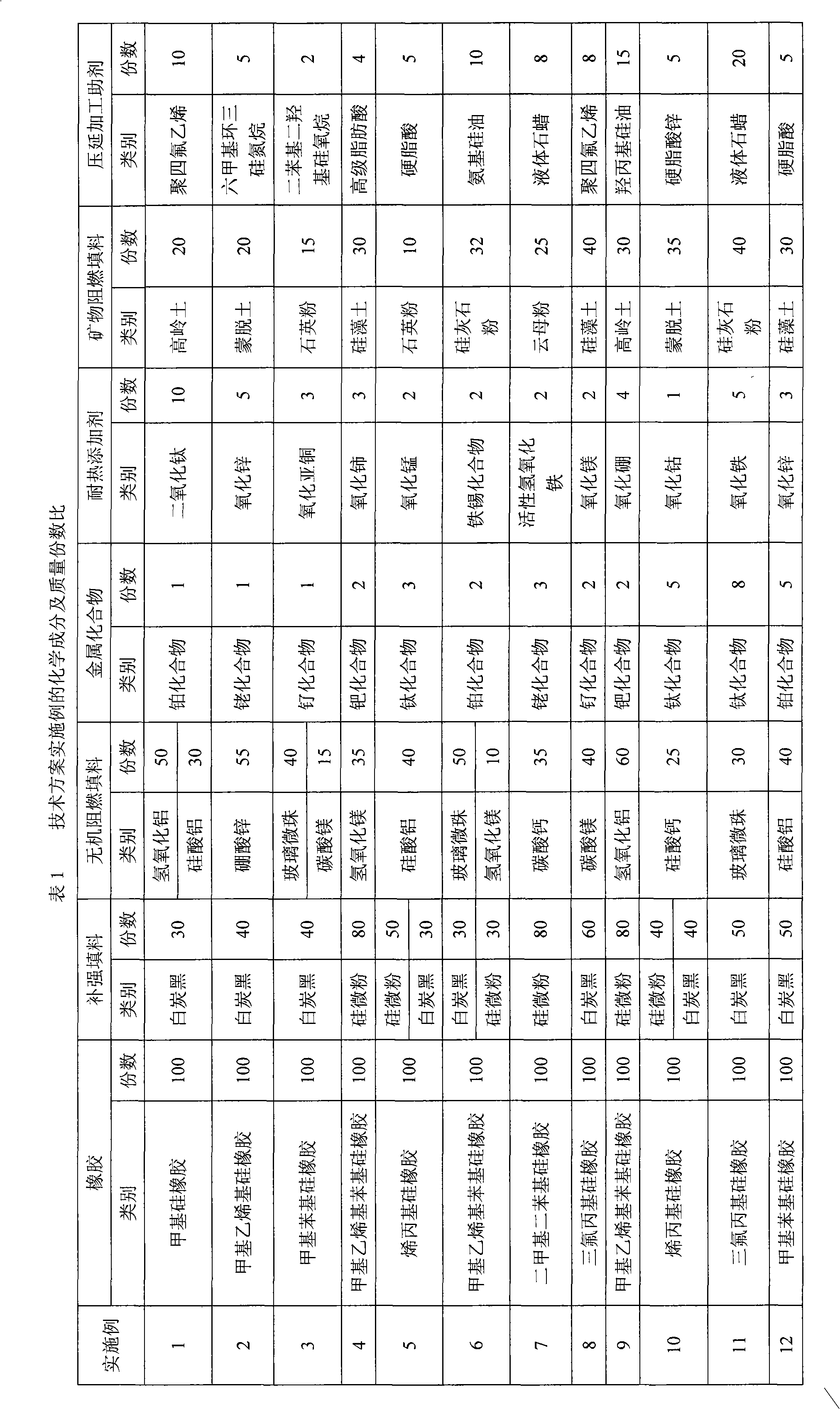

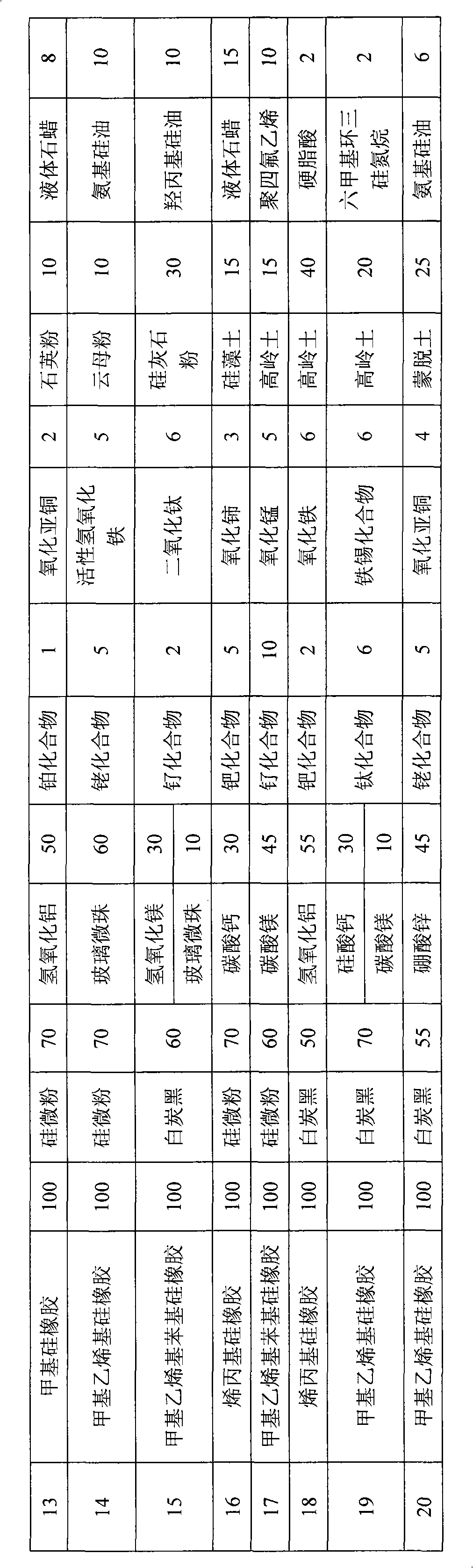

Preparation method for inflaming retarding ethylene propylene rubber tent cloth

The invention belongs to the technical field of rubber materials, and relates to inflaming retarding ethylene propylene rubber tent cloth and a preparation method for the inflaming retarding ethylene propylene rubber tent cloth. The tent cloth adopts ethylene propylene rubber to serve as base rubber, the ethylene propylene rubber is matched with reinforcing packing, inorganic inflaming retarding packing, mineral inflaming retarding packing, a fire retardant, an anti-aging agent system, a vulcanization system and a rolling processing assistant agent to prepare the inflaming retarding ethylene propylene rubber which is in composition with reinforced fabric through a rolling machine, and the ethylene propylene rubber tent cloth is prepared after forming vulcanization. The oxygen index of the prepared rubber tent cloth can reach 30 above, 45-degree burning performance can reach a fire-retardant level, longitudinal strength>=3000N / 30mm, latitudinal strength>=3000N / 30mm, and fatigue performance is excellent. The tent cloth can achieve non-breakage after 20% tension for 50 thousand times and has good ozone resistance, climate resistance, hot air aging resistance, chemical medium resistance, water resistance and electricity insulation performance, and the temperature range for use is from-60 DEGC to 120 DEGC. The preparation method for the inflaming retarding ethylene propylene rubber tent cloth can be widely applied to rubber wind shields of low speed trains and low-speed-trains-to-be and rubber cloth for vessels.

Owner:BAIMTEC MATERIAL CO LTD

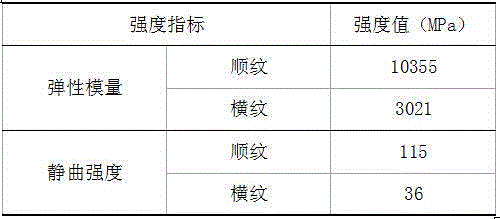

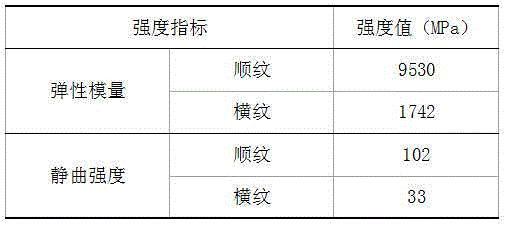

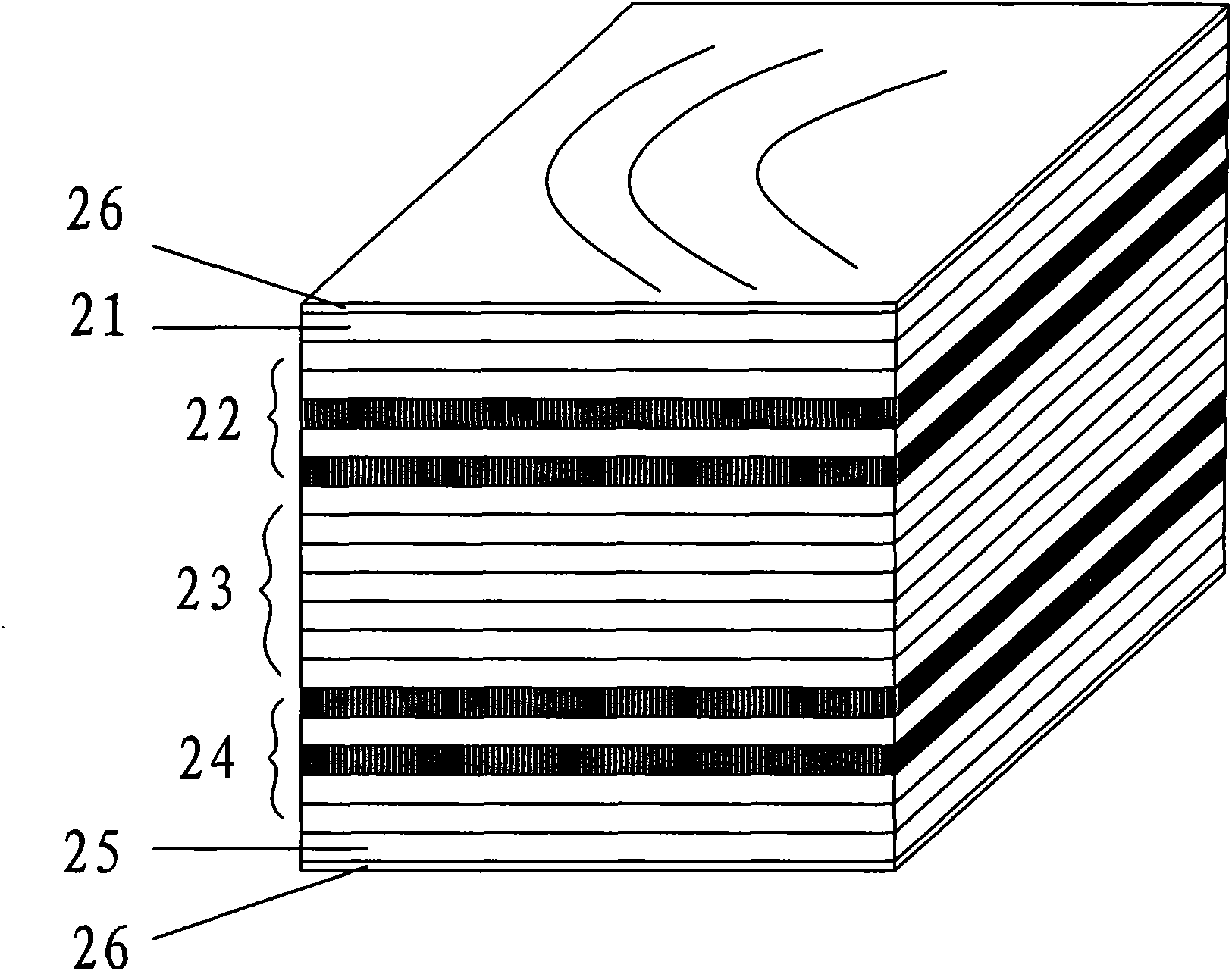

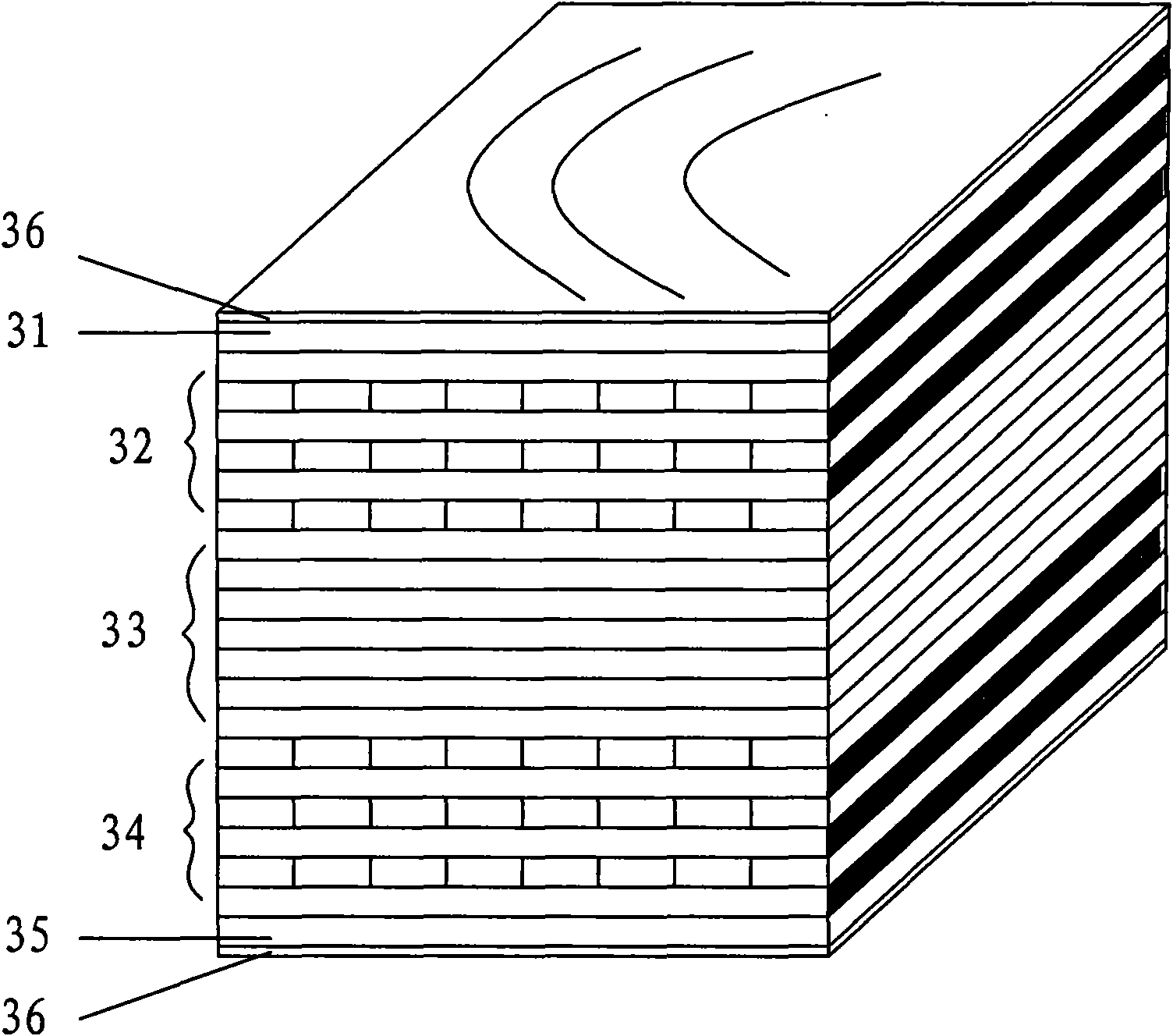

Manufacturing method of bamboo-wood composite laminated timber

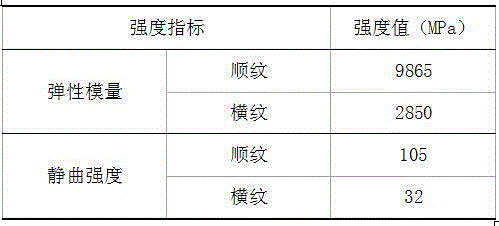

InactiveCN105196368AImprove longitudinal strengthReduce horizontalCane mechanical workingWood veneer joiningComposite laminatesFiber array

The invention provides a manufacturing method of a bamboo-wood composite laminated timber and belongs to the technical field of bamboo-wood processing. The manufacturing method comprises the following process steps: (1) preparing raw materials; (2) drying; (3) braiding bamboo bundles; (4) immersing in glue; (5) drying; (6) assembling; (7) prepressing; (8) hot pressing; and (9) ageing. Compared with a traditional process for manufacturing recombined bamboo by adopting a mold pressing manner, mechanization is realized in a manufacturing process of a bamboo bundle single board; the spreading of a plate blank is similar with the spreading of a plywood; and compared with the spreading of a recombined bamboo plate blank, the spreading is relatively simple, and the production efficiency is relatively high. Meanwhile, a traditional recombined bamboo product has the same fiber array direction so that the longitudinal strength of the product is remarkably higher than transverse strength. According to the bamboo-wood composite material manufactured by the manufacturing method, the method is carried out by symmetrically assembling the bamboo bundle single board and a wood single board, so that the difference of the transverse strength and the longitudinal strength of the material is reduced and the transverse strength is remarkably improved.

