Patents

Literature

1860 results about "Metallic particle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Magnetic decontamination device and method

InactiveUS6350296B1Water/sewage treatment by magnetic/electric fieldsFiltration separationPowder mixtureStream flow

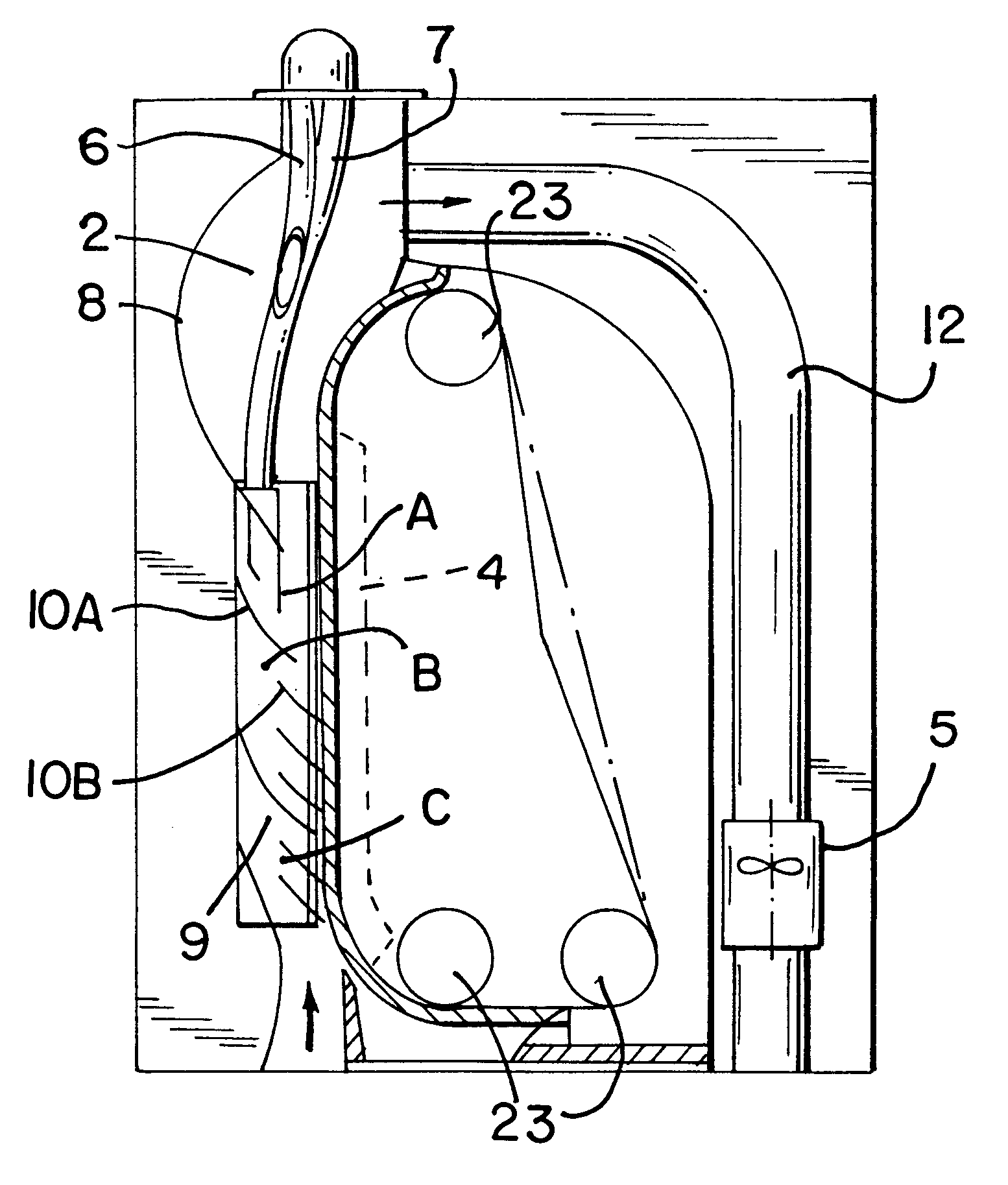

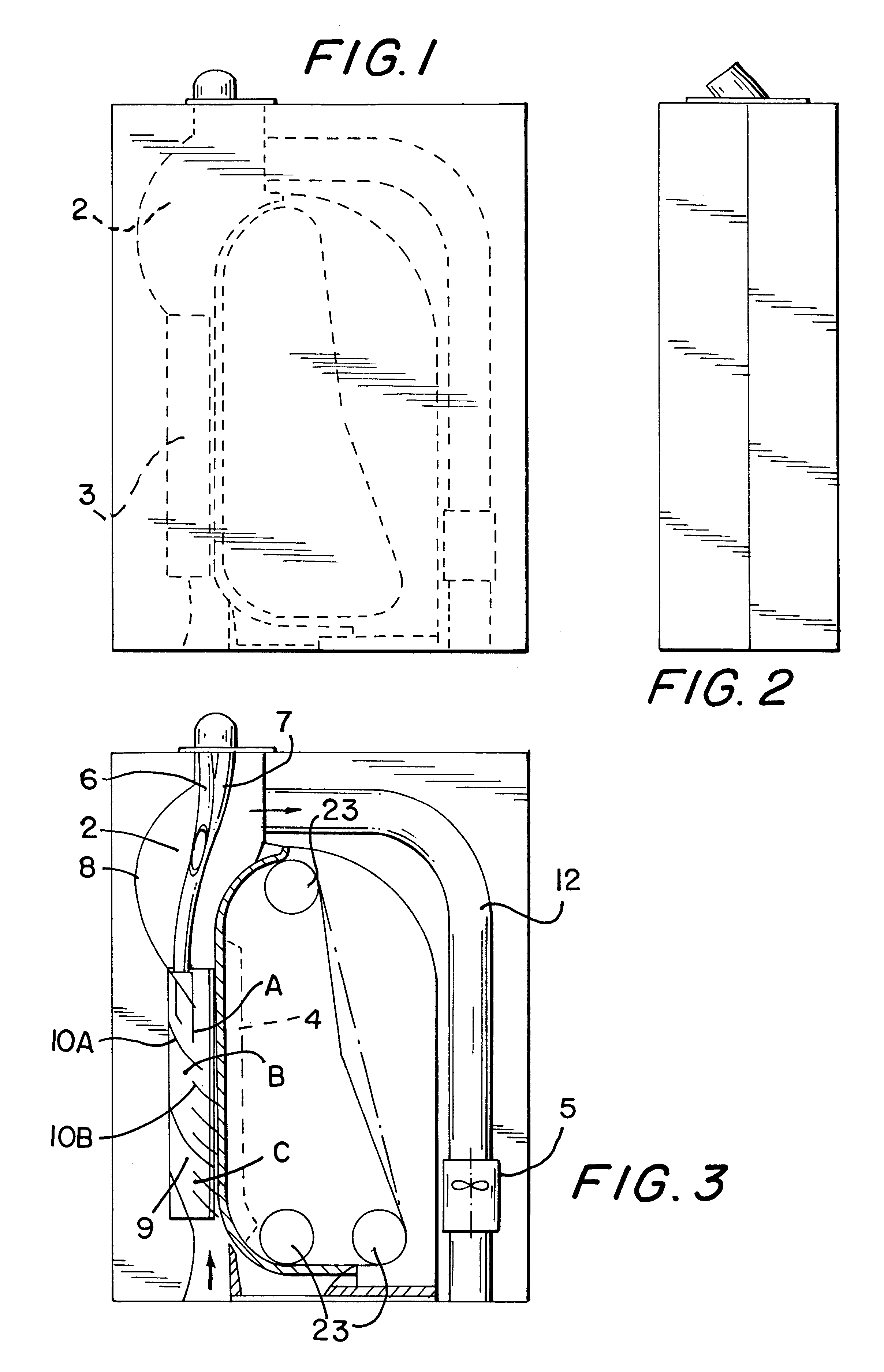

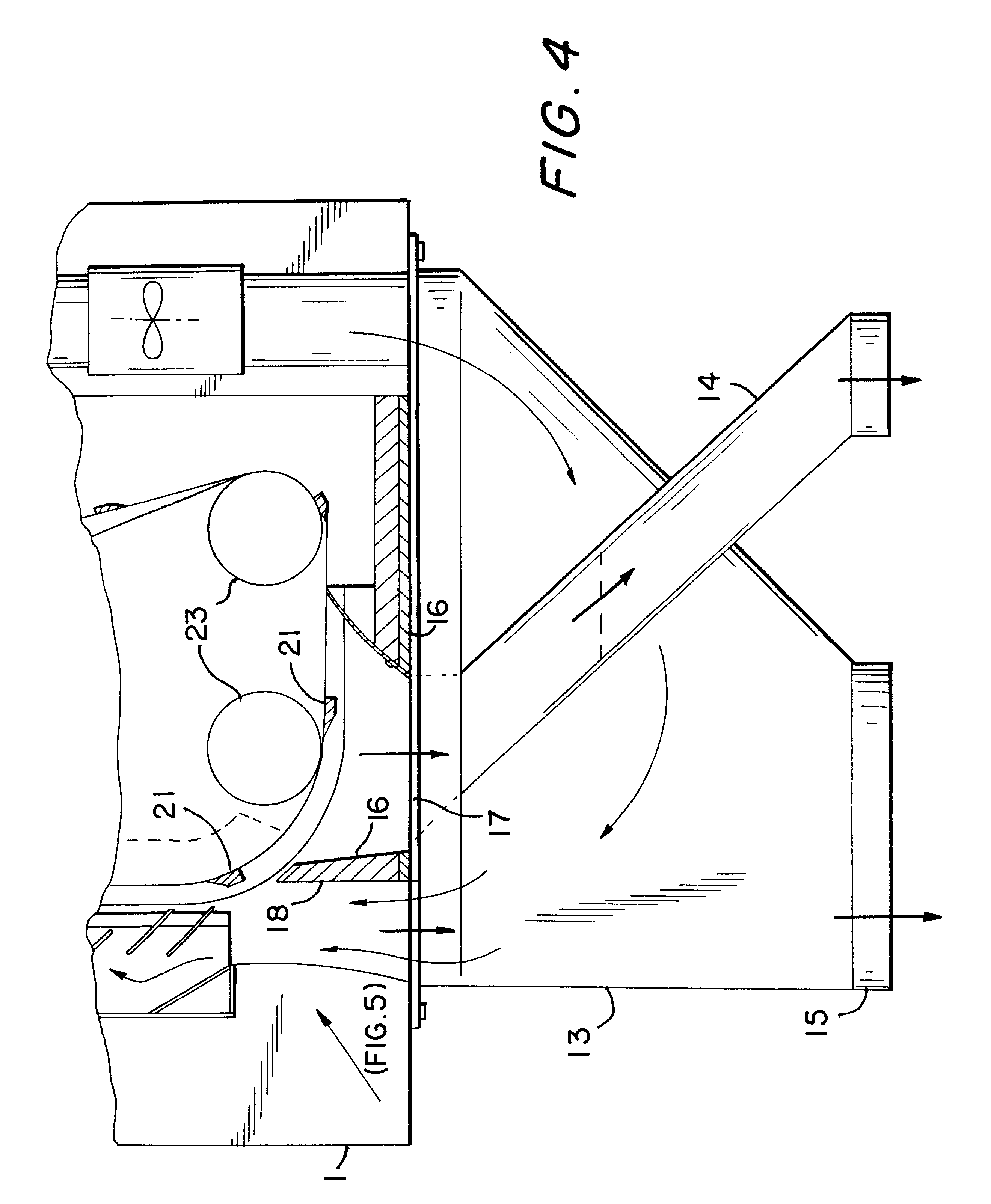

A device and method for removing metalliferous particles from a powder so that the powder can be reused. A contaminated powder fluid stream flows down tube (6 / 7) into zones A, B and C adjacent the surface of a magnet (4). The flow flows past the surface of the magnet (4) and is directed towards the surface of the magnet (4) by baffles (10A, 10B). The magnet (4) separates metallic particles from powder particles and these metallic particles are removed from the face of the magnet (4) by scraper bars (21) conveyed by endless belts (22) supported by roller sets (23). The device can also include a fan (5) for promoting the movement of air in a counter direction to the delivered powder mixture.

Owner:WARNER CLIFFORD ROY

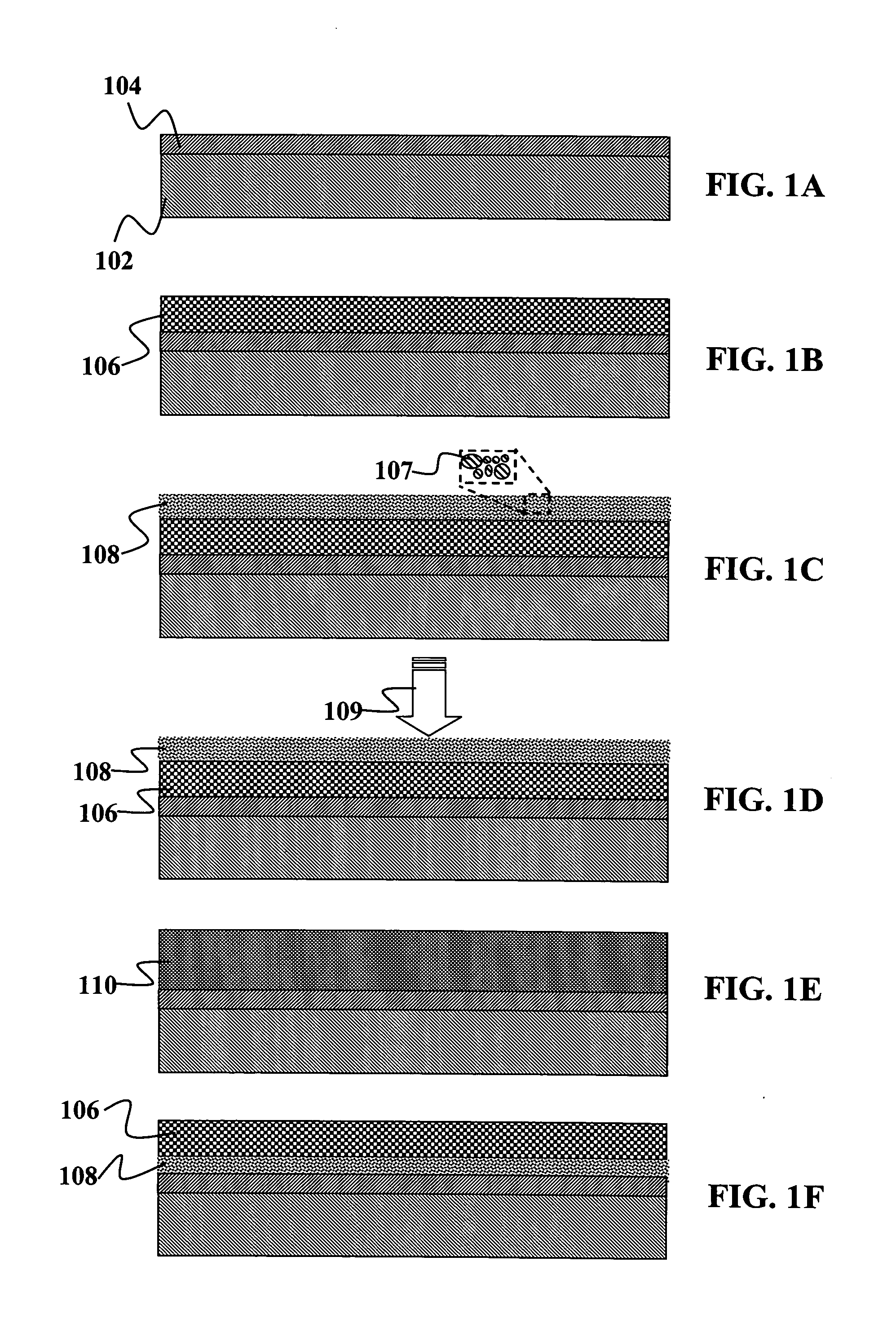

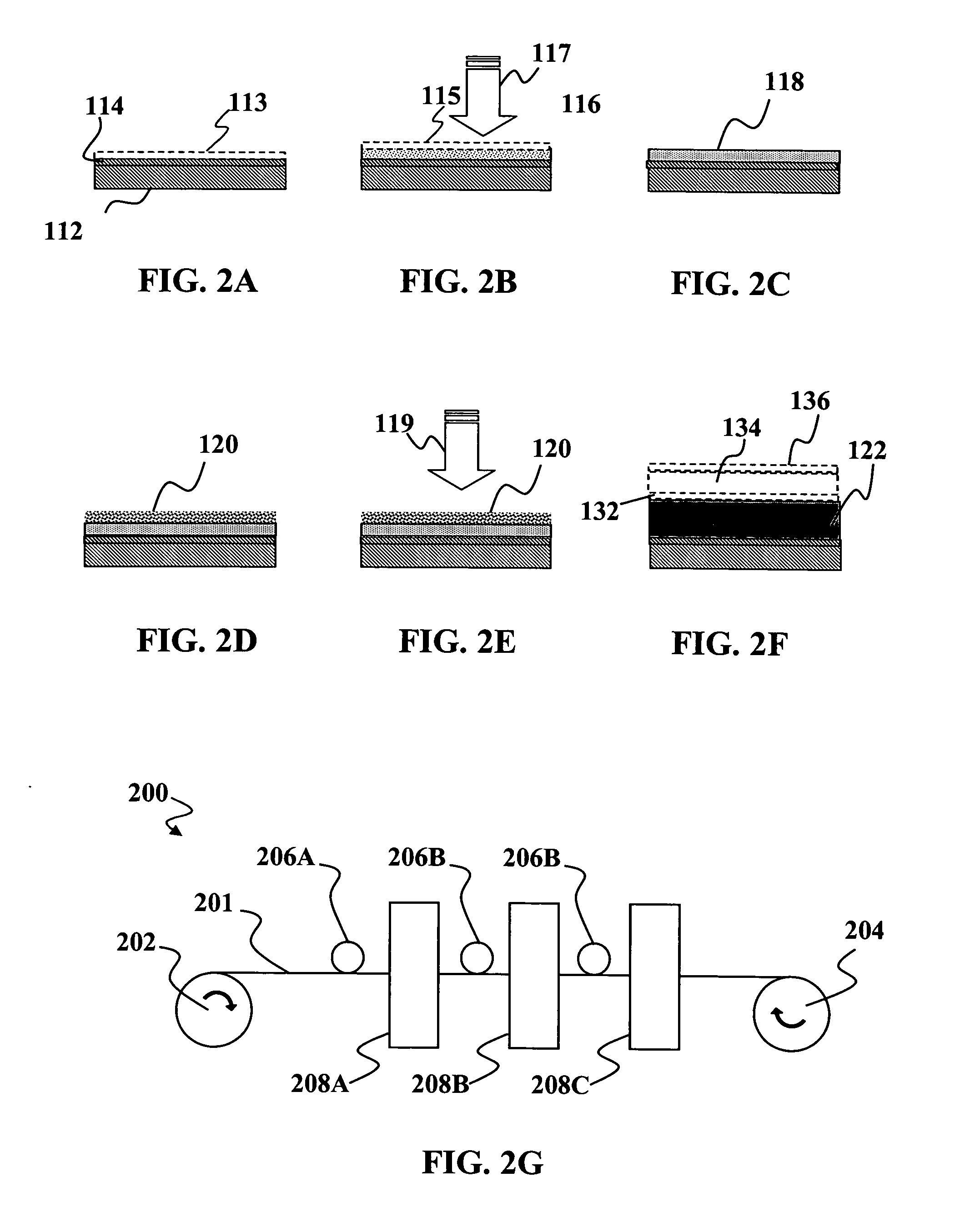

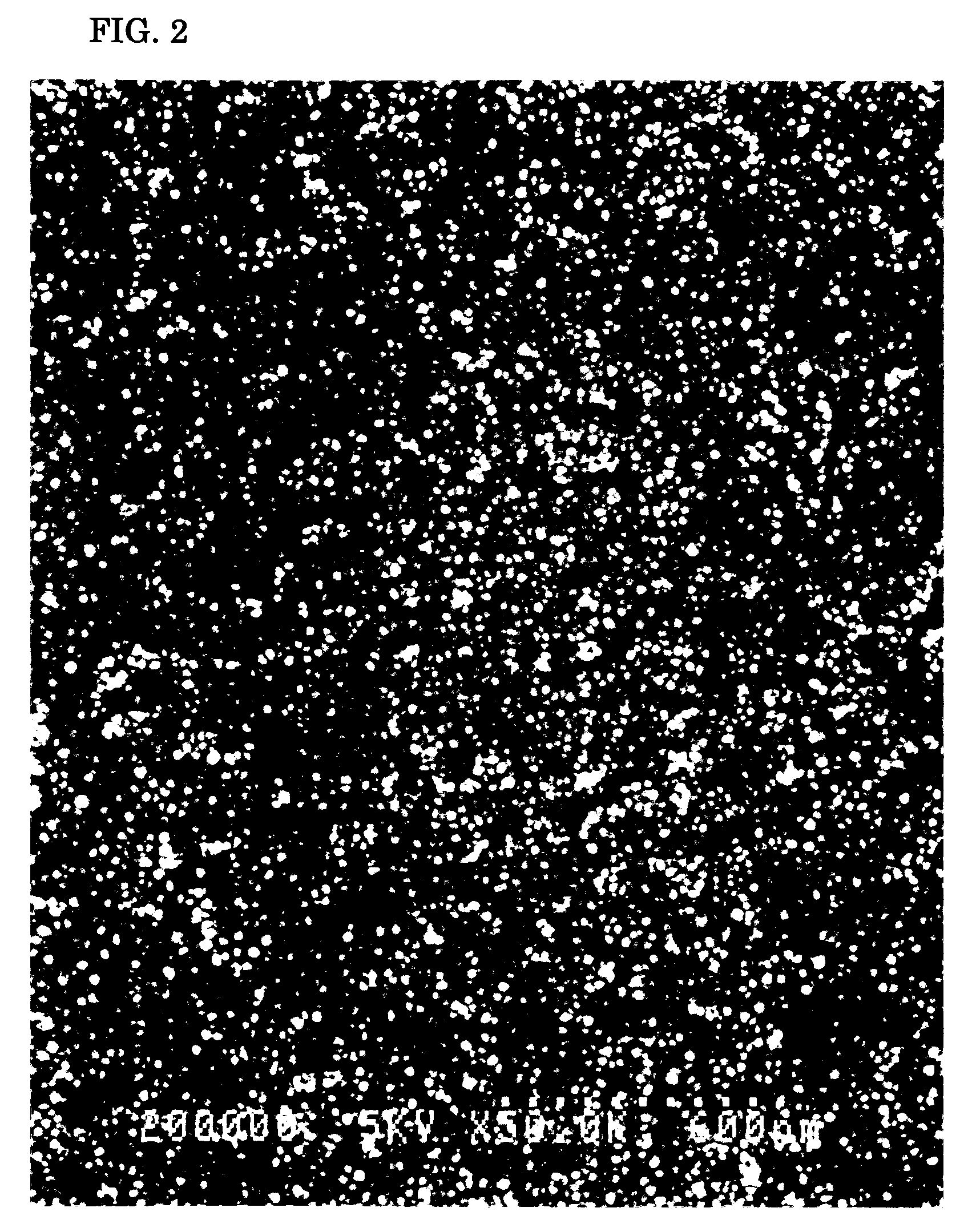

High-throughput printing of chalcogen layer and the use of an inter-metallic material

InactiveUS20070163643A1Reduce the temperaturePretreated surfacesLiquid/solution decomposition chemical coatingNanoparticleSulfur

Methods and devices for high-throughput printing of a precursor material for forming a film of a group IB-IIIA-chalcogenide compound are disclosed. In one embodiment, the method comprises forming a precursor layer on a substrate, wherein the precursor layer comprises one or more discrete layers. The layers may include at least a first layer containing one or more group IB elements and two or more different group IIIA elements and at least a second layer containing elemental chalcogen particles. The precursor layer may be heated to a temperature sufficient to melt the chalcogen particles and to react the chalcogen particles with the one or more group IB elements and group IIIA elements in the precursor layer to form a film of a group IB-IIIA-chalcogenide compound. At least one set of the particles in the precursor layer are inter-metallic particles containing at least one group IB-IIIA inter-metallic alloy phase. The method may also include making a film of group IB-IIIA-chalcogenide compound that includes mixing the nanoparticles and / or nanoglobules and / or nanodroplets to form an ink, depositing the ink on a substrate, heating to melt the extra chalcogen and to react the chalcogen with the group IB and group IIIA elements and / or chalcogenides to form a dense film.

Owner:NANOSOLAR

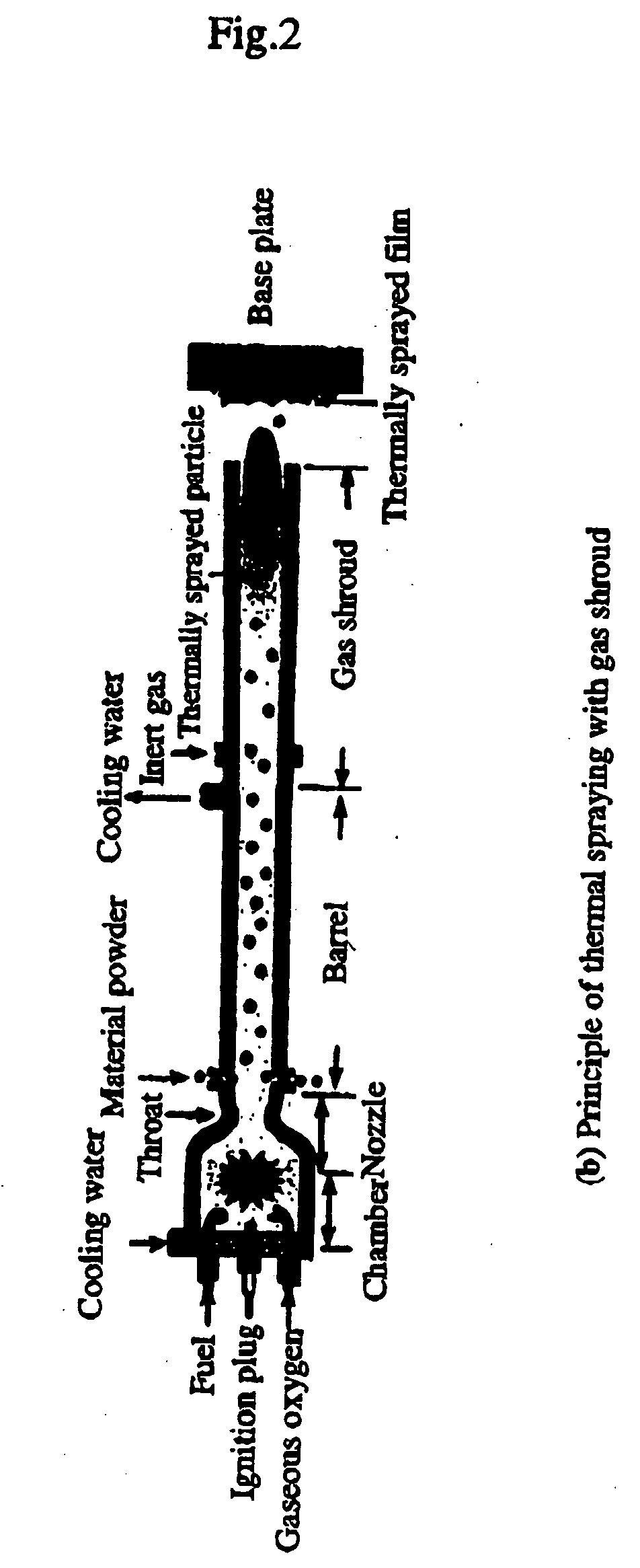

Nanosize electropositive fibrous adsorbent

InactiveUS6838005B2Improve the immunityEfficient precipitationIon-exchanger regenerationLoose filtering material filtersFiberParticulates

Aluminum hydroxide fibers approximately 2 nanometers in diameter and with surface areas ranging from 200 to 650 m2 / g have been fount to be highly electropositive. When dispersed in water they are able to attach to and retain electronegative particles. When combined into a composite filter with other fibers or particles they can filter bacteria and nano size particulates such as viruses and colloidal particles at high flux through the filter. Such filters can be used for purification and sterilization of water, biological, medical and pharmaceutical fluids, and as a collector / concentrator for detection and assay of mirobes and viruses. The alumina fibers are also capable of filtering sub-micron inorganic and metallic particles to produce ultra pure water. The fibers are suitable as a substrate for growth of cells. Macromolicules such as proteins may be separated from each other based on their electronegative charges.

