Patents

Literature

304results about How to "Reduce magnetic loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Current transformer iron core of amorphous and nano-crystalline magnetically soft alloy and preparation method thereof

ActiveCN105047348AReduce magnetic lossReduce lossTransformers/inductances magnetic coresInductances/transformers/magnets manufactureChemical compositionAlloy

The invention discloses a current transformer iron core of amorphous and nano-crystalline magnetically soft alloy and a preparation method of the current transformer iron core. The chemical component atomic percent of the iron core is FeaSibBcMdCueM'f, wherein a is not more than 85 and is not less than 65; b is not more than 25 and is not less than 5; c is not more than 15 and is not less than 0; d is not more than 15 and is not less than 0; e is not more than 5 and is not less than 0, and f is not more than 1 and is not less than 0, and a plus b plus c plus d plus e plus f equals to 100, and M is at least one of Nb, Mo or V, and M' is at least one of Sn, Al, Y and Sb. The preparation method comprises the steps as follows: preparing materials according to atomic percent and smelting to prepare a mother alloy; then crushing the prepared mother alloy to re-melt and covering steel-making slagging constituent to prevent oxidation and deslagging; preparing amorphous alloy ribbons with the re-melted mother alloy by using a single roll rapid solidification ribbon preparation method under ordinary pressure, and finally winding the amorphous alloy ribbons as the amorphous iron core, and performing isothermal annealing crystallization in a vacuum annealing furnace to obtain the amorphous and nano-crystalline magnetically soft alloy of a mutual inductor iron core. The iron core of the invention has high saturation flux density, high permeability, and low magnetic loss so that the mutual inductor has ultrahigh precision and accuracy class.

Owner:NEW MATERIALS TECH JIANGSU AMORPHD +1

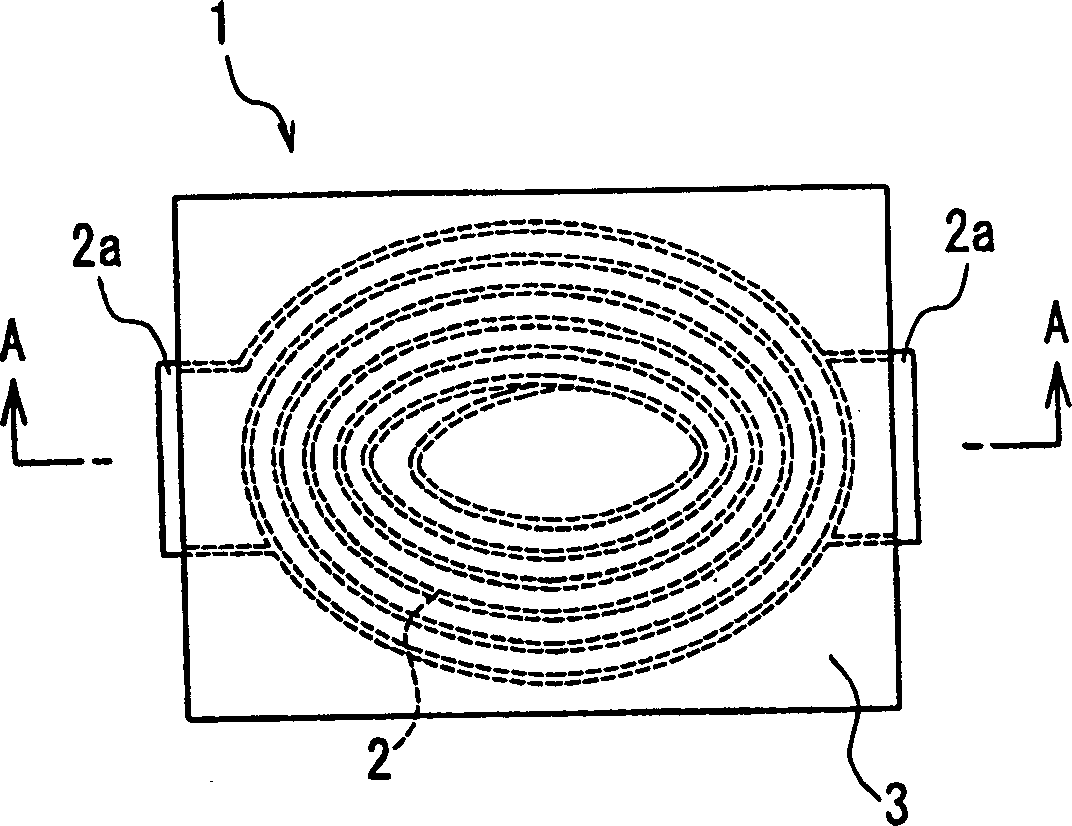

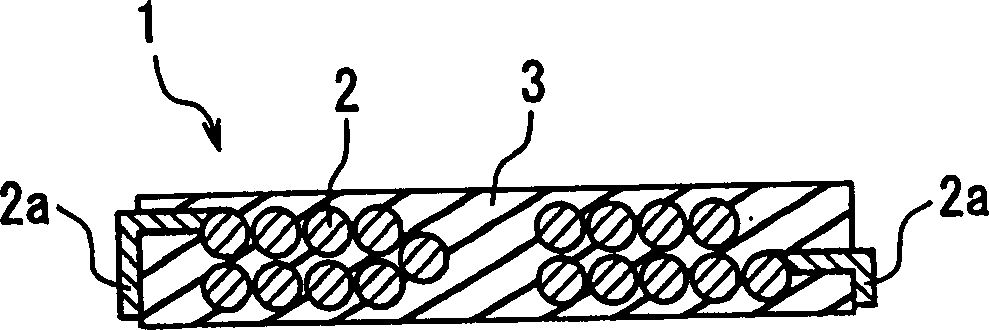

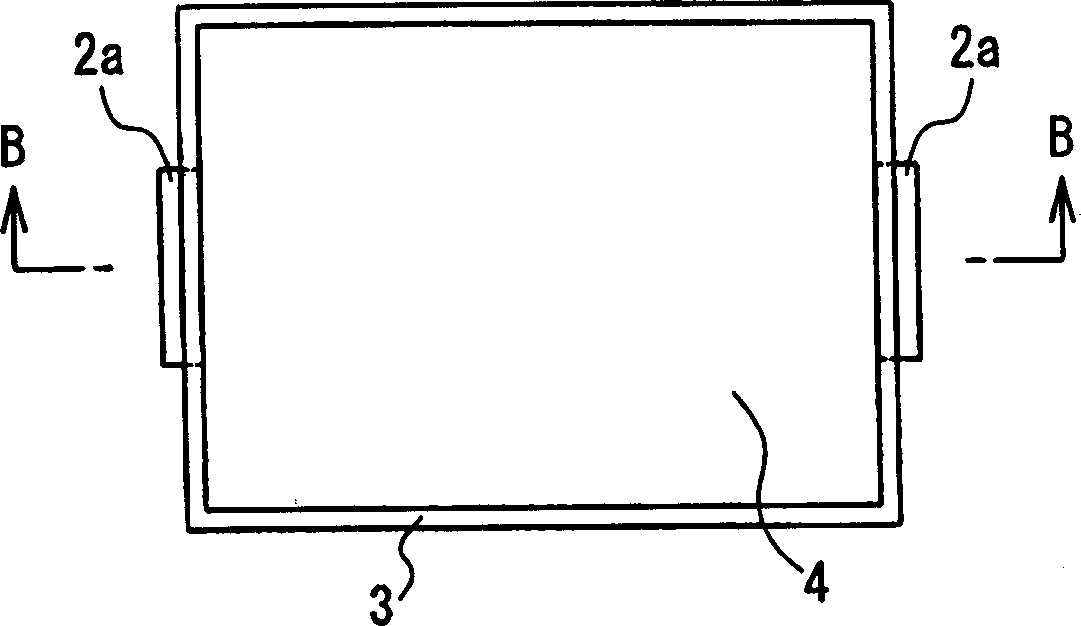

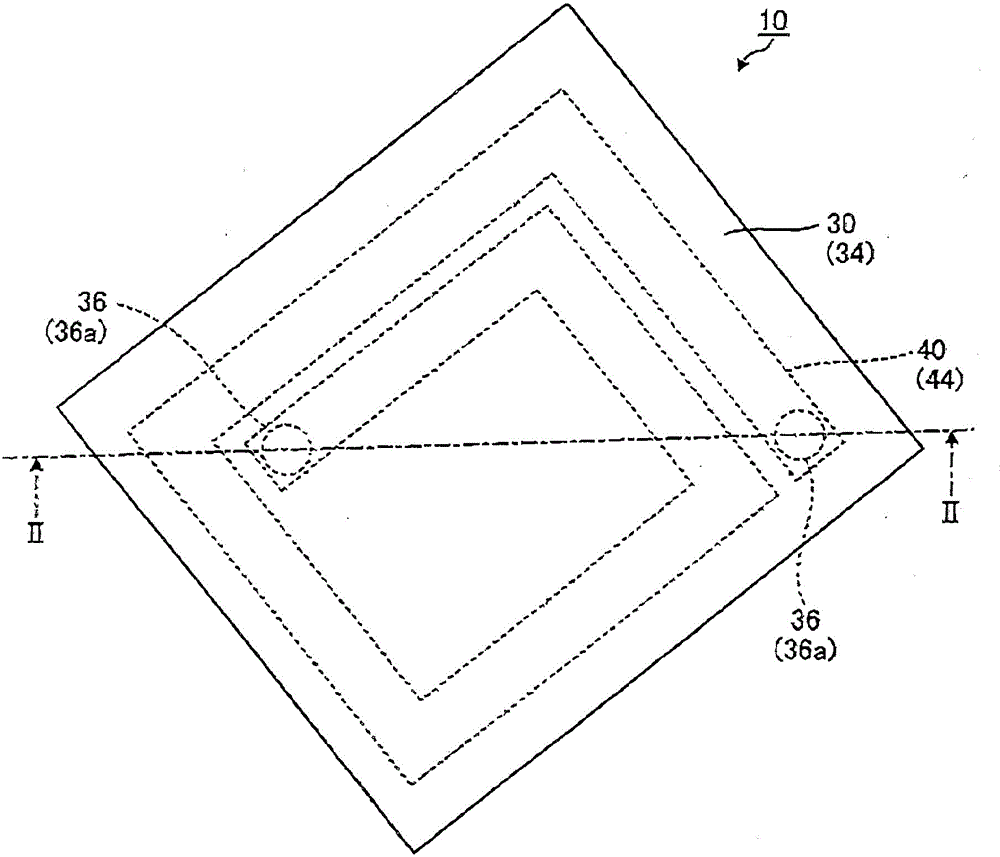

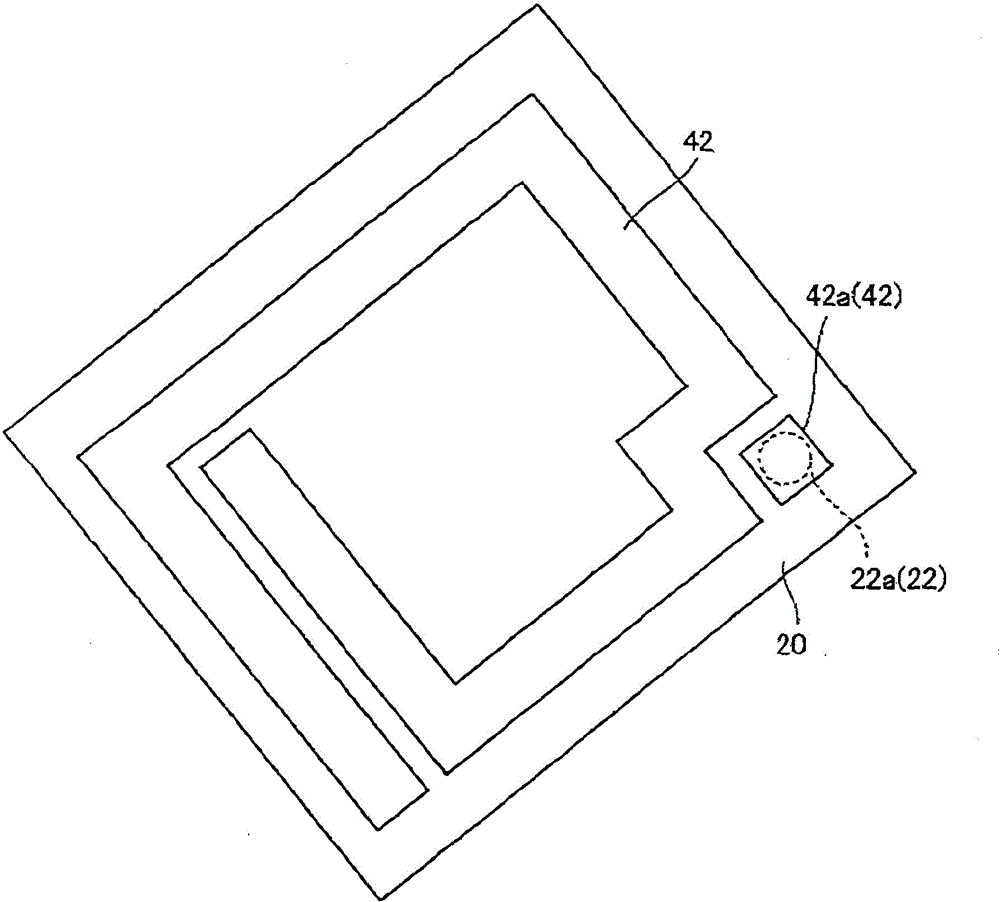

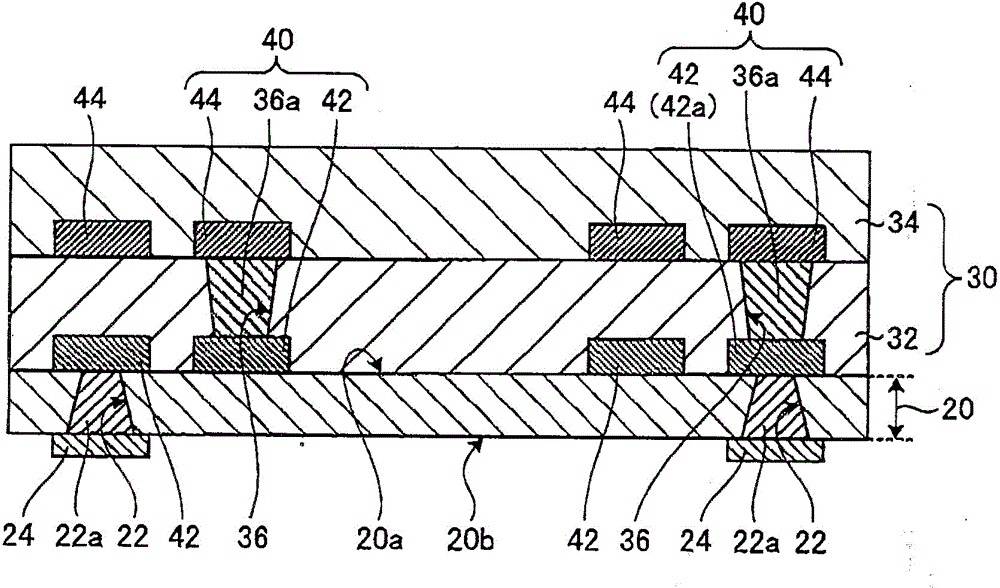

Magnetic element and its manufacture, power supply module therewith

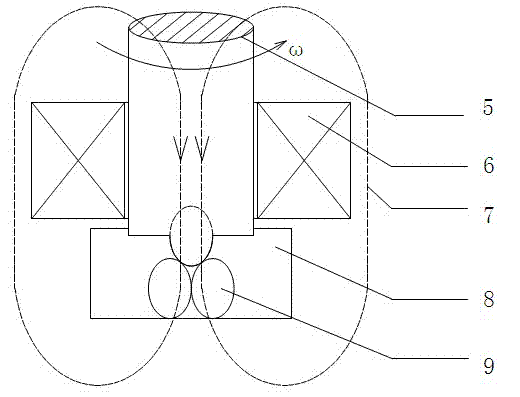

InactiveCN1407564AReduce magnetic lossIncrease the inductance valueTransformers/inductances coils/windings/connectionsEncapsulation/impregnationElectrical conductorComputer module

A magnetic device includes a sheet-type coil including a planar conductive coil and an insulating substance; and a sheet-type first magnetic member disposed on at least one of upper and lower surfaces of the sheet-type coil, where a magnetic permeability of the insulating substance is smaller than a magnetic permeability of the first magnetic member. The magnetic device preferably includes a second magnetic member provided at a predetermined area of the sheet-type coil, the second magnetic member being made of a resin containing a magnetic powder and having a permeability larger than the insulating substance and smaller than the first magnetic member. The predetermined area is at least one position selected from a center portion and a peripheral portion of the sheet-type coil where a conductor constituting the planar conductive coil is not present. Further, a power supply module of the present invention includes the magnetic device according to the present invention.

Owner:PANASONIC CORP

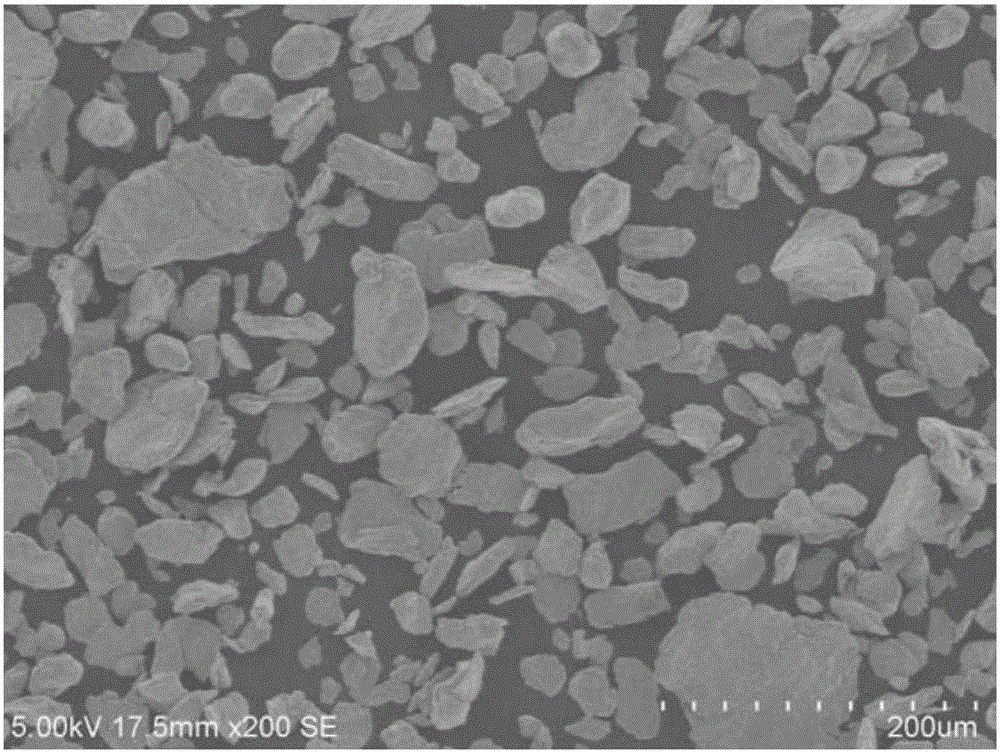

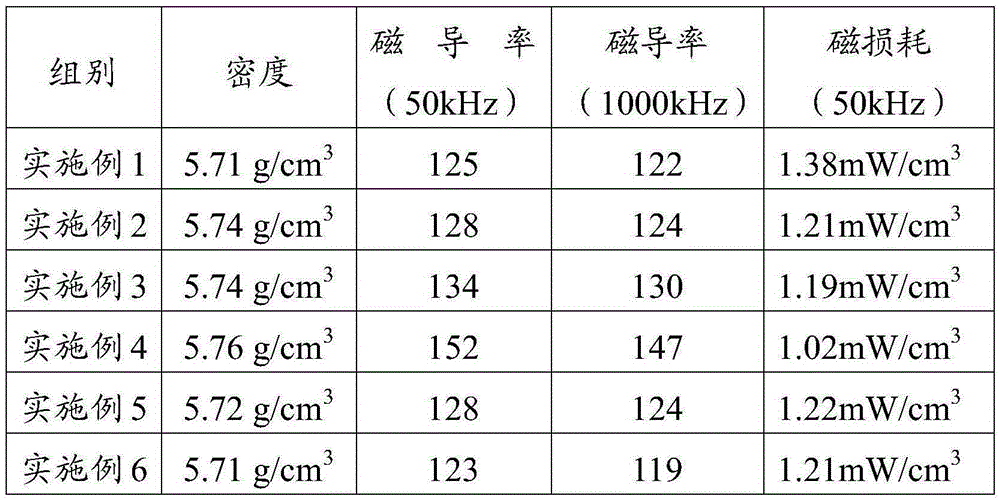

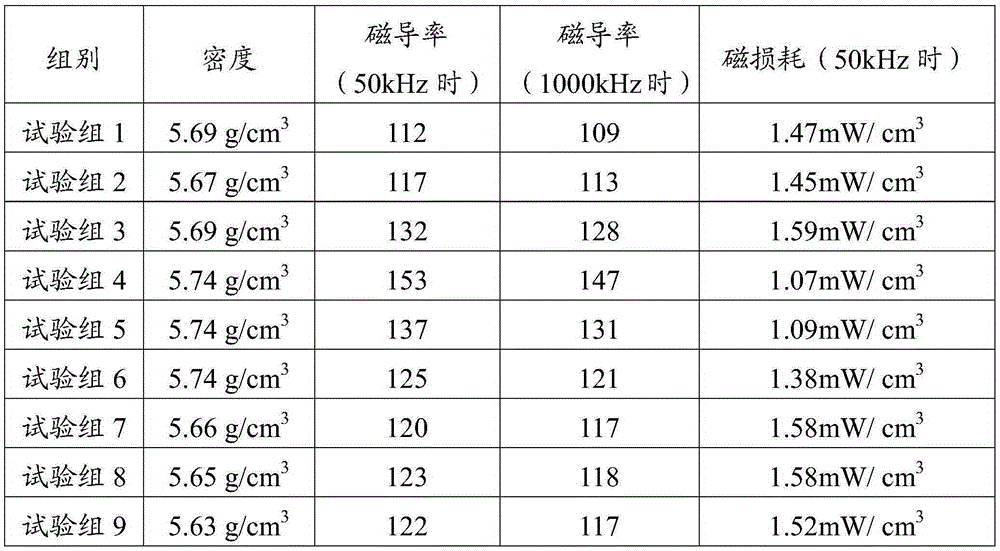

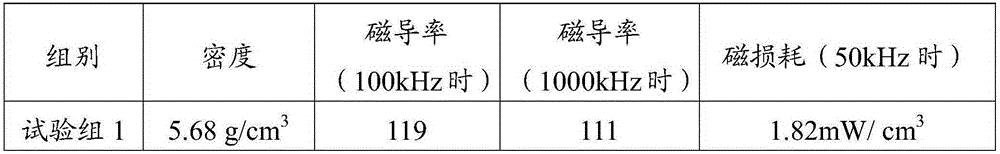

Preparation method of Fe-based metal soft magnetic powder core

ActiveCN105185560APowder moldingEasy to shapeInorganic material magnetismInductances/transformers/magnets manufactureEpoxyMaterials preparation

The invention relates to a preparation method of a Fe-based metal soft magnetic powder core, and belongs to the technical field of magnetic material preparation. The method comprises the following steps: with Fe-based flake-like metal soft magnetic powder as raw material powder, carrying out annealing treatment; carrying out passivation and insulated coating treatment on the annealed powder; carrying out drying treatment on the passivated and insulated powder; pressing the dried metal powder into a magnetic powder core blank, and adopting zinc stearate powder as a releasing agent; and carrying out annealing treatment on the molded magnetic powder core blank and spraying a layer of epoxy resin insulating paint on the surface of the magnetic powder core blank, so as to obtain the metal soft magnetic powder core. The density of the magnetic powder core prepared by the method is greatly improved; the density distribution is even; the magnetic powder core has relatively high compactness and good mechanical strength; and meanwhile, the magnetic powder core has relatively high magnetic conductivity and relatively low magnetic loss. In addition, the prepared magnetic powder core also has the characteristics of high magnetic conductivity, high quality factor and low loss.

