Patents

Literature

43results about How to "Realize production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

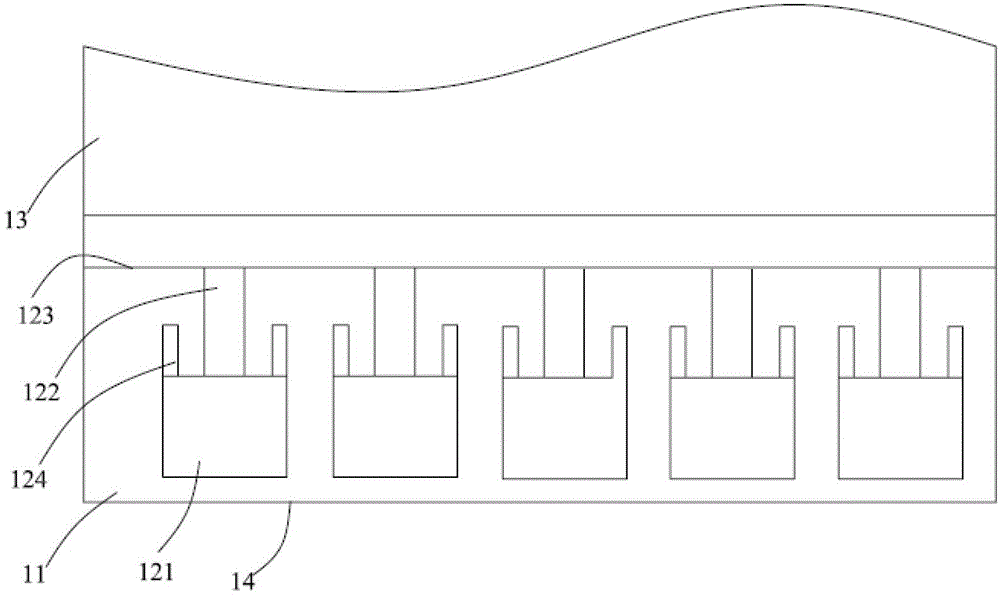

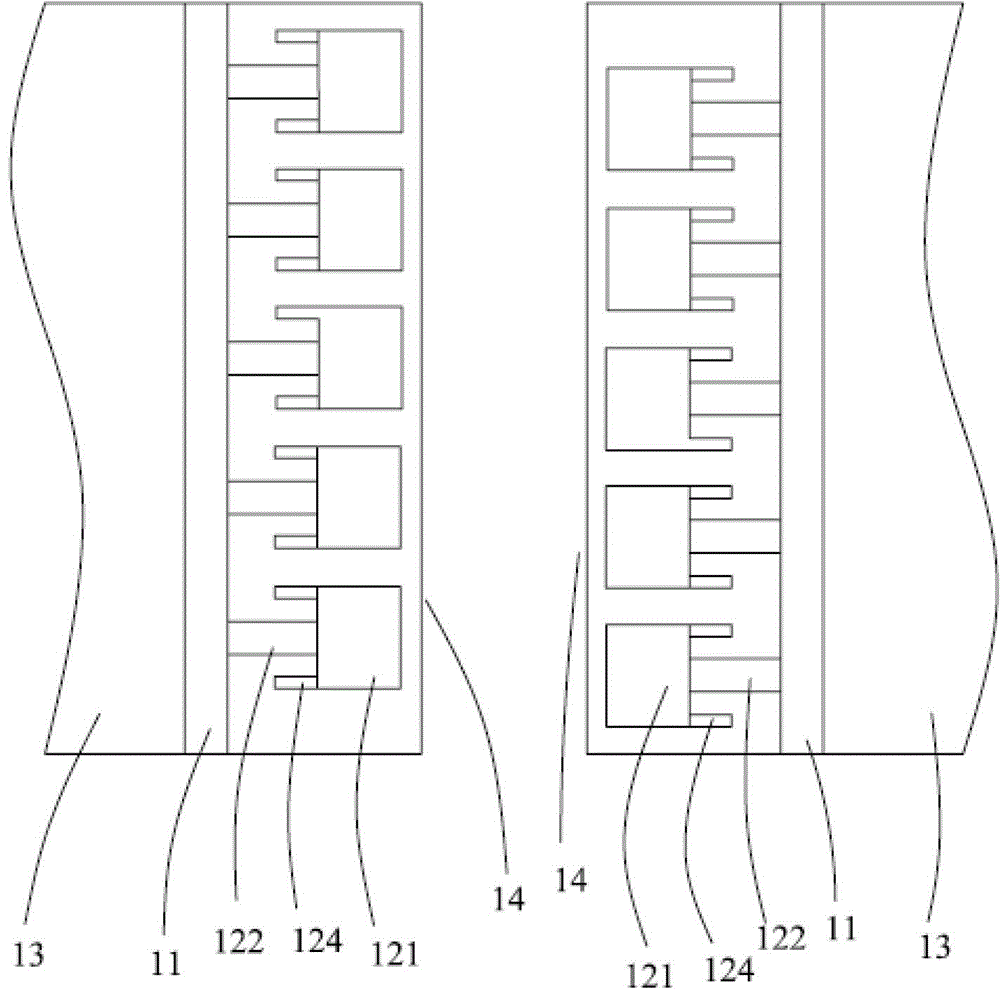

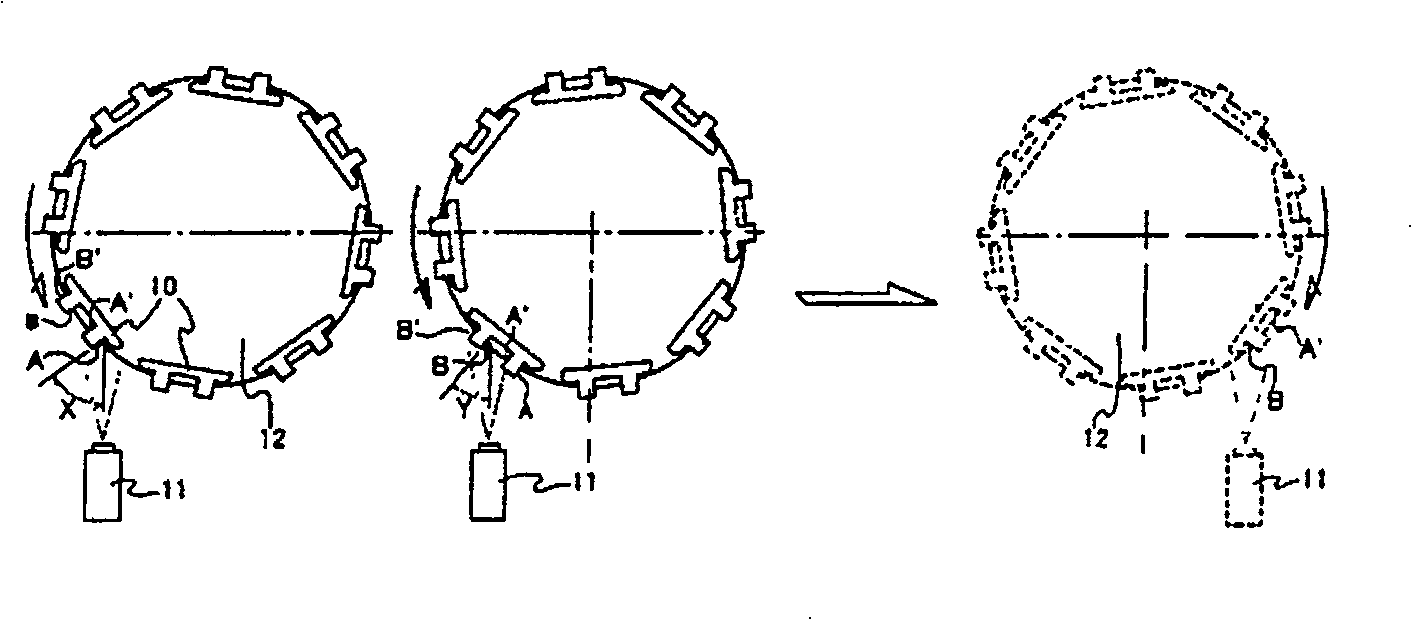

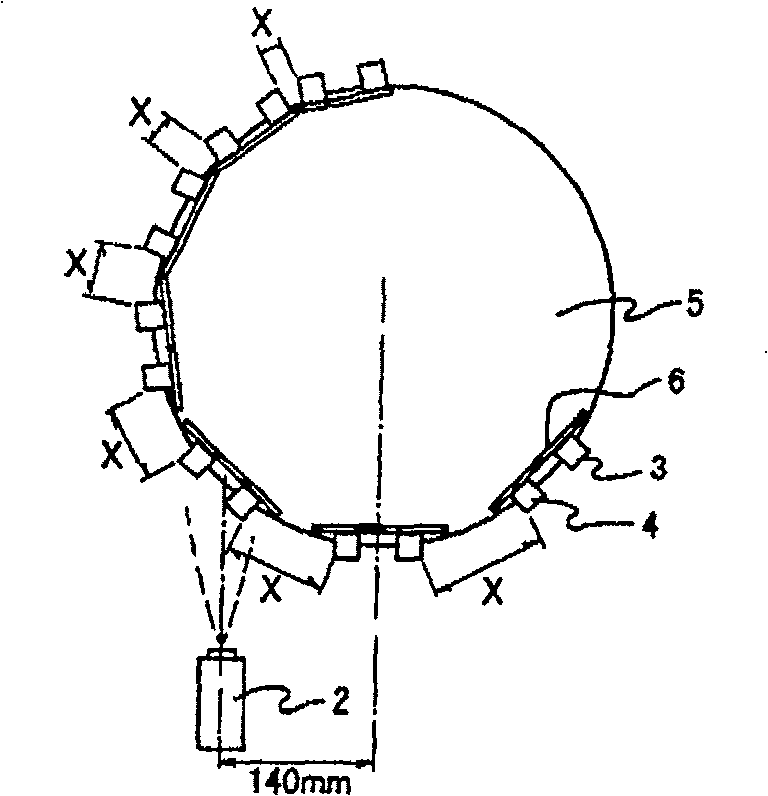

Manufacture method for gold finger circuit board and circuit board manufactured by method

ActiveCN103153000ARealize productionGuaranteed thicknessElectrical connection printed elementsPrinted element electric connection formationFinger structureEngineering

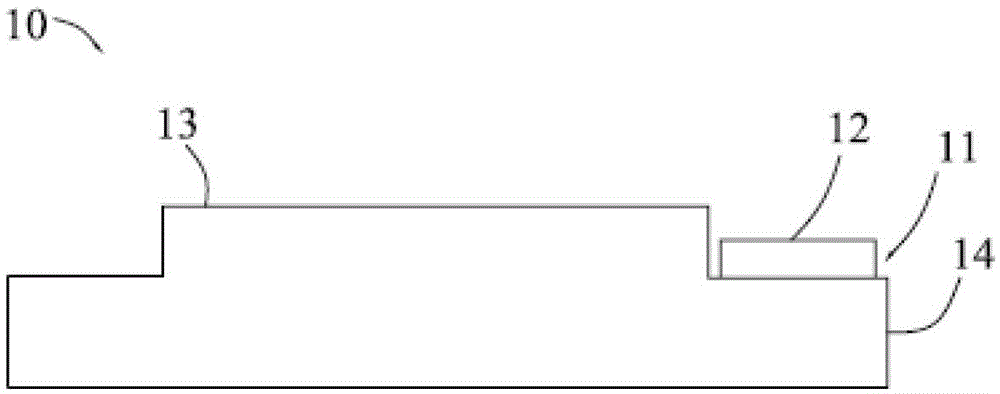

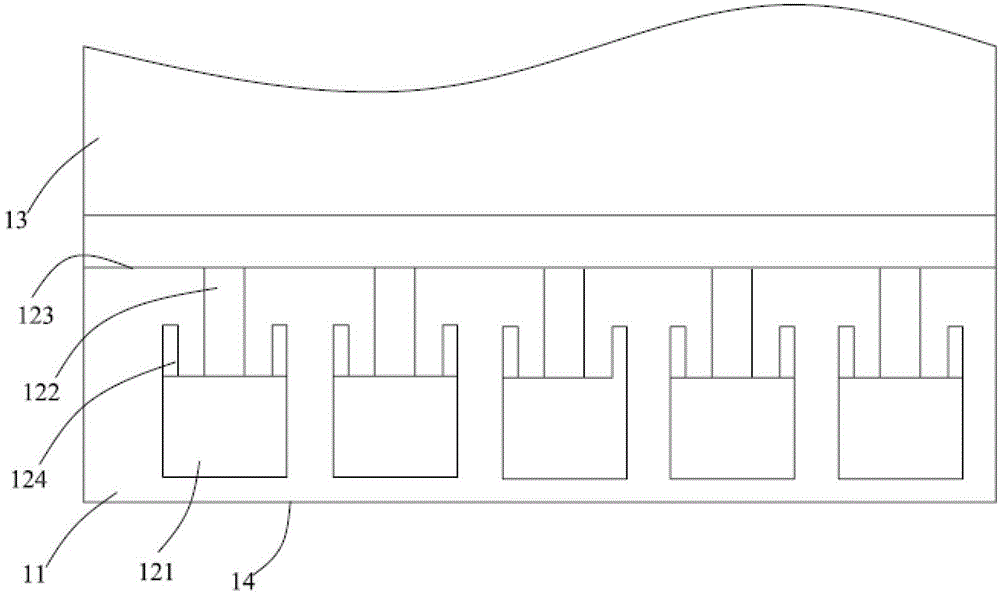

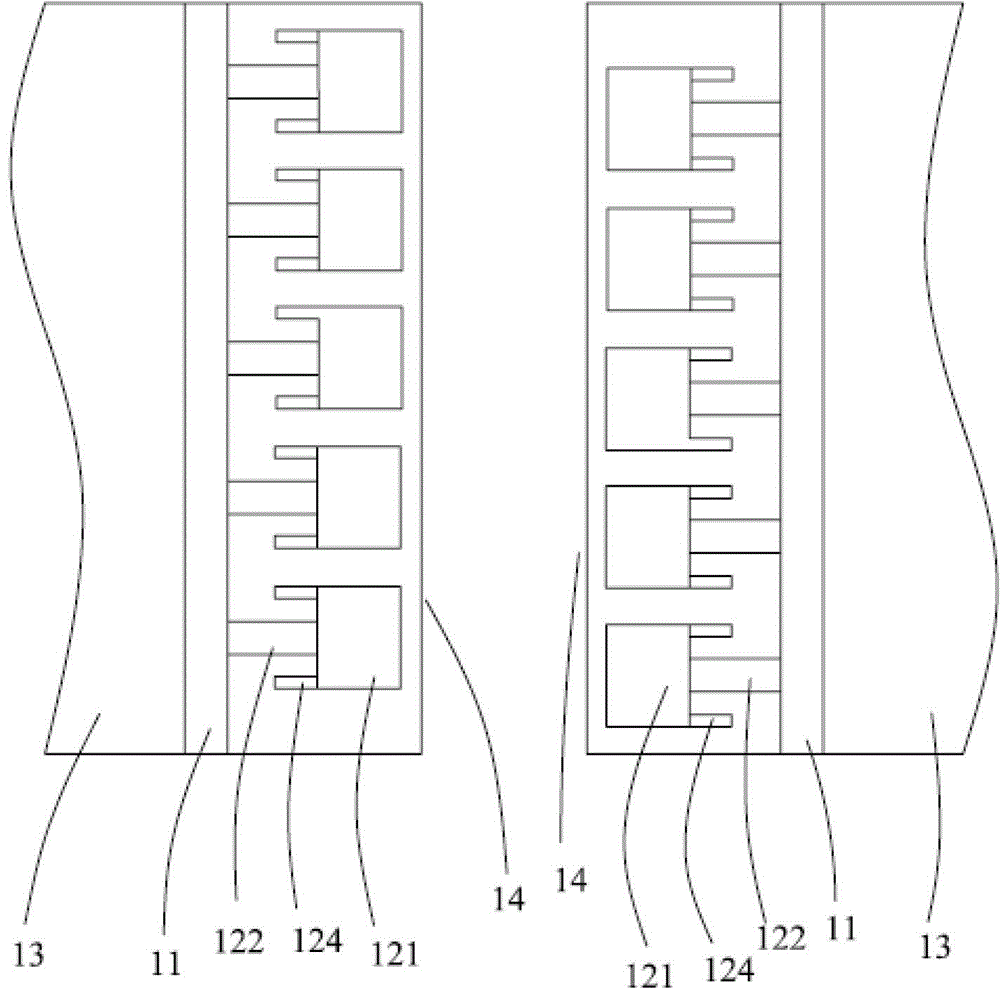

The invention provides a manufacture method for a gold finger circuit board and the circuit board manufactured by the method. The manufacture method for the gold finger circuit board comprises the steps of offering a base board with a ladder groove, manufacturing a gold finger structure inside the ladder groove, wherein the gold finger structure comprises a gold finger figure and a lead wire connected with the gold finger figure, covering heat resisting solder resisting ink on the surface of the lead wire, coating heat resisting adhesive tape on the surface of the gold finger figure in an attached mode, offering a plurality of plates which are arranged inside the ladder groove in a stack mode, pressing the plurality of plates in a fit mode, milling a top plate corresponding to the adhesive tape in the stacked plates, taking out a sandwich plate clamped between the plate at the top of the plates and the heat resisting adhesive tape, removing the heat resisting adhesive tape covered on the surface of the gold finger figure, electroplating the gold finger figure, forming a gold finger, and obtaining the required gold finger circuit board. The manufacture method can accurately manufacturing the thickness of the required circuit board, can achieve manufacture of the gold finger inside the ladder groove, and is simple in process.

Owner:DONGGUAN SHENGYI ELECTRONICS

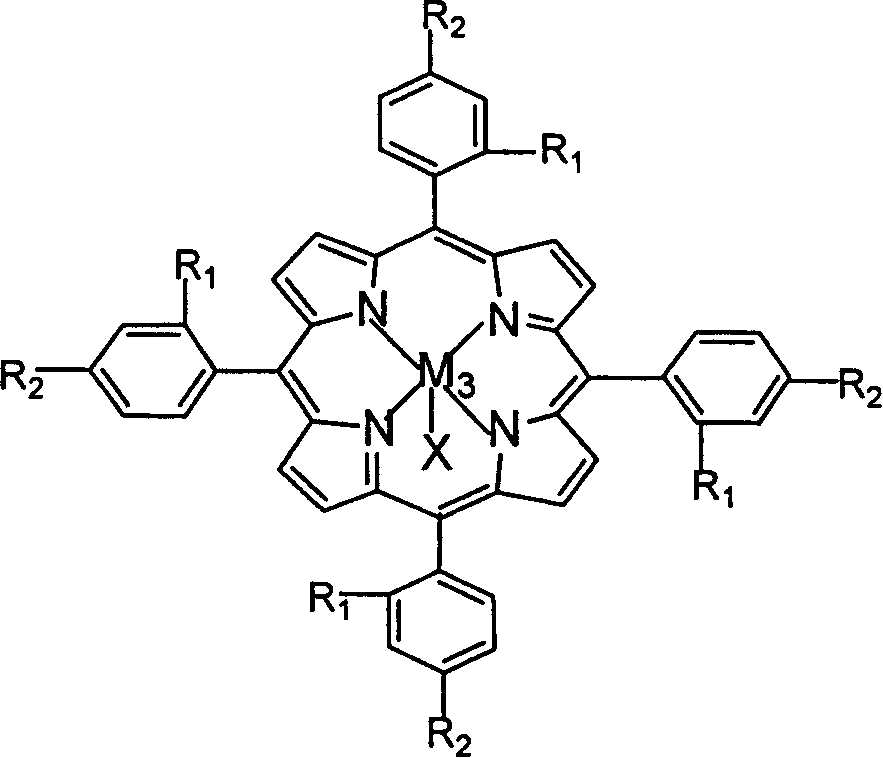

Method of preparing adipinic acid using bionic catalytic oxggen to oxidize cyclohexane

InactiveCN1556088AHigh catalytic activity and selectivityOxidation depth is easy to controlOrganic compound preparationCarboxylic compound preparationSolventCyclohexane