Owner:ARGONIDE CORP

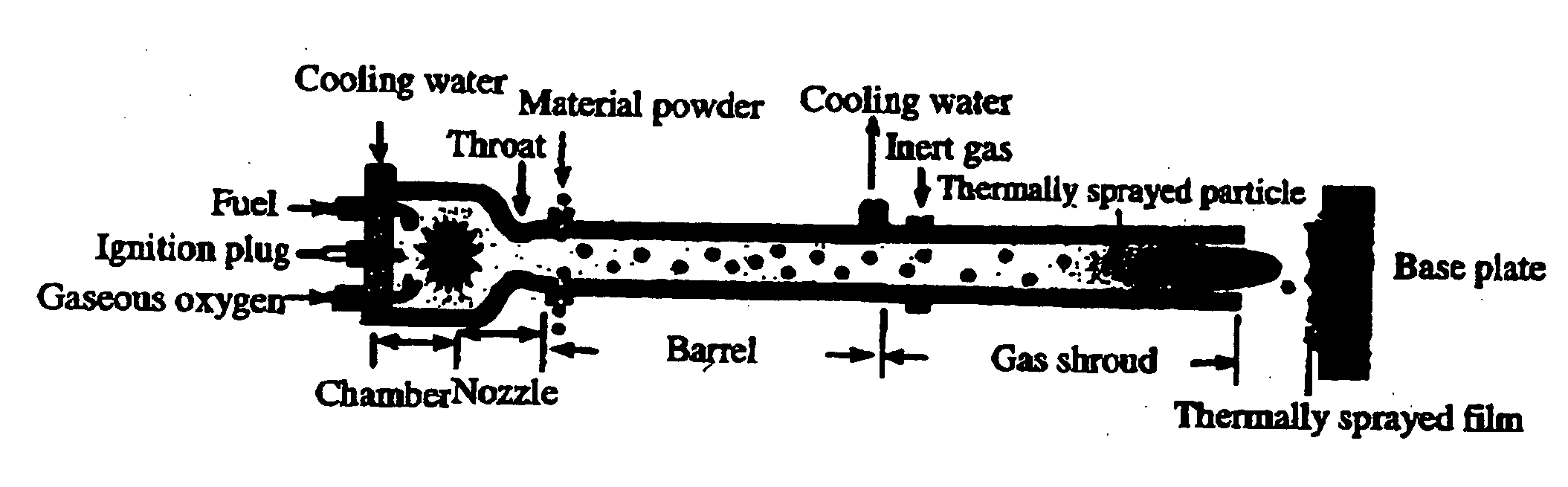

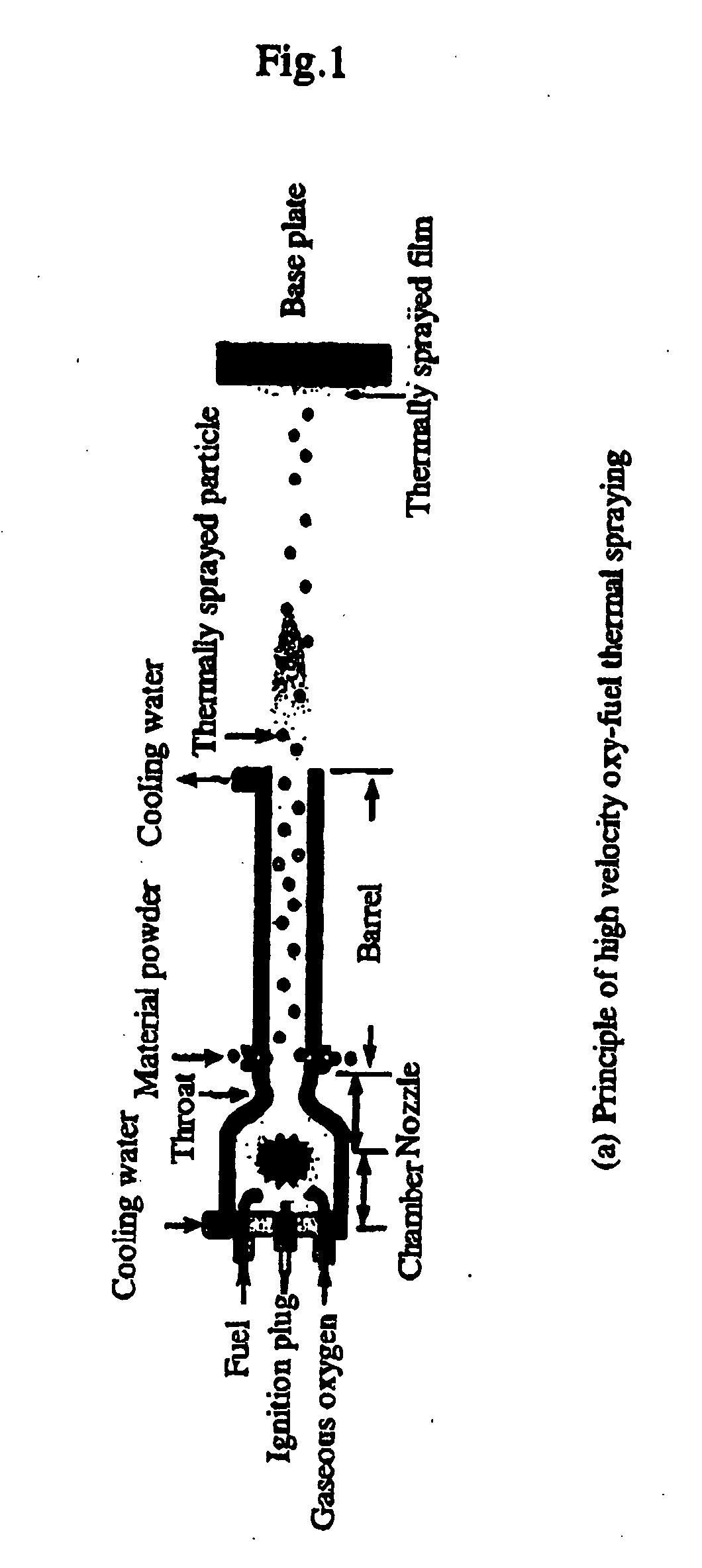

Method of forming metal coating with hvof spray gun and thermal spray apparatus

InactiveUS20050199739A1Function increaseLiquid surface applicatorsMolten spray coatingThermal sprayingOxygen content

There are provided a thermal spraying method and a thermal spraying apparatus therefor, in which a gas shroud is disposed in an HVOF thermal spraying gun barrel, the velocity of metallic particles is energized and accelerated with respect to the metallic particle to be thermally sprayed from the gun, and inert gas is supplied into the space defined inside of the shroud through a circumferential slit formed in such a manner as to shield the metallic particles from the atmosphere so as to collide with the surface of a base member, thereby forming a thermally sprayed dense film having a small oxygen content without overheating the base plate by an HVOF method.

Owner:NAT INST FOR MATERIALS SCI

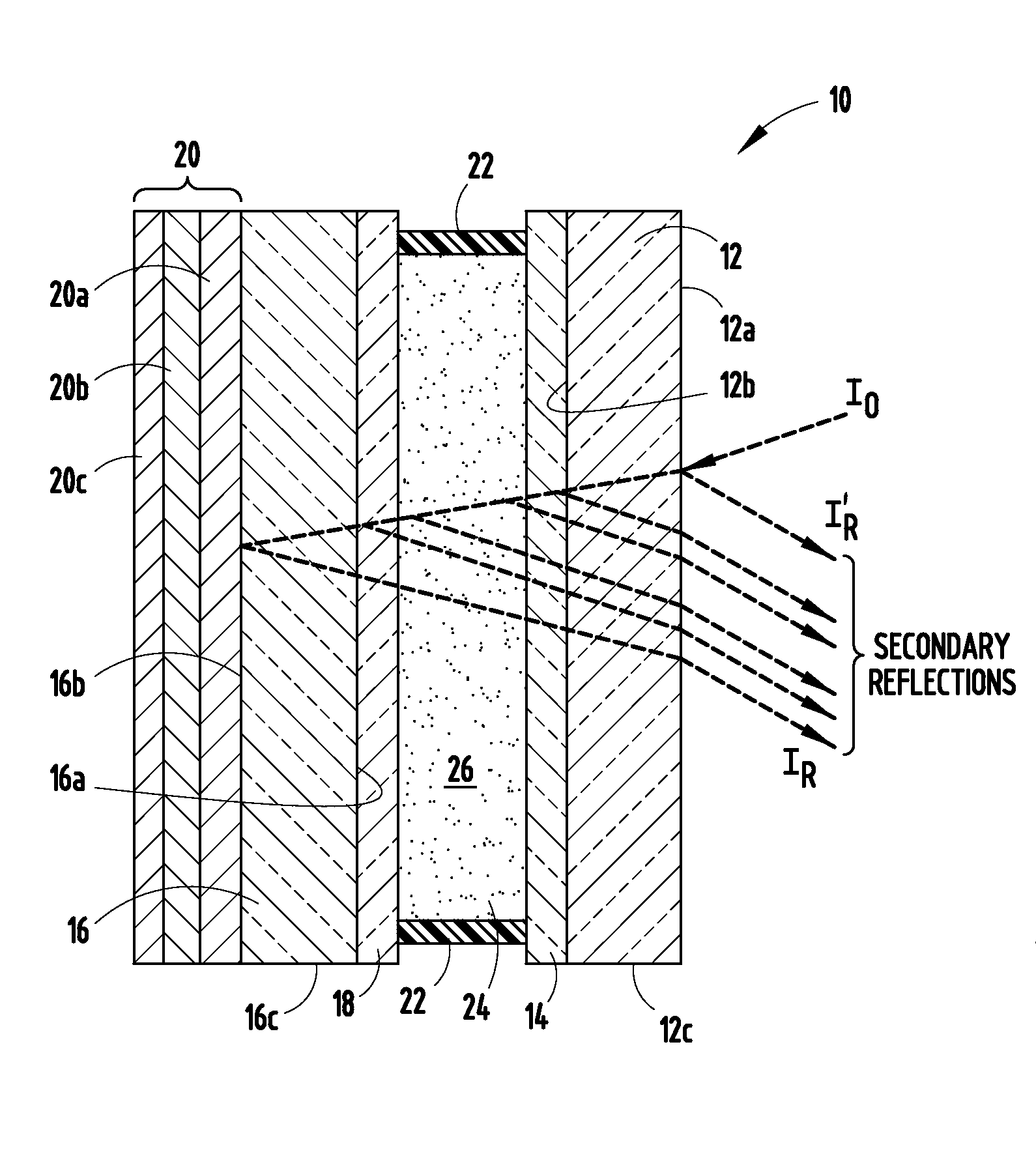

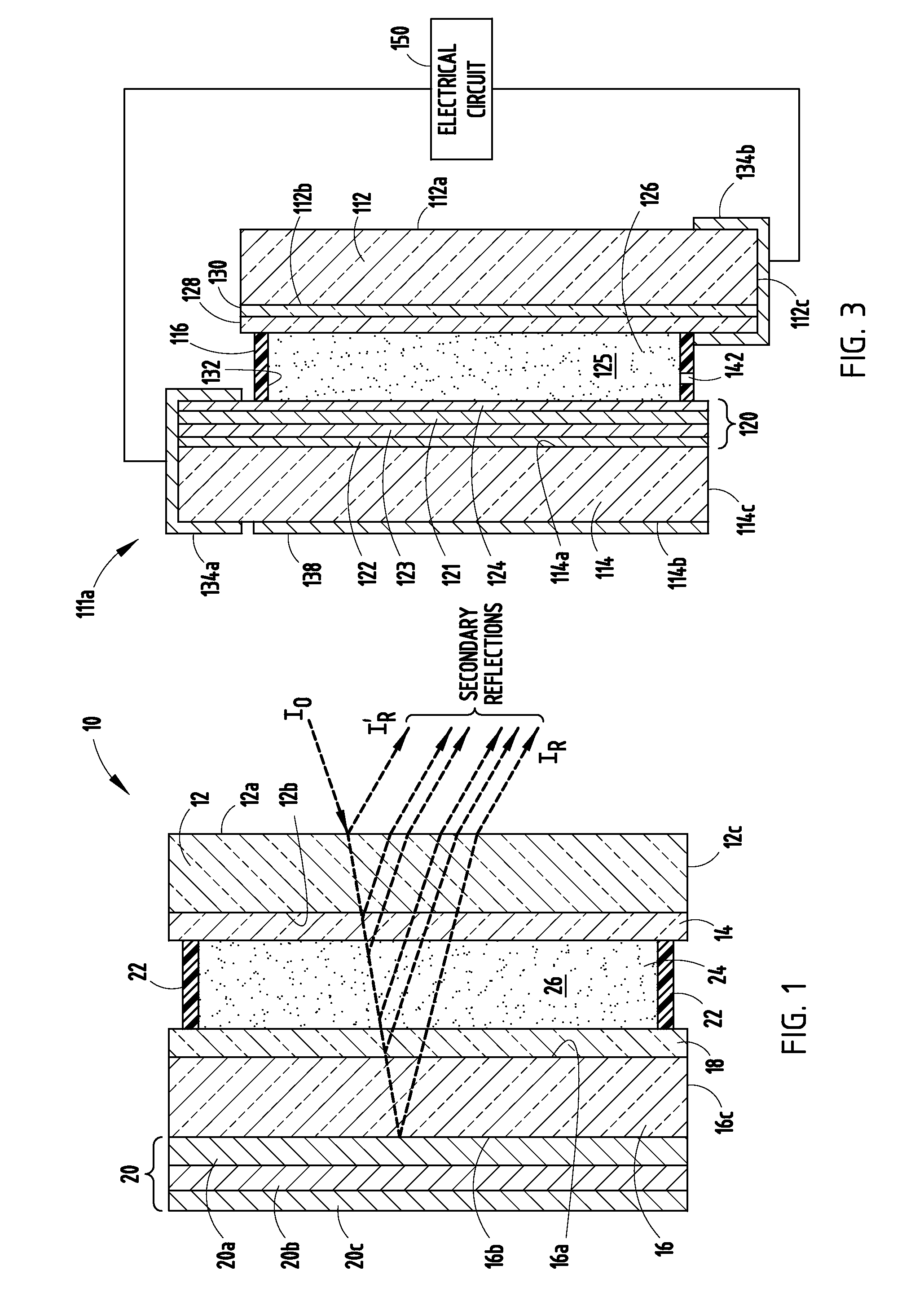

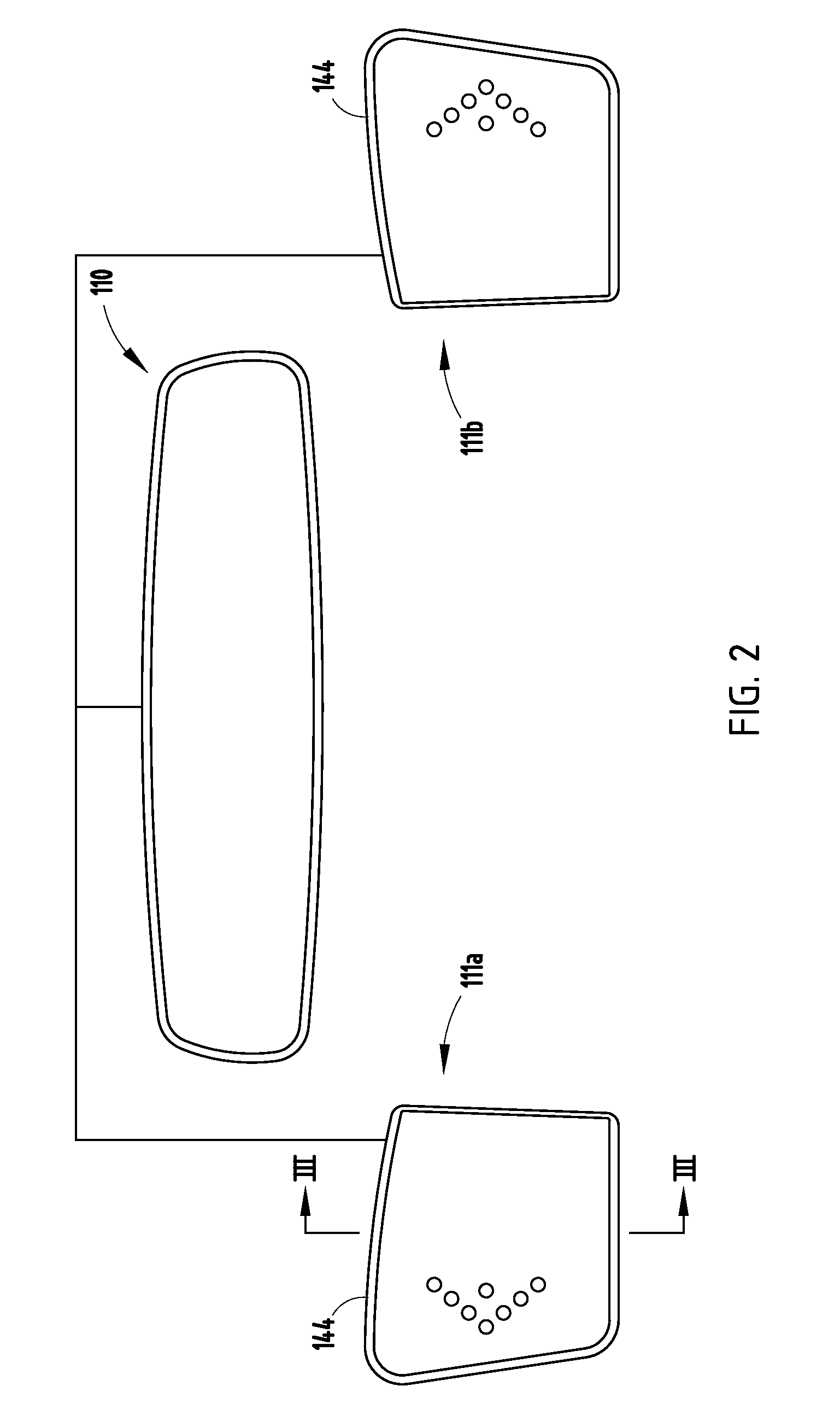

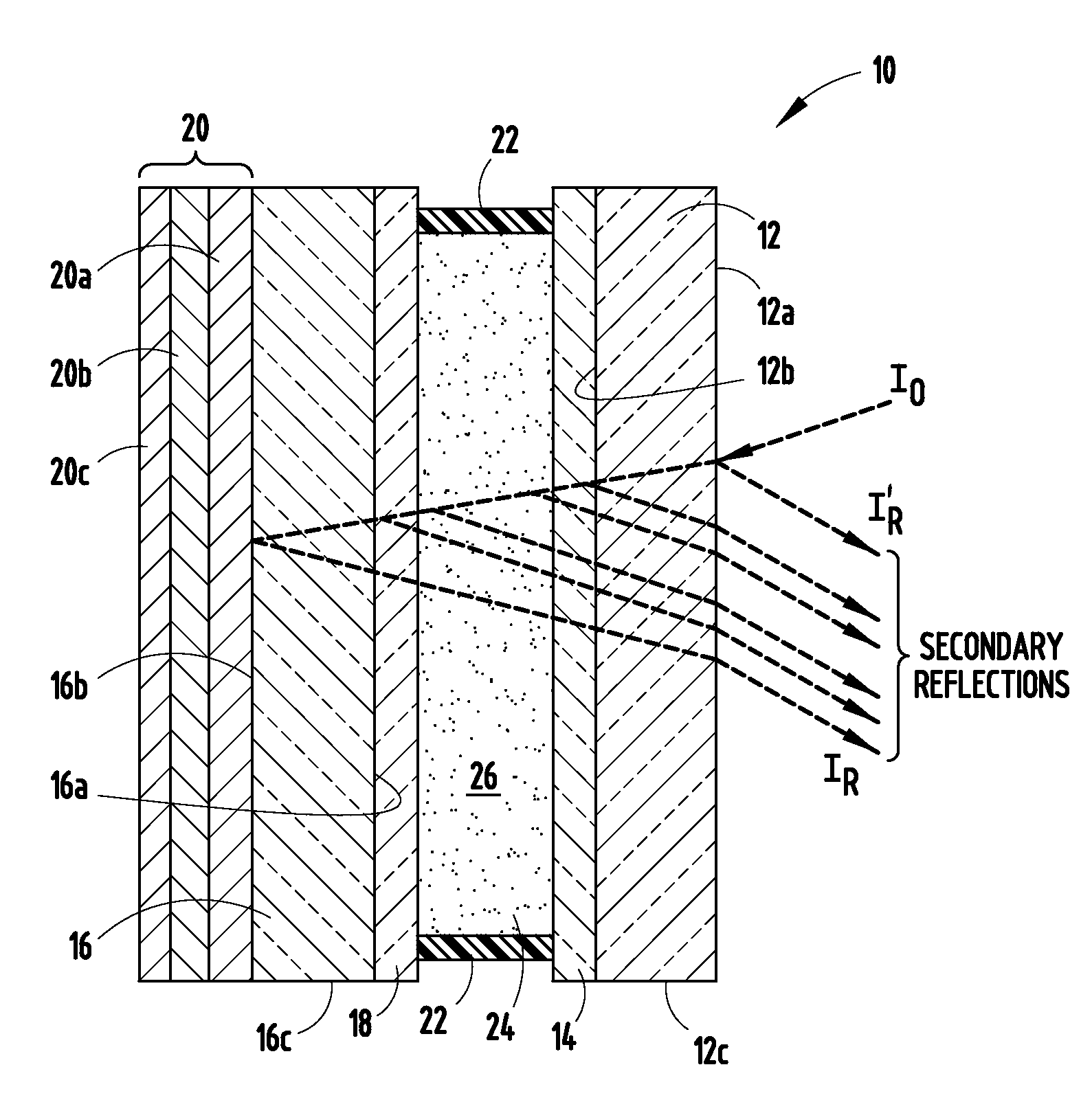

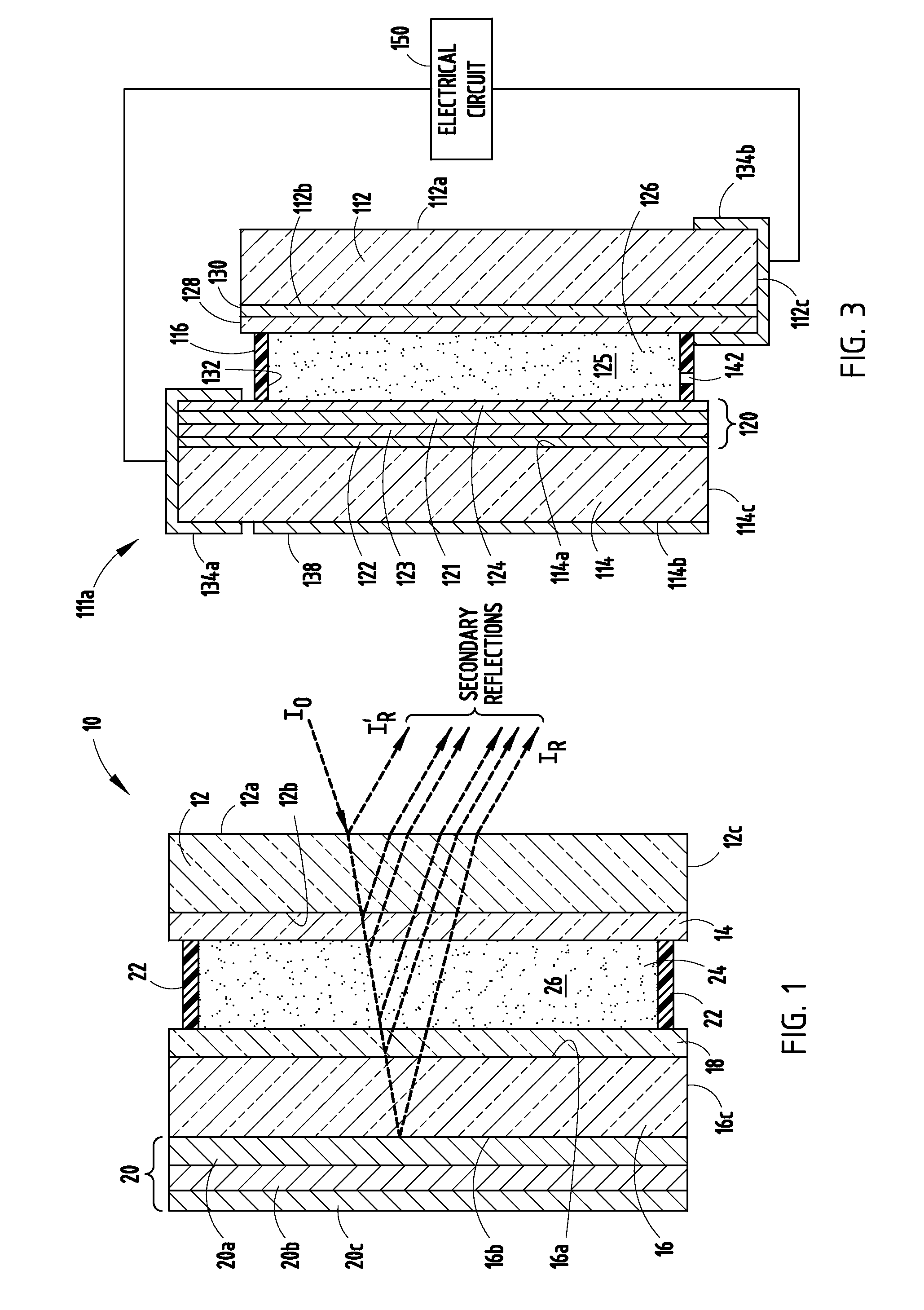

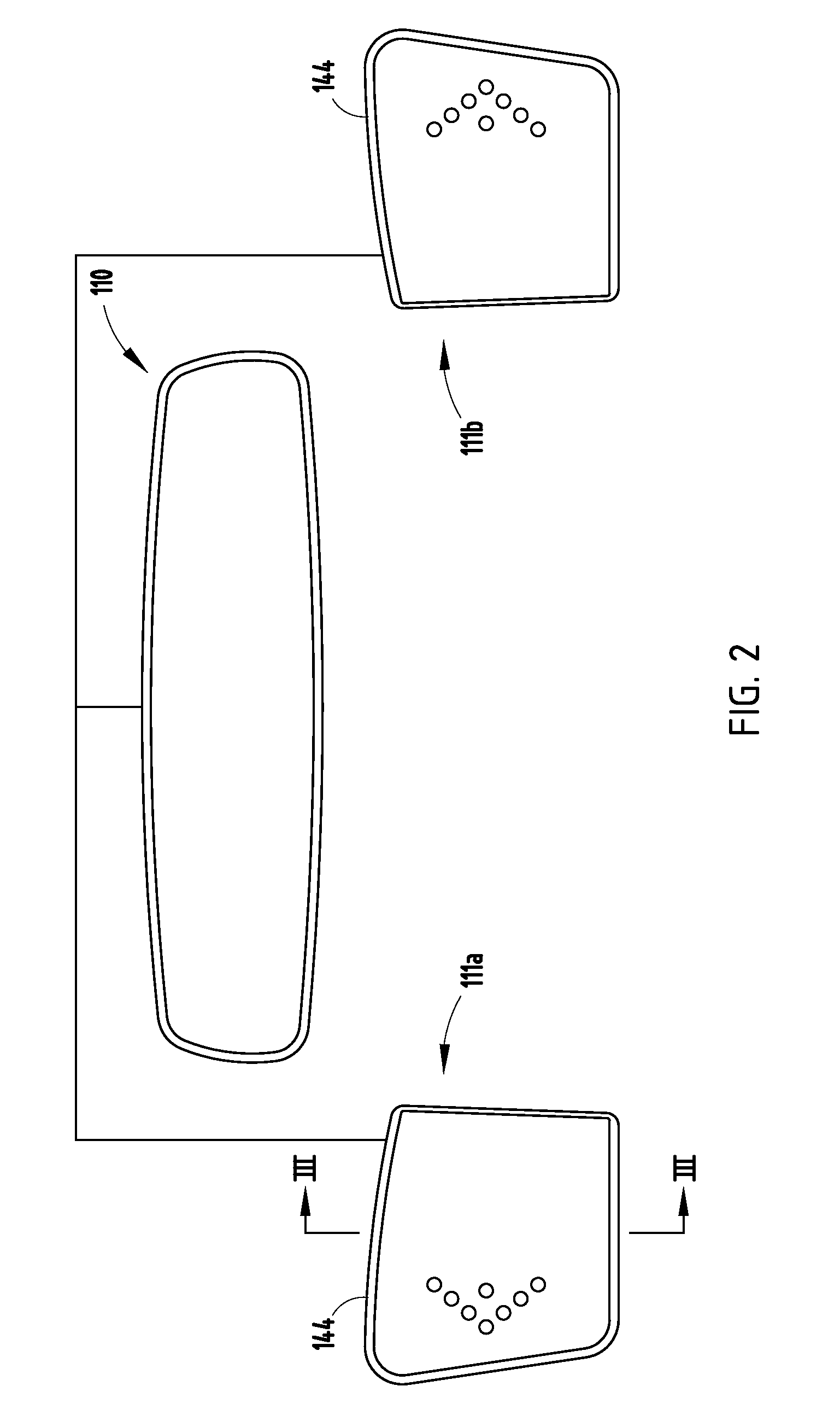

Electro-Optical Element Including Metallic Films and Methods For Applying The Same

A method for manufacturing an electrochromic element comprises providing a first substrate having first and second surfaces and a first edge surface, providing a second substrate having third and fourth surfaces and a second edge surface, the third surfaces facing the second surface, providing an electrochromic medium located between the first and second substrates, the medium having a light transmittance that is variable upon application of electric field thereto, applying a conductive layer on a portion of at least one of the surfaces, wherein applying the layer is accomplished at substantially atmospheric pressure, and applying at least one of metallic particles, an organometallic, a metallo-organic, and combinations thereof, wherein the conductive layer has a bulk resistivity of greater than or equal to 150 μΩ·cm. The conductive layer may be applied via ink jetting, ultrasonic spraying, auger or jet pumping.