Owner:有研增材技术有限公司

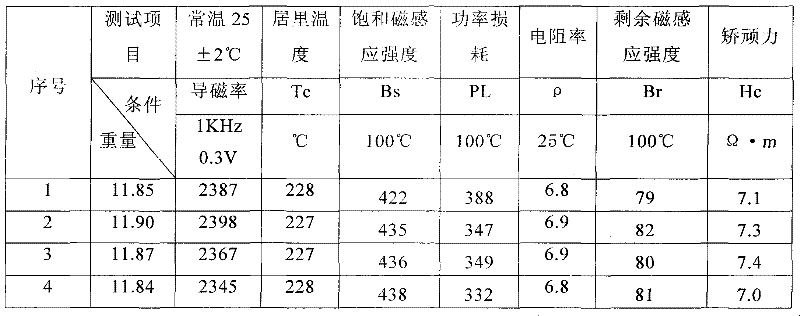

Soft magnetic ferrite material and preparation process thereof

ActiveCN102194561AHigh saturation flux densityReduce magnetic lossInorganic material magnetismMetallurgyMaterials science

The invention discloses a soft magnetic ferrite material and a preparation process thereof. The soft magnetic ferrite material comprises the following components: 52 to 55 mol of Fe2O3, 39 to 42 mol of Mn3O4, 5-8 mol of ZnO, 0.1 to 0.6 mol of additive 1, 0.1 to 0.2 mol of additive 2 and 0.006 to 0.06 mol of ZrO2, wherein the additive 1 is one or more of SnO2, CaCO3 and V2O5; and the additive 2 isone or more of Nb2O5, K2CO3, CaCO3, Ta2O5, SnO2 and V2O5. The soft magnetic ferrite material prepared by the process overcomes defects of the prior art and has the advantages of high frequency, high saturation magnetic flux density and low magnetic loss.

Owner:WUXI SPINEL MAGNETICS

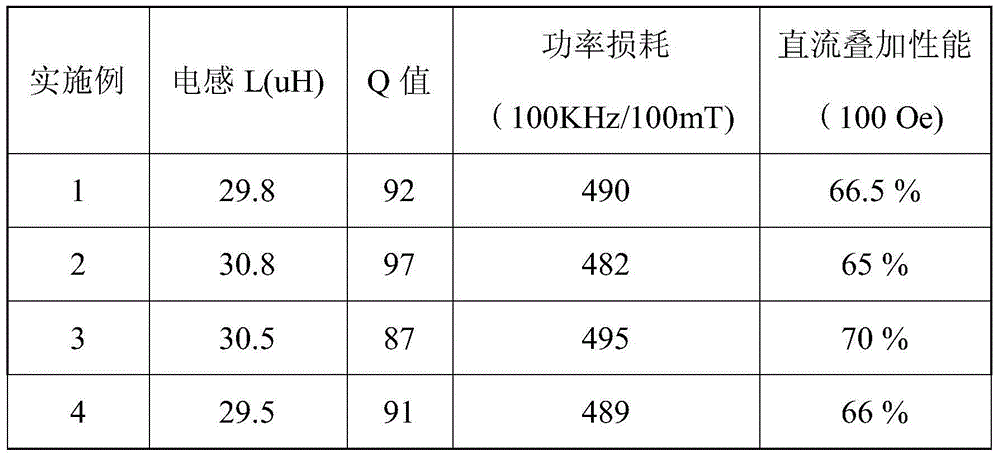

Preparation method of low-loss amorphous magnetic powder core

ActiveCN104575913AReduce lossHigh strengthInorganic material magnetismUltimate tensile strengthMaterials science

The invention discloses a preparation method of a low-loss amorphous magnetic powder core, and aims to provide a preparation method of the low-loss amorphous magnetic powder core with low magnetic loss and good direct current bias. The amorphous magnetic powder core with magnetic conductivity between 60-90 and higher strength is prepared by adding a proper high-temperature resistant insulating material, selecting a proper insulating coating method, and using compression moulding and high temperature annealing technologies. The preparation method has the following beneficial effects that the magnetic loss is low, the loss is lower than 500mW / cm<3> under the condition of 100K / 100mT; the direct current bias is good, the direct current bias is between 65-70% under the condition that the magnetic field intensity is 100Oe.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

Fabrication method of soft magnetic alloy materials

ActiveCN104008844AReduce magnetic lossImprove magnetismInorganic material magnetismInductances/transformers/magnets manufactureProduction rateHigh intensity

The invention relates to a fabrication method of soft magnetic alloy materials. The fabrication method includes flattening, drying and annealing, and post-treating. The surface of soft magnetic alloy powder is provided with a metal oxide film, so that magnetic loss of the powder is reduced on the premise of not reducing magnetic conductivity of the powder and magnetic performance of the powder is improved. The fabrication method is simple, low in cost, and suitable for large-scale batch production; the soft magnetic alloy materials fabricated can meet the high requirements for high saturation flux density, high magnetic conductivity, low iron loss, high strength and high productivity.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

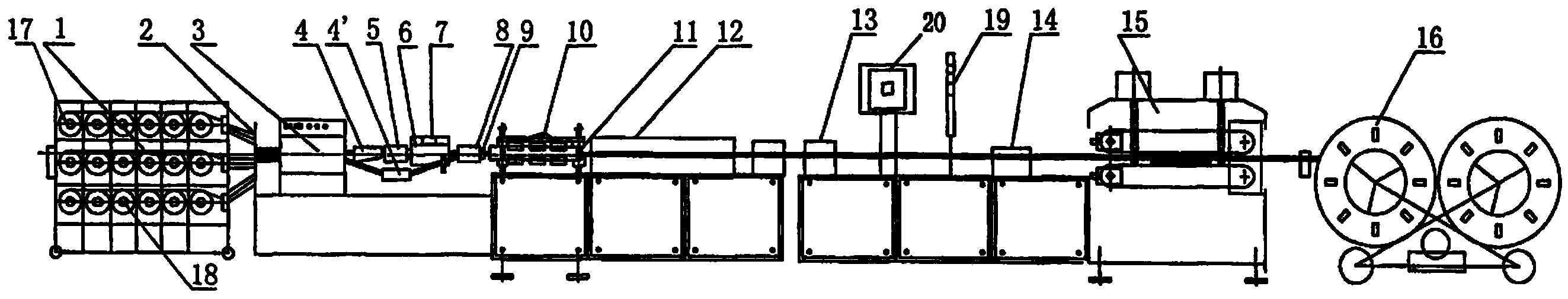

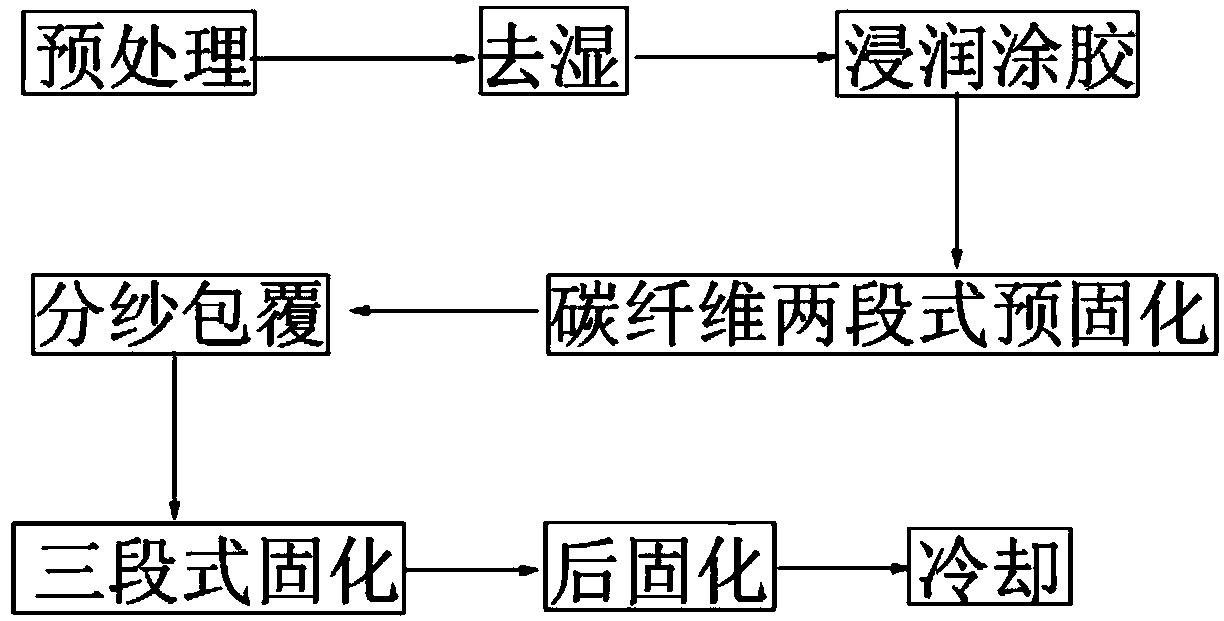

Electric transmission line carbon fiber composite core manufacturing method

InactiveCN103413629AImprove conductivityImprove performanceCable/conductor manufactureElectric power transmissionBasalt fiber

An electric transmission line carbon fiber composite core manufacturing method mainly includes the following steps of conducting preprocessing, dehumidification and glue infiltration, pre-hardening carbon fibers in a two-section heating mode, enabling high-strength glass fibers or basalt fibers to cover a pre-hardened carbon fiber core according to certain rules, hardening the carbon fiber core covered by the high-strength glass fibers or the basalt fibers in a three-section mode, and conducting post curing and cooling, wherein consumed epoxy resin is high-temperature-resistant special type pultrusion epoxy resin which is prepared by adding modified anhydride compounds in the glue infiltration process. The electric transmission line carbon fiber composite core manufacturing method has the advantages that the carbon fibers are preformed in a pultrusion mode to be in a semi-hardened state after being infiltrated, heating temperature sections are controlled so that the carbon fiber core with excellent performance can be obtained, particularly, heating and hardening are conducted in the three-section mode in the final covering and forming process, therefore, the rigidity of final products is ensured, the smoothness of production and production efficiency are improved, and the carbon fiber composite core produced through combination can completely meet the requirements of electric power transmission.

