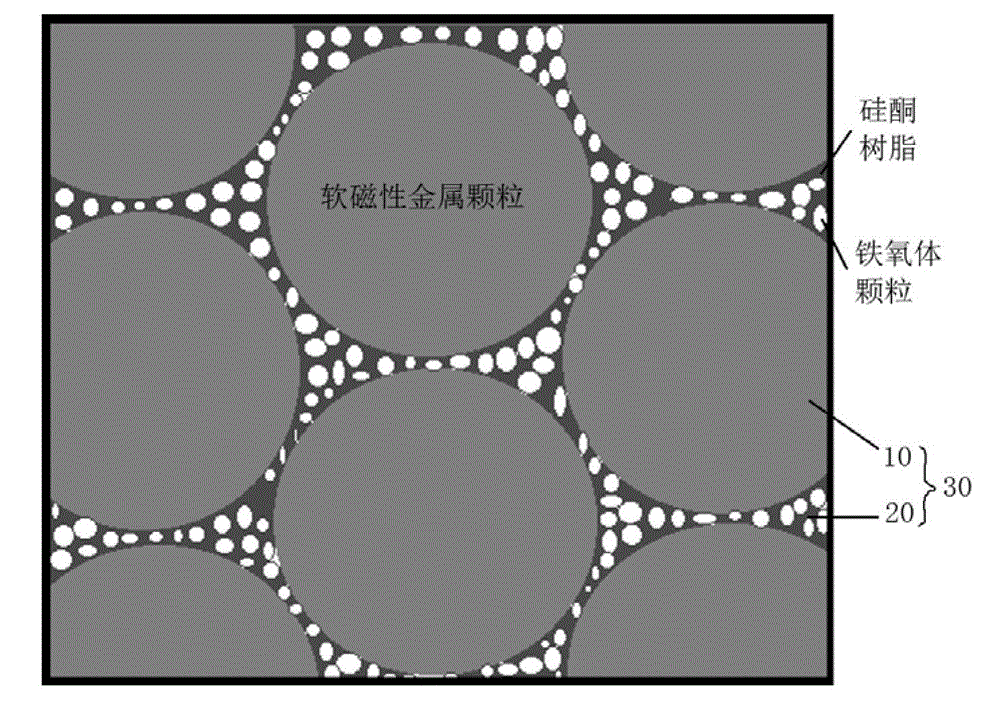

Composite silicone rein-ferrite-coating soft magnetic powder core and preparation method thereof

A technology of silicone resin and composite coating agent, applied in the direction of magnetism of inorganic materials, can solve the problems of high temperature annealing, uneven coating of insulating film, low magnetic permeability of soft magnetic powder core, etc., and achieve high magnetic permeability. rate, improve adhesion, improve the effect of resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