Owner:GENTEX CORP

Electro-optical element including metallic films and methods for applying the same

A method for manufacturing an electrochromic element comprises providing a first substrate having first and second surfaces opposite one another and a first edge surface, providing a second substrate having third and fourth surfaces opposite one another and a second edge surface, wherein the third surfaces faces the second surface, and providing an electrochromic medium located between the first and second substrates, wherein the electrochromic medium has a light transmittance that is variable upon the application of electric field thereto. The method further complies applying a conductive layer on at least a portion of at least a select one of a first, second, third, and fourth surfaces and the first and second edge surfaces, wherein applying the conductive layer is accomplished at substantially atmospheric pressure and including applying at least a select one of metallic particles, an organometallic, a metallo-organic, and combinations thereof, and wherein the conductive layer has a bulk resistivity of less than or equal to 150 μΩ·cm. Other aspects of this invention comprise applying the conductive layer via ink jetting, ultrasonic spraying, auger pumping and jet pumping.

Owner:GENTEX CORP

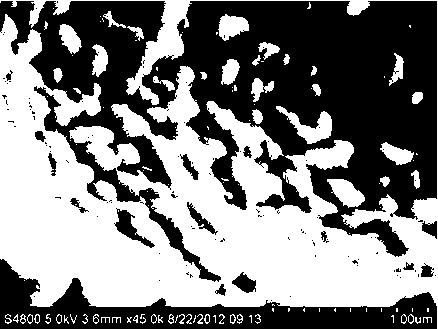

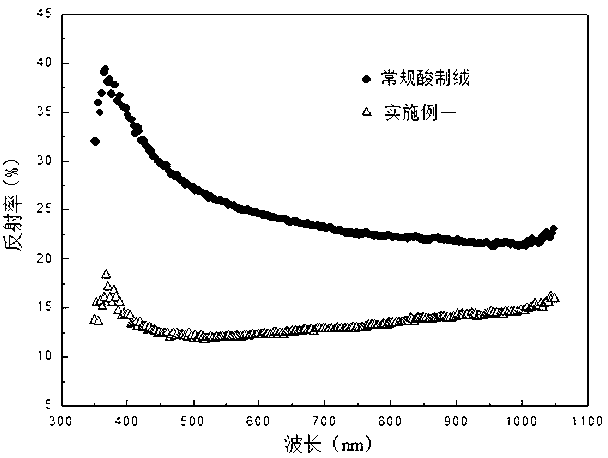

Textured structure of crystalline silicon solar cell and preparation method thereof

ActiveCN103219428AImprove conversion efficiencySimple manufacturing methodPhotovoltaic energy generationSemiconductor devicesMicrometerSpins

The invention discloses a preparation method of a textured structure of a crystalline silicon solar cell. The method includes the steps of (1) cleaning and texture preparation, (2) soaking a silicon wafer in a solution containing metal ions to enable the surface of the silicon wafer to be coated with a layer of metal nanometer particles, (3) corroding the surface of the silicon wafer to form a nanometer-grade texture, (4) cleaning to remove the metal particles, (5) carrying out microstructure amendment etching in second chemical corrosive liquid, and (6) cleaning and spin-drying. As is proved by a test, the size of the textured structure is between 100nm-500nm; the textured structure is of a nanopore shape with a large hole diameter and a small depth, or a nanometer pyramid with edge angles, or of a nanometer pit shape structure with an edge angle nanometer cone body or with an edge angle; and compared with a nanometer-micrometer composite textured structure disclosed in CN102610692A, the textured structure enables conversion efficiency of a cell piece to be improved by about 0.2%-0.5%, and an unexpected effect is achieved.

Owner:SUZHOU UNIV +1

Paste for back contact-type solar cell

InactiveUS20080230119A1Reduce contact resistanceExcellent electrical propertiesFinal product manufactureConductive materialFritMetal alloy

Disclosed is a paste for a back contact-type solar cell that includes: (a) electrically conductive particles containing silver particle and added particles selected from the group consisting of (i) metal particles selected from the group consisting of Mo, Tc, Ru, Rh, Pd, W, Re, Os, Ir and Pt particles, (ii) a metal alloy containing the metal particles, and (iii) particles loaded with the metal particles, (b) glass frit, and (c) a resin binder.

Owner:EI DU PONT DE NEMOURS & CO

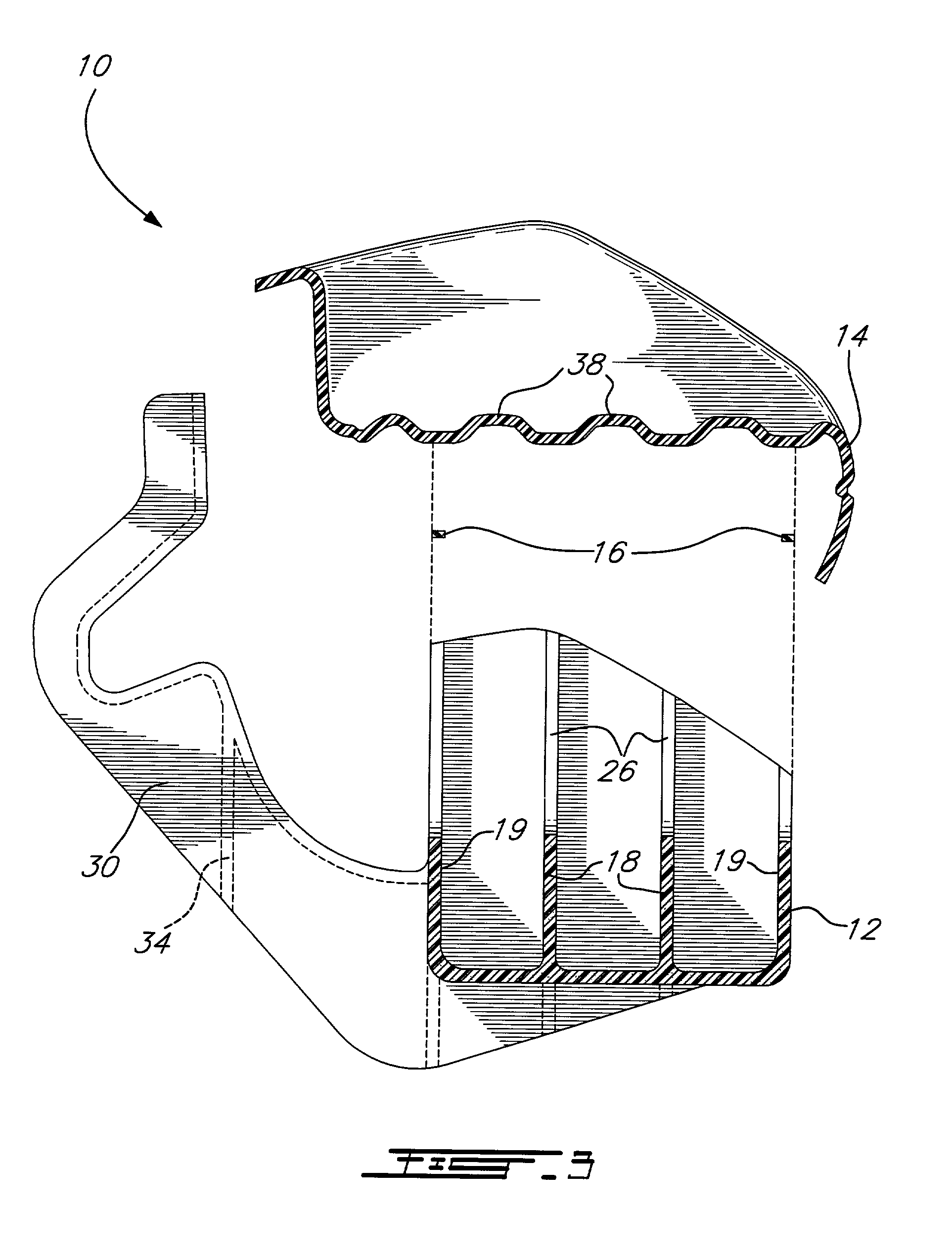

Radiation-curable metal particles and curable resin compositions comprising these particles

InactiveUS6521677B2High refractive indexHigh hardnessMaterial nanotechnologyConductive materialPolymer scienceMeth-

Provided is a liquid curable resin composition which can produce transparent cured products with a high refractive index, high hardness, and superior abrasion resistance, and which can be suitably used as a coating material. The liquid curable resin composition comprises: (A) a poly-functional (meth)acrylic compound having at least three (meth) acryloyl groups in the molecule; (B) a reaction product obtained by the reaction of a compound having a polymerizable unsaturated group and alkoxysilyl group in the molecule and particles metal oxide, the metals being preferably selected from the group consisting of zirconium, antimony, zinc, tin, cerium, and titanium; and (C) a radiation polymerization initiator.

Owner:JSR CORPORATIOON

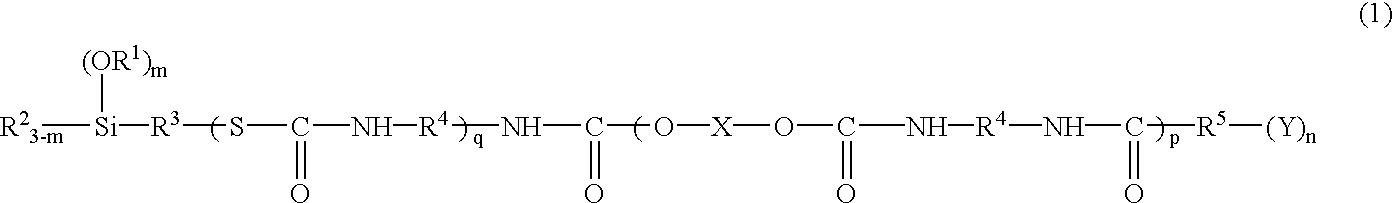

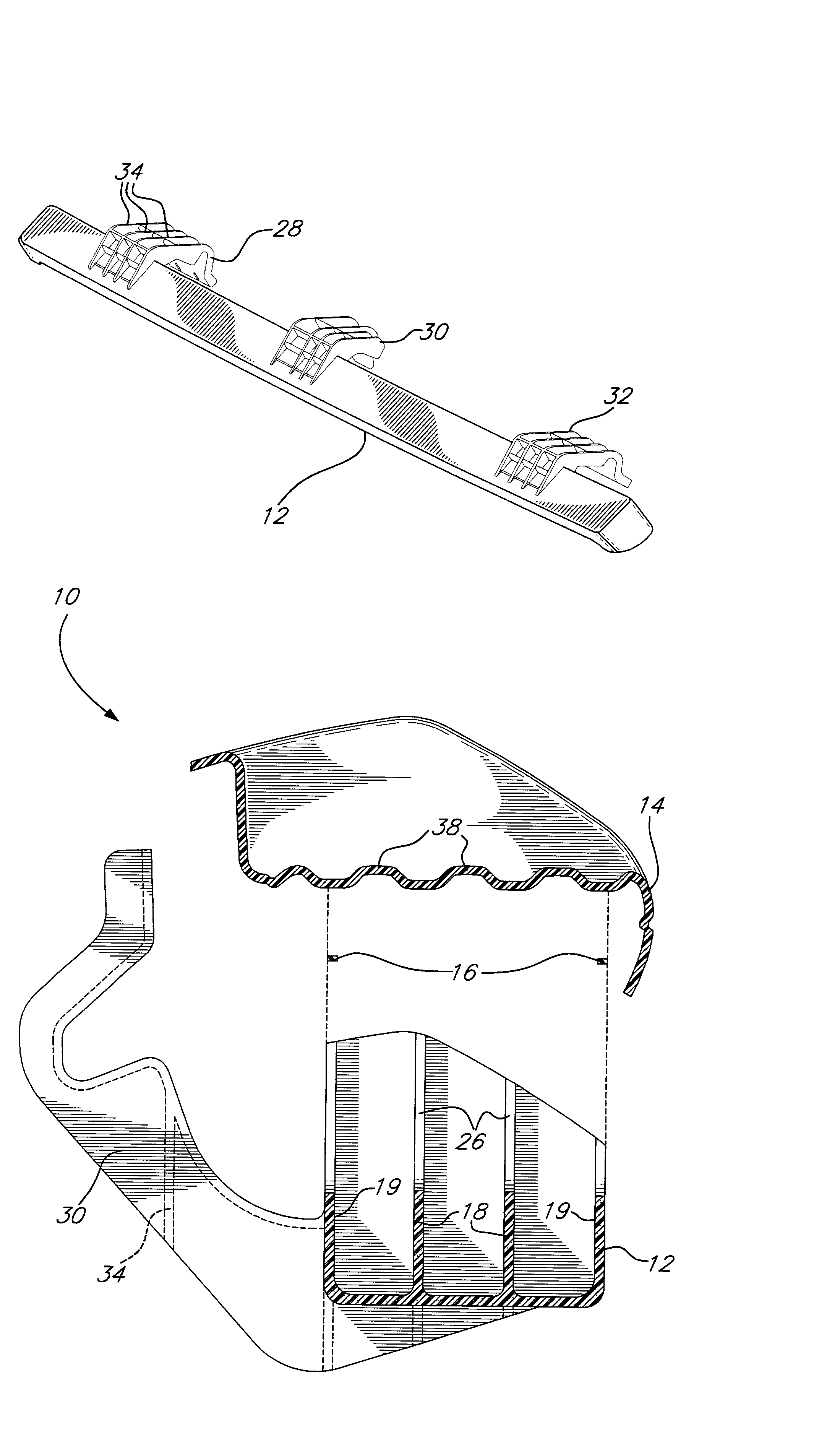

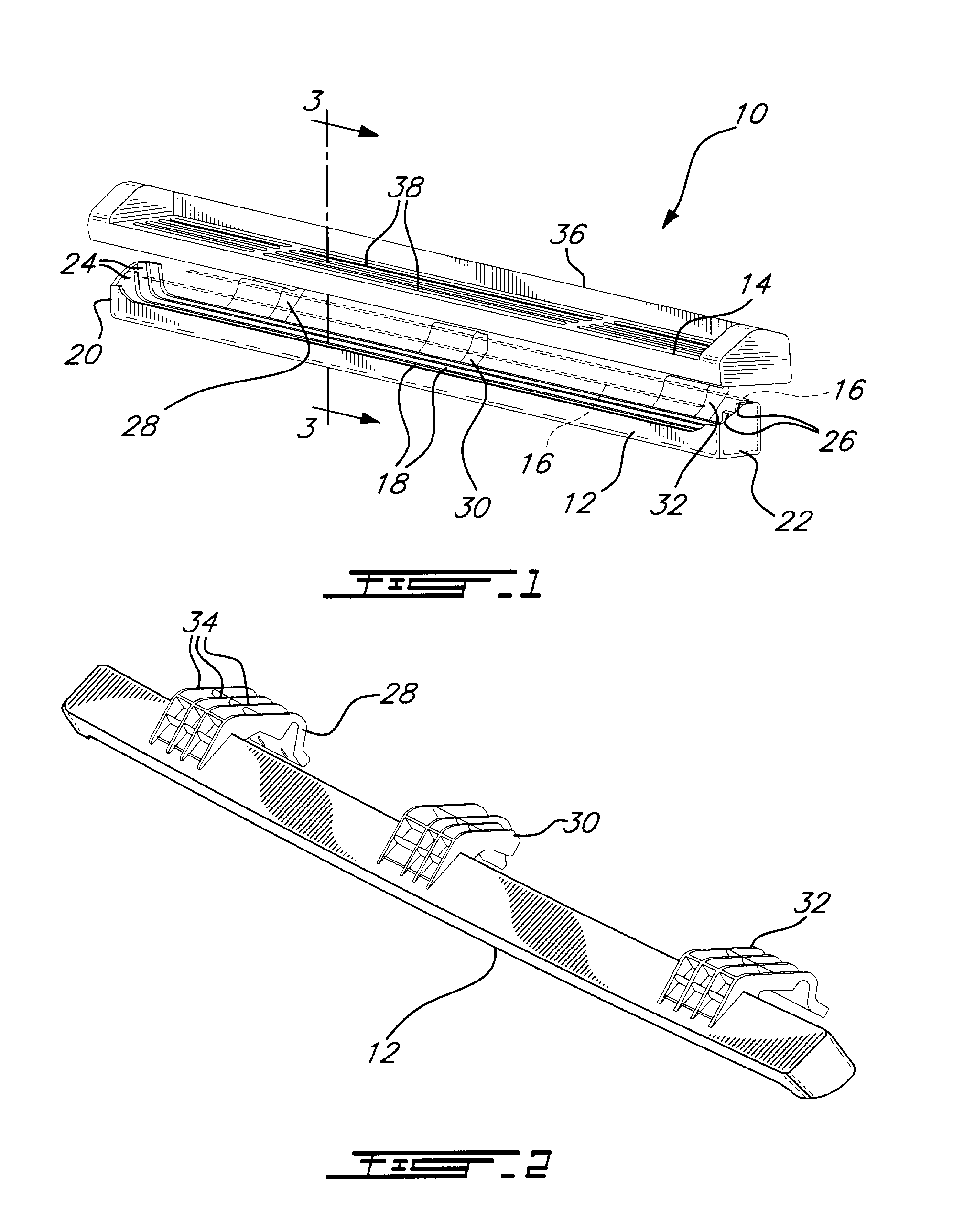

Molded running board

A molded running board provided with a support portion and a top portion is described herein. The support portion is made of plastic material and provided with reinforcing ribs and the top portion is made of a plastic material that is advantageously compatible with the plastic material forming the support portion. A method for the assembly of such a molded running board is also described herein. This method includes the welding of a top portion to a support portion via the use of a thin strand of plastic material compatible with material used in the top portion and the support portion and metallic particles in an electromagnetic press, for example.