Owner:SUZHOU SUYUE NEW MATERIAL

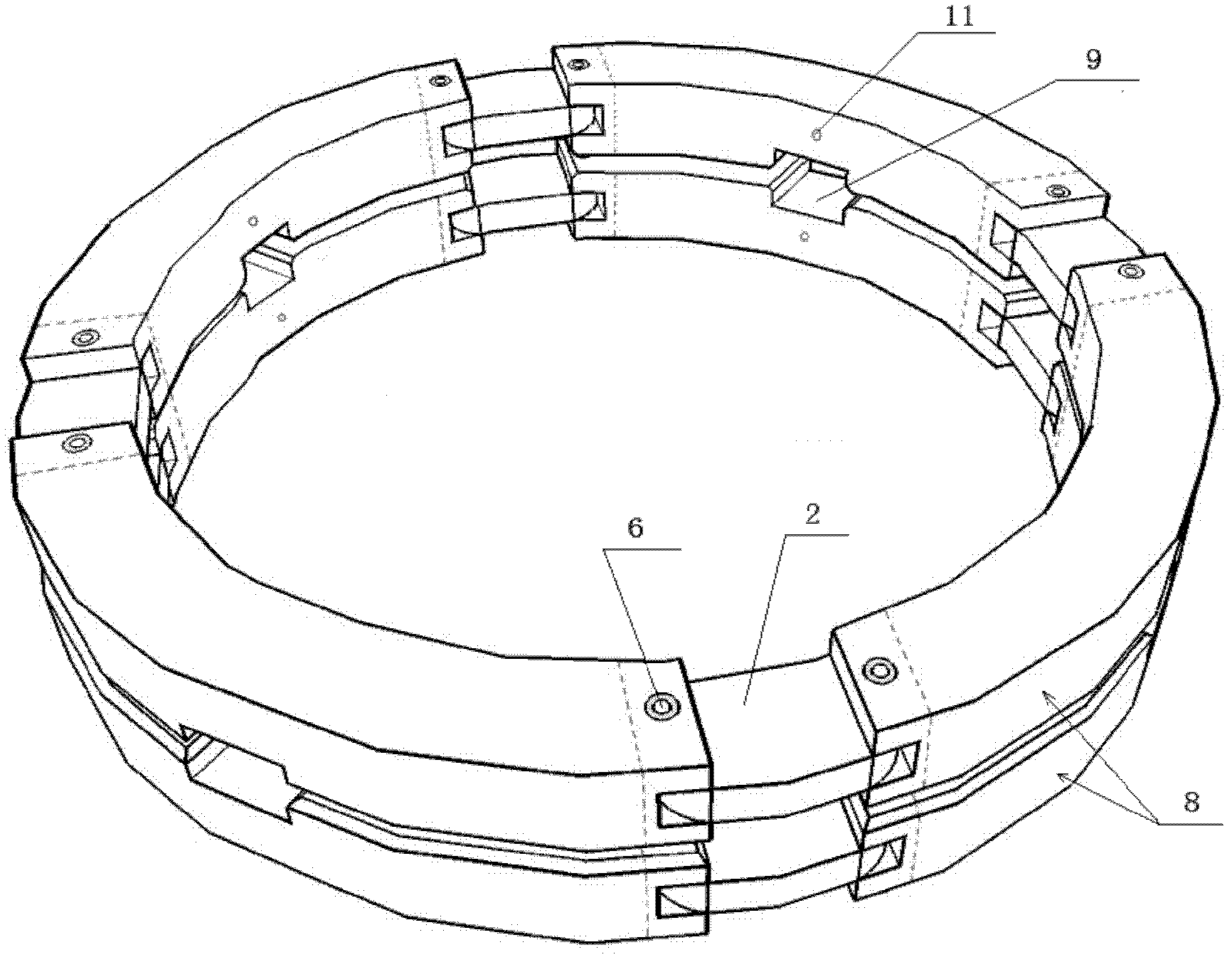

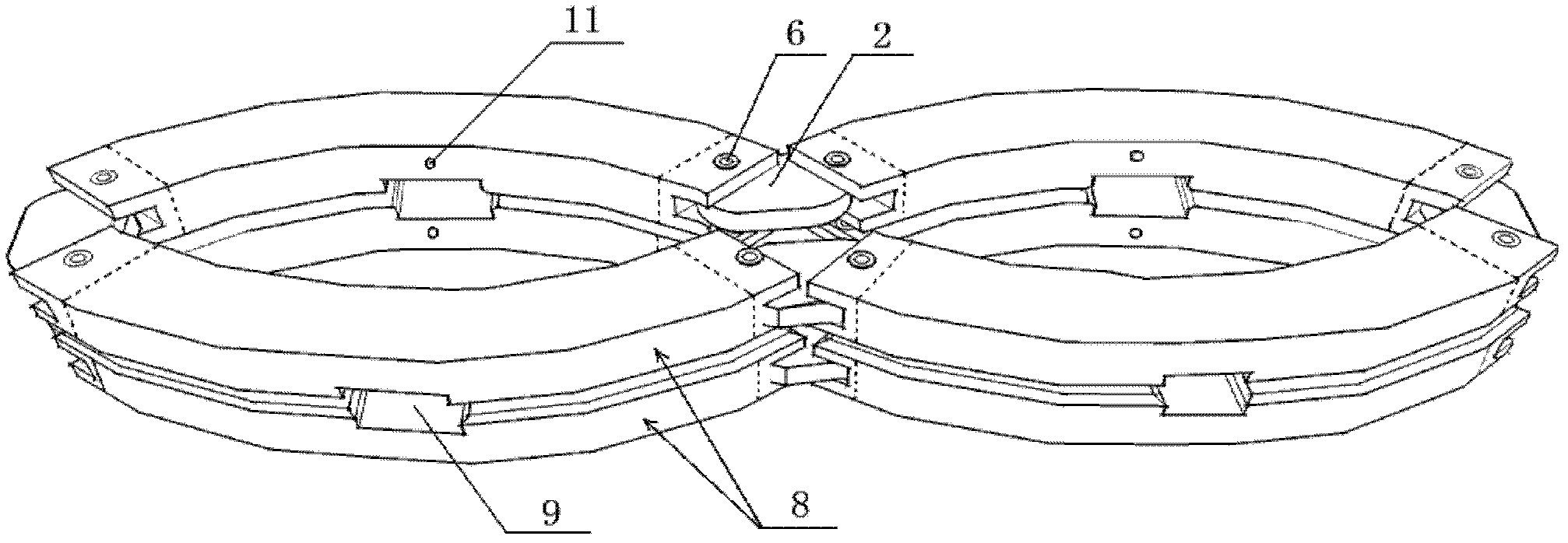

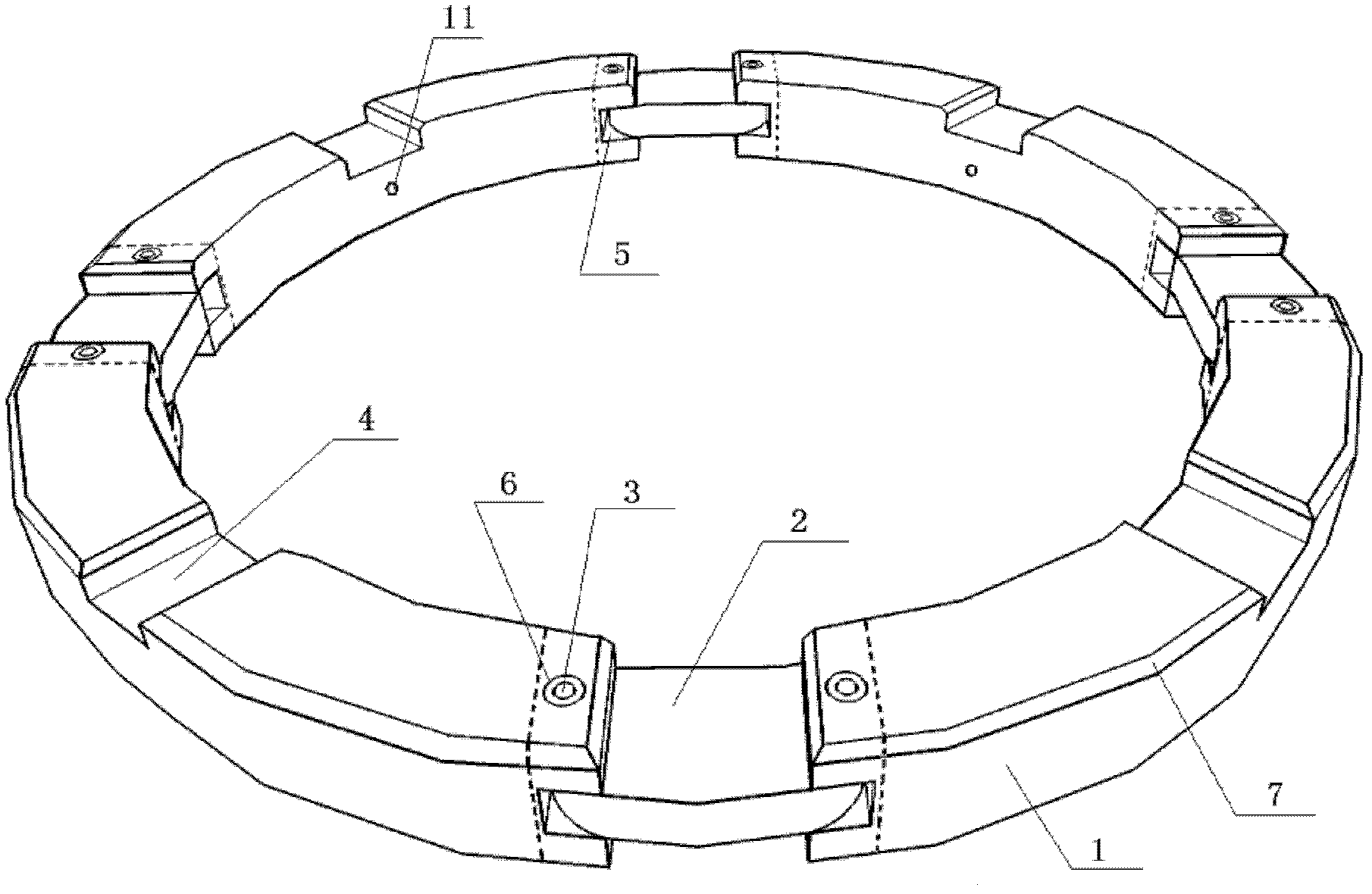

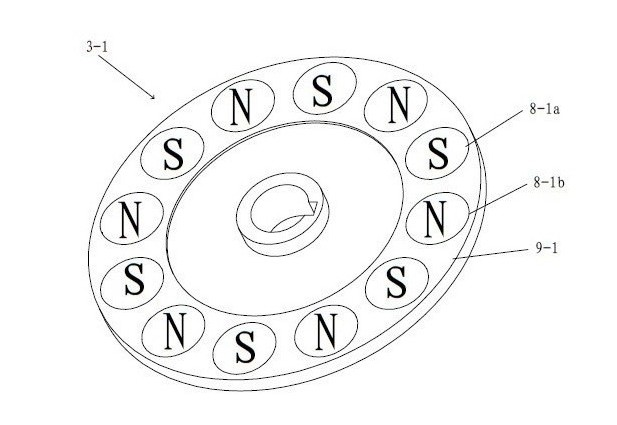

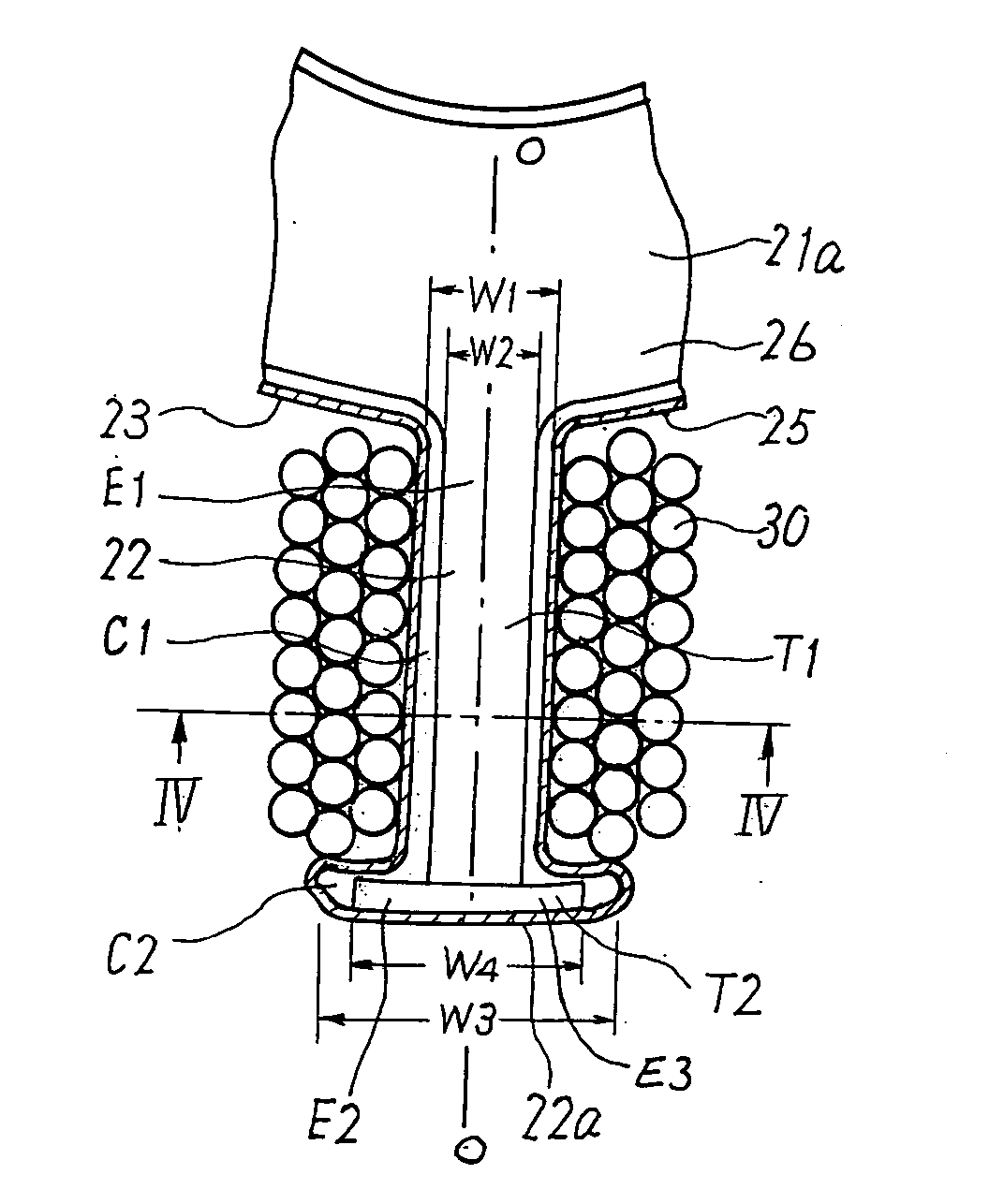

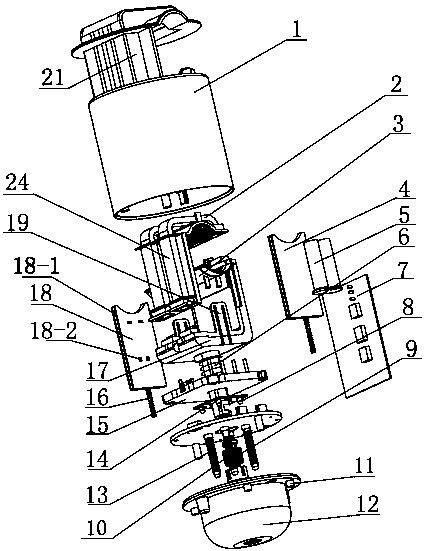

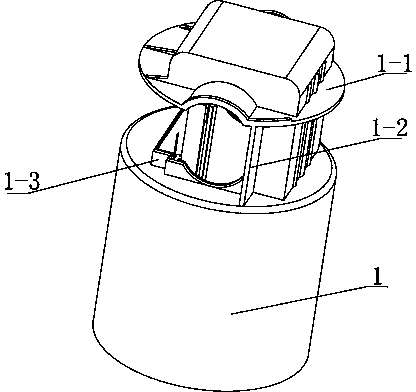

Discontinuous deformable surgical anastomosing magnetic ring

ActiveCN102525587ASimple structureFlexible and stable structureSurgical staplesRing blockMagnetic poles

The invention relates to a discontinuous deformable surgical anastomosing magnetic ring. The discontinuous deformable surgical anastomosing magnetic ring is provided with two magnetic ring bodies, wherein the magnetic ring bodies are the same in structure and opposite in magnetic poles and are arranged in a piling up manner; each magnetic ring body comprises a plurality of arc-shaped magnetic ring blocks and a plurality of connecting pieces; the arc-shaped magnetic ring blocks are movably connected in an end-to-end manner by the connecting pieces respectively through rivets so as to form the magnetic ring bodies; a plurality of discontinuous anastomosing gaps are formed in the upper surfaces of the arc-shaped magnetic ring blocks of one magnetic ring body; a plurality of discontinuous anastomosing gaps are formed in the lower surfaces of the arc-shaped magnetic ring blocks of the other magnetic ring body; the connecting pieces of the two magnetic ring bodies arranged in a piling up manner are oppositely arranged; and the discontinuous anastomosing gaps of the two magnetic ring bodies are arranged in an abutting manner so as to form a discontinuous anastomosing port. The discontinuous deformable surgical anastomosing magnetic ring is light in weight and large in magnetic force, is deformable, and can be easily discharged from a human body, the stability and the involutory accuracy of the magnetic ring are enhanced, and the magnetic losses are reduced; and the discontinuous deformable surgical anastomosing magnetic ring has the characteristics of surgical discontinuous anastomosis, and pressure gradients can be locally formed at the anastomosing port further, so that the tissue healing is better, and the discontinuous deformable surgical anastomosing magnetic ring can be applied to the fields, such as PPH (Procedure for Prolapse and Hemorrhoids), rectal low-order anus-preserving operation, circumcision, colostomy, minimally invasive endoscopic resection and anastomosis, and the like.

Owner:广东省虚拟医学科技有限公司

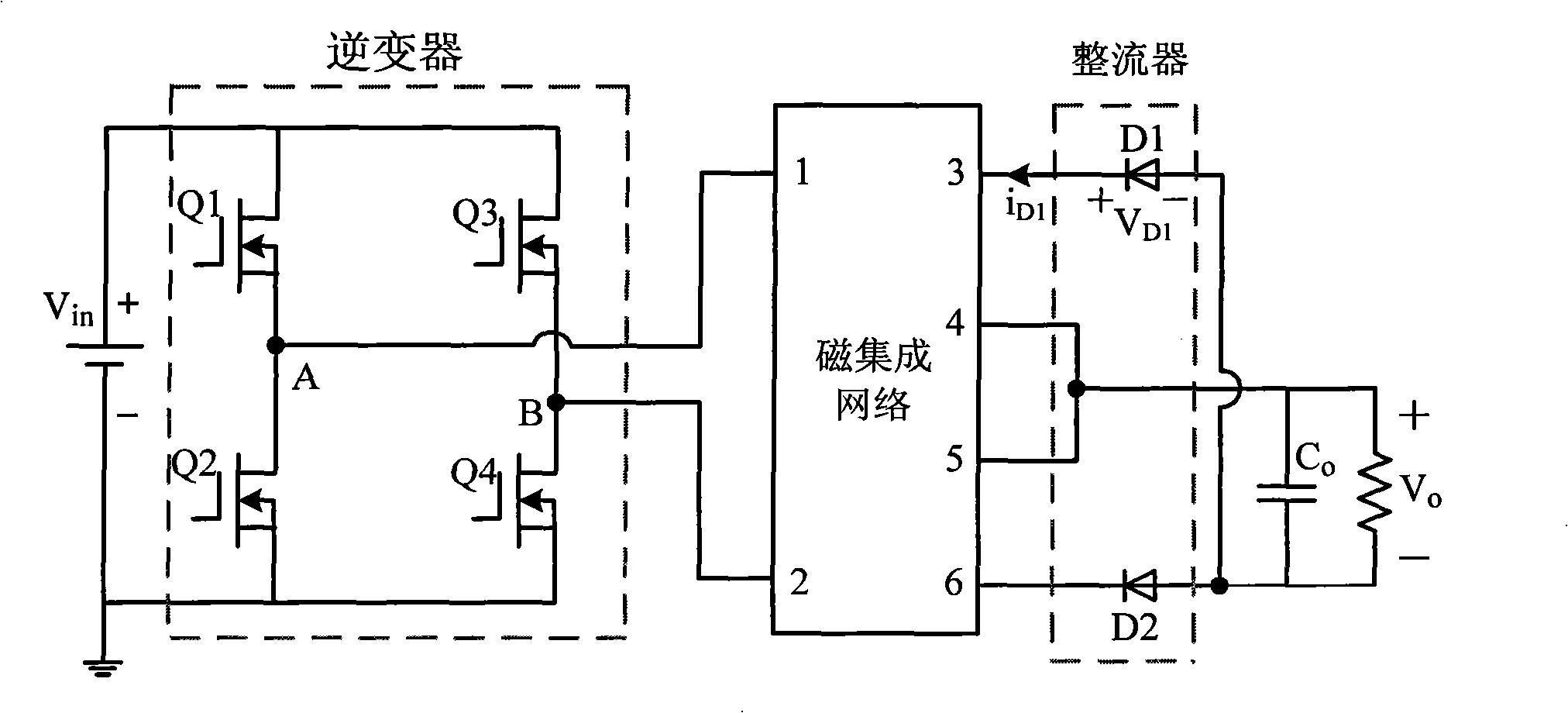

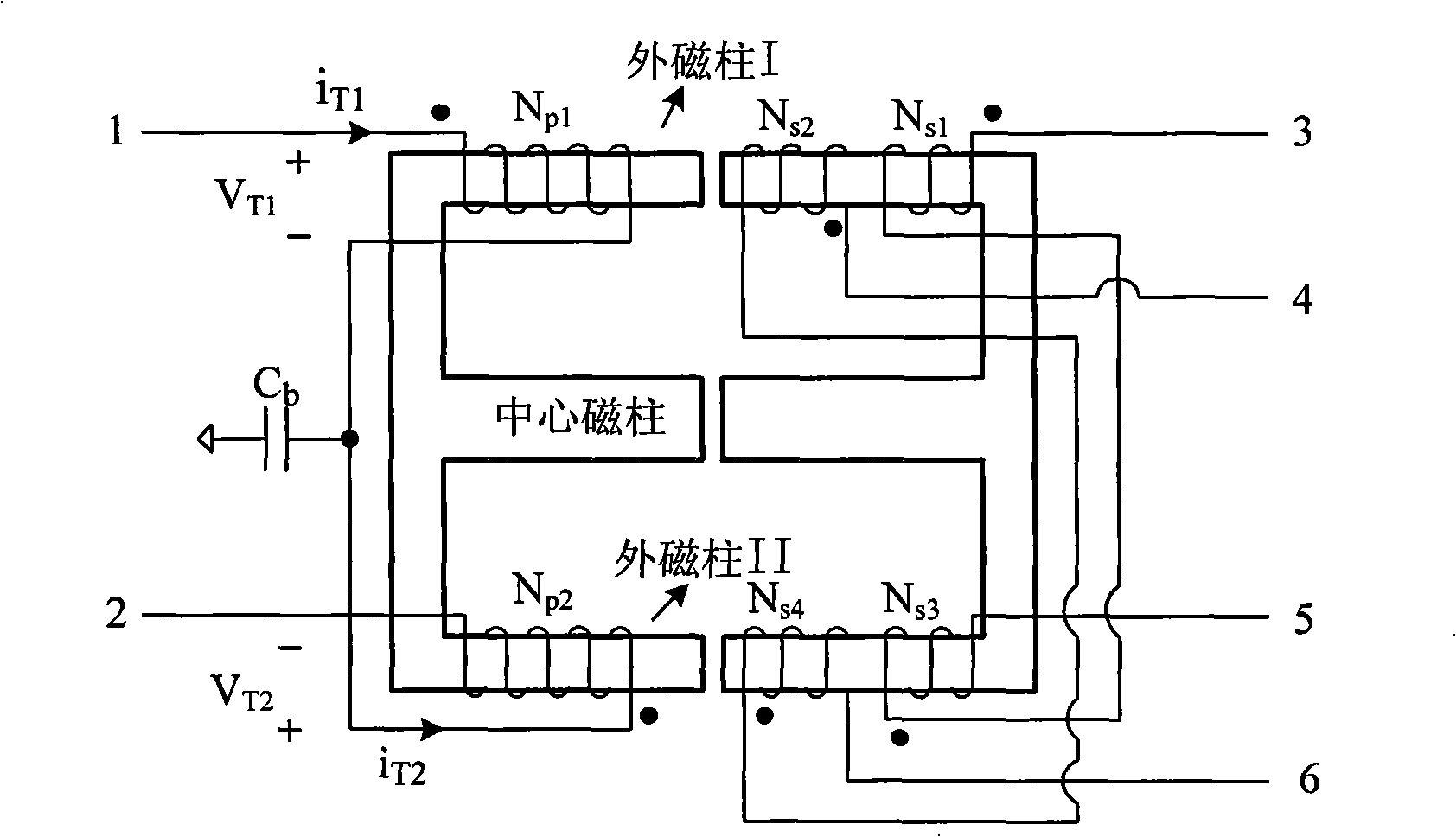

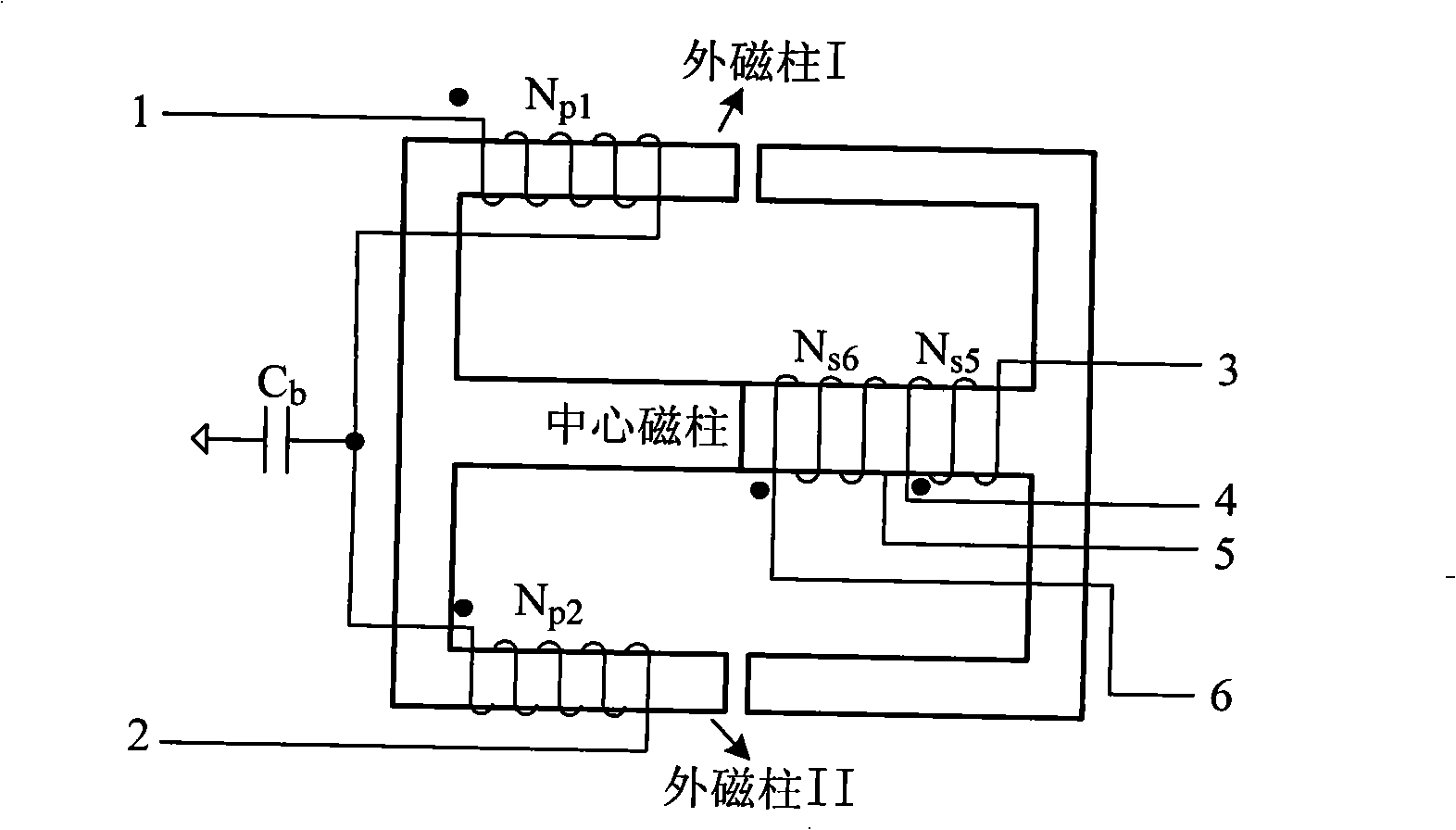

Magnetic-integrated zero-voltage zero-current soft switch full bridge circuit

InactiveCN101355308ARealize zero current operationReduce magnetic lossEfficient power electronics conversionDc-dc conversionFull bridgeEngineering

The present invention relates to a magnetically integrated zero voltage zero current soft-switching full-bridge circuit. The circuit is characterized in that the circuit comprises an inverter, a magnetically integrated network, a rectifier, and an output filter capacitor (Co).The magnetically integrated network integrates a transformer function, an energy storage inductor function and an auxiliary inductor function for realizing soft-switching in a magnetic element. The magnetically integrated network also has various topology variation types to meet the requirements of different application occasions. The whole converter has only one magnetic element so that the number of the magnetic elements is largely reduced and the power density is improved. Furthermore, the zero voltage cutover of all primary switch tubes is realized by using exciting current without an additional auxiliary soft-switching network. A commutation diode at the secondary side can realize the zero current switching. The switching loss is largely reduced, and the switching frequency is improved. The circuit can adopt the phase-shifting control, and also can adopt the unsymmetrical PUM control, thereby having good theoretical research value and use value.

