Patents

Literature

126 results about "Isothermal annealing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-silicon high-manganese type high-thermal stability hot work die steel and thermal treatment process thereof

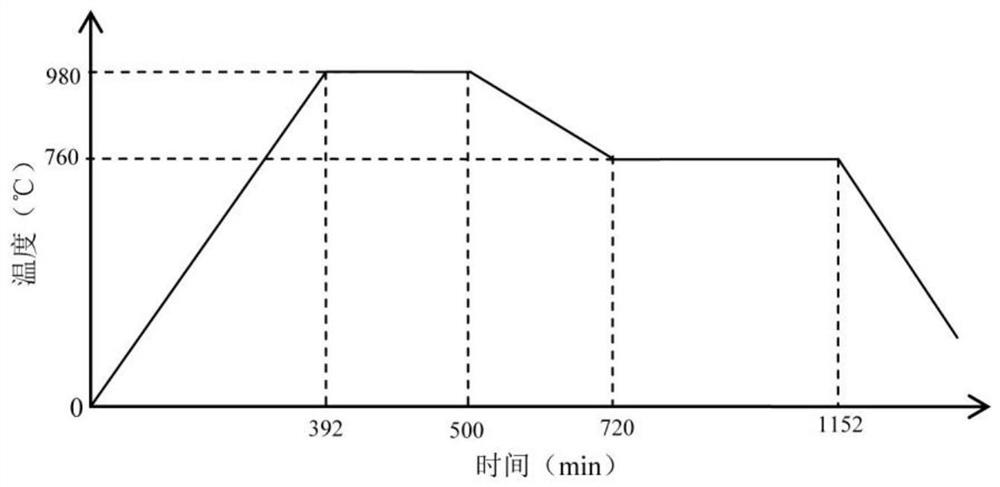

The invention relates to high-silicon high-manganese type high-thermal stability hot work die steel and a thermal treatment process thereof, and belongs to the technical field of alloy steel manufacturing process. The hot work die steel is characterized in that the ratio of high silicon to high manganese in chemical components is kept to be 1 to 1 and main alloy elements by mass percent comprise 0.25-0.45% of C, 0.8-2.0% of Si, 0.8-2.0% of Mn, 3.5-4.5% of Cr, 0.6-1.2% of Mo, 0.4-0.8% of V, less than 0.02% of P, less than 0.02% of S and Fe for the rest. A preparation process for the hot work die steel comprises the steps as follows: firstly, preparing materials, smelting and casting; secondly, carrying out electroslag remelting; carrying out high temperature homogenization thermal treatment, and carrying out multi-direction forging hot working; thirdly, carrying out superfine thermal treatment and isothermal annealing treatment; and lastly, carrying out quenching and tempering thermal treatment, namely heating to be 980-1100 DEG C for austenitizing, carrying out oil cooling or mist cooling, and tempering for two to three times at a temperature of 540-600 DEG C. The hot work die steel has the advantages of high thermal stability, high flexibility and good thermal fatigue performance.

Owner:SHANGHAI UNIV

Current transformer iron core of amorphous and nano-crystalline magnetically soft alloy and preparation method thereof

ActiveCN105047348AReduce magnetic lossReduce lossTransformers/inductances magnetic coresInductances/transformers/magnets manufactureChemical compositionAlloy

The invention discloses a current transformer iron core of amorphous and nano-crystalline magnetically soft alloy and a preparation method of the current transformer iron core. The chemical component atomic percent of the iron core is FeaSibBcMdCueM'f, wherein a is not more than 85 and is not less than 65; b is not more than 25 and is not less than 5; c is not more than 15 and is not less than 0; d is not more than 15 and is not less than 0; e is not more than 5 and is not less than 0, and f is not more than 1 and is not less than 0, and a plus b plus c plus d plus e plus f equals to 100, and M is at least one of Nb, Mo or V, and M' is at least one of Sn, Al, Y and Sb. The preparation method comprises the steps as follows: preparing materials according to atomic percent and smelting to prepare a mother alloy; then crushing the prepared mother alloy to re-melt and covering steel-making slagging constituent to prevent oxidation and deslagging; preparing amorphous alloy ribbons with the re-melted mother alloy by using a single roll rapid solidification ribbon preparation method under ordinary pressure, and finally winding the amorphous alloy ribbons as the amorphous iron core, and performing isothermal annealing crystallization in a vacuum annealing furnace to obtain the amorphous and nano-crystalline magnetically soft alloy of a mutual inductor iron core. The iron core of the invention has high saturation flux density, high permeability, and low magnetic loss so that the mutual inductor has ultrahigh precision and accuracy class.

Owner:NEW MATERIALS TECH JIANGSU AMORPHD +1

Chromium-molybdenum-vanadium hotwork tool-die steel and heat treatment process thereof

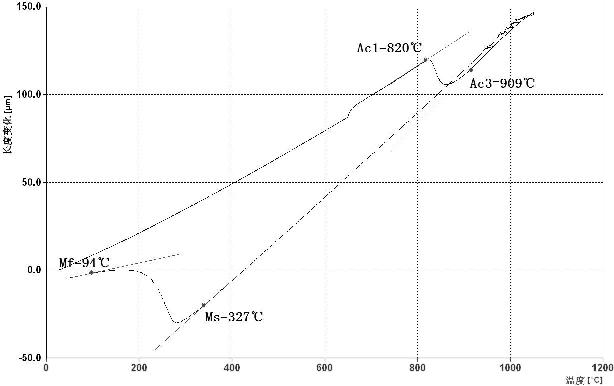

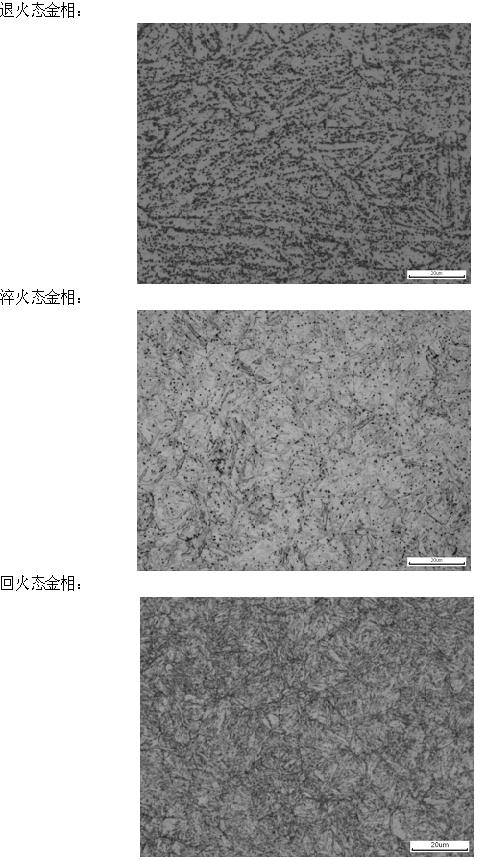

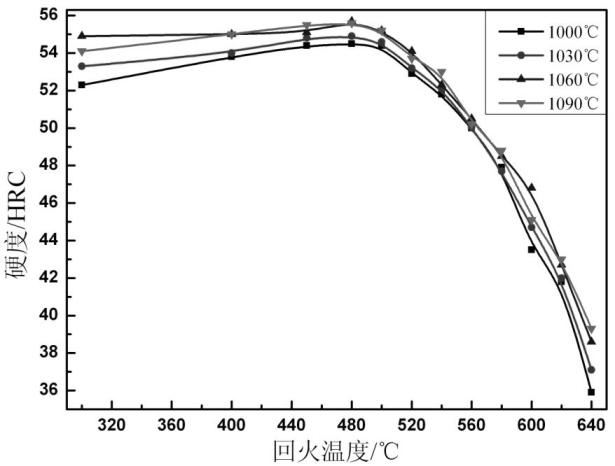

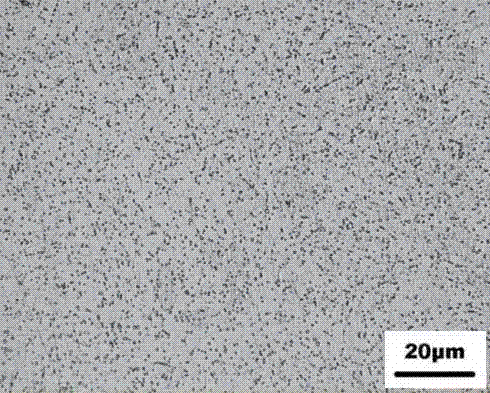

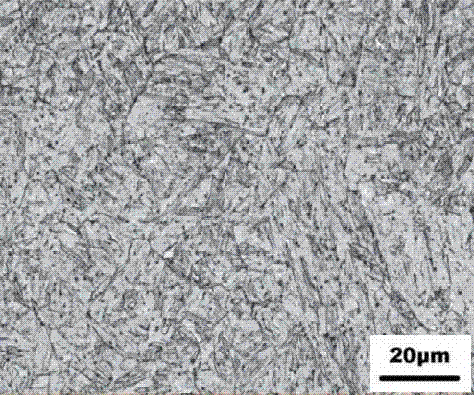

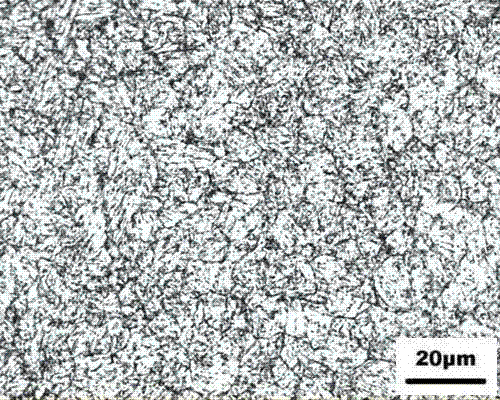

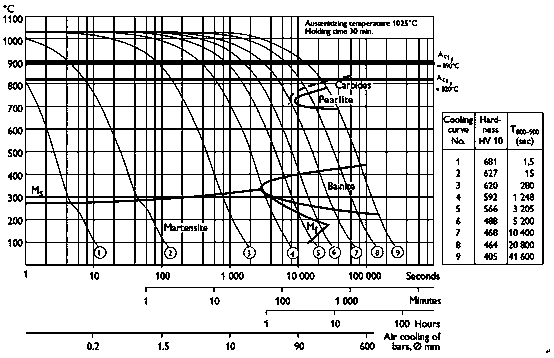

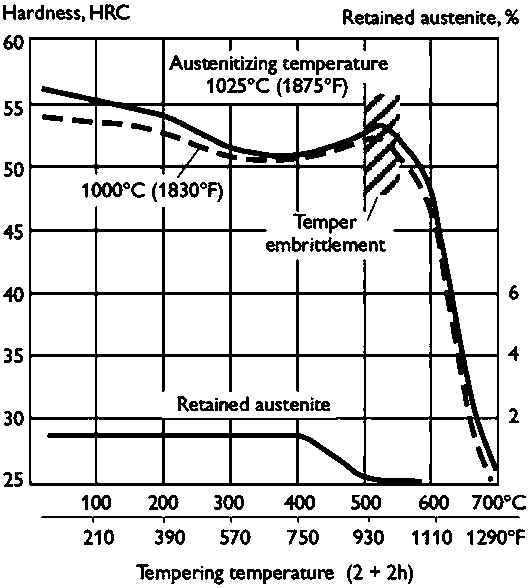

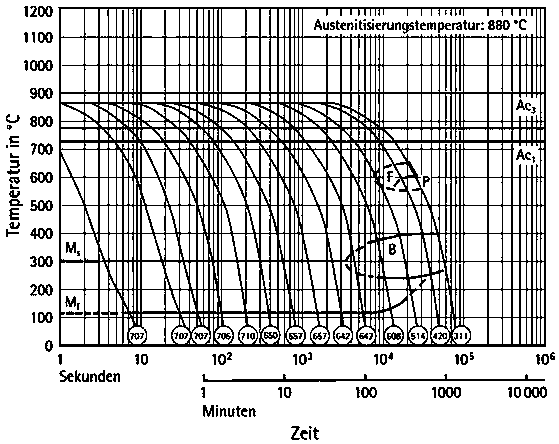

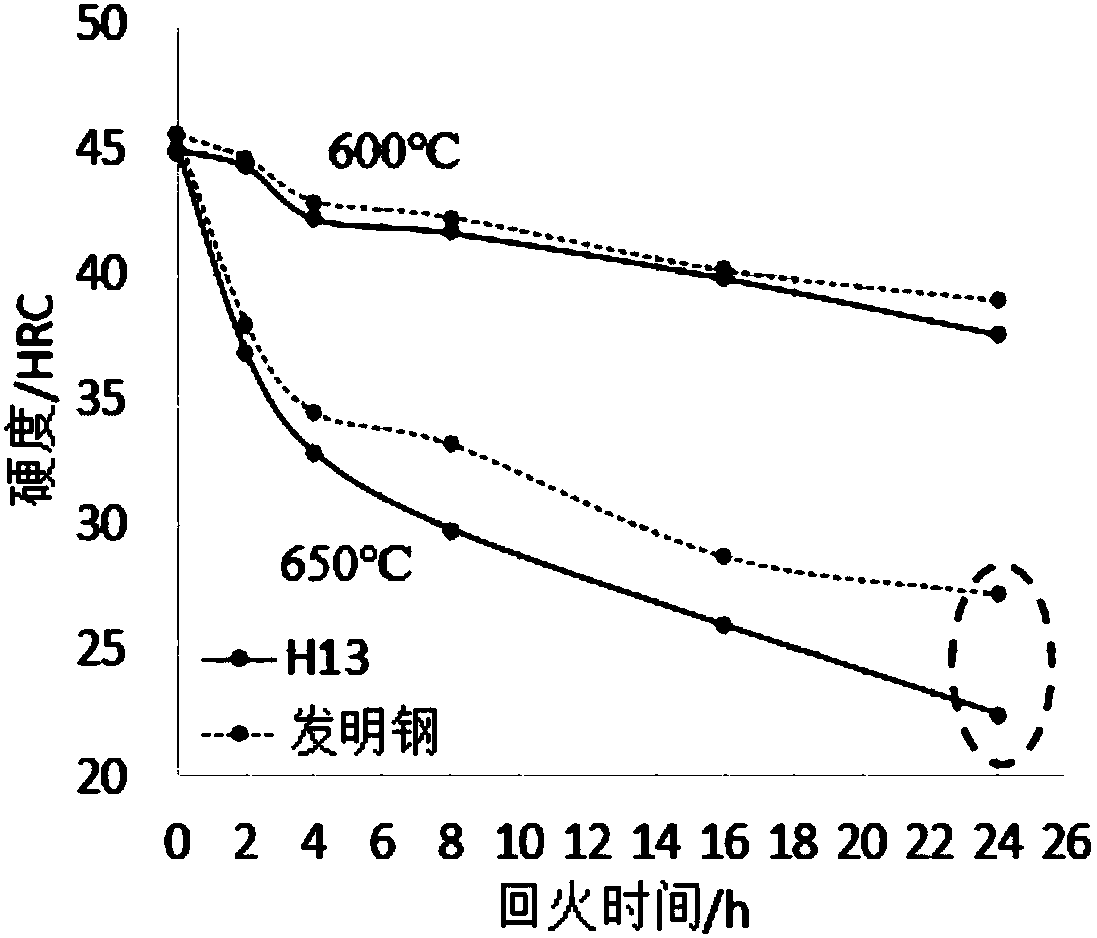

The invention relates to low-cost chromium-molybdenum-vanadium hotwork tool-die steel and a heat treatment process thereof and belongs to the technical field of alloy steel manufacturing processes. The steel comprises the following components by weight percent: 0.3-0.4% of C, 0.6-1.2% of Si, 0.6-1.2% of Mn, 3.5-4.5% of Cr, 0.8-1.2% of Mo, 0.4-0.8% of V, less than 0.02% of P, less than 0.02% of S and the balance of Fe. The preparation process of the hotwork tool-die steel is as follows: mixing, smelting, casting and then remelting electroslag; carrying out homogenization treatment at 1200-1280 DEG C for 8-10 hours, then forging, and carrying out ultrafining heat treatment and isothermal annealing treatment; and finally quenching and tempering, namely heating steel ingots to 1000-1100 DEG C to be austenitized and carrying out tempering two to three times at 560-620 DEG C after carrying out oil quenching or high pressure gas quenching. The hotwork tool-die steel has the advantages of high heat stability and roughness and good heat fatigue property.