Owner:DECOMA INT

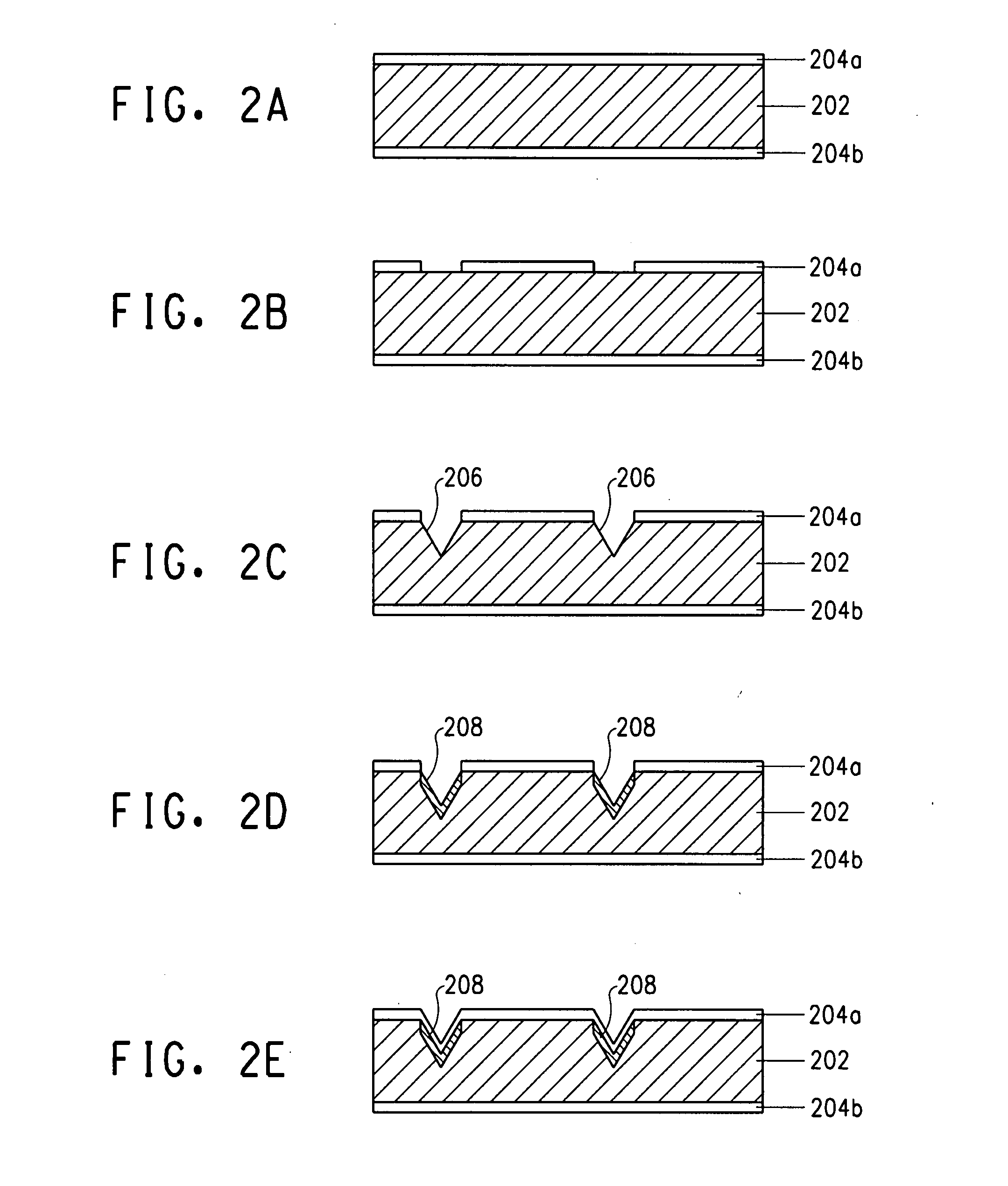

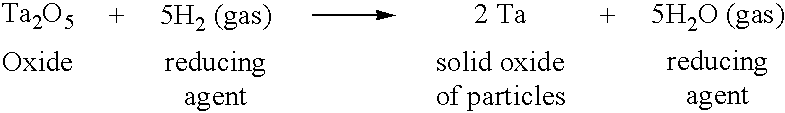

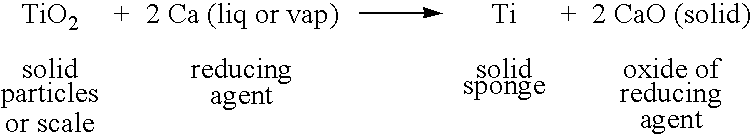

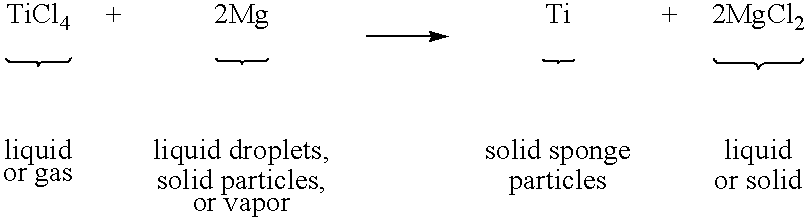

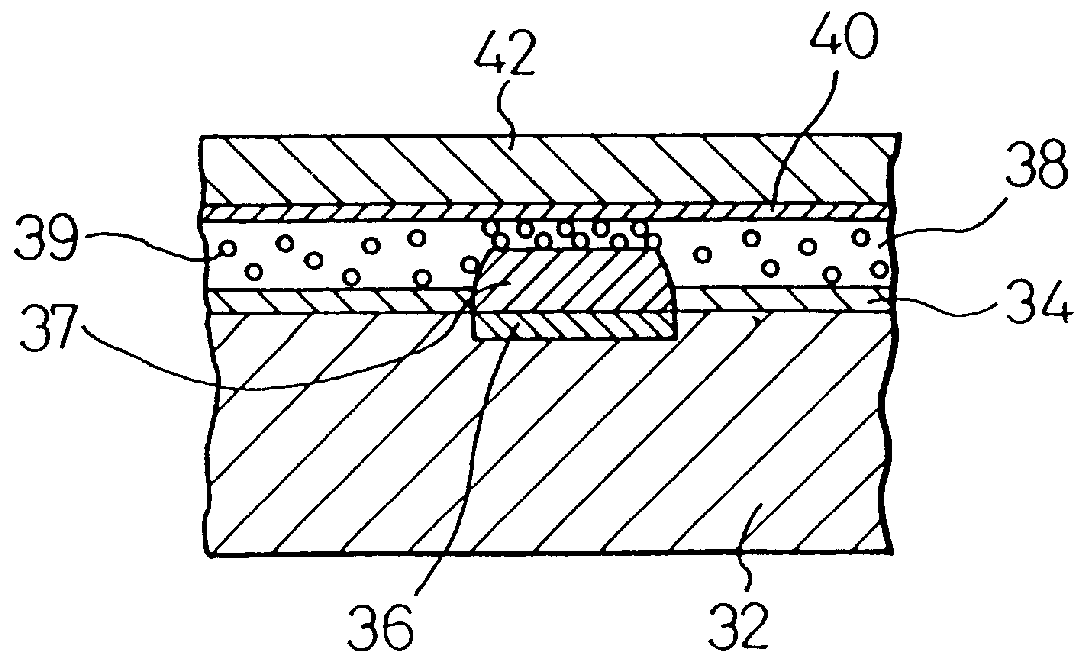

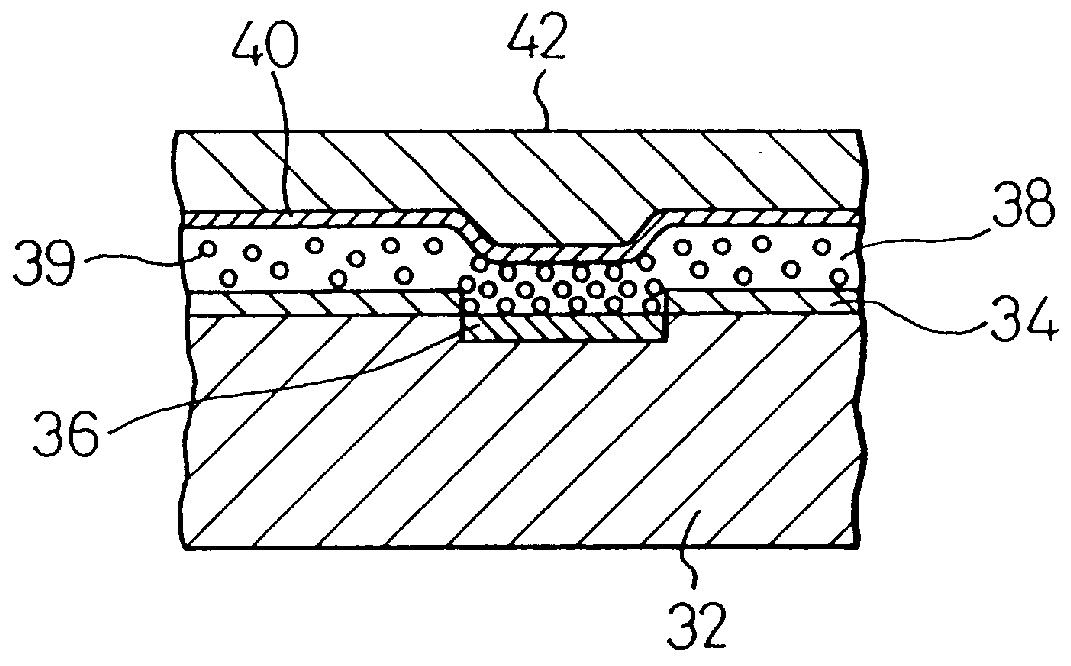

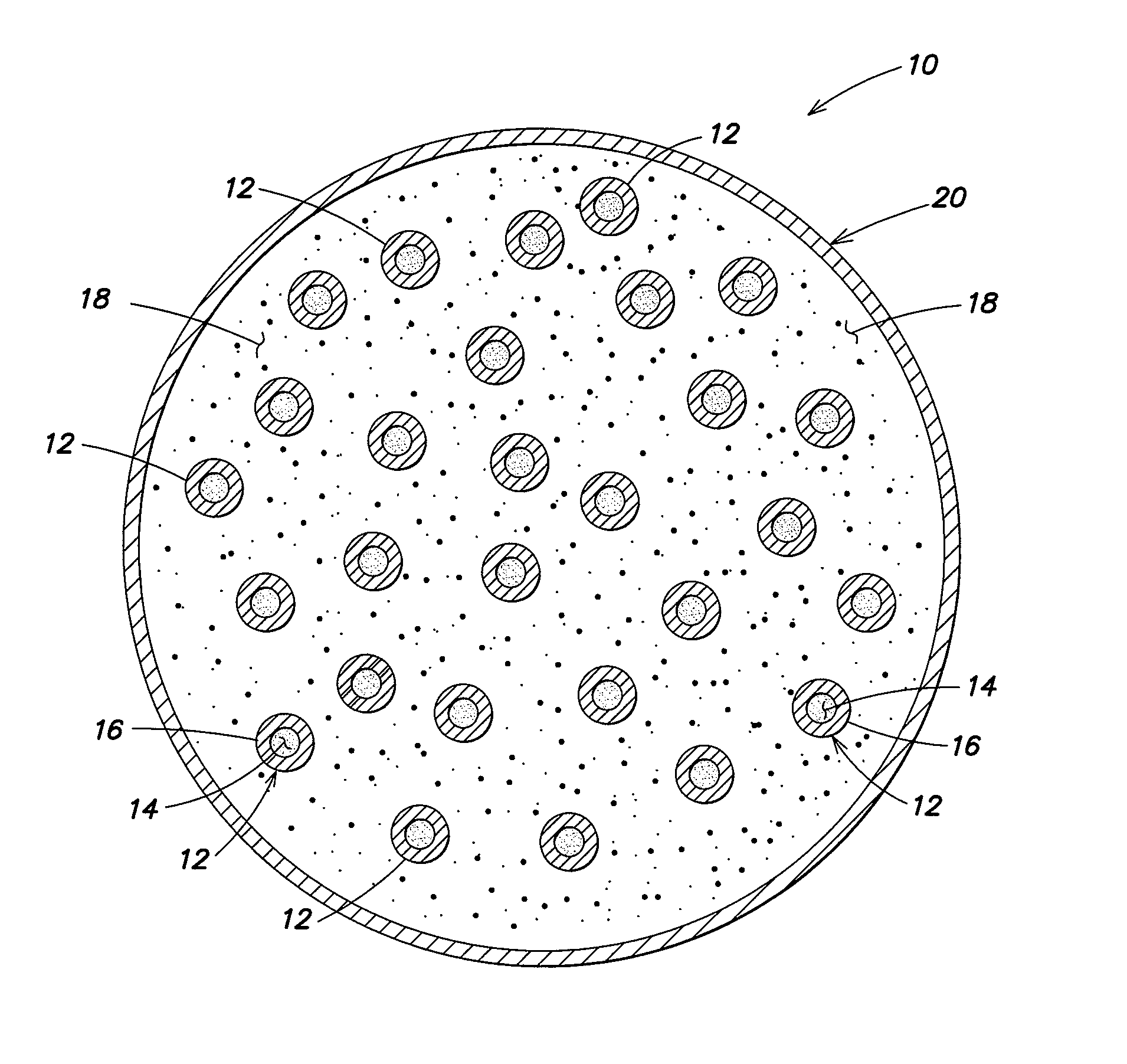

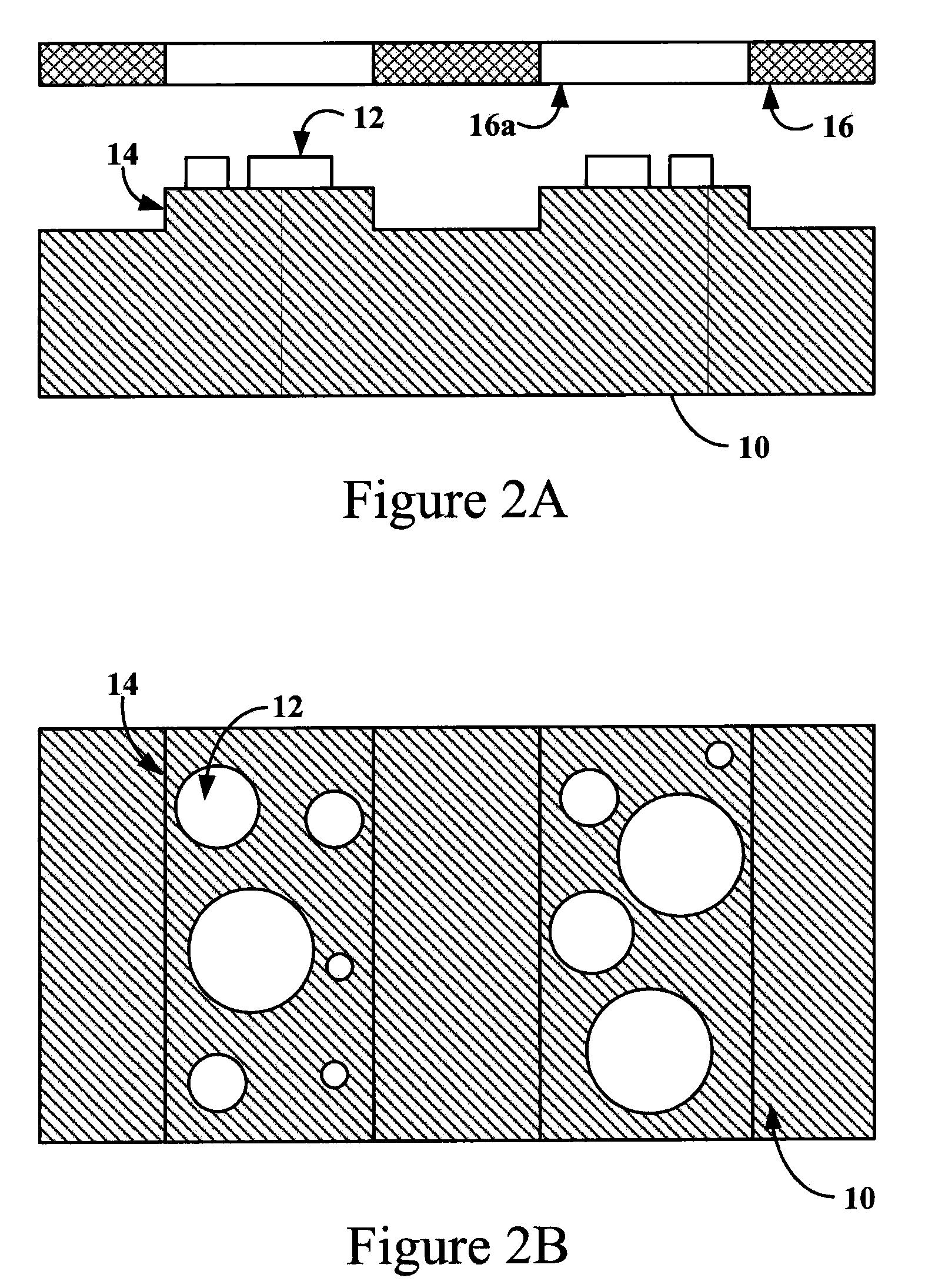

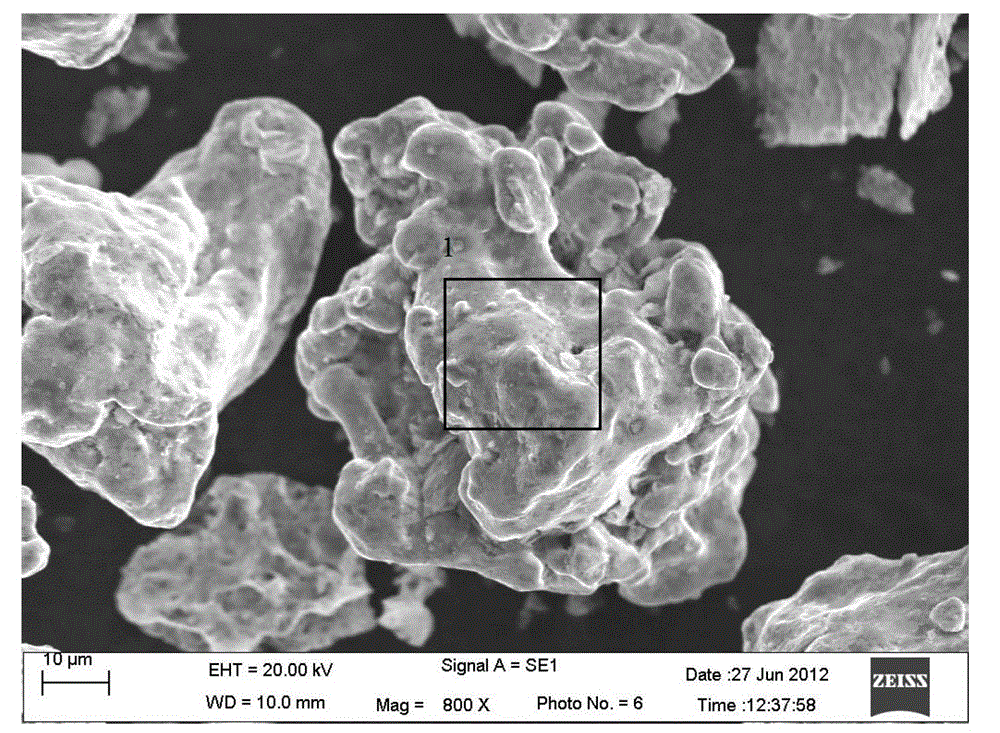

High power capacitors from thin layers of metal powder or metal sponge particles

InactiveUS20030169560A1Increase surface areaSmall sizeFixed capacitor dielectricSolid-state devicesDielectric strengthHigh surface area

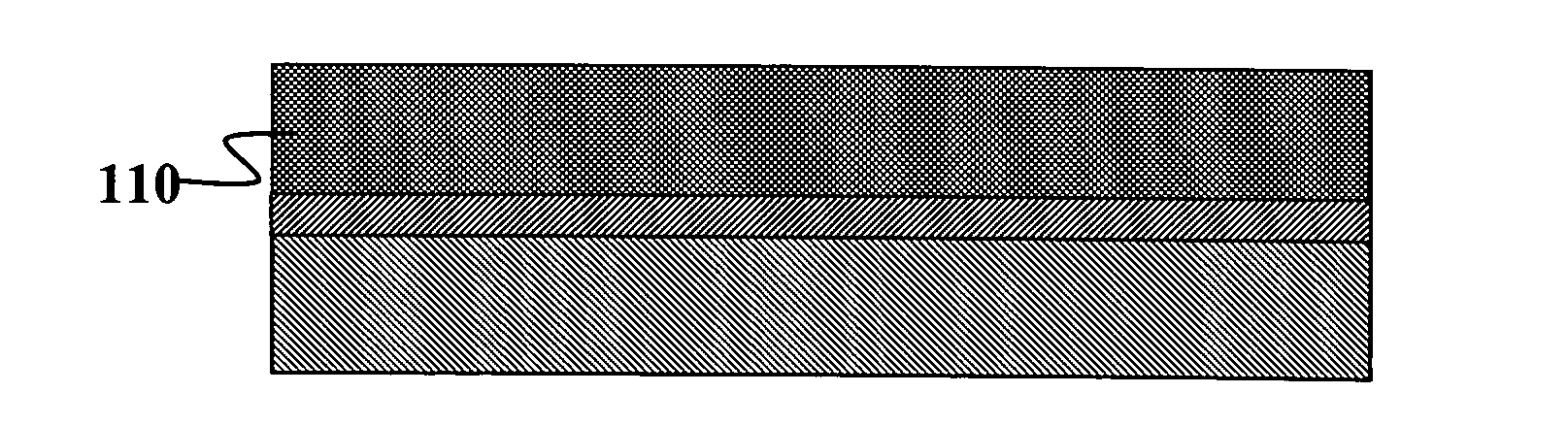

An anode (14, 208, 410) and / or cathode (12, 212, 420) of a capacitor has a large surface area. The high surface area of the anode is provided by forming the anode from a thin, electrically conductive layer (16) formed from metal particles (18) or an electrically conductive metallic sponge (416). These materials provide a porous structure with a large surface area of high accessibility. The particles are preferably directional or non-directional sponge particles of a metal, such as titanium. The conductive layer hasa dielectric film (36, 236, 414) on its surface, formed by anodizing the particle surfaces. The dielectric film has a combination of high dielectric constant and high dielectric strength. The cathode (12, 212, 420) of the capacitor is either a conventional solid material or, more preferably, has a large surface provided by forming the surface from a sponge or particles analogously to the anode. The high dielectric strengths obtainable from the capacitor allow for extreme miniaturization, making the capacitor particularly suited for integrated circuit applications.

Owner:TITANIUM POWER TECH

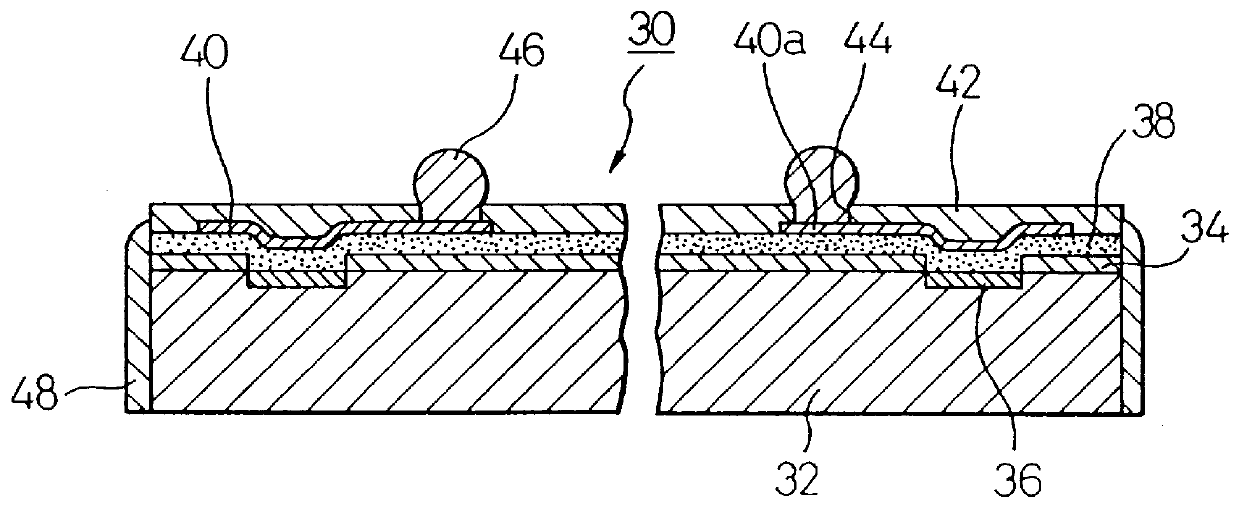

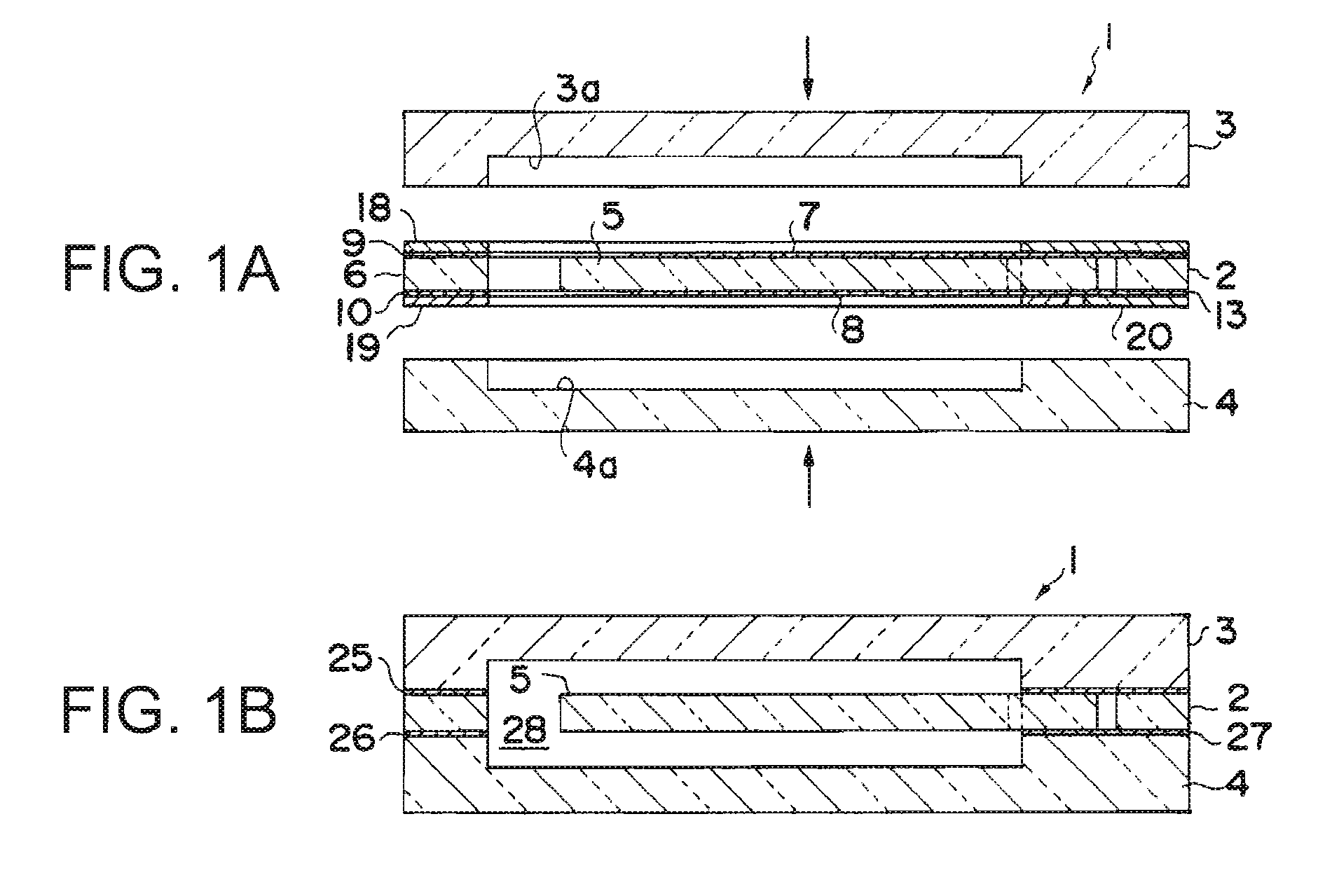

Anisotropic conductive sheet and printed circuit board

InactiveUS6121688APrinted circuit assemblingSemiconductor/solid-state device detailsOptoelectronicsPrinted circuit board

An anisotropic conductive sheet material includes a resin and conductive fillers, such as metallic particles, added in the resin. A conductive layer is formed on one of the surfaces of the anisotropic conductive sheet material. A circuit board includes a substrate having first and second surfaces and a circuit pattern being formed on the first surface of the substrate, an anisotropic conductive sheet having first and second surfaces, a circuit pattern being formed on the first surface thereof. The second surface of the anisotropic conductive sheet is adhered to the first surface of the substrate in such a manner that the circuit patterns are electrically connected to each other by means of the anisotropic conductive sheet. An electrically insulative layer formed on the first surface of the anisotropic conductive sheet to cover the circuit pattern thereof, except that external connecting portions thereof are exposed.

Owner:SHINKO ELECTRIC IND CO LTD

Aerogel and metallic compositions

InactiveUS7378450B2Improve performanceLess utilizationMaterial nanotechnologyOther chemical processesFuel cellsMaterials science

Metallic aerogel compositions comprising an aerogel, e.g., RF or carbon aerogel, having metallic particles dispersed on its surface are disclosed. The aerogel compositions can have a uniform distribution of small metallic particles, e.g., 1 nanometer average particle diameter. Also disclosed are processes for making the aerogel compositions comprising contacting an aerogel with a supercritical fluid containing a metallic compound. The aerogel compositions are useful, for example in the manufacture of fuel cell electrodes.

Owner:AEROGEL COMPOSITE LLC +1

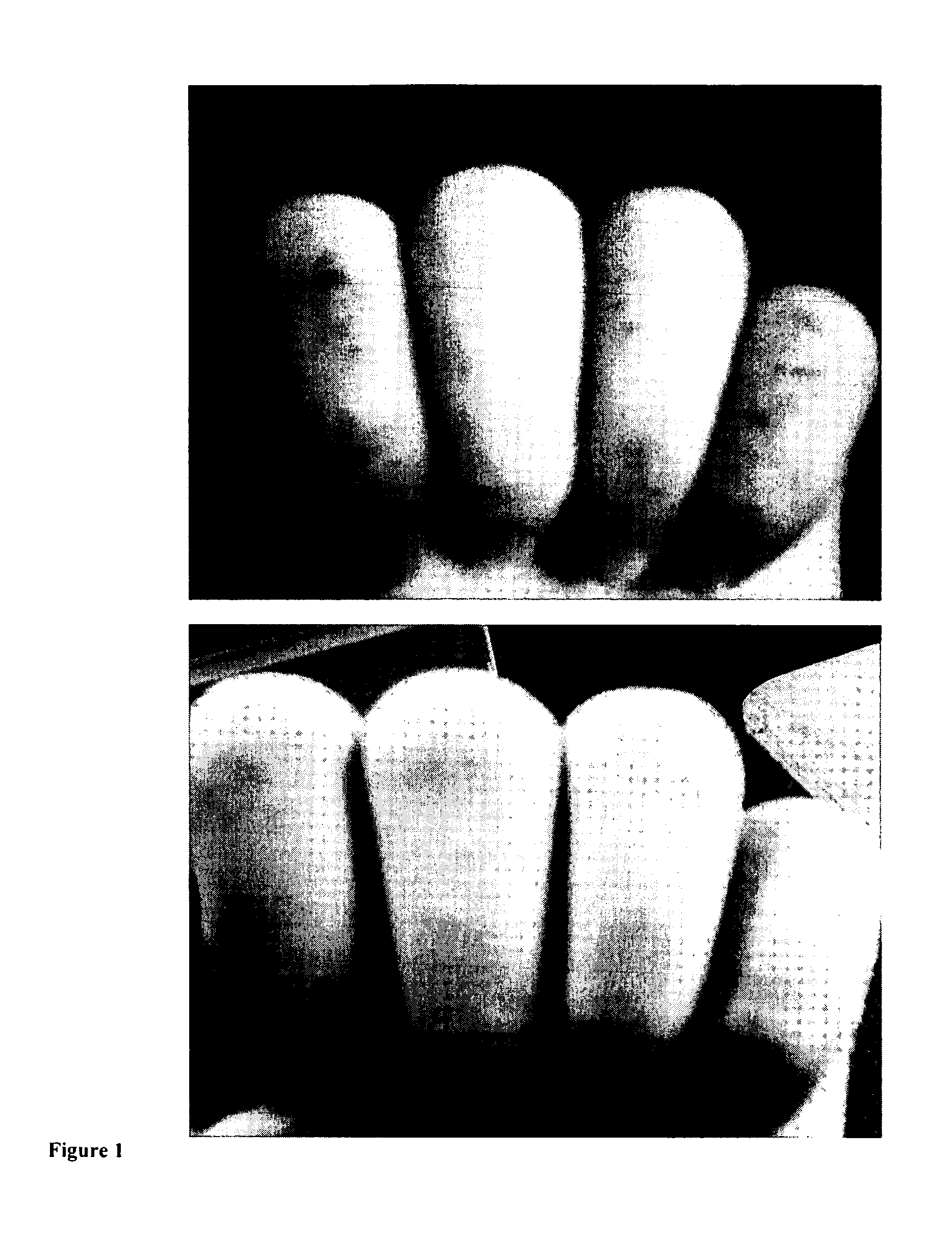

Compositions containing lipid micro- or nanoparticles for the enhancement of the dermal action of solid particles

The invention is related to compositions which can be used as dermal formulations for supporting the skin to restore normal conditions in case of e.g. irritated skin, or to support medical therapy of skin with atopic dermatitis symptoms, atopic dermatitis, psoriasis or related diseases (e.g. accompanied by distorted barrier function of the skin and microbial load). The compositions of the invention can be used for dermo-cosmetic products but also for pharmaceutical / -medical products, depending on the composition and the additional actives incorporated (cosmetic actives or drugs). The invention is based on the synergistic effect of metallic particles, in particular silver particles (such as microsilver, nanosilver) and lipid particles (lipid nanoparticles or lipid microparticles). As alternatives to silver particles, other metallic particles (e.g. zinc, copper) or nanocrystalline actives can be incorporated (e.g. replacing the anti-oxidative silver by anti-oxidative nanocrystals of plant molecules such as hesperitin). This leads to combinations of lipid particles with nanocrystals for dermal use.