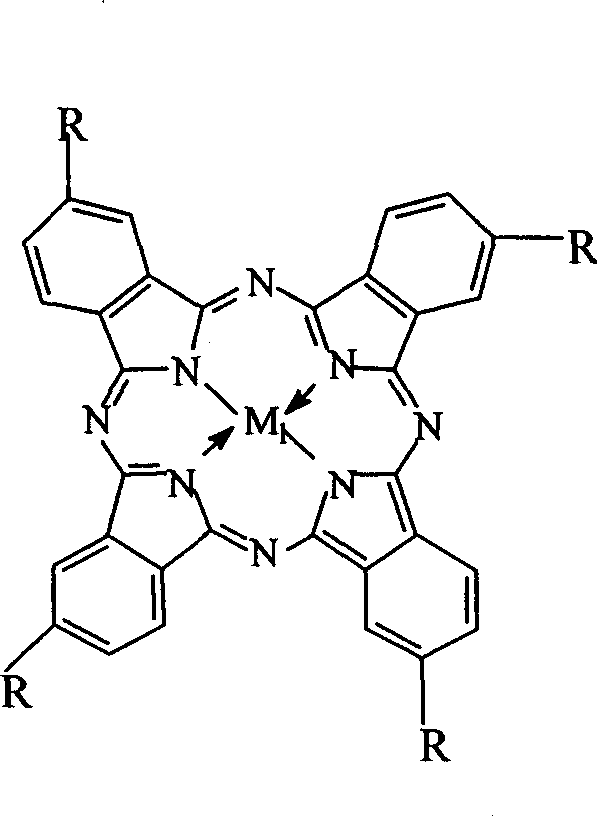

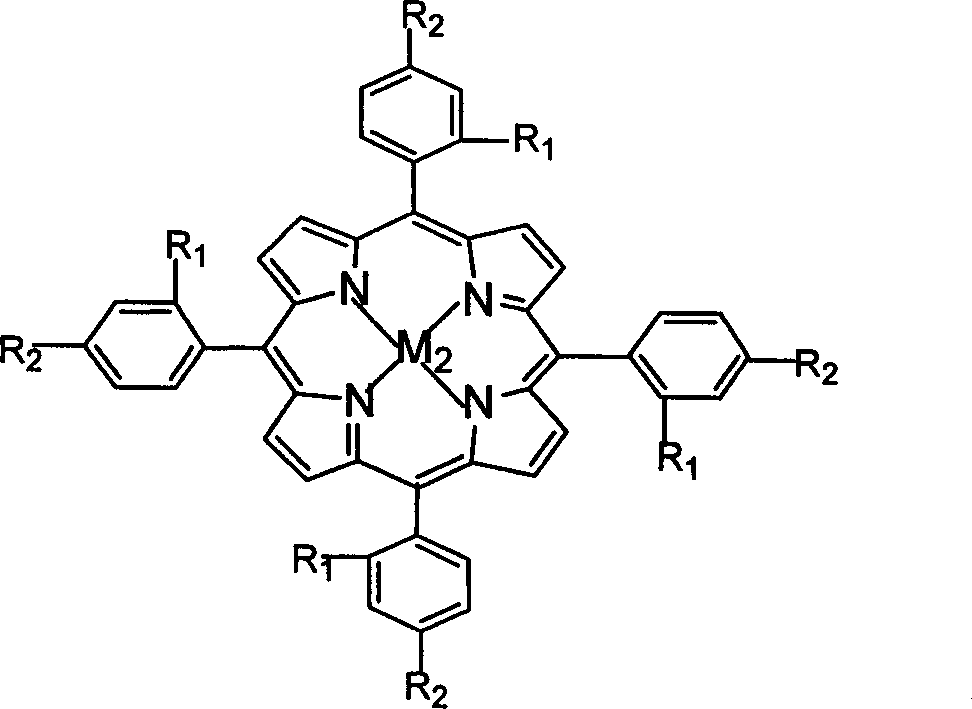

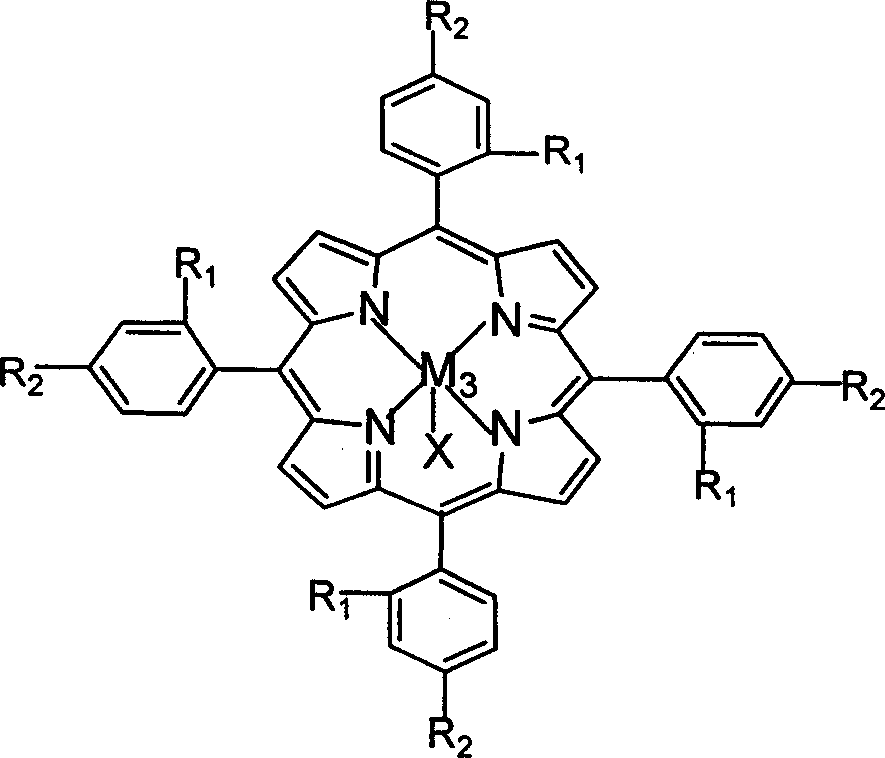

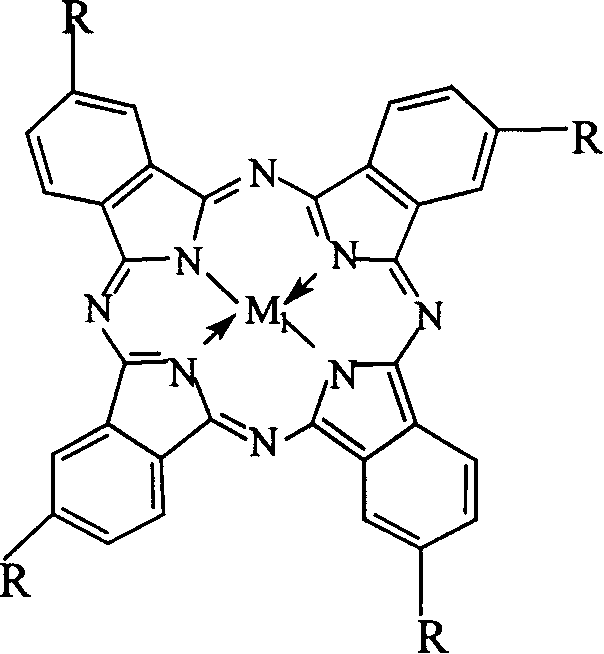

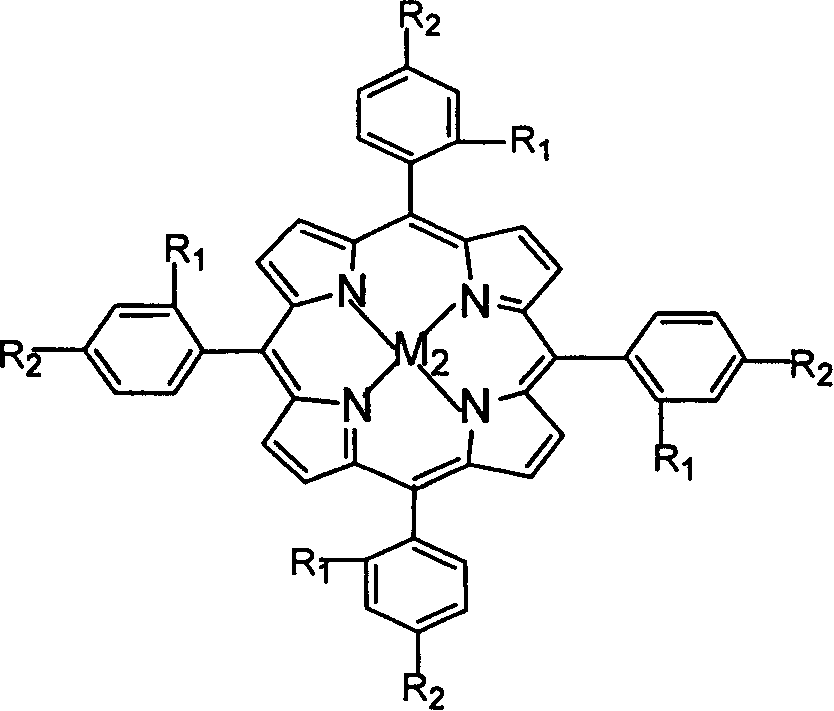

A bionic process for preparing hexanedioic acid by catalytic oxidation of cyclohexane features that under existance of catalyst which may be metallic phthalocyanine, single-nucleus metallic porphyrin, or mu-oxy-dual-nucleus metallic porphyrin, the hexane and O2 take part in oxidizing reaction at 110-160 deg.C for 4-32 hr.

Owner:BEIJING UNIV OF TECH

Method of preparing adipinic acid using bionic catalytic oxggen to oxidize cyclohexane

InactiveCN1231449CReduce dosageHigh catalytic activityOrganic compound preparationCarboxylic compound preparationRecyclable catalystEnzyme structure

