Method for preparing refractory metal powder

A technology for melting metals and refractory metals, which is applied in the field of producing refractory metal powders, and can solve problems such as complex equipment, polluted solvent environment, and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

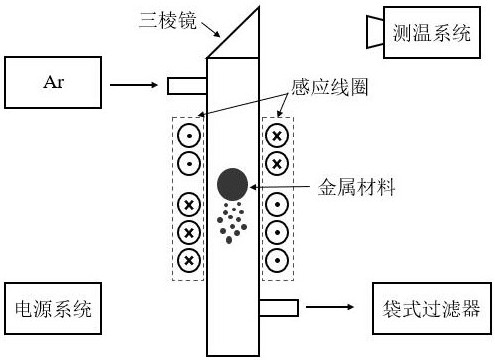

[0032] Such as figure 1 Shown, this method for preparing refractory metal powder, it may further comprise the steps:

[0033] Step 1: Carry out wire-cutting and grinding of refractory metal raw material niobium, and process it into granules, wherein the granule size is 10mm;

[0034] Step 2: Place 3.5g of the granular raw material obtained in Step 1 in the induction coil of the electromagnetic levitation refining equipment, pass through the protective gas of pure Ar (gas flow rate is 1.0L / min), ventilate for 3 minutes, turn on the coil cooling water and power on , Control power supply system: input current 400A, input power 4500W, input frequency 400kHz, after the power is turned on, metal particles are suspended and melted into liquid and suspended in the air;

[0035] Step 3: Continue to suspend and smelt the metal particles suspended in step 2. When the temperature reaches 2950K, the molten droplets start to evaporate, and the metal powder produced is suspended in the prot...

Embodiment 2

[0040] Such as figure 1 Shown, this method for preparing refractory metal powder, it may further comprise the steps:

[0041] Step 1: wire-cut and grind the refractory metal raw material titanium, and process it into granules, wherein the granule size is 11mm;

[0042] Step 2: Place 2.5g of the granular raw material obtained in Step 1 in the induction coil of the electromagnetic levitation refining equipment, pass through the protective gas pure Ar (gas flow rate is 1.0L / min), ventilate for 3 minutes, turn on the coil cooling water and power on , Control power supply system: input current 300A, input power 4000W, input frequency 330kHz, after the power is turned on, the metal particles are suspended and melted into liquid and suspended in the air;

[0043] Step 3: Continue suspending and smelting the metal particles suspended in step 2. When the temperature reaches 2133K, the molten droplets start to evaporate, and the metal powder produced is suspended in the protective gas....

Embodiment 3

[0048] Such as figure 1 Shown, this method for preparing refractory metal powder, it may further comprise the steps:

[0049] Step 1: Carry out wire cutting and grinding of refractory metal raw material nickel, and process it into granules, wherein the granule size is 10mm;

[0050] Step 2: Place 3.2g of the granular raw material obtained in Step 1 in the induction coil of the electromagnetic levitation refining equipment, pass through the protective gas of pure Ar (gas flow rate is 1.5L / min), ventilate for 3 minutes, turn on the coil cooling water and power on , Control power supply system: input current 280A, input power 3500W, input frequency 220kHz, after the power is turned on, the metal particles suspend and melt into a liquid state and suspend in the air;

[0051] Step 3: Continue suspending and smelting the metal particles suspended in step 2. When the temperature reaches 1928K, the molten droplets start to evaporate, and the metal powder produced is suspended in the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com