Patents

Literature

38 results about "Accuracy class" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Accuracy classes are defined and used in IEC and ANSI standards. Classes are denoted by either a letter or percentage. For example, Class B is a temperature accuracy from IEC-751 that requires accuracy of ± 0.15 degrees Celsius. Class 0.5 is an ANSI C12.20 accuracy class for electric meters with absolute accuracy better than ± 0.5% of the nominal full scale reading.

Current transformer iron core of amorphous and nano-crystalline magnetically soft alloy and preparation method thereof

ActiveCN105047348AReduce magnetic lossReduce lossTransformers/inductances magnetic coresInductances/transformers/magnets manufactureChemical compositionAlloy

The invention discloses a current transformer iron core of amorphous and nano-crystalline magnetically soft alloy and a preparation method of the current transformer iron core. The chemical component atomic percent of the iron core is FeaSibBcMdCueM'f, wherein a is not more than 85 and is not less than 65; b is not more than 25 and is not less than 5; c is not more than 15 and is not less than 0; d is not more than 15 and is not less than 0; e is not more than 5 and is not less than 0, and f is not more than 1 and is not less than 0, and a plus b plus c plus d plus e plus f equals to 100, and M is at least one of Nb, Mo or V, and M' is at least one of Sn, Al, Y and Sb. The preparation method comprises the steps as follows: preparing materials according to atomic percent and smelting to prepare a mother alloy; then crushing the prepared mother alloy to re-melt and covering steel-making slagging constituent to prevent oxidation and deslagging; preparing amorphous alloy ribbons with the re-melted mother alloy by using a single roll rapid solidification ribbon preparation method under ordinary pressure, and finally winding the amorphous alloy ribbons as the amorphous iron core, and performing isothermal annealing crystallization in a vacuum annealing furnace to obtain the amorphous and nano-crystalline magnetically soft alloy of a mutual inductor iron core. The iron core of the invention has high saturation flux density, high permeability, and low magnetic loss so that the mutual inductor has ultrahigh precision and accuracy class.

Owner:NEW MATERIALS TECH JIANGSU AMORPHD +1

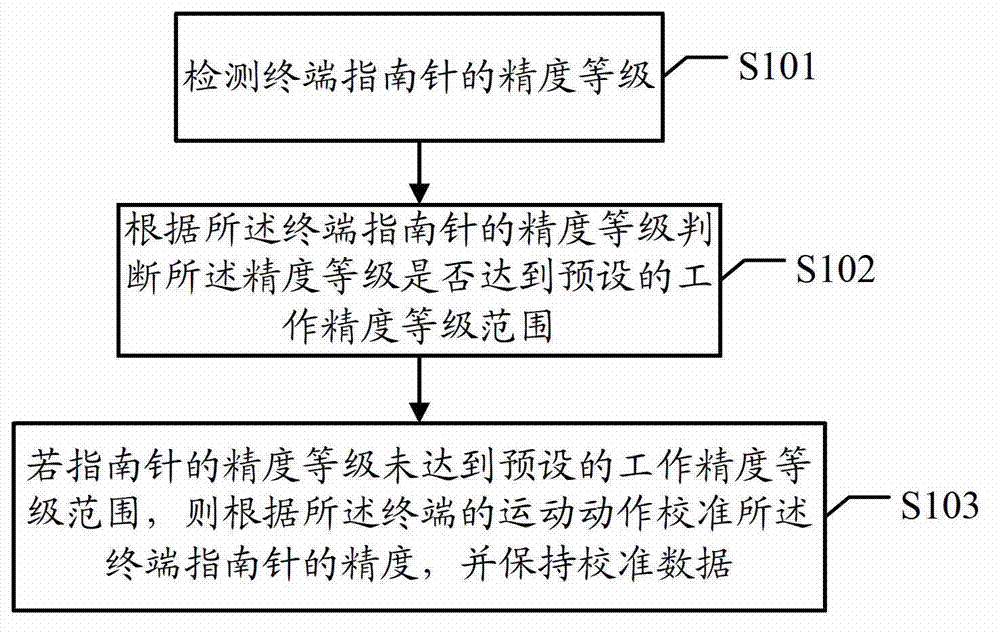

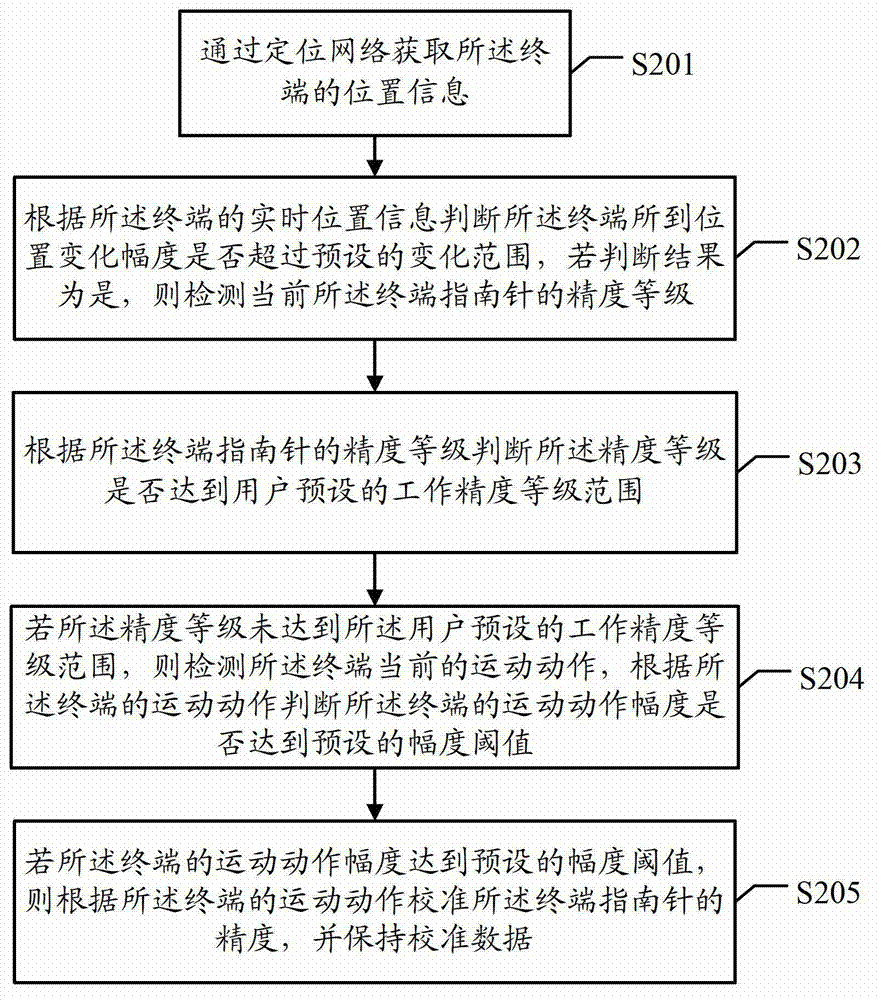

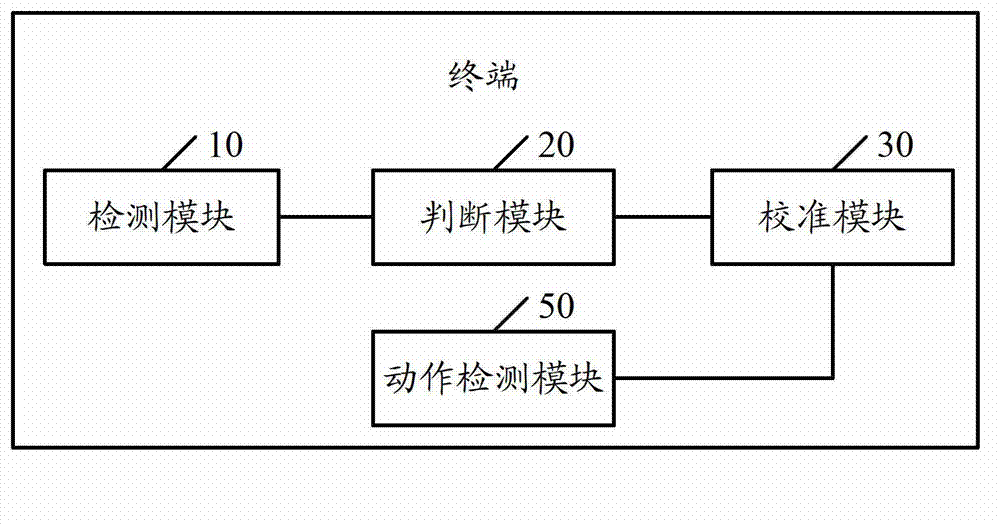

Terminal compass calibrating method and terminal compass calibrating device

InactiveCN103167166AImprove the level of intelligenceImprove experienceSubstation equipmentLocation information based serviceComputer visionArtificial intelligence

The invention discloses a terminal compass calibrating method which comprises the steps of detecting accuracy classes of a terminal compass, judging if the accuracy class reaches a preset work accuracy class range according to the accuracy classes of the terminal compass, and calibrating the accuracy of the terminal compass and keeping calibrating data according to the motions of a terminal if the accuracy class of the compass does not reach the preset work accuracy class range. The invention further discloses the terminal. The method and the terminal have the advantages that intellectualization level of the terminal is improved, and the user experience effect of the terminal compass is enhanced.