Owner:BEIJING UNIV OF TECH

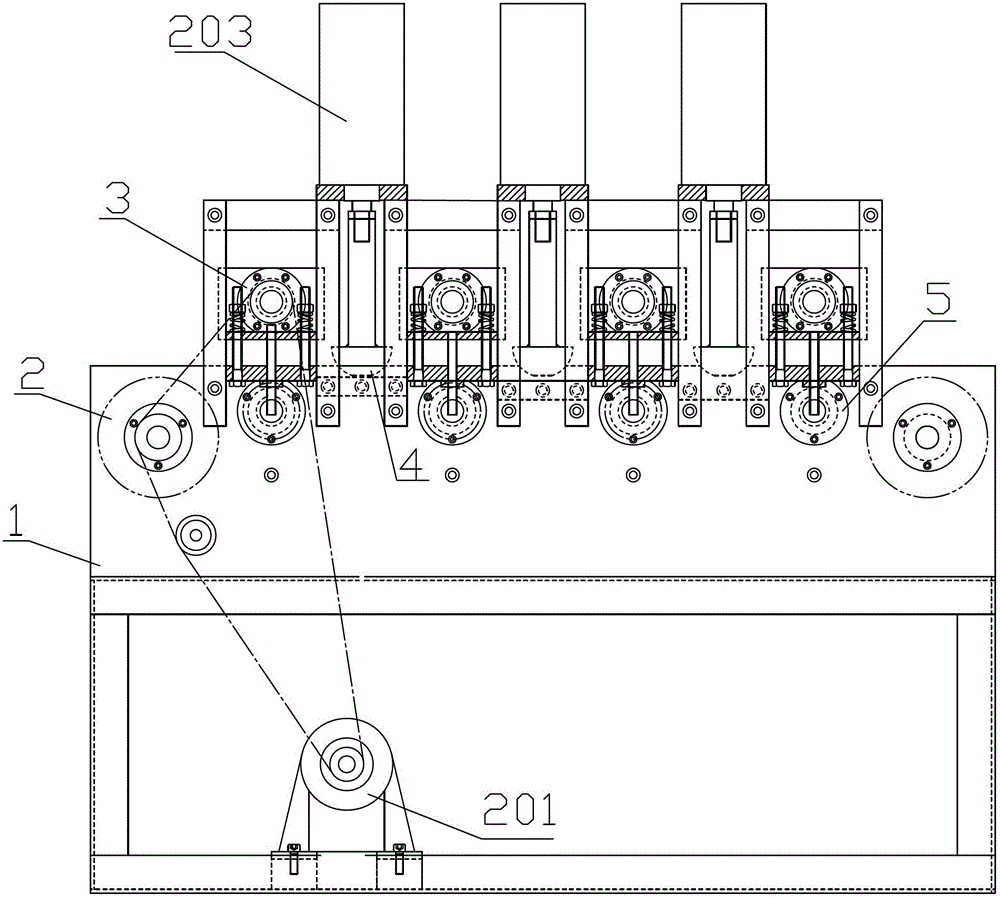

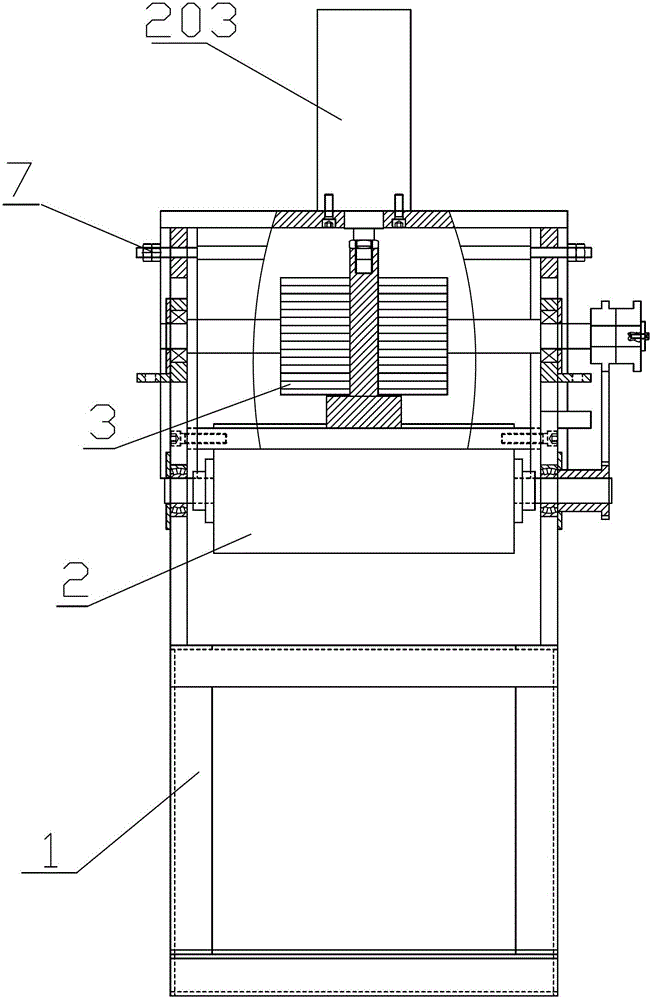

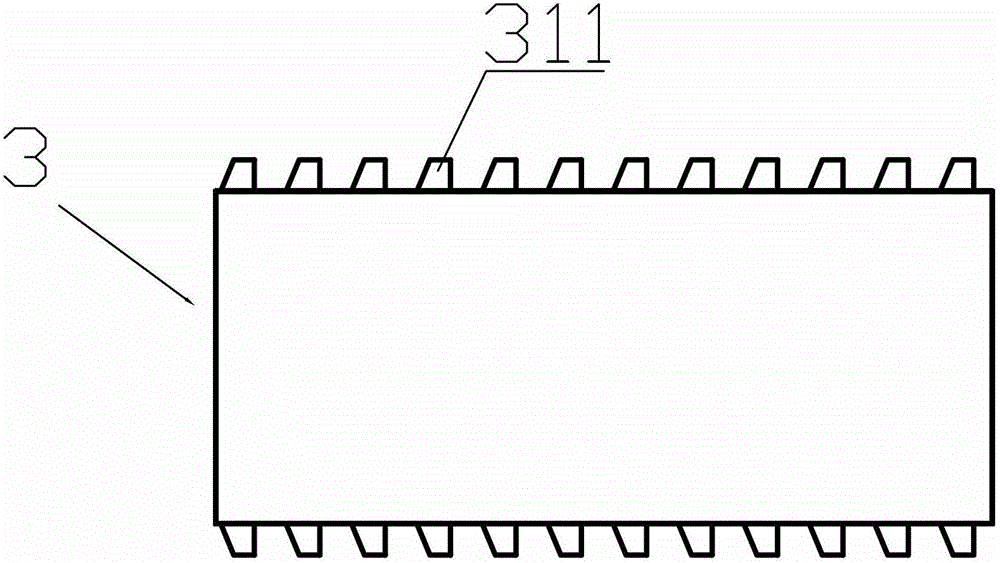

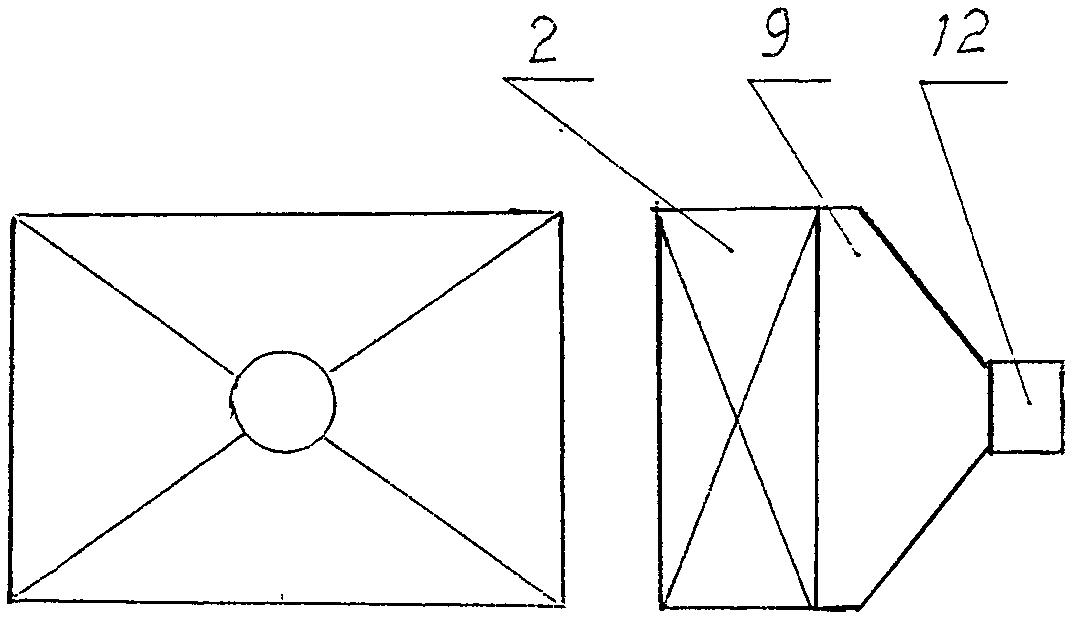

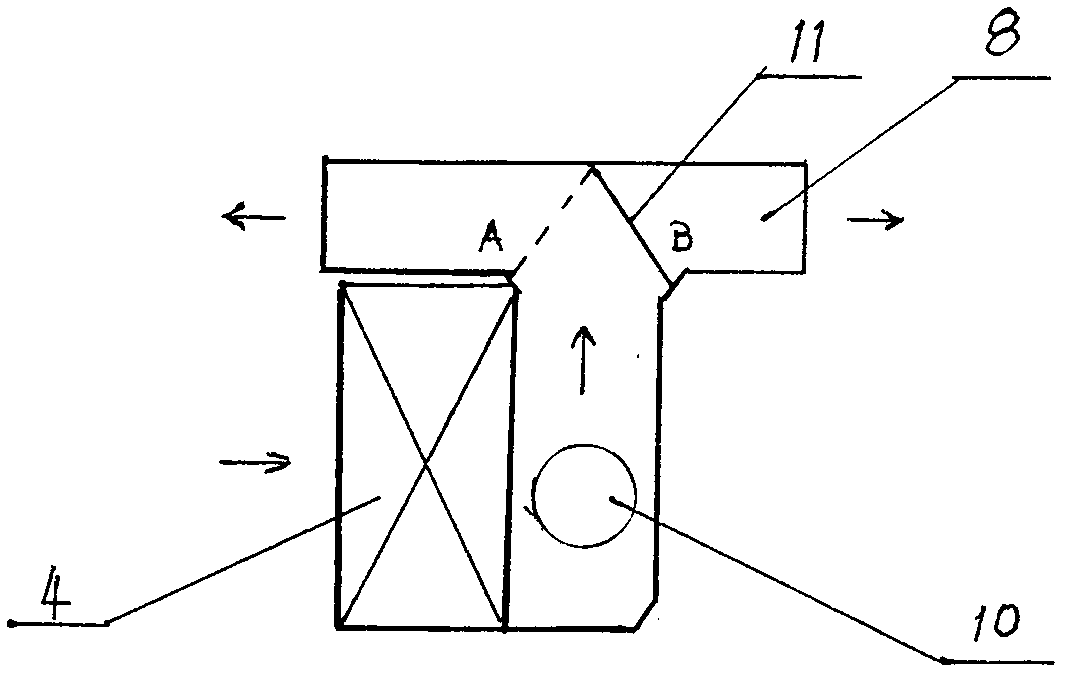

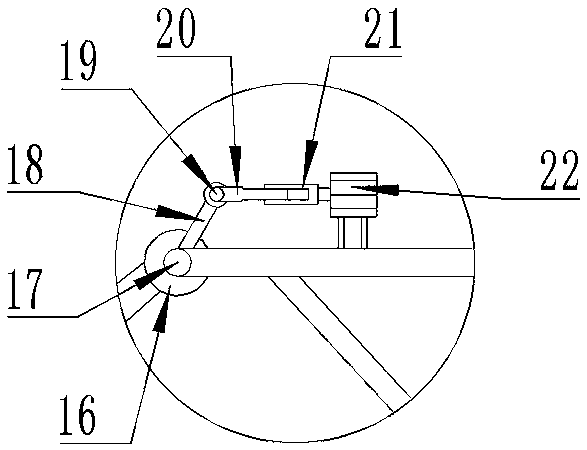

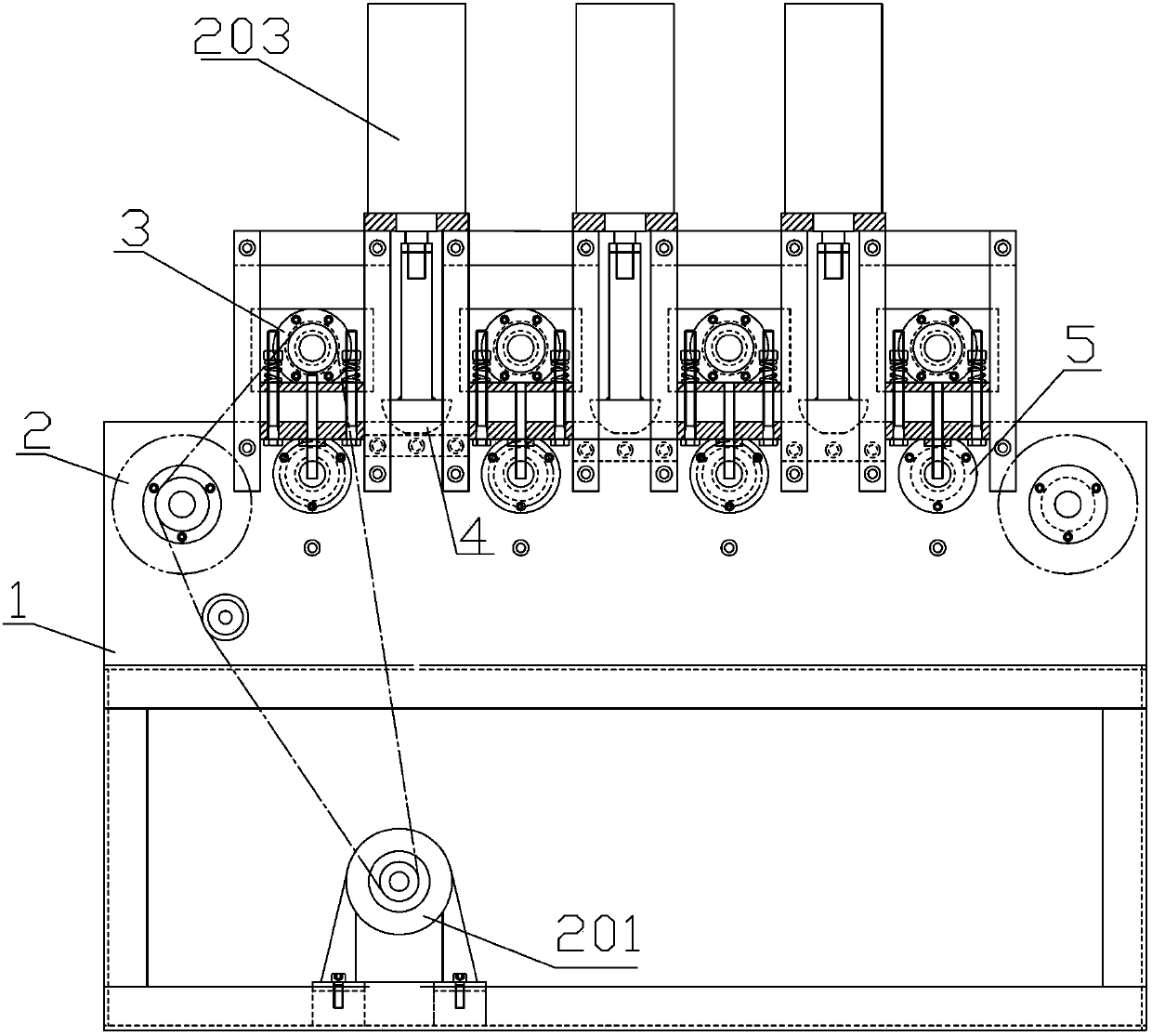

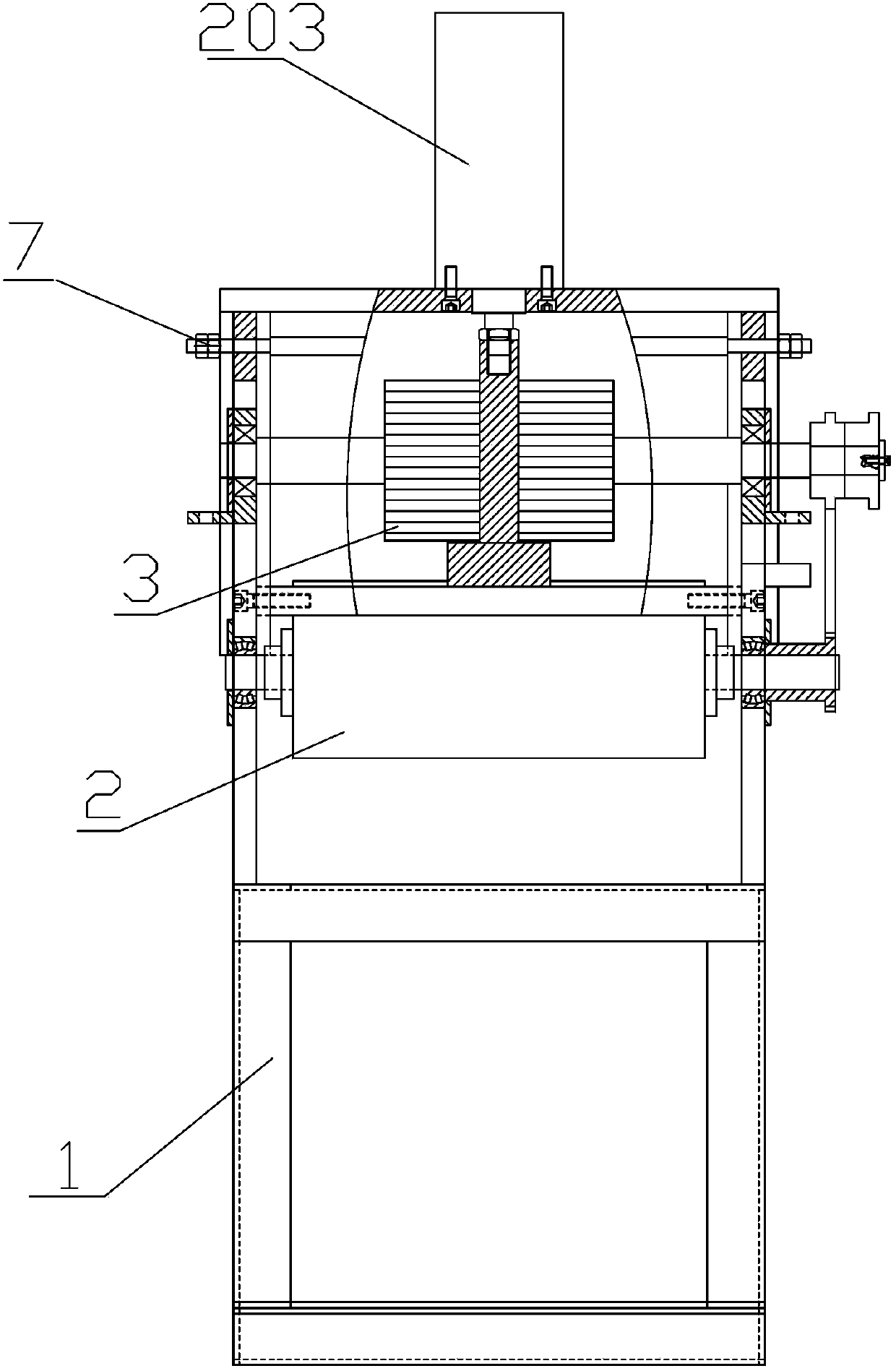

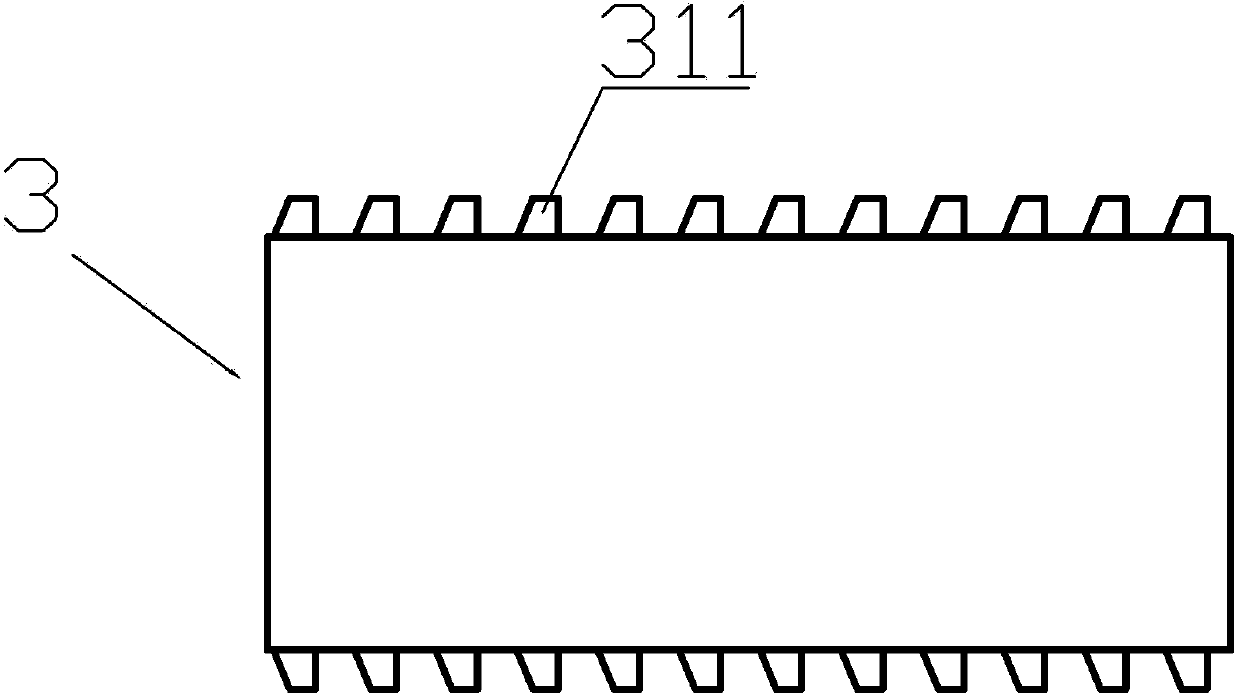

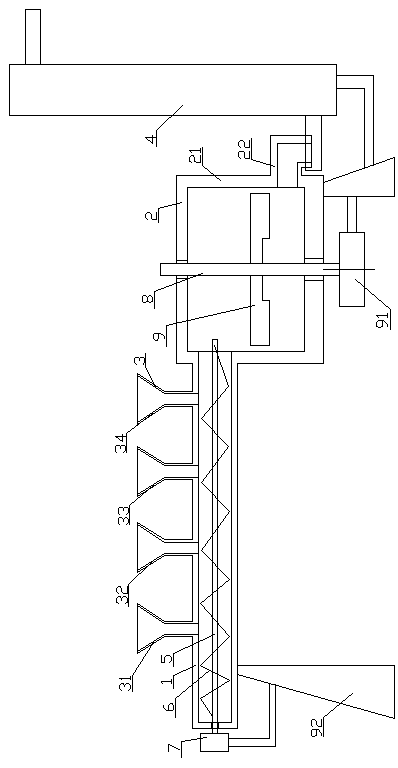

Bamboo fibrillating-rolling device

ActiveCN102909767ARealize productionReduced transverse strengthWood working apparatusFiber bundleModular design

A bamboo fibrillating-rolling device comprises a frame, a fibrillating mechanism, a rolling mechanism, a hammering mechanism, a skin-removing mechanism, a conveying mechanism and a power unit. The frame is provided with areas for fibrillating, rolling, hammering and skin removing. The fibrillating mechanism at least comprises one fibrillating roller set consisting of an upper and lower opposing paired fibrillating rollers, wherein at least the upper fibrillating roller is provided with fluffing teeth. The rolling mechanism consists of one or paired rolling rollers. The hammering mechanism comprises a plurality of hammers. The skin-removing mechanism is provided with metal wire brush rolls or scrapers for skin removing. The conveying mechanism is used to convey material to be processed to transversely pass through the areas for fibrillating, rolling, hammering and skin removing. The power unit powers the fibrillating mechanism, the rolling mechanism, the hammering mechanism, the skin-removing mechanism and the conveying mechanism respectively or simultaneously. The bamboo fibrillating-rolling device is available for efficiently producing bamboo fiber bundles with low transvers strength and reserved longitudinal strength. The skin-removing mechanism, the rolling mechanism, the fibrillating mechanism and the hammering mechanism are all in modular design and can be designed into a complete set for assembly and disassembly.