Owner:ZHEJIANG UNIV

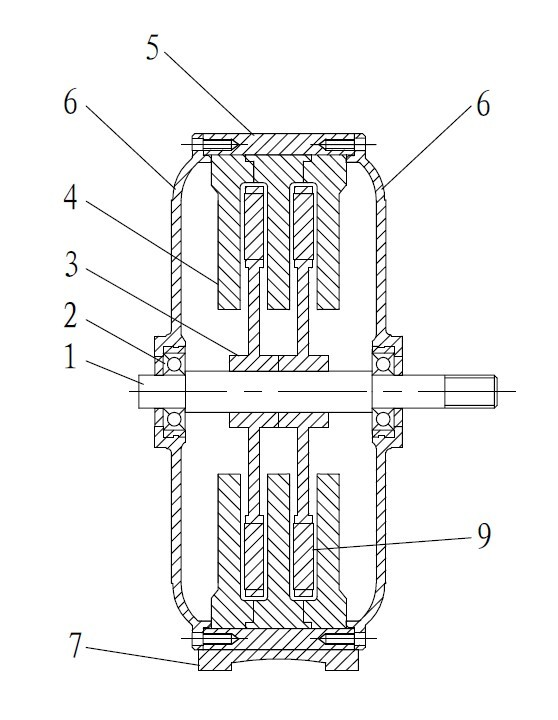

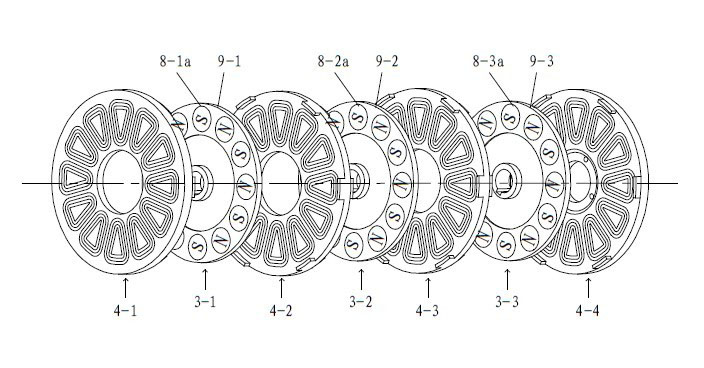

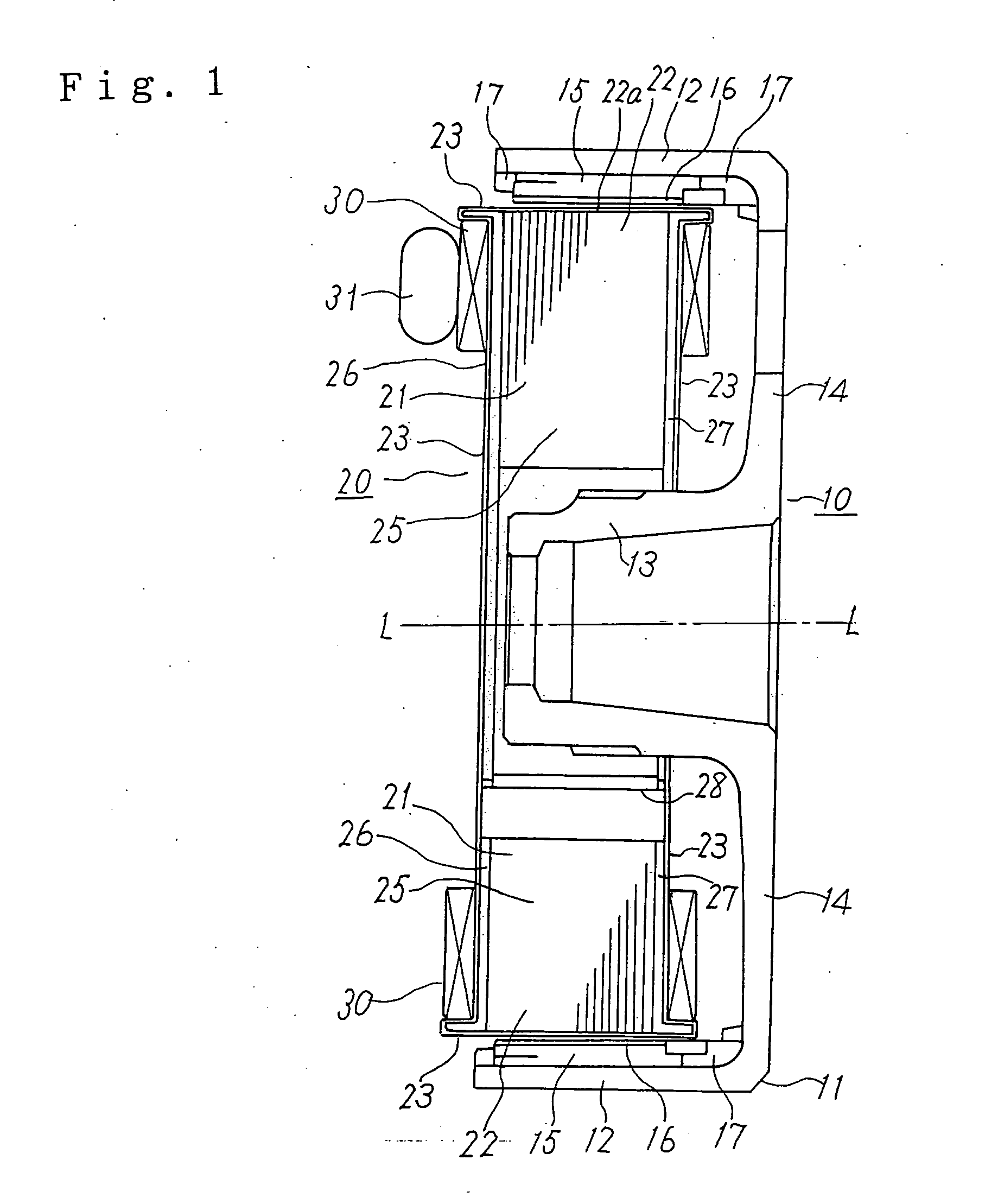

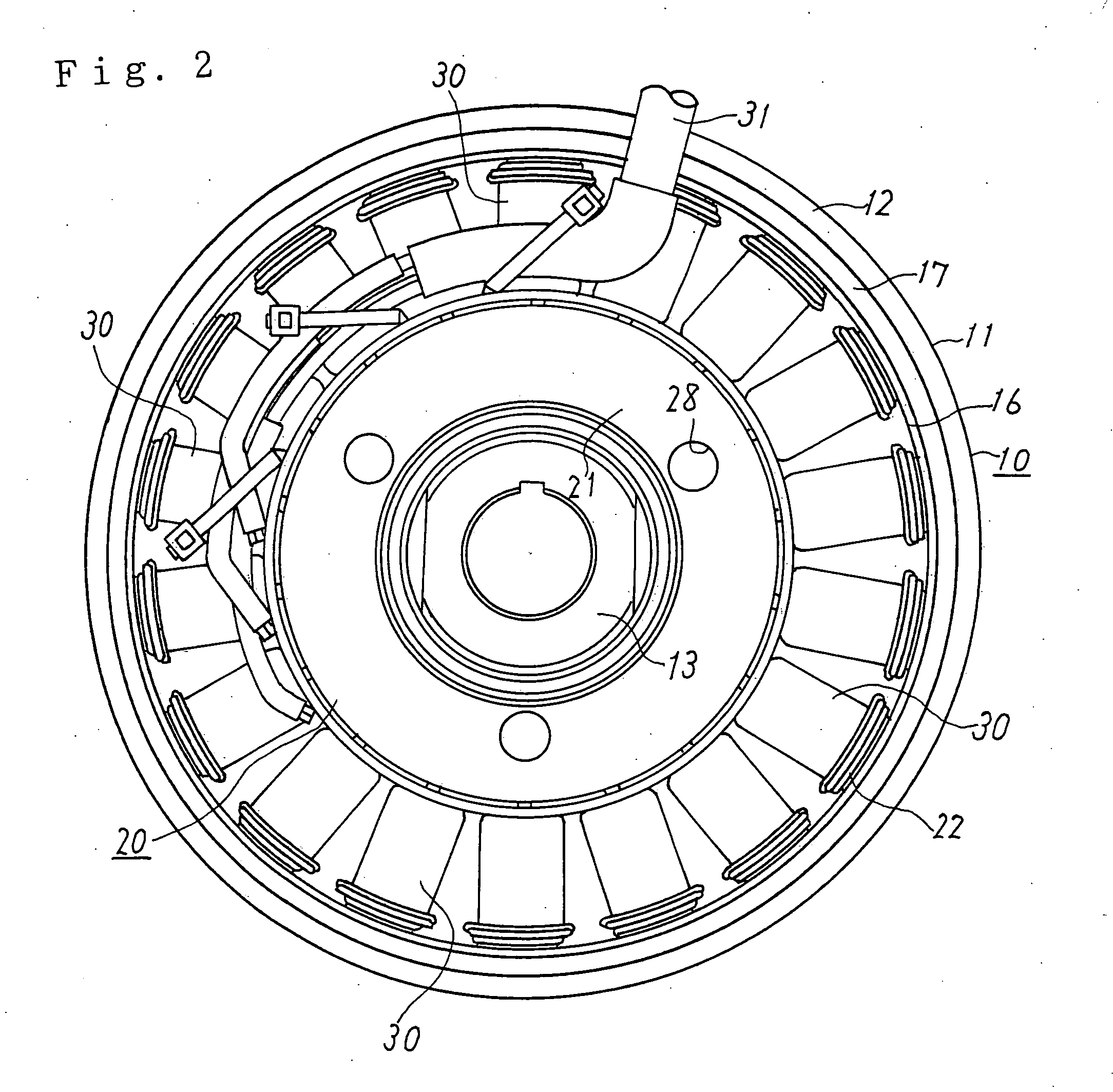

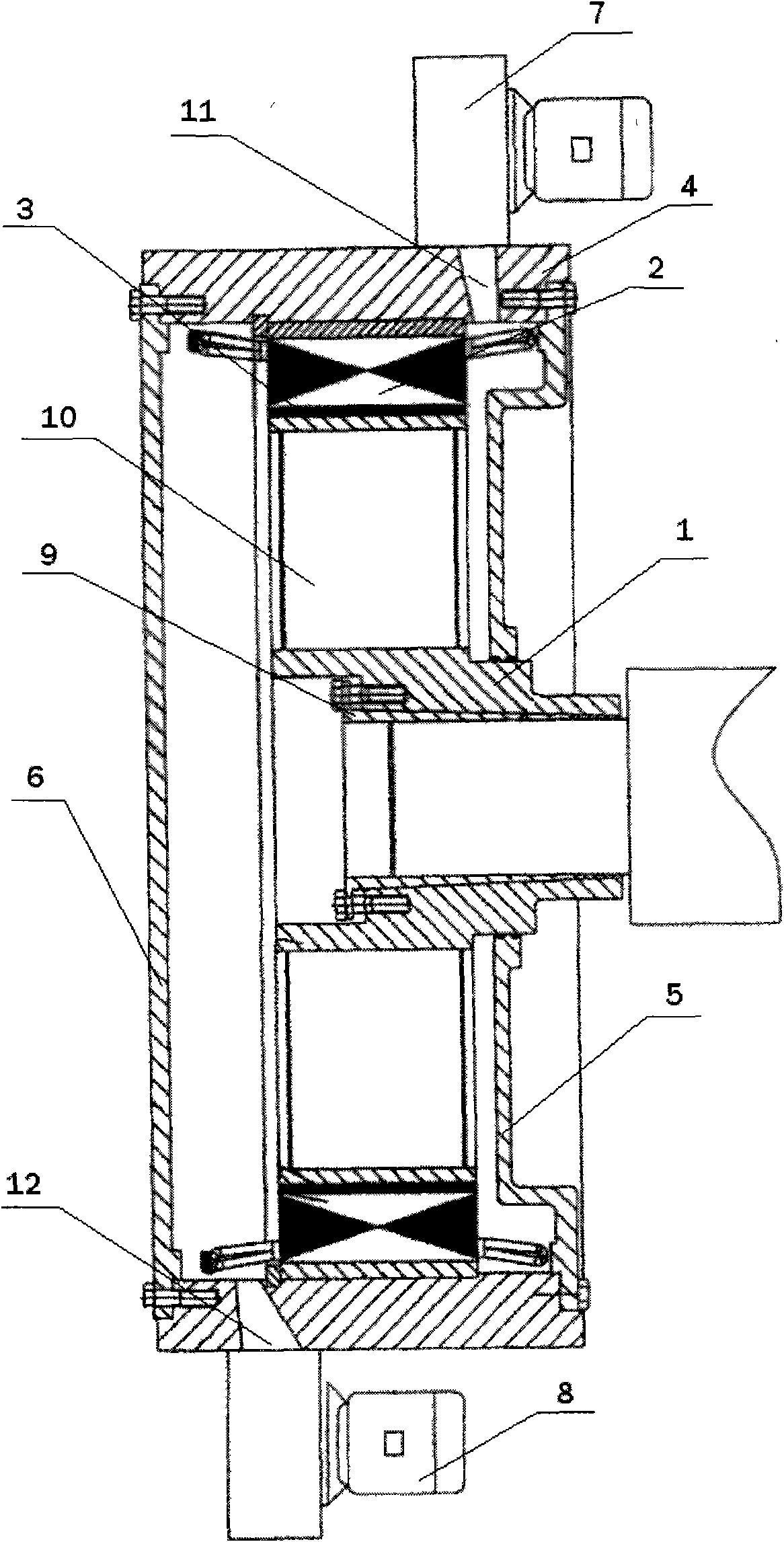

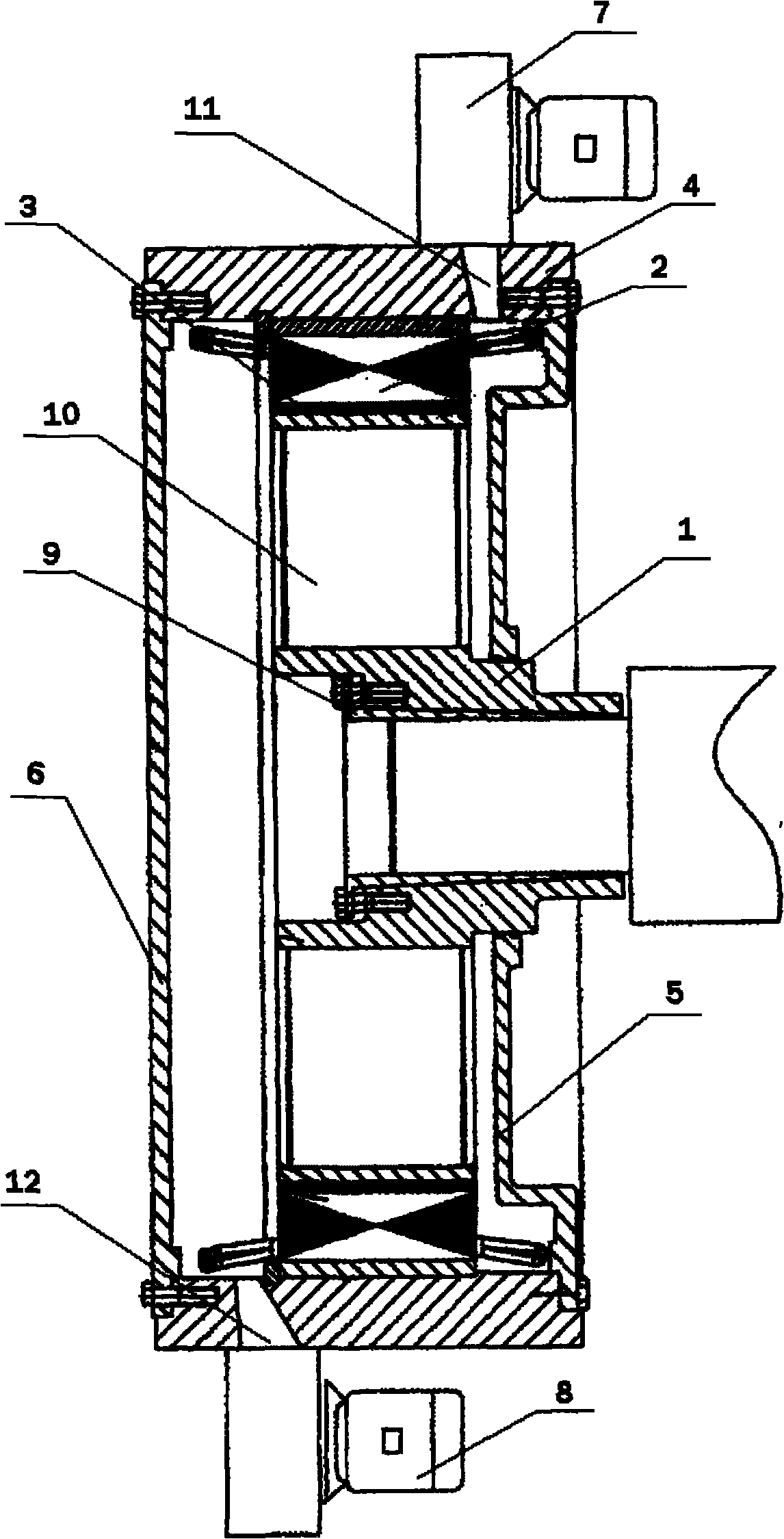

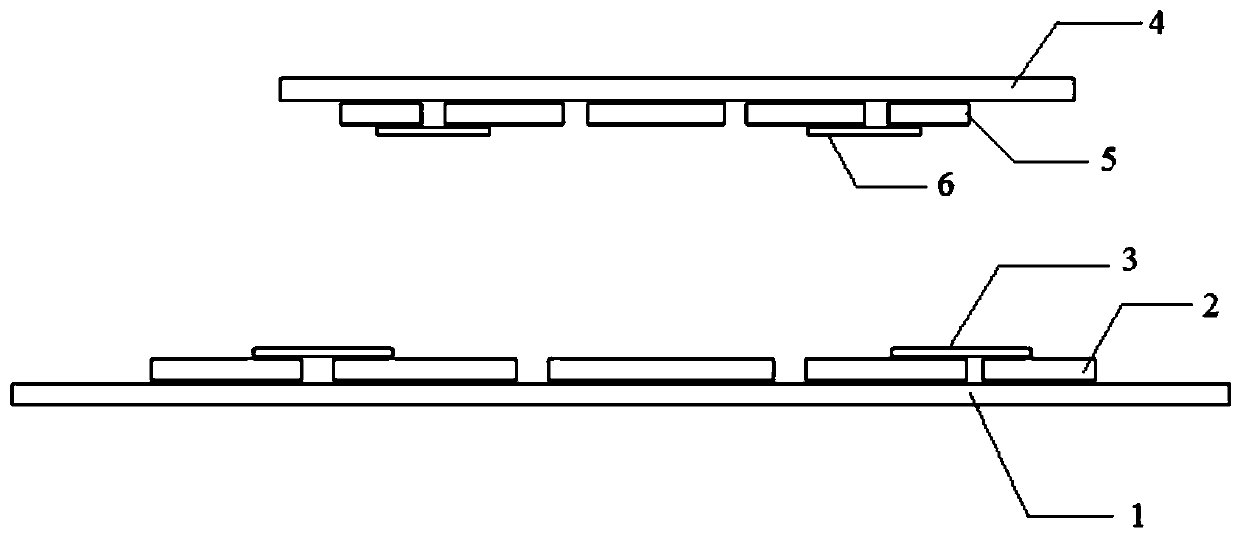

Multi-magnetic circuit disk type motor

InactiveCN102324818ACompact structureReduce volumeMagnetic circuit rotating partsWindings conductor shape/form/constructionCoil arrayMagnetic poles

The invention relates to a multi-magnetic circuit disk type motor, which comprises end covers (6), a rotor main shaft (1), m-1 rotors (3) and m stator windings (4), wherein m is a positive integer more than 2. The m-1 rotors (3) are all fixedly connected with the rotor main shaft (1) and arranged at intervals with the stator windings. The outmost two stator windings are fixedly connected with adjacent end covers. The rotor comprises a rotor disk and a plurality of magnetic steels, wherein each magnetic steel runs through the rotor disk, so that two magnetic poles of each magnetic steel are exposed on the two sides of the rotor disk respectively; and the magnetic steels are arranged on the same side of the rotor disk in a way that the magnetic poles are alternate. The stator winding comprises a winding disk and a coil array. Due to the adoption of a design in which the stator winding acts on the rotors on the two sides of the stator winding, the number of the stator windings is decreased; moreover, the stator winding of the multi-magnetic circuit disk type motor does not adopt a structure in which coils are wound by silicon steel sheets, so production cost is further decreased.

Owner:WUHAN ZHENXING TIANDI ELECTROMECHANICAL

Adhesive film

ActiveCN104910823AImprove magnetic permeabilityImprove reliabilityNon-macromolecular adhesive additivesPrinted circuit detailsFilling materialsChemistry

An adhesive film capable of forming an insulating layer is provided. The insulating layer improves magnetoconductivity, reduces magnetic loss and is excellent in reliability. The adhesive film comprises a support body and a resin composition layer arranged on the support body, wherein the resin composition layer contains (A) thermosetting resin, (B) magnetic filler, and (C) inorganic filling material. When the involatile constituent in the resin composition of the resin composition layer is set as 100 volume %, the content B is greater than 100 volume %, and the content of the C divided by the content B falls in the scope of 0.3-3.0.

Owner:AJINOMOTO CO INC

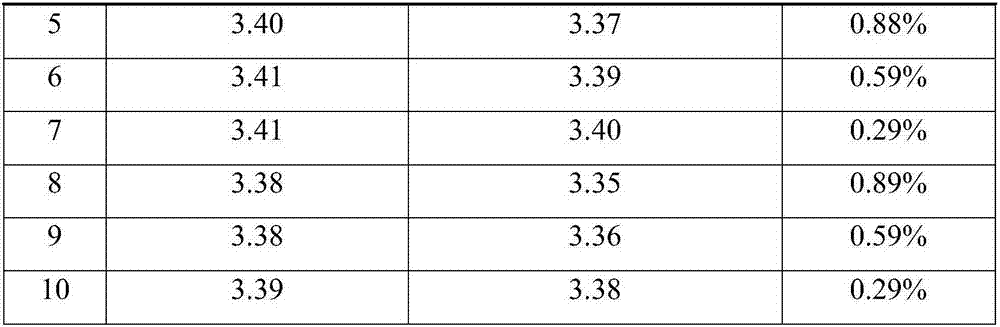

NdFeB magnetic steel surface plating method

The invention discloses an NdFeB magnetic steel surface plating method. The method includes the steps that plating is conducted on an NdFeB magnetic steel surface, and a pre-galvanizing layer, a strong complexing copper or zinc alloy plating layer, a neutral nickel plating layer, a non-cyanide copper plating layer and a nickel plating layer are sequentially arranged from inside to outside; the galvanizing layer serves as a bottom layer, and then the strong complexing copper or zinc alloy plating layer is added, so that an NdFeB magnetic steel plating layer is high in bonding strength, high in preservative activity and small in magnetic loss. Through improvement, the binding force is increased by 10%-20% on average compared with a conventional process, and the average magnetic loss rate is lowered to 1%-5% from 5%-10% in the conventional process; and the quality of a magnetic steel surface electroplated layer is greatly improved, and the product percent of pass is increased.