Owner:SHENZHEN GIONEE COMM EQUIP

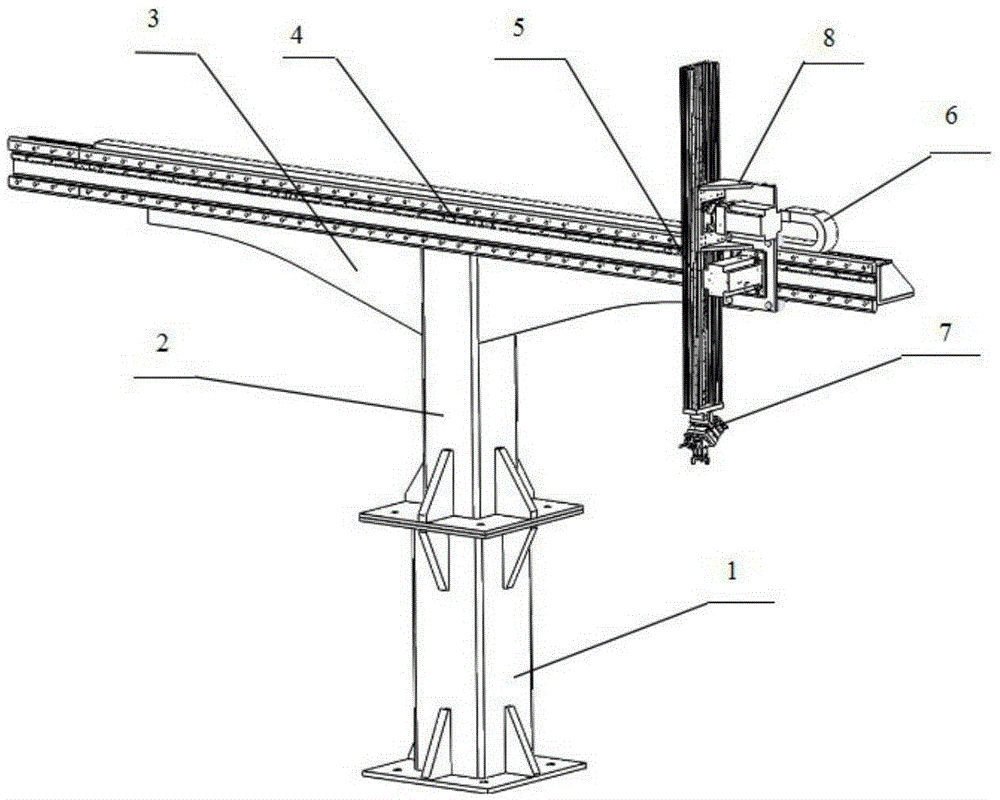

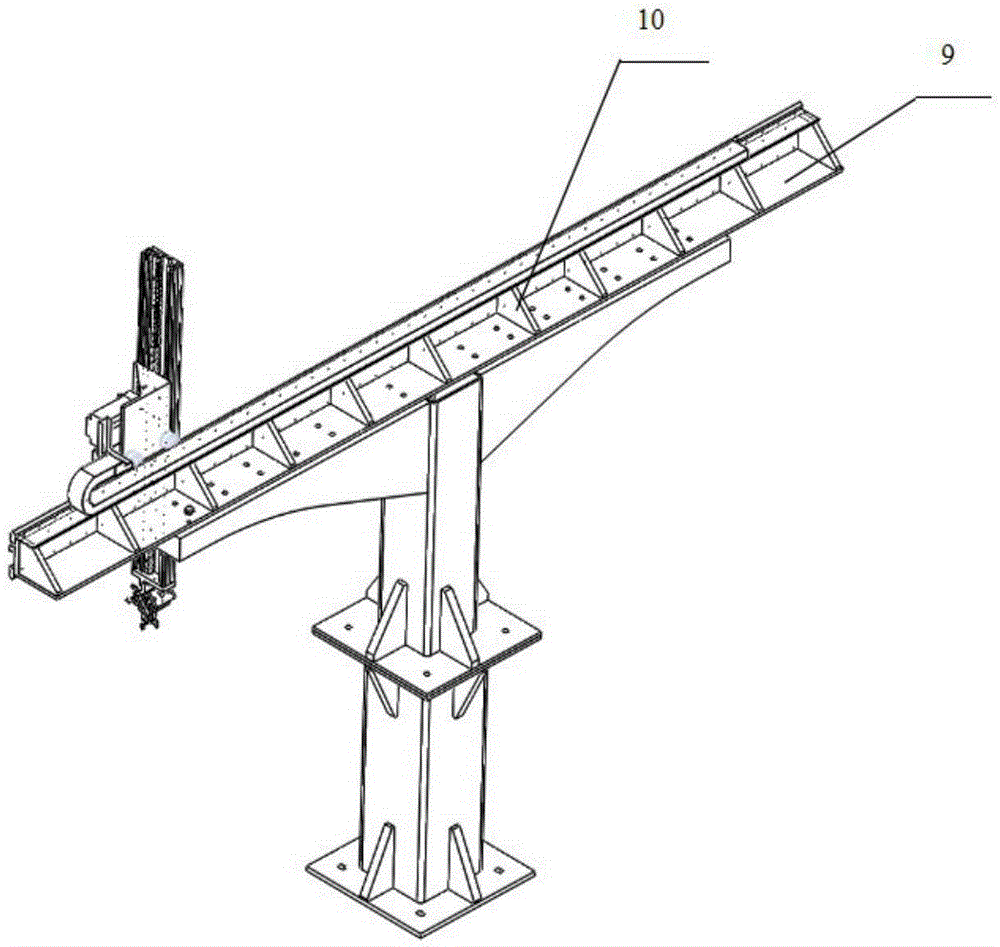

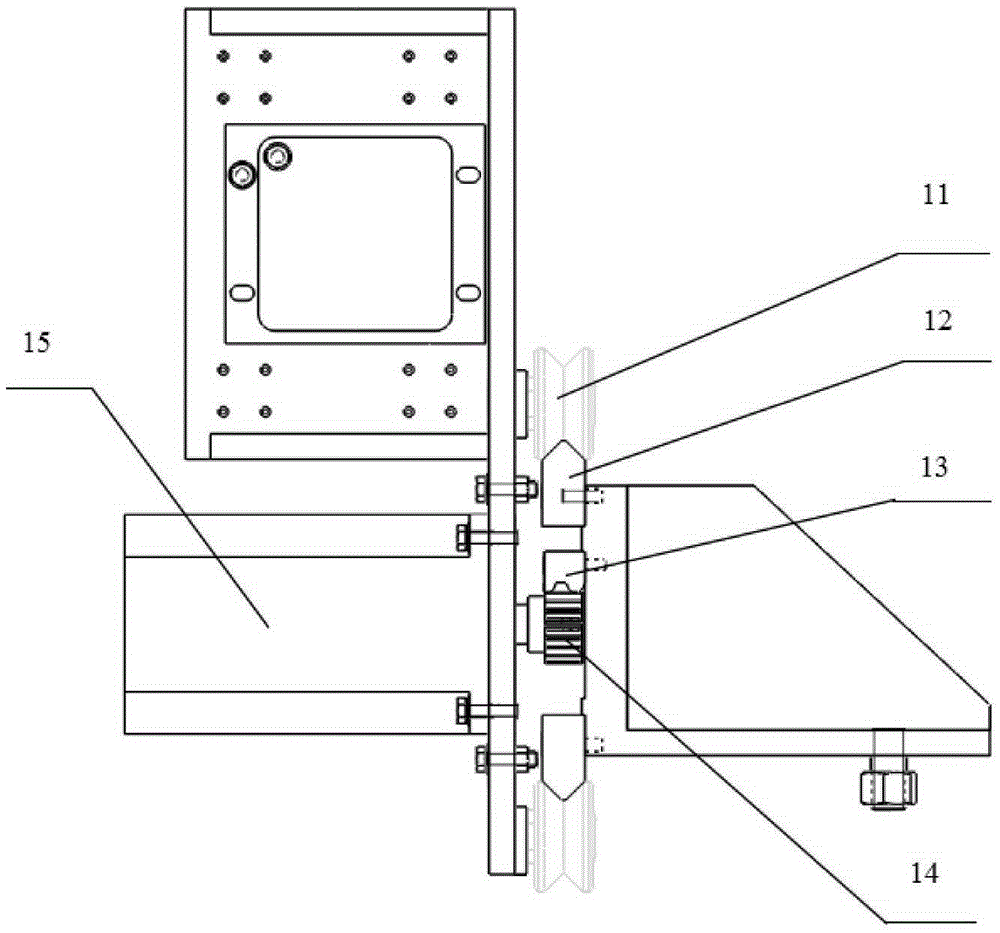

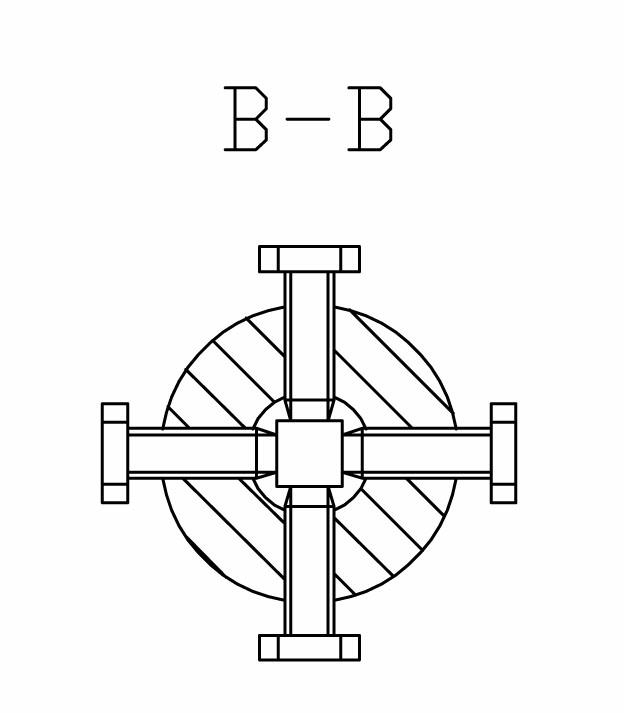

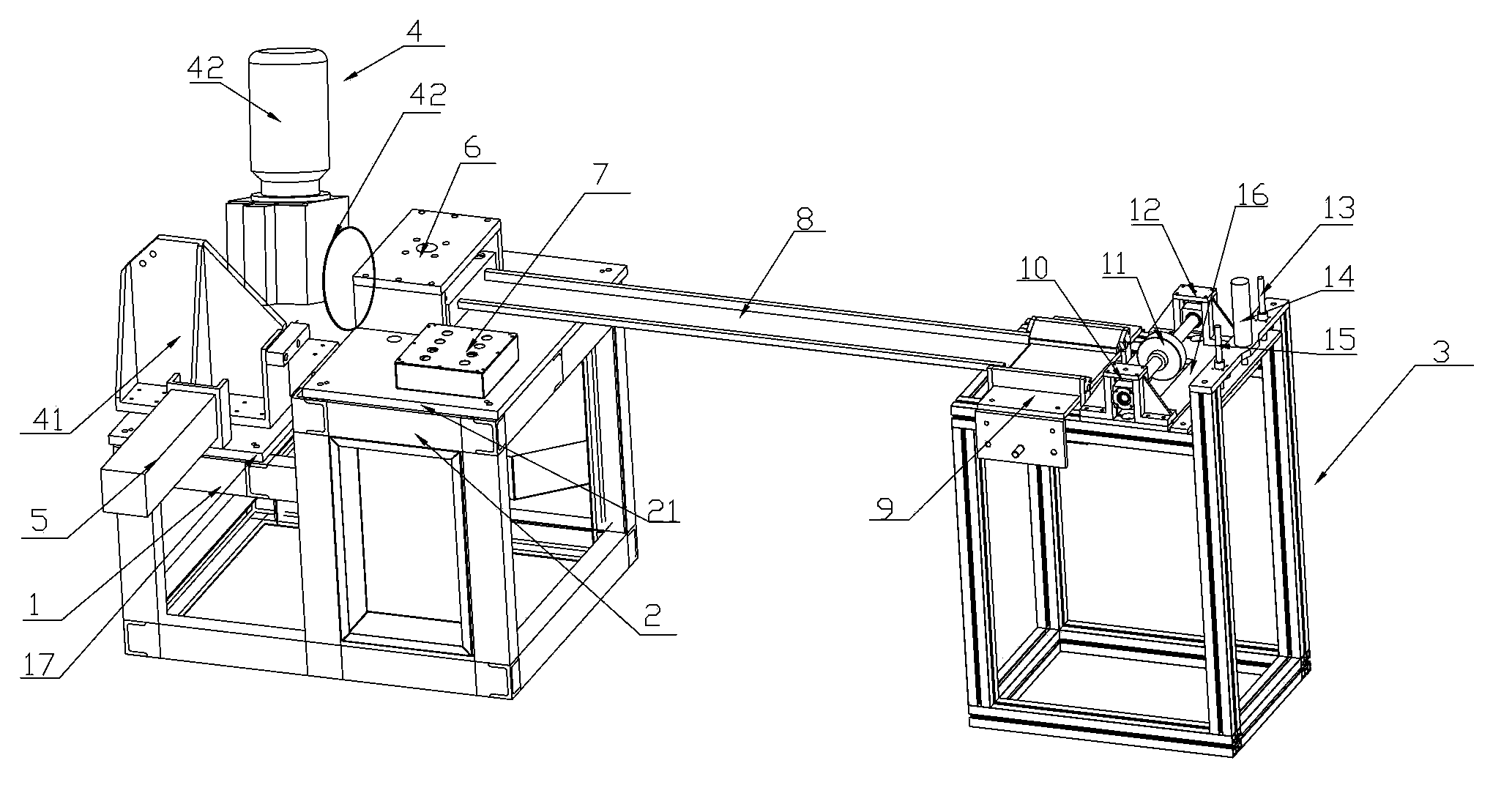

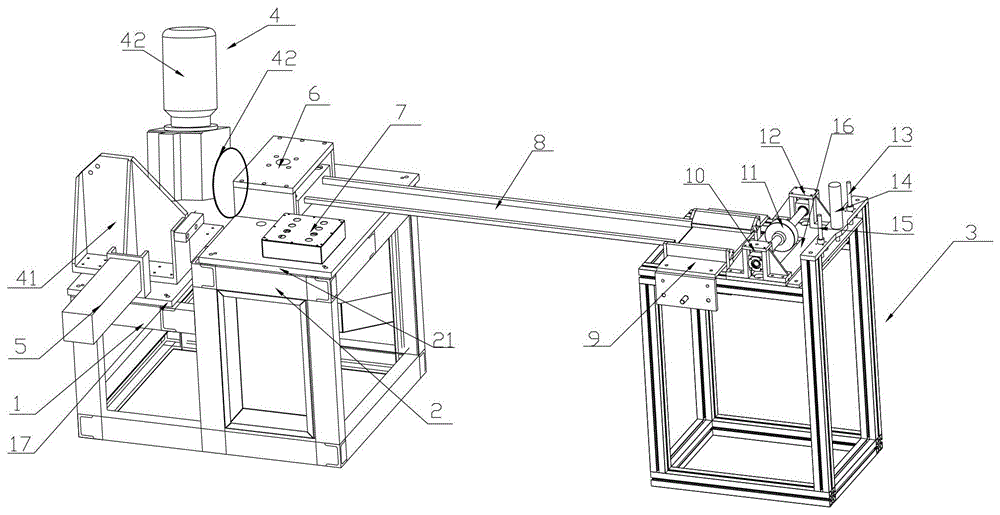

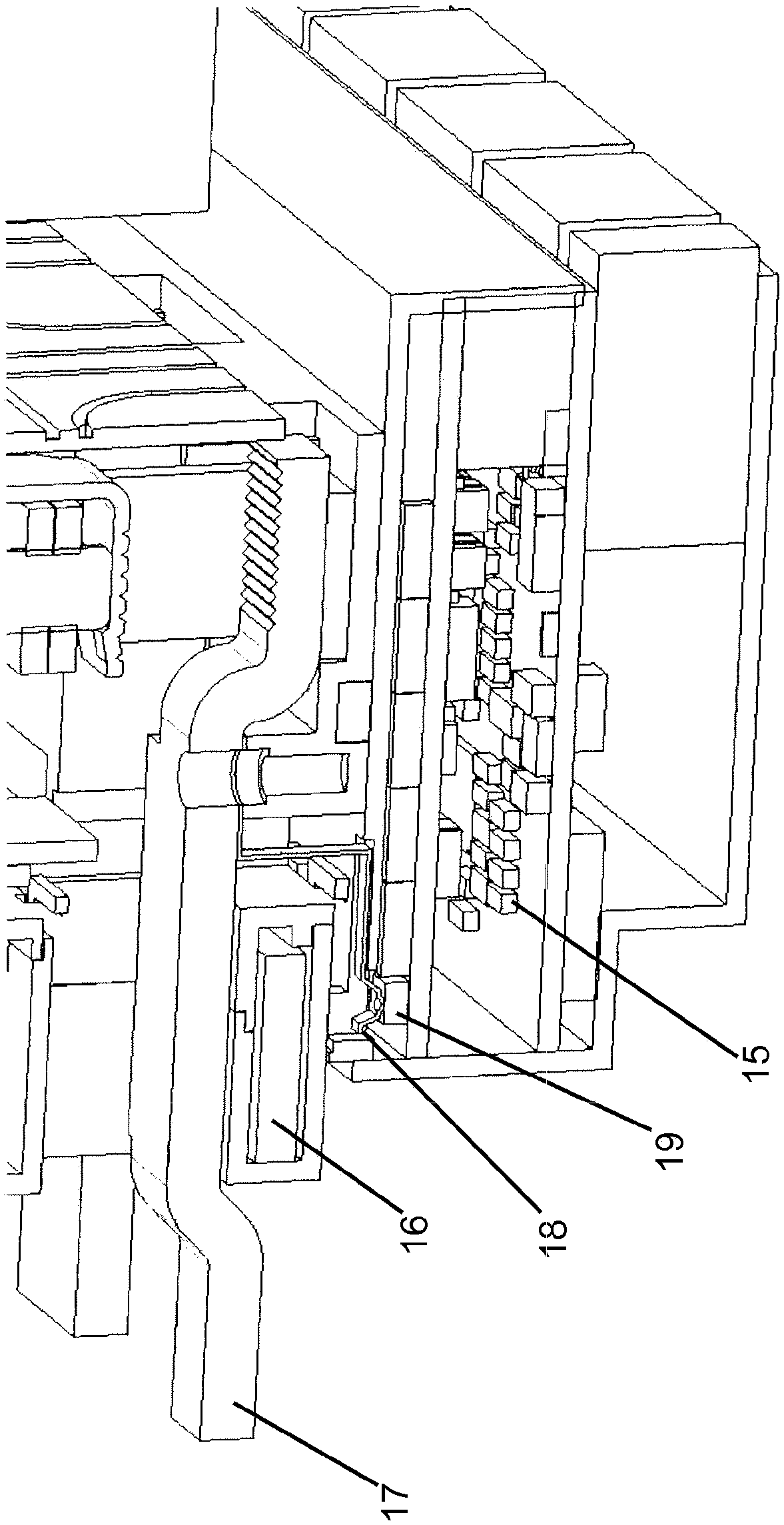

Truss manipulator for loading and unloading

InactiveCN105364932AHigh strengthIncrease stiffnessProgramme-controlled manipulatorGear wheelEngineering

The invention relates to a truss manipulator for loading and unloading. The truss manipulator for loading and unloading is composed of a support structure, a horizontal movement assembly, a vertical movement assembly, an automatic handgrip, and a transition connection plate between two shafts, wherein the horizontal movement assembly is fixedly installed at the top end of the support structure; the vertical movement assembly runs on the horizontal movement assembly; and the automatic handgrip is installed at the bottom end of the vertical movement assembly. According to the invention, a single-vertical-column supporting main body structure is adopted, and reinforcing ribs are designed and used for improving the strength and the rigidity of the truss main body structure; and transmission in a horizontal movement is realized in a manner of matching a V-shaped slide rail with independent gear and rack, each of the gear and the rack is provided with modulo-two oblique teeth with an accuracy class of 6, the transmission manner can greatly meet requirements on a high speed, and the transmission accuracy can be controlled to be less than 0.1mm.

Owner:TIANJIN TIANSEN INTELLIGENT EQUIP CO LTD

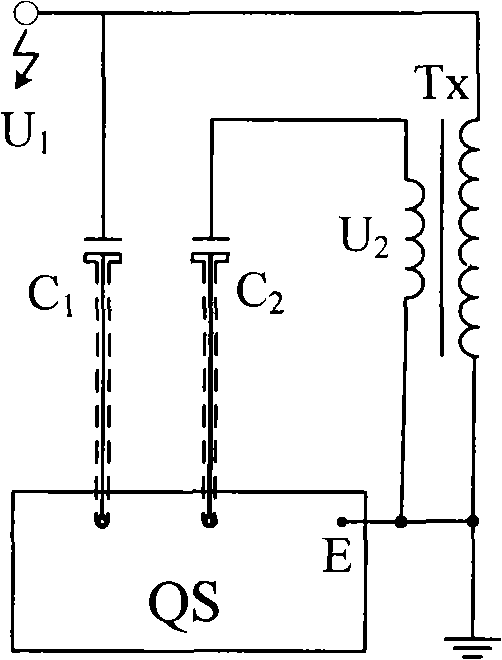

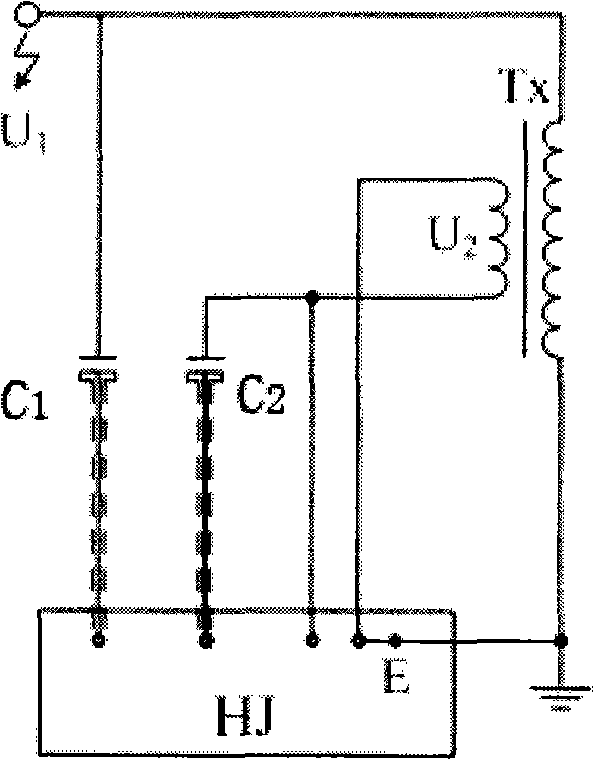

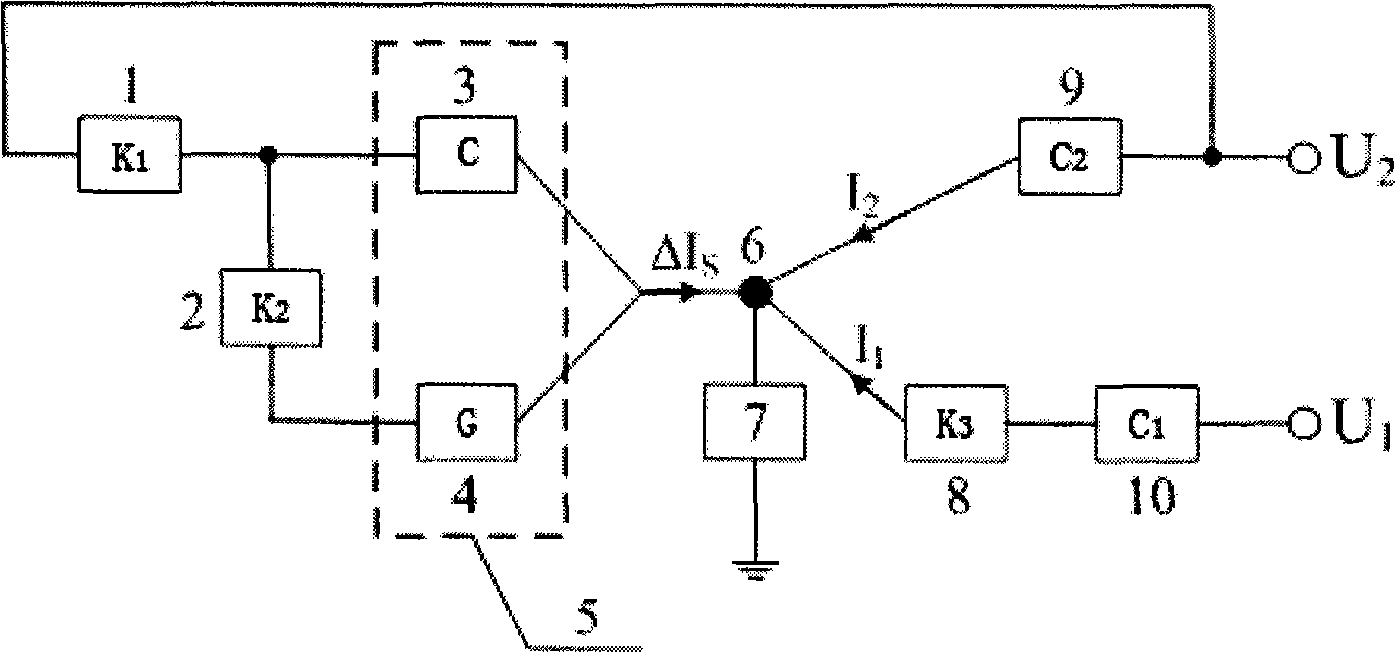

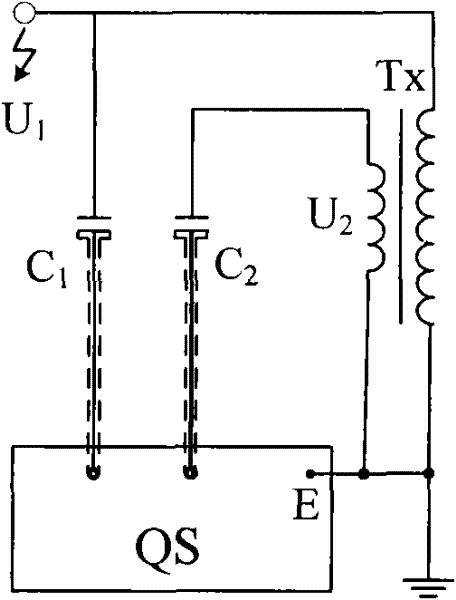

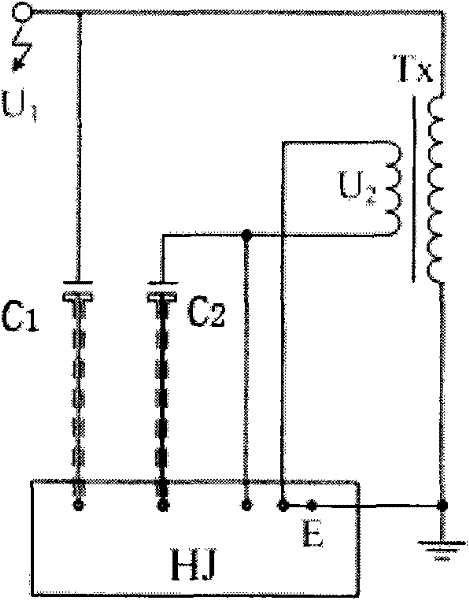

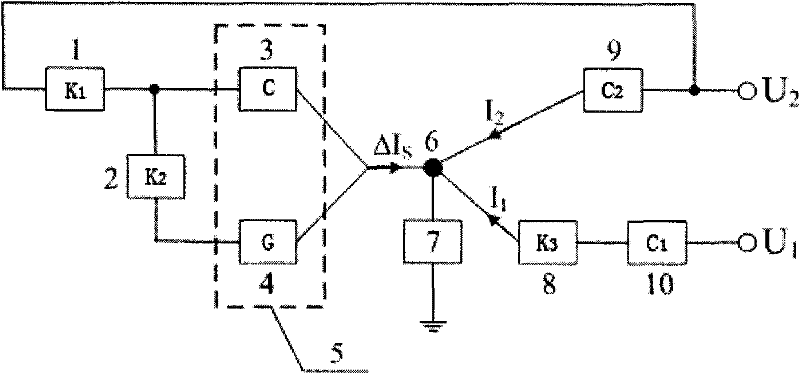

Verifying apparatus for measuring extra-high voltage transformer error

ActiveCN101493509AImprove anti-interference abilityLower performance requirementsElectrical measurementsCapacitanceMeasurement device

The invention provides a calibration device used for error measurement of a super-high voltage transformer, comprising an admittance network consisting of a standard capacitance box and a standard conductive box, a precise voltage divider, an induction-typed shunt and a null instrument. The calibration device can be used as the error measurement device when the voltage transformer is being calibrated by the capacitance-typed voltage proportion standard, adopts the difference value measurement principle to calibrate the ratio difference and the phase difference of the voltage transformer to be tested, realizes directly reading the ratio difference and phase difference of the voltage transformer to be calibrated by the conductivity quantity and capacitance quantity of the admittance network, and can calibrate the electromagnetism-typed or capacitance-typed voltage transformer within the voltage range of 110-1000KV. When calibrating the voltage transformer used for the measurement with the accuracy class of 0.05 or above, the uncertainty introduced by the calibration device is less than or equal to 5.3*10 and when calibrating the voltage transformer used for the power with the accuracy class of 0.05 or above, the uncertainty introduced by the calibration device is less than or equal to 2.3*10.