Owner:INT CENT FOR BAMBOO & RATTAN

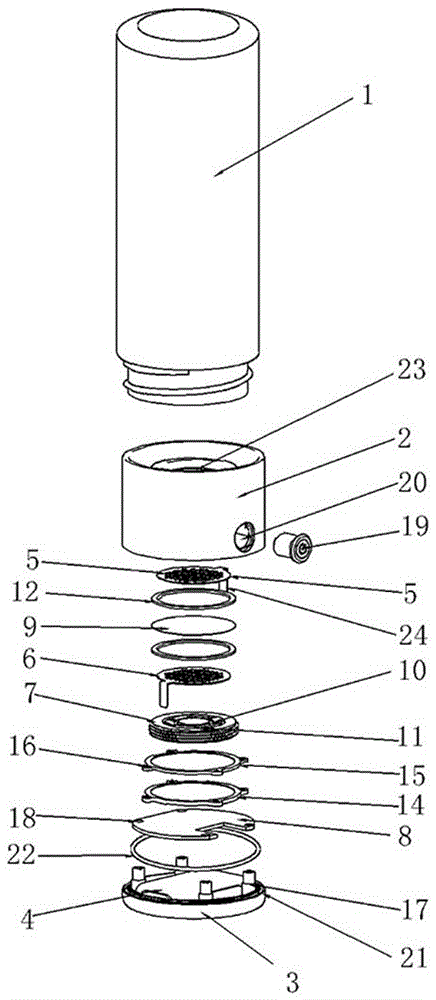

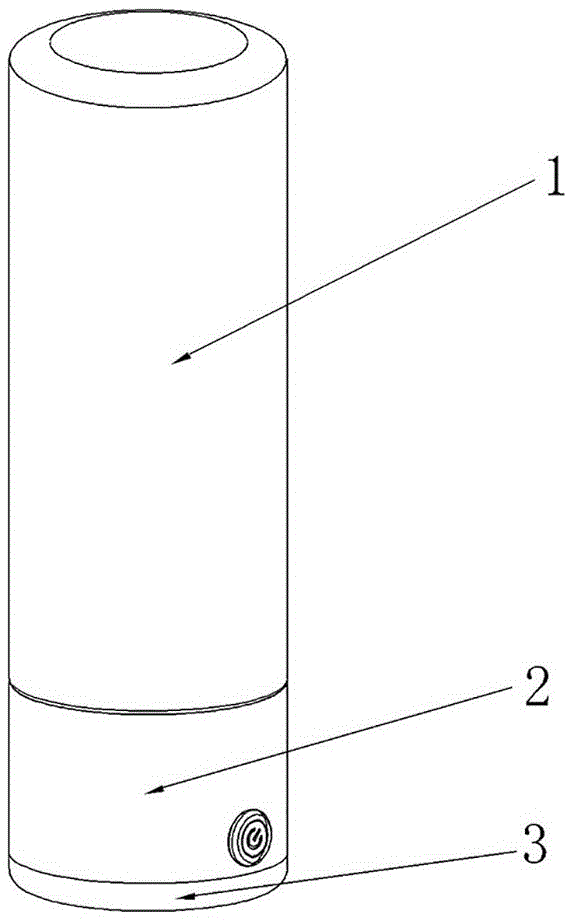

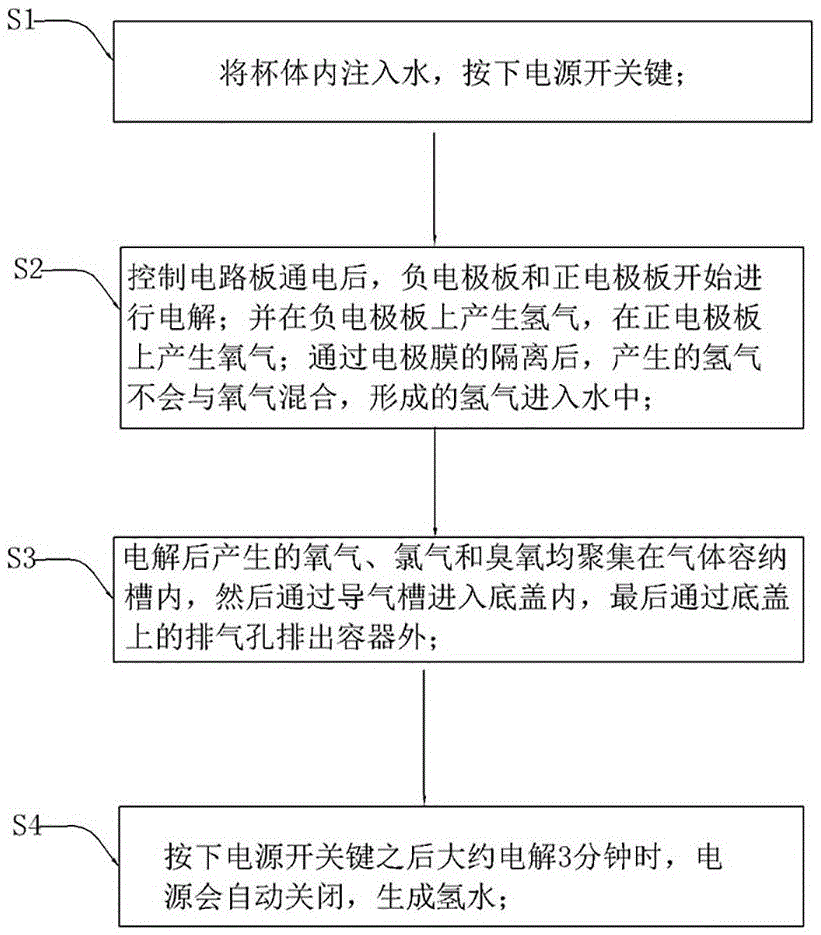

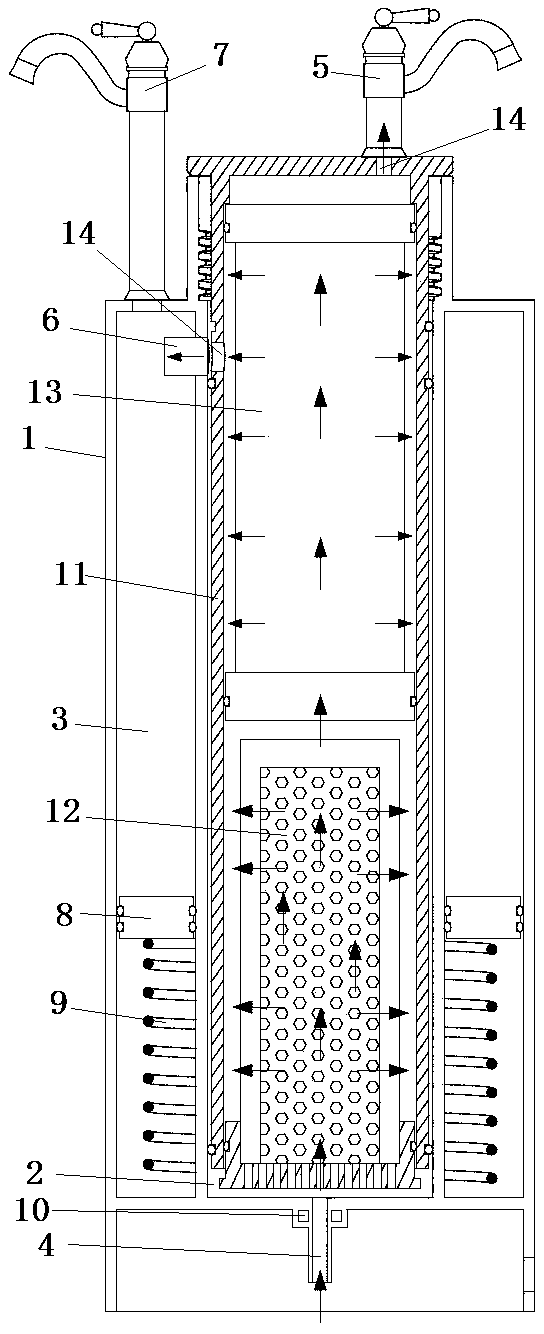

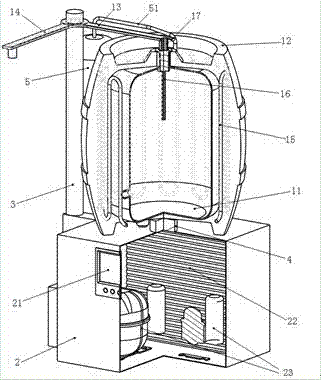

Hydrogen water cup and manufacturing method of hydrogen water thereof

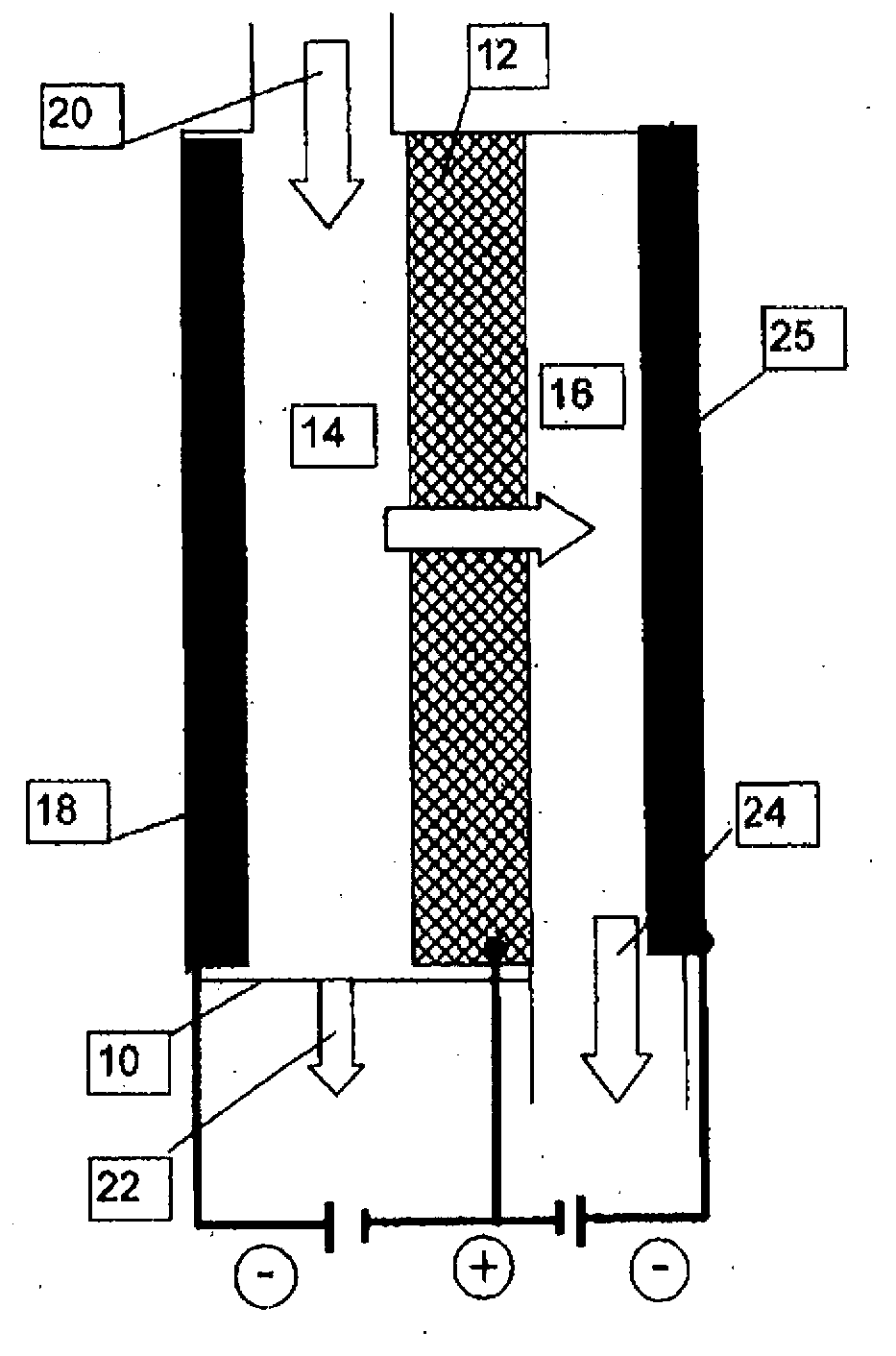

The invention discloses a hydrogen water cup and a utilization method thereof. The hydrogen water cup comprises a cup body, a cup base and a bottom cover, wherein one end of the cup base is detachably connected with the cup body; a lithium battery is fixed to the bottom cover; the bottom cover is fixed at the other end of the cup base; the bottom cover and the other end of the cup base are fixedly connected to define a cavity; a negative electrode plate, a positive electrode plate, a thread plug and a control circuit plate are sequentially arranged inside the cavity from up to down; the control circuit plate is fixed to the bottom cover and is electrically connected with the lithium battery; each of the negative electrode plate and the positive electrode plate leads out an electrode strip in the bottom cover direction; the two electrode strips are electrically connected with the control circuit plate; an electrode membrane is arranged between the positive electrode plate and the negative electrode plate; and oxygen, chlorine and ozone generated after electrolysis are gathered in a gas accommodating tank through the gas accommodating tank in the thread plug and are discharged through an exhaust hole in the bottom cover. According to the hydrogen water cup, oxygen and other gases are completely separated from hydrogen, then, hydrogen is prepared, and hydrogen is dissolved in water to form hydrogen water for people to drink.

Owner:SHENZHEN HEPOCH TECH CO LTD

Two-step production method for microalgae bio-oil

ActiveCN105001971AReduce nitrogen contentReduce the cost of quality improvementPeptide preparation methodsFatty-oils/fats productionHydrogenNitrogen

Relating to the technical field of microalgae bio-oil extraction, the invention discloses a two-step production method for microalgal bio-oil to solve the problem of high quality improvement cost caused by large nitrogen content of microalgae bio-oil. The method includes: firstly extracting protein contained in microalgae cells of a microalgae raw material to obtain a protein water solution and microalgae residue; then separating the protein precipitate from the protein water solution to obtain protein and a water phase; then adjusting the solid content of the microalgae residue with the water phase to obtain a microalgae residue suspension; and then taking the microalgae residue suspension as the raw material, and utilizing hydrothermal liquefaction method to produce microalgae bio-oil. Compared with conventional hydrothermal liquefaction methods, the microalgae bio-oil obtained by the method has a nitrogen content reduced by 40%, thus greatly saving the dosage of hydrogen during subsequent microalgae bio-oil quality improvement, reducing catalyst intoxicating phenomenon in the quality improvement process, and also realizing secondary utilization of the water phase at the same time. The two-step production method for microalgal bio-oil provided by the invention is used for extraction of microalgae bio-oil.