Owner:PHARMASOL +1

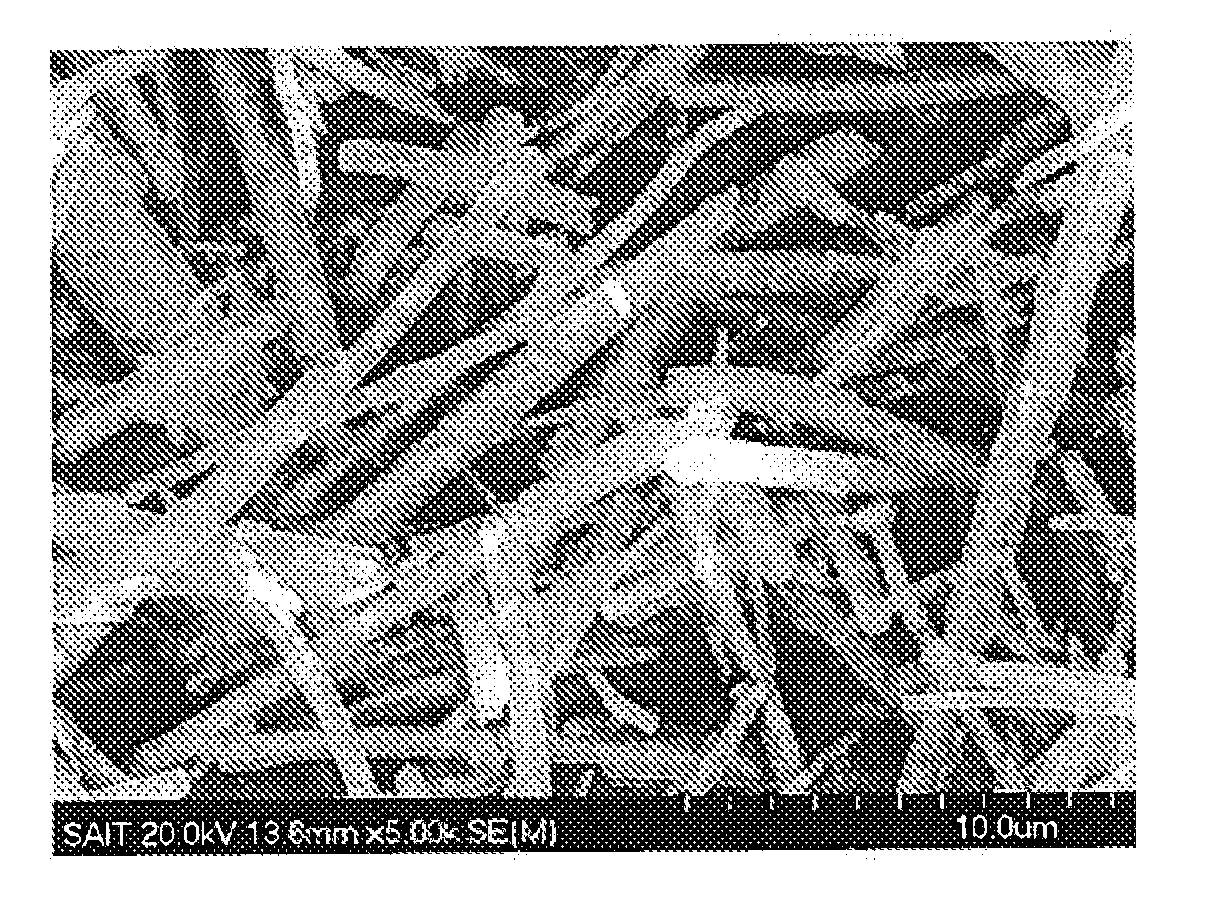

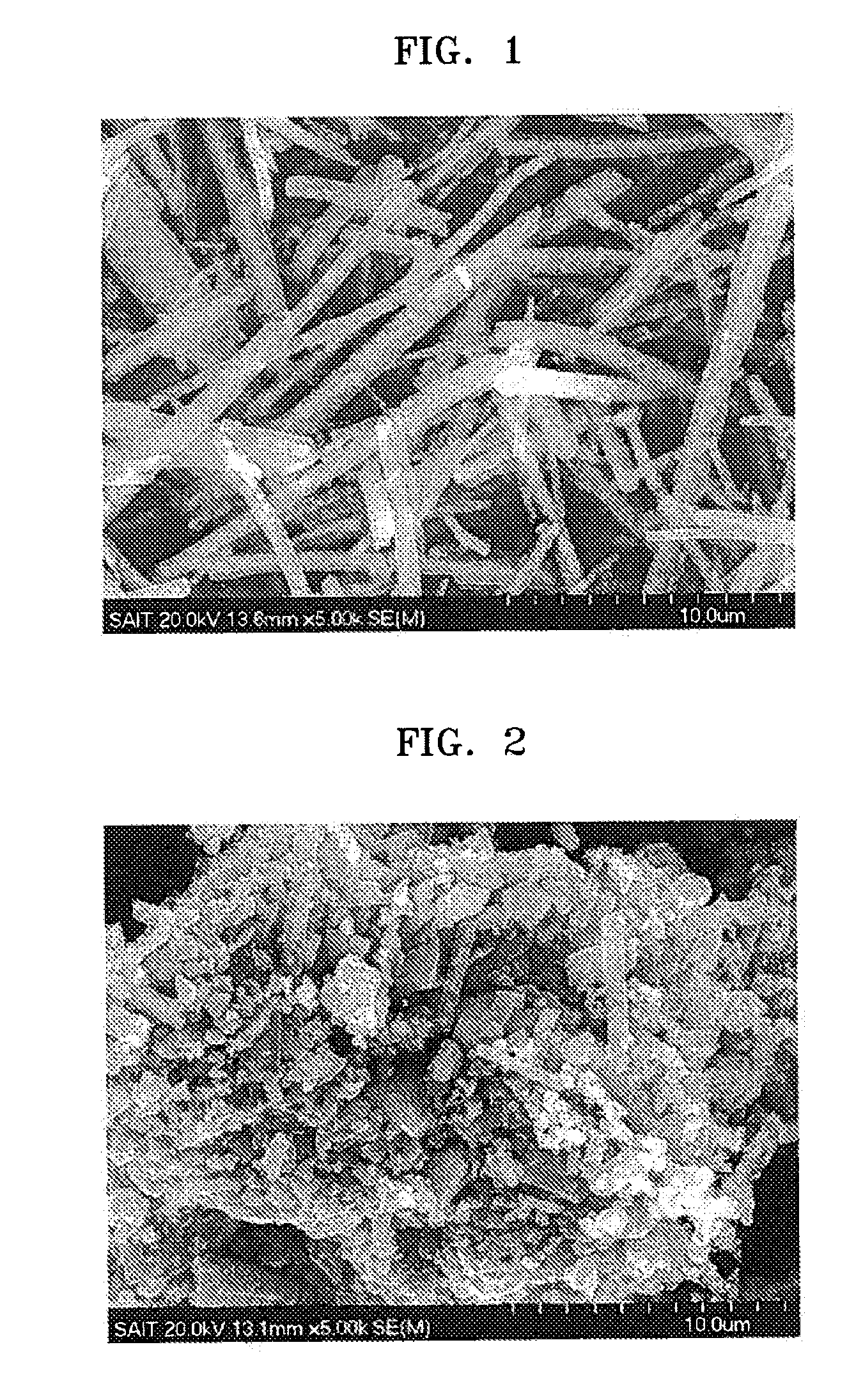

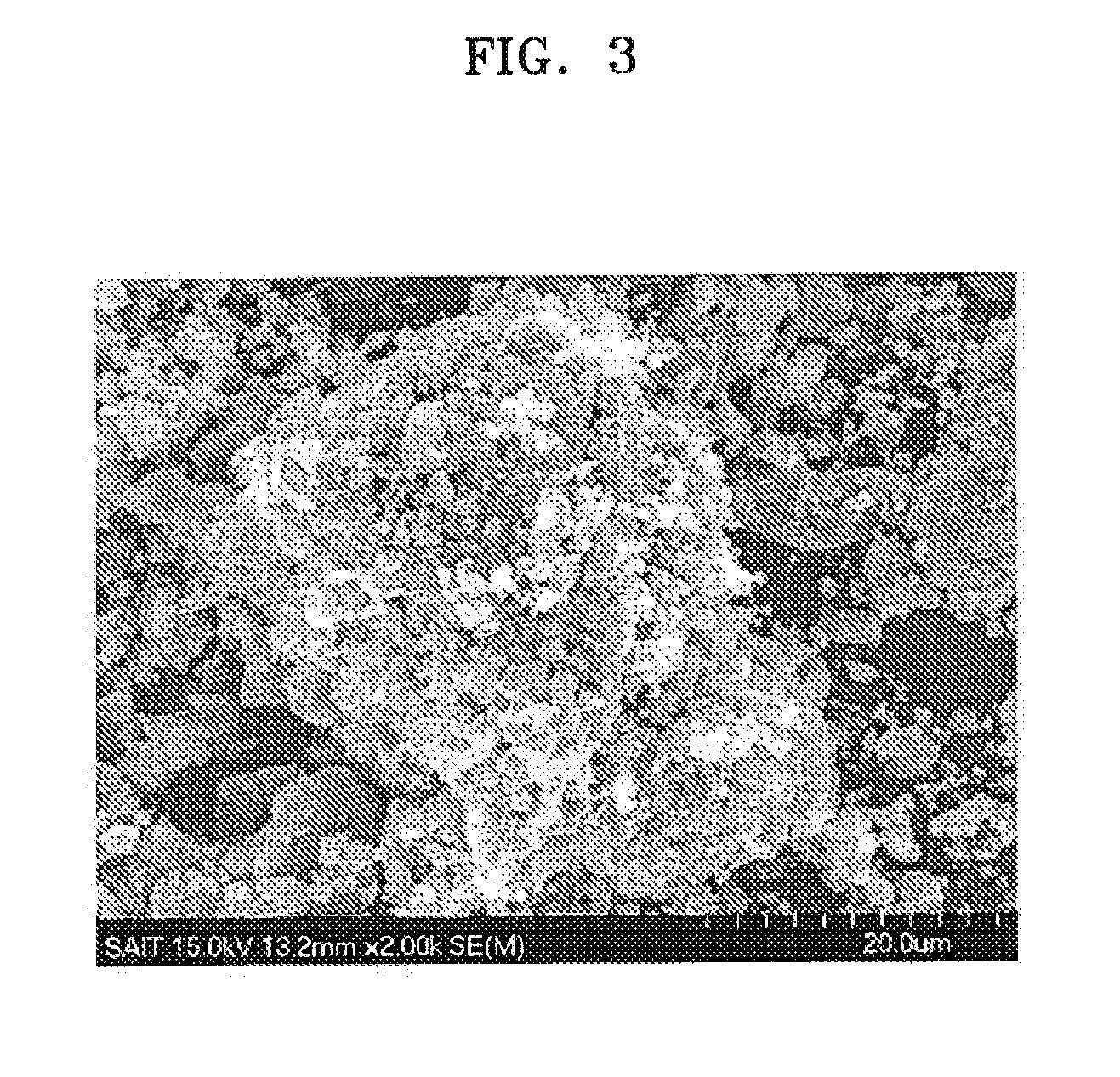

Anode active material and method of preparing the same

InactiveUS20070243469A1Improving battery cycle characteristicImprove initial efficiencyElectrode thermal treatmentConductive materialMaterials scienceAnode

Anode active materials and methods of preparing the same are provided. One anode active material includes a carbonaceous material capable of improving battery cycle characteristics. The carbonaceous material bonds to and coats metal active material particles and fibrous metallic particles to suppress volumetric changes.

Owner:SAMSUNG SDI CO LTD

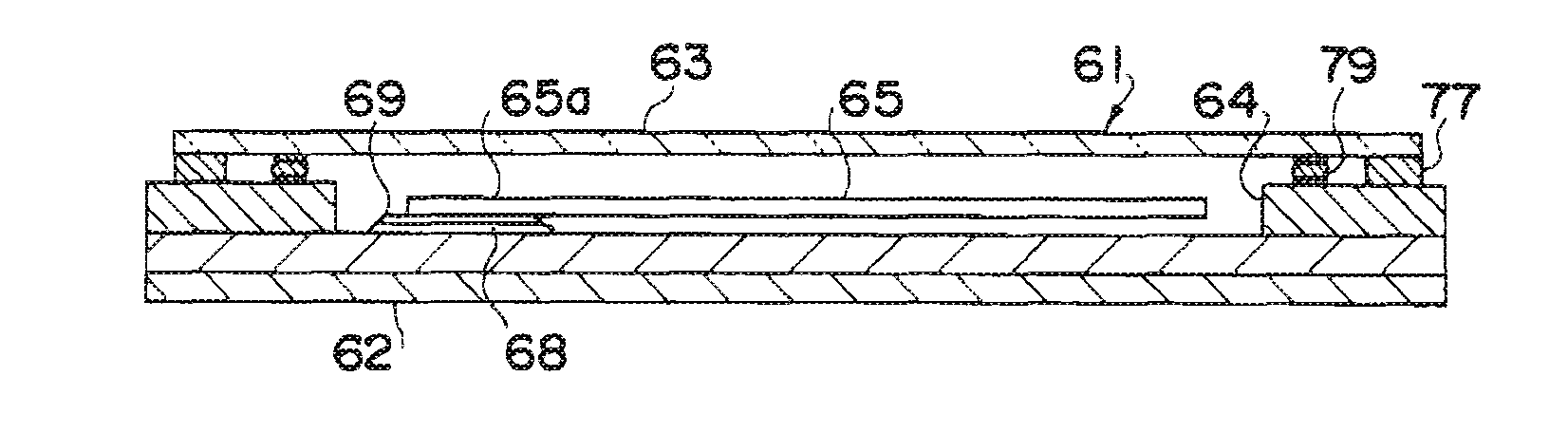

Quartz crystal device and method for sealing the same

ActiveUS20080231145A1High bonding strengthImprove reliabilityPiezoelectric/electrostriction/magnetostriction machinesImpedence networksOrganic solventHermetic seal

A quartz crystal device includes a crystal resonator element and a package including a plurality of components. The plurality of components are bonded using a metal paste sealing material containing a metallic particle having an average particle size from 0.1 to 1.0 μm, an organic solvent, and a resin material in proportions of from 88 to 93 percent by weight from 5 to 15 percent by weight, and from 0.01 to 4.0 percent by weight, respectively, to hermetically seal the crystal resonator element in the package.

Owner:SEIKO EPSON CORP

Metallic colloidal solution and inkjet-use metallic ink

InactiveUS20050189520A1Easy to handleUniform particle sizeLiquid surface applicatorsConductive materialWater basedOrganic solvent

A metallic colloidal solution (a) includes a water-based dispersion medium that is easy in handling with regard to safety and environment and metallic particles having a uniform particle diameter and being excellent in properties such as conductivity and (b) has properties suitable for various printing methods and ink-applying methods. In addition, an inkjet-use metallic ink incorporating the metallic colloidal solution has properties suitable for the inkjet printing method. The metallic particles are deposited by reducing metallic ions in water and have a primary-particle diameter of at most 200 nm. The dispersion medium is made of a mixed solvent of water and a water-soluble organic solvent. The metallic particles are dispersed in the dispersion medium under the presence of a dispersant having a molecular weight of 200 to 30,000.

Owner:SUMITOMO ELECTRIC IND LTD

Method of making composite particles with tailored surface characteristics

InactiveUS20060150770A1Low production costCost-effective and scalableTransportation and packagingMetal-working apparatusElectrochemistryMaterials science

The invention describes a procedure to make metal containing composite particles and composite particle suspensions. The procedure is versatile and can produce particles with a variety of particle sizes and compositions. For some applications the metal composite particles can provide the functionality of wholly metallic particles including configurations where the metal is located on the particle surface. Such metals have application in a wide variety of fields, including accomplishing electrochemical reduction and catalysis.

Owner:ONMATERIALS

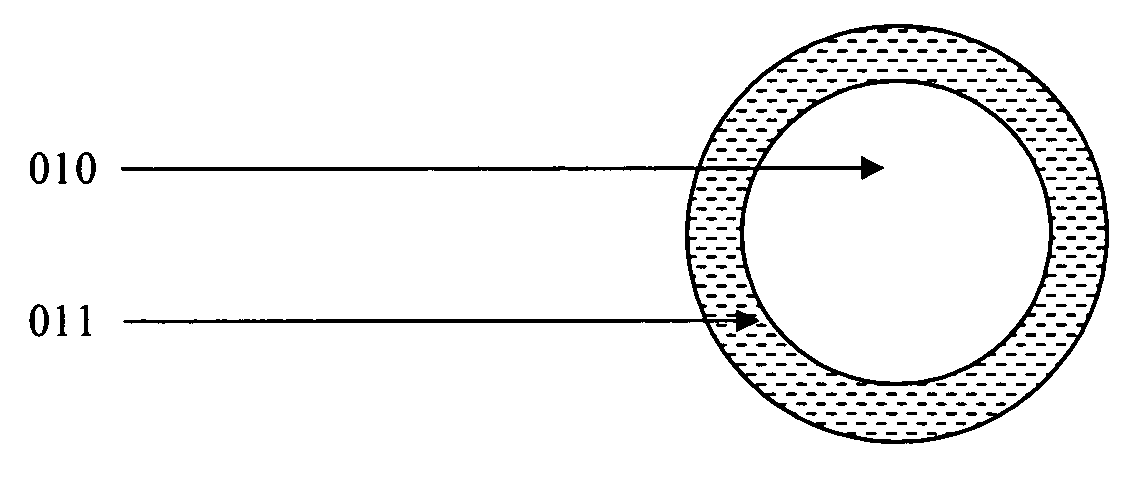

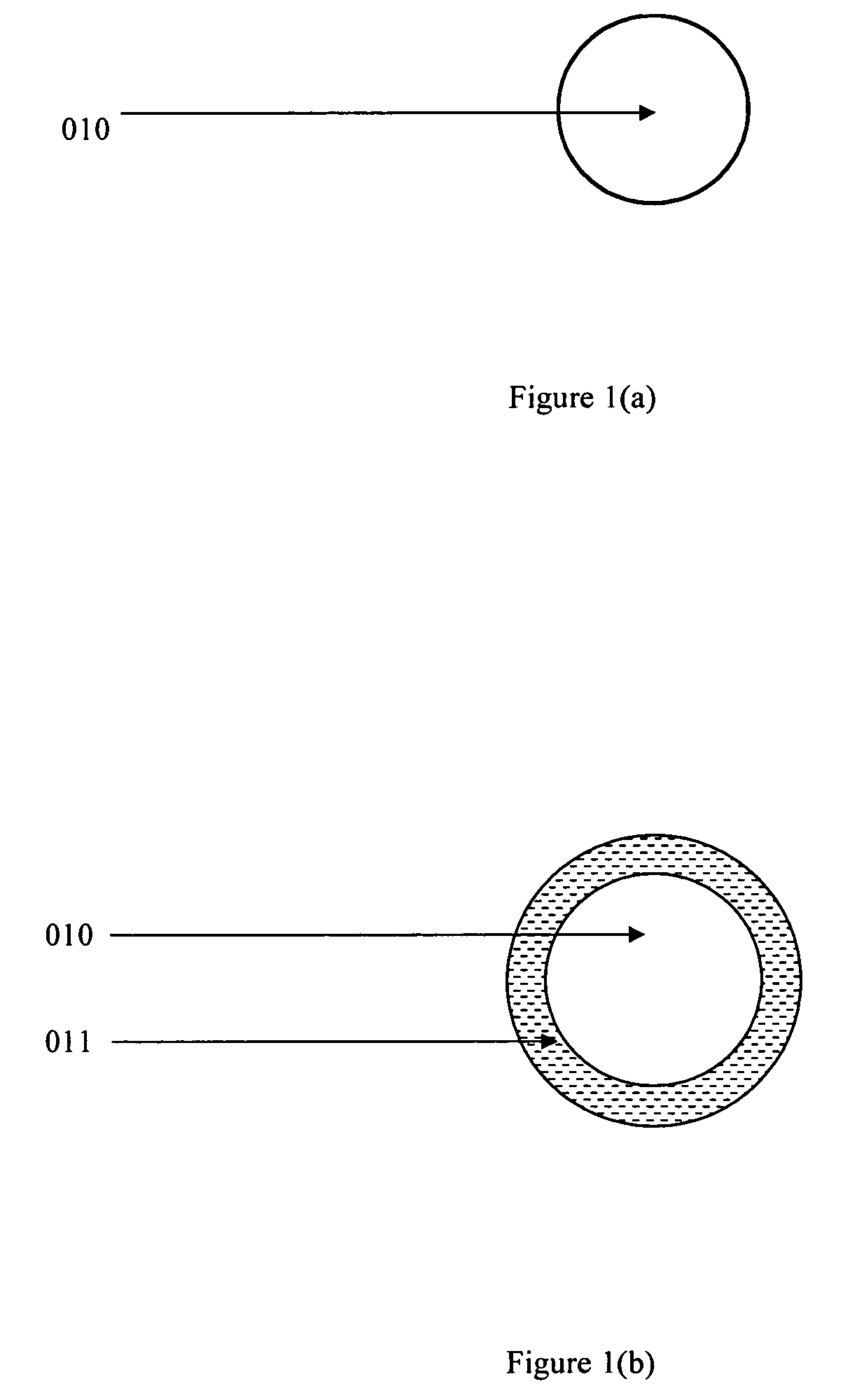

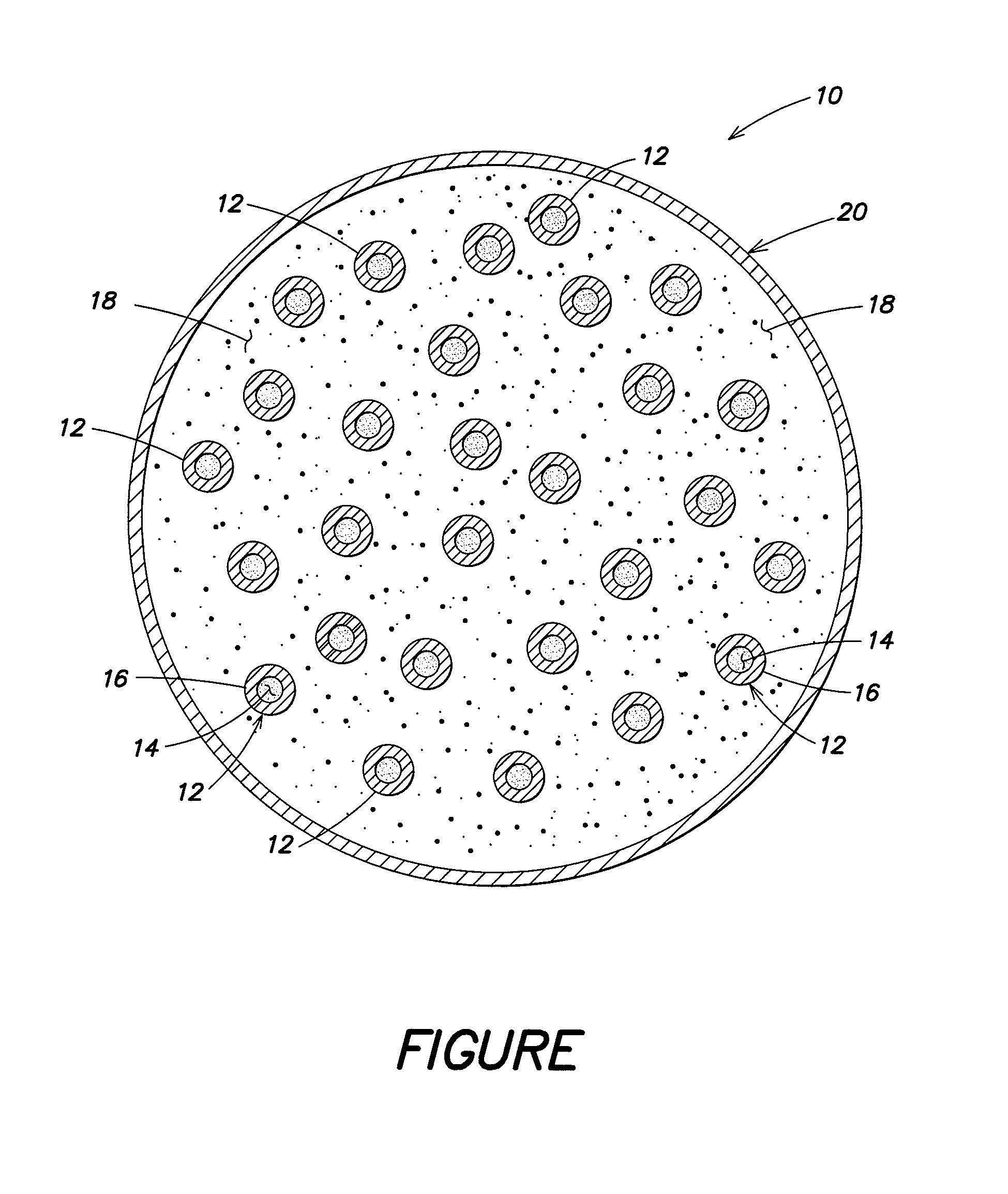

Exothermic alloying bimetallic particles

InactiveUS20090090440A1Enhance alloying processLiberating heatLiquid surface applicatorsMetal-working apparatusBiological activationSolvent

The compositions of different energetic metallic particles and corresponding coatings are chosen to take advantage of the resulting exothermic alloying reactions when the metals are combined or alloyed through heat activation. Bimetallic particles composed of a core / shell structure of differing metals are chosen such that, upon achieving the melt point for at least one of the metals, a relatively substantial amount of exothermic heat of alloying is liberated. In an embodiment, the core metal is aluminum and the shell metal is nickel. The nickel may be applied to the outer surface of the aluminum particles using an electroless process from a metal salt solution with a reducing agent in an aqueous solution or a solvent media. The aluminum particles may be pretreated with zinc to remove any aluminum oxide. The resulting bimetallic particles may be utilized as an enhanced blast additive by being dispersed within an explosive material.

Owner:ENSIGN BICKFORD AEROSPACE & DEFENSE

Aerogel and metallic compositions

InactiveUS20070142222A1Equivalent and enhanced performanceLess utilizationMaterial nanotechnologyCell electrodesFuel cellsCompound (substance)

Metallic aerogel compositions comprising an aerogel, e.g., RF or carbon aerogel, having metallic particles dispersed on its surface are disclosed. The aerogel compositions can have a uniform distribution of small metallic particles, e.g., 1 nanometer average particle diameter. Also disclosed are processes for making the aerogel compositions comprising contacting an aerogel with a supercritical fluid containing a metallic compound. The aerogel compositions are useful, for example in the manufacture of fuel cell electrodes.

Owner:AEROGEL COMPOSITE LLC +1

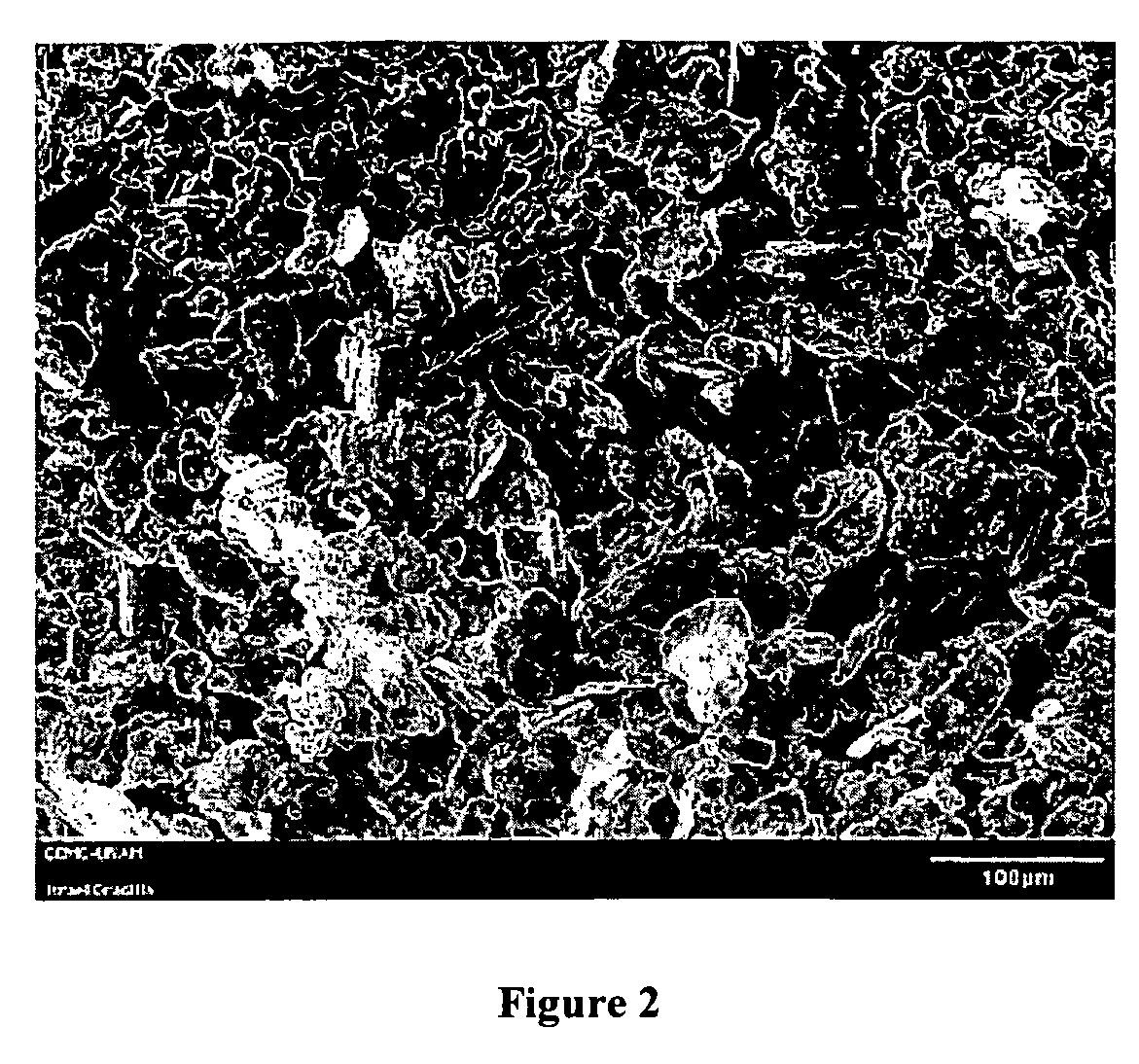

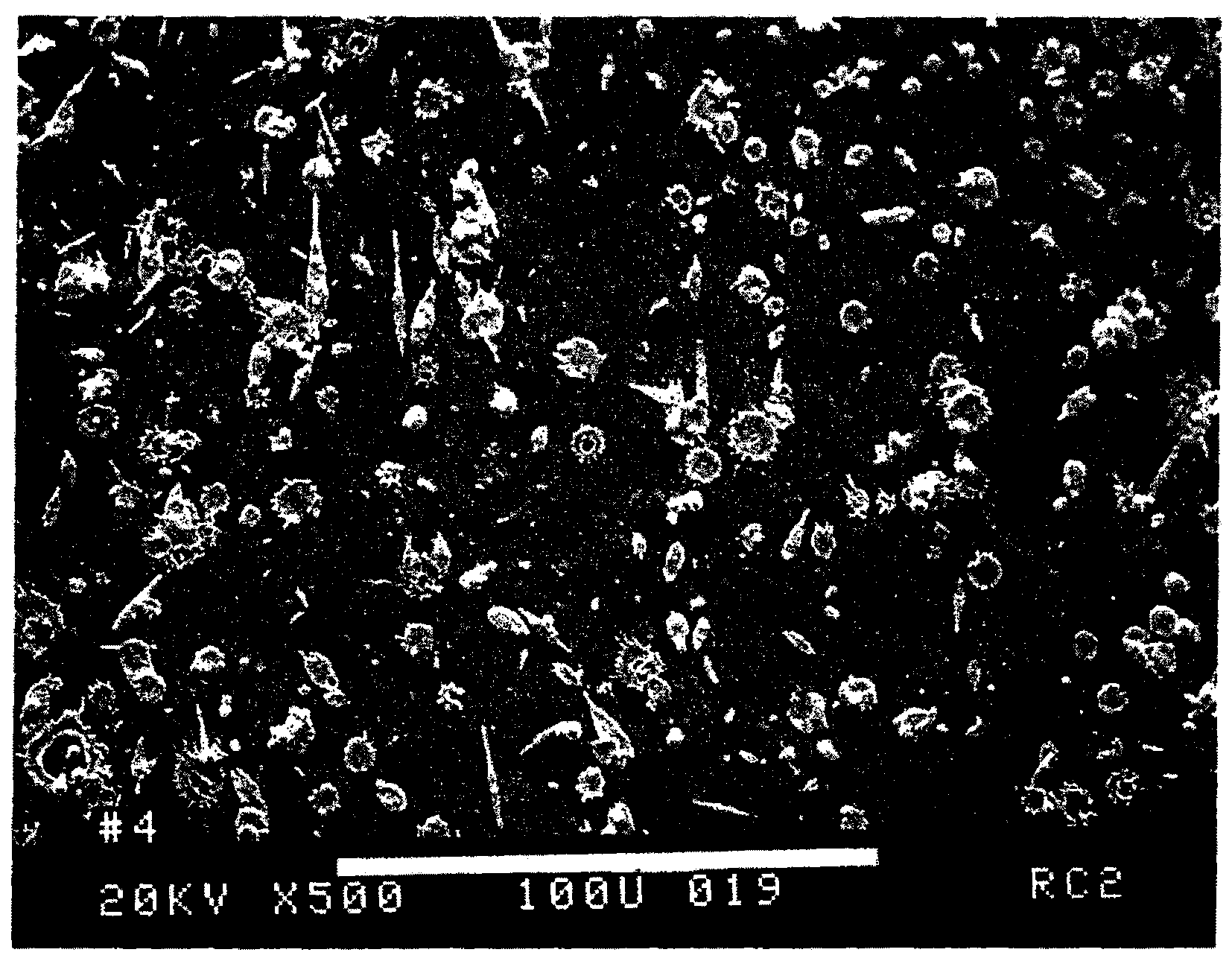

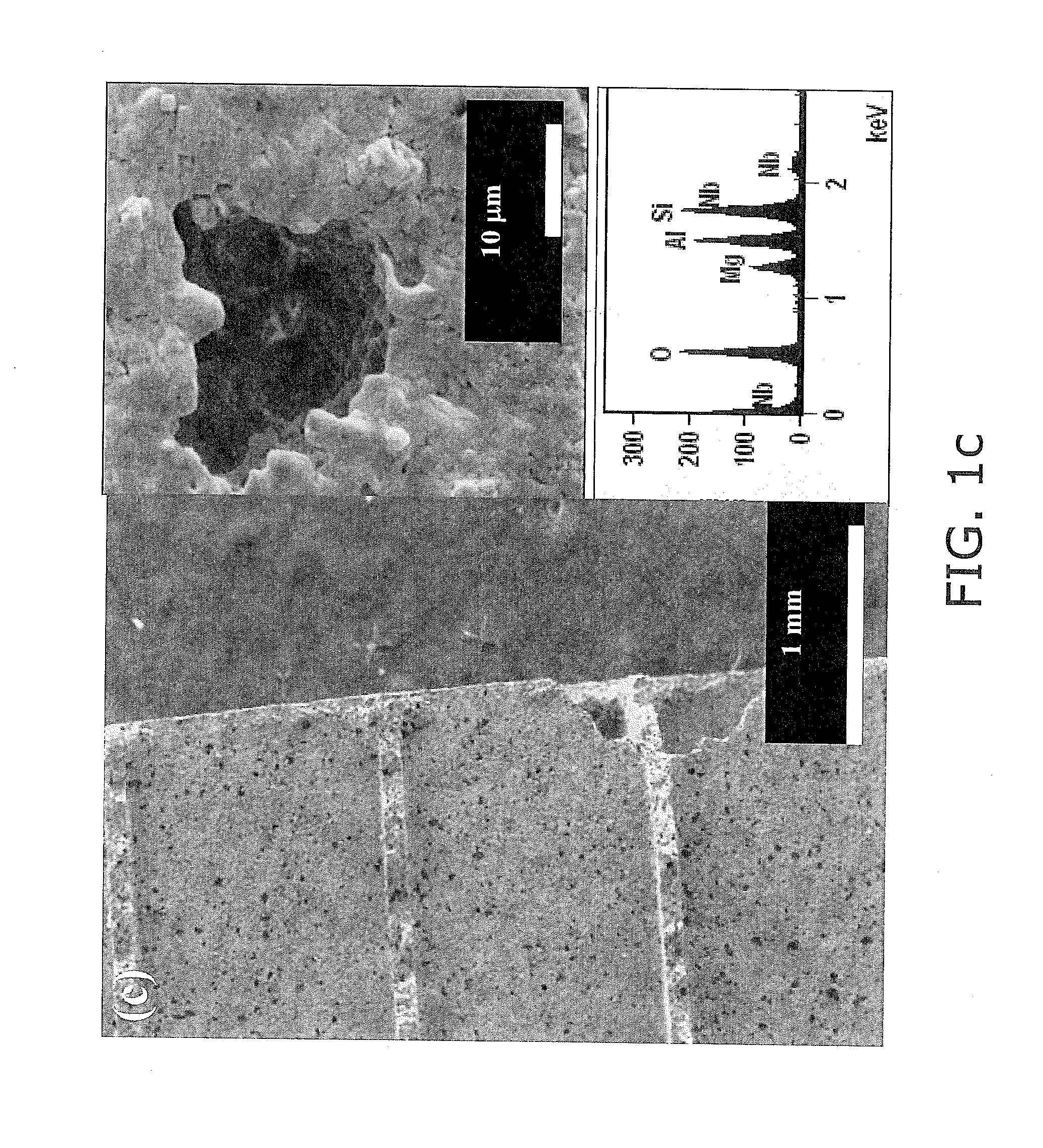

Highly electrically conductive surfaces for electrochemical applications

A method is described that can be used in electrodes for electrochemical devices and includes disposing a precious metal on a top surface of a corrosion-resistant metal substrate. The precious metal can be thermally sprayed onto the surface of the corrosion-resistant metal substrate to produce multiple metal splats. The thermal spraying can be based on a salt solution or on a metal particle suspension. A separate bonding process can be used after the metal splats are deposited to enhance the adhesion of the metal splats to the corrosion-resistant metal substrate. The surface area associated with the splats of the precious metal is less than the surface area associated with the top surface of the corrosion-resistant metal substrate. The thermal spraying rate can be controlled to achieve a desired ratio of the surface area of the metal splats to the surface area of the corrosion-resistant metal substrate.