Owner:陈治

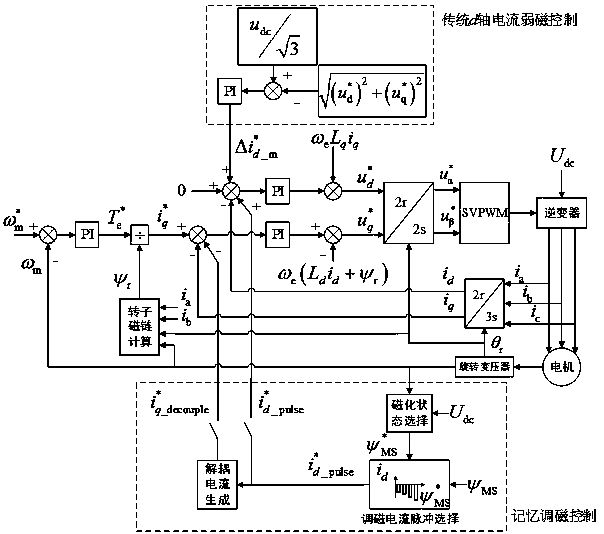

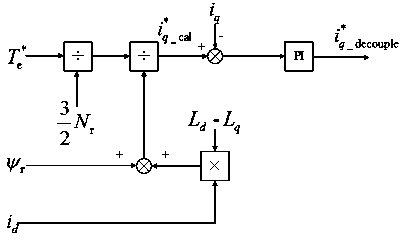

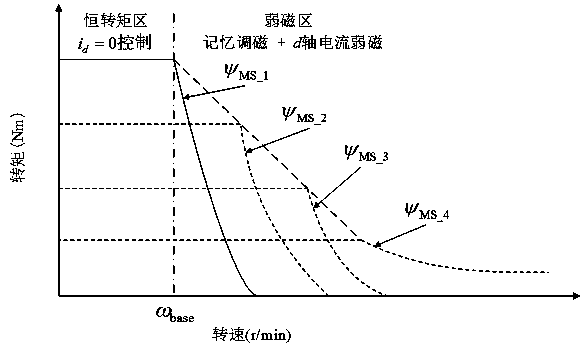

A method for restraining the flux-adjusting torque ripple of a memory motor based on current decoupling

InactiveCN109150022AImprove efficiencyReduce magnetic lossTorque ripple controlMemory motorControl theory

The invention discloses a method for restraining the flux-adjusting torque ripple of a memory motor based on current decoupling, including setting given values of d, q-axis current, Both and d, The deviation from the q-axis current setpoint is input to the PI regulator, the output of the d-axis current PI regulator is subtracted from omega eLqiq to obtain the d-axis voltage given value, To the output of q-axis current PI regulator, [omega]e(Ldid + [psi]r) is added to get the given value of q-axis voltage. D, q-axis voltage is controlled by coordinate transformation and SVPWM modulation to drive the inverter motor. When the rotational speed of the motor is higher than the base speed, the magnetization state of the permanent magnet is adjusted discretely by using the memory magnetization method, and the d-axis current weakening method is used to continuously adjust the magnetization state in each magnetization state, and the q-axis decoupling current is applied at the same time as the d-axis current is applied, so as to keep the torque constant during the magnetization adjustment period and suppress the torque ripple during the magnetization adjustment period.

Owner:SOUTHEAST UNIV

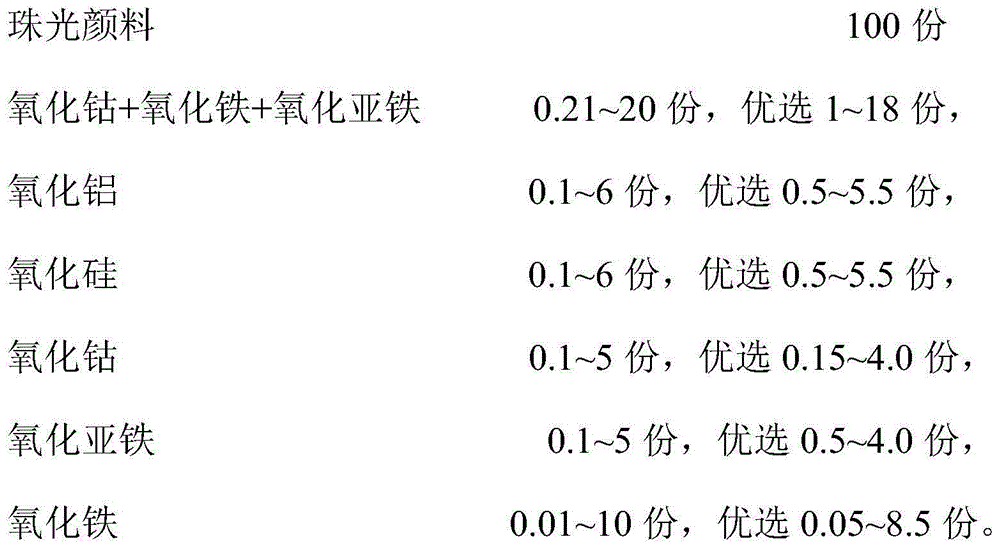

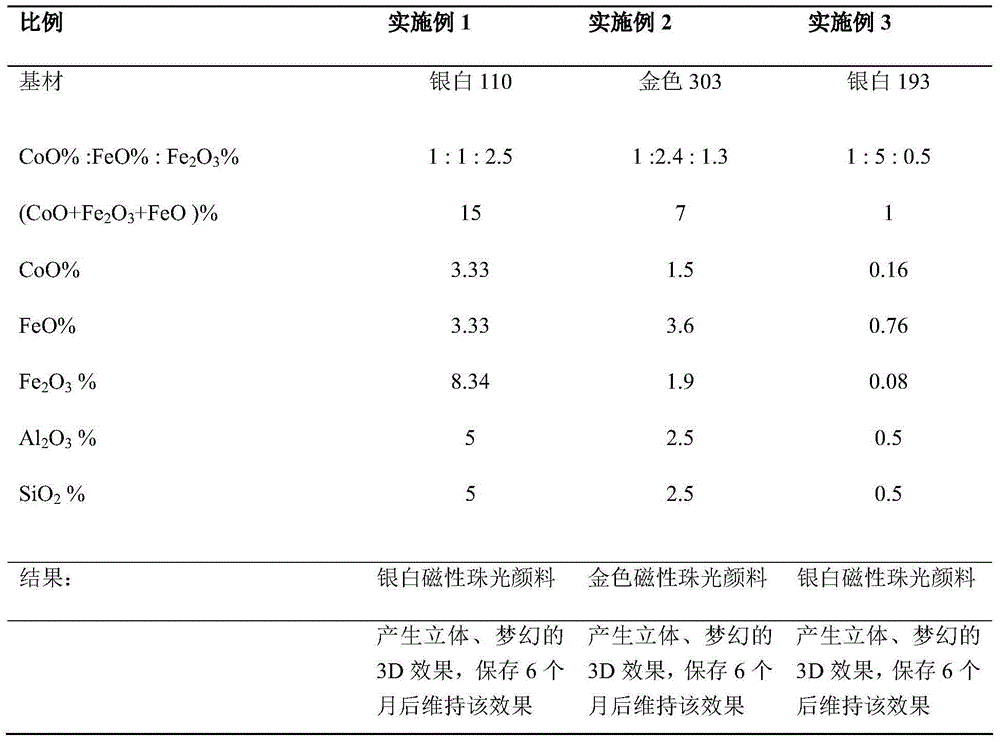

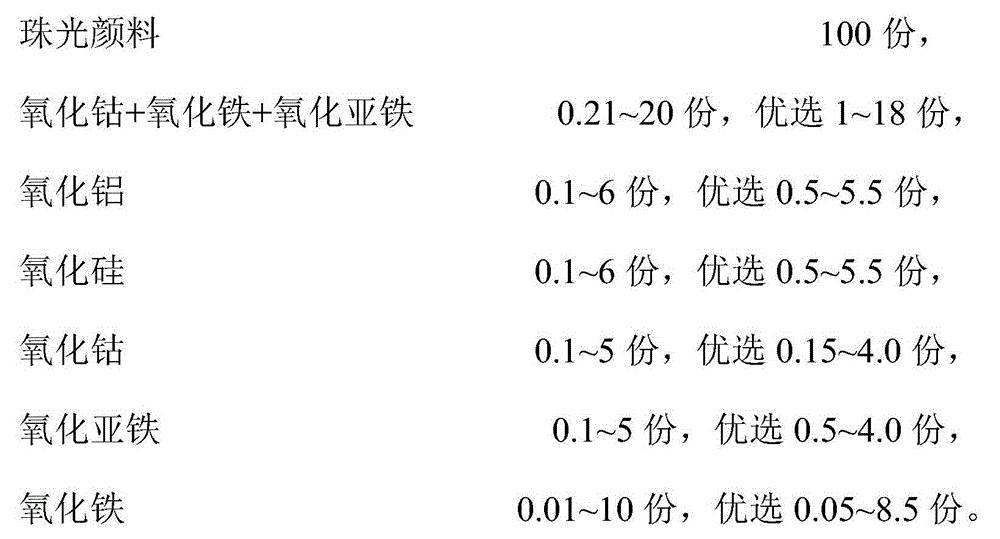

Magnetic pearlescent pigment with 3D (three-dimensional) effect and preparation method of magnetic pearlescent pigment

ActiveCN104893366AReduce the loss of ferroferric oxideReduce magnetic lossInorganic pigment treatmentCobalt oxideChemistry

The invention discloses magnetic pearlescent pigment with a 3D (three-dimensional) effect and a preparation method of the magnetic pearlescent pigment. The magnetic pearlescent pigment comprises pearlescent pigment, a magnetic coating and a protecting layer, wherein the magnetic coating is located on one or more pearlescent pigment layers and comprises cobalt oxide, iron oxide and iron protoxide; the protecting layer is located on the magnetic coating; the pearlescent pigment comprises a base material and one or more pearlescent pigment layers. The prepared magnetic pearlescent pigment with the 3D effect can have a stereoscopic and dreamlike 3D effect by utilizing the magnetic tracking phenomenon of a surface magnetism material. By means of the preparation method of the magnetic pearlescent pigment with the 3D effect, the problem that ferrous iron is easily oxidized in the prior art can be solved, loss of ferroferric oxide is reduced, magnetic loss is reduced, part of produced iron cobaltate is stable and not prone to oxidation, and long-time storage of the pigment is guaranteed.

Owner:GUANGXI CHESIR PEARL MATERIAL CO LTD

Magneto-generator

ActiveUS20050067914A1Rigid enoughImprove insulation performanceWindings insulation shape/form/constructionMagnetic circuit rotating partsStatorElectric generator

Two end plates of a stator core are made of a metal material to increase their rigidity and thereby hold, in a prescribed shape, generation coils that are wound on teeth of the stator core. To increase the insulation between the generation coils and the teeth, the circumferential width of a first portion, extending in the radial direction, of each of the end plates is made smaller than that of a corresponding first portion of a laminated core. At least a second portion of at least one of the two end plates is made of a non-magnetic metal material, whereby the magnetic loss is reduced and the temperature characteristic and the power generation characteristic are improved.

Owner:MITSUBISHI ELECTRIC CORP

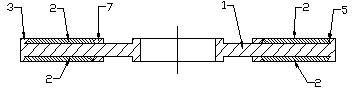

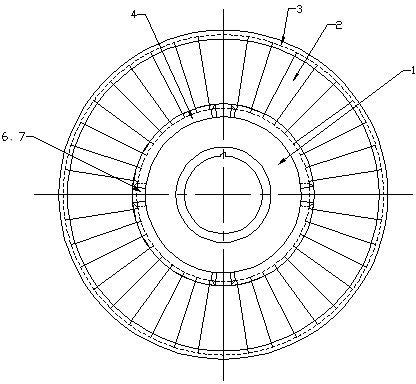

Disc type motor rotor

InactiveCN102624114AEasy and reliable installationIntegrity guaranteedMagnetic circuit rotating partsEngineeringMagnetic flux

The invention relates to components of a motor, in particular to a disc type motor rotor used in a permanent magnetic disc type motor with axial magnetic flux. The disc type motor rotor comprises a disc-shaped rotor tray and a plurality of magnetic steel arranged on the rotor tray. An outer circle of at least one end face of the rotor tray is provided with an annular outer protruding rib, an inner circle of the end face is provided with an annular inner protruding rib, and the inner protruding rib and the outer protruding rib form an annular dovetail groove. The magnetic steel is sector-shaped, a radial section of the magnetic steel is in a dovetail shape matched with the dovetail groove, and the magnetic steel is distributed in the dovetail groove in annular mode. A plurality of installing notches for the magnetic steel to enter the dovetail groove are arranged on the inner protruding rib and sealed through pressing blocks arranged inside the installing notches. The disc type motor rotor can keep completeness of magnetic performance and good mechanical performance of the magnetic steel. The rotor can form a required magnetic circuit structure, reduces magnetic loss of the magnetic steel and yoke of the rotor, improves efficiency of the motor, and prolongs service life of the motor.

Owner:腾达电子科技服务镇江有限公司

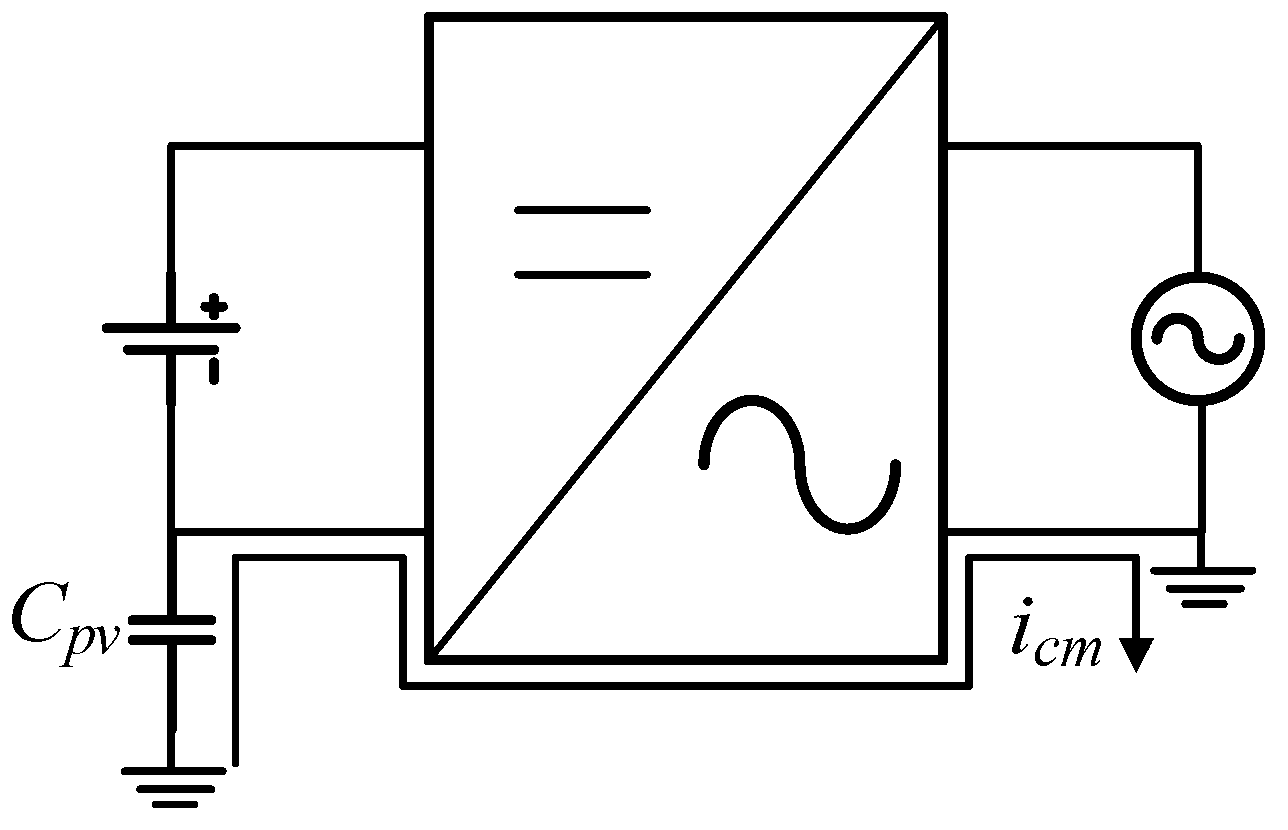

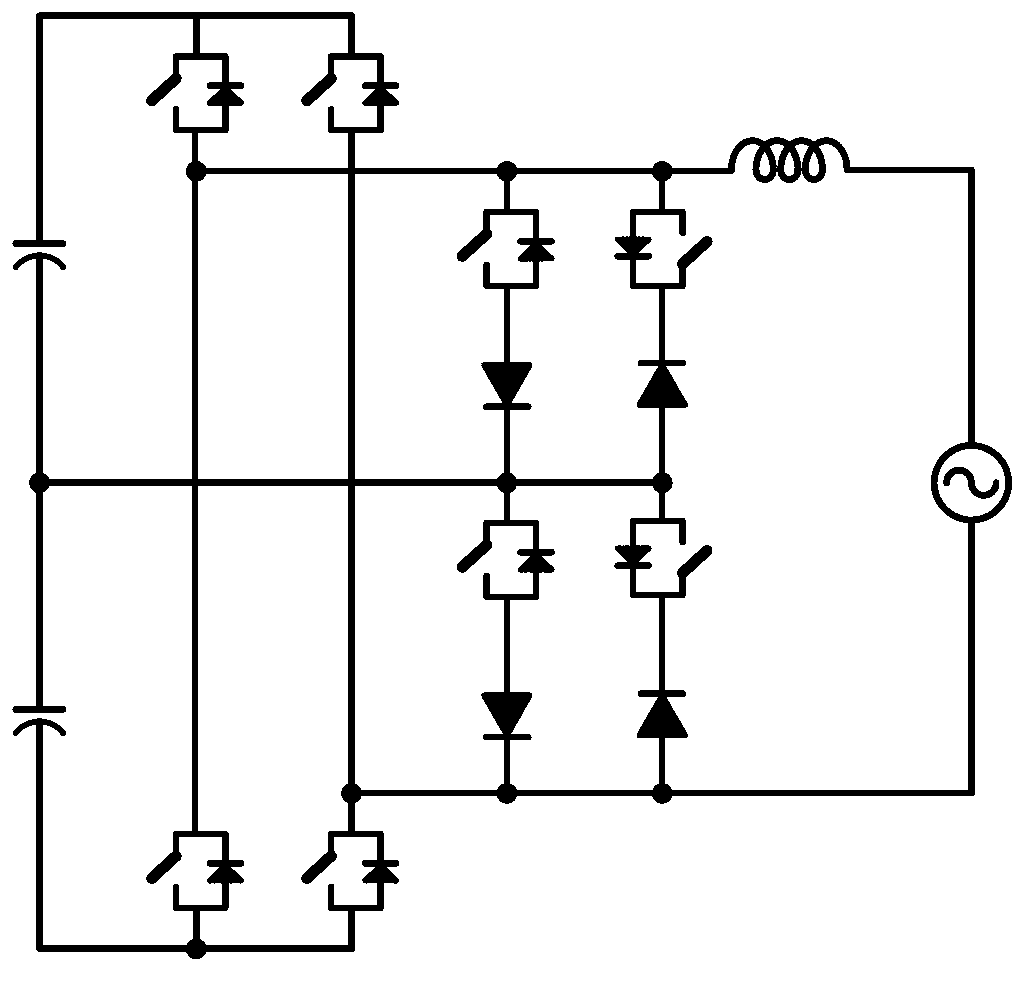

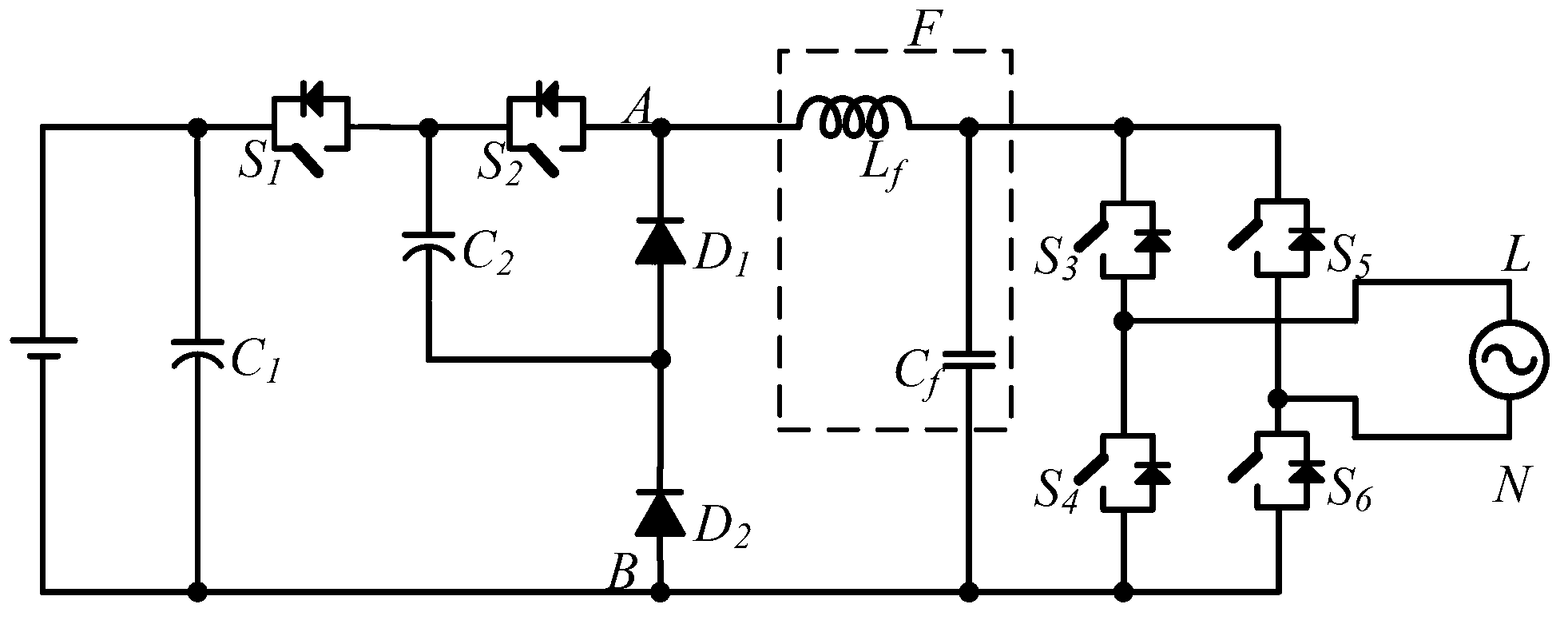

One-phase five-level inverter

ActiveCN103326606AReduce distractionsEnsure personal safetyAc-dc conversionDc-dc conversionPower inverterThree level

The invention discloses a one-phase five-level inverter. The one-phase five-level inverter comprises a common ground type three-level switching circuit, a filter circuit and a power frequency inversion circuit. For being realized specifically, the inverter comprises six power switches from S1 to S6, two diodes from D1 to D2, and a one-phase output filter F. The output of the inverter is five levels, and the inverter has the advantages of being high in inversion efficiency and reliability and simple in control mode. Meanwhile, through the voltage clamp mode, the inverter can eliminate high-frequency common mode current danger in a non-isolated type grid-connected inverter system effectively. Thus, the inverter is especially suitable for being applied to a non-isolated type photovoltaic grid-connected system.