Owner:ENN SCI & TECH DEV

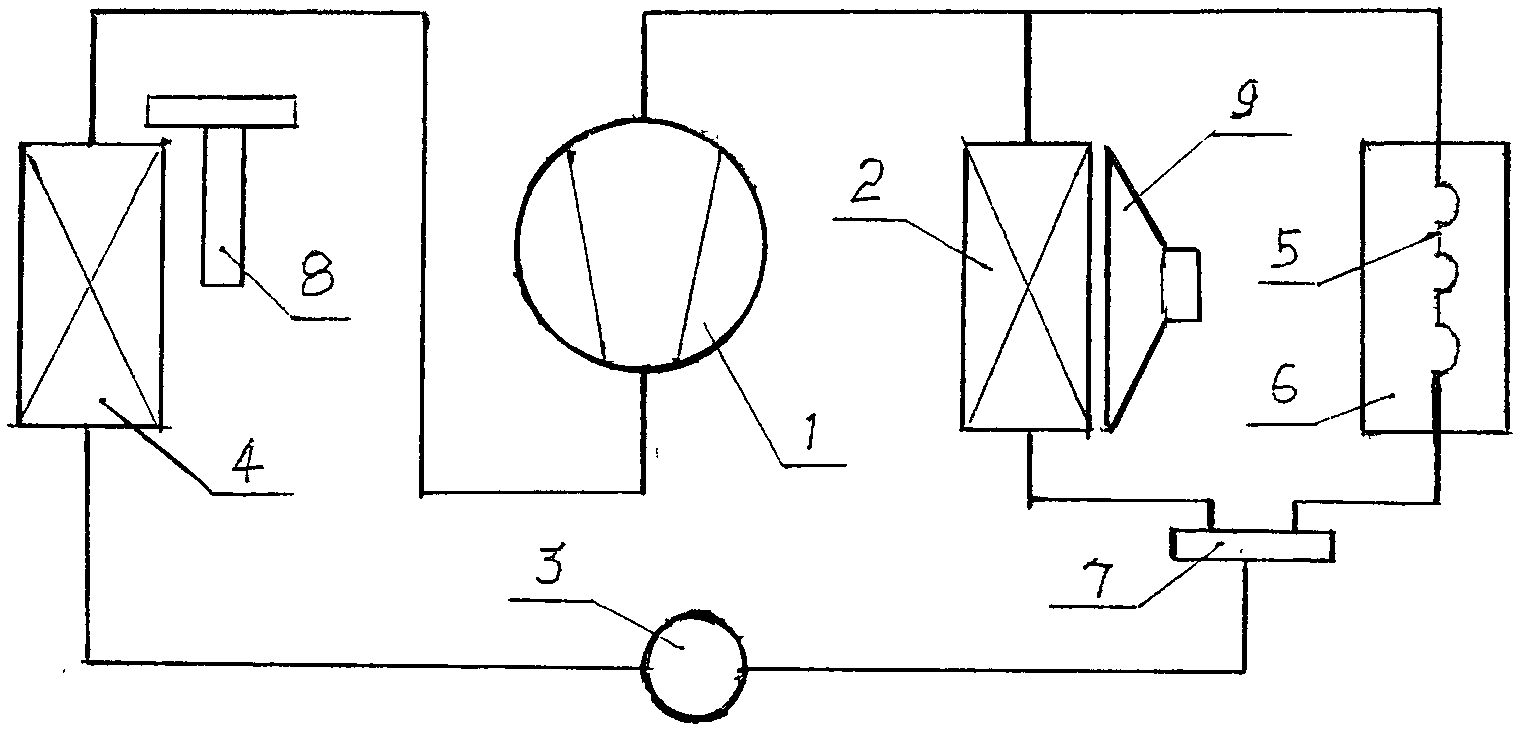

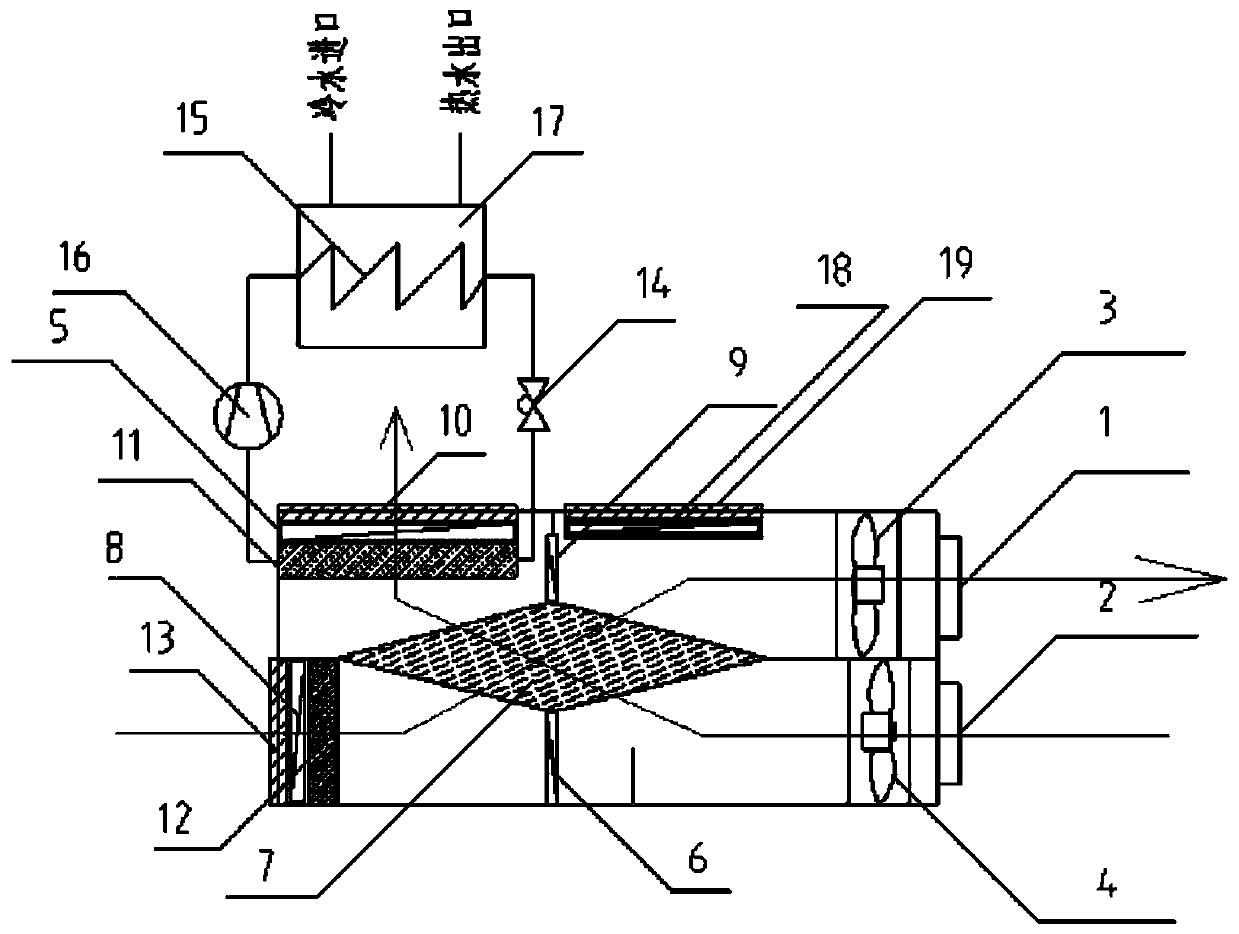

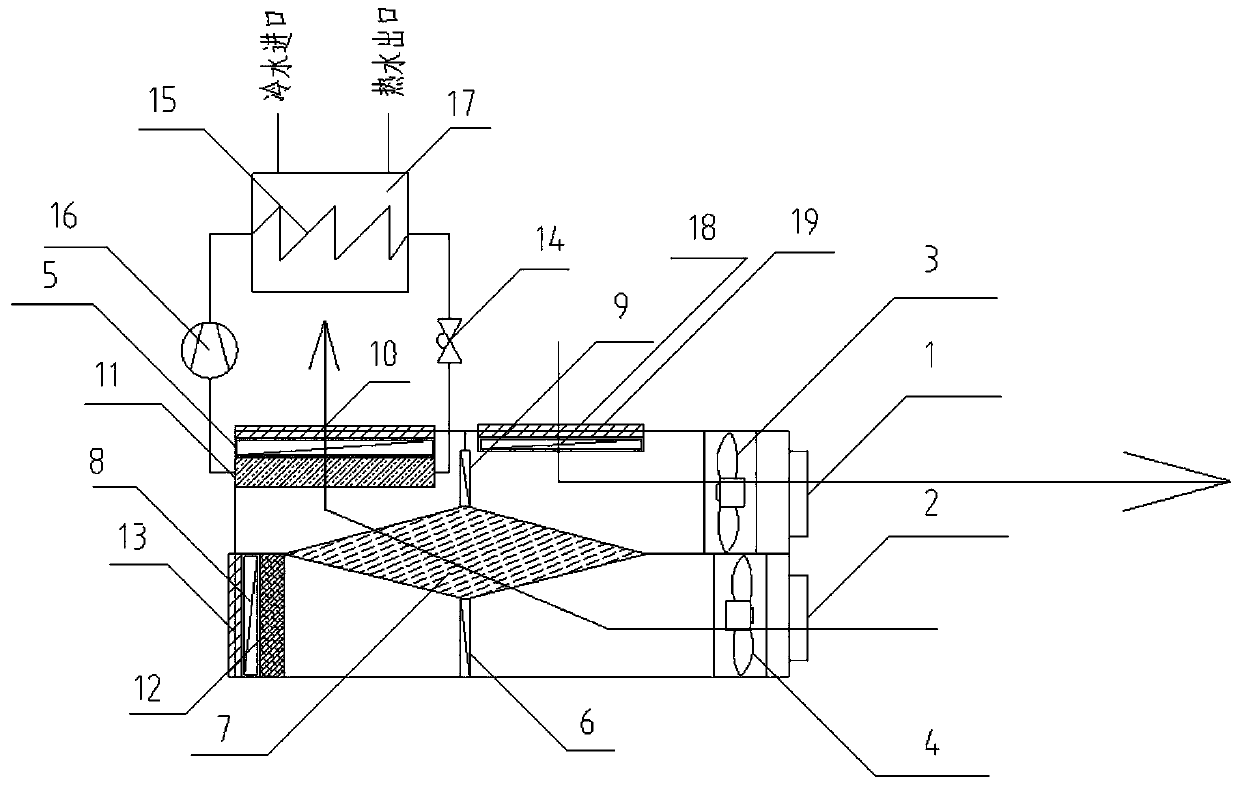

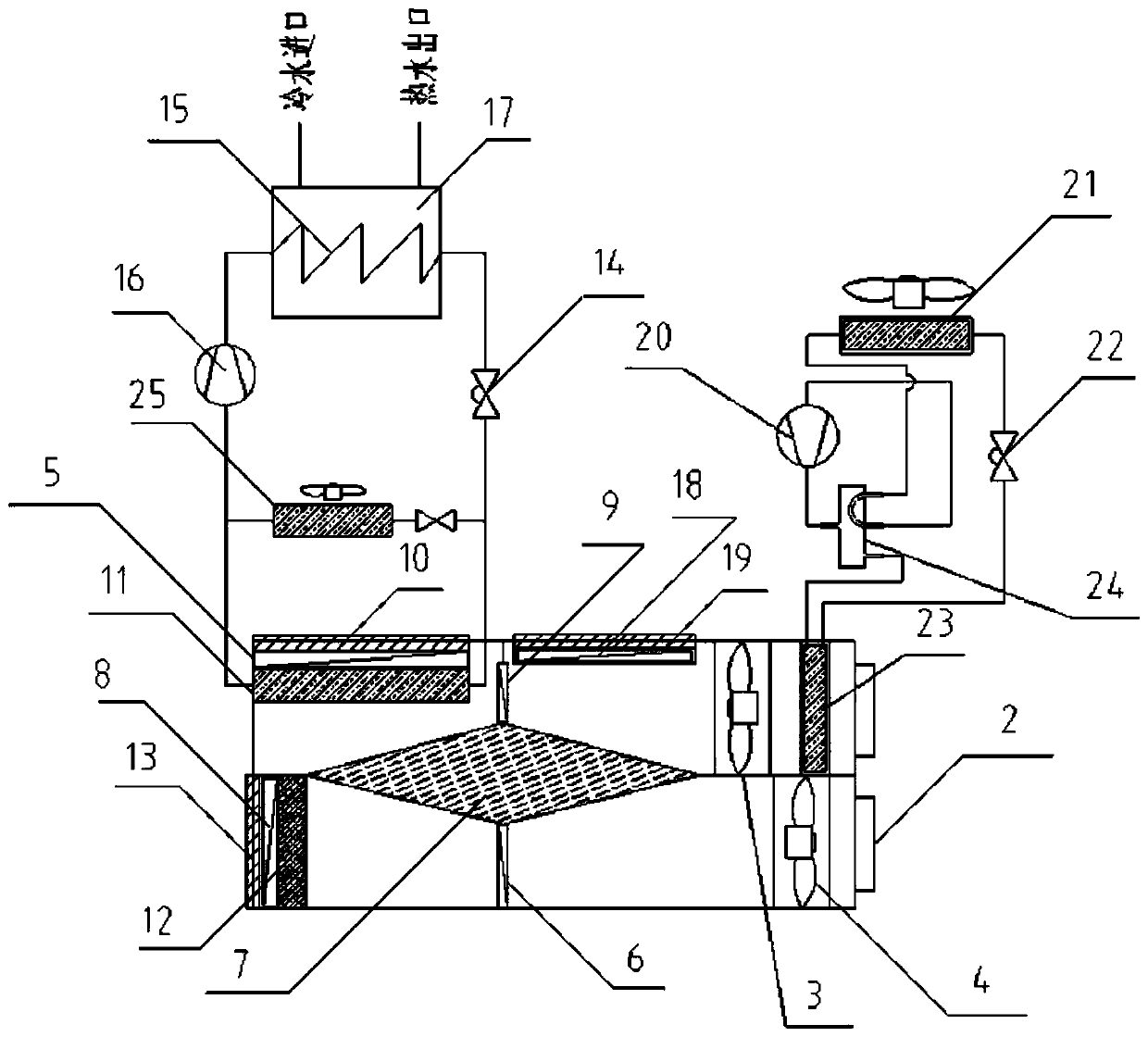

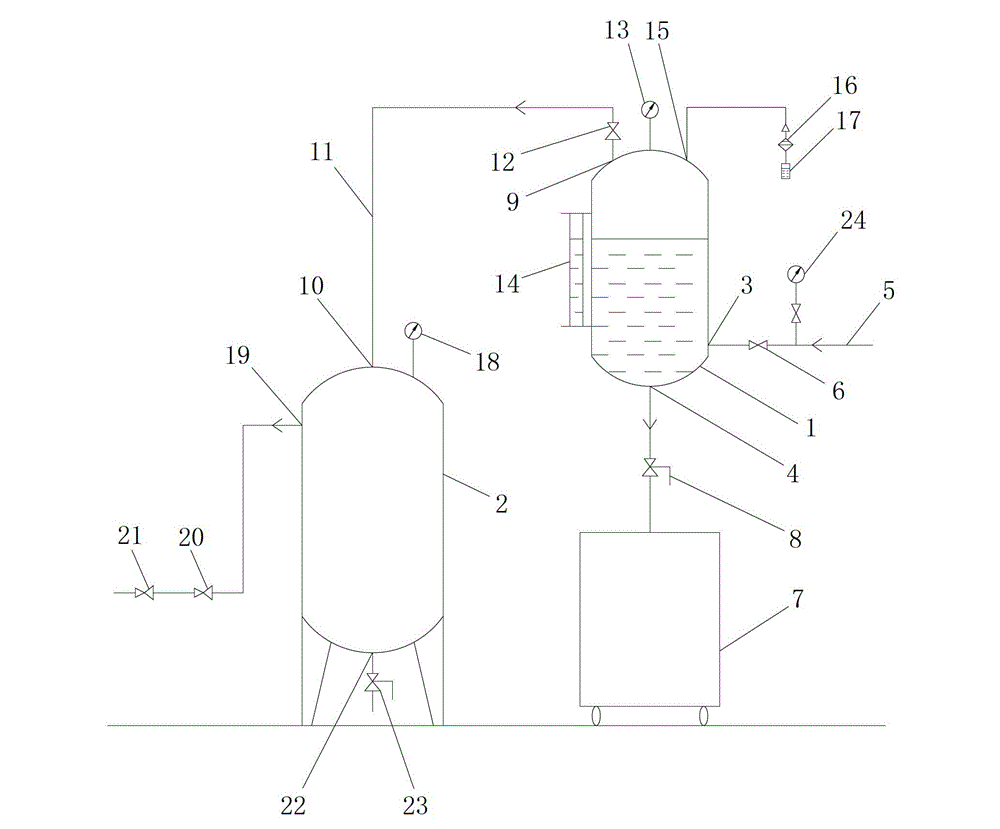

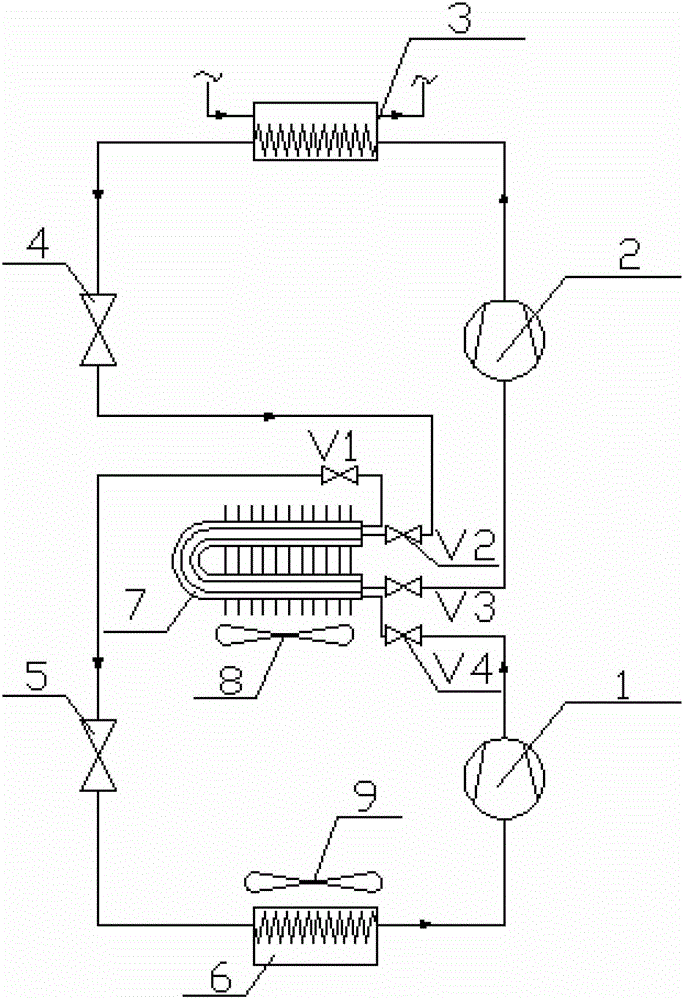

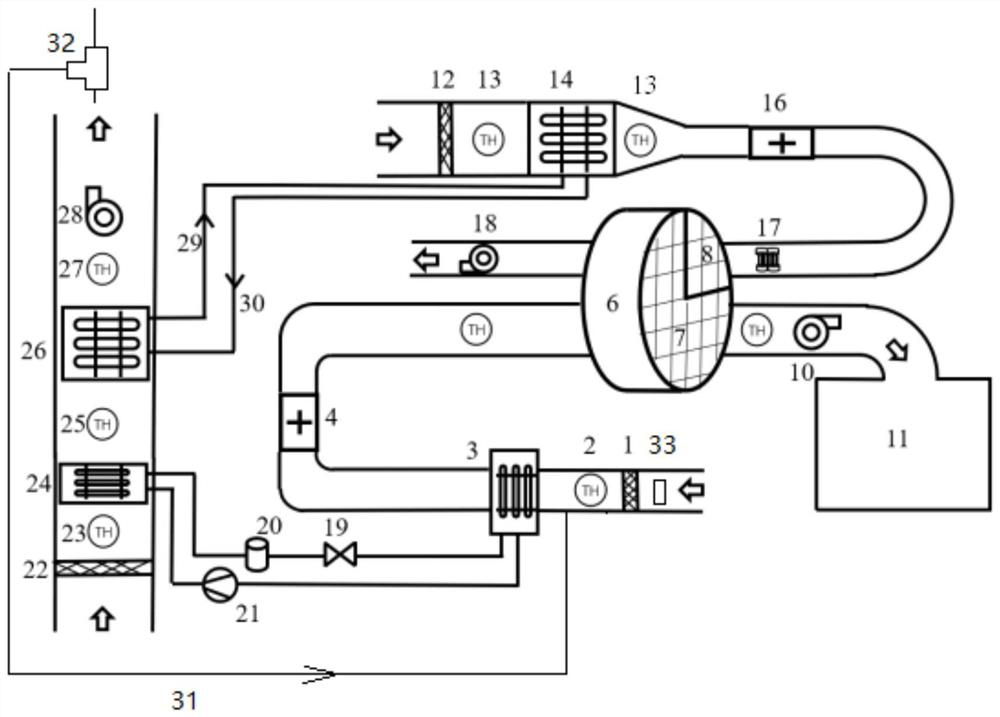

Air-energy air conditioner and water heater all-in-one machine

InactiveCN103017270ARealize the cooling effectRealize productionCondensate preventionFluid circulation arrangementThermal energyElectricity

The invention provides an air-energy air conditioner and water heater all-in-one machine. Most of air-energy water heaters and common air conditioners in the prior art have single functions and belong to two types of products; particularly, the air-energy water heaters can only be used in South China and the geographical limitation is very great; and when the air conditioners are operated, plenty of generated heat and naturally-formed low-temperature condensed water are wasted. The all-in-one machine disclosed by the invention is additionally provided with a water storage bucket on the basis of an integrated air conditioner; the water storage bucket is internally provided with a condensing pipeline which is in parallel to a condenser of the air conditioner; and under the effect of a control element, the air-energy air conditioner and water heater all-in-one machine can independently refrigerate, can independently obtain hot water, and can also obtain the hot water while refrigerating. The machine introduces the condensed water which is wasted in the prior art into the condenser to be reasonably utilized, so that the energy efficiency ratio is improved and 75% of electricity can be saved all the year round. The air-energy air conditioner and water heater all-in-one machine is simple in structure, is placed indoors, is not limited by regions and is suitable for all types of the regions in China for use.

Owner:曹同禄 +2

Preparation method of novel tea leaf volatile flavoring substance and application of novel tea leaf volatile flavoring substance in cigarettes

InactiveCN102068029AQuality improvementIncrease aromaTobacco preparationEssential-oils/perfumesDistillationAbsorption column

The invention relates to a preparation method of a novel tea leaf volatile flavoring substance and application of the novel tea leaf volatile flavoring substance in cigarette flavoring. The novel tea volatile aromatic substance is prepared with the method comprising the following steps of: taking tea leaves; distilling with vapor; collecting distillate; separating with an absorption column; and obtaining the tea leaf volatile flavoring substance. After the tea leaf volatile flavoring substance is added to tobacco shreds of the cigarettes, the cigarettes can have pleasant fresh and sweet tastes, which can improve the fragrance quality and the grade of the cigarettes, increase tobacco original fragrance, ensure rich, sweet, pure and mild smoke, suppress irritants and reduce impurities. The invention has the advantages that the technology of combining vapor distillation and absorption column separation is used for preparing the novel tea leaf volatile flavoring substance for the first time, and the substance is applied to cigarette flavoring, which obtains good expected effect, thus the invention provides a new technology for extracting and processing natural plants, provides a novel and important natural flavoring material for cigarette aromatization, and lays a certain foundation for researching various tea leaves in fragrance compensation of cigarettes.

Owner:广州华芳烟用香精有限公司

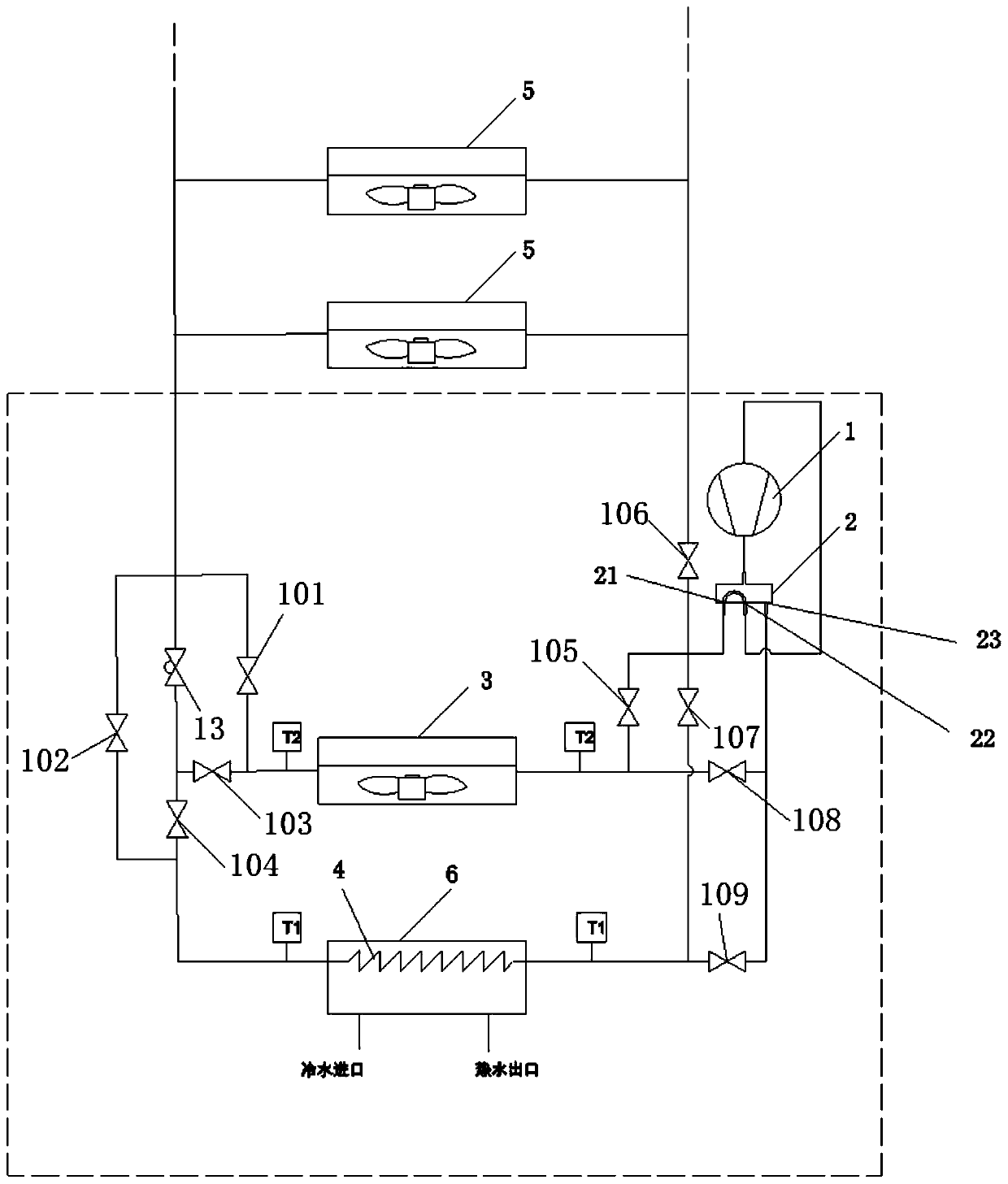

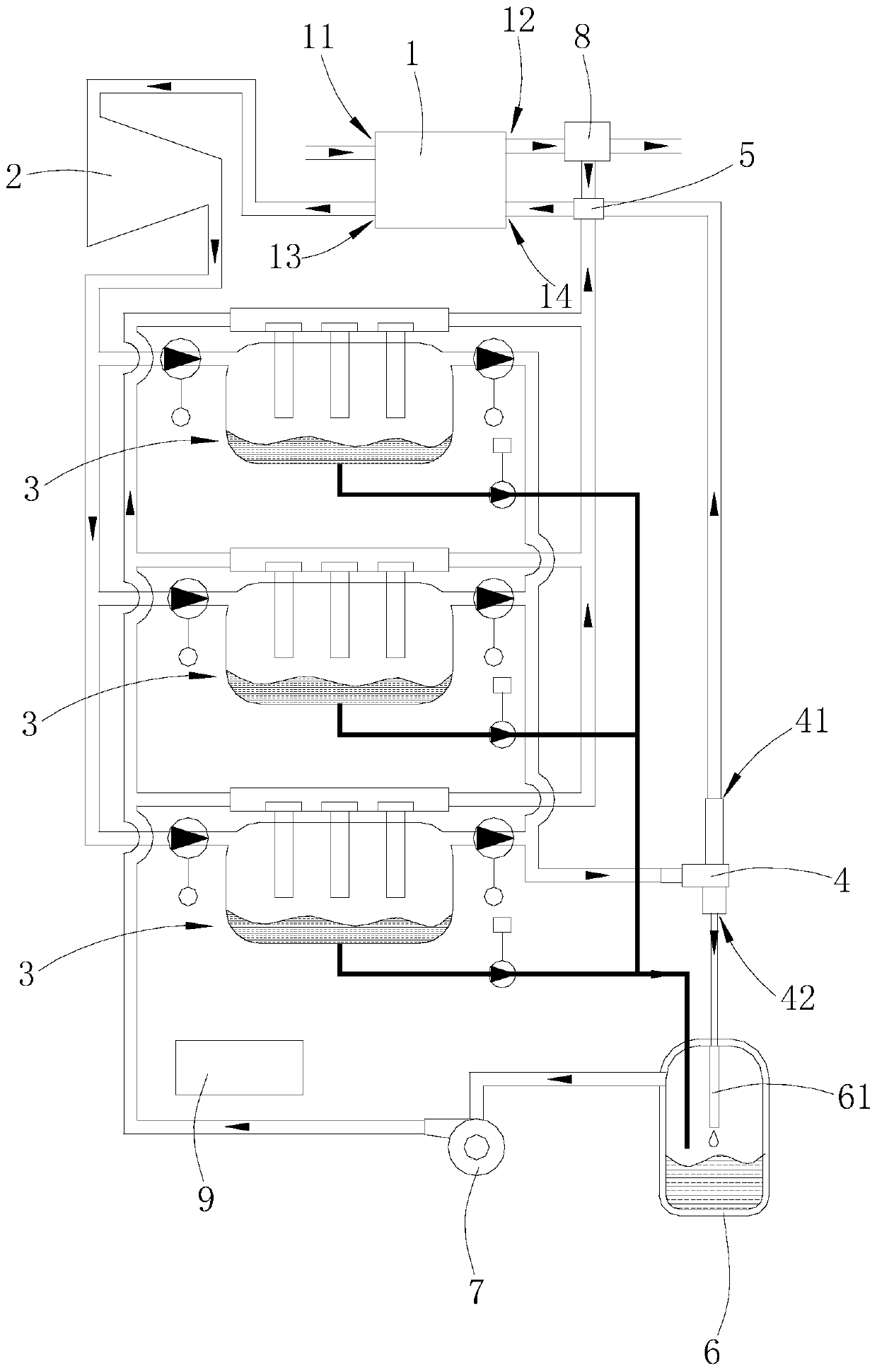

Air conditioner, fresh air heat pump circulation pipeline thereof and heat recovery control system and method

PendingCN110230864AImprove heat recovery efficiencyIncrease temperatureEnergy recovery in ventilation and heatingFluid heatersControl systemWater storage tank

The invention discloses an air conditioner, a fresh air heat pump circulation pipeline thereof and a heat recovery control system and method. The fresh air heat pump circulation pipeline comprises a fresh air circulation assembly comprising a first fresh air passage, a second fresh air passage, an exhaust passage and a selector switch, and a heat pump circulation assembly, wherein when the selector switch is in a first operation state, the first fresh air passage is connected, and the second fresh air passage is disconnected; when the selector switch is in a second operation state, the first fresh air passage is disconnected, and the second fresh air passage is connected; the heat pump circulation assembly comprises a first evaporator arranged in the exhaust passage, a water storage tank and a condenser arranged in the water storage tank; and a refrigerant pipe of the first evaporator is connected into the water storage tank and connected with the condenser condenser in the water storage tank. In this way, the air conditioner with the fresh air heat pump circulation pipeline avoids waste of heat, and can provide domestic hot water for user at the same time, and the exhaust air heatrecovery efficiency is improved.

