Automatic rotary coating method and coating apparatus

A coating method, a rotary technology, applied to the surface coating liquid device, spray device, coating, etc., can solve the problems of uneven coating surface, difficult to use, enlarging the rotary table, etc., to achieve the goal of coating The installation quality is stable, the unqualified rate is reduced, and the effect of production is realized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

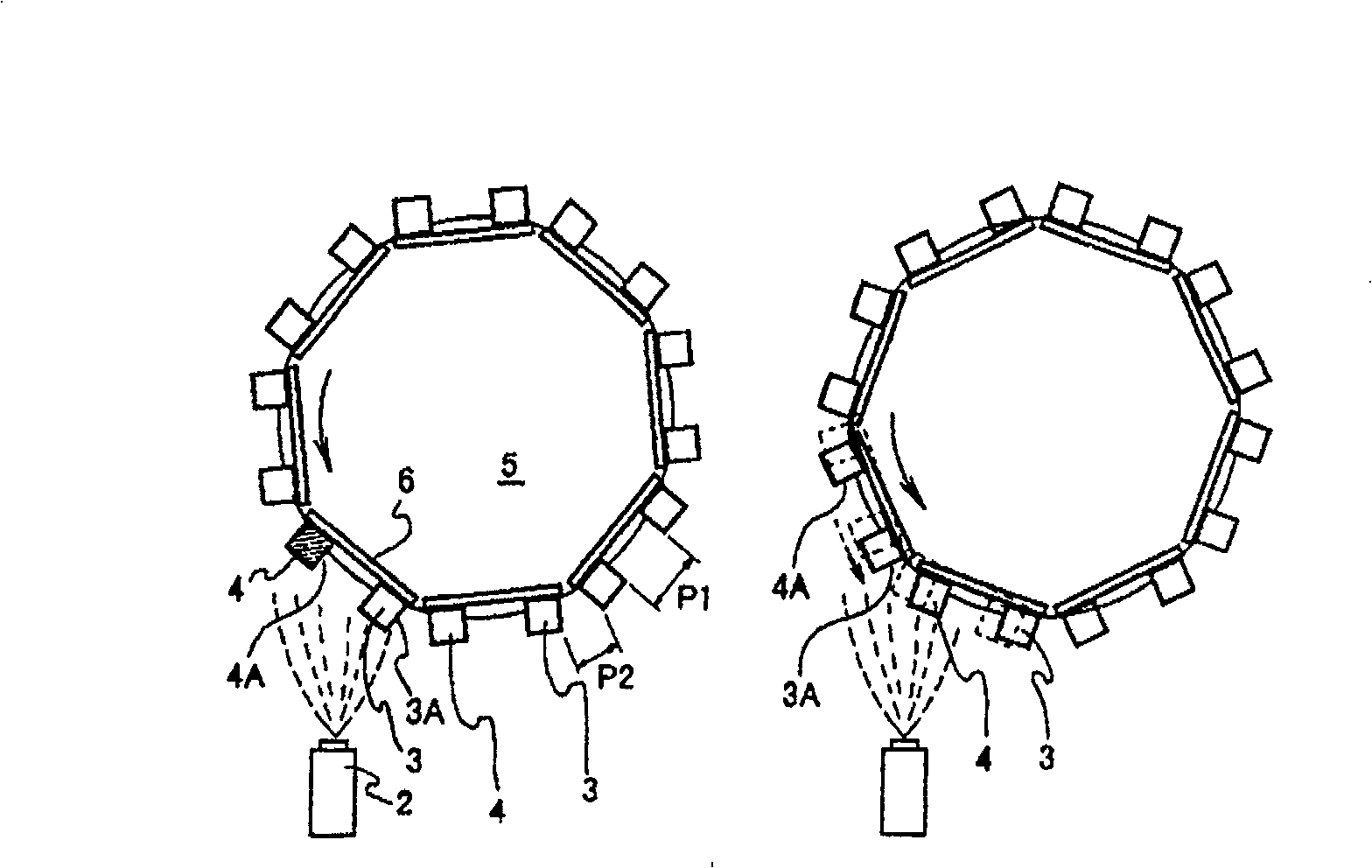

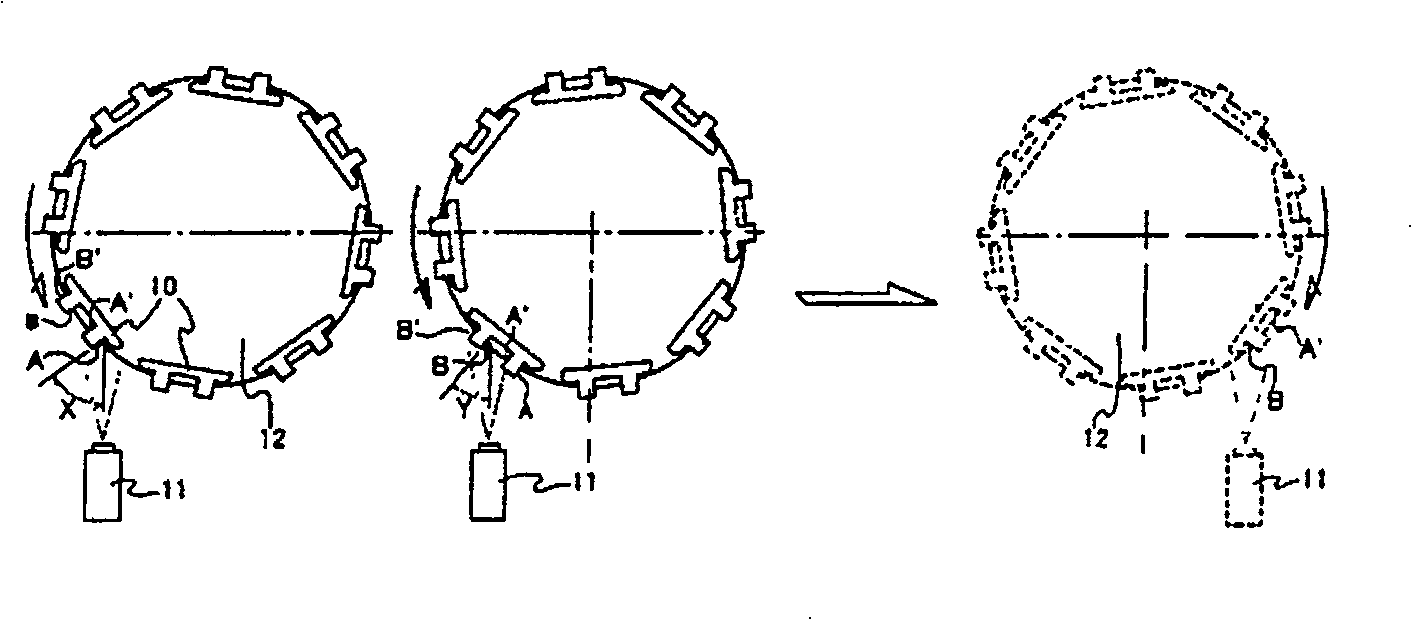

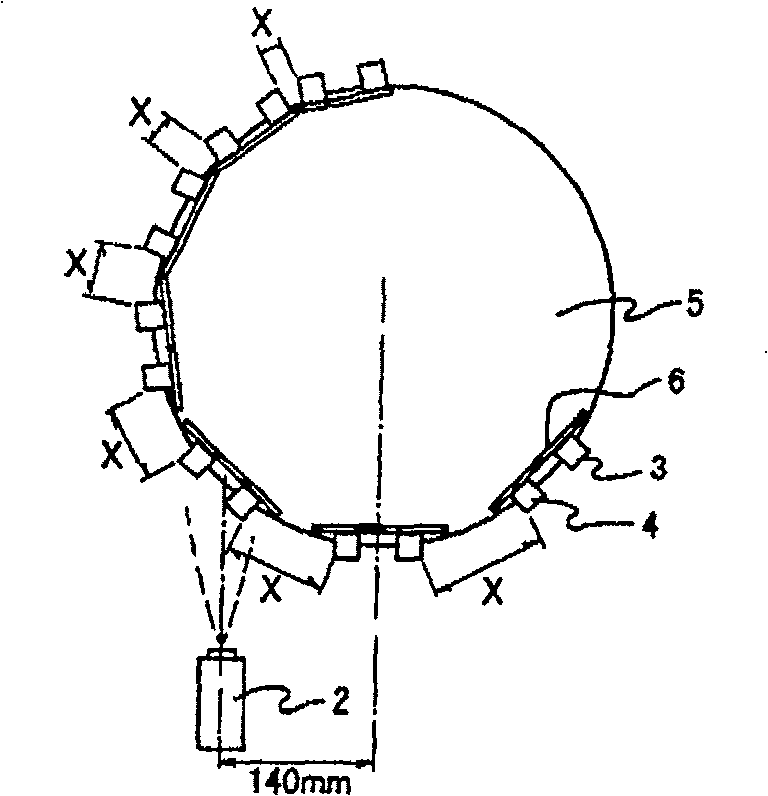

[0023] Hereinafter, the present invention will be described with reference to the accompanying drawings. As an example of rotary coating figure 1 The objects 3 and 4 to be painted which are painted by the spray gun 2 are each mounted on a jig 6 which is circumferentially arranged on the rotating table 5 . The jig 6 is in the shape of a flat plate, and is mounted on the concentric circle of the above-mentioned table 5 in parallel to the tangent thereof, and can be freely attached and detached as required. This example is an example in which eight jigs 6 are installed.

[0024] The installation position of the spray gun and the direction of the spray axis are provided in a position parallel to and eccentric from the center of rotation, and have a positional relationship in which the object to be painted is painted from an oblique direction. Furthermore, when the upper and lower surfaces of the object to be coated need to be painted, the spray gun is sprayed with the upper and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com