Short process manufacturing method of large 30crni2mov steel parts

A manufacturing method and short-process technology, which is applied in the short-process manufacturing of 30CrNi2MoV steel parts and the forging field of large-scale 30CrNi2MoV steel parts, can solve the problems of difficult performance guarantee, high cost, and complicated manufacturing process, and achieve low manufacturing cost and high production efficiency High, short manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

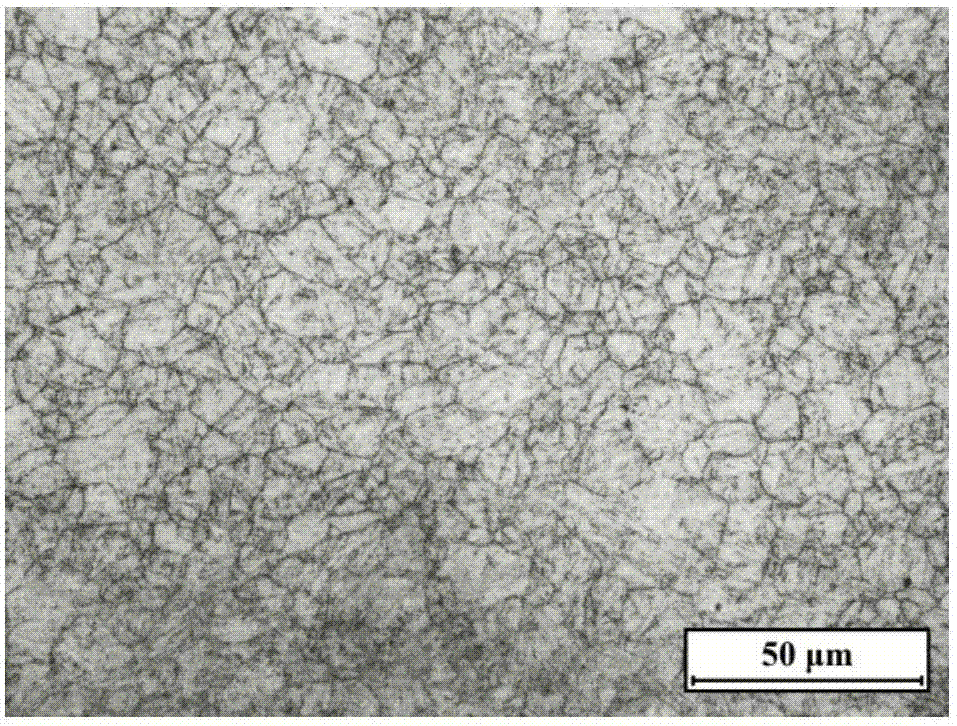

[0031] The 30CrNi2MoV steel forging billet is forged with 2 times of upsetting and 1 time of upsetting, and the total forging ratio is 10; then it is quenched with oil cooling after 860°C´6h+780°C´2h heat preservation + 600°C´16h oil cooling after heat preservation of tempering.

[0032] The 30CrNi2MoV steel forgings subjected to such heat treatment have an average grain size of 10-30mm ( figure 1 ), low temperature impact toughness A at -40°C KV (-40°C) is 103J, and the tensile strength at room temperature is R m is 1161.6 MPa, room temperature elongation A 5 was 37.8%.

