PCD (pitch circle diameter) drill bit with chip breaker groove

A chip breaker and drill bit technology, which is used in repairing drills, drilling tool accessories, drilling/drilling equipment, etc., can solve the problems of inability to meet mass production, scratch the hole wall, low efficiency, etc., and save processing time. , The effect of improving surface roughness and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment:

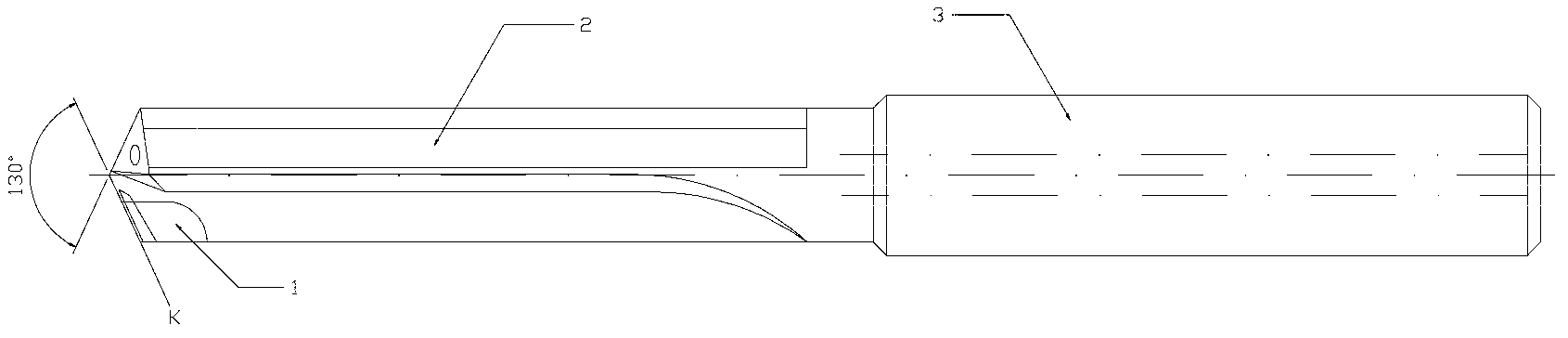

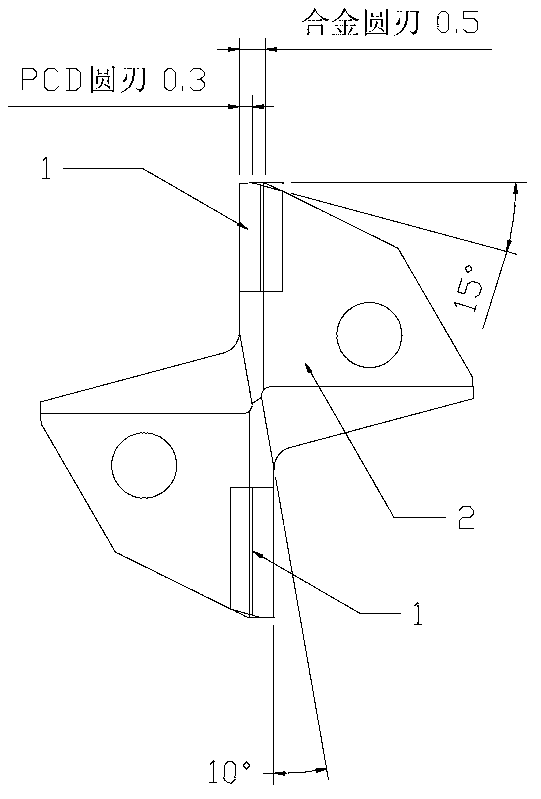

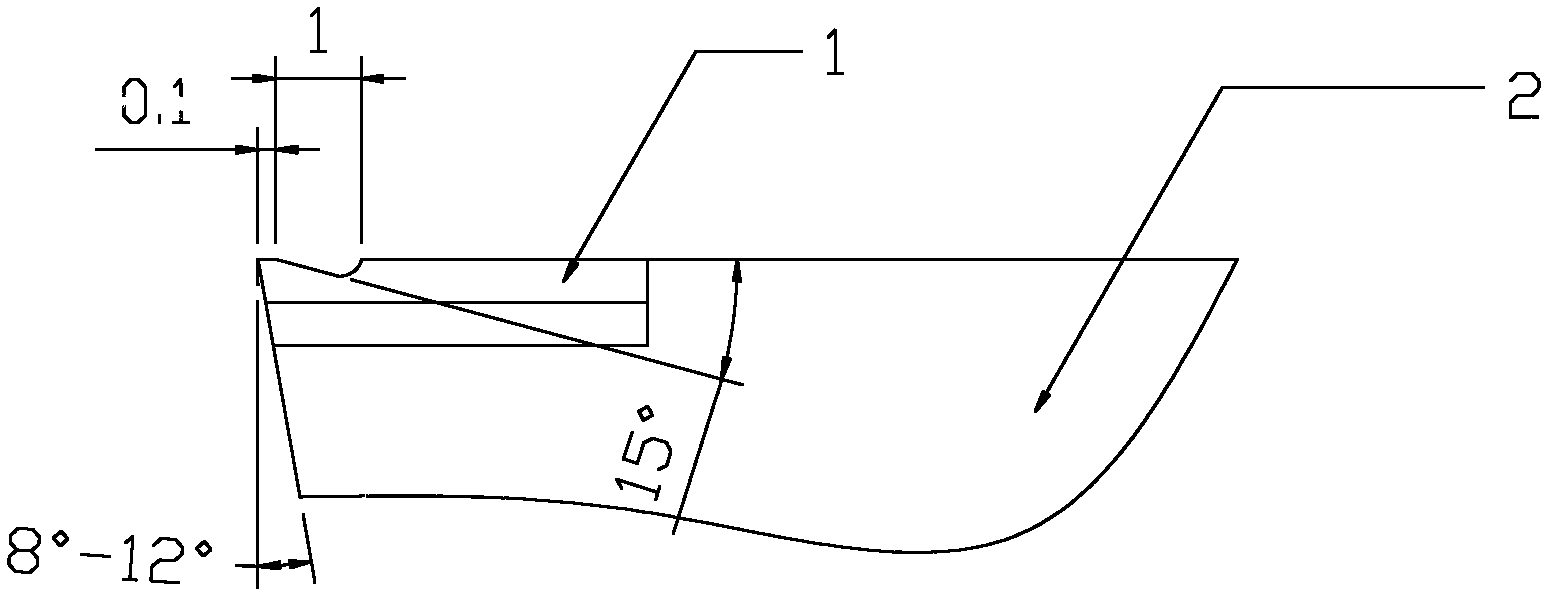

[0013] A PCD drill with a chip breaker, such as Figure 1-3 As shown, it includes tool handle 3, cutter body 2, and PCD insert 1. There are two coolant holes running through the tool handle 3 and cutter body 2 along the axial direction of the cutter body 2. The cutter body 2 has two chip containers along its axial direction. The flute and the chip flute are anti-symmetrical in the end view, accounting for a quarter of the circumference. There are two PCD inserts 1 inlaid and welded on the front end of the cutter body as the drill edge. 8-12 degrees, chip splitter angle is 10 degrees, PCD round edge is 0.3mm, round edge relief angle is 15 degrees, cutter body 2 round edge is 0.5mm, on the PCD upper surface, 0.1mm away from the end edge of the drill There is a 15 degree rake angle and a chip breaker with a width of 1mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com