Owner:STATE GRID ELECTRIC POWER RES INST +3

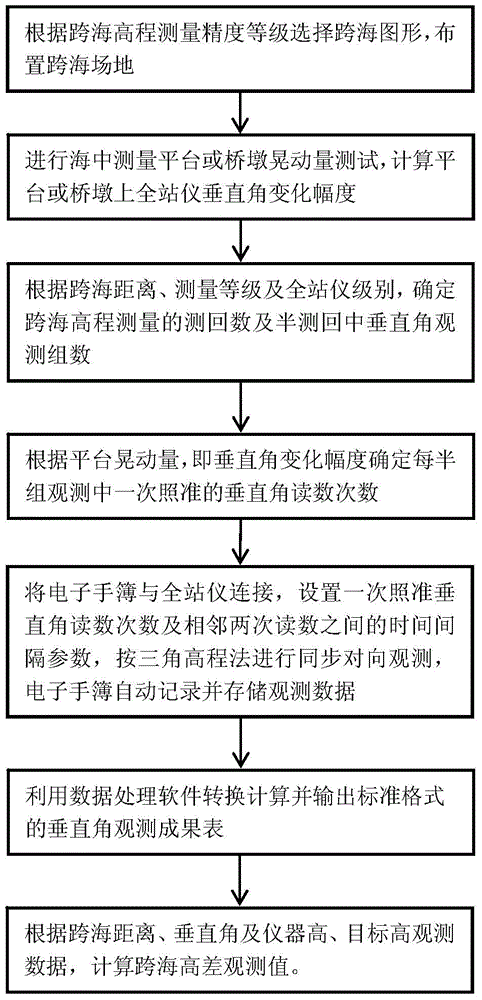

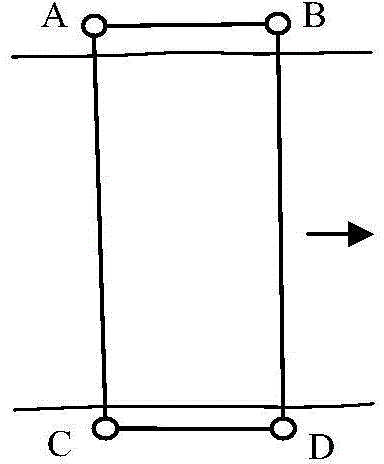

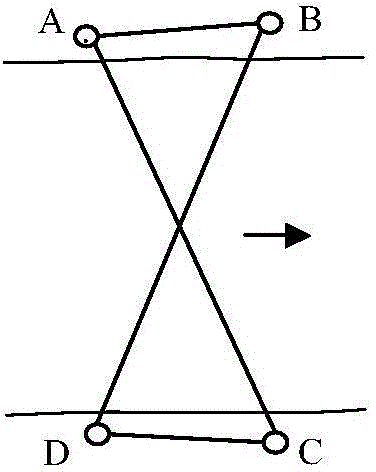

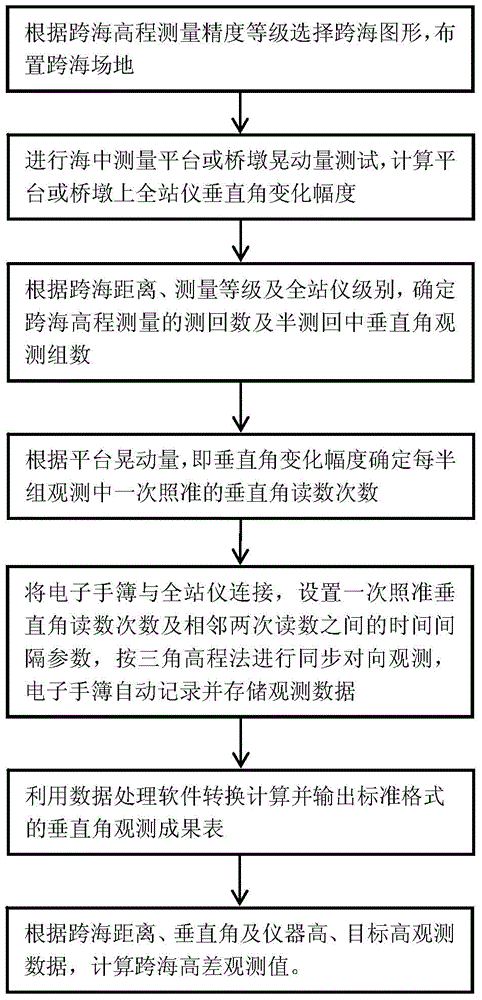

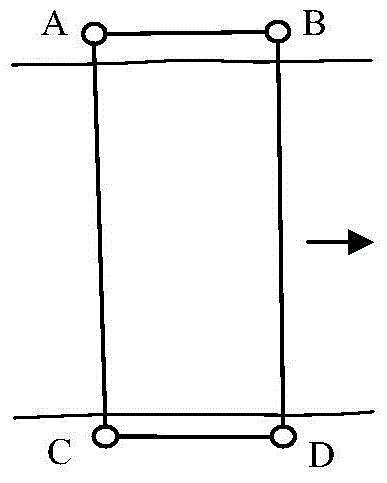

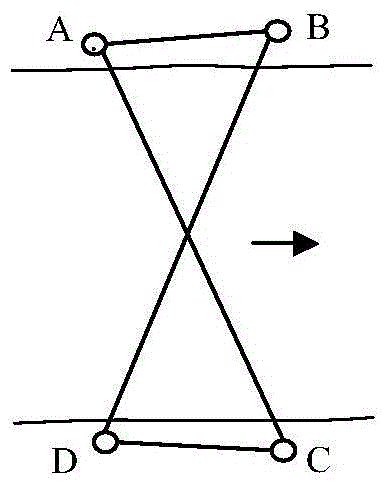

Transmitting and measuring method of sea-crossing height

ActiveCN104567800AReduce adverse effectsHigh precisionHeight/levelling measurementGeomorphologyObservation data

The invention relates to a transmitting and measuring method for a sea-crossing height. The method comprises the following steps: according to the measurement accuracy class of the sea-crossing height, choosing a sea-crossing graph, and arranging a sea-crossing site; measuring the waggle quantity of an offshore platform so as to obtain a change range of a vertical angle of a total-station instrument of the platform; according to the sea-crossing distance, the measurement class and the level of the instrument, determining the survey time number of the sea-crossing height measurement and an observing and surveying group number of the vertical angle during semiobservation; according to the wobble quantity of the platform, determining the number of times of reading the vertical angle collimated once; connecting an electronic data recorder with the total-station instrument, setting parameters of the number of the times of reading the vertical angle collimated once, a time interval between the twice adjacent reading and the like, performing synchronous opposite direction observation by a triangulated height method, and automatically recording and storing observation data by the electronic data recorder; calculating and outputting an observing and surveying outcome table of the vertical angle in a standard format by using interior work software; according to observation data of the sea-crossing distance, the altitude of the vertical angle, the altitude of the instrument, the altitude of a target and the like, calculating a sea-crossing altitude difference observing and surveying value. The transmitting and measuring method disclosed by the invention is particularly suitable for transmitting and measuring the sea-crossing height of the total-station instrument of a measuring station under the condition of wobble.

