Thermal treatment method for eliminating structural heredity of high-toughness steel

A heat treatment method and a technology of tissue inheritance, applied in the field of heat treatment to eliminate tissue inheritance of high-strength and tough steel, can solve the problems of strong tissue inheritance, and achieve the effect of eliminating tissue inheritance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

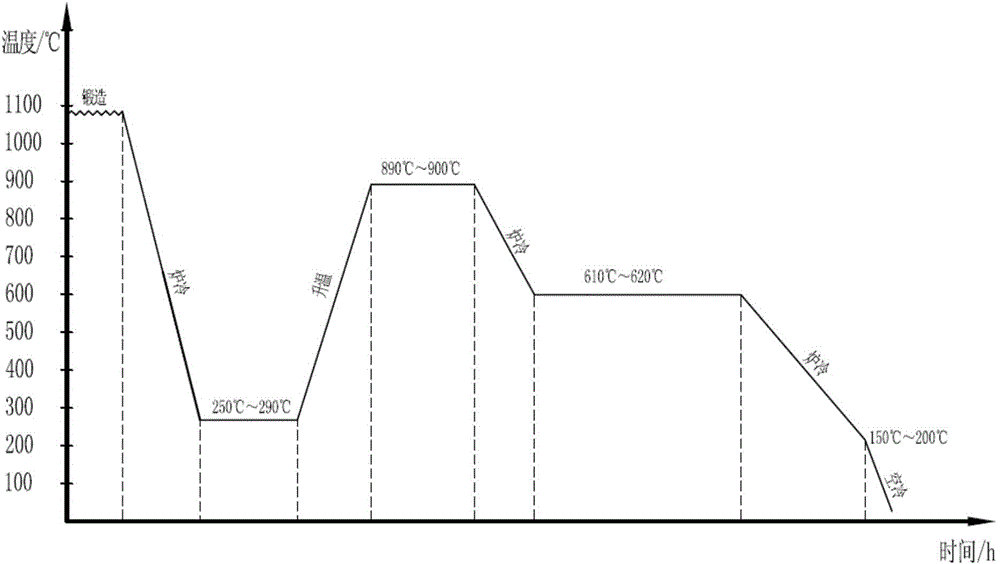

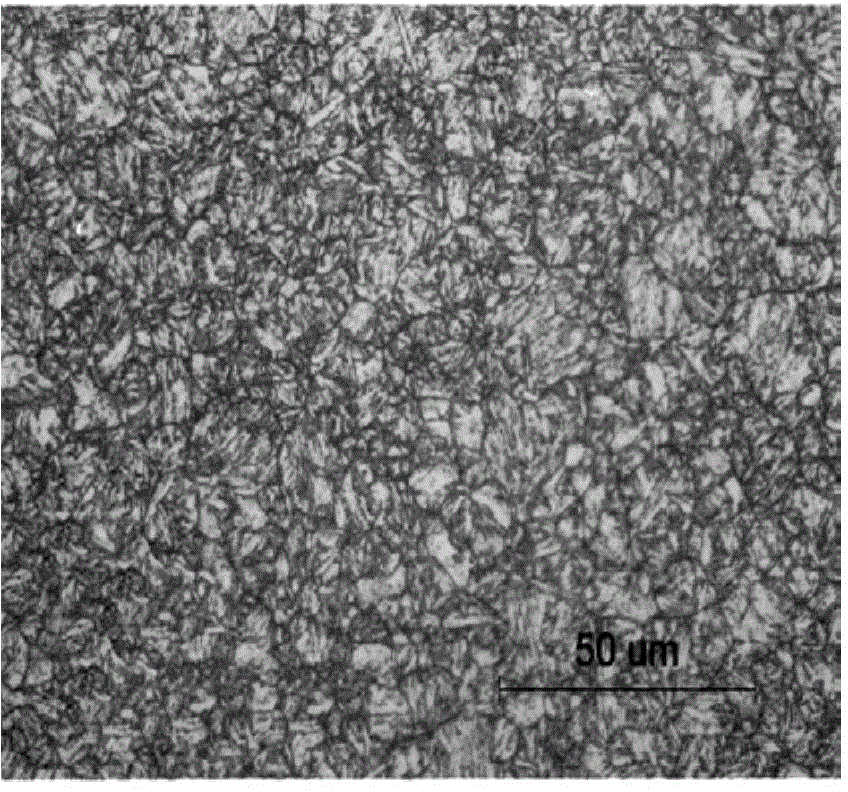

[0011] The present invention is for 38CrNi3MoVA high-strength toughness steel part, according to figure 1 Method After the forging is completed, enter the furnace as soon as possible and cool to 250°C for heat preservation. After heat preservation for 1 hour, the temperature rises. The heating temperature is 890°C, and the heat preservation time is 6 hours. , out of the oven and air cooled to room temperature. Since the 38CrNi3MoVA high-strength and tough steel parts with martensite or bainite non-equilibrium structure after forging are re-austenitized at a heating temperature of 890°C, the recrystallization of the α phase is realized, and the temperature is kept at 610°C After 55 hours, the structure is fully transformed, and a balanced structure composed of fine carbide particles and ferrite structure is obtained. See 2 for the metallographic structure diagram.

Embodiment 2

[0013] The present invention is for 38CrNi3MoVA high-strength toughness steel part, according to figure 1 Method After the forging is completed, enter the furnace as soon as possible and cool to 250°C for heat preservation. After 2 hours of heat preservation, the temperature rises. The heating temperature is 890°C, and the heat preservation time is 6 hours. , out of the oven and air cooled to room temperature. Since the 38CrNi3MoVA high-strength and tough steel parts with martensite or bainite non-equilibrium structure after forging are re-austenitized at a heating temperature of 890°C, the recrystallization of the α phase is realized, and the temperature is kept at 610°C After 55 hours, the structure is fully transformed, and a balanced structure composed of fine carbide particles and ferrite structure is obtained. See 2 for the metallographic structure diagram.

Embodiment 3

[0015] The present invention is for 38CrNi3MoVA high-strength toughness steel part, according to figure 1 Method After the forging is completed, put it into the furnace as soon as possible and cool it to 270°C for heat preservation. After heat preservation for 1 hour, the temperature rises. The heating temperature is 890°C, and the heat preservation time is 6 hours. , out of the oven and air cooled to room temperature. Since the 38CrNi3MoVA high-strength and tough steel parts with martensite or bainite non-equilibrium structure after forging are re-austenitized at a heating temperature of 890°C, the recrystallization of the α phase is realized, and the temperature is kept at 610°C After 55 hours, the structure is fully transformed, and a balanced structure composed of fine carbide particles and ferrite structure is obtained. See 2 for the metallographic structure diagram.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com