Owner:SHANGHAI UNIV

High-performance hot work die steel and manufacturing technology thereof

InactiveCN109280849AImprove thermal stabilityReduce carbon contentManufacturing technologyHeat stability

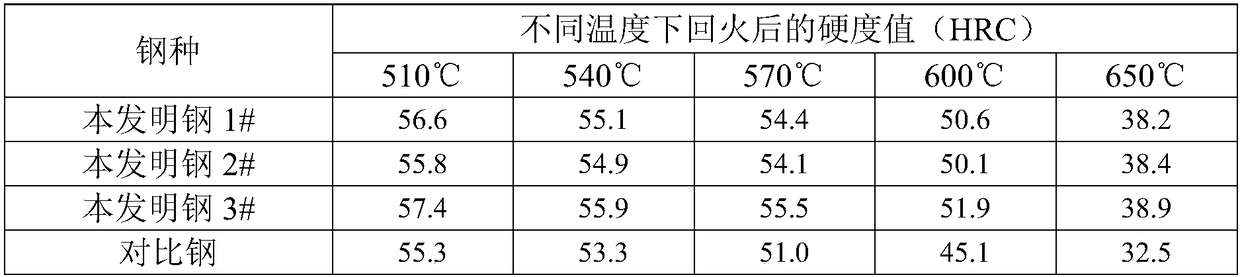

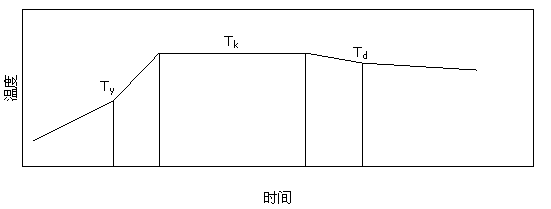

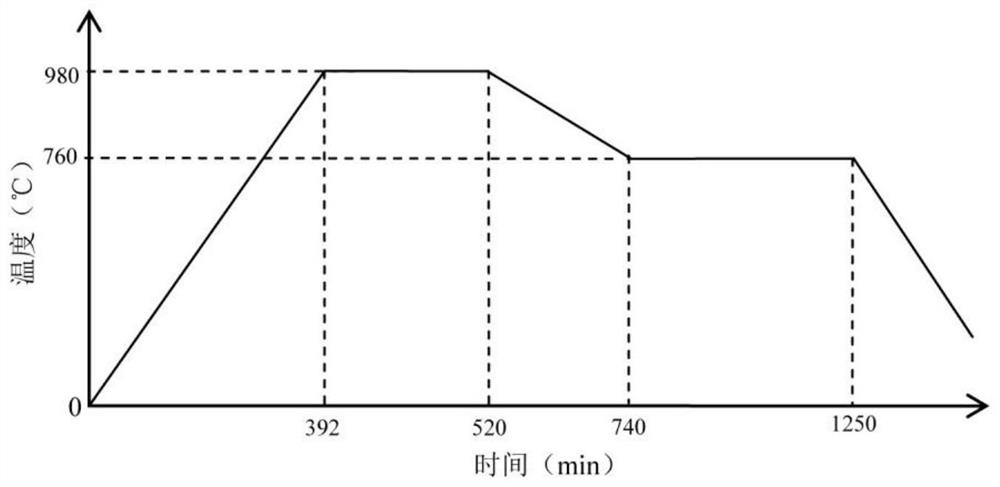

The invention relates to high-performance hot work die steel and manufacturing technology thereof. The high-performance hot work die steel comprises, by mass percent, 0.20%-0.30% of C, 0.40%-0.80% ofSi, 0.40%-0.80% of Mn, 3.10%-4.00% of Cr, 1.60%-2.00% of Mo, 0.5%-1.00% of W, 0.10%-0.30% of V, smaller than 0.010% of P, smaller than 0.005% of S and the balance Fe. The manufacturing process of thedie steel includes the following steps that burdening, smelting and pouring are conducted; then electroslag remelting is conducted; high-temperature diffusion heat treatment is conducted, then multidirectional forging hot working is conducted, and controlled cooling is conducted after forging; then secondary carbide refining heat treatment and isothermal annealing treatment are conducted; and finally, quenching and tempering heat treatment are conducted. The high-performance hot work die steel and manufacturing technology thereof have the beneficial effect that the quenching degree, the heat stability, the impact toughness and the thermal fatigue performance of the hot work die steel are superior to H13 steel, the hot work die steel can be machined into large die casting dies with the weight of the single piece reaching 5 tons or higher, and the good use performance is achieved; and in addition, the steel ingot smelting cost can be reduced, and the service life of dies is prolonged.

Owner:RUGAO HONGMAO HEAVY FORGING

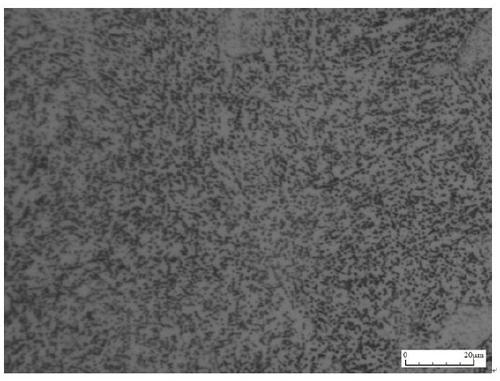

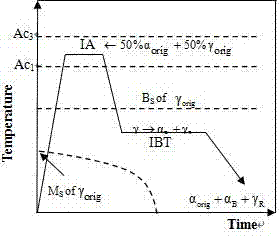

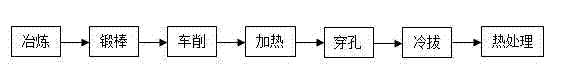

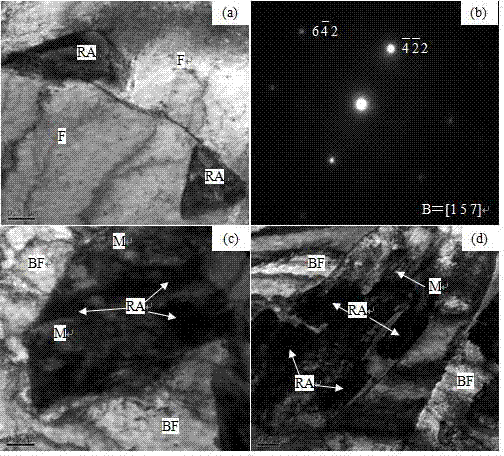

Method for producing transformation induced plasticity (TRIP) seamless tube

InactiveCN102407245AAustempering achievedReduce contentFurnace typesHeat treatment furnacesAustemperingChemical composition

The invention belongs to the field of preparation of steel tubes, and in particular relates to a method for producing a transformation induced plasticity (TRIP) seamless tube. The method comprises the following steps that: a smelted ingot is forged into a rod, turned, heated, punched and subjected to cold drawing to obtain a seamless cold drawing steel tube, and the seamless cold drawing steel tube is placed in a resistor furnace for critical region isothermal annealing for 180-1200 seconds at the temperature of 780-850 DEG C, and then is rapidly placed in a salt bath furnace for bainite region isothermal annealing for 120-1800 seconds at the temperature of 380-470 DEG C so as to obtain the TRIP seamless tube. According to the technical scheme in the invention, the chemical components of common low carbon steel can be used for producing the TRIP seamless tube with good comprehensive mechanical properties, high yield strength up to 580MPa, high tensile strength up to 763MPa and high product of strength and elongation up to 22029MPa.%. The method is easy to realize in industrialized production, has the advantages of relatively stable process and relatively low cost, and is suitable for producing TRIP seamless steel tubes with different chemical components and sizes.

Owner:NORTHEASTERN UNIV LIAONING

High-performance hot stamping die steel and manufacturing process thereof

The invention relates to high-performance hot stamping die steel and a manufacturing process thereof. The high-performance hot stamping die steel comprises the following components of, in percentage by mass, 0.66% - 0.80% of C, 0.80% - 1.20% of Si, 0.20% - 0.50% of Mn, 5.00% - 6.50% of Cr, 1.50% - 2.00% of Mo, 0.40% - 0.80% of V, less than 0.015% of P, less than 0.015% of S and the balance Fe. Themanufacturing process of the die steel comprises the following steps of carrying out burdening, smelting, casting, electroslag remelting; carrying out high-temperature diffusion thermal treatment, multi-direction forging and hot machining and cooling control after forging; then carrying out secondary carbide refining thermal treatment and isothermal annealing treatment; and finally carrying out quenching and tempering thermal treatment. The high-performance hot stamping die steel and the manufacturing process thereof has the advantages that the hardenability, the thermal stability, the wear resistance and the thermal fatigue performance of the hot-work die steel are superior to the hardenability, the thermal stability, the wear resistance and the thermal fatigue performance of H13 steel,and the hot-work die steel can be machined into a large-scale hot stamping die with the single-piece weight reaching 5 tons or above, and the usability is good.

Owner:RUGAO HONGMAO HEAVY FORGING

Low-remanence nanocrystalline magnetic core and preparation method thereof

ActiveCN107256793AAvoid direct contactImprove high temperature stabilityInorganic material magnetismInductances/transformers/magnets manufactureRemanenceWater cooling

The invention relates to the technical field of high frequency inverter power supplies, in particular to a low-remanence nanocrystalline magnetic core and a preparation method thereof. The preparation method includes the following steps: performing vacuum isothermal annealing on a Fe-Ni based nanocrystalline ribbon prepared by the single roller melt rotation rapid quenching method, and water-cooling the Fe-Ni based nanocrystalline ribbon to the indoor temperature; crushing the Fe-Ni based nanocrystalline ribbon into nanocrystalline metallic powder, performing ball-milling and shaping on the nanocrystalline metallic powder, screening the powder into first powder and second powder; evenly mixing the processed first powder and the processed second powder, pressing the mixed powder into a magnetic core; putting the formed magnetic core in a vacuum annealing furnace to perform heat treatment; performing heat treatment again; and performing glue dipping and curing treatment on the nanocrystalline magnetic core. The preparation method is simple in process, and is low in production cost; the acquired magnetic core finished product has high saturation flux density, low a loss value, low coercivity, low remanence, and high temperature resistance, is excellent in comprehensive performance, will not be damaged, and is improved in reliability.

Owner:DONGGUAN DAZHONG ELECTRONICS

High-carbon and high-chromium 9Cr18 martensite stainless steel shaft forging preparation technology

ActiveCN104259361AEasy to controlImprove segregationMetal-working apparatusAdditive ingredientIsothermal annealing

The invention relates to a high-carbon and high-chromium 9Cr18 martensite stainless steel shaft forging preparation technology. During smelting, the weight percentage of carbon in stainless steel is controlled to be 0.90-0.92%, and the weight percentages of other ingredients are as follows: 17.0-17.5% of Cr, 0.50-0.55% of Si and 0.40-0.45% of Mn; the casting temperature is controlled to be 1450-1480 DEG C; 10.5 ton of electroslag ingots are adopted for forging, the electroslag ingots are hot-charged and heated up, the heating temperature is 1140-1180 DEG C, the initial forging temperature is 1000-1120 DEG C, the finish forging temperature is higher than or equal to 950 DEG C, and the returning heating-up time cannot exceed 2 hours; after forging, normalizing and isothermal annealing are conducted, the normalizing temperature is 850-950 DEG C, and air cooling is conducted to obtain the temeprature of 650-750 DEG C for isothermal annealing. The high-carbon and high-chromium 9Cr18 martensite stainless steel shaft forging preparation technology provided by the invention controls the chemical compositions, the forging heating, the initial forging temperature, the finish forging temperature, the deformation mode, the deflection and the after-forging heat treatment temperature of steel to enable twin-crystal carbides in the steel to be moved or improved.

