Optical current measurement device

A current measuring device and optical technology, applied in the direction of measuring device, only measuring current, measuring electrical variables, etc., to achieve the effect of eliminating external magnetic field interference and improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

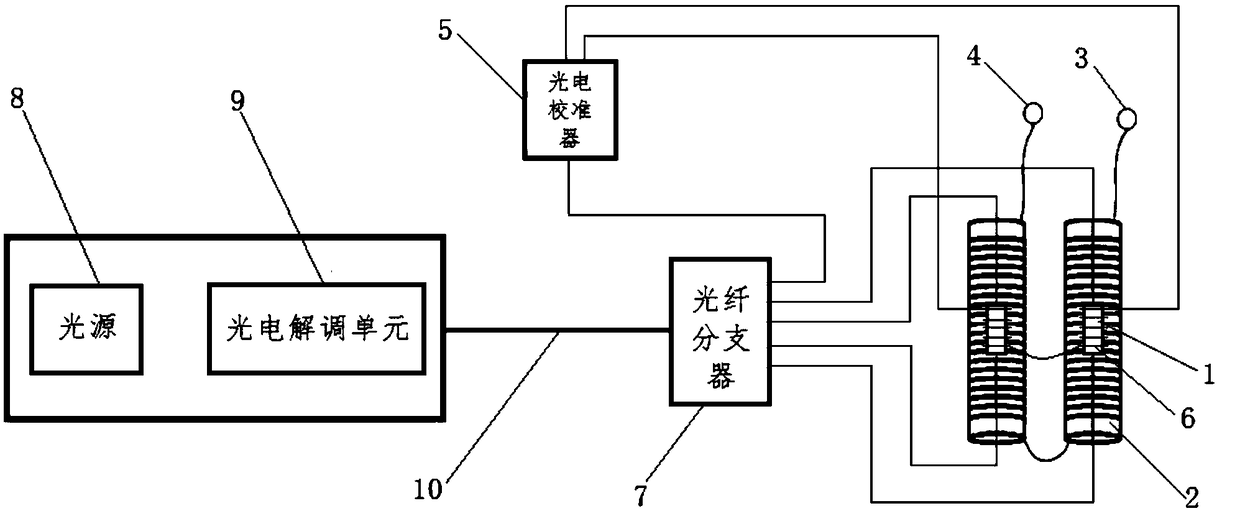

[0021] The invention discloses an optical current measuring device, which includes a sensing head system, a dynamic correction system, a photoelectric demodulation system and an optical fiber splitter 7;

[0022] The sensor head system includes a crystal light valve magnetic field sensor 1, a solenoid 2, P1 current terminal 3 and P2 current terminal 4, the crystal light valve magnetic field sensor 1 is fixed in the solenoid 2, and Set coaxially with the solenoid 2, the length of the crystal light valve magnetic field sensor 1 is shorter than the length of the solenoid 2, when the solenoid 2 is one, the P1 current terminal 3, P2 current terminal 4 is drawn from both ends of the solenoid 2, the P1 current terminal 3 and the P2 current terminal 4 are connected to the measured current, and the two ends of the crystal light valve magnetic field sensor 1 are connected to the downlink optical interface of the optical fiber splitter 7 through an optical fiber , the number of the cryst...

Embodiment 2

[0033] see figure 1 , the present invention discloses an optical current measuring device, including a sensing head system, a dynamic correction system, a photoelectric demodulation system and an optical fiber splitter 7;

[0034] The sensing head system includes two crystal light valve magnetic field sensors 1, two solenoids 2, P1 current terminal 3 and P2 current terminal 4, and the crystal light valve magnetic field sensor 1 is fixed in the solenoid 2 , and is arranged coaxially with the solenoid 2, the length of the crystal light valve magnetic field sensor 1 is less than the length of the solenoid 2, and when there are two solenoids 2, one of the solenoids 2 The first solenoid connected in sequence leads to P1 current terminal 3, and the last solenoid connected in sequence leads to P2 current terminal 4, and P1 current terminal 3 and P2 current terminal 4 are connected to the measured current. , both ends of the crystal light valve magnetic field sensor 1 are connected t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com