Owner:国家林业局竹子研究开发中心 +1

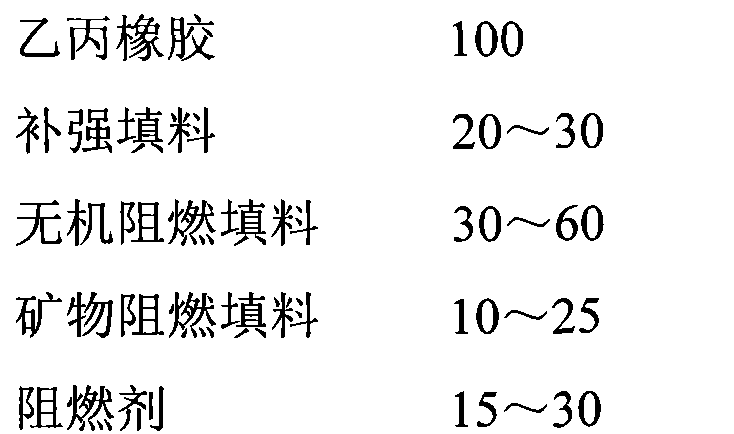

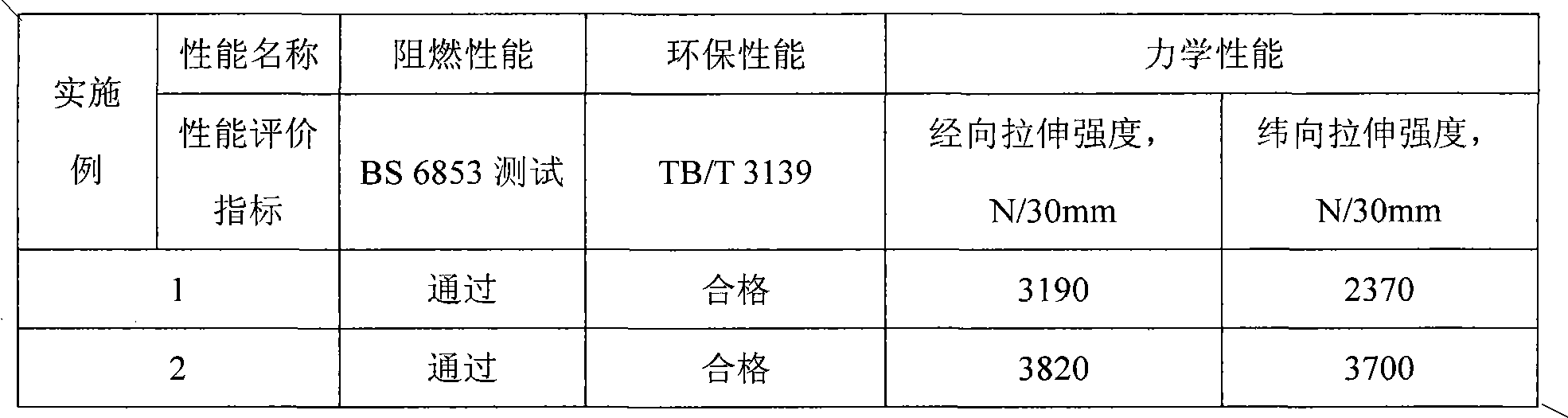

Process for preparing environment-friendly silicon rubber shed or awning cloth

ActiveCN102002863AExcellent ultra-low smokeImprove environmental friendlinessHeating/cooling textile fabricsRubber layered productsCode of practicePolymer science

The invention discloses a process for preparing environment-friendly silicon rubber shed or awning cloth. The process comprises the following steps of: matching silicon rubber serving as a base with a reinforcing filler, an inorganic flame-retardant filler, a mineral flame-retardant filler, a metallic compound, a heat-resistant additive and a rolling aid to prepare flame-retardant silicon rubber;compounding the flame-retardant silicon rubber with a single-layer or multi-layer reinforced fabric treated by a coupling agent; and vulcanizing to prepare the silicon rubber shed (awning) cloth witha sandwich structure. The combustion performance of the prepared silicon rubber shed (awning) cloth passes Britain BS 6853 Code of Practice for Fire Precautions in the Design and Construction of Passenger Carrying Trains, and the silicon rubber shed (awning) cloth passes the certification of TB / T 3193 Decorating Materials and Indoor Air Limit of Harmful Substance for Railway Locomotive and Vehicle, and has the longitudinal strength of more than or equal to 3,000K / 30mm, the latitudinal strength of more than or equal to 2,300K / 30mm, good sealing property, high and low temperature resistance andanti-fatigue performance. Compared with the prior art, the environment-friendly silicon rubber shed or awning cloth comes up to or exceeds the similar products abroad, fills a blank in the field of China, and can be widely applied to rubber vestibule diaphragms at ends of underground and ground high-speed and superspeed rail trains.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

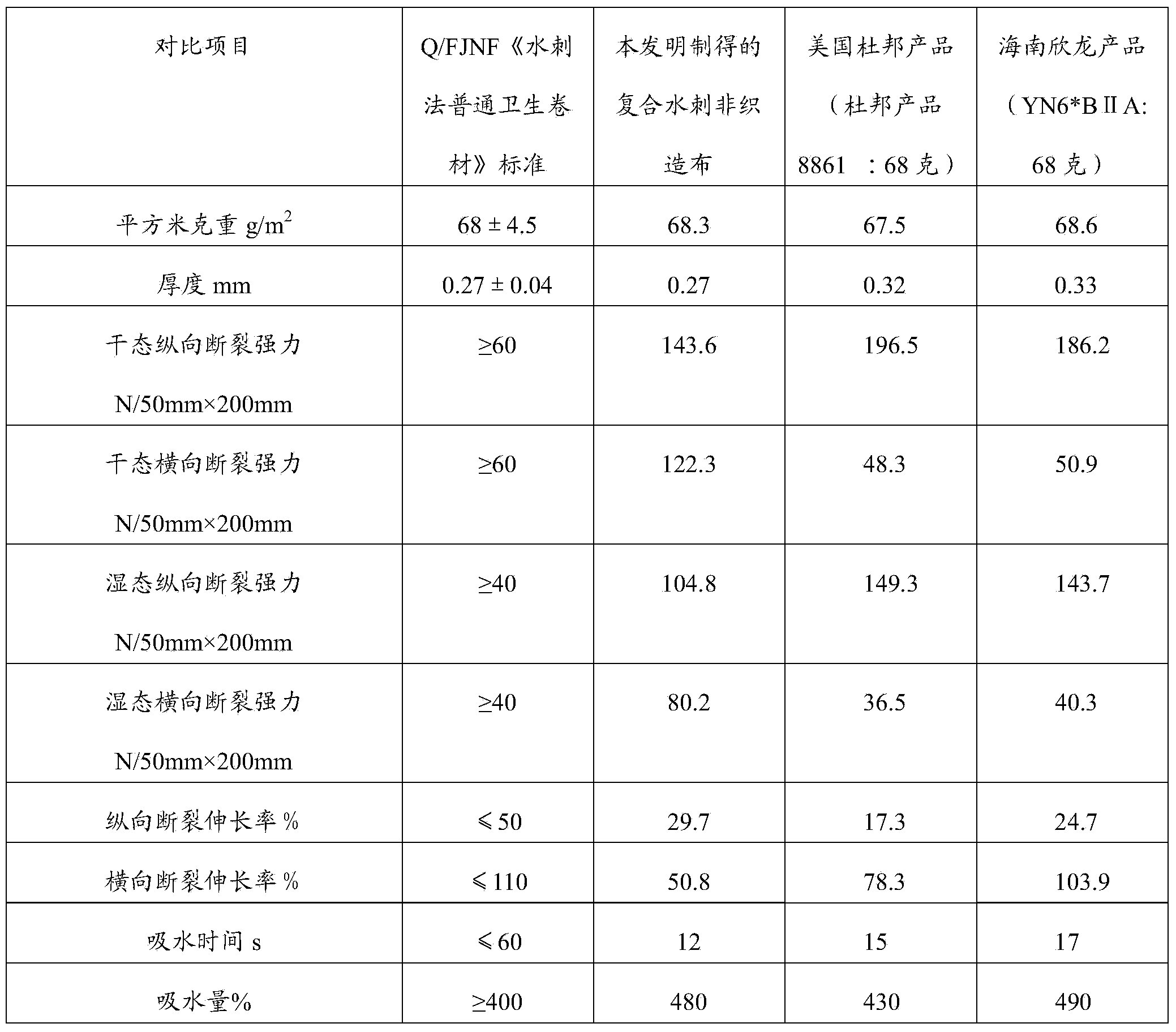

Composite spunlaced nonwoven fabric and preparation method thereof

The invention relates to a composite spunlaced nonwoven fabric which comprises a wiping layer and a non-wiping layer, wherein the wiping layer is formed by 100% wood pulp paper material; the non-wiping layer is formed by 100% polyester fiber material; the non-wiping layer is manufactured by carrying out cross lapping and spunlace on the 100% polyester fiber; the wiping layer and the non-wiping layer are compounded together by spunlace. The invention also relates to a preparation method of the composite spunlaced nonwoven fabric. The ratio of the longitudinal strength to the transverse strength of the composite spunlaced nonwoven fabric is controlled to be less than 2: 1, and the longitudinal strength is close to the transverse strength, so that the composite spunlaced nonwoven fabric is not easily deformed; the CD transverse strength of the composite spunlaced nonwoven fabric reaches up to 100N / 5cm; the composite spunlaced nonwoven fabric is thin, does not drop scraps, and is soft after absorbing moisture and good in wiping property; the composite spunlaced nonwoven fabric is good in wear resistance, the wiping efficiency is increased by 20%, the service life is prolonged by 30%, and the service performance of wiping cloth is effectively improved.

Owner:福建福能南纺卫生材料有限公司

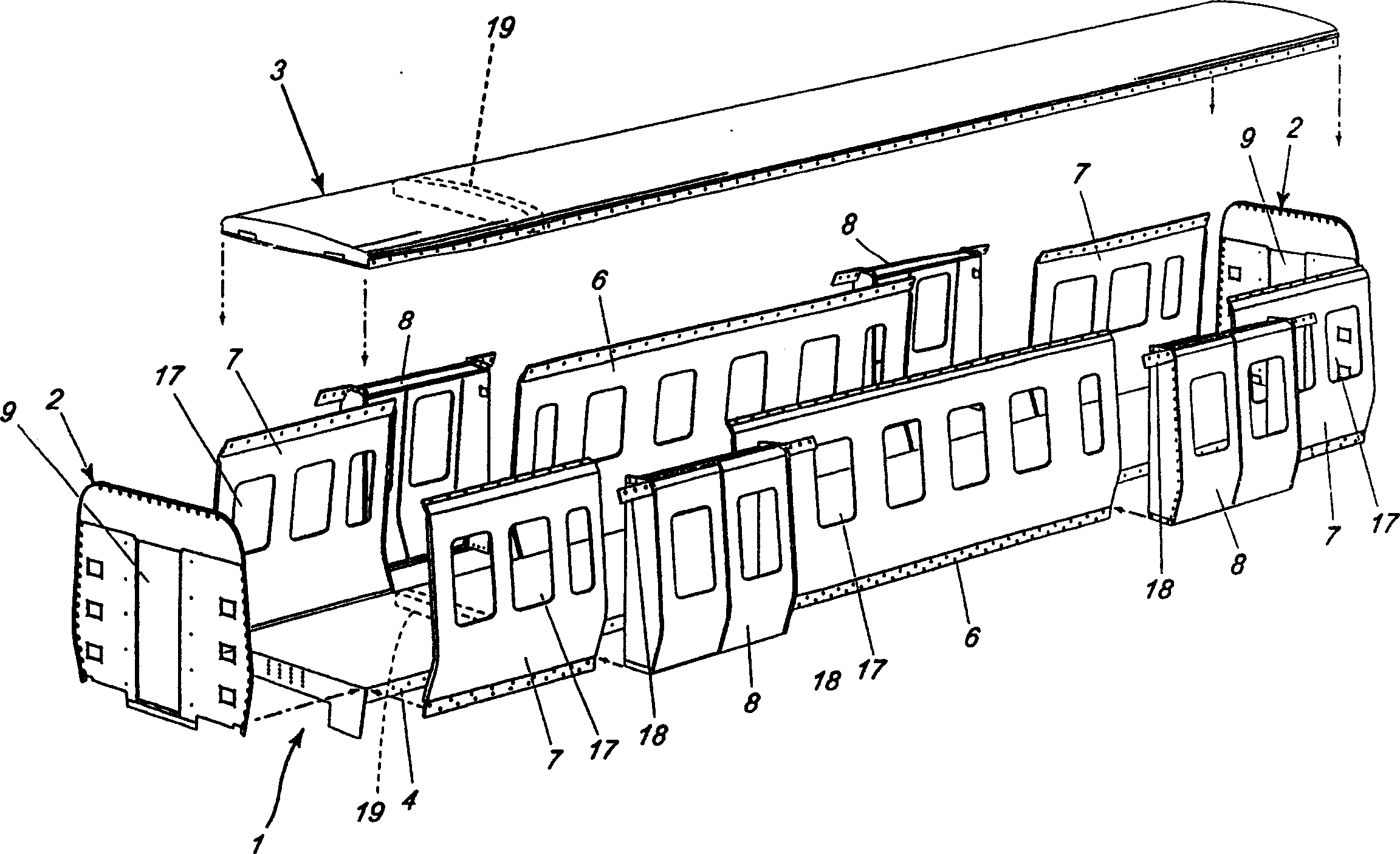

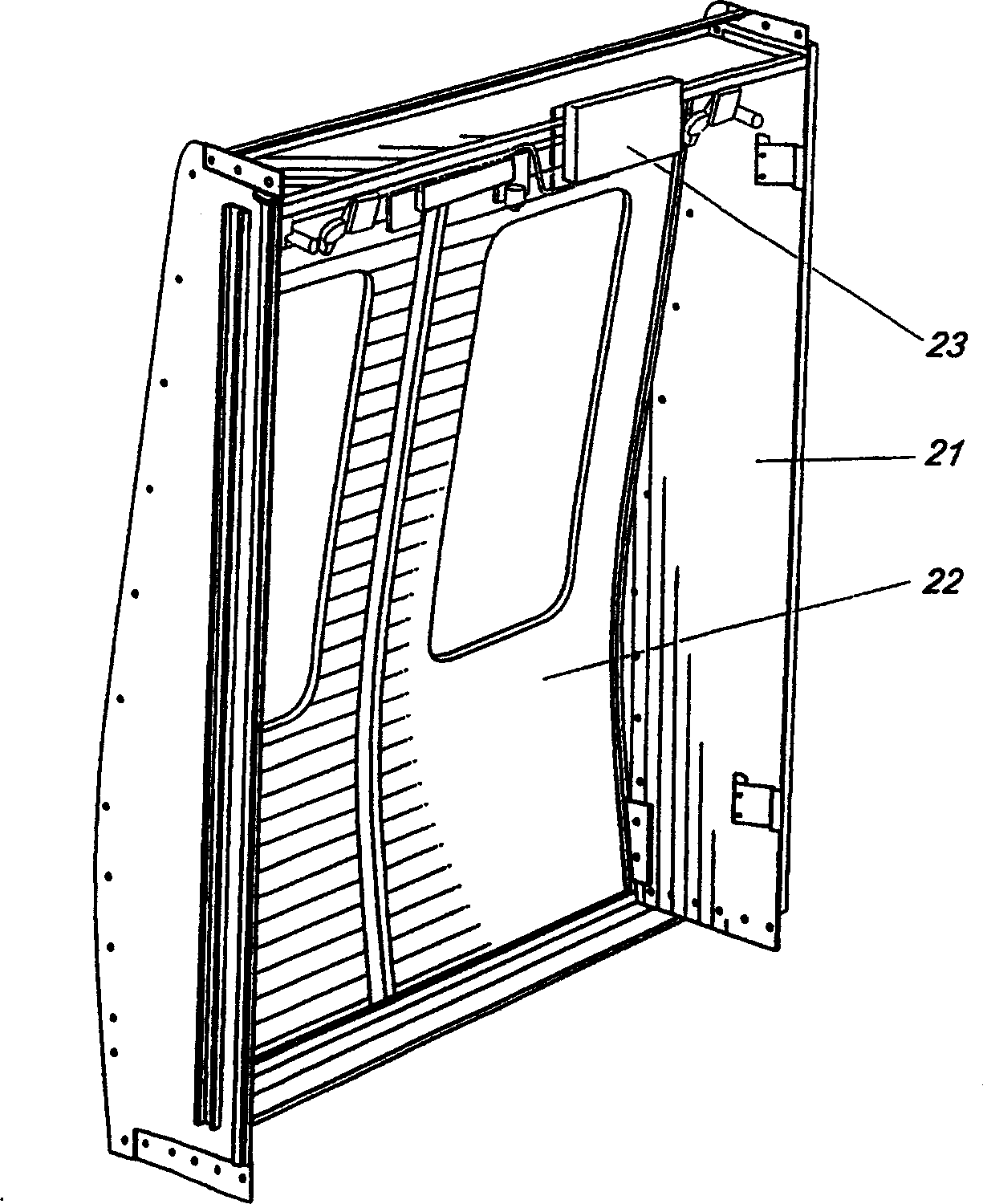

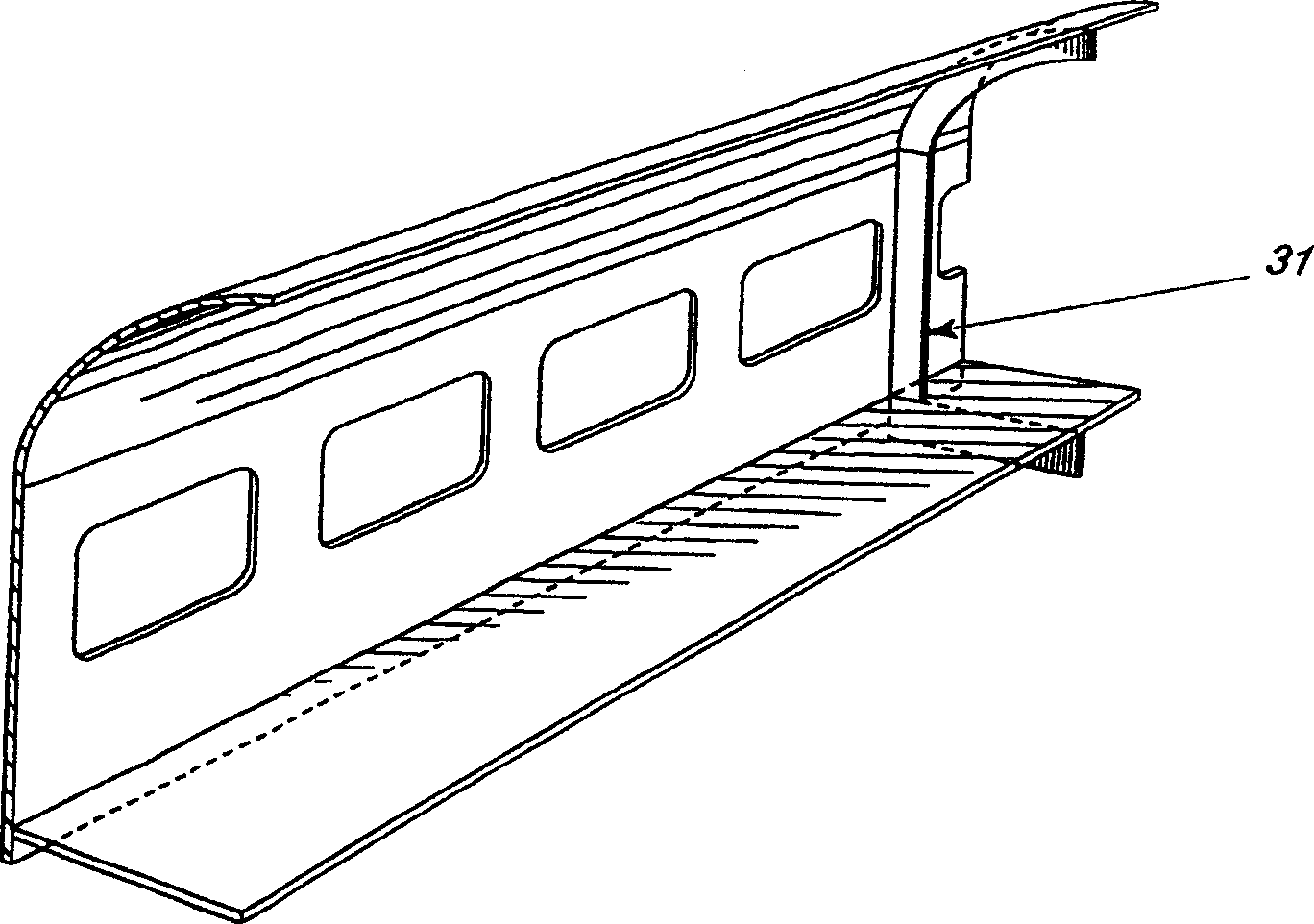

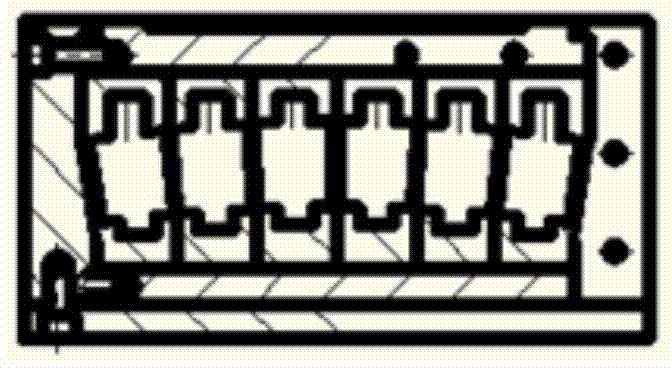

Rail vehicle carbody of modular construction

InactiveCN1489537AAvoid WeldingReduce weightAxle-box lubricationRailway bodiesModular constructionCar door

A carbody for a railbound vehicle of a modular construction comprising a floor module (1), a roof module (3), each forming single piece, self supporting structures, two end structures (2) and sides. The sides comprise vertical elements that are joint at the top to the roof module and at the bottom to the floor module and at the side to an adjoining vertical element or to an end structure. The vertical elements comprise wall modules (6, 7) and door modules (8). The door modules are self-supporting, structural parts mainly contributing to the cross-sectional strength of the vehicle, and the wall modules are thin, self-supporting structures and mainly contributes to the longitudinal strength of the vehicle. The door modules and said wall modules are the only structural parts of the sides. All joints are made with cold joining methods only.

