Furnace monocrystal isothermal annealing method and tool

An isothermal annealing, single crystal technology, applied in the direction of single crystal growth, chemical instruments and methods, crystal growth, etc., can solve the problems of single crystal cracks, increase costs, etc., to simplify the process, reduce the risk of cracks, and reduce single crystal heat. effect of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

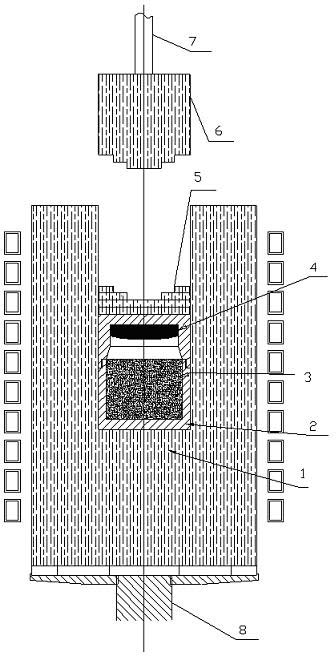

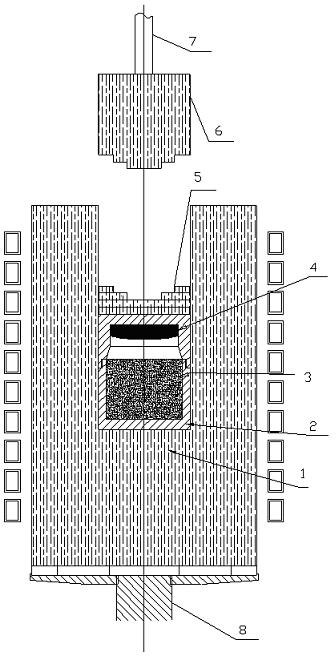

[0015] Before growing the silicon carbide single crystal by the physical vapor transport method, the insulation plug 6 is separated from the heat dissipation channel 5 by about 400mm in advance, so that there is a temperature gradient during the growth of the single crystal. After the growth is over, lower the above-mentioned insulation plug 6 by about 400 mm through the pull rod 7 on the upper end of the insulation plug 6, tightly cover the heat dissipation channel on the upper part of the seed crystal, and reduce the heating power by 70% at the same time, so as to prevent the grown single crystal from being damaged due to excessive temperature. After being sublimated and then kept warm for 1 hour, the whole single crystal can reach the annealing start temperature uniformly. Finally, the method of isothermal annealing with the furnace is adopted, and the temperature is lowered to room temperature within 24 hours to obtain a silicon carbide single crystal without thermal stress....

Embodiment 2

[0017] Before using the physical vapor transport method to grow the aluminum nitride single crystal, the insulation plug 6 is separated from the heat dissipation channel 5 by about 10mm in advance, so that there is a temperature gradient during the growth of the single crystal. After the growth is over, raise the crucible 2 by about 10mm through the tie rod 8 at the bottom of the insulation tube 1, tightly cover the heat dissipation channel on the upper part of the seed crystal, and reduce the heating power by 10% at the same time, so as to prevent the grown single crystal from being sublimated due to excessive temperature , and then keep it warm for 48 hours, so that the whole single crystal can evenly reach the annealing starting temperature, and finally use the method of isothermal annealing with the furnace to drop to room temperature within 24 hours, and obtain an aluminum nitride single crystal with small thermal stress. However, if the aluminum nitride single crystal gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com