Heat treatment method of thick-wall P92 steel pipe

A heat treatment method and steel pipe technology, applied in the field of heat-resistant steel pipe manufacturing, can solve the problems of inconsistent grain size and large performance differences between different batches of products, and achieve the effects of good structure state, elimination of hot-rolled structure inheritance, and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

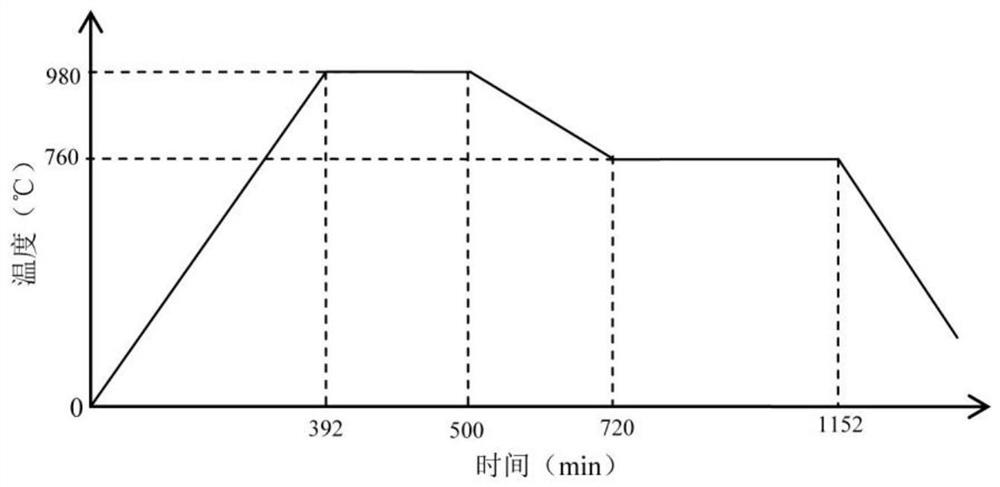

[0048] The heat treatment method of a OD314×72mm thick-walled P92 steel pipe provided in this embodiment, the length of the P92 steel pipe is ≤12500mm, includes the following steps:

[0049] (1) Put the P92 steel pipe into the heat treatment furnace and raise the temperature to 980°C at a heating rate of 150°C / h; hold for 108min;

[0050] (2) Furnace cooling to 760°C at a cooling rate of 1°C / min; hold for 432min;

[0051] (3) out of the furnace and air-cooled; the schematic diagram of steps (1) to (3) is as follows figure 1 shown.

[0052] (4) Normalize at 1050°C, keep warm for 108min, take out the furnace and place it on the cooling bed for air cooling, and air cool until the surface temperature of the steel pipe reaches 95°C;

[0053] (5) Temper at 765°C, keep warm for 180 minutes, take it out of the oven and place it on a cooling bed for air cooling.