Owner:CHINA MAJOR BRIDGE ENERGINEERING

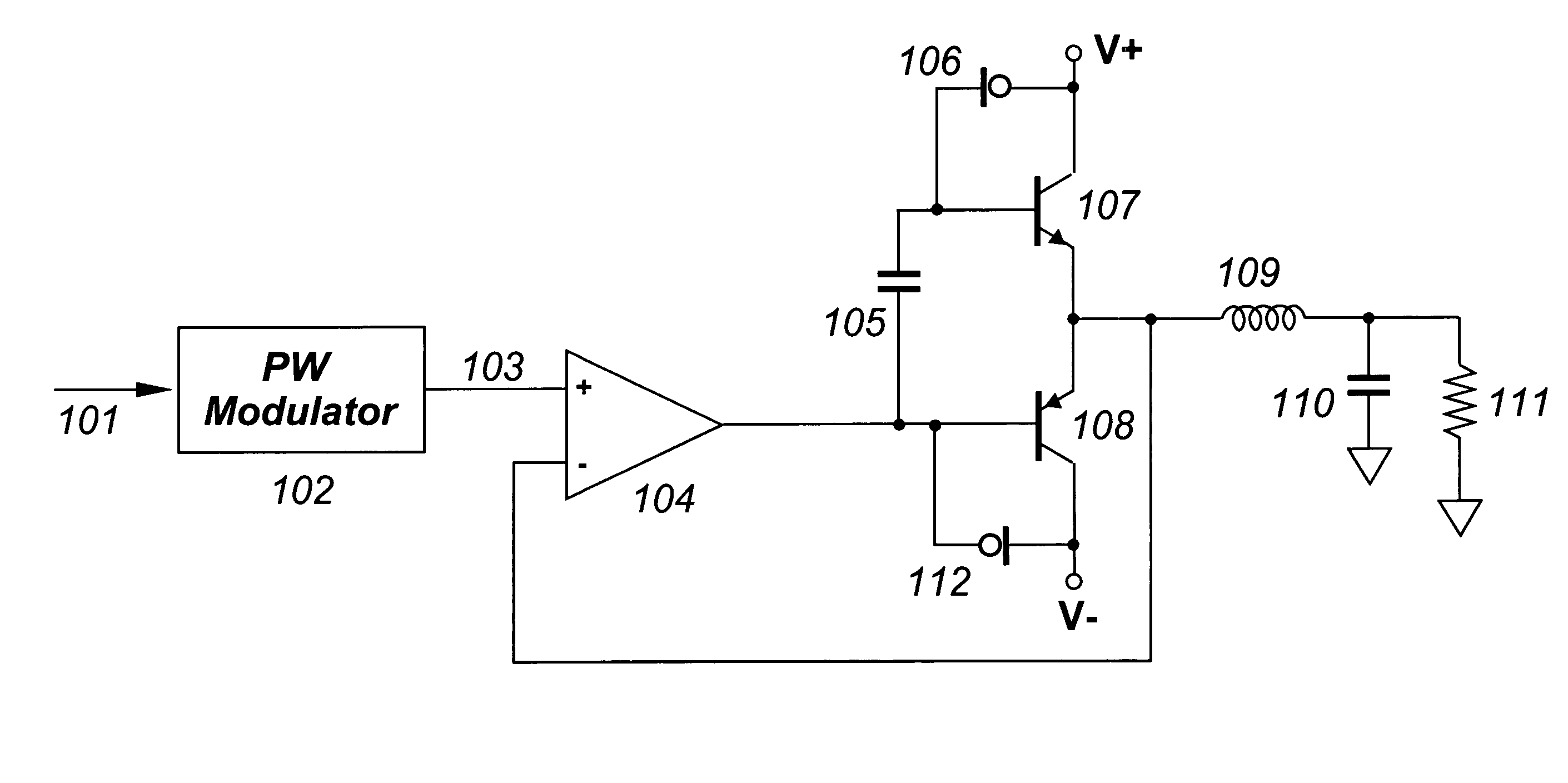

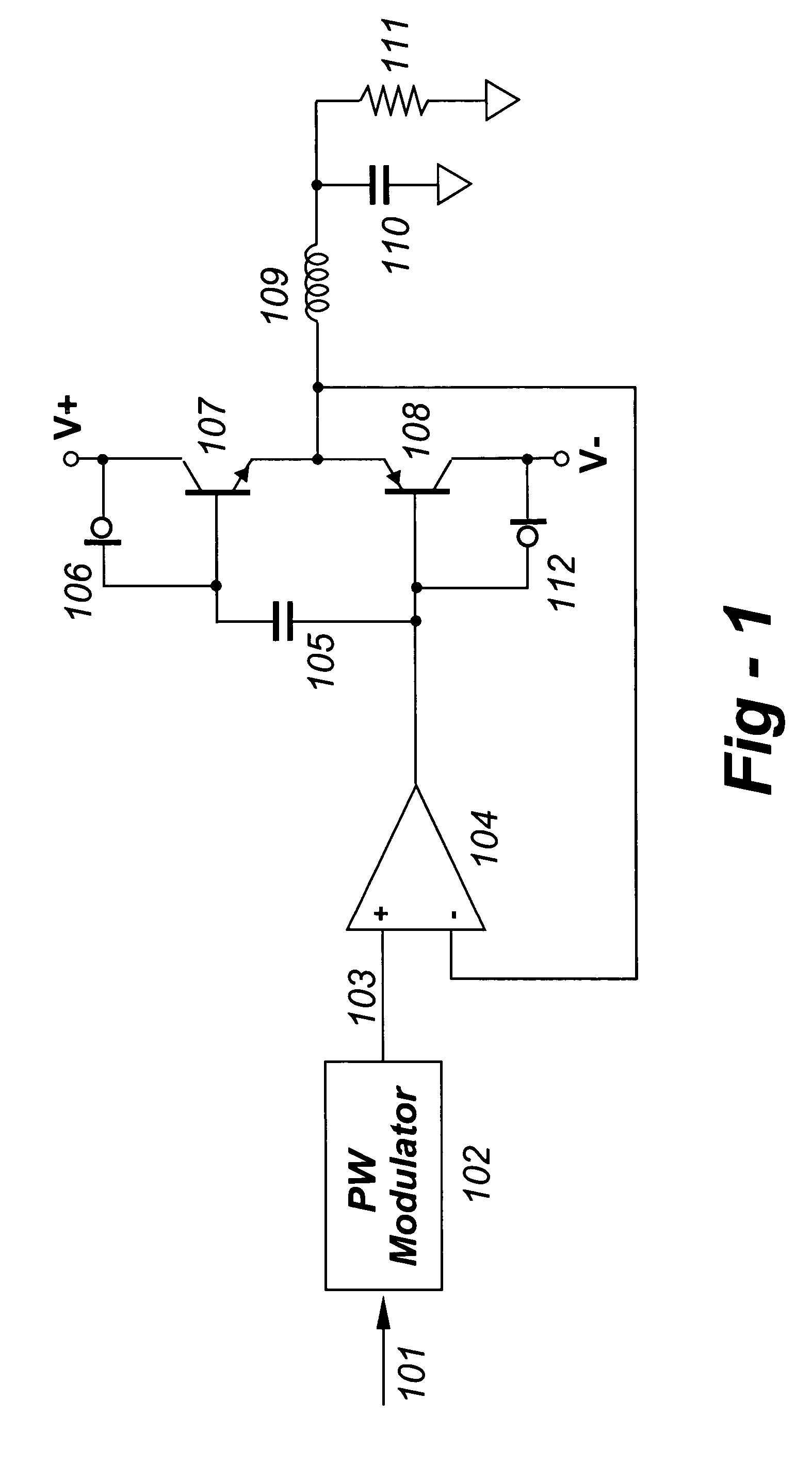

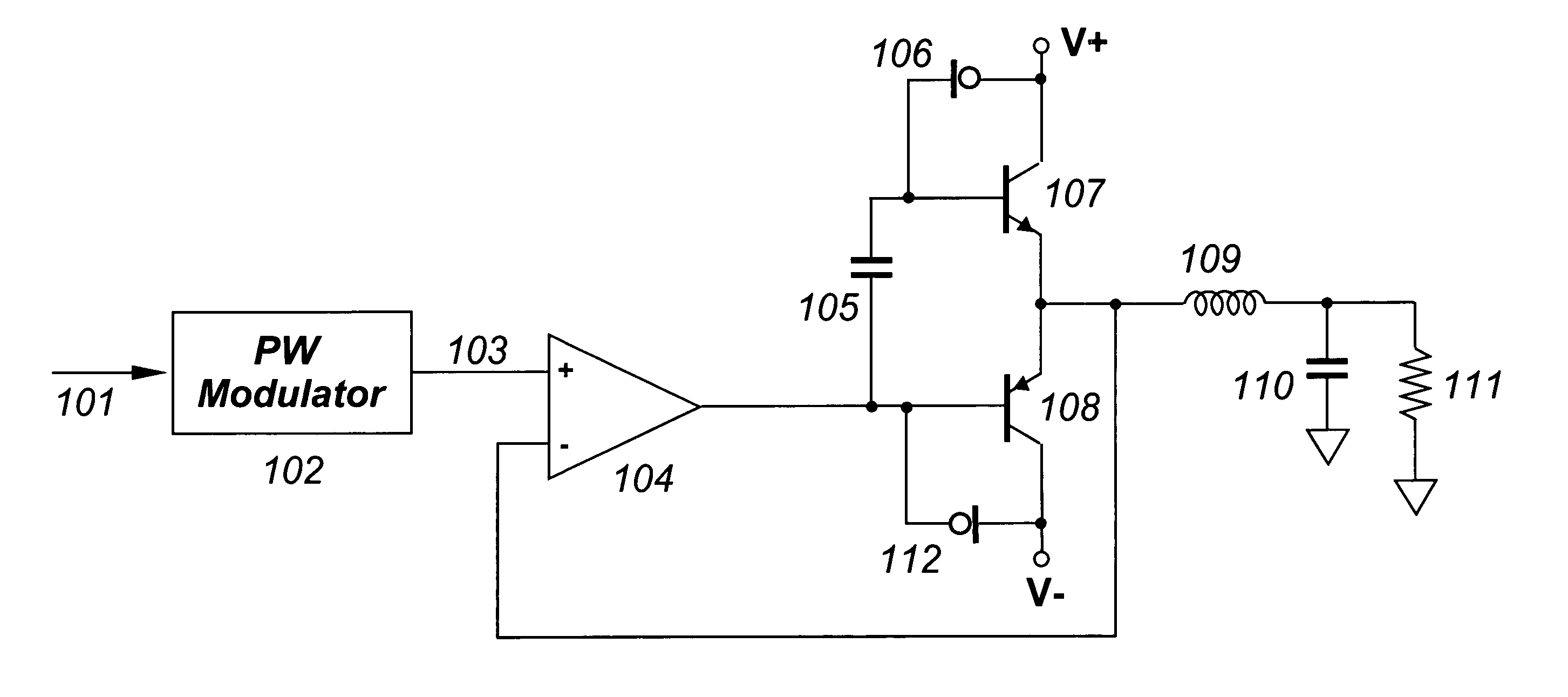

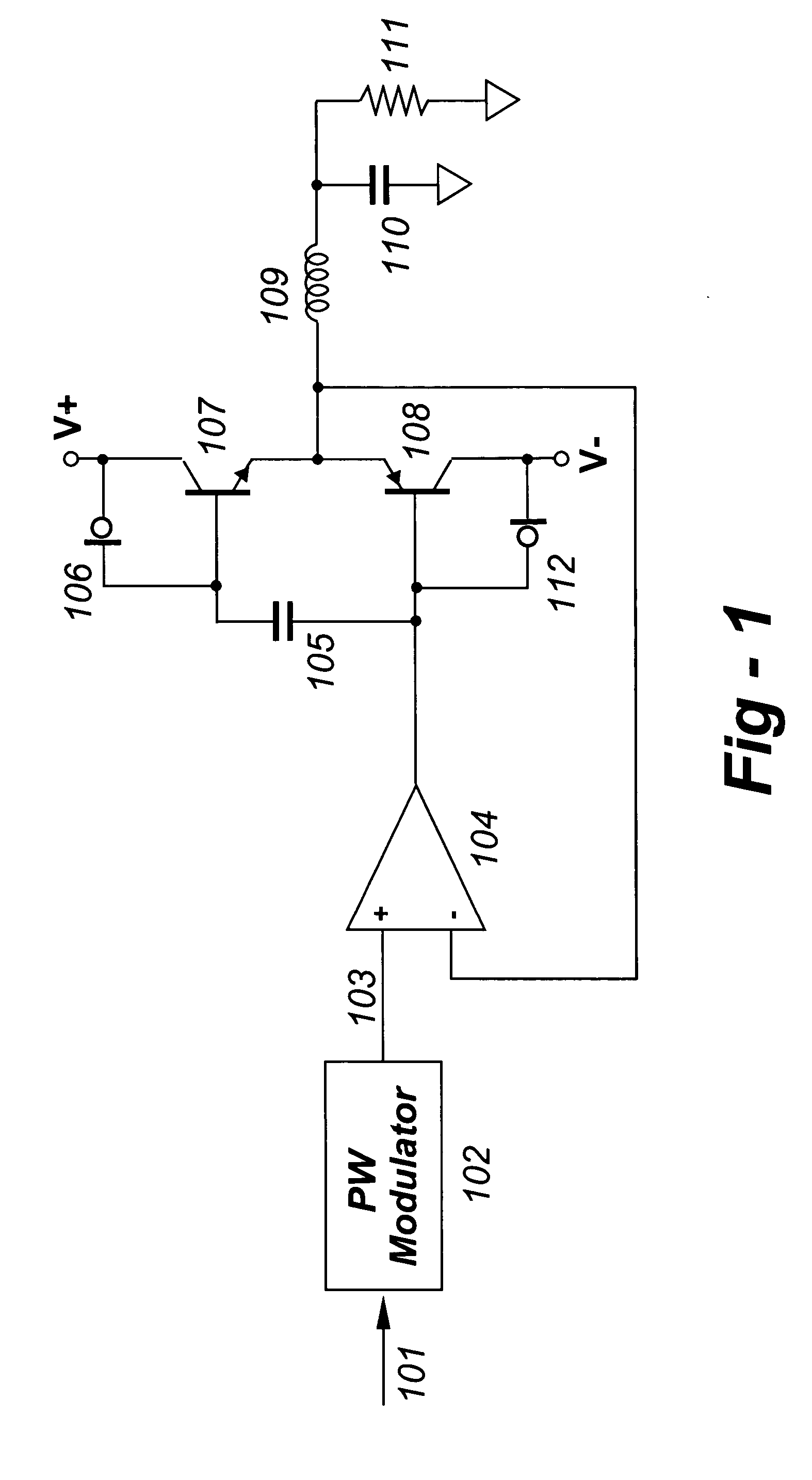

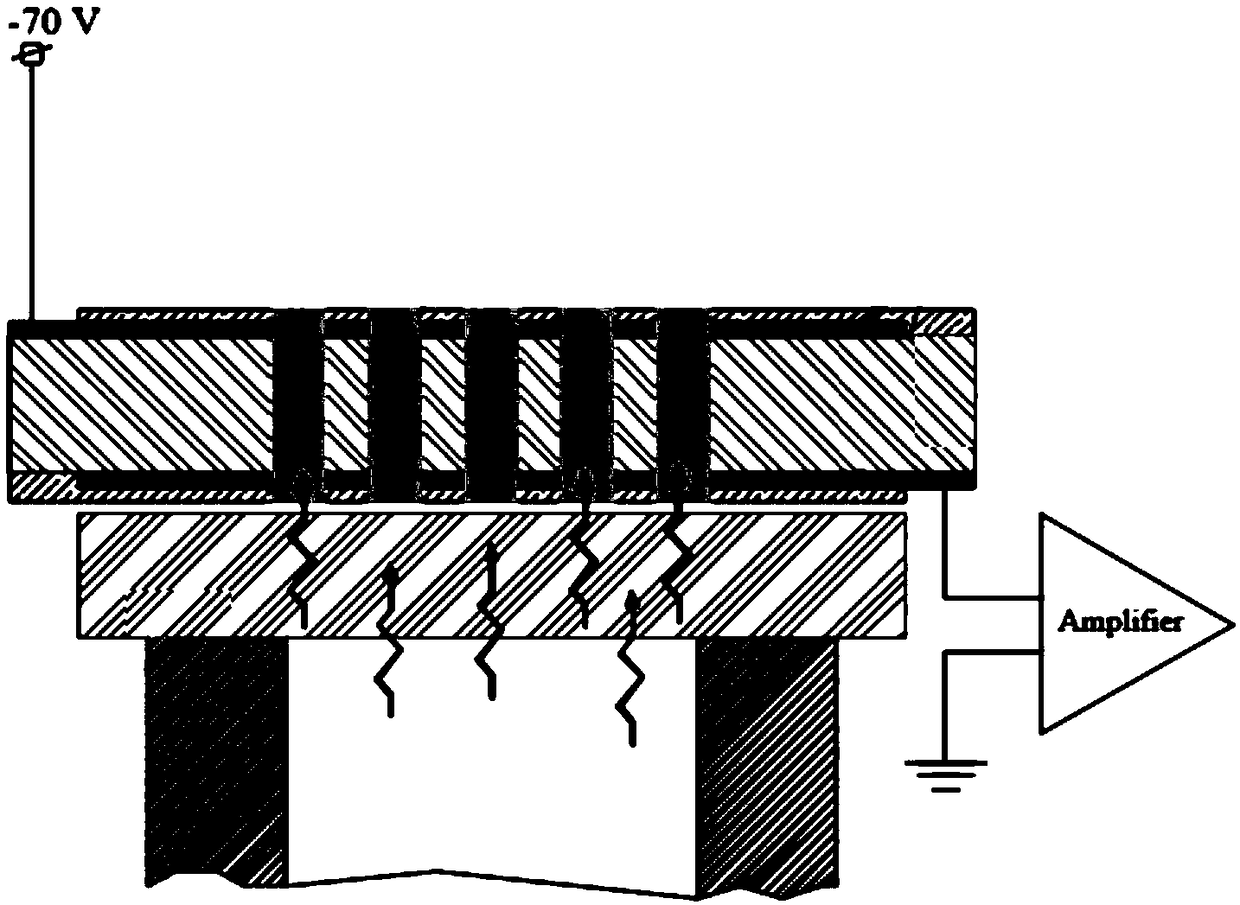

Switching class A-B amplifier

A circuit configuration and a method enables less-expensive bipolar switching devices to be employed in high-accuracy class D amplifiers. A constant-bias current is provided between the switching devices of a class D amplifier, and, through feedback or appropriate alternative implementation, the output levels of the class D amplifier achieve deterministic voltage levels regardless of current.

Owner:CHARTOLEAUX

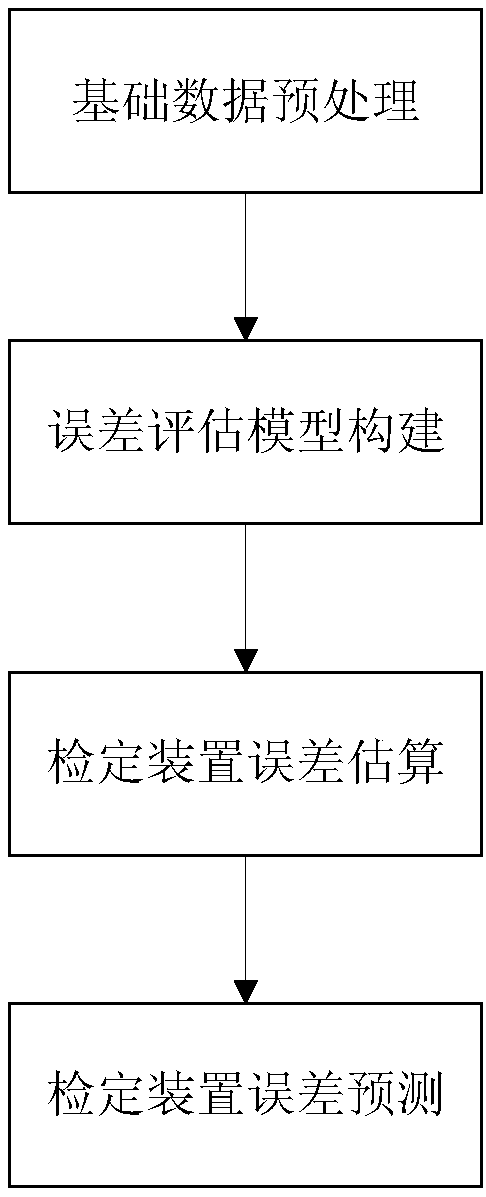

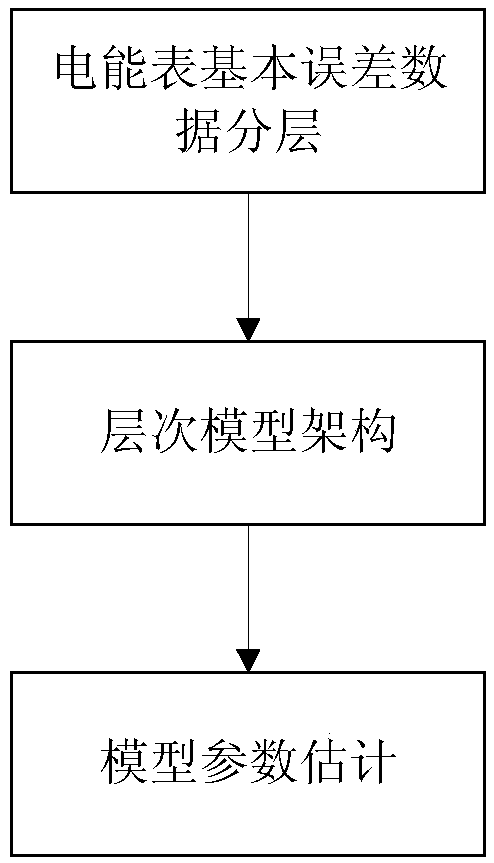

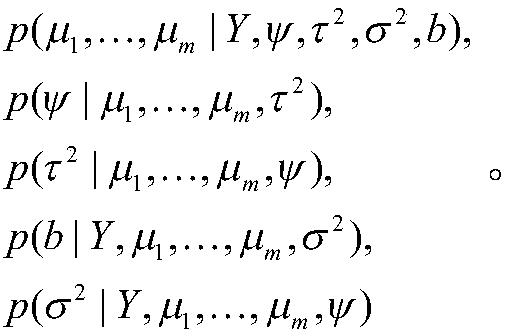

Electric energy meter calibrating device error online evaluation method

ActiveCN108445435AImprove normativeImprove economyElectrical measurementsTrend predictionErrors and residuals

The invention discloses an electric energy meter calibrating device error online evaluation method, including the following steps: (1) pre-processing basic data; (2) establishing an error evaluation model; (3) estimating errors of a calibrating device, using electric energy meter basic error experimental data as input, and using an error evaluation algorithm, to obtain calibrating device error distribution, so as to obtain statistical information of error distribution mean values and mid-values, and complete calibrating device error estimation; (4) predicting errors of the calibrating device,based on electric energy meter calibrating device error estimation history, using a time sequence prediction method to complete calibrating device error trend prediction. The method integrates large amount of basic error experimental data of low-accuracy class electric energy meters into a virtual standard electric energy meter equivalent to high accuracy level, and performs real-time online monitoring and trend prediction on errors of the electric energy meter calibrating device, and completes electric energy meter calibrating device error online evaluation, so as to improve normalization, economical efficiency, and timeliness of calibrating device error evaluation.

Owner:NARI TECH CO LTD +4

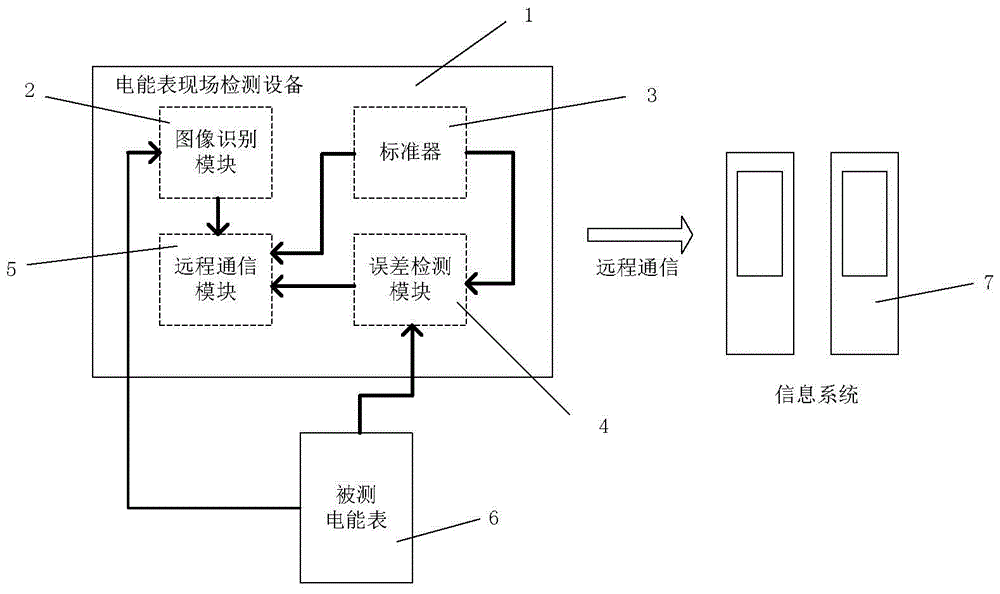

Electric energy meter field detection equipment having automatic quantity value source tracing function

InactiveCN106405474ARealize automatic value traceability functionImprove work efficiencyElectrical measurementsCommunications securitySecurity authentication

The invention discloses electric energy meter field detection equipment having an automatic quantity value source tracing function. The electric energy meter field detection equipment comprises four parts of an image identification module, an etalon, an error detection module and a remote communication module. The image identification module identifies the meter number, the model number, the specification and the accuracy class of a detected electric energy meter through an optical sensor. The etalon has an electric energy metering standard value measurement function and provides an equipment unique electronic identifier. The error detection module is internally provided with a value comparator and used for electric energy meter error detection. The remote communication module is provided with a security authentication submodule which is internally provided with an information security encryption algorithm so that the communication security between the electric energy meter field detection equipment and a metering management center information system can be guaranteed and automatic quantity value source tracing can be realized. The electric energy meter field detection equipment is suitable for the field of electric energy metering, electric power system automation and the like so as to have the characteristics of being accurate and efficient, secure and reliable and convenient to configure and have wide market prospect.

Owner:CHINA ELECTRIC POWER RES INST +1

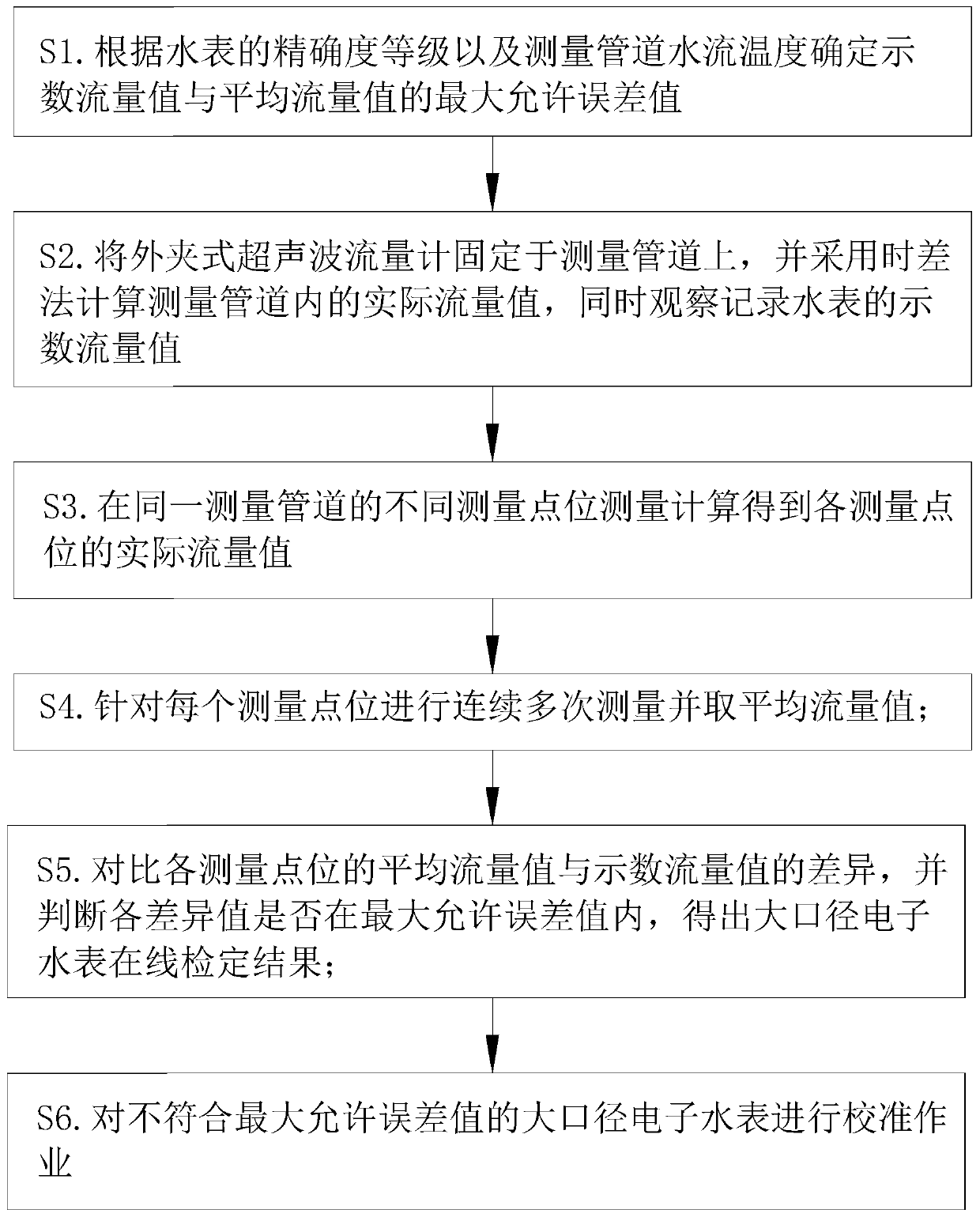

Large-diameter electronic water meter online verification method

ActiveCN110274669AWill not affect normal lifeRealize online verification workTesting/calibration for volume flowMeasurement pointWater flow

The invention discloses a large-diameter electronic water meter online verification method and relates to the technical field of water meter verification. The method comprises the following steps of: S1, determining the maximum allowable error value of a water meter according to the accuracy class of the water meter and the temperature of a water flow; S2, fixing an externally clamped ultrasonic flowmeter to a measured pipeline to measure an actual flow value in the pipeline; S3, measuring the actual flow values of various measurement points at the respective measurement points of the measured pipeline; S4, measuring each measurement point multiple times and taking an average flow value; and S5, obtaining a difference between the average flow value and a displayed flow value to obtain the online verification result of the large-diameter electronic water meter. In the verification process, the externally-clamped ultrasonic flowmeter measures the actual flow value in the measured pipeline, which does not affect the normal living and production water of residents and factories, and does not occupy or interrupt the normal use of the large-diameter electronic water meter, namely achieves the online verification of the large-diameter electronic water meter.