Embodiment 2

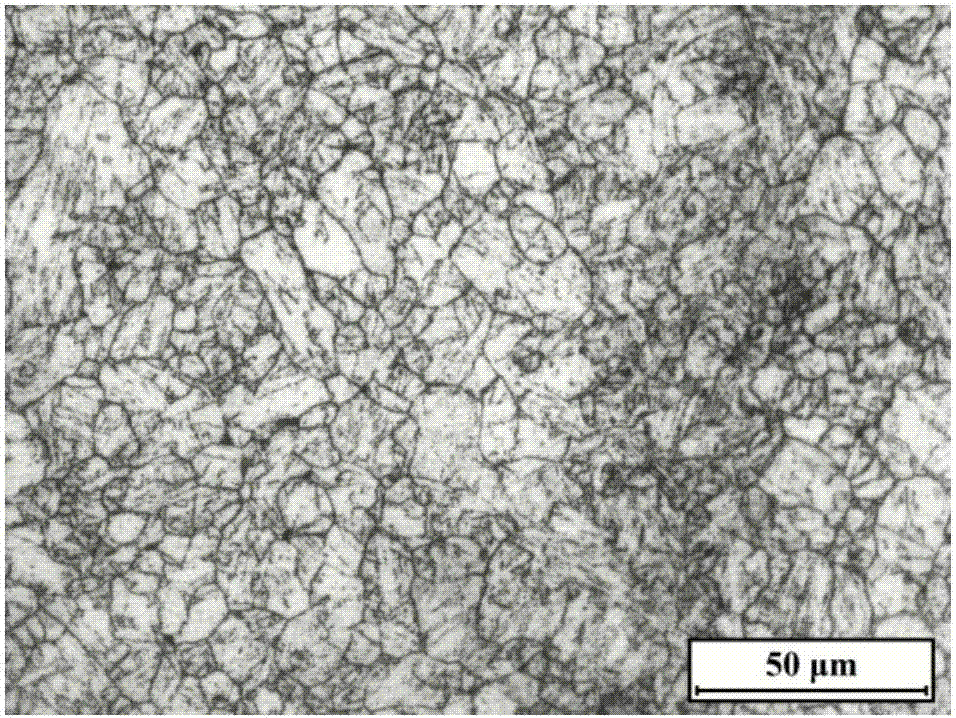

[0034] The 30CrNi2MoV steel forging billet is forged with 2 times of upsetting + 1 time of upsetting + 1 time of elongation, the total forging ratio is 14; then it is quenched with oil cooling at 860℃´6h+780℃´2h after heat preservation + 600℃´ After 16 hours of heat preservation, oil-cooled tempering.

[0035]The 30CrNi2MoV steel forgings subjected to such heat treatment have an average grain size of 10-30mm ( figure 2 ), low temperature impact toughness A at -40°C KV (-40°C) is 87J, and the tensile strength at room temperature is R m 1157.4 MPa, room temperature elongation A 5 was 36.13%.

Embodiment 3

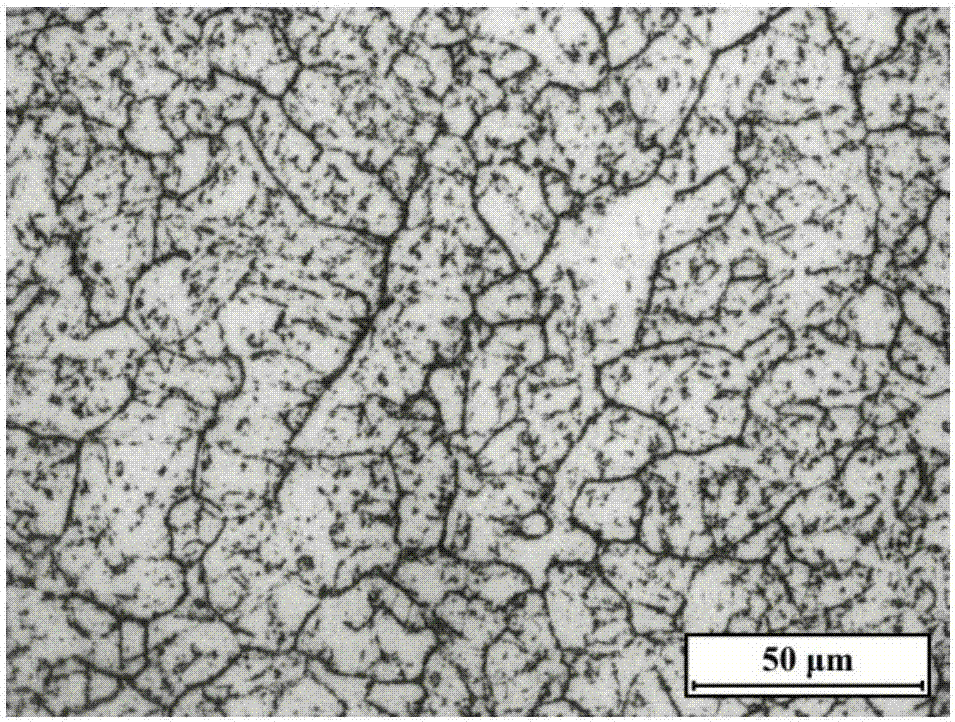

[0040] The 30CrNi2MoV steel forging billet is forged with 2 times of upsetting and 1 time of upsetting, and the total forging ratio is 10; then it is quenched by oil cooling after 860°C´6h heat preservation + 600°C´16h heat preservation and then air-cooled tempering.

[0041] The 30CrNi2MoV steel forgings subjected to such heat treatment have an average grain size of 10-30mm ( Figure 4 ), low temperature impact toughness A at -40°C KV (-40°C) is 87.67J, the tensile strength at room temperature R m 1215.5 MPa, room temperature elongation A 5 was 35.53%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com