Owner:HENAN ZHONGYUAN SPECIAL STEEL EQUIP MFG CO LTD

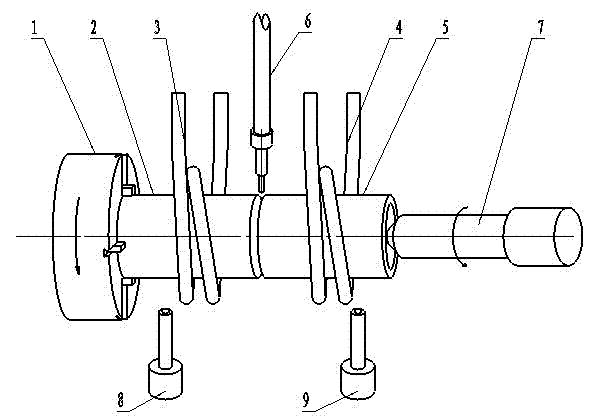

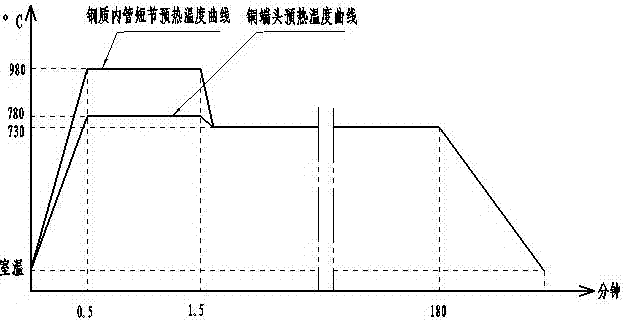

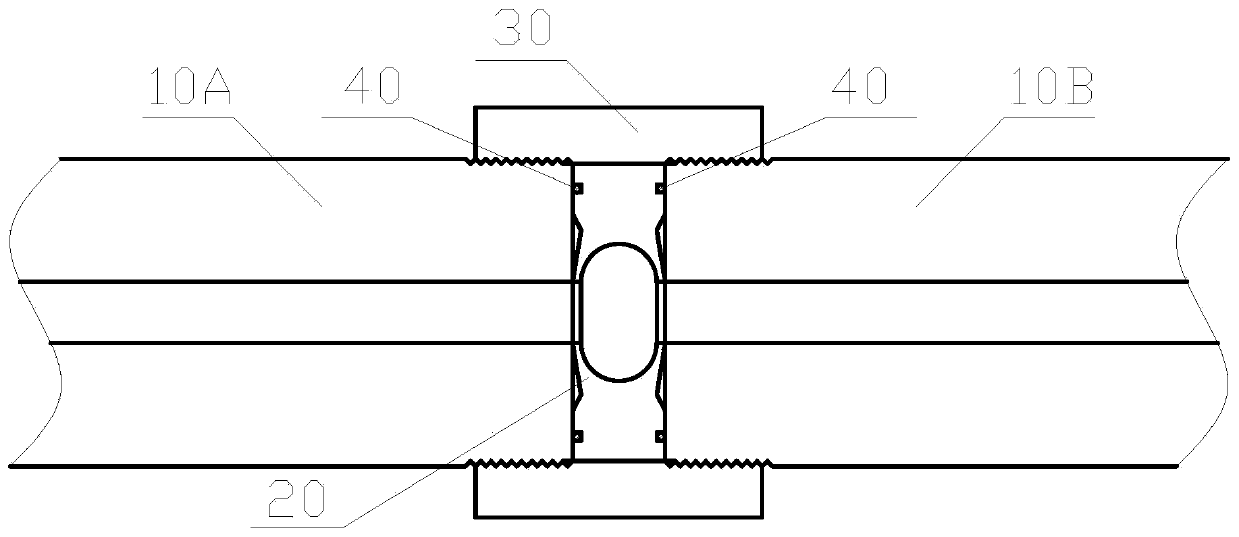

Method for welding copper oxygen lance end for steelmaking with steel pipe sub

ActiveCN102554401AGuarantee welding qualityGuaranteed welding strengthArc welding apparatusFurnace typesPower flowCopper

A method for welding a copper oxygen lance end for steelmaking with a steel pipe sub uses a medium frequency induction heating device, the copper end and the inner and outer steel pipe sub are rapidly heated by two induction heating coils to respectively reach different optimal preheating temperatures in a short time and then are welded, and induction heating and isothermal annealing treatment is performed for a welding line after welding to sufficiently eliminate residual stress. By adjusting the current strength of an induction heater, the preheating temperatures of the copper end and the inner and outer steel pipe sub can be precisely regulated and controlled according to process requirements, heating is rapidly performed, an oxidation layer is decreased, the strength of the welding line is improved, and production efficiency is improved while the welding quality of the oxygen lance end is ensured.

Owner:石家庄巨力科技股份有限公司

Manufacturing process of high-pressure regulating valve disc for ultra-supercritical steam turbine

The invention discloses a manufacturing process of a high-pressure regulating valve disc for an ultra-supercritical steam turbine. The manufacturing process comprises the following steps: blanking, heating before forging, forging, annealing, oxide skin removal by rough turning, normalizing, isothermal annealing, tempering heat treatment and finish turning processing. The high-pressure regulating valve disc manufactured by the manufacturing process can meet the following technical requirements: the tensile strength Rm (MPa) is 900-1050, the yield strength Rp 0.2 (MPa) is more than or equal to 750, the elongation rate A (percent) is more than or equal to 12, the percentage Z (percent) of area reduction is more than or equal to 40, the hardness HB is 262-311, the impact power (J) of a V-shaped notch is more than or equal to 20, and the average grain size is not thicker than grade 2 regulated in GB / T 6394; a microscopic structure is uniform tempered martensite, the content of delta ferrites in a most serious field of view is less than 5 percent, and the content of average delta ferrites is less than 3 percent; nonmetallic inclusions meet the following requirements: A: the thickness isless than or equal to 1.5, and the fineness is less than or equal 1.5; B: the thickness is less than or equal to 1.5, the fineness is less than or equal 1.5; C: the thickness is less than or equal to1.5, and the fineness is less than or equal 1.5; D: the thickness is less than or equal to 1.5, and the fineness is less than or equal 1.5; the sum of all kinds is less than or equal to 3.5.

Owner:ZHANGJIAGANG HAILU ANNULAR FORGINGS

Iron-based amorphous nanocrystalline soft magnetic alloy and preparation method thereof

InactiveCN103602931AImprove liquidityEnhanced Amorphous Formation AbilityMagnetic materialsRoom temperatureIngot

The invention relates to an iron-based amorphous nanocrystalline soft magnetic alloy and a preparation method thereof. The composition of the alloy is expressed by a chemical formula of Fe73Cu1Nb3.5-xVxSi13.5B9, wherein x is more than 0 and less than or equal to 3. The preparation method comprises the following steps: proportioning master alloy raw materials; repeatedly melting the master alloy raw materials, and pouring into an alloy ingot; crushing the alloy ingot and performing ultrasonic cleaning; preparing the cleaned bulk alloy into an amorphous thin belt by adopting a single-roller rapid quenching method; performing isothermal annealing treatment on the amorphous thin belt, and performing furnace cooling to room temperature, thus obtaining the iron-based amorphous nanocrystalline soft magnetic alloy thin belt. Compared with the prior art, the iron-based amorphous nanocrystalline soft magnetic alloy has the advantages that Nb is partially replaced by element V belonging to the VB group in a periodic table of elements together with Nb to prepare the iron-based amorphous nanocrystalline soft magnetic alloy thin belt, and the liquidity of the alloy in the fusion and belt injection process is improved, so that the amorphous forming ability of the iron-based amorphous nanocrystalline soft magnetic alloy is enhanced, i.e., strips are easily formed, and the low-cost low-loss iron-based amorphous nanocrystalline soft magnetic alloy is prepared.

Owner:TONGJI UNIV

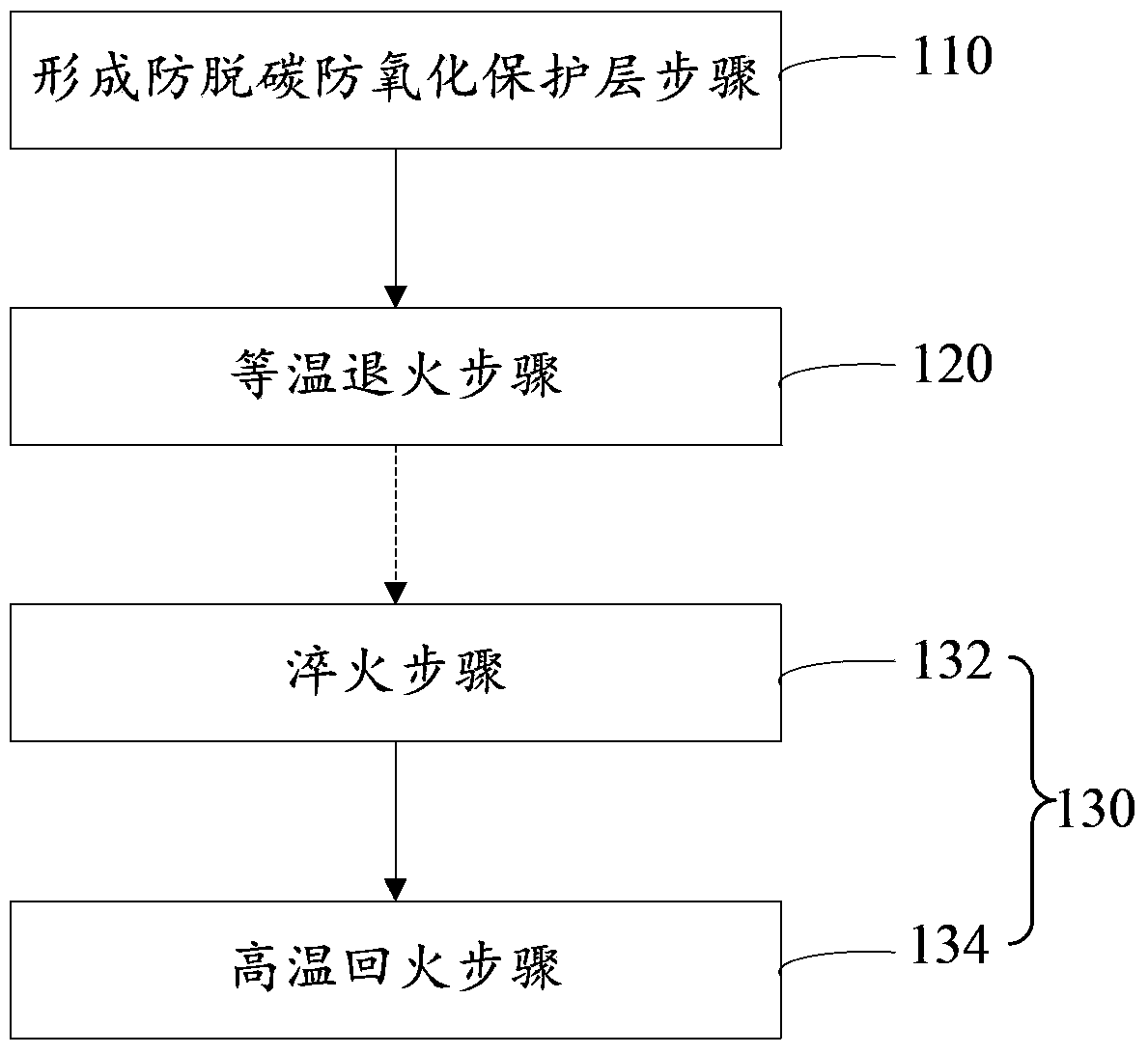

Heat treatment method of alloy steel after forging

The invention relates to a heat treatment method of alloy steel after forging. The method comprises the steps of forming a decarburization-preventing and oxidation-resistant protective layer on a surface of an alloy steel workpiece; and then carrying out isothermal annealing on a to-be-treated alloy steel workpiece with the decarburization-preventing and oxidation-resistant protective layer. The heat treatment method of the alloy steel after forging can effectively prevent the surface of the to-be-treated alloy steel workpiece from decarburization and oxidation and shorten a heating period, thereby being beneficial to improve comprehensive mechanical performance of the to-be-treated alloy steel workpiece.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

Preparation method of titanium alloy seamless pipe in petroleum and natural gas industry

InactiveCN109280787AImprove plasticityImprove impact performanceFurnace typesMetal rolling arrangementsSelf consumptionBeta phase

The invention discloses a preparation method of a titanium alloy seamless pipe in the petroleum and natural gas industry. The preparation method comprises the following steps that S1, electrodes are prepared according to nominal compositions of the titanium alloy in the petroleum and natural gas industry, vacuum self-consumption smelting and vacuum casting are conducted, and titanium alloy skew rolling punching rod blanks are obtained after high temperature homogenization heat treatment; S2, the titanium alloy skew rolling punching rod blanks are subjected to skew rolling punching to obtain titanium alloy punching pipe blanks; S3, the titanium alloy punching pipe blanks are subjected to diameter determining and rolling to obtain titanium alloy seamless pipes; and S4, the titanium alloy seamless pipes are subjected to isothermal annealing heat treatment to obtain titanium alloy seamless pipes for the petroleum and natural gas industry. The titanium alloy cast rod blanks prepared by vacuum self-consumption smelting and vacuum casting are subjected to high temperature homogenization heat treatment, and are subjected to skew rolling punching at the beta phase transformation point to obtain the punching pipe blanks, the casting process is omitted, procedures are shortened, and the yield rate is improved. With combination of isothermal annealing heat treatment above the beta phase transformation point, microstructure uniformity is improved. The mechanical property of products is improved, and application in the petroleum and natural gas industry is achieved.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

High-heat-resistance and high-impact-toughness hot-work die steel for hot forging and preparation method

ActiveCN108220815AImprove heat strengthImprove impact toughnessMetal-working apparatusRare-earth elementIsothermal annealing

The invention discloses high-heat-resistance and high-impact-toughness hot-work die steel for hot forging and a preparation method thereof, and belongs to the technical field of die steel. The die steel comprises the following chemical components, by weight ratio: 0.40-0.50% of C, 0.30-0.60% of Si, less than or equal to 0.006% of S, less than or equal to 0.01% of P, 0.60-0.9% of Mn, 1.80-2.80% ofMo, 3.00-3.80% of Cr , 0.40-0.60% of V, 0.80-1.40% of Ni, 0.3-0.6% of Al, 0.50-1.10% of Co, 0.002-0.008% of rare earth elements and the balance Fe and inevitable impurities. The preparation method comprises the steps that steel is subjected to smelting and ingot casting, after a prepared steel ingot is subjected to high-temperature diffusing heat treatment, multi-directional forging and hot working are carried out, controlled cooling after forging is carried out, microstructure homogenization is carried out, refining heat treatment is carried out, and isothermal annealing treatment is carriedout. The die steel has the advantages of being relatively high in heat resistance, impact toughness and hardenability and particularly suitable for manufacturing a hot-work die with high heat resistance and impact toughness and with the large cross section with the thickness of 400mm or larger.

Owner:CENT IRON & STEEL RES INST

Manufacturing method of high-temperature jet steel

The invention relates to a manufacturing method of high-temperature jet steel. A homogenizing method is adopted to overcome the defect that nitrogen is contained in gaps in the jet steel. The subsequent treatment process for the jet steel in the method comprises the steps: isothermal annealing; homogenizing; strong forging; grain refining; and complete annealing. By using the manufacturing method, not only is the defect that nitrogen is contained in gaps in a jet steel ingot eliminated, but also large-particle carbides inevitably generated in a molten jet steel solidification process can be decomposed, so that an alloy element is homogenized microcosmically, and die steel with high ductility, high toughness and uniform performances is produced. The high-grade die steel produced by using the method disclosed by the invention is low in cost and extremely wide in market prospect.