Owner:BOMBARDIER TRANSPORTATION GMBH

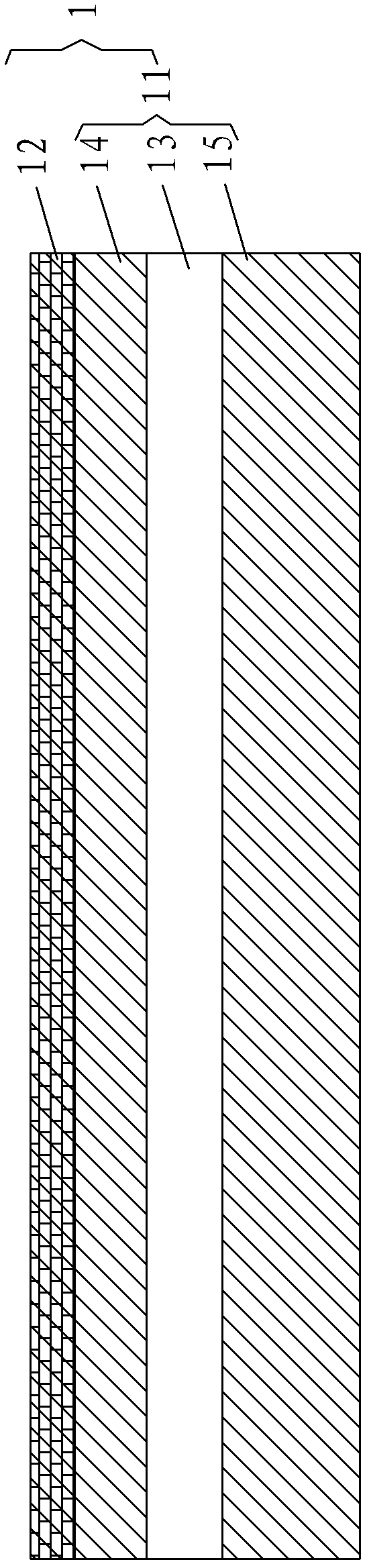

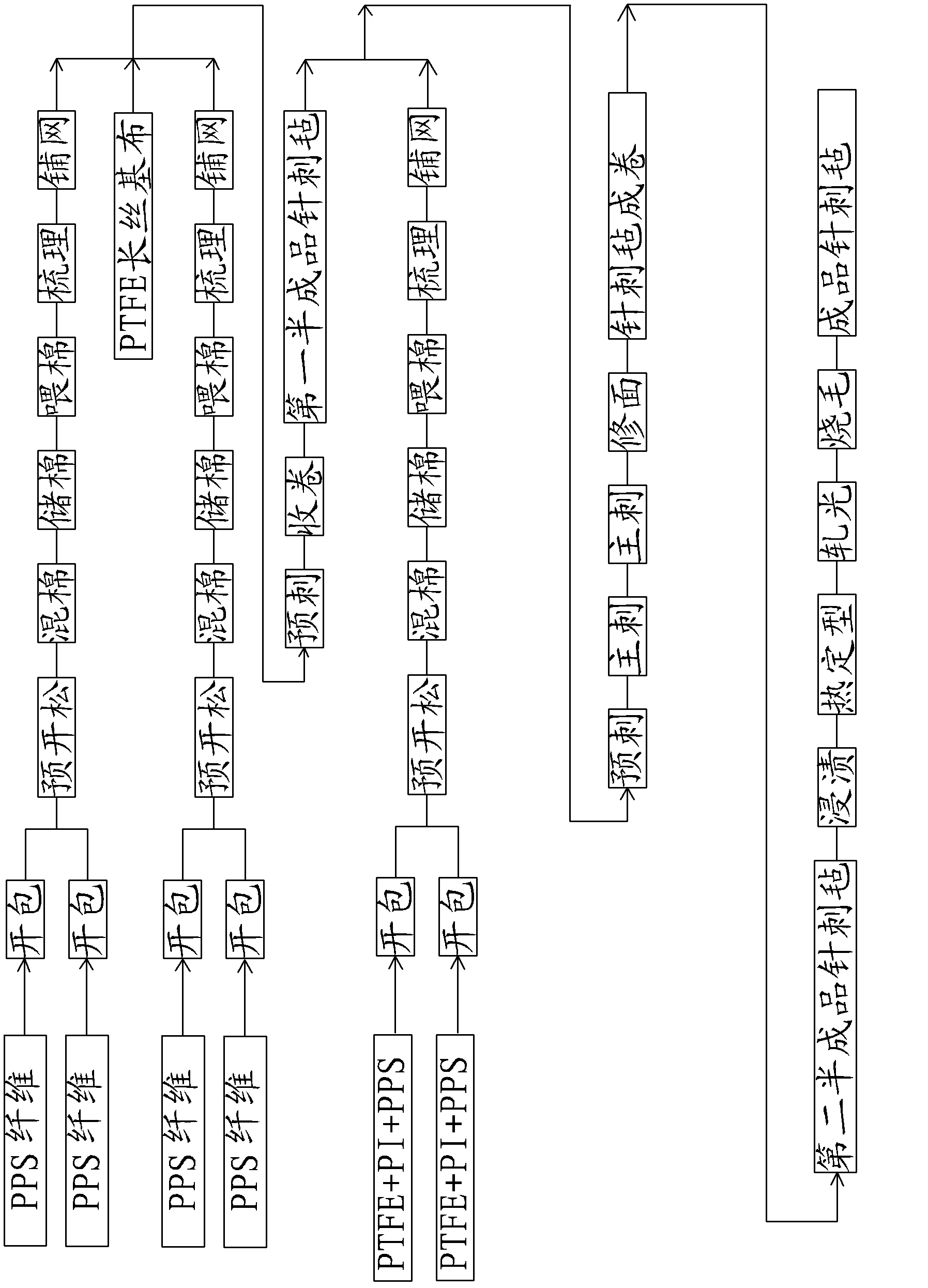

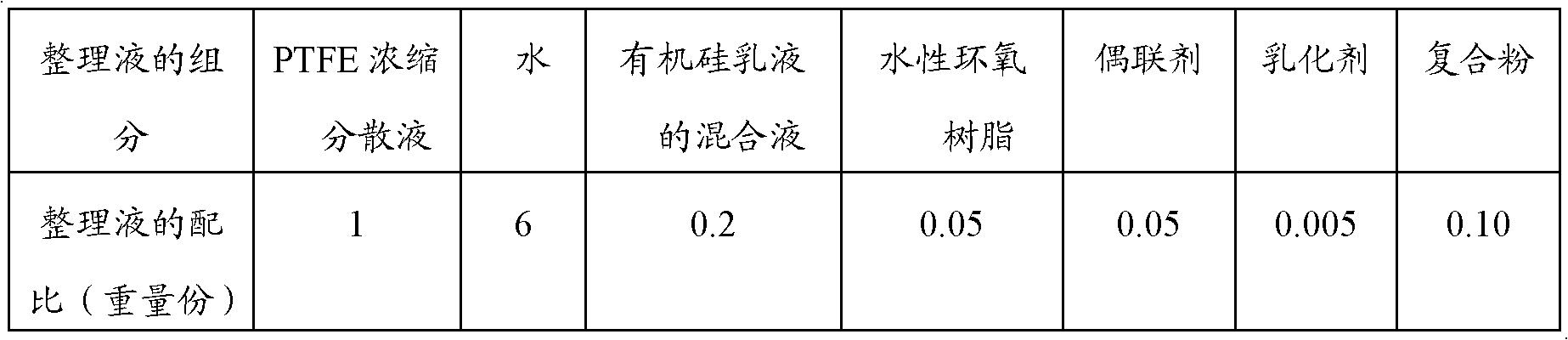

Special-purpose needled felt for complex condition coal fired power plants and preparation method thereof

ActiveCN102671467AExtended service lifeIncrease the instantaneous use temperatureFibre treatmentSingeingOxidation resistantEngineering

The invention discloses a special-purpose needled felt for complex condition coal fired power plants, which comprises a dust receiving surface, an auxiliary filter layer, an strengthen base cloth layer and a support layer which are orderly composited together by needling, wherein the dust receiving surface is blended by polyphenylene sulfite (PPS) fibers, polytetrafluoroethylene (PTFE) fibers and polyimide (PI) fibers according to proportion of 1:(0.2-0.5):(0.2-0.5), the auxiliary filter layer and the support layer are respectively needled by the PPS fibers, and the strengthen base cloth layer is interlaced by PTFE filament yarns in longitude and latitude. The invention further discloses a method for preparing the special-purpose needled felt for the complex condition coal fired power plants. The dust receiving surface is blended by the PPS fibers, the PTFE fibers and the PI fibers, thereby being low in cost, and increasing transverse and longitudinal strength of the special-purpose needled felt. Probability of intercept and filter precision of dust are increased through element felt preparation, immersion treatment, calendering processing and singeing process, thereby leading instantaneous using temperature of the special-purpose needled felt to increase and to be less affected by ozone, increasing oxidation resistance, prolonging service life, being further capable of improving strip ratio of the dust, increasing ventilation property of the special-purpose needled, and reducing operation energy consumption.