Owner:HOYMILES POWER ELECTRONICS INC

Method for preparing iron-silicon-aluminum soft magnetic powder core through warm-pressing

ActiveCN105344993AReduce internal stressImprove permeabilityTransportation and packagingMetal-working apparatusPolyethylene glycolVolumetric Mass Density

The invention discloses a method for preparing an iron-silicon-aluminum soft magnetic powder core through warm-pressing. The method comprises the following steps that (1) initial soft magnetic alloy powder is subjected to passivating treatment through a passivator, and drying is conducted; (2) the dried soft magnetic alloy powder is evenly mixed with a binder; (3) the mixed powder is dried and sieved, and then an insulator is added for mixing coating; (4) the coated soft magnetic alloy powder is mixed with lubricant, the mixture is put into a die, then pressurization and heating are conducted simultaneously, and warm-pressing forming is conducted; and (5) the warm-pressing formed magnetic powder core is subjected to annealing treatment. The initial soft magnetic alloy powder comprises, by weight, 8.5%-10.5% of silicon, 4.5%-6.5% of aluminum, and the balance iron. The lubricant in the step (4) is the mixture of zinc stearate and polyethylene glycol. According to the method, the density and the magnetic conductivity of the prepared soft magnetic powder core can be effectively improved, and the magnetic loss is significantly reduced.

Owner:GUANGDONG UNIV OF TECH +1

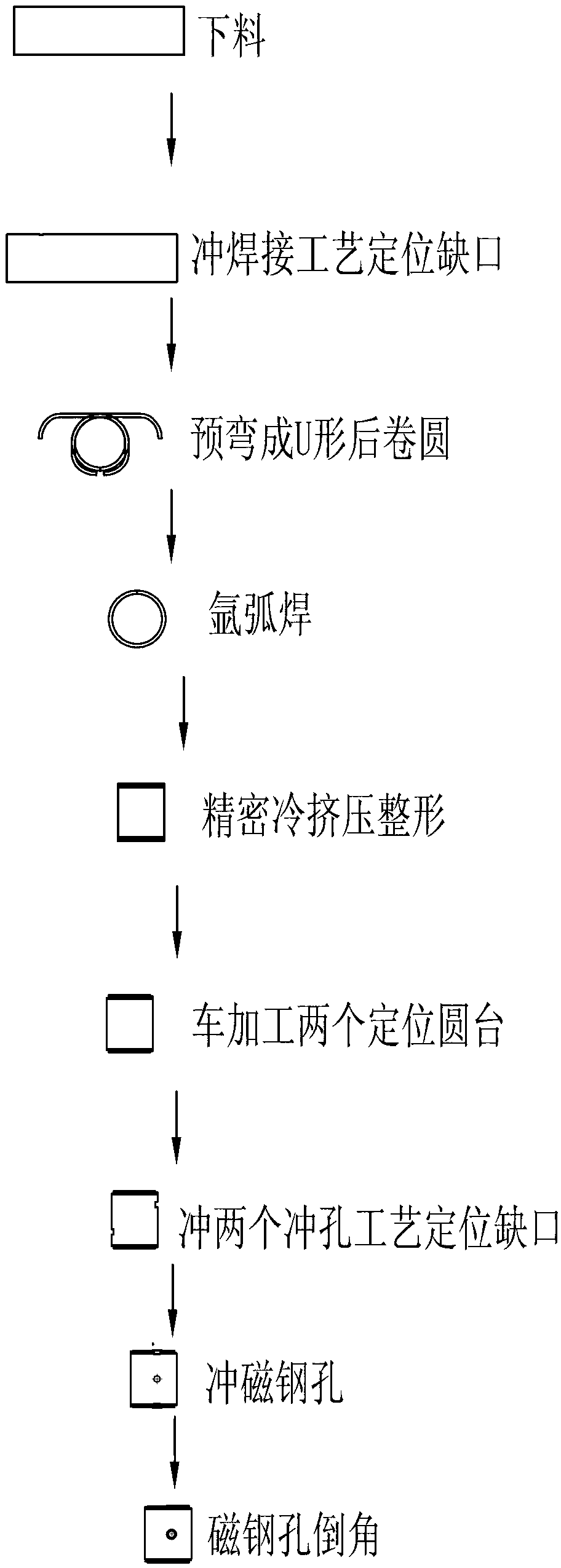

Machining process of automotive starter motor cases

InactiveCN103264258AReduce carbon contentReduce the remanence coefficientPerforating toolsPunchingEngineering

The invention discloses a machining process of automotive starter motor cases. The process includes the steps of blanking, punching to obtain welding process positioning notches, pre-bending to obtain U shapes before rolling, performing argon arc welding, performing precision cold extrusion and shaping, punching to obtain two punching process positioning notches, turning to obtain two positioning cone frustums, punching steel magnet holes, and chamfering the steel magnet holes. Compared with the traditional method of machining starter motor cases with seamless steel pipes, the machining process has the advantages of convenience in machining, low production cost, fine uniformity, long service life and the like.

Owner:CHONGQING LINZHENG MACHINERY

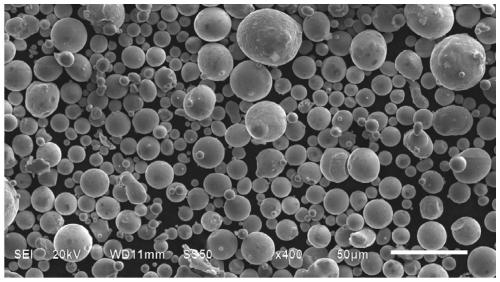

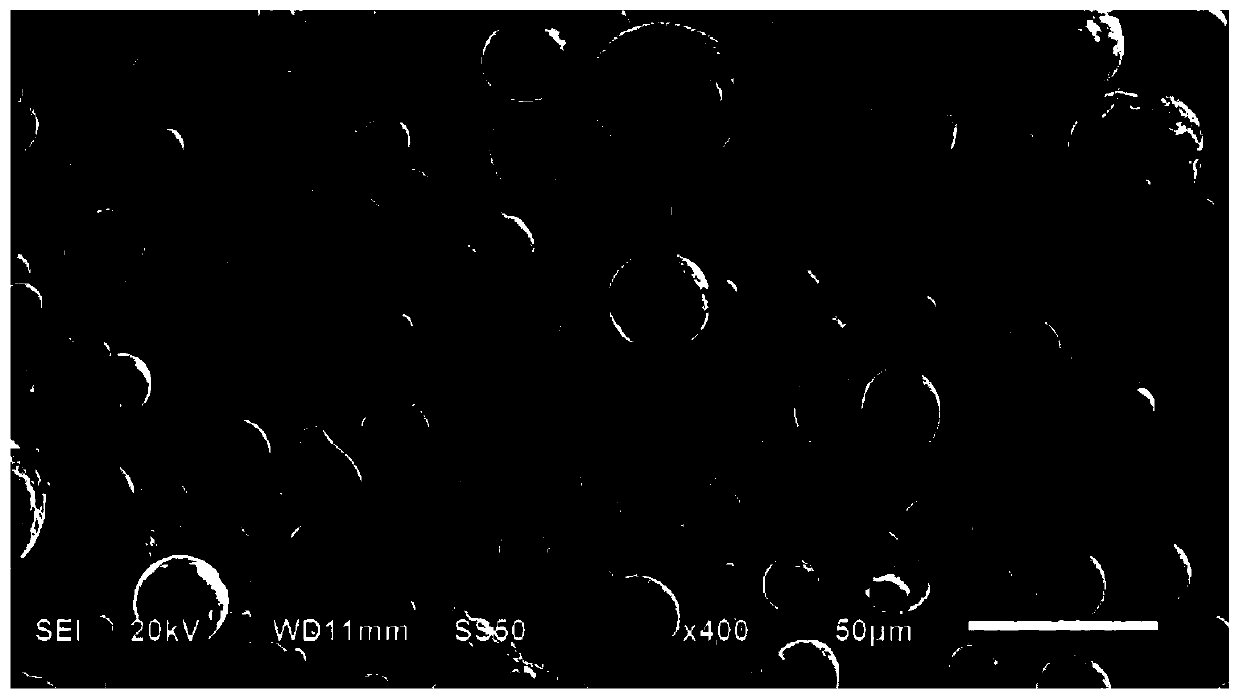

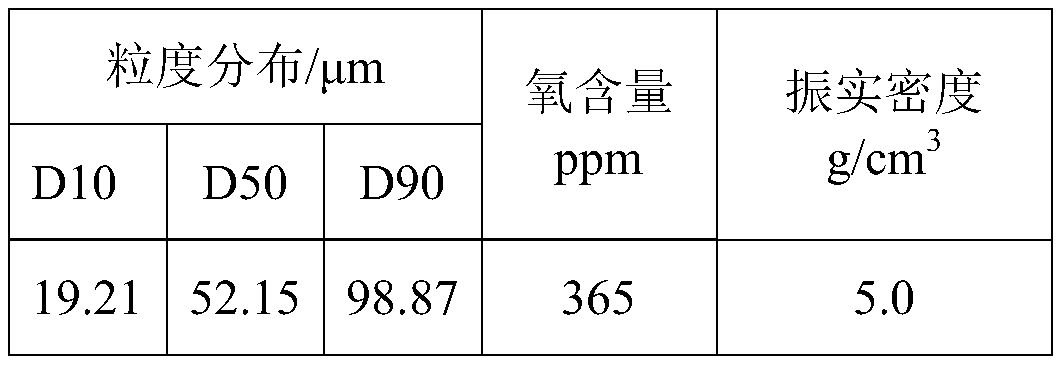

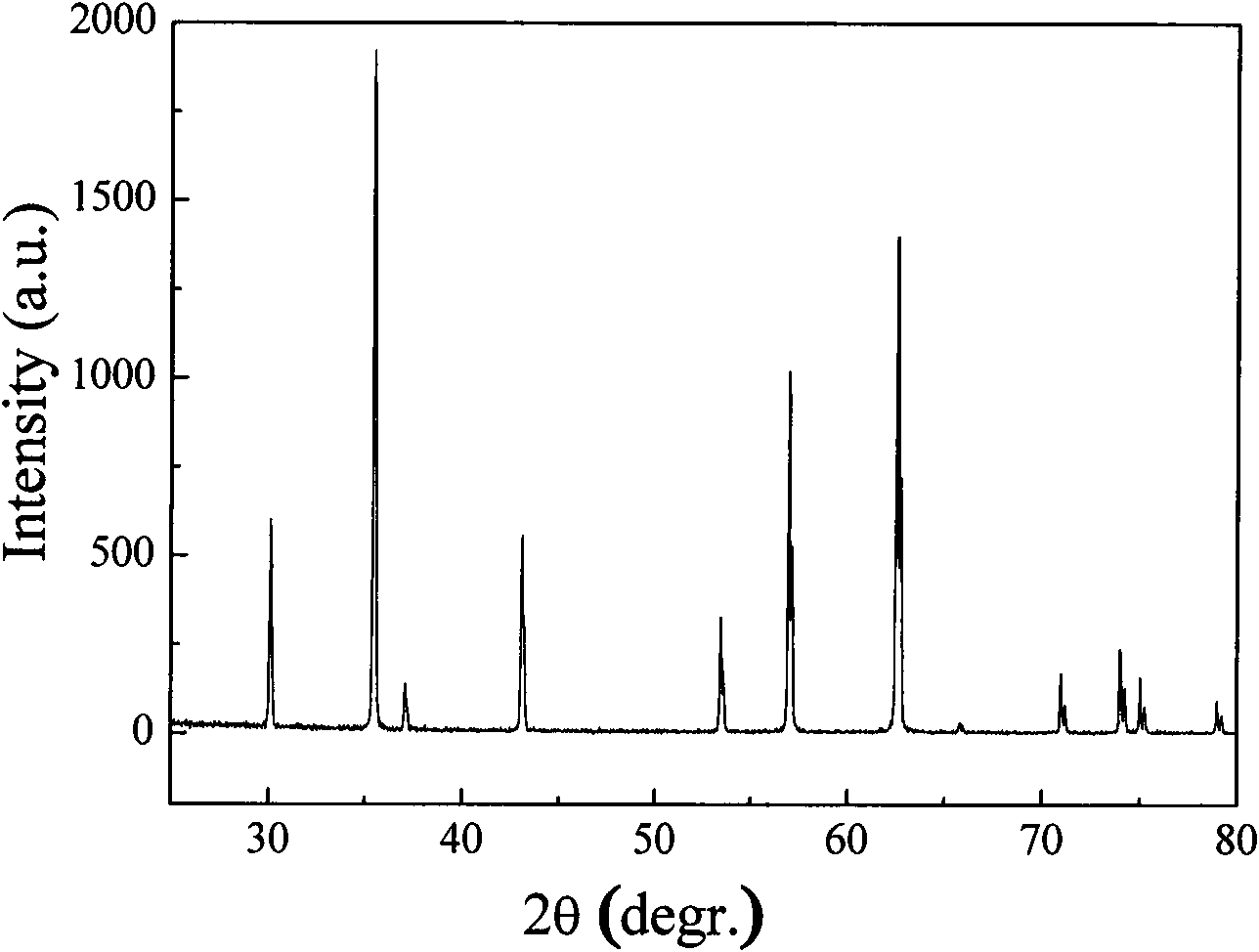

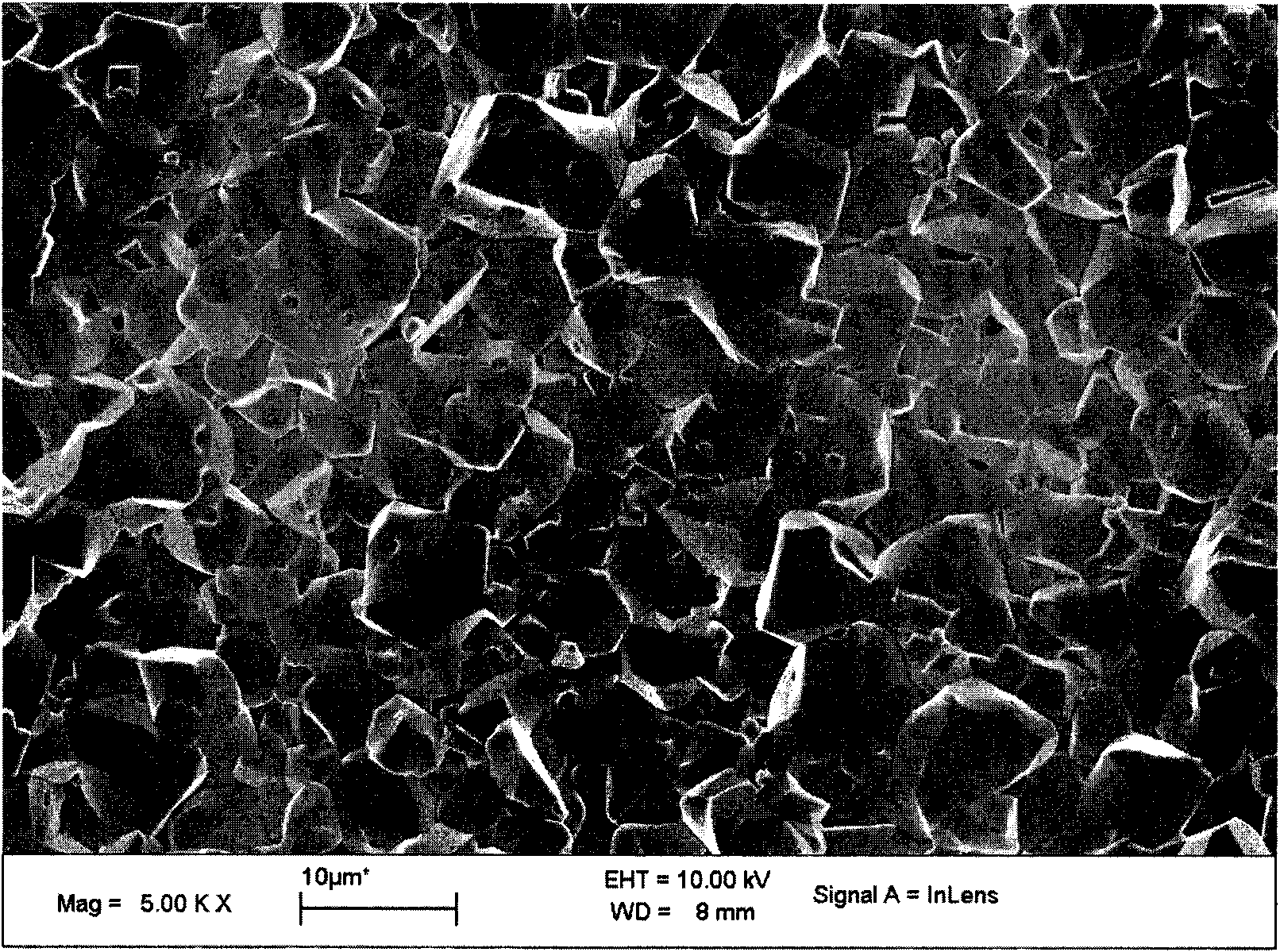

Preparation method of FeSi alloy powder with high direct current superposition characteristics

ActiveCN110039060AHigh tap densityImprove DC Superposition CharacteristicsTransportation and packagingMetal-working apparatusManganeseAlloy

The invention discloses a preparation method of FeSi alloy powder with high direct current superposition characteristics, and belongs to the technical field of alloy powder preparation. The FeSi alloypowder is mainly made of pure iron and metal silicon, and a small amount of manganese and chromium are added. The preparation method comprises the following steps of weighing the ingredients according to a specific proportion, carrying out non-vacuum melting to obtain the alloy melt of required components, and then atomizing to prepare alloy raw powder with an inert gas, obtaining fine powder after the raw powder is collected, screened and graded. According to the preparation method of FeSi alloy powder with high direct-current superposition characteristics, the alloy powder with uniform components and high purity can be obtained, and the powder spherical degree is high; the uniform and compact insulating layer can be easily formed after insulation coating, so that the contact of the alloy matrix is effectively blocked, and the pressed magnetic powder core has good direct-current superposition characteristics.

Owner:马鞍山新康达磁业股份有限公司

Method for plating zinc and nickel on neodymium-iron-boron material

InactiveCN104233408AImprove corrosion resistanceReduce magnetic lossElectrogalvanizationSulfosalicylic acid

The invention relates to a method for plating zinc and nickel on a neodymium-iron-boron material, and belongs to the field of alloy plating processes. The method comprises the following steps of: (1) firstly carrying out roll finish chamfer treatment on the neodymium-iron-boron material by adopting vibrating type roll finish; (2) placing the neodymium-iron-boron material into a deoiling solution and carrying out ultrasonic deoiling; (3) then carrying out derusting treatment by adopting a nitric acid solution with the volume fraction of 10%; (4) carrying out hole sealing treatment by using a low-temperature particule plugging agent; (5) then carrying out activating treatment under the condition of room temperature by using a sulfosalicylic acid solution; (6) plating the neodymium-iron-boron material subjected to the treatment; (7) carrying out polishing treatment on the plated neodymium-iron-boron material, and then carrying out zinc-nickel alloy plating layer passivating treatment; (8) finally carrying out subsequent impregnation treatment by adopting passivated impregnating resin. The method for plating zinc and nickel on the neodymium-iron-boron material, which is disclosed by the invention, greatly enhances the corrosion-resistant capacity of a neodymium-iron-boron surface after the neodymium-iron-boron surface is treated and reduces the magnetic loss through the improvement of a process and has the advantages of simple process and easiness for popularization and use.