Owner:TREADSTONE TECH INC

Metal oxide nanorod arrays on monolithic substrates

ActiveUS20140256534A1Improve thermal stabilitySulfur poisoningMolecular sieve catalystsLayered productsCerium(IV) oxideMetal particle

A metal oxide nanorod array structure according to embodiments disclosed herein includes a monolithic substrate having a surface and multiple channels, an interface layer bonded to the surface of the substrate, and a metal oxide nanorod array coupled to the substrate surface via the interface layer. The metal oxide can include ceria, zinc oxide, tin oxide, alumina, zirconia, cobalt oxide, and gallium oxide. The substrate can include a glass substrate, a plastic substrate, a silicon substrate, a ceramic monolith, and a stainless steel monolith. The ceramic can include cordierite, alumina, tin oxide, and titania. The nanorod array structure can include a perovskite shell, such as a lanthanum-based transition metal oxide, or a metal oxide shell, such as ceria, zinc oxide, tin oxide, alumina, zirconia, cobalt oxide, and gallium oxide, or a coating of metal particles, such as platinum, gold, palladium, rhodium, and ruthenium, over each metal oxide nanorod. Structures can be bonded to the surface of a substrate and resist erosion if exposed to high velocity flow rates.

Owner:UNIV OF CONNECTICUT

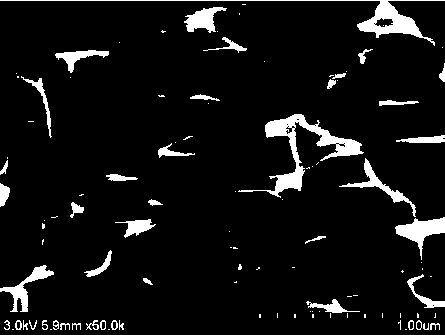

Preparation method of polycrystalline black silicon of micro-nano composite suede structure

InactiveCN104393114AReduce surface reflectivityConducive to removalAfter-treatment detailsFinal product manufactureIonMicro nano

The invention discloses a preparation method of polycrystalline black silicon of a micro-nano composite suede structure. The method comprises the following steps: imbedding polycrystalline silicon chips into etchant solution to obtain polycrystalline silicon chips with micro-meter suede structures; transferring the polycrystalline silicon chips with the micro-meter suede structures into a metal ion compound solution to deposit metal nanoparticles on the micro-meter suede; transferring into an etching solution to etch so as to obtain the polycrystalline silicon chips with the micro-nano composite suede structures; washing to remove metal particles residual on the surface; feeding into an alkaline solution to modify and etch the micro-nano composite suede structure; then drying to obtain the product. According to the method, the wet chemical etching method is carried out to prepare the micro-nano composite suede structure on the surface of the polycrystalline black silicone; such structure is extremely low in reflectivity; meanwhile, the preparation method is highly compatible with the general polycrystalline silicon suede preparation process; therefore, the preparation method can be quickly applied to the current general polycrystalline black silicon solar cell industry; the light absorbing efficiency can be obviously raised, and as a result, the efficiency of a solar cell is increased.

Owner:48TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

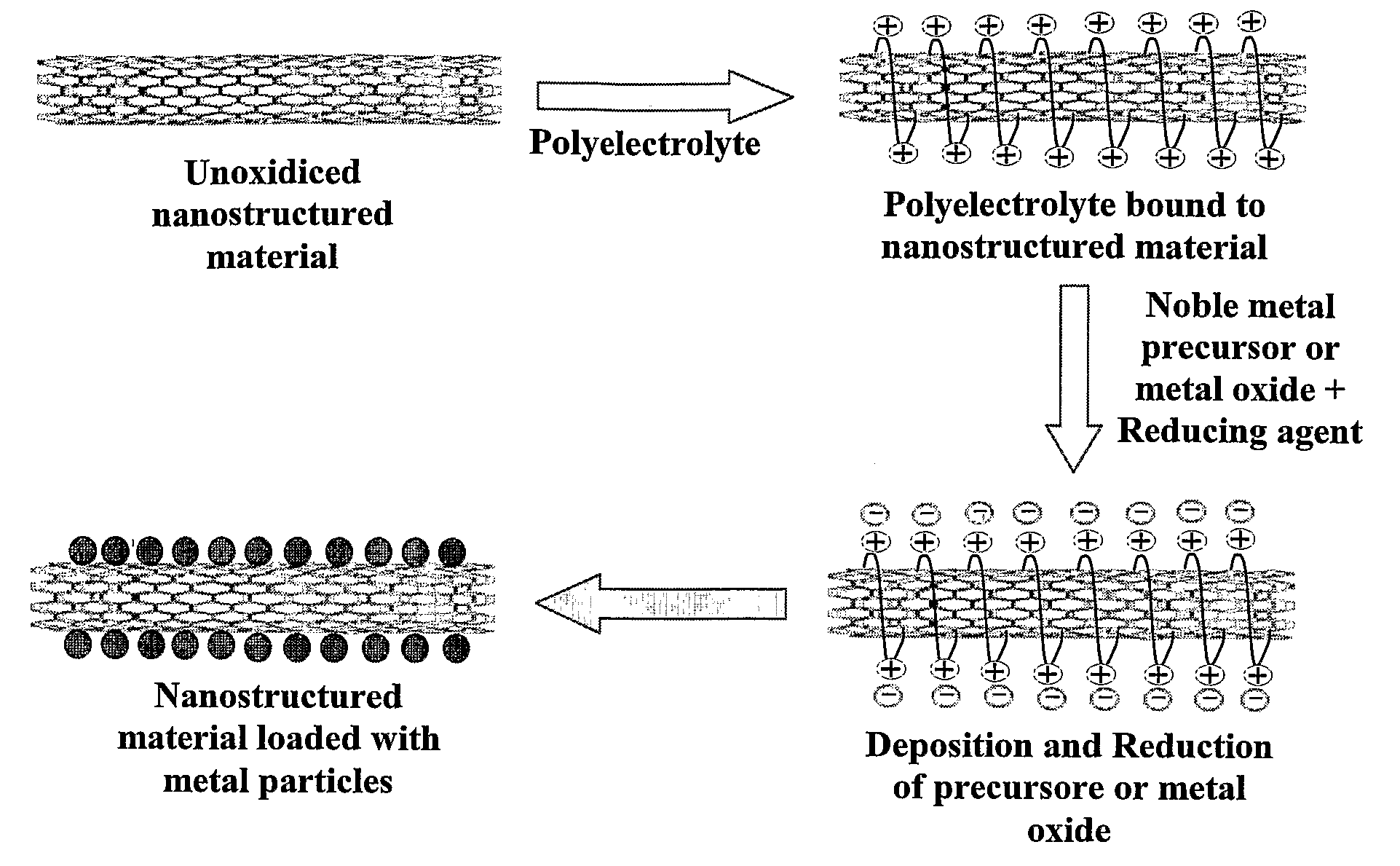

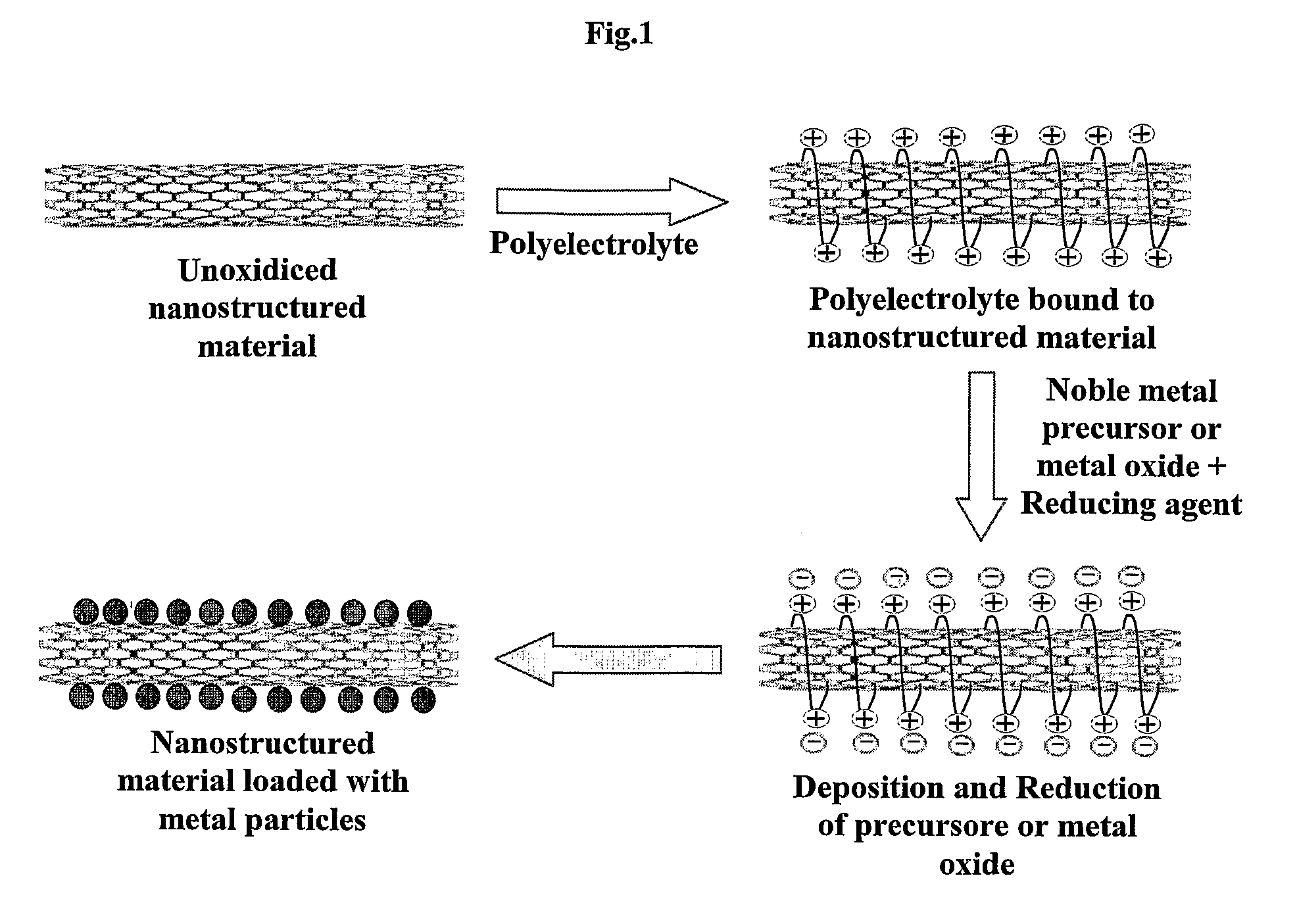

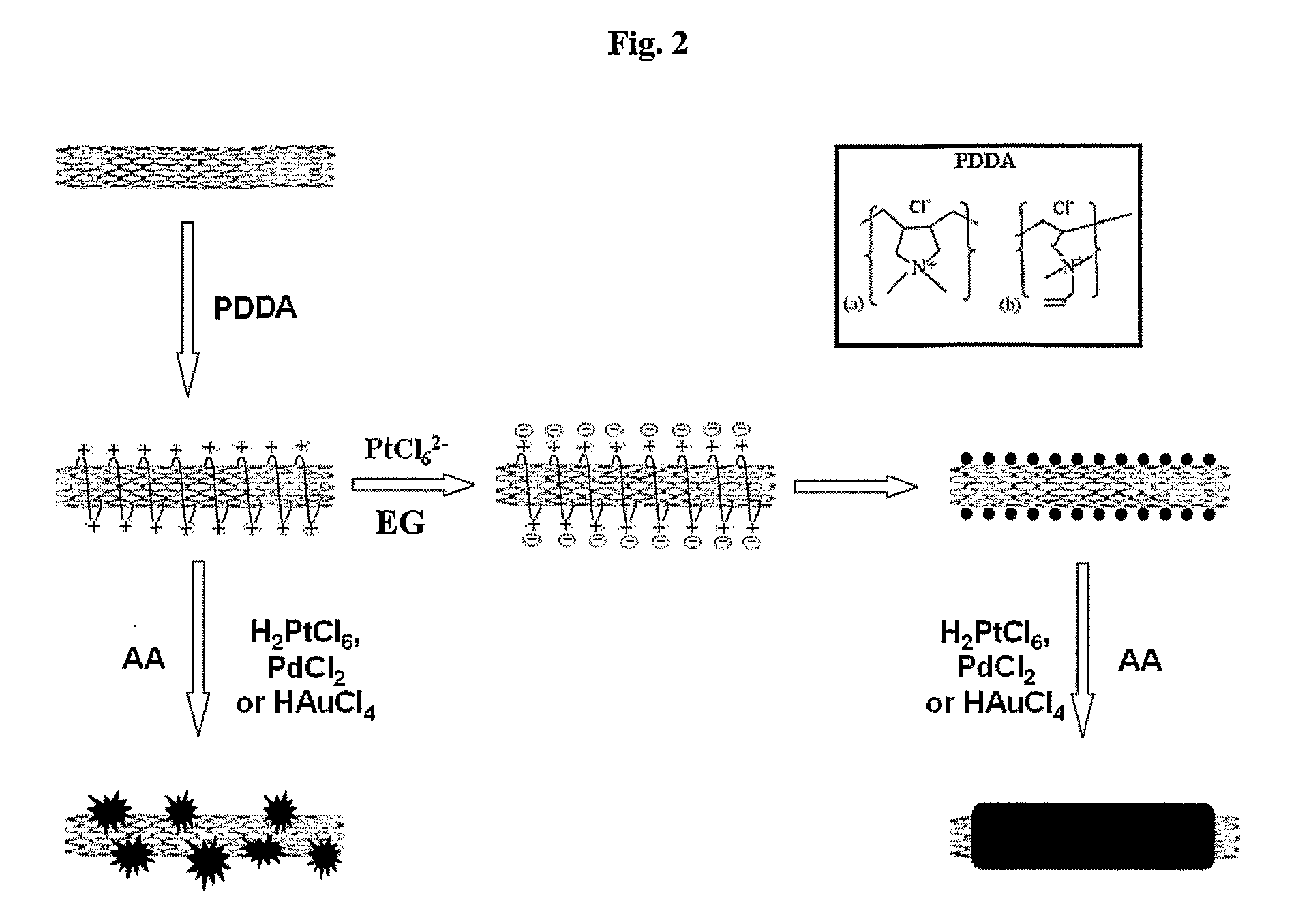

Nanostructured material loaded with noble metal particles

The present invention refers to a method of manufacturing a nanostructured material loaded with noble metal particles and a nanostructured material loaded with noble metal particles obtained by this method. The present invention further refers to an electrode for a fuel cell or a metal-hydride battery comprising a nanostructured material loaded with metal particles of the present invention and a method for manufacturing an electrode that can be used for the manufacture of a fuel cell or a metal-hydride battery.