Owner:HEYE SPECIAL STEEL

Low-cost Fe-Si-B-Cu-Nb-Al-Ni nanocrystalline magnetic core preparation method for high-frequency electronic transformer

ActiveCN103700482AIncrease saturation magnetic inductionReduce manufacturing costInductances/transformers/magnets manufactureMagnetic materialsAluminoxanePolyvinyl alcohol

The invention discloses a low-cost Fe-Si-B-Cu-Nb-Al-Ni nanocrystalline magnetic core preparation method for a high-frequency electronic transformer. The method specifically comprises the following steps of performing vacuum isothermal annealing on an iron-based amorphous thin strip to obtain a nanocrystalline thin strip; crushing the obtained nanocrystalline thin strip to obtain nanocrystalline metal powder; classifying the nanocrystalline metal powder into unequal parts of materials A and B; adding gamma-(methacryloxypropyl) trimethoxy aluminoxane and mica powder into the material A for treatment, and treating the material B sequentially by using triethanolamine, aluminum nitride, hexamethylenetetramine and polyvinyl alcohol; uniformly mixing the treated materials A and B, adding a sodium aluminate aqueous solution, performing compression molding, coating the surface of a molded magnetic core with magnetic core glue G500, and performing curing to obtain a finished product. According to the method, Nb is added into the magnetic core, so that the saturation magnetic induction intensity of the magnetic core is favorably improved; Al is added, so that the coercive force is favorably reduced; in addition, the production cost of a FeSiBCuNb magnetic core can be remarkably lowered.