Owner:XIAN SANWEI SECURITY TECH

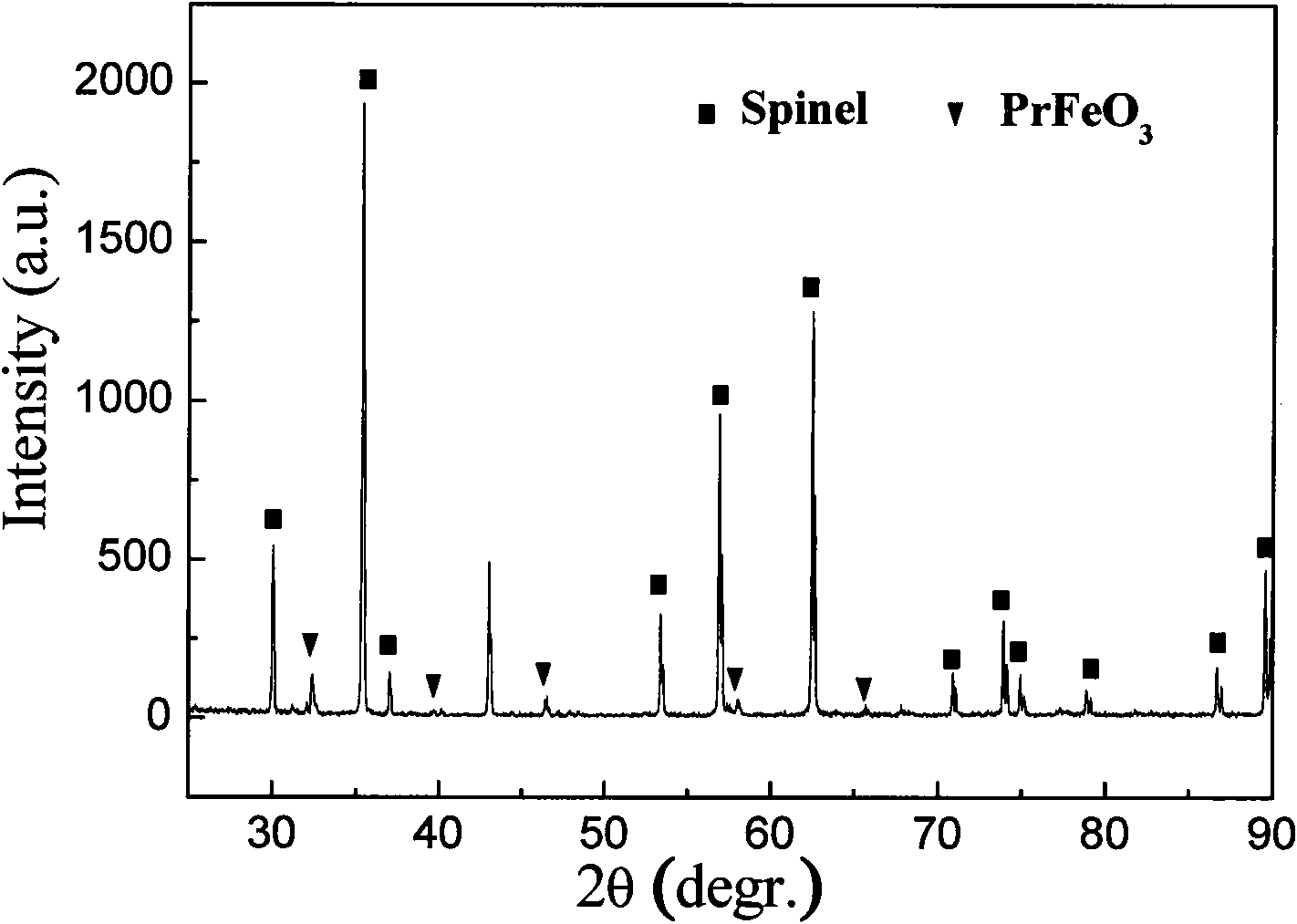

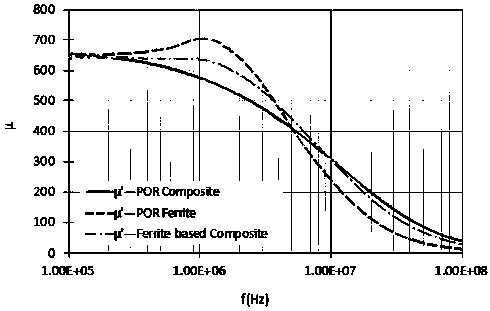

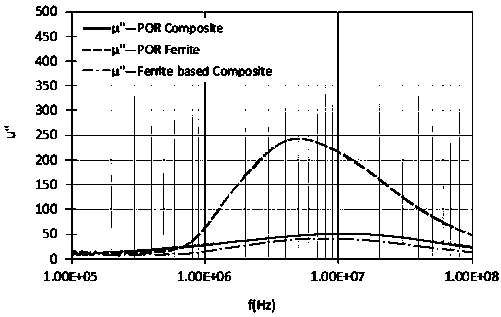

High performance soft magnetic ferrite materials doped with Ni-Zn series and preparation method thereof

ActiveCN101640090AExcellent overall performanceReduce volumeInorganic material magnetismCurie temperatureMetallic Nickel

The invention relates to a high performance soft magnetic ferrite material doped with Ni-Zn series and a preparation method thereof, belonging to the technical field of electronic ceramic preparationand application. The main components of the material comprise 47.0-50.0 mol% of Fe2O3, 24.0-26.0 mol% of ZnO and 24.0-26.0 mol% of NiO; the extra assistant components comprise 0.5-5.0 wt% of Bi2O3 and0.5-5.0 wt% of MnCO3 and at least one of the following doped components: 0-75 mol% of Al2O3, 0.1-10 mol% of Pr6O11 and 0.2-10 mol% of WO3. The preparation method of the material comprises the processes and steps of 'batching->high energy ball milling->drying->mixing and granulating->sieving->pressure forming->sintering' in turn; only a ferrite sintering and synthesizing step is needed, thus the method is economical, simple and reliable. The sintering body of the Ni-Zn series soft magnetic ferrite material prepared by the preparation method provided by the invention according to the formula has an average crystal particle size of 1-10 mu m; the initial permeability mui is at least 100 when the frequency is 1 MHz; the Curie temperature (Tc) is at least 300 DEG C; the coercive force is lessthan 4.5 Oe; the cut-off frequency fr is greater than 10 MHz; the magnetic loss (mu'' / mu') is less than 2.00 in 1k-100 MHz; the dielectric loss (epsilon'' / epsilon') is less than 0.03; and the comprehensive performance is good, so that the sintering body is particularly suitable for the application of high frequency great magnetic field communication device.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING) +1

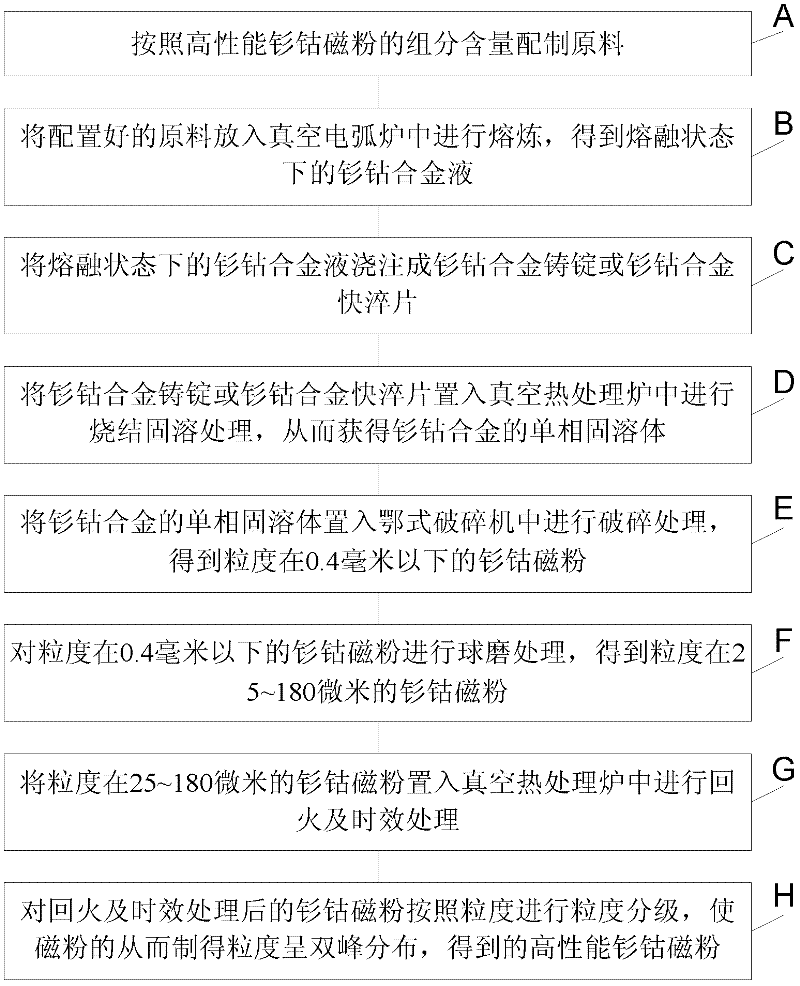

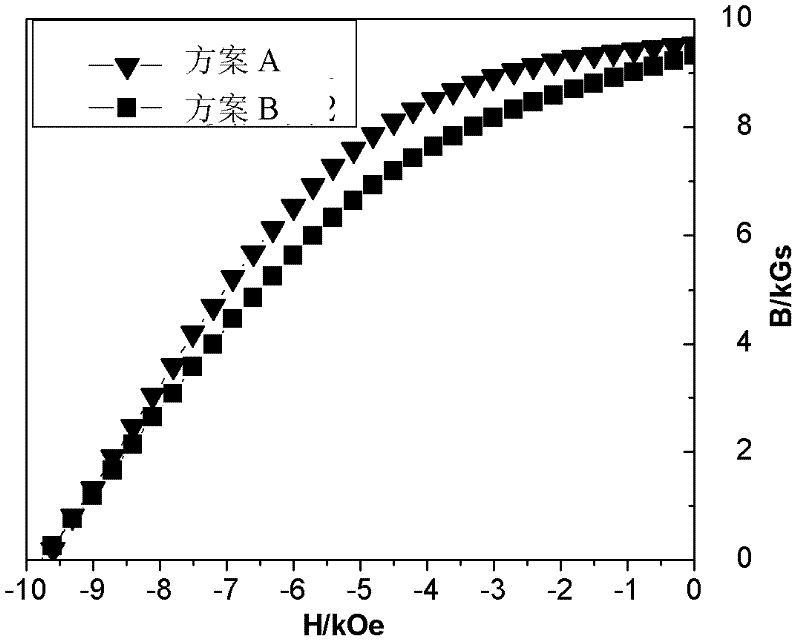

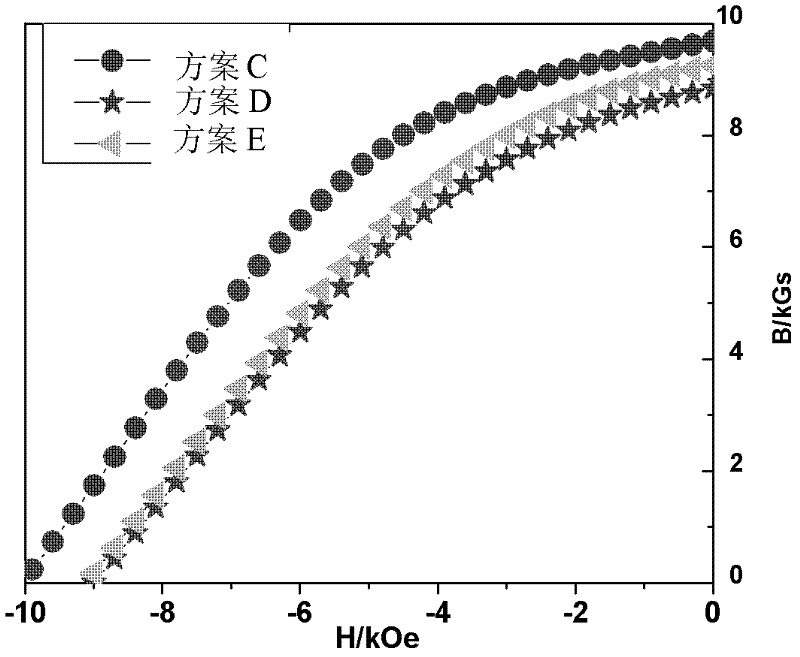

High-performance samarium-cobalt magnetic powder and preparation method thereof

ActiveCN102543340AImprove performanceImprove consistencyInorganic material magnetismMetallurgySamarium

The invention discloses high-performance samarium-cobalt magnetic powder and a preparation method thereof. The general formula is as follows: Sm.alpha.Co. 1-alpha-gamma-delta-psi-omega.Fe.gamma.M.delta.Q.psi.R.omega., and the balance of Co wherein M is at least one of Cu or Zr; Q is at least one of Er, Gd, Dy or Ho; R is at least one of V, Cr, Mn, Sr, Al or Cs; alpha is greater than 20 wt percent and less than 28 wt percent; gamma is greater than 14 wt percent and less than 25 wt percent; delta is greater than 0.5 wt percent and less than 15 wt percent; psi is greater than 0.1 wt percent and less than 5 wt percent; and omega is greater than 0.1 wt percent and is less than 5 wt percent. Due to the composition, the consistency of columnar crystals growth can be promoted, so that the performances of the samarium-cobalt magnetic powder are improved; and the preparation method comprises the following steps of: compounding, smelting, pouring, sintering, solutioning, crushing, aging, adjusting granularity, and the like, so that the magnetic powder with the granularity in bimodal distribution can be prepared, the filler content of the magnetic powder is favored to be improved, and performances of the prepared samarium-cobalt magnetic powder are improved.

Owner:BEIKUANG MAGNETS FUYANG CO LTD

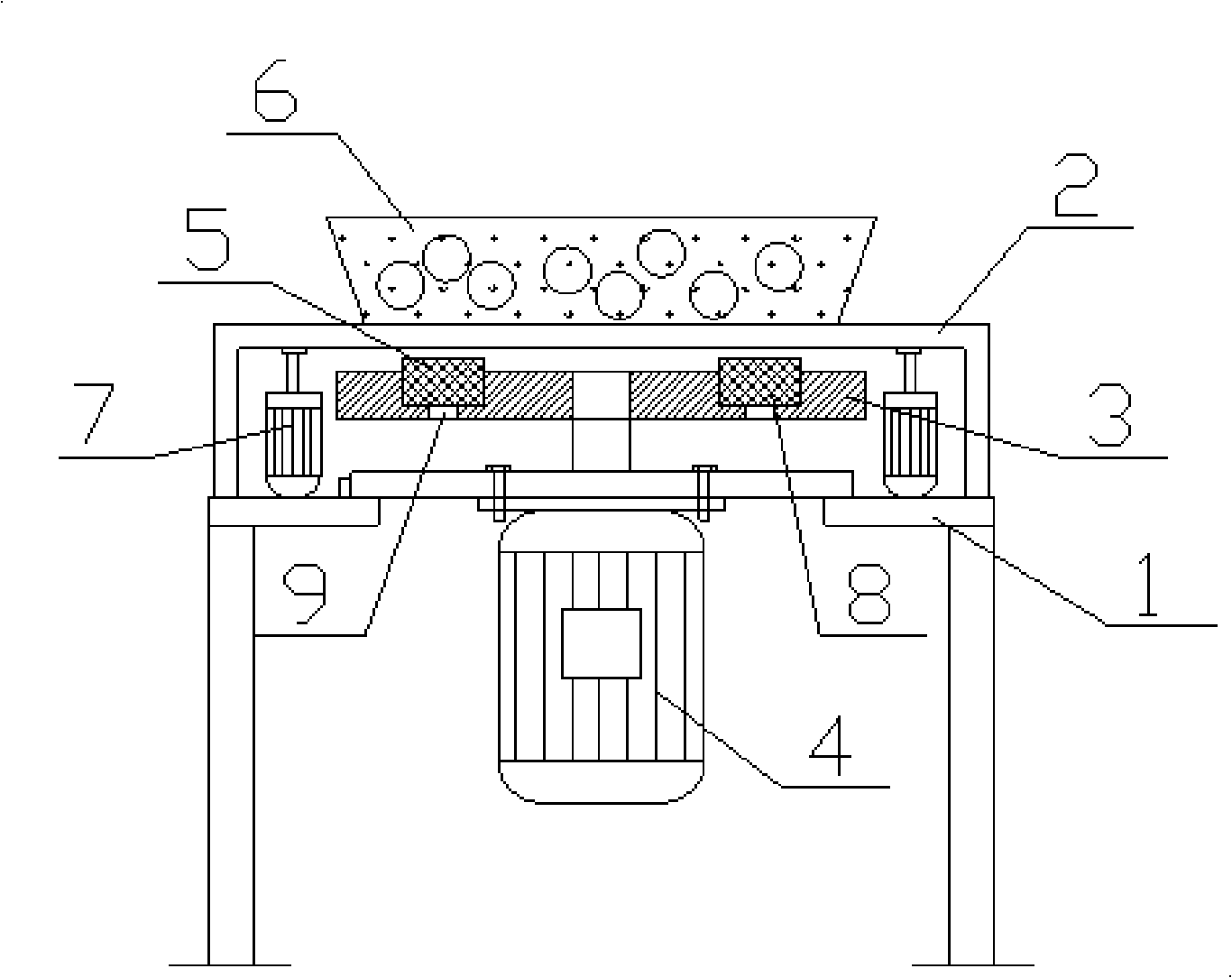

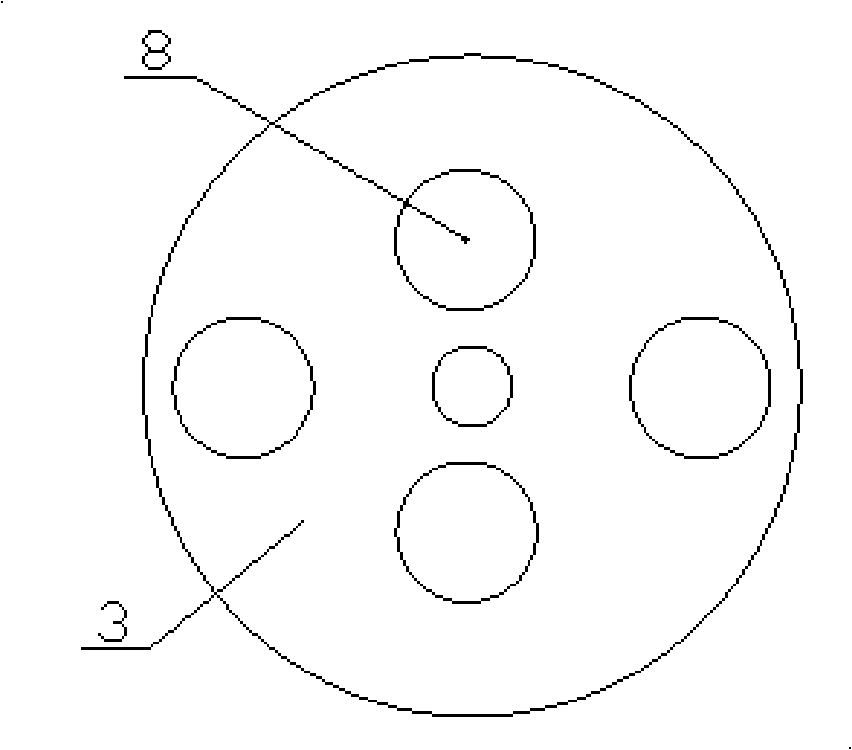

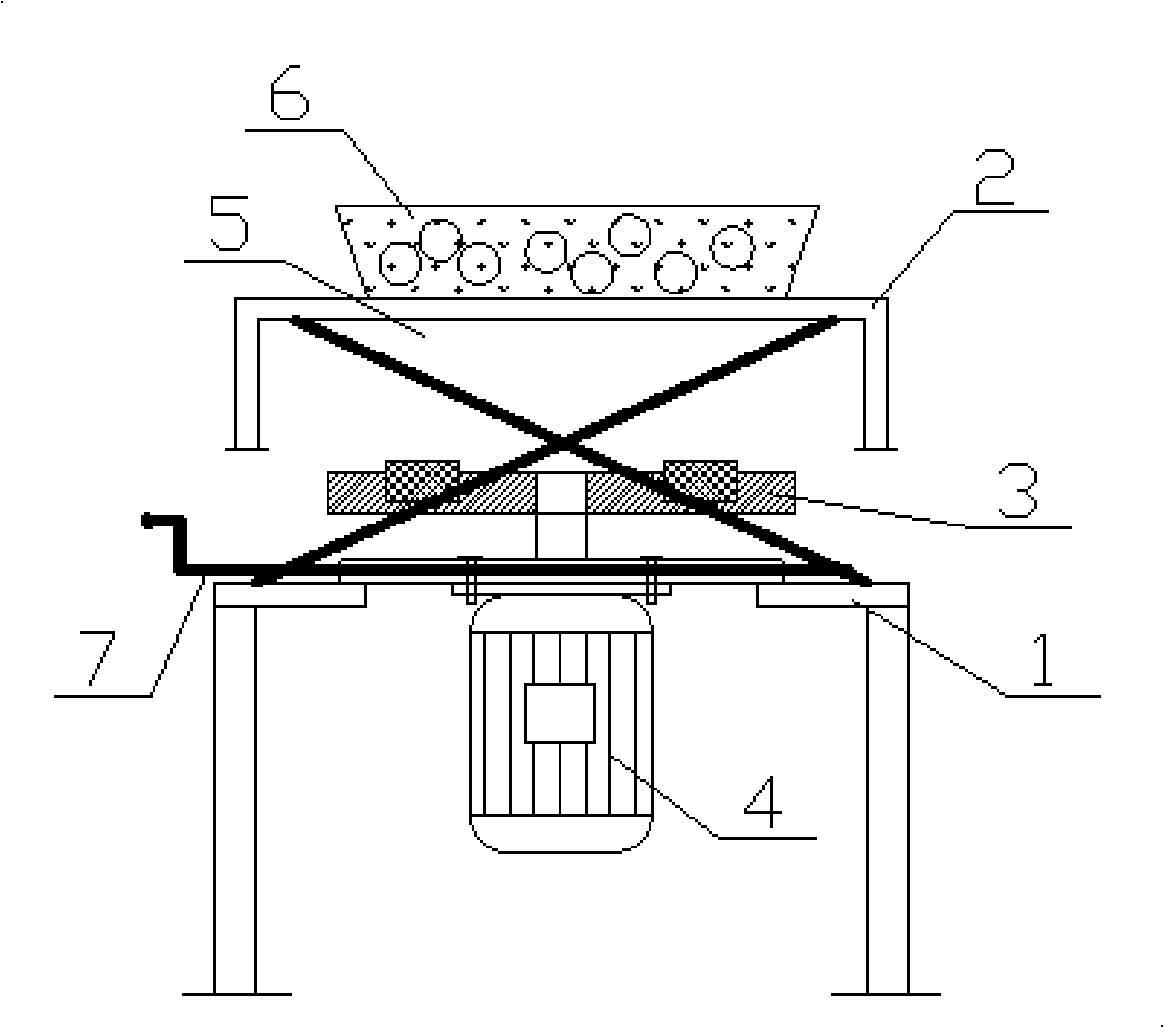

Manufacturing method of magnetic grinder and magnetic grinder thereof

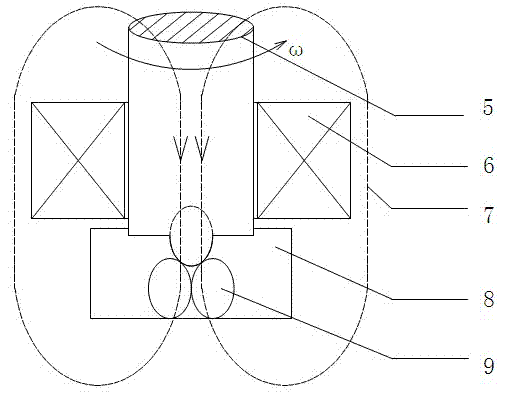

InactiveCN101537598AImprove efficiencyEasy to processEdge grinding machinesPolishing machinesMagnetic polesEngineering

The invention discloses a magnetic grinder and a manufacturing method thereof which comprises the following steps: rotating magnetic lines are adopted to cause that grinding materials in a containing vessel move irregularly to implement the grinding operation to a workpiece; strong magnets arranged on a rotating tray are arranged asymmetrically to increase a magnetic action region of the magnetic grinder; a magnetic distance adjusting device for adjusting a distance between the rotating tray and the containing vessel is arranged on a support platform which is provided with the rotating tray and the containing vessel so as to ensure that the operation of the magnetic grinder is more convenient; the strong magnets arranged on the rotating tray of the magnetic grinder are arranged into two pairs, and magnetic poles of two adjusting strong magnets are opposite and arranged asymmetrically, thereby a nonmagnetic region in the middle of the magnetic grinder is reduced, the magnetic action region in the vessel is increased, the dead angle during the ground finish is decreased, and the efficiency and the processing effect of the magnetic grinder are further promoted. The magnetic distance adjusting device can reduce the action force between the strong magnets and a grinding pin, leads the vessel to be uplifted easily during the discharging and decreases the collision between the vessel and the support platform while placing the vessel.