Owner:上海市供水水表强制检定站有限公司

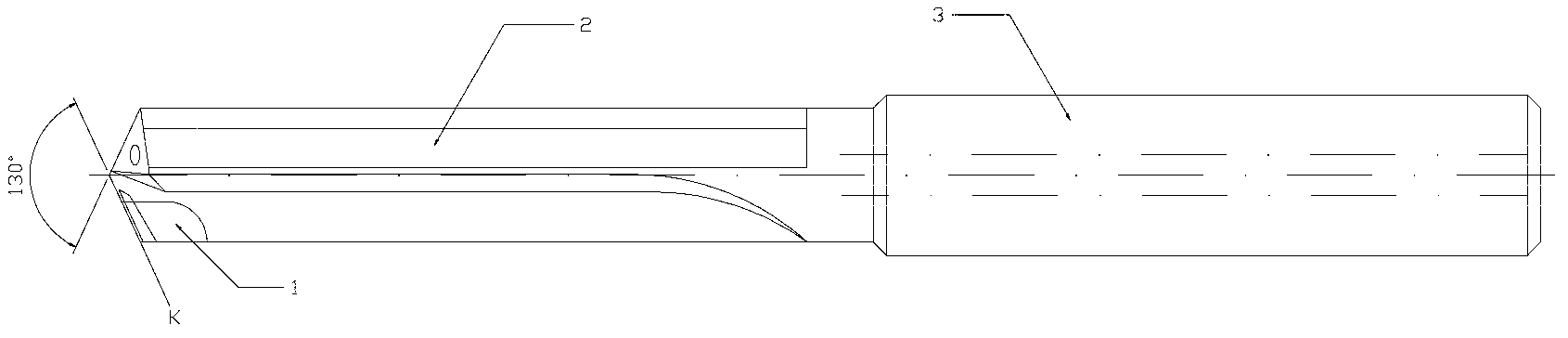

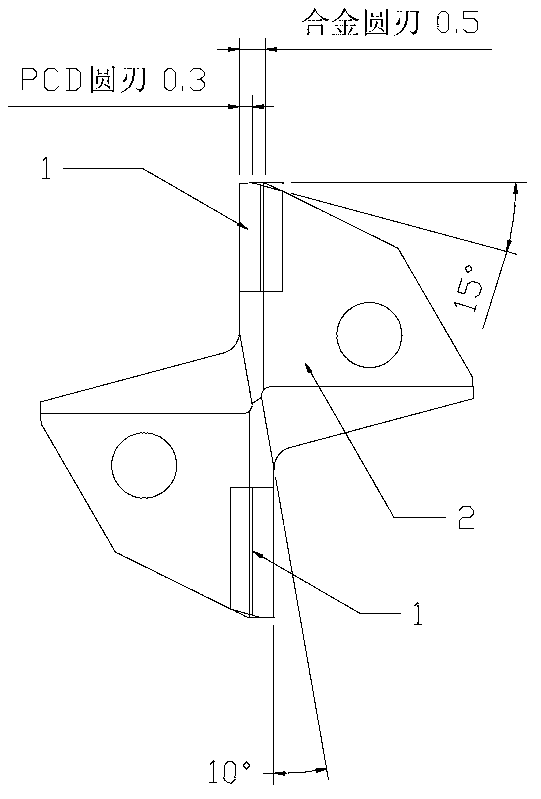

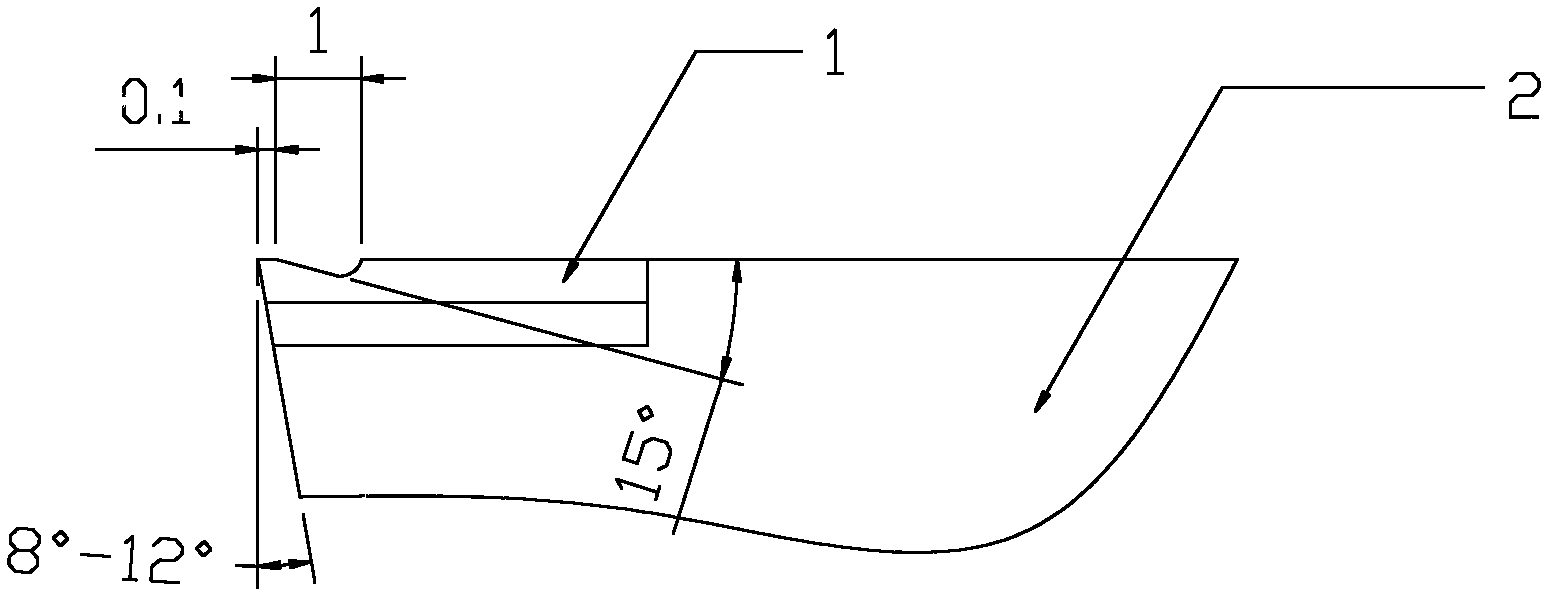

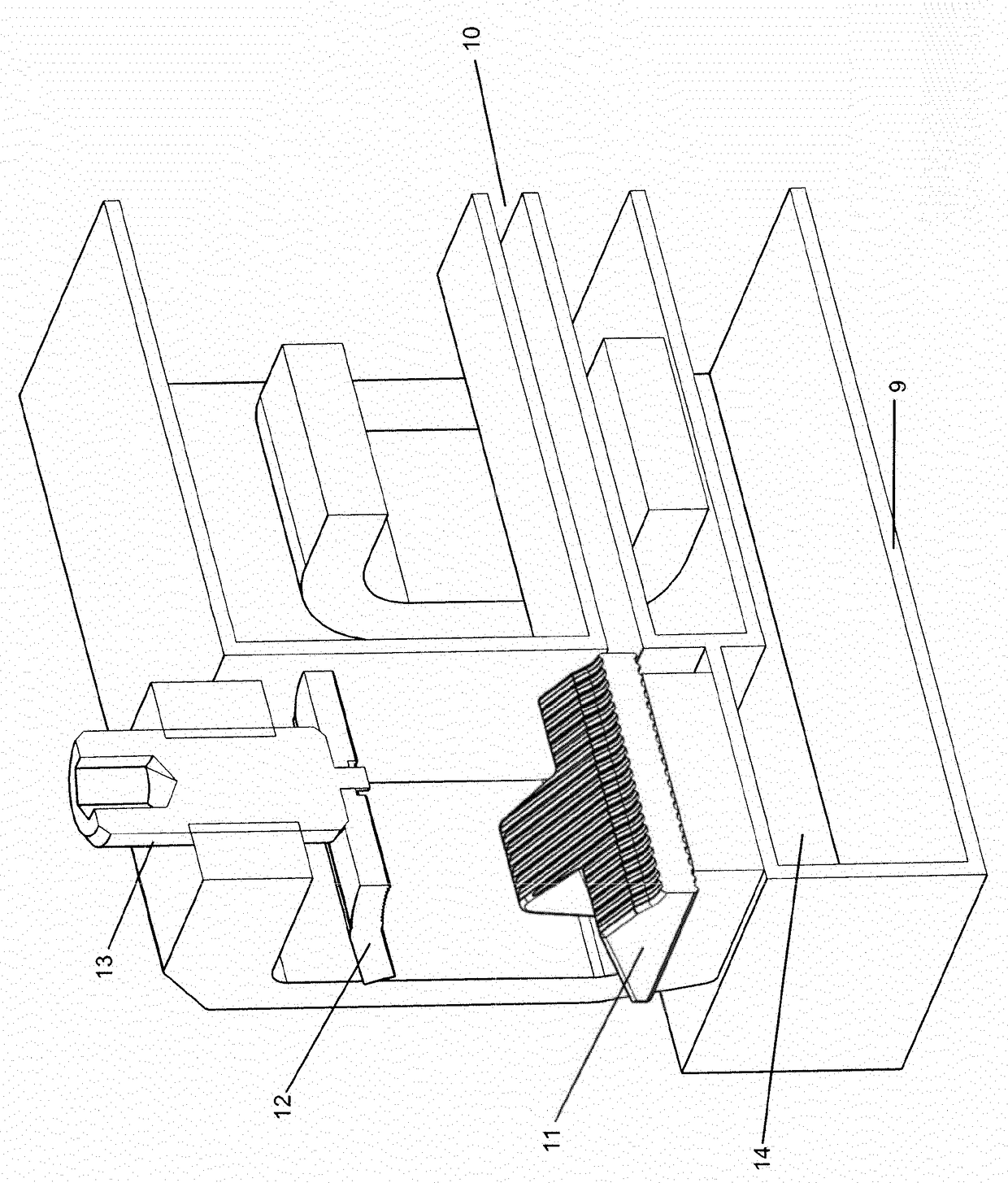

PCD (pitch circle diameter) drill bit with chip breaker groove

ActiveCN103008735AImprove surface roughnessSatisfy the requirements of precision gradeTransportation and packagingTrepanning drillsSurface roughnessMachining time

The invention discloses a PCD (pitch circle diameter) drill bit with a chip breaker groove, which comprises a shank, a cutter body and PCD blades, wherein two cooling liquid holes are formed in the axial direction of the cutter body and penetrate through the shank and the cutter body; two chip pockets are formed on the cutter body in the axial direction thereof, are oppositely symmetrical in an end-view, occupy one quadrant of circle; the two PCD blades are embedded at the front end of the cutter body as drill lips in a welding way; the vertex angle at the drill tip is 130 degrees; the relief angle at the end edge of the drill bit is 8 to 12 degrees; the angle of a chip separating groove is 10 degrees; a PCD round blade is 0.3 mm; the relief angle of the round blade is 15 degrees; a round blade of the cutter body is 0.5 mm; and a chip breaker groove which has a 15-degree front angle and the width of 1 mm is formed at the place which is 0.11 mm near the end edge of the drill bit on a PCD upper surface. When the PCD drill bit is used for cutting machining, as the end edge of the drill bit has the function of chip breaking, the original long chip can be turned into short chip to be smoothly discharged from a chip space without scratching a hole wall, so that the surface roughness of the hole can be improved, the accuracy class requirement of the hole can be easily met, a lot of machining time can be saved, and the production cost can be reduced.

Owner:博澳精密工业(大连)有限公司

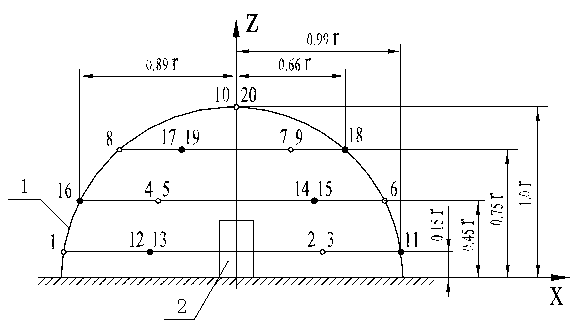

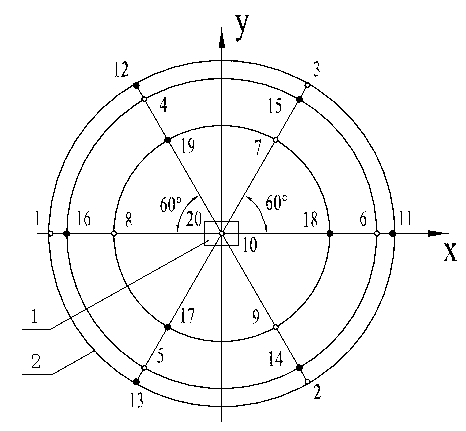

Method of determining noise measuring point arrangement based on mean deviation

ActiveCN103226037AMeet the uncertainty requirementsSubsonic/sonic/ultrasonic wave measurementUsing electrical meansSound powerAccuracy class

The invention relates to the field of noise measuring, in particular to a method of noise measuring point arrangement. The method of determining the noise measuring point arrangement based on a mean deviation comprises the steps that a mean deviation threshold of the measuring point arrangement is obtained according to a noise measuring accuracy class; a measuring distance is determined; a measuring surface is obtained; positions and quantity of initial noise measuring points are determined according to the accuracy class and the measuring distance; a mean deviation measured value is calculated according to a noise measuring result; the mean deviation measured value and the mean deviation threshold of the measuring point arrangement are compared; measuring point arrangement completion or measuring point increase is decided; and the measuring points are rearranged until the mean deviation measured value is smaller than or equal to the threshold. The method is used for determining the noise measuring point arrangement based on the mean deviation, so that the measuring uncertainty caused by noise measuring point arrangement factors can be quantified, and can be controlled effectively; and therefore, the uncertainty of a noise sound power level measuring result can meet an uncertainty requirement specified by the corresponding accuracy class.

Owner:SAIC MOTOR

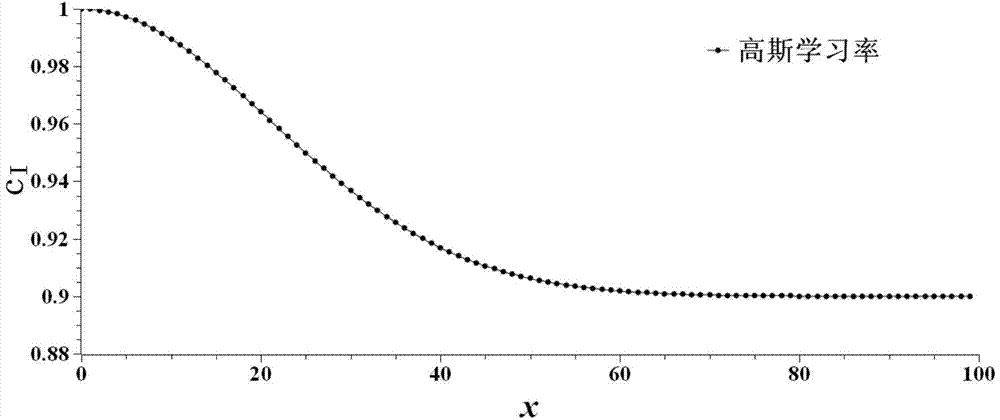

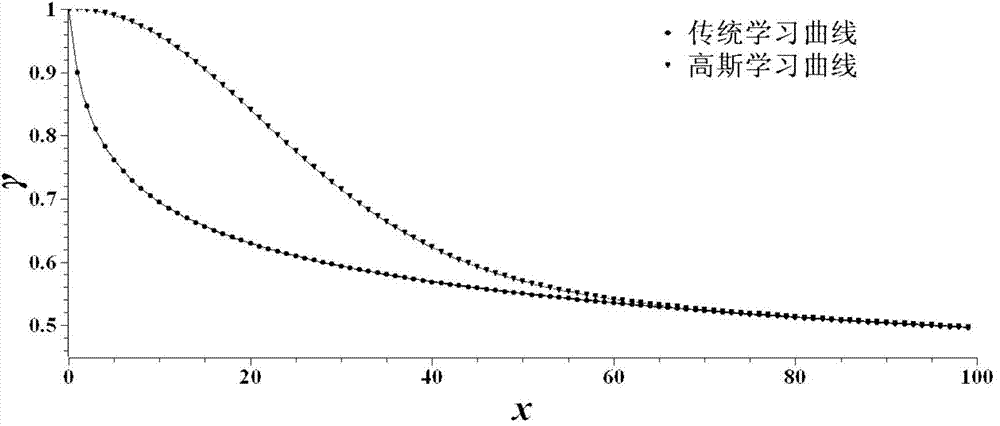

Method for calculating production capability of airplane assembly line workers

InactiveCN104123672AImprove the accuracy of annual output solutionAvoid subjective amplificationData processing applicationsAssembly lineUltimate tensile strength