Owner:TONGLING SANJIA TRANSFORMER

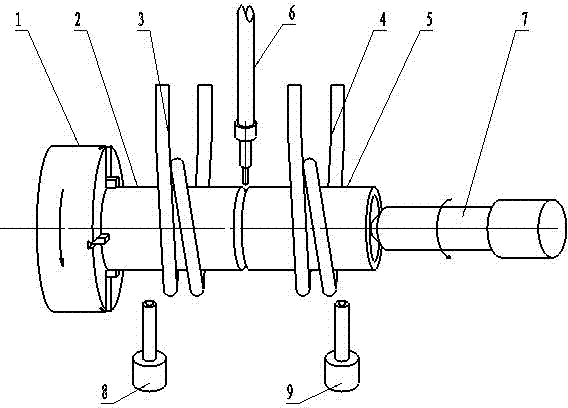

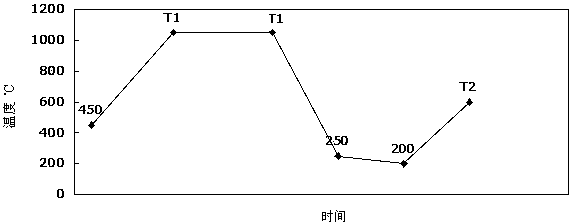

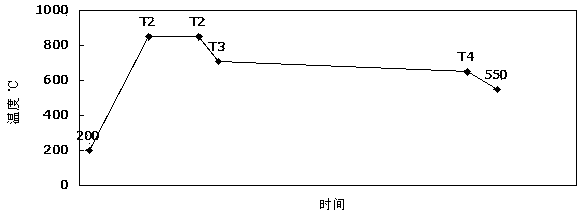

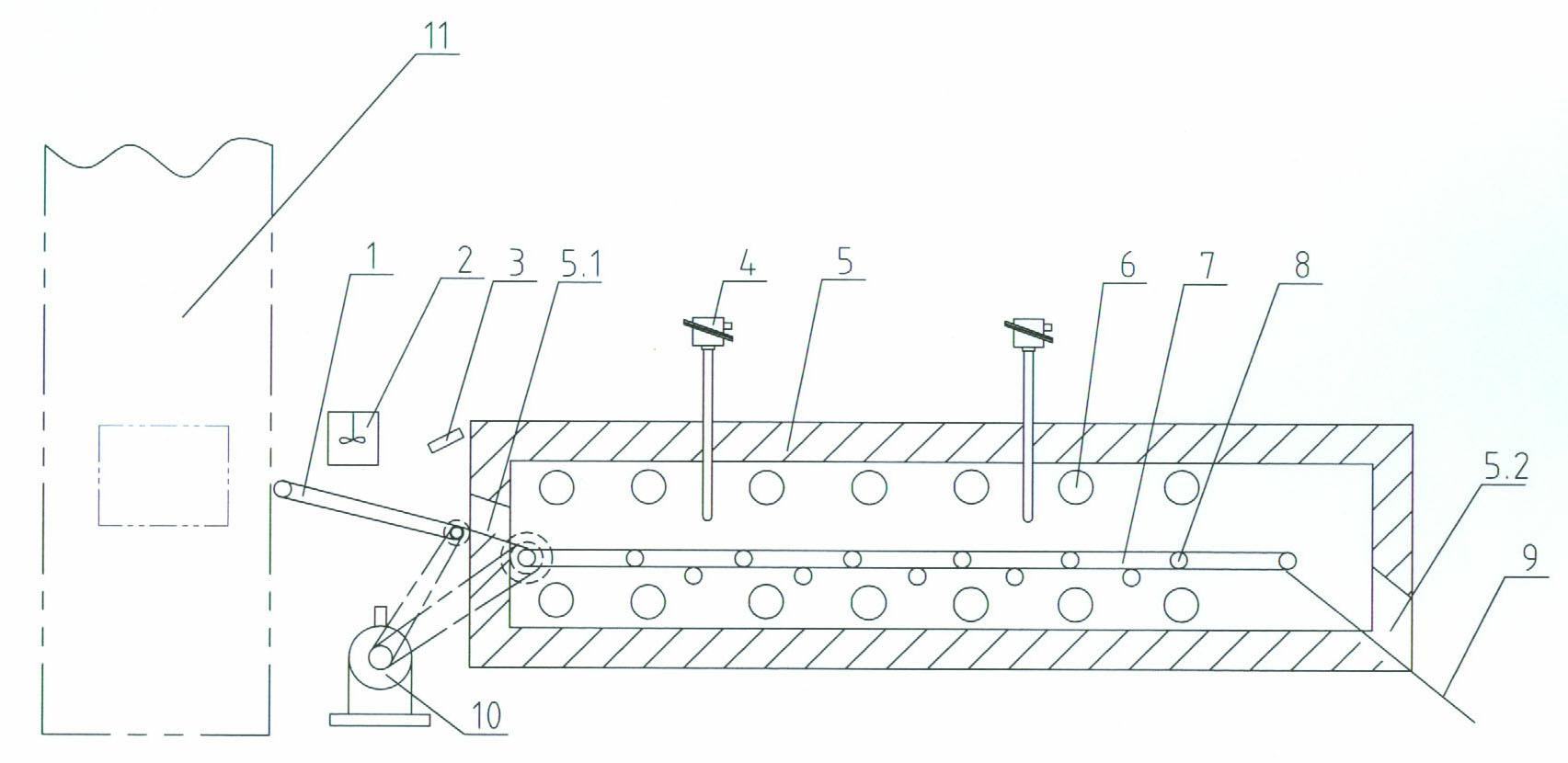

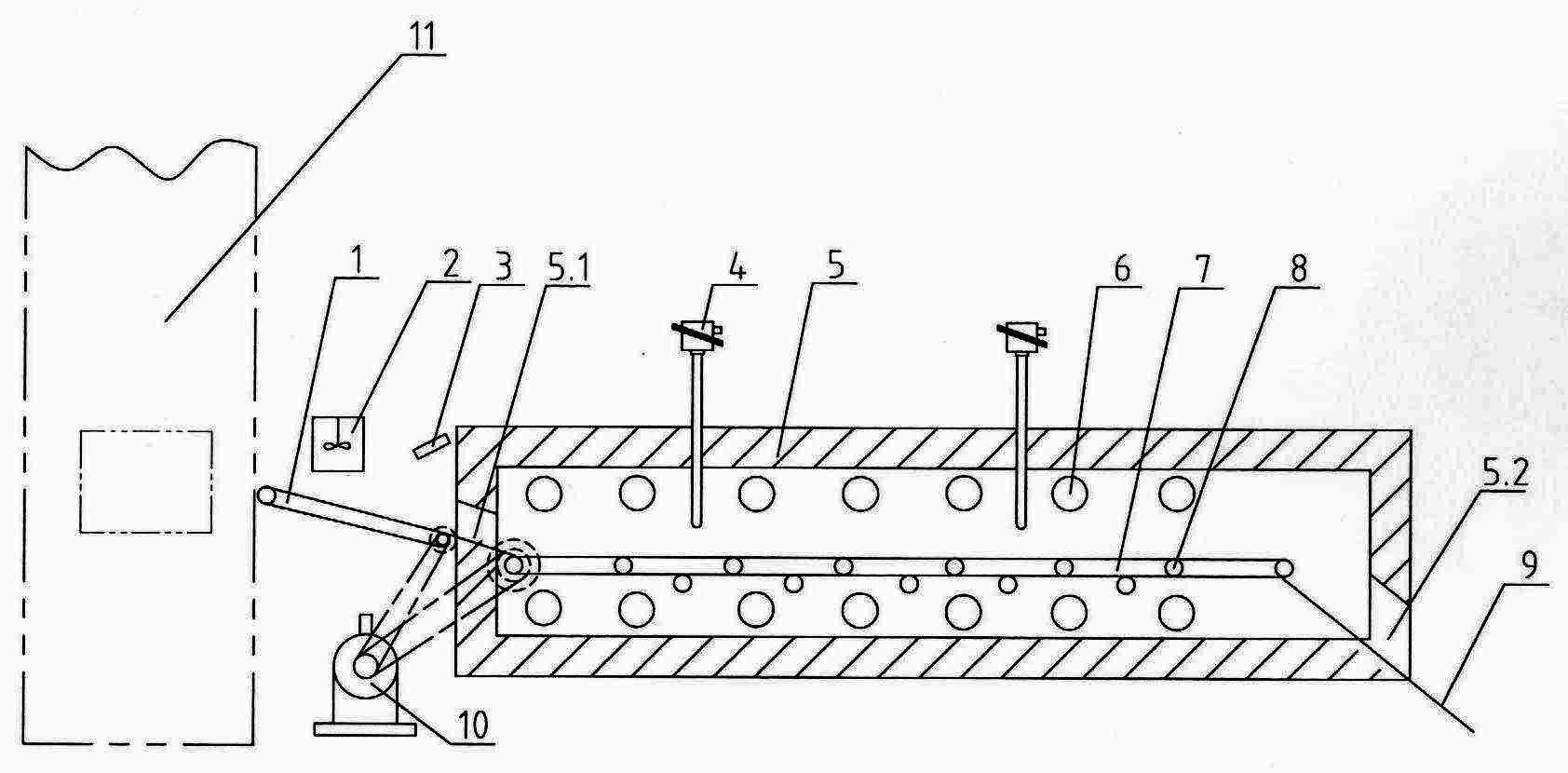

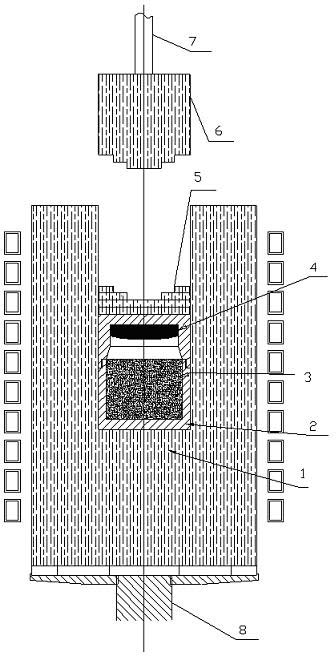

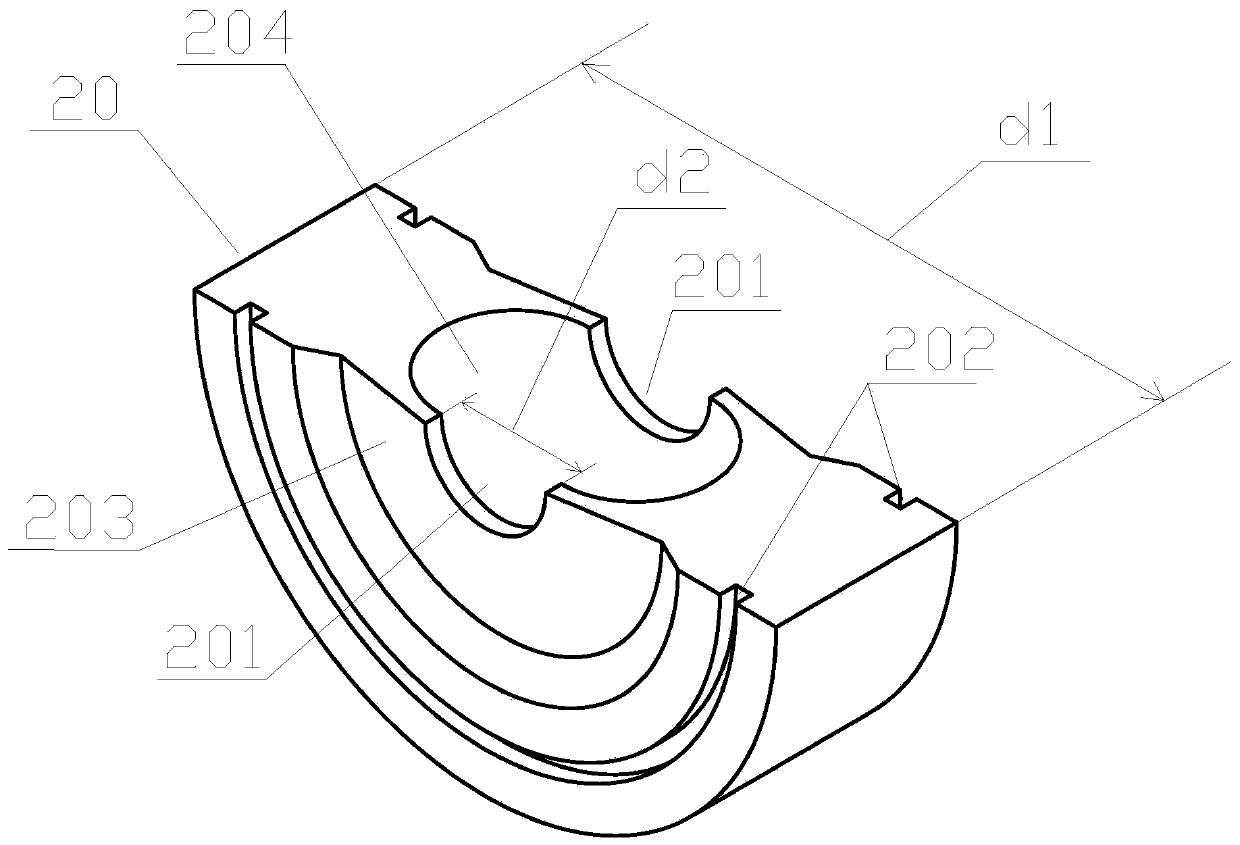

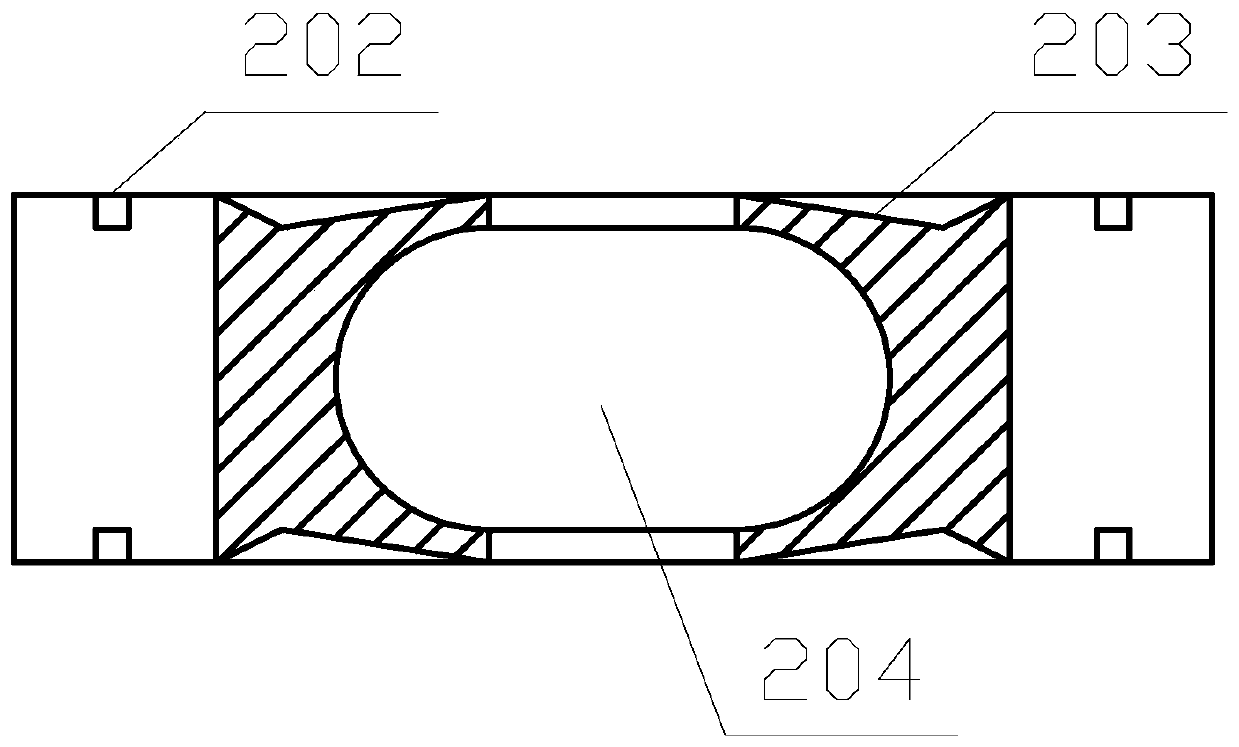

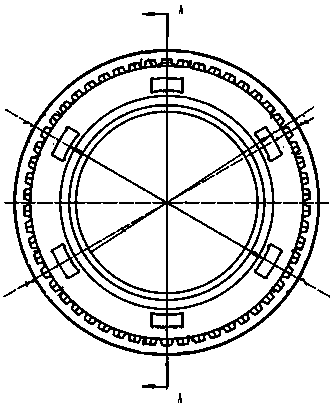

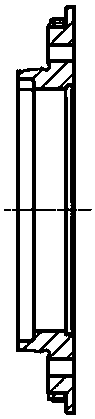

Isothermal annealing device using gear blank forging waste heat

InactiveCN102154542ASimple structureEasy to manufactureFurnace typesHeat treatment furnacesTemperature controlIsothermal annealing

The invention discloses an isothermal annealing device using gear blank forging waste heat. The device comprises a temperature control component, an annealing furnace and a driving mechanism, wherein the temperature control component comprises an infrared temperature measurer, a fan and thermocouples; the driving mechanism comprises a reducing mechanism, a driving belt, a mesh belt and supporting rollers; one side, facing a forging press, of the furnace body of the annealing furnace is provided with an inlet, and the other side of the furnace body is provided with an outlet which is downwardly and slantwise formed; a guide plate is arranged between the outlet and the mesh belt; heat radiation tubes are arranged in the furnace body; the driving belt is arranged between the forging press and the inlet of the furnace body; the mesh belt and the supporting rollers are arranged in the furnace body; the driving belt and the mesh belt are together driven by the reducing mechanism; and both the fan and the reducing mechanism are driven by matched variable frequency motors. Gear blanks which are just demoulded are cooled to a set annealing temperature through the fan before phase change and then are fed into the annealing furnace for isothermal annealing in sequence. The annealed gear blanks have more uniform hardness and structures, so that subsequent cold finishing and mechanical cutting are facilitated. In the invention, reheating is not required, so that the device has a good energy saving effect and high production efficiency.

Owner:JIANGSU PACIFIC PRECISION FORGING

Manufacturing method for magnetic core of iron-based nanocrystalline high-power switching power supply transformer

ActiveCN103700480AImprove frequency characteristicsReduce high frequency eddy current lossInductances/transformers/magnets manufactureO-Phosphoric AcidTransformer

The invention discloses a manufacturing method for a magnetic core of an iron-based nanocrystalline high-power switching power supply transformer. The method comprises the following specific steps: performing vacuum isothermal annealing on an iron-based amorphous ribbon to obtain a nanocrystalline ribbon; crushing the obtained nanocrystalline ribbon to obtain nanocrystalline metal powder; performing phosphorization and insulated coating treatment on the nanocrystalline metal powder in sequence, adding zinc stearate and silicon carbide micro powder, and performing compression molding. After phosphorization is performed on the components of ammonium molybdate, phosphoric acid, diammonium hydrogen phosphate and sodium fluoride in the nanocrystalline metal powder, a layer of phosphate film is formed on the surface of the powder, so that the frequency characteristic of the magnetic core can be improved remarkably, and the high-frequency magnetic loss is reduced; after the phosphorization, alloy powder is coated in an insulated way by the substances of polyamide-imide resin and nano-attapulgite, so that the resistivity among powder particles is increased, and the high-frequency eddy current loss of the magnetic core is reduced.

Owner:TONGLING SANJIA TRANSFORMER

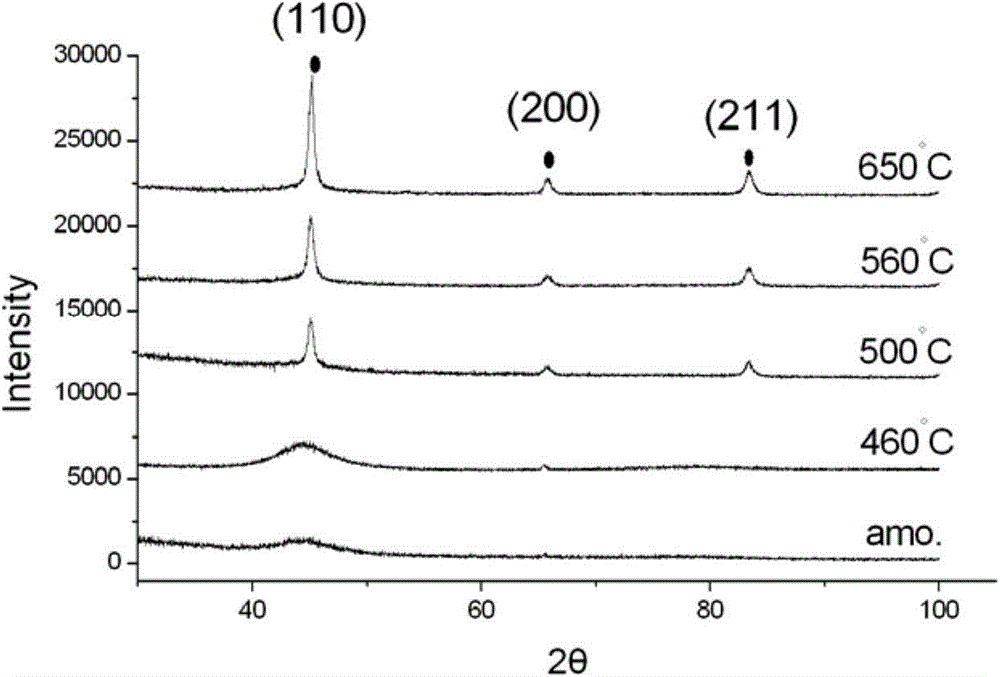

Low-temperature formation of polycrystalline semiconductor films via enhanced metal-induced crystallization

ActiveUS8043943B2Simple materialReduce the temperaturePolycrystalline material growthFrom solid stateSemiconductor materialsMetal-induced crystallization

