A multifunctional hydraulic cleaning and filtering method

A filtration method and multi-functional technology, applied in the direction of fluid pressure actuating device, fluid pressure actuating system components, fluid pressure actuating system testing, etc. Solve problems such as replenishing oil, and achieve the effect of facilitating maintenance, fault diagnosis, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing.

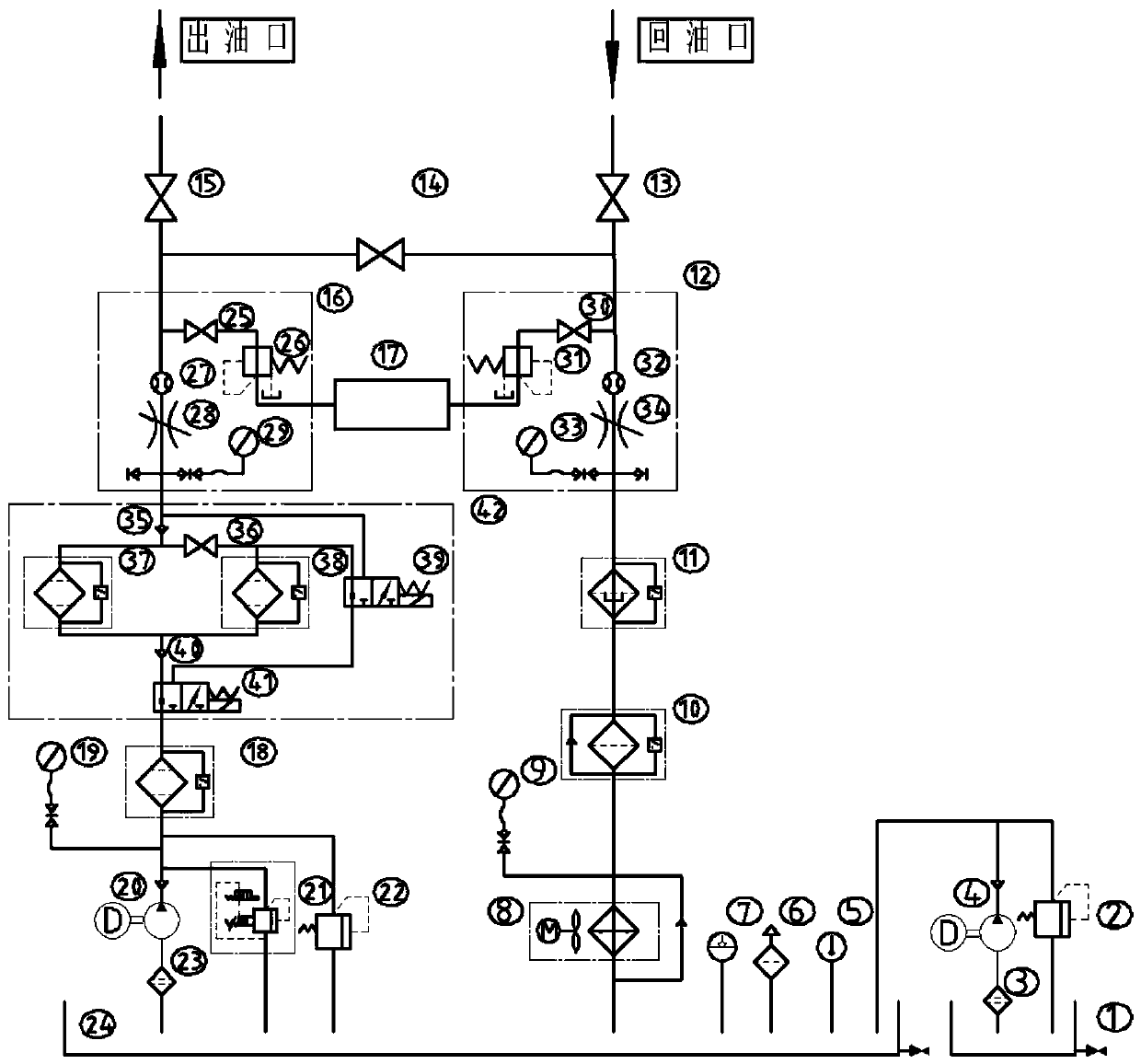

[0031] Such as figure 1 Shown, a kind of multi-function hydraulic cleaning filter method, specifically as follows:

[0032] (1) Oil return filter cleaning process

[0033]Connect the oil return port of the oil return joint with the hydraulic system that needs to be filtered. The oil passes through the oil return stop valve 13, and then successively passes through the oil return flow meter 32, the oil return throttle valve 34, the oil return pressure gauge 1 33, and the magnetic return valve. Filter 11, coarse filter 10, return oil pressure gauge two 9, radiator 8 enter main oil tank 24. The flow adjustment of the return flow process is realized by adjusting the oil return throttle valve 34 , and is observed through the oil return flow meter 32 . The output port of the oil return cut-off valve 13 is connected to the detection device through the oil return sampling stop va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com