Owner:NORTHWESTERN POLYTECHNICAL UNIV

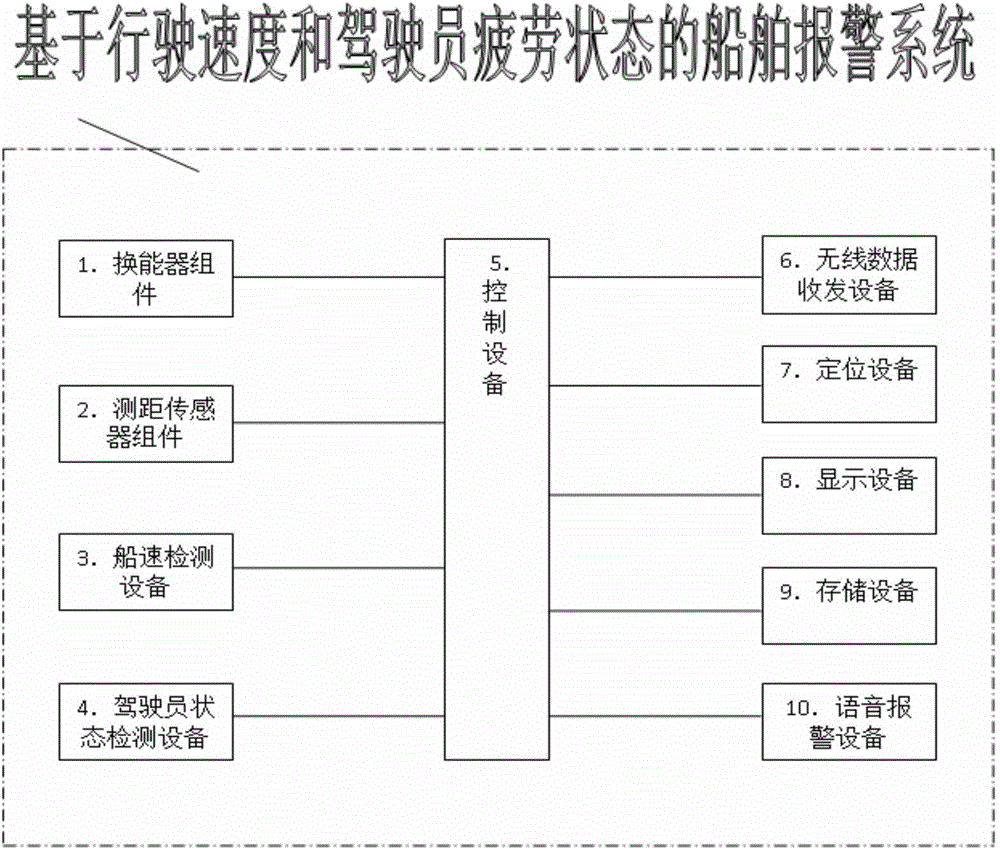

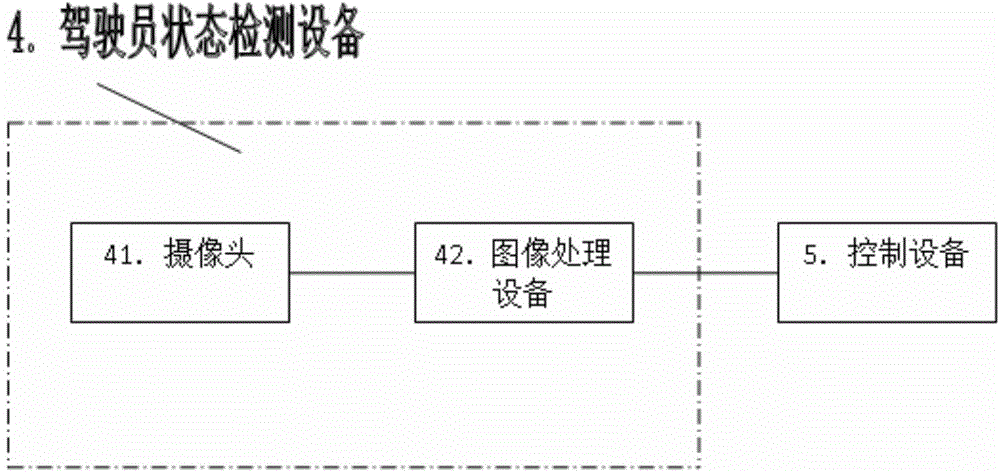

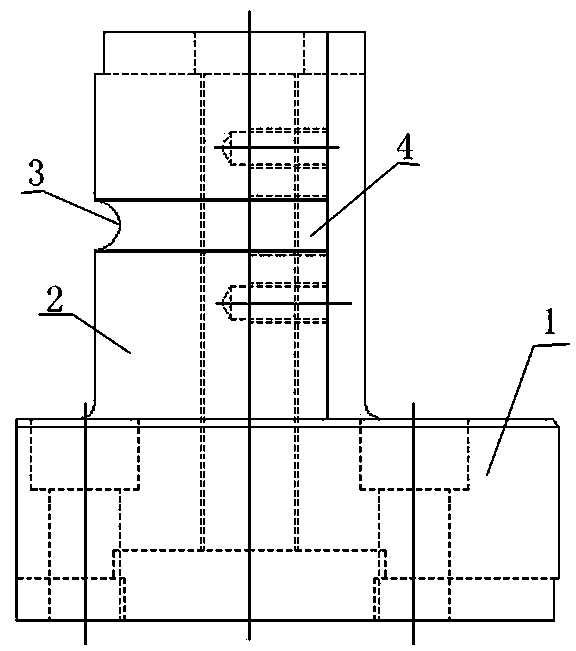

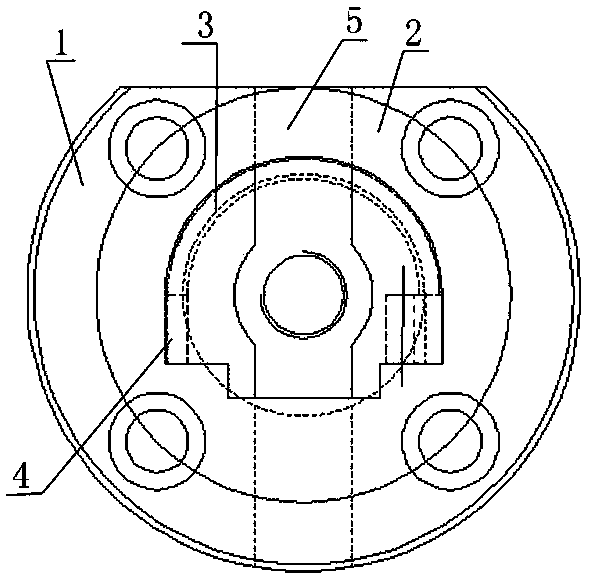

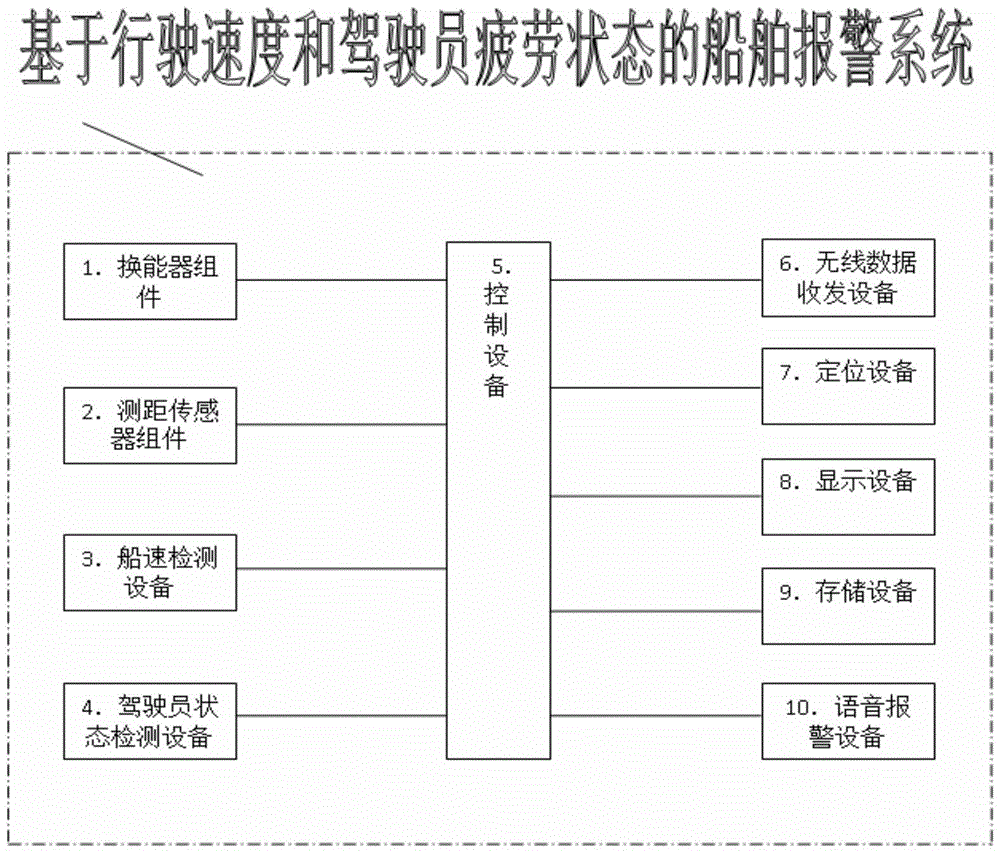

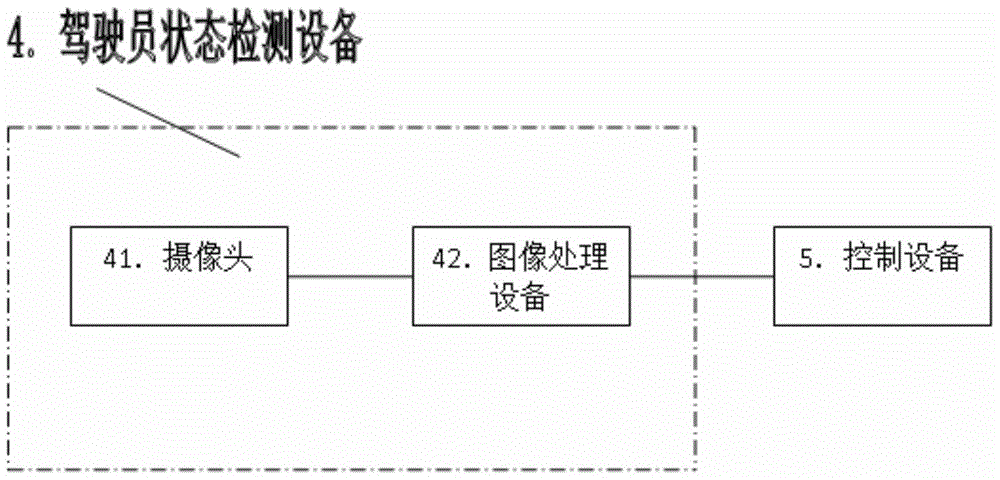

Ship alarming method

InactiveCN104485021AFlexible determination of maximum speedTimely deliveryNavigational aid arrangementsMarine craft traffic controlDriver/operatorMarine engineering

The invention relates to a ship alarming method which comprises a step of providing a ship alarming system based on the traveling speed and a driver's fatigue state. The system comprises a transducer assembly, a distance measuring sensor assembly, ship speed detection equipment, control equipment and driver's fatigue state detection equipment, wherein the control equipment is connected with the transducer assembly, the distance measuring sensor assembly, the ship speed detection equipment and the driver's fatigue state detection equipment respectively; the measurement accuracy class of the transducer assembly is controlled on the basis of the ship traveling speed output by the ship speed detection equipment; whether the ship traveling speed is alarmed is determined on the basis of measurement results of the transducer assembly and the distance measuring sensor assembly; and whether the driver's fatigue state is alarmed is determined on the basis of the detection result of the driver's fatigue state detection equipment. With adoption of the ship alarming method, the ship traveling safety is improved, accidents of ship hull collision are avoided, economic loss of a ship operator is reduced, and the screw and goods on the ship are prevented from damage.

Owner:CHONGQING JIAOTONG UNIVERSITY

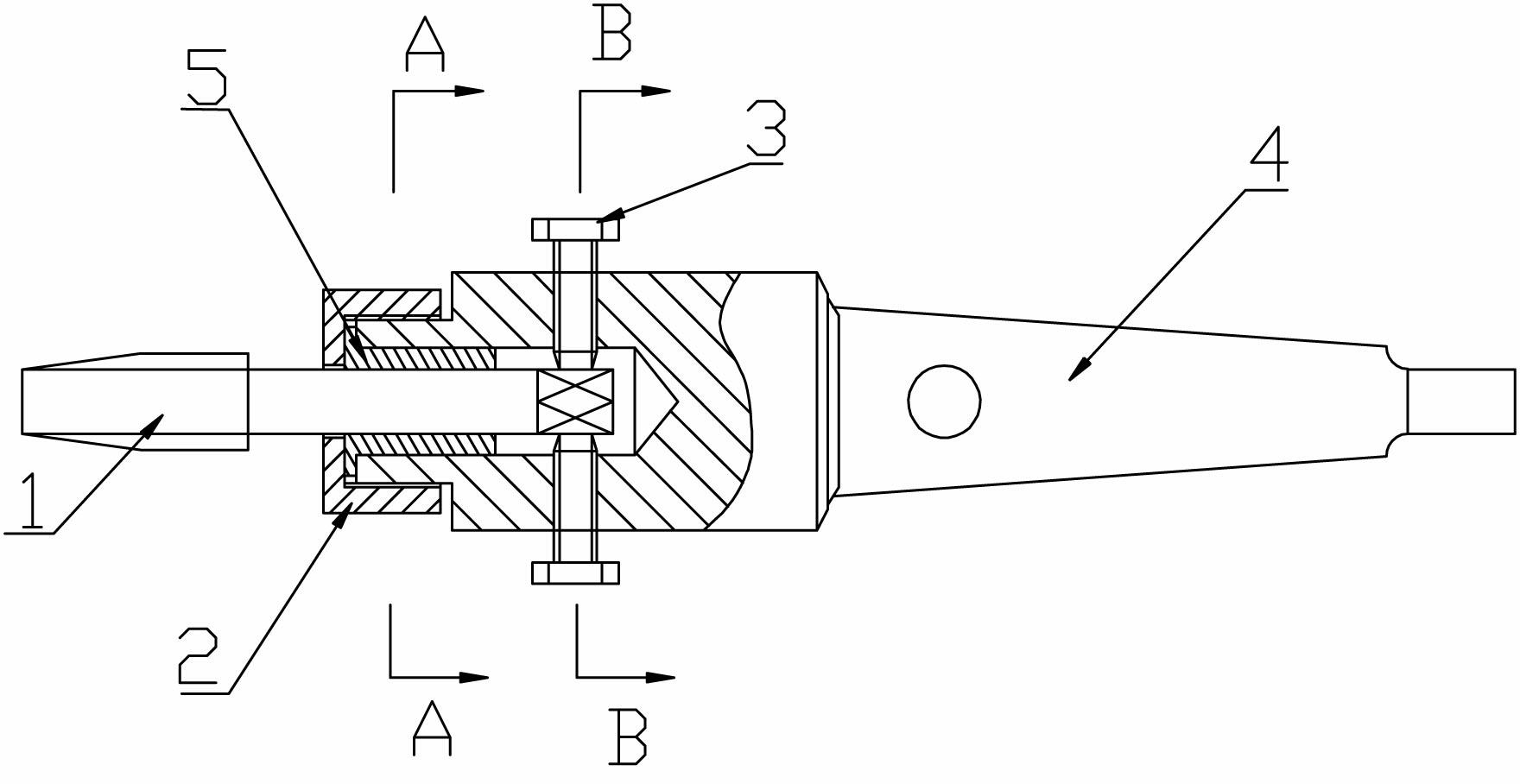

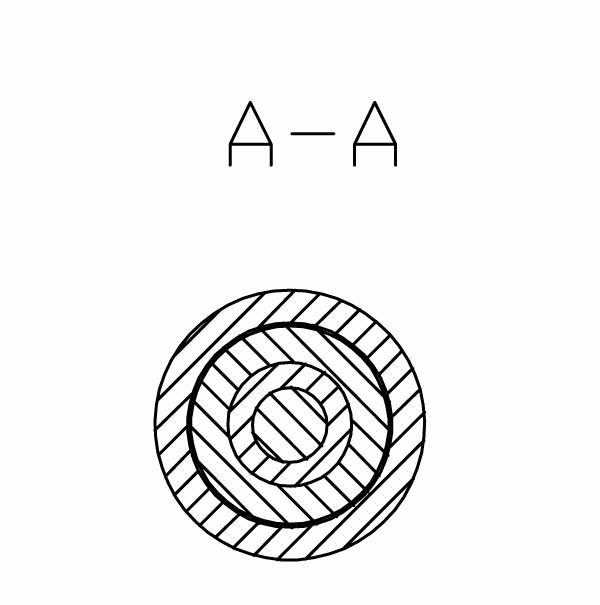

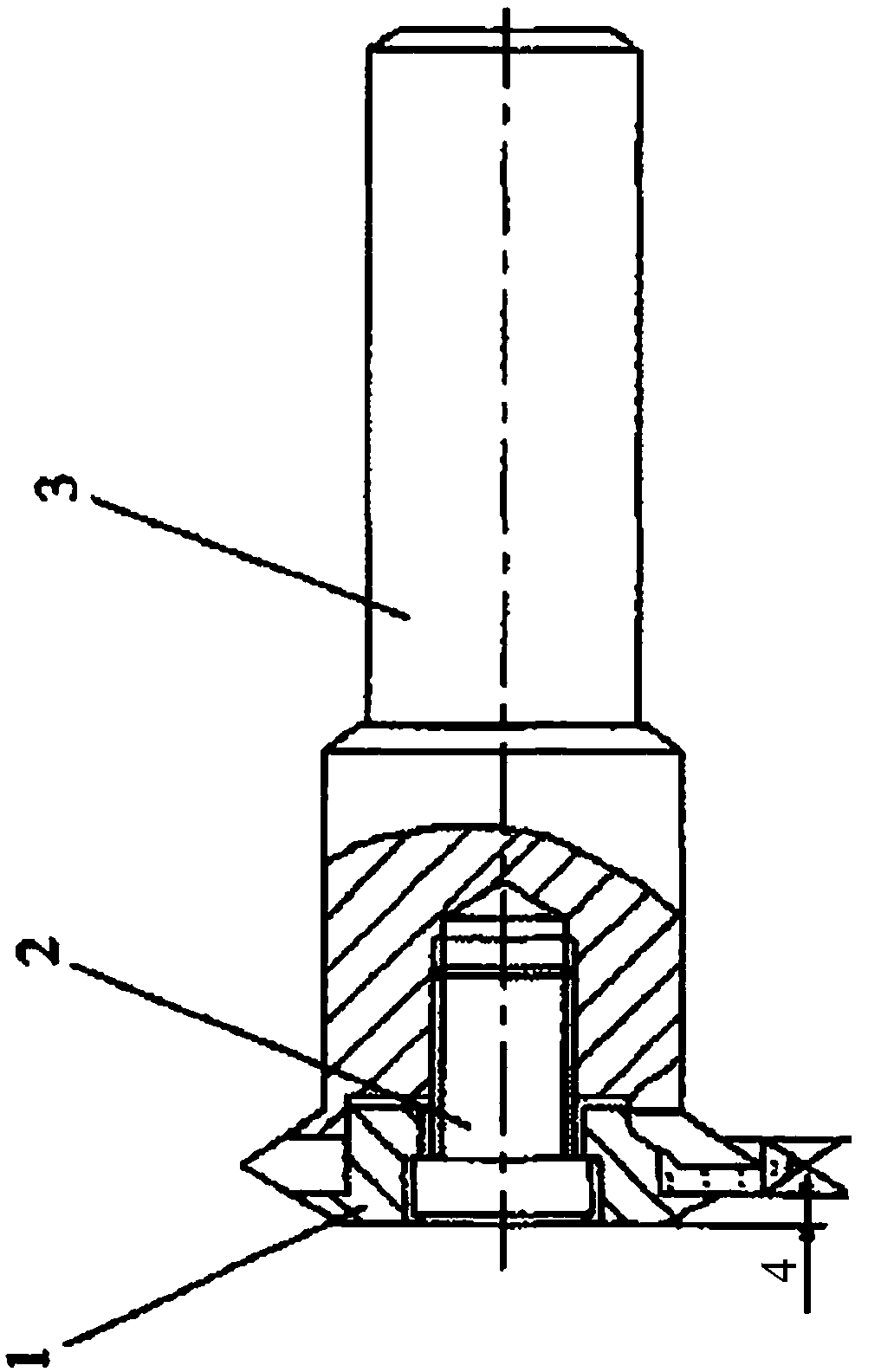

Mechanical thread tapper

InactiveCN102463398ATapping torque is not largeImprove coaxialityThread cutting machinesAccuracy classIndustrial engineering

The invention discloses a mechanical thread tapper. A conical rod is arranged at one end of a clamping body; a clamping surface is formed at one end of the conical rod; a clamping hole is formed at the other end of the clamping body; a positioning sleeve is arranged in the clamping hole by a clamping sleeve; and a plurality of positioning bolts are arranged at positions on the same section of the clamping hole. The mechanical thread tapper can improve tapping efficiency; the adopted four positioning bolts can conveniently adjust the coaxiality of a screw tap; meanwhile, the positioning sleeve has a smaller volume and can be processed to higher accuracy class conveniently, so that the tapping accuracy is improved; and the high-precision positioning sleeve is also favorable for the coaxiality of the screw tap such as the coaxiality and perpendicularity with a drilling machine, so that the vibration of the screw tap at work is reduced, and the instantaneous stress of the screw tap is reduced. After the specification of the screw tap is changed, only the corresponding positioning sleeve is required to be installed. In the invention, the coaxiality and perpendicularity can ensure that the tapping torque of the screw tap is small, so a standard screw tap can be used for processing on the drilling machine, the cost is saved, and the tapping efficiency is greatly improved.

