Method of making composite particles with tailored surface characteristics

a surface characteristic and composite particle technology, applied in metal-working apparatus, transportation and packaging, coatings, etc., can solve the problems of difficult or impossible to transport coarse micro-scale particles through the subsoil, product unsuitable for many applications, and limited commercial use of materials, etc., to achieve cost-effective and scalable, inexpensively produced on a large scale, and superior reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Aluminum Oxide with Spherical Carbon Steel Ball Bearings

[0067] 1240 g of 0.5 mm diameter spherical case hardened steel ball bearings (Union Process, Akron Ohio), 230 g of solvent (diethylene glycol monoethyl ether), and 2.2 g dispersant (Disperbyk® 180, ALTANA Chemie, Wessel Germany) were added to a disc mill with a 750 mL vertical mixing chamber (HDDM-01 disc mill, Union Process, Akron, Ohio). The mill speed was set to 2500 RPM and was operated at a constant temperature of 30° C. in a nitrogen atmosphere. Subsequently about 490 g of roughly spherical aluminum oxide particles (RCHP, Baikowski Malakoff, Malakoff, Tex.) were added in stages to help maintain a fluid suspension. As the softer metal contacted the alumina particles, metal was deposited onto exposed surfaces. The particle slurry, initially white, became darker with increasing time. This indicated that iron was deposited onto the particle surface. After 3 hr. slurry was harvested by decanting the mixture into a vessel. Th...

example 2

Aluminum Oxide with Ultrasoft® Steel Shot

[0068] About 1060 g of roughly spherical steel blasting grit (Ultrasoft® US-280, Peerless Metal Detroit, Mich.), 250 g of solvent (diethylene glycol monoethyl ether), and 2.3 g dispersant (Disperbyk® 180) were added to the HDDM-01 disc mill with a 750 mL vertical mixing chamber. The mill speed was set to 2500 RPM and was operated at a constant temperature of 30° C. in a nitrogen atmosphere. Subsequently about 425 g of roughly spherical aluminum oxide particles (P730, Almatis, Pittsburgh, Pa.) was added in stages to help maintain a fluid suspension. After 3 hr., slurry color was dark metallic gray and the metal source particles were separated by settling. Powder surface area was measured at about 12 m2 / g.

example 3

Aluminum Oxide with AT40.29 Iron Particles

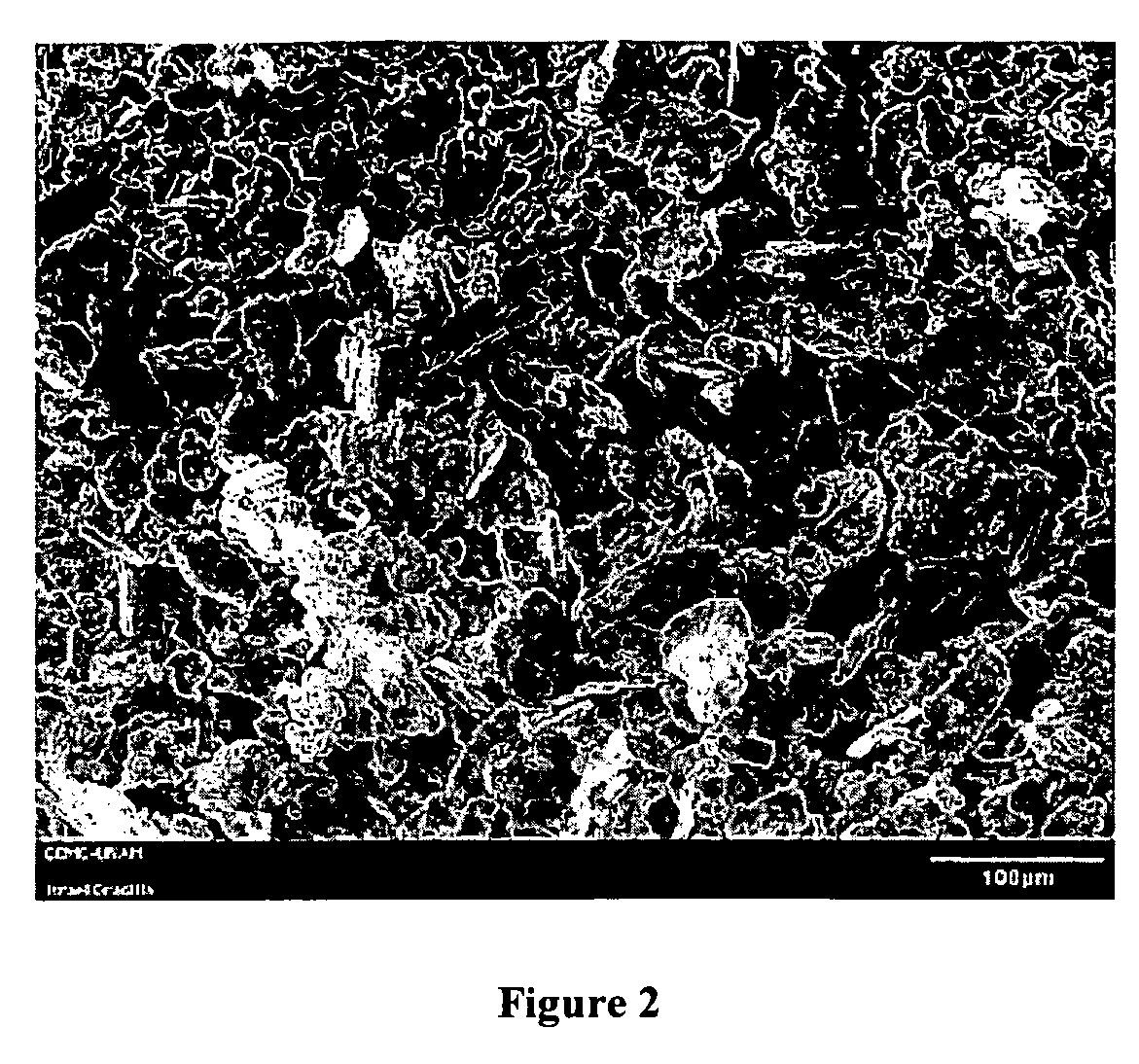

[0069] About 1050 g of roughly spherical iron particles (AT40.29, North American Hoganas, Hollsopple, Pa.) and 250 g of solvent (diethylene glycol monoethyl ether) were added to the HDDM-01 disc mill with a 750 mL vertical mixing chamber. The mill speed was set to 3000 RPM and was operated at a constant temperature of 30° C. in a nitrogen atmosphere. Subsequently about 425 grams of roughly spherical aluminum oxide particles (P10 Feinst, Almatis) was added in stages. After 3 hr. slurry color was dark metallic gray. The mill speed was reduced to 1500 RPM and 4.2 g of dispersant (Disperbyk® 180) was added to reduce viscosity and enable separation of iron source particles by settling. Powder surface area was measured at about 19 m2 / g. FIG. 3 is a scanning electron microscope (SEM) picture showing the discreet sub-micrometer particles, generally free of agglomerates and aggregates.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com