Owner:北京晶海科技有限公司

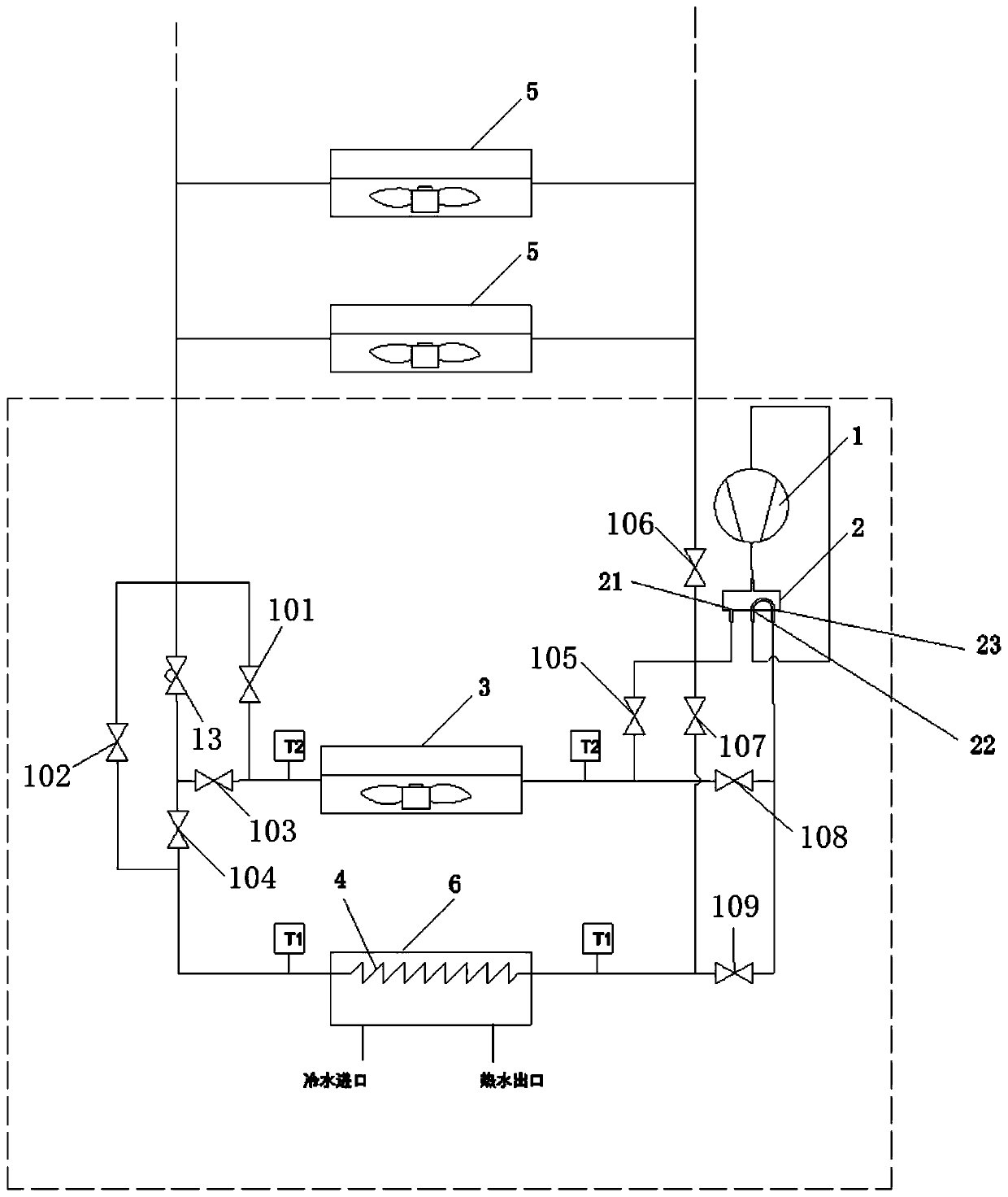

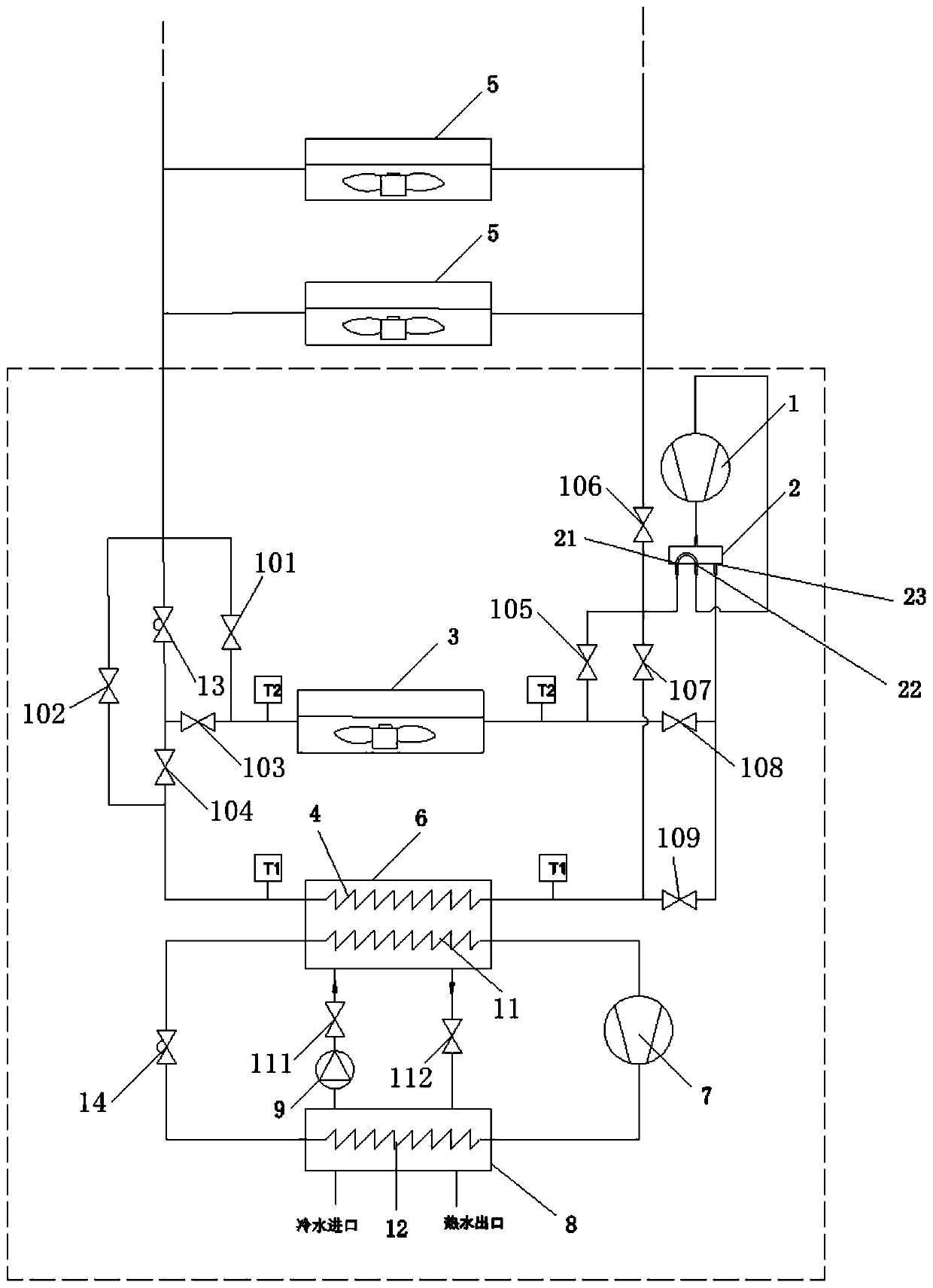

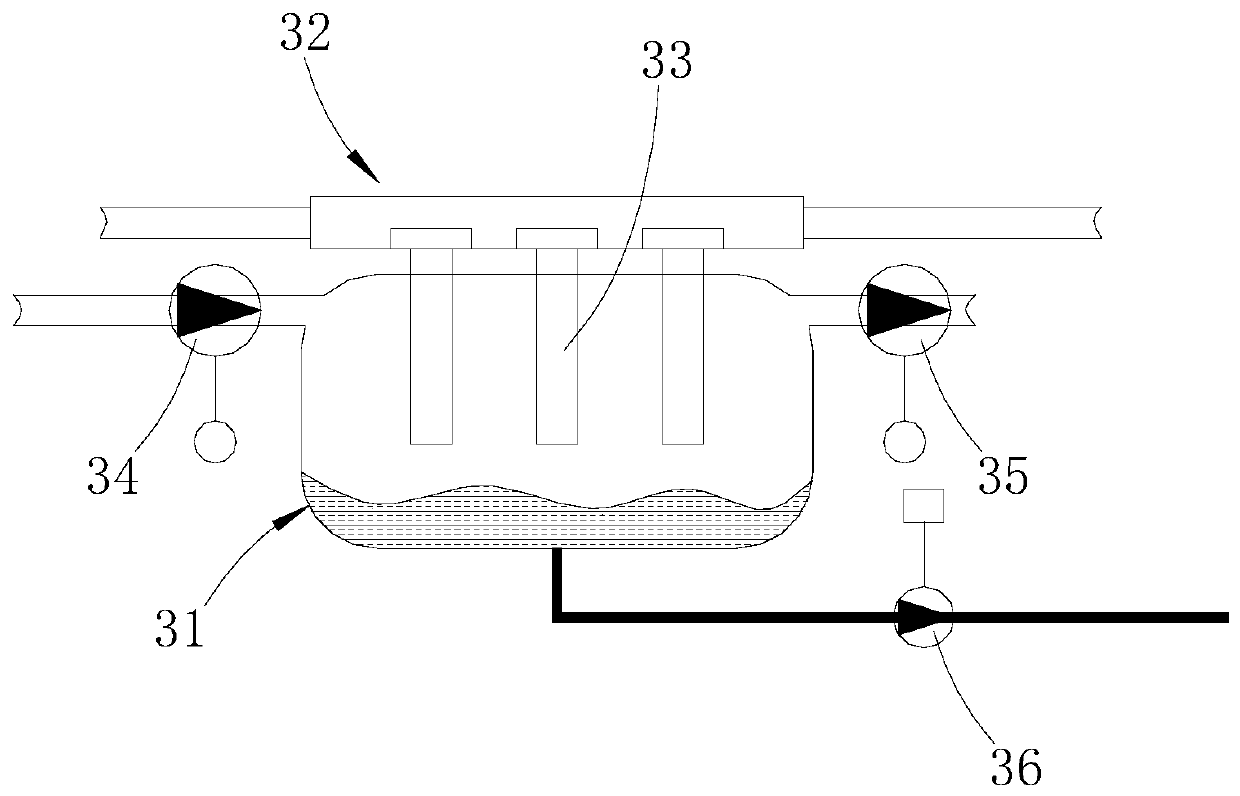

Air conditioner and integrated circulating pipeline system thereof

PendingCN109945374AAvoid wastingRealize productionEnergy recovery in ventilation and heatingMechanical apparatusWater storage tankEngineering

The invention discloses an air conditioner and an integrated circulating pipeline system thereof. The integrated circulating pipeline system comprises: a refrigeration and heating circulating system,and a heat pump hot water circulation system; the refrigeration and heating circulating system comprises a first compressor, a reversing valve, a first throttling device, a condenser, a first heat exchange pipeline and an indoor evaporator, wherein the condenser is arranged in parallel with the first heat exchange pipeline; the heat pump hot water circulation system comprises a water storage tank,wherein the water storage tank is provided with a cold water inlet and a hot water outlet; and the first heat exchange pipeline is arranged in the water storage tank. In the working process, heat generated by the condenser is subjected to heat exchange with water in the water storage tank through the first heat exchange pipeline, so that the water in the water storage tank is heated, and production of domestic hot water is achieved. Therefore, the air conditioner and the integrated circulating pipeline system thereof adopt the water storage tank to absorb condensation heat of outdoor unit ofthe air conditioner, so that heat waste is avoided; and domestic hot water can be provided for users.

Owner:北京晶海科技有限公司

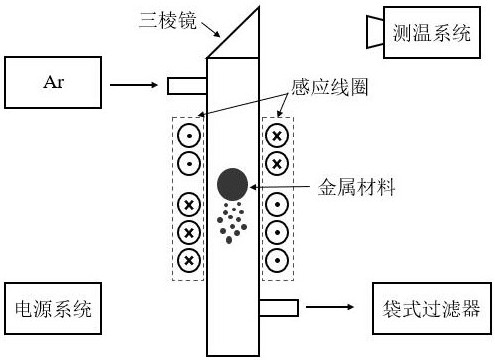

Method for preparing refractory metal powder

The invention relates to a method for preparing refractory metal powder, and belongs to the technical field of preparation of metal powder. The method comprises the steps of processing refractory metal raw materials into granular raw materials; placing the obtained granular raw materials into an induction coil of electromagnetic suspension refining equipment, charging protective gas namely pure Ar, enabling an electric source to be switched on, and enabling the metal granules to suspend and melt into liquid suspending in air; continuing performing suspension melting on the suspending metal granules, when the temperature of liquid metal molten drops is far greater than melting temperature, enabling the liquid metal to begin to evaporate, producing metal powder suspending in protective gas,performing condensing, and collecting condensed powder in the protective gas at the position of a gas outlet; and performing drying treatment on the condensed powder to obtain the refractory metal powder. By the method, the problem of preparation of refractory metal material powder can be solved, and quick, simple and environment-friendly preparation of the refractory metal powder can be realized.

Owner:KUNMING UNIV OF SCI & TECH

Device and method for preparing compressed air by using kinetic energy of tap water

InactiveCN102943960ARealize productionEfficient use ofContainer discharging methodsContainer filling under pressureInlet valveEngineering

The invention relates to a device and a method for preparing compressed air by using lost kinetic energy of tap water during usage. The device comprises a pressure converter and an air storage tank, wherein a water inlet is arranged on the pressure converter and connected with a tap water pipe, an inlet valve is arranged at the water inlet, a water outlet is arranged at the bottom of the pressure converter, a drain valve is arranged at the water outlet, an air discharge port and an air suction port are arranged at the upper end of the pressure converter respectively, the air discharge port is connected with an air inlet of the air storage tank through the pipe, an air outlet valve is arranged on a pipe of the air discharge port, a pressure gauge is arranged on the tap water pipe, a first pressure gauge and a liquid indicator are arranged on the pressure gauge, and a second pressure gauge is arranged on the air storage tank. According to the device and the method, energy saving is achieved, kinetic energy loss of the tap water during usage is reduced, lost kinetic energy of the tap water during release is used for preparing compressed air, the preparing process is simplified, and the cost is reduced.

Owner:殷冰清

Hot water air conditioning device of sleeve and fin type heat exchanger

InactiveCN103353187AImprove energy efficiencyReduce the number of devicesFluid circulation arrangementHeating and refrigeration combinationsRefrigerantEvaporator

The invention discloses a hot water air conditioning device of a sleeve and fin type heat exchanger. The air conditioning device comprises a first compressor, an evaporator, a first throttling device, the sleeve and fin type heat exchanger, a second compressor, a water heater, a second throttling device, a first blower, a second blower, a second stop valve, a third stop valve and a fourth stop valve, wherein a refrigerant air outlet end of the first compressor is connected with a first port on a refrigerant side of the sleeve and fin type heat exchanger; a third port on the refrigerant side of the sleeve and fin type heat exchanger is connected with an inlet end of the first throttling device; an outlet end of the first throttling device is connected with an inlet of the evaporator; an outlet of the evaporator is connected with an inlet end of the first compressor; an inlet of the first blower is connected with an outlet in an air side of the evaporator; and the second blower is connected with an outlet in an air side of the sleeve and fin type heat exchanger. The hot water air conditioning device can replace conventional water heaters such as an electrical heater, a boiler heater and the like, an efficient, safe and pollution-free water heating process is realized, particularly when the hot water air conditioning device is used in a building in a tropical zone, air conditioning cooling and hot water preparing can be realized at the same time, heat transferred from an air conditioning area is effectively used, and the energy benefit of a whole system is high.

Owner:ZHEJIANG SCI-TECH UNIV

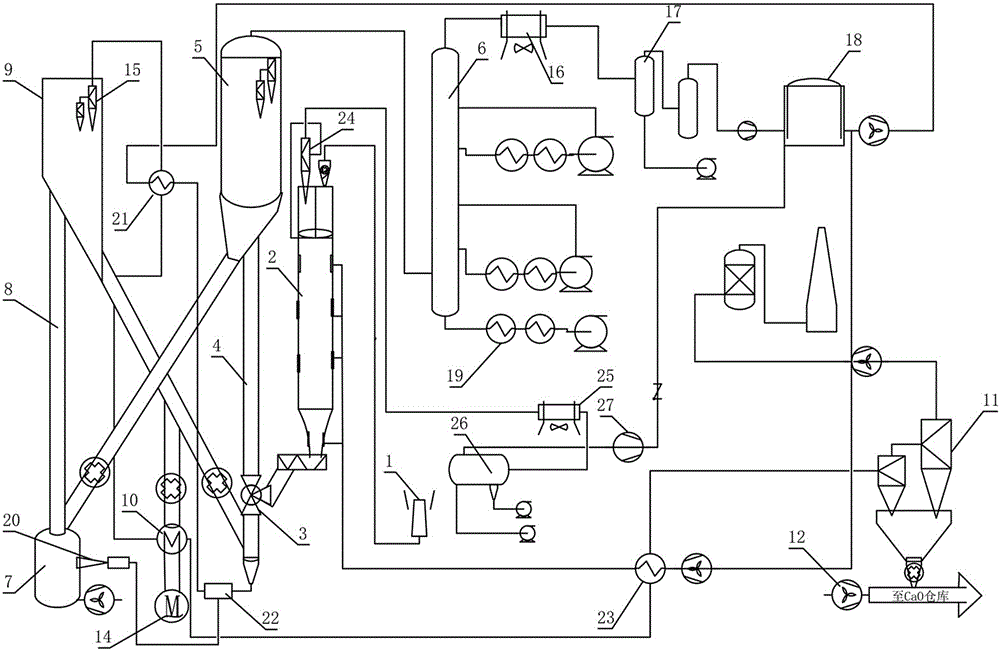

Device for joint production of fuel oil and cement semi-finished products by oil and sand pyrolysis

ActiveCN106085489ASave heatReduce processing costsSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningPulverizerWork in process

The invention provides a device for joint production of fuel oil and cement semi-finished products by oil and sand pyrolysis. The device comprises a crusher, a first material discharger, a preheating dewatering tower, a material mixer, a lifting pipe and a pyrolysis reactor, wherein a material outlet of the crusher is connected with an inlet of the preheating dewatering tower through the first material discharger; a solid material outlet pipeline of the preheating dewatering tower is sequentially connected with the material mixer; the material mixer is positioned on the bottom part of the first lifting pipe; an outlet of the first lifting pipe is connected with the pyrolysis reactor; an air outlet of the pyrolysis reactor is connected with a fractionating tower; the downstream part of the fractionating tower is connected with a receiving device; a solid outlet pipe on the lower part of the pyrolysis reactor is connected with a heater. The device for joint production of fuel oil and cement semi-finished products by oil and sand pyrolysis has the advantage that the production cost is low.