Owner:福建鑫华股份有限公司

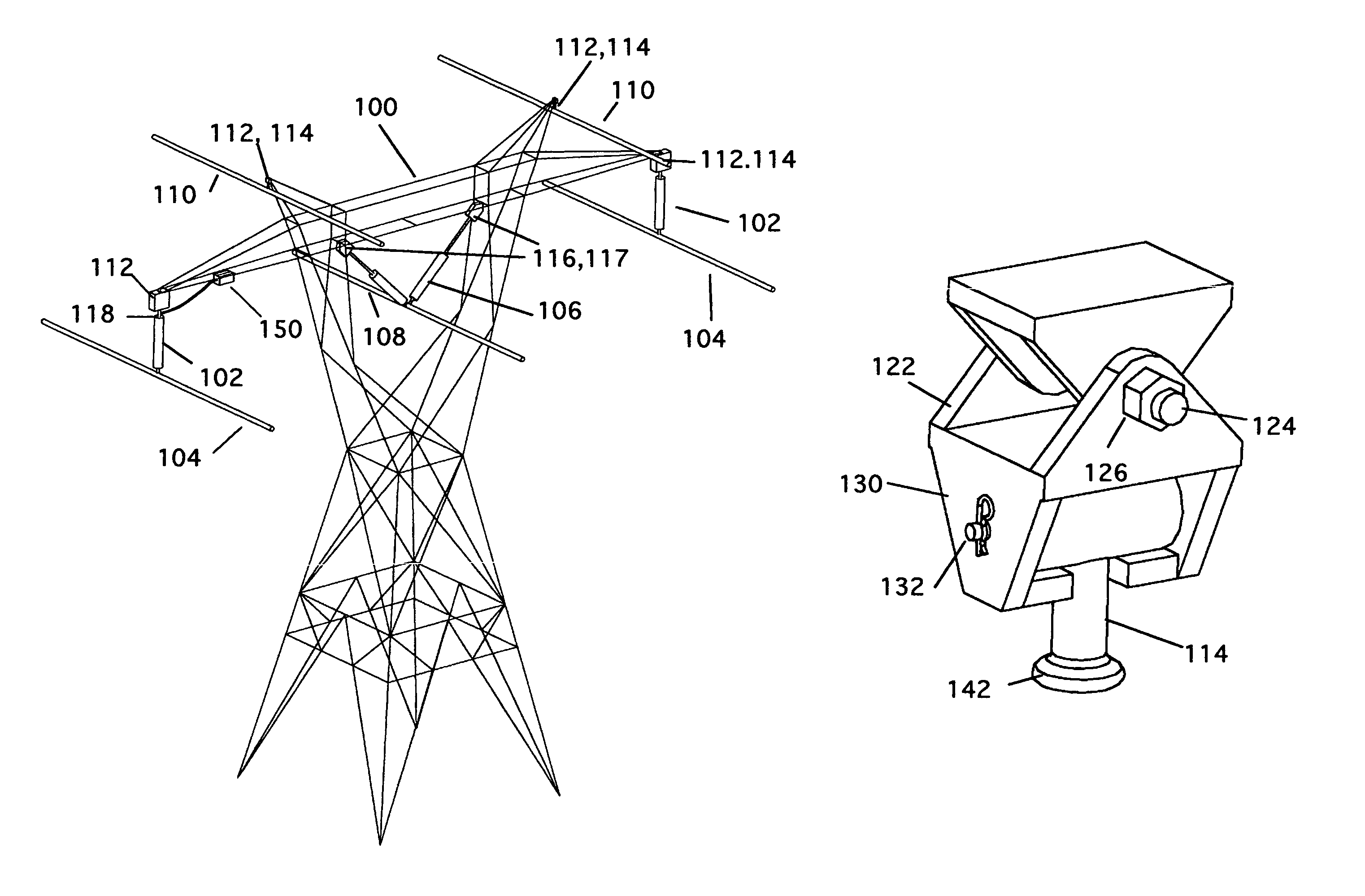

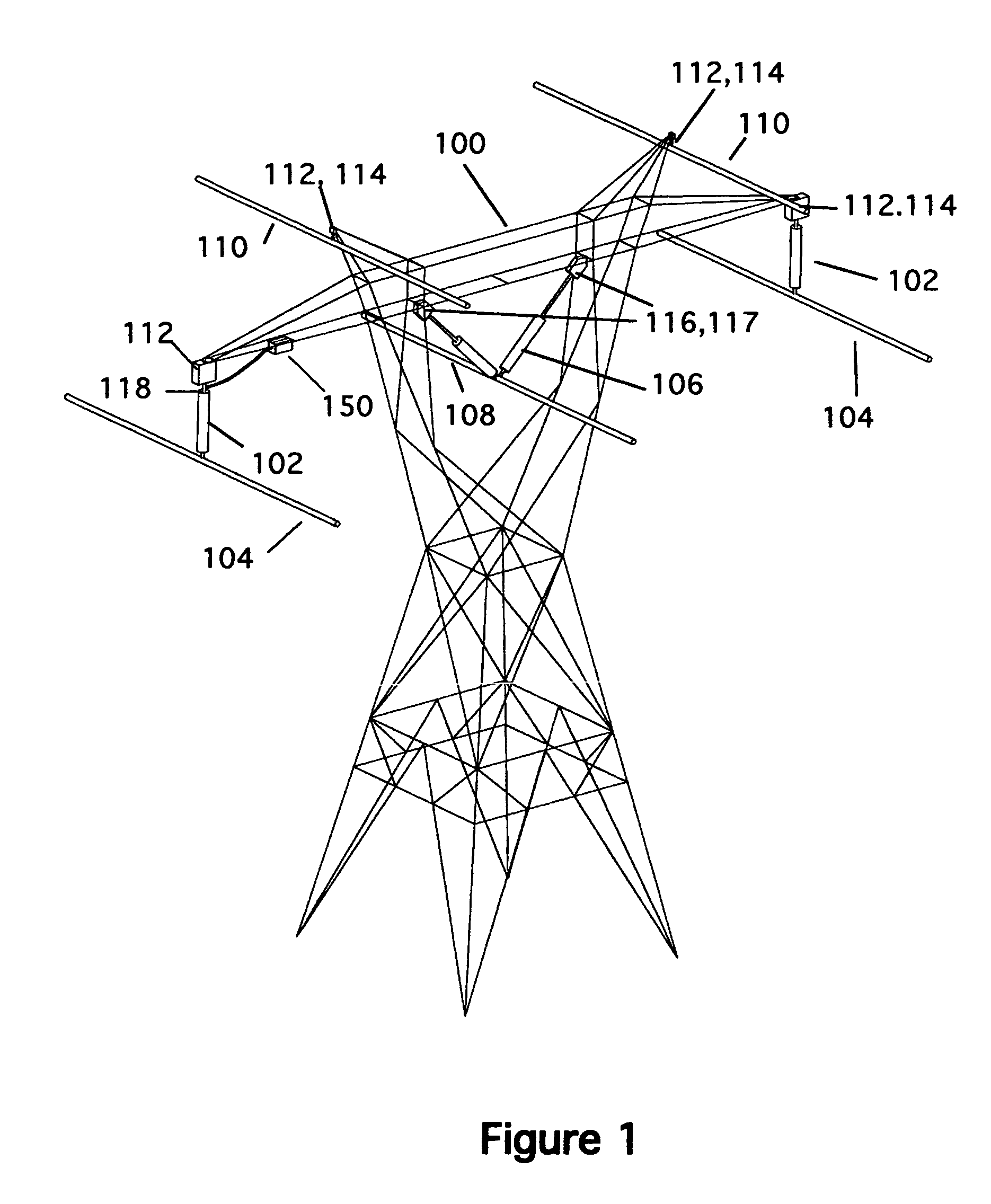

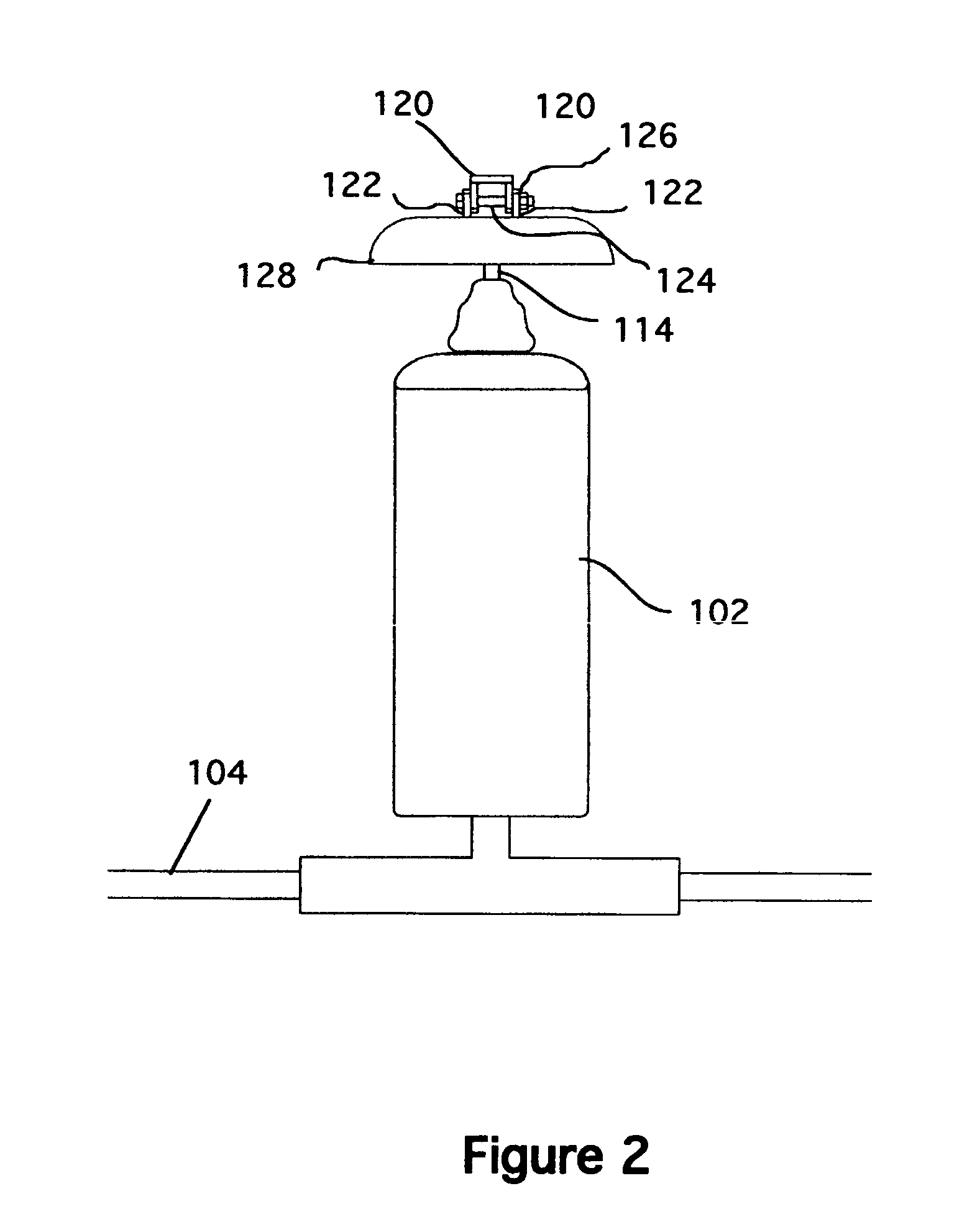

Longitudinal load limiting devices for transmission lines and the like

InactiveUS7732708B1Absorb energyPrevent freezingMaintaining distance between parallel conductorsPipe supportsEngineeringTower

A device for limiting loads on towers that limits loads only in the longitudinal direction and does not affect the manner in which vertical and transverse loads are resisted by the structure. The device incorporates a shield to prevent ice buildup that could affect its operation. It also has optional antifriction bearings to provide a consistent release force independent of the amount of ice that may accumulate on the wires. The device is of simple construction. The device includes an optional energy absorber, such as that used in U.S. Pat. No. 3,211,260 that can provide a resisting force that is within the longitudinal strength of the tower. The device includes both a mechanical fuse and an energy absorbing mechanism that is used to arrest the wire movement. The energy absorber can extend as much as 50 ft to safely absorb the energy released by broken wires with heavy ice coatings.

Owner:PEABODY ALAN B

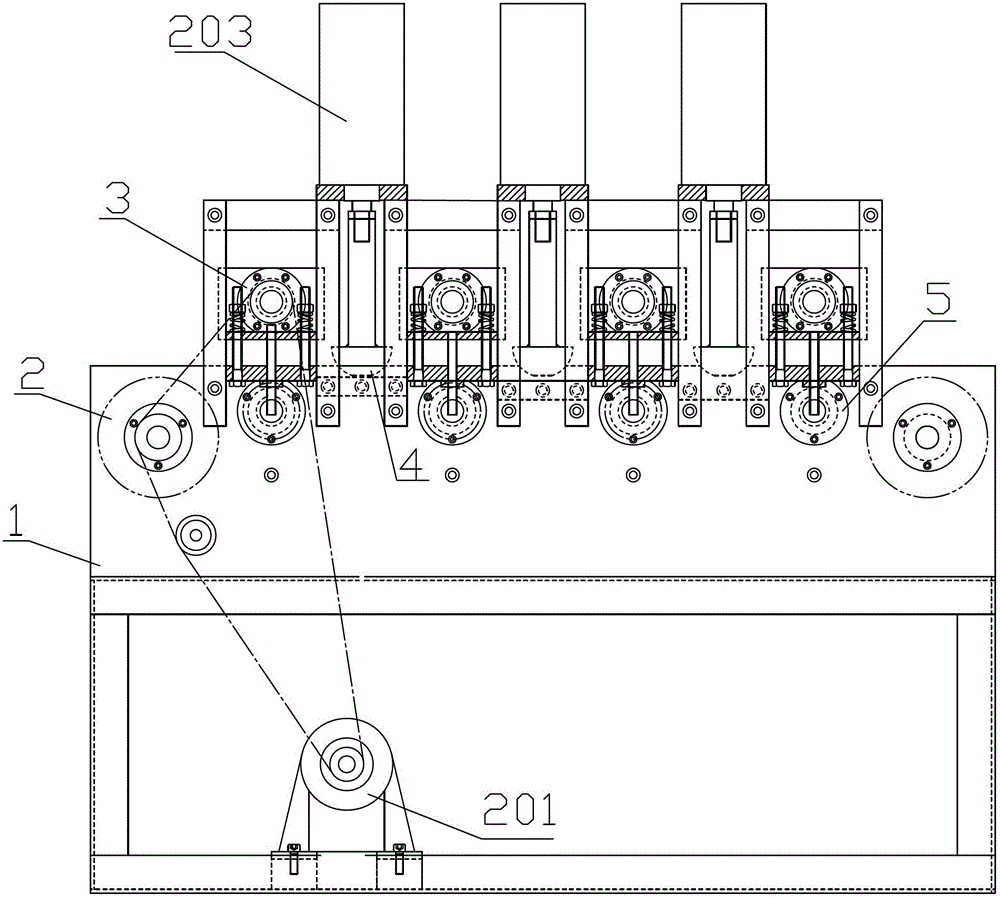

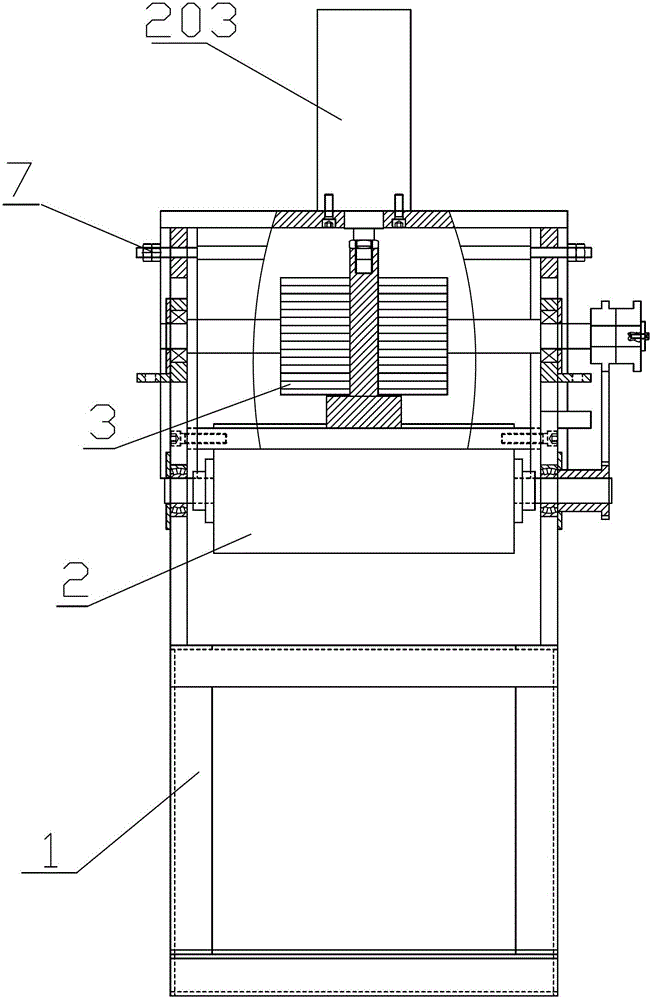

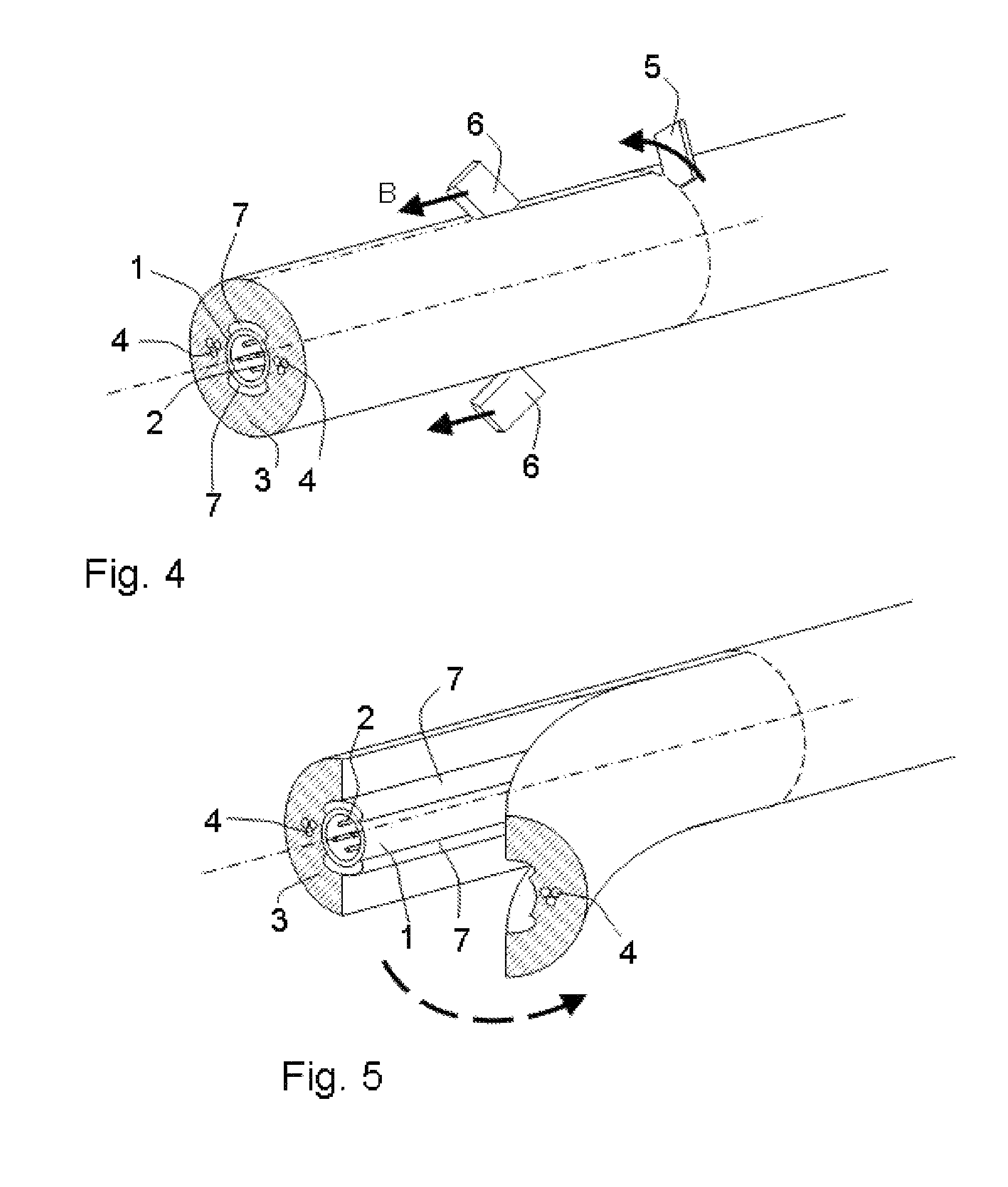

Bamboo fibrillating-rolling device

ActiveCN102909767ARealize productionReduced transverse strengthWood working apparatusFiber bundleModular design

A bamboo fibrillating-rolling device comprises a frame, a fibrillating mechanism, a rolling mechanism, a hammering mechanism, a skin-removing mechanism, a conveying mechanism and a power unit. The frame is provided with areas for fibrillating, rolling, hammering and skin removing. The fibrillating mechanism at least comprises one fibrillating roller set consisting of an upper and lower opposing paired fibrillating rollers, wherein at least the upper fibrillating roller is provided with fluffing teeth. The rolling mechanism consists of one or paired rolling rollers. The hammering mechanism comprises a plurality of hammers. The skin-removing mechanism is provided with metal wire brush rolls or scrapers for skin removing. The conveying mechanism is used to convey material to be processed to transversely pass through the areas for fibrillating, rolling, hammering and skin removing. The power unit powers the fibrillating mechanism, the rolling mechanism, the hammering mechanism, the skin-removing mechanism and the conveying mechanism respectively or simultaneously. The bamboo fibrillating-rolling device is available for efficiently producing bamboo fiber bundles with low transvers strength and reserved longitudinal strength. The skin-removing mechanism, the rolling mechanism, the fibrillating mechanism and the hammering mechanism are all in modular design and can be designed into a complete set for assembly and disassembly.

Owner:INT CENT FOR BAMBOO & RATTAN

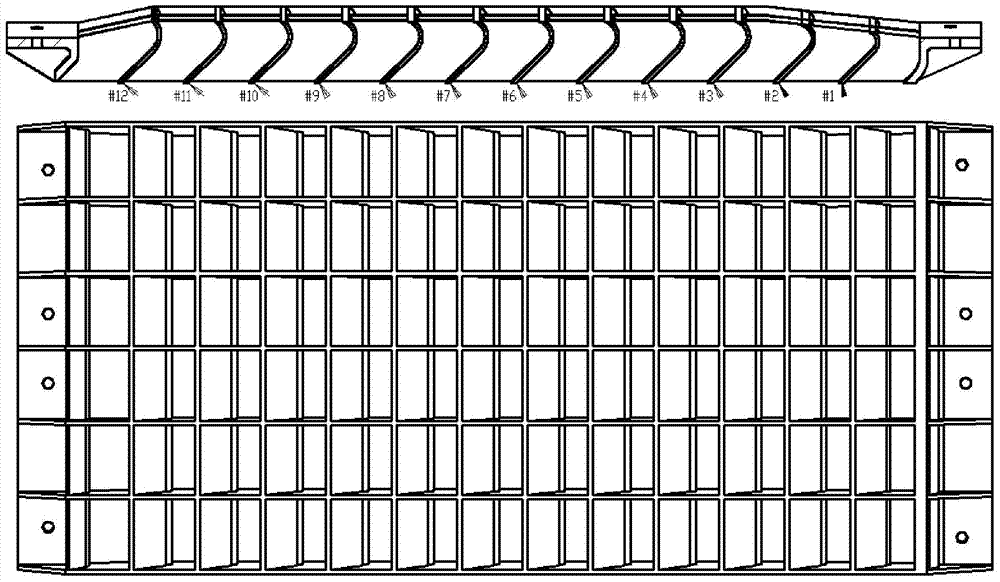

RTM (resin transfer molding) molding method for carbon-fibre composite complex grid structure

The invention discloses an RTM molding method for a carbon-fibre composite complex grid structure. According to the invention, a grid is manufactured by using RTM technology, a dry woven fabric (a five-end satin fabric with designable lateral strength and longitudinal strength) is employed for prefabrication and molding, and RTM glue injection is carried out so as to complete molding of the grid; strength at two directions can be guaranteed at the same time, a laying layer is flat, a compression ratio is small, mould-filling extruding force is small, and the produced grid has small porosity and high linearity at lateral and longitudinal directions; since a hard metal mold and a soft silicone rubber mold are cooperatively used for glue injection of a composite material and an autoclave molding method is adopted, a metal mold used for manufacturing the grid is substantially simplified; the molding method for the grid is simple and easily practicable; the soft silicone rubber mold can be repeatedly used and is applicable to batch production of the grid, so the beneficial effects of low manufacturing cost for the mold, easy and convenient operation, a high product qualification ratio, etc.