Owner:HUZHOU XING XING ABRASIVE

Non-axis motor

InactiveCN102055277ASimple structureExtended service lifeCooling/ventillation arrangementSupports/enclosures/casingsAir blowerOperating temperature

The invention relates to a motor, in particular to a non-axis motor which is combined with a slurry pump. The non-axis motor comprises a rotor, a stator, a permanent magnet and an enclosure, and is characterized in that the rotor is internally provided with an installation cavity and externally provided with a rotor auxiliary iron, permanent magnetic blocks, the stator and the enclosure in sequence; the permanent magnetic blocks are distributed on the outer end of the rotor auxiliary iron; two opposite positions on the enclosure are respectively provided with a through hole; and one through hole is communicated with an air blower, and the other through hole is communicated with an induced-draught fan. The non-axis motor has the advantages that the motor can be directly installed on a driven device, thus reducing manufacturing cost; the devices can realize synchronous revolving speed and balanced rotation; the structure layout is compact, thereby decreasing the occupied area; the circulating air radiation is adopted, thus ensuring reasonable control of operating temperature, and having good heat dissipation effect; and the motor operation is safe and stable, and saves electric energy.

Owner:DALIAN YULIN ELECTRIC MOTOR

Iron powder surface coating processing method

InactiveCN103862033AHigh resistivityReduce magnetic lossInorganic material magnetismIndustrial scaleHigh resistivity

The invention relates to an iron powder surface coating processing method and belongs to the technical field of functional material and powder metallurgy. The process comprises the following steps of: placing iron powder in phosphorizing liquid, stirring for 15 to 60min at a temperature of 20 to 50 DEG C, and filtering, washing and drying; then placing the obtained product in silane treating fluid, stirring for 30 to 120min at a temperature of 20 to 70 DEG C, filtering and washing; and finally, drying at a temperature of 50 to 120 DEG C to obtain coated powder of which the surface is simultaneously provided with a phosphate layer and a siloxane layer. The method adopts the simple preparation process, has high efficiency, is complete to coat, is easy to form the industrial scale; the phosphate coating layer on the surface has high resistivity and can effectively reduce magnetic loss of an iron powder core; and the siloxane coating layer can improve brittleness of the phosphate layer and can improve heat resistance of the coated iron powder.

Owner:CENT IRON & STEEL RES INST

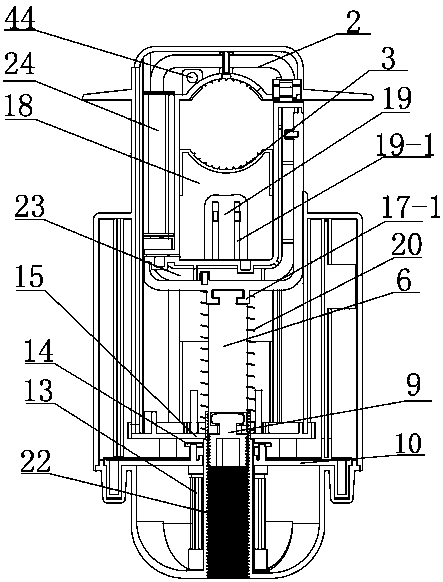

Safe and intelligent fault indicator for overhead line

ActiveCN104181440AReduce difficultySimple structureFault locationFault indicatorElectric power system

The invention relates to a safe and intelligent fault indicator for an overhead line. A main housing is internally provided with a mutual inductor, a direct-pushing-type locking device and a circuit system. The lower end of the main housing is provided with a transparent lampshade cooperated with the main housing. The mutual inductor comprises two groups of iron cores in parallel arrangement, wherein the two groups of iron cores are respectively cut into two portions, the inclined plane angle forming a 45-degree angle with the cross section of the iron core, so that the problems of low work efficiency, expensive equipment and being incapable of volume produce since an original C-type mutual inductor coil winding needs to be installed to an annular winding machine with the iron cores synchronously; through adopting a U-shaped iron core structure of the diagonal plane, magnetic loss is reduced; and the intelligent fault indicator can enable fault or short circuit information of the overhead line and load terminal equipment to be selectively encrypted through a security chip ESAM and the encrypted is then sent to an electric management master station and mobile phones of operation and maintenance personnel, thereby realizing remote detection management, fault location and high-efficiency processing, and providing powerful guarantee for an electric system.

Owner:HAIYAN LINGYUNWEI ELECTRONICS +2

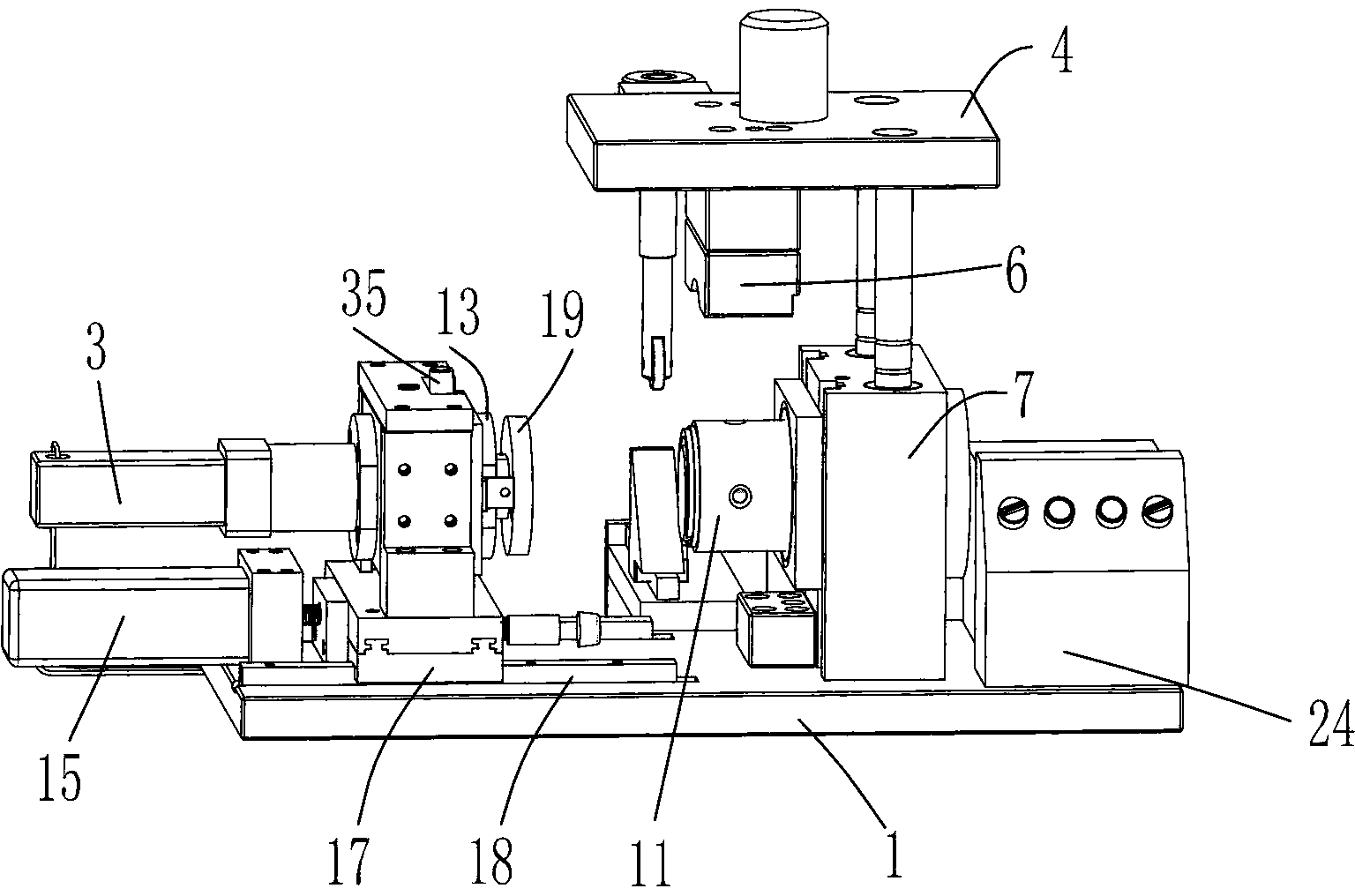

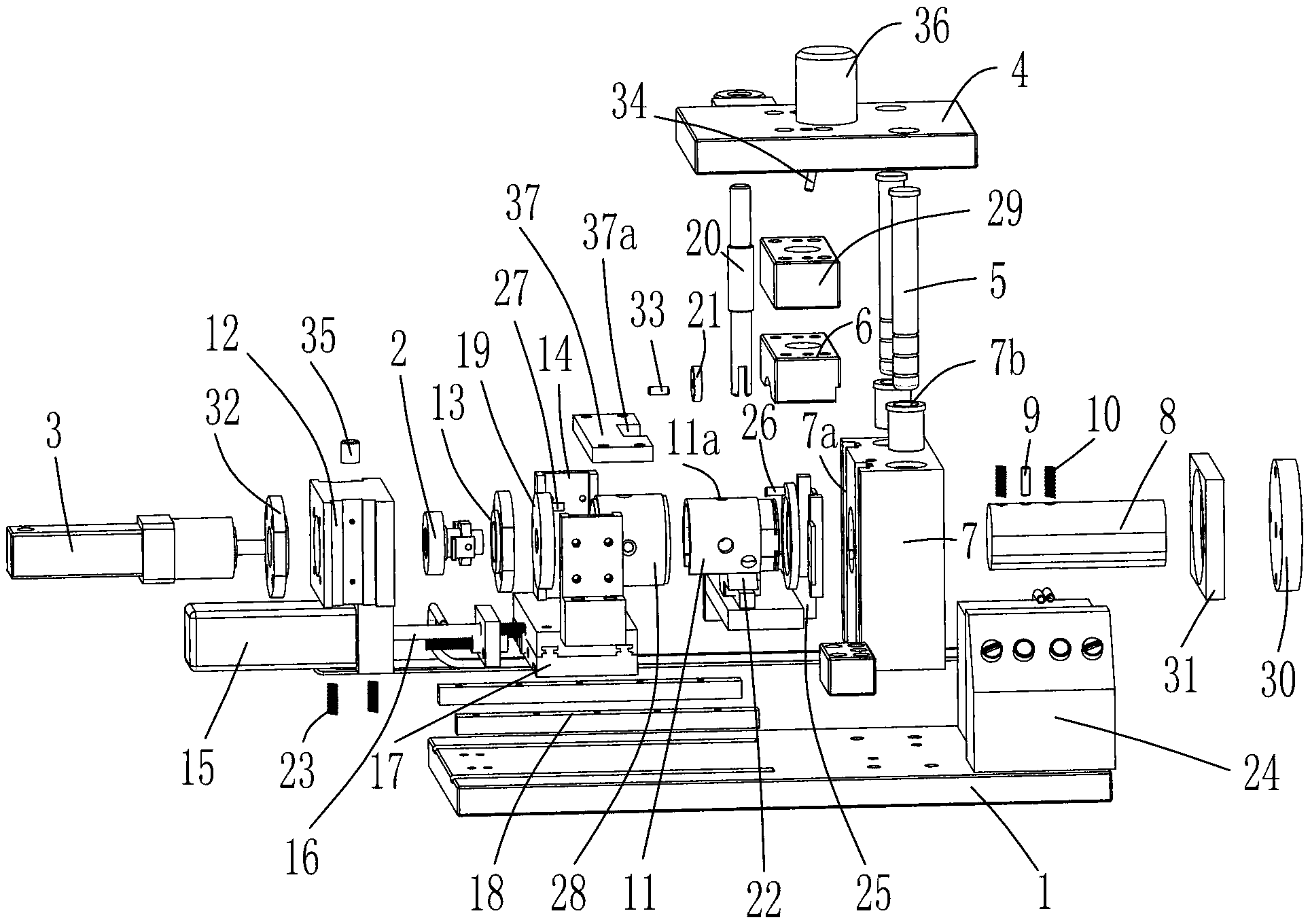

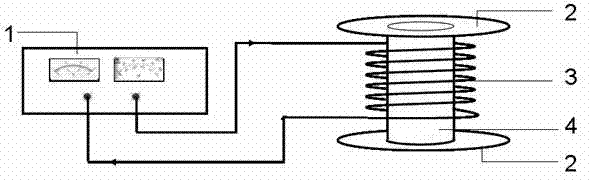

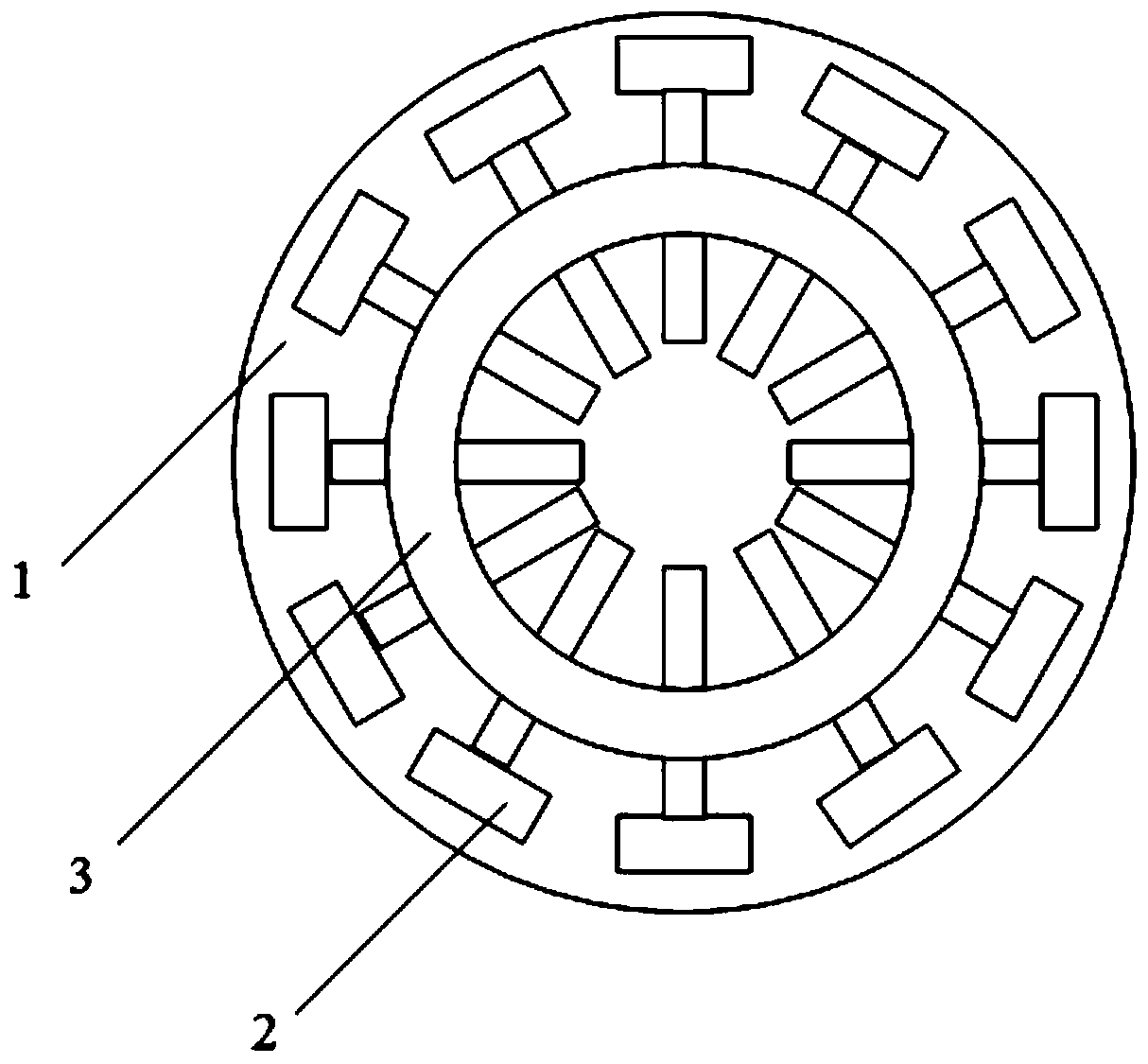

Device for detecting frictional wear characteristics of magnetorheological fluid under magnetic field

InactiveCN102359917AImprove stabilityReduce magnetic lossInvestigating abrasion/wear resistanceMagnetic currentMagnetorheological fluid

The invention relates to a device for detecting frictional wear characteristics of magnetorheological fluid under a magnetic field. In a magnetic induction coil of a magnetic generating module of the device, a copper enamelled wire is used as a lead, magnetic conduction low-carbon steel is used as a winding shaft, and an aluminum product is used as a baffle plate, so magnetic loss is reduced effectively, the stability of the operation of the magnetic field is improved, and a detection platform is provided for the evaluation of the frictional wear characteristics of the magnetorheological fluid under the magnetic field. In the device for the frictional wear characteristics of the magnetorheological fluid under the magnetic field, an induction magnetic field which is perpendicular to the motion direction of a friction pair can be formed at a contact point of the friction pair according to test requirements, the variable regulation of the magnetic field can also be realized by changing a value of current inputted to the coil, and the regulation can be performed continuously, so that the condition is provided for inspecting the frictional wear characteristics of the magnetorheological fluid systematically.

Owner:LOGISTICAL ENGINEERING UNIVERSITY OF PLA

Wireless charging and electromagnetic coupling structure and design method thereof

PendingCN110077246AReduce volumeReduce weightBatteries circuit arrangementsCharging stationsElectromagnetic couplingResonance

The invention is applied to the technical field of wireless charging, and discloses a wireless charging and coupling structure and a design method thereof. The wireless charging and coupling structurecomprises a transmitting end and a receiving end which are arranged oppositely, an air gap is formed between the transmitting end and the receiving end, and the receiving end and the transmitting endare arranged coaxially. The transmitting end sequentially comprises a first aluminum plate, a first magnetic core arranged on the first aluminum plate and a first resonant coil arranged on the firstmagnetic core from outside to inside, wherein the first resonant coil is arranged concentrically with the first magnetic core; the receiving end sequentially comprises a second aluminum plate, a second magnetic core arranged on the second aluminum plate and a second resonance coil arranged on the second magnetic core from outside to inside, wherein the second resonance coil is arranged concentrically with the second magnetic core; and the radius of the first magnetic core is larger than the radius of the second magnetic core, and the radius of the second resonance coil is larger than the radius of the second resonance coil. According to the resonant type electric automobile wireless charging and electromagnetic coupling structure, the coupling degree is improved, the magnetic leakage is reduced, the magnetic loss is reduced, the charging efficiency is improved, the volume and the weight of the magnetic cores are reduced, and the anti-migration capability of the system is improved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

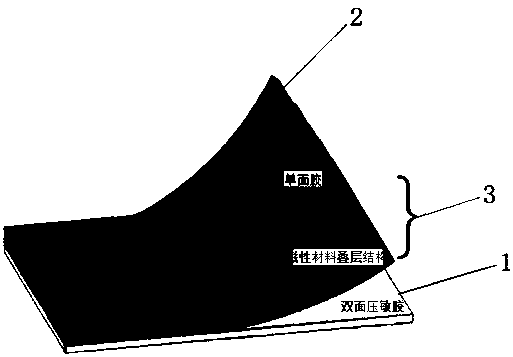

High-performance and high-frequency responsivity ferrite-based composite having laminated structure

ActiveCN108597793AHigh magnetic saturationHigh strengthCircuit arrangementsInorganic material magnetismAdhesiveResponsivity

The invention discloses a high-performance and high-frequency responsivity ferrite-based composite having a laminated structure, which is formed by superposing an underlying material, a top layer material and a sandwich material in sequence, wherein the underlying material is a layer of black or sub-black non-transparent double-sided pressure-sensitive adhesive; the top layer material is a layer of black or sub-black single-sided glue; and the interlayer material is a magnetic material laminated structure which is formed by alternately laminating any two or three kinds of soft magnetic materials such as ferrite, nanocrystal and amorphous. Compared with the conventional ferrite, nanocrystalline and amorphous soft magnetic materials, the ferrite-based composite having the laminated structureprovided by the invention has the advantages of high magnetic saturation strength, wide frequency band and high-sensitive frequency response, high magnetic permeability, low magnetic loss and the like. The ferrite-based composite in the invention is applicable to a next generation of wireless charging transmitting end and receiving end and is particularly suitable for a non-contact resonant A4WPwireless charging scheme.

Owner:苏州威斯东山电子技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com