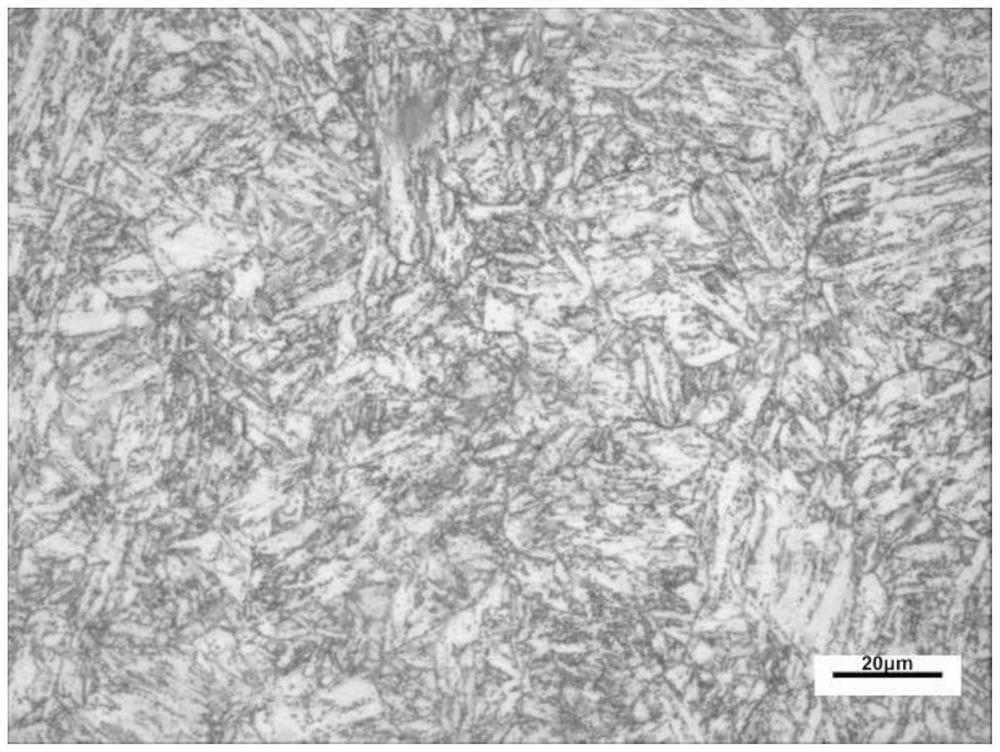

[0054] Sampling microscope to examine microstructure, such as figure 2 As shown, the microstructure of the sample is t...

Embodiment 2

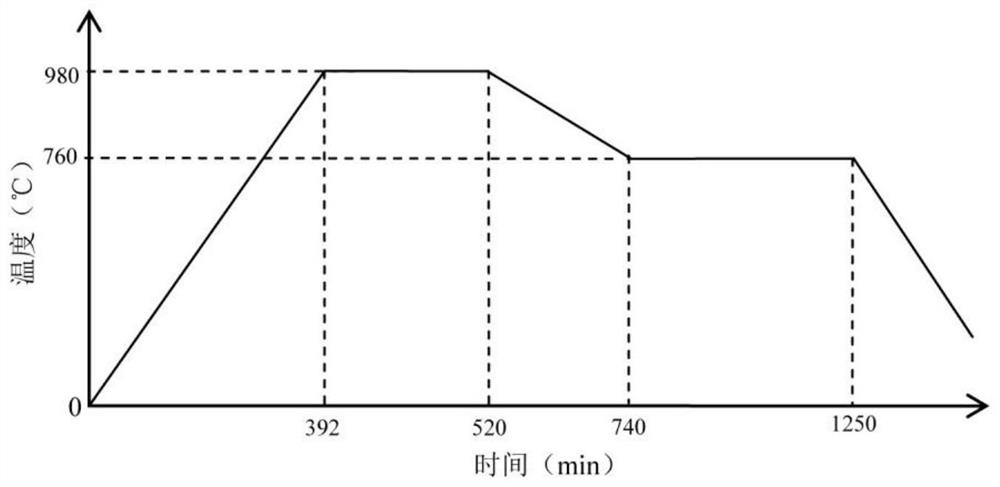

[0060] The heat treatment method of a OD483×85mm thick-walled P92 steel pipe provided in this embodiment, the length of the P92 steel pipe is ≤12500mm, includes the following steps:

[0061] (1) Put the P92 steel pipe into the heat treatment furnace and raise the temperature to 980°C at a heating rate of 150°C / h; hold for 128min;

[0062] (2) Furnace cooling to 760°C at a cooling rate of 1°C / min; keep warm for 510min;

[0063] (3) out of the furnace and air-cooled; the schematic diagram of steps (1) to (3) is as follows image 3 shown.

[0064] (4) Normalize at 1065°C, keep warm for 128min, take out the furnace and place it on a cooling bed for air cooling, and air cool until the surface temperature of the steel pipe reaches 95°C;

[0065] (5) Temper at 775°C, keep warm for 213 minutes, take it out of the oven and place it on a cooling bed for air cooling.

[0066] Sampling microscope to examine microstructure, such as Figure 4 As shown, the microstructure of the sample i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com