Owner:SHANGHAI COMPOSITES SCI & TECH CO LTD

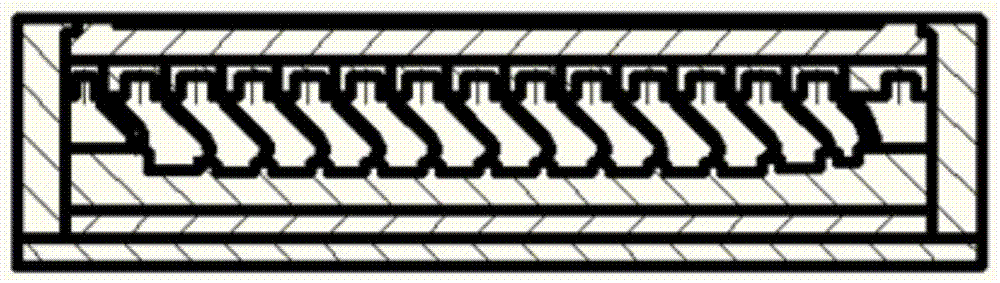

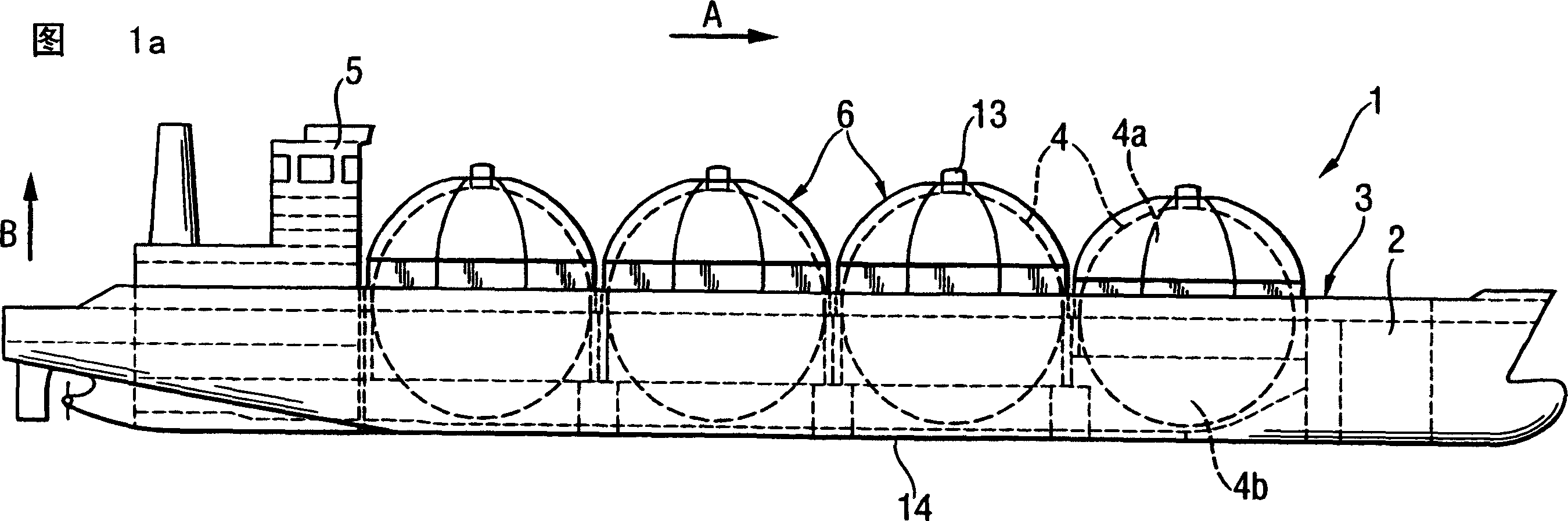

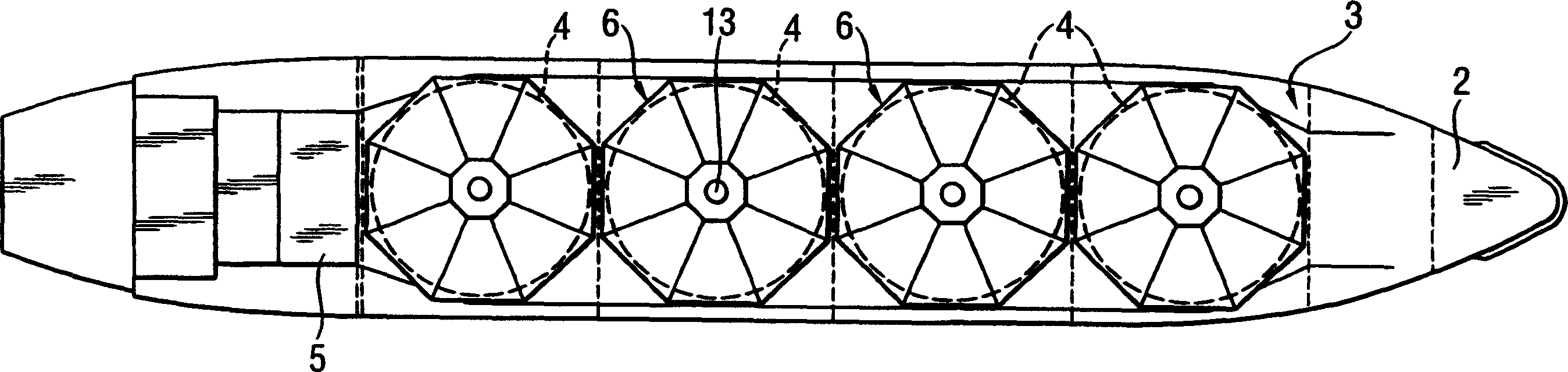

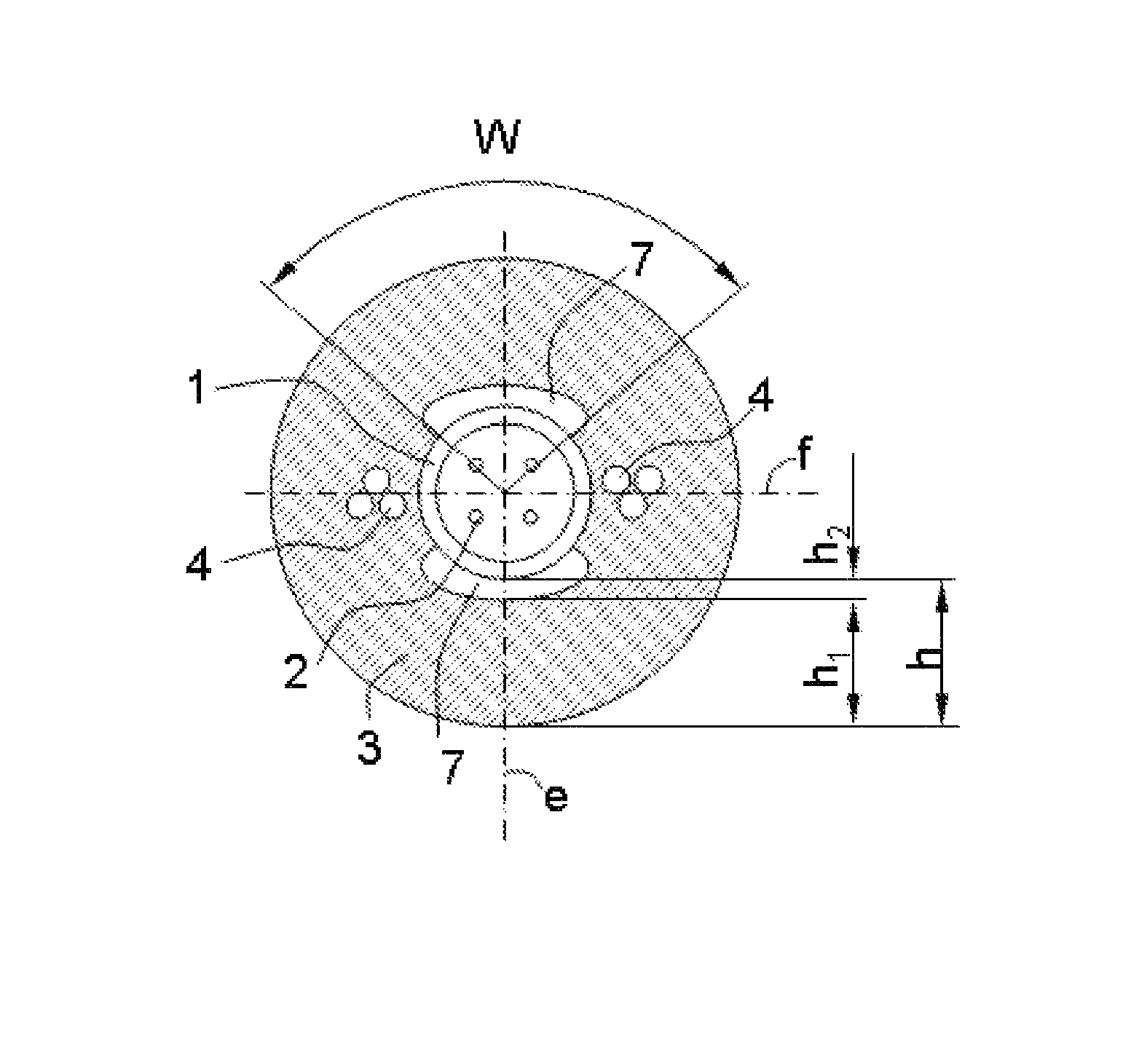

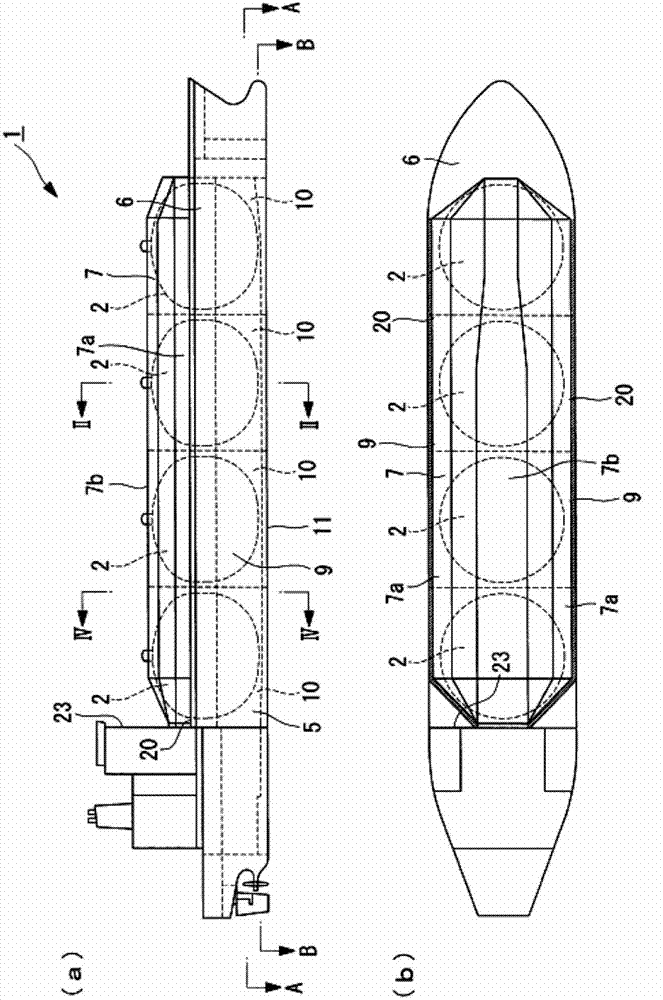

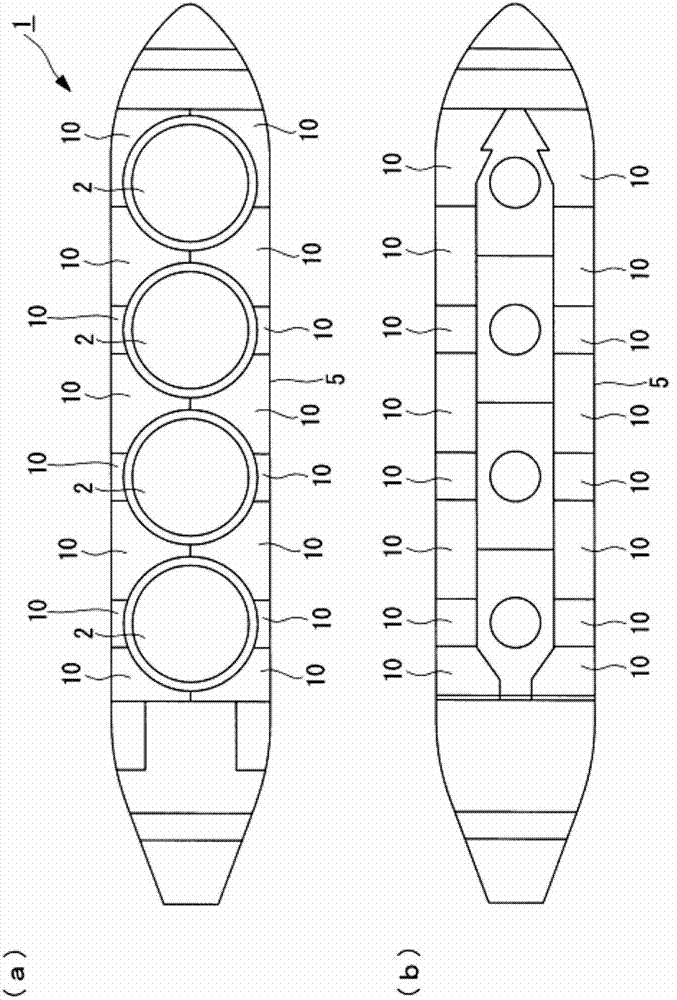

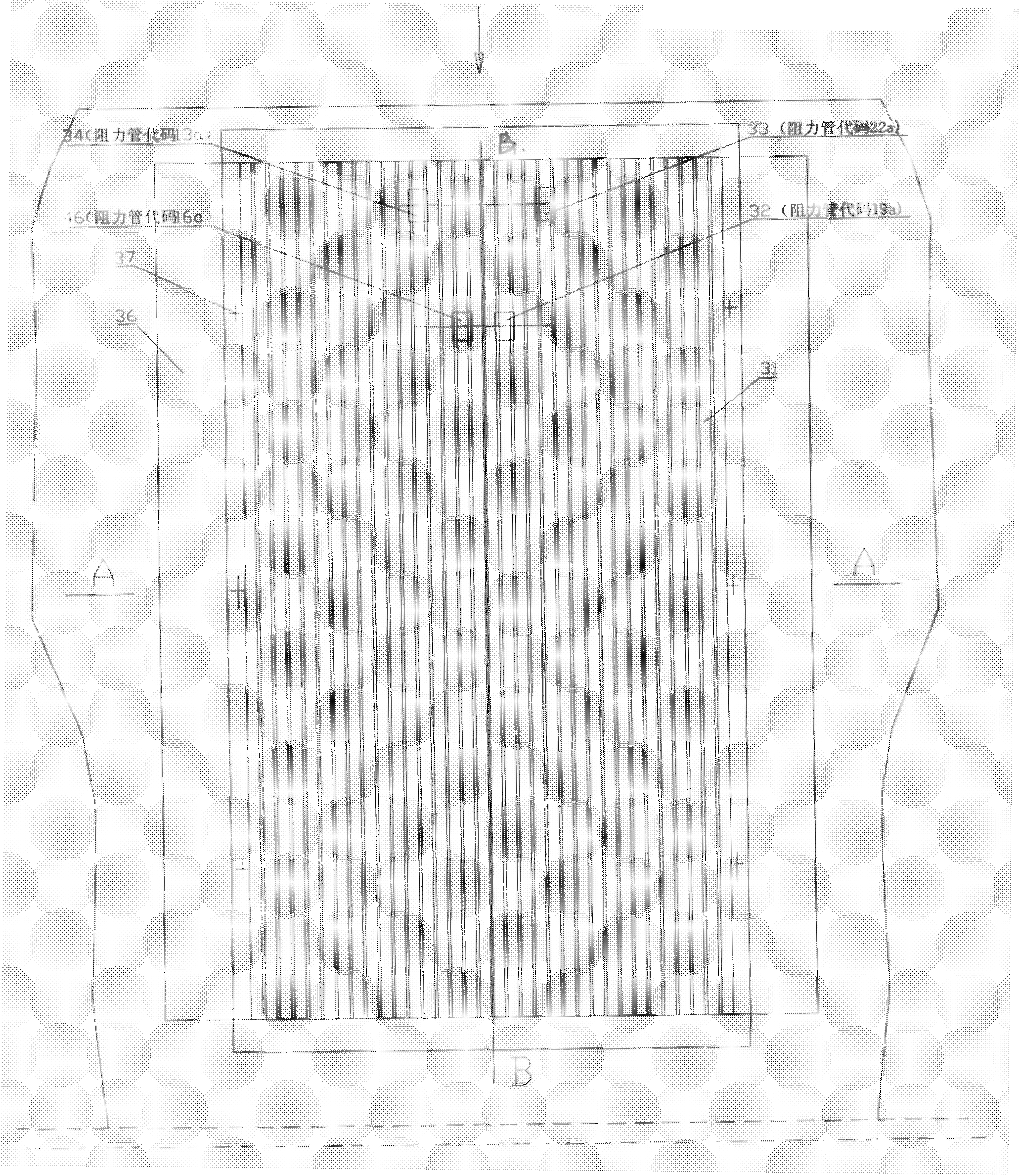

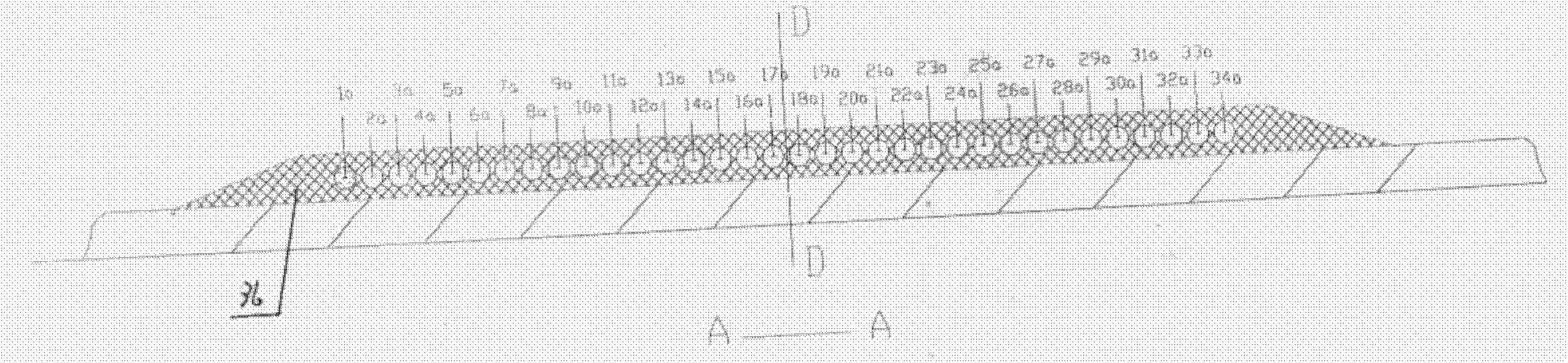

A method and an arrangement for reducing the weight and optimizing the longitudinal strength of a water-craft

InactiveCN1642808AEasy to manageHigh strengthVessel superstructuresVessel mastsMarine engineeringUltimate tensile strength

A method and arrangement for reducing the weight and optimizing the longitudinal strength of a water-craft (1), which is especially suitable for transportation of liquefied natural gas (LNG) or other corresponding mediums and comprises a hull (2), which has a deck (3) extending over at least the main part of the water-craft (1) and a number of substantially spherical cargo tanks (4) arranged successively in the longitudinal direction (A) of the water-craft (1) and a deckhouse (5), which extend substantially above the said deck (3). The hull (2) of the water-craft (1) is provided with a continuous protective casing structure (6) known as such and which is arranged on top of the cargo tanks (4). The said deck (3) of the water-craft is arranged on the hull (2) so that the proportion of its height measured from the bottom of the water-craft to the height of the uppermost continuous portion of the protective casing structure (6) on top of the cargo tanks (4) is at most 0.55, preferably at most 0.5. In addition said protective casing structure (6) is fixed to said deck (3) and / or other structures (7) supported to the hull (2) and is dimensioned together with the other parts of the hull (2) so that together they constitute an essential part of the overall strength of the water-craft.