Owner:浙江华耘环保科技有限公司

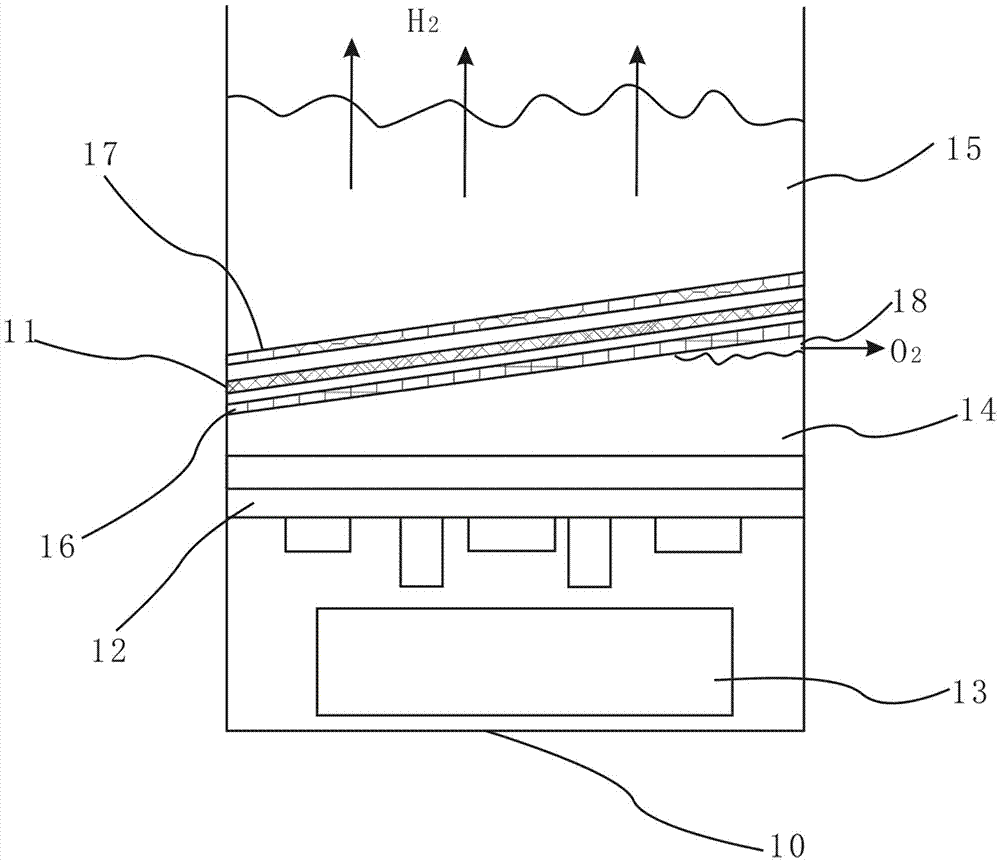

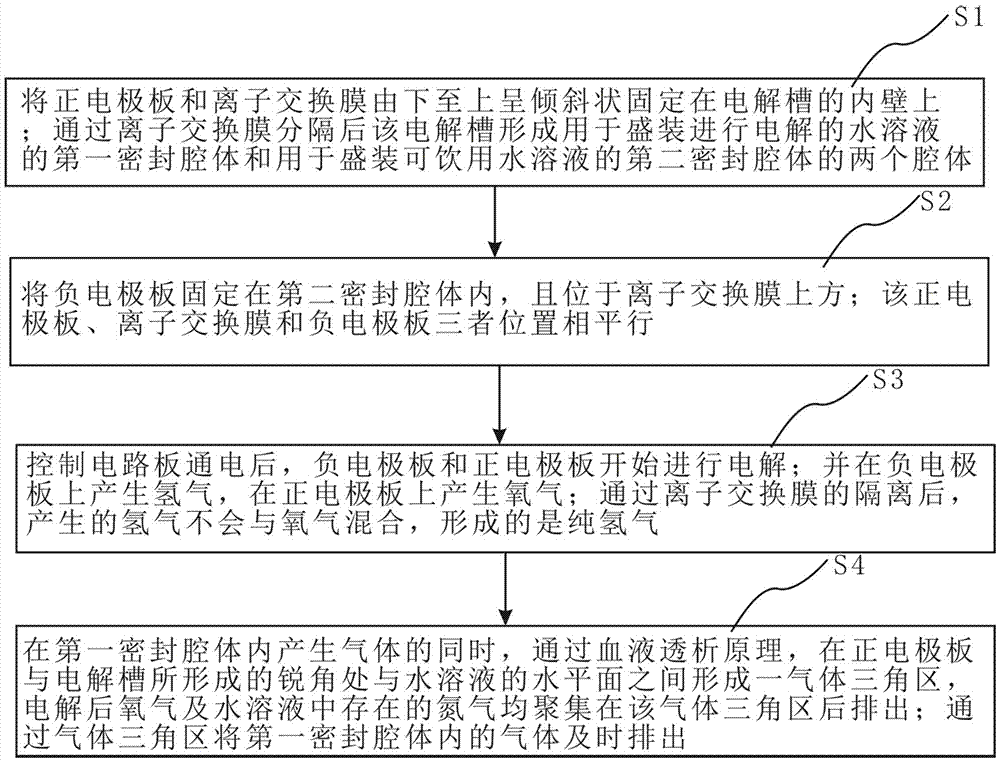

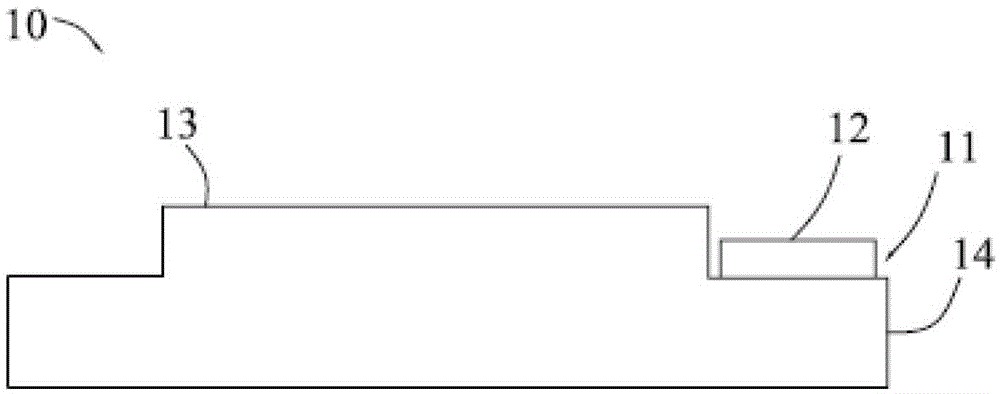

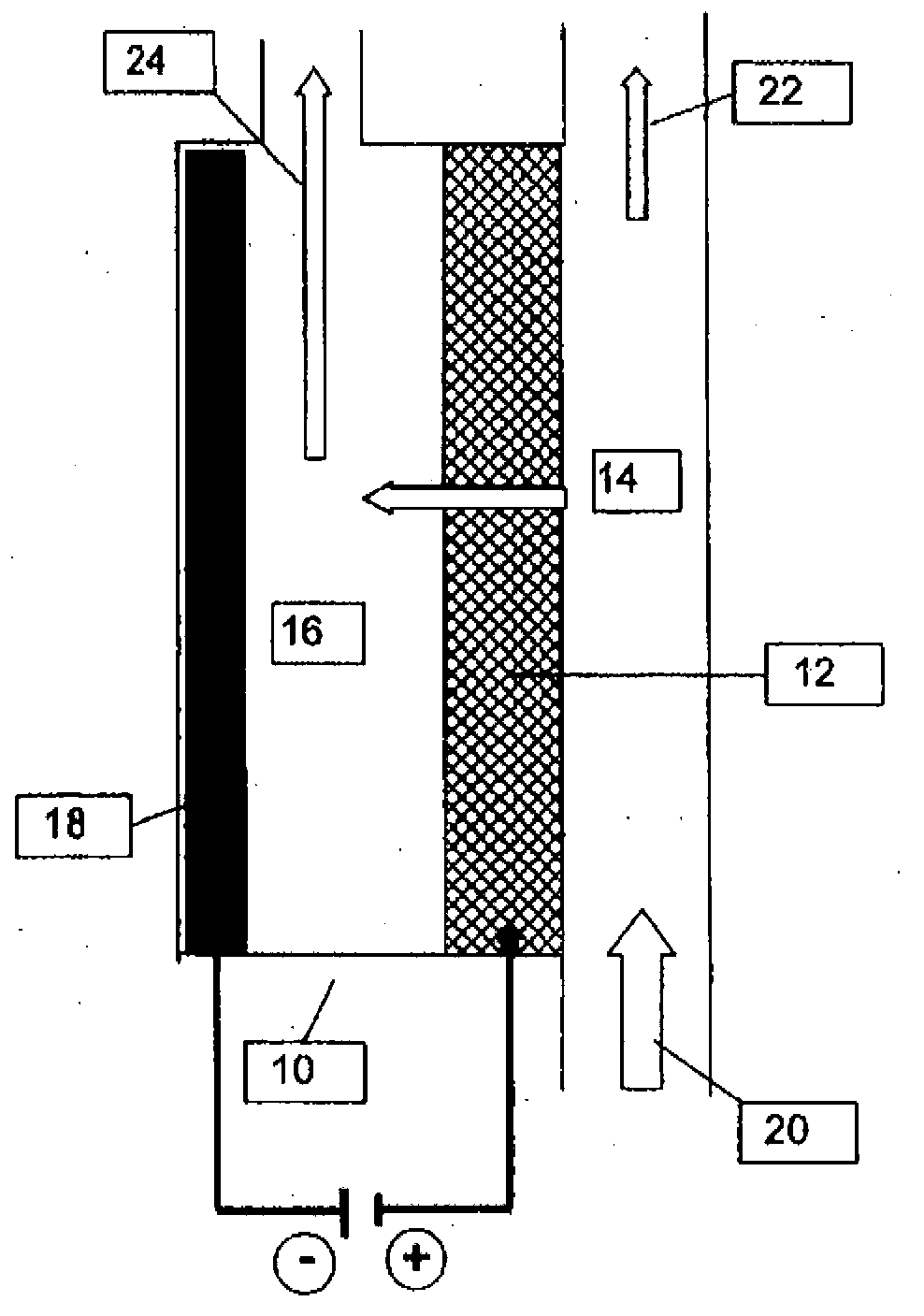

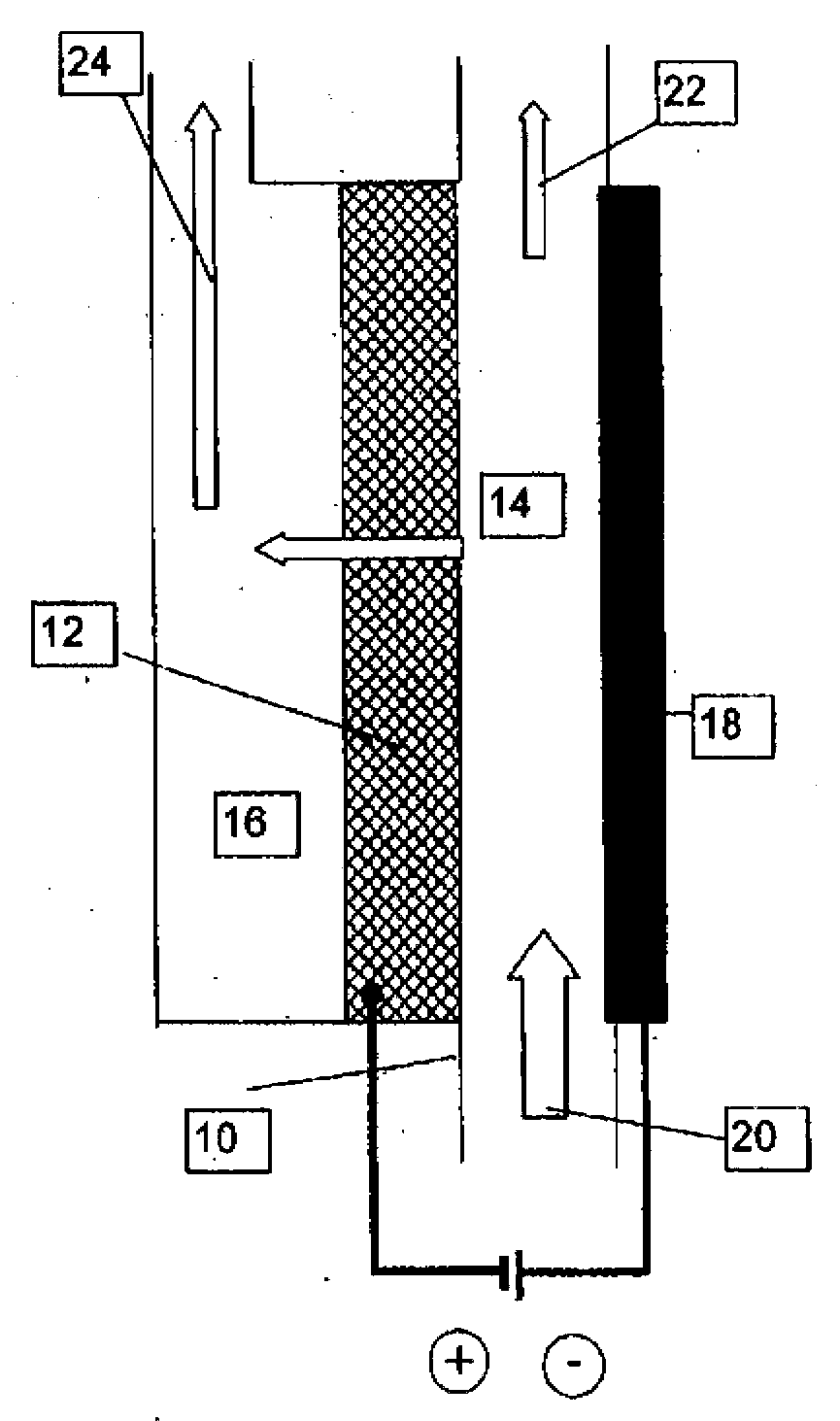

Separated cavity type hydrogen and oxygen separating electrolyser and method thereof

The invention discloses a separated cavity type hydrogen and oxygen separating electrolyser and a method thereof. The device comprises an electrolyzer, an ion exchange membrane, a control circuit board and a lithium battery, wherein the edge of the ion exchange membrane is hermetically fixed on the inner wall of the electrolyzer, the electrolyzer forms a first sealed cavity body and a second sealed cavity body through the partitioning of an ion exchange membrane, the first sealed cavity body is positioned below the ion exchange membrane, and the second sealed cavity body is positioned above the ion exchange membrane; a positive electrode plate parallel to the ion exchange membrane and positioned below the ion exchange membrane is fixed inside the first sealed cavity body, and a negative electrode plate parallel to the ion exchange membrane and positioned above the ion exchange membrane is fixed onside the second sealing cavity body; the ion exchange membrane is obliquely fixed on the inner wall of the electrolyzer, and when water approaches an acute water level, an air trigonum is formed among the water, the positive electrode plate and the inner side wall of the electrolyzer. The separated cavity type hydrogen and oxygen separating electrolyser achieves complete separation of oxygen and other gases from hydrogen, and further the preparation of pure hydrogen is achieved.

Owner:SHENZHEN HEPOCH TECH CO LTD

Manufacture method for gold finger circuit board and circuit board manufactured by method

ActiveCN103153000BRealize productionGuaranteed thicknessElectrical connection printed elementsPrinted element electric connection formationFinger structureHigh heat

Owner:DONGGUAN SHENGYI ELECTRONICS

Apparatus for water treatment using filtration or a membrane separation method

InactiveCN103153875ASmall deviceLow costMembranesWater/sewage treatment bu osmosis/dialysisChemistryWater treatment

An apparatus for water treatment is proposed that comprises a means for mechanical separation constructed as a membrane (12) or filter surface, such that the means for mechanical separation is constructed as an anode and a cathode (18) is arranged at a distance therefrom.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

Tube fin heat exchanger hot water air conditioning equipment

InactiveCN103353187BEfficient use ofReduce the number of devicesMechanical apparatusFluid circulation arrangementEngineeringAir conditioning

The invention discloses a hot water air conditioning device of a sleeve and fin type heat exchanger. The air conditioning device comprises a first compressor, an evaporator, a first throttling device, the sleeve and fin type heat exchanger, a second compressor, a water heater, a second throttling device, a first blower, a second blower, a second stop valve, a third stop valve and a fourth stop valve, wherein a refrigerant air outlet end of the first compressor is connected with a first port on a refrigerant side of the sleeve and fin type heat exchanger; a third port on the refrigerant side of the sleeve and fin type heat exchanger is connected with an inlet end of the first throttling device; an outlet end of the first throttling device is connected with an inlet of the evaporator; an outlet of the evaporator is connected with an inlet end of the first compressor; an inlet of the first blower is connected with an outlet in an air side of the evaporator; and the second blower is connected with an outlet in an air side of the sleeve and fin type heat exchanger. The hot water air conditioning device can replace conventional water heaters such as an electrical heater, a boiler heater and the like, an efficient, safe and pollution-free water heating process is realized, particularly when the hot water air conditioning device is used in a building in a tropical zone, air conditioning cooling and hot water preparing can be realized at the same time, heat transferred from an air conditioning area is effectively used, and the energy benefit of a whole system is high.

Owner:ZHEJIANG SCI-TECH UNIV

Novel composite water production device

PendingCN110847286AIncrease profitImprove overall efficiencyDrinking water installationHeat conservationLiquid storage tank

The invention provides a novel composite water production device. The novel composite water production device comprises a wheel-mounted dehumidifier, an air compressor, an air storage tank, a vortex tube, a heat preservation liquid storage tank, a component proportional divider, an air mixer, a centrifugal fan, a heat pipe, a heat dissipation air flue, an electromagnetic air valve and an electromagnetic water valve, wherein the heat pipe and the heat dissipation air flue are installed at the upper end of the air storage tank, and the electromagnetic air valve and the electromagnetic water valve are used for controlling a system to work. According to the novel composite water production device, water can be produced from air at a low temperature and low environmental humidity, pressure energy of the air compressor is fully utilized and converted into heat energy and low-temperature air energy, water in the air is gradually extracted by heat energy of compressed air through multiple links and multiple mechanisms, and energy generated in the operation process of various devices is comprehensively utilized. The novel composite water production device is suitable for producing water from air under an extreme condition, meanwhile, the storage environment of the obtained water is guaranteed, and the obtained water is hermetically stored at low temperature.

Owner:ANHUI TIANZHU GREEN ENERGY SCI & TECH

A method for reducing residual ink in black and white laser printing waste paper deinking pulp

ActiveCN106283797BReduce the binding forceReduce volumePaper recyclingPulp bleachingFiberLithium hydroxide

The invention relates to a method for reducing residual ink of black and white laser printing wastepaper deinked pulp. The method comprises the following steps: adding a mixed solvent prepared by combination of 1-butyl-3-methylimidazolium acetate and LiNO3 .2H2O into black and white laser printing wastepaper; then, adding lipase and lithium hydroxide, uniformly mixing chemicals and wastepaper with a medium-rich mixer, heating the mixed material to a preset temperature, and performing ultrasonic treatment to a preset time; and beating, washing and deinking the treated materials, leading a cleaning solution to flow into a solvent recycling system, and recycling the reclaimed solvent. The method can be used for effectively swelling fibers of black and white laser printing wastepaper and weakening the connection between fibers and black and white laser printing ink particles, so that the ink particles of black and white laser printing wastepaper can be effectively removed, the physical strength and optical performance of finished paper can be improved, the product quality of deinked pulp can be promoted, and environment-friendly processing of wastepaper fibers can be realized since the adopted mixed solvent has stable properties and can be easily reclaimed.

Owner:QILU UNIV OF TECH

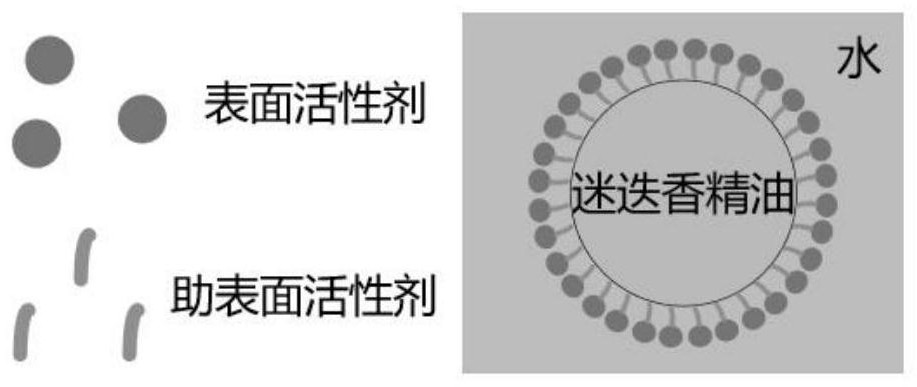

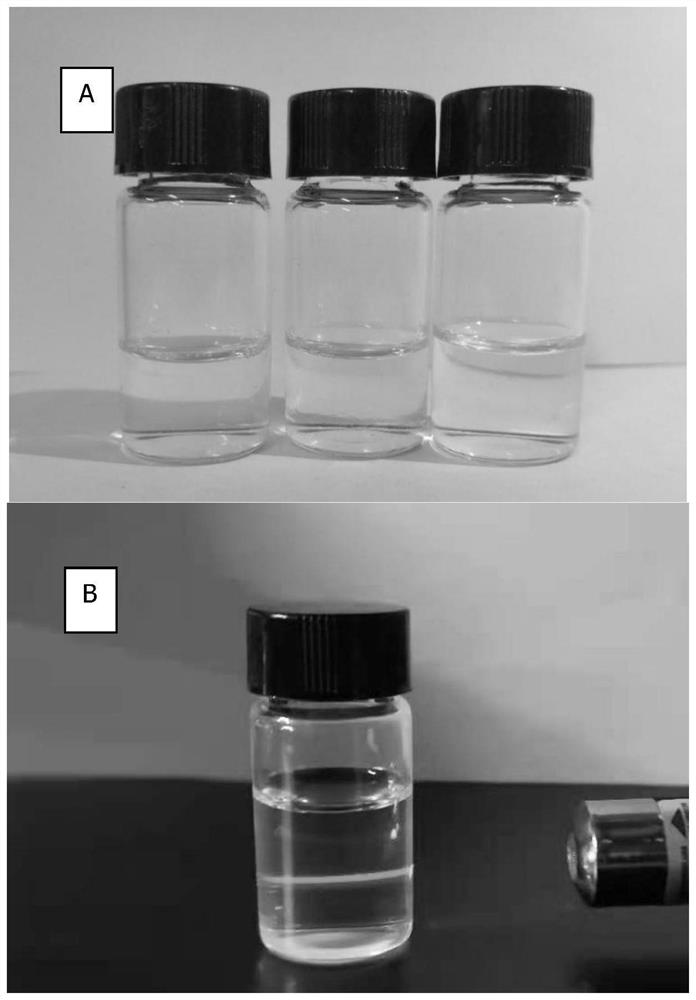

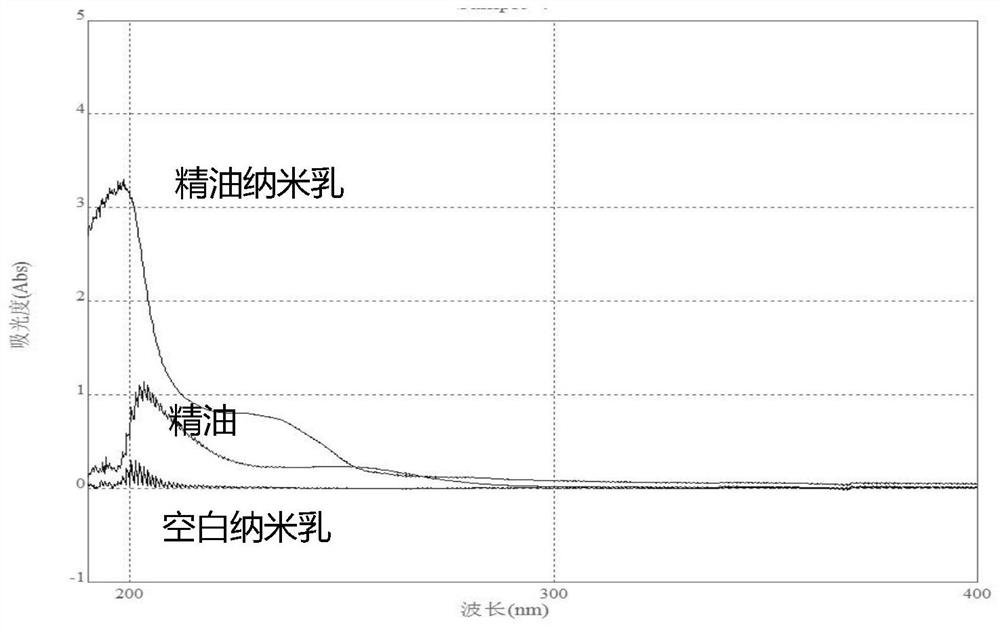

Rosmarinus officinalis essential oil nanoemulsion gel, and preparation method and application thereof

PendingCN113952292AStrong irritantGood anti-inflammatory effectAntibacterial agentsAntimycoticsRosmarinusDrug delivery

The invention provides a Rosmarinus officinalis essential oil nanoemulsion gel, and belongs to the technical field of medicaments. The Rosmarinus officinalis essential oil nanoemulsion gel is prepared from the following raw materials in percentage by weight: 1-3.5 wt% of carbomer, 5-15 wt% of glycerol, 5.5-10.5 wt% of propylene glycol, 0.5-2.0 wt% of Rosmarinus officinalis essential oil nanoemulsion and the balance of water. The Rosmarinus officinalis essential oil nanoemulsion gel provided by the invention has a moisturizing effect, is likely to spread, is good in skin feeling, and plays an important role in a transdermal drug delivery system. Compared with a Rosmarinus officinalis essential oil product, the prepared gel preparation is small in irritation and high in stability, and bioavailability is greatly improved. The Rosmarinus officinalis essential oil nanoemulsion gel has a swelling property, thixotropy and adhesiveness, so that the adhesion of the nanoemulsion to the skin can be enhanced.