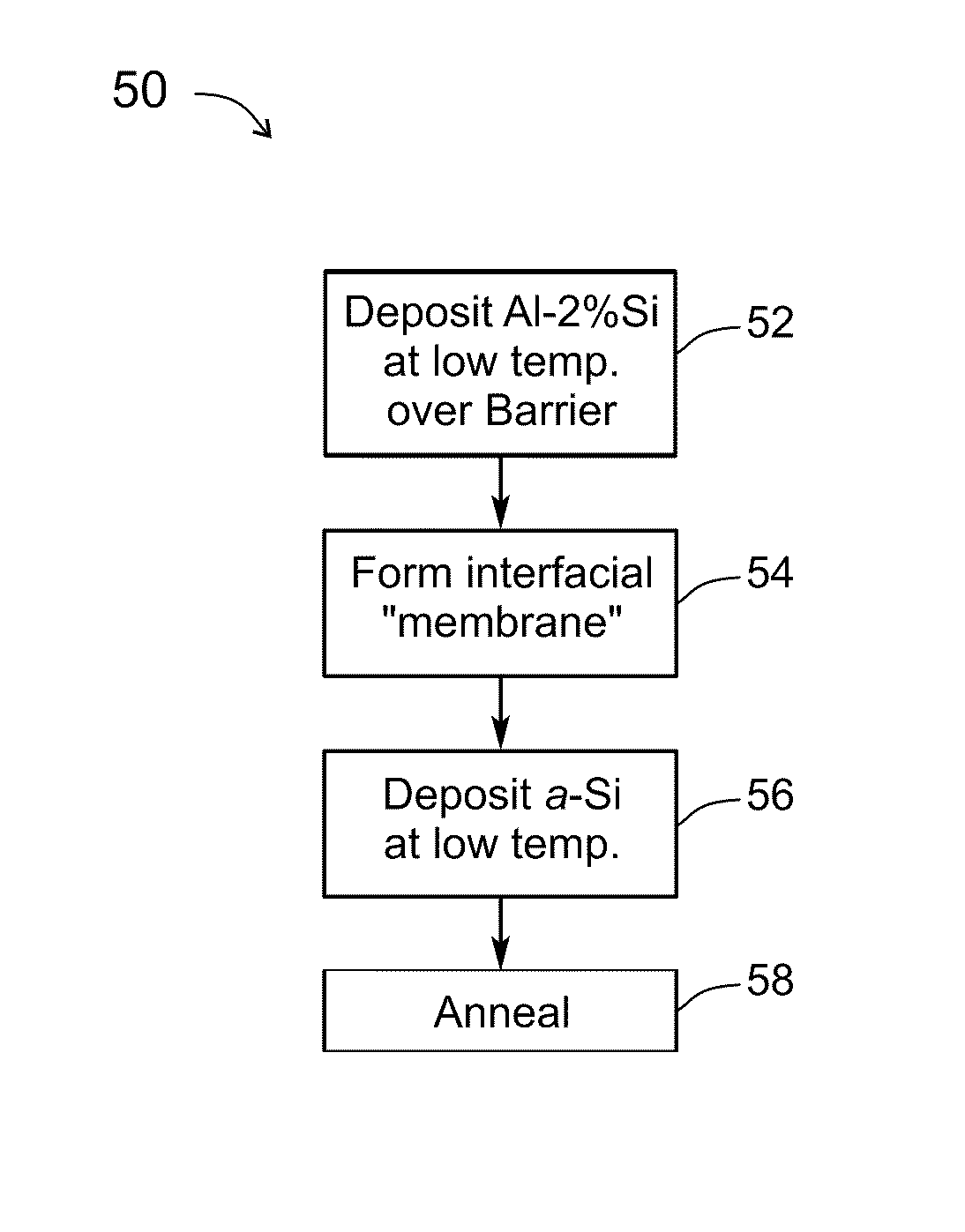

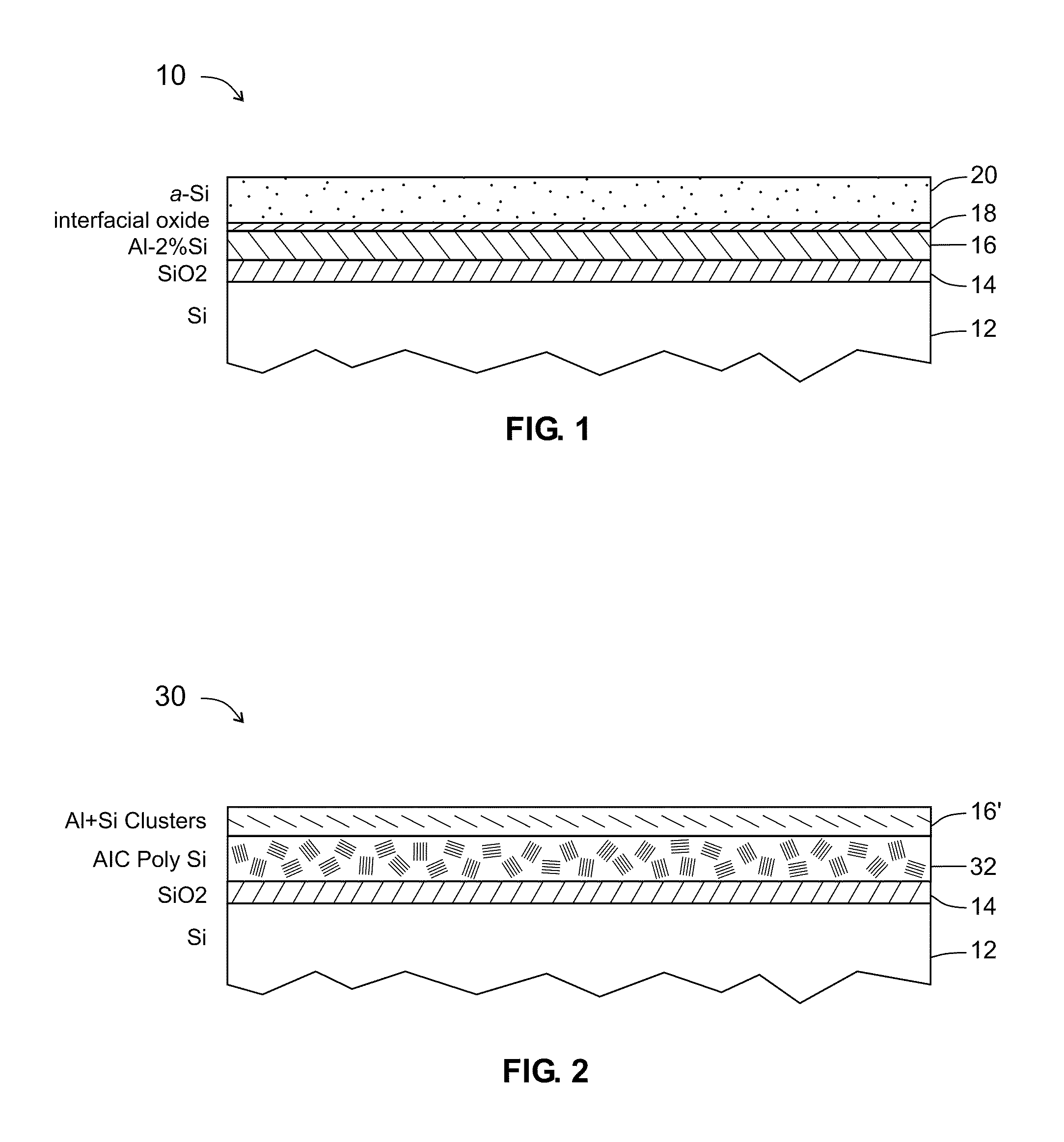

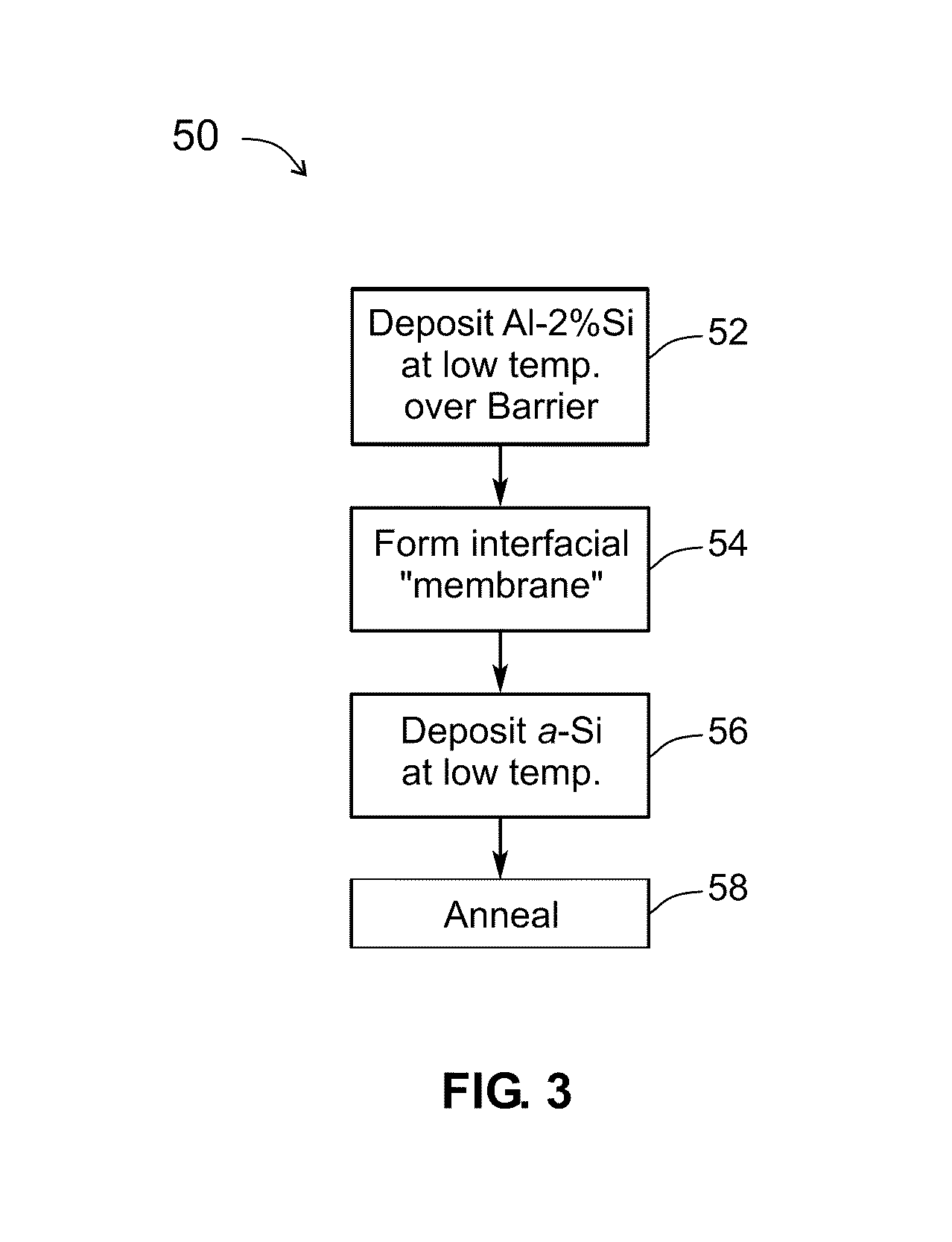

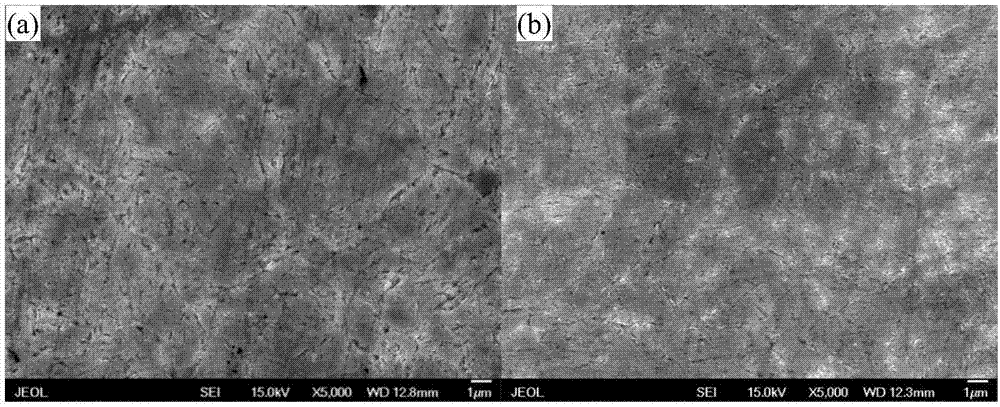

A method for forming polycrystalline semiconductor film from amorphous semiconductor film at reduced temperatures and / or accelerated rates. The inclusion of a small percentage of semiconductor material, such as 2% within the metal layer, reduces the temperatures required for crystallization of the amorphous semiconductor by at least 50° C. in comparison to the use of the metal layer without the small percentage of semiconductor material. During a low temperature isothermal annealing process adjacent Al-2% Si and a-Si films undergo a layer exchange resulting in formation of a continuous polycrystalline silicon film having good physical and electrical properties. Formation of polycrystalline-semiconductor in this manner is suitable for use with low temperature substrates (e.g., glass, plastic) as well as with numerous integrated circuit and MEMs fabrication devices and practices.

Owner:RGT UNIV OF CALIFORNIA

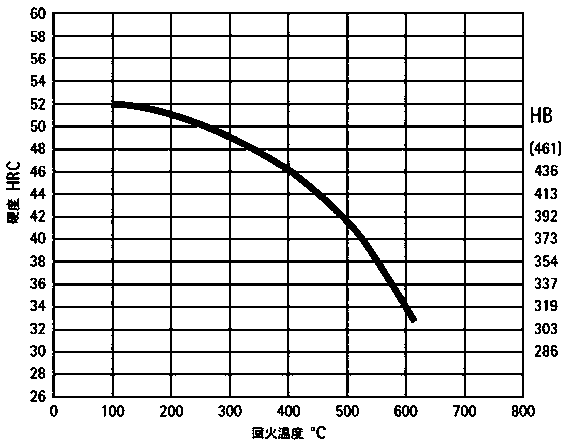

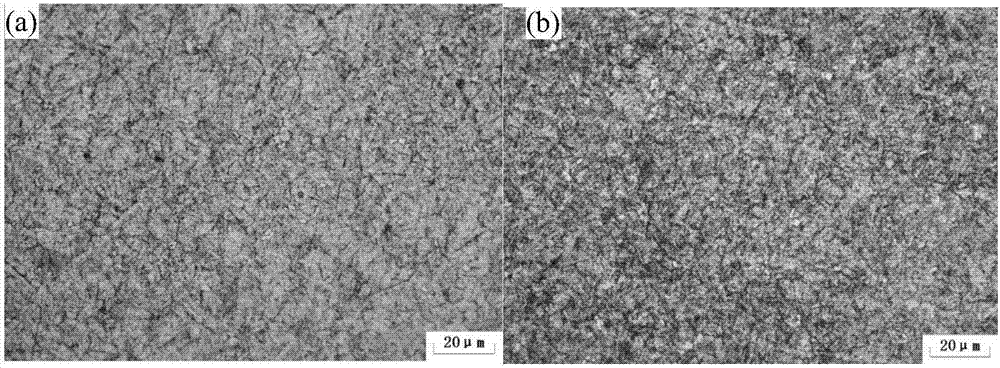

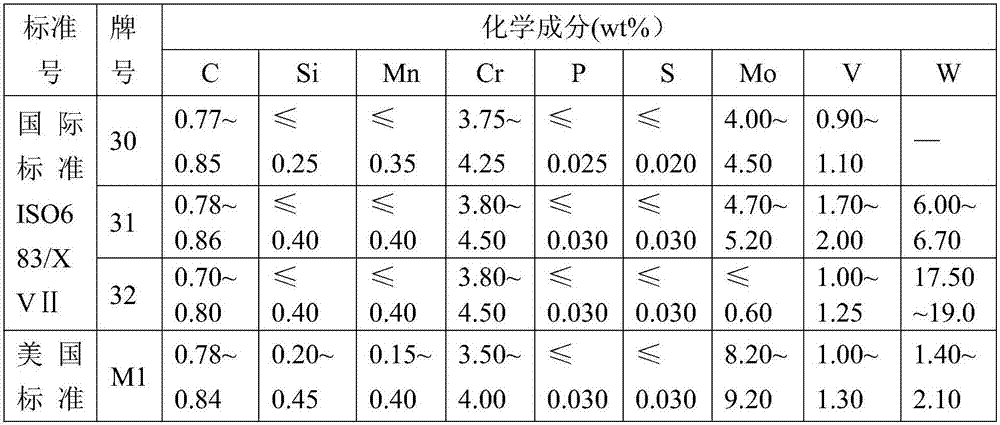

Preparation method of bearing steel capable of resisting high temperature of 400 DEG C

The invention belongs to the field of development of high temperature bearing steel, and mainly relates to a preparation method of bearing steel capable of resisting high temperature of 400 DEG C. A bearing machined from the bearing steel can be used at the high temperature of 400 DEG C. The high temperature bearing steel is subjected to dual-vacuum smelting through a vacuum induction furnace and a vacuum electroslag remelting, and is prepared from 4.5 to 5.28 percent of Cr, 3.75 to 4.10 percent of Mo, 0.56 to 0.80 percent of V, 0.30 to 0.34 percent of Mn, 0.21 to 0.26 percent of Ni and 0.2 to 0.29 percent of Si. A thermal treatment process comprises the following steps: heating the bearing steel to 800 to 870 DEG C for heat preservation, cooling the bearing steel to 700 to 800 DEG C for isothermal annealing, and then slowly cooling the bearing steel to room temperature; heating the bearing steel to 1,050 to 1,070 DEG C for solution treatment, and carrying out heat preservation and oil quenching in sequence; and heating the bearing steel to 510 to 550 DEG C for tempering for 2 to 2.5 hours, and then carrying out tempering for three times according to the process. According to the novel high temperature bearing steel disclosed by the invention, by reduction of the vanadium content, carbides can be thinned and dispersed, so that generation of fatigue crack sources can be reduced; meanwhile, the hardness is further improved; and the room temperature hardness is not less than 62 HRC, and the hardness at the high temperature of 400 DEG C is not less than 658 HV, so that the bearing steel can meet application under a high temperature condition.

Owner:UNIV OF SCI & TECH BEIJING

Milling cutter machining process

The invention discloses a milling cutter machining process, and relates to the field of machining. The milling cutter machining process comprises the following steps: forging blank, carrying out isothermal annealing, carrying out machining, quenching, tempering, and phosphating. According to the milling cutter machining process, alloy tool steel with a trade mark of W18Cr4V is selected as a raw material for manufacturing a milling cutter, and the W18Cr4V steel is high-speed steel with good comprehensive mechanical properties and great hardness, so that the manufactured milling cutter is good in wear resistance. The tempered milling cutter is soaked into an acidic dilute aqueous solution comprising a phosphating solution, so that a layer of phosphating film is formed on the surface of the milling cutter, and therefore, the corrosion resistance of the milling cutter is improved.

Owner:NANJING VOCATIONAL UNIV OF IND TECH

Furnace monocrystal isothermal annealing method and tool

InactiveCN102605421AReduce thermal stressReduced risk of crackingAfter-treatment detailsFrom condensed vaporsCrucibleIsothermal annealing

The invention belongs to the technical field of monocrystal preparation, and relates to a furnace monocrystal isothermal annealing method and tool, in particular to an annealing method and tool after the growth of monocrystal with a physical vapor transportation method is finished. The method comprises the steps of: covering an insulating plug on a radiating channel at the top of a crucible after the growth of monocrystal with the physical vapor transportation method is finished, reducing the heating power by about 10-70%, and then insulating for 1 hour to 48 hours; and finally adopting isothermal furnace annealing method to cool to room temperature, thus obtaining monocrystal with small thermal stress. The furnace monocrystal isothermal annealing tool comprises the crucible, wherein the radiating channel is arranged at the top of the crucible, the insulating plug is arranged above the radiating channel, and the insulating plug or the crucible can move up and down. Compared with the prior art of gradient cooling with temperature and additional annealing, the method and tool provided by the invention not only can greatly decrease the thermal stress of the monocrystal and lower the crack risk of monocrystal, but also can simplify the process and lower the cost as the monocrystal can be directly machined after the growth is finished and the furnace annealing is completed.