Owner:STX FINLAND OY

Modification method of large-scale crane ship

InactiveCN101913412AIncrease the areaSatisfy the requirements of floating state controlHull decksSpecial purpose vesselsWork performanceHoneycomb like

The invention discloses a method in the technical field of shipping hoisting, in particular to a modification method of a large-scale crane ship based on a large-scale oil tanker with longer parallel middle body. The floating force is increased through assembling a modified ship bow and box-shaped floating bodies at the two sides of a ship body, and the modification of the large-scale crane ship is realized through replacing a main deck by a beamless flat deck, arranging a crane and reinforcing the interior of the ship body. The invention meets the requirement on controlling the floating state during the working of the large-scale crane ship, improves the total longitudinal strength of the shipping through the arrangement of a modified deck and a centerline bulkhead, and meets the requirement on local intensity through the design of a barrel-shaped honeycomb structure. Rapid dispensation of ballast water during working is realized through the optimized design of a ballast tank and the arrangement of a ballast water pump; the work performance and the control performance are improved through configuring an auxiliary machine, an anchoring machine, a winch and a bow thruster so as to realize that the large-scale oil tanker is modified into the large-scale crane ship on the basis of little modification, therefore, the time and the cost are saved; and the method has larger economic effect and finds a new way for developing old ships.

Owner:SHANGHAI JIAO TONG UNIV +1

Optical cable with improved strippability

ActiveUS8798418B2Reduce thicknessEasy outFibre mechanical structuresUltimate tensile strengthBiomedical engineering

An optical cable includes a buffer tube housing at least one optical fiber, a sheath surrounding such buffer tube and at least one longitudinal strength member embedded in the sheath, in which at least one separation element is provided between a portion of the outer surface of the buffer tube and the inner surface of the sheath, laying in an axial plane not containing the at least one strength member.

Owner:PRYSMIAN SPA

Super flexible S/S stereoscopic two-component spunbond non-woven material and preparing method thereof

InactiveCN106811870ASolve the hard textureSolve the problem of rough feelingFilament/thread formingNon-woven fabricsGramNonwoven fabric

The invention provides a super flexible S / S stereoscopic two-component spunbond non-woven material and a preparing method thereof. The non-woven material is prepared from polypropylene a, polypropylene b, a softening agent and color master batch. Non-woven fabric made of the super flexible S / S stereoscopic two-component spunbond non-woven material has the advantages of being good in hydrophilicity, high in softness, compact in texture and small in gram weight, and fitting to skin, the surface density of the material is 30-80 g / m<2>, the longitudinal strength is 80-240 N / 5cm, the longitudinal elongation at break is 90%-120%, the longitudinal bending rigidity is 200-800 cN. cm, the longitudinal bending length is 2-4 cm, the transverse strength is 50-180 N / 5cm, the transverse longitudinal elongation at break is 60%-100%, the transverse bending rigidity is 160-480 cN. cm, the transverse bending length is 3-7 cm, and the stereoscopic thickness of the material is 0.5-2 mm.

Owner:CHTC JIAHUA NONWOVEN CO LTD

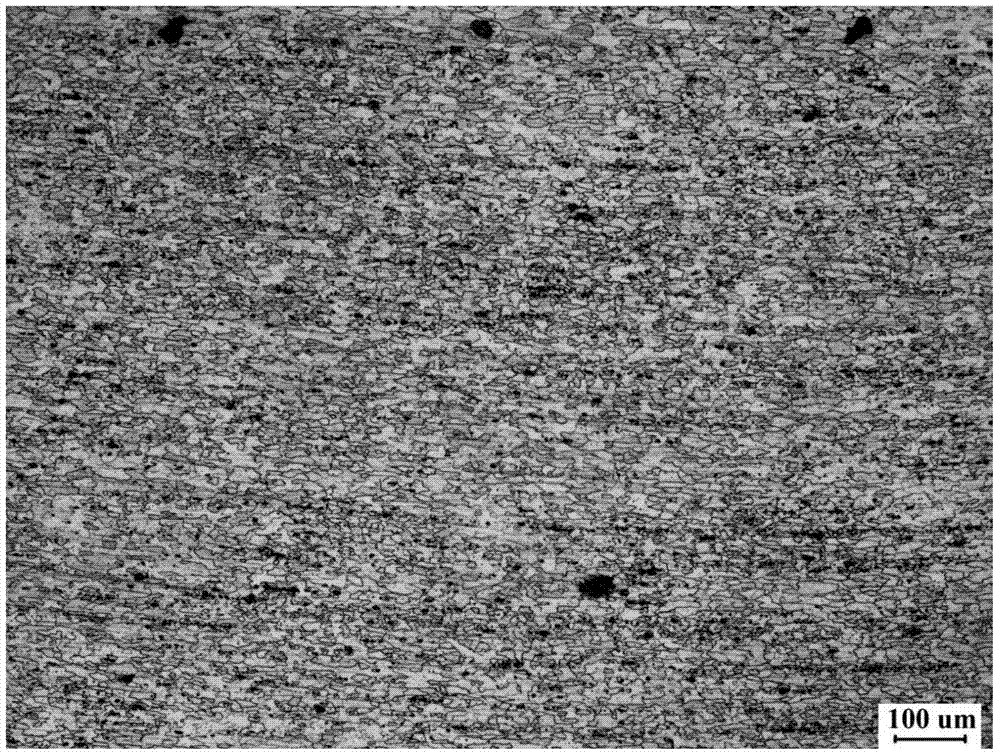

Non-oriented electrical steel for ultrahigh-effect constant-frequency compressor and preparation method of non-oriented electrical steel

InactiveCN110241359AHigh dimensional accuracyReduce iron consumptionChemical compositionConstant frequency

The invention discloses non-oriented electrical steel for an ultrahigh-effect constant-frequency compressor and a preparation method of the non-oriented electrical steel. The non-oriented electrical steel for the ultrahigh-effect constant-frequency compressor comprises the following chemical components of, in percentage by weight, 1.0%-1.90% of Si, 0.20%-0.9% of Als, 0.10%-0.60% of Mn, 0.01%-0.02% of P, less than or equal to 0.01% of C, less than or equal to 0.02% of S, less than or equal to 0.02% of N, less than or equal to 0.01% of Ti, less than or equal to 100 ppm of C+S+N+Ti, and the balance Fe and inevitable impurity elements. According to the reasonable component design, the technological technologies such as hot rolling, normalizing, cold rolling, continuous annealing and the like are matched to optimize, so that the non-oriented electrical steel for the ultrahigh-effect constant-frequency compressor is obtained, which the thickness of 0.5mm, P1.0 / 50 is less than or equal to 3.20W / kg, B5000 is greater than or equal to 1.72T, the yield strength Rp0.2 is less than or equal to 350 MPa, and the transverse longitudinal strength difference delta Rp0.2 is less than or equal to 10 MPa.

Owner:MAANSHAN IRON & STEEL CO LTD

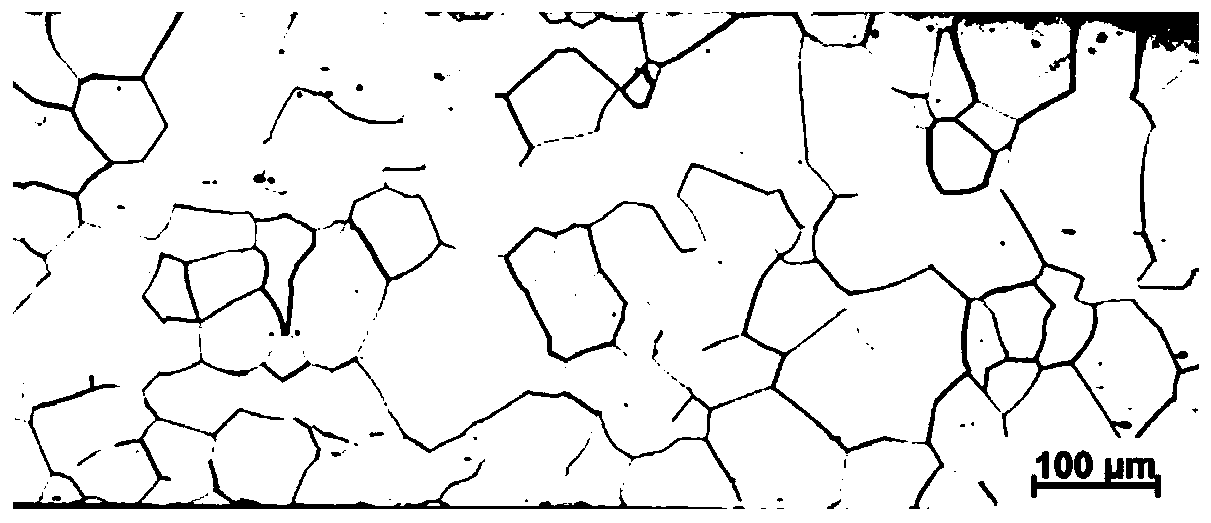

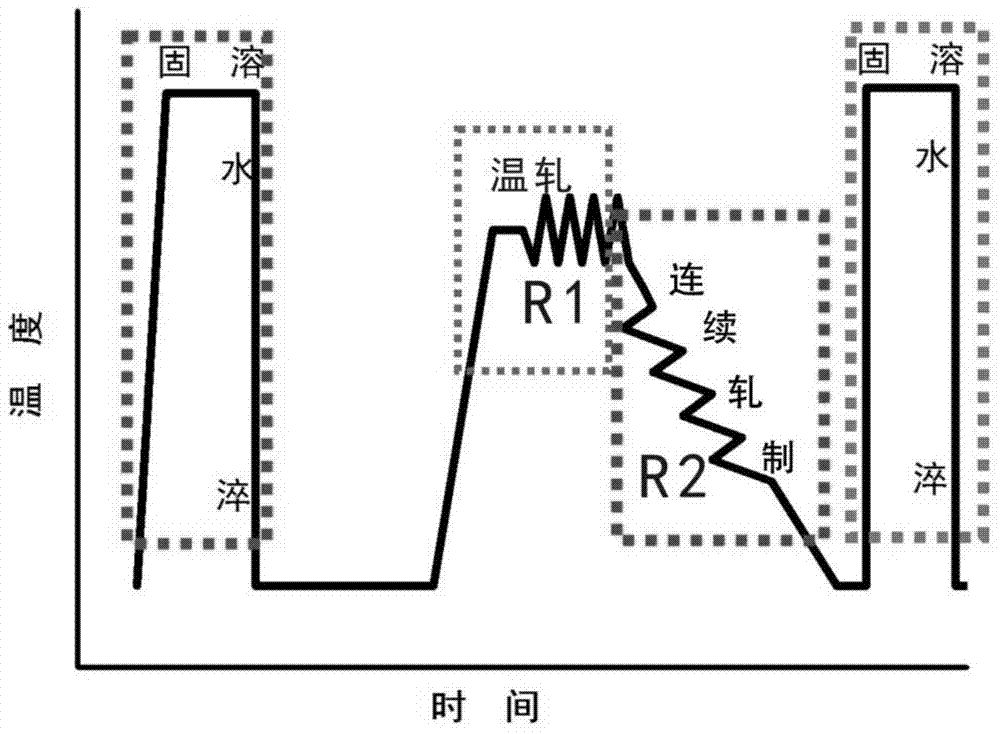

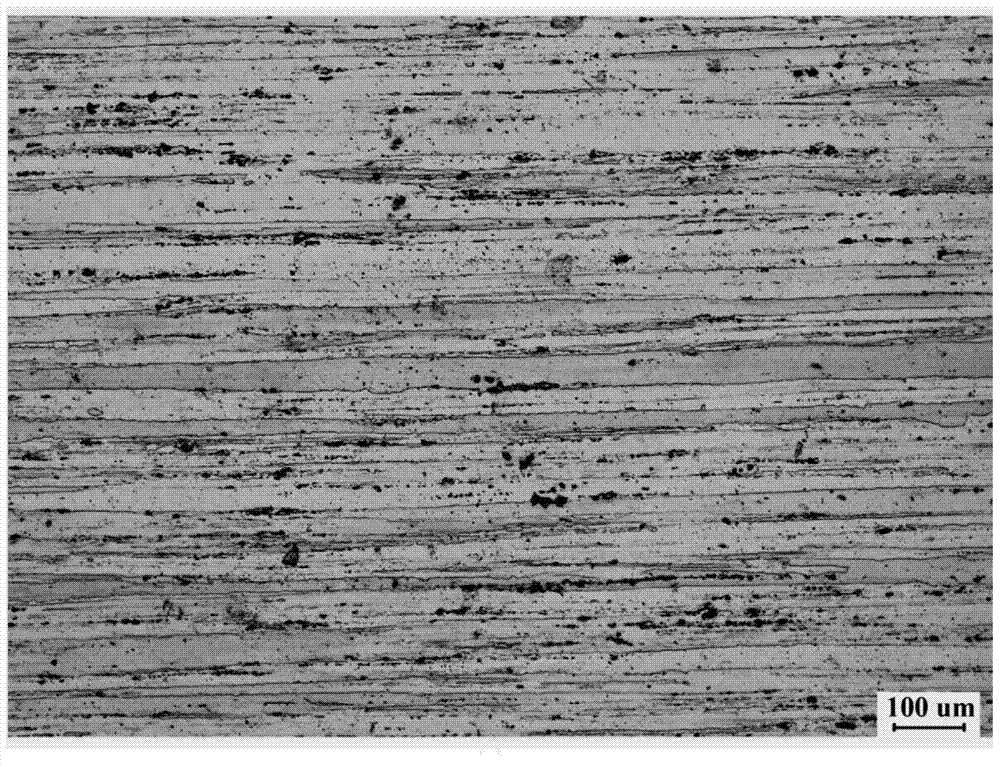

Grain refinement method of 7000 series aluminum alloy

The invention relates to a grain refinement method of 7000 series aluminum alloy. The grain refinement method of the 7000 series aluminum alloy comprises the following specific steps: (1) solid solution treatment; (2) rolling deformation; (3) continuous rolling deformation; (4) short-time solid solution recrystallization. According to the grain refinement method, the grain size of aluminum alloy can be refined from more than 200 microns to 10 microns and even below; after a proper aging treatment to a fine grain structure, transverse and longitudinal strengths of an aluminum alloy plate at room temperature are equivalent with those of a plate obtained according to the conventional hot rolling process, while the break elongation is greatly improved; the grain refinement method is simple in process, short in cycle and low in energy consumption, and has great application potential and value in industrial production.

