Preparation method of bearing steel capable of resisting high temperature of 400 DEG C

A bearing steel and high temperature technology, which is applied in the field of composition development and heat treatment process of new high temperature bearing steel, can solve problems such as uneven distribution, irregular shape, fatigue cracks, etc., to prolong service time, reduce cracks, and improve hardness value effect

Active Publication Date: 2017-06-27

UNIV OF SCI & TECH BEIJING

View PDF8 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0008] The detection of high-temperature bearings that failed after service found that large, irregular-shaped, and unevenly distributed primary carbides were found on the working surface or sub-surface of the bearing, which caused the generation and expansion of fatigue cracks and seriously affected the service life of the bearing steel.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0020] Specific embodiments of the present invention are given below and described in conjunction with the accompanying tables.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention belongs to the field of development of high temperature bearing steel, and mainly relates to a preparation method of bearing steel capable of resisting high temperature of 400 DEG C. A bearing machined from the bearing steel can be used at the high temperature of 400 DEG C. The high temperature bearing steel is subjected to dual-vacuum smelting through a vacuum induction furnace and a vacuum electroslag remelting, and is prepared from 4.5 to 5.28 percent of Cr, 3.75 to 4.10 percent of Mo, 0.56 to 0.80 percent of V, 0.30 to 0.34 percent of Mn, 0.21 to 0.26 percent of Ni and 0.2 to 0.29 percent of Si. A thermal treatment process comprises the following steps: heating the bearing steel to 800 to 870 DEG C for heat preservation, cooling the bearing steel to 700 to 800 DEG C for isothermal annealing, and then slowly cooling the bearing steel to room temperature; heating the bearing steel to 1,050 to 1,070 DEG C for solution treatment, and carrying out heat preservation and oil quenching in sequence; and heating the bearing steel to 510 to 550 DEG C for tempering for 2 to 2.5 hours, and then carrying out tempering for three times according to the process. According to the novel high temperature bearing steel disclosed by the invention, by reduction of the vanadium content, carbides can be thinned and dispersed, so that generation of fatigue crack sources can be reduced; meanwhile, the hardness is further improved; and the room temperature hardness is not less than 62 HRC, and the hardness at the high temperature of 400 DEG C is not less than 658 HV, so that the bearing steel can meet application under a high temperature condition.

Description

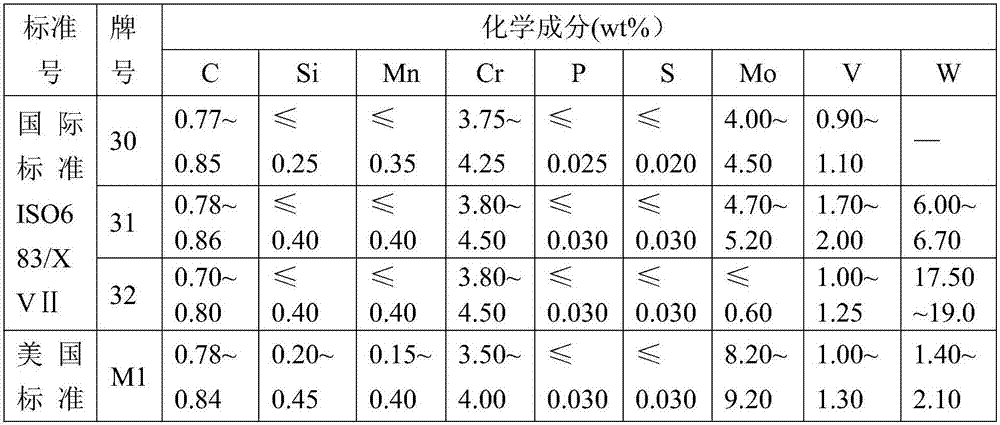

technical field [0001] The invention belongs to the technical field of component development and heat treatment process of high temperature bearing steel, and mainly relates to the component development and heat treatment process of a new type of high temperature bearing steel. Background technique [0002] High temperature bearing steel is mainly used in main shaft bearings in aero-engines, used in aircraft or rockets. The higher the bearing hardness value, the better the bearing fatigue life and the longer the service time. With the current development of gas turbines, higher hardness at high temperature is required to meet the long-term operation of gas turbines. Therefore, it is necessary to improve the room temperature hardness and high temperature hardness of bearing steel. See Table 1 for the steel grades of widely used high temperature bearing steels and their international, American and domestic standards. Among them, M50 (equivalent to 8Cr4Mo4V in China) is the ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22C38/44C22C38/46C22C38/04C22C38/02C22C38/50C21D1/26C21D1/18C21D8/00

CPCC21D1/18C21D1/26C21D8/005C22C38/001C22C38/002C22C38/02C22C38/04C22C38/44C22C38/46C22C38/50

Inventor 罗海文杨平

Owner UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com