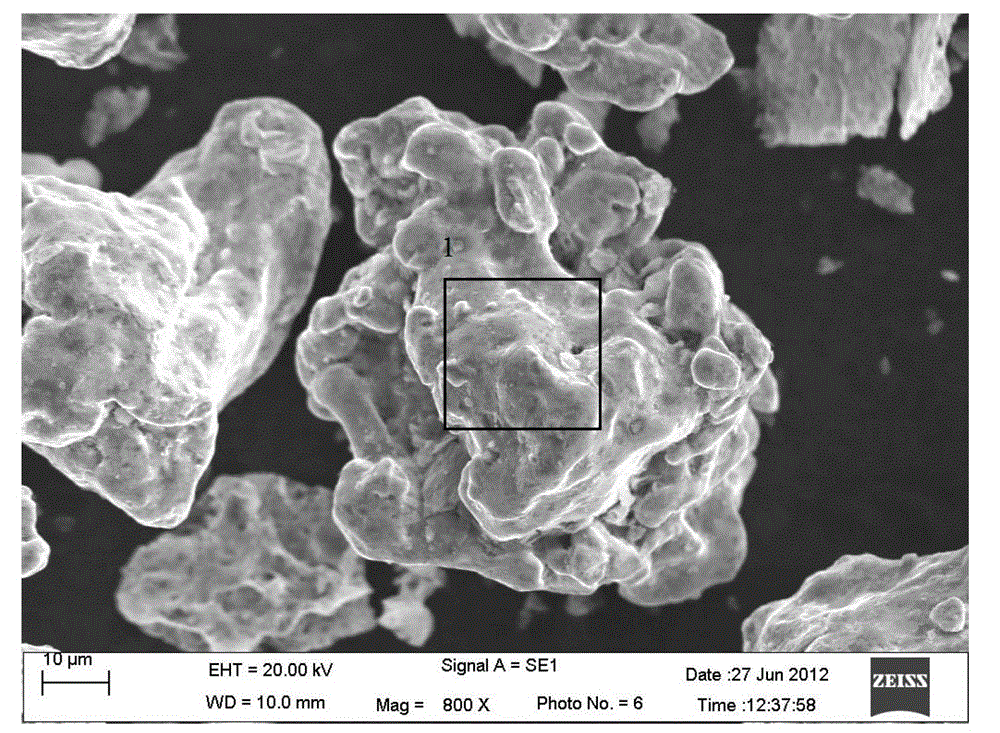

[0035] (1) Select 100g of industrially produced reduced iron powder with a particle size distribution of 100-500 mesh and an Fe element content greater than 98%, wash the iron powder three times with analytical pure acetone solution, and place the cleaned iron powder in a PH=9 In dilute ammonia solution, stir at 40-60°C for 15-30 minutes to obtain surface-modified iron powder;

[0036] (2) Put the surface-modified iron powder into the silane coupling agent diluent, the mass ratio of coupling agent to iron powder is 1:100, and the diluent of the coupling agent diluent is 5vol% deionized Water and 95vol% alcohol, after rapid stirring for 2 hours, wash with alcohol three times to remove excess silane coupling agent, and then vacuum dry at 50°C for 1 hour;

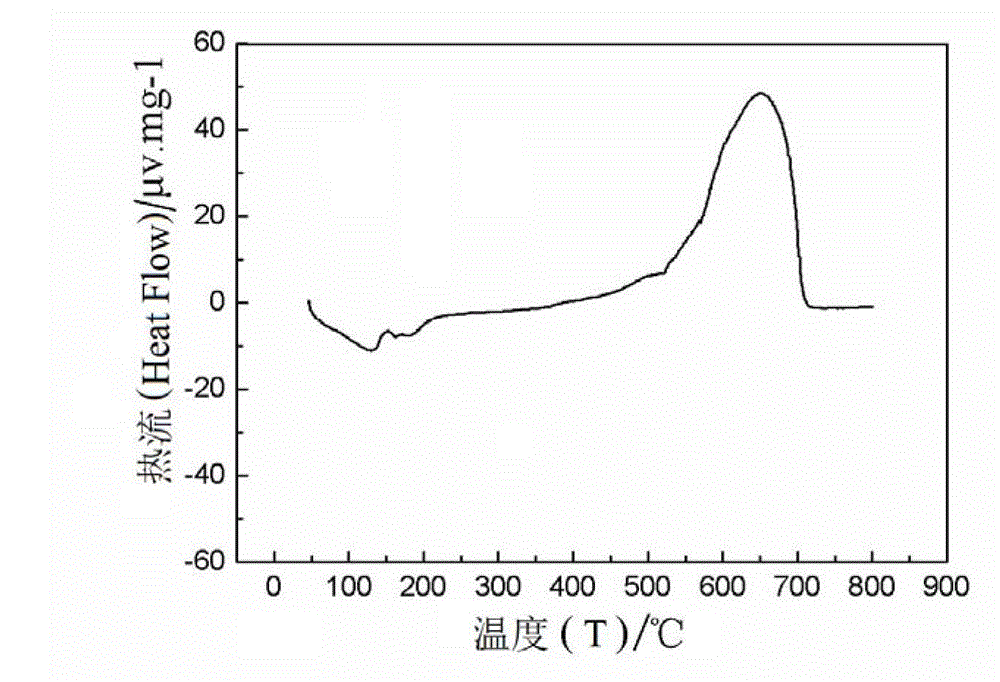

[0037] (3) According to the nominal formula Mn 0.8 Zn 0.2 Fe 2 o 4 Dissolve the corresponding manganese nitrate, zinc nitrate and ferric nitrate (all of analytical grade) in 600ml of deionized water, then add citric acid a...

Embodiment 2

[0043] (1) Select 100g of industrially produced reduced iron powder with a particle size distribution of 100-500 mesh and an Fe element content greater than 98%, wash the iron powder three times with analytical pure acetone solution, and place the cleaned iron powder in a PH=9 In dilute ammonia solution, stir at 40-60°C for 15-30 minutes to obtain surface-modified iron powder;

[0044] (2) Put the surface-modified iron powder into the silane coupling agent diluent, the mass ratio of coupling agent to iron powder is 1:100, and the diluent of the coupling agent diluent is 5vol% deionized Water and 95vol% alcohol, after rapid stirring for 2 hours, wash with alcohol three times to remove excess silane coupling agent, and then vacuum dry at 50°C for 1 hour;

[0045] (3) According to the nominal formula Ni 0.5 Zn 05 Fe 2 o 4 Dissolve the corresponding nickel nitrate, zinc nitrate and ferric nitrate (all analytically pure) in 800ml of deionized water, then add citric acid at a mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com