Owner:UNIV OF SCI & TECH BEIJING

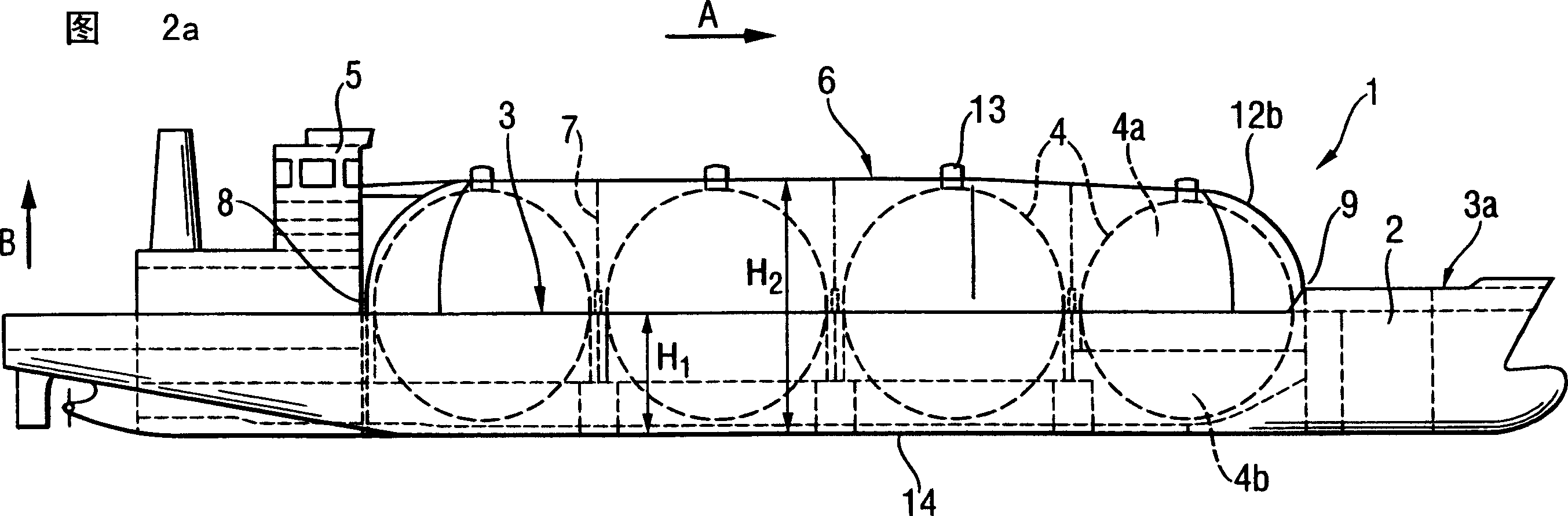

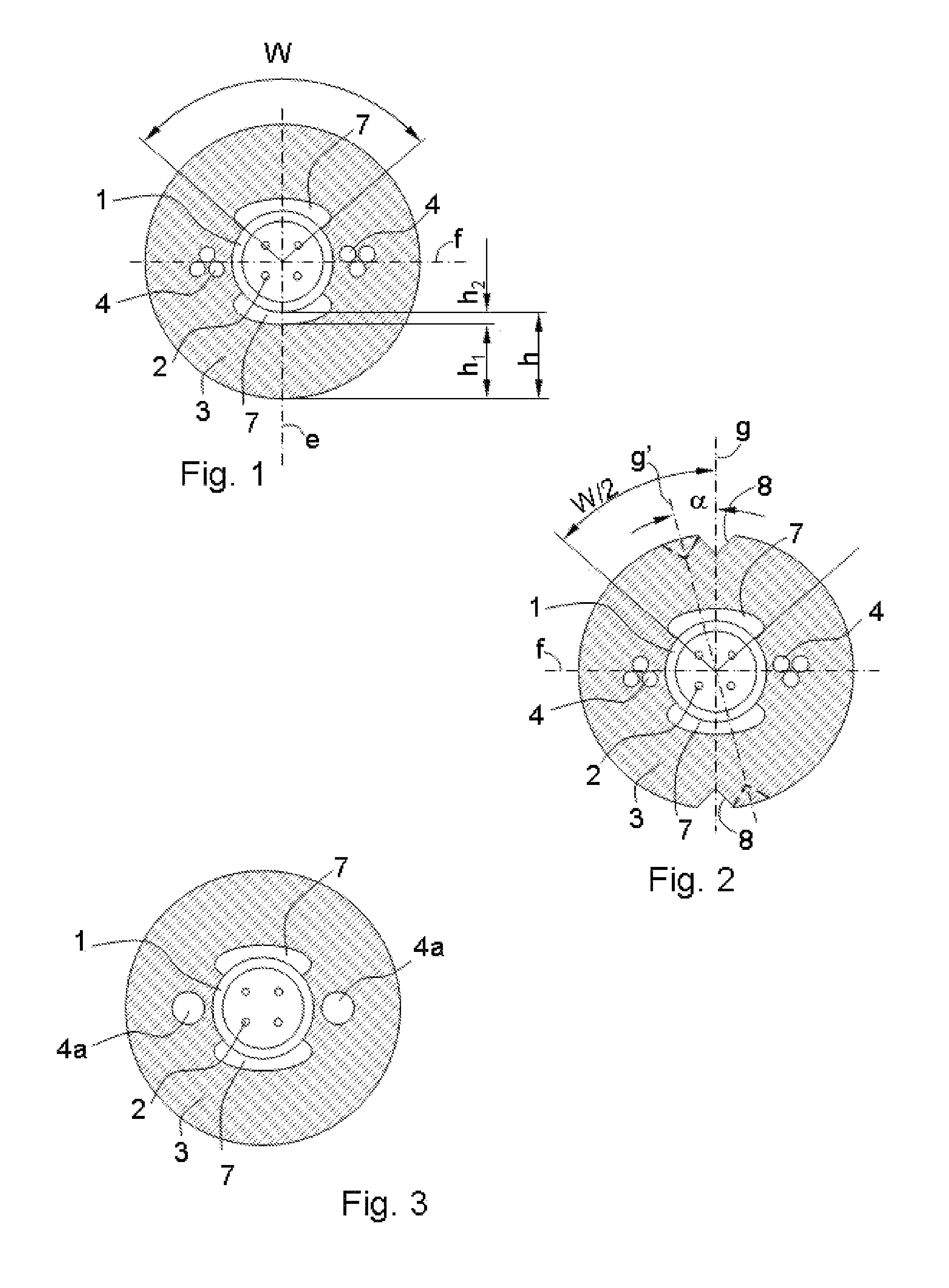

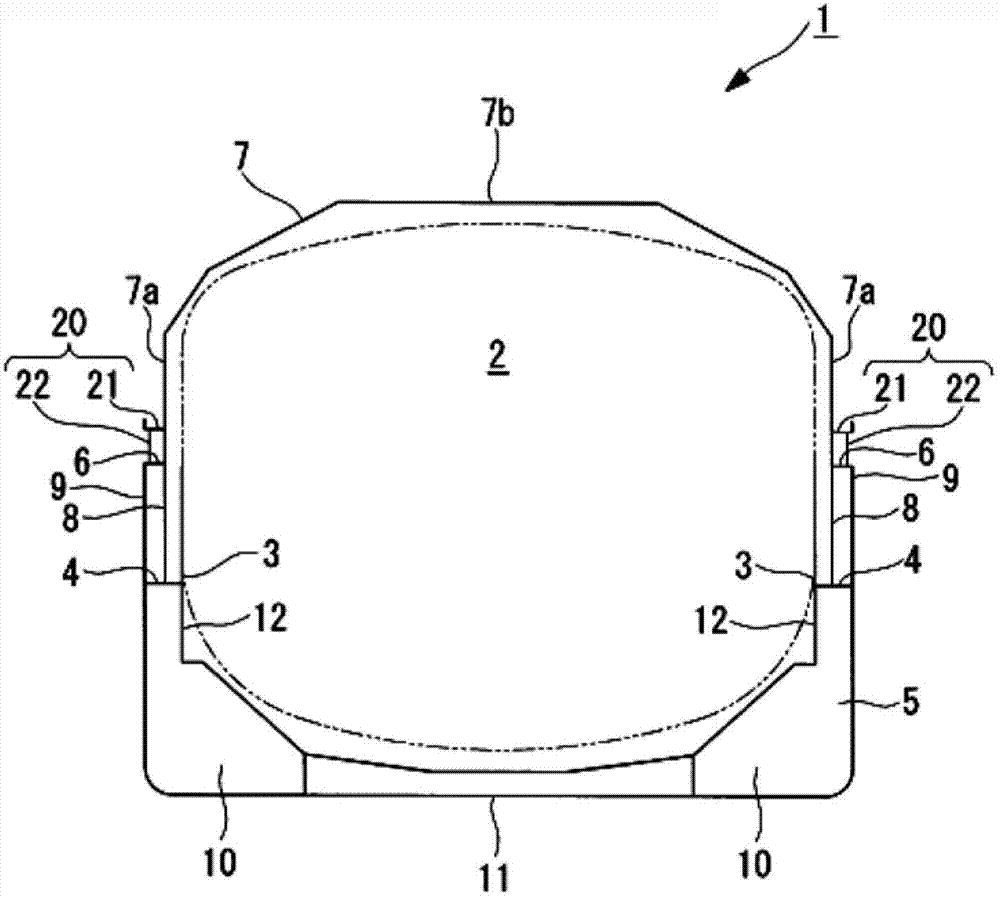

Liquefied gas carrying ship

ActiveCN102958797AReduce pressure areaImprove stabilityVessel superstructuresHull decksMarine engineeringUltimate tensile strength

In order to reduce the pressure receiving area of the entire ship body, reduce the air pressure resistance, lower the position of the center of gravity of the ship, and improve the stability of the ship body, a liquefied gas carrying ship (1) is provided with: flat spherical tanks (2) for storing a liquefied gas therein, the flat spherical tanks (2) being arranged in the bow-stern direction of the ship and affixed to the ship body (5) through skirts (3); and a single continuous tank cover (7) for covering the upper half of the flat spherical tanks (2) and extending along the bow-stern and width directions of the ship. The tank cover (7) is rigidly joined to the ship body (5) and ensures, integrally with the ship body (5), the longitudinal strength.

Owner:MITSUBISHI SHIPBUILDING CO LTD

Coaxial transducer

InactiveUS7985924B1High strengthPower cables with screens/conductive layersInsulated cablesLead zirconate titanateElectrical conductor

A coaxial transducer that uses lead zirconate titanate ceramic or other suitable material as an isolator between the conductors in a coaxial cable to transmit acoustic power at useful levels. The lead zirconate titanate ceramic is diced into thin disks and placed in between spacers made of much stronger insulating material. The coaxial cable is then integrated into a conventional double-armored steel tow cable with a typical diameter of 1″. This provides substantial longitudinal strength and provides crushing resistance to the lead zirconate titanate ceramic when the cable is being deployed or retrieved over a sheave under tension.

Owner:UNITED STATES OF AMERICA NAVAL UNDERSEA WAREFARE CENT DIV NEWPORT OFFICE OF COUNSEL THE

Veneer for container base plate

InactiveCN101549505AReasonable structureReasonable structural designWood veneer joiningWood layered productsMechanical engineeringLongitudinal strength

The invention relates to a veneer for a container base plate, belonging to the technical field of veneers. The veneer has reasonable structural design and enhances the horizontal and longitudinal strength of floors, thereby giving full play to the maximum performance of various materials and obtaining a more reasonable compounding floor structure; with the mixed structure, the veneer for the container base plate is ensured to meet the using requirement of the container base plate; materials used by the veneer for container base plate have extensive sources and lower cost, thus the production cost of the container base plate is reduced.