Owner:NANYANG TECH UNIV

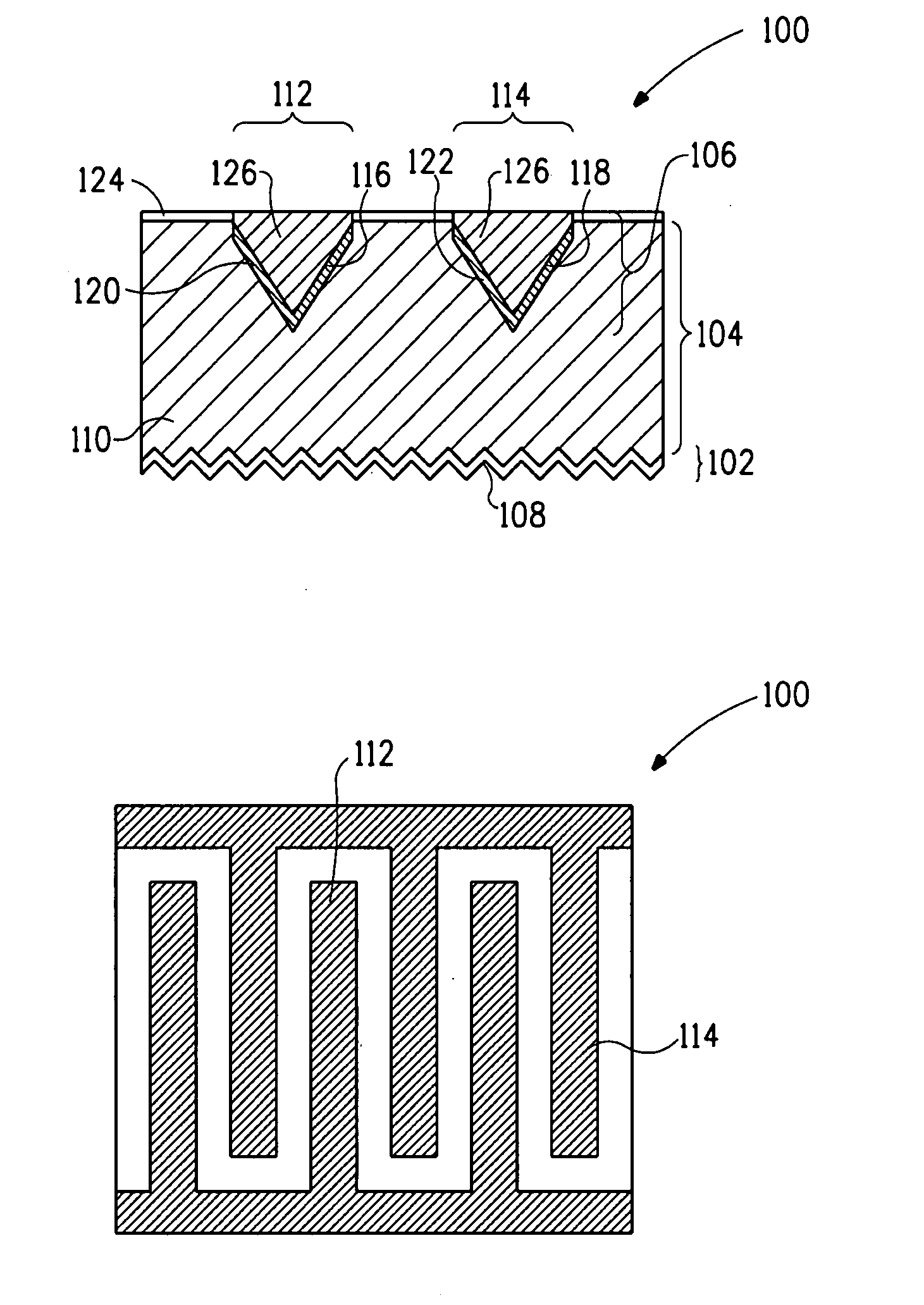

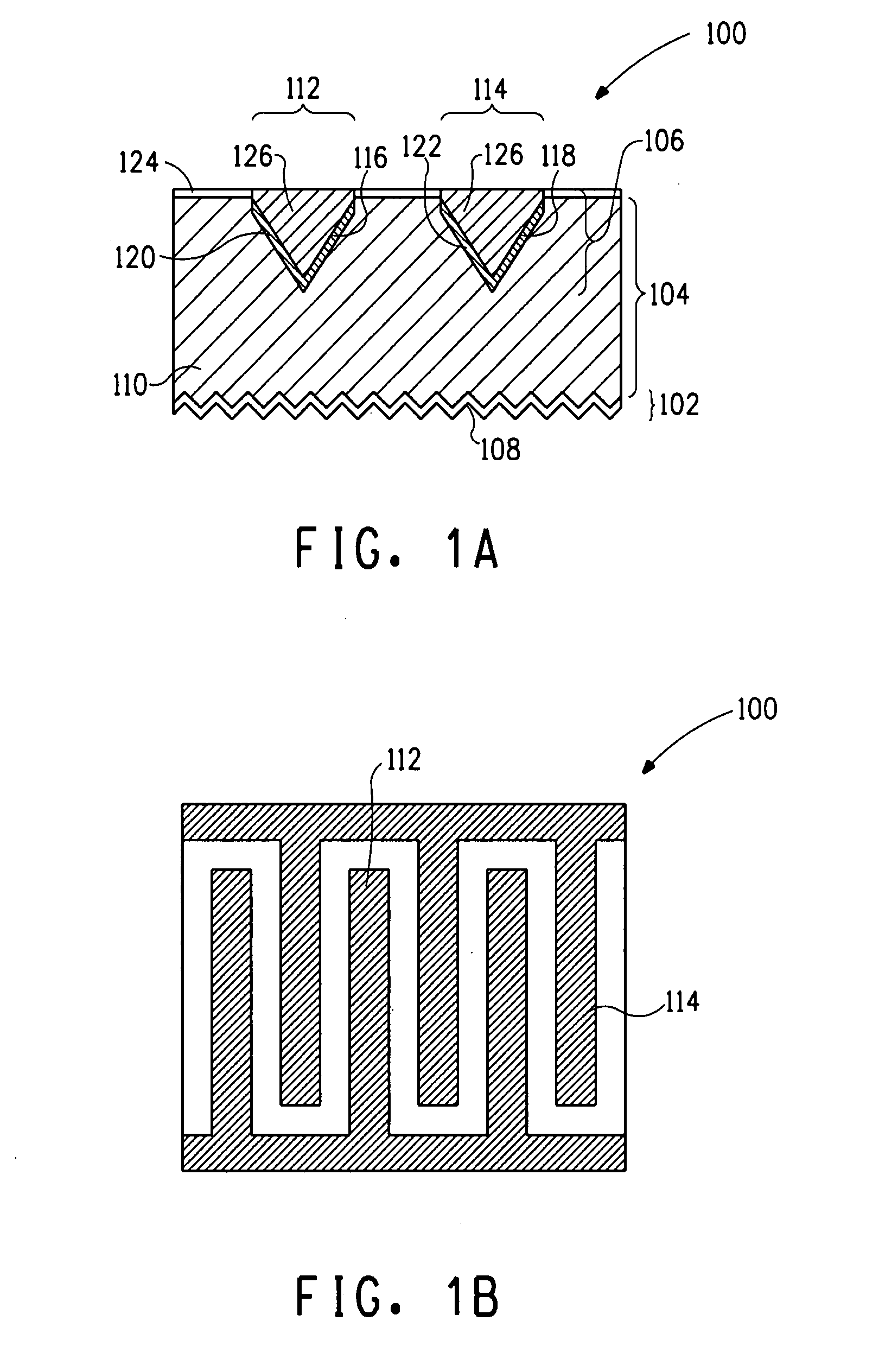

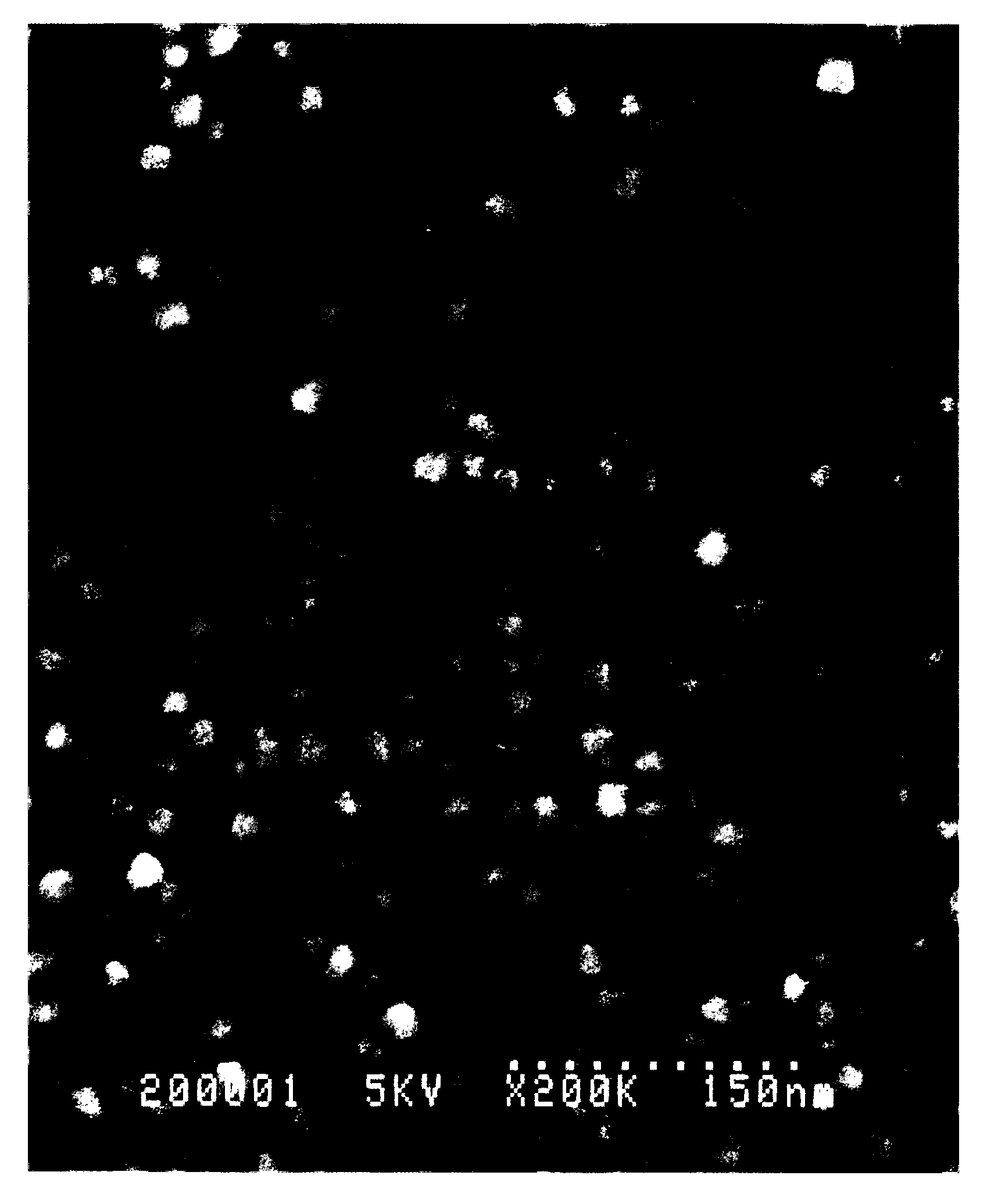

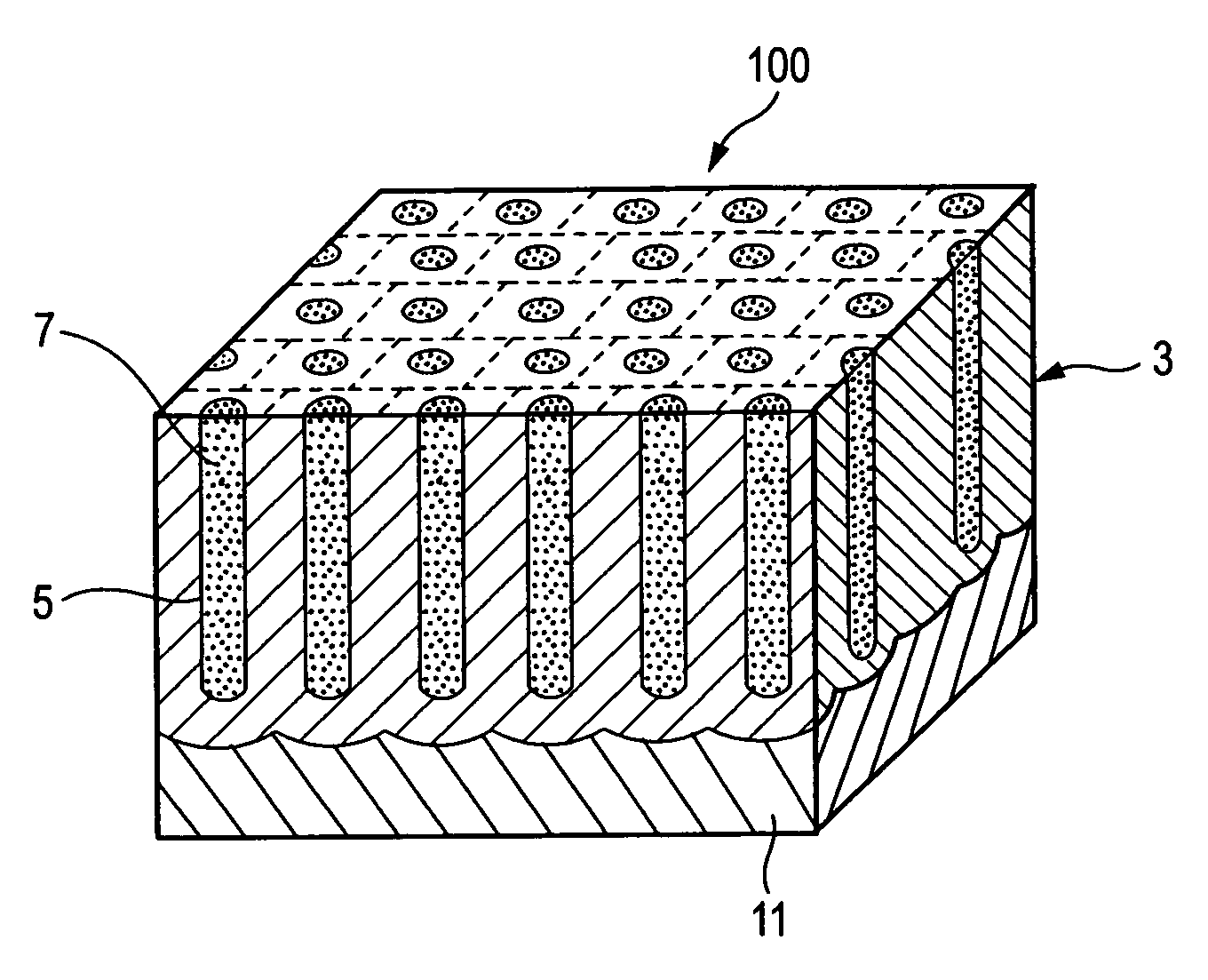

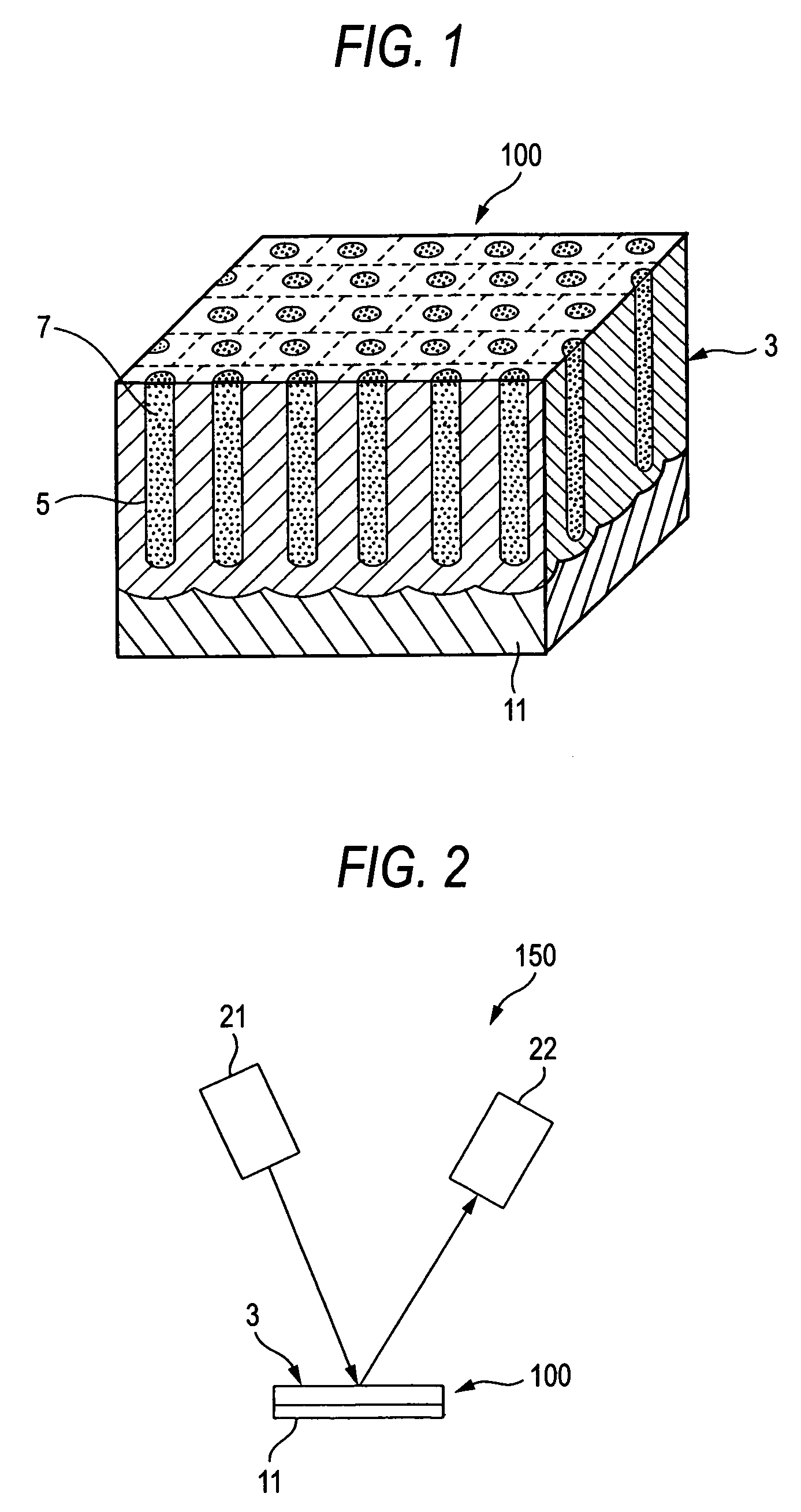

Structure, structure manufacturing method and sensor using the same

InactiveUS7079250B2Enhance and stabilize sensor sensitivityRegularly arrangedBioreactor/fermenter combinationsBiological substance pretreatmentsResonanceAluminium oxide

A plasmon resonance device 100 according to an example of a structure is characterized in that metallic particles 7 isolated from each other are formed in each of a plurality of pores 5 of anodic oxidized alumina 3. As a method of manufacturing the plasmon resonance device 100, a metal is coated on the anodic oxidized alumina 3 opening the pores 5 and a metal coated element provided on the opening surface of the pore in the anodic oxidized alumina 3 is removed. Consequently, metallic particles isolated from each other are formed in the respective independent pores. The plasmon resonance device 100 can be used as a sensor utilizing a localized plasmon resonance phenomenon.

Owner:FUJIFILM CORP

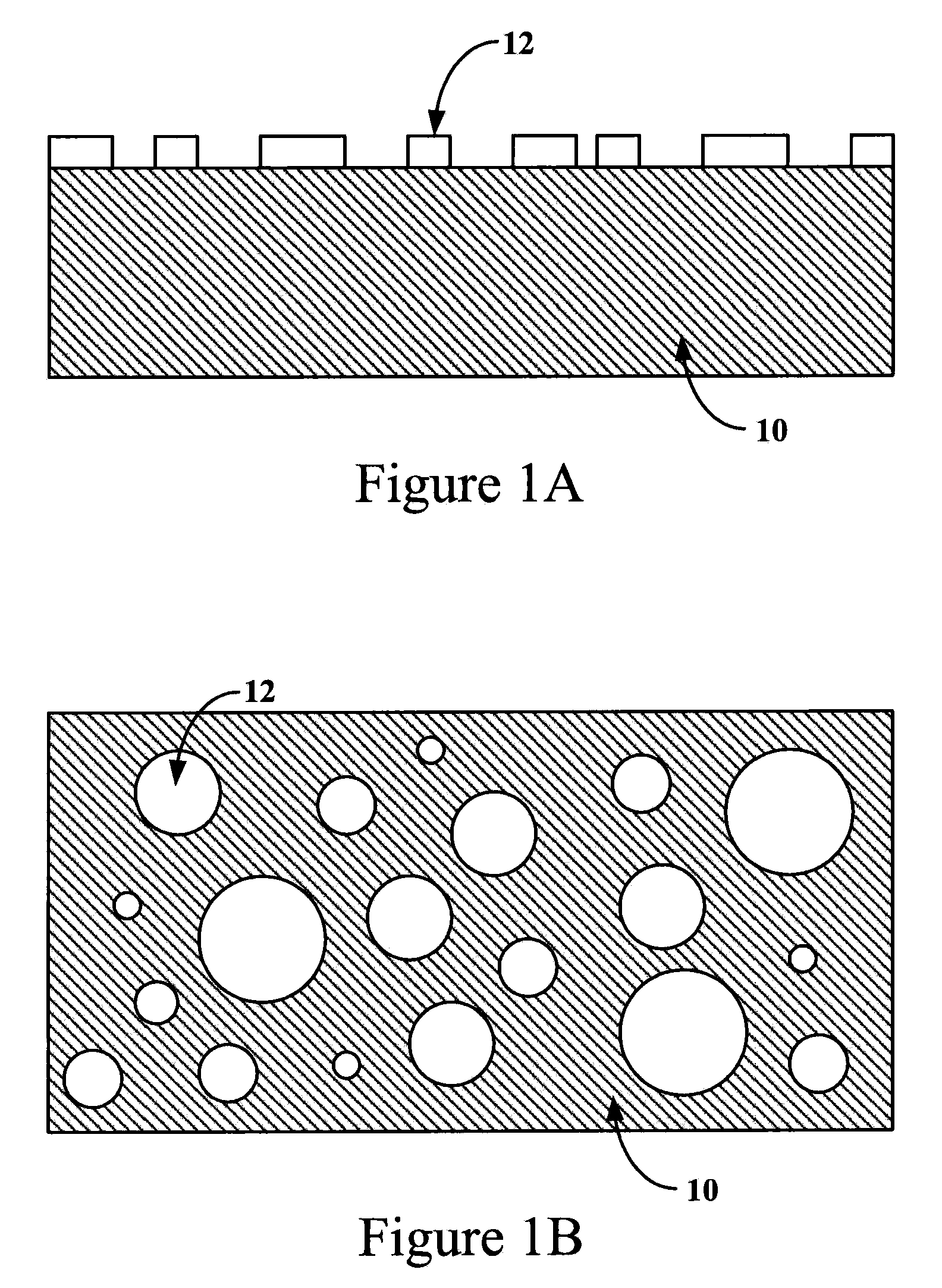

Forming metal foam structures

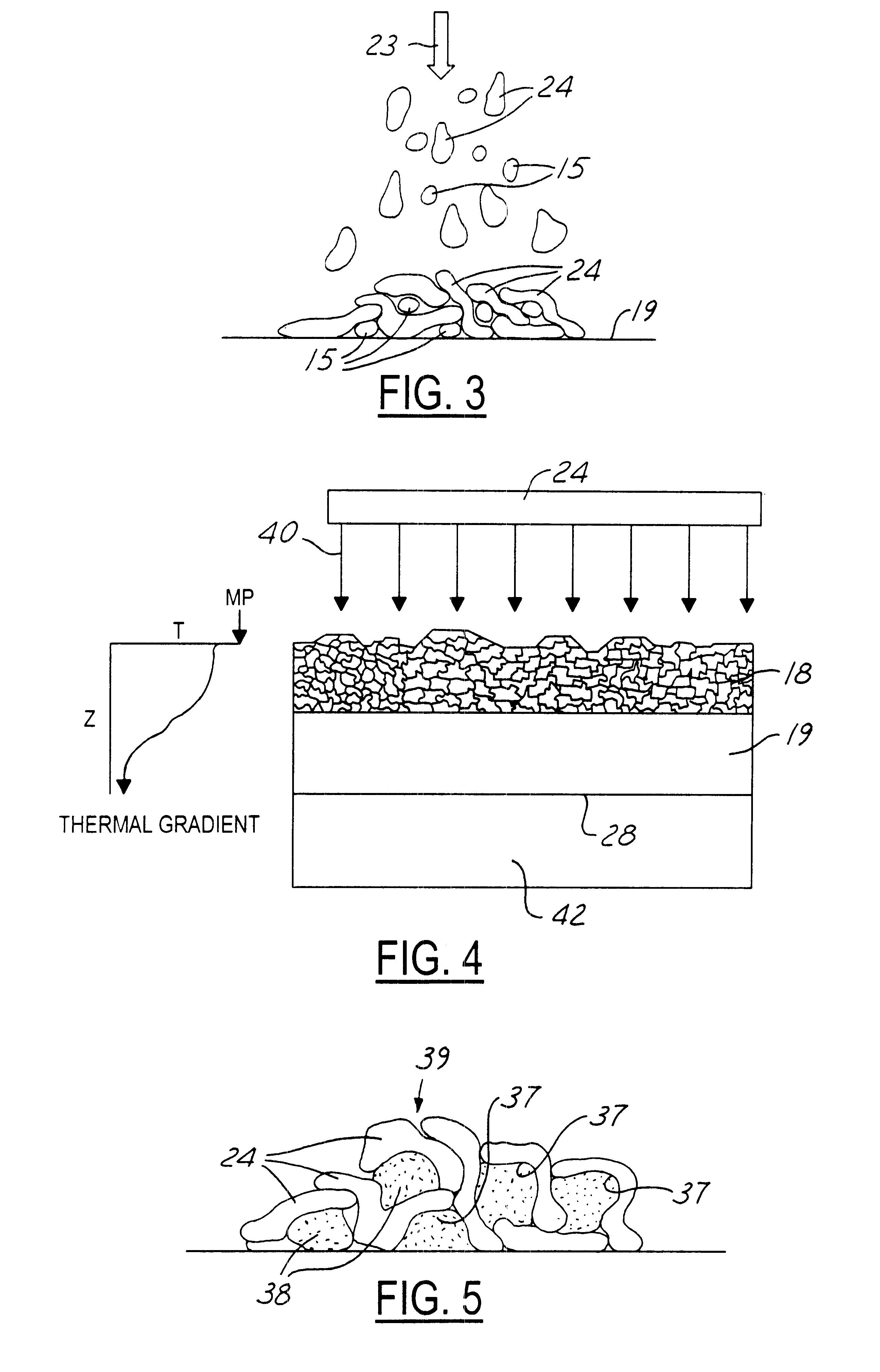

A method of fabricating a foamed metal structure using a powder supply of metal particles, comprising: (a) introducing the powder supply along with foaming agent particles into a propellant gas to form a gas / particle mixture stream; (b) projecting the mixture stream at a critical velocity of at least sonic velocity onto a metallic substrate to create a deposit of pressure-welded metal particles containing the admixed foaming agent; and (c) subjecting at least the coating of the substrate to a thermal excursion effective to activate expansion of the foaming agent while softening the metal particles for plastic deformation under the influence of the expanding gases.

Owner:FORD GLOBAL TECH LLC

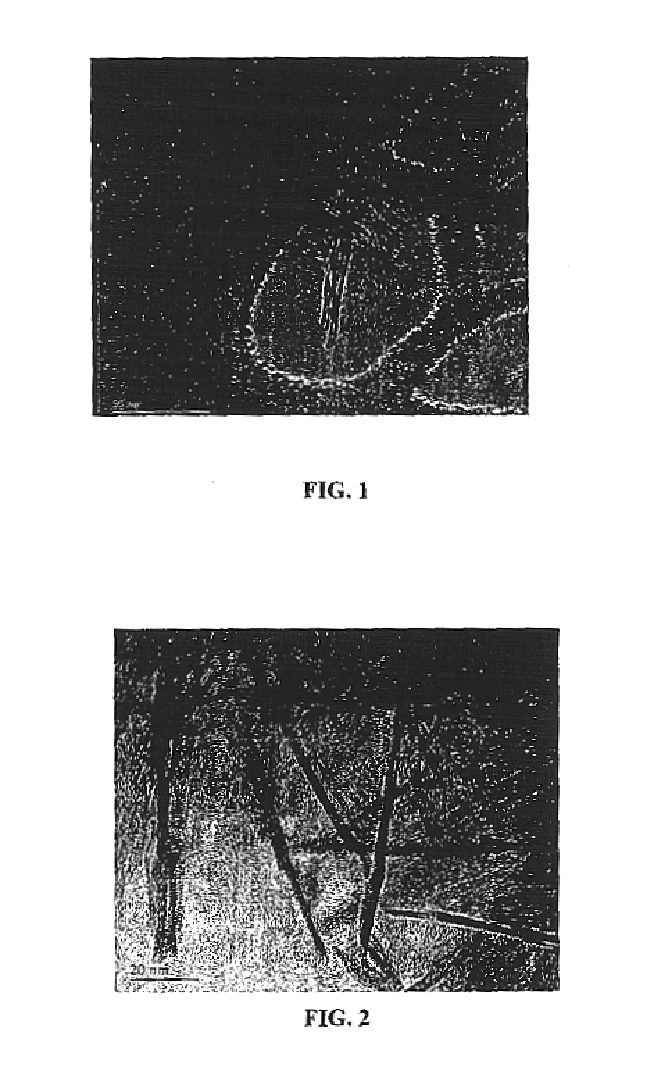

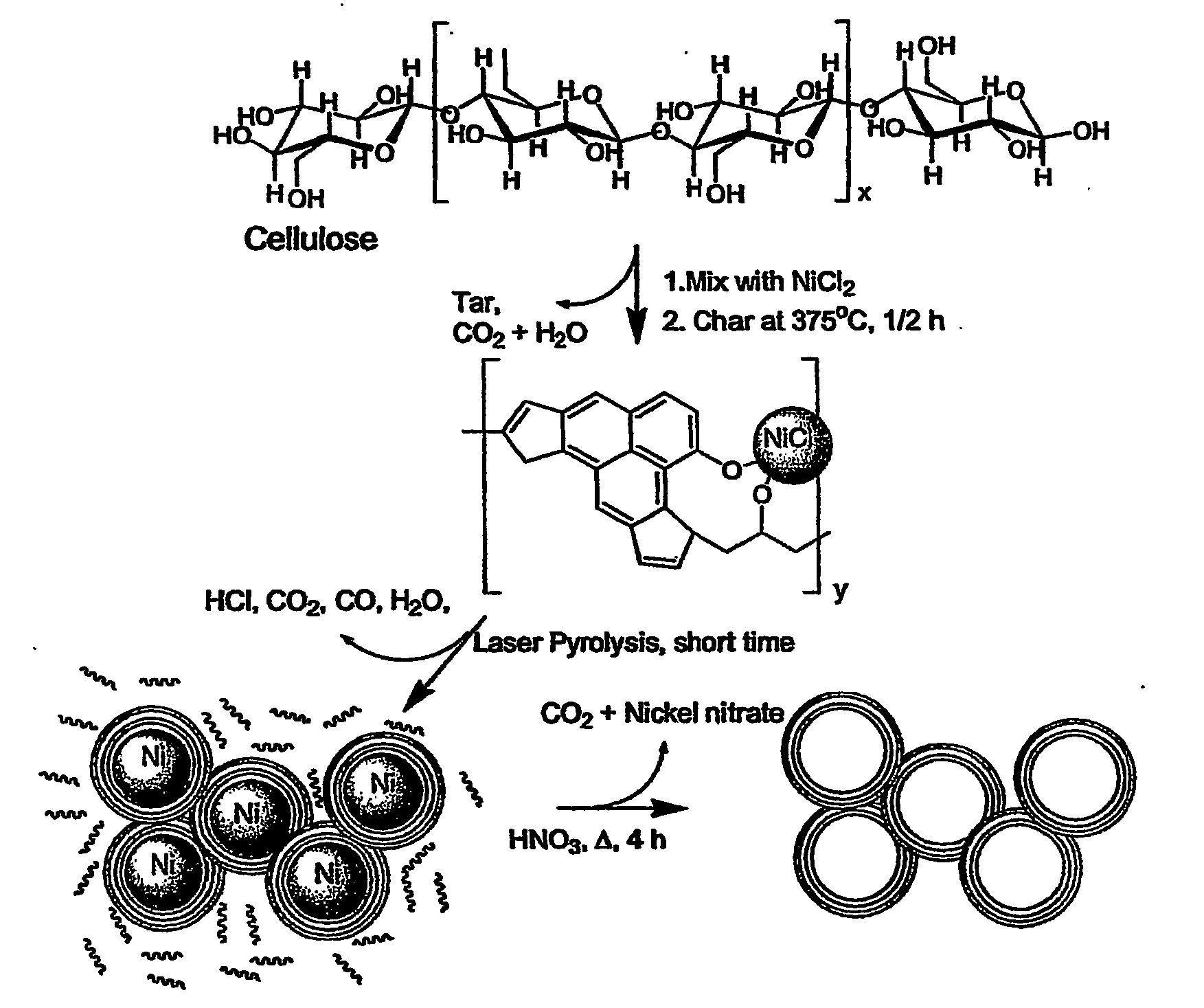

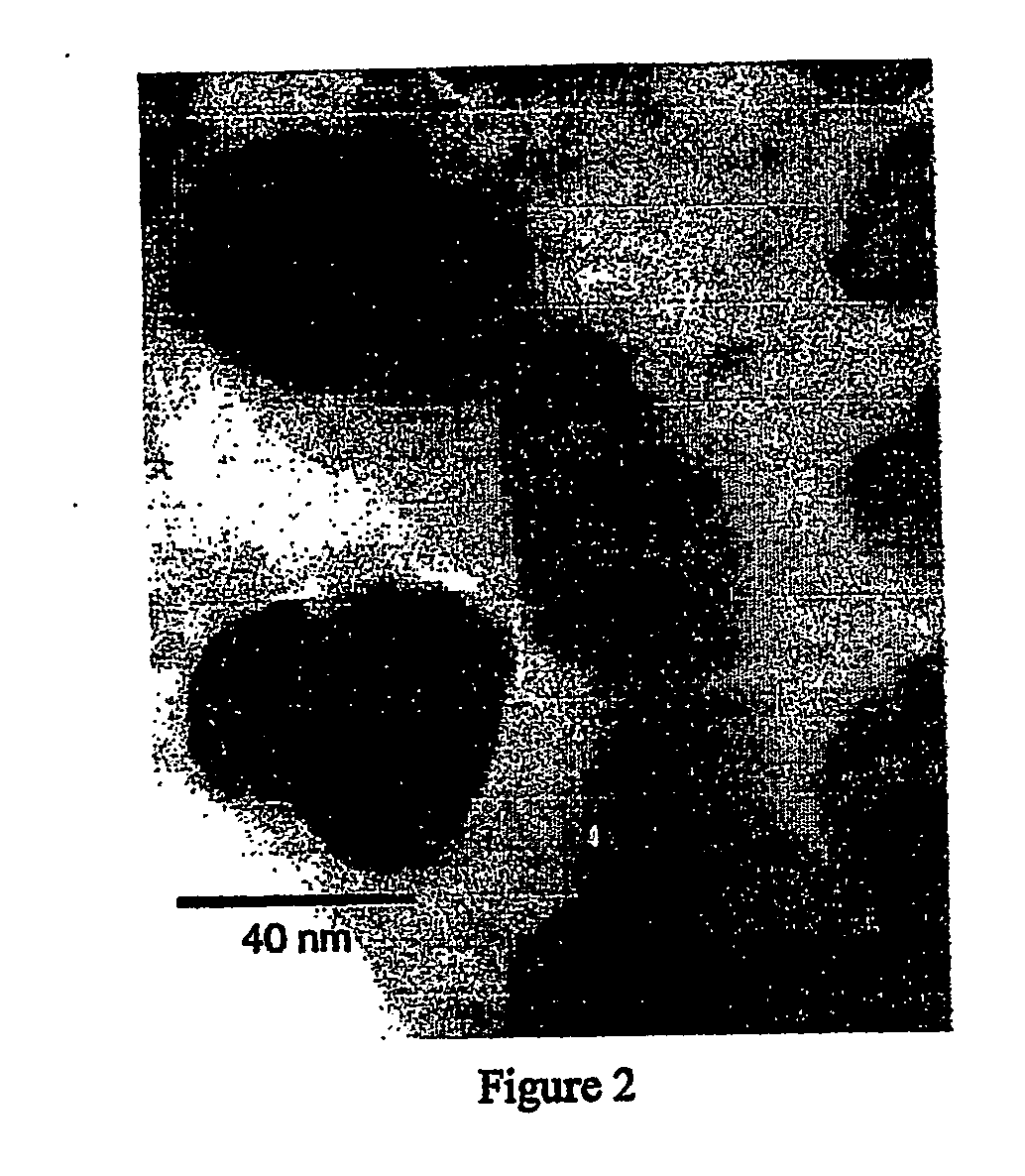

Laser pyrolysis method for producing carbon nano-spheres

InactiveUS20060137487A1High purityImprove homogeneityMaterial nanotechnologyCell electrodesNanometreGraphite

The present invention encompasses methods and apparatus for creating metal nanoparticles embedded in a carbonanceous char, the conversion of an carbonaceous char with embedded metallic nanoparticles to graphite-encased nano-sized metal particles surrounded by char, the separation of the graphite encased metal particles from the char matrix, and the related preparation and isolation of carbon nanosphere materials with or without the enclosed metal nanoparticles, and the uses of such carbon nanospheres and graphite enclosed metal nanoparticles as supports and enhancers for fuel cell electrocatalysts and other applications.