Owner:BEIJING HUAJINCHUANGWEI ELECTRONICS CO LTD

Heat treatment method of thick-wall P92 steel pipe

ActiveCN113234899AEliminate geneticsGrain refinementFurnace typesProcess efficiency improvementTemperingIsothermal annealing

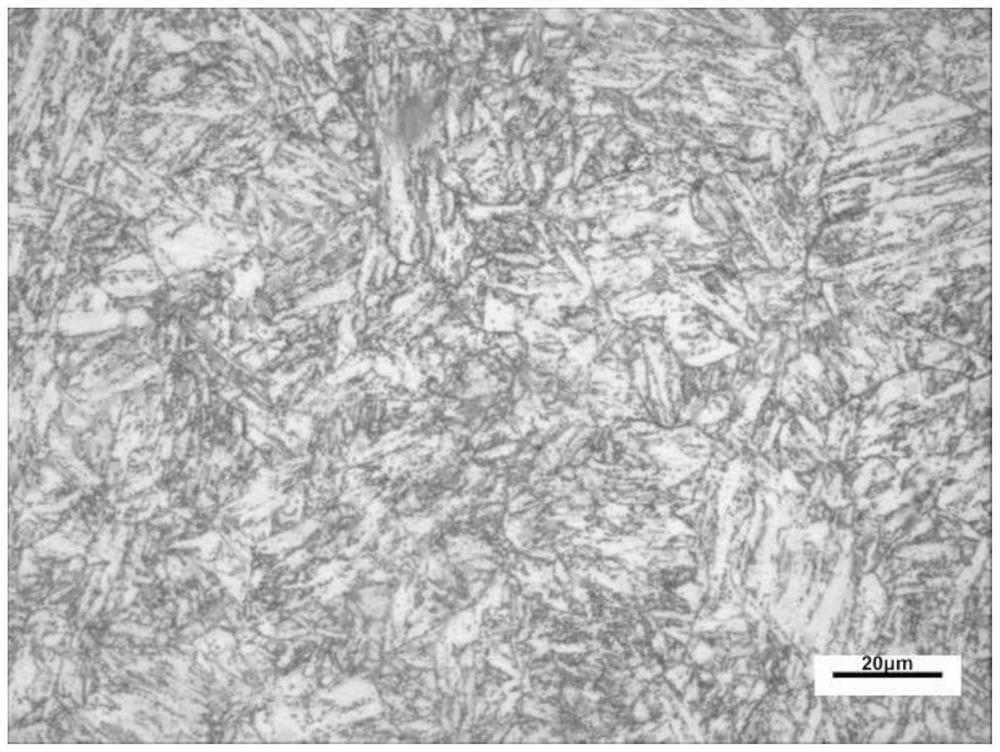

The invention provides a heat treatment method for a thick-wall P92 (10Cr9MoW2VNbBN) steel pipe, and aims to solve the technical problems that in the prior art, the grain size in P92 steel pipe production does not meet standard specifications, and the performance difference of products in different batches is large. According to the heat treatment method for the thick-wall P92 steel pipe, the P92 steel pipe is subjected to high-temperature austenitizing and isothermal annealing and then subjected to normalizing and tempering, the temperature rise before austenitizing heat preservation can be achieved through rapid temperature rise, and therefore the heating speed of the steel pipe is increased, and the nucleation rate of austenite is increased. According to the method, a manufactured product is good in structure state, the microscopic structure is tempered martensite, the grain size is larger than or equal to the fifth grade, and the grade difference does not exceed the third grade, the mechanical property meets the ASME SA-335-2019 and GB / T 5310-2017 standard requirements, and the comprehensive performance reaches the international advanced level.

Owner:DAYE SPECIAL STEEL CO LTD

Design and manufacturing method of high-pressure hydrogen contact self-tightening combined seal

ActiveCN111440929AImprove organizational stabilityPhase change is not easy to occurFurnace typesIncreasing energy efficiencyIsothermal annealingCryogenic treatment

The invention discloses a design and manufacturing method of a high-pressure hydrogen contact self-tightening combined seal. The method comprises the steps that a self-tightening metal structure is designed; the self-tightening metal structure after structural design is subjected to mechanical machining; the surface of the self-tightening metal structure after mechanical machining is subjected togrinding and rolling treatment; deep cooling treatment is performed on the self-tightening metal structure subjected to grinding and rolling treatment on the surface; the self-tightening metal structure after deep cooling treatment is subjected to isothermal annealing treatment or circular annealing treatment; and metallographic structure inspection is performed on the self-tightening metal structure after isothermal annealing treatment or circular annealing treatment, if a martensitic structure is not found in the inspection, it is indicated that manufacturing of the self-tightening metal structure is completed, and if the martensitic structure is found in the inspection, the self-tightening metal structure after deep cooling treatment is subjected to isothermal annealing treatment or circular annealing treatment again. The design and manufacturing method not only improves the sealing reliability under complex working conditions such as pressure change, but also improves the tissue stability of the material that is the austenitic stainless steel and the anti-fatigue performance of the self-tightening metal structure.

Owner:HEFEI GENERAL MACHINERY RES INST

Combined gear ring manufacturing method of hybrid new energy vehicle transmission

The invention discloses a combined gear ring manufacturing method of a hybrid new energy vehicle transmission. Discharge equipment is used for discharging; a scale on the surface of a blank is removed; the blank is heated to 950-1050 DEG C; the forging is performed on an electric spiral press after heating; the final forging is performed on the electric spiral press at a temperature of not lower than 900 DEG C; the hot trimming is performed; the mechanical drilling is performed; the isothermal annealing is performed; the shot blasting is performed to remove the scale; the sorting is performed to actuate the surface phosphorus saponification for a qualified product; and a gear sharp angle of a product combined gear is coldly extruded, meanwhile, six arc holes are punched, and the six arc holes are once molded by punching. The combined gear ring manufacturing method finishes the extrusion molding of the gear sharp angle of the combined gear and precise punching of six arc holes in one procedure, can guarantee the gear shape precision of the combined gear and the position precision of six arc holes, greatly improves the gear shape precision and the size precision, is high in production efficiency, improves the material utilization rate highly, reduces the process difficulty of the transmission combined gear ring, and reduces the machining cost.

Owner:CHONGQING CHUANGJING WARM FORGING FORMING

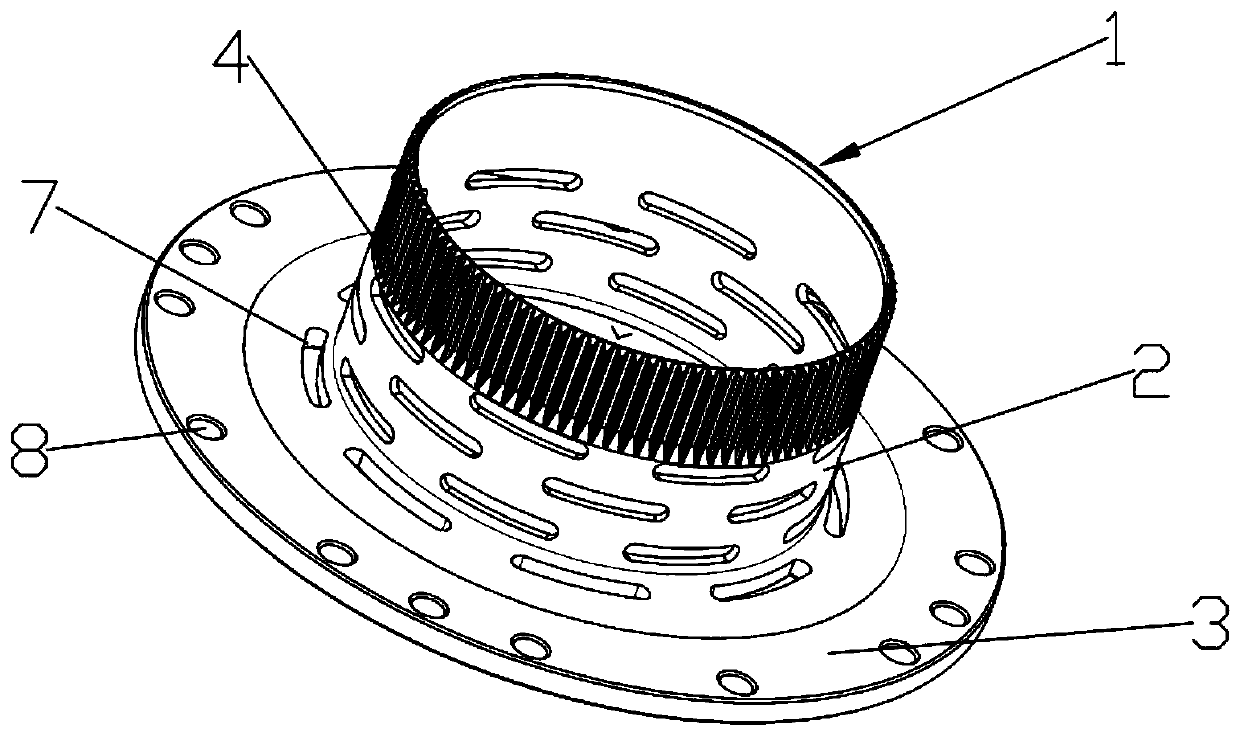

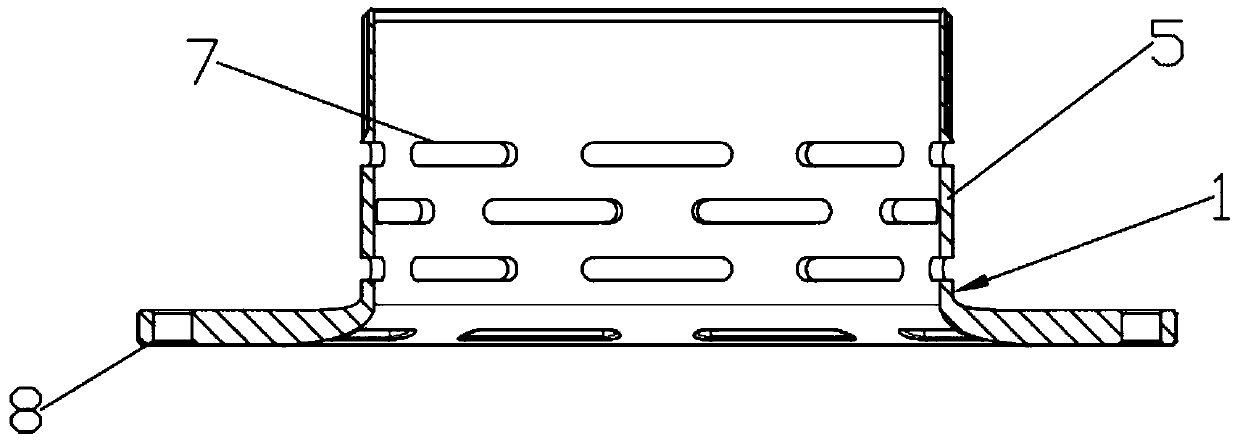

Flexible gear with destressing holes and preparation technology thereof

InactiveCN109538730AIncrease stress relief holesImprove fatigue lifePortable liftingGearing detailsManufacturing cost reductionHobbing

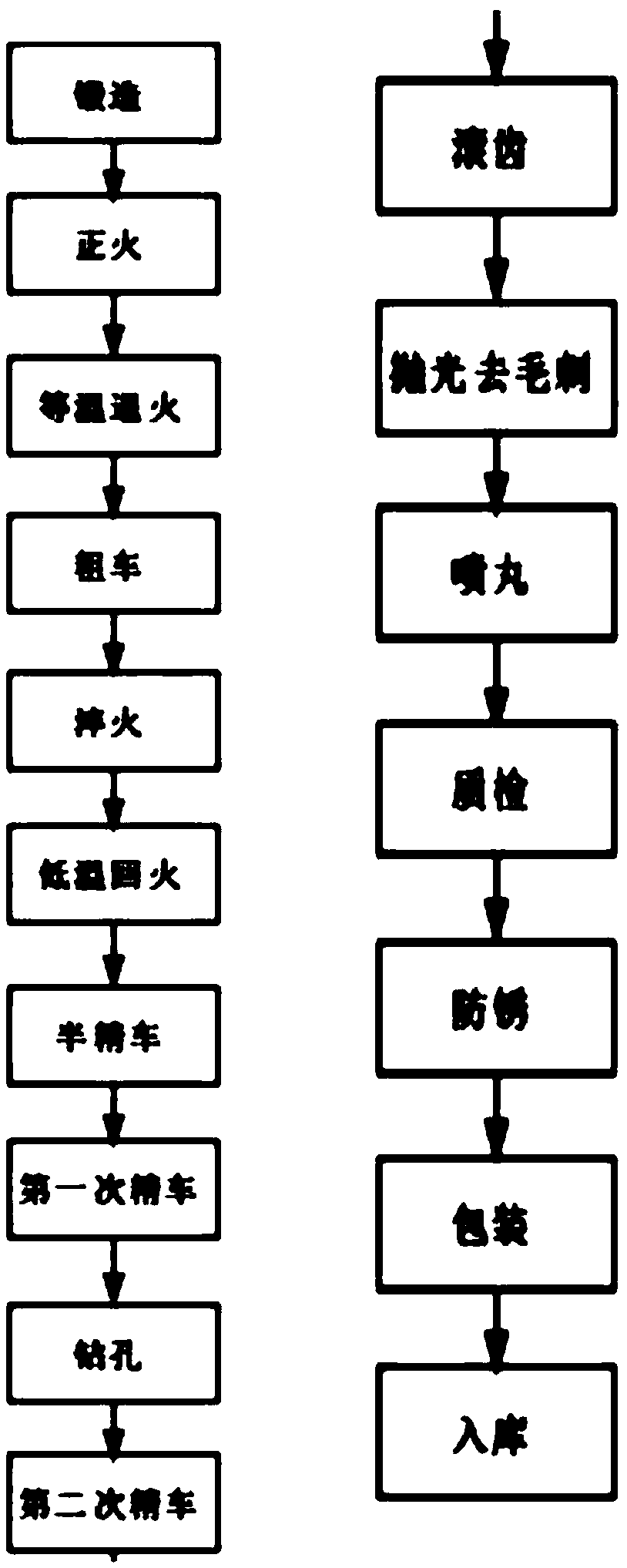

The invention relates to a harmonic reducer, in particular to a flexible gear with destressing holes. The flexible gear comprises a flexible gear body which is of a hollow structure; the flexible gearbody comprises a cylinder body and a fixing platform, and the cylinder is located over the fixing platform and arranged along the inner diameter of the fixing platform; and the flexible gear body isprovided with the destressing holes, and the destressing holes are evenly formed in the cylinder body and the fixing platform at intervals and penetrate through the cylinder body and the fixing platform. A preparation method of the flexible gear with the destressing holes comprises the processes of forging, normalizing, isothermal annealing, rough turning, quenching, low-temperature tempering, semi-fine turning, first-time fine turning, drilling, second-time fine turning, hobbing, polishing and burr removing, shot blasting, quality testing, rust preventing, packaging and warehousing. Accordingto the flexible gear with the destressing holes, the destressing holes of the flexible gear are additionally formed, therefore, the internal stress of the flexible gear is completely released, the fatigue life of the flexible gear is prolonged, the flexible gear machining technology is simplified, the production yield is increased, the manufacture cost is reduced, the product wall thickness is increased, and the torsional rigidity of the harmonic reducer is improved.