Owner:SHENGSHI CONTAINER MANAGEMENT SHANGHAI

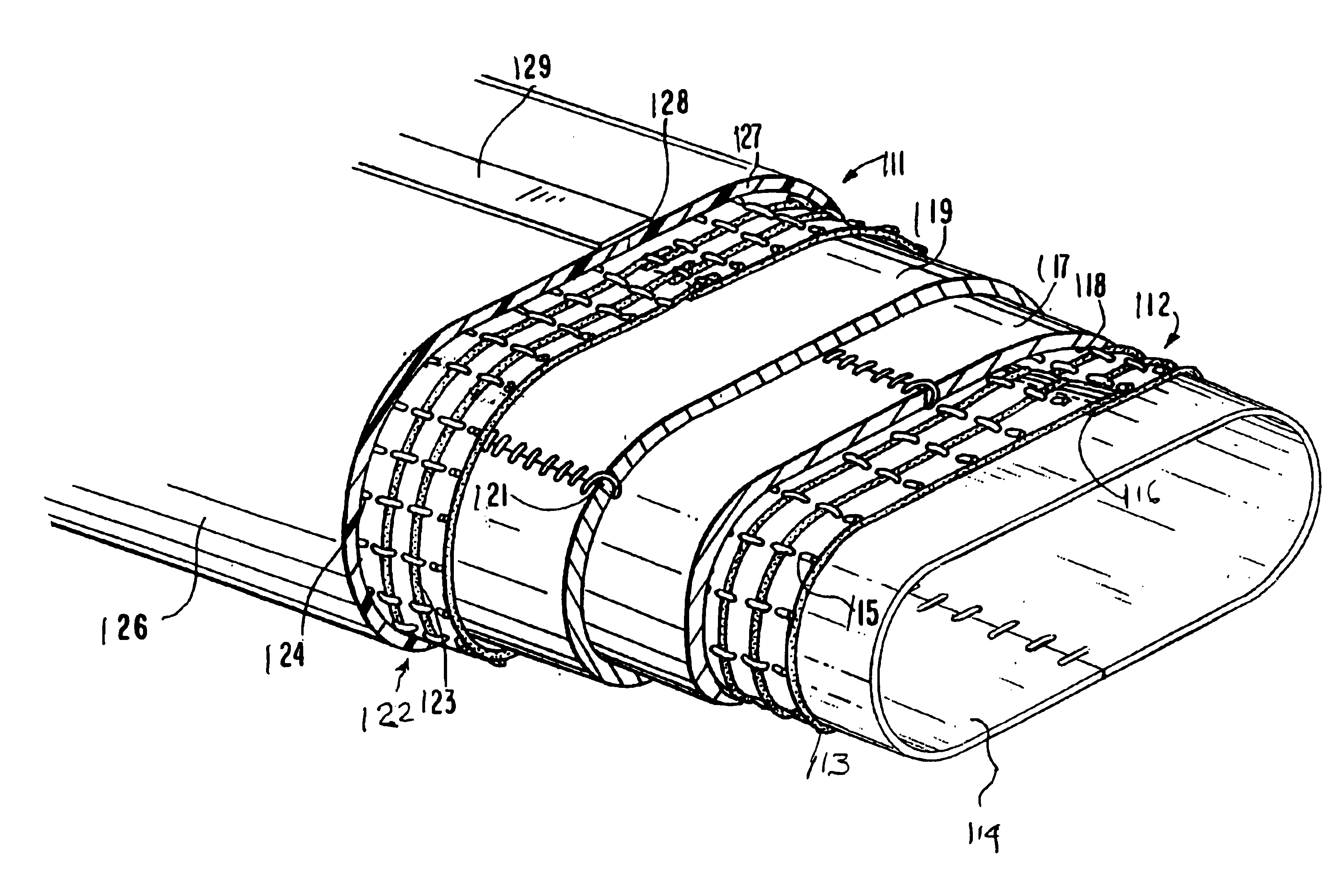

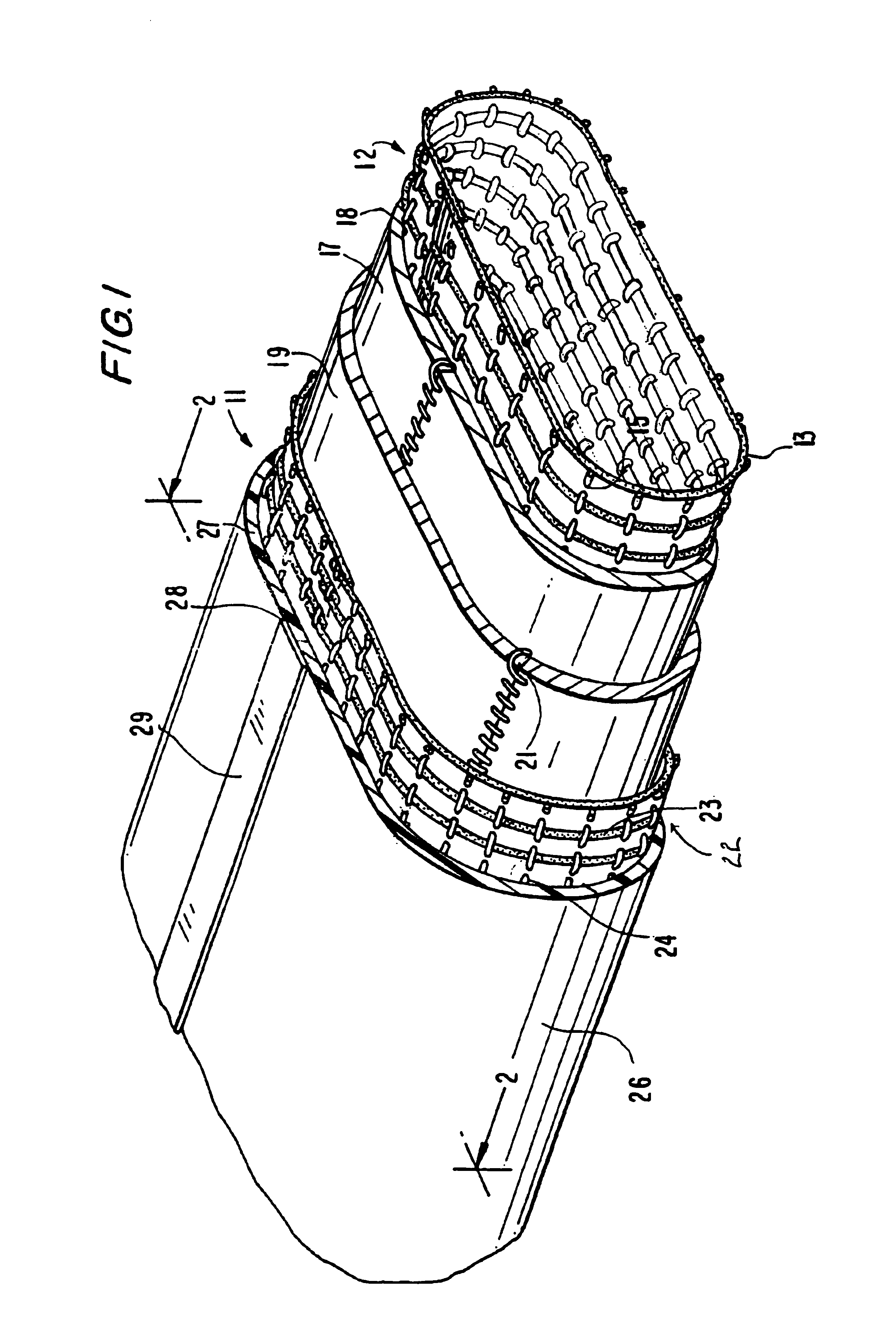

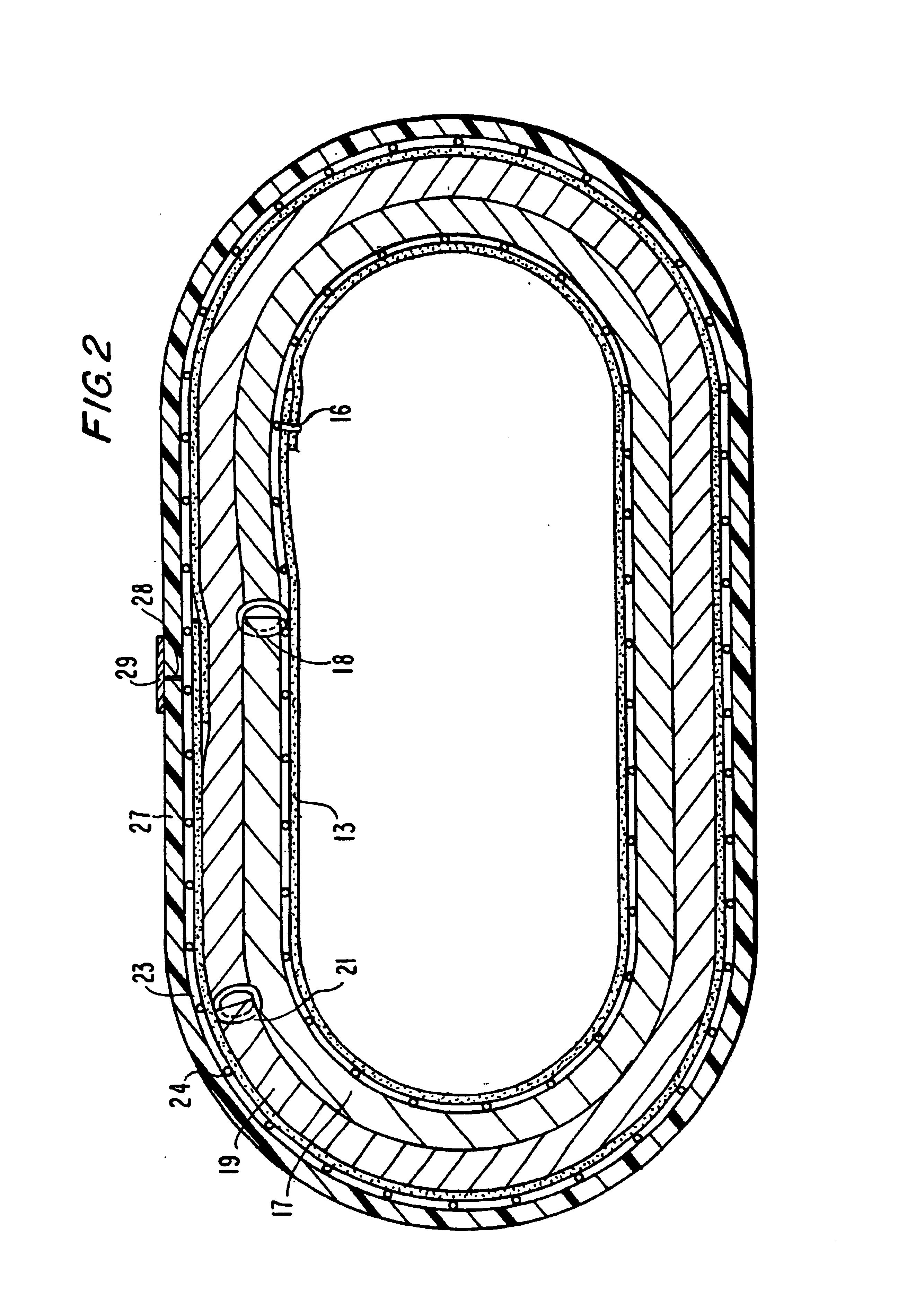

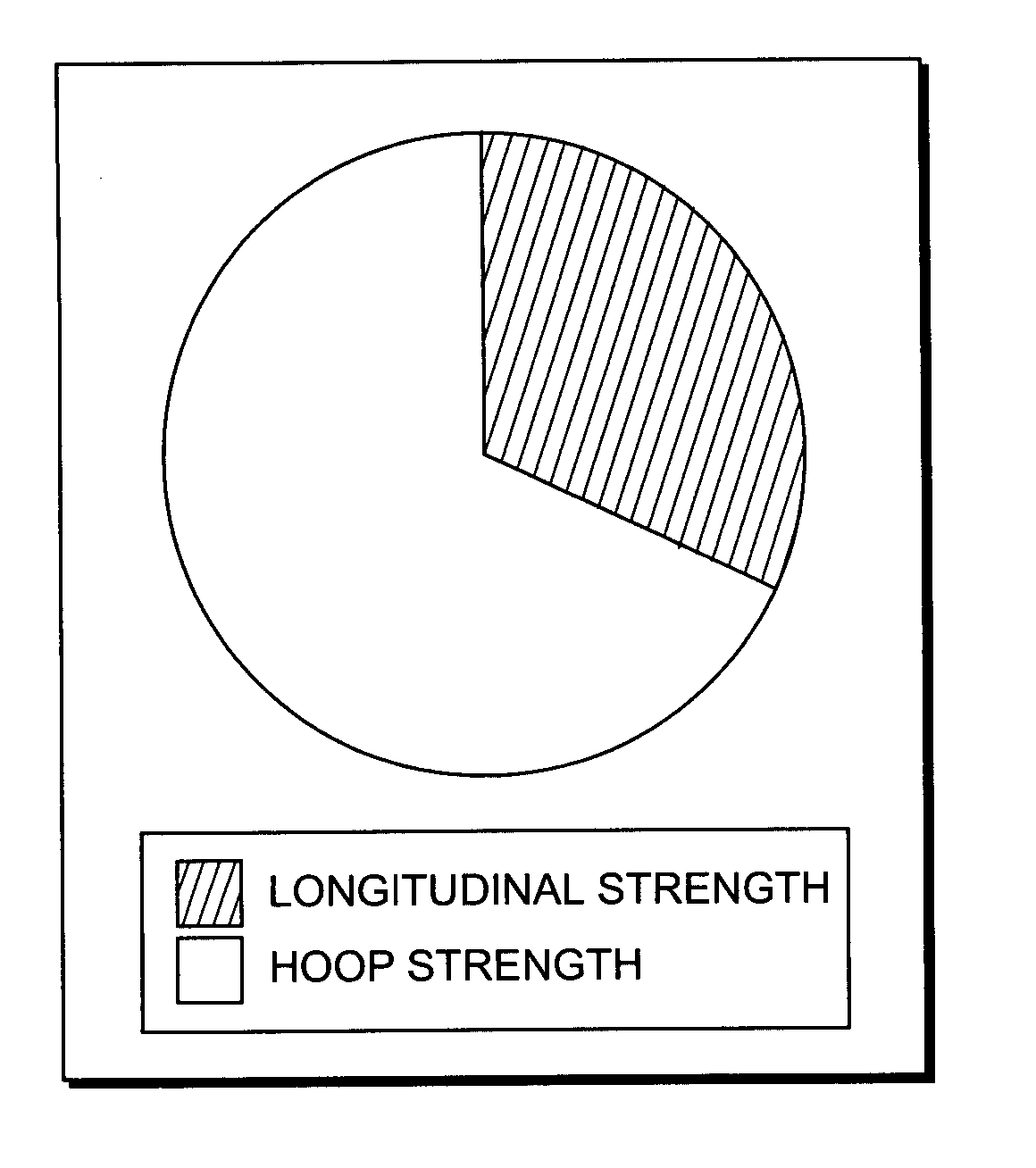

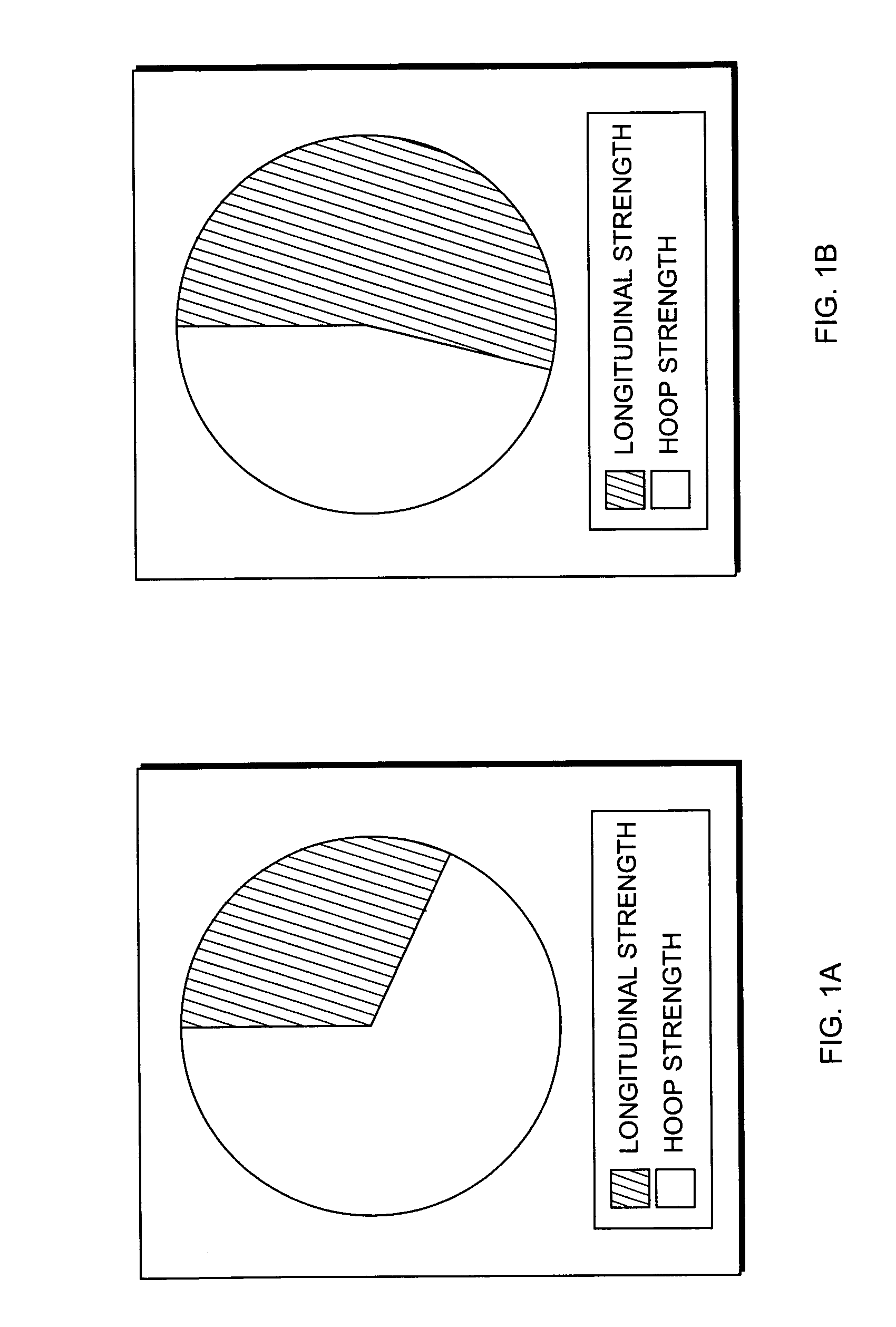

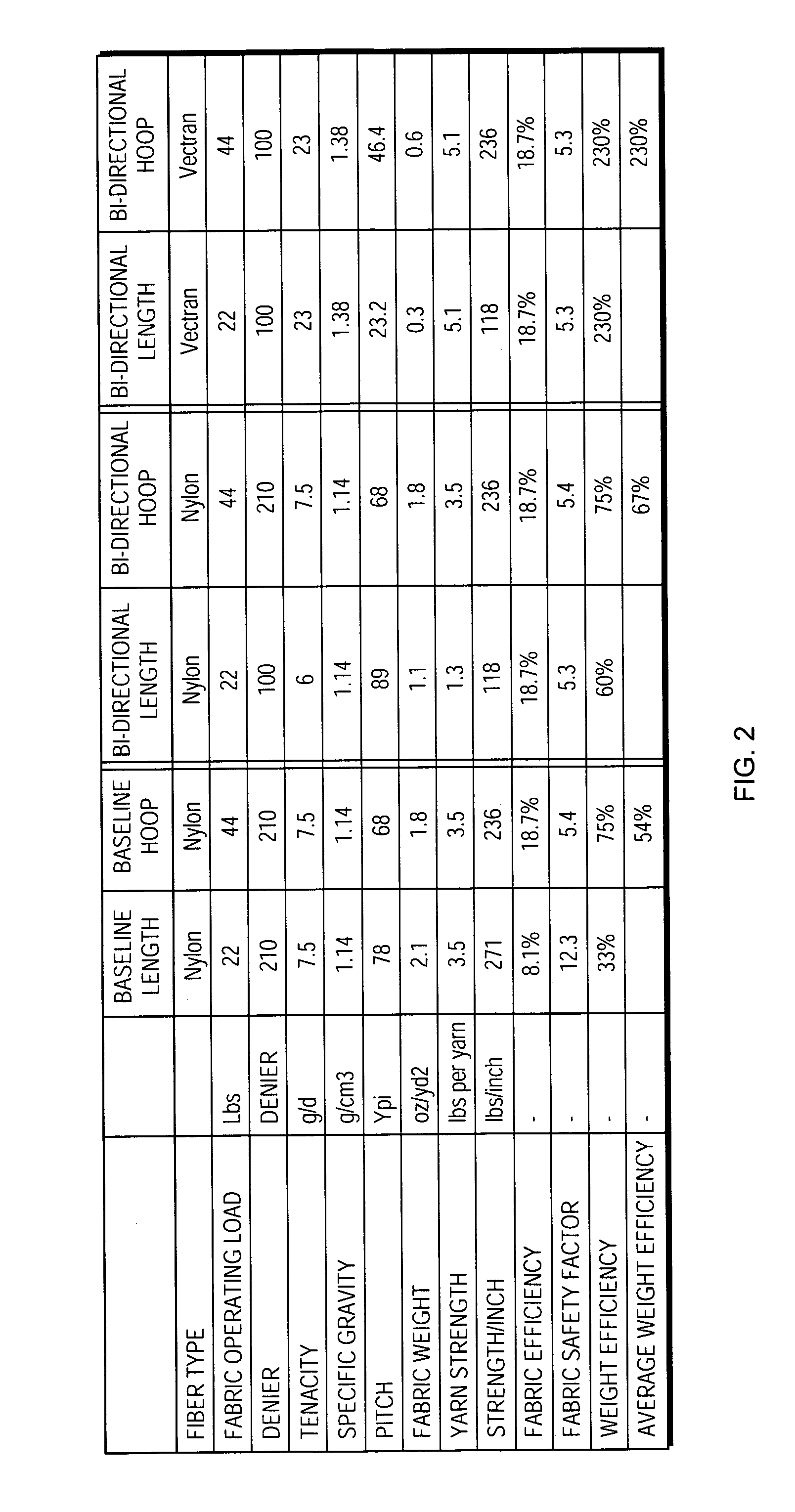

Bi-directional substrate design for aircraft escape slide airbeams

A coated, bi-directional substrate design for an aircraft escape slide airbeam, where the longitudinal strength and hoop strength of the substrate and the coating applied thereto are optimized to the application. Less than 45% of the total substrate fiber content is in the longitudinal direction of the substrate, and the longitudinal strength of the substrate is approximately 50% of the hoop strength. The substrate is constructed of nylon, polyester, aramid, para-aramid or liquid crystal polymer fibers, and either polyurethane coatings and adhesives or polyether polyurethane coatings and adhesives. The warp yarns are less than ½ the denier of the fill yarns and are woven in groups of 2 or more yarns to improve the tear strength of the fabric in the warp direction.

Owner:WARWICK MILLS INC

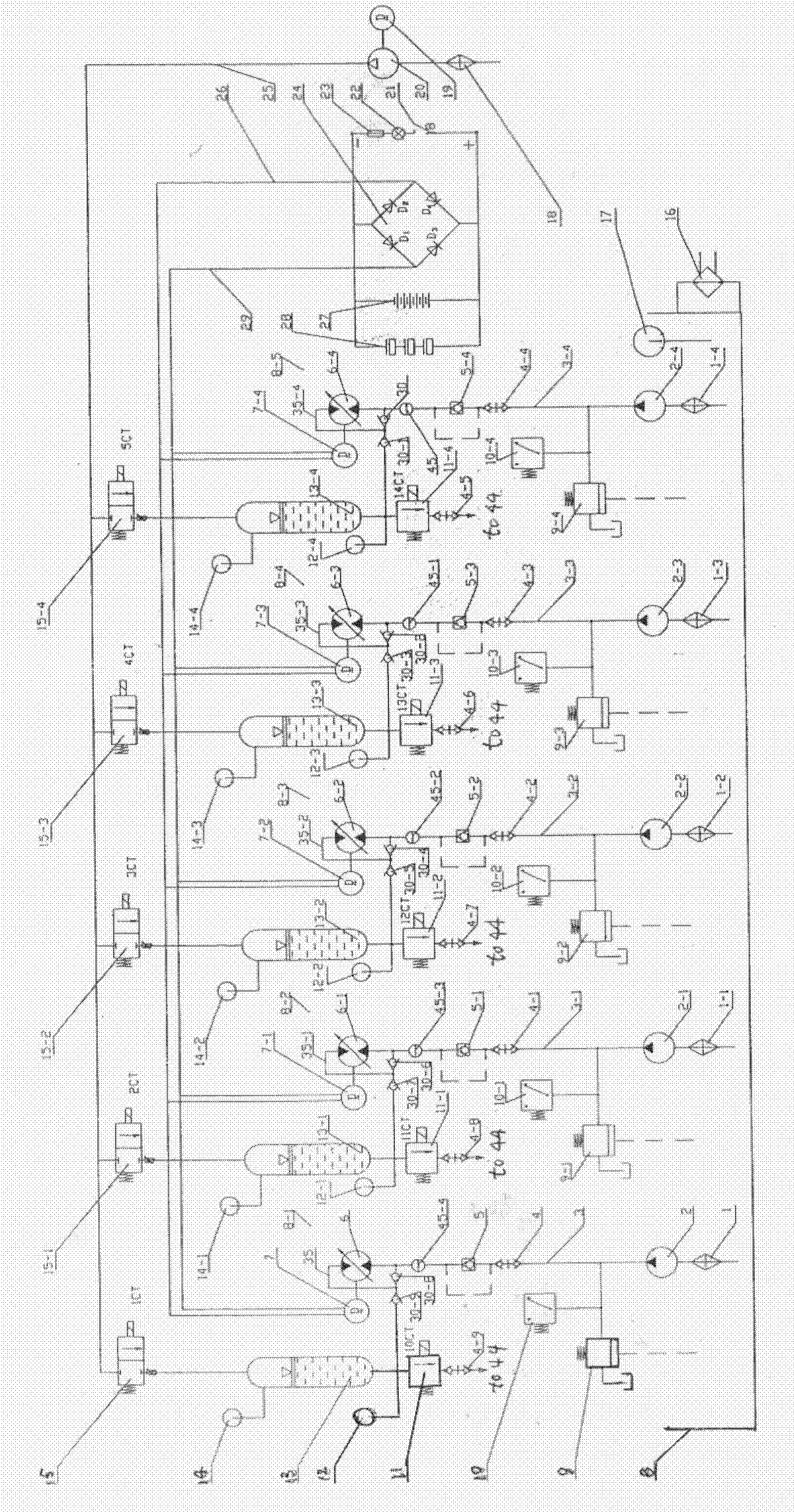

Safe carrier landing and high-efficiency energy recycling device of carrier aircraft

InactiveCN102514720APrecisely control the length of the distanceFine-tuning trajectoryArresting gearAircraft landing aidsElectricityMechanical energy

A safe carrier landing and high-efficiency energy recycling device of a carrier aircraft is characterized by comprising a resistance pad component, an oil squeezing component, an oil return component, an oil supplementing component, an oil circulation control component and a hydraulic-electric conversion component. Squeezed oil is transmitted to the hydraulic-electric conversion component from the resistance pad component via the oil squeezing component, output of the hydraulic-electric conversion component and input of the oil return component are connected so as to form oil channel circulation, output of the oil supplementing component is connected with the oil return component, the oil circulation control component controls the speed of oil circulation, and the hydraulic-electric control component converts oil pressure mechanical energy into electric energy. The safe carrier landing and high-efficiency energy recycling device is reasonable in structure, light in weight, easy in maintenance and reliable, safe and steady in braking process, realizes safe carrier landing and high-efficiency energy recycling, occupies few decks of a warship, and realizes energy conservation and emission reduction. In addition, tail hooks of the aircraft for being hooked with arresting ropes can be omitted, and accidents of unhooking of the arresting rope are avoided. Besides, requirements of 'front blocking and rear dragging' and repeated setting of a plurality of stopping devices are omitted, accident possibility is reduced, the weight of a carrier is lightened, and the number of warships parked on decks is increased. Further, longitudinal strength of warship bodies does not need to be specially strengthened.

Owner:GUANGDONG FUXING FOOD MACHINERY

High-strength polylactic acid SMS composite non-woven material and preparation method thereof

InactiveCN105584171AOvercome the disadvantages of low strengthImprove mechanical propertiesSynthetic resin layered productsLaminationVolumetric Mass DensityLayered structure

The invention relates to a high-strength polylactic acid SMS composite non-woven material which is in a three-layered structure and includes: an upper layer and a lower layer, which are formed by modified polylactic acid spunbond non-woven materials, and a middle layer which is formed by a modified polylactic acid melt-blow non-woven material. The high-strength polylactic acid SMS composite non-woven material is 20-100 g / m<2> in surface density, is 50-160 N / 5cm in longitudinal strength, is 63-130% in longitudinal breaking elongation, is 60-180 N / 5cm in transversal strength and is 60-120% in transversal breaking elongation. The high-strength polylactic acid SMS composite non-woven material is excellent in mechanical performance and biodegradability. The invention also provides a preparation method of the high-strength polylactic acid SMS composite non-woven material.

Owner:ZHANGJIAGANG JUNMA NON WOVEN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com