Owner:长航集团宜昌船厂有限公司

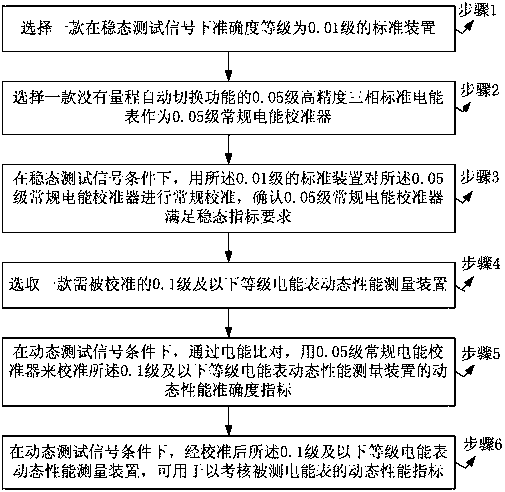

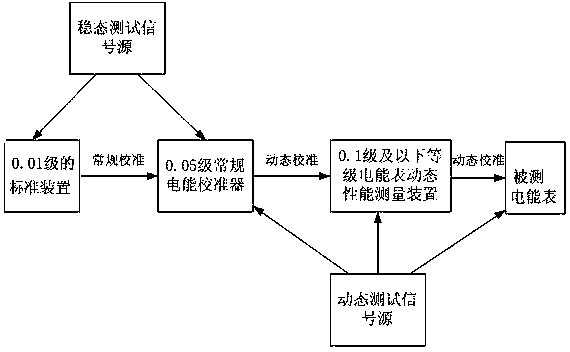

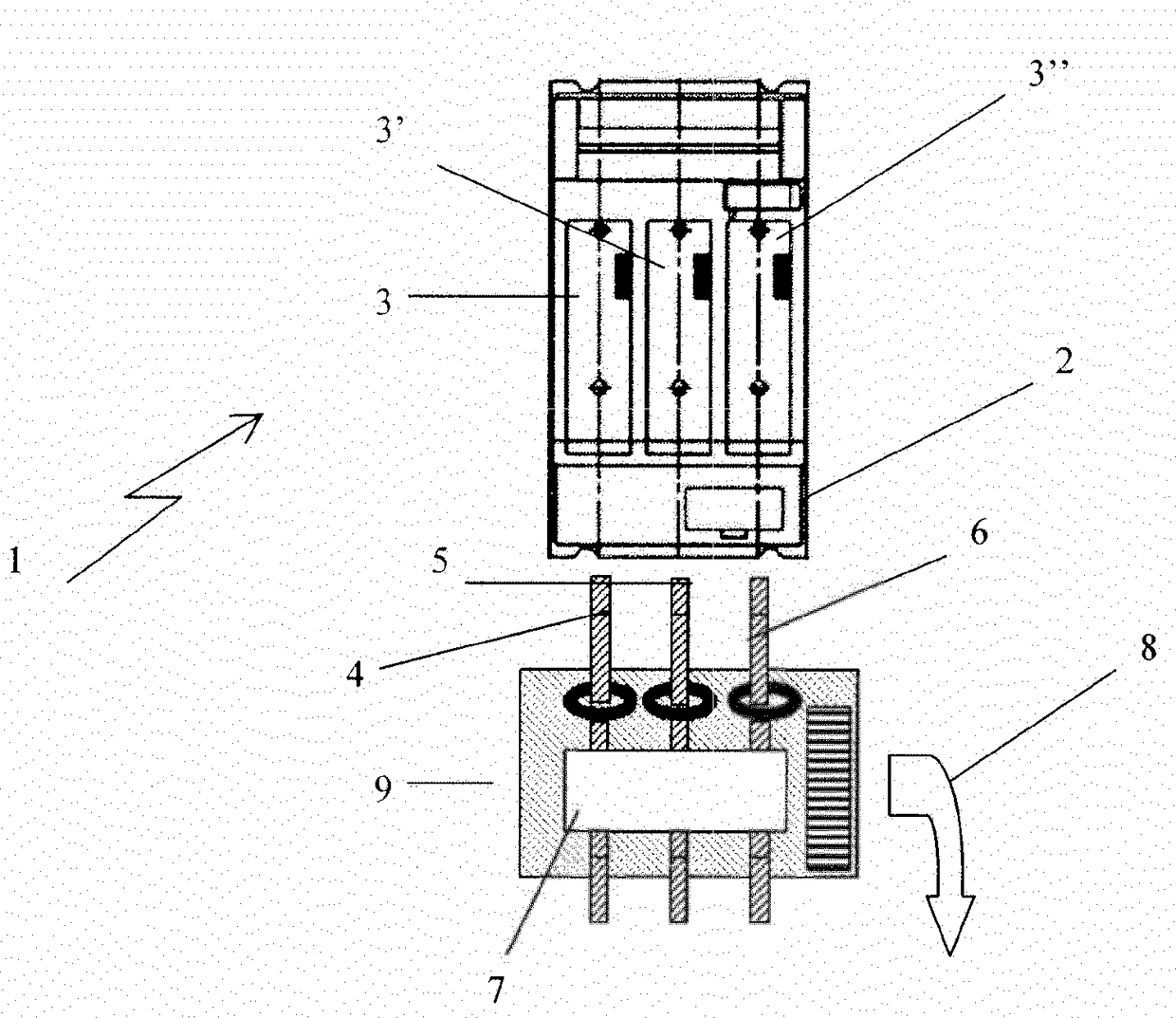

Conventional electric energy calibrator-based dynamic performance tracing method

ActiveCN107589396ASolve the traceability problemRealize traceabilityElectrical measurementsMeasurement deviceThree-phase

A conventional electric energy calibrator-based dynamic performance tracing method is disclosed and comprises the following steps: (1) a standard device which is 0.01 grade in accuracy class in a steady state test signal condition is chosen; (2) 0.05 grade high precision three phase standard electric energy meter without any automatic measuring range switching function is chosen as a 0.05 grade conventional electric energy calibrator; (3) in the steady state test signal condition, the 0.01 grade standard device is used for subjecting the 0.05 grade conventional electric energy calibrator to conventional calibration, and that the 0.05 grade conventional electric energy calibrator meets requirements for steady state indexes is ensured; (4) a 0.1 grade electric energy meter dynamic performance measurement device which needs to be calibrated is chosen; (5) in a dynamic test signal condition, the 0.05 grade conventional electric energy calibrator is used for calibrating dynamic performanceaccuracy indexes of electric energy meter dynamic performance measurement devices which are 0.1 grade and less than 0.1 grade in accuracy class via electric energy comparison; (6) in the dynamic testsignal condition, the calibrated electric energy meter dynamic performance measurement devices are used for calibrating the dynamic performance accuracy indexes of a detected electric energy meter.

Owner:STATE GRID JIANGXI ELECTRIC POWER CO LTD RES INST +1

Switching class A-B amplifier

A circuit configuration and a method enables less-expensive bipolar switching devices to be employed in high-accuracy class D amplifiers. A constant-bias current is provided between the switching devices of a class D amplifier, and, through feedback or appropriate alternative implementation, the output levels of the class D amplifier achieve deterministic voltage levels regardless of current.

Owner:CHARTOLEAUX

A Trans-sea Elevation Transfer Measurement Method

ActiveCN104567800BReduce adverse effectsHigh precisionHeight/levelling measurementGeomorphologyObservation data

Owner:CHINA MAJOR BRIDGE ENERGINEERING

Mechanical clamping type inner thread turning cutter

InactiveCN103521859AImprove processing efficiencyGood effectThread cutting toolsSurface roughnessEngineering

The invention relates to a cutter, in particular to a mechanical clamping type inner thread turning cutter. The cutter comprises a cylindrical cutter rod, wherein one end of the cutter rod is provided with a cutter head, the cutter head is fixedly provided with a blade, and the cutter point of the blade is 0.3-0.5mm higher than the center of a main shaft of the cutter rod. When the mechanical clamping type inner thread turning cutter is used for cutting a high-hardness inner thread with a large nominal diameter, the surface roughness of the thread is low, the accuracy class can reach more than 2 levels, machining efficiency can be improved by about 4 times than that of a common cutter, and the effect is good.

Owner:SHAANXI SHENGMAI PETROLEUM

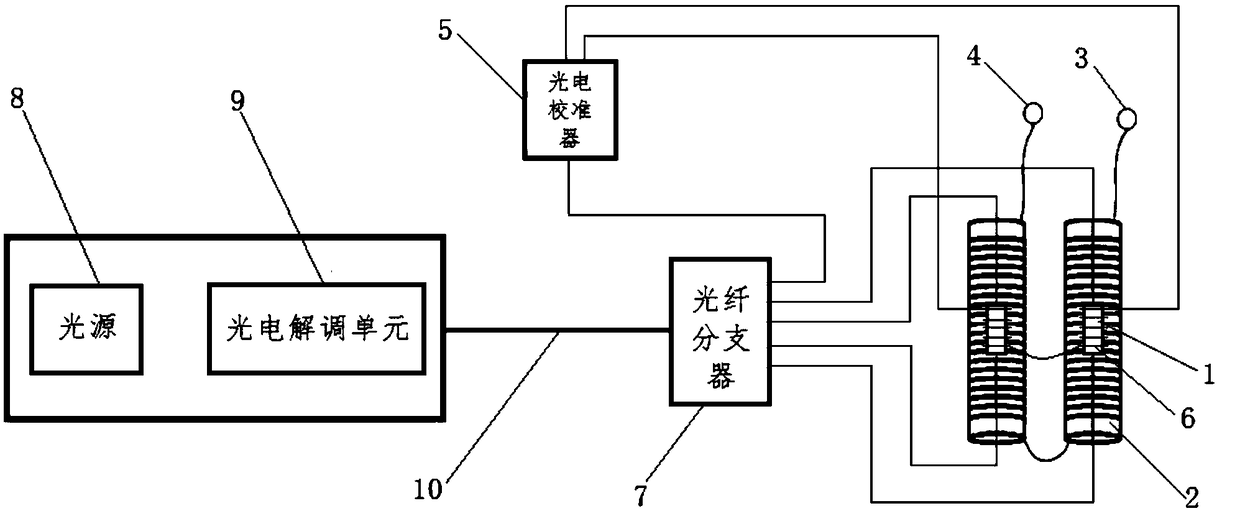

Optical current measurement device

InactiveCN108802470AEliminate distractionsHigh measurement accuracyCurrent measurements onlyVoltage/current isolationMeasurement deviceTransformer

The invention discloses an optical current measurement device. The optical current measurement device comprises a sensing head system, a dynamic calibration system, a photoelectric demodulation systemand an optical fiber splitter, wherein the sensing head system comprises one or more crystal light valve magnetic field sensors, one or more solenoids, a P1 current terminal and a P2 current terminal, wherein the two ends of each crystal light valve magnetic field sensor are connected with the optical fiber splitter through optical fibers; the dynamic calibration system is connected with a downlink optical interface of the optical fiber splitter through an optical fiber; the photoelectric demodulation system comprises a light source, a photoelectric demodulation unit and an optical cable andis connected with the optical fiber splitter through the optical cable. According to the optical current measurement device, influence of factors such as temperature, magnetic field and the like is eliminated, a current signal is amplified once by the solenoids, meanwhile, by means of differential dual-optical-path detection, external magnetic field interference is eliminated, measurement precision of an optical transformer is greatly improved, the minimum rated current capable of being measured is 0.5 A, and the accuracy class is 0.2S level.

Owner:江苏鑫航电力设备工程有限公司

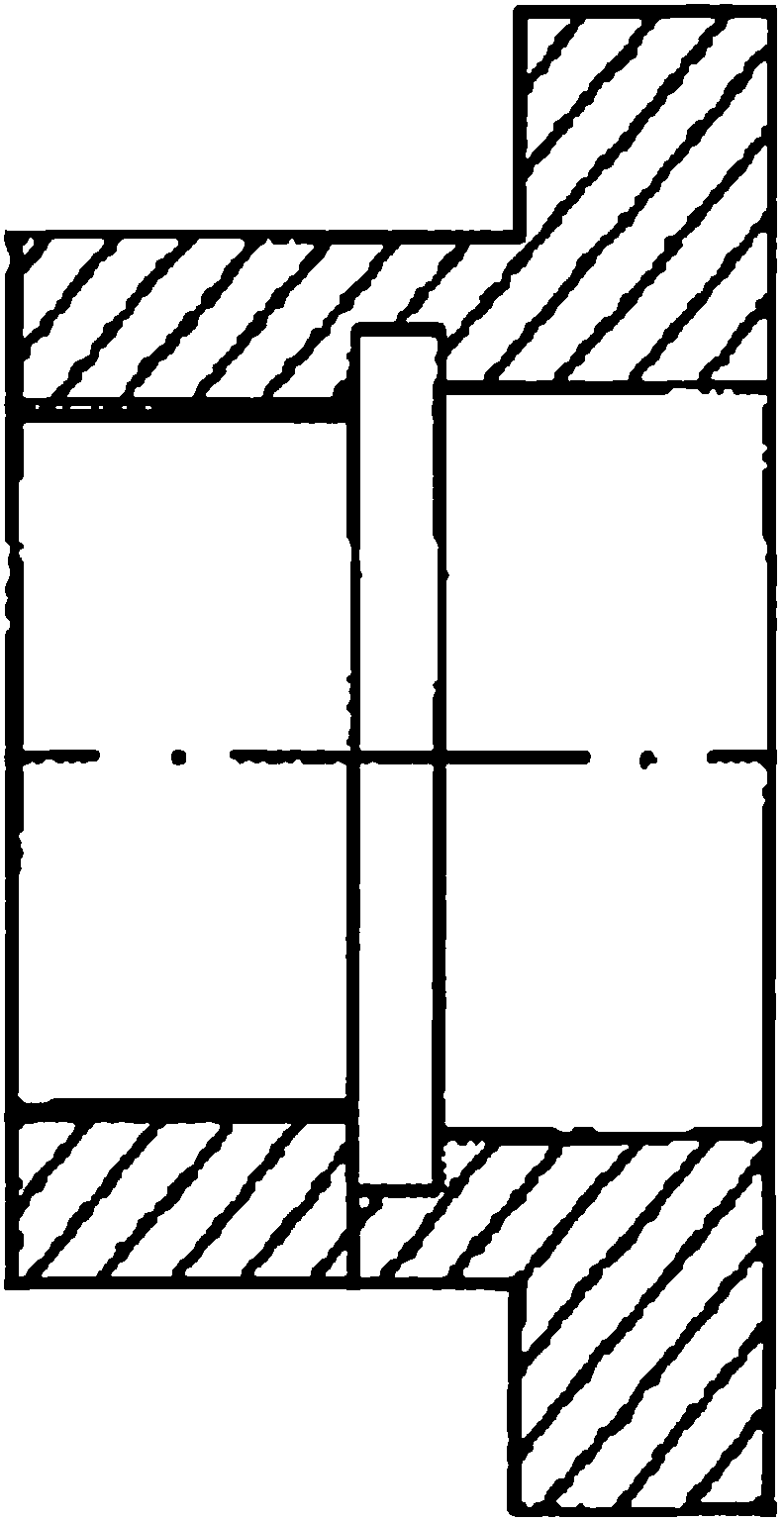

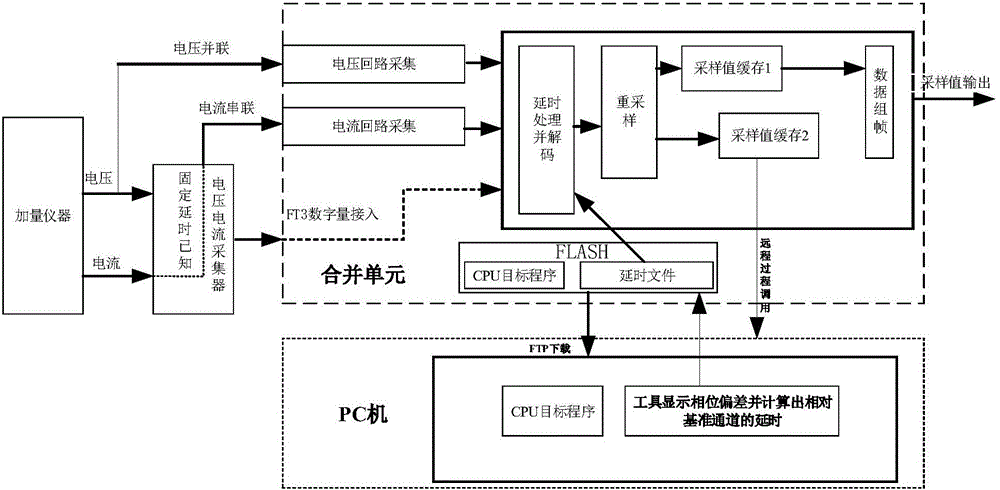

Analog input type merging unit phase adjustment method

InactiveCN106324543AMeet the accuracy levelSolve low work efficiencyElectrical measurementsTest channelRelative phase

The invention provides an analog input type merging unit phase adjustment method, which comprises the steps of firstly selecting a reference channel of a merging unit, connecting one path of the output end of an added amount tester to a tested channel of the merging unit, connecting another path of the output end of the added amount tester to the reference channel of the merging unit through a rated time delay collector, then collecting the output of each channel of the merging unit, calculating a relative phase error of each channel by taking the output of the reference channel as a benchmark, converting the relative phase error into time delay, and thus performing phase adjustment on each channel. The technical scheme provided by the invention can meet an accuracy class required by the merging unit, is simple in operation, and solves a problem of low work efficiency in the process of phase adjustment for the merging unit.

Owner:XUJI GRP +3

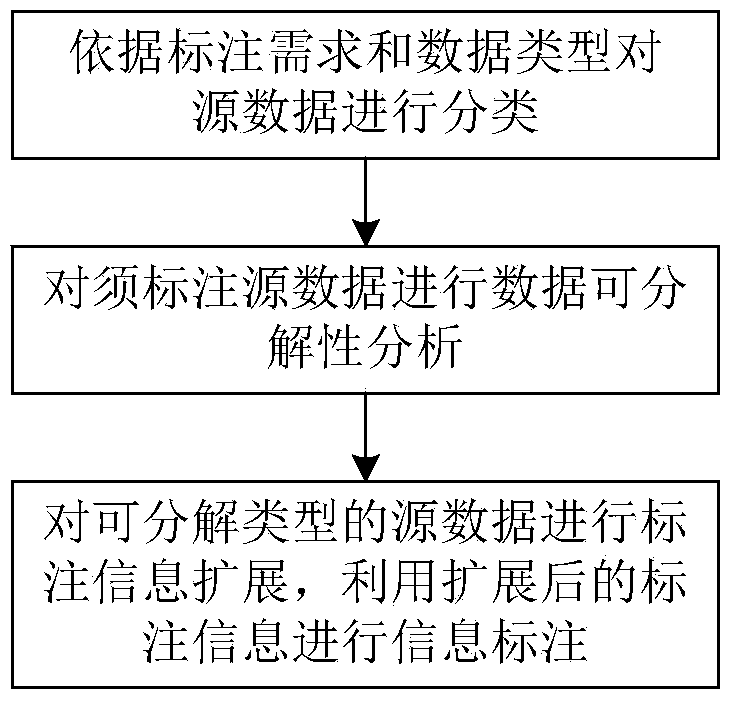

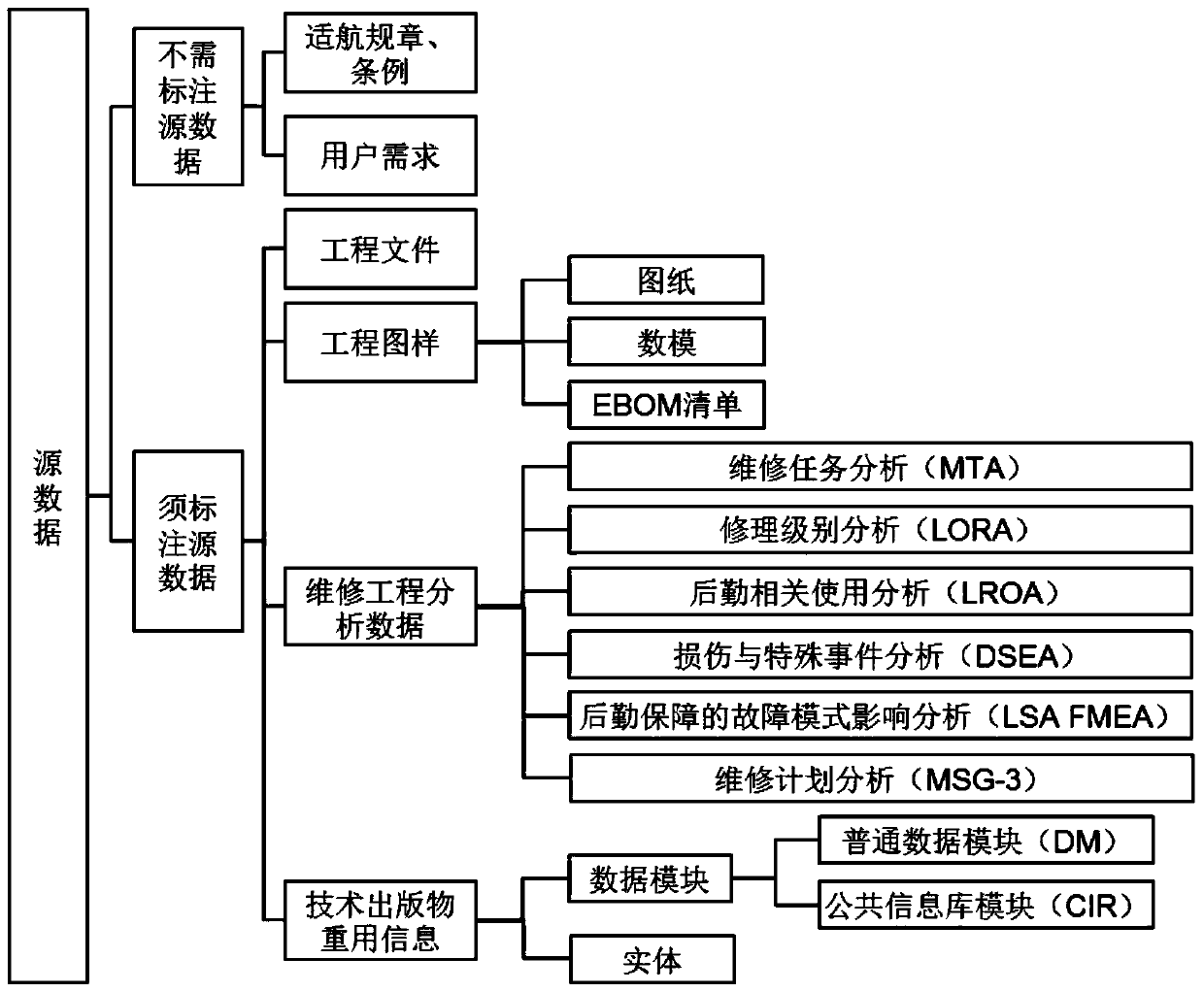

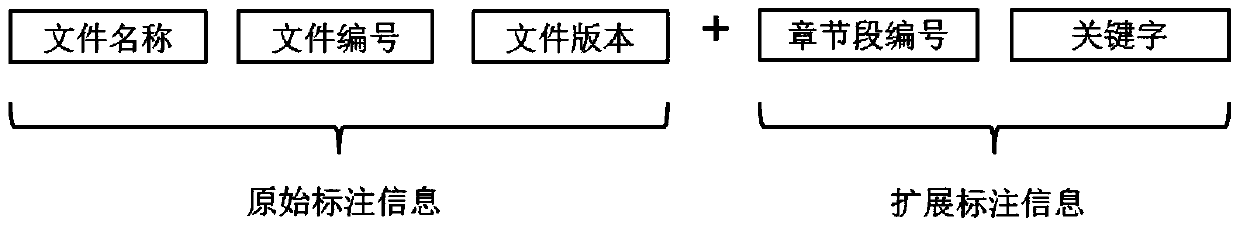

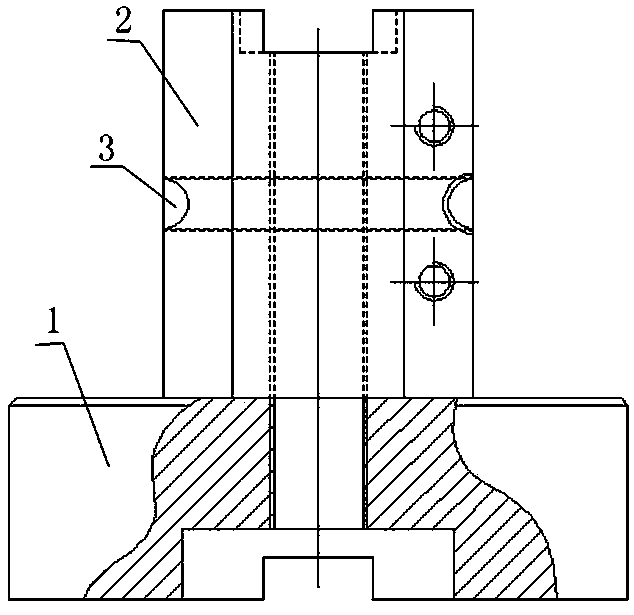

An Extended Method for Source Data Annotation of Civil Aircraft Technical Publications

