Method for manufacturing fine-grain 35CrNi3MoV steel large forging stock

A manufacturing method and fine-grained technology, applied in the field of manufacturing large forgings, can solve problems such as obvious tissue inheritance, long production cycle, and complicated manufacturing process, and achieve the effect of eliminating tissue inheritance, significant effect, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

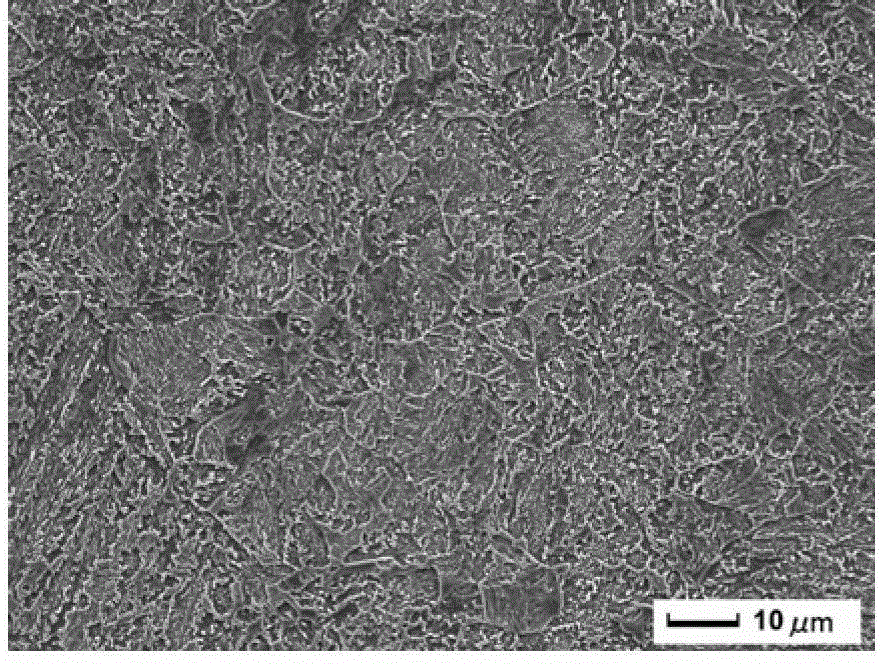

[0023] 15 tons of 35CrNi3MoV steel large forging blanks are used for forging. Since the weight of the forging billet exceeds 10 tons, the forging billet should be forged at least 4 times first, the forging ratio of a single forging (1 pier and 1 pullout) is about 3, and the total forging ratio is about 10; then, with 100± Heat the sample from room temperature to 650±10°C at a rate of 10°C / h for about 9 hours, then heat at a rate of 25±5°C / h from 650±10°C to 850±10°C for about 12 hours to ensure that the sample Tensitization is uniform, then cooled at a rate of 30±5°C / h to 640°C±10°C and kept for about 60 hours to form a pearlite-based structure, thereby eliminating tissue inheritance, and then cooled to room temperature; then cooled to room temperature at 100±10 Heat the sample to 650±10℃ and keep it for about 4h at the rate of ℃ / h, then heat it to 860±10℃ at the rate of 25±5℃ / h and keep it for about 15h, and finally take it out and cool it in air to obtain the average grain s...

