Truss manipulator for loading and unloading

A manipulator and truss technology, applied in the field of mechanical engineering intelligent control, can solve the problems of large installation space for automated production, cumbersome overall structure, and low precision, and achieve the effects of beautiful and simple overall structure, material saving, and transmission accuracy guarantee.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings; the present embodiments are descriptive, not restrictive, and cannot thereby limit the protection scope of the present invention.

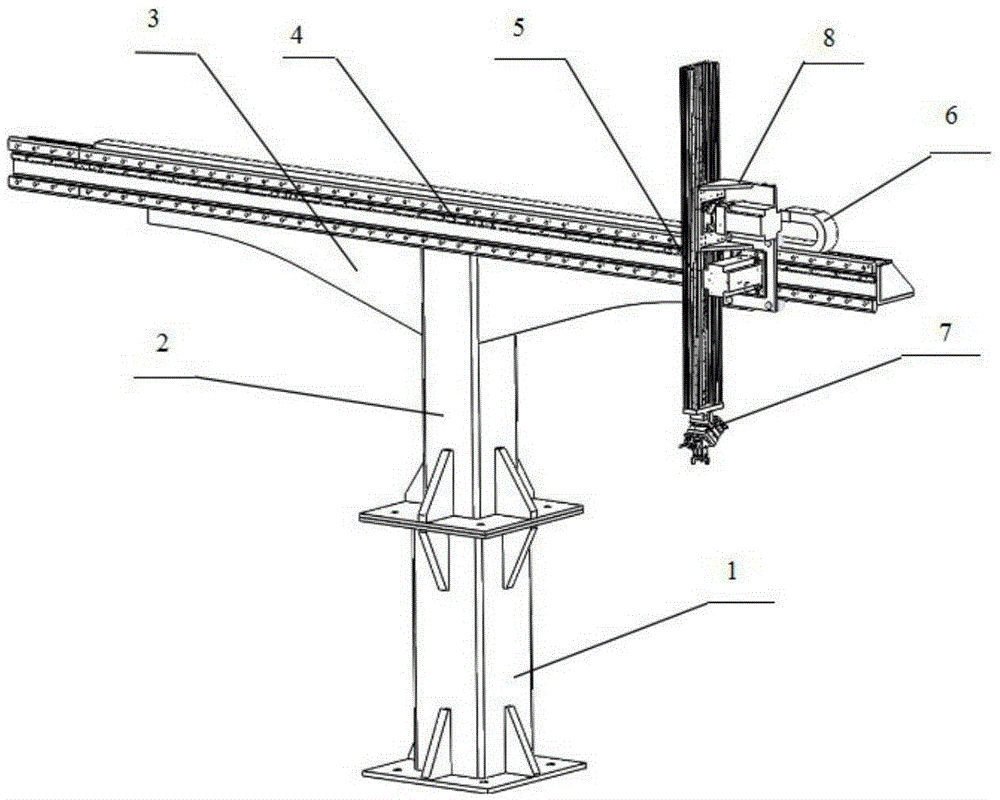

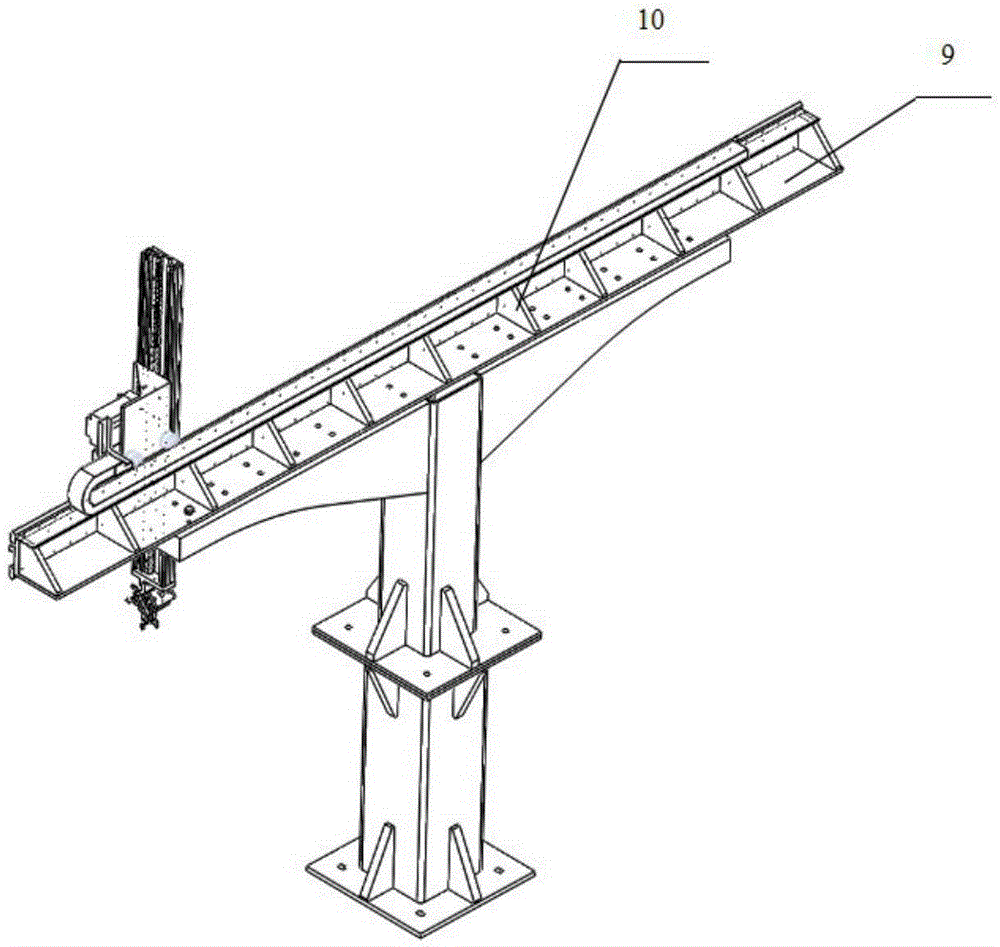

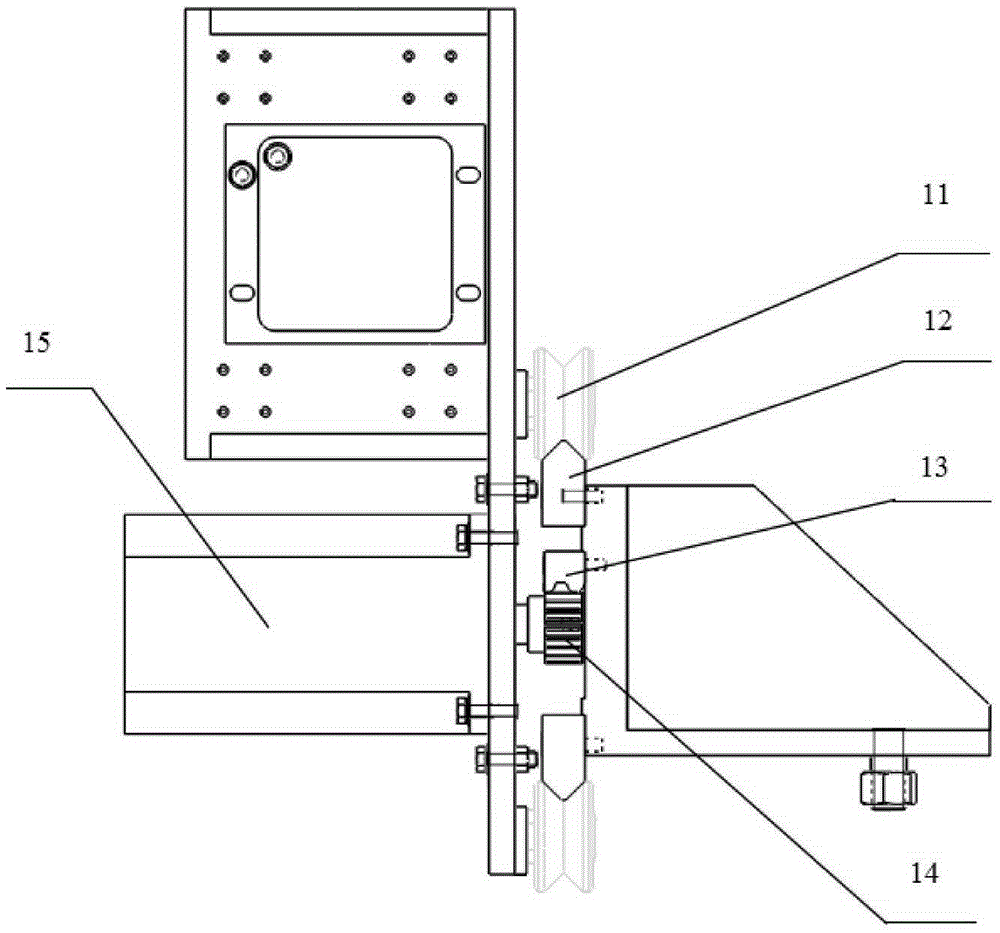

[0022] A truss manipulator for loading and unloading, consisting of a support structure, a horizontal movement component 4 (X axis), a vertical movement component 5 (Z axis), an automatic hand grip 7 and a transition connecting plate 8 between the two axes, the support structure The top of the horizontal movement assembly is fixed, the vertical movement assembly runs on the horizontal movement assembly, the automatic hand grip is installed at the lower end of the vertical movement assembly, and a two-axis transition connecting plate is installed between the horizontal movement assembly and the vertical movement assembly.

[0023] The lower part of the supporting structure is composed of two parts, the coaxially fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com