Owner:HENAN UNIV OF CHINESE MEDICINE

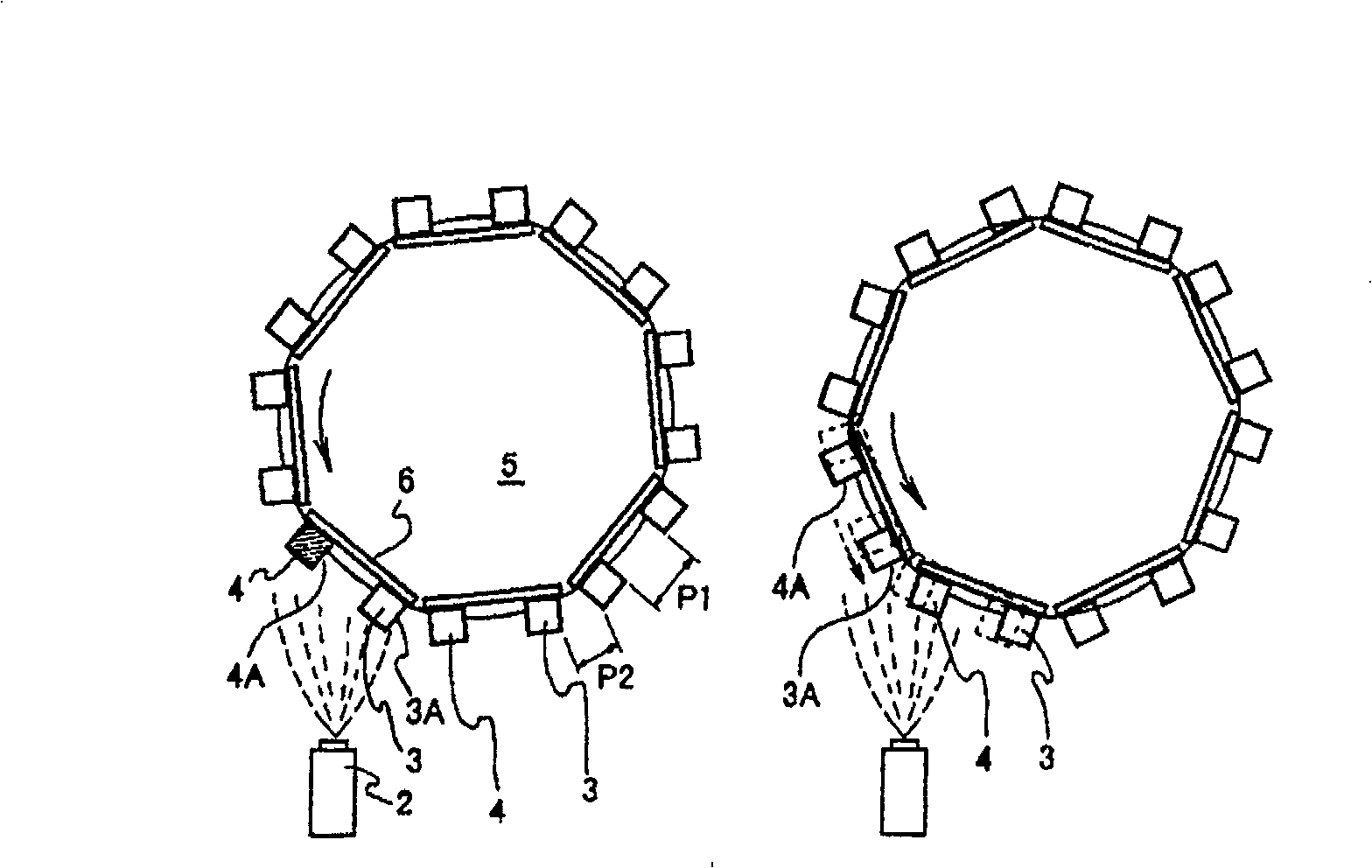

Automatic rotary coating method and coating apparatus

InactiveCN100411751CExpand the scope ofRealize productionLiquid surface applicatorsSpraying apparatusEngineeringAlternative methods

The invention relates to a rotary automatic coating method, which is characterized in that: a rotary coating can be implemented by reducing the interval configuration of the object to be coated in relation to the side of the coated object with more coating, so the coated object in the front can be covered. The workpiece pitch at an adjacent flat is less than the workpiece pitch at the flat in relation to the coating object arranged on the flat. As an alternative method, a rotating device for straight line movement area is arranged at the spraying and coating area, and the rotating device is rotated without the influence of spraying angle. The rotary automatic coating method has the advantages of maintaining the effect of rotary coating, and improving the uniformity of the paint film and the coating quality .

Owner:ANEST IWATA CORP

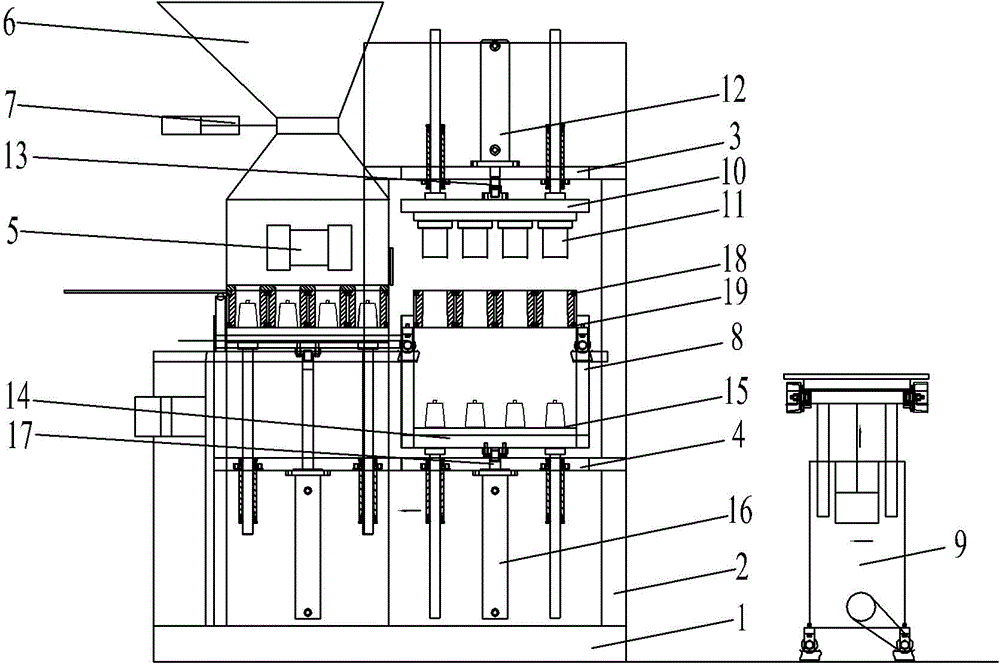

Dead head production equipment

InactiveCN104668468ARealize productionIncrease productivityFoundry mouldsFoundry coresEngineeringUltimate tensile strength

The invention provides dead head production equipment. The dead head production equipment is simple to operate and has the advantages that the efficiency and the quality of manufacturing a dead head can be greatly improved and the labor intensity of an operator is also reduced. The dead head production equipment comprises a base, wherein a core receiving trolley is arranged at the front part of the base; the upper end of the base is fixedly provided with an upper pressing die transverse plate by a stand column; a lower pressing die transverse plate is fixed under the base through the stand column; a charging barrel, which is arranged in parallel, is horizontally mounted under the upper pressing die transverse plate in a sliding manner; a hopper is arranged above the charging barrel; a gate air cylinder is arranged at the connection part of the hopper and the charging barrel; an upper die structure is arranged at the lower end of the upper pressing die transverse plate; a middle die structure is fixed on the relative stand column under the upper die structure and is fixedly connected with the base; a pore plate is arranged at the part, corresponding to the middle die structure, of the charging barrel; and the base is fixed on the stand column and a lower die structure is arranged in the base.

Owner:WUXI SHUANGQUAN MECHANICAL FACTORY

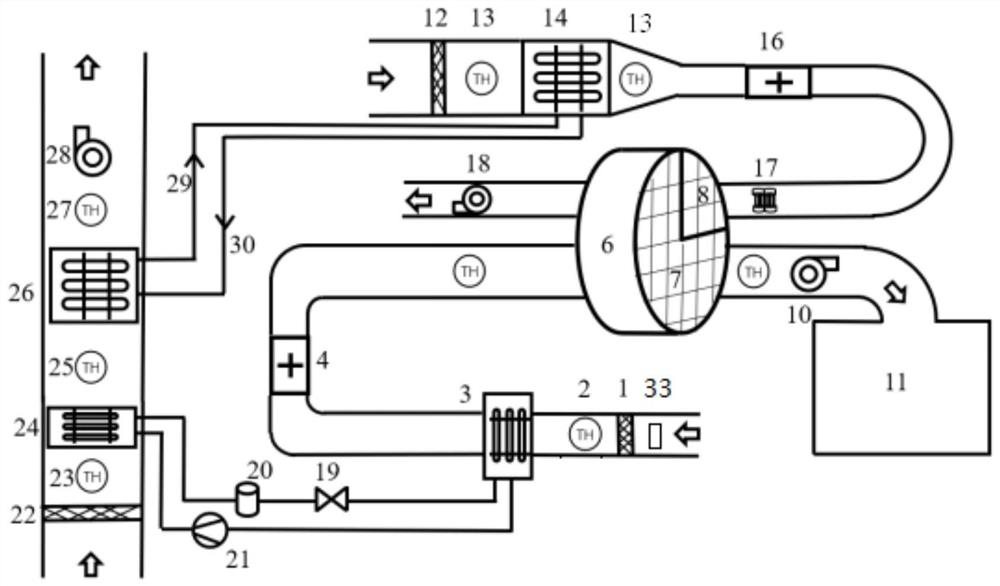

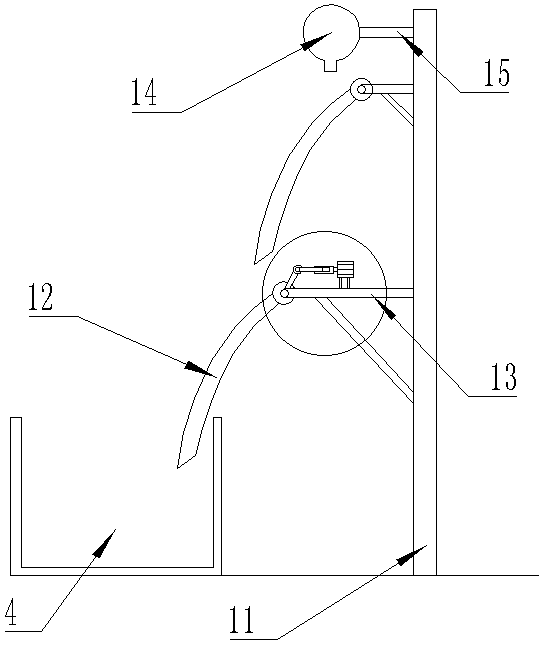

Suspension bridge main cable composite dehumidification system for recovering condensation heat through separated heat pipes

PendingCN113713576ACondensing heat tastes goodIncrease heatDispersed particle separationVapor condensationHeat regenerationSteam condensation

The invention provides a suspension bridge main cable composite dehumidification system for recovering condensation heat through separated heat pipes. The suspension bridge main cable composite dehumidification system comprises a dehumidification rotating wheel, a humid air treatment system used for cooling and condensing humid air entering the dehumidification rotating wheel treatment area and comprising an evaporator, a compressor and a condenser, a regeneration air system which supplies heat to air flowing into a regeneration area of the dehumidification rotating wheel and comprising a separation type heat pipe condensation section for preheating the air, an electric heater and a regeneration fan, and a condensation heat recovery system that provides steam for the separation type heat pipe condensation section of the regeneration air system; and the separation type heat pipe evaporation section, a steam ascending pipe, the separation type heat pipe condensation section, a liquid descending pipe and a separation type heat pipe evaporation section of the condensation heat recovery system are sequentially connected to form a circulation loop. The system is large in dehumidification amount, low in rotating wheel dehumidification dew point temperature, high in condensation heat grade, large in heat, good in separated heat pipe heat transfer performance, convenient to arrange and high in environmental adaptability.

Owner:南京东达智慧环境能源研究院有限公司

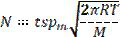

Pressure water storage tank with water purification function and using method thereof

ActiveCN105776724BWith water purification functionSimple structureWater contaminantsTreatment involving filtrationWater storageWater volume

The invention relates to a pressure water storage tank having a water purifying function. The pressure water storage tank comprises a tank body, wherein a filter core chamber in which a filter core is mounted is arranged in the tank body; a water storage chamber is formed between the outer wall of the filter core chamber and the inner wall of the tank body; the lower side of the filter core chamber is communicated with a tap water connector; a non-direct drinking water tap is arranged on the top of the filter core chamber; the side part of the filter core chamber is communicated with the water storage chamber through a one-way valve; a direct drinking water tap is connected to the water storage chamber; a piston tightly clung to the wall of the water storage chamber is arranged in the water storage chamber; a spring is arranged below the piston. The pressure water storage tank having the water purifying function is simple in structure and can realize preparation of non-direct drinking water and direct drinking water; the non-direct drinking water is not treated with an ultrafiltration member, has large water volume, and is used for washing the ultrafiltration membrane during use; the direct drinking water is treated with the ultrafiltration membrane and has a high purifying degree, and when water preparation stops when the water pressure in the water storage chamber and the elasticity of the spring are balanced, water storage is realized.

Owner:FUZHOU PINXING TECH DEV

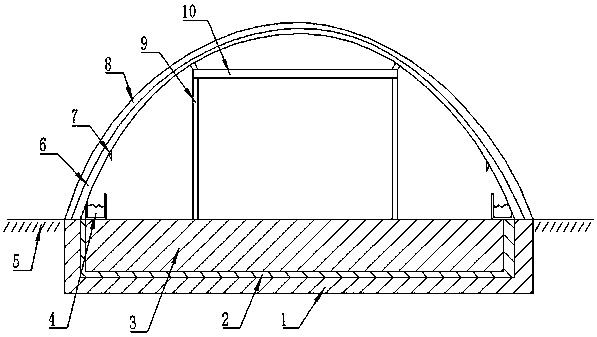

Seawater planting salt-manufacturing greenhouse control system

InactiveCN107743795AAchieve productionRealize comprehensive utilizationClimate change adaptationGreenhouse cultivationLand resourcesEvaporation

The invention discloses a seawater planting salt-manufacturing greenhouse control system. The seawater planting salt-manufacturing greenhouse control system comprises a base, wherein the base is arranged under the ground surface, a waterproof layer is arranged on the inner wall of the base, and a planting soil layer is arranged on the waterproof layer; the two ends of the base are connected through an arc dragon skeleton, and a greenhouse wall is arranged on the dragon skeleton; seawater evaporation tanks are arranged at included angles between the inside of a greenhouse and a ground, and seawater evaporators are arranged in the greenhouse nearby the seawater evaporation tanks; a sodium chloride crystallizing pond is arranged in the greenhouse, a water inlet of the sodium chloride crystallizing pond is connected with the seawater evaporation tanks, and a halide salt crystallizing pond is connected to the water outlet end of the sodium chloride crystallizing pond. Land resources and sunshine of seaside deserts can be fully used, and production of grain crops is achieved; using of seawater is achieved, and more fresh water resources can also be generated through the greenhouse in theproduction process; the temperature in the greenhouse is rapidly adjusted, and high-efficiency production is achieved; salt preparing can be achieved, and economic benefits are improved.

Owner:宋宏婷

Bamboo fibrillating-rolling device

ActiveCN102909767BRealize productionReduced transverse strengthWood working apparatusFiber bundleModular design

A bamboo fibrillating-rolling device comprises a frame, a fibrillating mechanism, a rolling mechanism, a hammering mechanism, a skin-removing mechanism, a conveying mechanism and a power unit. The frame is provided with areas for fibrillating, rolling, hammering and skin removing. The fibrillating mechanism at least comprises one fibrillating roller set consisting of an upper and lower opposing paired fibrillating rollers, wherein at least the upper fibrillating roller is provided with fluffing teeth. The rolling mechanism consists of one or paired rolling rollers. The hammering mechanism comprises a plurality of hammers. The skin-removing mechanism is provided with metal wire brush rolls or scrapers for skin removing. The conveying mechanism is used to convey material to be processed to transversely pass through the areas for fibrillating, rolling, hammering and skin removing. The power unit powers the fibrillating mechanism, the rolling mechanism, the hammering mechanism, the skin-removing mechanism and the conveying mechanism respectively or simultaneously. The bamboo fibrillating-rolling device is available for efficiently producing bamboo fiber bundles with low transvers strength and reserved longitudinal strength. The skin-removing mechanism, the rolling mechanism, the fibrillating mechanism and the hammering mechanism are all in modular design and can be designed into a complete set for assembly and disassembly.

Owner:INT CENT FOR BAMBOO & RATTAN

Mortar ash mixing station applying packing auger blade conveying and preparing method and application thereof

PendingCN111452224AImplement segmented injectionRealize productionDischarging apparatusCement mixing apparatusMechanical engineeringStorage tank

The invention discloses a mortar ash mixing station applying packing auger blade conveying and a preparing method and application thereof. The station comprises a material elevator (4) used for discharging a mortar ash raw material into a mortar ash storage tank, a stirring device used for mixing combination component materials of mortar ash to form the mortar ash raw material, a packing auger conveying device used for discharging the combination component materials of the mortar ash into the stirring device, and a bin hopper set (3) mounted on the packing auger conveying device and used for serving as a combination component material feeding port of the mortar ash, through a packing auger conveying device and the bin hopper set (3), segmented injection of the combination component materials of the mortar ash can be achieved, through the stirring device, making of the mortar ash raw material can be achieved, through the material elevator (4), transferring of the mortar ash raw materialcan be achieved, continuous making of the mortar ash raw material can be achieved, and the mortar ash preparing efficiency can be improved.

Owner:山东新大地环保建材股份有限公司

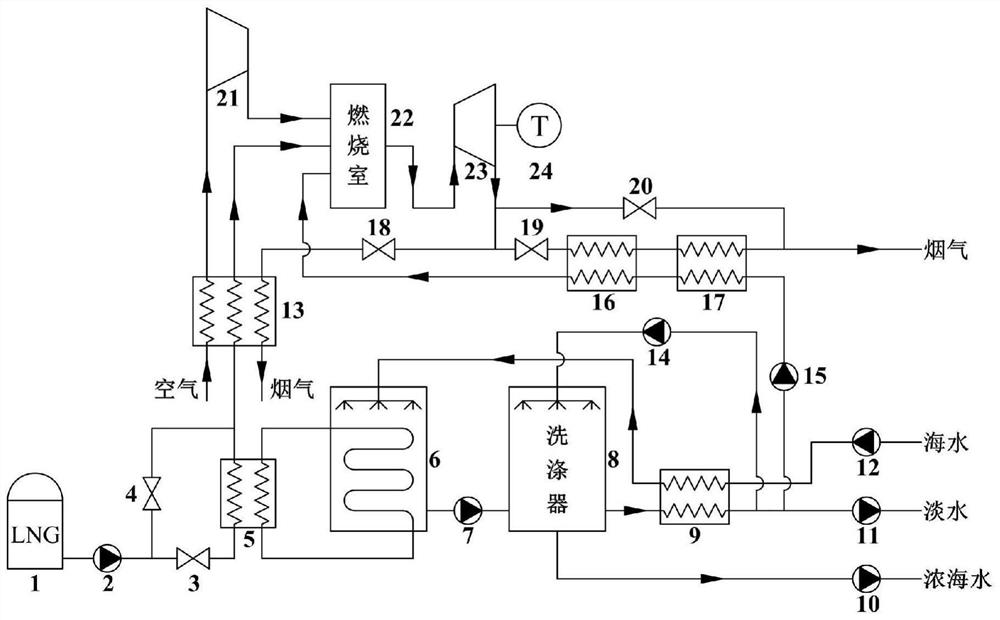

A low-nitrogen combustion system for gas turbines on lng-powered ships

ActiveCN109989828BAvoid wastingSolve the problem of fresh water sourceGeneral water supply conservationSeawater treatmentLow nitrogenSuperheater

The invention discloses a gas turbine low-nitrogen combustion system for an LNG-powered ship, which includes an LNG gas supply subsystem, a seawater desalination subsystem, a power output subsystem, a flue gas waste heat recovery subsystem, and a steam generation subsystem, wherein the LNG gas supply subsystem It is connected with the seawater desalination subsystem through the LNG-intermediate medium heat exchanger, the LNG gas supply subsystem is connected with the power output subsystem and the flue gas waste heat recovery subsystem through a multi-stream heat exchanger, and the power output subsystem is connected with the The flue gas waste heat recovery subsystems are connected through a gas turbine, the seawater desalination subsystem is connected with the steam generation subsystem through the third fresh water pump, the flue gas waste heat recovery subsystem and the steam generation subsystem are connected through a steam superheater and connected to the steam generator. The invention utilizes LNG cold energy to realize desalination of seawater, satisfies the demand for fresh water for gas turbine reinjection steam, reduces nitrogen oxide discharge, and has huge economic and ecological benefits.

Owner:NORTHEASTERN UNIV LIAONING

Intelligent refreshing barrel

InactiveCN107324268AGuaranteed external surface propertiesThe temperature is not easy to conductLiquid dispensingDomestic articlesEngineeringPendulum

The invention relates to the technical field of wine fresh-keeping, and discloses an intelligent fresh-keeping wine barrel. The fresh-keeping wine barrel includes a barrel body, a low-temperature cooling control box and a column, wherein the barrel body includes a barrel inner body and an outer thermal insulation layer of the barrel, and the top of the barrel inner body is connected to the column by rotating a pendulum The arm is fixed on the top of the tank body in the barrel, a motor is arranged in the hollow shaft of the swing arm, and a wine spear is installed under the motor. Cooling water pipes are arranged along the circumference in the interlayer of the outer insulation layer of the wine barrel. The fresh-keeping wine barrel can be disassembled for disinfection, which can make up for the uncertainty of manual pressurization; there is no need for manual pressurization operation when there is a small amount of wine left, and at the same time, it ensures that the barrel will not be damaged by leakage when it is replaced. have destructive effects.

Owner:闫艳

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com