Embodiment 2

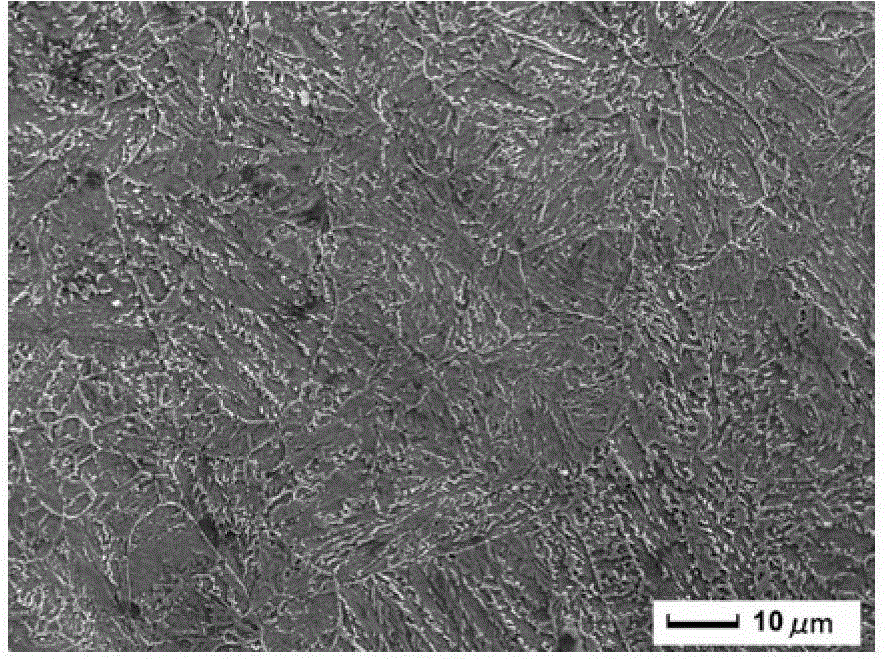

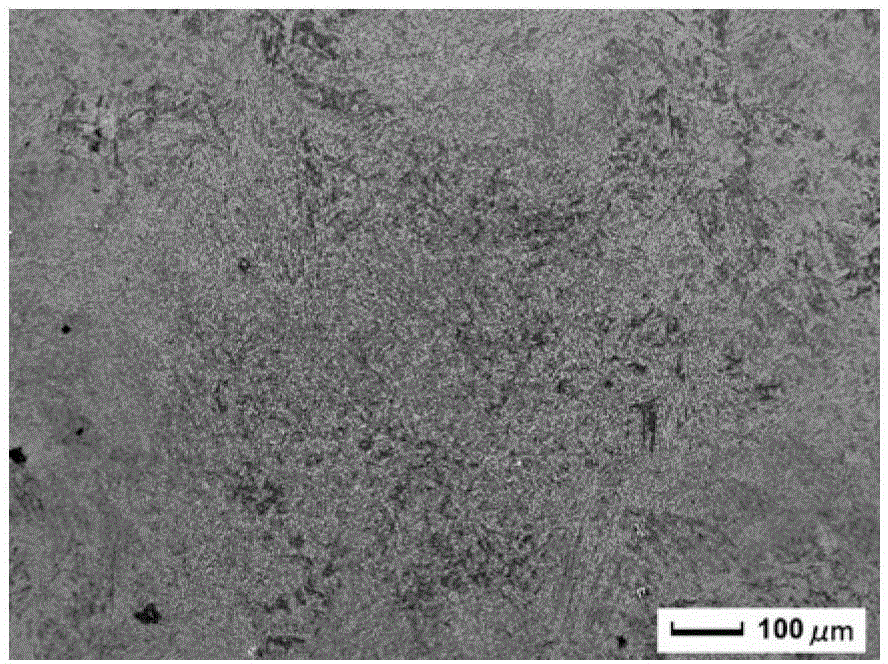

[0027] 7 tons of 35CrNi3MoV steel large forging billet is used for forging. Since the weight of the forging is less than 10 tons, the forging billet can be forged twice at first, the forging ratio of a single forging (1 pier and 1 pull) is about 3, and the total forging ratio is about 5; then, at 100±10°C / Heat the sample from room temperature to 650±10°C for about 9 hours at a rate of h, and then heat it from 650±10°C to 850±10°C for about 12 hours at a rate of 25±5°C / h to ensure that the sample is austenitized Uniform, then cooled to 640°C±10°C at a rate of 30±5°C / h and kept for about 60h to form a pearlite-based tissue, thereby eliminating tissue inheritance, and then cooled to room temperature; followed by 100±10°C / h Heat the sample at a rate of 650±10°C for about 4 hours, then heat it at a rate of 25±5°C / h to 860±10°C for about 15 hours, and finally take it out and cool it in air. The average grain size of prior austenite obtained is 20 ~30mm (such as figure 2 Shown), ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com