Owner:东莞市国森科精密工业有限公司

Method for preparing Fe-Cu-Nb-Ni-P-B nanocrystalline magnetic core

ActiveCN103680916AAvoid direct contactReduce loss valueInductances/transformers/magnets manufactureMagnetic materialsCelluloseCarboxymethyl cellulose

The invention discloses a method for preparing a Fe-Cu-Nb-Ni-P-B nanocrystalline magnetic core. The method specifically comprises the following steps that vacuum isothermal annealing is conducted on an iron-based amorphous thin band, so that a nanocrystalline thin band is manufactured; the manufactured nanocrystalline thin band is broken, so that nanocrystalline metal powder is obtained; the nanocrystalline metal powder is then divided into a material A and a material B which are unequal in quantity; isopropyl tri(dioctylpyrophosphate) titanate is added to the material A so that the material A can be treated, and the material B is firstly treated by glycerin and wool fat and then treated by carbamide, wollastonite in powder and carboxymethyl cellulose; the treated material A and the treated material B are evenly mixed, a cationoid phenylalanine solution is added, a mixture of the material A and the material B is compressed, the surface of the formed magnetic core is coated with magnetic core glue 400-36, the glue is solidified, and therefore the finished product is obtained. The finished magnetic core prepared through the method has the advantages of being low in loss value, resistant to high temperature, good in overall performance and the like.

Owner:青县择明朗熙电子器件有限公司

Preparation method of stainless steel bearing steel pipe and ferrule

The invention discloses a preparation method of a stainless steel bearing steel tube. The method can improve yield and production efficiency and comprises the steps of: 1) heating and perforating: heating a round bar to 1,040 DEG C-1,070 DEG C, carrying out thermal insulation for 20-30 minutes, perforating at a speed of 10-18 meters per minute, thus obtaining a tube blank; 2) annealing at equal temperature: heating the tube blank to 830-850 DEG C, carrying out thermal insulation for 2-3 hours, then cooling to 700-720 DEG C at a cooling speed less then 30 DEG C per hour, and then discharging under the condition that a cooling speed is less than 50 DEG C per hour; 3) rolling: heating the annealed tube blank to 250-300 DEG C, and then rolling the annealed tube blank into a bearing steel tubewith a given size at a speed of 7-8mm per minute; and 4) stress relief annealing: increasing the temperature of the rolled bearing steel tube to 760-780 DEG C, carrying out thermal insulation for 2-3hours, then discharging under the condition that a cooling speed is less than 50 DEG C per hour. By adopting the preparation method, the stainless steel round bar made from 3Cr13 can be manufactured into the bearing steel tube meeting the requirement.

Owner:张家港市逸洋制管有限公司

High-performance nanocrystalline magnetic core preparation method for high-frequency electronic transformer

ActiveCN103700481ASignificant rise in temperatureImprove qualityInductances/transformers/magnets manufactureTransformerSilanes

The invention discloses a high-performance nanocrystalline magnetic core preparation method for a high-frequency electronic transformer. The method specifically comprises the following steps of performing vacuum isothermal annealing on an iron-based amorphous thin strip to obtain a nanocrystalline thin strip; crushing the obtained nanocrystalline thin strip to obtain nanocrystalline metal powder; classifying the nanocrystalline metal powder into unequal parts of materials A and B; treating the material A by using sodium alcohol ether sulphate, sodium polymethacrylate and sodium hexametaphosphate, and treating the material B sequentially by using vinyl trimethoxy silane, kaolin, polyisobutylene, phytic acid, nanocarbon and polyacrylic acid; uniformly mixing the treated materials A and B, adding a sodium silicate aqueous solution, performing compression molding, coating the surface of a molded magnetic core with magnetic core glue G500, and performing curing to obtain a finished product. According to the method, the prepared magnetic core has the advantages of excellent high-temperature and high-frequency characteristics, low loss value and the like, and is high in comprehensive performance.

Owner:TONGLING SANJIA TRANSFORMER

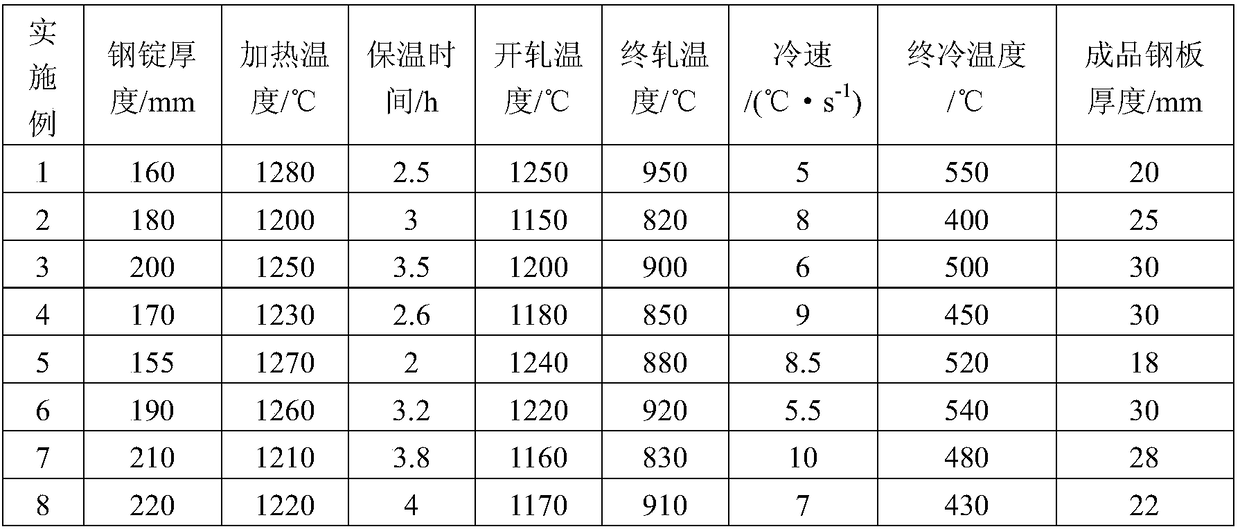

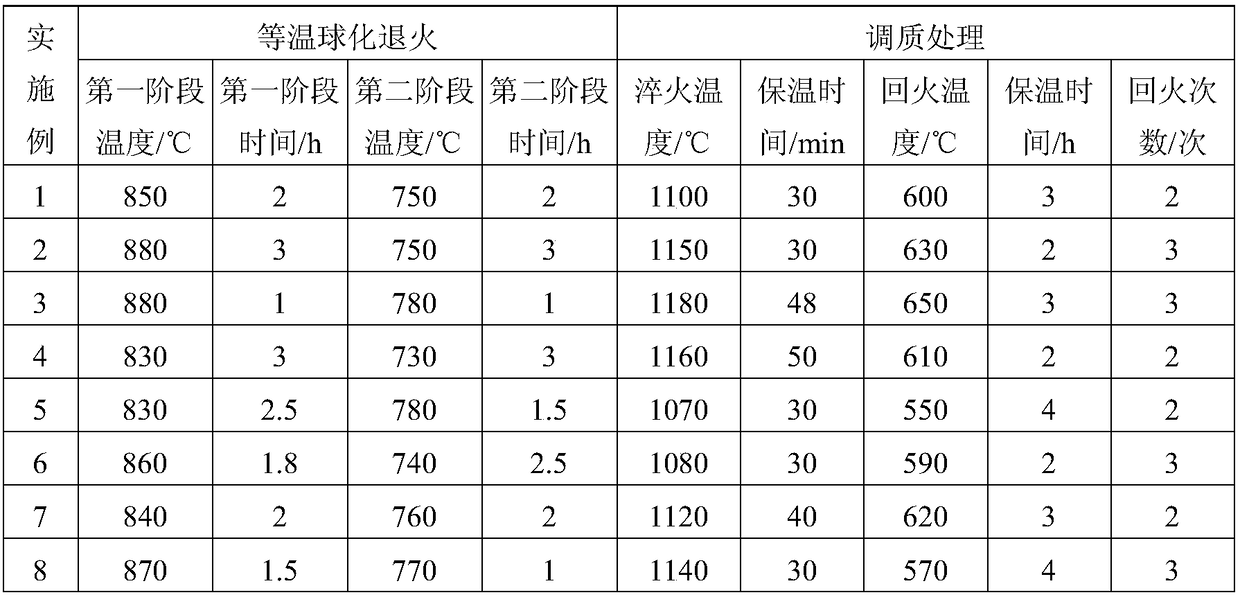

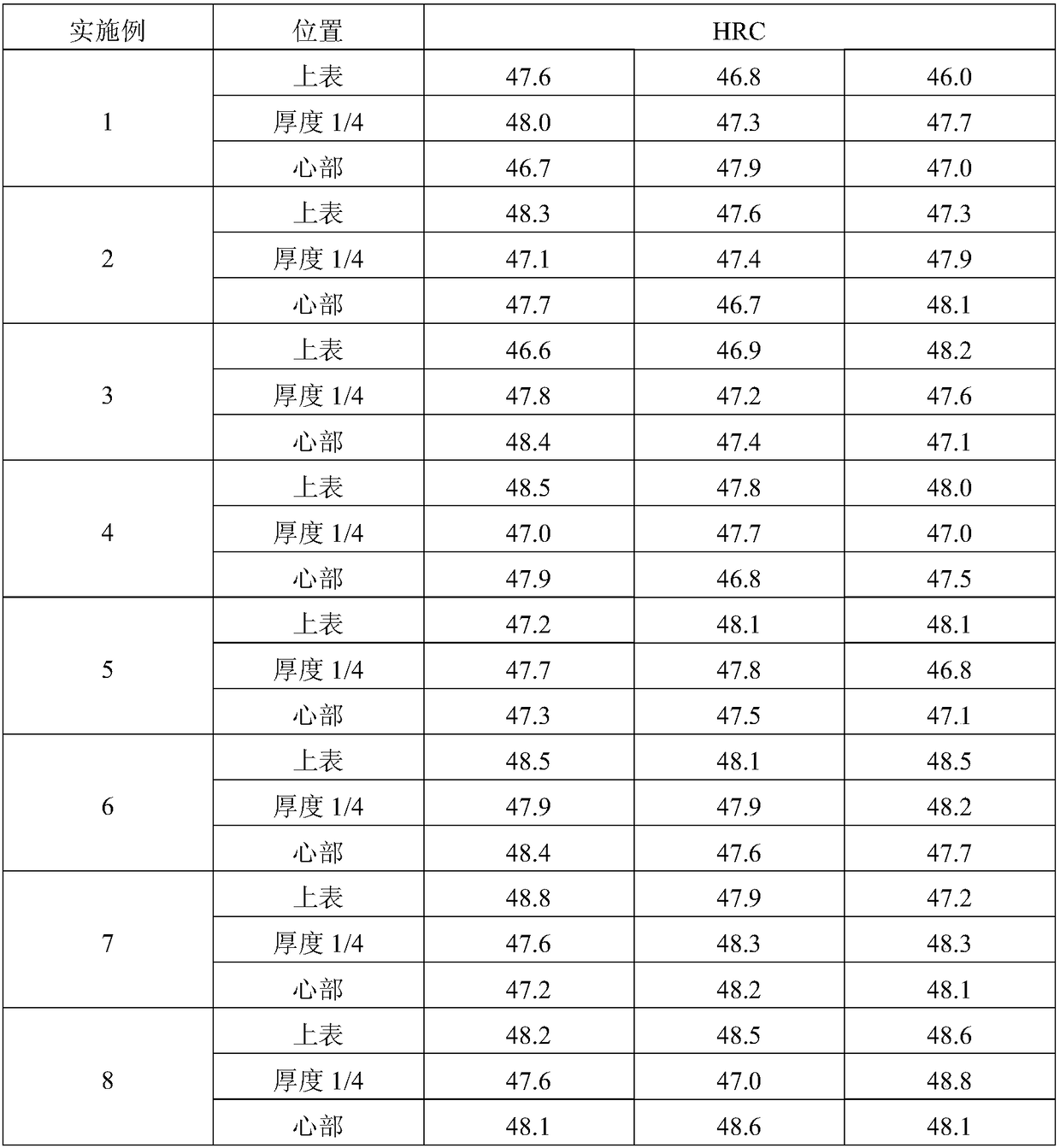

Hot work die steel and production method thereof

The invention discloses a hot work die steel and a production method thereof. The steel contains 0.45% to 0.55% of C, 5.50% to 6.50% of Cr, 0.85% to 1.10% of Si, 0.30% to 0.50% of Mn, 1.20% to 1.50% of Mo, 0.60% to 1.00% of V, less than or equal to 0.013% of P, less than or equal to 0.03% of S, 0.15% to 0.25% of Gd, 0.10% to 0.15% of La, 0.10% to 0.15% of Y, and the balance of Fe and unavoidable impurities. According to the invention, electric furnace smelting is carried out, the billet heating temperature is 1200-1280 DEG C, heat preservation is carried out for 2-4h, the rolling temperature is 1150 -1250 DEG C the finishing temperature is 820-950 DEG C, the cooling rate is 5 to 10 DEG C / s, and the final cooling temperature is 400 to 550 DEG C. The first-stage isothermal annealing temperature is 830-880 DEG C; the second-stage isothermal annealing temperature is 730-780 DEG C; the quenching temperature is 1050 to 1150 DEG C, and the tempering temperature is 550 to 650 DEG C. The produced hot work die steel has high isotropic performance and impact resistance.

Owner:ANGANG STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com