InactiveCN104965814BEasy to manageEasy to storeSpecial data processing applicationsDecompositionData source

Owner:BEIHANG UNIV +1

Novel rolling wheel for pipe bending machine

InactiveCN109201796ASolve the phenomenon that cannot be bentGuarantee product qualitySEMI-CIRCLEEngineering

The invention relates to a novel rolling wheel for a pipe bending machine. The rolling wheel is arranged on a rolling wheel seat; guide slots are circumferentially formed in a shaft neck of the rolling wheel; a straight-line guide slot is formed outside each guide slot; and a semi-circle line, on the shaft neck of the rolling wheel, of each straight-line guide slot is a starting point, and a sinking step is arranged outside each straight-line guide slot, so that at the time, the rolling wheel forms the stepped rolling wheel with one surface being a circular arc surface and the other surface being provided with the sinking steps. The novel rolling wheel for the pipe bending machine has the further improvement that a process slot perpendicular to the semi-circle line is vertically formed inthe circular arc surface of the rolling wheel and divides the rolling wheel into structural bodies with the guide slots in two sides. According to the novel rolling wheel for the pipe bending machineprovided by the invention, the rolling wheel forms the stepped rolling wheel with one surface being the circular arc surface and the other surface being provided with the sinking steps, so that the problem that a straight line section is too short to bend is solved, and the product quality is ensured; and particularly, the accuracy class of a bush and the external diameter accuracy class of a high-pressure oil pipe are the same, and the coaxiality of the bush behind a pier head and the high-pressure oil pipe is within 0.03, so that the claim for compensation is reduced, and the competitivenessof enterprises is improved.

Owner:东实管路系统(湖北)有限公司

A kind of ship alarm method

InactiveCN104485021BFlexible determination of maximum speedTimely deliveryNavigational aid arrangementsMarine craft traffic controlMarine engineeringTransducer

The invention relates to a ship alarming method which comprises a step of providing a ship alarming system based on the traveling speed and a driver's fatigue state. The system comprises a transducer assembly, a distance measuring sensor assembly, ship speed detection equipment, control equipment and driver's fatigue state detection equipment, wherein the control equipment is connected with the transducer assembly, the distance measuring sensor assembly, the ship speed detection equipment and the driver's fatigue state detection equipment respectively; the measurement accuracy class of the transducer assembly is controlled on the basis of the ship traveling speed output by the ship speed detection equipment; whether the ship traveling speed is alarmed is determined on the basis of measurement results of the transducer assembly and the distance measuring sensor assembly; and whether the driver's fatigue state is alarmed is determined on the basis of the detection result of the driver's fatigue state detection equipment. With adoption of the ship alarming method, the ship traveling safety is improved, accidents of ship hull collision are avoided, economic loss of a ship operator is reduced, and the screw and goods on the ship are prevented from damage.

Owner:CHONGQING JIAOTONG UNIVERSITY

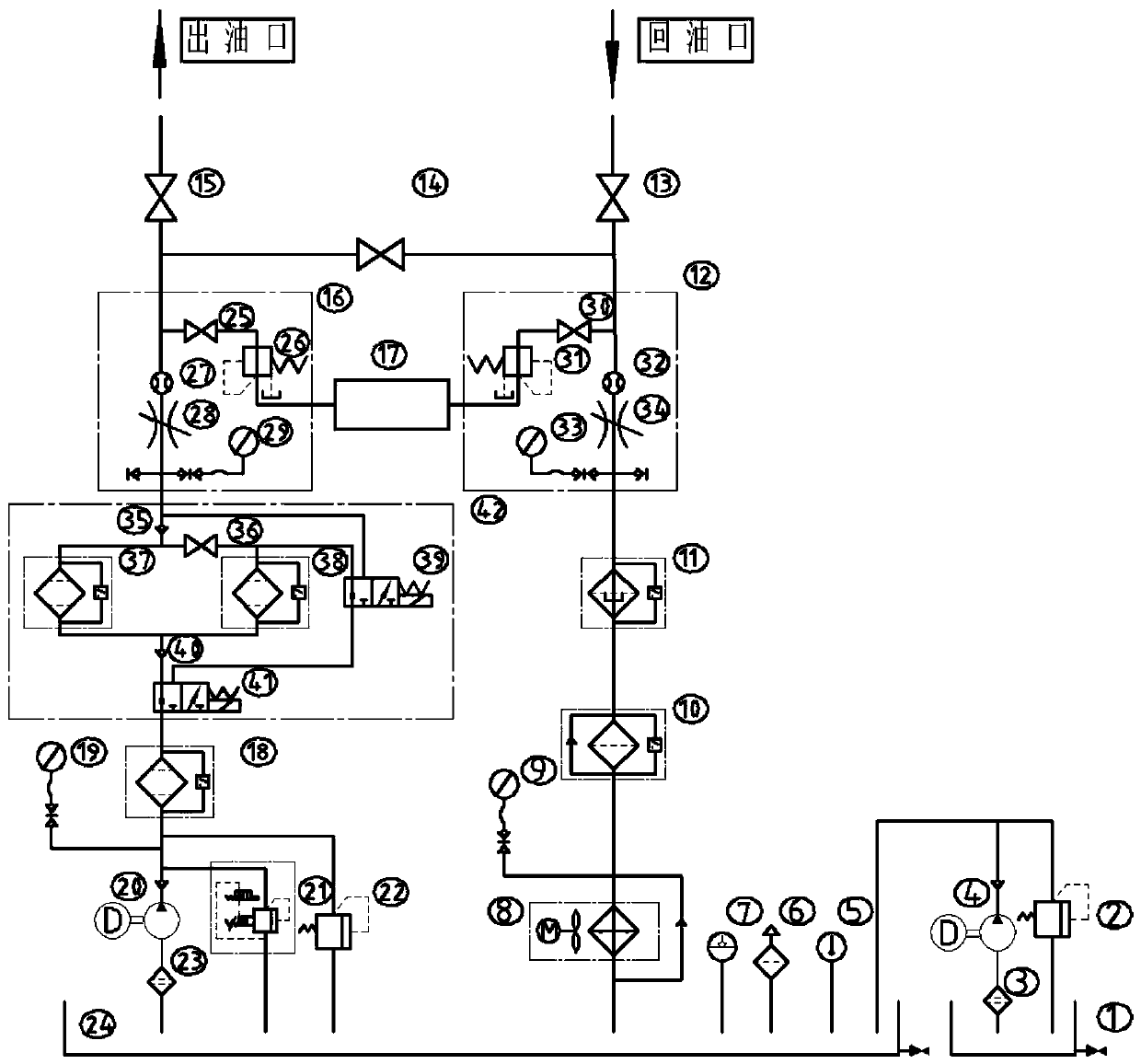

A multifunctional hydraulic cleaning and filtering method

ActiveCN108561376BExtend working lifeImprove site adaptabilityFluid-pressure actuator testingFluid-pressure actuator componentsFuel tankAccuracy class

Owner:HANGZHOU DIANZI UNIV

Planar sawing machine

ActiveCN103801761AReduce volumeStable outputMetal sawing devicesFully automaticUltimate tensile strength

The invention provides a planar sawing machine. The planar sawing machine comprises a first bracket, a second bracket, a third bracket, a sawing device, a steel plate and a conveying device, wherein the sawing device is arranged on the first bracket, the conveying device is arranged on the third bracket, one end of the steel plate is arranged on the second bracket, the other end of the steel plate is arranged below the conveying device on the third bracket, the steel plate is conveyed to the interior of a guider of the second bracket through a transmission wheel by the conveying device, and the sawing device which is used for sawing the steel plate is arranged at an opening of the guider; the sawing device is arranged in the direction that the sawing device and the first bracket form an angle of 90 degrees. The planar sawing machine provided by the invention is fully-automatic, the angle can be adjusted, the size is small, the yield is stable, the quality is good, particularly, the accuracy class cannot be achieved by conventional tool / instrument machining, and a machining process is low in labor intensity and is pollution-free.

Owner:ZHEJIANG MAILANG ELECTRIC

Verifying apparatus for measuring extra-high voltage transformer error

ActiveCN101493509BImprove anti-interference abilityLower performance requirementsElectrical measurementsCapacitanceMeasurement device

Owner:STATE GRID ELECTRIC POWER RES INST +3

A plane sawing machine

The invention provides a planar sawing machine. The planar sawing machine comprises a first bracket, a second bracket, a third bracket, a sawing device, a steel plate and a conveying device, wherein the sawing device is arranged on the first bracket, the conveying device is arranged on the third bracket, one end of the steel plate is arranged on the second bracket, the other end of the steel plate is arranged below the conveying device on the third bracket, the steel plate is conveyed to the interior of a guider of the second bracket through a transmission wheel by the conveying device, and the sawing device which is used for sawing the steel plate is arranged at an opening of the guider; the sawing device is arranged in the direction that the sawing device and the first bracket form an angle of 90 degrees. The planar sawing machine provided by the invention is fully-automatic, the angle can be adjusted, the size is small, the yield is stable, the quality is good, particularly, the accuracy class cannot be achieved by conventional tool / instrument machining, and a machining process is low in labor intensity and is pollution-free.

Owner:ZHEJIANG MAILANG ELECTRIC

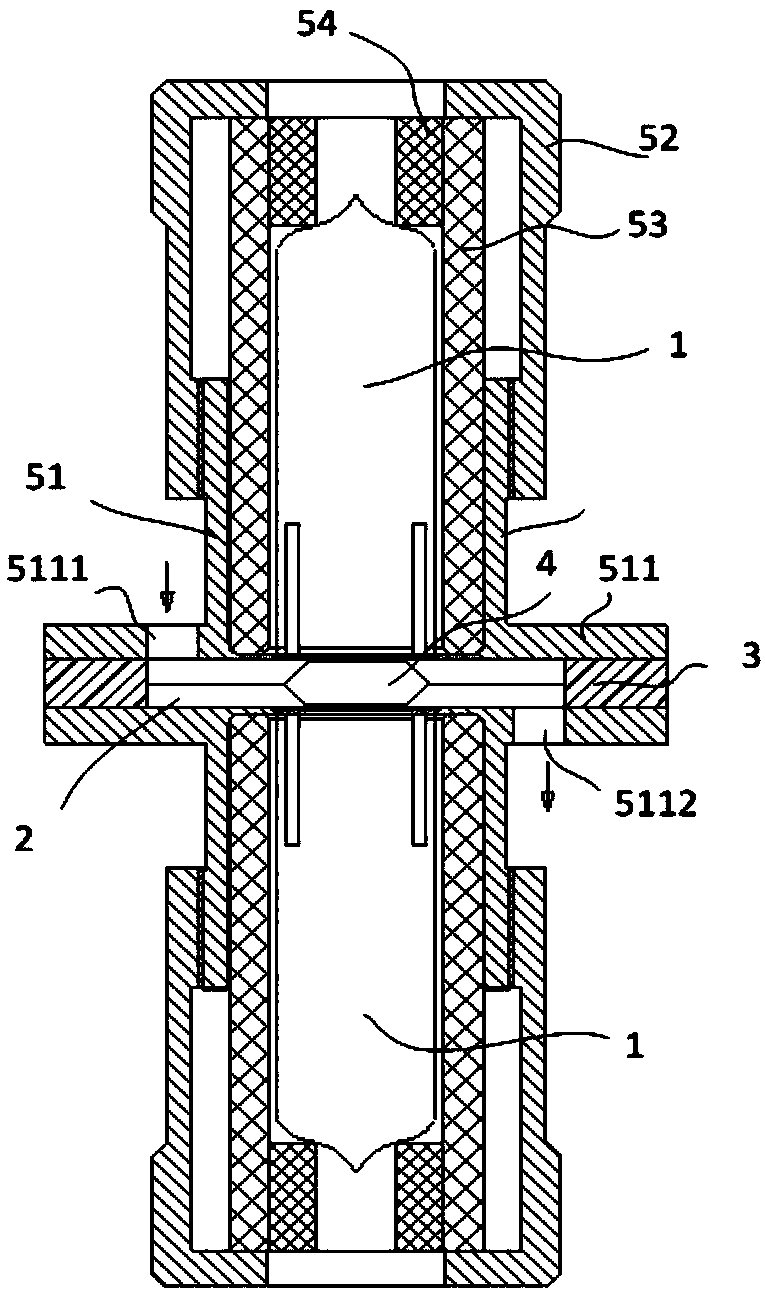

Current transformers and load interrupters having such current transformers

The present invention relates to a current transformer system having a current transformer, which detects a current flowing through the current transformer and converts said current into a measurement voltage, and evaluation electronics which, on the basis of the measurement voltage, determine at least one of the characteristic variables from the group G consisting of I, In, Ist, Imin, ITR, IMAX, U, Un, f, fn, PF, where I = electrical current flowing through the current transformer; In = stated reference current intensity for which the current transformer has been designed; Ist = lowest stated value of I at which the current transformer measures electrical active energy with a power factor of one; Imin = value of I above which the deviation is within the error limits; ITR = value of I above which the deviation is within the lowest error limits corresponding to the accuracy class stated for the current transformer system; IMAX = maximum value of I at which the deviation is within the error limits; U = electrical voltage applied to the current transformer; Un = stated reference voltage; f = frequency of the voltage applied to the current transformer; fn = stated reference frequency; PF = power factor = cos&phgr; = cosine of the phase shift &phgr; between I and U.

Owner:EFEN

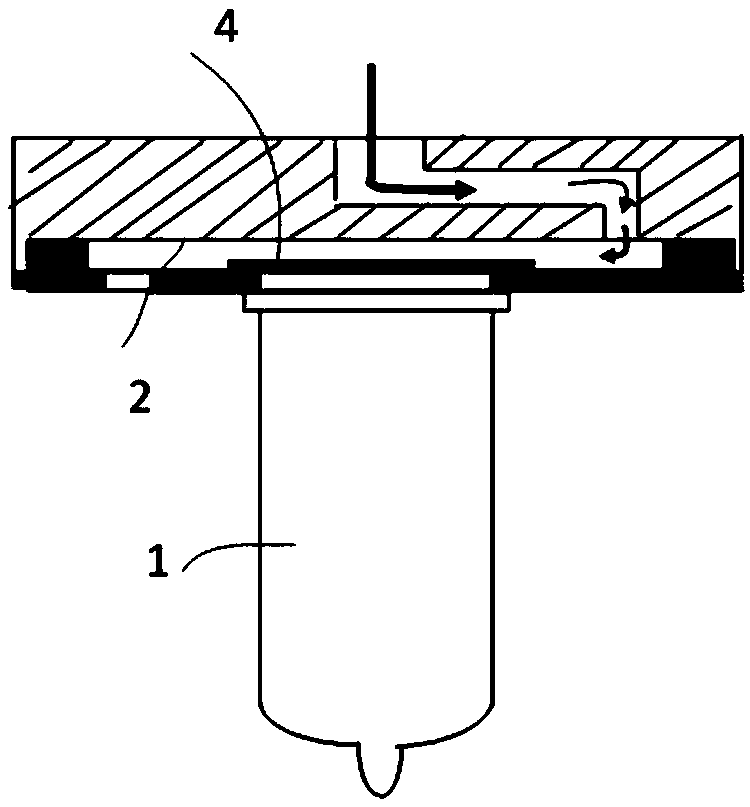

Dual optical path photoionization gas detector and detector

ActiveCN106124609BIncrease radiation intensityIncrease the cross-sectional areaMaterial analysis by electric/magnetic meansGas detectorOptoelectronics

The invention discloses a dual optical path ionized gas detector and a detection instrument. The detector comprises two photoionization light sources, a substrate and an electrode, wherein a through hole is formed in the substrate; light windows of the two photoionization light sources are oppositely arranged across the through hole, the inner wall of the through hole and the two photoionization light sources define an ionization chamber, and the ionization chamber is communicated with the outside by virtue of an air inlet passage and an air outlet passage; and the electrode extens into the ionization chamber. The detection instrument comprises the detector. The detector disclosed by the invention has the advantages that dual optical path design is smartly adopted, so that radiation intensity of a light source is greatly improved; receiving sectional area of the electrode is increased in a multiplying manner; detection result of the detection instrument can be improved by one measurement accuracy class, measurement response time is also greatly shortened, and response is faster; meanwhile, the detector has a self-cleaning function.

Owner:王宏盘

Method of determining noise measuring point arrangement based on mean deviation

ActiveCN103226037BMeet the uncertainty requirementsSubsonic/sonic/ultrasonic wave measurementUsing electrical meansSound powerAccuracy class

The invention relates to the field of noise measuring, in particular to a method of noise measuring point arrangement. The method of determining the noise measuring point arrangement based on a mean deviation comprises the steps that a mean deviation threshold of the measuring point arrangement is obtained according to a noise measuring accuracy class; a measuring distance is determined; a measuring surface is obtained; positions and quantity of initial noise measuring points are determined according to the accuracy class and the measuring distance; a mean deviation measured value is calculated according to a noise measuring result; the mean deviation measured value and the mean deviation threshold of the measuring point arrangement are compared; measuring point arrangement completion or measuring point increase is decided; and the measuring points are rearranged until the mean deviation measured value is smaller than or equal to the threshold. The method is used for determining the noise measuring point arrangement based on the mean deviation, so that the measuring uncertainty caused by noise measuring point arrangement factors can be quantified, and can be controlled effectively; and therefore, the uncertainty of a noise sound power level measuring result can meet an uncertainty requirement specified by the corresponding accuracy class.

Owner:SAIC MOTOR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com