Owner:MCKINNON J THOMAS +2

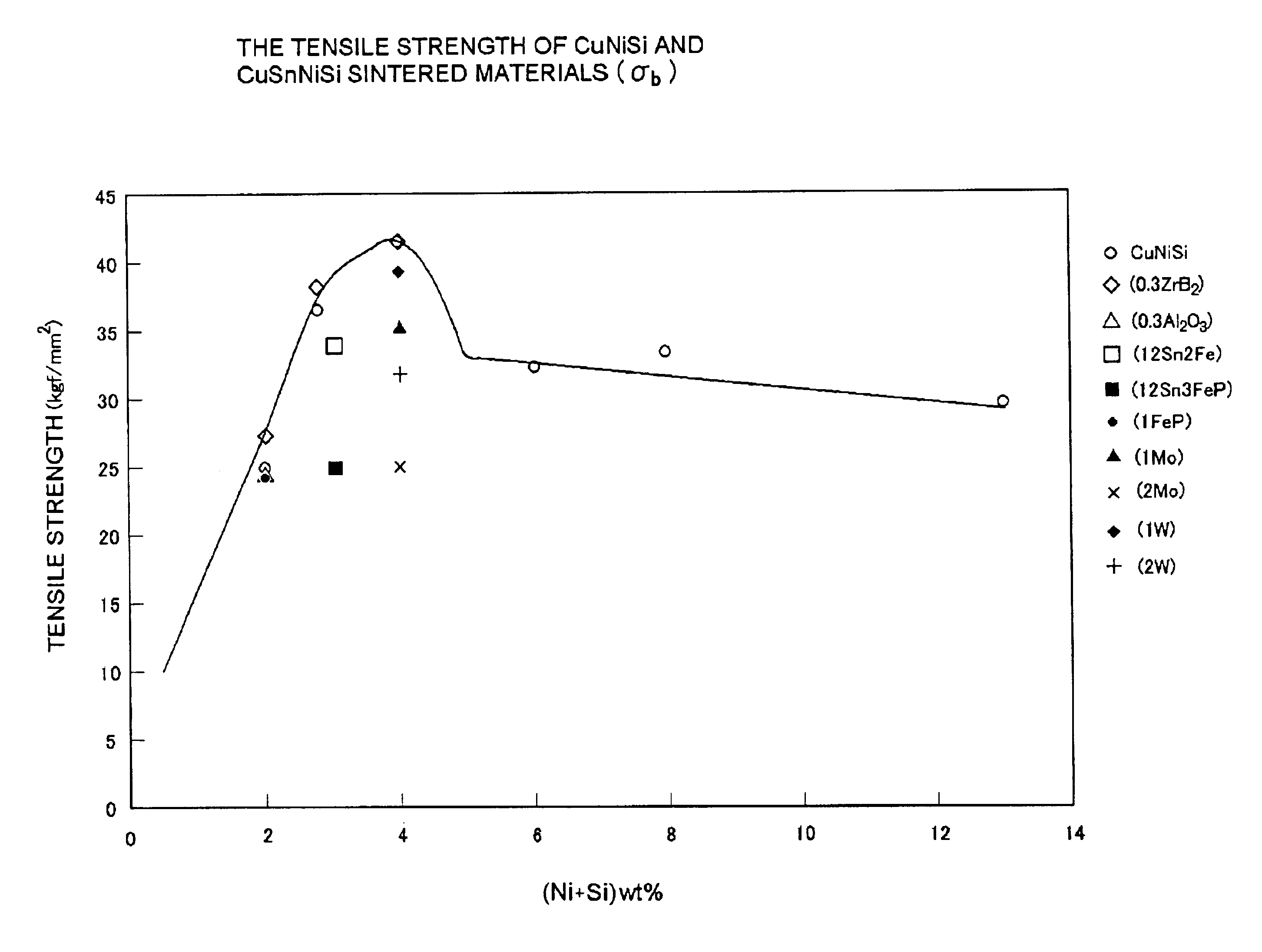

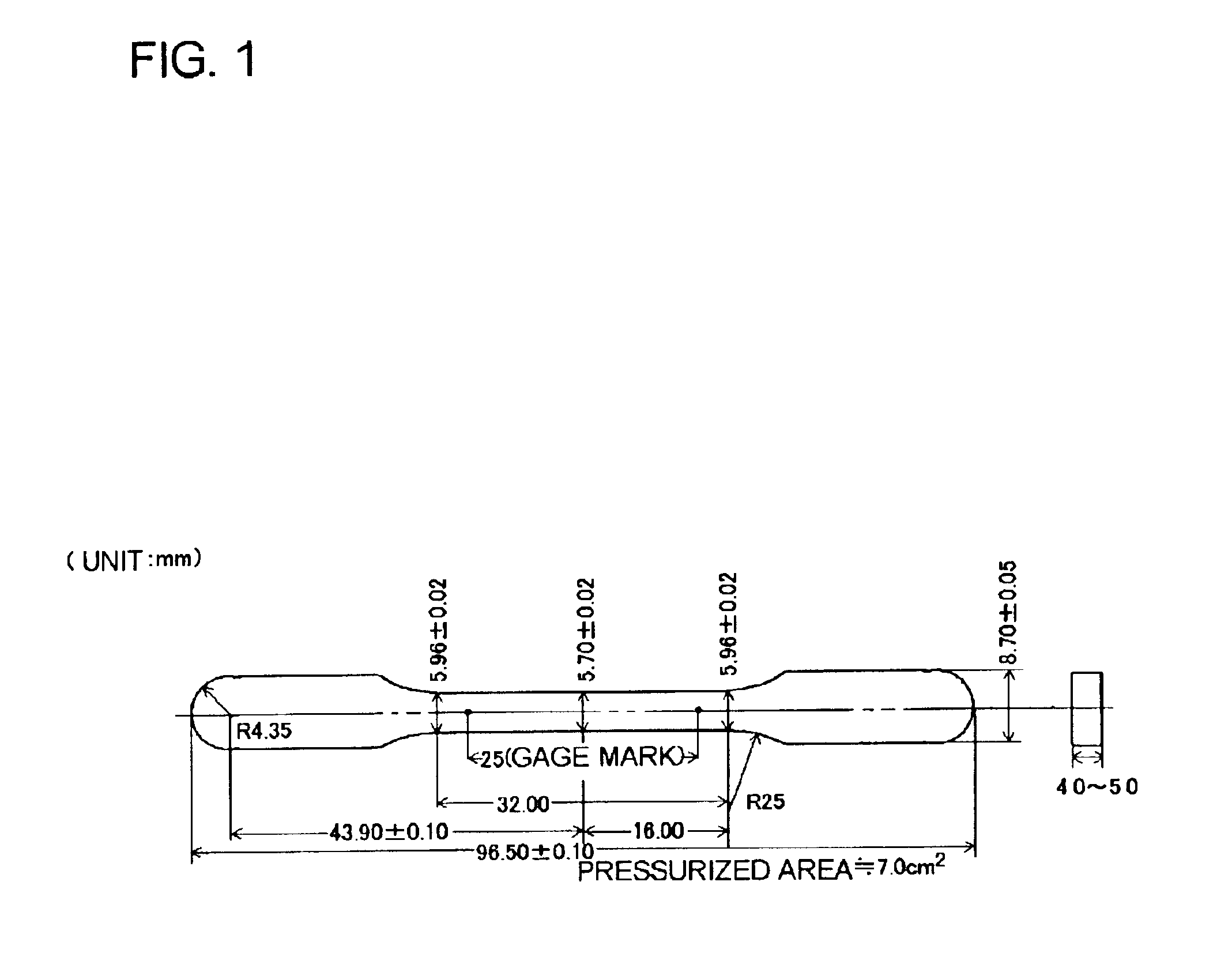

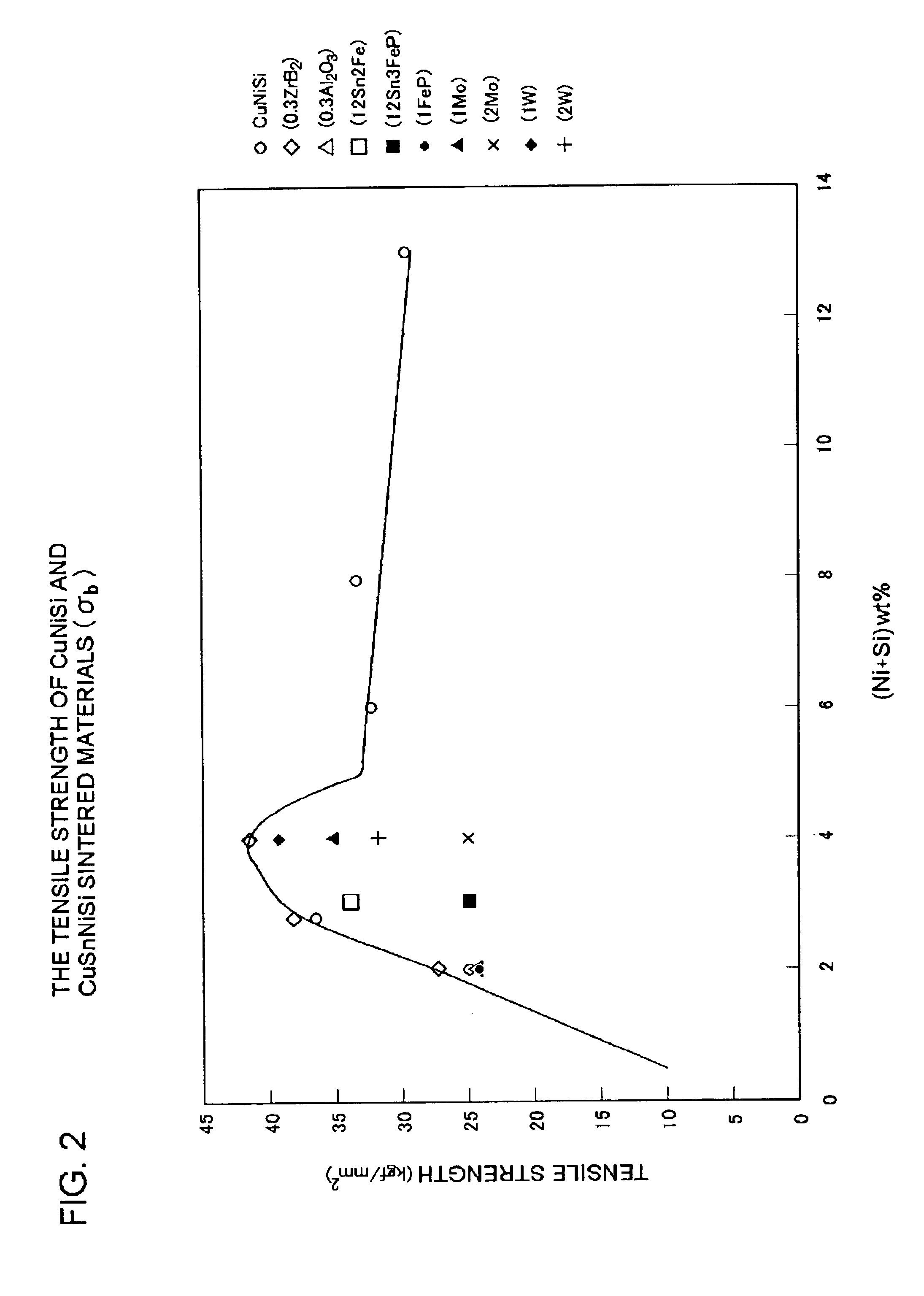

Copper based sintered contact material and double-layered sintered contact member

With the objectives of alleviating the property of attacking on the mating member by scratching-off of local agglutinates on the sliding contact surface, achieving improved wear resistance, and achieving improved seizure resistance through restraint of frictional heat generation by a hard phase, a copper based sintered contact material contains shock-resistant ceramics in an amount of 0.05 to less than 0.5 wt % as non-metallic particles composed of one or more substances selected from pulverized oxides, carbides and nitrides. The shock-resistant ceramics are comprised of SiO2 and / or two or more substances selected from SiO2, Al2O3, LiO2, TiO2 and MgO.

Owner:KOMATSU LTD

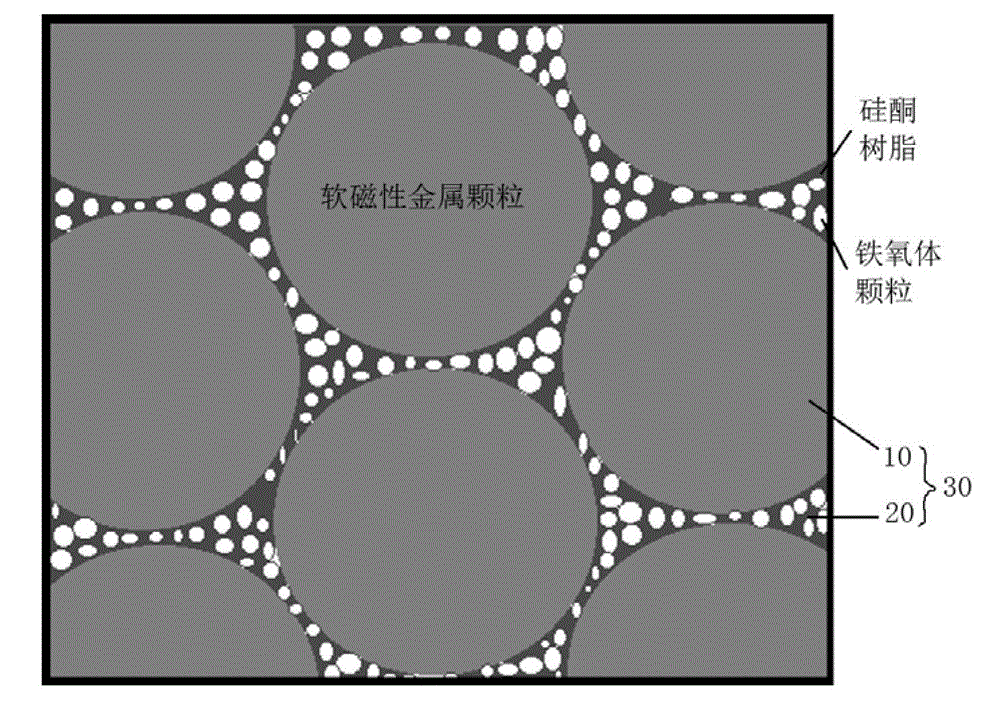

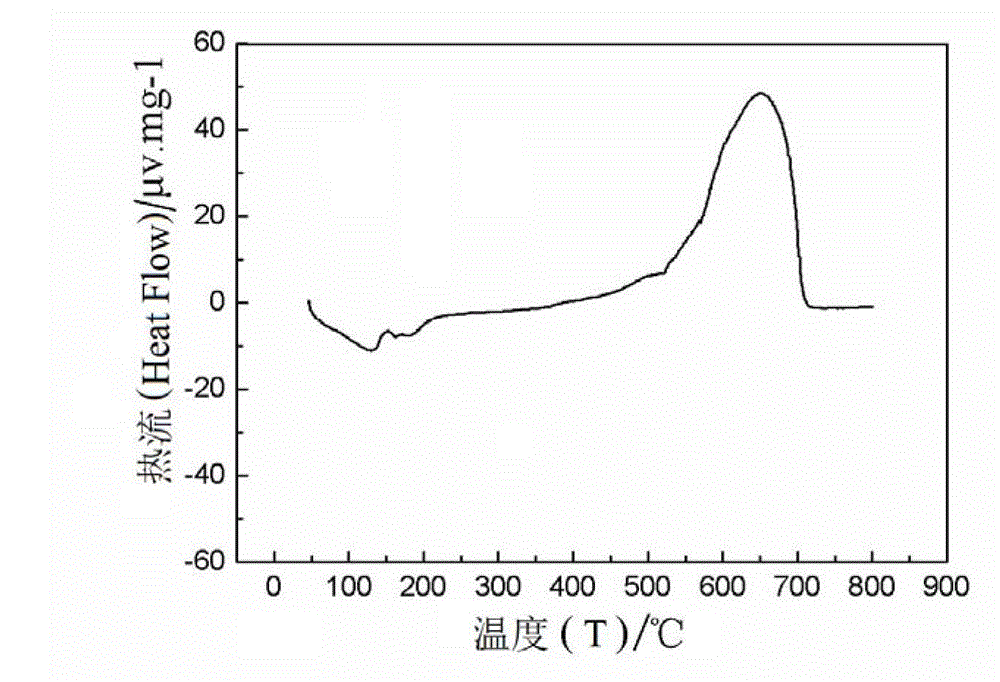

Composite silicone rein-ferrite-coating soft magnetic powder core and preparation method thereof

InactiveCN103151134AImprove adhesionHigh resistivityInorganic material magnetismInsulation layerVolumetric Mass Density

The invention discloses a composite silicone rein-ferrite-coating soft magnetic powder core and a preparation method thereof, and belongs to the metallurgical industry of magnetic functional material and powder. The soft magnetic powder core is formed by pressing and forming composite magnetic particles, wherein each composite magnetic particle comprises a soft magnetic metal particle and a composite insulation film, and each composite insulation film is coated on the surface of each soft magnetic metal particle. The preparation method of the soft magnetic powder core comprises the following steps of surface modification and coupling treatment of the soft magnetic metal particles, forming of the composite insulation coating around each soft magnetic metal particle, pressing and forming, and high-temperature heat treatment at 300 DEG C to 650 DEG C. Compared with the prior art, the soft magnetic powder core and the preparation method have the advantages that the adopted organic resin can resist the high temperature of 600 DEG C; since the soft magnetic ferrite power is added into the composite coating agent, the damage of the insulation layer to the magnetic performance of a substrate is reduced; and the magnetic conductivity is high, the density is high, the rapture strength is high, the loss is low, and the industrial production is easy.

Owner:UNIV OF SCI & TECH BEIJING

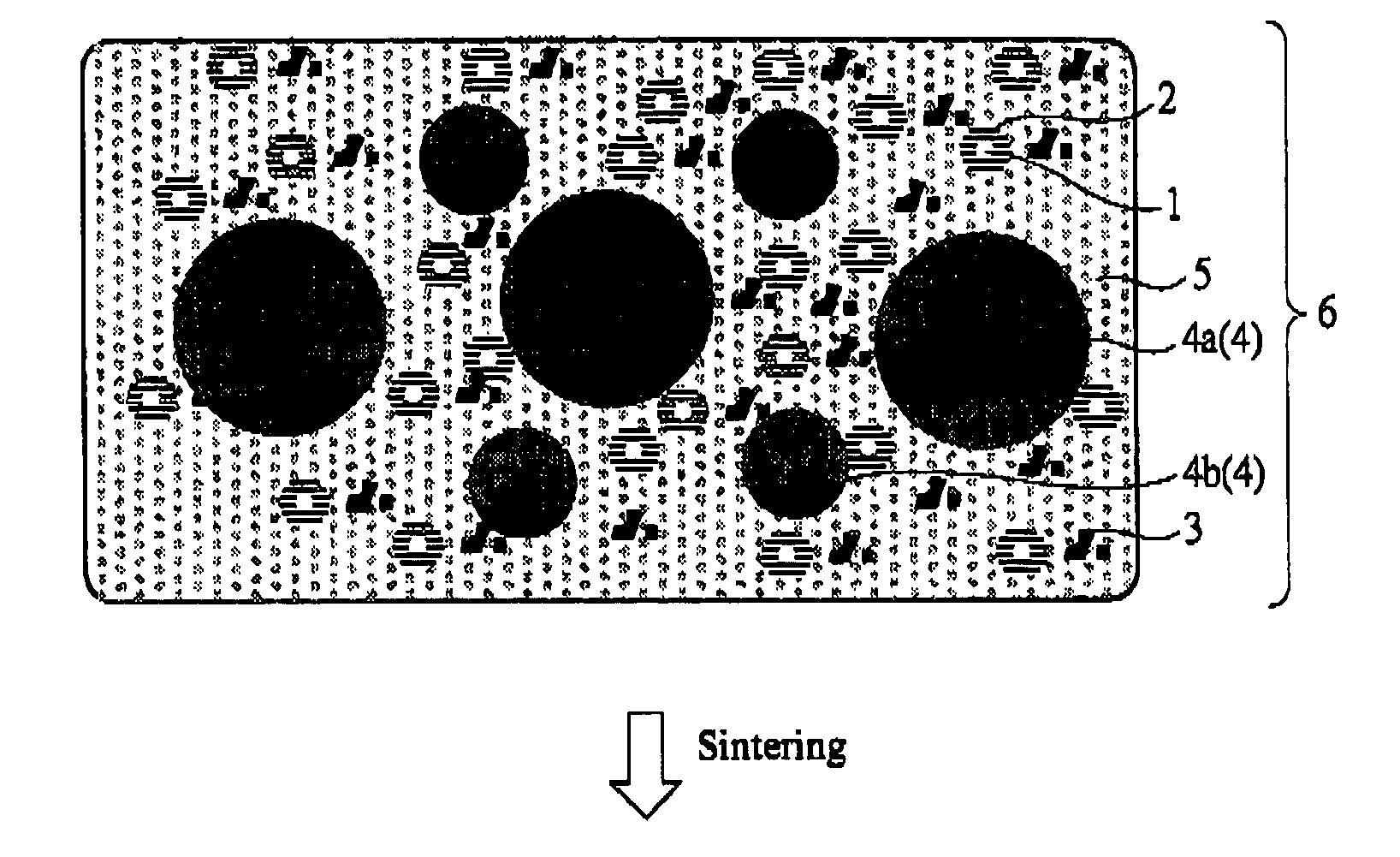

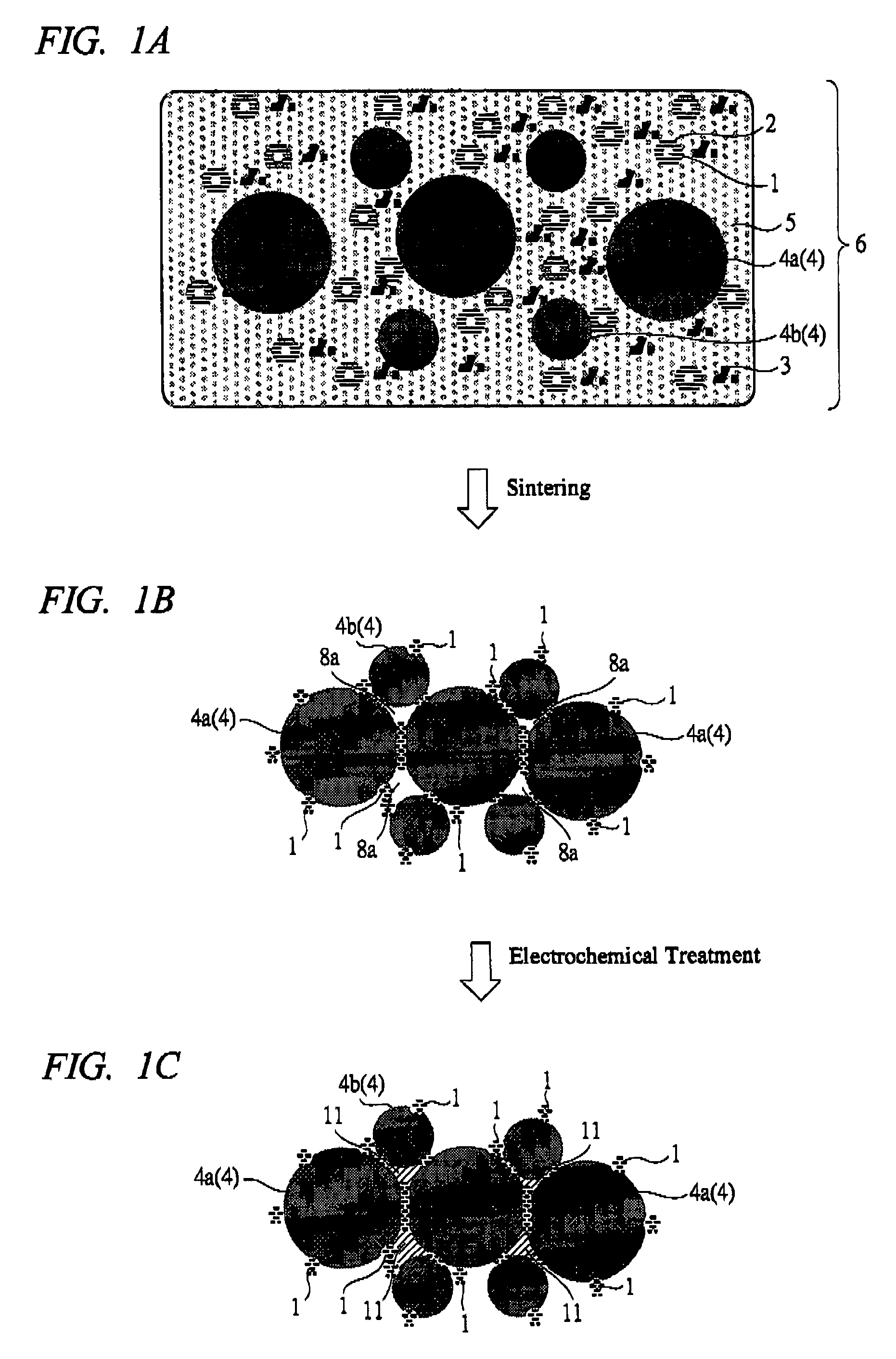

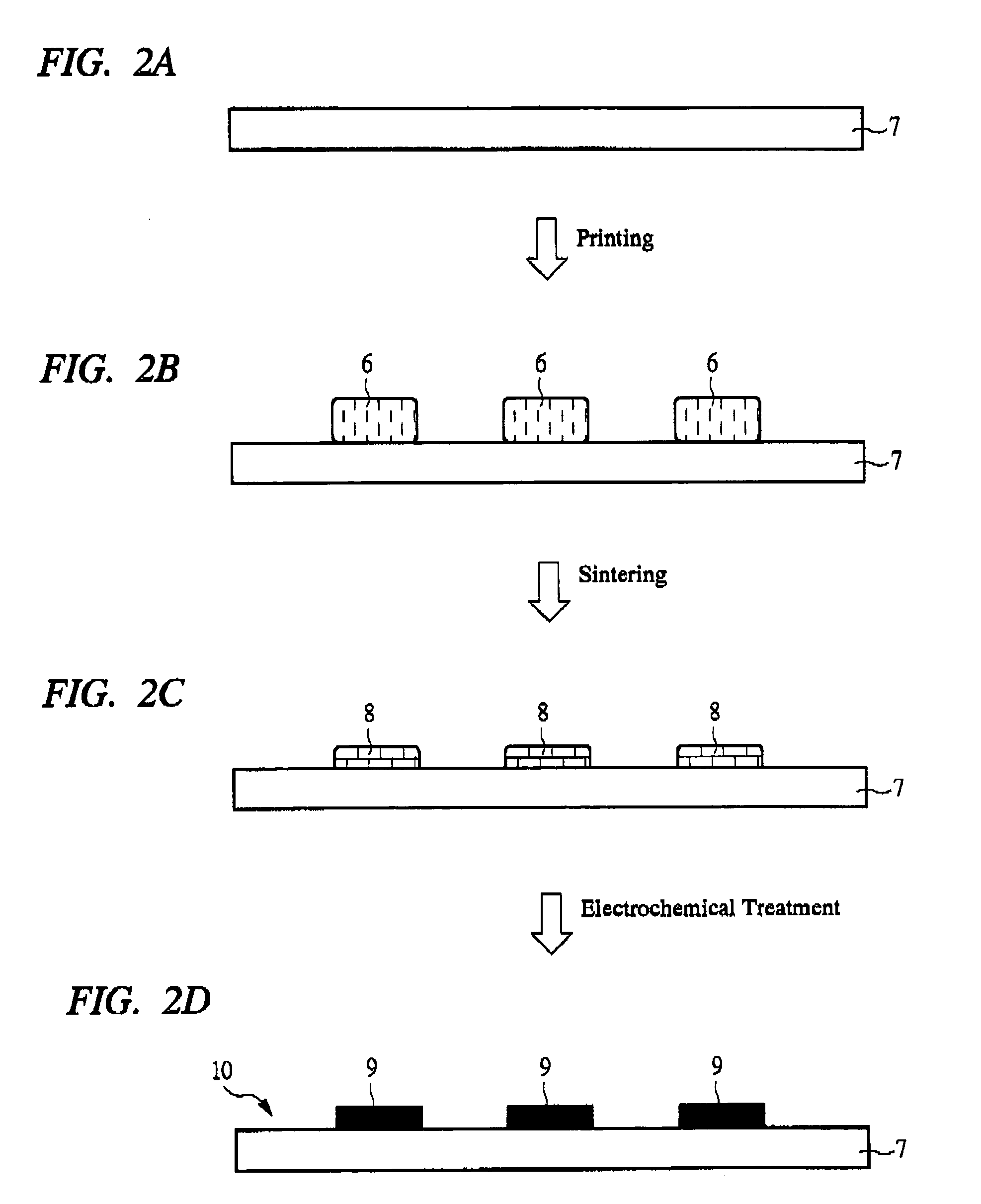

Compound for forming wiring conductor, fabrication method of circuit board using the same and circuit board

InactiveUS20050207930A1Electrical resistance formed at the wiring conductor portion can be reducedHigh strengthMaterial nanotechnologyConductive materialScreen printingSimple Organic Compounds

The present invention sufficiently secures conductor component content ratio in wiring formed on a multilayer circuit board and increases reliability by fabricating the multilayer circuit board by steps of drawing wiring precursor patterns containing a paste of compound for forming wiring conductor containing (a) superfine metal particles (metal nanoparticles) whose average particle size is 1-10 nm; (b) an organic coating compound coated on the surface of the superfine metal particle in the film thickness of 1-10 nm; (c) a latent reactive organic compound reacting with the organic coating compound in the range of 100-250° C., (d) metal particles whose average particle size is 0.5-10 μm, and (e) dispersion medium that stably disperses components (a) through (d) on a substrate by screen printing, sintering by heating the patterns to 100-250° C., and electrochemically treating the patterns to allow the conductor to deposit in a desired cross-sectional area in the inside.

Owner:HITACHI CABLE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com